Patents

Literature

68results about How to "Guaranteed quenching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

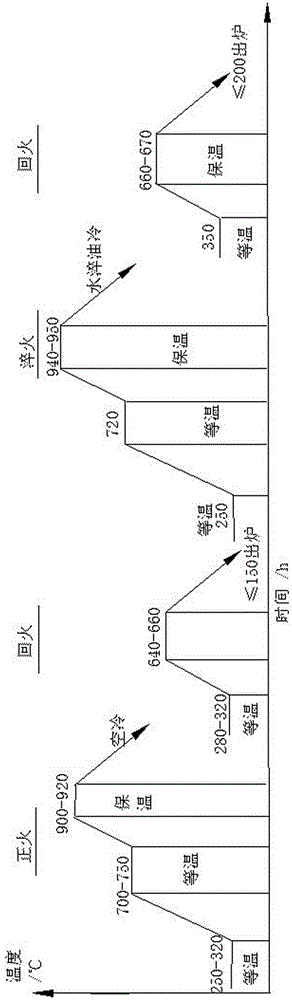

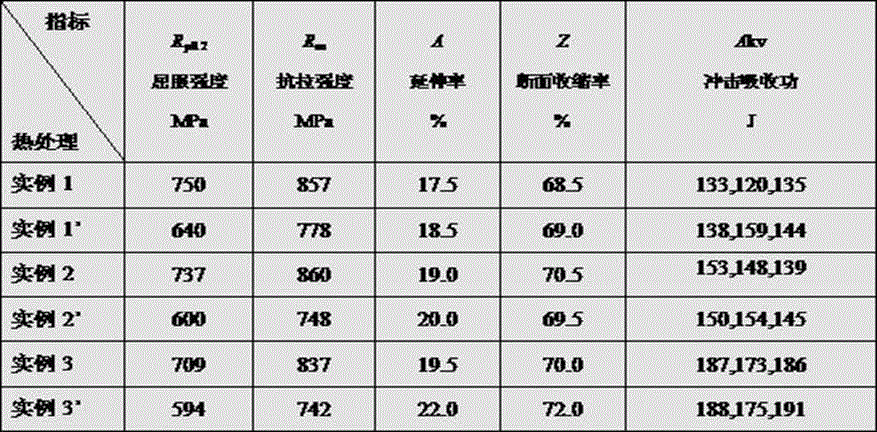

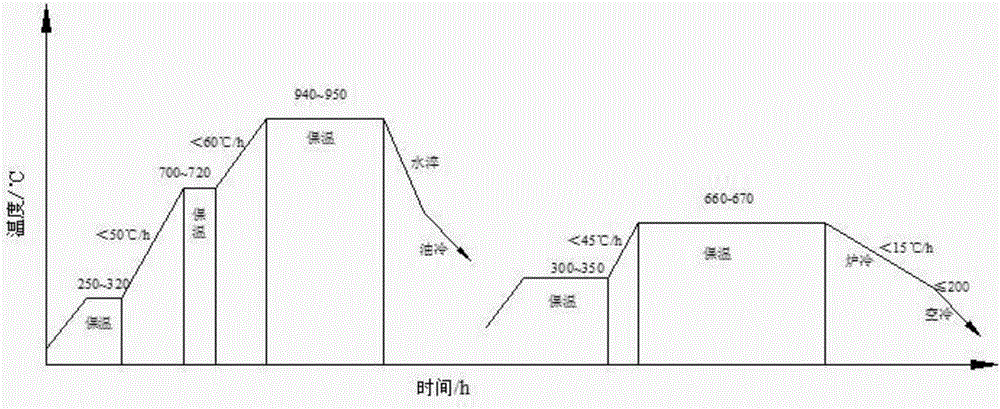

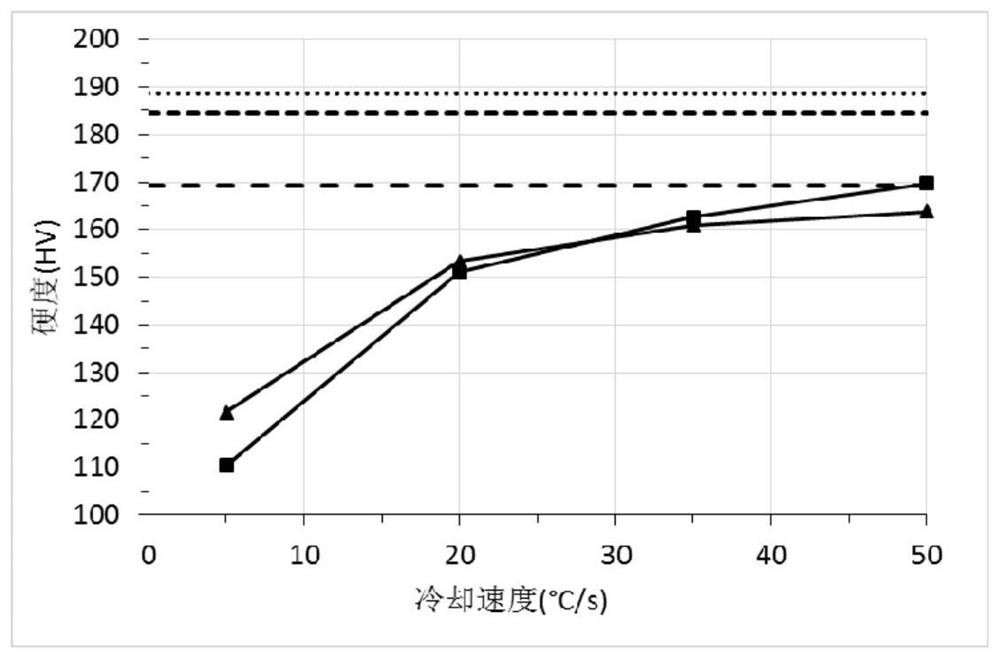

Heat treatment method for strength of 28CrMoNiV steel capable of improving industrial steam turbine rotor forge piece

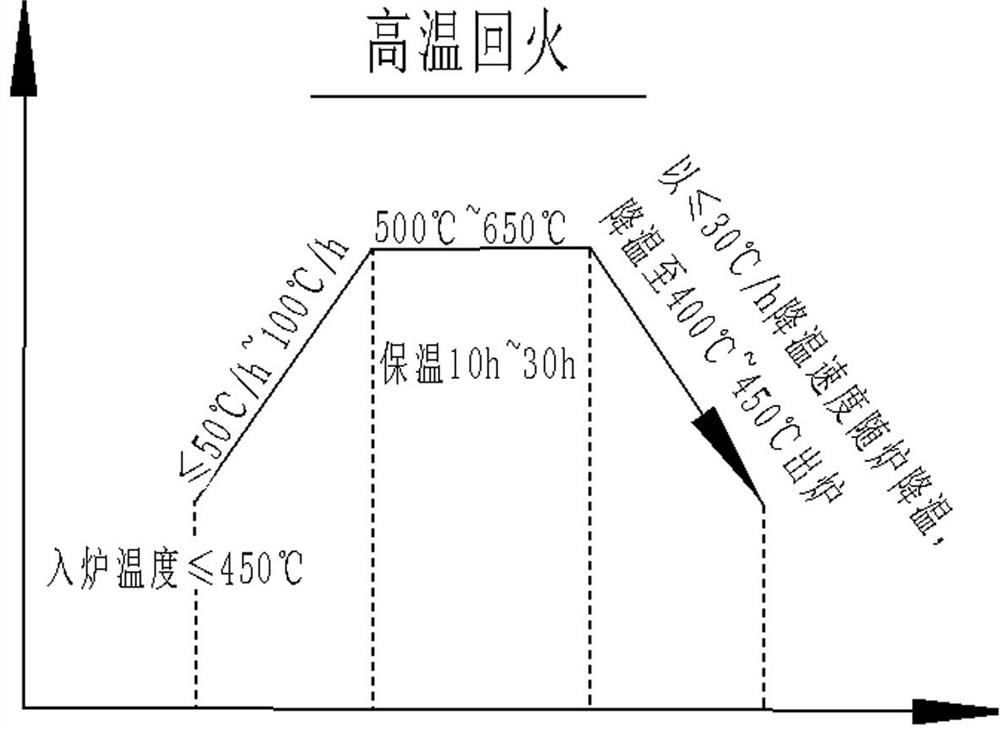

A heat treatment method for strength of 28CrMoNiV steel capable of improving an industrial steam turbine rotor forge piece. The technology comprises the steps that (1), a normalizing and tempering manner is adopted in a preparation heat treatment technology and is used for refining crystalline grains and improving a material internal tissue, residual stress is reduced, and the good foundation is laid for conditioning heat treatment; a ladder heating manner is adopted in heating of normalizing and quenching, and fast heating is avoided; in the rising process, if the heating speed is too high, residual stress obtained after quenching is overlapped, and the problems that the defect of the forge piece is expanded, and even, the forge piece is cracked are possibly caused; in a quenching cooling process, a water quenching oil cooling manner is adopted, the cooling speed of a workpiece in the high-temperature stage is improved, and meanwhile, the cooling speed of a Martensite transition zone is reduced; in the water cooling initial stage, the workpiece vertically moves in a front-and-back manner in water, the quenching effect of the workpiece is fully ensured, and meanwhile, the structural stress and heat stress are reduced; in the medium heat treatment, the tempering temperature is properly reduced, impact toughness is ensured, and meanwhile, the strength of the force piece is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

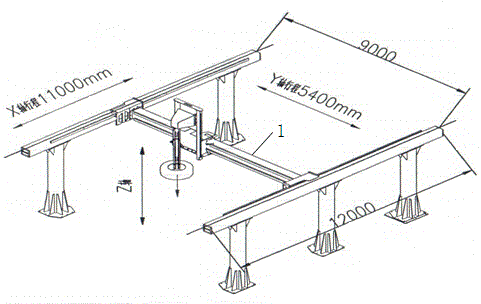

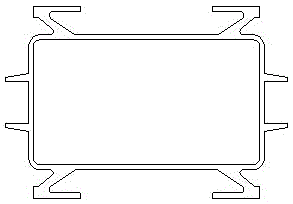

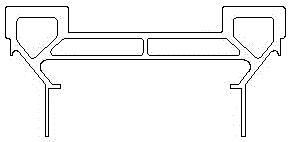

Manufacturing method of aluminum alloy mechanical arm track girder hollow profile

ActiveCN105039805AReduced risk of weakeningMeet the use requirementsUltimate tensile strengthAluminium alloy

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to a manufacturing method for producing an aluminum alloy mechanical arm track girder hollow profile through an aluminum alloy replacing rolled steel. The manufacturing method comprises the steps that firstly, the intensity and the capacity of resistance to deformation of a steel cross beam are evaluated; secondly, the aluminum alloy is selected; thirdly, the structure of the aluminum alloy mechanical arm track girder hollow profile is designed; fourthly, the movement track and deformation of the aluminum alloy mechanical arm track girder hollow profile in a stressed state are simulated through a computer; fifthly, a mould of the aluminum alloy mechanical arm track girder hollow profile is manufactured; sixthly, the aluminum alloy mechanical arm track girder hollow profile is extruded and quenched online; seventhly, the aluminum alloy mechanical arm track girder hollow profile is aged; eighthly, the aluminum alloy mechanical arm track girder hollow profile is sampled; ninthly, the aluminum alloy mechanical arm track girder hollow profile is riveted; and tenthly, the aluminum alloy mechanical arm track girder hollow profile is packaged and delivered, and the aluminum replaces the steel to produce the aluminum alloy mechanical arm track girder hollow profile.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

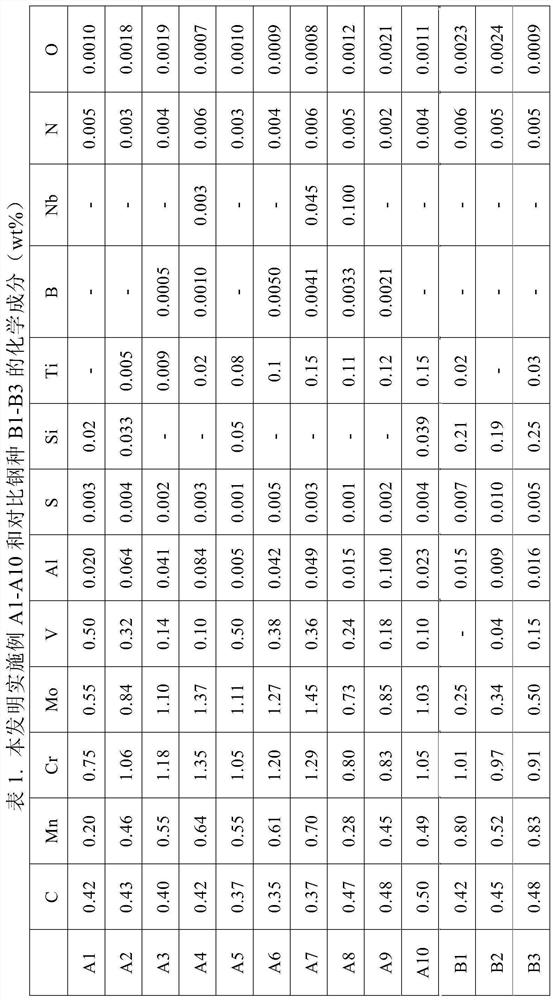

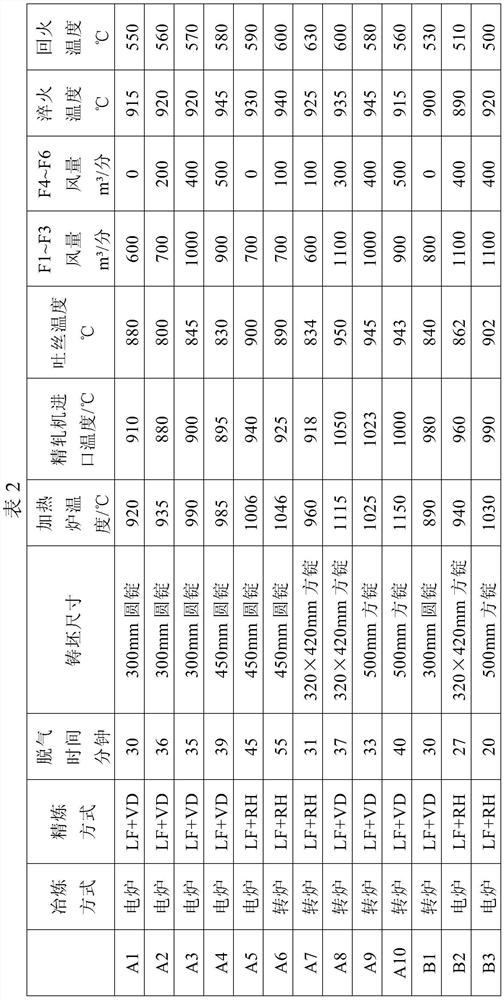

High-strength bolt steel with excellent delayed fracture resistance and preparation method thereof

