Heterogeneous chain extension synthesis method for waterborne polyurethane

A technology of water-based polyurethane and synthesis method, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of small usage, low allophanate content, inability to obtain high temperature resistance, high hardness waterborne polyurethane emulsion, etc. problems, to achieve the effect of increasing the amount of use, improving the leveling performance, and effectively controlling the heat of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

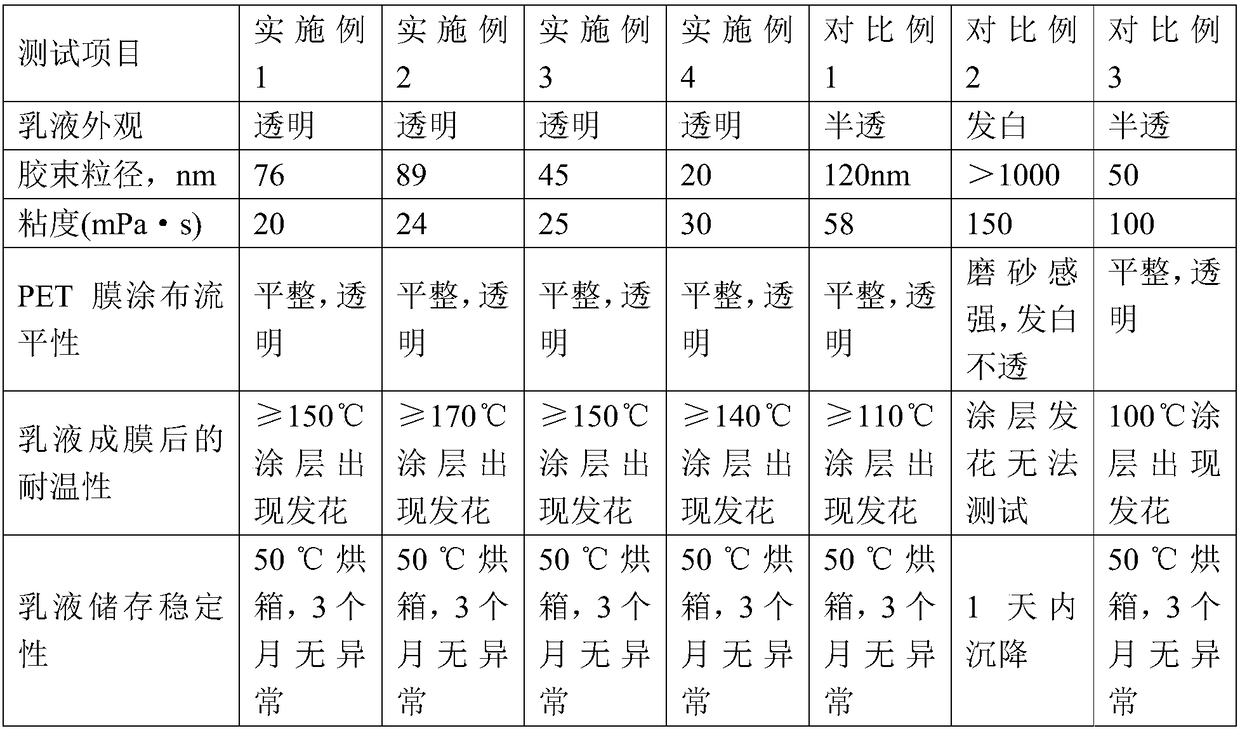

Examples

Embodiment 1

[0046] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of heterogeneous chain extension, comprises the following steps:

[0047] (1) Add 367 parts of adipic acid polyester diol with a number average molecular weight of 2000 to a drying reactor equipped with a stirrer, a thermometer, and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0048] (2) Add 326 parts of isophorone diisocyanate, heat up to 80° C. and carry out polymerization reaction for 3 hours to obtain material b;

[0049] (3) When the mass percent content of isocyanate groups in material b reaches 15.6%, add 47 parts of dimethylolpropionic acid to material b, maintain the temperature at 75-80°C, add 26 parts of trimethylolpropane, 150 Part of acetone, insulation 3h obtains material c;

[0050] (4) When the mass percent content of isocyanate groups in the material c reaches 6.4%, add 30 parts of triethylamine and 200 pa...

Embodiment 2

[0056] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of heterogeneous chain extension, comprises the following steps:

[0057] (1) Add 244 parts of adipic acid polyester polyol with a molecular weight of 2000 to a drying reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0058] (2) Add 410 parts of isophorone diisocyanate, heat up to 80° C. and carry out polymerization reaction for 3 hours to obtain material b;

[0059] (3) When the mass percent content of isocyanate in material b reaches 22%, add 69 parts of dimethylol propionic acid to material b, add 10 parts of trimethylolpropane, 400 parts of acetone, and maintain the temperature at 75-80 ℃, heat preservation for 3h to obtain material c;

[0060] (4) When the mass percent content of isocyanate groups in the material c reaches 8.5%, add 50 parts of triethylamine and 40...

Embodiment 3

[0066] The present invention relates to a kind of preparation method of the aqueous polyurethane resin of low solvent consumption, comprises the following steps:

[0067] (1) Add 123 parts of polycarbonate diol with a molecular weight of 1000 to a dry reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, raise the temperature to above 100° C., and dehydrate to obtain material a.

[0068] (2) Add 170 parts of diphenylmethane diisocyanate, heat up to 70-90°C to carry out polymerization reaction for 2-4 hours to obtain material b;

[0069] (3) When the content of isocyanate groups in material b reaches 17.6% (mass ratio), add 20 parts of dimethylol butyric acid to material b, maintain the temperature at 75-80°C, and add 8 parts of trimethylolethane , 180 parts of acetone, heat preservation for 3h to obtain material c;

[0070] (4) When the isocyanate group content in material c reaches 7.0% (mass ratio), add 12 parts of N, N dimethylethanolamine and 20 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com