Patents

Literature

258 results about "Laser trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

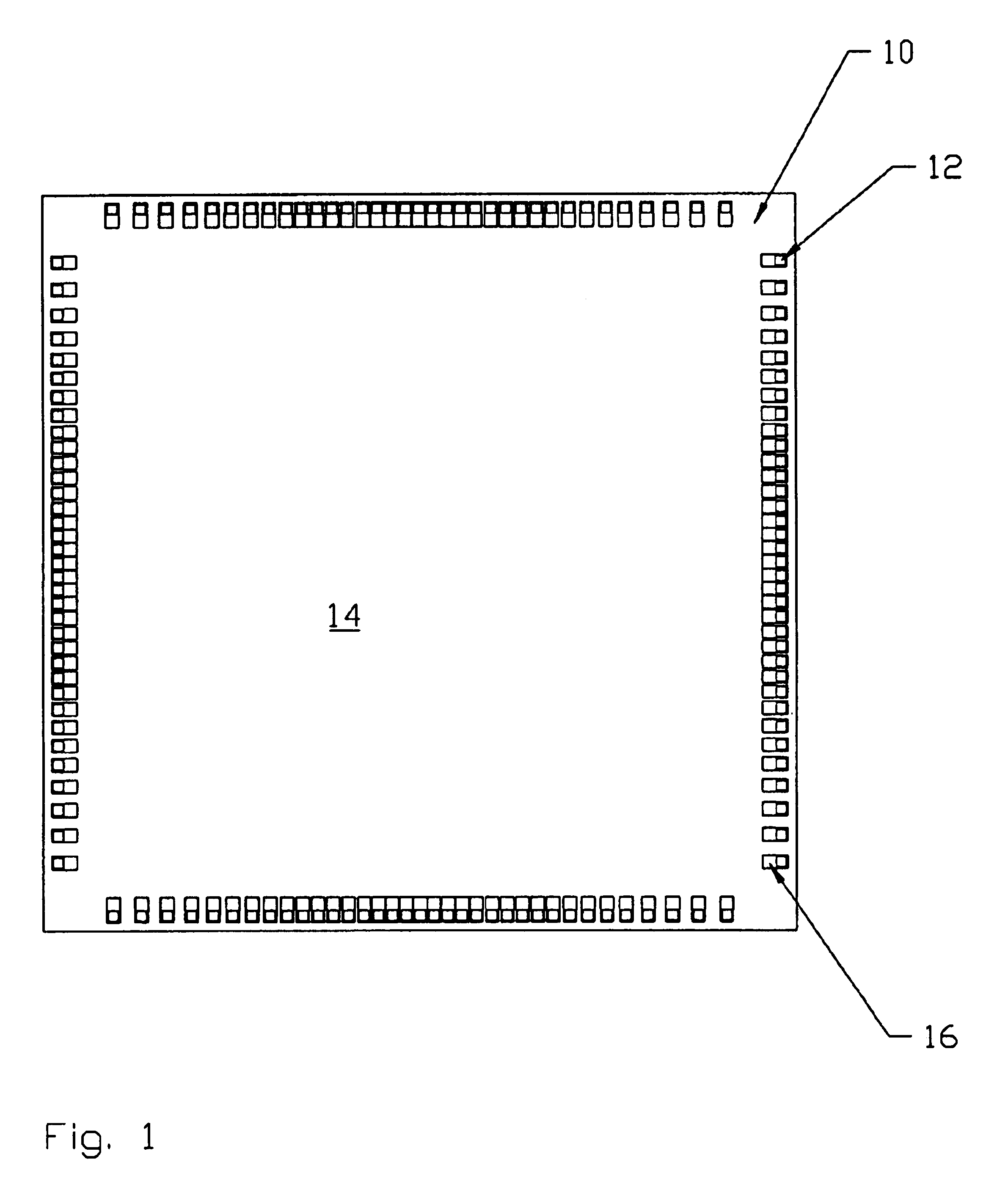

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

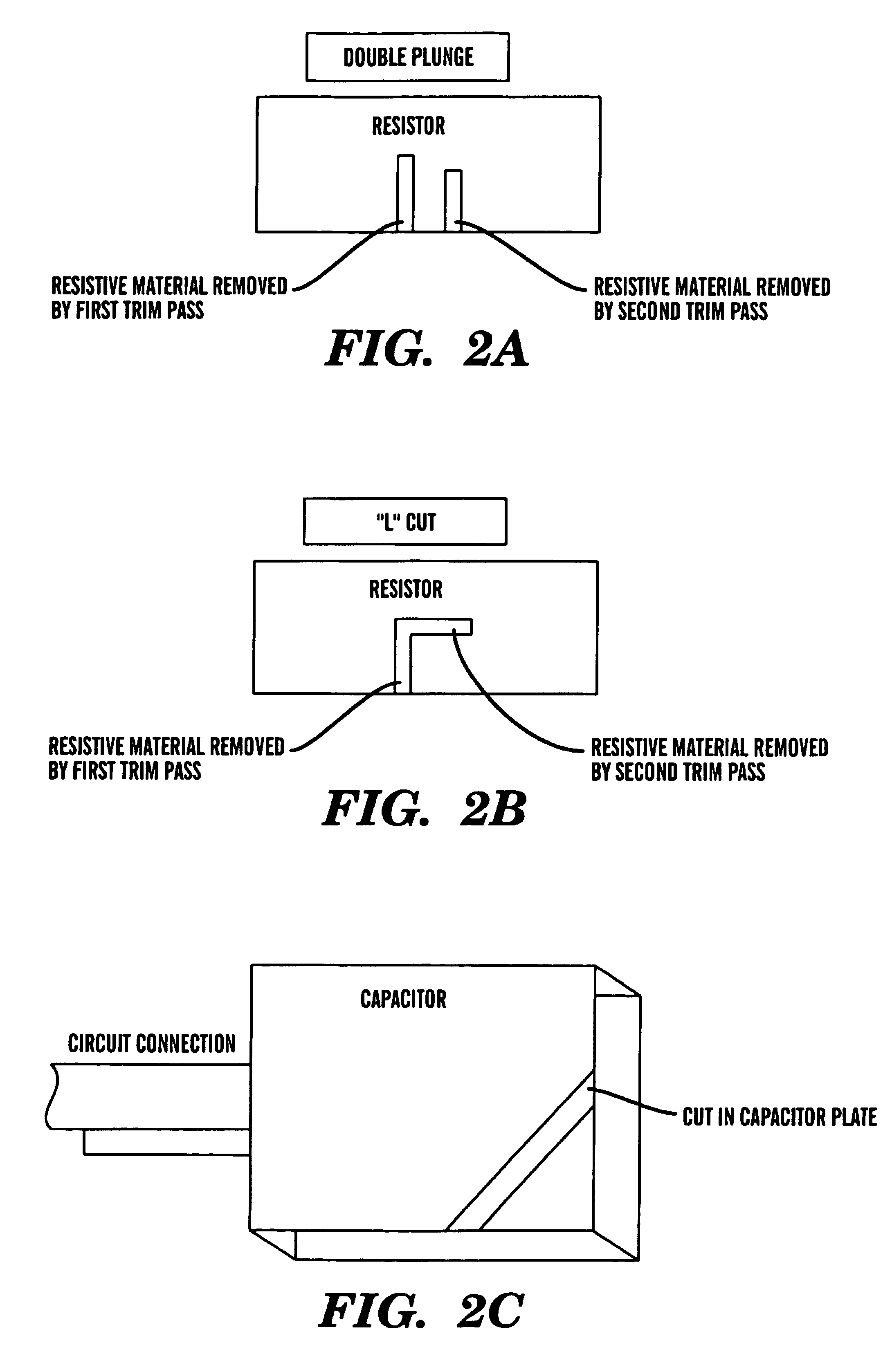

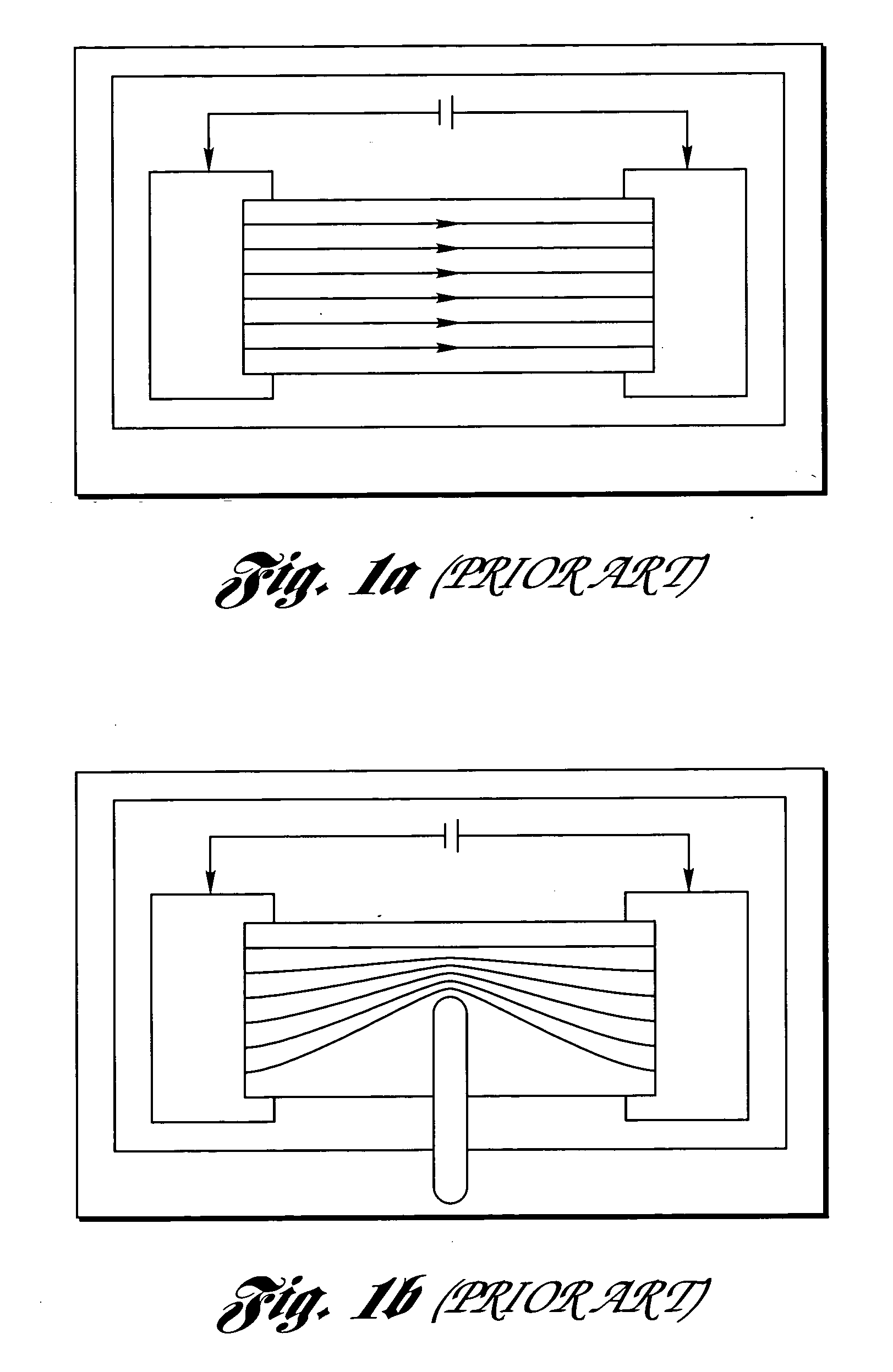

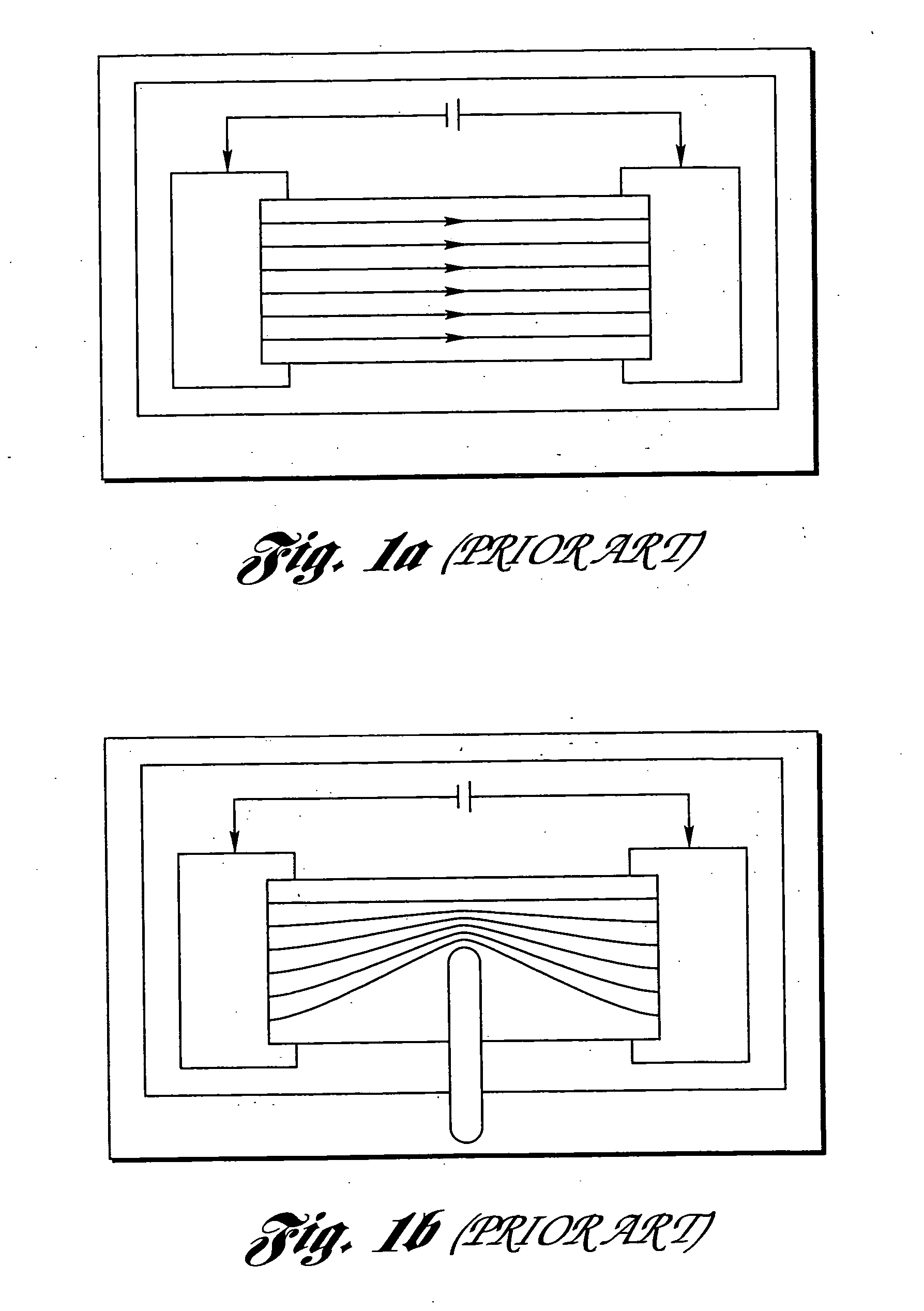

Laser trimming is the manufacturing process of using a laser to adjust the operating parameters of an electronic circuit. One of the most common applications uses a laser to burn away small portions of resistors, raising their resistance value. The burning operation can be conducted while the circuit is being tested by automatic test equipment, leading to optimum final values for the resistor(s) in the circuit.

