Patents

Literature

70results about How to "Uniform reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

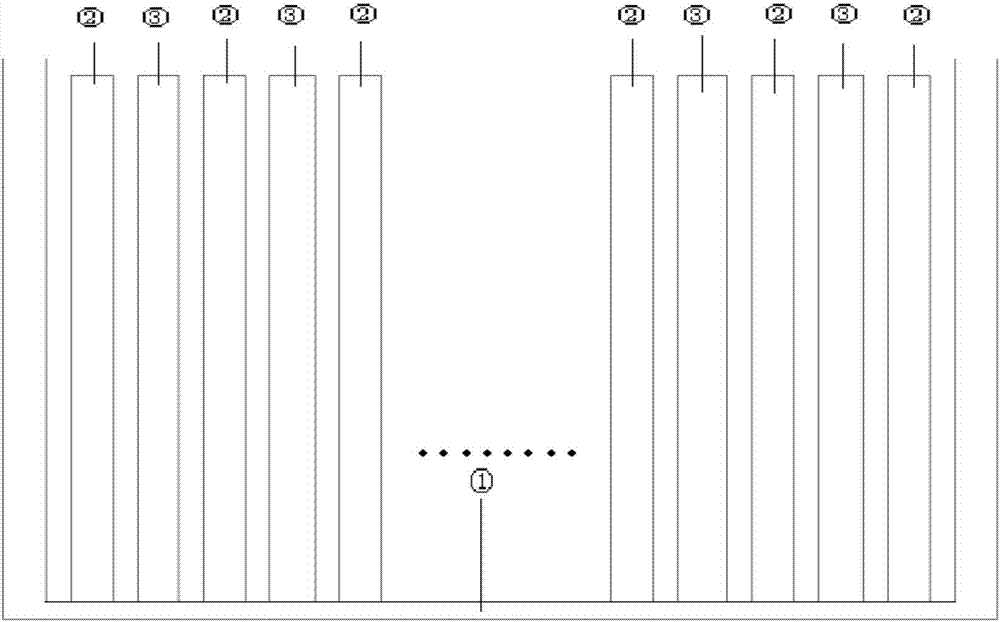

Battery

InactiveCN102569866AStable temperatureConsistent temperatureFinal product manufactureCell temperature controlHeat conductingReaction temperature

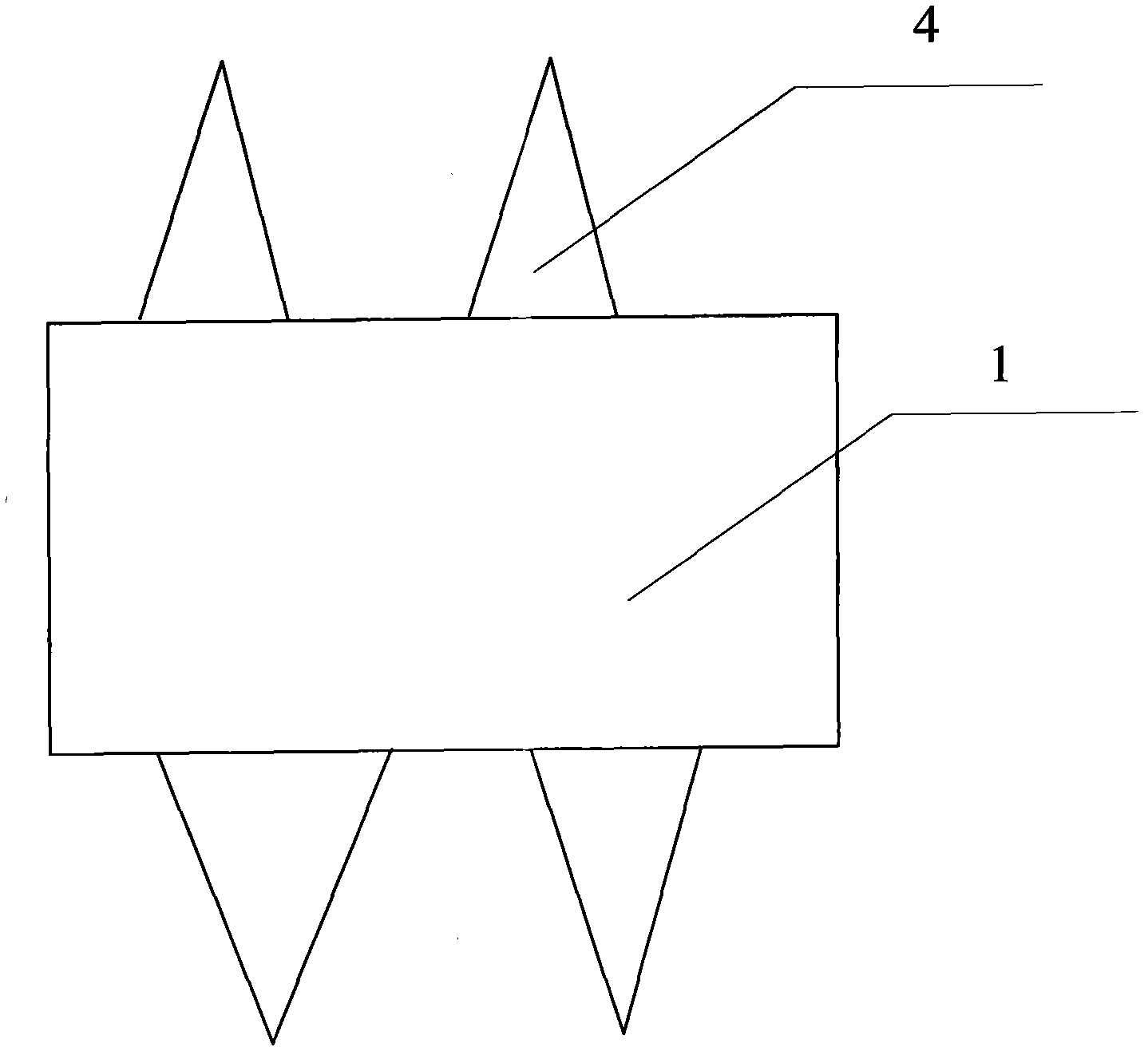

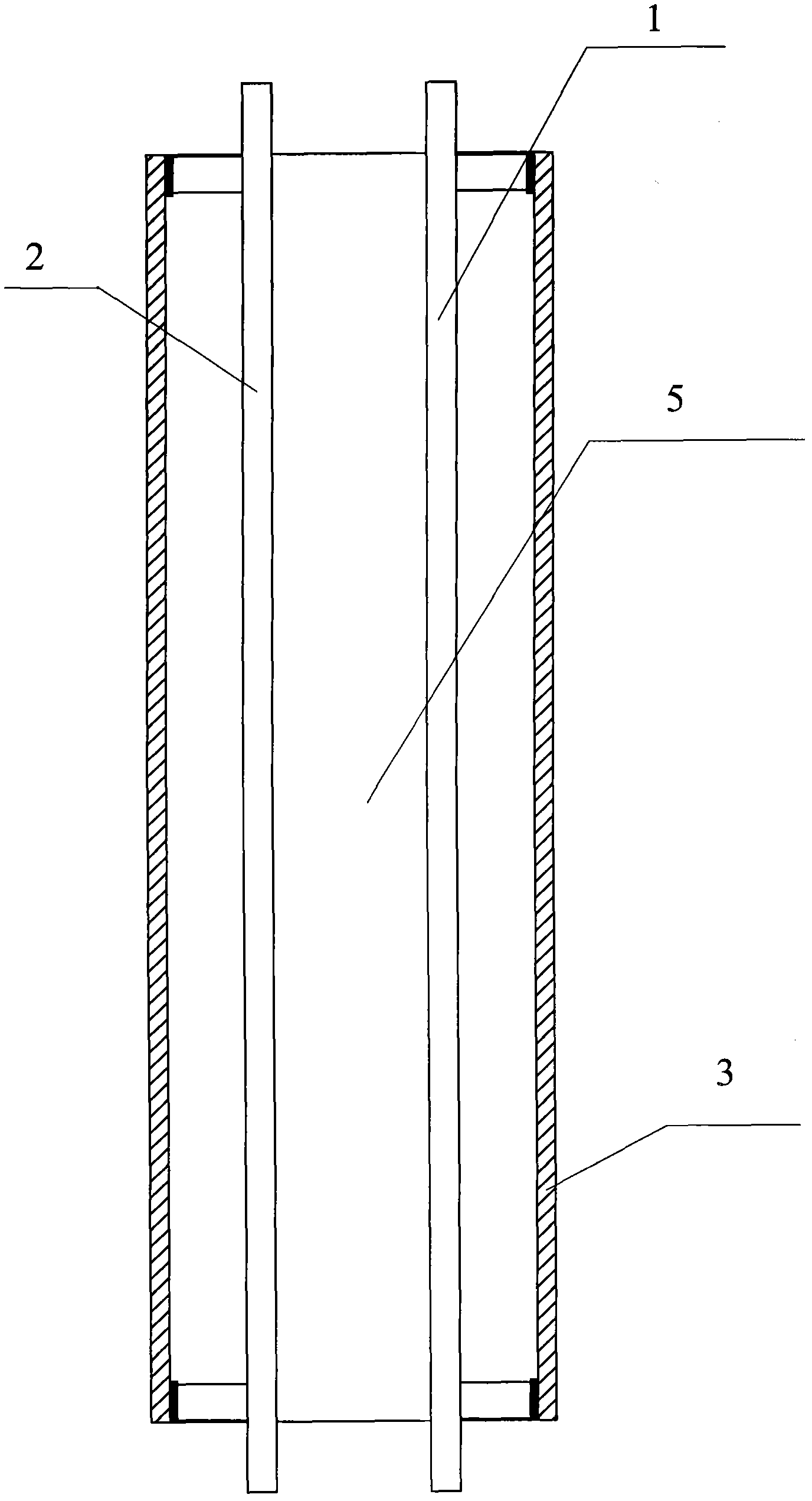

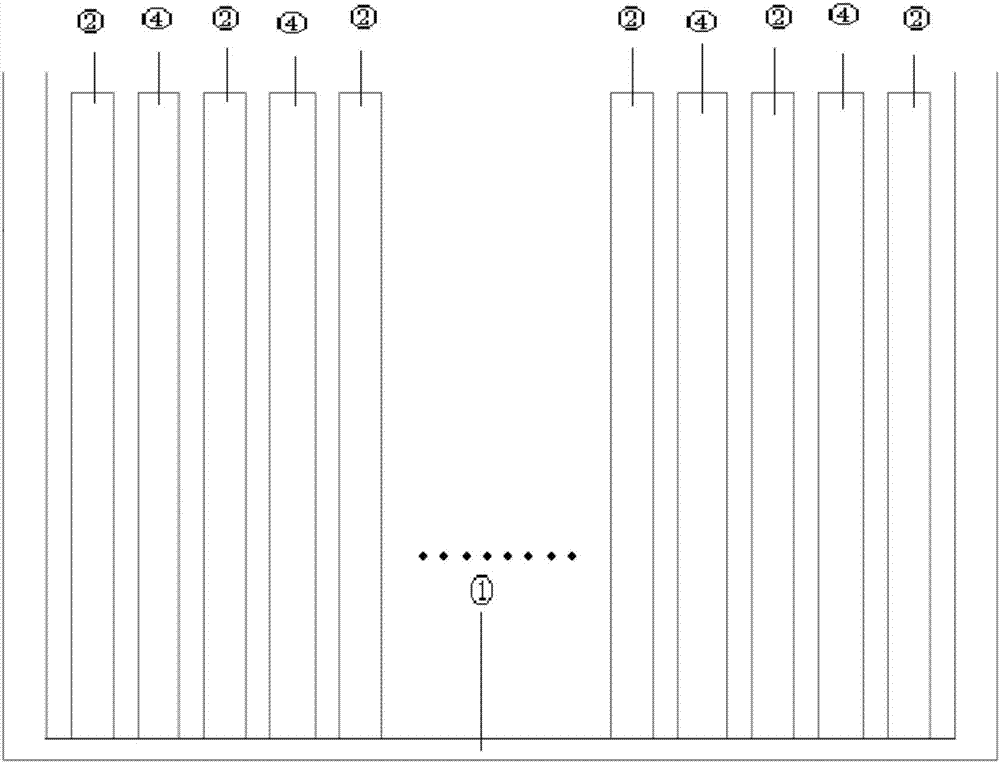

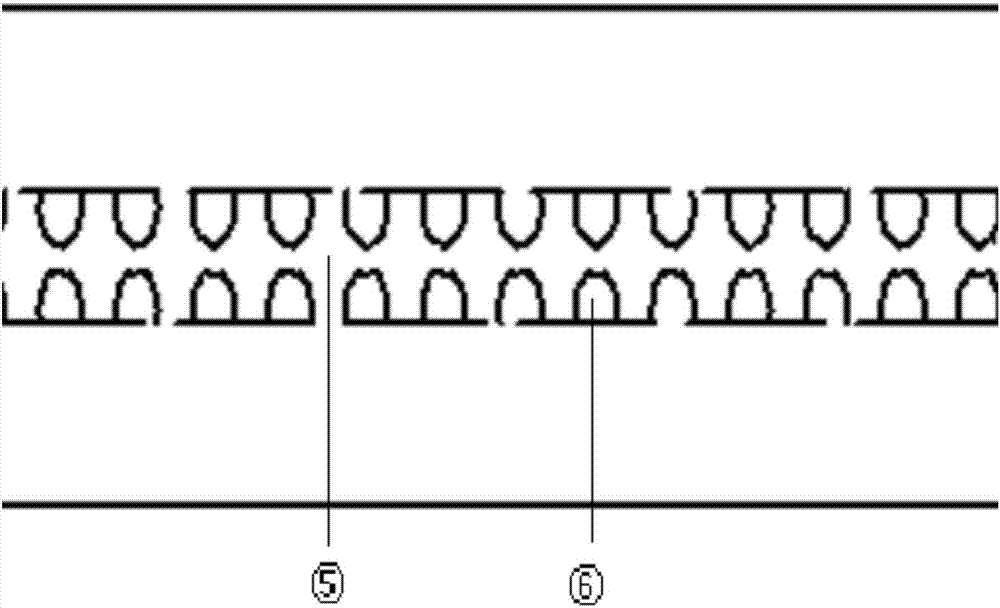

The invention provides a battery, comprising a cover plate, a shell, a battery cell and electrolyte. The battery cell and the electrolyte are sealed in the shell of the battery, and the cover plate is hermetically connected with the shell. The battery cell comprises a positive polar plate, a negative polar plate and a diaphragm arranged between the positive polar plate and the negative polar plate. A positive polar lug is arranged on the positive polar plate, and a negative polar lug is arranged on the negative polar plate. The battery cell is further internally provided with a positive polar current and heat conducting member and a negative polar current and heat conducting member, and the positive polar current and heat conducting member and the negative polar current and heat conducting member are mutually insulated. The positive polar current and heat conducting member and the positive polar lug are conducted; the negative polar current and heat conducting member and the negative polar lug are conducted; the positive polar current and heat conducting member and / or the negative polar current and heat conducting member penetrate(s) through the cover plate to leading out current. According to the invention, the internal heat of the battery cell can be reduced rapidly, substances on the polar plates can be prevented from further thermal reaction, and thus, the safety performance of the battery is increased. Meanwhile, the stability of the internal temperature of the battery cell is guaranteed, the cyclic performance and the like of the battery are improved. In addition, the temperature at all parts in the battery cell can be ensured to be consistent so as to eliminate temperature differences and make the reaction temperature of all parts of the polar plates consistent. Meanwhile, the current and heat conducting members can play roles of backbone and support to support the battery cell, and is beneficial to not only assembly but also winding of the battery cell.

