Patents

Literature

67results about How to "Reduce thermal gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

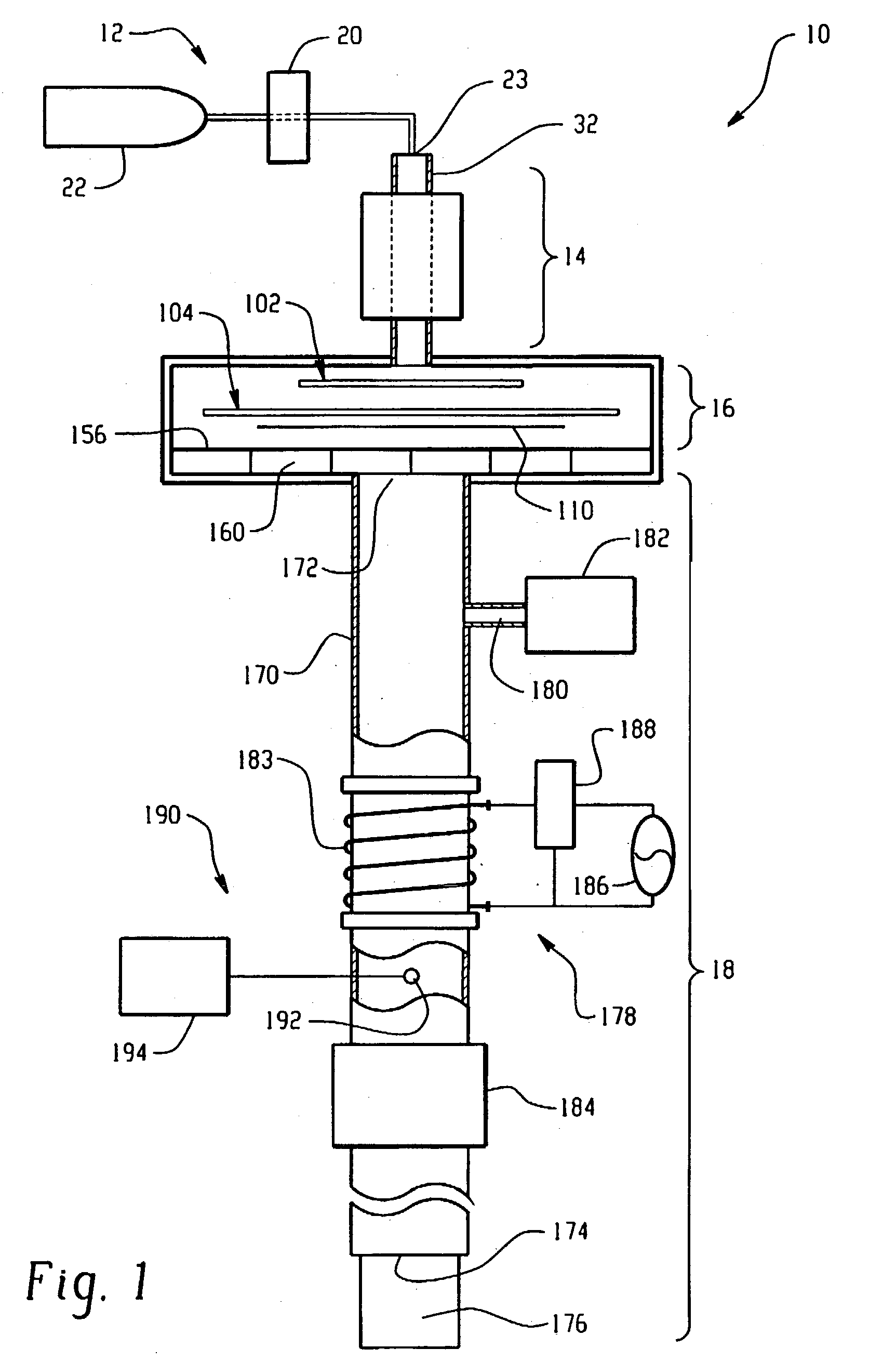

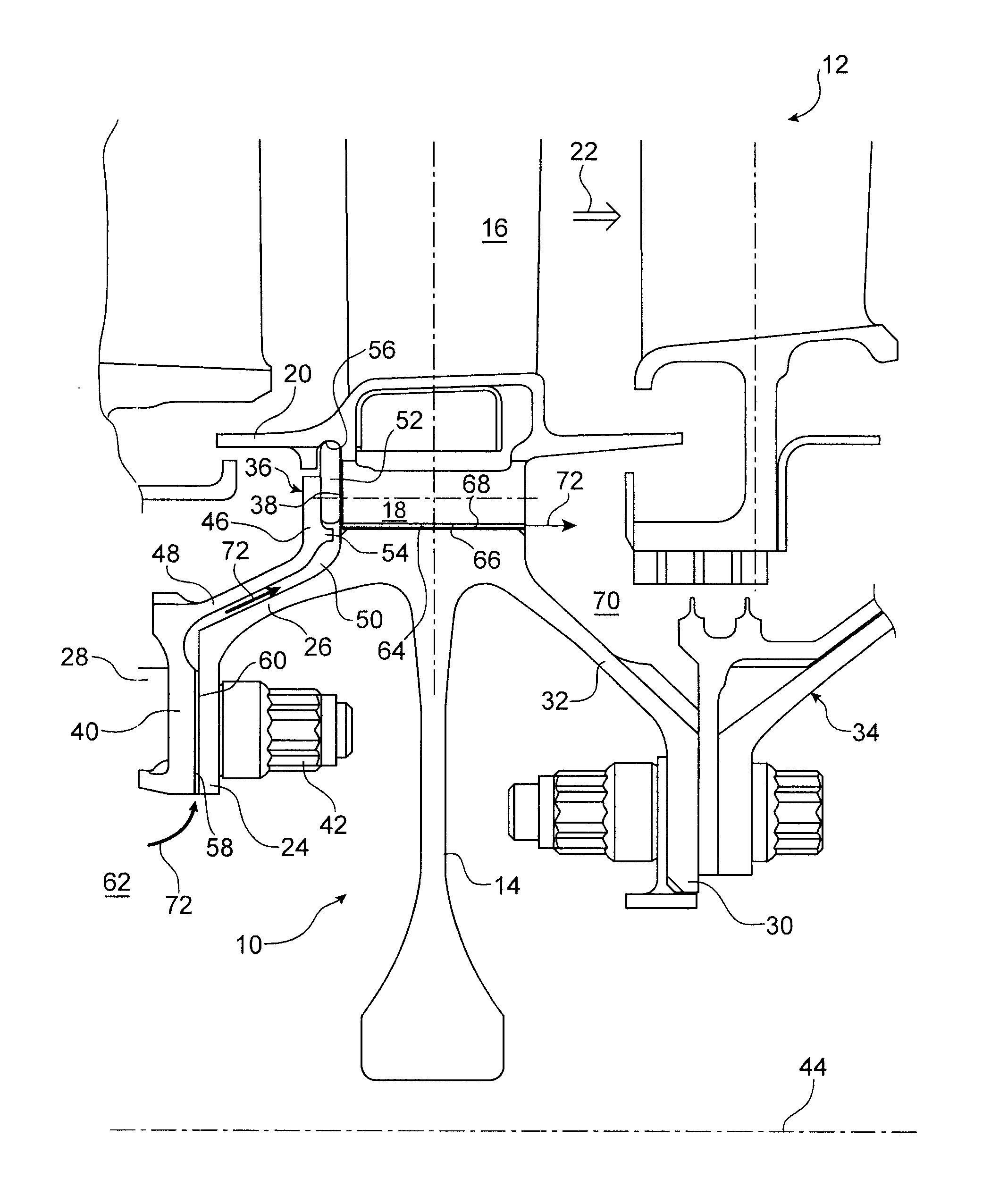

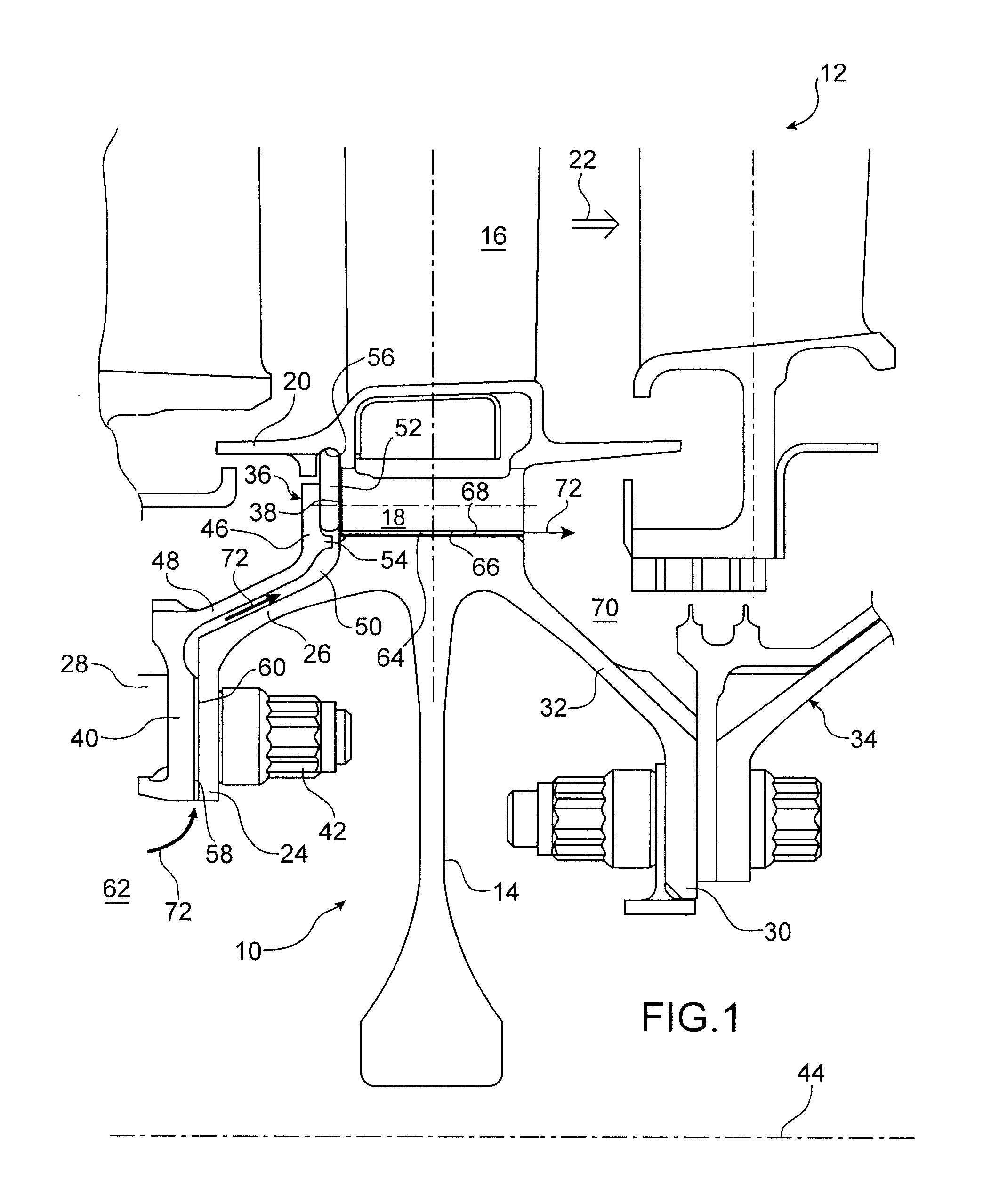

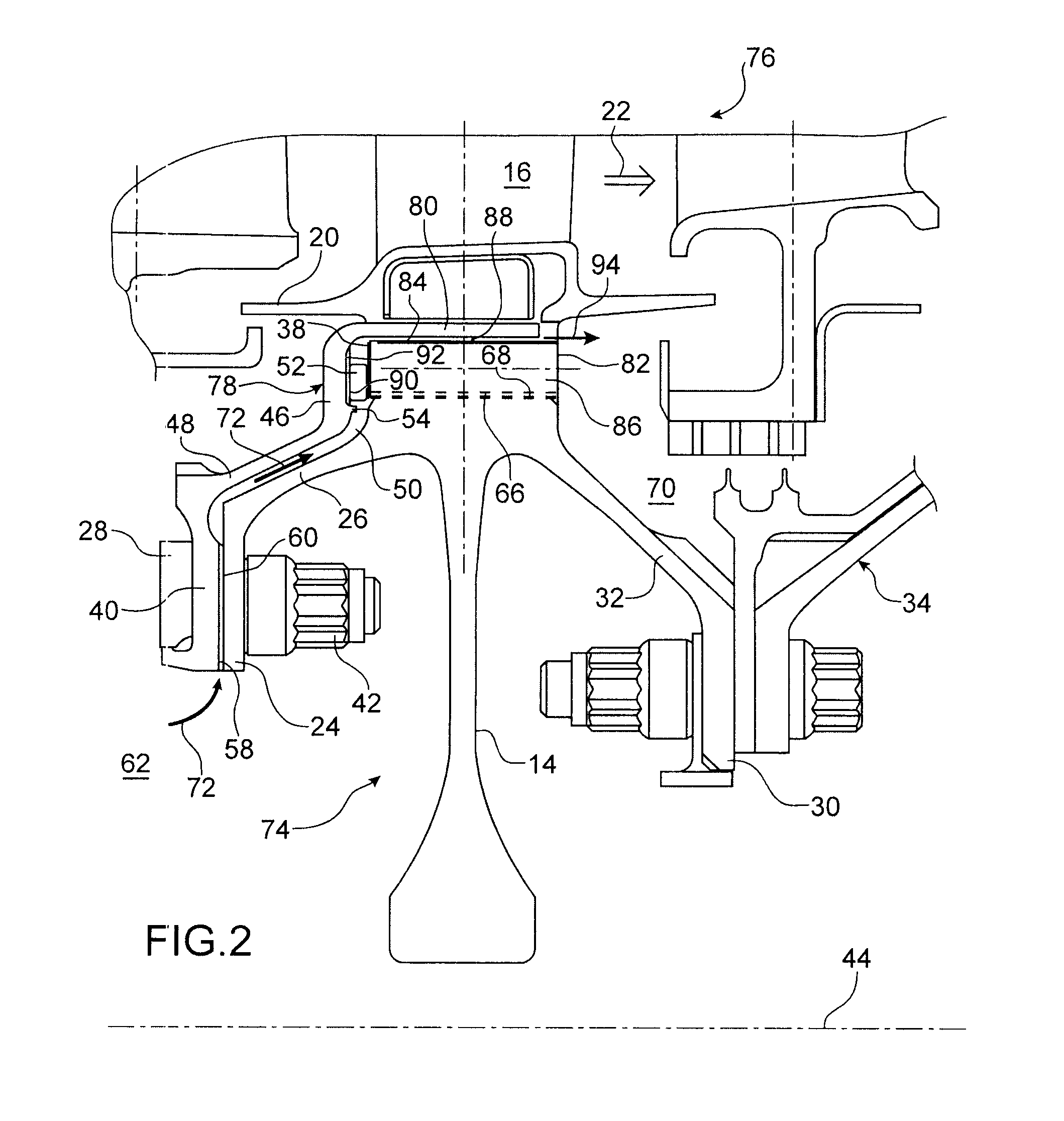

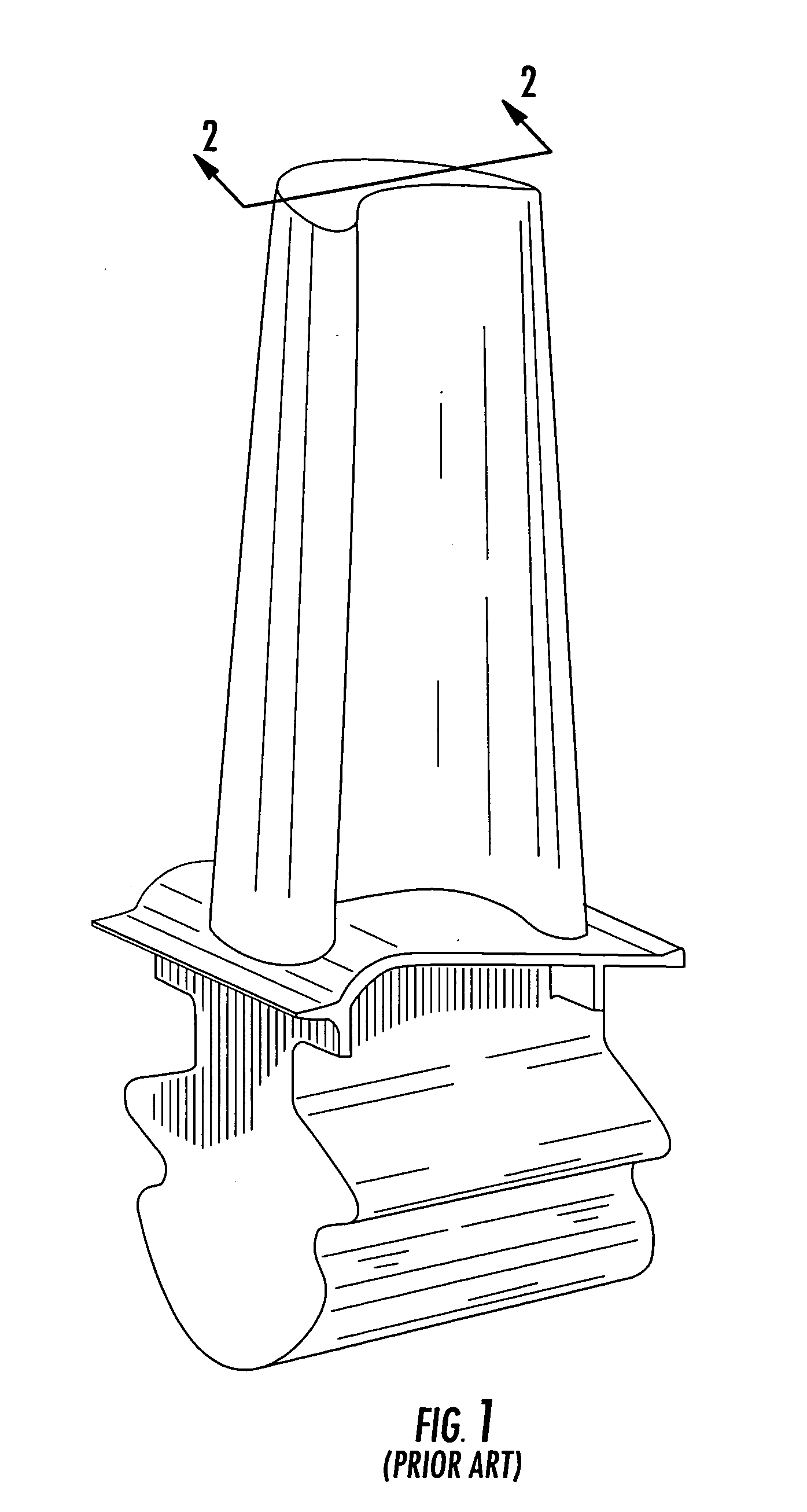

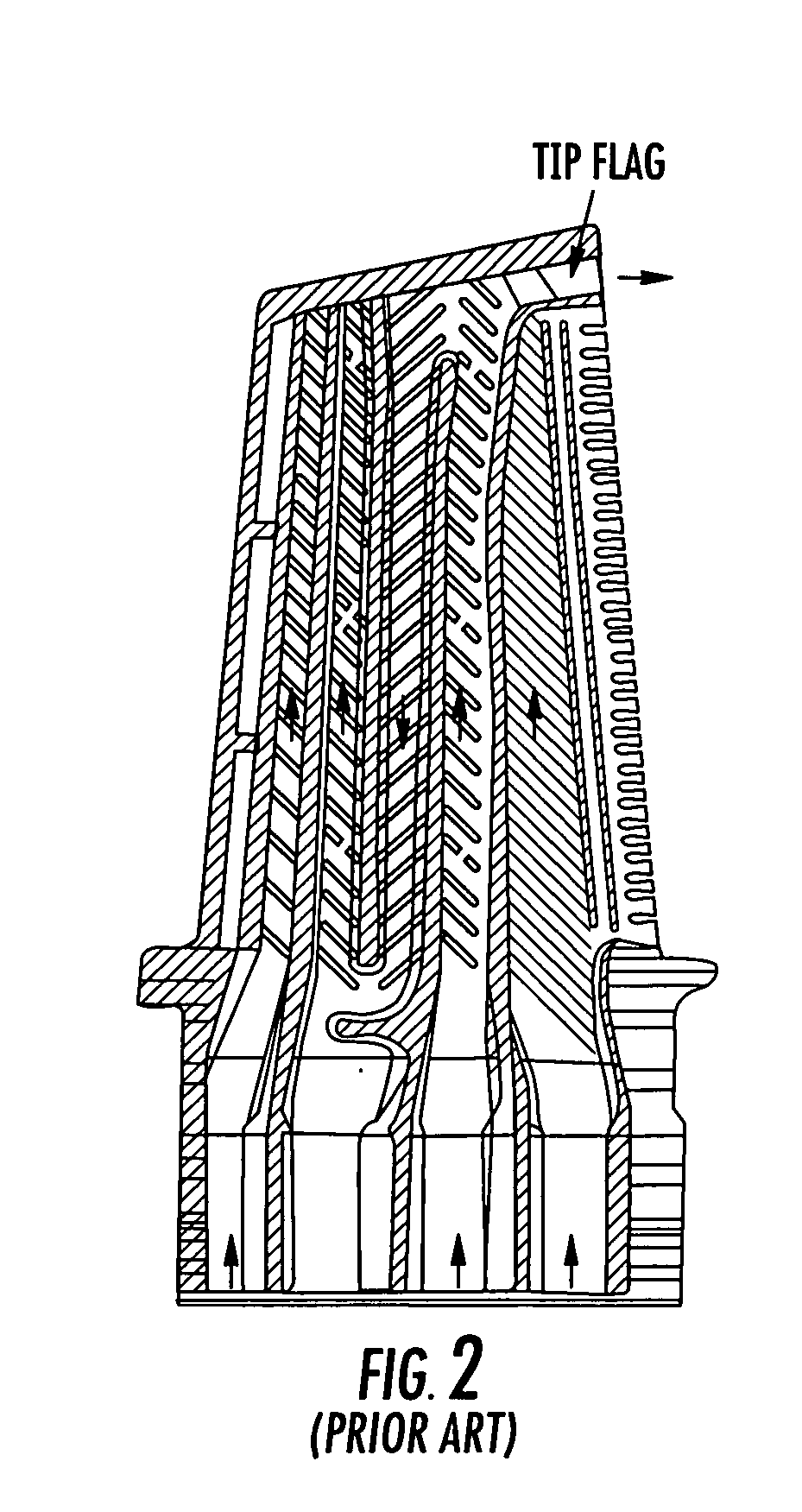

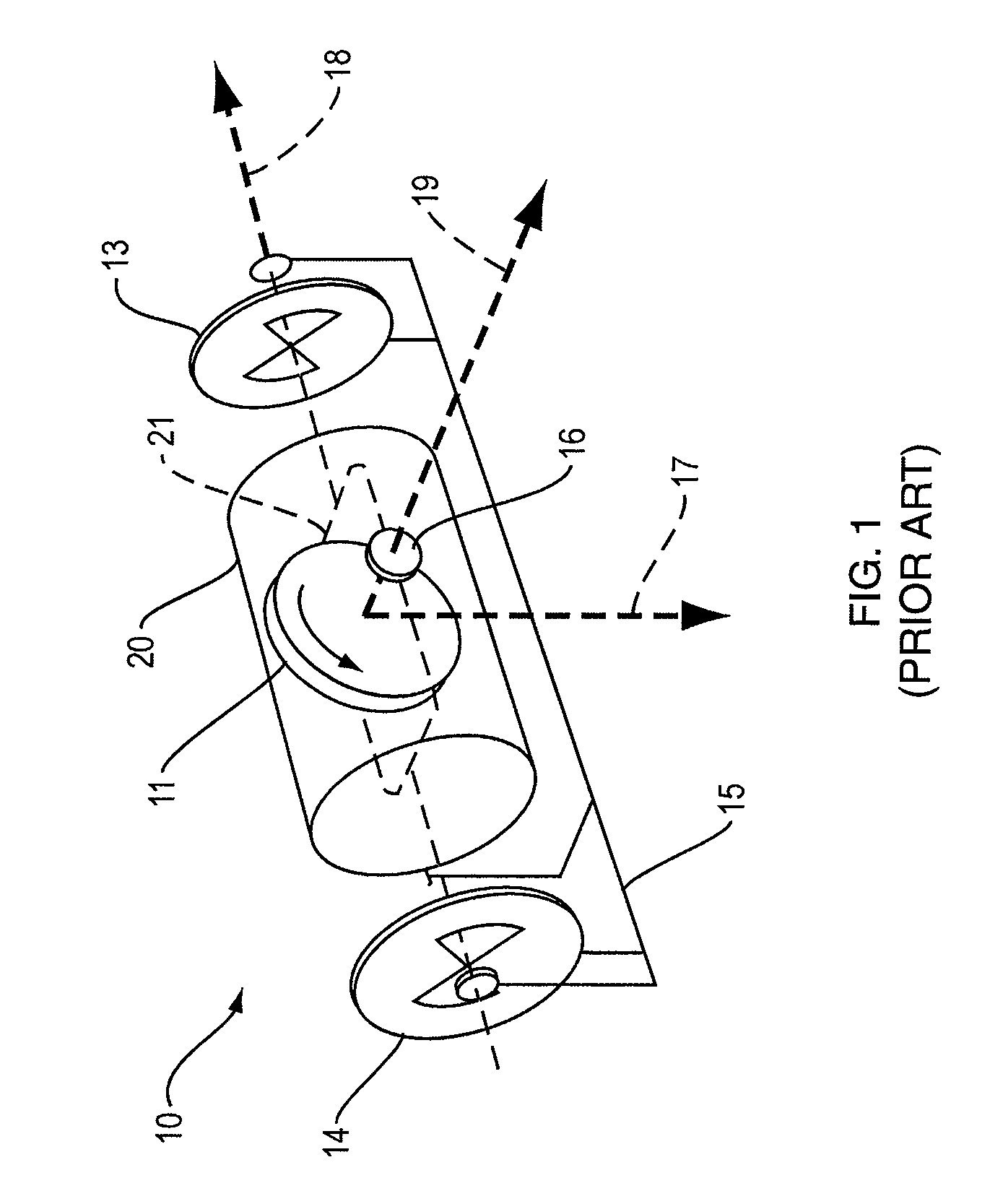

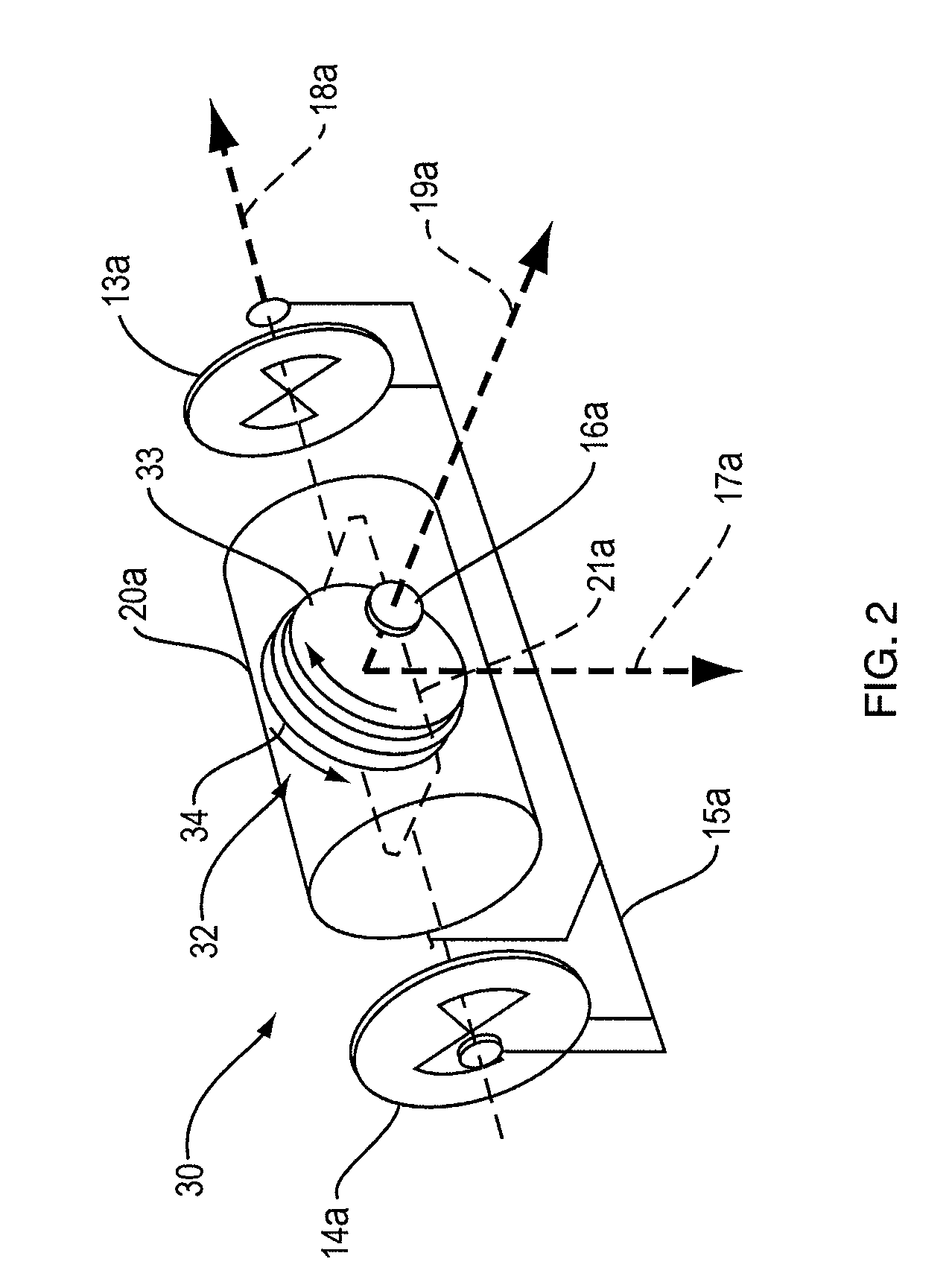

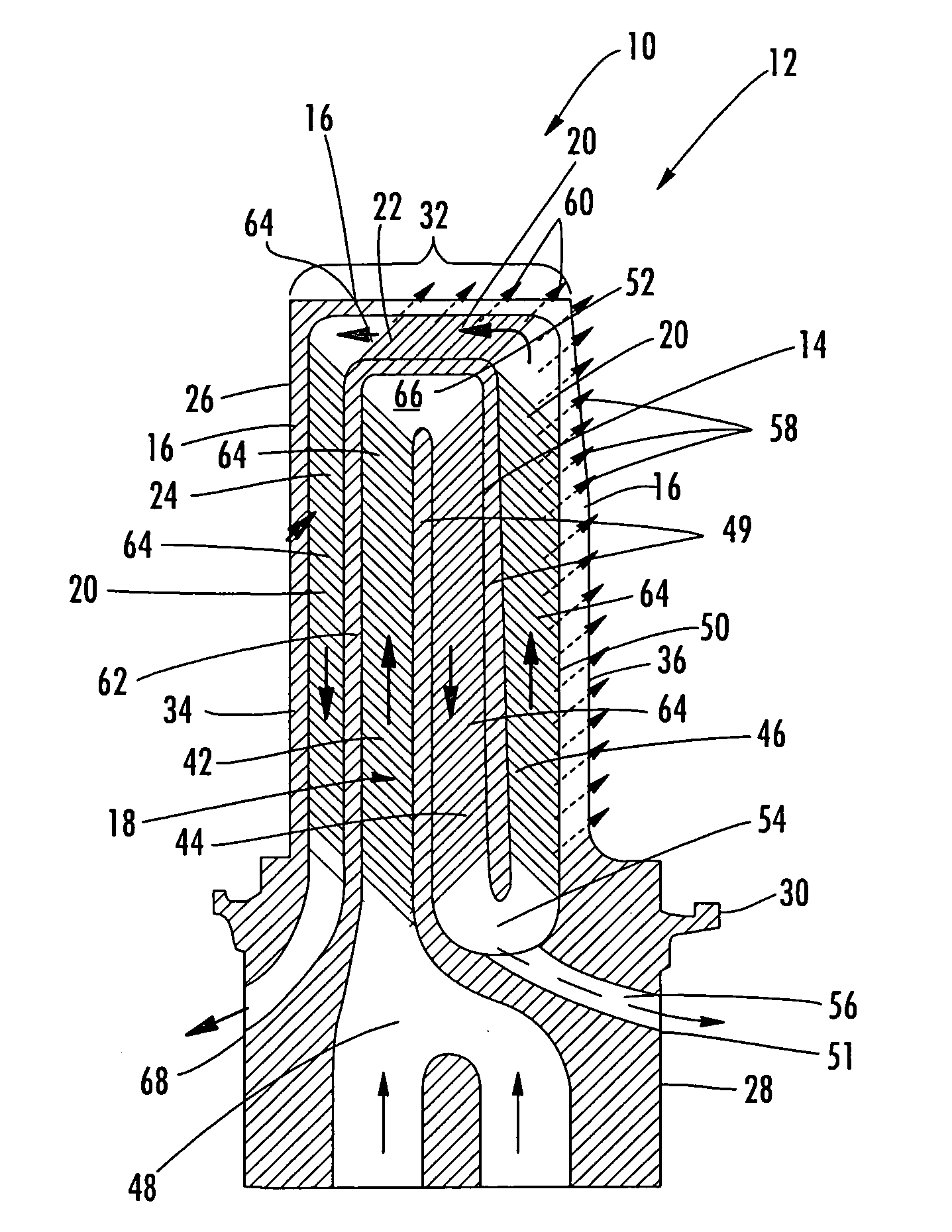

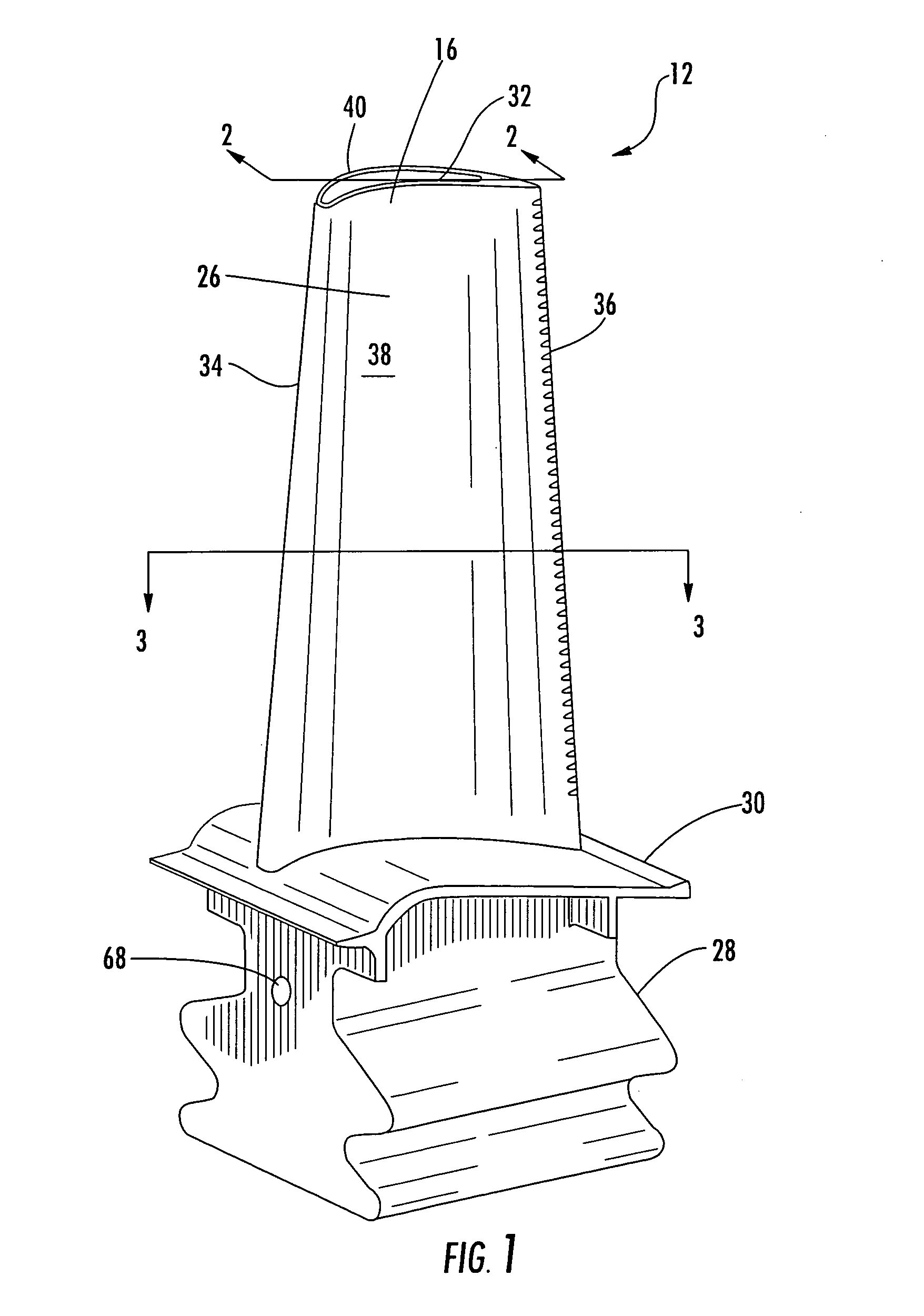