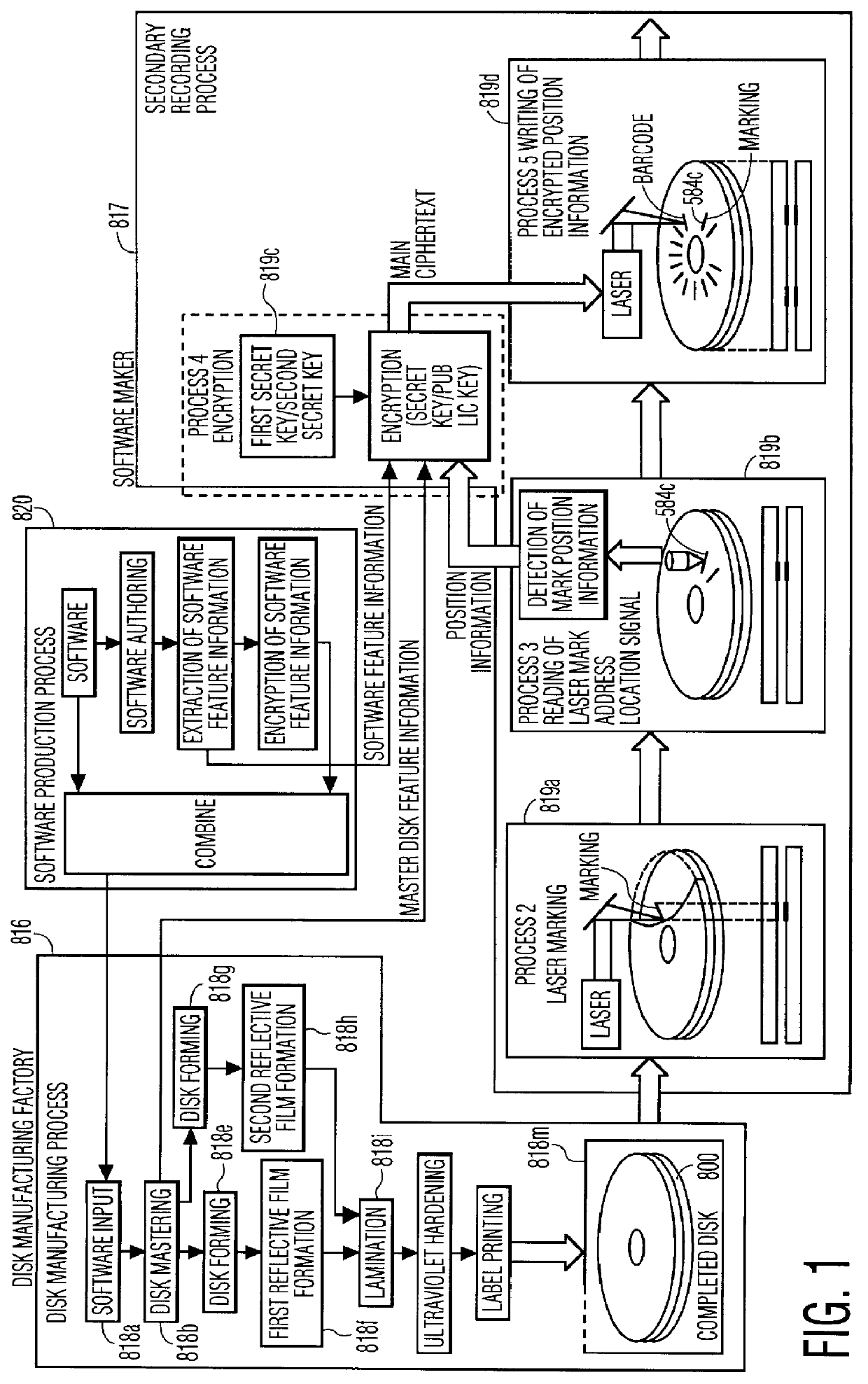

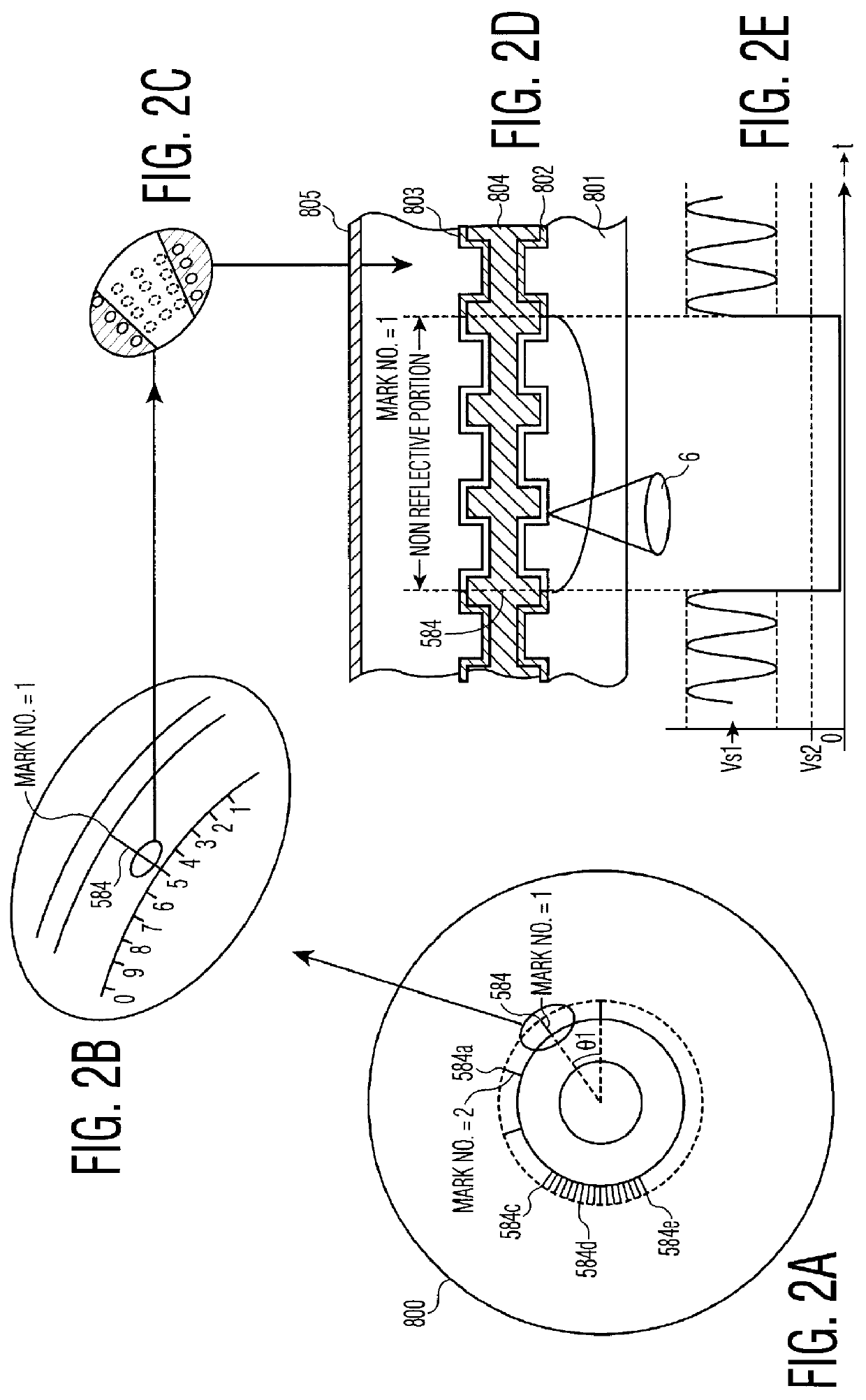

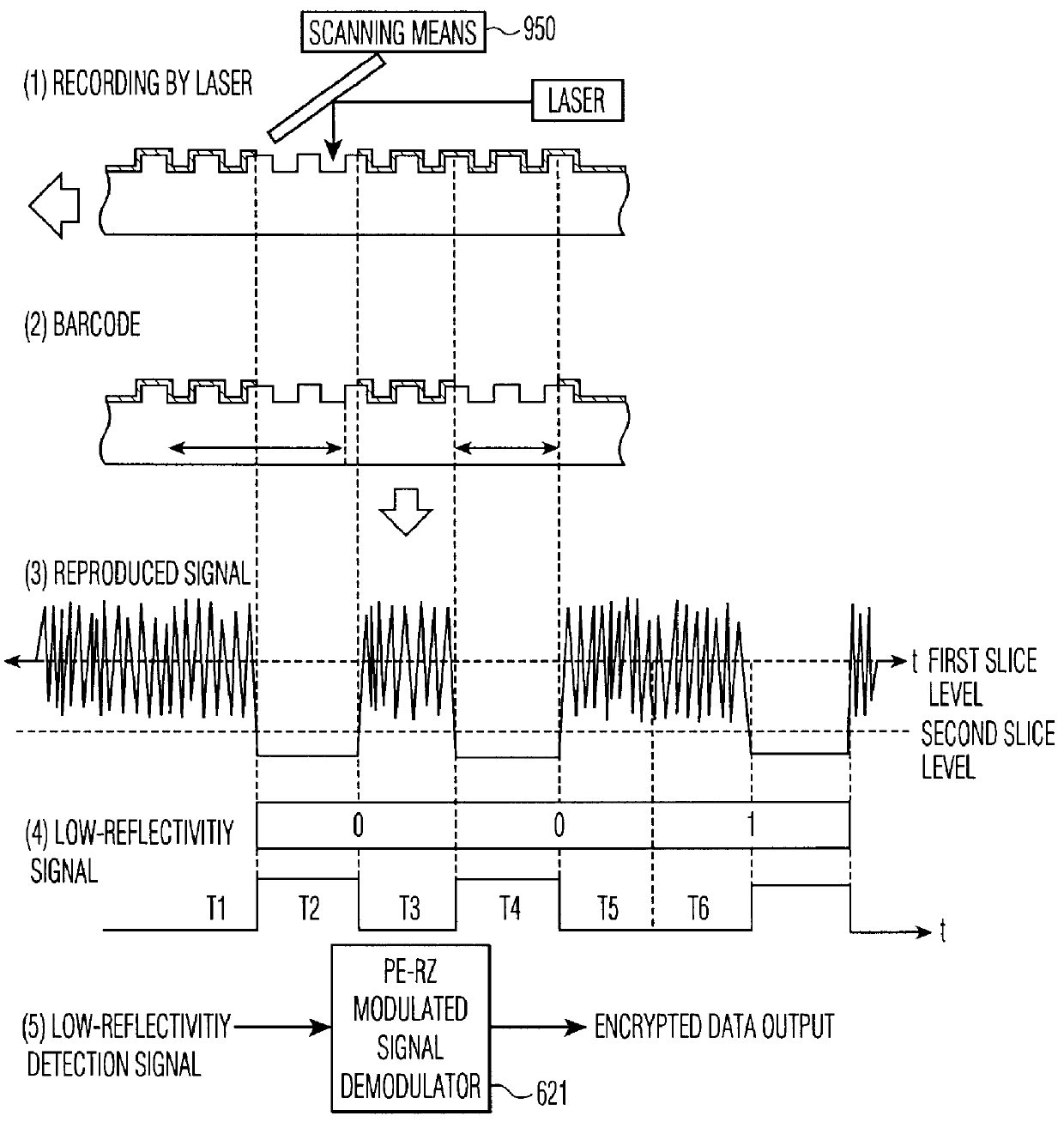

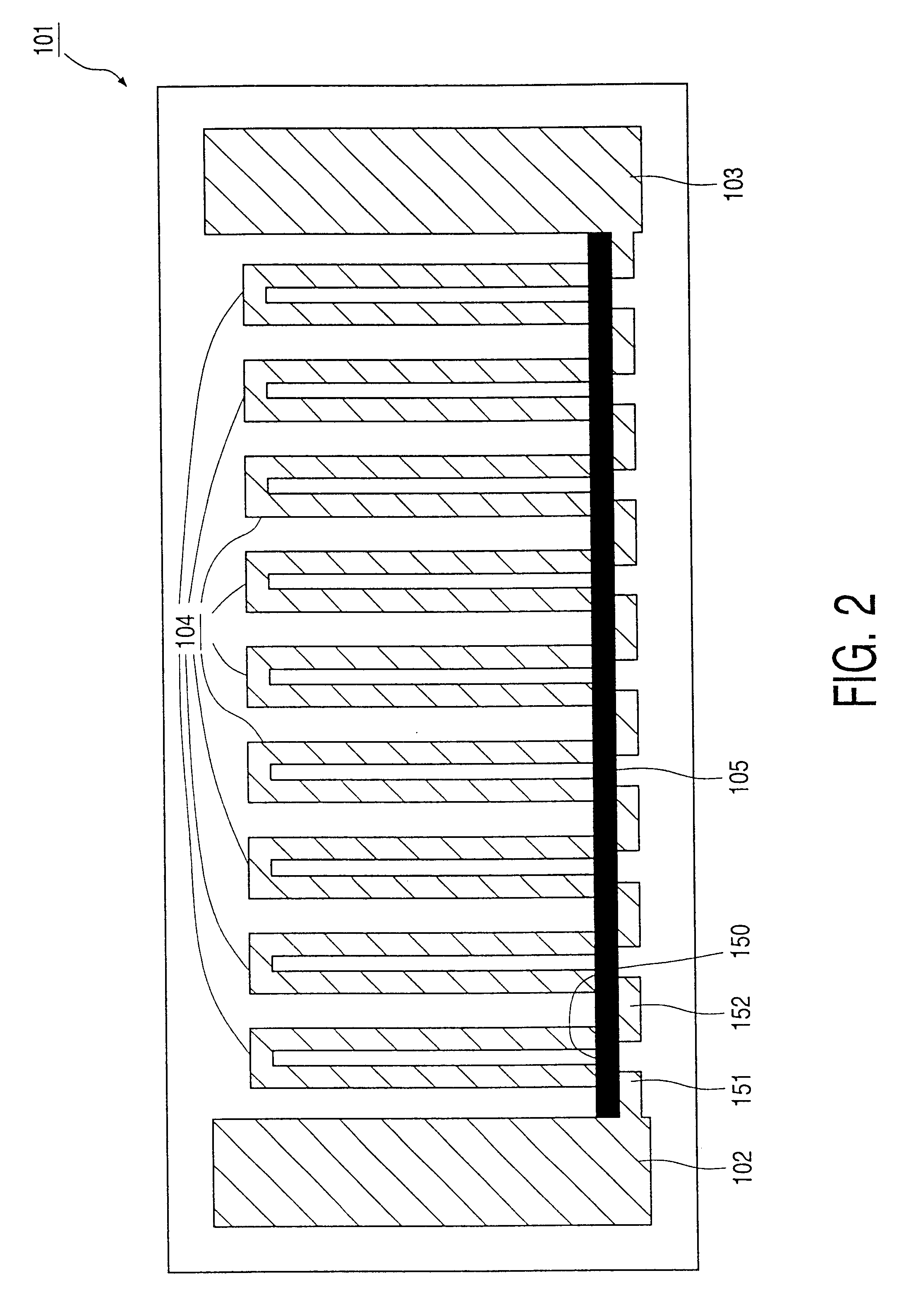

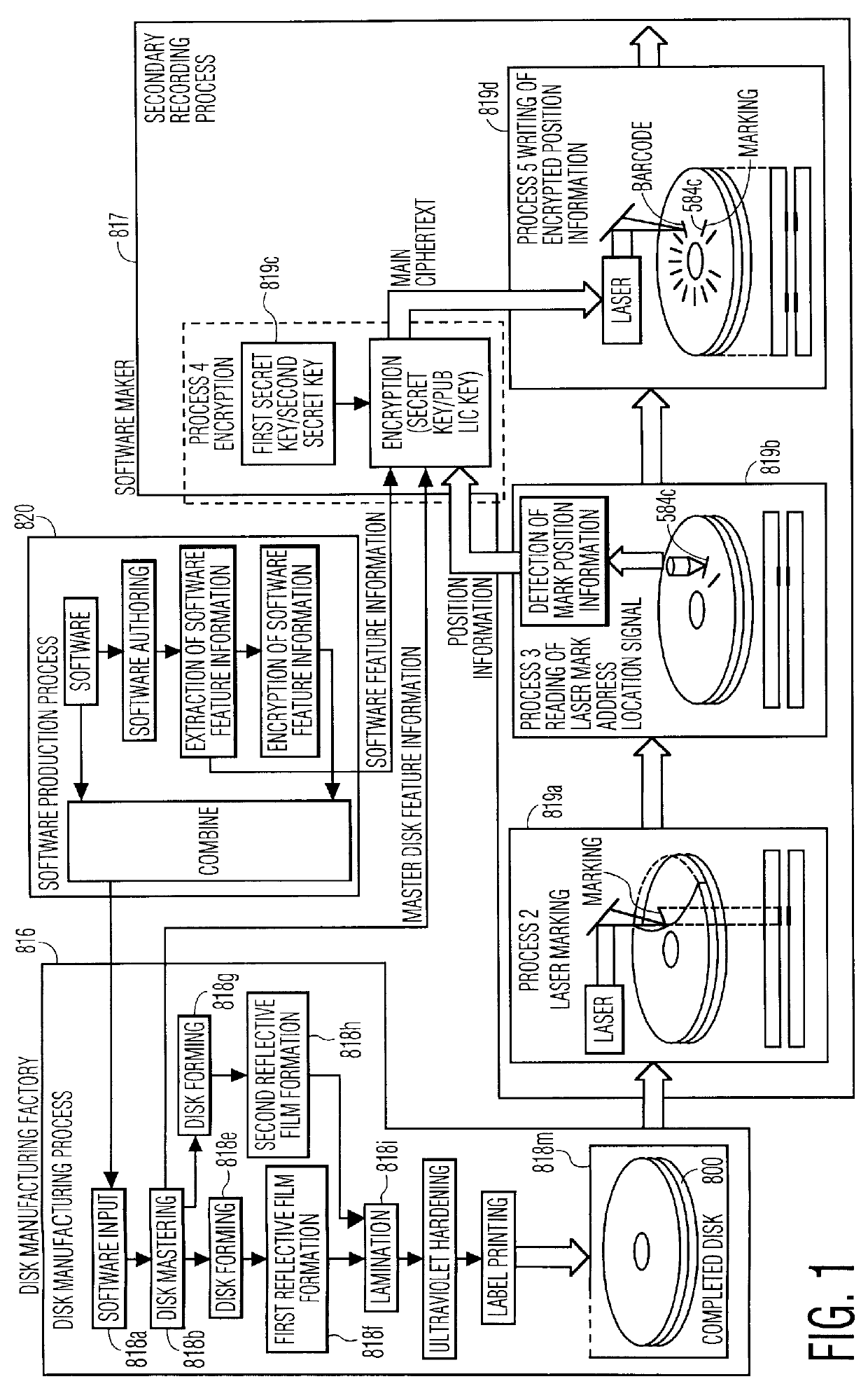

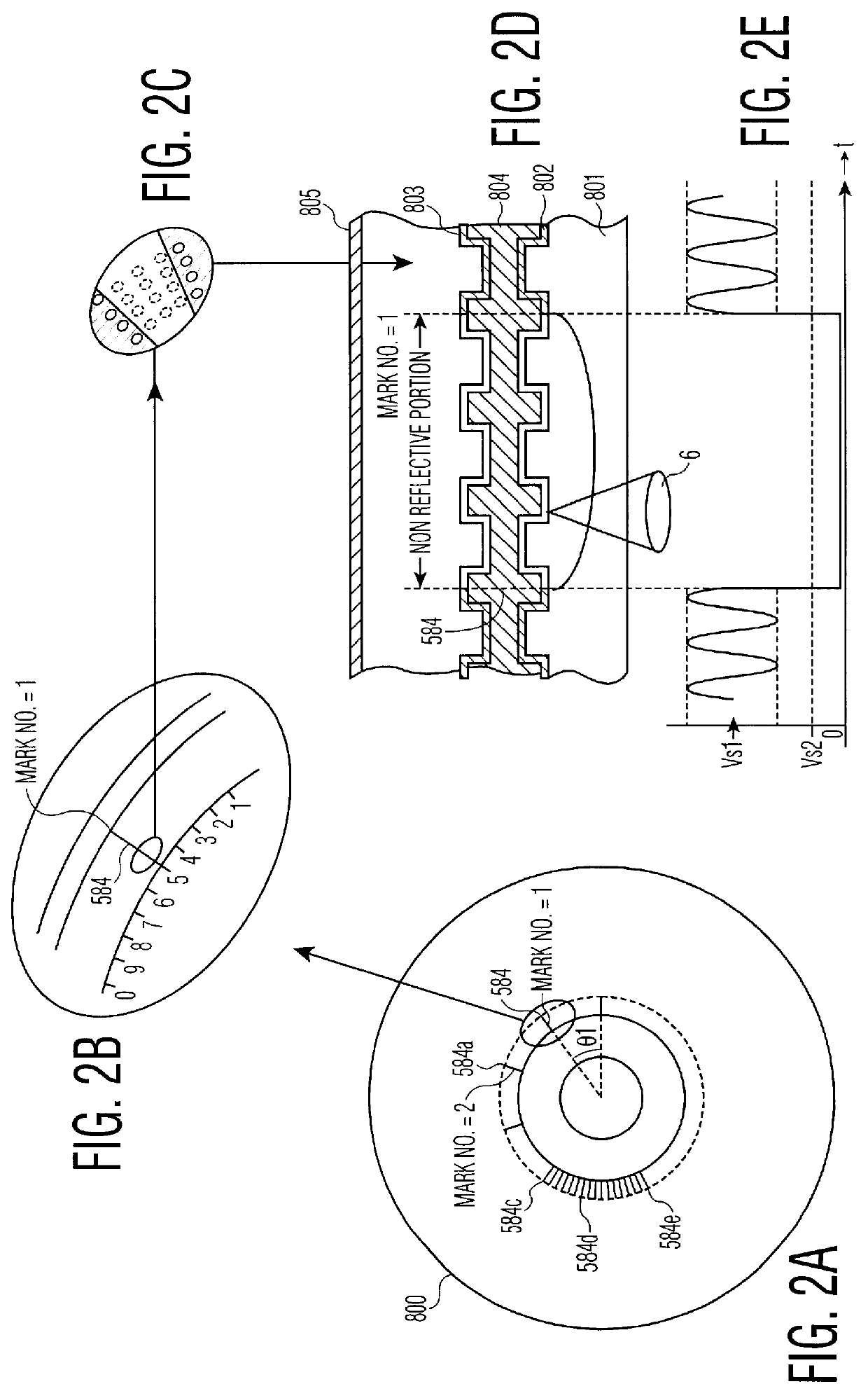

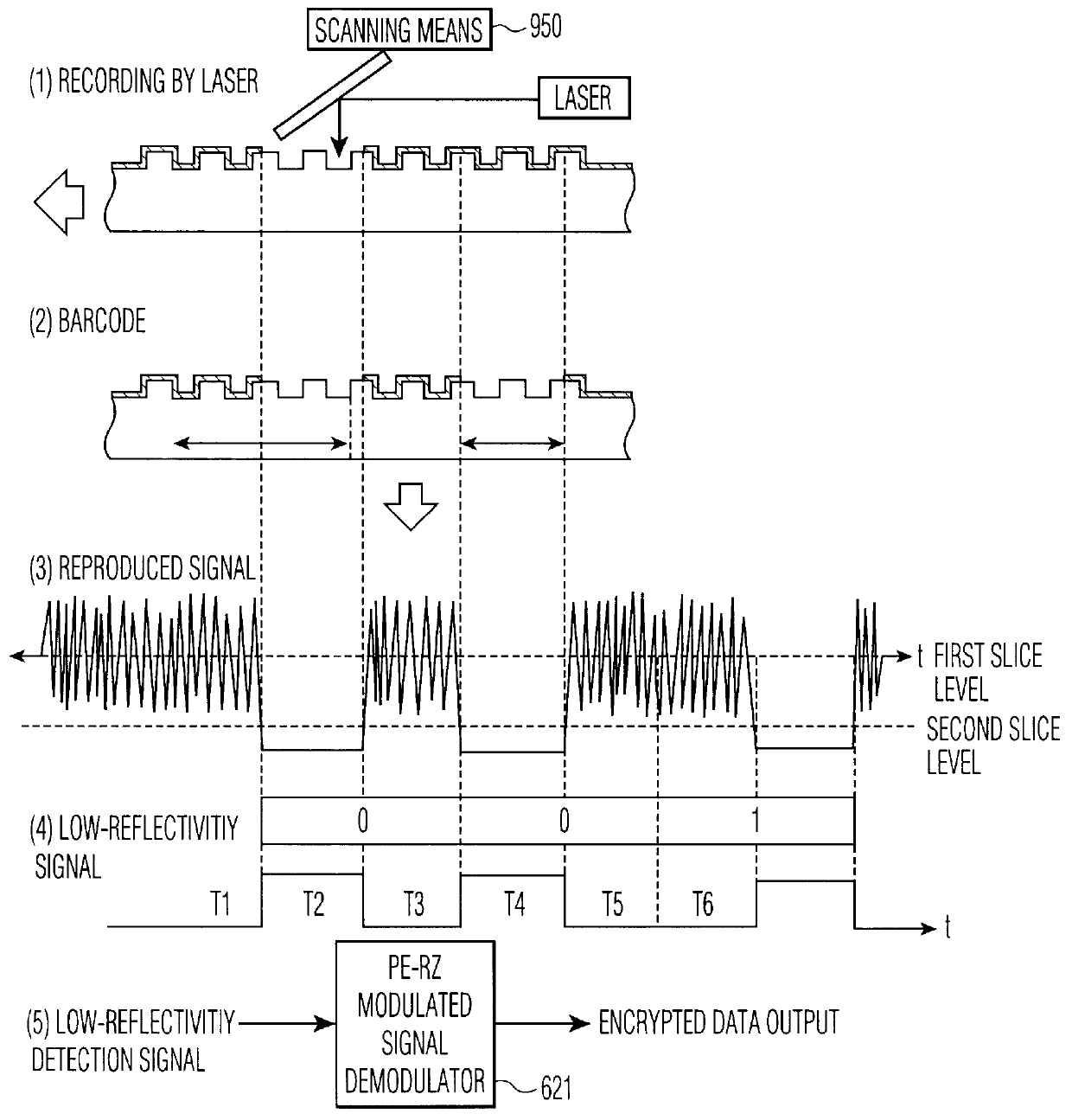

Optical disk, an optical disk barcode forming method, an optical disk reproduction apparatus, a marking forming apparatus, a method of forming a laser marking on an optical disk, and a method of manufacturing an optical disk

InactiveUS6052465APossible to separateDigitally marking record carriersDigital data processing detailsOptical pickupBarcode

Disclosed is an optical disk barcode forming method wherein, as information to be barcoded, position information for piracy prevention, which is a form of ID, is coded as a barcode and is recoded by laser trimming on a reflective film in a PCA area of an optical disk. When playing back the thus manufactured optical disk on a reproduction apparatus, the barcode data can be played back using the same optical pickup.