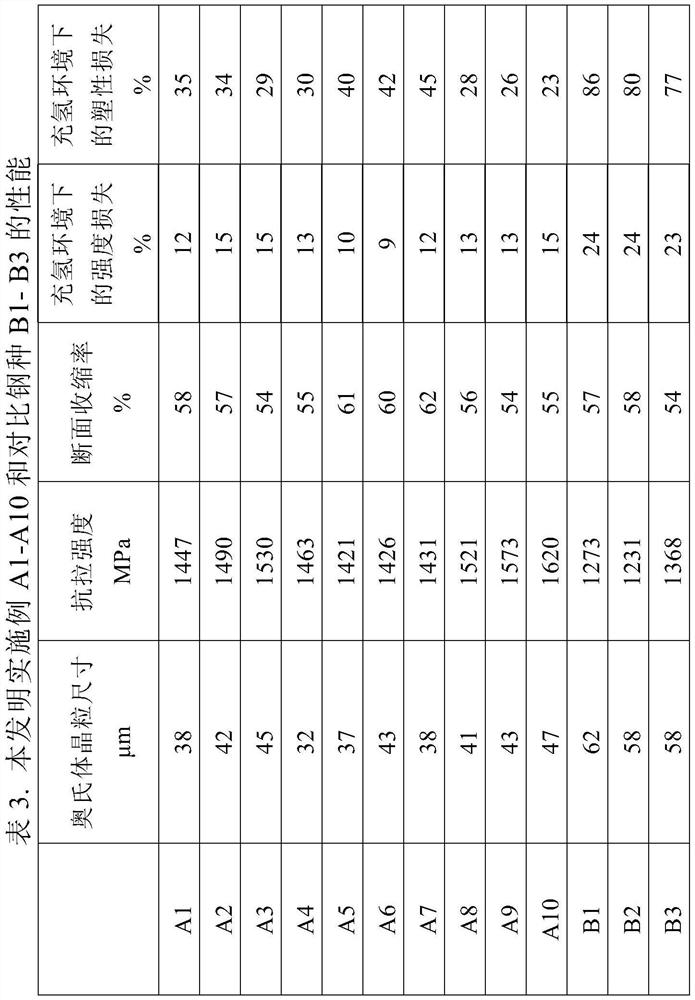

The invention provides high-strength bolt steel with excellent delayed fracture resistance and a preparation method thereof. The high-strength bolt steel comprises the following components in percentage by weight: 0.35-0.50% of carbon, 0.20-0.70% of manganese, 0.75-1.35% of chromium, 0.55-1.45% of molybdenum, 0.10-0.50% of vanadium, 0.005-0.10% of aluminum, 0-0.005% of sulfur, 0.02-0.05% of silicon, 0.005-0.15% of titanium, 0.0005-0.003% of oxygen, 0.001-0.007% of nitrogen, and the balance iron and other inevitable impurities; the content of titanium is not less than 3.5 times of the content of nitrogen; the sum of the contents of chromium, molybdenum and vanadium is not lower than 1.75%; and the sum of the contents of sulfur, oxygen and nitrogen is not higher than 0.01%. The high-strength bolt steel is high in purity and refined in grains, can be used for manufacturing high-strength bolts with tensile strength not lower than 1400MPa, has a section shrinkage rate not lower than 50%, is excellent in delayed fracture resistance, and can be applied to automobiles and mechanical parts.

