Patents

Literature

135results about How to "Eliminate energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Base material for artificial leather and process for producing the same

ActiveUS20110039055A1Improve compactnessFlat surfaceSynthetic resin layered productsFilament/thread formingFiber bundleEngineering

Owner:KURARAY CO LTD

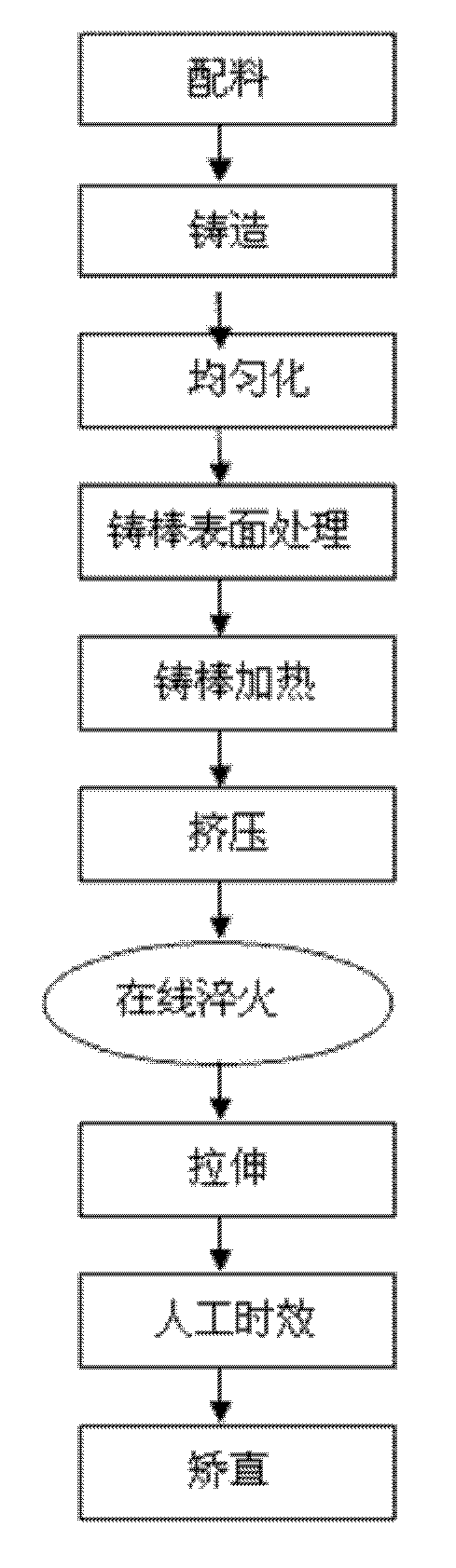

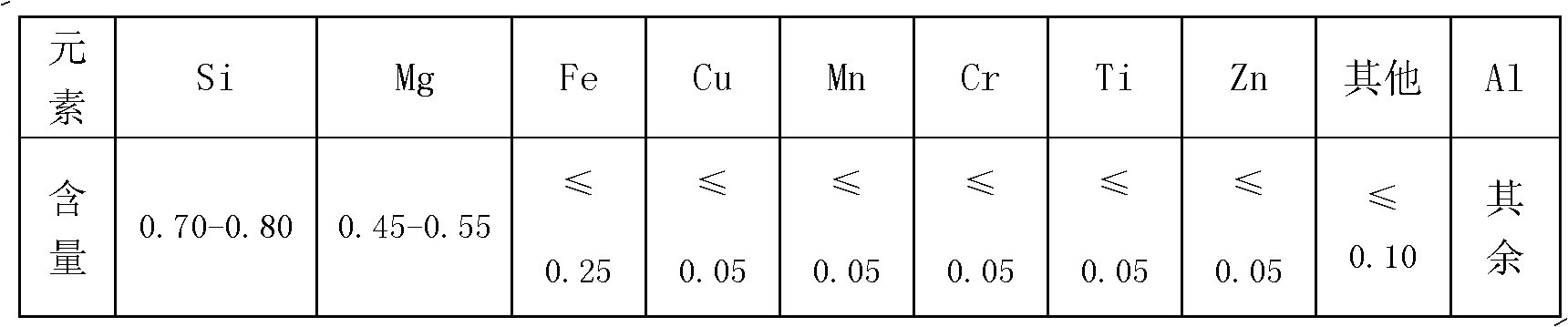

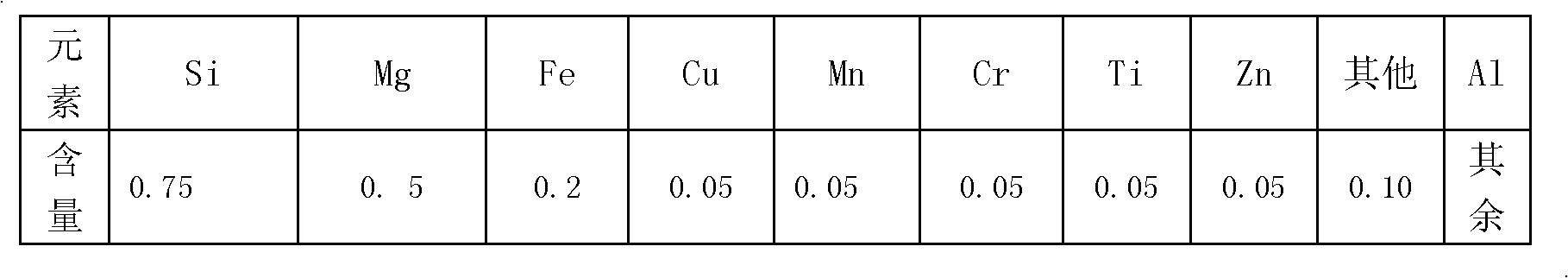

Extruding processing technology of aluminium alloy tubing with large diameter

InactiveCN102492877AReduce residual stressHigh strength propertiesExtrusion control devicesFailure rateHigh energy

The invention discloses an extruding processing technology of an aluminium alloy tubing with large diameter. The method comprises steps of a. proportioning, b. casting, c. uniformization, d. surface treatment on casting rod, e. casting rod heating, f. extrution, g. on-line quenching, h. stretching, i. artificial aging and j. straightening, etc. Strict control on each parameter can solve problems of extruding production of tubing with large diameter, eliminate disadvantages of long production period, low production efficiency, high energy consumption, huge environmental pollution and expensiveauxiliary equipment of rolling and drawing, save cost, simplify arrangement of auxiliary equipment and further reduce failure rate of an apparatus. The energy consumption of the present invention is merely 1 / 4 that of rolling and drawing, and water consumption is 1 / 8 that of a steam jet pump set; therefore, the invention brings obvious economic effects.

Owner:CHINA ZHONGWANG

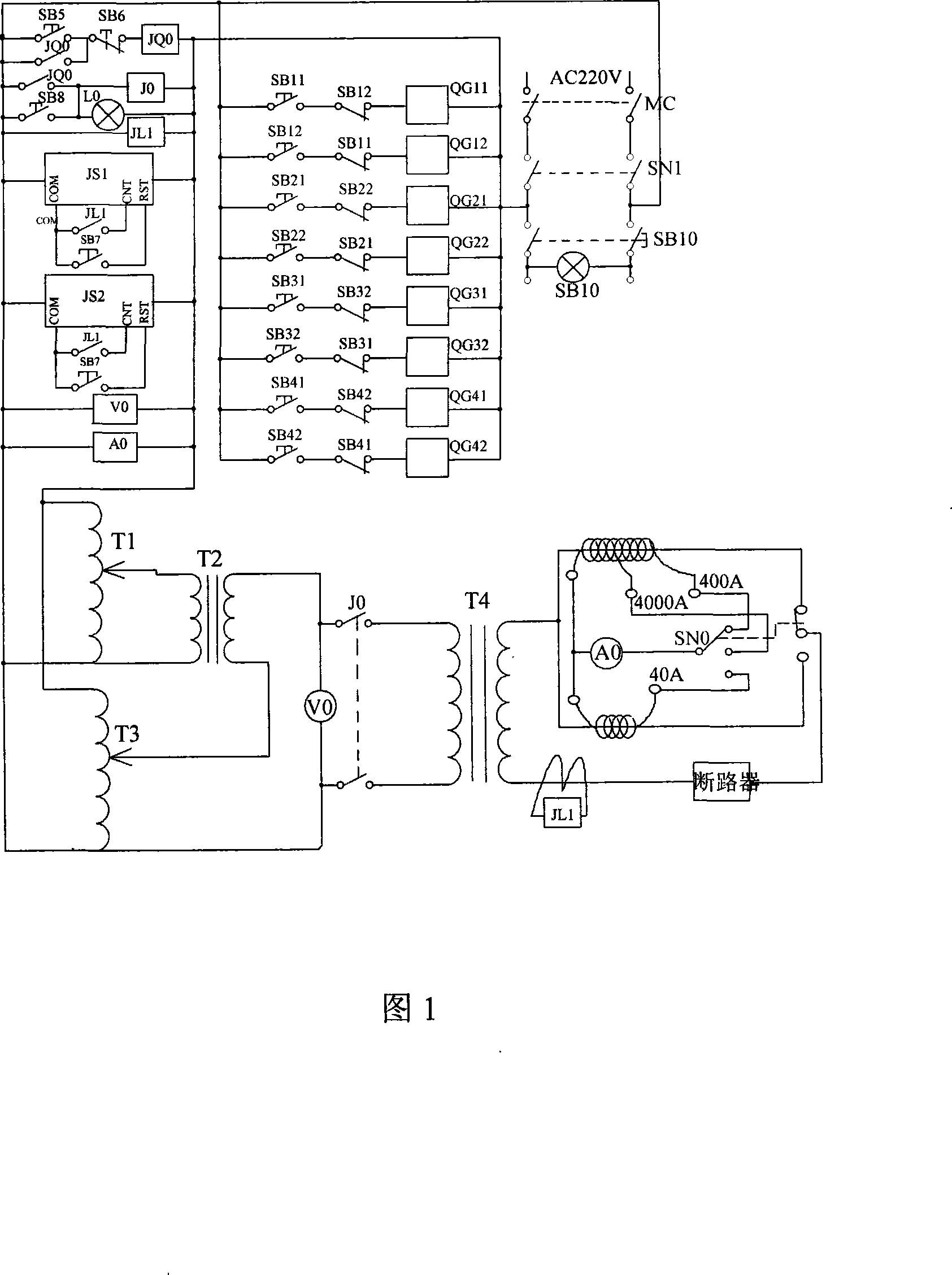

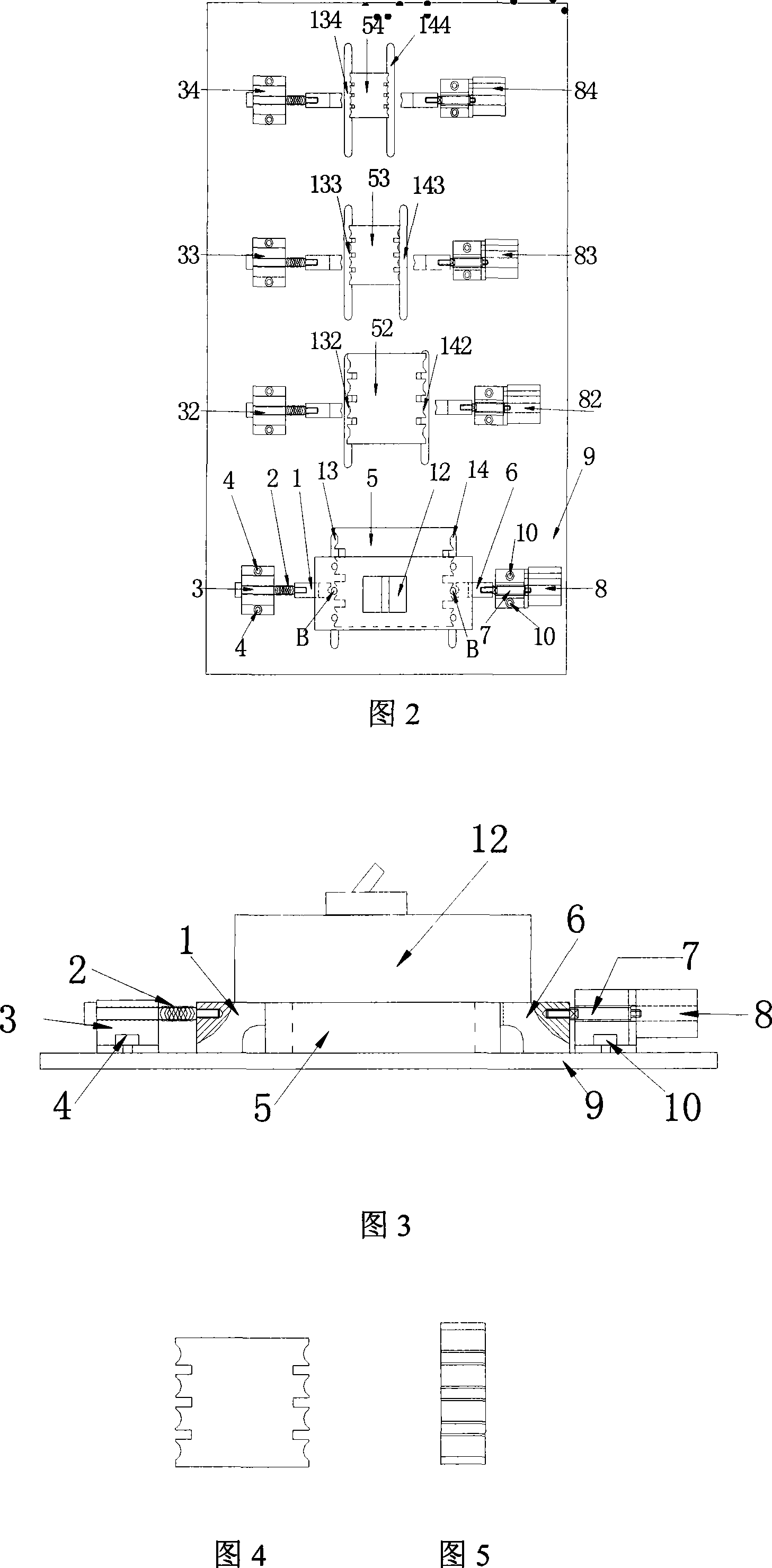

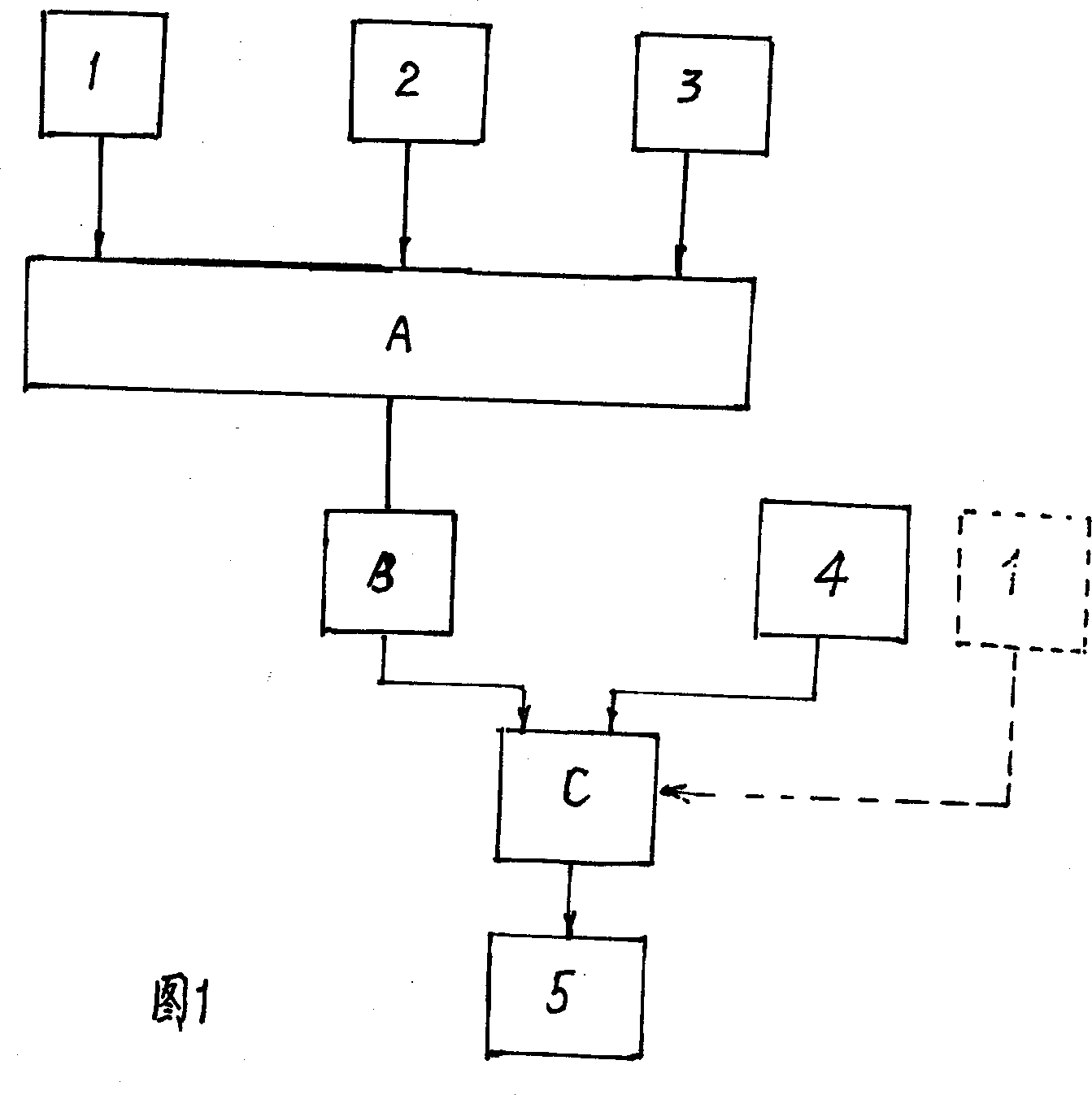

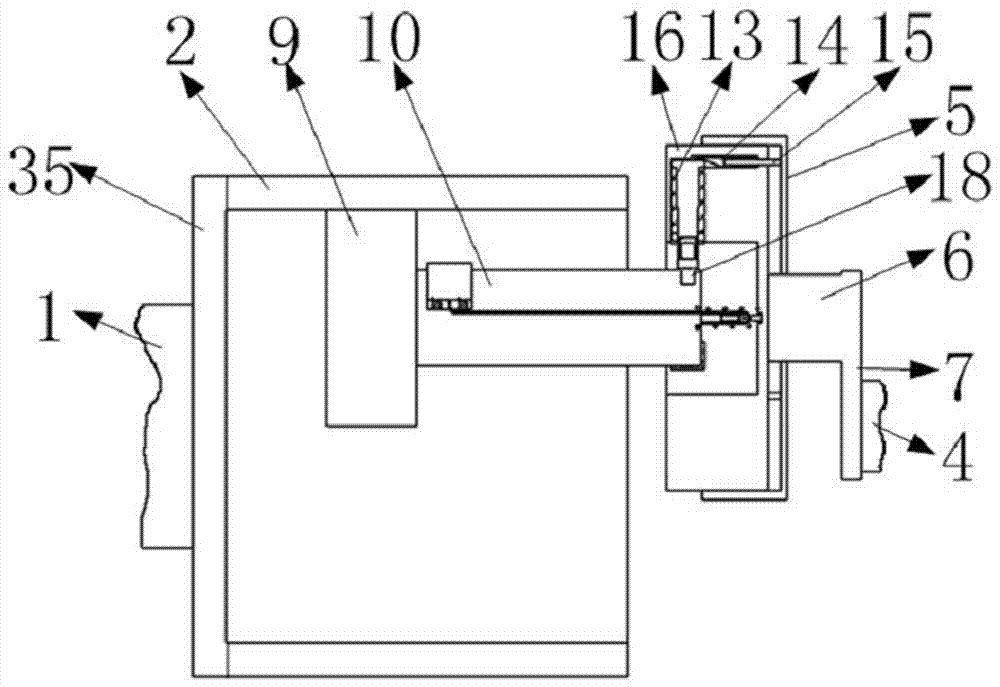

Board back insertion type circuit breaker characteristic detection and test device

InactiveCN101169468ALow investment costImprove space utilizationCircuit interrupters testingEngineeringInstrumentation

The invention relates to a test device for detecting and testing the characteristics of a plug-in circuit breaker behind a panel. It includes the control circuit and mechanical mechanism of the device; the control circuit is composed of four cylinder circuits used to connect and disconnect the test electrode and the tested circuit breaker electrode in the control mechanical mechanism and used to provide the test power supply for the tested circuit breaker Regulate the voltage and test the circuit connected to the instrument; the mechanical mechanism includes a pneumatic clamping device fixed on the workbench and a positioning fixture installed on the electrode of the circuit breaker to be tested. The invention can realize that various case circuit breakers are concentrated on one test bench for characteristic detection, thereby saving the cost of the test bench and improving the space utilization rate. The pneumatic pressing device eliminates the energy consumption and variance caused by artificial crimping, and the test current realizes 0-4000A continuous and fine-tuning, which ensures the accuracy of the test current. And the multi-tap transformer realizes gear switching, and the display value of the test current is the actual value, which improves the detection accuracy and efficiency.

Owner:TIANJIN BAILI ELECTRIC CO LTD

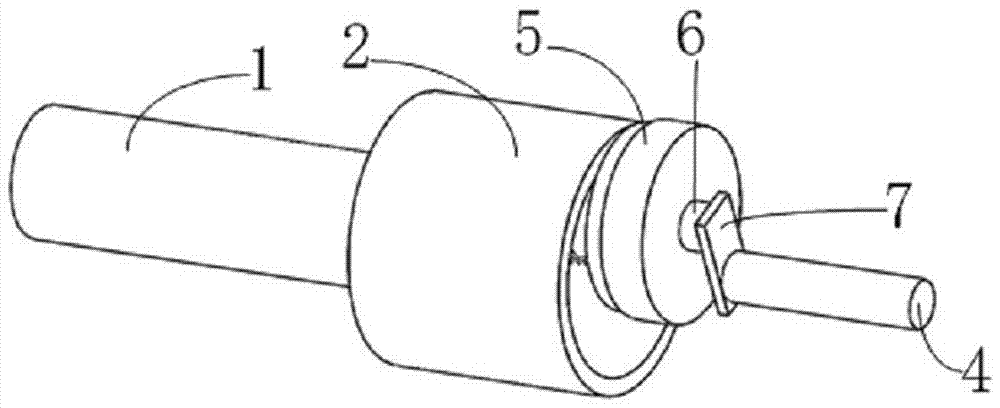

Lubricating oil conveying device of internal combustion engine with four cylinders surrounding shaft

ActiveCN105041405ASimple structureReduce volumeMachines/enginesPressure lubricationCombustionExternal combustion engine

The invention discloses a lubricating oil conveying device of an internal combustion engine with four cylinders surrounding a shaft, and relates to the field of internal combustion engines. The lubricating oil conveying device solves the problems that an existing internal combustion engine is large in machining difficulty, prone to abrasion, high in energy consumption and the like. The lubricating oil conveying device is provided with oil suction backflow preventing valves, oil spray backflow preventing valves, oil suction pipes and oil spray pipes; the lower ends of lower shaft sleeves are fixed at the bottom of a lubricating oil tank, the oil suction pipes and the oil spray pipes are both communicated with the bottom ends of the lower shaft sleeves, the opening ends of the oil suction pipes are placed on a base plate of the lubricating oil tank, and openings of the oil spray pipes are placed on the outer side of an air suction valve cam of a cam plate; the oil spray backflow preventing valves are fixedly connected to the oil suction pipes, and the oil spray backflow preventing valves are fixedly connected to the oil spray pipes. The lubricating oil conveying device has the advantages of being simple in structure, convenient to use, small in energy consumption and capable of lowering the cost and saving the space.

