Patents

Literature

51results about How to "Reduce local hot spots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desorption and regeneration method for organic matter adsorbent

InactiveCN103447015AReduce dosageReduce separation loadCombustible gas purificationEnergy based chemical/physical/physico-chemical processesDesorptionWater vapor

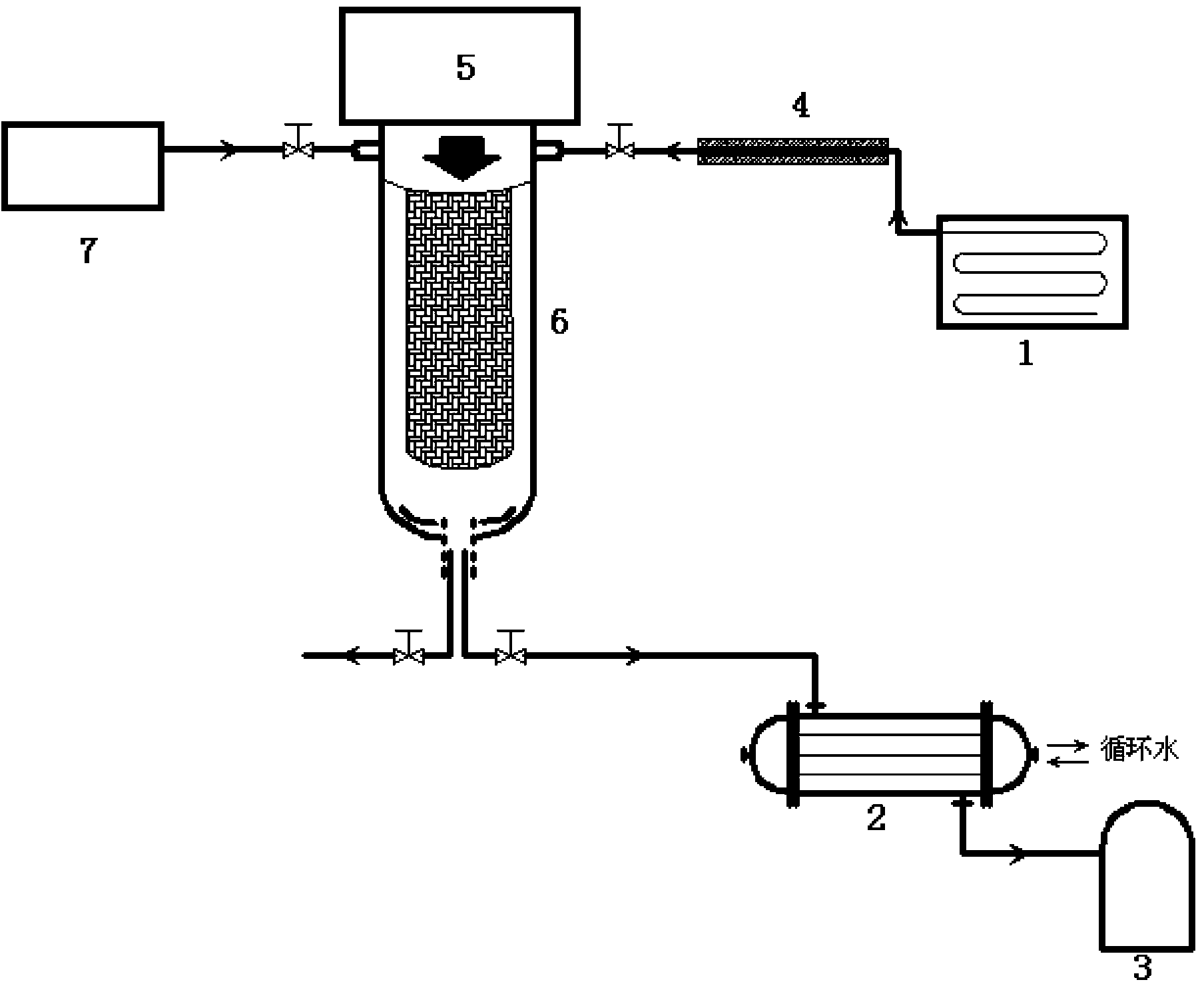

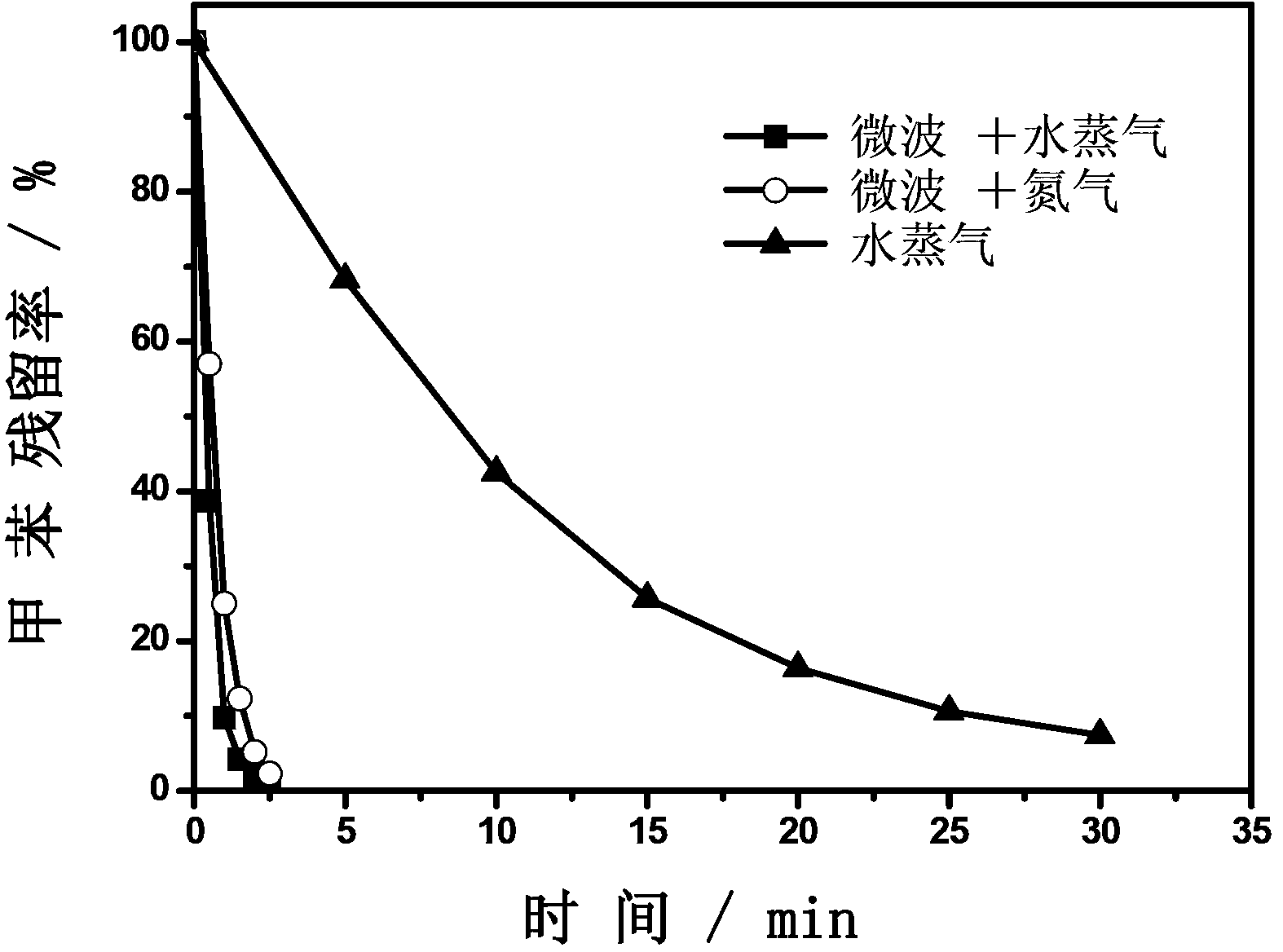

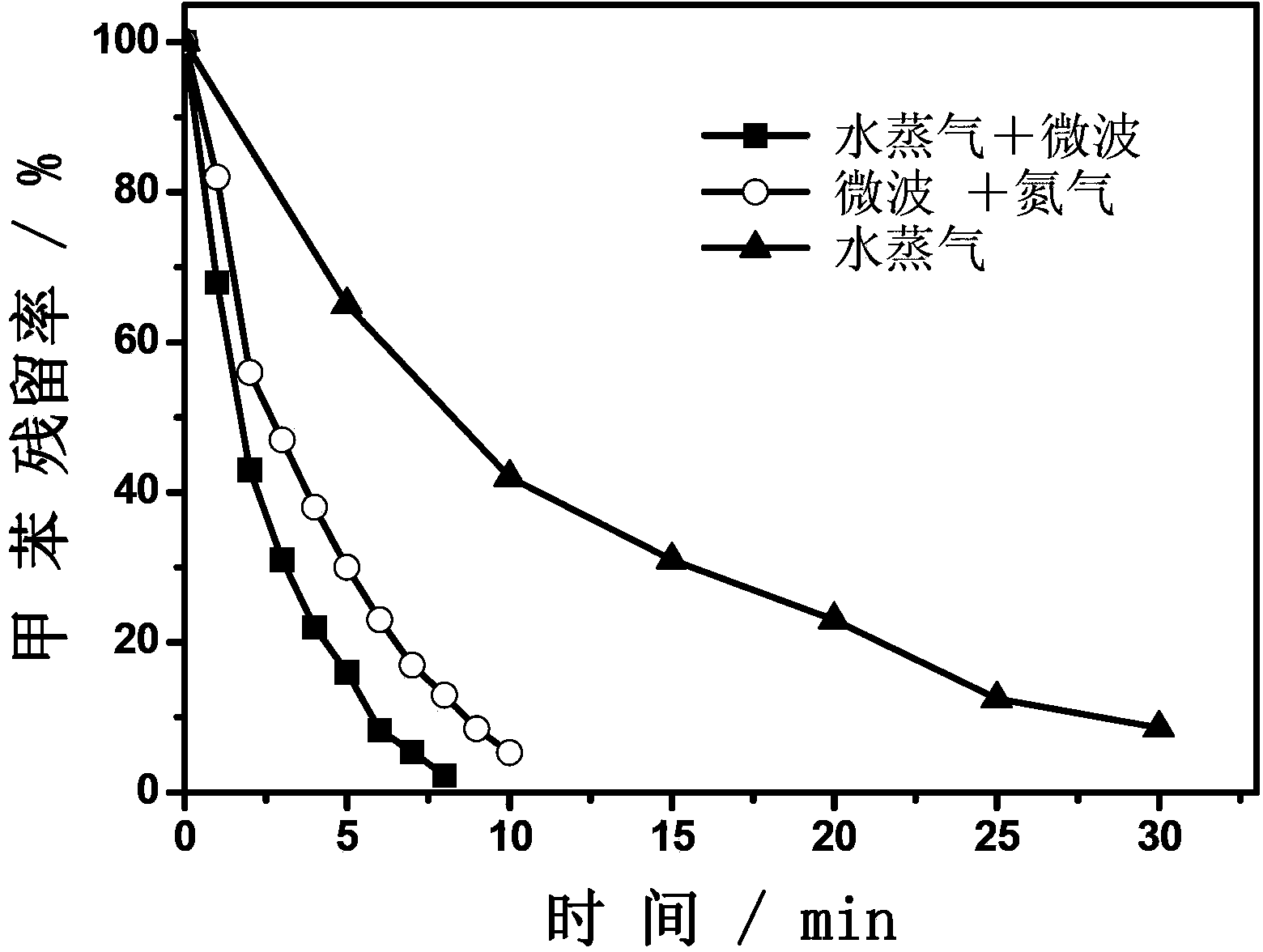

The invention discloses a desorption and regeneration method for an organic matter adsorbent. The method is characterized in that an organic matter adsorbent desorption and regeneration device of a microwave generator is arranged in a desorption tower; the to-be-desorbed adsorbent with organic matters is put in the desorption tower; steam is aerated from the top of the desorption tower; the microwave generator is started, wherein the microwave power is 500-10000W; desorption is carried out for 2-30 minutes; the desorbed organic matters and steam flow out from a steam outlet at the bottom of the desorption tower and enter a condenser for condensation; then the steam is cut off, nitrogen is aerated from the top of the desorption tower, and the nitrogen flows out from the bottom, wherein the microwave power is 200-2000W; drying treatment is carried out for 2-20 minutes; the microwave generator is turned off, and the nitrogen is cut off; the desorbed adsorbent is obtained. According to the method, the desorption rate is improved by a large margin by combining steam and the microwave technology, and less desorption residue is left.

Owner:ZHEJIANG UNIV OF TECH

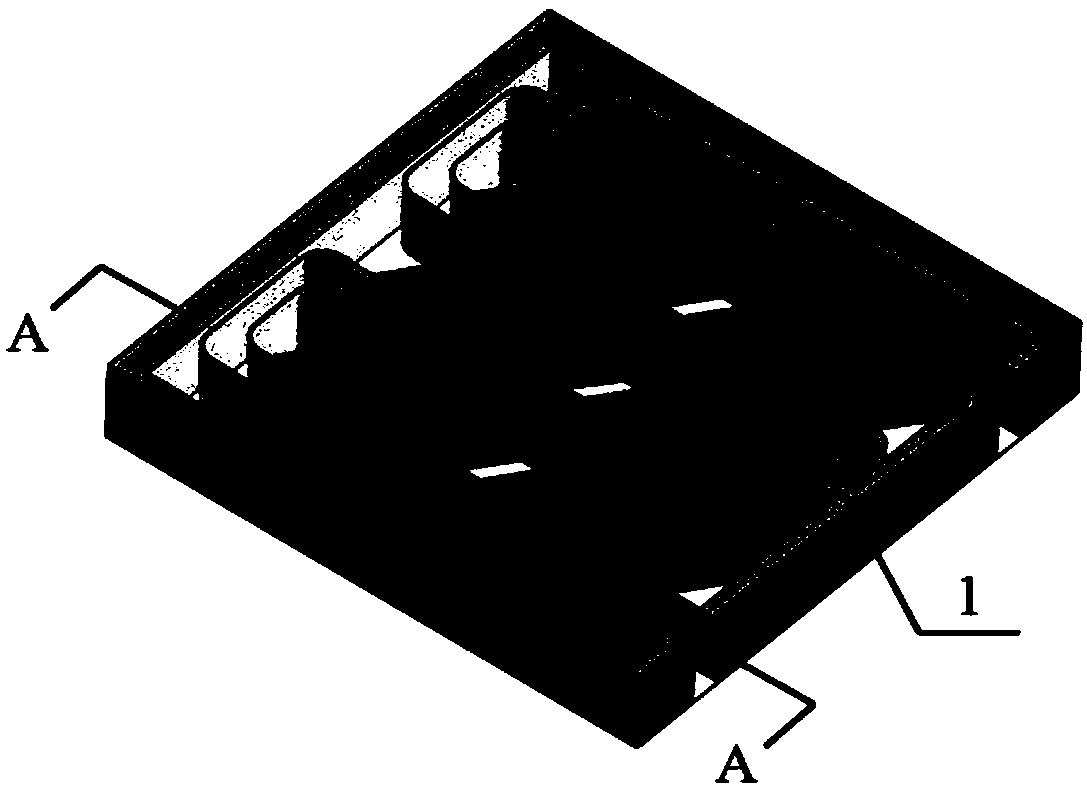

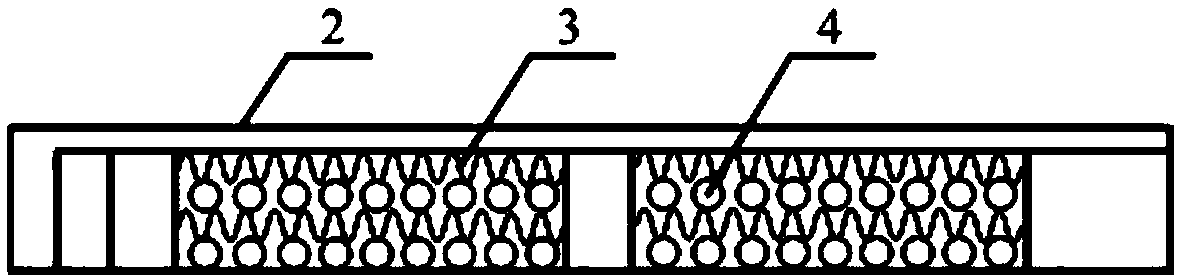

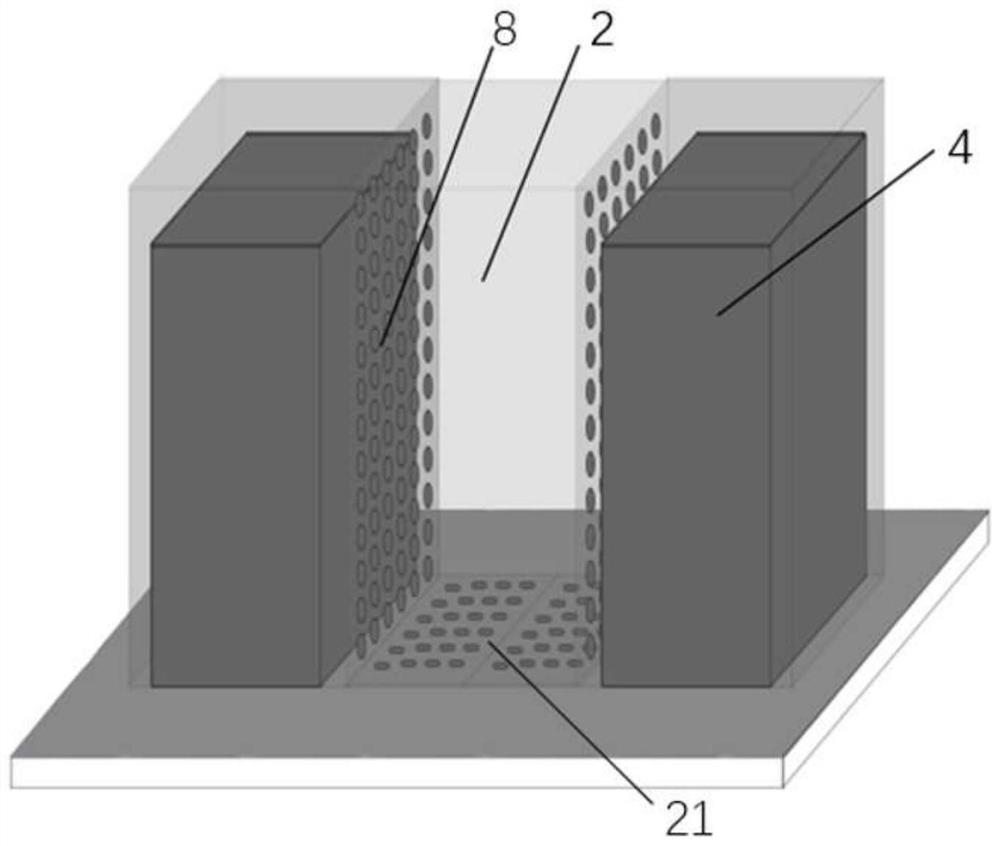

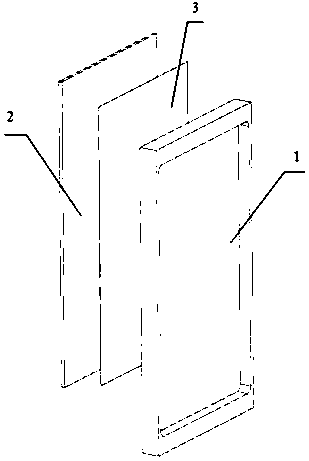

Data center immersed-type liquid-cooling cabinet based on heat pipe technology

InactiveCN108124408AReduce energy consumptionReduce local hot spotsCooling/ventilation/heating modificationsData centerEngineering

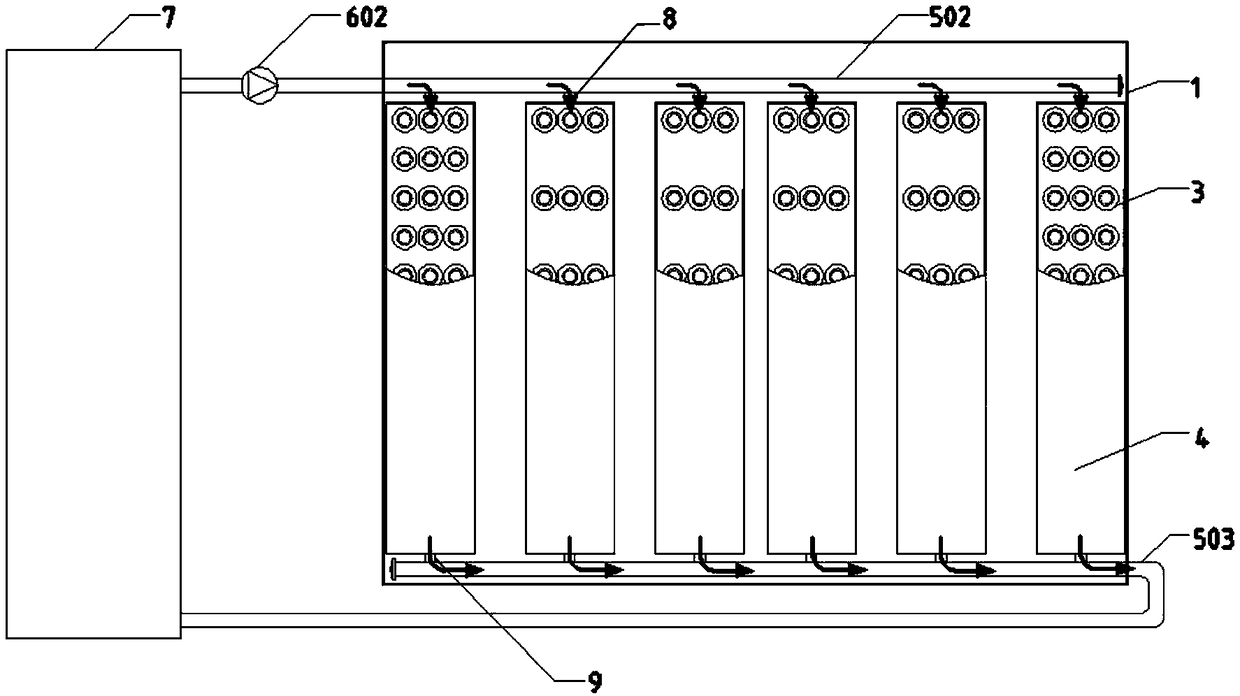

The invention discloses a data center immersed-type liquid-cooling cabinet based on the heat pipe technology. A plurality of added cooler cabinets are vertically arranged outside a first side wall ofthe liquid-cooling cabinet. A plurality of server groups are disposed in a length direction parallel to the first side wall at a staggered manner, and are closely attached to the first side wall and asecond side wall facing the first side wall at intervals so as to form a first flow channel. A first refrigerant circulation pipe is communicated with the first flow channel. The interior of each added cooler cabinet is vertically provided with a plurality of heat pipe groups, and each heat pipe group comprises a plurality of horizontal heat pipes. A part of heat pipes stretch into the liquid-cooling cabinet, and are fixedly connected to the added cooler cabinets in a sealed manner. The interior of each added cooler cabinet forms a second flow channel through the gaps between the heat pipes,and a second refrigerant circulation pipe is communicated with the second flow channel and is connected with a refrigerating machine. The liquid-cooling cabinet can quickly dissipate the heat of a server, reduces local hotspots of the cabinet, improves the overall heat dissipation efficiency of a machine room, and reduces the energy consumption of a data center heat dissipation system.

