Method for welding cut surface butt joint formed by thin welding base materials

A technology of butt joint and base metal, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high welding cost, incomplete penetration, and long welding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1: For specifications of The stainless steel pipe group is welded to form a cut-butt joint

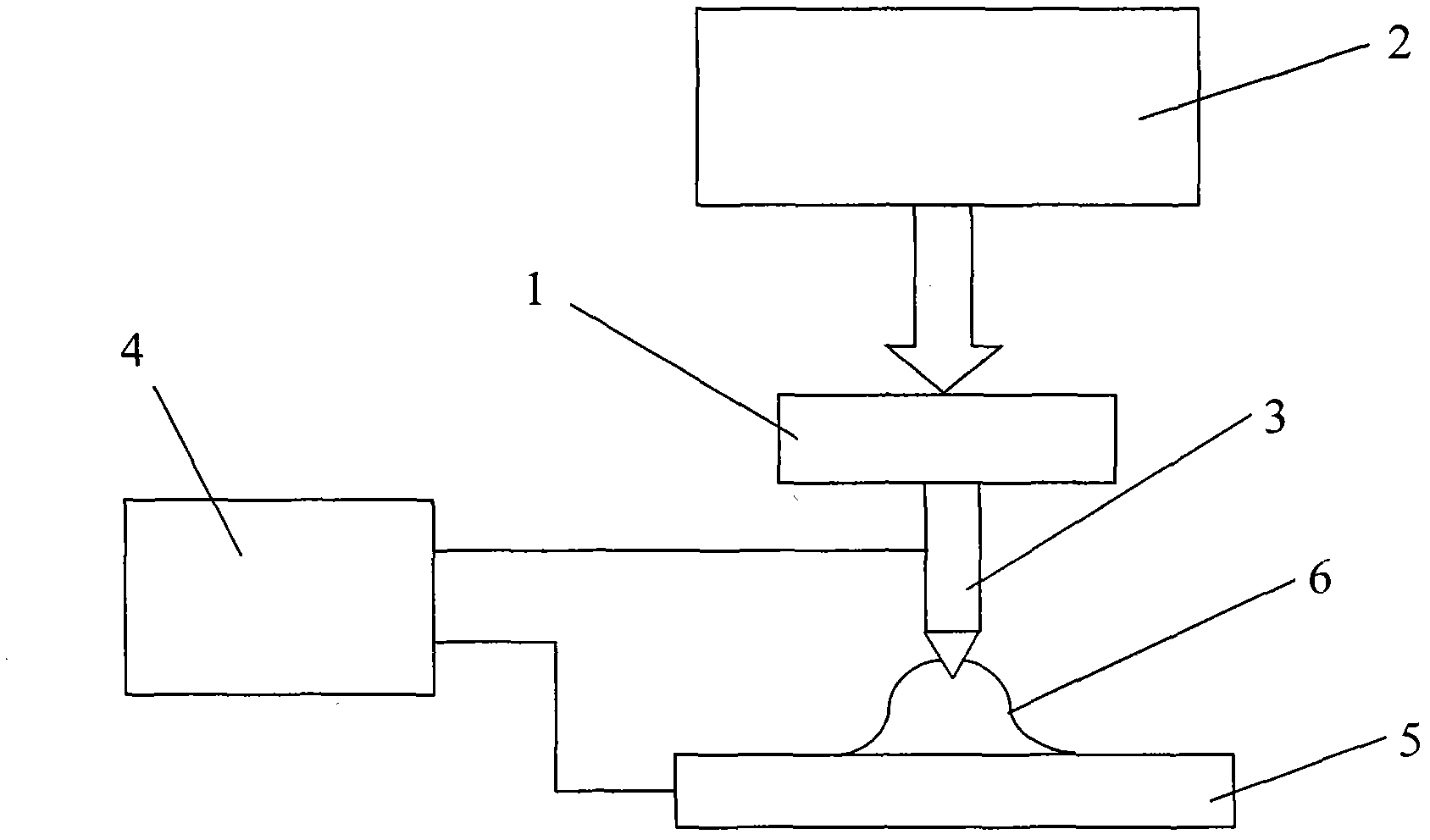

[0070] The pipe diameter of the pipe to be welded is 88.9 mm, and the pipe wall thickness H is 3.05 mm. The welding power source is German STAPLA ultrasonic and TIG composite arc welding machine, and the welding equipment is cantilever automatic welding equipment.