Owner:齐艳华

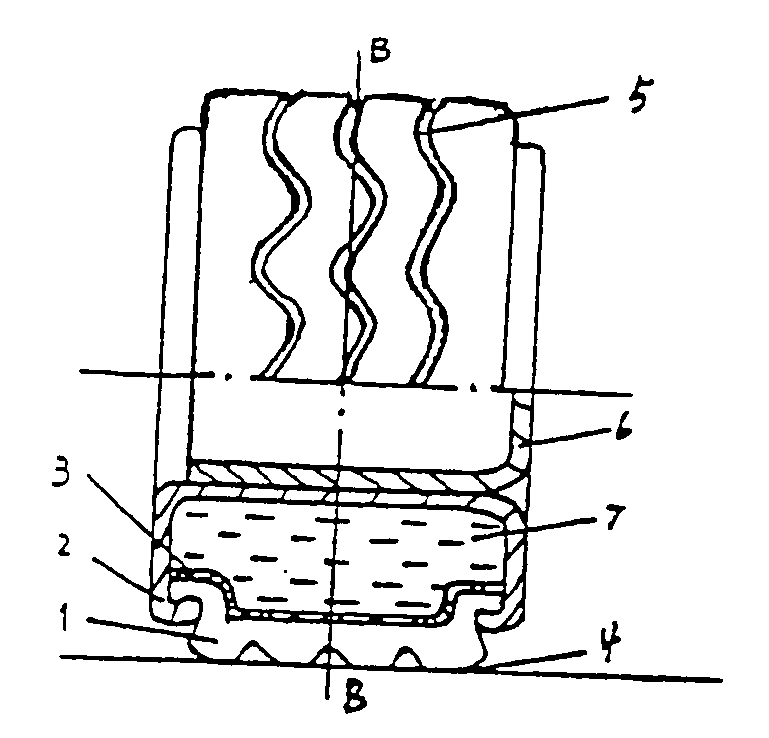

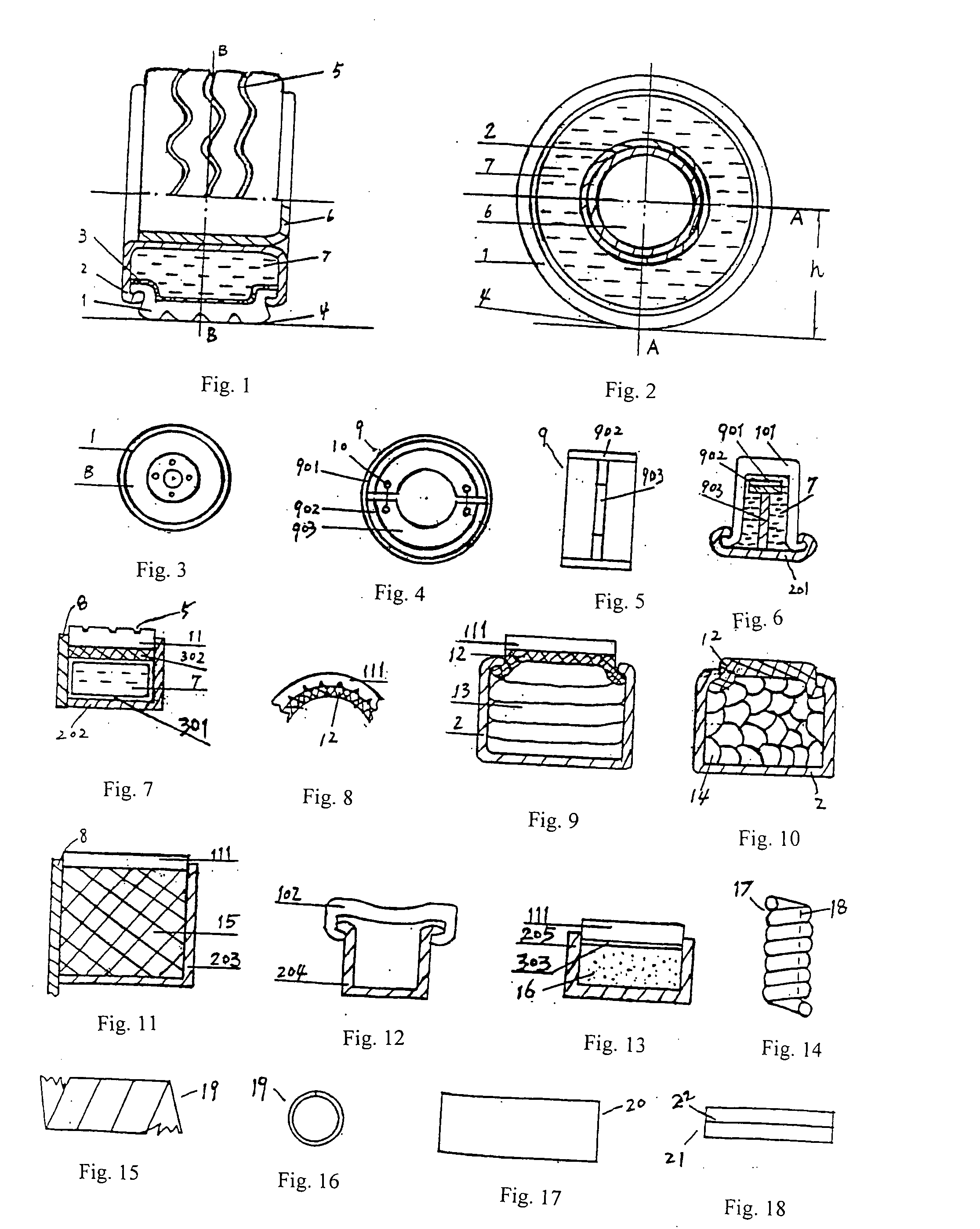

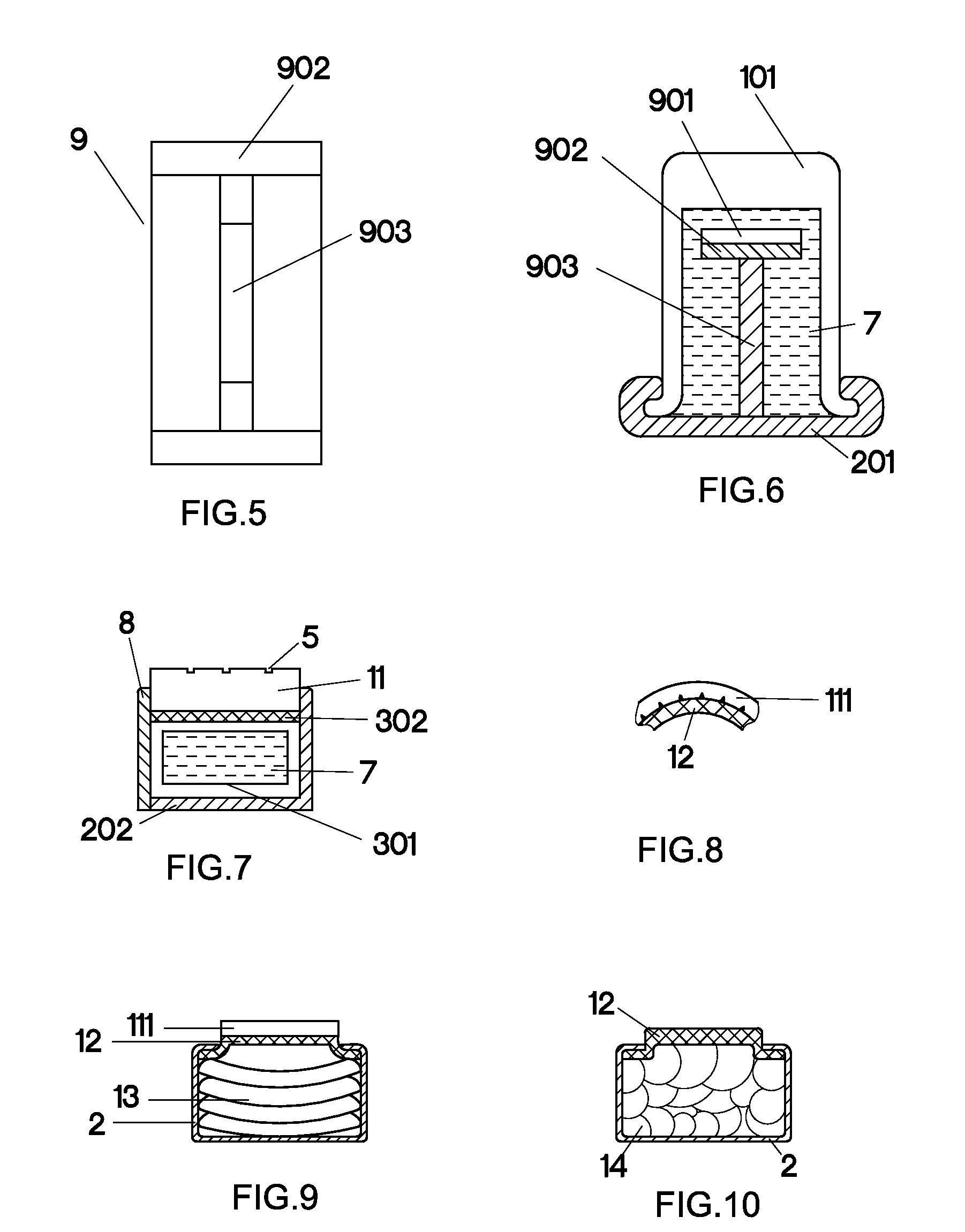

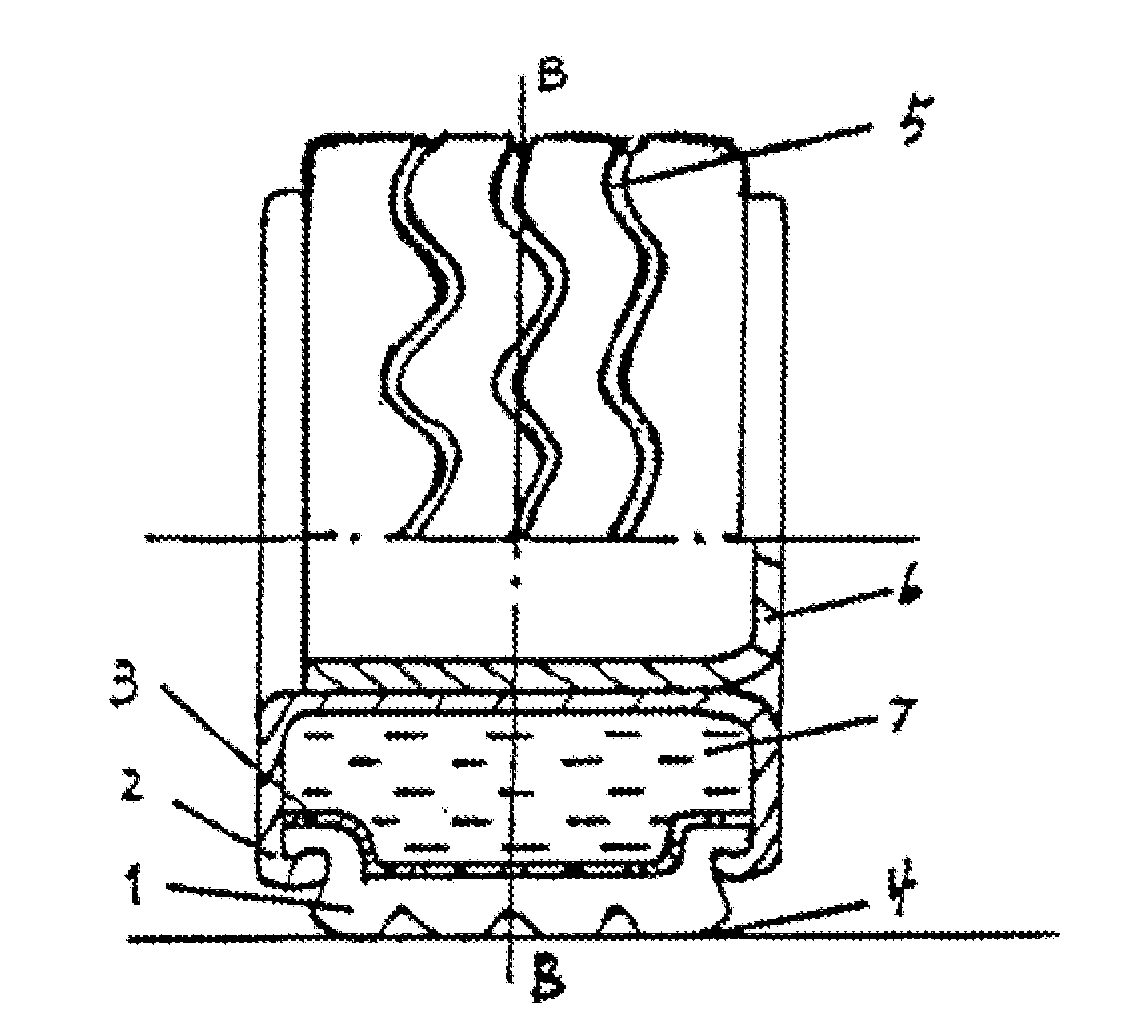

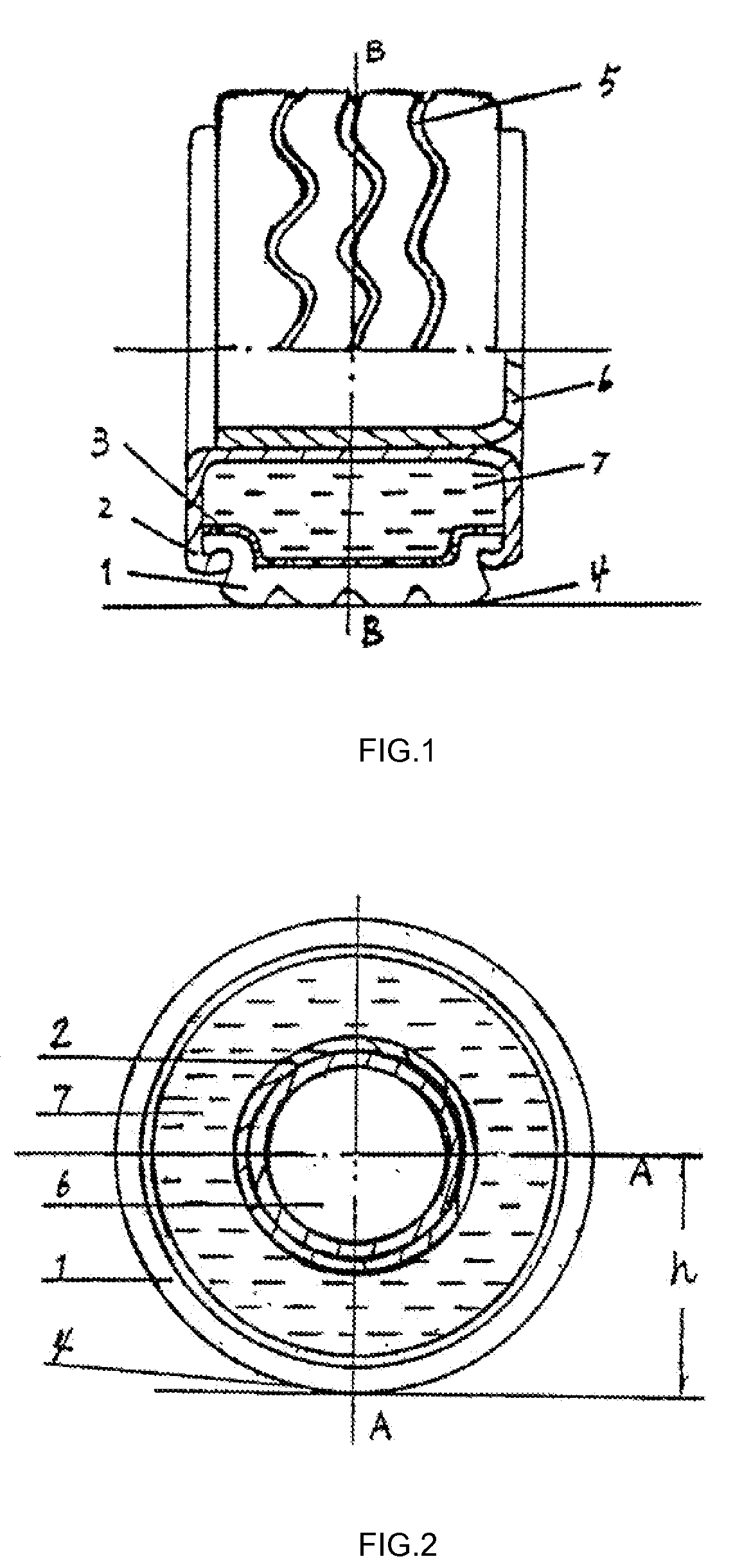

Inner tube with film

InactiveUS20050211357A1Improve energy consumptionEnergy chargeElectrical storage systemBatteries circuit arrangementsEnergy storageMechanical engineering

The present invention discloses a type of secure and efficient wheel assembly using fluid or solid stuffing materials so as to minimize the blowout risks, a wheel rim transmission assembly, an energy exchanging arrangement used in transporting system, and a vehicle energy storage system, as well as corresponding methods for manufacturing and preparing such assemblies and arrangements in applications.

Owner:WUHAN RUNLIN SCI & TECH DEVMENT

Efficient calcium thioaluminate type bulking agent and its preparing process

InactiveCN1369455ANo reduction in quality requirementsLower quality requirementsGypsumMaterials science

An efficient calcium thioaluminate type bulking agent, an improvement on CAS-type one, features that the lime stone, gypsum and bauxite are first calcined in rotary kiln to prepare clinker, which is them mixed with gypsum and ground while lime stone is added to generate CAS-type bulking agent. Its advantages are high performance and low content of alkali.

Owner:陈智丰

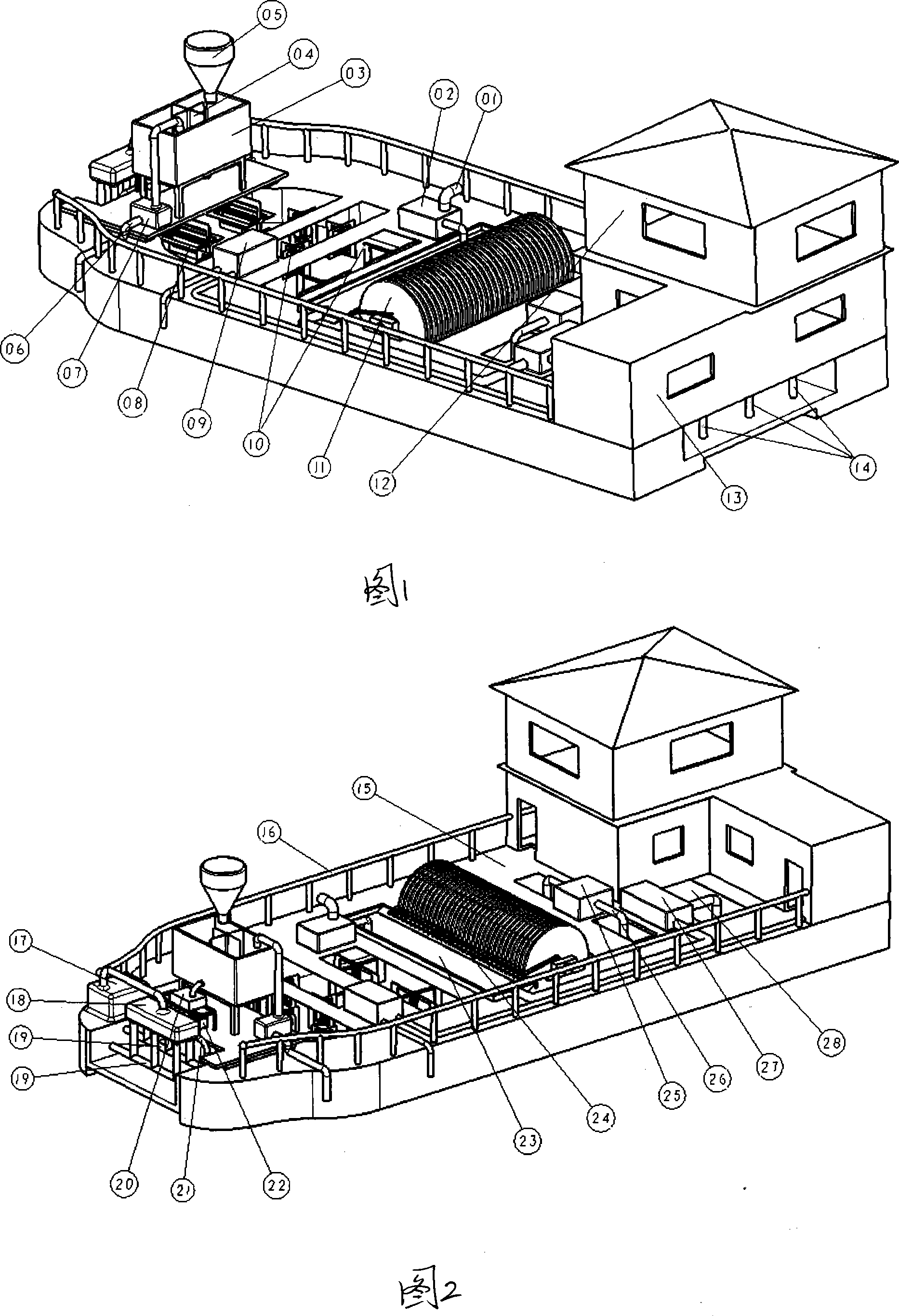

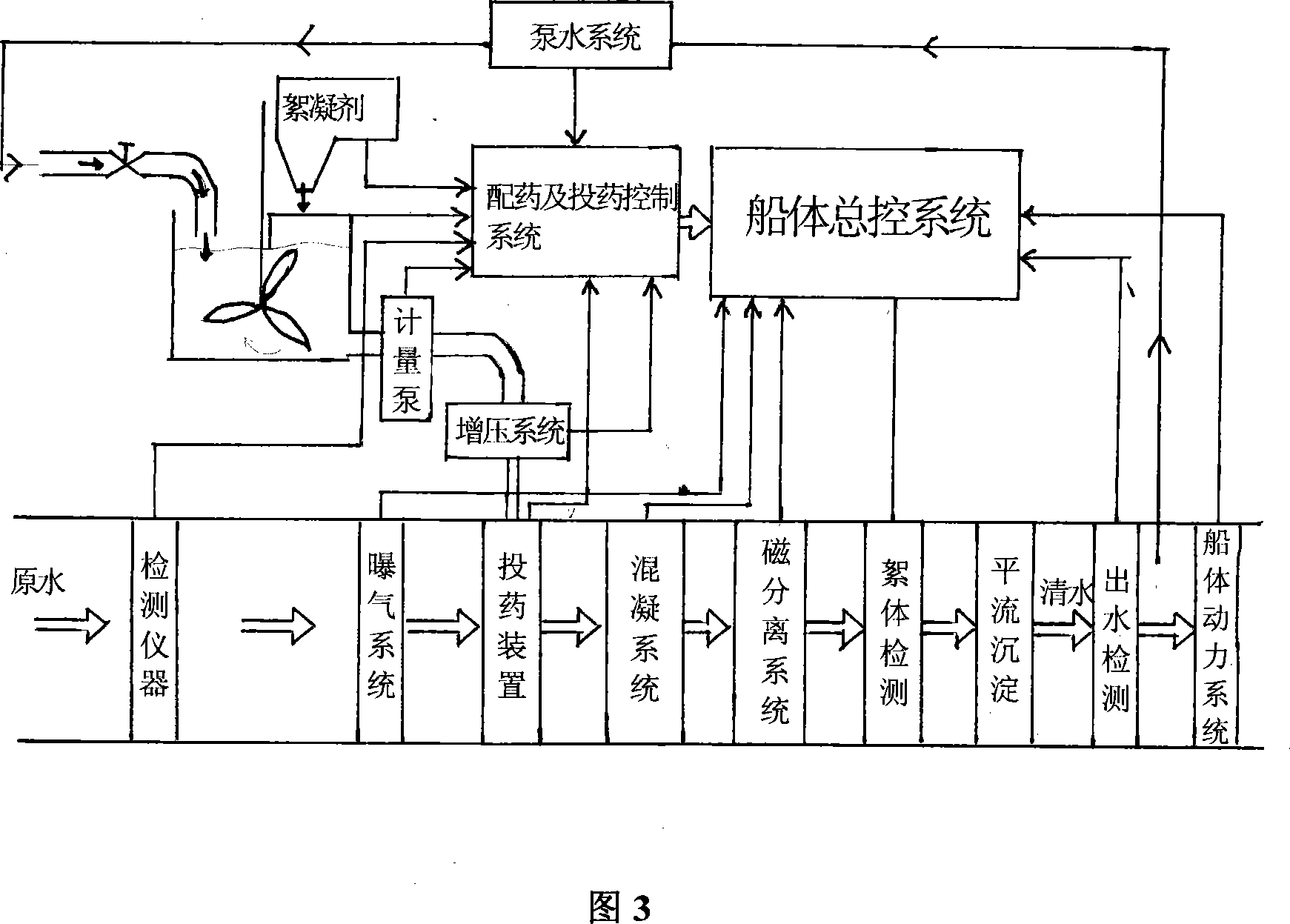

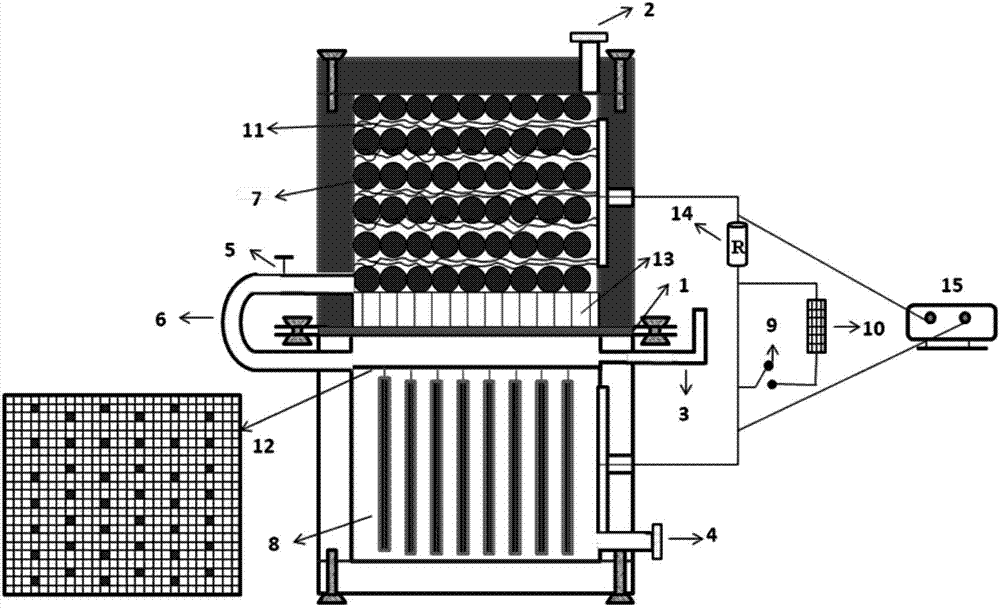

Method and device for removing eutrophication material from lake water body

ActiveCN101186367AResistant to large loads of temperature changesGuaranteed uptimeWater cleaningWater/sewage treatment by flocculation/precipitationEutrophicationAeration system

