Patents

Literature

198results about How to "Reduce deformation stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

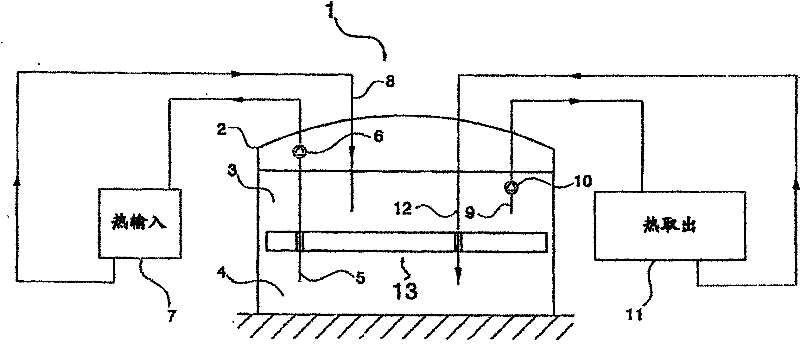

Method for melting and coating anti-rust wear-resistant alloy on steel rail surface

ActiveCN101144160AImprove efficiencyEasy to operateArc welding apparatusMetallic material coating processesBonding strengthWhite light

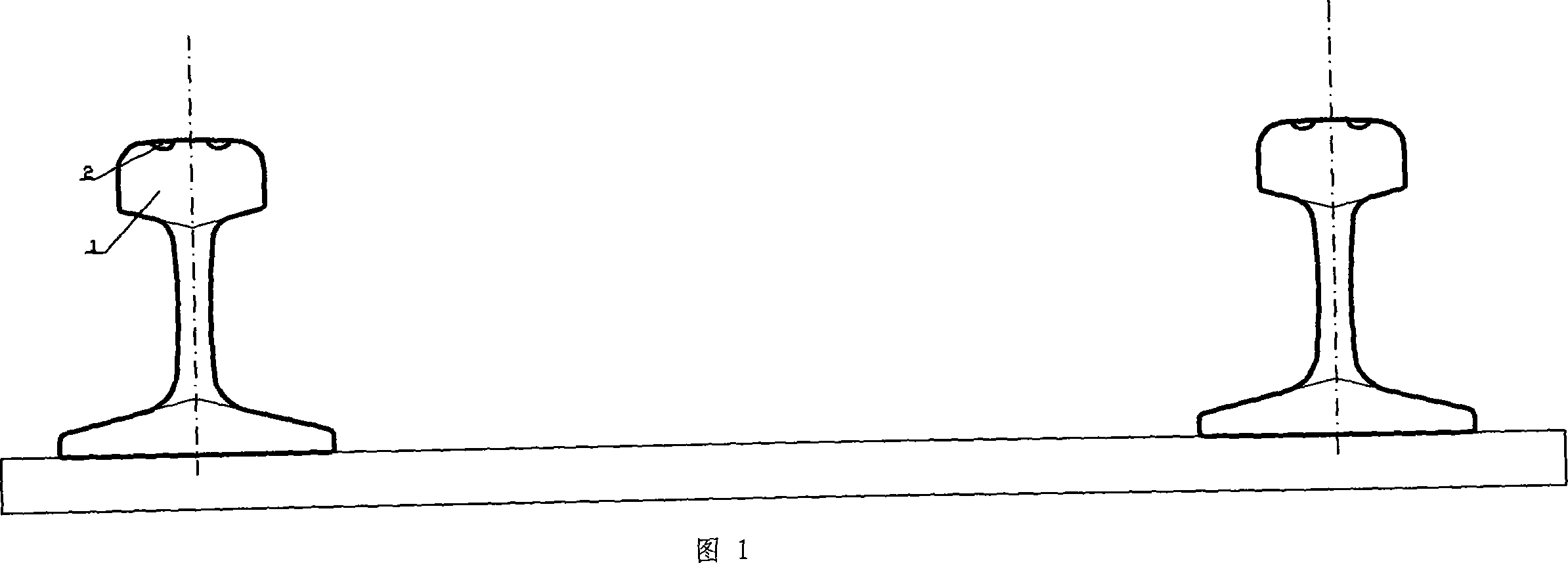

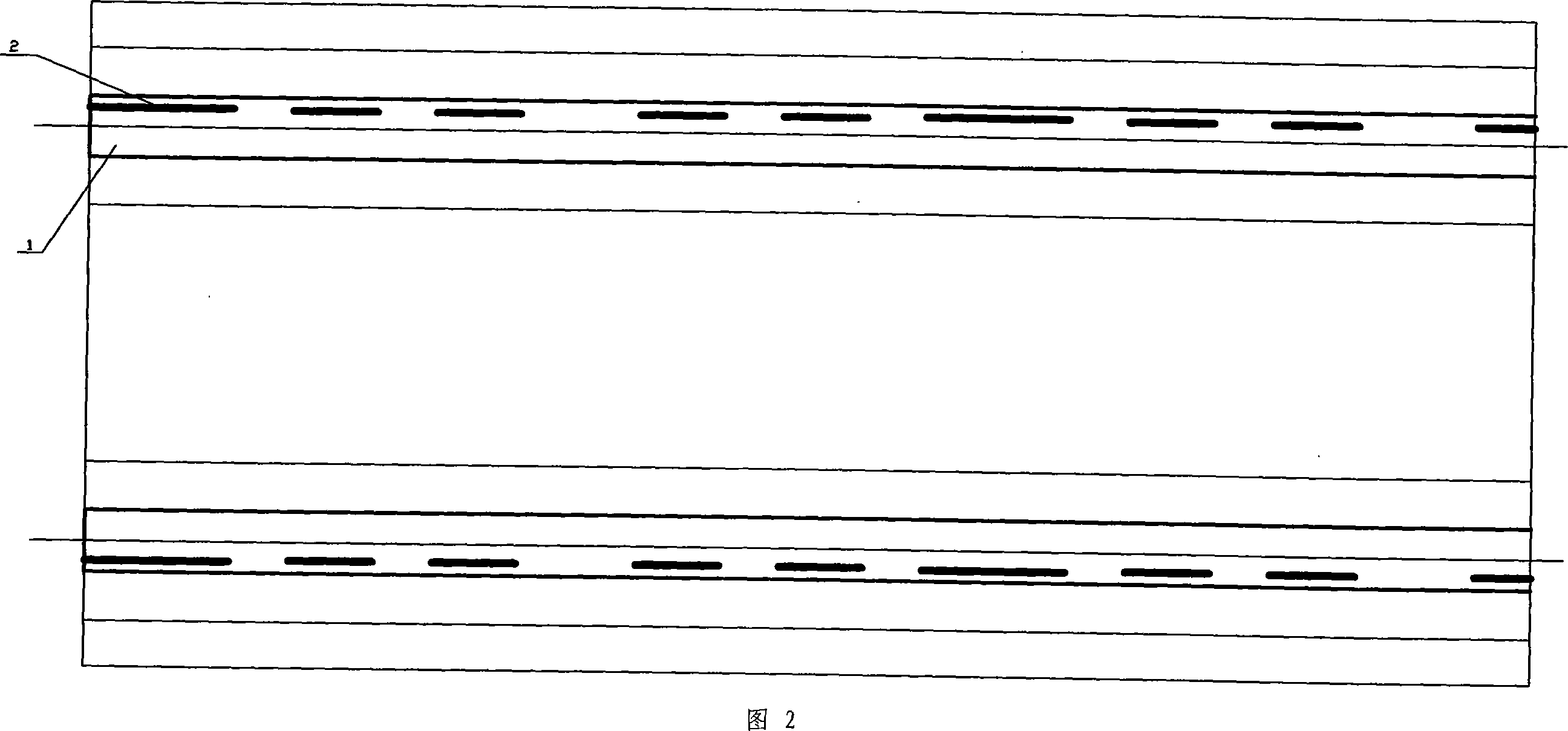

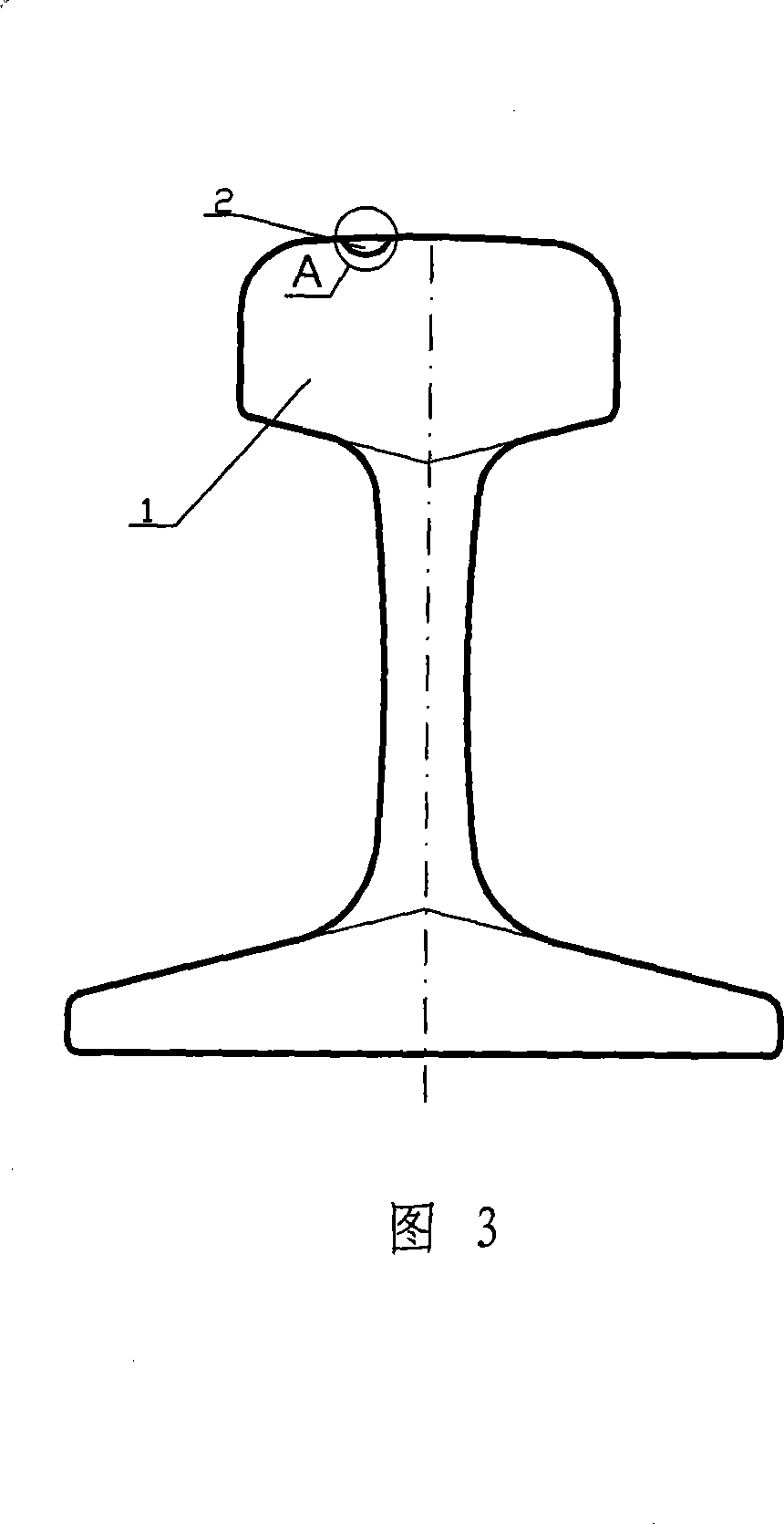

The present invention discloses a method for smelting rust preventing and wear resistant alloy on the surface of a steel rail. The position needing alloy smelting on the surface of the steel rail head is heated by supersonic frequency or medium frequency induction-heating equipment, the induction heater is arranged above the position needing alloy smelting on the surface of the steel rail head, and the preheating temperature is 290-450 DEG C; the alloy is smelted on the surface of the steel rail head by using plasma smelting or arc welding smelting, when the preheating temperature is 290-450 DEG C, and the welding gun of plasma build up welding or arc welding equipment is moved to the position needing alloy smelting, the alloy powder, the alloy electrode or the alloy welding wire are automatically smelted; the railroad steel rail adopting the present invention can ensure that the train wheels and the rust preventing and wear resistant alloy layer are always in a contacting and compacting state, thereby the rail circuit works normally, and the white light zone phenomenon is completely eliminated; the cracking and breaking phenomena of the steel rail do not occur, the smelted alloy has good rust preventing and wear resistant properties, high bonding strength with the steel rail, and long service life.