Owner:CENT SOUTH UNIV

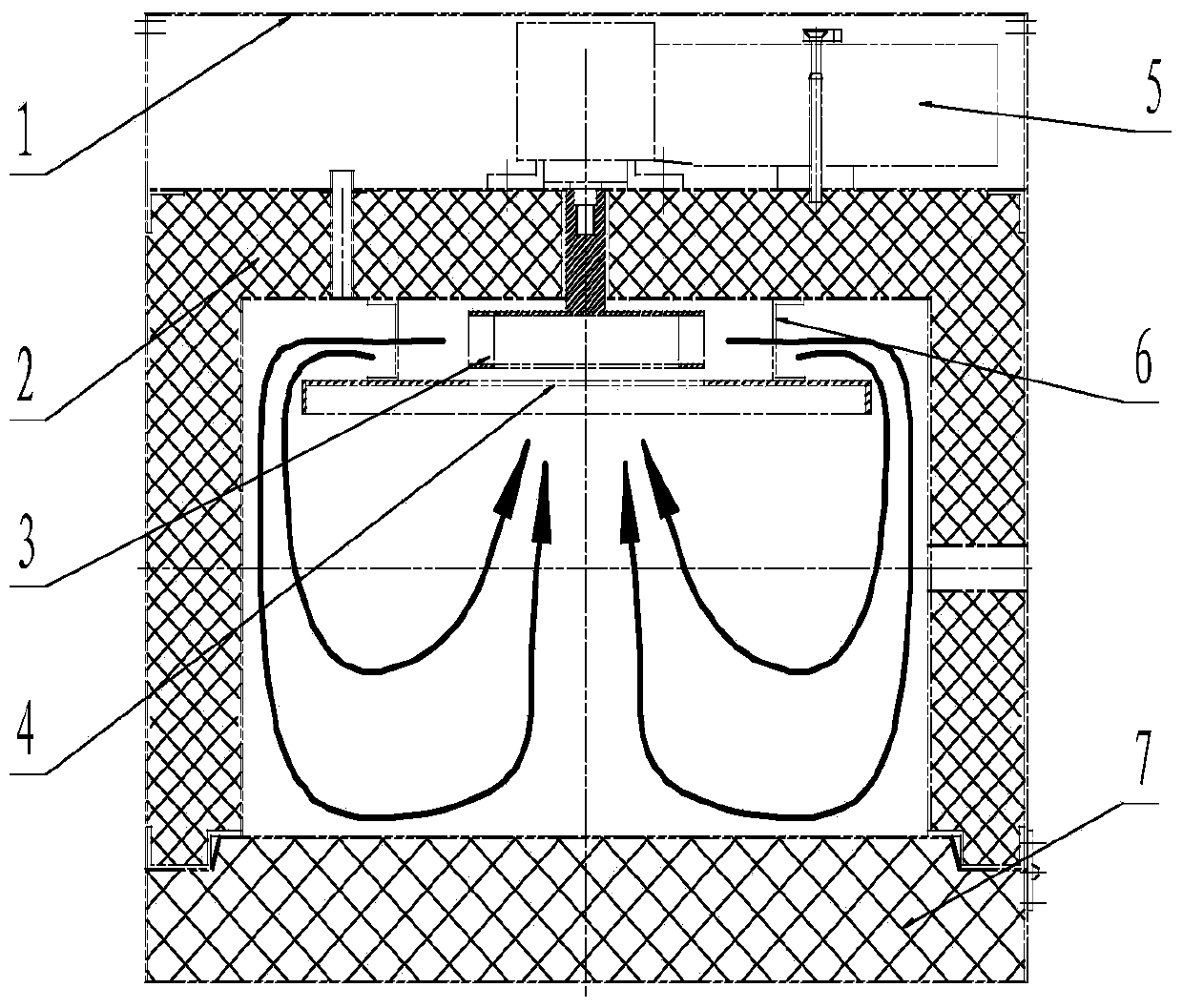

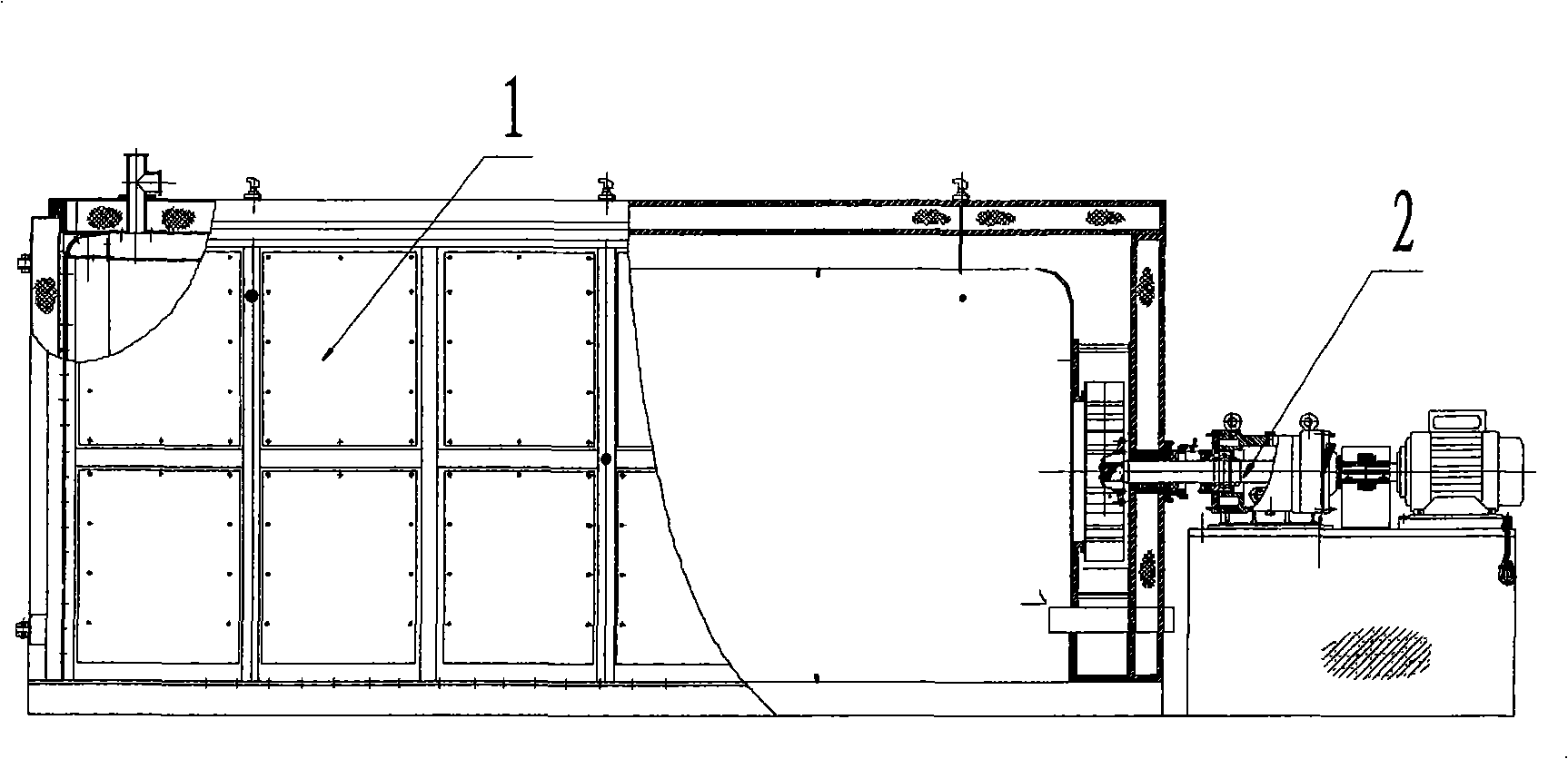

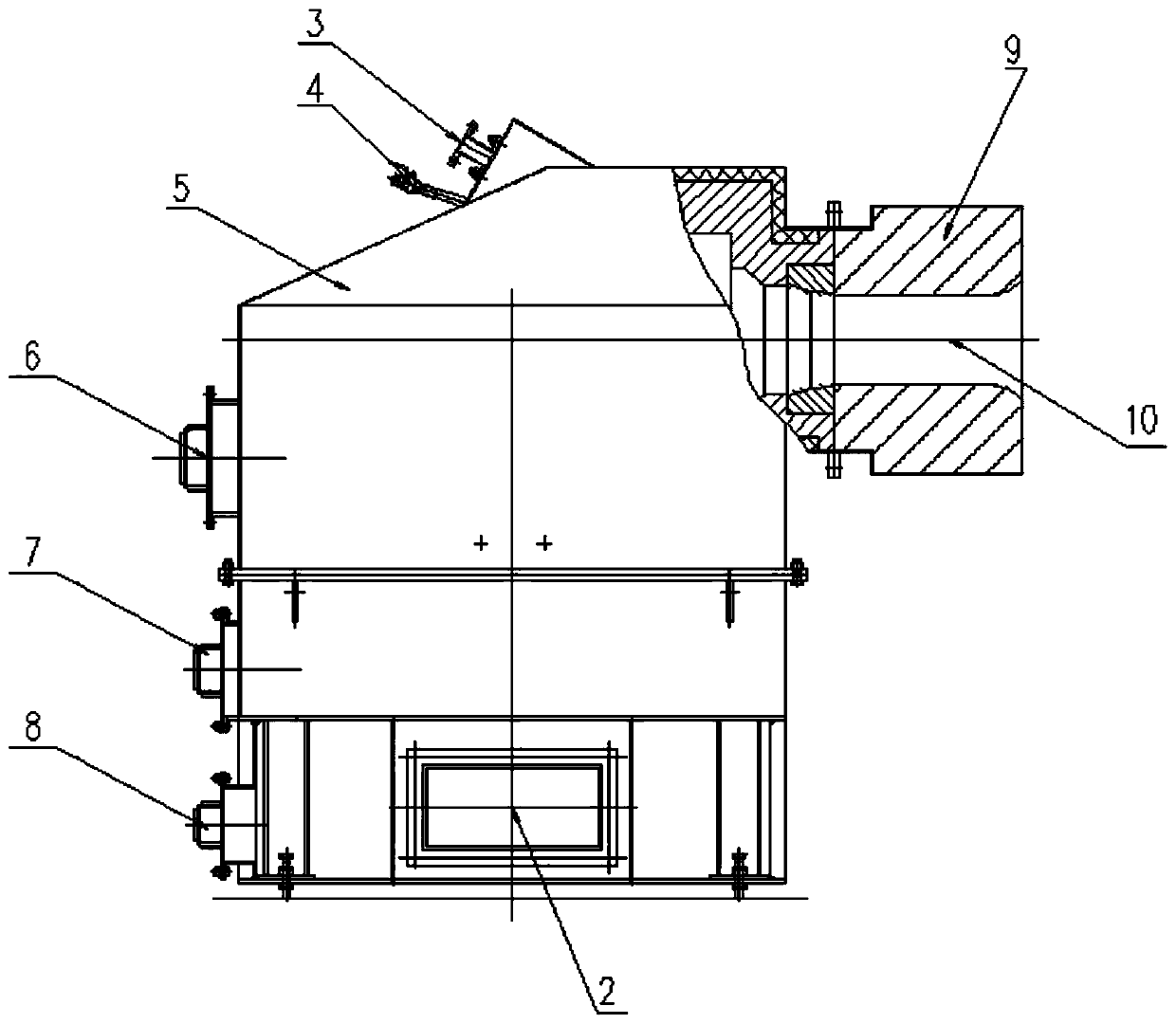

Aerodynamic heating furnace

InactiveCN103629838AAchieving High UniformityReduce consumptionOther heat production devicesThermal energyEngineering

The invention provides an aerodynamic heating furnace. An impeller is located in a furnace body. A guide plate is installed in the furnace body through a guide plate support and is fixed to the inner surface of a rear wall plate of the furnace body. Two surfaces, adjacent to the impeller, of the guide plate are spaced. An air inlet hole is formed in the center of the guide plate, and the air inlet hole and the center of the impeller are concentric. A plurality of airflow holes are evenly distributed in the circumference of an annular impeller support. The sum of the sectional areas of the airflow holes is 1-2 times the circumference area of the impeller. A guide edge protruding in the axial direction is arranged on the outer circumference of the guide plate and the guide edge faces towards an inner wall of the furnace body. Turbulence is increased by the right-angled guide edge and heating uniformity and the heating depth are improved by the right-angle guide edge. According to the aerodynamic heating furnace, wind energy is used as a heating medium, the impeller is driven by a motor, so that the wind energy is converted into thermal energy, high-uniformity of a temperature field is achieved through flowing of the wind energy, heating elements such as a heating tube can be omitted, the number of parts used for keeping the uniformity of the temperature field is reduced, the number of partial high temperature points is reduced, the furnace body heat capacity is reduced, the number of furnace body heat bridges is reduced, and therefore the purposes that energy consumption is reduced and the energy-saving effect is achieved are achieved.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

