Heat treatment process for large-size 20CrMnMoB guide rail

A large-scale, guide-rail technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of uneven mechanical properties testing results of the whole section, excessive quenching and cooling of workpieces, and inability to finish machining due to workpiece deformation. Quenching effect and uniformity, small deformation of workpiece, effect of reducing deformation and cracking of workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A heat treatment process for a large-scale 20CrMnMoB guide rail.

[0023] Steel type: 20CrMnMoB

[0024] Chemical composition: C=0.19%, Si=0.27%, Mn=1.39%, Cr=1.69%, Ni=0.27%, S=0.002%, P=0.012%, Mo=0.49%, B=0.0028%.

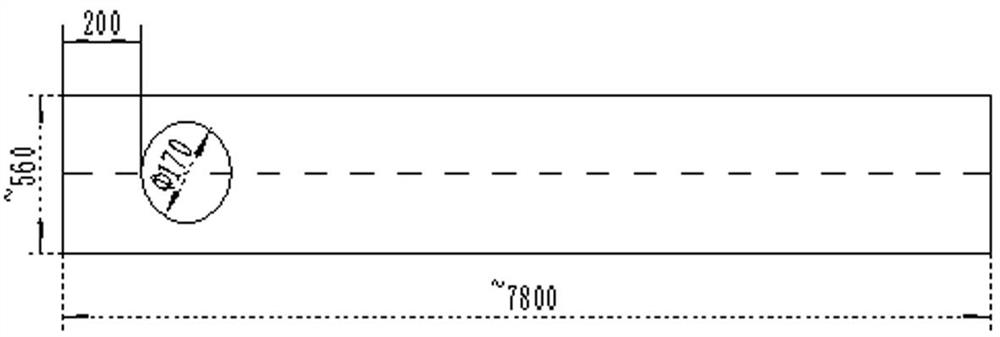

[0025] Specifications: 560*230mm*7895mm

[0026] The heat treatment process steps are as follows:

[0027] Step 1), process a central hole of φ170mm in the middle part of the sample at 200mm from the riser end of the workpiece, and use a φ165mm threading rod to pass through the central hole during heat treatment to hang the workpiece and place it in a 12-meter deep well furnace heating furnace;

