Patents

Literature

274results about How to "Reduce the temperature difference between inside and outside" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

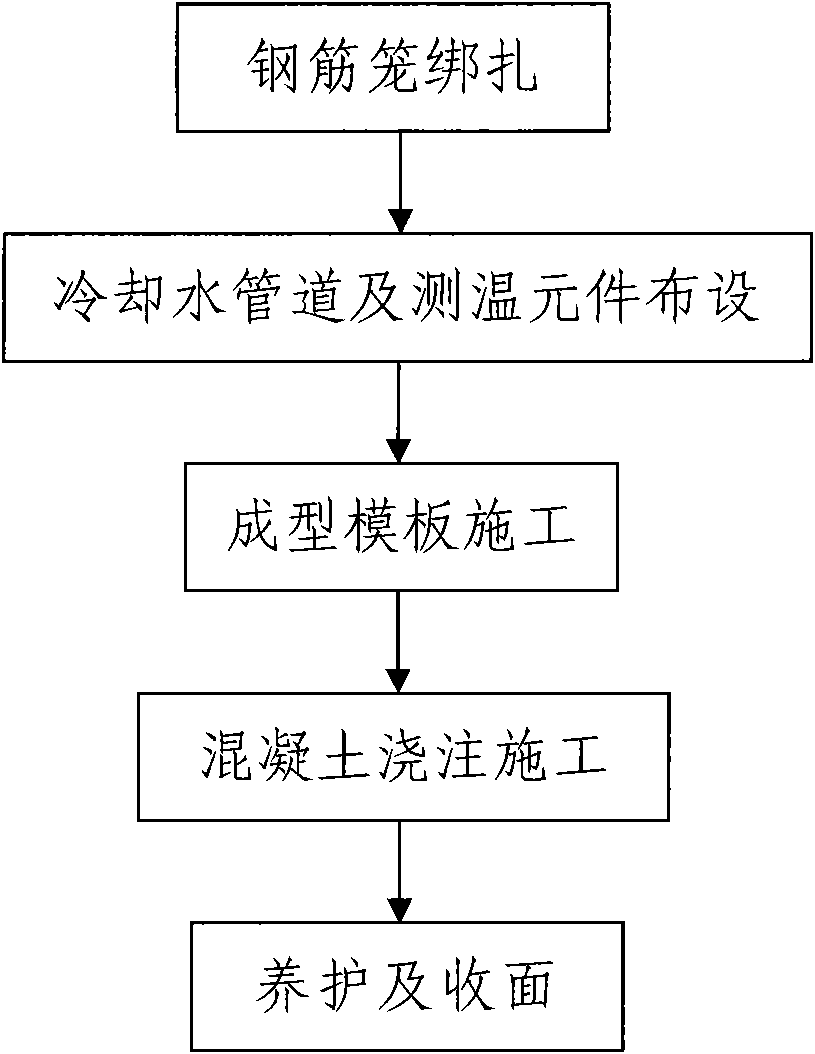

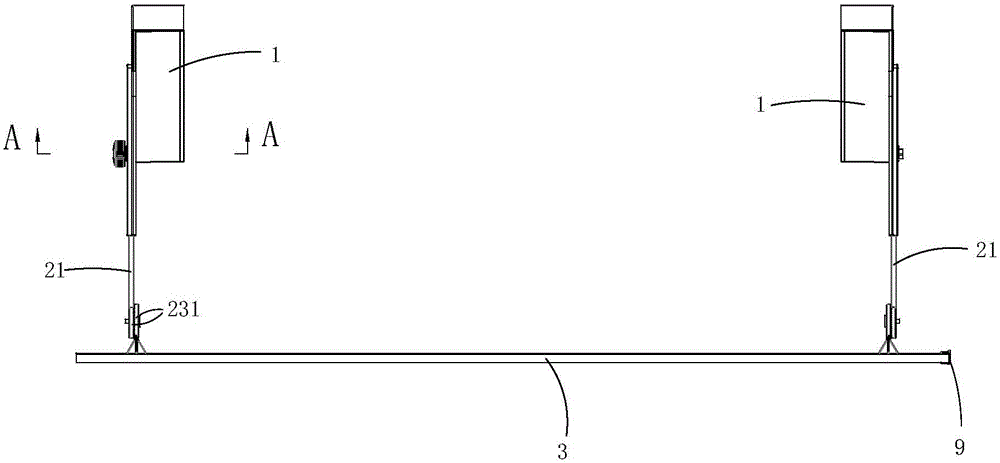

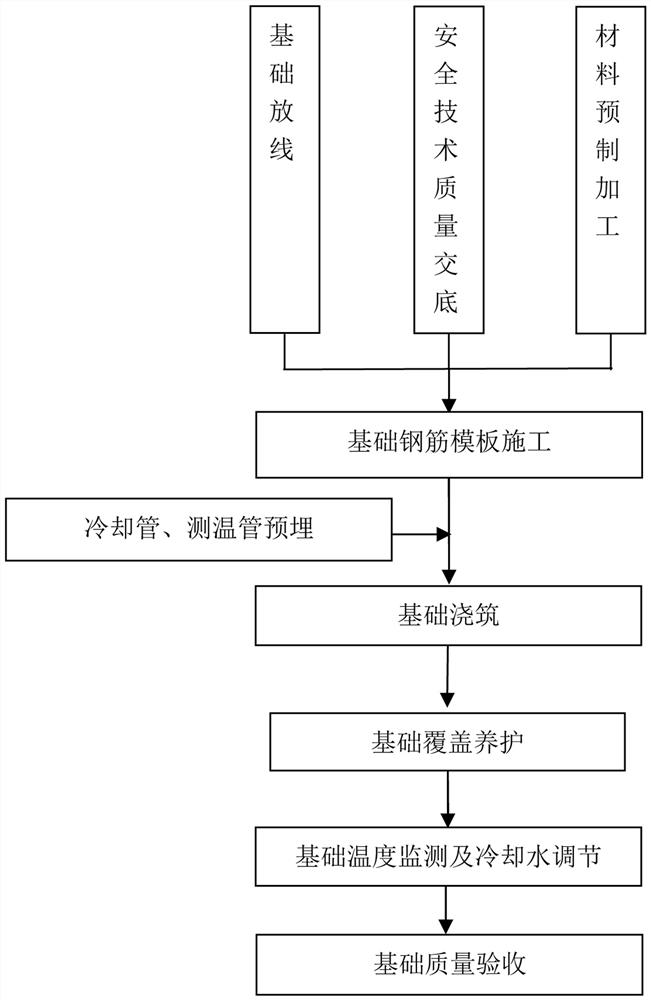

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

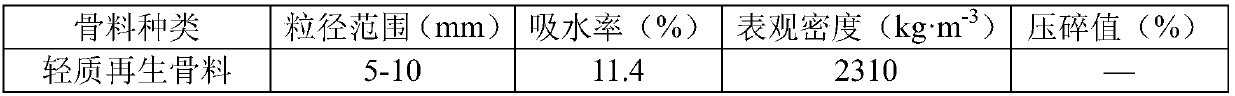

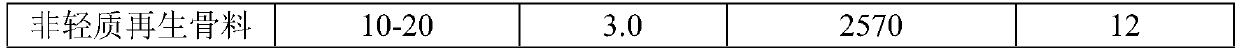

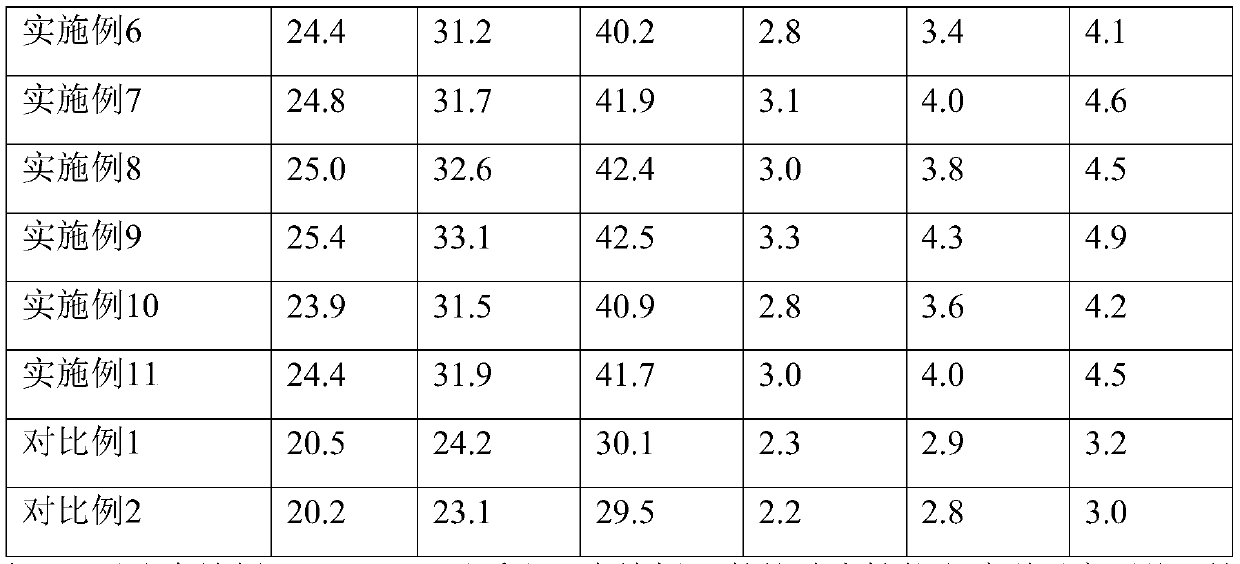

Modified recycled aggregates and preparation method therefor

ActiveCN109608077AReasonable ratioReduce hydrothermalizationSolid waste managementPorosityGlass fiber

The invention belongs to the technical field of reclaimed concrete and discloses a preparation method for modified recycled aggregates. The method comprises the step of soaking recycled aggregates ina modification solution for 1 to 3 hours, wherein the modification solution comprises the ingredients in parts by weight: 60-80 parts of water glass with a mass concentration of 5%, 5-10 parts of silane coupler, 10-20 parts of silicone resin and 5-10 parts of kaolin. Prepared modified reclaimed concrete has relatively low porosity. The invention further discloses reclaimed concrete. The reclaimedconcrete comprises the following ingredients in parts by weight: 250-300 parts of cement, 80-130 parts of fly ash, 50-85 parts of mineral powder, 685-735 parts of sand, 646-874 parts of gravels, 202-398 parts of the modified recycled aggregates, 140-175 parts of water, 5-9 parts of water reducer and 10-15 parts of glass fibers. The prepared reclaimed concrete still has relatively high compressivestrength under the condition that a large volume of reclaimed concrete is utilized.