Owner:BYD CO LTD

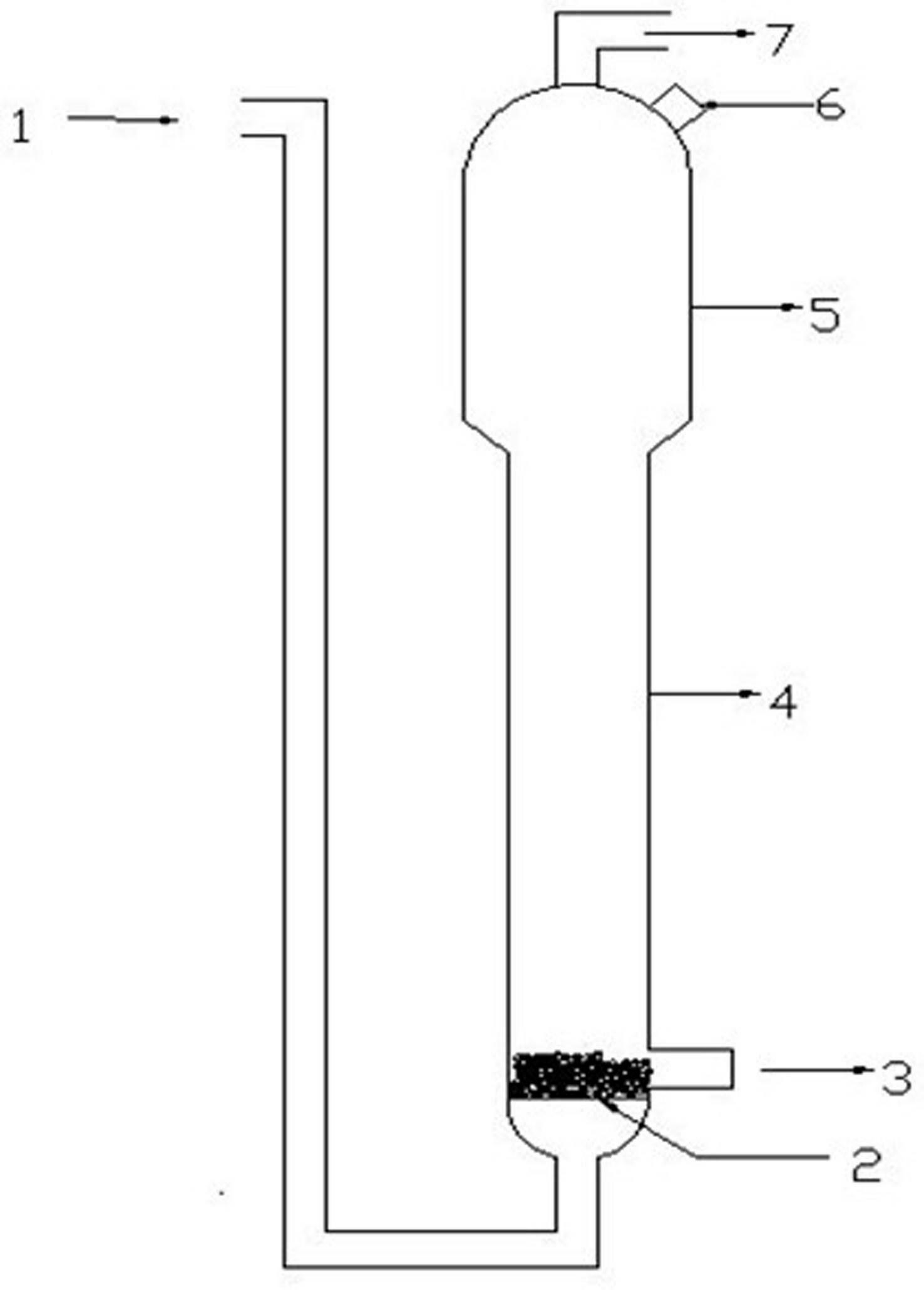

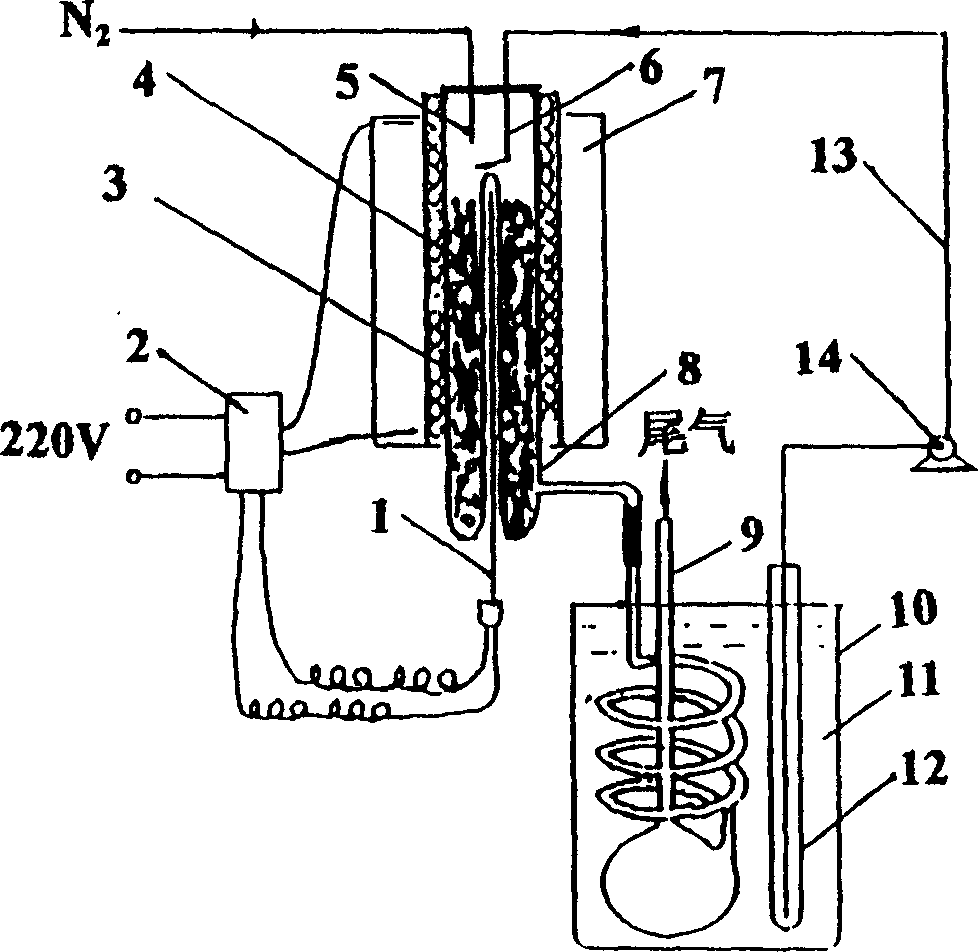

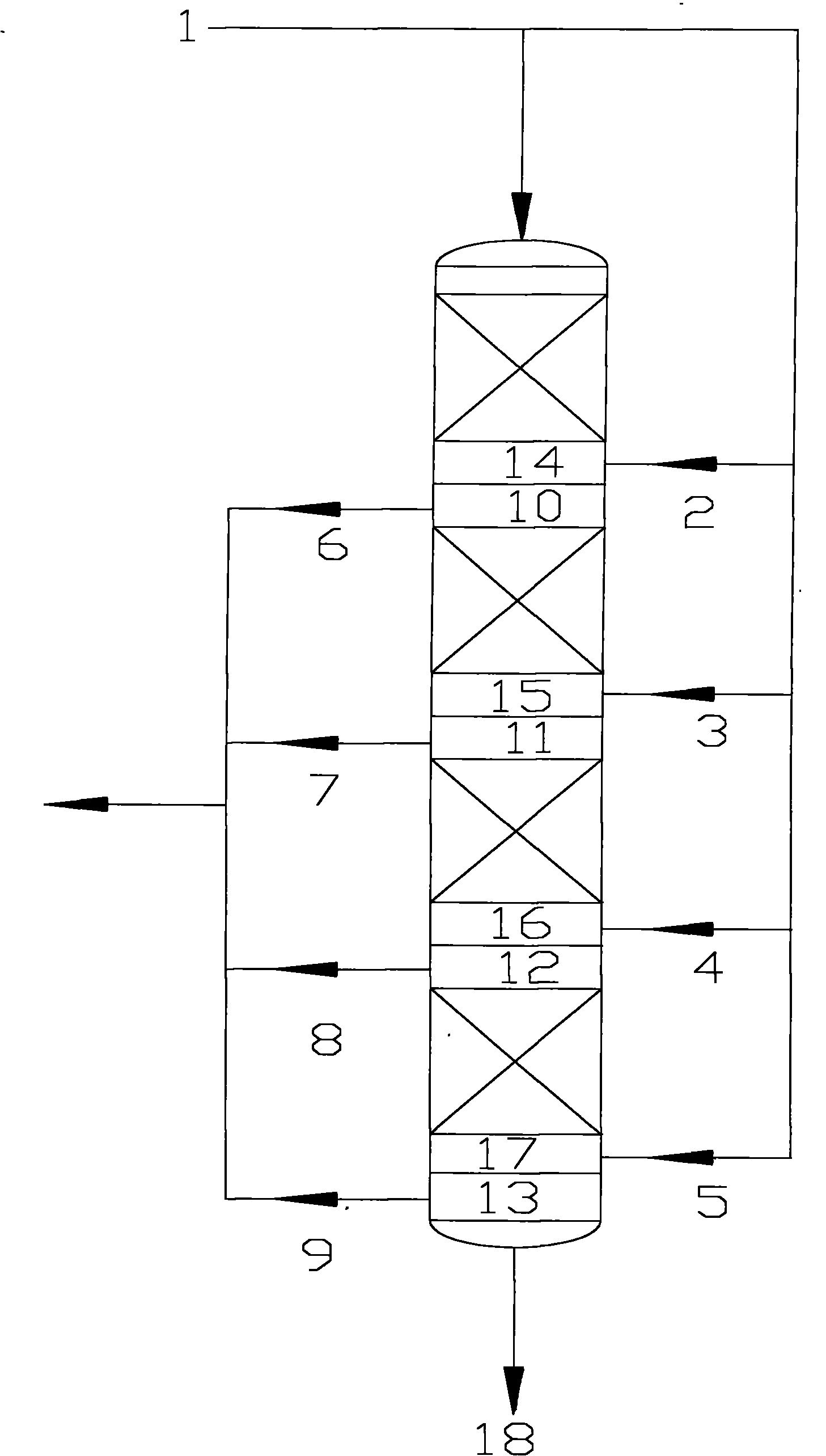

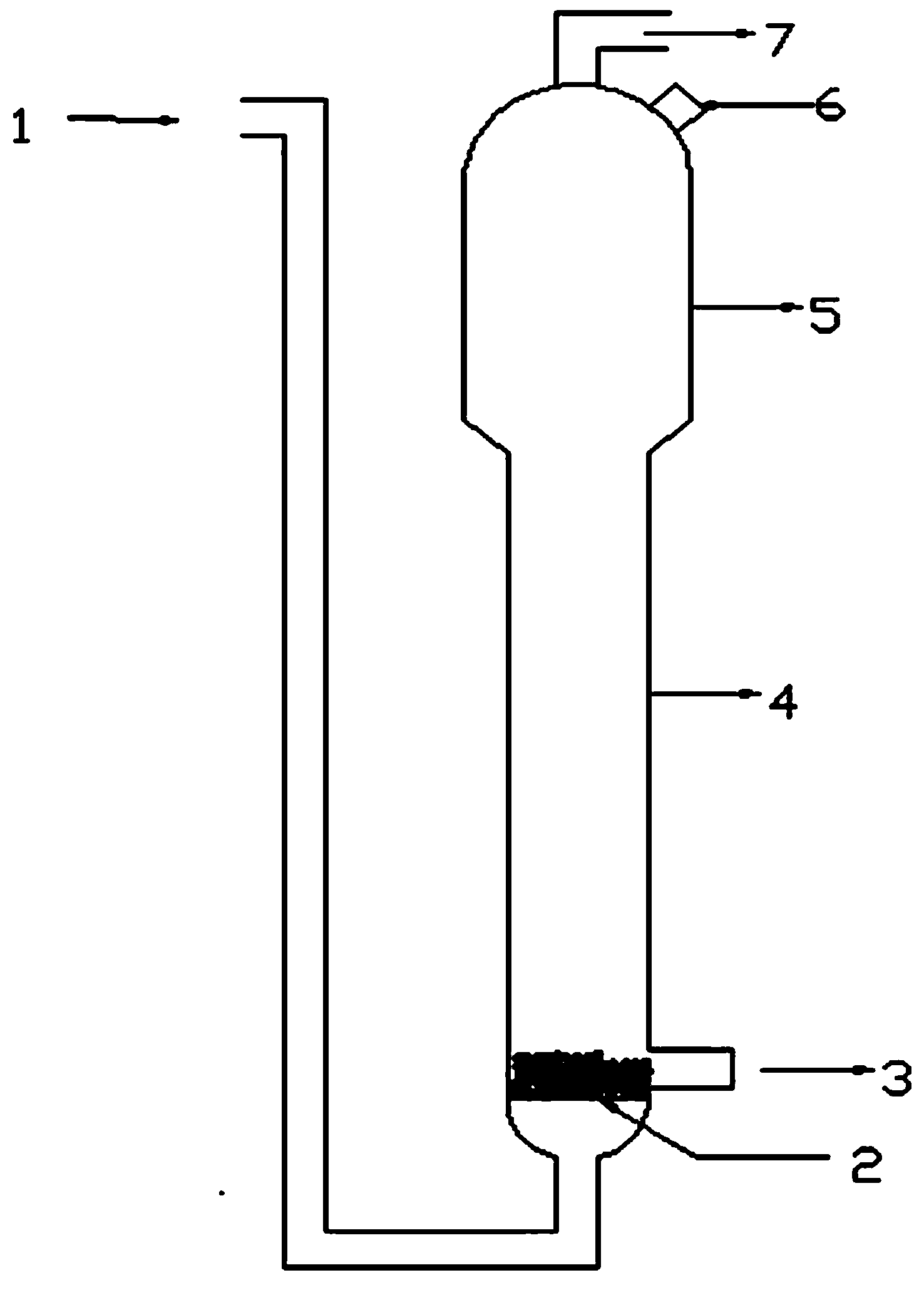

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225AExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

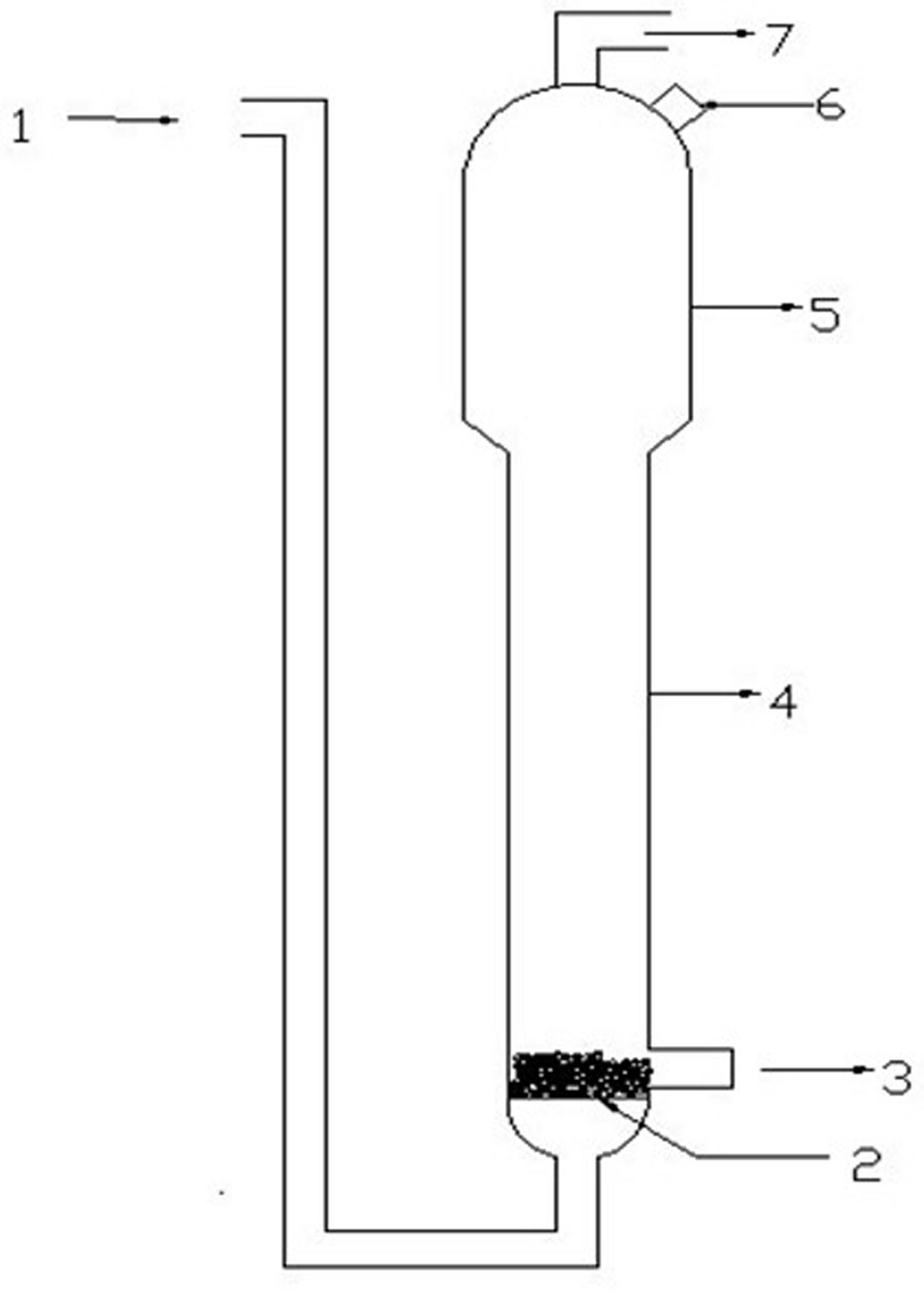

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

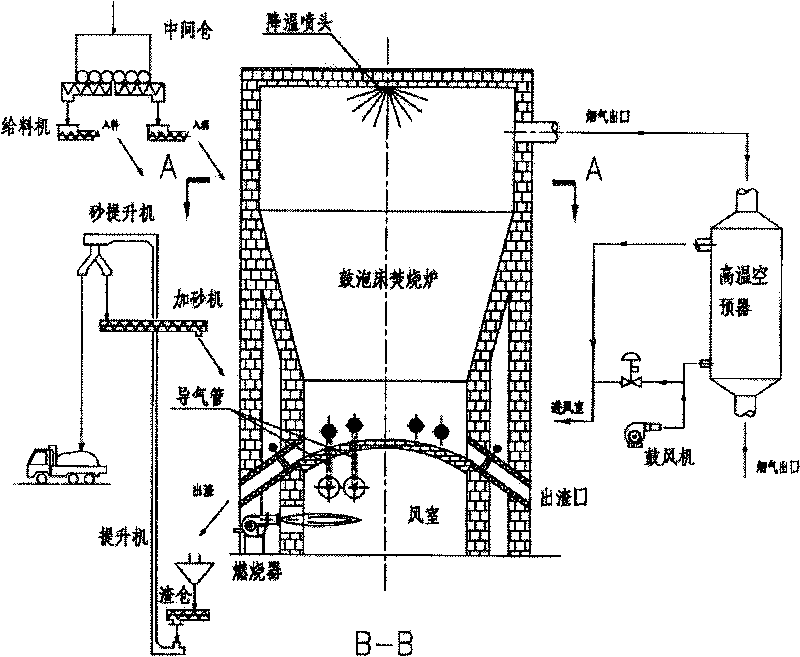

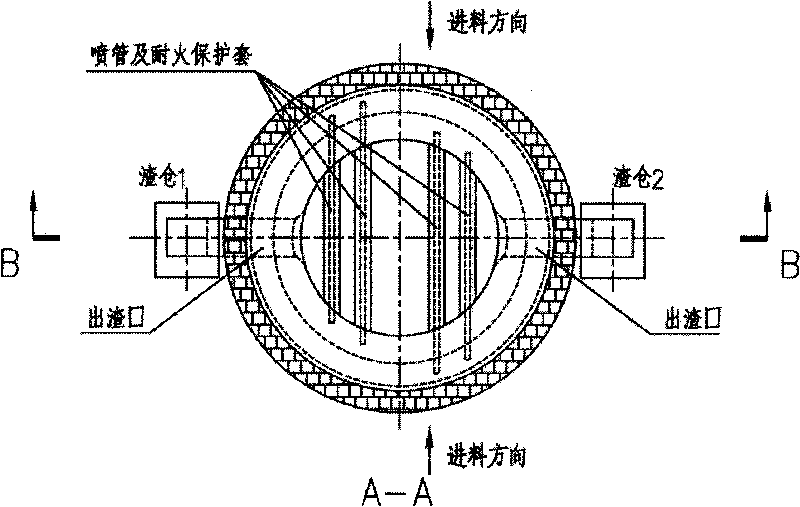

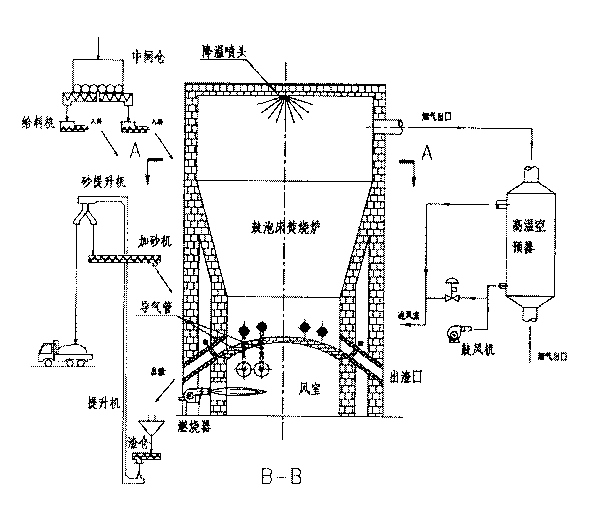

Sludge incinerator with no auxiliary fuel

InactiveCN101713543AIncineration stableMass transfer speedSludge treatment by oxidationByproduct vaporizationAir preheaterFailure rate

The invention relates to the field of environmental engineering, in particular to sludge incineration technology. The sludge incinerator with no auxiliary fuel overcomes the disadvantage that sludge incineration in the prior art requires the auxiliary fuel such as coal. The sludge incinerator with no auxiliary fuel mainly comprises a boiling section, a suspension chamber, a spray pipe, a gas-guide pipe, a support arch, a slag outlet, a cooling spray nozzle, a combustor, an air chamber and a high-temperature air pre-heater, a slag cabin, a sand hoisting machine, a sand feeder, a middle cabin and a feeding machine. The sludge incinerator with no auxiliary fuel has the following advantages that: the incinerator adopting the technology can realize stable incineration of the sludge under the condition of not adding the coal so as to achieve innocent treatment of the sludge; the sludge incinerator using the technology can store a large amount of heat inside, and a bed has a uniform reaction temperature, so that partial overheat phenomenon is prevented and the temperature in the bed is easy to be controlled; the sludge incinerator is also safe for treating sludge containing a lot of volatile substances (such as oil-containing sludge); a fluidized bed has a simple structure, a low failure rate and a low construction cost, and is provided with a mechanical transmission component; the sludge incinerator can lower the coefficient of excess air and can reduce power consumption; the sludge incinerator has wide fuel adaptability so as to realize controlling harmful gases, such as SO2, NOx and the like easily and to obtain higher combustion efficiency; and ash produced by sludge incineration has a plurality of applications.

Owner:刘沪滨

Preparation method of ethyl acetate and/or isopropyl acetate

InactiveCN102757341AReduce concentrationInhibition of the alignment reactionOrganic compound preparationCarboxylic acid esters preparationEsterification reactionReaction system

The invention provides a preparation method of ethyl acetate and / or isopropyl acetate. Catalytic dry gas from an oil refinery is used as a dilute ethylene and / or dilute propylene raw material and is introduced into a reaction system with a strong solid acidic catalyst to perform an addition esterification reaction so as to produce ethyl acetate and isopropyl acetate. The dry gas required by the method directly comes from a dry gas desulfurization treatment device of the refinery, the addition reaction pressure is low, continuous production of the ethyl acetate and isopropyl acetate can be realized by using dilute ethylene and / or dilute propylene, i.e., low-concentration ethylene and / or propylene, serving as raw material(s), the device investment is saved, the energy consumption is low, and the preparation method belongs to an advanced technology for new utilization of the catalytic dry gas.

Owner:CHINA PETROCHEMICAL CORP

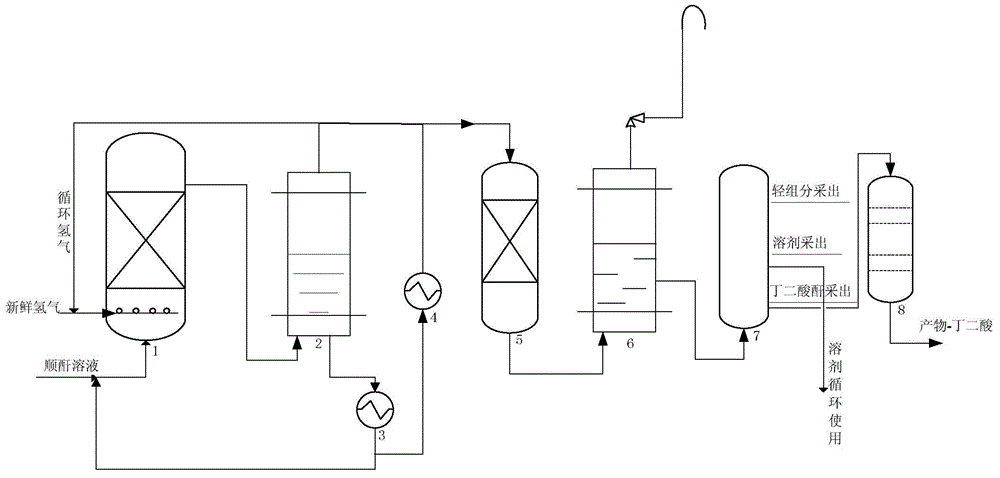

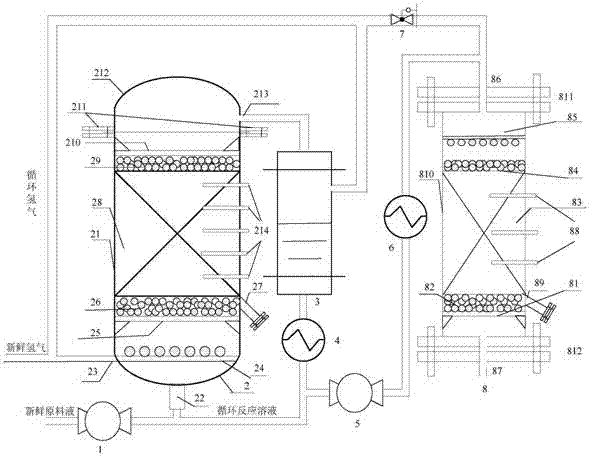

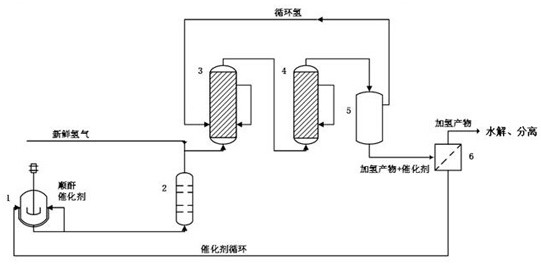

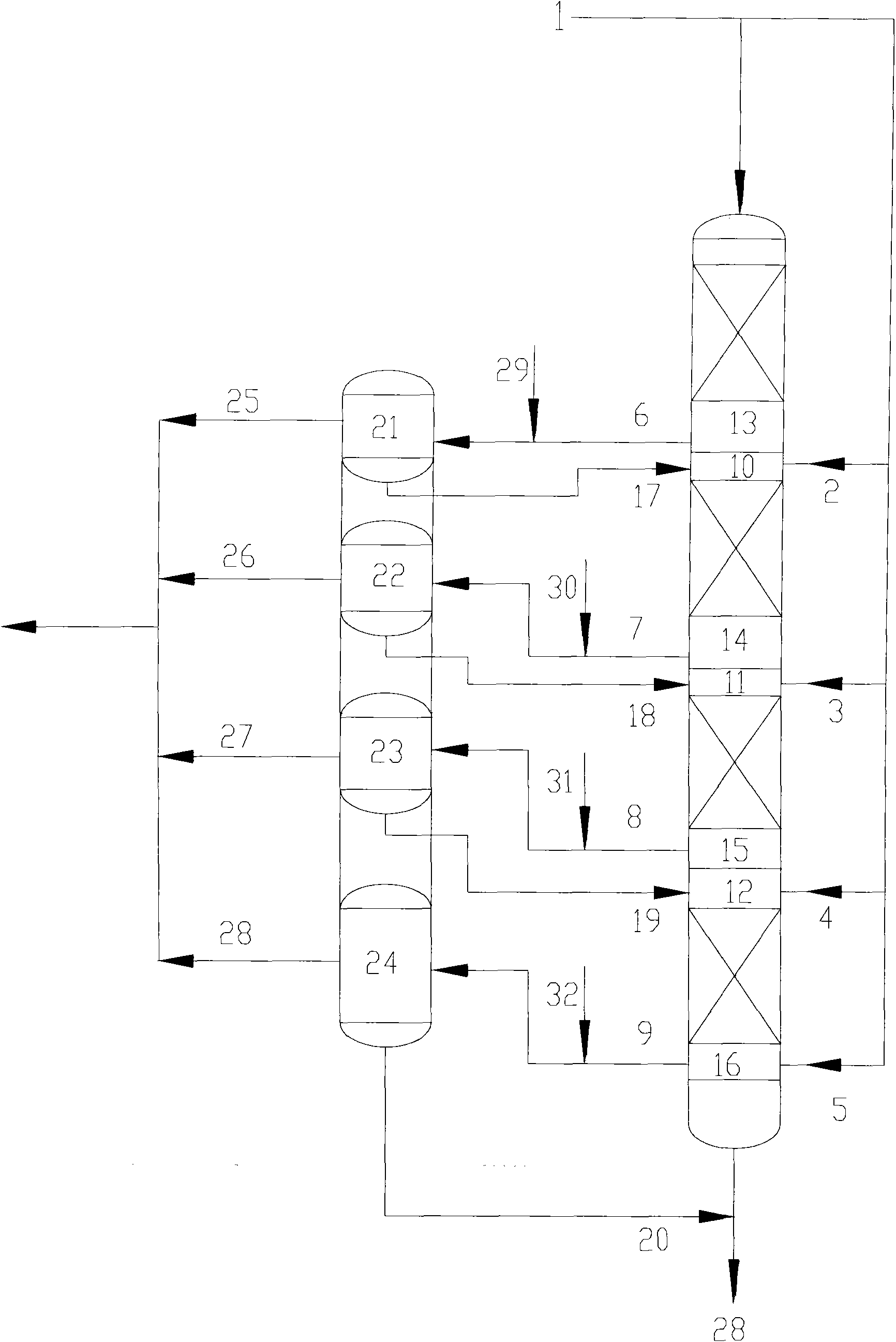

Technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride hydrogenation

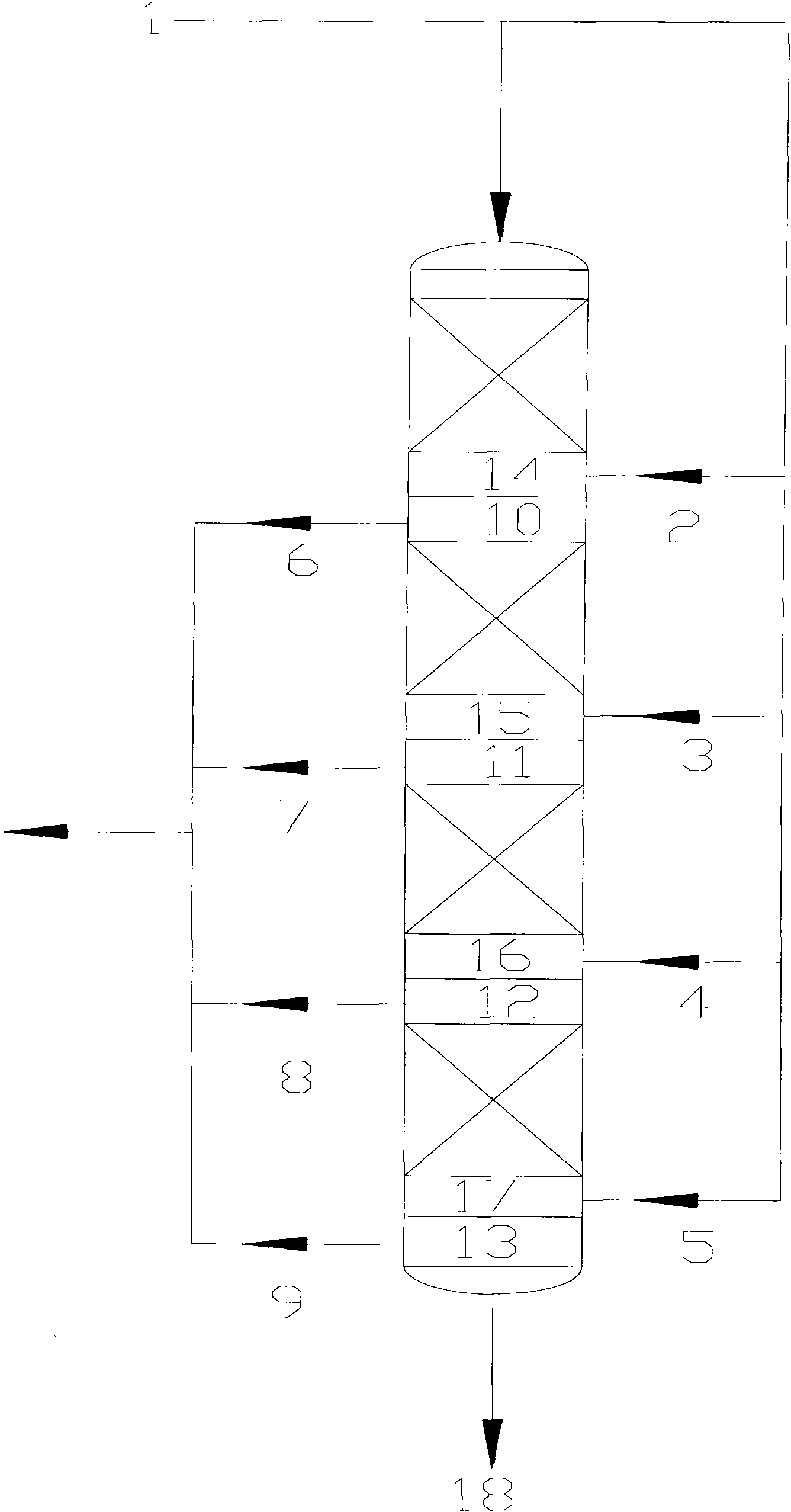

ActiveCN103570650BControl the average operating temperatureUniform reaction temperaturePreparation from carboxylic acid anhydridesFixed bedReaction temperature

The invention discloses a technological process for continuously producing succinic anhydride and co-producing succinic acid through maleic anhydride catalytic hydrogenation. The whole process comprises three steps, namely, reaction, rectification and hydrolysis, wherein two stages of hydrogenation reactors are used for reaction, a primary hydrogenation reactor is a fixed bed reactor with hydrogen entering from the lower part and reaction liquid exiting from the upper part, and a secondary hydrogenation reactor is a trickle bed reactor with hydrogen and reaction liquid entering from the upper part and exiting from the lower part. The technological process adopts an external circulating heat radiation manner, and reaction heat is uniformly removed, so that the average operation temperature of the whole reactor is effectively controlled, and the reaction temperature in the whole main reactor is balanced. Furthermore, the primary hydrogenation reactor adopts the manner that both the maleic anhydride solution and hydrogen flow upward simultaneously, so that the reaction temperature of the whole reactor is controlled to be balanced, local hot spot temperature is effectively controlled and lowered, and the reactants are prevented from polymerizing and depositing carbon or coking.