Owner:CHENGDU ZHONGGUI TECH CO LTD

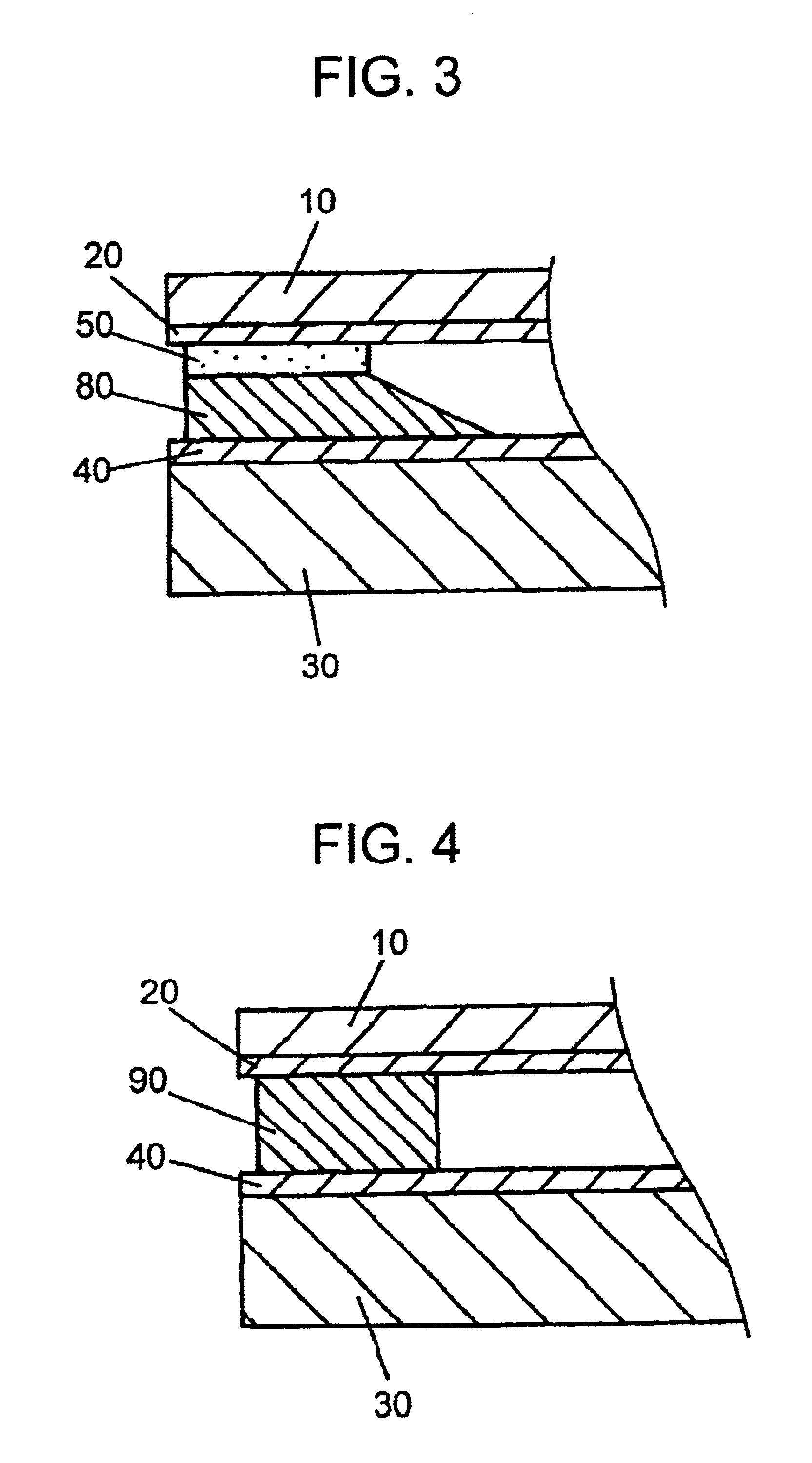

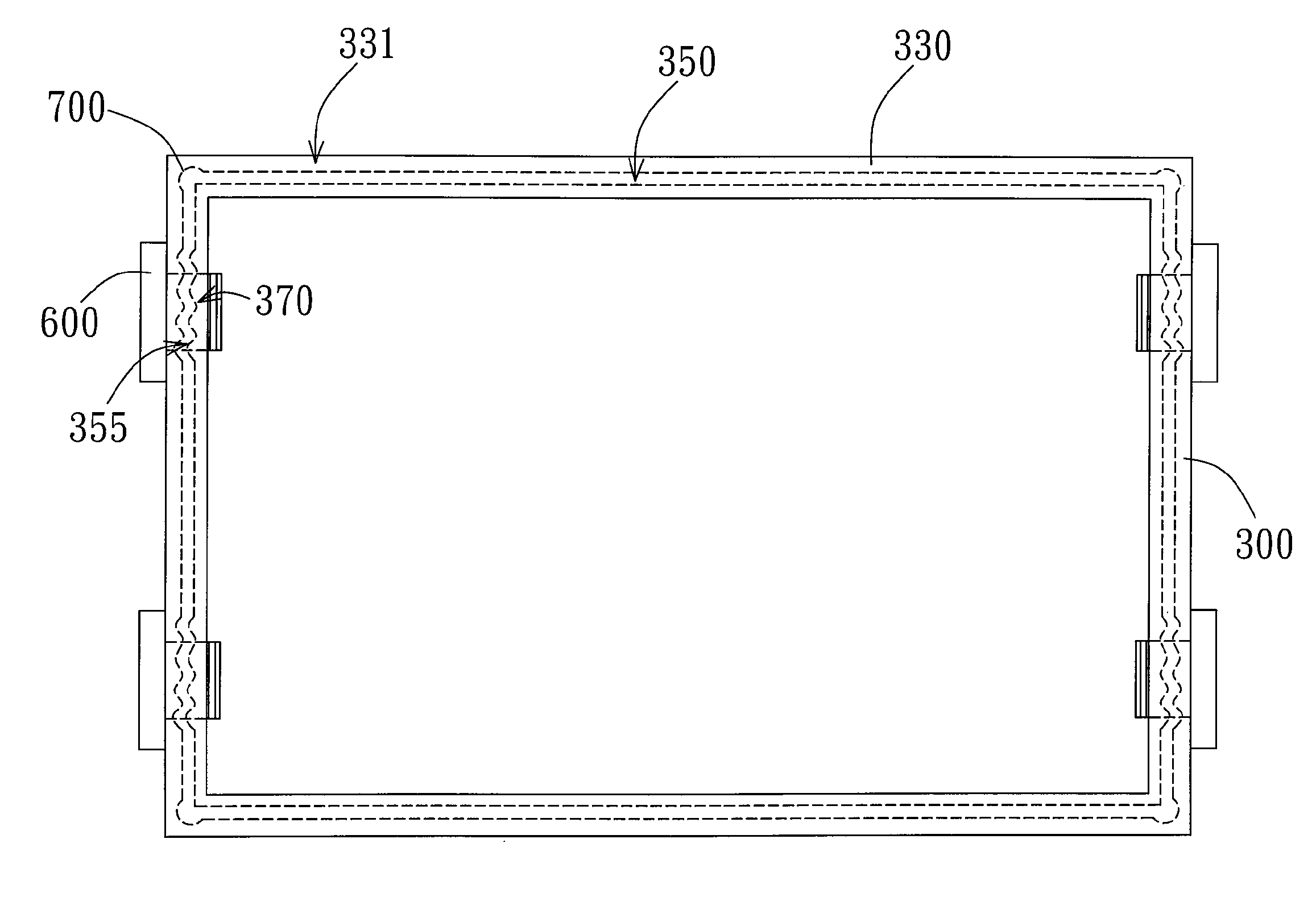

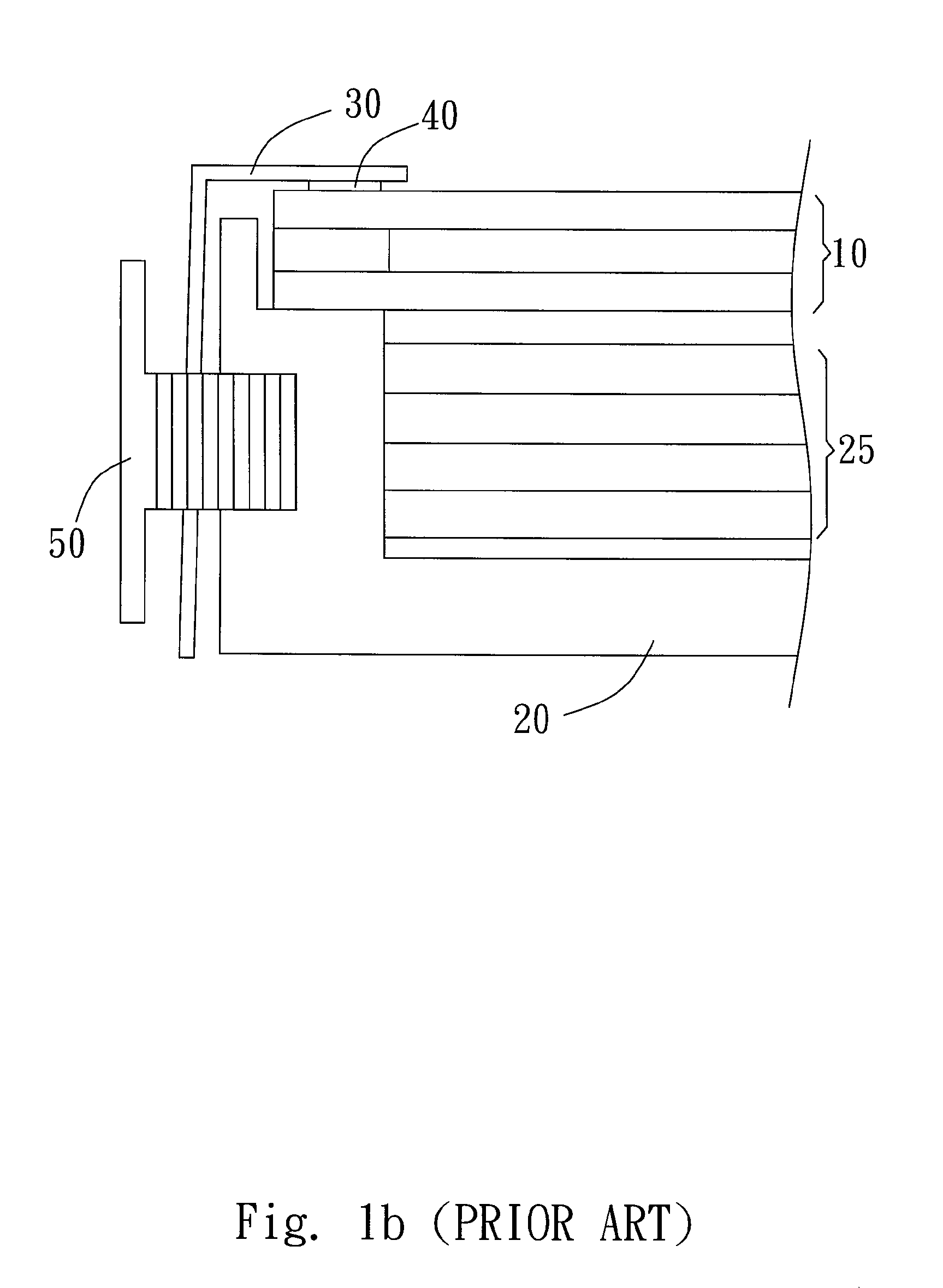

Touch panel switch

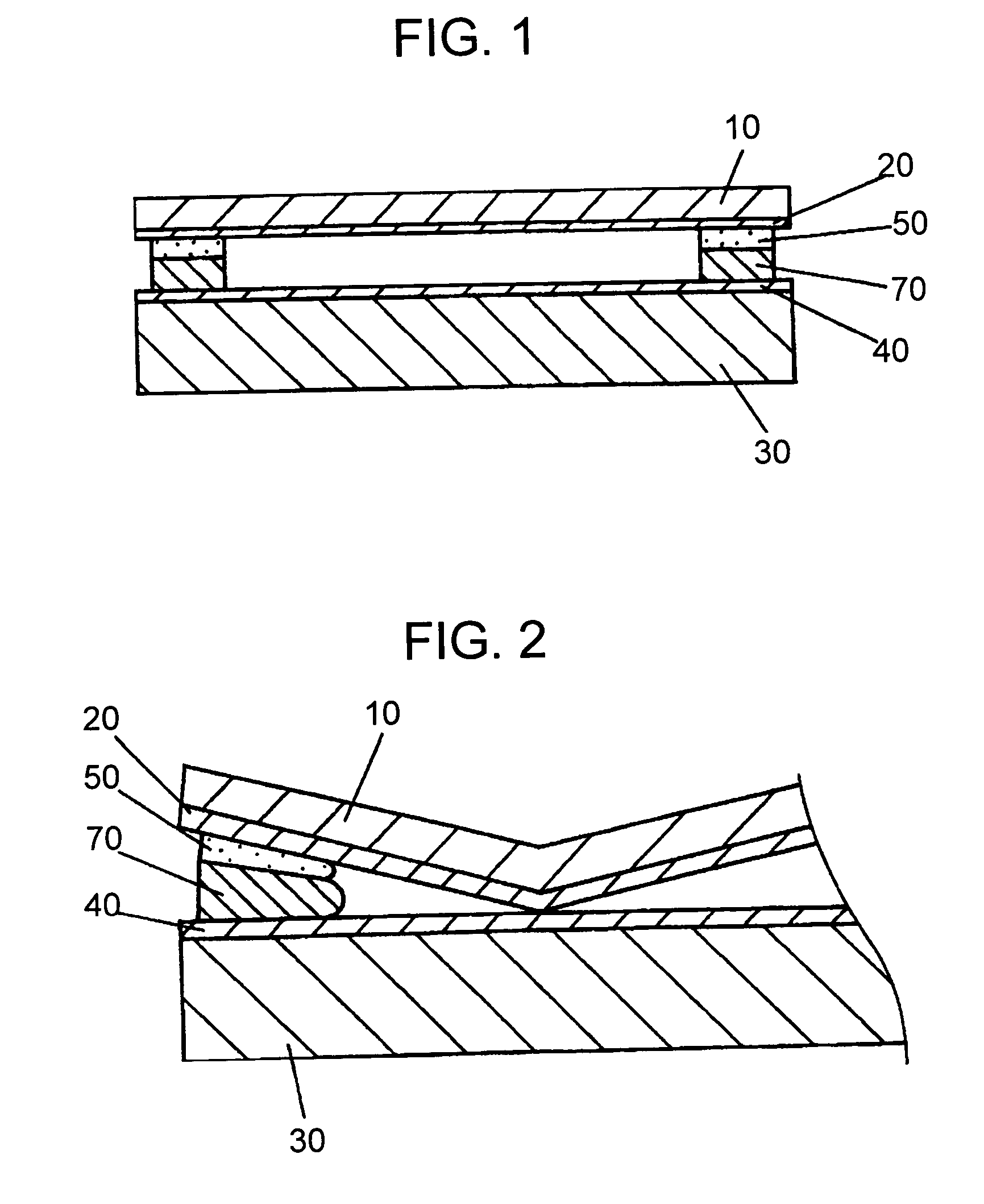

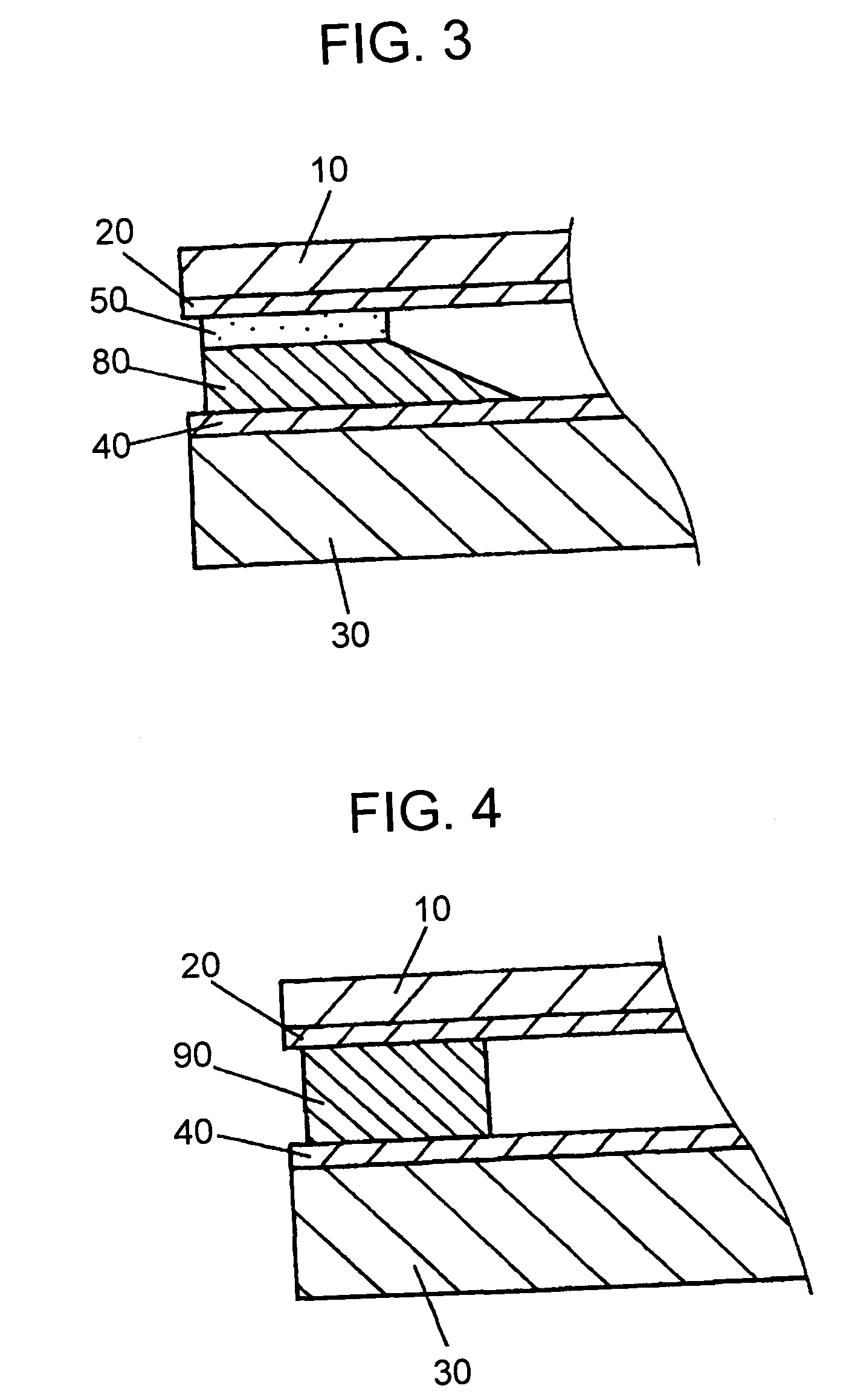

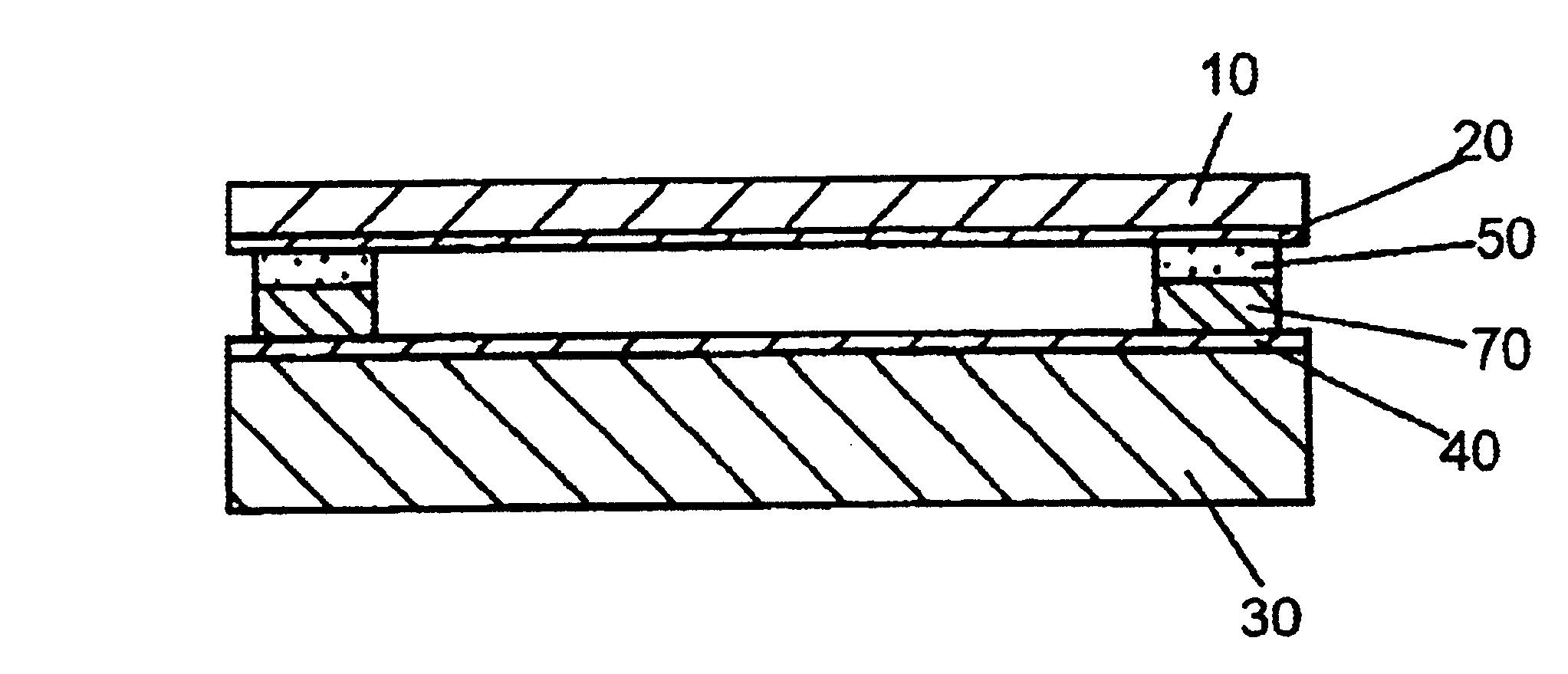

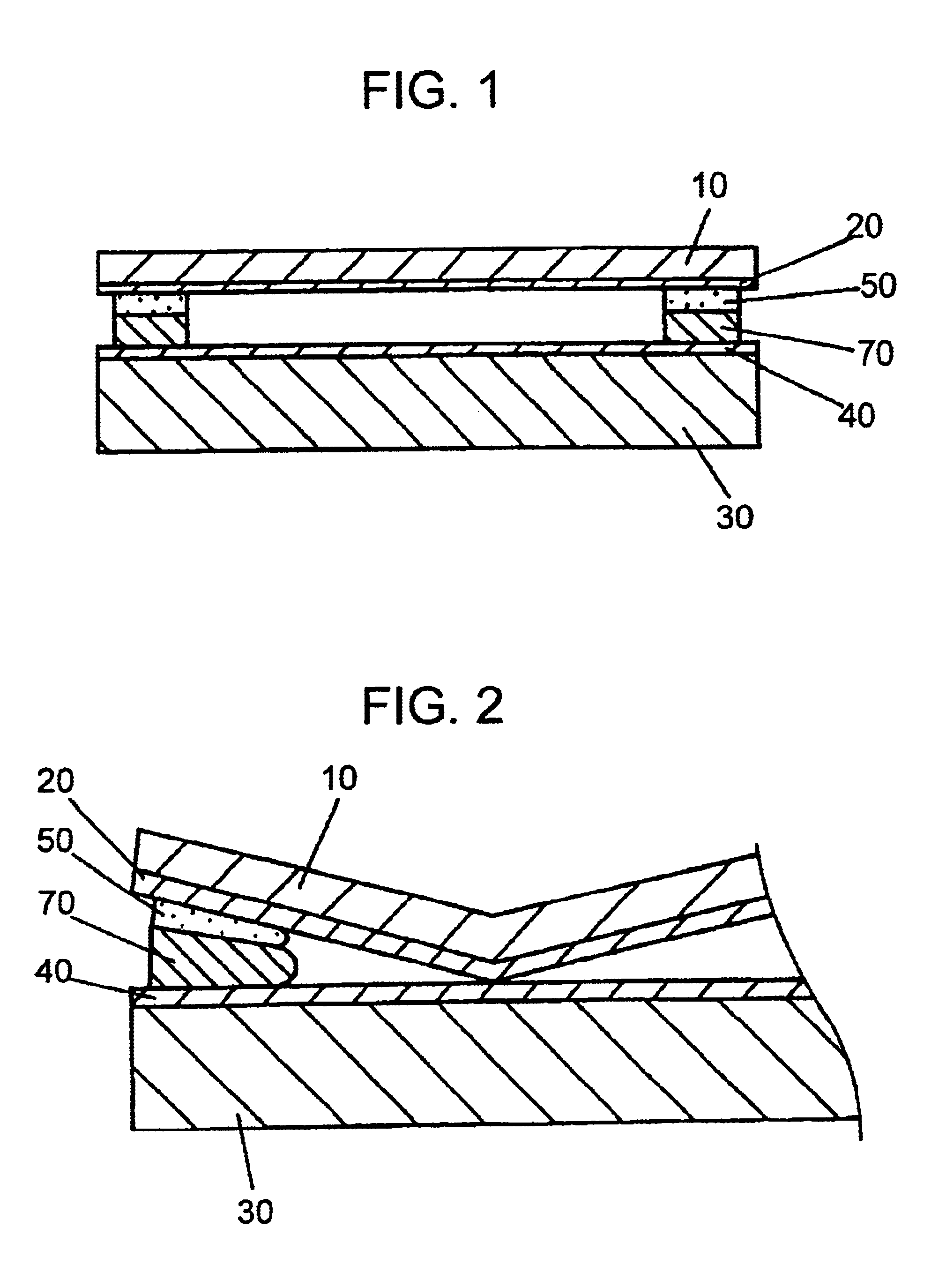

InactiveUS20040027761A1Reduce deformation stressLow costContact surface shape/structureEmergency protective arrangements for automatic disconnectionElastic modulusTouch panel

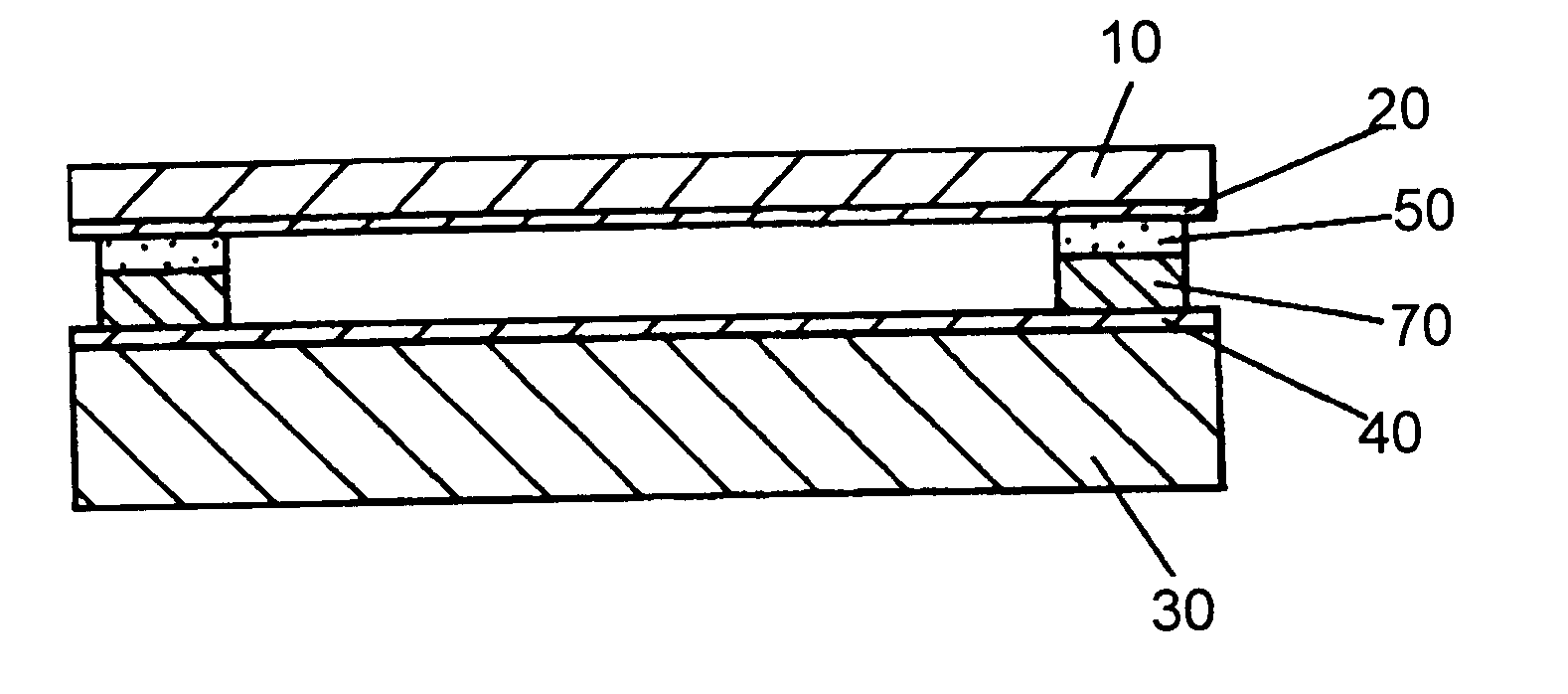

A touch panel switch having a wide usable operating range and thus a large effective use area and having electrodes disposed opposedly to each other through a spacer installed around the periphery thereof, the spacer formed in an elastic body of 1x10<5 >to 1x10<7 >dyne / cm<2 >in elastic modulus comprising an insulation layer and an adhesive layer, the insulation layer further comprising a clearance holding part with a uniform thickness and a gradient part with a thickness gradually decreasing from the clearance holding part into a substrate having the electrodes formed thereon.

Owner:PANASONIC CORP

Touch panel switch

InactiveUS6831241B2Reduce thicknessReduce deformation stressContact surface shape/structureInput/output processes for data processingInsulation layerDyne

A touch panel switch having a wide usable operating range and thus a large effective use area and having electrodes disposed opposedly to each other through a spacer installed around the periphery thereof, the spacer formed in an elastic body of 1x10<5 >to 1x10<7 >dyne / cm<2 >in elastic modulus comprising an insulation layer and an adhesive layer, the insulation layer further comprising a clearance holding part with a uniform thickness and a gradient part with a thickness gradually decreasing from the clearance holding part into a substrate having the electrodes formed thereon.

Owner:PANASONIC CORP

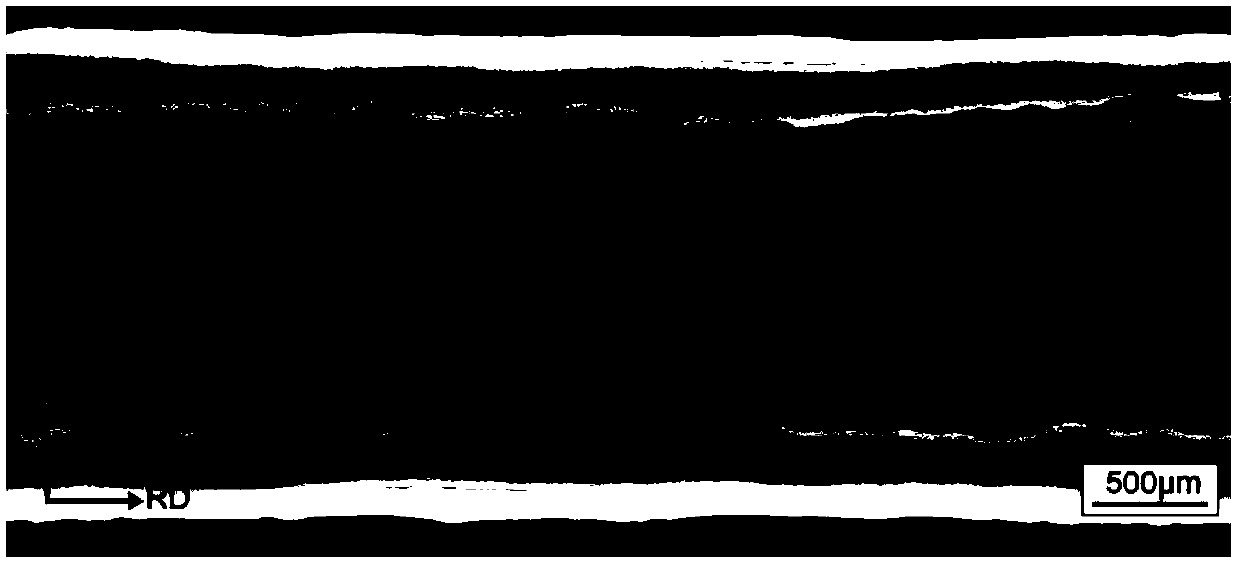

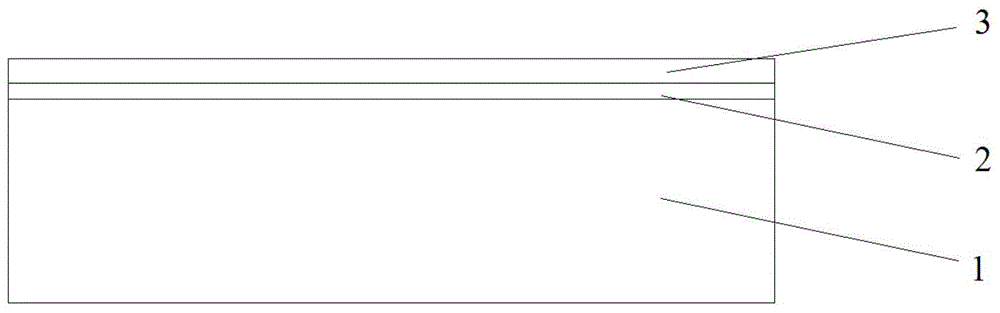

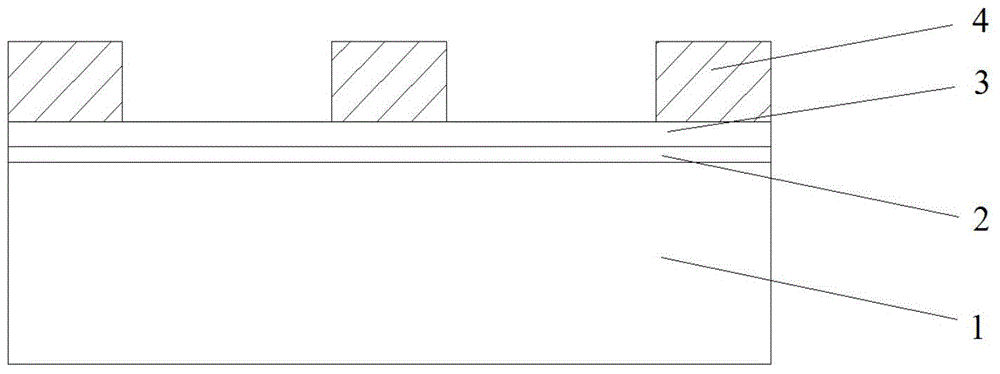

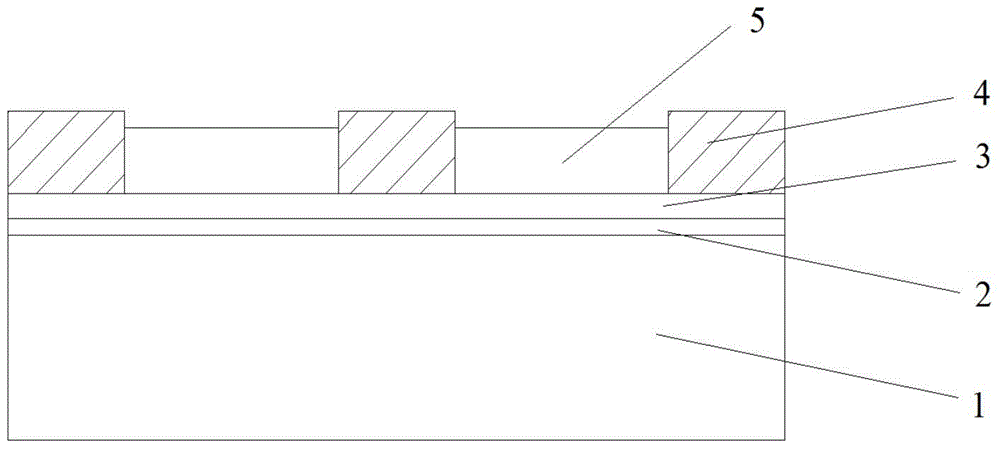

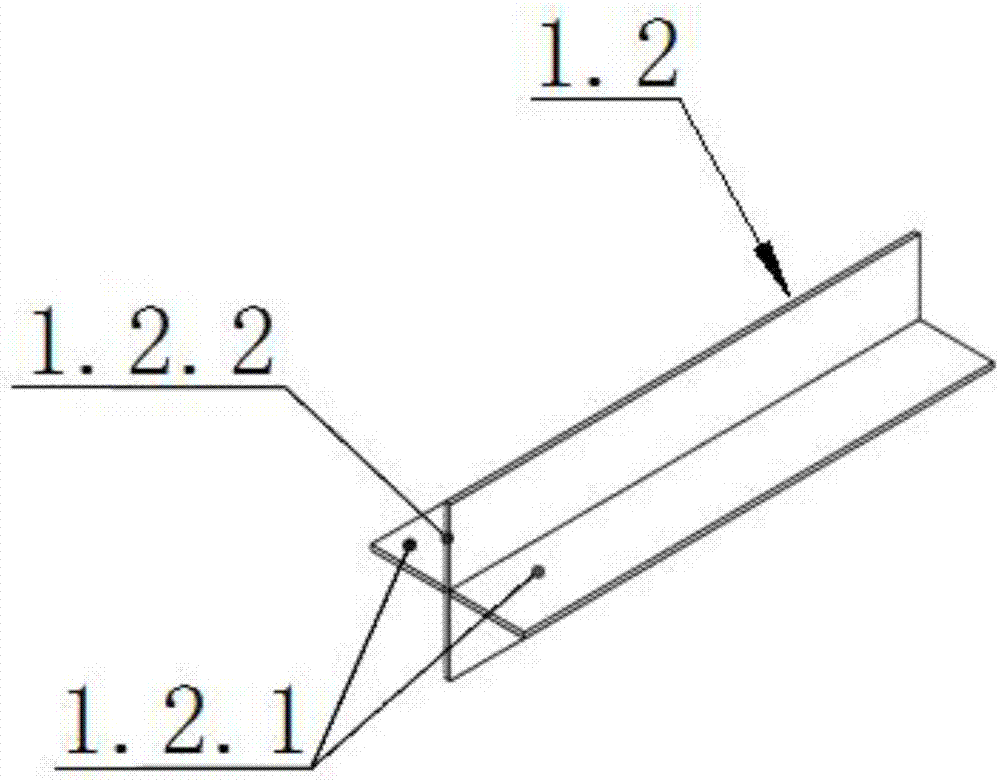

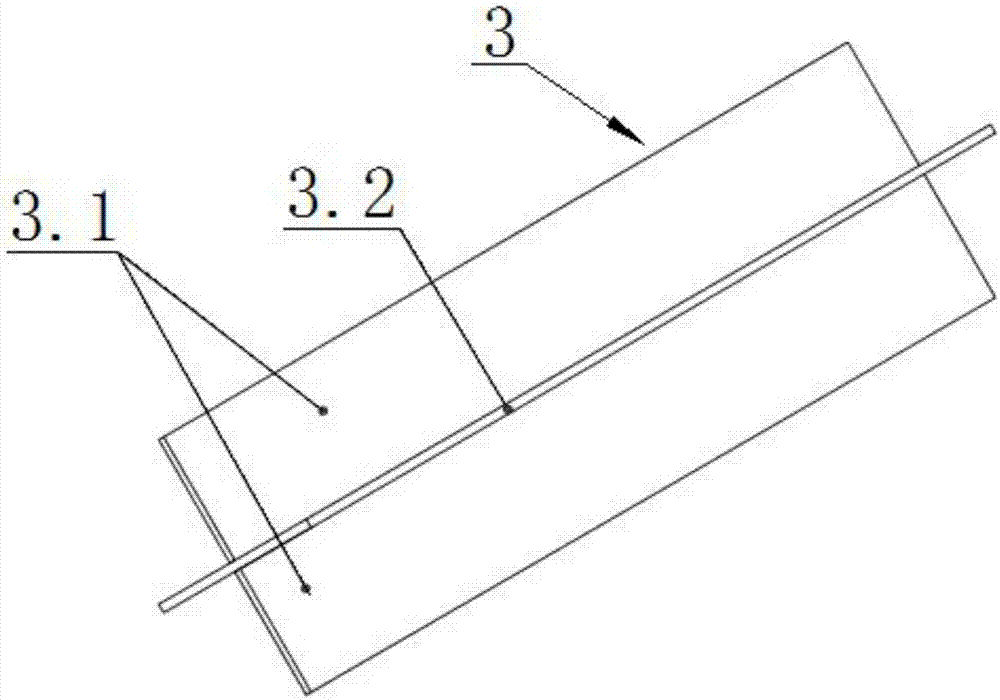

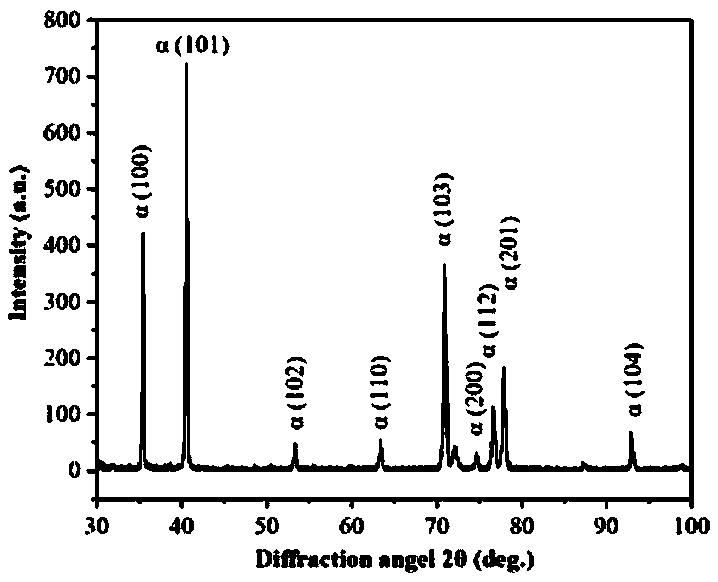

Method for sheathing and rolling as-cast TiAl alloy platebased on composite structural design

The invention belongs to the manufacturing field of intermetallic compound material plates, in particular to a method for sheathing and rolling an as-cast TiAl alloy plate based on a composite structural design. The method comprises the following steps of: obtaining a TiAl alloy cast ingot through vacuum consumable electric arc smelting, and annealing, cutting and grinding the TiAl alloy cast ingot to obtain a rolling material; selecting an inner-layer sheathing material which is chemically stable and has a heat insulating effect, an outer-layer sheathing material with good high-temperature strength and an anti-oxidization coating / isolating metal of a contact interface, and performing soldering and sealing after designing a composite structure and a layer-thickness ratio, thereby obtainingcomposite sheathed slab; sheathing and rolling the as-cast TiAl alloy, and controlling process parameters such as a rolling temperature, pass deformation amount and rolling speed, thereby finally obtaining a high-quality TiAl alloy thin plate with a target dimension. The method improves deformation matching performance and stability of the sheathed rolled slab, reduces deformation stress, directly prepares the as-cast TiAl alloy high-quality thin plate, is simple and stable in process, effectively improves production efficiency and reduces the board cost.

