Patents

Literature

782results about How to "Take away quickly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

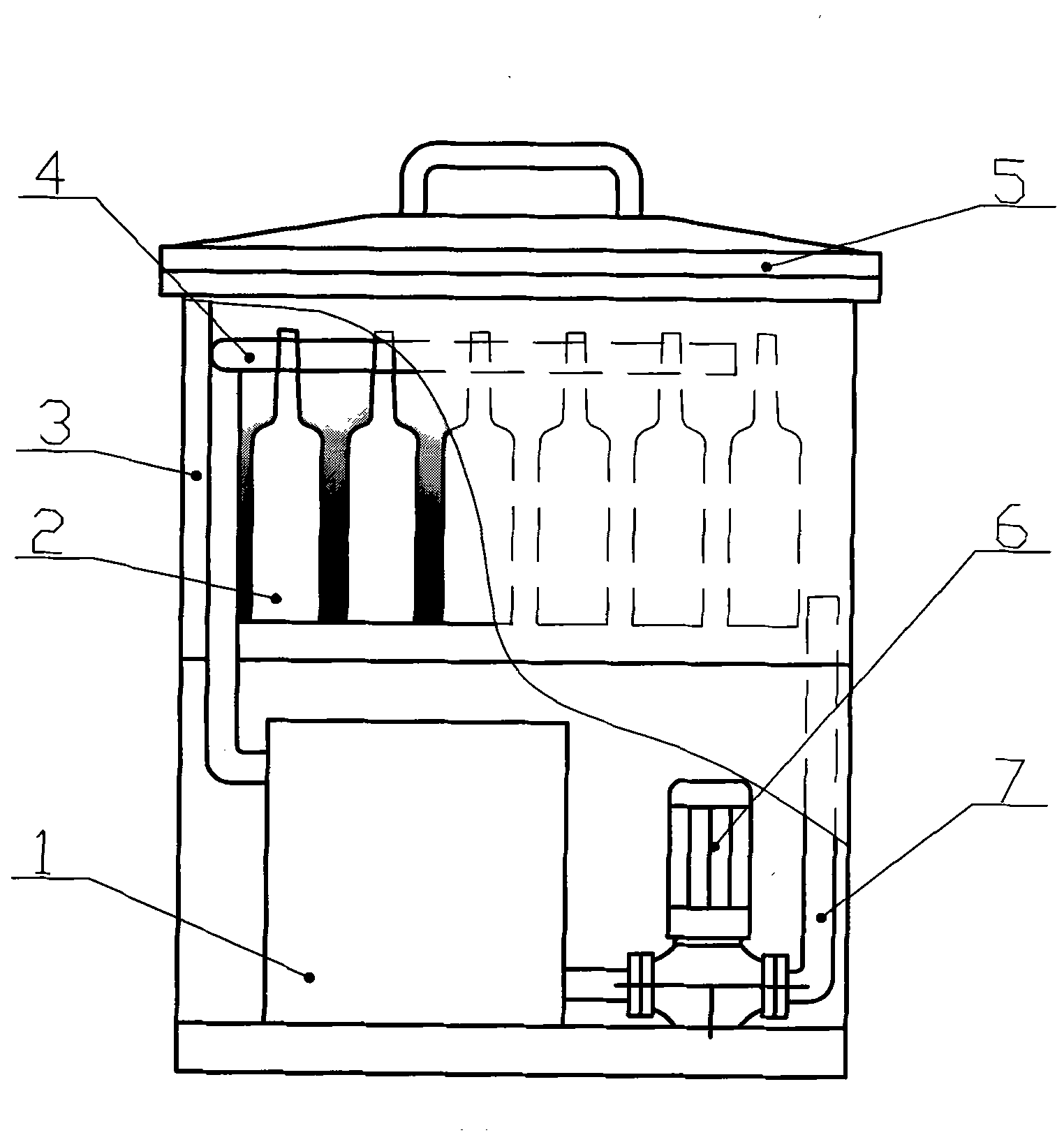

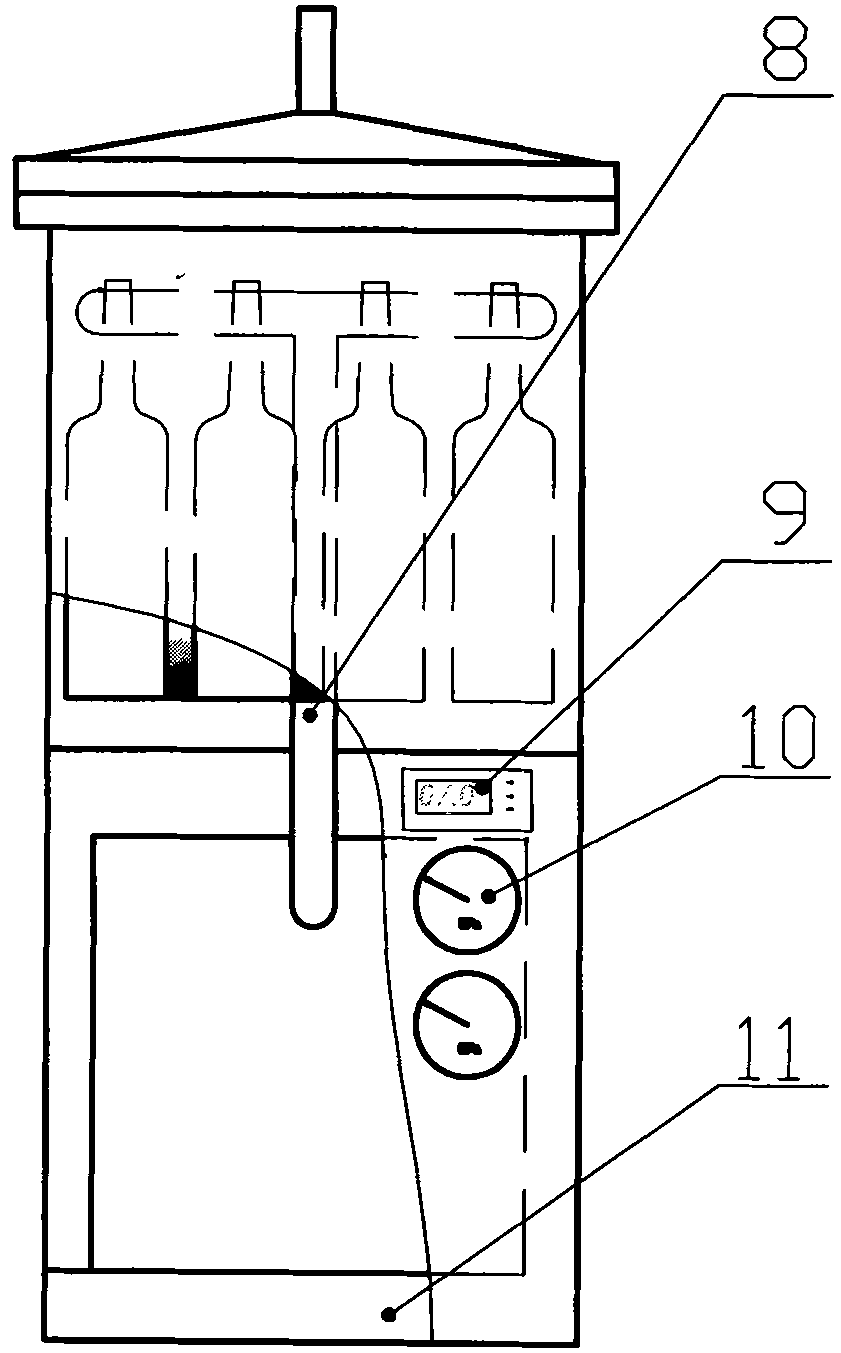

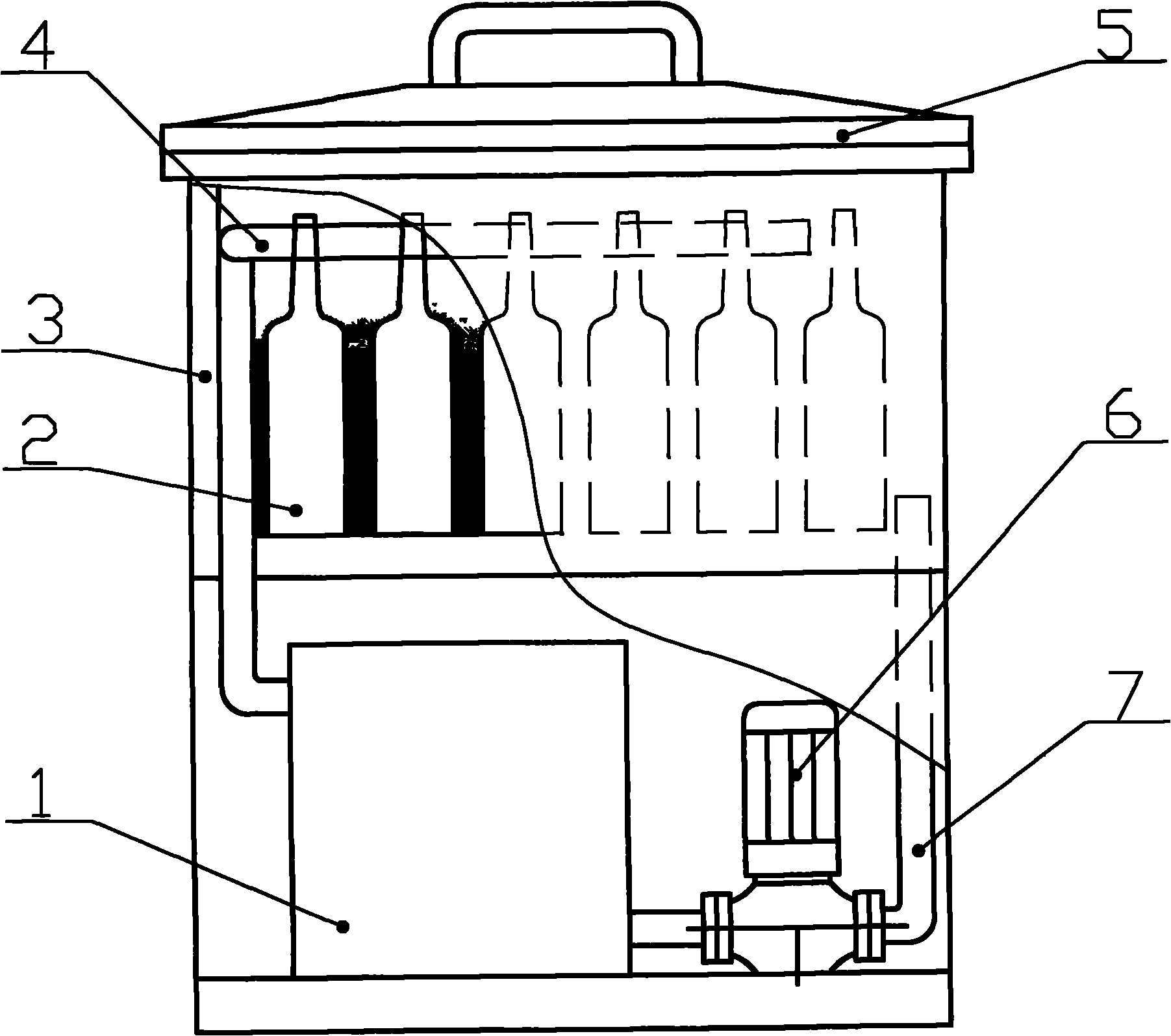

Small packaged beer and beverage rapid cooling device

InactiveCN101806528ARapid coolingSuitable for tasteDomestic cooling apparatusLighting and heating apparatusEngineeringSmall footprint

The invention discloses a small packaged beer and beverage rapid cooling device. The device comprises a refrigerating unit, a cooling tank and an electrical control part, wherein a water circulation system is arranged between the refrigerating unit and the cooling tank, the evaporator of the refrigerating unit is connected with the cooling tank through a water inlet pipe; and after cold water performs heat transfer in the cooling tank, the obtained water flows back to the evaporator of the refrigerating unit through a return pipe and a circulating pump. The invention utilizes the refrigeration technology and heat conduction theory, uses the refrigerating medium for continuous cooling and adopts the types of flow and direct contact to fast cool beverage. Compared with the common air-cooling method, the method of the invention has the advantages of fast cooling rate, large yield, adjustable capacity, simple operation, low operating cost, wide application range, small floor space, light weight and the like.

Owner:林崇实

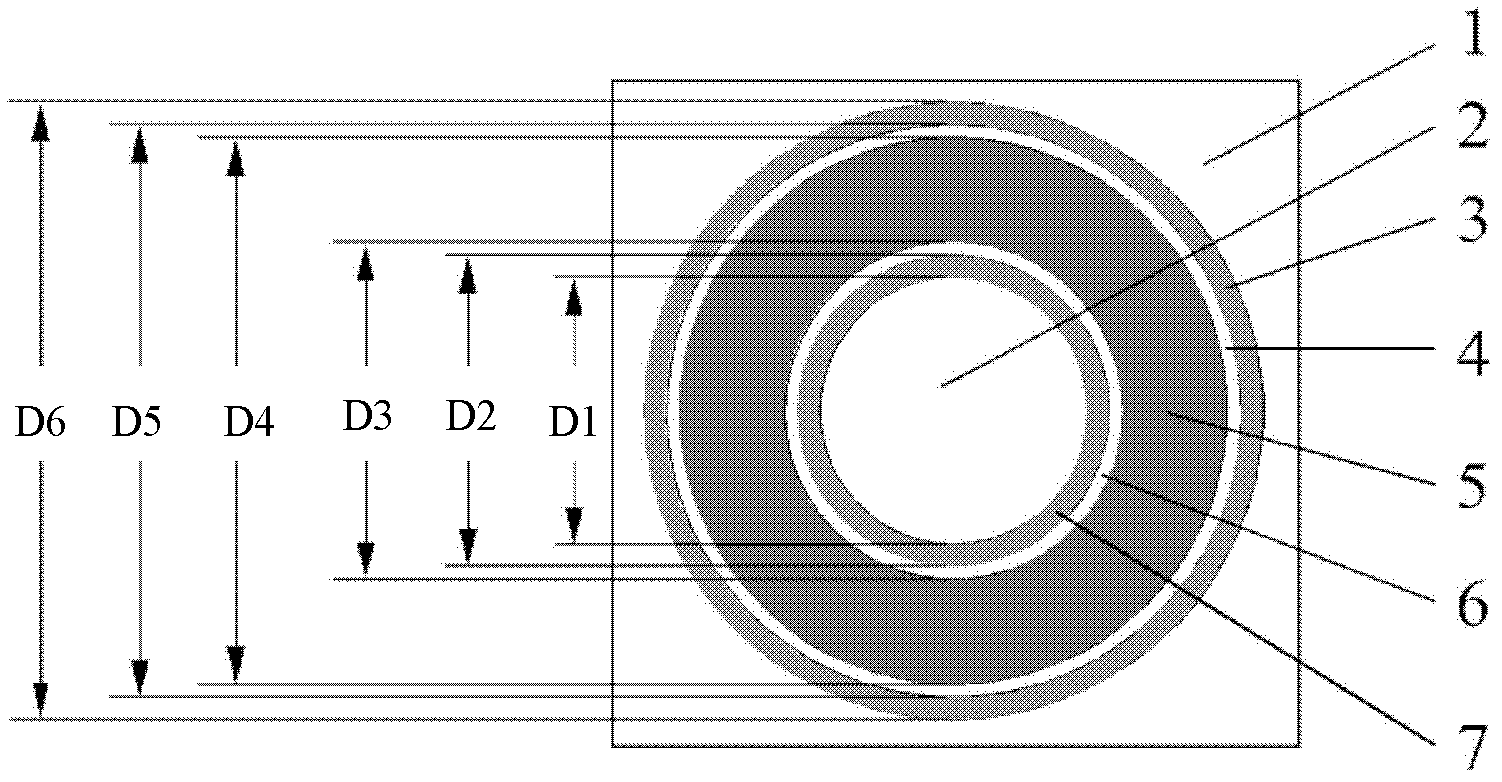

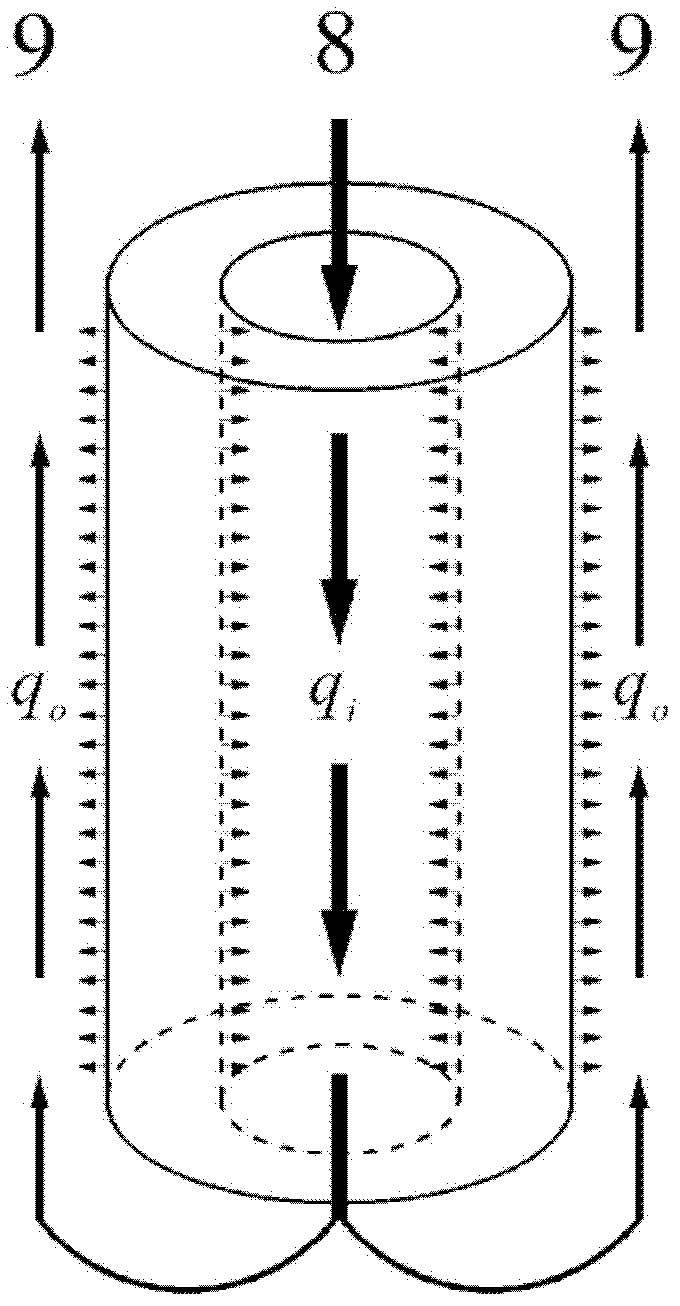

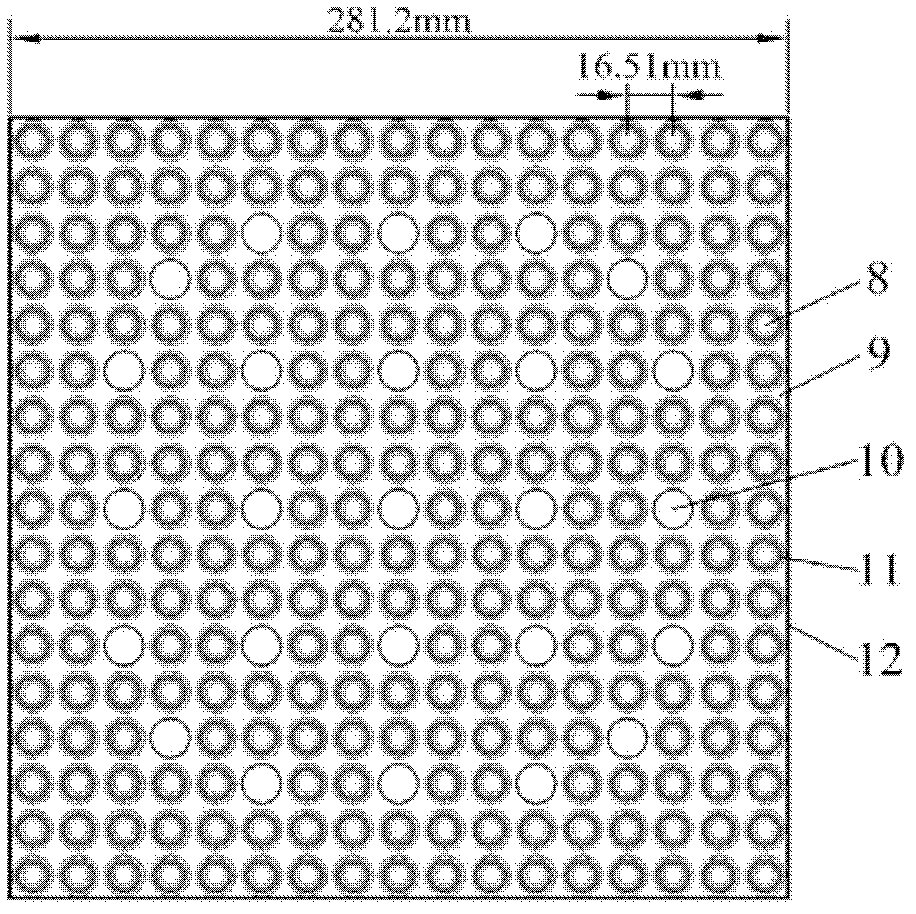

Annular fuel element and annular fuel supercritical water reactor

InactiveCN102354539AReduce radial power factorTake away quicklyFuel elementsNuclear energy generationNuclear engineeringPower factor

The invention discloses an annular fuel element and an annular fuel supercritical water reactor. The annular fuel element is a cylindrical structure of which the cross section is annular, and consists of an outer wrapping shell, an outer gas gap, a fuel core block, an inner gas gap and an inner wrapping shell from an outer layer to an inner layer. The water reactor consists of a pressure container, a descending section, a reactor core basket and an annular fuel assembly from outside to inside, wherein the annular fuel assembly is formed by arranging a plurality of square annular fuel assemblies or a plurality of hexagonal annular fuel assemblies axially in parallel. In the annular fuel element and the annular fuel supercritical water reactor, the temperature of the fuel core block and the wrapping shells are reduced by increasing a heat transfer area effectively; and low-temperature water serving as a moderator is positioned in an inner channel of the fuel element, so the physical feedback is more uniform, and radial power factors can be reduced effectively.

Owner:XI AN JIAOTONG UNIV +1

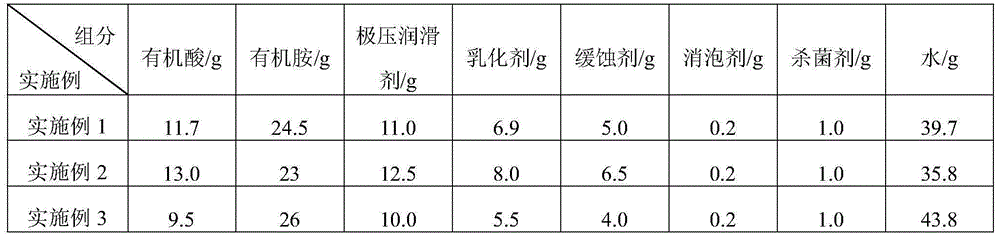

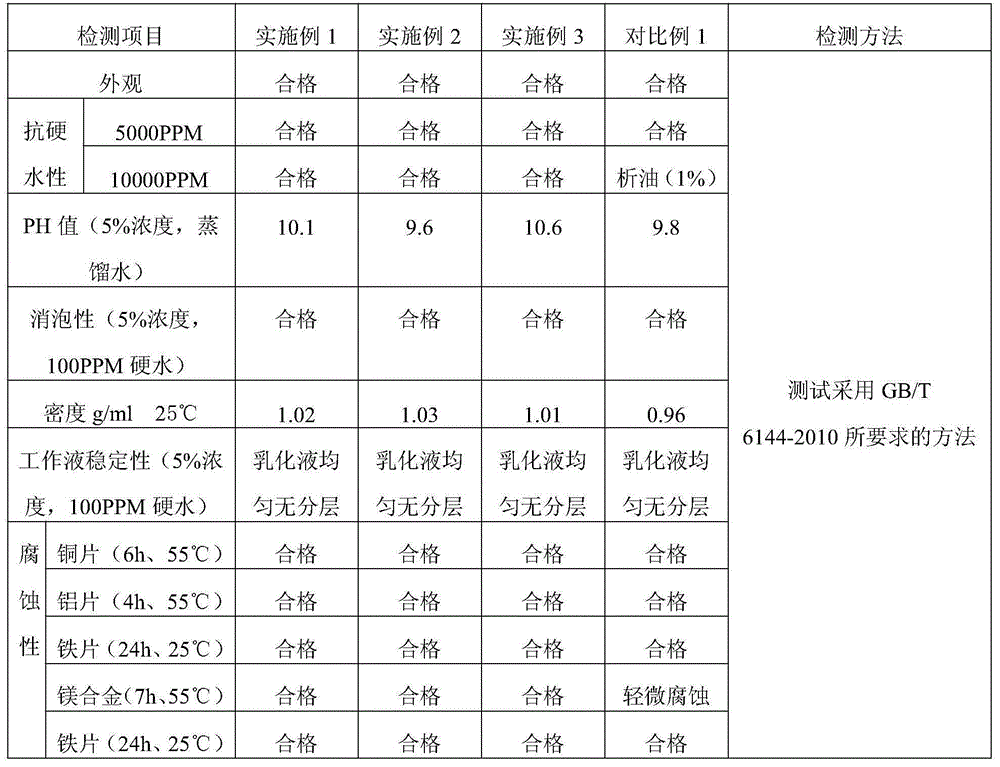

Environment-friendly water-soluble cutting fluid for magnesium alloy cutting

InactiveCN105038942AExtended service lifeImprove wear resistanceLubricant compositionOrganic acidHydrogen

The invention relates to an environment-friendly water-soluble cutting fluid for magnesium alloy cutting, which comprises the following components in parts by weight: 5-20 parts of organic acid, 15-30 parts of organic amine, 5-16 parts of lubricant, 3-11 parts of emulsifier, 1-6 parts of corrosion inhibitor, 0.1-0.5 part of defoaming agent, 0.1-3.5 parts of bactericide and 15-70 parts of water. The magnesium alloy cutting fluid has the advantages of favorable abrasion resistance, favorable hard water resistance, favorable rust and corrosion resistance, and is capable of effectively protecting the cutter and prolonging the service life of the cutter. The water-soluble cutting fluid can quickly take away the heat generated in the machining process, lower the temperature of the machined surface and effectively avoid the defect of high flammability of the magnesium chips due to high temperature. The aluminum-magnesium alloy cutting fluid provided by the embodiment of the invention does not release hydrogen when being used for magnesium alloy cutting, thereby ensuring the safe proceeding of the production process.

