Patents

Literature

593results about How to "Shorten welding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

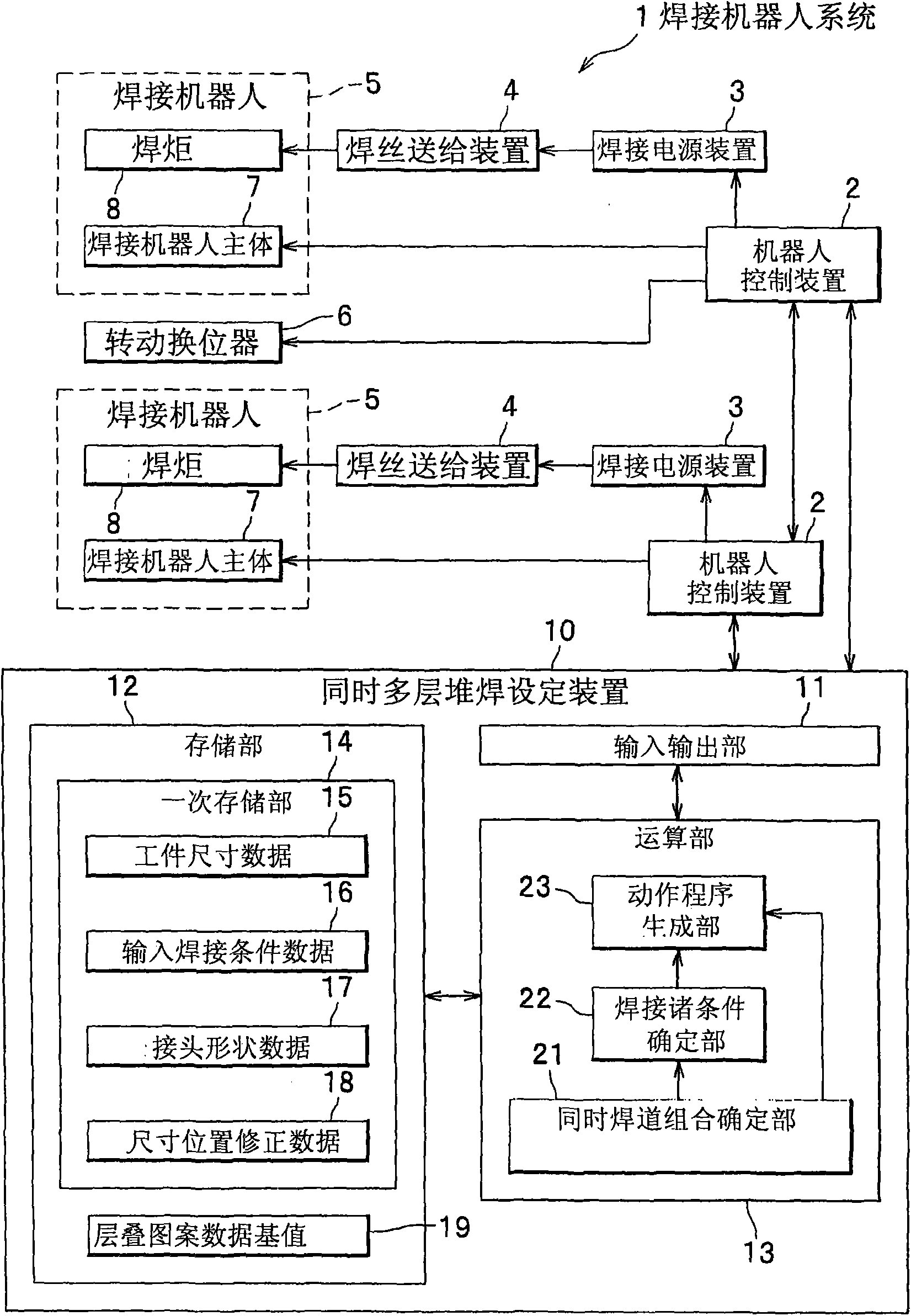

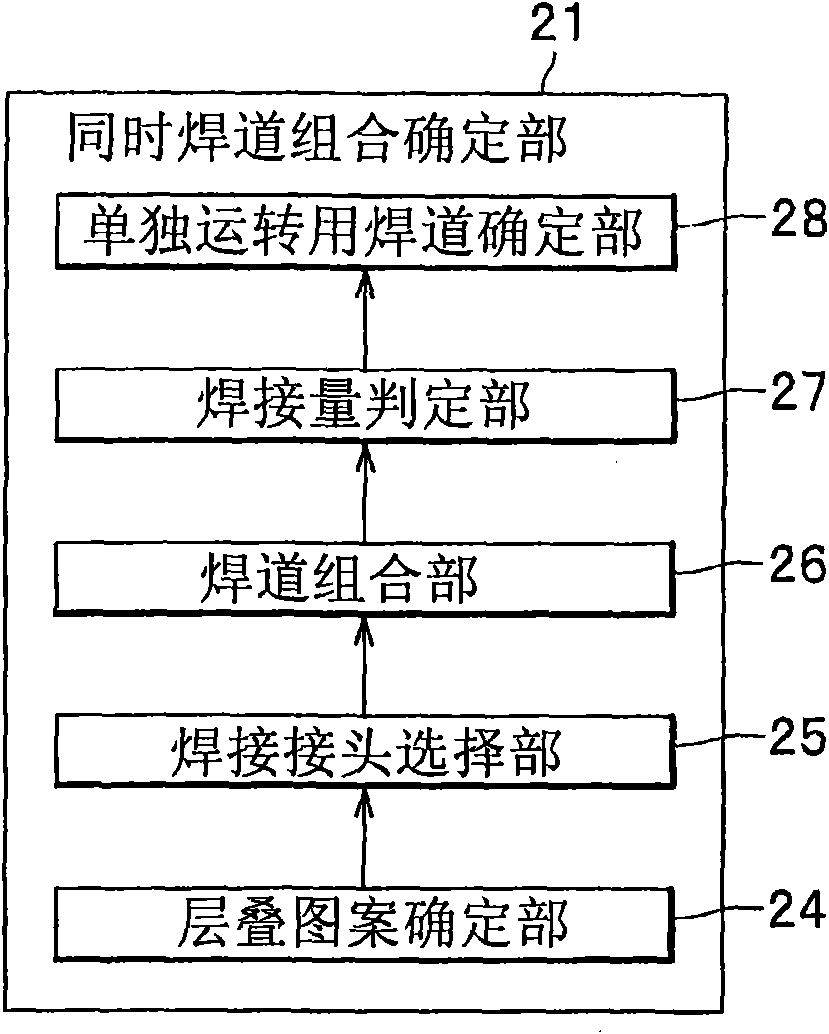

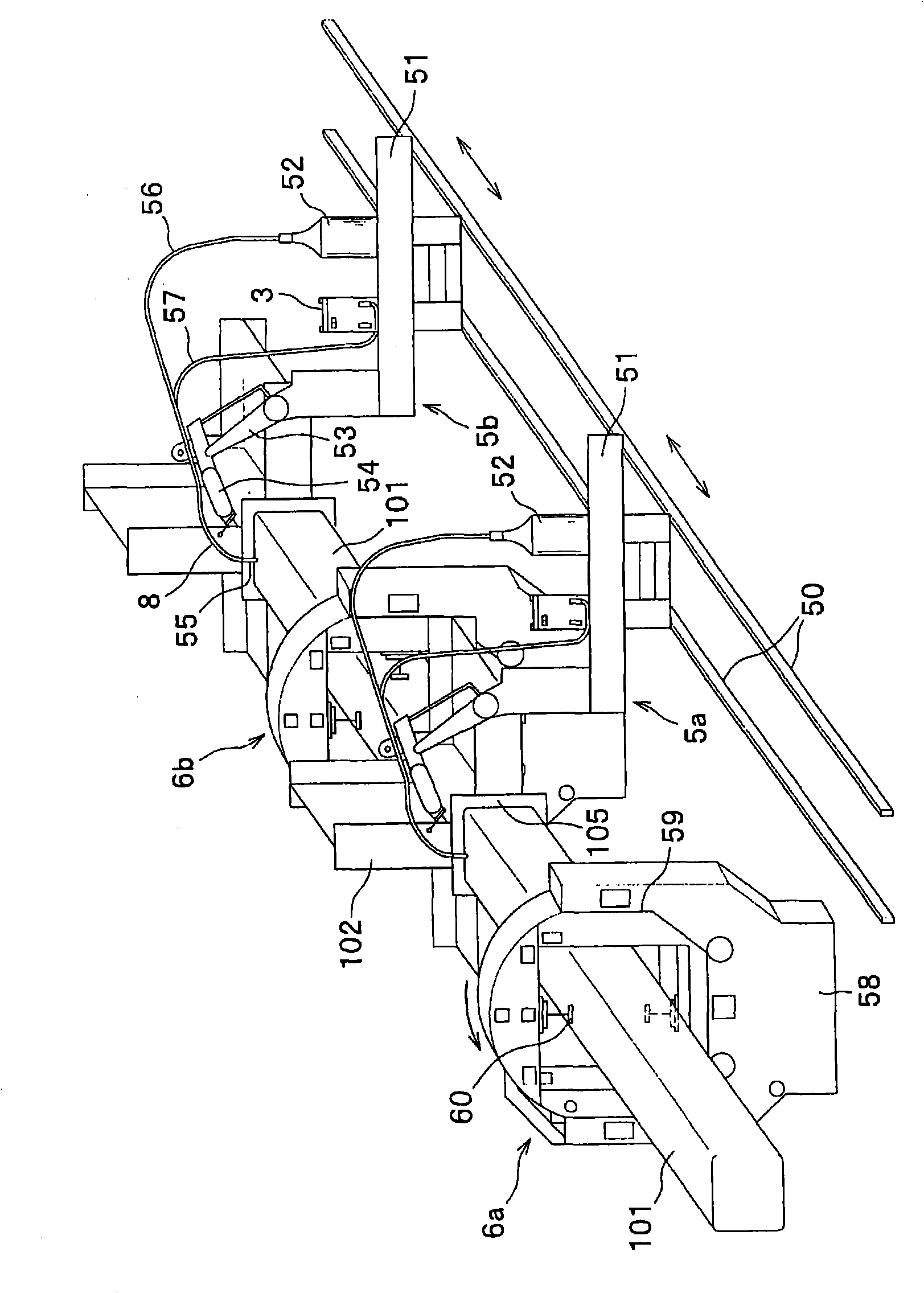

Welding setting device, welding robot system and welding setting method

The invention provides a simultaneous multiple-layer welding setting device, comprising a cascading pattern determining part for determining the cascading pattern of a welding pass corresponding to joints of objects based on basic values of each input data and the cascading pattern data; a welding pass determining part for independently running which is used for determining the welding combination after excluding the welding pass with a large sectional area as the welding pass for independently running when the difference value of the sectional area of a deposited metal quantity is over the predetermined threshold value when combining the welding passes in the cascading pattern of two joints of the objects; a welding conditions determining part for determining each welding pass welding condition comprising current values corresponding to a welding wire feeding speed calculated based by an input welding condition and a seam forming position; and an action procedure generating part for generating a robot action procedure based on the determined welding conditions, and setting in a robot controlling device. The simultaneous multiple-layer welding setting device shortens the welding time of simultaneously welding a plurality of layers of a plurality of welding joints of a steel structure by two welding robots.

Owner:KOBE STEEL LTD

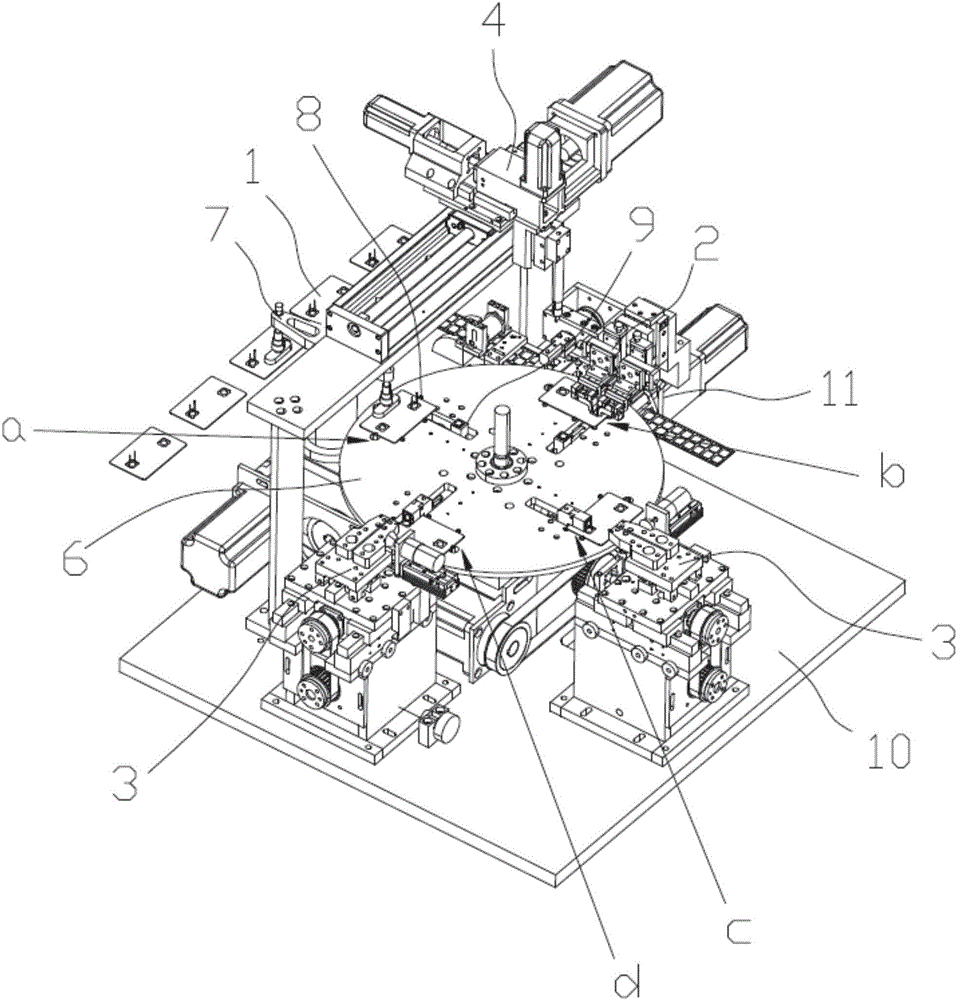

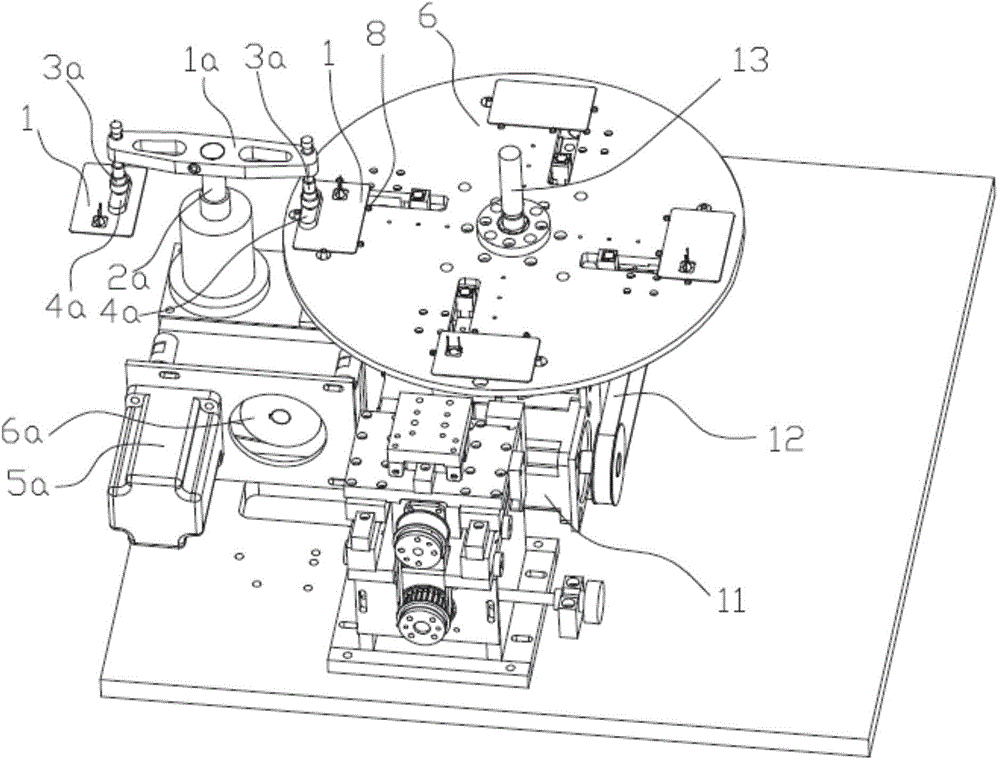

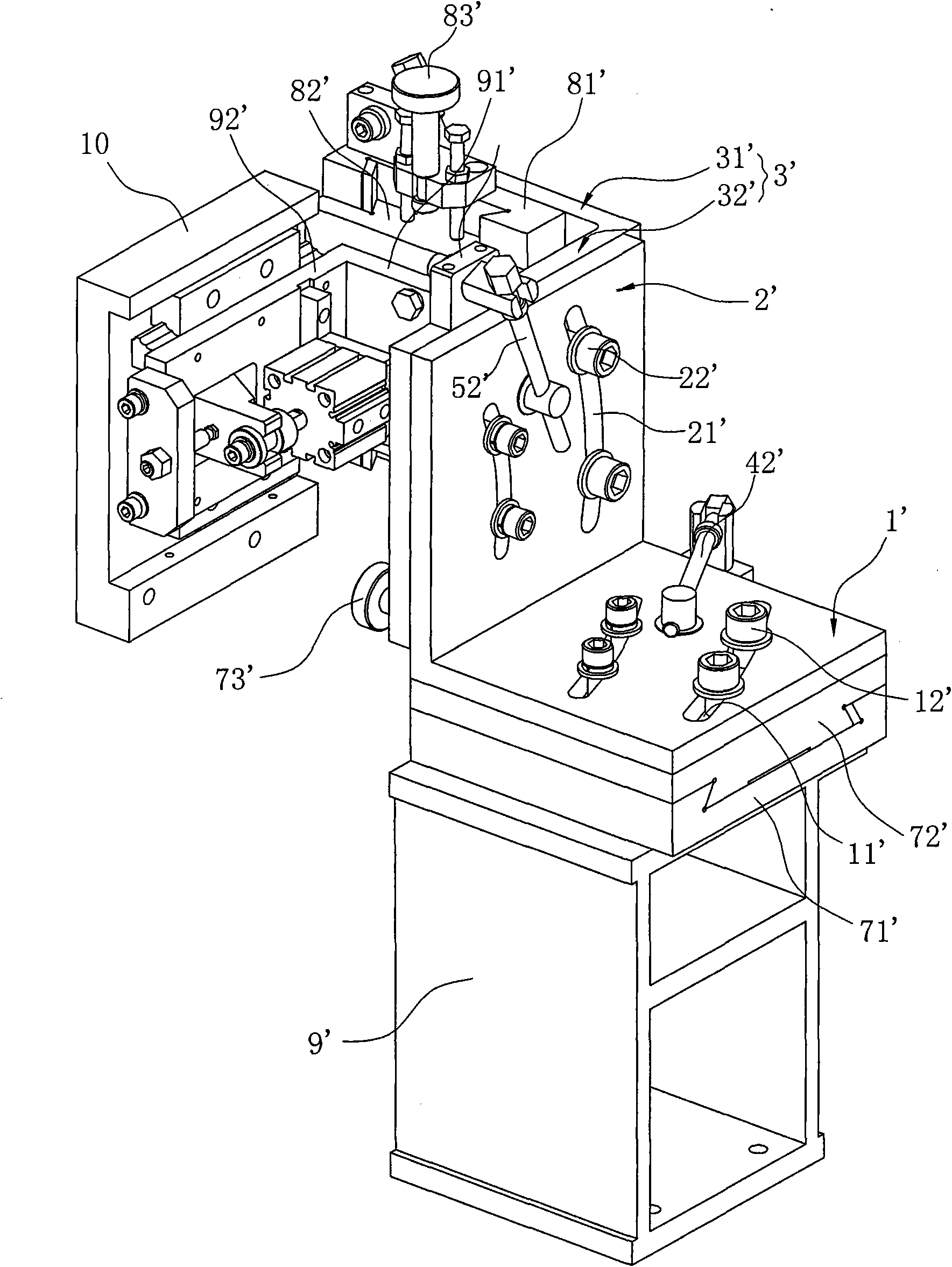

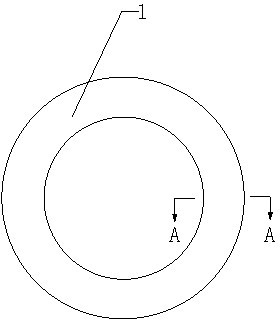

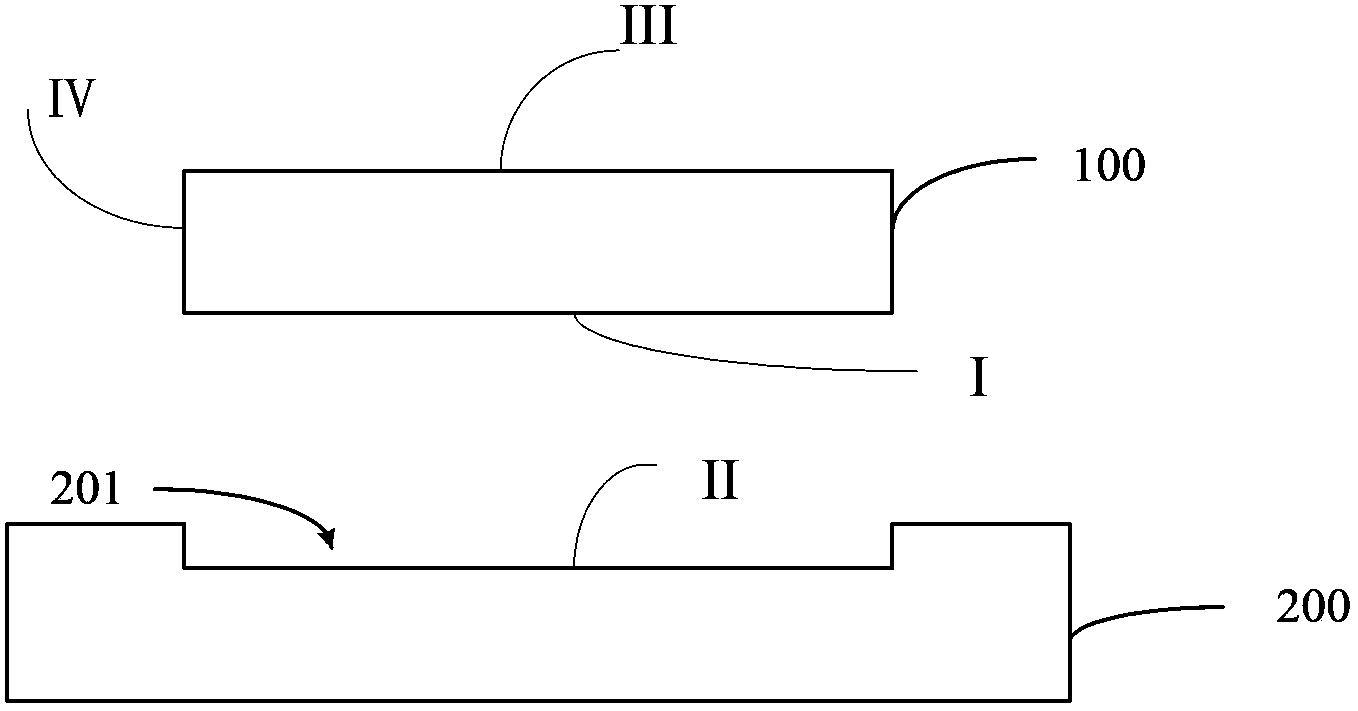

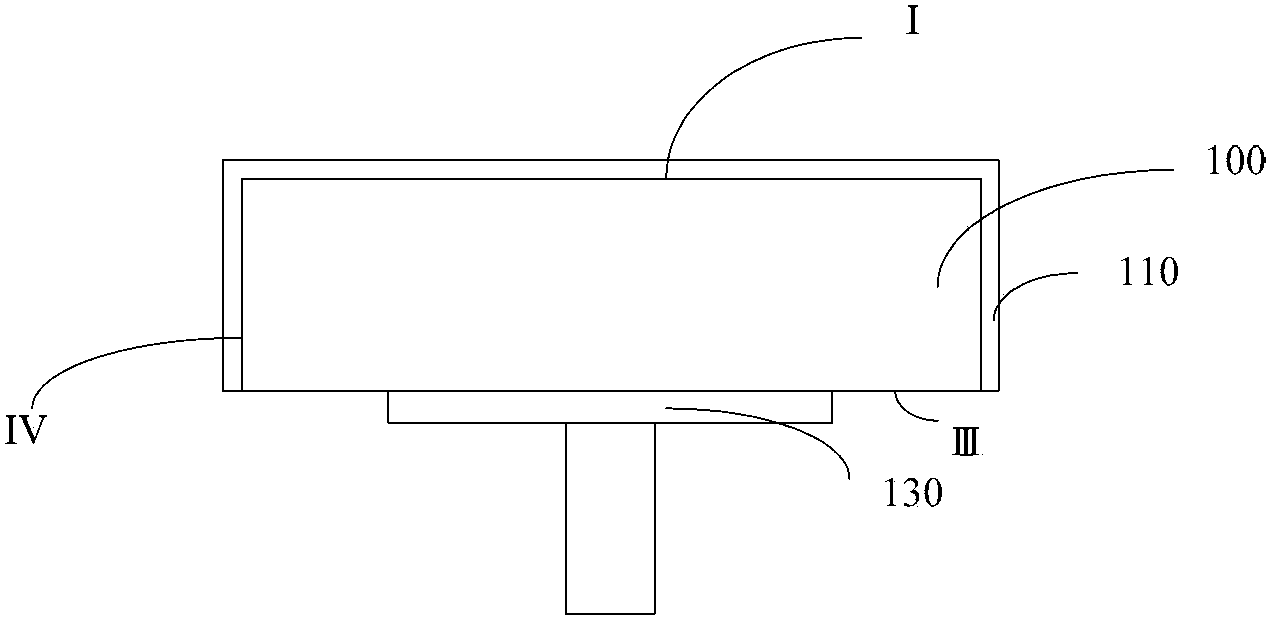

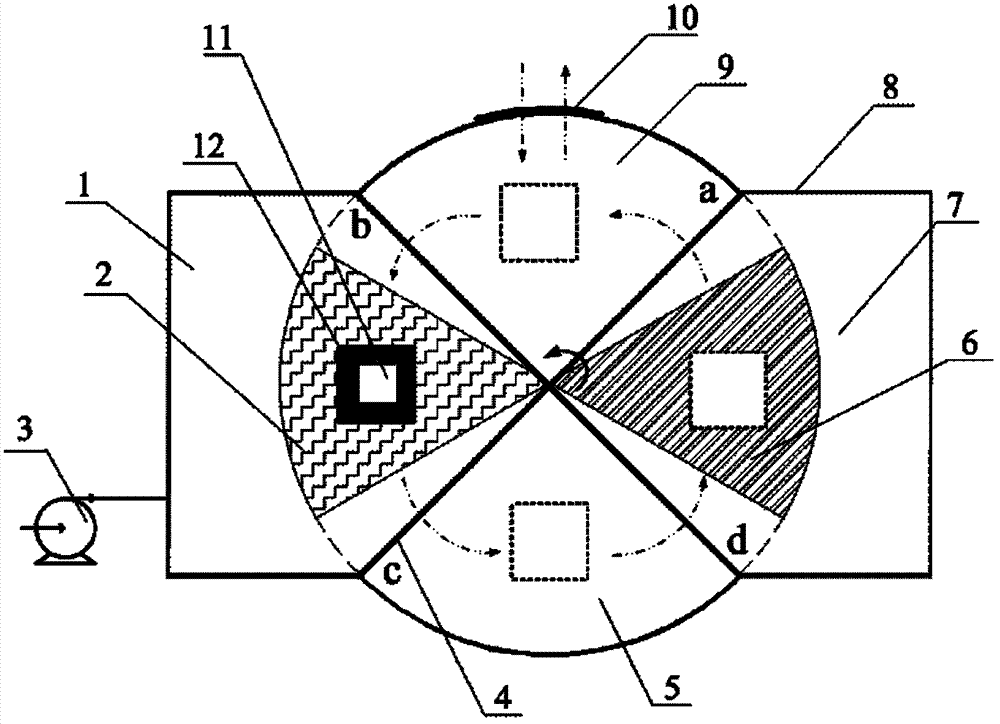

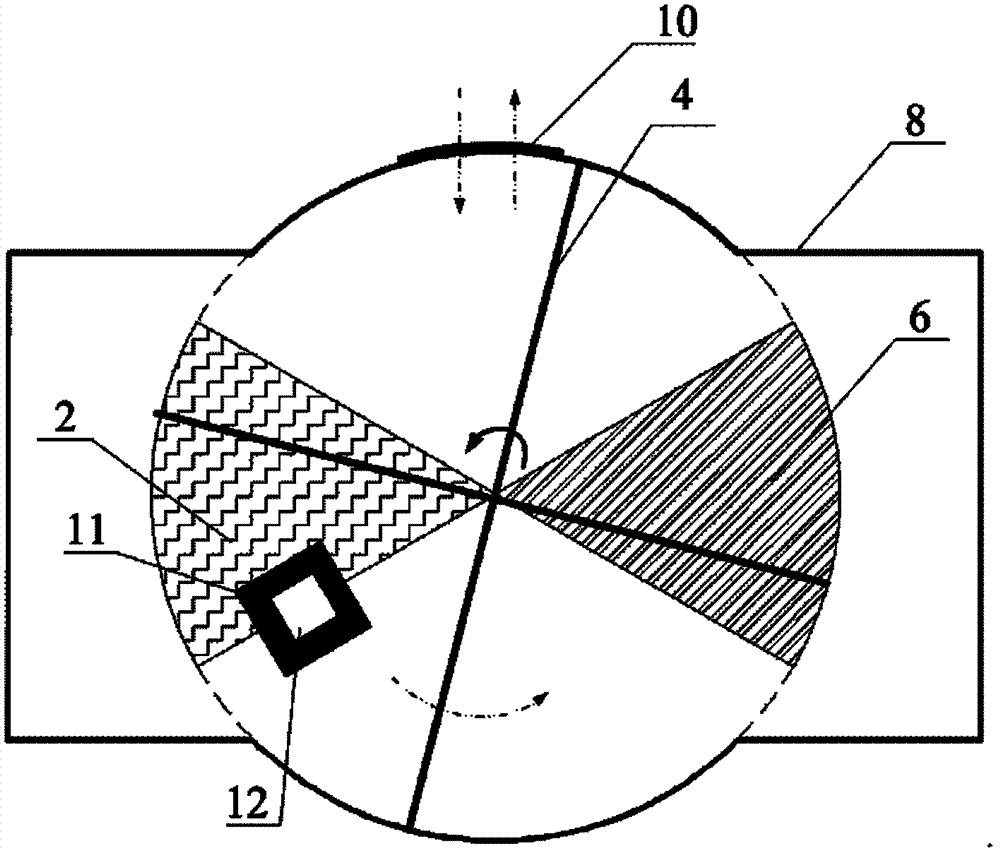

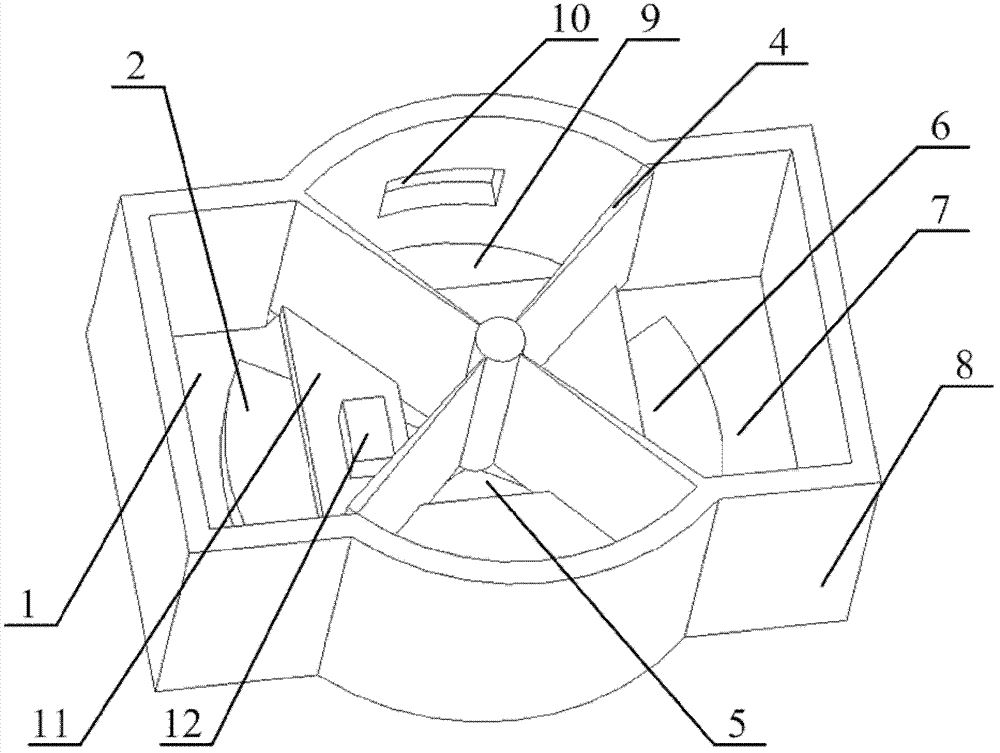

Equipment and method for efficiently welding chips of double-interface intelligent cards

ActiveCN104148834AImprove efficiencyIncrease productivityPrinted circuit assemblingWelding/cutting auxillary devicesSmart cardWork unit

The invention discloses equipment and a method for efficiently welding chips of double-interface intelligent cards. The equipment for efficiently welding the chips comprises a card transfer mechanism, a chip transportation mechanism, chip turnover mechanisms, an antenna correcting device, welding devices and a turntable. The card transfer mechanism is used for transferring each to-be-welded card to a card access station and fetching each welded card from the card access station, the chip transportation mechanism is used for transporting each chip to the card access station, the chip turnover mechanisms are used for turning the chips in horizontal states so that the chips can be in vertical states, the antenna correcting device is used for correcting the perpendicularity of the ends of each antenna, the welding devices are used for welding the ends of the antennas at corresponding welding spots of the chips, the turntable has an intermittent precision stopping function, a plurality of working units which are circumferentially and uniformly distributed are arranged on the turntable, and a card positioning mechanism and the corresponding chip turnover mechanism which can intermittently rotate along with the turntable are arranged in each working unit; working stations which are circumferentially and uniformly distributed are fixedly arranged at the outer periphery of the turntable, and the quantity of the working stations is identical to that of the working units. The equipment and the method have the advantages of high welding efficiency, good welding quality, convenience in use and maintenance and the like.