Owner:NORTHEASTERN UNIV

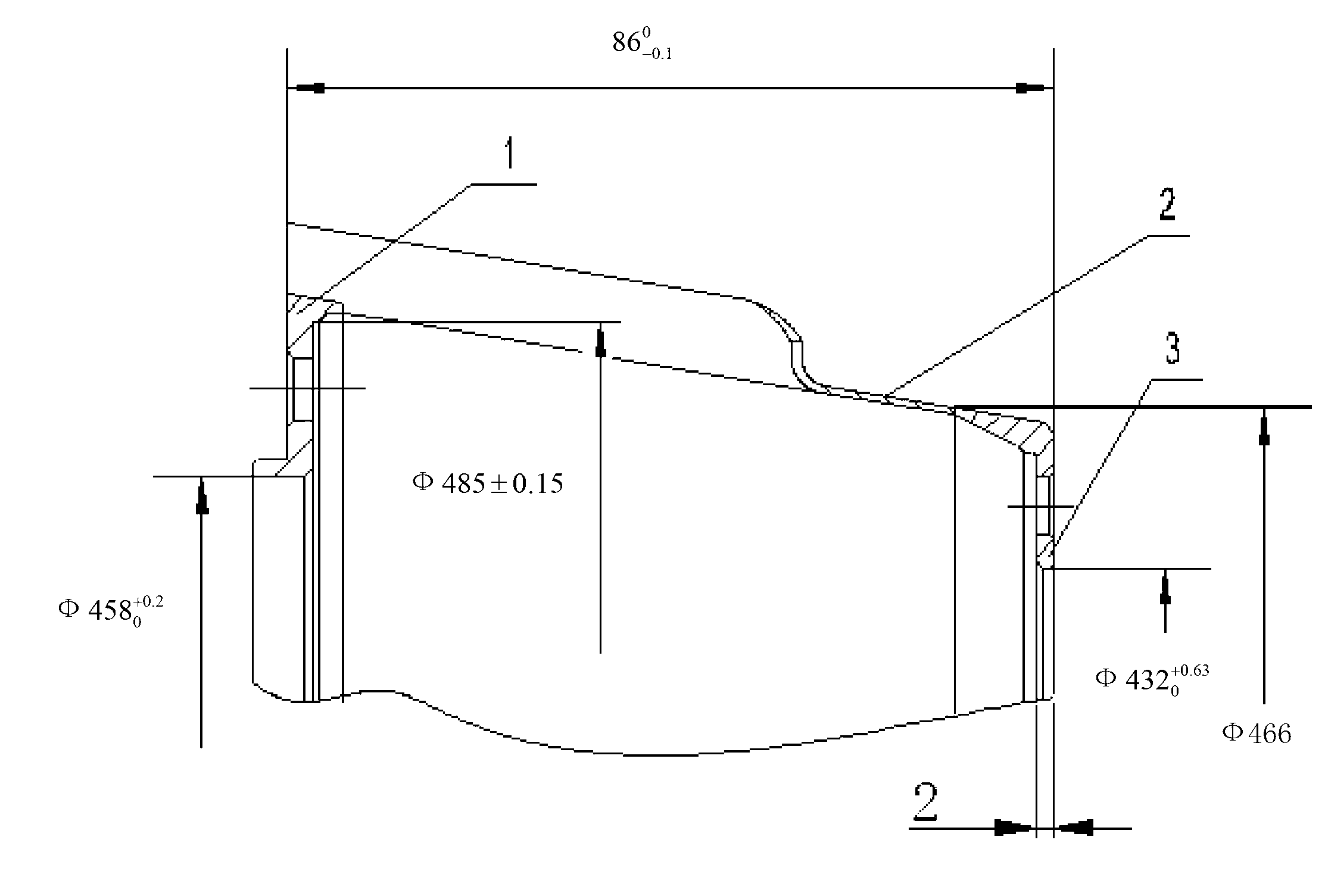

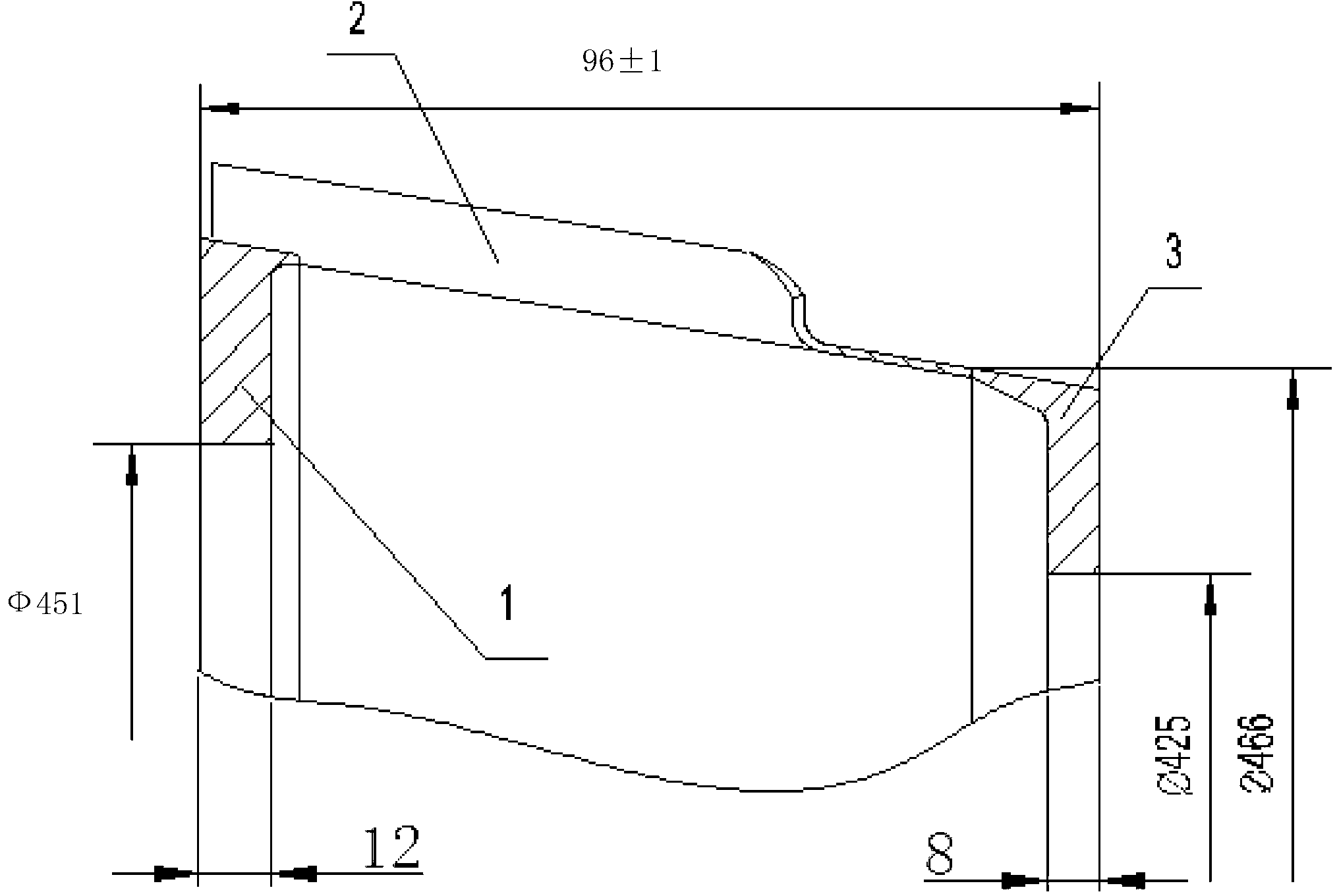

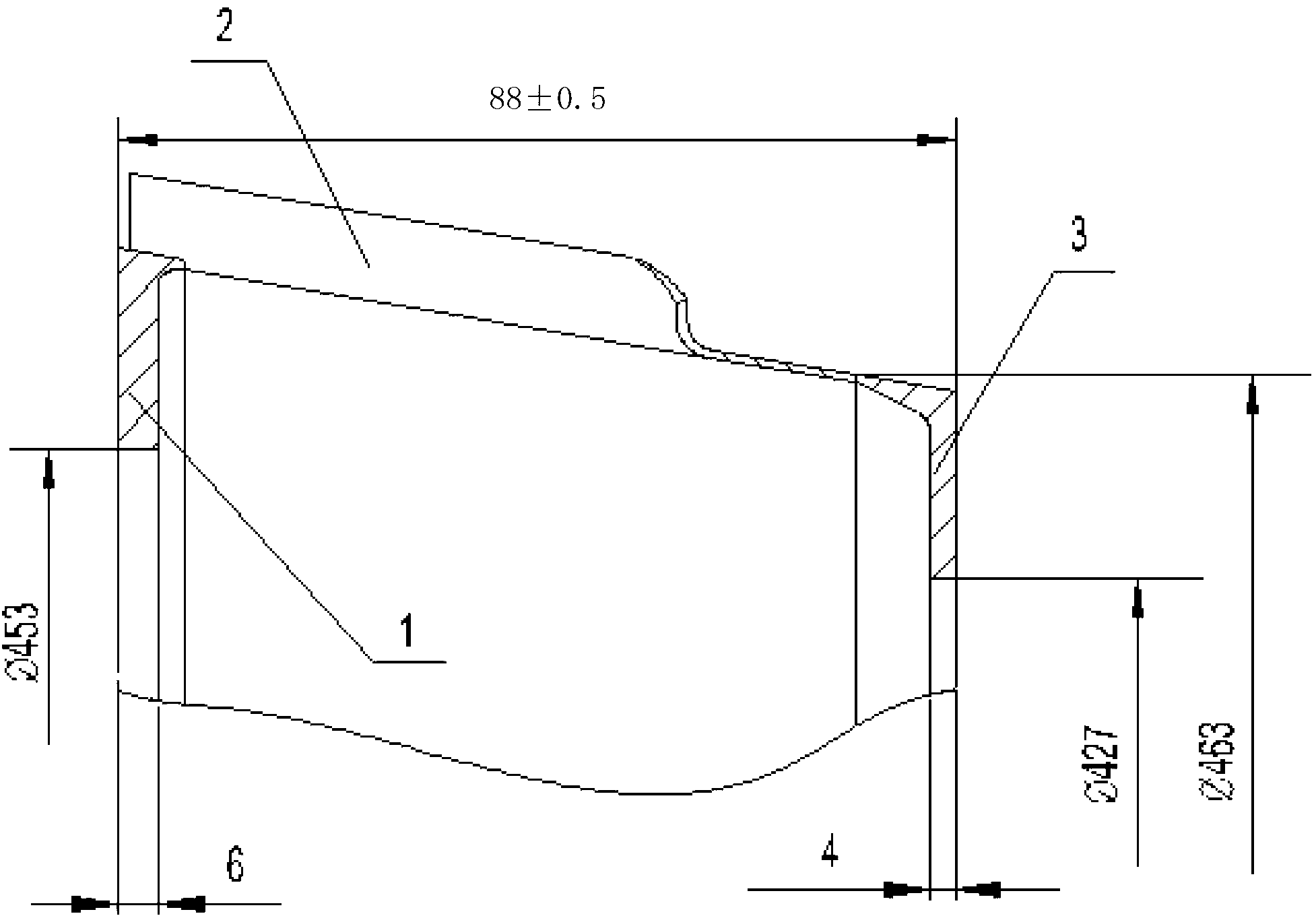

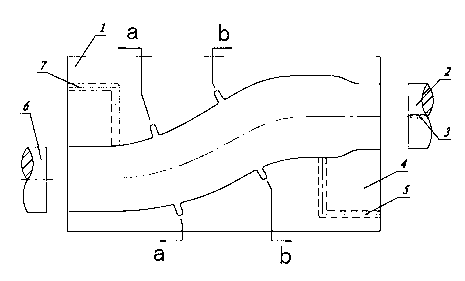

Method for processing thin wall welder cases of revolving body structures

InactiveCN102794610ASolve the structural sizeSolve the coaxial problem of front and rear installation side weldingArc welding apparatusPre deformationEngineering

The invention discloses a method for processing thin wall welder cases of revolving body structures, belonging to the technical field of aero-engine metal plate forming and welding. According to the invention, a whole pre-deformation welding / forming method is used for solving the problems that sizes of mounting edges are out of tolerance, coaxiality of front and rear mounting edges with main bodies after welding is out of tolerance and residual stress distribution of welding components is unbalanced. The method provided by the invention comprises the following steps of: carrying out technological structure welding deformation allowance compensation design on a mounting edge and a main body of a thin wall welder case before the welding according to the plastic deformation characteristics of materials; plastically forming an expansion block according to an expander work part, size and final structural size requirement of parts; carrying out automatic argon arc welding on the mounting edge and the main body; assembling the welded welder case and expansion block on the expander work part to carry out expansion plastic forming and controlling the expansion forming size through adjusting pressure of the expander; and unloading the pressure of the expander, recovering the expander work part and unloading the parts to complete the welding / forming process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Integral forming process method of thin-wall hooped tube workpieces

The invention discloses an integral forming process method of thin-wall hooped tube workpieces. The technical scheme comprises the flowing steps of: 1, preparing a mould: firstly forming overflow holes in corresponding parts on the mould, welding reinforcing ribs in a thin-wall tubing without welded lines in advance and placing into a mould cavity, performing spotting on the mould, sealing ends of a tube blank, filling a strain rate sensitive medium between the mould and the tube blank, then filling liquid forming medium in the tube blank and applying certain pressure; 2, forming: increasing the pressure of the inside liquid, meanwhile adjusting the flow state of the strain rate sensitive medium to cause a tube body and a reinforcing plate to be deformed in a coordinated way to form qualified parts; and 3, picking up the parts: reducing the pressure to 0MPa, opening the mould and then taking out the parts from the mould. The integral forming process method of the thin-wall hooped tube workpieces has the advantages of few forming processes, low manufacturing cost, high mechanical property of formed members, high dimension precision and the like, and is particularly suitable for forming thin-wall hooped tube workpieces with a sealed complex section shape.

Owner:HARBIN INST OF TECH AT WEIHAI +1

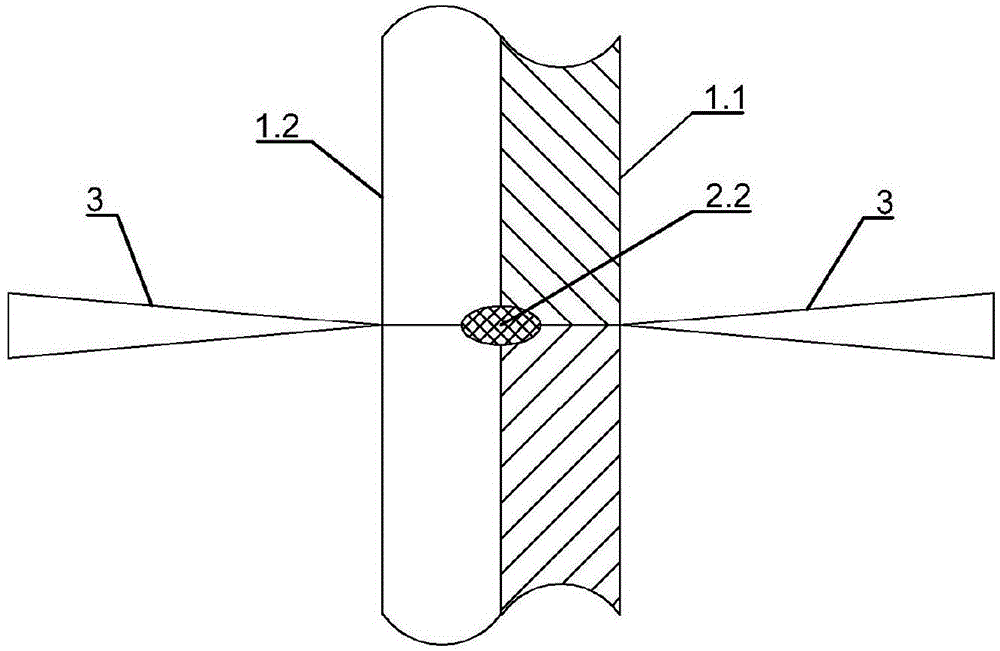

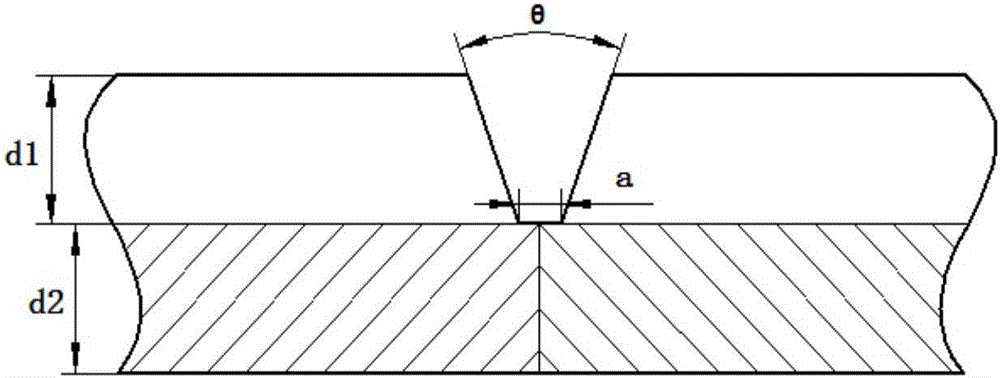

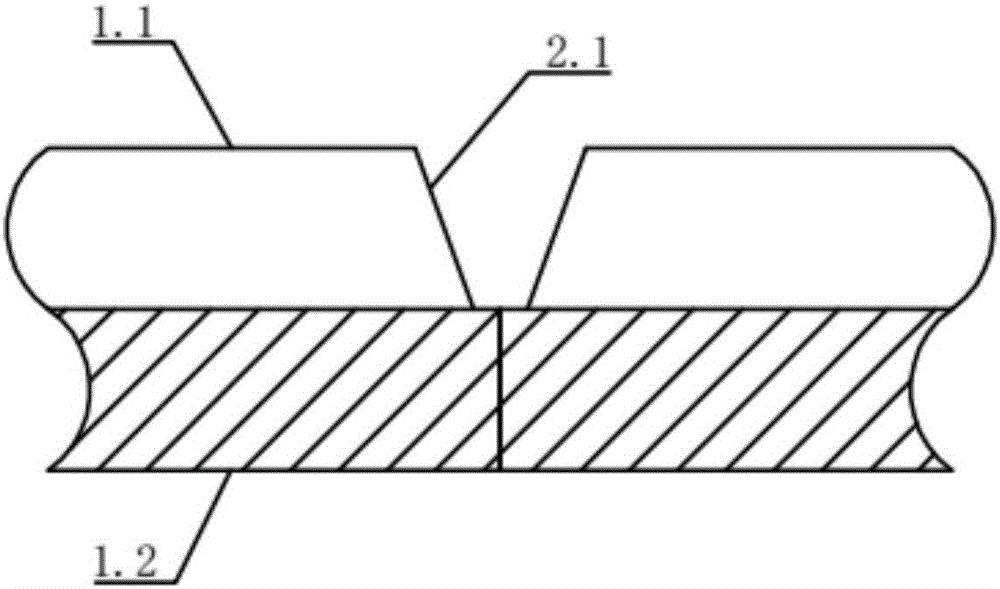

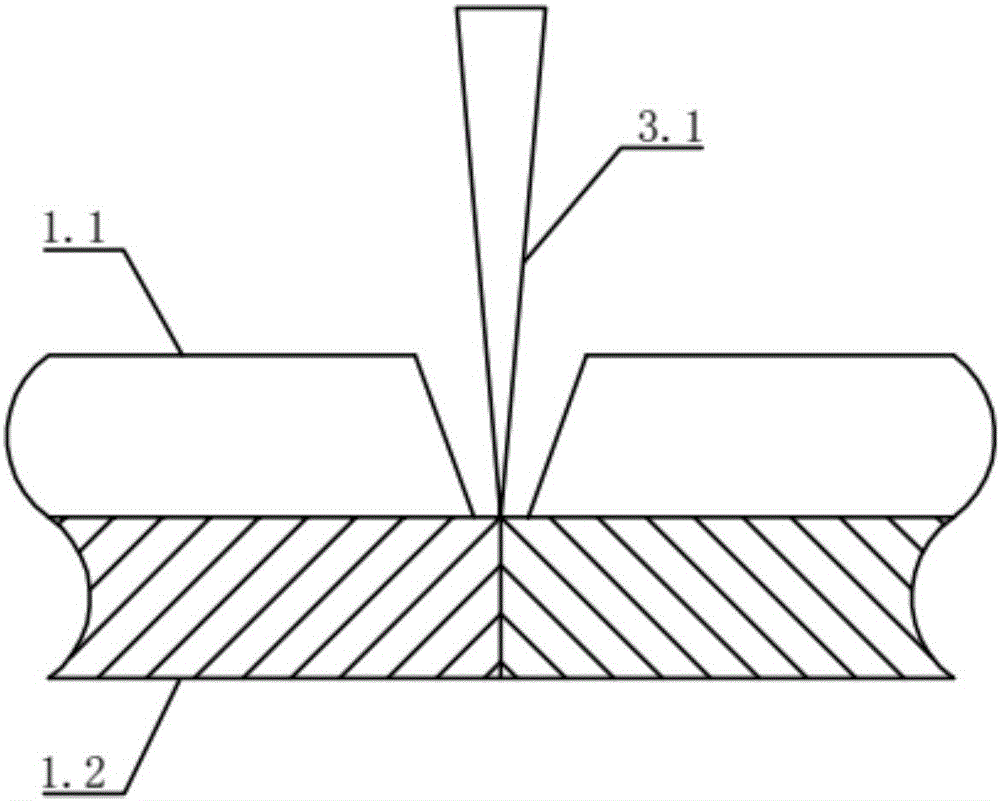

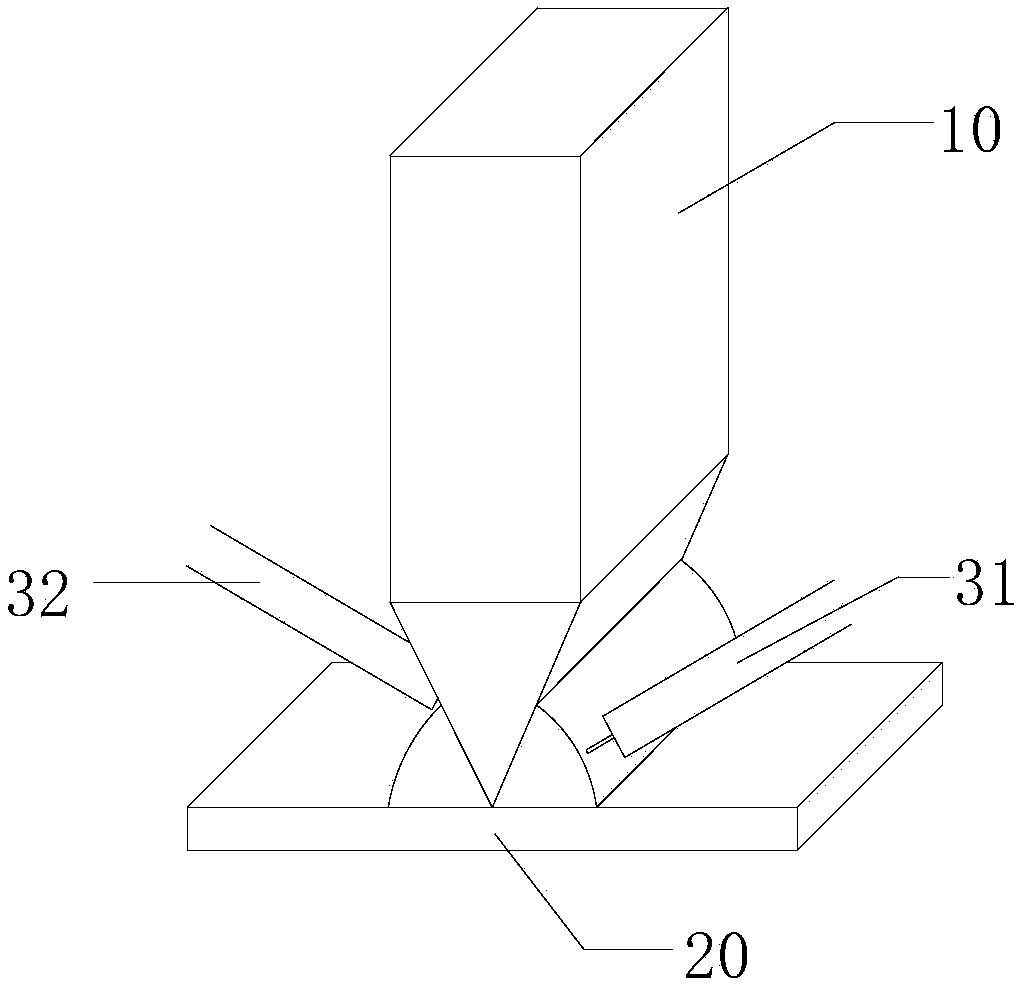

Double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control

ActiveCN106425100ASimplified Soldering TechniquesImprove welding efficiency and qualityWelding/soldering/cutting articlesLaser beam welding apparatusTitaniumEngineering

Provided is a double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control. The method is suitable for welding of titanium-steel clad plates. The double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control is provided in order to solve the problems that in the existing titanium-steel clad plate welding process, operation is complex, accumulated heat input is large, welding stress deformation is large, and the welding efficiency is low. The method comprises following steps that 1, semi-elliptical groove is prepared along a titanium-steel clad plate interface; 2, a welding area is cleaned; 3, a transition layer is prepared, wherein the transition layer is prepared by mixing a certain proportion of metal powder to be uniform; 4, laser welding is conducted on both sides, wherein after assembling and clamping are conducted, the titanium-steel clad plate is preheated to 100 DEG C to 120 DEG C, synchronous welding is conducted on the two sides with laser, and when welding is conducted, metal on the two sides is merged uniformly by controlling the linear energy. According to the double-sided laser titanium-steel clad plate full penetration welding method based on transition layer control, by means of control of the transition layer, the mechanical property of a welded joint of the titanium-steel clad plate is improved, an existing welding technology is simplified, and high-quality and high-efficiency welding is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