Owner:深圳市奥科宝特种油剂有限公司

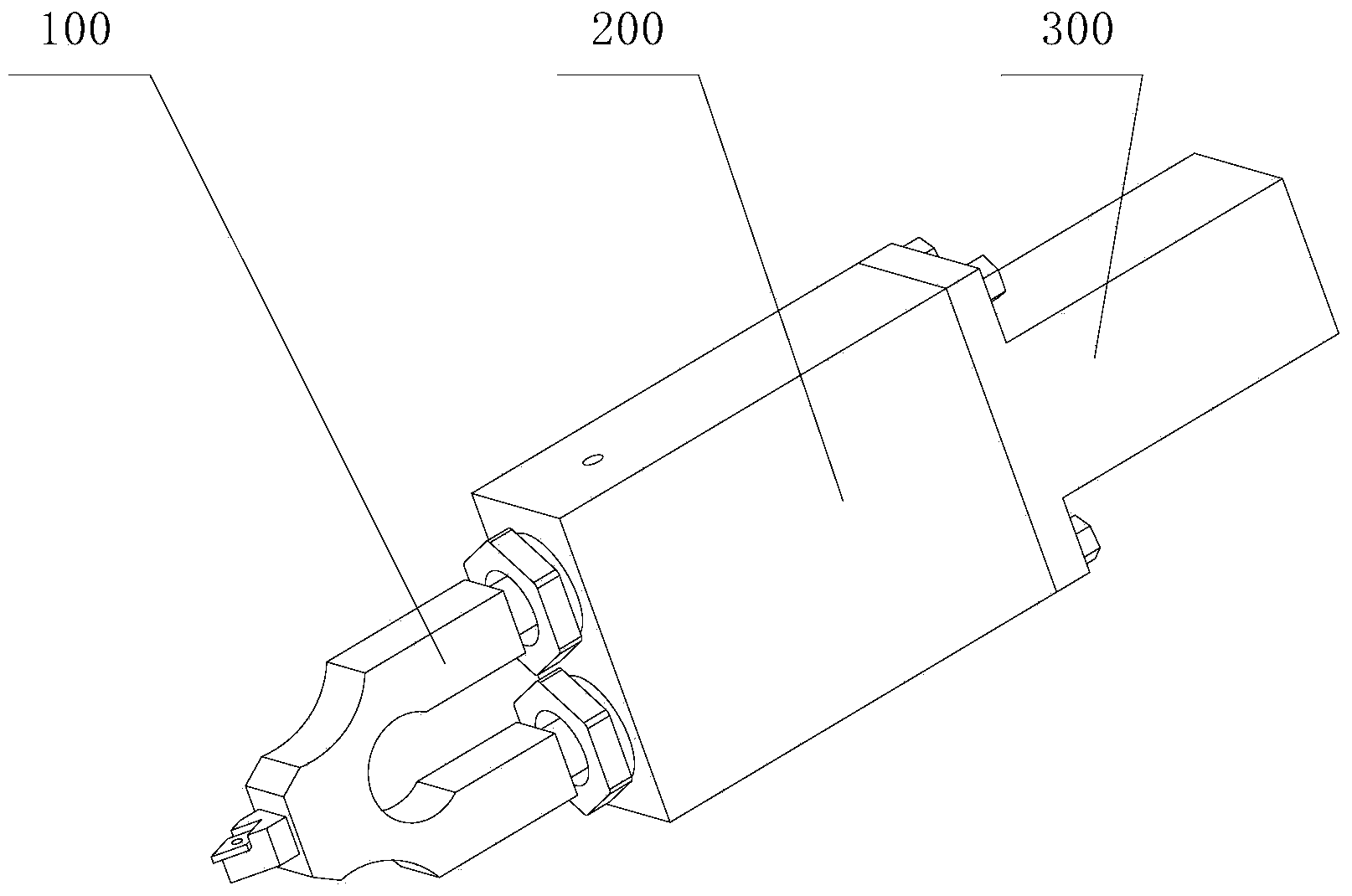

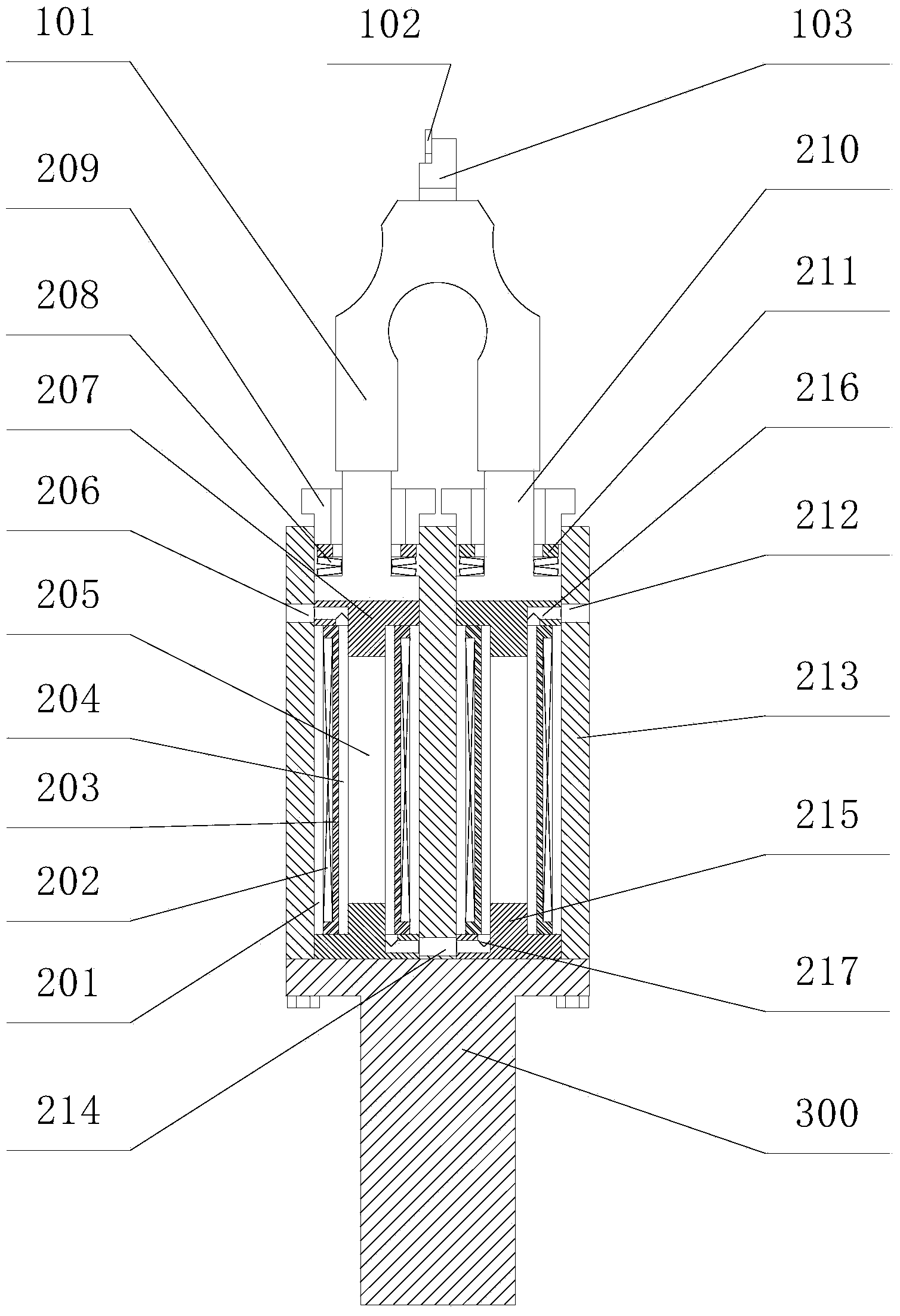

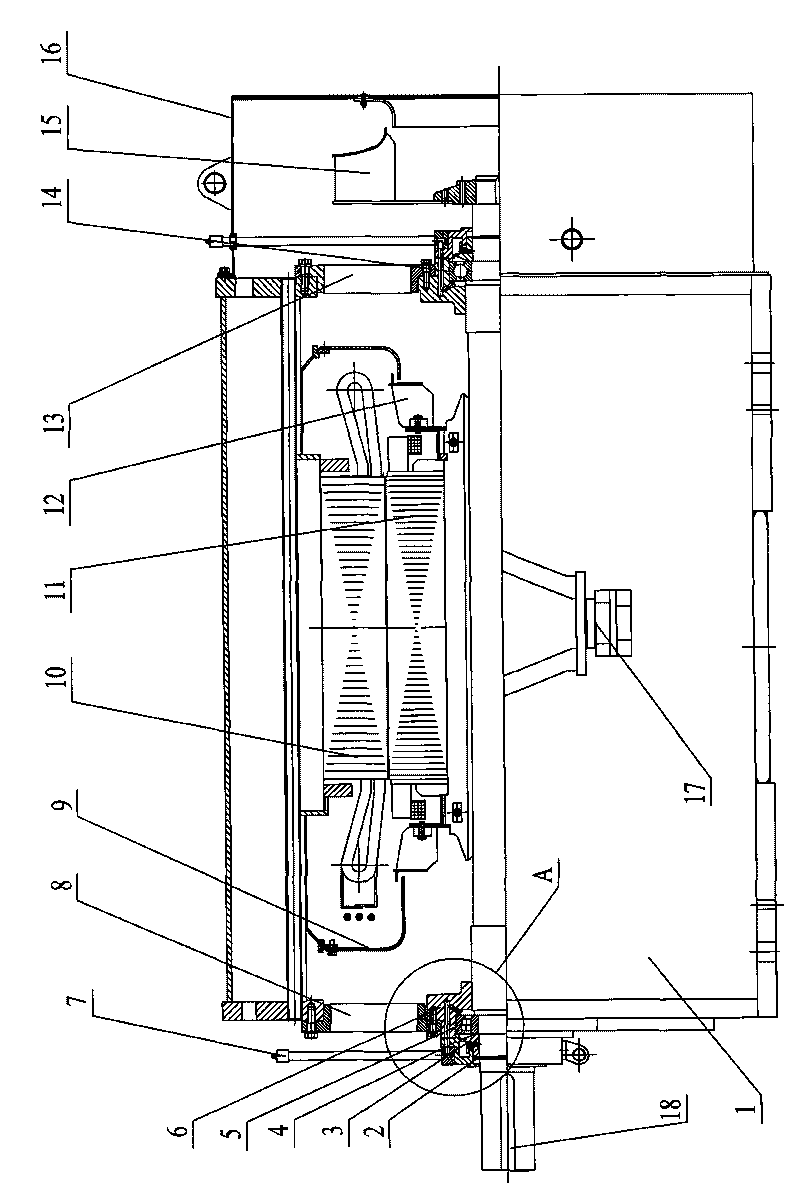

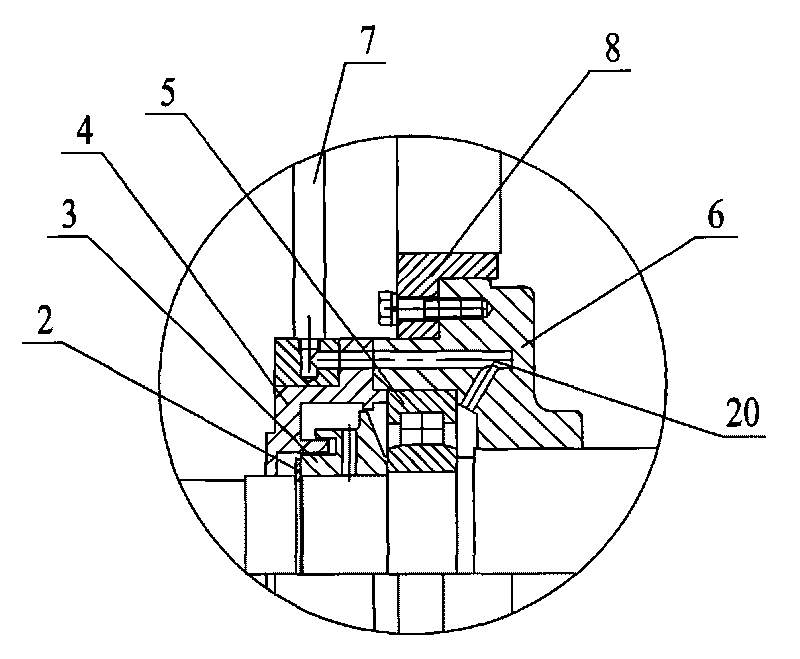

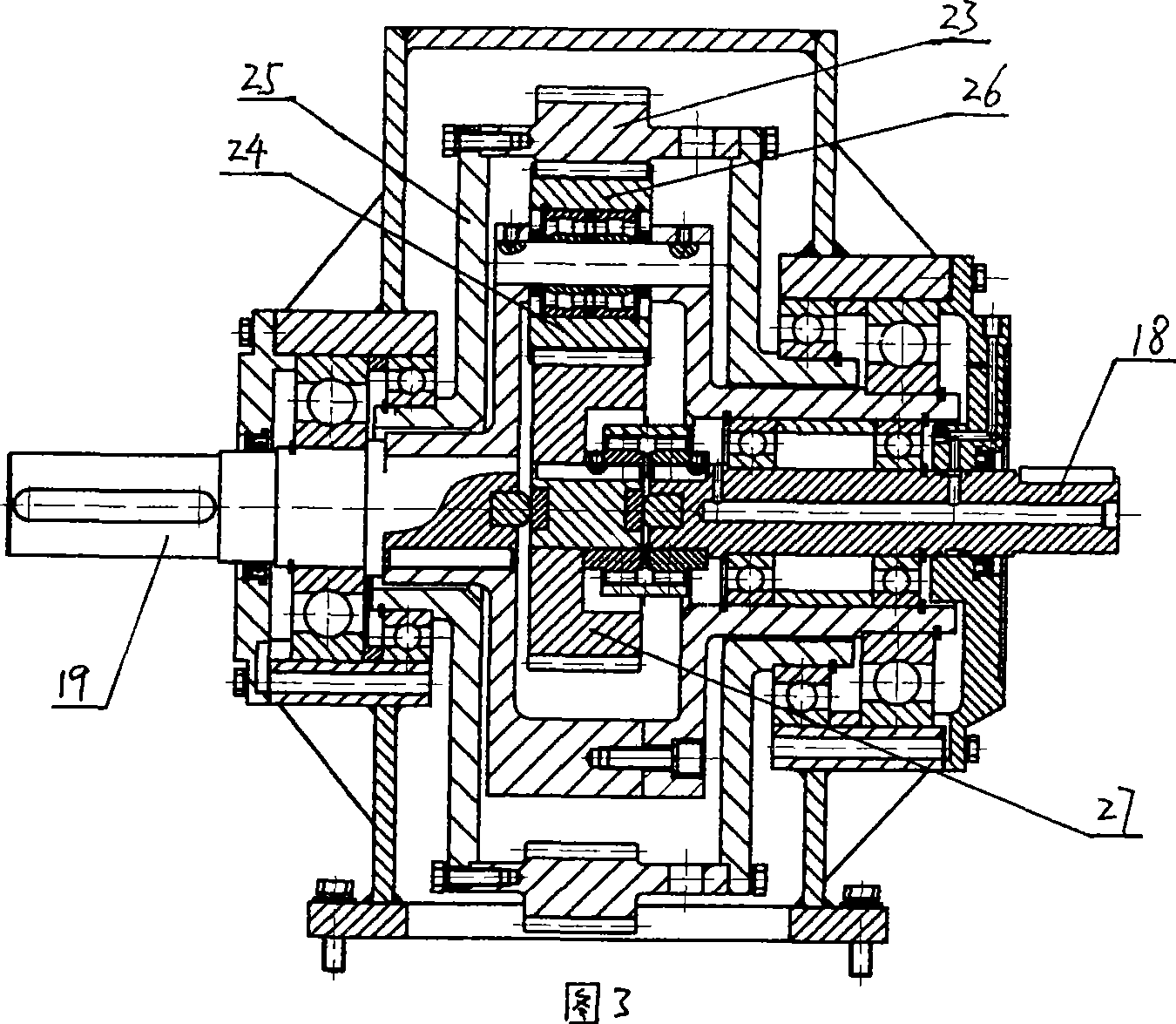

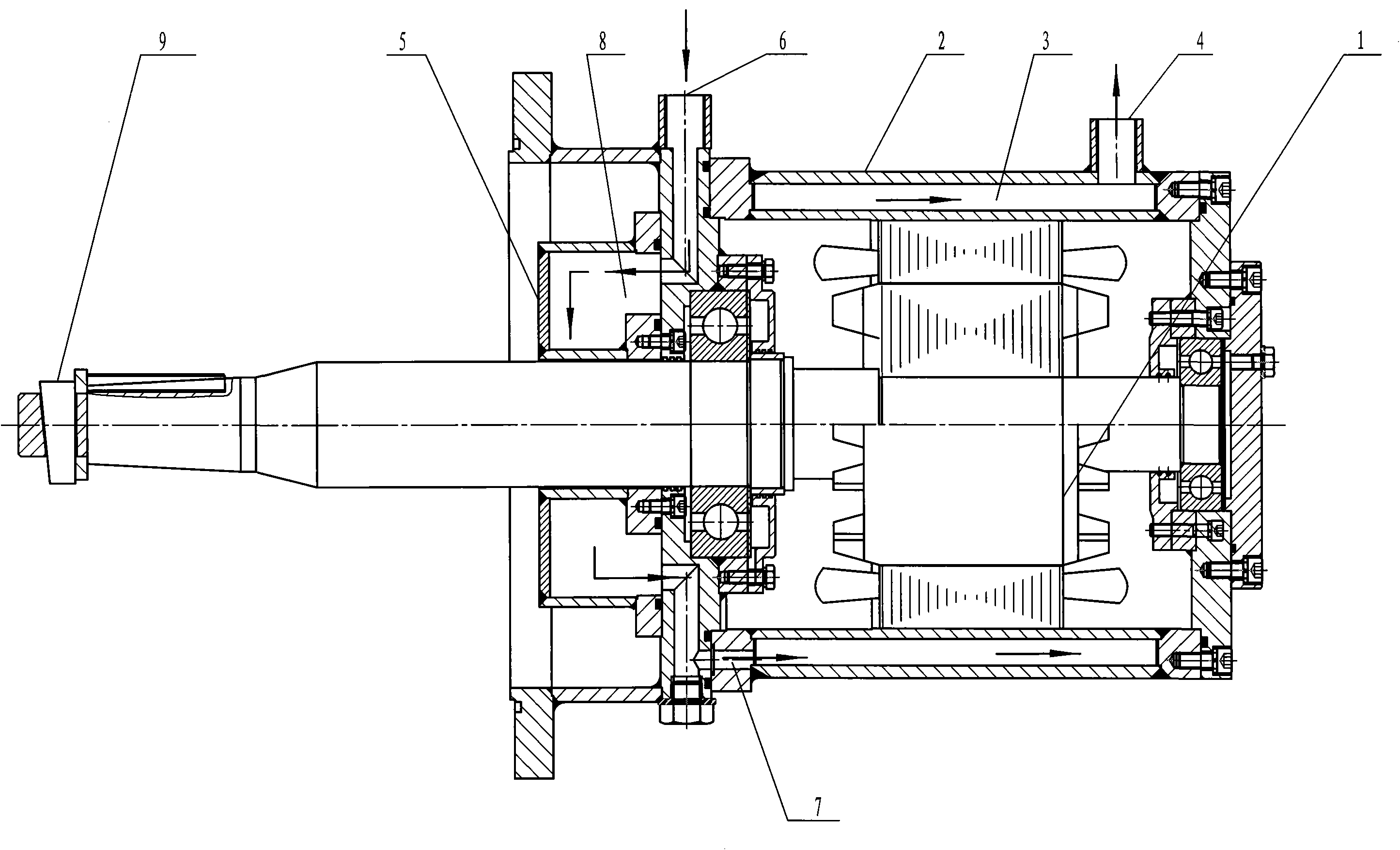

Double-stimulation ultrasonic elliptical vibration processing device

InactiveCN103586192ALarge magnetostrictive strainIncrease output powerMechanical vibrations separationSonificationTransducer

Provided is a double-stimulation ultrasonic elliptical vibration processing device. A giant magnetostrictive material is adopted to serve as a drive element, two sets of giant magnetostrictive transducers are arranged in parallel, large-area one-way water-cooling systems are arranged in the transducers, and flexible hinge connection is adopted at vibration output ends. The device has the advantages of being high in output power, loading capacity and energy conversion efficiency, wide in bandwidth, compact and reasonable in structure and the like, and can be widely applied to various ultrasonic elliptical vibration processing operating conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

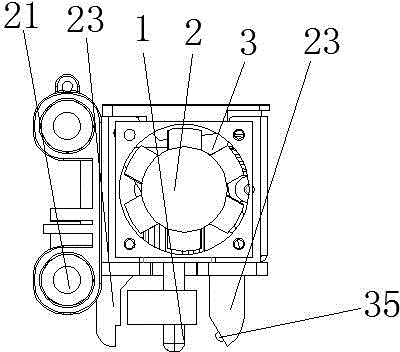

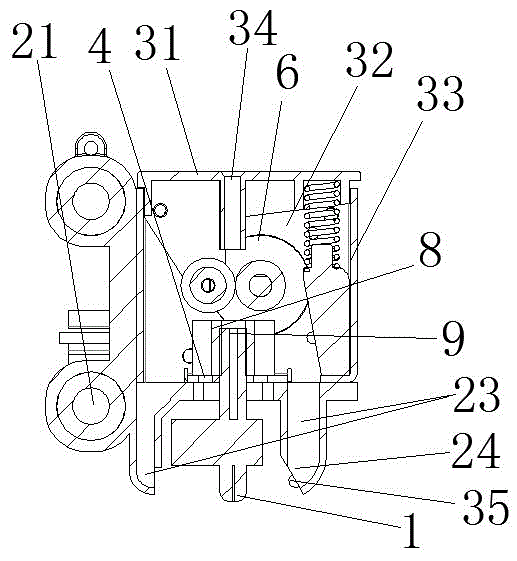

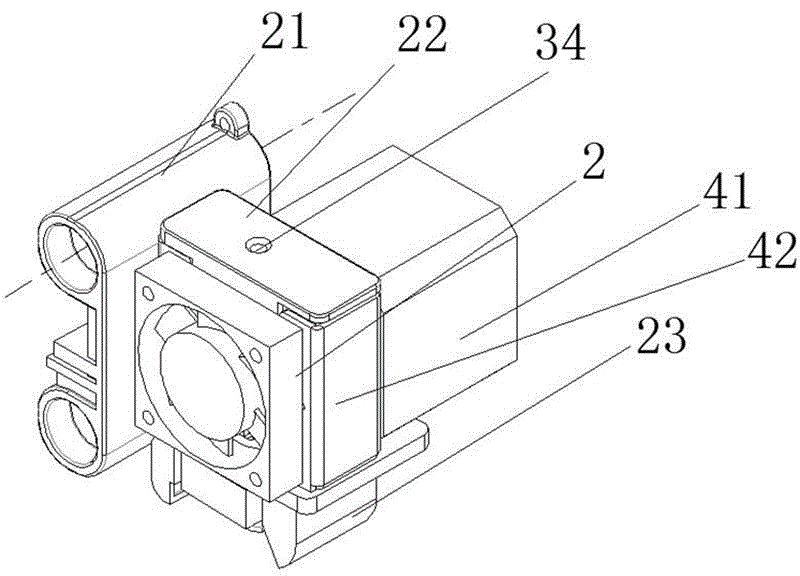

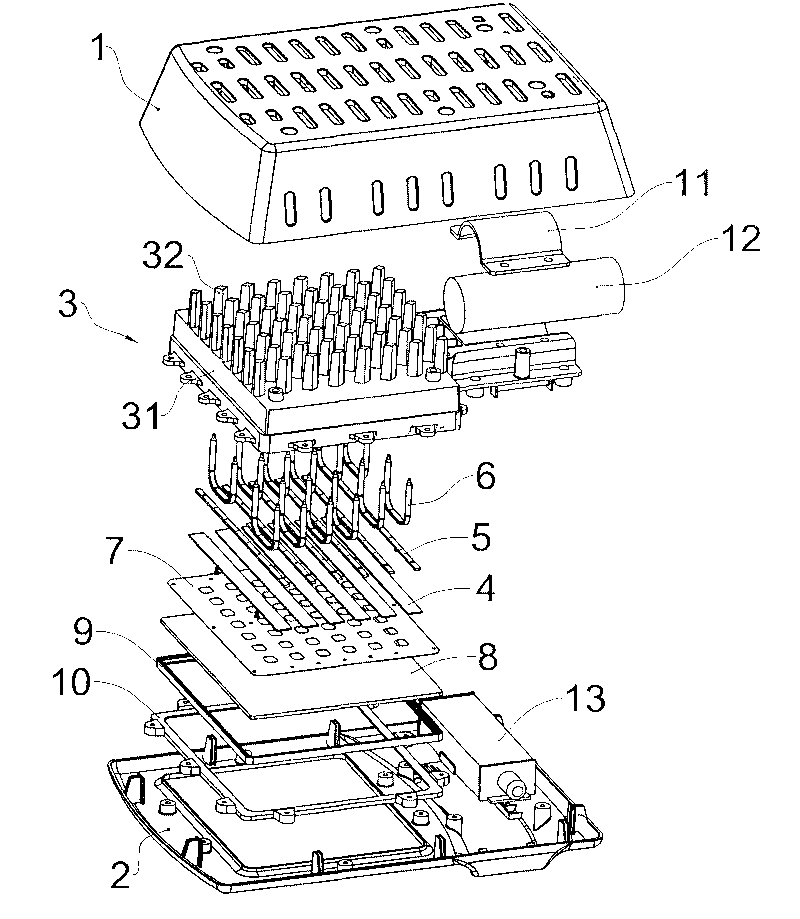

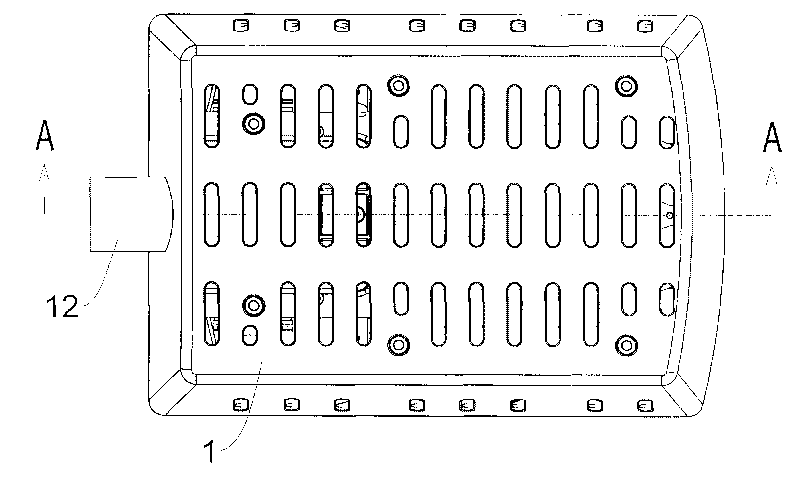

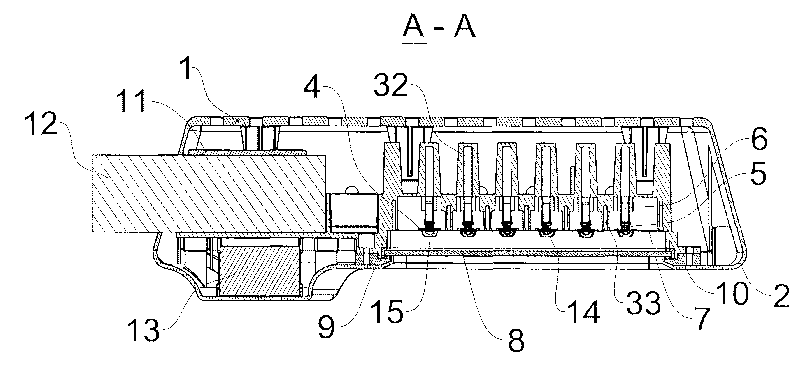

Air-cooling device for printing head of 3D (three-dimensional) printing machine

InactiveCN104786510AHigh efficiency of active coolingSmall footprintManufacturing platforms/substratesAdditive manufacturing with liquids3d printerWorking space

The invention discloses an air-cooling device for a printing head of a 3D (three-dimensional) printing machine. The printing head is arranged at a slide rod of the printing machine in a sleeving manner by lug rings and axially slides; the air-cooling device is integrated on the printing head; a wire conveying mechanism is arranged in a seat housing cavity body of the printing head; a cooling fan aligned to the wire conveying mechanism is arranged on one axial side of the seat housing cavity body; a printing head nozzle is formed in the lower part of the seat housing cavity body; the seat housing cavity body is provided with air guide pipelines leading to the printing head nozzle. The air-cooling device improves heat dissipation of the printing head of the printing machine and enables occupied working space of the printing head to be further reduced, thereby being favorable for improving the portability of the folding-type 3D printing machine.