Owner:PANASONIC CORP

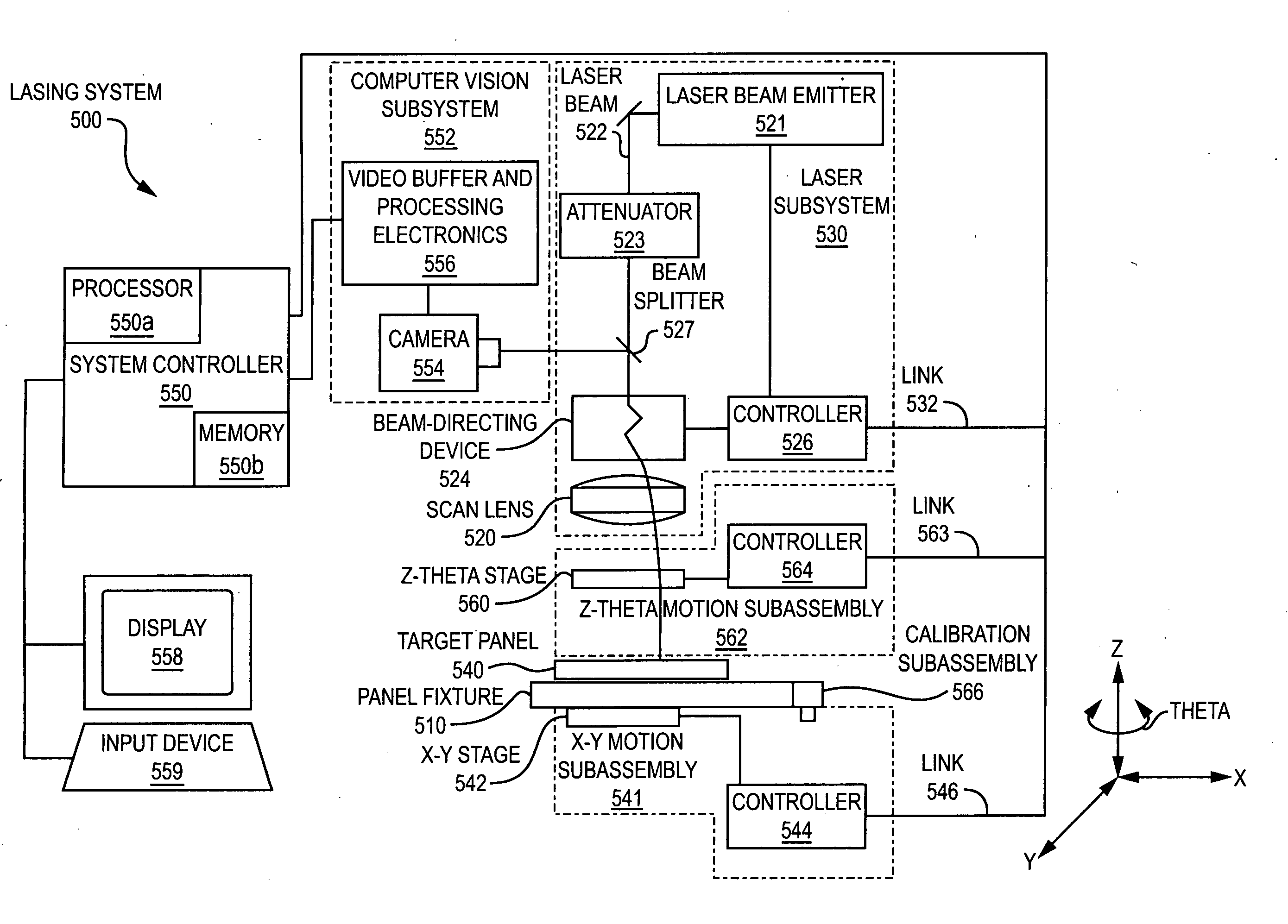

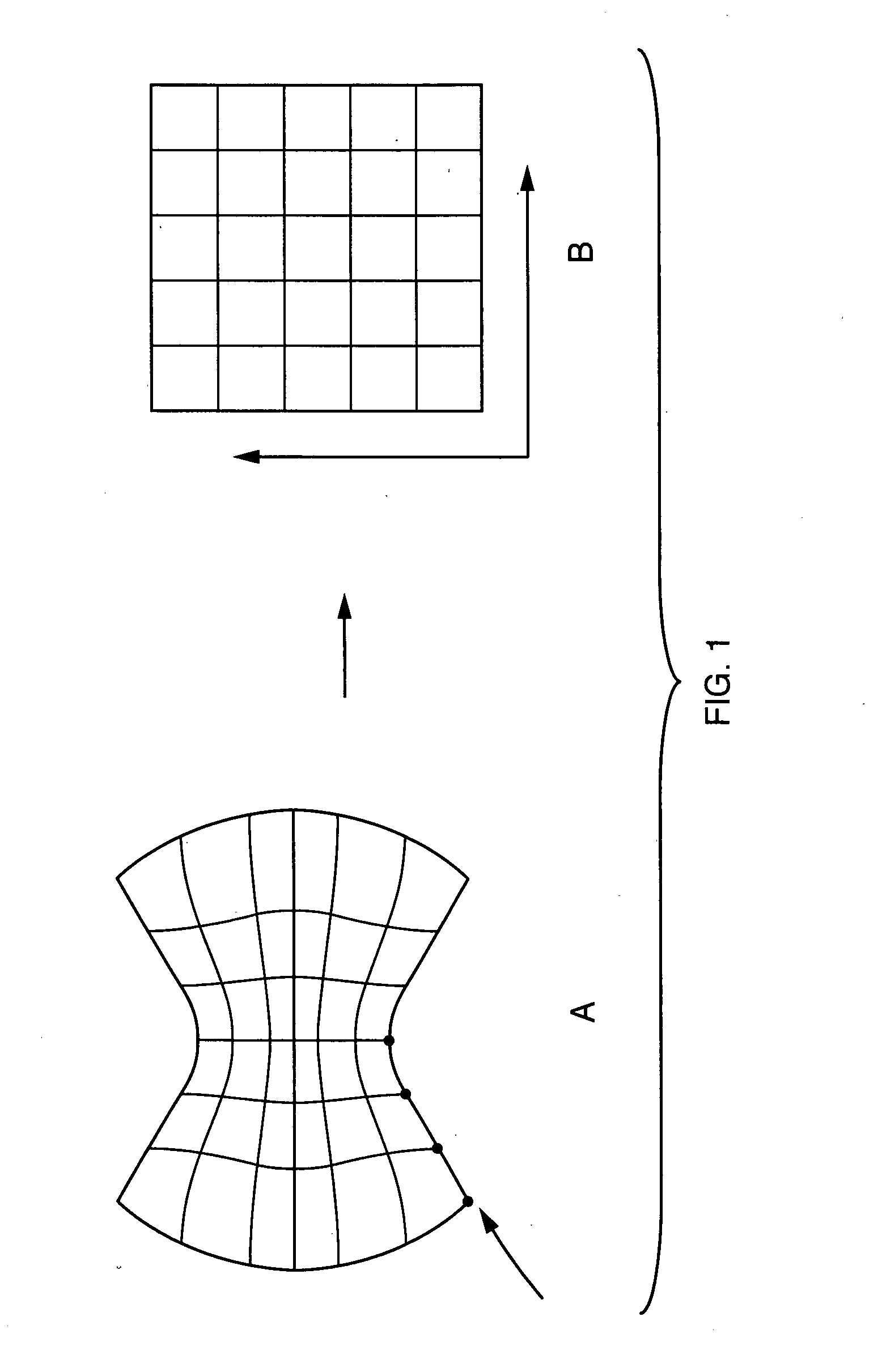

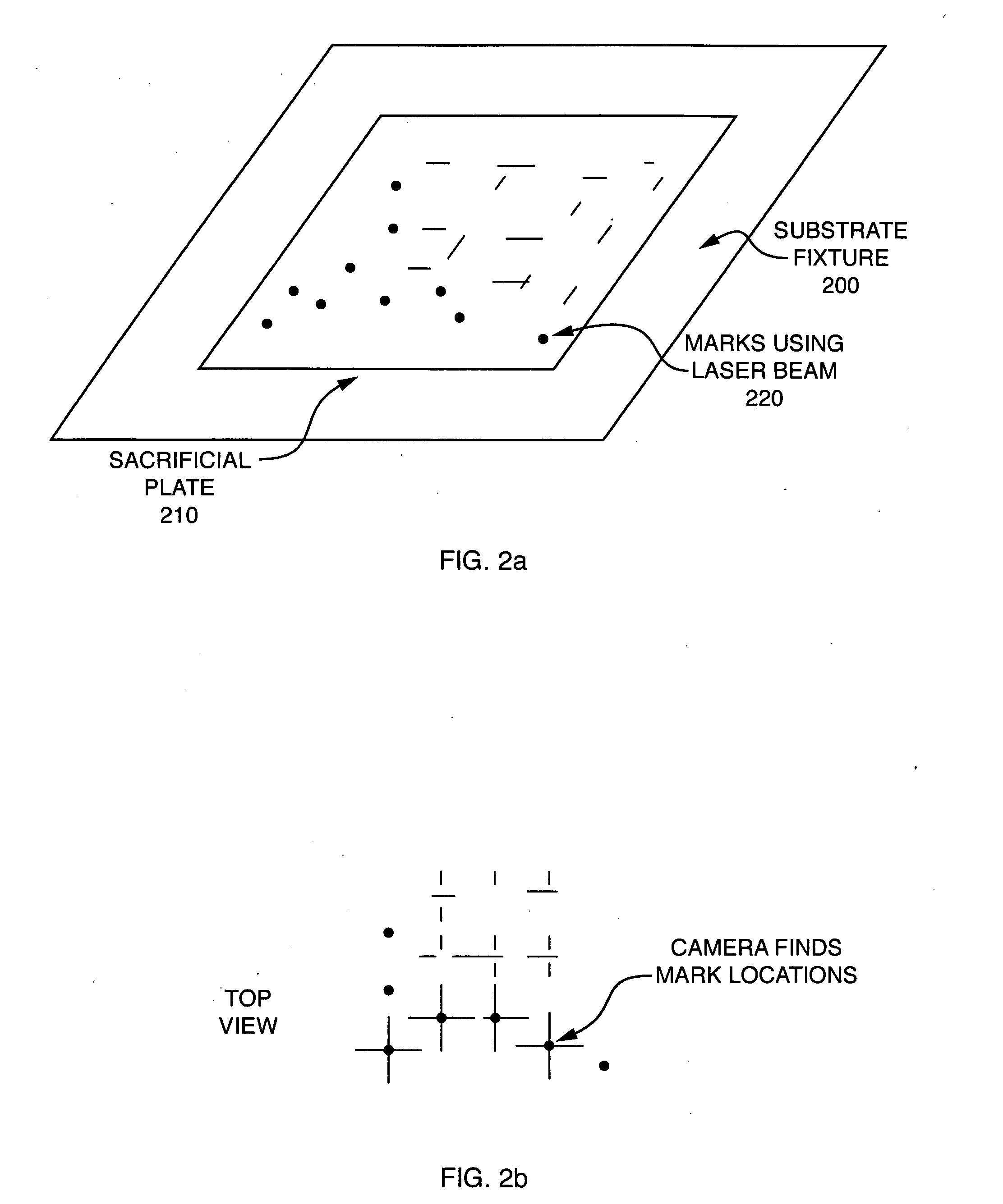

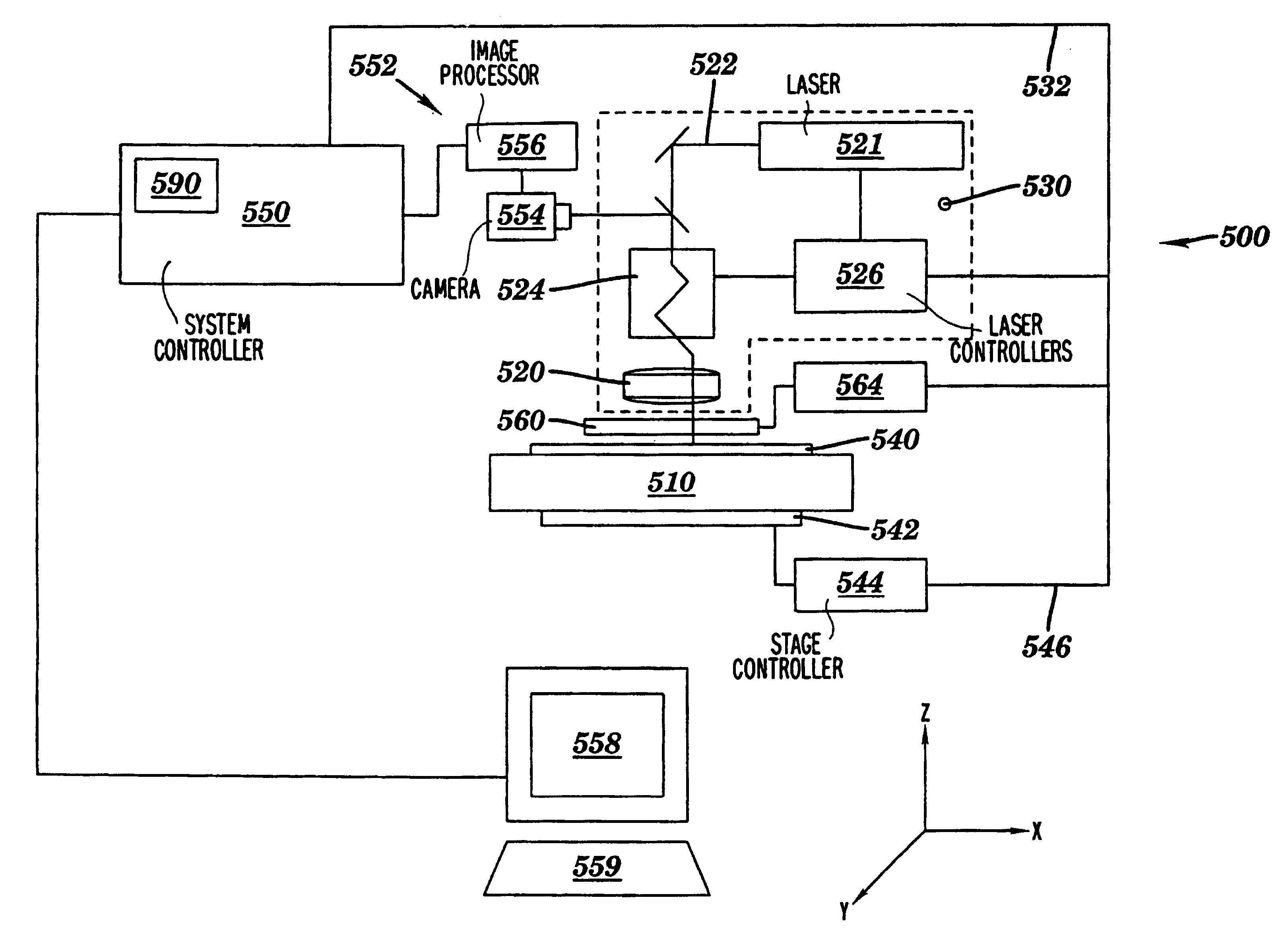

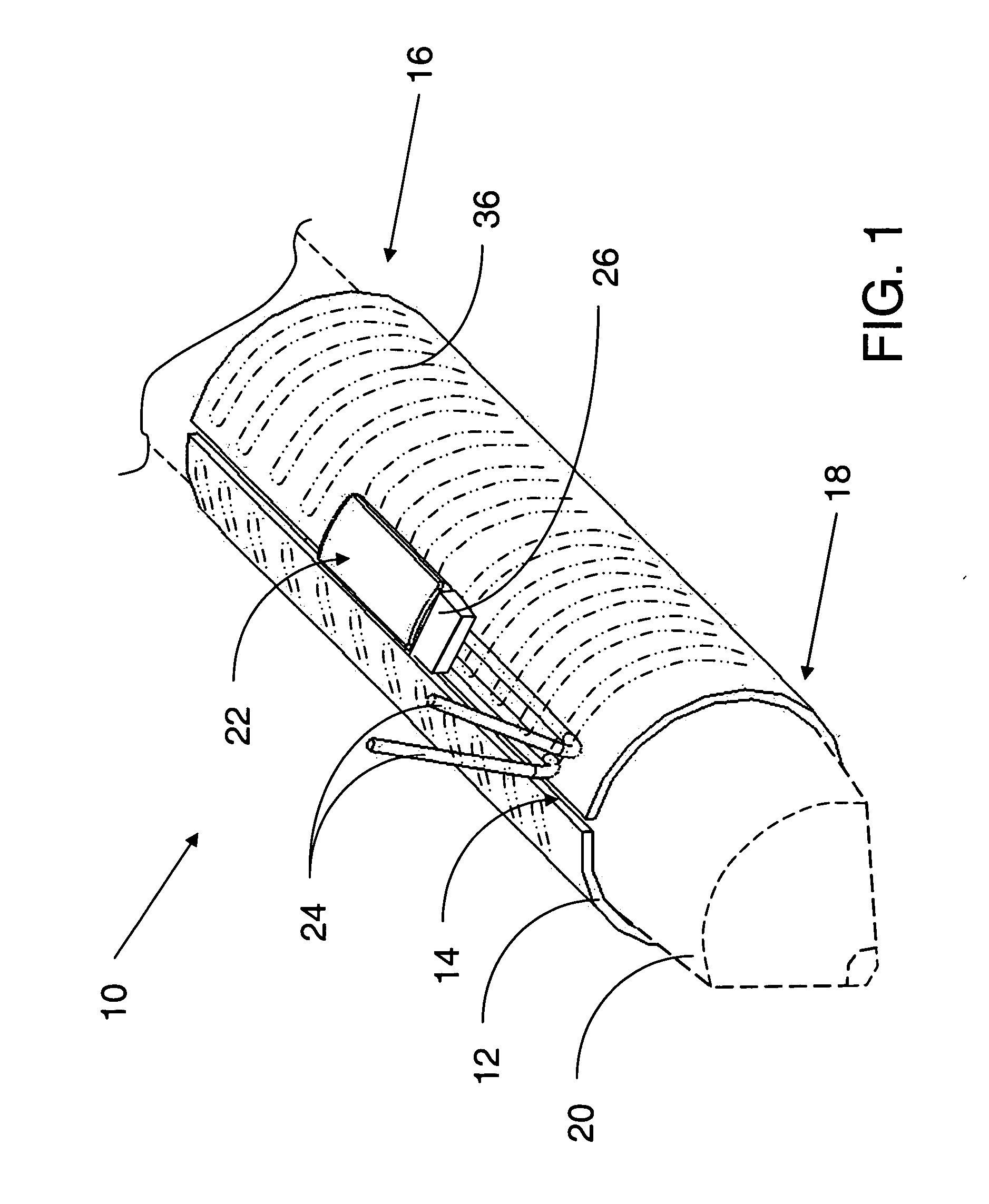

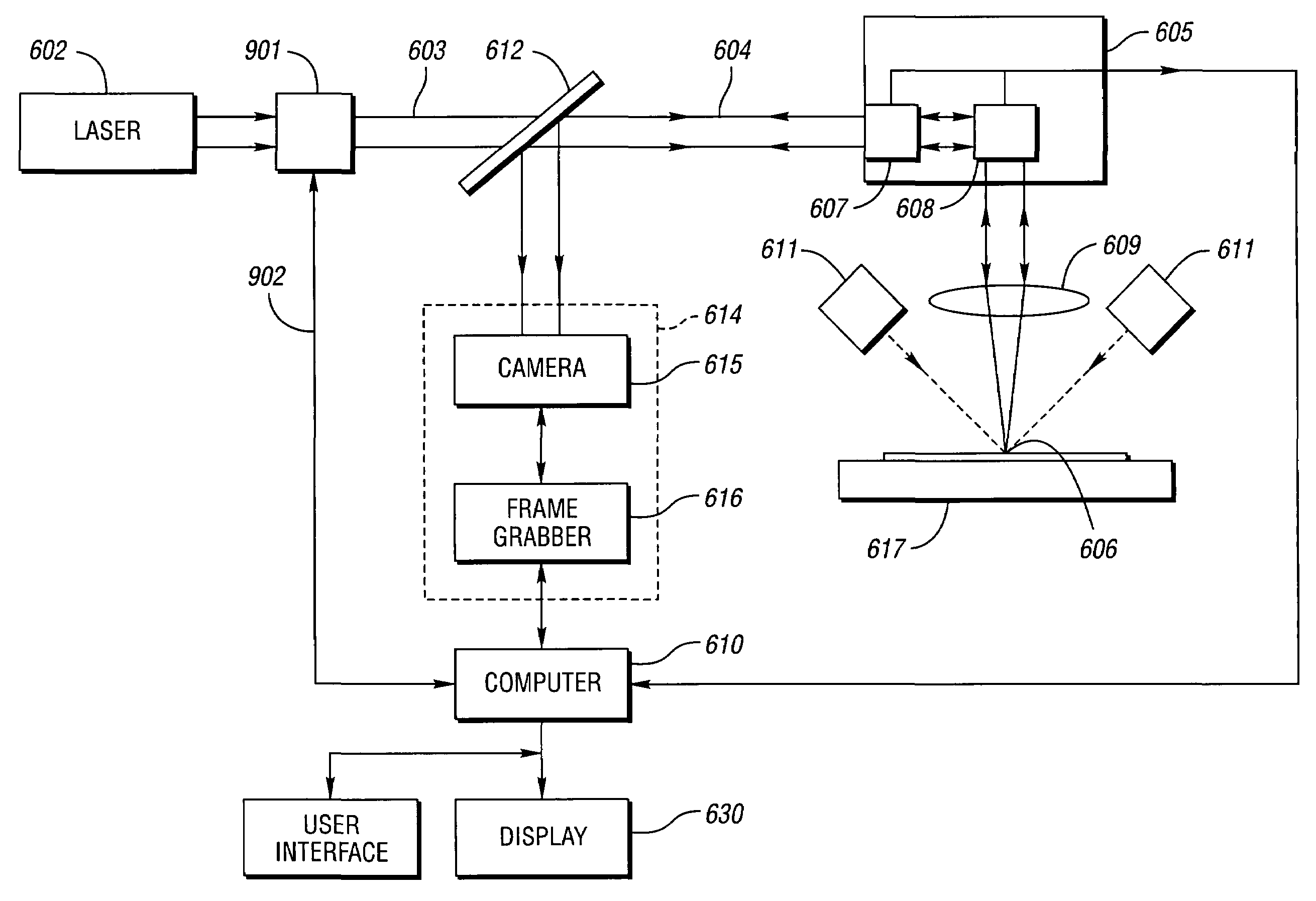

Laser trim motion, calibration, imaging, and fixturing techniques

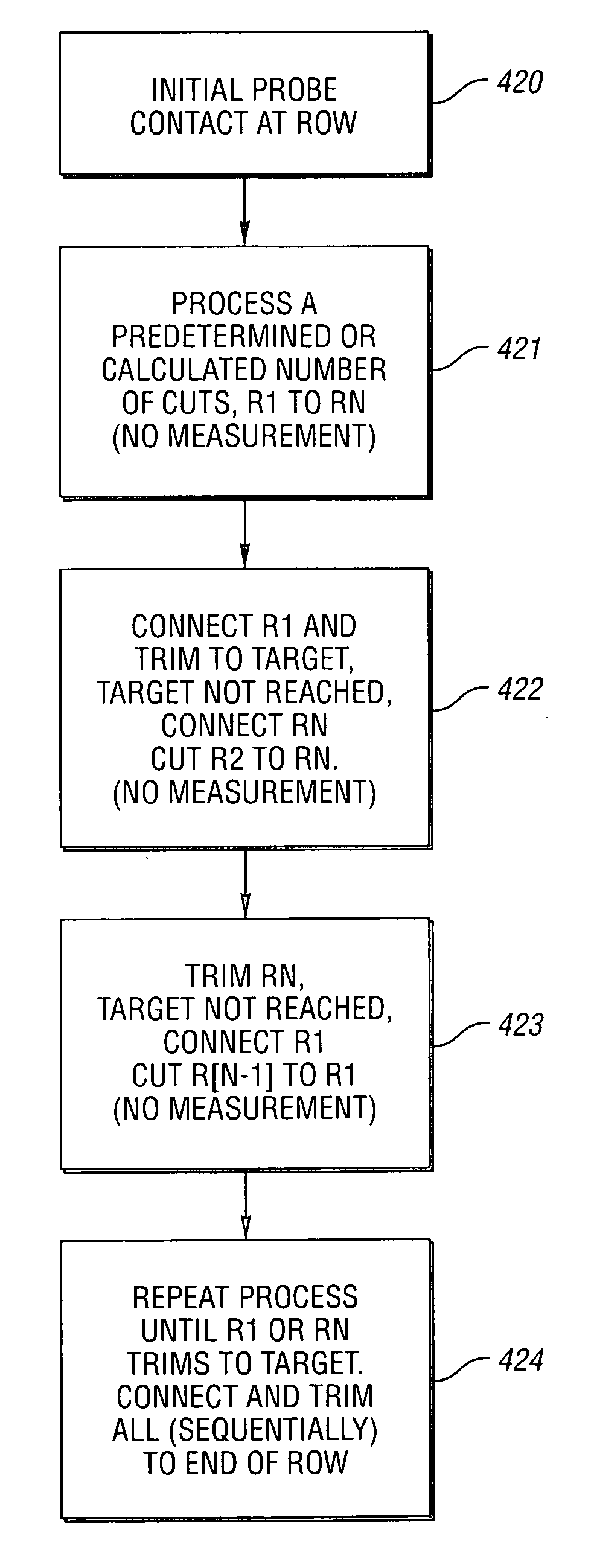

InactiveUS20050205778A1Optimal lasing procedureOptimal procedureMaterial analysis using wave/particle radiationPrinted circuit aspectsBiomedical engineeringLaser trimming

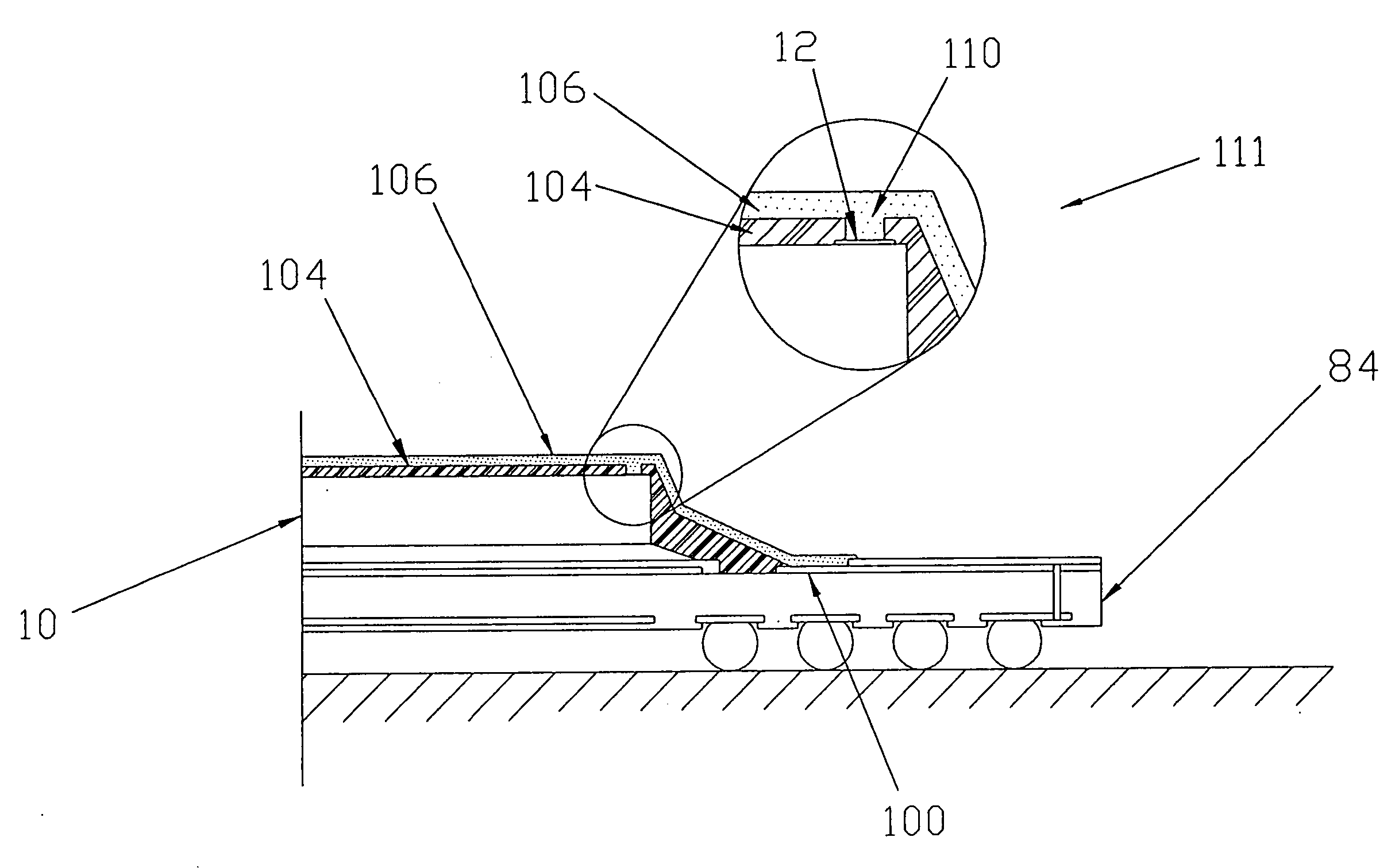

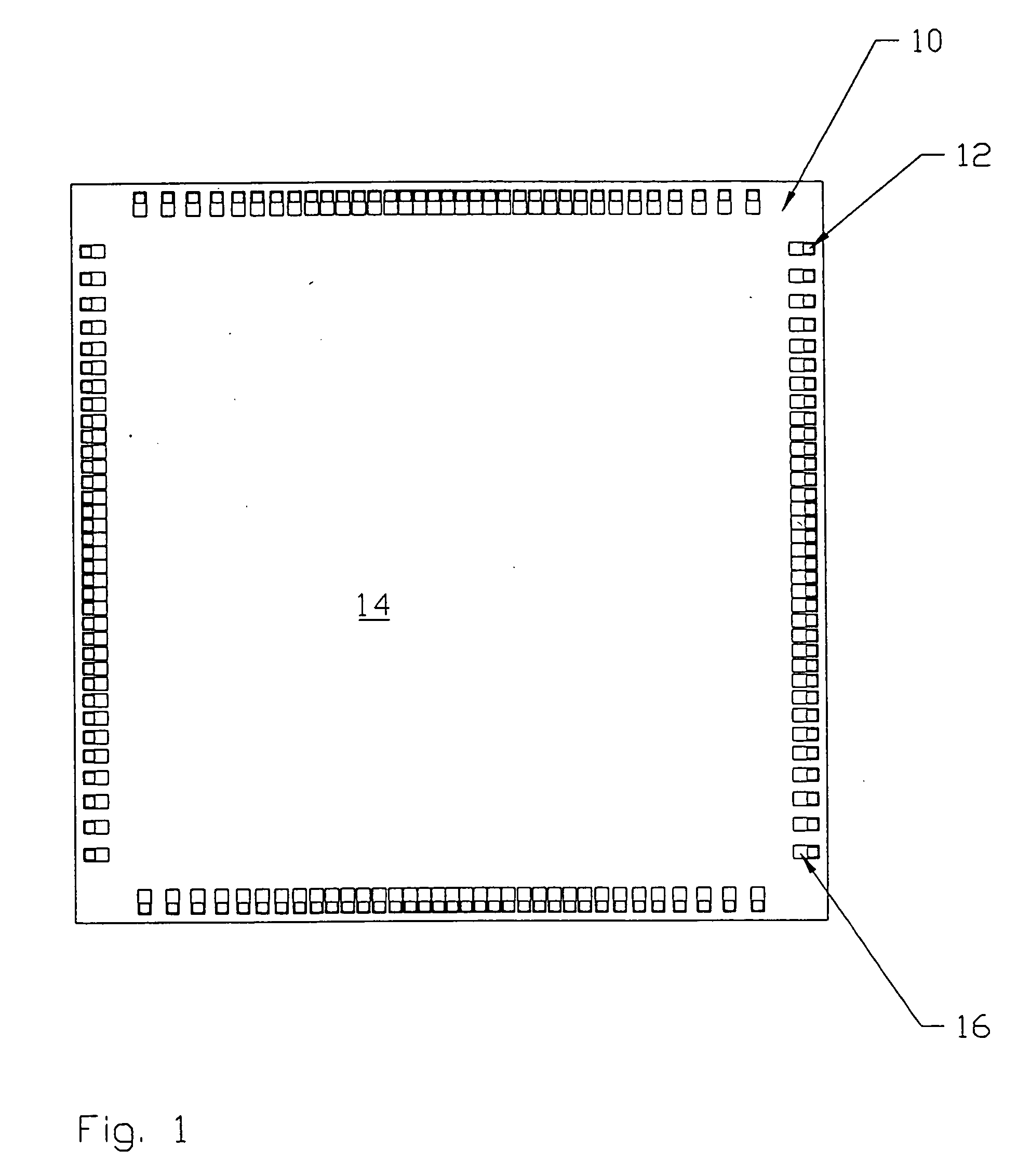

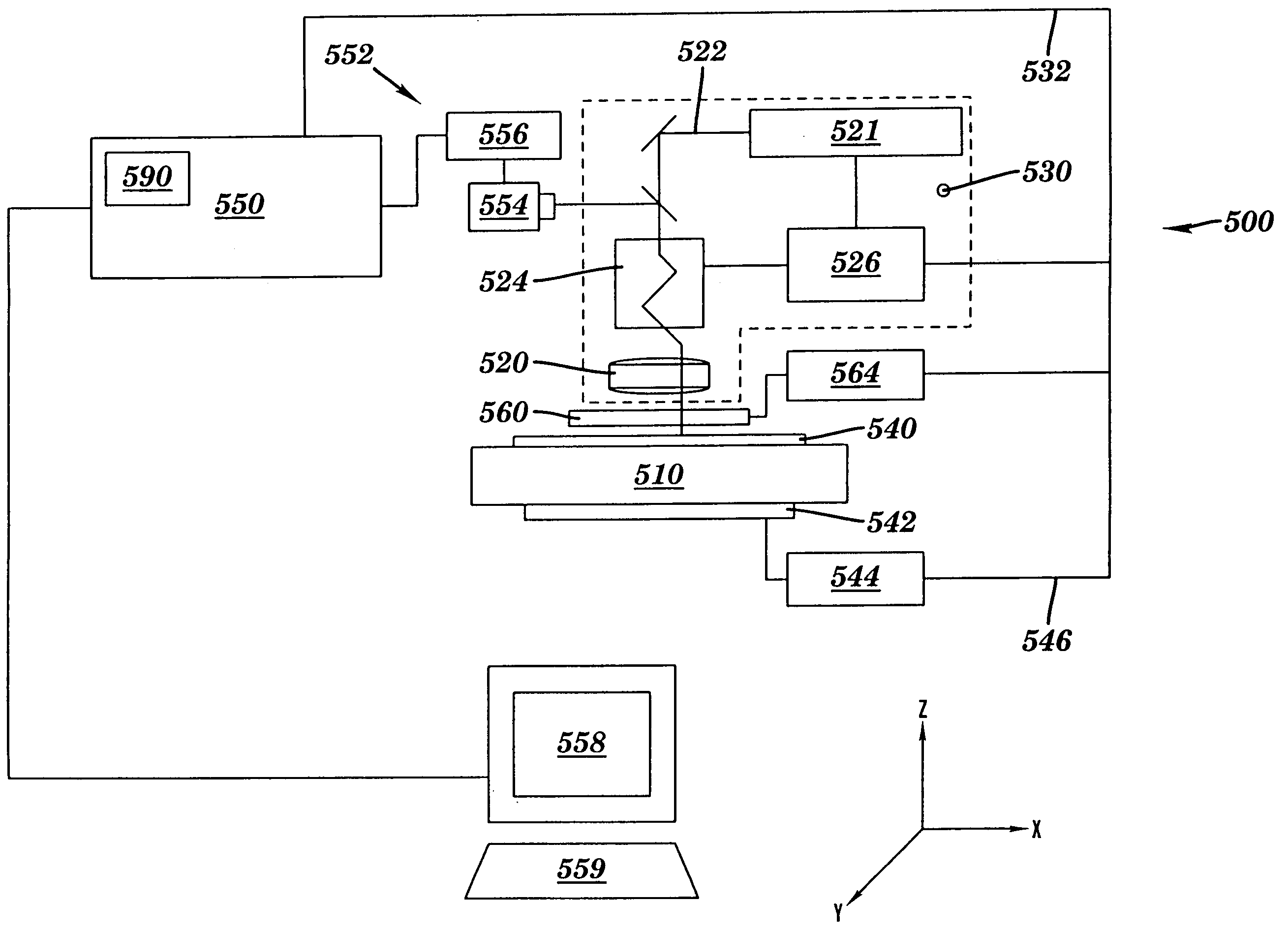

A system for probing circuit elements, includes a panel fixture, probe holder and stage. The fixture has a platen surface to support a work piece having work piece surface. The work piece surface is substantially parallel to the platen surface and has a target element thereon. The probe holder is configured to support a probe for detecting a characteristic of the target element. A stage rotates the probe holder about an axis substantially orthogonal to the platen surface, to align the probe with probe locations associated with the circuit element, so that the characteristic of the circuit element can detected by the probe. Fixturing motion can be optimized for efficient work piece manufacturing. Calibration and vision subassemblies are also provided.

