Welding method of large-thickness plate T-shaped joint welding

A welding method and technology for large and thick plates, which are applied in welding equipment, arc welding equipment, edge parts of workpieces, etc., can solve the problems of low assembly accuracy, aggravate the lack of fusion at the root, and reduce the reserved gap, so as to reduce the welding angle. Deformation and residual stress, reducing the amount of welding consumables, and reducing the effect of reserved gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

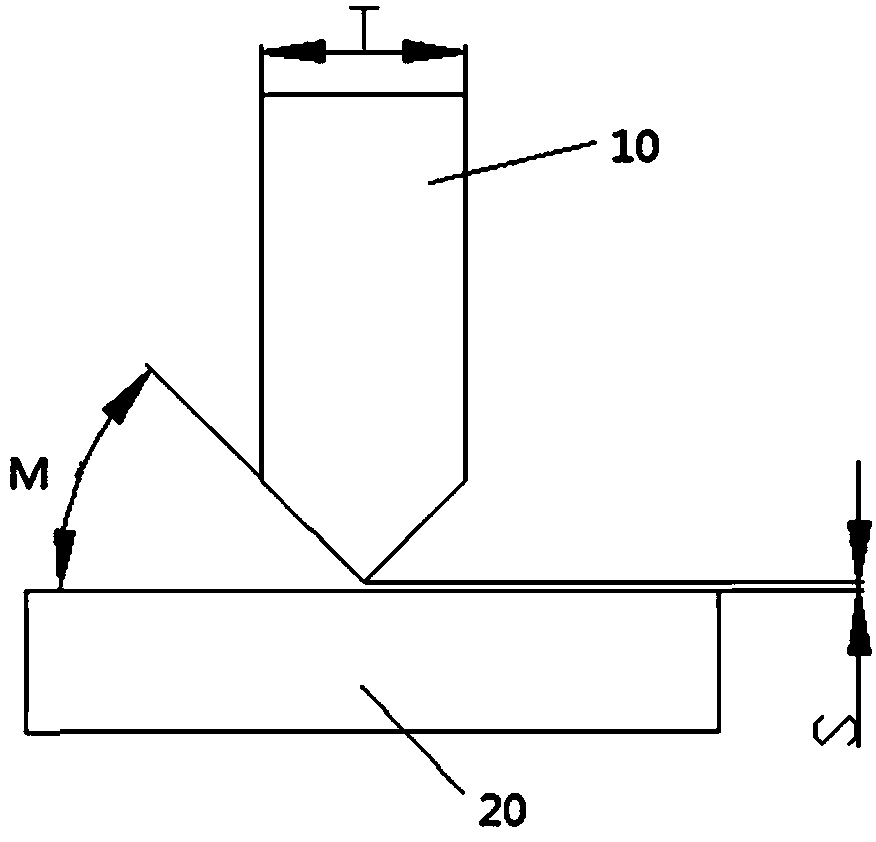

[0056] Taking the high-strength steel Q345B steel with a plate thickness of 50mm as an example, double-sided double-MAG welding with no clear root is realized. The thickness T of the vertical plate is 50mm, no gap is reserved at the root, 85% Ar+15% CO 2 Mixed gas protection, using JM-56, Φ1.2mm solid welding wire. It adopts K-shaped symmetrical 45° groove, asymmetrical asynchronous MAG welding is used for the bottoming, and no carbon planing is required on the back. The filling welding adopts symmetrical synchronous MAG welding.

[0057] 1. Preparation before welding

[0058] Before welding, process K-shaped symmetrical 45° grooves without blunt edges; complete the jigsaw installation of 50mm thick Q345BT joints (without leaving a gap at the root), spot welding; remove rust and oil stains on the grooves and within 20mm around them before welding . Preheat to 68°C before welding.

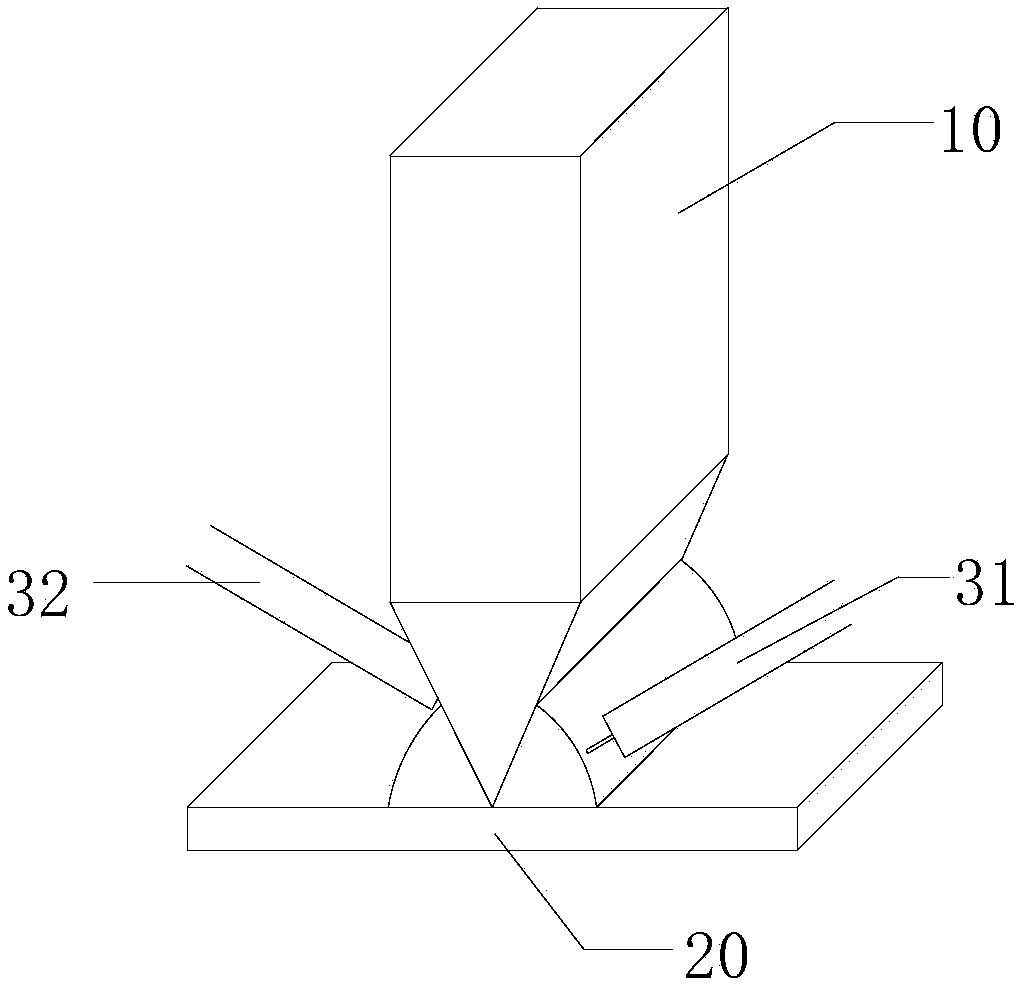

[0059] 2. Double-sided asynchronous bottoming MAG welding

[0060] The dry wire length of ...

Embodiment 2

[0068] The difference between this embodiment and Embodiment 1 lies in the welding parameters adopted by the front welding torch 31: the current is 290-340A, the voltage is 28-29V, and the welding speed is 6mm / sec. The welding parameters adopted by the rear welding torch 32 are: the current is 290-340A, the voltage is 28-29V, and the welding speed is 6mm / sec. Other processing conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com