Patents

Literature

50results about How to "Reduce machining time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

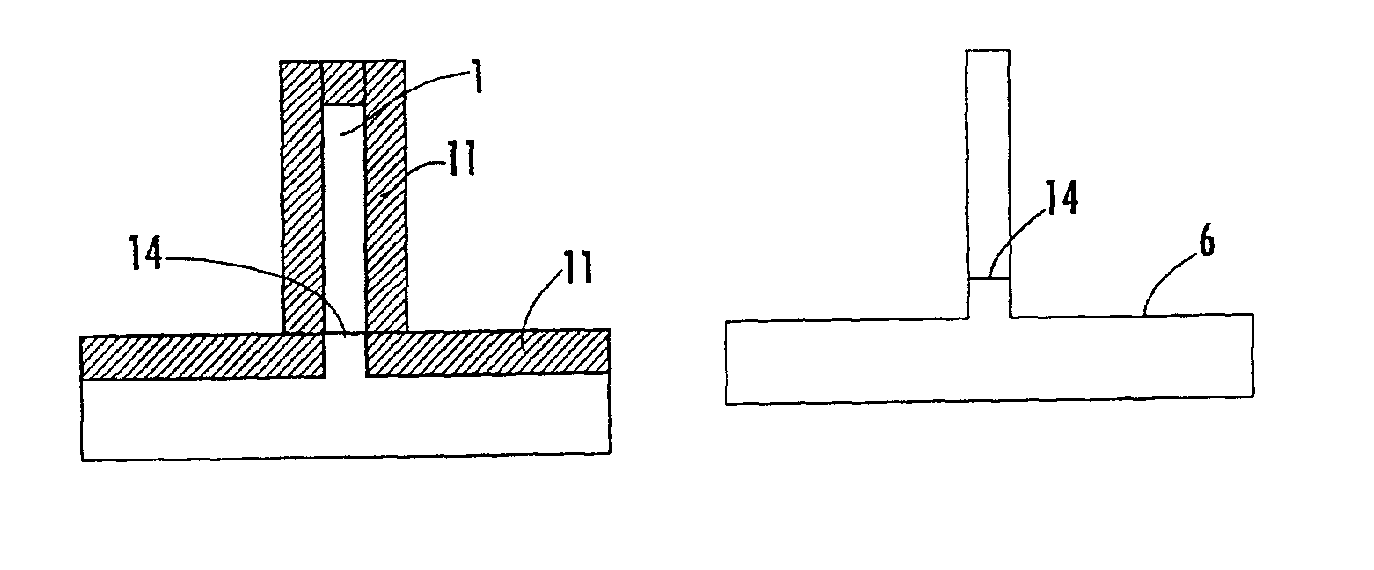

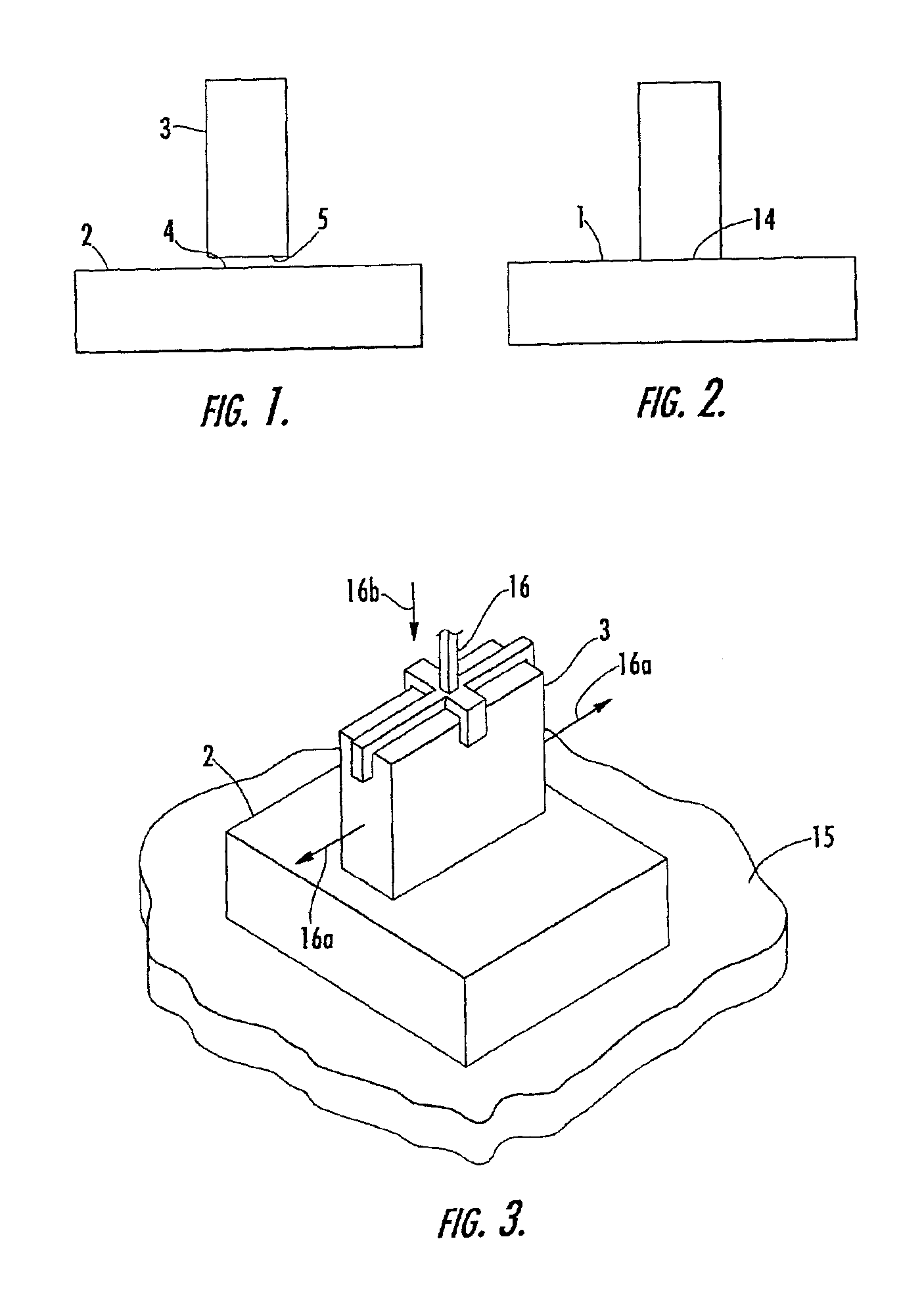

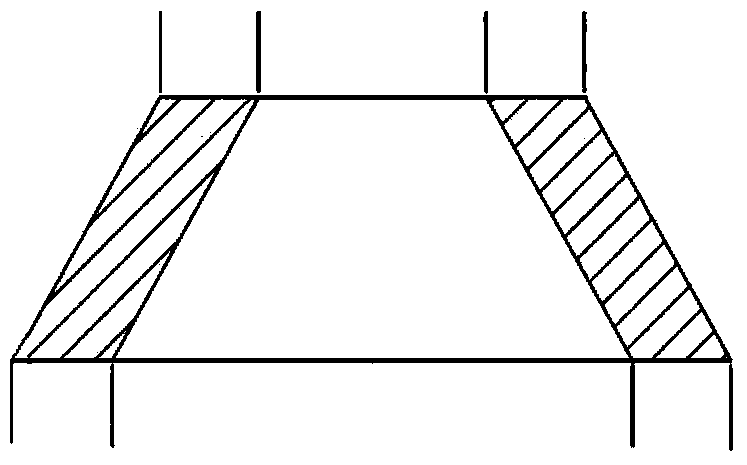

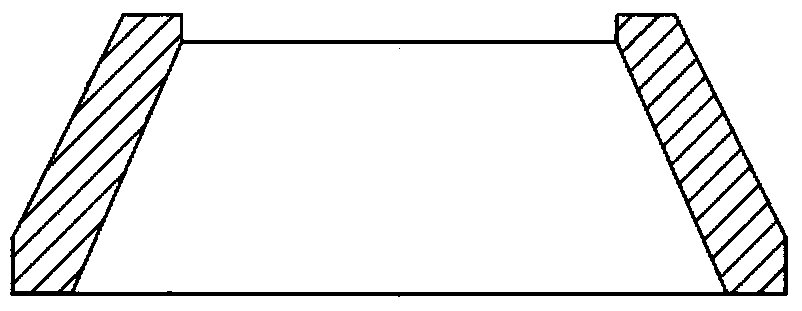

Preforms for forming machined structural assemblies

InactiveUS6910616B2Reduce material wasteReduce machining timeWelding/cutting auxillary devicesAuxillary welding devicesStructural elementStructural component

A method of constructing a preform for use in forming a machined structural assembly is provided. The method includes determining the dimensions of the machined structural assembly. First and second structural members are selected based on the predetermined dimensions of the machined structural assembly. The first structural member is positioned adjacent the second structural member so as to define at least two contact surfaces. The contact surfaces of the first and second structural members are friction welded to construct the preform such that the preform has dimensions approximating the dimensions of the machined structural assembly to thereby reduce material waste when forming the machined structural assembly. A machined structural assembly having predetermined dimensions is formed from the preform by machining away excess material.

Owner:THE BOEING CO

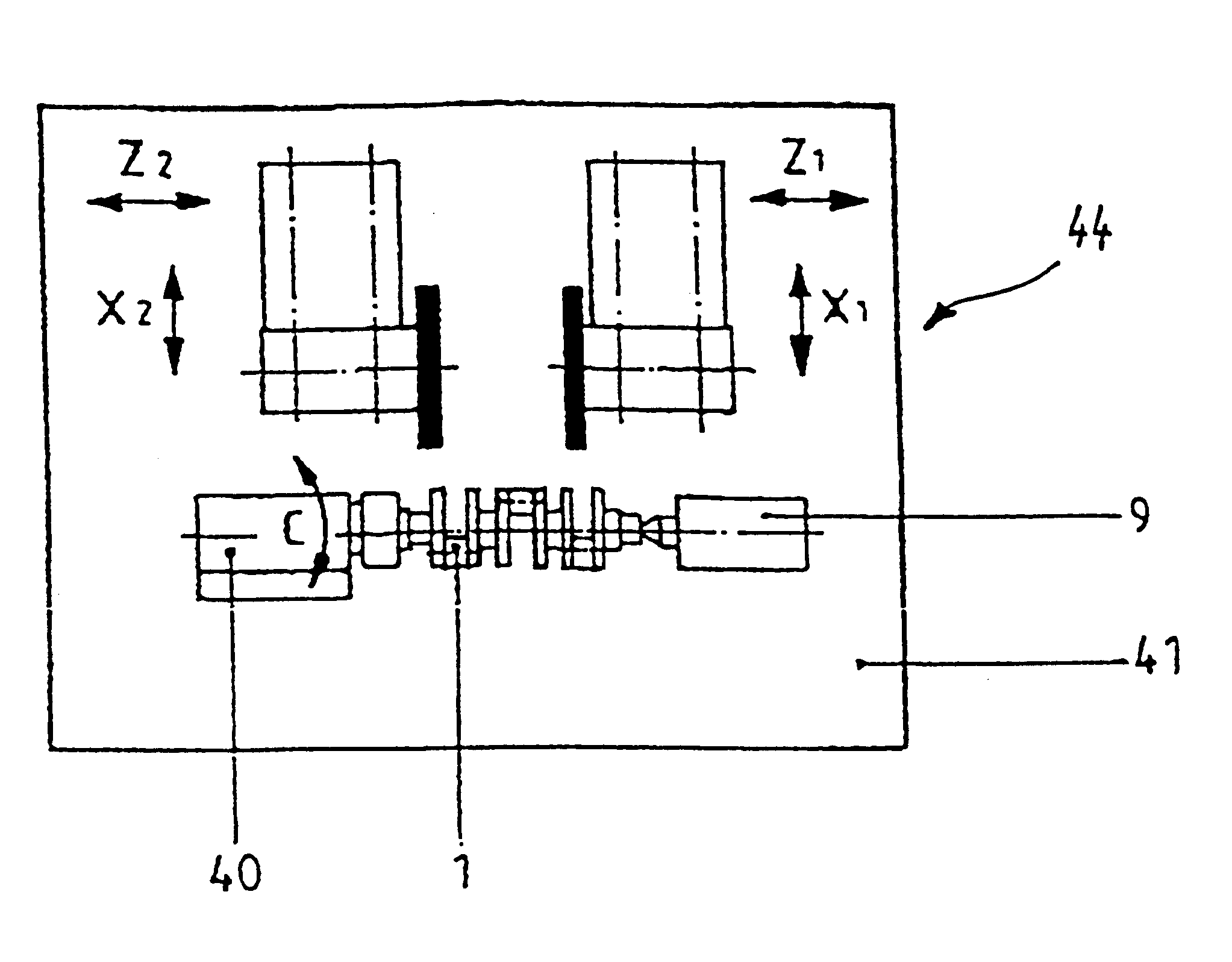

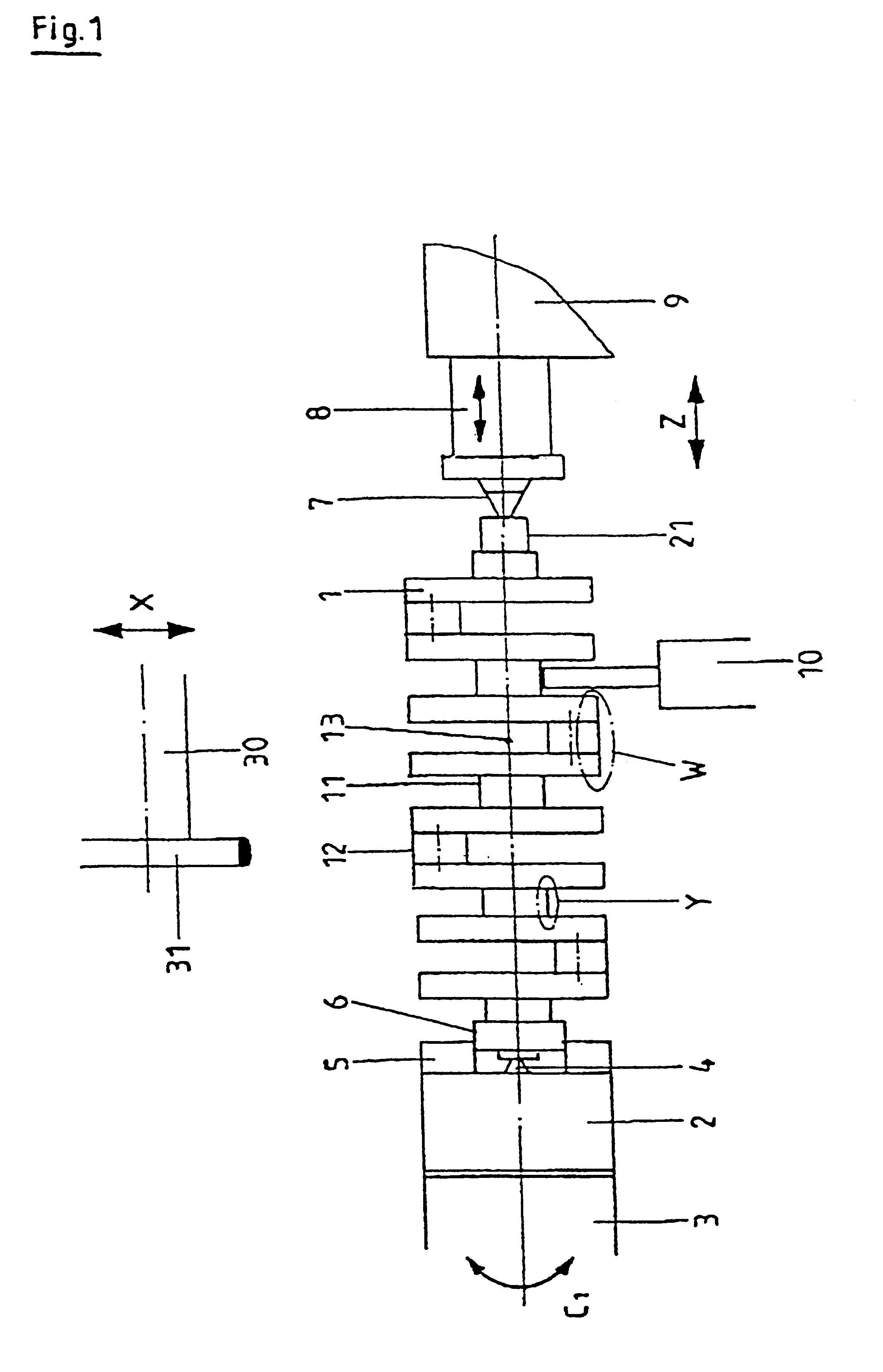

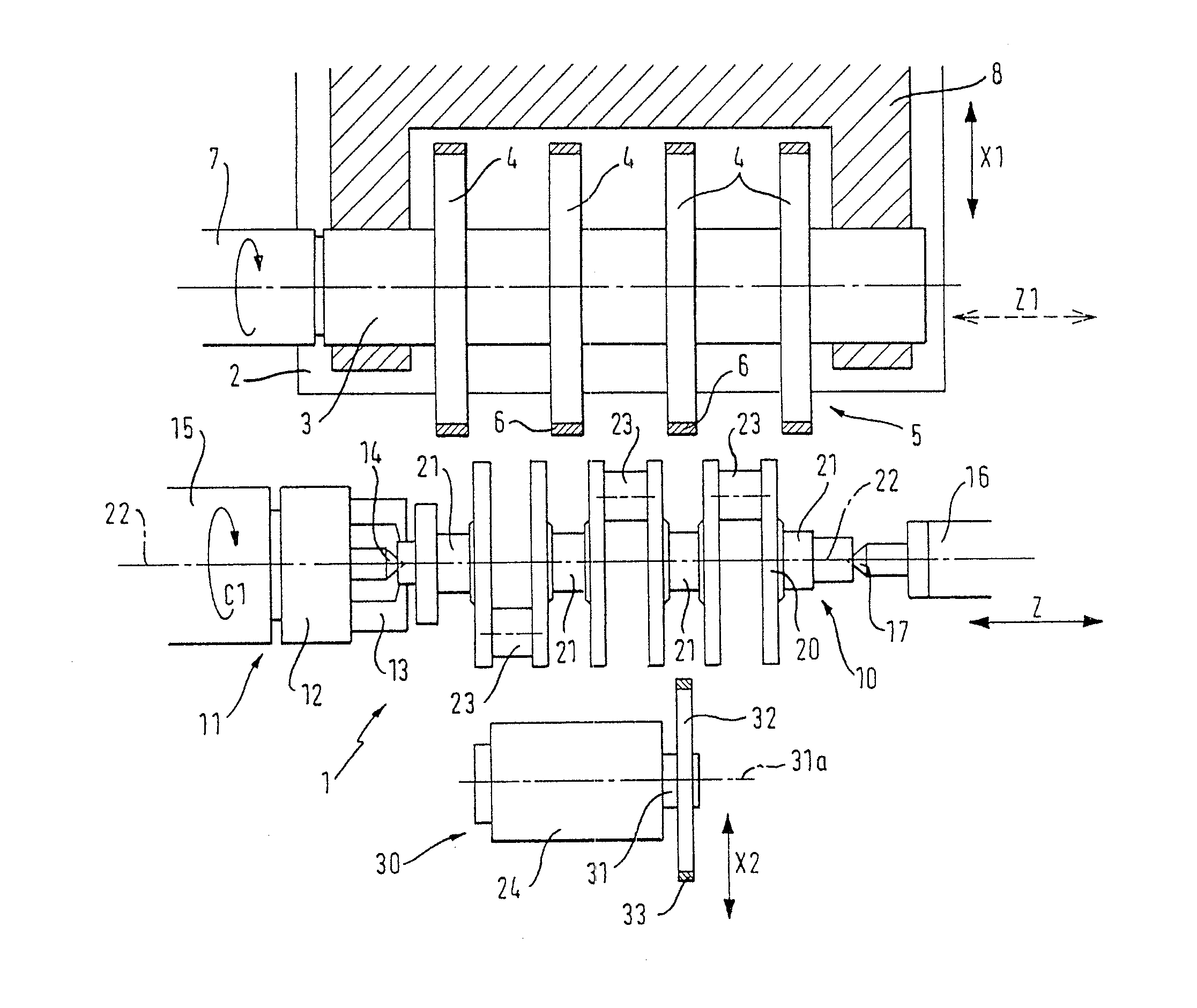

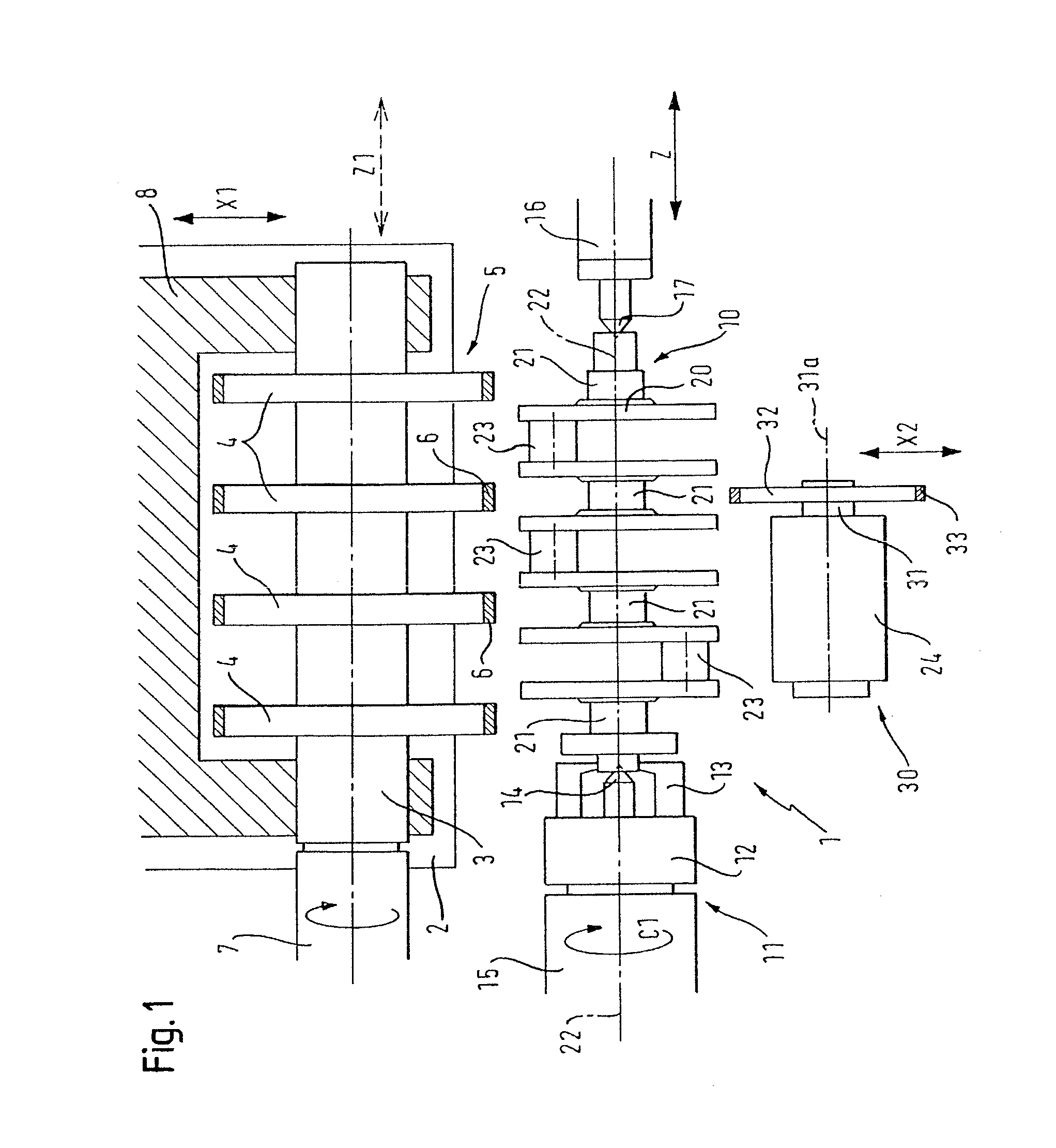

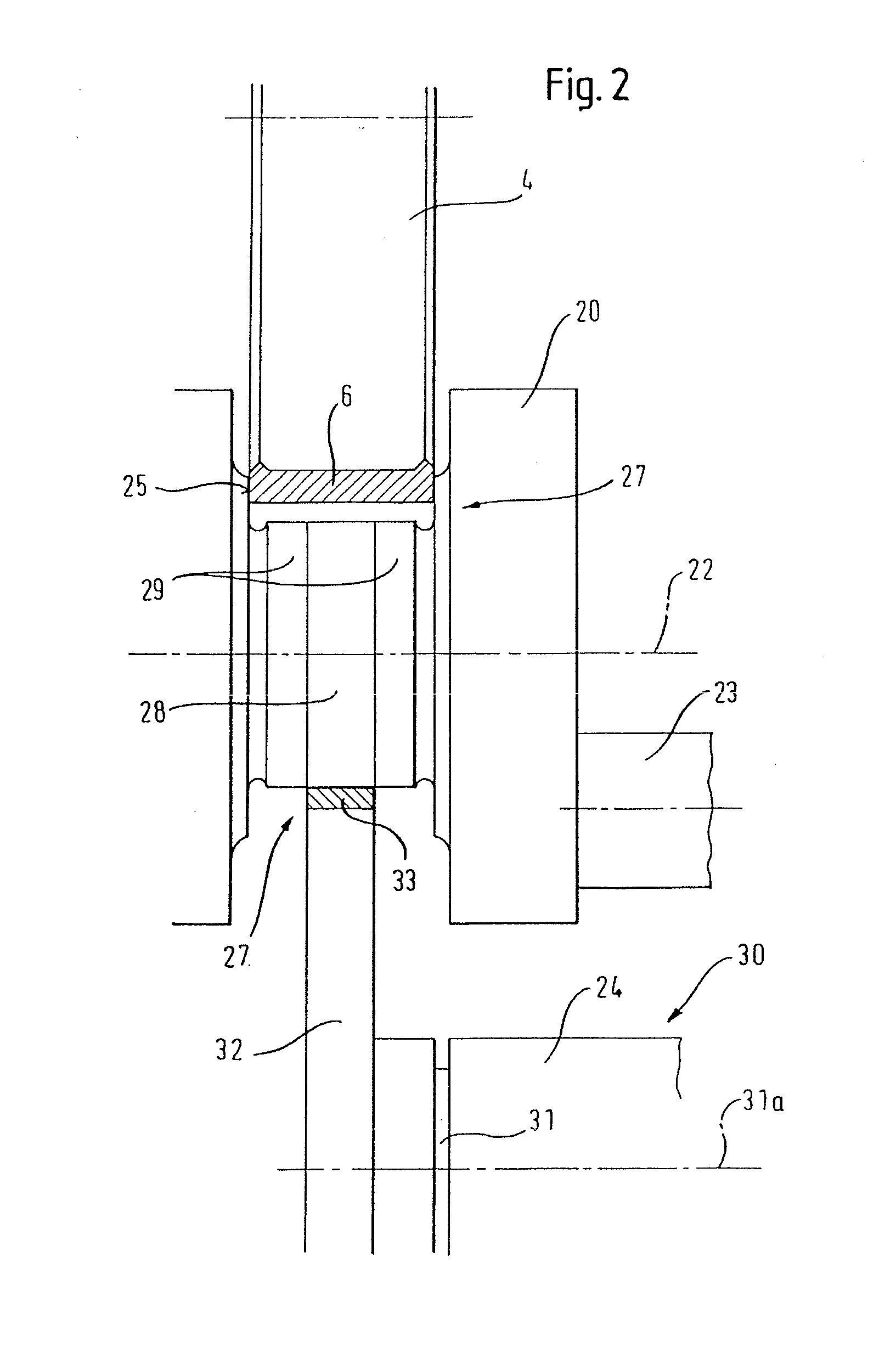

Rough- and finish-grinding of a crankshaft in one set-up

InactiveUS6878043B1Reduce machining timeWell formedRevolution surface grinding machinesOther manufacturing equipments/toolsAlloy steelEngineering

Method of grinding a concentrically clamped crankshaft, a crankshaft grinding machine for carrying out the method, and a crankshaft of high-alloy steel or cast material. The method provides for pin journals and main journals of the crankshaft to be ground in one set-up such that first, at least the main journals are rough-ground and then the pin journals are finish-ground and after that the main journals are finish-ground. The crankshaft grinding machine forms a machining center by means of which corresponding rough-grinding and finish-grinding is possible in a single set-up.

Owner:ERWIN JUNKER MASCHNINENFAB

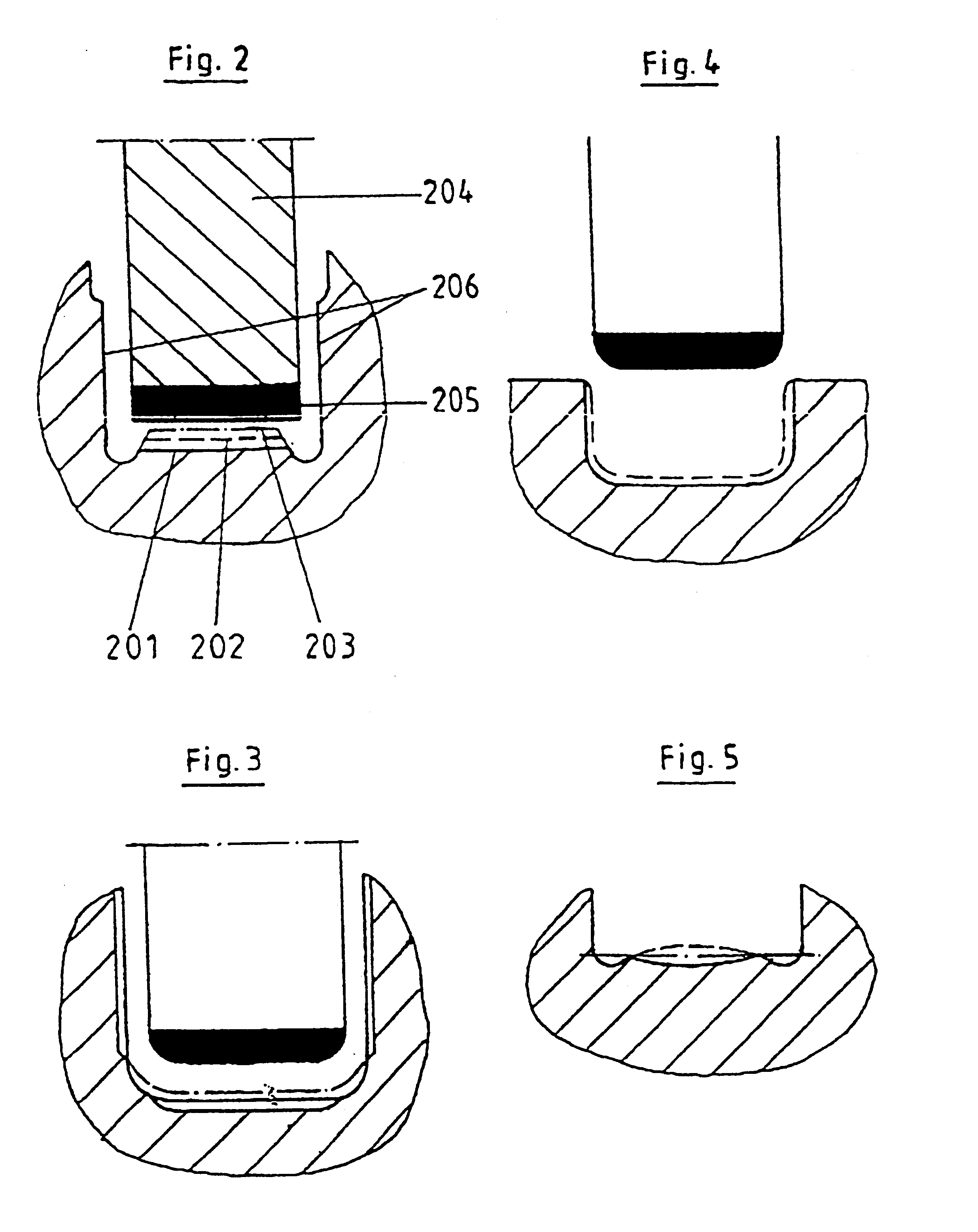

Method for manufacturing box shell of large special-shaped low-pressure turbine used for aircraft engine

The invention discloses a method for manufacturing a box shell of a large special-shaped low-pressure turbine used for an aircraft engine. A GH 4169 alloy blank is chamfered by R20mm and is heated in a three-section heating mode at the temperature of 845-855 DEG C, 975-985 DEG C and 1015-1025 DEG C, the heat-preservation time of each heating temperature section is 6min / 10mm, then upsetting, punching, hole expanding and trestle chambering are carried out, and ultimately the box shell is finished through forged forming. According to the method, a large special-shaped bearing ring supercritical rolling technique replaces a traditional rectangular ring rolling technique, part metal flow lines are complete, large amounts of mechanical machining is needless, performance is excellent, the use rate of materials is high, raw materials are saved, manufacturing cost is low, the manufacturing cycle is short, structural stress inside a product is basically eliminated, and follow-up machining performance of the product is guaranteed.