Owner:FUZHOU ZHANXU ELECTRONICS

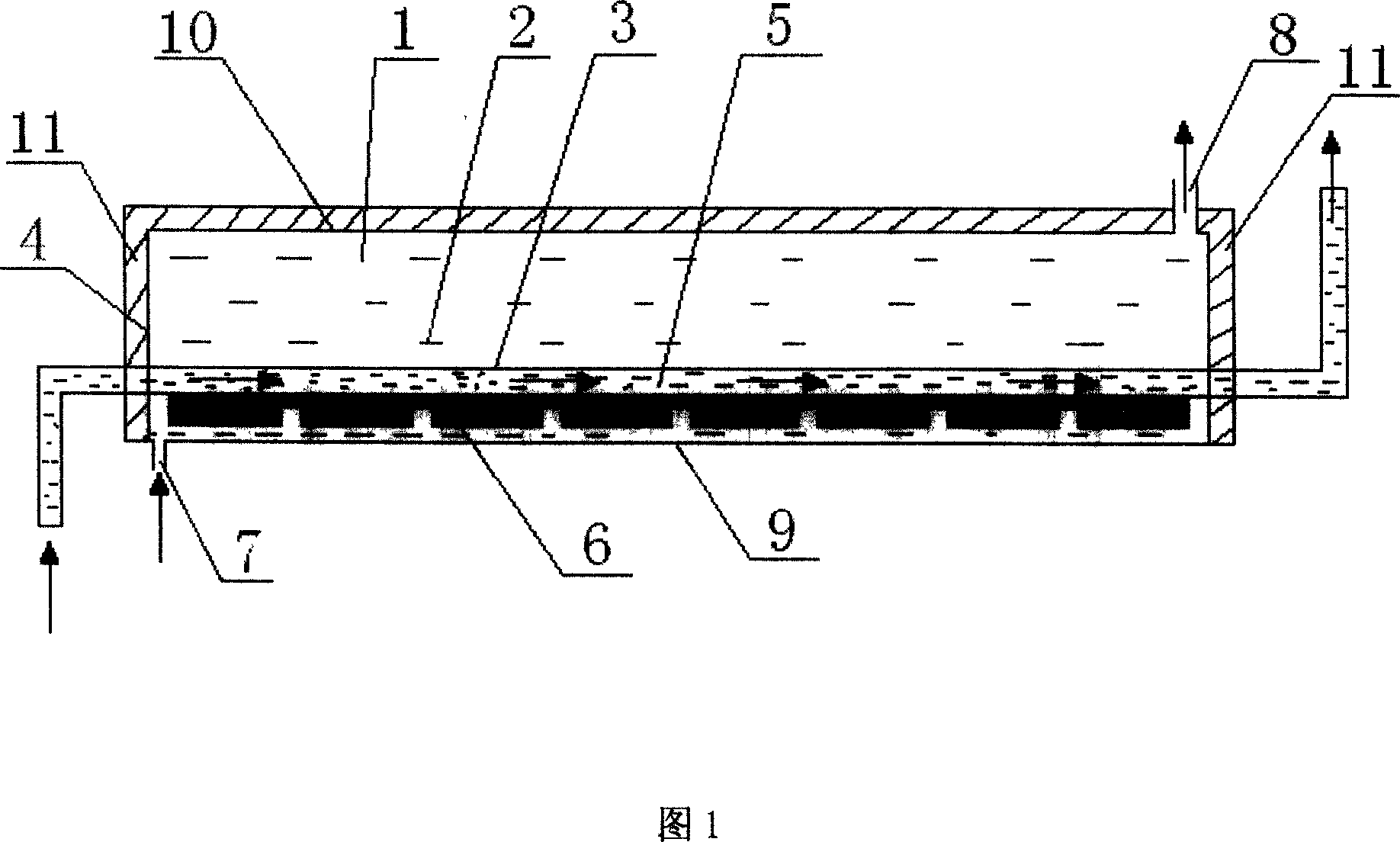

Electrothermal combined using device for solar cell

InactiveCN1988183AUniform surface temperatureImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationElectricityWorking fluid

This invention discloses a common use device for electricity and heat of a solar cell including a liquid container with heat collection working fluid, in which, hot tubes are set on the side walls of the container and set with phase change heat- carry working fluid, a solar cell is connected with the tubes in the container fixedly, an inlet is set at the bottom of the container and an outlet is set at the top of the container, the bottom face is transmissive, heat preservation materials are set at outside of the top and outside of the side wall of the container. This invention can carry away solar heat not changed to electricity quickly by dipping a solar cell in a heat-collection working fluid and connecting to the hot tubes.

Owner:TIANJIN UNIV

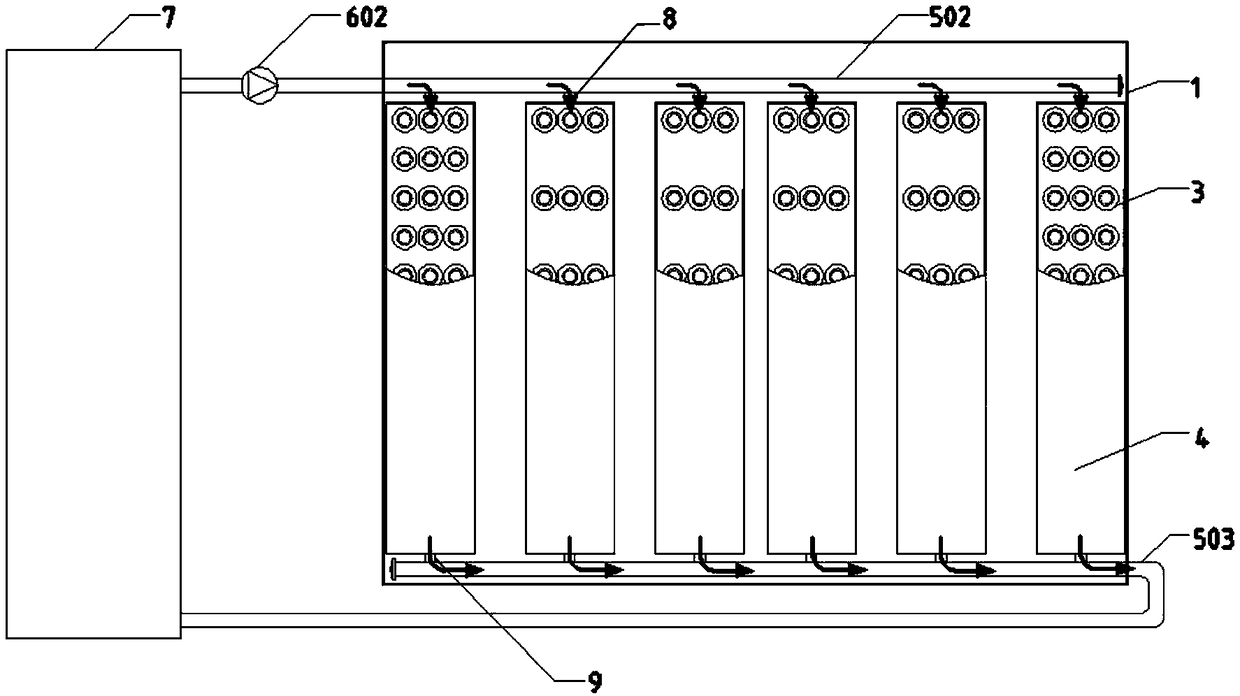

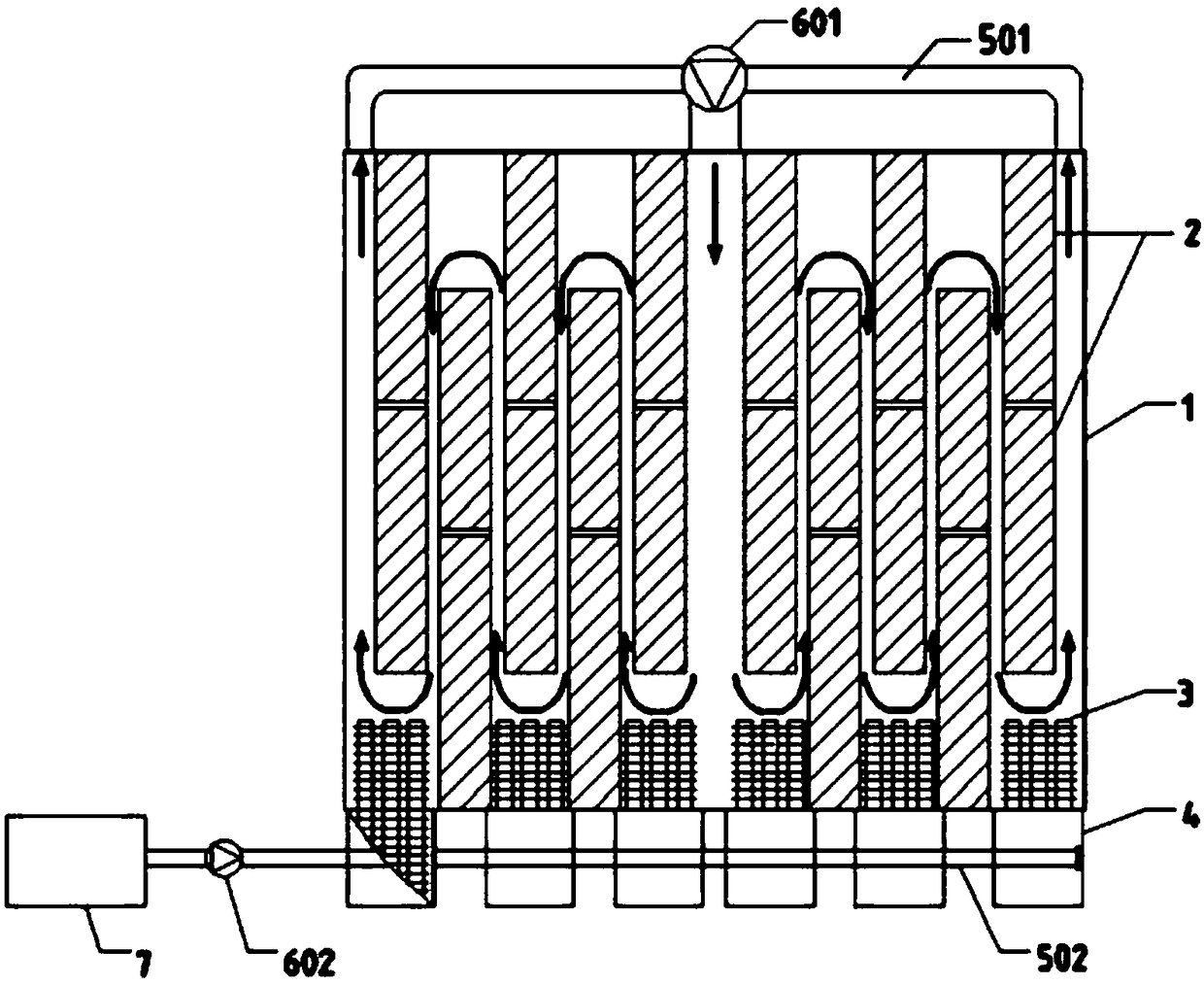

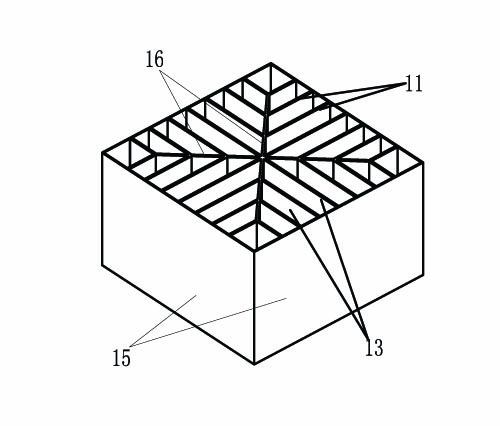

Data center immersed-type liquid-cooling cabinet based on heat pipe technology

InactiveCN108124408AReduce energy consumptionReduce local hot spotsCooling/ventilation/heating modificationsData centerEngineering

The invention discloses a data center immersed-type liquid-cooling cabinet based on the heat pipe technology. A plurality of added cooler cabinets are vertically arranged outside a first side wall ofthe liquid-cooling cabinet. A plurality of server groups are disposed in a length direction parallel to the first side wall at a staggered manner, and are closely attached to the first side wall and asecond side wall facing the first side wall at intervals so as to form a first flow channel. A first refrigerant circulation pipe is communicated with the first flow channel. The interior of each added cooler cabinet is vertically provided with a plurality of heat pipe groups, and each heat pipe group comprises a plurality of horizontal heat pipes. A part of heat pipes stretch into the liquid-cooling cabinet, and are fixedly connected to the added cooler cabinets in a sealed manner. The interior of each added cooler cabinet forms a second flow channel through the gaps between the heat pipes,and a second refrigerant circulation pipe is communicated with the second flow channel and is connected with a refrigerating machine. The liquid-cooling cabinet can quickly dissipate the heat of a server, reduces local hotspots of the cabinet, improves the overall heat dissipation efficiency of a machine room, and reduces the energy consumption of a data center heat dissipation system.

Owner:CENT SOUTH UNIV

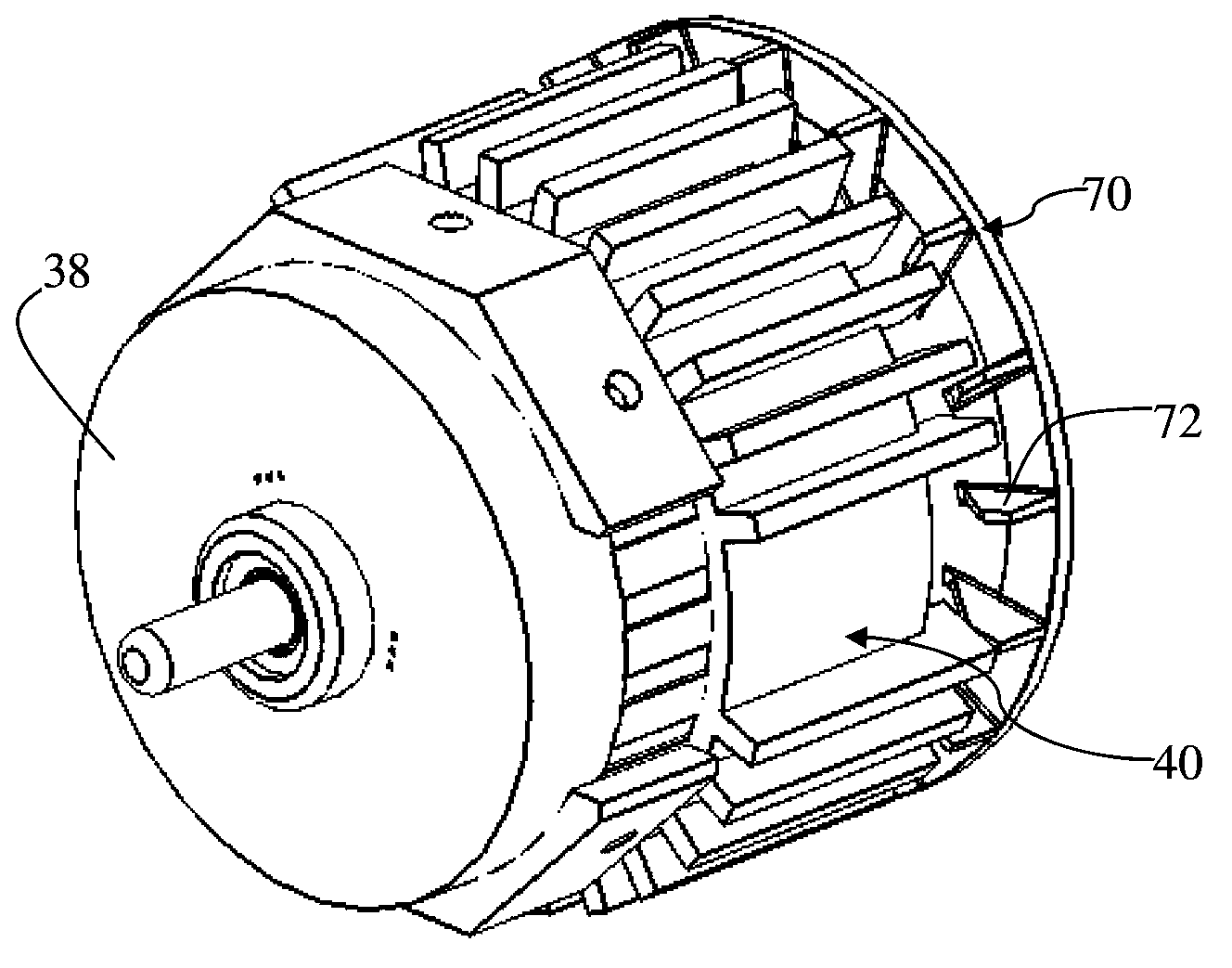

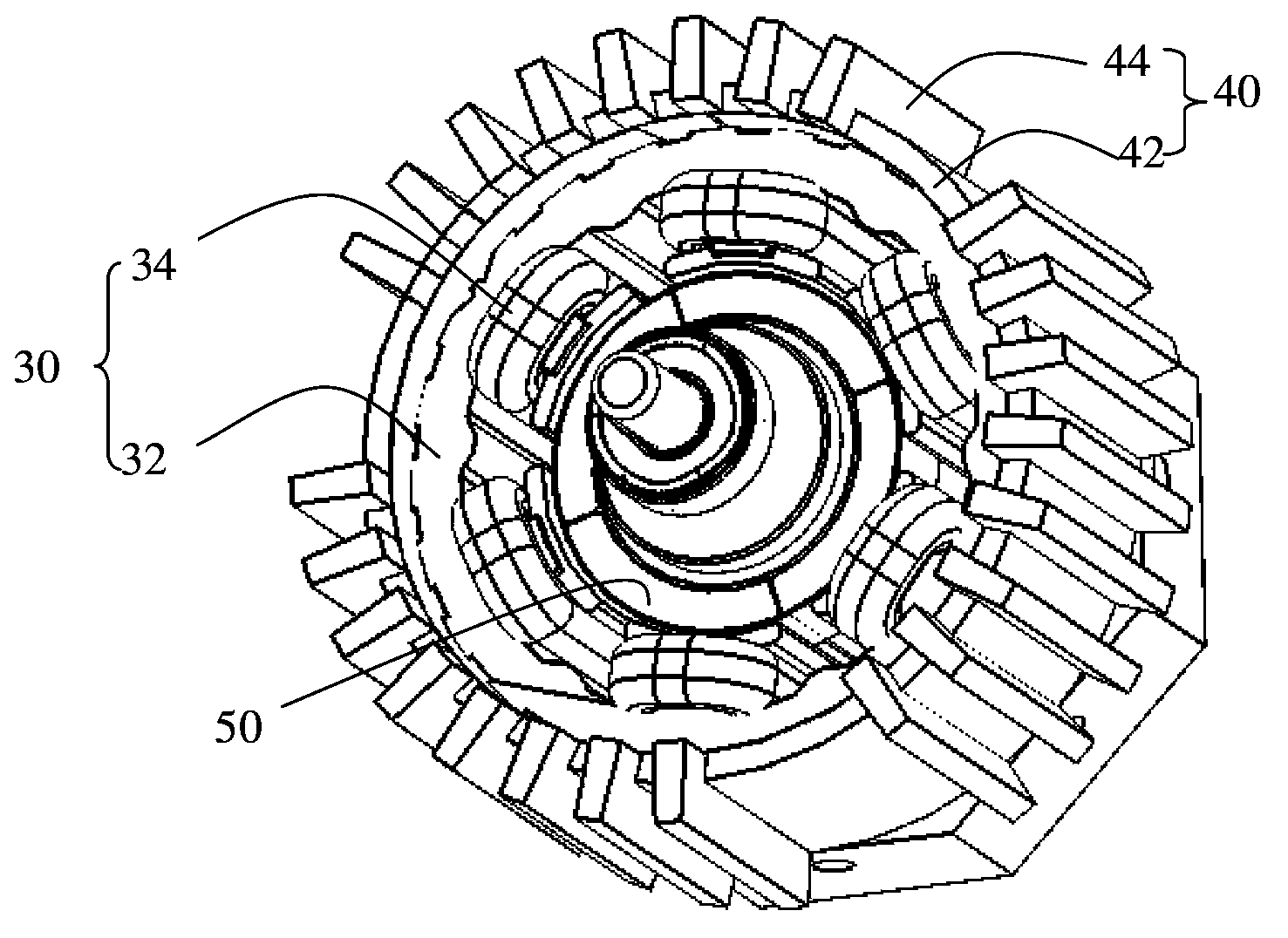

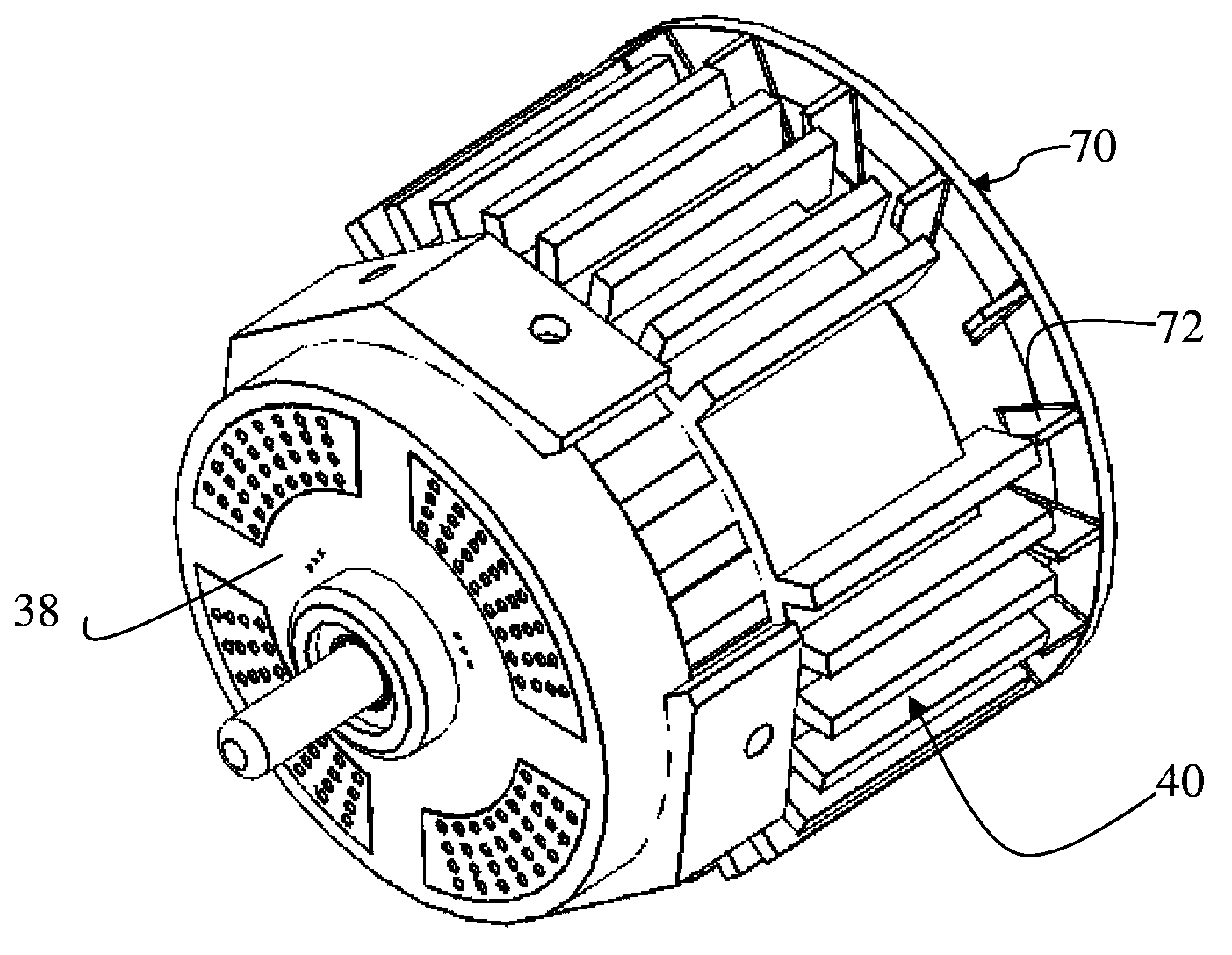

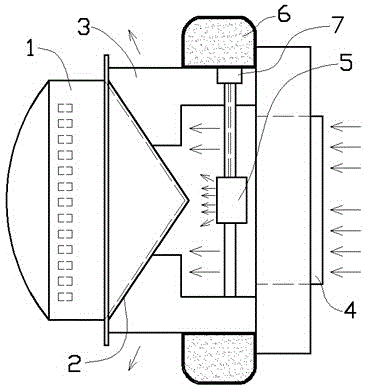

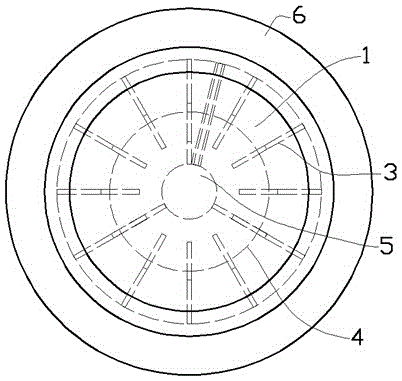

Motor assembly and household appliance comprising motor assembly

InactiveCN104079119ATake away quicklyCooling/ventillation arrangementSupports/enclosures/casingsHeat sinkCentrifugal force

A motor (10) comprises a stator (30) and a rotor (50) configured to rotate inside the stator (30). A heat sink (40) has a base portion (42) disposed around and thermally connected to an outer surface of the stator (30) and a plurality of cooling fins (44) extending from the base portion (42). A centrifugal fan (70) is attached to one end of an output shaft (52) of the rotor (50), positioned such that the heat sink (40) is near an axial end of the fan (70). During operation, the centrifugal fan (70) generates an air flow over the heat sink (40), thus providing cooling for the motor (10).