Owner:中建西部建设北方有限公司

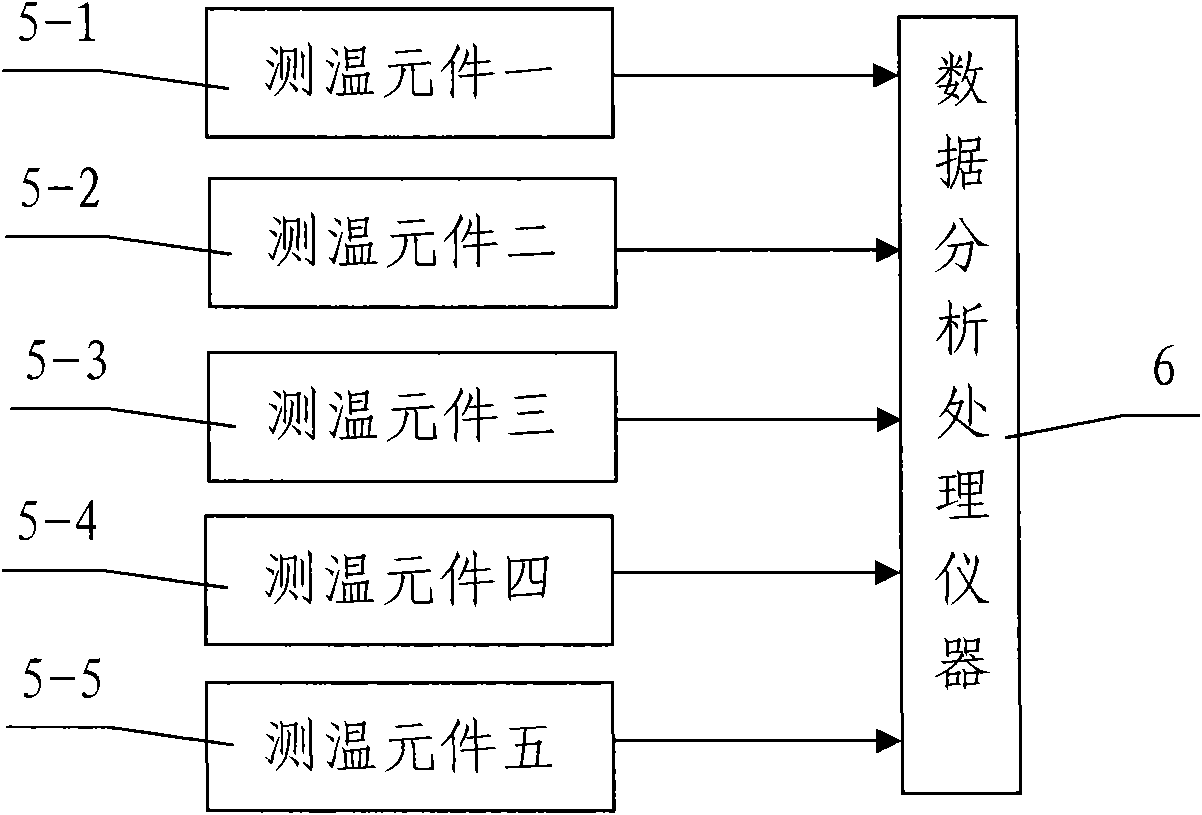

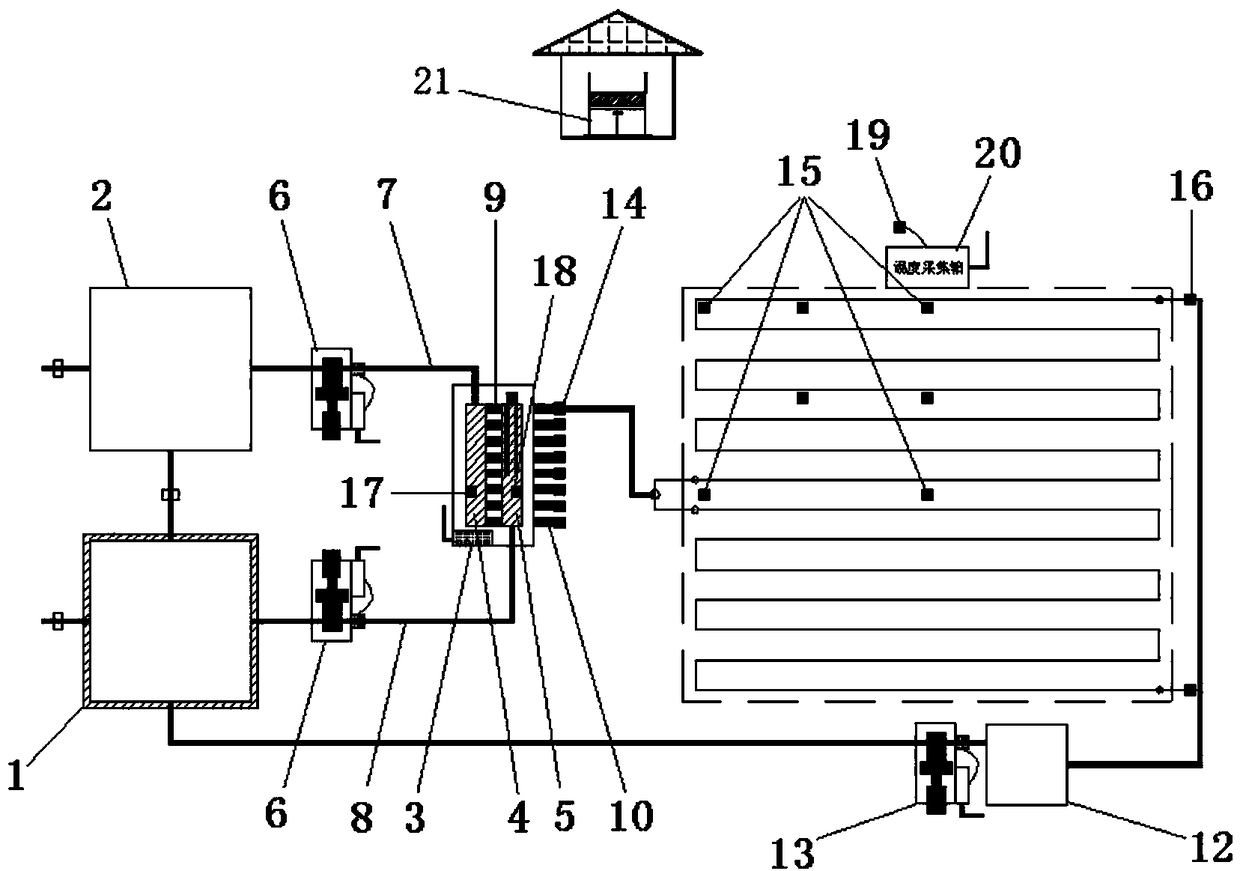

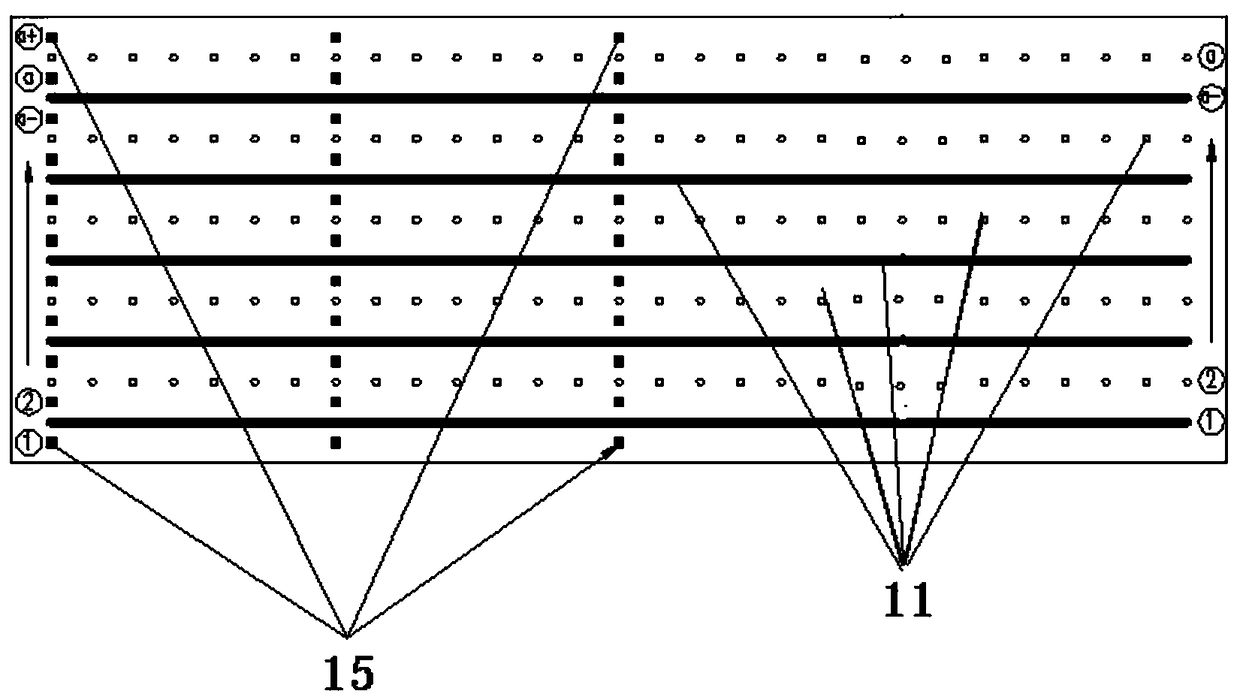

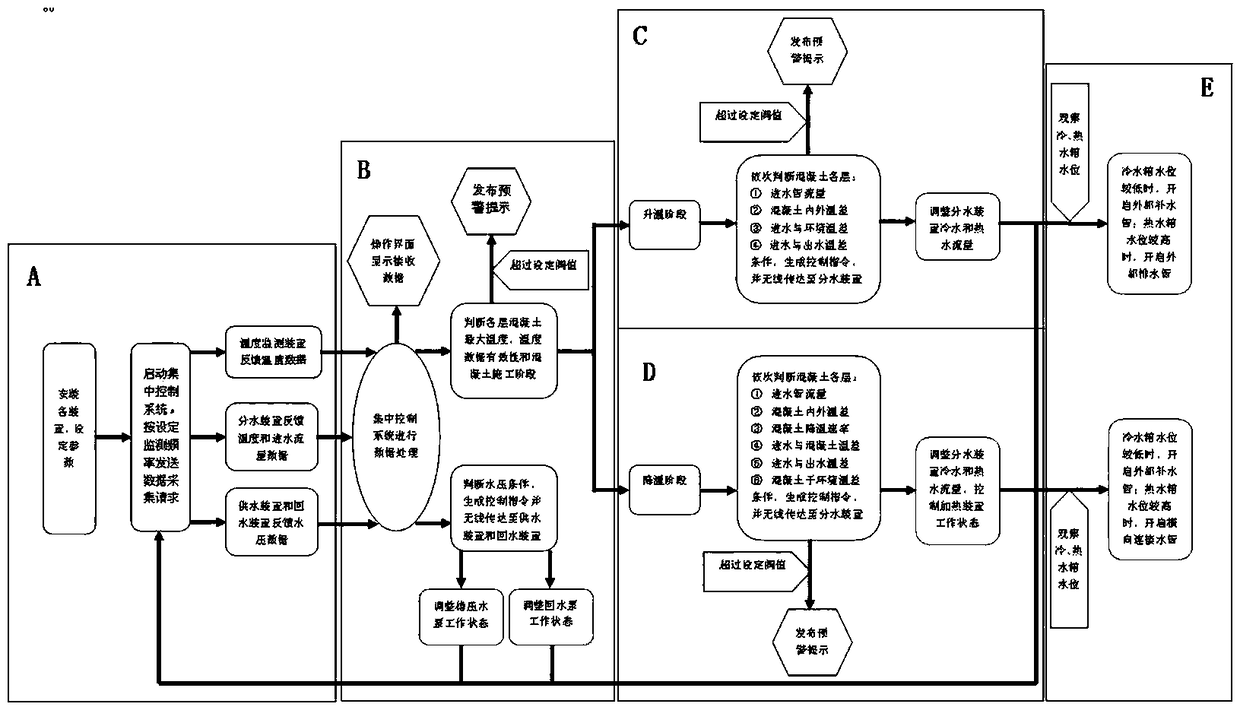

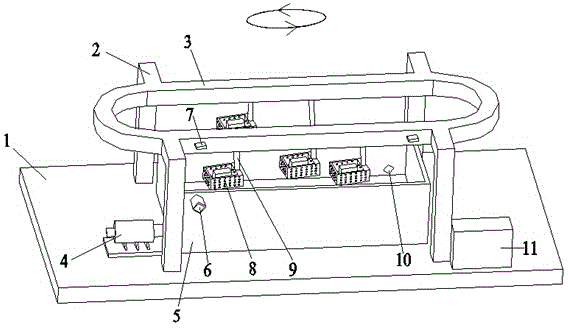

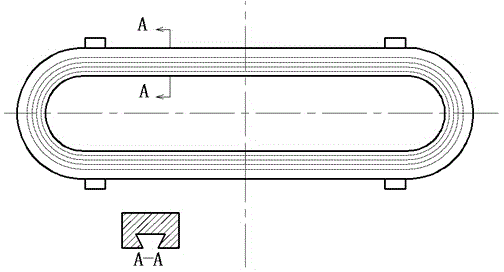

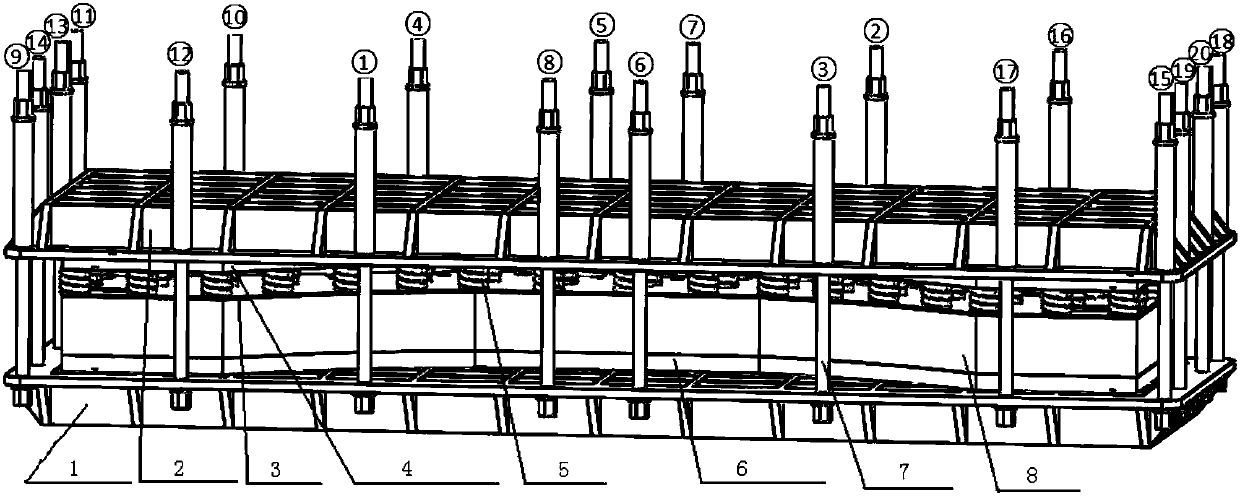

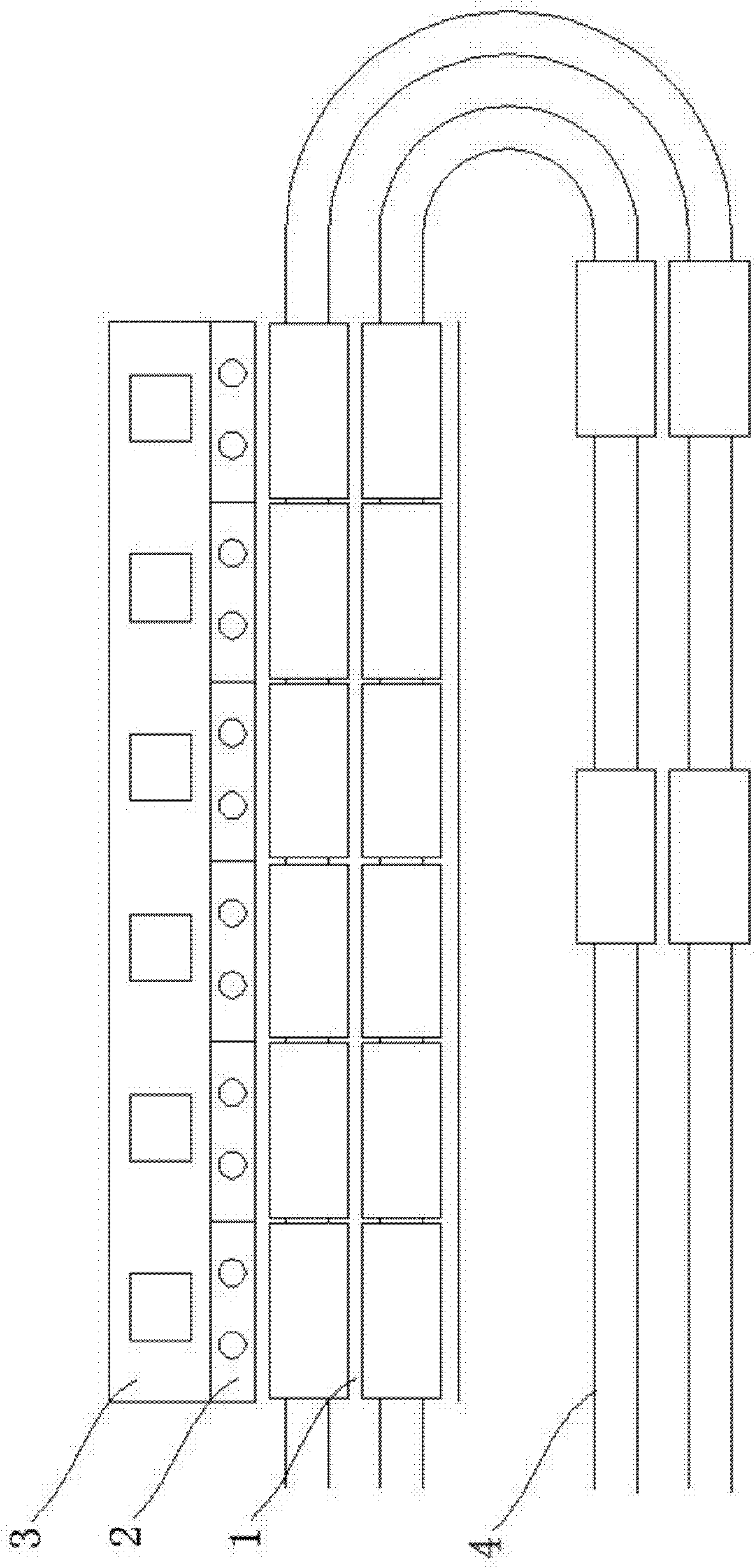

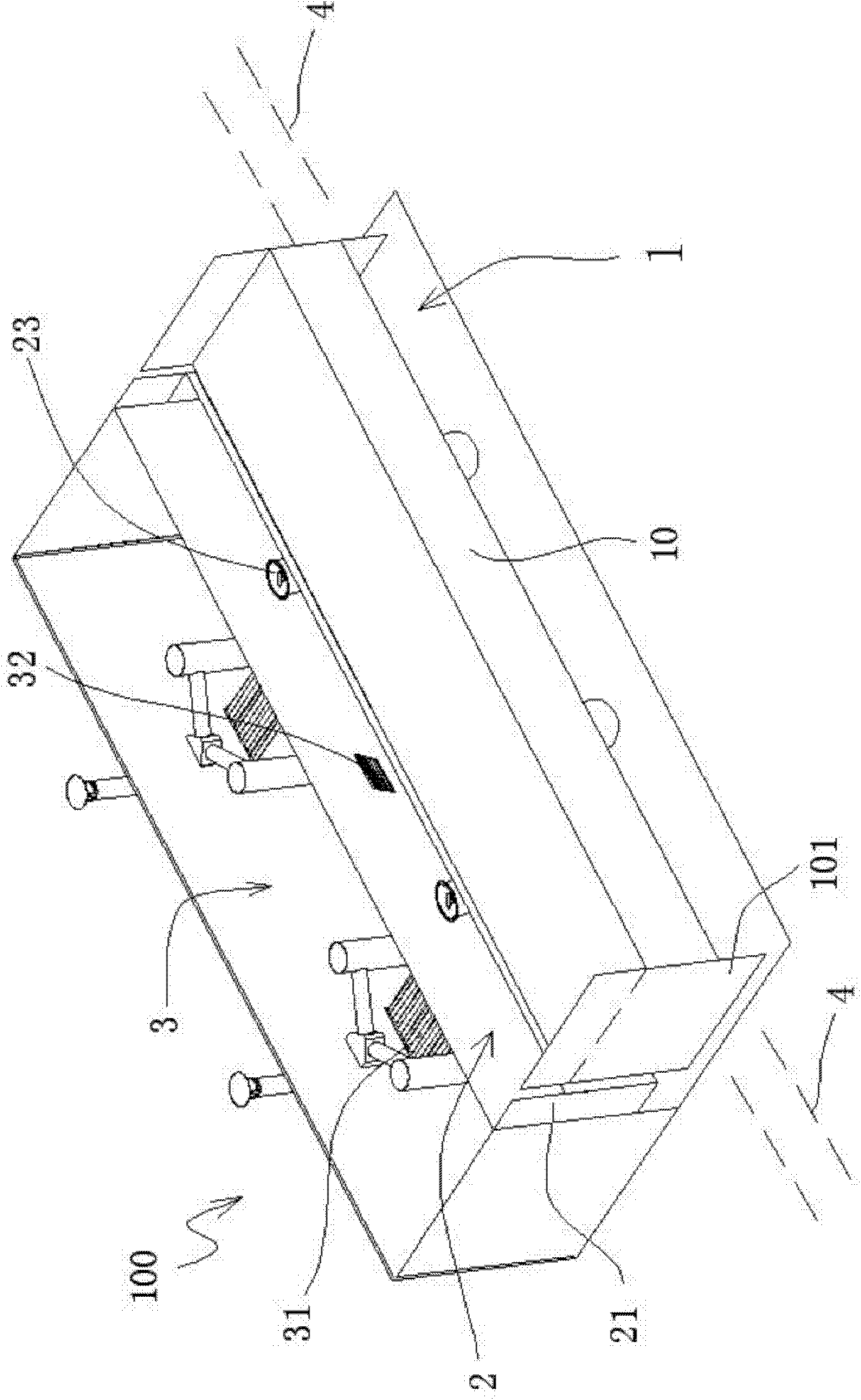

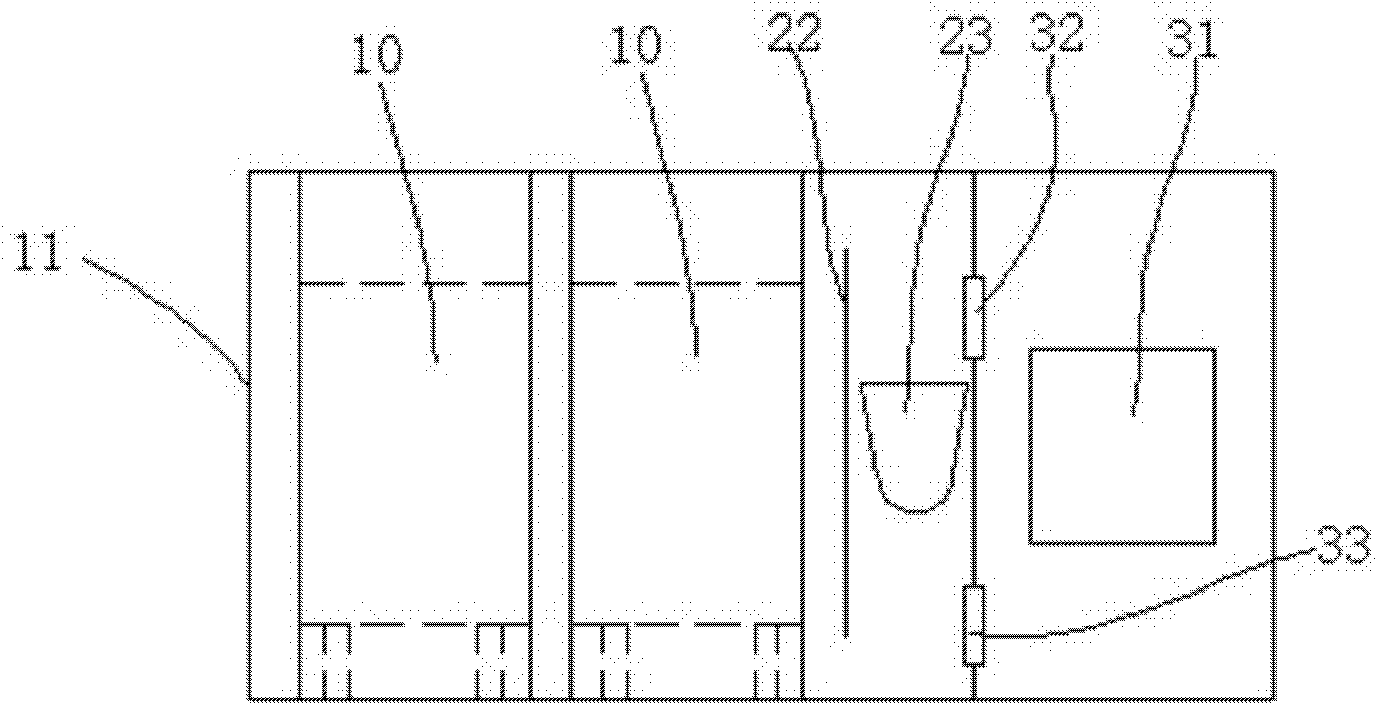

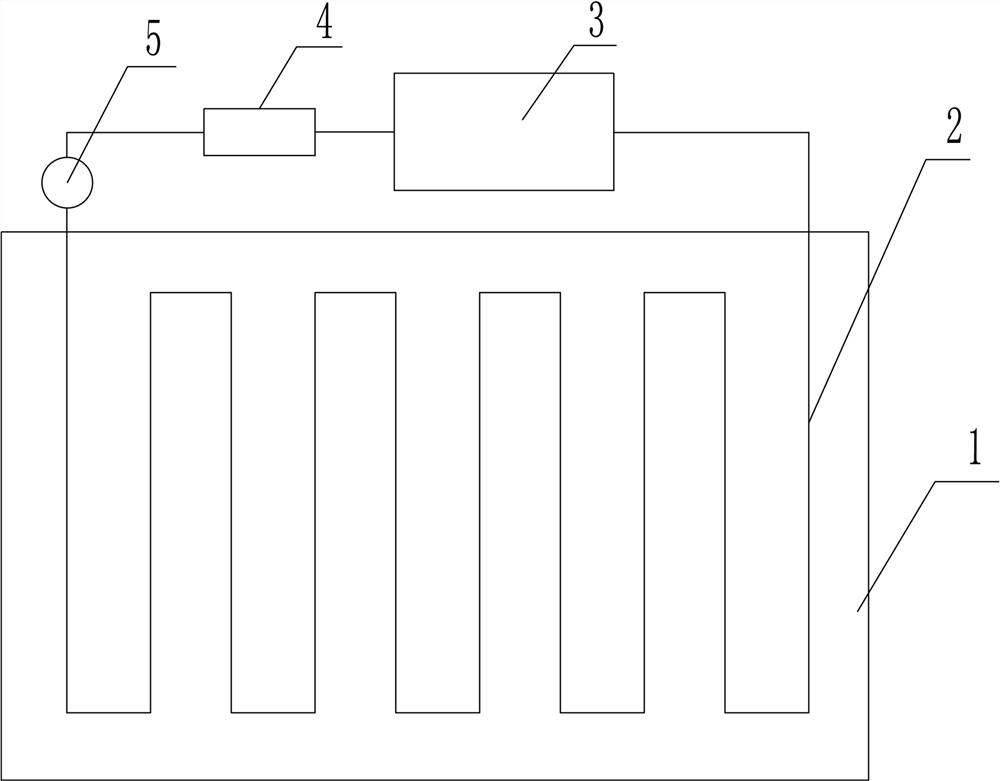

Mass concrete temperature intelligent monitoring and controlling device and method

InactiveCN109471468AControl the maximum temperatureControl cooling rateTemperatue controlPressure stabilizationData acquisition

The invention discloses a mass concrete temperature intelligent monitoring and controlling device, which comprises a circulating pipeline formed by sequentially connecting a water supply device, a water distribution device, a concrete cooling system and a water return device, wherein the concrete cooling system is internally provided with a temperature monitoring device; and a centralized controlsystem which is respectively connected with the water supply device, the water distribution device, the concrete cooling system and the water return device. The concrete cooling system comprises a cooling water pipe arranged in the concrete. Usage of the device comprises a concrete cooling system setting step, a monitoring device setting step, a water distribution device setting step, a water supply device setting step, a water return device setting step, a mass concrete construction preparation step, a data acquisition step, a water supply pressure stabilization step, an alarm step, a hot water tank drainage step and a cold water tank water replenishing step. By the adoption of the mass concrete temperature intelligent monitoring and controlling device, water supply pressure can be stabilized, different water inlet temperatures and flow rates of each layer can be dynamically adjusted, temperature field change in the mass concrete can be developed according to a target of temperature control, and an alarm function is equipped, so that the problems that a temperature difference of each region of the mass concrete is too large and cracks are easy to generate are solved.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