Owner:GUIZHOU AVIATION TECHN DEV

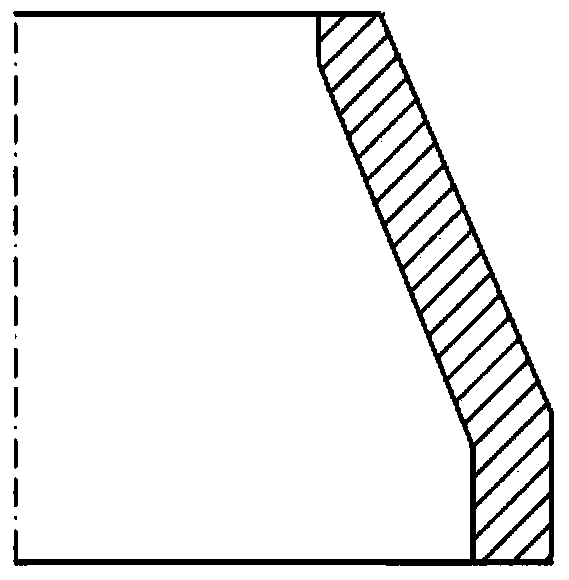

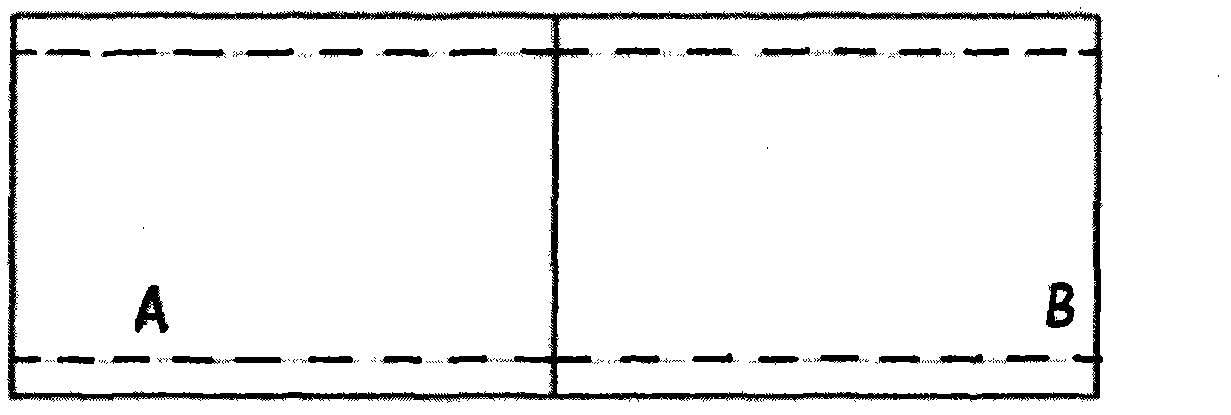

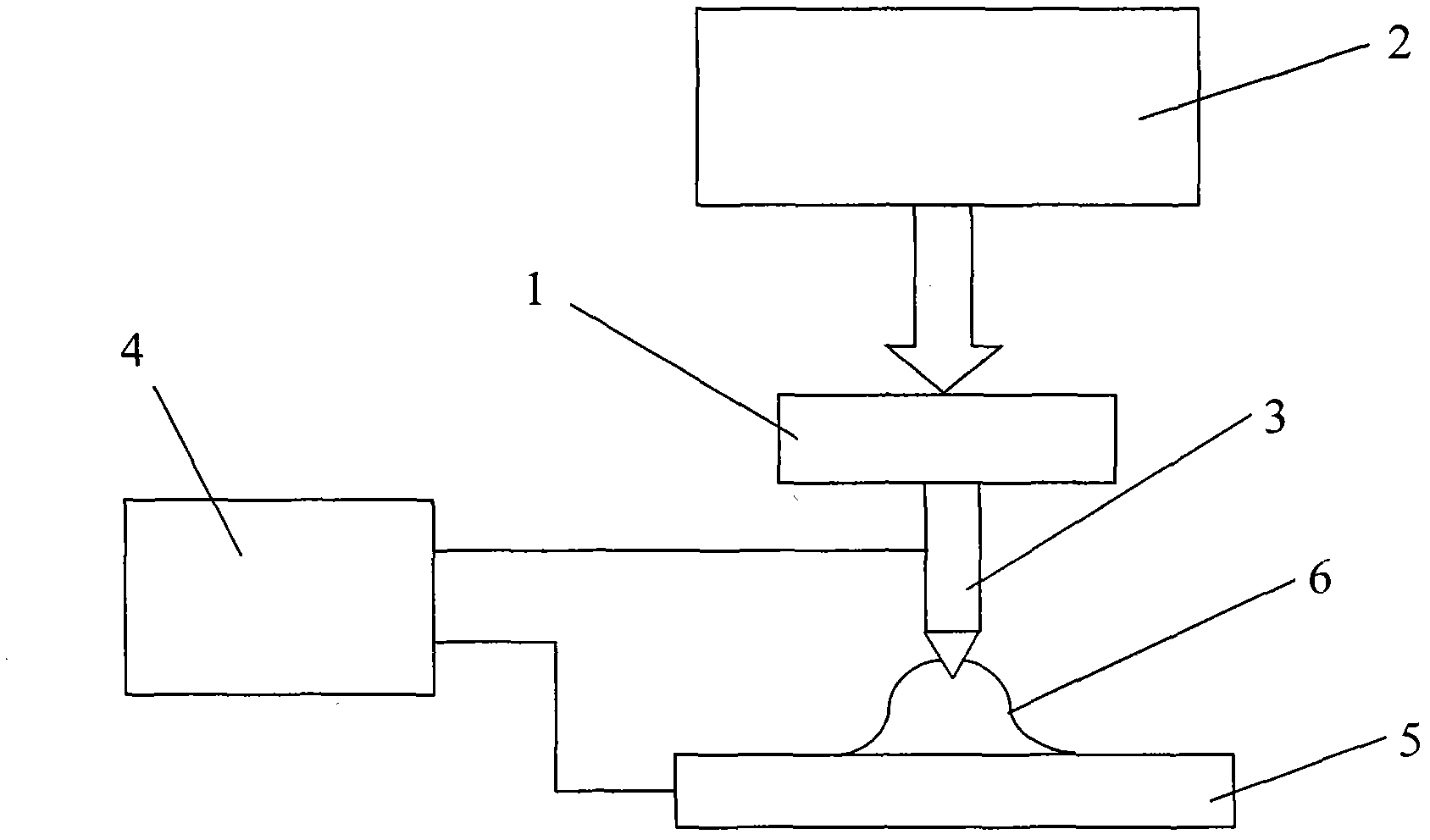

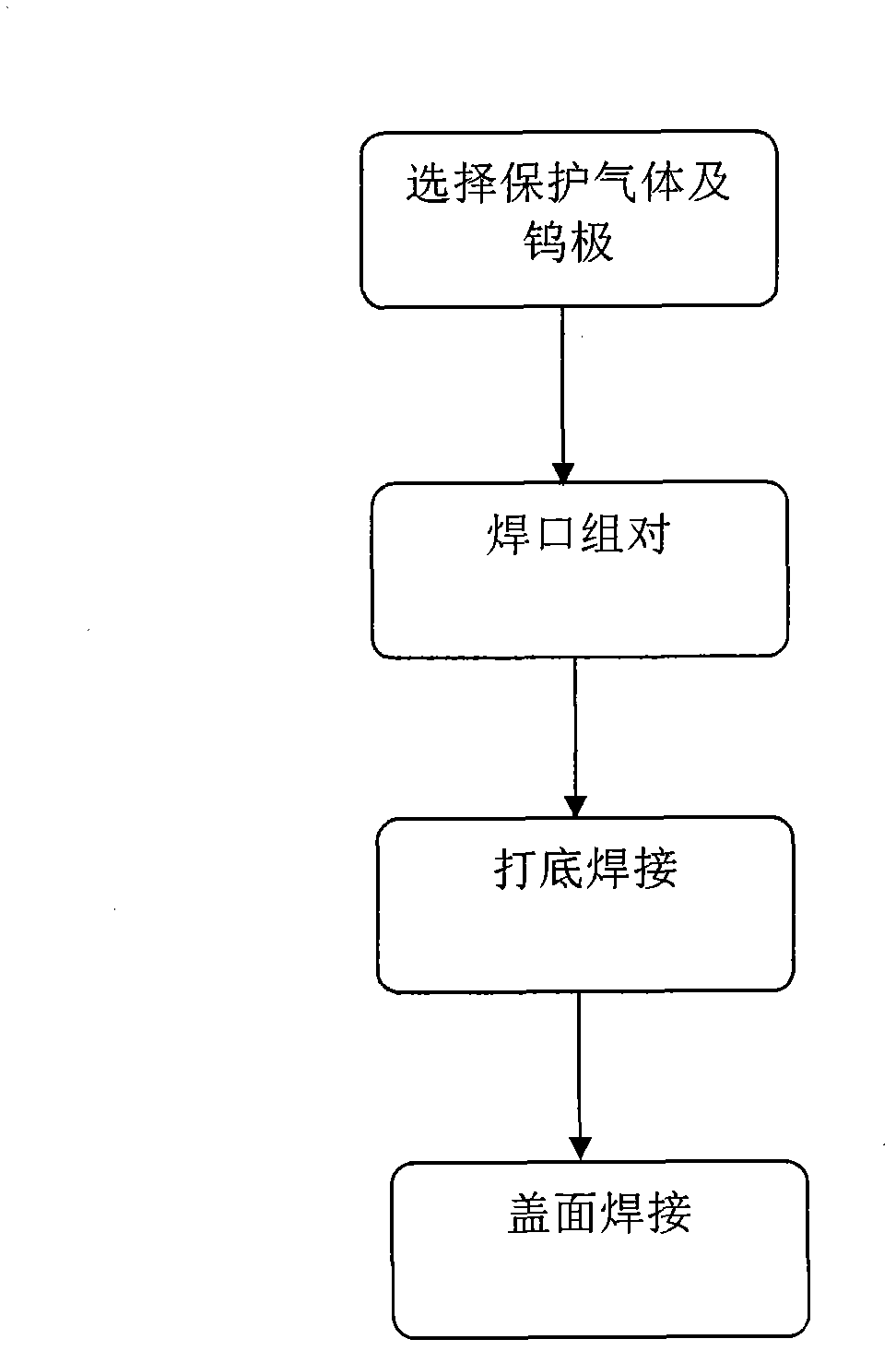

Method for welding cut surface butt joint formed by thin welding base materials

ActiveCN102699545AReduce process stepsReduce consumptionArc welding apparatusSignal onFilling materials

The invention relates to a method for a welding cut surface joint formed by assembling cut surface ports, in particular to a method for welding a cut surface butt joint formed by thin welding base materials in nuclear power engineering, and aims to solve the problems that the machining period of tubes and welding period are relatively long, the welding cost is high, and part of the materials are not completely welded in the prior art. According to the method, the thickness of each welding base material is less than or equal to 6.0mm. The method comprises the following steps of: selecting protective gas and a tungsten electrode; assembling craters; overlapping an ultrasonic electrical signal on pulse welding current to generate a stable ultrasonic- tungsten inert gas (TIG) combined weld electric arc by taking ultrasonic waves and TIG combined electric arc welding machine as a welding power supply of automatic welding equipment, and performing backing welding on the surface butt joints without feeding wires; performing cosmetic welding, and finishing welding. By the welding method, the processing step of forming a groove is eliminated, so that the welding workload, the consumption of welding filling materials and the welding cost are reduced, and the welding efficiency is improved.

Owner:CHINA NUCLEAR IND 23 CONSTR

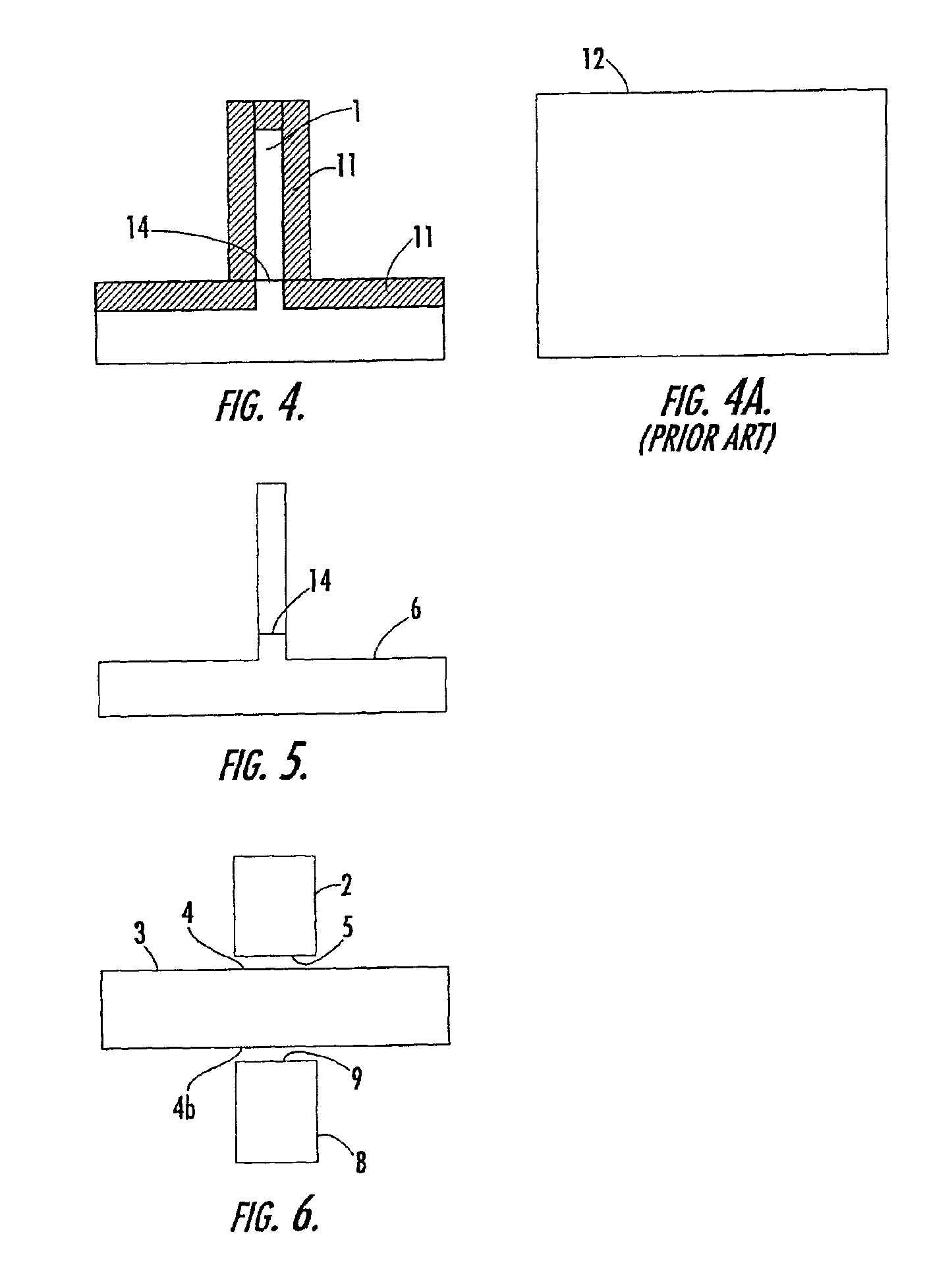

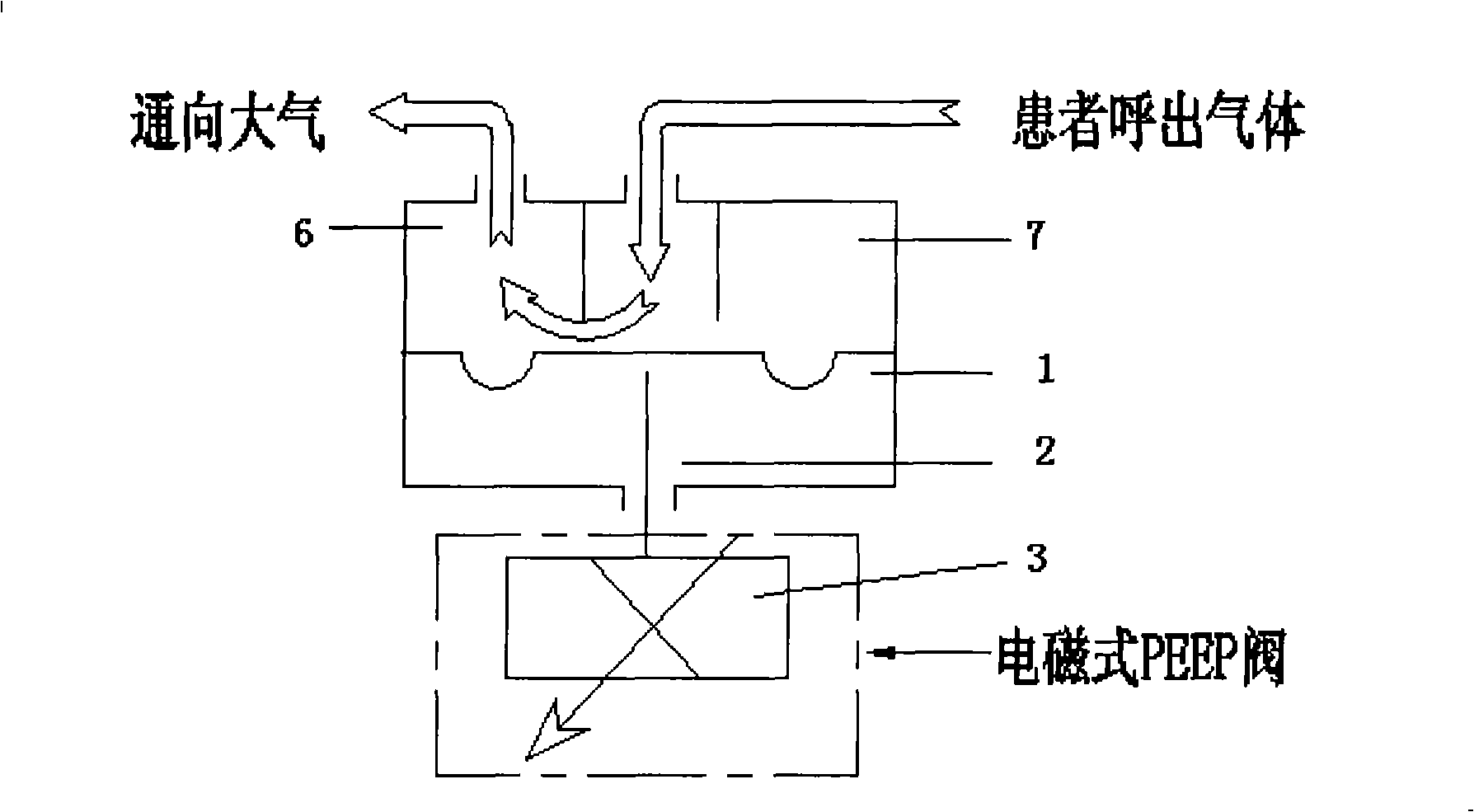

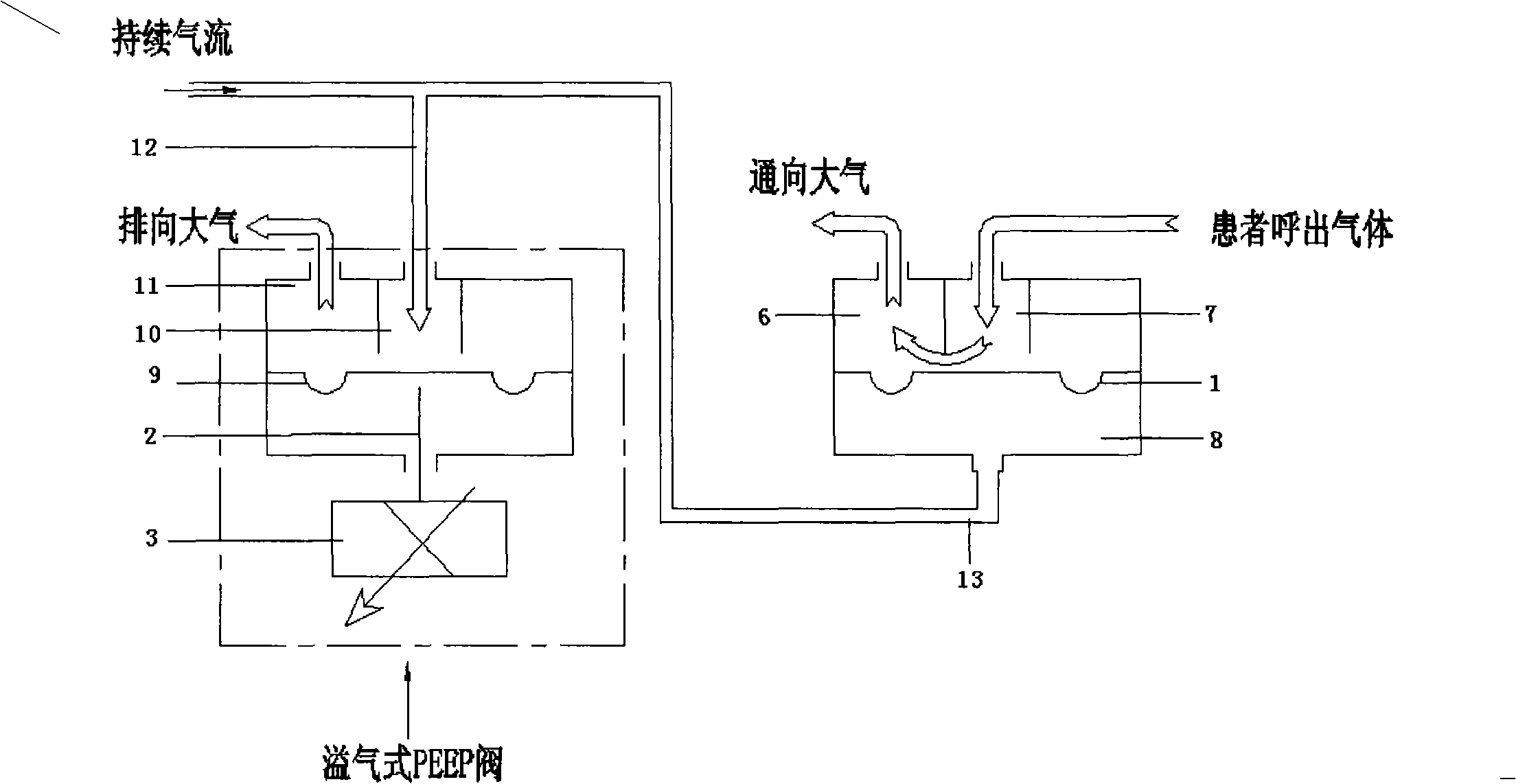

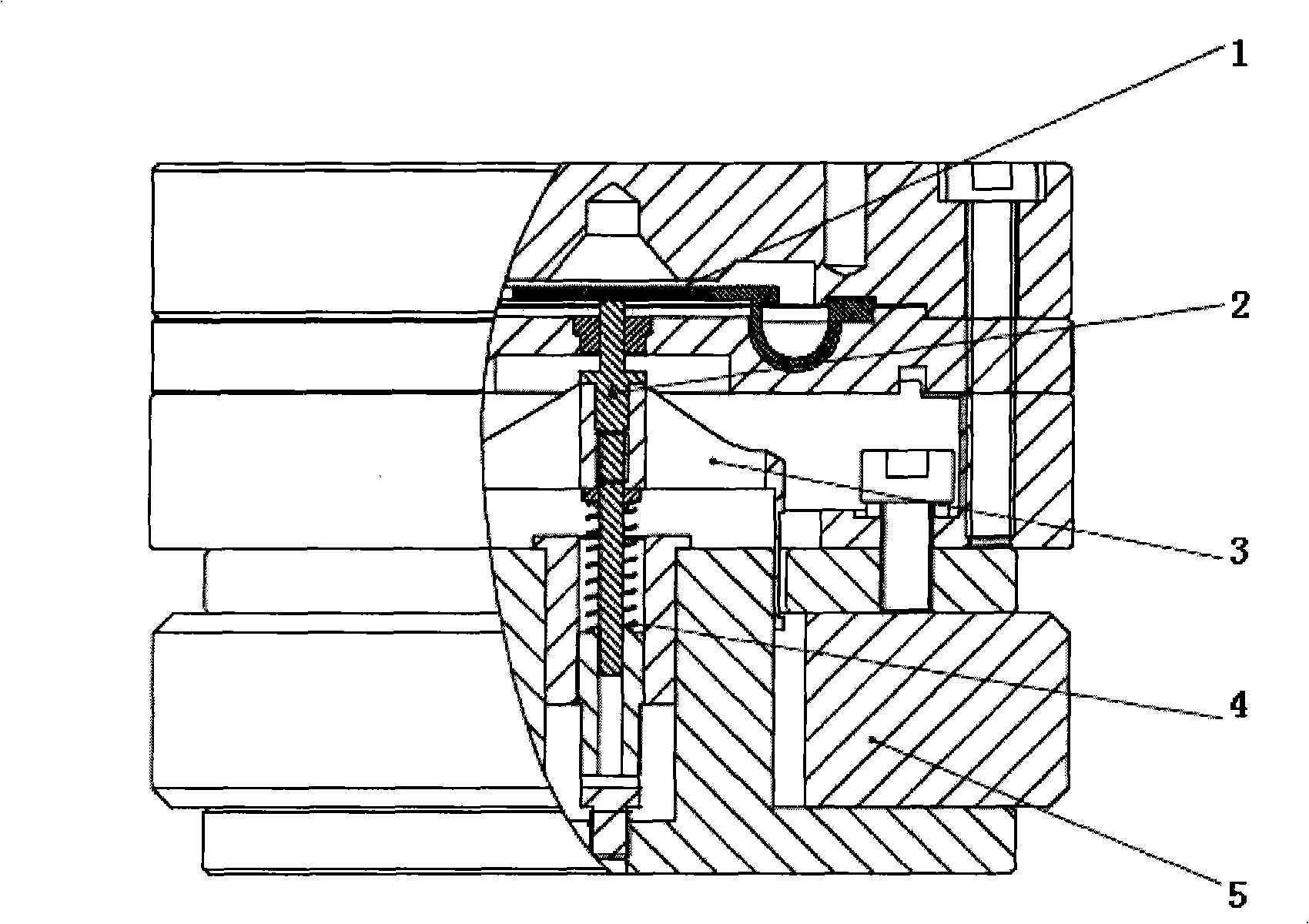

Device and method for controlling expiratory valve

InactiveCN101310792ALower work of breathingImprove ventilation comfortRespiratorsPressure functionExpiratory valve

The invention provides a device and a method for controlling an exhalation valve, the device for controlling the exhalation valve comprises: a film disk (9); an electromagnetic valve which is positioned at first side of the film disk (9); a first exhaust chamber (11) and an air inlet chamber (10), which are positioned at second side of the film disk (9), and the film disk (9) can selectively block off the air inlet chamber (10) and a channel between the first exhaust chamber (11) and the air inlet chamber (10) by a valve rod (2) of the electromagnetic valve. The method for controlling the exhalation valve comprises that: the electromagnetic valve is controlled to lead the film disk (9) to move towards the direction of an electromagnet under the input pressure function of the air inlet chamber (10); the input air flow of the air inlet chamber (10) is exhausted from the first exhaust chamber (11) from an air flow channel; the air flow is controlled to be directly flowed into an air containing chamber of the exhalation valve, thus pushing an exhalation valve body of the exhalation valve to block off an exhalation chamber of the exhalation valve. The device has fast response time and high control precision.

Owner:BEIJING AEONMED

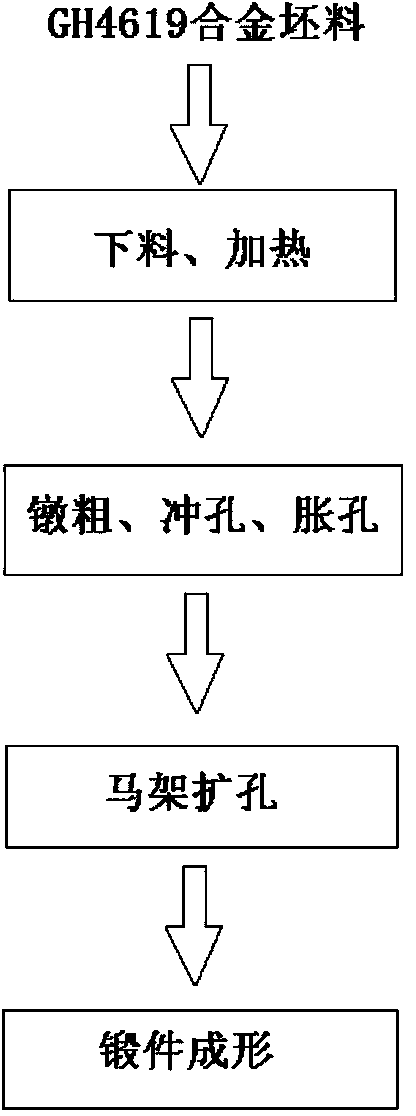

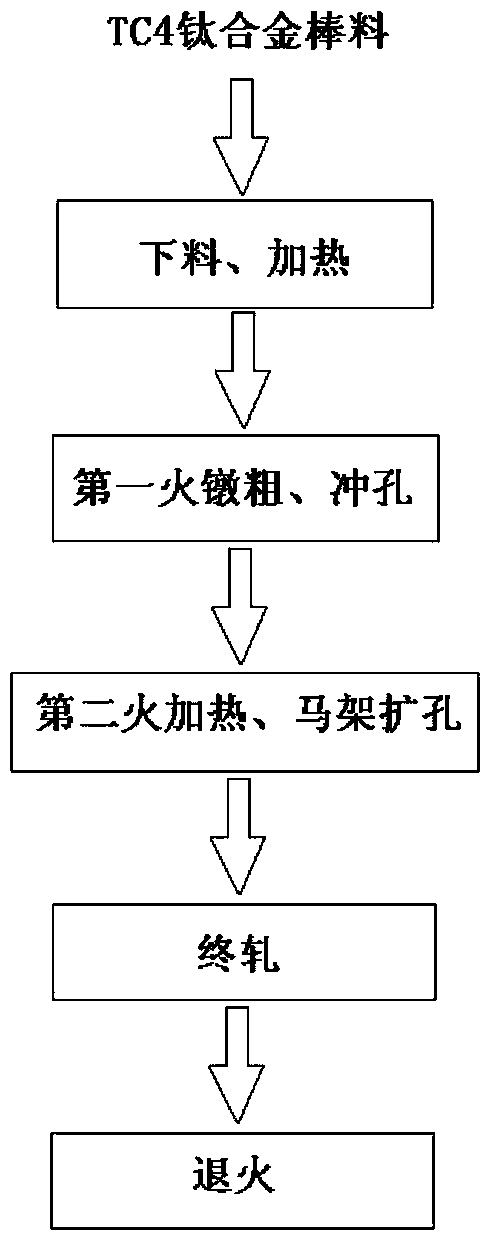

Manufacturing method of TC4 titanium alloy ring for aero-engine outer duct

The invention discloses a manufacturing method of a TC4 titanium alloy ring for an aero-engine outer duct. The method comprises the following steps: rounding a TC4 titanium alloy blank to form a fillet R20; heating to a deformation temperature which is 30-50 DEG C below a phase transformation point; determining the heat-preserving time by 6 minutes per 10 millimeters; performing primary upsetting and punching and secondary heating, mandrel supporter broaching and final rolling; and annealing, preserving heat at 715-725 DEG C for 85-95 minutes, and performing air cooling treatment. According to the method, special-shaped rings of similar shapes are adopted, so that the machining amount is reduced, the material utilization ratio is increased, and the machining time is shortened; meanwhile, an original streamline is better protected, and the product has more excellent performance.