Owner:JOHNSON ELECTRIC SHENZHEN

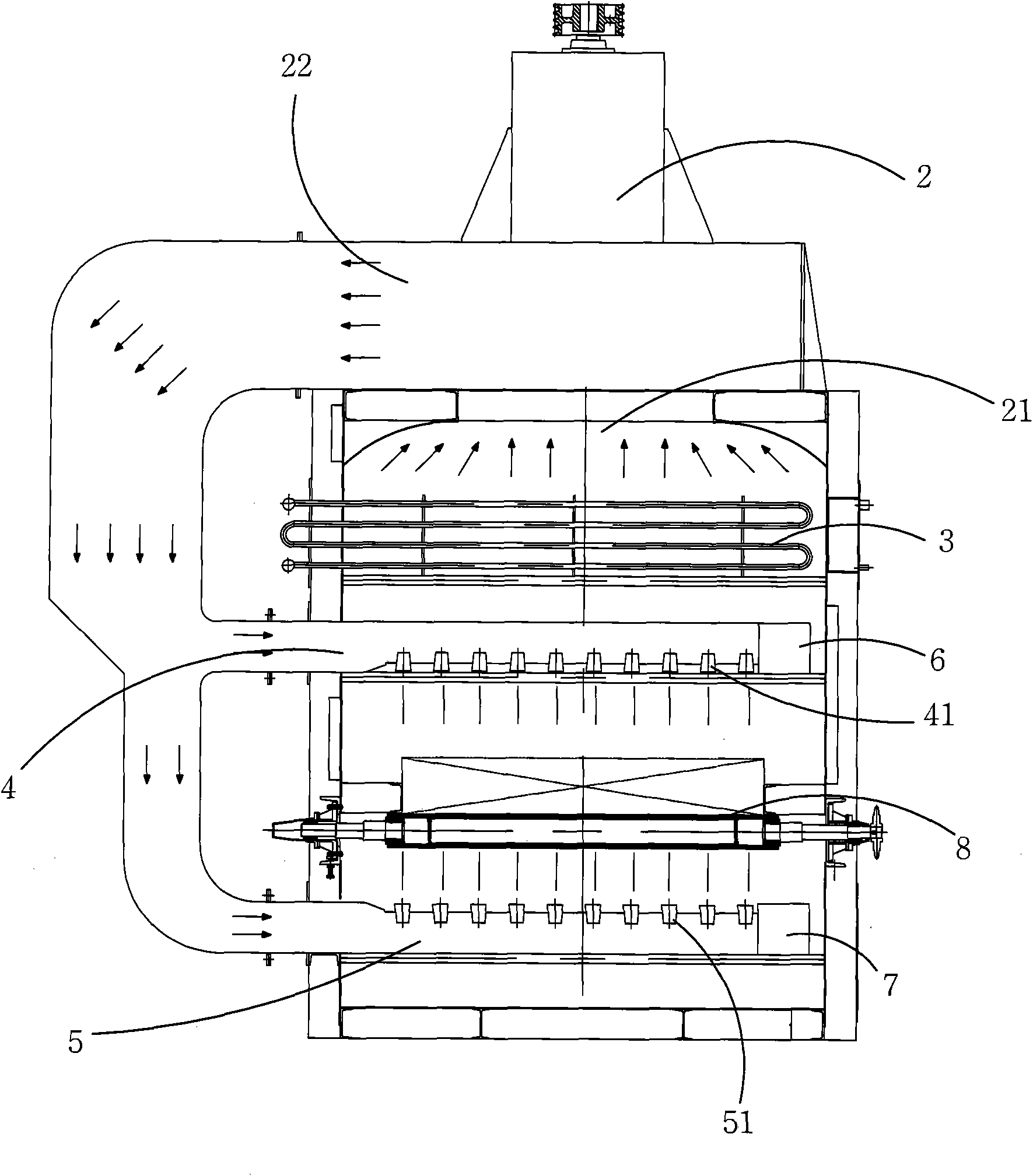

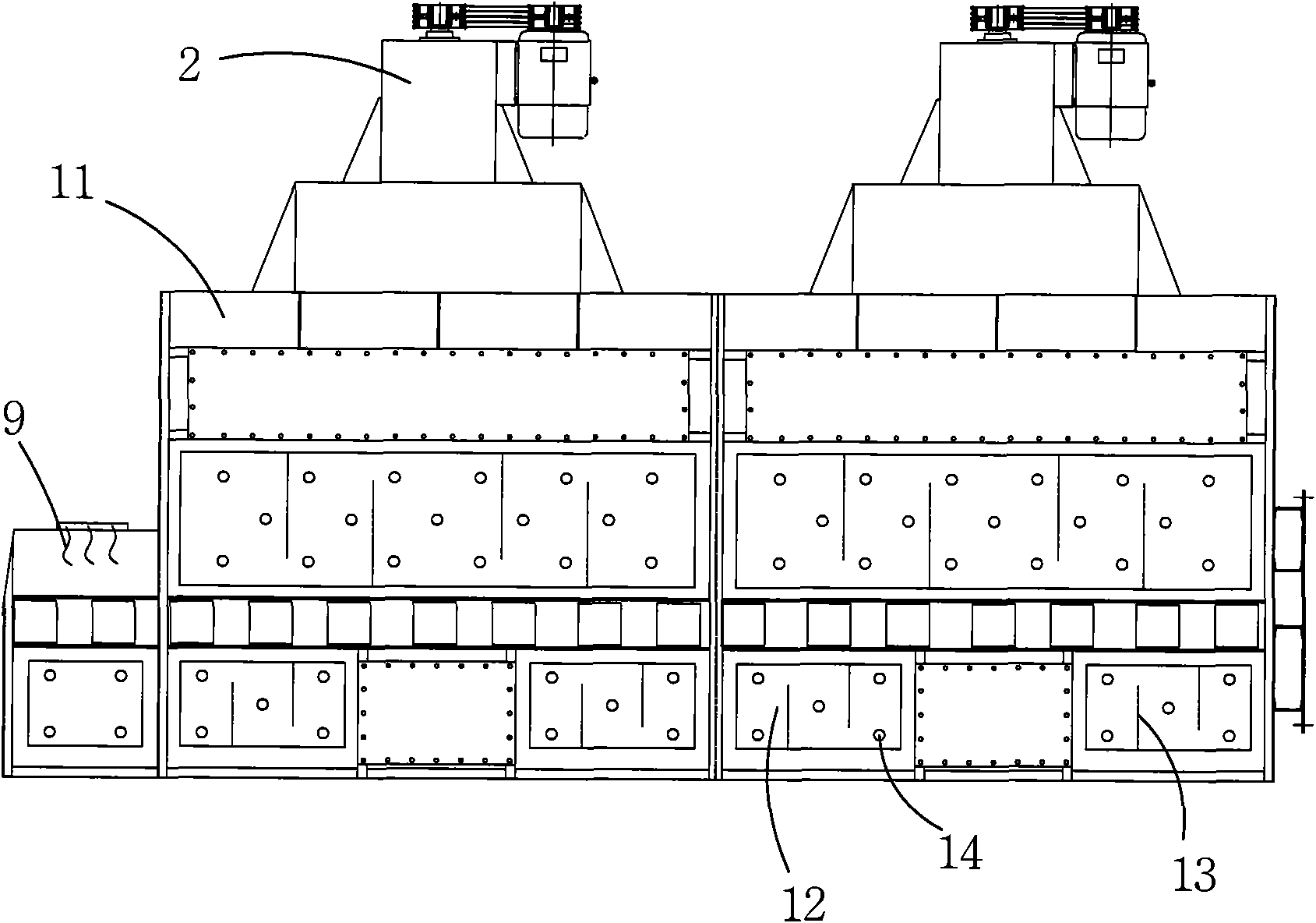

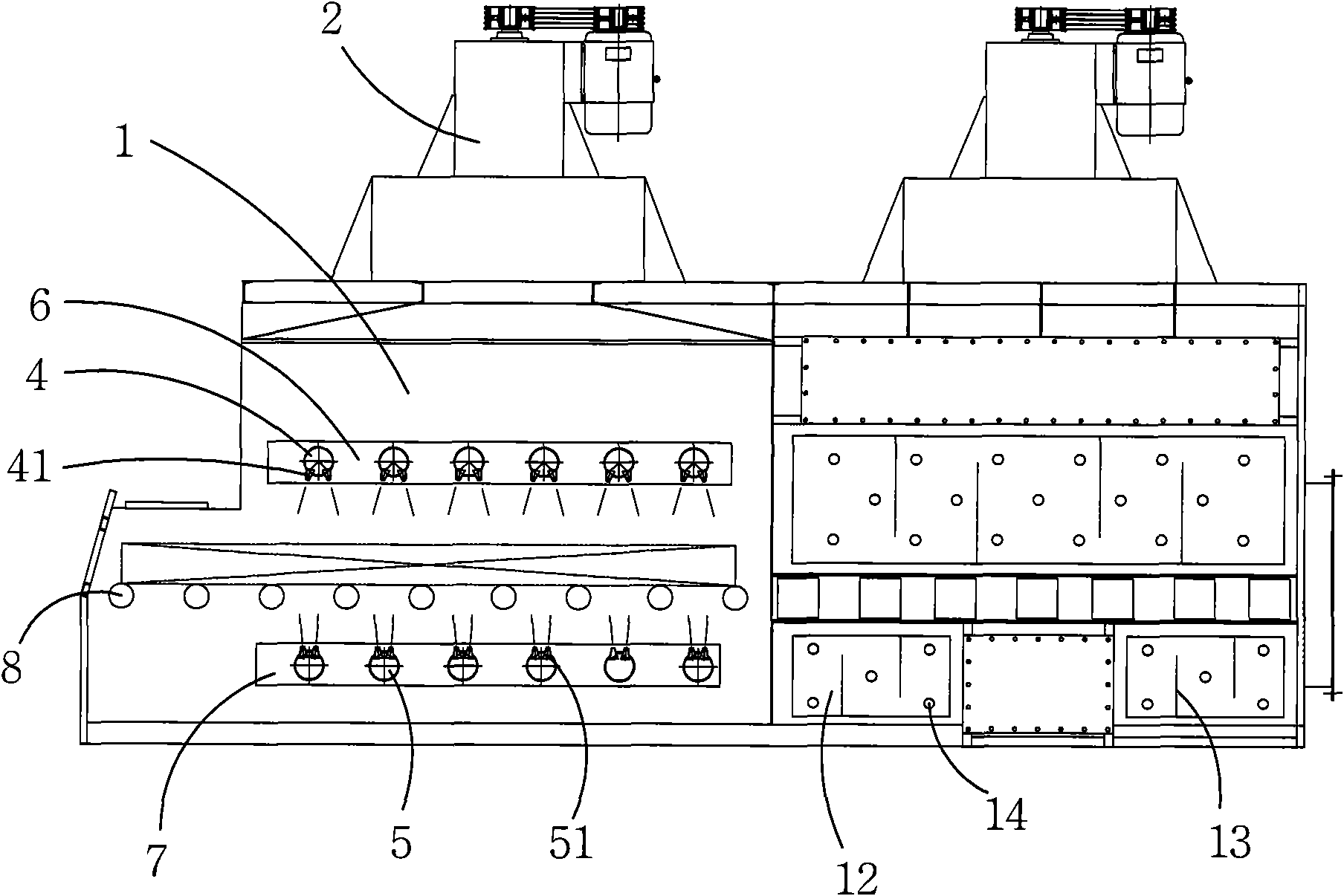

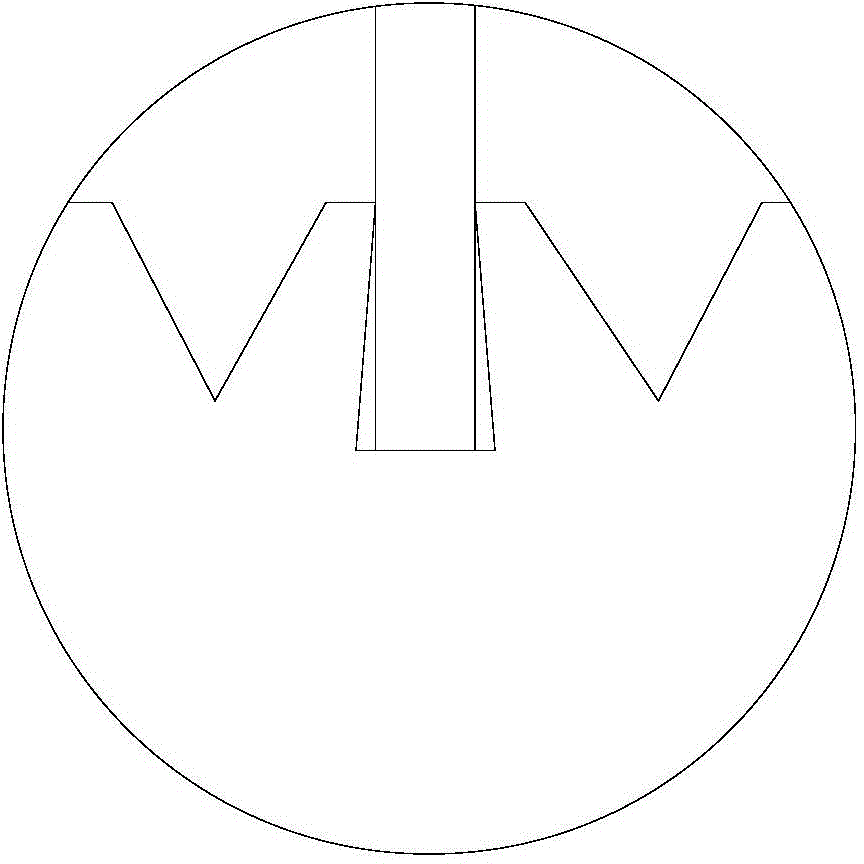

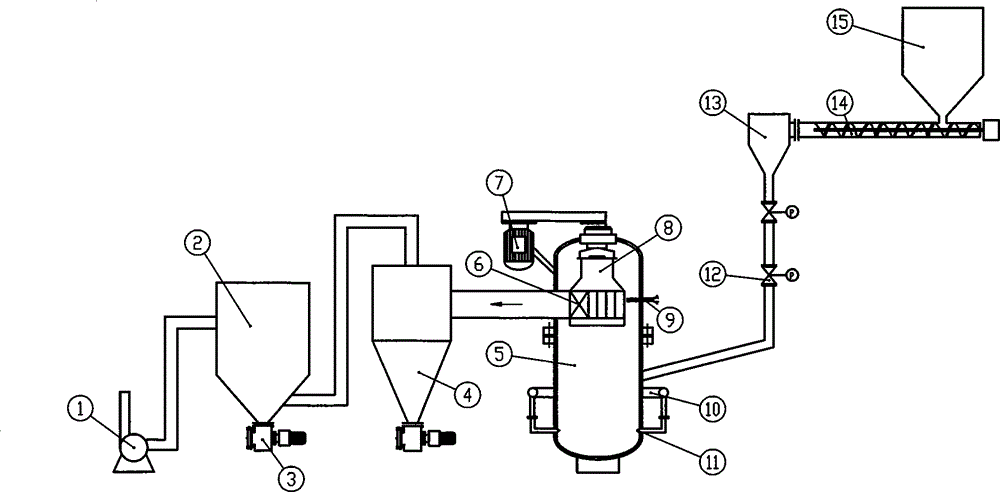

Strong loop quick cooling chamber

The invention relates to a strong loop quick cooling chamber, comprising a wind cooling chamber which is composed by a outer shell, a feed port and a discharge port are arranged on the both ends of the wind cooling chamber, a horizontal production line is arranged between the feed port and the discharge port, a plurality of upcast ventilation pipes and downcast ventilation pipes are arranged inside the wind cooling chamber. The upcast ventilation pipes and downcast ventilation pipes are separately arranged at the upper side and the lower side of the horizontal production line, a plurality of top nozzles which can jet air down are arranged on the upcast ventilation pipes, a plurality of lower nozzles which can jet air up are arranged on the downcast ventilation pipes, a gas circulator is arranged in the wind cooling chamber, an air inlet opening of the gas circulator is communicated with the wind cooling chamber, an air outlet opening of the gas circulator is communicated with the interior of the upcast ventilation pipes and downcast ventilation pipes, a built-in heat exchanger is arranged at the air inlet opening of the gas circulator. By arranging ventilation pipes on the upward side and lower side of the horizontal production line, strong convection can be formed by the cold air which is jeted from the nozzles of the upcast ventilation pipes and the downcast ventilation pipes and the heat on the devices can be quickly removed.

Owner:SUZHOU ZHONGMENZI TECH

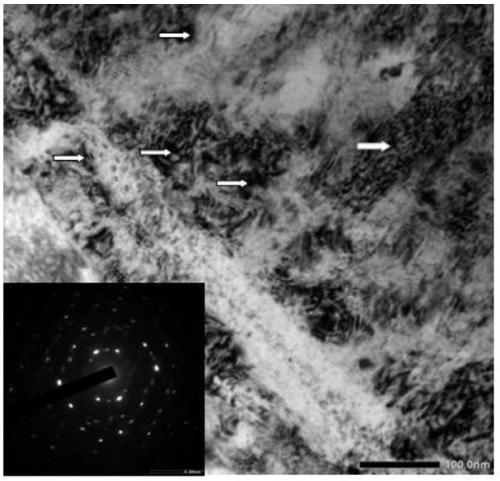

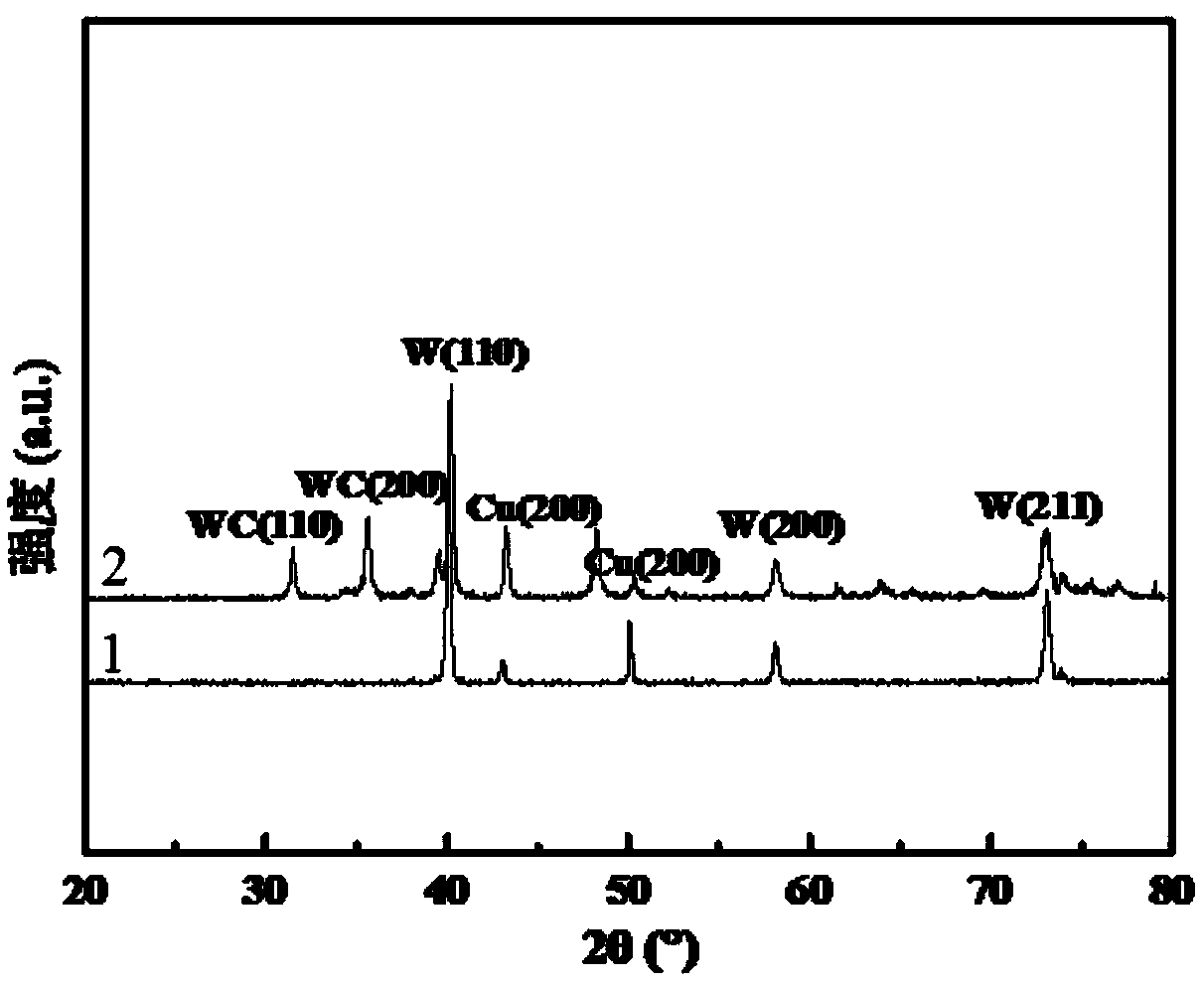

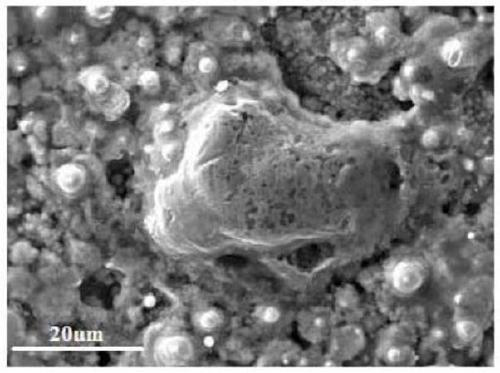

Method for synergistically improving arc ablation performance of CuW contact material

ActiveCN108950279AImproved arc ablation performanceImprove protectionContactsElectrolysisMaterials science

The invention discloses a method for synergistically improving the arc ablation performance of a CuW contact material. The method comprises the steps that firstly, spherical electrolytic copper powderis rolled into a sheet, then reduced tungsten powder is added for ball milling, even mixing is conducted, and tungsten-copper modified mixed powder is obtained; secondly, expanded graphite is sequentially subjected to low temperature intercalation oxidation, medium temperature intercalation oxidation and high temperature intercalation oxidation, and graphene oxide is obtained; thirdly, the tungsten-copper mixed powder and the graphene oxide are added into an ethanol-water mixed solution to be mixed evenly, drying is conducted, graphene oxide / tungsten-copper composite powder is obtained and then subjected to low-temperature thermal reduction, and reduced graphene oxide / tungsten-copper composite powder is obtained; and fourthly, the reduced graphene oxide / tungsten-copper composite powder issubjected to discharge plasma liquid phase sintering, and the CuW contact material is obtained. The graphene oxide is added into the tungsten-copper modified mixed powder, thermal reduction is conducted at first, the reduced graphene oxide is obtained, then discharge plasma liquid phase sintering is conducted, tungsten carbide nanoparticles are generated, and the arc ablation performance and mechanical performance of the CuW contact material are synergistically strengthened through the reduced graphene oxide and the tungsten carbide nanoparticles.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Low voltage high-power threephase asynchronous motor

InactiveCN101764486AAvoid damageImprove reliabilityAsynchronous induction motorsCooling/ventillation arrangementGlass fiberPunching

The invention relates to a low voltage high-power three-phase asynchronous motor. According to the technical scheme of the invention, a front end cover and a back end cover are installed at both ends of a motor base, a stator is installed in the motor base, and is fixed on the front end cover and the back end cover, the stator is connected with a junction box, a rotor is installed in the motor base, the front end and the back end of the rotor are installed on the front end cover and the back end cover by a front bearing and a back bearing, the front bearing and the back bearing are fixed by an external bearing cover, an internal bearing cover and a bearing retainer ring, an external fan is installed at the tail end of the rotor and is fixed by the bearing retainer ring, an external fan shield is fixed on the back end cover, and a key is installed in a key slot at the front of the rotor. The invention has the characteristics that the stator punching is made of silicon steel, a stator winding is made by adopting modified high strength polyester paint to coat circular copper wires in double-layer lap wound embedding mode, and the end part of the stator winding is coated by epoxy glass fiber tapes. The invention has reasonable stator winding, good safety, skillful complete motor structure, good heat dispersion, low running noise, high intensity and safe and smooth operation.

Owner:SEC ELECTRIC MACHINERY

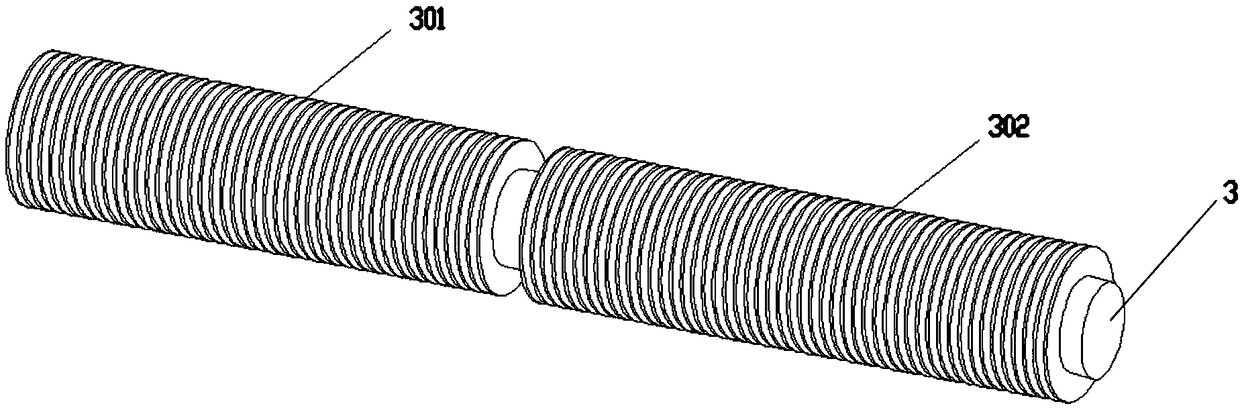

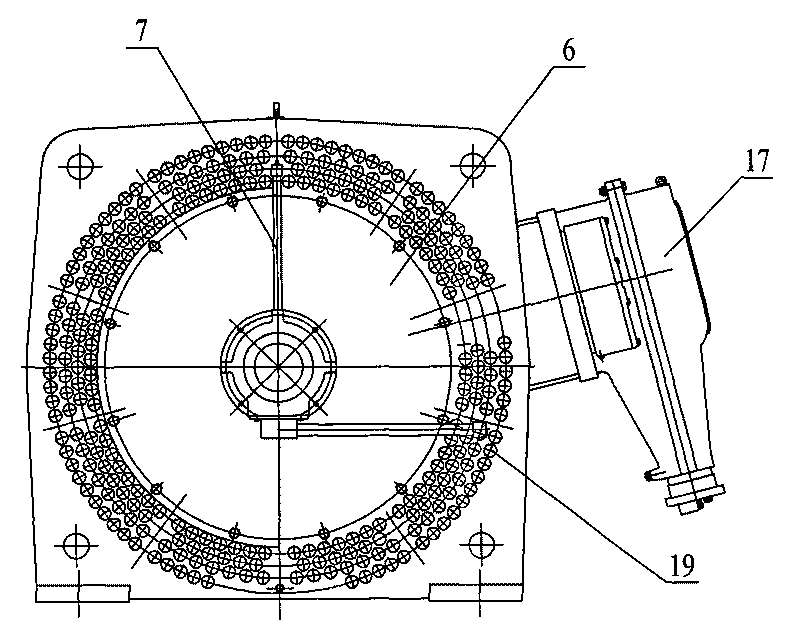

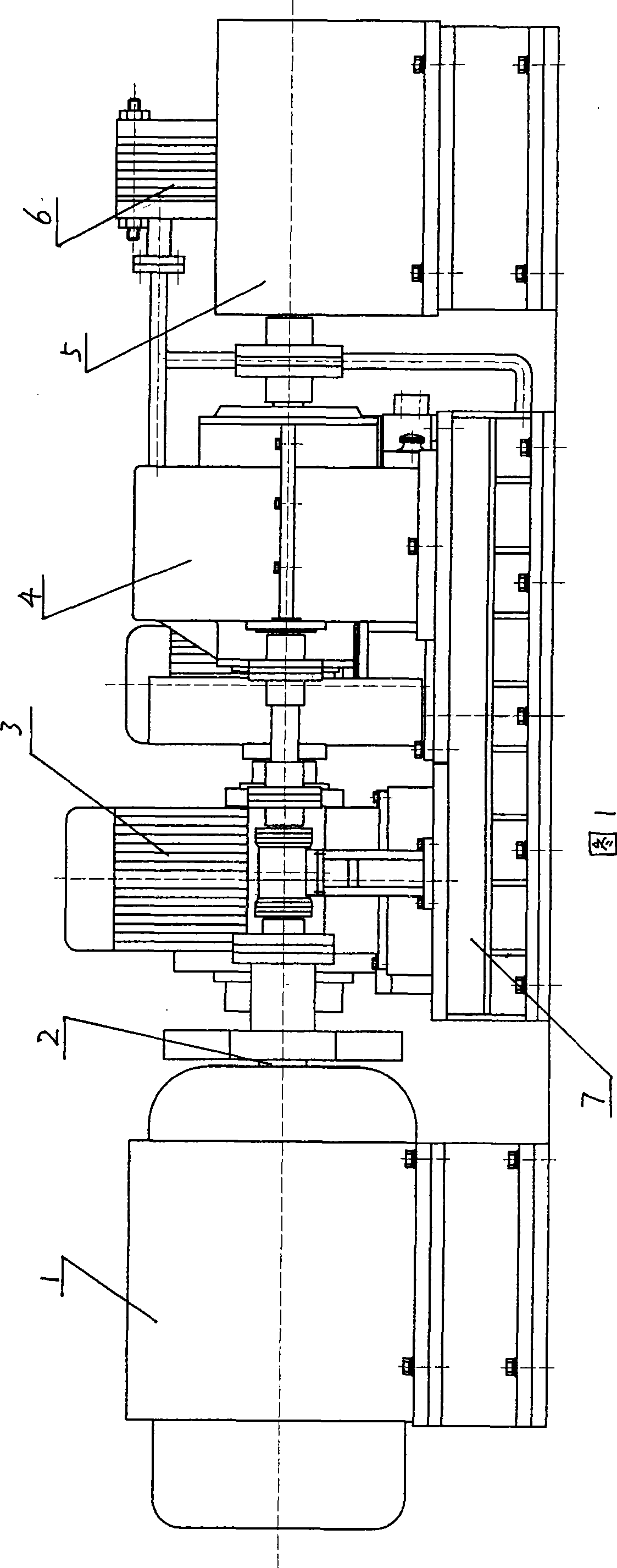

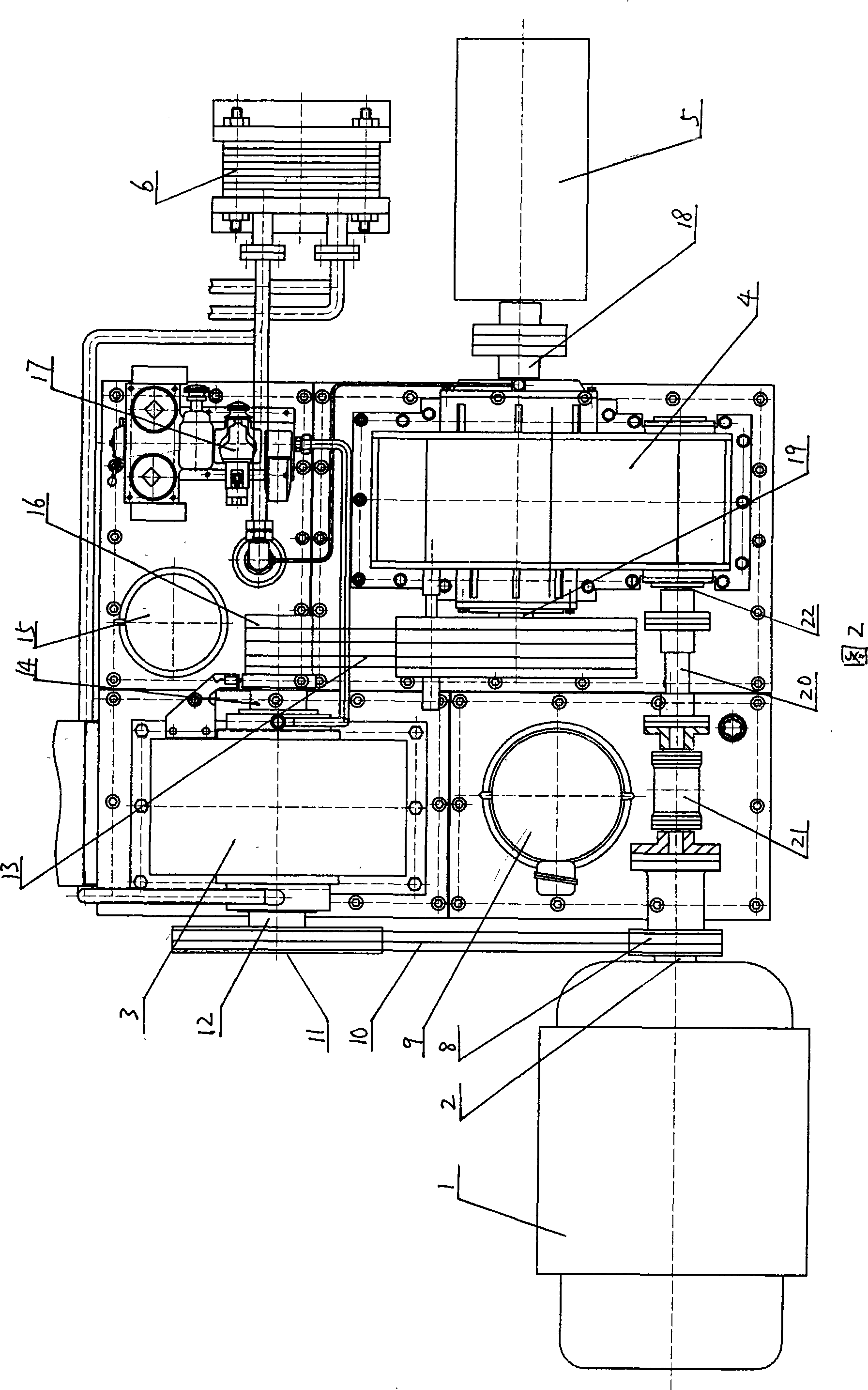

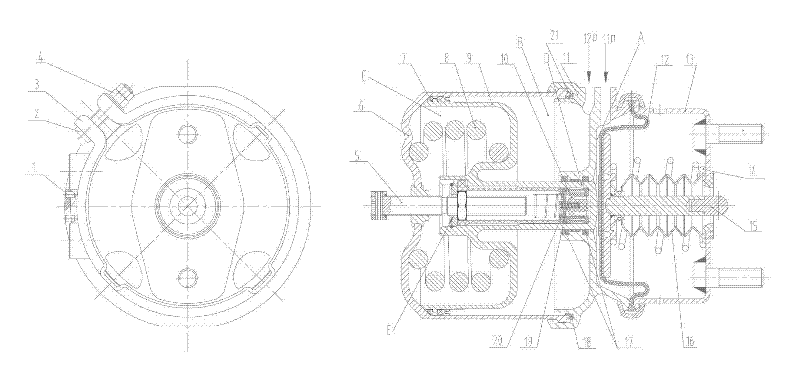

Liquid sticky planetary speed regulating device

InactiveCN101440865ATake away quicklyReduce volumeGearing controlFluid gearingsTransmission beltDrive shaft

The invention discloses a liquid viscous planetary speeder which comprises a liquid viscous speed regulating system and a planetary speed regulator; outer teeth are arranged on an outer gear sleeve of the planetary speed regulator; teeth of a gear shaft are engaged with the outer teeth of the outer gear sleeve; the gear shaft is rotatably positioned on a gear box body; an output shaft of a prime motor is directly connected with the gear shaft of the planetary speed regulator through a direct coupling shaft and a connecting shaft; a transmission wheel is arranged on the output shaft of the prime motor and is connected with a synchronizing transmission wheel of a drive shaft of a speed regulator core of the liquid viscous speed regulator through a transmission belt or a chain; a transmission wheel of an output shaft of the speed regulator core is connected with an input shaft of the planetary speed regulator through the belt or the chain; and an output shaft of the planetary speed regulator is connected with a main shaft of a loading machine. The liquid viscous planetary speeder realizes the aim of using the small-power liquid viscous speed regulator to control the large-power loading machine and has the advantages of small size, small occupied area, simple structure, low cost and reliable operation.