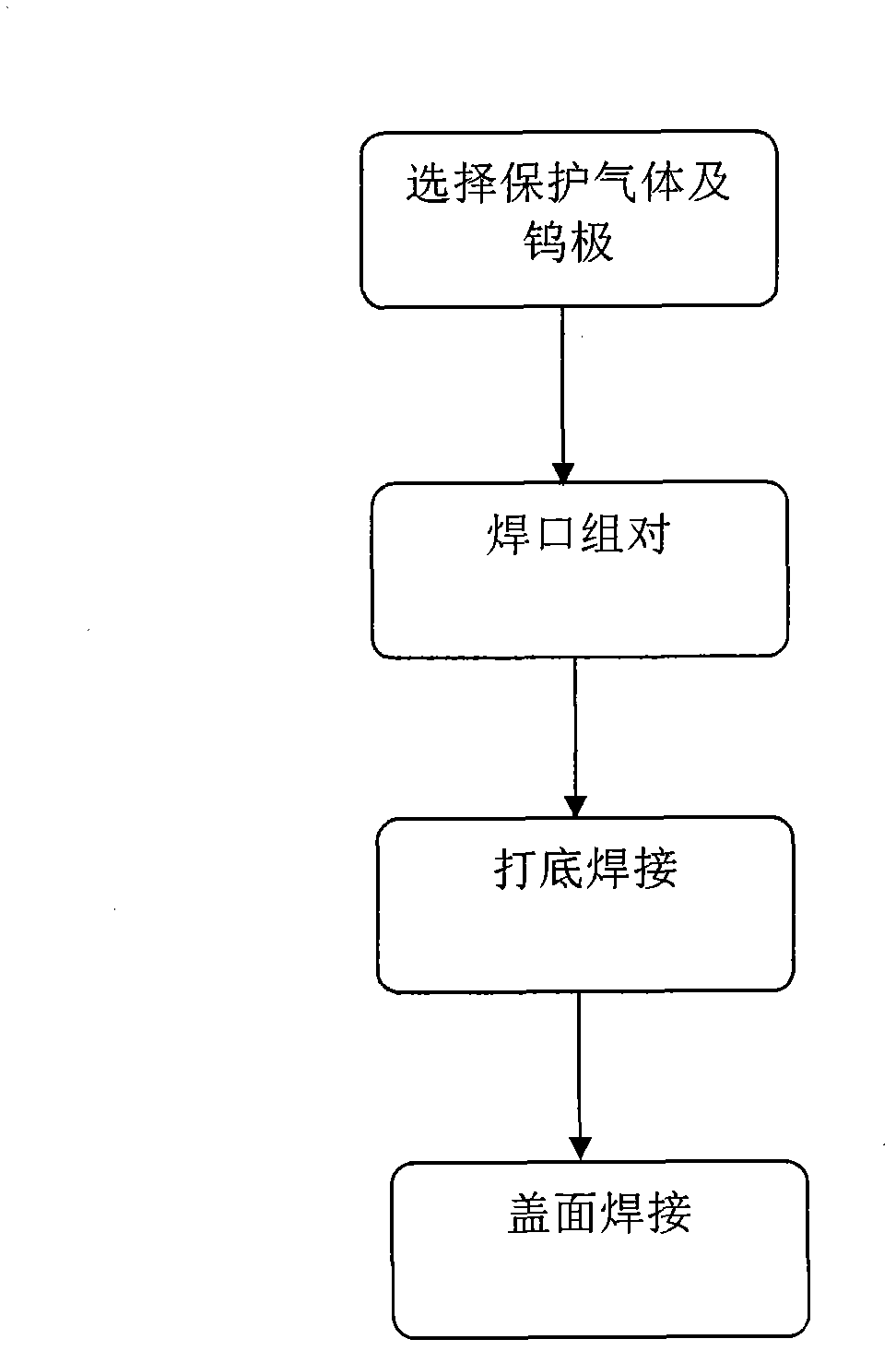

[0071] (1) Select shielding gas and tungsten electrode:

[0072] ①Select the protective gas: the protective gas is argon with a purity of 99.99%.