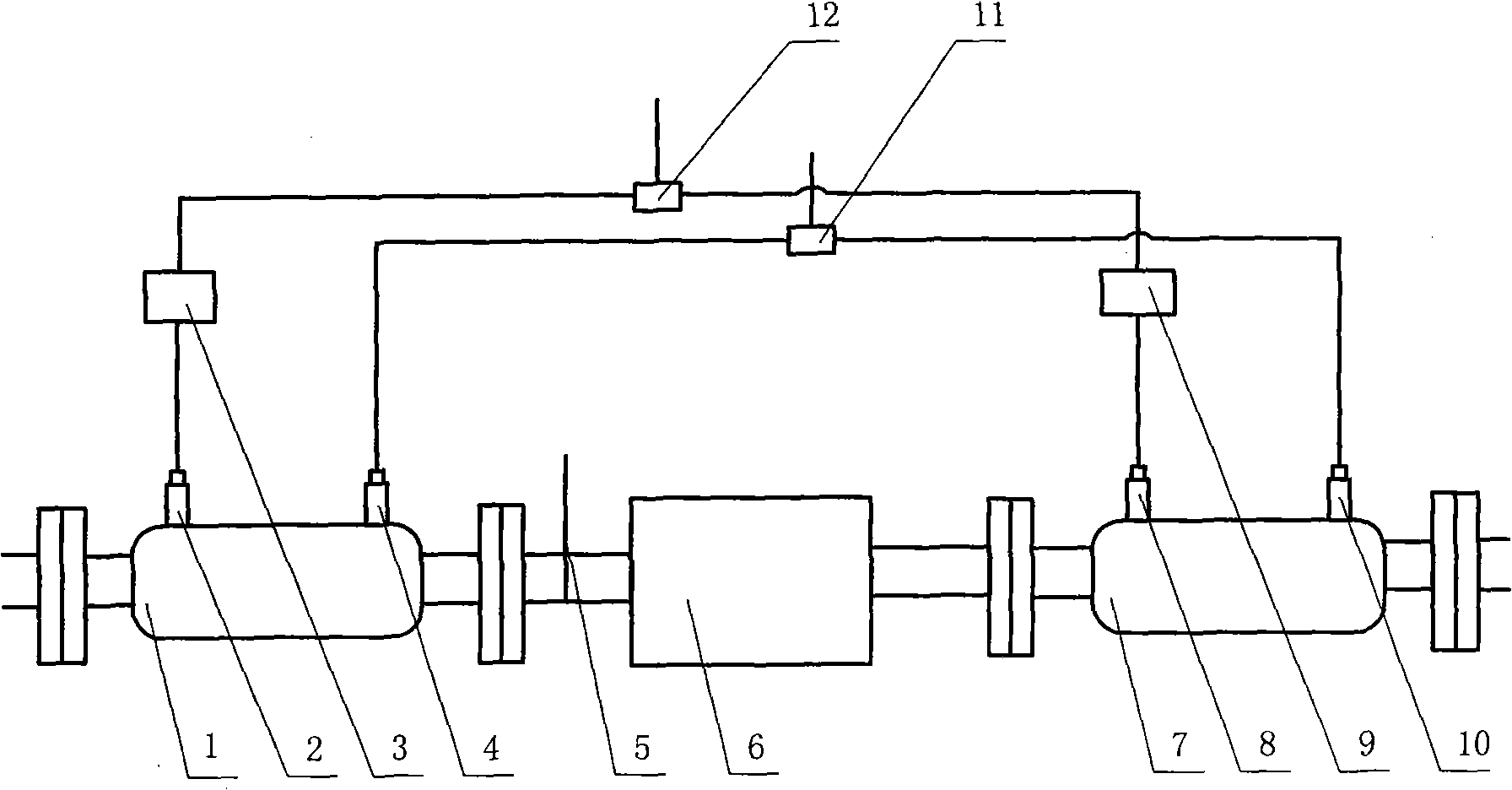

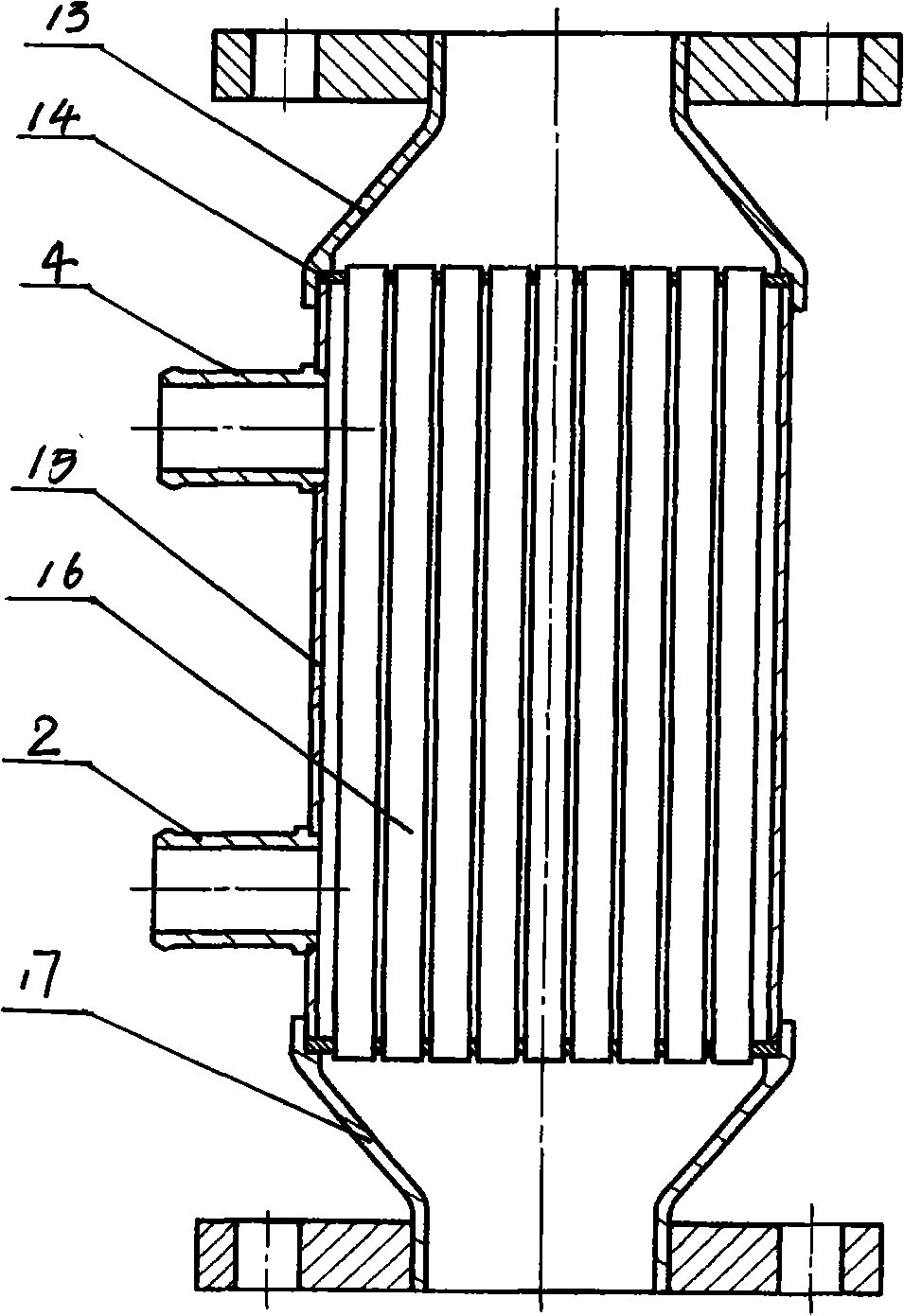

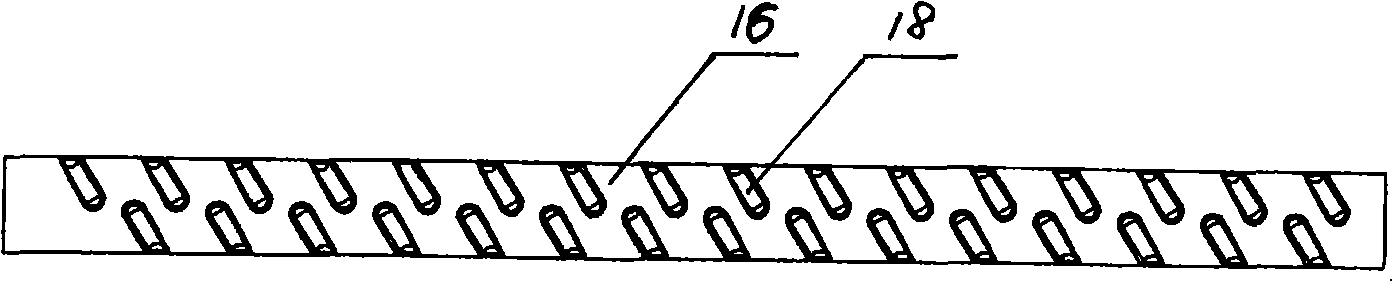

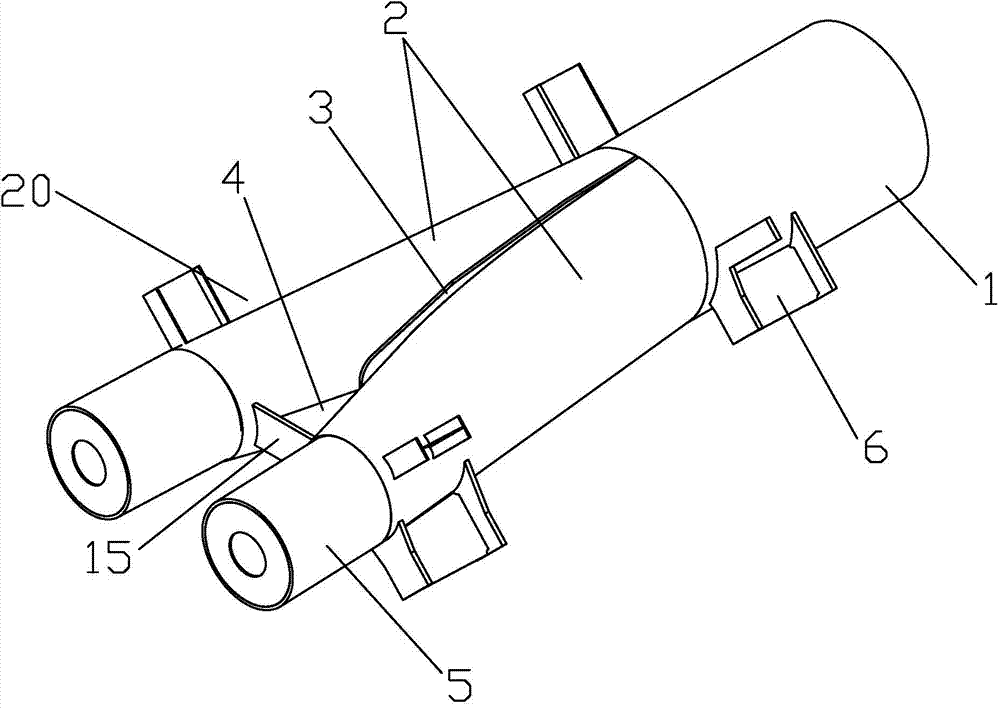

Waste gas high-efficiency cooling system with high EGR efficiency

InactiveCN101526048ASmall sizeIncreased durabilityNon-fuel substance addition to fuelInternal combustion piston enginesNuclear engineeringExhaust fumes

The invention relates to a waste gas high-efficiency cooling system with high EGR efficiency, which comprises a cooler and an EGR valve and has the innovative points: the system includes a precooler, an aftercooler and an EGR valve; wherein, the precooler is used for cooling high temperature large flow rate waste gas introduced from an exhaust system; the aftercooler is used for cooling the circulated waste gas which is introduced from the precooler and cooled by the precooler; and the EGR valve is connected and installed between the precooler and the aftercooler in series, and used for adjusting the flow rate of the waste gas. The invention is scientific and reasonable in design, and is especially used for high EGR efficiency (70-80%) waste gas cooling in an oxy-fuel combustion engine based on waste gas recycling. The waste gas high-efficiency cooling system has the advantages of high cooling efficiency, small occupying space, convenient installation, high durability, etc.

Owner:TIANJIN UNIV

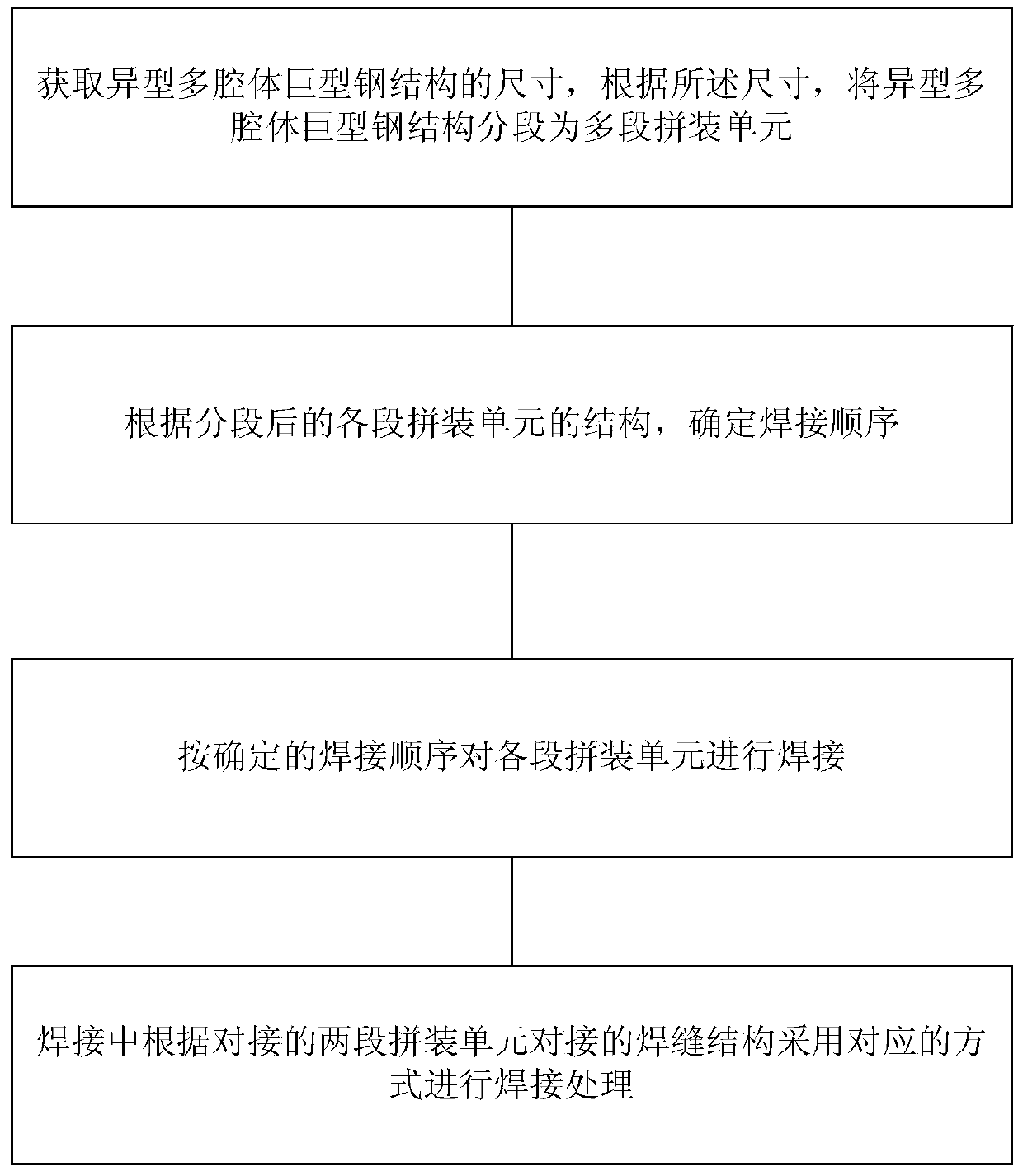

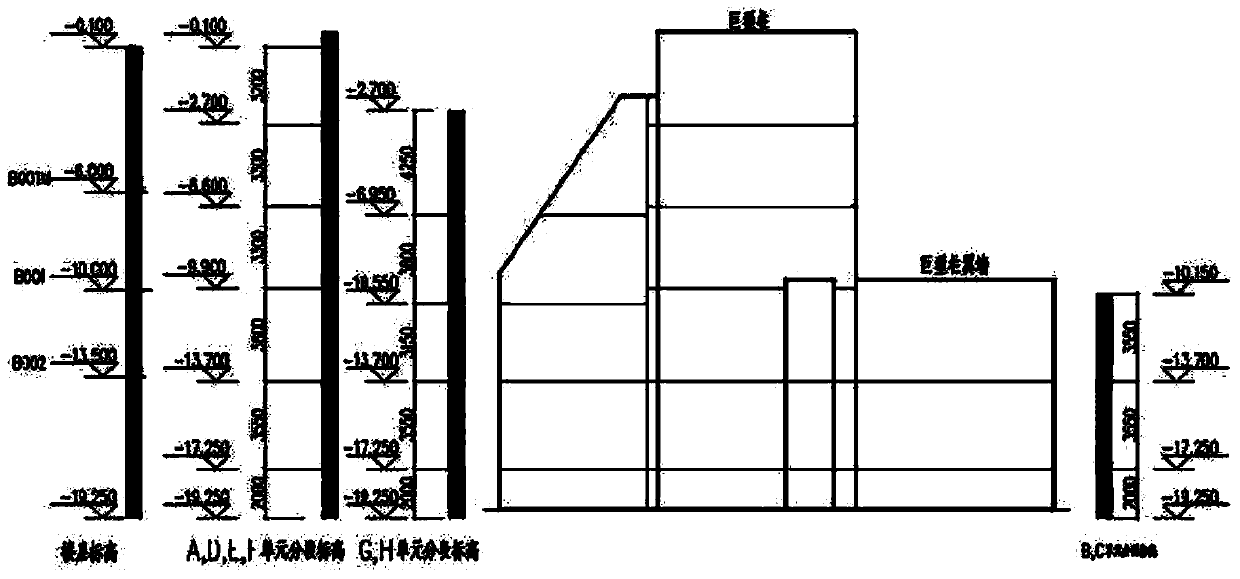

Method for welding large special-shaped multicavity steel structure

ActiveCN103624410AReduce the amount of welding workReduce harmWelding apparatusStress concentrationButt joint

The invention discloses a method for welding a large special-shaped multicavity steel structure, and belongs to the field of steel structure construction. The method includes the steps that the size of the large special-shaped multicavity steel structure is obtained, and the large special-shaped multicavity steel structure is divided into a plurality of sections of splicing units according to the size; a welding sequence is determined according to the structures of all the segmented splicing units; all the splicing units are welded in accordance with the determined welding sequence; welding treatment in corresponding modes is conducted according to the structure of a welding seam formed by every two sections of splicing units in a butt joint mode in the welding process. By the adoption of the method, the reasonable welding length is determined through segmentation, the condition of large welding deformation and the condition of welding stress concentration due to excessively concentrated welding seams are effectively avoided, and the welding work amount inside cavities is reduced to the maximum degree; the reasonable welding seam mode can be helped to be determined through segmentation, damage of operation such as welding and back gouging inside the cavities of the steel structure to operating personnel is lowered, and construction is made to be safer; welding deformation and residual stress are reduced, correcting time after welding is saved, and the welding seam repair rate is lowered.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

Display device, a front frame used therein, and a method of manufacture thereof

ActiveUS7936416B2Reduce deformation stressLow production costSubstation/switching arrangement detailsDigital data processing detailsDisplay deviceEngineering

A display device, a front frame used therein, and a method of manufacture thereof are provided. The display device includes a display panel and the front frame. The display panel has a display surface which is partially covered by the front frame. The front frame includes a side wall corresponding to the sides of the display panel, a top plate extending from the side wall towards the center of the display panel, and cushion filler. The top plate has an inner surface featuring a groove distributed along the side wall. The cushion filler is contained within the groove while its top protrudes from the groove and contacts the display surface outside an active area.

Owner:AU OPTRONICS CORP

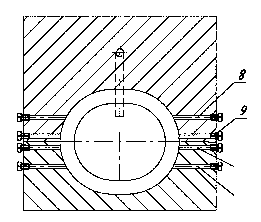

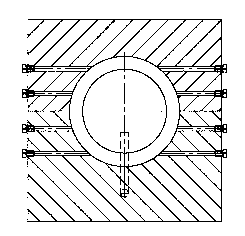

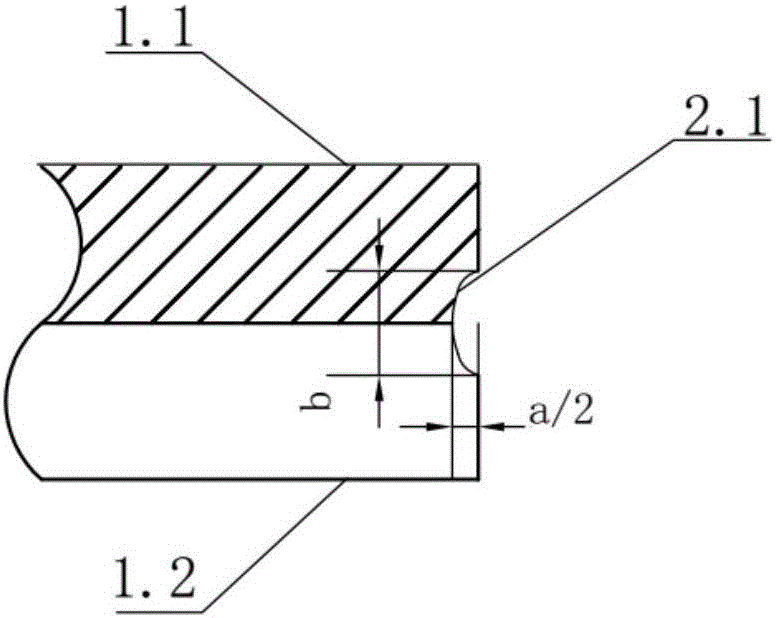

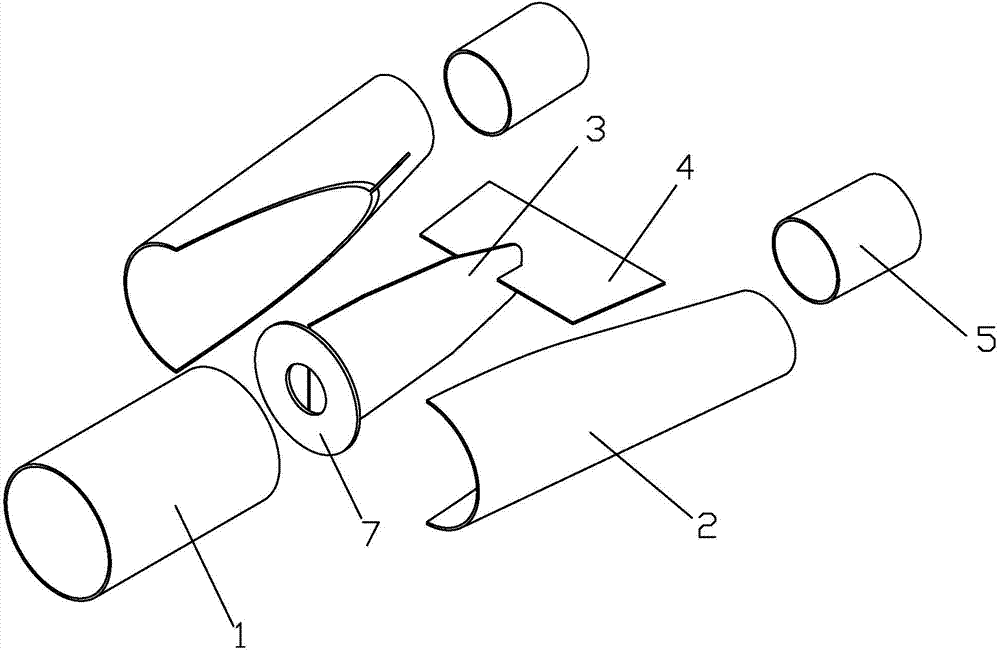

Limb type circular tube node transferring structure and manufacturing method thereof

InactiveCN104847020AReduce deformation stressReduce residual stressBuilding constructionsMechanical engineeringIndustrial engineering

The invention belongs to the technical field of building steel structure, in particular relates to a limb type circular tube node transferring structure and a manufacturing method thereof. The limb type circular tube node transferring structure comprises a trunk circular tube, a fork transitional node which is connected to one end of the trunk circular tube, a limb supporting rod circular tube and a space bracket which is installed on the external surface of the integral node; the fork transitional node is formed by two sections of special cone tubes through a central pull rod and a transverse insertion plate by penetrating; two half tiles at the bottom of the fork transitional node are combined to be an integral circle which is connected with the trunk circular tube; the end portion of the fork transitional node is connected with the two fork supporting rod circular tubes. The limb type circular tube node transferring structure has the advantages of solving the design problem of the circular tube fork connecting node, being simple and reasonable in structural design, attractive in appearance design and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

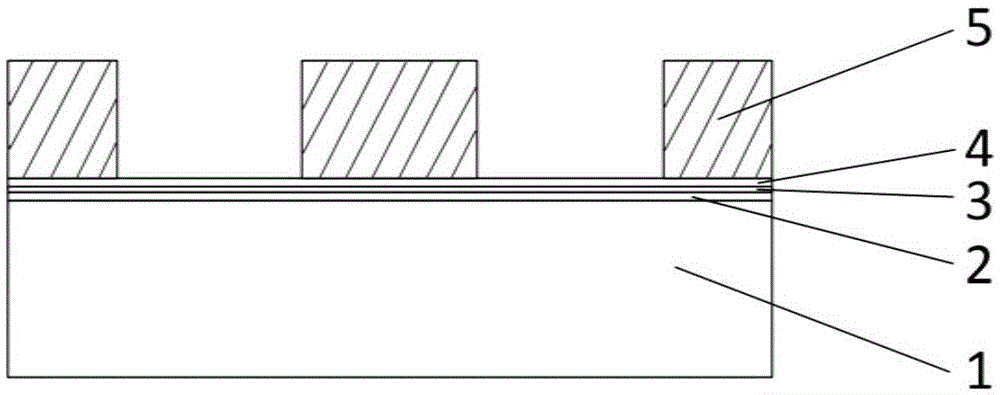

Copper nanometer wire-based copper-copper bonding process

InactiveCN104637831AHighly controllableProcess window widthSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistCopper nanowires

The invention discloses a copper nanometer wire-based copper-copper bonding process. An adhesion layer and a seed layer are sequentially precipitated on the surface of a substrate; a layer of photoresist is prepared on the seed layer, and a round hole is formed in the photoresist; copper is electroplated in the round hole to obtain a copper convex point; a Cu(OH)2 nanometer wire is grown on the surface of the copper convex point by a hydrothermal method; the residual photoresist is removed; the Cu(OH)2 nanometer wire is subjected to thermal decomposition to obtain a CuO nanometer wire; the CuO nanometer wire is reduced to obtain a copper nanometer wire; the copper nanometer wire is prepared on two substrates respectively by the steps, and the copper nanometer wires on the two substrates are bonded in a hot pressing way. The copper nanometer wires are prepared by reduction and are directly applied to subsequent bonding, an additional oxide layer removing step is avoided, a compact bonding layer can be obtained at relatively low temperature and pressure, the preparation process is simple, complex equipment is not required, the cost is low, and the bonding process has very high application value.

Owner:HUAZHONG UNIV OF SCI & TECH

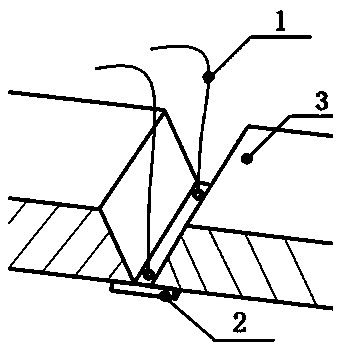

One-sided welding double-sided molding welding method for titanium steel composite pipe

ActiveCN106425104AGood for fusion transitionLow costWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyTitanium

The invention provides a one-sided welding double-sided molding welding method which is suitable for welding a titanium steel composite pipe. The one-sided welding double-sided molding welding method aims at solving the problems that in existing titanium steel composite pipe welding, operation of the welding process is complicated, the accumulated heat input is large, it is necessary to prepare special welding consumables, and the welding efficiency is low. The one-sided welding double-sided molding welding method for the titanium steel composite pipe comprises the following steps that (1), a flat bottom groove with a blunt edge is machined at the pipe end of the titanium steel composite pipe to be welded; (2), a welding area is cleaned; (3), a titanium alloy layer of the titanium steel composite pipe is welded through a laser welding method; (4), acetone is used as a binder so that evenly-mixed transition layer metal powder can be made into paste, the groove bottom is evenly welded, pressing is conducted, and drying is conducted; and (5), transition layer metal is molten through laser energy, the transition layer is formed firstly, and then filling of the steel metal layer is conducted through electric arc welding. By the adoption of the method, one-sided welding double-sided molding welding of the titanium steel composite pipe is achieved, and the welding quality of the titanium steel composite pipe is improved.