Owner:AVIC HUIYANG AVIATION PROPELLER +1

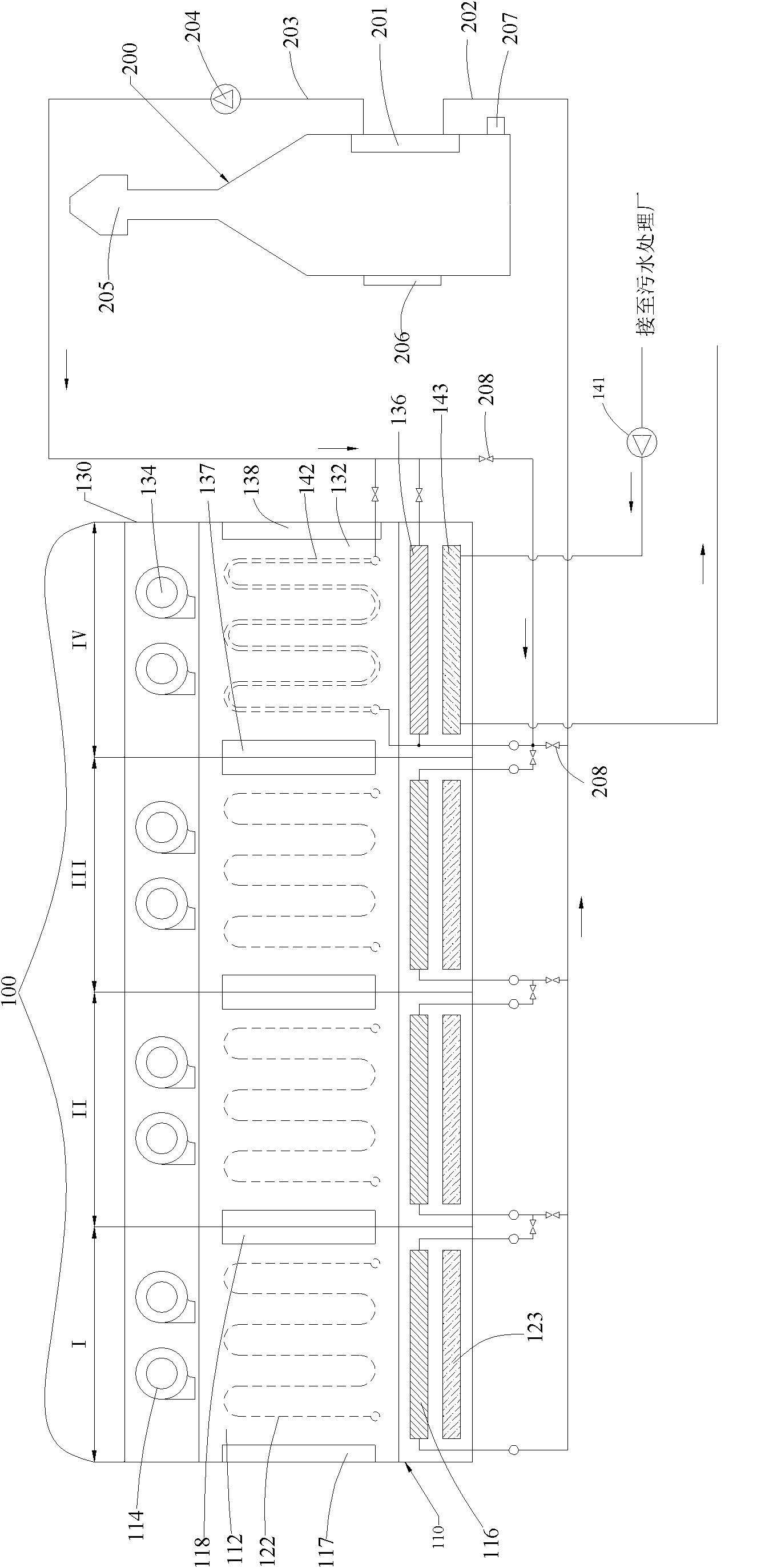

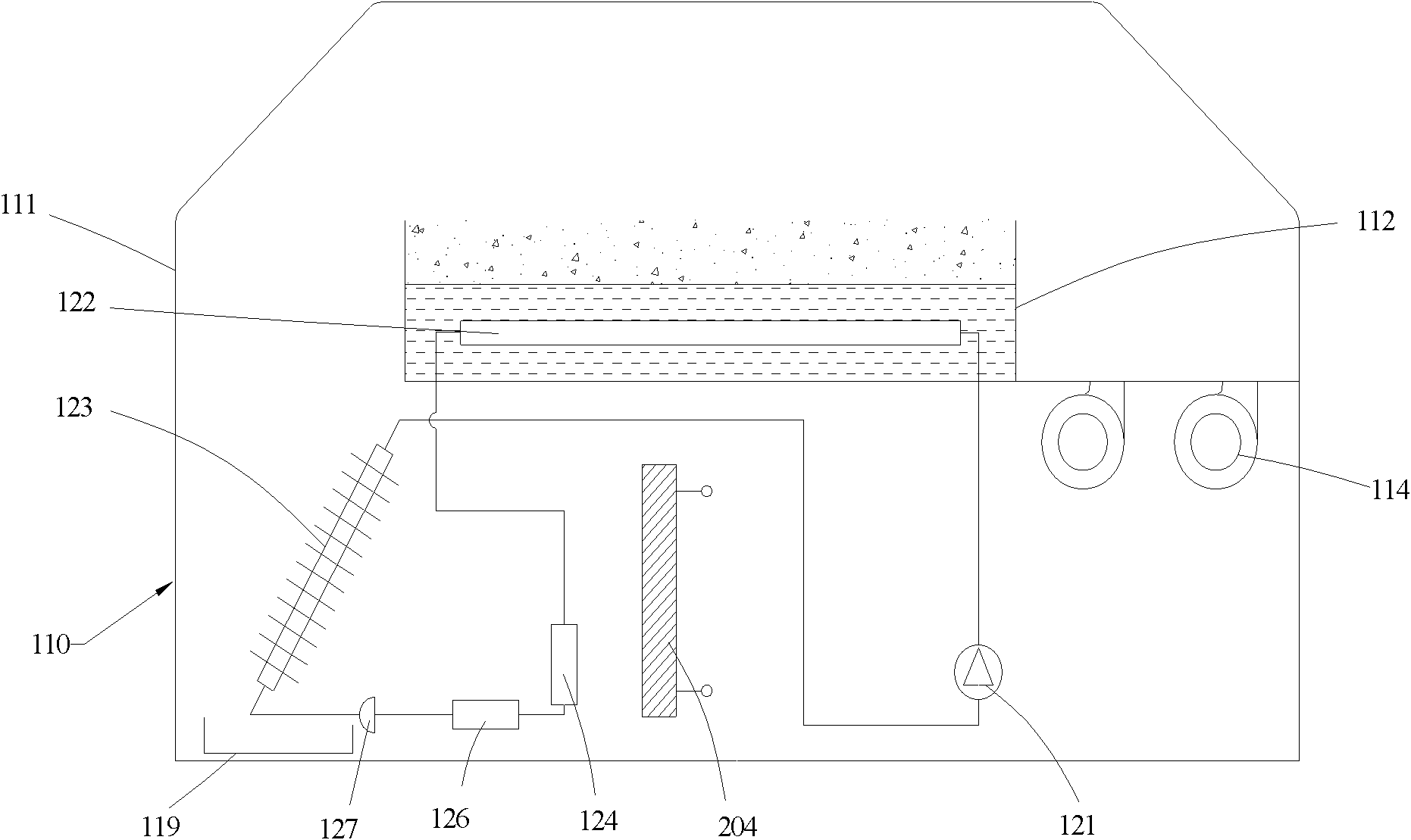

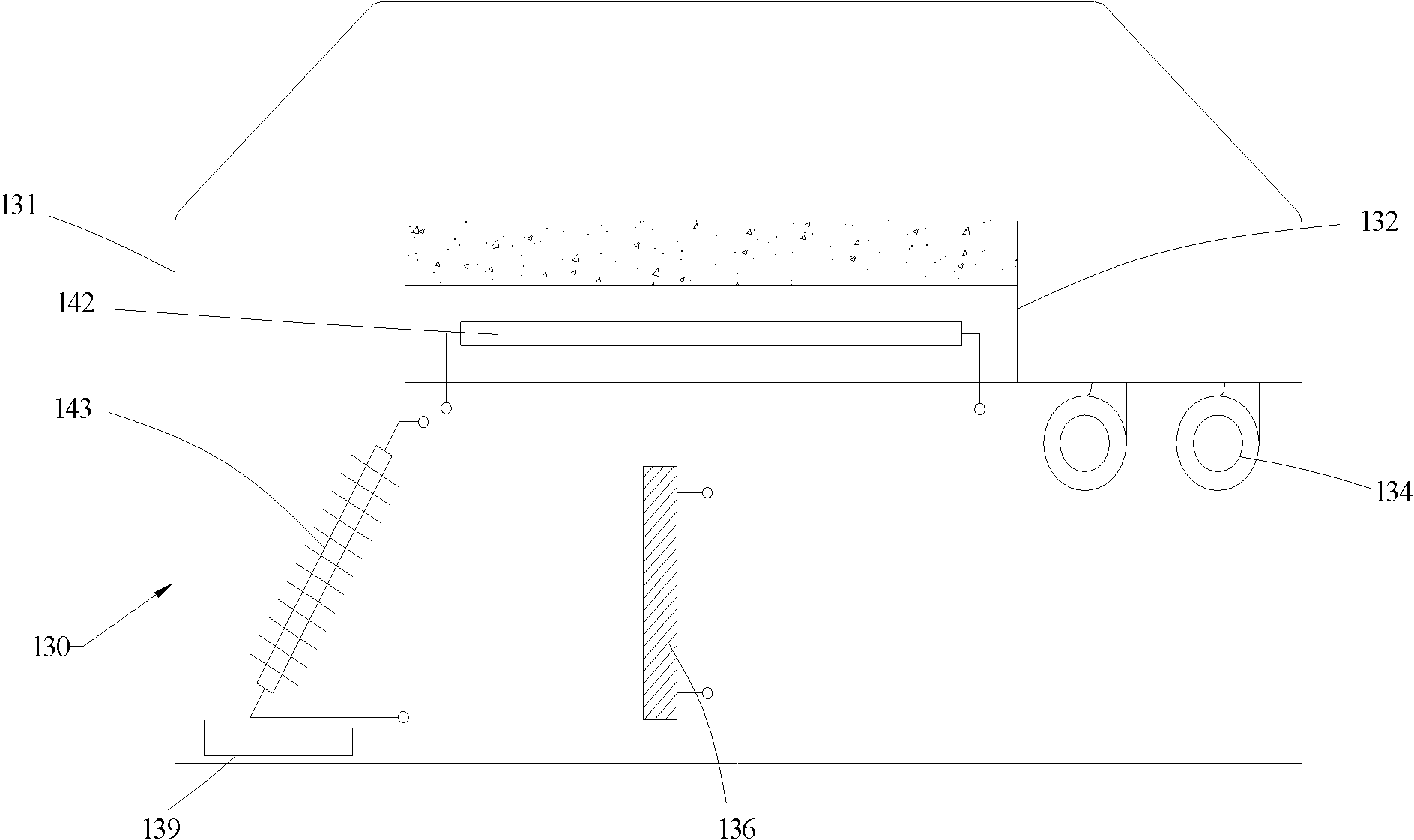

Sludge drying and incinerating system, sludge drying machine and sludge drying method

InactiveCN102180578AFast and energy-saving dryingImprove drying efficiencySludge treatment by de-watering/drying/thickeningIncinerator apparatusHeat conductingSludge

The invention relates to a sludge drying and incinerating system, which comprises a sludge drying machine and a heat source, wherein the sludge drying machine comprises at least one first sludge drying module; the first sludge drying module comprises a first enclosed shell, a first heat conducting sludge support plate, a scraping mechanism, a first fan, an evaporating and condensing device and a first surface cooler which is connected with the heat source; and the evaporating and condensing device comprises a compressor, a condenser and an evaporator which are connected to form a loop, a cold medium in the loop and a drainer. Heat is transferred to the first sludge support plate by the condenser to heat sludge; air is supplied by the first fan to form evaporation-accelerated air current on the surface of the sludge; circulating air is condensed and dehydrated by the evaporator; and the sludge can be dried quickly by hot air with low moisture content in an energy-saving way. Moreover, a plurality of first sludge drying modules a plurality of second sludge drying modules can be connected together and combined segmentally for drying, so that the sludge drying rate is effectively increased and the water content of sludge is lowered.

Owner:SHENZHEN WATECH

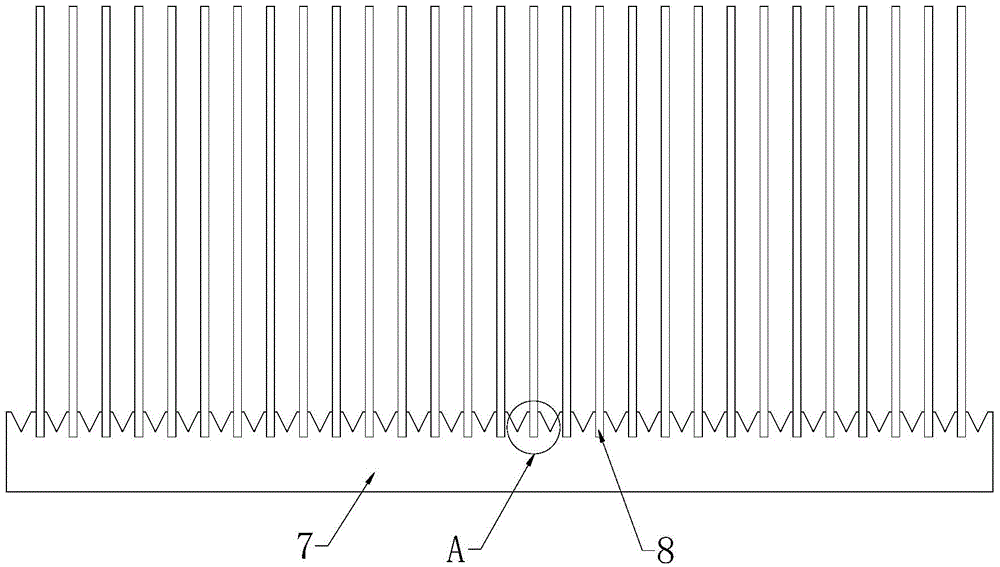

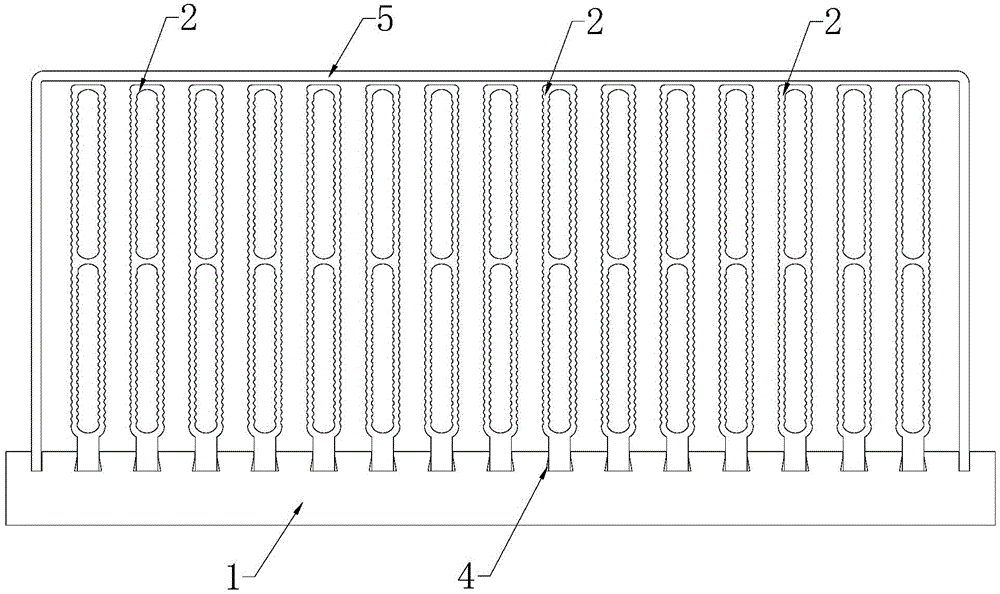

Air-cooling radiator and manufacturing method thereof

InactiveCN103987236ASmall temperature deviationReduce thermal resistanceCooling/ventilation/heating modificationsEngineeringHeat spreader

The invention discloses an air-cooling radiator and a manufacturing method thereof. The air-cooling radiator comprises a thermal conduction substrate and cooling fins. Fin insertion grooves are formed in the thermal conduction substrate. A connecting end of each cooling fin is fixed in the corresponding fin insertion groove in the thermal conduction substrate. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is filled with a thermal conduction medium. An air passing passageway is further formed in each cooling fin. The space between the connecting end of each cooling fin and the corresponding fin insertion groove is further filled with the corresponding thermal conduction medium, thermal resistance between the thermal conduction substrate and the cooling fins can be reduced through the thermal conduction mediums, thermal conduction is facilitated, and the heat dissipation effect of the air-cooling radiator is improved; the cooling fins can be more tightly attached to the side walls of the fin insertion grooves, and therefore thermal resistance can be further reduced; by the adoption of the design of the air passing passageways, air from an external fan can flow through the space outside the cooling fins and the air passing passageways, so that the inner portion and the outer portion of the cooling fins are fully cooled, and heat on the cooling fins can be rapidly taken away.

Owner:深圳市华盛源机电有限公司

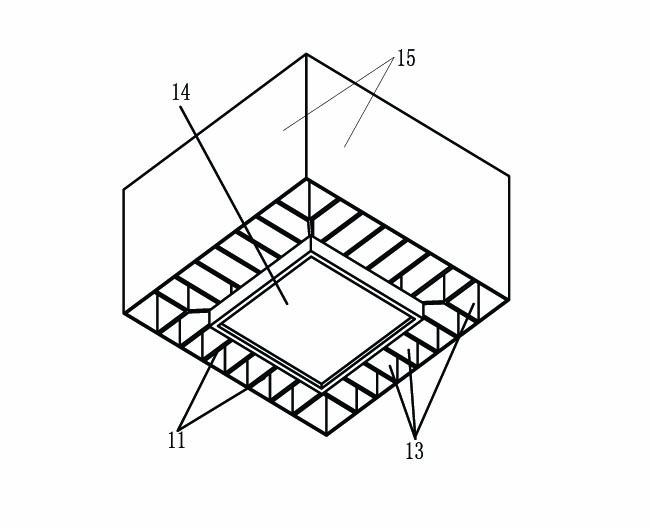

Vertical convector radiator and vertical convector radiating down lamp

ActiveCN102221189AAvoid heat island effectImprove heat dissipationLighting heating/cooling arrangementsElectric lightingUrban heat islandEngineering

The invention discloses a vertical convector radiator and comprises a vertical convector radiating down lamp of the vertical convector radiator. The vertical convector radiator comprises light source installation parts and a plurality of heat radiating fins of which the lower ends are connected with the light source installation parts in a heat conducting mode, wherein the vertical convector radiator comprises a plurality of convection passageways which penetrates through and is vertical to the upper surface and the lower surface of the convector radiator. When the vertical convector radiator in the technical scheme adopted operates, the lower end of the heat dissipation rectangular fin continuously heats the neighbouring air and the air rises, simultaneously, the neighbouring cold air can continuously complement to generate convection, thus the vertical convector radiator of the specific implement method can form a higher air velocity field even under the passive voice radiating condition, full heat exchange is generated between the cold air and the heat dissipation rectangular fin surface of the vertical convector radiator, the heat is rapidly take away, thereby avoiding the generation of the heat island effect in the bottom of the radiator, and the heat dissipation capacity is greatly improved.

Owner:KINGSUN OPTOELECTRONIC CO LTD

LED lamp with radiating structure

InactiveCN101713530AReduce the temperatureExtended service lifePlanar light sourcesPoint-like light sourceHeat conductingEngineering

The invention relates to a light emitting diode (LED) lamp with a radiating structure, comprising a radiator, a printed circuit board (PCB)and an LED light source arranged on the PCB. The radiator comprises a radiating base and a plurality of radiating posts distributed on the surface of the radiating base; the inner parts of the radiating posts are provided with hollow cavities; a heat conducting unit is arranged between the PCB and the radiator; the heat conducting unit is provided with heat conducting posts which can be inserted into the hollow cavities; and the heat conducting posts are contacted with the cavity wall of the hollow cavities. Because the heat conducting posts can be inserted into the inner part of the hollow cavities and are contacted with the cavity wall of the hollow cavities, the heat released by the LED light source on the PCB plate can be fast conducted to the radiator, and the heat can be fast radiated through the surface of the radiating posts, thereby reducing the temperature of the entire LED lamp, and prolonging the service life of the LED lamp. In addition, by adopting the rhombohedral radiating posts, natural wind can flow in any directions, and the heat can be fast taken away.

Owner:HUA TECH ZHUHAI IND CO LTD

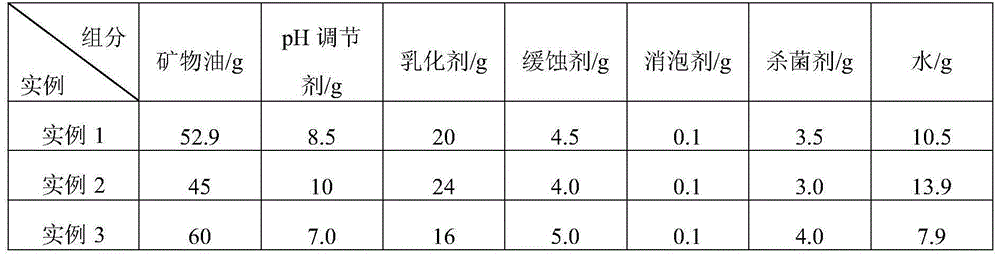

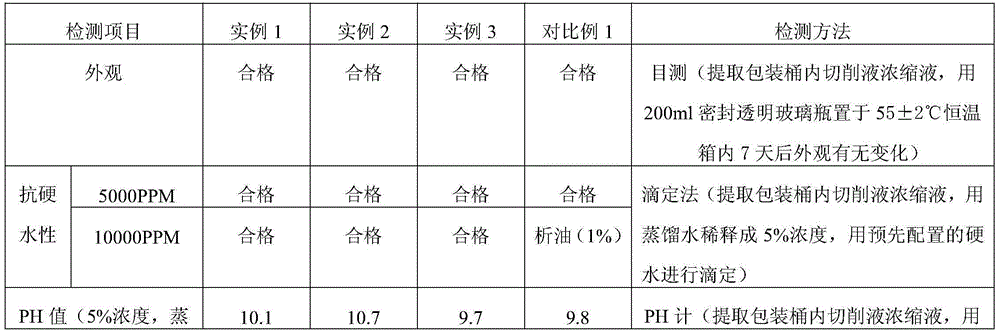

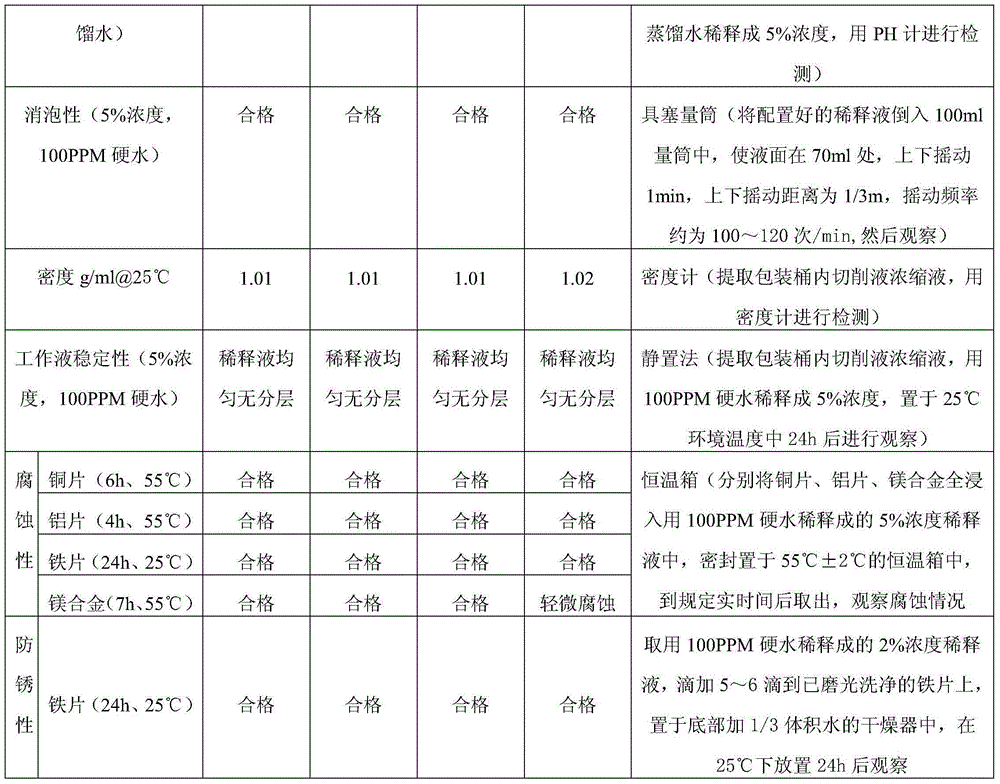

Semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting

InactiveCN105087129AImprove wear resistanceImprove hard water resistanceLubricant compositionHard waterSemi synthetic

The invention relates to semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting, comprising, by weight, 40 to 60 parts of mineral oil, 4 to 13 parts of pH regulator, 12 to 30 parts of emulsifier, 2.5 to 5 parts of corrosion inhibitor, 0.5 to 1.5 parts of stabilizer, 0.01 to 0.2 part of defoamer, 2 to 4 parts of sterilizing agent, and 5 to 20 parts of water. The semisynthetic micro-emulsified cutting fluid is good in abrasion resistance, hard water resistance and magnesium alloy corrosion resistance, is super-long in service life; adding the semisynthetic micro-emulsified cutting fluid for magnesium alloy cutting is required only, while replacing is not required.