Self-compacting concrete and preparation method thereof

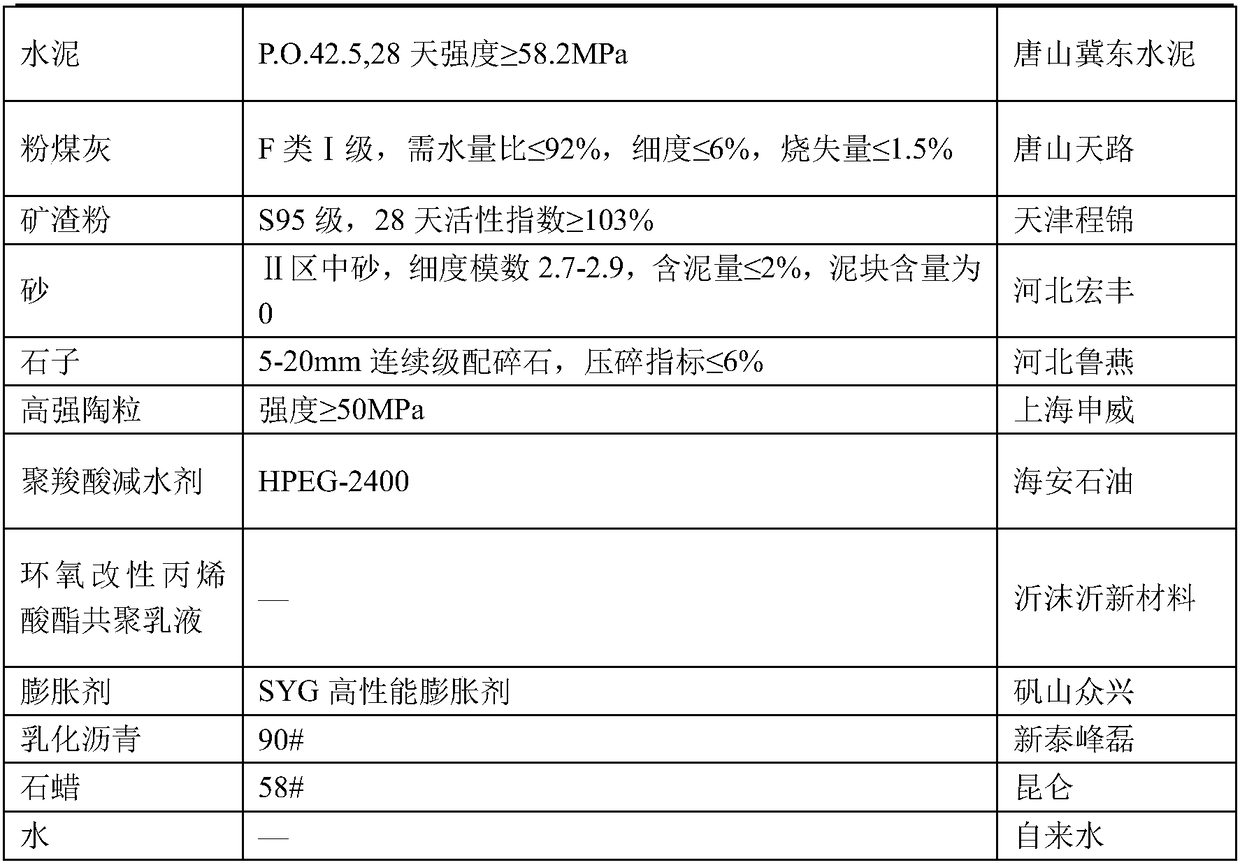

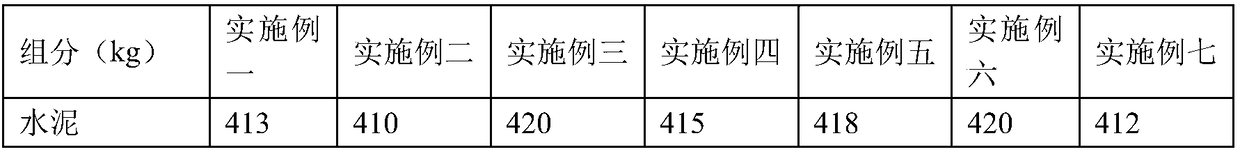

The invention relates to a self-compacting concrete. The self-compacting concrete comprises, by weight, 410 to 420 parts of cement, 50 to 60 parts of fly ash, 30 to 35 parts of slag powder, 750 to 760parts of sand, 970 to 980 parts of coarse aggregate, 10 to 15 parts of an additive, 28 to 35 parts of an expanding agent and 150 to 160 parts of water, wherein the coarse aggregate comprises cobblestone and phase-change ceramsite in a weight ratio 5: 1, and the additive comprises a polycarboxylate superplasticizer and a binder in a mass ratio of 2: 1. According to the invention, the expanding agent and a composite phase-change material are added into the concrete, so gaps in the self-compacting concrete are filled, and internal cracks in the concrete are reduced.

Owner:北京中实上庄混凝土有限责任公司

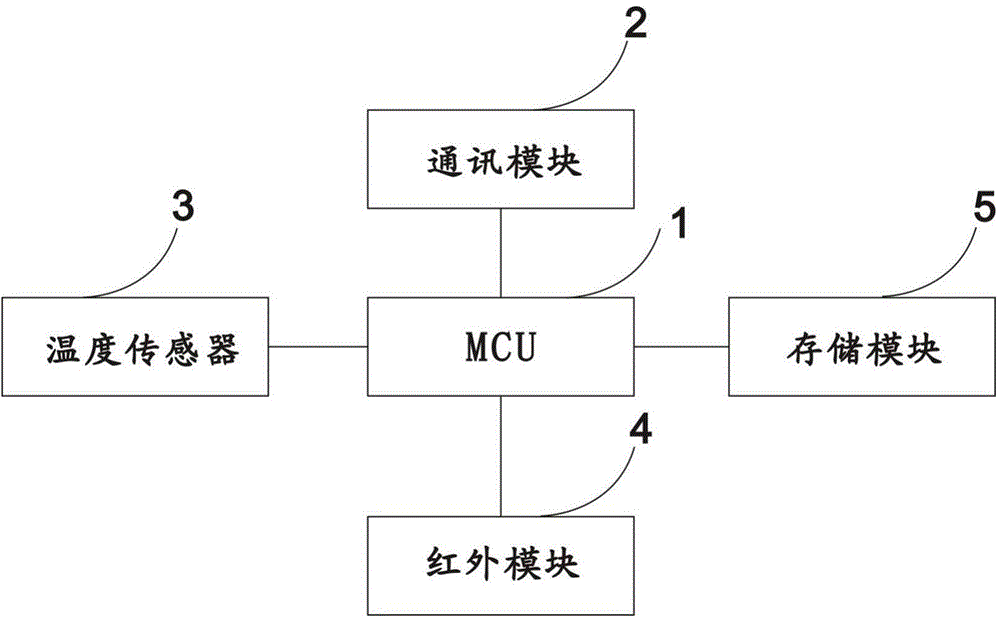

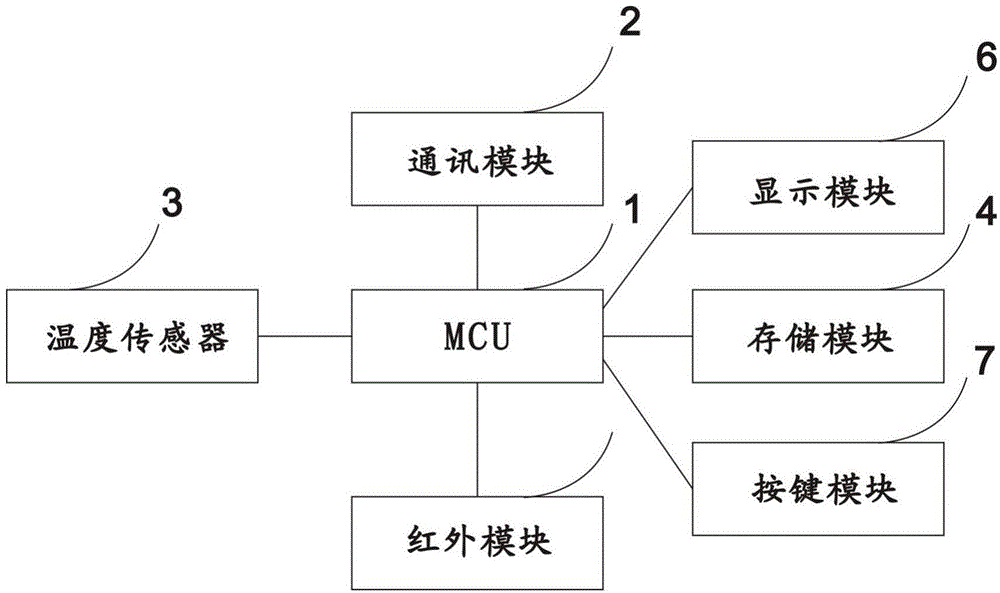

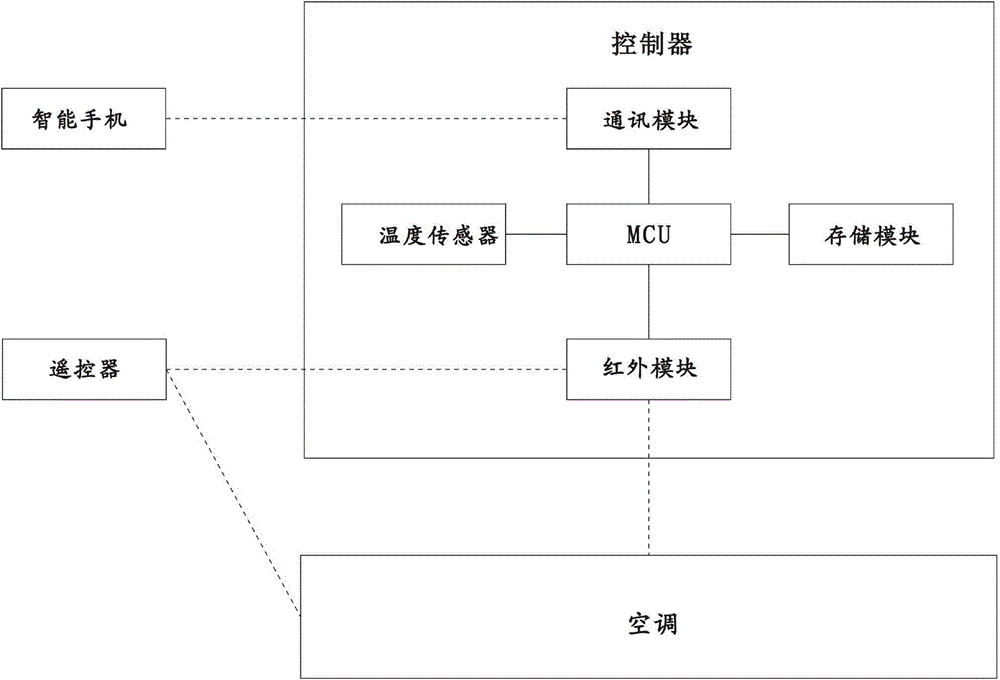

Controller capable of automatically adjusting parameters of equipment

InactiveCN104154631AReduce the temperature difference between inside and outsideSleep comfortablySpace heating and ventilation safety systemsLighting and heating apparatusComputer scienceControl unit

The invention provides a controller capable of automatically adjusting parameters of equipment. The controller comprises a communication module, a detection module, an infrared module, a storage module and an MCU (microprogrammed control unit), the MCU is connected with the communication module, the detection module, the infrared module and the storage module respectively, the detection module is a parameter sensor, the storage module stores parameters taking time and the parameters as coordinate axes and parameter curves corresponding to the time, the parameter curves are transmitted through an input information component out of the equipment and received through the communication module prior to being transmitted to the storage module via the MCU, the parameter sensor senses the parameter values on the periphery of the point where the controller is located and transmits the parameter values to the MCU, and the MCU automatically calculates difference values according to corresponding target parameter values of corresponding time point of the storage module and transmits the difference values to the equipment via the infrared module to perform adjustment. By the controller, the parameters of the equipment can be adjusted in real time so as to meet environmental parameter requirements preset by users, comfort required for a human body can be created, and energy-saving performance of the equipment during use can be improved.

Owner:吴生 +1

Mass concrete cracking proof construction technology

ActiveCN104264678AAvoid crackingReduce water consumptionFoundation engineeringProof constructionTemperature difference

The invention discloses a mass concrete cracking proof construction technology which can prevent the concrete from cracking and improve the concrete pouring quality. The mass concrete cracking proof construction technology comprises the following steps of firstly building a steel reinforcement framework and a template, then selecting the type and the ratio of the concrete, pouring the concrete, regulating the internal and external temperature difference and the maximum temperature of the concrete after concrete pouring is achieved; cooling the concrete by water-passing cooling, when the internal and external temperature difference of the concrete cannot be smaller than 25 DEG C by the water-passing cooling, reducing the internal and external temperature difference of the concrete by rising the temperature of the exterior of the concrete and maintaining naturally concrete temperature reducing when the internal and external temperature difference is smaller than 25 DEG C and the internal maximum temperature is smaller than 50 DEG C; removing the template when the concrete temperature is not changed to achieve construction of the concrete. According to the mass concrete cracking proof construction technology, cracking during a solidification process of the concrete is effectively avoided and the concrete quality is improved.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

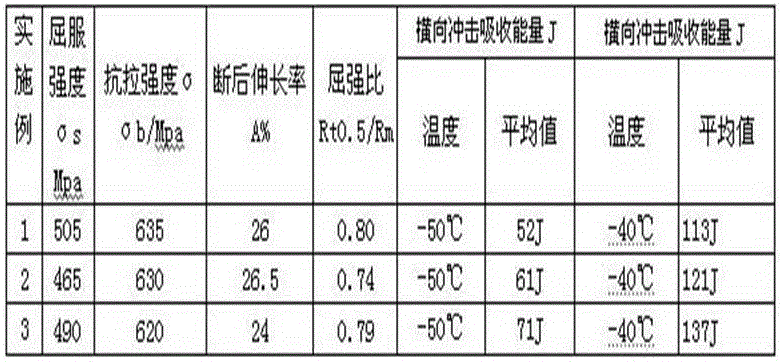

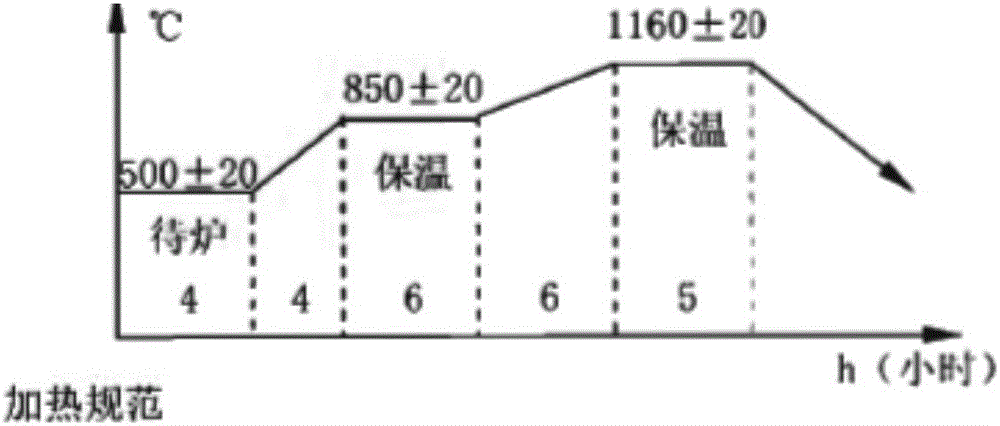

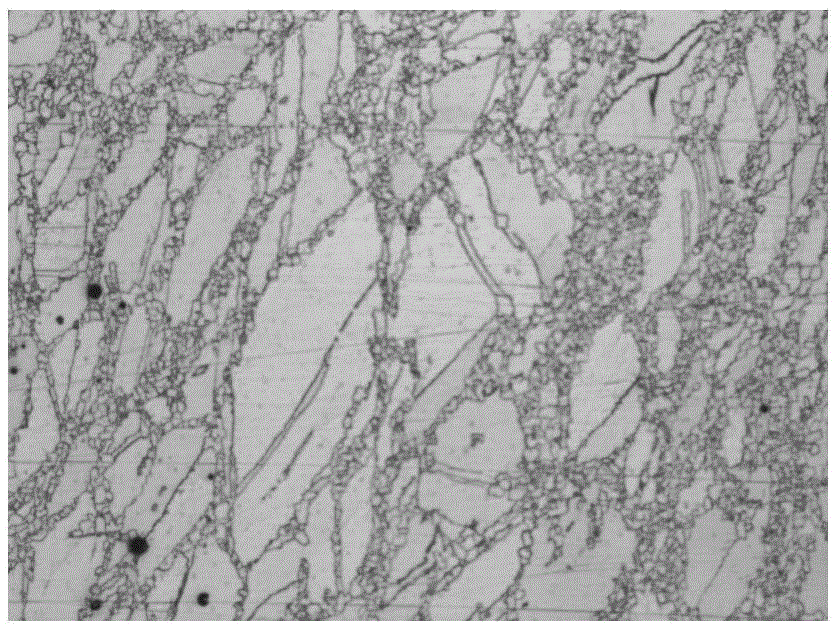

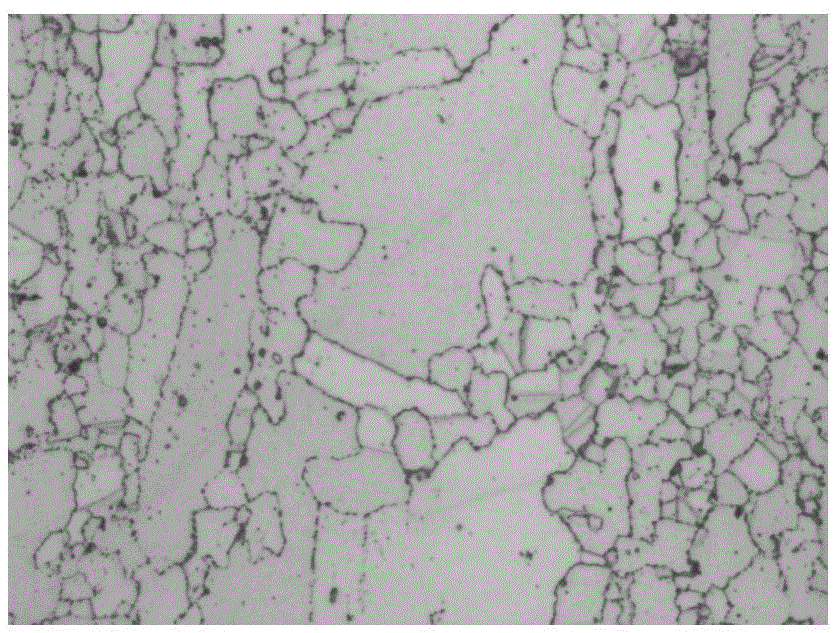

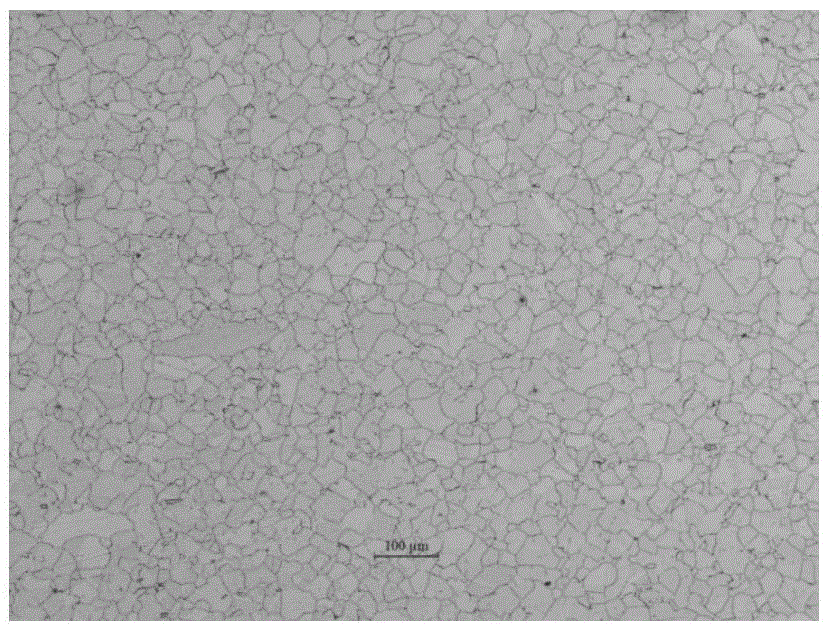

Q460E steel plate with thickness larger than 120 mm and manufacturing method of steel plate

The invention discloses a Q460E steel plate with the thickness larger than 120 mm. The steel plate comprises the following chemical components in percentage by mass: 0.15-0.19% of C, 1.5 -1.75% of Mn, 0.20-0.50% of Si, less than or equal to 0.01% of S, less than or equal to 0.015% of P, 0.03-0.055% of Nb, 0.015-0.03% of Ti, 0.07-0.14% of V, less than or equal to 0.06% of Al, less than or equal to 0.010% of N, less than or equal to 0.006% of O, less than or equal to 0.015% of Mo, 0.25-0.35% of Cu, 0.15-0.25% of Ni, less than or equal to 0.3% of Cr, 0.0005-0.0015% of Ca and the balance of Fe and inevitable impurity elements. A manufacturing process of the steel plate comprises the following steps: smelting and continuous casting, reheating, rolling, DQ rapid cooling and automatic temperature returning, stack cooling and normalizing. The obtained steel plate is 120 mm or above in thickness, the yield strength of the steel plate is improved to 460 MPa or above and the grain size of the steel plate reaches 8.0 level or above.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

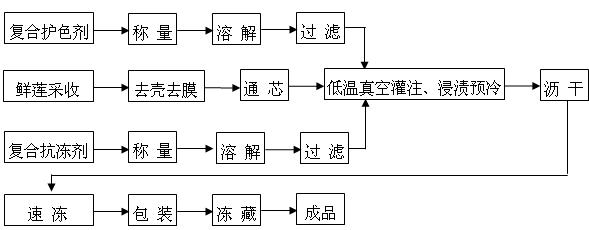

Method for processing quick-frozen fresh lotus

ActiveCN101965860AReduce damage and softenReduce the temperature difference between inside and outsideFruit and vegetables preservationBiotechnologyBrowning

The invention provides quick-frozen fresh lotus processing technology. In the technology, a quick-frozen fresh lotus finished product is obtained by the harvesting of fresh lotus, shelling, stripping, core hollowing, low-temperature vacuum filling, impregnation for pre-cooling, draining, quick-freezing, packaging and cold storage. Due to the adoption of the low-temperature vacuum filling technology to combine pre-cooling, color conservation and anti-freezing processes, the technology inhibits the activity of PPO and POD, prevents the browning of the quick-frozen fresh lotus in the processing and storage, reduces the damage and softening of tissue cells, endows the product with crisp texture and faint scent, improves the ion concentration and osmotic pressure of the cells of the fresh lotus, effectively rises the vitrification transition temperature, promotes the exhaust of air from tissues, reduces the swelling pressure of ice crystals, prevents low-temperature breakage, shortens the processing time, is easy to control, high in operability, less in energy consumption and suitable for the large-scale production of the quick-frozen fresh lotus, and develops a new way for the deep processing of the lotus industry. The product completely keeps the original taste and smell of the fresh lotus, has the faint scent and is convenient to take.