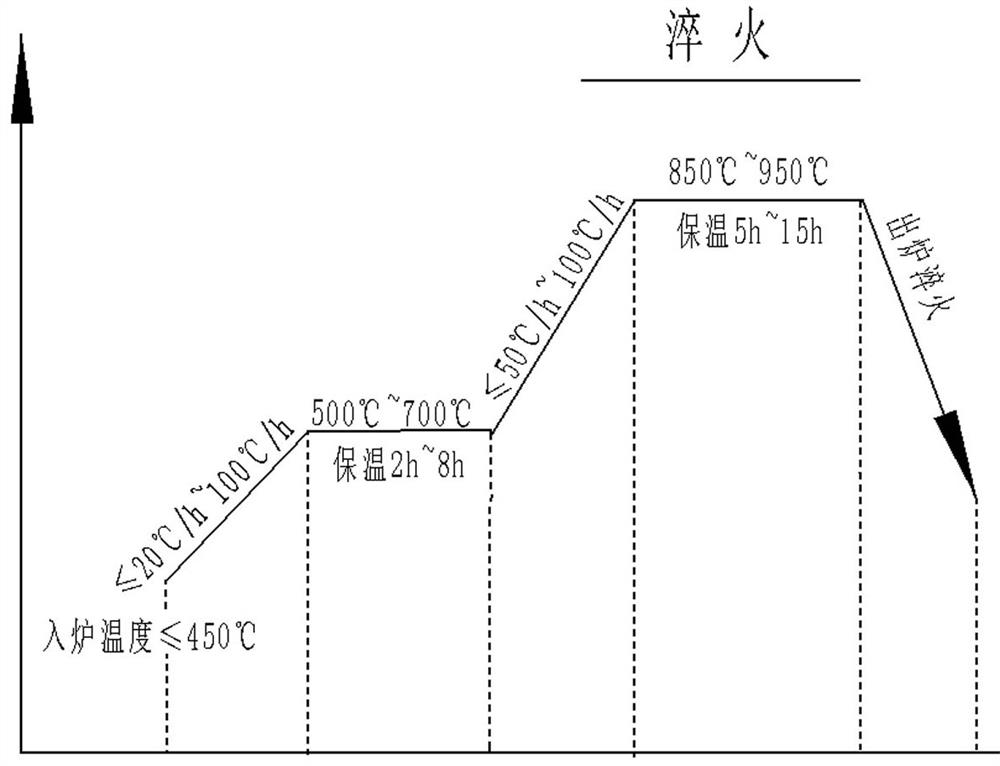

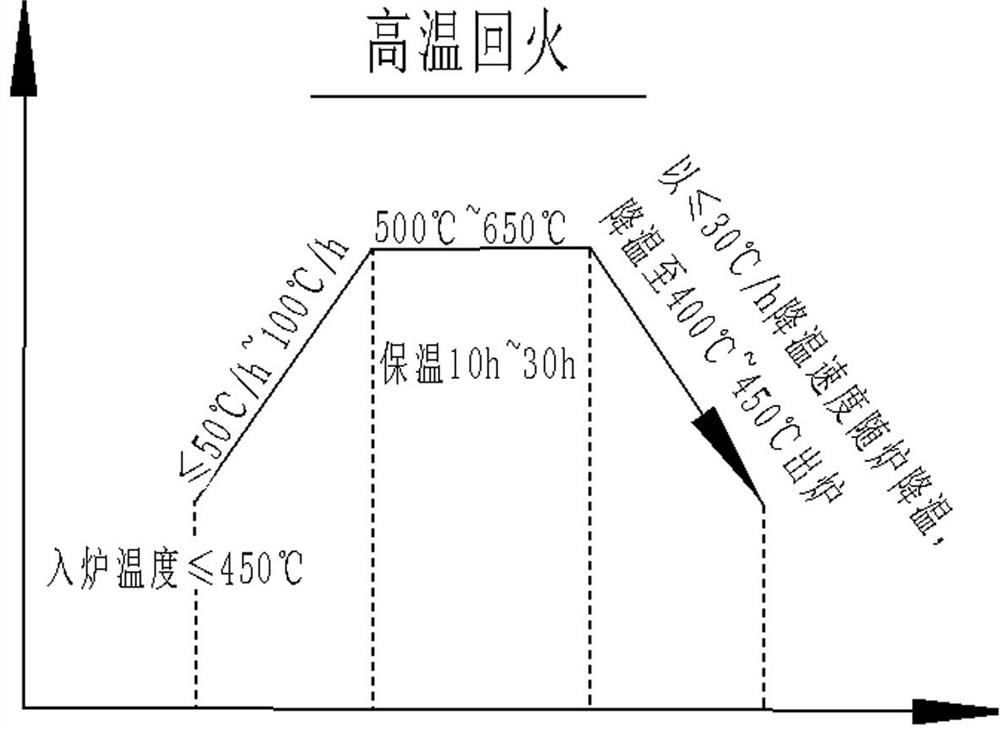

[0028] Step 2), after the completion of step 1), perform quenching: when the workpiece enters the furnace, the furnace temperature is ≤450°C, and the temperature is raised to 550°C-570°C at a heating rate of ≤50°C / h-70°C / h, and the heat preservation is carried out 2h~4h, then heat up to 880℃~900℃ at a heating rate of ≤50℃ / h~70℃ / h, keep warm for 5...

Embodiment 2

[0036] Embodiment 2: A heat treatment process for a large-scale 20CrMnMoB guide rail.

[0037] Steel type: 20CrMnMoB

[0038] Chemical composition: C=0.18%, Si=0.27%, Mn=1.38%, Cr=1.67%, Ni=0.08%, S=0.003%, P=0.011%, Mo=0.5%, B=0.0019%.

[0039] Specifications: 560*280mm*7800mm

[0040] The heat treatment process steps are as follows:

[0041] Step 1), process a central hole of φ170mm in the middle part of the sample at 200mm from the riser end of the workpiece, and use a φ165mm threading rod to pass through the central hole during heat treatment to hang the workpiece and place it in a 12-meter deep well furnace heating furnace;

[0042] Step 2), after the completion of step 1), perform quenching: when the workpiece enters the furnace, the furnace temperature is ≤450°C, and the temperature is raised to 550°C-570°C at a heating rate of ≤50°C / h-70°C / h, and the heat preservation is carried out 2h~4h, then heat up to 880℃~900℃ at a heating rate of ≤50℃ / h~70℃ / h, keep warm for 5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com