Owner:GUIZHOU AVIATION TECHN DEV

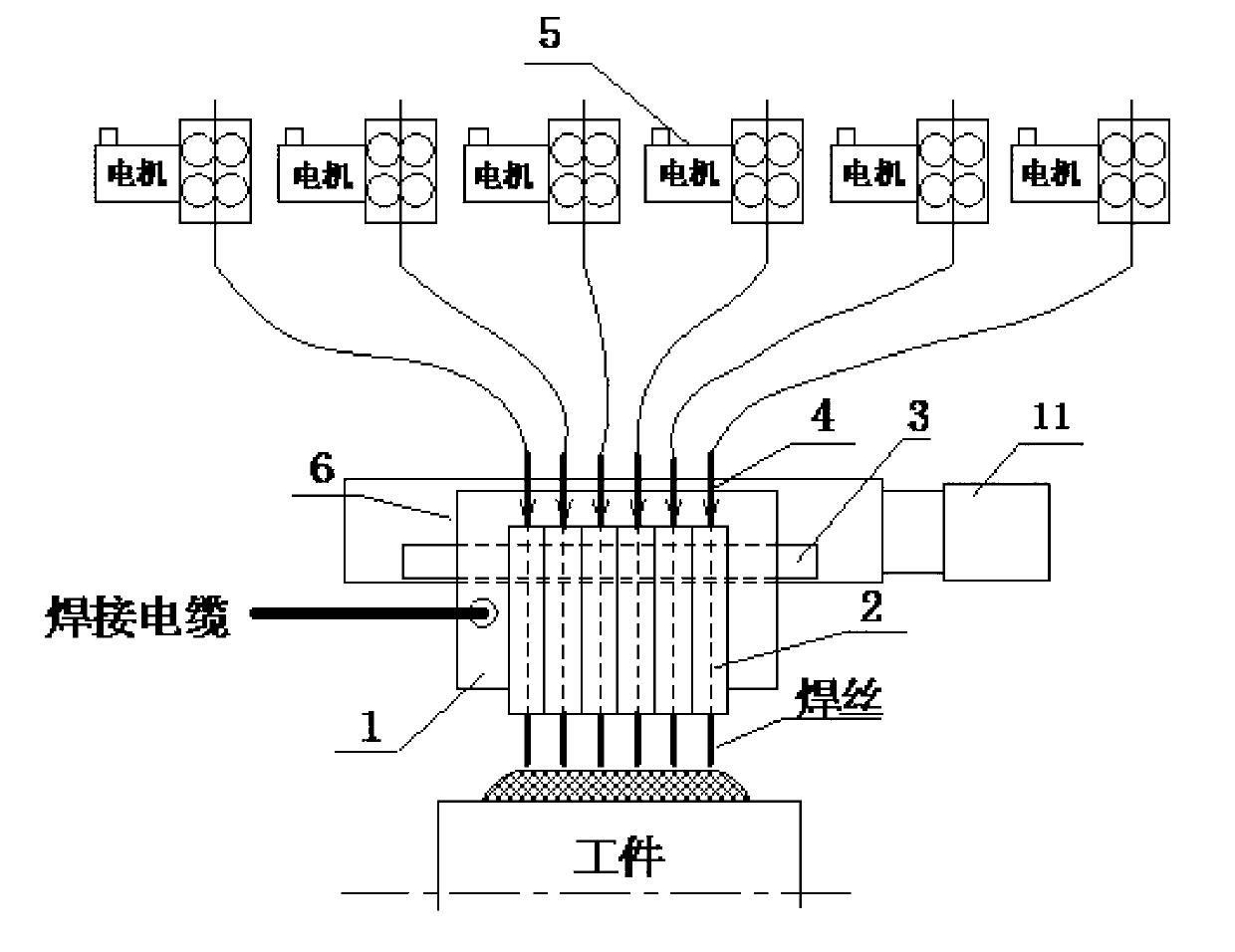

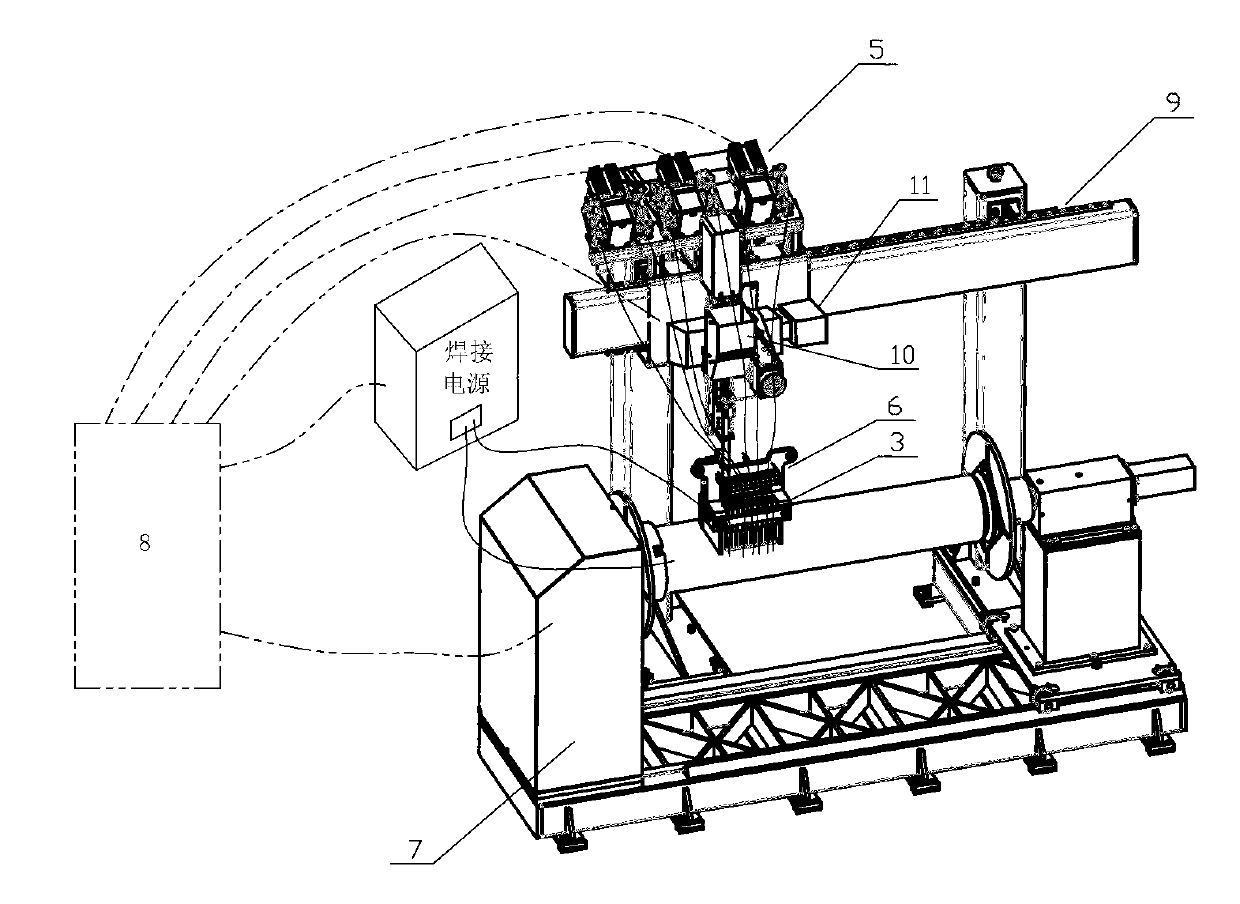

Multi-wire bead welding system and process thereof

ActiveCN103273169AConvenient sourceEasy parallel arrangementElectrode supporting devicesLap jointEngineering

The invention discloses a multi-wire (solid or flux-cored) bead welding system adopting an inert gas protection or submerged arc method, and a process of the multi-wire bead welding system. The multi-wire bead welding system and the process of the multi-wire bead welding system are used for replacing surfacing with band-electrode to obtainer higher production efficiency. The multi-wire bead welding system comprises a welding gun swing mechanism (11), a multi-wire welding gun (6), a wire-feeding pipe (4) and at least two wire-feeding machines (5). Compared with traditional bead welding, the multi-wire bead welding is higher in deposition rate. Due to the fact that a lap joint area of multi-wire bead welding is soother than that of traditional bead welding, the machining time needed to obtain a smooth surface is largely shortened. A machine head of the multi-wire bead welding system can swing in the welding process, the fusion ratio between bead welding materials and wood is improved while a wider weld joint is obtained, and the unique swing function can guarantee a bead welding layer to be more uniform.

Owner:AMET WELDING AUTOMATION TECH BEIJING +1

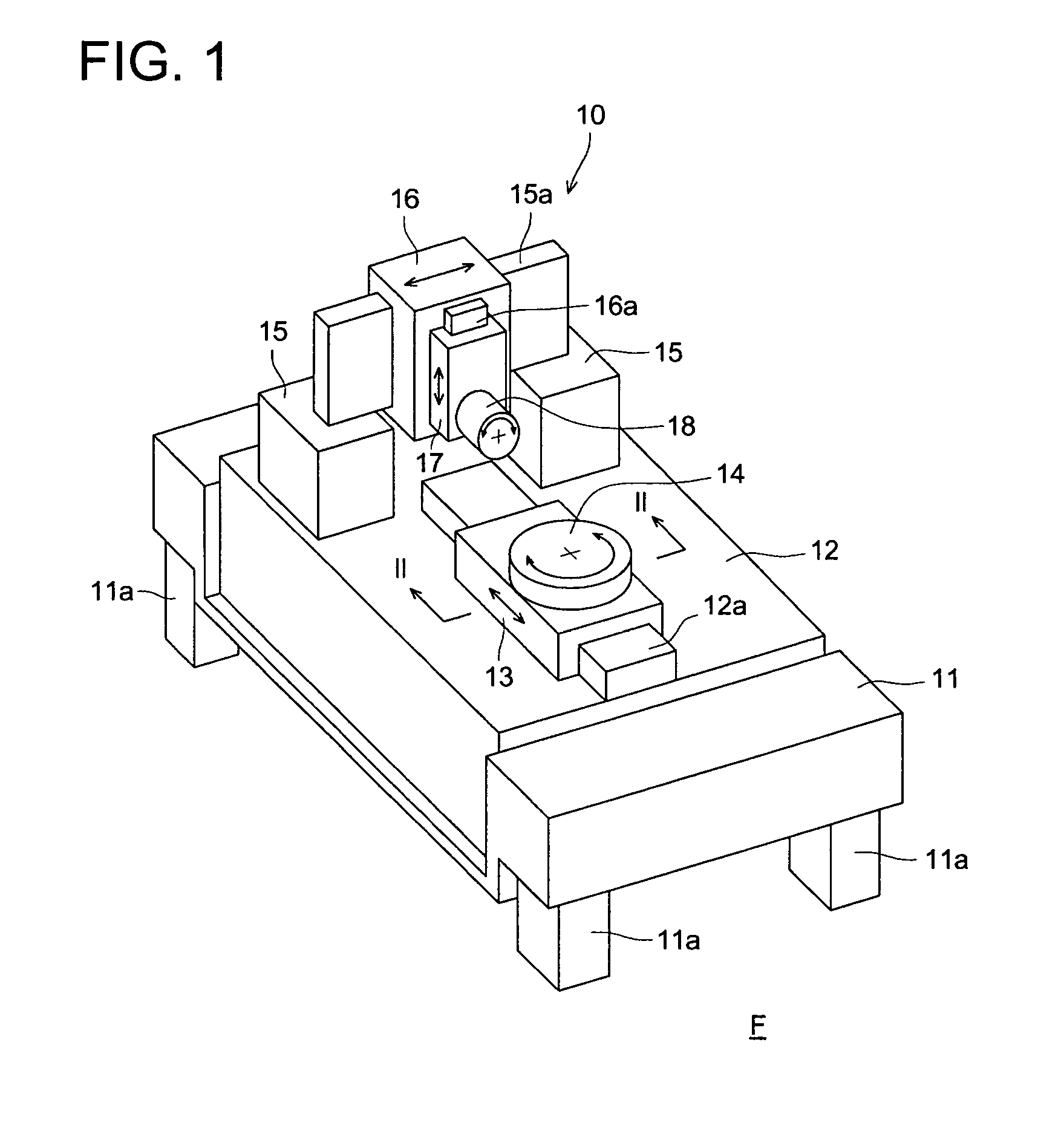

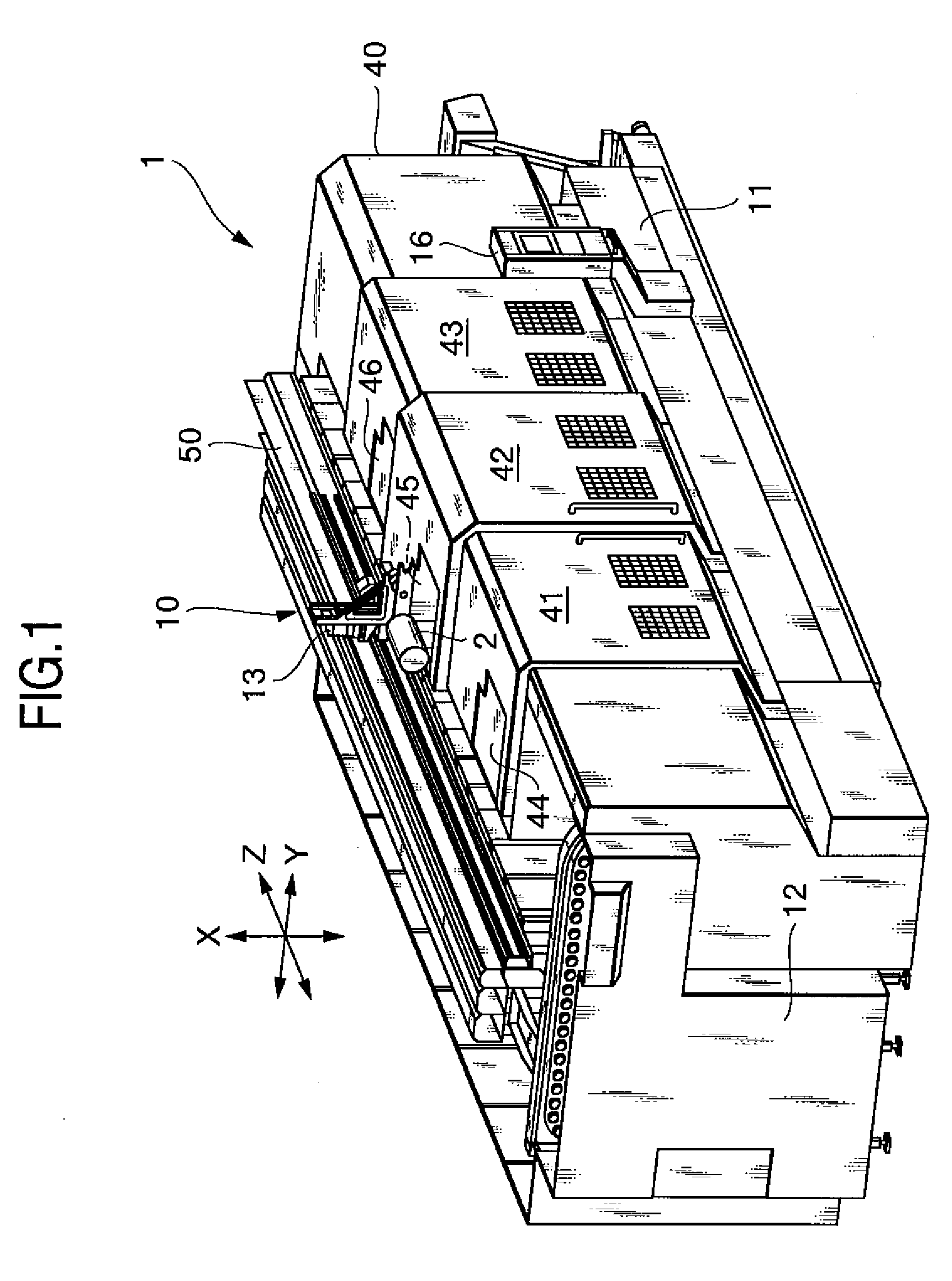

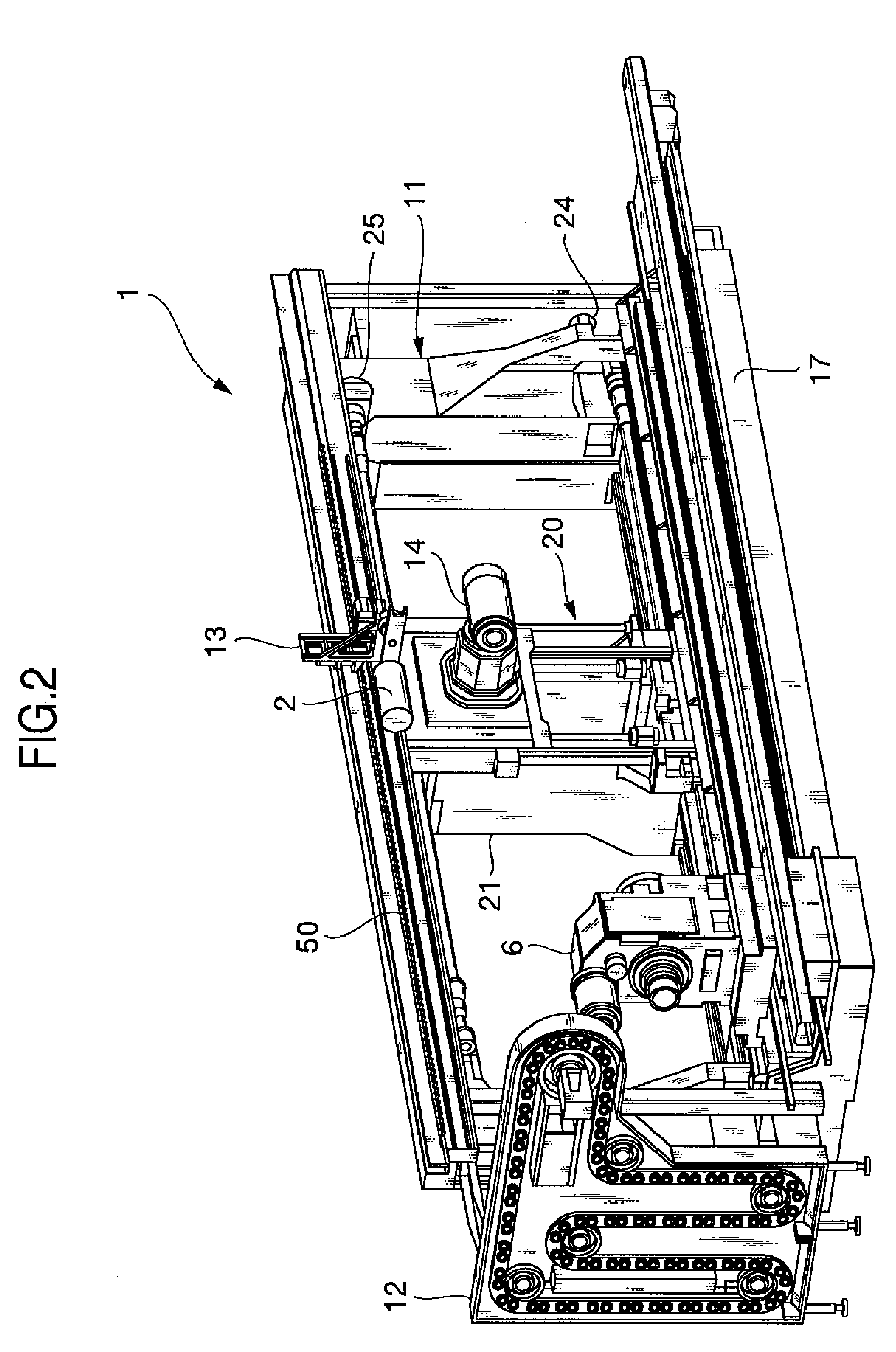

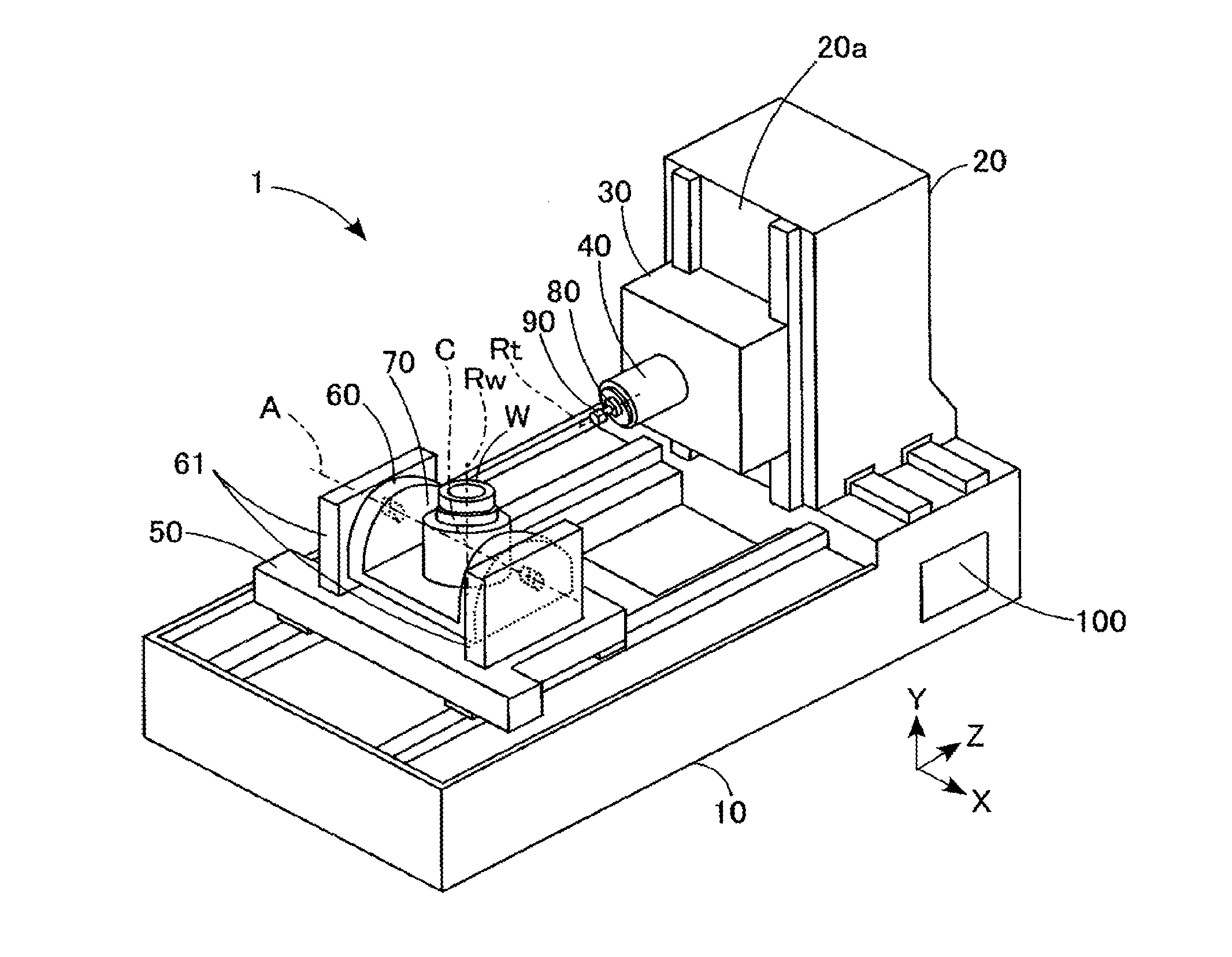

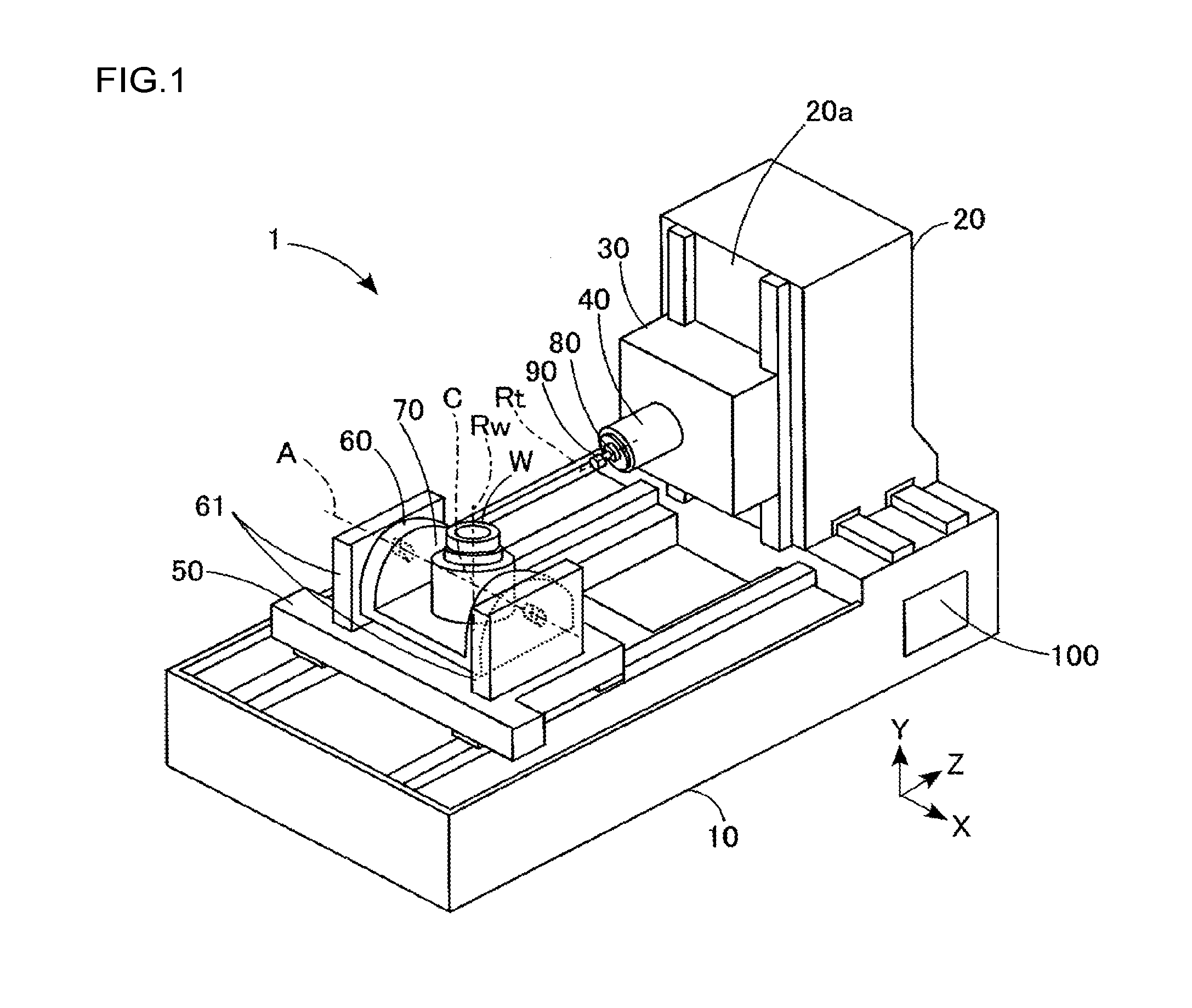

Machining apparatus

InactiveUS20050034289A1Reduce weightLittle changeRevolution surface grinding machinesOptical surface grinding machinesEngineeringMechanical engineering

A machining apparatus for conducting at least one of a cutting process and a grinding process, comprises a stationary base; and a working device mounted on the stationary base and having a degree of freedom of more than two axes to conduct at least one of a cutting process and a grinding process, the working device comprising a first working bench which is formed of a ceramic material and is movable linearly with a degree of freedom of not less than one axes or more while holding a work piece or a tool.

Owner:KONICA MINOLTA OPTO

Electronic beam welding method of sealing thin-wall aluminium alloy frame

ActiveCN102500905ASmall amount of welding deformationReduce machining timeElectron beam welding apparatusAluminium alloyRobot welding

The invention relates to an electronic beam welding method of a sealing thin-wall aluminium alloy frame, which comprises the following steps that: a, before a cover board and the upper opening of a cavity are welded, a circular table is firstly added around the opening of the cavity, and the cover board is assembled in the circuit table in an interference fit way; b, during welding, welding parameters are adjusted, then, positioned welding of positioned welding points is carried out along the interval of 5-10mm of a welding seam, during the positioned welding, the mode of firstly temporarily welding shot welding seams and then temporarily welding long welding seams is taken as a principle; and c, during electronic beam welding, a circle of welding is carried out clockwise or anticlockwise along the welding seams from the positioned welding points of a short side, and scanning welding is added in the electronic beam welding parameters, the welding seams which are subject to butt welding are subject to secondary modified welding so as to reduce welding defects. The invention has the beneficial effects that the purposes of reducing welding deformation quantity and shortening following mechanical processing time are realized; and by carrying out modified welding to the welding area, the quality of the welding seams is improved, the intergranular structure of the heat influence area is improved, the skeleton strength of the sealing thin-wall aluminium alloy frame is ensured, and the production efficiency is greatly improved.

Owner:ZHENGZHOU AIRCRAFT EQUIP +1

Metal material and its forming method

InactiveCN102260828AReduce machining timeImprove anti-wear performanceManufacturing cost reductionRoom temperature

The invention discloses a metallic material and a method for forming same. The invention solves the technical problem of enhancing the shock resistance and the abrasion resistance of the metallic material and lowering cost. The metallic material disclosed by the invention is made from the following materials in percentage by mass: 0.5-2.1% of C, 0.2-0.9% of Si, 0.69-3.3% of Mn, 0.015-0.05% of S, 0.015-0.05% of P, 0.8-4.6% of Cr, 0.6-3.8% of W, 0.6-6% of Ni, 0.69-1.5% of Mo, 0.05-0.8% of Co, 0.3-2.8% of Cu and the rest percent of Fe. Forming is casting; and demolding of the metallic material is realized by being put in heat-preserving medium or a heat-preserving box body for cooling to room temperature and annealing. Compared with the prior art, the metallic material is once formed by casting without quenching or nitriding, thus the shock resistance and the abrasion resistance of the metallic material are enhanced, the time for mechanically machining of metallic parts or dies is saved and the manufacturing cost is lowered.

Owner:武燕萍

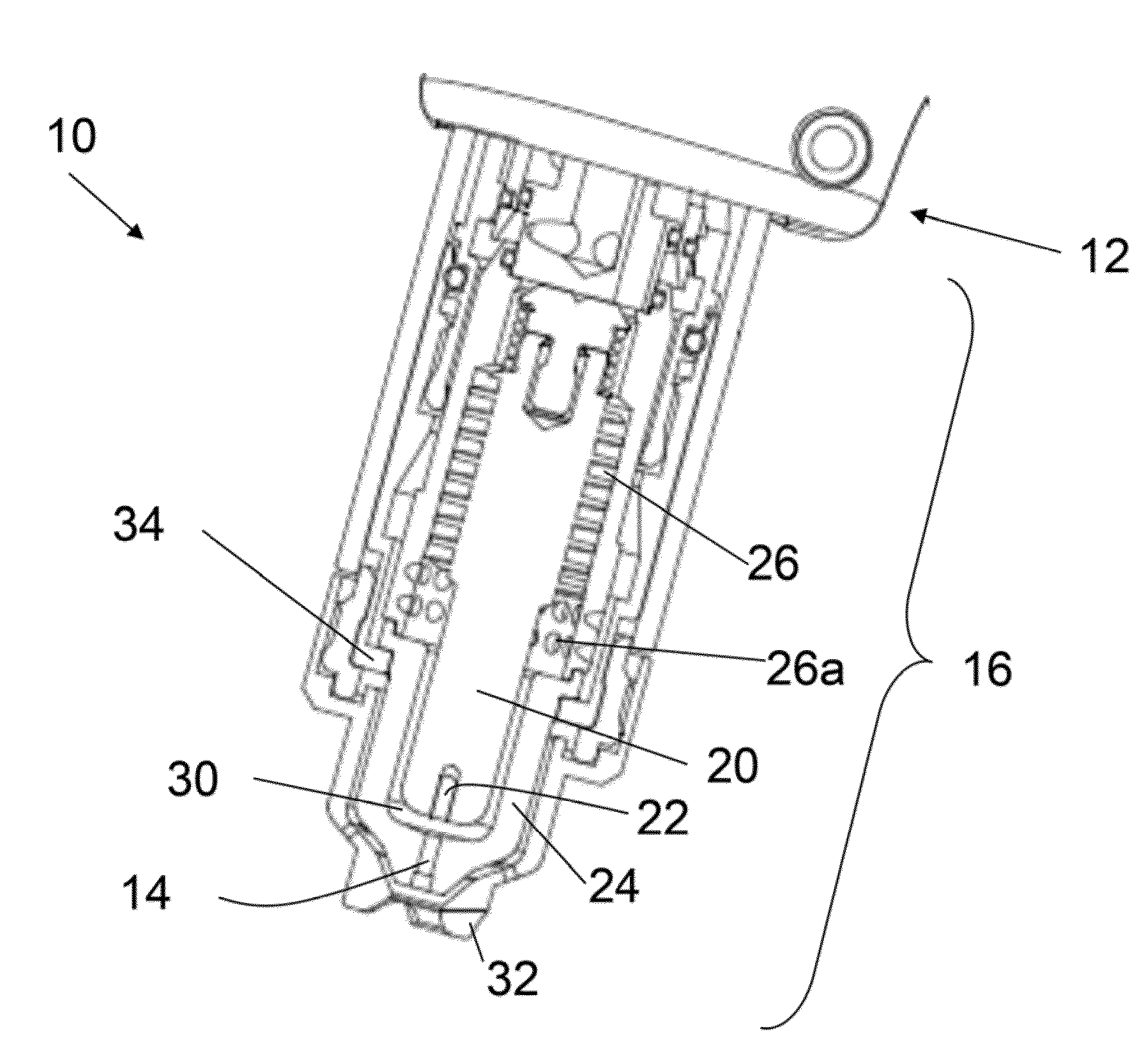

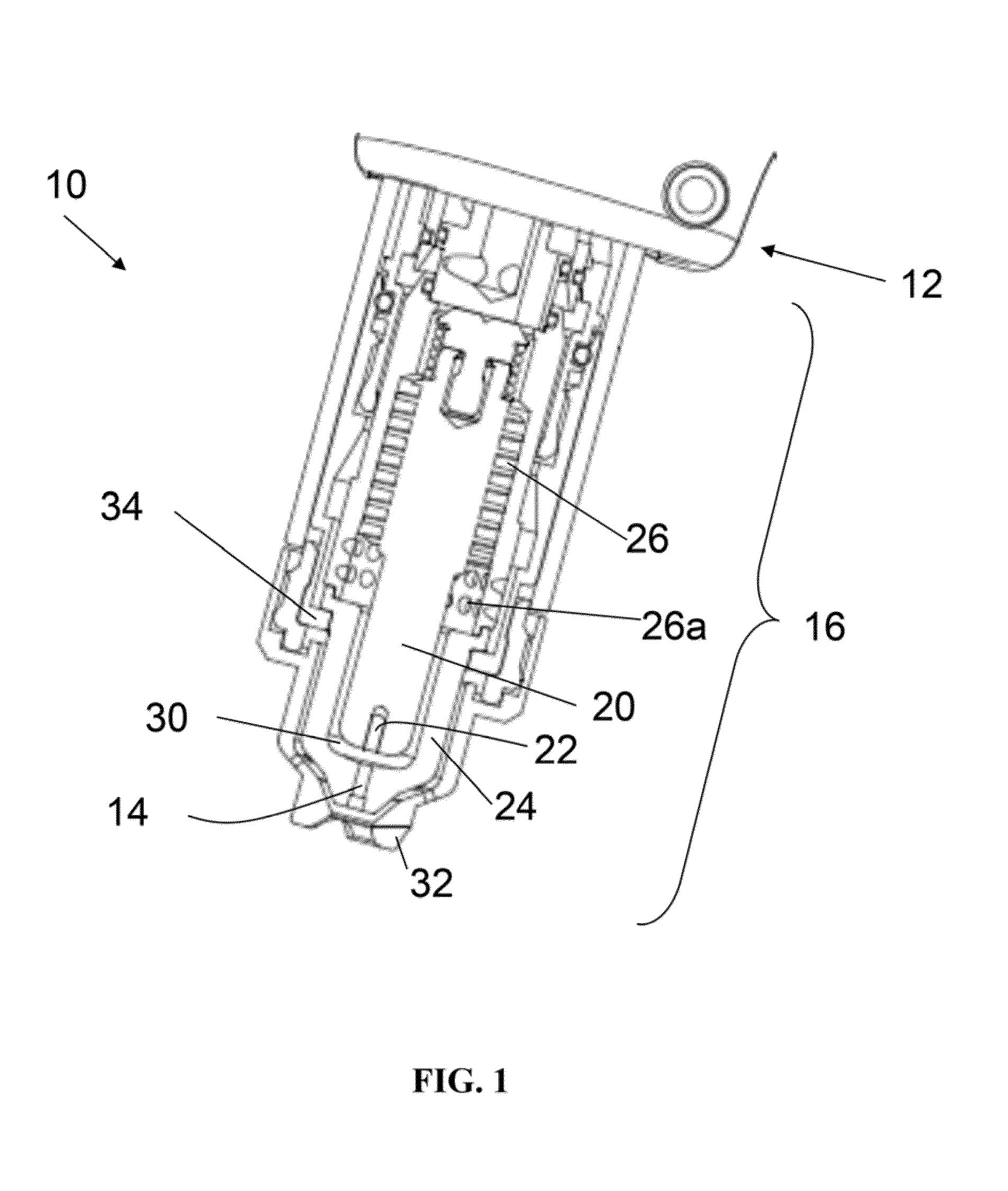

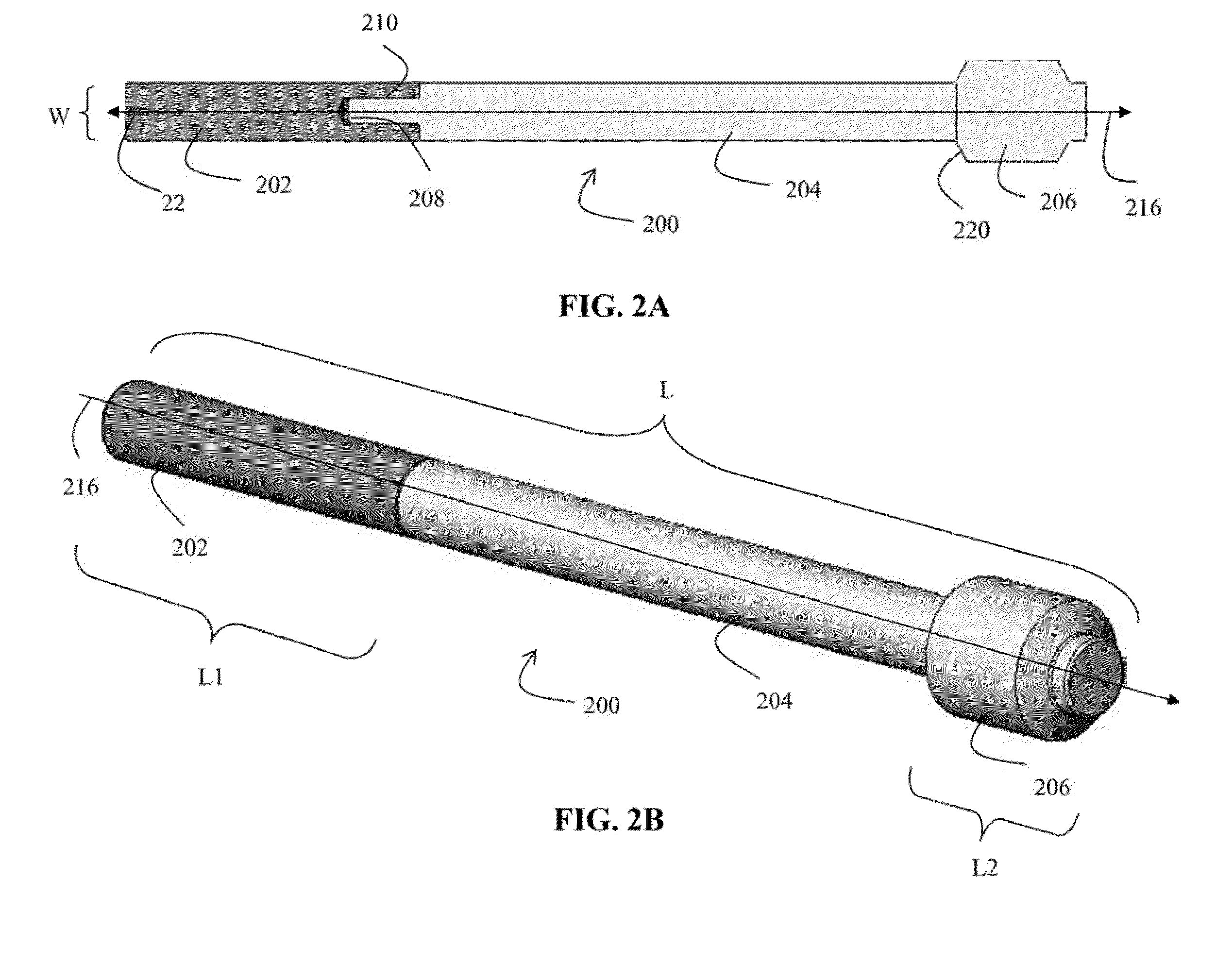

Composite Consumables for a Plasma Arc Torch

ActiveUS20150041444A1Reduce cost timeReduce machining timeContact member manufacturingArc welding apparatusEngineeringConductive materials

An electrode is provided for use in a plasma arc torch. The electrode includes a body having an elongated forward portion and a ring-shaped aft portion. The forward portion is configured to provide an electrically conductive path from the distal end to the proximal end. The forward portion comprises a first conductive material. The ring-shaped aft portion, defining a hollow center, is configured to substantially surround a portion of the forward portion when the forward portion is located inside of the hollow center. The aft portion includes a pneumatic reaction region for receiving a biasing flow of a pressurized gas. The aft portion comprises a second material. In some embodiments, the first conductive material is the same as the second material.