Owner:GUANGZHOU MINGSEN TECH CO LTD

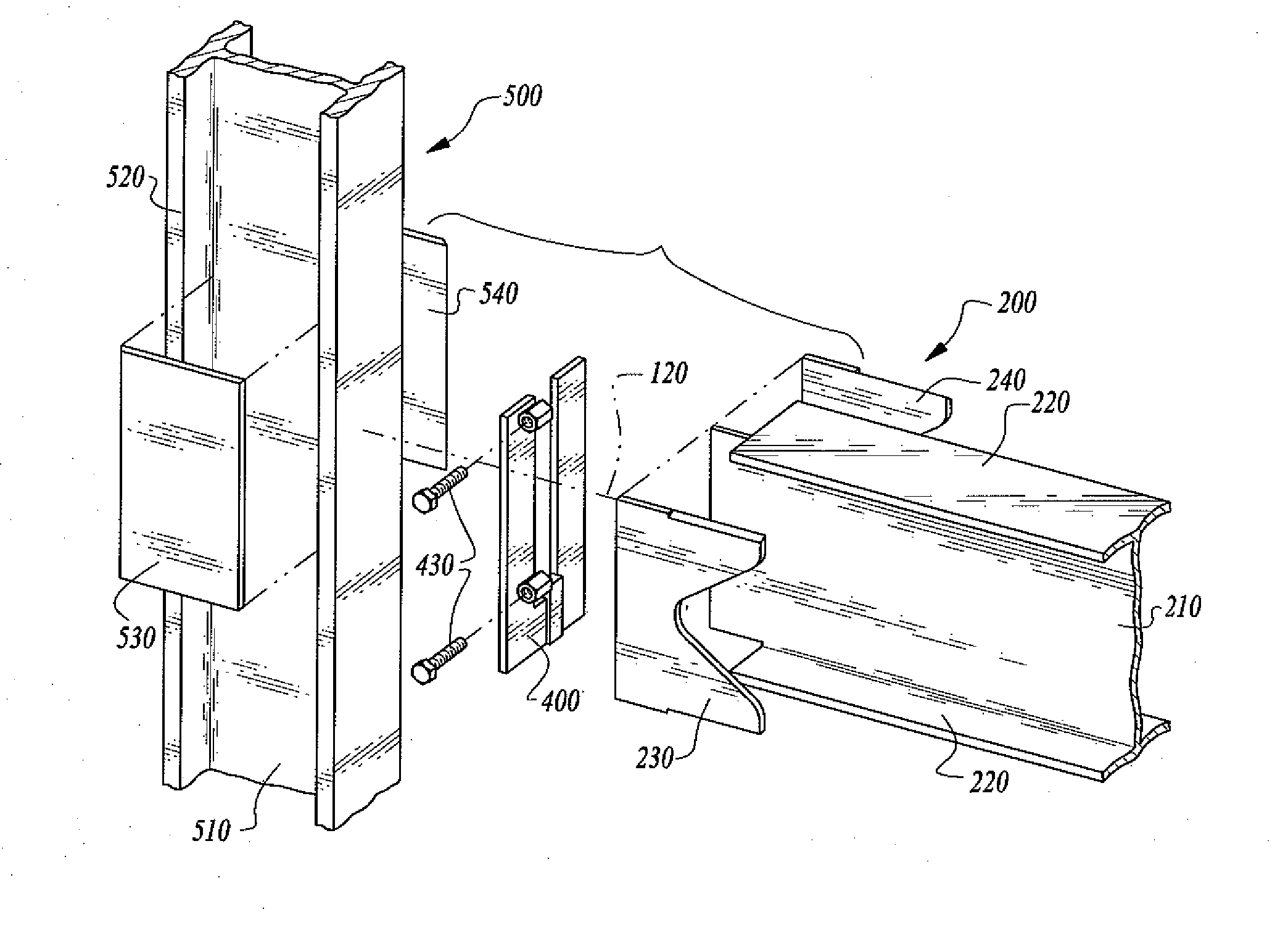

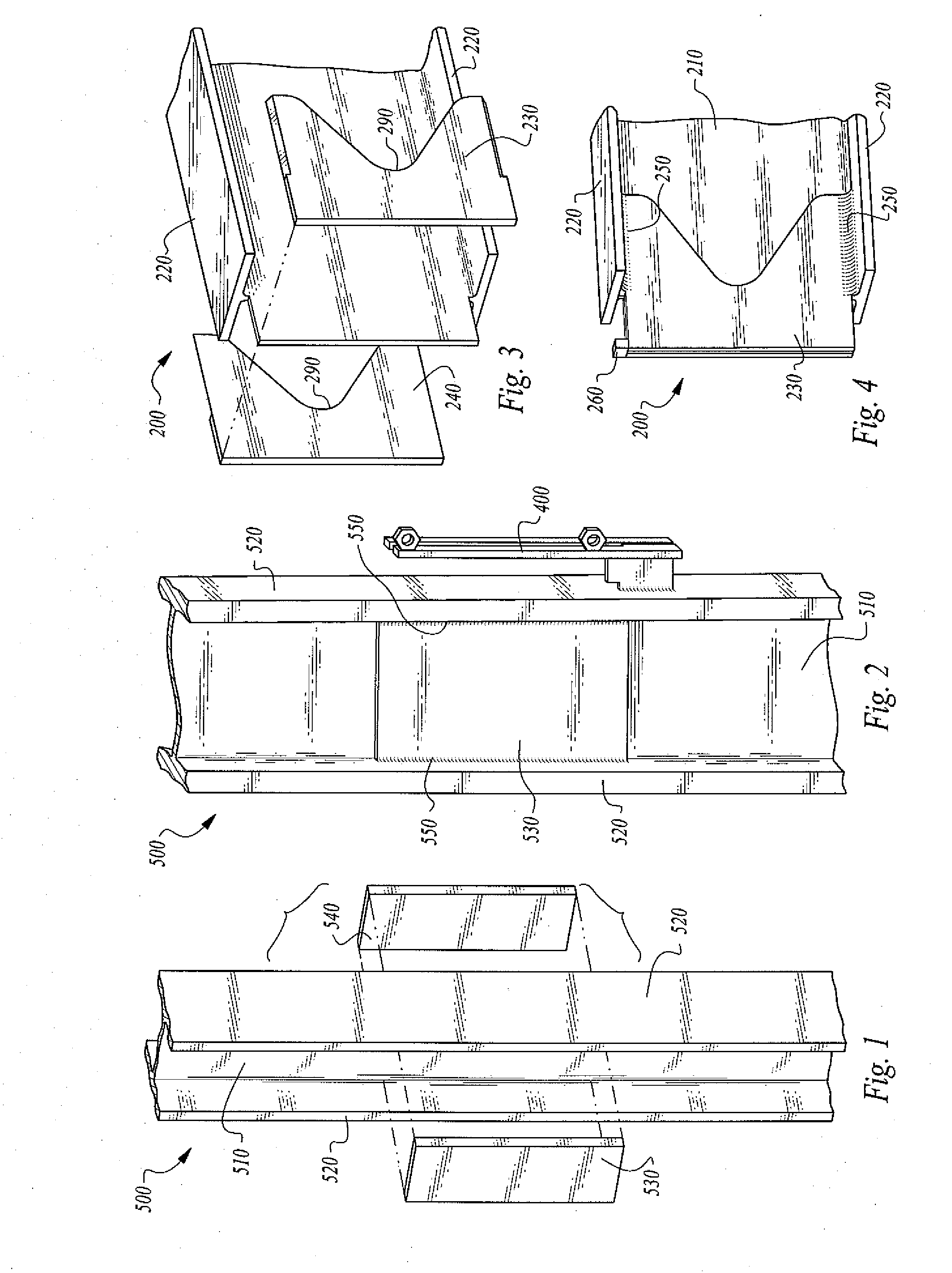

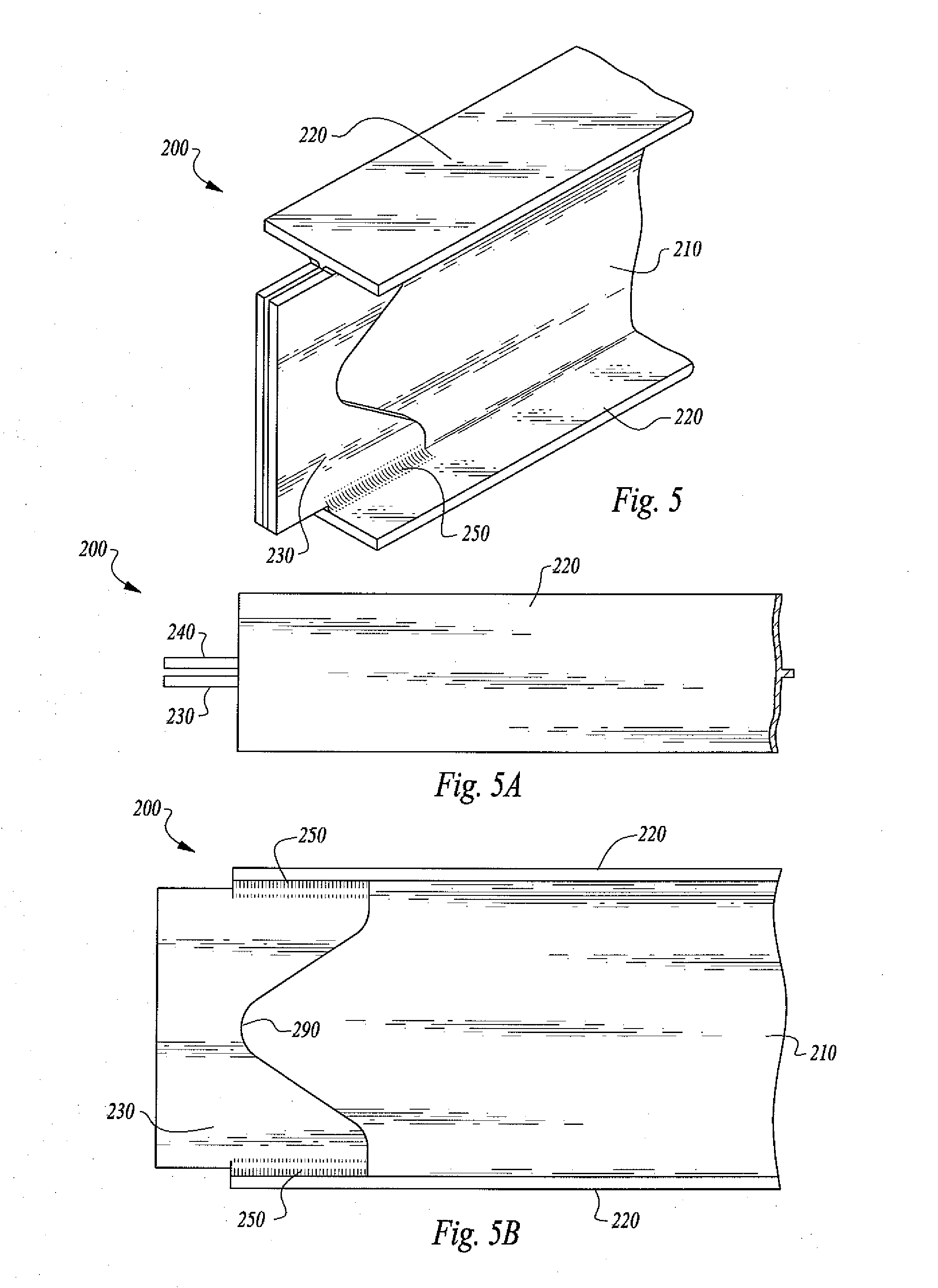

Assembly, system and method for automated vertical moment connection

InactiveUS20100205891A1Facilitate the speed of erecting a low-riseFirmly connectedLoad-supporting pillarsGirdersElectricityEngineering

An automated assembly, system and method for a narrow-gap Electroslag-welded moment connection welded between horizontal beam to vertical column flanges includes vertical column doubler plates affixed to the column web and horizontal beam doubler plates affixed to the beam web with alignment of the respective webs / doubler plates to carry the moment load through the vertical support columns. An embodiment includes a radius in each horizontal beam doubler plate. The assembly, system and method is readily applicable to overdesign moment load factors.

Owner:ESKANDARI AMIR

Method for fixing printed circuit board (PCB) with mark point location function

ActiveCN102974964ADoes not affect welding accuracyShorten welding timePrinted circuit assemblingWelding/cutting auxillary devicesProgramming processPrinted circuit board

Disclosed is a method for fixing a printed circuit board (PCB) with a mark point location function. The method is characterized by including the following steps: (1) firstly obtaining two mark point images on a reference PCB with a camera when programs are made, (2) obtaining two mark point images which are matched with two chosen mark point positions in the programming process and are on the detected PCB with the camera in the process of welding, and (3) comparing two groups of mark points which are captured in the step (1) and the step (2). If the two groups of the mark points are not out of position, the board position is normal, and if skewing exists, the PCB can be compensated. By the means of the method for fixing the PCB with the mark point location function, welding precision can not be influenced by the factors such as the size, the height and the skewing of the PCB, and simultaneously, welding time is deceased and welding speed is increased.

Owner:廖怀宝

Preparation method of super-thick alloy steel plate

ActiveCN103692166AShorten welding timeAvoid Crack SensitivityWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyWelding joint

The invention belongs to the technical field of metallurgy and particularly relates to a preparation method of a super-thick alloy steel plate. The preparation method comprises steps that surface treatment is performed on two alloy steel continuous casting slabs matched in length and width dimension; the alloy steel continuous casting slabs are overlapped on a steel feeding swing arm of a tilting gear and align to each other; the alloy steel continuous casting slabs are fed into a vacuum chamber and welded through a structure with two electronic guns; when carbon equivalent of the continuous casting slabs to be compounded is smaller than 0.3%, a front electronic gun begins to perform welding from ends of the alloy steel continuous casting slabs, and a rear electronic gun begins to perform welding from middles of the alloy steel continuous casting slabs; when carbon equivalent of the continuous casting slabs to be compounded is higher than or equal to 0.3%, the distance between the two electronic guns is shortened, an electron beam of the front electronic gun is regulated into a defocusing mode, the front electronic gun preheats welding joints, and the rear electronic gun performs welding soon afterwards; heating rolling is performed on the welded slabs to obtain the super-thick alloy steel plate. By means of the technical scheme, compound interfaces between the continuous casting slabs to be compounded completely align, and yield of the super-thick alloy steel plate is increased.

Owner:沈阳科安捷材料技术有限公司

Semi-automatic welding method of metal flux cored filler rod conduit root

ActiveCN101417364AQuality improvementReduce cleanup costsArc welding apparatusWorkpiece edge portionsShielding gasMetal powder

The invention relates to the technical field of welding of a long distance pipeline and is a semi-automatic welding method of root welding of a pipeline with metal powder core welding wire; the root welding layer welding is carried out as follows: the metal powder core welding wire and short arc control technology are adopted, protective gases are added to carry out welding of root welding bead of full position; the welding parameters are as follows: welding current is 140A to 200A; the welding voltage is 15V to 18V; the welding speed is 16cm / min to 26cm / min; the wire feed speed is 350cm / min to 500cm / min; the wire extension is 8mm to 12mm; and the pendulum deflection is based on that weld metal is deposited to the edge of a welding pipeline. The method solves the bottleneck problem of restraining the flow construction operation of the semi-automatic welding, effectively solves the problems of undercut, depression and the like of the back surface of welding seams of circular welding joints, reduces the cost of cleaning of the surface of welding pipelines, reduces the labor intensity of workers, increases the thickness of deposited metal, reduces the welding layers, greatly improves welding production efficiency, obtains high-quality welding seams and improves the welding speed, can reduce one third time of welding compared with manual welding and reduces the operation cost.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

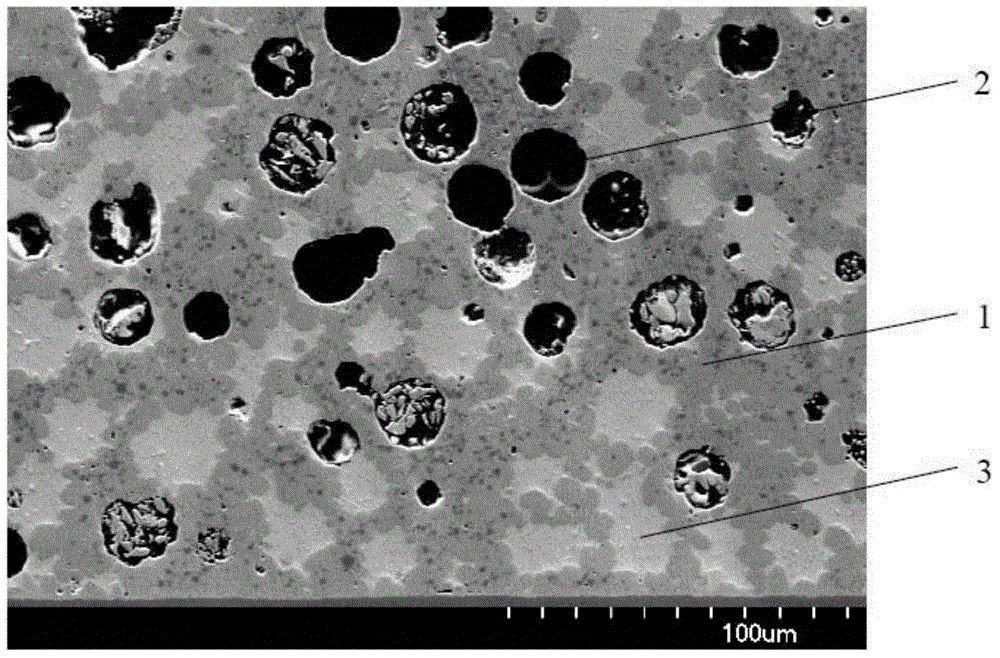

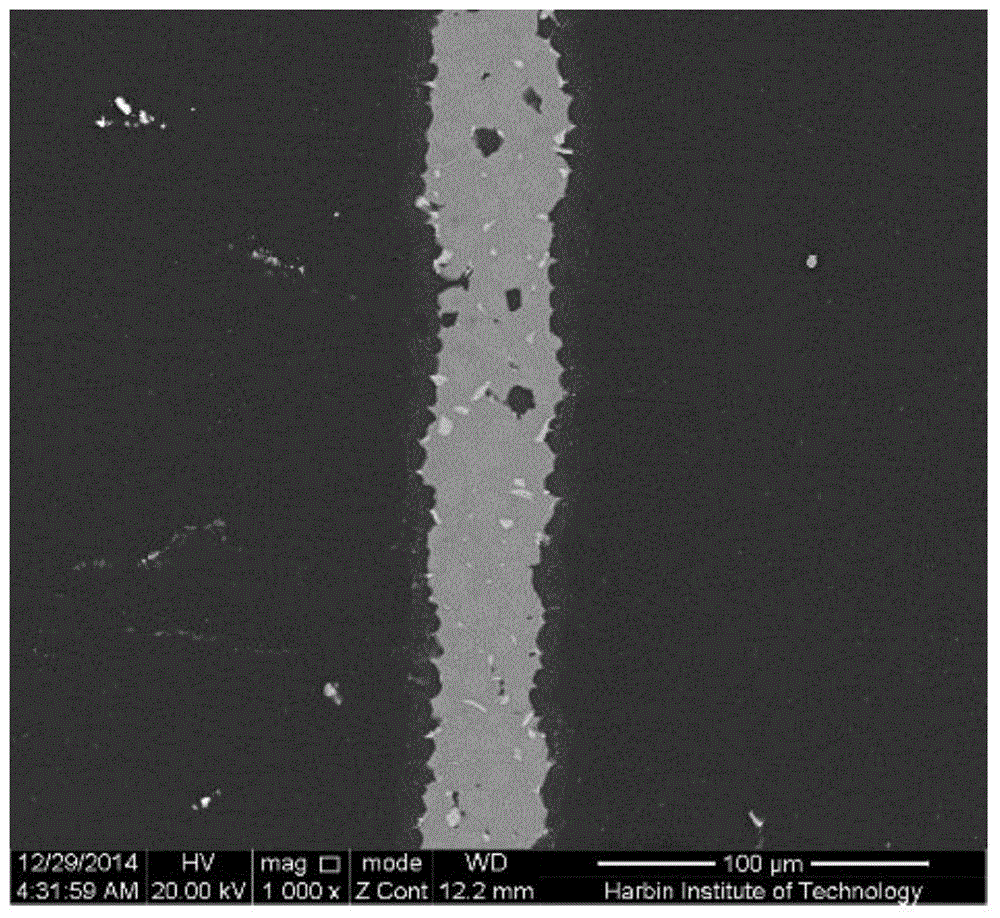

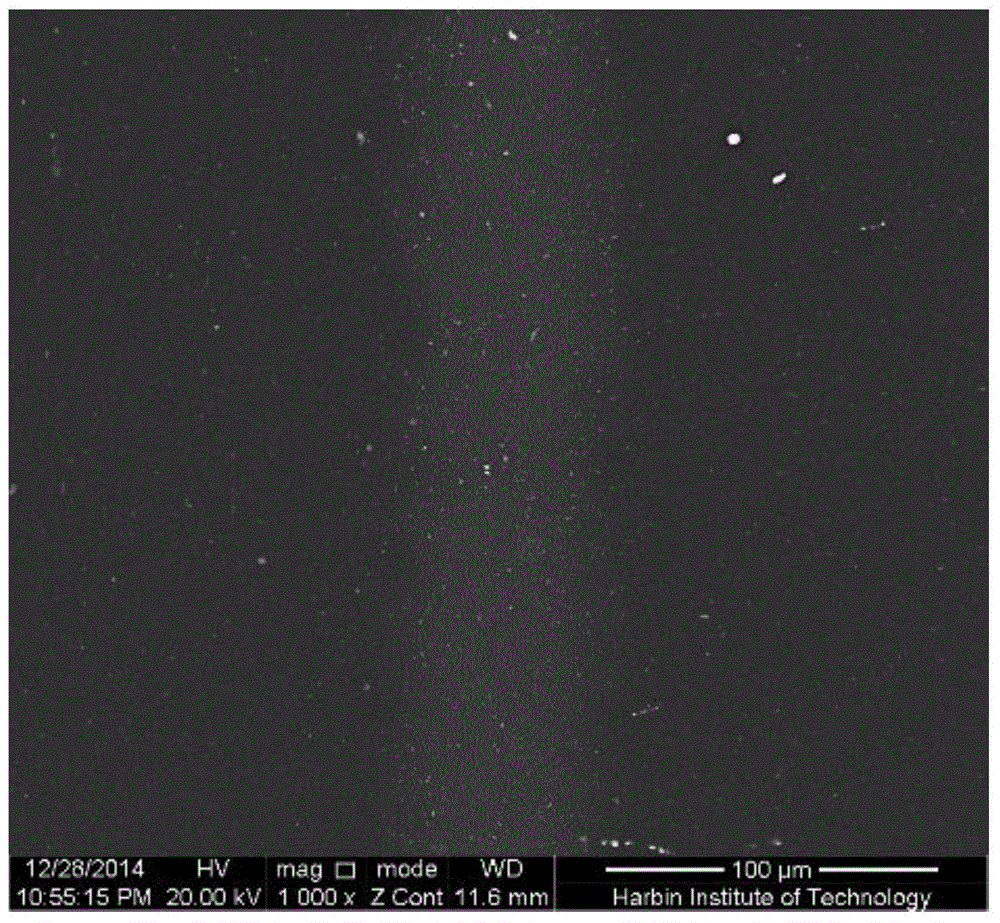

Tin-radical welding flux/copper particle composite welding flux capable of forming high-temperature welding spots rapidly at low temperature

ActiveCN104625466AImprove general performanceSimple preparation processWelding/cutting media/materialsSoldering mediaMicrometerInterconnection

The invention provides a tin-radical welding flux / copper particle composite welding flux capable of forming high-temperature welding spots rapidly at a low temperature. The tin-radical welding flux / copper-particle composite welding flux is composed of tin-radical welding flux powder, copper particle powder and welding paste, wherein the weight ratio of the tin-radical welding flux powder and the copper-particle powder lies between 5:2 and 2:3, the weight ratio of the remaining welding paste is 4%-20%, the particle size of the tin-radical welding flux powder is preferentially from 5 micrometers to 60 micrometers, and the particle size of the copper particle powder is from 0.1 micrometer to 10 micrometers. By means of the tin-radical welding flux / copper particle composite welding flux, the characteristics of a low melting point of the tin-radical welding flux and good wetting reaction of tin-copper are utilized, the high-melting intermetallic compound (IMC) interconnection welding spots can be formed within a short moment at the low temperature and without any pressure, and the tin-radical welding flux / copper particle composite welding flux is applicable to leading wire interconnection of electronic devices when a high temperature is caused during the service process or which performs the service at the high temperature. According to the tin-radical welding flux / copper particle composite welding flux capable of forming the high-temperature welding spots rapidly at the low temperature, the technology is simple, the cost is low, the practicability is great, and the problems of high cost, long welding time and high welding temperatures in existing chip packaging materials are solved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

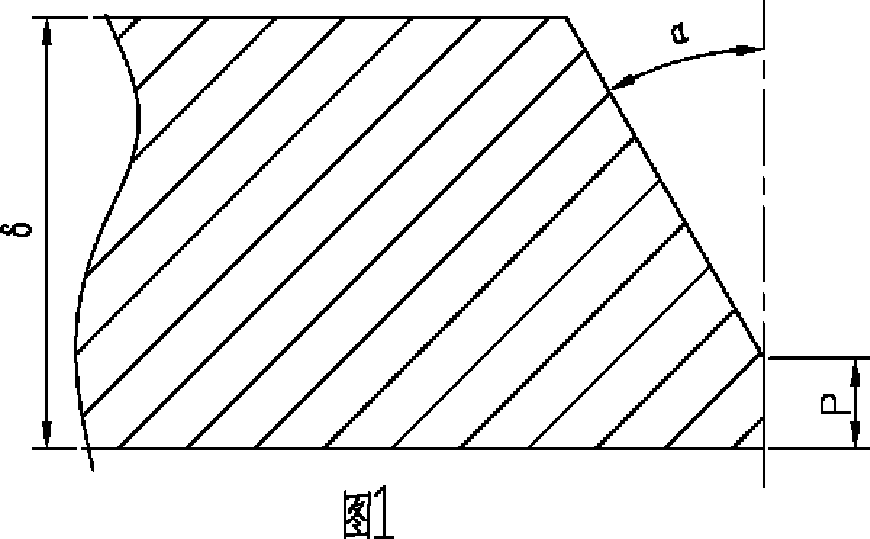

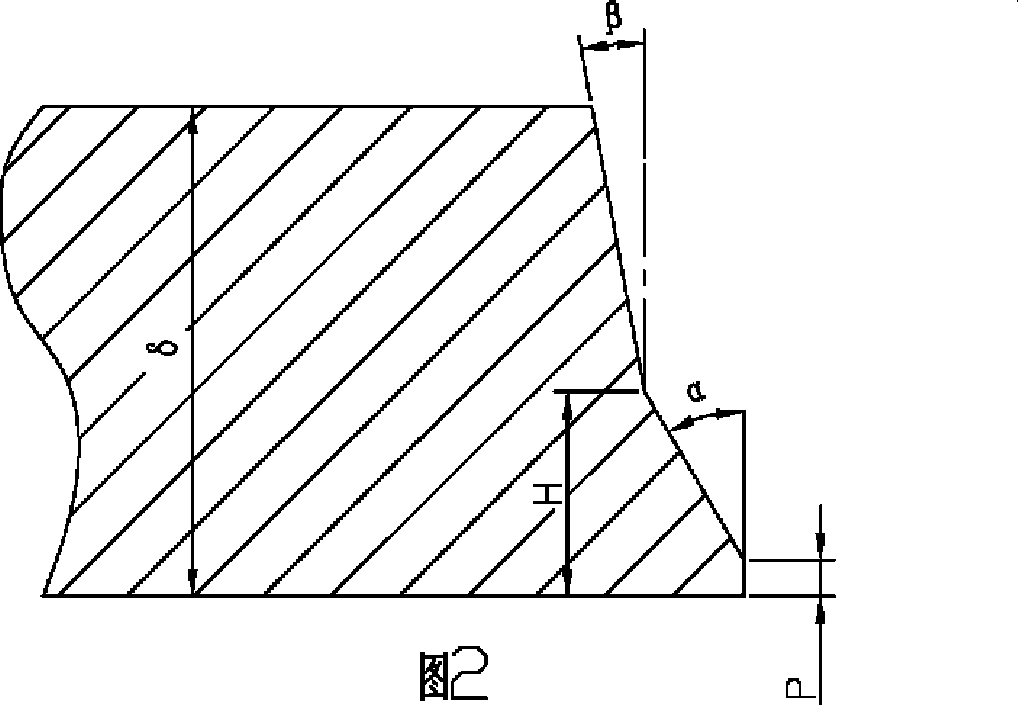

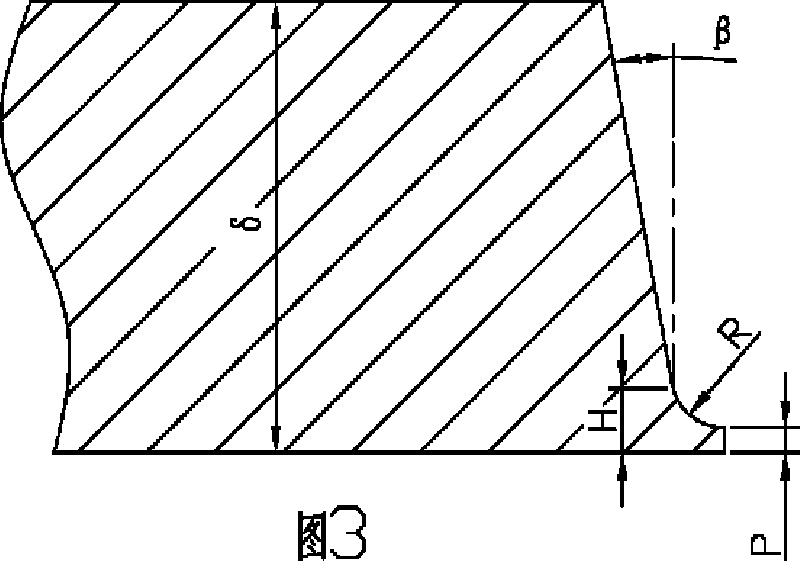

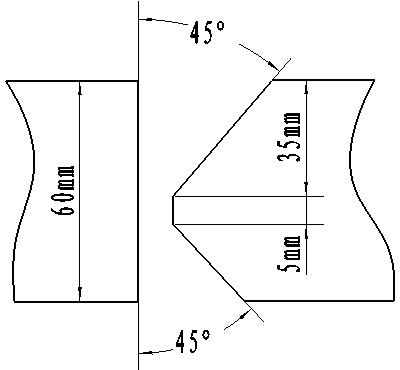

Submerged-arc welding root welding and back chipping process of thick plate with K-type groove