Owner:THE GSI GRP LLC

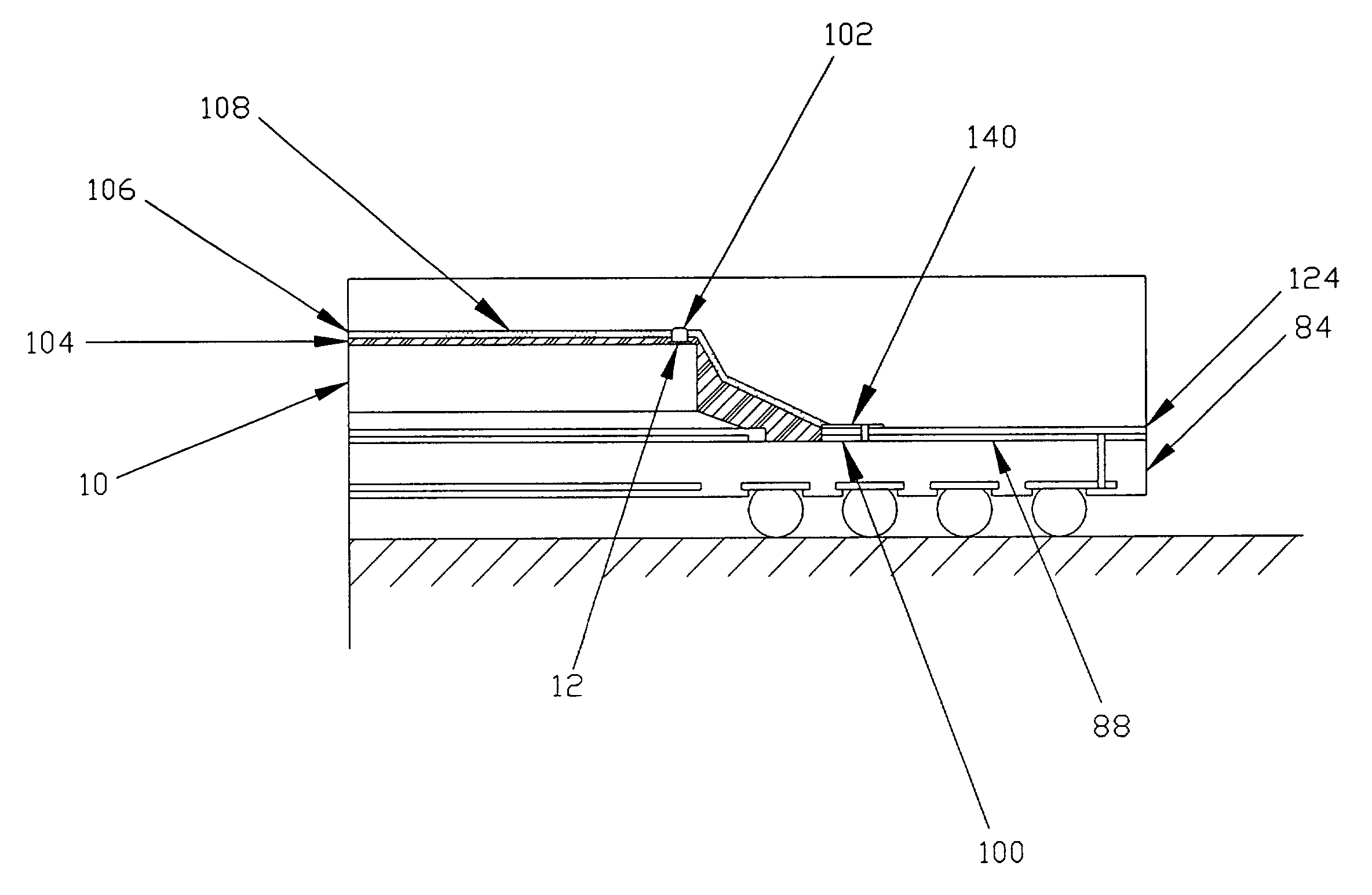

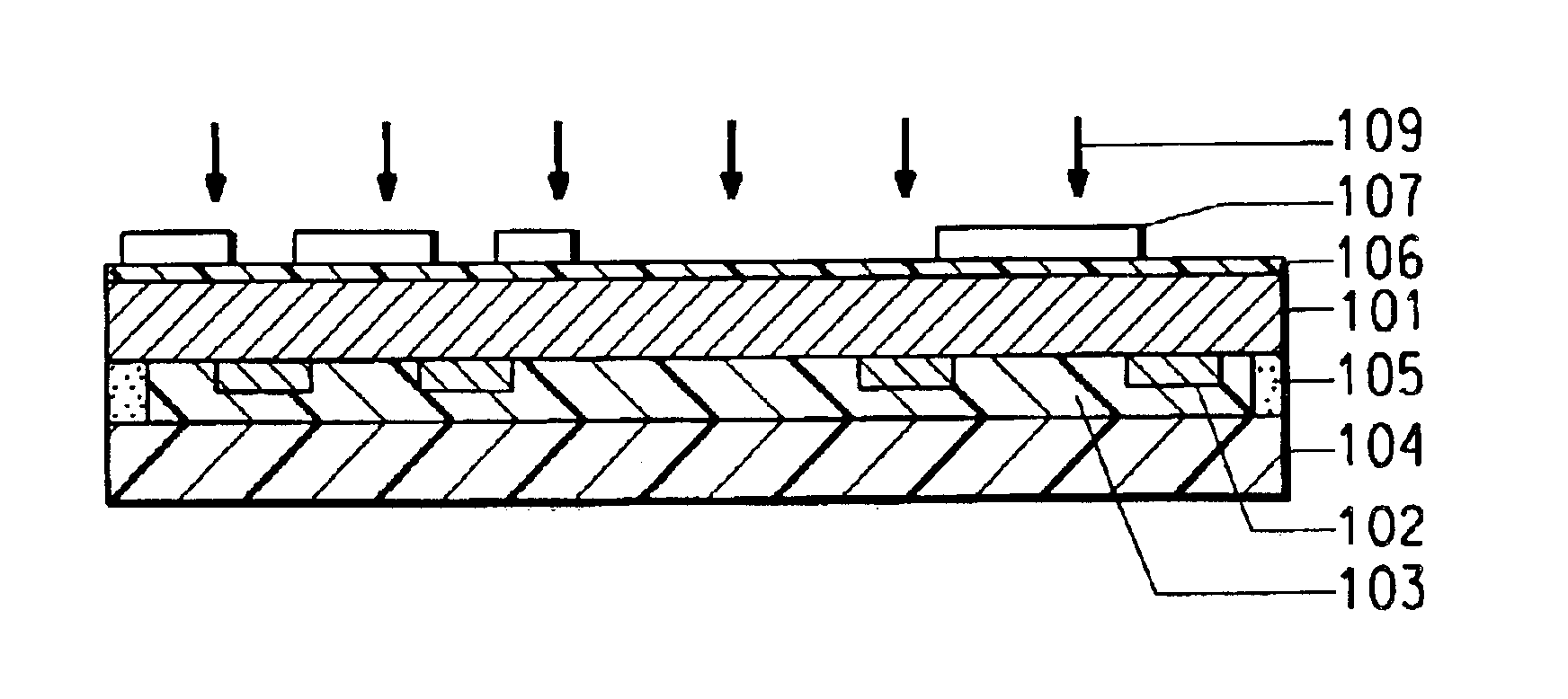

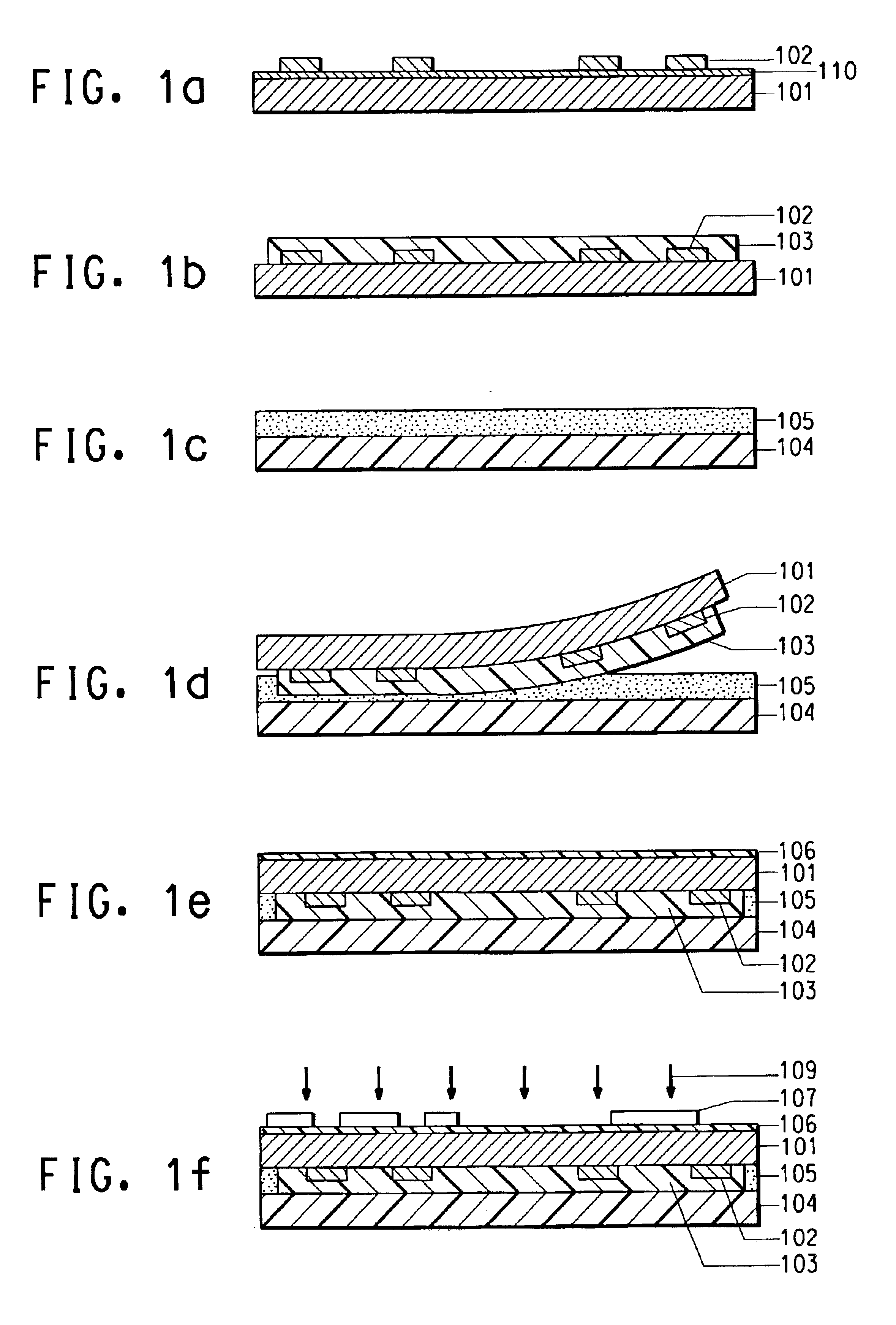

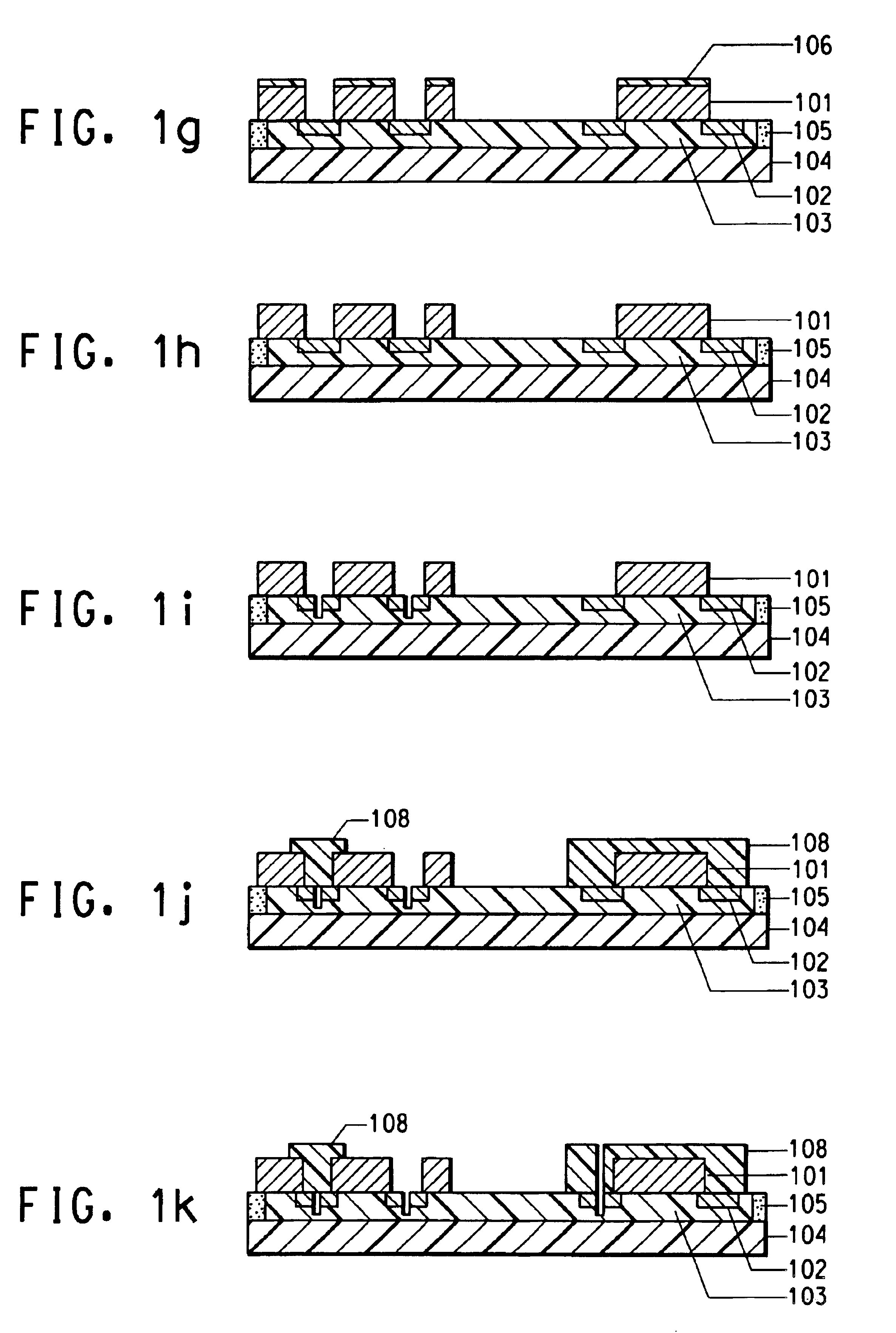

Multilayer laser trim interconnect method

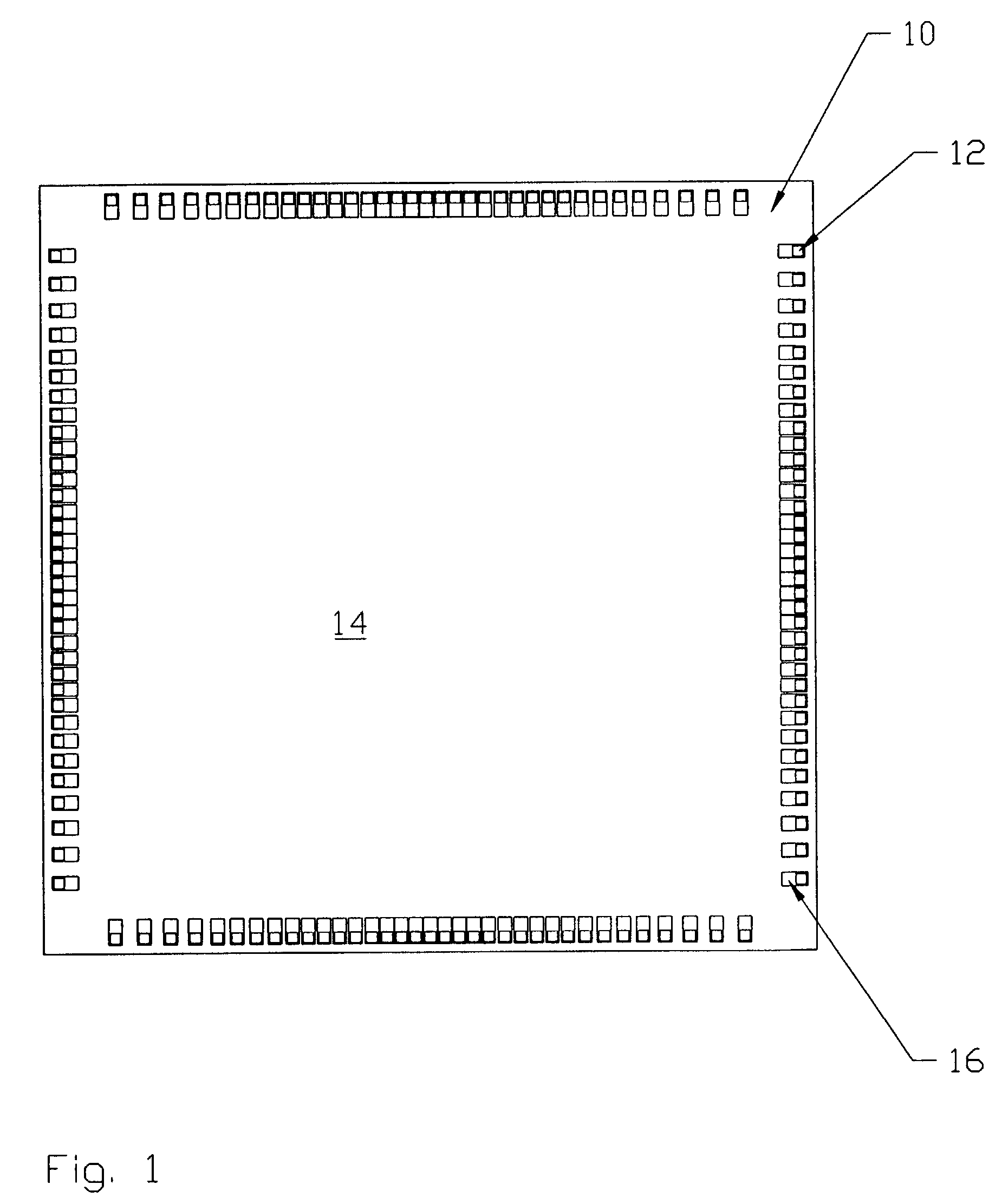

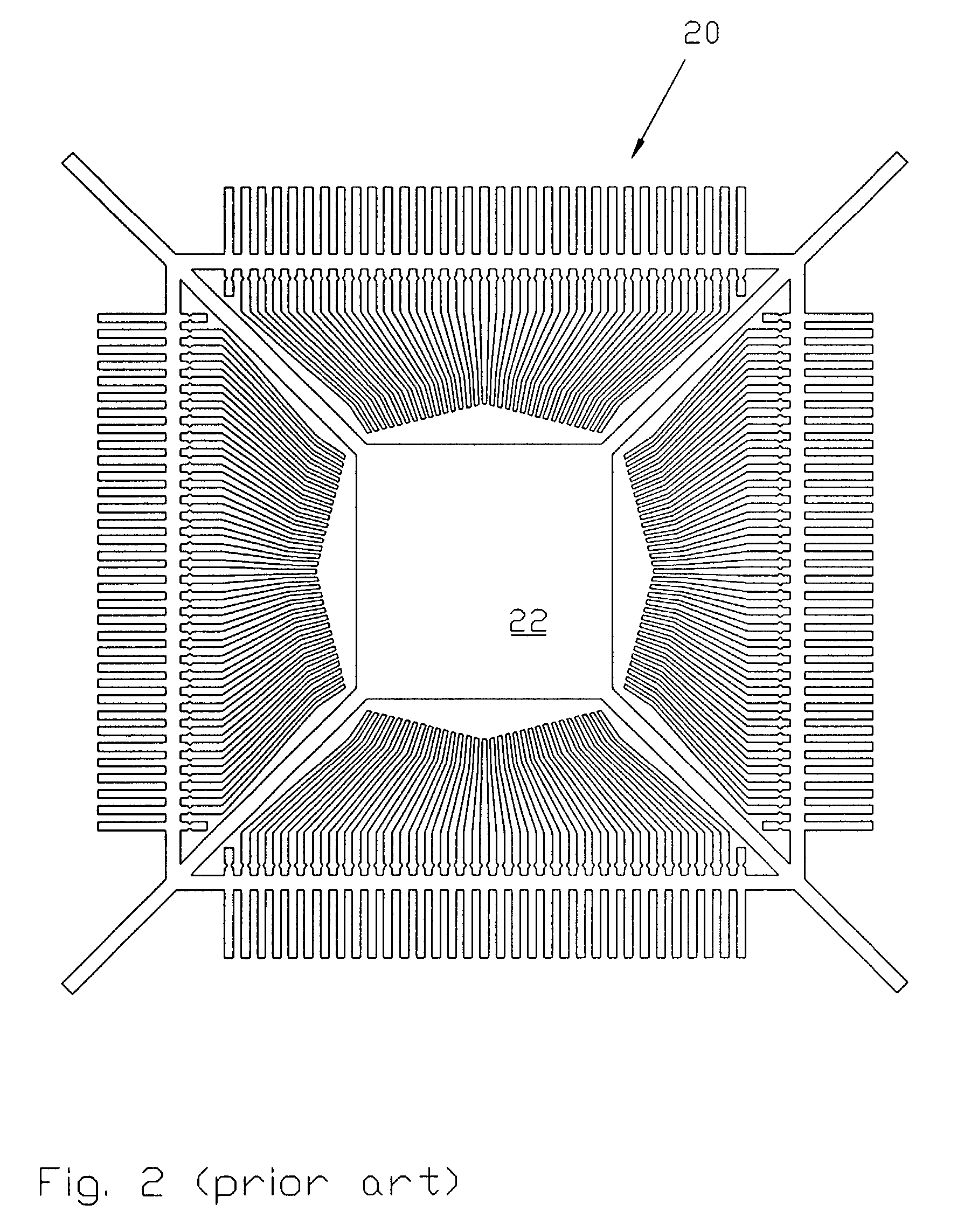

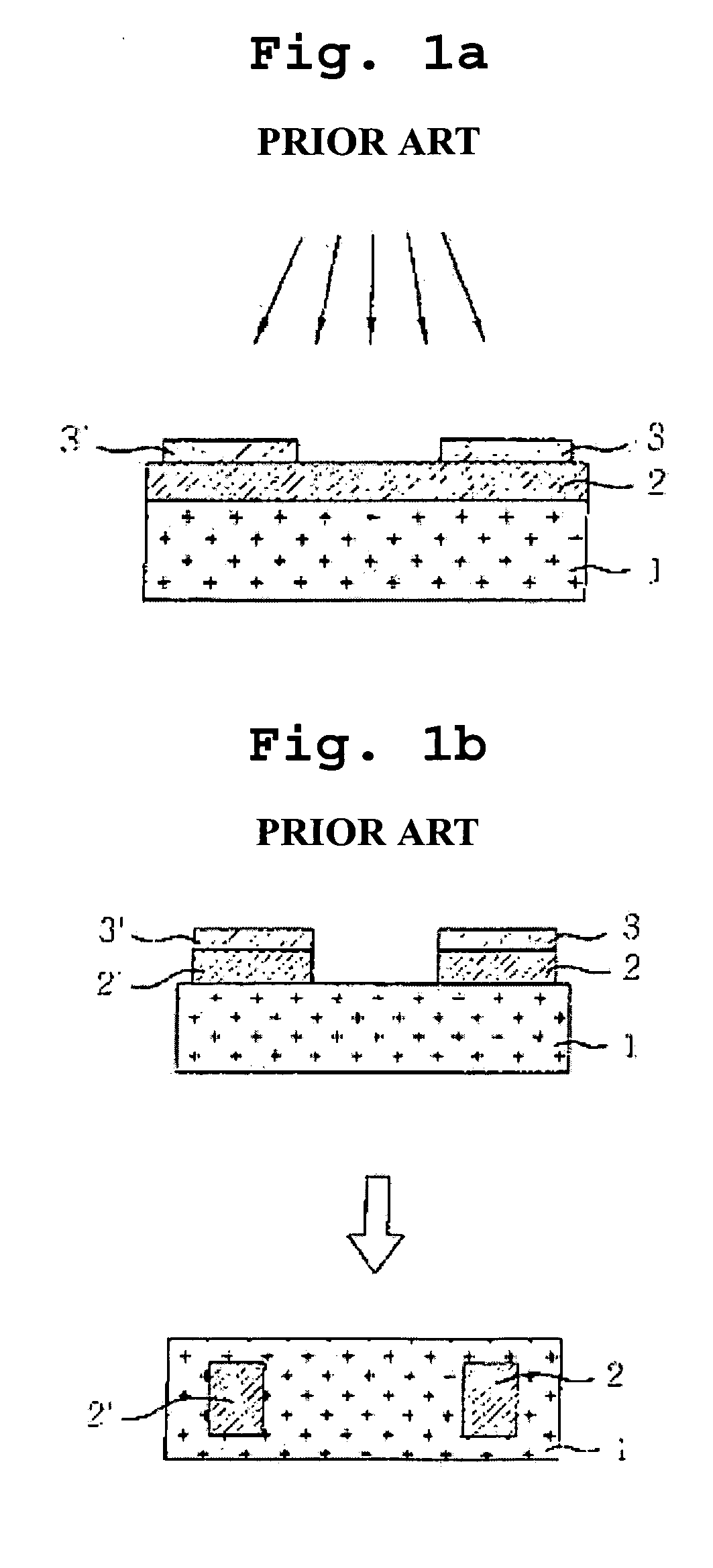

InactiveUS6756252B2Semiconductor/solid-state device detailsSolid-state devicesContact padEngineering