Owner:深圳市奥科宝特种油剂有限公司

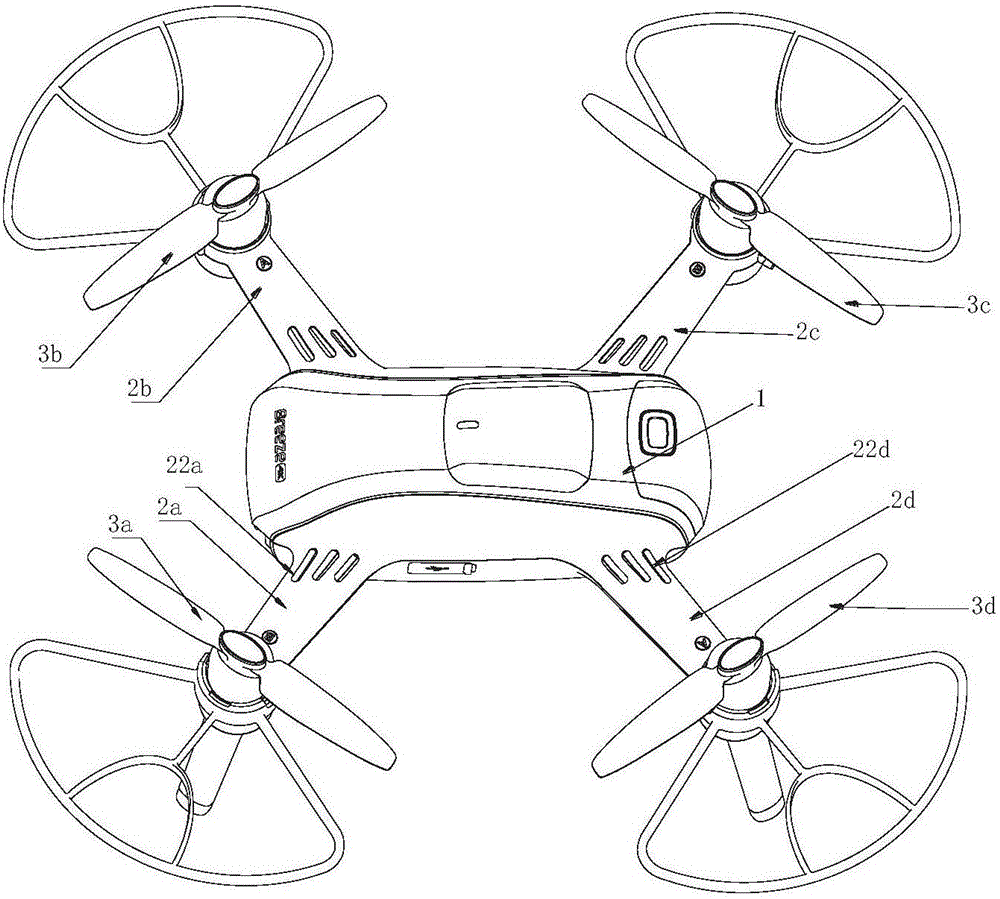

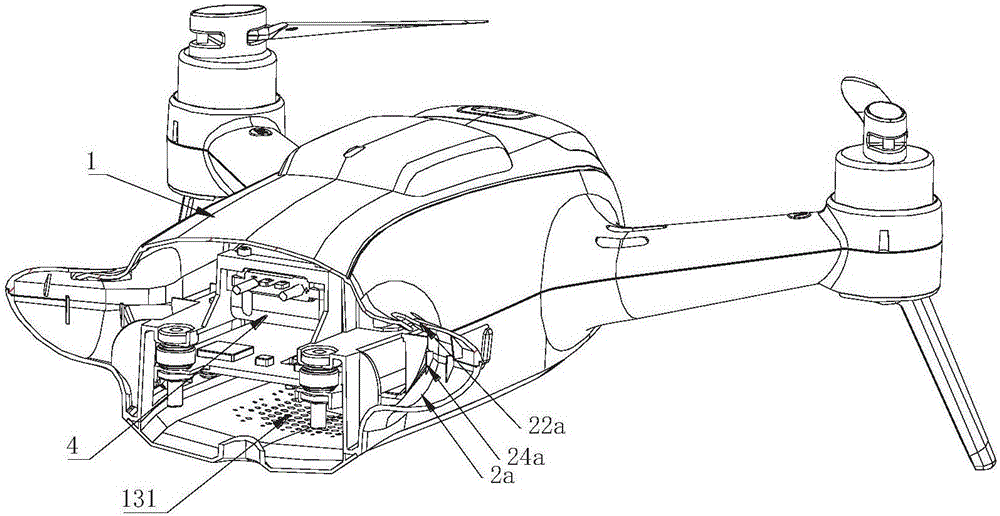

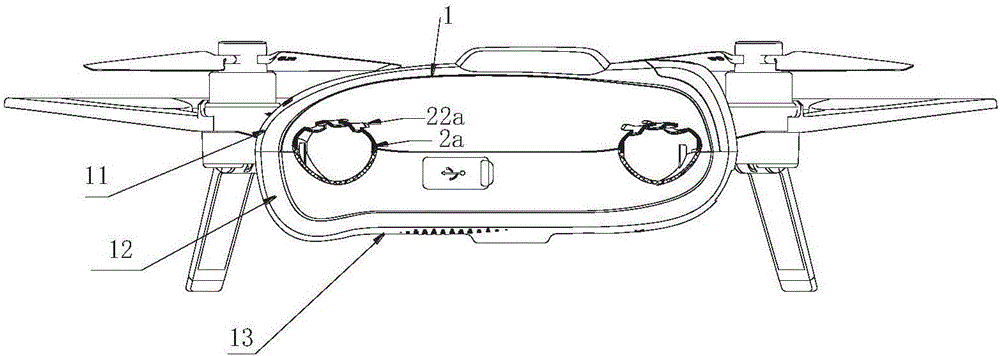

Cooling air path system of unmanned aerial vehicle

InactiveCN106672225AEfficient physical coolingExempt from usingAir-treatment apparatus arrangementsRotocraftUncrewed vehicleSource area

The invention provides a cooling air path system of an unmanned aerial vehicle. The cooling air path system comprises an airflow source, air guiding holes, an air path and air outlets, wherein the airflow source is generated by rotation of paddles on all vehicle arms, the air guiding holes are formed in the portions, corresponding to paddle tail rotating areas, of the top faces of all the vehicle arms, the air path is a gap channel between the inner wall of a vehicle body and internal modules of the vehicle body, and the air outlets are formed in the position, corresponding to a heating source area, of the bottom of the vehicle body. The airflow source guides airflow into the inner sides of the vehicle arms through the air guiding holes, and the airflow enters the air path, flows through the heating source area and then is exhausted from the air outlets. The cooling air path system of the unmanned aerial vehicle is good in whole vehicle cooling performance and low in noise.

Owner:YUNEEC INT (CHINA) CO LTD

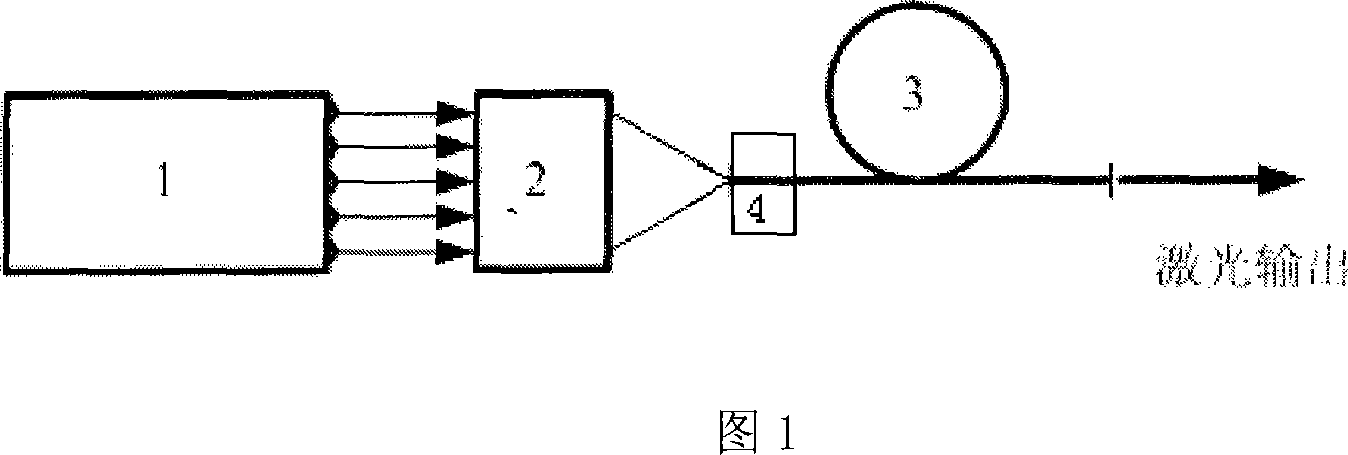

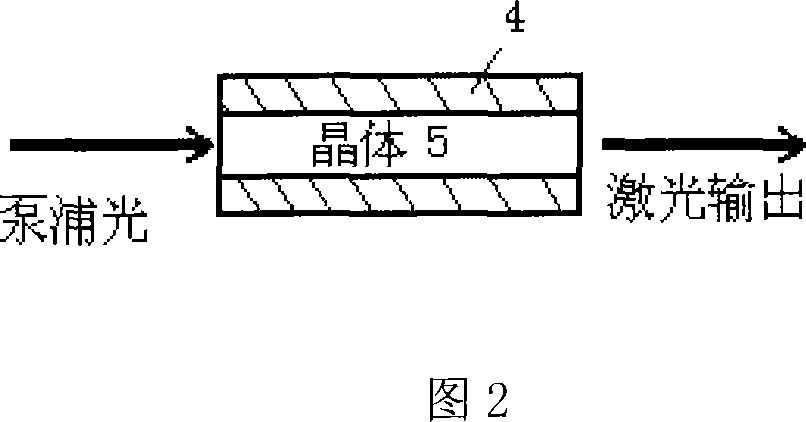

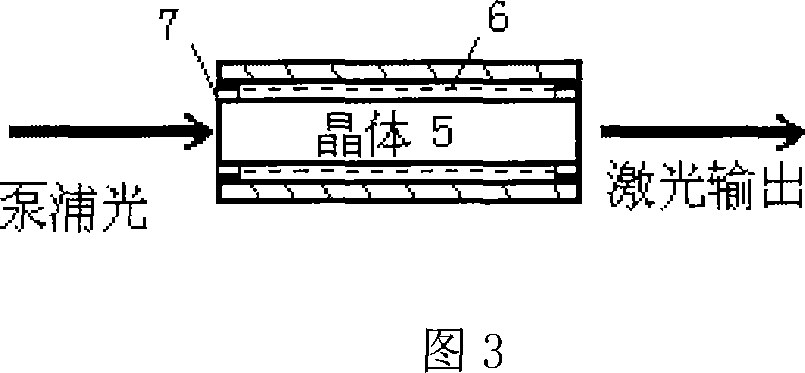

Method and apparatus for liquid guided pump beam

InactiveCN101043118AReduce reflectionEliminate radiationLaser cooling arrangementsCirculator pumpLight beam

A liquid leading pump beam method and device belongs to field of optics and laser photoelectron technique. It includes pumping light source, optical coupling device, liquid leading device and fiber. Thereinto: the optical coupling device receives the pumping light omitted by the pumping light source; liquid nozzle, the pumping beam coupled by the optical coupling device is coupled with liquid column spurted by the liquid nozzle; the central line of cooling fluid collector is aimed at the central line of the liquid nozzle; return flexible hose and liquid-in end are connected with the cooling fluid collector; radiator and circlulating pump are in series, the liquid-in port of the radiator and the liquid-out port of the return flexible hose are connected, the output end of the circlulating pump is connected with the lower end of the liquid nozzle; the liquid nozzle, the cooling fluid collector, the return flexible hose, the radiator and the circlulating pump are in series to form a liquid leading device. The invention resolves the high power pumping problem in solid laser and fiber laser, and the output power of laser can be increased, stability and reliability of laser system can be guaranteed.

Owner:TSINGHUA UNIV

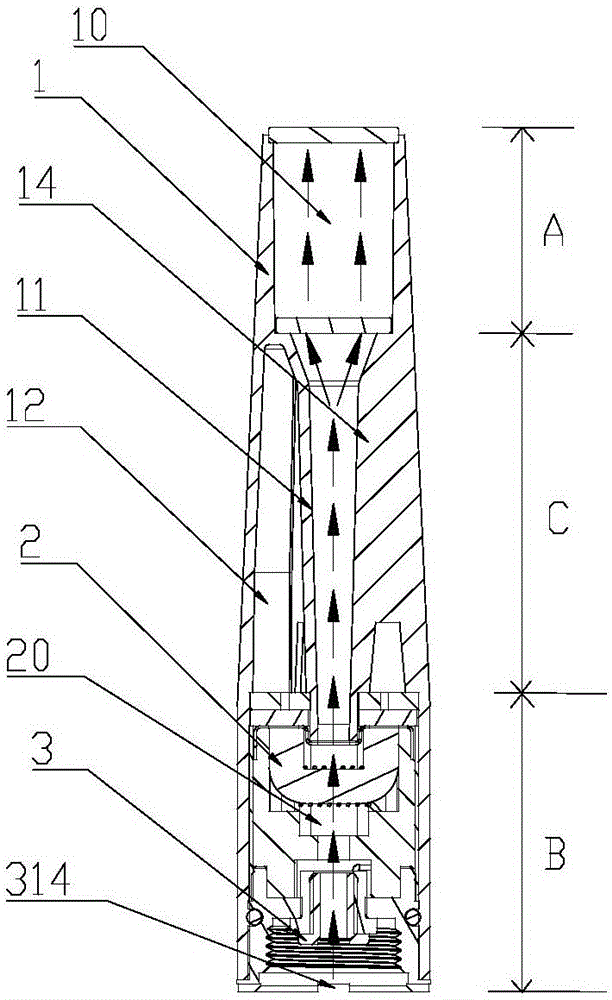

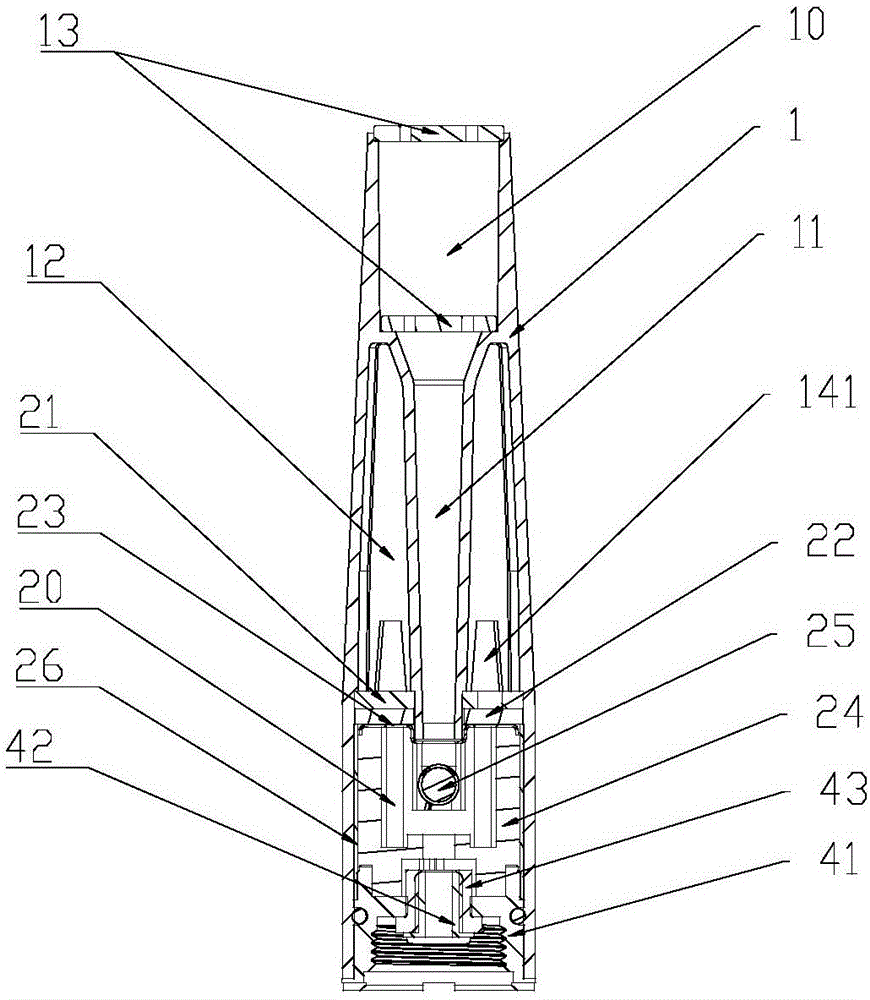

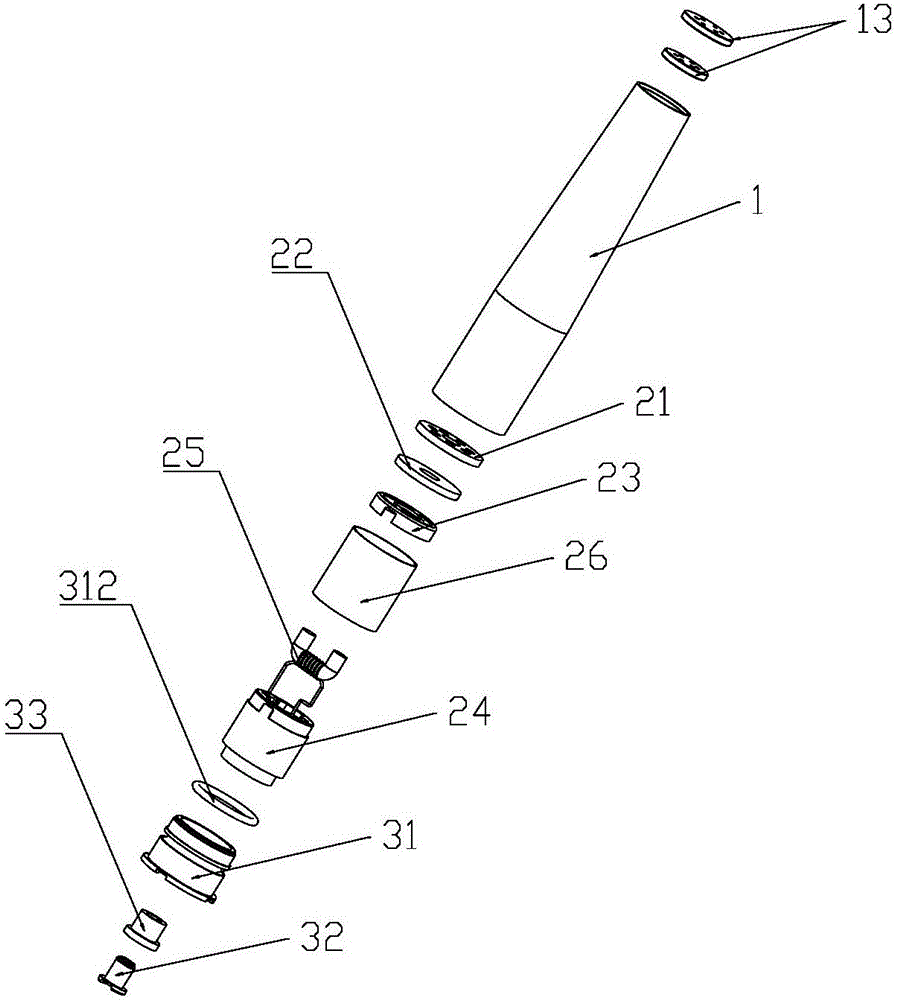

Electronic cigarette atomizer with divergent smoke outlet pipe

The invention discloses an electronic cigarette atomizer with a divergent smoke outlet pipe. The electronic cigarette atomizer comprises an atomizer pipe, an atomization device and a connecting part; one end of the atomizer pipe is provided with a suction nozzle segment, the other end of the atomizer pipe is provided with an atomization connecting segment, the middle of the atomizer pipe is provided with a liquid storage segment, a suction nozzle containing cavity which has the large section and can contain additives is formed in the suction nozzle segment, the smoke outlet pipe which is integrally formed with the atomizer pipe is arranged at the central axis inside the liquid storage segment, the two ends of the smoke outlet pipe are communicated with an atomization cavity and the suction nozzle containing cavity respectively, and the inner diameter of the smoke outlet pipe is gradually increased from one end of the atomization cavity to one end of the suction nozzle containing cavity; a liquid storage cavity used for storing cigarette liquid is formed between the smoke outlet pipe and the atomizer pipe; the atomization device is connected with the liquid storage cavity and the smoke outlet pipe, so that the cigarette liquid in the liquid storage cavity is atomized and then exhausted through the smoke outlet pipe. The electronic cigarette atomizer has the advantages that the volume of smoke sucked from a suction nozzle is increased, the smoke flow rate of the end, located in the atomization cavity, of the smoke outlet pipe is increased, therefore, it is guaranteed that air in the atomization cavity fully flows and quickly brings the smoke out, and the atomization efficiency is improved.