InactiveCN102554416AShorten welding auxiliary timeShorten welding timeArc welding apparatusThick plateSlag

The invention discloses a submerged-arc welding root welding and back chipping process of a thick plate with a K-type groove. The K-type groove is an asymmetric K-type groove, an upper open angle and a lower open angle of the groove are both 45 degrees to 50 degrees, and truncated edges are not reserved at the root. During assembly, groove clearance of 2mm to 3mm is reserved. During welding, solid gas protection welding wires under pulse current are adopted for backing welding of a root pass of the front side of a K-type groove test piece, and after the root pass is thoroughly fused, a part of weld metal penetrates through the reverse side of the groove to achieve backing welding. After welding, back chipping of the reverse side is performed. Finally, gas shielded welding under large current is adopted for fusion welding of the roof of the reverse side groove, and gas rich in argon is used as protective gas. The submerged-arc welding root welding and back chipping process reduces time for slag removal of root pass of submerged-arc welding and polishing and finishing of the reverse side groove of the welding test piece, improves welding efficiency by more than 30%, removes a carbon arc gouging process, decreases welding noises and dust emission, lowers labor intensity of welders and reduces time for damaging workers under high-decibel noises.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

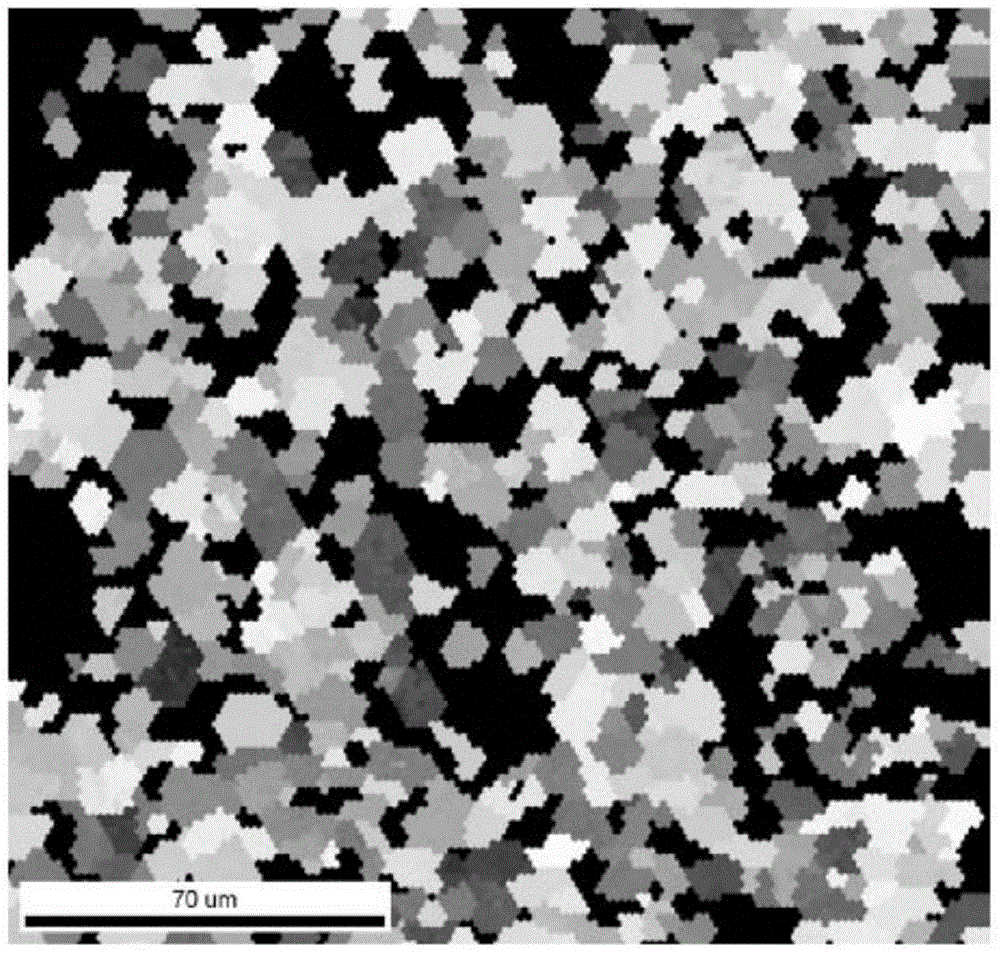

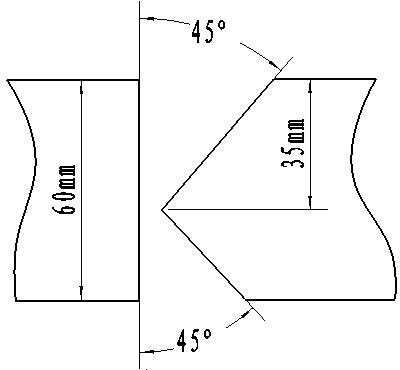

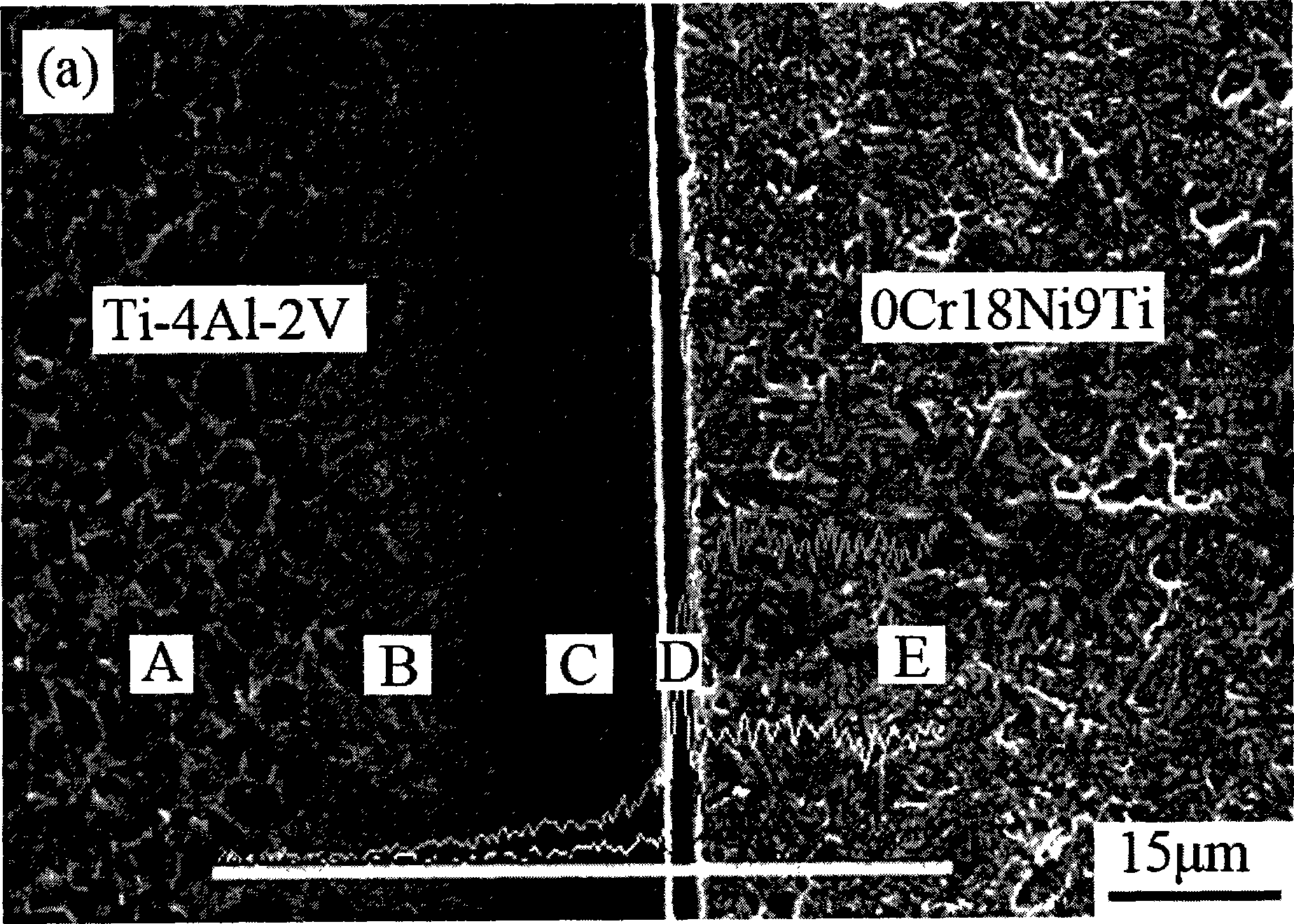

Self-nano-structure diffusion welding technique for titanium alloy and stainless steel surface

InactiveCN101244483AIncrease the diffusion coefficientImprove mechanical propertiesPolishing machinesNon-electric welding apparatusNano structuringTitanium alloy

The invention discloses a titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft; wherein, the same diameter titanium alloy and stainless steel rod are selected; the surface self-nanocrystallization of the end face of the welding terminal is processed; the constant temperature and constant pressure diffusion welding or the impact pressurizing diffusion welding are processed. The titanium alloy and stainless steel surface self-nanocrystallization diffusion welding craft has the advantages of raising the diffusion coefficient of the titanium alloy and stainless steel in the process of diffusion welding, shortening the welding time, raising the welding efficiency, reducing the thickness of intermetallic compounds layer, refining the joint crystalline grain, and raising the mechanical property of the diffusion welding joint of titanium alloy and stainless steel.

Owner:CHONGQING UNIV

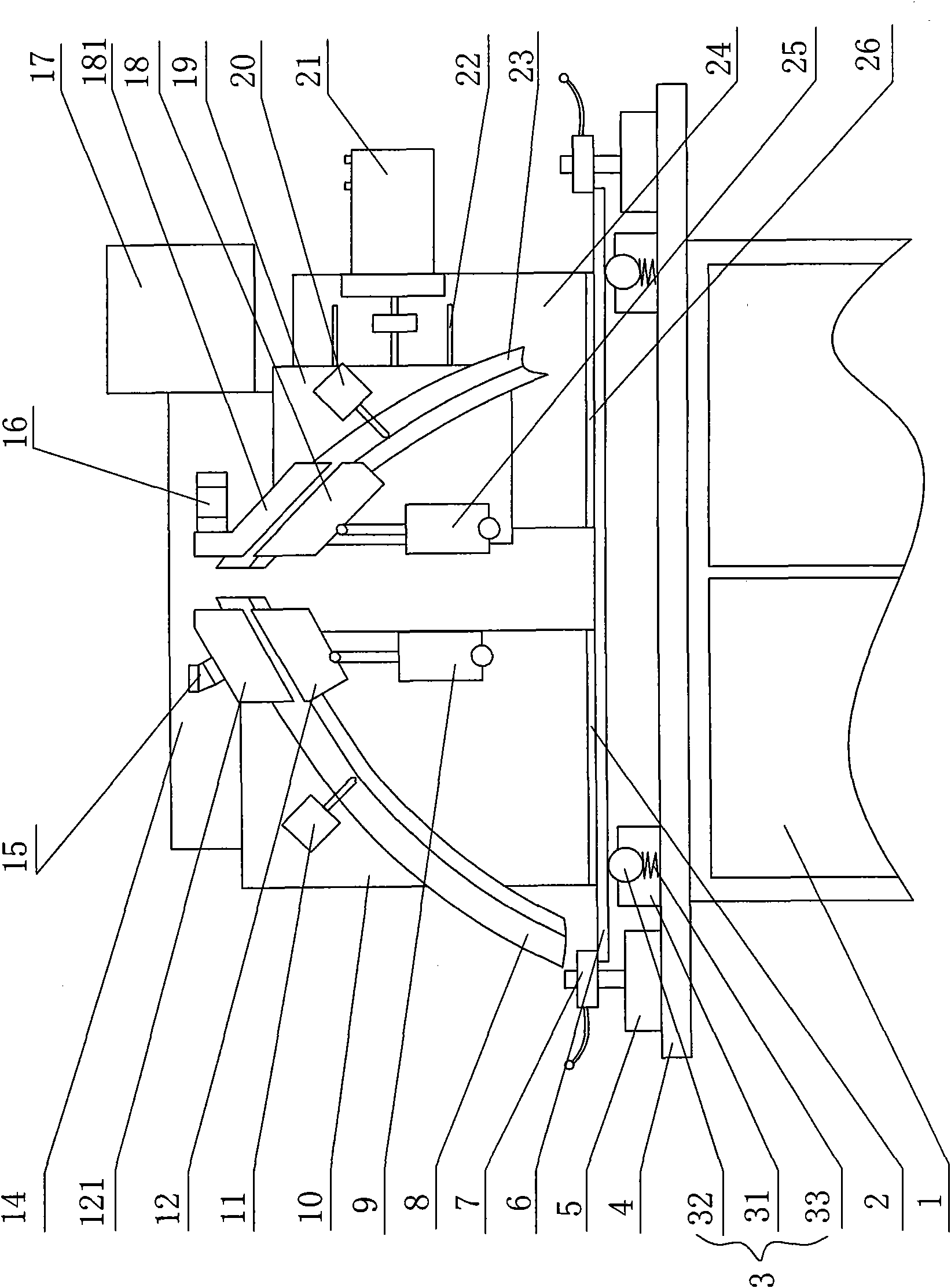

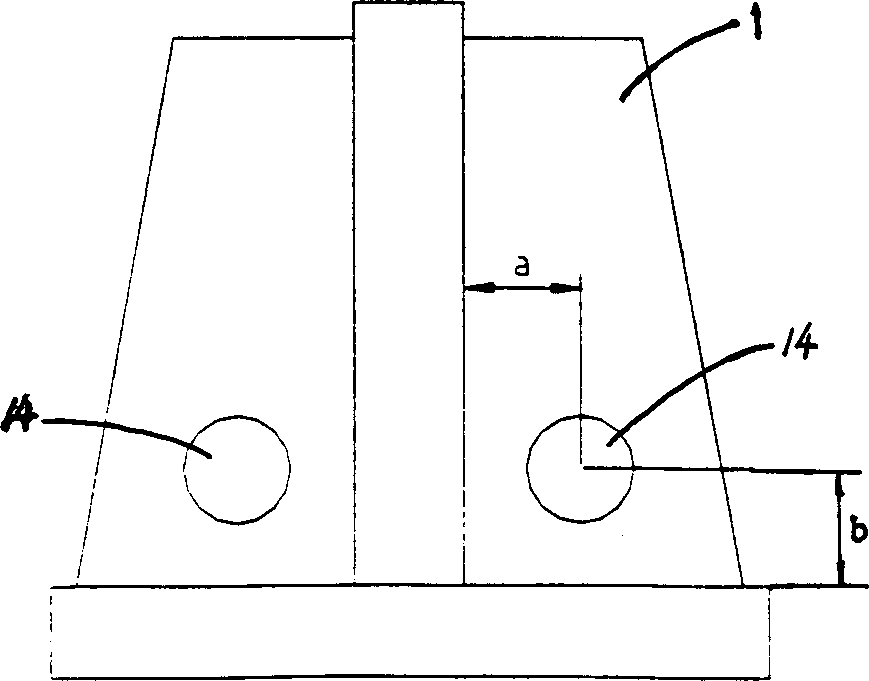

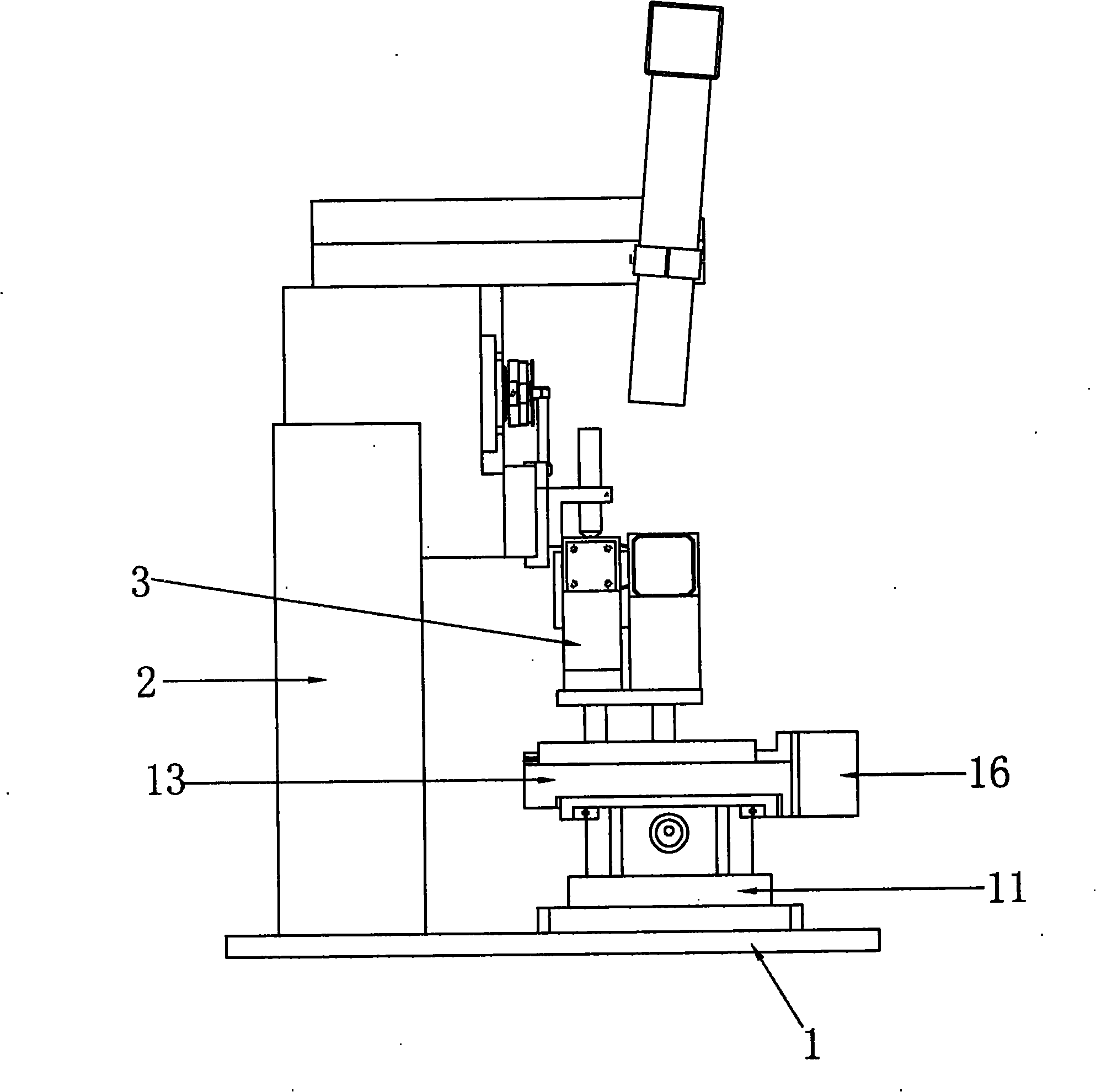

Flash butt welding machine for vehicle door corner welding

ActiveCN101979208AEffortless pushLabor-saving operationResistance welding apparatusButt weldingServo drive

The invention discloses a flash butt welding machine for vehicle door corner welding, which comprises a base, clamping devices, an upsetting mechanism and an electric controller, wherein the clamping devices comprise a first clamping device for clamping a right welding piece and a second clamping device for clamping a left welding piece. The flash butt welding machine is characterized by also comprising a clamp adjusting device and an adjusting bottom plate capable of moving freely in a space, wherein the second clamping device is fixedly arranged on the adjusting bottom plate; an upsetting device comprises a guide rail seat, a moving component slipping along the guide rail seat and a servo driving device for driving the moving component to move; the first clamping device is fixedly arranged on the moving component; and a first insulating plate is arranged between the bottom of the clamp adjusting device and the base, and a second insulating plate is arranged between the bottom of theguide rail seat and the base. Compared with the prior art, the flash butt welding machine can randomly adjust the space placing position of the welding piece to ensure the welding quality and the appearance and profile requirements of a welded product; and the clamp adjusting device is convenient and simple in operation, and improves the welding efficiency.

Owner:NINGBO XINTAI MACHINERY

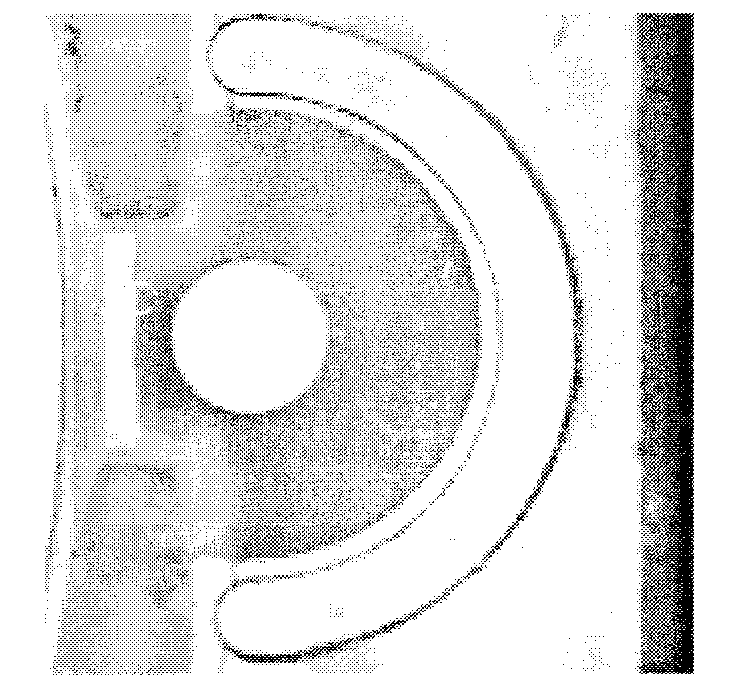

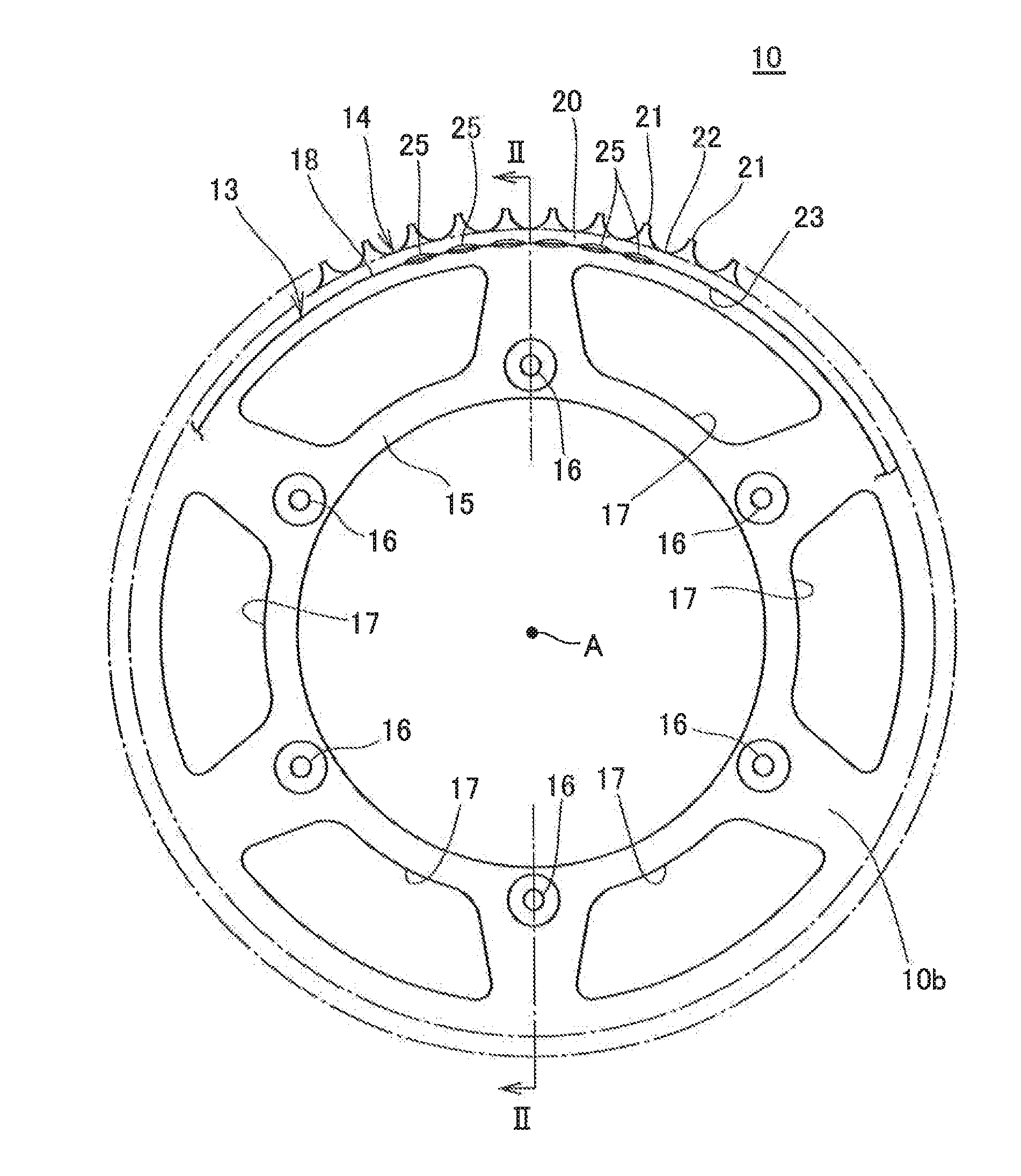

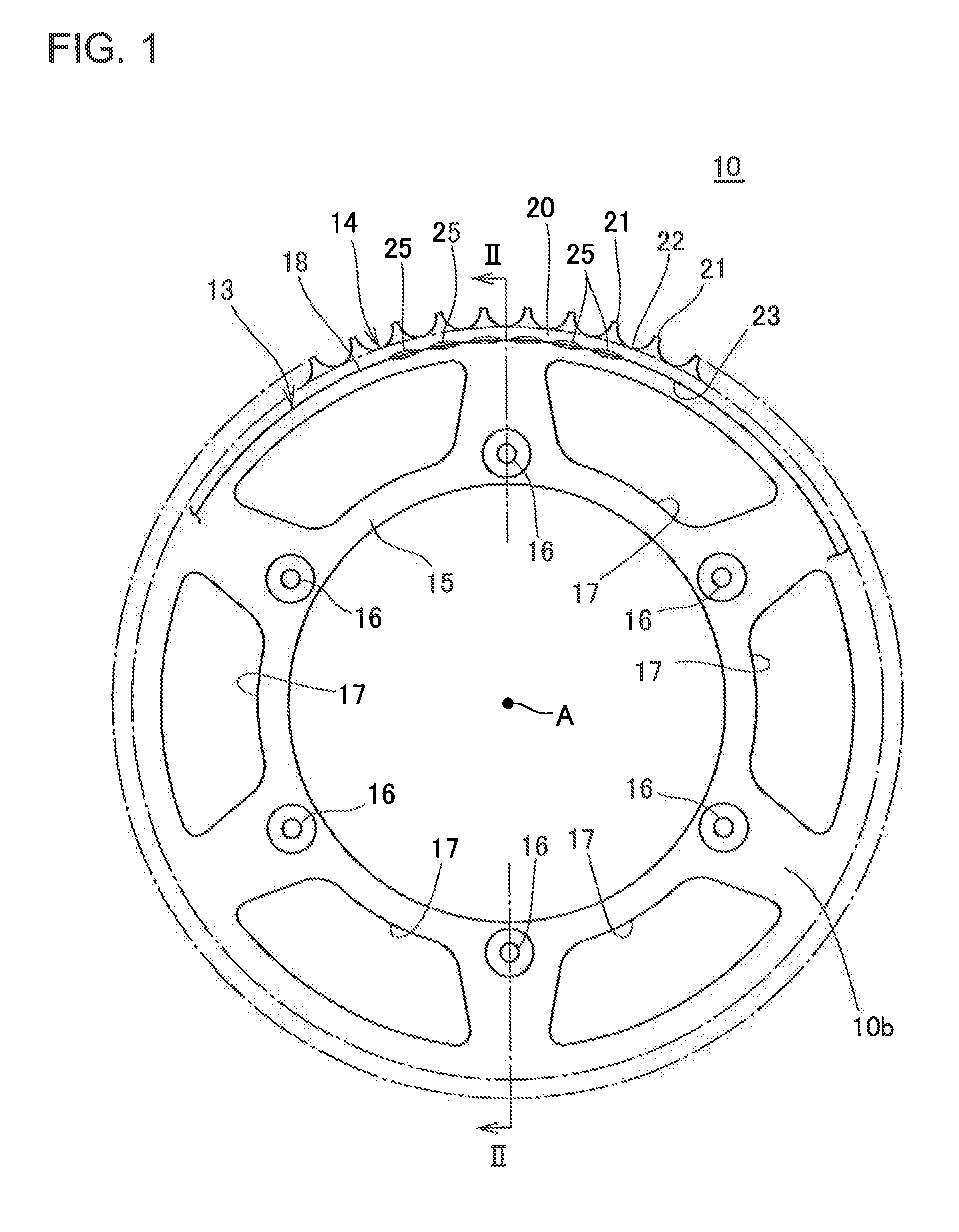

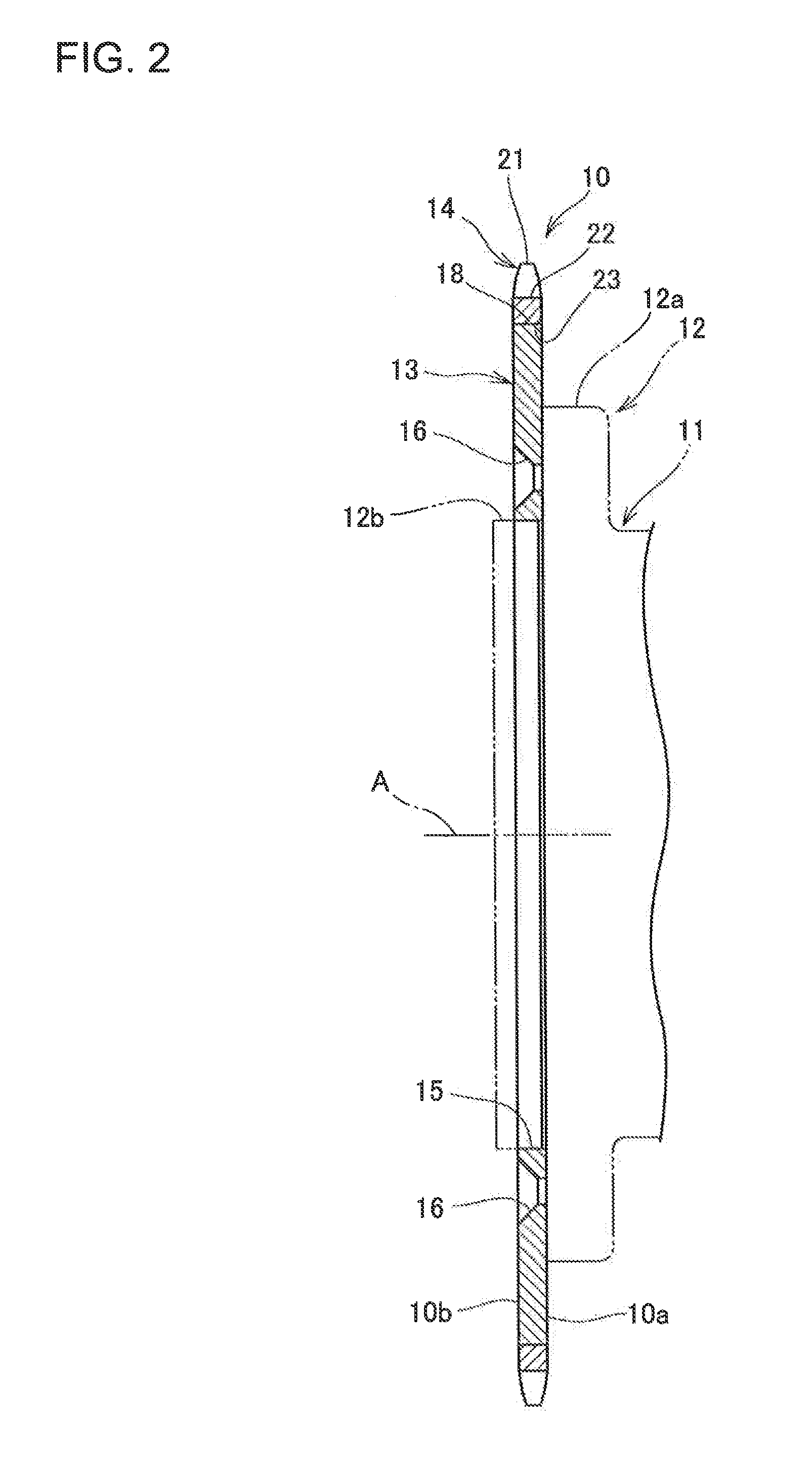

Bi-metallic sprocket, and method of making same

ActiveUS20150211623A1Reduce weightHigh bonding strengthPortable liftingElectron beam welding apparatusEngineeringSprocket

A sprocket assembly, formed of dissimilar materials, includes at least one tooth member made of ferrous material and a circular disk made of a light metal such as aluminum or an aluminum alloy. The circular disk supports the tooth member on an outer peripheral surface thereof. The tooth member is dissimilar-metal welded to the circular disk, either by laser welding or by electronic beam welding. Optionally, multiple individual tooth members may be fitted into notches formed in an outer periphery of the circular disk, and welded therein. A method of making a sprocket assembly is also described.