Owner:HYPERTHERM INC

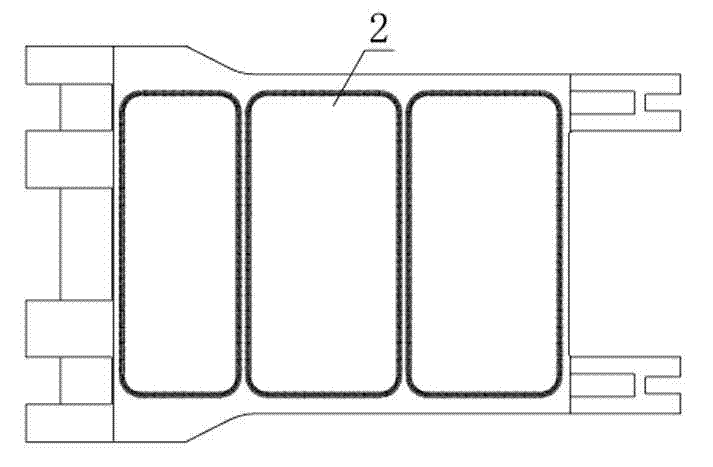

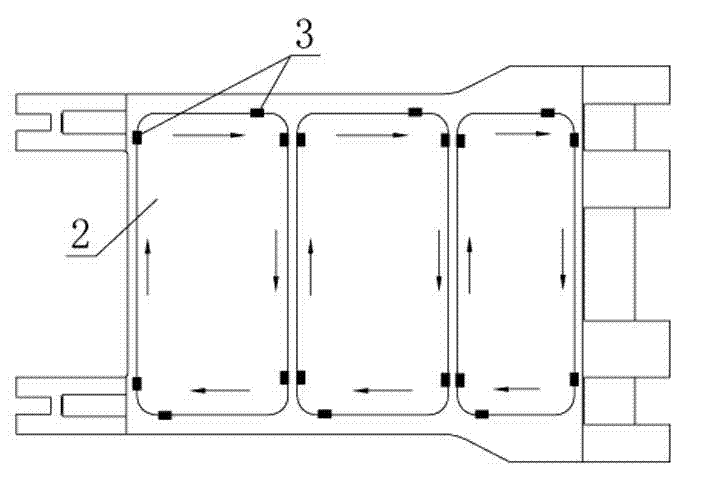

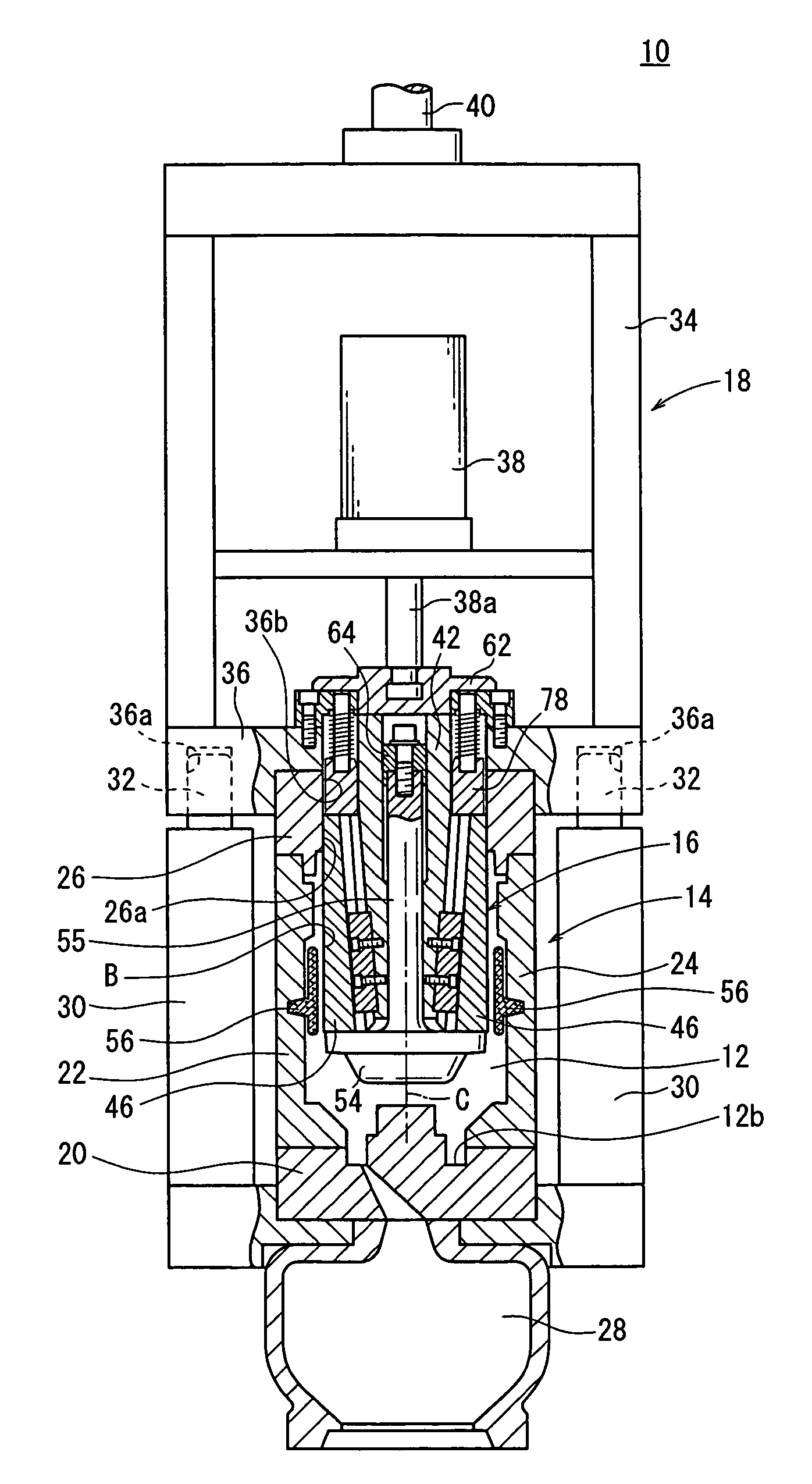

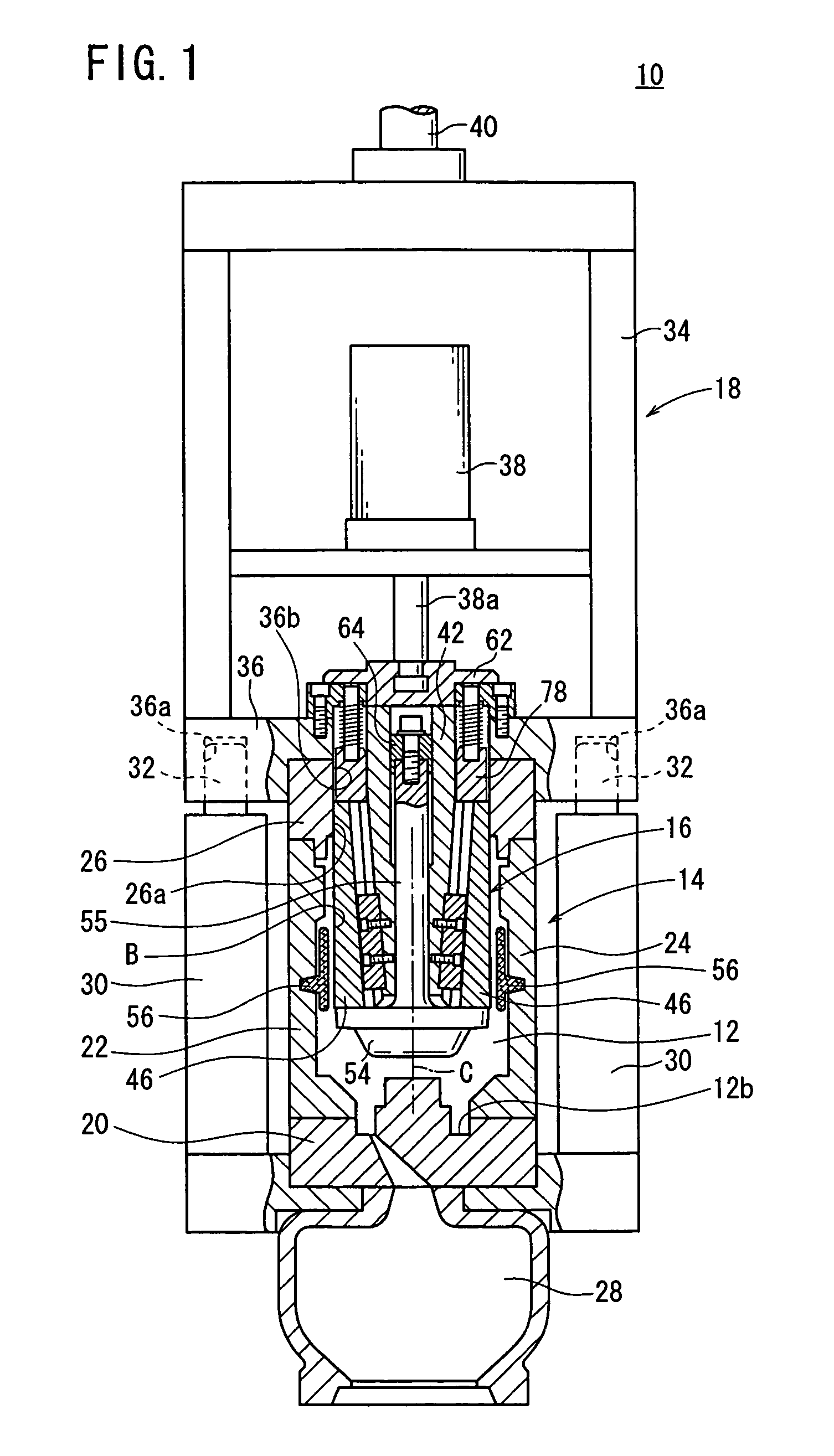

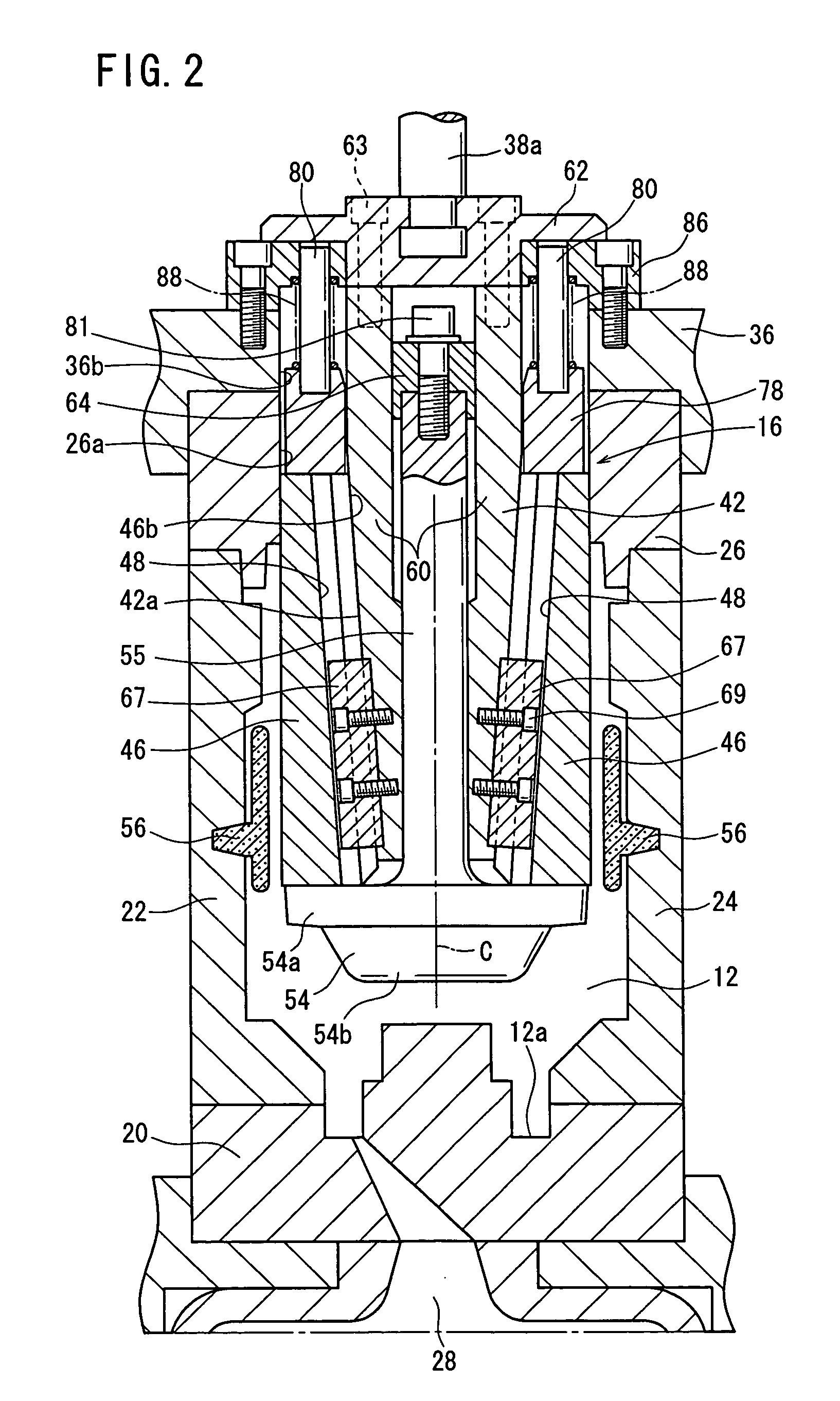

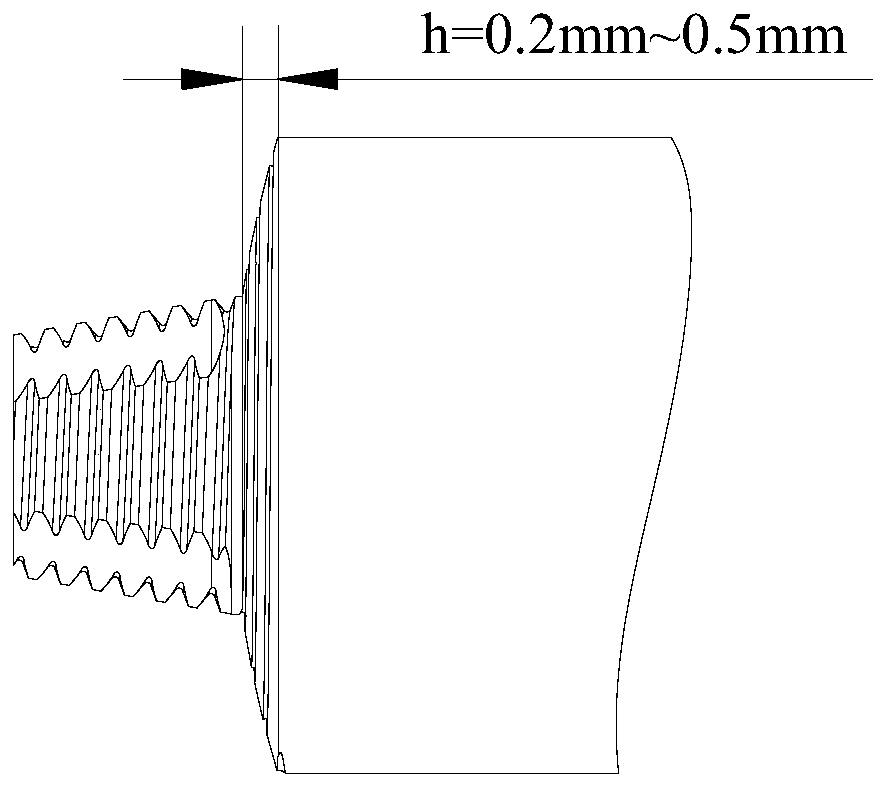

Mold Device and Method of Manufacturing Cylinder Block

InactiveUS20080274289A1Reduce machining timeHigh qualityCylinder headsFoundry mouldsPush outCylinder block

A mold device and a method of manufacturing a cylinder block. The mold device comprises a split core having two first split cores formed so that the tip parts thereof may be in a tapering shape, two second split cores installed between the first spilt cores, and an inner core is installed at the center part and pushing out the first split cores in the direction receding from the center axis thereof. When the inner core is pushed out to push out and position the first spilt cores, both end parts of the second split cores are brought into contact with the tip parts of the adjacent first split cores, and the outer side-faces of the first split cores and the outer side-faces of the second split cores form a cylindrical shape. When the inner core is raised, the first split cores and the second split cores are pulled to the axial center by first engagement pieces and second engagement pieces.

