Braze soldering method for welding aluminum-base composite materials and titanium alloys and enabling intermetallic compound particles in weld seams to be dispersed and reinforced

An aluminum-based composite material and particle dispersion strengthening technology, which is applied in the direction of welding/welding/cutting articles, welding equipment, metal processing equipment, etc., can solve the problems of low joint performance, achieve high welding efficiency, and flexible solder composition ratio , a wide range of effects can be selected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

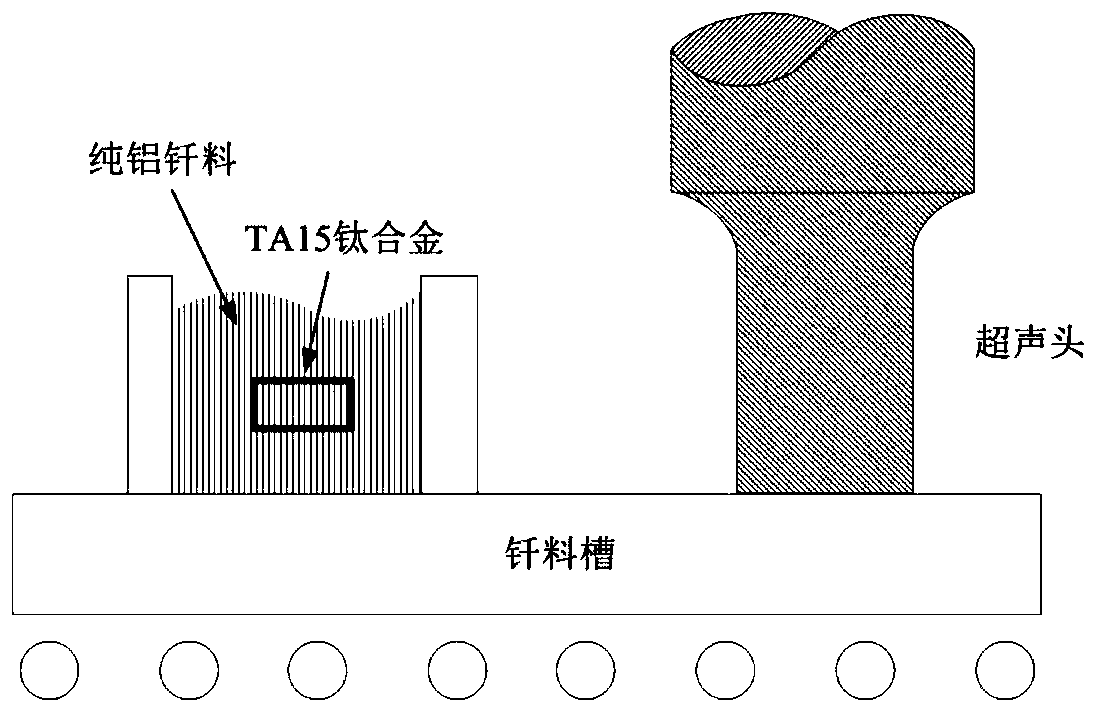

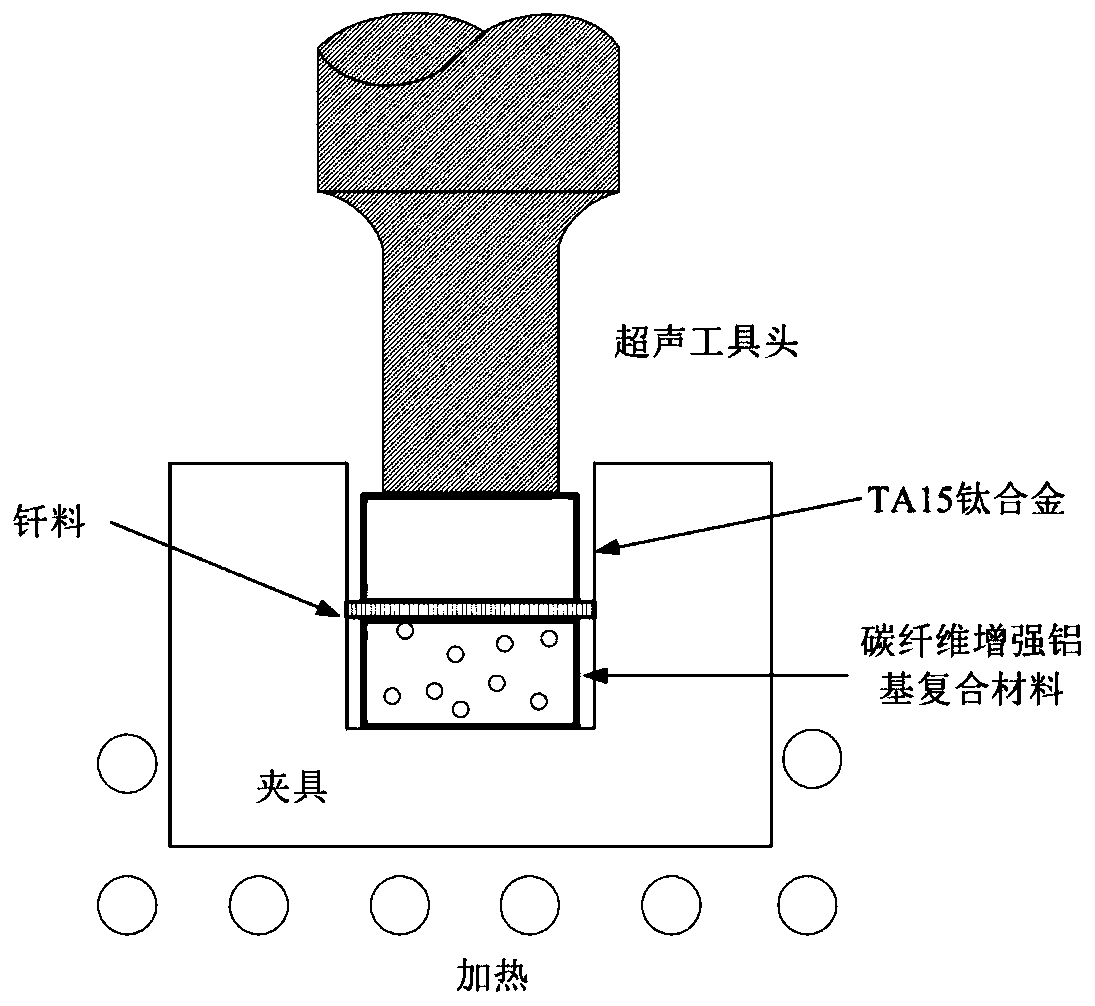

[0034] Specific implementation mode 1: In this implementation mode, the brazing method of welding aluminum-based composite materials and titanium alloys to make the dispersion strengthening of intermetallic compound particles in the weld seam is specifically carried out according to the following steps:

[0035] 1. Put the pure aluminum ingot into the solder tank, heat and melt to obtain the modified melt;