Owner:SOUTHWEST JIAOTONG UNIV

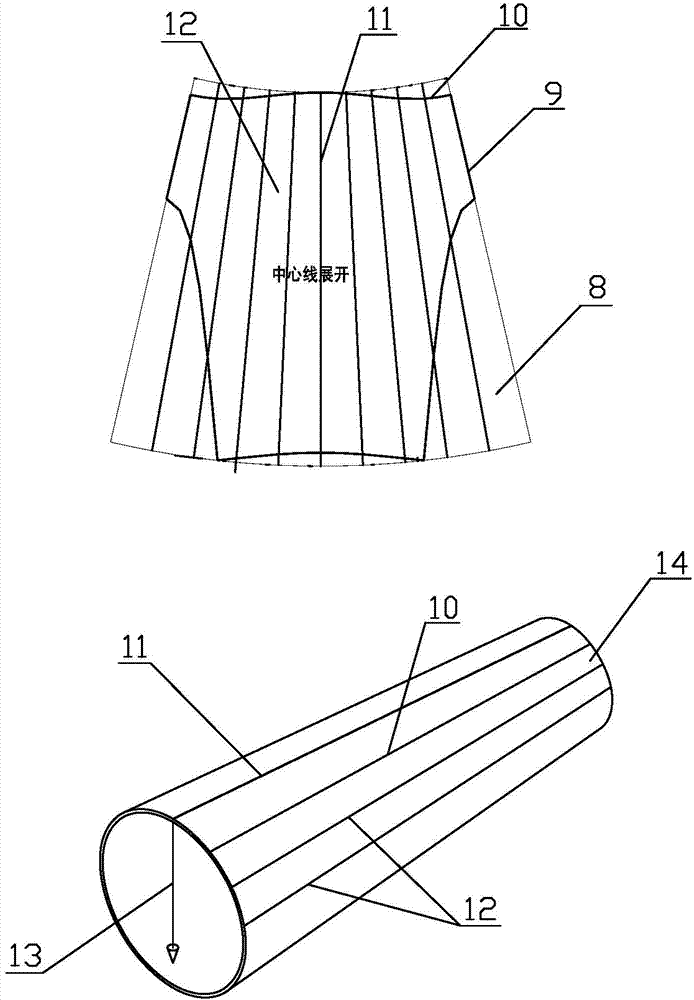

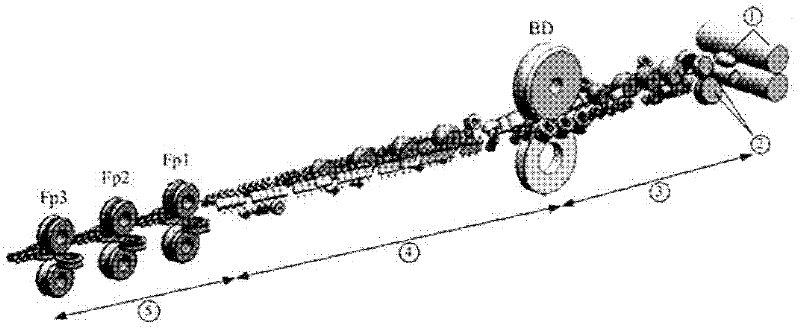

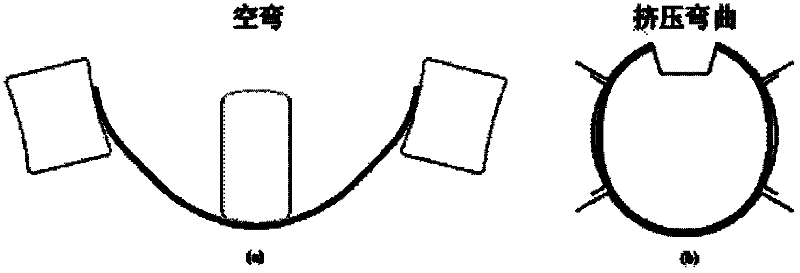

Variable Radius Bending Method for Longitudinal Welded Pipe Roll Forming

InactiveCN102266885AOvercome the problem of unreasonable distribution of deformationReduce edge stretchManufacturing technologyStrip steel

A straight seam welded pipe roll forming variable radius bending method in the field of straight seam welded pipe manufacturing technology, adopting the longitudinal deformation form and strip transverse bending mode in the strip steel forming formed by the downhill method, and according to the strip steel space shape in the forming process The three transverse bending sections of the strip and the transverse and longitudinal positions of the edge of the strip are obtained from the position, and finally the welded pipe is manufactured. The invention solves the problem of the roll forming process of the straight seam welded pipe in the prior art, which is mainly based on empty bending, and the profile of the formed section of the strip calculated by the variable radius bending method is in good agreement with the result measured after production by the method .

Owner:SHANGHAI JIAO TONG UNIV +1

Robot arm and robot

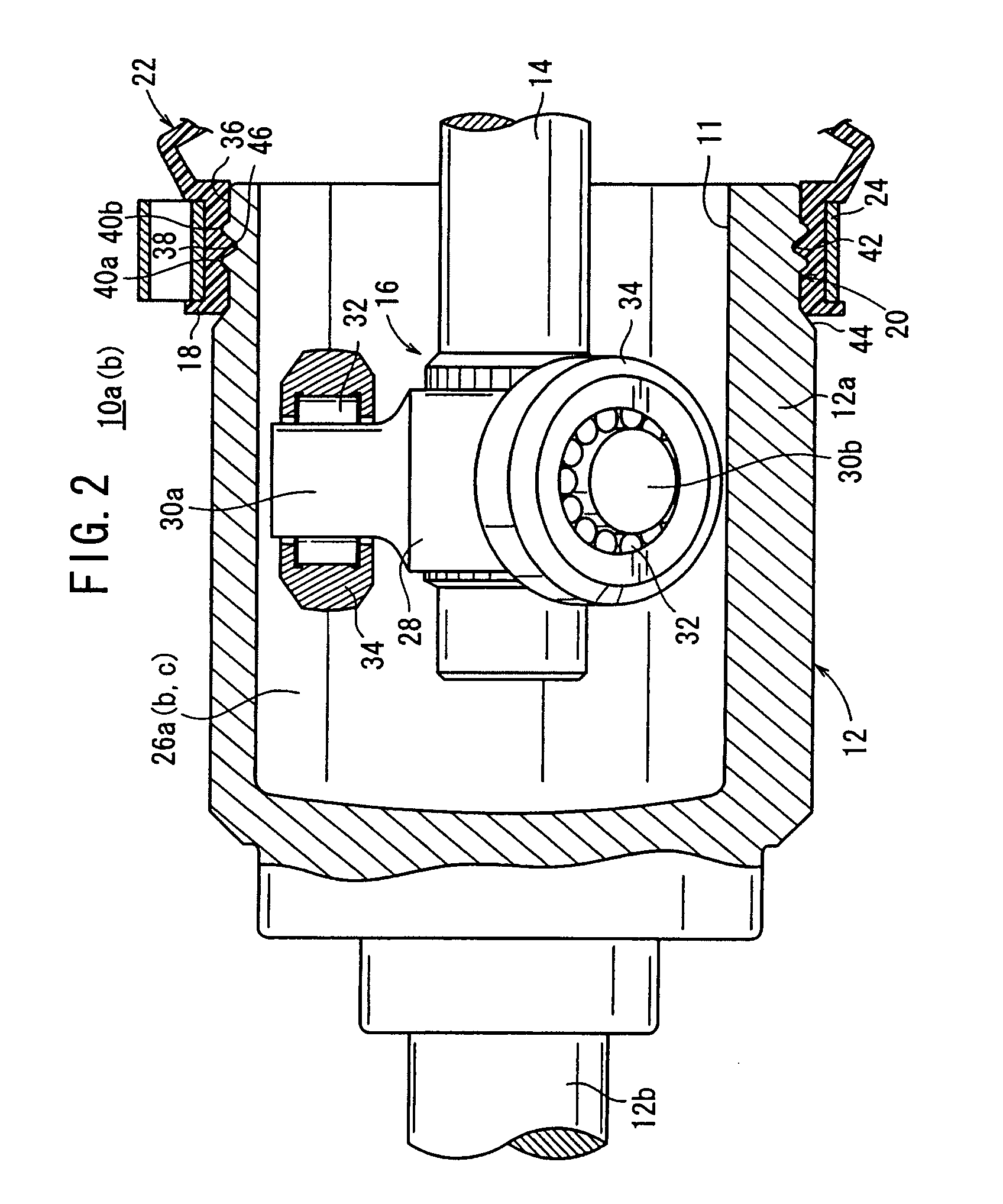

ActiveUS20150068349A1Suppress interferenceExtended range of motionProgramme-controlled manipulatorMechanical apparatusGear wheelDrive shaft

A joint driving device includes: a reduction gear output shaft that transmits a torque to a second link; a transmission shaft that transmits reaction of the torque to a first link; a transmission shaft outer cylinder arranged on the outer circumference of the transmission shaft and connected to the transmission shaft; a reduction gear output shaft outer cylinder arranged in the outer circumference of the reduction gear output shaft and connected to the reduction gear output shaft; and a wire body arranged between the first link and the second link and including at least one of a wire and a pipe. The transmission shaft includes the motor frame as at least a part. The wire body is housed in a space between the transmission shaft outer cylinder and the transmission shaft, and a space between the reduction gear output shaft outer cylinder and the reduction gear output shaft.

Owner:SEIKO EPSON CORP

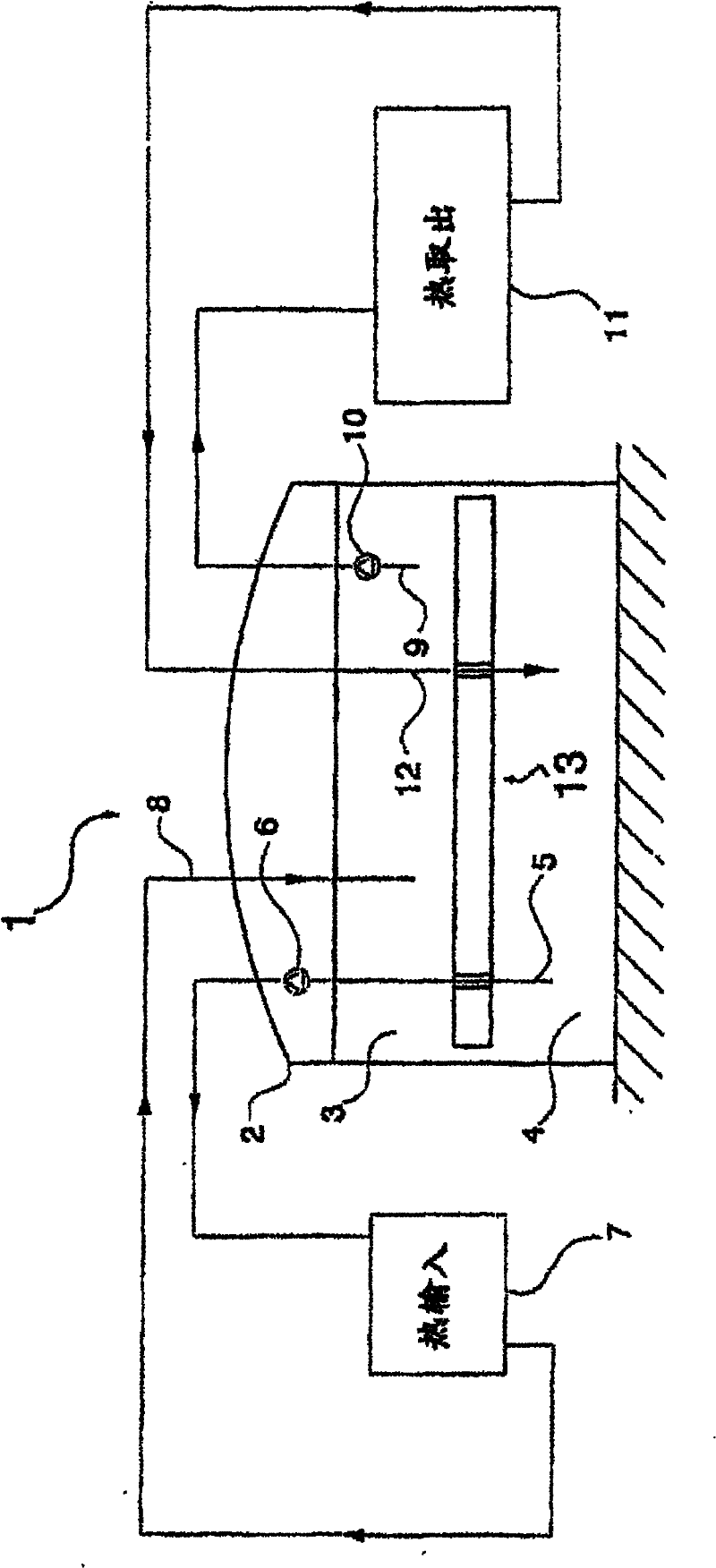

Dual-temperature energy storage tank

InactiveCN102132122AEliminates any problems related to thermal distortionAdjust densitySolar heating energyCentral heating with accumulated heatThermoclineThermal energy storage

The invention relates to a thermocline storage tank including a barrier element which floats between two fluids stored at different temperatures, physically separating said fluids and isolating same. The floating barrier has multiple design characteristics that broaden the scope of application thereof, enabling same to be used in fields such as those involving the use of heat storage systems of solar generating plants.

Owner:SENER ING Y SISTEMAS

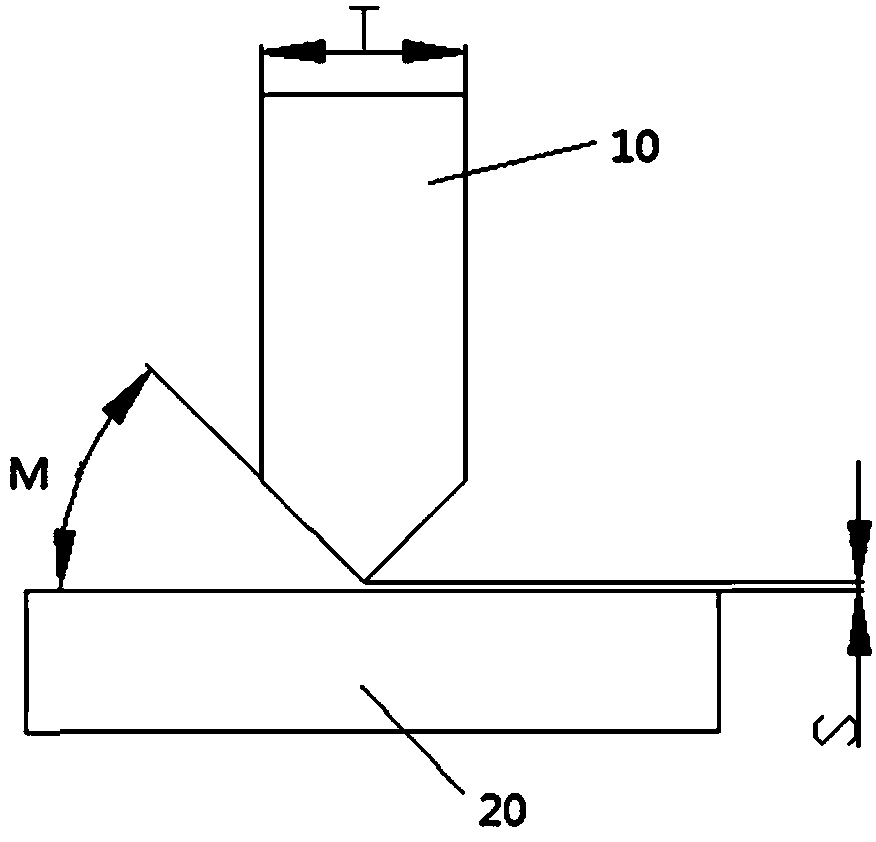

Welding method of large-thickness plate T-shaped joint welding

ActiveCN107598340AReduce deformation stressReduce residual stressArc welding apparatusWorkpiece edge portionsThick plateWeld seam

The invention provides a welding method of a large-thickness plate T-shaped joint. The welding method is suitable for the plates with the thickness larger than 30 mm. The welding method comprises thefollowing steps: welding guns are placed on the two sides of a middle plate of the large-thickness plate T-shaped joint; double-sided asynchronous backing MAG welding is adopted during backing welding; the two welding guns maintain a certain arc distance; and full penetration of a root part is achieved by increasing the heat input of the welding guns and reducing the arc distance between the welding guns so that narrow gap welding without back gauging can be realized. Double-sided synchronous filling MAG welding is adopted during filling welding, the two welding guns are synchronous, on one hand, the welding speed is increased, and on the other hand, welding angle deformation and residual stress are reduced. Due to the facts that the back gauging is not required to be carried out on a backface through a carbon gouging, corner deformation does not exist and reserved gaps are reduced, the metal filling amount of a welding seam is reduced by more than 40% compared with that of traditional welding, the one-time qualified rate of the products is improved by 40%, and the production efficiency is improved by more than 5-10 times.

Owner:SHANGHAI ZHENHUA HEAVY IND

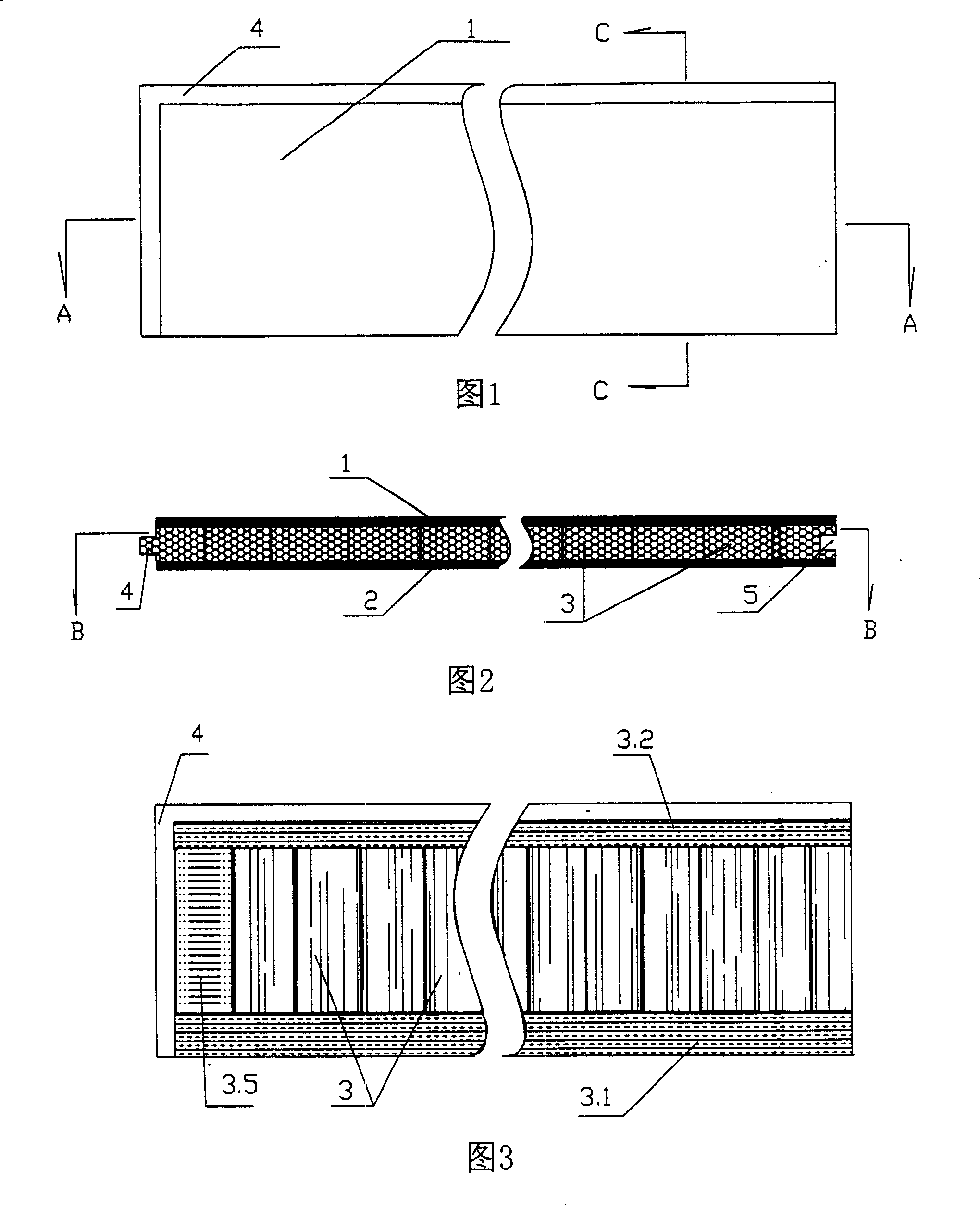

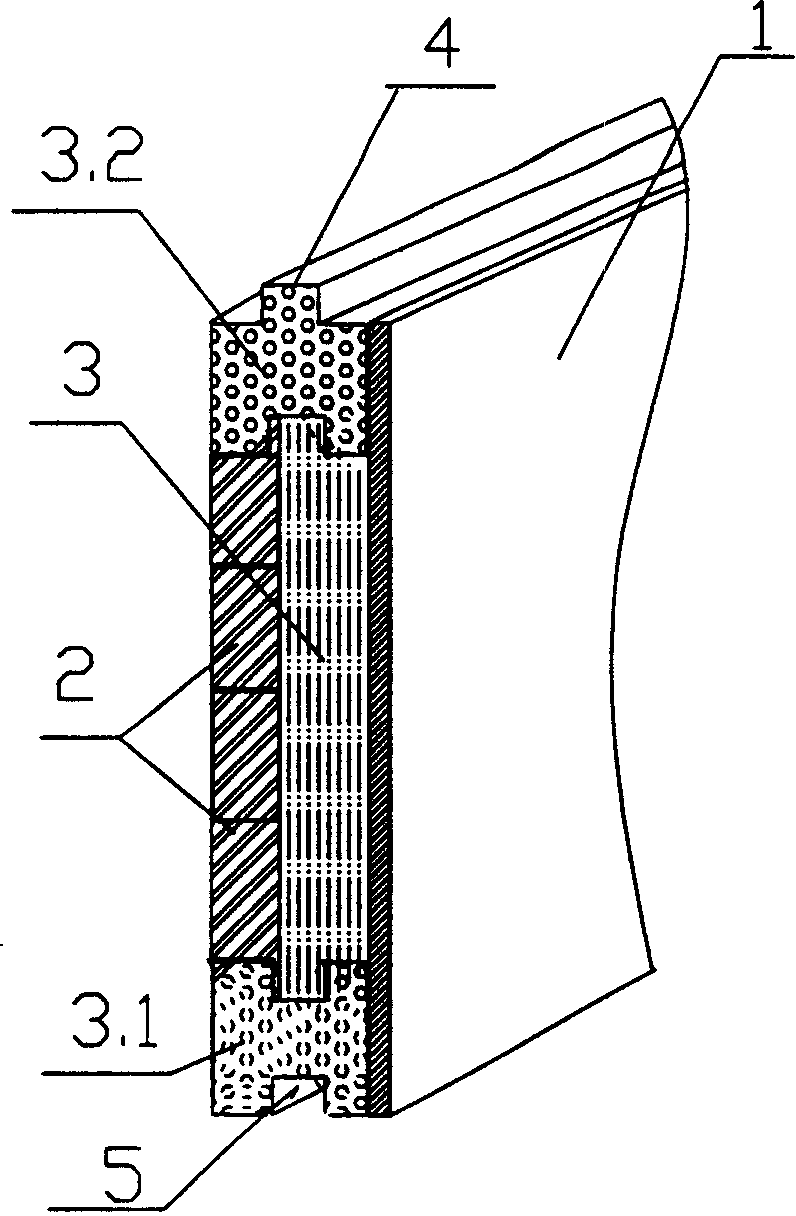

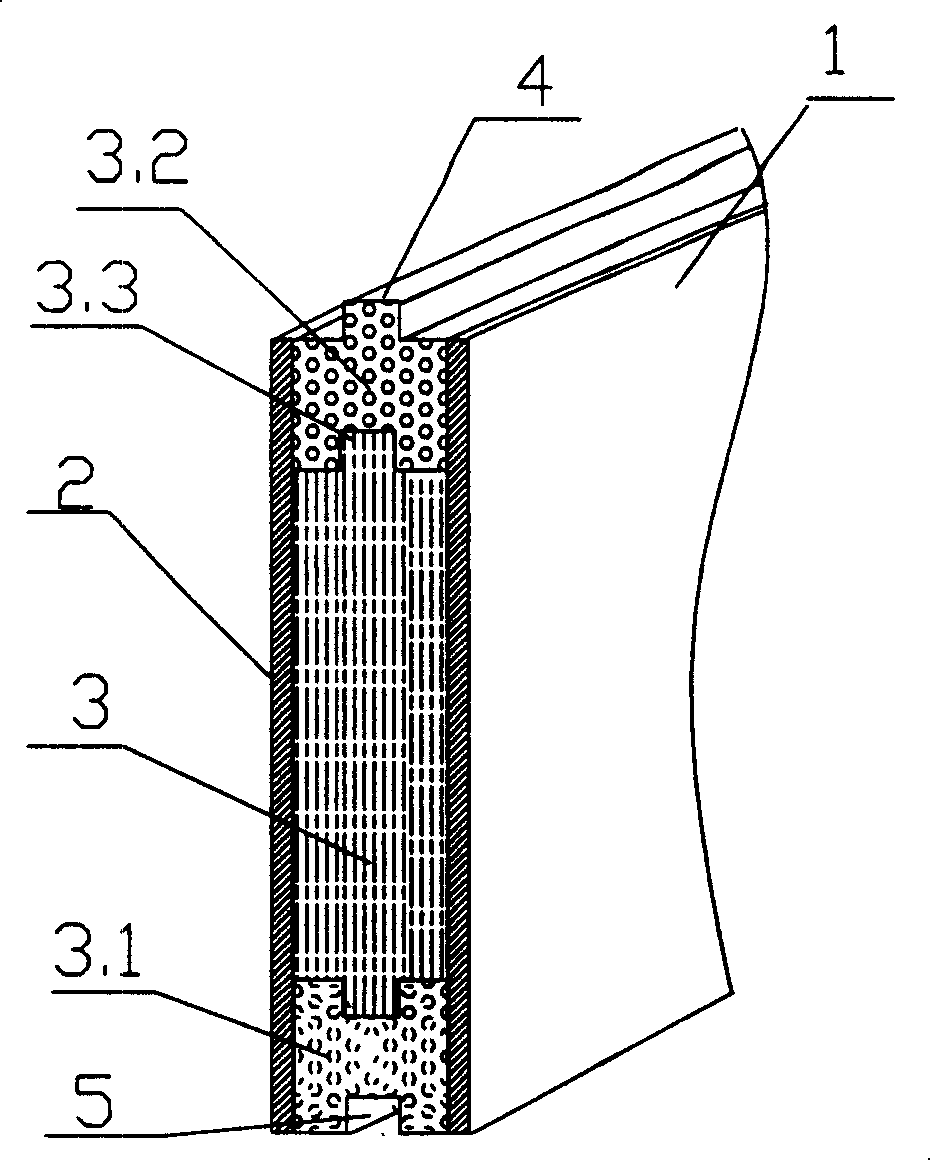

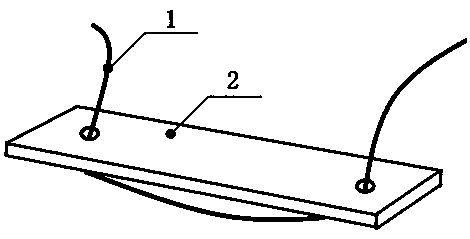

Frame type wooden floor

The invention provides a frame-type solid wood floor, which comprises a floor body, a tenon tongue and tenon slot which are around the floor body, wherein the floor body comprises a surface layer, a substrate slab, wherein the surface layer takes a longitudinal direction, the substrate slab is composed of a central filled slab, a bottom layer and filler rods which are arranged on two sides, and the tenon tongue and the tenon slot which are arranged on two sides are arranged outside the filler rods which are arranged on two sides. The central filled slab is tenon-jointed or finger jointed with the filler rods which are arranged on two sides. The central filled slab is composed of a plurality sections of short slabs on the length direction, the wood grains direction of the short slabs is arranged in a cross mode with the wood grain direction of the surface layer, the bottom layer which covers a plurality sections of central filled slabs and the filler rods which are arranged on two sides is arranged on the lower portion, the central filled slabs are combined with the bottom layer into integrity and tenon-jointed or finger jointed with the filler rods which are arranged on two sides. The wood grains of a section of short slab which are located on one end of the tenon tongue are in horizontal direction with the wood grain direction of the surface layer. The central filled slab is laminated by one or three layers on the thickness direction, the wood grain direction of each layer is arranged in the cross mode. The thickness of the surface layer is 0.6-6mm. The width of the filler rods which are arranged on two sides is 15-30mm. The bottom layer can be laminated by a plurality of strips on the transverse direction.