Owner:HONDA MOTOR CO LTD

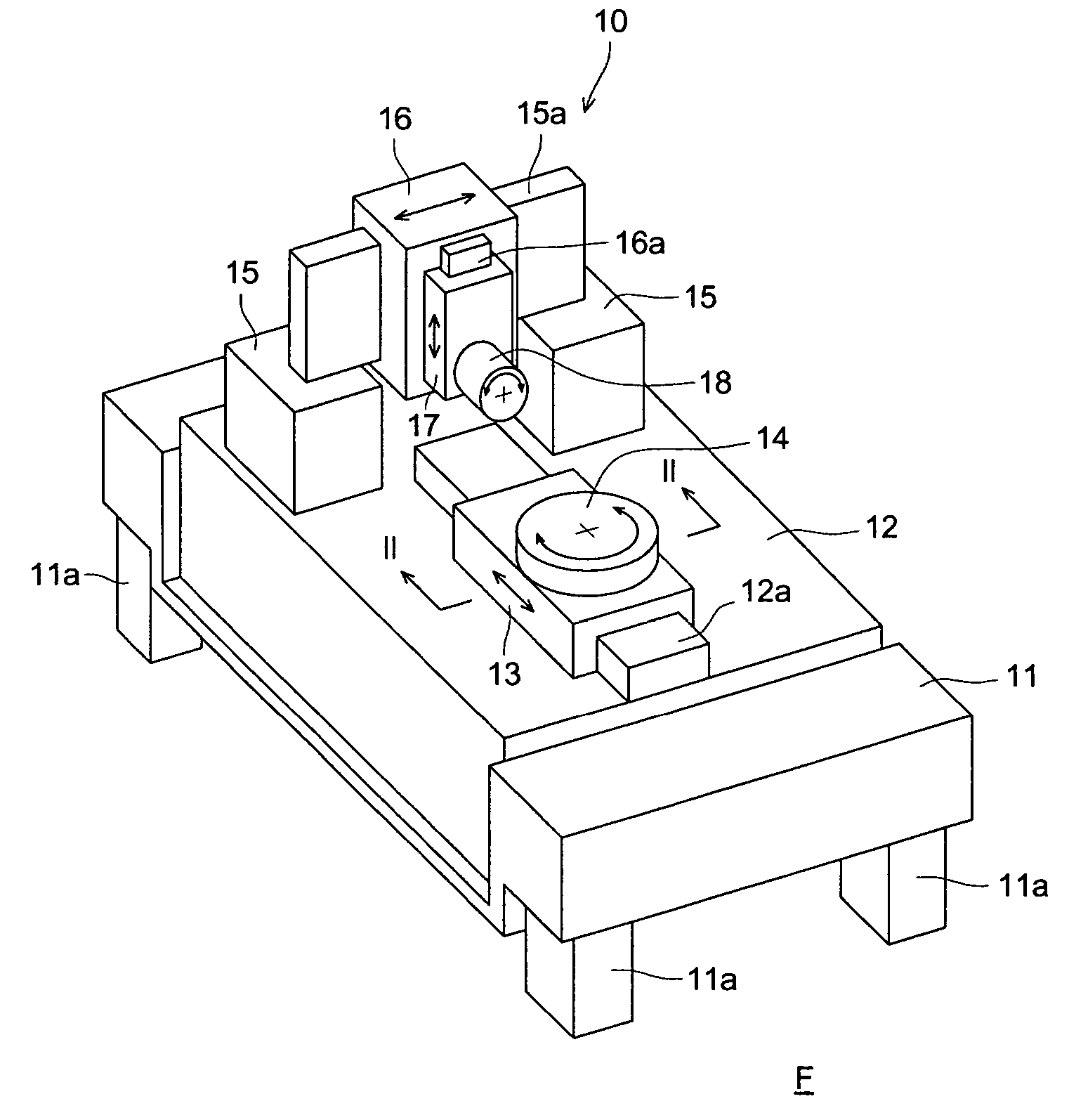

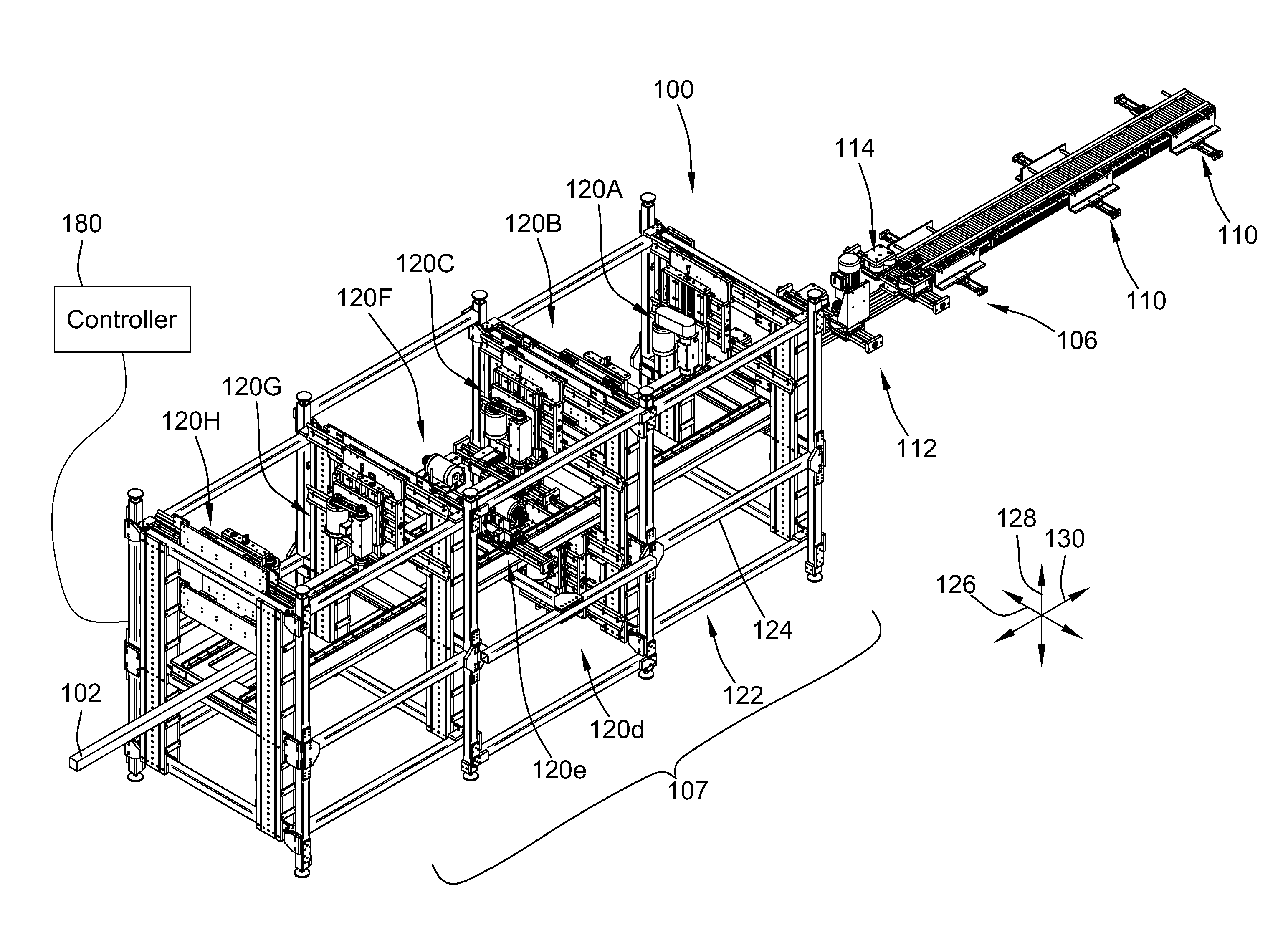

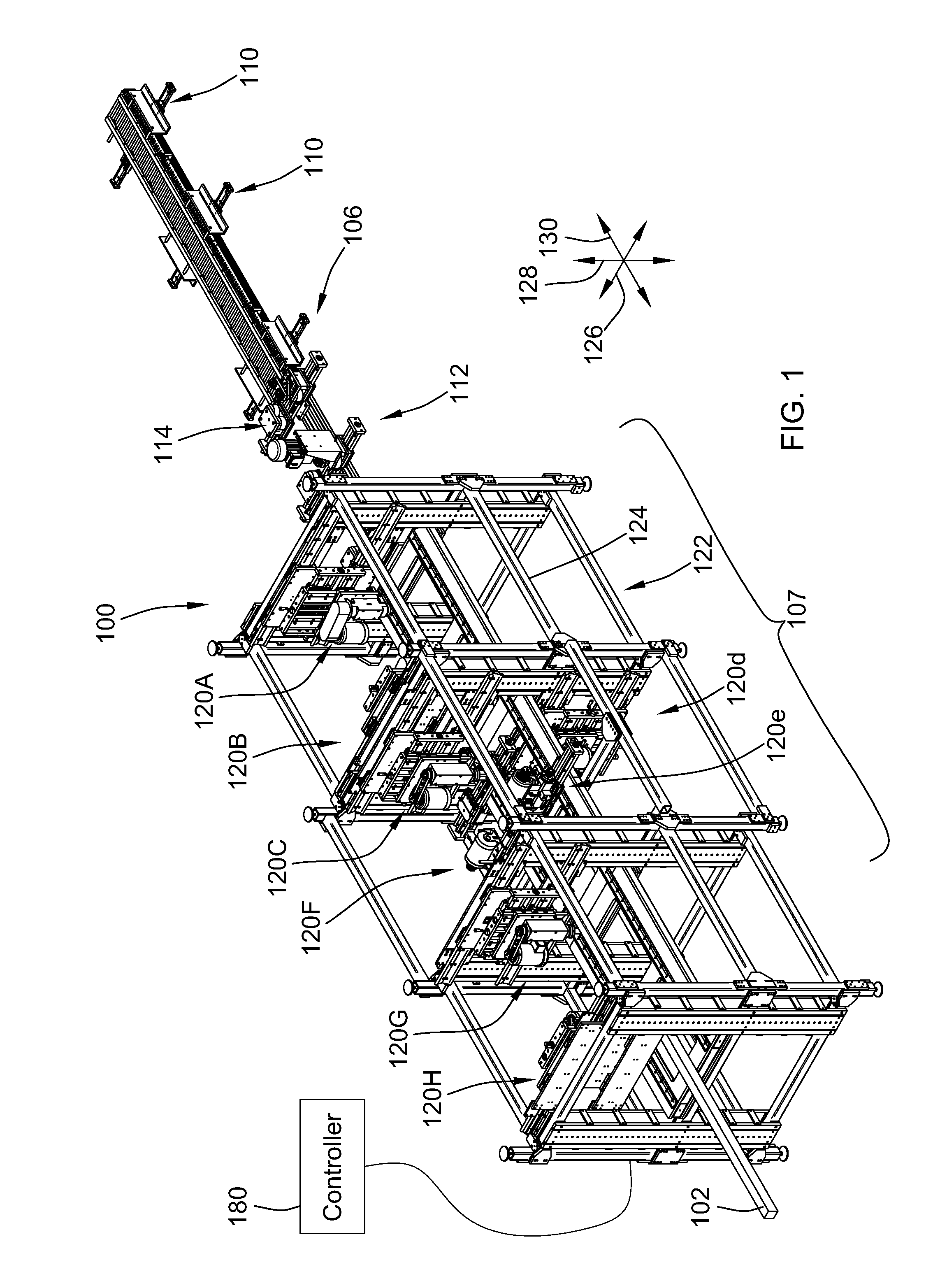

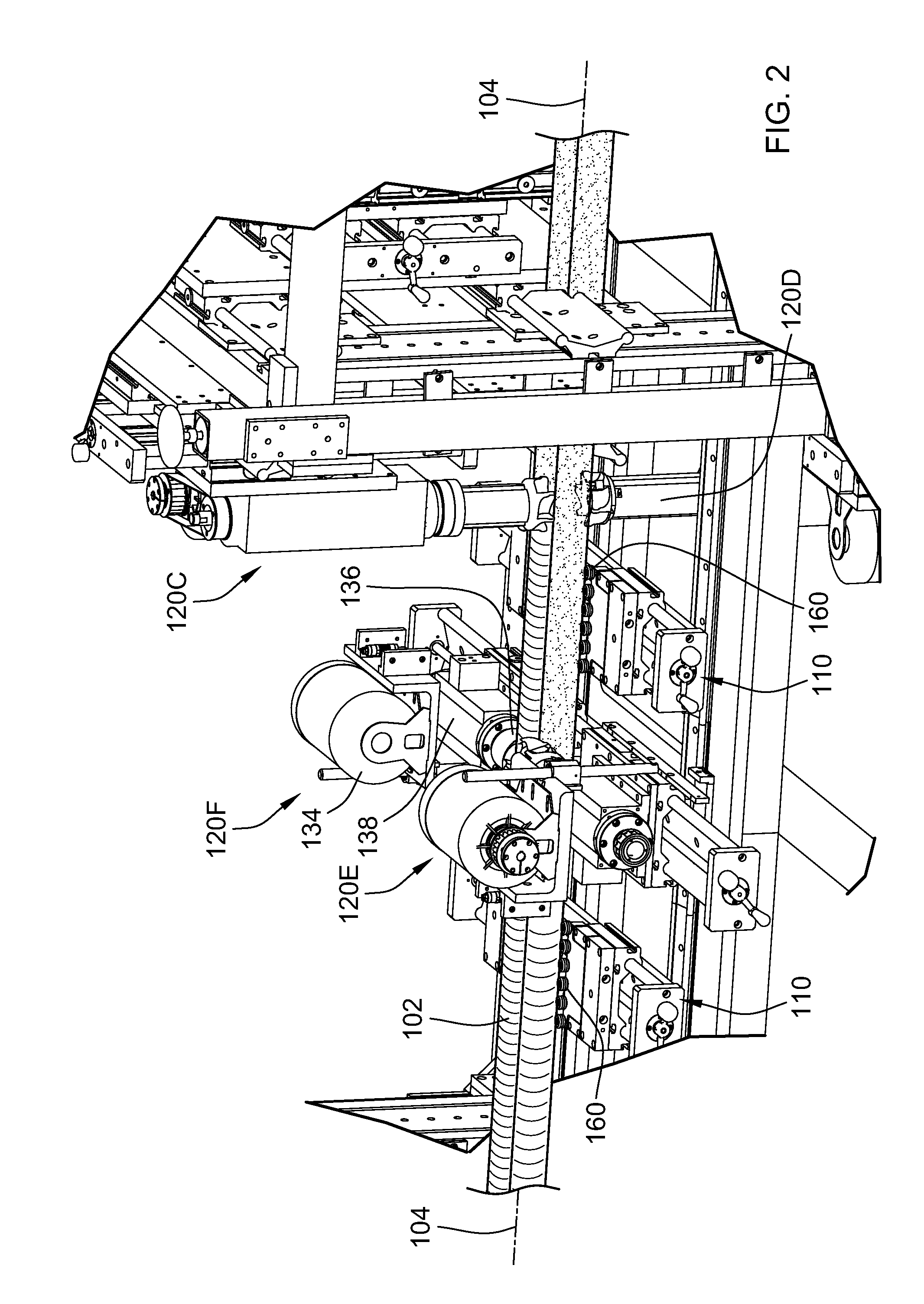

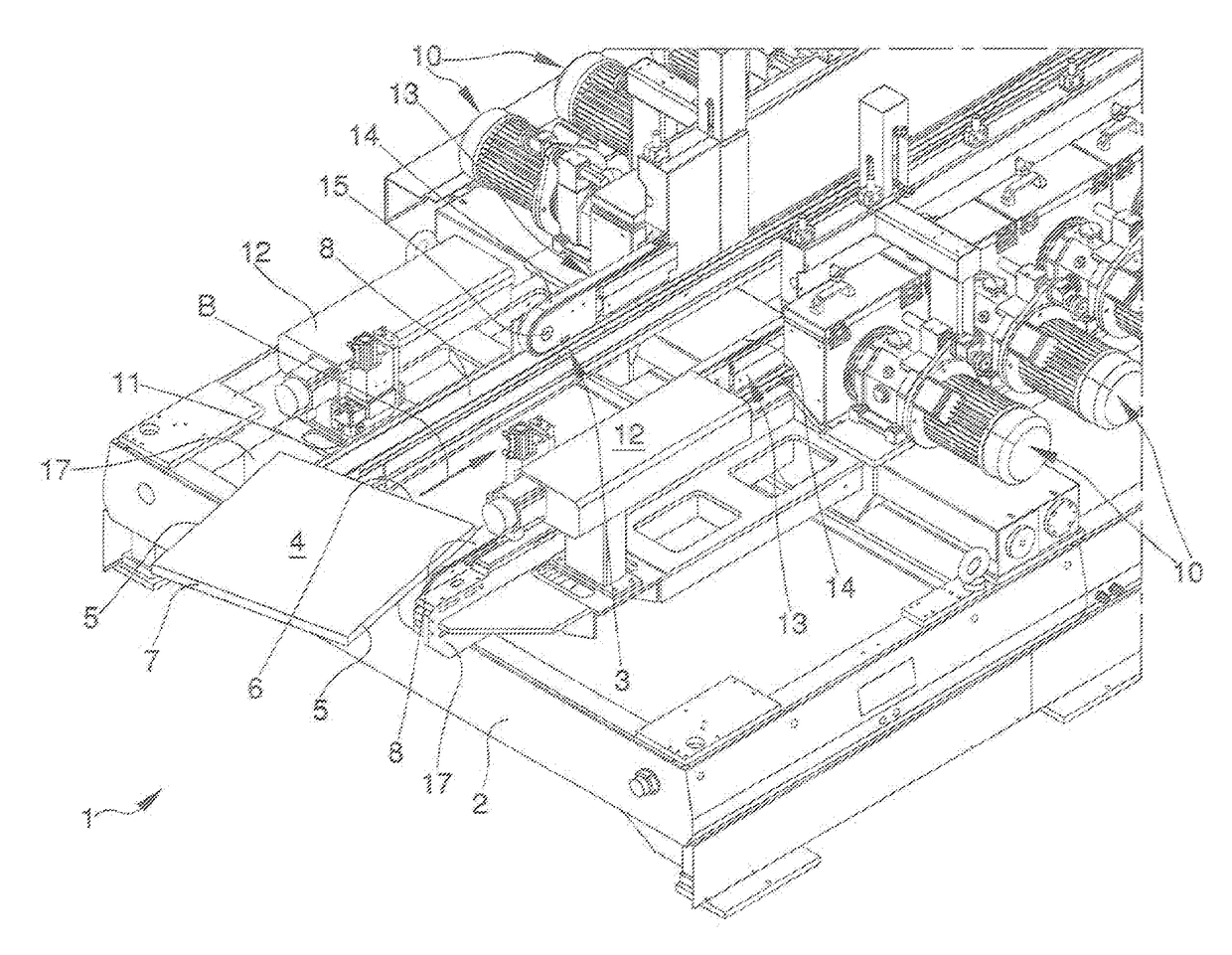

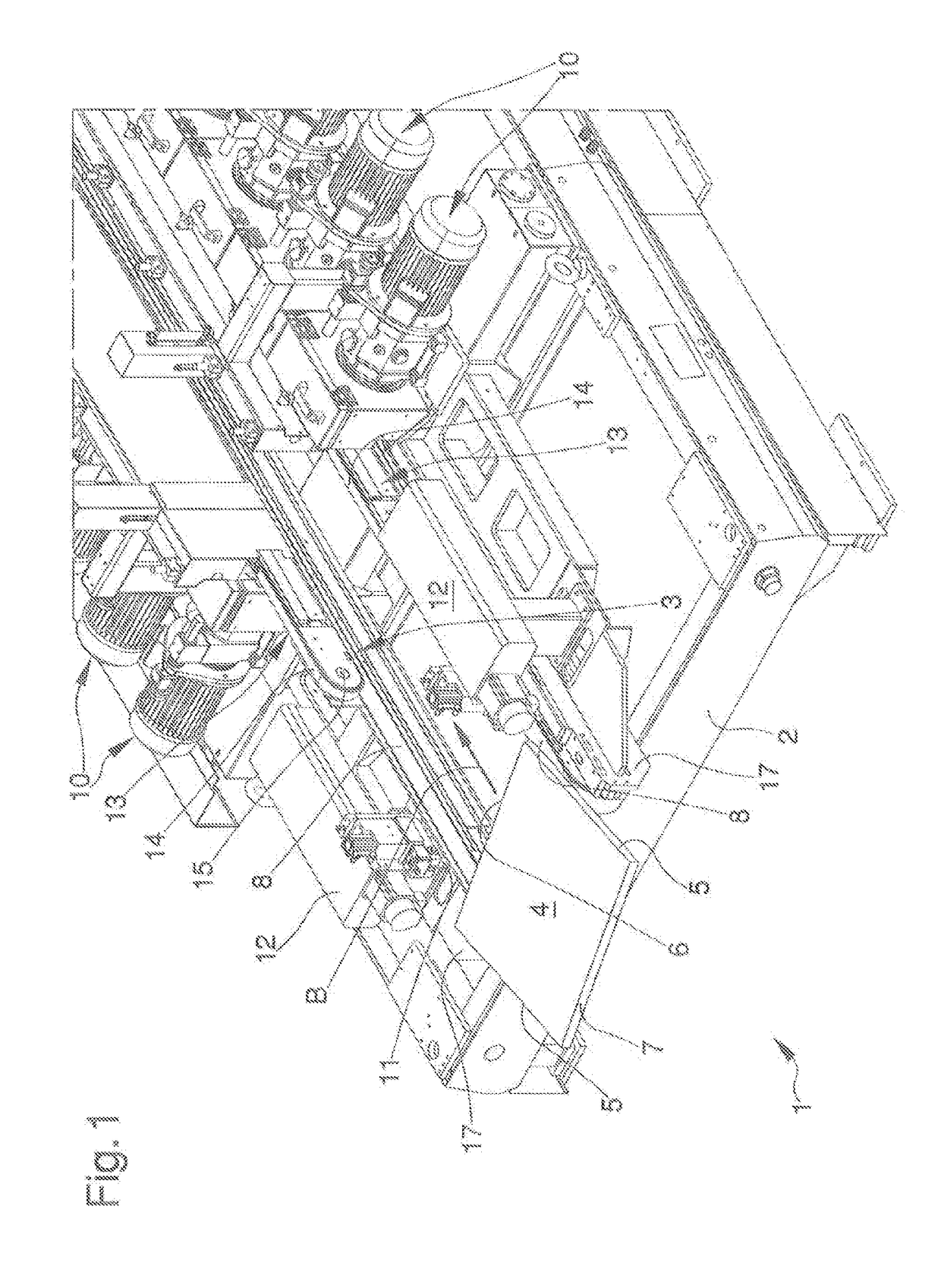

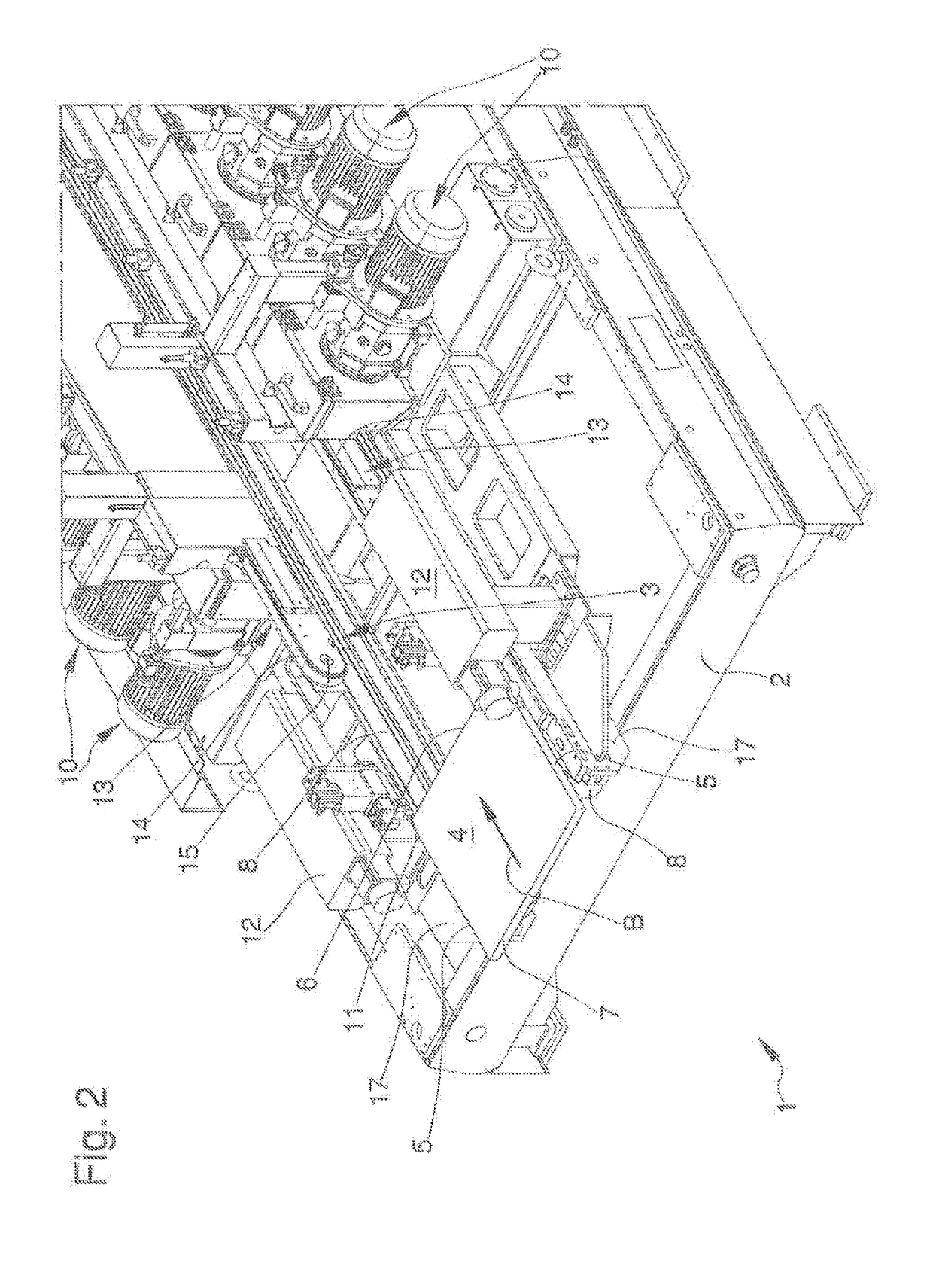

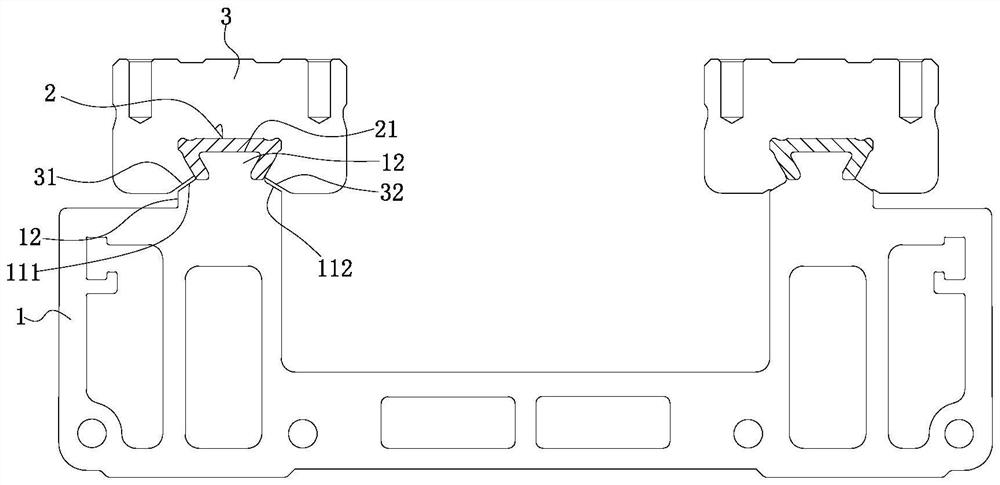

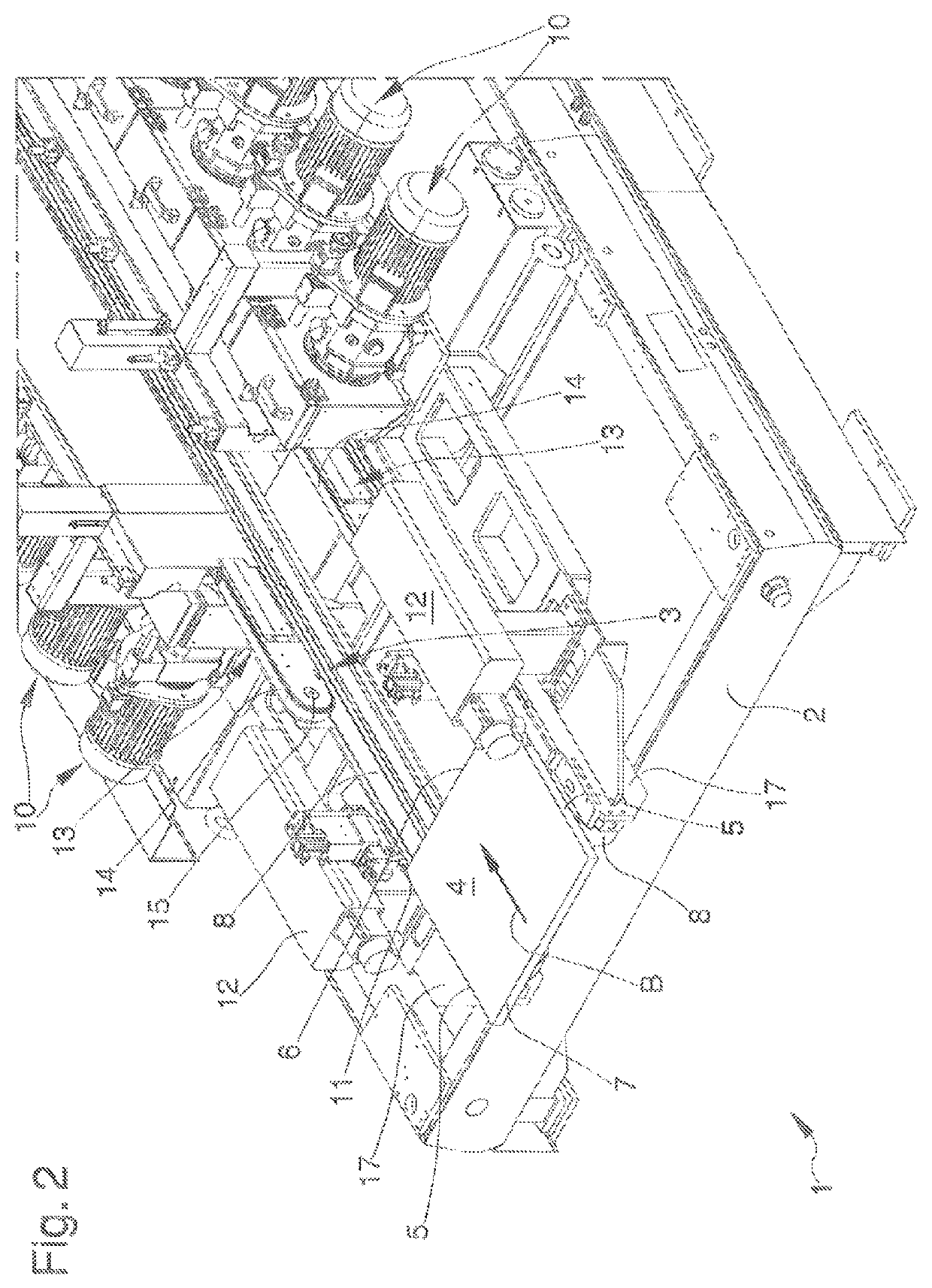

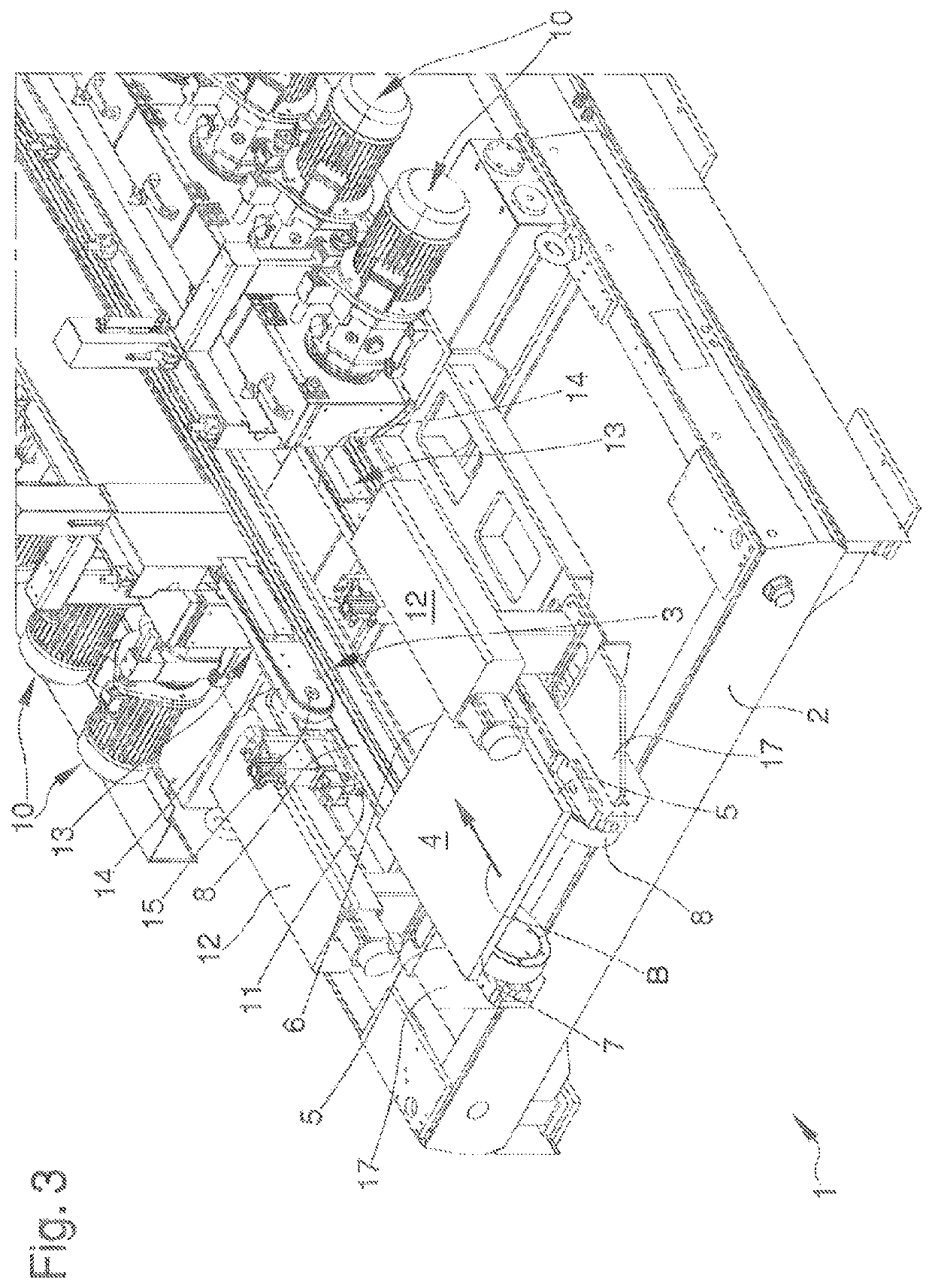

Simultaneous Integral Milling Operation Machine

InactiveUS20110308066A1Reduce machining timeImprove dimensional accuracyAutomatic control devicesLinear bearingsEngineeringSingle pass

A machining apparatus and method of machining a work piece are provided. The method generally includes machining a plurality of independent surfaces of the work piece as the work piece travels along a work path and through a plurality of machining stations in a single pass. The machining apparatus includes a frame and first and second machining stations mounted to the frame. Each machining station is configured to form an independent surface in a work piece passed through the machining apparatus. The machining apparatus also includes a feed arrangement for feeding the work piece through the apparatus along a feed path and relative to the first and second machining stations and the frame while machining is performed on the work piece.