Owner:HONDA MOTOR CO LTD

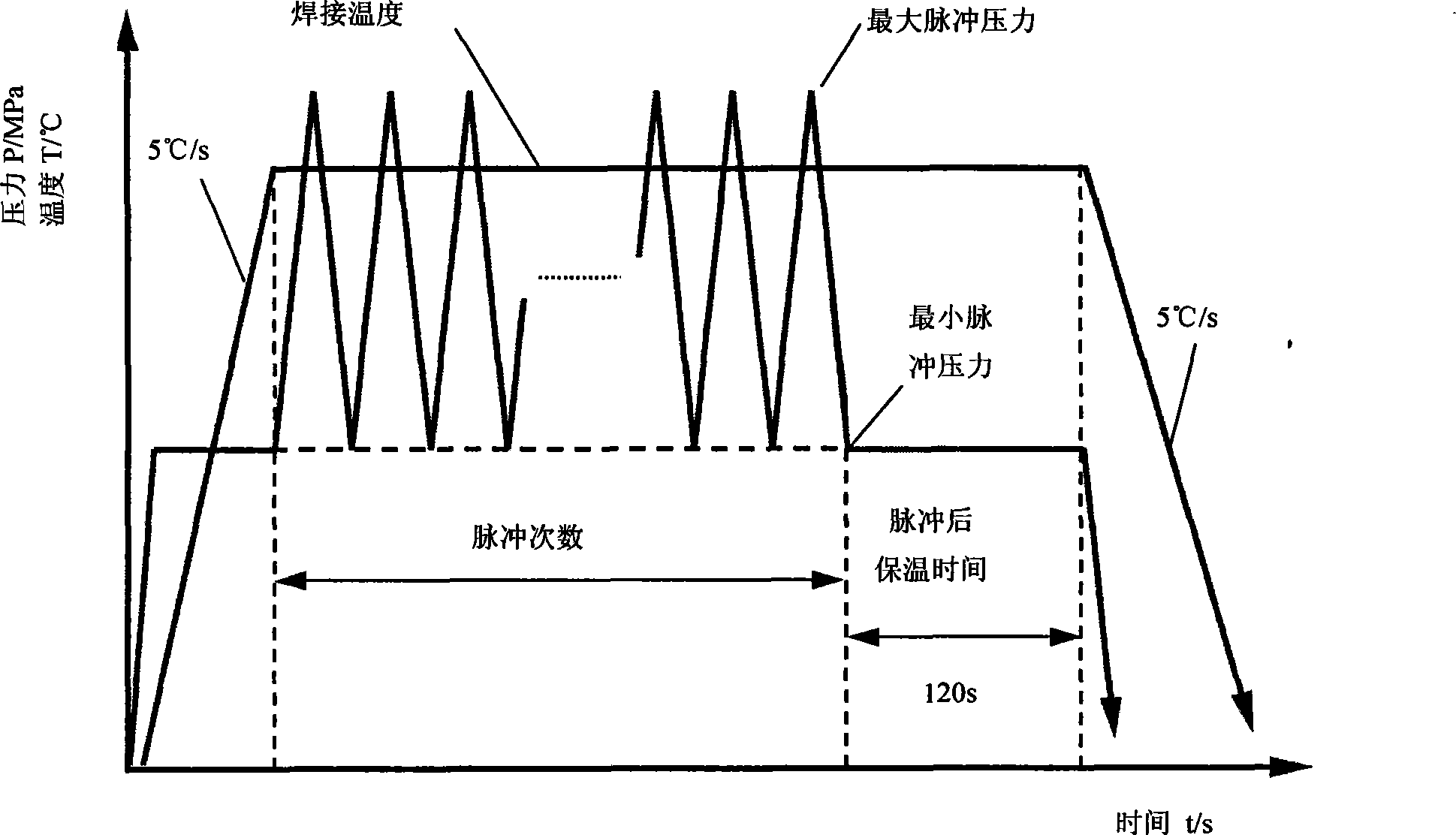

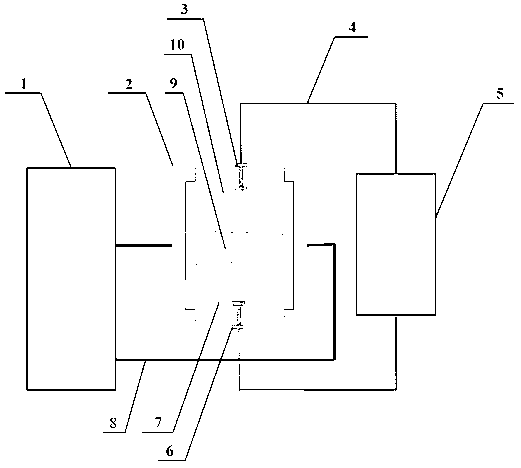

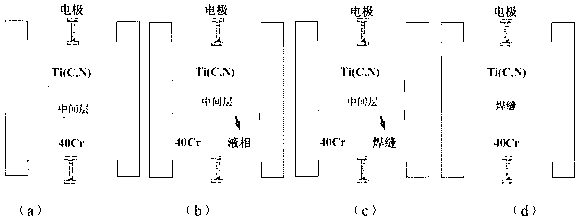

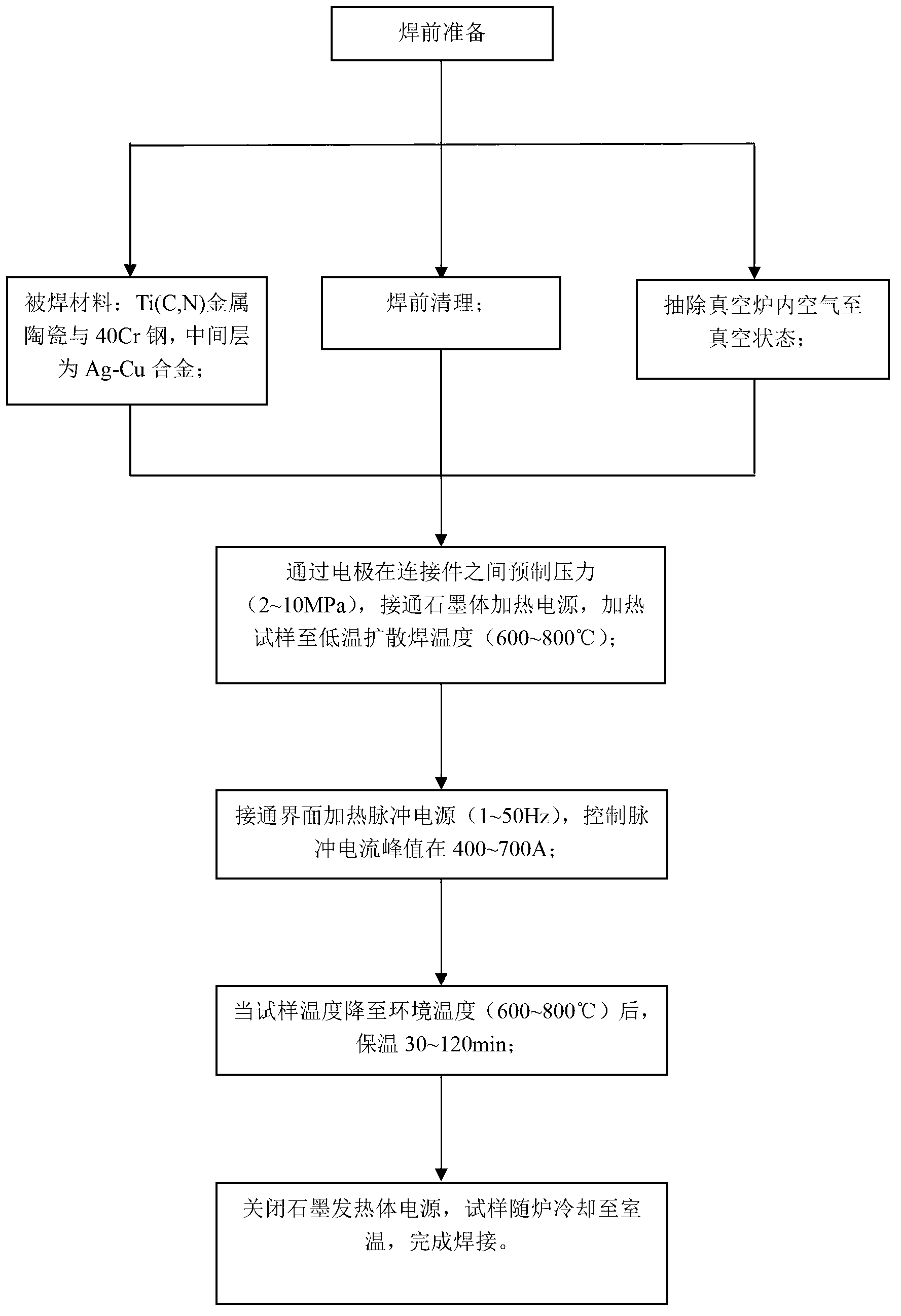

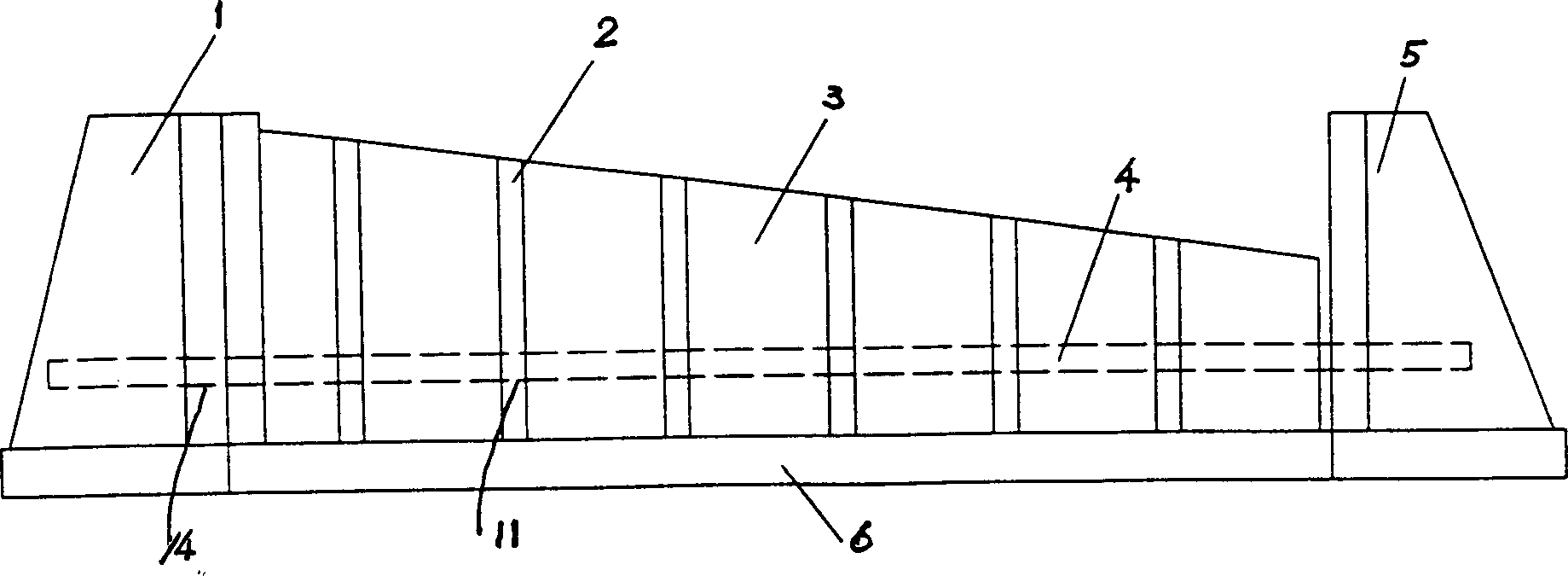

Low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating

ActiveCN102699520APromote fragmentationLow machining accuracy requirementsNon-electric welding apparatusRadiant heatPulse power supply

The invention discloses a low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating. The device comprises a graphite body heating power supply, a graphite body, electrodes, an interface heating pulse power supply and a sample. According to the method, graphite body radiant heat is mainly used, welding interface contact resistance heat and discharge heat are used as accessory, an original liquid phase is formed by the resistance heat and discharge heat which are formed at an interface to be connected by the pulse current, and diffusion welding is realized by virtue of less externally-applied extrusion force. The device and the method can be used for reducing the residual stress, obviously shortening the welding time, requiring smaller applied pressure and preventing workpieces from being subjected to serious deformation in a pressurization direction, are conductive to crushing oxidation films on the surfaces of materials and simultaneously can be used for reducing the material surface processing precision requirement; and the device disclosed by the invention is simple in process, smart in design and convenient in use, and can be widely applied to the diffusion welding of various nonmetals and metals.

Owner:JIANGSU UNIV OF SCI & TECH

Low-speed diesel engine frame welding method

InactiveCN1405482ASolving Concentricity ProblemsSolve the deformationMachine framesWelding apparatusLow speedEngineering

A method for welding the frame of a low speed diesel engine. It includes the following steps: 1) By passing locating iron pipes through the screw holes in small iron plates, a number of small iron paltes are located between two bed-jigs according to the requirements of design, and spot welded on a guide plate and a triangle plate to form guide plate components. 2) The bilateral symmetric and located guide plate components are put symmetrically side by side and located by butt strap welding. 3) The welded and located bilateral guide plate component are welded in symmetry. 4) After welding, butt straps are removed, and the bila-teral guide plate components are separated. 5) with the help of the bed-jig, the bilateral guide plate components and a division plate are located on a cast-iron platform.

Owner:HUDONG HEAVY MACHINERY +1

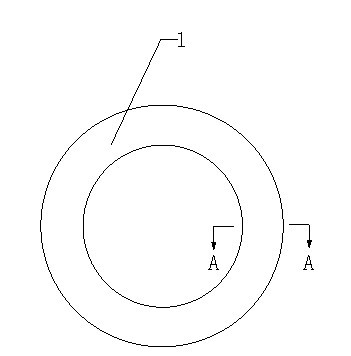

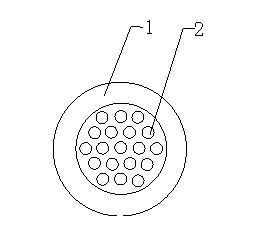

Brazing aluminium soldering ring for welding aluminum or aluminum alloy product and manufacture method of brazing aluminium soldering ring

InactiveCN102658439ASmall activation temperature rangeImprove wettabilityWelding/cutting media/materialsSoldering mediaSilicon alloyHazardous substance

The invention discloses a welding device, and in particular relates to a brazing aluminium soldering ring for welding an aluminum or aluminum alloy product and a manufacture method of the brazing aluminium soldering ring. The brazing aluminium soldering ring comprises an annular brazing aluminium soldering ring housing, wherein aluminum-silicon alloy wires are arranged in the brazing aluminium soldering ring housing, alloy powder is filled among the aluminum-silicon alloy wires, the brazing aluminium soldering ring housing and the aluminum-silicon alloy wires respectively comprise the following chemical components in percent by weight: not more than 3 percent of Si, not more than 20 percent of Cu, not more than 98 percent of Zn, not more than 0.01 percent of Mn, not more than 5 percent of Ag, not more than 3 percent of Ni and the balance of Al; and the alloy powder comprises eutectics of KAlF4 and K3AlF6 or eutectics of KAlF4 and K3AlF6 and silicon powder and accounts for 15-30 percent of the total weight of the brazing aluminium soldering ring. The brazing aluminium soldering ring has the advantages of being small in activating temperature range of a brazing agent, improving wettability and flowability of brazing materials, saving soldering time, being free of cleaning after welding, according with the requirement of ROHS (Restriction of the use of certain Hazardous Substances) environment protection, and being excellent in anti-corrosion property, high in heat conduction and electricity conduction properties and excellent in processability.

Owner:LICHUANG TAISHAN ELECTRONICS TECH

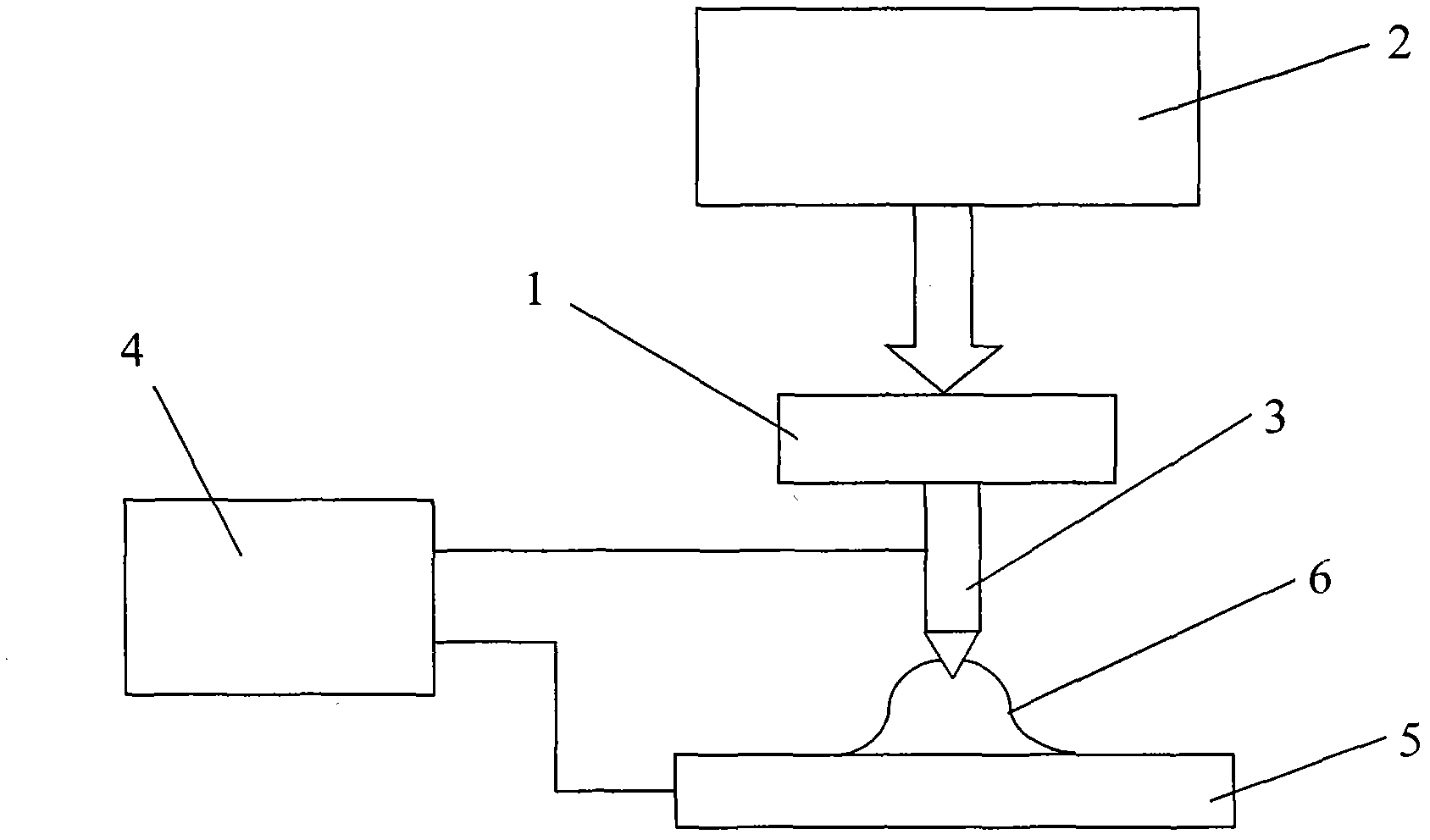

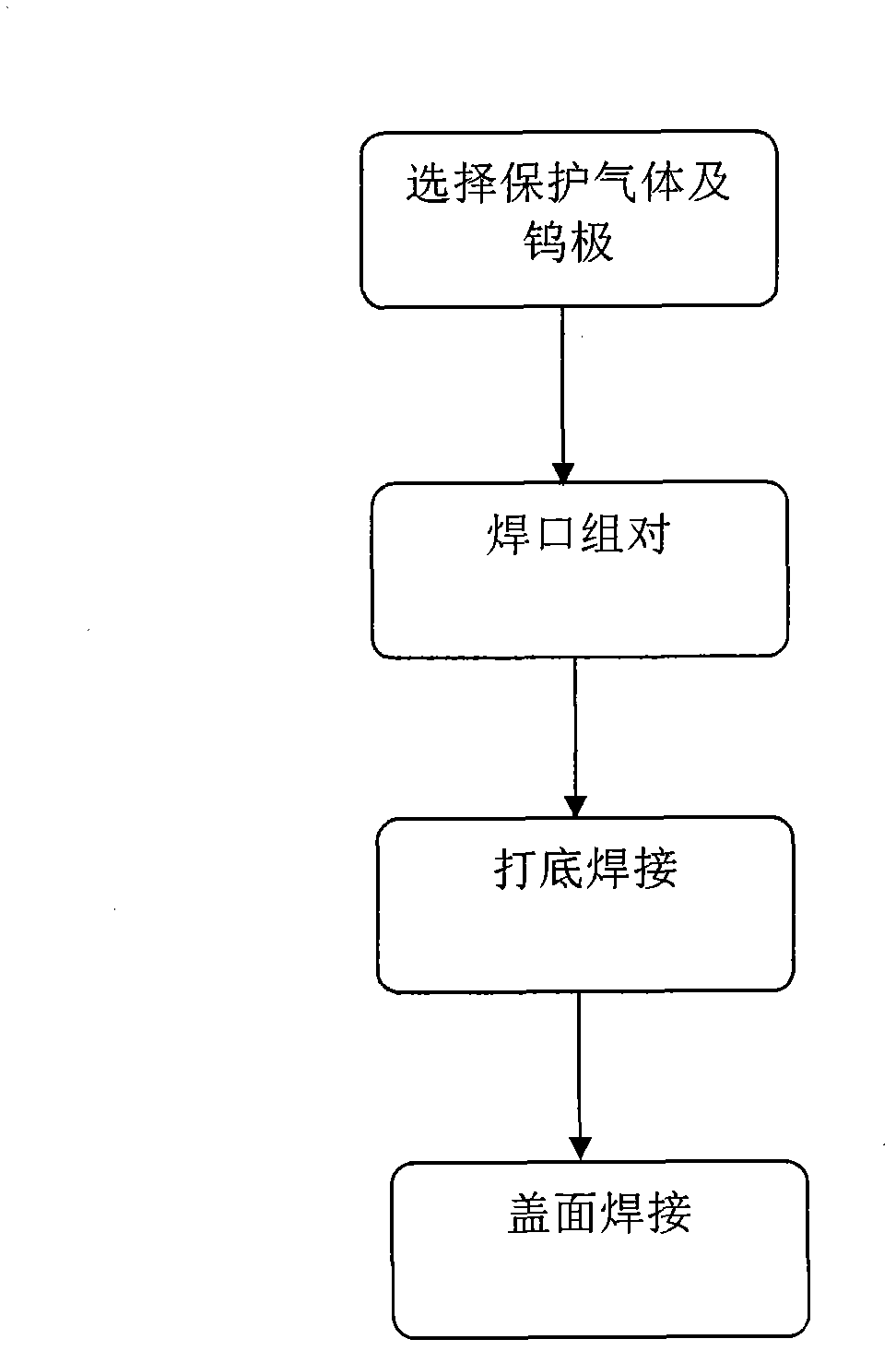

Method for welding cut surface butt joint formed by thin welding base materials

ActiveCN102699545AReduce process stepsReduce consumptionArc welding apparatusSignal onFilling materials

The invention relates to a method for a welding cut surface joint formed by assembling cut surface ports, in particular to a method for welding a cut surface butt joint formed by thin welding base materials in nuclear power engineering, and aims to solve the problems that the machining period of tubes and welding period are relatively long, the welding cost is high, and part of the materials are not completely welded in the prior art. According to the method, the thickness of each welding base material is less than or equal to 6.0mm. The method comprises the following steps of: selecting protective gas and a tungsten electrode; assembling craters; overlapping an ultrasonic electrical signal on pulse welding current to generate a stable ultrasonic- tungsten inert gas (TIG) combined weld electric arc by taking ultrasonic waves and TIG combined electric arc welding machine as a welding power supply of automatic welding equipment, and performing backing welding on the surface butt joints without feeding wires; performing cosmetic welding, and finishing welding. By the welding method, the processing step of forming a groove is eliminated, so that the welding workload, the consumption of welding filling materials and the welding cost are reduced, and the welding efficiency is improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