The invention discloses a eutrophic substance removing method for lake water body and a device. A groove shaped water channel is arranged in the middle of a floating bed, and an aeration system, a flocculant automatic distribution and a feeding system, a stirrer set, a magnetic separation system and a settlement tank or a filtering net are arranged on the channel in front-to-back sequence, and the front end and the back end of the channel are respectively provided with a water quality automatic detecting device. When the floating bed walks in the water body, water flow passes through the channel and is added with the flocculant, stirred, and flocs is formed, absorbed by the magnetic separation system and removed. The eutrophic substance removing method for lake water body can be industrialized and continuously operated with a large water treatment quantity conveniently and simply. The method is quite suitable for the treatment of the eutrophic substances in lakes.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

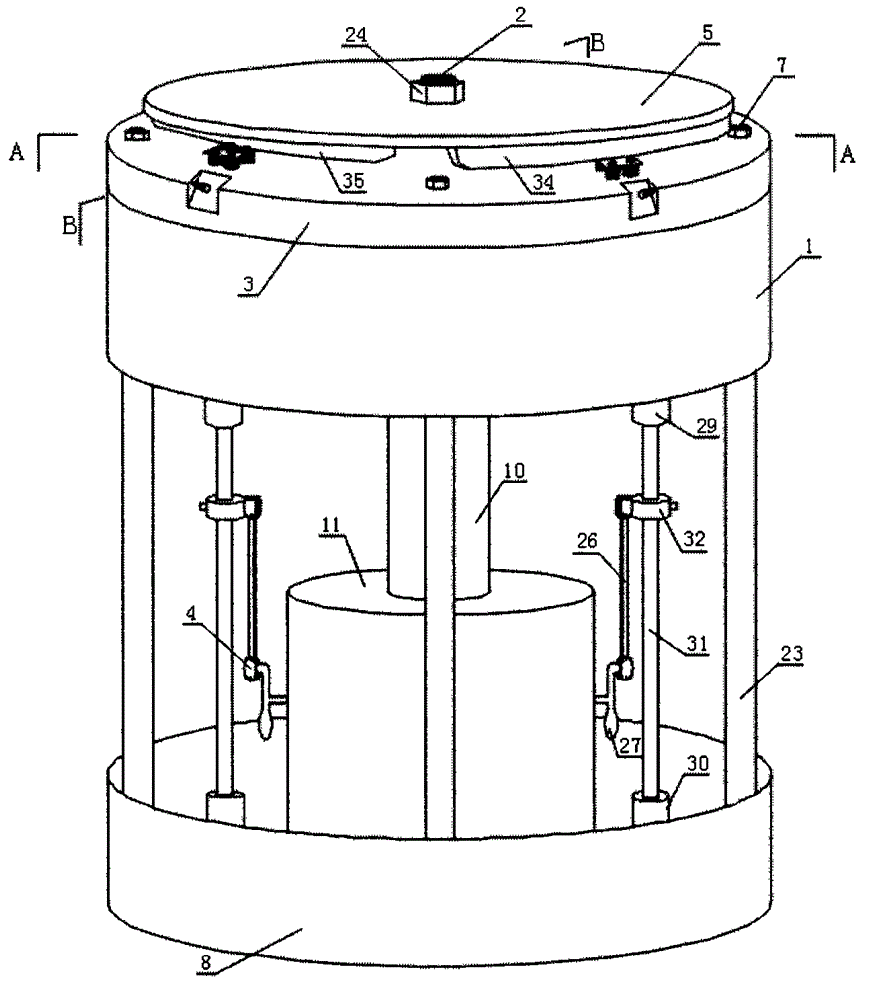

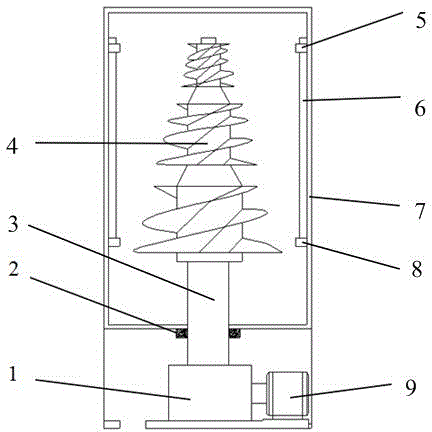

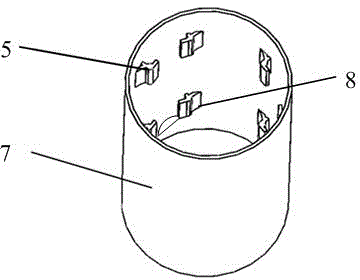

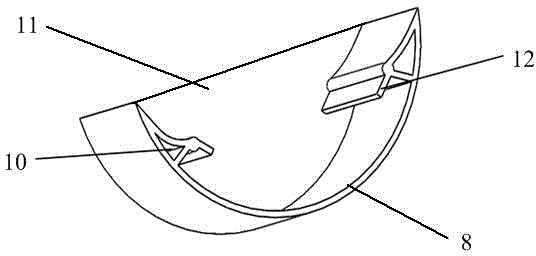

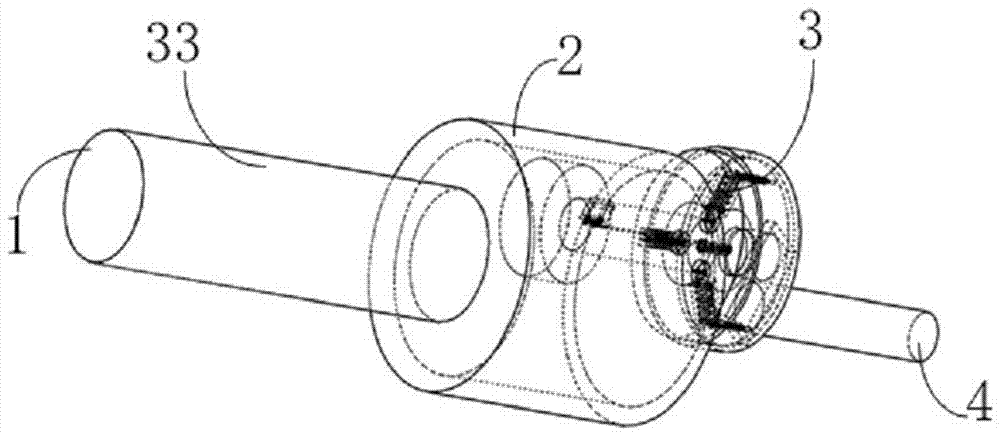

Pulper low in power consumption and noise

The invention provides a pulper low in power consumption and noise. The pulper mainly comprises a cylinder wall, a motor, a reducer, a seal device, a spindle, a spiral blade rotor, upper vortex board grooves, lower vortex board grooves and vortex boards. The pulper is characterized in the motor provides power, and the power is transmitted to the spiral blade rotor sequentially through the reducer and the spindle. By the inner and outer crescent arc transitions of the upper and lower vortex board grooves and the crescent cylindrical four-side arc structures at the inner edges of the vortex boards, flows can stably generate four vortexes at the four-side arcs of the vortex boards, vortex kinetic energy pulping is achieved, and low power consumption is achieved. Due to the fact that the hollow holes in two sides of the upper and lower vortex board groove retaining plates and in the middle portions of the vortex boards can be filled with damping and sound absorbing materials, fluid exciting force and solid noises can be absorbed, and low noise is achieved.

Owner:UNIV OF JINAN

Inner Tube with Film

InactiveUS20100052408A1Cumbersome and laborious air-refilling process could be eliminatedReduce resistanceElectrical storage systemBatteries circuit arrangementsTransport systemEngineering

The present invention discloses a type of secure and efficient wheel assembly using fluid or solid stuffing materials so as to minimize the blowout risks, a wheel rim transmission assembly, an energy exchanging arrangement used in transporting system, and a vehicle energy storage system, as well as corresponding methods for manufacturing and preparing such assemblies and arrangements in applications.

Owner:WUHAN RUNLIN SCI & TECH DEVMENT

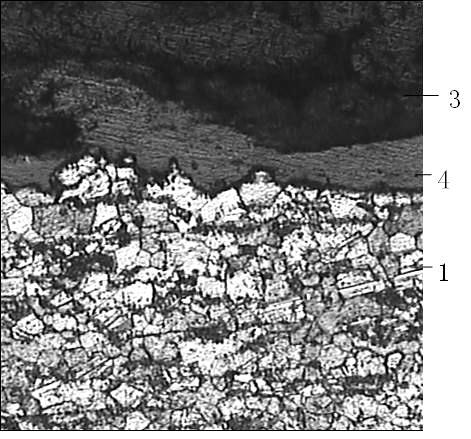

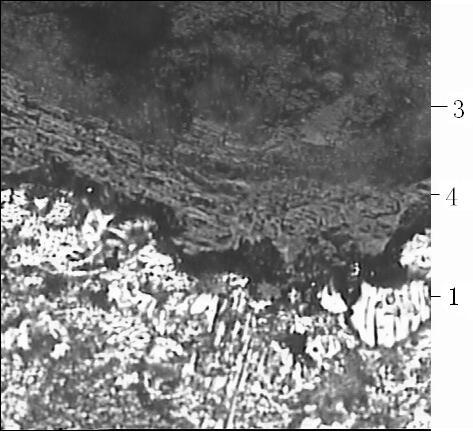

Annealing process for growing large-size sapphire crystal by kyropoulos method

InactiveCN103540998AReduce dislocation densityReduce internal stressPolycrystalline material growthAfter-treatment detailsThermal insulationSingle crystal

The invention relates to an annealing process for growing a large-size sapphire crystal by a kyropoulos method. After a large-size sapphire crystal grows by a kyropoulos method, the vacuum degree in a single crystal furnace is maintained, the heater power is gradually reduced, and the cooling is performed in five stages until the heater power is zero; through staged thermal insulation annealing, the dislocation density of large-size sapphire can be effectively reduced, internal stress of the crystal is eliminated, and the quality and the utilization rate of the crystal are improved; the annealing time is short, the energy consumption is reduced, and the growth period of the large-size sapphire crystal is shortened; moreover, the sapphire crystal is rotated in a thermal insulation stage so that the sapphire crystal annealing is uniform and the influence of non-uniform temperature field in annealing is eliminated.

Owner:江西东海蓝玉光电科技有限公司

Micropore ceramic filter element and preparation method thereof

InactiveCN101780353AReduce manufacturing costReduce production cost inputOther chemical processesFiltration separationWater basedPunching

The invention relates to a micropore ceramic filter element, in particular to a micropore ceramic filter element and a preparation method thereof. In the process of preparing the micropore ceramic filter element, raw materials are weighed according to the percentage in the formula, are added, mixed and uniformly stirred according to specified steps, and then are extruded or punched by an extruder or a punching machine into a blank, then the blank is dried at certain temperature to be shaped, and then the polyporous micropore ceramic filter element is formed. The micropore ceramic filter element is made of kaolin and diatomaceous earth which are bonded by a water-based adhesive, and has the advantages of low manufacturing cost, safety and environment protection. Simultaneously, the blank is molded by extrusion or punching, so cumbersome technology in the grouting process is eliminated, only moisture in the blank needs to be removed in the molding process, the existing energy-consuming process of long-time high-temperature calcination is avoided, and the production cost is greatly reduced.

Owner:张顺 +1

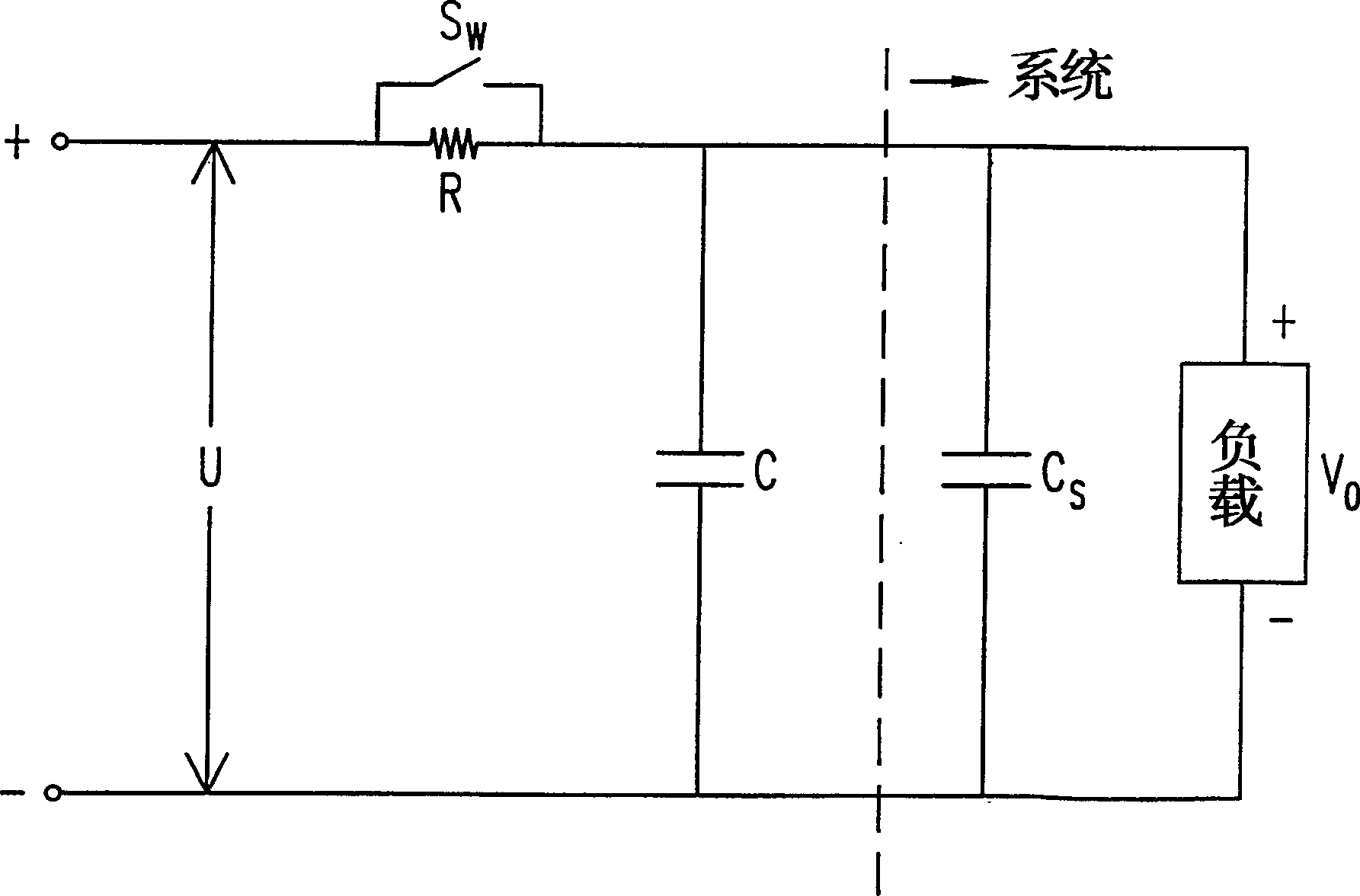

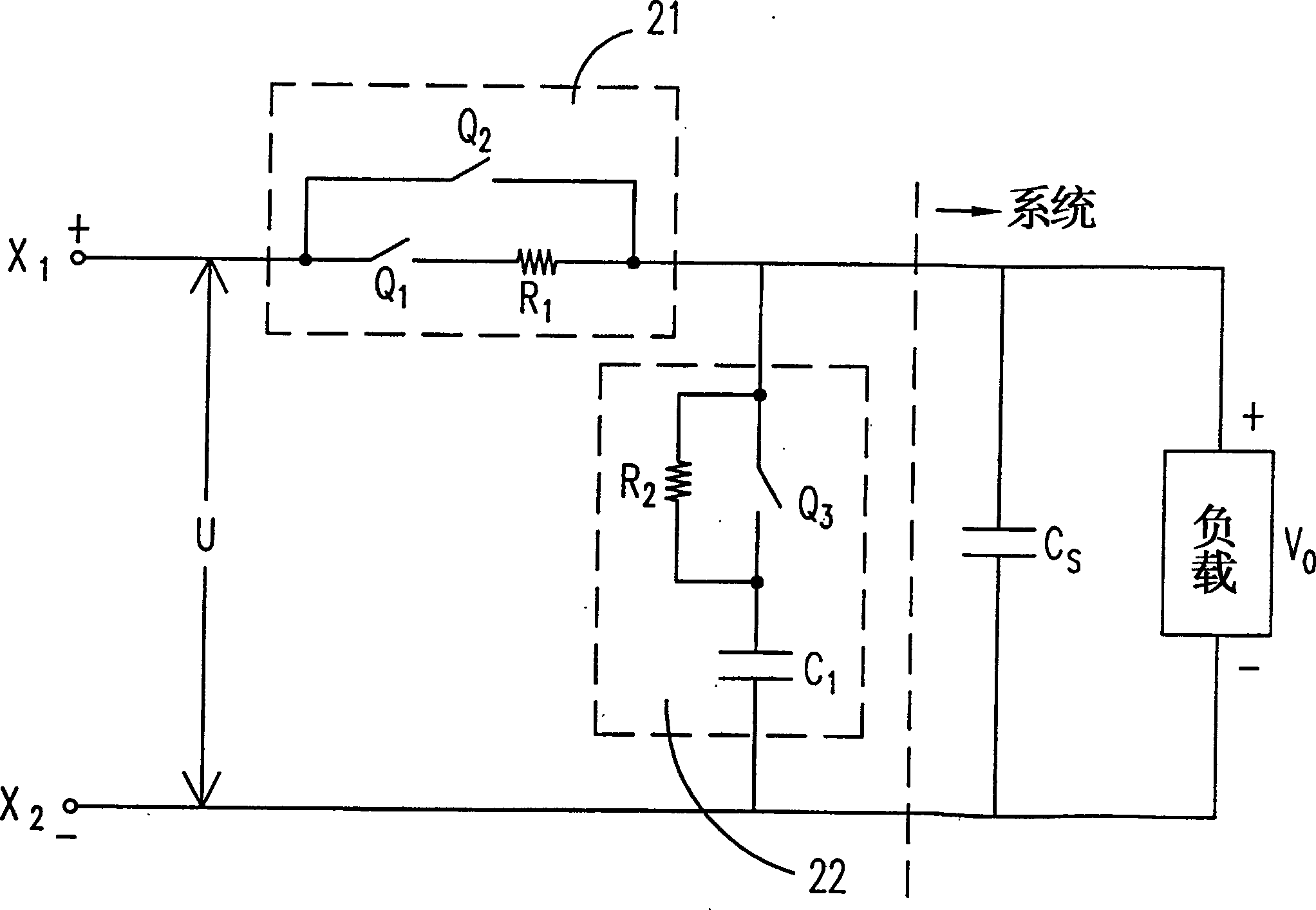

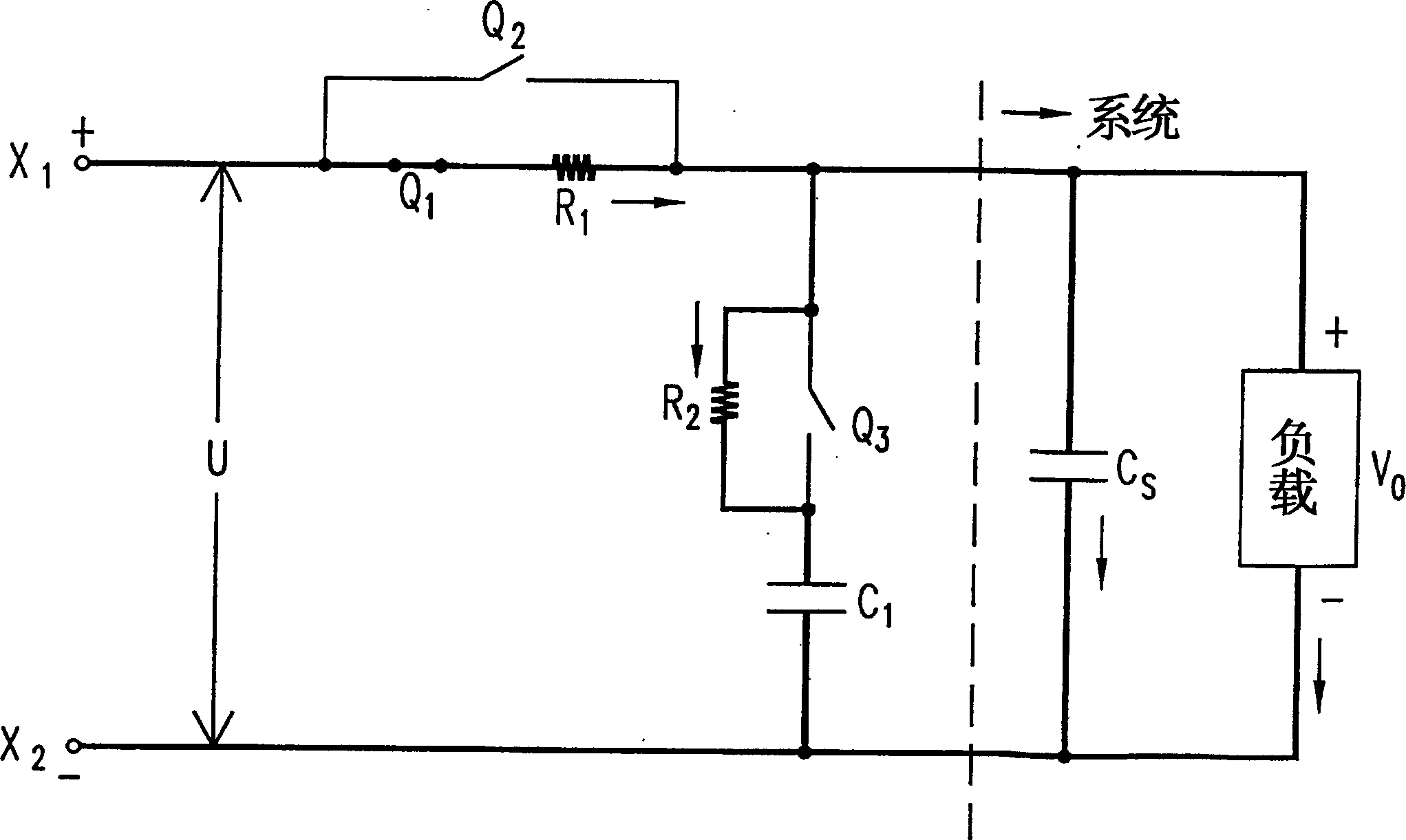

Circuit for restraining surge current

InactiveCN1431747AFree from vulnerable disadvantagesEliminate energy consumptionEmergency protective arrangements for limiting excess voltage/currentElectrical resistance and conductanceCapacitance

The circuit for restraining the surge current is located between the DC voltage and a load. The load has the parallel energy storage capacitnace. The suppressing circuit includes the first current-limited circuit and the second current-limited circuit. The first current-limited circuit includes the first resistance, the first controlled switch and the second controlled switch. The first resistance is connected to the first controlled switch in series. The connection between the second current-limited circuit and the first resistance as well as the first controlled switch is the parallel connection. The second current-limited circuit includes the second resistance and the third controlled switch-capacitor. The second resistance is connected to the third controlled switch in parallel as well as connected to the energy storage capacitor in series.