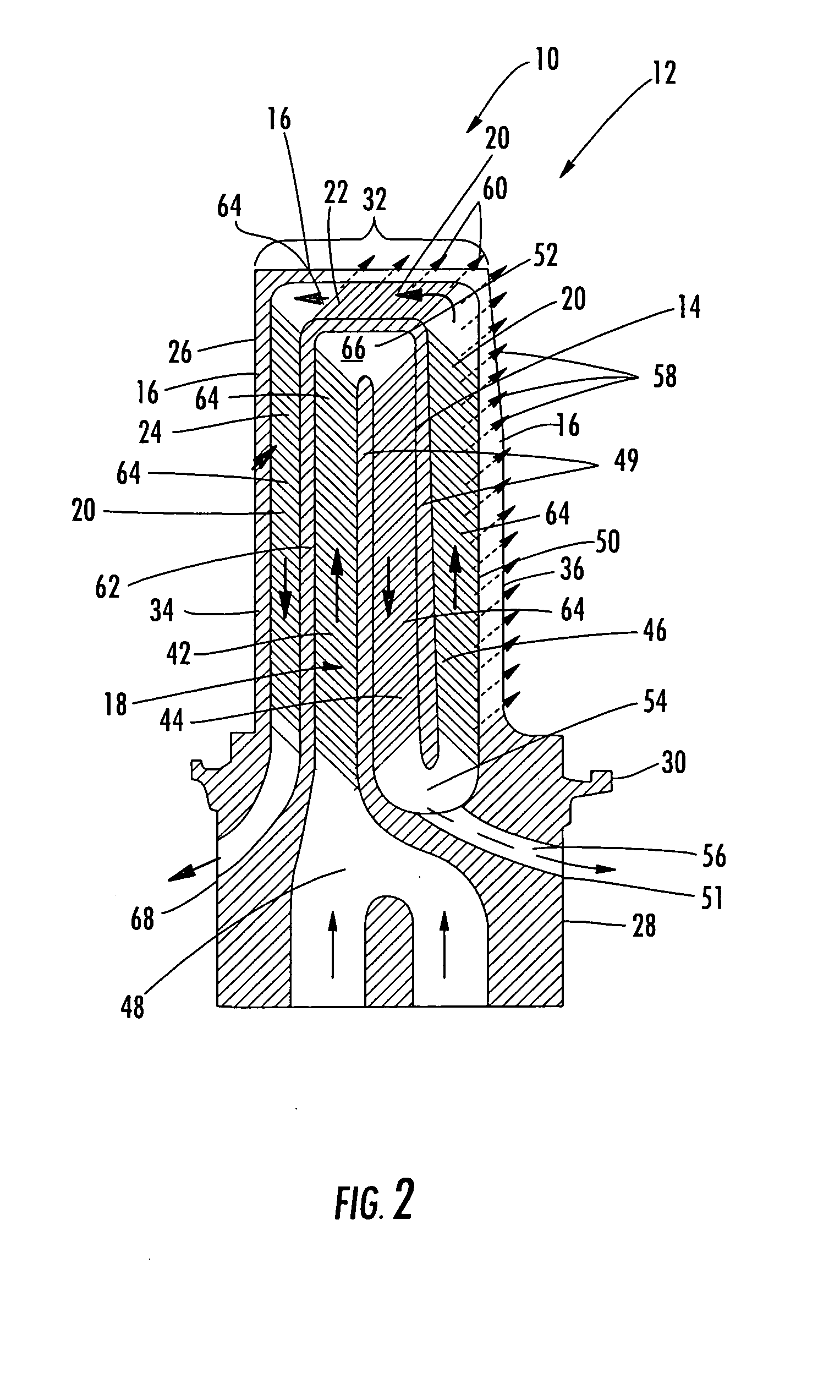

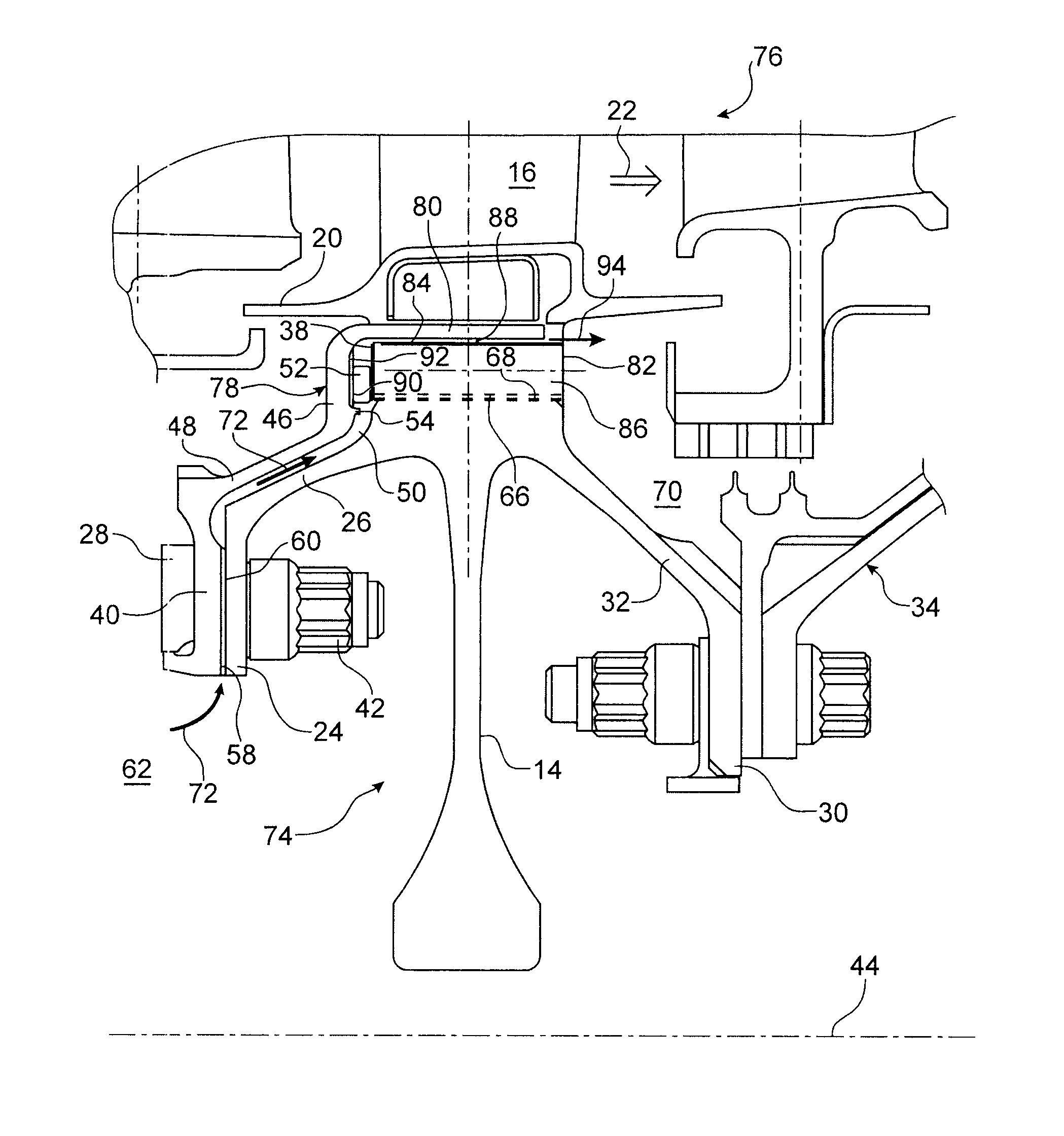

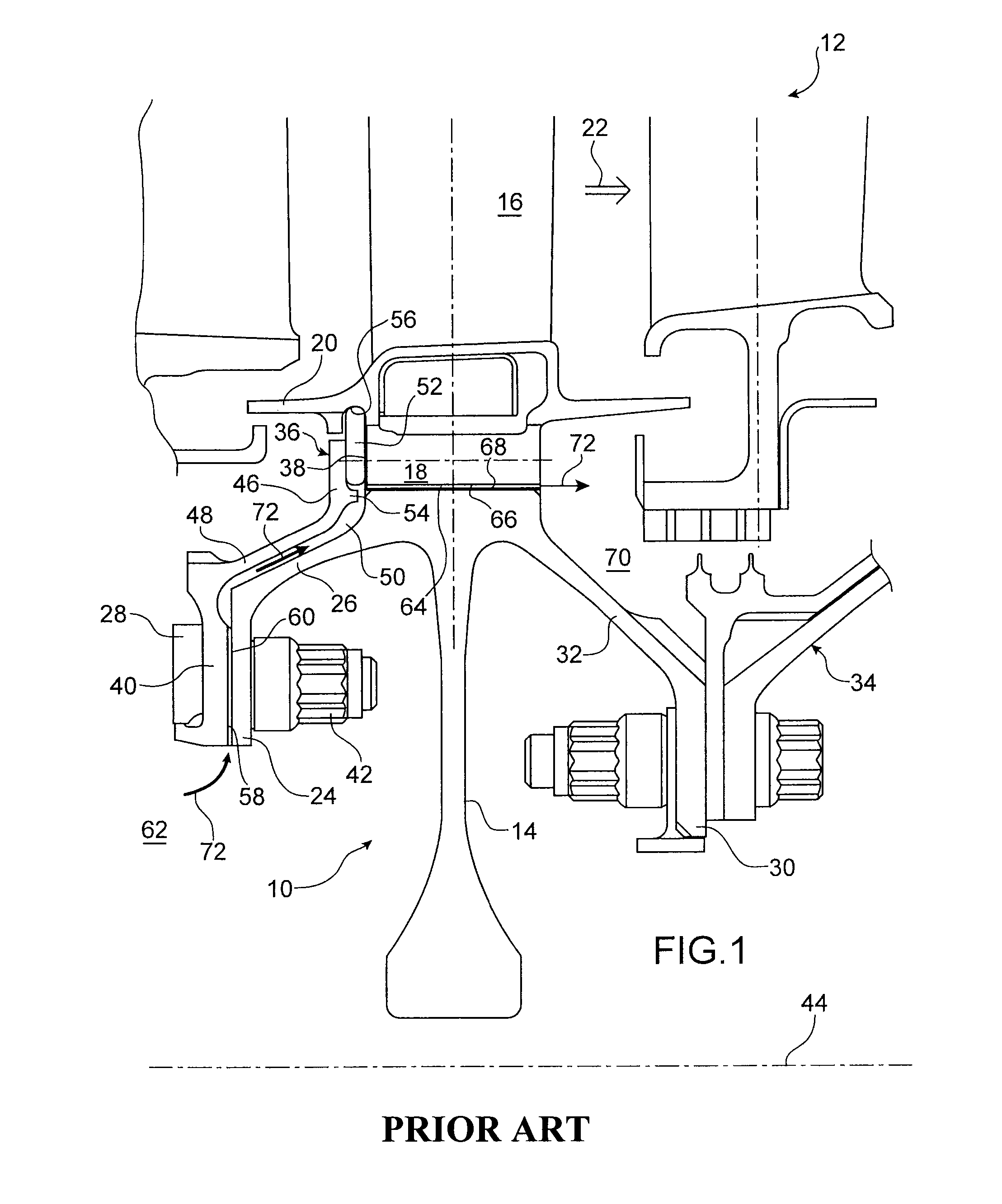

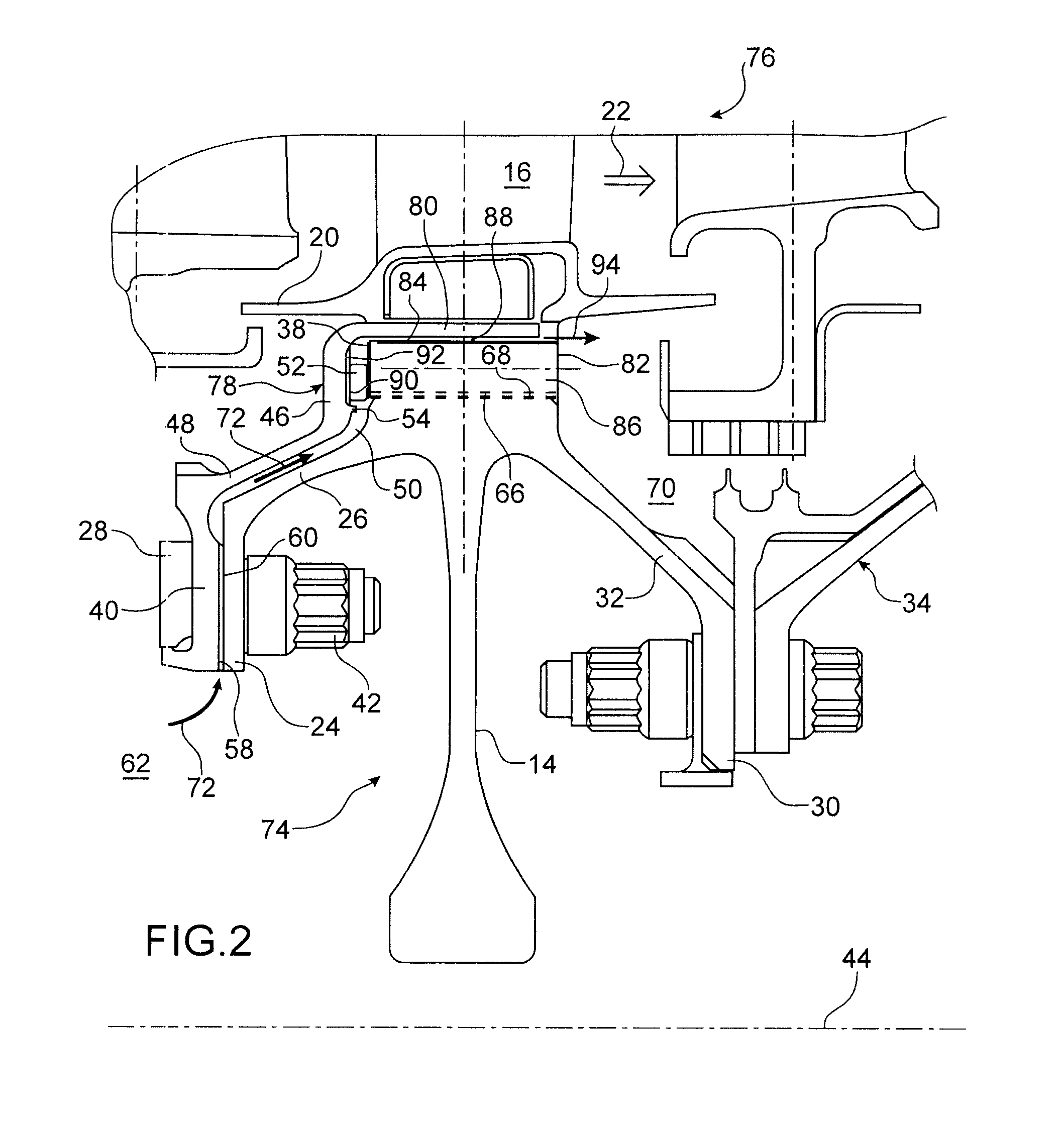

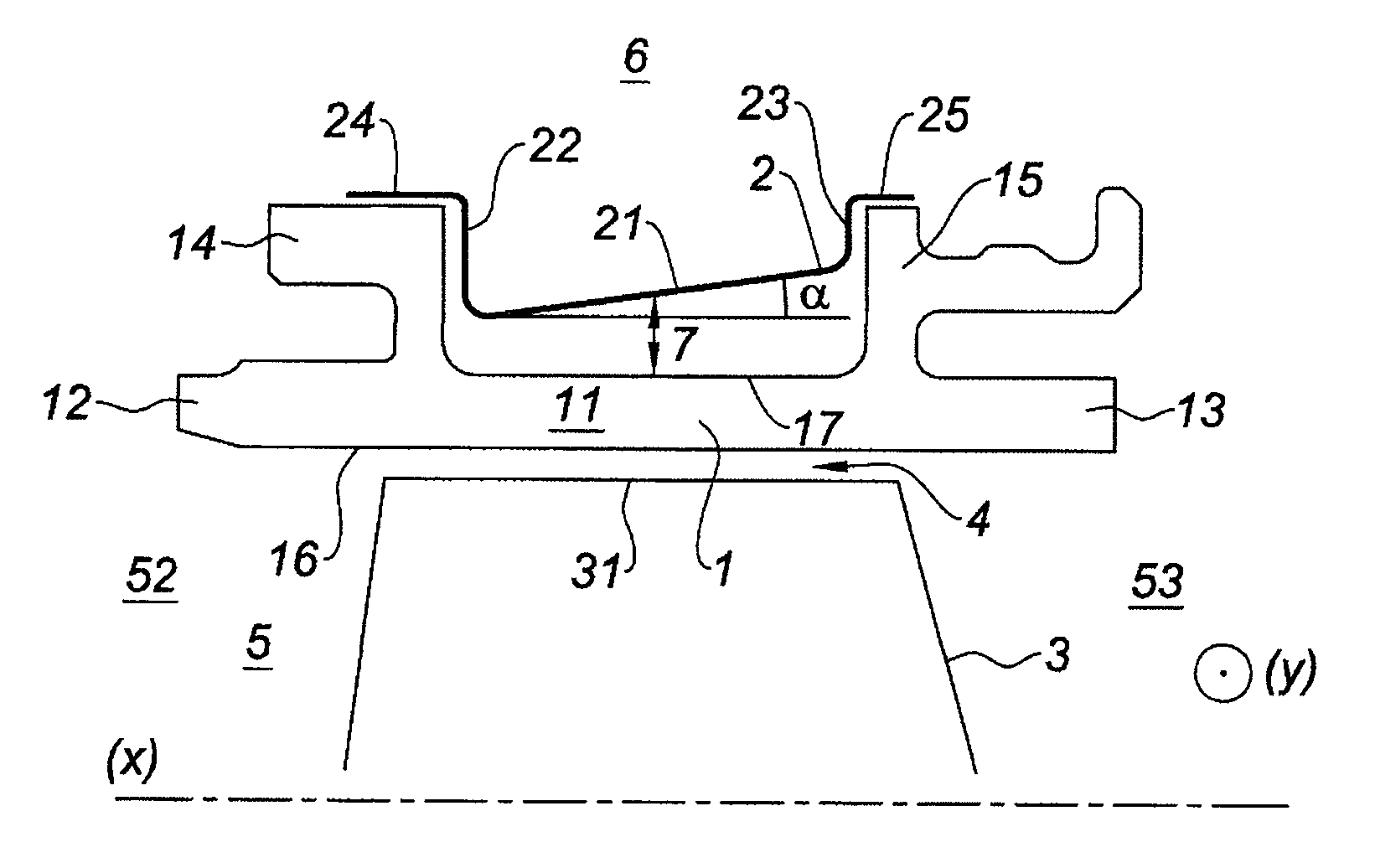

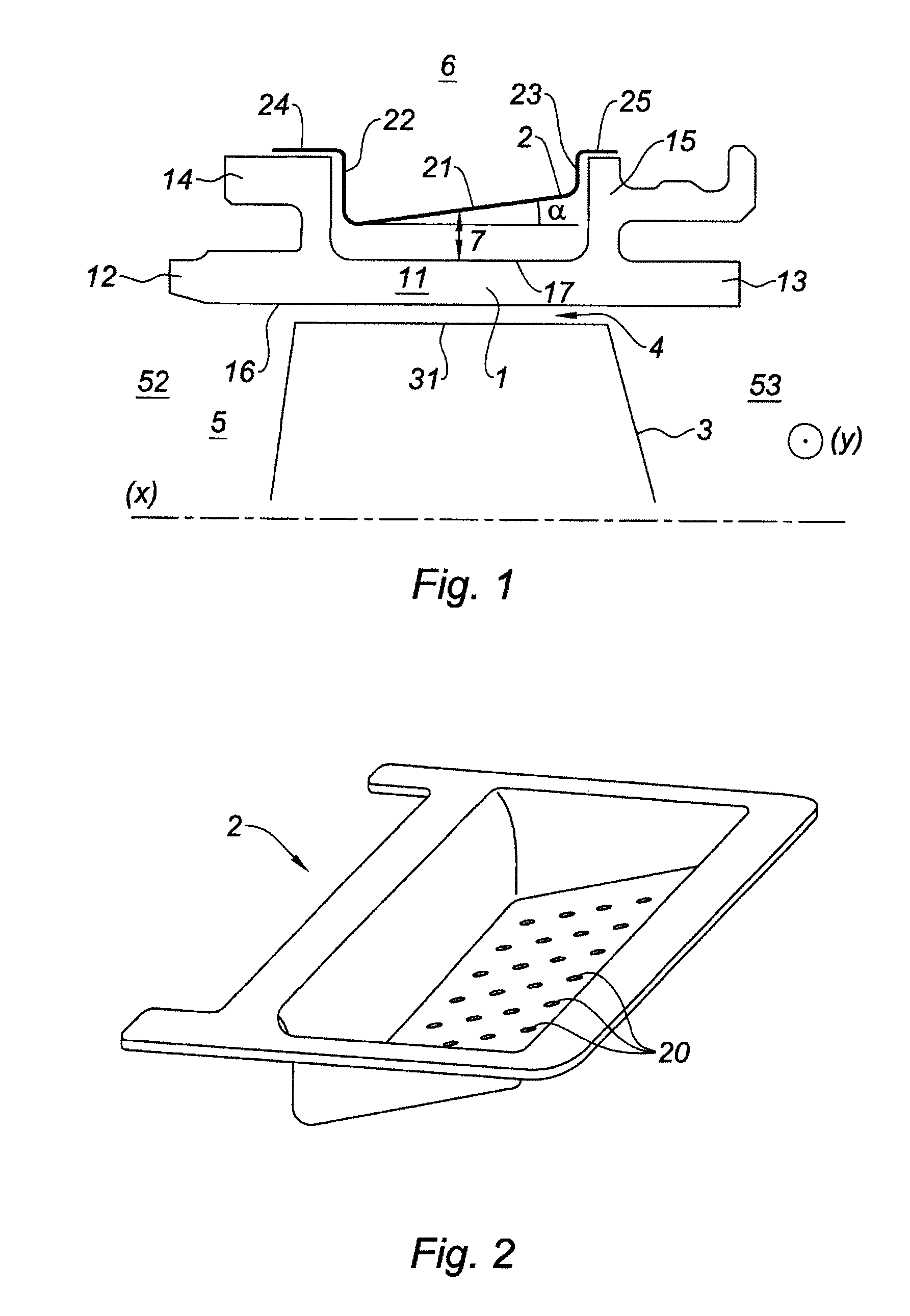

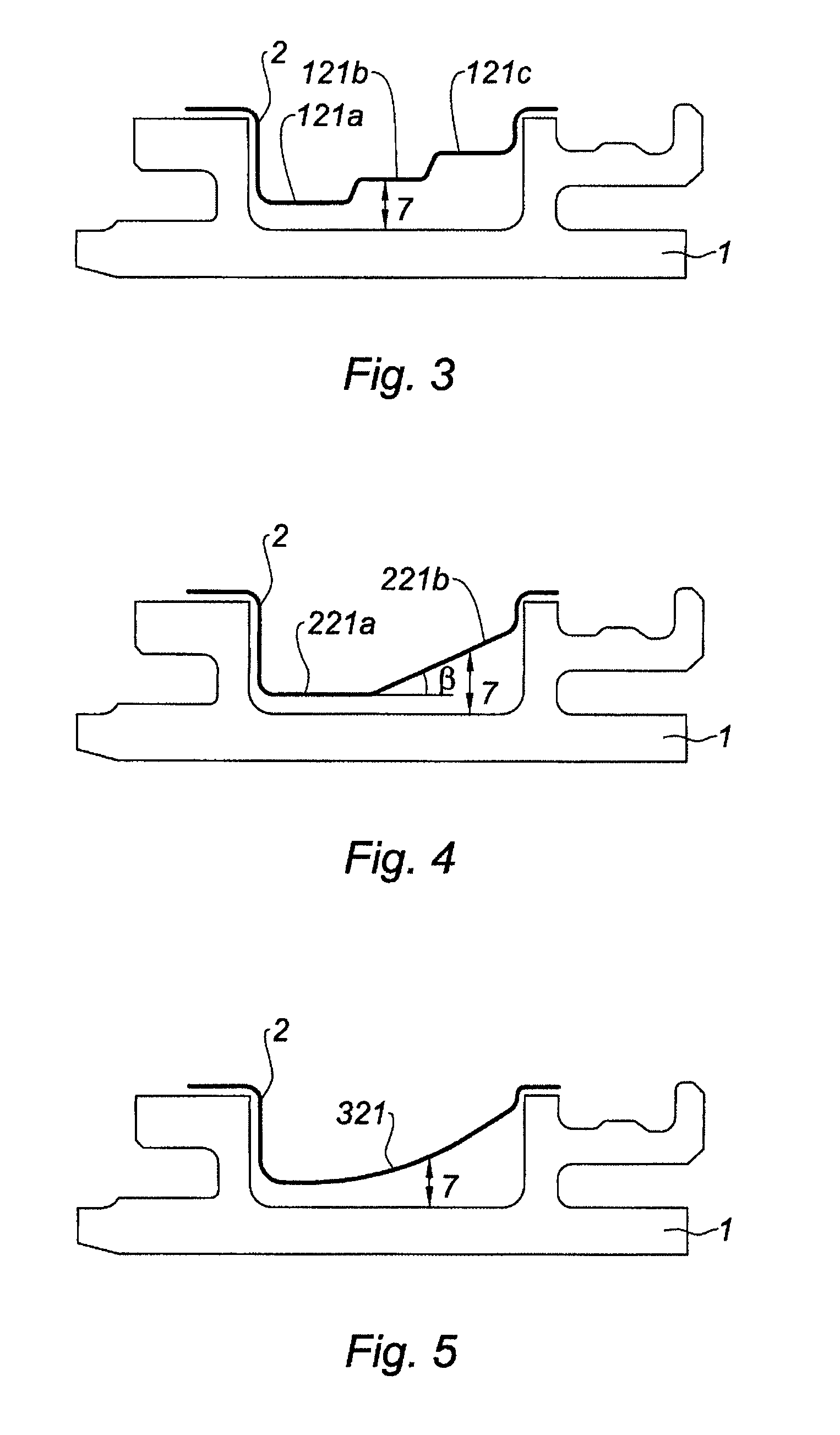

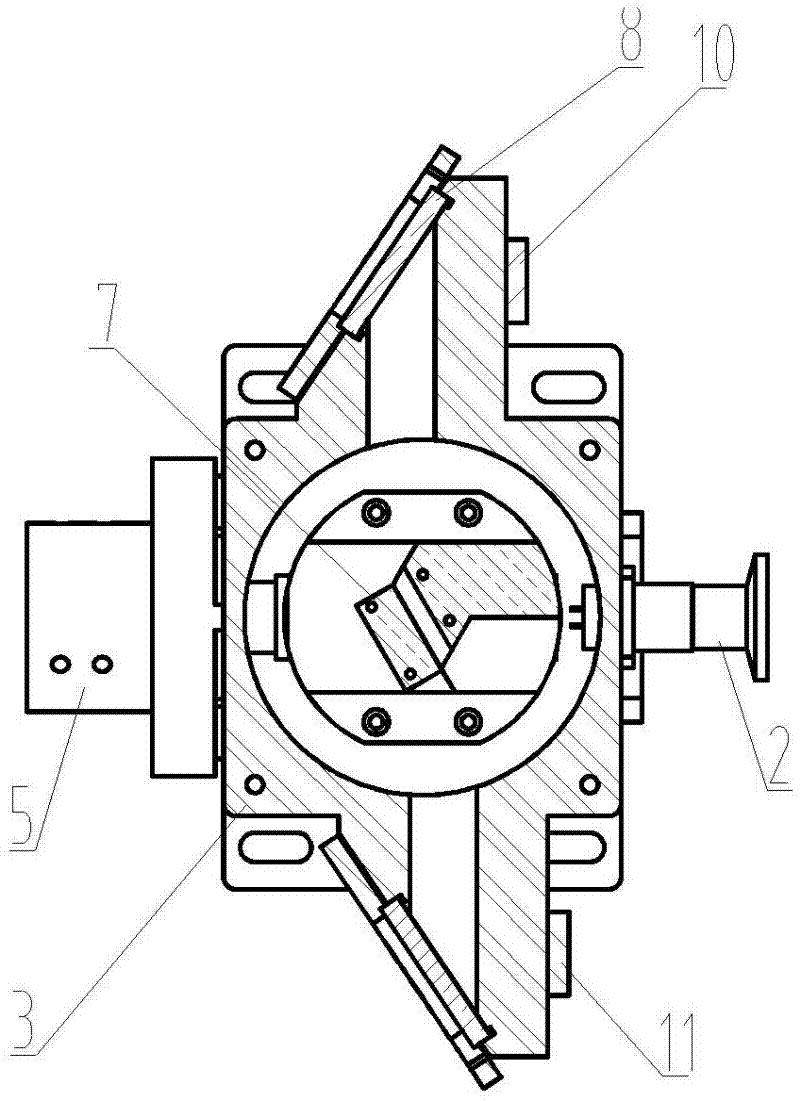

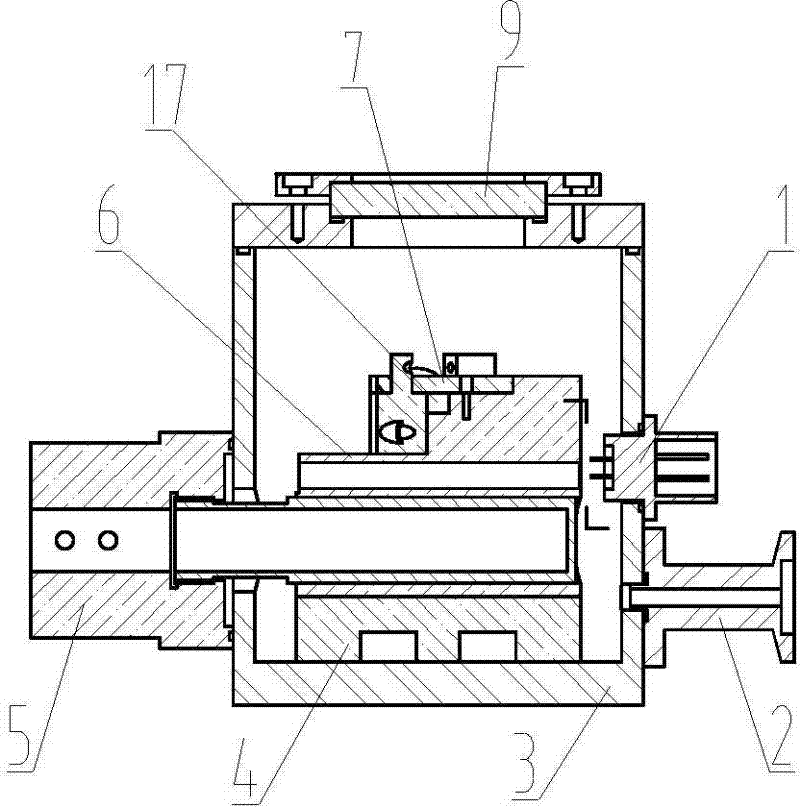

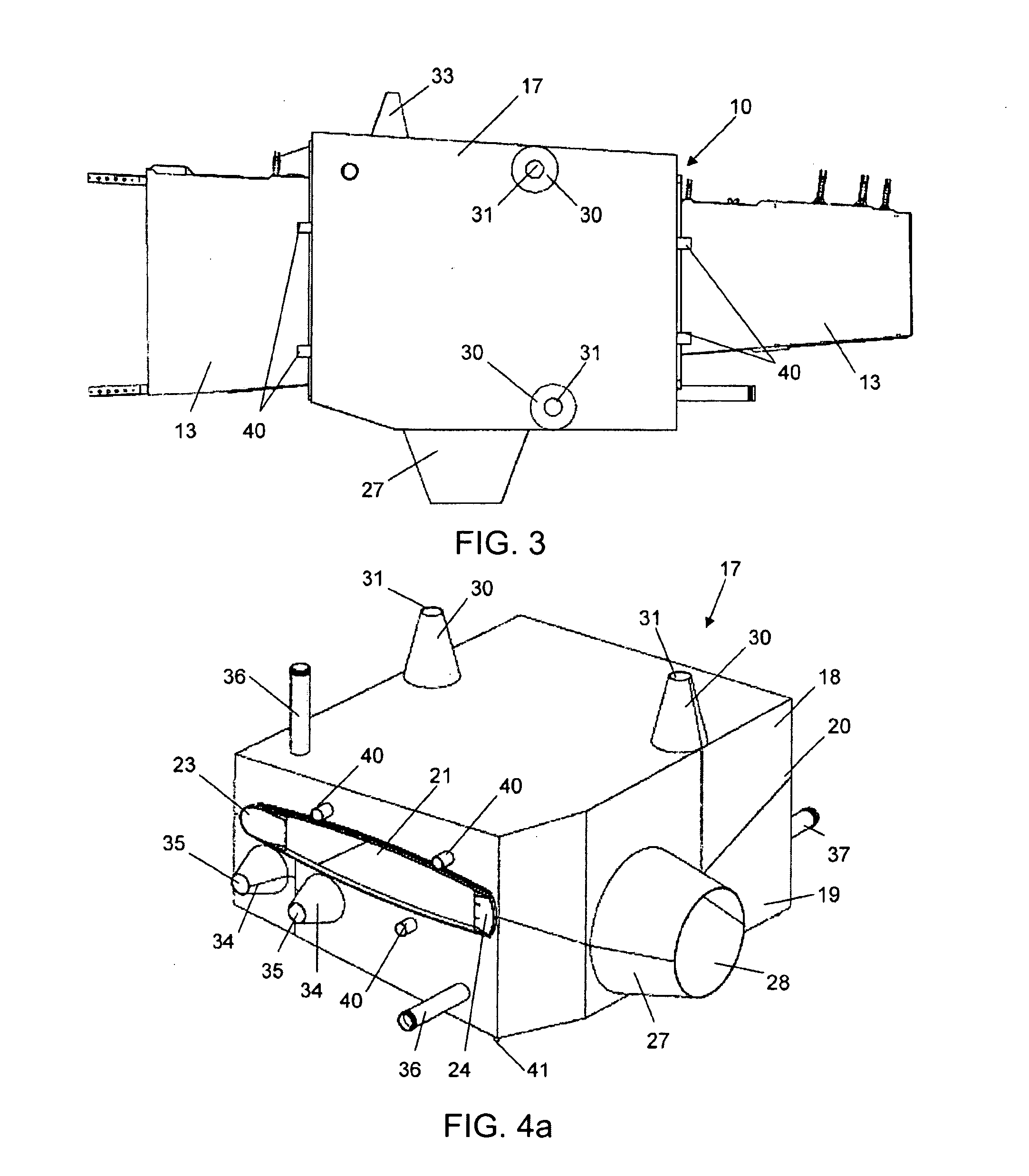

Impeller which includes improved means of cooling

ActiveUS20110027103A1Reduce thermal gradientReduce gradientPump componentsEngine fuctionsImpellerTurbine