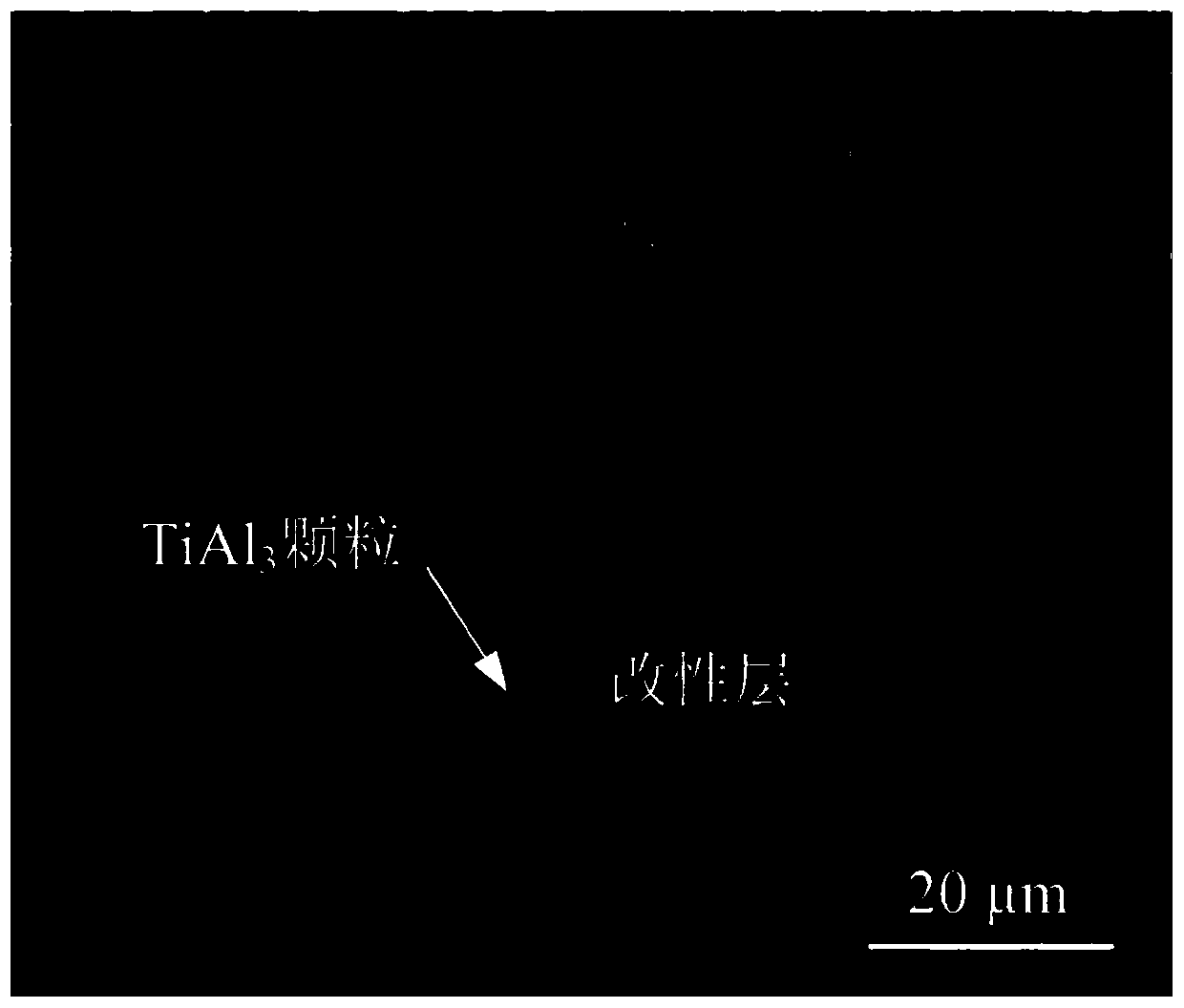

[0036] 2. Immerse the titanium alloy in the modified melt obtained in step 1, apply ultrasonic waves to modify the surface of the titanium alloy, then keep it warm for 10 minutes to 1 hour, take it out, cool it in air, and perform surface grinding to obtain a titanium alloy with a modified layer;

[0037] 3. Put brazing filler metal between the aluminum matrix composite material and the titanium alloy with the modified layer obtained in step 2, and carry out ultrasonic welding to complete the method.

[0038] In the second step of this embodiment, the acoustic cavitation o...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the pure aluminum ingot is melted by heating to 700-720°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the titanium alloy in step two is industrial pure titanium TA1-4, TA15 titanium alloy, TC1-26 titanium alloy, TA5-28 titanium alloy or TB2- 11 titanium alloy. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com