Owner:林光榕

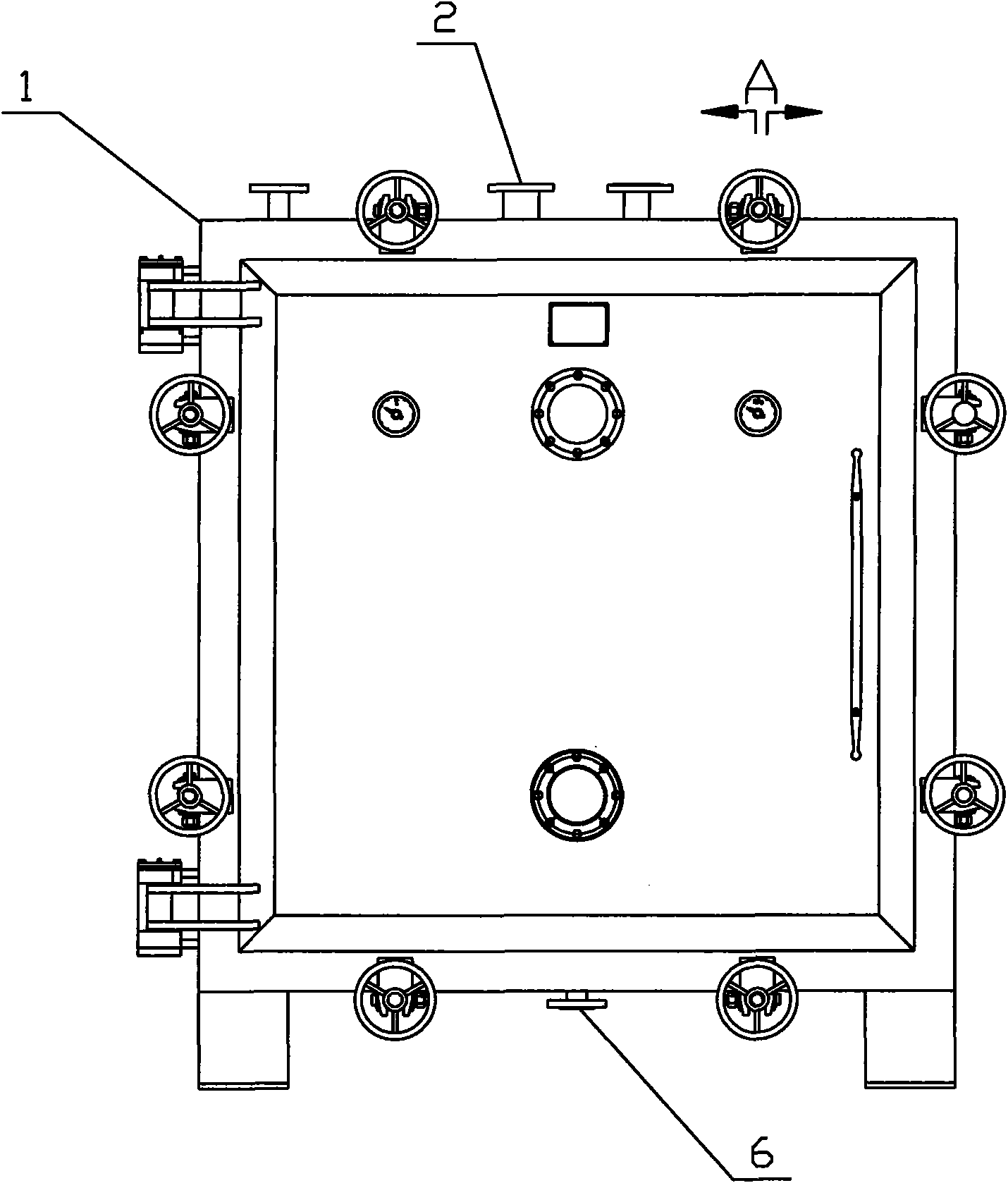

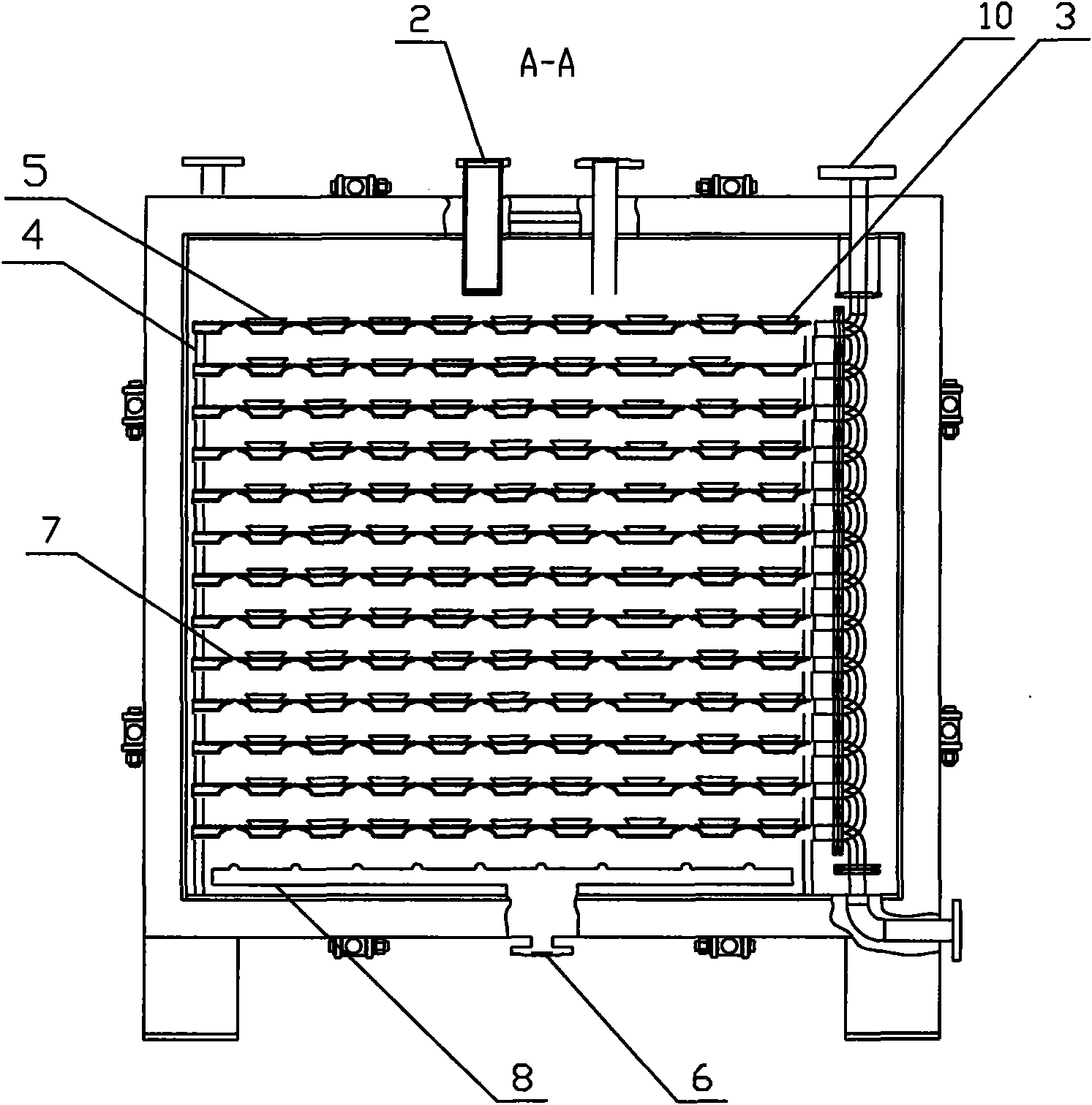

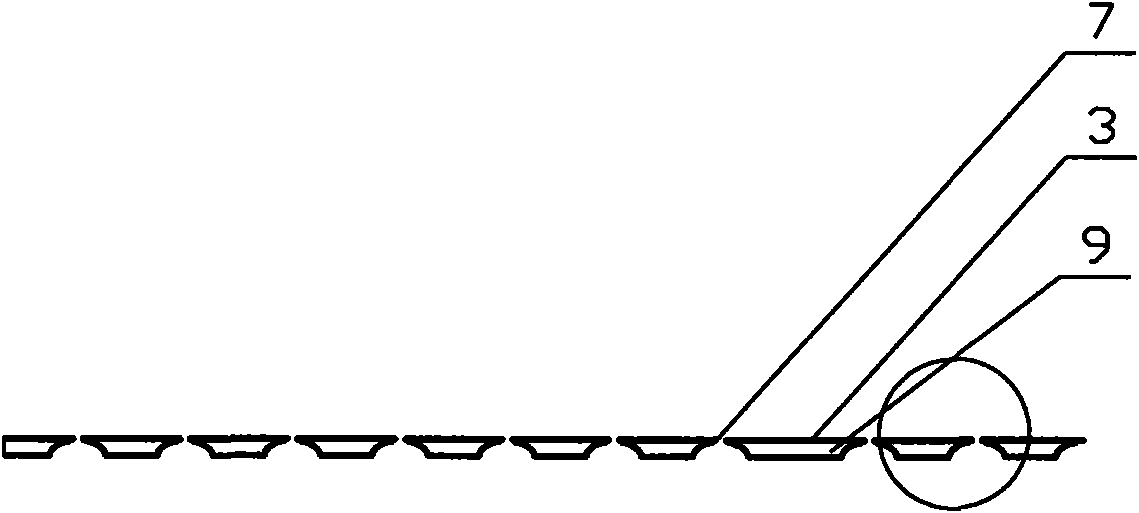

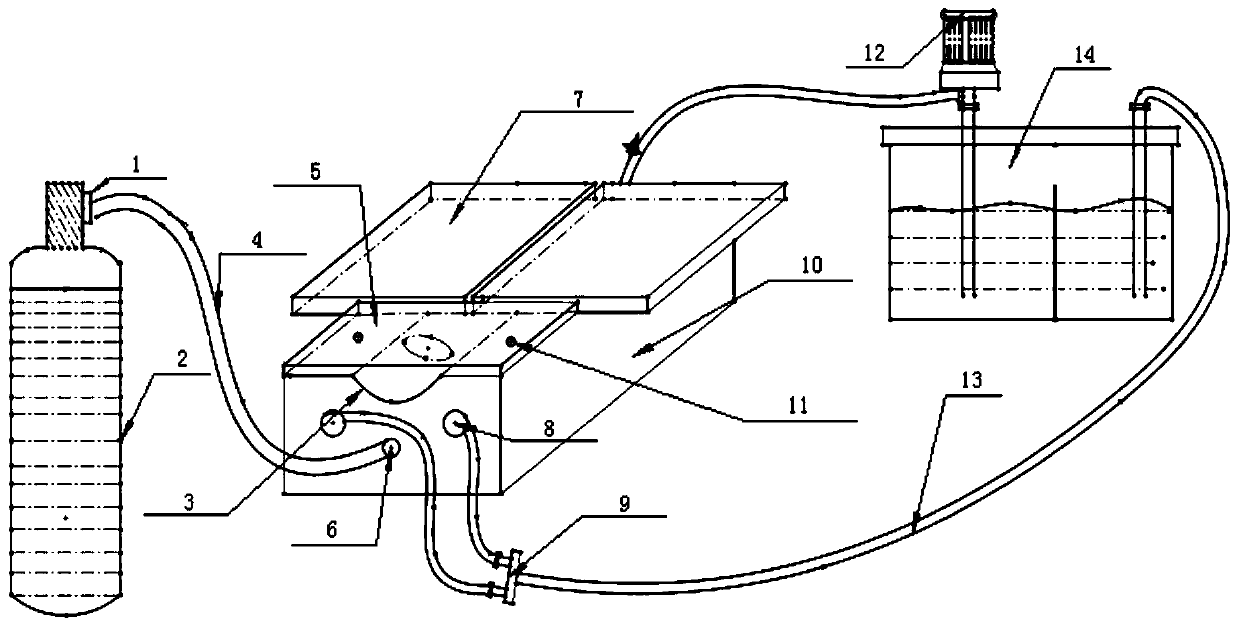

Novel drying oven and drying method thereof

ActiveCN101818985ATake away quicklyReduce steam pressureDrying using combination processesDrying solid materials with heatSteam pressureNitrogen

The invention discloses a novel drying oven. The novel drying oven comprises an oven shell, an air exhaustion hole, an air inlet, a flat plate and a support used for placing the flat plate, wherein a tray used for placing dried materials is arranged on the flat plate; the flat plate is an air-permeable type flat plate; and an air inlet tube is arranged on a drying box for inlet nitrogen or carbon dioxide or inert gases. In the novel drying oven, steam evaporated from wet materials to be dried can be quickly exhausted through an air-permeable structure due to the adoption of the air-permeable type flat plate, and the mass transfer is rapid, so steam pressure of the evaporated steam is lowered, the steam is not easily detained and condensed, and the drying speed is greatly improved; and under the condition of introducing a proper gas such as nitrogen into the air inlet tube, permeable holes can obviously improve the flowing and distribution of the nitrogen in the drying oven, so the steam at all parts of the drying oven can be quickly taken away along with the nitrogen, and the drying speed is further quickened.

Owner:康纳新型材料(杭州)有限公司

Single-sided welding copper liner device with water cooling and back protection and corresponding welding method

ActiveCN109865966ACompact structureReduce weightWelding/cutting auxillary devicesAuxillary welding devicesWeld seamElectric arc

The invention belongs to the technical field of welding, and particularly relates to a single-sided welding copper liner device with water cooling and back protection and a corresponding welding method. By circulating cooling water and shielding gas inside a copper liner, the good welding forming effect of workpieces to be welded is ensured, many beneficial effects of reducing welding deformation,prolonging the service life of the liner, preventing oxidation inclusion on the back of a weld seam, refining weld seam grains, improving the tensile strength of the weld seam and the like are realized, and the single-sided welding copper liner device is suitable for various electric-arc welding methods.

Owner:WUHAN UNIV OF TECH +1

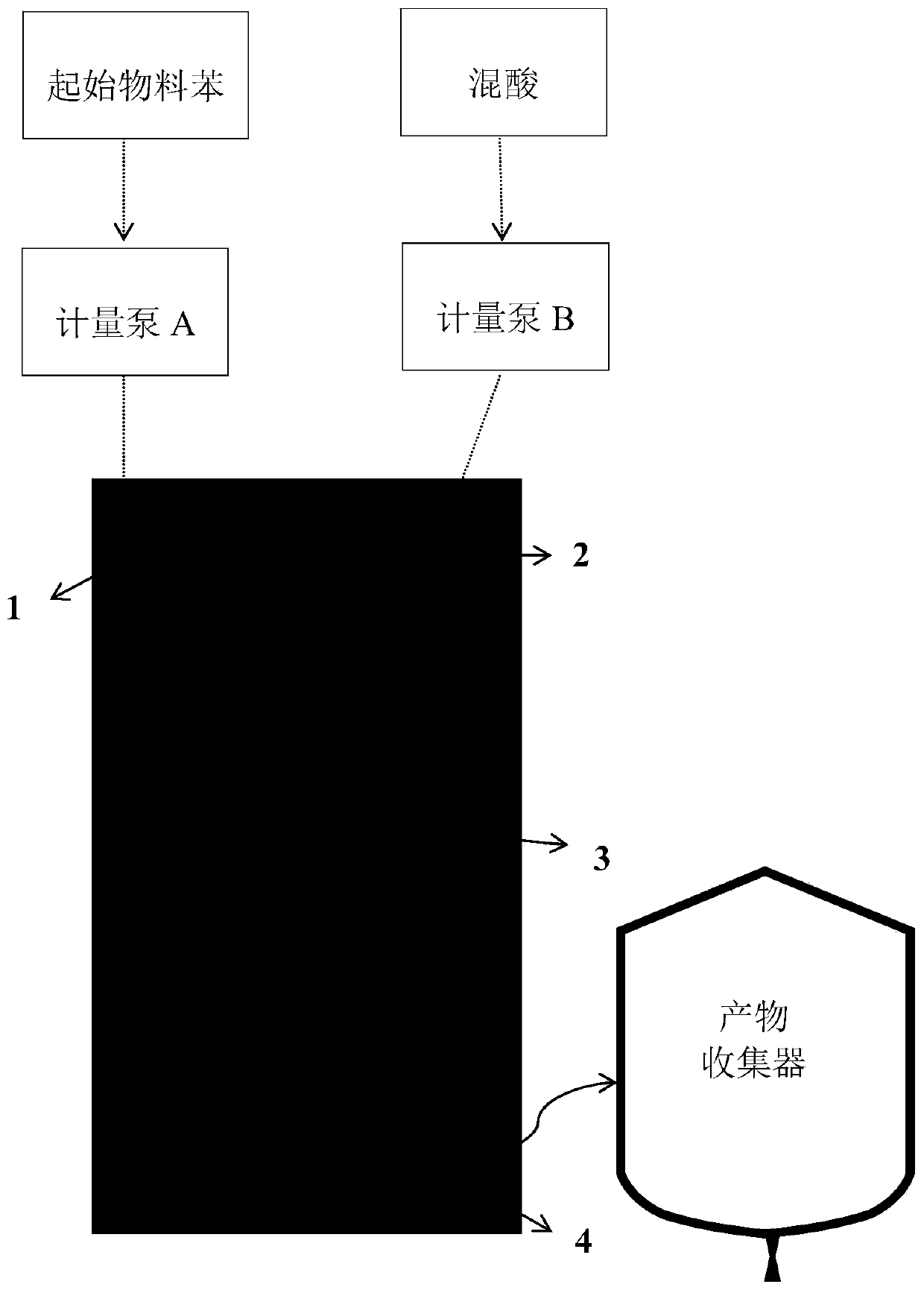

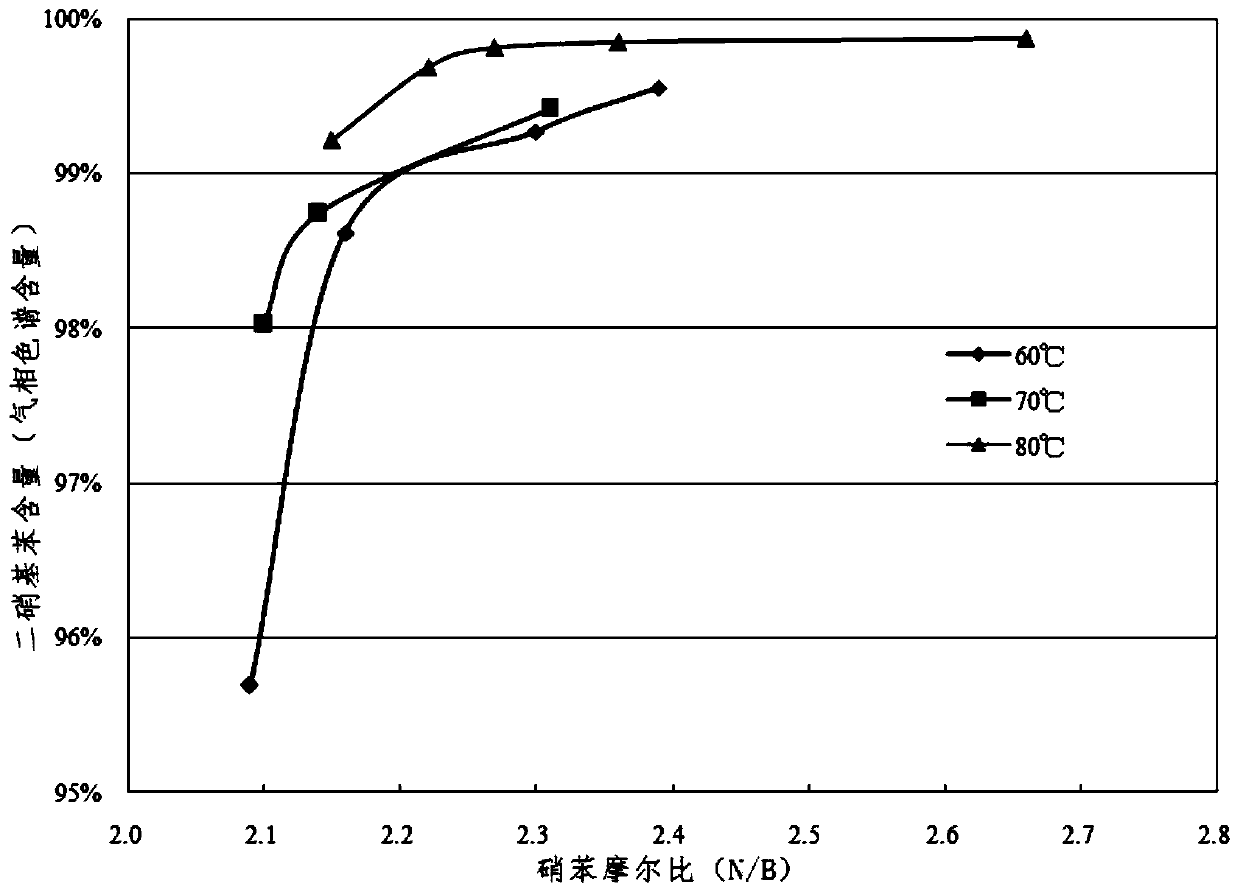

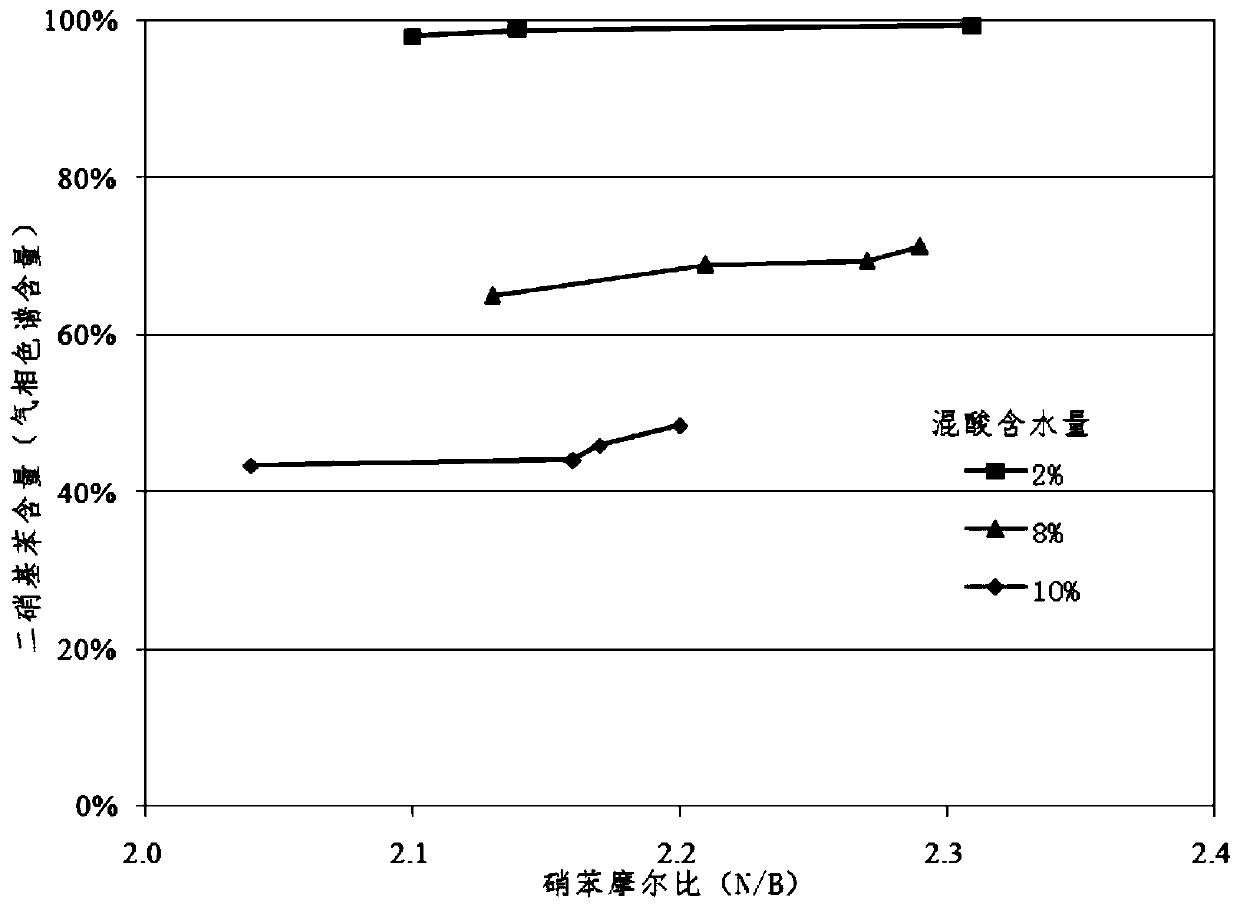

Micro-channel synthesis method of dinitrobenzene

InactiveCN111018715APut an end to seriousnessTake away quicklyNitro compound preparationBenzeneMicroreactor

The invention relates to a synthetic method of dinitrobenzene in a micro-channel reactor. The method comprises the following steps: (1) preparing a mixed acid solution of nitric acid and sulfuric acidat a molar ratio of 0.2-1.0; (2) respectively and simultaneously conveying initial reactants benzene and the mixed acid solution into two inlets of the micro-reactor by a metering pump; (3) mixing reactant benzene and the mixed acid solution in the micro-channel reactor and reacting, wherein the reaction residence time is 8-500 seconds; (4) outputting an obtained reaction material to a collectorfrom a channel of the micro-reactor, and continuously carrying out heat-preservation stirring reaction for 0-1 hour; and separating, washing and drying on the basis of a conventional method to obtaina target product. According to the method, dinitrobenzene synthesis is achieved through the efficient mass and heat transfer capacity of the micro-channel reactor, the process is safe and efficient, the conversion rate is close to 100% under the optimized condition, the yield of the obtained dinitrobenzene is higher than 99%, and the yield of the main product 1, 3-dinitrobenzene reaches 84%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

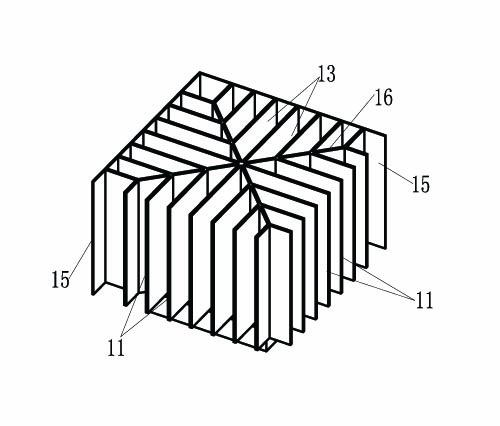

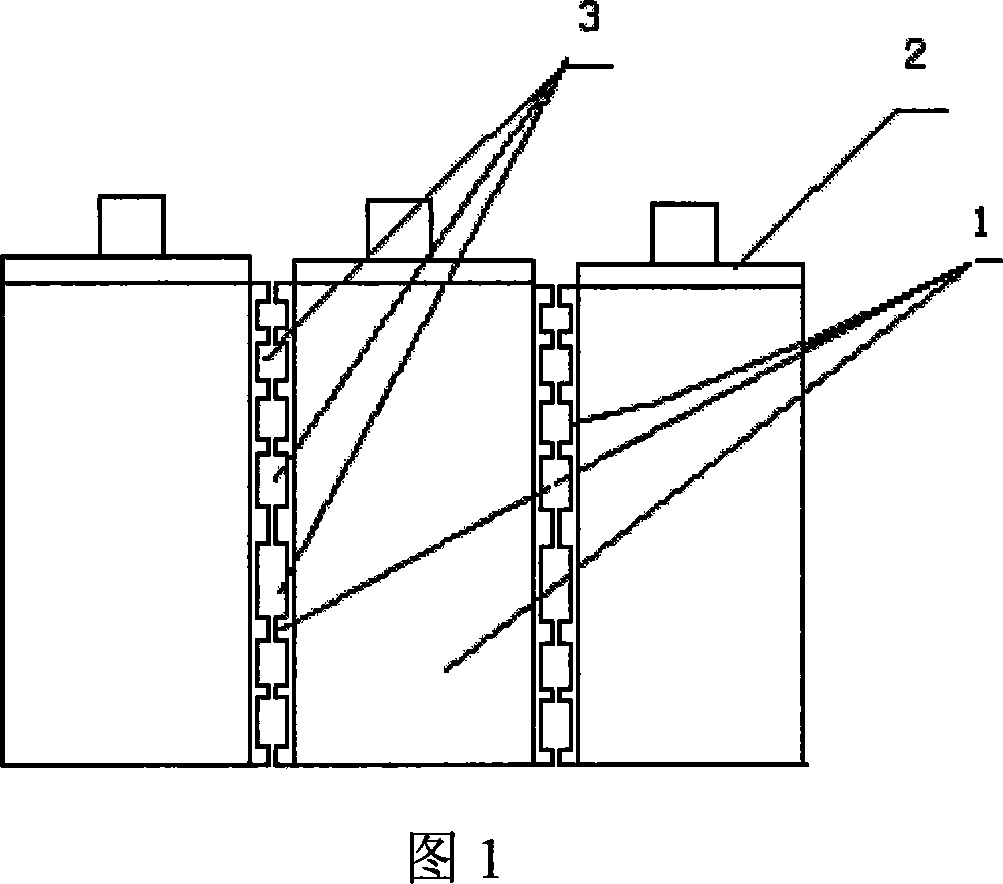

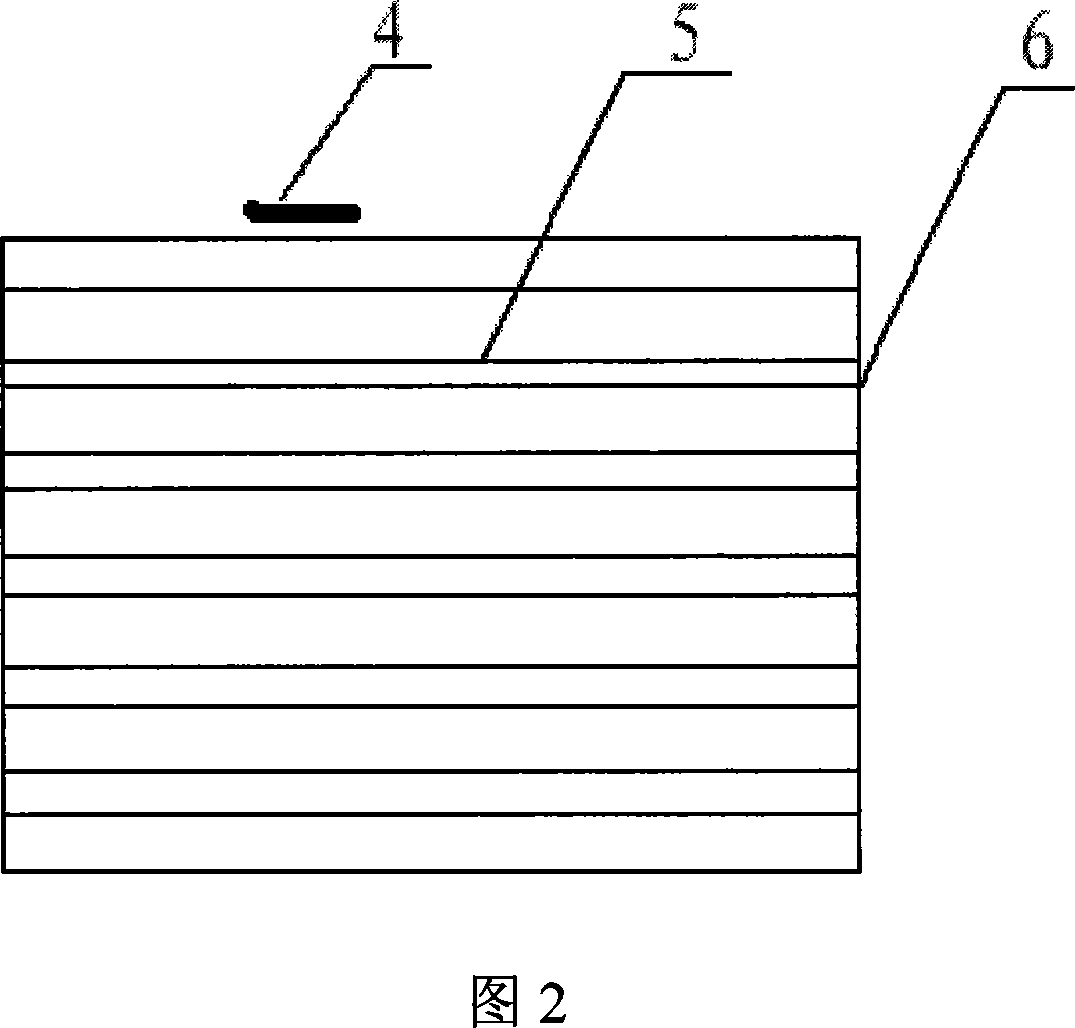

System for cooling and radiating super-capacity, battery and other energy-storage devices

The invention comprises: a battery or a super capacitor. It features the radiating fins covering said battery and super capacitor; both ends of battery or super capacitor are uncovered; multi batteries or super capacitors are combined to form a battery pack compartment or super capacitor compartment. The invention can used to cool the batteries or capacitors.