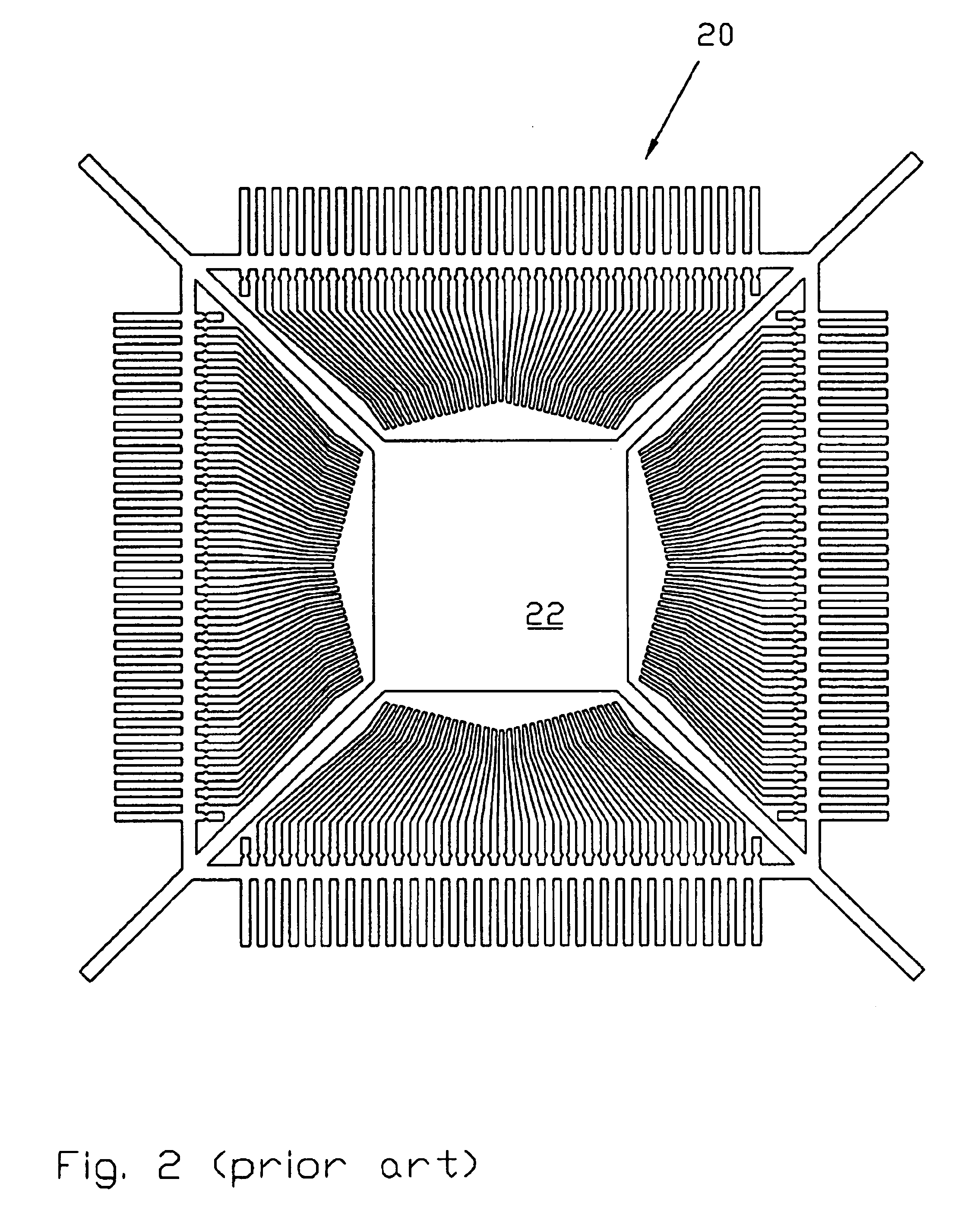

A method for creating electrical interconnects between a semiconductor die and package. In the preferred embodiment, an insulating material is applied over the die and extends to the substrate contact pads, leaving a portion of each contact pad exposed. Holes are then trimmed through the insulating material, exposing at least a portion of each die bond pad. A conductive material is then applied over the die, flowing into the holes, contacting the die bond pads, and extending out to contact at least a portion of each substrate contact pad. In another preferred embodiment, an electrically conductive bump may be formed on each die bond pad, protruding through said non-conductive material and at least partially through said conductive material. The conductive layer is then laser trimmed, forming conductive patches that serve as electrical interconnects between the die and package substrate.

Owner:TEXAS INSTR INC

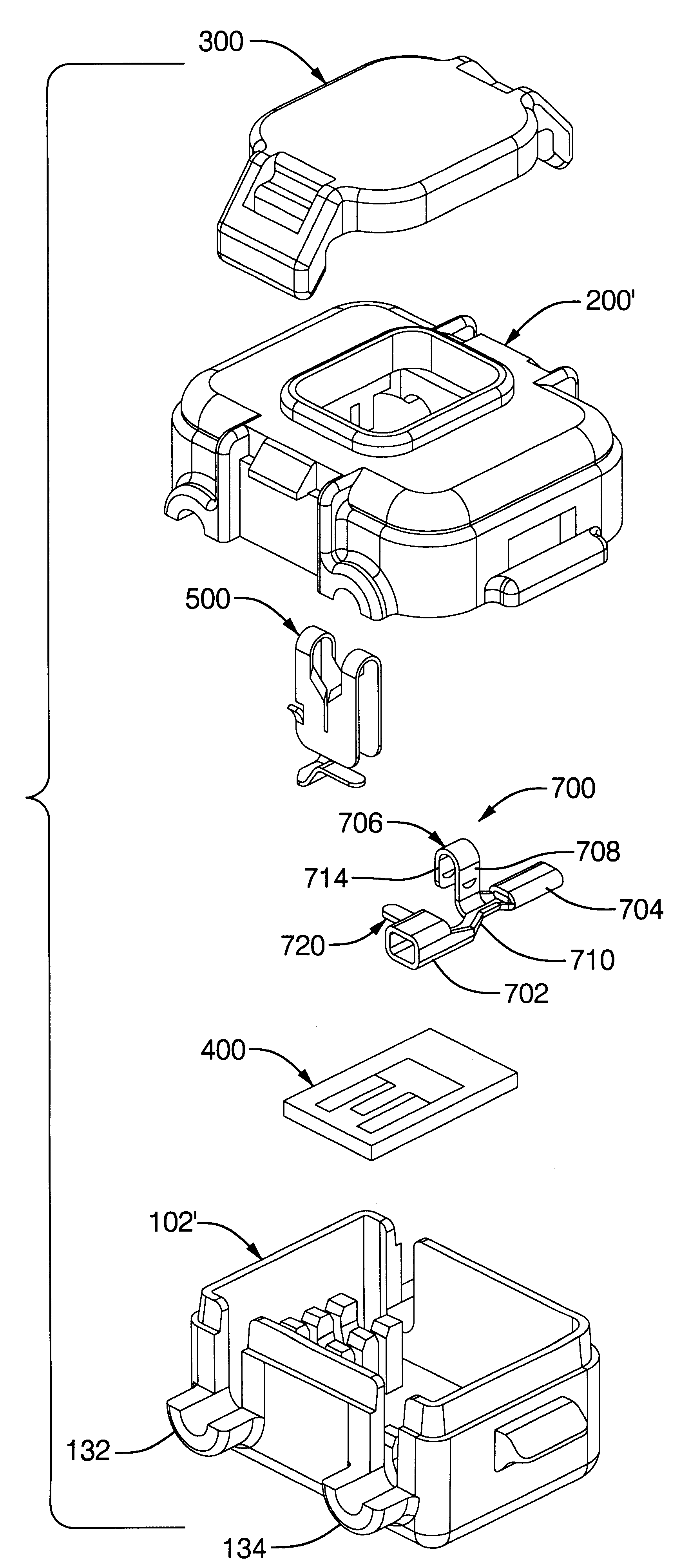

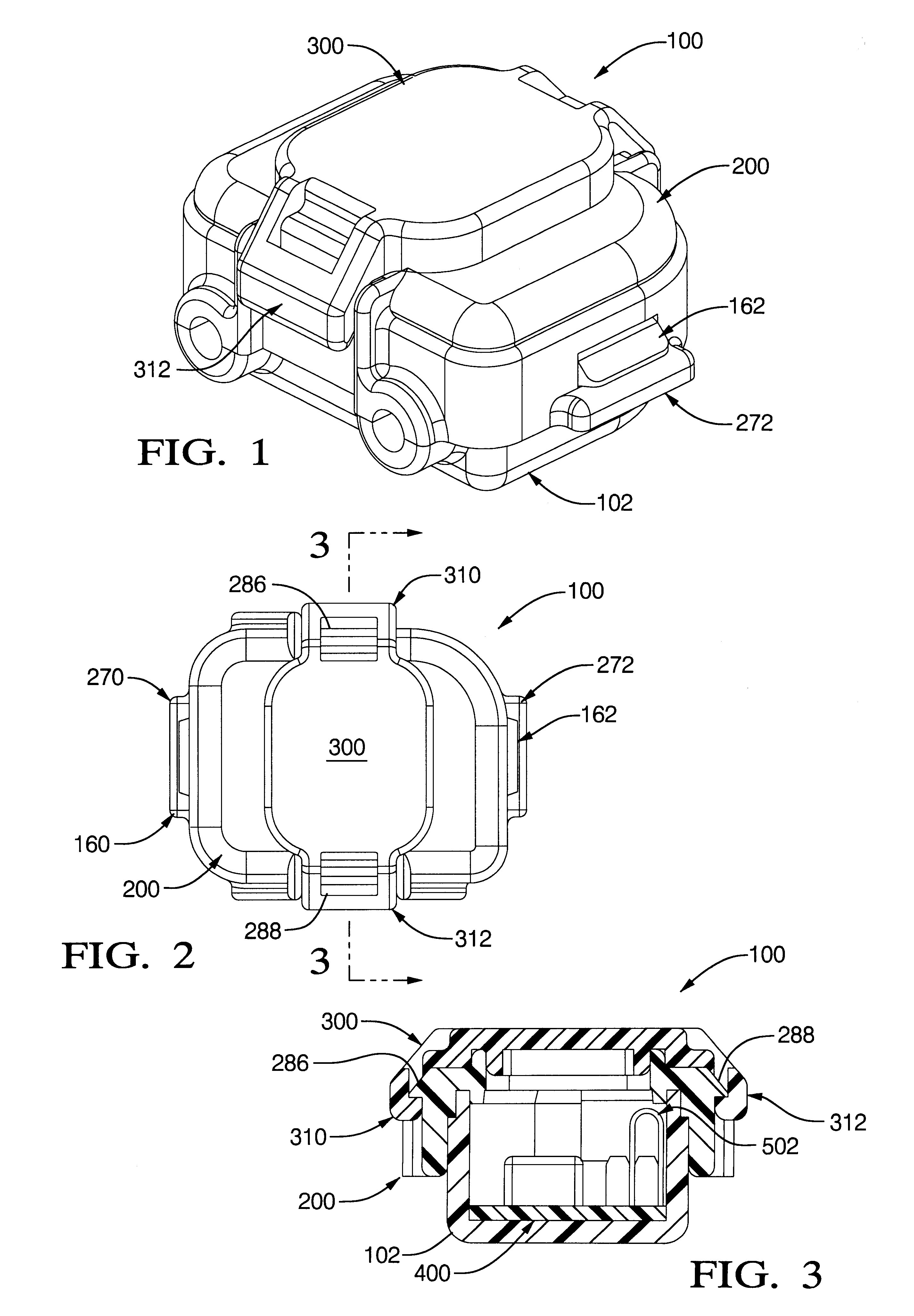

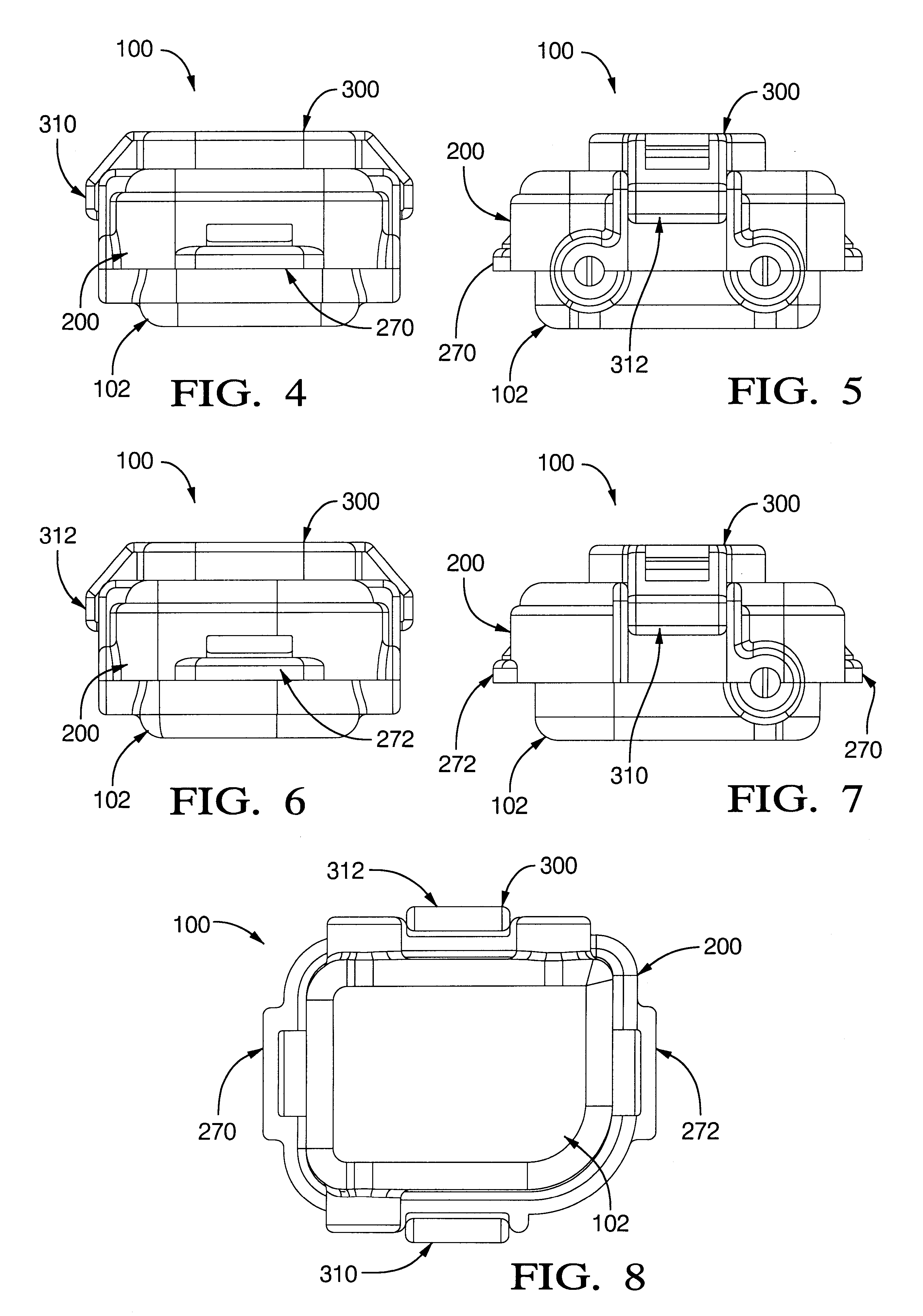

Trim resistor connector and sensor system

InactiveUS6208233B1Overcome disadvantagesFixed resistors with intervening connectorsFluid pressure measurement by electric/magnetic elementsSealantSensor system

An improved IDC trim resistor connector assembly made up of a generally open top cup shape connector with side wall slots and an interior first array of terminal posts arranged for passage therethrough of a first lead wire of sensor circuitry. A first stamped metal IDC terminal is push-on mounted on the terminal posts for IDC cradling and electrically and mechanically receiving and connecting to the first lead wire. A conventional trim resistor substrate is loose mounted but accurately positioned on the connector bottom wall and has an "E" pattern of resistive material adapted for center leg laser trimming to calibrate the associated sensor circuitry. A first IDC terminal spring leg overlap contacts one side leg of the trim resistor E-pattern and thereby spring clamps the resistor substrate. A cover is snap-latch mounted on the connector and has an access opening to enable laser trimming of the trim resistor after cover installation. One end of a second lead wire is received in a second IDC metal terminal in turn mounted on a second array of connector-interior terminal posts and also having a spring leg overlap electrically contacting and clamping the other E-pattern side leg. Spring barbs on the terminals anchor the same once fully inserted downwardly onto the terminal posts. Connector locking tangs and cover locking ears provide snap-on retention of the cover on the connector, and press-in / keeper internal cover projections cause push-down assembly of the lead wires as the cover is latched onto the connector. Cover locking tangs and cap latching ears provide snap-together locking of a cap on the cover when the cap is pushed down on the cover to seal the access opening after completion of laser trimming and in-filling of the covered container with sealant. In a second embodiment a crimp-type terminal, also provided with a spring clamping leg, is fastened to the second lead wire and has a barbed mounting strap clasping a modified second terminal post array when fully installed thereon.

Owner:DELPHI TECH INC

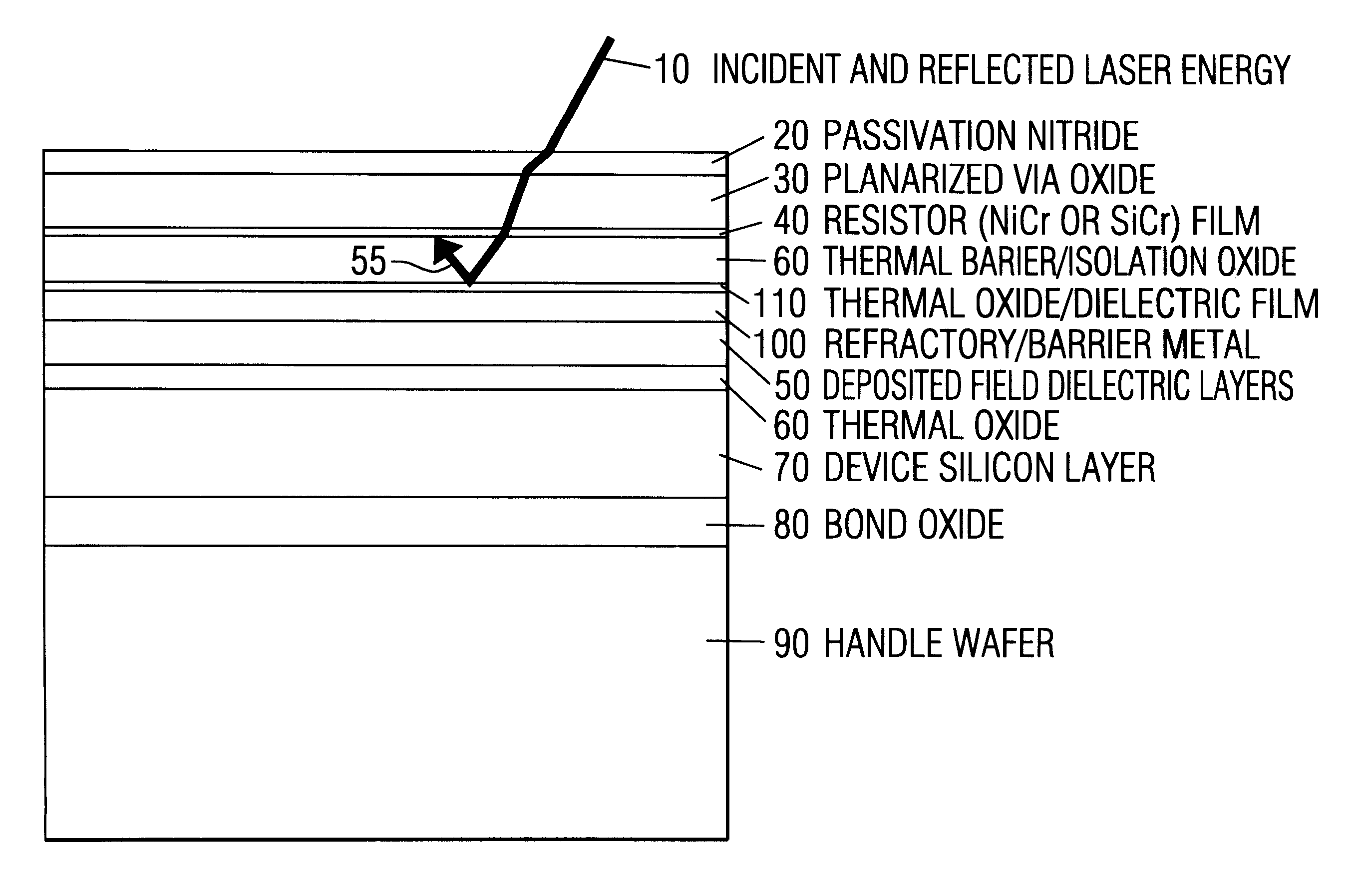

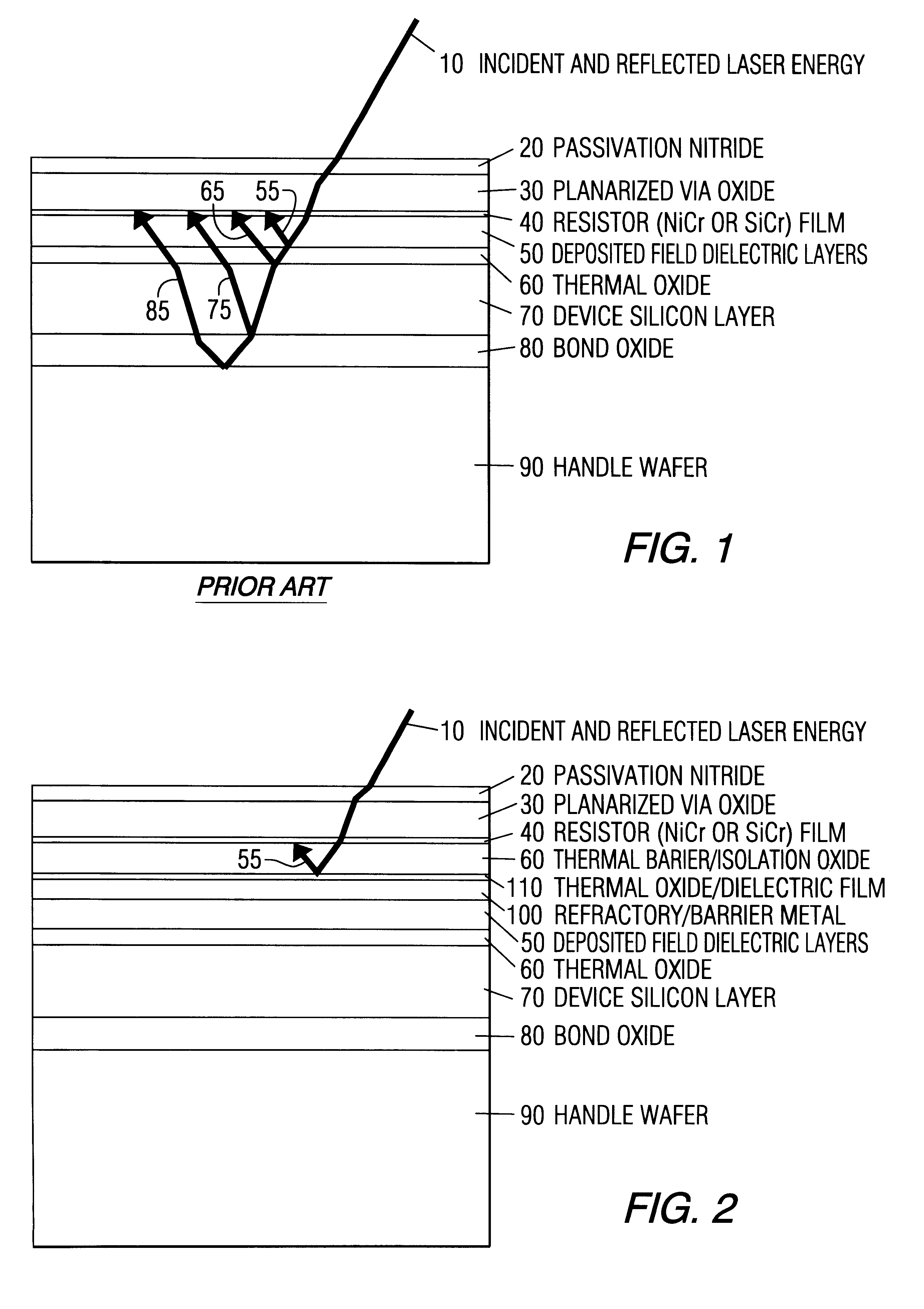

Use of barrier refractive or anti-reflective layer to improve laser trim characteristics of thin film resistors

InactiveUS6259151B1Reducing inaccuracy behaviorOptical wave guidanceSolid-state devicesTitaniumReflective layer

A precision resistor of NiCr or SiCr has a refractive and thermal barrier layer beneath the resistor. The refractive barrier is a layer of refractory metal. The refractory metal prevents the incident laser beam of a laser trimmer penetrating lower layers of the device. Unwanted reflections and refractions caused by lower layers are avoided. The reflective barrier layer is a material selected from the group consisting of tungsten, titanium, molybdenum, TiSi2l3,14, CoSi215, MoSi2, TaSi2 and WSi2.

Owner:INTERSIL INC

Multilayer laser trim interconnect method

InactiveUS20040014309A1Avoid problemsMore assembledSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A method for creating electrical interconnects between a semiconductor die and package. In the preferred embodiment, an insulating material is applied over the die and extends to the substrate contact pads, leaving a portion of each contact pad exposed. Holes are then trimmed through the insulating material, exposing at least a portion of each die bond pad. A conductive material is then applied over the die, flowing into the holes, contacting the die bond pads, and extending out to contact at least a portion of each substrate contact pad. In another preferred embodiment, an electrically conductive bump may be formed on each die bond pad, protruding through said non-conductive material and at least partially through said conductive material. The conductive layer is then laser trimmed, forming conductive patches that serve as electrical interconnects between the die and package substrate.