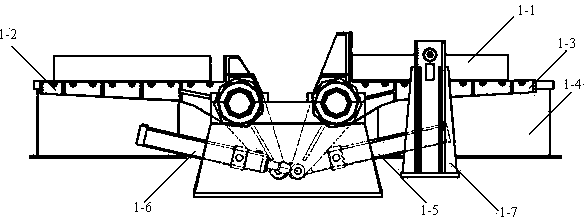

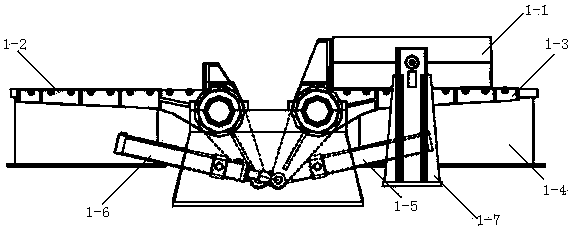

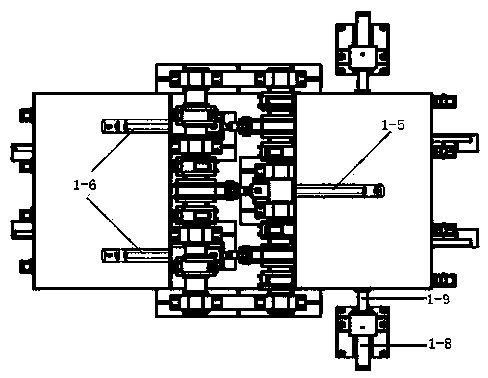

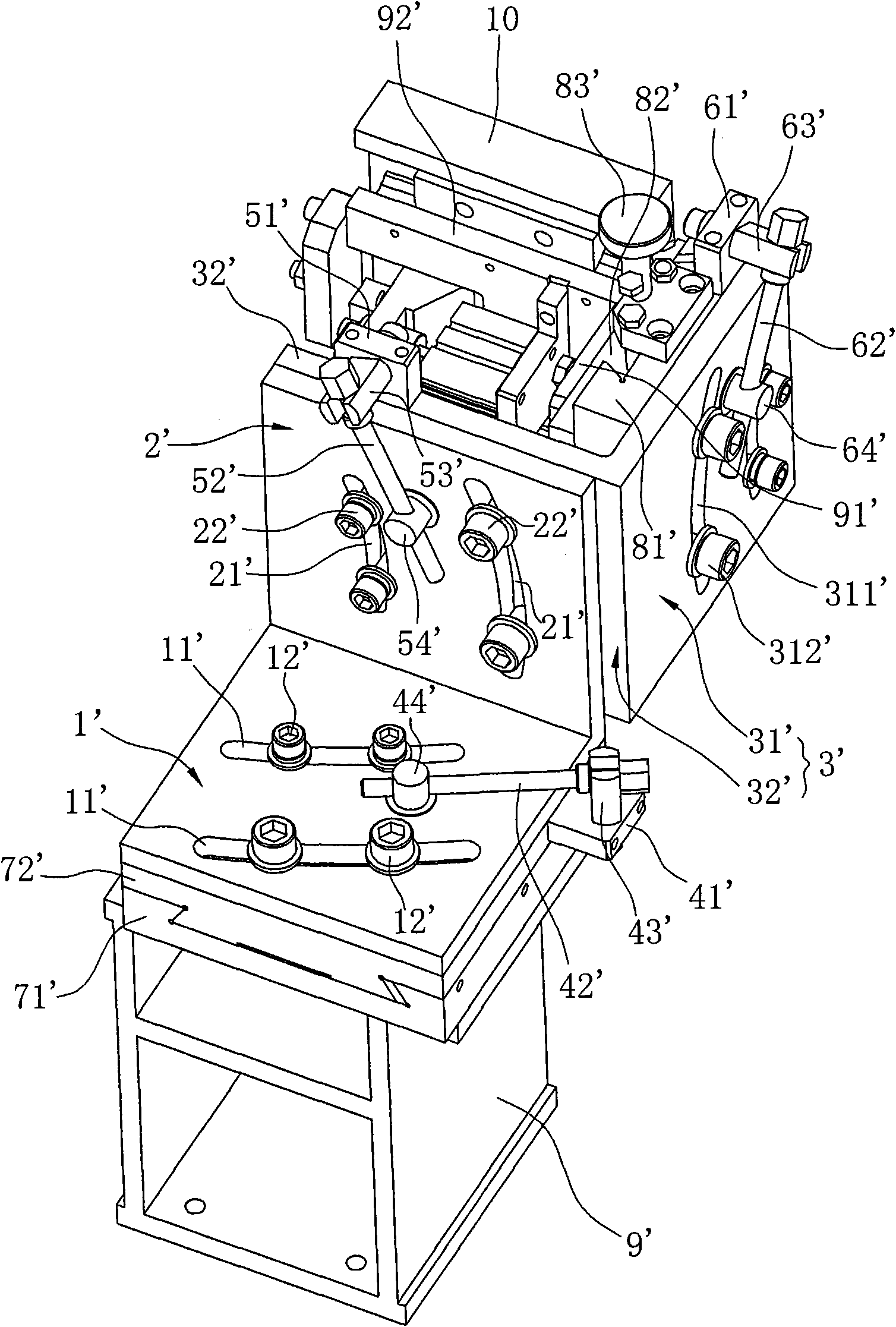

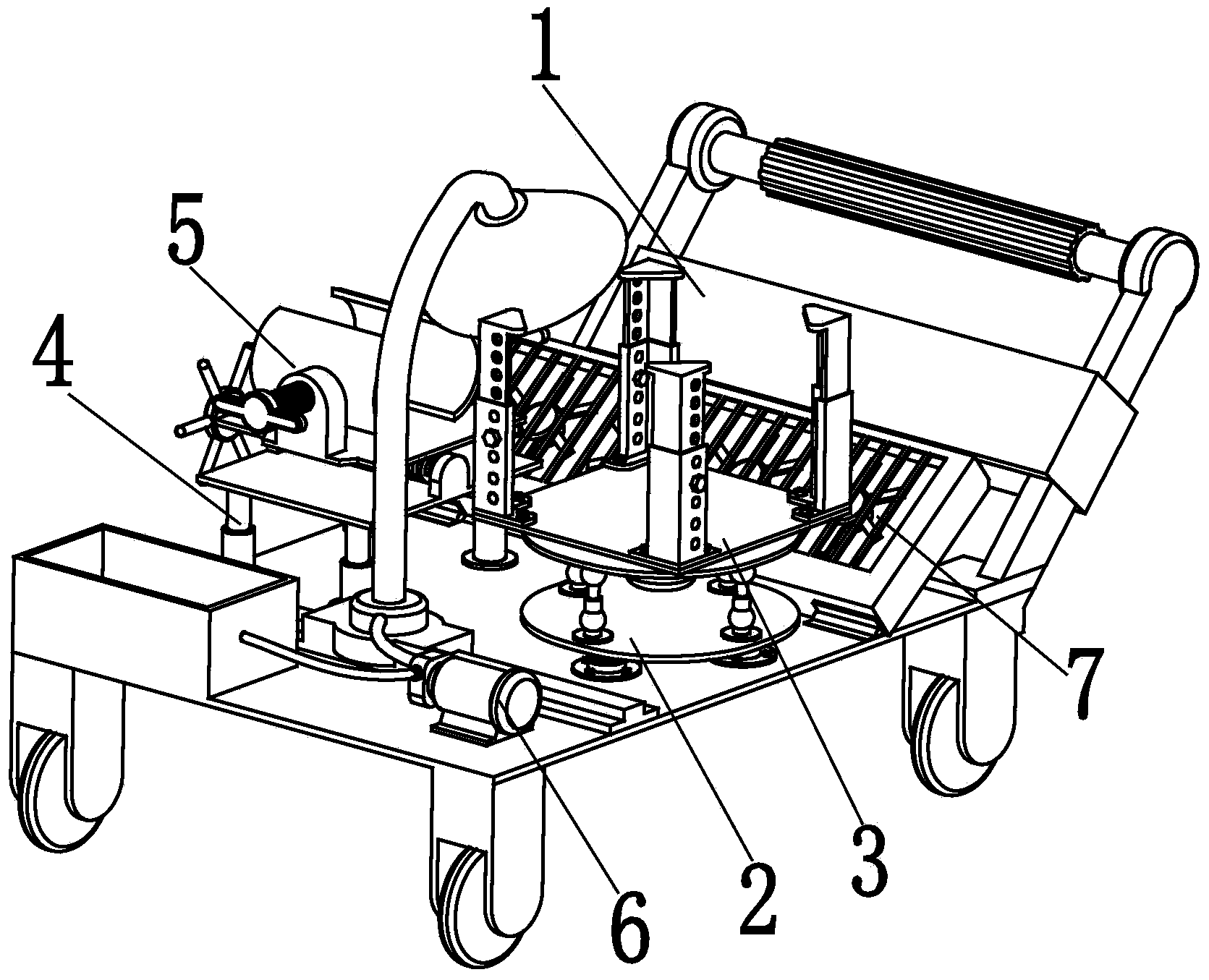

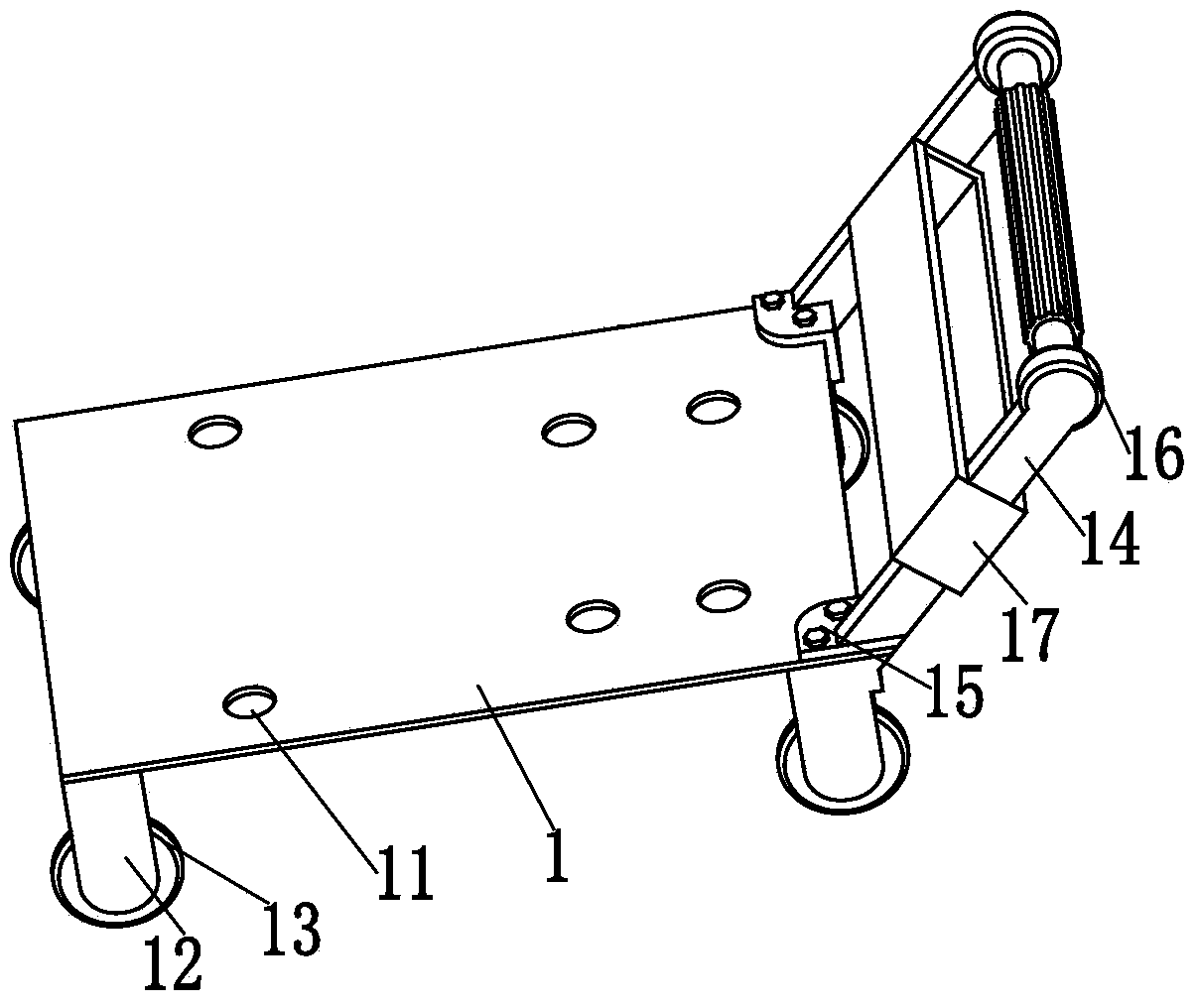

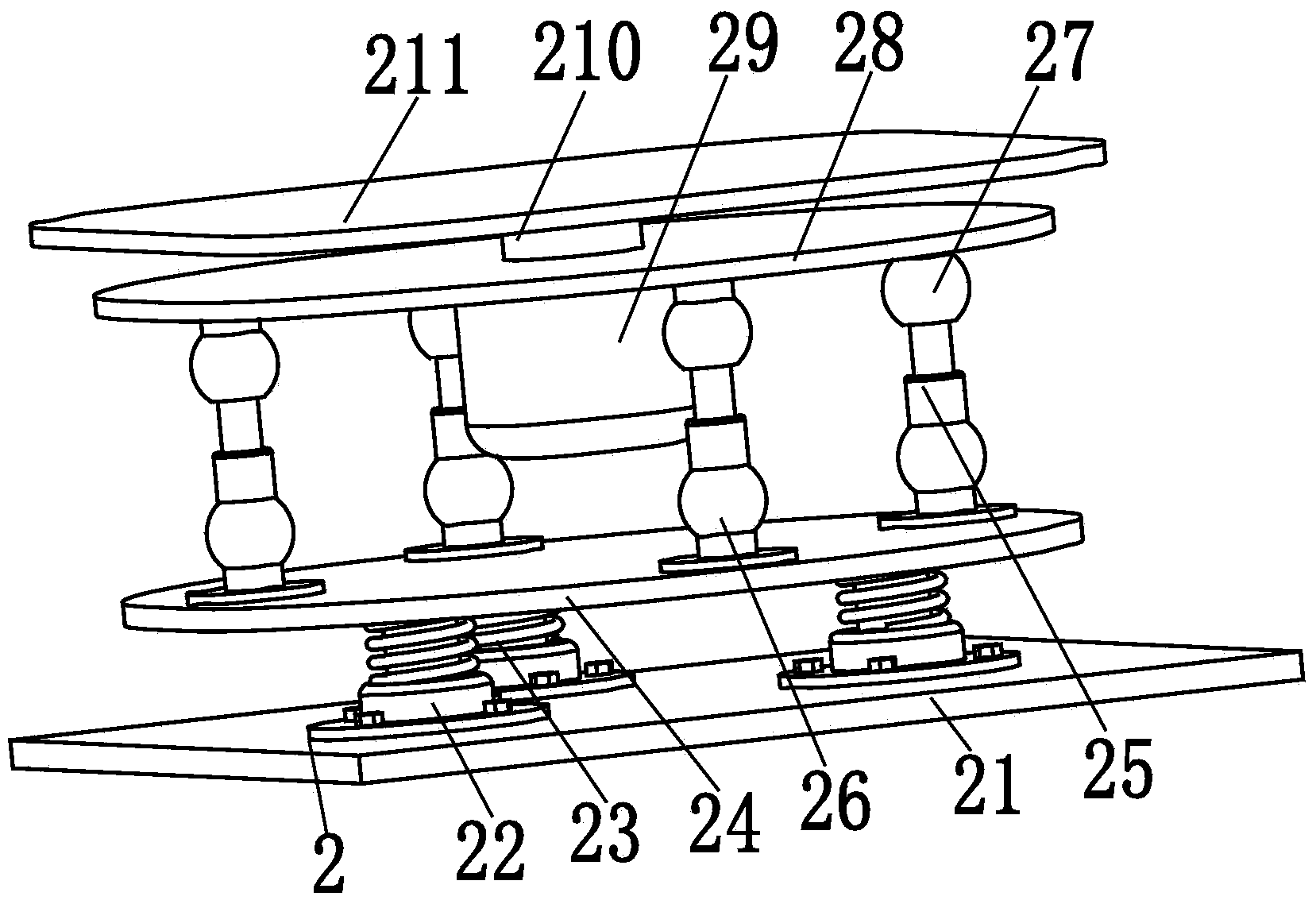

Special platform for welding multifunctional cylinder cube

InactiveCN104384761AAchieve circumferential lockingRealize the function of radial lockingWelding/cutting auxillary devicesDirt cleaningDegrees of freedomEngineering

The invention relates to a special platform for welding a multifunctional cylinder cube. The platform comprises a movable trolley, a support rack, a cube clamping device, an adjusting platform, a cylinder locking device, a dust collection smoke discharge device and a cooling device, wherein the support rack is mounted in the middle position of the movable trolley; the cube clamping device is mounted above the support rack; the adjusting platform is positioned at the left side of the cube clamping device; the cylinder locking device is mounted rightly above the adjusting platform; the dust collection smoke discharge device is positioned at the front side of the movable trolley; and the cooling device is positioned at the back side of the movable trolley. The platform can realize the functions of peripheral locking of a cube welding workpiece and radial locking of a cylinder welding workpiece, can realize a space movement function in a direction of four degrees of freedom of three-translation and one-rotation in the welding process of the cube welding workpiece through the support rack, can achieve a multi-angle welding effect, can realize quick cooling treatment for the welded workpiece through the cooling device, and improves the welding efficiency.

Owner:WUHU HUAYI VALVE MFG

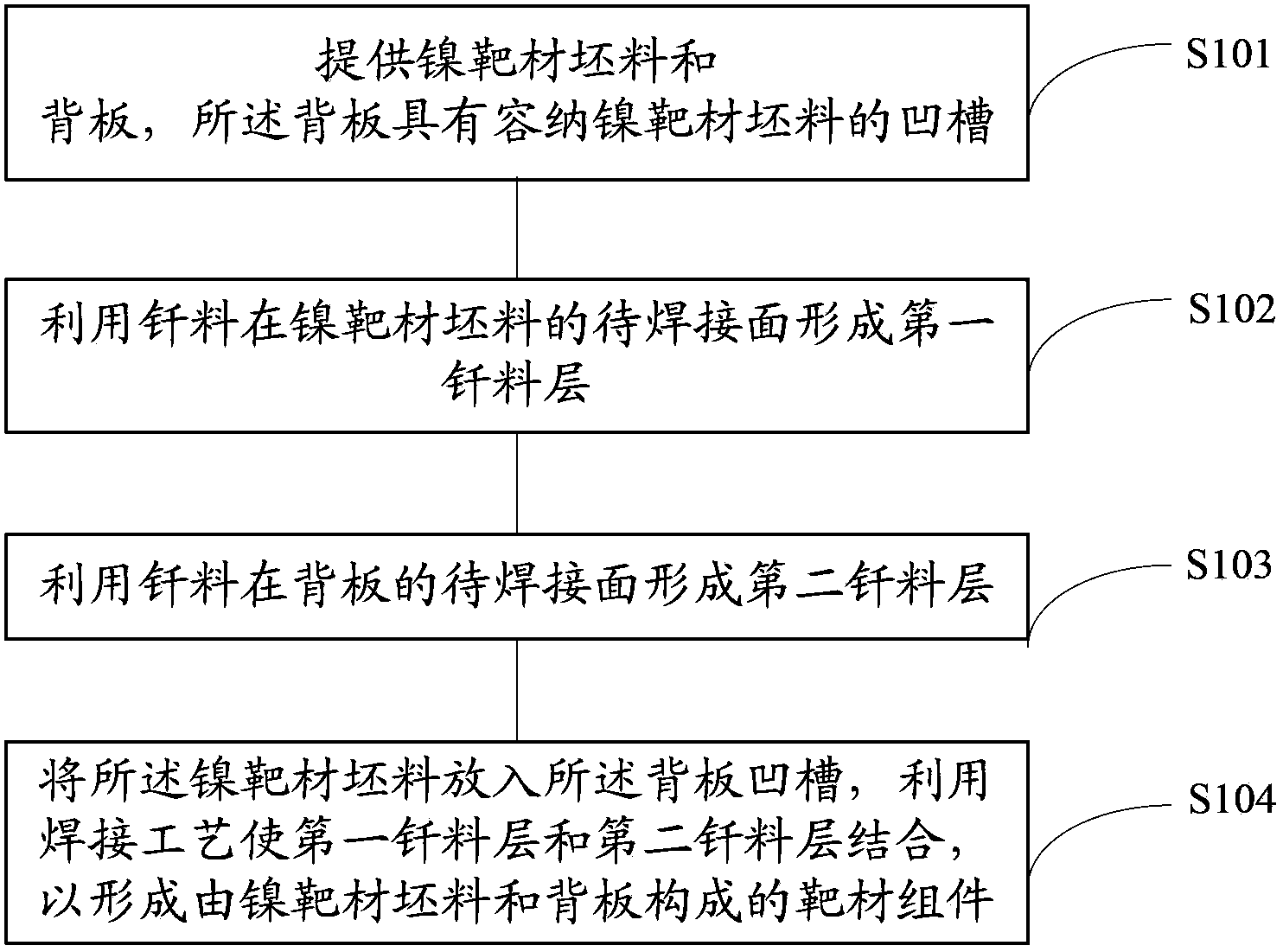

Target material assembly manufacturing method

ActiveCN103506725AEvenly distributedIncrease coverageSoldering apparatusWelding/soldering/cutting articlesWelding defectFiller metal

A target material assembly manufacturing method comprises the steps of providing nickel target material blank and a back plate, wherein the back plate is provided with grooves for containing the nickel target material blank; utilizing brazing filler metal to form a first brazing filler metal layer on a face, to be welded, of the nickle target material blank; utilizing brazing filler metal to form a second brazing filler metal layer on a face, to be welded, of the back plate; placing the nickel target blank into the groove of the back plate, and utilizing the welding technology to combine the first brazing filler metal layer and the second brazing filler metal layer so as to form a target material assembly composed of the nickel target blank and the back plate. The target material assembly manufacturing method enables ultra-pure nickle target materials to be reliably combined with the back plate, is high in welding efficiency and small in welding defect rate, and can meet requirements of long-term stable production and utilization of target materials.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

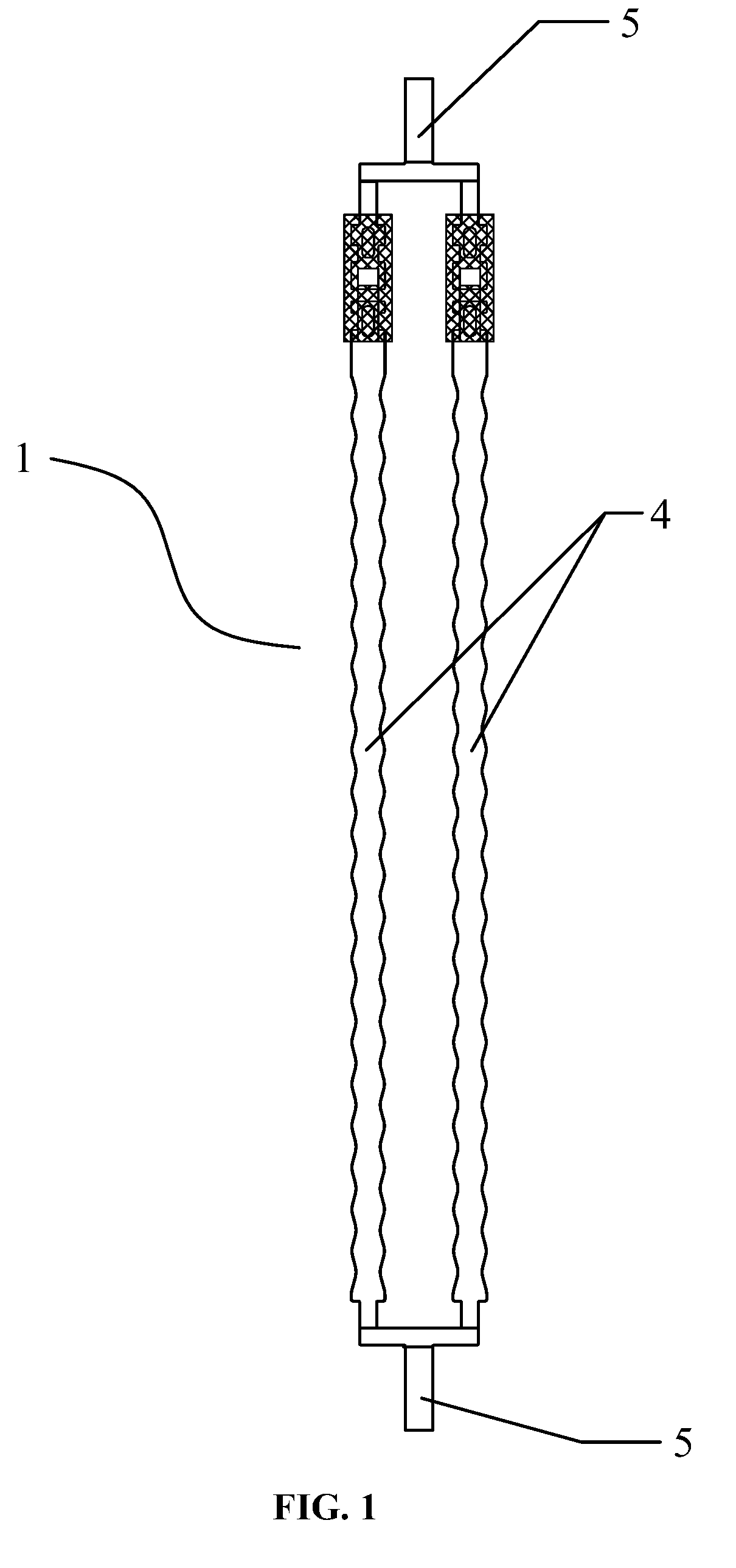

Parallel-connected LED illuminant and LED light lamp

ActiveUS20170167667A1Enlarge effective heat dissipation areaProlong service lifeLight source combinationsElongate light sourcesLong axisEngineering

A parallel-connected LED illuminant, including: a parallel-connected bracket, LED light emitting unit groups, and fluorescent powder layers. The parallel-connected bracket includes two or more than two linear substrate monomers. The linear substrate monomers are disposed in parallel. Each of the LED light emitting unit groups is disposed in the straight line on each of the linear substrate monomers along the long axis thereof. The LED illuminant is connected in series with electrode pins disposed at two ends of the parallel-connected bracket. The surface of each linear substrate monomer where each LED light emitting unit group is disposed is coated with each of the fluorescent powder layers.

Owner:SHANDONG PROSPEROUS STAR OPTOELECTRONICS TECH CO LTD

Welding control system and control method thereof

InactiveCN106826001AAvoid the hassle of manual selection programsShorten the timeWelding/cutting auxillary devicesAuxillary welding devicesImaging processingControl system

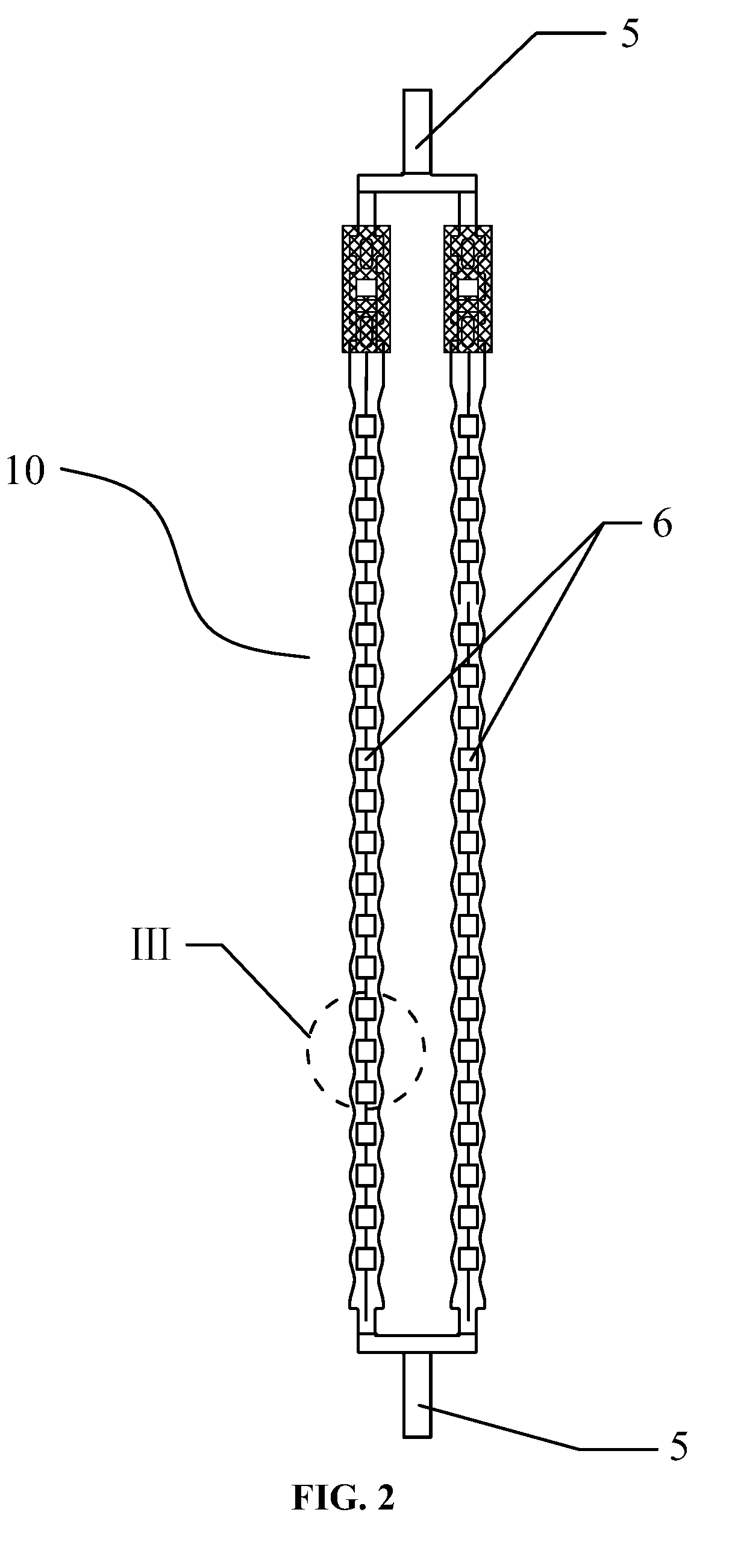

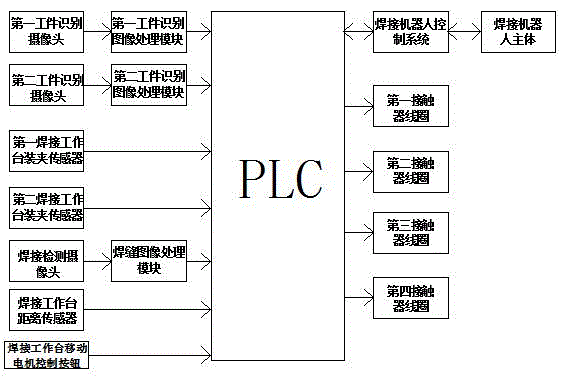

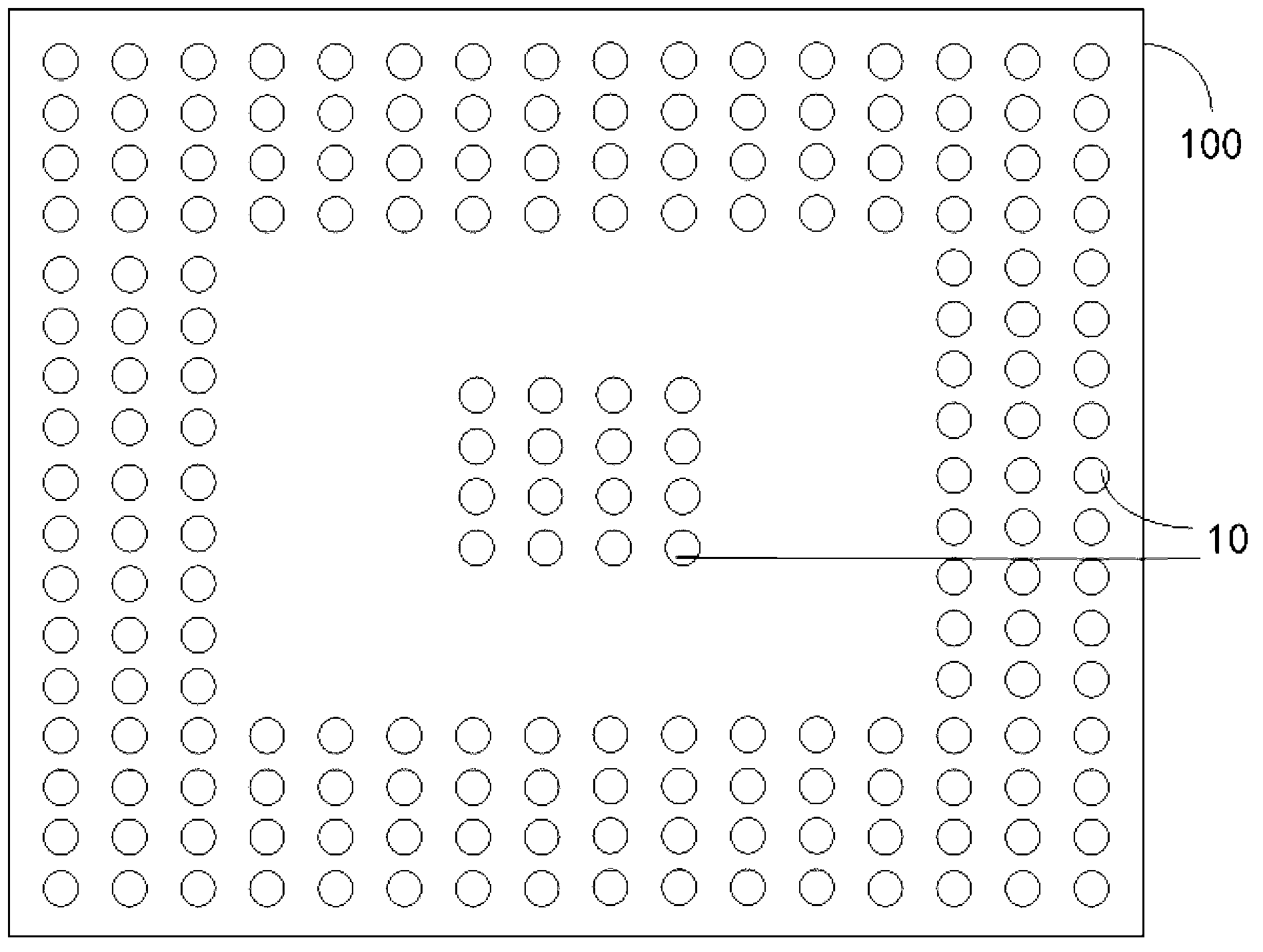

The invention discloses a welding control system and a control method thereof, the first image acquisition module, the second image acquisition module, the first welding workbench clamping sensor, the second welding workbench clamping sensor, the welding workbench distance The sensor and the welding table moving motor control button are respectively connected to the input port of the PLC; the welding detection camera is connected to the weld image processing module, and then the weld image processing module is connected to the input port of the PLC; one end of the welding robot control system is connected to the PLC , the other end is connected to the main body of the robot; the first contactor coil, the second contactor coil, the third contactor coil and the fourth contactor coil are connected to the output end of the PLC. The control system can automatically identify the workpiece type, thereby automatically selecting the processing program, and can automatically detect the welding quality. The control method of the control system can reduce processing time and reduce the standby time of the welding torch.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

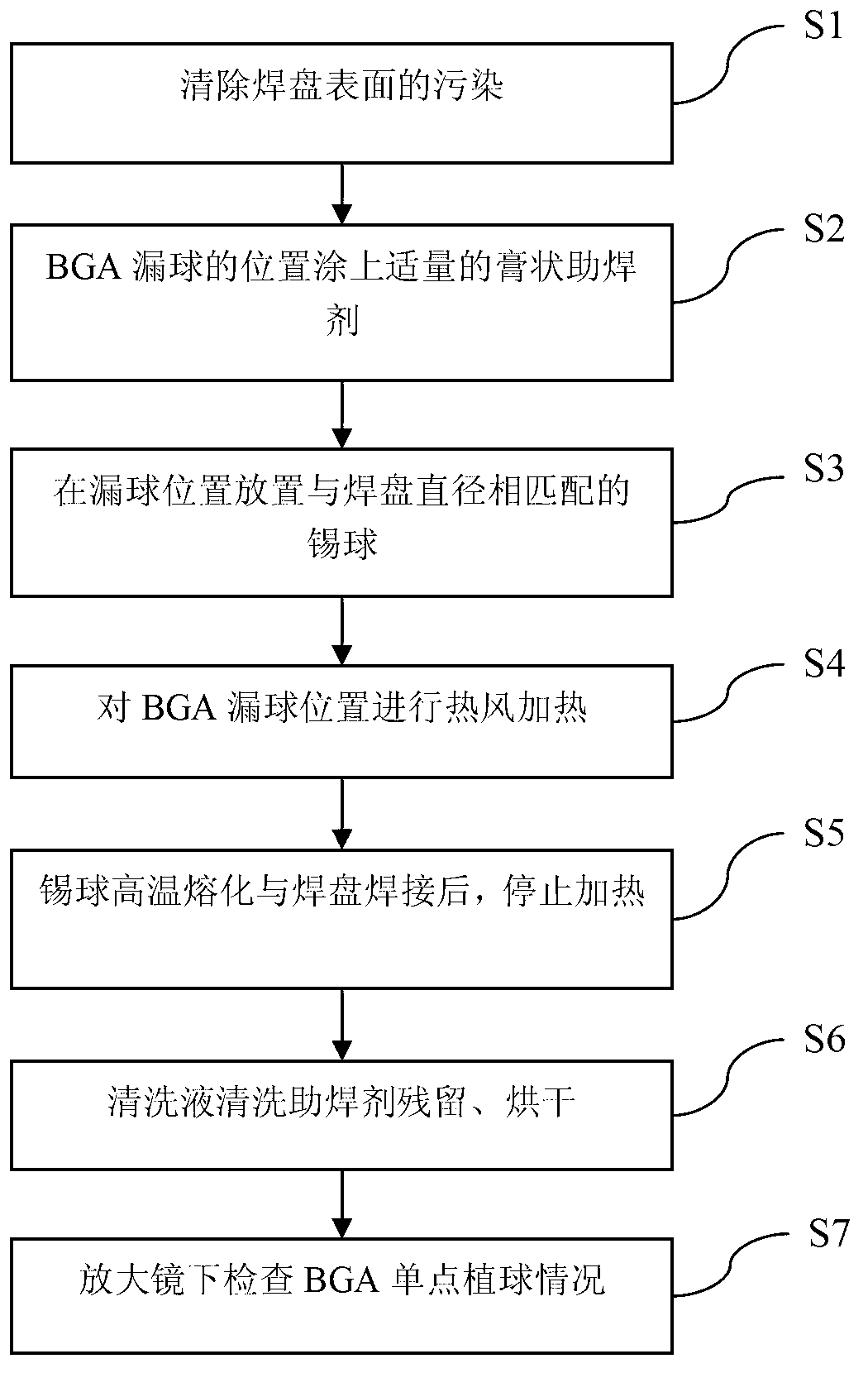

Ball grid array (BGA) balling single-point repair method

ActiveCN103231138AReduce heat exposureLife-span-reducing effectsSoldering apparatusSemiconductor/solid-state device manufacturingSolder ballEngineering

The invention provides a ball grid array (BGA) balling single-point repair method. The BGA balling single-point repair method includes: step one, removing an oxide layer and pollutants on the surface of a ball leaking pad on the bottom surface of a BGA chip; step two, taking paste scaling powder, and spreading the paste scaling powder on the ball leaking pad; step three, placing a solder ball with the diameter matched with that of the pad on the pad coated with the paste scaling powder in the step two; step four, heating the position where the solder ball is placed by using a heat gun in a mode that output air of the heat gun is perpendicular to the bottom surface of the BGA chip; and step five, closing the heat gun after the solder ball is melted, and detecting whether repair is successful after the heat gun is closed.