Owner:福建闽江源绿田实业投资发展有限公司

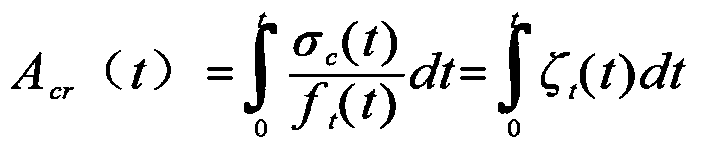

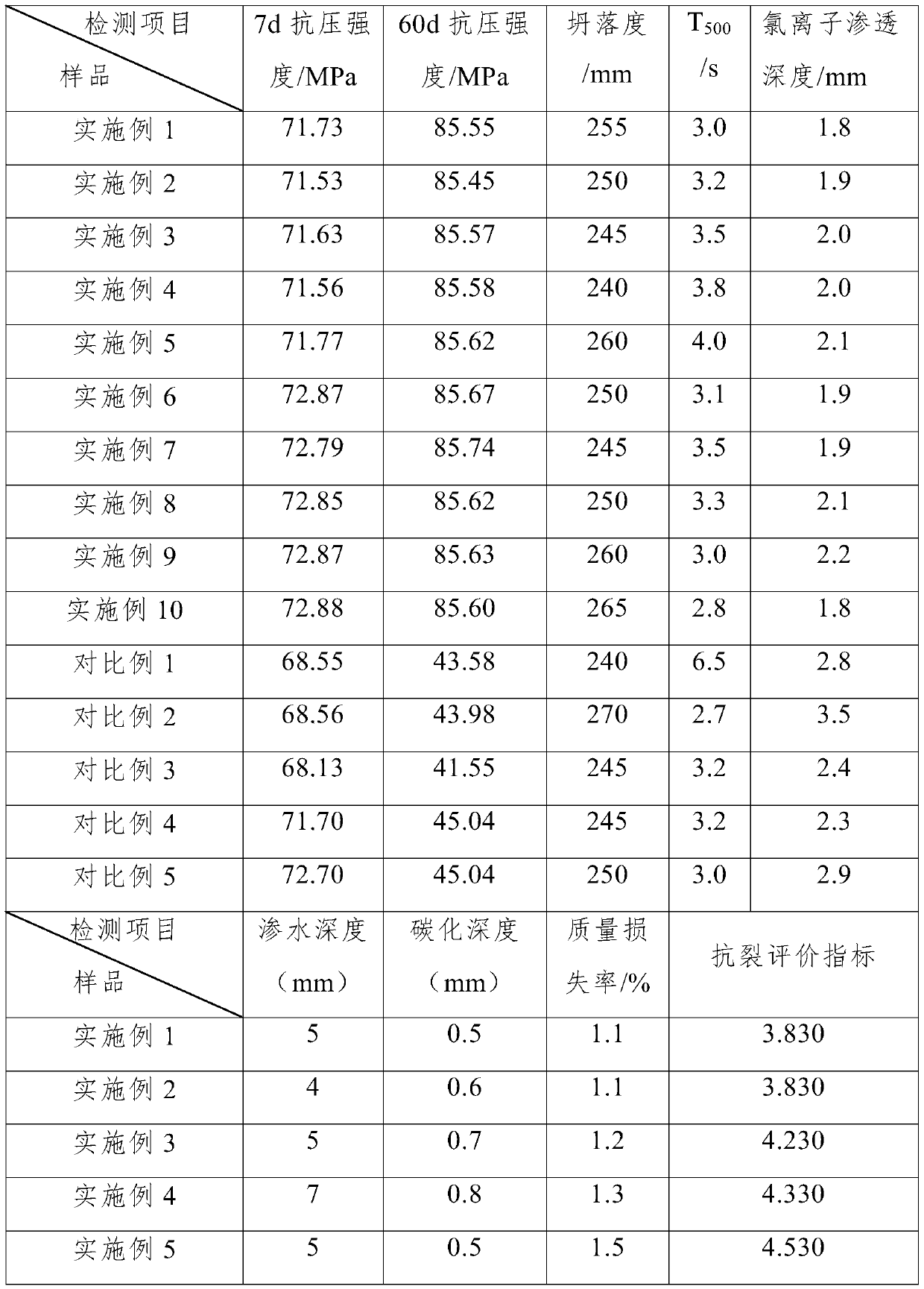

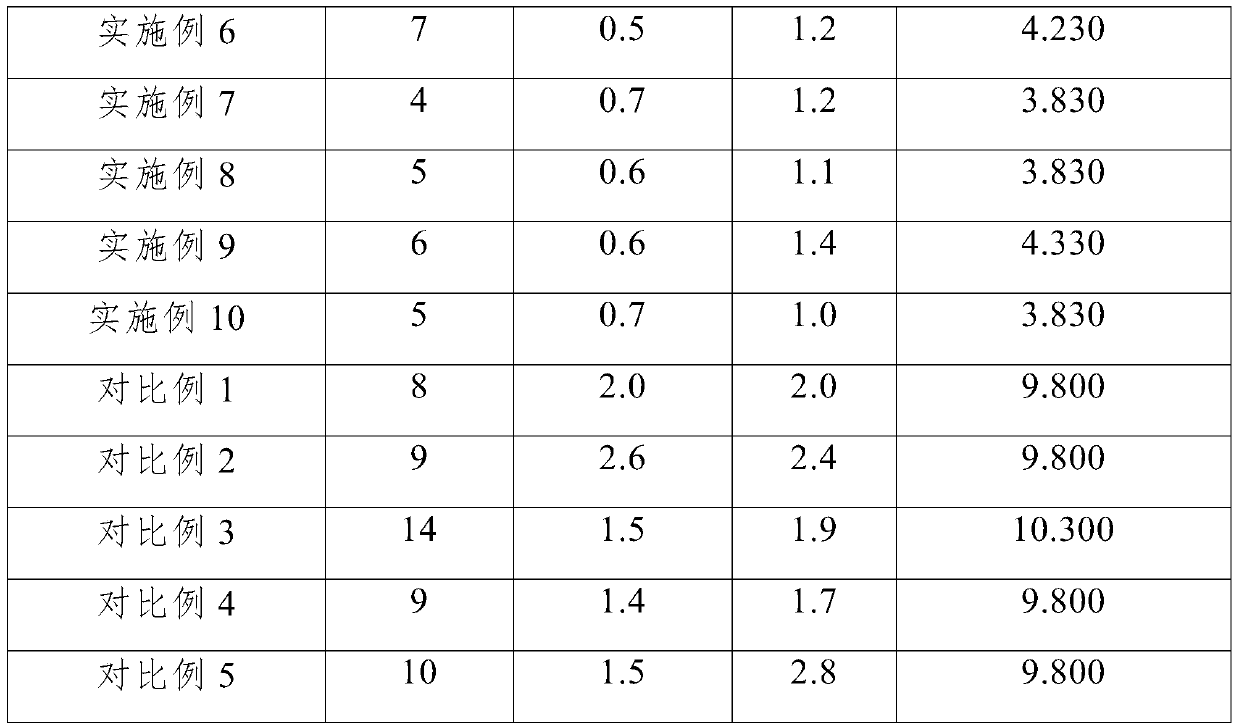

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

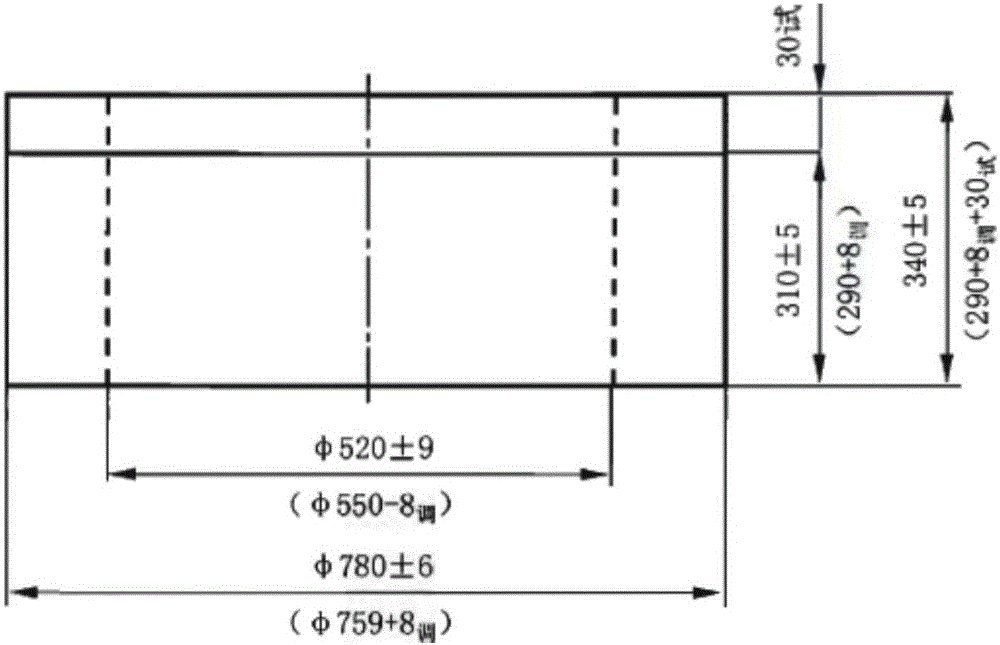

Manufacturing method of valve forged piece for ultra-supercritical turbine and valve forged piece

InactiveCN106480253AImprove yieldUpgrade the smelting processValve arrangementsMachines/enginesHardenabilitySupercritical fluid

The invention discloses a manufacturing method of an FB2 valve forged piece for an ultra-supercritical turbine. The method comprises the following steps of smelting, forging, valve forged piece heat treatment, machining and heat treatment. The invention further discloses a valve forged piece manufactured by the adoption of the manufacturing method of the FB2 valve forged piece for the ultra-supercritical turbine. According to the manufacturing method, operation is reasonable, effective boron is contained, hardenability of the forged piece reaches the standard, the grain size of the final forged piece is larger than or equal to the grade 3, and according to the manufacturing method of the FB2 valve forged piece for the 625 DEG C ultra-supercritical turbine and the FB2 valve forged piece, the situation that Y-shaped cracks appear in the center of the forged piece is avoided.

Owner:SHANGHAI TENGHUI FORGING +2

Food nutrition freezing method

InactiveCN107751713APreserve nutritional qualityReduce qualityFood freezingFood preservationMuscle tissueNutrition

The invention relates to a food nutrition freezing method. The food nutrition freezing method comprises the following stages at least: (1), a cooling stage, namely cooling food materials at a coolingrate of 2 DEG C / minute or below until a critical freezing temperature point is reached, and entering the next stage; and (2), a first freezing stage, namely rapidly lowering the temperature of the food materials to N DEG C within 30 minutes, wherein N is equal to or higher than 5 DEG C below zero and equal to or lower than 1 DEG C below zero. Compared with the prior art, muscle tissue contractioncaused by coldness is prevented in the cooling stage, and ice crystals are formed inside and outside cells, wherein the formed ice crystals are tiny so that damages to tissues are small; and thus, nutritional quality of the foods is improved.

Owner:JOYOUNG CO LTD

Prefabrication method capable of preventing mass concrete components from cracking

InactiveCN107867813AReduce the temperature difference between inside and outsideSolve crackingTemperature stressConstruction aggregate

A prefabrication method capable of preventing mass concrete components from cracking comprises steps as follows: modeling, concrete configuration, pouring, curing and form stripping. The temperature difference between inside and outside of mass concrete is effectively reduced while design strength requirements of a prefabricated component are met through optimization of structure sizes, selectionof high-quality cement, reasonable use of a mineral additive and reasonably graded aggregate, initially set matching rate calculation and test of the concrete as well as measures including concrete temperature stress, heat insulation temperature rise checking calculation and the like, so that the problem of cracking of prefabricated mass concrete components is solved.