Owner:TEXAS INSTR INC

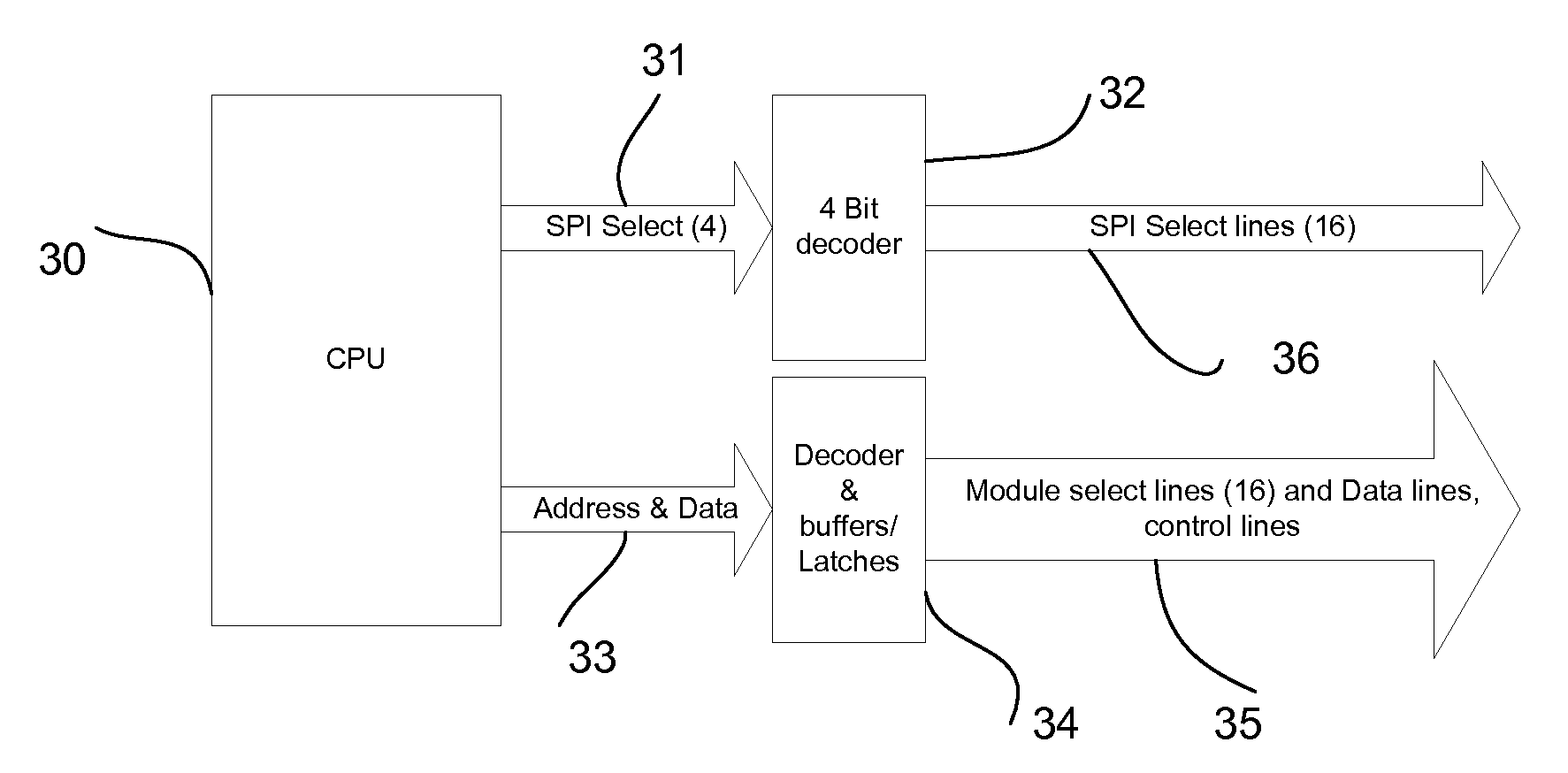

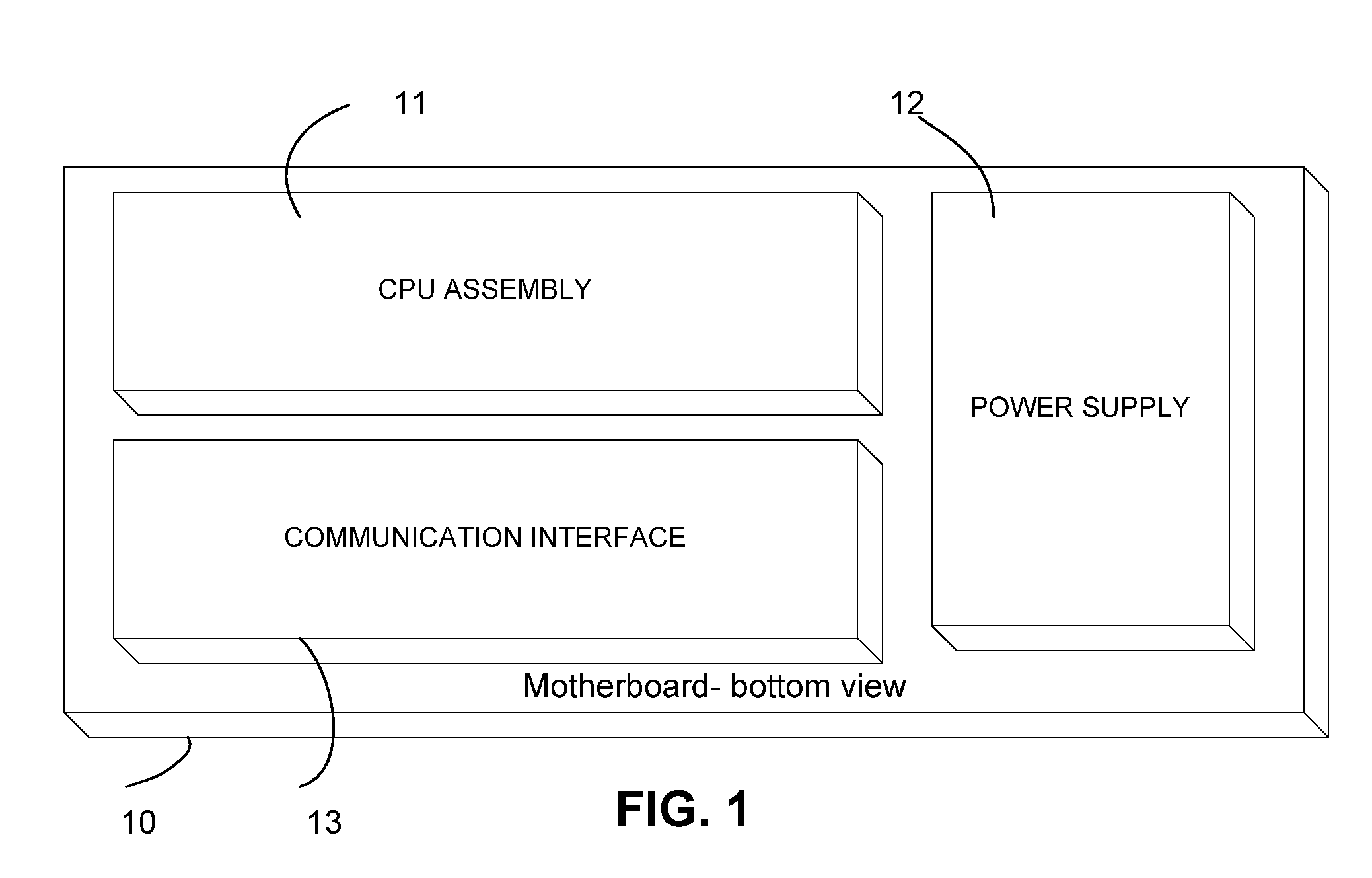

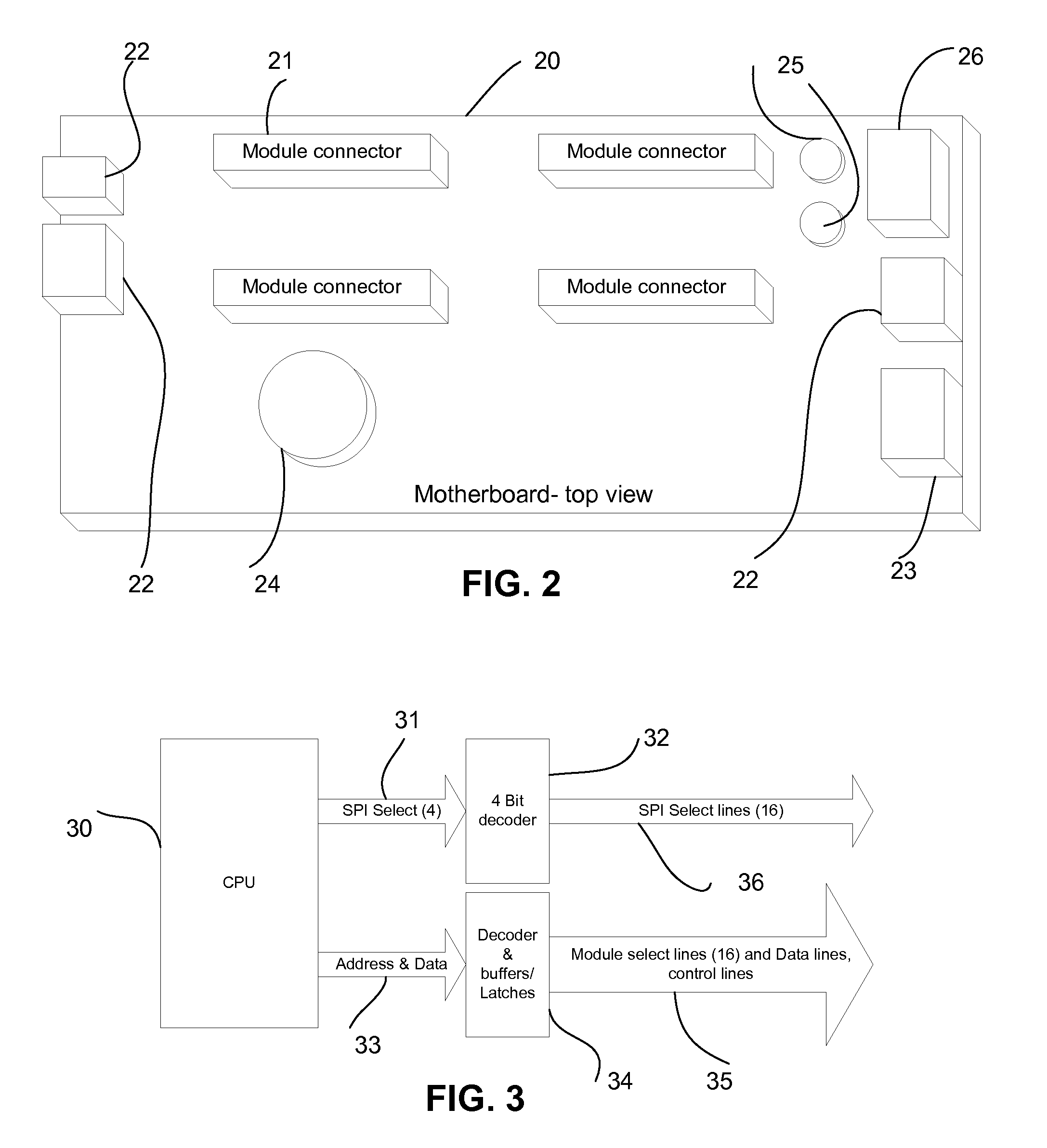

Compact modular programmable logic controller

InactiveUS20070173960A1Programme control in sequence/logic controllersAdaptive controlElectrical resistance and conductanceProgrammable logic controller

A compact lower cost programmable logic controller with modular I / O is described. SPI bus is used for accessing multi-byte data from I / O modules, while 8 bit data bus is used to access single byte data from I / O modules. Compact I / O modules with use with the PLC are described. The include short circuit proof DC output modules, Relay output with built-in electromagnetic shield, analog modules with laser trimmed resistors, and high speed counter modules.