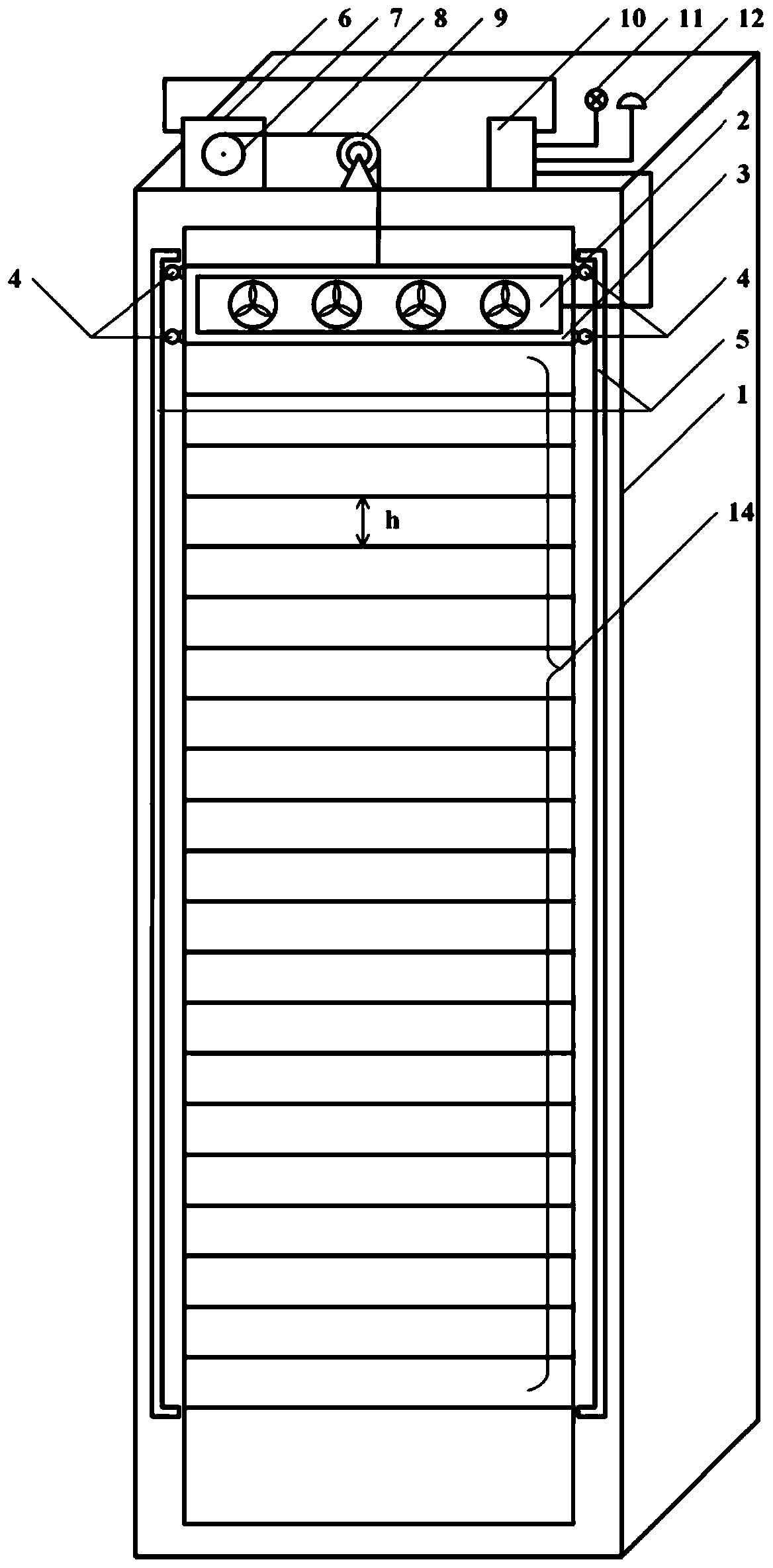

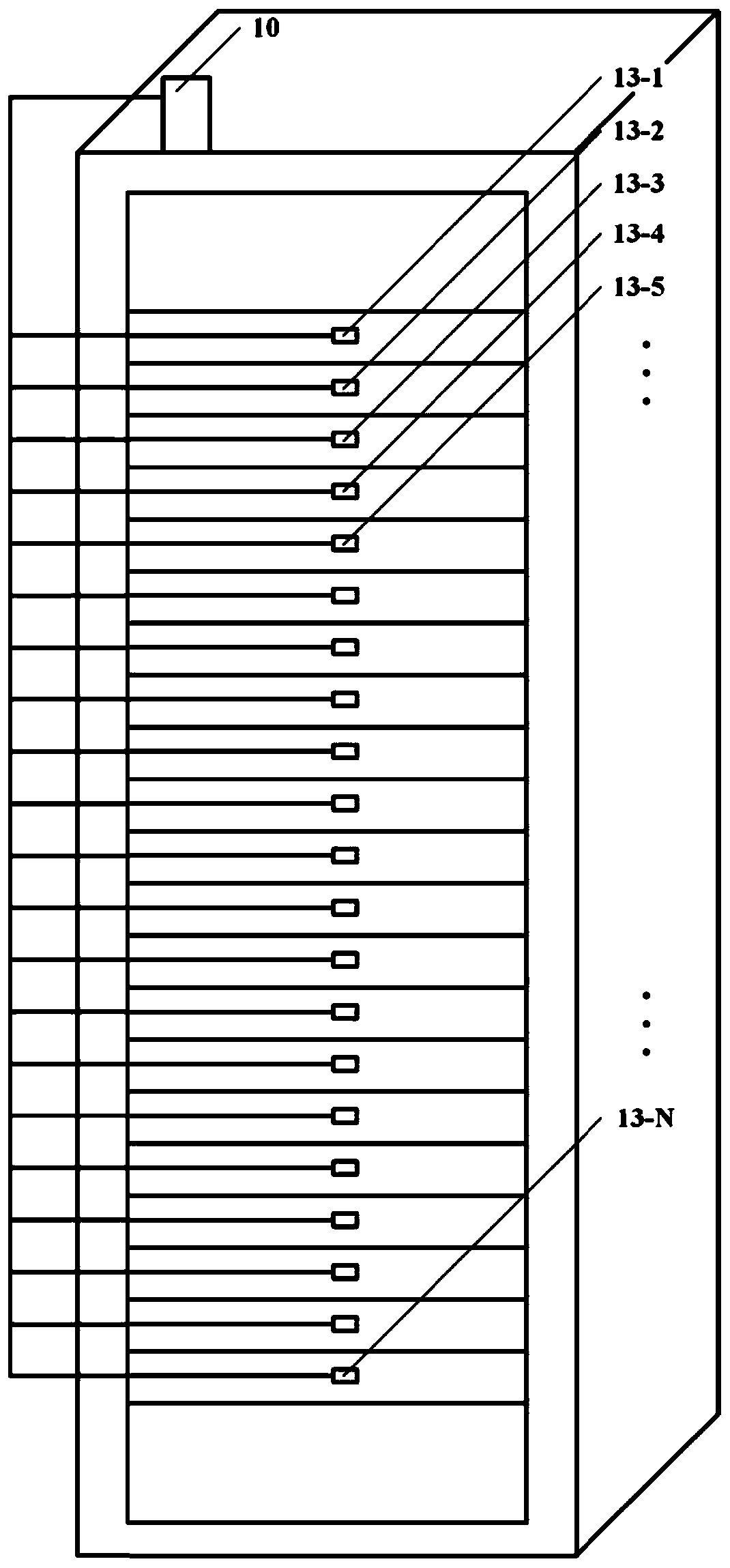

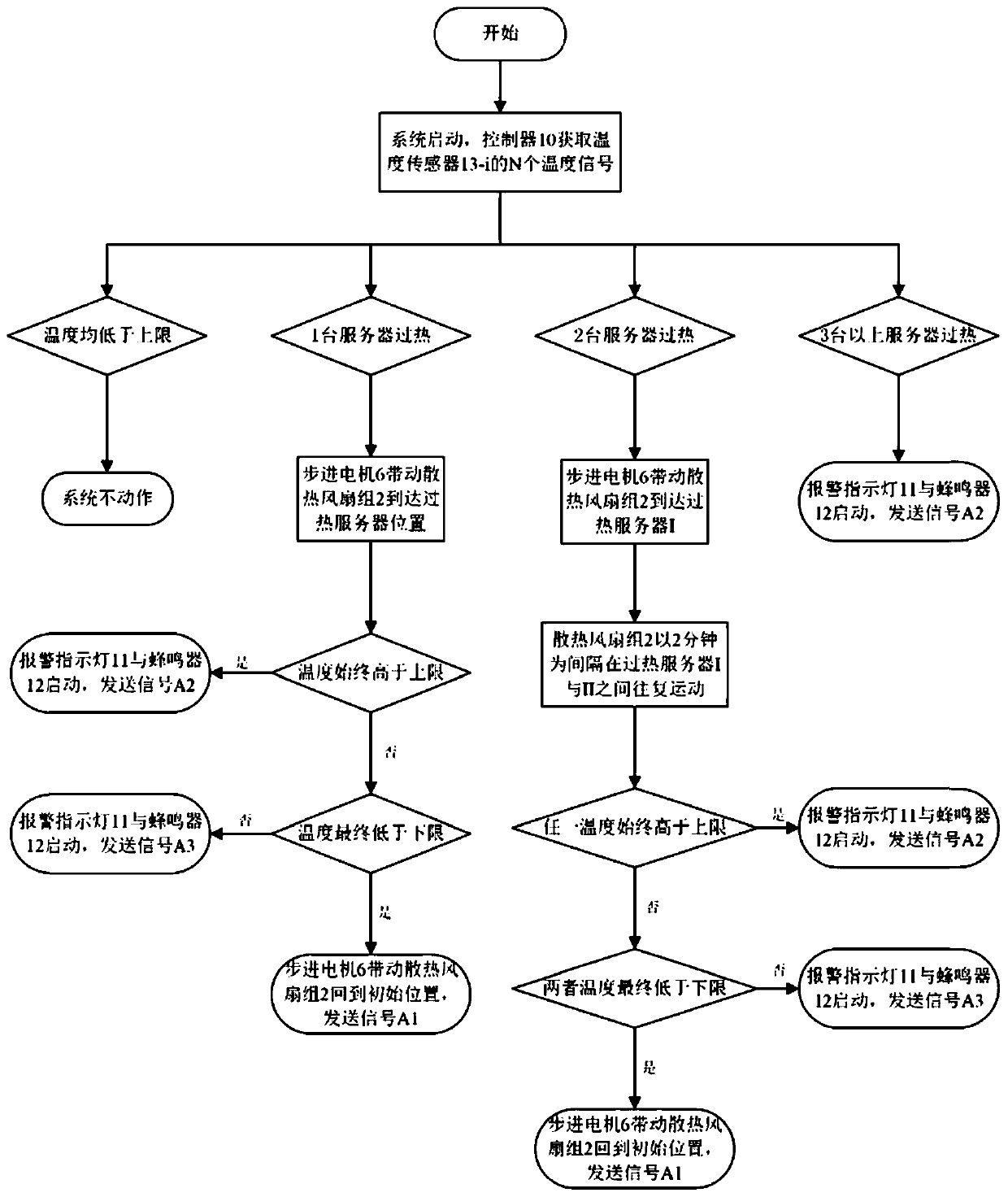

System and method for eliminating local hot spots of server cabinet at data center

ActiveCN110099546AGuaranteed uptimeExtended service lifeModifications using gaseous coolantsEngineeringEnergy consumption

The invention discloses a system and method for eliminating local hot spots of a server cabinet at a data center. The system comprises a server cabinet, a cooling fan group, a fan bracket, a guide rail, a stepping motor, a traction rope, a fixed pulley, a controller and temperature sensors, wherein the stepping motor is connected with the cooling fan group through the traction rope and can drive the cooling fan group to move up and down along the guide rail; and the controller detects local hot spots of the cabinet through the temperature sensors, so that the stepping motor is driven to rotatefor a certain number of turns, the cooling fan group is enabled to reach the air inlet position of an overheated server to increase the air supply volume at the position, enhance heat dissipation andeliminate the local shot spots. The system can automatically carry out accurate air supply on the overheated server, thereby lowering the temperature, ensuring the stable operation of the server, andprolonging the service life. Meanwhile, the air conditioner temperature is avoided from being lowered, and the energy consumption of the data center is reduced.

Owner:SOUTHEAST UNIV +1

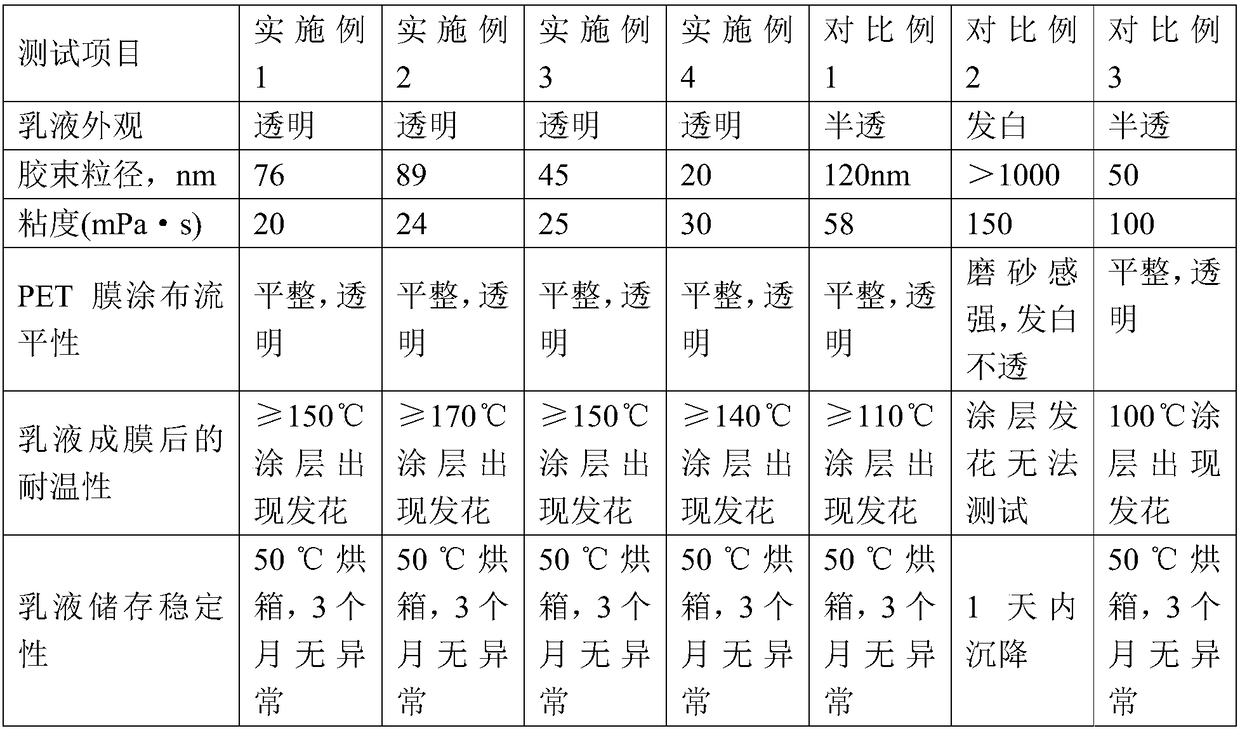

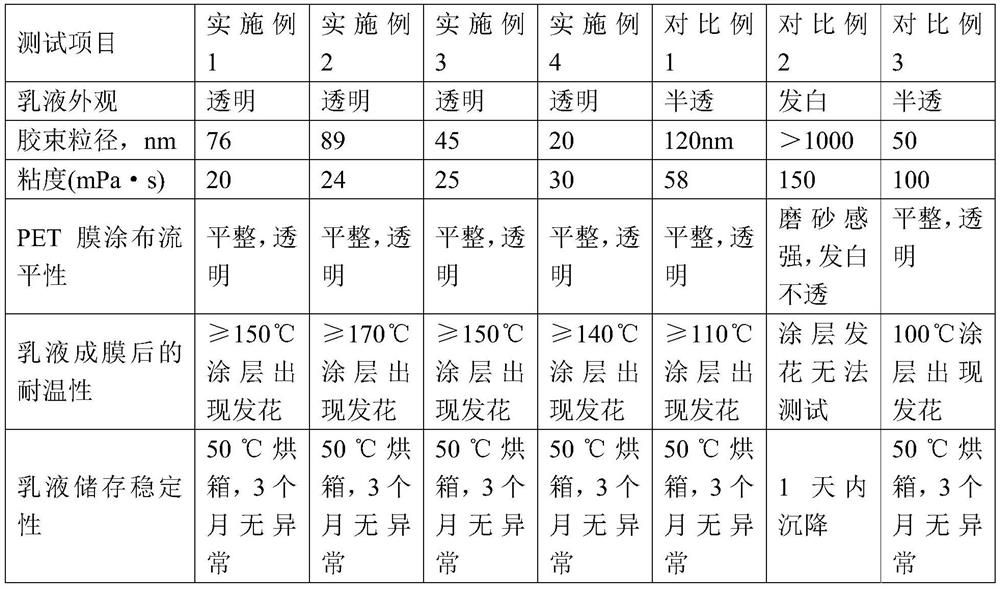

Heterogeneous chain extension synthesis method for waterborne polyurethane

ActiveCN108264621AImprove temperature resistanceSlow reaction ratePolyurea/polyurethane coatingsPolyesterCross-link

The invention provides a heterogeneous chain extension synthesis method for waterborne polyurethane. The method comprises the following steps: S1, pre-polymerizing: dehydrating polyester polyol, and performing a pre-polymerization reaction on the dehydrated polyester polyol and diisocyanate; S2, performing hydrophilic chain extension and cross-linking: adding a hydrophilic chain extender, a cross-linking agent and a diluent to a material obtained in step S1, and performing a chain extension and cross-linking reaction; S3, neutralizing and extending the chain: adding neutralizing amine, water,the diluent, a pH buffer agent and fatty amine to a material obtained in step S2, and ending the reaction to obtain a prepolymer; S4, performing dispersing emulsification: adding water to a material obtained in step S3 to achieve emulsification in order to uniformly disperse the prepolymer in water; and S5, performing a post-chain extension reaction: adding a post-chain extension amine to a material obtained in step S4, performing chain extension in water, and performing reduced pressure distillation to remove the solvent in order to obtain the waterborne polyurethane. The method uses fatty amine to carry out chain extension in a heterogeneous state in order to synthesize the waterborne polyurethane resin with high content of allophanate; and the obtained emulsion has the advantages of small micelle particle size, low viscosity, good leveling property and good storage performance.

Owner:SHANGHAI WEIKAI CHEM +1

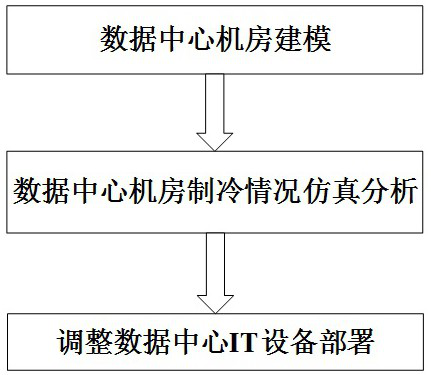

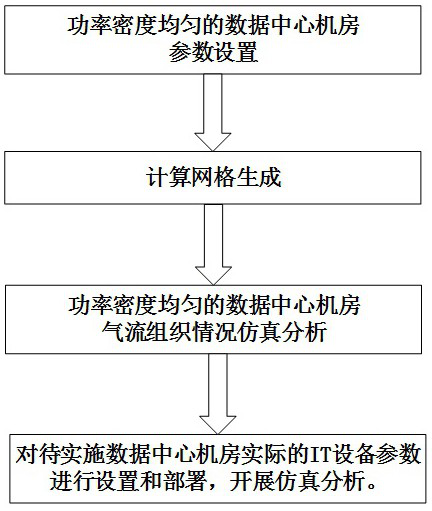

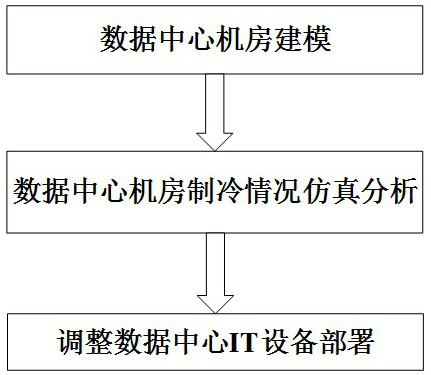

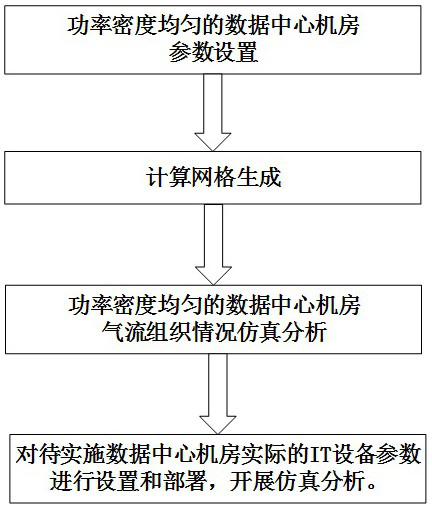

Data center machine room equipment layout method based on fluid mechanics simulation

ActiveCN113779689AImprove construction efficiencyMake full use of spaceGeometric CADDesign optimisation/simulationIt equipmentProcess engineering

The embodiment of the invention provides a data center machine room equipment layout method based on fluid mechanics simulation, relates to the technical field of data center machine room layout methods, and aims to improve the utilization efficiency of a data center refrigeration system and increase the capacity of data center machine room IT equipment power consumption. The method comprises the following steps of: constructing an equipment layout model in a data center machine room; carrying out modeling according to the overall layout of to-be-transformed data center machine room equipment, wherein the modeling content comprises the length, the width and the height of the data center machine room, the size, the position, the air supply and return position as well as the air supply and return temperature of an air conditioner in the data center machine room, and the size of a cabinet in the data center machine room; when an air flow organization mode of air supply under the floor is adopted, determining the height of the floor and an aperture ratio of a cold channel floor; performing air distribution simulation analysis on the IT equipment in the data center machine room; and adjusting the position of the IT equipment in the data center machine room according to the result of the airflow organization simulation analysis.

Owner:军事科学院系统工程研究院网络信息研究所

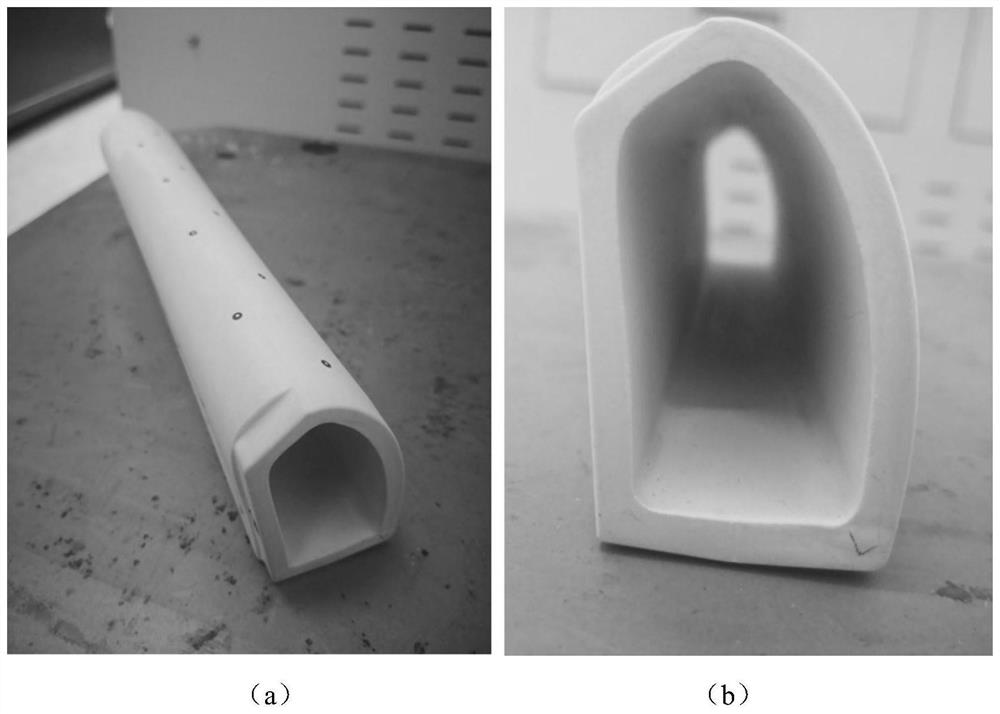

Hollow ceramic core stuffing method for expendable pattern precision casting

InactiveCN111673050AReduce loose tendencyComplete appearanceFoundry mouldsFoundry coresSlurryPrecision casting

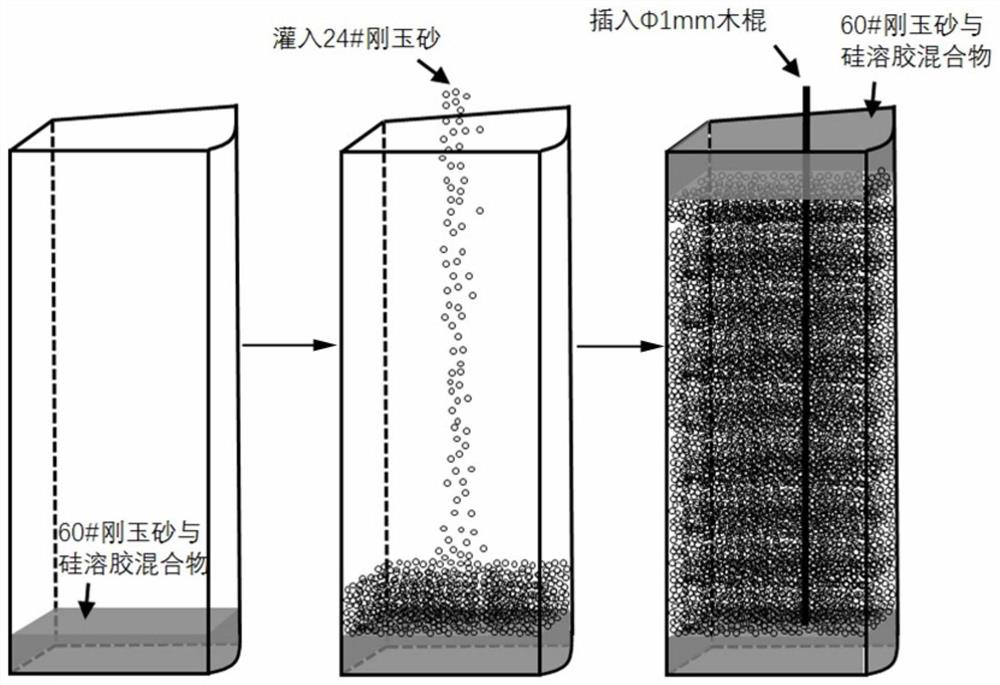

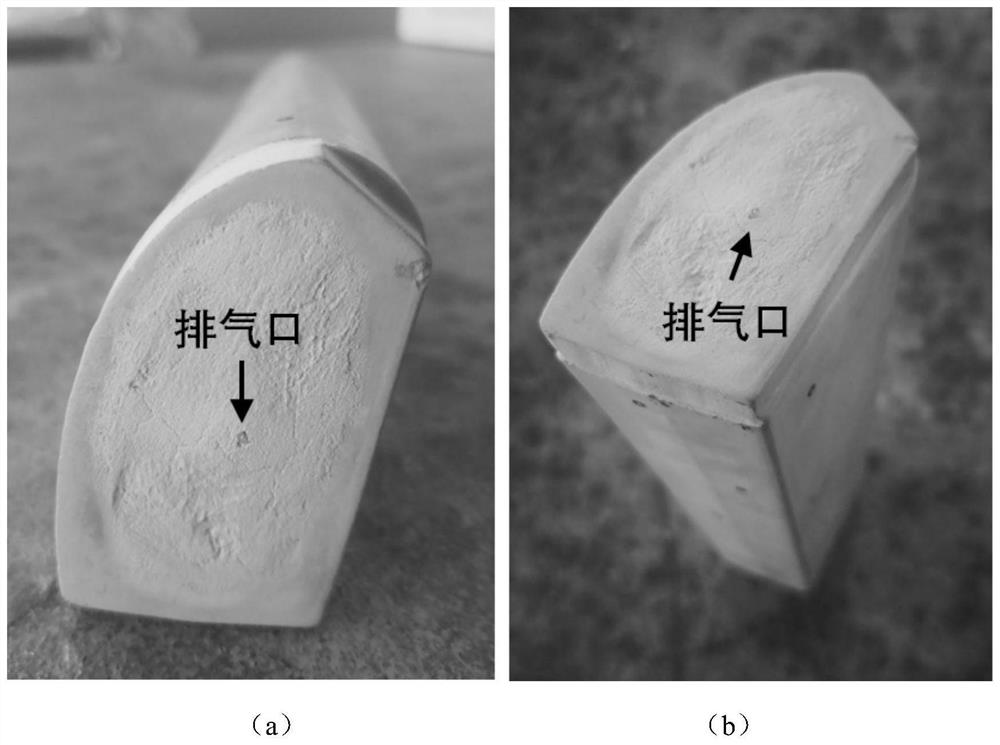

The invention discloses a hollow ceramic core stuffing method for expendable pattern precision casting, and belongs to the technical field of expendable pattern precision casting. The method comprisesthe following steps of plugging one end of a cavity of a hollow ceramic core with a plugging material I; taking 24# emery, performing pouring from the other end of the hollow ceramic core, and when the end is to be stuffed completely, plugging the other end of the cavity of the hollow ceramic core with a plugging material II; inserting a wood stick in the cavity of the hollow ceramic core; afterthe plugging materials at two ends of the hollow ceramic core are completely solidified and dried, removing the exposed part of the wood stick, and burnishing two exposed ends until a smooth state isachieved and granules are not remained; and finally, cleaning the outer surface of the ceramic core, so that remaining slurry and fine sand do not exist. In expendable pattern precision casting tests,the appearance of the stuffed ceramic core always maintains complete, the thermal conductivity is good, local heating segments are reduced, loosening trend of casts is notably reduced, and the technology stability is good.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