Owner:CCCC SHANGHAI DREDGING

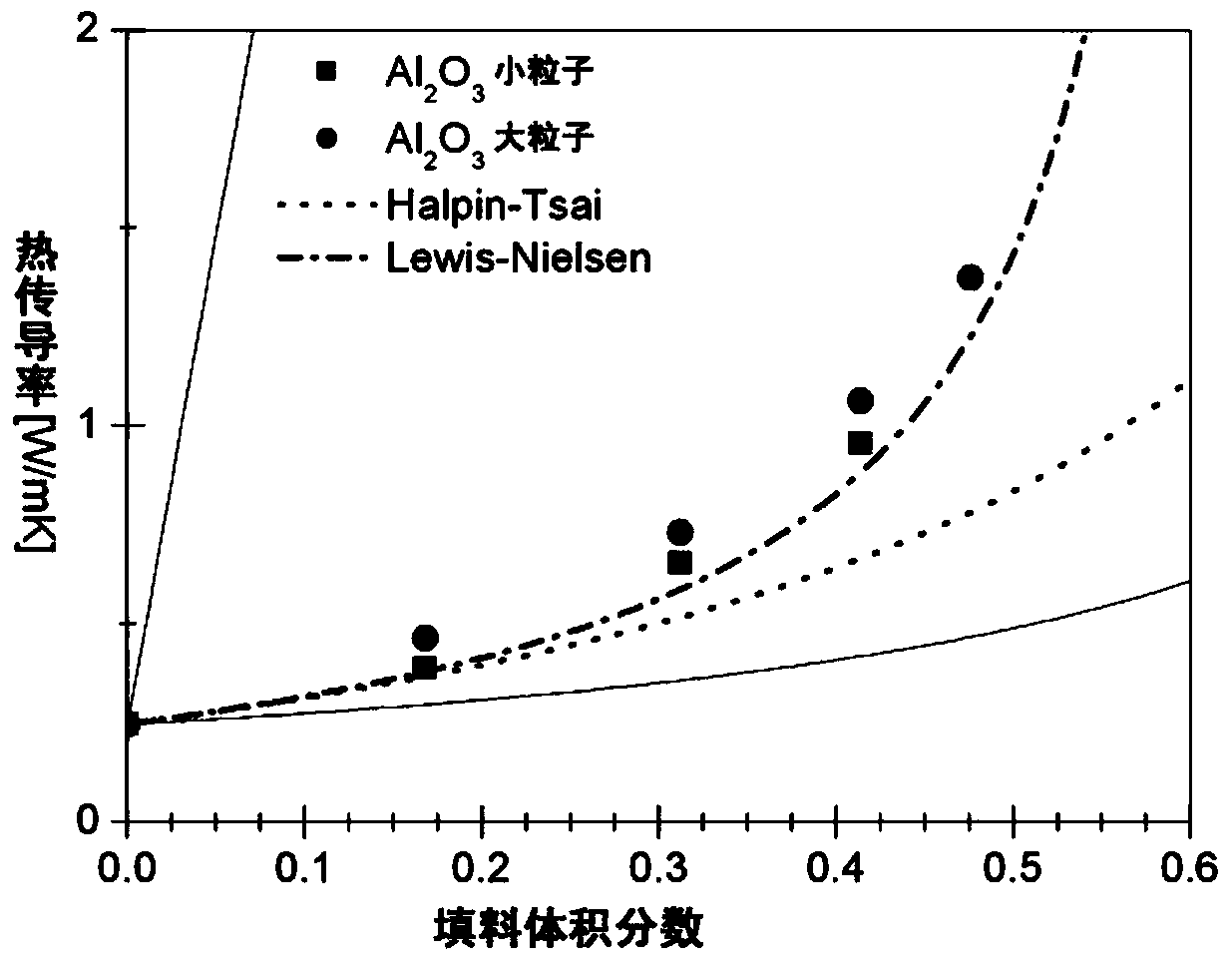

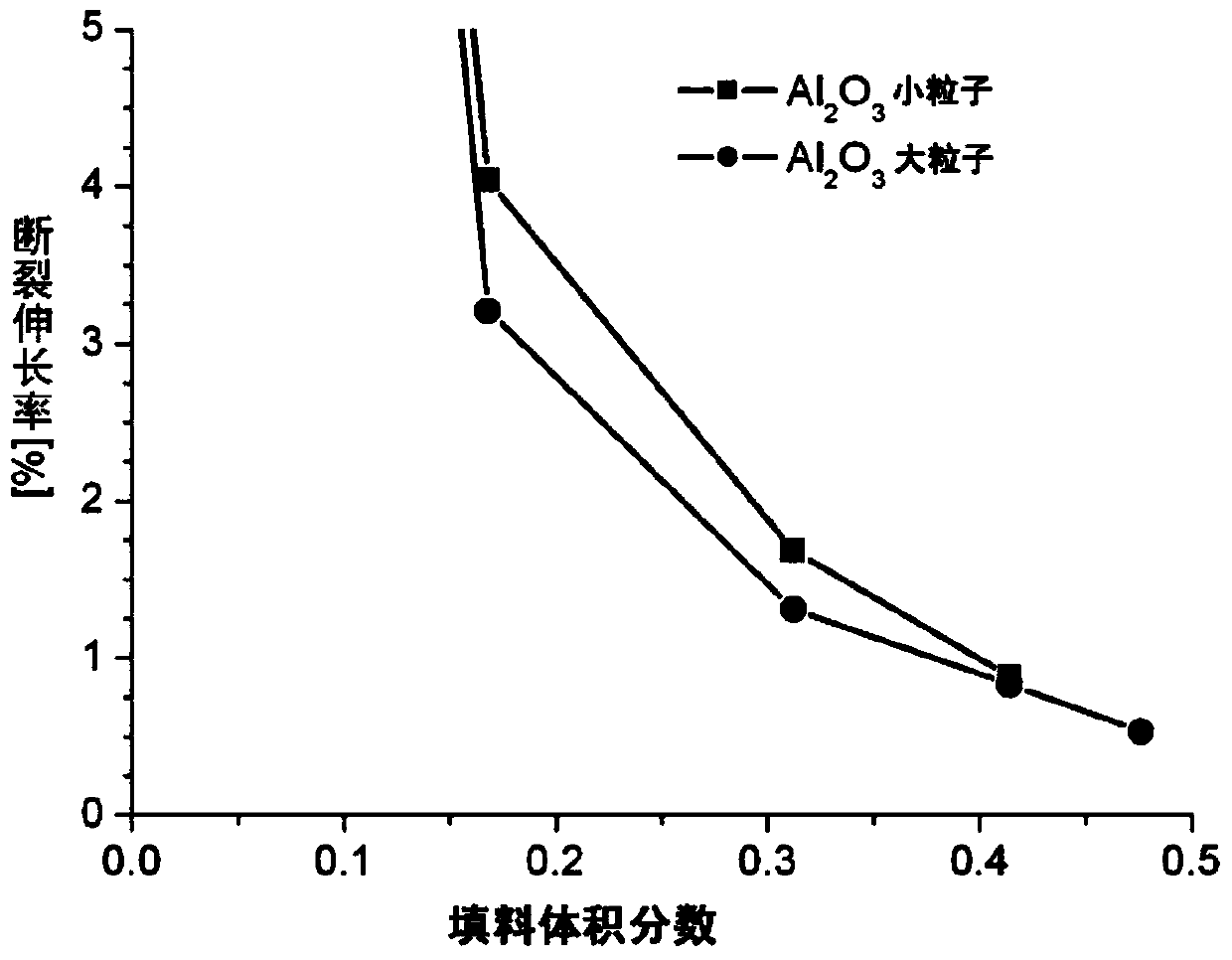

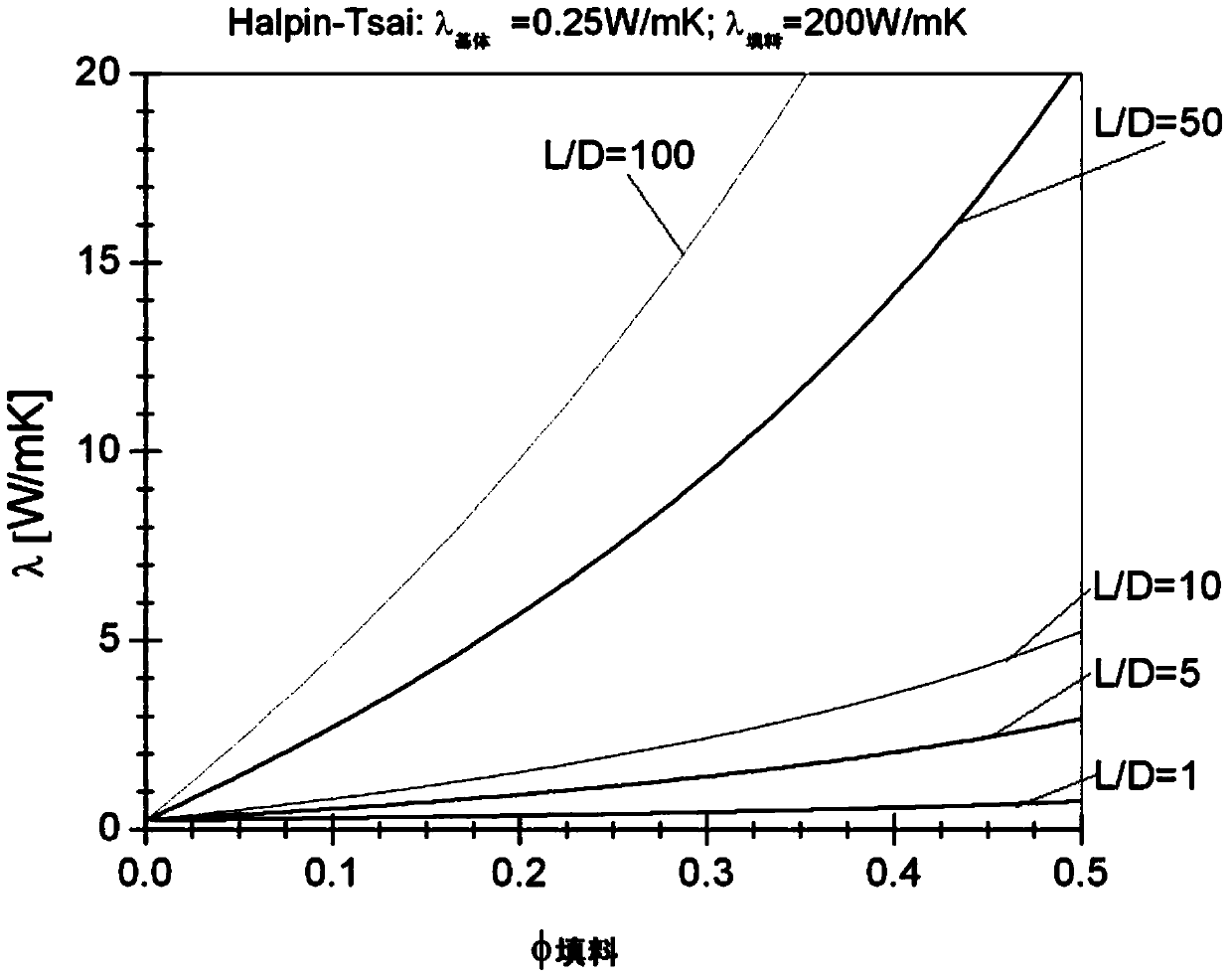

High-heat conductivity composite material for LED (light-emitting diode) lamp, heat-conducting filler and production equipment

The invention relates to a high-heat conductivity composite material for an LED (light-emitting diode) lamp, a heat-conducting filler and production equipment. A surface coupling agent solution and an inorganic heat-conducting filler are mixed according to the ratio of (0.3-0.9):(100-300) in parts by weight; the concentration of a surface coupling agent in the solution is 10-25wt%; a solvent of the solution is a water-acetone solution; the ratio of water to acetone is (5-10):(90-95); the draw ratio of the inorganic heat-conducting filler is 15-100; the high-heat conductivity composite material is composed of 59.5-64.5% of fatty polyamide in total weight, 35-40% of modified heat-conducting filler and 0.5% of lubricant; the heat conductivity of the composite material is 10-12 W / mk; a twin-screw extruder for preparing the composite material utilizes 2-3 groups of inclined toothed plates to replace a kneading block at a shear section; and an extrusion section utilizes 2-3 groups of straight toothed plates to replace a conveying block. By adopting the composite material disclosed by the invention, the heat gradient produced when insulating plastics are used is greatly reduced to be close to a numerical value of metal, the radiating requirements of the LED lamp can be well met, and the temperature difference between an inside and an outside is very small.

Owner:SHANGHAI FANHE POLYMER MATERIAL

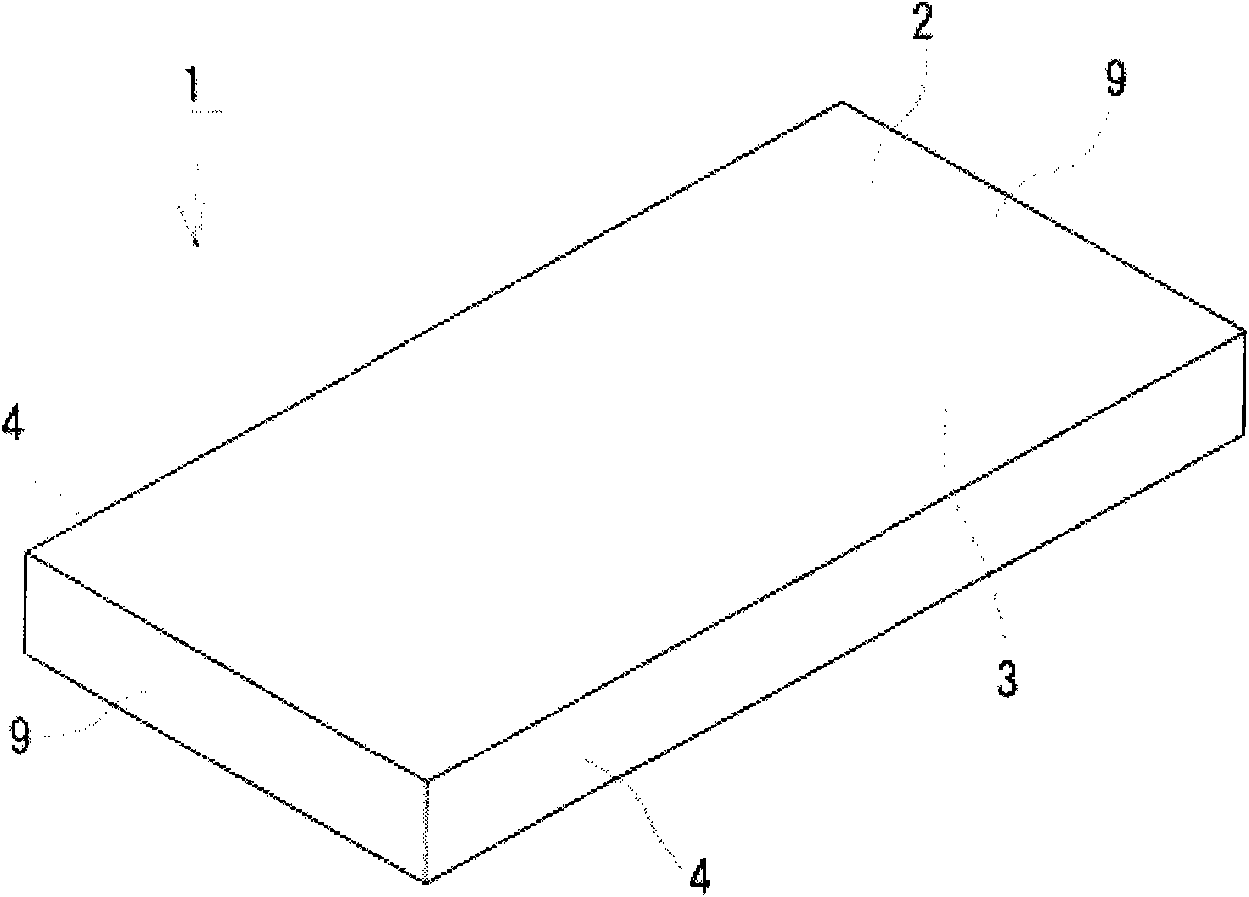

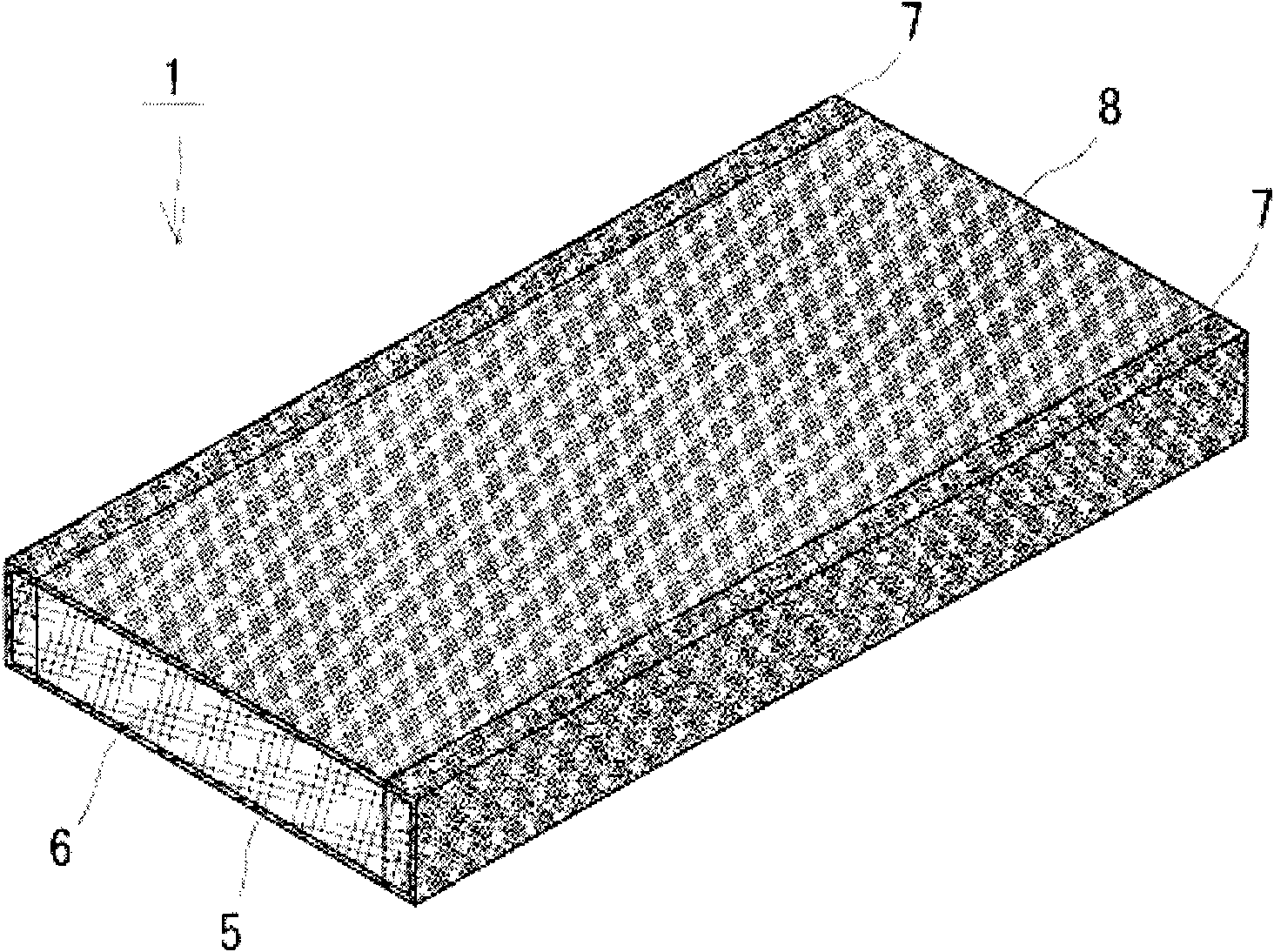

Damp-proof mattress and manufacture method thereof

InactiveCN101874691AGood for healthBeneficial antibacterial effectUpholstery manufactureStuffed mattressesApparent densityEngineering

The invention provides a good mattress capable of preventing dewing and dispensing, characterized in that: the thermal plasticity resin as the raw material or the main raw material melts to be extruded into lines and a large amount of lines are wounded out of order and welded into annular aggregates of the lines and the aggregates are formed into the plate-like shape and then cooled and solidified, therefore a three-dimensional net structure is formed. The left, right relatively-long side-surfaces have side-surface firmness parts with high apparent density.

Owner:C ENG CO LTD

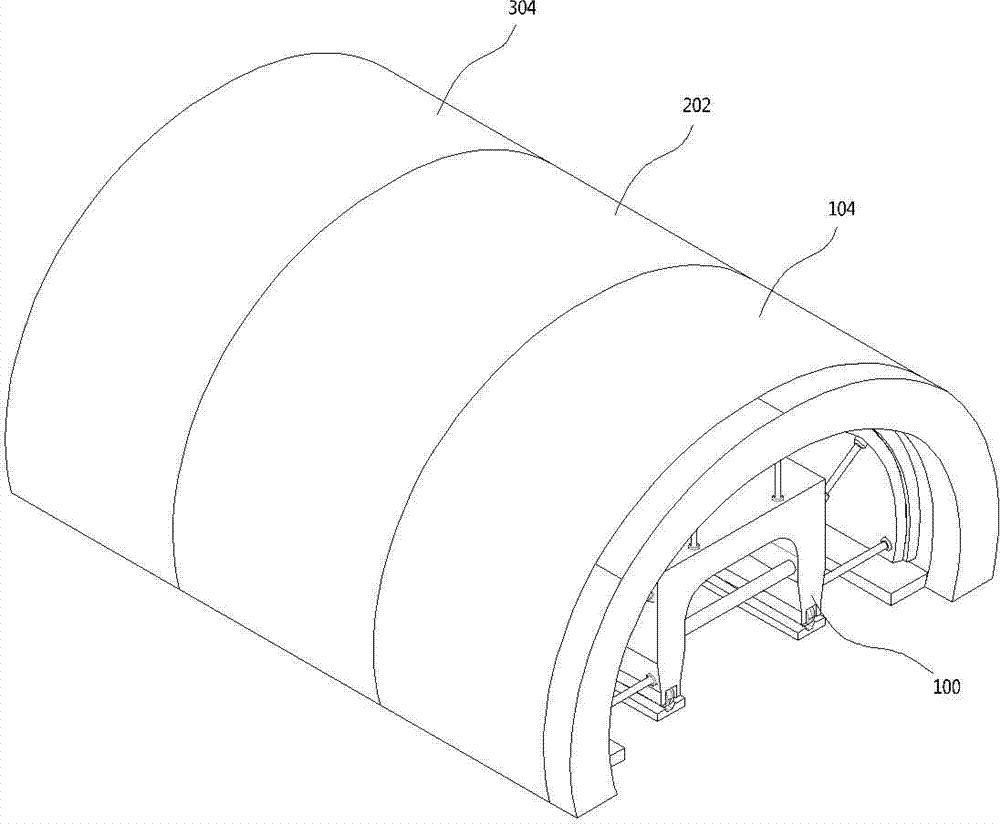

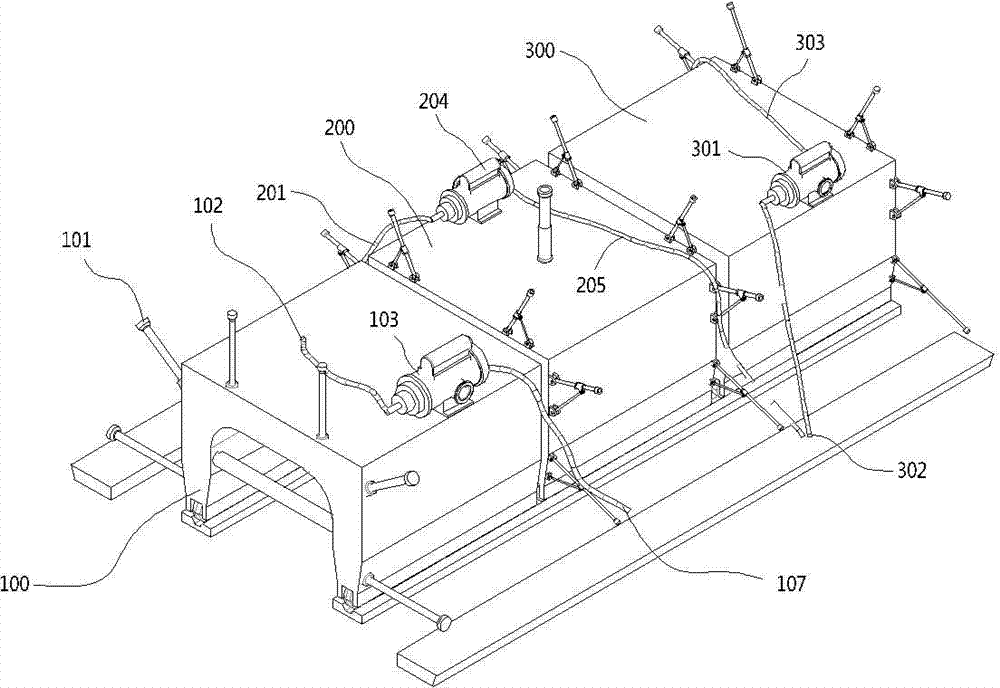

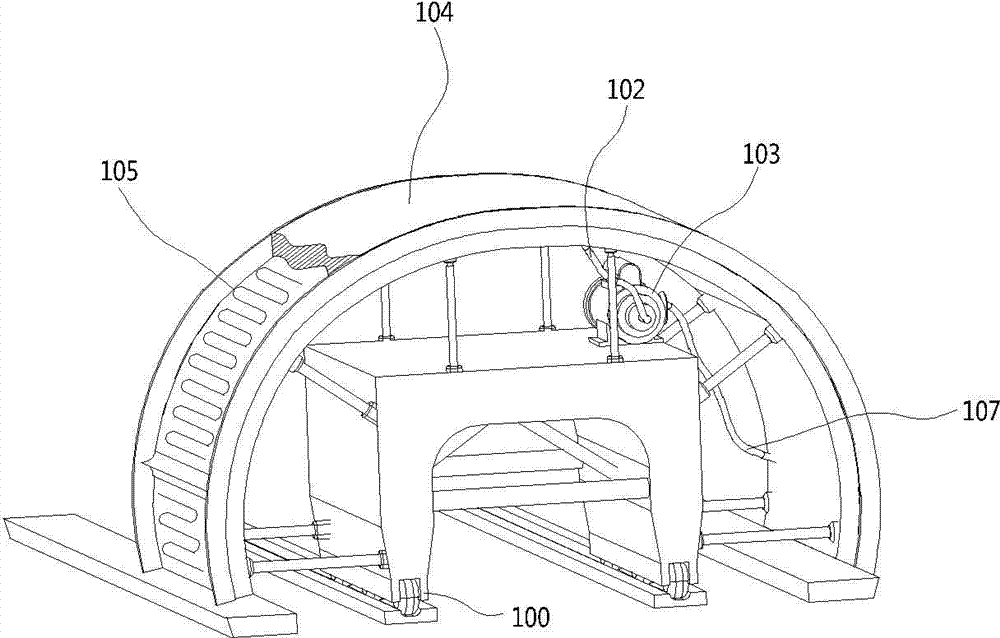

Tunnel lining concrete heat preserving and maintaining construction device

InactiveCN104712345APrevent frost heaveReduce the temperature difference between inside and outsideUnderground chambersTunnel liningArchitectural engineeringStructural engineering

Disclosed is a tunnel lining concrete heat preserving and maintaining construction device. The tunnel lining concrete heat preserving and maintaining construction device is characterized by comprising a first trolley, a second trolley and a third trolley which are sequentially connected, or comprising a first trolley and a second trolley which are sequentially connected, or comprising a second trolley and a third trolley which are sequentially connected, or comprising a first trolley and a third trolley which are sequentially connected, wherein the three trolleys are each provided with a template supported through a supporting rod. The tunnel lining concrete heat preserving and maintaining construction device has the advantages that the three construction trolleys conduct heat preservation on secondary lining at first, the temperature difference between the interior and the exterior is decreased, then, heat preservation and moisture retention are carried out on concrete, concrete frost heaving is avoided, and finally the concrete is slowly cooled through a cooling layer, so that the quality problem generated by the large temperature difference between pre-construction and post-construction is avoided. The tunnel lining concrete heat preserving and maintaining construction device has the advantages of being stable in construction quality and low in manufacturing cost and has the wide market prospect.