Owner:KUMAR SHALABH

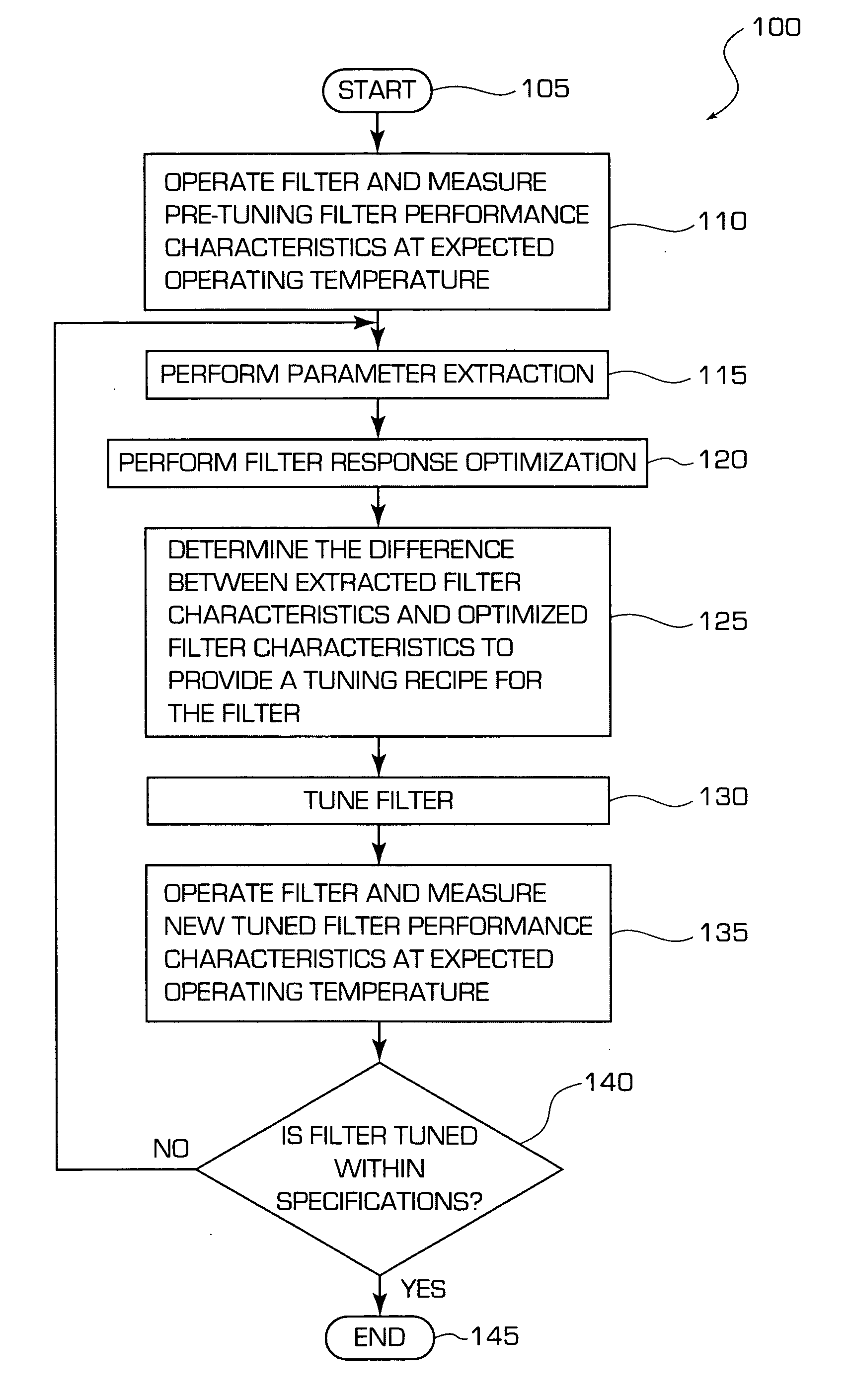

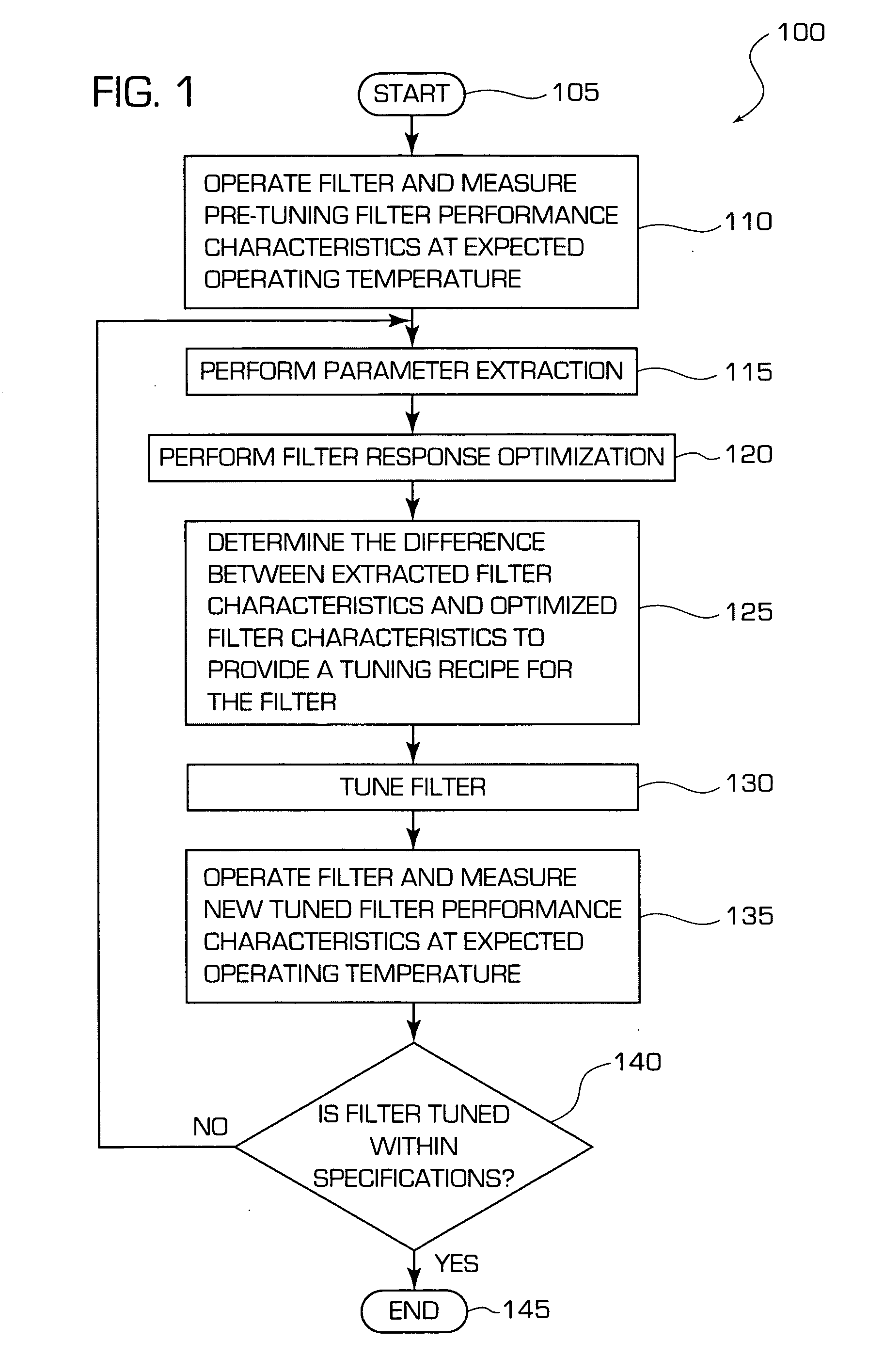

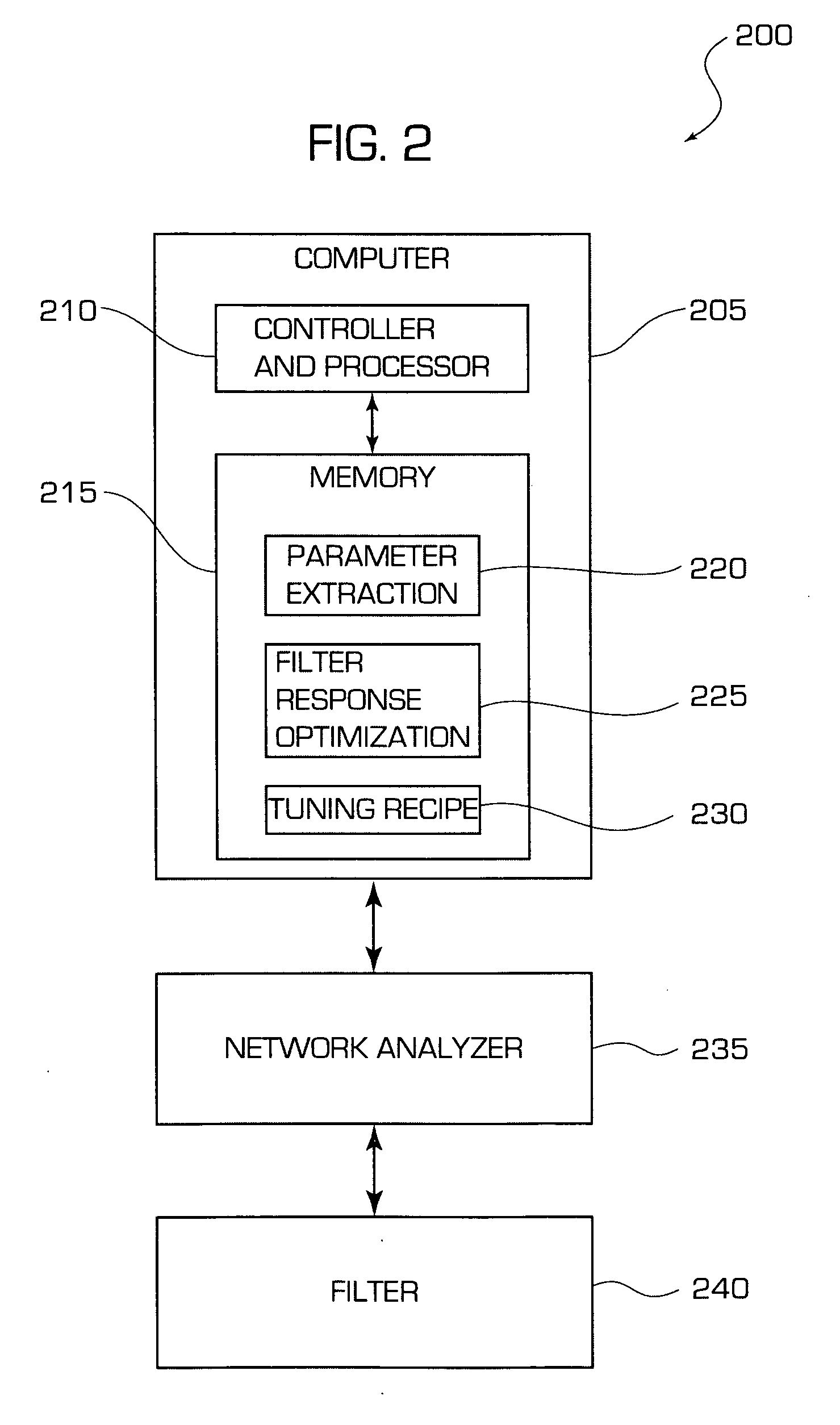

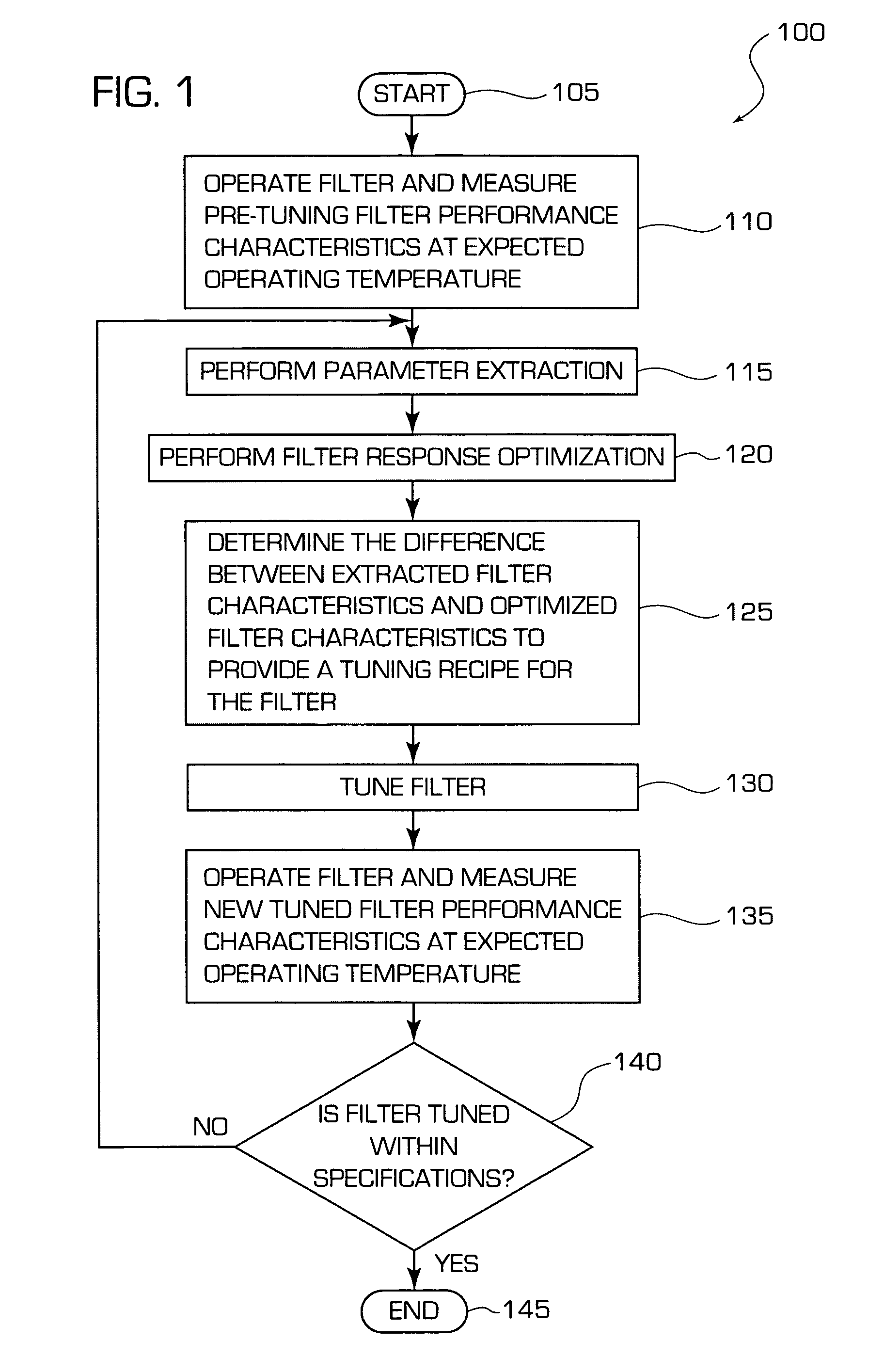

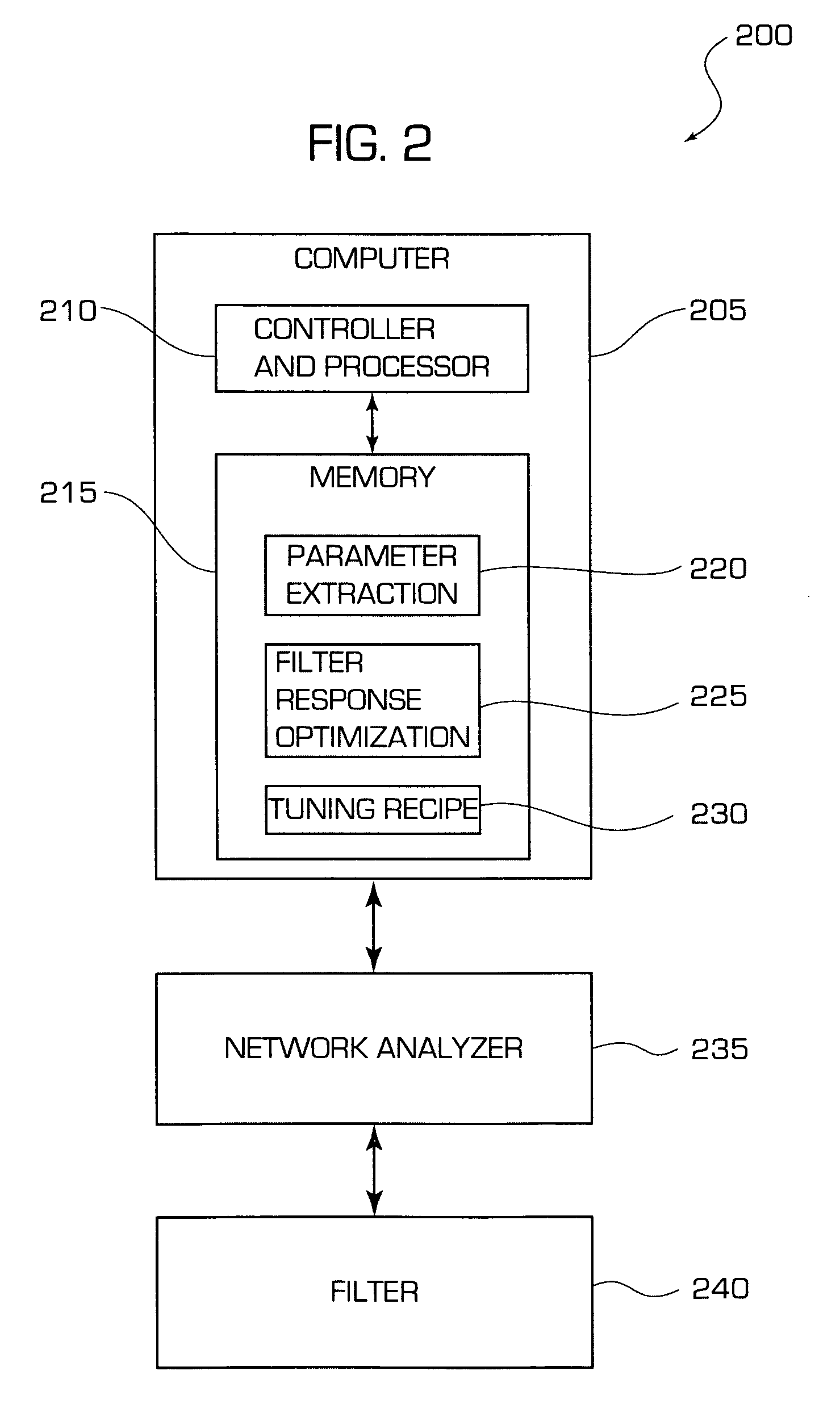

Systems and methods for tuning filters

InactiveUS20060202775A1Reduce sensitivityError in sensitivityTransmission control/equlisationSignal/carrier strength dependant limiting amplitudeFir filter designTrim tab

Methods, systems and apparatus for filter design, analysis and adjustment are provided. Various embodiments may include, for example, methods, systems and apparatus for electric signal filter tuning. Embodiments may also include design techniques for planar electric signal (e.g., RF signals) filter tuning. In at least an embodiment of the present invention a technique for filter tuning is provided which may include parameter extraction, optimization and tuning recipes techniques that may require only a single permanent filter tuning. In at least another embodiment a system and method of filter design, analysis and adjustment according to the present invention includes use of tuning that may be set using a mechanical scribing tool or a laser trimming device. In at least one other embodiment, a filter tuning technique may be provided and include providing trimming tabs on a resonator edge that may be disconnected or trimmed for filter tuning.

Owner:SUPERCONDUCTOR TECHNOLOGIES INC

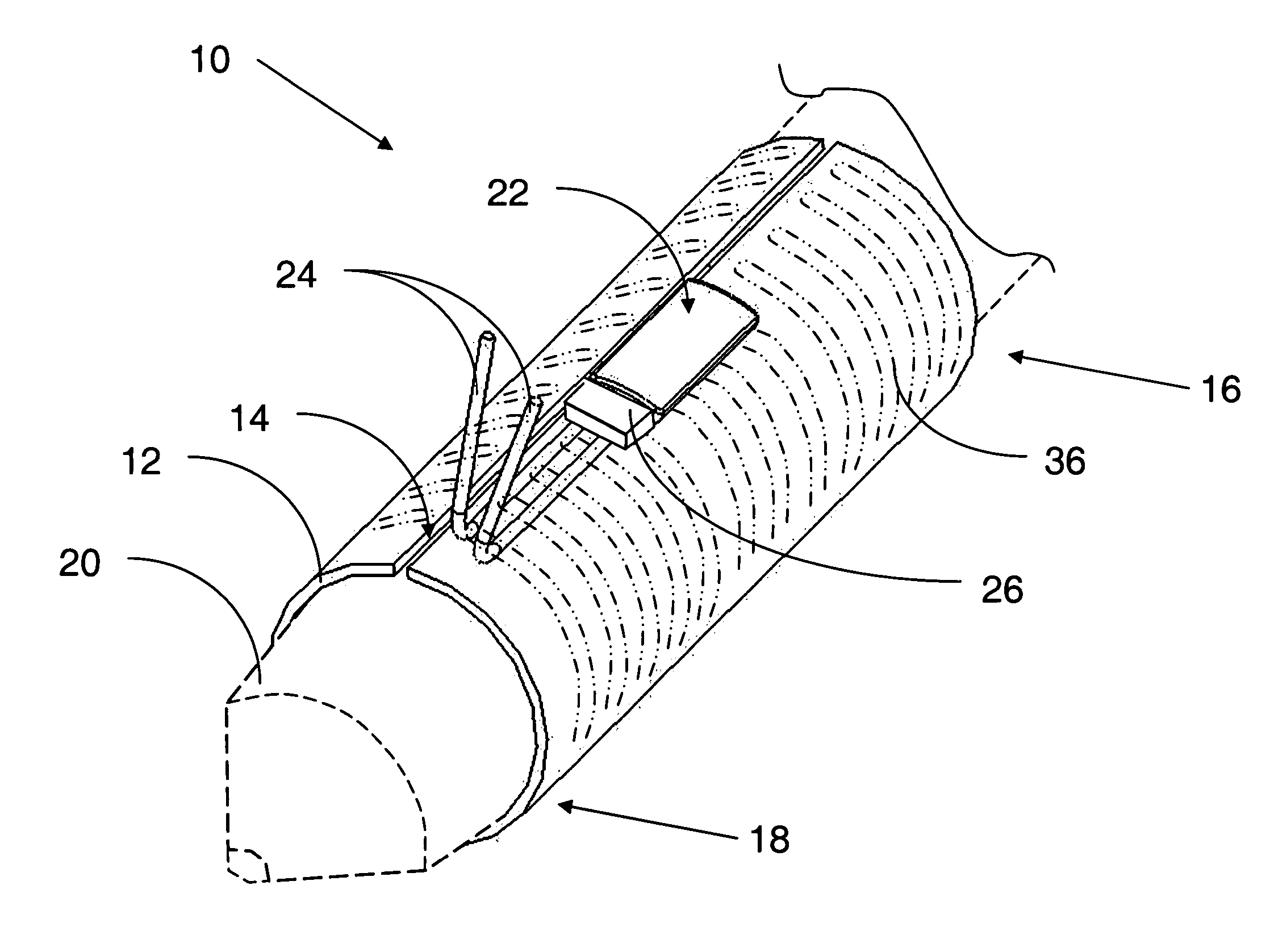

Method to embed thick film components

InactiveUS6860000B2Printed circuit assemblingInsulating substrate metal adhesion improvementEngineeringMetallic substrate

The invention is directed to a method to embed a thick film resistor composition into a printed wiring board comprising the steps of applying a reinforcing composition onto a resistor composition disposed on a metallic substrate forming an assembly wherein the resistor composition is at least partially coated with the reinforcing composition; processing the assembly; and applying the assembly onto at least one side of an organic substrate forming a component wherein the organic substrate is at least partially coated with an adhesive layer and wherein the reinforcing composition side of the assembly is embedded into the adhesive layer. The reinforcing composition allows laser trimming of the fired resistor and also eliminates cracking during lamination steps of the invention.

Owner:CHEMTRON RES

Drift-sensitive laser trimming of circuit elements

InactiveUS6875950B2Improve throughputPrinted electric component incorporationResistor trimmingInductorCapacitor

Owner:ELECTRO SCI IND INC

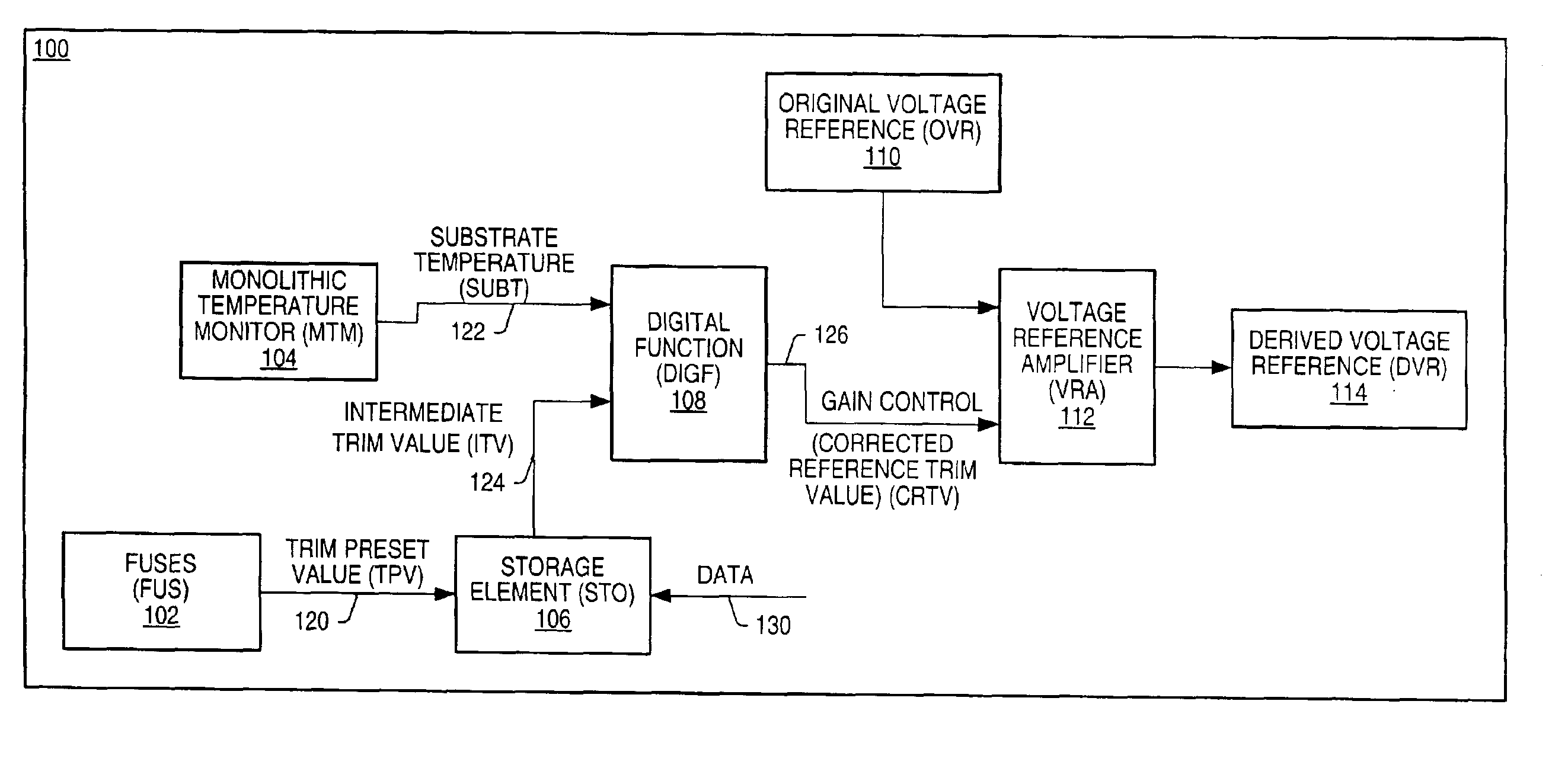

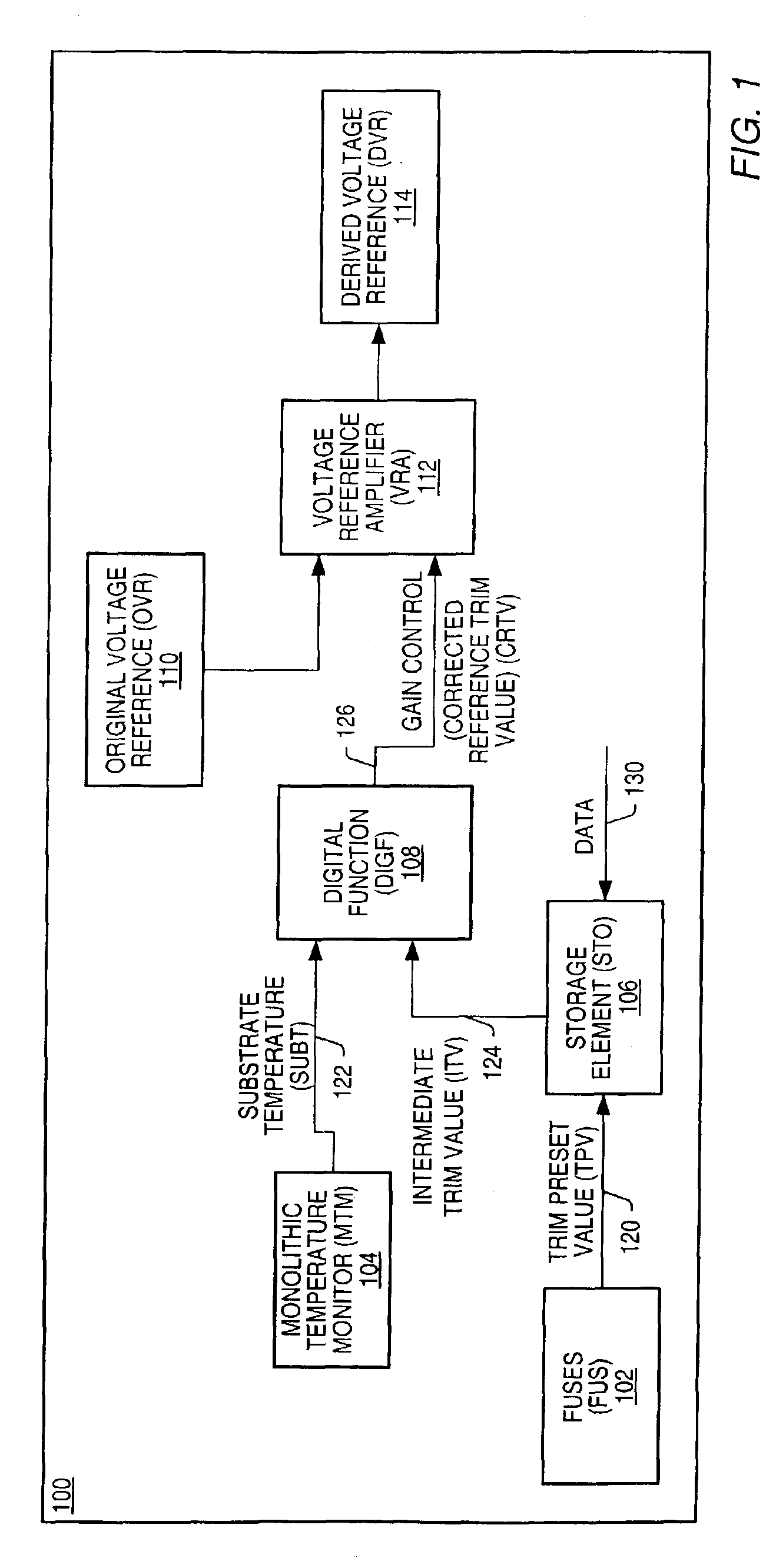

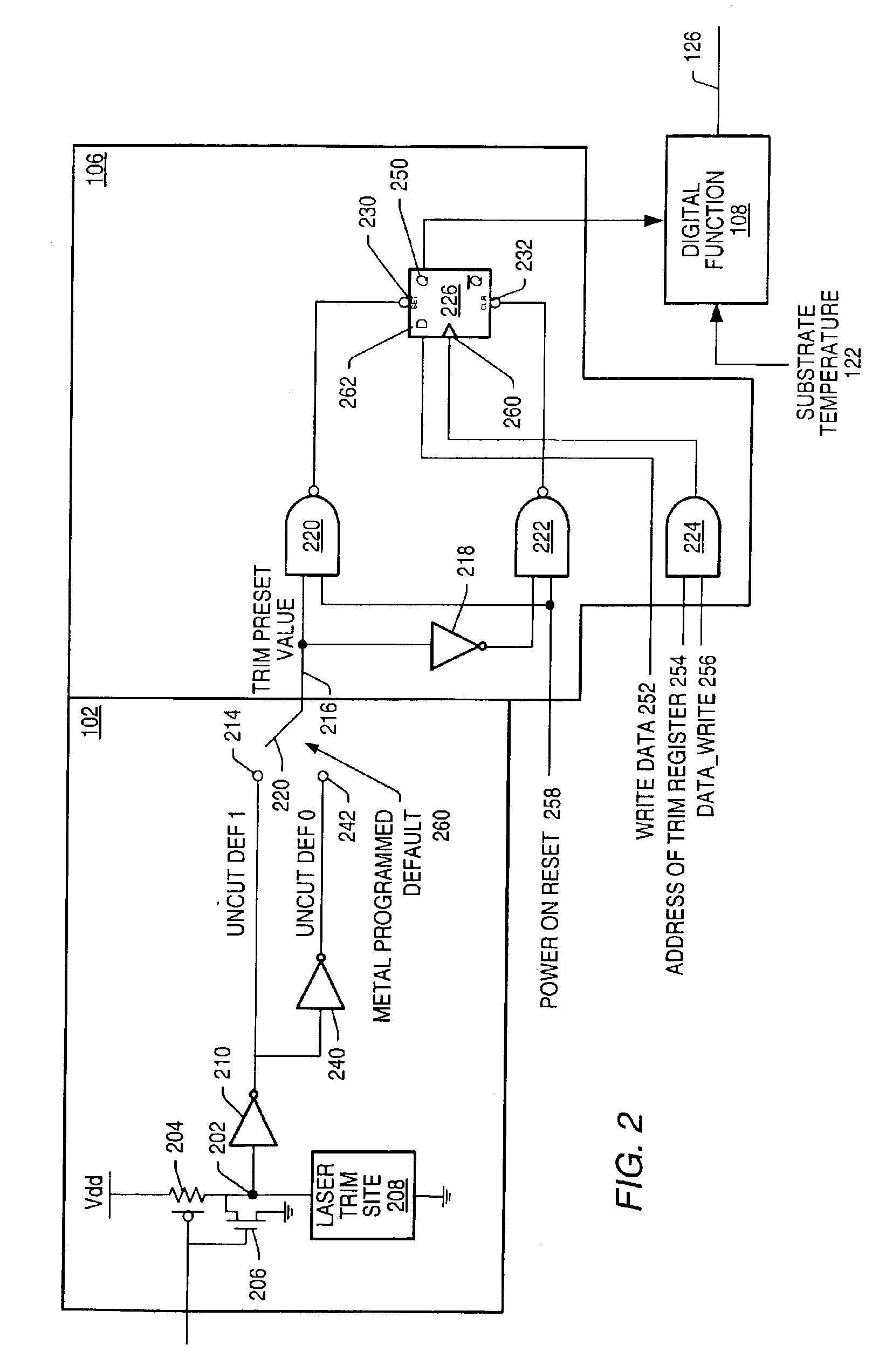

Dynamic, digitally controlled, temperature compensated voltage reference

ActiveUS6885243B2Volume/mass flow measurementMultiple digital computer combinationsAudio power amplifierProcessor register

A voltage reference is dynamically and digitally controlled by a digital function. The digital function may be implemented as a digital calculation or look up table. Inputs to the function include a modifiable trim value stored in a trim register, and a substrate temperature value. The preset value of the trim register is a trim preset value generated by cutting fuses and / or leaving fuses uncut. The cutting may be performed using laser trimming-devices. The output of the digital function is a corrected reference trim value that controls the gain of a voltage reference amplifier whose input is a band gap based voltage reference, and whose output is a derived voltage reference. The substrate temperature value is provided by a monolithic temperature monitor whose sensor may be on the same die as the derived voltage reference. The derived voltage reference provides a stable reference voltage that is dynamically and digitally controllable, to a host system that requires a voltage reference.

Owner:MICROCHIP TECH INC

Method and system for high-speed precise laser trimming, scan lens system for use therein and electrical device produced thereby

InactiveUS20060160332A1Small spot sizeTight toleranceSemiconductor/solid-state device manufacturingResistor manufactureElectricityHigh absorption

A method, system and scan lens system are provided for high-speed, laser-based, precise laser trimming at least one electrical element. The method includes generating a pulsed laser output having one or more laser pulses at a repetition rate. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The method further includes selectively irradiating the at least one electrical element with the one or more laser pulses focused into at least one spot having a non-uniform intensity profile along a direction and a spot diameter as small as about 6 microns to about 15 microns so as to cause the one or more laser pulses to selectively remove material from the at least one element and laser trim the at least one element while avoiding substantial microcracking within the at least one element. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance and high absorption, but not so short so as to cause microcracking.