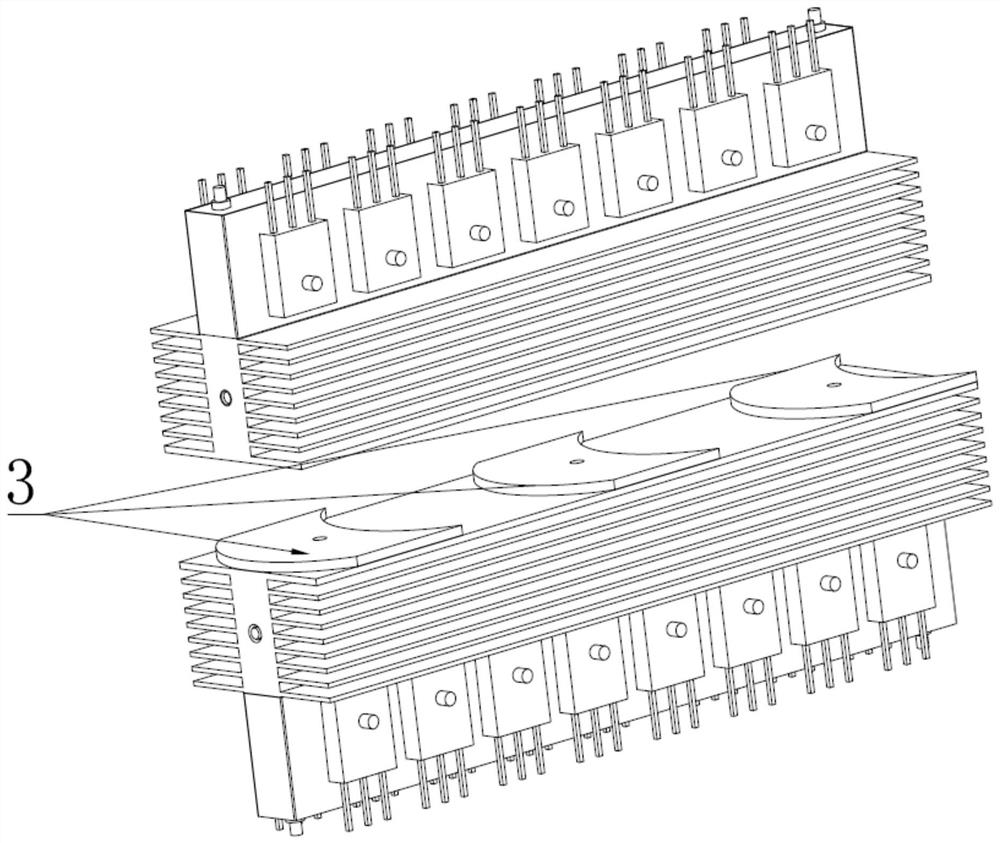

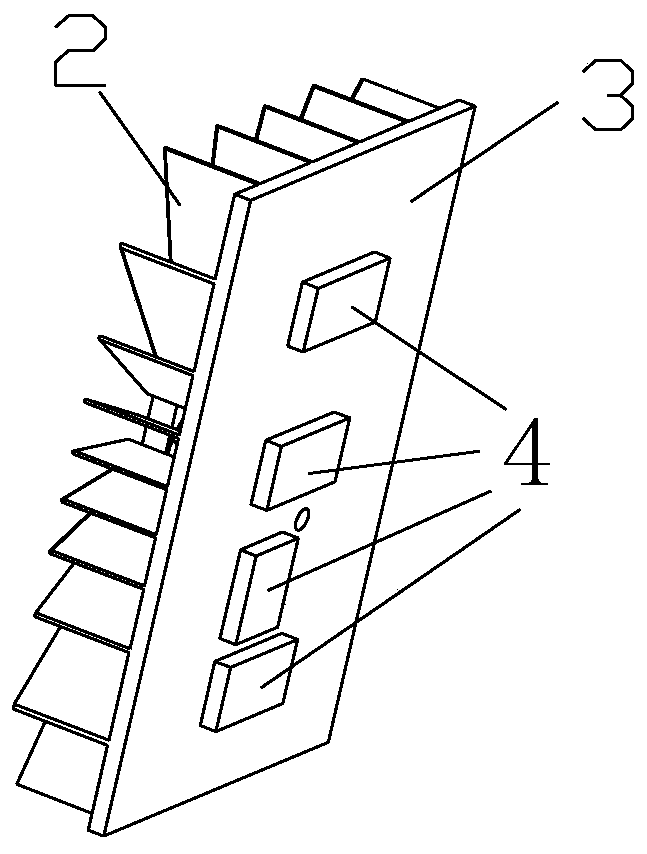

Heat dissipation structure and power module

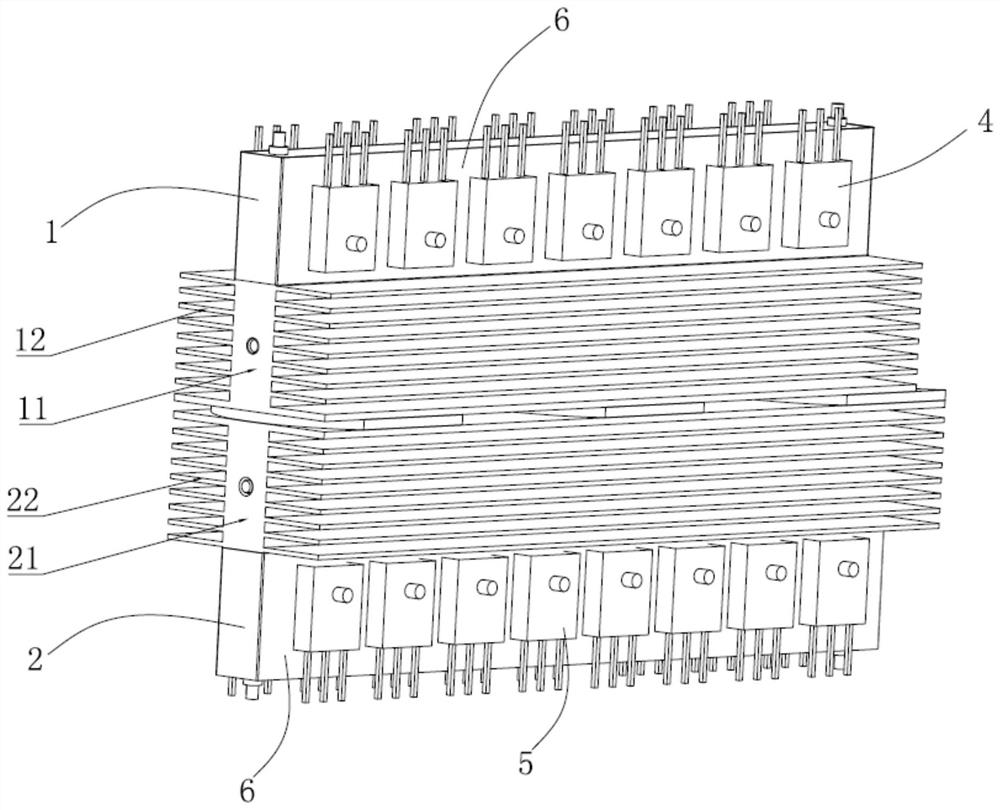

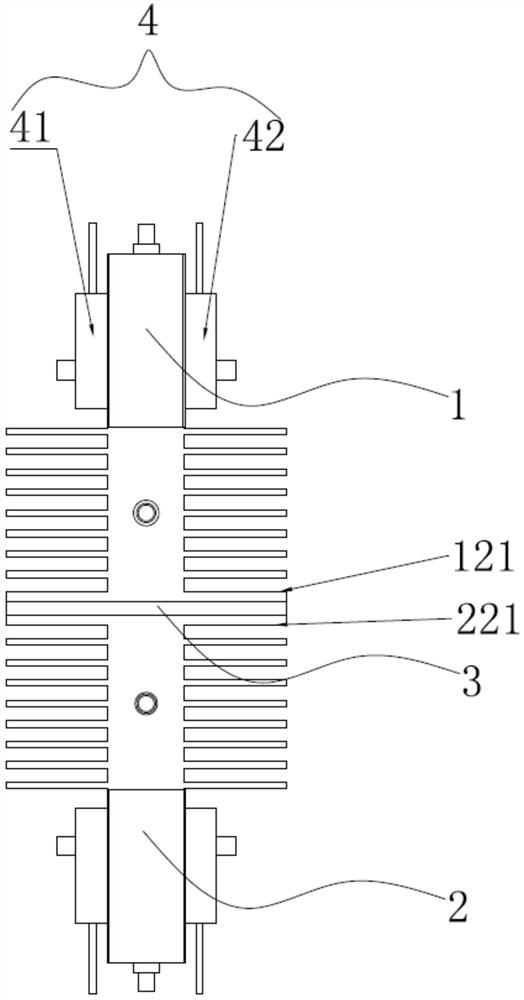

ActiveCN111816630AImprove heat transfer efficiencyImprove temperature uniformitySemiconductor/solid-state device detailsSolid-state devicesThermodynamicsEngineering

The invention discloses a heat dissipation structure, which comprises a first radiator, a second radiator and a heat conduction unit, wherein the first radiator is used for dissipating heat of a firstpower unit, and is provided with a first heat dissipation pedestal having first heat dissipation fins; the second radiator is arranged opposite to the first radiator, is used for dissipating heat ofa second power unit, and is provided with a second heat dissipation pedestal having second heat dissipation fins; and the two surfaces, deviating from each other and parallel to each other, of the heat conduction unit are attached to the opposite end faces of the first heat dissipation pedestal and the second heat dissipation pedestal correspondingly, and the heat conduction unit is used for conducting heat between the first radiator and the second radiator. Correspondingly, the invention further provides a power module adopting the heat dissipation structure. According to the heat dissipationstructure and the power module, the heat of the first radiator and the heat of the second radiator are conducted, local high-temperature points of the first power unit and the second power unit are reduced, the temperature is more balanced, and therefore the heat dissipation structure and the power module can cope with different limit working conditions, and the heat dissipation efficiency is improved under the condition of the same cost.

Owner:KEHUA DATA CO LTD +1

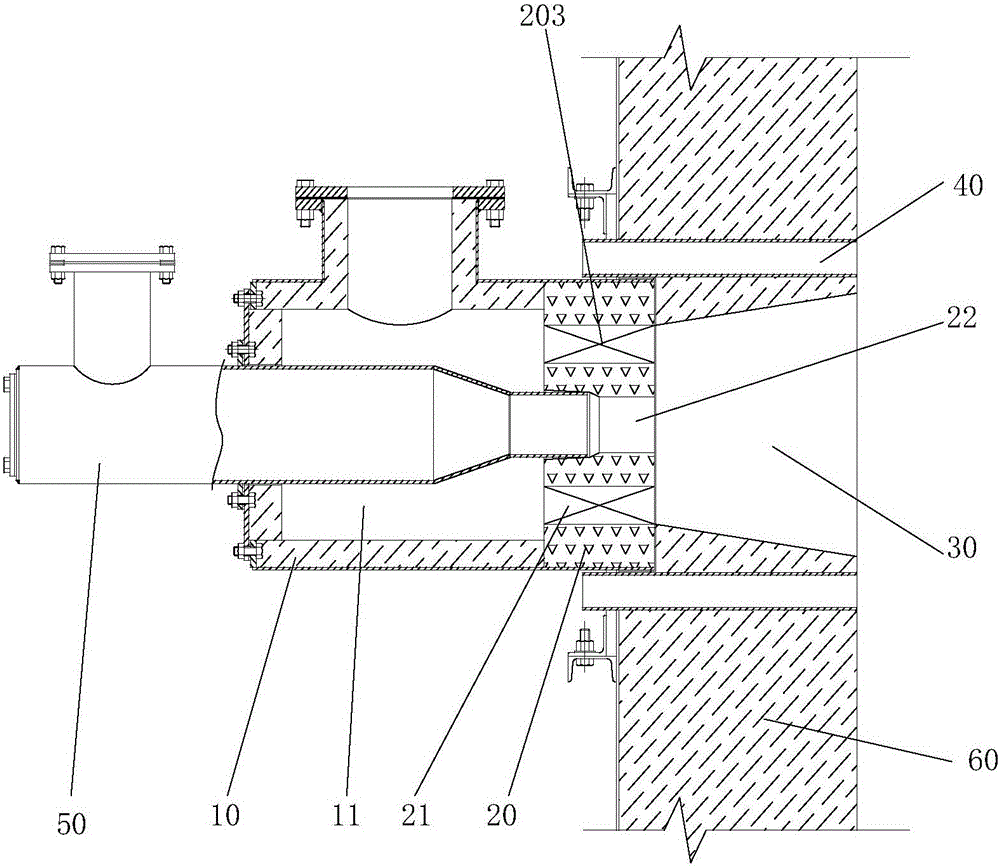

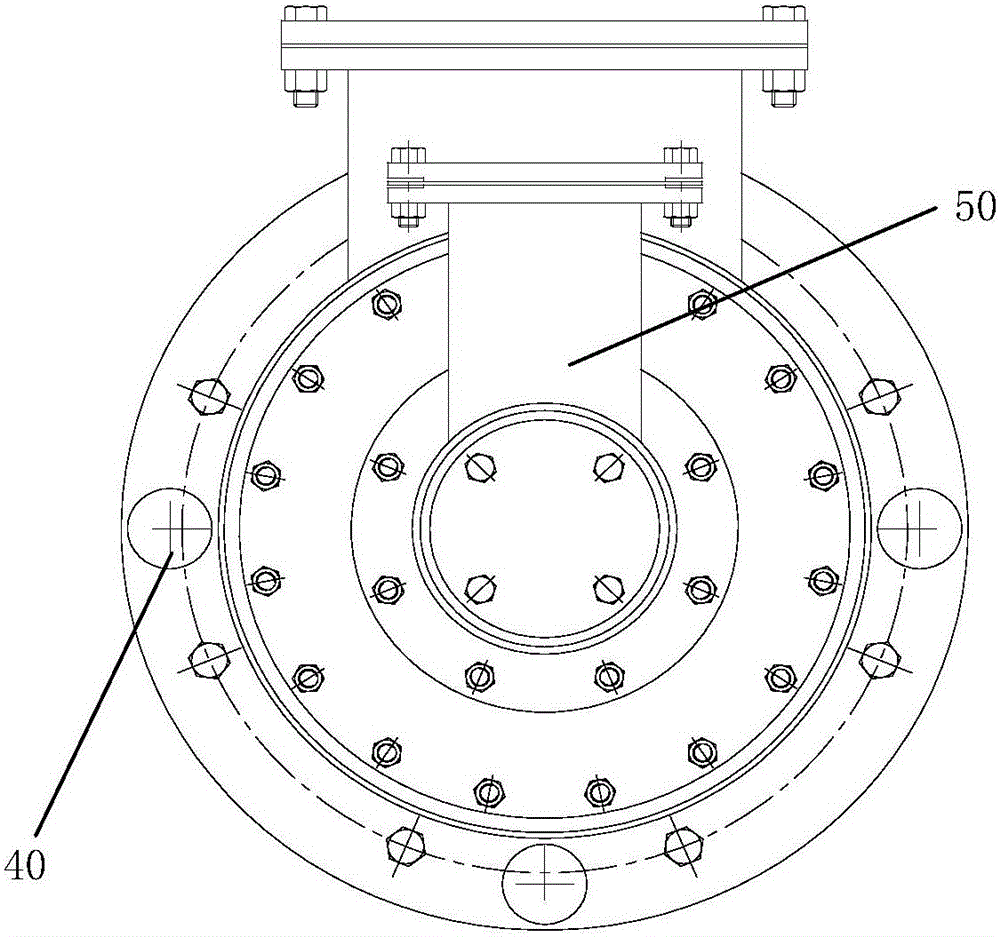

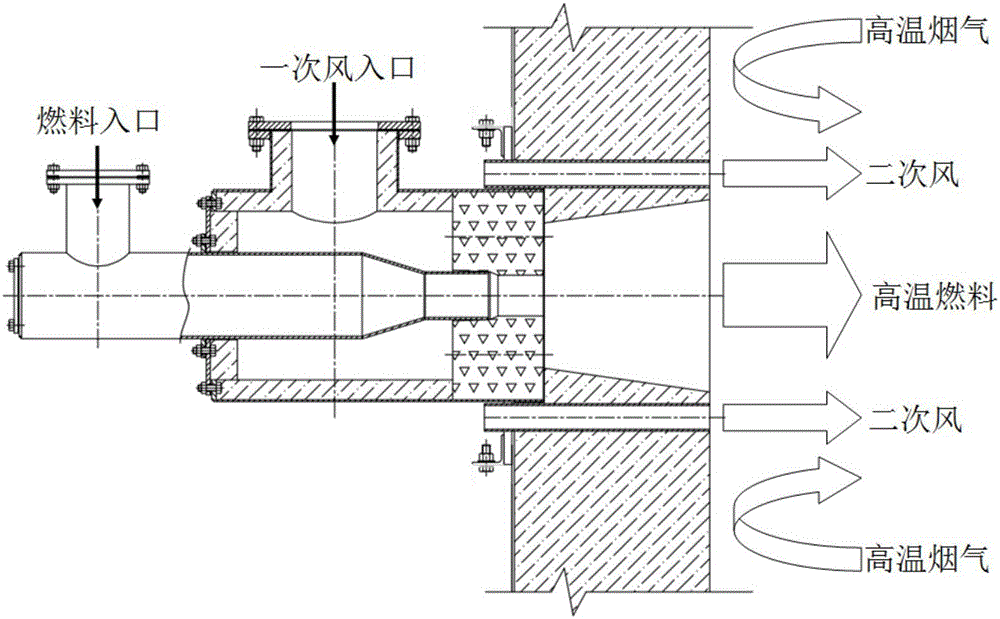

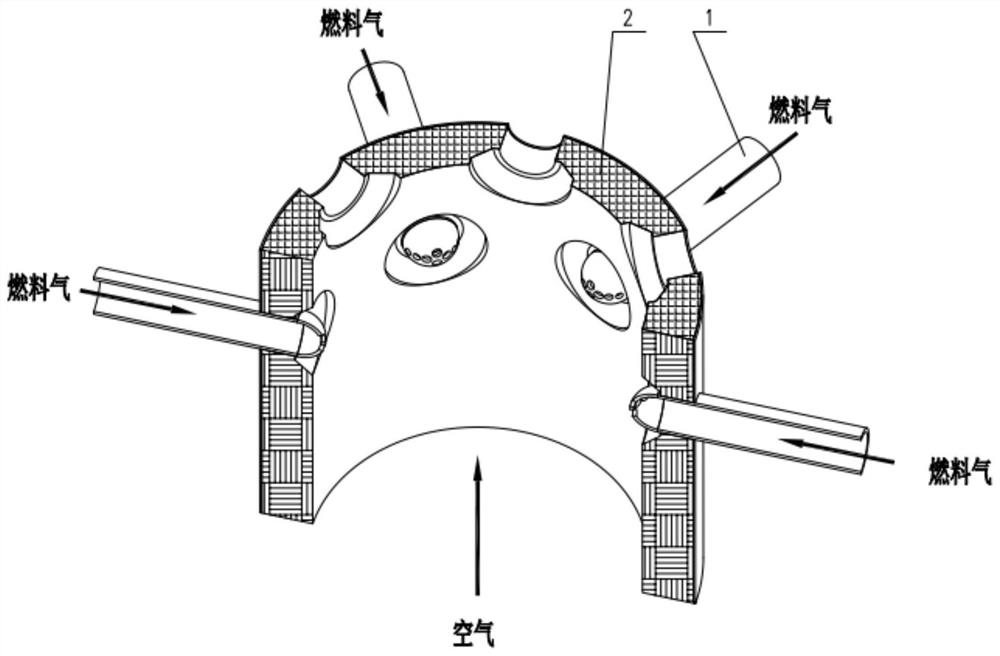

Staged oxygen-enriched flameless combustion gas burner and its control method

ActiveCN104235849BUnlimited calorific valueEfficient use ofIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringHeating furnace

The invention discloses a grading oxygen-enriched flameless combustion gas burner which comprises a burner shell, an air distribution plate, a pre-combustion chamber, secondary air spray pipes and a fuel spray pipe. The wall of a heating furnace is provided with a channel penetrating through the wall, the burner shell is arranged on one side of the channel, the pre-combustion chamber is formed in space in the channel, the burner shell is provided with a combustion-supporting air channel, the fuel spray pipe is provided with a fuel channel, the air distribution plate is provided with a primary air inlet and a fuel inlet, the secondary air spray pipes are arranged and provided with secondary air channels used for introducing oxygen-enriched air or air into a hearth of the heating furnace, the secondary air spray pipes penetrate through the wall of the heating furnace, and the secondary air channels are communicated with the hearth of the heating furnace. The grading oxygen-enriched flameless combustion gas burner optimizes temperature distribution in the furnace and meanwhile reduces emission of NOx.