Owner:JIANGNAN INST OF COMPUTING TECH

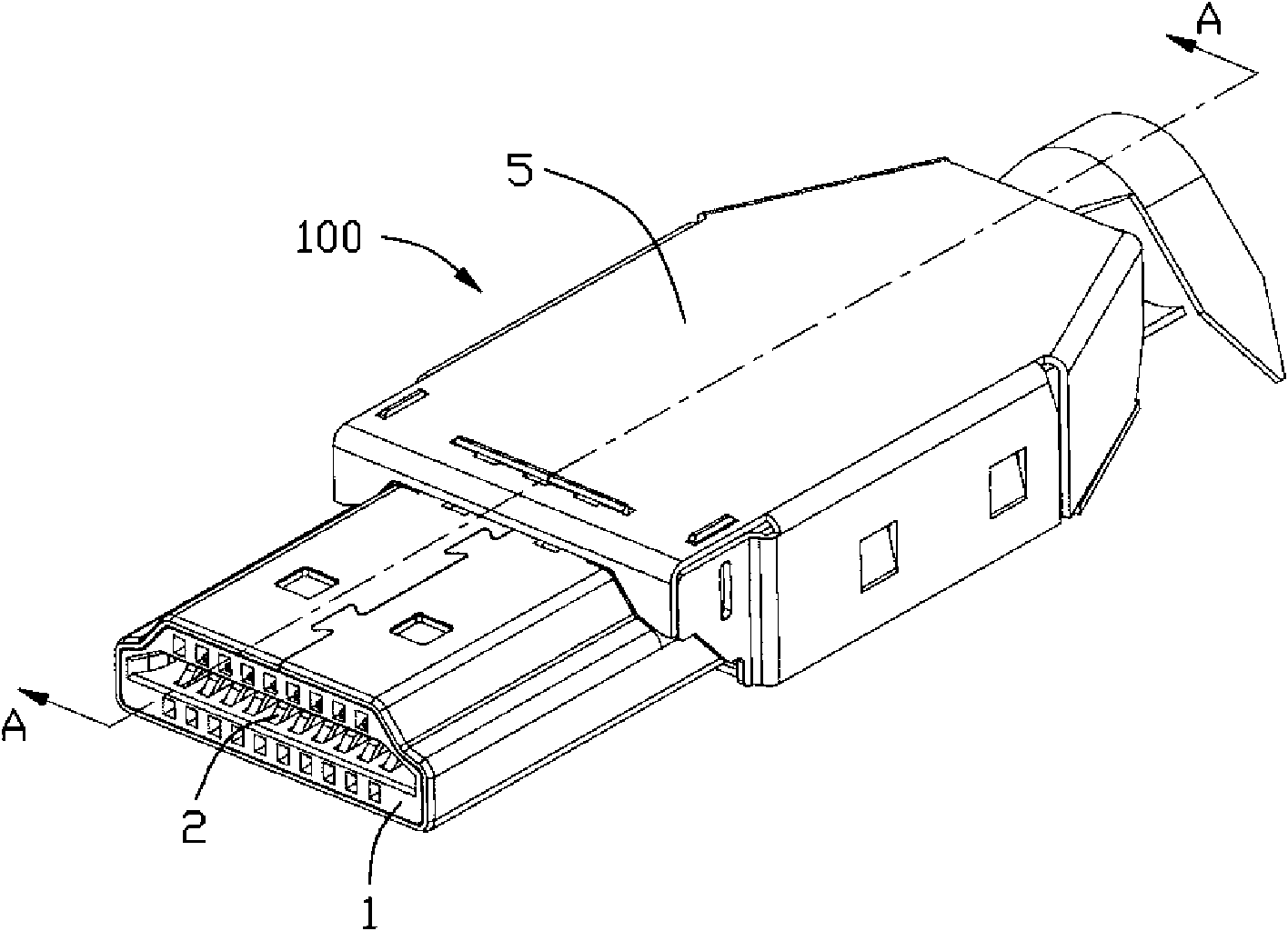

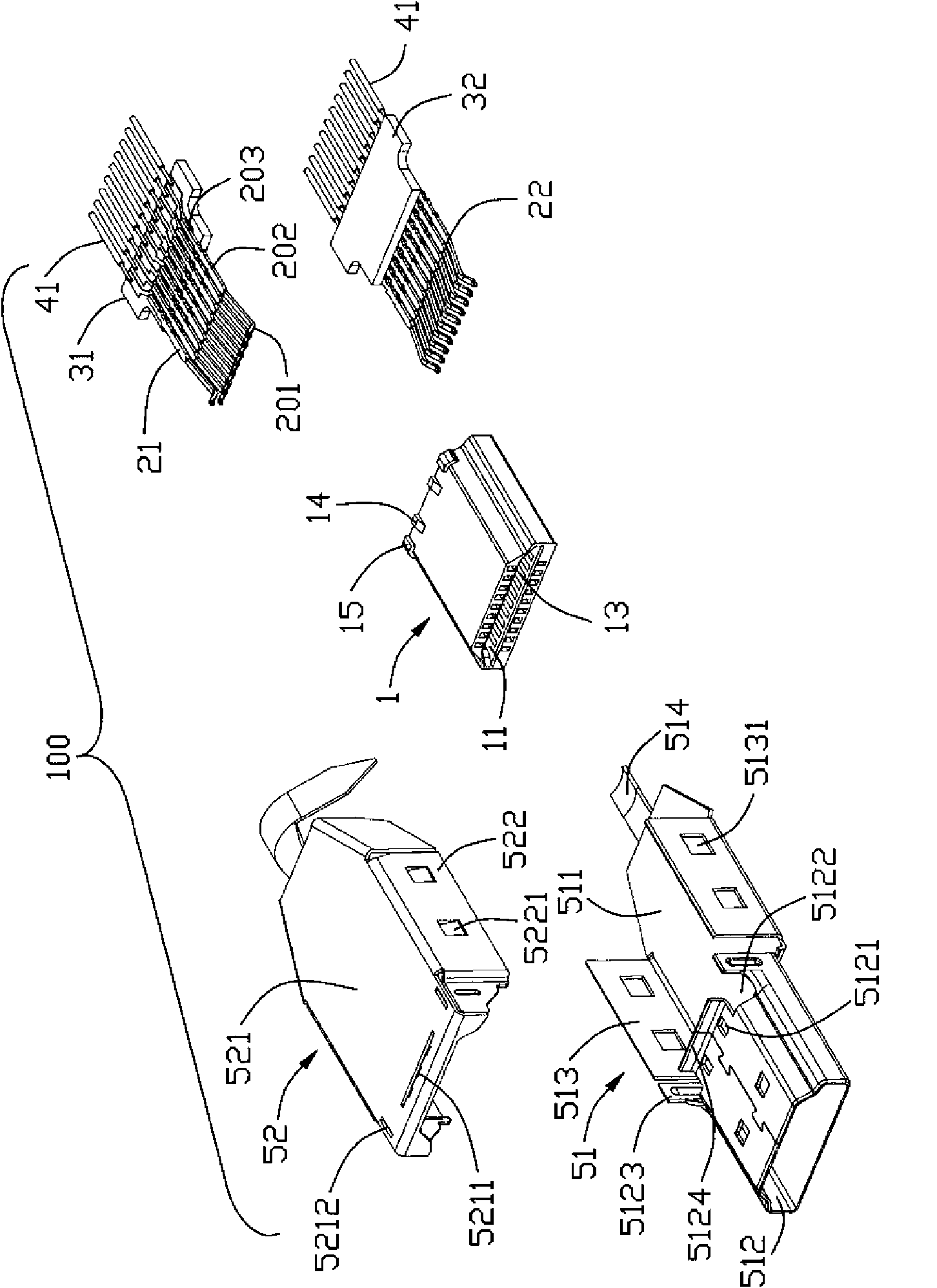

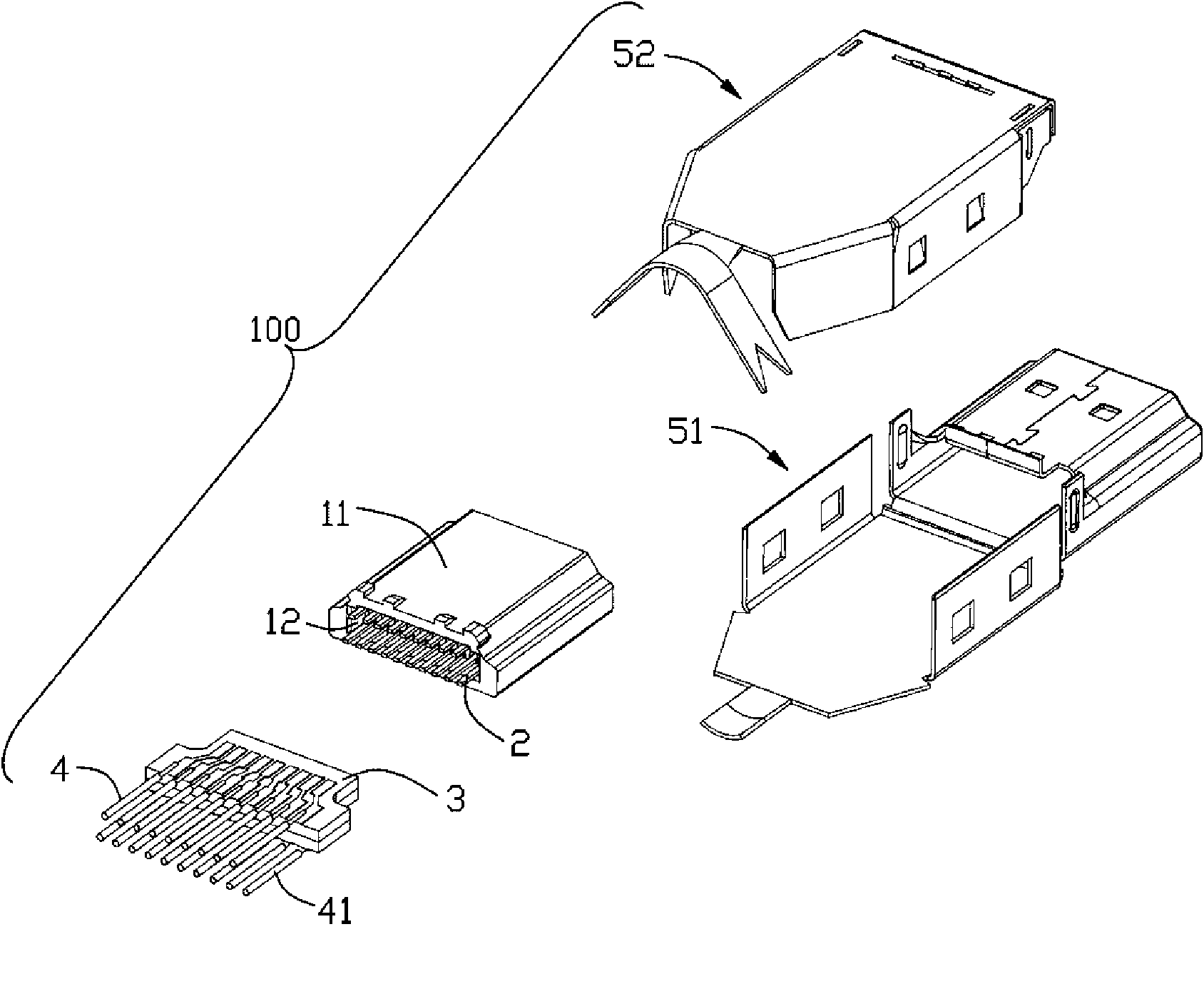

Cable connector component and manufacturing method thereof

InactiveCN102055087ALow costQuick assemblyContact member assembly/disassemblySecuring/insulating coupling contact membersElectrical connectionEngineering

A cable connector component comprises an insulating body, a plurality of conductive terminals, a printed circuit board (PCB), a cable and a metal shelter casing, wherein a concave cavity is arranged at the tail part of the insulating body; the conductive terminals are accommodated in the insulating body; the front end part of the PCB is accommodated in the concave cavity of the insulating body and electrically connected with the conductive terminals; the cable is electrically connected with the rear end part of the PCB; the insulating body and the PCB are coated by the metal shelter casing; and the PCB comprises an upper circuit board and a lower circuit board. As the electrical connection of the upper and the lower circuit boards and the cable can be finished through once welding, the cable connector component has the advantage of high assembly efficiency.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

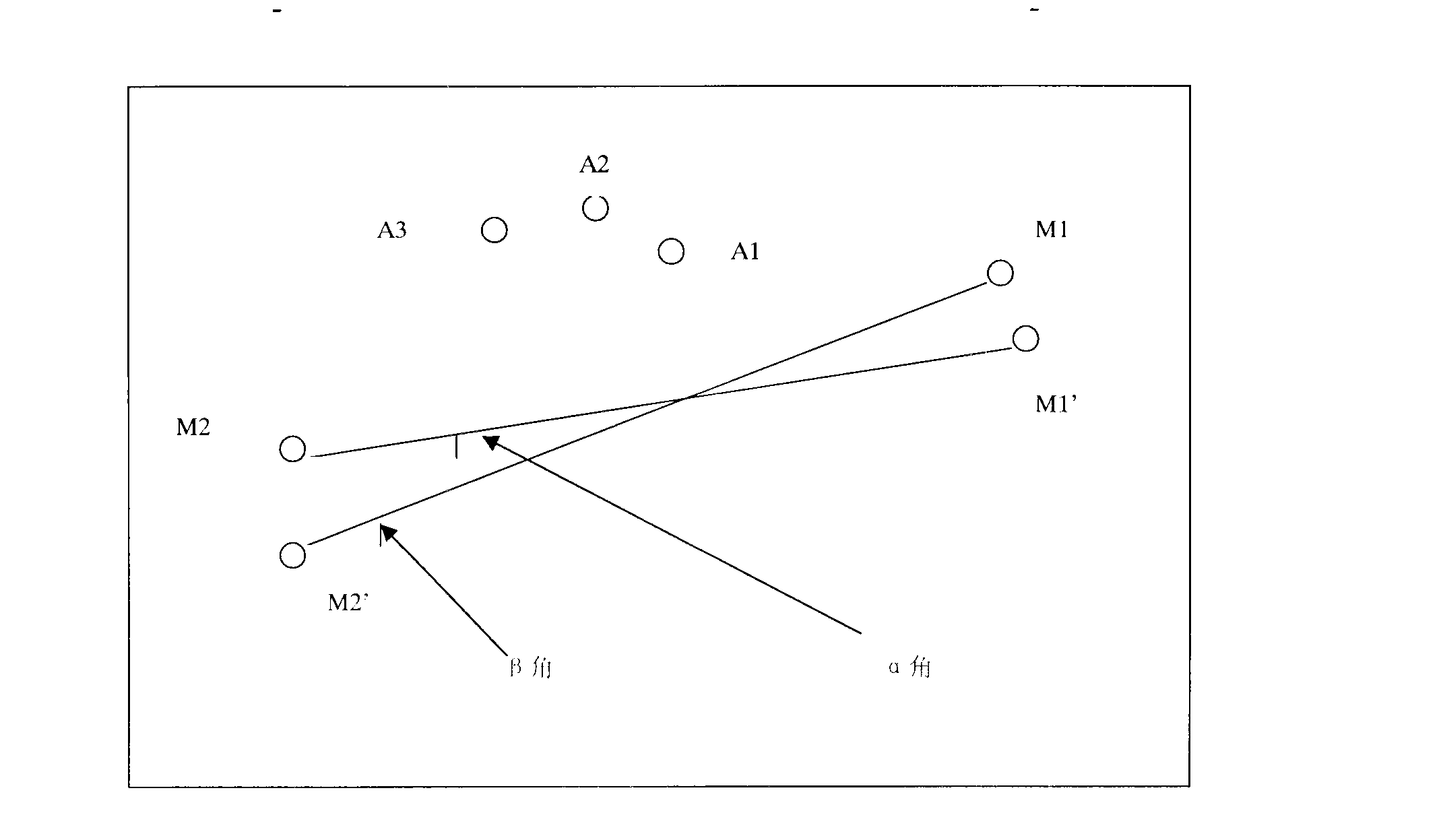

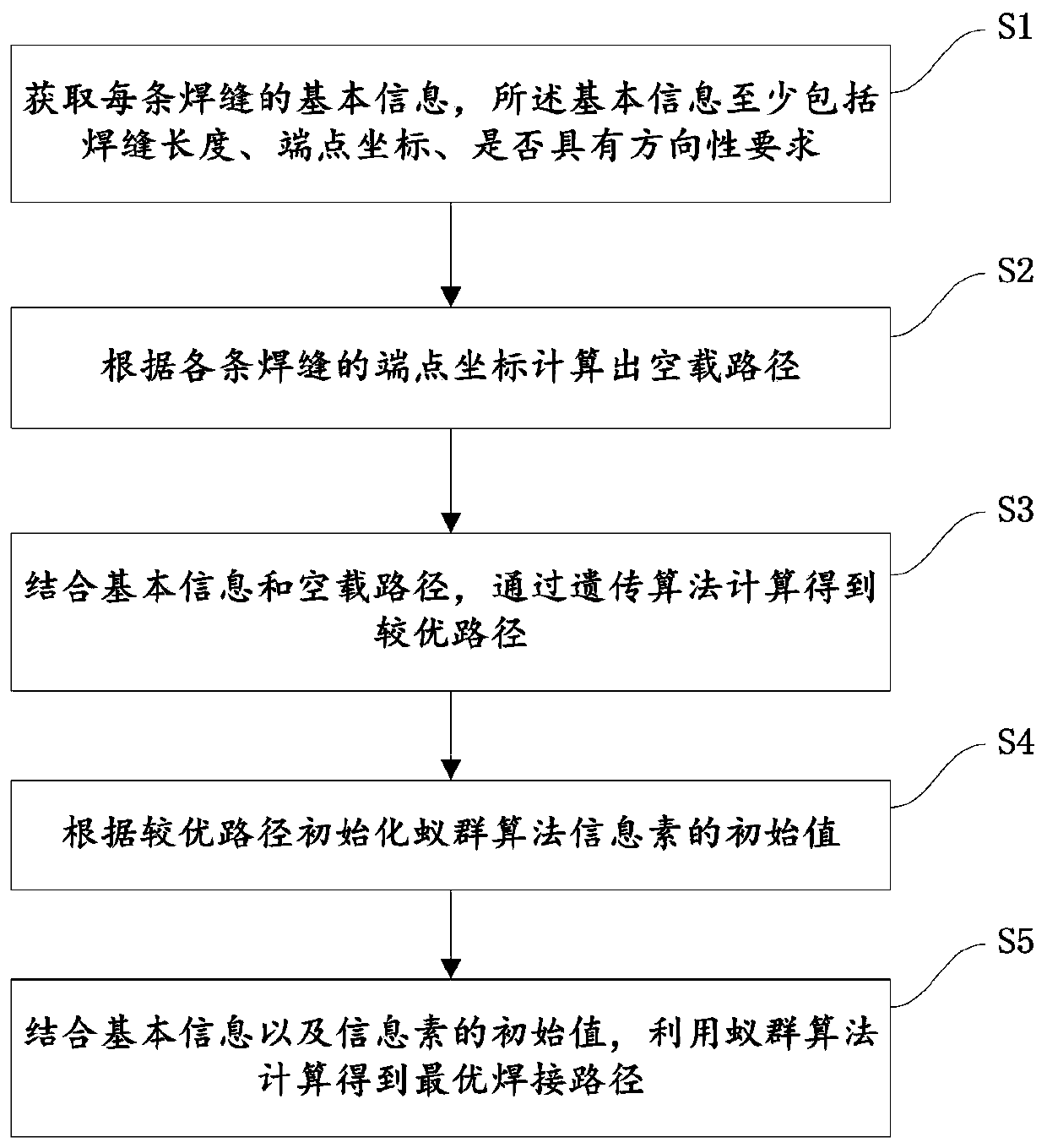

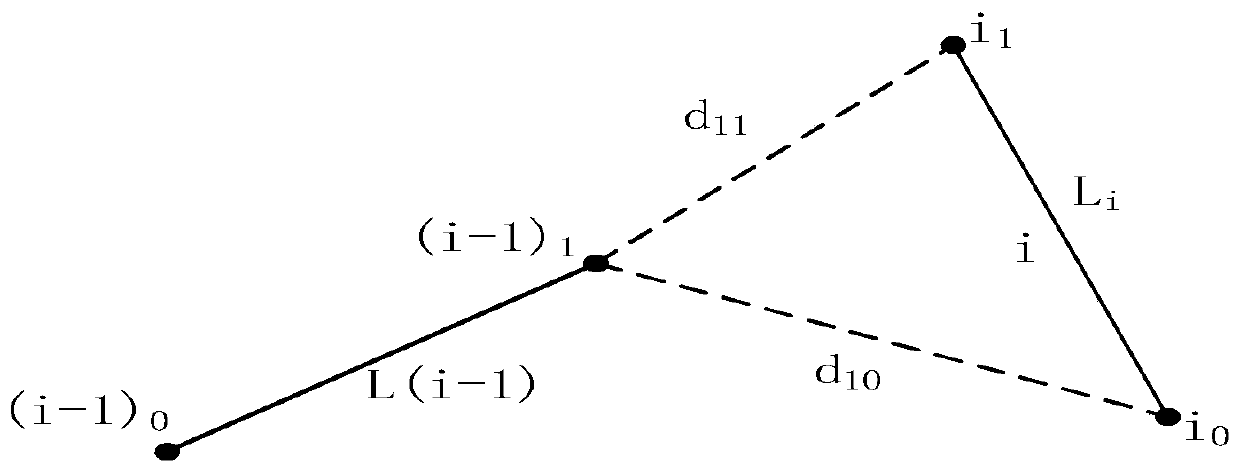

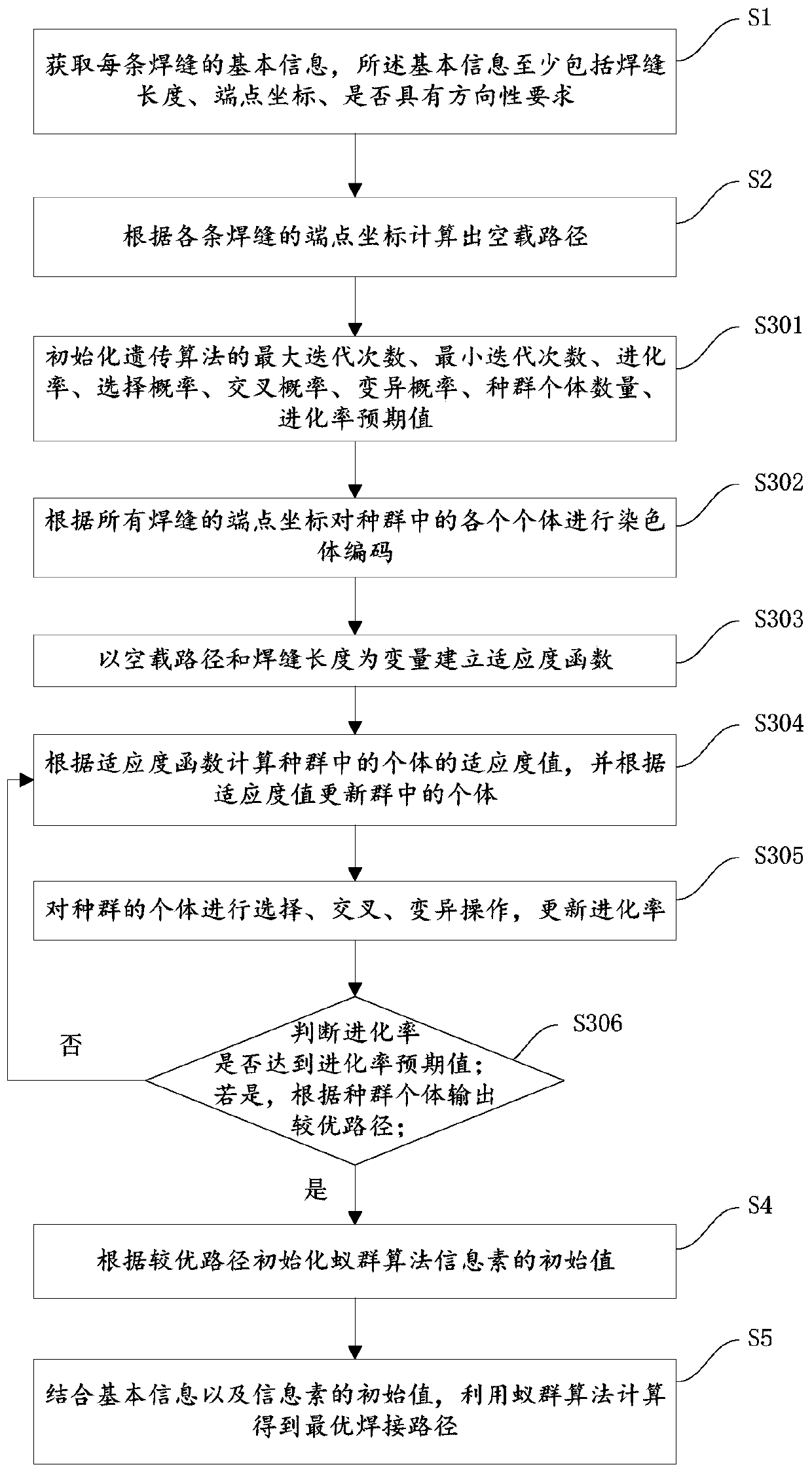

Robot path planning method applied to weld joints

ActiveCN109940623AImprove welding qualityImprove welding efficiencyProgramme-controlled manipulatorGenetic algorithmRobot path planning

The invention provides a robot path planning method applied to weld joints. The method comprises the following steps of acquiring basic information of each weld joint, wherein the basic information comprises the length of a weld joint, endpoints coordinates, and whether having the directivity requirement or not; calculating a no-load path according to the endpoints coordinates of each weld joint;combining the basic information and the no-load path, calculating to obtain an optimal path through a genetic algorithm by ; initializing an initial value of the ant colony algorithm pheromone according to the optimal path; and combining the basic information and the initial value of the pheromone, calculating to obtain an optimal welding path by utilizing an ant colony algorithm. The method can be used for carrying out more effective process constraint on a robot moving path by acquiring the basic information of the weld joints, so that the weld joints meet the directivity requirements; an optimal solution obtained by utilizing the genetic algorithm is used for initializing the pheromone of the ant colony algorithm, so that the ant colony algorithm can quickly and effectively obtain the optimal solution; and the advantages of the two algorithms are complemented, so that the welding path capable of saving welding time and meeting the weld joints requirements is effectively planed.