Owner:郑向东 +15

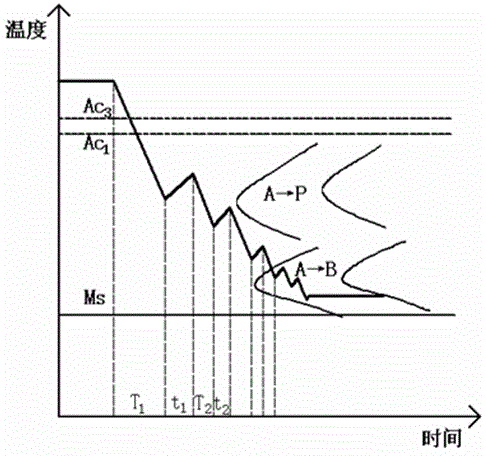

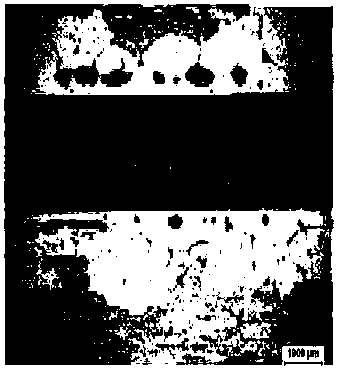

Method and device for progressive austempering heat treatment of bainite and martensite complex-phase steel/iron

ActiveCN104561462AReduce the temperature difference between inside and outsideReduce or prevent quenching cracking tendencyQuenching agentsQuenching devicesMartensite transformationMetallic materials

The invention relates to a method and device for progressive austempering heat treatment of bainite and martensite complex-phase steel / iron, and belongs to the technical field of metallic material heat treatment processes. The method comprises the following steps: performing water cooling on an austenitized workpiece for a certain period of time, taking out the workpiece for air cooling, and enabling the inner and outer temperatures of the workpiece to be close to each other by using waste heat temperature returning, thereby finishing a heat treatment cycle; putting the inner and outer parts of the workpiece into a lower bainite transformation temperature zone after finishing multiple heat treatment cycles; then performing isothermal transformation by using waste heat temperature returning or heat preservation by an insulation can; and finally performing air cooling to finish martensite transformation. By adopting the method, the defect that a workpiece with a relatively large wall thickness is easy to crack and generate early cracks during quenching can be overcome, and the obtained product is uniform in structure, good in comprehensive mechanical property, reliable in operation and low in cost and is green and environmentally-friendly.