Owner:WISDRI WUHAN WIS IND FURNACE

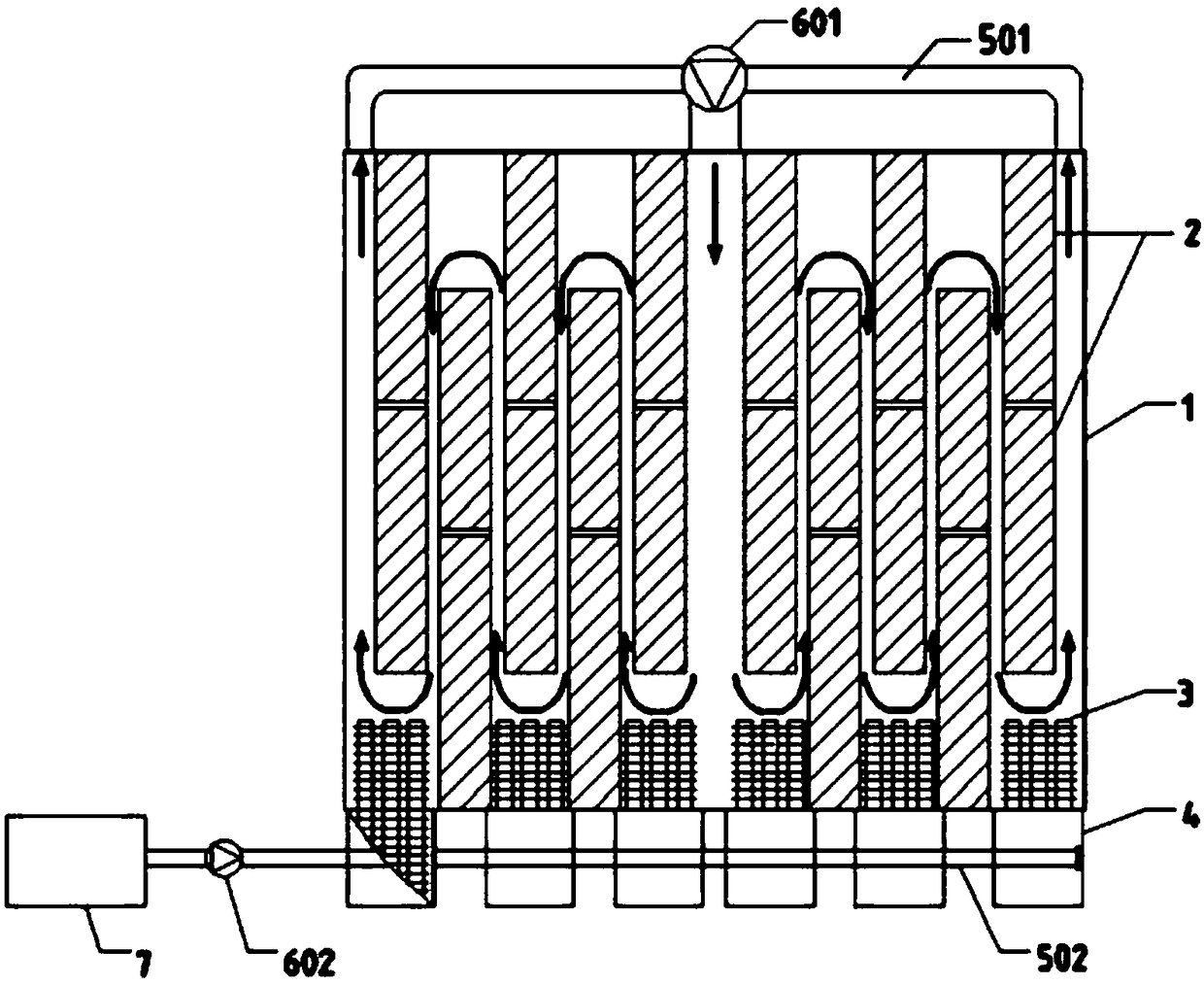

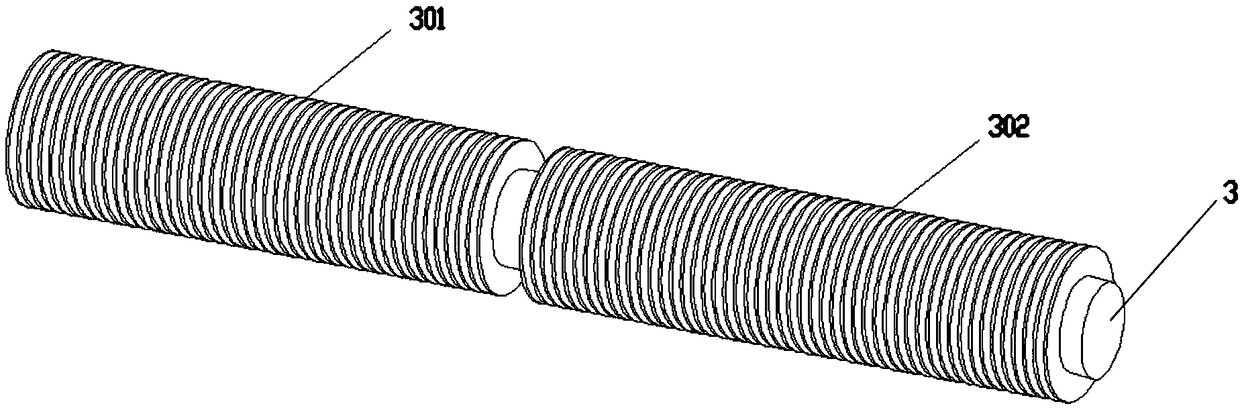

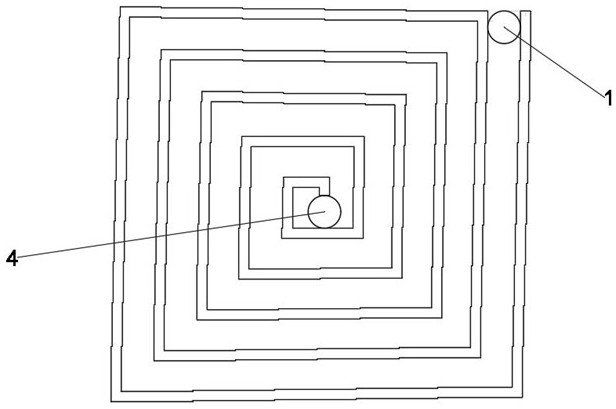

Variable runner metal wire-rock heat storage type solar heat collector

PendingCN109028606AImprove heat transfer performanceExtended use timeSolar heating energySolar heat storageEngineeringFiller metal

The invention discloses a variable runner metal wire-rock heat storage type solar heat collector. A heat collection and storage section of a variable-diameter runner is filled with metal wires and rock particles, so that increase of a heat exchange area is realized, heat exchange time is prolonged, and continuous disturbance of fluid can be realized, and therefore, the heat exchange effect of a system is further strengthened; the heat collector has an automatic heat sensible and storage function while quickly collecting heat, and has the characteristics of high heat collection and transfer speed, a wide heat collection material source, a wide heat storage material source, a low price, high thermal stability and heating efficiency, small thermal loss, a high outlet air temperature, and energy conservation and environment protection.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

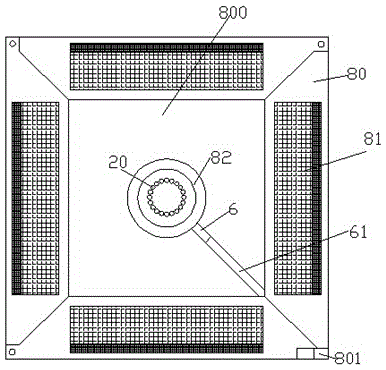

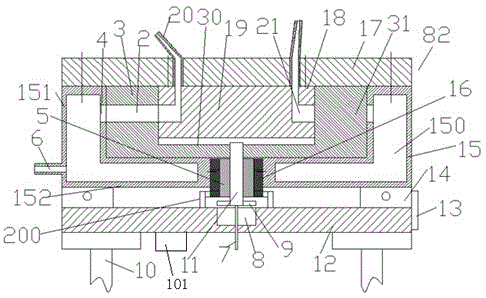

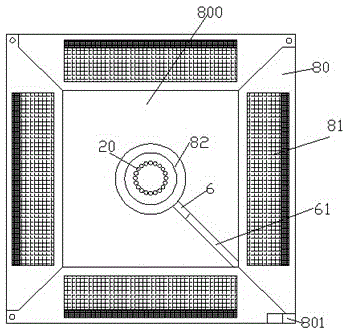

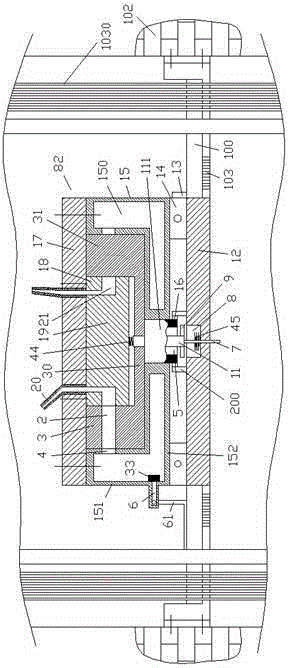

Cabinet-type computer apparatus with adjustable operation speed

InactiveCN105159414AReduce movable structureAvoid unstable factorsDigital processing power distributionEngineeringNozzle

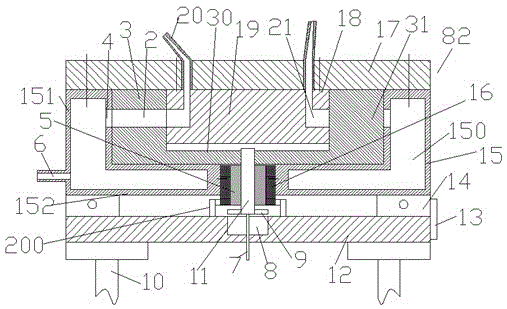

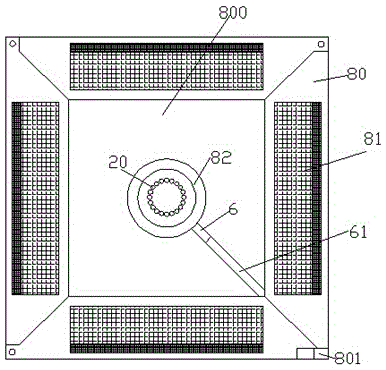

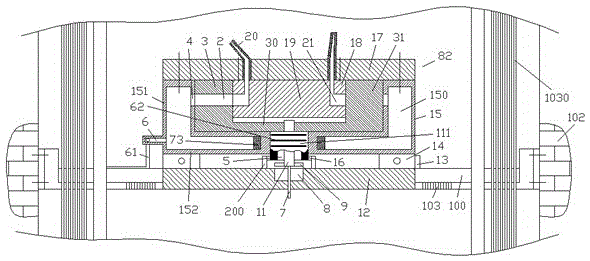

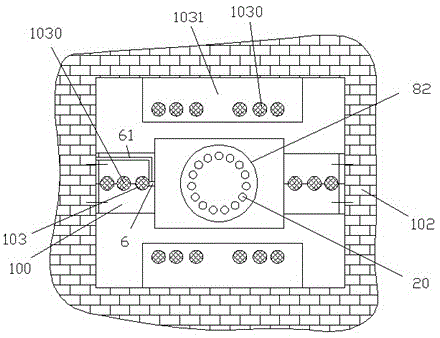

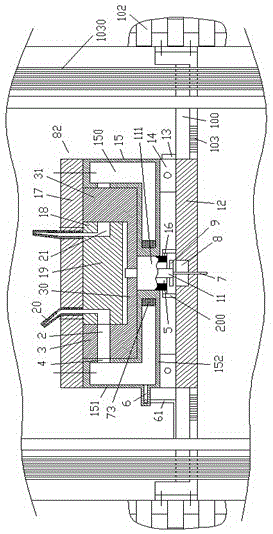

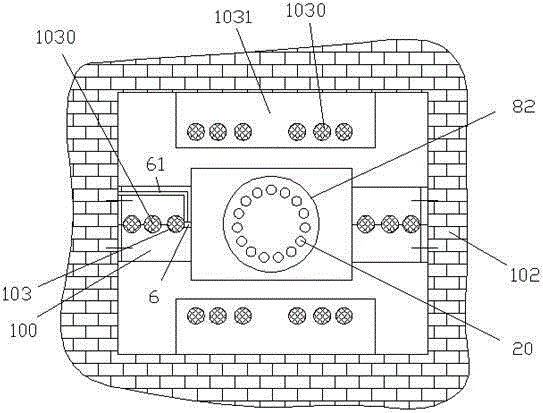

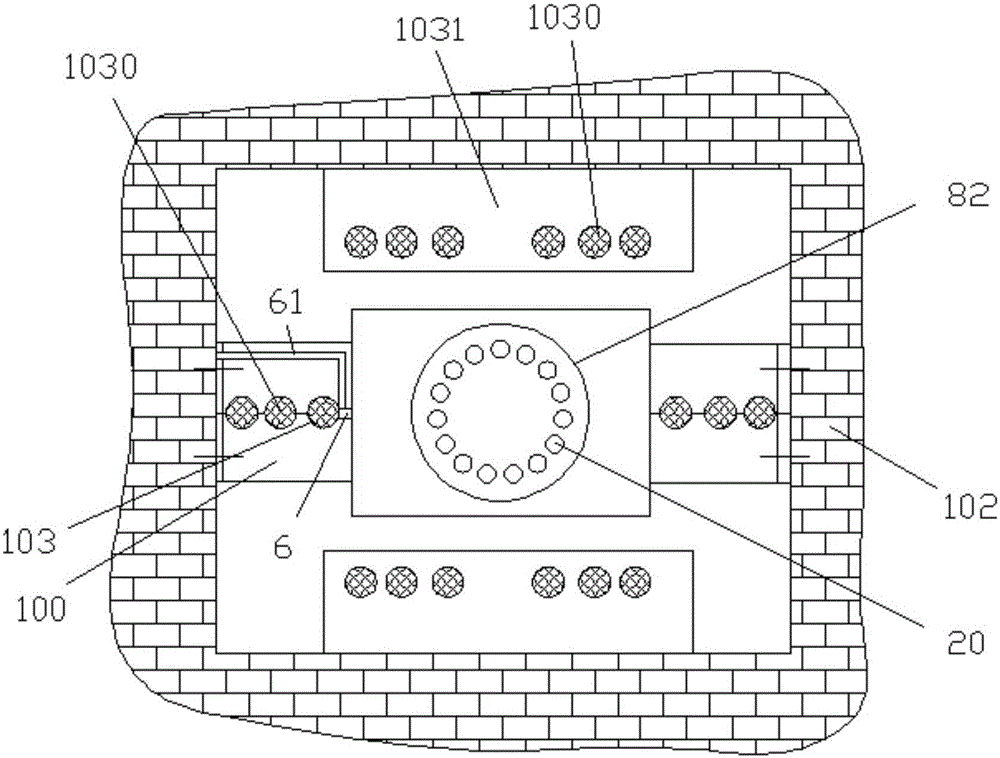

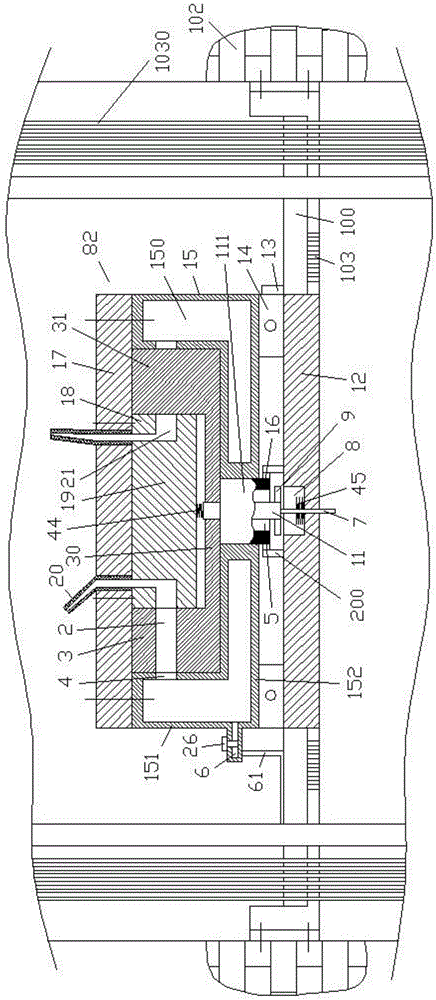

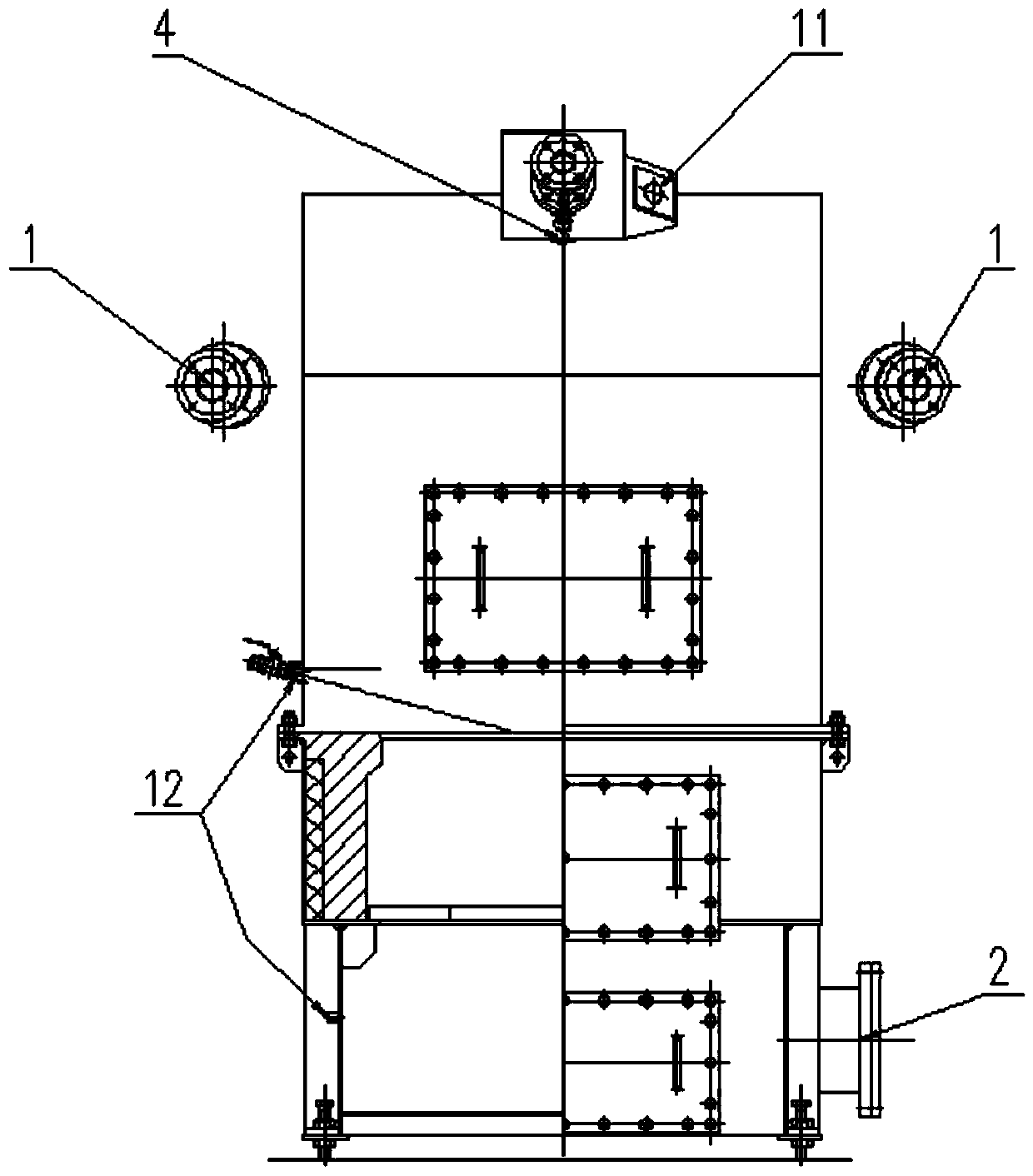

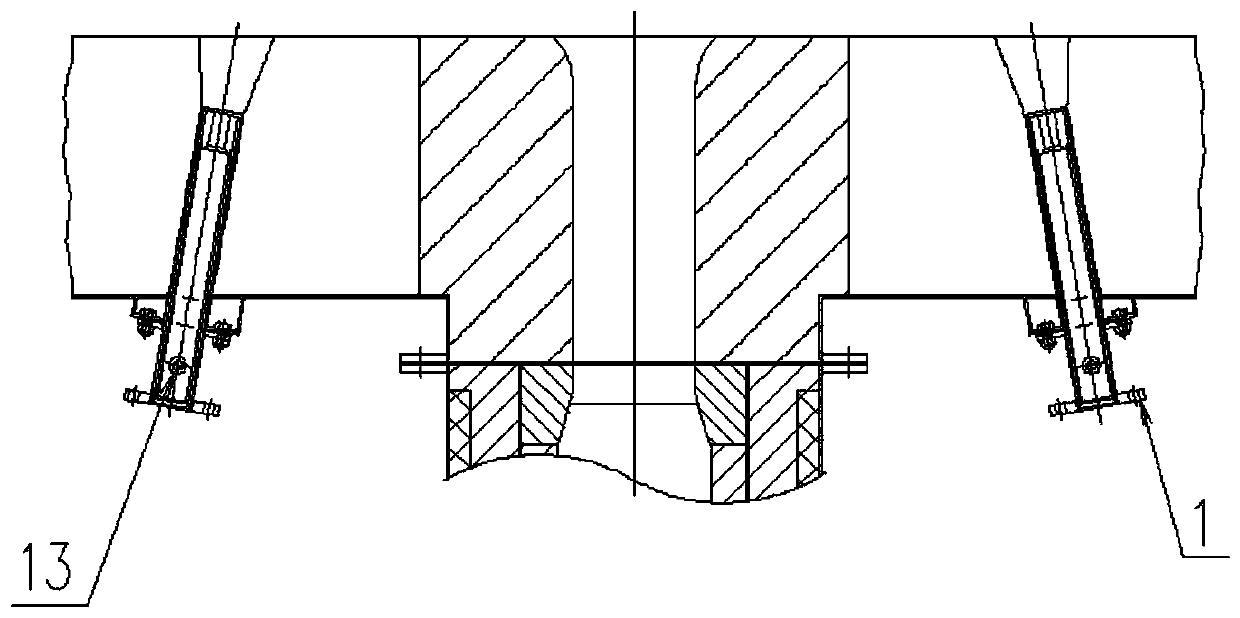

A cabinet-type computer apparatus with an adjustable operation speed comprises four foldable sections which can be folded to define a regular quadrangular contour shape with a hollow column body part (800) and can be pivoted and unfolded into a linear segment shape, wherein each foldable section comprises a cabinet body part (80) and a server unit (81) arranged in the cabinet body part (80); a cooling air-blowing apparatus (82) to which an air conveying pipe (61) supplies air is arranged at the bottom of the hollow column body part (800); and the cooling air-blowing apparatus (82) comprises an annular cavity housing (15) which is provided with an air inlet nozzle (6) to be communicated with the air conveying pipe (61).