Owner:王仁忠 +2

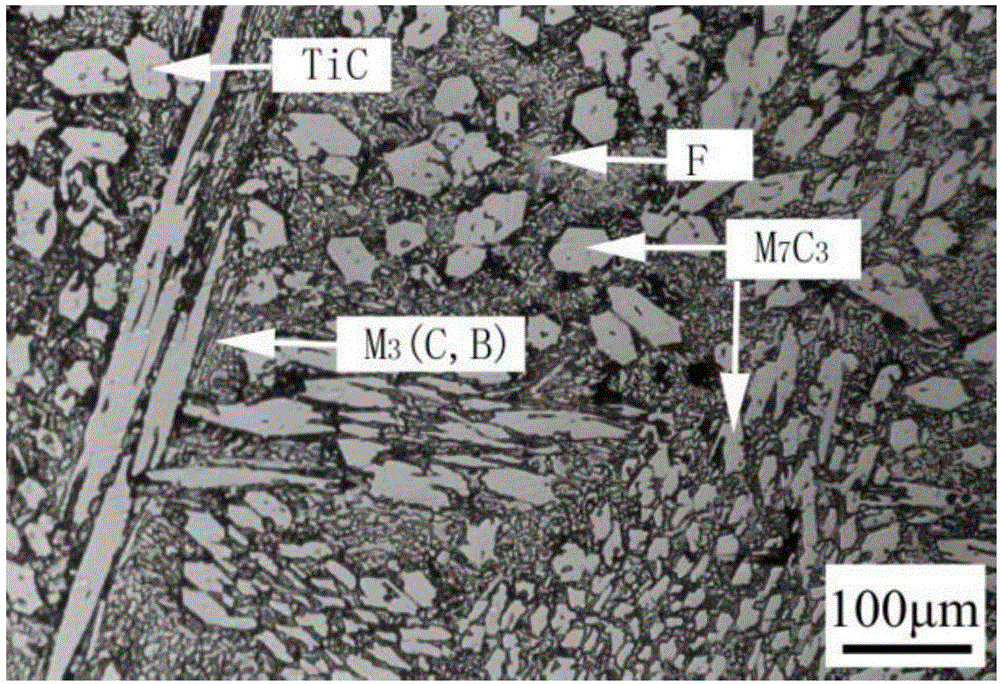

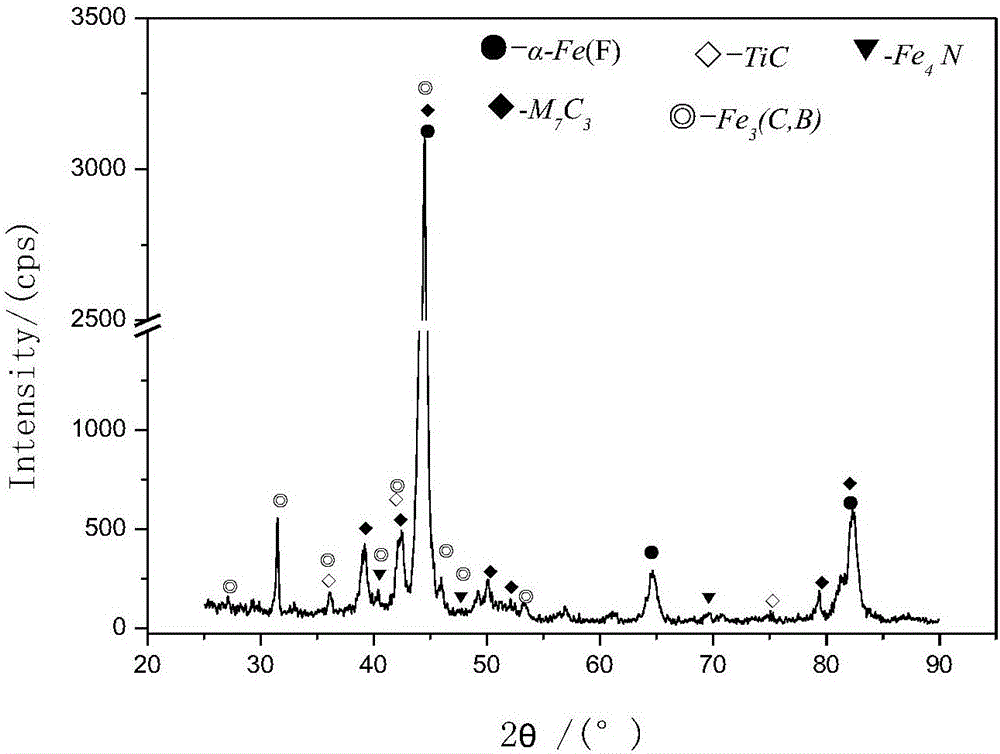

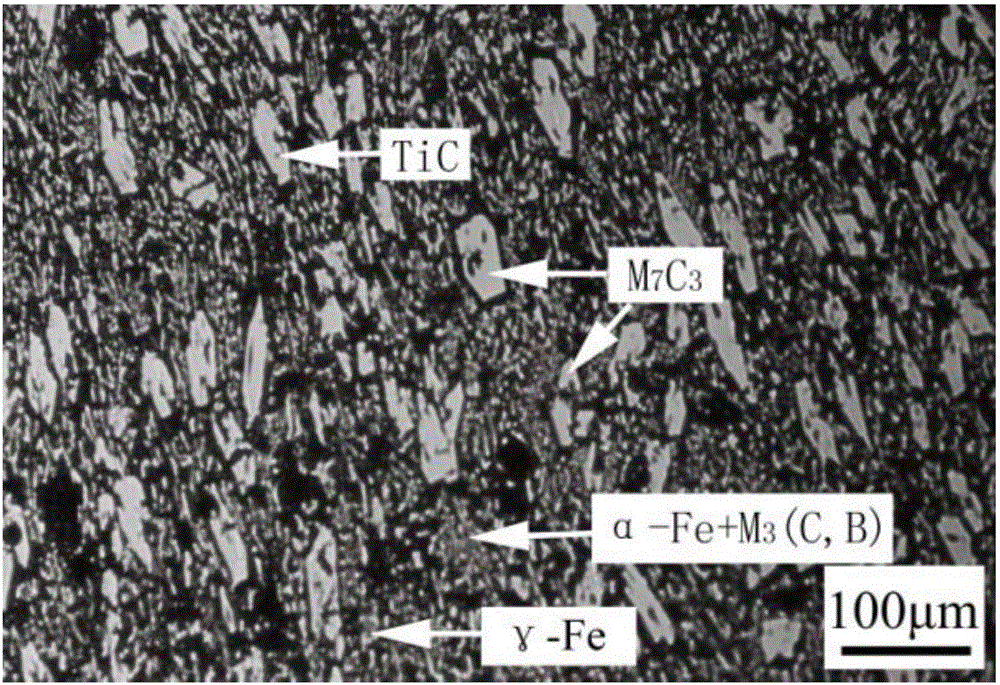

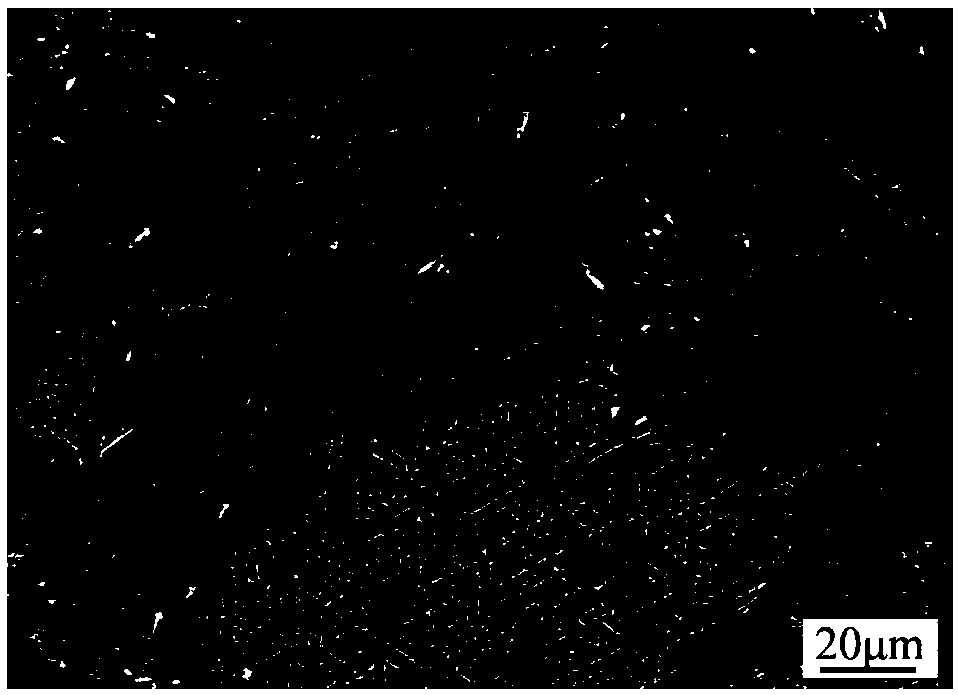

Pre-prepared alloy powder type flux-cored wire and self-protection open arc surfacing welding method of high-chromium alloy

ActiveCN106041361AIncreased welding deposition efficiencyRemarkable effect of energy saving and consumption reductionArc welding apparatusWelding/cutting media/materialsHigh carbonFerrosilicon

The invention discloses a pre-prepared alloy powder type flux-cored wire and a self-protection open arc surfacing welding method of a high-chromium alloy. The adopted technical scheme lies in that a cold rolled thin steel strip manufactured through low-carbon steel H08A as an outer coating, high carbon ferro-chrome, ferrosilicon, graphite and other metal powder are blended inside the coating to form a powder core of the flux-cored wire, and high carbon ferro-chrome, ferroboron, ferrosilicon and reduced iron powder are blended to form pre-prepared alloy powder; and before welding, the alloy powder is placed on a welding bead in advance, the surfacing welding current control value is set, a regulating melt mode combined with the mass of the pre-prepared alloy powder type flux-cored wire is set, a nonhomogeneous melt containing liquid high carbon ferro-chrome atom clusters formed through melting high carbon ferro-chrome particles is formed, and the concretionary high-chromium alloy which adopts the liquid high carbon ferro-chrome atom clusters as component donors, nucleates and grows into primary M7C3 abrasion-resistance phases is formed. According to the method, the problems that the source of components of surfacing welding alloys is single and the chromium content of the surfacing welding alloys is not liable to increase are solved, and the method is widely applied to surfacing welding manufacturing and repairing of parts with the requirement of abrasive wear resistance.

Owner:XIANGTAN UNIV

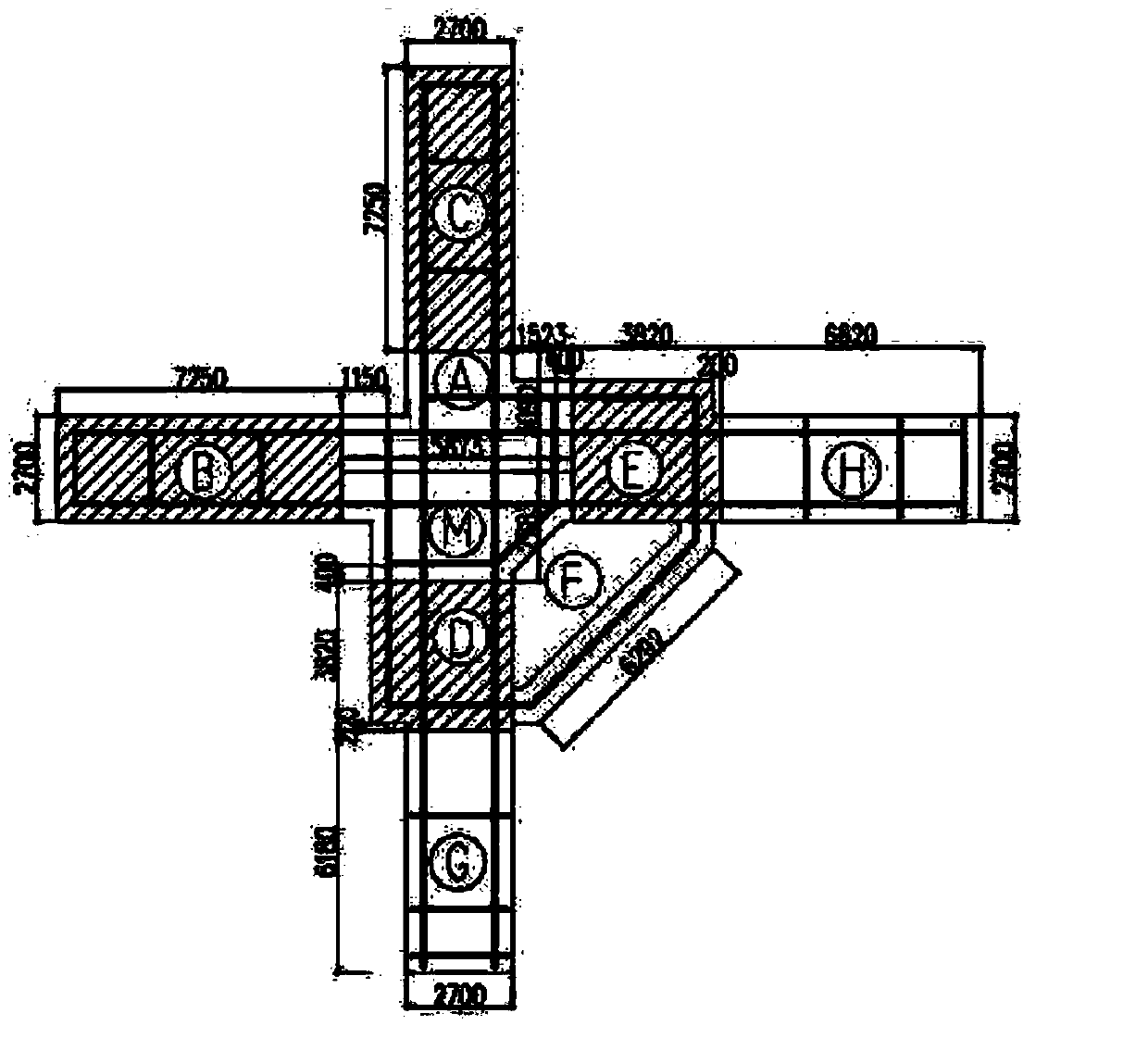

Manufacturing method for cross-shaped column rotation circular pipe column structure and cross-shaped column rotation circular pipe column structure thereof

ActiveCN107335903AThe overall structure has good force bearing effectGood operabilityStrutsArc welding apparatusStress effectsColumn structure

The invention discloses a manufacturing method of a cross-shaped column rotation circular pipe column structure. The method comprises the following steps that four annular flange plates and four annular H-shaped bracket webs are assembled into a first annular H-shaped bracket; in reference to the assembling method of the first annular H-shaped bracket, a second annular H-shaped bracket is assembled; a cross-shaped column web is assembled; a cross-shaped stiffening plate is assembled; a box type part and a cross-shaped column part are assembled, and two box type part flange plates, two box type part webs, the cross-shaped column web and the cross-shaped stiffening plate are assembled into the box type part and the cross-shaped column part; a circular pipe part is assembled, and the cross-shaped stiffening plate and four arc plates are assembled into a circular pipe part; sealing plates are assembled, and the eight sealing plates are assembled to an upper port and a lower port of the circular pipe part; and the two annular H-shaped brackets are assembled to the outer wall of the circular pipe part. The manufacturing method has the beneficial effect that the integral stress effect of the structure is good. The invention further discloses the cross-shaped column rotation circular pipe column structure adopting the manufacturing method of the cross-shaped column rotation circular pipe column structure.