Owner:PACIFIC BEARING

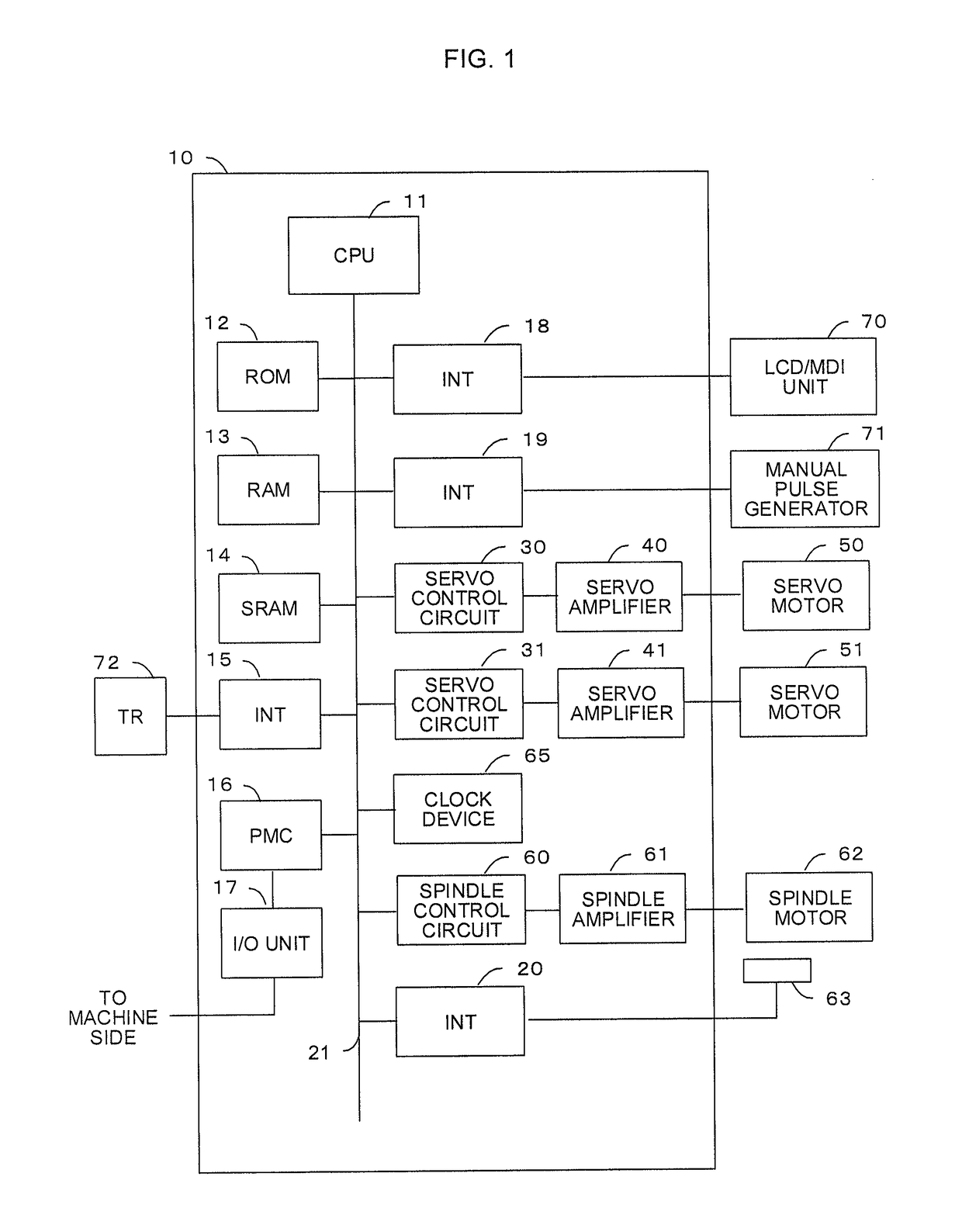

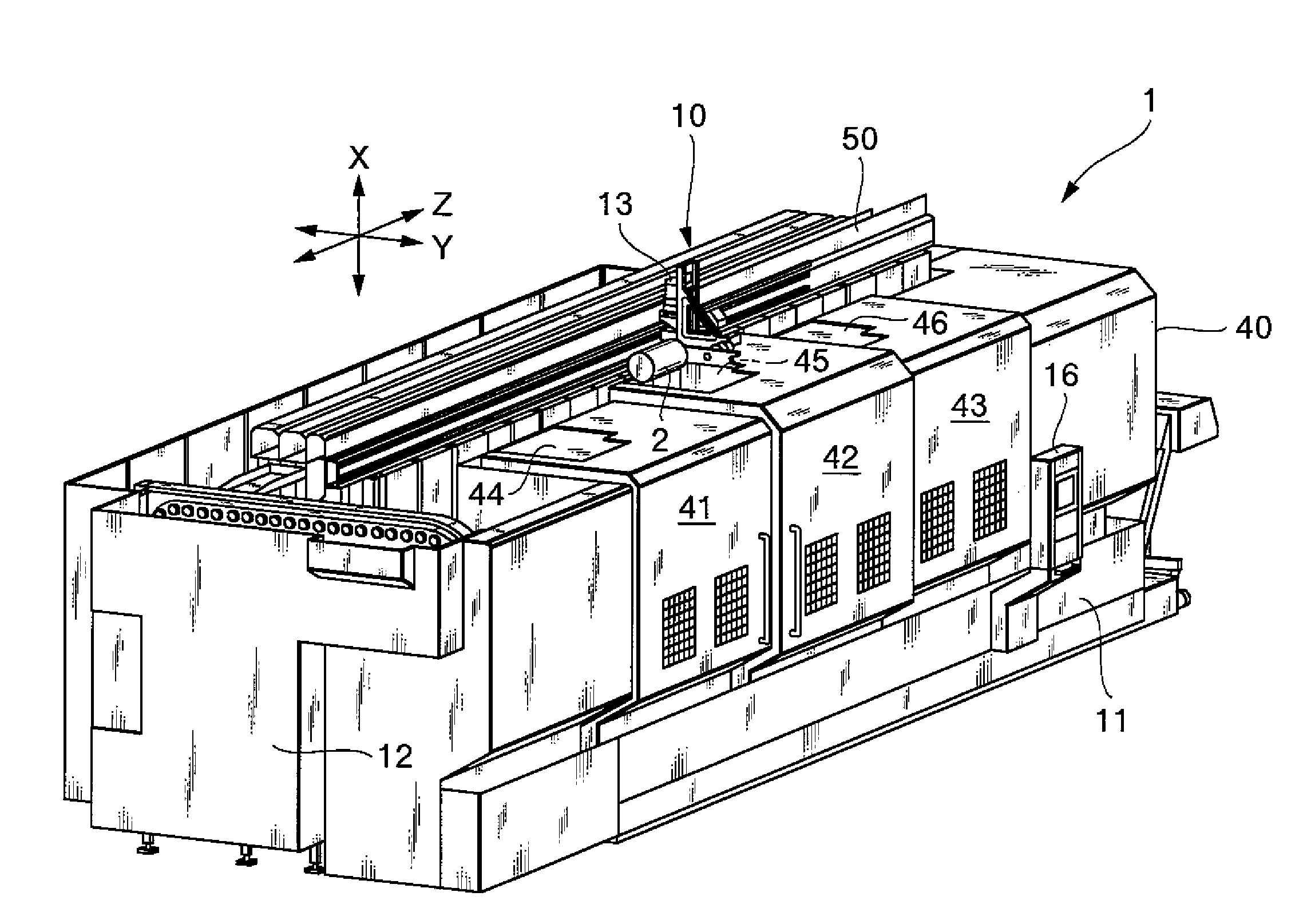

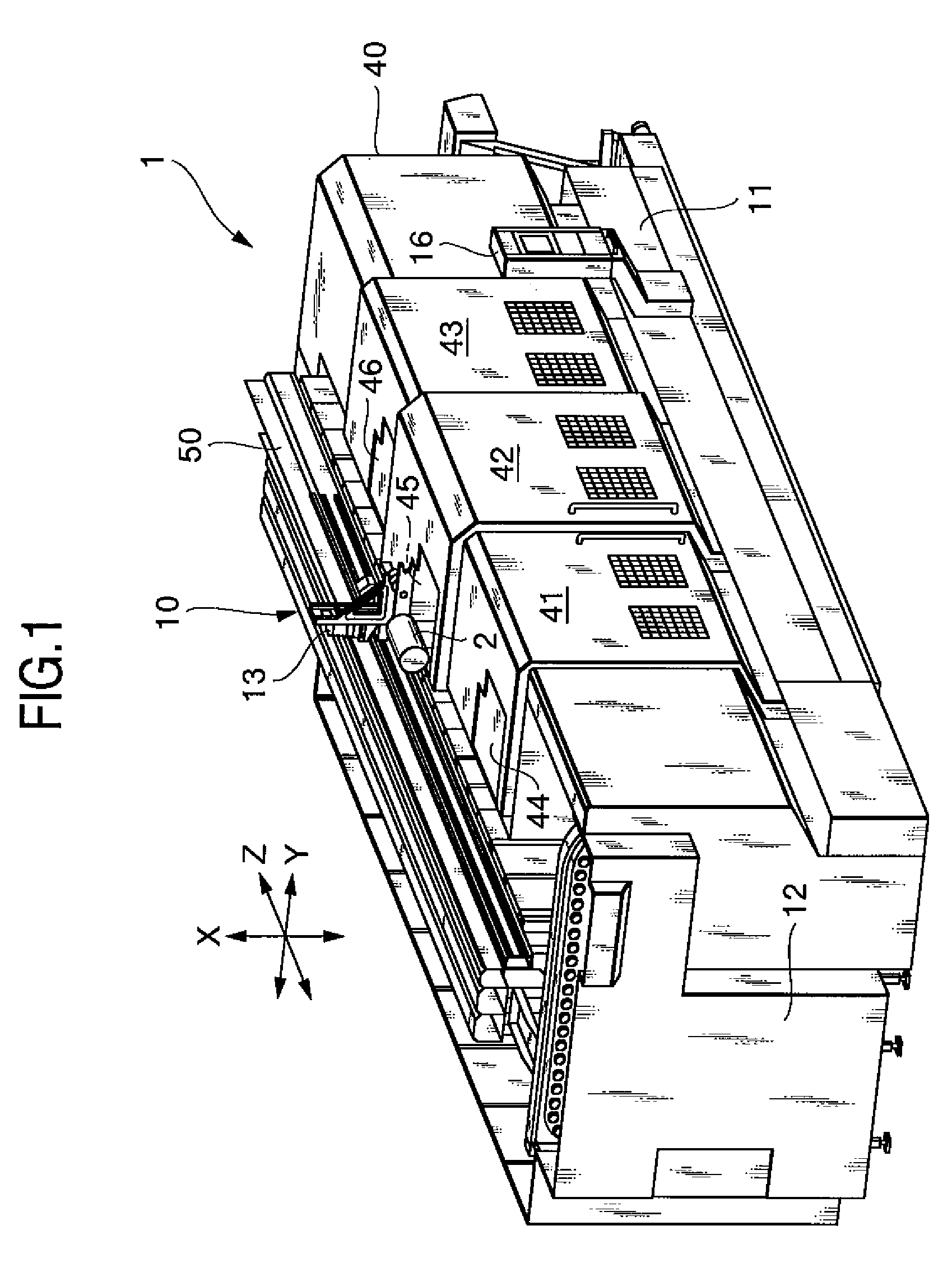

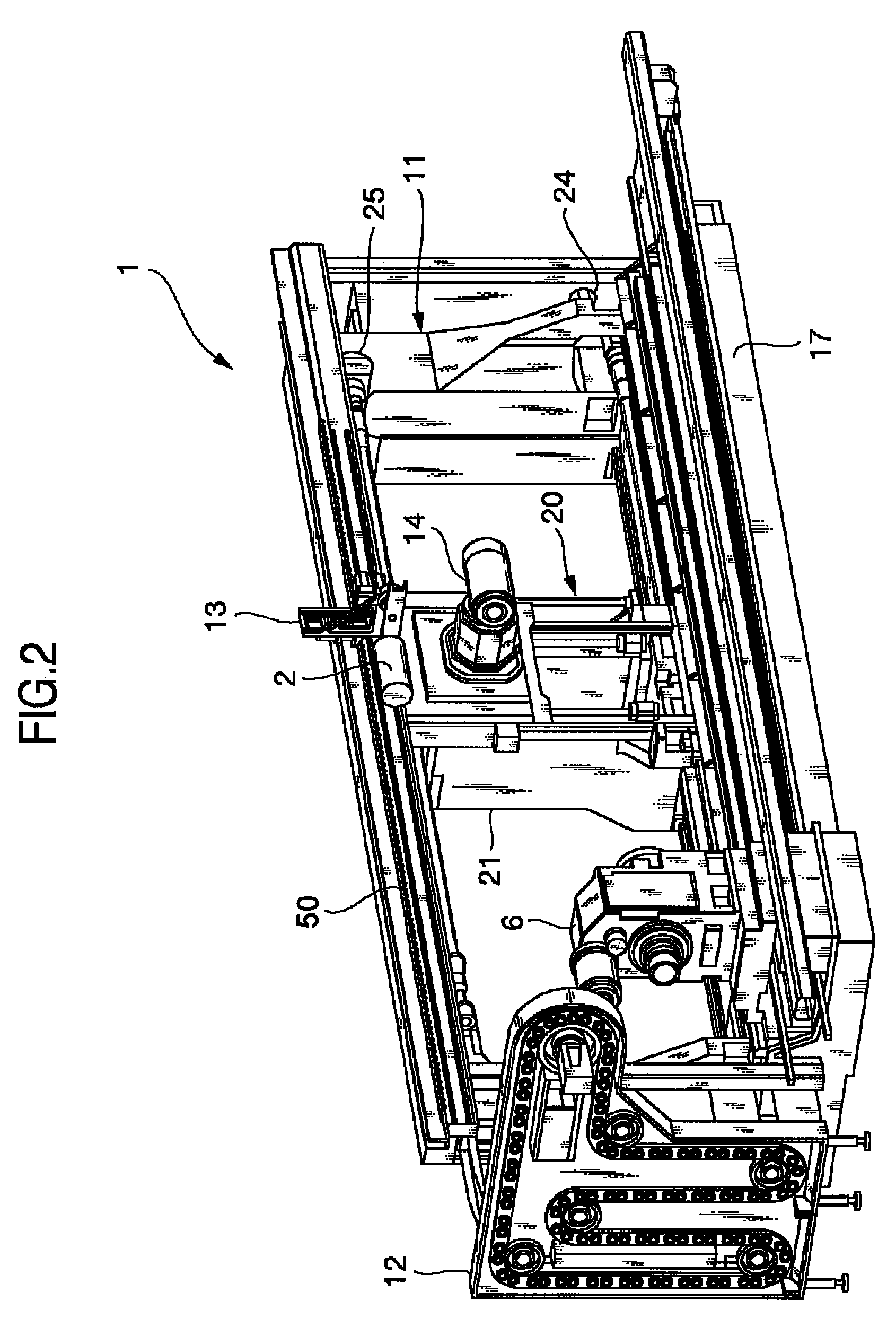

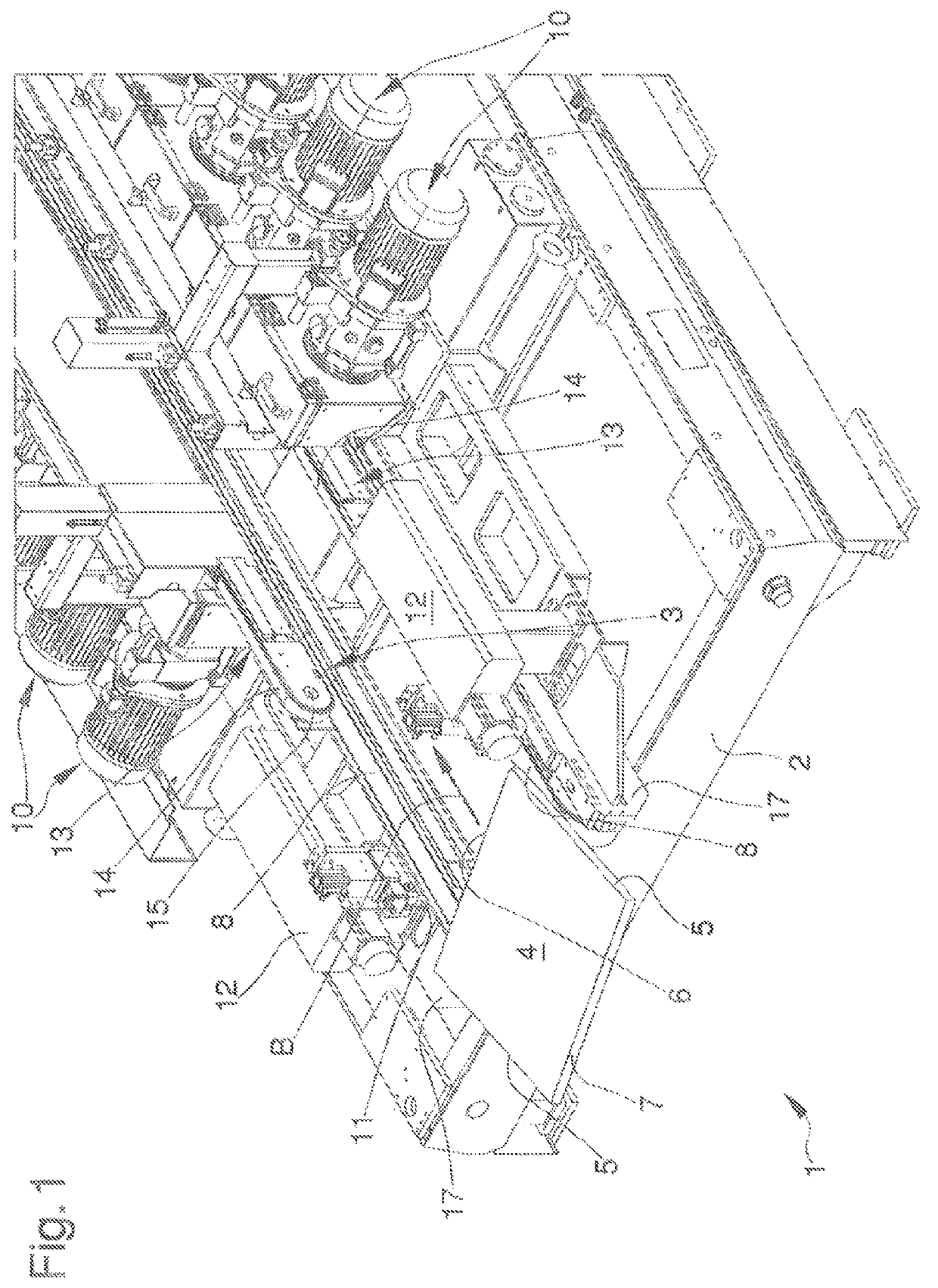

Machine tool with automatic tool changer

ActiveUS20090036282A1Reduce machining timeReduce distanceSpeed/accelaration controlFeeding apparatusShortest distanceChange positions

A tool changing unit moves between a magazine position and a changing position to transfer a tool. A machine tool has a plurality of tool changing positions. One of the tool changing positions is selected in advance for changing the tools next time. The tool changing unit and the tool mounted on a tool spindle move to the selected changing position for changing the tools in the selected changing position. Accordingly, the tool changing unit and the tool spindle move respective short distances for changing the tools, thereby shortening the non-machining time of a machine tool combined with the automatic tool changer.

Owner:DMG MORI CO LTD

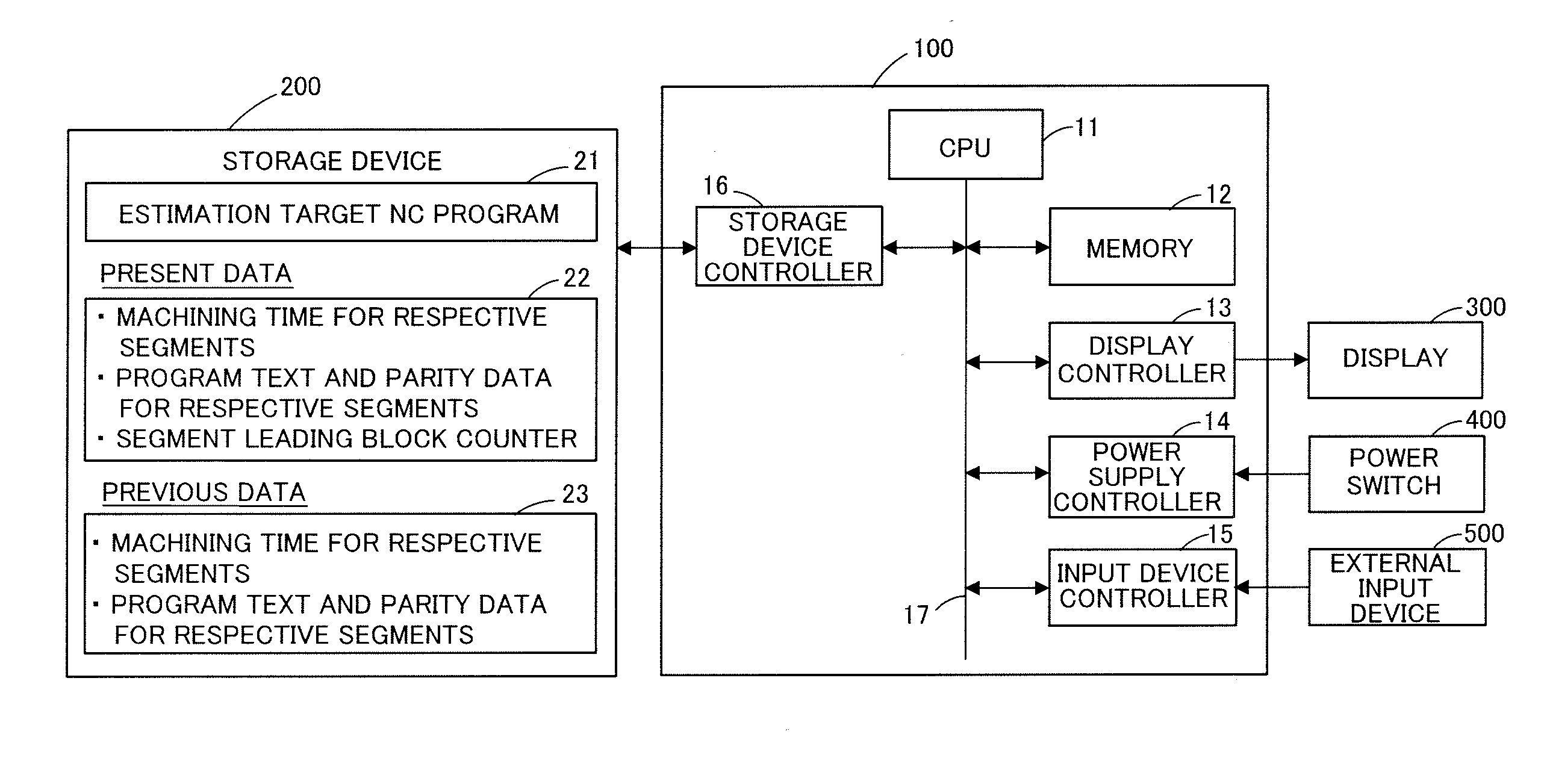

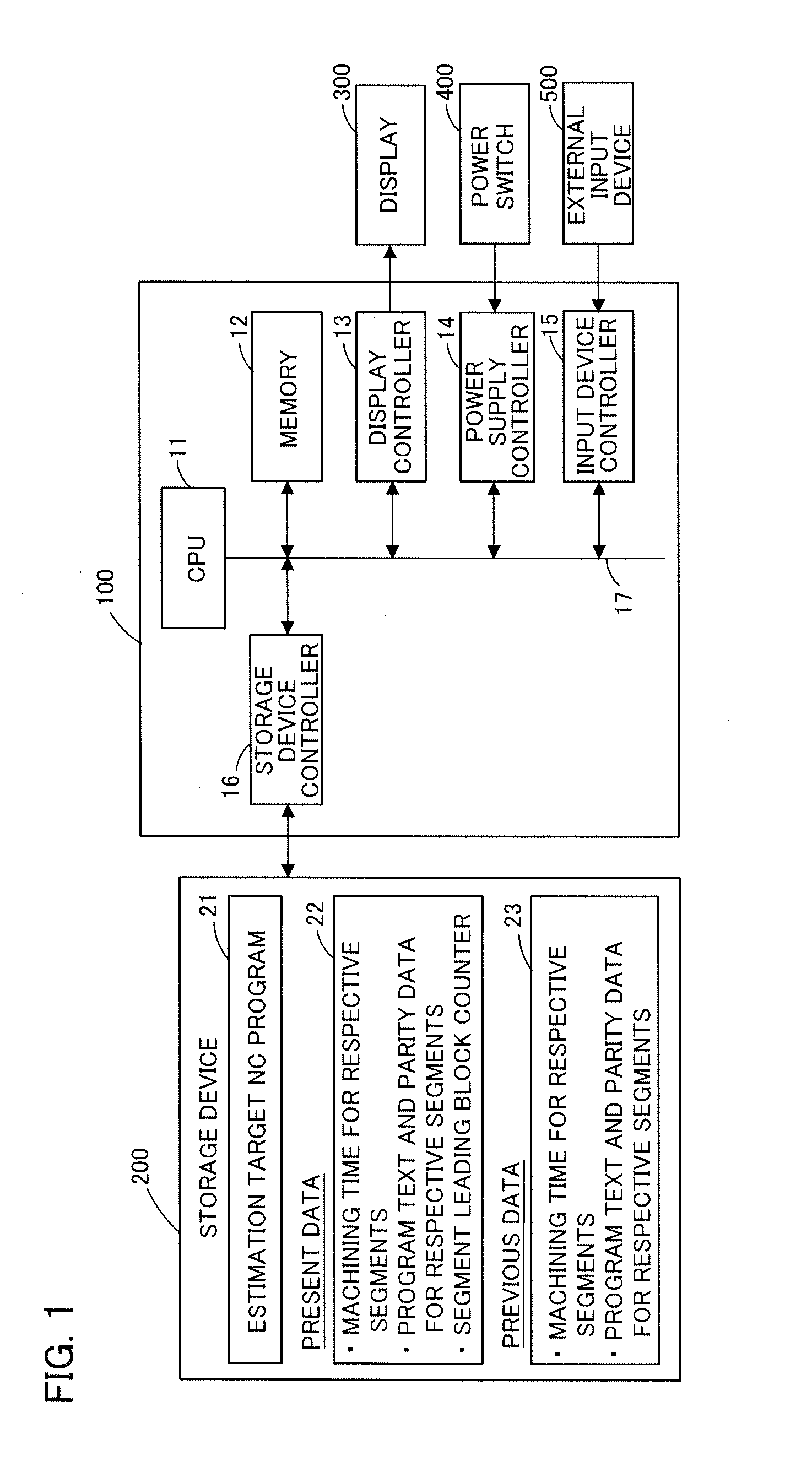

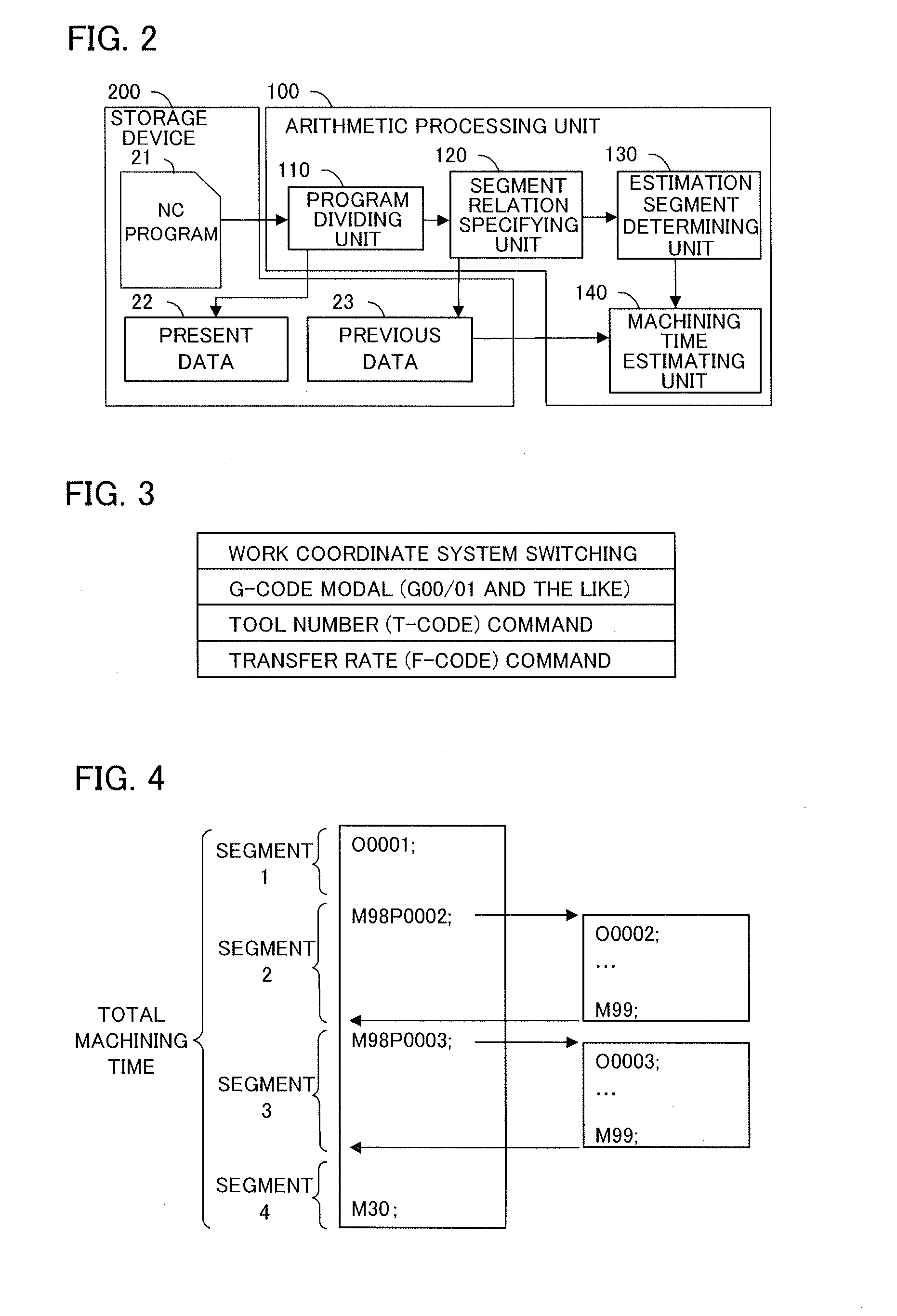

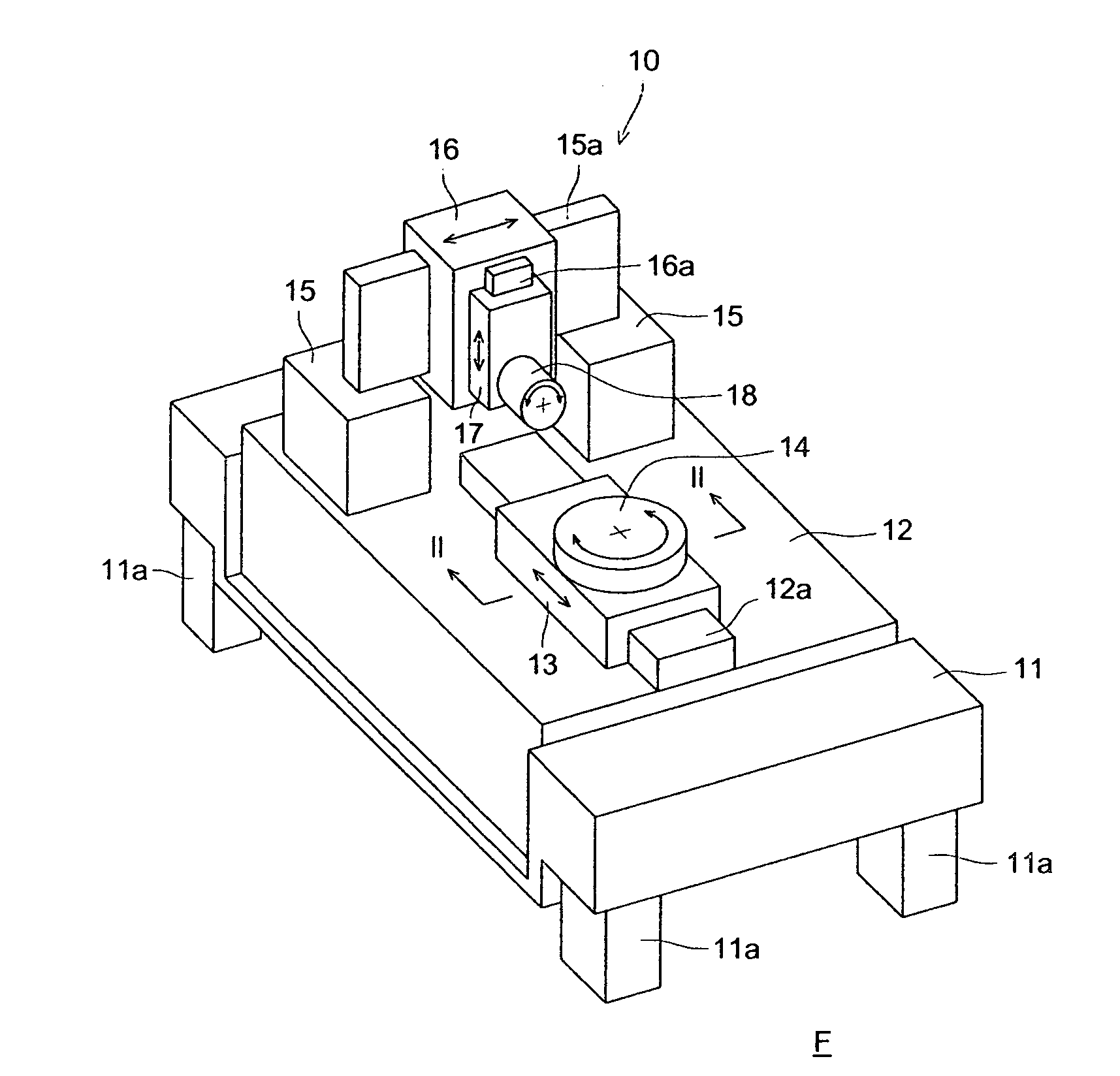

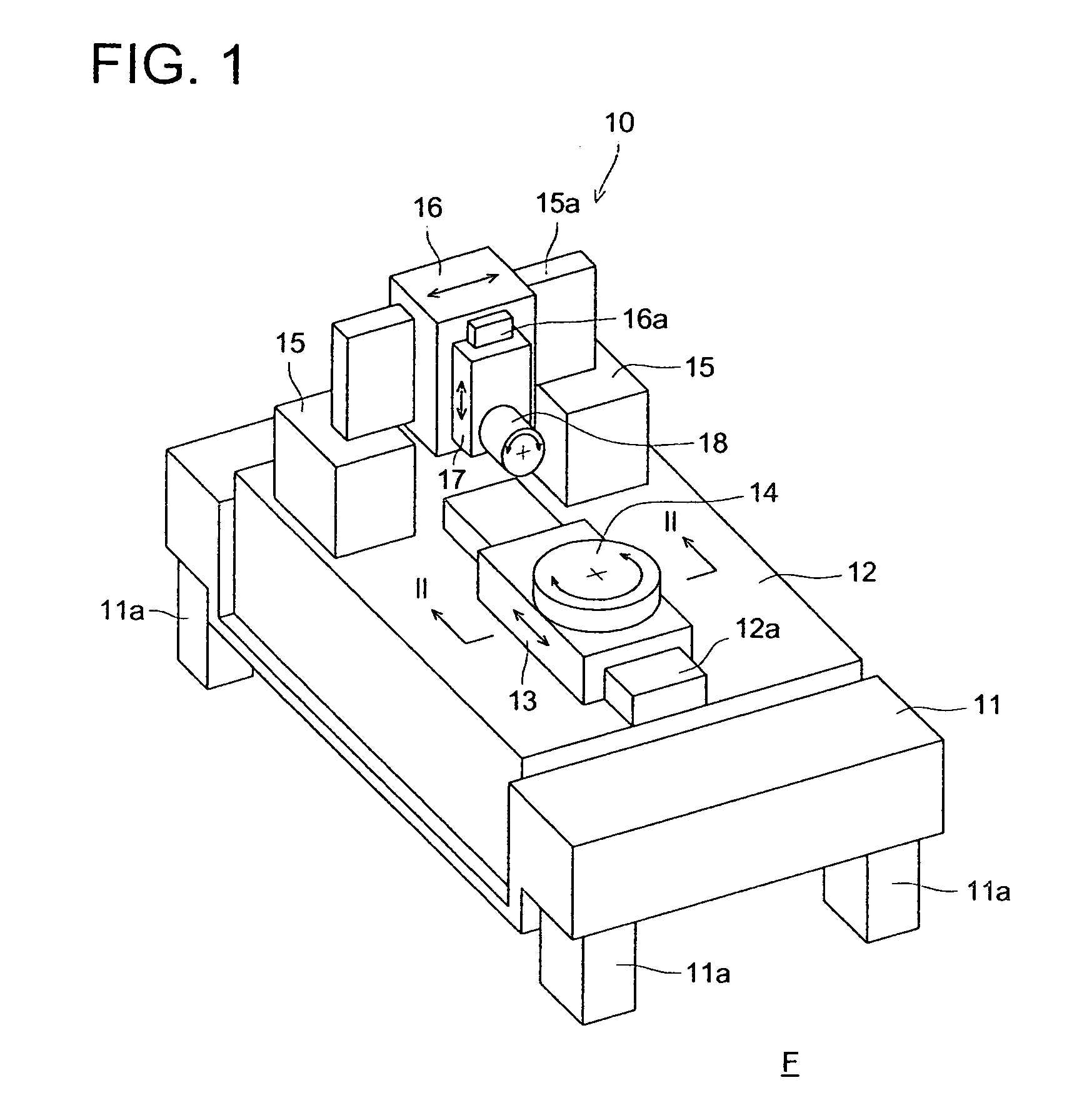

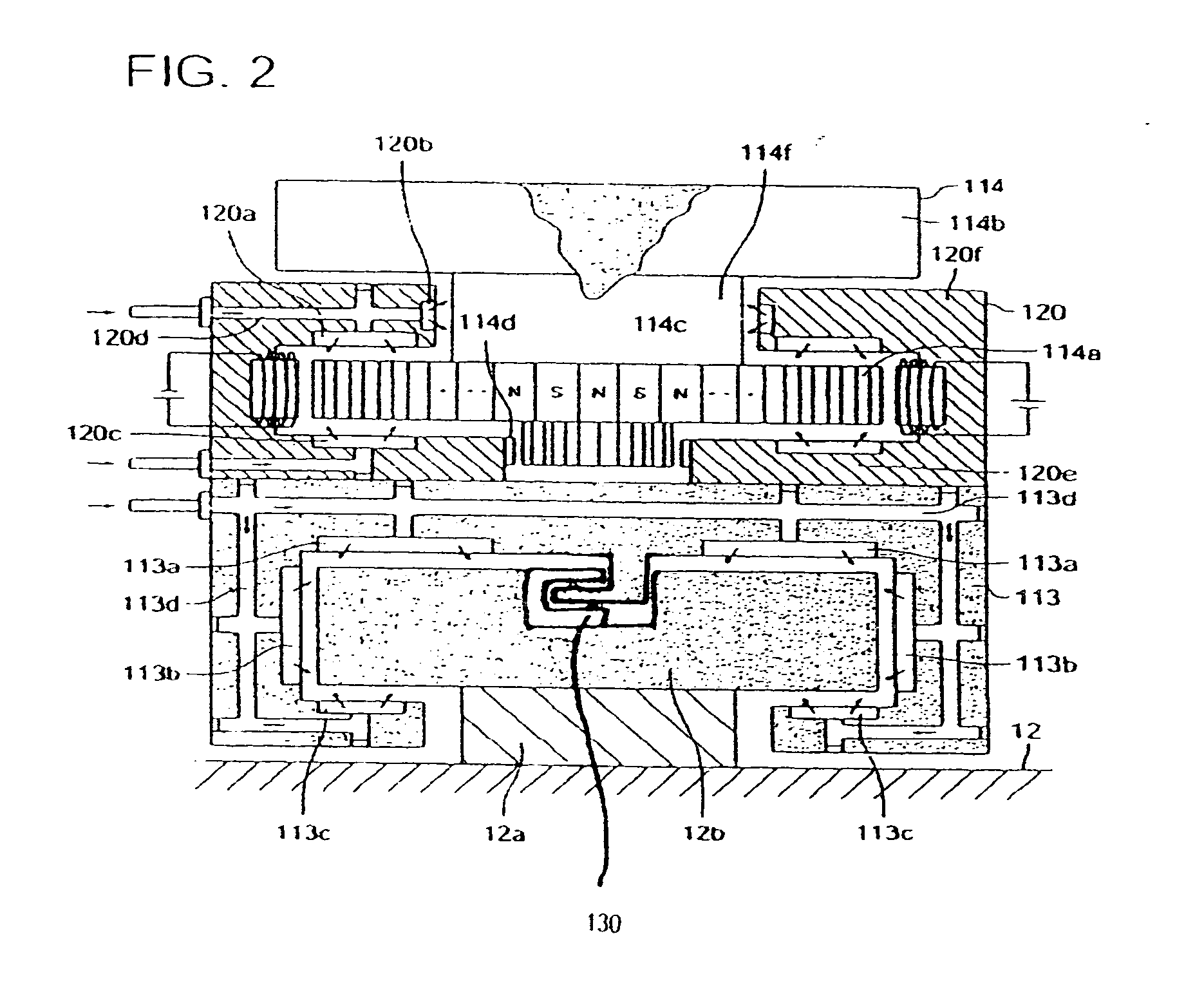

Machining time estimating device for estimating machining time after modification of nc program

ActiveUS20160026167A1Reduce machining timeReduce processing timeTotal factory controlSpecial data processing applicationsArithmetic processing unitMachine tool control

An arithmetic processing unit divides a modified NC program into a plurality of segments and determines a machining time estimation target segment among the plurality of divided segments. When estimating the machining time required for the machining of a machine tool controlled based on the modified NC program, the arithmetic processing unit shortens the time required for the machining time estimation process by reutilizing an estimated machining time for an NC program before modification with respect to segments other than the machining time estimation target segment.

Owner:FANUC LTD

Machining apparatus

InactiveUS20070006436A1Little changeReduce processing timeOptical surface grinding machinesMachine tool componentsDegrees of freedomEngineering

A machining apparatus for conducting at least one of a cutting process and a grinding process, comprises a stationary base; and a working device mounted on the stationary base and having a degree of freedom of more than two axes to conduct at least one of a cutting process and a grinding process, the working device comprising a first working bench which is formed of a ceramic material and is movable linearly with a degree of freedom of not less than one axes or more while holding a work piece or a tool.