Owner:XIAMEN BOLUOGE TRADE

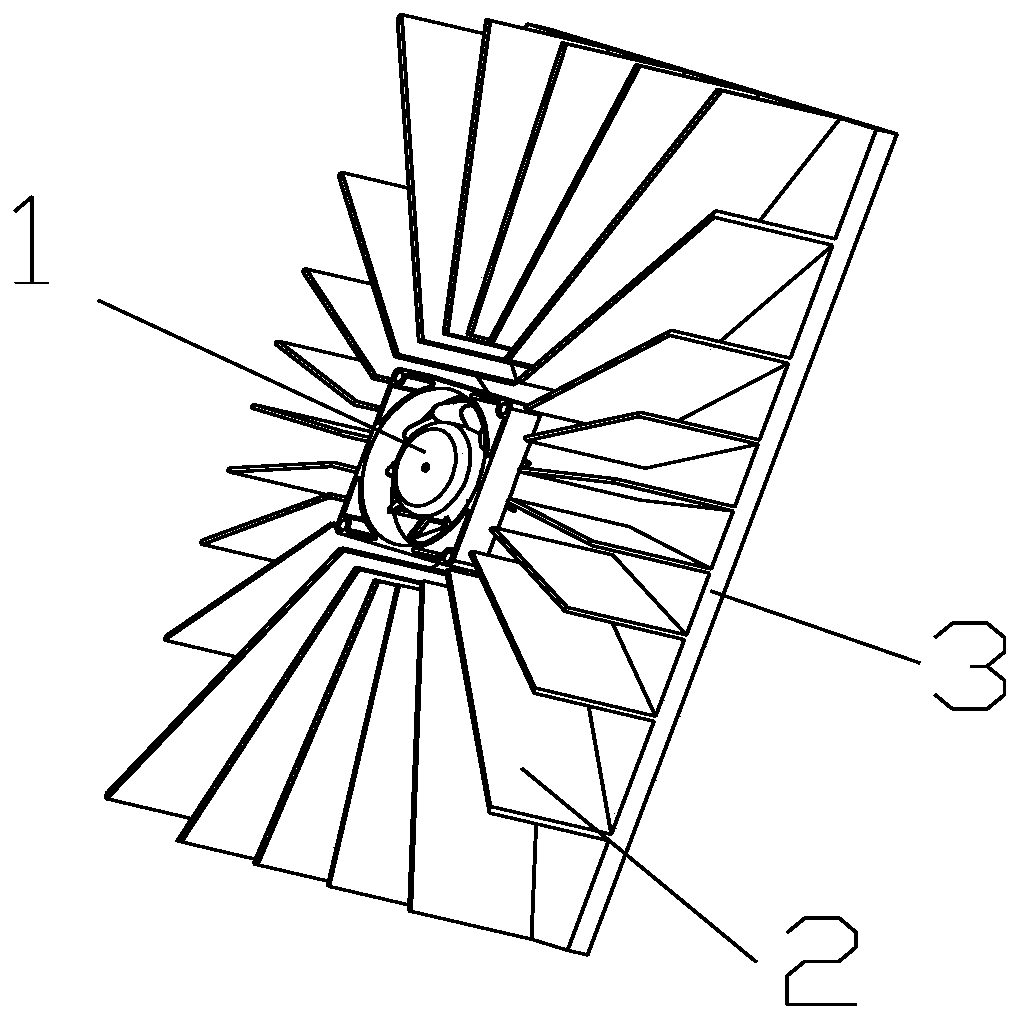

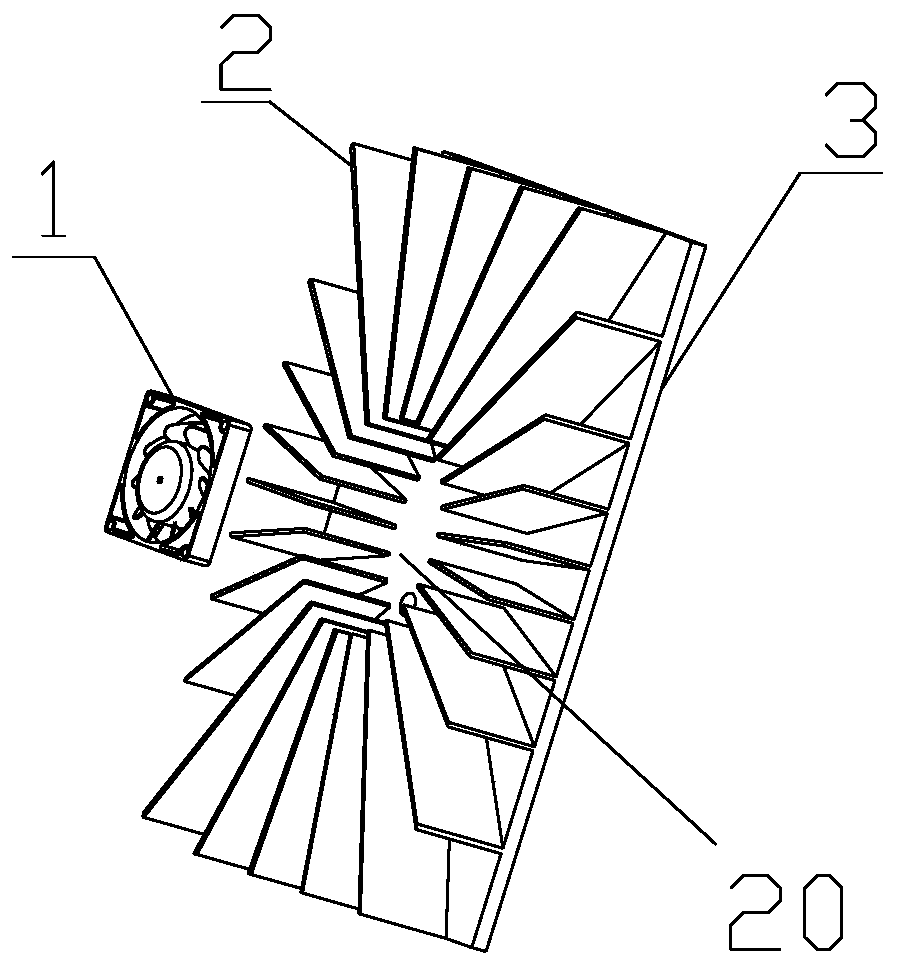

Controller heat dissipation assembly, control method and air conditioner

PendingCN111397002AImprove heat exchange utilizationImprove heat transfer effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringVariable frequency control

The invention provides a controller heat dissipation assembly, a control method and an air conditioner. The controller heat dissipation assembly comprises a heat dissipation substrate, a plurality ofheat dissipation fins and a fan assembly, one side of the heat dissipation substrate is attached to a heating component, the other side of the heat dissipation substrate is provided with the pluralityof heat dissipation fins, a cavity is formed in the heat dissipation fins, the fan assembly is arranged in the cavity in the heat dissipation fins, and the heat dissipation of the heating component is controlled by controlling the opening or closing of the fan assembly and / or controlling the rotating speed of the fan assembly when the fan assembly is opened. According to the controller heat dissipation assembly, air flow can be sucked or blown out from the interiors of the heat dissipation fins, local high-temperature points of components can be reduced, the problems that the temperature of the components of an air conditioner variable frequency controller is too high and the temperature of the components is uneven and inconsistent are solved, and meanwhile a system is fed back and adjusted according to the operation condition of the fan assembly in a radiator, and the temperature of the component is ensured to be within a reasonable range.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

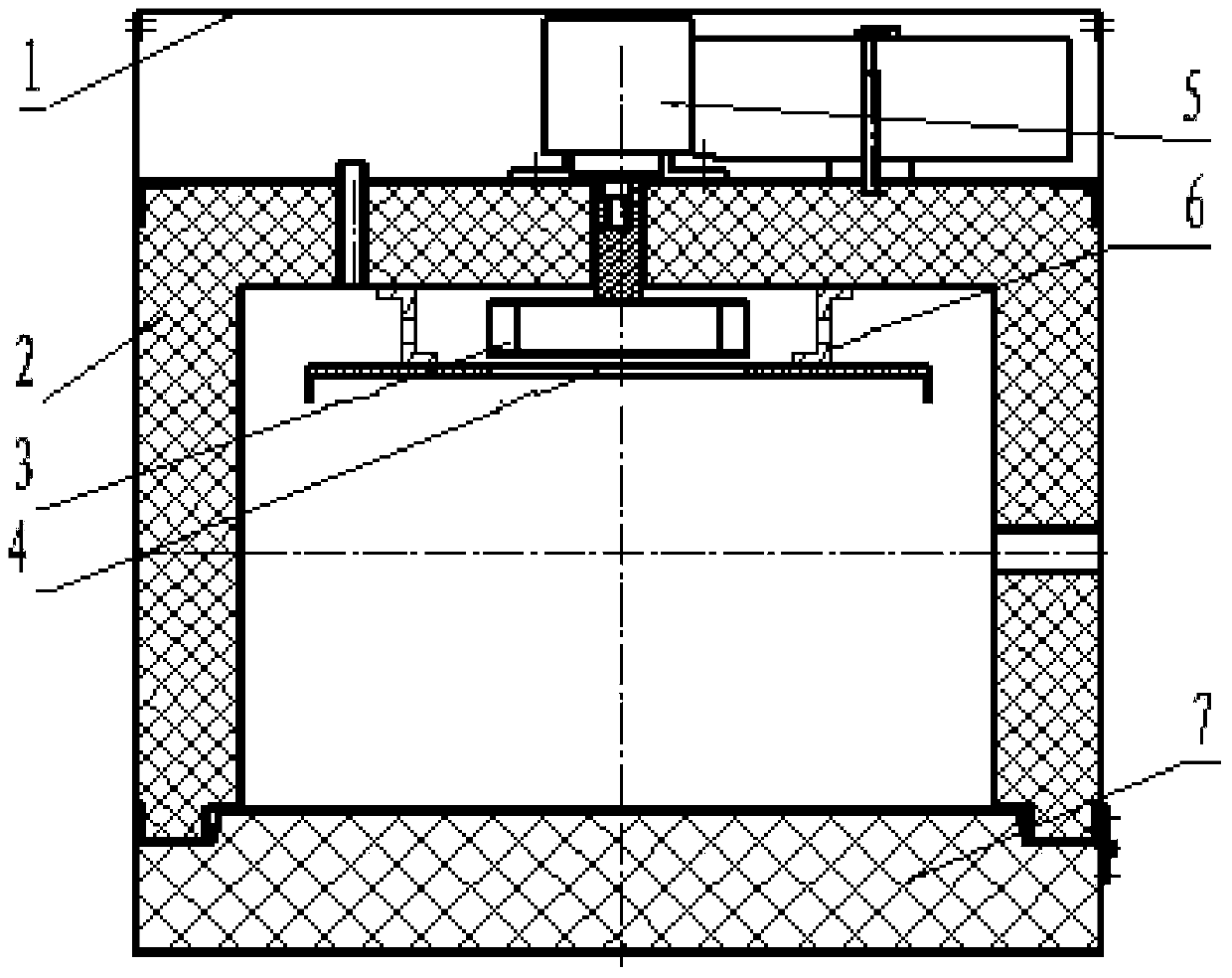

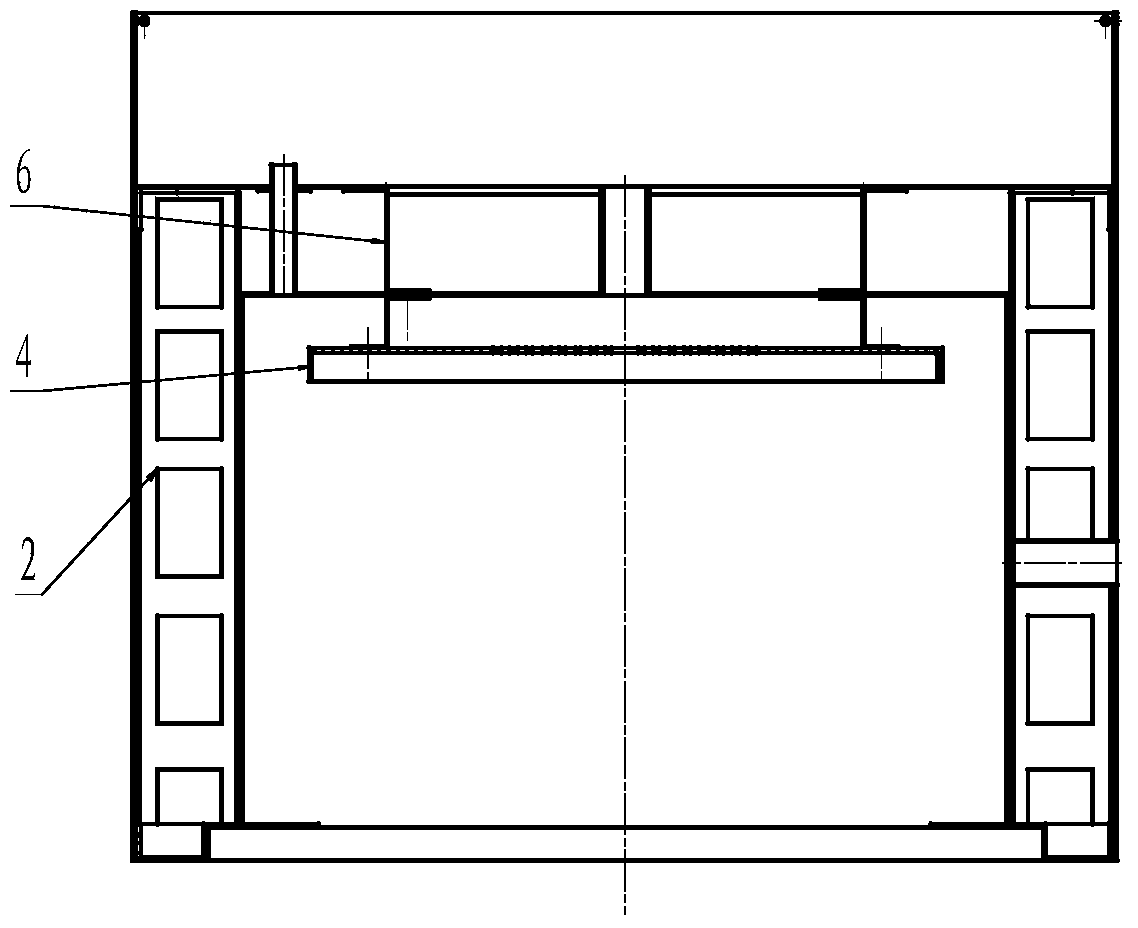

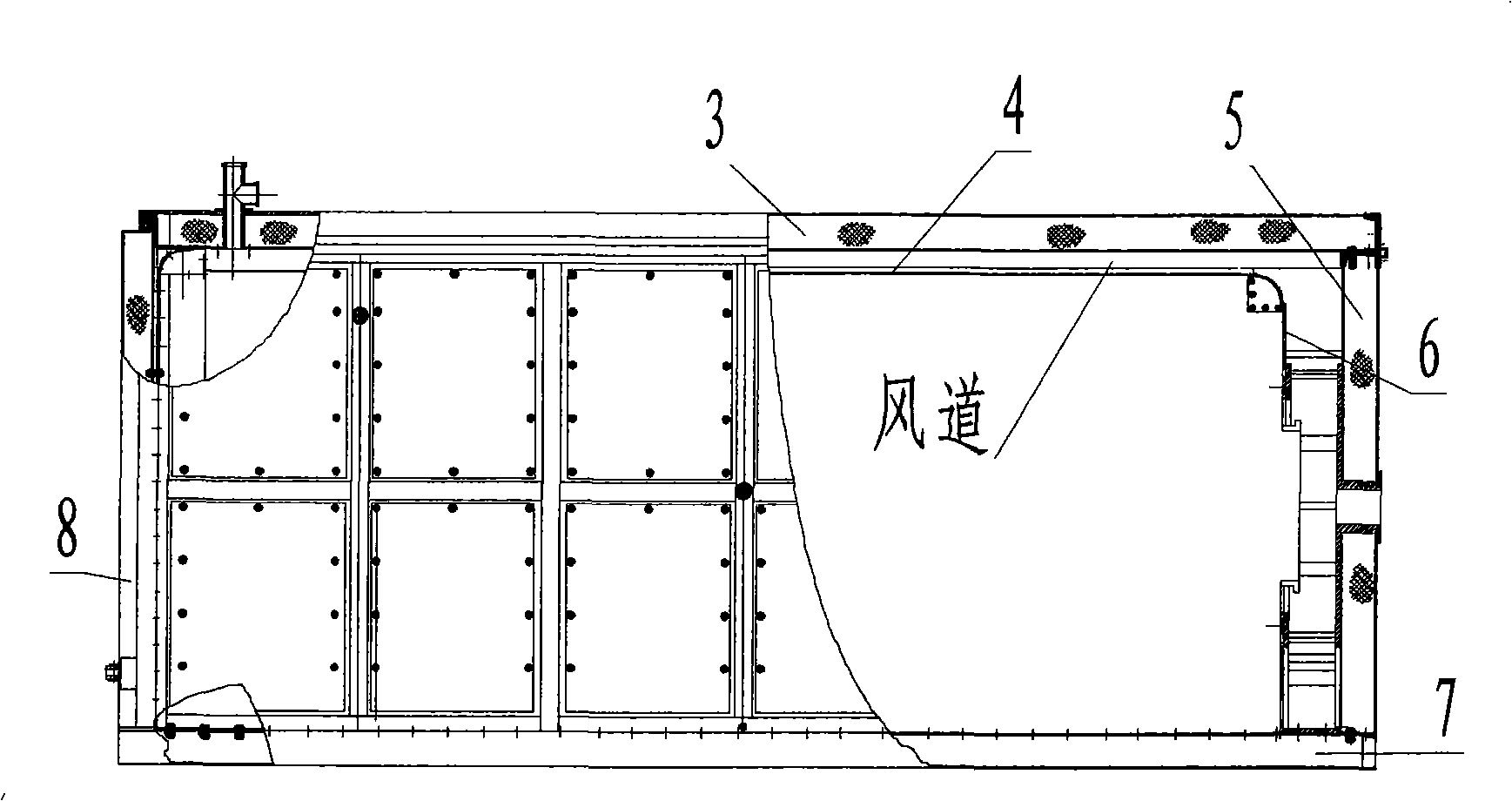

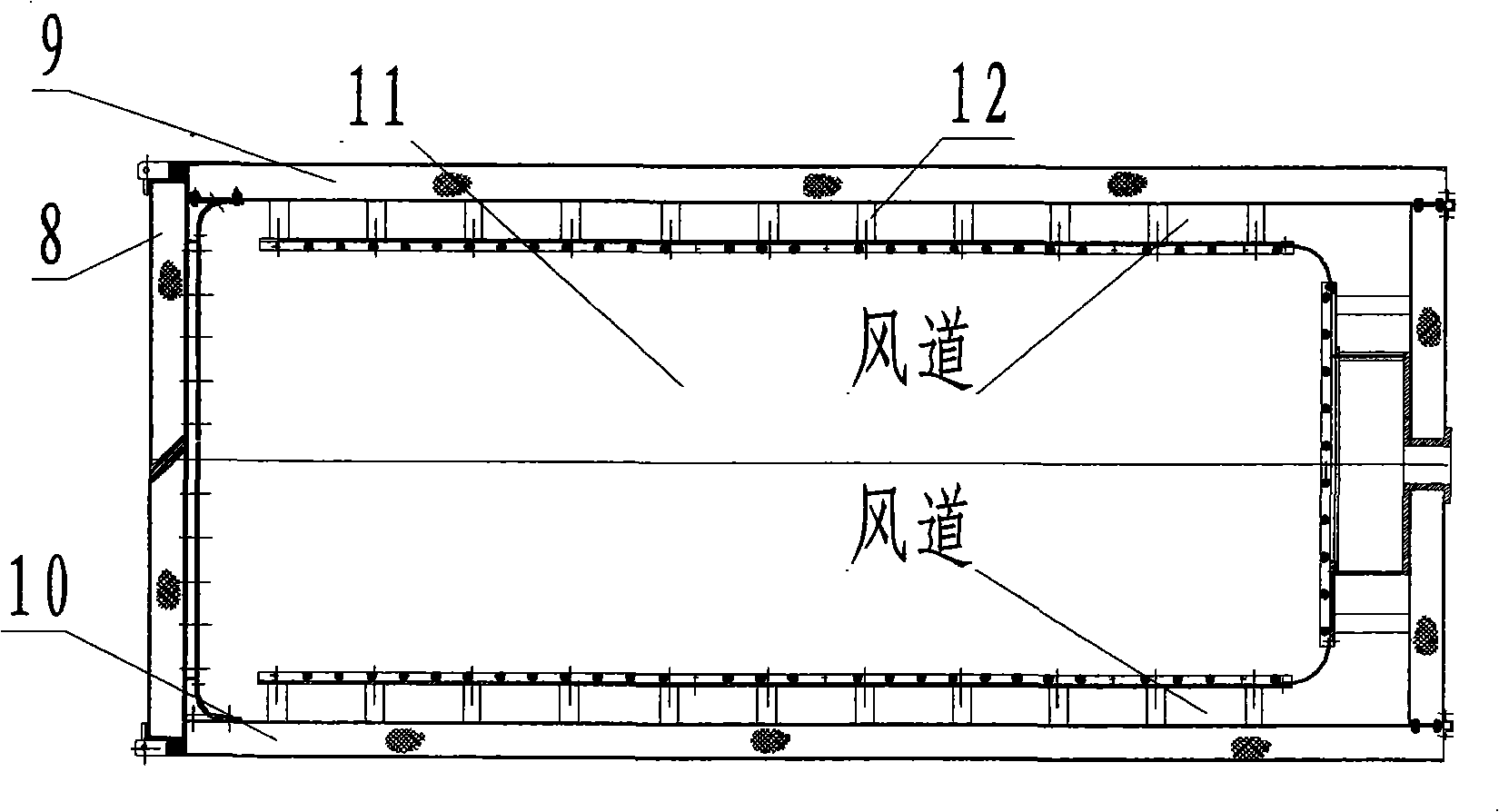

Aeroheating furnace and method for generating heat energy

InactiveCN101520248BAchieving High UniformityReduce consumptionOther heat production devicesNatural sources for heatingThermal energyEnergy expenditure