Impeller for turbine engine which includes a disk provided with blade retention teeth, wherein associated with each tooth there are means for channelling a flow of cooling air which covers the crest of said tooth so that the latter is swept by the air flow.Turbine of turbine engine which includes an impeller of this type.Turbine engine for aircraft which includes a turbine of this type.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

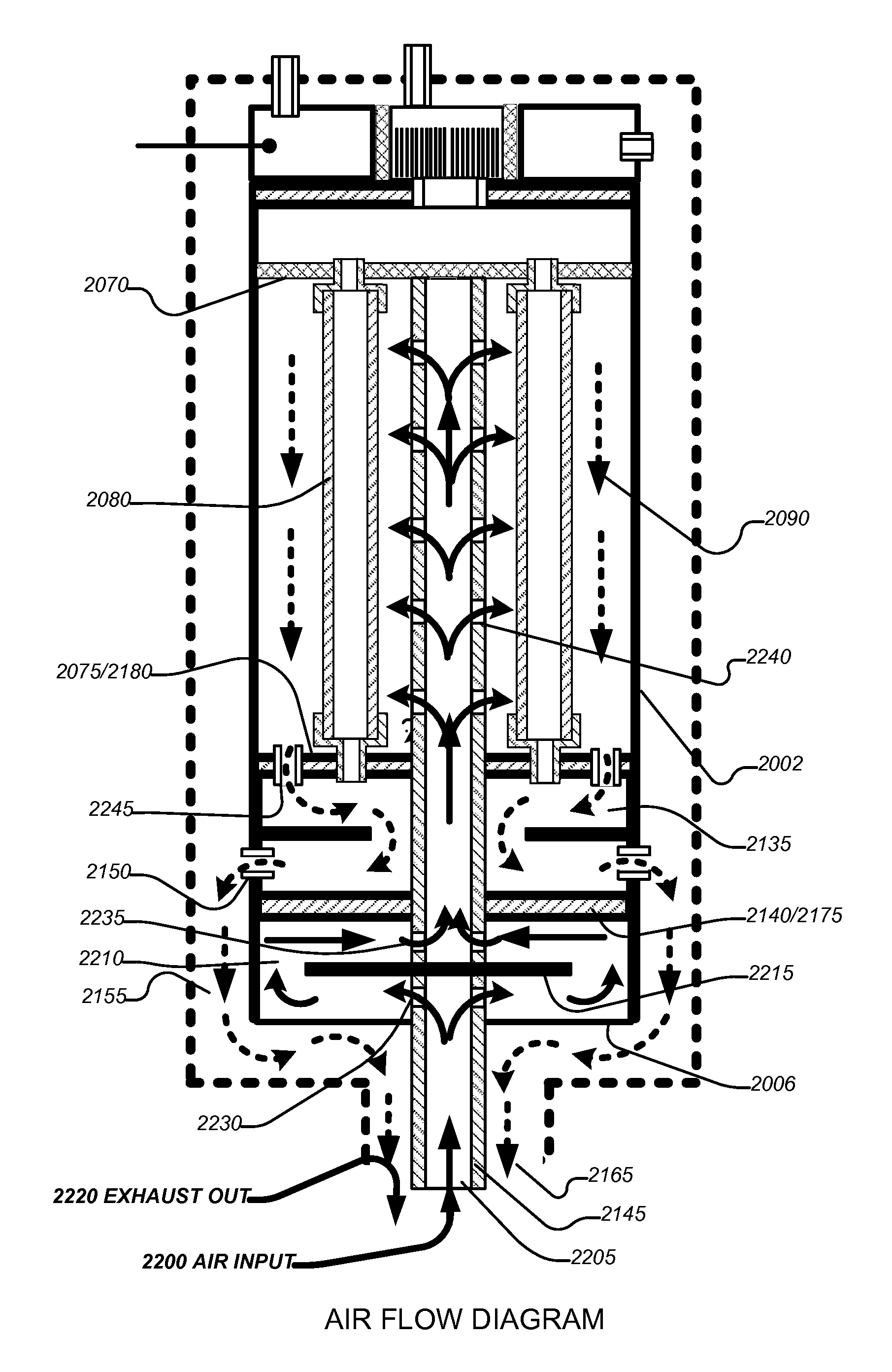

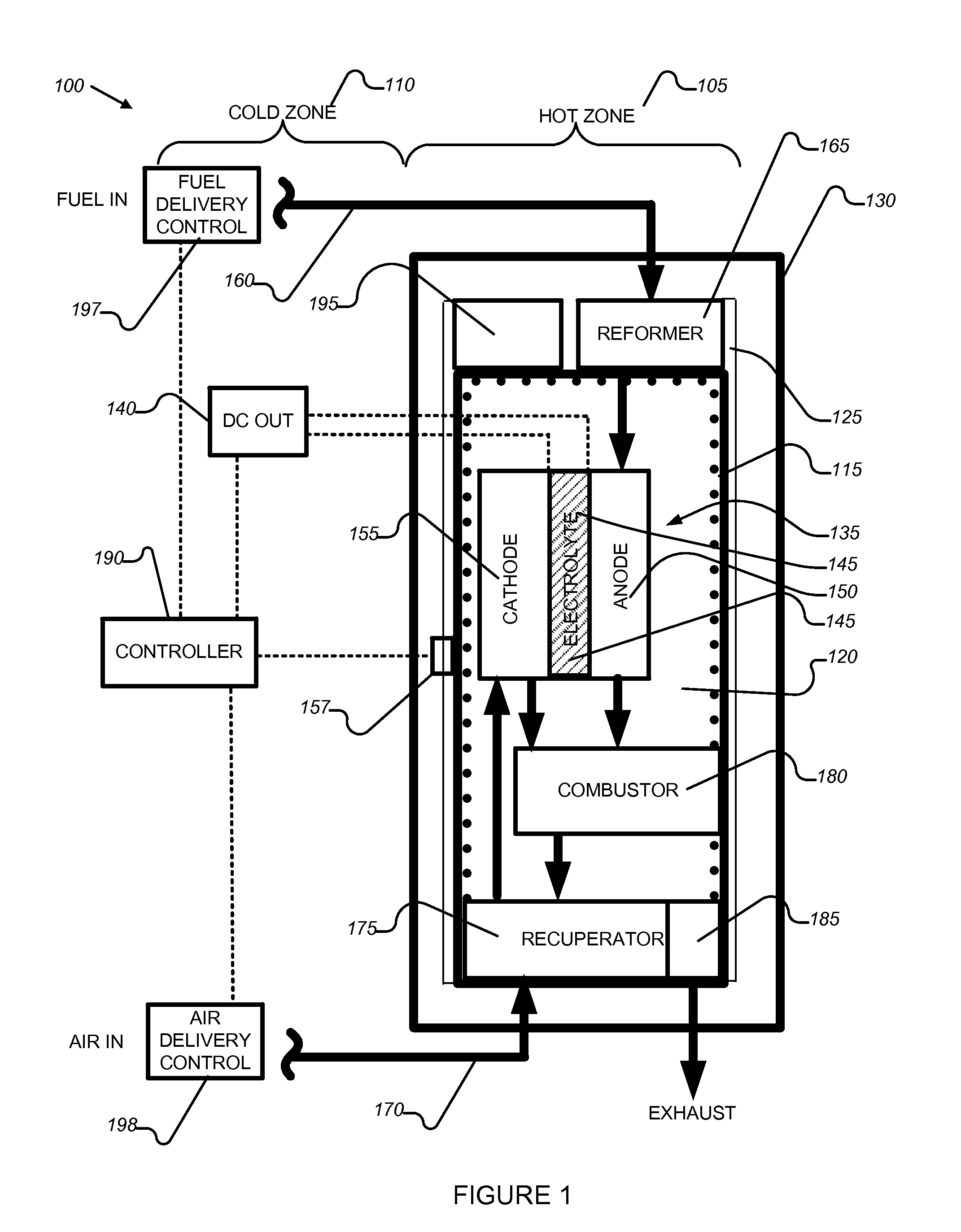

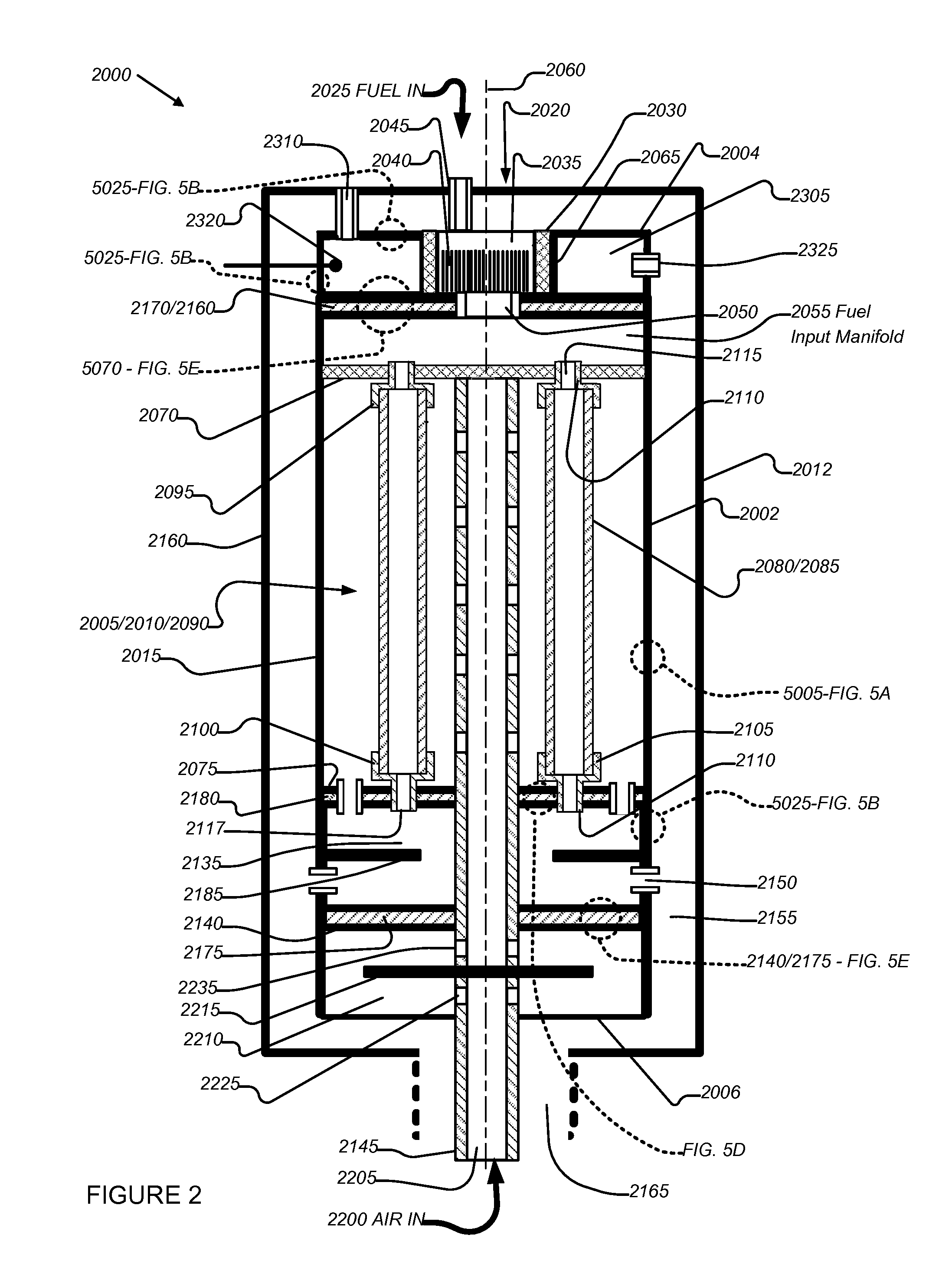

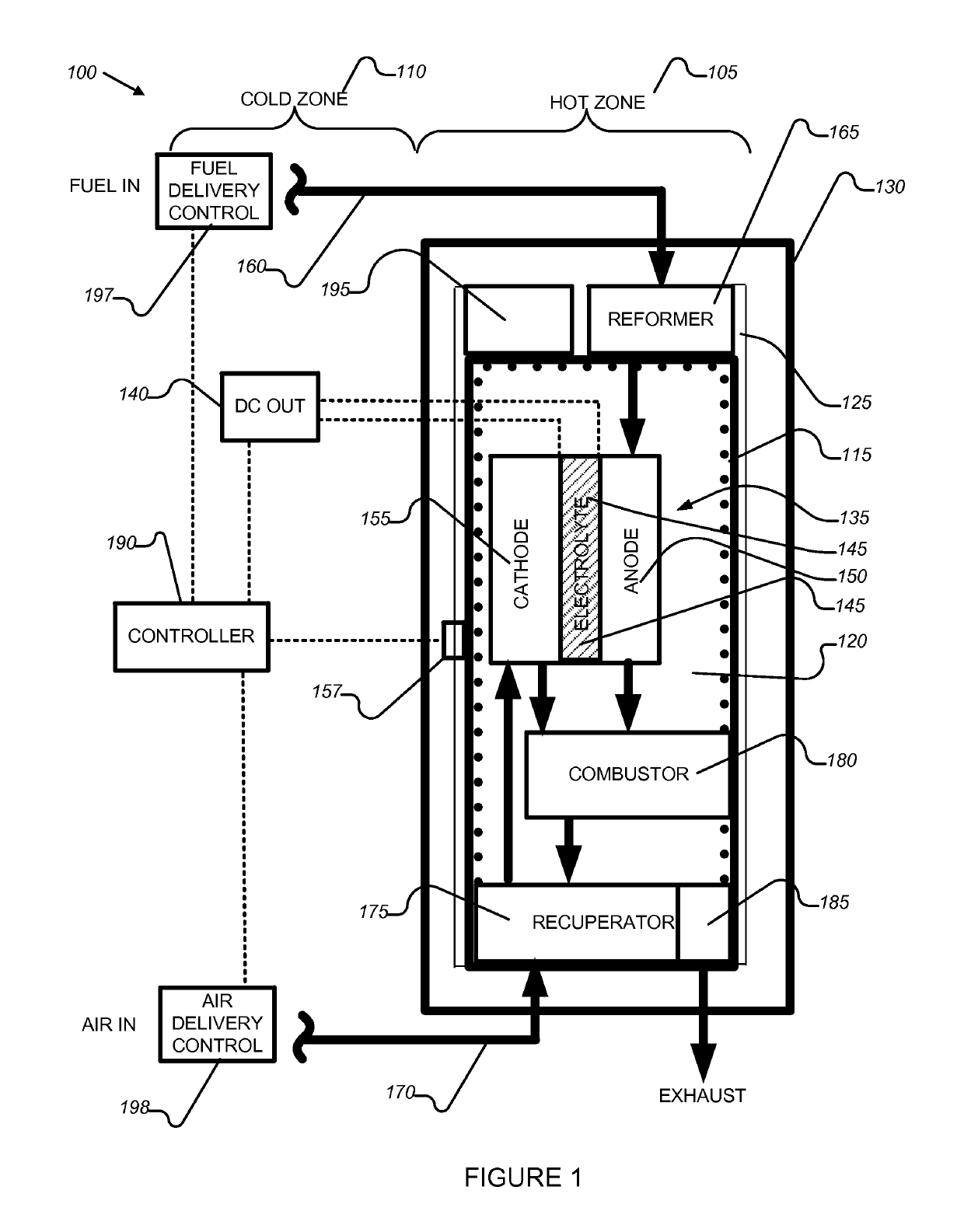

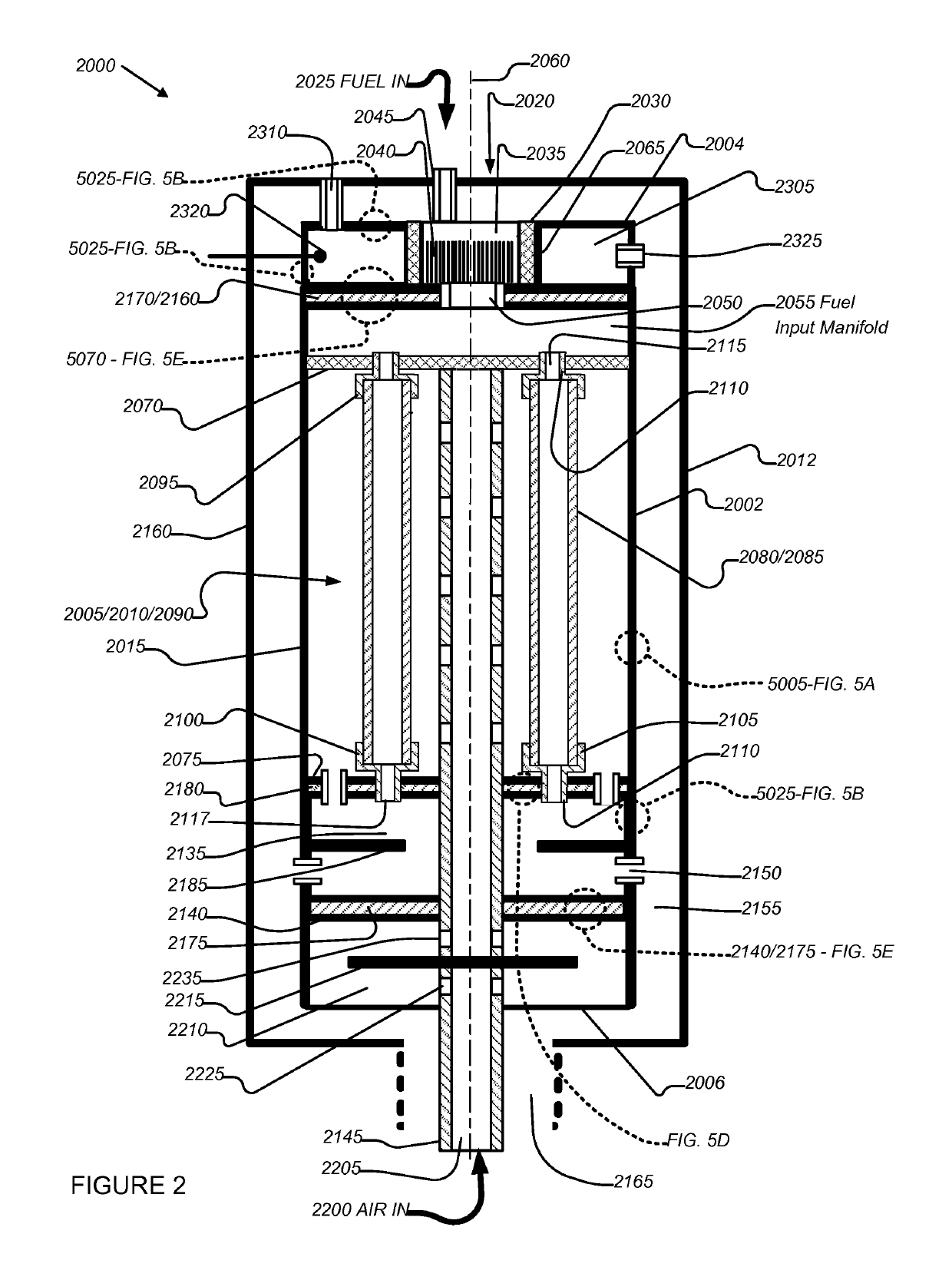

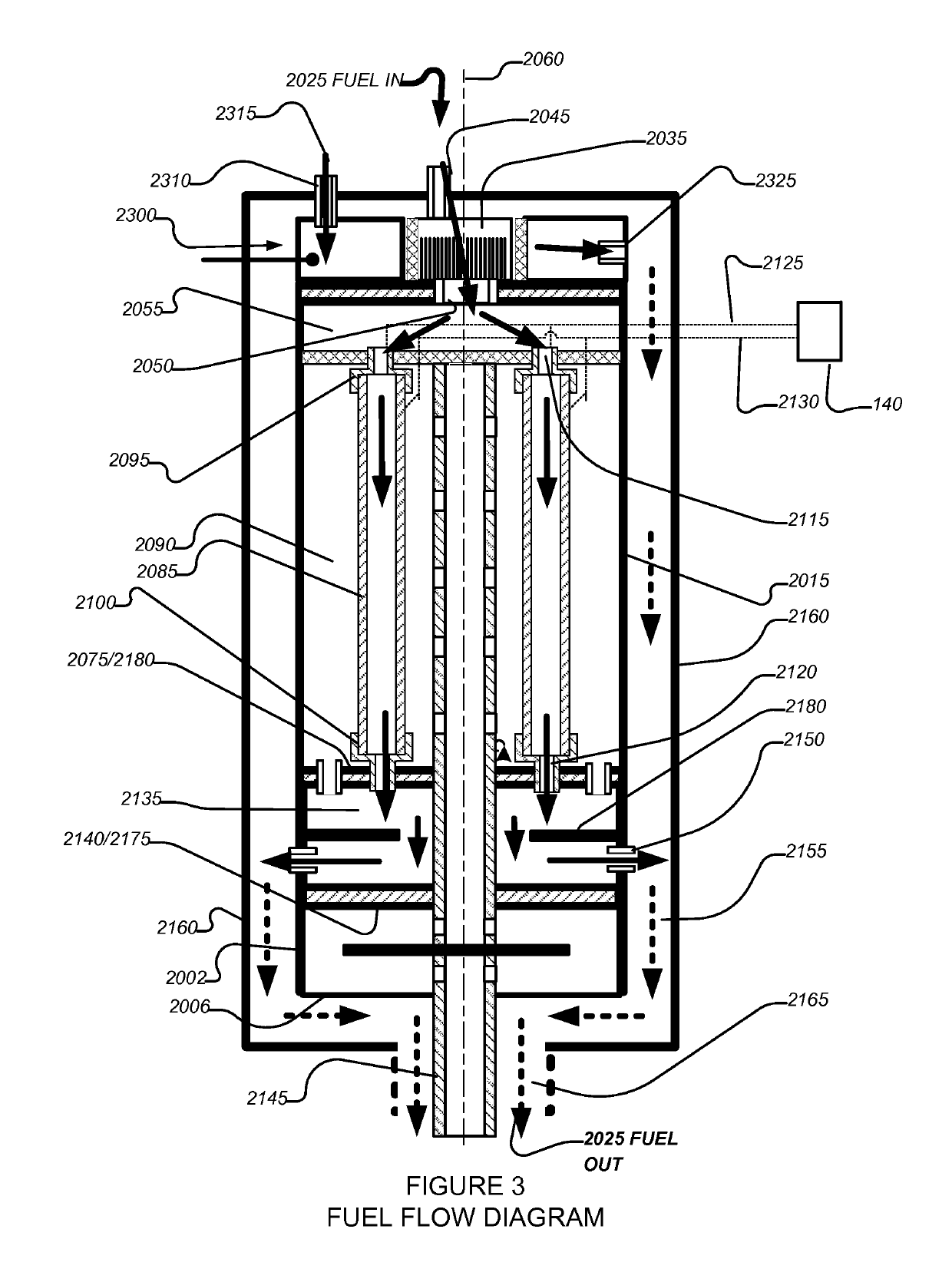

Sofc-conduction

ActiveUS20160099476A1Reduce gradientStable temperatureFuel cell auxillariesElectrolytesThermal energyCombustion chamber

A solid oxide fuel cell (SOFC) system included high thermal conductivity materials such as copper to increase thermal energy transfer by thermal conduction. The copper is protected from oxidation by nickel electroplating and protected from thermal damage by providing Hastelloy liners inside combustion chambers. Monel elements are used in the incoming air conduits to prevent cathode poisoning.