Owner:KONICA MINOLTA OPTO

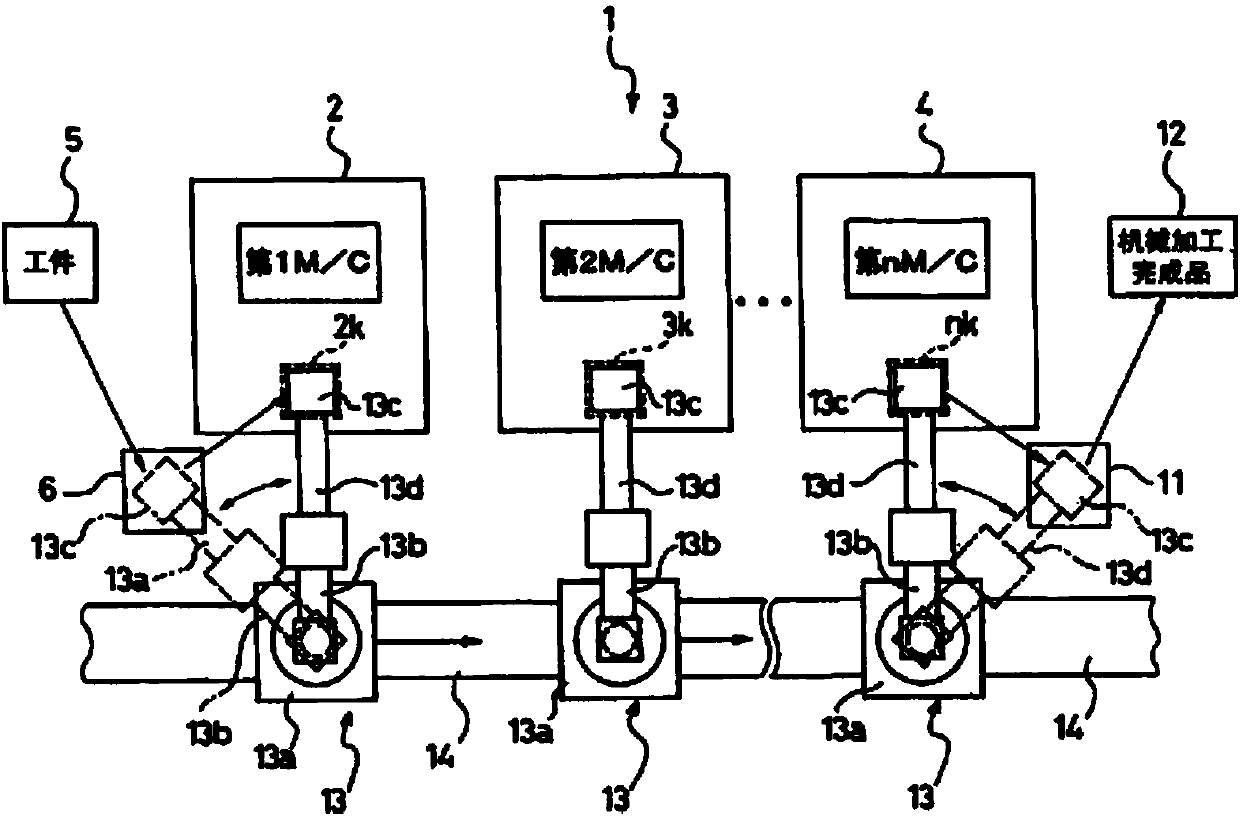

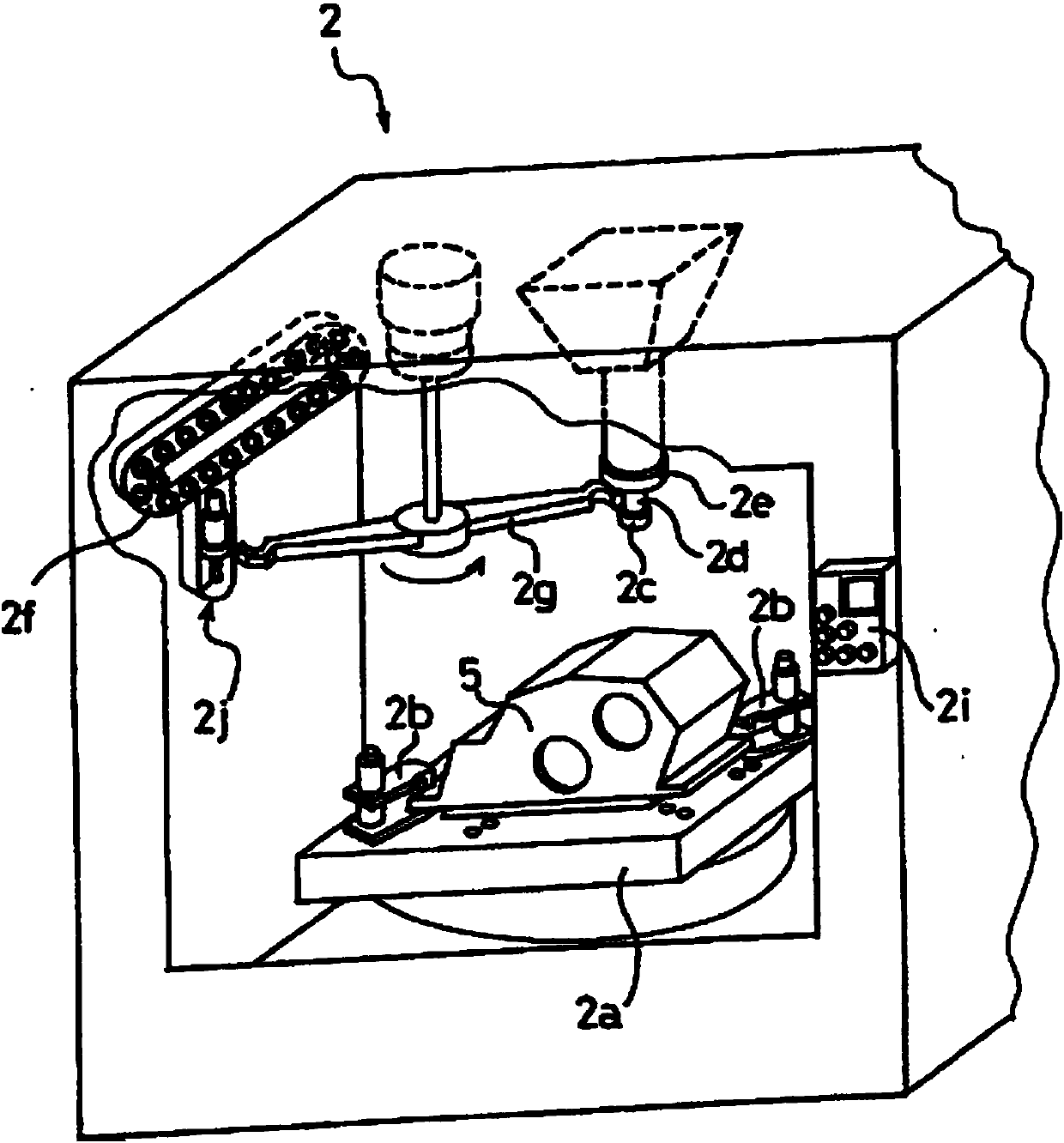

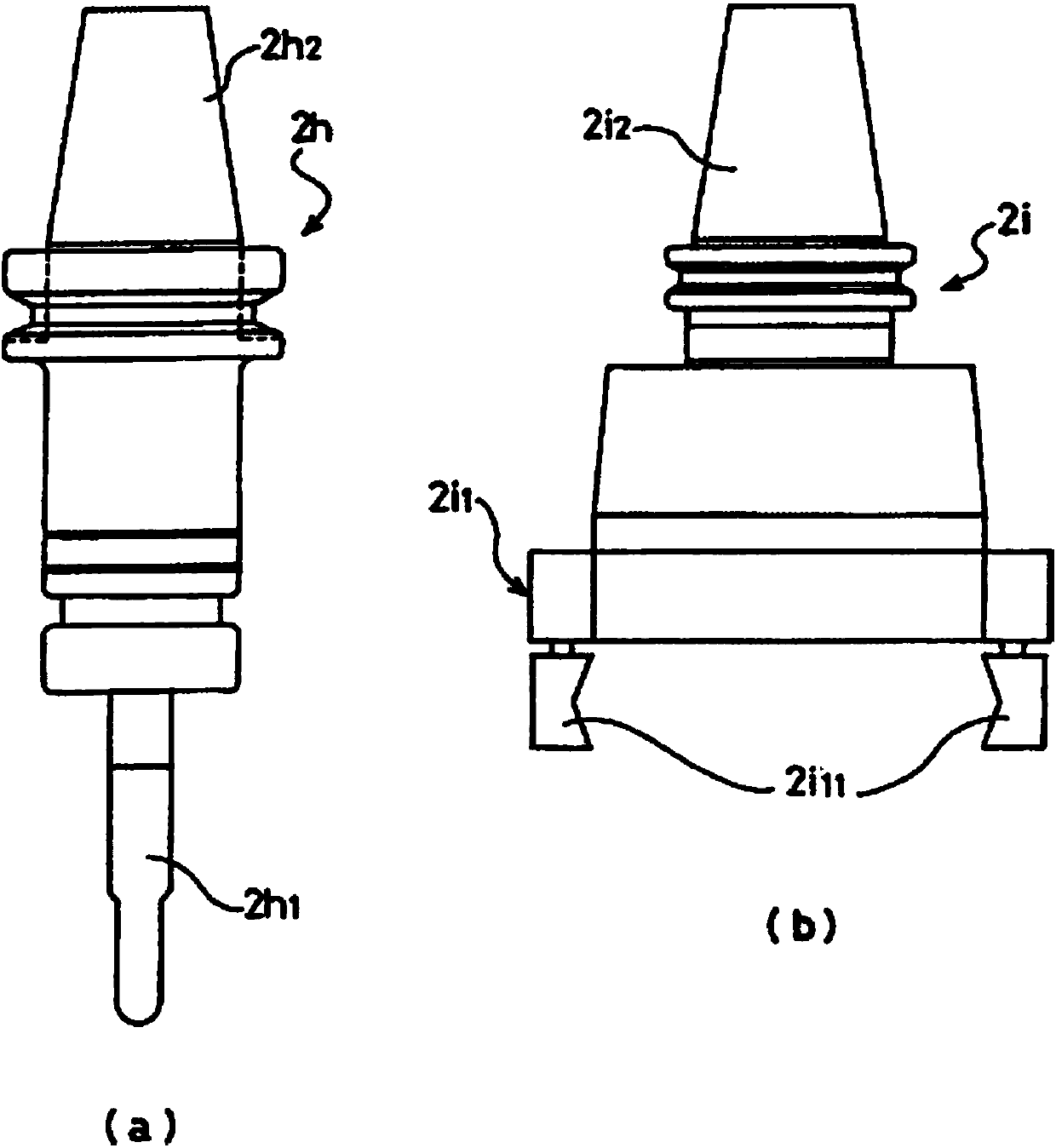

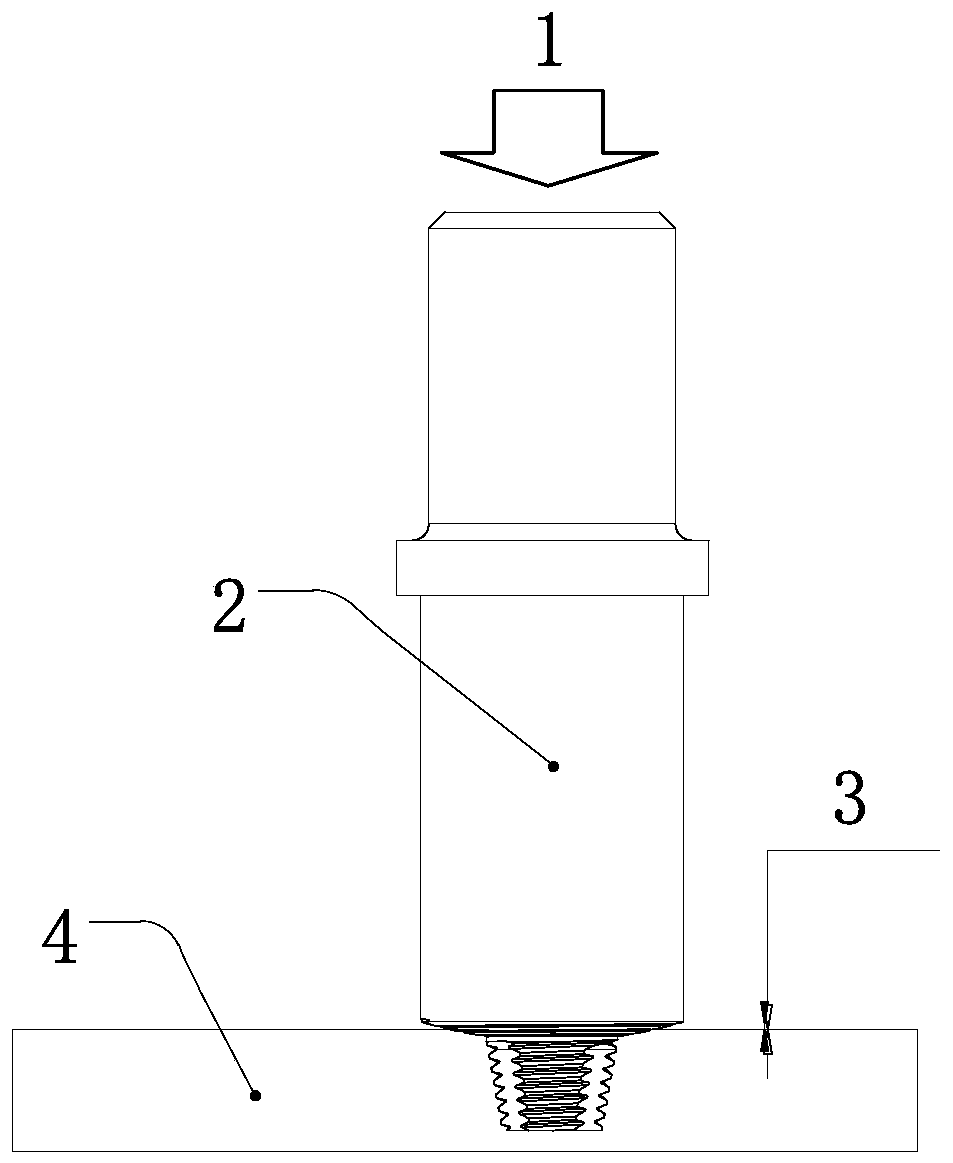

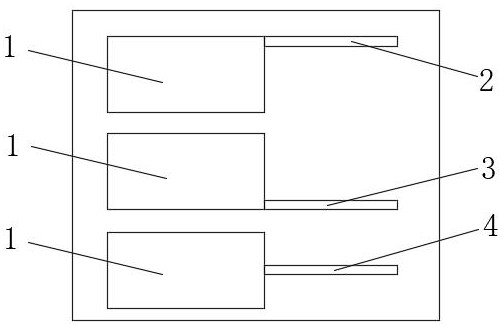

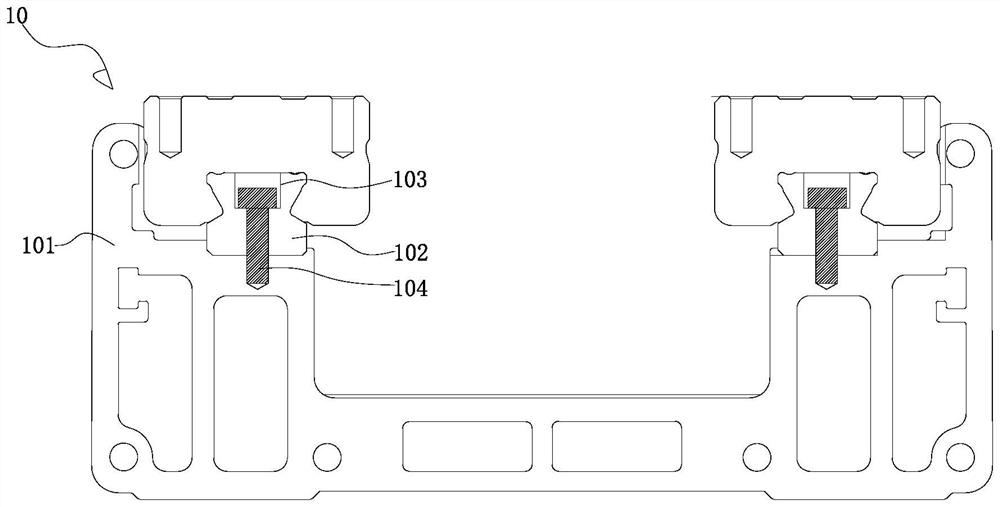

Machining machine and machining production line with machining machine

InactiveCN109834311AEasy to operateImprove efficient exchangeMetal working apparatusPositioning apparatusProduction lineEngineering

The invention provides a machining machine and a machining production line with the machining machine. and a workpiece (5) on an M / C table (2a) is subjected to piercing processing through a drill bit(2h) arranged at a connection portion (2d); after the piercing processing is completed, the drill bit (2h) is removed from the connection portion (2d);a workpiece jig (2i) is arranged at the connection portion (2d); then, the connection portion (2d) is lowered, the workpiece jig (2i) clamps the pierced workpiece (5) to lift the connection portion (2d), and the workpiece (5) is temporarily held onthe M / C table; and under the state, a next workpiece (5') is carried onto the M / C table(2a). By temporarily holding the pierced workpiece (5) on the M / C table, the next workpiece (5) can be easily carried onto the M / C table. Therefore, the carrying and unloading operations of the workpieces can be easily carried out; at the same time, a temporary storage field is no longer required; and the machining efficiency is improved.

Owner:成都宁翔机械制造有限责任公司

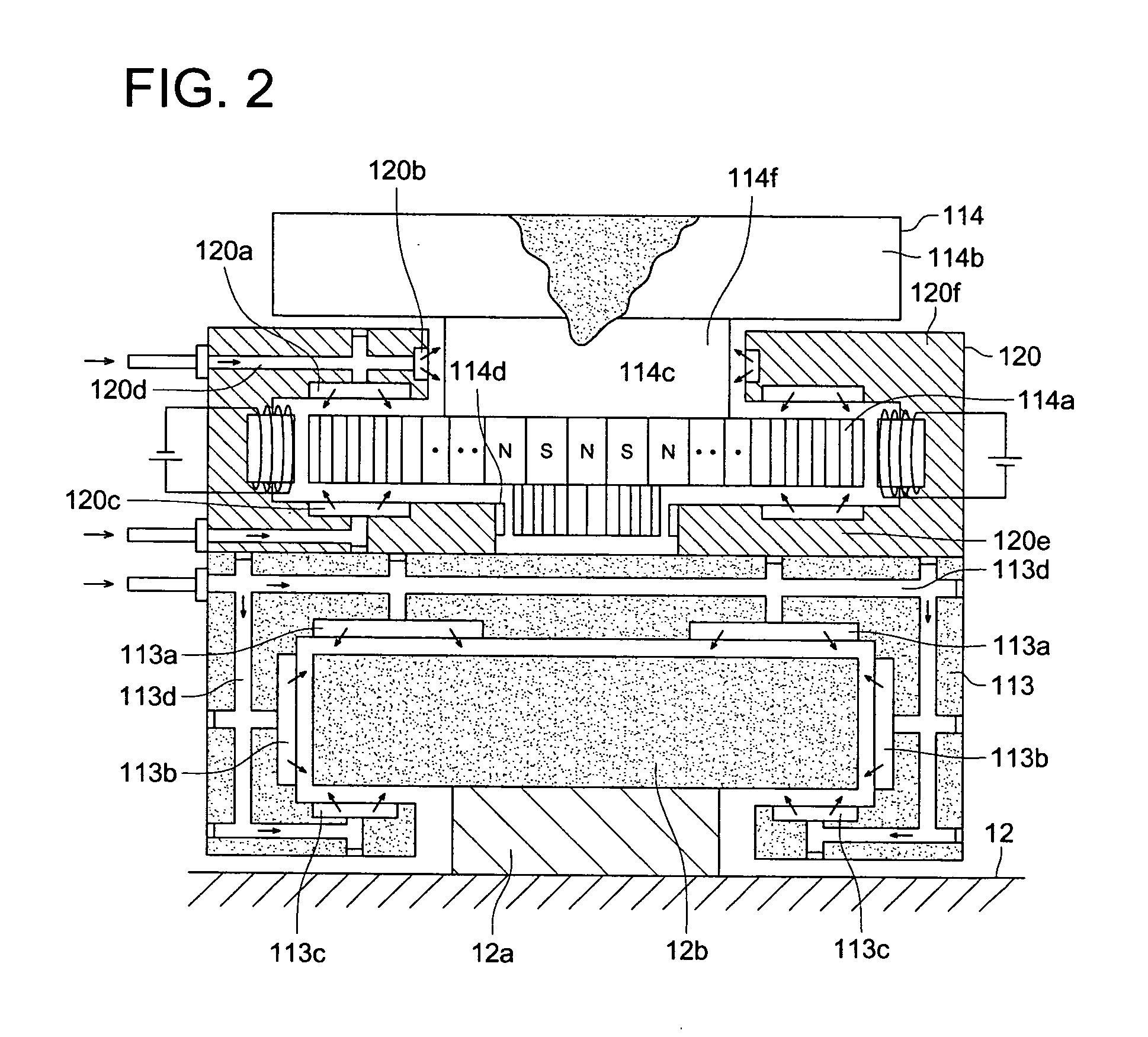

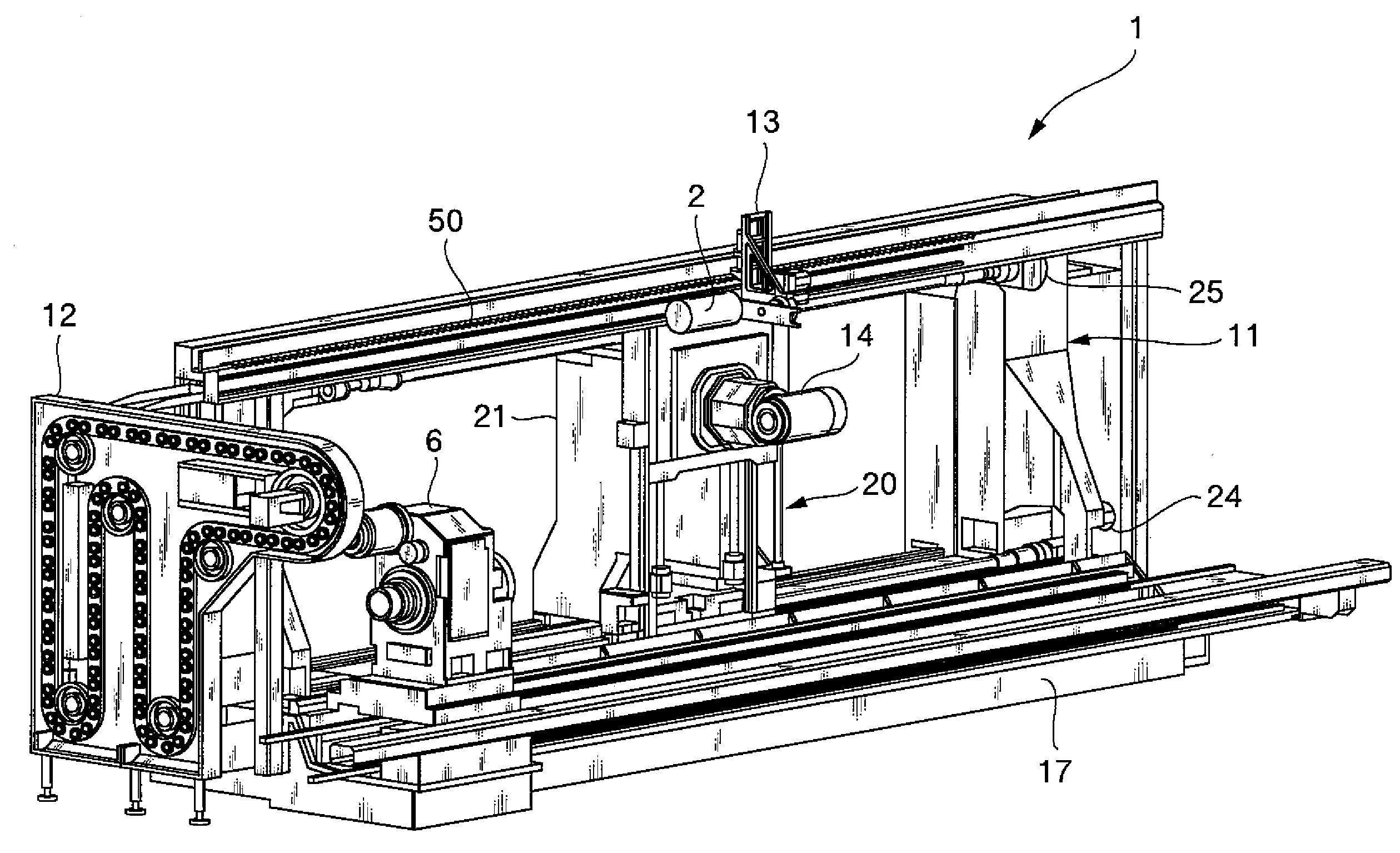

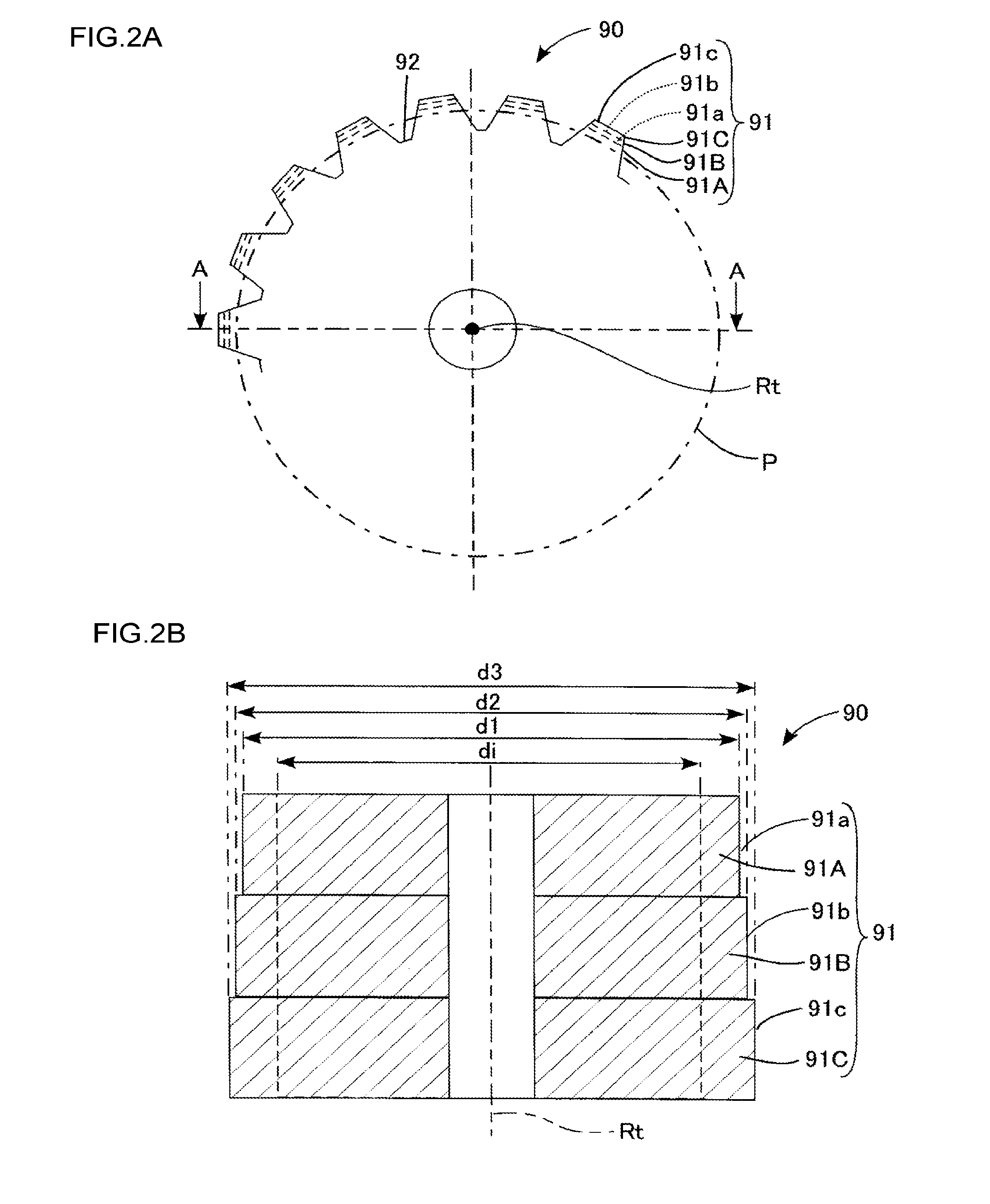

Grinding-supporting device

ActiveUS20150246422A1Reduce machining timeReduce processing timeRevolution surface grinding machinesGrinding drivesMain bearingEngineering

In an apparatus for multiple-bearing grinding of workpieces, such as crankshafts, wherein a support element seat occurs at a bearing point at the same time as the grinding of the main bearing, a grinding-supporting unit is used that contains a grinding spindle head having at least one grinding disk and support elements in the form of support jaws or support bodies that can be swiveled in. After the support point seat is ground, the support elements are brought into contact there-with and support the workpiece during the further machining. The simultaneous grinding of the support point seat and several, bearing points results in a reduction in the machining time in the grinding of the workpiece compared to the prior art.

Owner:ERWIN JUNKER MASCHNINENFAB

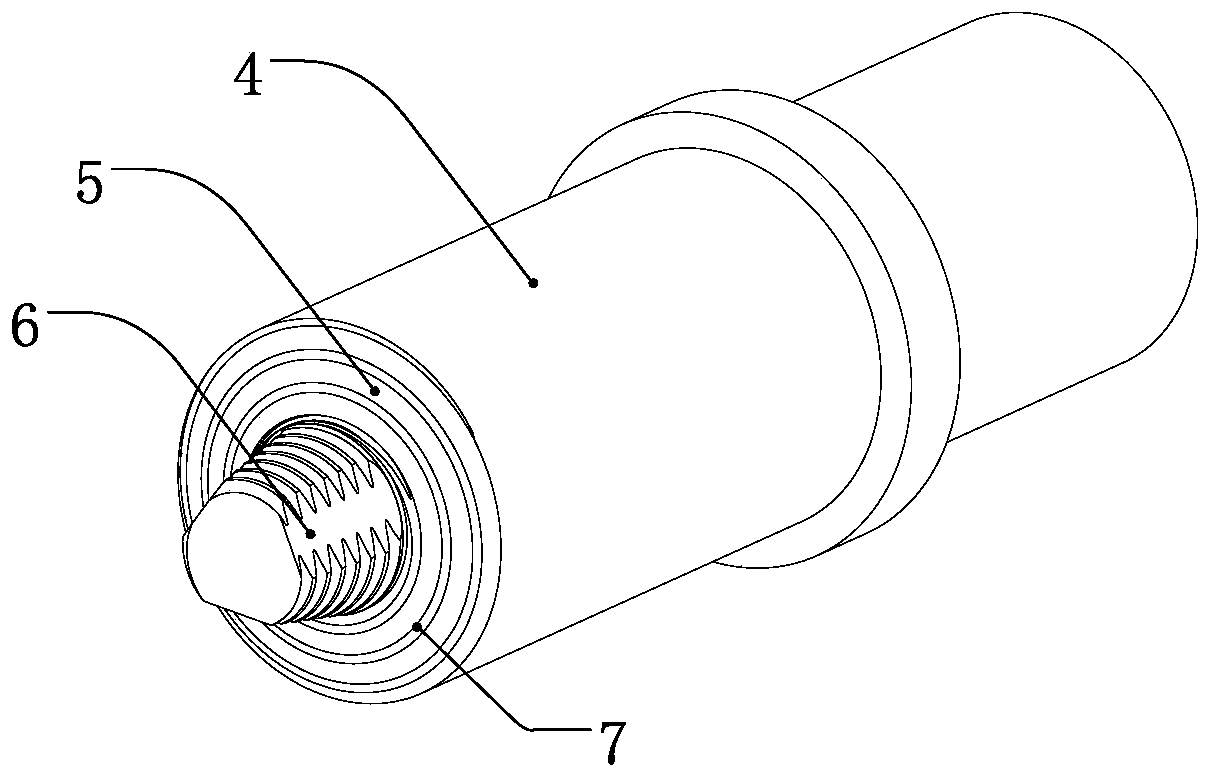

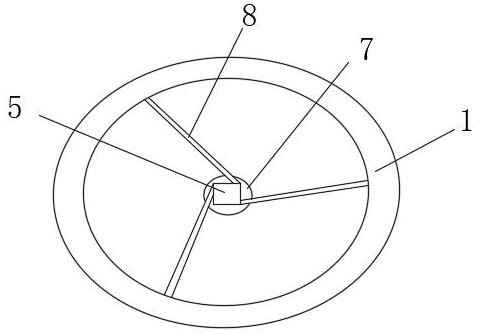

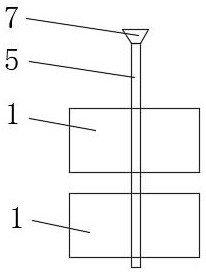

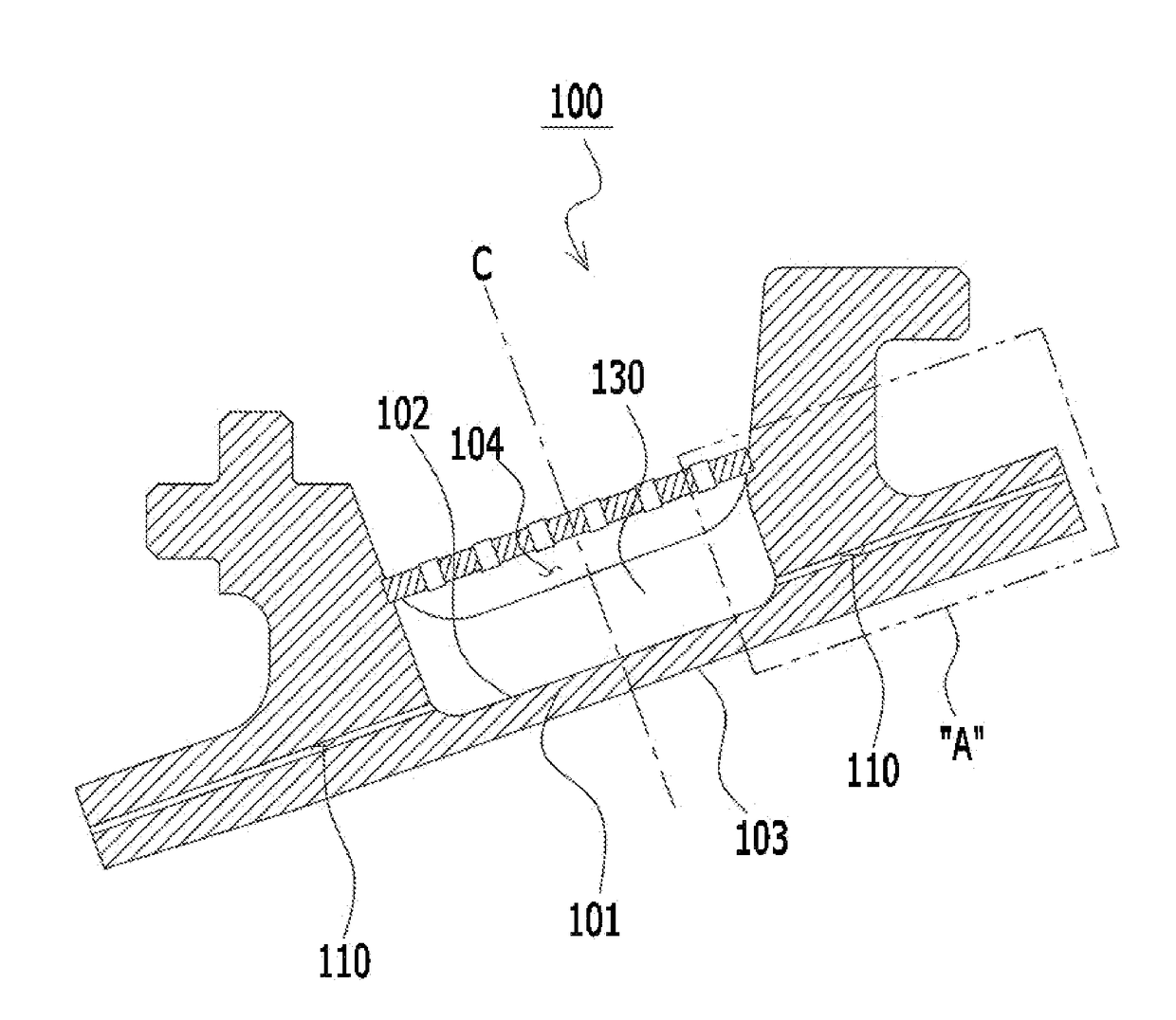

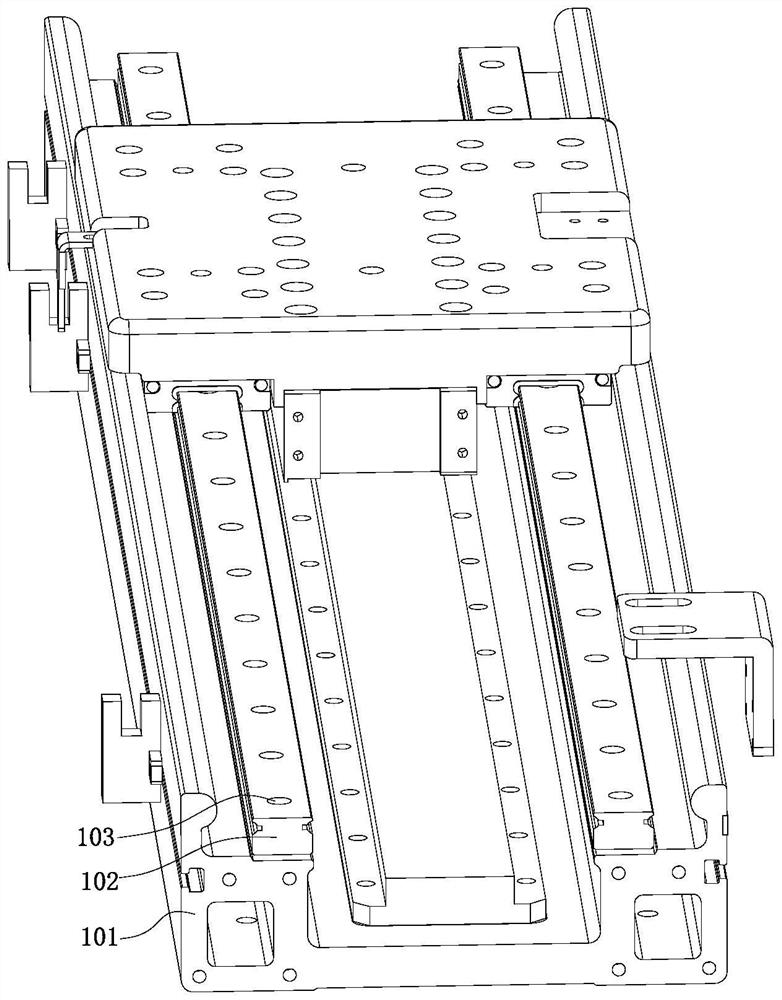

A friction stir welding device and method for realizing weld thickening

ActiveCN109365991BHigh fatigueSolve thinning problemNon-electric welding apparatusAxial pressureEngineering

A friction stir welding device capable of realizing weld thickening, the device comprising a zero-tilt-angle welding module (3), a constant pressure control module (1) and a stirring tool module (2). By means of the zero-tilt-angle welding module (3), a center line of a stirring tool always remains parallel to the normal direction of a surface of a workpiece to be welded during welding. The constant pressure control module (1) keeps an axial pressure of the stirring tool on the workpiece constant during welding. The stirring tool module (2) comprises a shaft shoulder (5), a stirring pin (6) and a clamping end (4). A method for welding using the friction stir welding device is further provided. By means of zero-tilt-angle welding, the requirements for a welding apparatus during two-dimensional and three-dimensional welding of welds are reduced, thereby omitting a tilt angle adjustment mechanism and expanding the application range of friction stir welding. Material addition can be implemented in a weld area without filling with an external material, thereby solving the problem of weld thinning and improving the fatigue performance of the weld area.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Novel method for stamping back door avoiding part at rear part of car top cover product

InactiveCN109530540AReduce rectification timeReduce development costsVehicle componentsPunchingHigh volume manufacturing

The invention discloses a novel method for stamping a back door avoiding part at the rear part of a car top cover product, and belongs to the field of automobile accessory machining. The method sequentially comprises the steps of OP10 drawing, OP20 trimming and punching side shaping, OP30 trimming and punching flanging shaping and OP40 trimming and punching side punching side flanging. According to the method, due to the fact that the shape is increased at the position of the drawing die male die in the side shaping area, so that the length of the shaping area line is improved so that the sideshaping required material can be stored enough for the OP20 side shaping area, the problems of dark cracking, slippage and wrinkling in the side shaping step are solved, and the die debugging time isshortened, so that the cost of the whole product in the die development stage is reduced; during mass production, the probability of unqualified products can be effectively avoided, and the generatedeconomic benefits are not neglected. The competitiveness of an enterprise in market economy is improved when the market competition is fierce; and the method is simple, practical, stable, reliable, and is convenient to popularize.

