Preparation process of succinic acid

A technology of succinic acid and succinic anhydride, which is applied in the preparation of carboxylic anhydride, metal/metal oxide/metal hydroxide catalyst, organic chemistry, etc. The effect of small internal and external mass transfer resistance, simple process and uniform reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

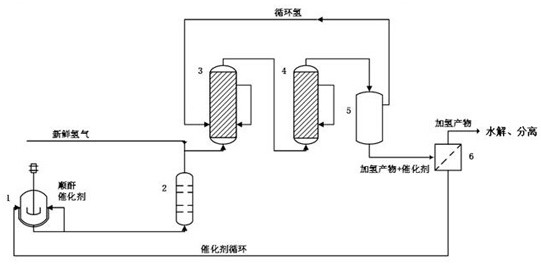

Image

Examples

Embodiment 1

[0060] 1.1 Catalyst preparation process:

[0061] Take successively 1000 g of alumina microsphere carrier with a particle size distribution of 2-20 μm and 2 L of palladium chloride solution with a concentration of 5 g / L. Add the alumina microsphere carrier to the rotary evaporator, set the temperature of the water bath to 60°C, and set the speed to 100 rpm, spray the palladium chloride solution onto the surface of the carrier, after the palladium chloride solution is sprayed, continue the rotary evaporation Until the catalyst precursor dries into a flowable powder. The catalyst precursor was placed in a muffle furnace and calcined at 350° C. for 3 hours.

[0062] The calcined catalyst precursor was reduced in a nitrogen-hydrogen mixed atmosphere, V (hydrogen): V (nitrogen) = 5:95, the reduction temperature was 200 ° C, and the time was 6 hours to obtain a pre-reduced catalyst.

[0063] 1.2 Maleic anhydride hydrogenation-hydrolysis to prepare succinic acid:

[0064] (1) Weig...

Embodiment 2

[0071] Adopt the catalyst of embodiment 1 to carry out maleic anhydride hydrogenation-hydrolysis and prepare succinic acid, comprise the steps:

[0072] (1) Weigh 0.3Kg of the hydrogenation catalyst prepared in Example 1, and add the catalyst to the catalyst feeding tank;

[0073] (2) Weigh 20Kg of industrial maleic anhydride, add it to a raw material tank with a volume of 50L, heat the raw material tank to 65°C, and after the maleic anhydride is completely melted, transfer the catalyst in step (1) from the catalyst feeding tank to the raw material tank Middle; turn on the raw material tank agitator to stir, start the raw material liquid circulation pump, the raw material slurry enters the circulation pump from the bottom of the raw material tank, and returns to the raw material tank from the middle of the raw material tank;

[0074] (3) The raw material slurry is preheated to 120°C in the preheater, flows in parallel with hydrogen, and enters the catalyst bed from the bottom ...

Embodiment 3

[0079] 3.1 Preparation of catalyst:

[0080] Sequentially take 500 g of alumina microsphere carrier with a particle size distribution of 10-30 μm and 1 L of palladium chloride solution with a concentration of 10 g / L. Add the carrier to the rotary evaporator, set the temperature of the water bath to 60°C, and set the speed to 100 rpm, spray the palladium chloride solution onto the surface of the carrier, after the palladium chloride solution is sprayed, continue the rotary evaporation until the catalyst precursor Dried into a mobile powder. The catalyst precursor was placed in a muffle furnace and calcined at 350° C. for 3 hours.

[0081] The calcined catalyst precursor was reduced in a nitrogen-hydrogen mixed atmosphere, V (hydrogen): V (nitrogen) = 5:95, the reduction temperature was 200 ° C, and the time was 3 hours to obtain a pre-reduced catalyst.

[0082] 3.2 Preparation of succinic acid:

[0083] (1) Weigh 0.4Kg of the pre-reduced hydrogenation catalyst, and add the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com