Method for separating paper plastic-aluminum composite packing waste

A separation method and aluminum composite technology, which is applied to the separation agent of paper-plastic-aluminum composite packaging waste and the separation field of paper-plastic-aluminum composite packaging waste, can solve the problems of high construction and operation costs, low utilization value, and difficulty in plastic materials, etc. problems, to achieve the effect of promoting recycling, increasing the value of recycling and recycling, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

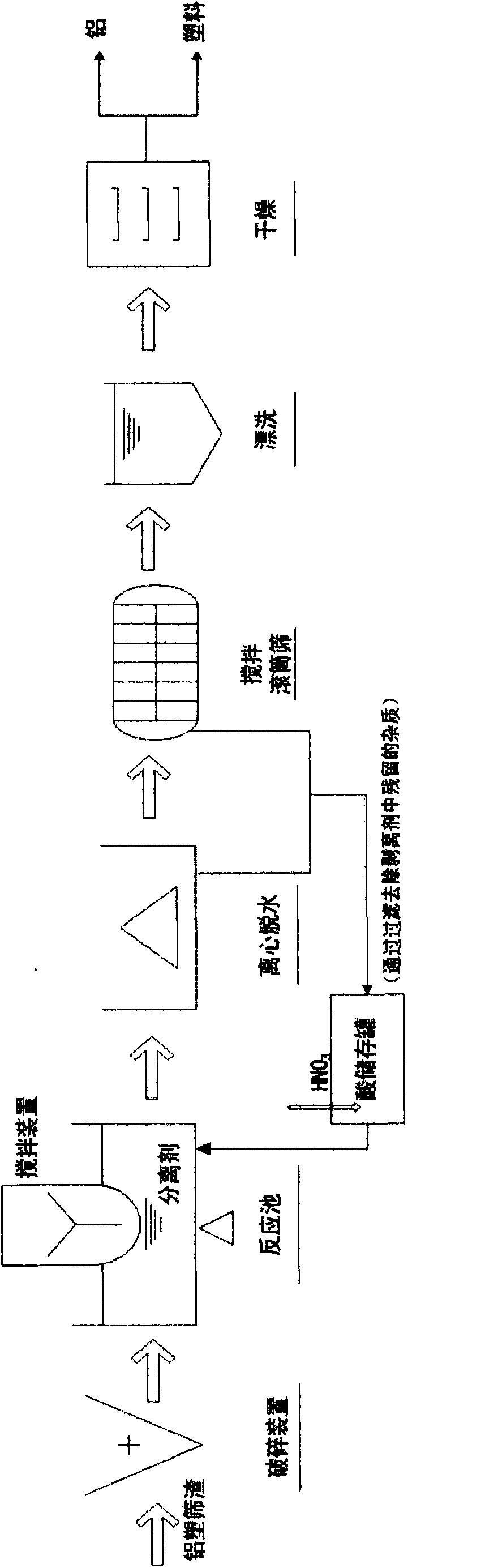

[0050] 1) Crushing treatment - the aluminum-plastic screen slag is mechanically crushed through a crushing device. Use a crusher with a screen aperture of 10cm to reduce the particle size of the waste, make the waste texture uniform, and facilitate subsequent treatment and disposal; this can increase the specific surface area of the material in the subsequent soaking and peeling reaction, making the waste The contact area between it and the separating agent increases, which makes it easier to peel off the materials of each layer; at the same time, it is convenient for feeding and discharging, and prevents the pipeline from being blocked.

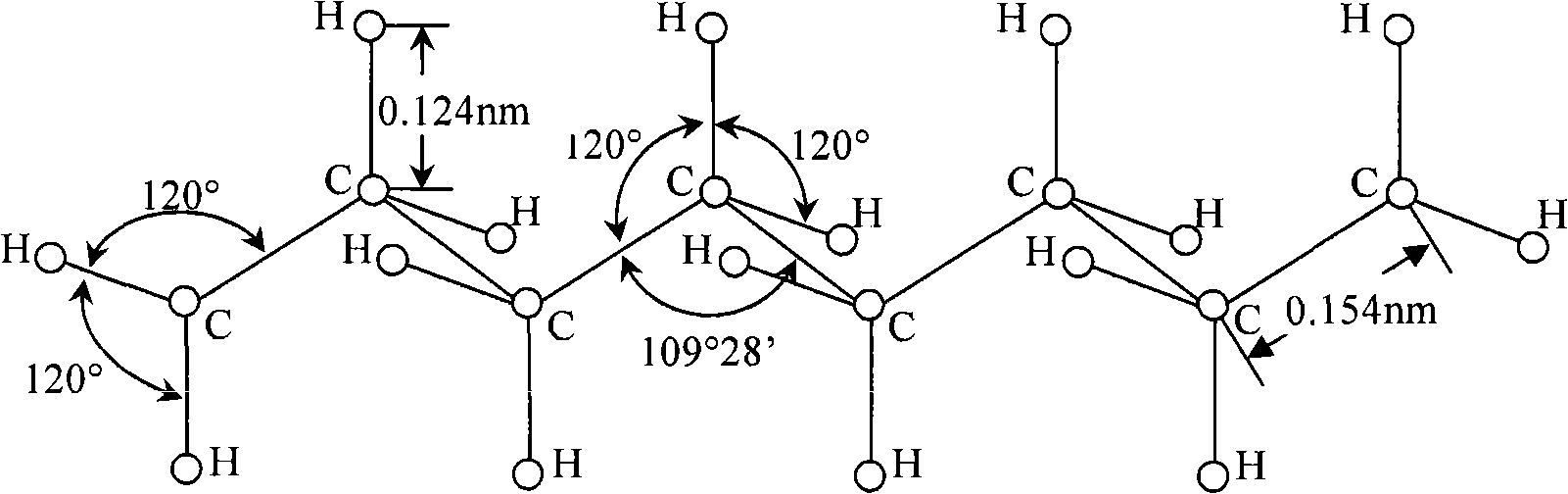

[0051] 2) Preparation of separation agent - prepare a formic acid solution with a concentration of 3-5mol / L as a separation agent, and maintain the temperature at 40-60°C.

[0052] 3) Soaking and peeling reaction - put the crushed aluminum-plastic sieves in the reaction tank and soak them in the separating agent, preferably with a liquid-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com