The invention relates to an aeroheating furnace and a method for generating heat energy. The aeroheating furnace realizes heating by adopting the principle of converting wind energy into heat energy aThe invention relates to an aeroheating furnace and a method for generating heat energy. The aeroheating furnace realizes heating by adopting the principle of converting wind energy into heat energy al cavity channels of the furnace body and a furnace cavity to realize the conversion from wind energy to heat energy. The aeroheating furnace is essentially different from industrial furnaces generaall cavity channels of the furnace body and a furnace cavity to realize the conversion from wind energy to heat energy. The aeroheating furnace is essentially different from industrial furnaces generating heat by means of fuel combustion or directly converting electric energy into heat in principle. Moreover, the aeroheating furnace carries out heating and heat air circulation at the same time toting heat by means of fuel combustion or directly converting electric energy into heat in principle. Moreover, the aeroheating furnace carries out heating and heat air circulation at the same time torealize even height of temperature field inside the furnace body; in addition, the furnace does not adopt heating elements such as electrothermal tubes and reduces energy consumption to realize the efrealize even height of temperature field inside the furnace body; in addition, the furnace does not adopt heating elements such as electrothermal tubes and reduces energy consumption to realize the effect of energy saving.fect of energy saving.nd is characterized by comprising a furnace body and a power device, wherein the inside of the furnace body is provided with flow deflector arranged parallelly to the top wall, side walls and the backnd is characterized by comprising a furnace body and a power device, wherein the inside of the furnace body is provided with flow deflector arranged parallelly to the top wall, side walls and the backwall of the furnace body; wall cavity channels communicated upwards, leftwards, rightwards and backwards are formed in gaps between the flow deflector and the furnace walls, and are communicated with wall of the furnace body; wall cavity channels communicated upwards, leftwards, rightwards and backwards are formed in gaps between the flow deflector and the furnace walls, and are communicated with the intracavity of the furnace body at the front part of the furnace body; the power device comprises an electric motor, a transmission shaft and an impeller; the transmission shaft is fixed by a coothe intracavity of the furnace body at the front part of the furnace body; the power device comprises an electric motor, a transmission shaft and an impeller; the transmission shaft is fixed by a cooling support seat; and the electric motor is controlled by a control system to drive the impeller to rotate through the transmission shaft, thereby ensuring that high-speed air circulates inside the wling support seat; and the electric motor is controlled by a control system to drive the impeller to rotate through the transmission shaft, thereby ensuring that high-speed air circulates inside the wal

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

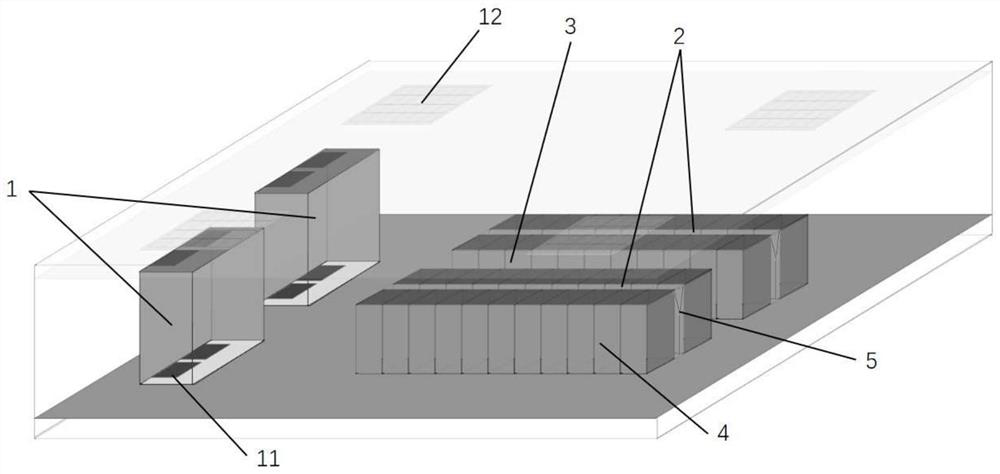

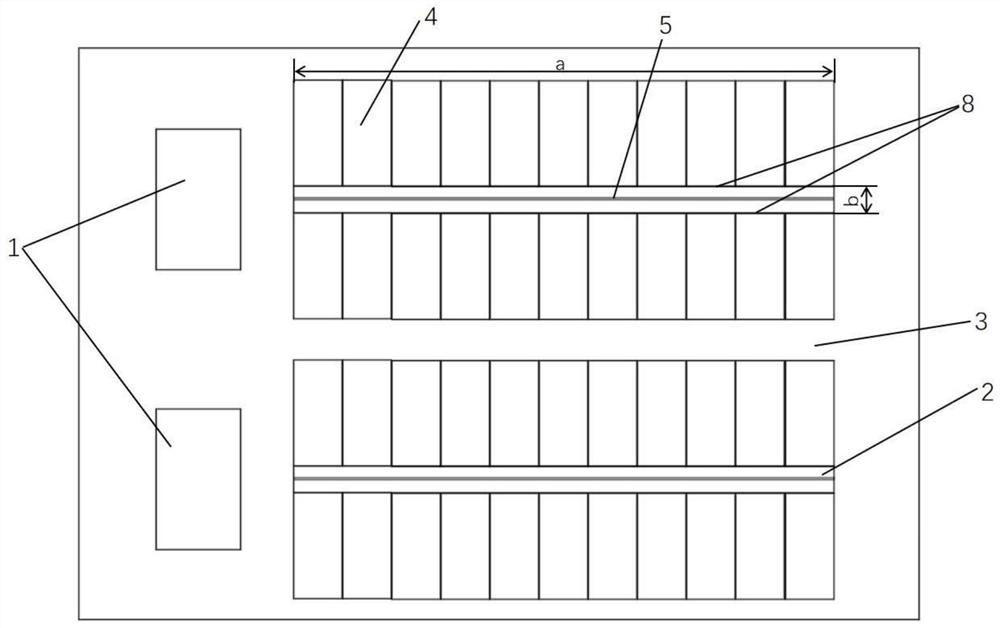

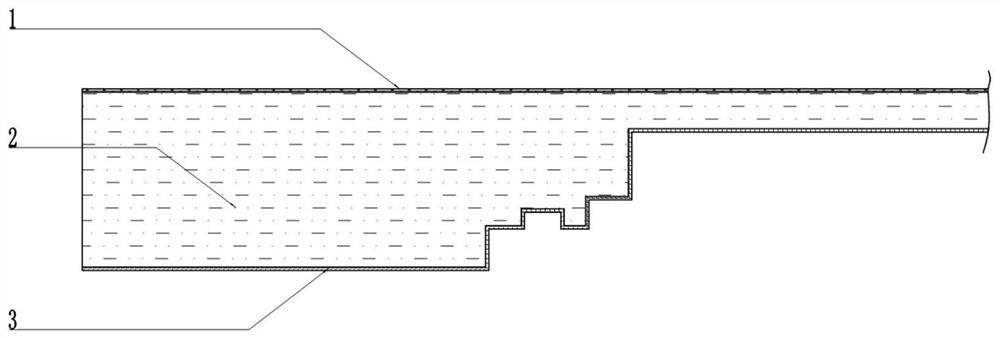

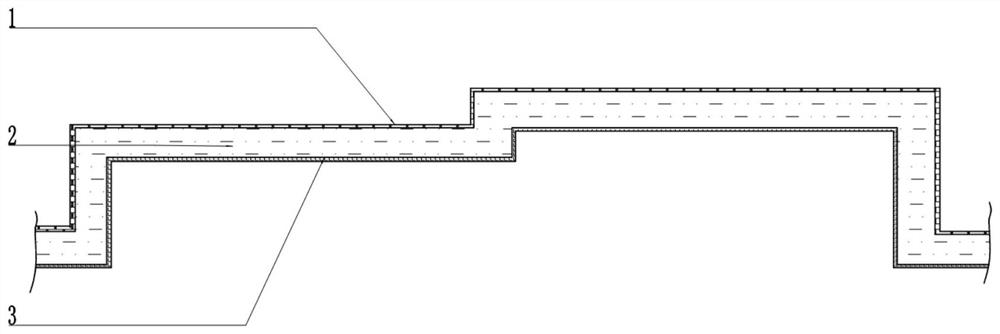

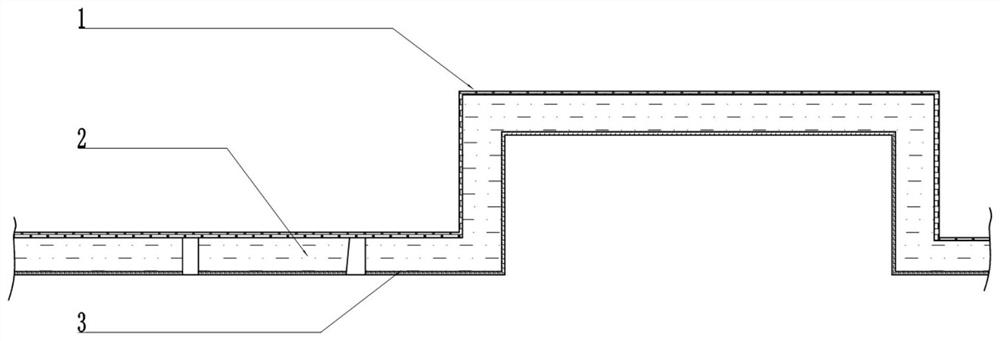

Data center with variable cross-section cold channel

ActiveCN113316366AReduce local hot spotsReduce cooling costsEnergy efficient computingCooling/ventilation/heating modificationsCold airData center

The invention relates to the technical field of data center machine room ventilation and heat dissipation, in particular to a data center with a variable cross-section cold channel. The data center comprises a temperature adjusting unit, more than two columns of cabinet units used for bearing servers and a cold and hot channel arranged between the adjacent cabinet units, the cold and hot channel comprises a closed cold channel and a hot channel communicated with the temperature adjusting unit, and an adjustable partition plate is arranged in the closed cold channel; the closed cold channel is divided into two independent temperature adjusting spaces with adjustable sizes by the adjustable partition plate, each independent temperature adjusting space comprises a part of closed cold channel floor, and cold air outlet holes are formed in the closed cold channel floor. The section shape of the closed cold channel is changed through the adjustable partition plate, the airflow uniformity of the closed cold channel, especially the airflow uniformity of the closed cold channel in the vertical direction is optimized, and the problem that the cooling capacity in the closed cold channel is not evenly distributed can be greatly solved.

Owner:NANJING NORMAL UNIVERSITY

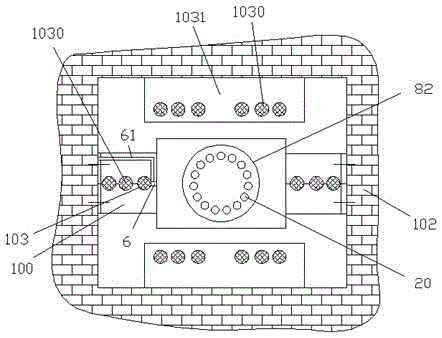

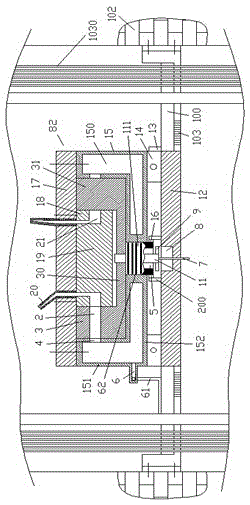

Cooling device assembly capable of cooling for power well in building

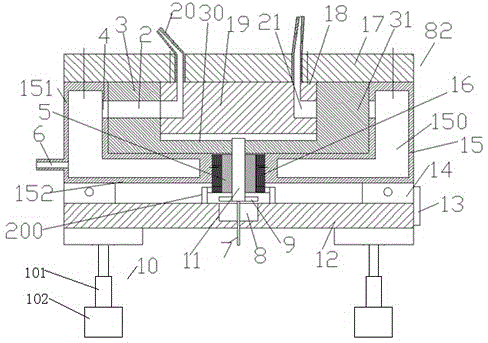

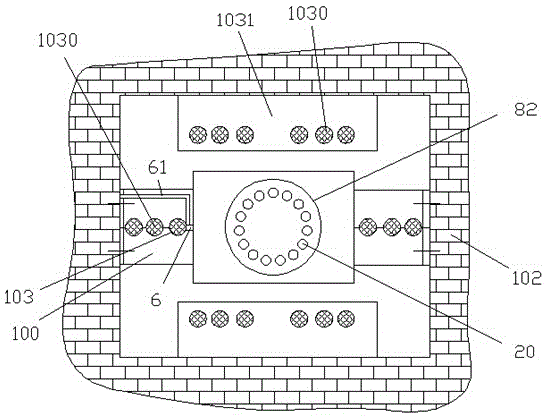

InactiveCN105140839AReduce movable structureAvoid unstable factorsElectrical apparatusElectric powerGas transmission

A cooling device assembly capable of cooling for a power well in a building comprises a plurality of cooling devices, wherein the cooling devices are separately arranged along a vertical direction of the power well, a gas is supplied to the cooling devices through a gas transmission pipe (61), each cooling device comprises a cooling device body (82) and fixed supports (100), the fixed supports (100) are arranged at the two sides of the cooling device body (82) and used for being fixed at two opposite side walls (102) of the power well, cable fixing holes (103) are formed in the fixed supports (100) and used for a power supply cable (1030) to pass through, the cooling device body (82) comprises an annular cavity shell (15), and the annular cavity shell (15) is provided with a gas inlet nozzle (6) communicated with the gas transmission pipe (61).

Owner:SHISHI CHUANLANG MACHINERY DESIGN CO LTD

Cabinet type computer device serving as network server

InactiveCN105068614AReduce movable structureAvoid unstable factorsDigital processing power distributionEngineeringInternet service

The invention relates to a cabinet type computer device serving as a network server, comprising four foldable areas capable of folding and enclosing to form a square prism shape with a hollow column part (800) and capable of pivoting and unfolding to form a linear segment shape. Each foldable area comprises a cabinet part (80) and a server unit (81) arranged in the cabinet part (80). A cooling air blowing device (82), the air of which is provided by an air delivery pipe (61), is arranged at the bottom of the hollow column part (800). The cooling air blowing device (82) comprises an annular cavity shell (15) provided with an air inlet nozzle (6) for communication with the air delivery pipe (61).

Owner:方流生

Novel cabinet-type computer apparatus

InactiveCN105159415AReduce movable structureAvoid unstable factorsDigital processing power distributionEngineeringNozzle

A novel cabinet-type computer apparatus comprises four foldable sections which can be folded to define a regular quadrangular contour shape with a hollow column body part (800) and can be pivoted and unfolded into a linear segment shape, wherein each foldable section comprises a cabinet body part (80) and a server unit (81) arranged in the cabinet body part (80); a cooling air-blowing apparatus (82) to which an air conveying pipe (61) supplies air is arranged at the bottom of the hollow column body part (800); and the cooling air-blowing apparatus (82) comprises an annular cavity housing (15) which is provided with an air inlet nozzle (6) to be communicated with the air conveying pipe (61).

Owner:ZHUJI SIBAINEI TEXTILES CO LTD

Building power well cooling device assembly powered by solar energy and capable of dissipating heat

InactiveCN105071311AReduce movable structureAvoid unstable factorsElectrical apparatusPower cableEngineering

A building power well cooling device assembly powered by solar energy and capable of dissipating heat comprises a plurality of cooling devices, where air is fed via a gas delivery pipe (61) and which are separately arranged in the vertical direction of a power well. Each cooling device comprises a cooling device body (82) and fixation supports (100) which are arranged at the two sides of the cooling device body (82) and which are fixed to the two opposite side walls (102) of the power well. Each fixation support (100) is provided with a cable fixation hole (103) for allowing a power cable (1030) to pass through. The cooling device body (82) comprises an annular cavity housing (15) provided with a gas inlet tube mouth (6) and communicated with the gas delivery pipe (61).

Owner:吴平芳

Solar-powered cooling device assembly for electric power well in building

InactiveCN105098672AReduce movable structureAvoid unstable factorsElectrical apparatusElectric power systemEngineering

The invention relates to a solar-powered cooling device assembly for an electric power well in a building. The cooling device assembly comprises a plurality of cooling devices which are separately arranged along the vertical direction of the electric power well, and is characterized in that a gas delivering pipe (61) provides gas for the cooling devices, each cooling device comprises a cooling device body (82) and fixed brackets (100) which are arranged at two sides of the cooling device body (82) and used for being fixed on two opposite side walls (102) of the electric power well respectively, each fixed bracket (100) is internally provided with cable fixing holes (103) provided for electric power cables (1030) to pass through, and each cooling device body (82) comprises an annular cavity shell (15) which is provided with a gas inlet pipe nozzle (6) so as to be communicated with the gas delivering pipe (61).

Owner:温岭市锦鹏日用品有限公司

Cooling device assembly with top pressure spring and gas cooler used for electric power well in building

InactiveCN105186407ADistribute quicklyReduce movable structureElectrical apparatusElectric power systemEngineering

A cooling device assembly with a top pressure spring and a gas cooler used for an electric power well in a building comprises a plurality of cooling devices which are separatedly arranged along a vertical direction of the electric power well, wherein gas transmission pipes (61) are used to provide a gas in the cooling devices. Each cooling device comprises a cooling device body (82) and fixing supports (100) which are arranged on two sides of the cooling device body (82) and are fixed on two opposite side walls (102) of the electric power well. Cable fixing holes (103) are arranged in the fixing supports (100), wherein an electric power cable (1030) passes through each cable fixing hole (103). Each cooling device body (82) comprises an annular cavity shell (15) which is provided with a gas inlet pipe nozzle (6) and is connected to each gas transmission pipe (61).

Owner:吴平芳

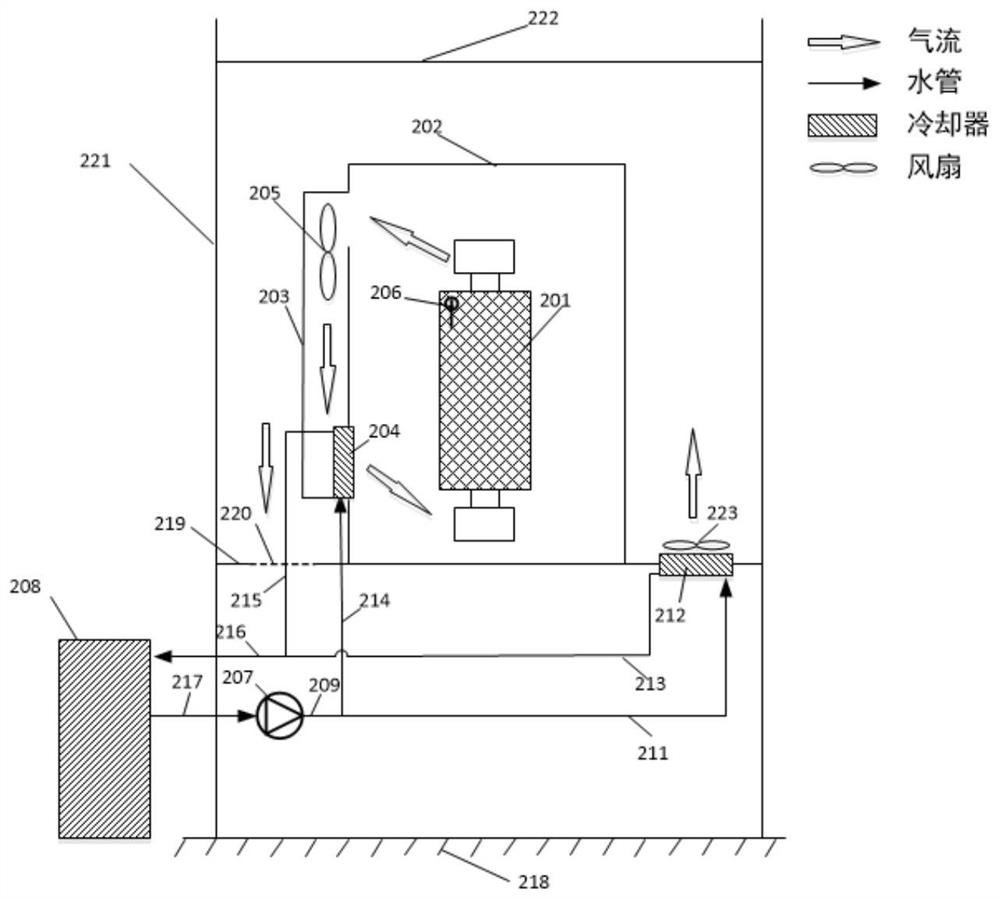

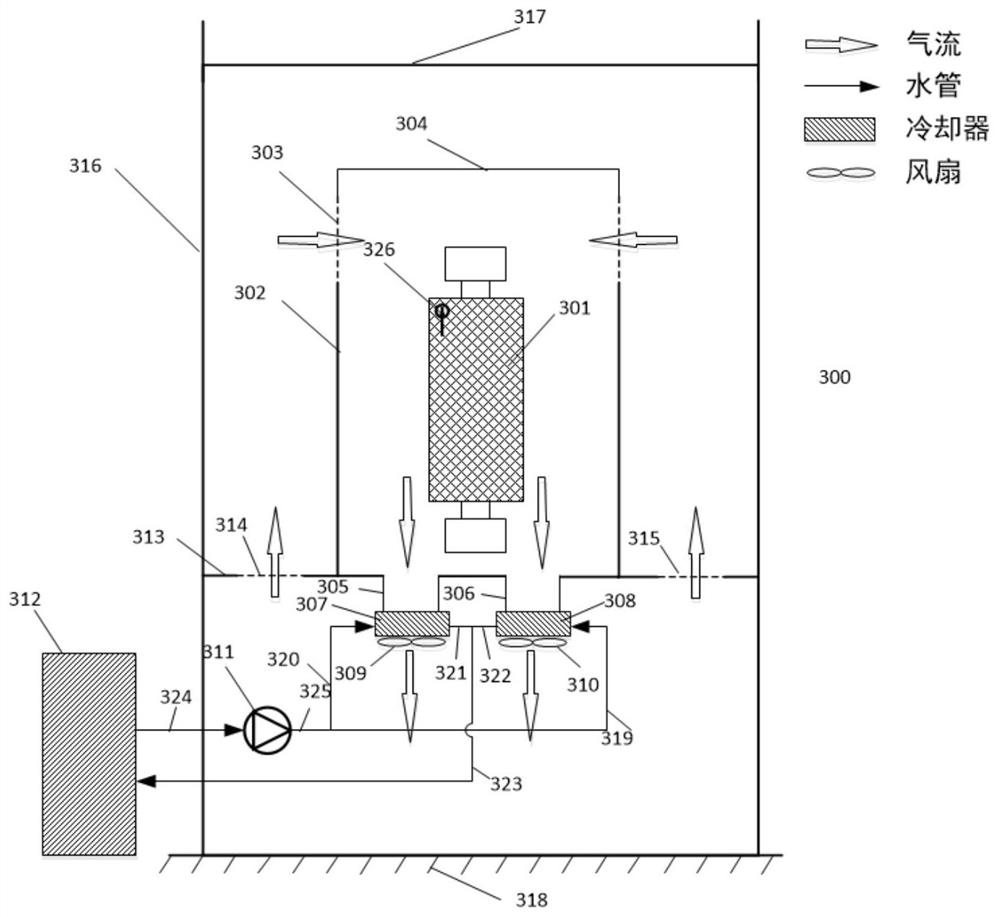

Semi-open high-power equipment cooling system and cooling method

ActiveCN113539629AReduce self-consumptionSelf-consumption mitigationTransformers/inductances coolingWind energy generationThermodynamicsProcess engineering