Owner:DELTA ELECTRONICS INC

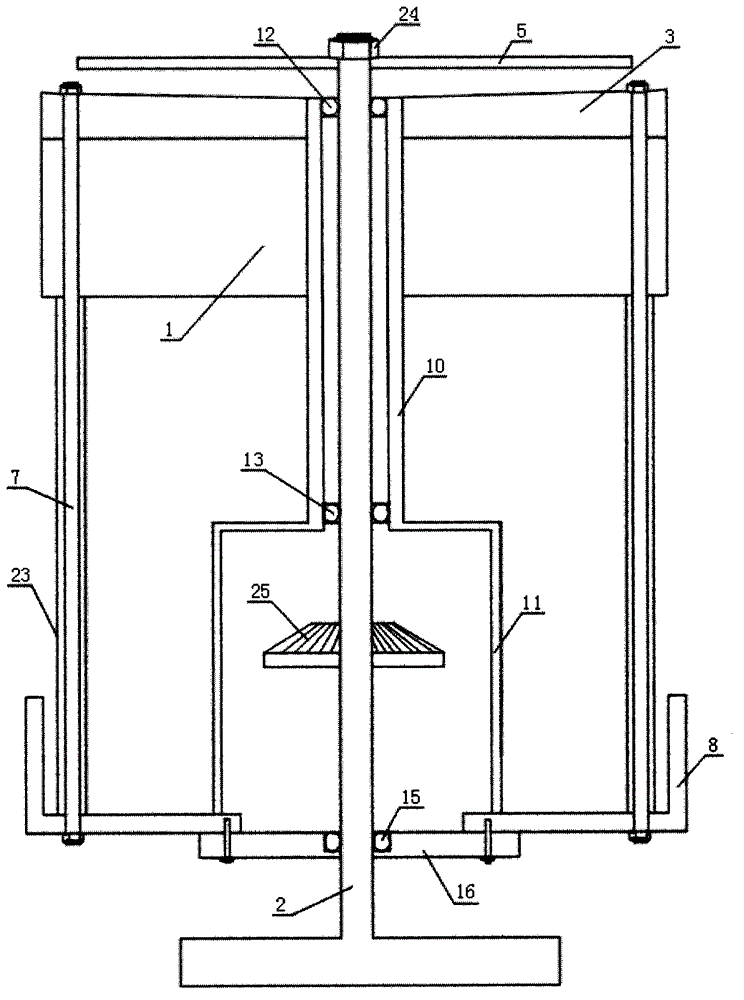

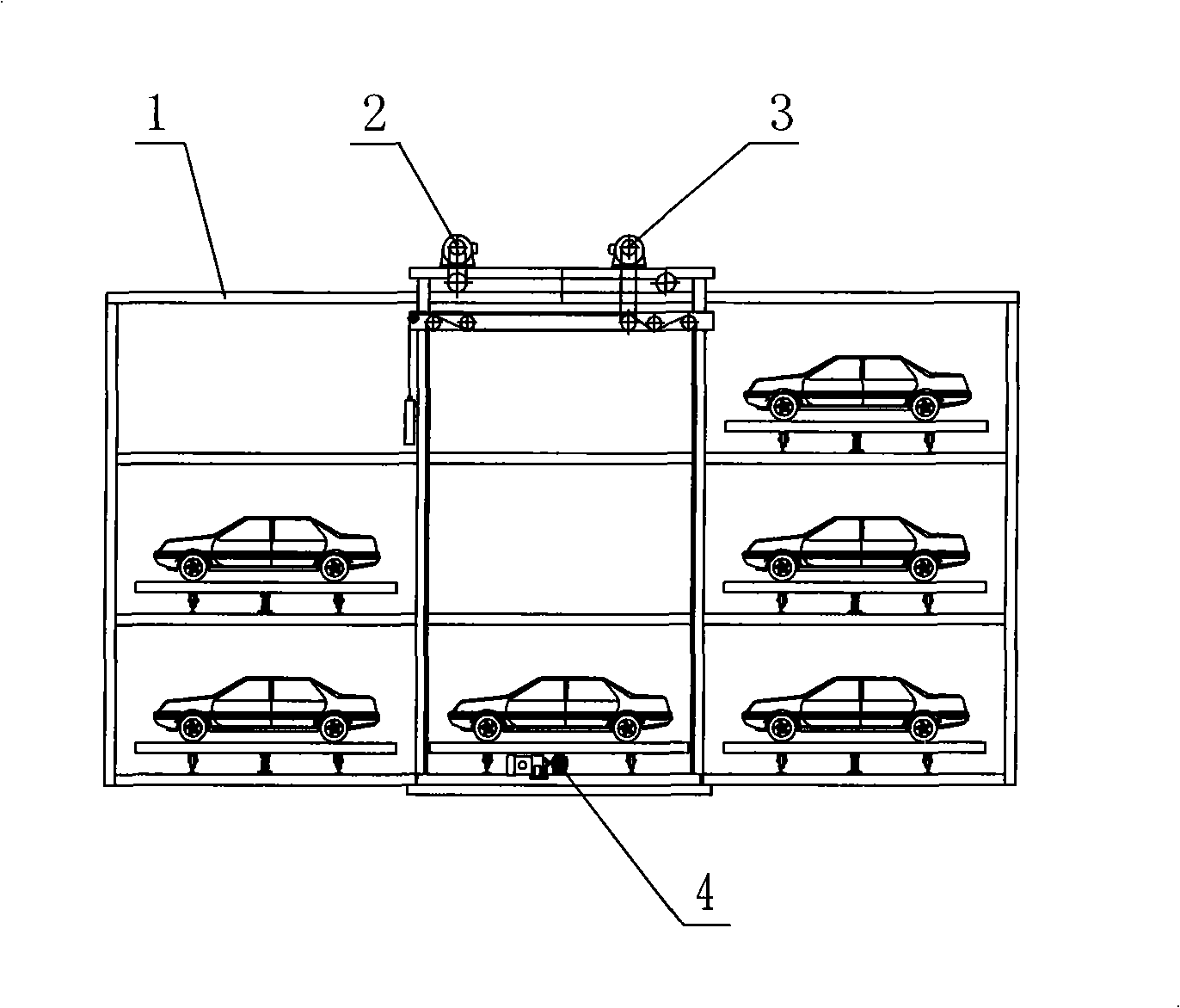

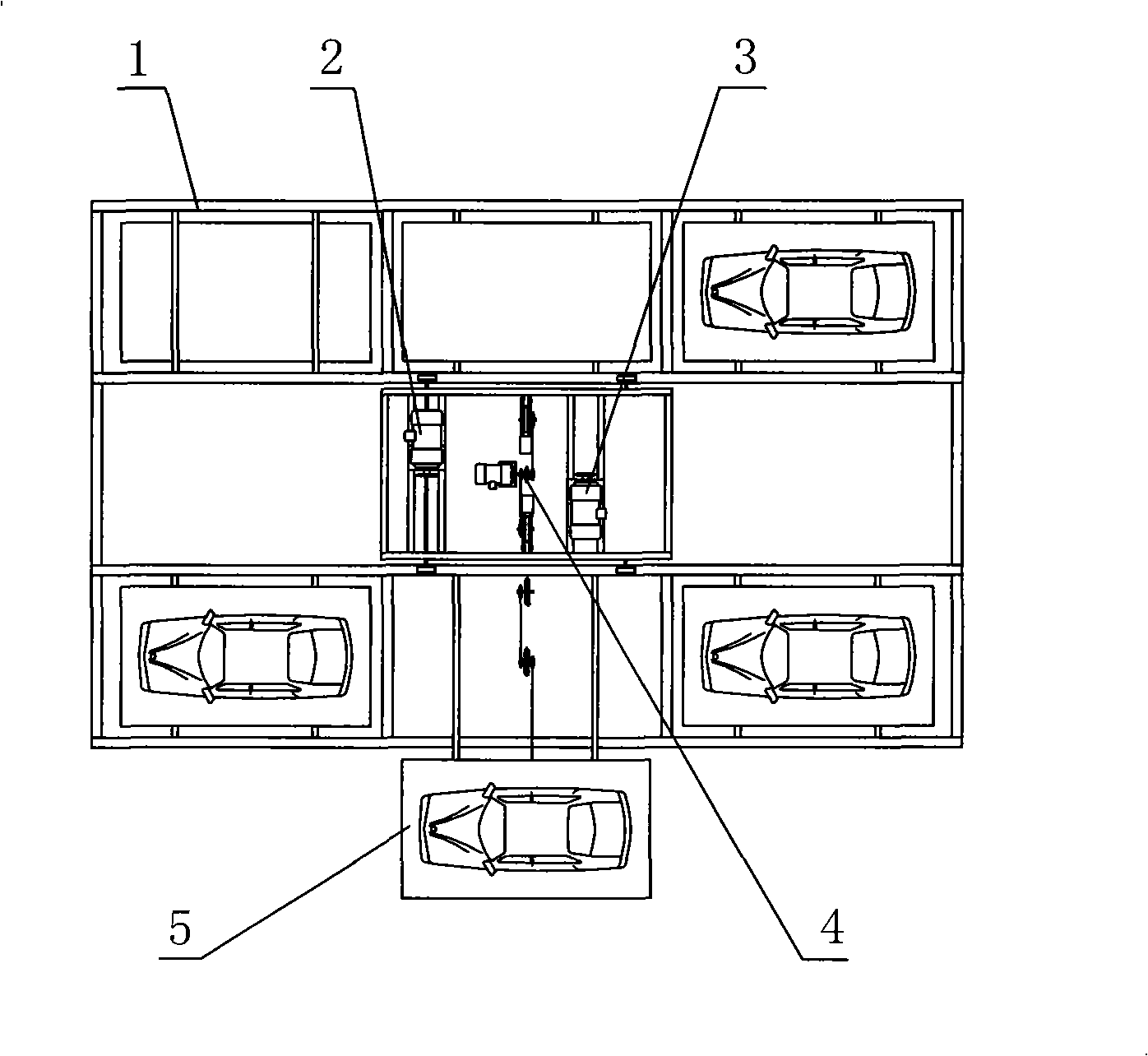

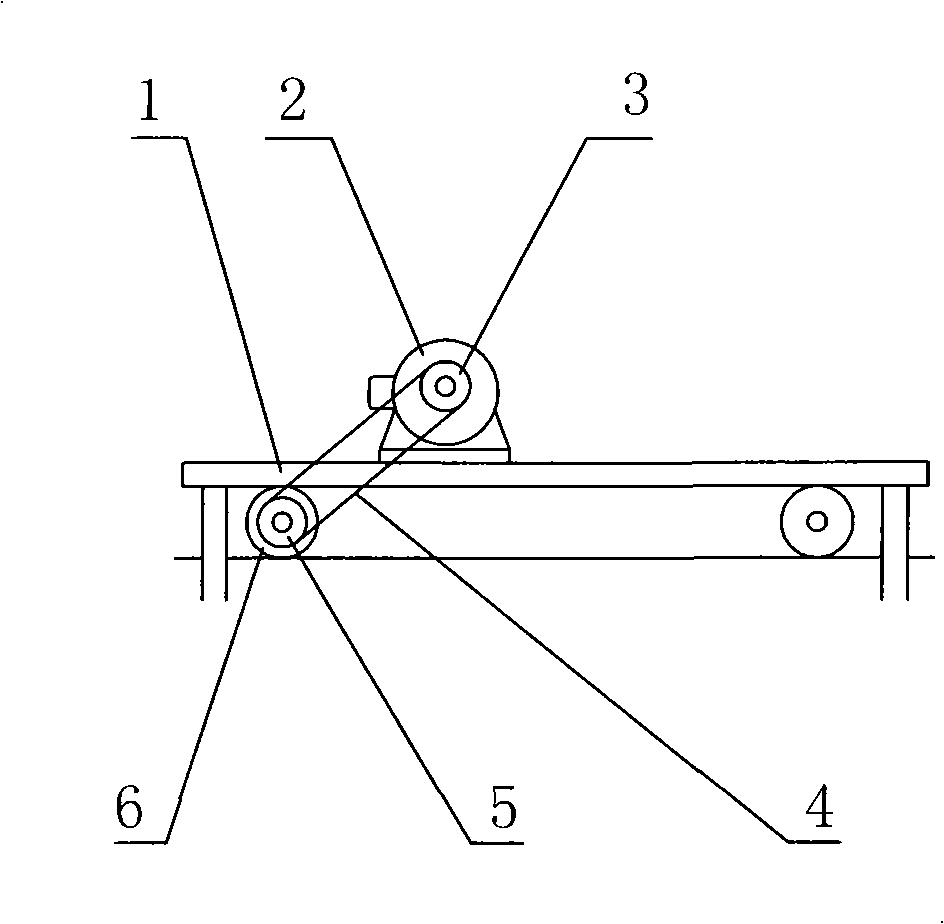

Transversely-moving automatic entrance and exit type solid garage

The invention relates to a transversely-moving automatic entrance and exit type solid garage, which is used for accessing medium and small-sized vehicles. The transversely-move automatic egress and ingress type solid garage consists of vehicle-mounted parking lots, a garage body, a conveying robot, a vehicle-mounted supporting plate and a control system, and relates to the technical fields of civil engineering, steel structures, mechanical transmission, automatic control, and the like. The outside of a garage door is used for parking the vehicles, and the conveying robot is used for automatically controlling the egress and the ingress, so that the transversely-moving automatic egress and ingress type solid garage has the advantages of convenient access and quick egress and ingress. A piece of equipment is used for accessing all the vehicles in one garage, and the transversely-move automatic egress and ingress type solid garage has the advantages of simple structure and low manufacturing cost. The vehicle-mounted parking lots outside the garage door are parallel with the garage body, and the supporting plate carries the vehicles to come in and out transversely. The occupation space of the transversely-move automatic egress and ingress type solid garage is small, and the construction is suitable for various different area conditions so as to be favorable for the promotion and popularization of mechanical solid garages.

Owner:蓝家瑞

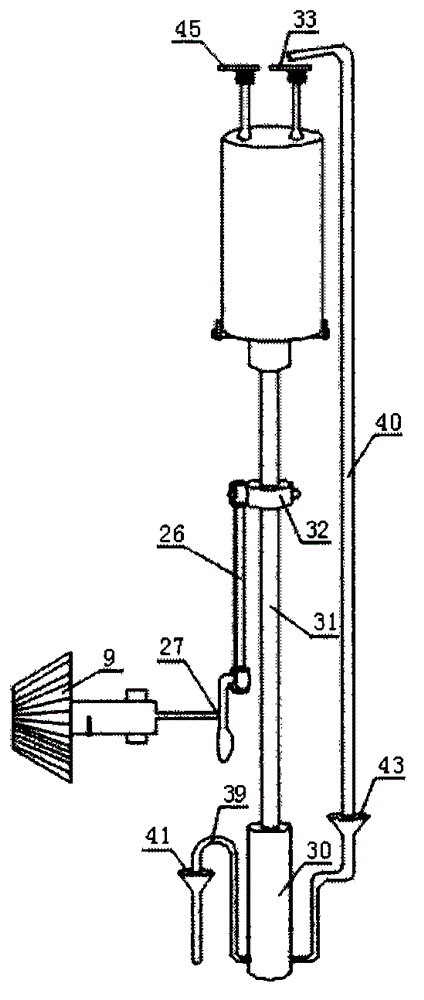

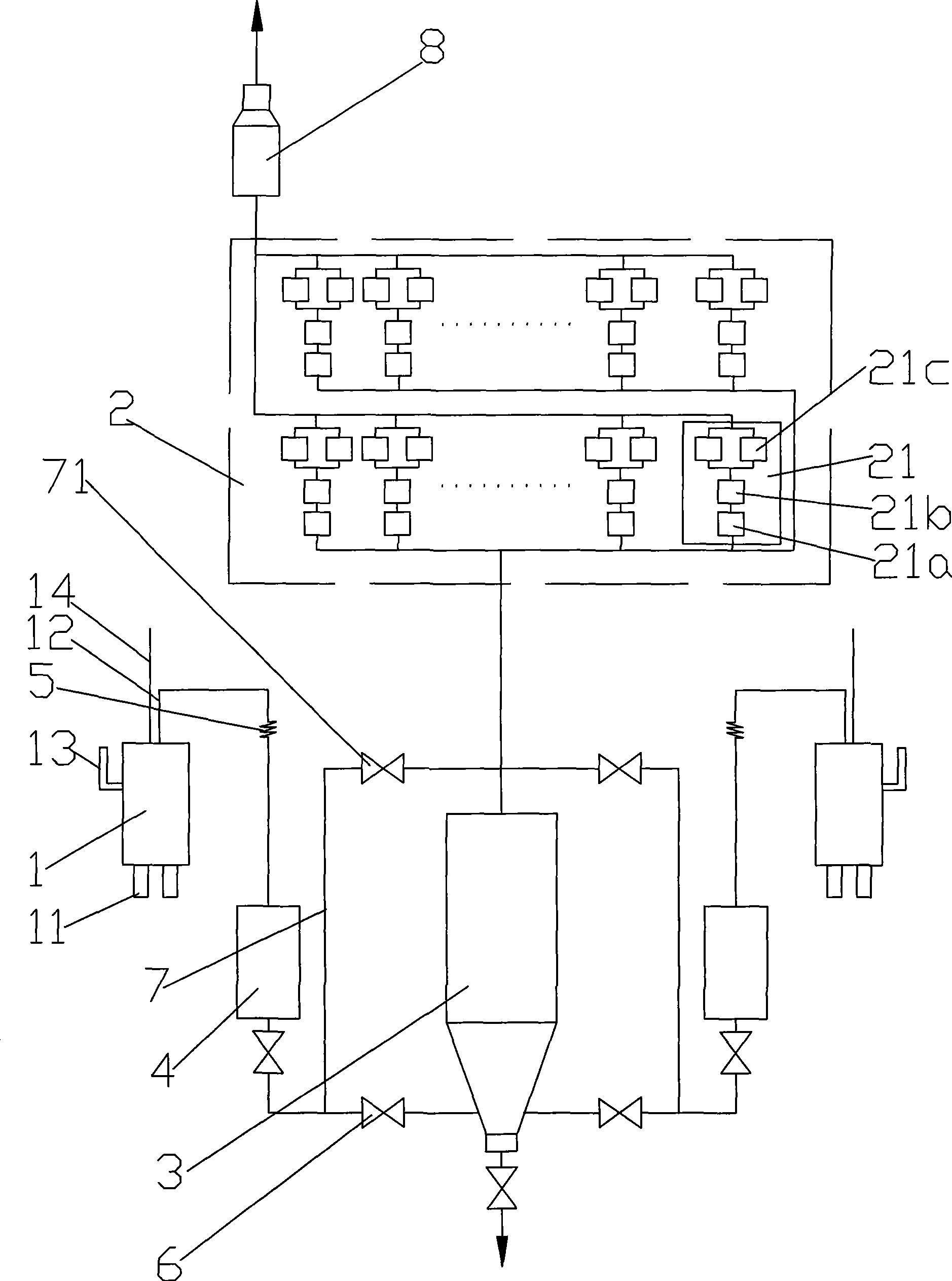

RH dry type vacuum refining apparatus

ActiveCN101476022AEliminate energy consumptionEliminate the disadvantage of high water consumptionFailure ratePulp and paper industry

The invention discloses a RH dry type vacuum refining apparatus comprising a vacuum groove and an evacuating device. The vacuum groove is provided with a varnished tube and a hot-bending tube, the inlet of the evacuating device is communicated with the hot-bending tube, the evacuating device is a dry vacuum pump apparatus. The evacuating device of the invention adopts a dry vacuum pump group, therefore, a high-vacuum degree desired by molten steel refining operation can be obtained, defects that the energy-consumption and water-consumption of the existing steam jet apparatuses are high are overcome, the cost is saved, the setting of auxiliary assemblies is simplified, furthermore, the failure rate of the apparatus is reduced, and a long period operation of the RH vacuum refining apparatus and an effect of external refining of molten steel can be both guaranteed. The RH dry type vacuum refining apparatus which solves the technical problem in the replacing of a steam jet device by a dry type vacuum device for many years at home and abroad has an energy-consumption which is one thirteenth of that of a steam jet pump group and a water-consumption which is one tenth of that of a steam jet pump group.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

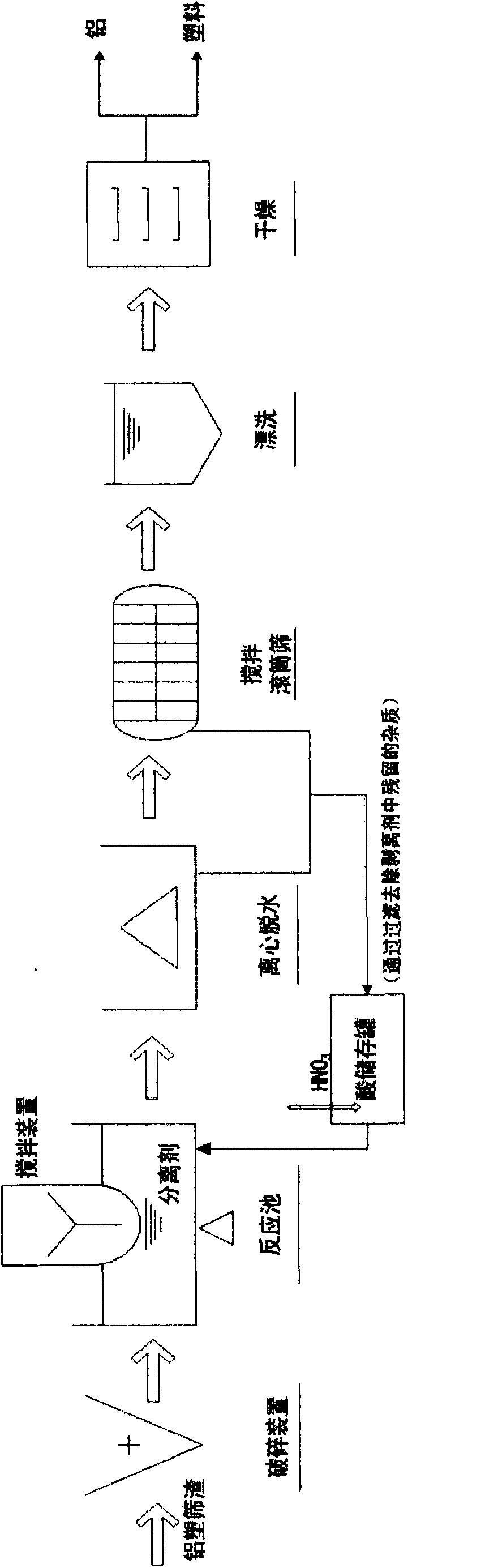

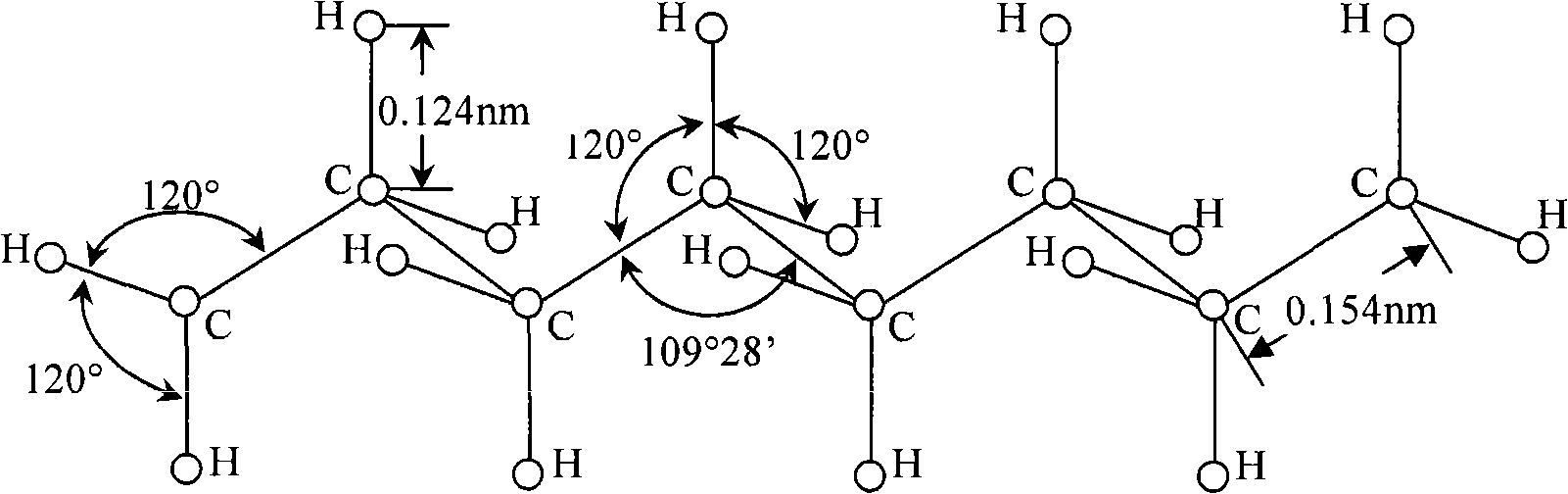

Method for separating paper plastic-aluminum composite packing waste

InactiveCN101891903AGuaranteed separation time and separation effectSerial productionPlastic recyclingSeparating agentAluminum composites