Owner:BAOSHAN IRON & STEEL CO LTD

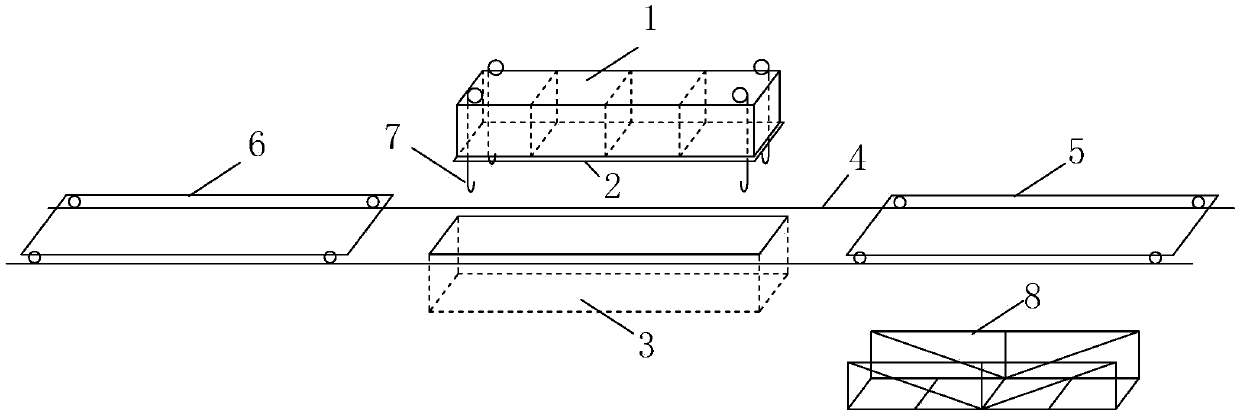

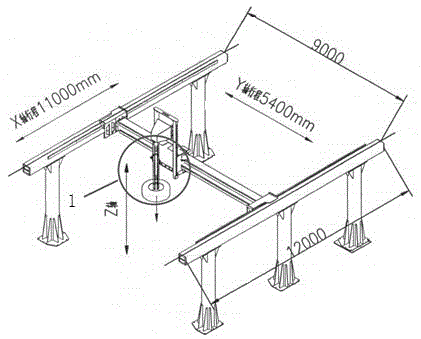

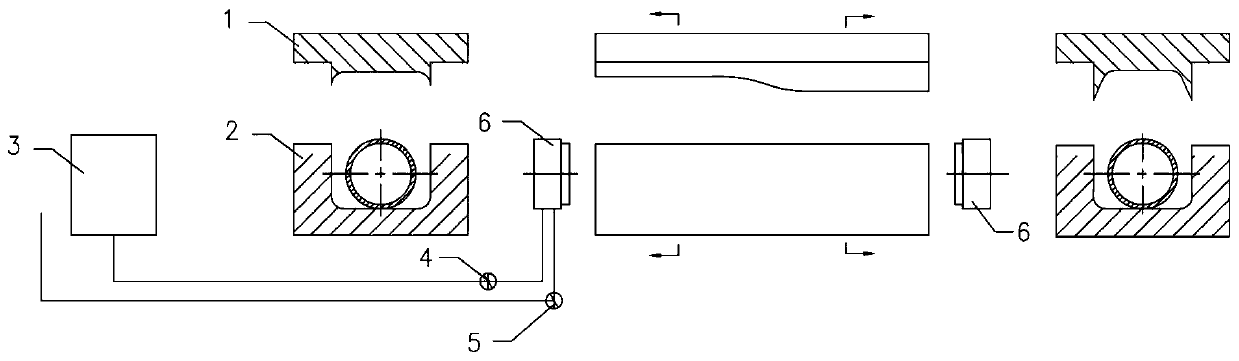

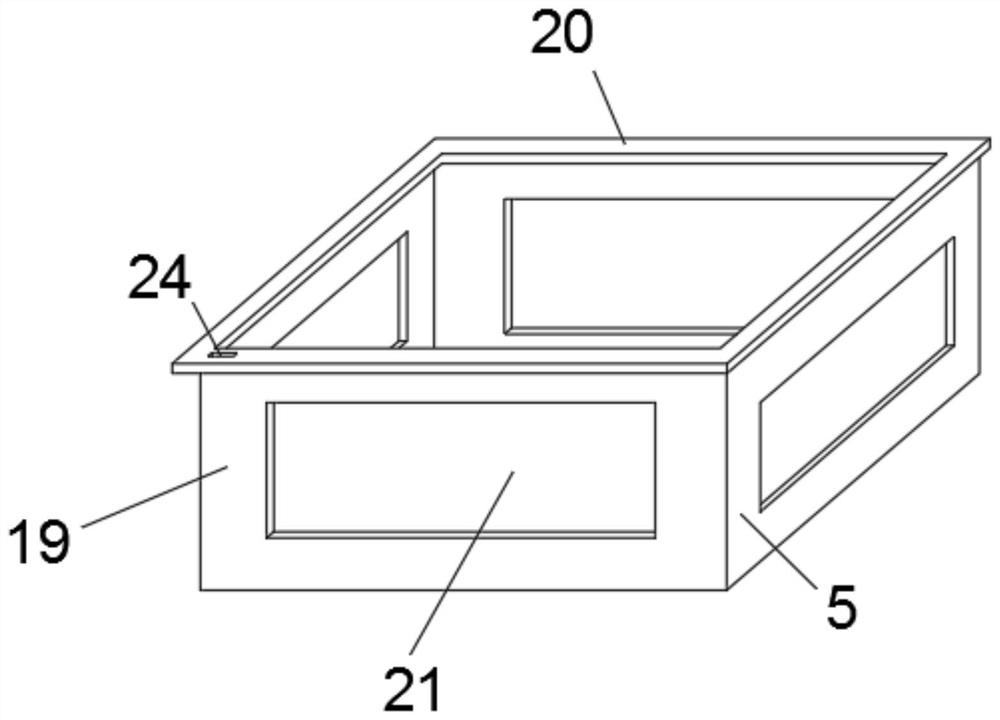

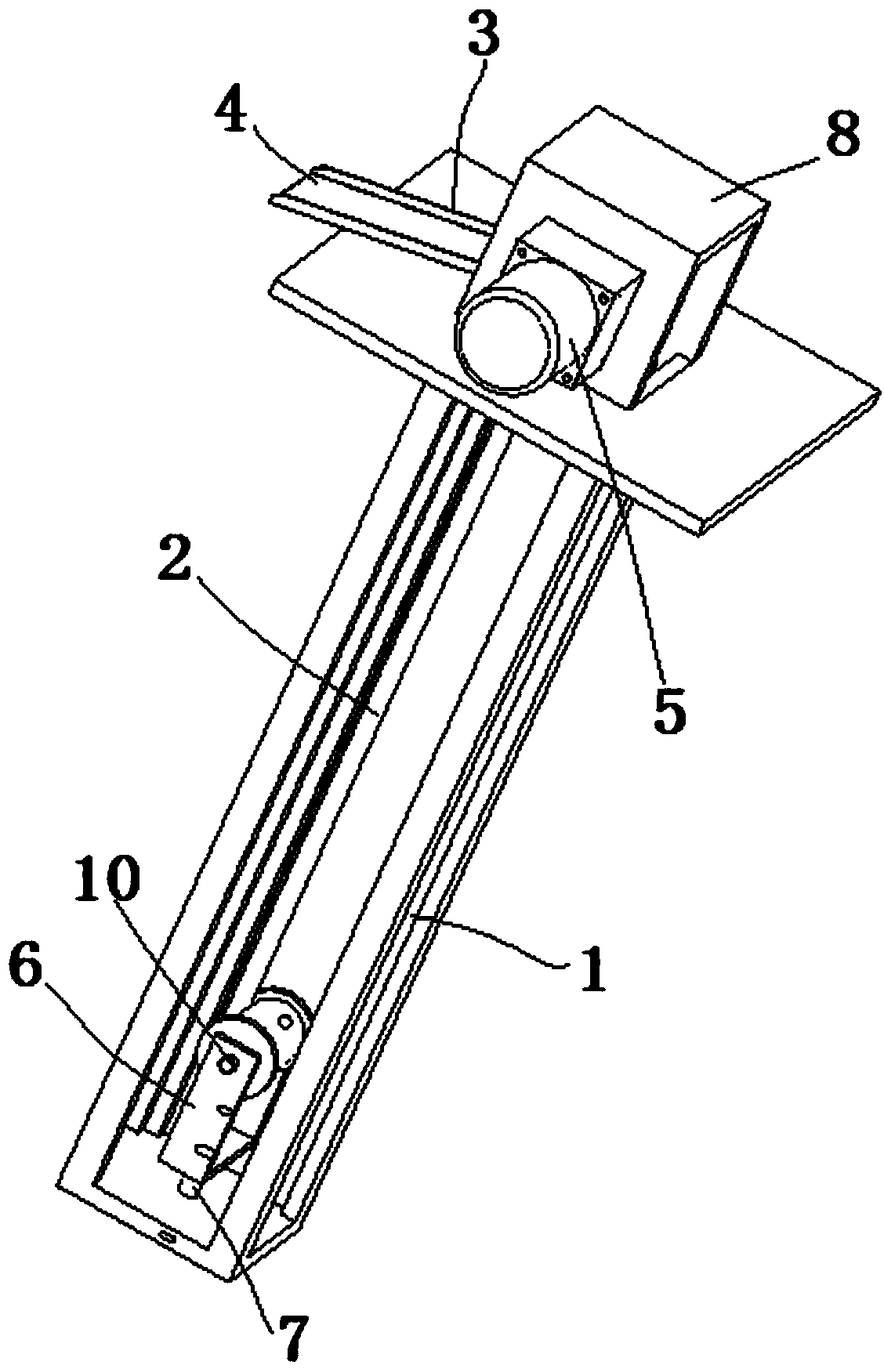

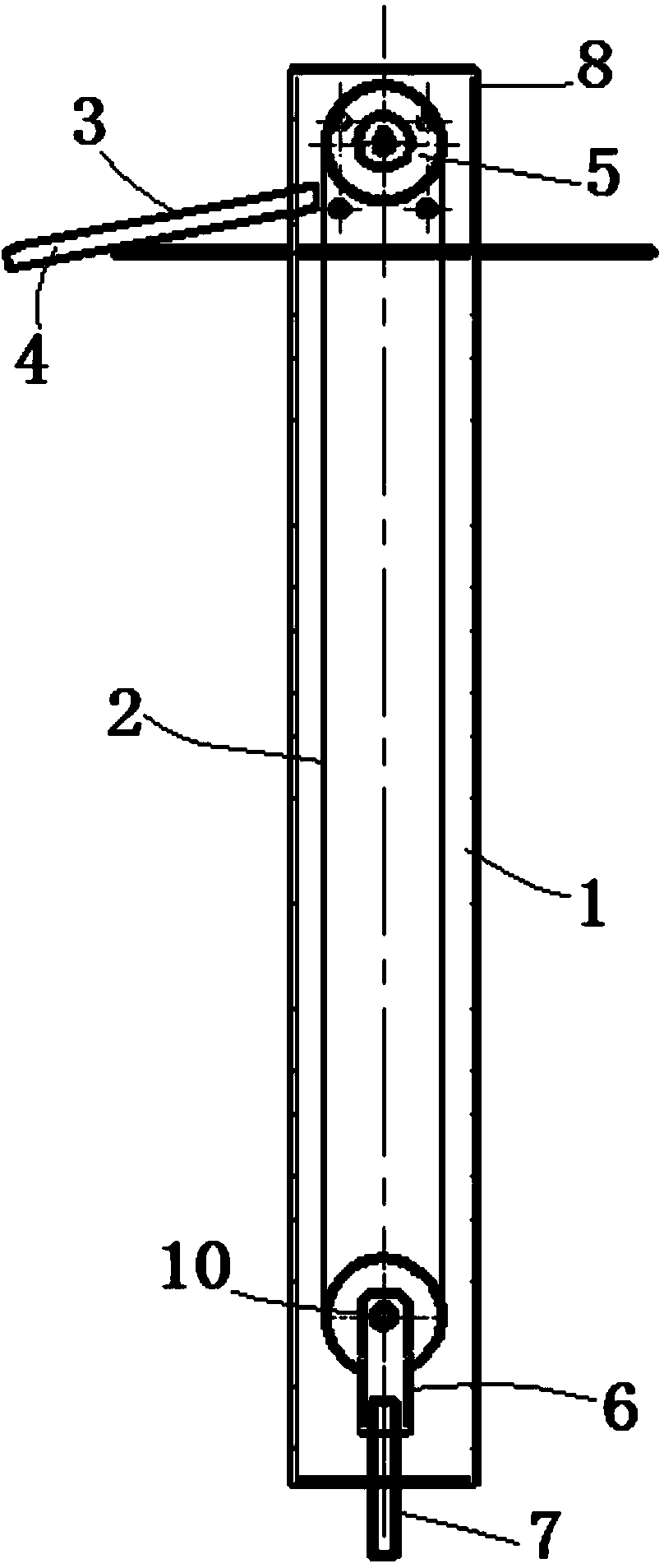

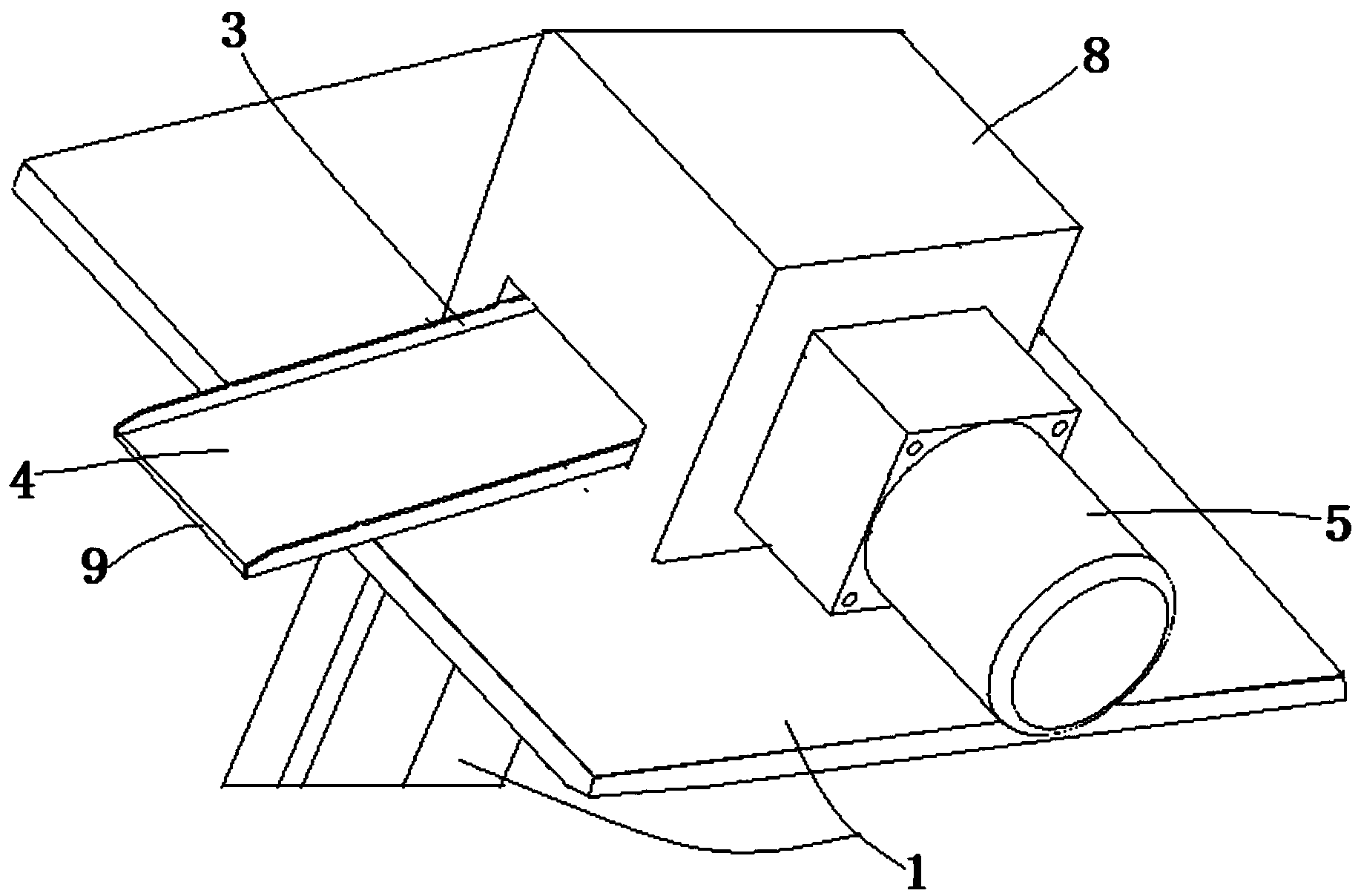

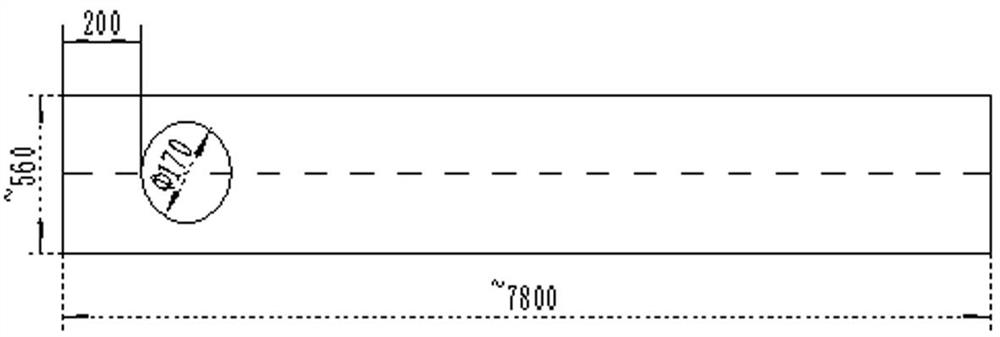

Thermal treatment device and thermal treatment technology of ultra-long aluminum extrusion

ActiveCN109536683AAchieving solution quenchingAchieve annealingFurnace typesHeat treatment furnacesMaterials processingHeating furnace

The invention discloses a thermal treatment device and a thermal treatment technology of an ultra-long aluminum extrusion, and belongs to the technical field of material processing. The thermal treatment device comprises a heating furnace, a quenching water well, a feeding and discharge rail, a feeding trolley, a discharge trolley, a lifting device and a material basket, wherein a furnace body isan ultra-long horizontal furnace composed of a plurality of regions of which the temperature is independently controlled; and a product is horizontally stacked in the material basket, and enters the furnace body or the quenching water well through the feeding trolley, the discharge trolley and the lifting device to be subjected to thermal treatment. According to the thermal treatment device and the thermal treatment technology, horizontal furnace horizontal heating and inclined descend soaking quenching technologies are adopted to replace traditional vertical quenching and roller hearth type quenching technologies, the quenching cooling speed is high and uniform, quenching deformation of the product is low, surface quality is good, and performance is uniform; solid-solution quenching, annealing and ageing functions can be achieved, production scheduling is flexible, length of a biggest product of thermal treatment is large, charge batch is large, production efficiency and heat utilization rate are high, and operation is safe and reliable; and besides, deep well, heat-resistant roller, spraying devices, and the like are not required, basic requirements on equipment are low, and investment is low.

Owner:广西百矿冶金技术研究有限公司

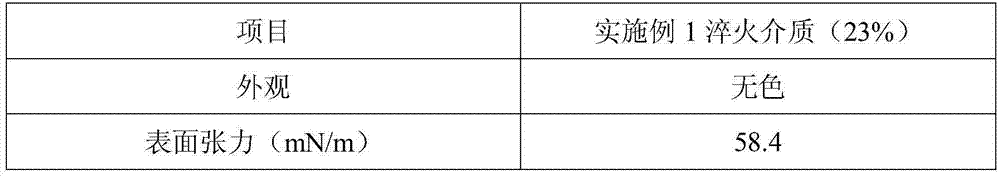

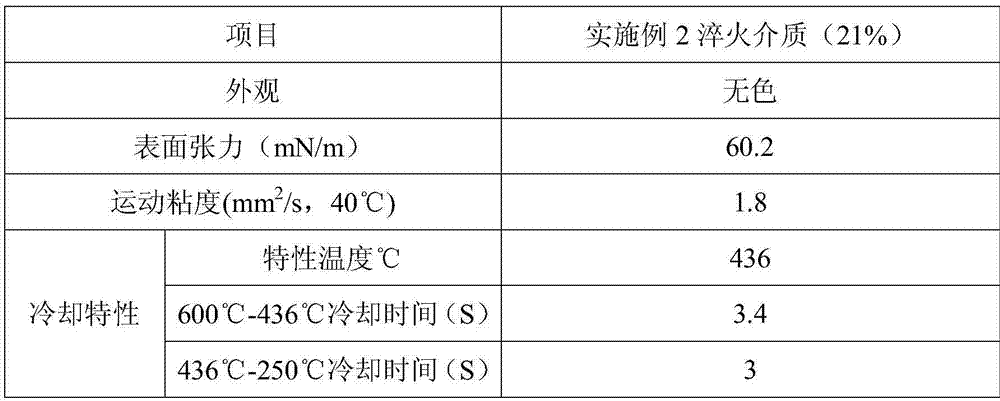

Water-soluble quenching medium for aluminum alloy precision part

InactiveCN104726656AReduce deformation stressReduce residual stressQuenching agentsWater solubleMechanical property

The invention discloses a water-soluble quenching medium for an aluminum alloy precision part and belongs to the metal heat treatment quenching agent technology. The water-soluble quenching medium comprises, by weight, 18-22% of polyalkylene glycol (with molecular weight of 8000), 0.6-1.0% of an antiseptic, a proper amount of an antifoaming agent and a settling agent, and the balance water. The water-soluble quenching medium has the advantages that 1, the problem that cold water as an aluminum alloy quenching medium has a fast cooling rate so that quenched residual stress is very large and the part can deform and crack is solved, and 2, it is solved that in hot water quenching, a cooling rate can be adjusted but quenching effects do not satisfy usage requirements. The water-soluble quenching medium can reduce an aluminum alloy initial cooling speed, has a strong cooling capability at a temperature of 440-250 DEG C, has good cooling characteristics and does not corrode a workpiece. The water-soluble quenching medium can reduce aluminum alloy part quenched residual stress, does not influence quenching effects and mechanical properties after aging and belongs to the field of metal heat treatment quenching agents.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Press roll for pressing secondary battery electrode and producing process thereof

InactiveCN102181799AHigh hardnessImprove wear resistanceElectrode manufacturing processesIncreasing energy efficiencyTungstenLanthanum

The invention relates to a press roll for pressing a secondary battery electrode and a producing process thereof, belonging to the technical field of mechanical manufacture and electrochemical power sources. The producing process of the press roll used for pressing the secondary battery electrode comprises the following steps of: performing a molding process on raw materials, namely rare earth alloy containing carbon, molybdenum, chromium, nickel, tungsten, silicon, manganese and lanthanum series and ferrous electroslag remelting steel ingots; heating and then forging and pressing to form a press roll blank by using a hydraulic press; performing balling heat treatment, performing furnace cooling, then raising the temperature, performing homeothermy to constant temperature; and finally performing postprocessing. In the invention, an ultradeep quenching treatment method is adopted, the treatment depth ranges from 10mm to 15mm below the surface of the press roll, thereby the hardness of the press roll is increased, the strength is improved, and high-precision electrode pressing is ensured; and the press roll produced by using the method has the advantages of high hardness, high strength and good wear resistance, can be widely applied to various precision presses, saves use cost, improves product quality and increases production efficiency.

Owner:珠海市光环自动化科技有限公司

Manufacturing method for aluminum alloy-made robot arm hollow profile

The invention belong to the technical field of aluminum alloy profile and concretely relates to a manufacturing method for slide rail hollow profile for robot arm movements with aluminum alloy replacing steel. The manufacturing method comprises first, analyzing steel connection member motion and stress conditions, second, selecting aluminum-alloy material, third, designing hollow profile, fourth, simulating aluminum profile connection member motion and stress conditions by a computer to determine whether the hollow profile meets demands, fifth, selecting an extruding machine and designing an aluminum alloy hollow profile connection member via a die, sixth, casting aluminum alloy ingot, seventh, extruding aluminum alloy hollow profile connection member and conducting online quenching, eighth, conducting aluminum alloy hollow profile connection member tension extension and aging treatment, ninth, sampling and checking the aluminum alloy hollow profile connection member, and tenth, hardening and packing the aluminum alloy hollow profile. Motion and stress conditions of the aluminum alloy hollow profile connection member can be simulated by the computer; strength and plasticity meet use requirements; and hollow profile can be manufactured in batches by the use of the method.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