Owner:湖北精工钢结构有限公司

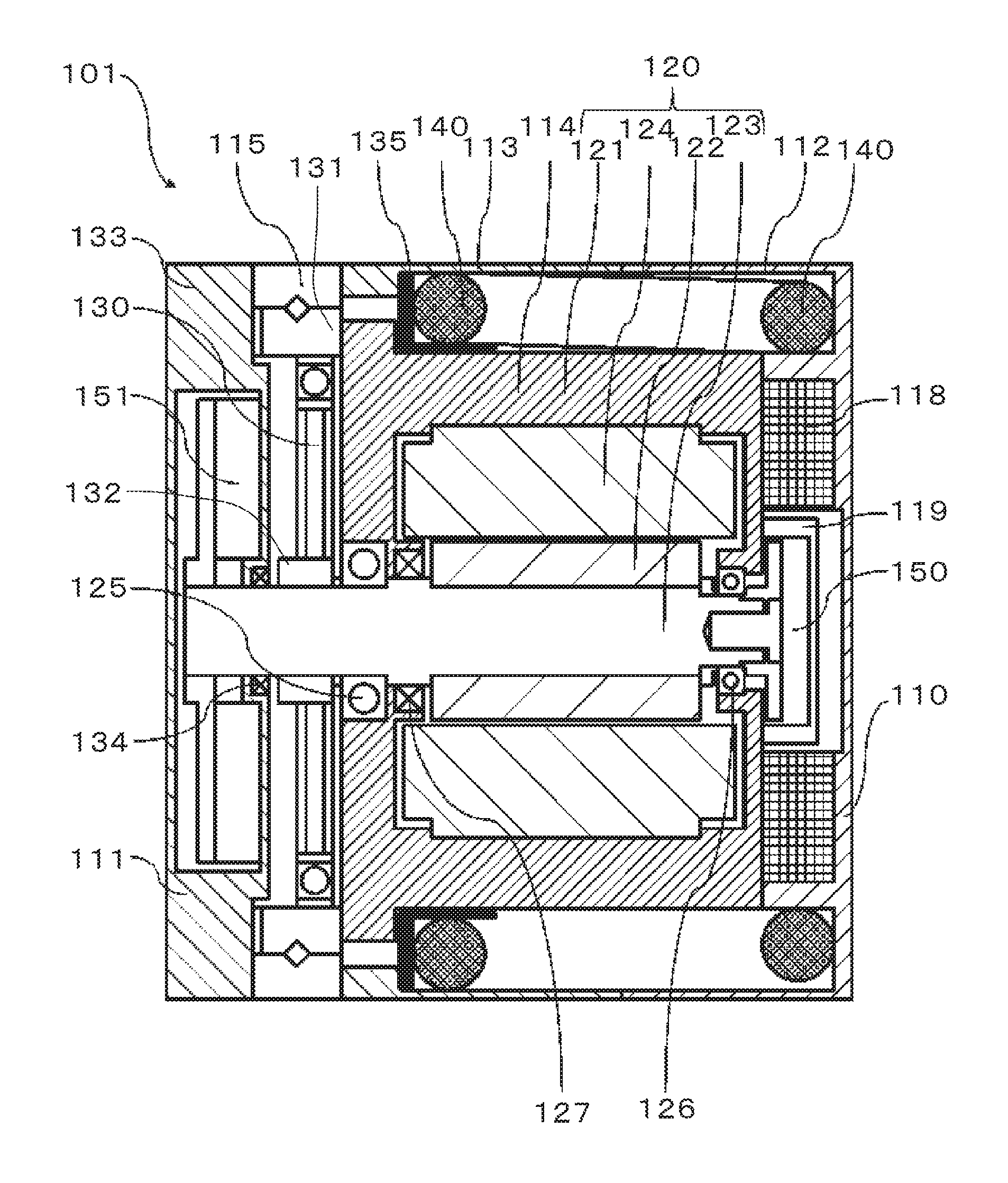

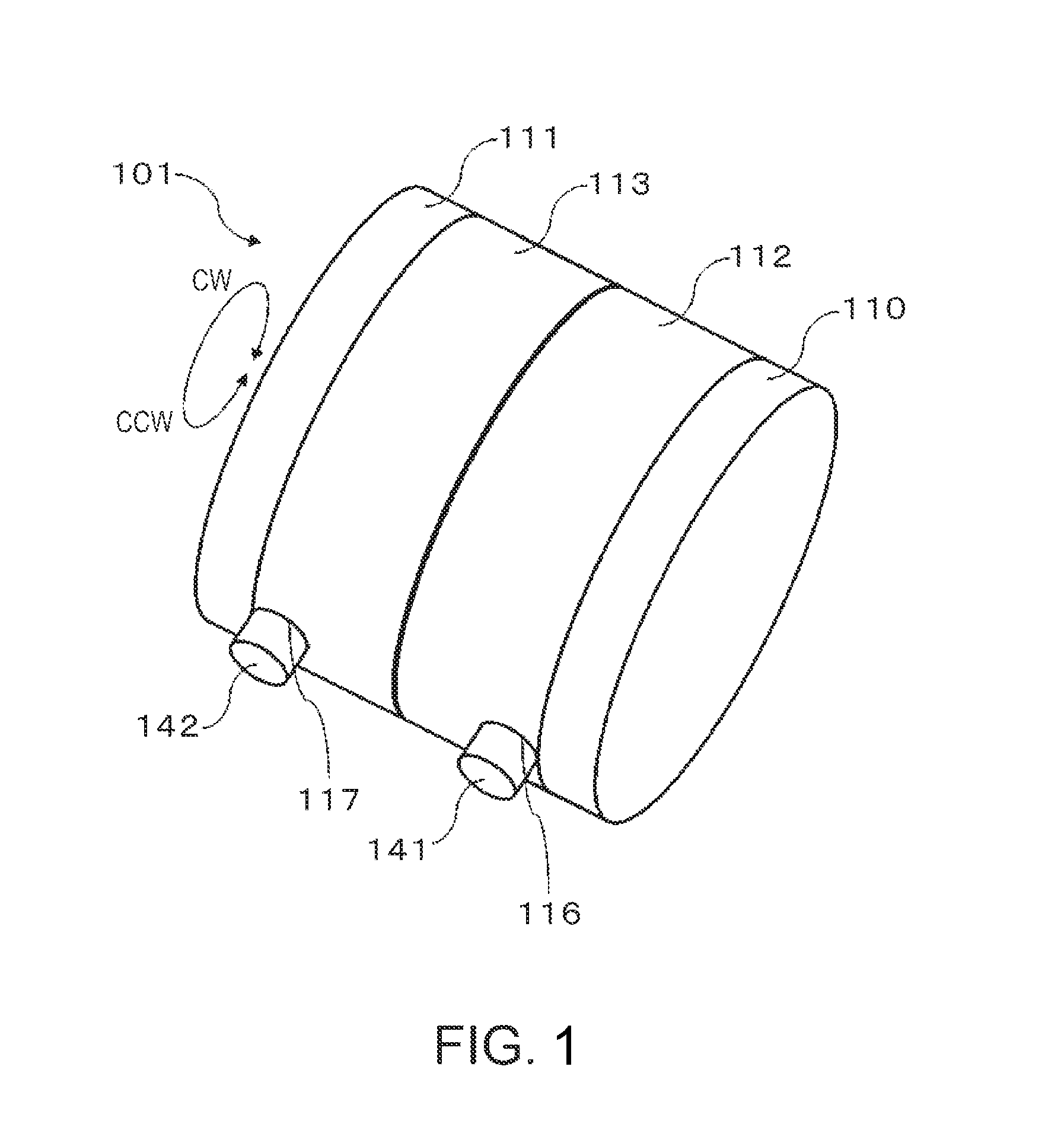

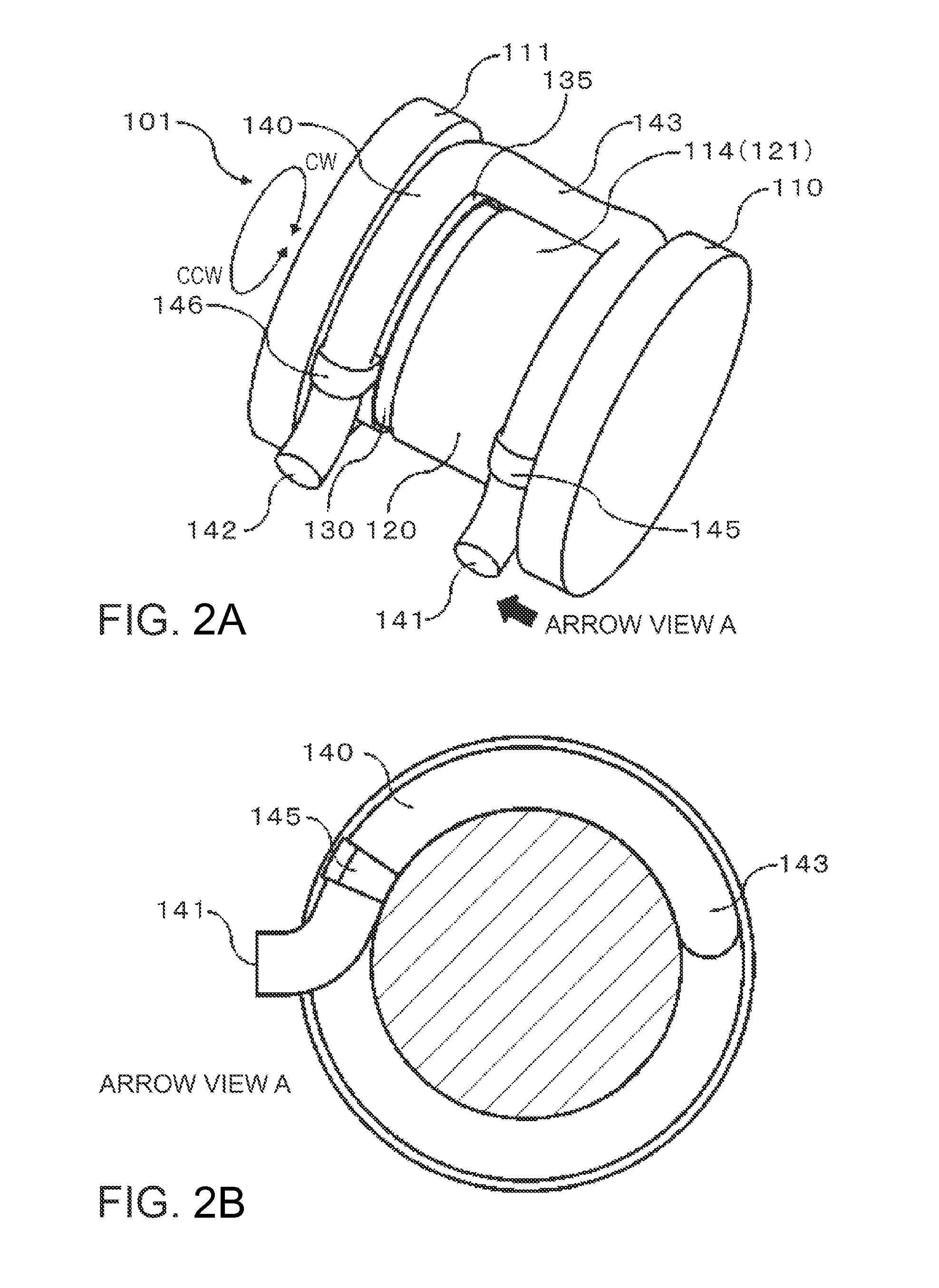

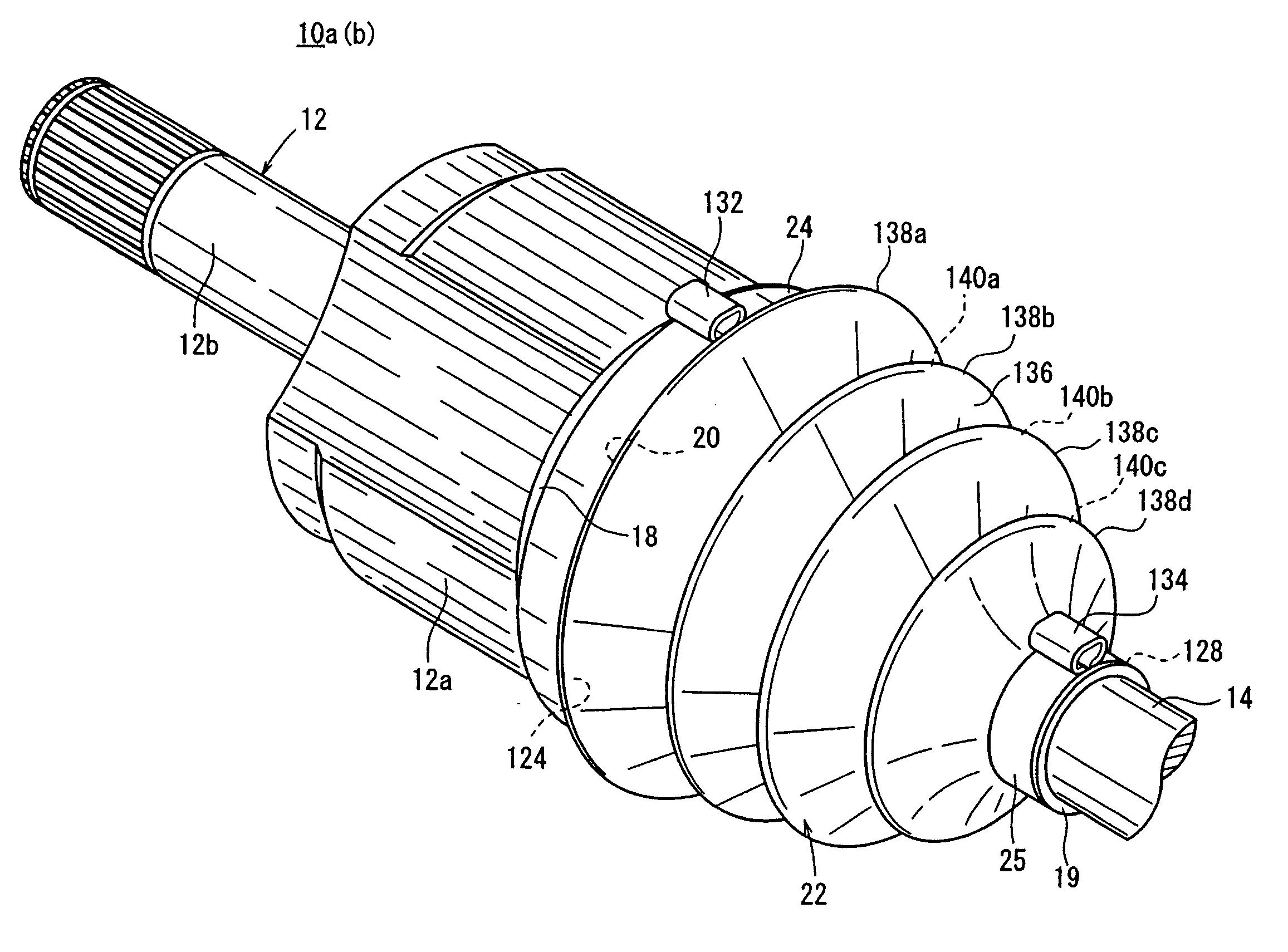

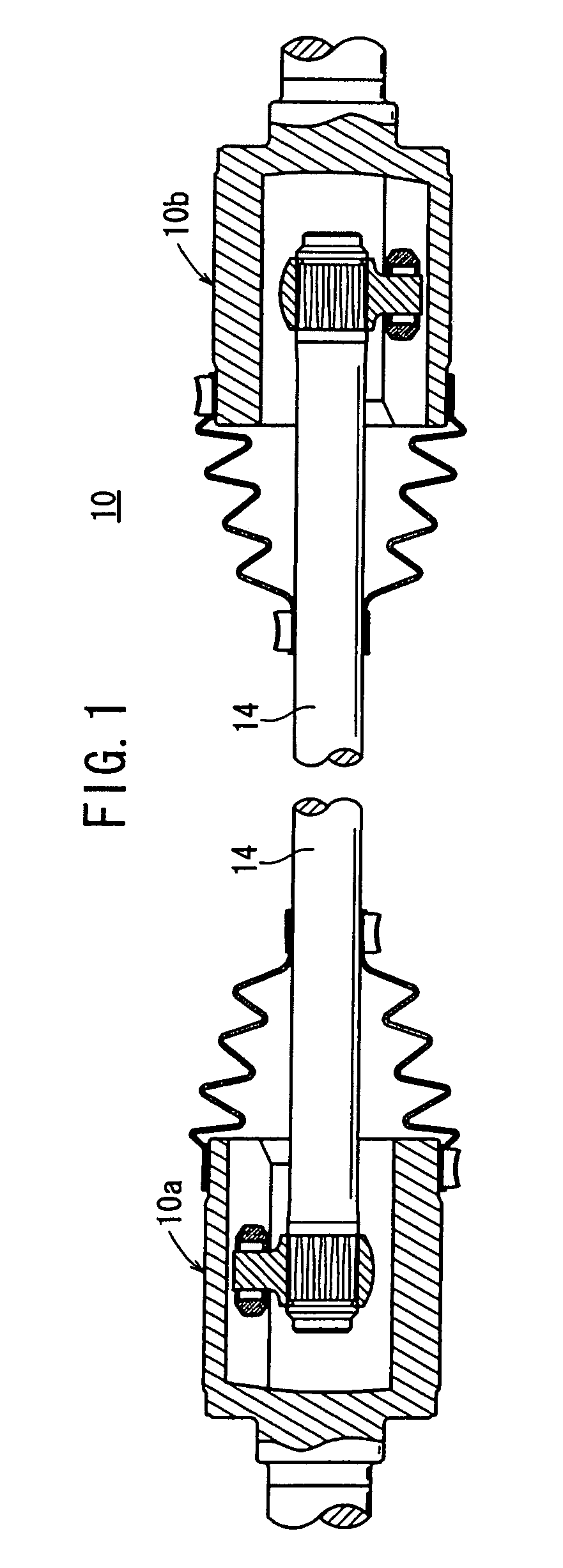

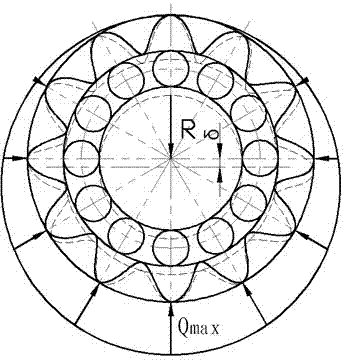

Rotation Drive Force Transmission Mechanism, Constant Velocity Universal Joint and Resin Joint Boot Constructing the Mechanism, and Method of Tightening Clamp Band for Constant Velocity Universal Joint

InactiveUS20090017923A1Control lengthEasy to set upYielding couplingMetal working apparatusUniversal jointEngineering

A rotation drive force transmission mechanism has tripod constant-velocity joints coupled to respective ends of a shaft in opposite phase. Outer members of the tripod constant-velocity joints and portions of the shaft are covered with boots. When the large-diameter tube of each of the boots is fastened to the corresponding outer member by a first fastening band, a band crimping ratio is managed so as to fall within a predetermined range. Each of the outer members has a boot mount whose shape is selected to satisfy predetermined equations.

Owner:HONDA MOTOR CO LTD

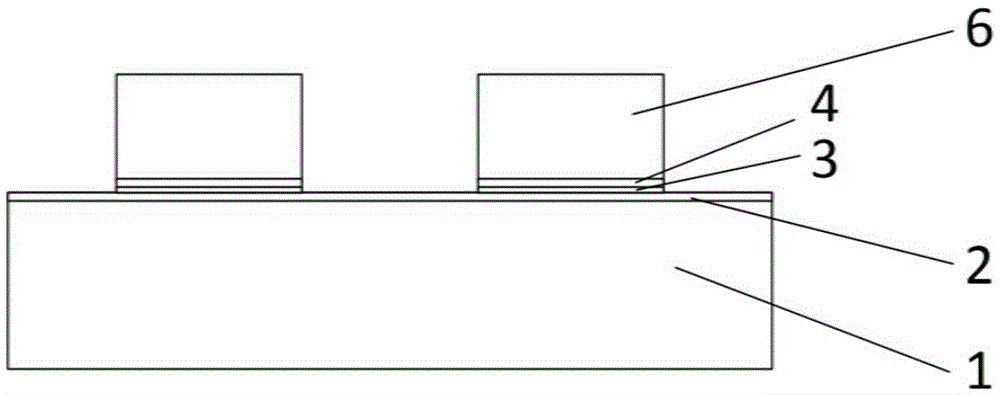

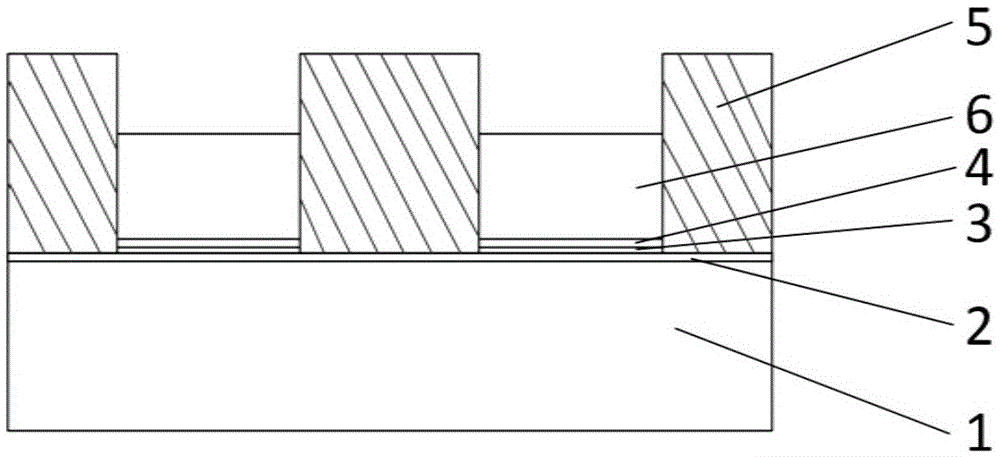

Copper nanorod based copper-tin-copper bonding process and structure

ActiveCN105679683ALower requirementLower bonding temperatureMaterial nanotechnologySemiconductor/solid-state device detailsBonding processCopper

The invention discloses a copper nanorod based copper-tin-copper bonding process and structure. The process comprises the following steps of sequentially depositing an insulation layer, an adhesion layer and a seed layer on the surface of a substrate; spin-coating a layer of photoresist on the seed layer, and fabricating round holes in the photoresist; electroplating copper in the round holes to obtain copper convex points; removing the photoresist, and removing the exposed seed layer and the exposed adhesive layer; spin-coating the photoresist on the surfaces and the peripheries of the copper convex points, and exposing the upper surfaces of the copper convex points; electroplating tin convex points on the copper convex points of one of two substrate units obtained according to the above steps, and removing the photoresist; depositing copper nanorods on the copper convex points of the other substrate unit, and removing the photoresist; and bonding the two substrate units by a hot-pressing mode. The copper-tin-copper bonding structure is acquired according to the bonding process. According to the bonding process and the bonding structure, the copper nanorods are applied to copper-tin-copper bonding, the bonding temperature can be effectively reduced, and a tight bonding surface is obtained; and the preparation process is simple and controllable, is low in cost, and has great application value.

Owner:HUAZHONG UNIV OF SCI & TECH

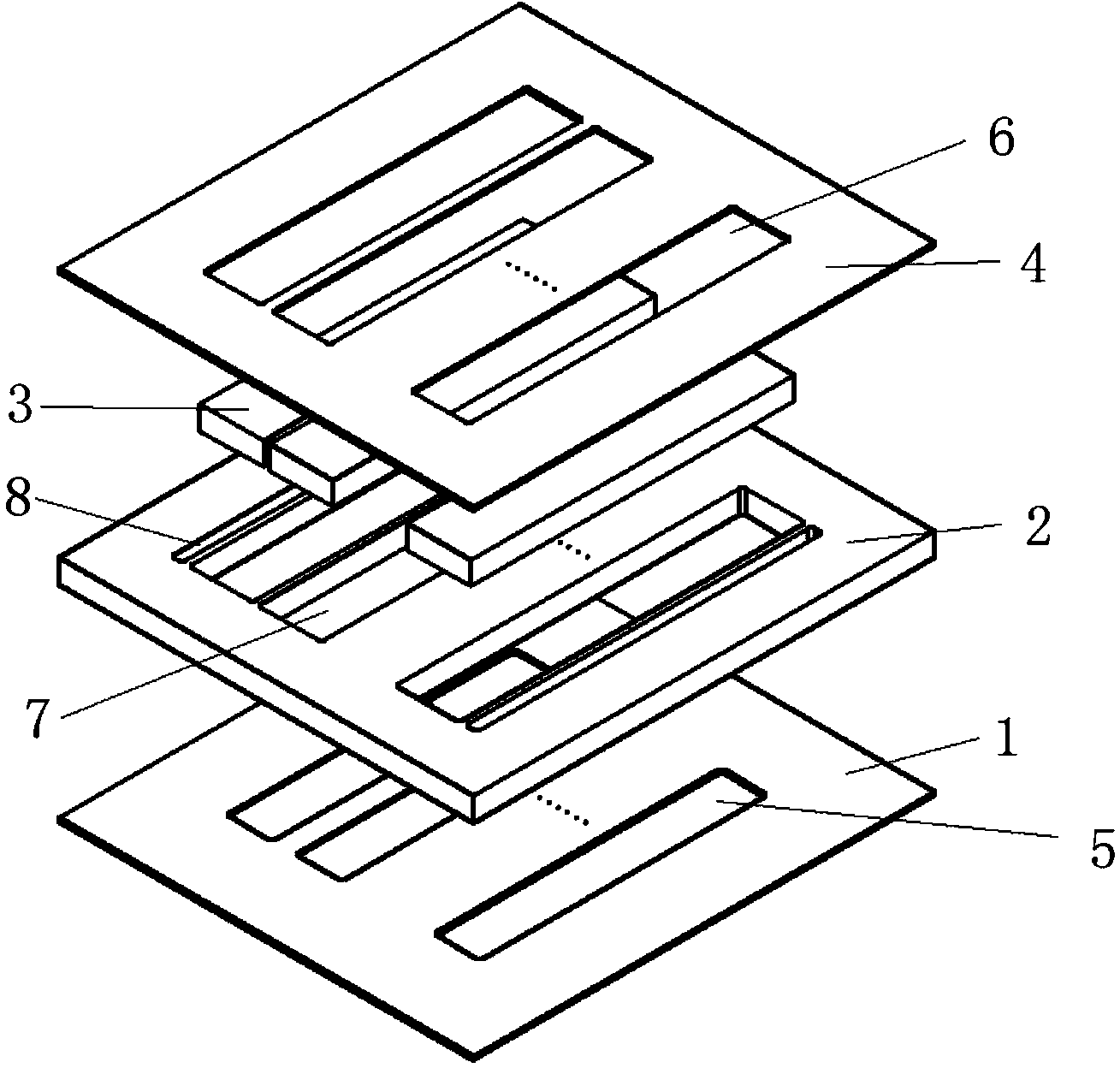

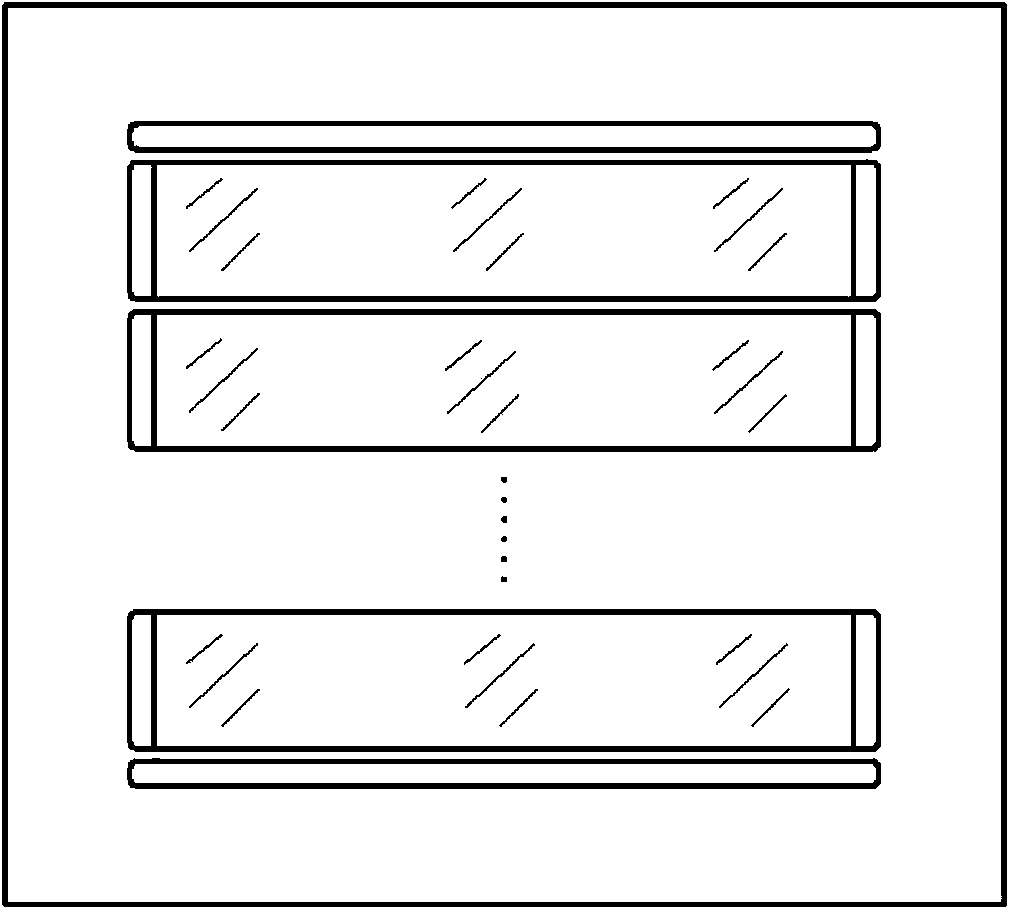

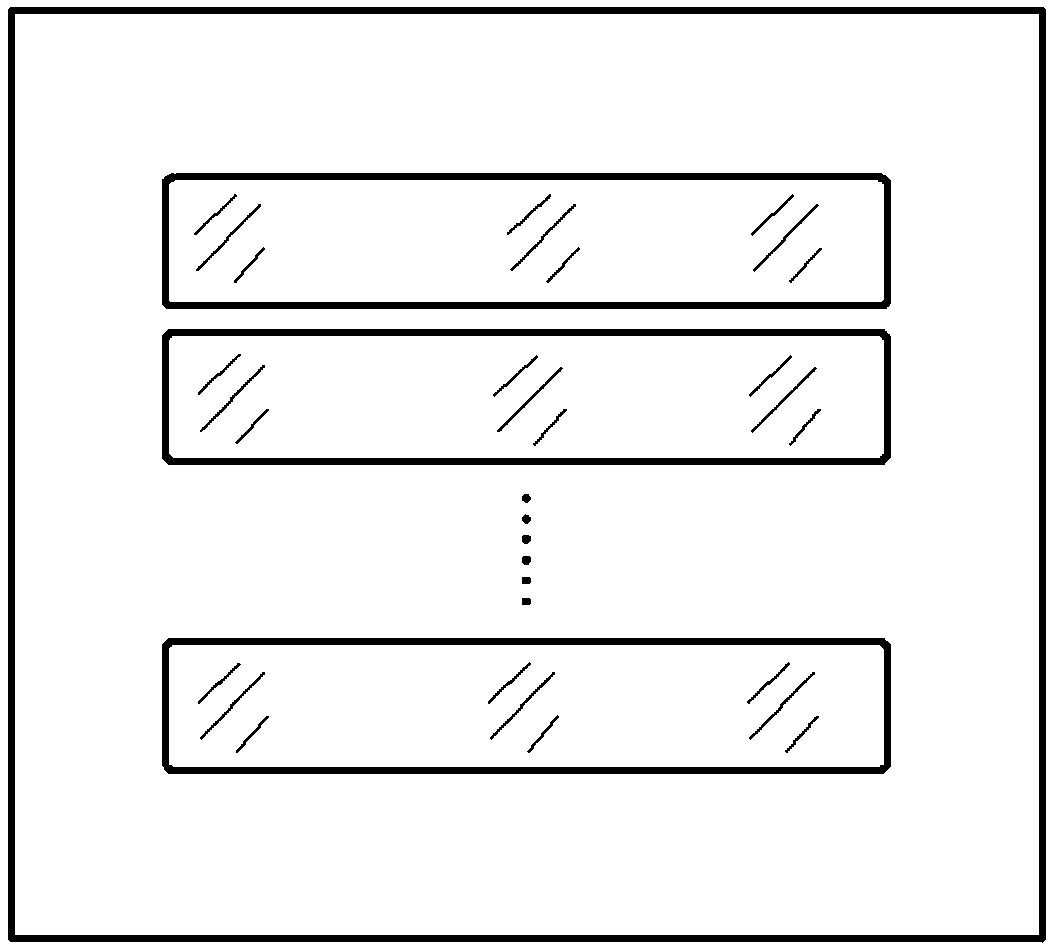

Narrow-slit spliced assembly of multi-waveband filters applied at low temperature

The invention discloses a narrow-slit spliced assembly of multi-waveband filters applied at a low temperature. The narrow-slit spliced assembly comprises a support plate, an installation limiting plate, the multi-waveband filters and an upper cover plate, wherein a plurality of light through holes are formed on the support plate and the upper cover plate; a plurality of optical filter installation grooves are formed on the installation limiting plate. During installation, a plurality of filters at different wavebands can be put in the installation grooves of the installation limiting plate in one time, thereby realizing precise assembly of the filters by using limiting barrier strips. In such a structure, the support plate, the installation limiting plate and the upper cover plate are all made from low-expansion alloy materials, and need surface blackening treatment before assembly, and a glue used for assembly is a low temperature resistant glue. The assembly has a low requirement on preparation of the multi-waveband filters, is simple in structure, low in optical crosstalk among channels and high in structural reliability, and can realize one-time cementing assembly of the optical filter at each waveband with a small splicing slit of the filters and high assembly precision.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

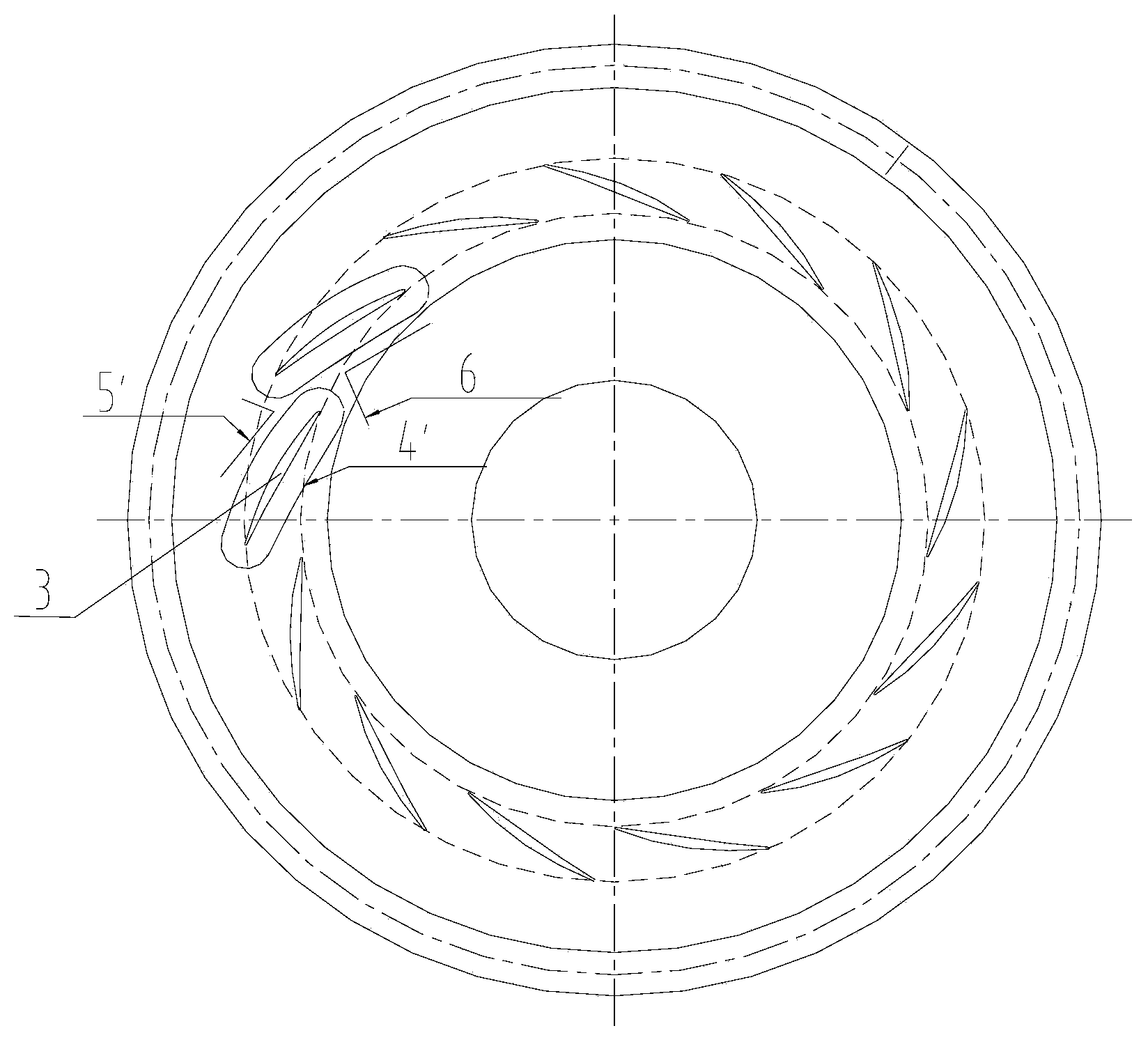

Milling method of diffuser

InactiveCN104227098AExtend your lifeLow costMilling equipment detailsEngineeringMechanical engineering

The invention relates to a milling method of a diffuser. The milling method comprises the following steps: a. with a route from an outlet blade-less section to an inlet blade-less section between two adjacent blades as a first milling route, roughly milling the blades in a layering manner according to the first milling route, and sequentially milling the outlet blade-less sections and the inlet blade-less sections between every two adjacent blades; and b. with a route at the periphery of the blades as a second milling route, milling the margins of the blades in one step according to the second milling route, thus sequentially milling all the blades. By adopting the milling method, the milling quality and milling efficiency of the diffuser can be improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