Owner:SHANXI UNIV

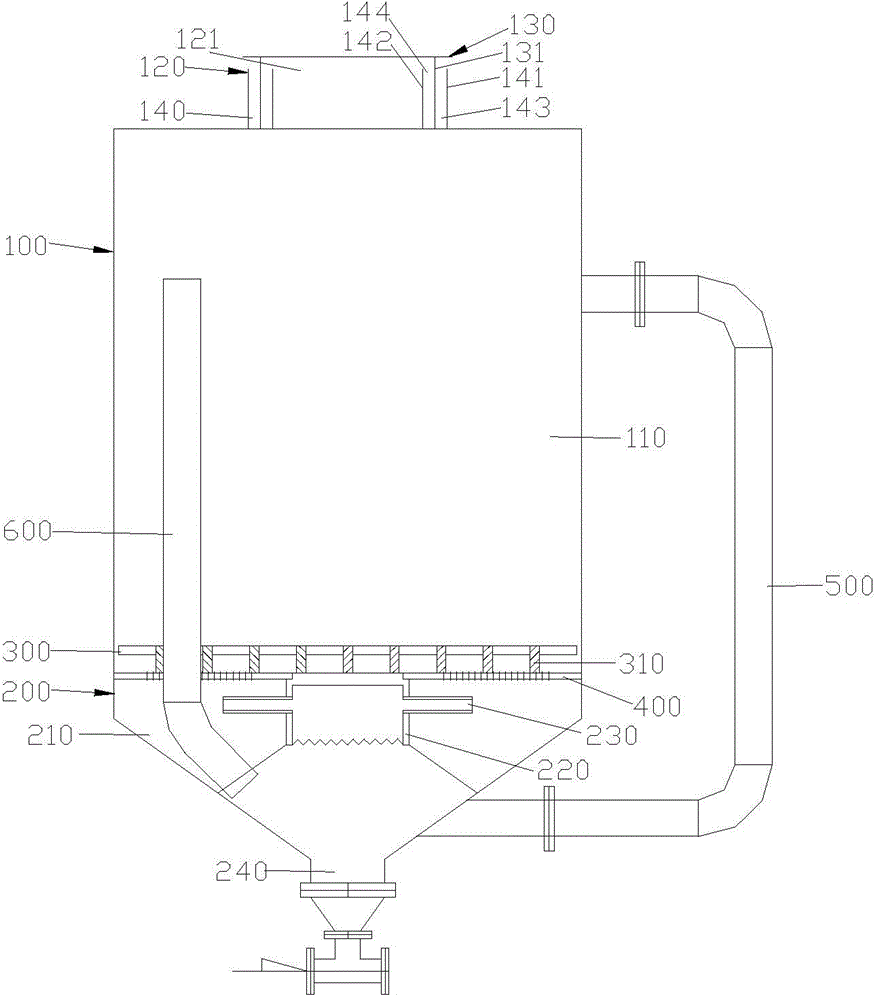

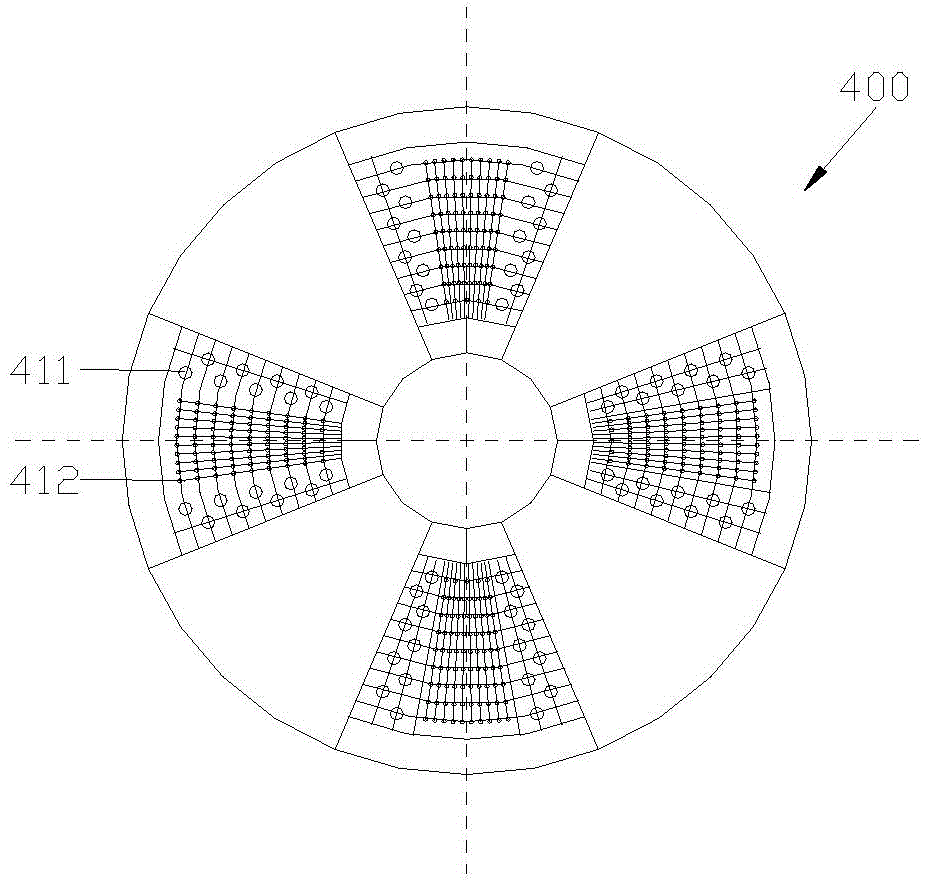

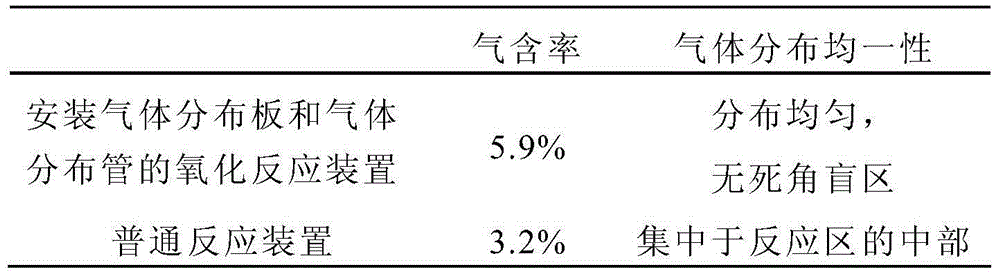

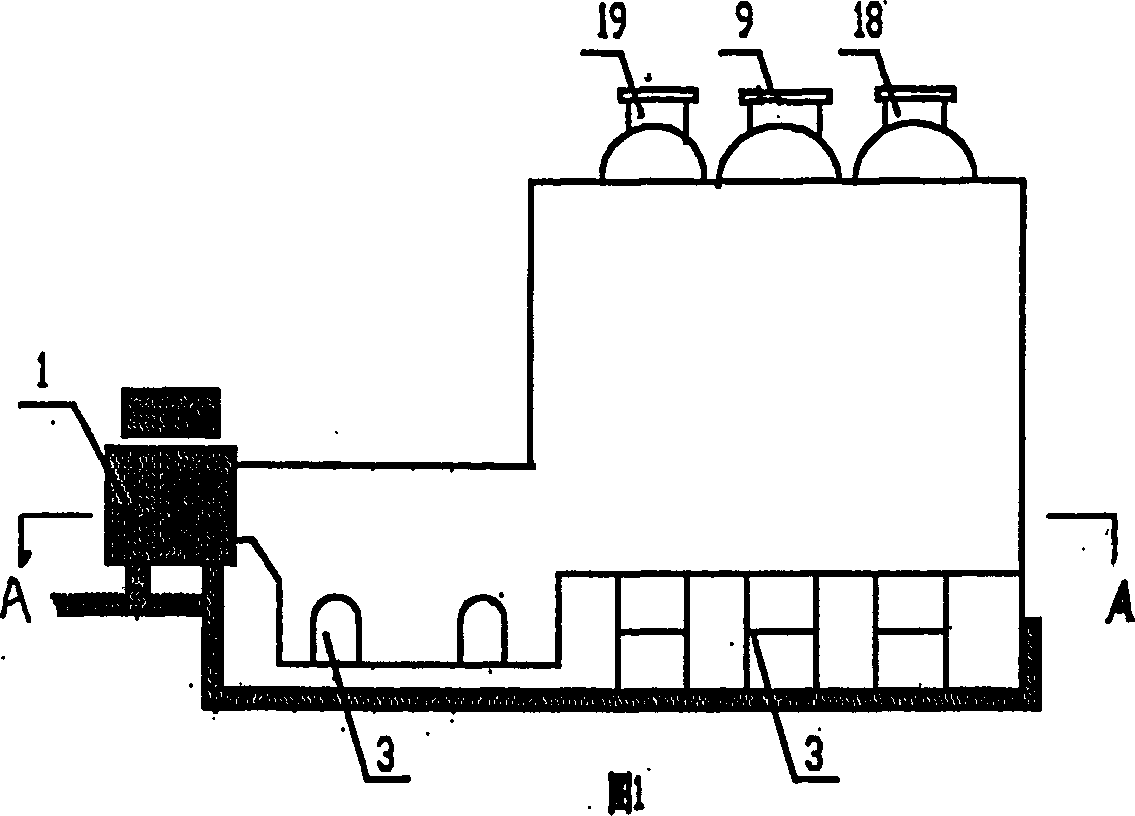

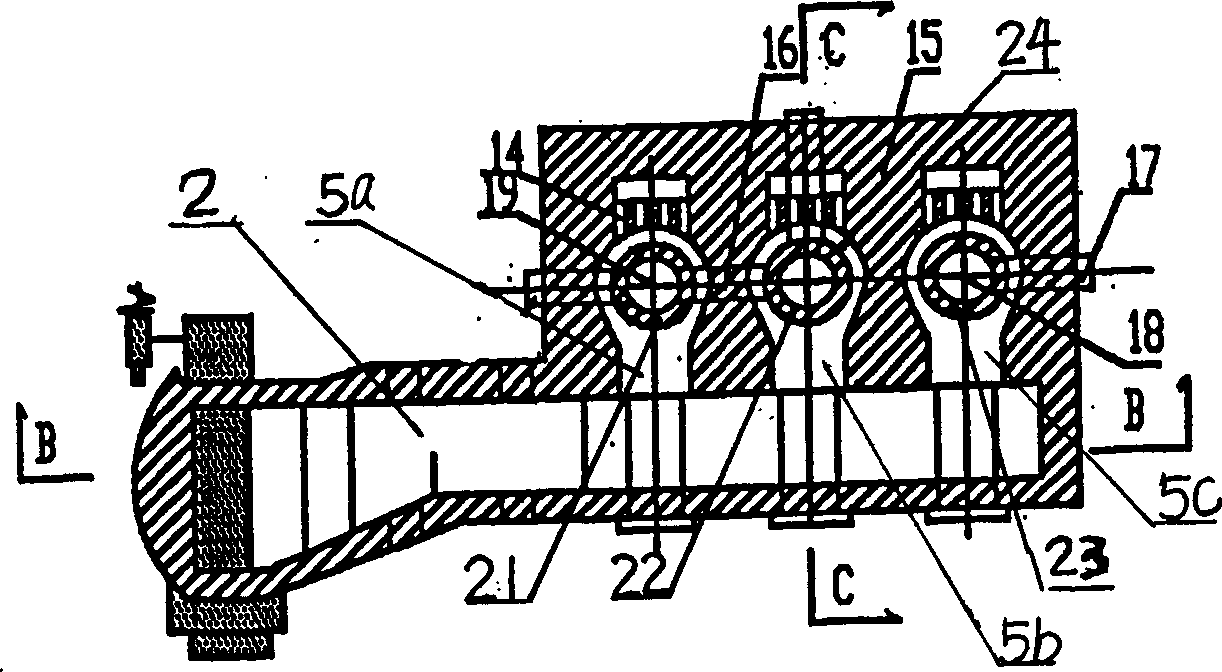

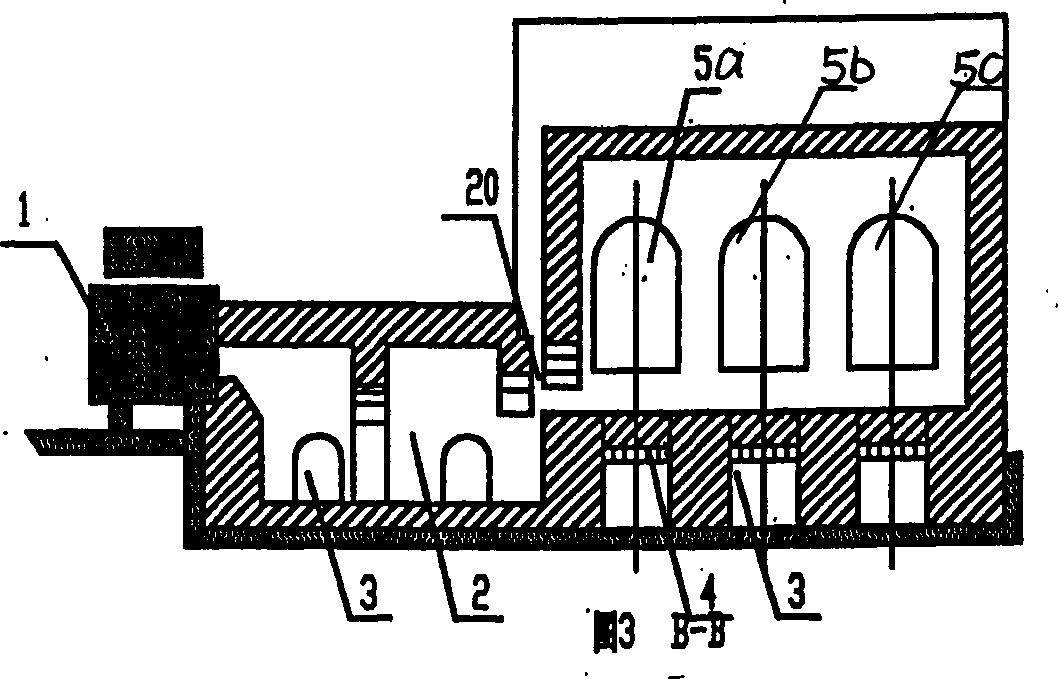

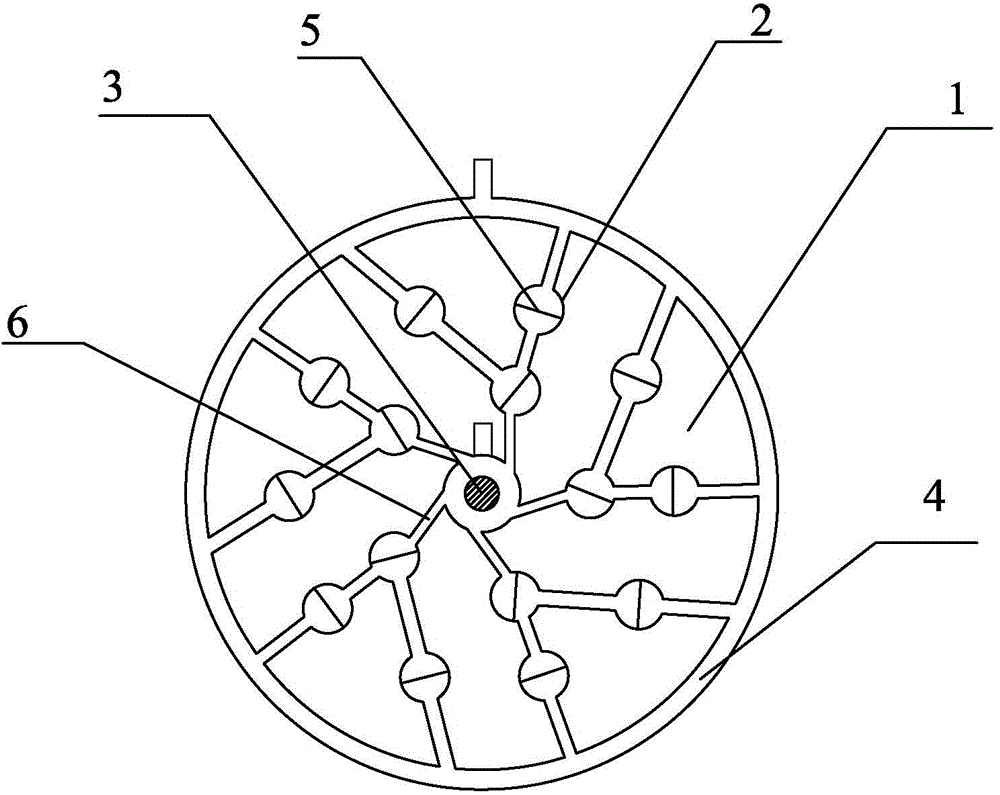

Oxidizing reaction device and use of oxidizing reaction device

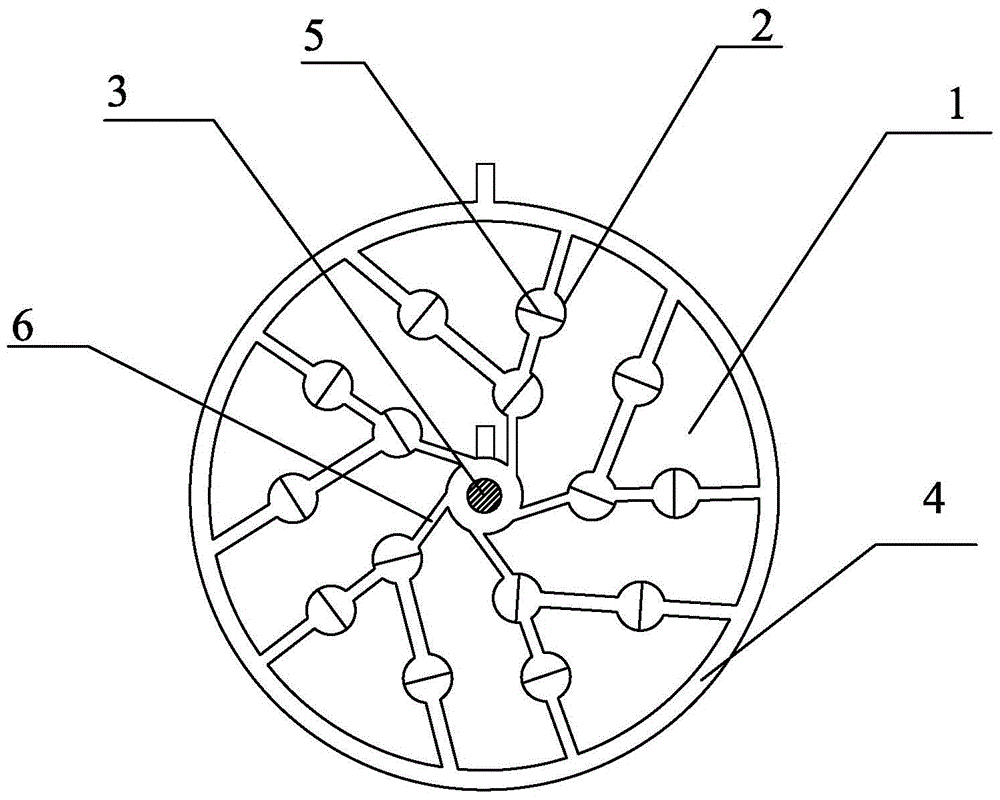

ActiveCN104689763AEvenly distributedPromote circulationIron oxides/hydroxidesChemical/physical processesEngineeringReaction speed

The invention relates to an oxidizing reaction device. The oxidizing reaction device comprises a reaction area, a gas-liquid distribution area and a material supporting member. The gas-liquid distribution area is arranged below the reaction area, and the material supporting member is used for supporting a reactant in a first cavity and arranged at the bottom end of the reaction area. The gas-liquid distribution area comprises a second cavity, a gas collection chamber, more than one gas distribution pipe and a ventilation opening, the gas collection chamber is arranged in the second cavity, one end of each gas distribution pipe is arranged at the peripheral edge of the gas collection chamber, and the ventilation opening is arranged below the gas collection chamber. At least one air hole is formed in each gas distribution pipe. By adopting the oxidizing reaction device, the gas, material liquid and temperature can be uniformly distributed in a reaction system, the reaction time is reduced, and the reaction speed is increased.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

CS2 reactor furnace

The CS2 reactor furnace includes inner furnace body of refractory material, outer furnace body of refractory material, and heating chamber between the inner surface body and the outer furnace body. In the peripheral of the inner surface body, there are sulfur gasifying furnace and carbon material preheating furnace, and the sulfur gasifying, furnace is connected via sulfur vapor duct to the bottom of the inner furnace body. The CS2 reactor furnace of the present invention has no sulfurizing and oxidizing corrosion of inner furnace body and thus long service life. The material preheating speeds the reaction and raise the product yield. Heating the coal-burning gas furnace via the main fire channel communicated with the furnace body can save fuel and stabilize furnace temperature.