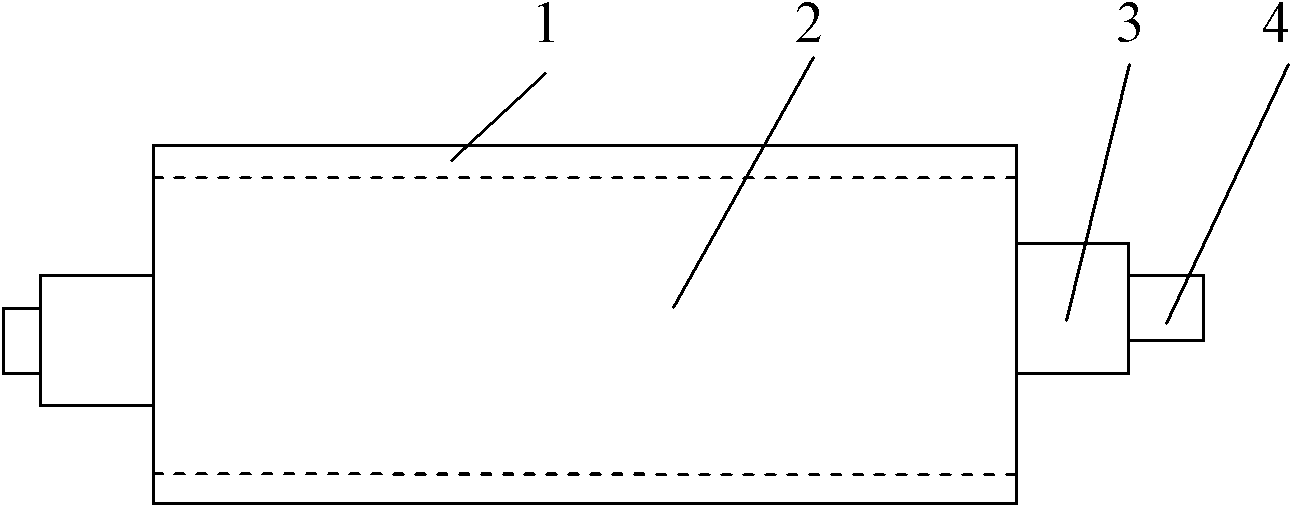

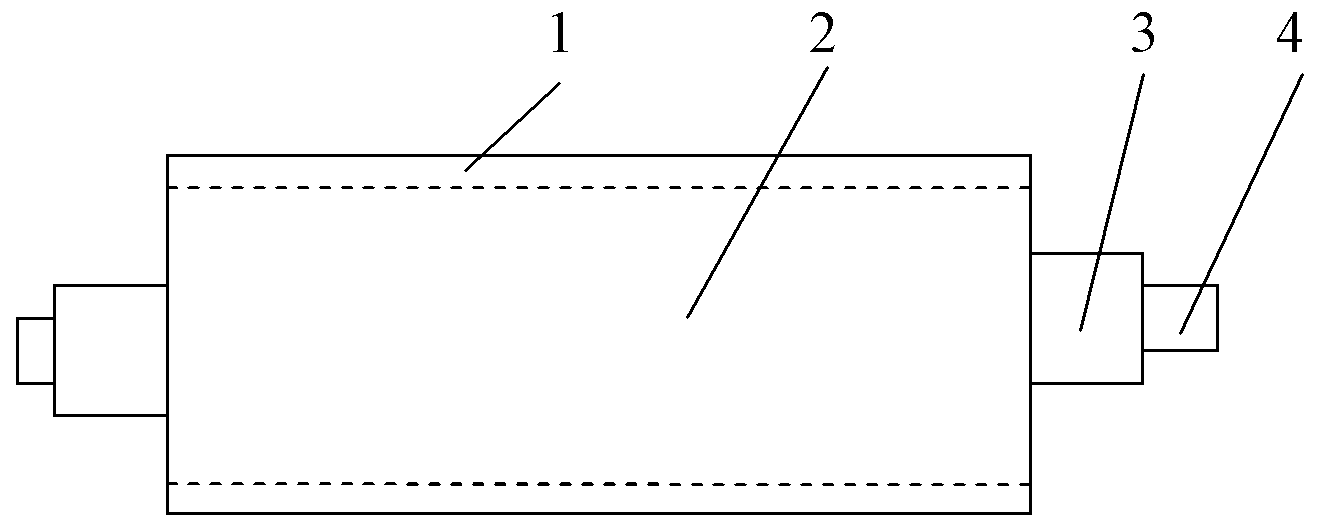

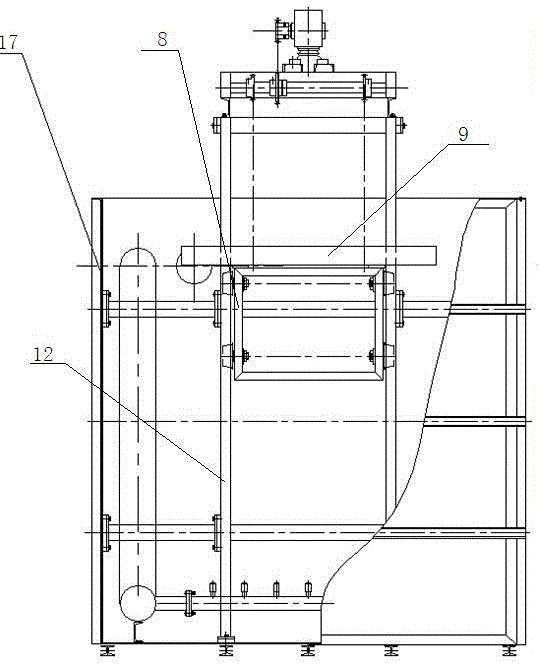

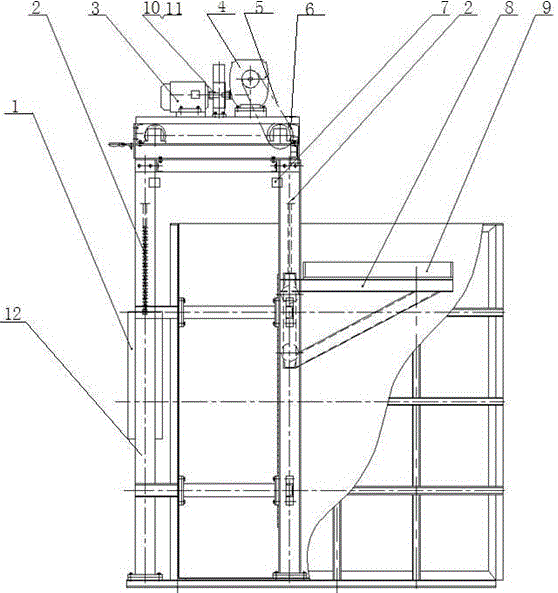

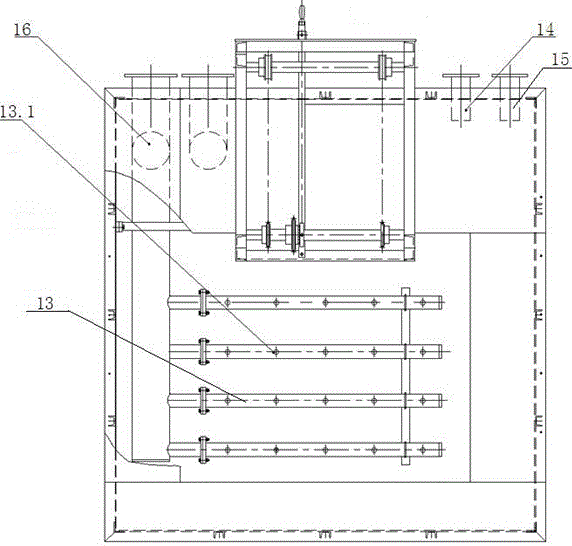

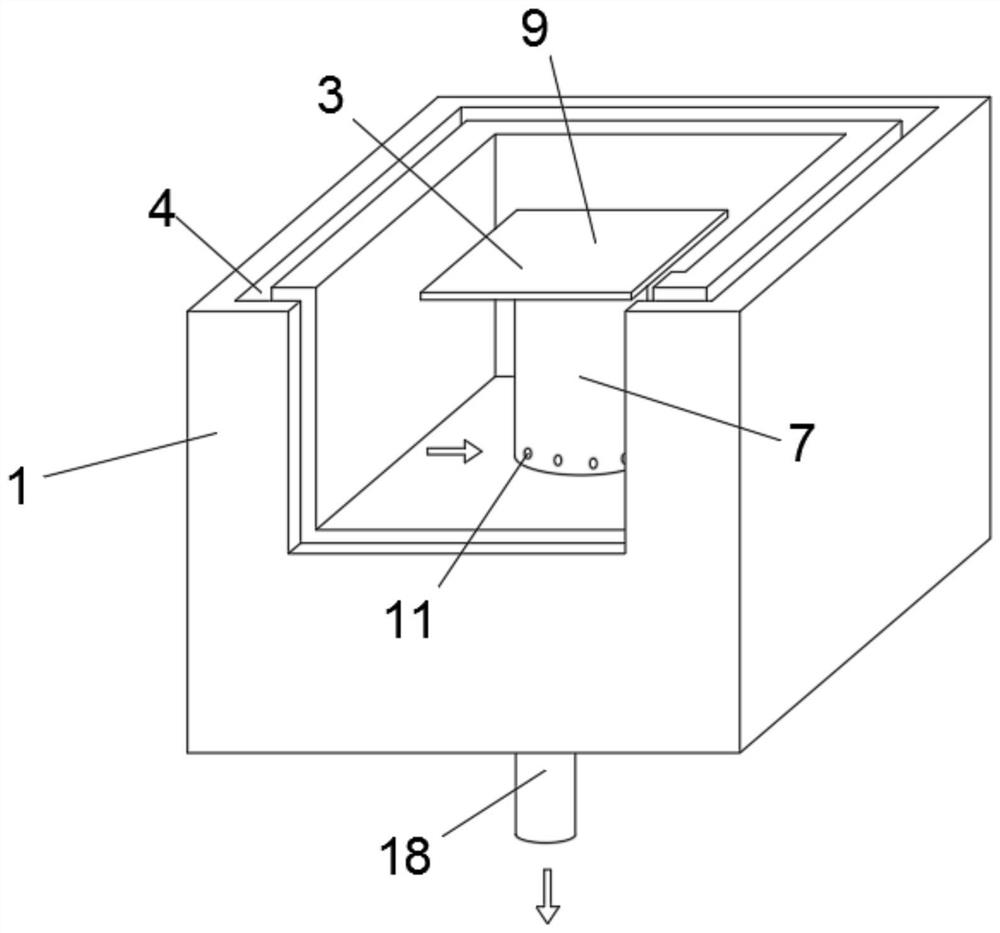

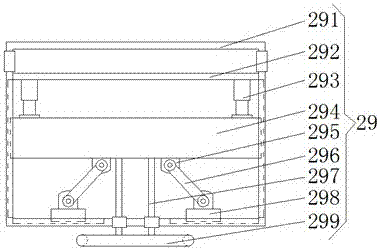

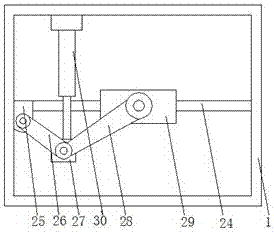

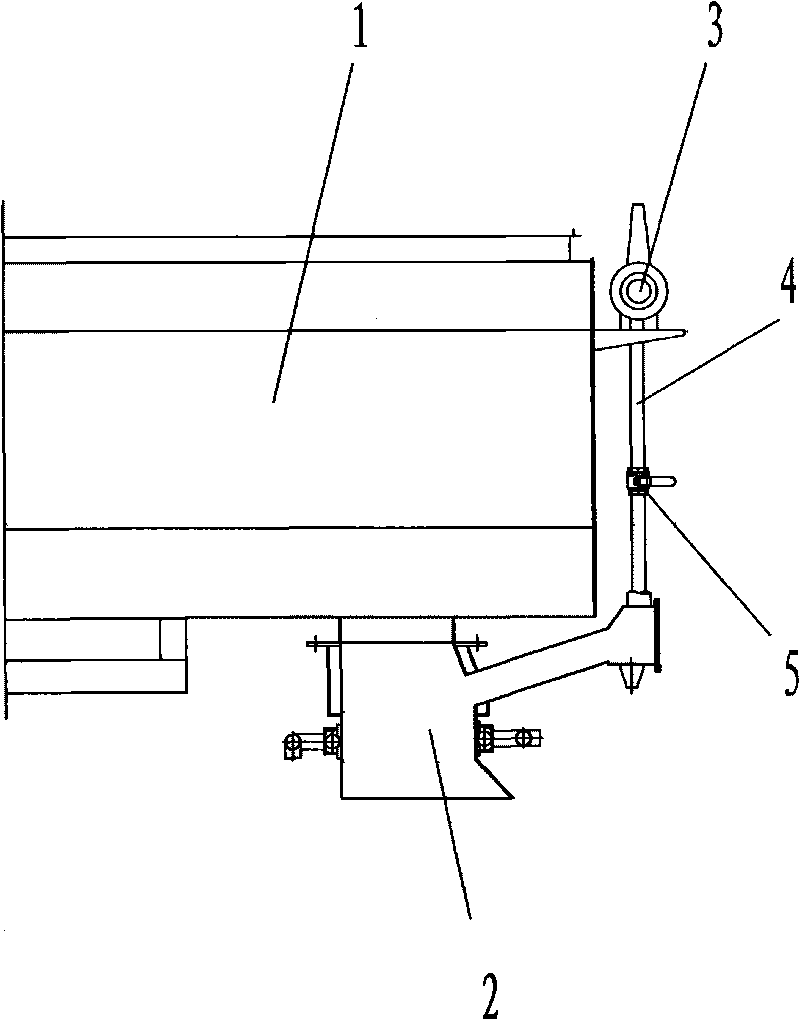

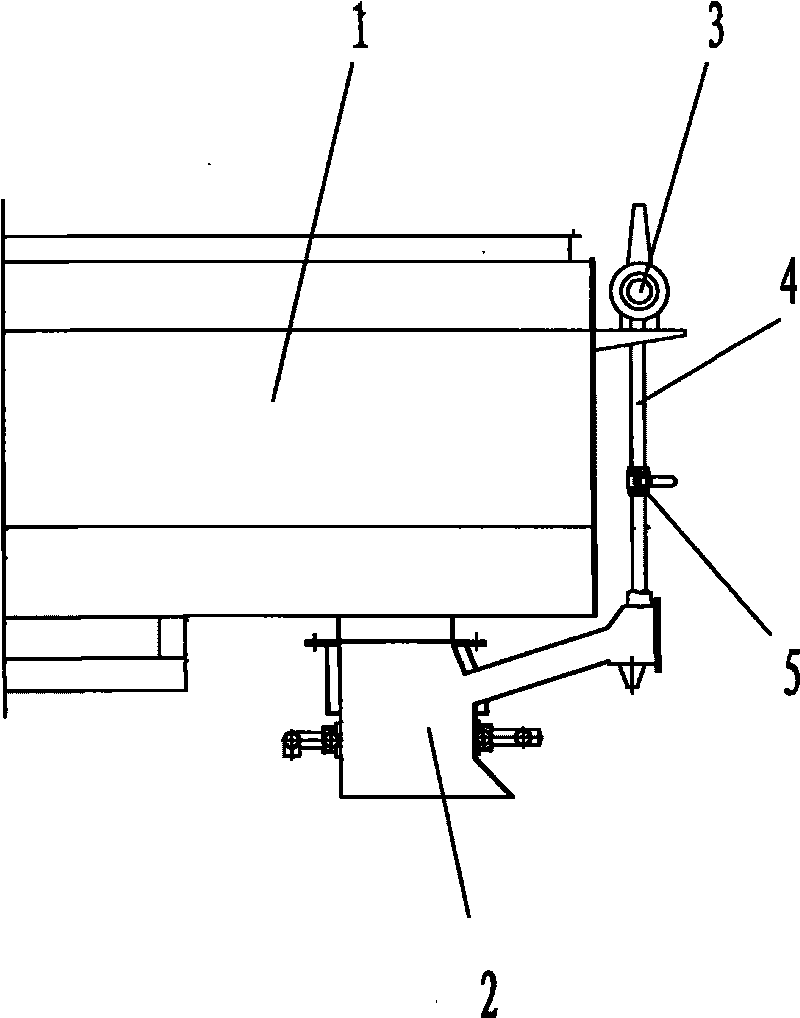

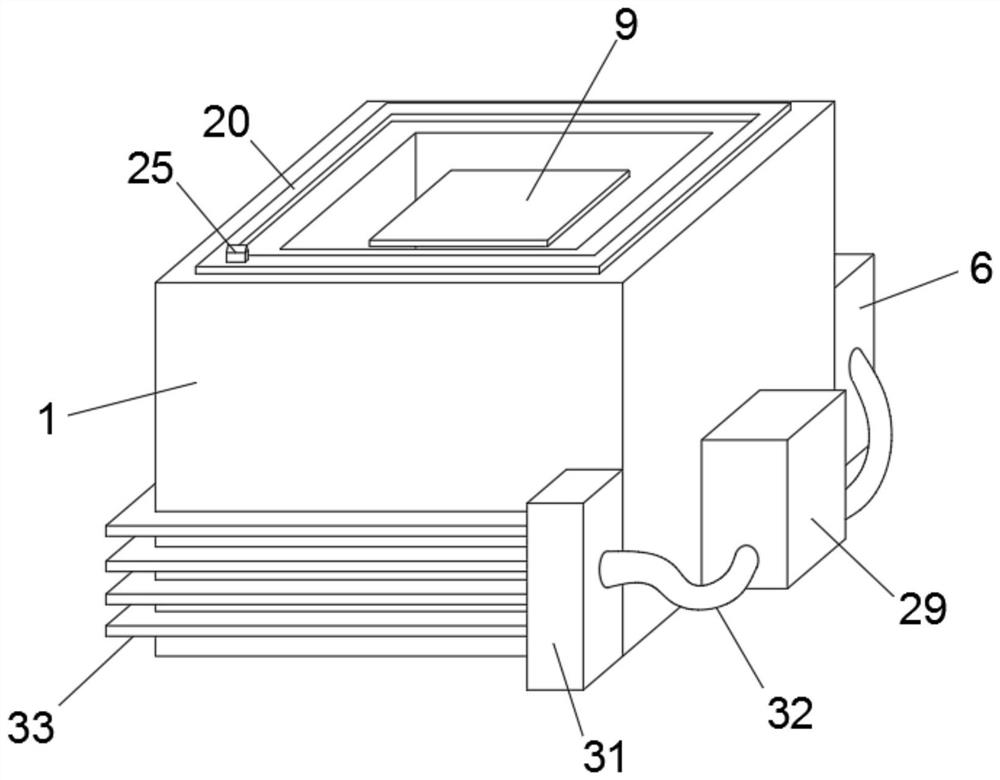

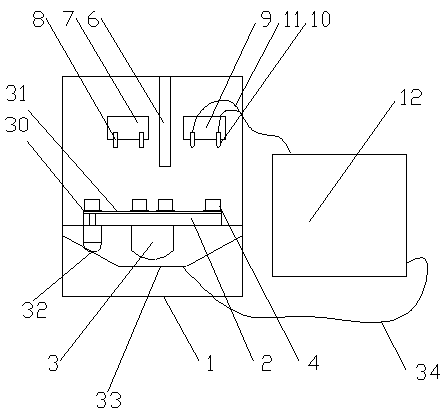

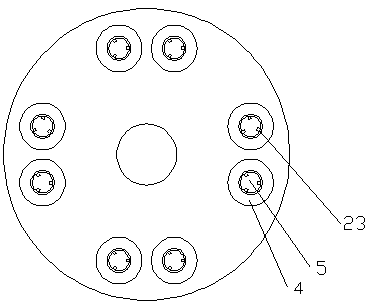

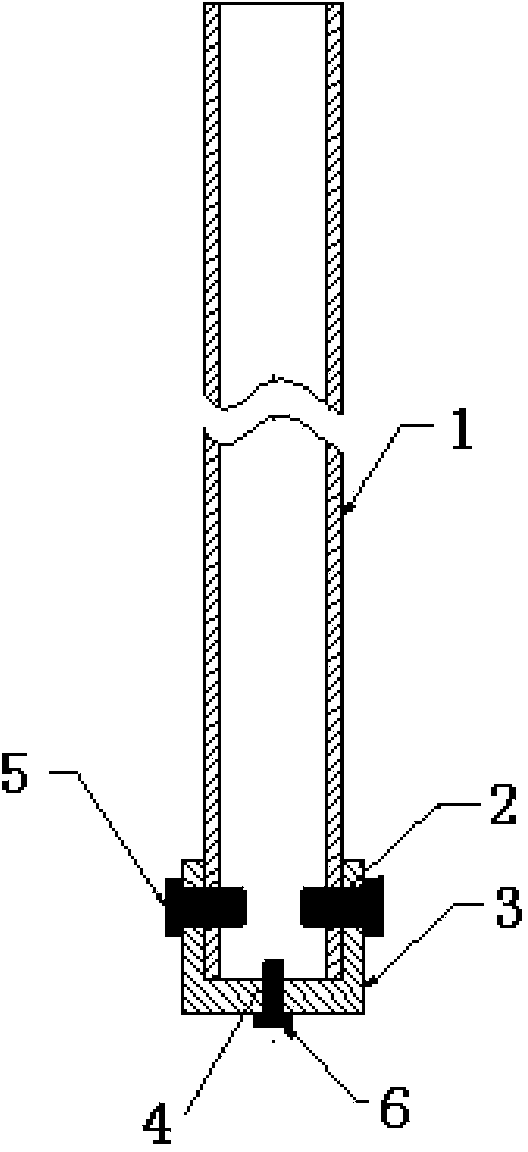

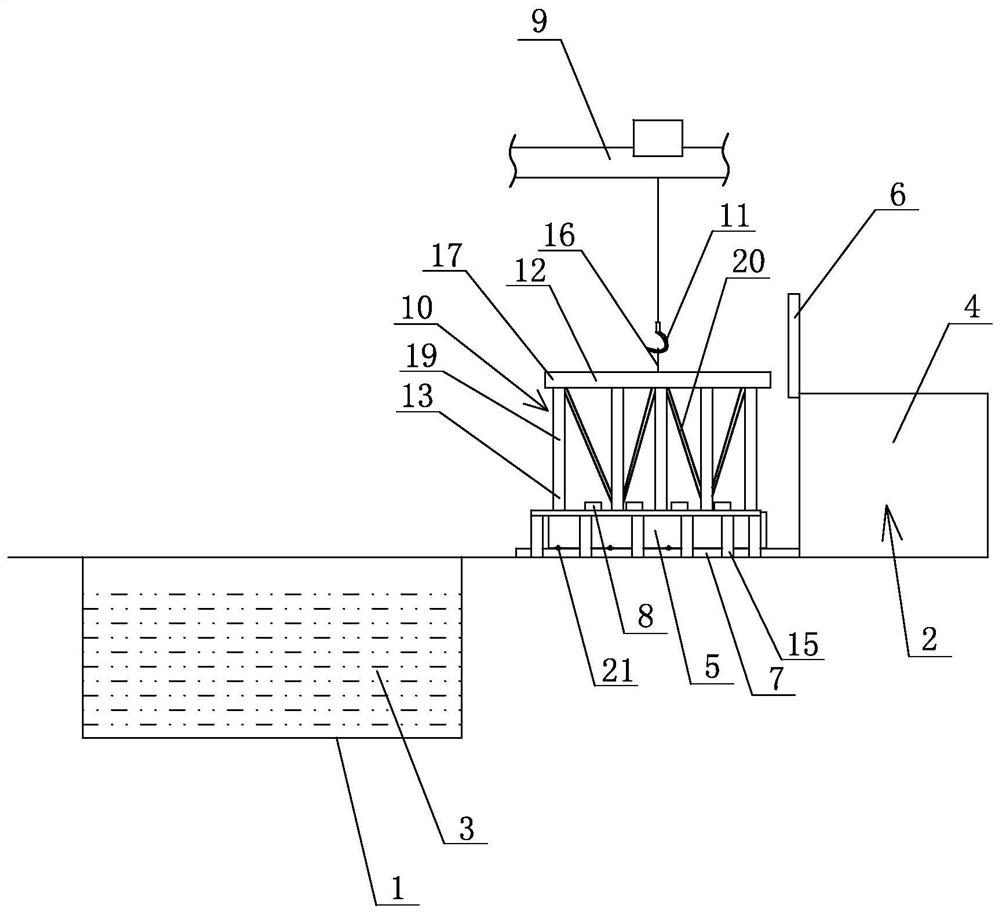

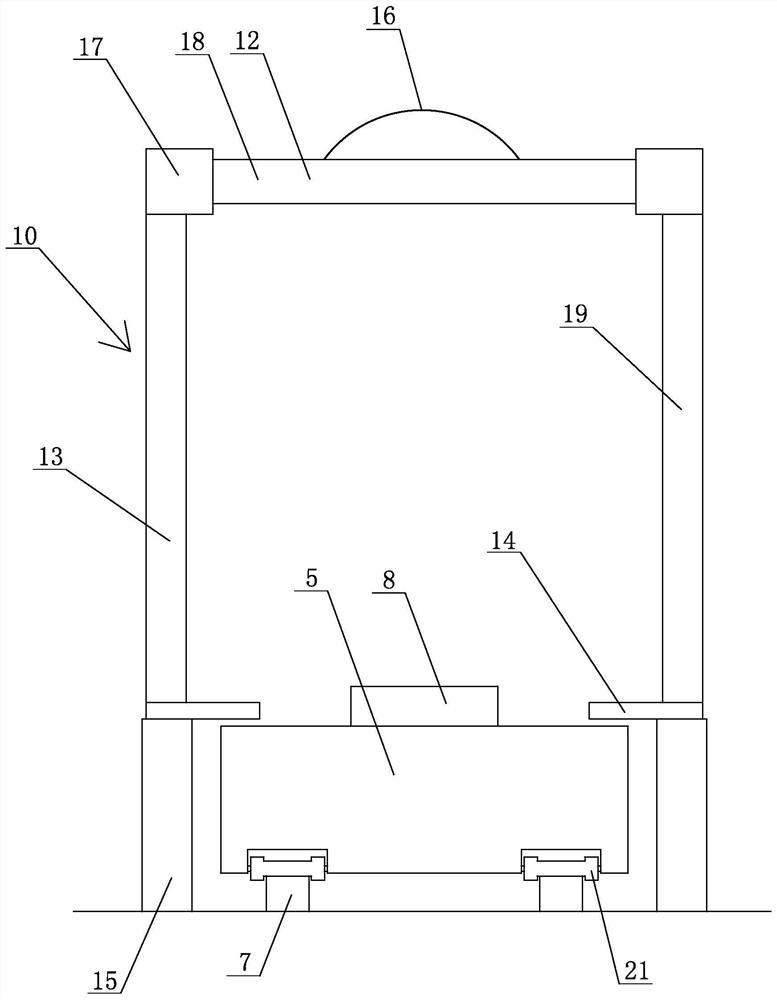

Automatic quenching oil groove and quenching method by utilizing automatic quenching oil groove

InactiveCN105002334AGuaranteed quenching effectImprove quenching uniformityQuenching devicesBiochemical engineeringQuenching

The invention provides an automatic quenching oil groove and a quenching method by utilizing the automatic quenching oil groove. According to the technical scheme, the automatic quenching oil groove comprises a groove body, a liquid spraying mechanism and an oil liquid circulating mechanism are arranged inside the groove body, a stand is arranged inside the groove body, a material containing mechanism is arranged on the stand, and a hoisting mechanism drives the material containing mechanism to move up and down along the stand. Automatic quenching on a workpiece is achieved, the manpower operation is lowered, the dangerousness is lowered, the efficiency is improved, and the production cost is lowered.

Owner:SHANTUI CONSTR MASCH CO LTD

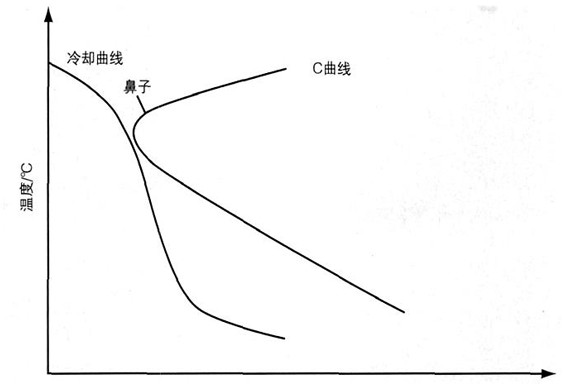

Special quenching agent for large shaft and preparation method of quenching agent

The invention discloses a special quenching agent for a large shaft and a preparation method of the quenching agent, belonging to the field of quenching agents. The quenching agent is prepared from the following components: sodium chloride, sodium hydroxide, sodium citrate, cis-butenedioic acid, mesotrione, lotus root starch, acrylic acid, p-cresol, metribuzin and water. Through adding reasonable components and strictly controlling the component proportion, when used for quenching a shaft which is made of 45# steel and has the diameter of 1.8-3.5m, the quenching agent has the following advantages that the workpiece cooling speed is high within the temperature range of 650-450 DEG C, and the cooling speed is low at the temperature of below 400 DEG C, so that a favorable quenching effect can be obtained, and a quenching crack condition can also be avoided. The preparation method of the quenching agent has the advantages that all components in the quenching agent are completely dispersed and uniformly distributed by controlling temperatures and adding sequences of raw materials, the quenching agent is similar to a colloid in shape, and the cooling speed at the temperature of below 400 DEG C is lowered.