Owner:GUANGDONG UNIV OF TECH

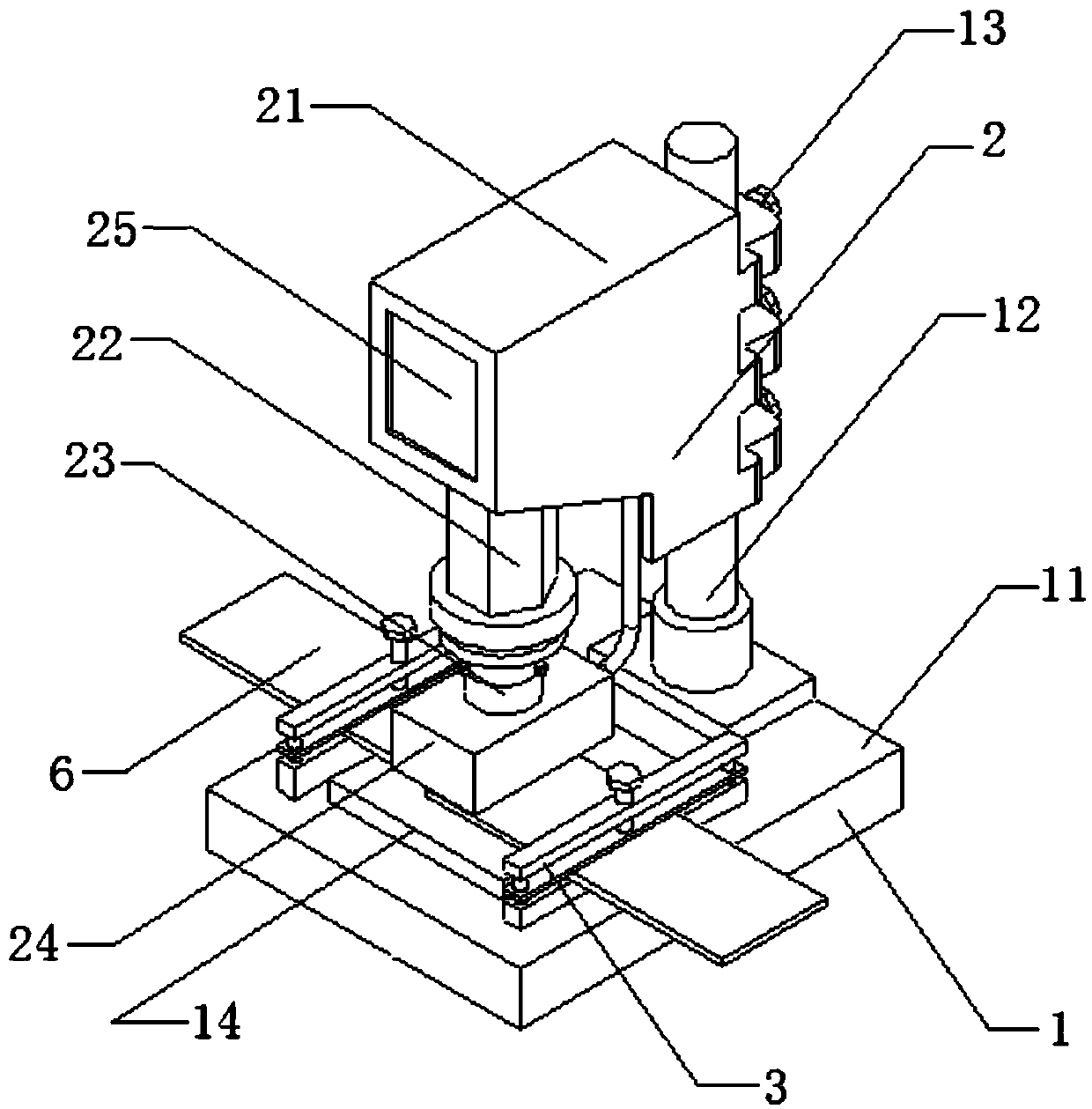

Ultrasonic and electromagnetic pulse composite welding device and composite welding method

PendingCN110732794AMeet the clamping and fixing requirementsMeet the separation distance requirementsWelding apparatusEngineeringElectromagnetic pulse

The invention discloses an ultrasonic and electromagnetic pulse composite welding device and a composite welding method. The composite welding device comprises a device base, a composite welding component and a welding part clamping device; the composite welding component is installed above a worktable of the device base; the welding part clamping device is installed on the worktable and can be lifted up and down; the composite welding component comprises a control box, an ultrasonic transducer, an amplitude-change pole and a welding head; the upper end of the ultrasonic transducer is installed inside the control box; the lower end of the ultrasonic transducer is connected with the amplitude-change pole; the lower end of the amplitude-change pole is connected with the welding head; and anelectromagnetic coil is positioned inside the welding head. According to the composite welding method, firstly welding positions of two welding plates are subjected to ultrasonic softening and oxide film removal by utilizing ultrasonic energy; and subsequently the welding positions are applied with transient high voltage electromagnetic force generated by the electromagnetic coil sot that weldingformation of the welding positions is realized. The composite welding device can meet the welding requirements of various dissimilar-material plates; and the composite welding method can improve the stability of the welding positions.

Owner:SOUTHWEST UNIVERSITY

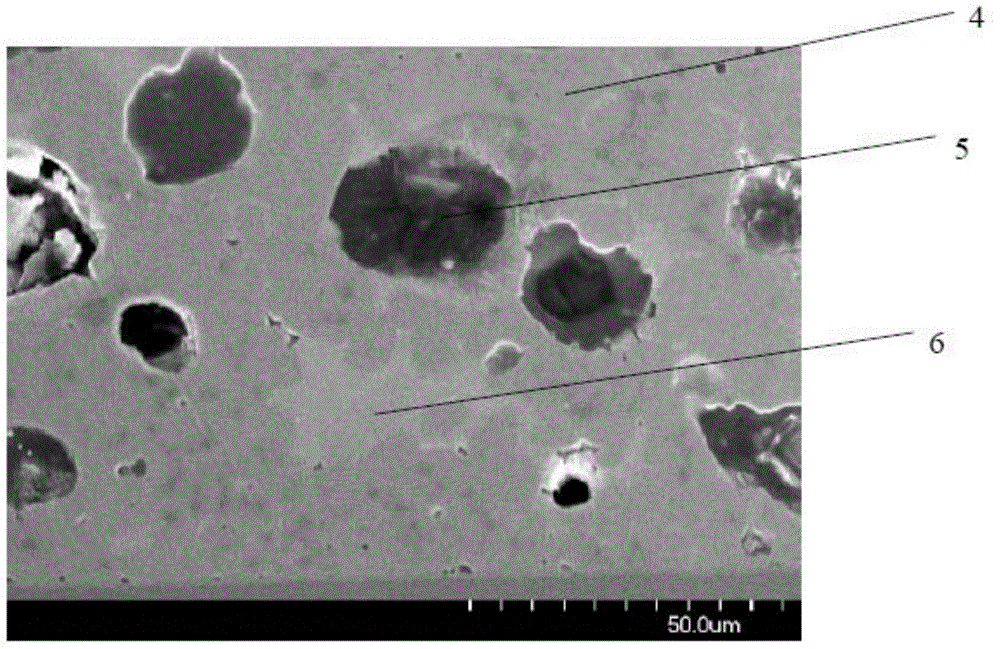

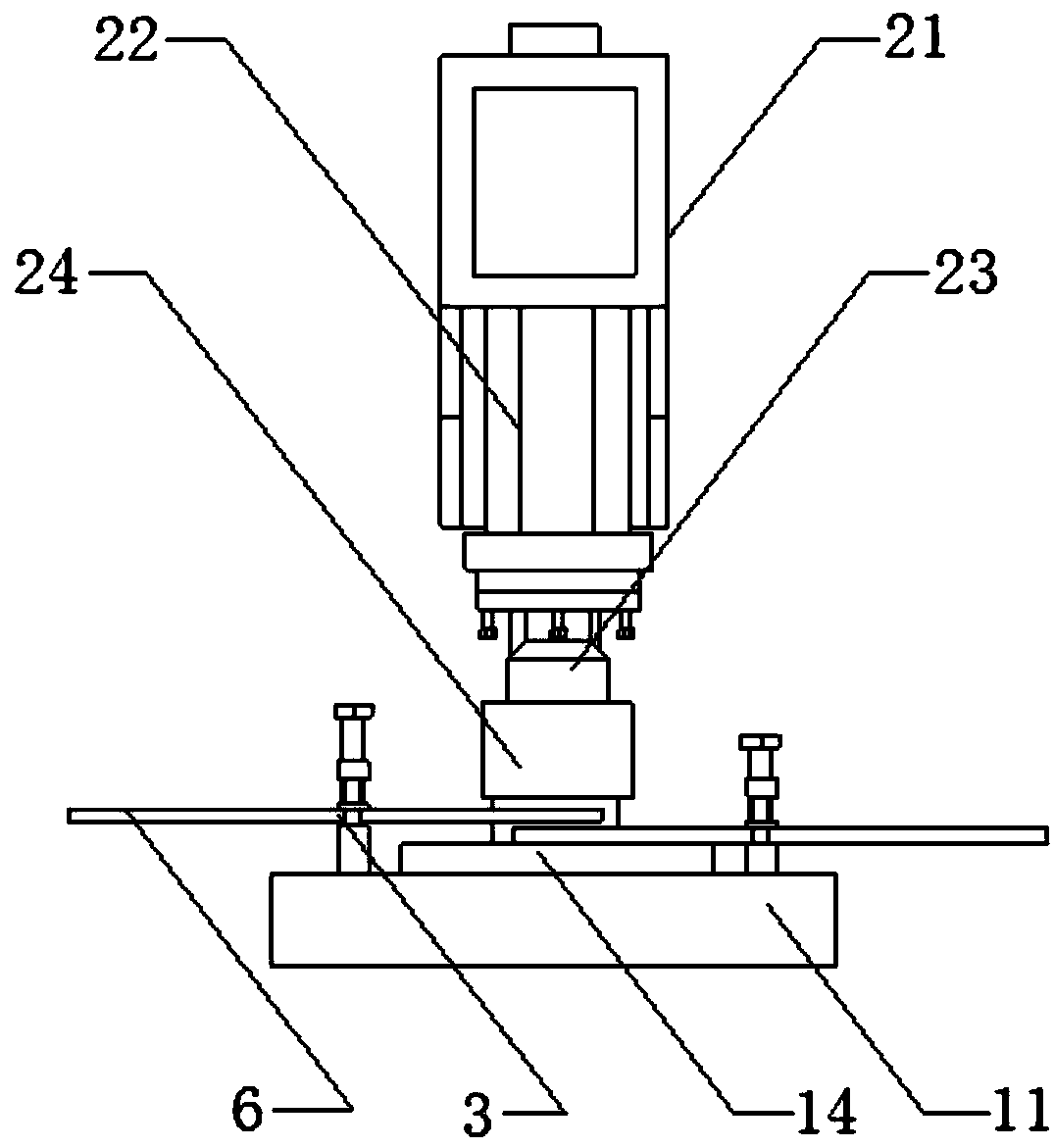

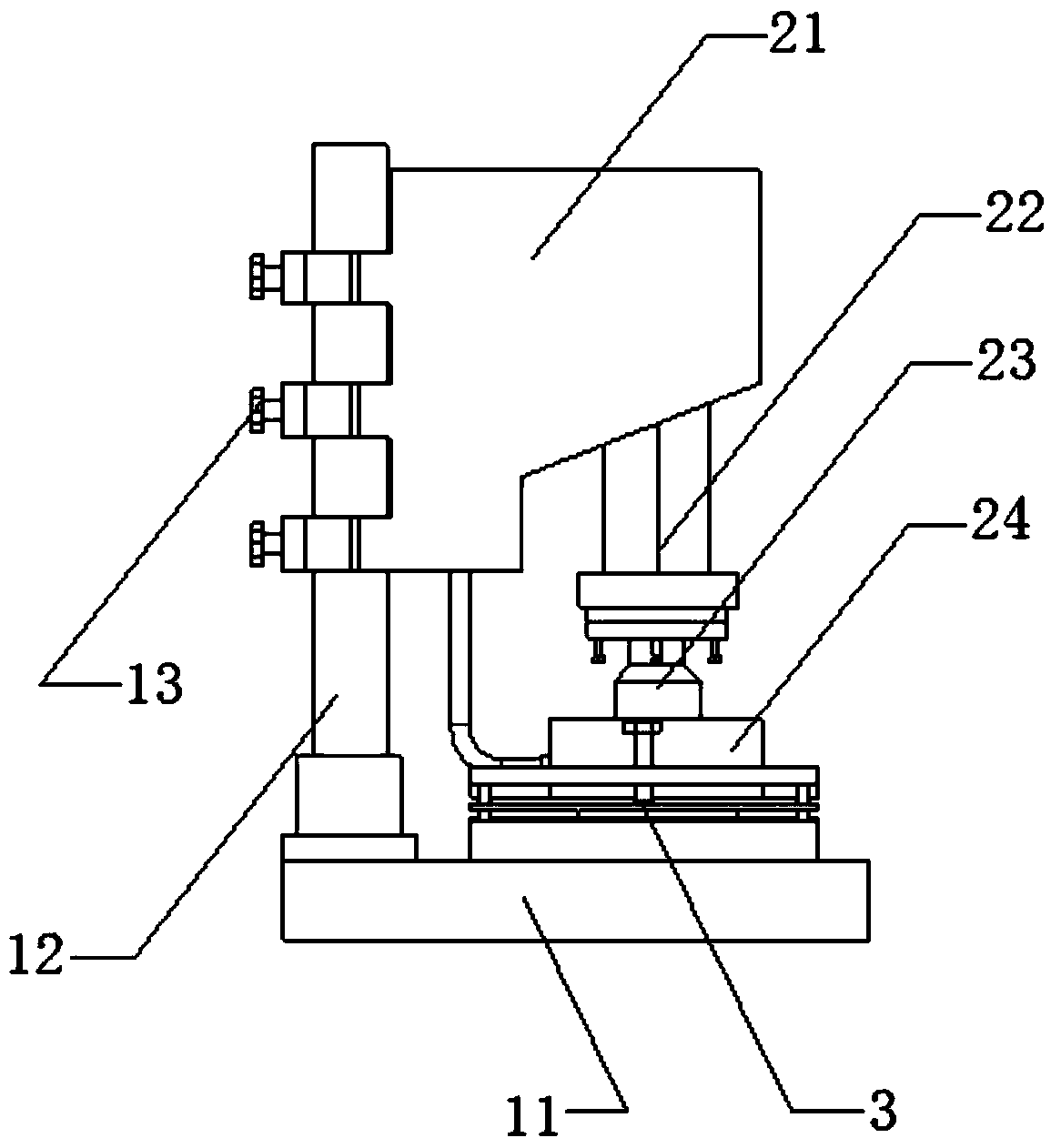

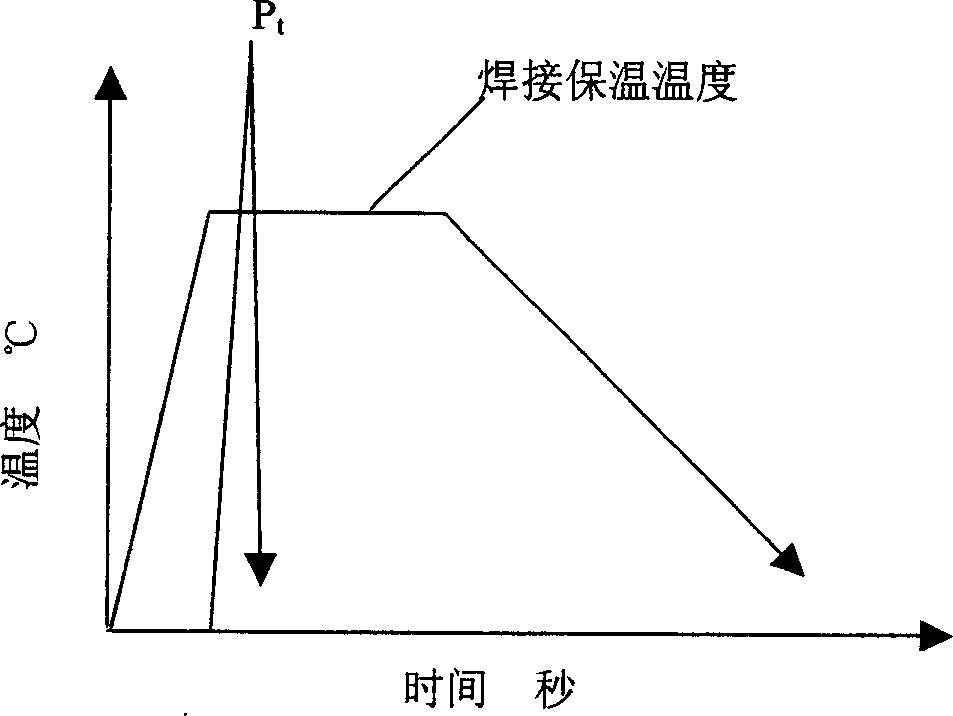

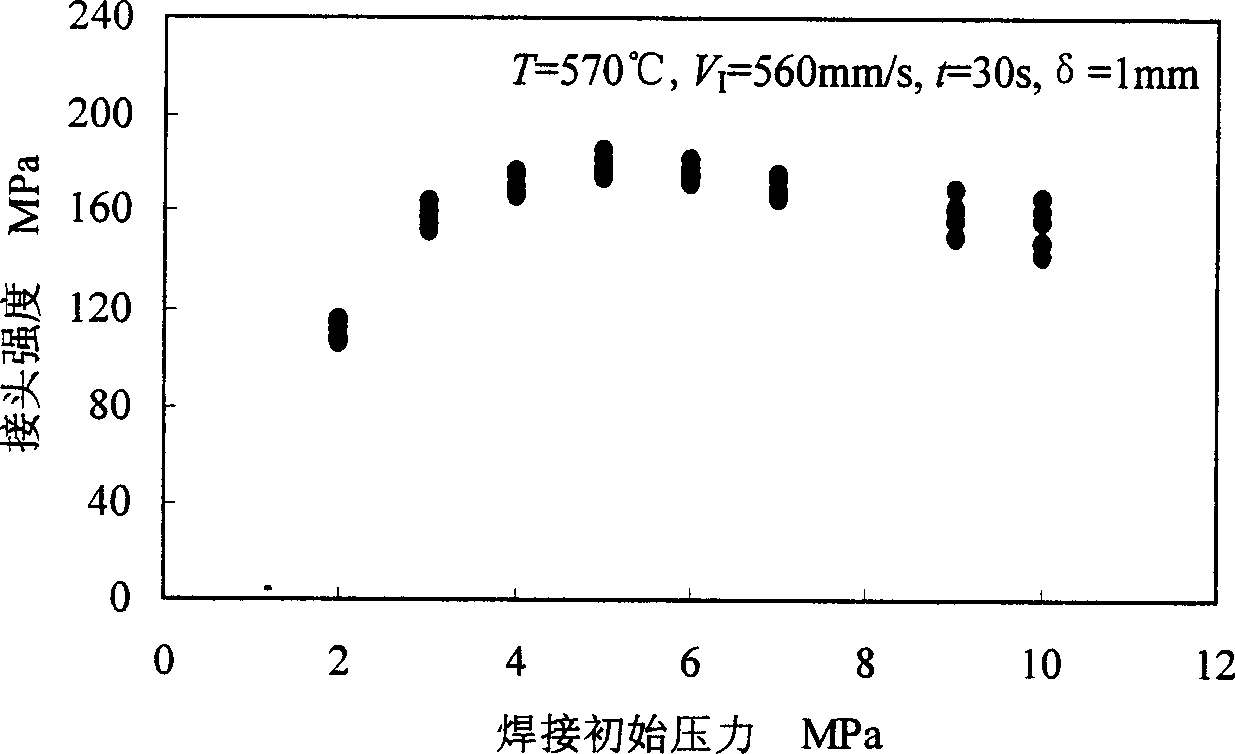

Novel process of liquid phase impact diffusion welding for aluminium-based composite material

InactiveCN1546269AImprove joint qualityImprove joint strengthNon-electric welding apparatusMetalDiffusion welding

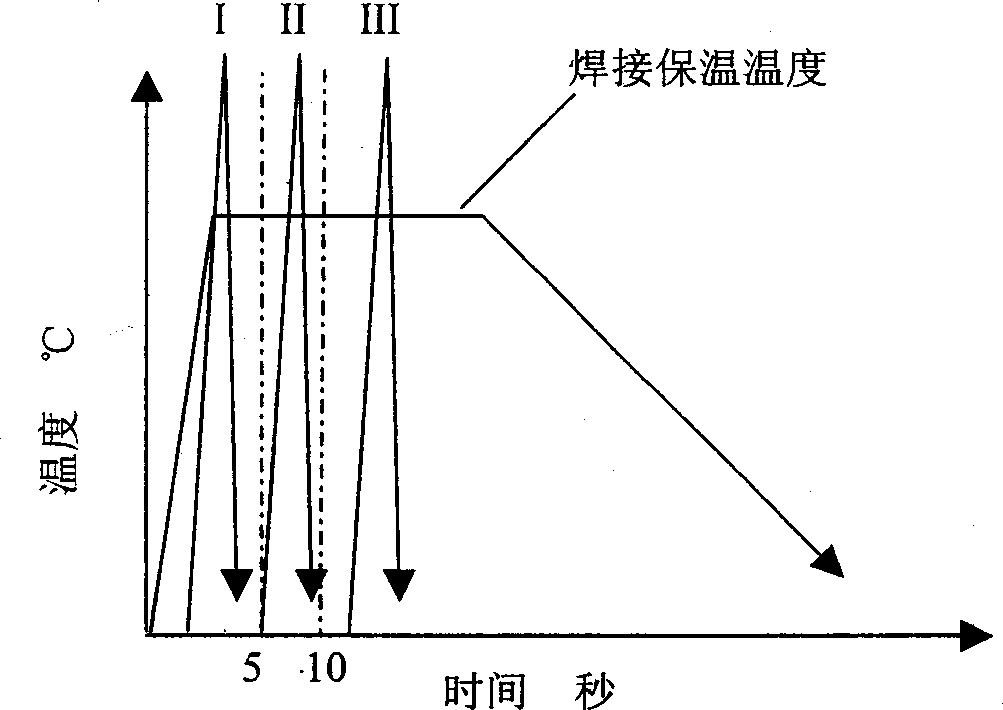

The invention proposes a new aluminium compound material liquid phase impacting diffusion welding process which belongs to diffusion welding technology field. The invention solves the low quality of aluminium compound material diffusion welding. The invention mainly includes: the welding thermal reservation selection is in the aluminium compound material liquid and solid phase temperature period, in the temperature range whose liquid phase volume piece-rate is 20-35% correspondent to the base body liquid phase, the thermal reservation time is 30 seconds, at first applies initial welding pressure is 5MPa, the impacting pressure is 80-120MPa, the impacting speed is applied after the welding temperature thermal reservation for 5-10 seconds, the impacting temperature is 350-700mm / s. the impacting allying time interval is 0.0001-0.01 seconds. The invention applies to aluminium compound material made up of aluminum material 6061, 6063, 2014, 2A12, 5A06, 6A02, 7A04, ZL101, ZL102 and enhancing material SiC, Al2O3, TiC, AIN.

Owner:HARBIN INST OF TECH

Rotation type reflow soldering furnace and soldering method thereof

InactiveCN103357981AReduce generationShorten welding timeHeating appliancesMetal working apparatusImpellerEngineering

A rotation type reflow soldering furnace comprises a furnace body, a furnace door, an impeller, a rotation control device, a tray, a tray position adjusting device, a vacuum pump and a temperature controller. The rotation type reflow soldering furnace is characterized in that the furnace body is formed by intersection of a cylinder and a cuboid equal in height, the furnace door is arranged on the wall of the furnace body, the furnace body is divided into a loading zone, a heating zone, a buffering zone and a cooling zone, a hot plate is arranged in the heating zone, a cold plate is arranged in the cooling zone, the impeller is arranged in the furnace body and connected with the rotation control device in a circuit manner, a to-be-soldered electronic component and a solder tray are placed between two blades, a vacuum pipe is connected with the heating zone via a pipeline, and the temperature controller is connected with the hot plate and the cold plate via circuits. The rotation type reflow soldering furnace has the advantages that the rotation type reflow soldering furnace has an independent heating system and an independent cooling system, and can perform non-interfering heating and cooling processes in a vacuum or protective atmosphere, repeated heating and cooling is not needed, and accordingly soldering time can be saved, power consumption is reduced, and working efficiency and soldering quality are improved.

Owner:WUHAN FINEMEMS

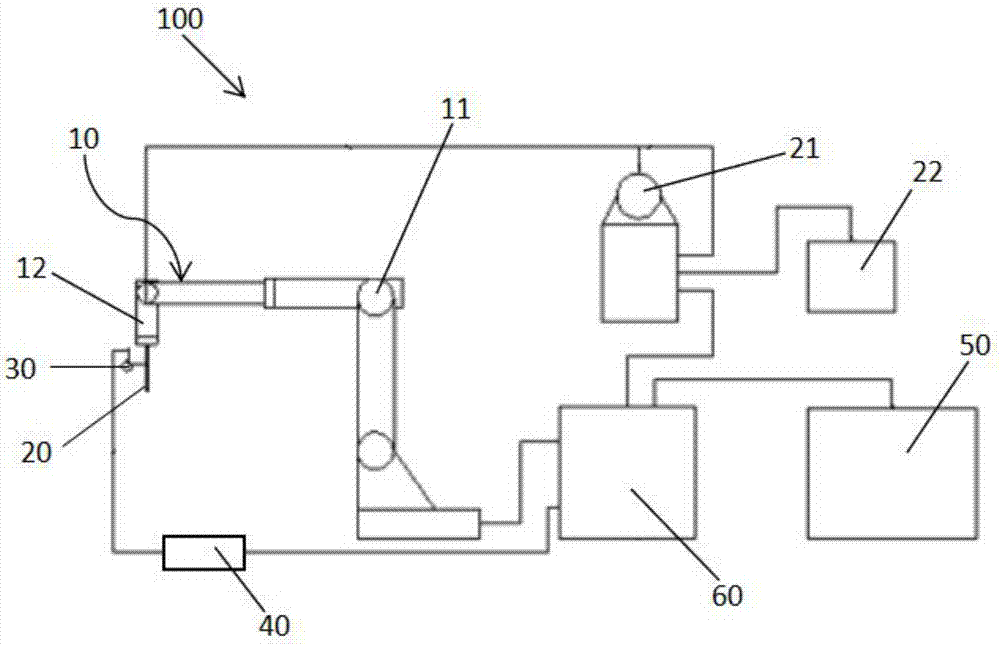

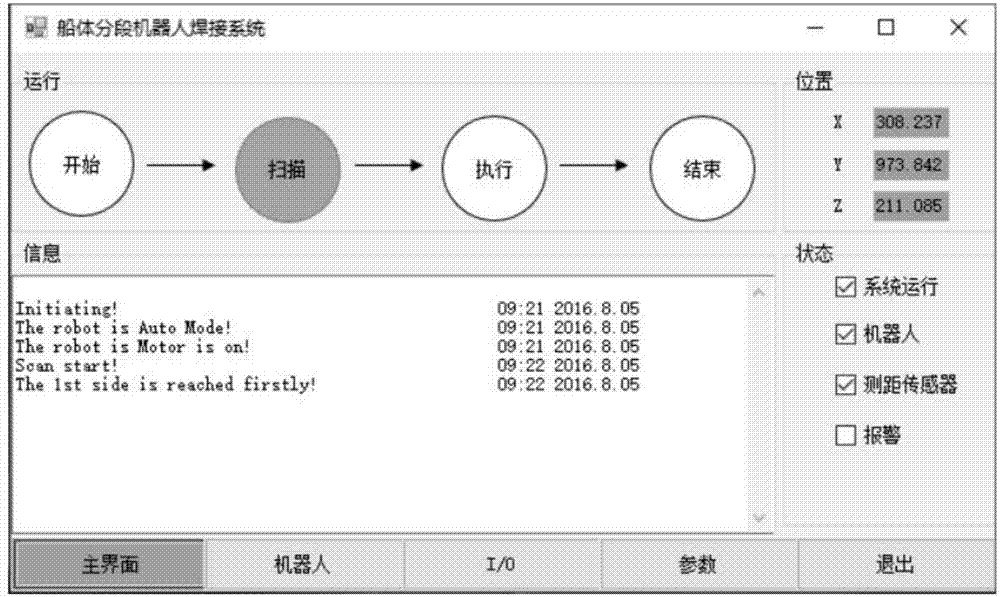

Device and method for detecting filet weld welding trace based on laser ranging

InactiveCN107322597AShorten welding timeObvious fluctuationsProgramme-controlled manipulatorFillet weldLaser ranging

The invention provides a device and method for detecting a filet weld welding trace based on laser ranging. The device for detecting the filet weld welding trace based on laser ranging adopts laser ranging and conducts autonomous locating and automatic welding on a weld joint of a filet weld piece. The device is characterized in that the device comprises a robot, a welding gun, a laser ranging sensor, a Beckhoff module, a main control computer and a robot controller, wherein the robot is provided with a robot body and a mechanical arm, the welding gun is arranged on the mechanical arm and used for welding the weld joint, and the laser ranging sensor is fixed to the end portion of the mechanical arm through a support and used for scanning the weld joint, and feature points of the weld joint on the spatial position are obtained; and the Beckhoff module is connected with the laser ranging sensor and used for collecting the feature points, and the positional information of the weld joint is obtained; and the main control computer is connected with the robot through the Ethernet network, and used for generating the welding sequence of the robot according to the positional information, and the robot controller is used for controlling the robot to conduct motion according to the welding sequence, so that welding is conducted on the weld joint.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

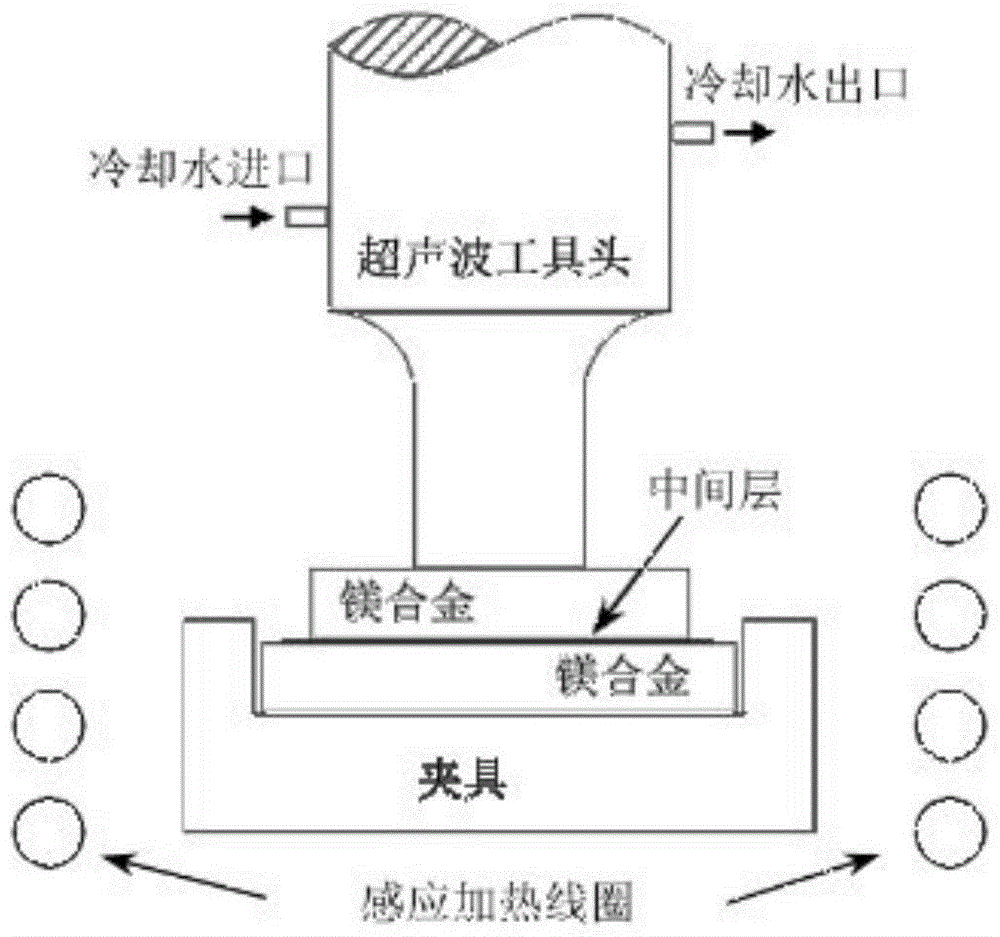

Ultrasonic-assisted transitional liquid phase bonding method

ActiveCN105234555AShorten the timeBreak the realizationNon-electric welding apparatusUltrasonic assistedBonding process

The invention relates to an ultrasonic-assisted transitional liquid phase bonding method. The ultrasonic-assisted transitional liquid phase bonding method aims to solve the problems that existing transitional liquid phase bonding processes need to be completed in vacuum or inert atmospheres and the consumed time is long. The ultrasonic-assisted transitional liquid phase bonding method comprises the steps of firstly, polishing base metal to be welded mechanically, cleaning the base metal to be welded and assembling assemblies to be welded; secondly, applying an ultrasonic tool head to the assemblies to be welded vertically, exerting force, heating the assemblies to be welded and applying ultrasonic vibration to complete isothermal solidification; thirdly, keeping heating the assemblies to be welded if the isothermal solidification time is longer than 10 minutes and then applying ultrasonic vibration to complete isothermal solidification; fourthly, naturally cooling the assemblies to be welded in a furnace to the room temperature so as to complete the operation. According to the invention, interface oxidation films can be broken through the acoustic plasticizing effect of ultrasonic waves in solid, the welding time can be shortened, and the filling rate of weld joints can be higher than 95%. The ultrasonic-assisted transitional liquid phase bonding method is applicable to the brazing field.

