Appearance structural part applied to intelligent terminal products and manufacturing method thereof

A technology of intelligent terminals and manufacturing methods, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as poor connection strength, large flatness, and low blank yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

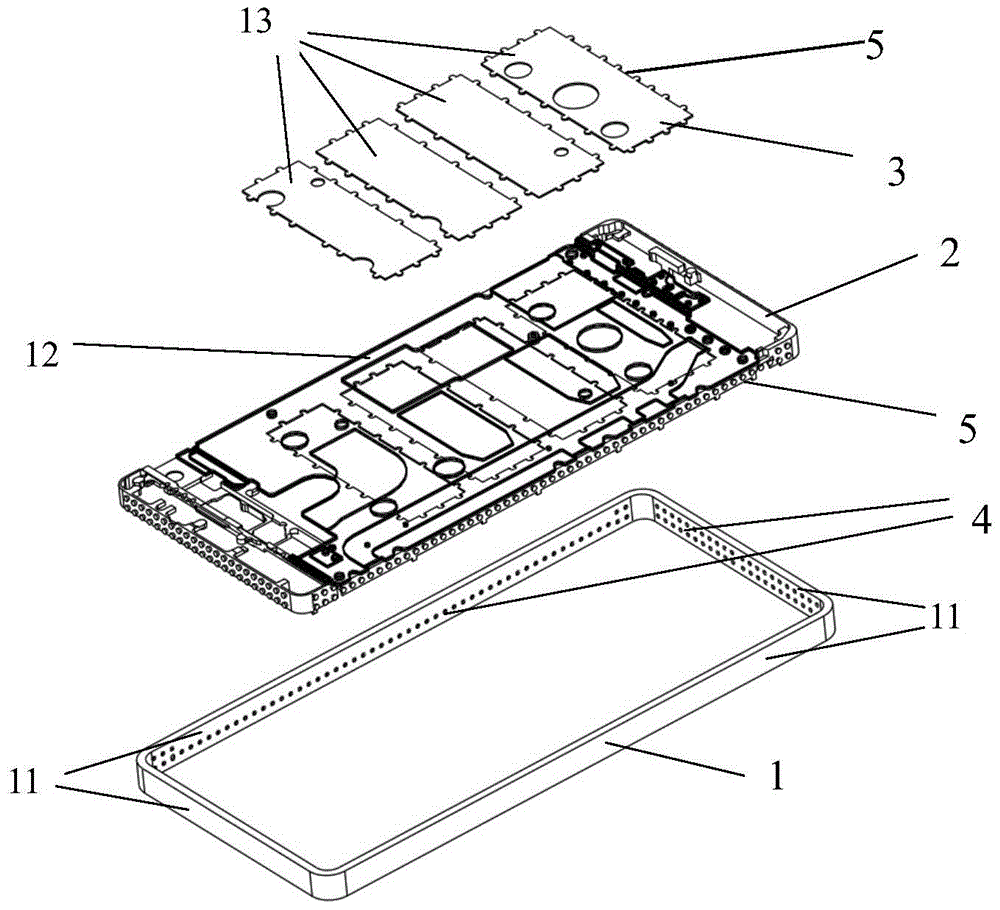

[0061] like figure 1 As shown, a metal mobile phone casing is divided into three layers using the mosaic module principle, which are the outermost layer outer frame 1, the middle layer 2 and the inner layer 3, and the length and width of the opposite outer layer in the two adjacent layers are respectively greater than the opposite The length and width of the inner layer, the outermost outer frame 1 is made of stainless steel, the middle layer 2 is made of aluminum alloy, and the inner layer 3 is made of aluminum alloy.

[0062] The outermost outer frame 1 is formed by metal stamping, forging or extrusion, and the outermost outer frame 1 includes four outer frames 11, and the horizontal width of the outer frames 11 is 0.3-3mm. The inner wall of the frame 11 is provided with a plurality of pits 4, and the pits 4 are formed by mechanical processing or chemical and physical treatment; the middle layer 2 and the inner layer 3 are divided and designed according to the mosaic module ...

Embodiment 2

[0070] The structure of the mobile phone shell of this example is the same as that of Example 1. The difference between this example and Example 1 is that the manufacturing method is different, and the materials of the outermost outer frame 1, the middle layer 2 and the inner layer 3 are also different; The outer frame 1 is made of stainless steel, the middle layer 2 is made of aluminum alloy, and the inner layer 3 is made of aluminum alloy.

[0071] The mobile phone shell of this example is prepared by the following steps:

[0072] Step S1: forming the outermost outer frame 1 by stamping, forging, extrusion or machining; forming a plurality of pits 4 on the inner wall of the outermost outer frame 1 by chemical etching;

[0073] Step S2: Put the outermost outer frame 1 into the mold, and mold the middle layer 2 on the outermost outer frame 1 by die-casting or casting to obtain the outer two layers of the composite mobile phone case; The edge forming concave cavity 5;

[0074...