The invention relates to the technical field of cooling systems, and provides a semi-open high-power equipment cooling system and method. The system comprises a semi-open high-power equipment structure, semi-open high-power equipment, inner radiators, inner radiator fans and a pipeline connection cooling system. The cooling requirements of the semi-open high-power equipment and a closed environment can be met at the same time, so that the total cost of the cooling system is greatly reduced. The convection heat transfer of the outer wall of the semi-open high-power equipment structure can be enhanced by 5-10 kW, and therefore self power consumption of the cooling system is remarkably reduced. A cooling backpack is omitted, and the plurality of inner radiators are arranged below the semi-open high-power equipment, so that the size limitation pressure of the high-power equipment in the layout in a closed environment is effectively relieved. Compared with single-side ventilation, double-side ventilation is adopted, so that local hot spots of a heating element are effectively reduced.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

Cooling device assembly with control valve and top pressure springs for electric power well in building

InactiveCN105098677AReduce movable structureAvoid unstable factorsElectrical apparatusElectric power systemEngineering

The invention relates to a cooling device assembly with a control valve and top pressure springs for an electric power well in a building. The cooling device assembly comprises a plurality of cooling devices which are separately arranged along the vertical direction of the electric power well, and is characterized in that a gas delivering pipe (61) provides gas for the cooling devices, each cooling device comprises a cooling device body (82) and fixed brackets (100) which are arranged at two sides of the cooling device body (82) and used for being fixed on two opposite side walls (102) of the electric power well respectively, each fixed bracket (100) is internally provided with cable fixing holes (103) provided for electric power cables (1030) to pass through, each cooling device body (82) comprises an annular cavity shell (15) which is provided with a gas inlet pipe nozzle (6) so as to be communicated with the gas delivering pipe (61), the gas inlet pipe nozzle (6) is provided with a control valve (26) so as to be used for controlling the gas supply amount of the gas inlet pipe nozzle (6), and the control valve (26) is an electromagnetic control valve.

Owner:林燕萍

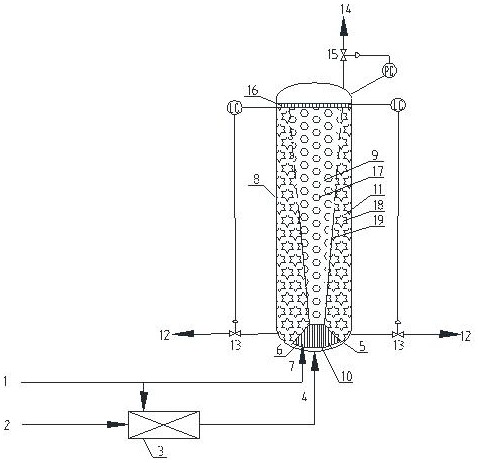

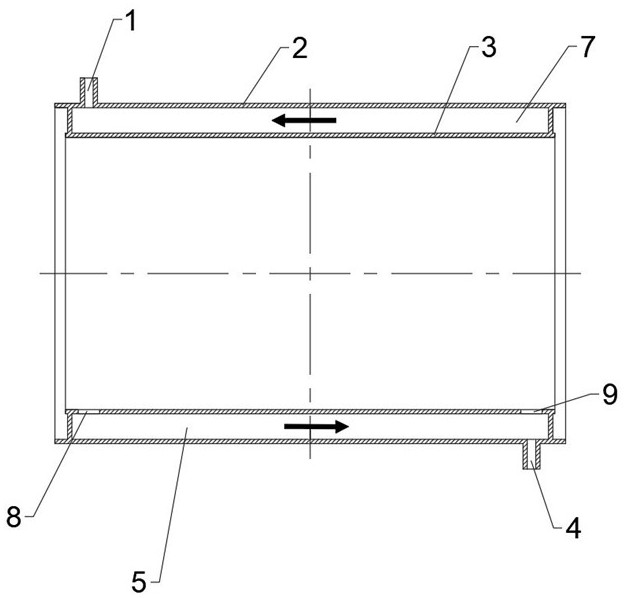

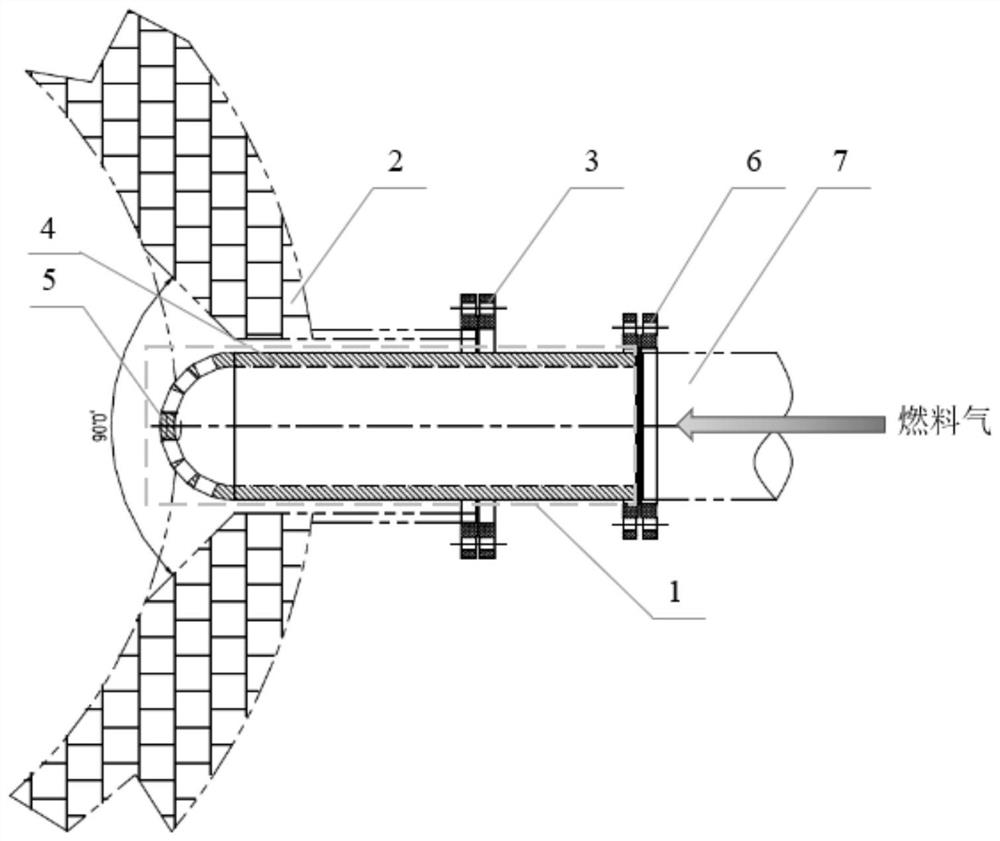

Flat dispersion flame low NOx gas heat storage combustion device

PendingCN110631010AIncrease in sizeReduce generationHeat storage plantsGaseous fuel burnerSlagFlue gas

The invention discloses a flat dispersion flame low NOx gas heat storage combustion device, and belongs to the technical field of industrial furnace heating gas combustion. The flat dispersion flame low NOx gas heat storage combustion device comprises a gas nozzle (1), an air inlet / flue gas outlet (2), an ignition gas nozzle (3), a flame detector connector (4), a heat storage tank (5), a heat storage body charging port (6), a heat storage body outlet (7), a heat storage body slag discharge port (8), a burner tile (9), an air / flue gas nozzle (10), an ignition electrode connector (11), a flue gas temperature detection port (12) and a gas nozzle cooling air (3). The flat dispersion flame low NOx gas heat storage combustion device has the advantages that the structure is small and simple, thefunctionality is strong, the mounting is convenient, and the service life is long.

Owner:BEIJING SHOUGANG INT ENG TECH

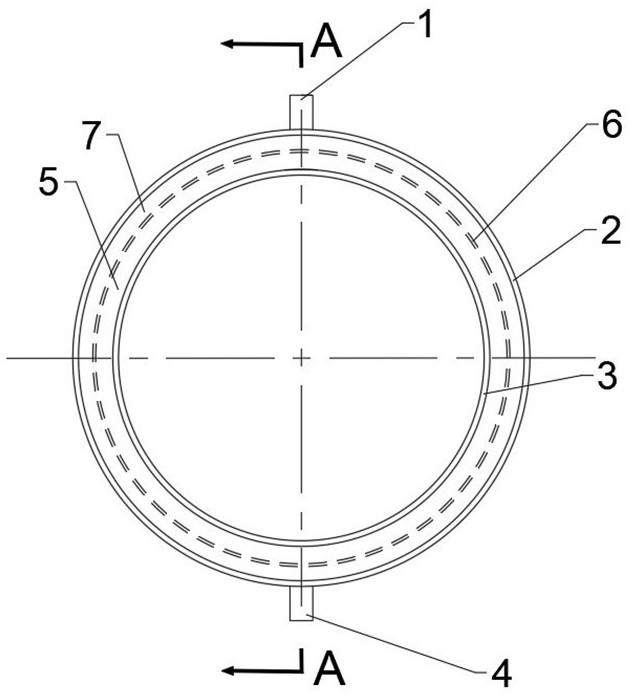

Novel cooling device for motor

InactiveCN112350498AImprove power densityMeet cooling requirementsCooling/ventillation arrangementSupports/enclosures/casingsThermodynamicsElectric machine

The invention relates to a novel cooling device for a motor, which comprises a water outlet, a casing outer sleeve, a casing inner sleeve, a water inlet, a hot air passage, a water passage partition plate, a spiral cooling water passage, an air inlet hole and an air outlet hole, the casing inner sleeve is provided with the hot air passage, the cooling water passage is provided a baffle plate, theaxial length of the casing outer sleeve is larger than that of the casing inner sleeve, and a gap between the spiral cooling water passage pipe body and the annular interlayer is filled with heat-conducting glue with good heat-conducting performance to form a heat-conducting glue layer. By adopting the cooling device, the temperature of each part in the motor can be effectively reduced, local overheating in the motor is avoided, and the power density of the motor is improved.

Owner:HARBIN UNIV OF SCI & TECH

A data center computer room equipment layout method based on fluid dynamics simulation

ActiveCN113779689BImprove construction efficiencyMake full use of spaceGeometric CADDesign optimisation/simulationIt equipmentProcess engineering

An embodiment of the present invention provides a data center computer room equipment layout method based on fluid dynamics simulation, which relates to the technical field of data center computer room layout methods, in order to improve the utilization efficiency of the data center refrigeration system and increase the capacity of IT equipment power consumption in the data center computer room . The method includes: constructing a model of the equipment layout in the data center computer room; modeling according to the overall layout of the equipment in the data center computer room to be transformed; the modeling content includes: the length, width and height of the data center computer room; the size of the air conditioner in the data center computer room , position, air supply and return air position, air supply and return air temperature; cabinet size in the data center computer room; when using the airflow organization method of underfloor air supply, determine the height of the floor and the opening ratio of the cold aisle floor; Carry out airflow organization simulation analysis of IT equipment in the data center computer room; adjust the position of IT equipment in the data center computer room according to the results of airflow organization simulation analysis.

Owner:军事科学院系统工程研究院网络信息研究所

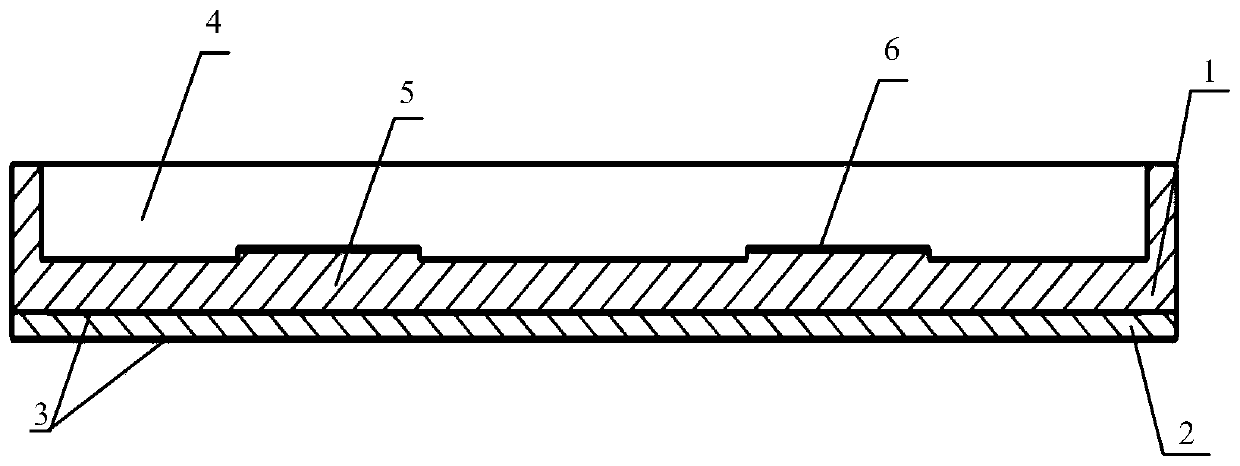

Solid cold plate based on low-dimensional thermal diffusion material

InactiveCN110430723AHigh thermal expansionImprove temperature uniformitySemiconductor/solid-state device detailsSolid-state devicesTemperature controlDiffusion

The present invention relates to a solid cold plate based on a low-dimensional thermal diffusion material. The solid cold plate comprises a cold plate substrate 1, a cold plate cover 2, and a two-dimensional high efficiency thermal diffusion coating (graphene coating) 3. One end of the cold plate cover 2 is coated with a graphene coating and is welded with the cold plate substrate 1 by adopting adiffusion welding method to allow the graphene coating to be in tight contact with the substrate to form the solid cold plate. A heating body is installed in a heating body mounting groove on the coldplate substrate 1 for heat dissipation, and a grapheme heat conduction pad is added between the heating body mounting groove and a boss to further reduce the heat resistance so as to ensure the extrahigh heat expansion of the cold plate on the two-dimensional plane. The solid cold plate has no liquid state working medium leakage danger, is high in reliability, reduces the process complexity, andhas an excellent anti-gravity performance; and moreover, the multi-layer graphene coating fully distributes heat on the two-dimensional plane, dissipates heat is large to facilitate control of the temperature of the heating body in an idea range, and therefore, the solid cold plate can be widely applied to heat dissipation of the electronic elements.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

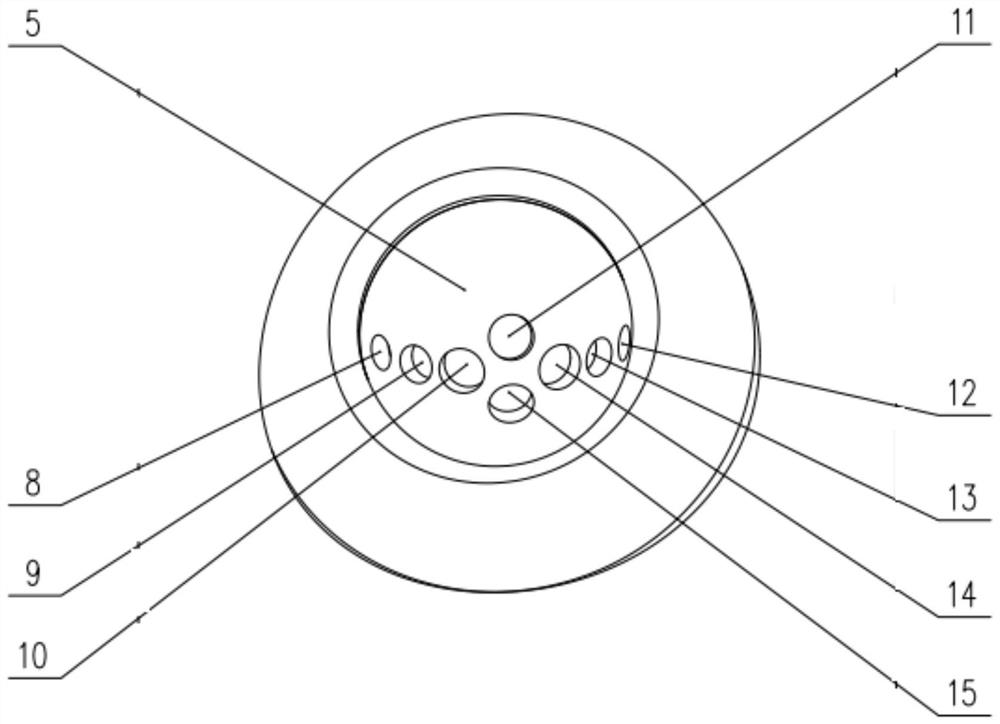

Reinforced mixed type gas low-nitrogen burner for aluminum hydroxide roasting furnace

PendingCN114413253AWell mixedArea Weighted Uniformity ImprovementCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorAluminium hydroxide

The invention provides a strengthened mixed type fuel gas low-nitrogen burner for an aluminum hydroxide roasting furnace, which comprises a burner body, the burner body is fixed on a furnace wall through a flange I, the burner body comprises a burner gun barrel and a burner gun head, the tail end of the burner gun barrel is communicated with a fuel gas supply pipe through a flange II, and the tail end of the burner gun barrel is communicated with a fuel gas supply pipe through a flange II; the head end of the burner gun barrel is fixedly connected with the burner gun head, the burner gun head extends into a furnace wall, a plurality of gas spraying holes are formed in the spherical surface of the burner gun head, and the sum of the areas of the gas spraying holes located in the center of the spherical surface is larger than the sum of the areas of the gas spraying holes located in the non-center of the spherical surface. And the sum of the areas of the gas spray holes is gradually reduced from the central position of the spherical surface to the two sides. Non-uniform distribution of fuel gas is achieved, the flow of the fuel gas injected to the center of the hearth is increased, the amount of fuel injected to the position near the furnace wall is reduced, the mixing effect of the fuel gas and air vertically flowing from bottom to top is enhanced, and generation of thermal NOx is reduced.

Owner:哈尔滨名诺环保科技有限公司

Method for preparing three-dimensional heat dissipation film and three-dimensional heat dissipation film

PendingCN113363159AAchieve Leapfrog CoolingReduce local hot spotsSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsMembrane technology

The invention relates to the technical field of heat dissipation films, and particularly discloses a method for preparing a three-dimensional heat dissipation film and the three-dimensional heat dissipation film prepared based on the method. The method comprises the steps of 1, obtaining the three-dimensional shape of a surface needing heat dissipation; and 2) forming a recess matched with the three-dimensional shape on the single-layer or multi-layer composite heat dissipation film to obtain the three-dimensional heat dissipation film. The method is simple in process and easy to operate, and the heat dissipation film in the three-dimensional shape is directly prepared through die cutting or die forming, so that the heat dissipation requirement of heating electronic devices in irregular shapes is met, and the defect that traditional heat conduction glue is low in heat dissipation efficiency is overcome.

Owner:STONEPLUS THERMAL MANAGEMENT TECH

A kind of synthetic method of aqueous polyurethane heterogeneous chain extension

ActiveCN108264621BImprove temperature resistanceSlow reaction ratePolyurea/polyurethane coatingsPolyesterPolymer science

The invention provides a heterogeneous chain extension synthesis method for waterborne polyurethane. The method comprises the following steps: S1, pre-polymerizing: dehydrating polyester polyol, and performing a pre-polymerization reaction on the dehydrated polyester polyol and diisocyanate; S2, performing hydrophilic chain extension and cross-linking: adding a hydrophilic chain extender, a cross-linking agent and a diluent to a material obtained in step S1, and performing a chain extension and cross-linking reaction; S3, neutralizing and extending the chain: adding neutralizing amine, water,the diluent, a pH buffer agent and fatty amine to a material obtained in step S2, and ending the reaction to obtain a prepolymer; S4, performing dispersing emulsification: adding water to a material obtained in step S3 to achieve emulsification in order to uniformly disperse the prepolymer in water; and S5, performing a post-chain extension reaction: adding a post-chain extension amine to a material obtained in step S4, performing chain extension in water, and performing reduced pressure distillation to remove the solvent in order to obtain the waterborne polyurethane. The method uses fatty amine to carry out chain extension in a heterogeneous state in order to synthesize the waterborne polyurethane resin with high content of allophanate; and the obtained emulsion has the advantages of small micelle particle size, low viscosity, good leveling property and good storage performance.

Owner:SHANGHAI WEIKAI CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com