Owner:深圳市新元特钢有限公司

Manufacturing method of 6A02T651 aluminum alloy seam pipe for air separators

The invention belongs to the technical field of aluminum alloy materials for air separators, in particular to a manufacturing method of a 6A02T651 aluminum alloy seam pipe for a low-temperature oxygen / nitrogen air separator, more particularly to a manufacturing method of a 6A02T651 (phi 411*30) aluminum alloy seam pipe. According to the manufacturing method, online quenching production of an ultralarge-diameter and large-wall-thickness seam pipe material for an air separator is realized; under the condition that the standard requirements are met, the labor productivity is raised, the cost is reduced and the ordering requirements of users are met.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

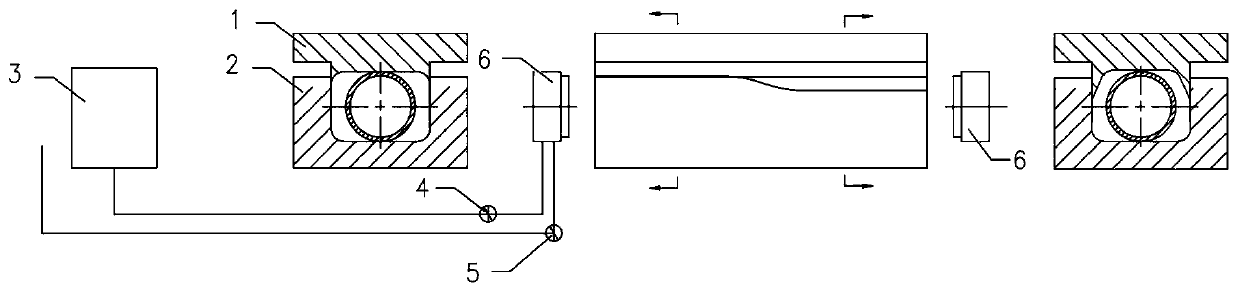

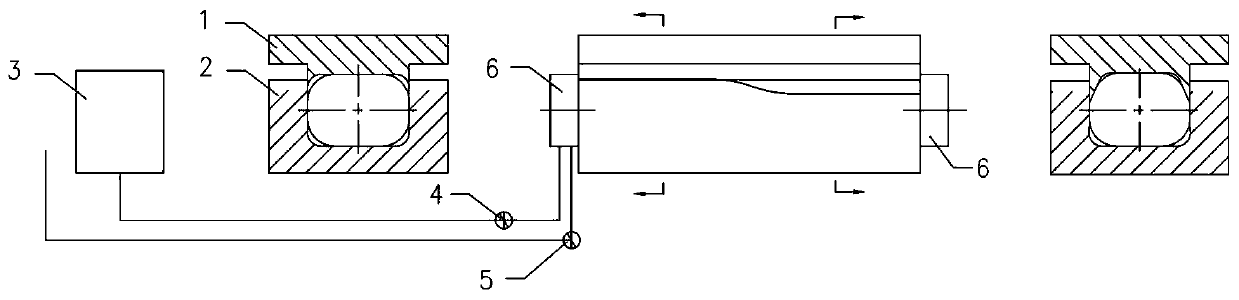

Integrated method for forming tubular part

ActiveCN111451351AGuaranteed quenching effectSolve the technical bottleneck that is difficult to fully moldedIncreasing energy efficiencyFurnace typesVALVE PORTHeat treating

The invention provides an integrated method for forming a tubular part. The method comprises the following steps that 1, an initial tube blank is selected; 2, a mold closing position A and a positionB are determined; 3, the initial tube blank is heated to the temperature T, and T is in the scope of 300 DEG C-1400 DEG C; 4, a die is opened, the initial tube blank is put in a lower die, and an upper die is closed to the position B; 5, the two ends of the initial tube blank are sealed, a first valve is opened, fluid medium with pressure P fills the interior of the initial pipe blank, the initialtube blank is expanded to partially attached to the die, and the sharp portion of the initial tube blank is not completely attached to the die; 6, the internal pressure of the initial tube blank is adjusted to pcr; 7, the upper die moves to the die closing position A to be completely attached to the die; 8, a second valve is opened, the die is quenched under an internal pressure support; 9, the first valve is closed, the sealing of the tube blank is removed, and the second valve is closed; and 10, the die is opened to take out a workpiece. According to the integrated method, the high-strengthsteel material forming and quenching integration is achieved, the shape precision and the heat treatment effect meeting the requirements are produced, and the manufacturing bottleneck is broken through.