Owner:UPSTART POWER INC

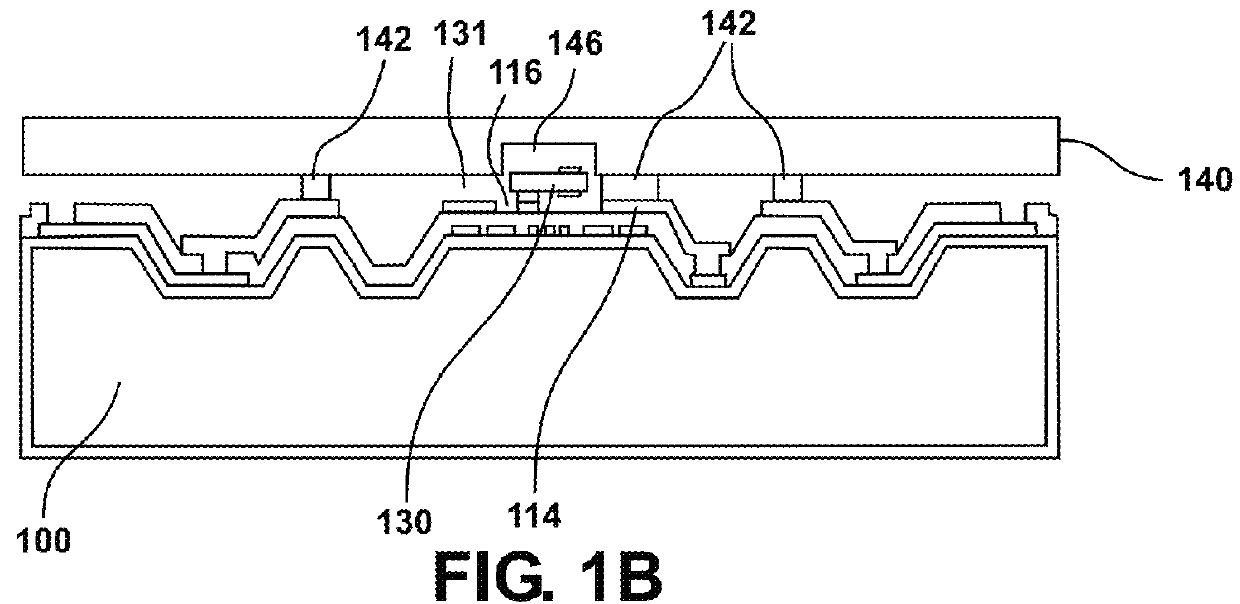

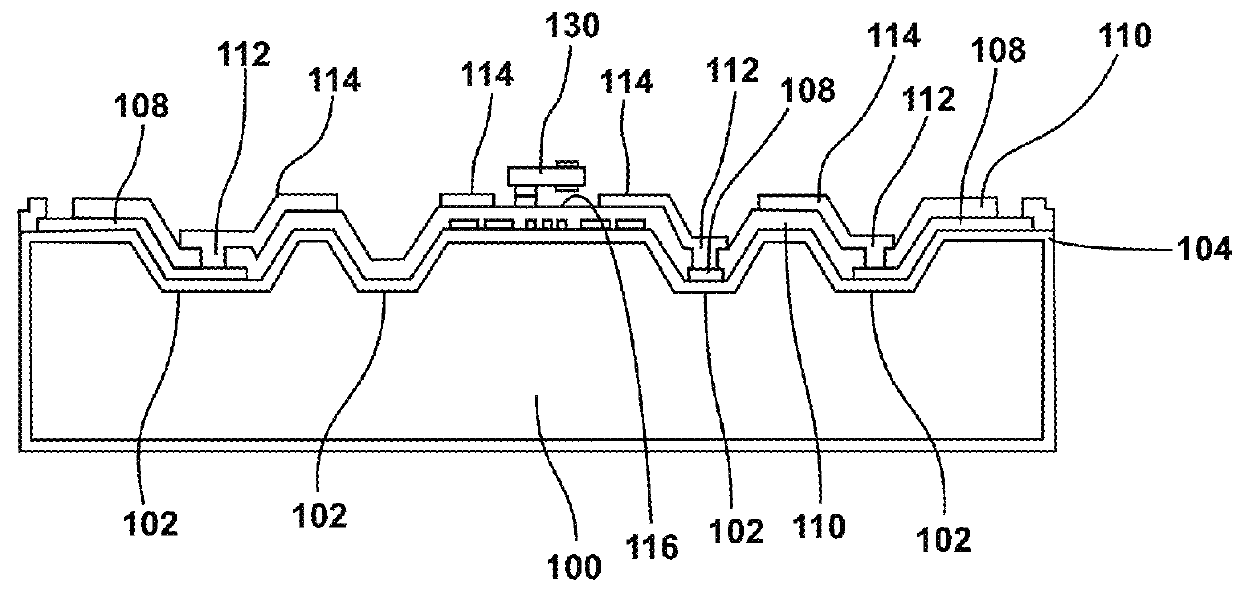

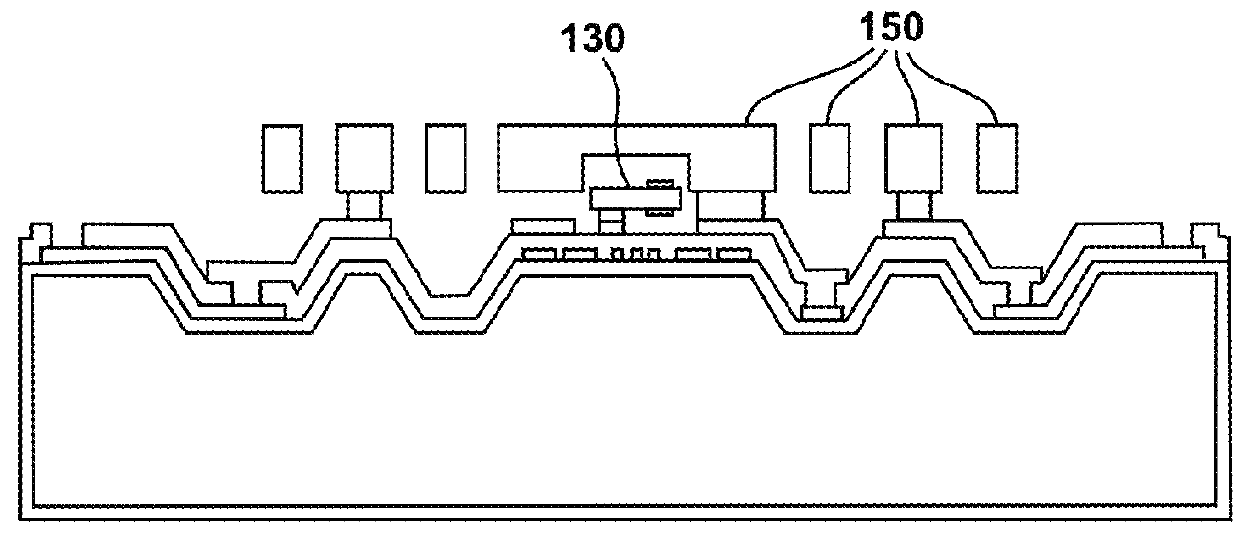

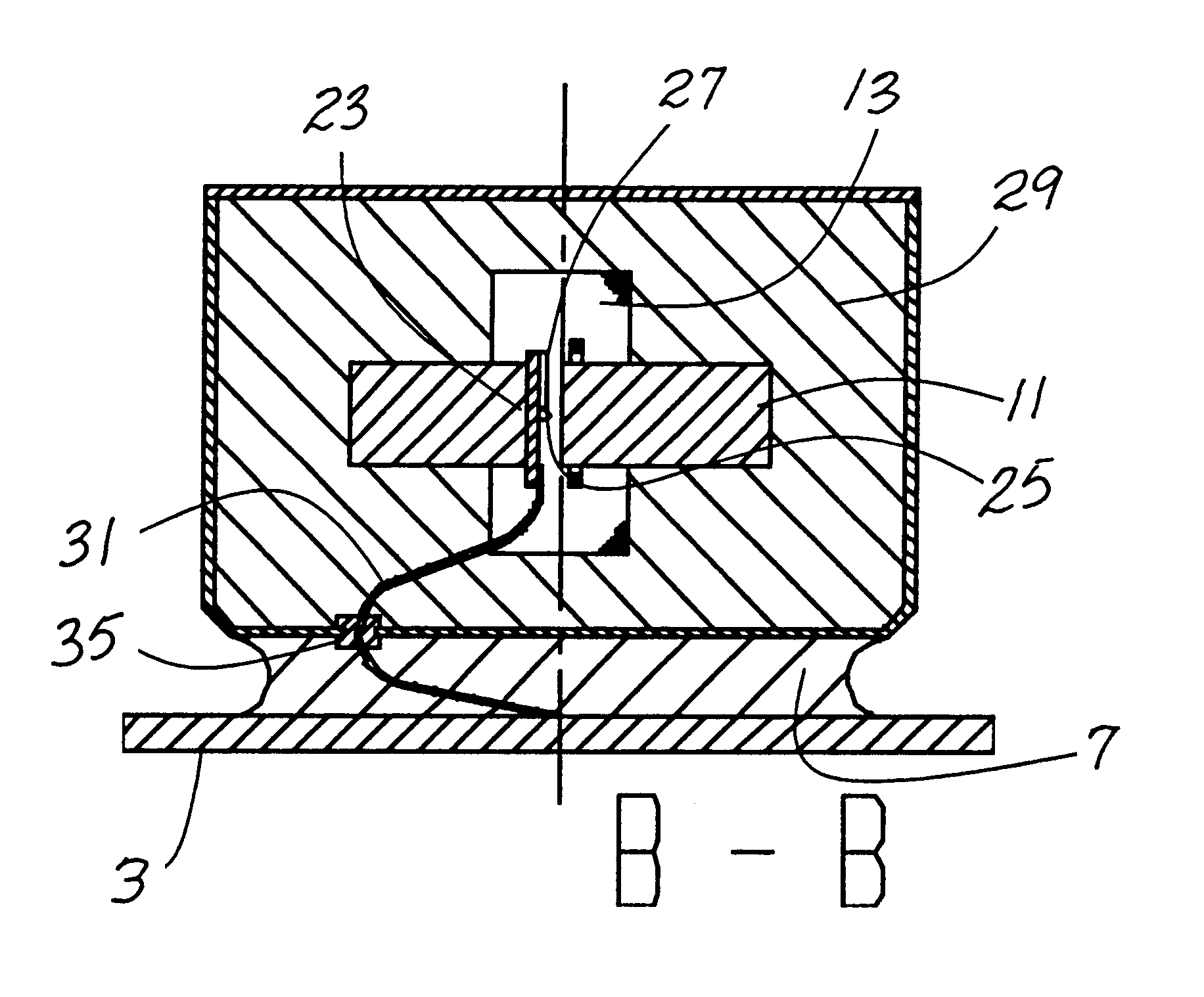

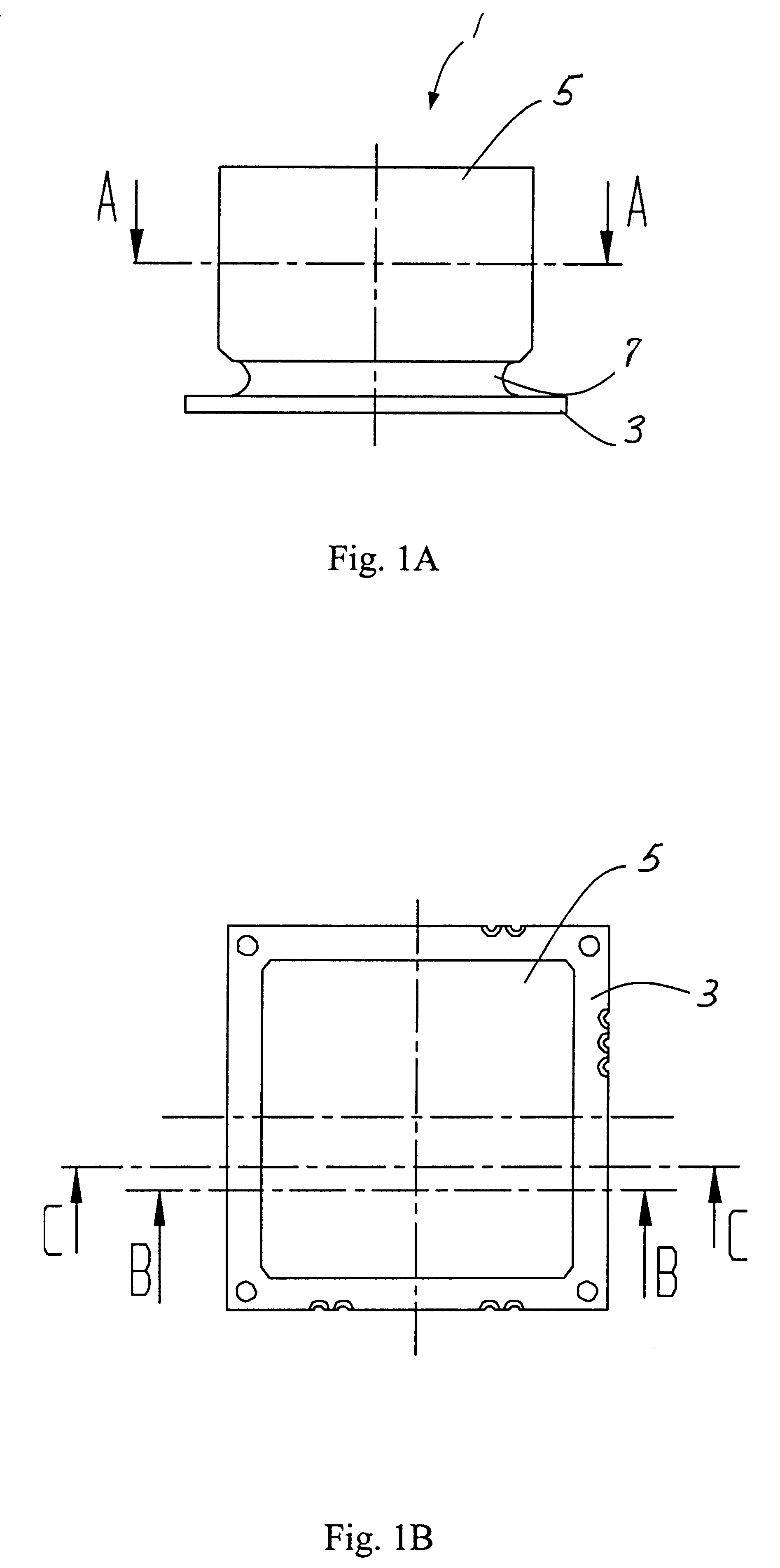

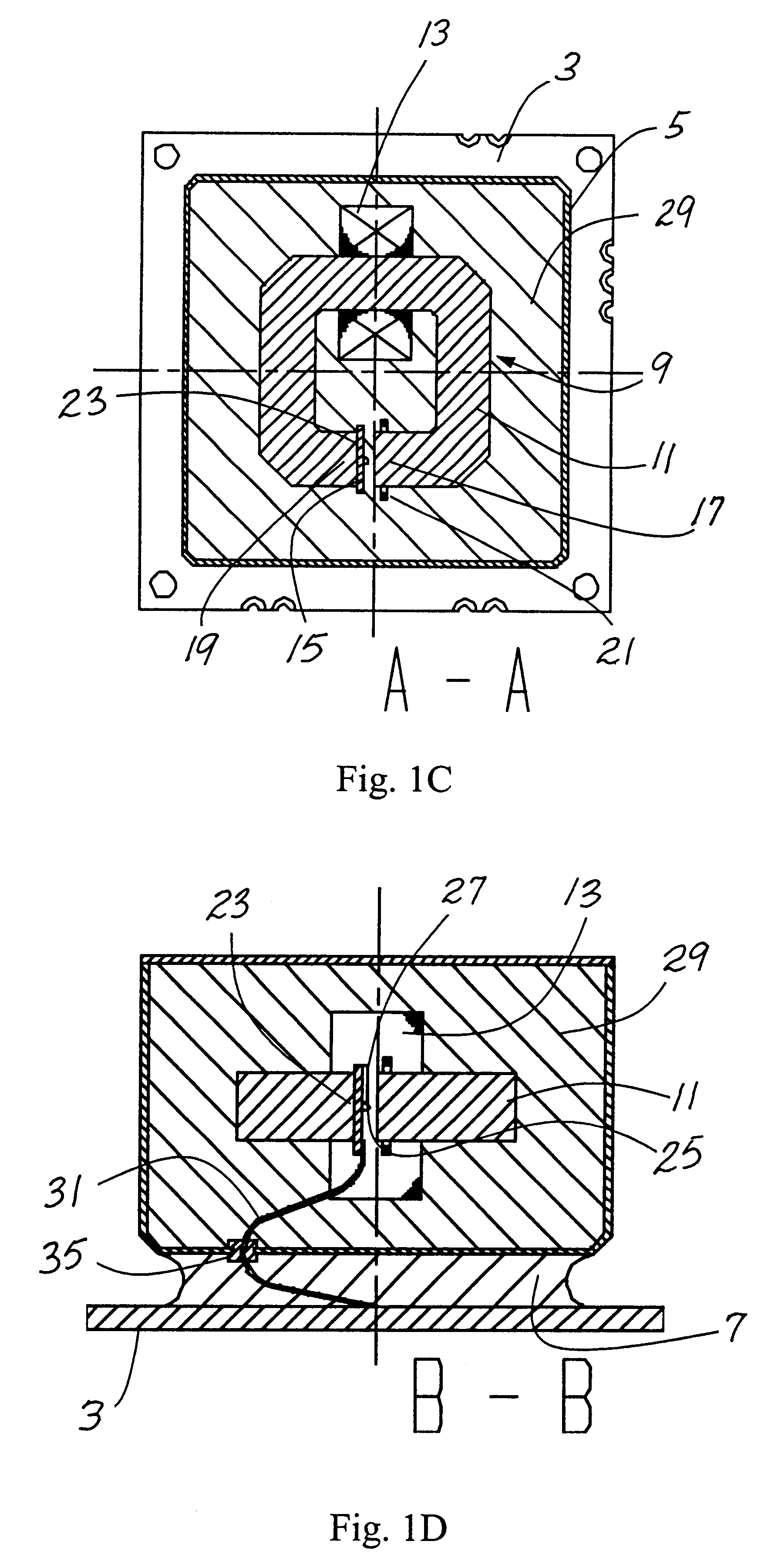

Resonator assembly comprising a silicon resonator and a quartz resonator

ActiveUS9250074B1Improve fidelityQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksGyroscopeQuartz resonator

A resonator assembly comprising a semiconductor substrate, a resonator gyroscope, the resonator gyroscope including a first resonator formed in a layer of a first material, and an oscillator on the semiconductor substrate, the oscillator including a second resonator formed of a second material, wherein the second resonator is attached in a cavity; the cavity comprising a first recess in said layer of a first material and the edges of the first recess being attached to the substrate, or the cavity comprising a second recess in said substrate and the edges of the second recess being attached to said layer of a first material.

Owner:HRL LAB

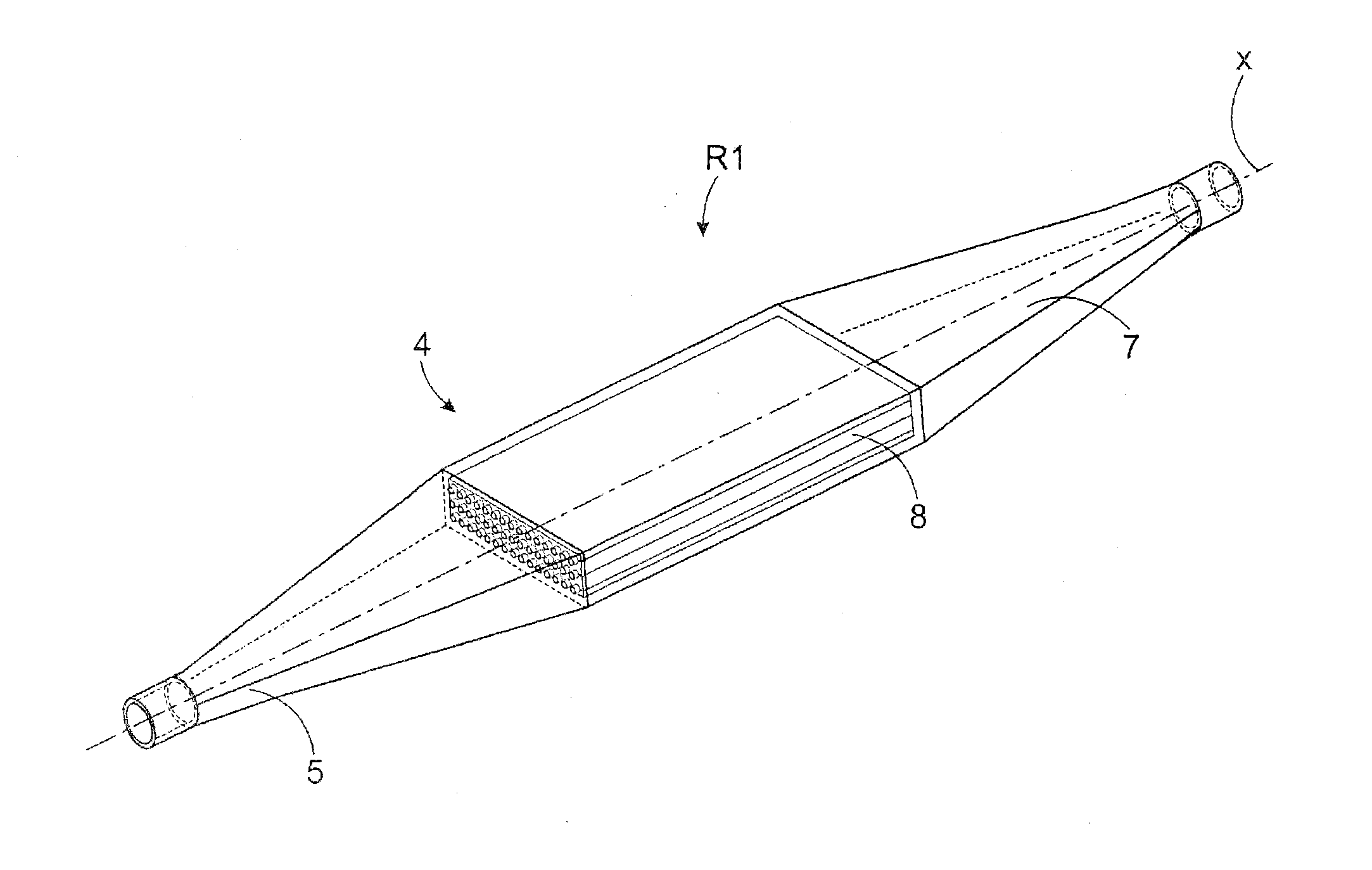

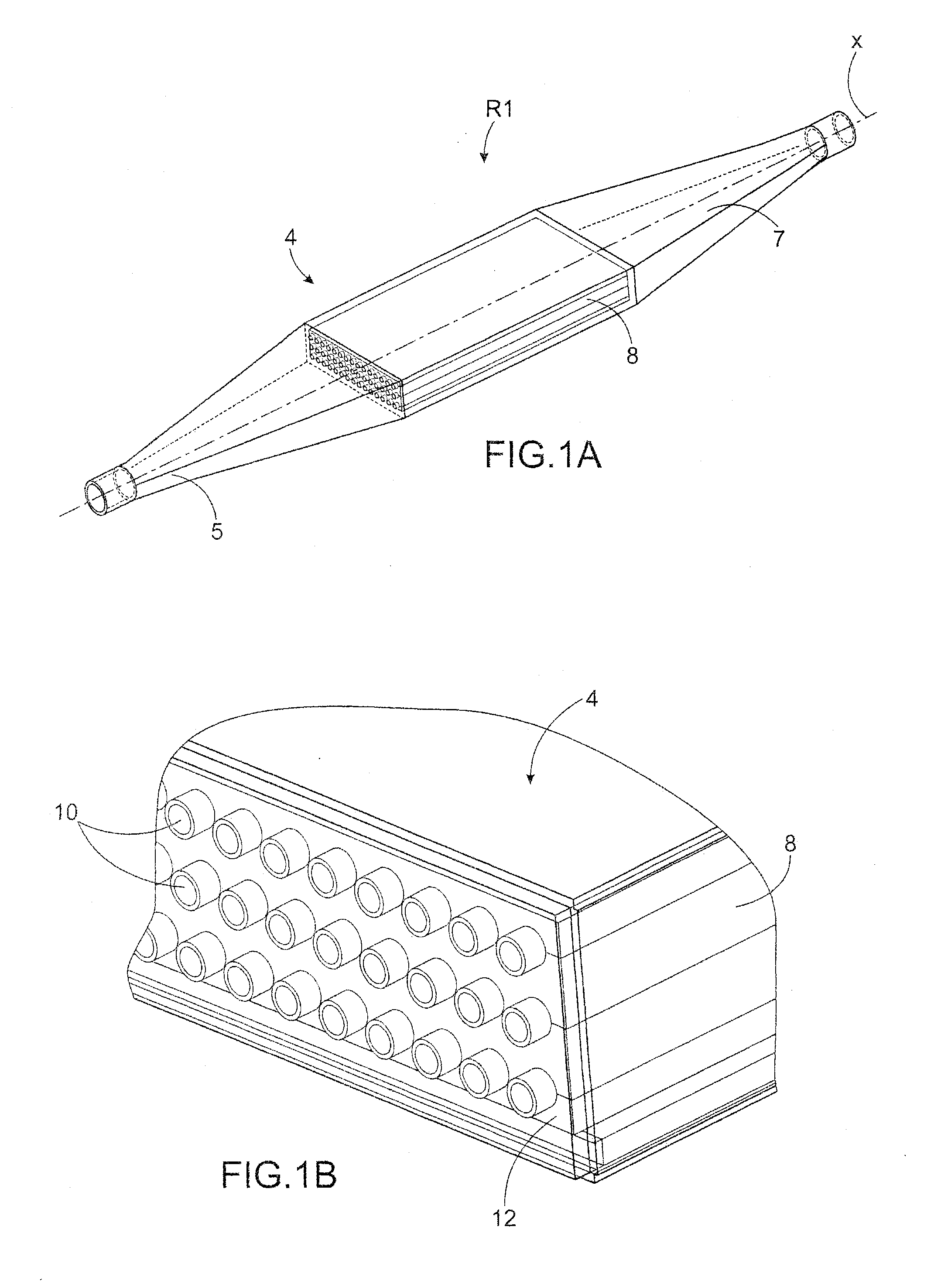

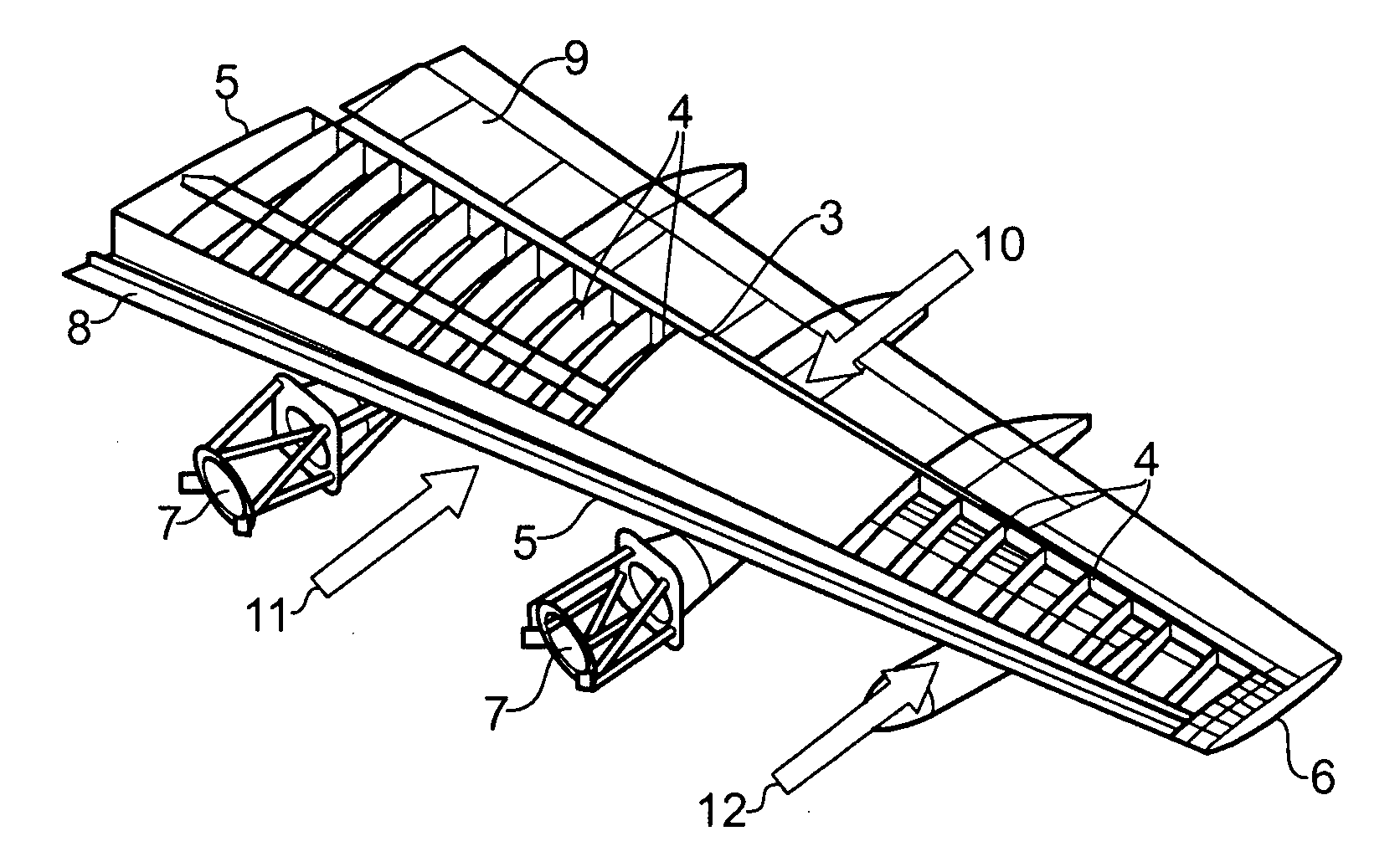

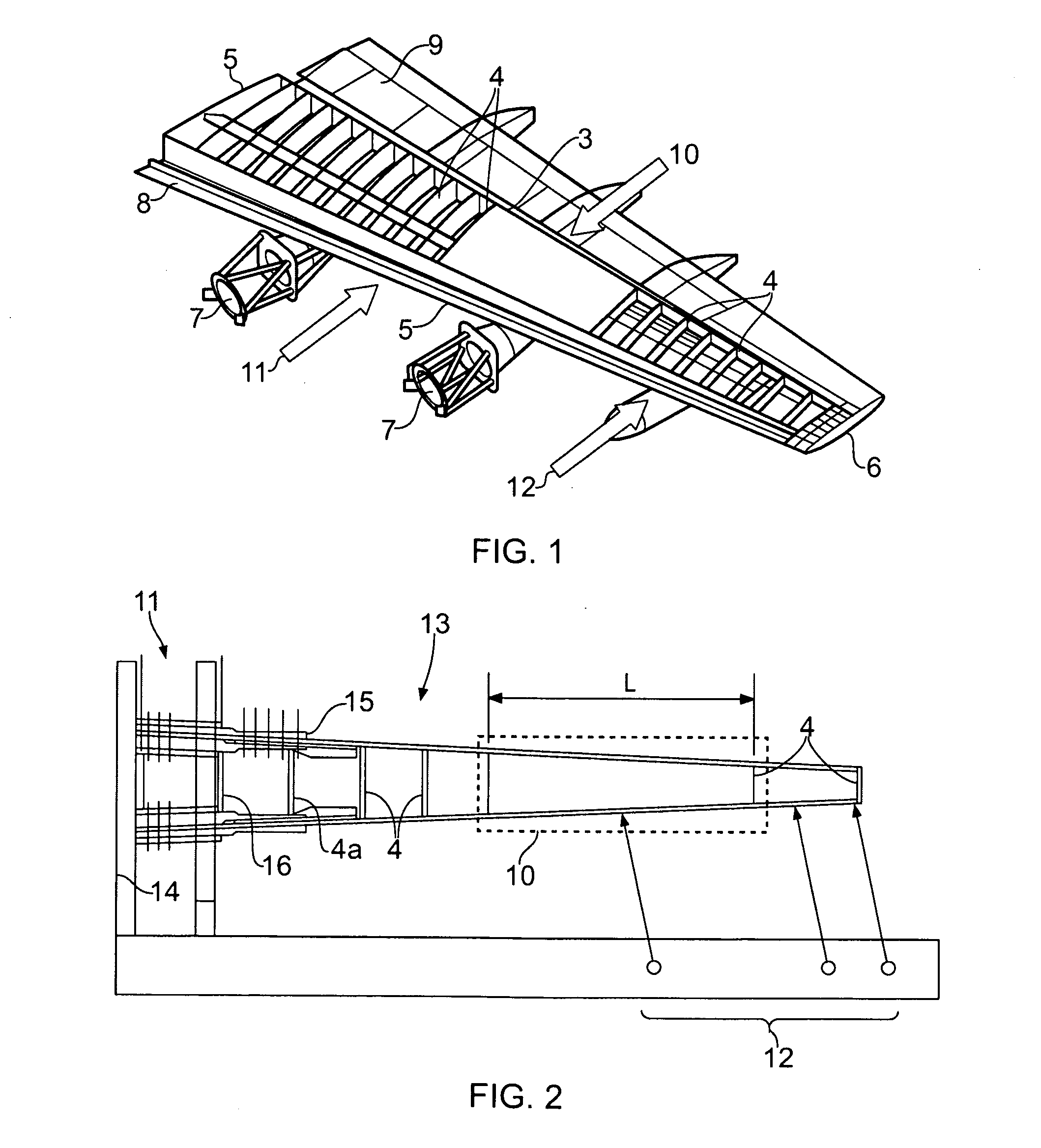

Solar receiver absorber and solar receiver comprising at least one such absorber

InactiveUS20130152917A1Reduce impactControl stressSolar heating energySolar heat devicesSolar power towerEngineering

A solar power tower solar receiver absorber including: an enclosure; at least one panel configured to be illuminated by solar flux; a core made of at least one material with heat conductivity at least partially encompassed by the enclosure; and a plurality of tubes passing through the core and extending substantially in a parallel direction with respect to the panel configured to be illuminated. The tube is configured for circulation of a fluid to be heated, for example a gas for operating a gas turbine.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

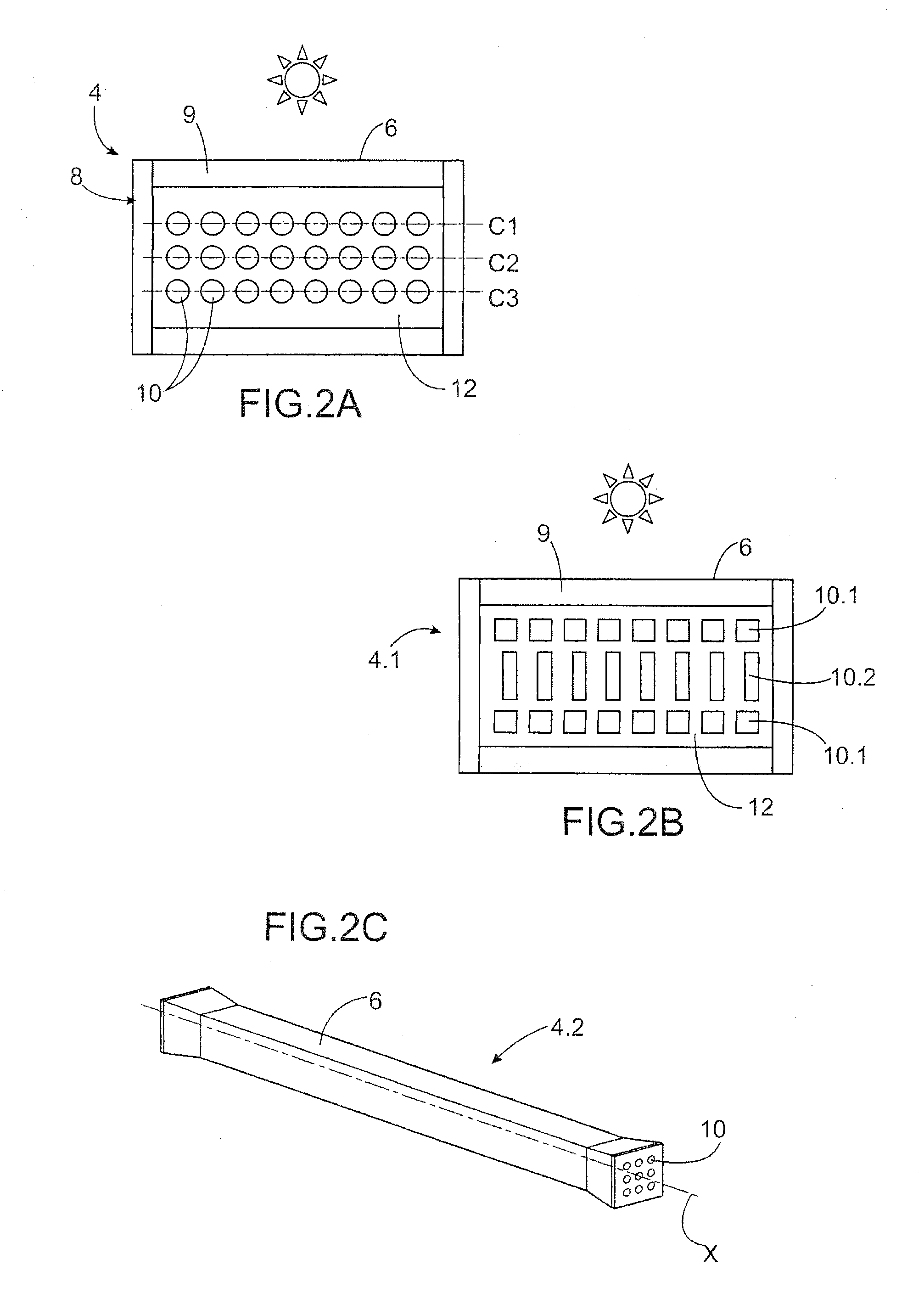

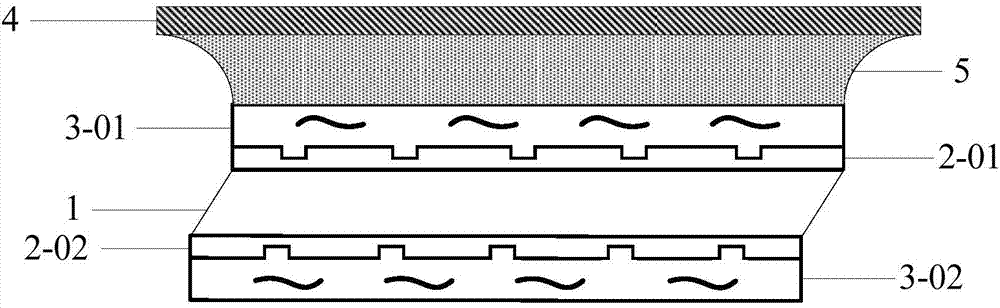

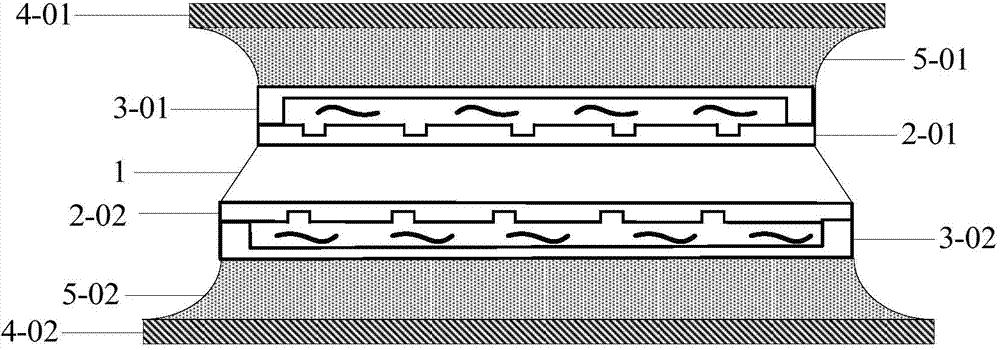

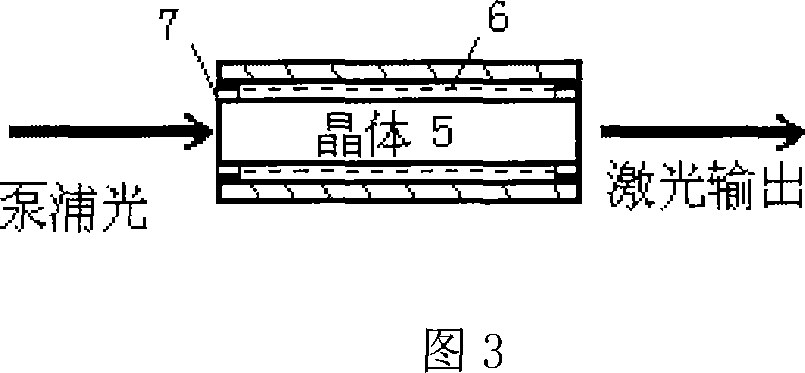

Large-face pumping slab laser module capable of efficient cooling

A large-face pumping slab laser module capable of efficient cooling comprises slab laser mediums, a transparent heat sink, a transparent cooling device and a semiconductor pumping source. According to the large-face pumping slab laser module capable of efficient cooling, the transparent heat sink high in heat conductivity and good in light transmission is bonded or manufactured on the large face of the solid slab laser mediums through optical cement, and the transparent cooling device is used for obtaining the large face of a slab laser and meanwhile serving as a cooling face or a pumping face so as to change the situation that for an existing large-face pumping slab module, only an upper surface and a lower surface can serve as a pumping face and a refrigerating face respectively, thermal gradient is easy to form in the longitudinal pump light direction due to single-surface refrigeration, output light beams are influenced, and quality of the light beams is not sufficient. The bonding or optical cement mode on the large face of the laser mediums is adopted for replacing the welding mode of the metallic heat sink so as to eliminate the stress on the laser mediums caused by welding, and therefore high-power and high-light-beam-quality laser output is achieved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preventing selective laser melting nickel-based superalloy from cracking

ActiveCN111906311AHigh densityNo crack defectAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSuperalloy

The invention provides a method for preventing a selective laser melting nickel-based superalloy from cracking, and belongs to the field of additive manufacturing. According to the method, a workpiecewhich is high in density, free of crack defects and excellent in mechanical property is prepared by reducing low-melting-point phase forming elements Zr and B in the nickel-based superalloy and adjusting the total content of Al and Ti in the alloy to be smaller than or equal to 4.5wt% in combination with special selective laser melting (SLM) process parameter control. Through the method, component design is reasonable, the preparation process is simple, and the obtained workpiece has excellent properties and is convenient to apply on a large scale.

