Method and apparatus for liquid guided pump beam

A technology for guiding devices and pumping light sources, which is applied in the direction of laser cooling devices, lasers, laser components, etc., can solve the problem that thermal effects and thermal stress cannot be effectively reduced, and cannot solve the problem of overheating of crystal end faces and centers, and uneven temperature distribution of crystals and other issues, to achieve significant implementation effects, solve high-power pumping problems, and solve heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

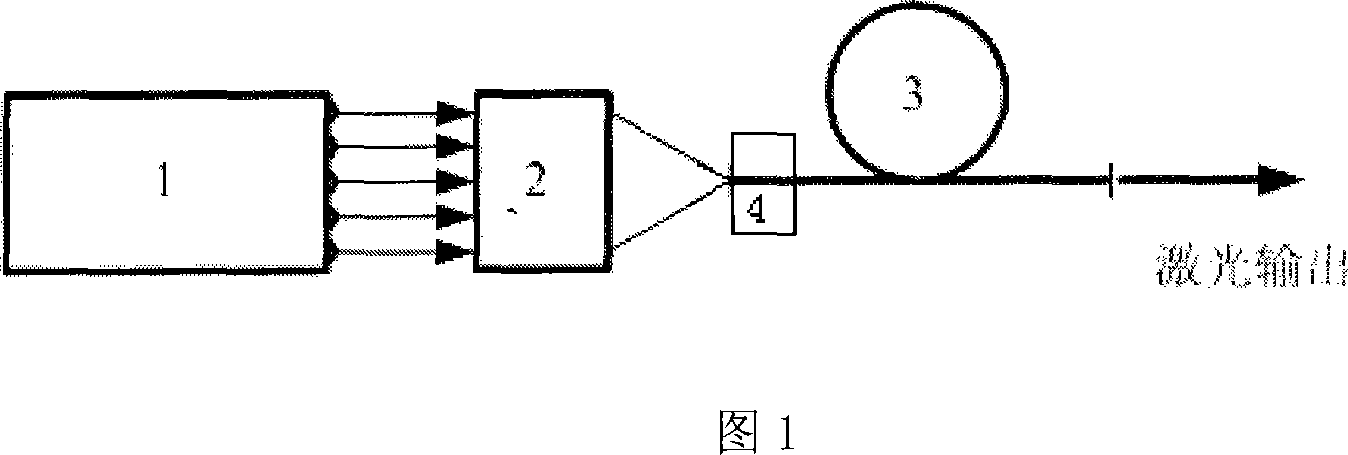

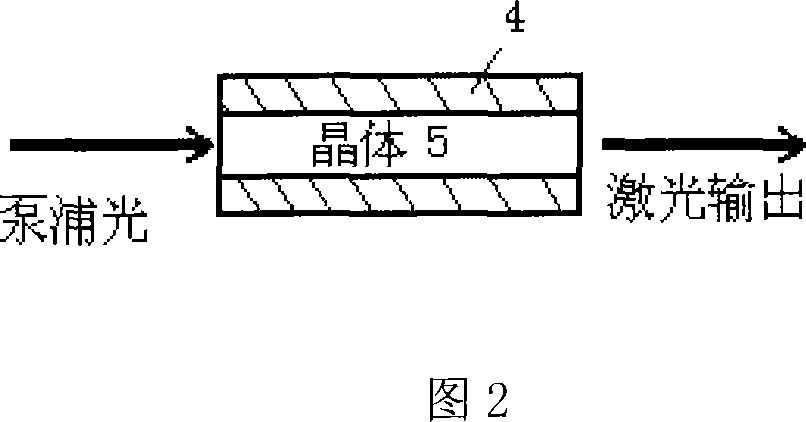

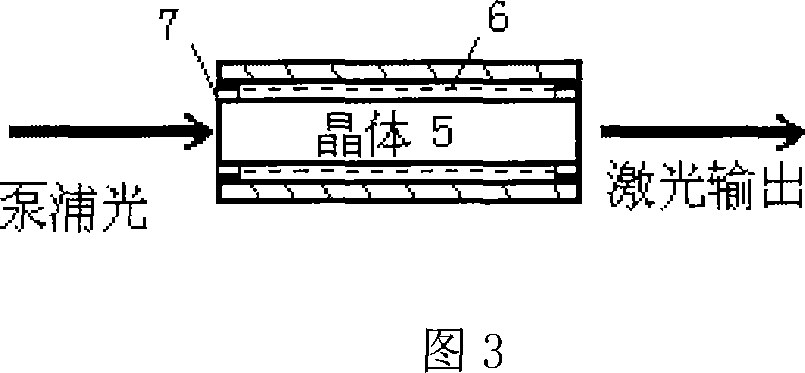

[0031] The present invention is described below in conjunction with accompanying drawing.

[0032] The first embodiment of the present invention is shown in FIG. 4 , the device of the present invention includes a coupling system 8 , a liquid guiding device 9 , and an optical fiber 3 for output. The liquid guiding device 9 is composed of a special liquid nozzle 10 , a coolant collector 11 , a liquid return pipe 12 , a circulating pump 13 and a radiator 14 . As shown in Figure 4, the feature of the present invention is that the pumping light through the coupling system 8 is coupled into the liquid column 15 ejected from the nozzle after passing through the special liquid nozzle 10 with a transparent window at the front end, and the center line of the liquid column 15 is accurate. Align the center line of the optical fiber 3, and seal the rear end of a tubular coolant collector 11 on the optical fiber 3. The front liquid inlet of the coolant collector 11 protrudes from the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com