Owner:SHANGHAI BAIJIN CHEM GROUP

External circular reaction device suitable for hydrogenation exothermic reaction

ActiveCN103566837AControl the average operating temperatureUniform reaction temperaturePreparation by hydrogenationChemical/physical processesReaction temperatureExothermic reaction

The invention discloses an external circular reaction device suitable for hydrogenation exothermic reaction. The external circular reaction device mainly comprises a first-stage hydrogenation reactor, a second-stage hydrogenation reactor, a hydrogen circulation loop and a liquid circulation loop. The liquid circulation loop in the reaction device is used for mixing a part of reacted solution and a fresh raw material solution, so that the concentration of raw materials in the reactor is reduced, the bed temperature rise generated by a heat release effect caused by hydrogenation is relieved, and the temperature inside the first-stage hydrogenation reactor is effectively controlled. A way that the raw material solution and hydrogen flow up in parallel is adopted in the first-stage hydrogenation reactor, a liquid phase is used as a continuous phase, and a catalyst is soaked into a reaction liquid, so that the reaction temperature of a catalyst bed keeps constant, meanwhile, the overhigh local temperature of a reaction site on the surface of the catalyst is avoided, furthermore, the occurrence of polymerization reaction of organic matters on the surface of the catalyst is effectively inhibited, the carbon deposition quantity on the surface of the catalyst is low, and the service life of the catalyst is remarkably prolonged. The external circular reaction device disclosed by the invention is suitable for continuously producing succinic anhydride by using maleic anhydride through catalytic hydrogenation and preparing 1- 4-butanediol by using butynediol through hydrogenation.

Owner:SHANXI UNIV

Gas phase catalytic esterification process for synthesizing butyl acetate

InactiveCN1184187CFully vaporizedWell mixedOrganic compound preparationCarboxylic acid esters preparationAcetic acidIt equipment

This invention relates to new technology of gaseous phase catalytic esterification and its equipment, it uses straight immobilized bed reactor with fluidic apparatus. The invented new technology is low in cost, higher raw material gas space velocity, uniform mixing of raw material, can reduce channeling and short circuit effectively. The ethyl butylate yield and selectivity can reach respectively to 85.41% and 95.43%.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Hydrogenation process for silicon tetrachloride and process for preparing high-purity silicon from trichlorosilane

InactiveCN107162003AImprove securityWell mixedSiliconHalogenated silanesHydrogenation processSilicon tetrachloride

The invention provides a hydrogenation process for silicon tetrachloride and a process for preparing high-purity silicon from trichlorosilane. The process for preparing high-purity silicon from trichlorosilane comprises the following steps: (1) introducing trichlorosilane gas and hydrogen into a micro-channel mixing and heating device for heating and mixing so as to obtain a heated gas mixture; (2) conveying the heated gas mixture into a micro-channel reactor, heating the gas mixture and carrying out a reaction in the presence of a catalyst so as to obtain a reacted mixture; and (3) cooling the reacted mixture and carrying out solid-gas separation so as to obtain high-purity silicon and a cooled gas mixture, and separating and recycling each component in the cooled gas mixture. The invention also discloses a hydrogenation process for silicon tetrachloride. Compared with the prior art, the hydrogenation process for silicon tetrachloride and the process for preparing high-purity silicon from trichlorosilane in the invention have the beneficial effects that the conversion rates of silicon tetrachloride and trichlorosilane can reach 50% or above; and through combination of the processes with micro-chemical technology, the conversion rates are increased, security of the production processes is improved, and energy consumption is reduced.

Owner:于志远

Bipyramid rotary superconducting waste cracking furnace

InactiveCN109424963AConducive to continuous cracking and gasificationLarge capacity reductionIncinerator apparatusActivated carbonFlue gas

The invention discloses a bipyramid rotary superconducting waste cracking furnace which is composed of a bipyramid superconducting isothermal rotary furnace body, a rotary furnace body driver, a heater and a feeding machine. The bipyramid rotary superconducting waste cracking furnace is characterized in that the bipyramid superconducting isothermal rotary furnace body is a bipyramid composite pipeisothermal superconducting rotary furnace body with two small ends and a thick middle composed of a metal inner pipe and a metal outer pipe which are concentric, the thick portion in the furnace bodyis a superconducting working medium heating pool, and a circumferential heating zone provided with heat exchange sheets is arranged on the periphery of the heating pool. The heater heats the furnacebody outside the furnace body through self-produced gas of the waste cracking furnace, produced radiant heat is rapidly and evenly transferred to waste in the rotary furnace through the circumferential heating zone, the heating pool and the bipyramid composite pipe isothermal superconducting rotary furnace body, and therefore the waste is rapidly and efficiently cracked and gasified. By means of the cracking furnace, the risk that bonding, bulging, blocking and coking are caused by local overheating of waste in the furnace is avoided, flue gas is prevented from being produced, pollution of harmful substances released by cracked materials to environment is avoided, dioxin emission is effectively restrained, and environment is protected; and cracked solid waste can be used as activated carbon for preparing chemical raw materials, and the overall economic benefits are obvious.

Owner:西安美润环保工程技术有限公司 +1

Hydrotreating method for heavy hydrocarbon raw materials

ActiveCN102465031AExtended operating cycleAchieve separationTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a hydrotreating method for heavy hydrocarbon raw materials. According to the invention, a fixed bed hydrogenation reactor is employed; at least two catalyst beds are arranged in the fixed bed hydrogenation reactor; a solvent is introduced at least from one gap formed by two adjacent catalyst beds and is mixed with reacting materials, and light components are extracted; the light components are introduced out from the reactor in an extraction and separation area between two adjacent catalyst beds, and heavy components enter into next catalyst bed for further reaction; extracted oil can directly enter into a gasoline / diesel hydrogenation device so as to obtain qualified gasoline / diesel and can also enter into an FCC main fractionating column for fractionation so as to obtain a crude product which enters into the gasoline / diesel hydrogenation device so as to obtain qualified gasoline / diesel. The method provided in the invention can effectively reduce pressure drop of beds in fixed bed hydrotreatment, prolong the service life of a catalyst, improve a total conversion rate of a fixed bed hydrogenation apparatus and enhance treating capacity of an apparatus under the condition of a same conversion rate, thereby creating greater benefits for an enterprise.

Owner:CHINA PETROLEUM & CHEM CORP +1

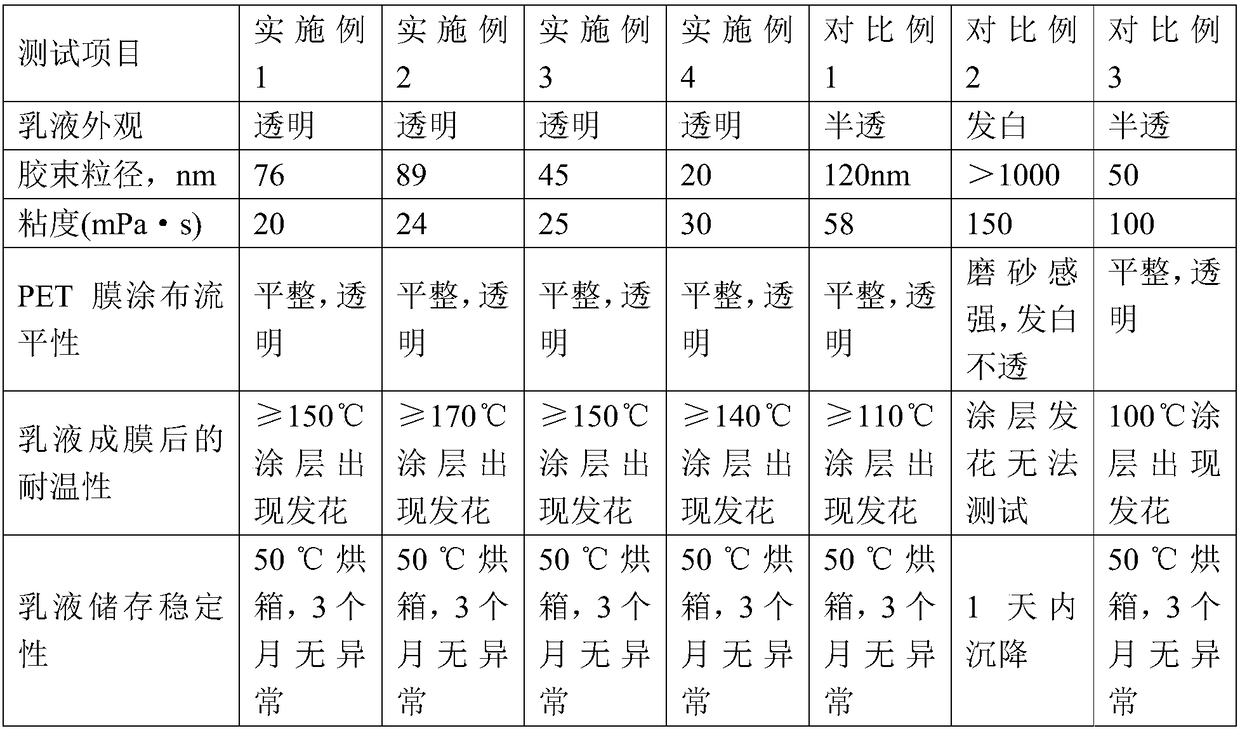

Heterogeneous chain extension synthesis method for waterborne polyurethane

ActiveCN108264621AImprove temperature resistanceSlow reaction ratePolyurea/polyurethane coatingsPolyesterCross-link

The invention provides a heterogeneous chain extension synthesis method for waterborne polyurethane. The method comprises the following steps: S1, pre-polymerizing: dehydrating polyester polyol, and performing a pre-polymerization reaction on the dehydrated polyester polyol and diisocyanate; S2, performing hydrophilic chain extension and cross-linking: adding a hydrophilic chain extender, a cross-linking agent and a diluent to a material obtained in step S1, and performing a chain extension and cross-linking reaction; S3, neutralizing and extending the chain: adding neutralizing amine, water,the diluent, a pH buffer agent and fatty amine to a material obtained in step S2, and ending the reaction to obtain a prepolymer; S4, performing dispersing emulsification: adding water to a material obtained in step S3 to achieve emulsification in order to uniformly disperse the prepolymer in water; and S5, performing a post-chain extension reaction: adding a post-chain extension amine to a material obtained in step S4, performing chain extension in water, and performing reduced pressure distillation to remove the solvent in order to obtain the waterborne polyurethane. The method uses fatty amine to carry out chain extension in a heterogeneous state in order to synthesize the waterborne polyurethane resin with high content of allophanate; and the obtained emulsion has the advantages of small micelle particle size, low viscosity, good leveling property and good storage performance.

Owner:SHANGHAI WEIKAI CHEM +1

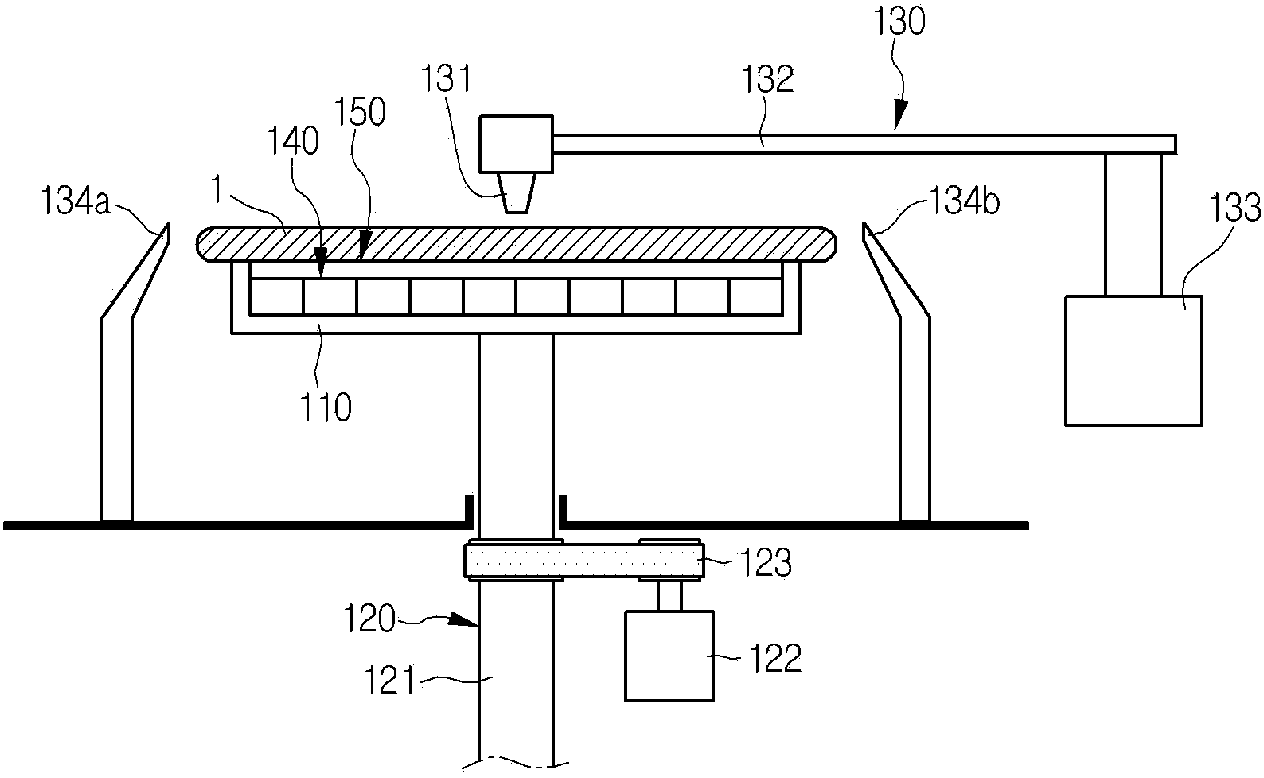

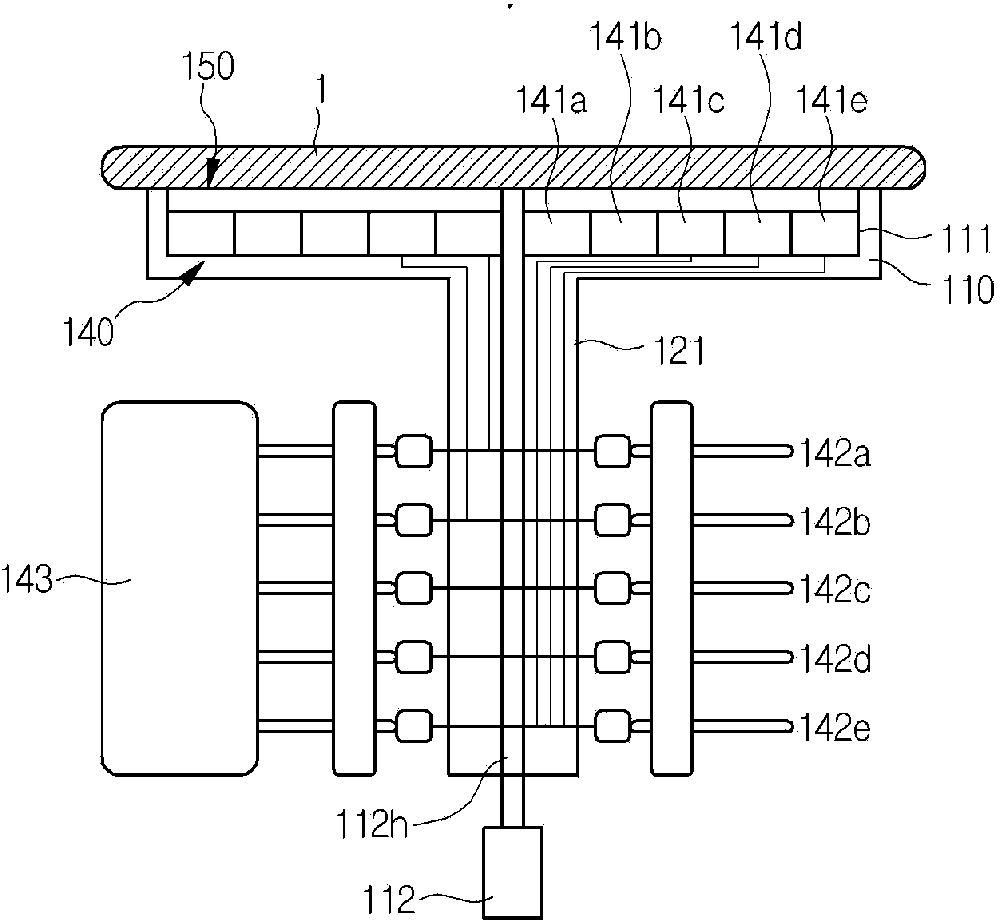

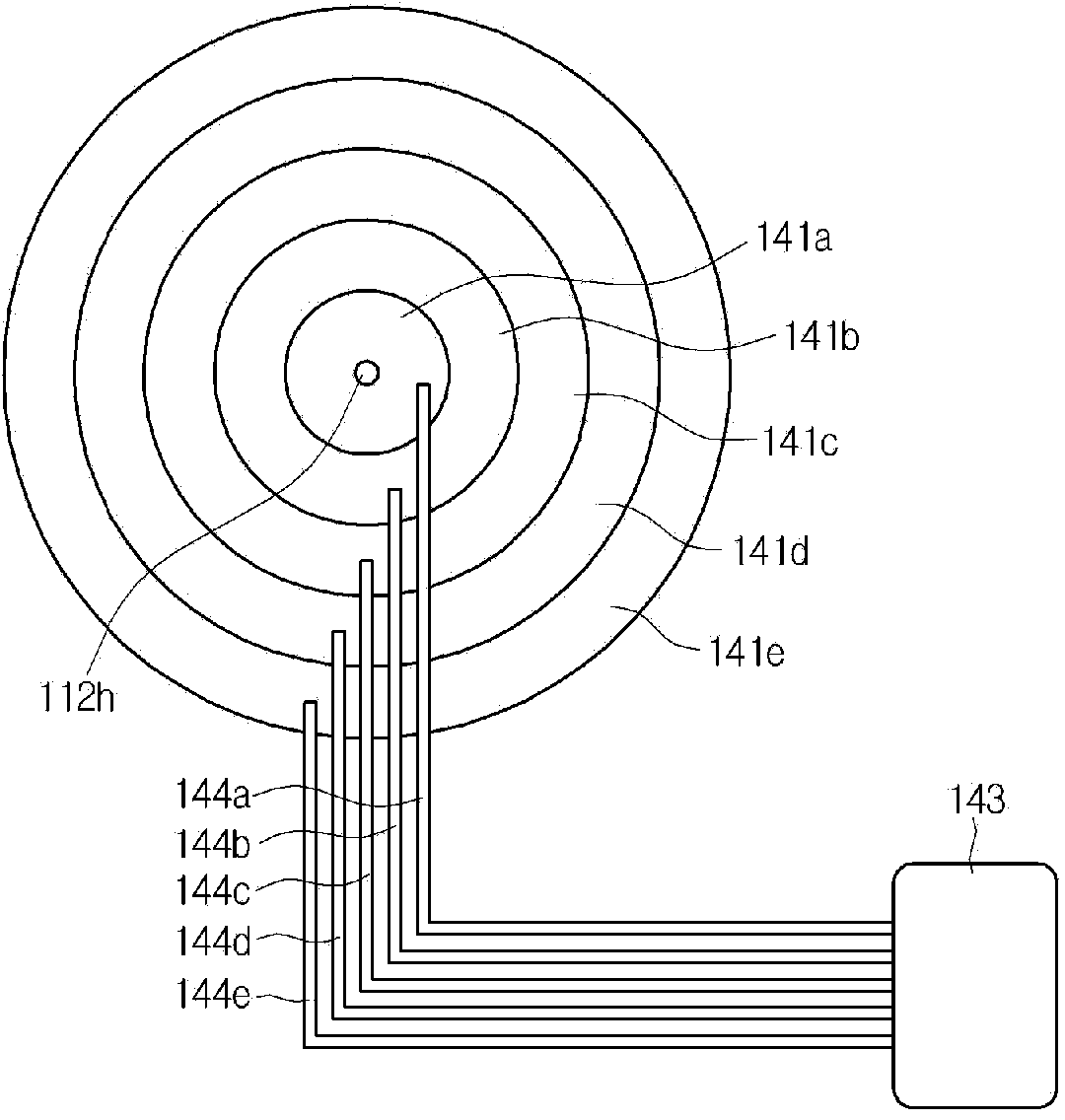

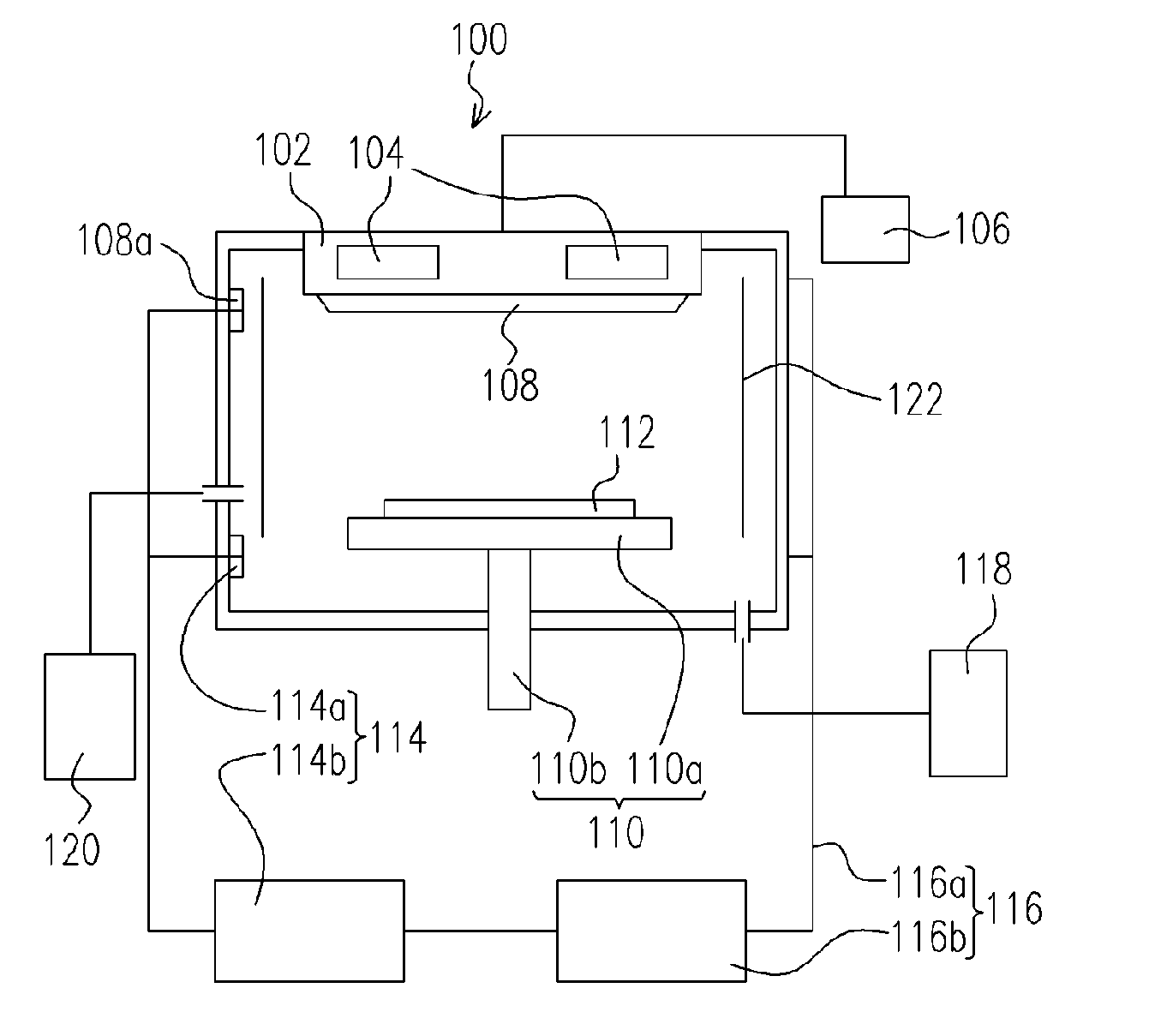

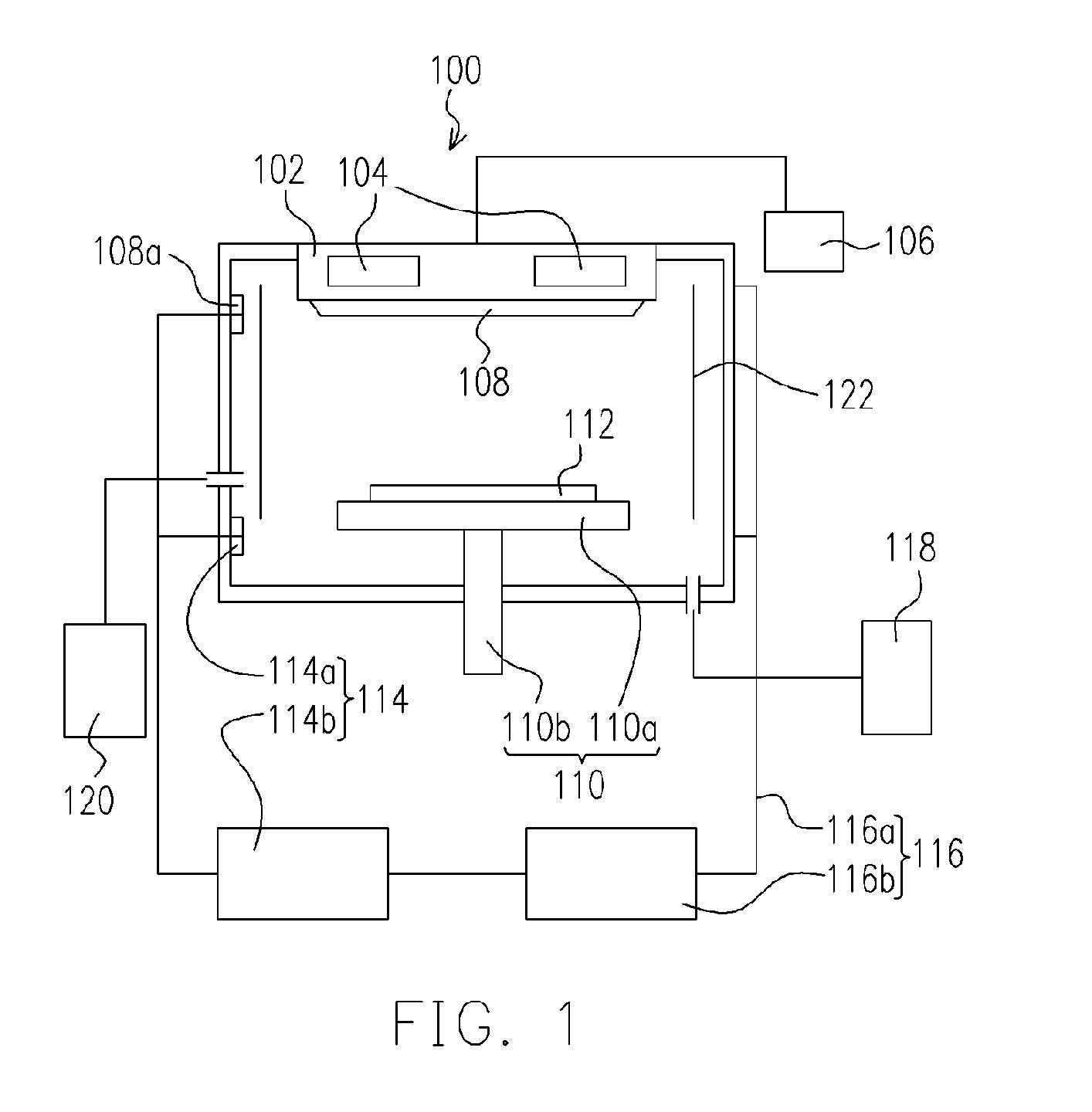

Apparatus for single wafer etching

ActiveCN103999197AAvoid adsorptionImprove flatnessSemiconductor/solid-state device manufacturingEtchingReaction temperature