Owner:初冠南

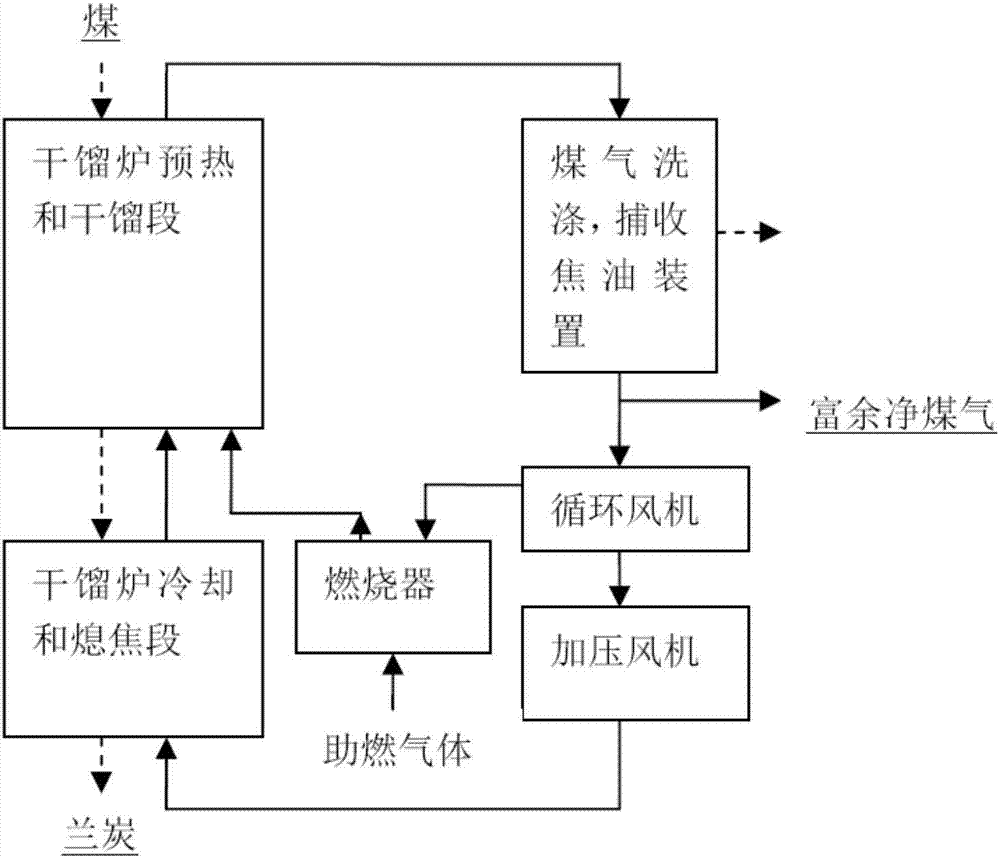

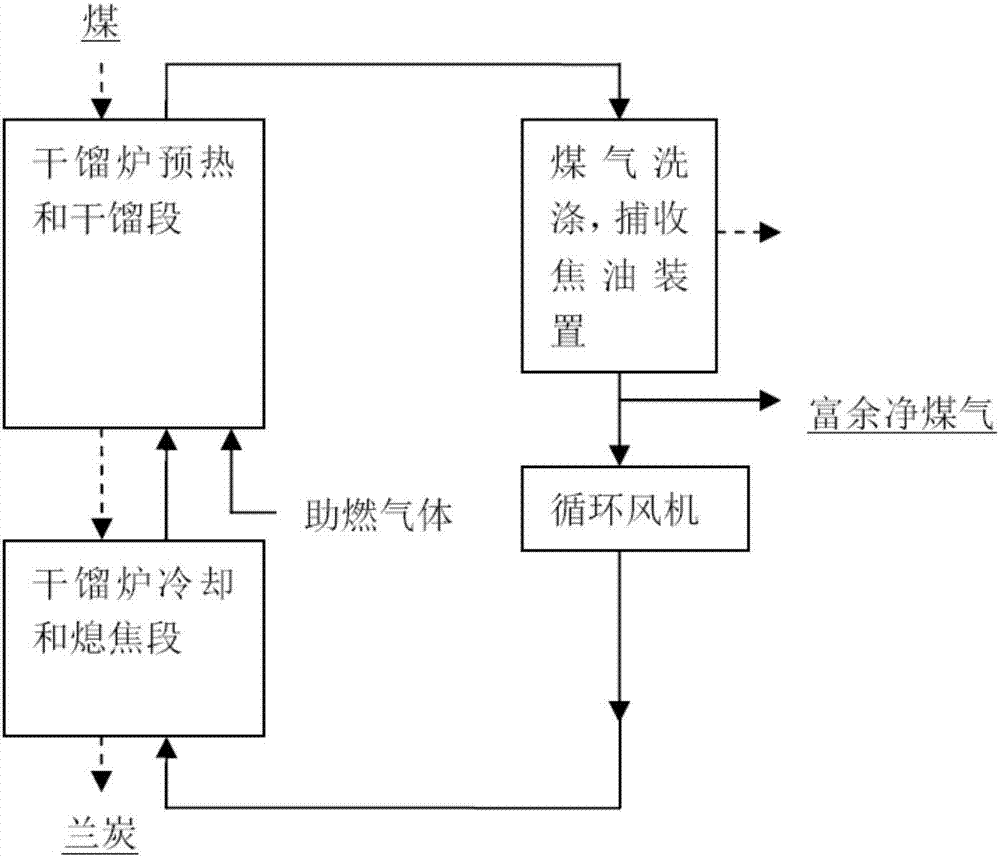

Dry quenching gas regulation method of coal internal heat low temperature pyrolysis

InactiveCN107189794AAchieve flameless combustionFlexible adjustmentCoke quenchingCombustible gas coke oven heatingCombustorQuenching

The invention discloses a dry quenching gas regulation method of coal internal heat low temperature pyrolysis. The method comprises: performing tar separation and collection to gas which is generated from a pyrolysis segment through pyrolysis, returning a part of cool purified gas to a quenching segment, allowing heat transfer to be carried out between hot semi-coke in the quenching segment and the part of cool purified gas to reduce the temperature of semi-coke to a non-reignition temperature, and discharging the hot gas; leading the hot gas after heat transfer from the quenching segment to the pyrolysis segment; leading a combustion-supporting gas from micropores of a lattice wall or a gas distribution channel to the pyrolysis segment, allowing the combustion-supporting gas to meet the hot gas for combustion; and mixing high-temperature gas produced from combustion with uncombusted hot gas to form high-temperature mixed gas meeting the temperature and flow of low temperature pyrolysis requirements, and performing heat transfer between the high-temperature mixed gas and coal in the pyrolysis segment so as to carry out coal pyrolysis. According to the method, in a situation that the circulating gas amount in the pyrolysis segment is basically kept constant, the gas circulating amount in the quenching segment is further increased, so that the quenching effect is ensued, and the physical heat of semi-coke can be fully used, and therefore, the energy saving effect is good. According to the method, since no dependent combustor, combustion gas blower fan, pipeline or valve is required, so that the system is further simplified.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

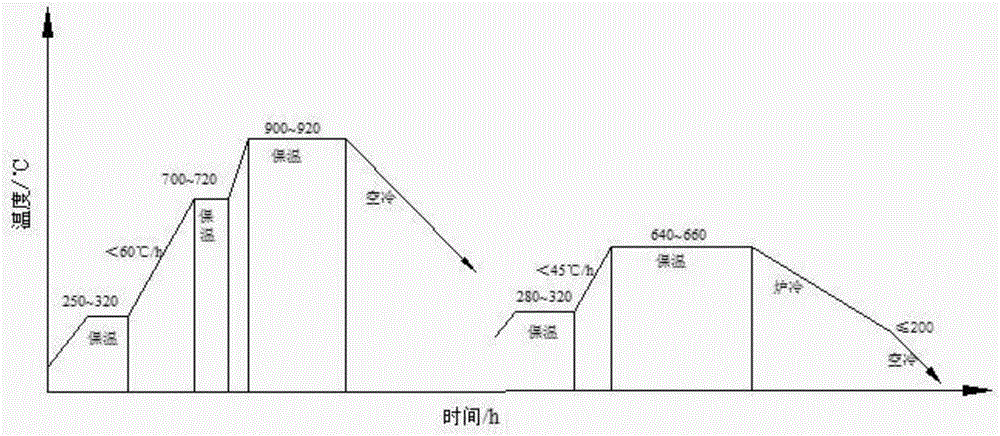

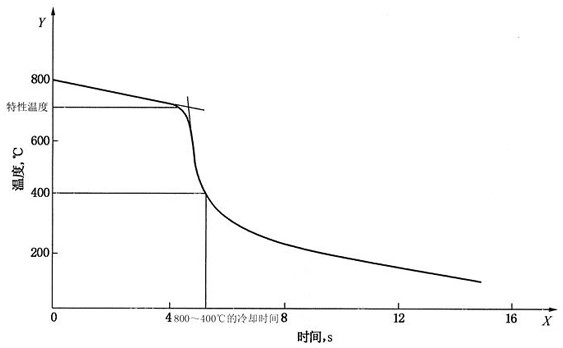

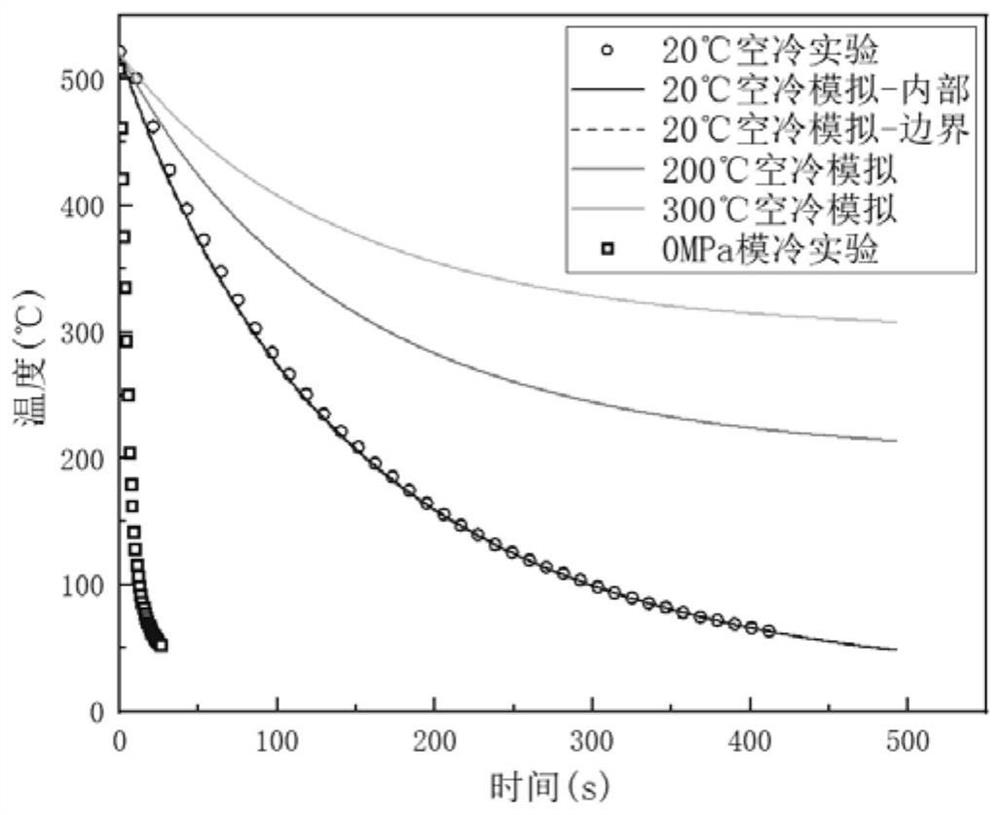

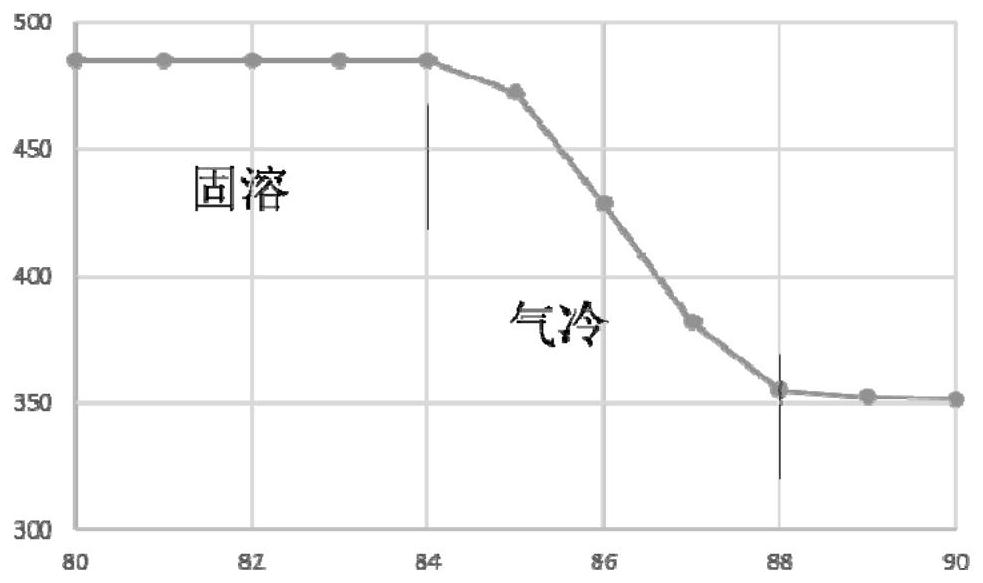

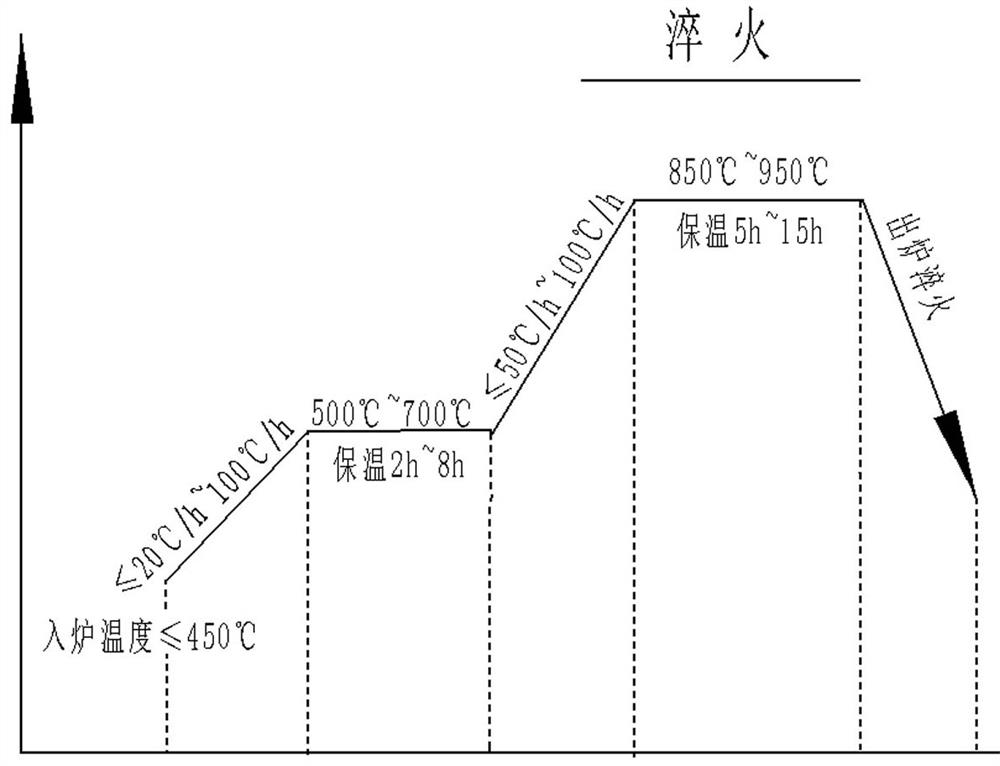

Heat treatment method of forged piece of industrial steam turbine rotor

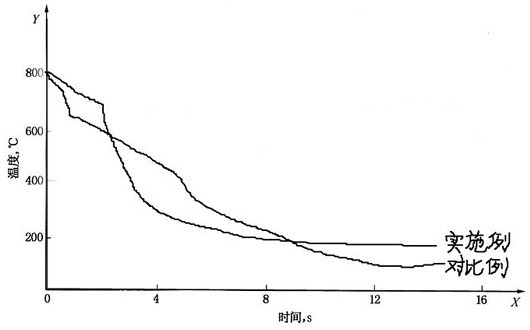

InactiveCN106086360AGuaranteed quenching effectHigh strengthFurnace typesHeat treatment furnacesWater coolingUltimate tensile strength

The invention discloses a heat treatment method of a forged piece of an industrial steam turbine rotor. The heat treatment method comprises preheat treatment and quenching and tempering treatment. Preheat treatment comprises the steps of normalizing and tempering, and quenching and tempering treatment comprises the steps of quenching and tempering. During quenching of the quenching and tempering treatment, the temperature is raised in a ladder heating manner, a cooling manner of combining water cooling and oil cooling is adopted during cooling, and the tempering temperature and the cooling speed are decreased through tempering. The heat treatment method of the forged piece of the industrial steam turbine rotor is more reasonable in process, the large-diameter forged piece of the industrial steam turbine rotor can be treated, the obtained strength of the large-diameter forged piece of the industrial steam turbine rotor can reach the grade of 670 MPa, obdurability matching is better, and then the efficiency of an industrial steam turbine unit is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