Owner:KUNMING UNIV OF SCI & TECH

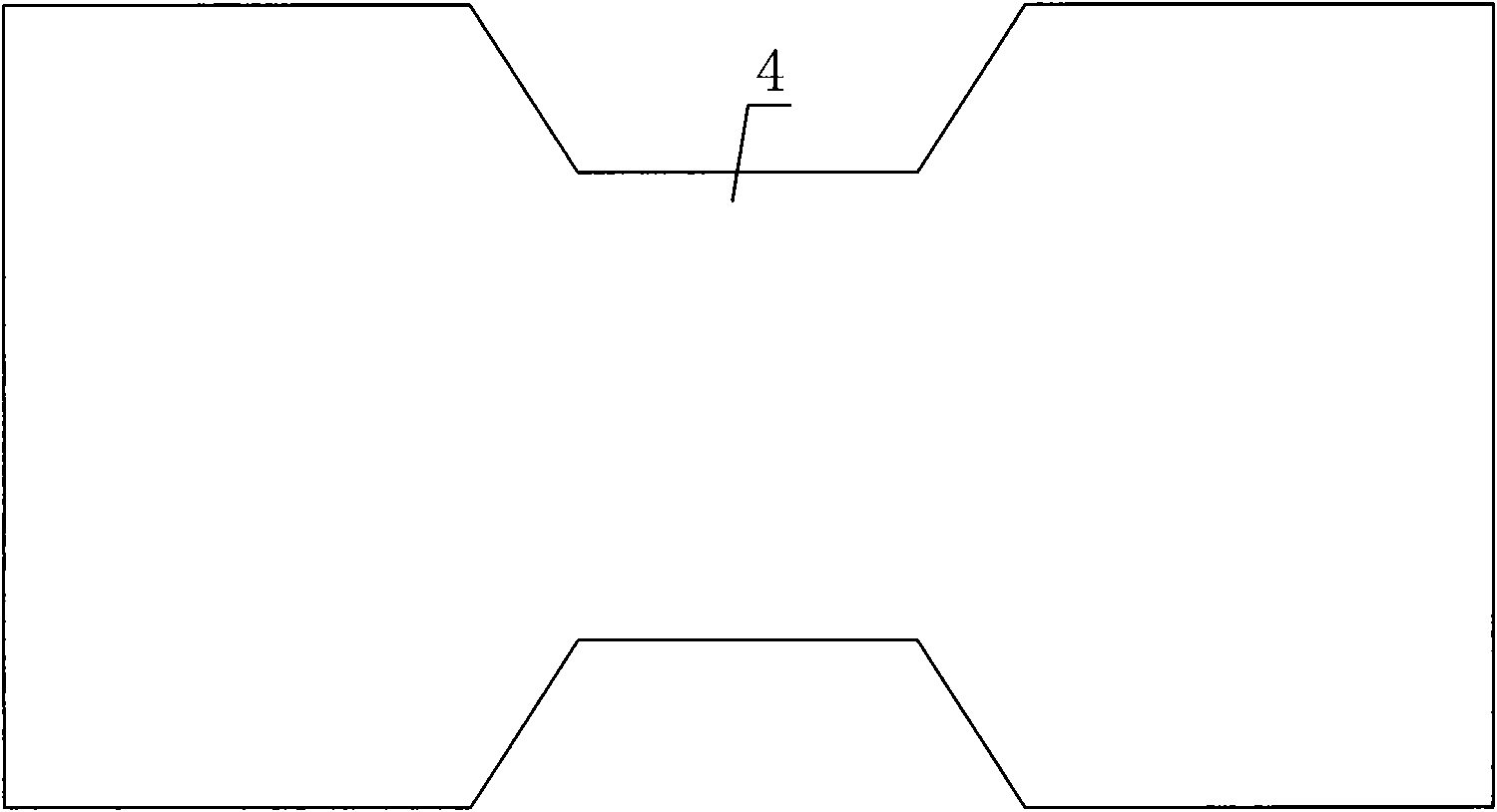

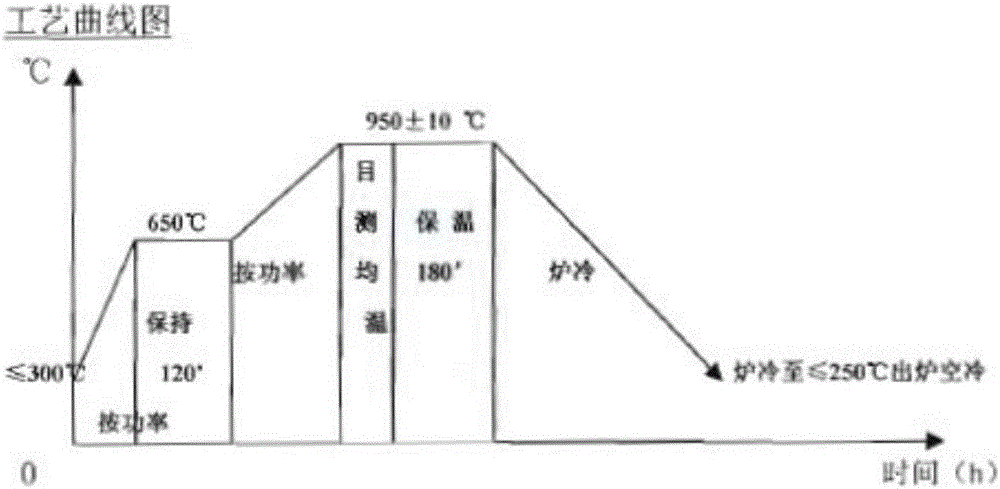

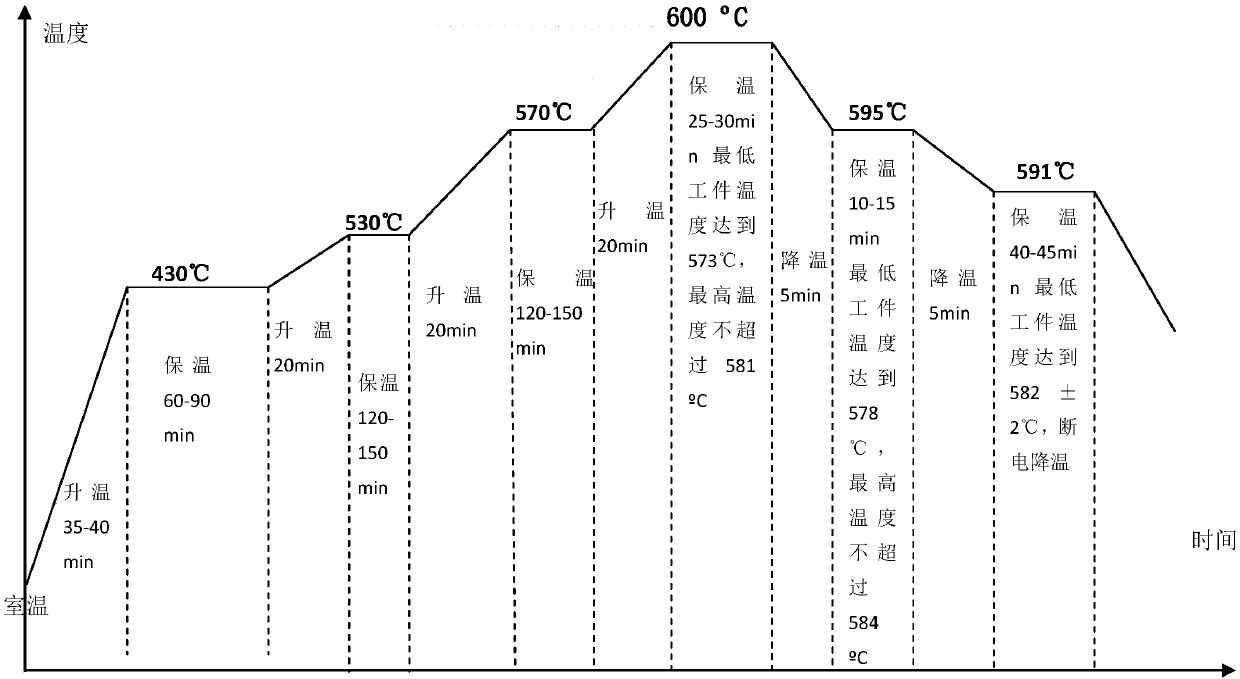

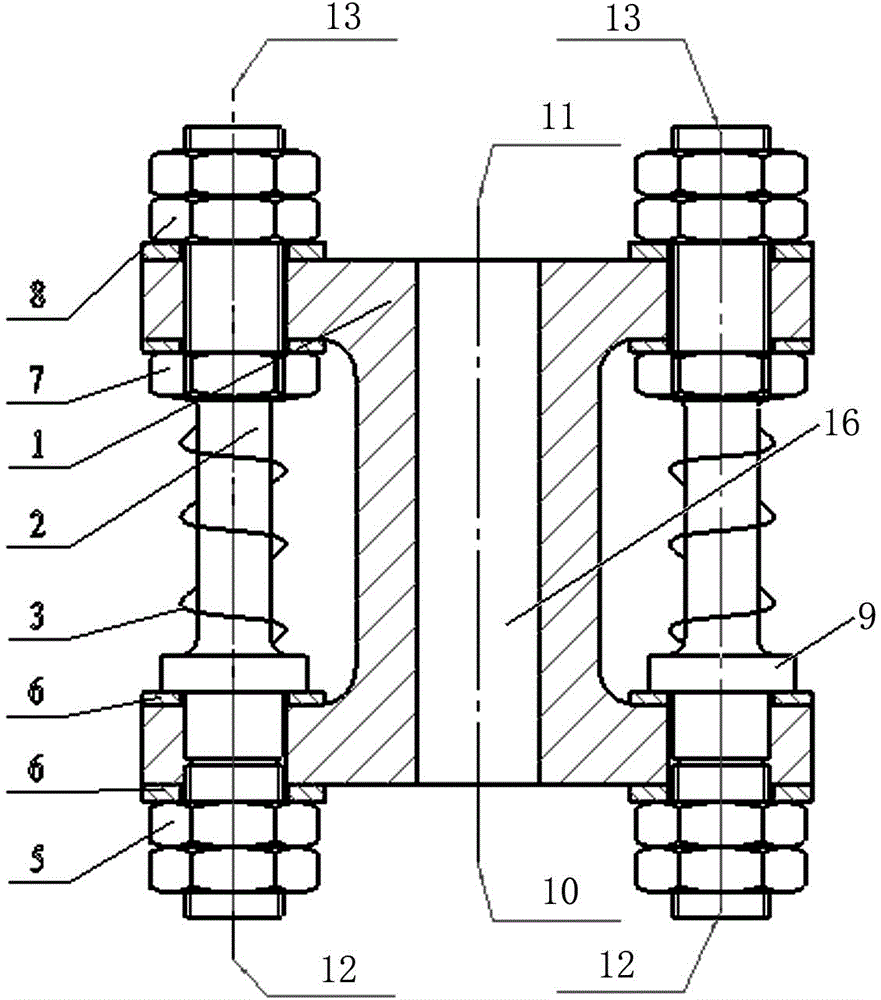

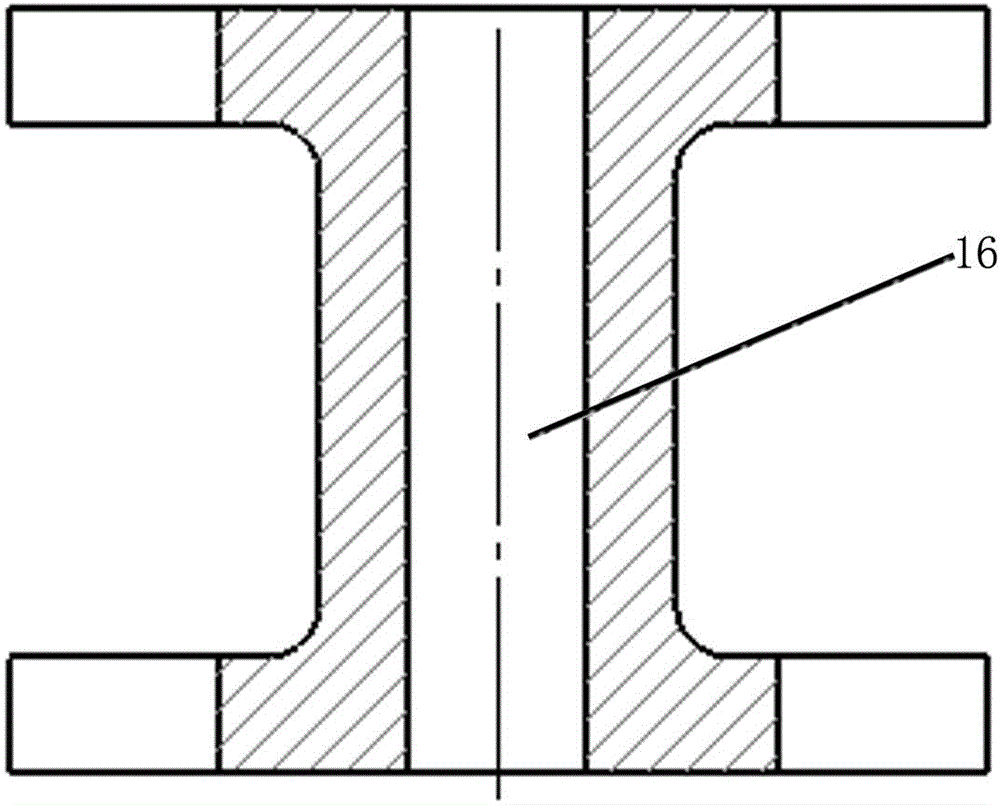

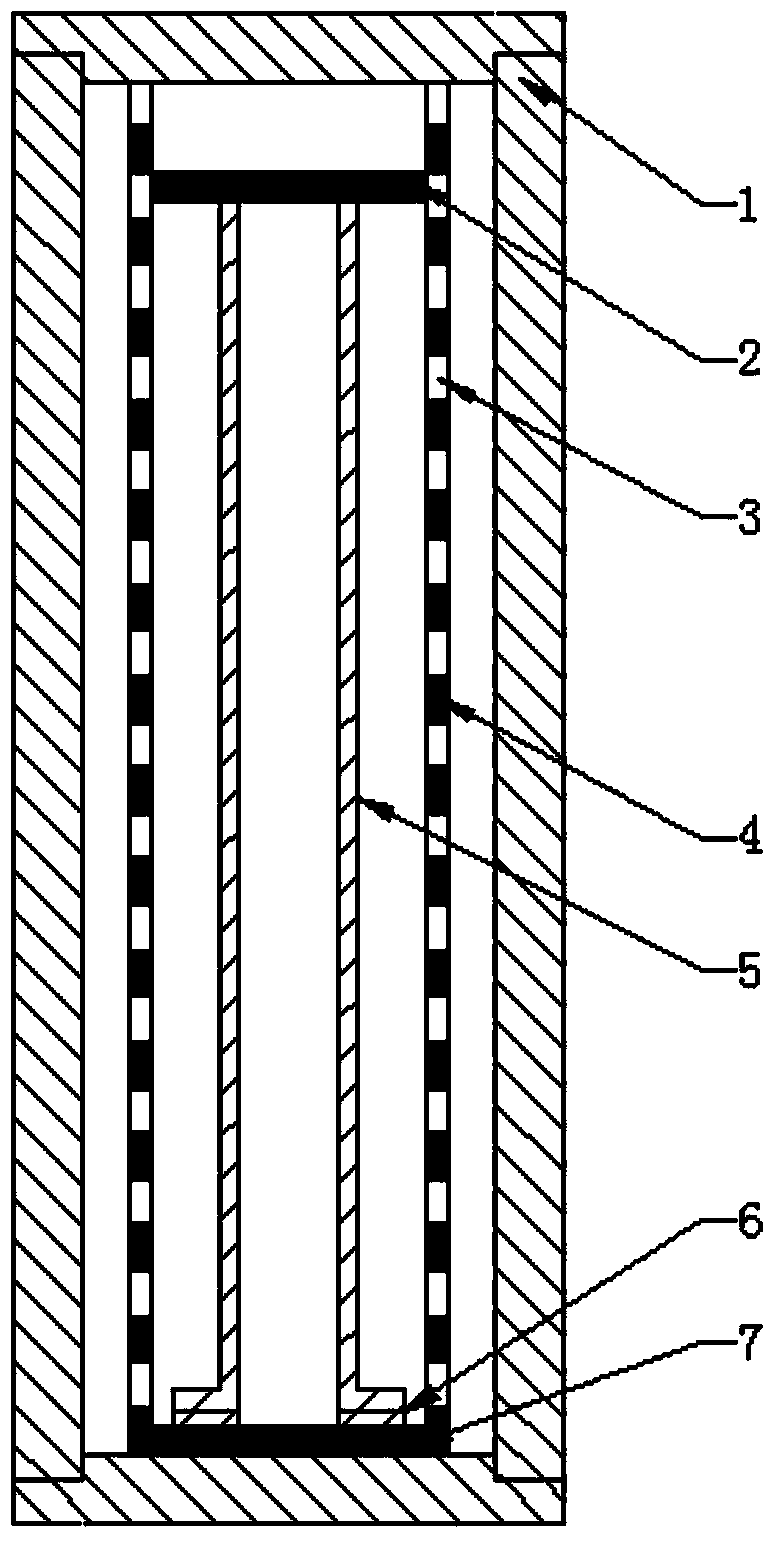

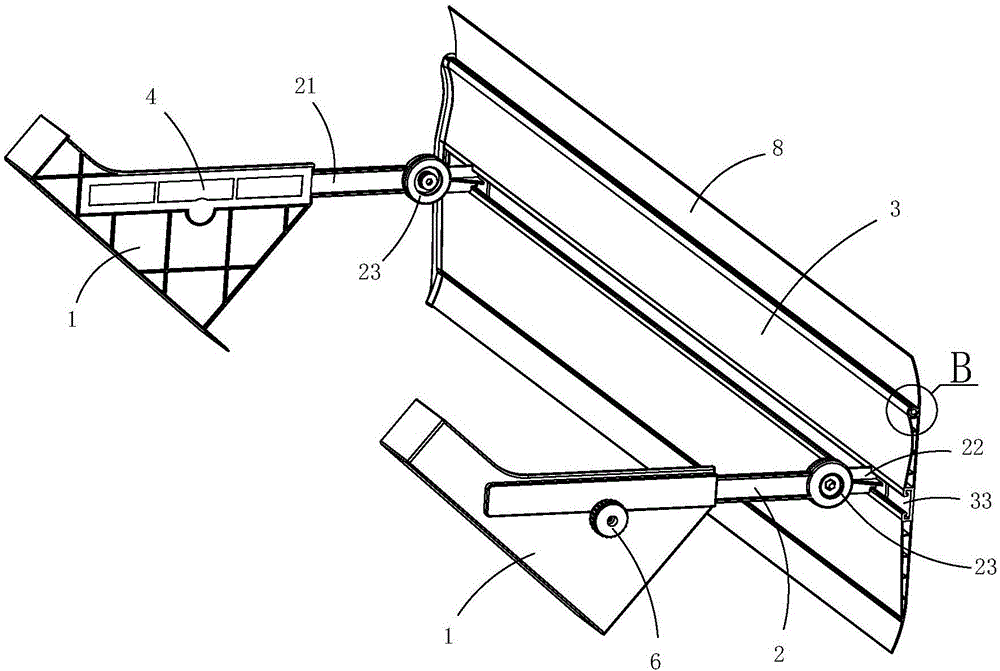

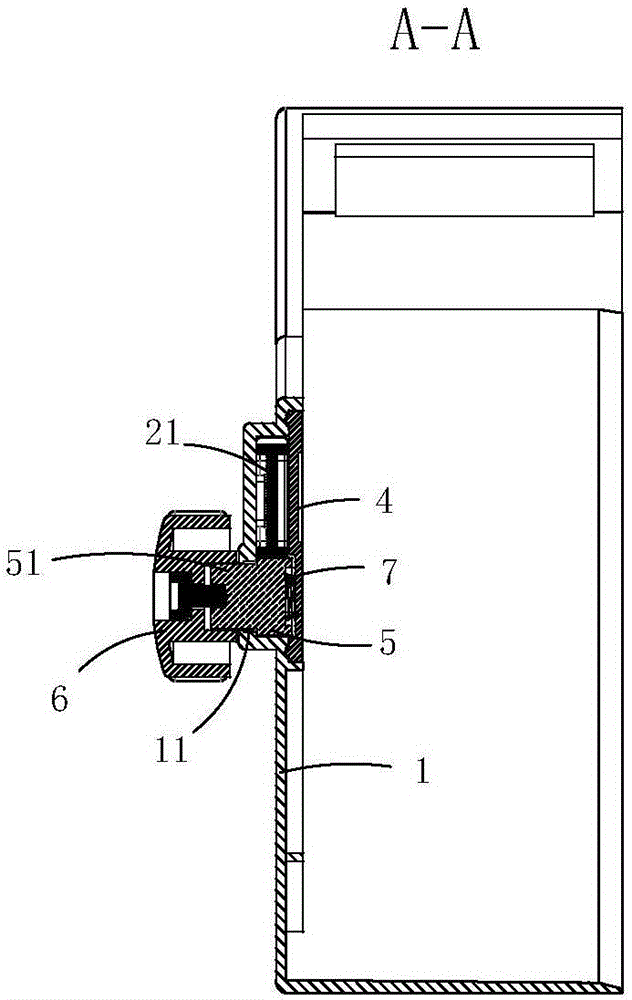

Process method for reducing vacuum brazing defects of 6061 aluminum alloy and clamp

ActiveCN107598318ALarge boardPrevent thinningWelding/cutting auxillary devicesAuxillary welding devices6061 aluminium alloySteel plates

The invention discloses a process method for reducing vacuum brazing defects of a 6061 aluminum alloy and a clamp. The clamp comprises an upper cover plate (2) and a lower cover plate (1) connected through a vertical rod (7); an upper stainless steel plate (4), a spring (5) and a gasket (3) are successively arranged below the upper cover plate (2); and a lower stainless steel plate (6) is arrangedabove the lower cover plate (1). According to the process method and clamp disclosed by the invention, curves of temperature-raising, insulating and cooling processes are adjusted during brazing. Thecold plates can be domesticated by adopting the processing method and the clamp, the vacuum brazing defects of the 6061 aluminum alloy are reduced greatly, the product quality is improved, and meanwhile the international image of an enterprise is enhanced.

Owner:贵州永红换热冷却技术有限公司

Thermal fatigue testing machine

The invention provides a thermal fatigue testing machine which is characterized by comprising a support and a thermal fatigue testing specimen, wherein the support is of a support pillar structure with an upper flange and a lower flange; the center of the support is provided with a support cooling water channel; the upper part of the thermal fatigue testing specimen is clamped at the upper flange of the support, while the lower part of the thermal fatigue testing specimen is clamped at the lower flange of the support; and the outer wall of the thermal fatigue testing specimen is wound with an induction heating coil. The thermal fatigue testing machine is reasonable in structure, scientific in operation, remarkable in effects and suitable to popularization and application in the field of thermal fatigue testing.

Owner:SHENYANG POLYTECHNIC UNIV

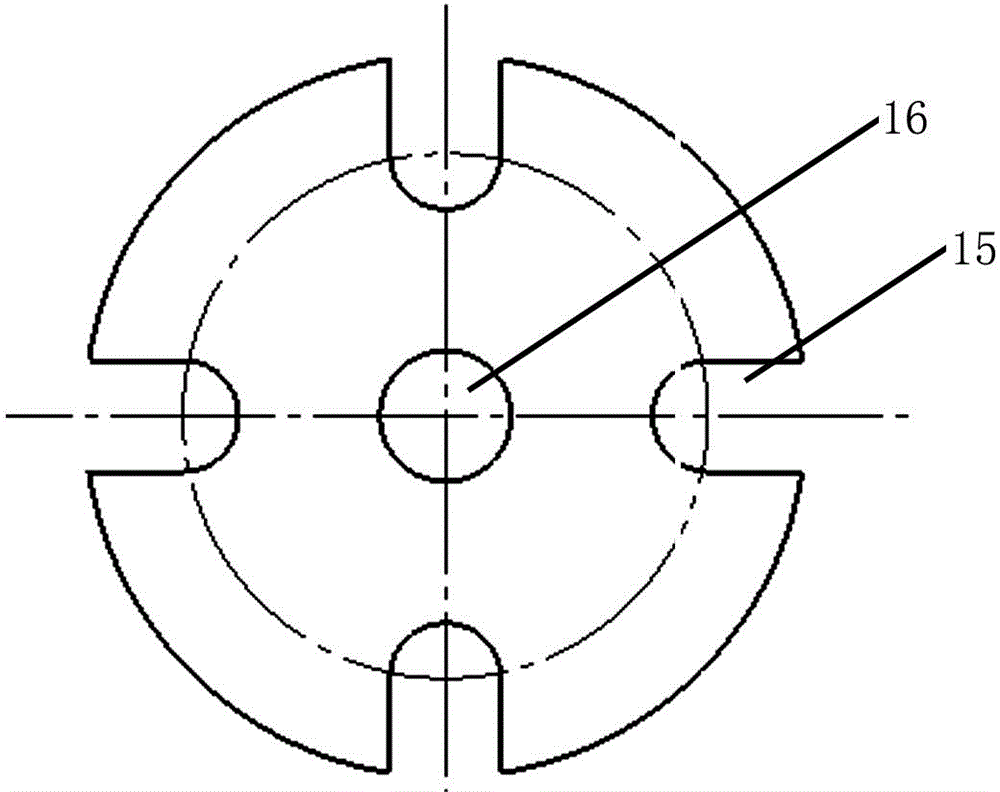

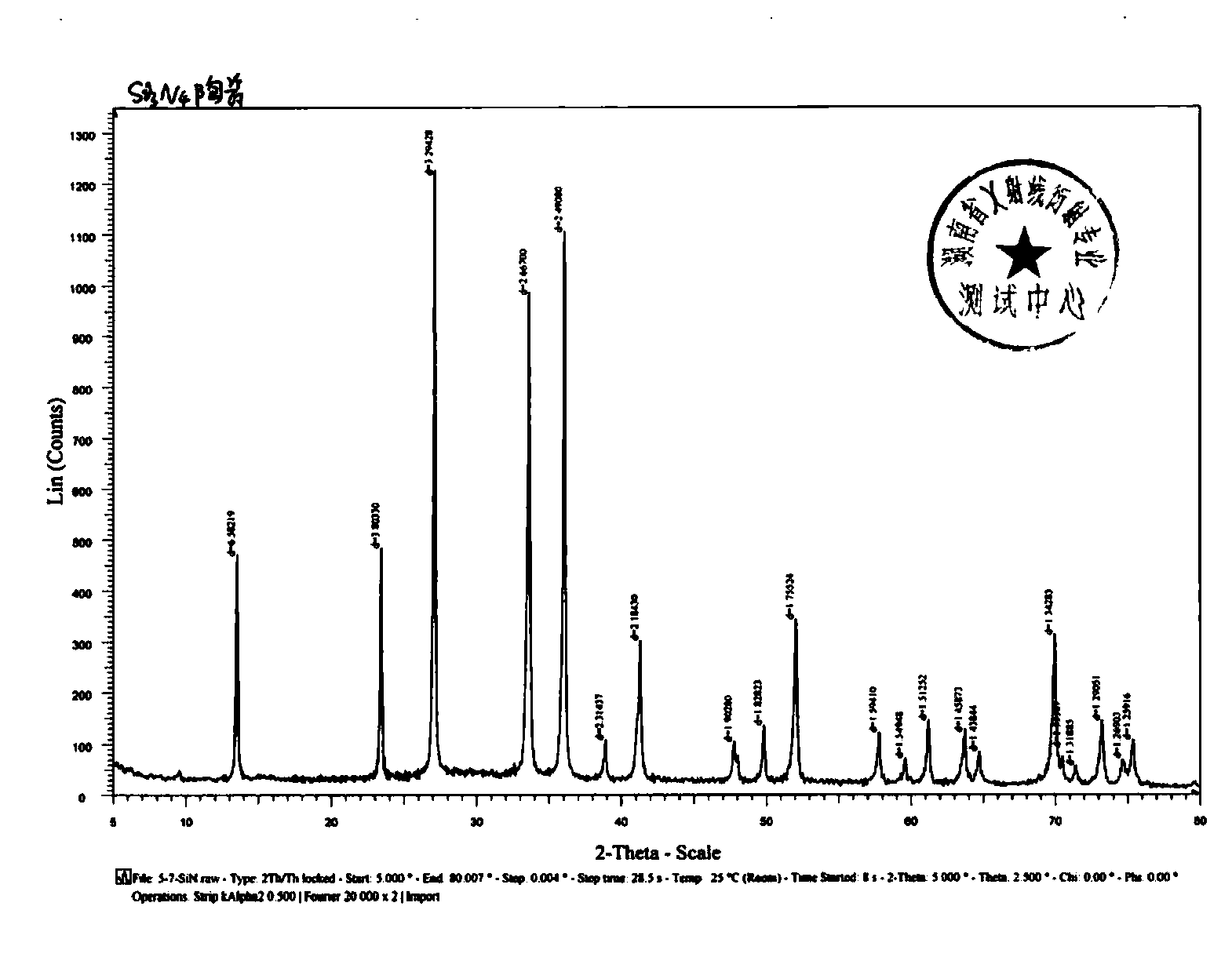

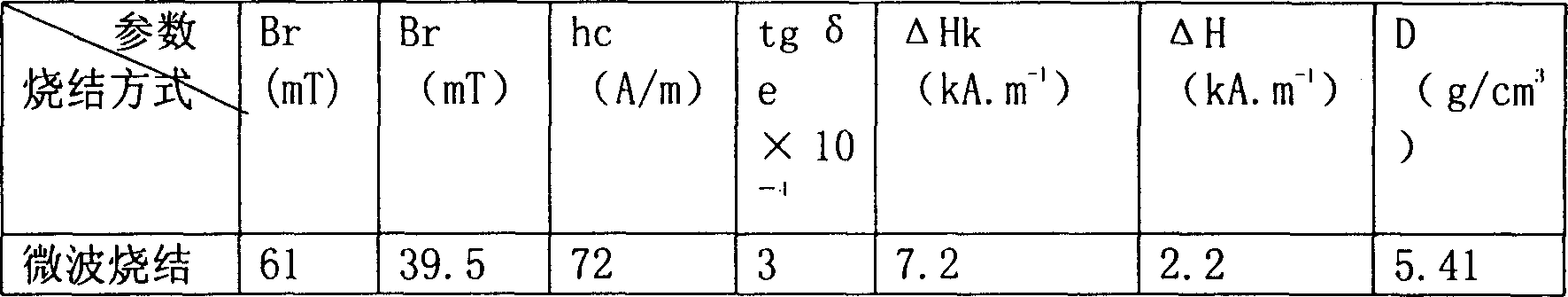

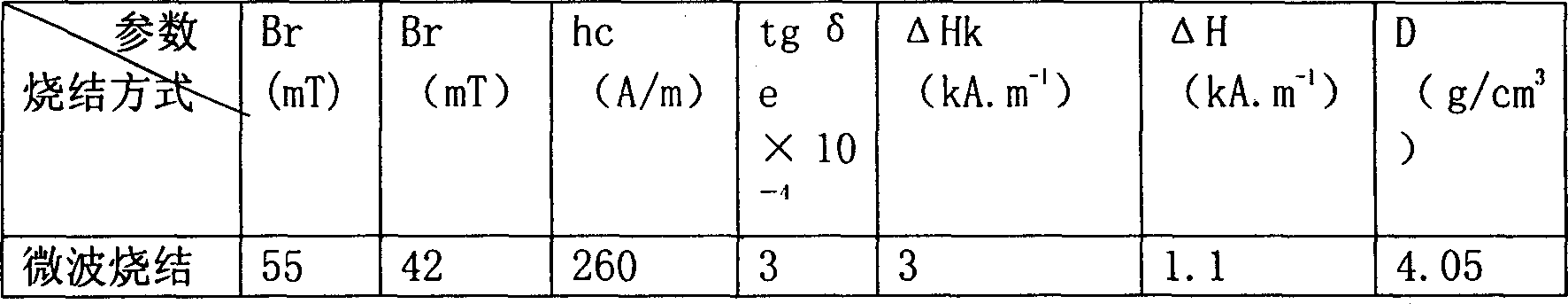

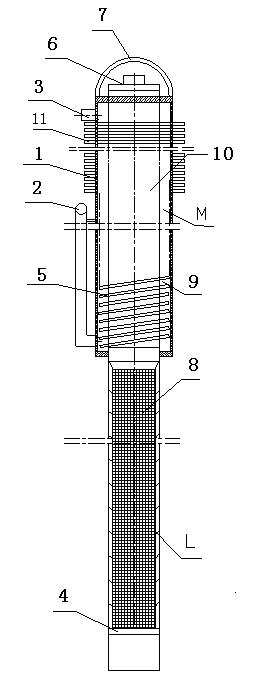

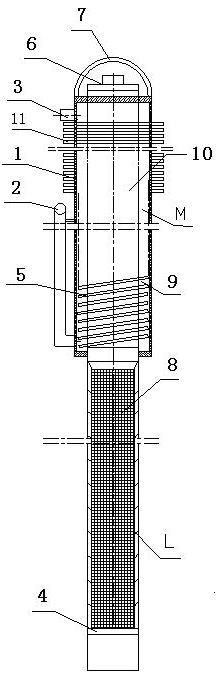

Microwave sintering preparation method of high purity silicon nitride ceramic lift tube for low-pressure casting

The invention discloses a microwave sintering preparation method of a high purity silicon nitride ceramic lift tube for low-pressure casting. The preparation method comprises the following steps: placing silicon nitride powder and an additive in a ball milling machine, carrying out wet method ball milling to obtain material slurry, drying and granulating the slurry, placing the granules into a mould, pressing, and forming so as to obtain a lift tube blank; and placing the blank into a sintering cavity to carry out microwave sintering so as to obtain the high purity silicon nitride ceramic lift tube; wherein the sintering cavity is prepared by overlapping corundum and mullite round tubes and graphite round tubes, and the upper opening and the lower opening of the sintering cavity are both provided with a graphite round plate. The preparation method utilizes the special wave bands of microwaves to couple the silicon nitride composite material to generate heats, the material is consumed to heat the composite material as a whole, the optimized microwave sintered structure is matched with the structural characteristics of high purity silicon nitride ceramic lift tube, and thus the utilization rate and efficiency of microwaves is maximized. The preparation method has the advantages of good sintering quality, high yield rate, low sintering temperature, short sintering time, and low sintering energy consumption.