Owner:CENT SOUTH UNIV

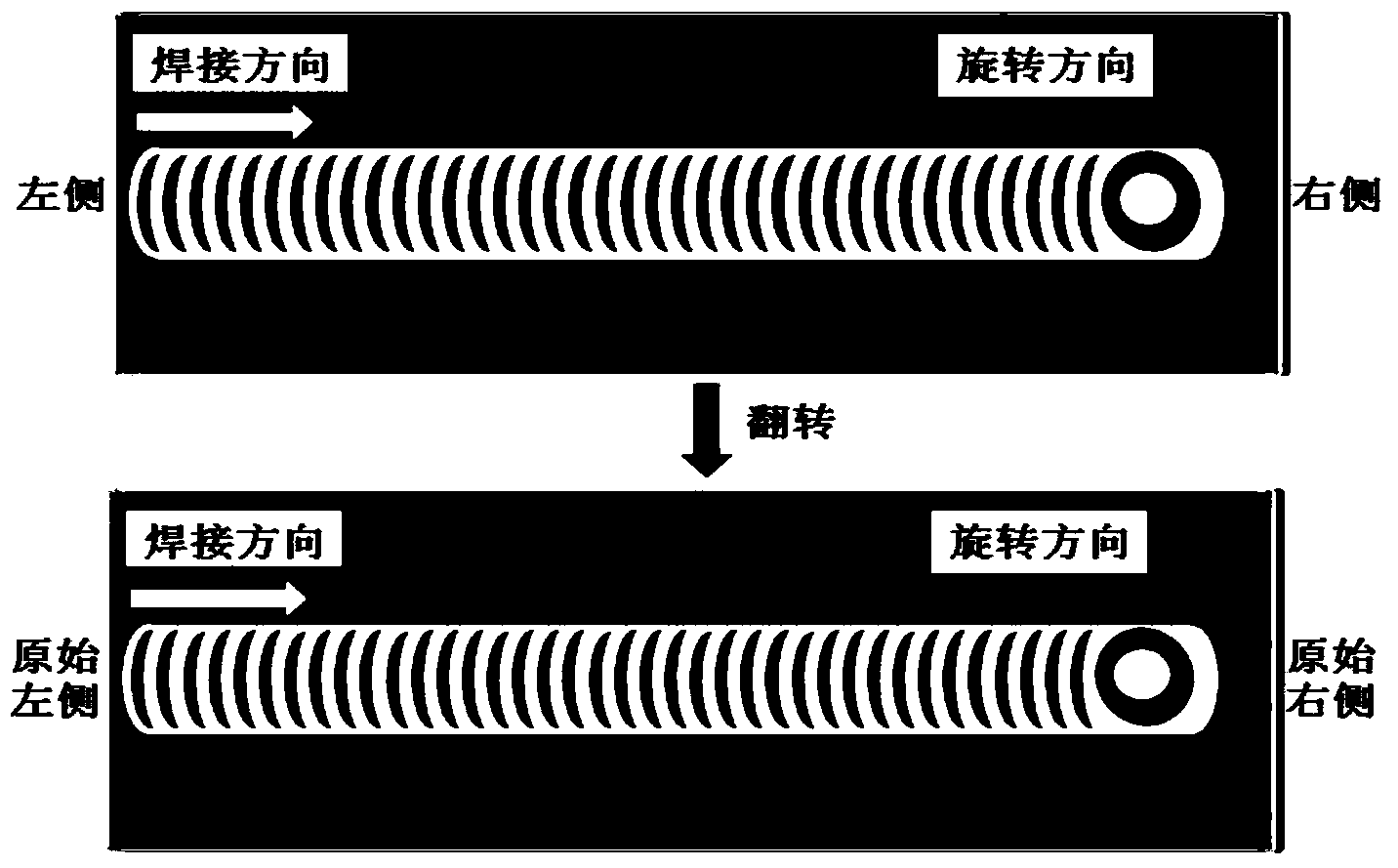

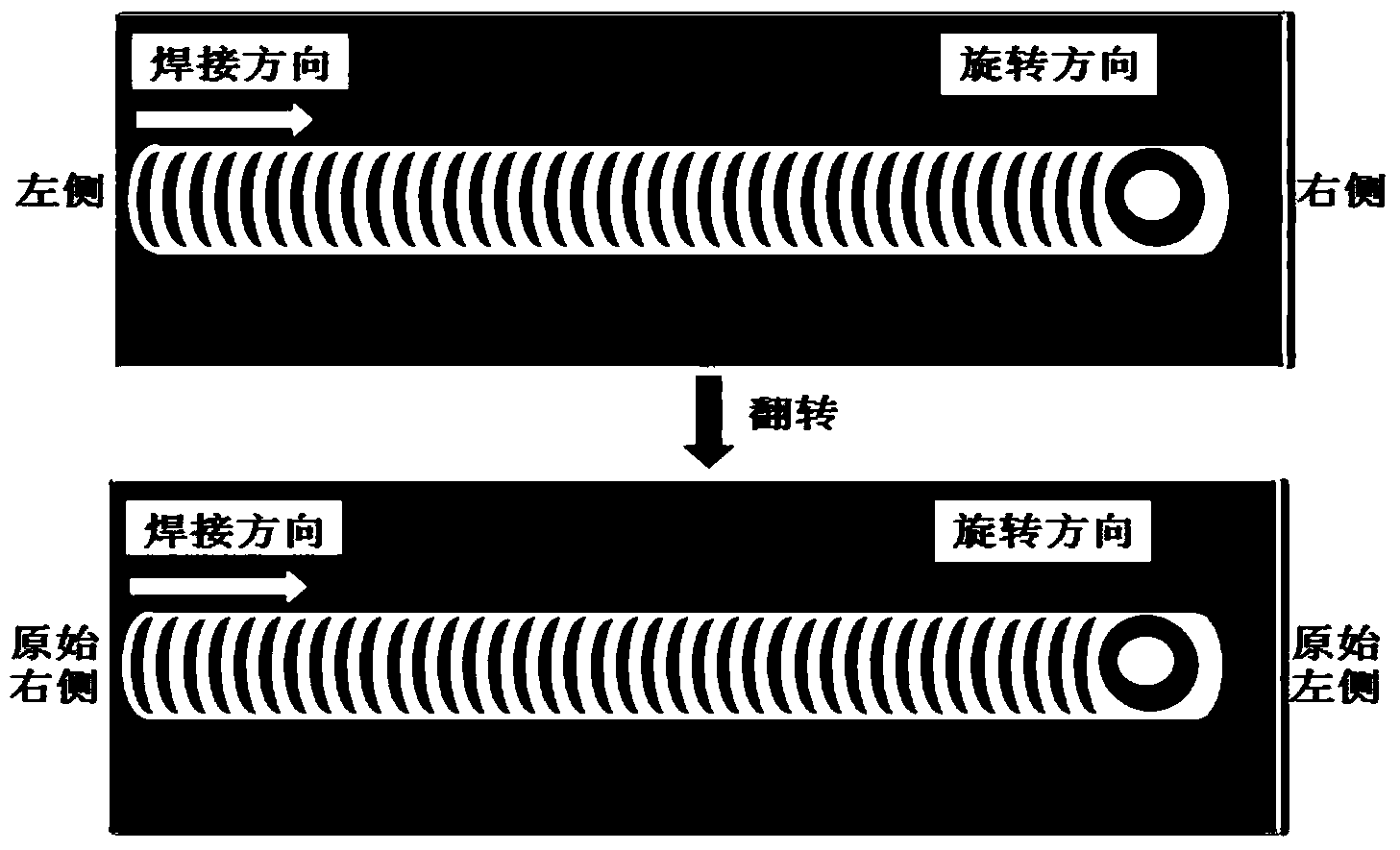

Stir friction both-side welding method for medium-thickness plate

InactiveCN103920986APromote plastic flowImprove mechanical propertiesWelding/soldering/cutting articlesMetal working apparatusSurface layerButt joint

The invention relates to a stir friction both-side welding method for a medium-thickness plate and belongs to a novel metal material connection method. The welding method includes the following steps that firstly, magnesium alloy plates to be welded are in butt joint and are fixed to a worktable; secondly; secondly an FSW device is used for performing both-side welding graded welding on the magnesium alloy plates, and primary welding joint welding is performed on a stirring head at the rotating speed omega, the welding speed Vh and the pressing amount h; thirdly, a workpiece is overturned, secondary welding joint welding is performed on the back of a primary welding joint, and welding parameters are identical to those in the second step. According to the stir friction both-side welding method, due to the fact that the initial position of a secondary welding joint is adjusted, the plastic flow of metal can be improved, asymmetry of heating power influence areas on the two sides of cross sections of welding joints is easily avoided, and the mechanical property on connectors is improved. The defect that the root of the medium-thickness plate is not welded thoroughly is overcome, and the possibility that the metal of the surface-layer welding joints is locally overheated is also reduced through twice welding.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

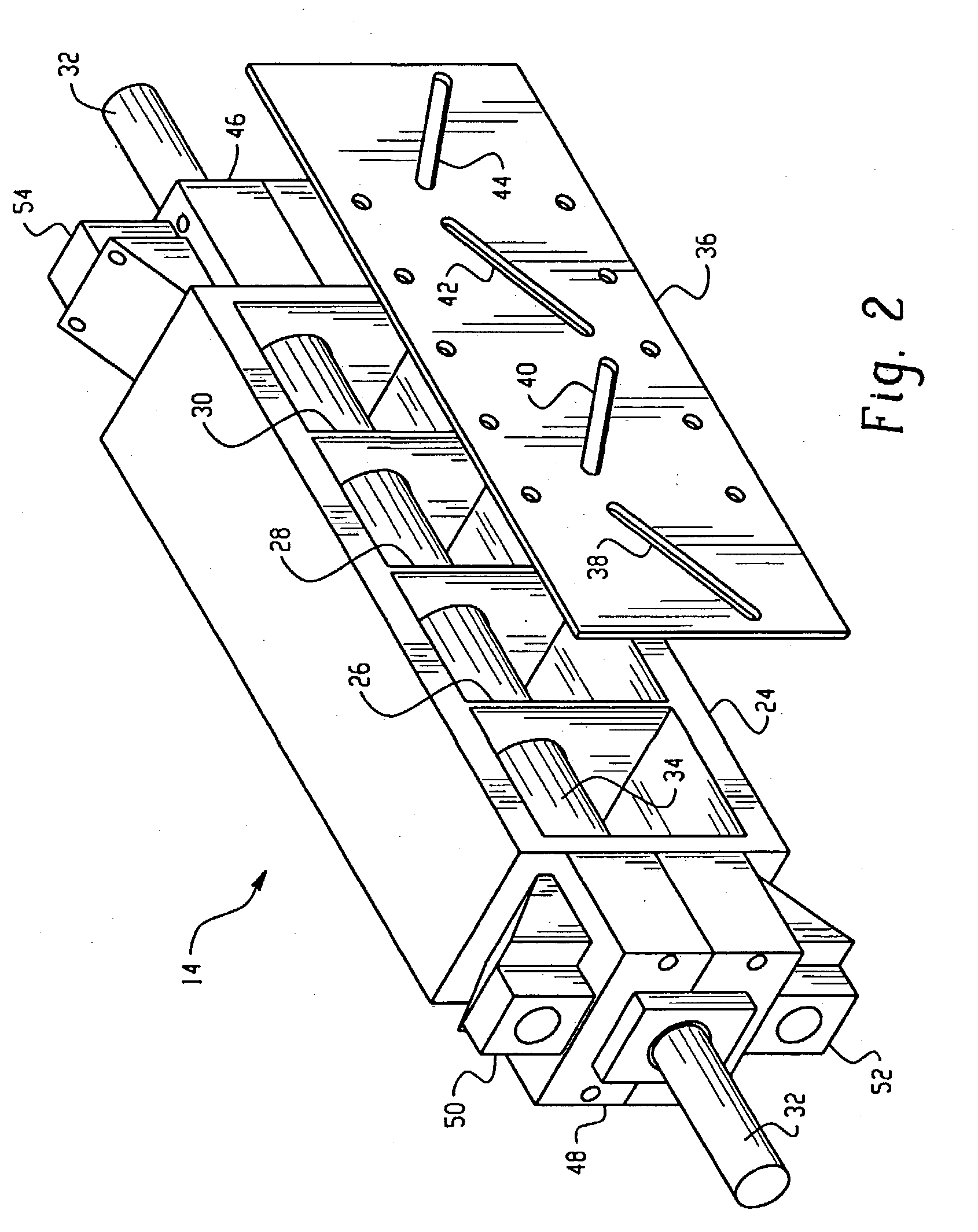

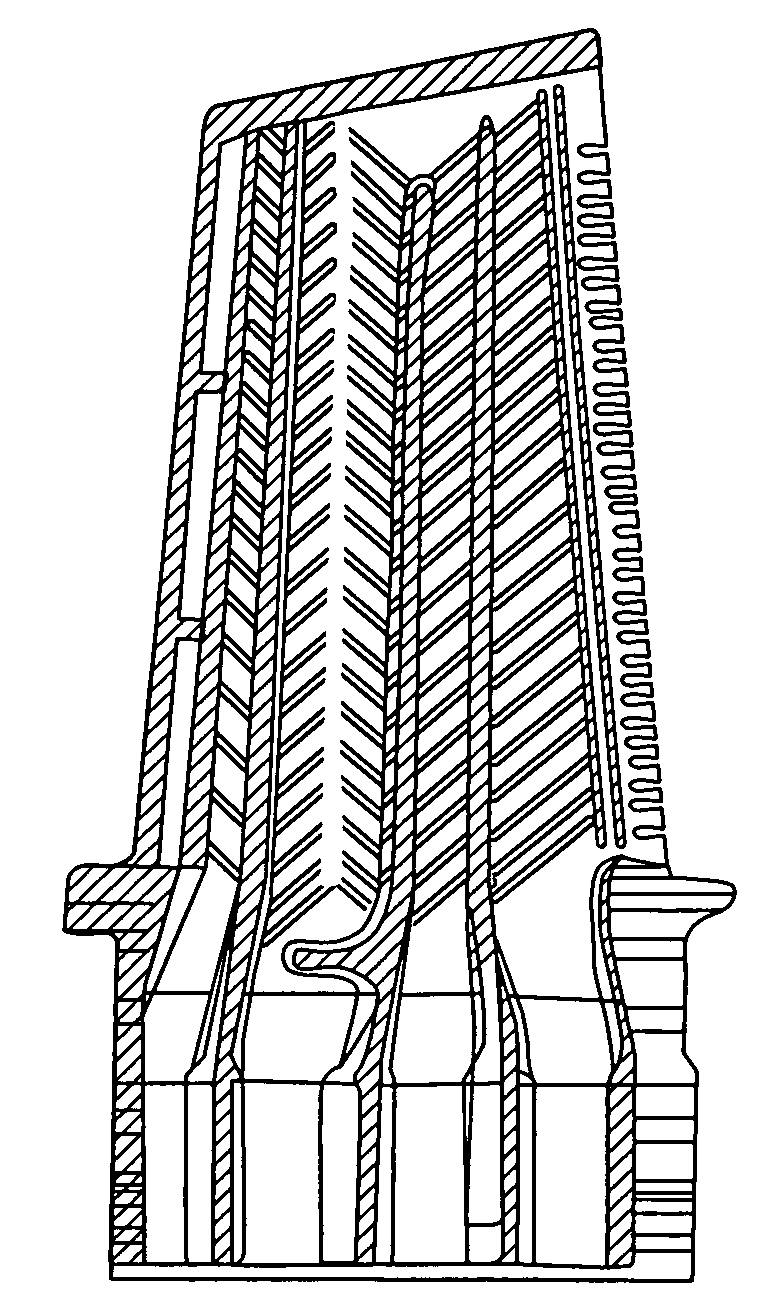

Turbine airfoil cooling system with spanwise equalizer rib

InactiveUS20080101961A1Reducing cooling air mass fluxLower turn lossEngine fuctionsBlade accessoriesSerpentine channelTrailing edge

A cooling system for a turbine airfoil of a turbine engine having an inflow mid-chord feed channel and a trailing edge feed channel that are separated by an equalizer rib having a plurality of supply holes. The supply holes enable cooling fluids to be supplied to the trailing edge from the mid-chord feed channel to satisfy the cooling requirements of the entire trailing edge, which is greater than the mid-chord region. A crossover hole may be positioned in the equalizer rib at the tip section to enable the cooling fluids to pass between the mid-chord feed channel and a trailing edge feed channel. The crossover hole may enable cooling fluids to pass from the trailing edge feed channel into the mid-chord feed channel along the tip section to reduce stagnation in the outboard turn of the mid-chord serpentine channel.

Owner:SIEMENS ENERGY INC

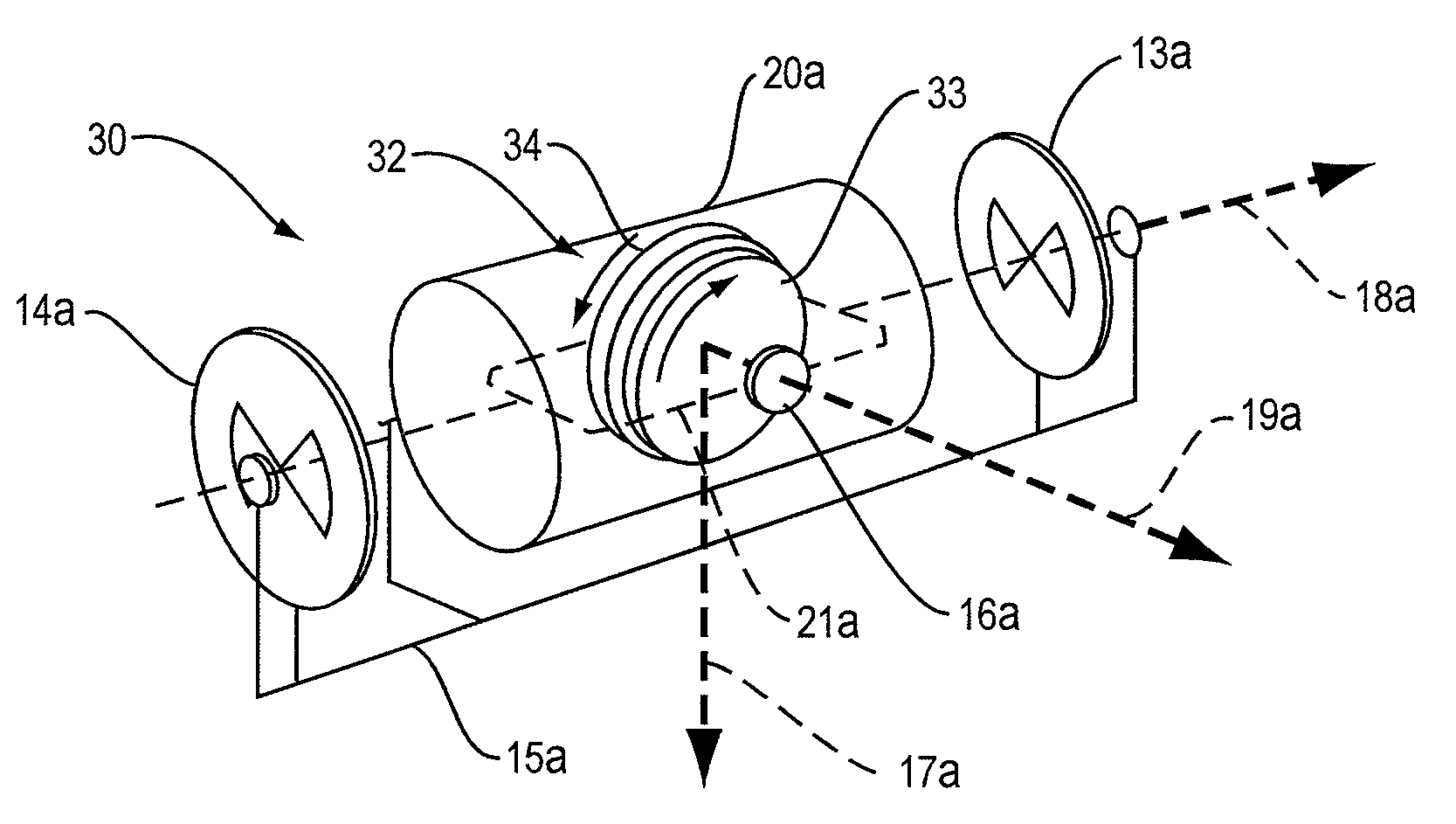

Gyroscope and pendulous gyroscopic accelerometer with adjustable scale factor, and gravity gradiometer using such

InactiveUS8079258B1Improve basic stabilityReduce thermal gradientAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsGravitationInstrumentation

Gyroscopes and pendulous gyroscopic accelerometers with adjustable scale factor are accomplished through control of the net angular momentum of a gyroscopic element such as a rotating or oscillating wheel or other mass. The sensitivity of a gravity gradiometer can be enhanced through use of such instruments, allowing the development of man-portable gravity gradiometers.

Owner:MILLI SENSOR & ACTUATOR SYST

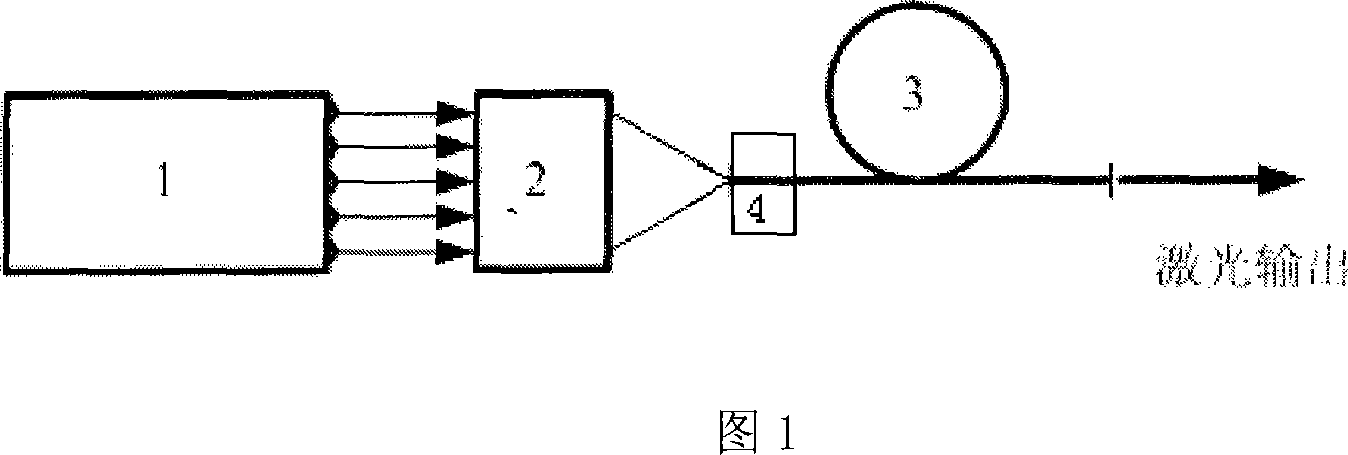

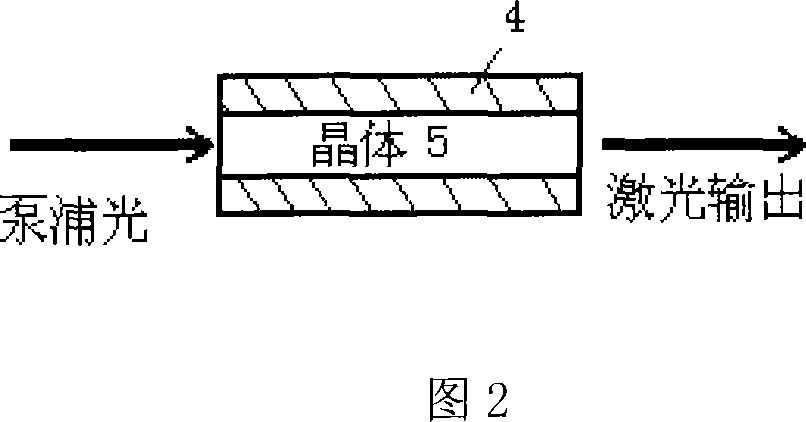

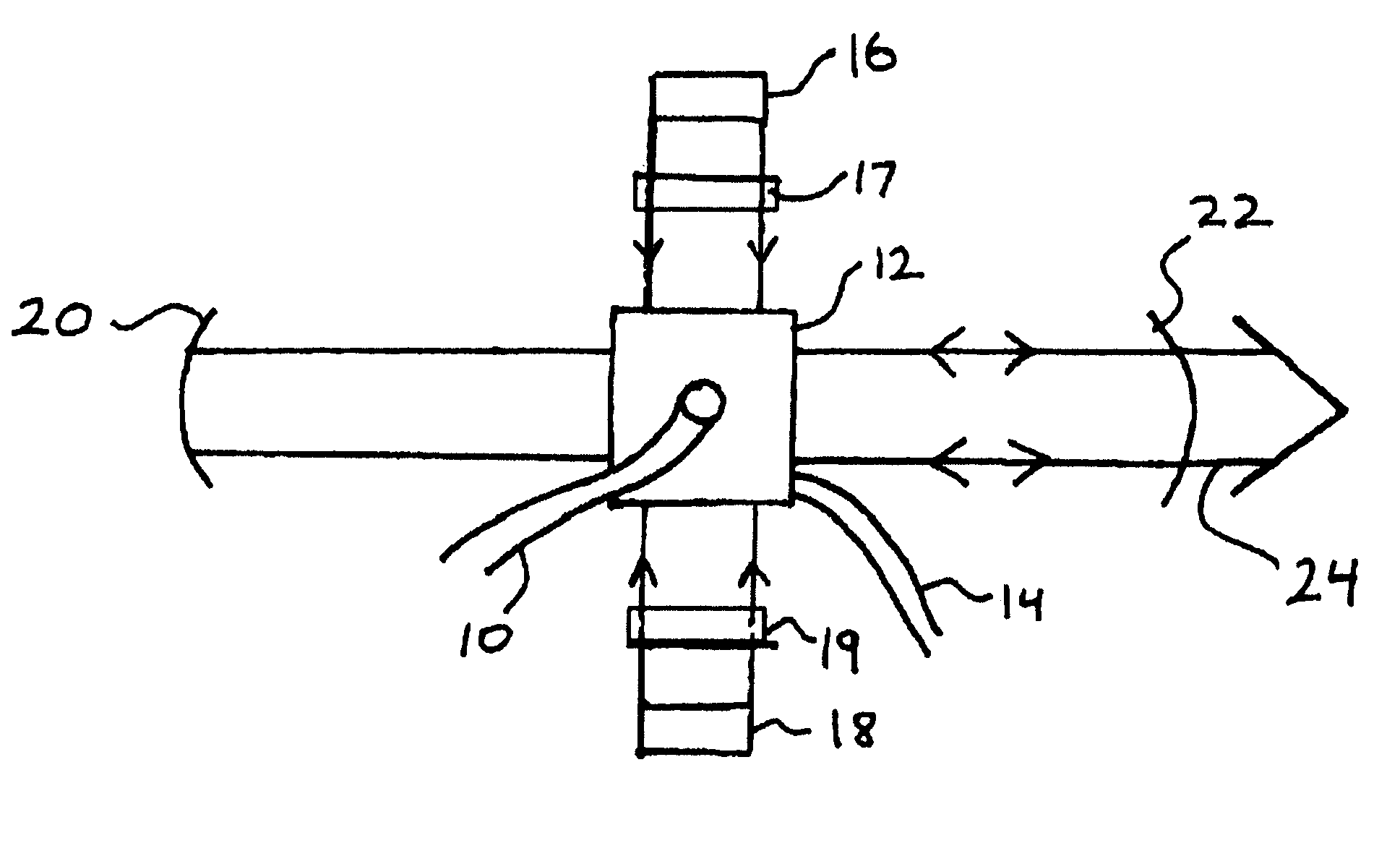

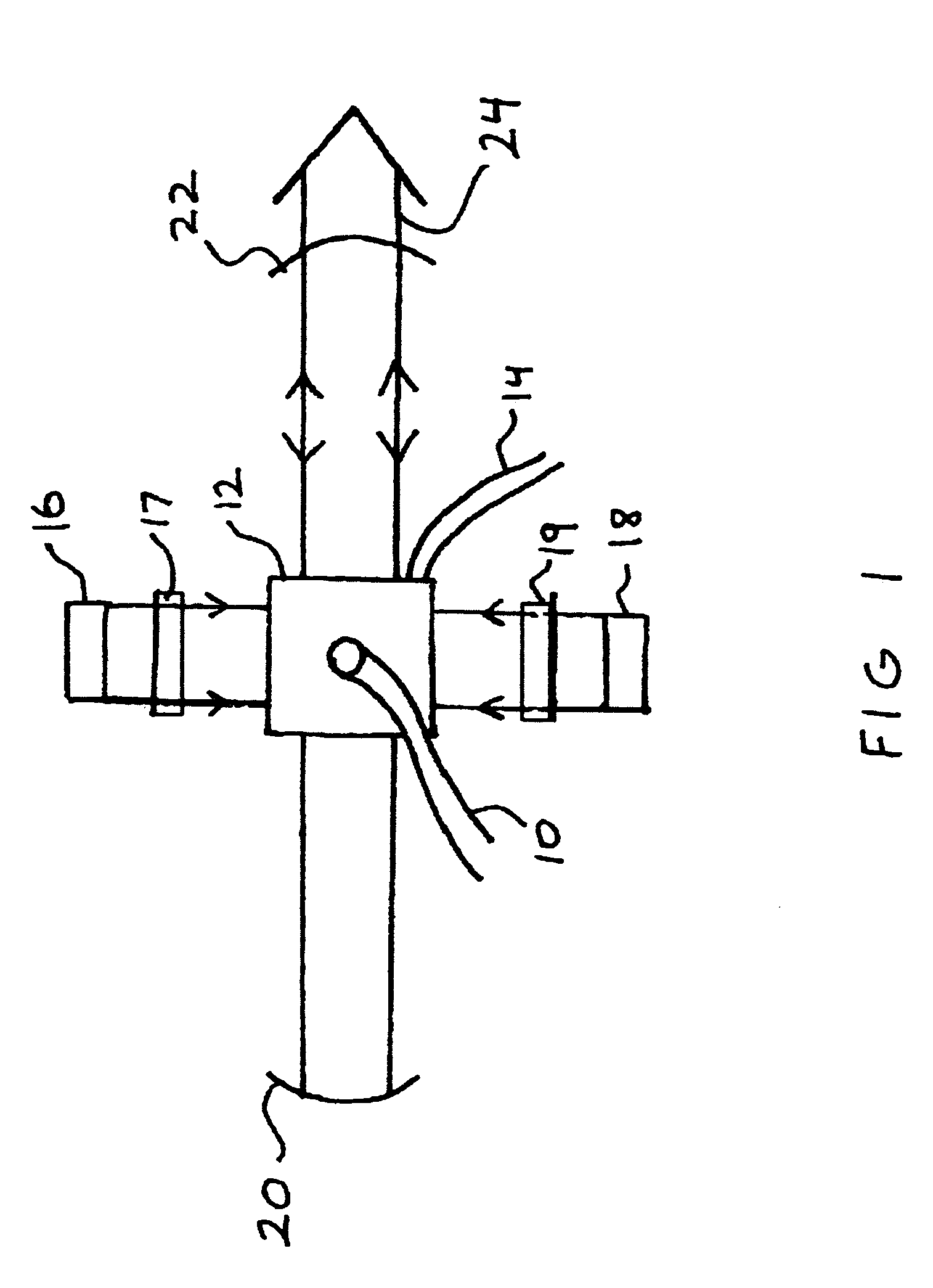

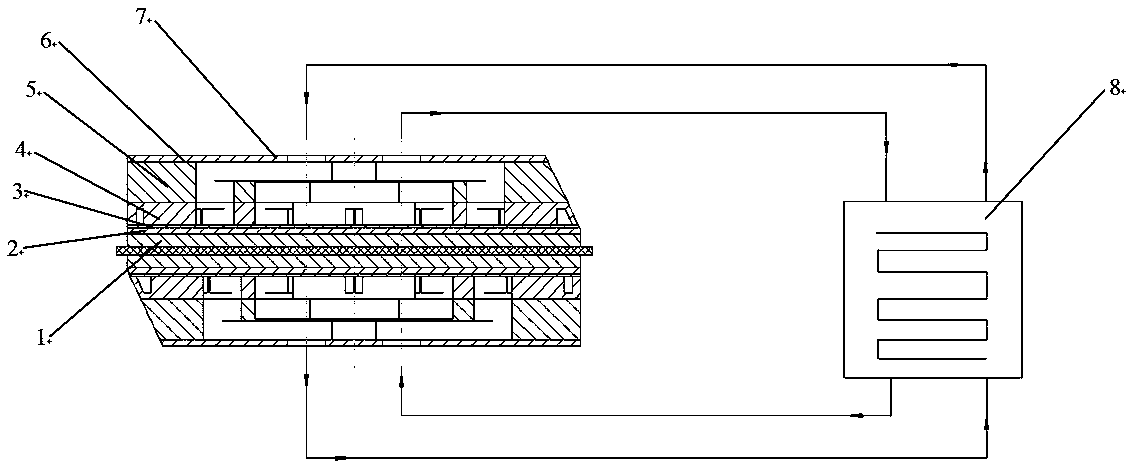

Method and apparatus for liquid guided pump beam

InactiveCN101043118AReduce reflectionEliminate radiationLaser cooling arrangementsCirculator pumpLight beam

A liquid leading pump beam method and device belongs to field of optics and laser photoelectron technique. It includes pumping light source, optical coupling device, liquid leading device and fiber. Thereinto: the optical coupling device receives the pumping light omitted by the pumping light source; liquid nozzle, the pumping beam coupled by the optical coupling device is coupled with liquid column spurted by the liquid nozzle; the central line of cooling fluid collector is aimed at the central line of the liquid nozzle; return flexible hose and liquid-in end are connected with the cooling fluid collector; radiator and circlulating pump are in series, the liquid-in port of the radiator and the liquid-out port of the return flexible hose are connected, the output end of the circlulating pump is connected with the lower end of the liquid nozzle; the liquid nozzle, the cooling fluid collector, the return flexible hose, the radiator and the circlulating pump are in series to form a liquid leading device. The invention resolves the high power pumping problem in solid laser and fiber laser, and the output power of laser can be increased, stability and reliability of laser system can be guaranteed.