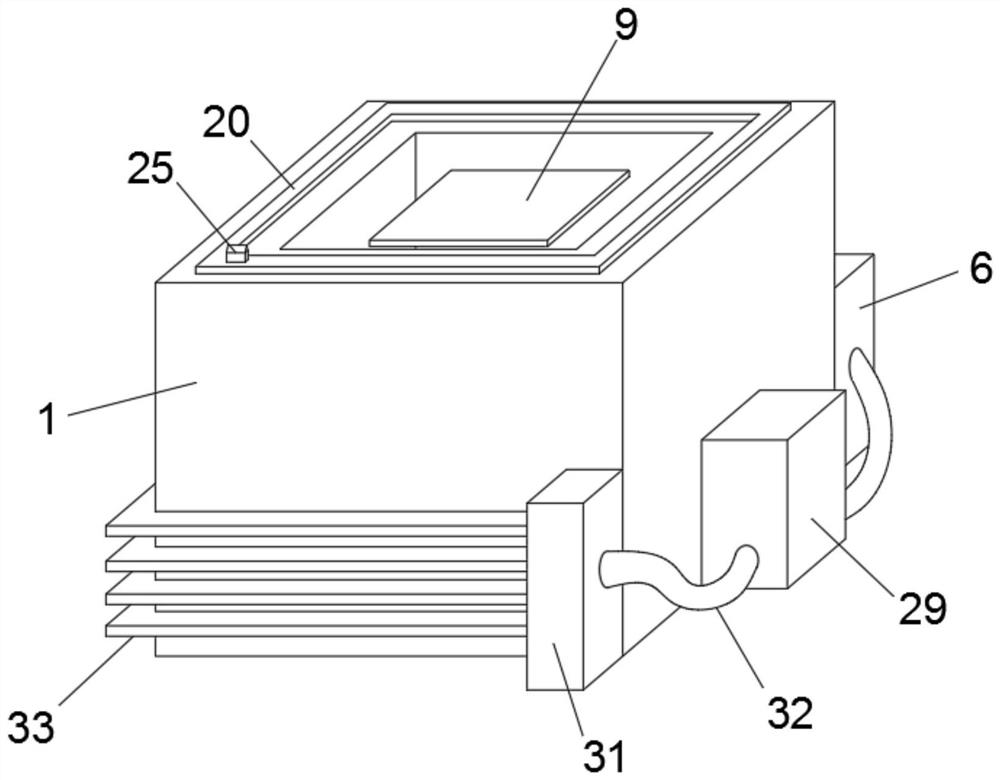

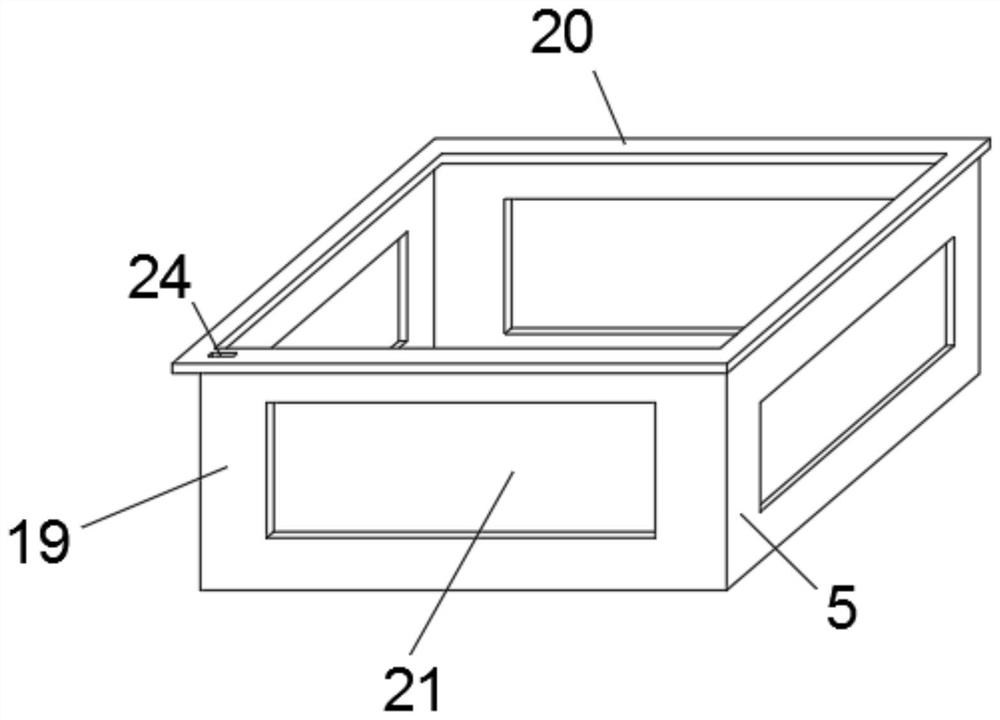

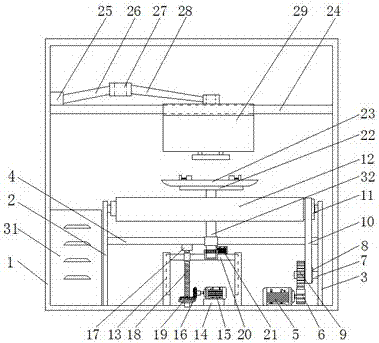

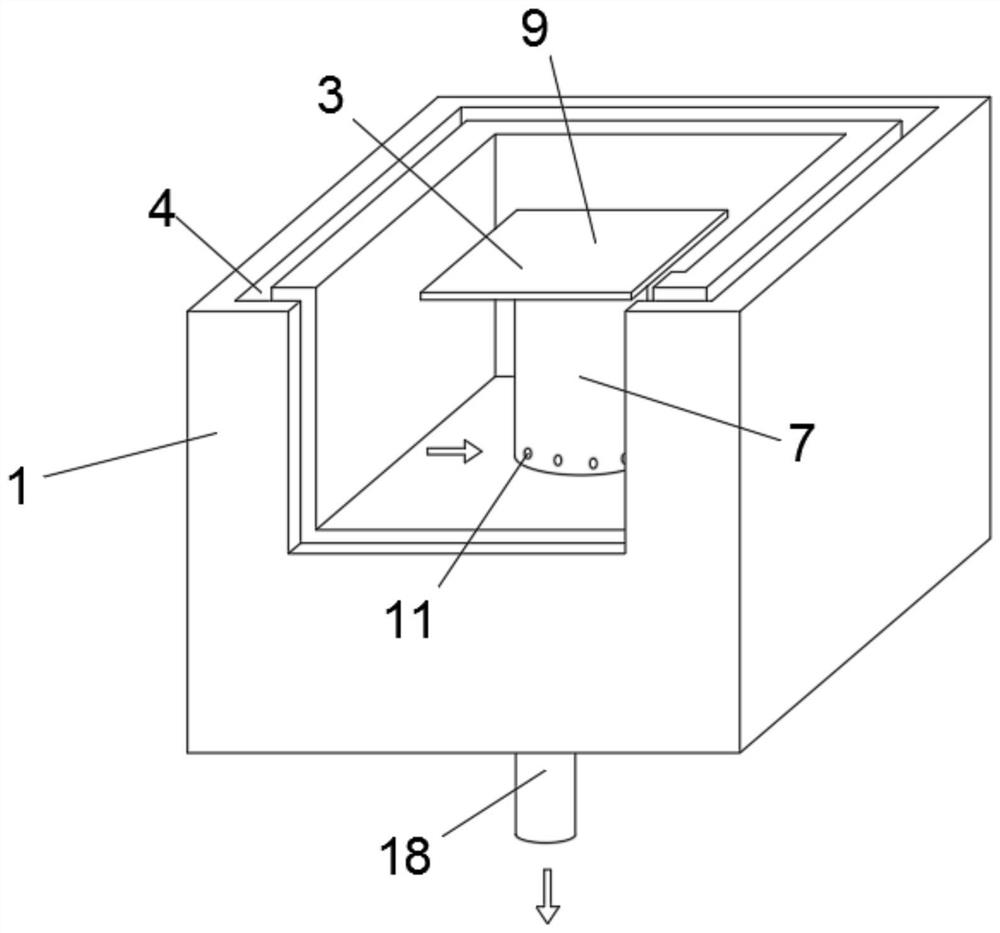

Safety guard device for iron and steel production

ActiveCN111850255AAvoid accidental injuryRemind work statusFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention belongs to the technical field of iron and steel production, and particularly relates to a safety guard device for iron and steel production. The safety guard device for iron and steel production comprises a liquid containing pool. The interior of the liquid containing pool is provided with a liquid containing chamber. Squeezing liquid is filled in the liquid containing chamber. Theliquid containing chamber is provided with a squeezing mechanism. One end of the squeezing mechanism penetrates through the center of the inner bottom of the liquid containing pool and extends to theinterior of the liquid containing pool. A mounting sink is arranged around the inner lateral side of the liquid containing pool, and the mounting sink is in the shape of a rectangular. The bottom of the mounting sink is communicated with the liquid containing chamber. The interior of the mounting sink is provided with a protecting mechanism. The outer lateral side of the liquid containing pool isfixedly connected with a cooling and returning mechanism. The cooling and returning mechanism is communicated with the liquid containing chamber. The safety guard device for iron and steel productionhas the advantages that during quenching operation of large metal castings, a protecting plate can be lifted automatically to make high-temperature fireballs or liquid splash into the surrounding environment without affecting the direct observation of a worker outside, which effectively improves the protection of personal safety.

Owner:朔州市欧鼎冶金有限公司

Quenching device for machining of cement production equipment

ActiveCN107312919AIncrease flexibilityImprove processing efficiencyFurnace typesHeat treatment furnacesSlide plateEngineering

The invention discloses a quenching device for machining of cement production equipment. The quenching device comprises a box body, wherein one side of the bottom of the inner wall of the box body is fixedly connected with a first motor; the output shaft end of the first motor is connected with a synchronous wheel through a gear in a meshing manner; the top of a vertical plate in the box body is connected with a roller in a rotatable manner; the roller is connected with the synchronous wheel through a synchronous belt; the surface of the roller is connected with a conveying belt in a transmission manner; the middle part of the bottom of the inner wall of the box body is vertically and fixedly connected with a pair of fixed plates; a sliding plate is connected between the fixed plates in a sliding manner; the bottom of the inner wall of the box body is fixedly connected with a second motor through a motor seat; a sliding rod is fixedly connected between two sides of the inner wall of the box body; and the surface of the sliding rod is connected with a quenching device body in a sliding manner. The invention relates to the technical field of machining of the cement production equipment. According to the quenching device for machining of the cement production equipment, the problems of long time and high labor intensity of a conventional quenching process are solved; meanwhile, the production efficiency is improved, and the labor intensity is reduced; and the quenching device is convenient to operate.

Owner:广西合山虎鹰建材有限公司

Environment-friendly high-temperature isothermal step quenching oil and preparation method thereof

The invention provides environment-friendly high-temperature isothermal step quenching oil. The environment-friendly high-temperature isothermal step quenching oil is prepared from 150BS bright oil, acooling accelerant, an antioxidant, a brightener, an antirust agent and an anti-foaming agent. The invention further provides a preparation method of the environment-friendly high-temperature isothermal step quenching oil. The oil has the most remarkable characteristics that high-temperature cooling is fast, low-temperature cooling is gentle, the flash point is high, the use temperature is high,the thermal oxidation resistance is good, the service life is long, the brightness and anti-rust performance are excellent, and the technical index requirements of the petrochemical industry standardSH / T 0564-93 heat treatment oil No. 2 isothermal step quenching oil in China are met. In addition, the production preparation process is simple, and the product is environment-friendly and stable in quality.

Owner:上海中孚油品集团有限公司

Heat treatment technique of lock case die carrier

InactiveCN105177266AUniform cooling rateConsistent hardnessFurnace typesQuenching agentsHardnessQuenching

The invention discloses a heat treatment technique of a lock case die carrier. The outline of the lock case die carrier is in a cuboid structure. The heat treatment process comprises the steps of heating and holding, quenching and tempering. The quenching medium adopted by the quenching after the heating and holding is saline water with the concentration of 8-12%; and when the lock case die carrier enters the quenching medium, an inclination angle of greater than 45 degrees is kept between the lock case die carrier and the horizontal surface of the quenching medium. By using the saline water with the concentration of 8-12% as the quenching medium, bubbles, which are generated when the die carrier enters the quenching medium, can quickly rupture, thereby lowering the quenching soft spot, ensuring the same cooling rate of the upper and lower die surfaces, and further ensuring the quenching soft spot hardness of the upper and lower die surfaces. The lock case die carrier is put into the quenching medium at the inclination angle of greater than 45 degrees, so that the bubbles can rupture and flow away, thereby ensuring the quenching effect and ensuring the upper and lower die surfaces to be respectively within the hardness range.

Owner:JIANGSU LEAP MACHINE

Hardening furnace with fume exhaust device

InactiveCN101760588AGuaranteed quenching effectReduce maintenance costsFurnace typesHeat treatment furnacesCarbon layerHearth

The invention discloses a hardening furnace with a fume exhaust device, which comprises a hearth of the hardening furnace, a fume deposition box, a fume exhaust tube, an adjusting valve and a fume exhaust machine. The hardening furnace with the fume exhaust device is characterized in that the fume deposition box is arranged at the lower part of the hearth of the hardening furnace; and the fume deposition box, the adjusting valve and the fume exhaust machine are sequentially communicated with each other through the fume exhaust tube. The hardening furnace exhausts excessive oil smoke in time and reduces deposited carbon of the hearth of the hardening furnace so as to guarantee hardening performance of the hardening furnace. A work for manually clearing a deposited carbon layer can be reduced by 1-2 times in one year, thereby the maintenance cost of the hardening furnace is reduced, and the production cost of a factory is reduced.

Owner:苏州新凌电炉有限公司

Method for preparing environment-friendly water-soluble hardening agent

ActiveCN103981343AReduce internal stressImprove cooling effectFurnace typesProcess efficiency improvementWater solubleHardening effect

The invention discloses a method for preparing an environment-friendly water-soluble hardening agent and belongs to the field of preparation of hardening agents. The invention belongs to divisional application, and the original Chinese patent application number of is 201310350402.X. According to the preparation method, all components of the hardening agent are guaranteed to be completely dispersed and uniformly distributed by virtue of controlling the feeding sequence of the raw materials and temperature and stirring time, so that the hardening agent meets the hardening requirement, can be used for strictly controlling the cooling speed of large shafts to prevent hardening crack, greatly lowering the initial cooling speed and the cooling speed at a temperature of below 400DEG C and lowering the internal stress of workpieces, has fast enough cooling speed for 650-450DEG C, and guarantees the hardening effect while guaranteeing the product not to be cracked by hardening; after being hardened, large workpieces are not cracked by hardening.

Owner:马鞍山金泉工业介质科技有限公司

A safety protection device for steel production

ActiveCN111850255BAvoid accidental injuryRemind work statusFurnace typesHeat treatment furnacesLiquid storage tankEngineering

The invention belongs to the technical field of iron and steel production, and in particular relates to a safety protection device for producing iron and steel. There is an extrusion mechanism. One end of the extrusion mechanism penetrates the center of the inner bottom of the liquid holding pool and extends to the inside. The side wall of the liquid holding pool is surrounded by an installation groove. The installation groove is rectangular. The liquid cavity is arranged in communication, and a protective mechanism is provided in the installation groove. A cooling return mechanism is fixedly connected to the outer wall of the liquid storage pool, and the cooling return mechanism is connected to the liquid storage cavity. The advantage is: when quenching large metal castings, the protective plate can be automatically lifted, so that the high-temperature fireball or liquid splashes into the surrounding environment, and at the same time it does not affect the direct observation of external staff, which is effective Improved protection for personal safety.