The invention discloses a method for separating a paper plastic-aluminum composite packing waste. The method comprises the main steps of: A) crushing aluminum plastic and putting the crushed aluminum plastic into a separating agent which is 3 to 5mol / L formic acid solution, and soaking the aluminum plastic at the temperature of between 40 and 60 DEG C with stirring till the aluminum foil and the plastic are separated; B) removing the separating agent from the aluminum foil and the plastic; C) putting the aluminum foil and the plastic into a stirring roller screen device to separate the aluminum foil and the plastic; D) rinsing the aluminum foil and the plastic by using water respectively to remove the residual separating agent; and E) drying the aluminum foil and the plastic. The method eliminates pollution and energy loss produced by purely filling and burning the paper plastic-aluminum composite packing waste; and meanwhile, because the aluminum foil and the plastic can be recycled respectively, the method reduces the development of new energy and materials and saves resources.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

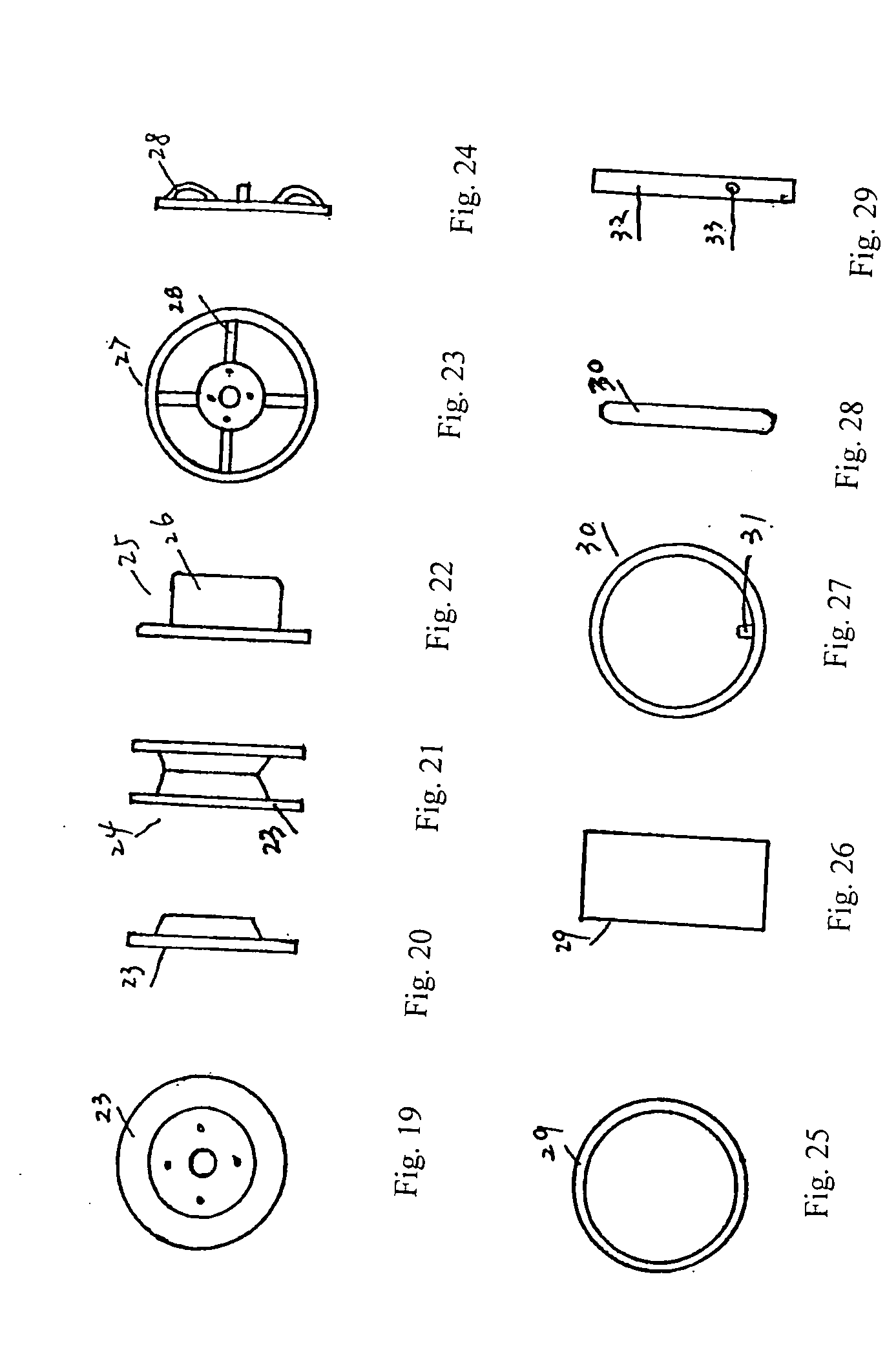

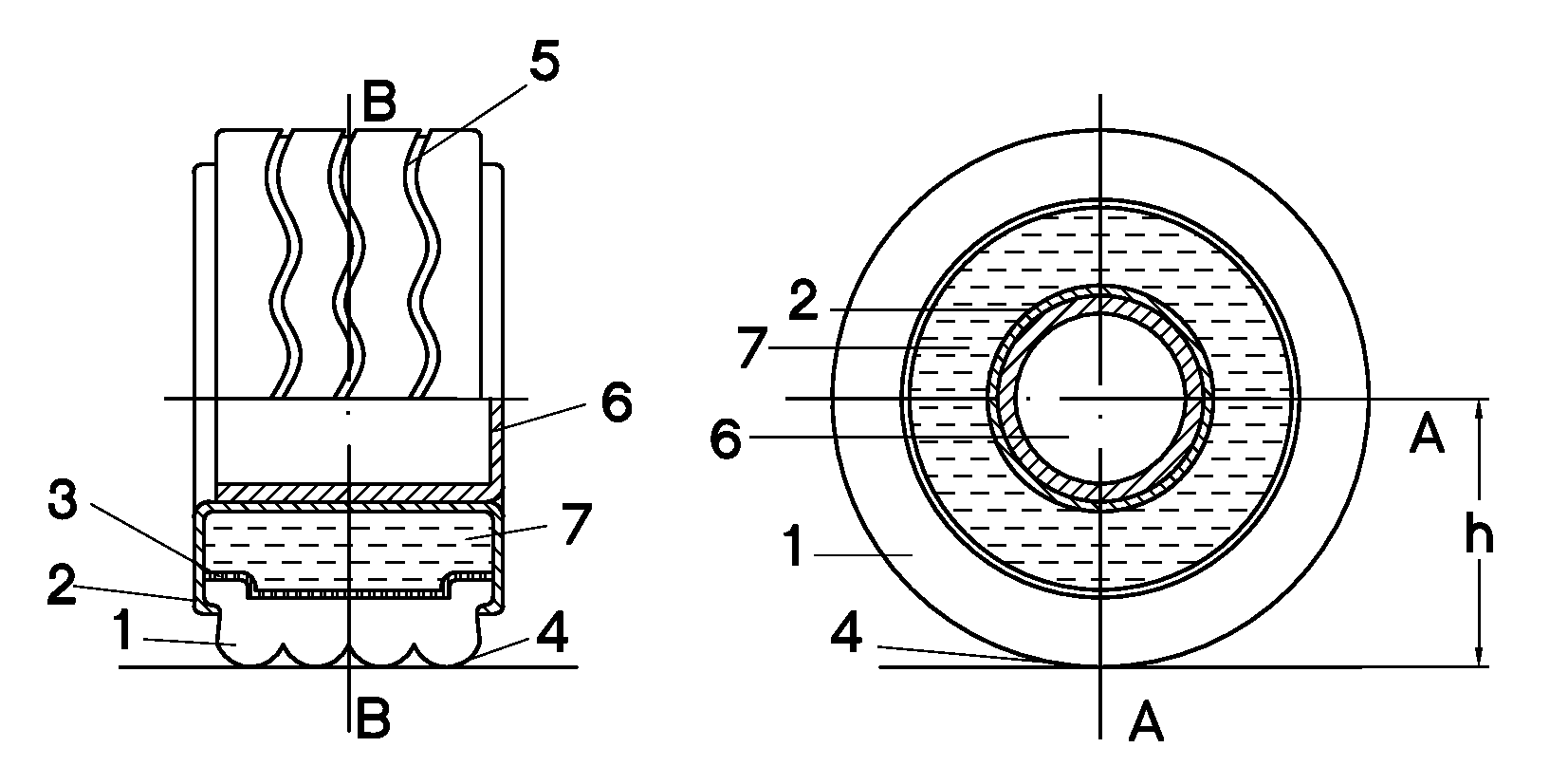

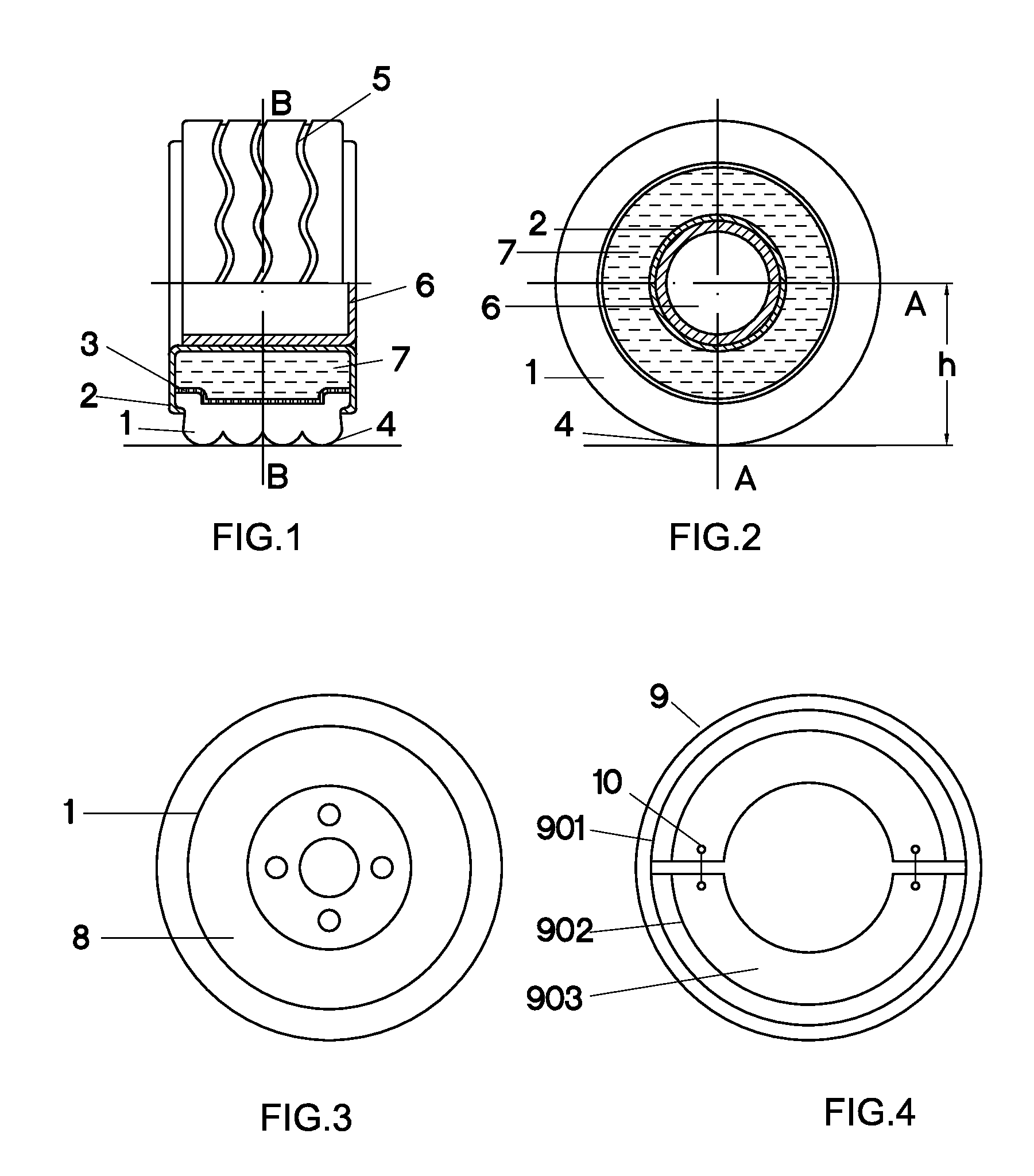

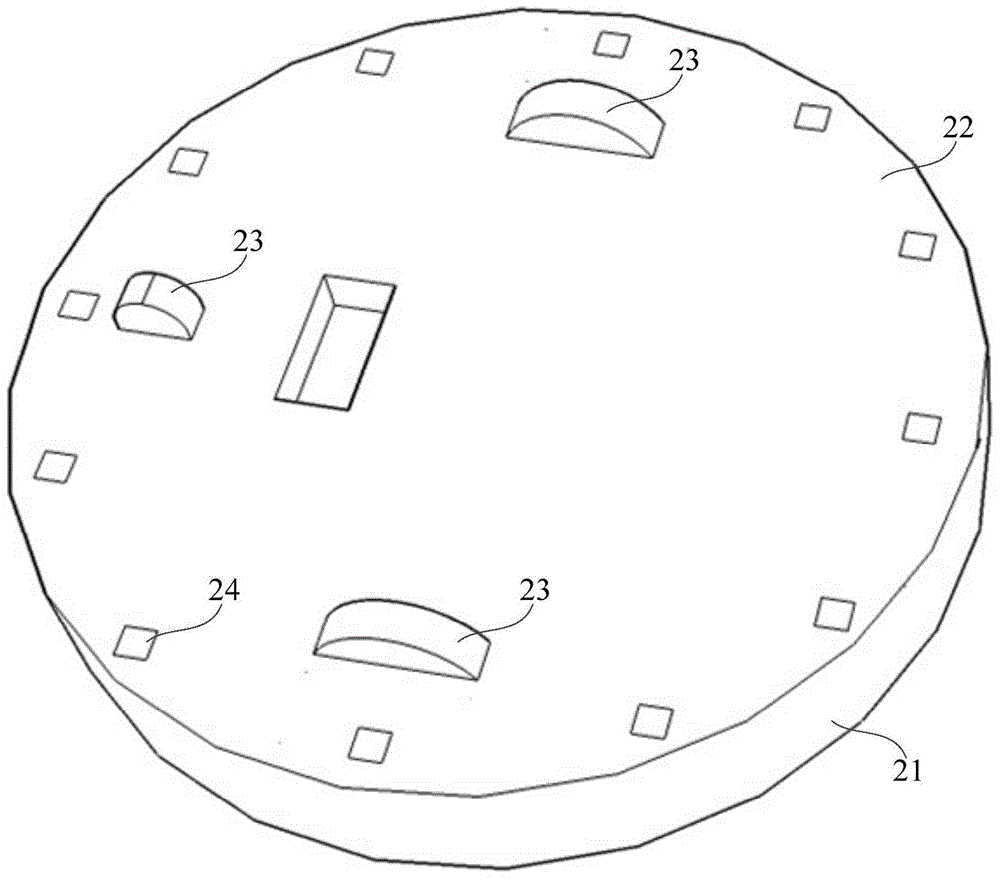

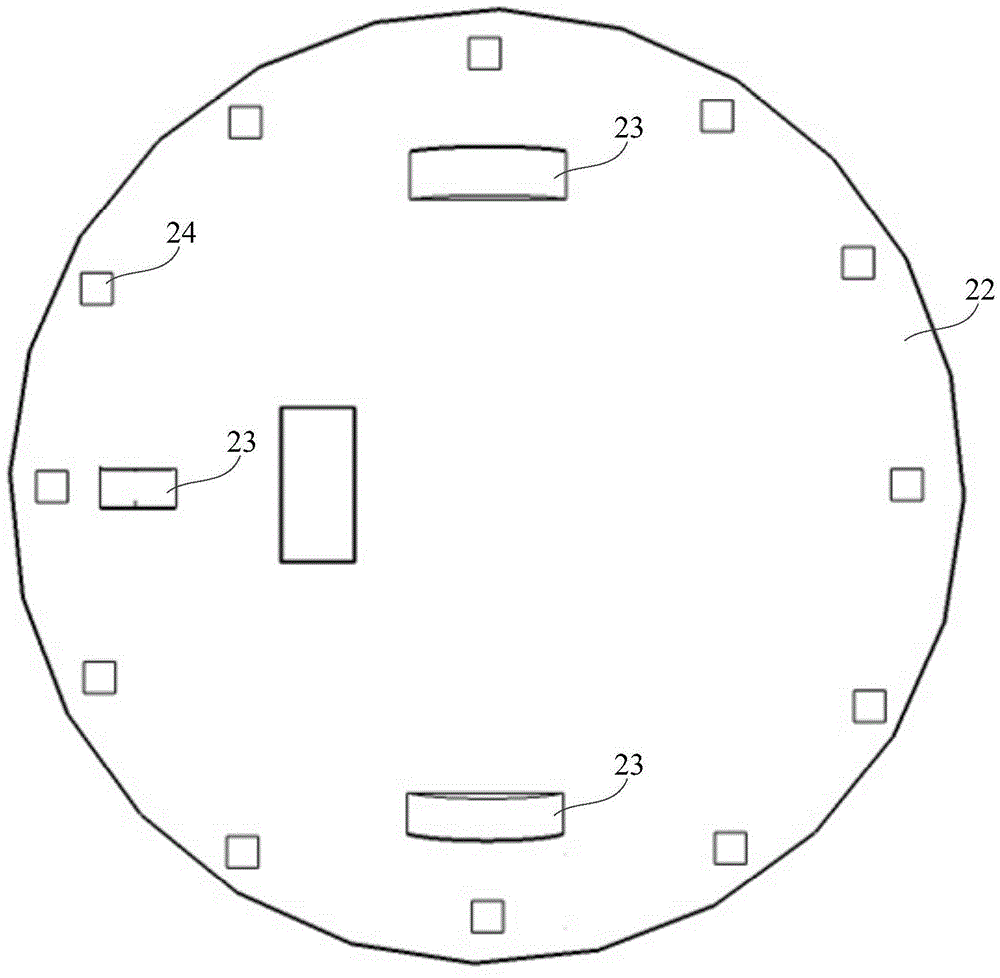

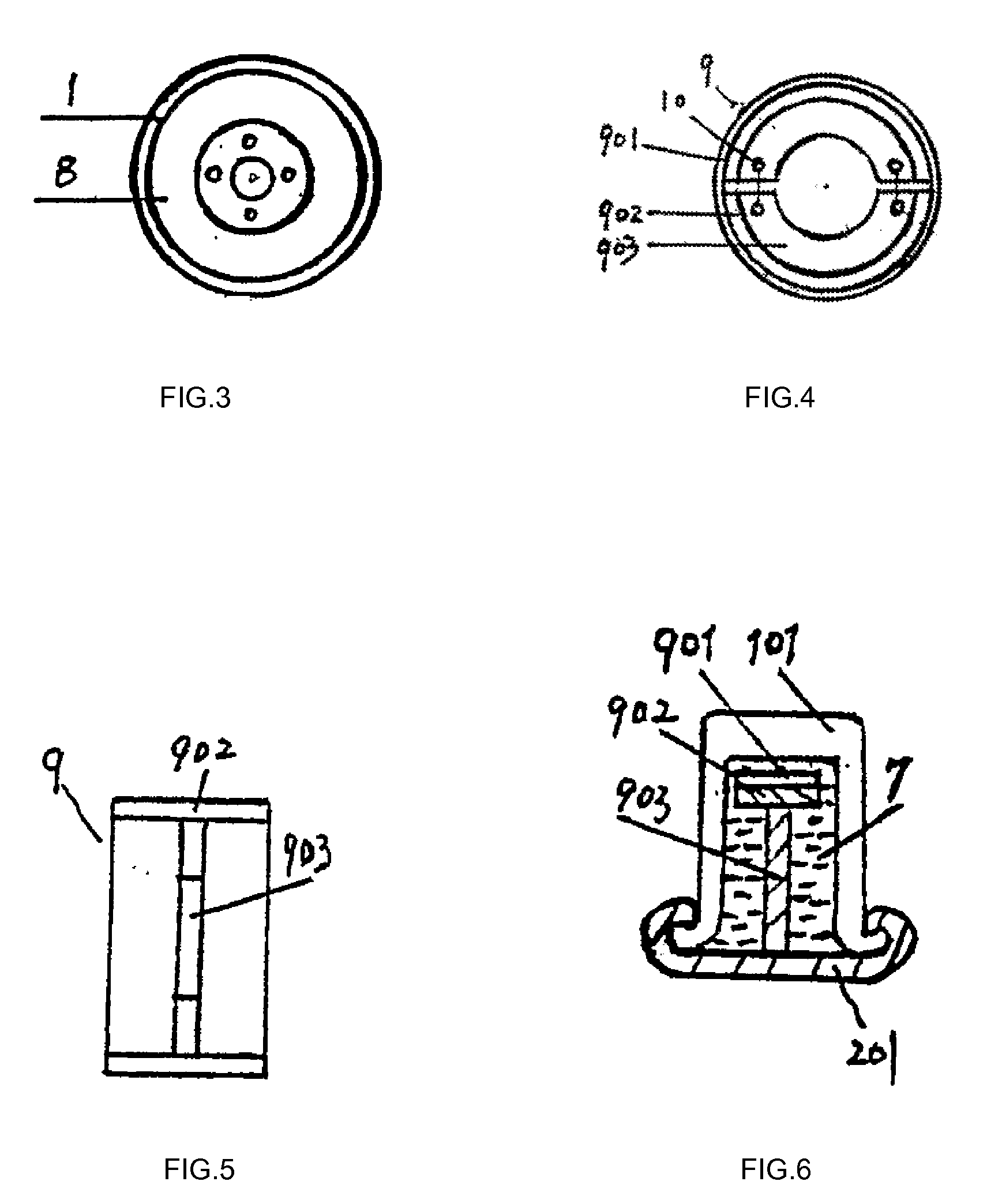

Torque limiter with adjustable critical value

InactiveCN107420457AEliminate energy consumptionAdjust critical torque valueAutomatic clutchesControl theoryTorque limiter

The invention belongs to the technical field of torque limiters, and particularly relates to a torque limiter with an adjustable critical value. The torque limiter with the adjustable critical value comprises a torque limiting mechanism and adjustment driving mechanisms, wherein the three adjustment driving mechanisms are uniformly mounted in the torque limiting mechanism in the circumferential direction; according to the torque limiter with the adjustable critical value, the torque limiting mechanism has the effect of supporting the adjustment driving mechanisms; the three adjustment driving mechanisms are uniformly mounted in the torque limiting mechanism in the circumferential direction and achieve the effect of rotating an input shaft continuously without driving an output shaft to rotate when a torque value required on the output shaft is greater than the set torque value of the torque limiting mechanism in the torque limiter with the adjustable critical value, so that the purpose of protecting an input end is achieved; and moreover, the critical value of the torque limiter can be adjusted.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

Electrochemical device and method for treating high-concentration ammonia organic wastewater and treatment method

ActiveCN107098459AImprove removal efficiencyAvoid negative effectsTreatment by combined electrochemical biological processesWater contaminantsHigh concentrationNitration

The invention provides an electrochemical device and a method for treating high-concentration ammonia organic wastewater and a method. The device is divided into an anode chamber and a cathode chamber through a diaphragm; a water inlet is formed in the top part of the anode chamber; a pipeline with a valve communicated with the top part of the cathode chamber is arranged on the bottom part of the anode chamber; a water outlet is formed in the bottom part of the cathode chamber; an alga-bacteria biofilm is arranged on the surface of a cathode; an ammonia nitrogen-resistant electroactive biofilm is arranged on the surface of an anode; the cathode and the anode are connected with an adjustable resistor and a photocell controlled by a timing relay. The device respectively removes an organic matter and ammonia nitrogen on the anode and the cathode, prevents the influence on the cathode caused by that a continuous flow from bringingcarrys the organic matters from the anode so as to influence the cathode, and eliminates the phenomenon that a nitration liquid reflows to the anode so as to bring oxygen and nitrate to influence on the anode caused by that nitration liquid reflows to the anode and brings oxygen and nitrate in. A cathode algae alternative dark light reaction and phycomycete synergism are utilized, so that multi-way denitrification such as bio-nitrification-denitrification, electrochemical reduction and algae absorption is realized. Meanwhile, the photocell discharges to intensify the operation of a drive device at night. The device is self-controlled in energy, and can be used for sustainably and high-efficiently treating the high-concentration ammonia organic wastewater.