Owner:TSINGHUA UNIV

Turbine airfoil cooling system with perimeter cooling and rim cavity purge channels

InactiveUS20080050242A1Enhances airfoil tip corner coolingReduce thermal gradientBlade accessoriesMachines/enginesLeading edgeTrailing edge

A cooling system for a turbine airfoil of a turbine engine having a perimeter cooling channel formed from a portion of a serpentine cooling channel, an airfoil tip cooling channel, and a leading edge cooling channel. The cooling system also includes cooling channels enabling cooling fluids to be discharged into the root of the airfoil to cool rim cavities and purge air therein. The cooling system may be configured such that the cooling fluids may pass into a mid-chord serpentine cooling channel, flow through the serpentine cooling channel generally in a chordwise direction from the leading edge toward the trailing edge, flow toward the tip section and along the trailing edge, flow from the trailing edge toward the leading edge in the airfoil tip cooling channel, flow along the leading edge in the leading edge cooling channel, through the root of the blade, and be exhausted into a rim cavity.

Owner:SIEMENS ENERGY INC

Impeller which includes improved means of cooling

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

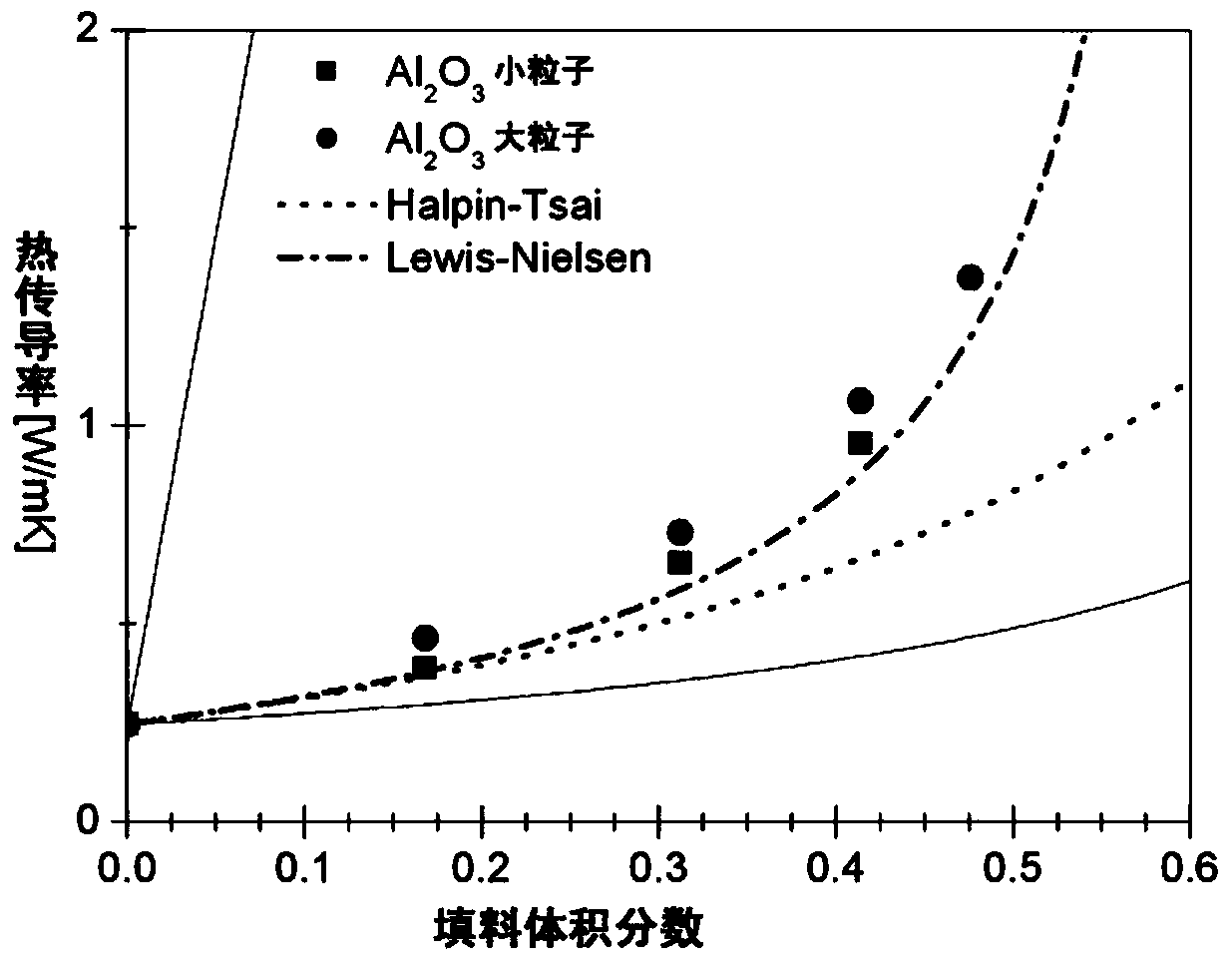

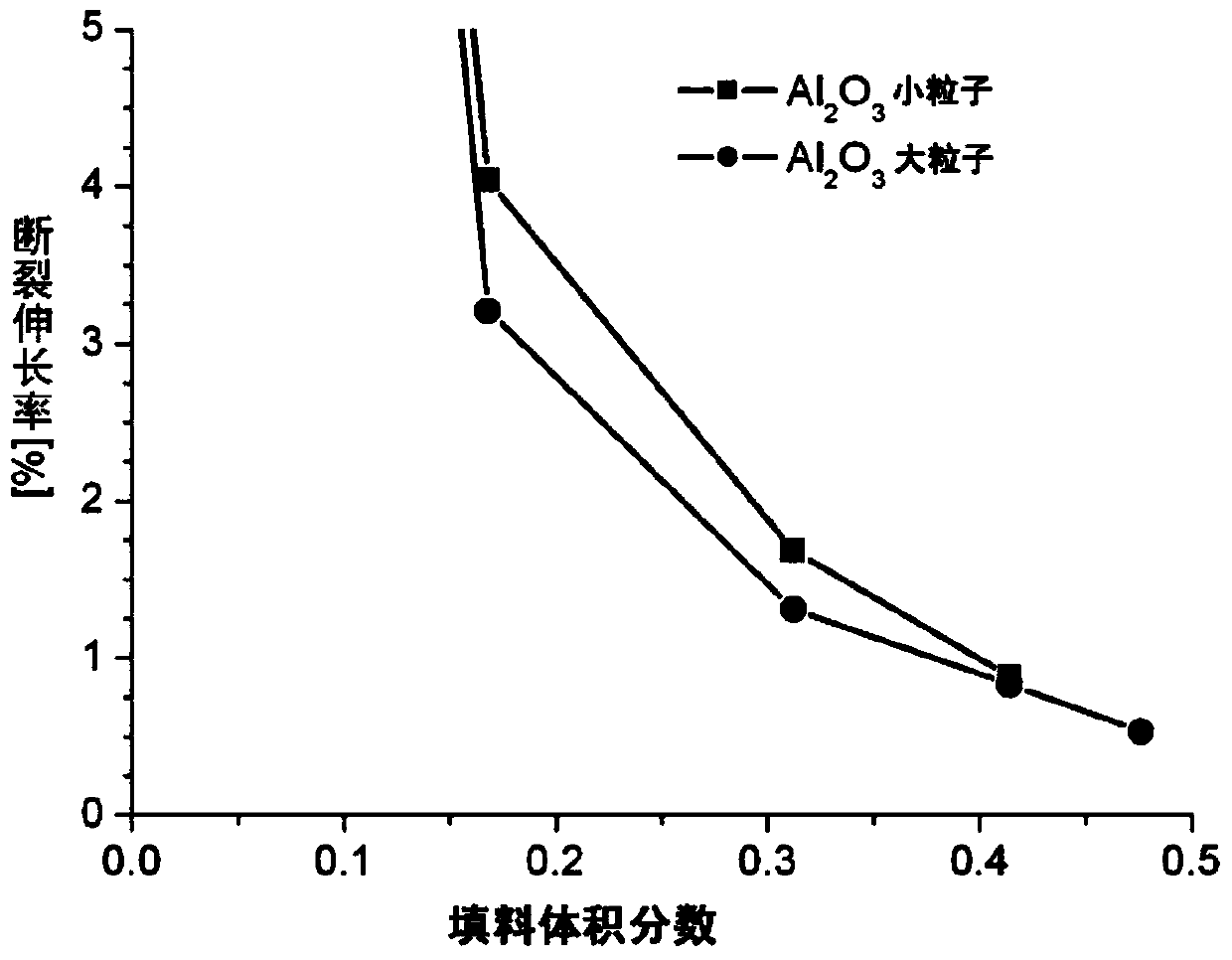

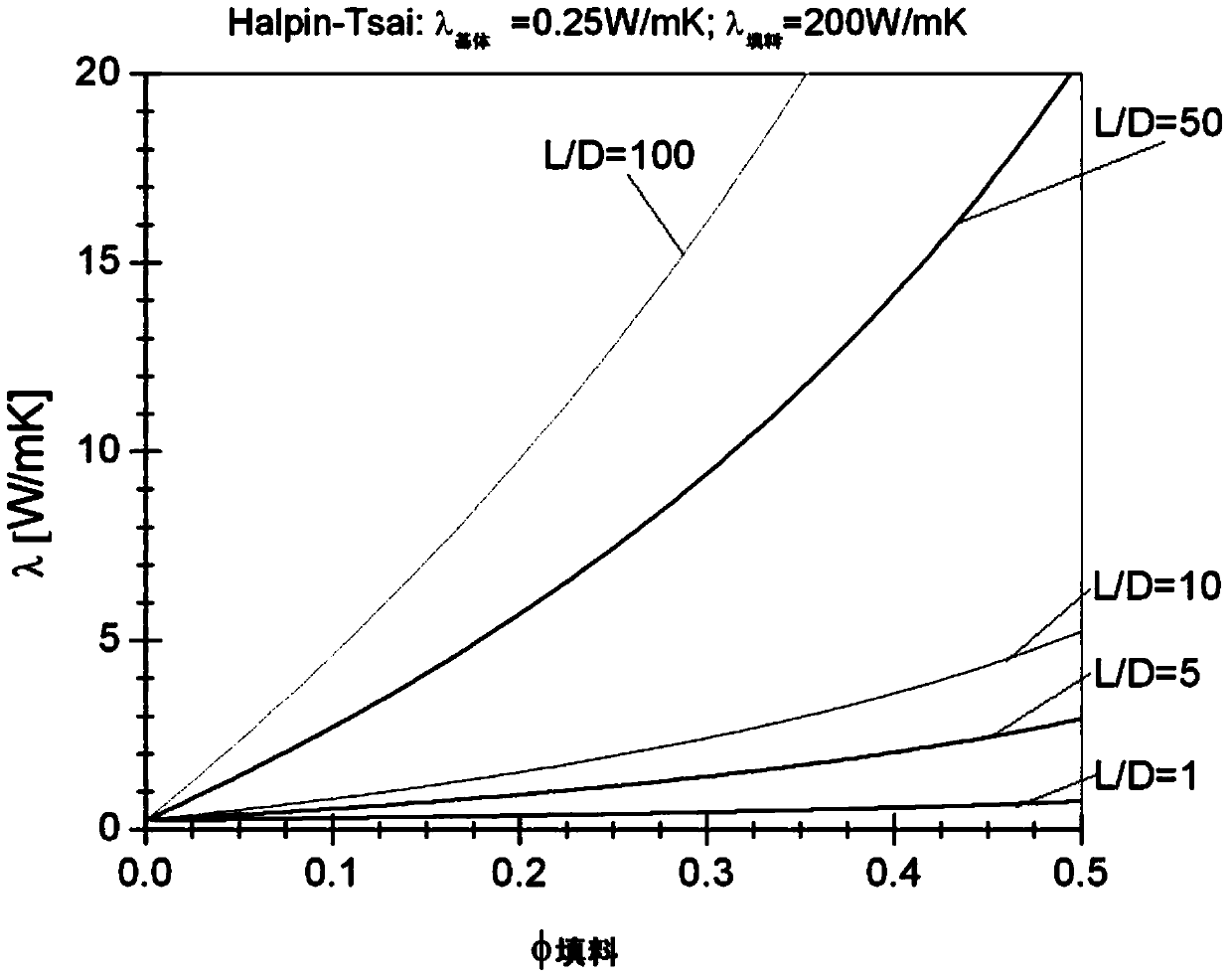

High-heat conductivity composite material for LED (light-emitting diode) lamp, heat-conducting filler and production equipment

The invention relates to a high-heat conductivity composite material for an LED (light-emitting diode) lamp, a heat-conducting filler and production equipment. A surface coupling agent solution and an inorganic heat-conducting filler are mixed according to the ratio of (0.3-0.9):(100-300) in parts by weight; the concentration of a surface coupling agent in the solution is 10-25wt%; a solvent of the solution is a water-acetone solution; the ratio of water to acetone is (5-10):(90-95); the draw ratio of the inorganic heat-conducting filler is 15-100; the high-heat conductivity composite material is composed of 59.5-64.5% of fatty polyamide in total weight, 35-40% of modified heat-conducting filler and 0.5% of lubricant; the heat conductivity of the composite material is 10-12 W / mk; a twin-screw extruder for preparing the composite material utilizes 2-3 groups of inclined toothed plates to replace a kneading block at a shear section; and an extrusion section utilizes 2-3 groups of straight toothed plates to replace a conveying block. By adopting the composite material disclosed by the invention, the heat gradient produced when insulating plastics are used is greatly reduced to be close to a numerical value of metal, the radiating requirements of the LED lamp can be well met, and the temperature difference between an inside and an outside is very small.

Owner:SHANGHAI FANHE POLYMER MATERIAL

Thermal conductive graphite blocks for blast-furnace bottom and hearth

InactiveCN101993246AReduce porosityImprove thermal conductivityBlast furnace componentsBlast furnace detailsPorosityHearth

The invention provides thermal conductive graphite blocks for a blast-furnace bottom and a hearth, belonging to the technical field of carbon refractory. The raw materials of the graphite blocks comprise the following components in parts by weight: 11-15 parts of petroleum coke with grain size of more than 2mm and less than or equal to 4mm, 10-14 parts of petroleum coke with grain size of more than 1mm and less than or equal to 2mm, 53-60 parts of petroleum coke with grain seize of more than 0.075mm and less than or equal to 0.15mm, 34-40 parts of petroleum coke with grain seize of less than or equal to 0.075mm, and 22-25 parts of mesothermal asphalt. In the formula of the thermal conductive graphite blocks for the blast-furnace bottom and the hearth, high-quality needle cokes with higherintensity and easy graphitization are used, a small grain formula is adopted, and a high-pressure multi-soaking and multi-baking method is adopted, so that an impregnant can penetrate through the holes of the graphite blocks, thus reducing the porosity of the graphite blocks, improving the compactness, volume density and intensity of the products, improving the coefficient of heat conductivity and alkali-resistant corrodibility of the graphite blocks greatly, fundamentally solving the problem of low coefficient of heat conductivity of the graphite blocks, and meeting the requirement on quality of the graphite blocks with high thermal conductivity for large blast furnaces.

Owner:HENAN FANGYUAN CARBON GRP

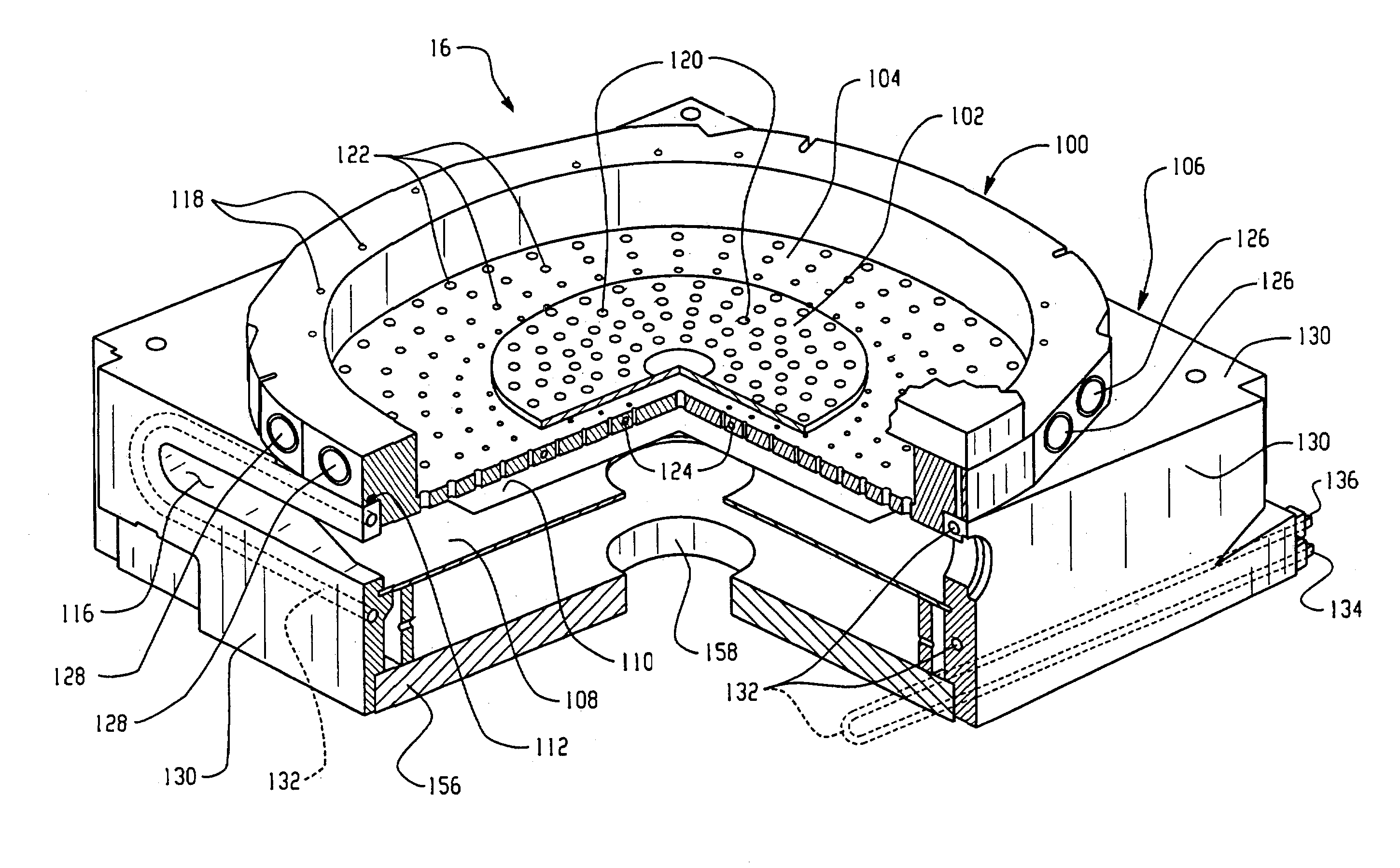

Turbomachine turbine ring sector

ActiveUS8348602B2Reduce thermal gradientExtended service lifeEngine manufacturePump componentsTurbineAerodynamics

A turbine ring sector is disclosed. The turbine ring sector includes a wall bounding an aerodynamic flowpath in which gases flow from the upstream region toward the downstream region, and a multiperforated plate, situated on the opposite side of the aerodynamic flowpath with respect to the wall. The multiperforated plate includes a bottom and side walls. The distance between the wall of the ring sector and the bottom of the multiperforated plate defines a gap which is progressive in an axial direction, from the upstream region toward the downstream region. The value of the gap situated at the upstream region is below the value of the gap situated at the downstream region.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