Embodiment 3

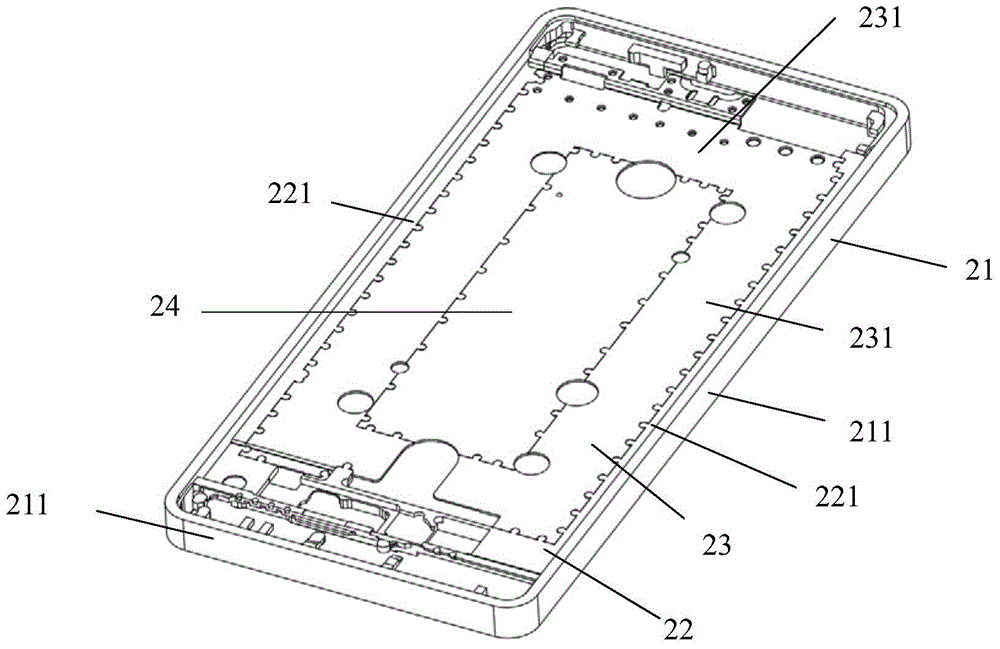

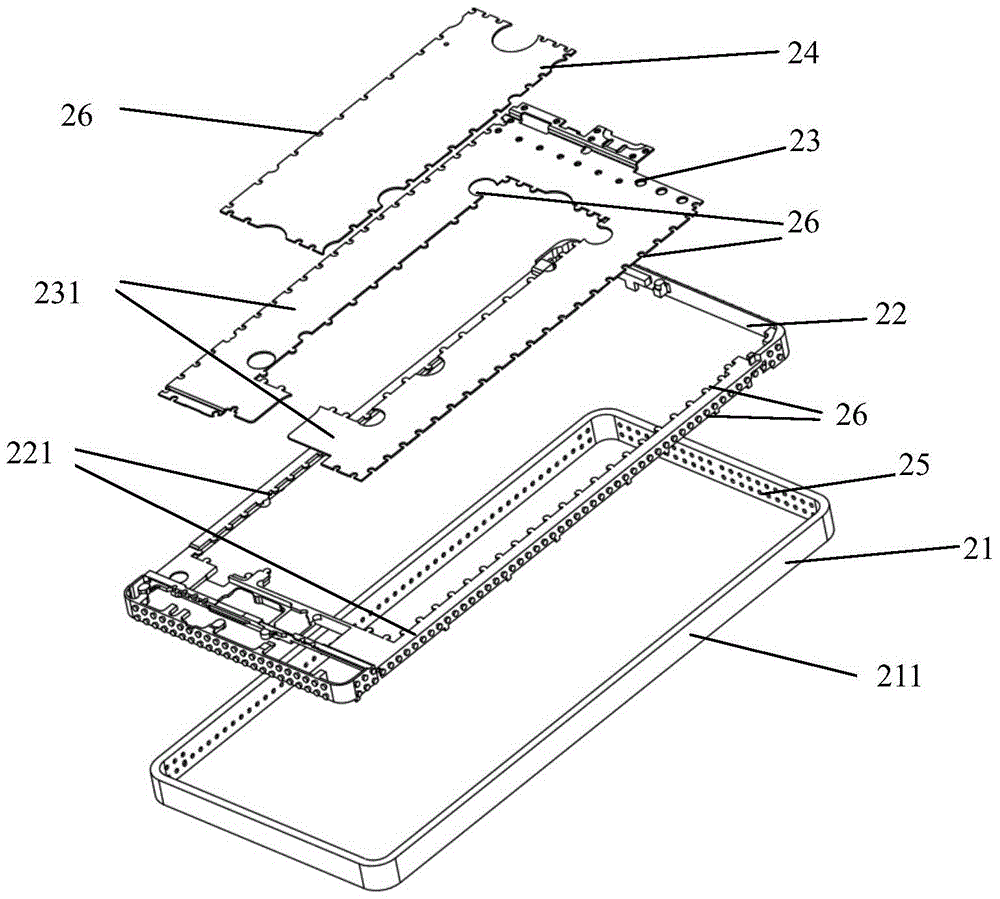

[0079] like figure 2 and image 3 As shown, a metal flat shell is divided into four layers by using the mosaic module principle, and from the outside to the inside are the outermost frame 21, the second layer 22, the third layer 23 and the fourth layer 24; two adjacent layers The length and width of the relative outer layer are respectively greater than the length and width of the relative inner layer, the outermost outer frame 21 is made of forged aluminum alloy, rolled aluminum alloy or profiled aluminum alloy, and the second layer 22 and the third layer 23 are made of aluminum alloy 23. The fourth layer 24 is made of magnesium alloy.

[0080] The outermost outer frame 21 is formed by metal stamping, forging or extrusion, and the outermost outer frame 21 includes four frames 211, the horizontal width of the frame 211 is 0.3 ~ 3mm, the frame 211 The inner wall is provided with a plurality of pits 26, and the pits 26 are formed by mechanical processing or chemical and physi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com