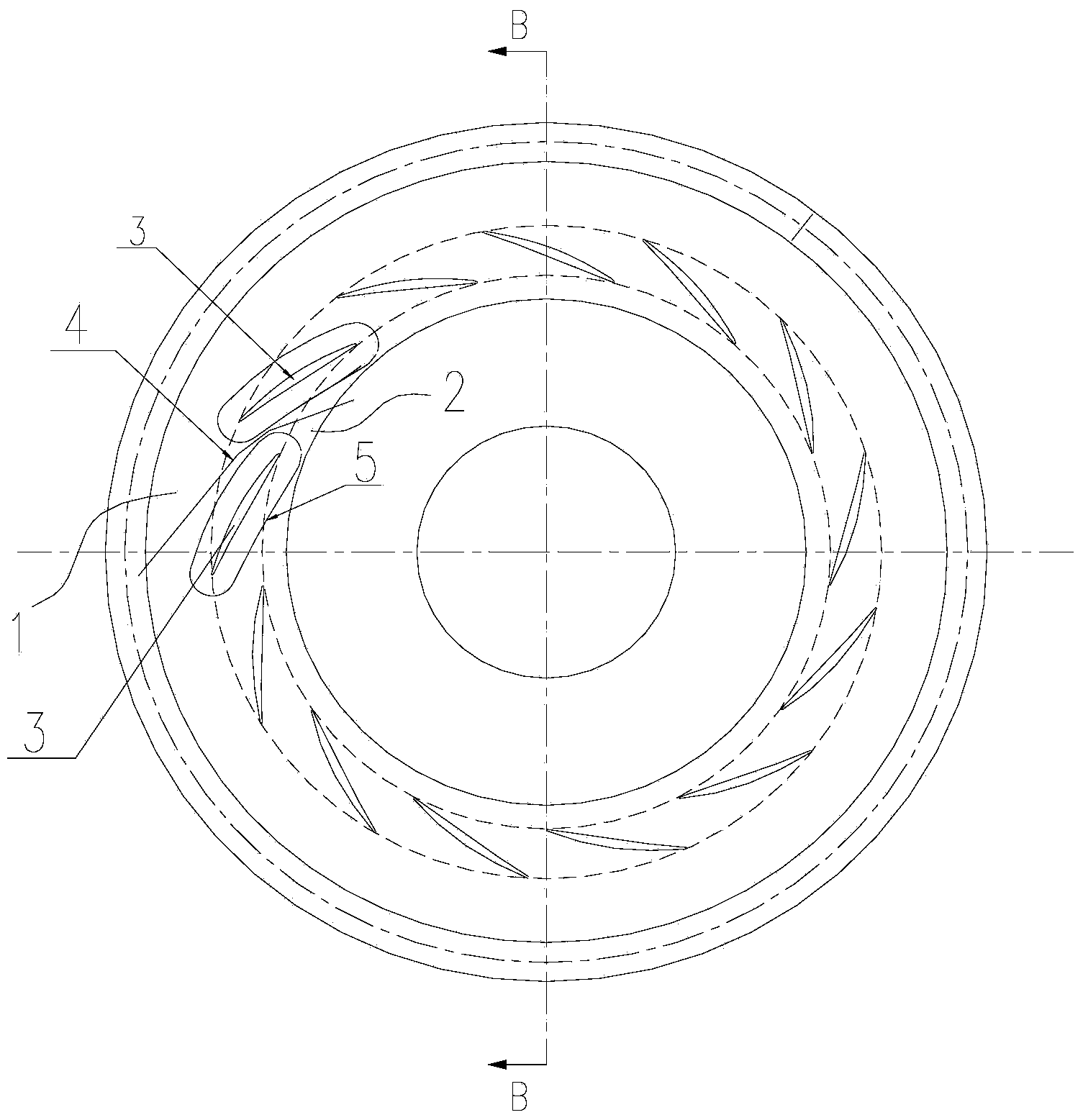

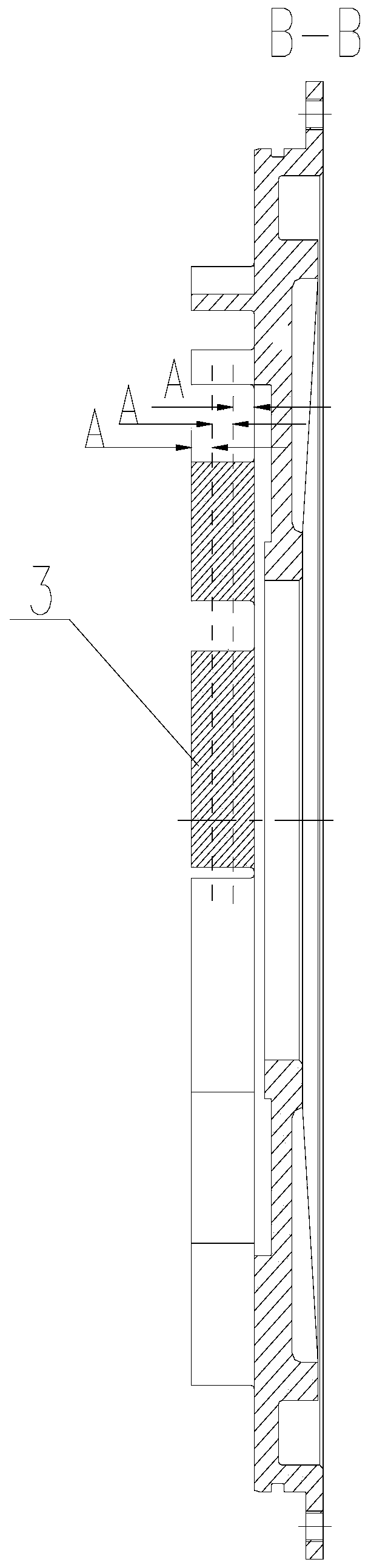

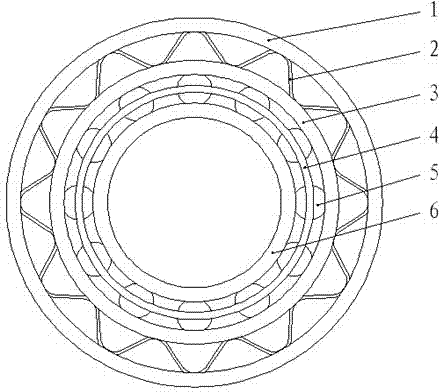

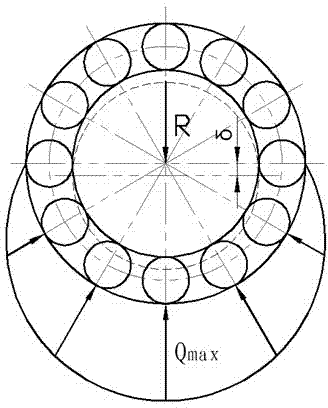

Elastic rolling bearing with wavy foil

InactiveCN104295600AReduced maximum contact stressReduce contact stressRolling contact bearingsEngineeringLubrication

The invention discloses an elastic rolling bearing with a circle of wavy foil. The rolling bearing comprises a second outer ring, an inner ring, rolling bodies and a retainer, wherein the circle of wavy foil is arranged between a groove in the outer cylindrical surface of the second outer ring and a groove in the inner cylindrical surface of a first outer ring; when the bearing is loaded, maximum contact stress between each rolling body and an inner roller path and between each rolling body and an outer roller path can be lowered by virtue of the deformation of the foil; the contact deformation is alleviated; the extrusion rupture of a lubricating oil film and the rapid friction increase are alleviated when a load is heavy; and thus the further temperature rise due to poor lubrication is avoided; when the bearing is heated so as to enable the parts to be subjected to heat expansion, the yield action can be caused by that the foil deforms, so that the space for expansion of other parts is provided; the deformation and internal stress of the two outer rings, the inner ring and the rolling bodies are reduced; moreover, the impact of the polygon effect of the rolling bodies on the axial system vibration also can be effectively alleviated by virtue of the deformation of the foil.

Owner:ZHEJIANG UNIV

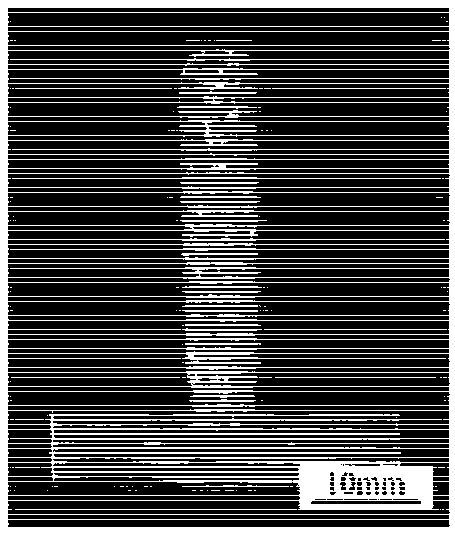

High-strength TA18 titanium alloy component preparing method based on electronic beam fuse wire additional material

ActiveCN109514067AWide variety of sourcesDirect formingElectron beam welding apparatusRapid scanHigh intensity

The invention discloses a high-strength TA18 titanium alloy component preparing method based on an electronic beam fuse wire additional material. The method comprises the following steps that the component transition area of a titanium alloy component is determined, a three-dimensional CAD solid model is established according to the titanium alloy component, and an implementable path is generatedaccording to the single-way deposition layer width W, the single-layer thickness L and the overlap rate gamma; electronic beam fuse wire additional material manufacturing is conducted according to theabove path, and single-layer titanium alloy wire deposition is finished; single-layer titanium alloy wire deposition is finished according to the above steps, and a small beam-current electronic beamis adopted for conducting rapid scanning in the direction perpendicular to the deposition direction; till all sheet layers are deposited, and component additional material manufacturing is finished;and the transition area part is cut away, and component annealing treatment is conducted. According to the method, the additional material raw material source is wide, finished TA2 and TC4 welding wires exist, and special making of TA18 welding wires is not needed. The method is high in production efficiency and low in production cost, direct complex component forming can be achieved, and the complex component manufacturing time is shortened.

Owner:NANJING UNIV OF SCI & TECH

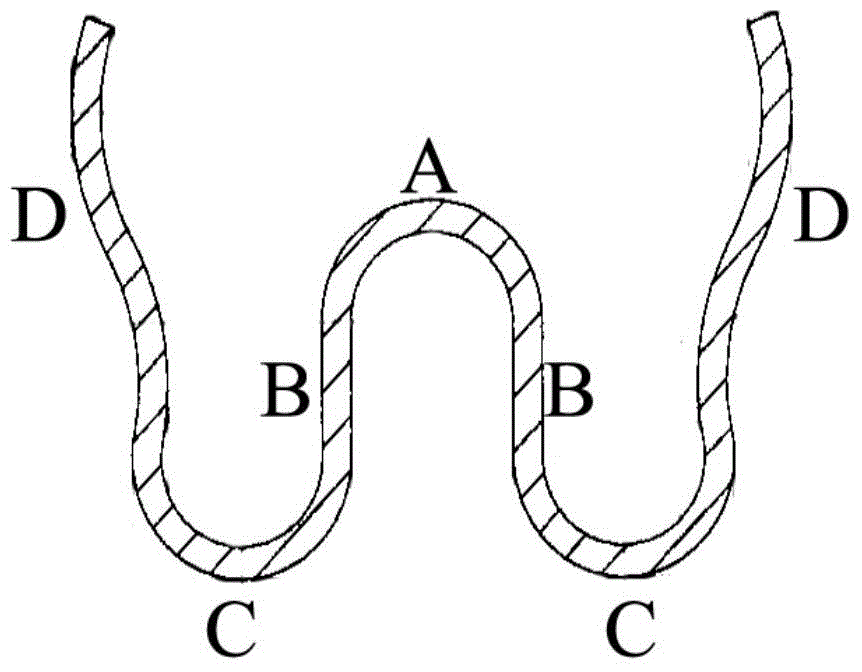

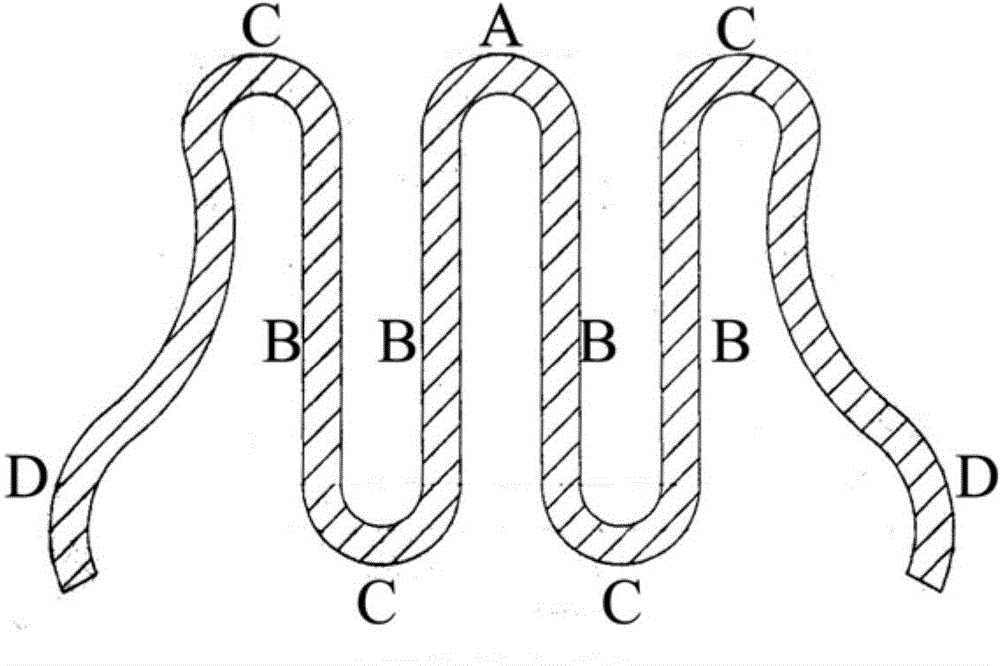

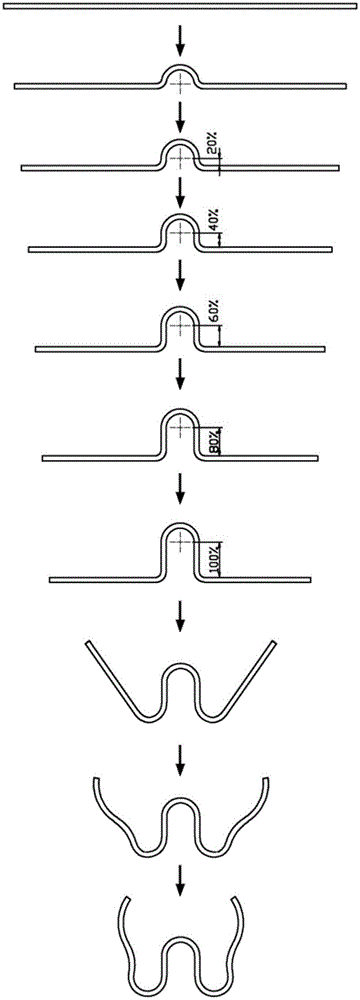

Forming technology for metal elastic sealing ring

The invention discloses a forming technology for a metal elastic sealing ring and belongs to the technical field of cold roll forming. The forming technology includes the following specific technology steps that a strip is cut to be in a corresponding width and a corresponding length according to the finished product size demand and welded to be in a ring shape; a strip ring is fixed, and spinning is conducted on the strip ring through a set of cold rolling rollers; the two sides of a circular arc are downwards extruded and deformed, a central bent circular arc (A) and a flat and straight connecting part (B) connected with the central bent circuit arc (A) are obtained, materials on the two sides of a section are bent upwards through a forming roller, and two elastic bent circular arcs (C) are formed; the obtained ring piece is arranged in a die roller, the two wings of the section are bent to form a left outwards-convex circular arc contact face (D) and a right outwards-convex circular arc contact face (D), and the ring piece is deformed after rotating by a circle; the left outwards-convex circular arc contact face (D) and the right outwards-convex circular arc contact face (D) are extruded from the two sides and are gathered in face-to-face mode and are deformed after rotating by a circle. The forming technology has the advantages that the surface quality of a product is good, the size deviation is small, and the variation of thicknesses of all parts of the section is small.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

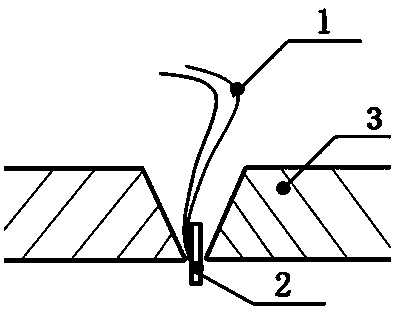

Repair welding method for penetration crack of sealing structure

ActiveCN109531043ASolve the problem that cannot be repaired by weldingStable Welding Repair WeldingArc welding apparatusNarrow rootsWelding deformation

The invention discloses a repair welding method for a penetration crack of a sealing structure. The repair welding method comprises the following steps that a) a crack is removed; b) welding groove processing is carried out; c) a welding base plate is modified; d) a base plate assembly is manufactured; e) the welding base plate is installed; f) a workpiece is preheated; and g) repair welding is carried out on the workpiece. According to the repair welding method for the penetration crack of the sealing structure, the effects that he welding base plate can smoothly penetrate through a welding groove of a narrow root gap and can be accurately placed on the inner wall of the structure, namely, the back part of the welding groove are achieved, and the method is also suitable for the bent and deformed cracks; and the process avoids the situation that process holes are additionally added in a closed structure, the base plate welding repair welding with stable quality is achieved, meanwhile,repair welding deformation and residual stress are greatly reduced, and the problem that a part of the sealing structure cannot be repaired through repair welding is solved.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

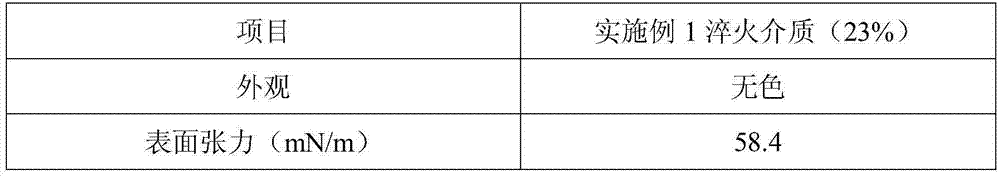

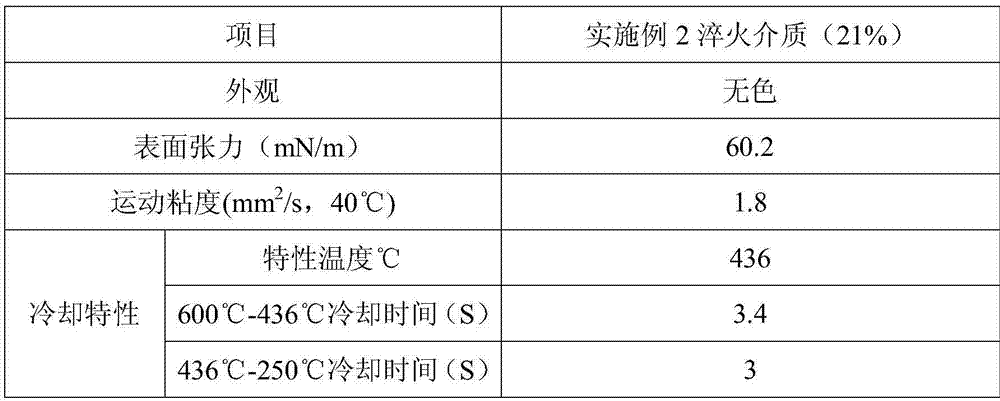

Water-soluble quenching medium for aluminum alloy precision part

InactiveCN104726656AReduce deformation stressReduce residual stressQuenching agentsWater solubleMechanical property

The invention discloses a water-soluble quenching medium for an aluminum alloy precision part and belongs to the metal heat treatment quenching agent technology. The water-soluble quenching medium comprises, by weight, 18-22% of polyalkylene glycol (with molecular weight of 8000), 0.6-1.0% of an antiseptic, a proper amount of an antifoaming agent and a settling agent, and the balance water. The water-soluble quenching medium has the advantages that 1, the problem that cold water as an aluminum alloy quenching medium has a fast cooling rate so that quenched residual stress is very large and the part can deform and crack is solved, and 2, it is solved that in hot water quenching, a cooling rate can be adjusted but quenching effects do not satisfy usage requirements. The water-soluble quenching medium can reduce an aluminum alloy initial cooling speed, has a strong cooling capability at a temperature of 440-250 DEG C, has good cooling characteristics and does not corrode a workpiece. The water-soluble quenching medium can reduce aluminum alloy part quenched residual stress, does not influence quenching effects and mechanical properties after aging and belongs to the field of metal heat treatment quenching agents.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

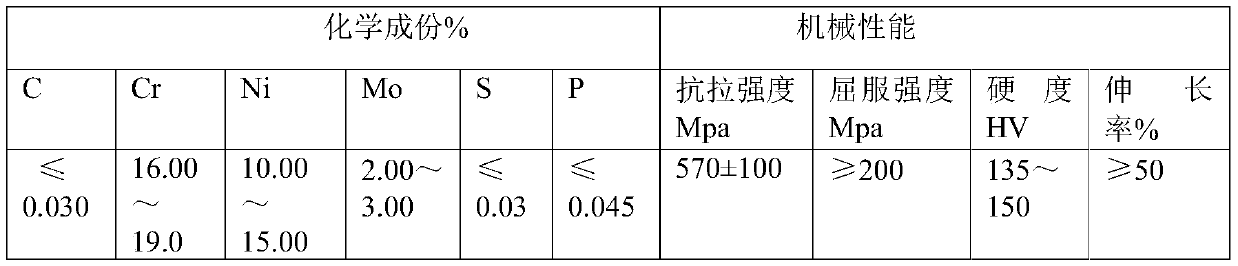

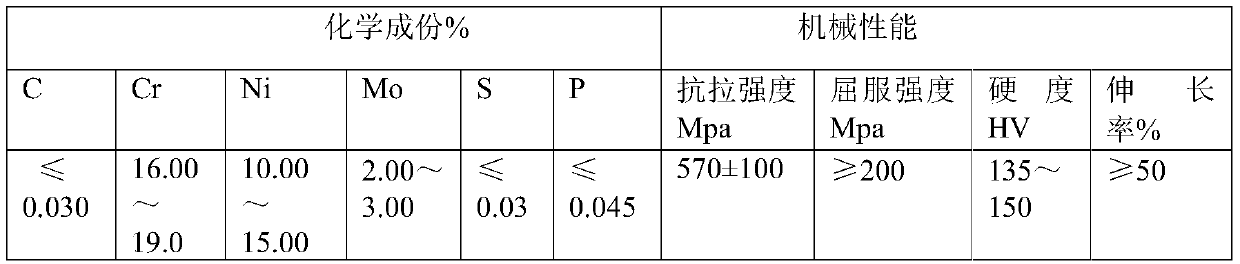

Forming method for high-precision metal bipolar plate required by fuel cell

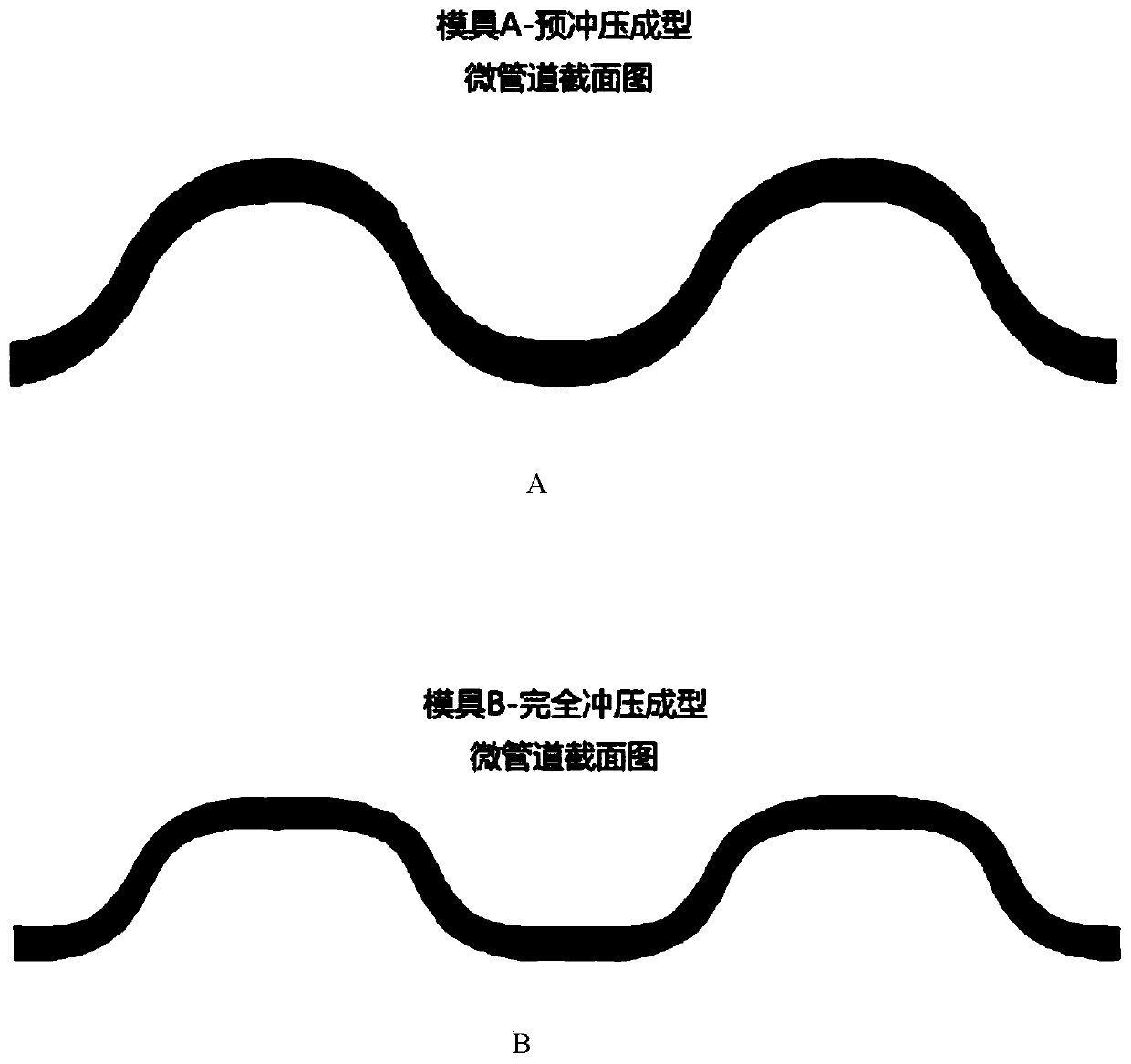

ActiveCN110534765AOptimizing the molding processReduce molding warpage and stress deformationShaping toolsFinal product manufactureEngineeringForming processes

The invention provides a forming method for a high-precision metal bipolar plate required by a fuel cell. The method specifically comprises the following steps of: selecting a bipolar plate raw material, designing and manufacturing a die 1 for bipolar plate punch forming and a die 2 for bipolar plate punch forming, carrying out pre-punch forming, performing complete punch forming, performing stamping and cutting, and performing welding to obtain the bipolar plate. The punch quality of the bipolar plate is improved through the first-step pre-forming and the second-step complete forming, the phenomena of buckling deformation, overlarge stress, insufficient groove depth, overlarge height difference between adjacent runners, high rejection rate, solder skips and the like in the forming processof the metal bipolar plate are avoided, and the fuel cell metal bipolar plate can be formed efficiently with high precision and low cost.

Owner:上海佑戈金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com