Owner:GUANGDONG UNIV OF TECH +2

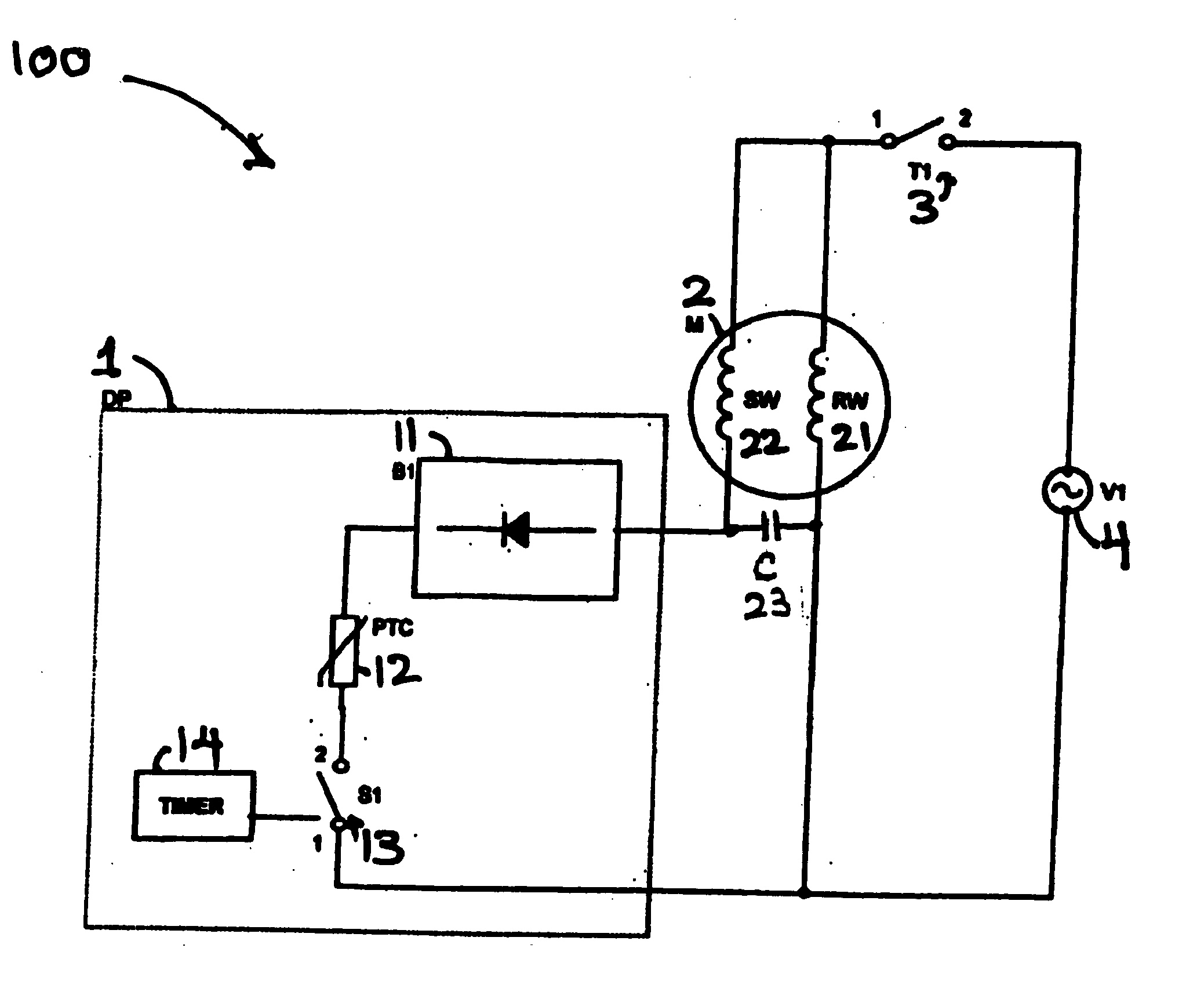

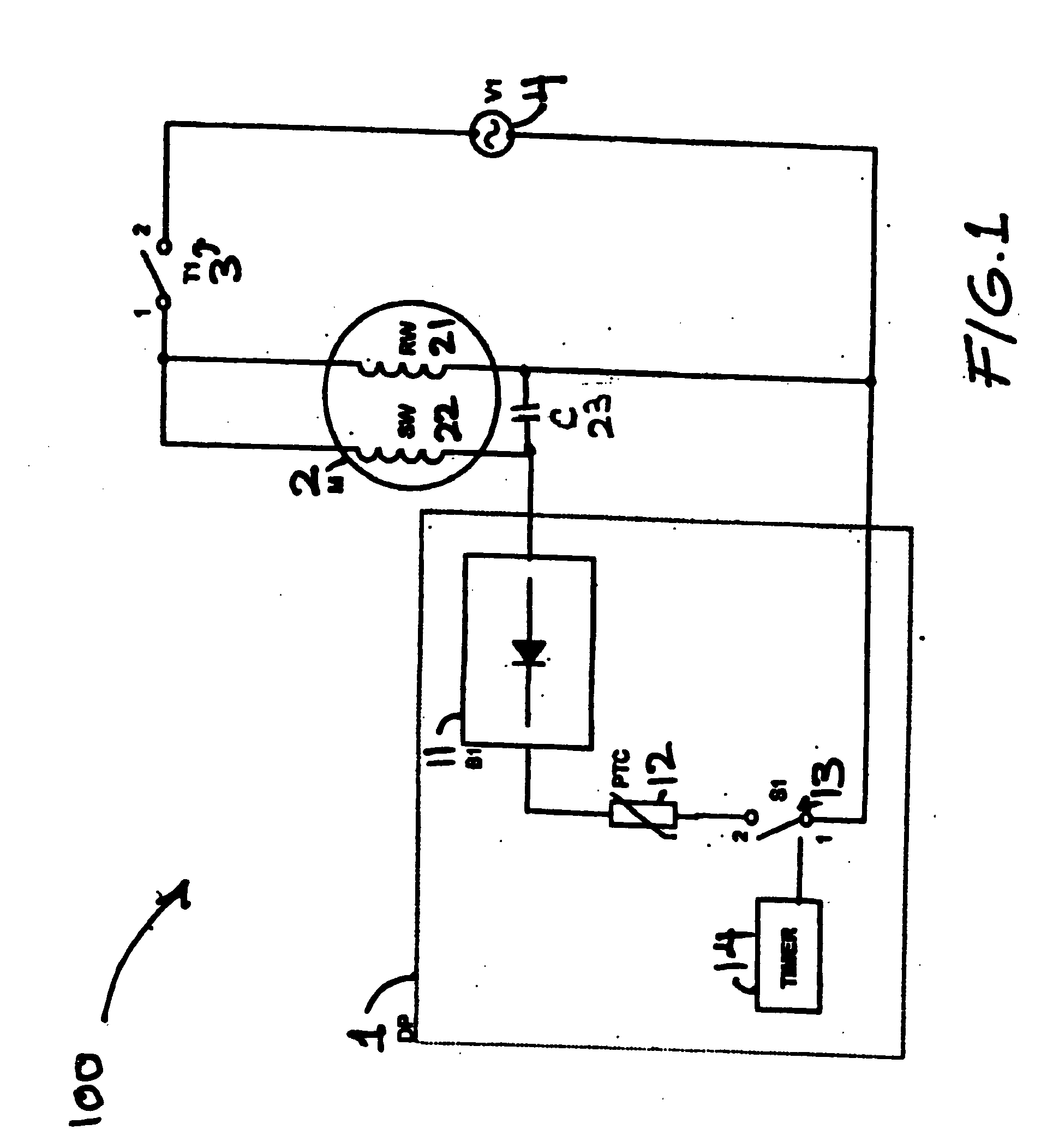

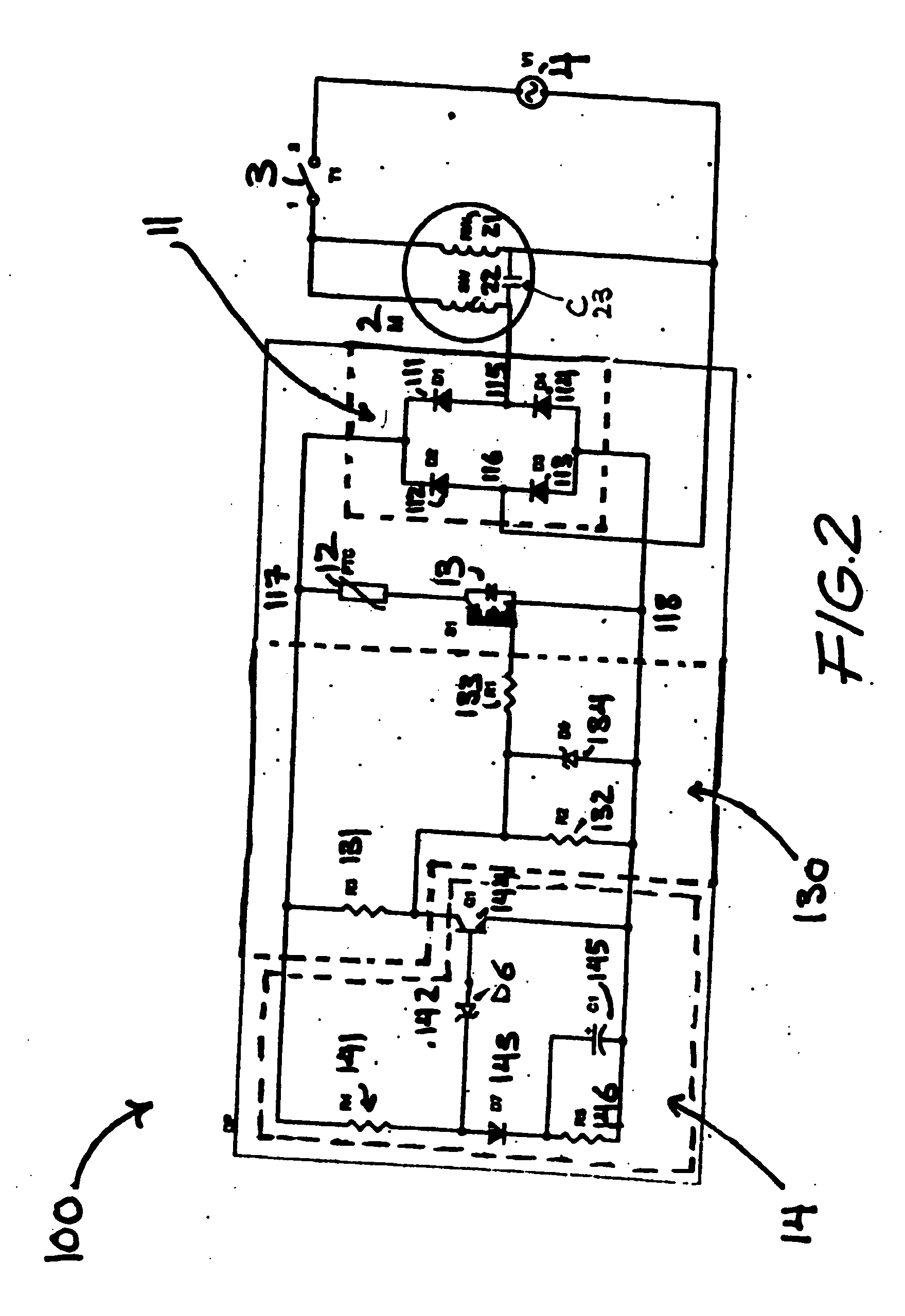

Electronic startup device for hermetic compressors

InactiveUS20060017417A1Easy to produceSmall dimensionSingle-phase induction motor startersAC motor controlStart timeFull wave

An electronic startup device and a method of using it for single phase induction motors, such as those used in hermetic compressors, and permanent capacitor motors may save energy by eliminating energy consumption after the startup period of the motor. The electronic startup device may comprise a circuit including a unidirectional electronic switch which connects a start winding of an induction motor to an alternating voltage source through a thermistor or a solid state pill, which defines the starting time of the motor, and to a full wave rectifier. A timing circuit may activate the unidirectional electronic switch disconnecting the thermistor from the rest of the circuit during an adjustable turning off time.

Owner:TECUMSEH DO BRASIL

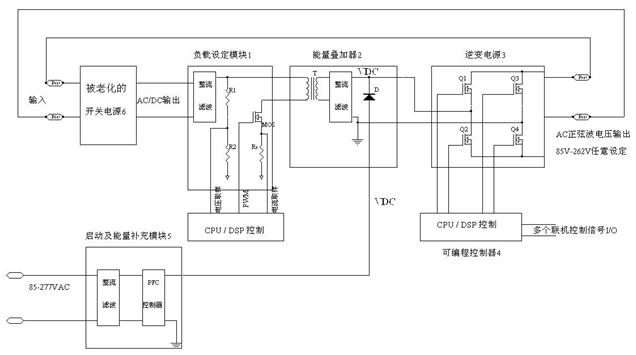

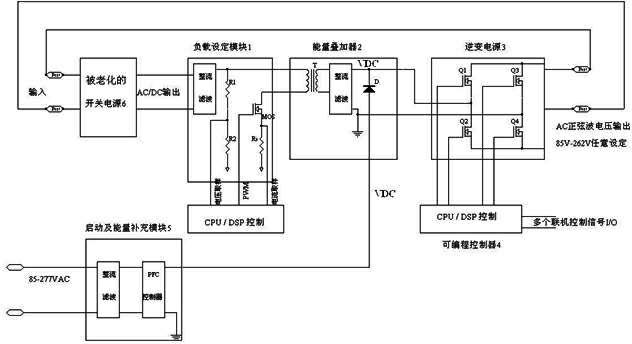

High-efficiency and energy-saving self-circulation electronic load

InactiveCN102255336ASolve wasteRealize the grid connection problemSingle network parallel feeding arrangementsPower supply testingElectronic loadComputer module

The invention relates to a high-efficiency and energy-saving self-circulation electronic load, comprising a load setting module, an energy superposition device, an inverted power supply, a programmable controller and a starting and energy supplementing module, wherein an alternating-current mains supply is connected to the energy superposition device via the starting and energy supplementing module, the energy superposition device is connected with the input end of the inverted power supply, the output end of the inverted power supply is connected to the input end of an aged switch power supply, the output end of the aged switch power supply is connected to the energy superposition device through the load setting module, and the programmable controller is connected with the driving end of the inverted power supply. According to the invention, experiment energy can be fed back so that the problem of electric energy waste is solved, in addition, the electric load has the advantages of high efficiency, energy saving performance, self circulation capability and simplicity and convenience for operation, can be realized at low cost and can be used for saving energy by more than 50%.