Owner:朔州市欧鼎冶金有限公司

Heat treatment technology of lock case mold base

InactiveCN109136479AFlat surfaceEasy to useFurnace typesQuenching agentsQuenchingHeating temperature

The invention discloses a heat treatment technology of a lock case mold base. The outer contour of the lock case mold base is of a cuboid structure, the heat treatment process of the lock case mold base comprises steps of heating insulation, annealing, quenching and tempering, the heating insulation treatment is performed in a mixed solution of sodium hydroxide, bamboo charcoal and nitrous acid, heating temperature is 1400-1500 DEG C, a quenching medium adopted for quenching after the heating insulation is saline water with concentration being 8%-12% and temperature being 50-80 DEG , the moldbase after tempering is completed is put in deionized water for cooling, and then the mold base is taken out and air-cooled to the room temperature. The saline water with concentration being 8%-12% isadopted as the quenching medium, bubbles produced when the mold base enters the quenching medium can be broken quickly, so that quenching soft spots are reduced, consistency of cooling speeds of upper and low mold surfaces is guaranteed, and consistency of hardness of the upper and lower mold surfaces is guaranteed; meanwhile, the lock case mold base is placed in the quenching medium at an inclined angle larger than 45 degrees, the bubbles can be further broken and flow away, therefore, the quenching effect is ensured, and hardness of the upper and lower mold surfaces is in the hardness range.

Owner:JIANGSU LEAP MACHINE

A method of manufacturing 6082t6 aluminum alloy large-scale rods for power equipment

The invention belongs to the technical field of aluminum alloy materials for electric power equipment and particularly relates to a method for manufacturing large-sized aluminum alloy bars with high strength and high electrical conductivity. The large-sized 6082 bars with high strength and high electrical conductivity, especially 6082T6 aluminum alloy bars with diameter from 150mm above to 300mm, are utilized for processing large-sized electrical elements with high strength and high electrical conductivity in the electric power equipment. An aluminum alloy ingot used in the method contains the following elements in percentage by mass: 1.0%-1.05% of Si, no more than 0.12% of Fe, no more than 0.10% of Cu, 0.55%-0.65% of Mn, 0.9%-0.95% of Mg, no more than 0.10% of Cr, no more than 0.10% of Zn, no more than 0.05% of Ti, no more than 0.05% of isolated impurity, no more than 0.15% of total impurities, and the balance being Al. According to the method, mass production and delivery can be achieved, the strength and the electrical conductivity of the large-sized aluminum alloy bars are enhanced, and processing and use are facilitated; the mechanical property and the electrical conductivity of the large-sized aluminum alloy bars obtained by the method are stable; in repeated operation, the bars can satisfy the Chinese standard of bars with diameter smaller than 150mm, the Chinese standard of bars with diameter from 150mm above to 300 mm can be supplemented or perfected and each performance index can be introduced into the Chinese standard.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

Controllable gas-assisted light alloy metal plate cold mold hot forming method

ActiveCN113828678AIncrease stressGood hardening effectShaping toolsSolution treatmentMaterials science

The invention relates to a controllable gas-assisted light alloy metal plate cold mold hot forming method. An adopted forming die comprises a female die, a male die and a blank pressing flange. The forming method comprises the steps of design and manufacturing of the forming die, light alloy solution treatment, light alloy cold die hot forming and light alloy part die assembly quenching. Aiming at the characteristics of heat exchange and non-uniform temperature field between a cold mold hot forming die and a plate blank, a cooling gas path is constructed on the forming die, and a controllable gas assisting manner is utilized, so that 1) in the forming process, the temperature field of the plate blank is regulated and controlled, the reasonable distribution of flow stress is realized, and the flow of a material is further controlled; and 2) in the die quenching process, the local cooling speed of a deformed part is regulated and controlled, controllable and adjustable gradient cooling is achieved, and then the structure and mechanical properties of the part are guaranteed. An advanced die manufacturing method is provided for hot forming of light alloy complex integral parts, and the problems of cracking and uneven performance and wall thickness distribution existing in hot forming of light alloy are solved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Electric tool processing device

InactiveCN107674967AEasy to processImprove work efficiencyFurnace typesProcess efficiency improvementElectric machineBiochemical engineering

The invention relates to an electric tool processing device, which comprises a processing tank, a quenching platform arranged in the tank, a plurality of placing plates arranged on the quenching platform, and a heating unit and a cooling unit arranged in the processing tank and sequentially distributed along the quenching platform. Each placing plate is driven by a drive motor to linkage through asynchronous belt; a groove is formed in the upper end of each placing plate; elastic limiting bulges are further arranged on inner walls of the grooves of the placing plates; a heat resisting clapboard is further arranged between the heating unit and the cooling unit; the cooling unit comprises a cooling installation plate; a pair of cooling nozzles are arranged on the cooling installation plate;and a cooling liquid recovery plate is further arranged in the processing tank. The electric tool processing device provided by the invention has the advantages that through interaction of the quenching platform, the placing plate group, the heating unit and the cooling unit, materials can be loaded, heated and cooled synchronously, cycle operation is carried out, processing can be carried out conveniently, and batch production is realized.

Owner:南通旭越光电科技有限公司

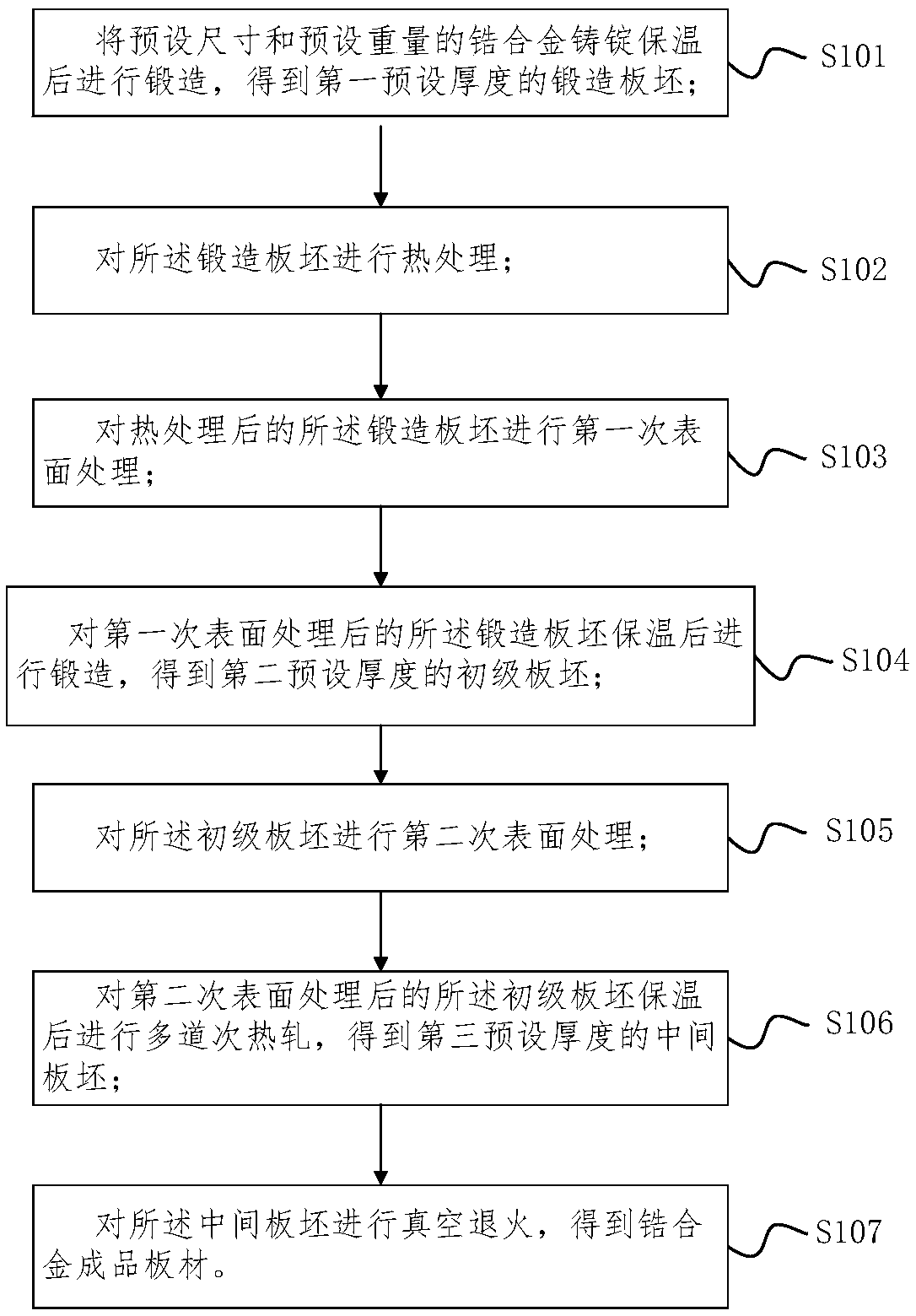

Preparing method of zirconium alloy hot rolled plate

ActiveCN110877050AImprove corrosion resistanceImprove mechanical propertiesTemperature control deviceMetal rolling arrangementsThick plateNuclear reactor

The embodiment of the invention discloses a preparing method of a zirconium alloy hot rolled plate. The method comprises the steps that zirconium alloy casting ingots with the preset size and the preset weight are subjected to heat preservation and then subjected to forging, heat treatment, primary surface treatment, forging after heat preservation, secondary surface treatment, multi-pass hot rolling and vacuum annealing. The manufactured zirconium alloy hot rolled medium and thick plate has the excellent anti-corrosion property and mechanical property, and has the uniform and fine structure,and the plate meets the technical standard requirement of zirconium alloy medium and thick plates for a nuclear reactor. The method is simple in process, flow in preparing flow, and low in productioncost. The situation that domestic high-property zirconium alloy medium and thick plates are dependent on import for a long time can be expected to be changed.

Owner:国核宝钛锆业股份公司

Device and method for removing oil stain in high-frequency quenching liquid for steering gear

InactiveCN104313269AEasy to installIncrease profitLiquid separationQuenching devicesFixed framePulp and paper industry

The invention discloses a device and method for removing oil stain in high-frequency quenching liquid for a steering gear. The device comprises a fixed frame and a conveying belt which is immersed into the quenching liquid; a scraping plate for scraping oil stain on the conveying belt is arranged on the fixed frame; one end of the scraping plate for scraping the oil stain is positioned on the outer side of the conveying belt, and the other end of the scraping plate is an oil stain output end; a belt wheel at one end of the conveying belt is connected with a motor fixed on the fixed frame; a belt wheel at the other end of the conveying belt is connected with the fixed frame through a belt tightness adjusting mechanism; in the method for removing oil stain, the oil stain in the quenching liquid is removed by using the device for removing oil stain in high-frequency quenching liquid for the steering gear; through the adoption of the device and the method disclosed by the invention, the automatic removing of the oil stain in the quenching liquid is achieved, so that the labor cost is reduced and the utilization rate of the quenching liquid is increased; the purity of the quenching liquid and the quenching quality are both guaranteed.

Owner:WUHU STERLING STEERING SYST

Processing method of aluminum profile for passenger vehicle

The invention provides a processing method of an aluminum profile for a passenger vehicle. The processing method comprises the following steps: selecting an Al-Mg-Si series aluminum alloy ingot with the weight percentage of Mg being 0.5-1.1%, the weight percentage of Si being 0.4-0.8% and the weight percentage of Fe being less than 0.6% as an extrusion raw material of the aluminum profile; raw material selection and provided extrusion parameters are reasonable, during extrusion, metal flow is uniform, efficient and rapid, the machining range is wide, the aluminum profile extrusion device can be suitable for machining aluminum profiles of passenger vehicles with various sections and sizes, and the extruded aluminum profiles are fine in crystal grain, high in straightness, good in strength, stable in performance and high in rate of finished products. According to the provided combined online quenching method, accurate cooling control can be carried out according to the temperature and the structure state of the profile, quenching cooling is uniform, the quenching requirements of aluminum profiles with different thicknesses and complex section structures can be met, the cooling range is wide, the application range is wide, the cooling efficiency of some aluminum profiles not suitable for online quenching can also meet the online quenching requirement, and the service life of the aluminum profiles is prolonged. And the process of independent quenching can be omitted, so that the equipment investment is reduced, and the production cost is reduced.

Owner:江阴协宏金属制品有限公司

Method for preventing slender tubular component from burning in oil quenching of heat treatment

ActiveCN104109751AGuaranteed quenching effectAvoid fire hazardsFurnace typesHeat treatment furnacesQuenchingMaterials science

The invention relates to a method for preventing a slender tubular component from burning in oil quenching of heat treatment. A cover-shaped plug matching with a tube orifice diameter of the slender tubular component is provided. An oil-leaking hole is arranged at the bottom of the plug. Before the component is subjected to the heat treatment, the cover-shaped plug is buckled to one end tube orifice of the component, so that the oil-leaking hole is blocked and then quenching treatment is carried out. With the above method, risks of burning can be effectively prevented; and a quenching effect of the tubular component is guaranteed, so that the component can be fully quenched rapidly.

Owner:XI'AN AIRCRAFT INTERNATIONAL

Heat treatment process for large-size 20CrMnMoB guide rail

InactiveCN113999952AReduce distortionHeating evenlyFurnace typesQuenching agentsThermodynamicsLiquid medium

The invention relates to a heat treatment process for a large-sized 20CrMnMoB guide rail, which effectively solves the phenomena of deformation, cracking and non-uniform cooling after heat treatment of the large-sized 20CrMnMoB guide rail. A central hole is processed in the middle of a dead head end of a workpiece, and during heat treatment, a penetrating rod penetrates through the central hole to hang the workpiece in a pit furnace for suspending, so workpiece deformation in the heat treatment heating and quenching process is reduced; the integral uniform heating of the workpiece is ensured by adopting speed-limiting temperature rise and stepped heat preservation modes, the temperature difference inside and outside the workpiece is reduced, the internal thermal stress of the workpiece is reduced, and cracking or deformation of the workpiece is avoided; during quenching, a water-based liquid medium with the concentration of 9-15% is adopted for quenching and cooling, and the quenching effect and uniformity are guaranteed; and speed-limiting furnace cooling is adopted after tempering is finished, the internal stress of the workpiece can be effectively removed, finish machining deformation is avoided, the large-specification 20CrMnMoB guide rail produced through the method is small in workpiece deformation after heat treatment, the mechanical property of the total cross section is uniform and consistent, and the detection result is qualified.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Quenching process and device for low-impurity ultra-low-carbon stainless steel

PendingCN111961816AReduce contact timeGuaranteed quenching effectQuenching agentsQuenching devicesEngineeringSS - Stainless steel

The invention discloses a quenching process and device for low-impurity ultra-low-carbon stainless steel. The method includes the steps that: firstly, a blank is put into a heating furnace and heatedto 1060-1200 DEG C; secondly, a sliding seat at the bottom of the heating furnace is pulled out, when the sliding seat is pulled out, the two sides of the bottom of the blank slide to the two sides ofa hanging basket, and thus the hanging basket can lift the blank; thirdly, the hanging basket is lifted through a crane, and in the process of lifting the hanging basket, the blank can be lifted by the hanging basket and thus be separated from the sliding seat of the heating furnace; fourthly, the blank is moved to the position above a quenching bath through the hanging basket, and then lowered,so that the high-temperature blank is put into quenching oil in the quenching bath, and the blank is completely submerged in the quenching oil for quenching; fifthly, the initial temperature of the quenching oil is 80-130 DEG C; and sixthly, quenching is conducted for 1 to 3 minutes and then completed. Through the quenching process and device, the product performance is improved, and potential safety hazards are reduced.

Owner:江阴市天虹金属铸造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com