Owner:四川成飞集成吉文汽车零部件有限公司

Production process for evaporative pattern centrifugal casting

The invention discloses a production process for evaporative pattern centrifugal casting. The production process comprises the following steps of S1, designing of a pouring gate; S2, designing of a riser; S3, a box loading (manufacturing) process; and S4, a pouring process. Meanwhile, a space with the size reduced due to solidification is filled with molten metal under the action of centrifugal force, and the feeding effect is good; meanwhile, a large number of crystal nuclei are generated through fracture of regrowth dendritic crystals under the action of the centrifugal force and exciting force, crystal grains are refined, and the density of a product is further improved; and the molten metal in the pouring gate and the riser (a slag collecting riser or a feeding riser) moves towards theinterior of a casting model under the action of the centrifugal force, the utilization rate of the molten metal is increased, the yield of centrifugal casting is also increased, and the machining amount of a centrifugal casting machine is reduced.

Owner:洛阳佳会机械科技有限公司

Grinding machine for plate-like elements, particularly ceramic tiles and plates, natural stones, glass or similar

ActiveUS20180193969A1Easy to operateEasy constructionEdge grinding machinesGuide fencesEngineeringSupport point

The machine for grinding sheet-like elements, particularly tiles and slabs made of ceramic material, natural stone, glass or the like, includes a base framework, means for advancing at least one sheet-like element on a movement plane (A) along an advancement direction (B), the sheet-like element being provided with a pair of opposite first sides to be ground and a front side transversal to the first sides and defining the advancement front of the sheet-like element, means for machining the first sides adapted to intercept the sheet-like element in the motion thereof along the advancement direction (B), means for square-positioning the sheet-like element on the movement plane (A) comprising at least one abutment element which defines at least two support points adapted to contact the front side for arranging it in a position orthogonal to the advancement direction (B).

Owner:ANCORA

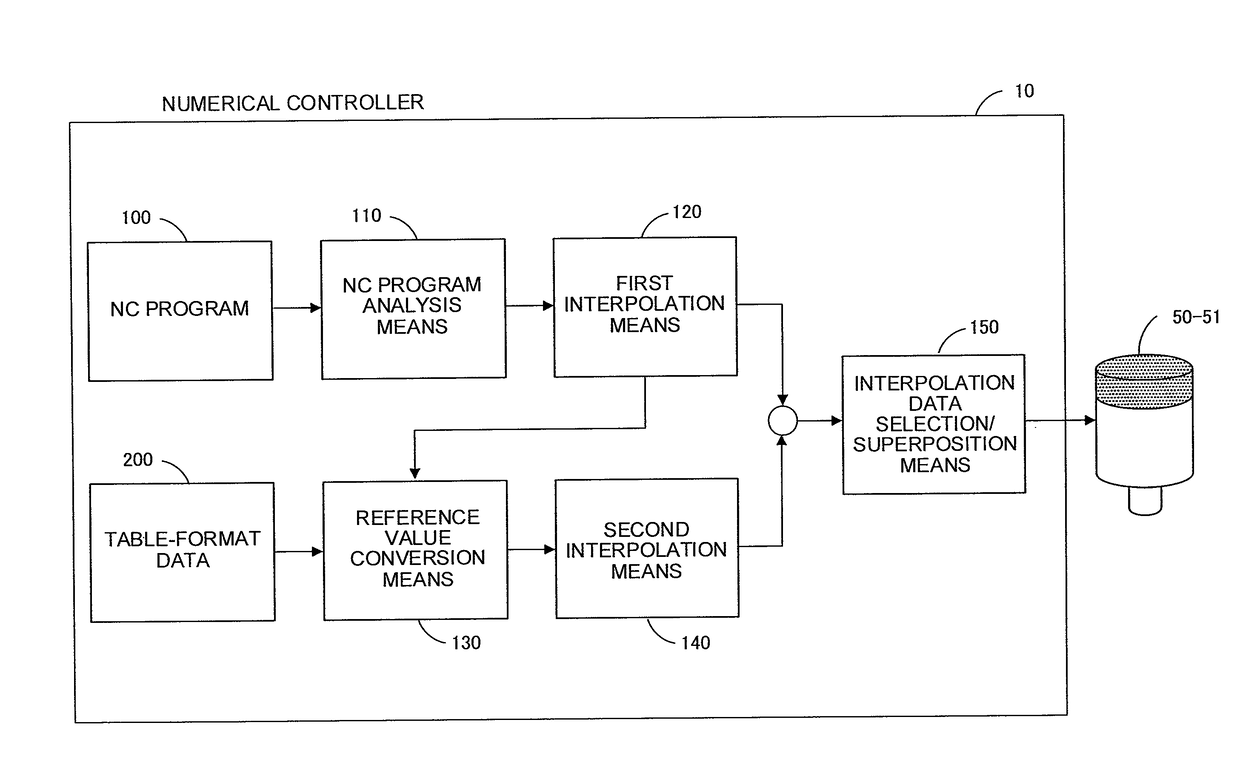

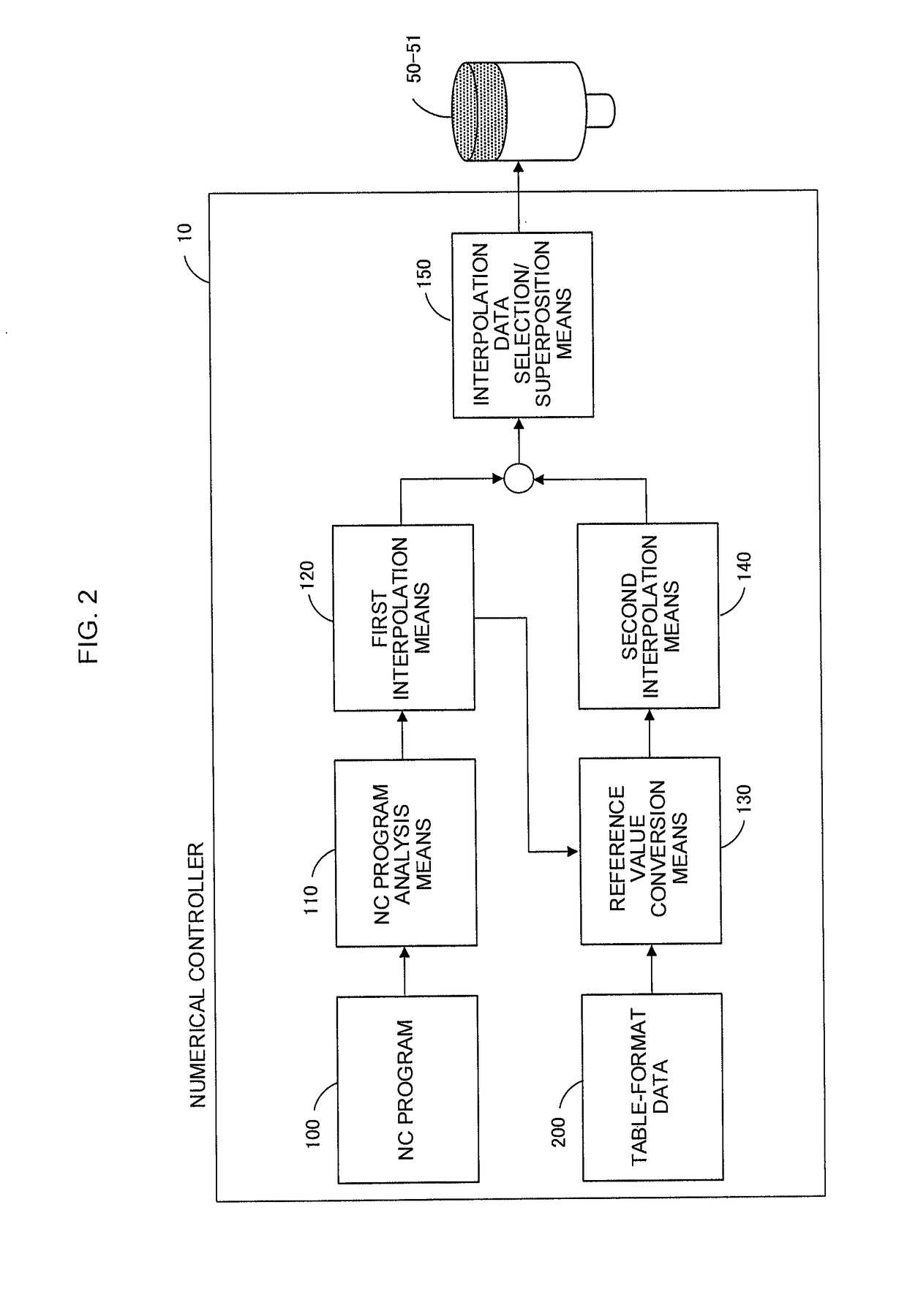

Numerical controller executing operation by a movement command and table-format data

ActiveUS10018987B2Reduce processing timeMore complicated geometric machiningProgramme controlComputer controlDrive motorMachine tool

A numerical controller drives motors for respective axes of a machine tool by using an NC program and table-format data that command positions of those axes with reference to a position of a reference axis. The numerical controller generates, based on a movement command commanded by the NC program, interpolation data for an axis to be controlled by the movement command, generates, based on the table-format data, interpolation data for an axis to be controlled by the table-format data, and further generates interpolation data obtained by selection from or superposition of these two pieces of interpolation data.

Owner:FANUC LTD

Machine tool with automatic tool changer

ActiveUS8114000B2Reduce machining timeReduce distanceSpeed/accelaration controlFeeding apparatusChange positionsShort distance

A tool changing unit moves between a magazine position and a changing position to transfer a tool. A machine tool has a plurality of tool changing positions. One of the tool changing positions is selected in advance for changing the tools next time. The tool changing unit and the tool mounted on a tool spindle move to the selected changing position for changing the tools in the selected changing position. Accordingly, the tool changing unit and the tool spindle move respective short distances for changing the tools, thereby shortening the non-machining time of a machine tool combined with the automatic tool changer.

Owner:DMG MORI CO LTD

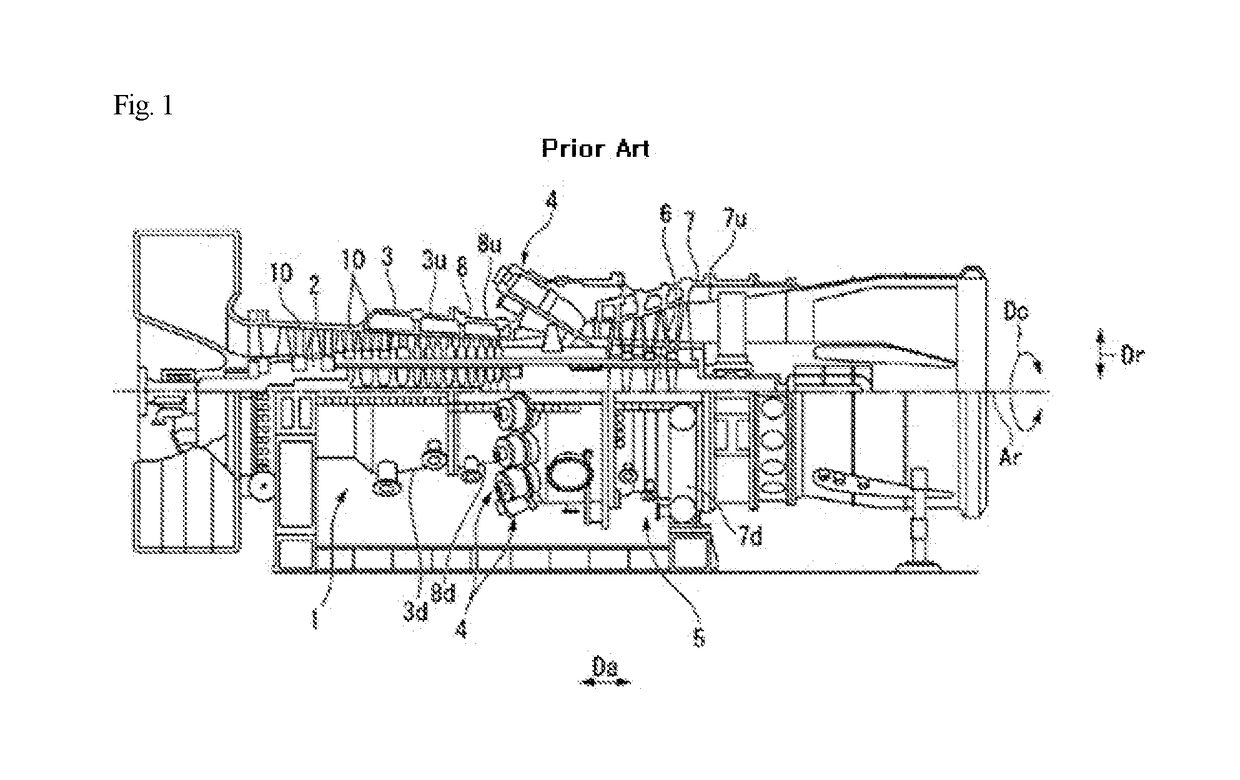

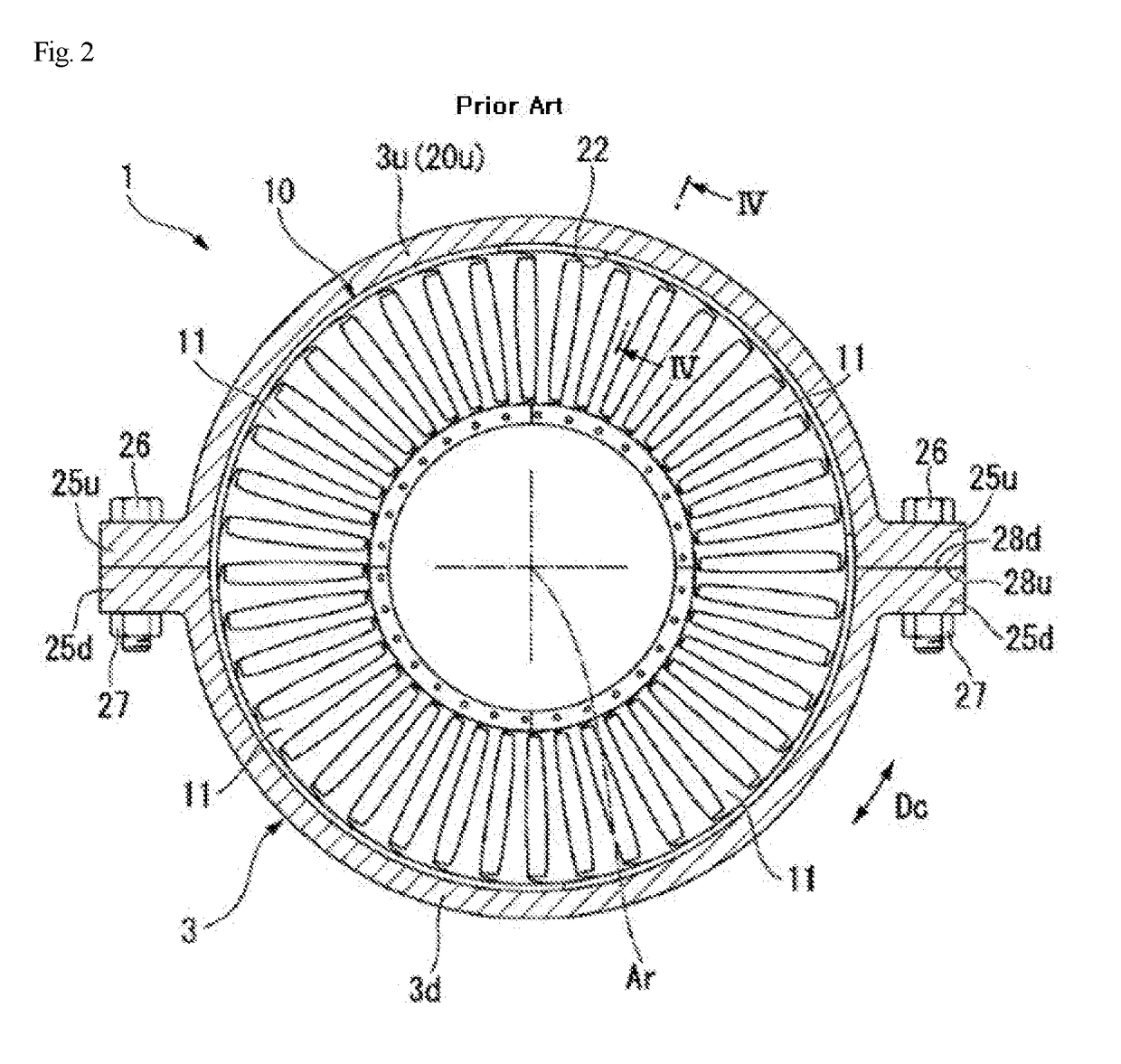

Gas turbine ring segment having straight cooling holes and gas turbine including the same

InactiveUS20180223687A1Improve cooling effectImprove structural stabilityEngine fuctionsBlade accessoriesTarget surfaceMachining time

A gas turbine ring segment for a gas turbine. The gas turbine ring segment includes an impingement target wall having an impingement target surface formed in one side, in a direction of a main cavity, and a hot side surface formed on the other side, in which the main cavity is located in a central portion in an axial direction. Cooling holes allowing an inside to communicate with an outside are arranged along the outer circumferential surface at predetermined distances from each other, each of the cooling holes having a straight structure communicating with the main cavity located in the central portion in the axial direction. This configuration consequently omits the structure comprised of a plurality of cooling holes, which has been necessary in the related art, such that the ceramic core that has been necessarily used during machining is unnecessary, thereby significantly reducing machining time and costs.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

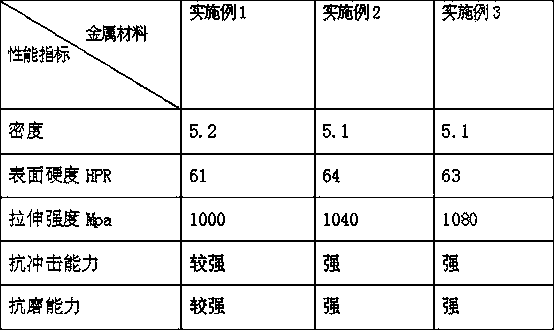

A kind of low-density impact-resistant metal material and its manufacturing method

ActiveCN104250714BLow densityStrong mechanical propertiesManufacturing cost reductionMetallic materials

The invention discloses a low density impact resistant metal material which comprises the following materials by weight: 1.5-3.1% of C, 1.2-1.9% ofSi, 1.69-2.32% of Mn, 0.033-0.042%of S, 0.021-0.025% of P, 1.8-3.6% of Cr, 1.6-3.6% of Ni, 1.56-2.25% of Mo, 0.45-0.68% of Co, 0.63-1.18% of Fe, and balance of Cu. The low density impact resistant metal material has the quality characteristics of strong mechanical properties, good plasticity and low density and the like. Through addition of a small amount of 1.6-3.6% of Ni, 1.56-2.25% of Mo, 0.45-0.68% of Co and 0.63-1.18% of Fe, the metal material self density is reduced further, the metal material quality is effectively guaranteed, by once casting forming, quenching or nitriding is not needed, the antiwear and impact resistant ability can be improved, at the same time, the processing time is saved, the manufacturing cost is reduced, and the production efficiency is increased.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Guide rail profile integrated module and manufacturing process thereof

The invention discloses a guide rail profile integrated module and a manufacturing process thereof, the guide rail profile integrated module comprises a carbon fiber profile made of a carbon fiber composite material and two guide rails arranged on the two sides of the upper end face of the carbon fiber profile, the guide rails protrude out of the upper end face of the carbon fiber profile, and the carbon fiber profile and the guide rails are fixed into a whole in an in-mold forming mode. The carbon fiber section bar is made of the carbon fiber composite material to replace an aluminum alloy section bar, so that the cost is lower, the processing is convenient, the overall weight of the module can be reduced, and the installation and the use are convenient; due to the fact that the guide rail and the carbon fiber section bar are fixed into a whole, deformation resistance strength is high, screw locking is not needed, machining time is saved, assembly precision between the guide rail and the carbon fiber section bar can be high, the guide rail can be machined into the final shape in advance, later meter calibration is not needed, parallelism can reach two to three times of meter calibration assembly precision, and the accuracy of meter calibration is improved. The guide rail is convenient to machine, machining procedures can be reduced, and product quality can be guaranteed.

Owner:东莞市华凯科技自动化设备有限公司

Grinding machine for plate-like elements, particularly ceramic tiles and plates, natural stones, glass or similar

ActiveUS10654143B2Easy to operateEasy constructionEdge grinding machinesGuide fencesEngineeringSupport point

The machine for grinding sheet-like elements, particularly tiles and slabs made of ceramic material, natural stone, glass or the like, includes a base framework, means for advancing at least one sheet-like element on a movement plane (A) along an advancement direction (B), the sheet-like element being provided with a pair of opposite first sides to be ground and a front side transversal to the first sides and defining the advancement front of the sheet-like element, means for machining the first sides adapted to intercept the sheet-like element in the motion thereof along the advancement direction (B), means for square-positioning the sheet-like element on the movement plane (A) comprising at least one abutment element which defines at least two support points adapted to contact the front side for arranging it in a position orthogonal to the advancement direction (B).

Owner:ANCORA

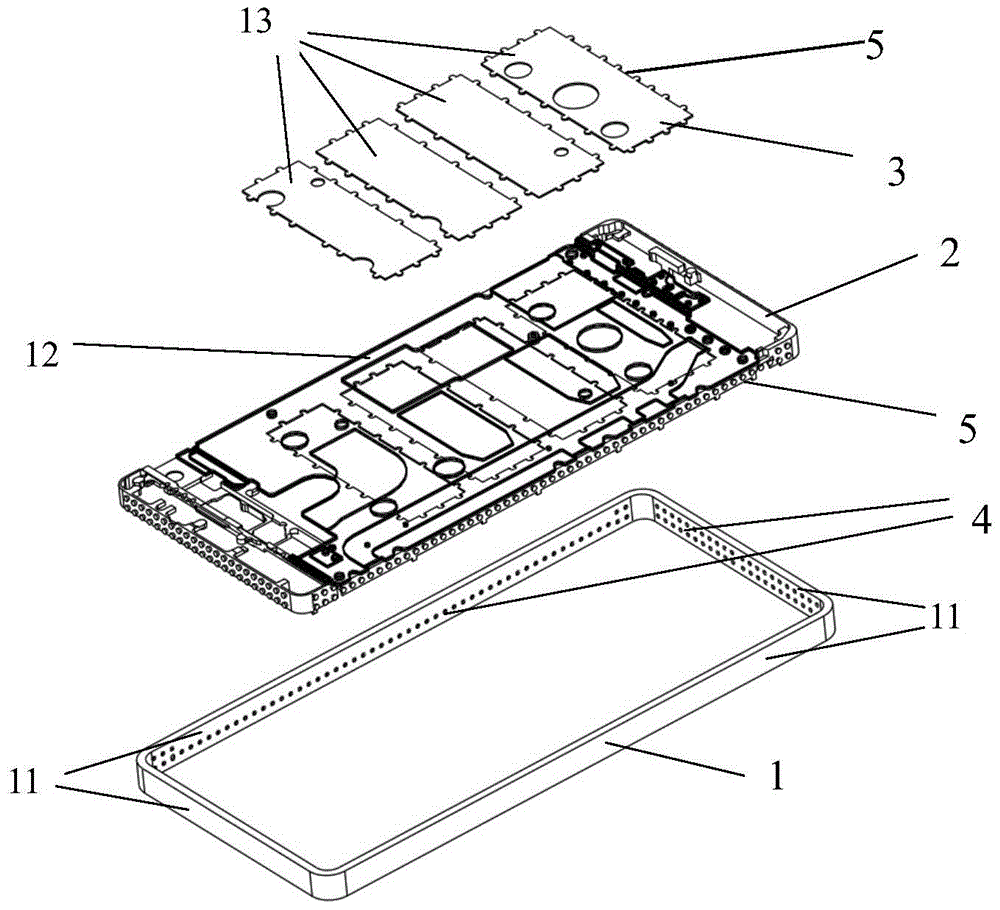

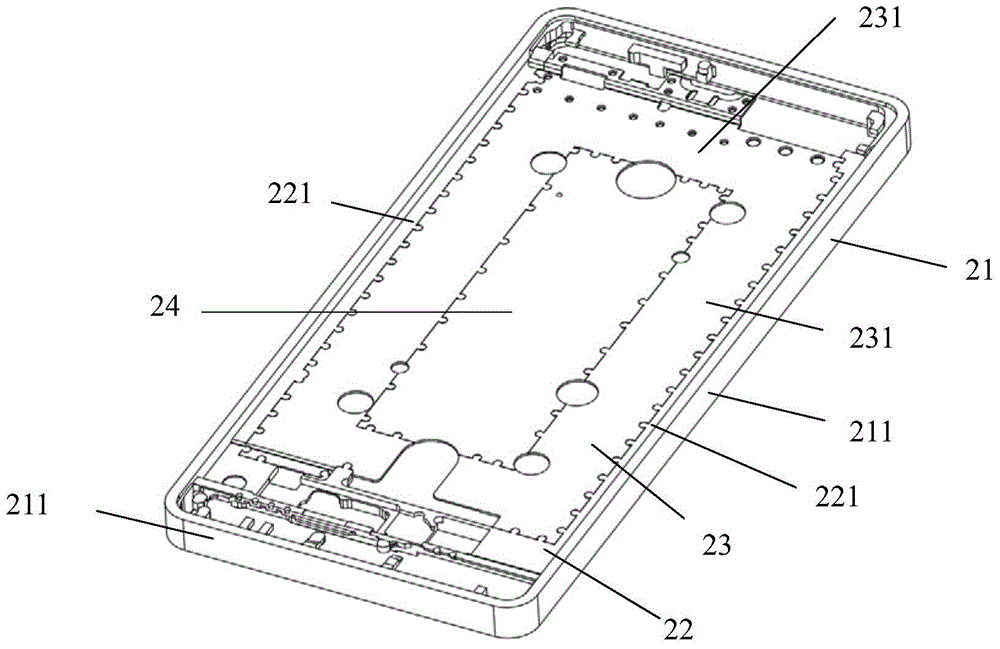

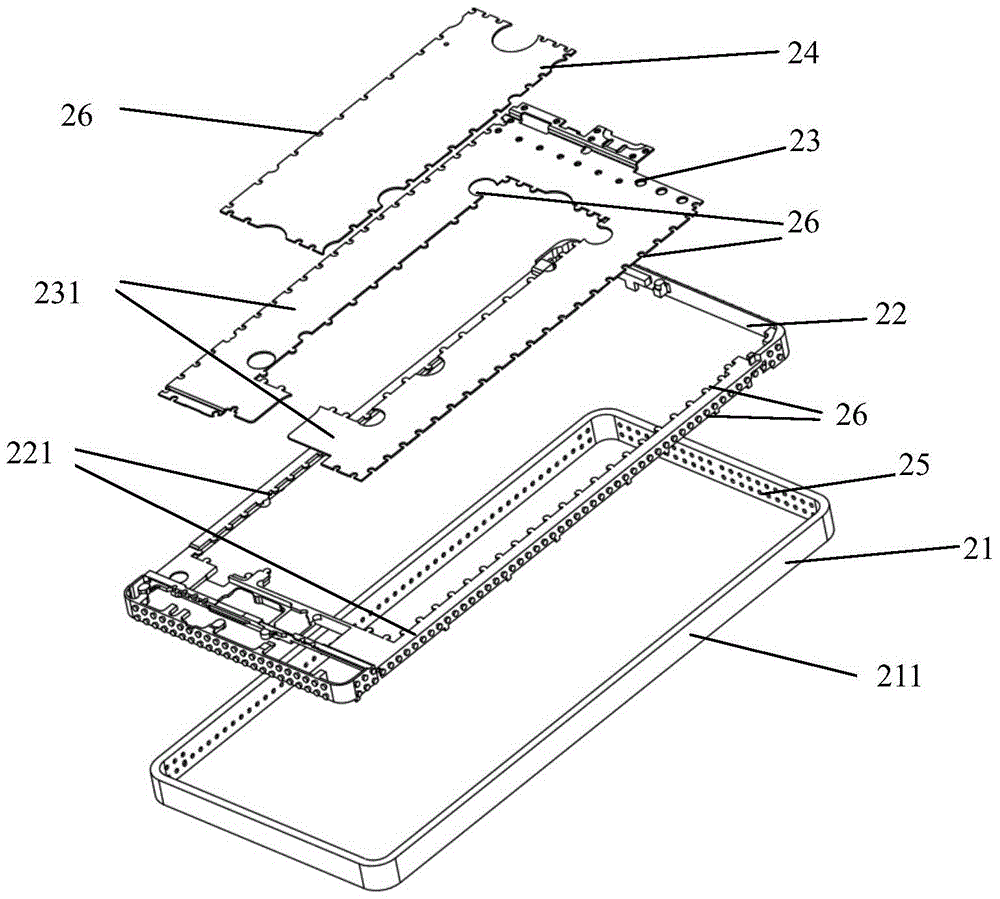

Appearance structural part applied to intelligent terminal products and manufacturing method thereof

InactiveCN104842603BReduce cooling shrinkageReduce deformation stressLamination ancillary operationsLaminationPressure castingFailure risk

Owner:深圳市华欣永业科技有限公司 +1

Gear machining apparatus

ActiveUS20170008103A1Reduce machining timeImprove tool lifeGear teeth manufacturing toolsGear teethMachine toolMachining

Owner:JTEKT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com