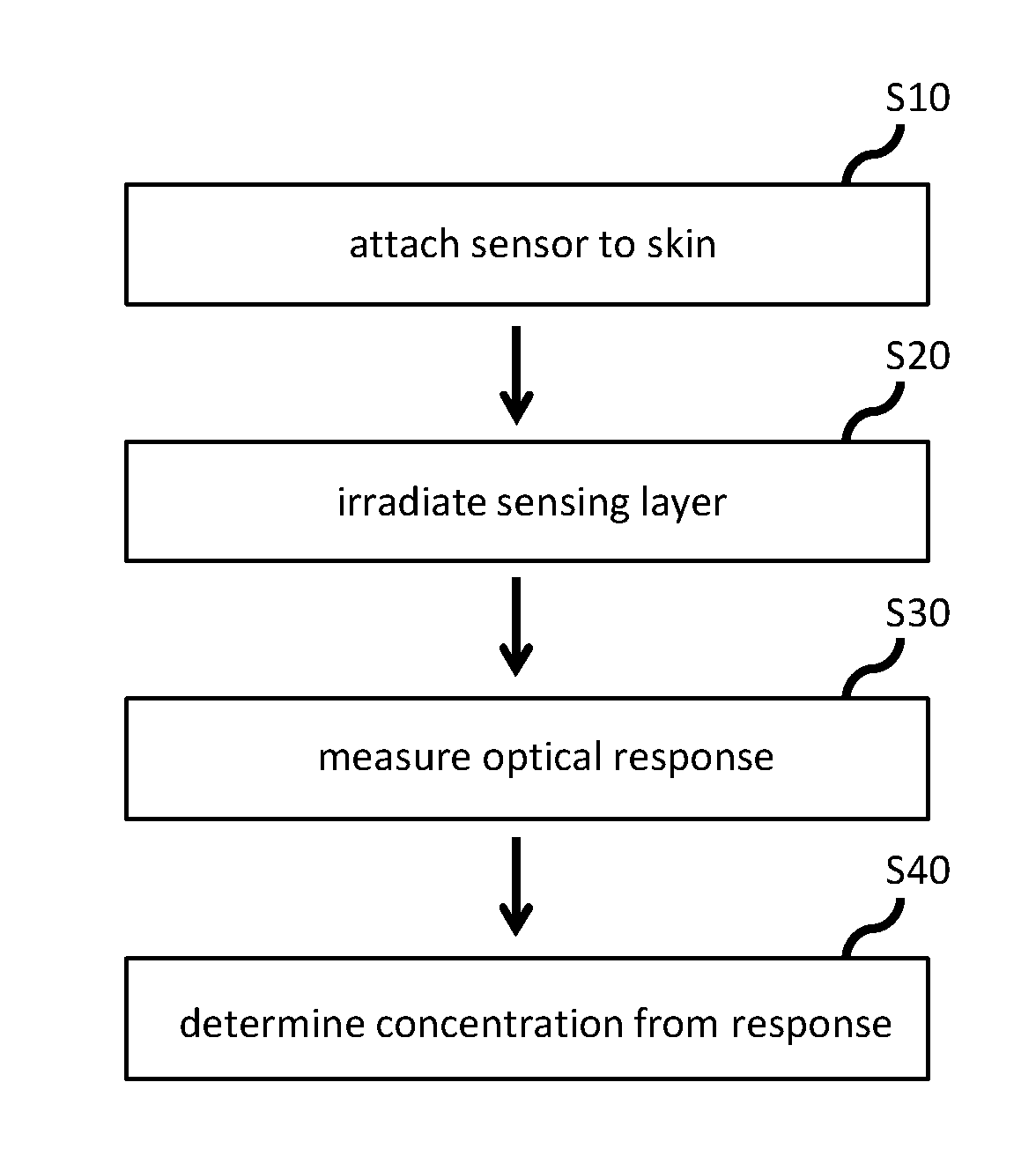

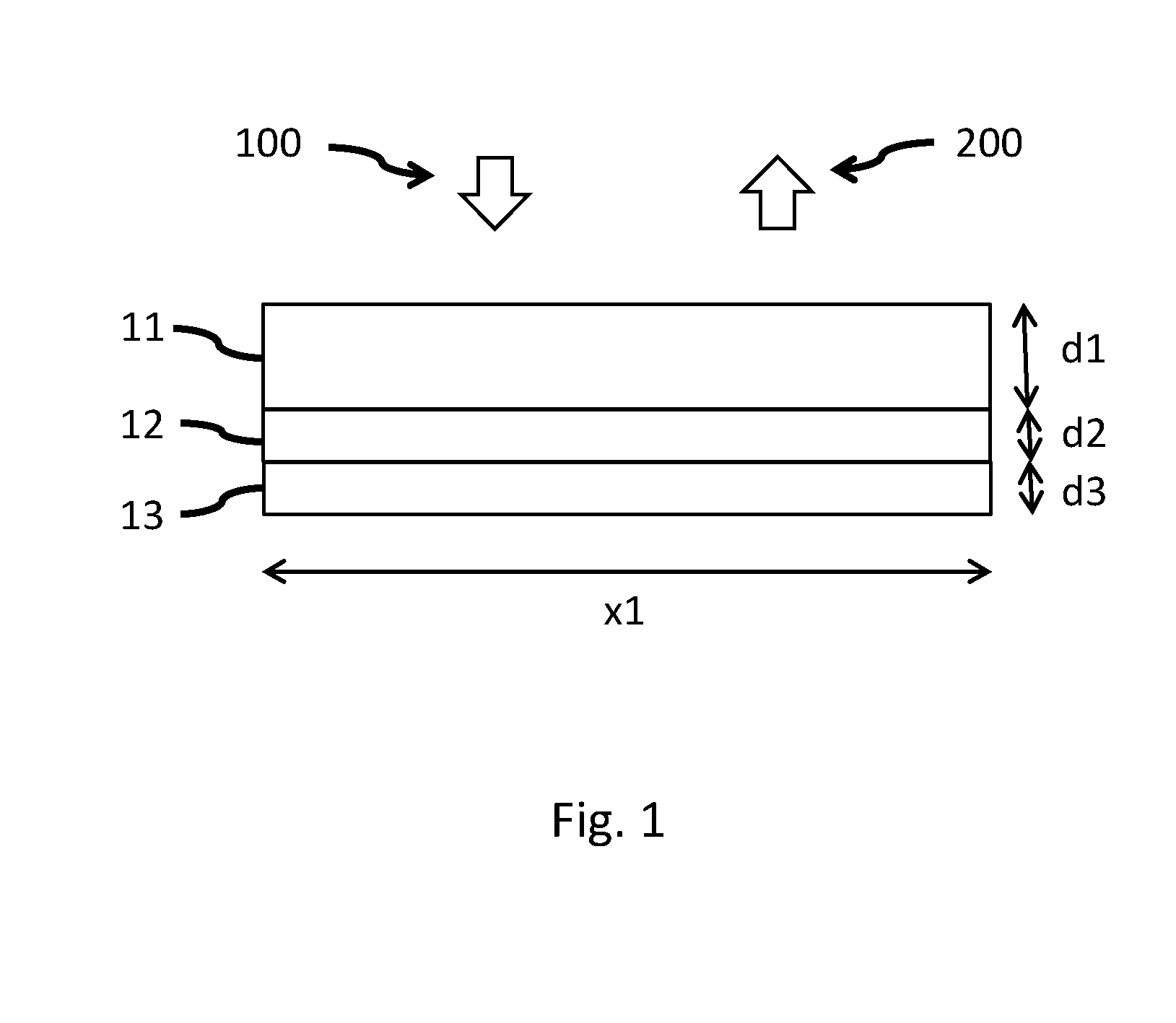

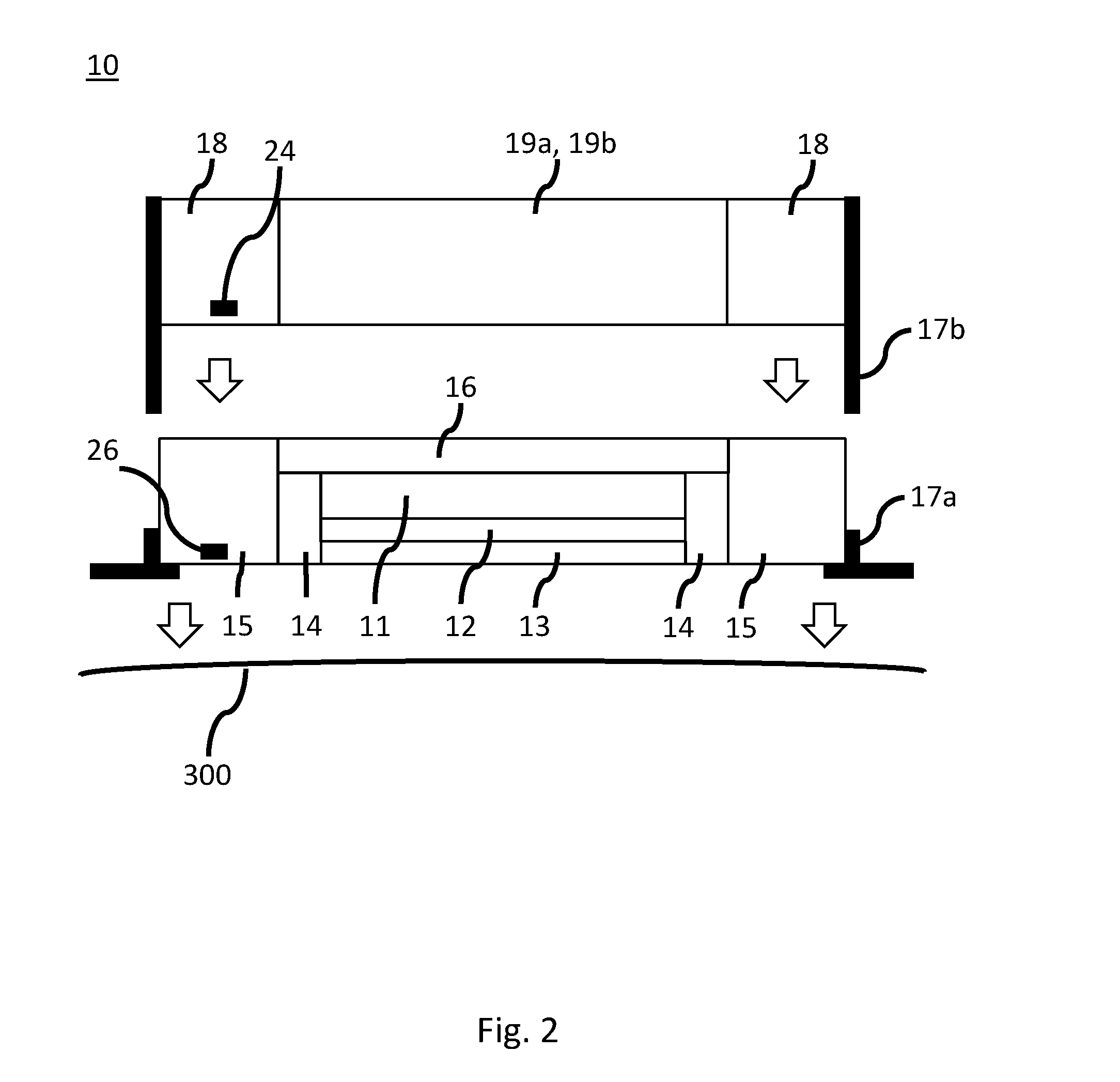

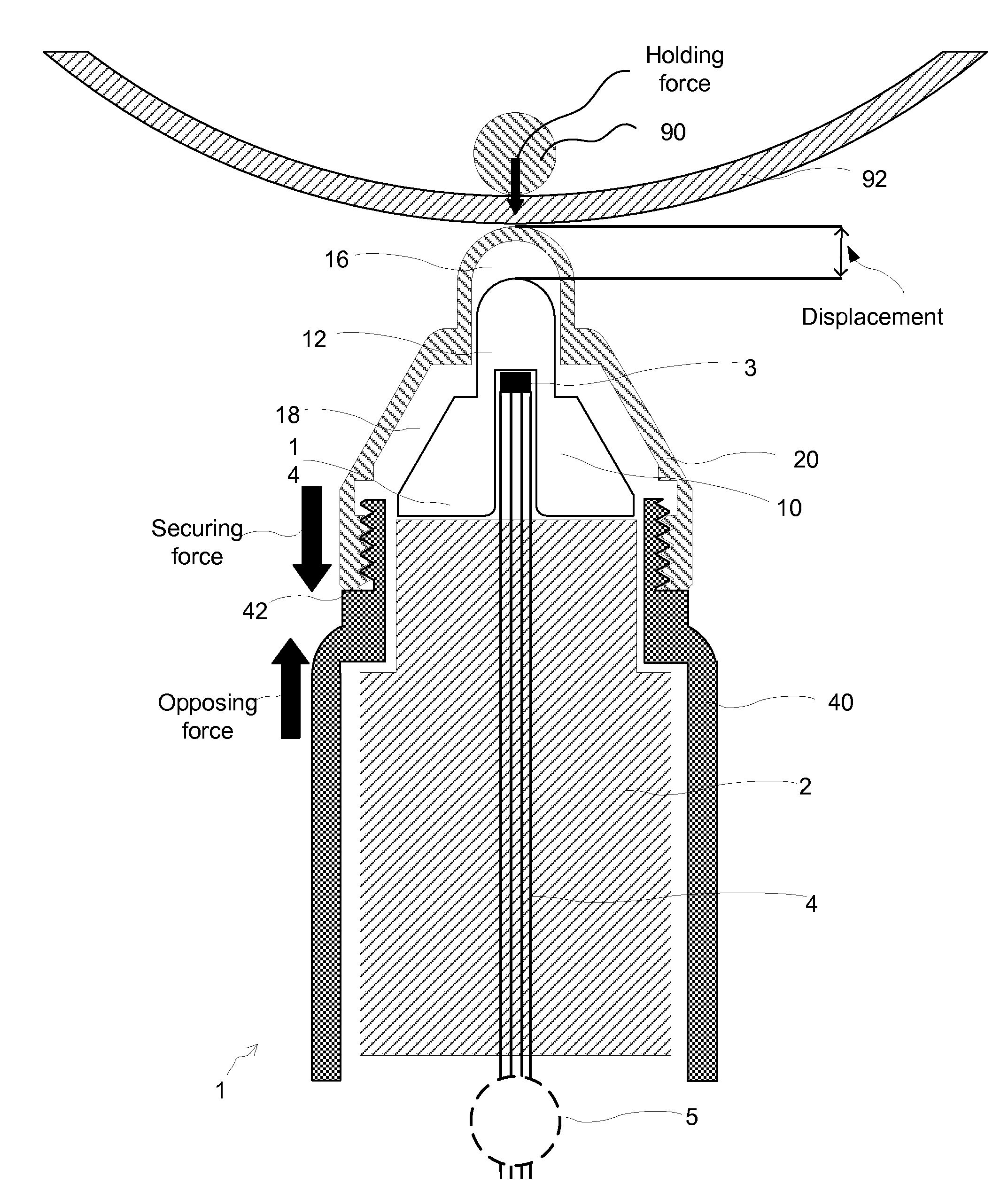

Sensor for determining gas concentration

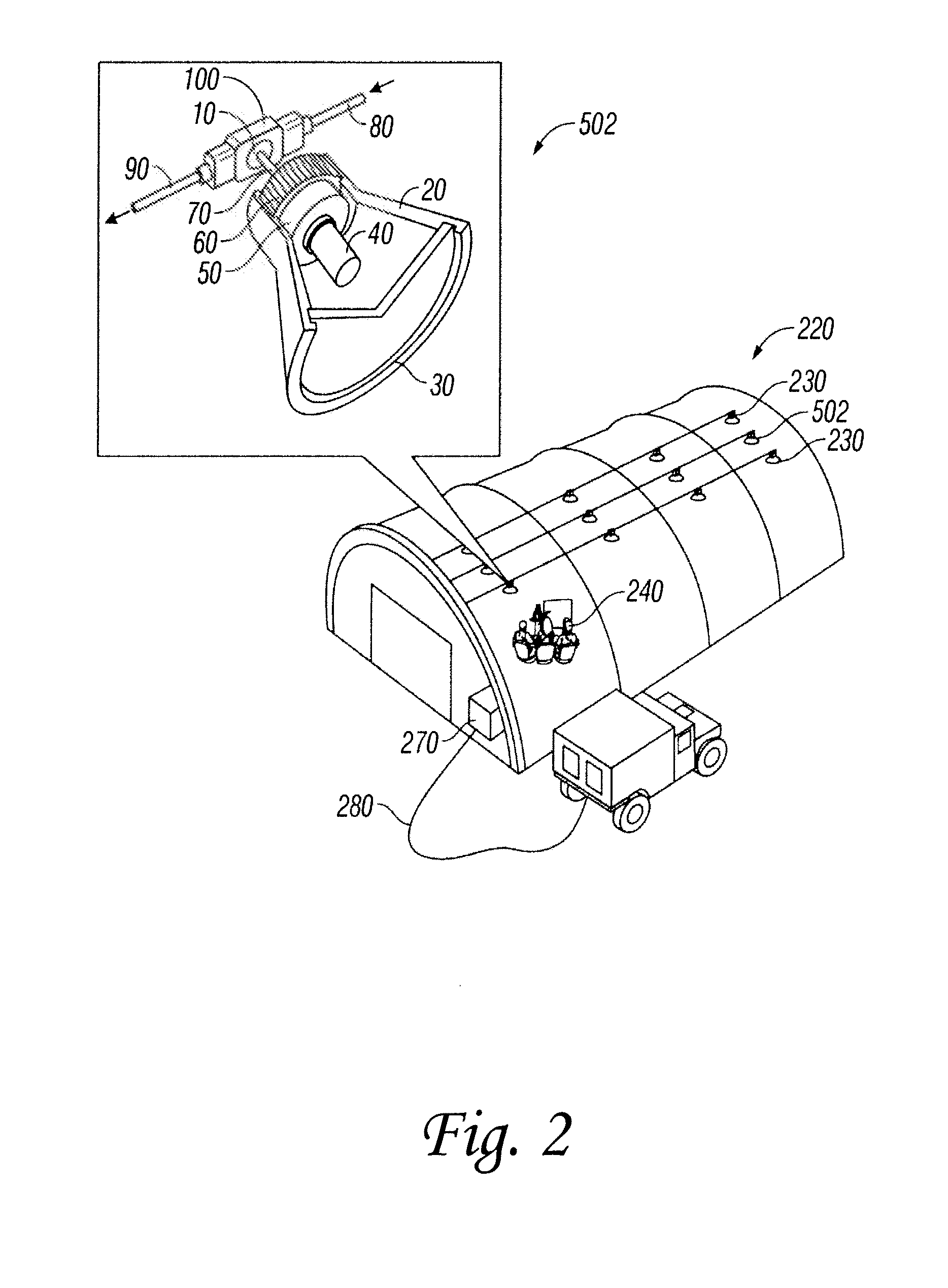

ActiveUS20160007894A1Good heat distributionReduce thermal gradientTransmissivity measurementsDiagnostic recording/measuringThermal insulationEngineering

The present invention provides an optical sensor unit (10) for measuring gas concentration, comprising: sensor means (12, 13) and first thermal insulation means (14, 16) at least partially surrounding said sensor means (12, 13). The sensor means (12,13) includes at least one sensing layer (12) adapted to be irradiated with a predetermined radiation (100), and at least one gas-permeable layer (13) adjacent to one side of the at least one sensing layer (12) and adapted to pass gas, which concentration is to measured, through the gas-permeable layer (13) towards the at least one sensing layer (12). The optical sensor unit (10) is adapted to measure an optical response of the at least one sensing layer (12), which optical response depends on the gas concentration.

Owner:KONINKLJIJKE PHILIPS NV

Liquid heat capacity lasers

InactiveUS20050243883A1Reduce thermal gradientReduced optical qualityActive medium materialLaser cooling arrangementsOptical pumpingEngineering

The heat capacity laser concept is extended to systems in which the heat capacity lasing media is a liquid. The laser active liquid is circulated from a reservoir (where the bulk of the media and hence waste heat resides) through a channel so configured for both optical pumping of the media for gain and for light amplification from the resulting gain.

Owner:RGT UNIV OF CALIFORNIA

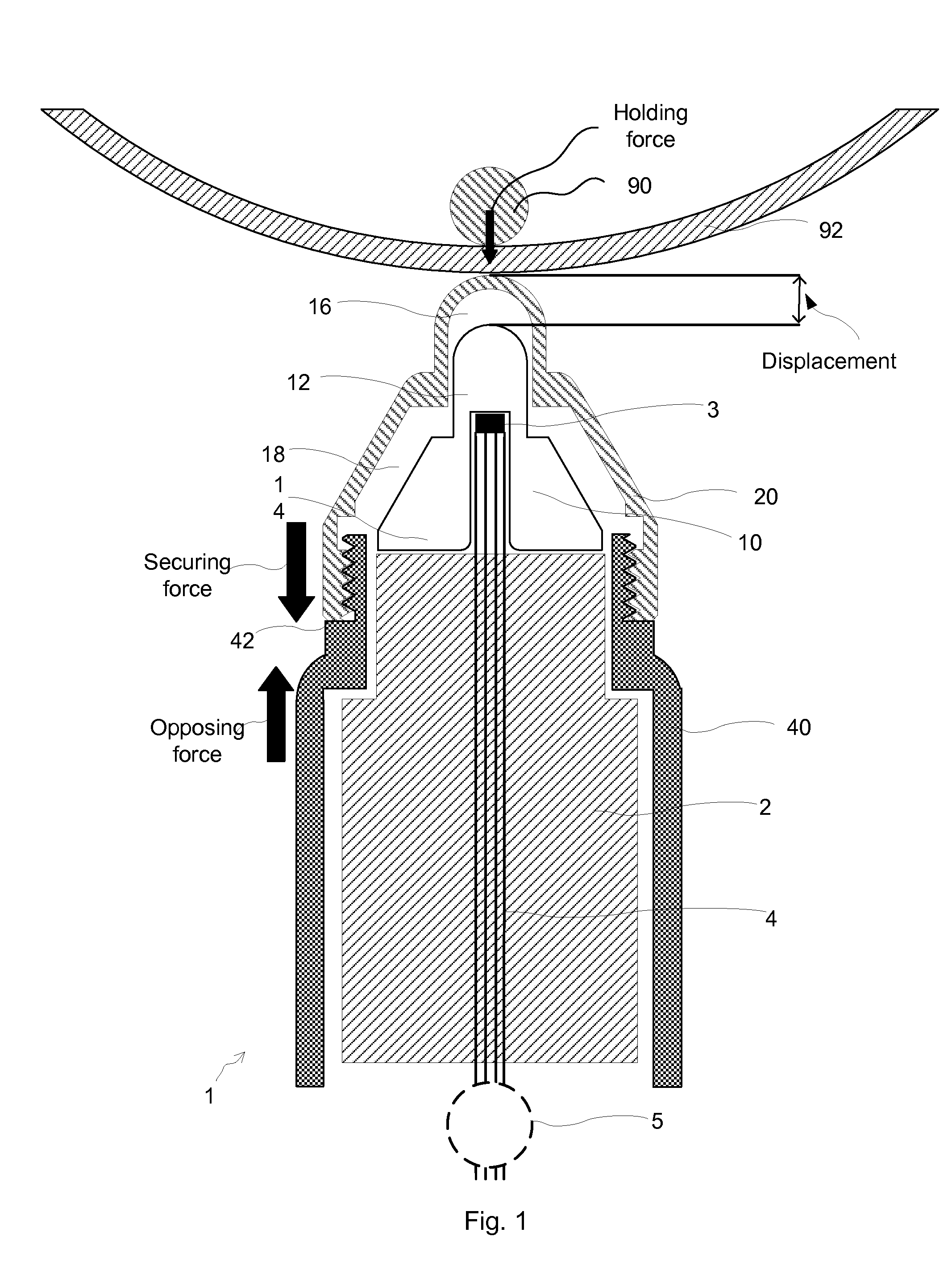

Hall effect probe with exchangeable wear tips

ActiveUS20140125330A1Relieve pressureReduce heat flowSemiconductor/solid-state device testing/measurementMagnetic property measurementsMagnetic susceptibilityWear coefficient

Disclosed is a Hall sensor probe that configured to be coupled with one of a plurality of magnetic targets for measuring the thickness of a non-ferromagnetic wall. The probe comprises a magnetic field source, a Hall sensor, a concentrator and a main housing. The novel aspects of the probe include a wear tip that is exchangeably affixed onto the main-housing, leaving a permanent gap from and disjoined from the concentrator in a manner that transfers stress from the tip directly onto the main-housing. To serve every aspects of the primary objective, being it mechanical, thermal and operational, the material of the tip preferably has a fracture toughness higher than 20 MPa·m1 / 2, wear coefficient higher than 100, and a magnetic susceptibility lower than 0.001.

Owner:OLYMPUS NDT

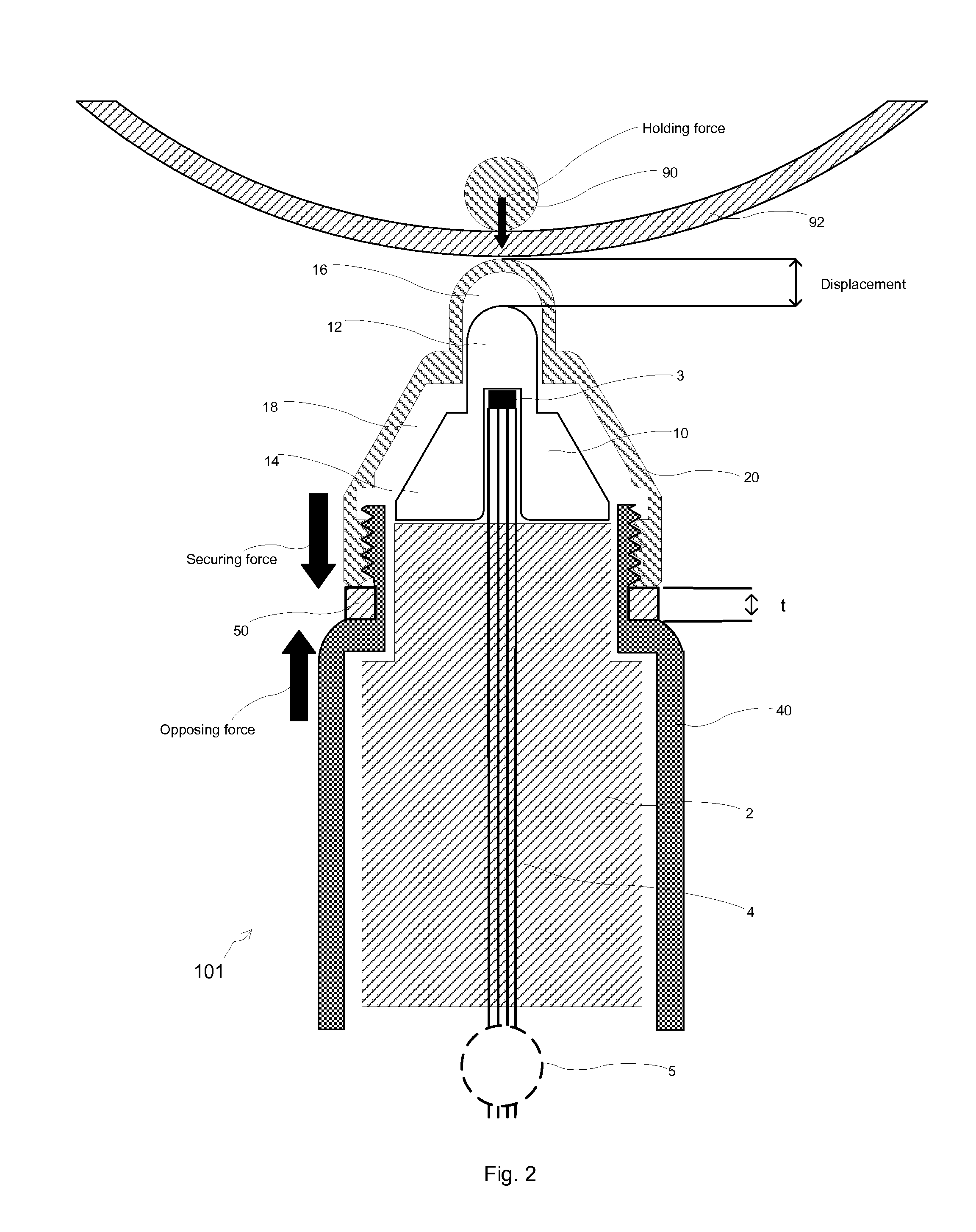

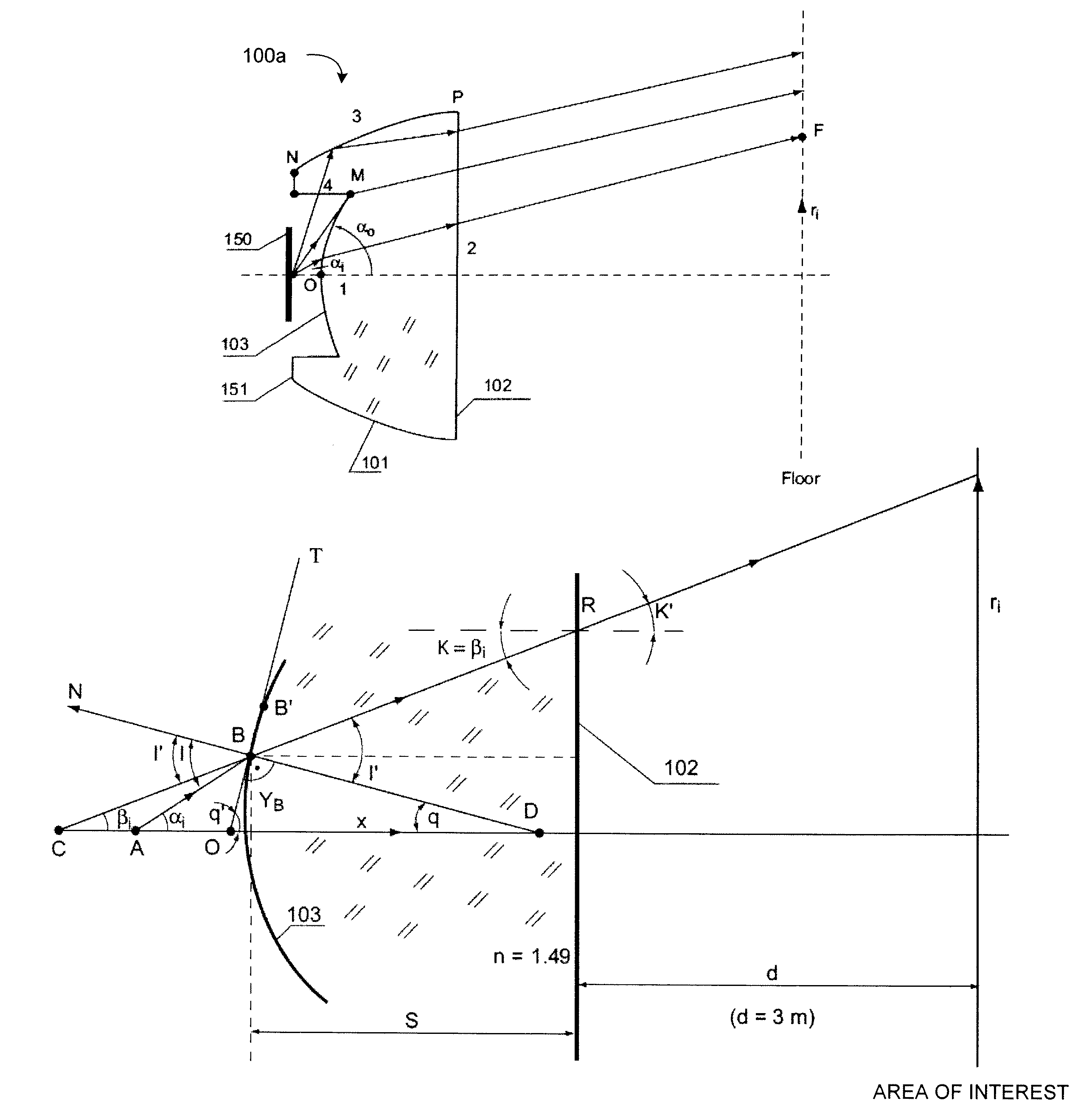

Luminaire illumination system and method

ActiveUS8576406B1Reduce light source requirementsReduce thermal gradientPoint-like light sourceUsing optical meansTransformerEffect light

A method of constructing a non-imaging beam transformer includes reducing a tailored illumination function from a predetermined light source to a source point response illumination function; calculating a plurality of transformation pairs for the predetermined light source, the transformation pairs identifying the radii of illumination of the light source at given source output angles; determining a desired lighting profile for light output at a region of interest to be illuminated by the beam transformer; determining a surface profile of a surface of the beam transformer such that for given output angles of the light source, the transformation pairs at those output angles are satisfied to correspond to the desired lighting profile; and constructing the beam transformer having the surface profile determined based on the transformation pairs. The method can include characterizing a specific angular output distribution of a light source to calculate the transformation pairs.

Owner:MERCURY MISSION SYST LLC

YIG oscillator with resilient support structure

InactiveUS6326856B1Reduce thermal gradientGenerator stabilizationOscillations generatorsFlexible circuitsEngineering

A YIG oscillator including a magnetic structure; an oscillator circuit board attached to the magnetic structure and carrying a YIG resonator positioned in an air gap of the magnetic structure; an interface circuit board including terminals for external connections, the interface circuit board supporting the magnetic structure by means of a resilient component attached to the interface circuit board; and a flexible circuit connected at one end to the oscillator circuit board and connected at the other end to the interface circuit board.

Owner:IMA AB SIVERS

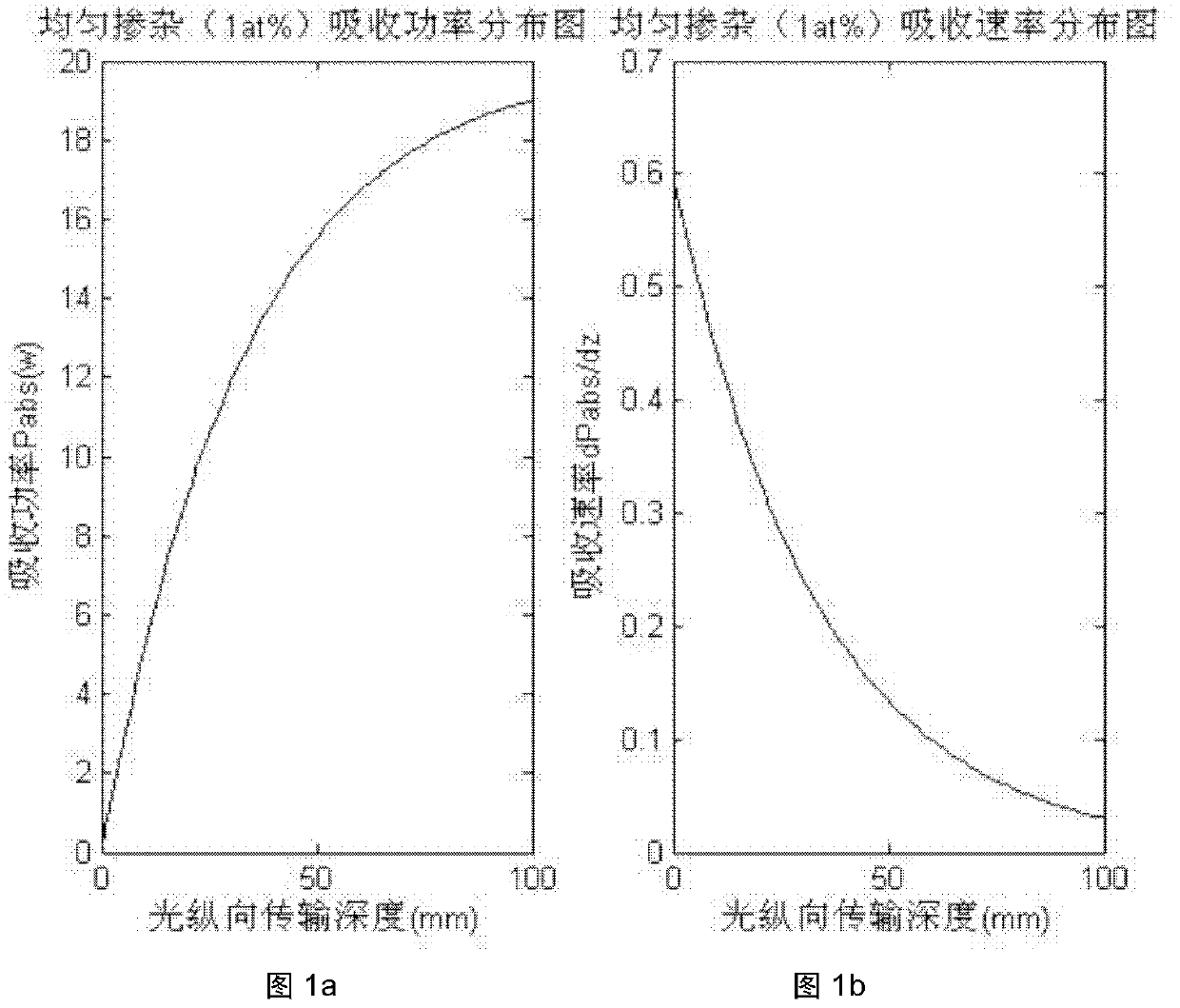

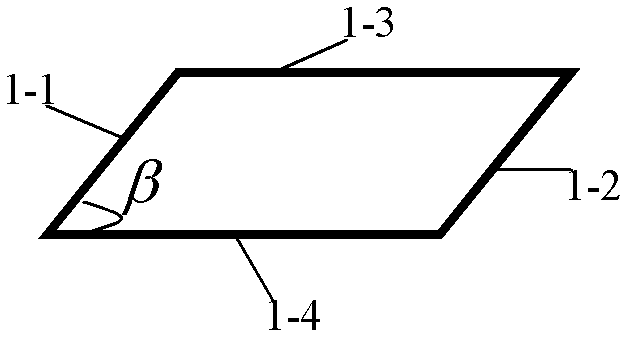

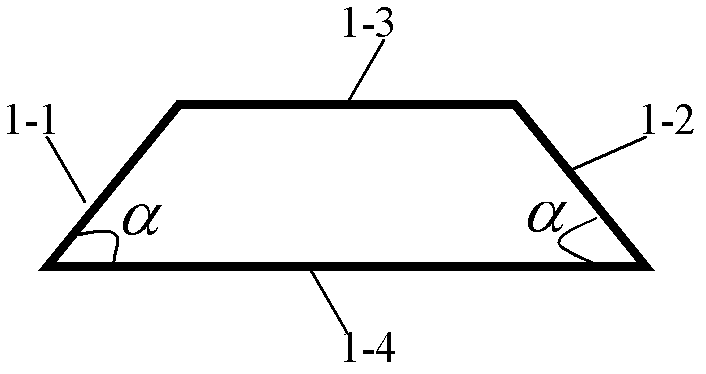

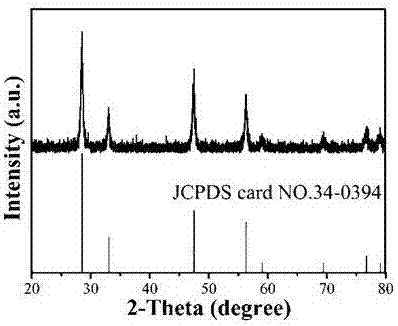

Function-doping based transparent ceramic slab pumping device

ActiveCN102891432AAbsorb evenlyImprove absorption efficiencyActive medium materialActive medium shape and constructionHigh concentrationLight beam

The invention relates to a function-doping based transparent ceramic slab pumping device. The pumping device comprises a laser gain medium, a pumping source, a laser resonator and a cooling temperature control device. According to the pumping device provided by the invention, slab transparent ceramic material is taken as the laser gain medium, a mode of pumping in large areas on upper and lower surfaces is adopted to increase the pumping area, reduce the reshaping difficulty of the pump light, and improve the maximum pumping power; and by using the characteristics of high-concentration doping and function doping of the transparent ceramic material, the high power pumping and the uniform absorption of the pumping light by the transparent ceramic material can be implemented, thereby reducing the internal longitudinal heat gradient of the transparent ceramic material, and improving the absorbing efficiency of the pumping light by the material and the output beam quality. Compared with an existing high-power slab laser pumping device, the pumping device provided by the invention is large in pumping area, low in reshaping difficulty of the pump light and small in internal heat gradient of the laser gain medium, and therefore, high-power pumping and the outputting of solid laser with high average power, high beam quality and high efficiency can be carried out.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

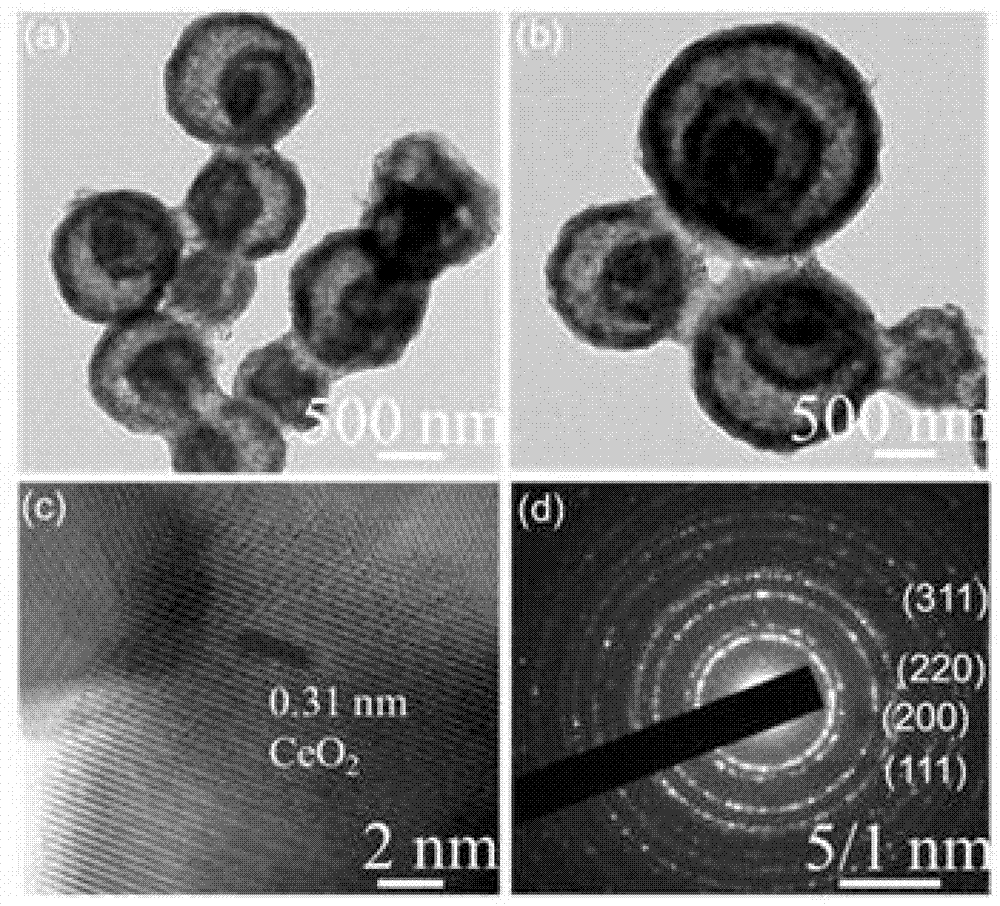

Preparation method of cerium dioxide nano hollow sphere

InactiveCN107043121AEfficient synthesisHigh purityRare earth metal oxides/hydroxidesMicroballoon preparationCerium nitrateHigh energy

The invention relates to a preparation method of cerium dioxide nano hollow sphere. The method is characterized in that cerium nitrate and pyridine-2,5-dicarboxylic acid are respectively dissolved in absolute ethyl alcohol and DMF, volume ratio of two solvents is 1:1, and a Ce(NO3)3 solution with the concentration of 0.01-0.2 mol / L is prepared after mixing stirring. The average particle size of the synthesized CeO2 nano hollow sphere having a multilayer core-shell structure is 300 nm, the distribution is uniform, multi-shell CeO2 has the porous core-shell hollow structure and has wide important latent application, such as for absorbing pollutant in sewage and sensing gas; and the method has the advantages of uniform heating, high products purity, high energy utilization rate, short reaction time, and clean heating environment.