Owner:上海中上汽车科技有限公司

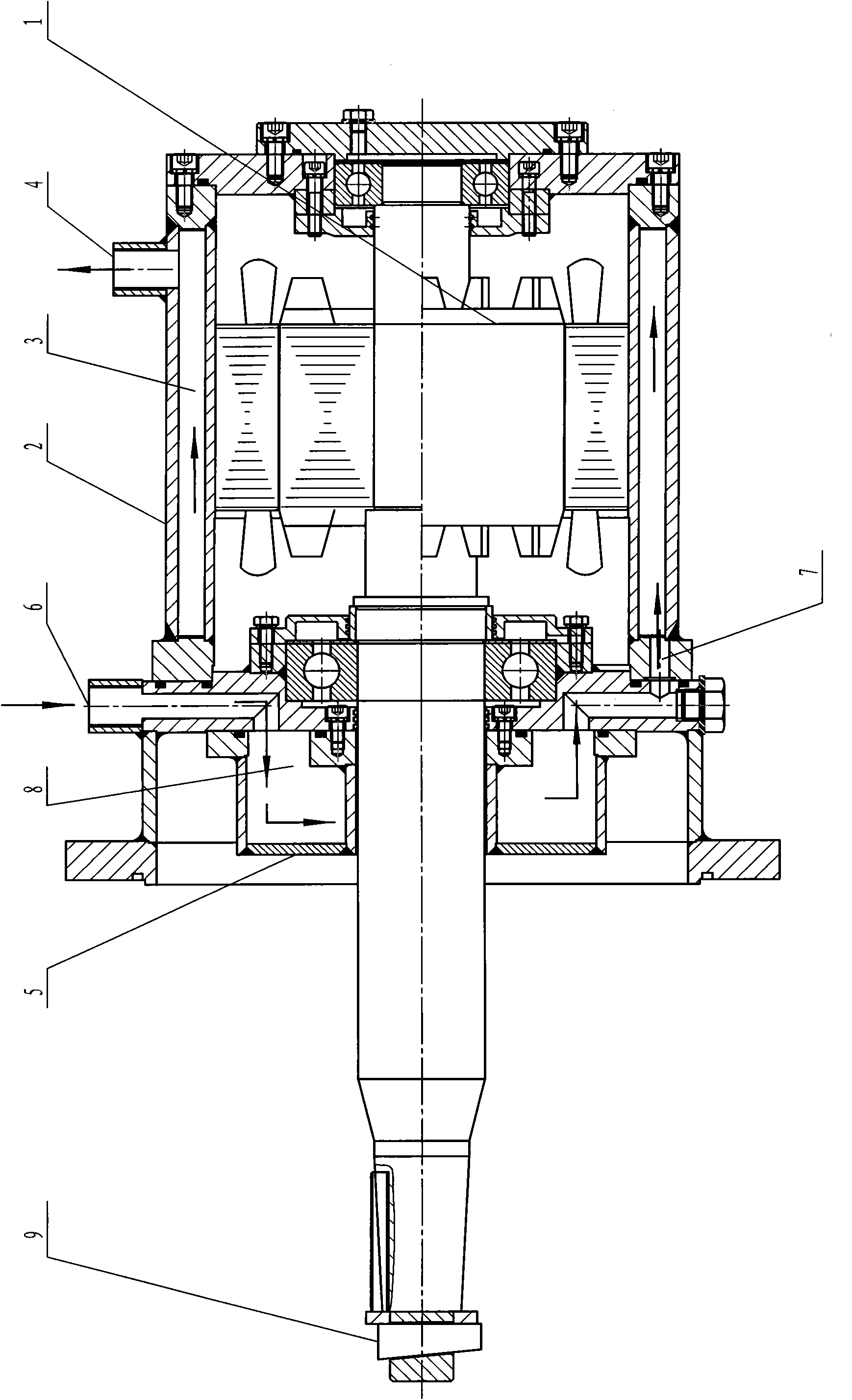

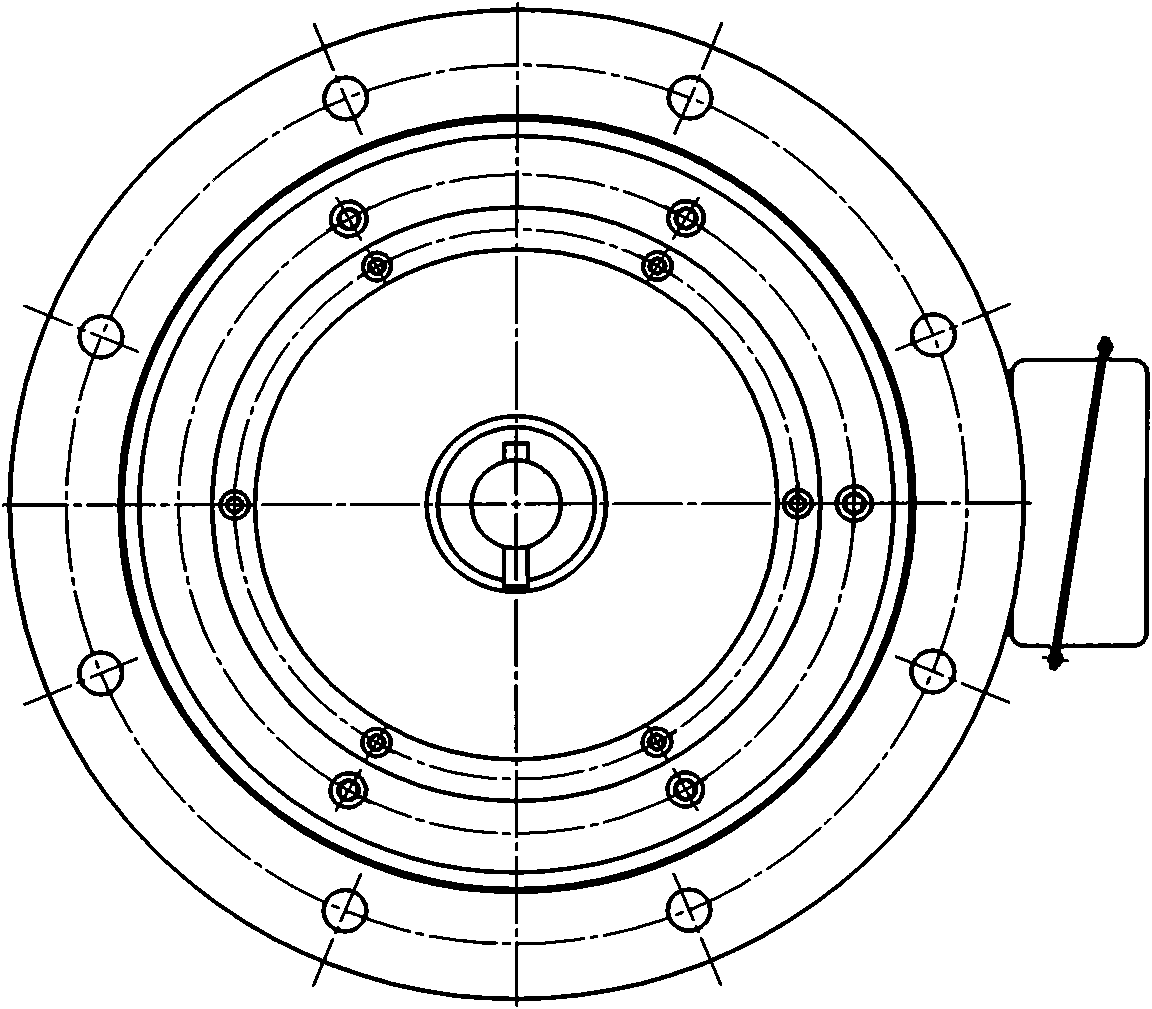

One-in and one-out double water-cooling sealing motor

InactiveCN101834491AReduces the possibility of water leaksConnections are no longer complicatedCooling/ventillation arrangementSupports/enclosures/casingsEngineeringWater circulation

The invention relates to a one-in and one-out double water-cooling sealing motor. A motor commonly used in the traditional thermal treatment equipment is in a two-in and two-out double water-cooling sealing structure, i.e., a front end cover is provided with a water inlet and a water outlet; and a shell is provided with a water inlet and a water outlet. Meanwhile, four water circulating connecting ports are provided, the motor has a plurality of leakage points, the connection of water paths is complex during the use; and the connection mode of the water paths of the motor is complex. The one-in and one-out double water-cooling sealing motor comprises a motor (1), wherein the shell of the motor is internally provided with a circulating water cavity (3) which is connected with a water outlet (4), the front of the shell of the motor is connected with a front end cover (5), the inner part of the front end cover is provided with a cooling water cavity (8), a water inlet (6) is arranged between the front end cover and the shell of the motor, the water inlet is connected with the cooling water cavity, and the cooling water cavity is connected with the circulating water cavity through an inner water hole (7). The one-in and one-out double water-cooling sealing motor is used as a motor applied in the thermal treatment equipment.

Owner:哈尔滨滨大科技有限公司

Atomization-vaporization heat dissipating type LED lamp

InactiveCN105003853ARapid coolingExtended service lifePoint-like light sourceLighting heating/cooling arrangementsVaporizationEngineering

The invention provides an atomization-vaporization heat dissipating type LED lamp which comprises a lamp panel and lamp holders evenly distributed on the lamp panel. The rear portion of the lamp panel is covered by a conical heat dissipating main plate, and heat dissipating fins which are evenly distributed in a ring shape along the axis of the lamp panel are designed on the rear portion of the heat dissipating main plate; the other ends of the heat dissipating fins are fixedly connected with a fan which is coaxially assembled with the lamp panel. An ultrasonic vibrating module is assembled between the fan and the heat dissipating main plate; a water storage module is assembled on the outer sides of the heat dissipating fins, and the inside of the water storage module is connected with the ultrasonic vibrating module through a pipeline. In the use process of the lamp, the water storage module is fully filled with clear water which flows into the ultrasonic vibrating module through the pipeline and then is vibrated and atomized, the atomized water is blown to the heat dissipating main plate to be quickly vaporized, and therefore rapid cooling is achieved, and the service life of the LED lamp is greatly prolonged.

Owner:中山市修本照明有限公司

Spin-riveting-type spring brake chamber, brake system adopting same and vehicle

ActiveCN102410322AImprove surface qualityHigh dimensional accuracyBrake actuating mechanismsActuatorsEngineeringBraking system

The invention discloses a spin-riveting-type spring brake chamber, a brake system adopting the same and a vehicle. The pin-riveting-type spring brake chamber is characterized in that a cylinder body is made by stretching and precisely cutting an aluminum magnesium alloy plate for a plurality of times, the surface quality of the cylinder body is good, the dimensional precision is high, and the contact surface at the joint between the cylinder body and a middle shell is large; and the cylinder body is assembled and riveted tightly through two cylindrical pins so that the cylinder body and the middle shell do not rotate relative to each other so as to ensure a firm connection.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

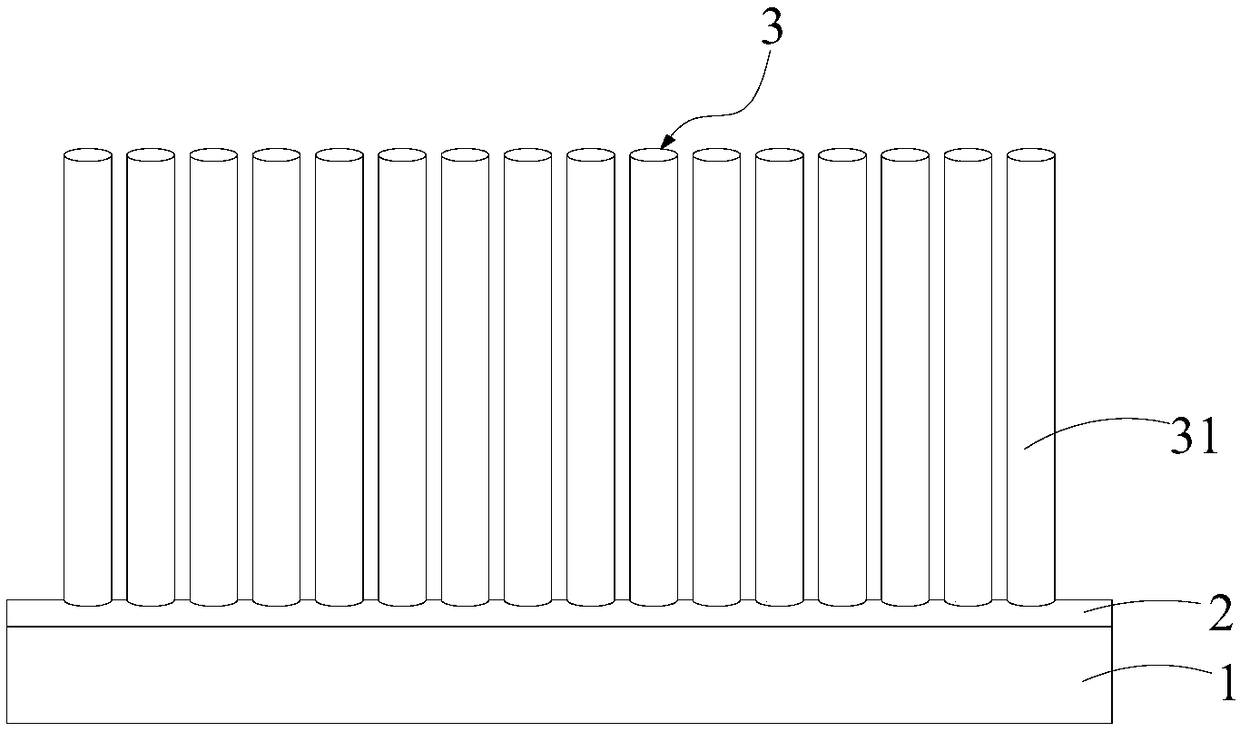

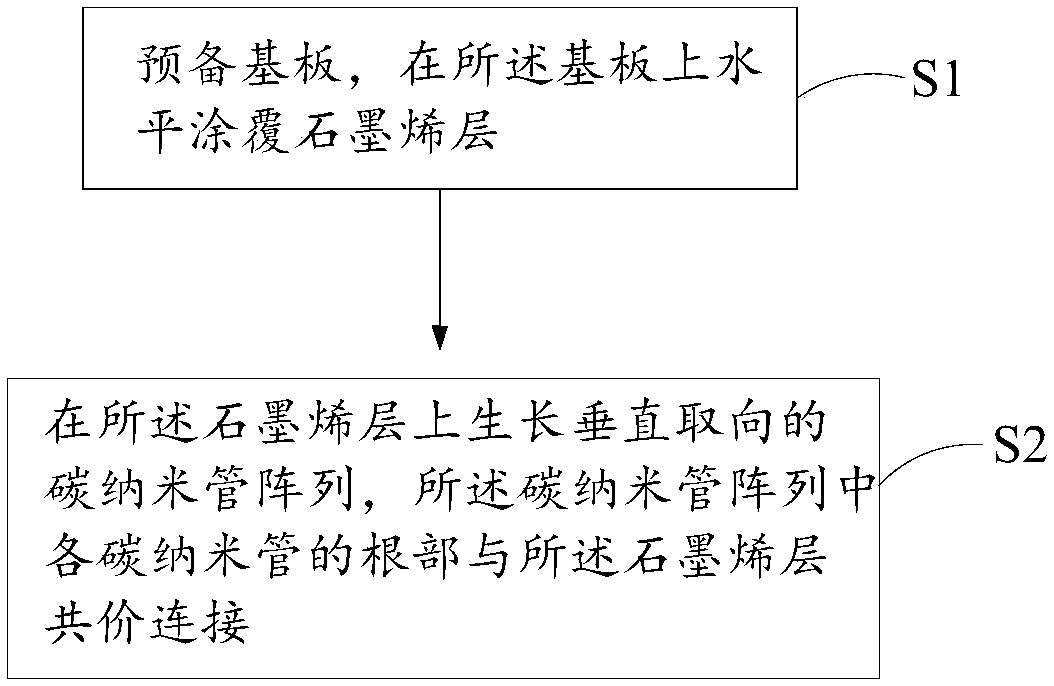

Carbon-nano-field emission cathode and manufacturing method and application

ActiveCN108172488ALaunch stableReduce the turn-on electric fieldCathode ray tubes/electron beam tubesX-ray tube electrodesElectrical resistance and conductancePower flow

The invention, which relates to the technical field of field emission, provides a carbon-nano-field emission cathode and a manufacturing method and application. The carbon-nano-field emission cathodecomprises a substrate, a graphene layer horizontally coated on the substrate, and a carbon nanotube array arranged on the graphene layer. Roots of all carbon nanotubes in the carbon nanotube array arein covalent linkage with the graphene layer. According to the invention, because the roots of all carbon nanotubes are in covalent linkage with the graphene layer, the interface resistance is extremely low and thus the carbon nanostructure has excellent conductivity, so that the opening electric field of the cathode is reduced obviously; the heat generated during the field emission process is lowand thus the cathode can be emitted stably at the high current, so that the operating current of the cathode is improved substantially. Moreover, because the three-dimensional covalent structure hasexcellent thermal conductivity, the emission stability of the cathode is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

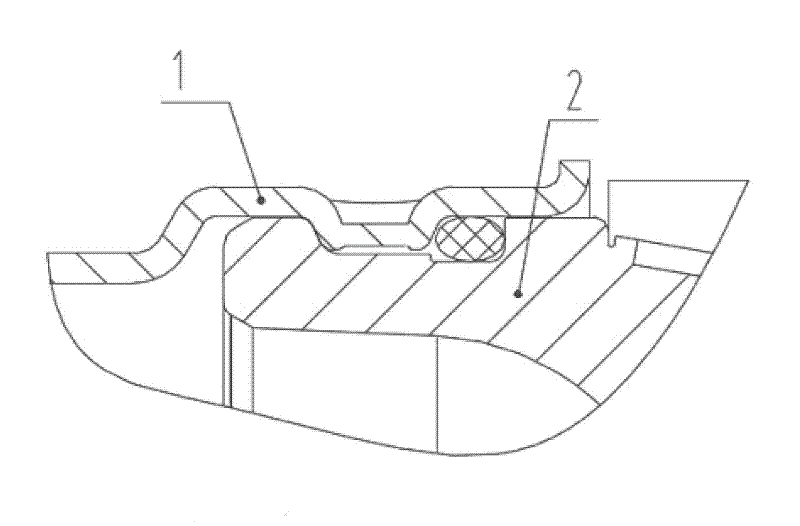

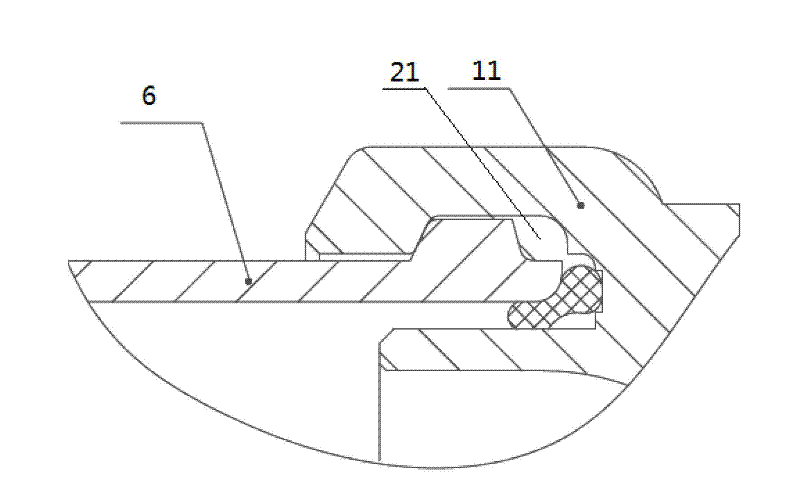

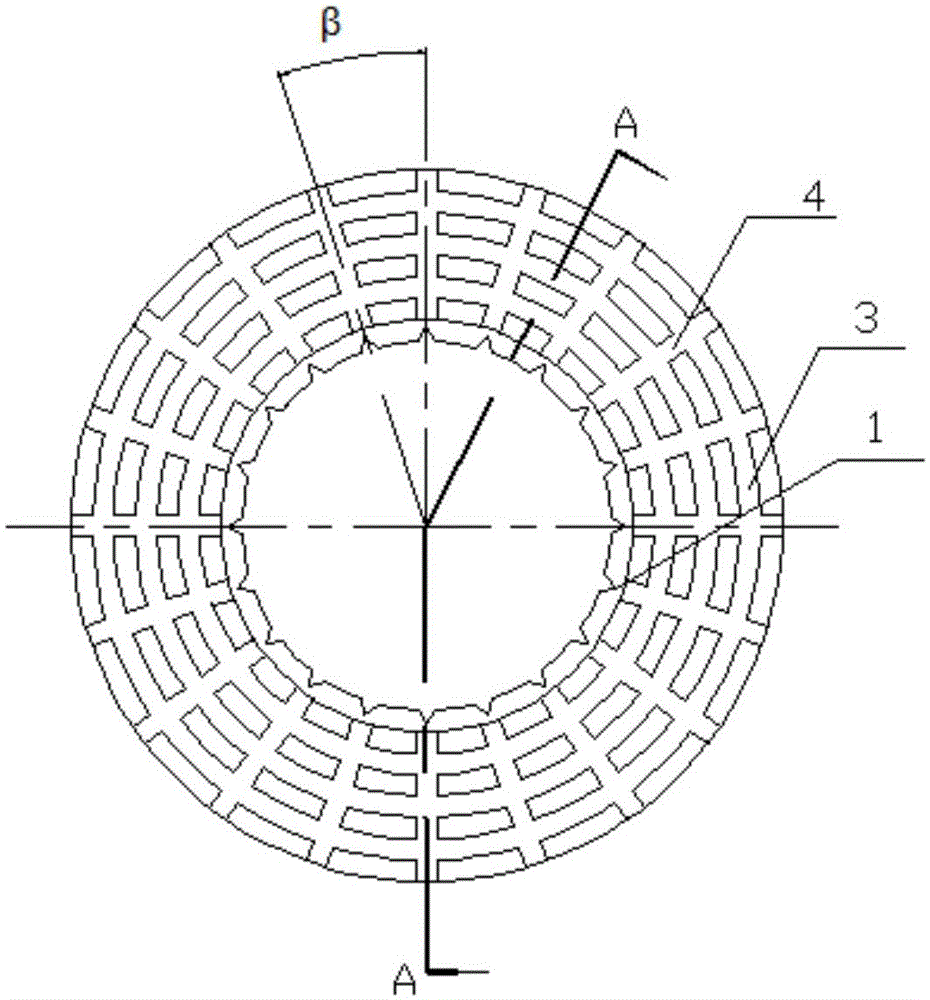

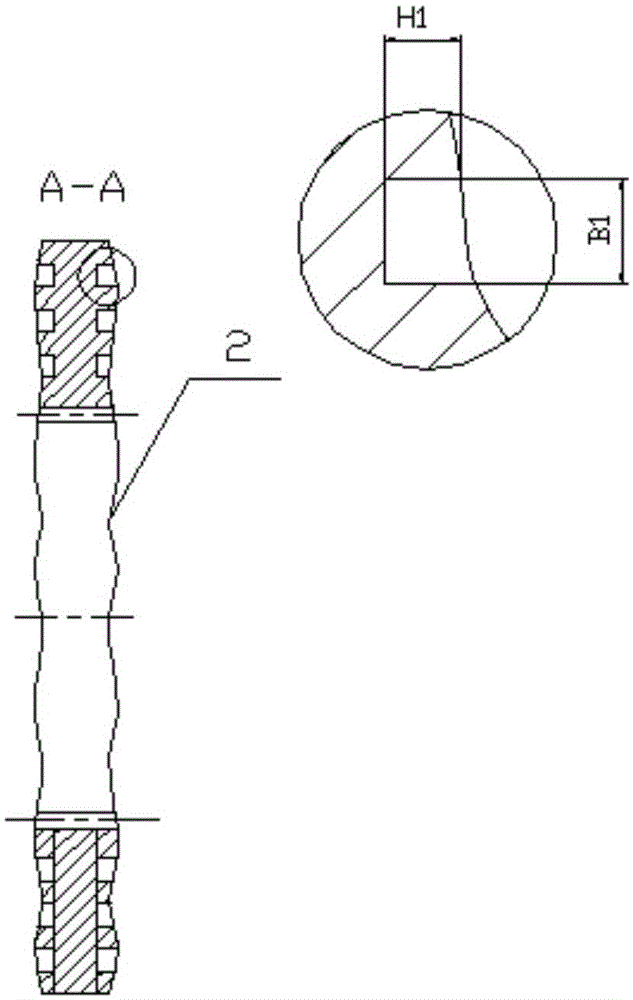

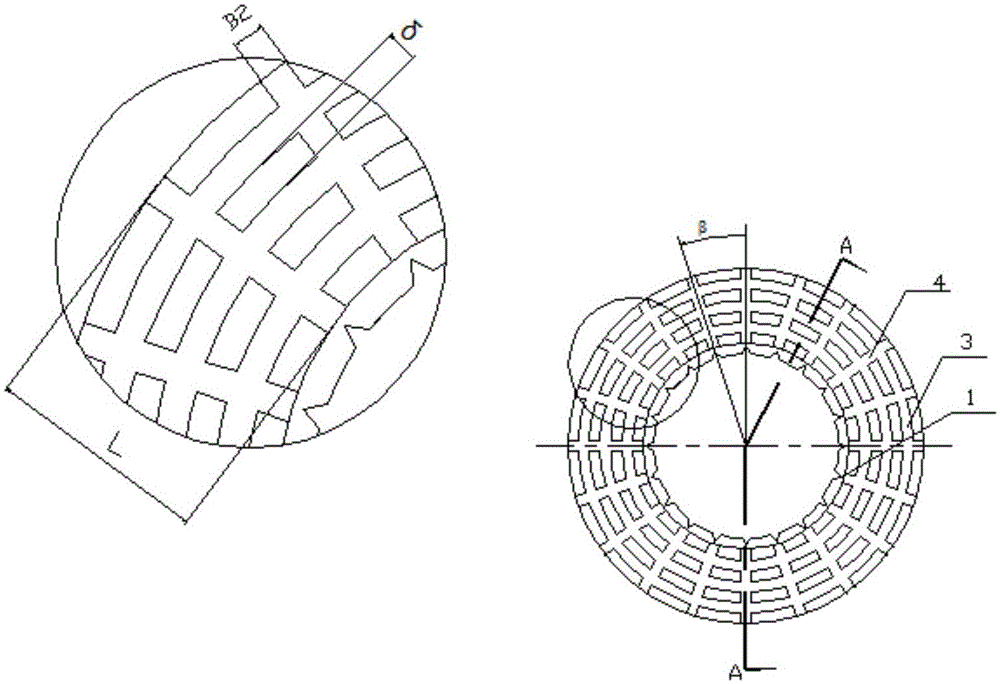

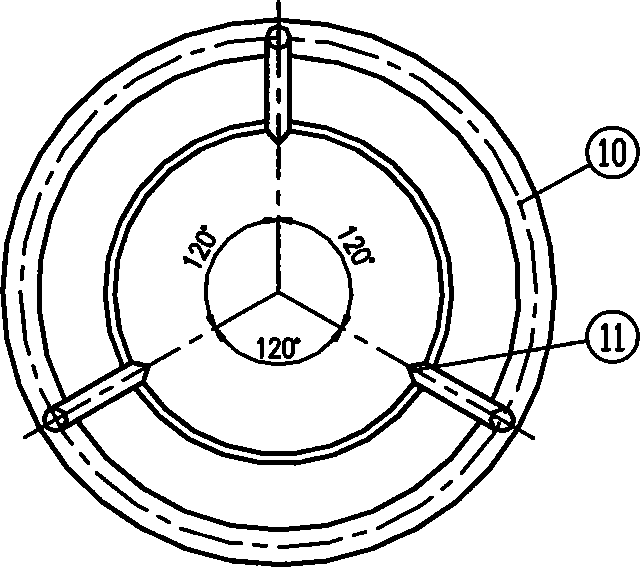

Anti-deformation dual disc of hydro-viscous speed regulating clutch

InactiveCN105041911AStable jobIncrease contact areaFluid clutchesFriction liningViscous liquidWork performance

The invention provides an anti-deformation dual disc of a hydro-viscous speed regulating clutch. The dual disc is a ring-shaped steel disc with the thickness being 2 to 5mm; and spline teeth are arranged on the inner ring or the outer ring of the ring-shaped steel disc. The anti-deformation dual disc is characterized in that the working surface of the dual disc is wavy, is uniformly provided with concentric ring-shaped grooves along the radial direction and is uniformly provided with radial rectangular grooves along the circumferential direction. The anti-deformation dual disc provided by the invention has the advantages that the radiating condition of friction pairs is improved, the film-forming capability and the kinetic-pressure bearing capability of viscous liquid medium among the friction pairs are enhanced, the thermal deformation of the dual disc of the hydro-viscous speed regulating clutch is reduced, the generation of non-thorough separation between a driving friction part and a driven friction part is prevented, the working performance of the hydro-viscous speed regulating clutch is improved and the service life of the hydro-viscous speed regulating clutch is prolonged.

Owner:JIANGSU UNIV

Device for producing nanometer silicon dioxide through rice husk deep oxidation

The invention discloses a device for producing nanometer silicon dioxide through rice husk temperature control complete oxidation. The device comprises an oxidation cylindrical shell, a particle selector, a group of high speed air nozzles, a material inlet and a material outlet. The upper end of the material inlet is provided with two pneumatic gate valves and is connected to a spiral conveyer. The material outlet is connected to an external cyclone separator, a filter and a high temperature induced draught fan. The high temperature-resistant oxidation cylindrical shell utilizes wear-resistant high temperature-resistant alloy steel, ceramic or silicon carbide as a lining and is provided with a heat preservation jacket at the outer part. The particle selector is installed at the upper end in the oxidation cylindrical shell, is tightly connected to the oxidation cylindrical shell through a transmission shaft and a mechanical seal and is driven through a high speed variable frequency motor. The high speed air nozzles are arranged at the lower part of the oxidation cylindrical shell, comprise odd number of nozzles and are installed at a small dip angle. The high speed air nozzles utilize high temperature high pressure compressed air. The produced silica has an amorphous nanometer structure, impurity carbon is completely oxidized and product purity is very high. The product is crushed to form very fine granules.

Owner:王开辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com