Provided is a single wafer etching apparatus etching wafers one at a time. According to the present invention, the single wafer etching apparatus may not only discharge gas by vibrating the wafer even in the case that gas, a byproduct of an etching reaction, is generated, but may also prevent the gas from adsorbing on a surface of the wafer. Also, since the single wafer etching apparatus may directly heat each region of the wafer, the single wafer etching apparatus may uniformly maintain a reaction temperature by heating to higher temperatures from a circumferential direction toward the center of the wafer, even in the case that the temperature of an etching solution increases from the center of the wafer toward the circumferential direction due to the fact that etching is performed while the etching solution moves from the center of the wafer toward the circumferential direction. Therefore, the single wafer etching apparatus may not only uniformly maintain a degree of etching regardless of a position on the wafer, but may also increase flatness.

Owner:LG SILTRON

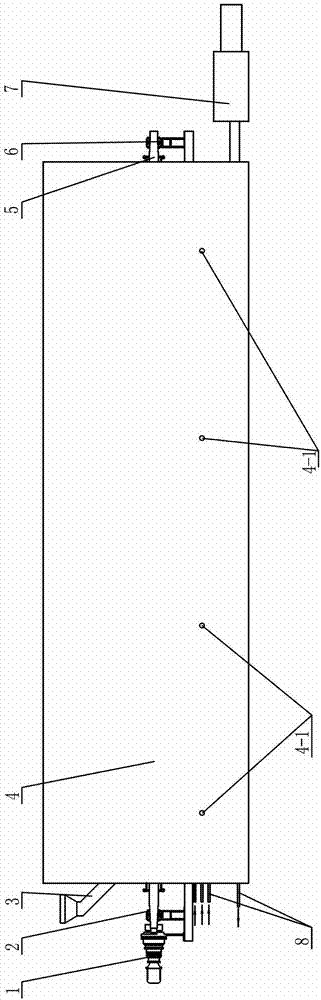

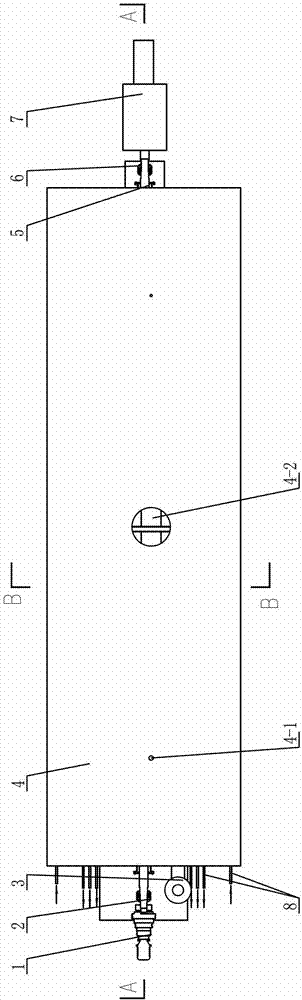

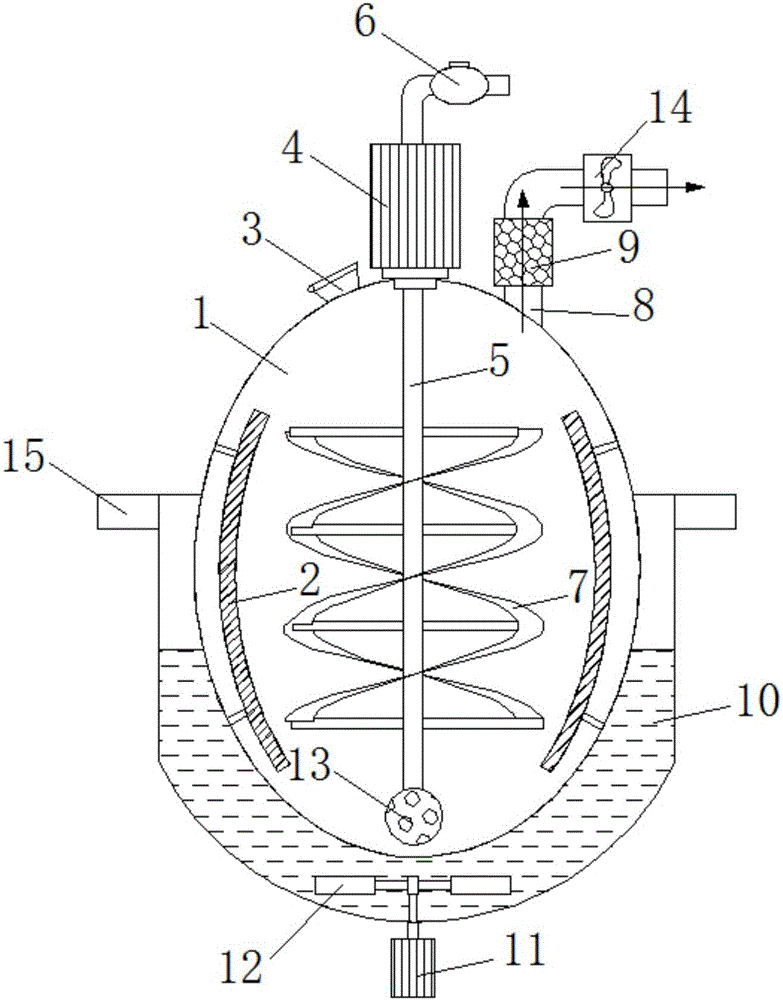

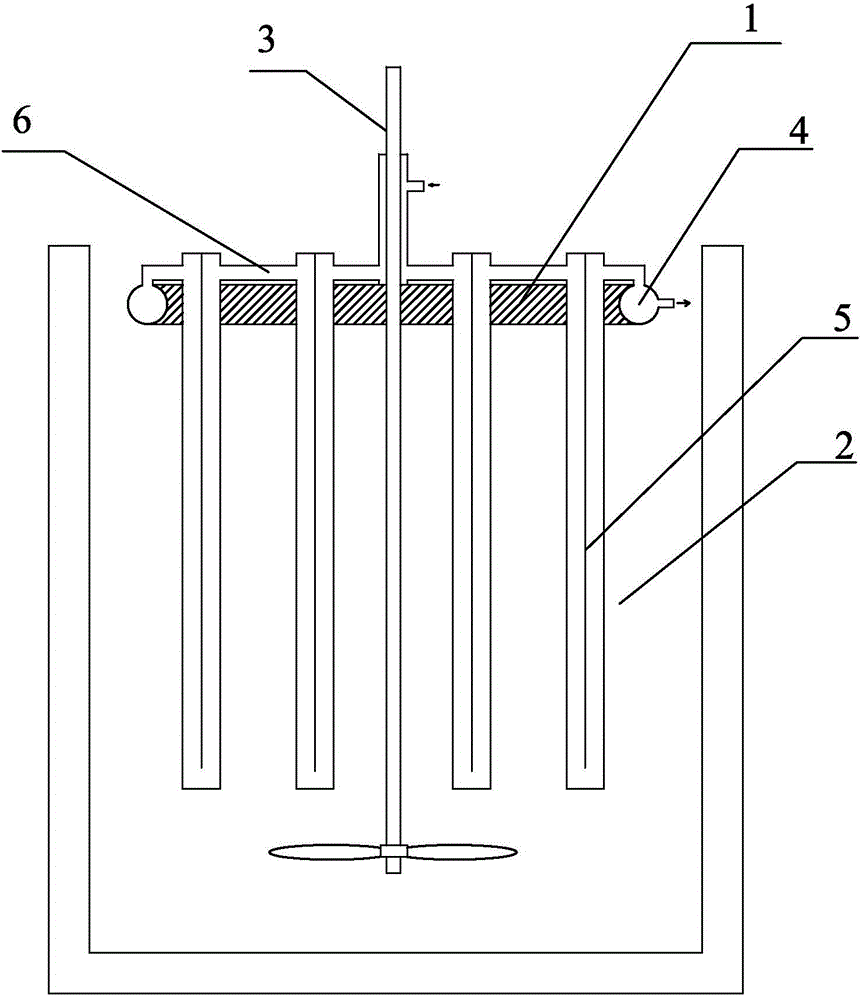

Dry-type anaerobic reaction treatment device

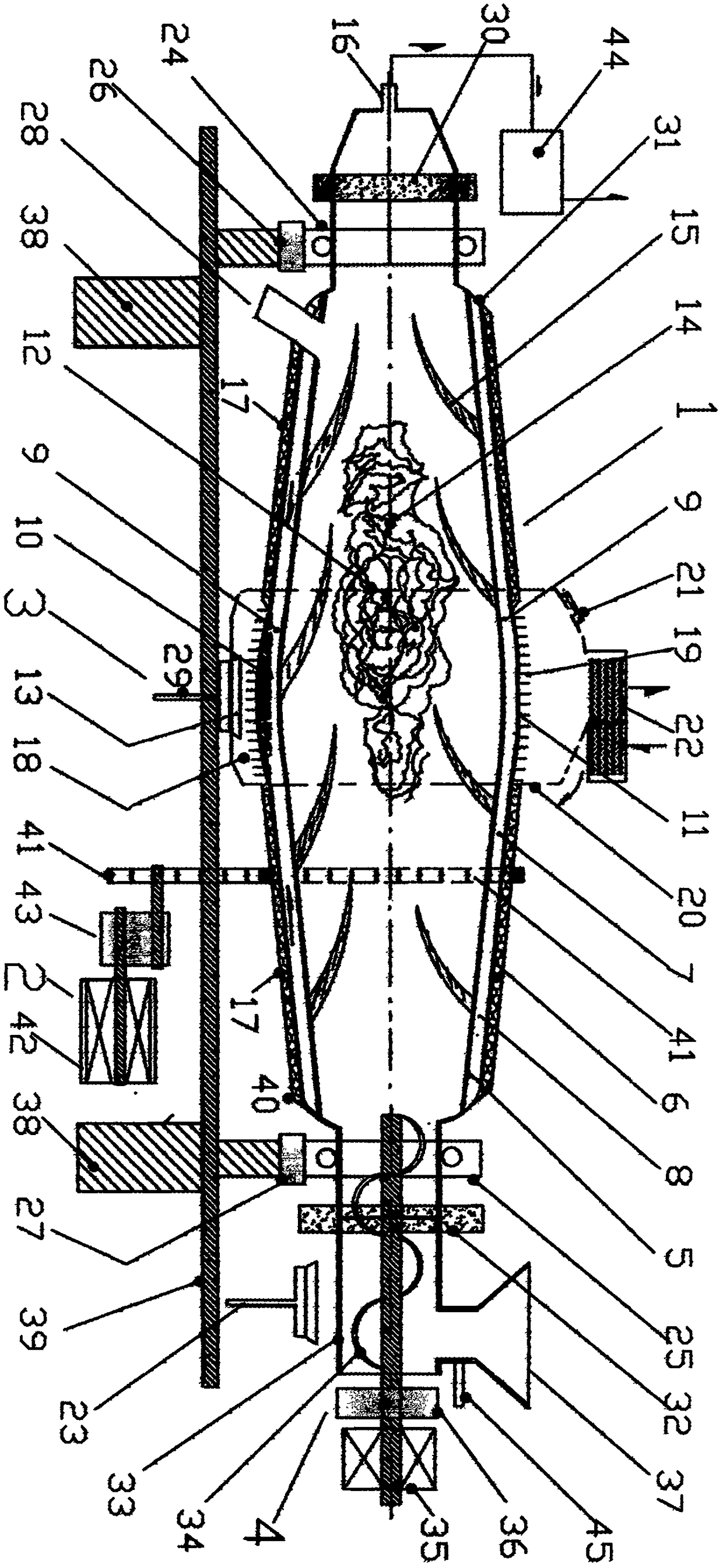

ActiveCN103387932BImprove securityUniform reaction temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringTreatment unit

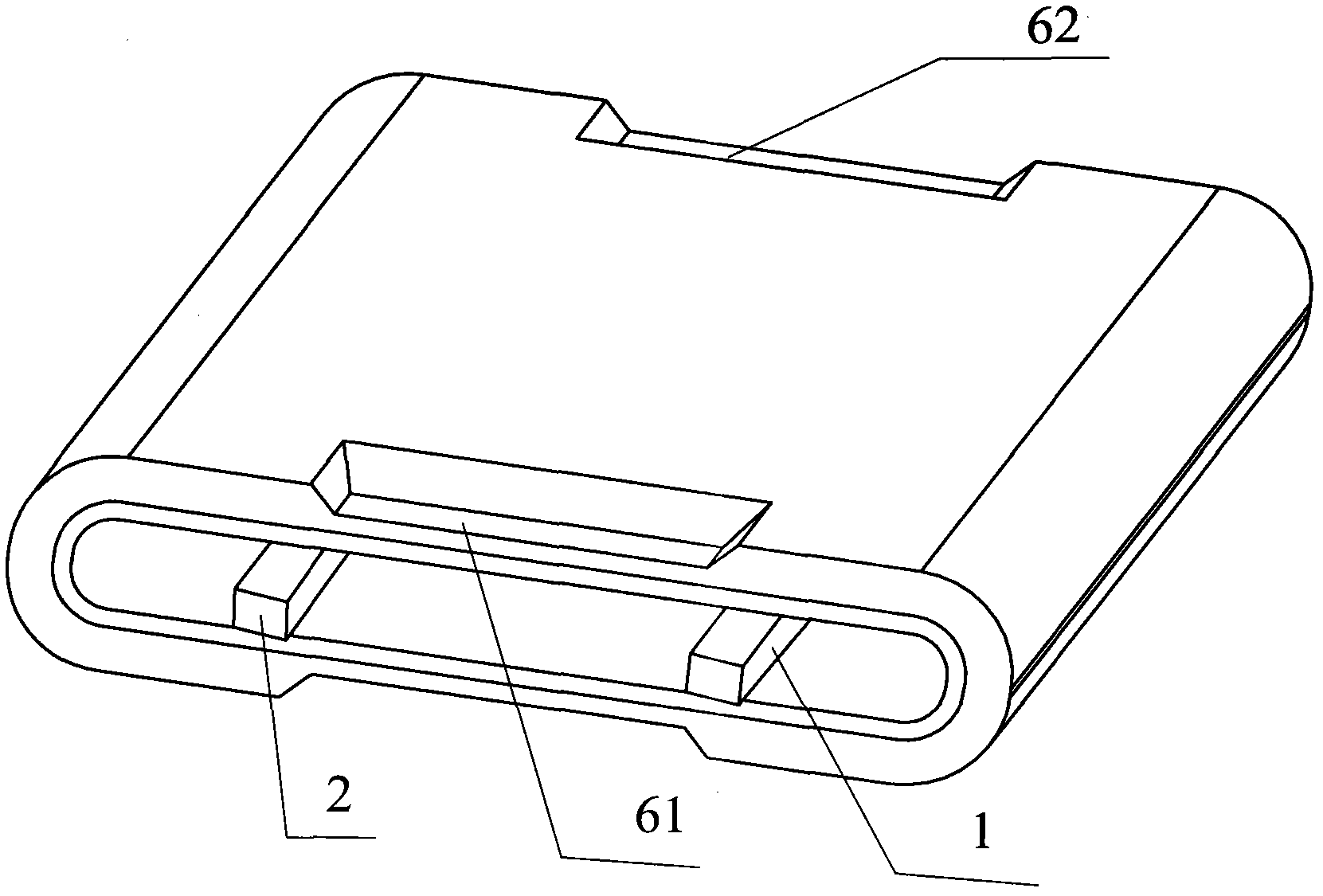

The invention relates to a dry-type anaerobic reaction treatment device. The dry-type anaerobic reaction treatment device comprises a reaction container and a stirring mechanism, wherein the stirring mechanism is supported on the reaction container; a charging mechanism is arranged on one side of the reaction container; a discharging mechanism is arranged on the other side of the reaction container; a heat preserving layer and a plurality of detection installation holes are formed outside the reaction container, and a methane collection port is formed in the top of the reaction container; the reaction container is divided into at least three heating regions from a charging side to a discharging side; two groups of heat exchangers are arranged at the side lower part of the reaction container respectively; each heat exchanger comprises at least three heat exchange tube groups; each heat exchange tube group penetrates through the reaction container from the charging side and is arranged in the corresponding heating region; a stirring shaft of the stirring mechanism, corresponding to each heating region, is provided with at least four stirring blades; all stirring blades are staggered in the circumferential direction along the axial direction of the stirring shaft; each stirring blade comprises a stirring box and a stirring arm; an opening is formed in the outer side of the stirring box; the stirring arm is fixed with the stirring shaft. The dry-type anaerobic reaction treatment device is reasonable in structure; the quantity of treatment units is small; the sewage treatment cost can be reduced; the anaerobic treatment efficiency can be improved.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

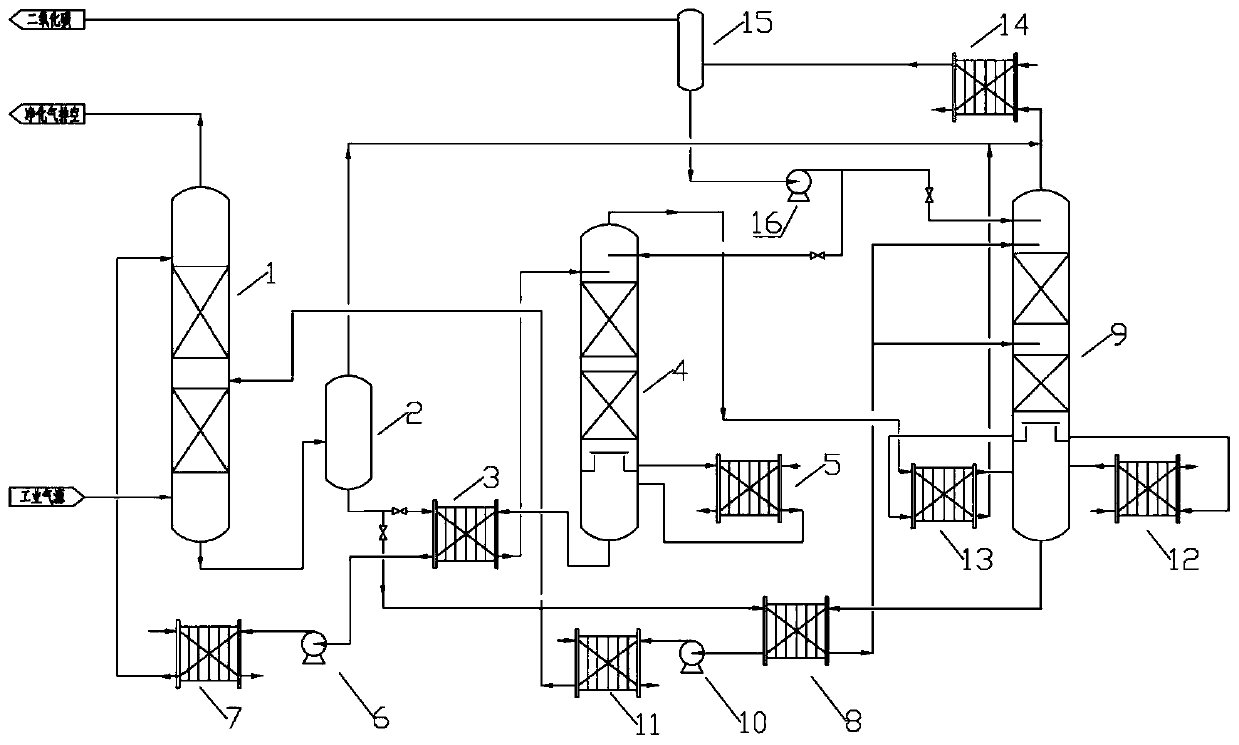

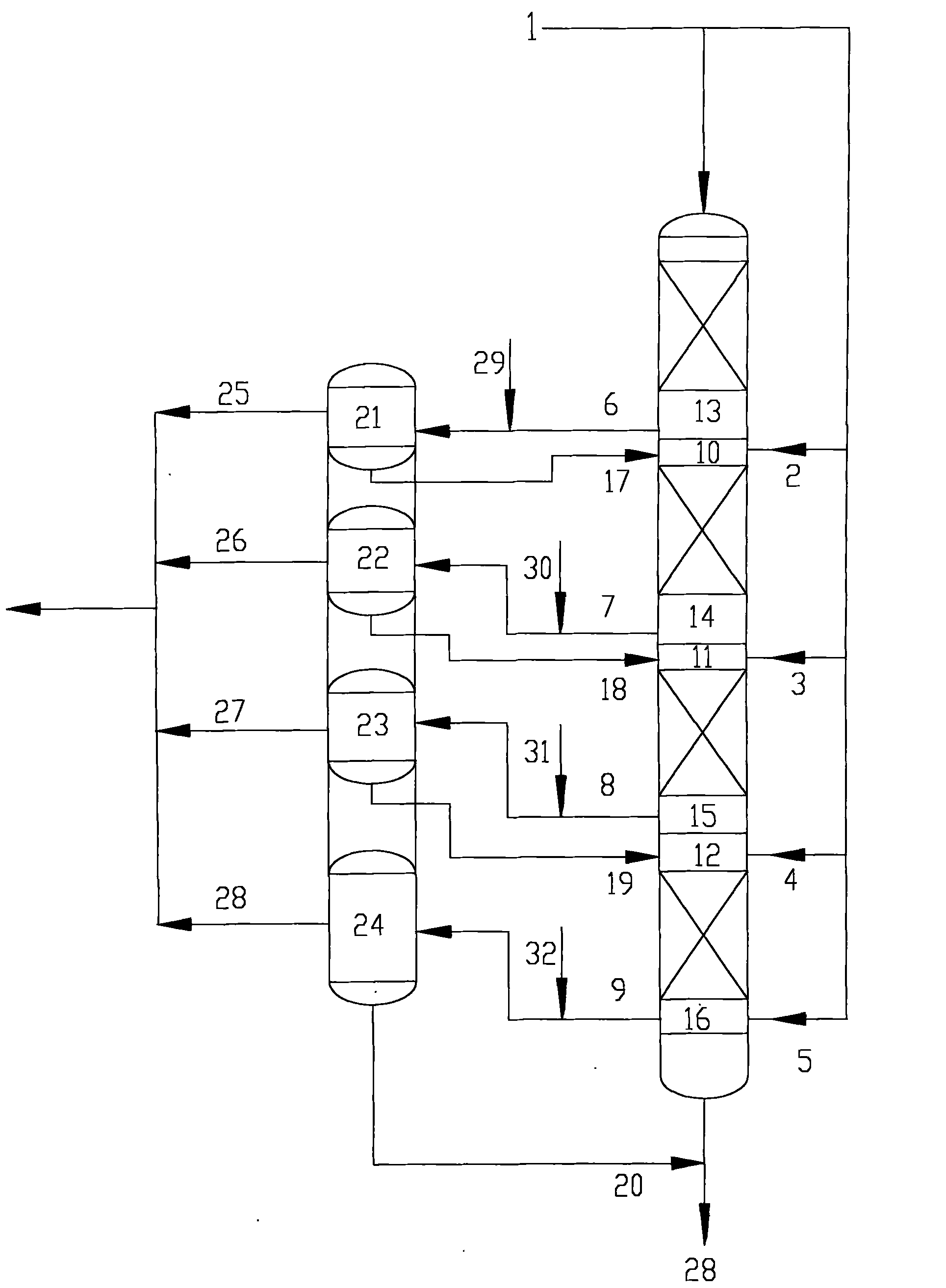

Separation system and method for carbon dioxide in medium-high pressure air source