Owner:河北宇天材料科技有限公司

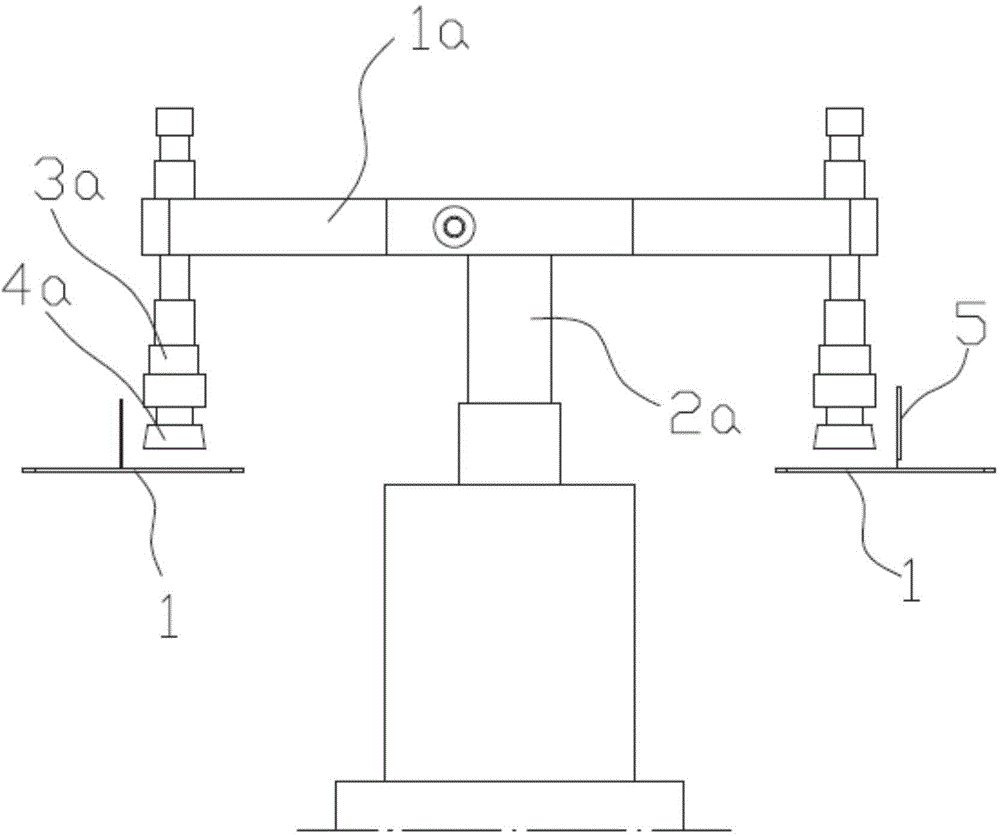

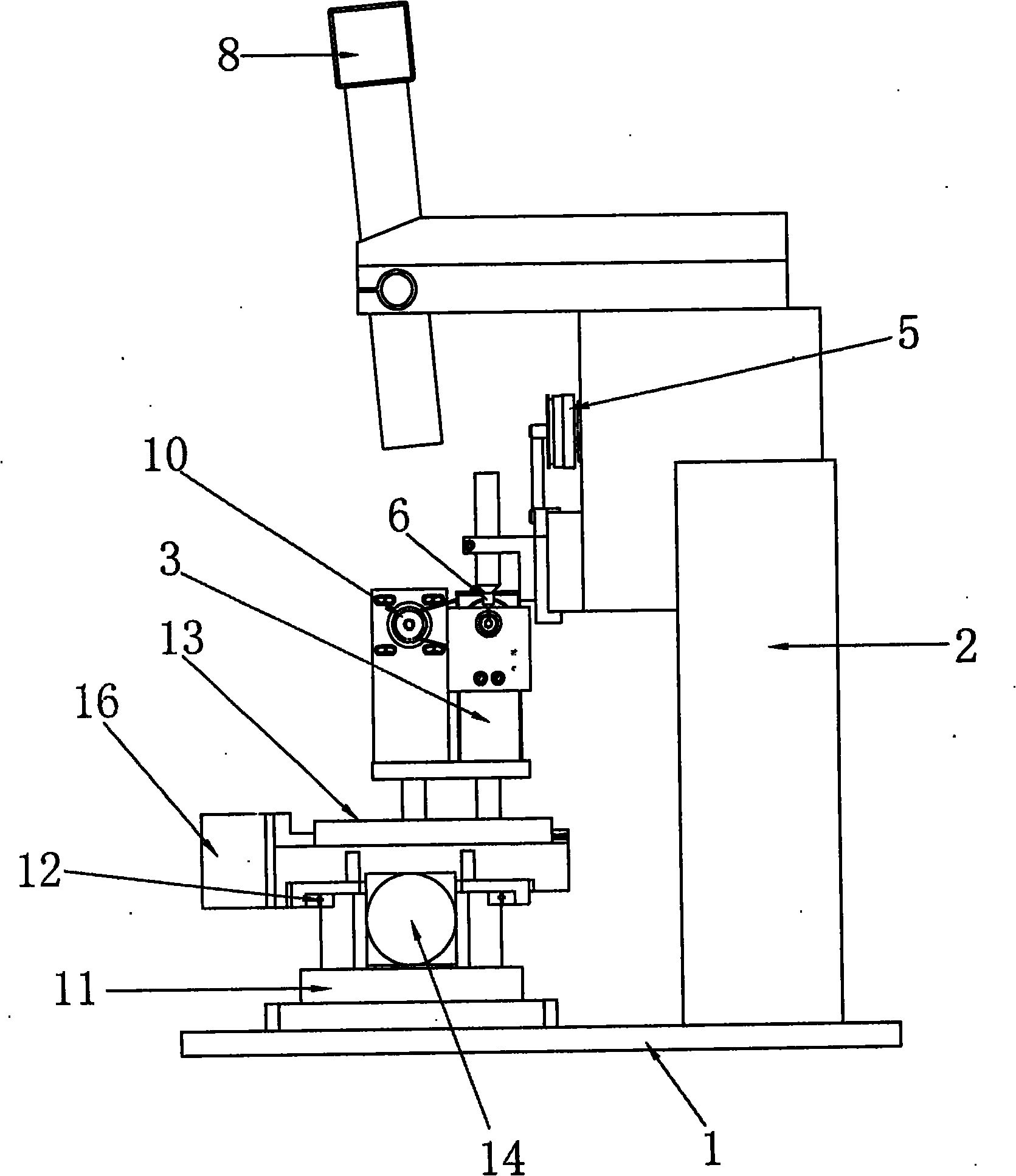

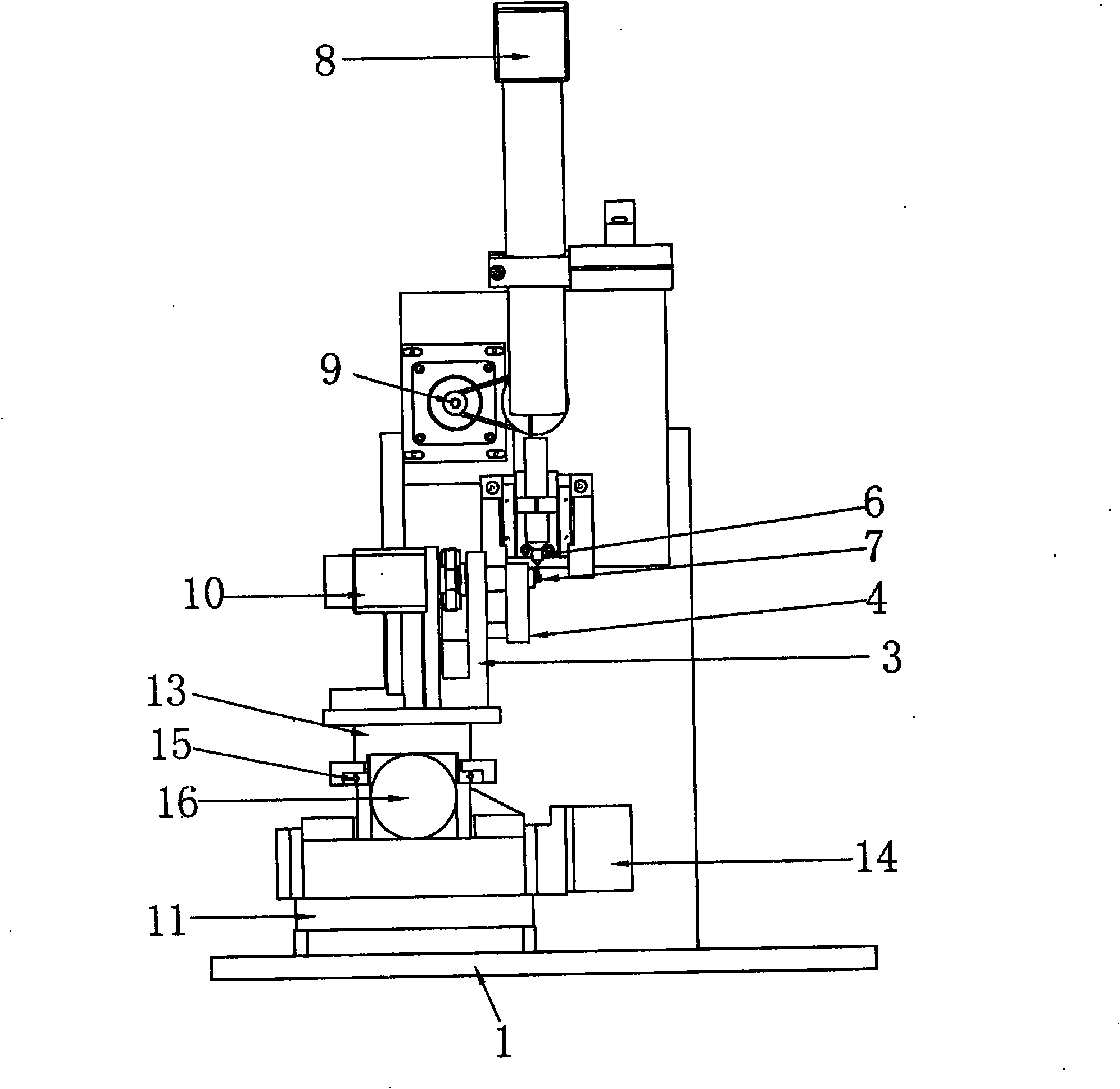

Numerical control rotating three-dimensional ultrasonic gold wire bonder

InactiveCN101774077ASolve Welding ProblemsShorten welding timeNon-electric welding apparatusEngineeringSpot welding

The invention discloses a numerical control rotating three-dimensional ultrasonic gold wire bonder, which is characterized by comprising a bottom plate, a base and a numerical control system, wherein the bottom plate is provided with X and Y axis mobile platforms; the X and Y axis mobile platforms are provided with a device clamp seat; the device clamp seat is provided with a heating block; the base is provided with a Z-axis worktable; the Z-axis worktable is provided with spot welding heads; the device clamp seat and the heating block are provided with device clamps; the positions of the spot welding heads correspond to those of the device clamps; the base is provided with a camera which can carry out camera shooting on devices on the device clamps and feeds back the shot information to the numerical control system; and the X and Y axis mobile platforms and the Z-axis worktable are connected with the numerical control system. Through the numerical control rotating three-dimensional ultrasonic gold wire bonder, the welding time can be shortened, the welding efficiency can be improved, a mass of human resources are saved and the problem that the conventional gold wire bonding machine cannot weld the internal leads of the polyhedral or irregular polyhedral large or small power devices is solved.

Owner:周志坚

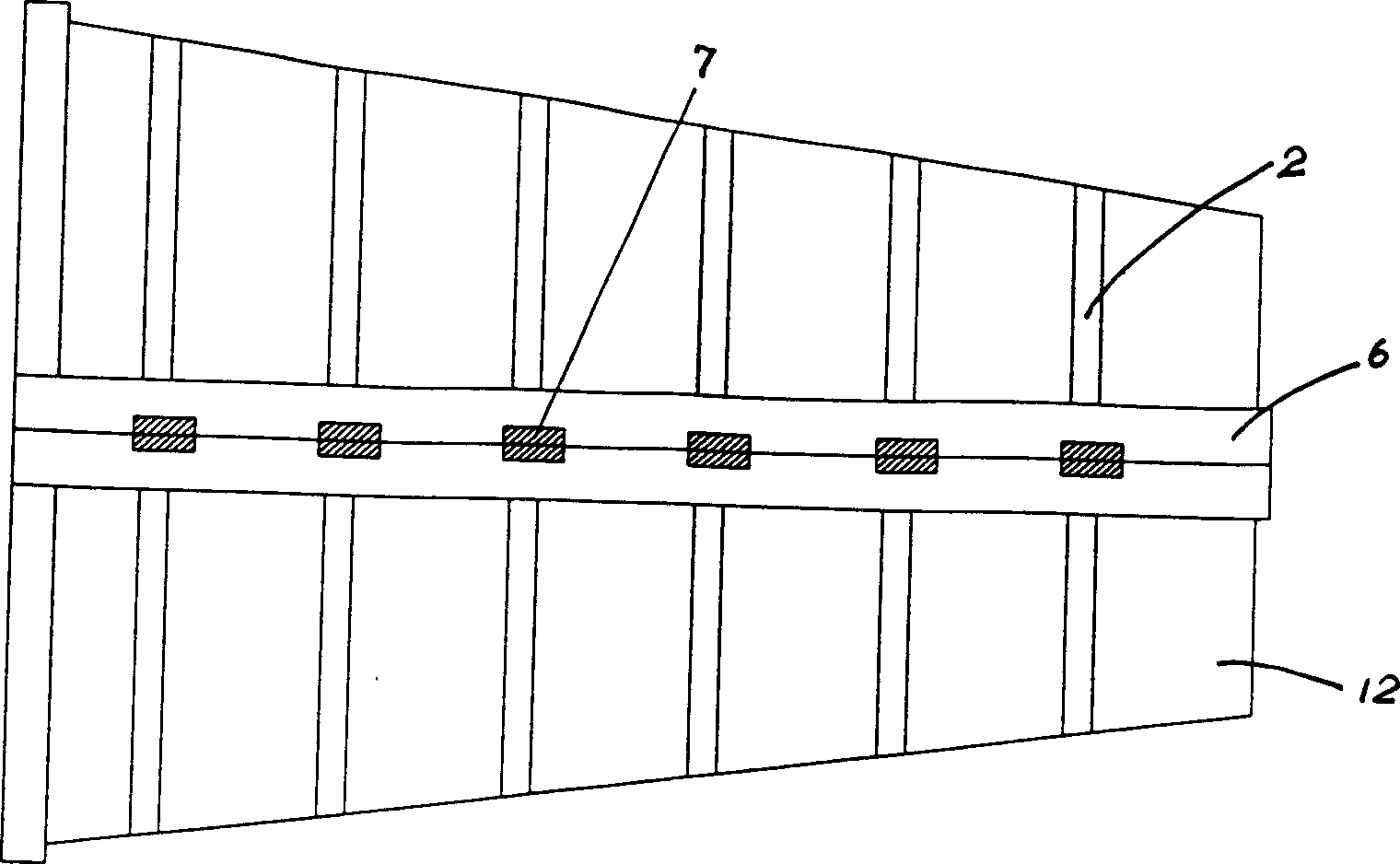

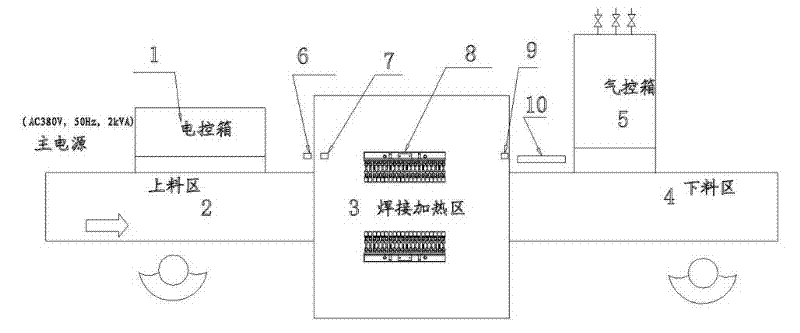

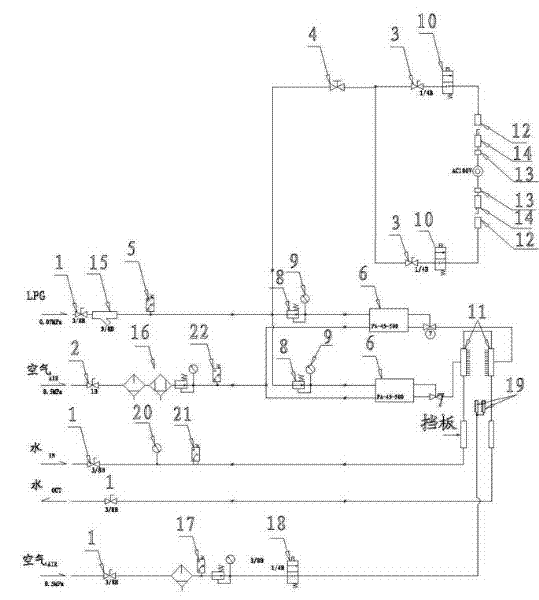

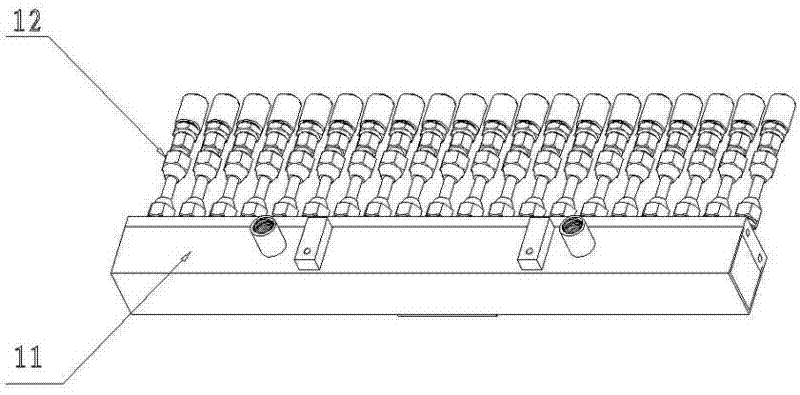

Digital display precision flow controllable and adjustable multi-column aluminum heat exchanger flame brazing equipment

The invention discloses torch soldering equipment which is used for linearly moving on a rail and is used for soldering the U-shaped tube of an all aluminum heat exchanger. The equipment is composed of an electric control unit, a material feeding area, a welding and heating area, a blanking area and a pneumatic control unit. Under the condition that liquefied petroleum gas (LPG), air, cooling water, a power supply and the like are switched on as required, the existing product specification (technological parameters, such as chosen transmission link speed, flame size and the like) is chosen, and then, ignition is carried out to start a conveyor, and a conveying chain is operated under a constant speed. Workpieces (parts and welding rings which are assembled as required) which need to be welded are continuously put in the material feeding area to a conveying link plate; products are conveyed to two sides of a welding area by the conveying link plate automatically at a constant speed to be heated and welded by symmetrical fire row flames; then the products are conveyed to the blanking area; and the products are continuously unloaded from a conveying link in the blanking area and simultaneously a welding effect is monitored.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

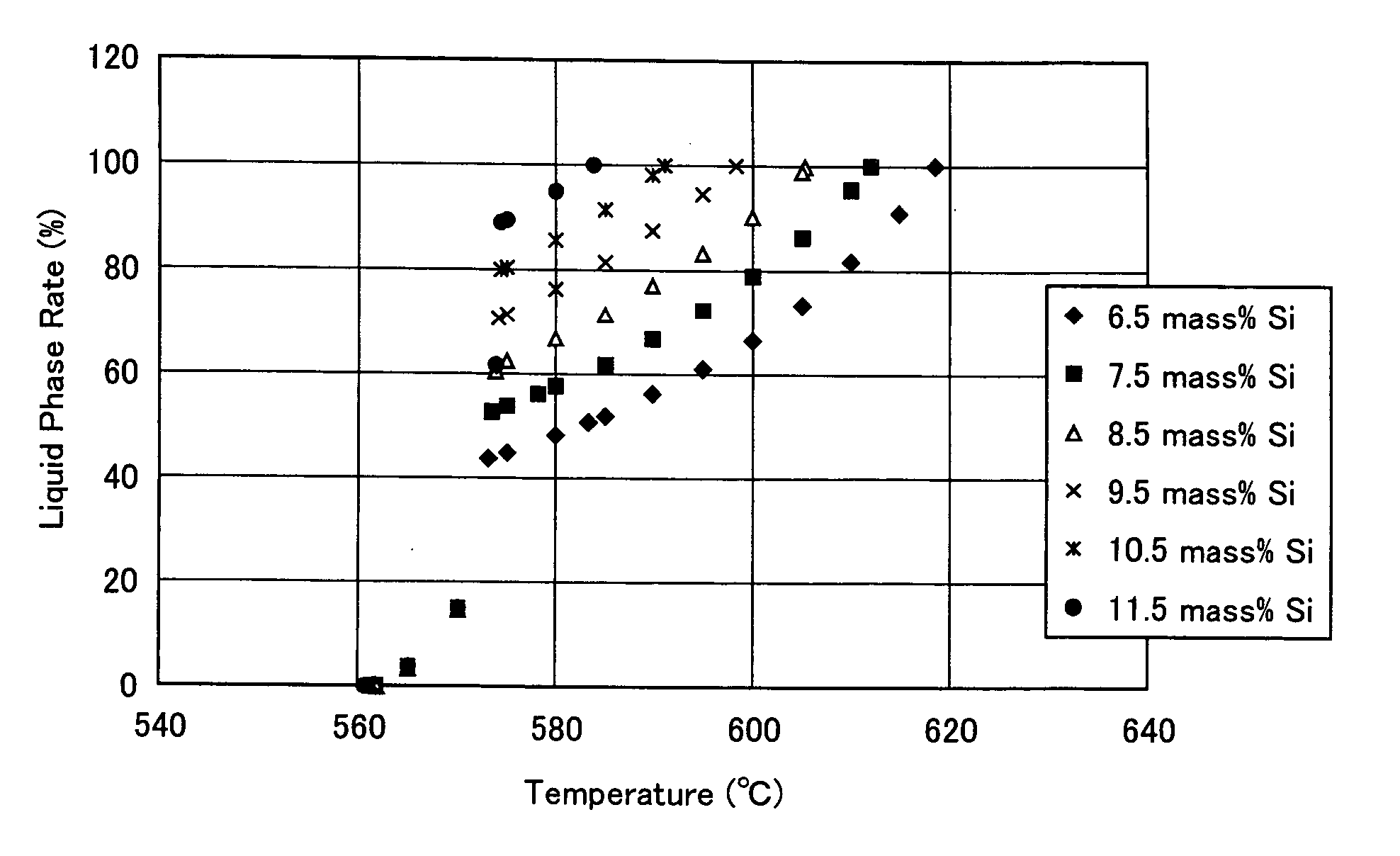

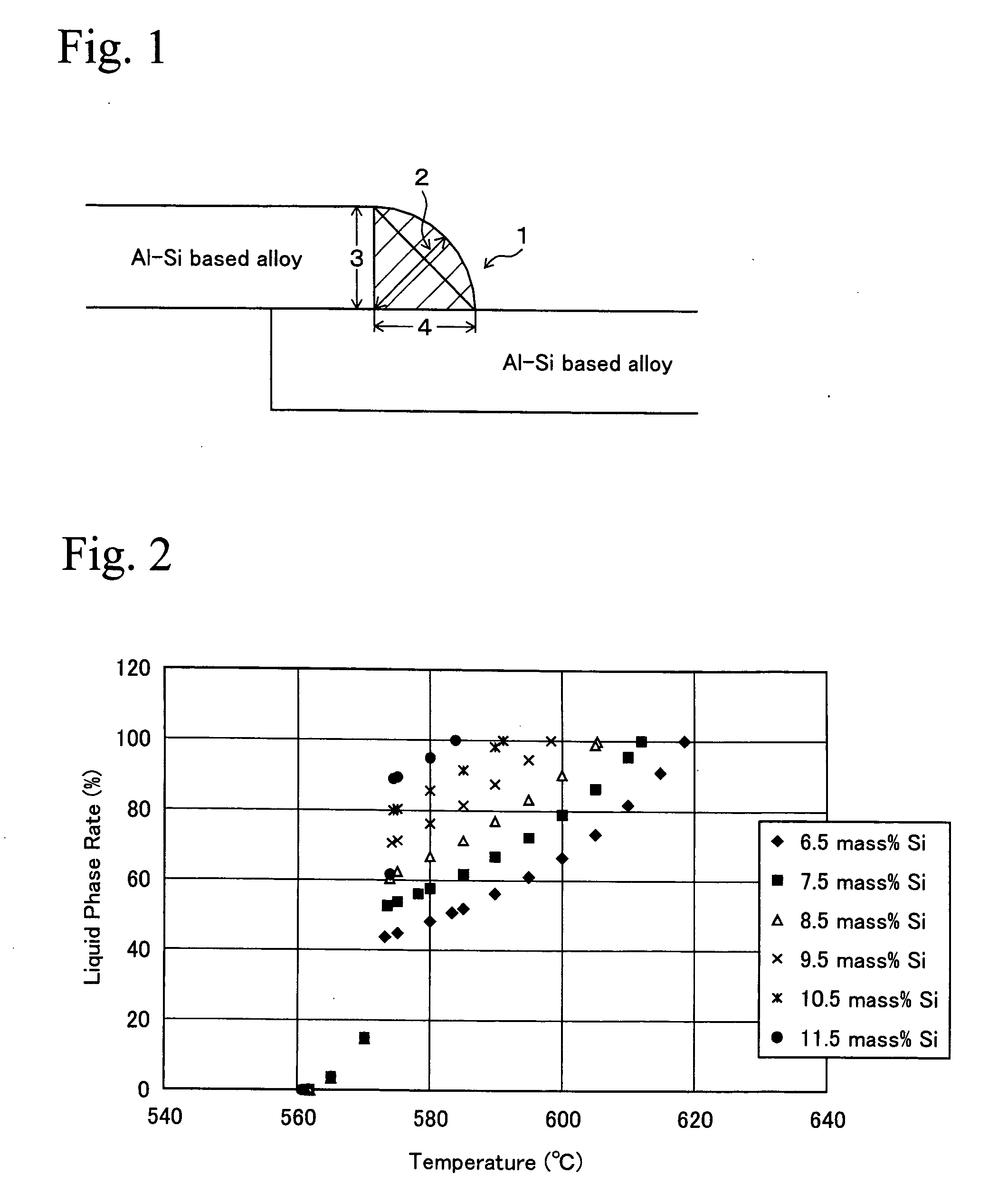

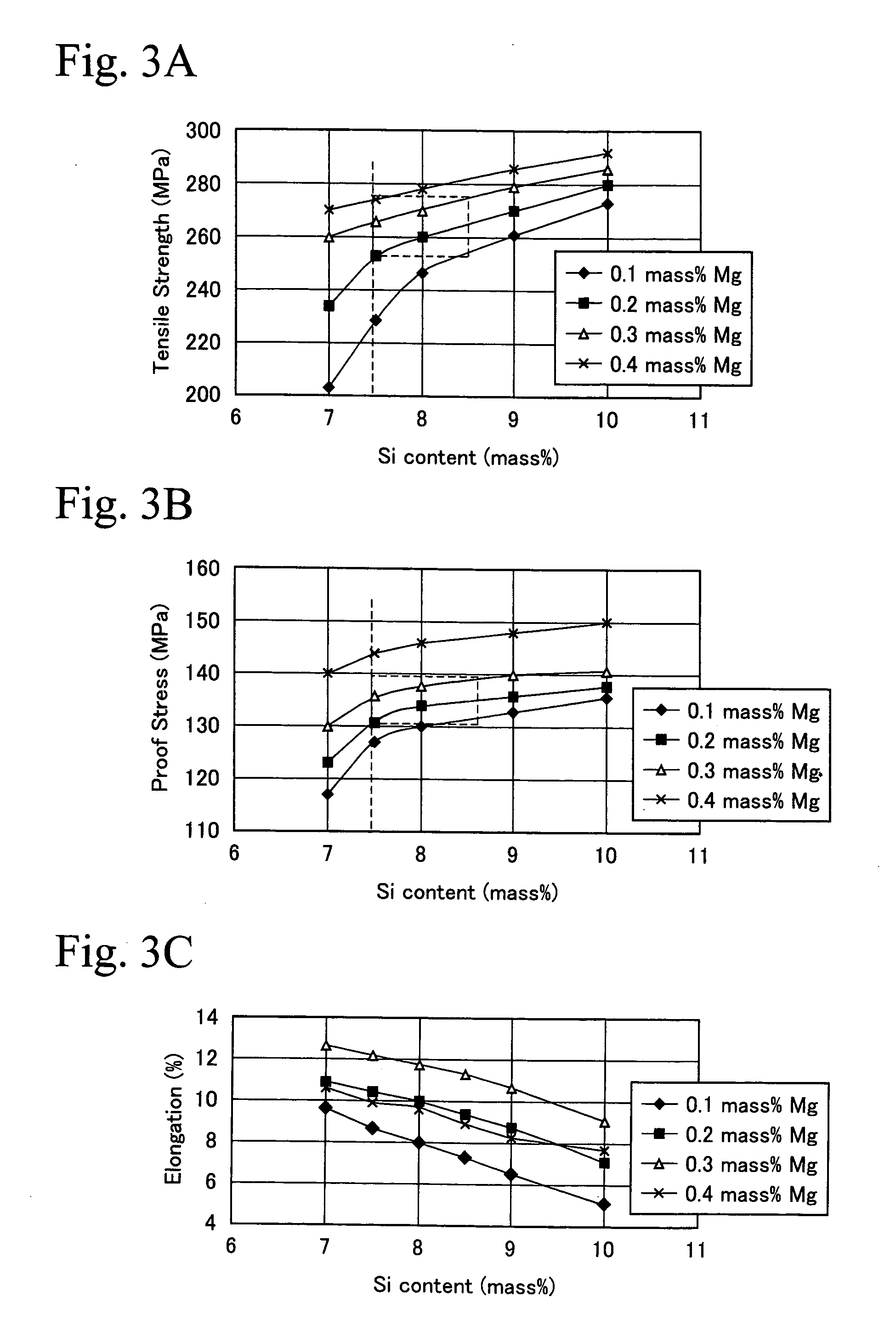

Al-Si based alloy and alloy member made therefrom

An Al—Si based alloy and an alloy member made of the alloy, in which when alloys produced by diecasting under high vacuum conditions are welded, weldability can be improved without increasing plate thickness of welded portions and reducing gas content in diecasting.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com