Owner:刘学军 +2

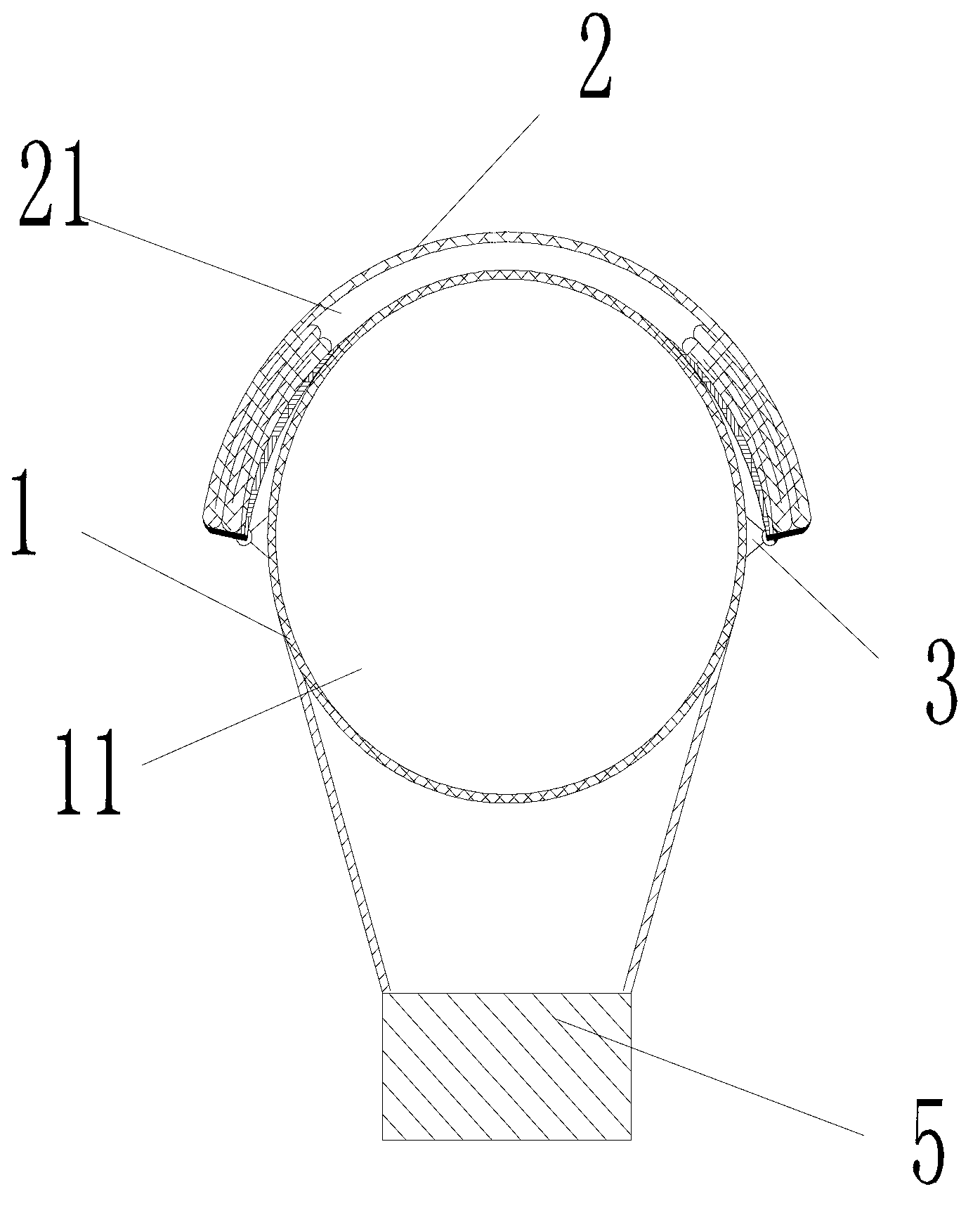

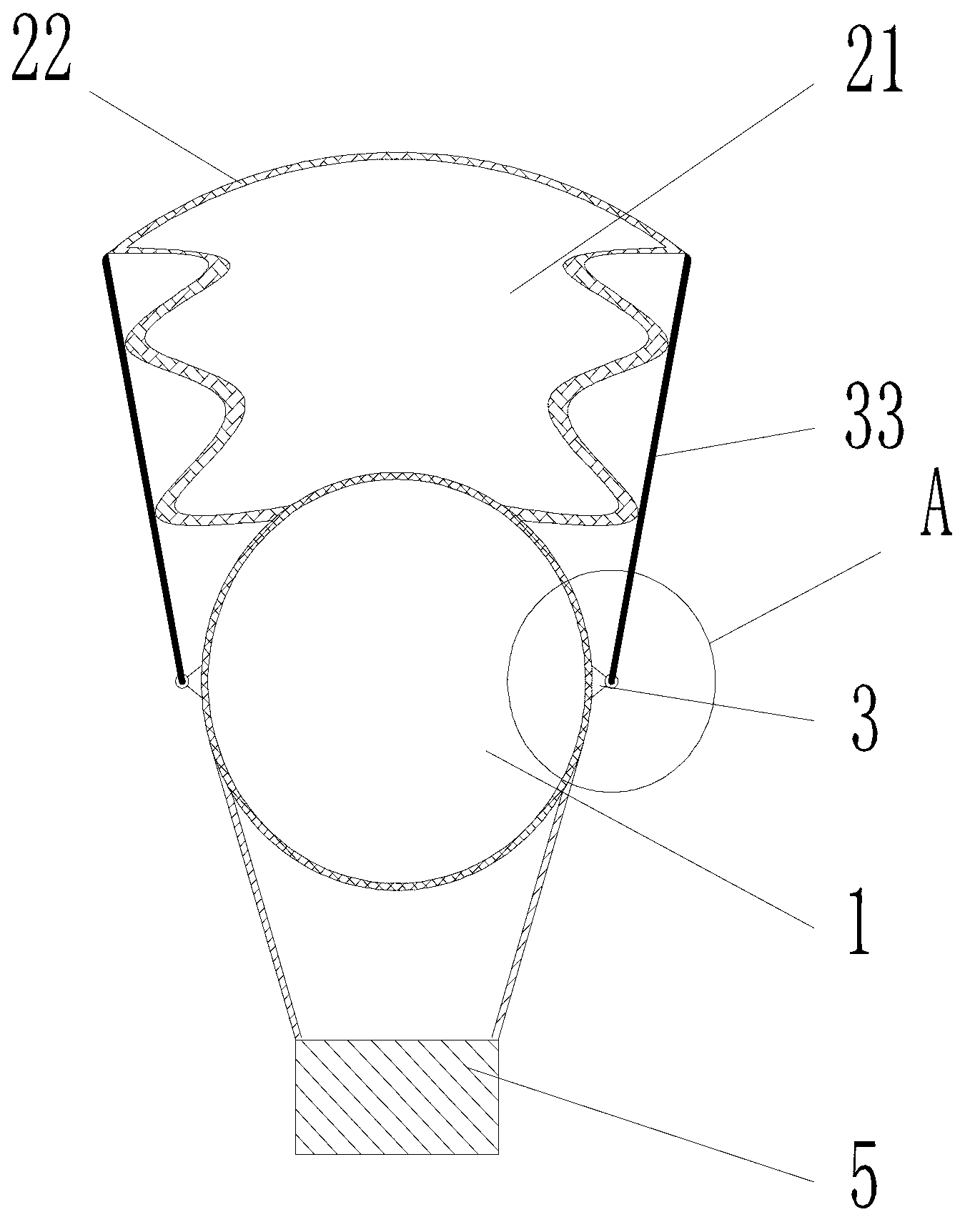

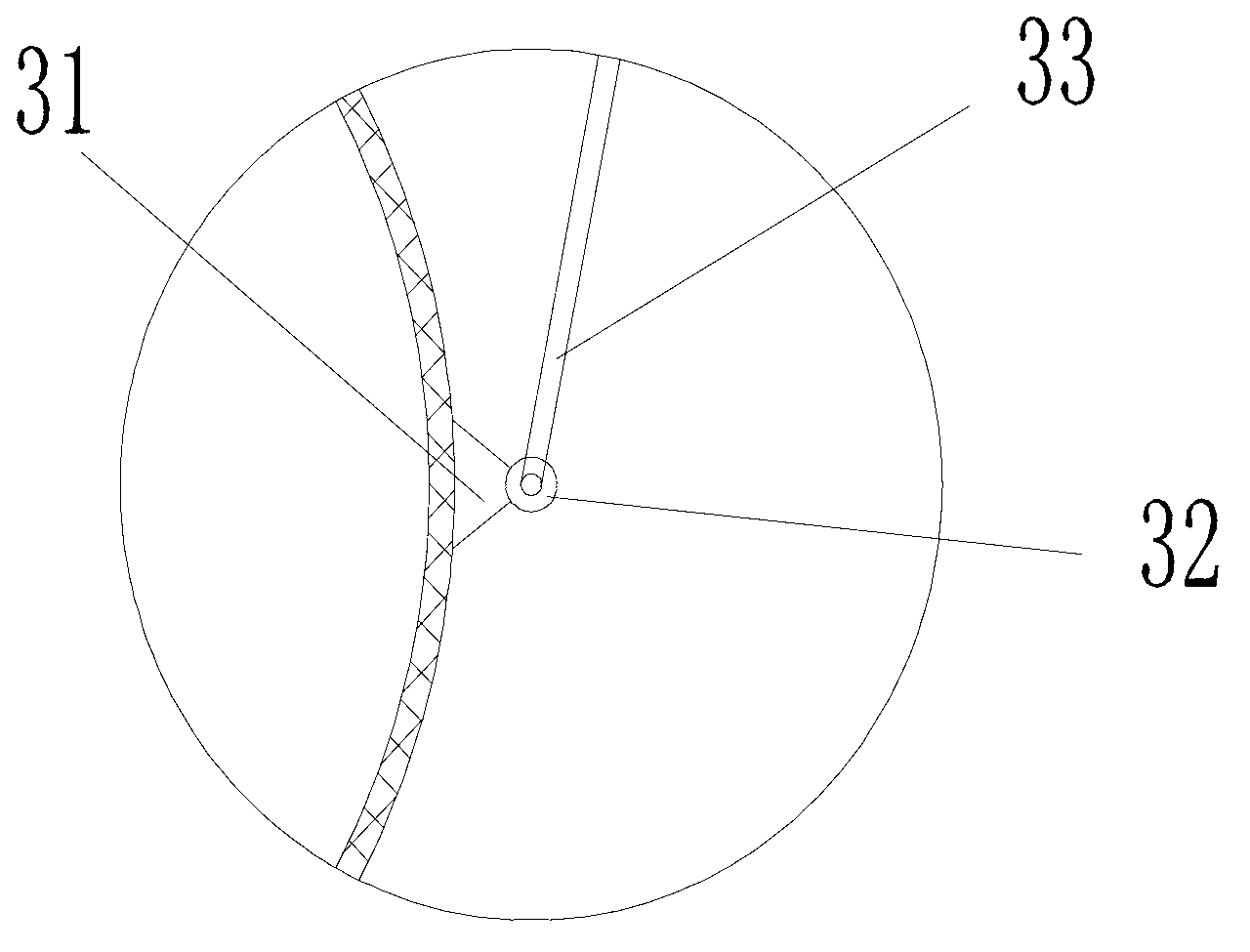

Soft and hard hybrid airship and control method thereof

The invention relates to a soft and hard hybrid airship and a control method thereof. An external capsule is arranged on a hard airship body, an external airbag of the external capsule is communicated with an internal airbag of the hard airship body through a controllable communicating valve; a connecting component capable of folding and unfolding the volume of the external capsule is arranged between the outer side of the external capsule and the hard airship body; when the soft and hard hybrid airship is in use, gas in the internal airbag enters the external airbag through opening the controllable communicating valve, so that the emptying volume of the airship is increased, and enough lifting force is ensured; and through compressing gas in the airship and compressing the gas in the internal gas by using the connecting component, the airship begins to descend as the volume of the airship is reduced. The soft and hard hybrid airship and the control method thereof have the benefits that through additionally hanging the external capsule, the remarkable rise of inside and outside pressure difference of the hard airship body is effectively avoided, so that the safety of the airship is ensured; and through increasing the volume of the external capsule, the air buoyancy is kept, so that the defect that the internal airbag releases helium outwards is overcome.

Owner:北京新誉防务技术研究院有限公司 +1

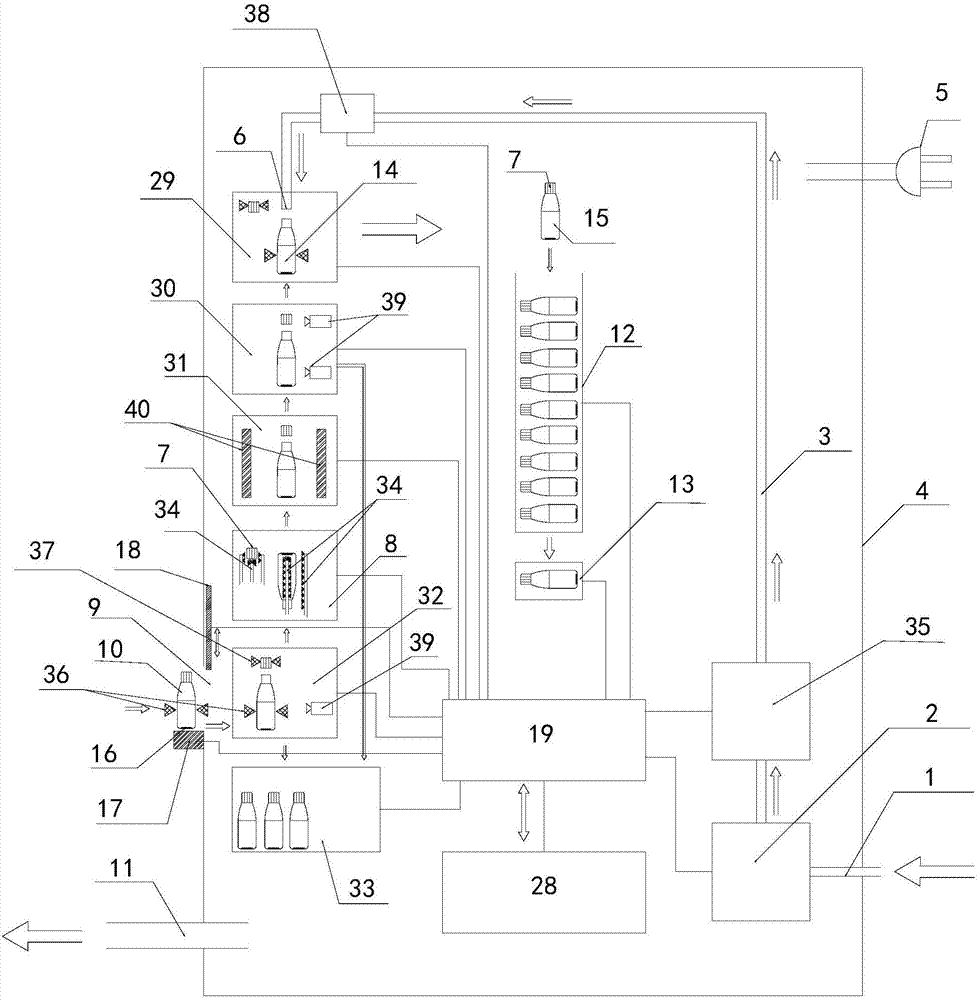

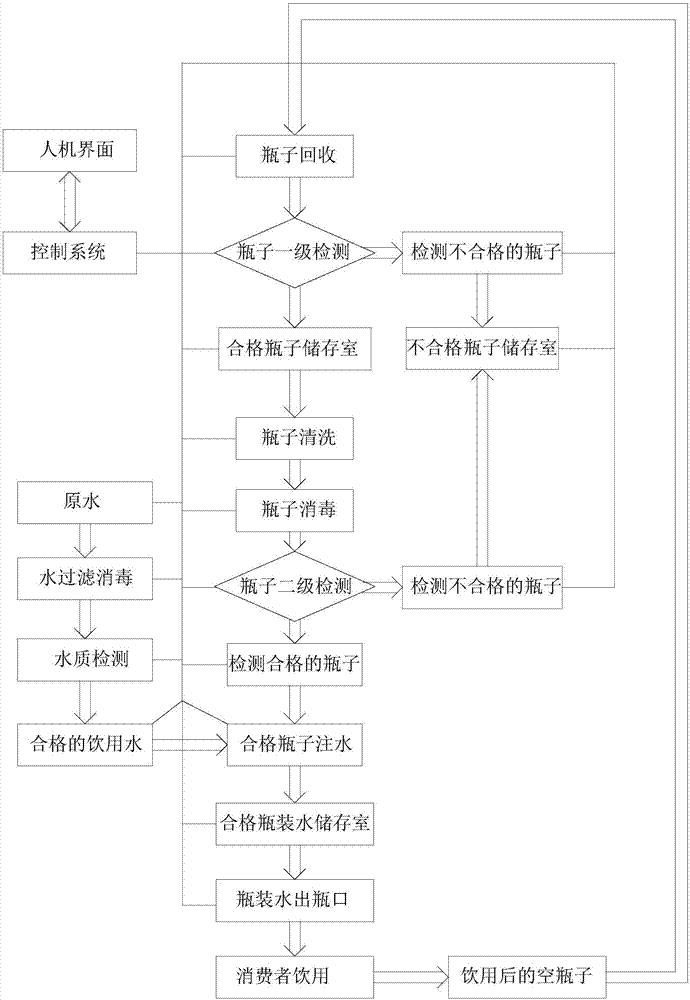

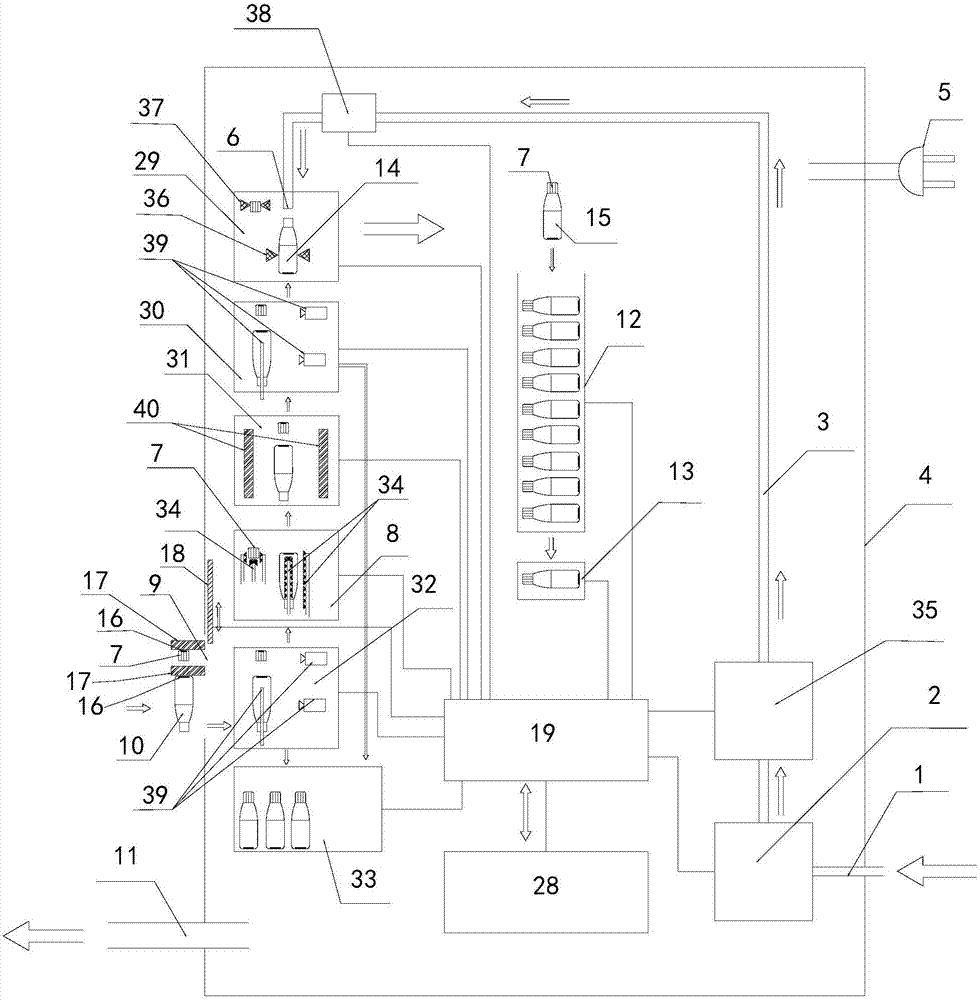

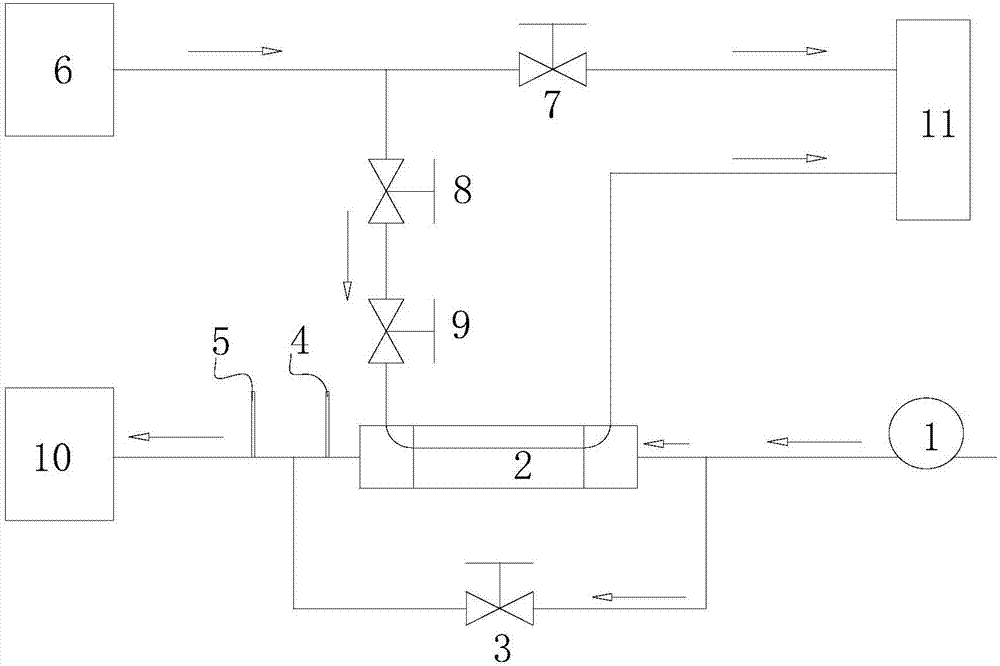

Water dispenser

PendingCN107324263AReduce drinking water costsAvoid wastingBottle-handling machinesLiquid bottlingWater sourceBottled water

The invention relates to a water dispenser. The water dispenser comprises a power supply device, a water supply system, fluid containers and a container recovery processing system, wherein the fluid containers can be used cyclically; the water supply system comprises a water inlet connected with a water source, a filling device for injecting water into the containers, a water purifying pipe for communicating with the water inlet and the filling device, a container storing chamber for storing the containers and a container outlet for outputting the containers; the container recovery processing system comprises a recovery port for recycling used containers and a washing disinfecting device; and the washing disinfecting device comprises a washing device for washing the used containers and a disinfecting device for disinfecting the containers washed by the washing device. The water dispenser can eliminate energy consumption and pollution caused by transporting of bottled water; and the containers self-provided by the water dispenser can be repeatedly put into use, so that recycling utilization is achieved, and the cost is lowered greatly while the environment is protected.

Owner:SHENZHEN SAILING ELECTRONICS FACTORY

Steam generator feed-water temperature control simulation system

ActiveCN107145175AFully warmed upImprove energy utilizationAuxillary controllers with auxillary heating devicesEngineeringControl valves

The present invention discloses a steam generator feed-water temperature control simulation system. A main feed-water pipe, arranged between a main feed pump and the secondary side inlet of a steam generator, passes through a heat regenerator, the secondary side outlet of the steam generator is connected with two parallel branch pipelines, one of the two parallel branch pipelines passes through the steam flow control valve of a main steam pipeline and is connected to a condenser, and the other one of the parallel branch pipelines passes through a steam by-pass stop valve, a steam by-pass flow control valve and the heat regenerator in order and then is connected with the condenser. According to the invention, high-temperature steam generated by the steam generator is employed as a heating source to perform preheating of feed water entering the steam generator to eliminate energy consumption caused by preheating depending on an extra power supply and improve the energy utilization rate of a test device, and high-temperature steam preheating output by the steam generator itself is employed to realize feeding water temperature control in a large flow variation range. The mode of combination of steam by-pass adjustment and feed-water by-pass adjustment is employed to rapidly, effectively and accurately realize adjustment of the feed-water temperature of the steam generator.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

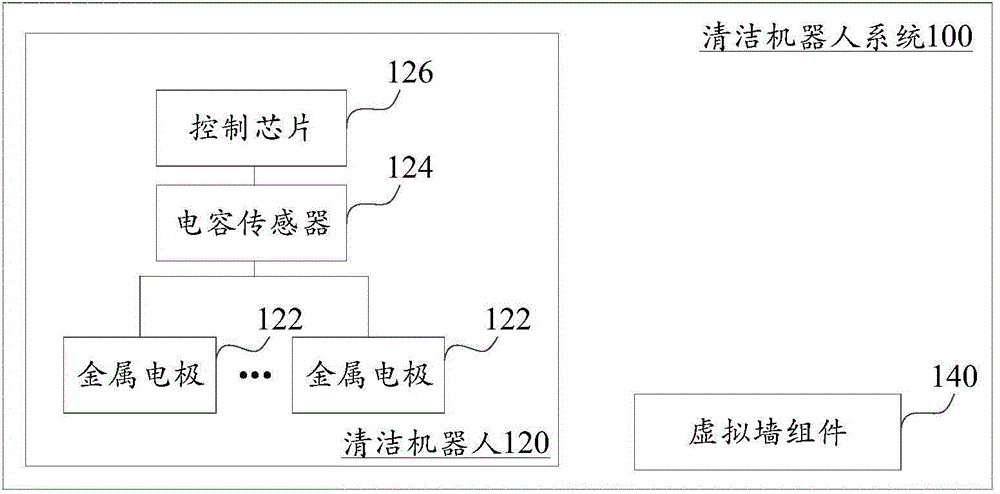

Cleaning robot system and virtual wall detection method

The invention discloses a cleaning robot system and a virtual wall detection method, and belongs to the field of cleaning machines. The cleaning robot system comprises a cleaning robot and a virtual wall assembly. The cleaning robot comprises at least one metal electrode, a capacitive sensor and a control chip. The metal electrode is arranged on a bottom plate of the cleaning robot. The metal electrode and the capacitive sensor are electrically connected. The capacitive sensor and the control chip are electrically connected. The virtual wall assembly is a belt-shaped object containing metal. The virtual wall assembly is used for being attaching to the plane where the cleaning robot advances. The problems that a virtual wall achieved in an infrared mode consumes energy and is high in cost are solved; the functions of the virtual wall are achieved through the belt-shaped object containing metal, and the effects of eliminating energy consumption of the virtual wall assembly and reducing the cost of the virtual wall ssembly are achieved.

Owner:XIAOMI INC +1

Method for improving volume of production of corn straw biogas with sodium hydroxide wet-type solid state treatment at normal temperature

InactiveCN101368190AEliminate energy consumptionSimple handling of equipmentWaste based fuelFermentationDry weightPre treatment

The invention relates to a method for improving the yield of corn stalk biogas through sodium hydroxide wet type solid normal temperature treatment, which belongs to the field of biomass energy. The liquid chemical pretreatment and the solid chemical pretreatment of corn stalks have the problems of higher use amount of NaOH, high cost and the like. The method is that sodium hydroxide with the amount of 2 percent of the dry weight of the corn stalks, water with the amount of 7.5 times of the weight of the corn stalks and crashed corn stalks are fully mixed evenly, are sealed for preservation for 3 days after reaching the water saturation state, then are discharged and added with pig manure digestive liquid to undergo the anaerobic digestion and produce biogas. The invention has the advantages that the cost is saved, the pretreatment time is reduced, the gas yield is improved and the like.

Owner:赤峰元易生物质科技有限责任公司

Method of coating battery electrode plates

InactiveCN109411696AEffective embeddingImprove adhesionElectrode collector coatingManufacture by sprayingConductive pasteEngineering

The invention discloses a method of coating battery electrode plates, belongs to the technical field of battery electrode processing, and solves the problems that a homogenizing process in existing battery electrode plate coating is complex and electrode plates have poor performance. The method herein includes the steps of A, selecting a current collector, and applying conductive paste to the surface of the selected current collector to form a conductive glue coating layer on the surface of the current collector; B, spraying positive activated material powder or negative activated material powder to the surface of the conductive glue coating layer; C, drying the sprayed plate, and rolling to obtain the corresponding battery electrode plate. The method herein has the advantages of simplified process and good plate performance.

Owner:台州钱江新能源研究院有限公司

Energy Consuming Body and A Method for Supplying Dynamic Force Energy to the Energy Consuming Body

InactiveUS20080272734A1Cumbersome and laborious air-refilling process could be eliminatedReduce resistanceBatteries circuit arrangementsWith separate inflatable insertsTransport systemEnergy exchange

The present invention discloses a type of secure and efficient wheel assembly using fluid or solid stuffing materials so as to minimize the blowout risks, a wheel rim transmission assembly, an energy exchanging arrangement used in transporting system, and a vehicle energy storage system, as well as corresponding methods for manufacturing and preparing such assemblies and arrangements in applications.