PendingCN109999618AReduce inputMeet energy consumptionDispersed particle separationDesorptionReaction temperature

The invention provides a separation system and method for carbon dioxide in a medium-high pressure air source. CO2 rich liquor from an absorption tower is subjected to pressure reduction and regenerated step by step in modes such as flash evaporation, high-pressure desorption and low-pressure desorption, the high-pressure characteristic of a CO2 air source is fully used, and input of external heatconsumption is reduced; the low-energy-consumption and low-cost requirements are met; high-temperature desorbed air of the tower top of a high-pressure desorption tower is introduced into a reboilerof a low-pressure desorption tower and used for a heating desorption heat source, external heat consumption required by the low-pressure desorption tower is reduced, and meanwhile the cooling-water consumption of a desorbed air cooler is reduced; barren liquor and semi-barren liquor from the high-pressure desorption tower and the low-pressure desorption tower enter from an upper-section filler anda lower-section filler of the absorption tower respectively, reaction temperatures at all portions of a tower body can be kept uniform, it is avoided that the local temperature is over high, and degradation and loss of an absorbent are reduced. According to the separation system and method for carbon dioxide in the medium-high pressure air source, the high-pressure characteristic of the CO2 air source is fully used, the input of the external heat consumption is reduced, and the low-energy-consumption and low-cost requirements are met.

Owner:HUANENG POWER INTERNATIONAL +1

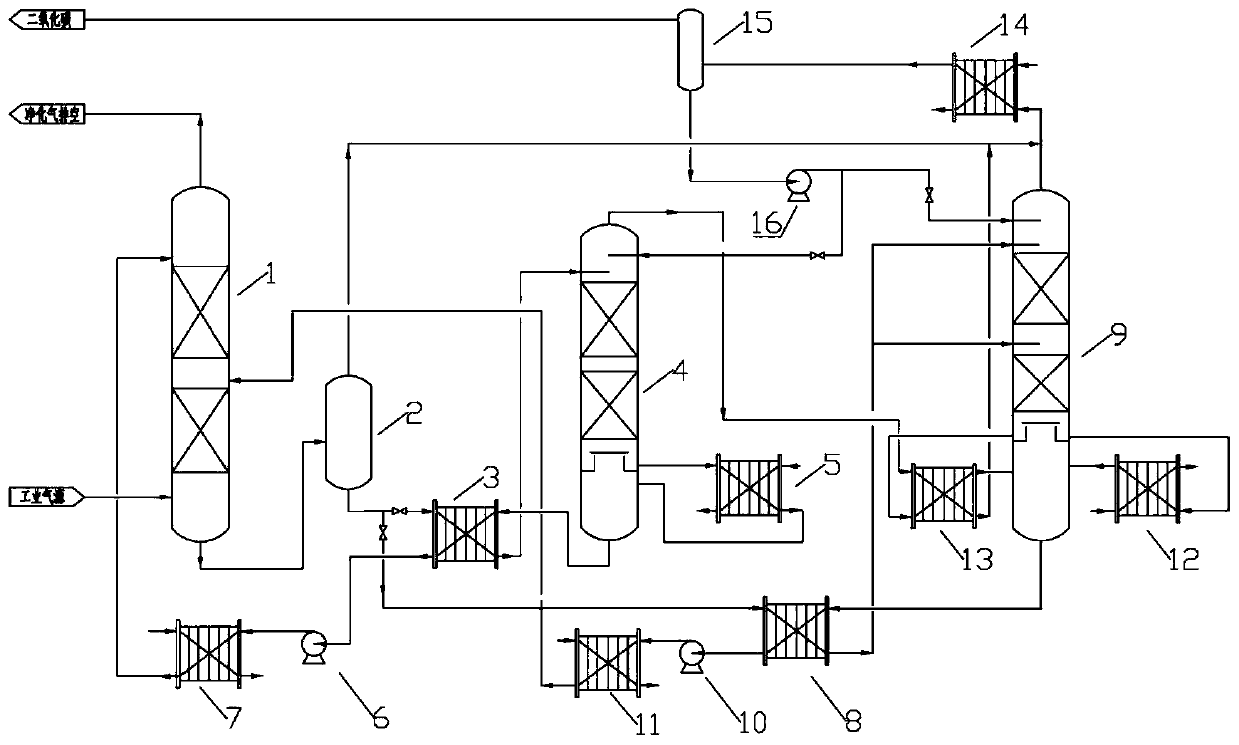

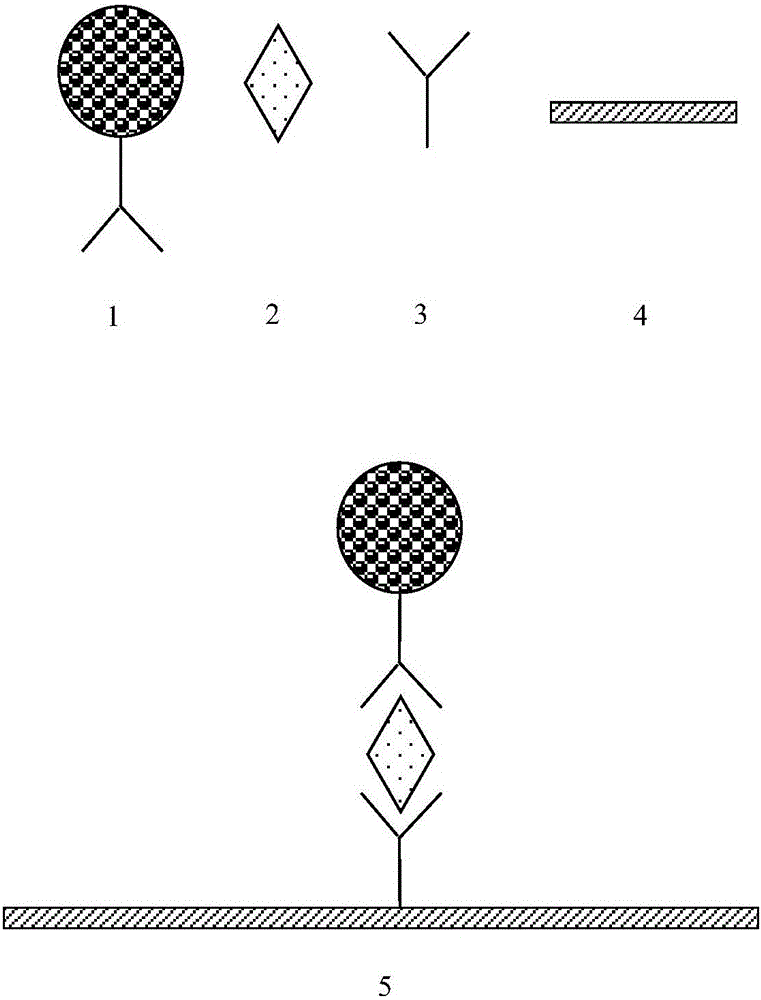

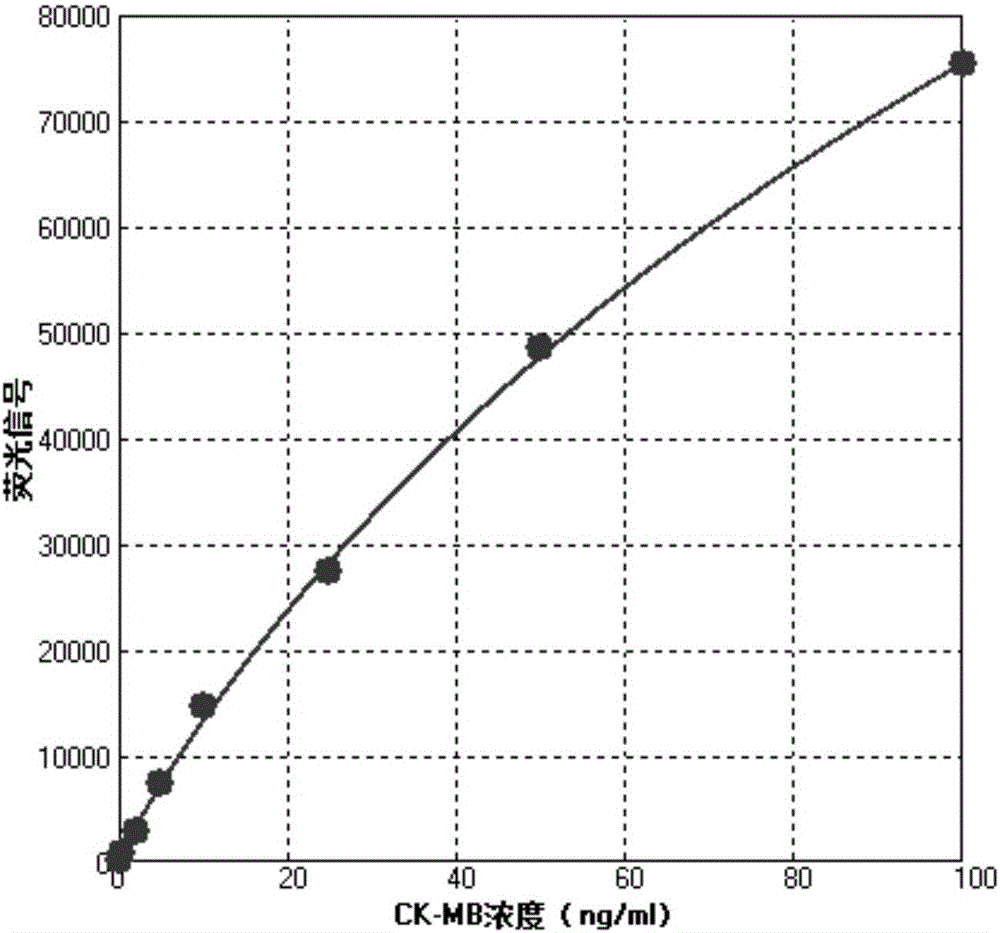

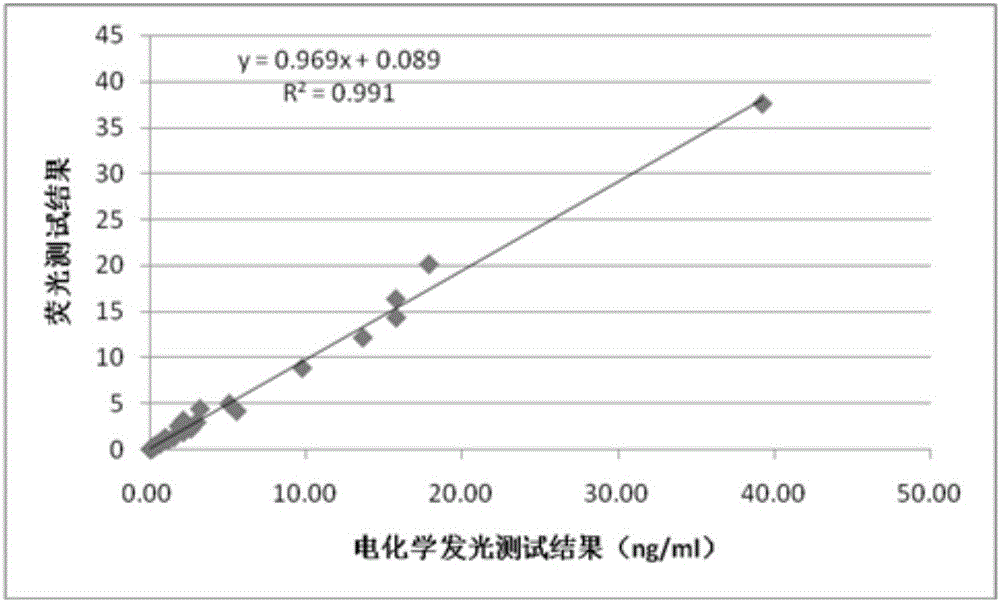

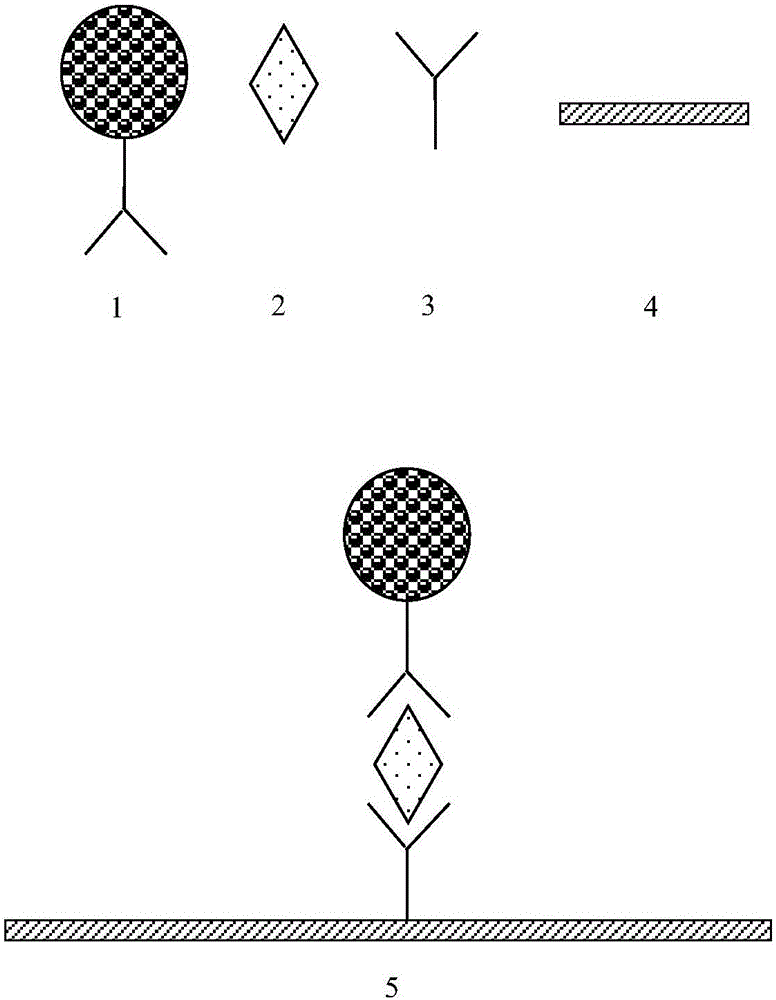

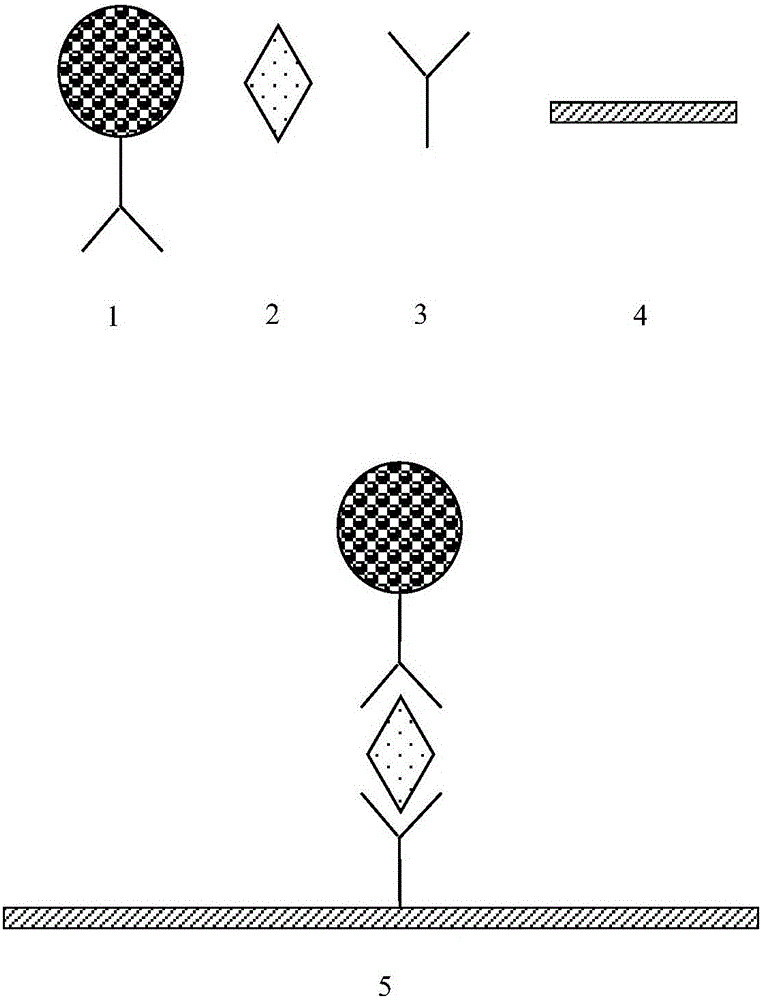

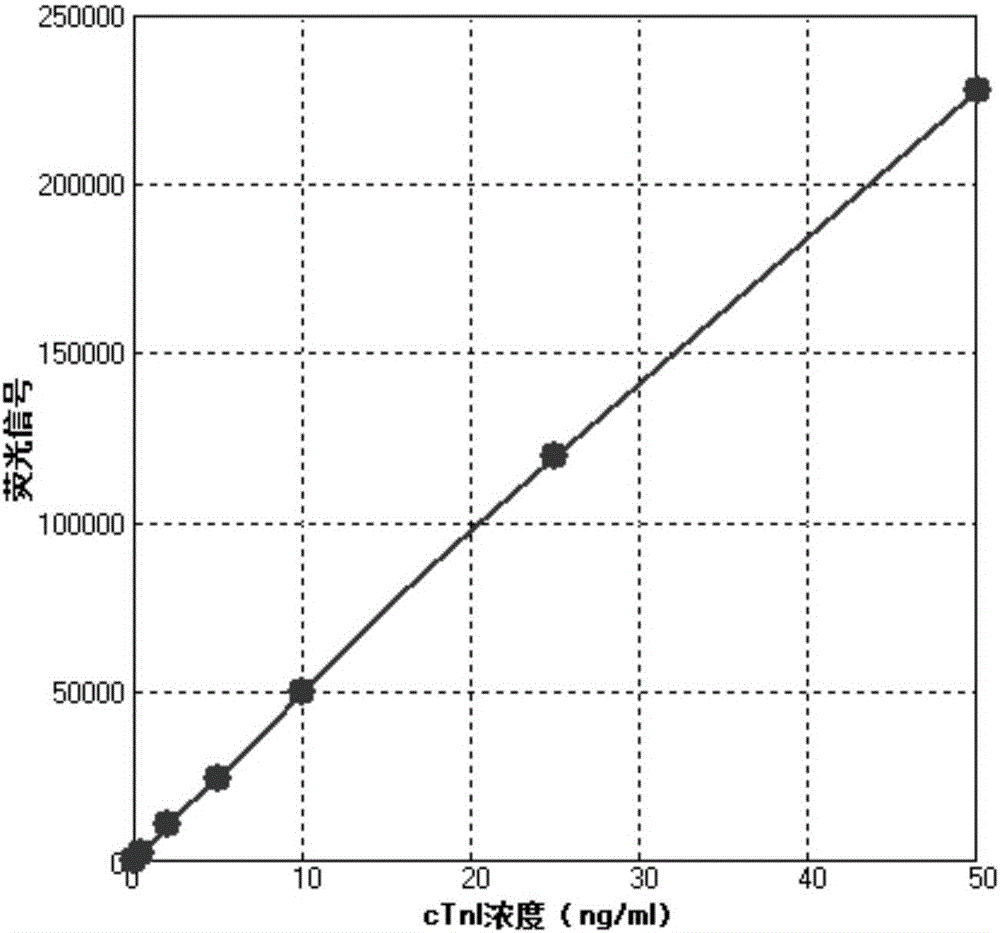

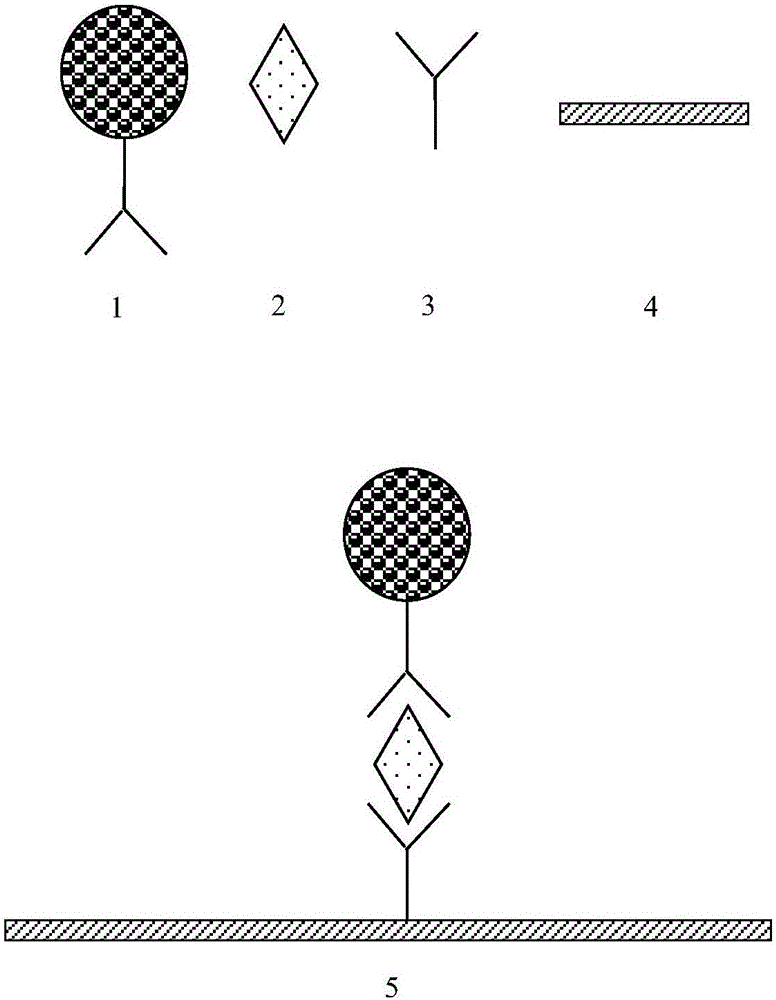

Microballoon-based cup-type time resolution fluorescent procalcitonin analysis kit, preparation method and application thereof

InactiveCN105758832ASimplify time-resolved fluorescence detection stepsShorten detection timeFluorescence/phosphorescenceSpecific detectionFluorescence

The invention belongs to the field of clinical medical diagnosis and especially relates to a microballoon-based cup-type time resolution fluorescent procalcitonin analysis kit, a preparation method and an application thereof. The kit comprises a detection reaction cup, a fluorescence labeling antibody and a cleaning fluid. The method comprises the following steps of: in specific detection process, firstly drawing a standard curve; adding a to-be-detected sample into the detection reaction cup; adding the fluorescence labeling antibody; incubating at 30-40 DEG C; washing with the cleaning fluid and removing the uncombined antibody and fluorescence labeling antibody; and comparing a fluorescence signal with the standard curve, thereby acquiring the concentration of procalcitonin of the to-be-detected sample. The detection method for the procalcitonin is ultrahigh in sensitivity, so that the automatic operation can be easily realized; the reaction temperature is uniform; the method is not influenced by the environmental factor; the accuracy is better; the precision is excellent.

