Water-soluble quenching medium for aluminum alloy precision part

A quenching medium, precision parts technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problems of large quenching residual stress, inability to take into account mechanical properties, small residual stress, etc., to achieve strong cooling capacity, reduce deformation and residual stress Stress, the effect of reducing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Configure a water-soluble quenching medium with a concentration of 23% suitable for aluminum alloy precision parts with a thin thickness (<1.5mm). In terms of mass percentage, the amount of polyglycol (molecular weight 8000) is 22%, and the amount of preservative nitrite 0.85%, the amount of defoamer polyether modified silicon is 0.1%, the amount of sedimentation compound alkali is 500ppm, and the amount of tap water is 77%.

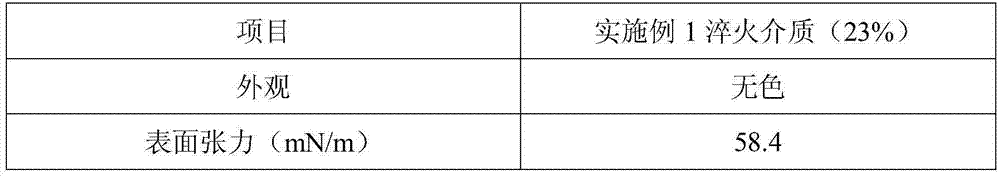

[0017] The performance and cooling characteristics of the configured 23% water-soluble quenching medium are shown in Table 1. Through the use of this quenching medium, the residual stress of aluminum alloy precision parts is significantly reduced,

[0018] And the mechanical properties meet the requirements of use, and there is no corrosion of the workpiece.

[0019] Table 1 Performance and cooling characteristics of the quenching medium in Example 1

[0020]

[0021]

Embodiment 2

[0023] Configure a water-soluble quenching medium with a concentration of 21% suitable for aluminum alloy precision parts with a medium thickness (1.5-4mm). In terms of mass percentage, the amount of polyglycol (molecular weight 8000) is 20%, and the amount of preservative nitrite 0.85%, the amount of defoamer polyether modified silicon is 0.1%, the amount of sedimentation compound alkali is 500ppm, and the amount of tap water is 79%.

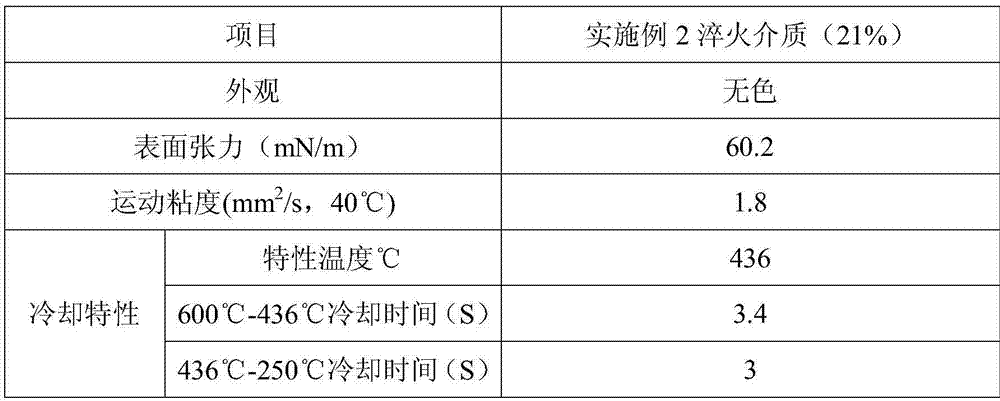

[0024] The performance and cooling characteristics of the configured 21% water-soluble quenching medium are shown in Table 2. Through the use of the quenching medium, the residual stress of aluminum alloy precision parts is significantly reduced, and the mechanical properties meet the requirements for use, and no workpiece corrosion occurs.

[0025] Table 2 Performance and cooling characteristics of the quenching medium in Example 2

[0026]

Embodiment 3

[0028] Configure a water-soluble quenching medium with a concentration of 19.15% suitable for aluminum alloy precision parts with a thicker thickness (>4mm). In terms of mass percentage, the amount of polyglycol (molecular weight 8000) is 18%, and the amount of preservative nitrite is 18%. 1.0%, the amount of defoamer polyether modified silicon is 0.1%, the amount of sedimentation agent compound alkali is 500ppm, and the amount of tap water is 80.85%.

[0029] The performance and cooling characteristics of the configured 19.15% water-soluble quenching medium are shown in Table 3. Through the use of the quenching medium, the residual stress of aluminum alloy precision parts is significantly reduced, and the mechanical properties meet the requirements for use, and no workpiece corrosion occurs.

[0030] Table 3 Performance and cooling characteristics of the quenching medium in Example 3

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com