Owner:JIANGXI NORMAL UNIV

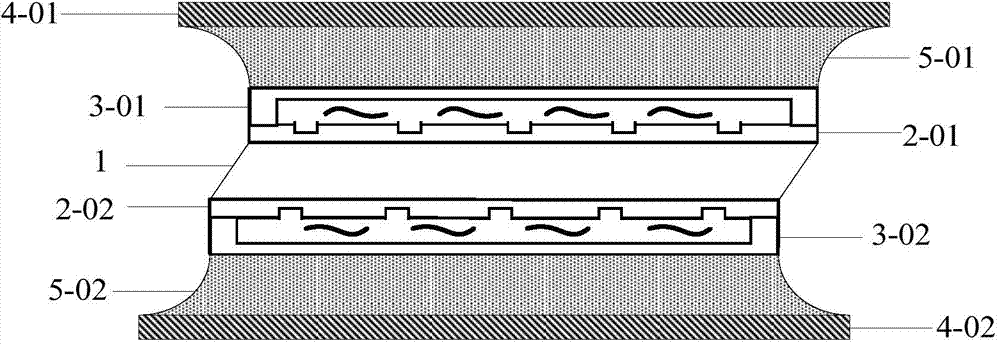

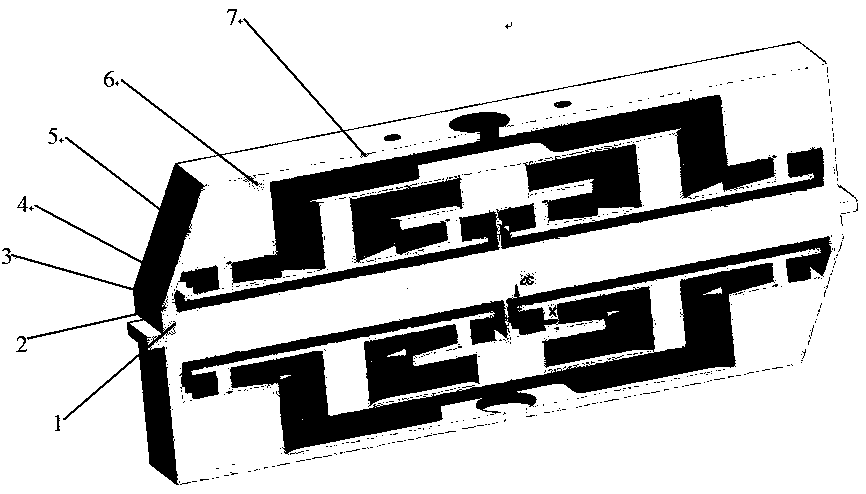

Longitudinal cooler system for laser crystal

InactiveCN105576482AWell mixedEvenly distributedLaser cooling arrangementsTemperature controlEngineering

The invention provides a longitudinal cooler system for laser crystal. An upper cover plate layer, a heat dissipation layer, a small-hole water diversion plate layer, a width water diversion plate layer, a cooling water merging layer, an auxiliary soldering tag layer and a bottom cover plate layer of the longitudinal cooler system are stacked up from the bottom up in sequence; the layers are tightly sealed through a welding manner; and a water incoming channel and a water outgoing channel between the layers form cooling loops with a water outlet and a water inlet of a temperature control refrigeration device. A heat dissipation channel formed through layer-by-layer subdivision of the water incoming channel enables the upper cover plate layer to be cooled into a heat dissipation surface, the temperature distribution of which is uniform, so that heat generated by the laser crystal attached on the heat dissipation surface in the working process can be taken away efficiently, uniformity of transverse temperature of the laser crystal is kept, thermal gradient and thermal stress in the laser crystal are reduced, and normal work of the laser is ensured.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

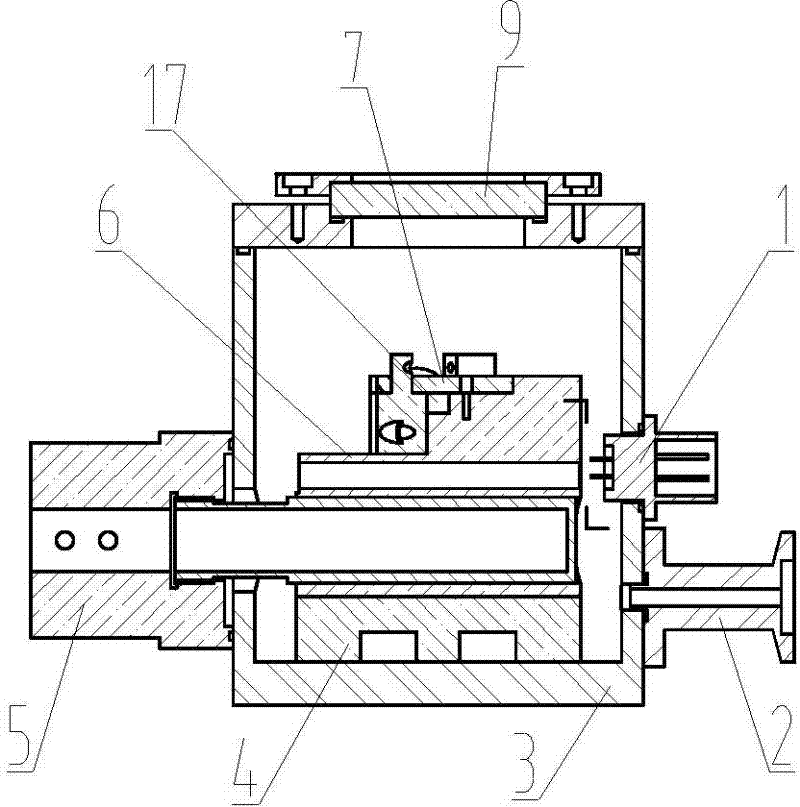

Cooling system for crystal used by laser

InactiveCN102394463AReal-time feedback and temperature controlReduce deliveryLaser detailsTemperature controlWater vapor

The invention provides a cooling system for a crystal used by a laser. The cooling system is provided with a cooling interface device, a vacuum device interface, a temperature measuring device interface and installation interfaces of a brewster form, wherein the cooling interface device is externally connected with a cryogenic cooling system, the vacuum device interface is externally connected with a vacuum system and the temperature measuring device interface is externally connected with a temperature control feedback system. The external cryogenic cooling system that is connected with the cooling interface device provides a stable low-temperature environment for a crystal inside a vacuum chamber. The external vacuum system that is connected with the vacuum device interface provides a vacuum heat insulation environment for the crystal inside the vacuum chamber. The temperature control feedback system that is connected with the temperature measuring device interface carries out real-time feedback and regulation and control on the crystal temperature. And temperature control sheets that are installed near the installation interfaces of the brewster form are used for adjusting steam partial pressures around the brewster form to be below a condensation point. Therefore, according to the invention, thermal conductivity of the crystal used by a laser is increased; the thermal gradient is reduced; and a thermal lens effect is reduced; meanwhile, an occurrence of a condensation phenomenon can be avoided and normal work of the whole laser can be ensured.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Immersion-type heat radiation cooling liquid used for power lithium batteries, and preparation method thereof

InactiveCN110055037AImprove cooling efficiencyImprove compatibilitySecondary cellsHeat-exchange elementsAntioxidantHydrofluoroether

The invention discloses an immersion-type heat radiation cooling liquid used for power lithium batteries, and a preparation method thereof, and belongs to the field of chemistry. The immersion-type heat radiation cooling liquid used for power lithium batteries is composed of, by weight, 30 to 70 parts of a hydrofluoroether compound, 30 to 50 parts of a halogenated hydrocarbon, 1 to 10 parts of analcohol compound, 0.01 to 0.5 part of an antioxidant, 0.01 to 0.5 part of a preservative, and 0.01 to 0.5 part of a nano metal oxide. According to the preparation method, the hydrofluoroether compoundis taken as a main component, and is mixed with the halogenated hydrocarbon, the alcohol compound, and the like to form an azeotrope, and the antioxidant, the preservative, and the non-conductive nano metal oxide additives are adopted as auxiliary additives to form the cooling liquid composition. The immersion-type heat radiation cooling liquid is excellent in heat radiation effect, is high in specific heat, low in expansion performance, low in toxicity, high in insulation performance, excellent in flame resistance, inert performance, and material compatibility, is capable of realizing heat transfer effect rapidly, is capable of solving power lithium battery heating and heat radiation problems effectively, prolonging battery service life, reducing failure risk, and improving battery safety performance.

Owner:ZHUOCONG SHANGHAI GREEN TECH DEV CO LTD

Thermal test apparatus and method

InactiveUS20110116528A1Easy to operateReduce quality problemsStructural/machines measurementMaterial flaws investigationTemperature controlEngineering

Thermal test apparatus comprising a specimen supported by a fixture, a thermal shroud comprising a flexible insulating fabric forming an enclosure around at least a portion of the specimen, and a temperature controlled air supply connected to an opening formed in the enclosure for delivering a supply of temperature controlled air into the enclosure. Also, a method of conducting a thermal test.

Owner:AIRBUS OPERATIONS LTD

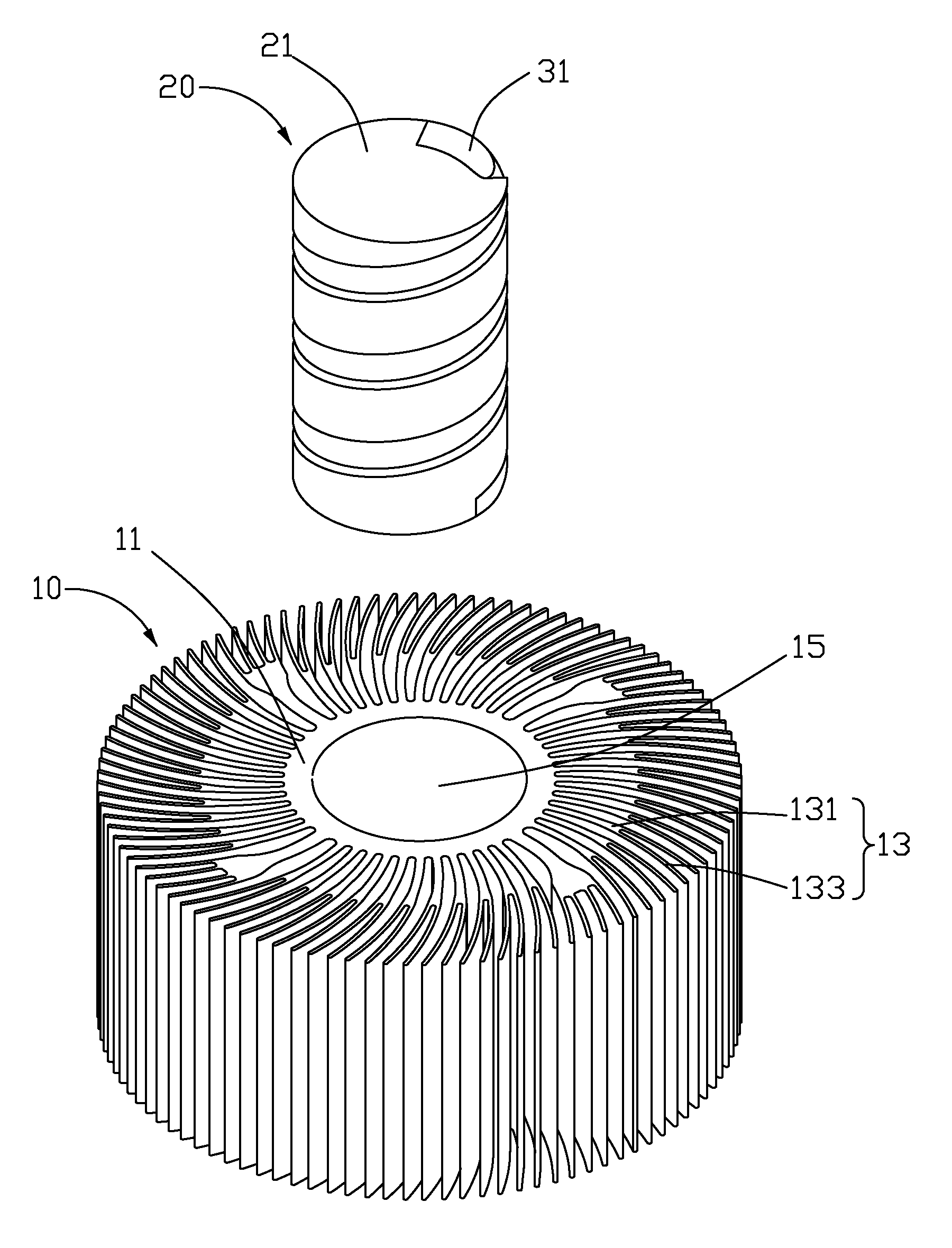

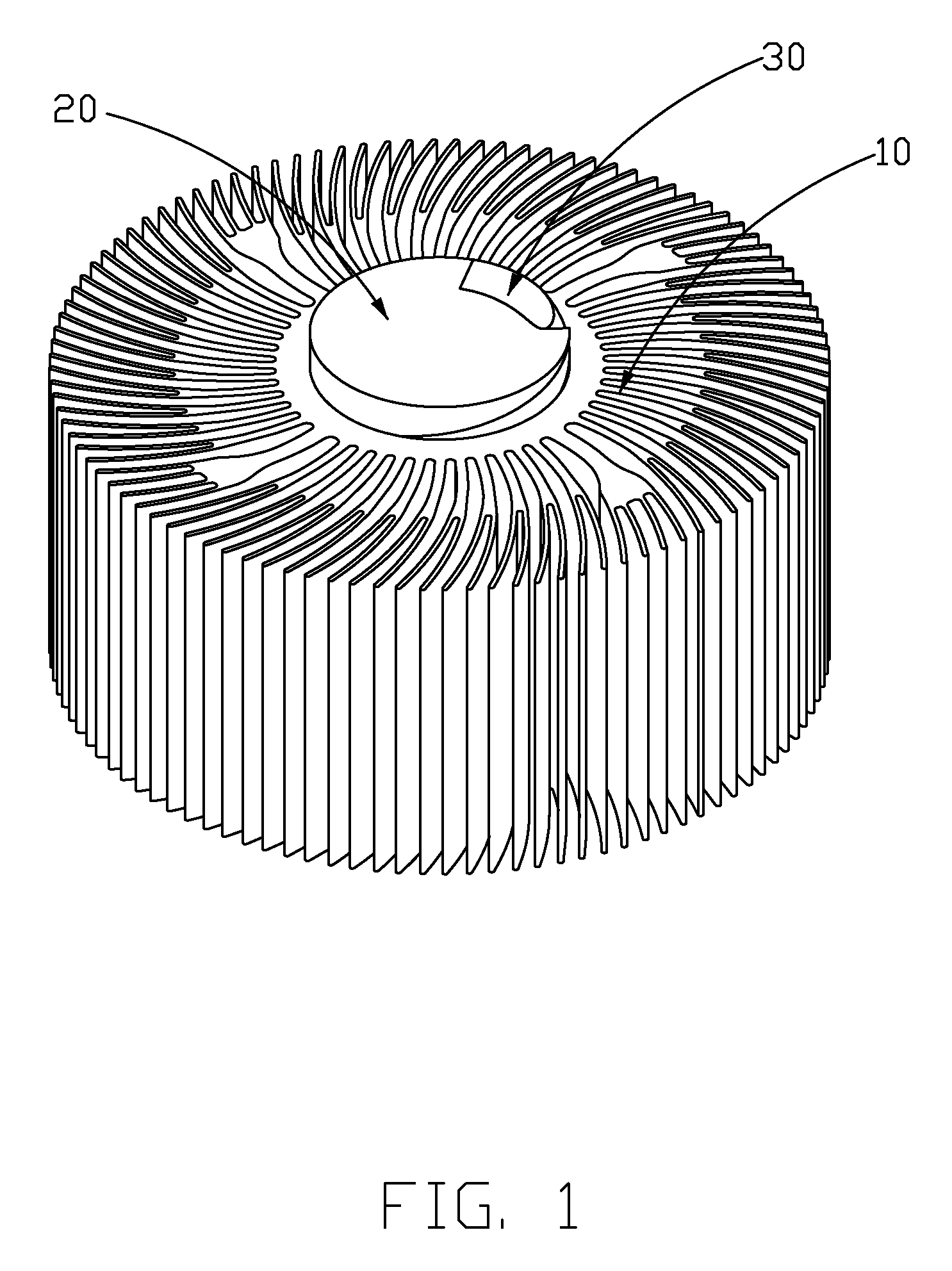

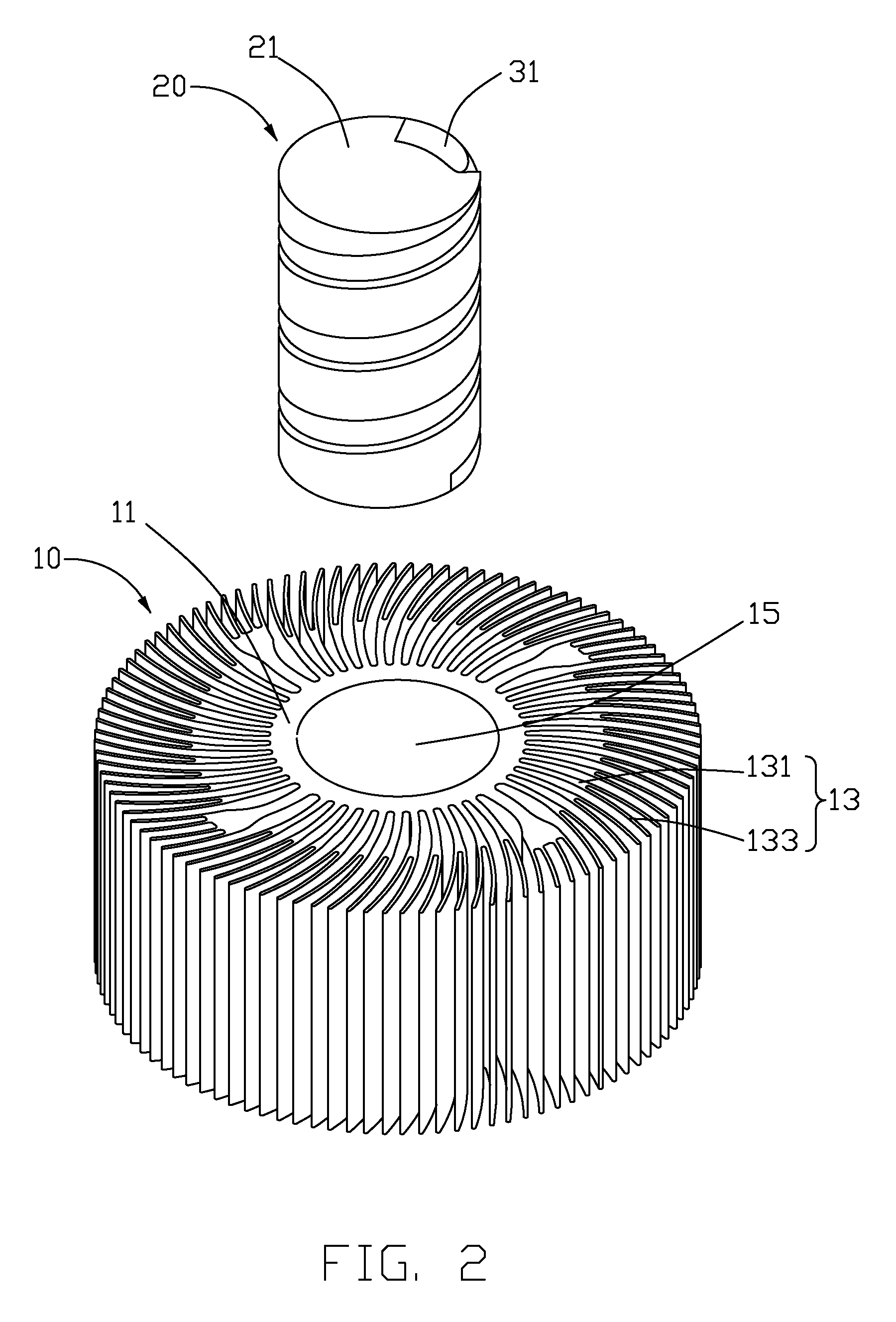

Heat dissipation device with a heat pipe

InactiveUS7870889B2Improve heat transfer performanceReduce thermal gradientSemiconductor/solid-state device detailsSolid-state devicesHeat pipeHeat spreader

A heat dissipation device comprises a radiator comprising a collar, a core received in the collar and a helical heat pipe embedded in a circumferential face of the core. The collar has a receiving hole and a plurality of fins extending radially and outwardly from an outer face of the collar. The core together with the heat pipe is received in the receiving hole of the radiator. The core has a flat bottom face and a top face opposite to the bottom face. The heat pipe is located between the radiator and the core and thermally contacts the collar of the radiator and the core. The heat pipe extends from the bottom face of the core to the top face of the core, and has a flattened bottom face coplanar with the bottom face of the core for contacting with an electronic device.

Owner:HON HAI PRECISION IND CO LTD +1

SOFC-conduction

ActiveUS10446858B2Reduce thermal gradientStable temperatureFuel cell heat exchangeSolid electrolyte fuel cellsThermal energyCombustion chamber

A solid oxide fuel cell (SOFC) system included high thermal conductivity materials such as copper to increase thermal energy transfer by thermal conduction. The copper is protected from oxidation by nickel electroplating and protected from thermal damage by providing Hastelloy liners inside combustion chambers. Monel elements are used in the incoming air conduits to prevent cathode poisoning.

Owner:UPSTART POWER INC

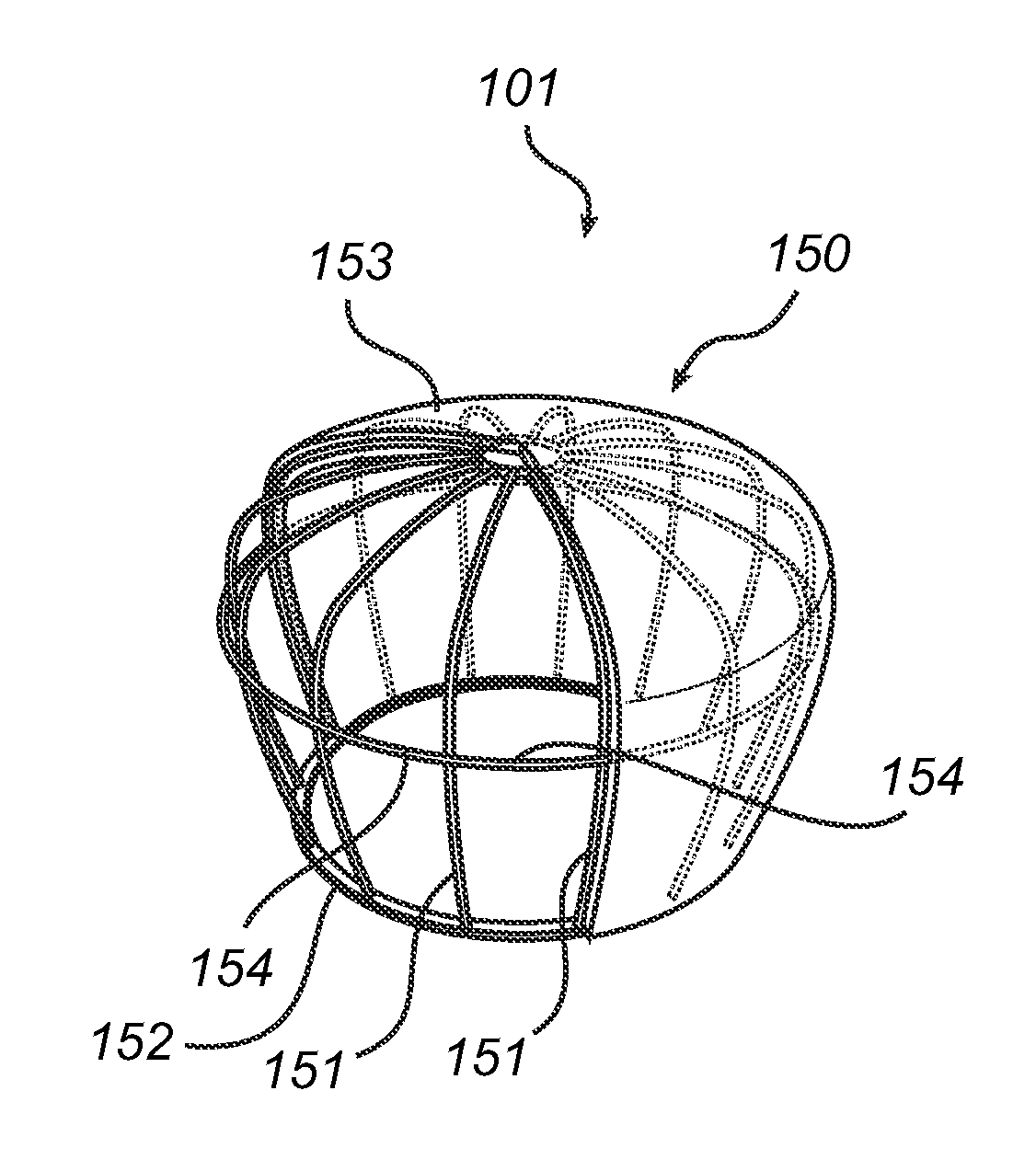

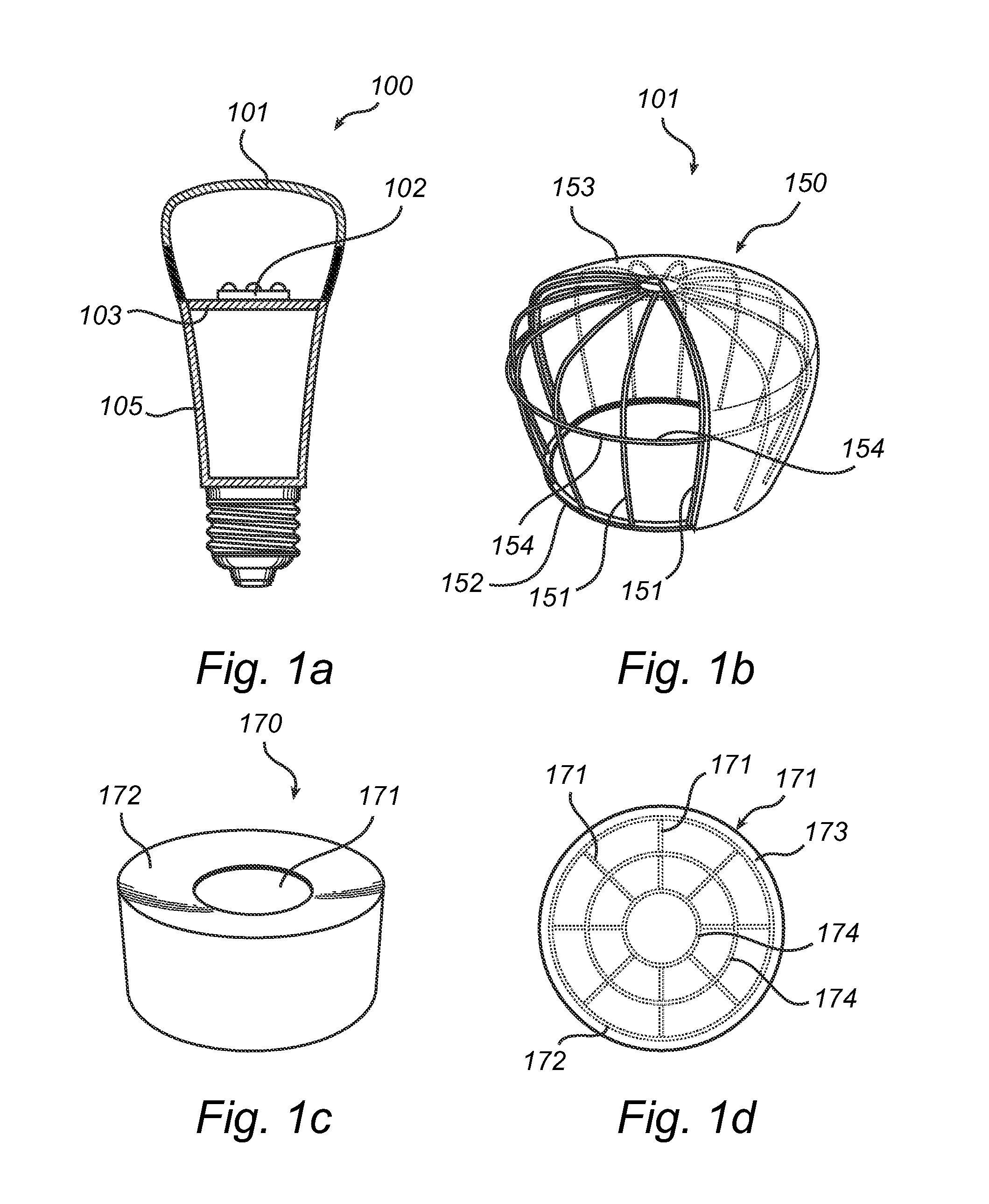

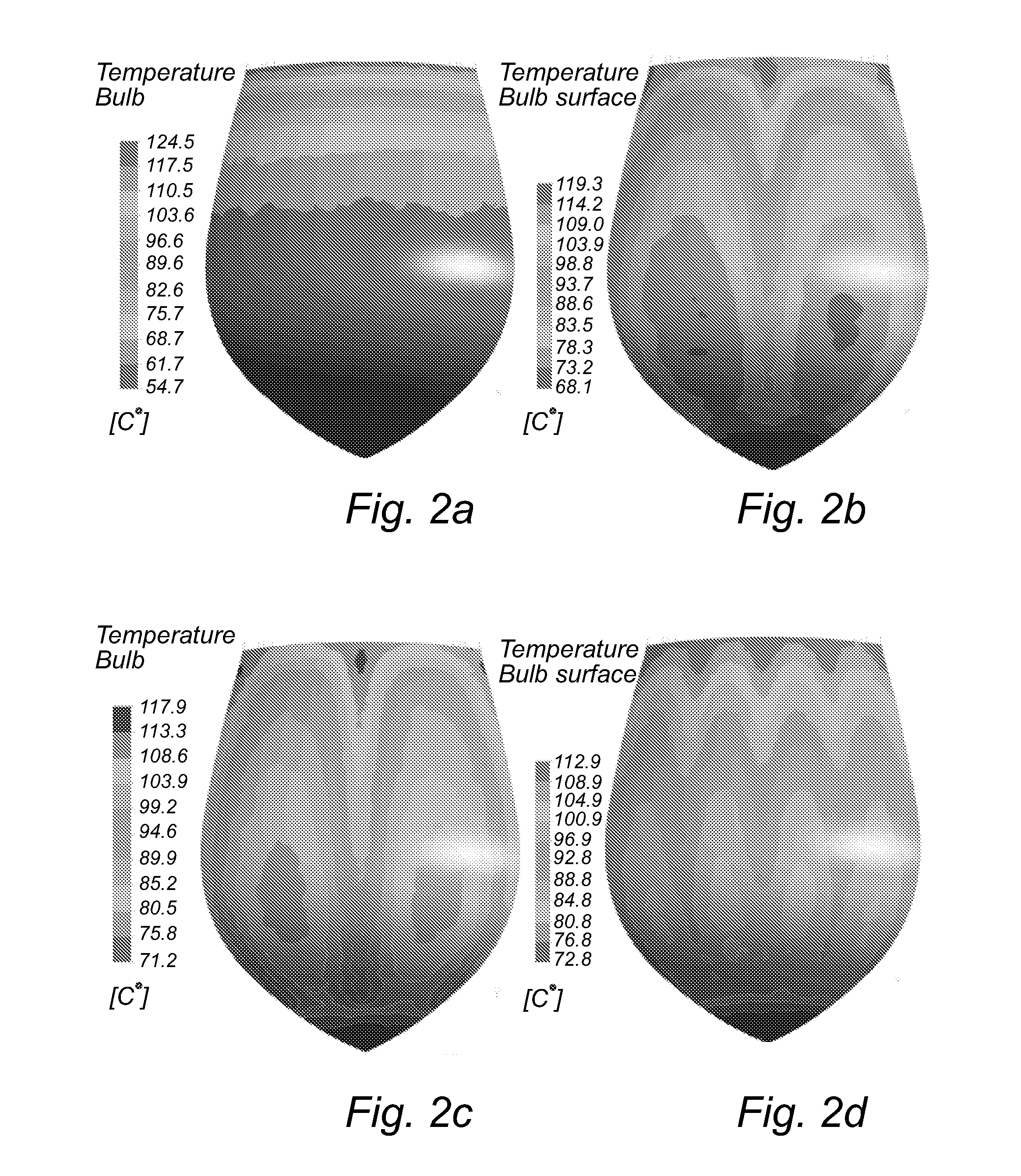

Lighting device with integrated lens heat sink

ActiveUS20150252996A1Efficient disseminationReduce thermal gradientPoint-like light sourceElectrical apparatusHeat conductingOptoelectronics

There is provided a lighting device 100 comprising at least one LED-based light source 102 for generating light, and a light exit element 101 which is optically and thermally coupled to the LED-based light source. The light exit element comprises a heat conducting structure 150 arranged for distributing heat generated by the LED-based light source over a predetermined sub area of the light exit element. The heat conducting structure may be embedded in or thermally connected to the light exit element and comprises aligned heat conducting paths 151. The introduction of heat conductive structures into the light exit element that spread heat in the light exit element and may be arranged to conduct heat from a heat sink into the light exit element or from the light exit element to a heat sink makes the light exit element to an integral part of the heat transferring external surface of the lighting device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com