Owner:HENGYANG KAIXIN SPECIAL MATERIAL TECH CO LTD

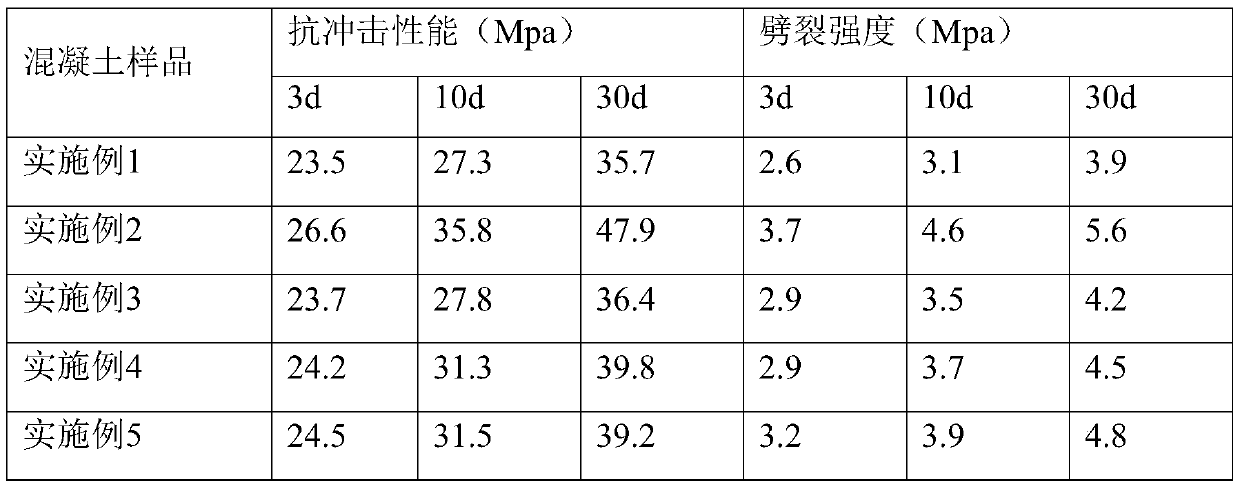

Anti-cracking concrete and production process thereof

InactiveCN110981328AImprove crack resistanceImprove bindingSolid waste managementPolymer scienceCarbon fibers

The invention discloses anti-cracking concrete, which is prepared by mixing the following components in parts by weight: 240-315 parts of cement, 635-705 parts of gravels, 410-515 parts of modified recycled aggregate, 715-835 parts of sand, 140-185 parts of water, 5-9 parts of a water reducing agent, 80-125 parts of fly ash, 18-25 parts of borax and 25-35 parts of modified combined fibers, whereinthe preparation method of the modified recycled aggregate comprises the following steps: mixing 65-75 parts by weight of water glass with a mass concentration of 5%, 12-18 parts by weight of an organic silicon resin and 4-8 parts by weight of borax to obtain an aggregate modification solution, soaking recycled aggregate into the aggregate modification solution for 30-40 minutes, taking out, and draining to obtain the modified recycled aggregate, and the preparation method of the modified combined fibers comprises the following steps: mixing 15-27 parts by weight of polyvinyl alcohol and 35-50parts by weight of water, carrying out heating melting, adding 2.4-3.2 parts by weight of polyethylene glycol, stirring to obtain a fiber modified solution, uniformly mixing polypropylene fibers andcarbon fibers according to a weight part ratio of (4-5):1, immersing into the fiber modified solution for 1-2 hours, taking out, and draining to obtain modified combined fibers. According to the invention, the anti-cracking concrete has characteristics of improved impact resistance, improved splitting strength and cracking reducing.

Owner:北京城建亚泰金砼混凝土有限公司 +1

Tunnel curing barn adopting humiture subdivision control of alternate wind direction

ActiveCN102735035AEvenly heatedDrain evenlyDrying gas arrangementsDrying machines with progressive movementsAir cellOne-hot

Disclosed is a tunnel curing barn adopting humiture subdivision control of alternate wind direction, and the tunnel curing barn is formed by a plurality of work cells, which are penetrated through and connected by a track. Each work cell comprises a baking cell, an air-mixing layer and a hot air cell. Each work cell is provided with one hot air cell or the plurality of work cells share at least one hot air cell. The air-mixing layer is located between the baking cell and the hot air cell. Material trolleys which pass through the baking cells respectively move a distance of one baking cell every time, and the material trolleys are used for being filled with materials to be baked. A circulating fan is installed in the air-mixing layer to produce an ascending airflow or a descending airflow. A heating or heat exchanging device is disposed in the hot air cell. The whole tunnel curing barn is separated into a plurality of independent work cells by separating plates which are provided at the front end and the rear end of the material trolleys in the baking cells, and each work cell forms an independent hot air self-circulating system. The material trolleys on the track move forward at intervals and are capable of moving at fixed time and fixed quantity and staying in different work cells for drying according to temperature and humidity required by materials at different times.

Owner:北京华珍烘烤系统设备工程有限公司

Process for heating foam ceramic

InactiveCN1793051AMeet the process needs of heatingNo pollution in the processCeramicwareHeating timeMicrowave

The invention relates to a heating method for bubble ceramic. According to the method, the bubble ceramic blank is set into the microwave heating device to take heating, under the condition of 300MHz-300GHz, 25-2000 degree centigrade heating time for 30-60 minutes, cooling. The method has simple technology, short producing cycle high production efficiency and high economic benefits.

Owner:长沙隆泰科技有限公司

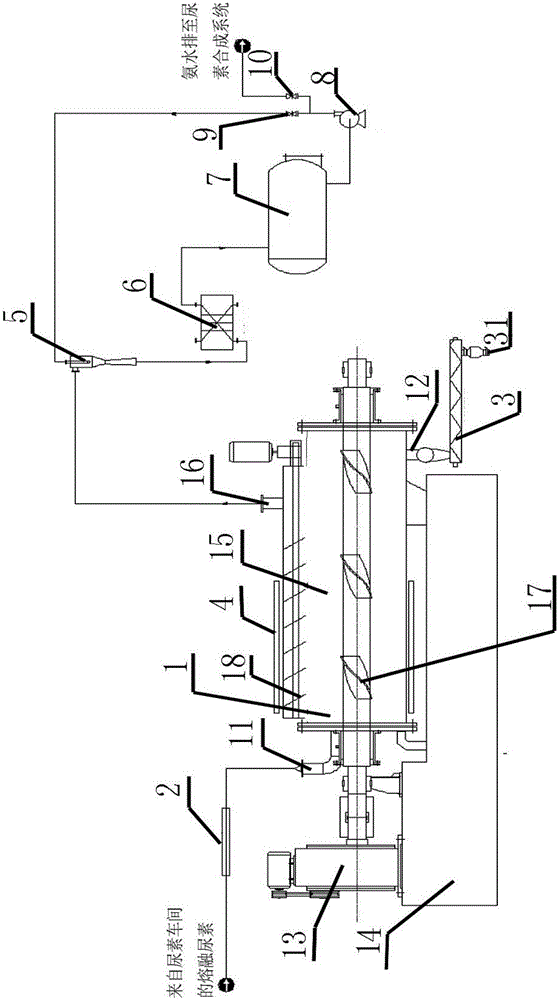

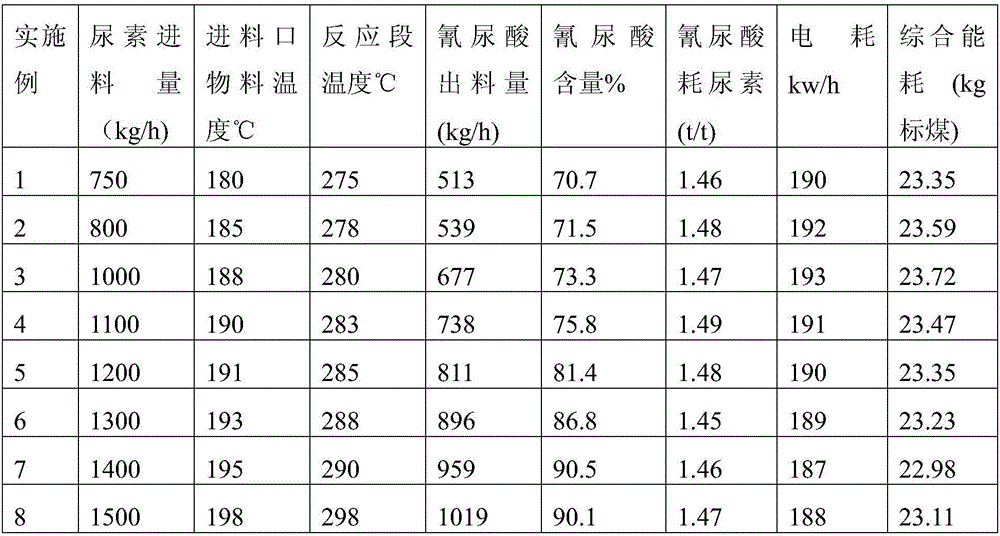

System and method for preparing crude cyanuric acid continuously by using urea

ActiveCN106008383AReduced granulation processReduce the heating and melting process of urea particlesOrganic chemistryTemperature controlWorking environment

The invention discloses a system and method for preparing crude cyanuric acid continuously by using urea. The system comprises: a differential stirring reactor for receiving urea melt and for deaminating it to produce crude cyanuric acid; a heating device disposed outside a reaction barrel of the differential stirring reactor and used for heating the reaction barrel; an ammonia recycling device connected with a gas outlet of the differential stirring reactor and used for recycling ammonia as a material for urea synthesis. The system and method enable continuous feeding, automated temperature control and automated discharging, rarely cause equipment blockage and blocking, reduce operation intensity of workers and improve work environment, optimize an operation process, and provide an organic integrity of human, machinery, material, process and environment.

Owner:河北冀衡集团有限公司

Process for microwave sintering gyromagnet ferrite material

The invention relates to a method of microwave sintering rotating magnetic ferrites material. It includes the following steps: putting the rotating magnetic ferrites blank into microwave furnace to take sintering by microwave energy, under the condition of 300MHz-300GHz microwave frequency, plenty oxygen, temperature rising to 2000 degree centigrade from room temperature keeping for 0-200 minutes, and cooling. The invention has simple technology, short producing cycle. It has great economic benefits.

Owner:长沙隆泰科技有限公司

GH864 high-temperature alloy die forging method

InactiveCN105478643AReduce the temperature difference between inside and outsidePrevent surface temperature dropMetal-working apparatusTemperature differenceSuperalloy

The invention relates to a GH864 high-temperature alloy die forging method. The GH864 high-temperature alloy die forging method comprises the following steps: a forging blank is fed in a heating furnace, the heating furnace is heated up to a forging temperature T according to convectional forging heating parameters, and the temperature T is kept by S1; the forging blank is taken out from the heating furnace, is wrapped with an insulation material, and is fed in the heating furnace for insulation again, the temperature of the heating furnace is higher than the temperature T by 10-20 DEG C, and the lasting time is 100-160 min; and the blank is discharged from the furnace, and the forging blank and the external insulation material are both fed in a forging machine for die forging until a forging is molded. The high-temperature alloy die forging method wraps the insulation material out of the heated forging blank to prevent quick lowering of the surface temperature of the blank to reduce internal and external temperature difference of the blank; the finally produced forging is uniform in structure and dense in grains; the crystal mixing phenomenon is obviously improved; and the product performance is improved.

Owner:中国第二重型机械集团德阳万航模锻有限责任公司

Air stop device of air conditioner

InactiveCN106705398AReduce the temperature difference between inside and outsideImprove insulation performanceCondensate preventionLighting and heating apparatusThermal insulationTemperature difference

The invention discloses an air stop device of an air conditioner. The device comprises a mounting frame, a connecting module and an air stop plate; the air stop plate is connected with the mounting frame through the connecting module; the air stop plate is a hollow plate structure, and is provided with a cavity inside penetrated in the length direction of the air stop plate; end covers for blocking two end openings of the cavity are respectively arranged at two ends of the air stop plate; the cavity can isolate the internal and the external of the air stop plate to a certain extent to reduce the internal and external temperature difference of the air stop plate, so that the generation of condensed water on the air stop plate can be inhibited, and the use effect of the air stop device of the air conditioner is improved; and further, the end covers are arranged at two ends of the air stop plate for closing two ends of the cavity to obtain relatively closed cavity in the air stop plate, so that the cavity thermal insulation effect is improved, and the formation of the condensed water is inhibited more effectively.

Owner:SHANGHAI LUMEX SYST

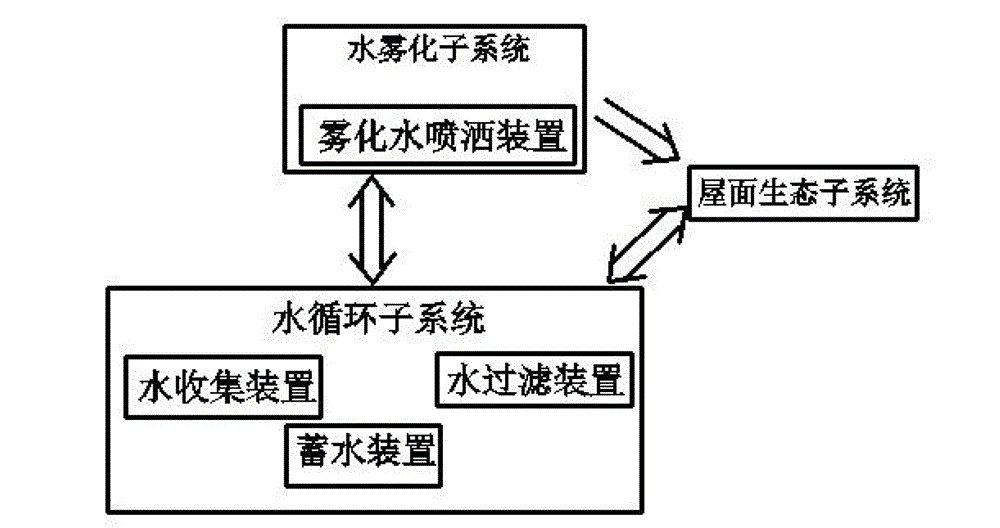

Energy-saving emission reduction building green ecological system construction method and system

ActiveCN102877659AReduce consumptionComfortable and healthy living environmentDomestic plumbingSpecial buildingWater savingNatural resource

The invention discloses an energy-saving emission reduction building green ecological system construction method which comprises the following steps of: (1) arranging a water circulating subsystem; (2) arranging a water atomization subsystem; and (3) arranging ecological subsystems around a building and on each floor or on a roof of the building for carrying out ecological utilization on atomized water. The invention also provides an energy-saving emission reduction building green ecological system for implementing the construction method. According to the energy-saving emission reduction building green ecological system provided by the invention, the idea of the green building can be sufficiently practiced, people return to the nature and the ecology in busy streets and the sustainable development building idea of land saving, water saving, energy saving, material saving and environment protection is sufficiently implemented; and the building constructed by the energy-saving emission reduction building green ecological system can provide a comfortable and healthy human settlement environment for people by the lowest natural resource consumption and the smallest negative effect on the outside environment, feeds back more farmlands and green areas to the nature and generates active influence on the outside environment.

Owner:邝成子

Mass concrete anti-crack construction method

PendingCN113718777ALow costAvoid accumulationFoundation testingElectronic temperatureHeat conservation

The invention discloses a mass concrete anti-crack construction method. The internal temperature of the concrete is monitored through an embedded electronic thermometer, the internal temperature of the concrete is regulated and controlled in real time, cracks are prevented, and the construction quality is guaranteed. The method of arranging water-cooling pipes inside concrete and covering heat preservation outside the concrete is adopted, the temperature difference inside and outside the concrete is controlled, cracks are prevented, the construction quality is guaranteed, the construction progress is guaranteed, and meanwhile the cost is saved. According to the method, multi-aspect measures are adopted for control, and multi-angle optimization from raw material control to construction process control is achieved, so that the overall hydration heat is released gently in the construction process, and heat accumulation is not likely to be formed; through real-time temperature monitoring, the situation that when the temperature changes rapidly, the internal and external temperature difference fluctuates greatly, and the reaction is not timely is avoided; internal cooling pipe water circulation is adopted, internal temperature accumulation is effectively controlled; when the internal temperature rises rapidly, the internal temperature can be effectively reduced, and the situation that the internal and external temperature difference is too large, and the concrete quality is affected is avoided.

Owner:CHINA NAT CHEM ENG NO 16 CONSTR

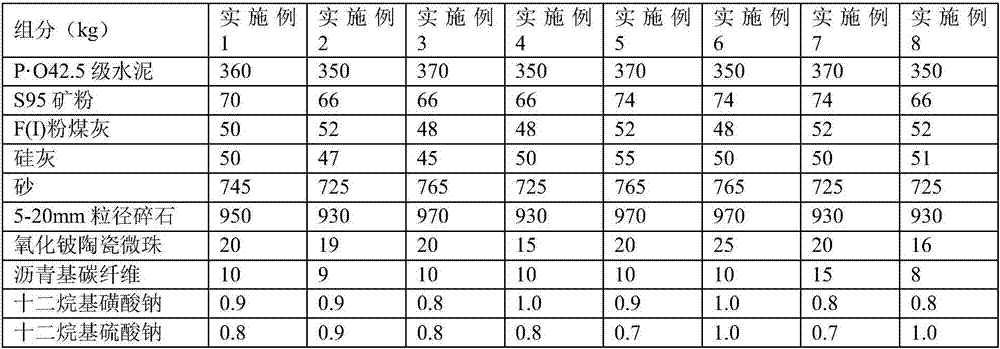

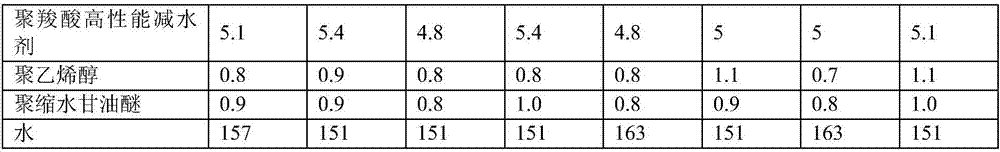

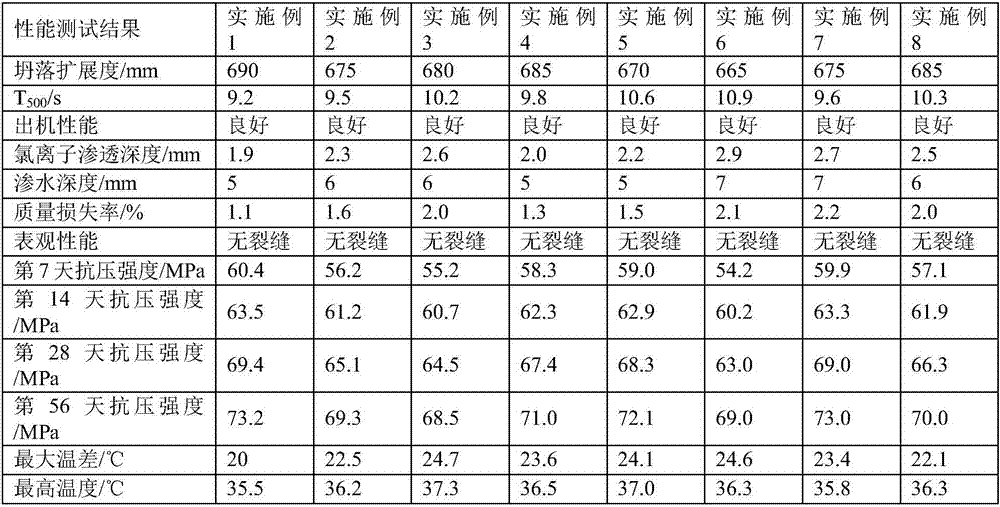

C60 ultrahigh pumping concrete

ActiveCN106977155AReduce the temperature difference between inside and outsideAvoid crackingCoalMaterials science

The invention relates to C60 ultrahigh pumping concrete. The C60 ultrahigh pumping concrete is prepared from the following raw materials in parts by weight: 350 to 370 parts of P.O42.5-grade cement, 66 to 74 parts of S95 mineral powder, 48 to 52 parts of F(I) coal ash, 75 to 85 parts of high-performance mineral admixture, 725 to 765 parts of sand, 930 to 970 parts of 5 to 20 mm particle-size gravel, 8.0 to 9.0 parts of additives, and 151 to 163 parts of water. The concrete not only has good mobility, but also meets the strength requirement of C60 concrete; and the internal heat conduction efficiency of the pouring molded concrete is high, the surface of the concrete in the hardening process hardly has a crack, and the safety potential hazard is reduced.

Owner:天津金隅混凝土有限公司

Cooling heat pipe heat exchanger of alumina decomposer

InactiveCN102249273AReduce the temperature difference between inside and outsideDoes not cause scabbingChemical industryAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPlate heat exchangerTemperature difference

The invention discloses a cooling heat pipe heat exchanger of an alumina decomposer, and the cooling heat pipe heat exchanger comprises a cooling section and a heated section, wherein the heated section is arranged at the lower part of the cooling section; the cooling section comprises an inner pipe and an outer jacket pipe, a water inflow pipe interface is welded to the lower part of the outer jacket pipe and a water outflow pipe interface is welded to the top of the outer jacket pipe; and the heated section is integrated with the inner pipe, and the heated section is characterized in that acylindrical metal wire net is arranged inside the heated section and a certain distance exists between the outer wall of the cylindrical metal wire net and the pipe inner wall of the heated section. In the cooling heat pipe heat exchanger of the alumina decomposer disclosed by the invention, the cylindrical metal wire net is arranged in the heated section, so that the fluid backflows in the cylindrical metal wire net and does not directly contact with the pipe wall of the heated section, thereby the temperature difference between inside and outside of the pipe wall of the heated section is reduced, scabbing on the pipe outer wall of the heated section is prevented, the heat transfer efficiency and work efficiency are greatly improved, and the service life of the cooling heat pipe heat exchanger disclosed by the invention is prolonged.

Owner:南京科臣节能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com