Owner:SHANGHAI UPPER BIO TECH PHARMA

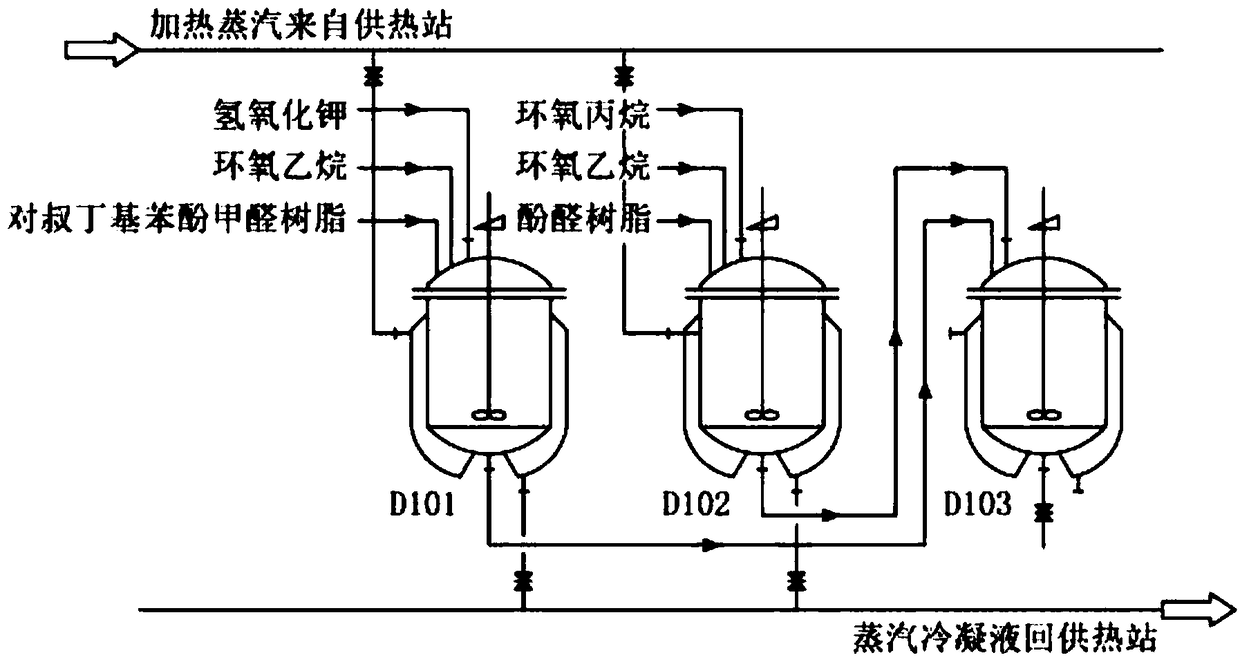

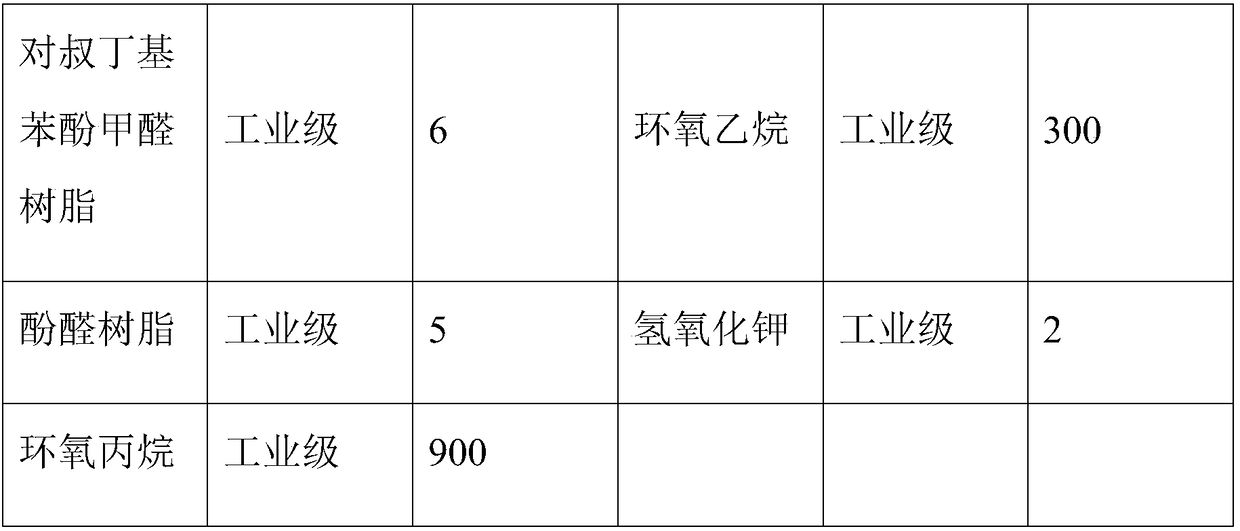

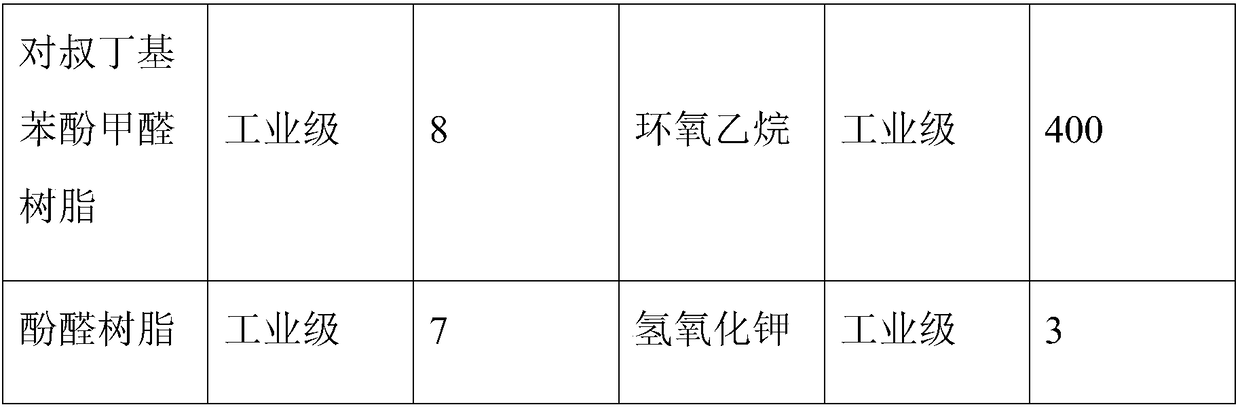

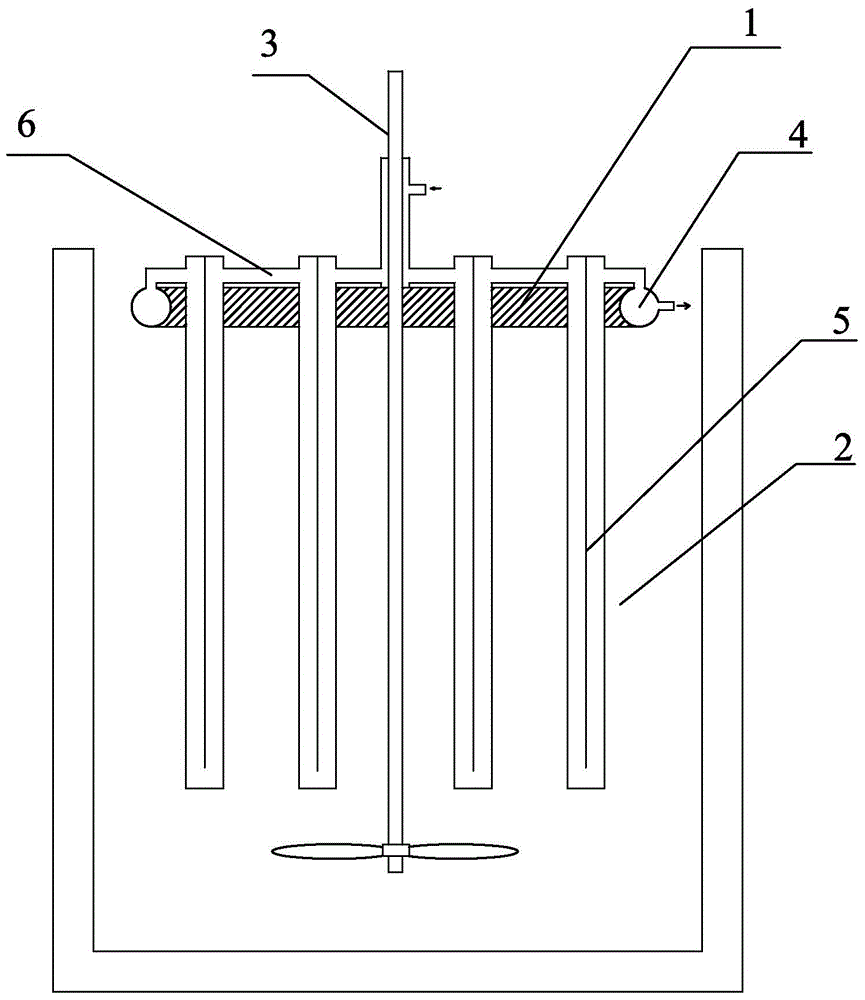

Production device of RI-01 crude oil demulsifier

InactiveCN108236885AUniform reaction temperatureWell mixedDewatering/demulsification with chemical meansChemical/physical/physico-chemical stationary reactorsDemulsifierProcess engineering

The invention discloses a production device of a RI-01 crude oil demulsifier. The production device mainly comprises an autoclave (D101), a reaction kettle (D102), and a mixing kettle (D103), whereinthe autoclave (D101) is connected with the mixing kettle (D103), the reaction kettle (D102) is connected with the mixing kettle (D103), and the autoclave (D101) has a nominal volume of 700-760 L.

Owner:CHENGDU HUI SI DUN TECH CO LTD

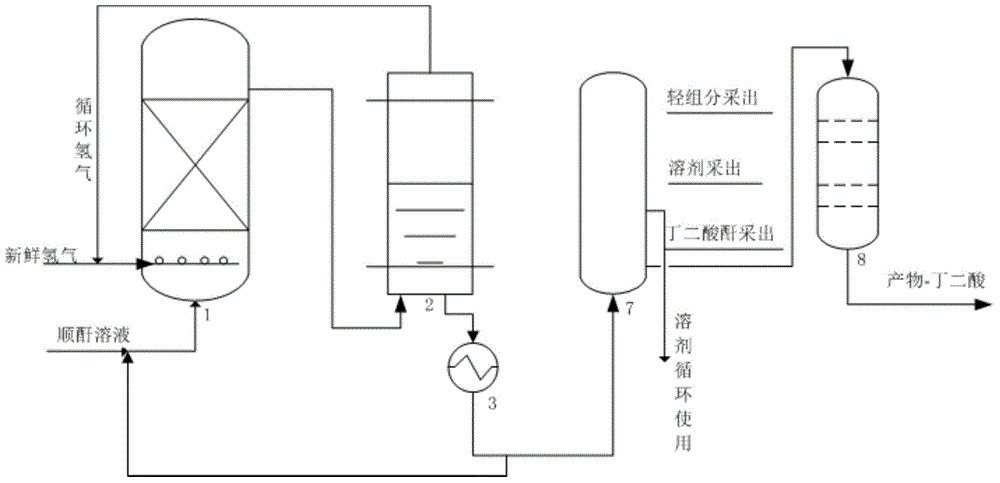

Preparation process of succinic acid

ActiveCN112661625AEliminate energy consumptionUniform reaction temperaturePreparation from carboxylic acid anhydridesMetal/metal-oxides/metal-hydroxide catalystsSlurry reactorButanedioic acid

The invention discloses a preparation process of succinic acid, which comprises the following steps: using maleic anhydride as a raw material; under the action of a microsphere catalyst, carrying out direct liquid-phase hydrogenation by using a slurry reactor to prepare succinic anhydride, and performing hydrolyzing to produce succinic acid, so that the reaction process is solvent-free, the energy consumption generated by separation is avoided, the materials are backmixed in the reactor, and external circulation heat removal is not required in the reaction process; meanwhile, a large amount of reaction liquid does not need to be circularly diluted, the reaction temperature is uniform, no hot spot exists in the reactor, and an over-temperature phenomenon does not occur even if the hydrogenation catalyst is applied to a strong exothermic reaction, so that the hydrogenation catalyst has good activity and stability, reaction materials do not need to be diluted by adopting a solvent, and energy consumption can be greatly reduced; in addition, no water is generated in the hydrogenation reaction process, no acid is generated through hydrolysis, and equipment does not need a special corrosion-resistant material.

Owner:CHINA CHEM TECH RES INST

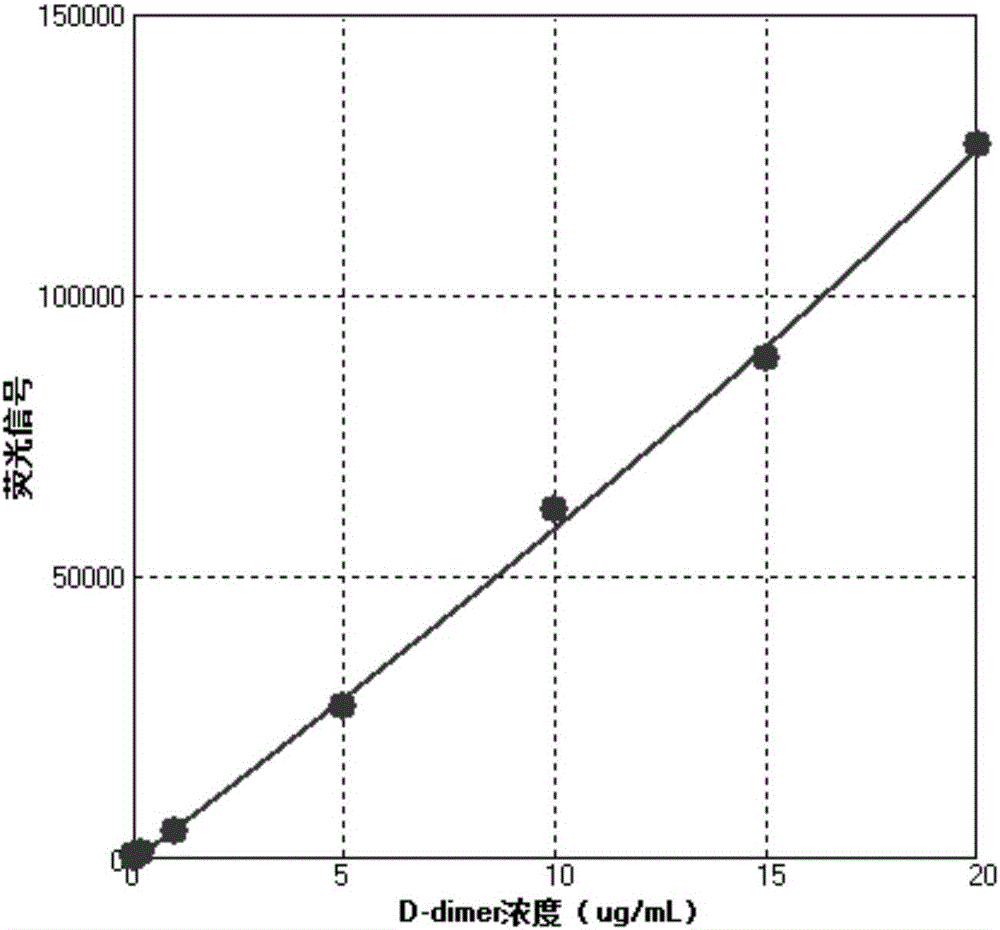

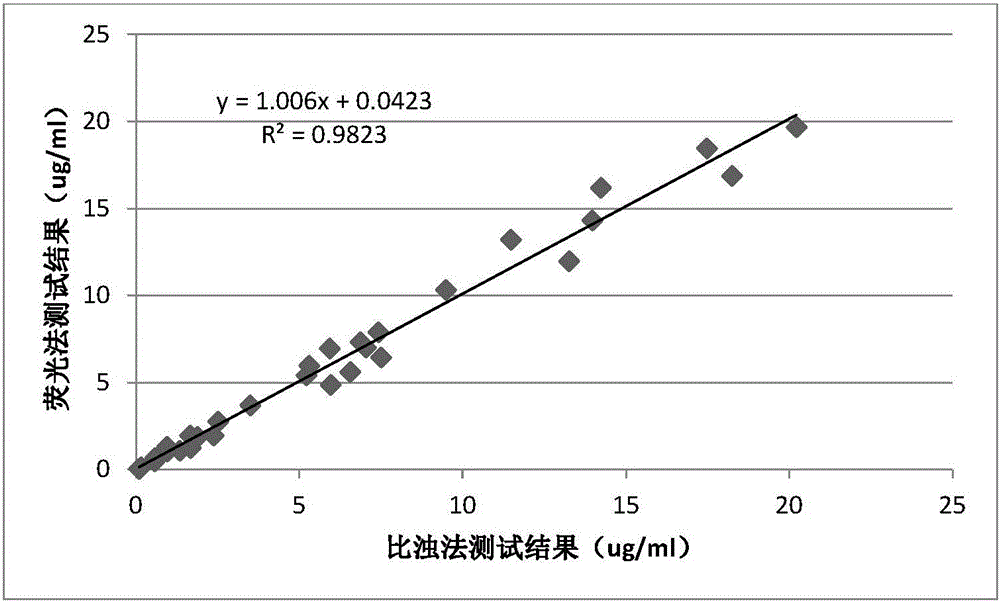

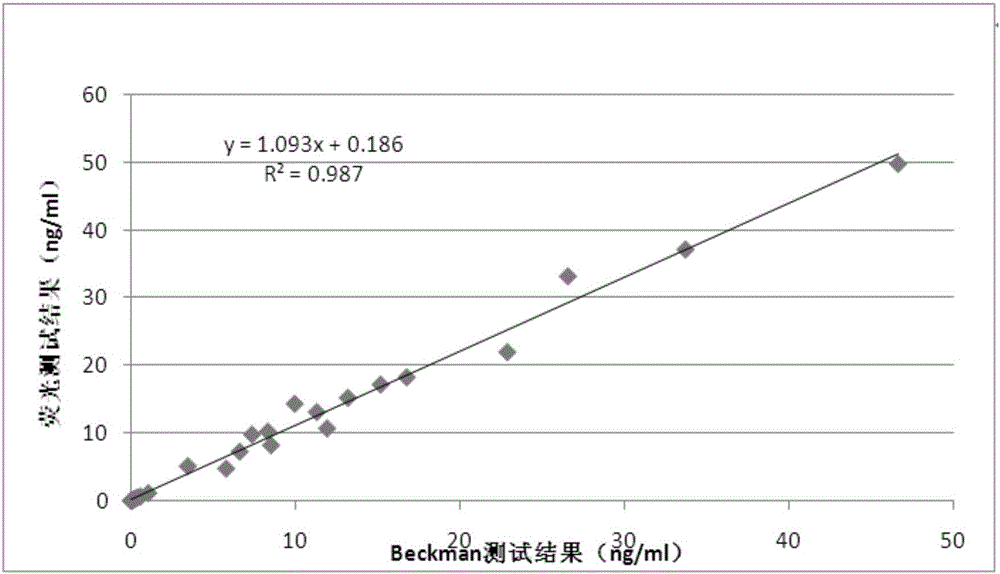

Cup type time-resolved fluorescence D-dimer analysis method and reagent kit based on microspheres

InactiveCN105891176ASimplify time-resolved fluorescence detection stepsShorten detection timeBiological testingFluorescence/phosphorescenceCross-linkMicrosphere

The invention discloses a cup type time-resolved fluorescence D-dimer analysis method and a reagent kit based on microspheres. The method includes the steps that the inner surface of a detection reaction cup is coated with D-dimer monoclonal antibodies or polyclonal antibodies; the time-resolved fluorescence microspheres and the D-dimer monoclonal antibodies or polyclonal antibodies are subjected to covalent bond cross-linking to prepare fluorescence-labeled antibodies; a D-dimer sample to be detected is added into the coated detection reaction cup, then the fluorescence-labeled antibodies are added, and incubation is carried out at 25-40 DEG C; cleaning is carried out to remove unbound antigens and fluorescence-labeled antibodies, and fluorescence signals in the detection reaction cup are tested under the excitation of 340-380 nm exciting light; the fluorescence signals are compared with a standard curve, and the D-dimer concentration of the D-dimer sample to be detected is obtained. By means of the method, detection can be completed within a short detection time, the detection time is shortened, and the detection sensitivity is effectively improved.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Slurry bubble column technology for preparing ethylene through acetylene hydrogenation and device thereof

InactiveCN102489225BExpand downstream fine chemical productsAvoid overwritingHydrocarbon by hydrogenationChemical/physical processesPtru catalystFixed bed

Provided are slurry bubble column technology for preparing ethylene through acetylene hydrogenation and a device thereof. The slurry bubble column technology includes adding water and then catalyst into a reactor, filling inert gases for replacing, heating, leading gas mixture of acetylene and hydrogen to enter in the reactor for reacting from the bottom of the reactor through a gas distributor, finally exhausting reaction products and unreacted feed gases from the top of the reactor, and separating to obtain the ethylene. The unreacted feed gases and the feed gases are mixed and then enter the reactor again for reacting. The reactor comprises a reaction gas inlet at the bottom, the gas distributor and a material liquid exhaust port, a reactor barrel body is arranged on an expended section on the upper portion of a slurry bubble column reactor, and a catalyst feeding port and a gas outlet are arranged at the top of the reactor. The slurry bubble column for preparing the ethylene through the acetylene hydrogenation is simple in structure, overcomes the phenomenon of temperature runaway in a fixed bed reactor and improves the conversion rate and selectivity of the reaction, and the operation is easy to control.