[0073] ②Select tungsten electrode:

[0074] The tungsten pole is a cerium tungsten pole with a diameter of 4.0mm and a taper of 40°, and a tungsten pole with a platform diameter of 0.0mm is used for bottom welding, and a tungsten pole with a platform diameter of 0.3mm is used for filling and cap welding. pole.

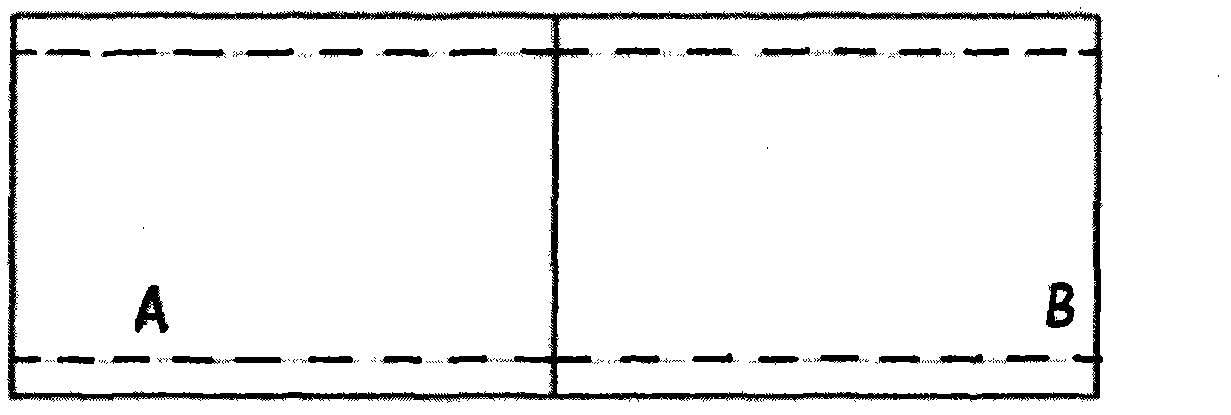

[0075] (2) Welding joint pair:

[0076] Before the assembly, the pipe is cut off with a band saw, and the section to be welded is smoothed with a g...

Embodiment 2

[0091] Example 2: For specifications of The stainless steel pipe group is welded to form a cut-butt joint

[0092] The pipe diameter of the pipe to be welded is 114.3 mm, and the pipe wall thickness H is 6.0 mm. The welding power source is German STAPLA ultrasonic and TIG composite arc welding machine, and the welding equipment is cantilever automatic welding equipment.

[0093] (1) Select shielding gas and tungsten electrode:

[0094] ①Select the protective gas: the protective gas is argon with a purity of 99.99%.

[0095] ②Select tungsten electrode:

[0096] The tungsten pole is a cerium tungsten pole with a diameter of 4.0mm and a tungsten pole taper of 40°. A tungsten pole with a platform diameter of 0.0mm is used for bottom welding, and a tungsten pole with a platform diameter of 0.5mm is used for filling and cap welding. pole.

[0097] (2) Welding joint pair:

[0098] Before the assembly, the pipe is cut off with a band saw, and the section to be welded is smoothed ...

Embodiment 3

[0108] Example 3: For specifications of The carbon steel pipe group is welded to form a face-to-face butt joint

[0109] The pipe diameter of the pipe to be welded is 168.0 mm, and the pipe wall thickness H is 4.37 mm. The welding power source is German STAPLA ultrasonic and TIG composite arc welding machine, and the welding equipment is cantilever automatic welding equipment.

[0110] (1) Select shielding gas and tungsten electrode:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com