Owner:WUHAN RUNLIN SCI & TECH DEVMENT

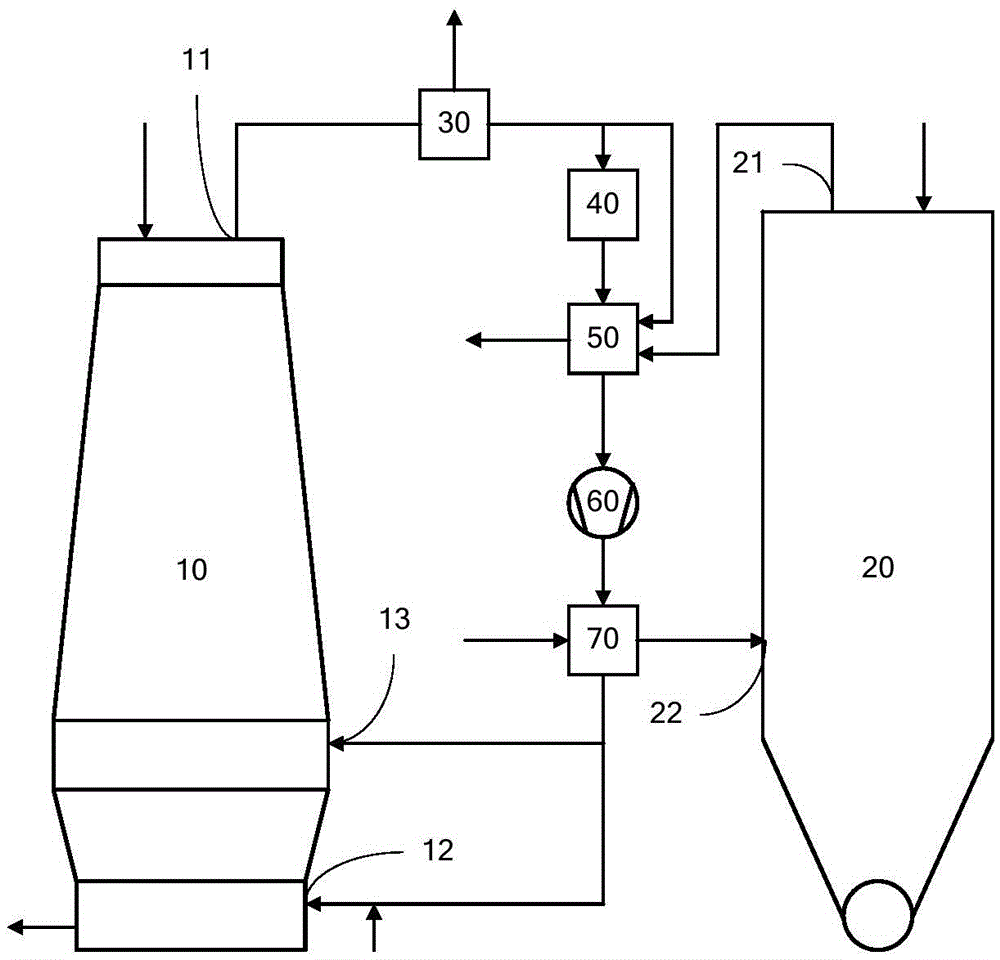

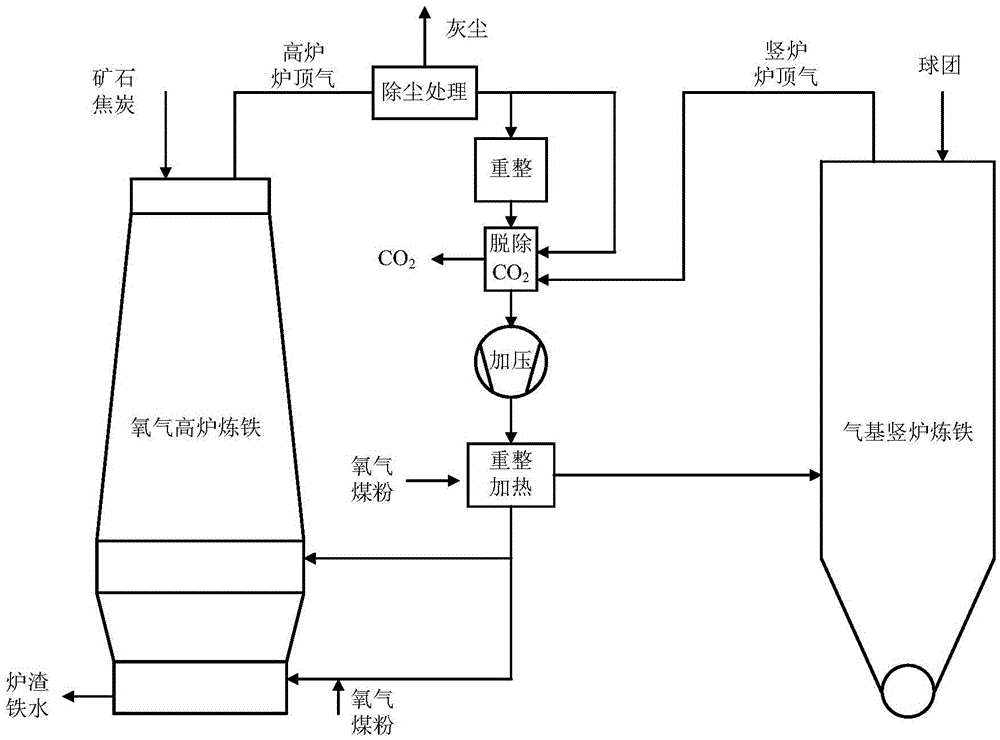

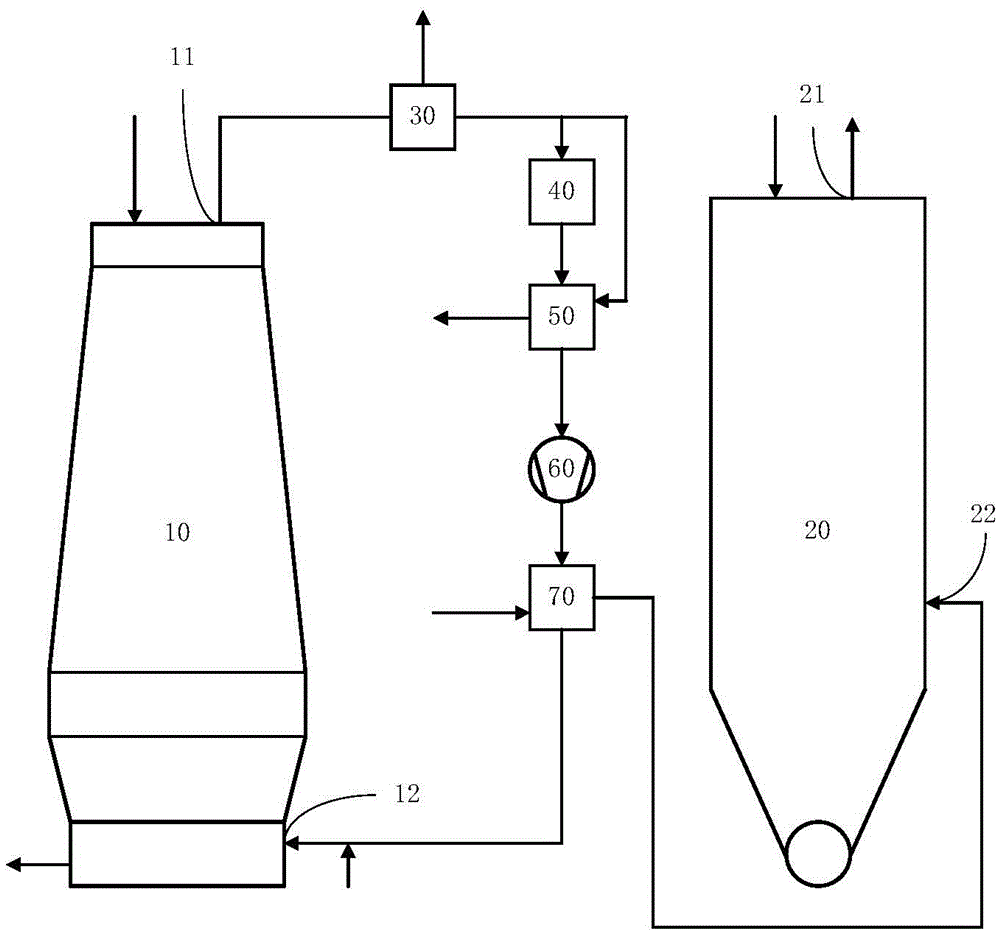

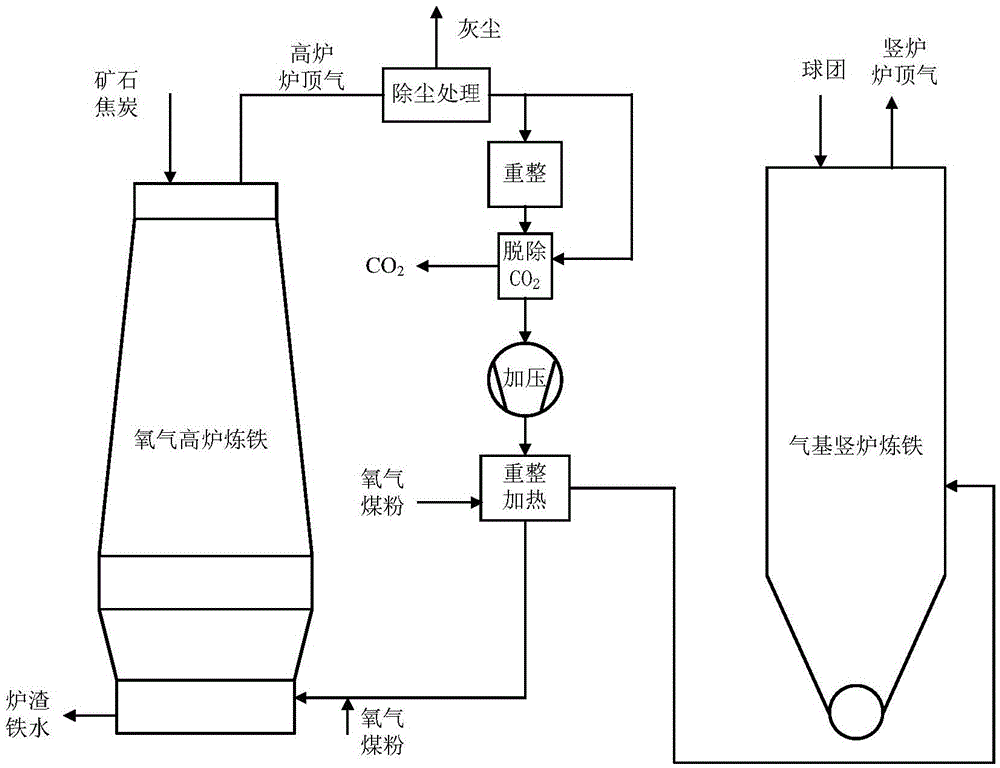

Joint production system and joint production method of oxygen blast furnace and gas-based shaft kiln

InactiveCN105586455ASolve the problem of insufficient air circulationEliminate energy consumptionBlast furnace detailsIncreasing energy efficiencyShaft furnaceOxygen

The invention discloses a joint production system and a joint production method of an oxygen blast furnace and a gas-based shaft kiln, wherein the joint production system of the oxygen blast furnace and the gas-based shaft kiln comprises the oxygen blast furnace, the gas-based shaft kiln, a dust removal device, a water-gas shift device, a carbon dioxide removal device, a pressurizer, and a gasification furnace; the dust removal device is connected to a blast furnace furnace-top gas outlet of the oxygen blast furnace; the water-gas shift device is connected to the dust removal device; the gas inlet of the carbon dioxide removal device is separately connected to the dust removal device, the water-gas shift device and the shaft kiln kiln-top gas outlet of the gas-based shaft kiln; the pressurizer is connected to the carbon dioxide removal device; and the gas inlet of the gasification furnace is connected to the pressurizer. The system can be used for effectively solving the problem that the oxygen blast furnace furnace-top gas circulation amount is insufficient, and also provides a sufficient gas source for the gas-based shaft kiln.

Owner:SHENWU TECH GRP CO LTD

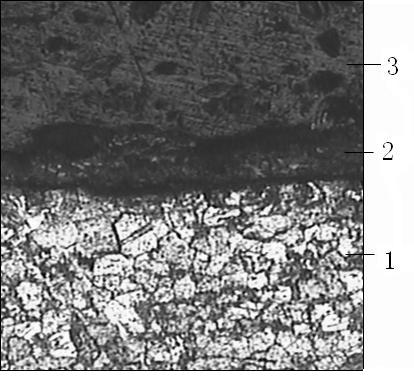

Sandblast-free corrosion-proof composite coating for thermal spraying and preparation process thereof

InactiveCN102408817AEliminate energy consumptionEliminate pollutionMolten spray coatingAnti-corrosive paintsEpoxyPhosphoric acid

The invention relates to a sandblast-free corrosion-proof composite coating for thermal spraying in the technical field of metal corrosion protection, comprising a rusty primer and a sandblast-free roughened layer, wherein rusty primer is obtained by mixing and applying the following materials: a rusty primer component A: a modified epoxy resin, a medium oil semidry alkyd resin, a highly iminatedbutyl-etherified melamine resin having the degree of etherification of 4, a solvent and a rusty primer component B; and the sandblast-free roughened layer is composed of a sandblast-free roughened layer component A: ferrophosphorus powder, aluminum trippolyhosphate, mica powder, an epoxy resin, propylene glycol methyl ether acetate, dimethylbenzene, a sandblast-free roughened layer component B and stuffing. The preparation process of the sandblast-free corrosion-proof composite coating for thermal spraying comprises applying the rusty primer to a corroded steel surface, and spraying the sandblast-free roughened layer to the rusty primer at the normal temperature in 24 h. Therefore, the problems of high energy consumption and pollution of sandblasting are eliminated; the steps of construction are simplified; the difficulty and cost of construction are reduced; the corrosion protection effect is guaranteed; the environmental pollution is reduced; and the application range of the composite coating is wider.

Owner:SHANDONG UNIV OF SCI & TECH

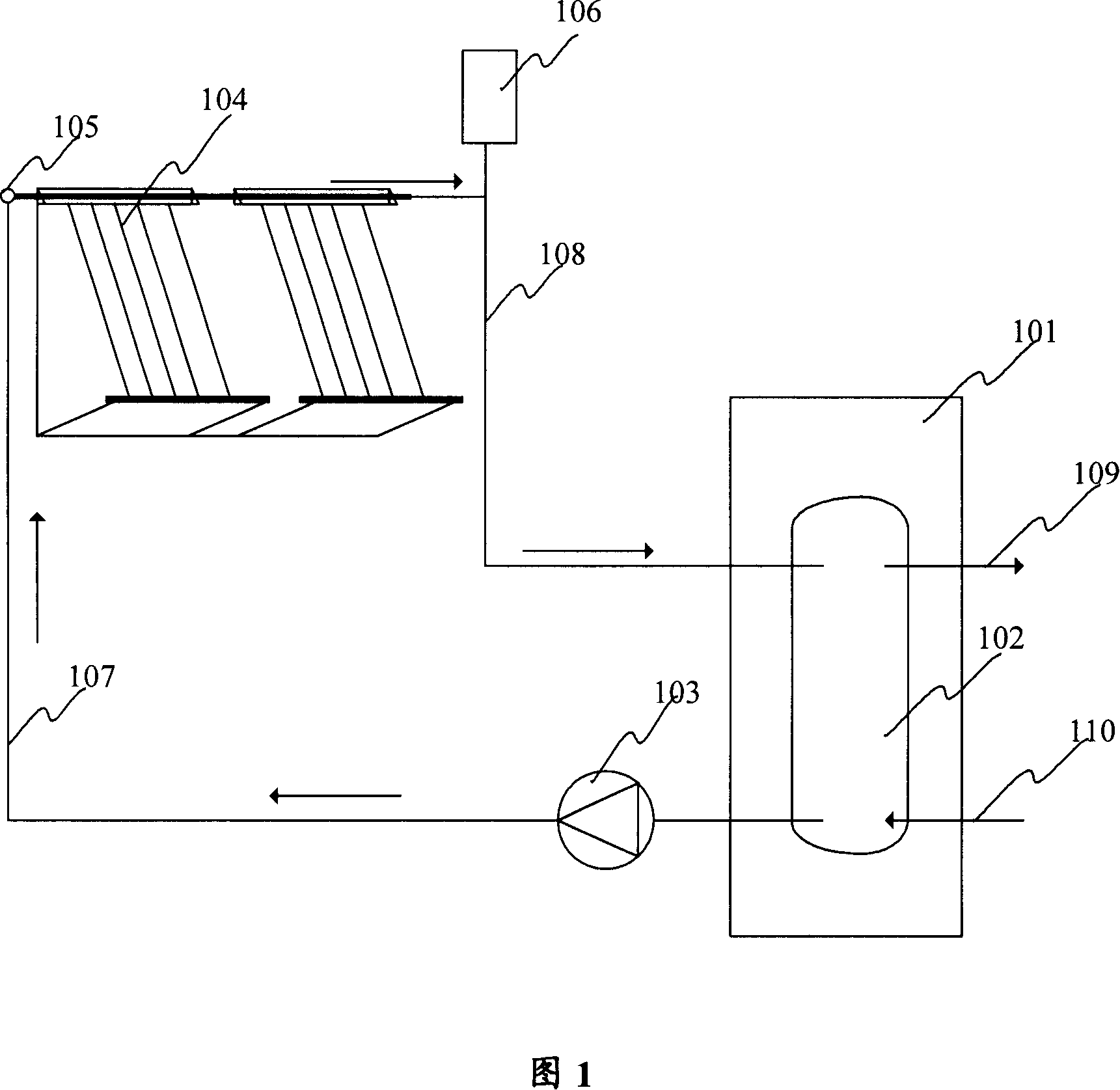

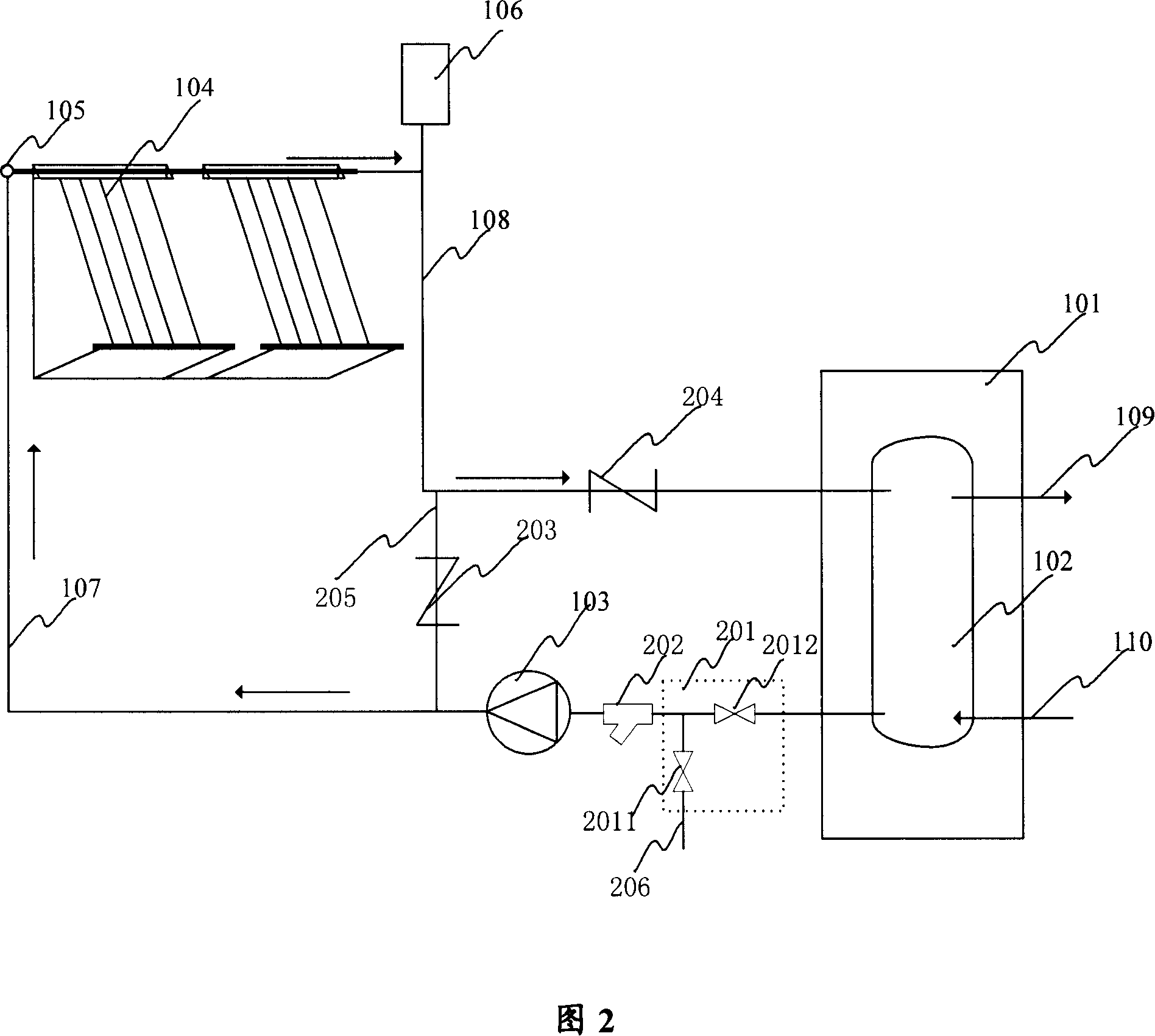

Solar energy water heater

InactiveCN101082453ARealize automatic emptyingTo achieve anti-freeze blockageSolar heat devicesSolar thermal energy generationElectricityCollector device

This invention discloses a sort of the soar water heater. It consists of the water tank, the heat collector. The infrastructure of the water bank connects with the water inlet of the heat collector by the outlet pipe, the outlet port of the heat collector connects with the superstructure of the water tank by the return line, and it is fitted a water pump in the outlet pipe in this invention, the position of the heat collector in this invention is hyper-water tank in this invention, the lower position of the water pipe in this invention connects with the downcomer that the exit locates adown by the three-port valve. This three-way valve consists of two valve, the first valve connects with the downcomer pipeline, the second valve connects with the outlet pipeline witch is between the downcomer and the water tank. When the three-port valve is electrified, the first valve closes and the second valve conducts. When the three-port valve is loss the current, the first valve conducts and the second valve closes. The soar water heater can remove the problem that it consumes the energy to prevent frostbite and stifled used the existing technique and it can obtain the effect in preventing frostbite and stifled in the estate of no electricity all the same.

Owner:HAIER GRP CORP +1

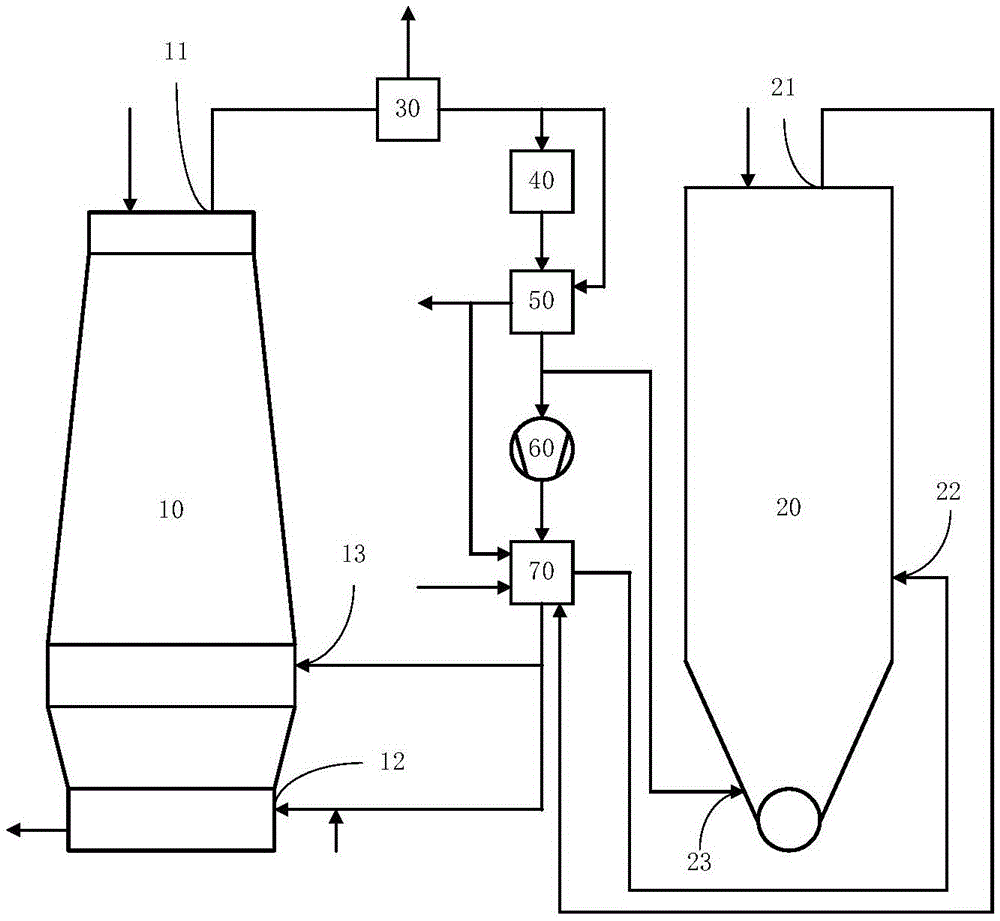

Joint production system and joint production method of oxygen blast furnace and gas-based shaft kiln

PendingCN105586456ASolve the problem of insufficient air circulationEliminate energy consumptionBlast furnace detailsIncreasing energy efficiencyOxygenShaft furnace

The invention discloses a joint production system and a joint production method of an oxygen blast furnace and a gas-based shaft kiln, wherein the joint production system of the oxygen blast furnace and the gas-based shaft kiln comprises the oxygen blast furnace, the gas-based shaft kiln, a dust removal device, a water-gas shift device, a carbon dioxide removal device, a pressurizer, and a gasification furnace; the dust removal device is connected to a blast furnace furnace-top gas outlet of the oxygen blast furnace; the water-gas shift device is connected to the dust removal device; the gas inlet of the carbon dioxide removal device is separately connected to the dust removal device and the water-gas shift device; the pressurizer is connected to the carbon dioxide removal device; the gas inlet of the gasification furnace is connected to the pressurizer; and the gas outlet of the gasification furnace is connected to a lower air inlet of the oxygen blast furnace and a reducing gas inlet of the gas-shaped shaft kiln. The system can be used for effectively solving the problem that the oxygen blast furnace furnace-top gas circulation amount is insufficient, and also provides a sufficient gas source for the gas-based shaft kiln.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com