Owner:TAIYUAN UNIV OF TECH

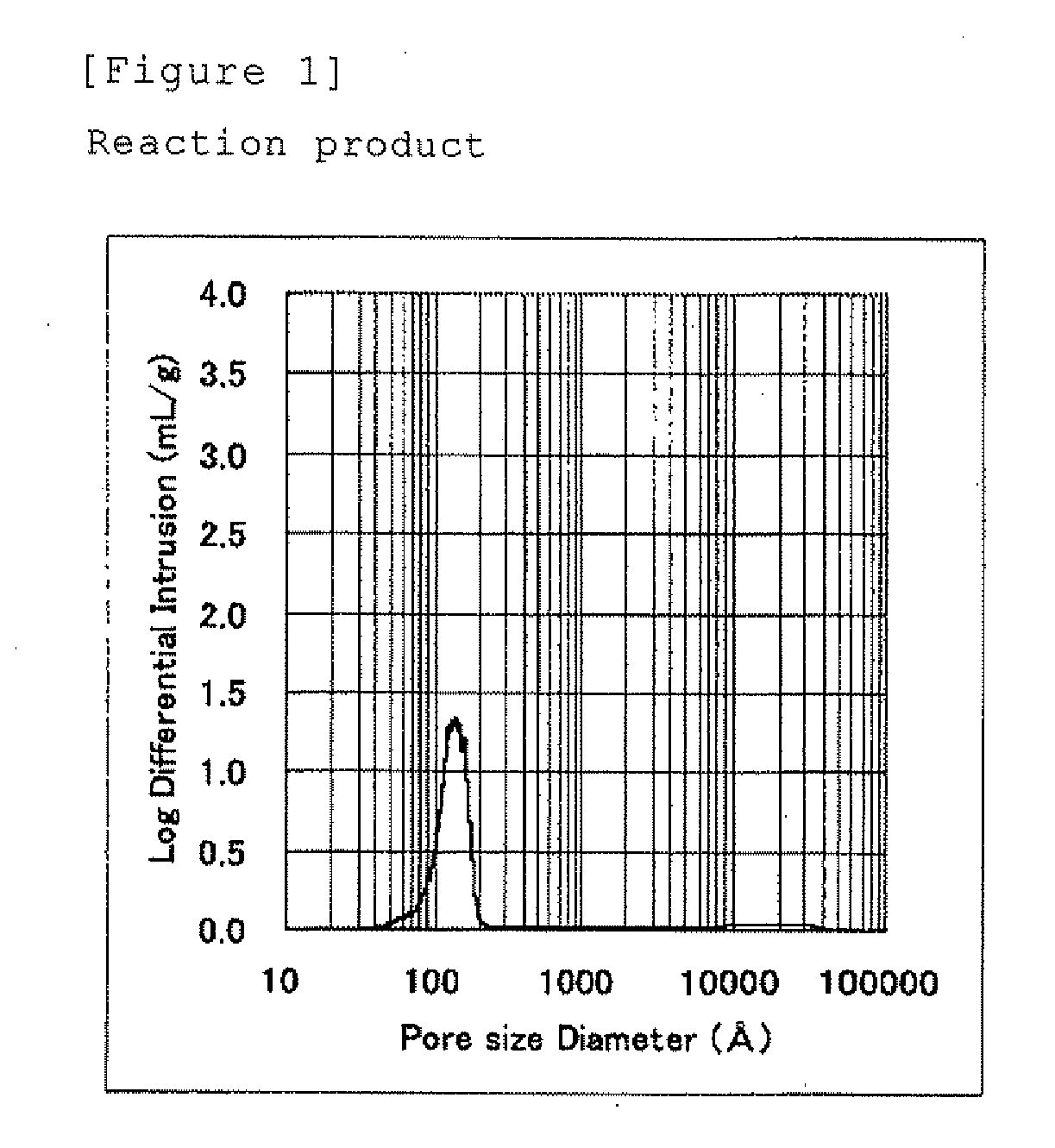

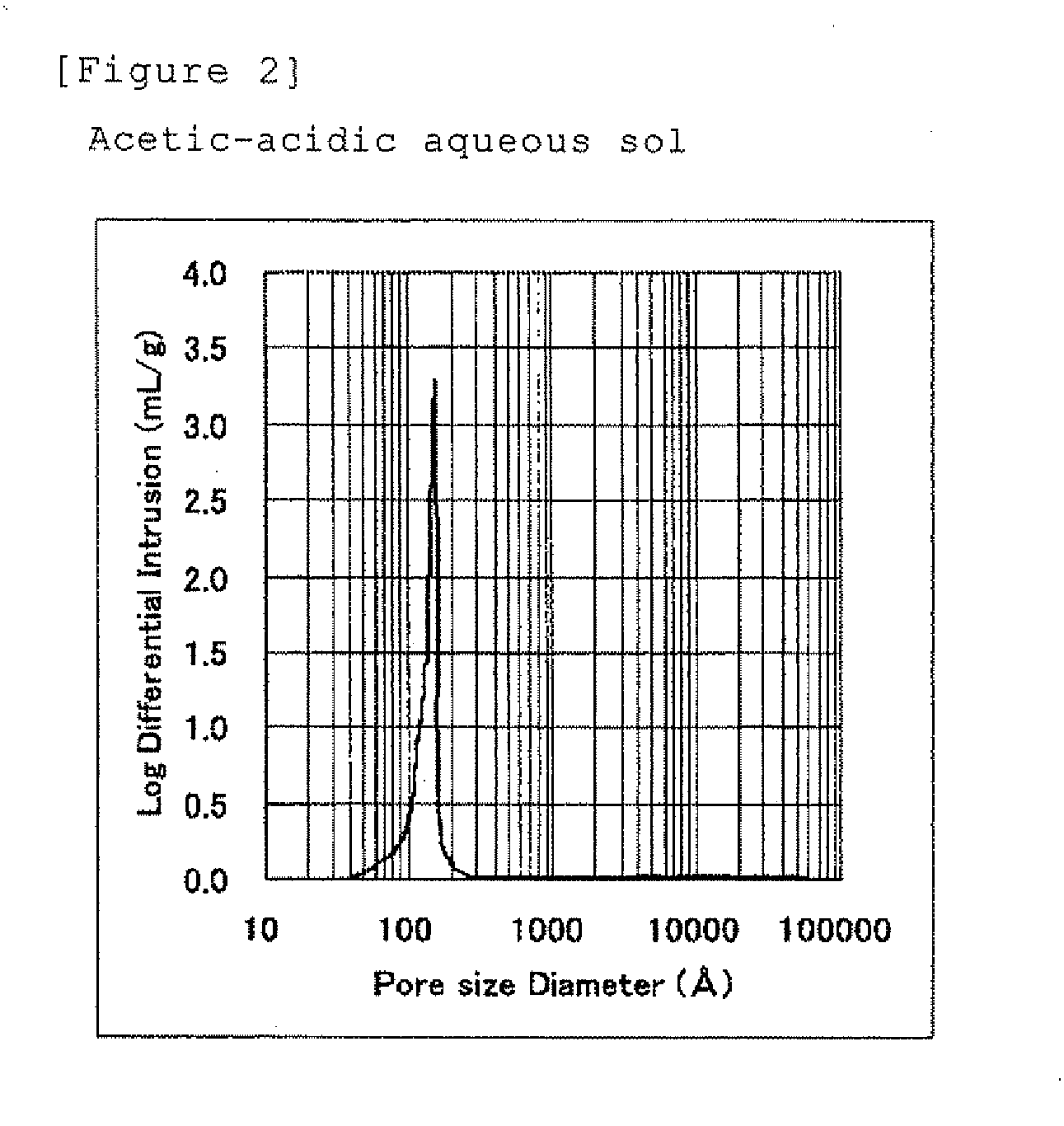

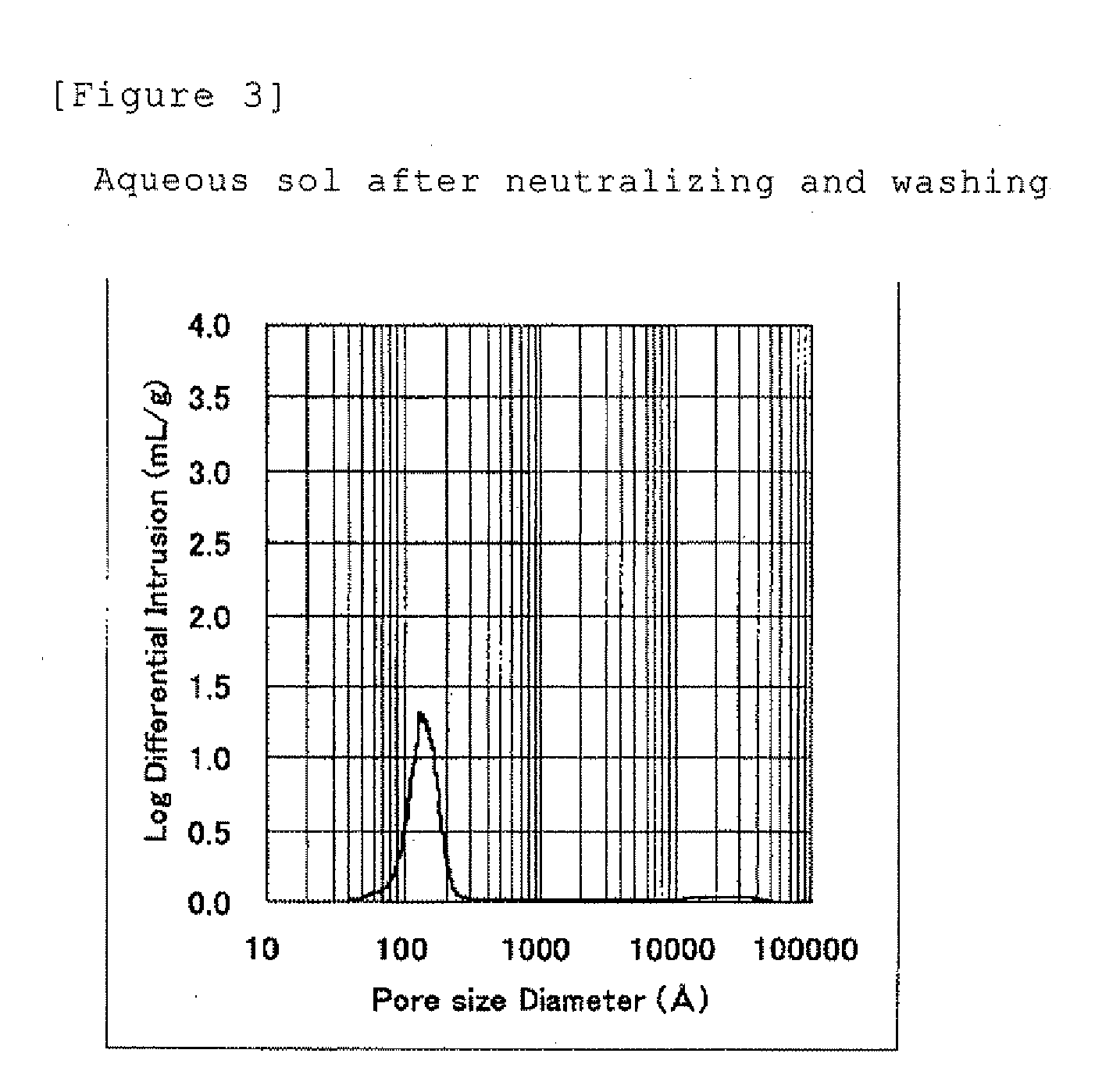

Particulate Alumina Composition and Process for Production Thereof

InactiveUS20090232727A1Increase heat transfer rateReduce pressureCatalyst activation/preparationAluminium oxides/hydroxidesParticulatesAlumina hydrate

A method for producing a particulate alumina composition includes the steps of preparing a wet particulate in a gas-liquid-solid three-phase system containing air by adding water and / or one or more compounds selected from an inorganic compound and an oxygen-containing organic compound to one or more alumina sources selected from an alumina hydrate and an alumina being rehydratable in the temperature range of 70 to 250° C., and to carry out a hydrothermal reaction in a temperature range of 70° C. to 250° C. Filtration and washing are carried out after the particulate alumina composition is preliminarily brought into contact with an alkaline component when an acid component is removed from the particulate alumina composition. The particulate alumina composition obtained by the method has a specific surface area in a dried product at 200° C. in the range of 40 to 300 m2 / g and contains crystalline boehmite having an aspect ratio of 10 or less.

Owner:SATO RES

Sputtering apparatus and manufacturing method of metal layer/metal compound layer by using thereof

InactiveUS20050042863A1Reduce depositionAvoid stickingElectric discharge tubesVacuum evaporation coatingTemperature controlReaction temperature

A sputtering apparatus is provided. The sputtering apparatus comprises cooling water system having a temperature-controlling device for controlling the temperature of the sidewalls of the reaction chamber. During the deposition process of titanium / titanium nitride, the sidewall temperature of the chamber is controlled at about 50° C.˜70° C. for reducing the difference of temperature distribution in the chamber so that the reaction temperature within the reaction chamber can be rendered substantially uniform.

Owner:LIU YU CHENG

Reaction kettle device for high-efficient chemical industry

InactiveCN106540643AEasy to controlImprove securityDispersed particle separationChemical/physical/physico-chemical stationary reactorsWater bathsChemical industry

The invention discloses a reaction kettle for high-efficient chemical industry, wherein a rotor of a rotating motor is coaxially connected with a stirring rod located in the middle of an inner cavity of a reaction kettle body; the rotor of the rotating motor and the stirring rod are internally hollow and connected to each other; the outer part of the rotor opening of the rotor motor is further connected with a material extracting motor, and one side at the top part of the reaction kettle body is further vertically provided with a waste gas outlet; the outer part of the waste gas outlet is equipped with an absorbing cavity, and the outer part of the reaction kettle body is sleeved with a water bath tank; the bottom part of the water bath tank is equipped with a stirring motor, and the outer part of the stirring blade at the outer part of the rotor of the stirring motor is fixe with an electric heating bar. The reaction kettle for high-efficient chemical industry is heated through a water bath method, so that the reaction temperature can be more accurately controlled; besides, the drawing type fetching and discharging structures are arranged, so that the working efficiency is higher; an waste gas absorbing structure can improve the safety of the chemical industry reaction.

Owner:ZHEJIANG RONGKAI TECH DEV

Microballoon-based cup-type time resolution fluorescent troponin I analysis kit as well as preparation method and application thereof

InactiveCN105758833ASimplify time-resolved fluorescence detection stepsShorten detection timeBiological testingFluorescence/phosphorescenceSpecific detectionMicrosphere

The invention belongs to the field of clinical medical diagnosis and especially relates to a microballoon-based cup-type time resolution fluorescent troponin I analysis kit as well as a preparation method and application thereof. The kit comprises a detection reaction cup, a fluorescence labeling antibody and a cleaning fluid. The method comprises the following steps of: in a specific detection process, firstly drawing a standard curve; adding a to-be-detected sample into the detection reaction cup; adding the fluorescence labeling antibody; incubating at 30-40 DEG C; washing with the cleaning fluid and removing the uncombined antibody and fluorescence labeling antibody; comparing a fluorescence signal with the standard curve, thereby acquiring the concentration of troponin I of the to-be-detected sample. The detection method for the troponin I is ultrahigh in sensitivity, so that the automatic operation can be easily realized; the reaction temperature is uniform; the method is not influenced by the environmental factor; the accuracy is better; the precision is excellent.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Method for synthesizing cinnamyl alcohol by selective hydrogenation of cinnamyl aldehyde

ActiveCN111116311AHigh selectivityContinuous responseMolecular sieve catalystsOrganic compound preparationPtru catalystFixed bed

The invention discloses a method for synthesizing cinnamyl alcohol through selective hydrogenation of cinnamyl aldehyde. A tubular reactor is adopted, a small-particle solid special catalyst is arranged in the tubular reactor, the cinnamyl aldehyde and hydrogen are used as reaction raw materials, and the cinnamyl alcohol is synthesized by catalyzing the cinnamyl aldehyde to be selectively hydrogenated under the conditions that the reaction temperature is 50-120 DEG C and the reaction pressure of hydrogen is 0.5-5.0 MPa. Compared with the traditional kettle type, fixed bed and trickle bed reactors, the method provided by the method can obtain higher cinnamyl alcohol selectivity, cinnamyl alcohol yield and stability, and has better economic benefits.

Owner:NANJING POLYTECHNIC INSITUTE

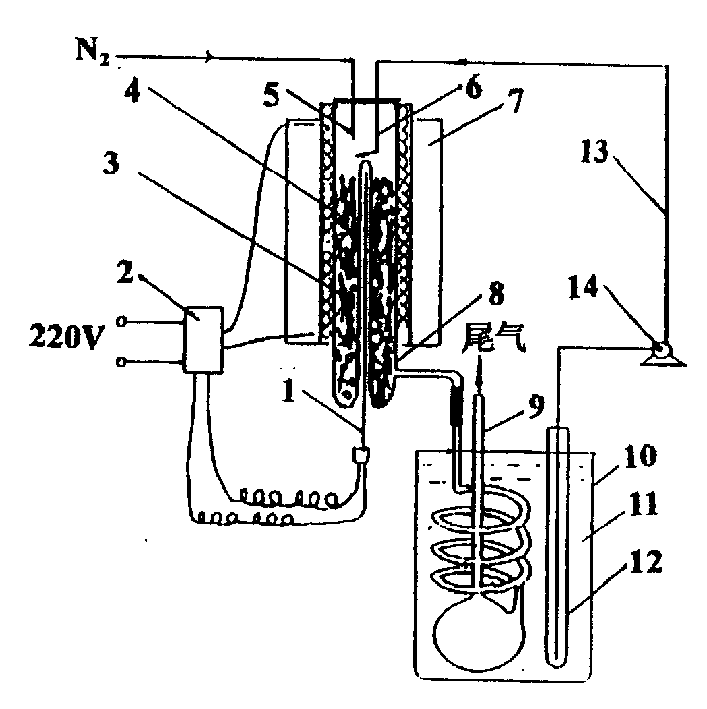

Preparation method of ultrahigh-molecular-weight polyacrylamide

ActiveCN104945548AUniform reaction temperaturePolymerization reaction temperature is stablePolyacrylamideAqueous solution

The invention discloses a preparation method of ultrahigh-molecular-weight polyacrylamide. The preparation method comprises the following steps: (1) preparing an acrylamide aqueous solution; (2) adding the acrylamide aqueous solution into a reactor provided with a liquid internal heat conduction device, introducing water of 6-7 DEG C into a water filling nozzle of the liquid internal heat conduction device, starting a stirrer of the liquid internal heat conduction device, introducing nitrogen to remove oxygen, and adding an initiating agent to perform polymerization reaction, thereby preparing a polymerization product; and (3) cutting and granulating the polymerization product, and then adding the polymerization product into a hydrolyzer to perform hydrolysis reaction, thereby preparing ultrahigh-molecular-weight polyacrylamide. According to the preparation method disclosed by the invention, by adopting reasonable proportioning, combining corresponding process conditions and adopting the self-made liquid internal heat conduction device to uniformize the reaction temperature and stabilize the molecular weight of polyacrylamide, the molecular weight of prepared polyacrylamide reaches 3.4*10<7>.

Owner:ZHEJIANG XINYONG BIOCHEM

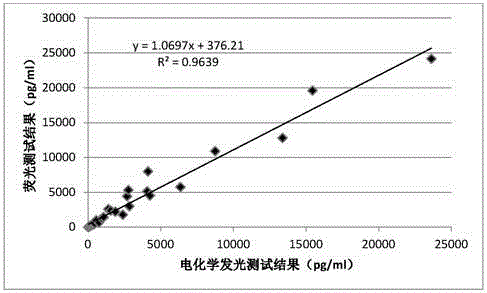

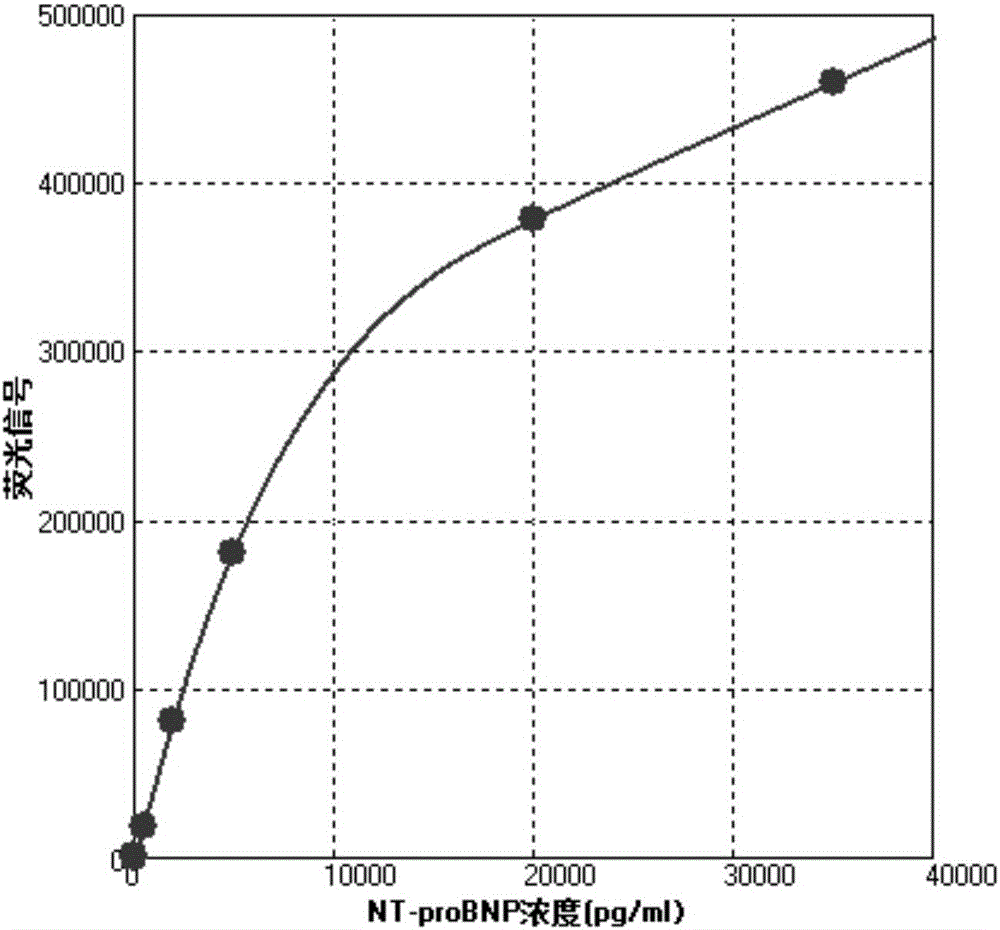

Cup-type time-resolved fluorescent analysis method and kit for NT-proBNP based on microspheres

InactiveCN105911283ASimplify time-resolved fluorescence detection stepsShorten detection timeFluorescence/phosphorescencePolyclonal antibodiesLength wave

The invention discloses a cup-type time-resolved fluorescent analysis method and kit for NT-proBNP based on microspheres. The method comprises the following steps: coating the interior surface of a detection reaction cup with a NT-proBNP monoclonal or polyclonal antibody; subjecting time-resolved fluorescent microspheres and the NT-proBNP monoclonal or polyclonal antibody to crosslinking via a covalent bond so as to prepare a fluorescence-labeled antibody; adding a to-be-detected NT-proBNP sample into the coated detection reaction cup, then adding the fluorescence-labeled antibody and carrying out incubation at 25 to 40 DEG C; carrying out cleaning to remove unbounded antigen and fluorescence-labeled antibody and testing a fluorescence signal in the detection reaction cup under the condition of excitation by exciting light with a wavelength of 340 to 380 nm; and comparing the fluorescence signal with a standard curve so as to obtain the concentration of NT-proBNP in the to-be-detected NT-proBNP sample. The method and kit provided by the invention can complete detection in short detection time, shortens detection time and improves detection sensitivity.

Owner:SHANGHAI UPPER BIO TECH PHARMA

Preparation method of ultra-high molecular weight polyacrylamide

ActiveCN104945548BStable molecular weightUniform reaction temperaturePolymer scienceReaction temperature

Owner:ZHEJIANG XINYONG BIOCHEM

Hydrotreatment method of heavy hydrocarbon raw material

ActiveCN102465032ASimple and fast operationEasy to operateTreatment with hydrotreatment processesGasolineFractionation

The invention relates to a hydrotreatment method of a heavy hydrocarbon raw material. The method adopts a fixed-bed hydrogenation reactor, which is provided with at least two catalyst bed layers inside. Between at least one adjacent catalyst bed layer, a liquid phase material is educed. The educed liquid phase material is mixed with a solvent, and then a light component is extracted. A light component-extracted heavy component is returned to the fixed-bed hydrogenation reactor so as to enter a next catalyst bed layer for continuous reaction. The extracted oil can directly enter a gasoline and diesel oil hydrogenation device so as to obtain qualified gasoline and diesel oil, or can enter a main fractionate tower of FCC (fluid catalytic cracking) for fractionation so as to obtain a crude product, which then enters a gasoline and diesel oil hydrogenation device so as to obtain qualified gasoline and diesel oil. The method of the invention not lonely can effectively reduce the pressure drop of a bed layer in subsequent hydrotreatment and prolong the service life of a catalyst, but also enhances the total conversion rate of a fixed-bed hydrogenation device simultaneously, or can improve the treatment capability of the device under a same conversion rate, as well as recovers part of light oil, thus being able to create greater benefits for enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com