Owner:ELECTRO SCI IND INC

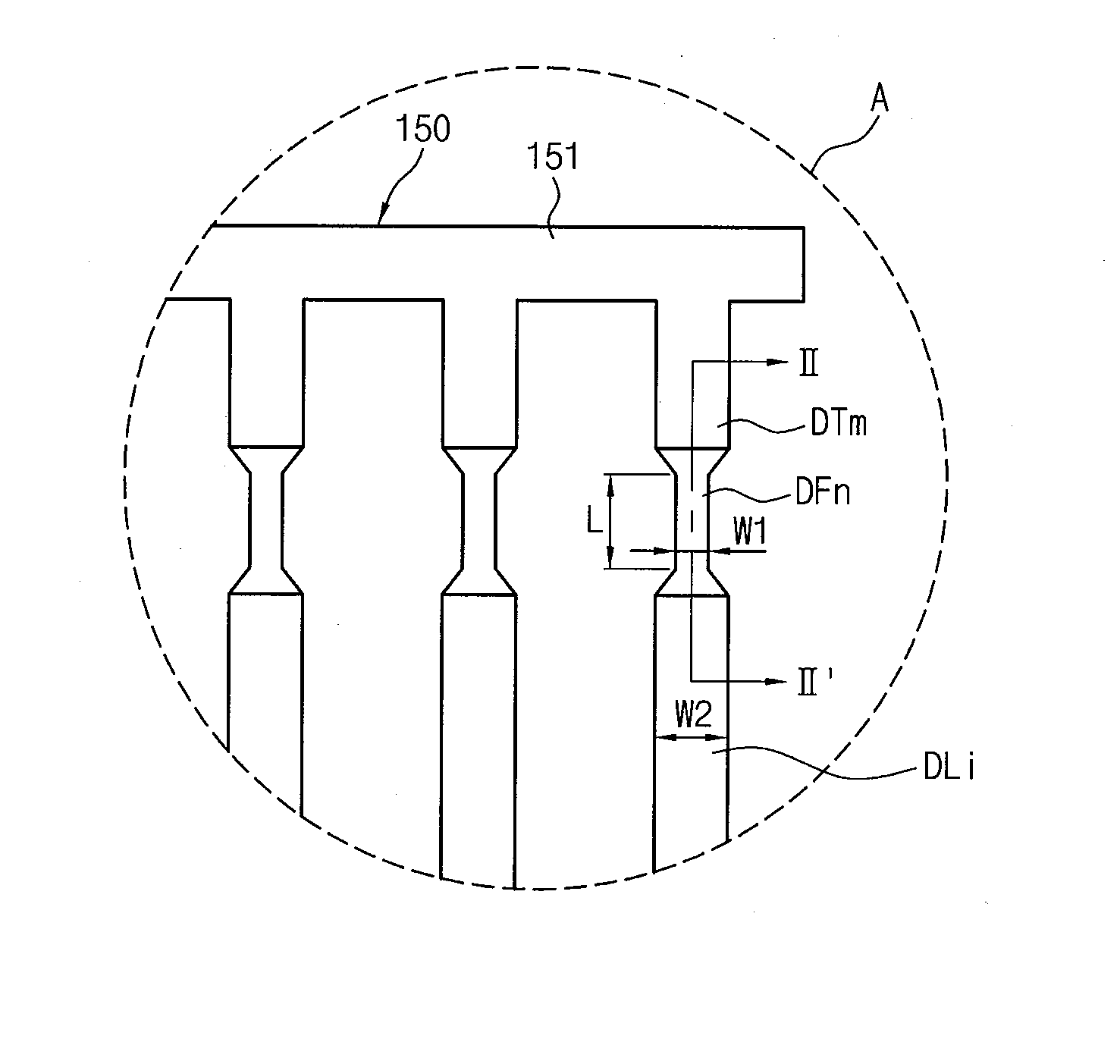

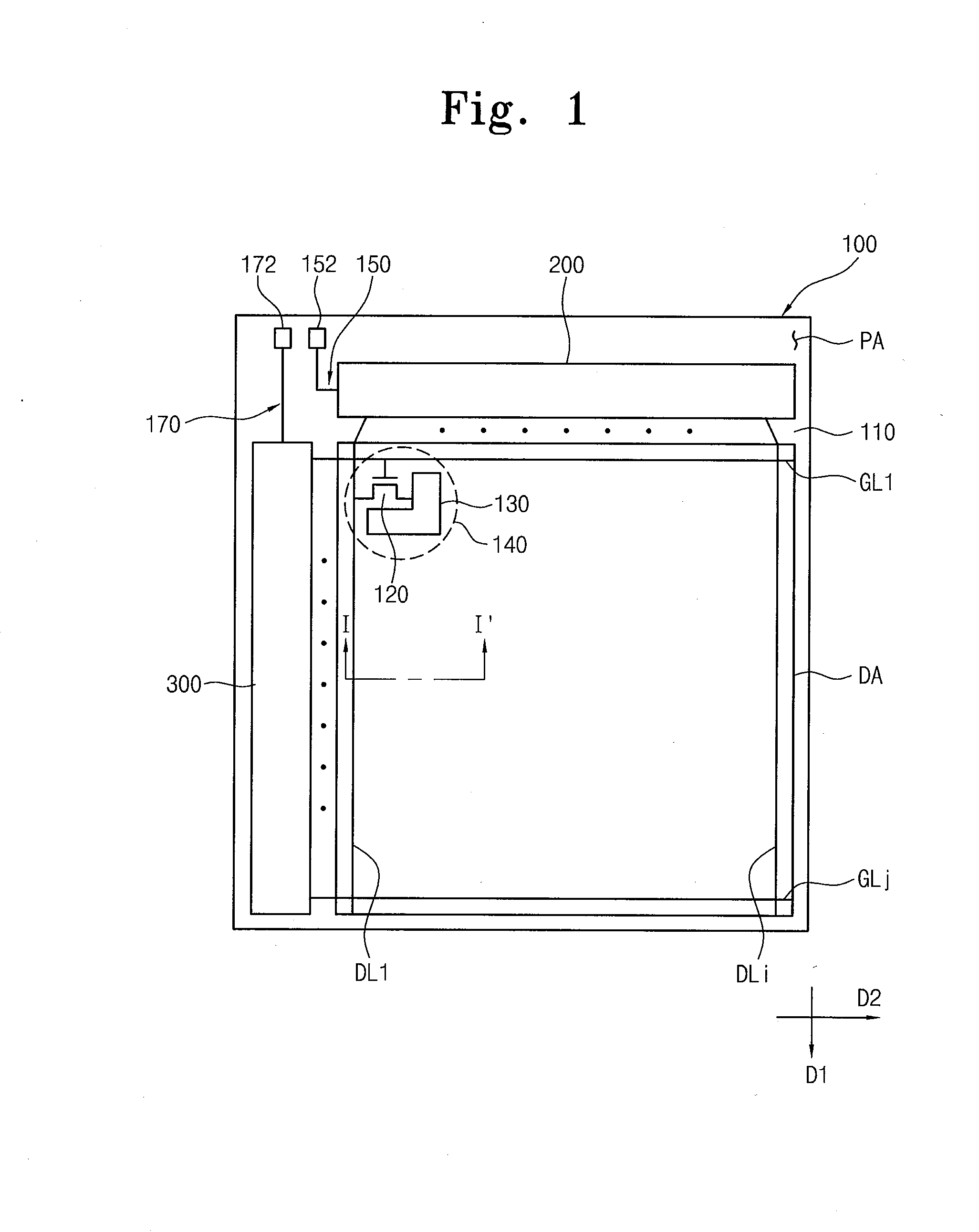

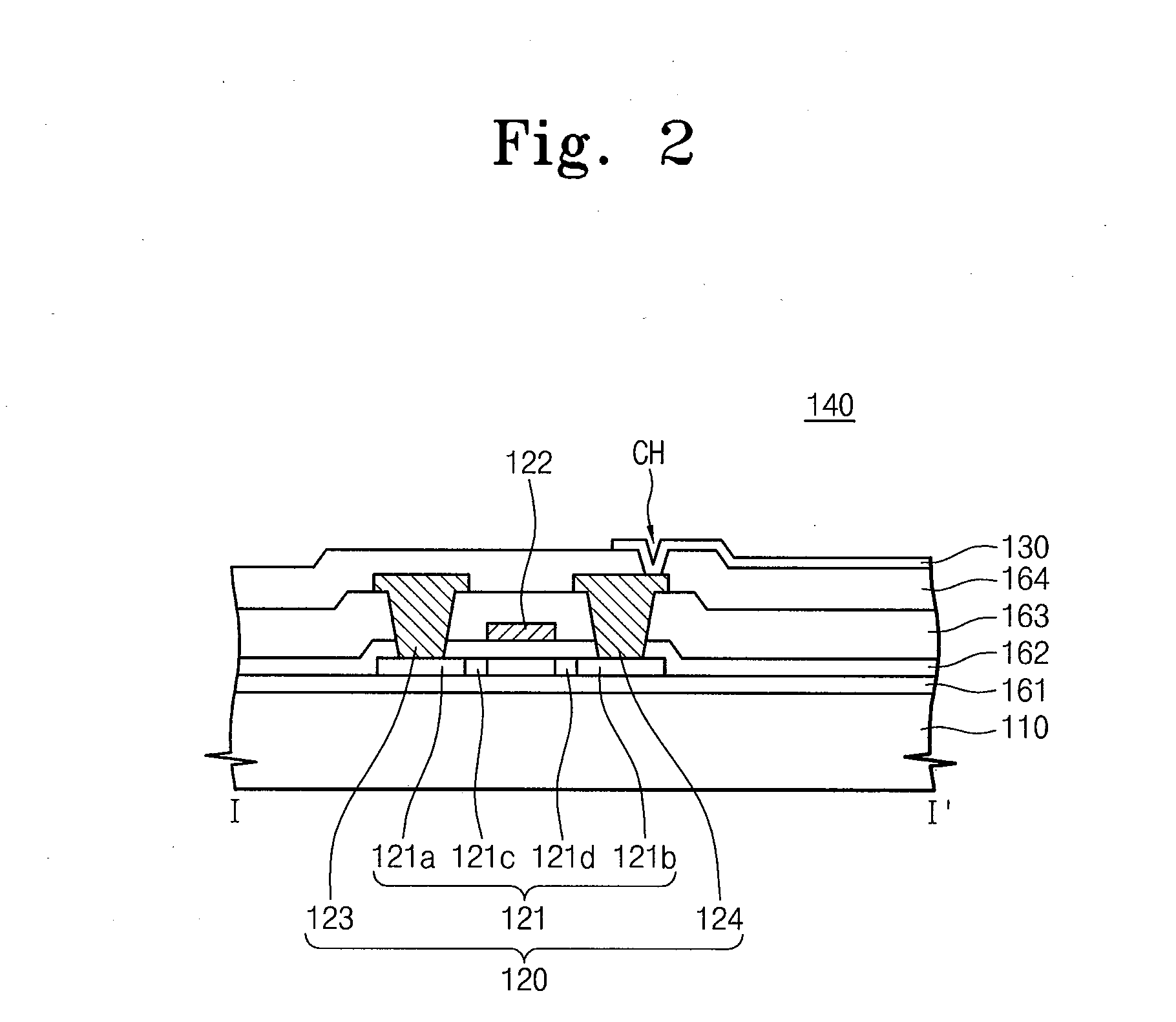

Array substrate for liquid crystal display and method of testing

InactiveUS20070284578A1Reduce processing timeImprove productivitySemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayReference current

An array substrate including a signal line, a test line to inspect the open of the signal line and fault of the pixels, and a fuse electrically connecting the signal line with the test line. The fuse is opened when a current higher than a reference current is applied thereto. Accordingly, a laser trimming process to insulate the signal line from the test line is not needed after the signal line and pixels have been tested, so that the processing time may be shortened.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of producing printed circuit board with embedded resistor

InactiveUS20050175385A1Improve workabilityResistance value change remains constantSemiconductor/solid-state device detailsSolid-state devicesProduction rateScreen printing

Disclosed is a method of producing a printed circuit board (PCB) with an embedded resistor, in which a resistor with a desired shape and volume is precisely formed using a resistor paste so that resistance values according to a position of the PCB are uniform, thereby a laser trimming process is omitted or minimally utilized. The method has advantages in that a production time of the PCB is shortened and productivity is improved because an operation condition is rapidly set without being greatly affected by the position precision of a printing device. Other advantages of the method are that the resistor paste with a relatively uniform thickness is secured through a screen printing process, thereby easily forming the resistor and improving resistance tolerance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

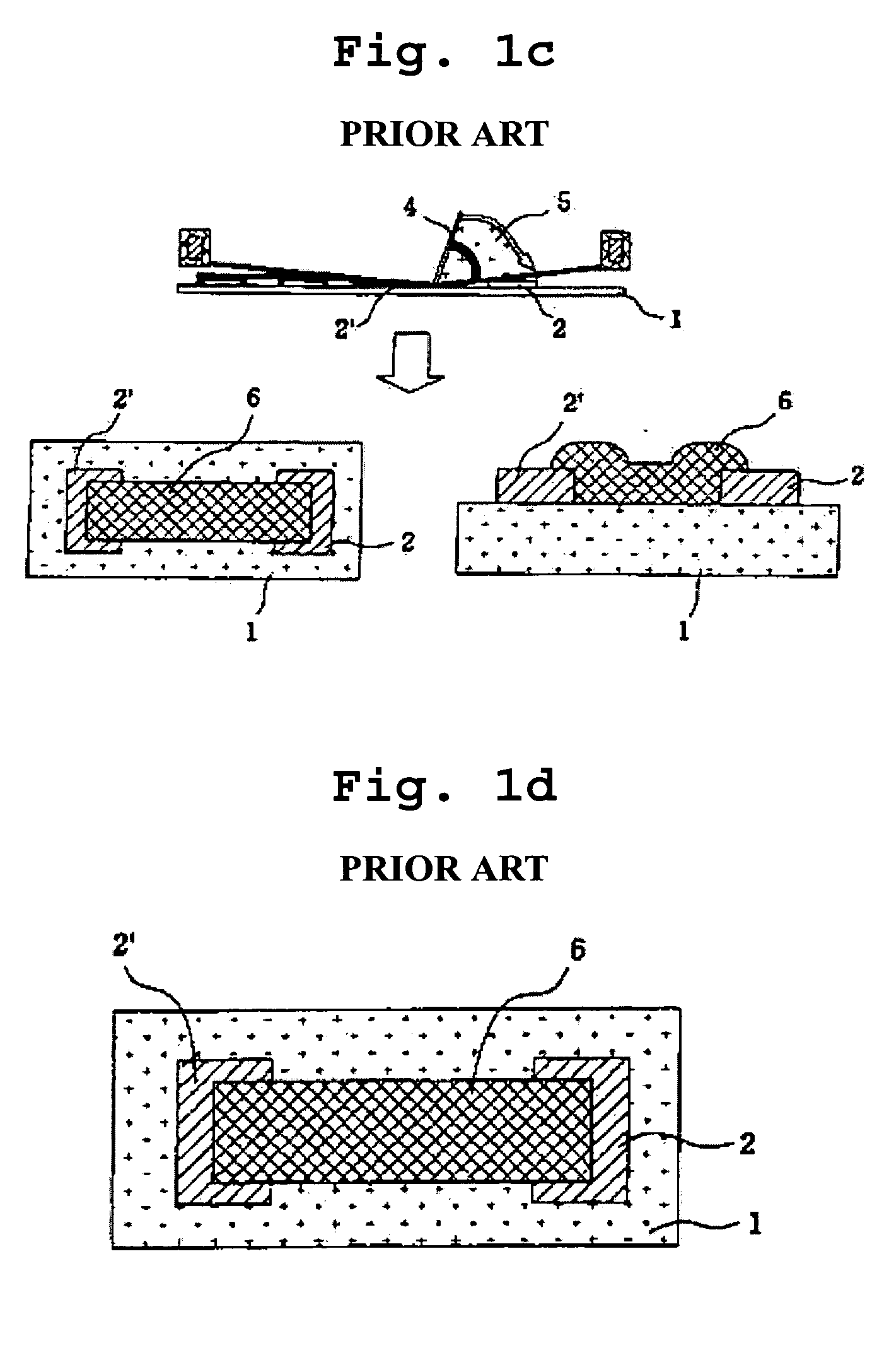

Laser trimming method for super-abrasive grinding wheel

InactiveCN101642895ANo lossImprove power densityAbrasive surface conditioning devicesNumerical controlControl signal

The invention discloses a laser trimming method for a super-abrasive grinding wheel, comprising the following steps: a, a grinding wheel is mounted on a numerical control grinding machine and is driven to rotate; b, a laser displacement sensor is aligned to the surface of the grinding wheel, does axial feeding movement relative to the grinding wheel and scans the surface of the grinding wheel, scanning data is input into a computer storing an ideal profile of the grinding wheel to form an actual profile of the grinding wheel on the surface, the actual profile is compared with the ideal profileof the grinding wheel to obtain a distribution condition of allowance removal; c. the computer sends trimming control signals to the numerical grinding machine and a laser through a microprocessor controller, so that the laser emits an appropriate laser pulse to burn a point to be trimmed on the grinding wheel according to the control signals, the laser displacement sensor detects present remained allowance of the point, and the allowance of the point in the computer is updated timely; and d, the step c is carried out repeatedly till the trimming precision as required is achieved.

Owner:HUNAN UNIV

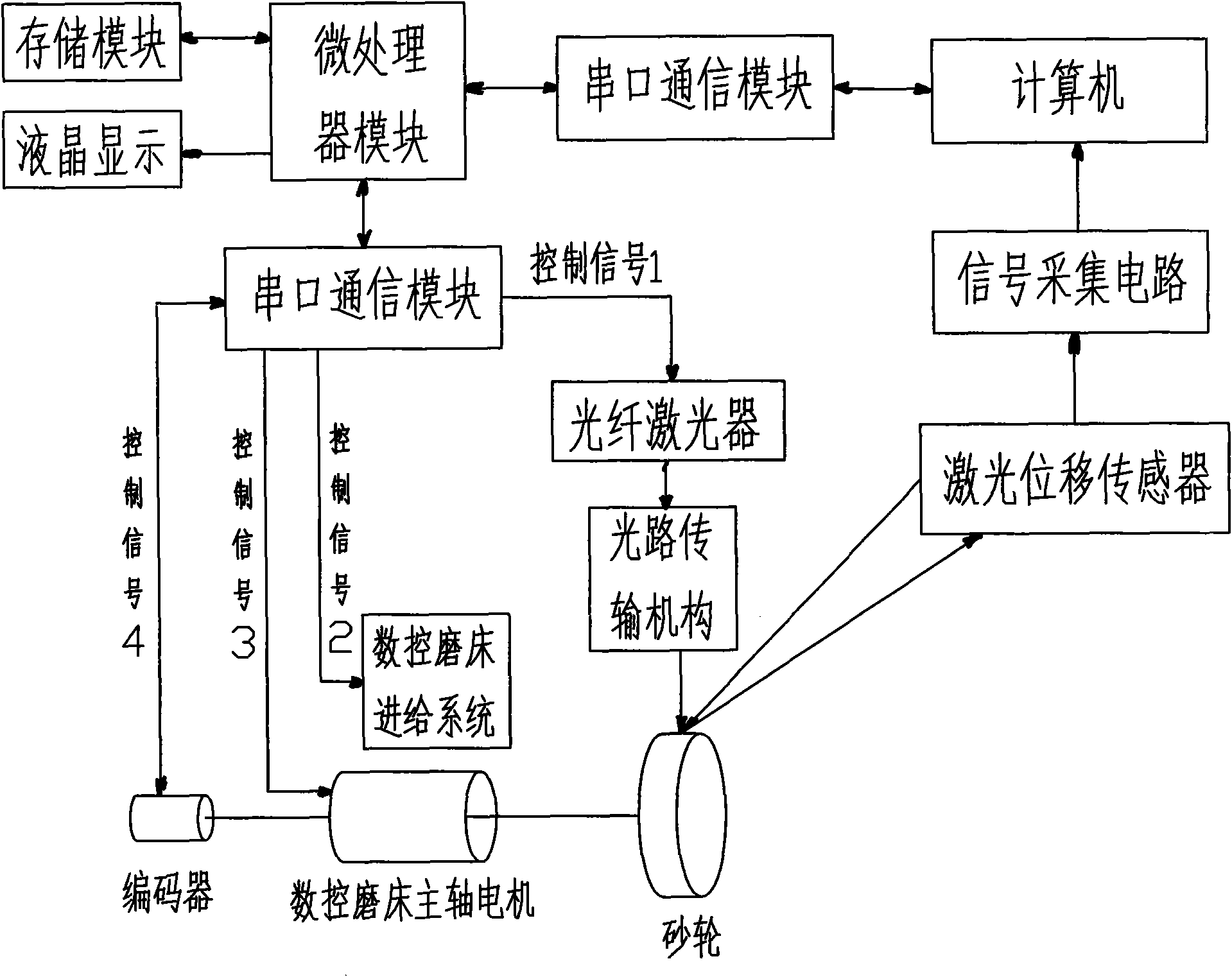

Hot runner nozzle heater and methods of manufacture thereof

A hot runner nozzle heater is provided that includes a sleeve defining a slot extending along a length of the sleeve. A first dielectric layer is disposed over an outer surface of the sleeve, and a resistive element layer is disposed over the first dielectric layer, wherein the resistive element layer defines a resistive circuit pattern that is preferably formed by a laser trimming process. A pair of terminal leads are secured to a portion of the resistive element layer thus defining a termination area, and the termination area is positioned proximate the slot and away from the proximal end and the distal end of the sleeve. A second dielectric layer is disposed over the resistive element layer but not over the termination area, a third dielectric layer is disposed over the termination area, and a protective layer disposed over the second dielectric layer and the third dielectric layer.

Owner:WATLOW ELECTRIC MFG

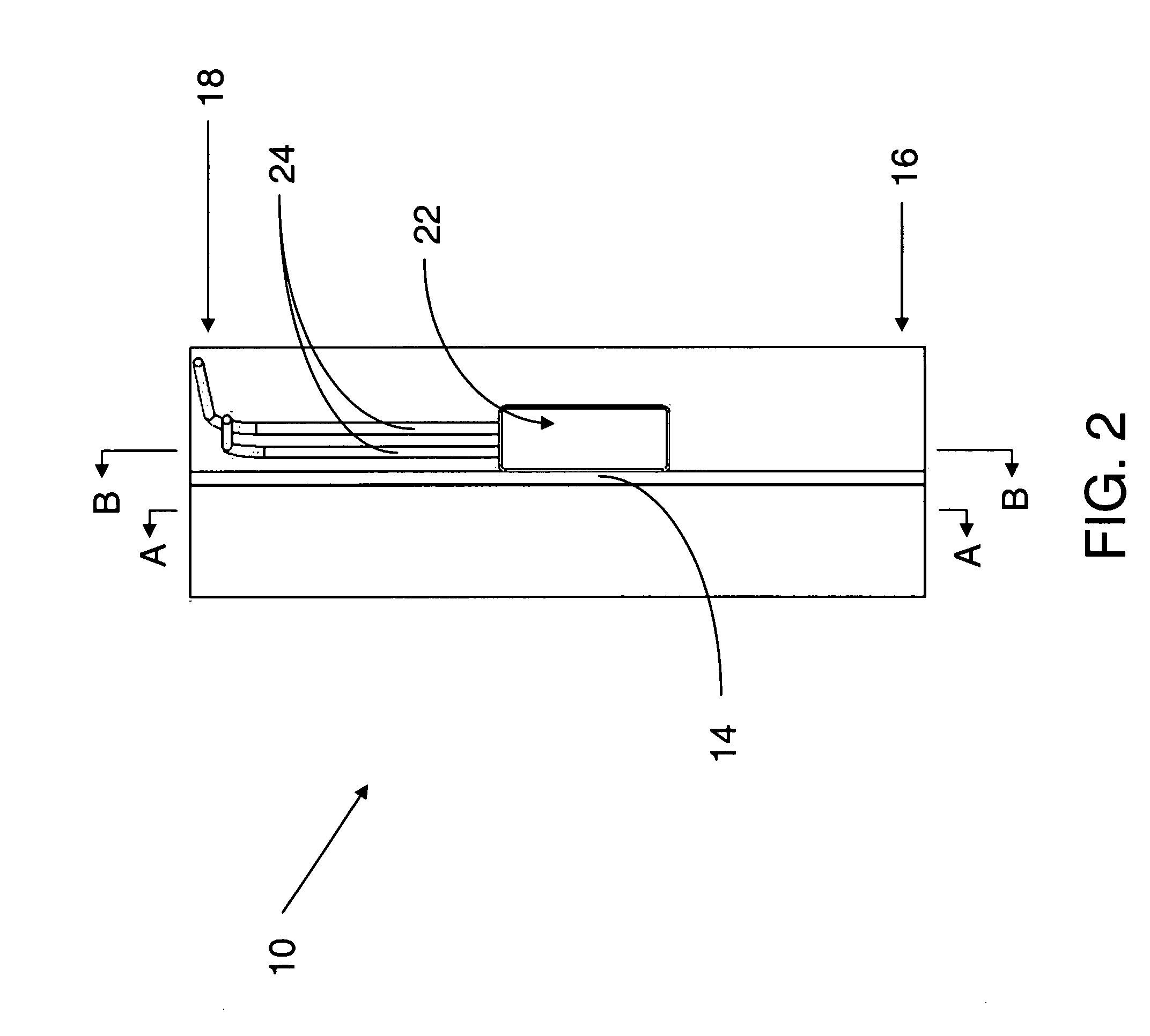

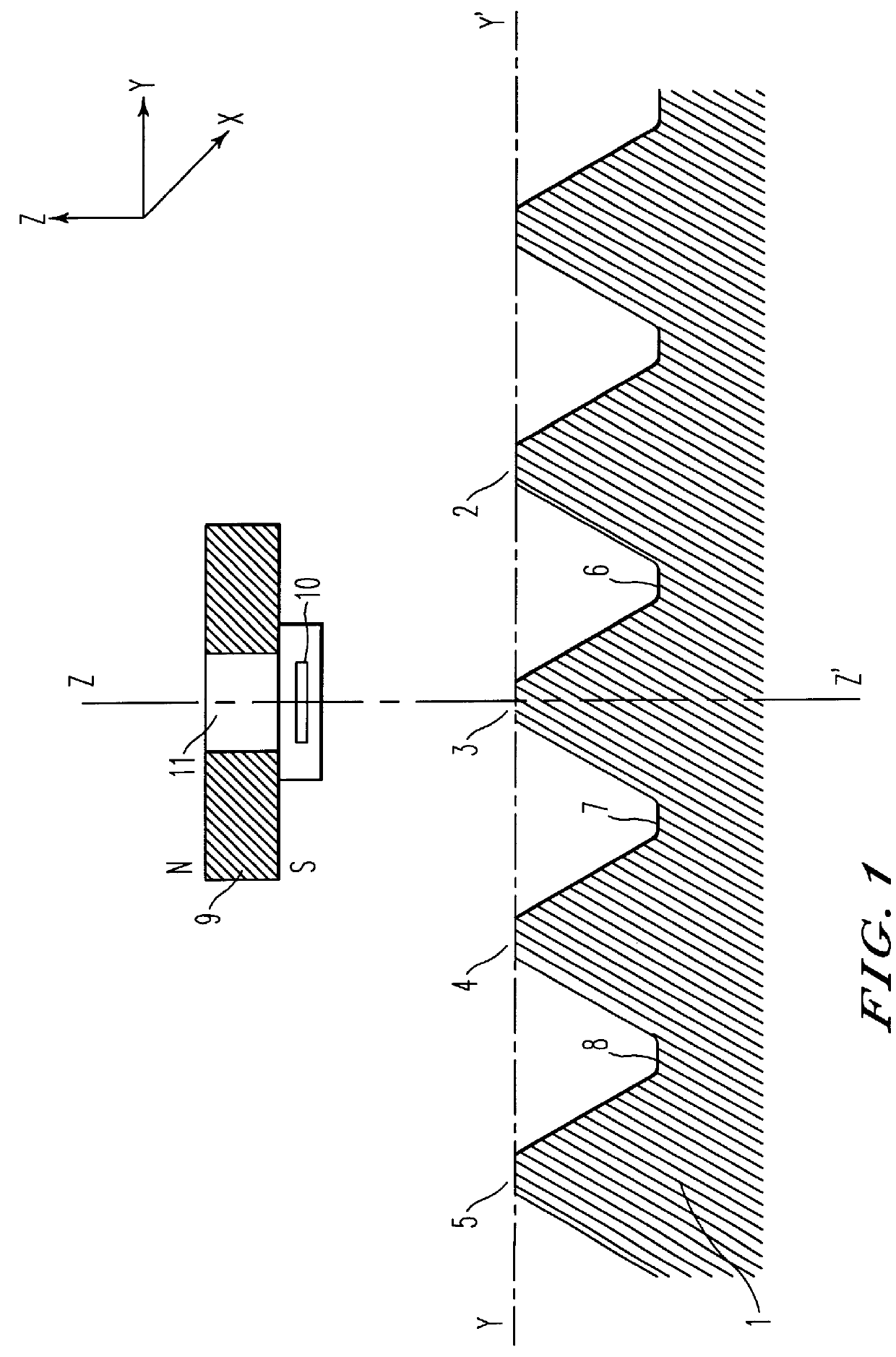

Incremental sensor of speed and/or position for detecting low and null speeds

InactiveUS6087827AImprove playbackReduce thicknessSolid-state devicesMagnetic field measurement using galvano-magnetic devicesLow speedSoft materials

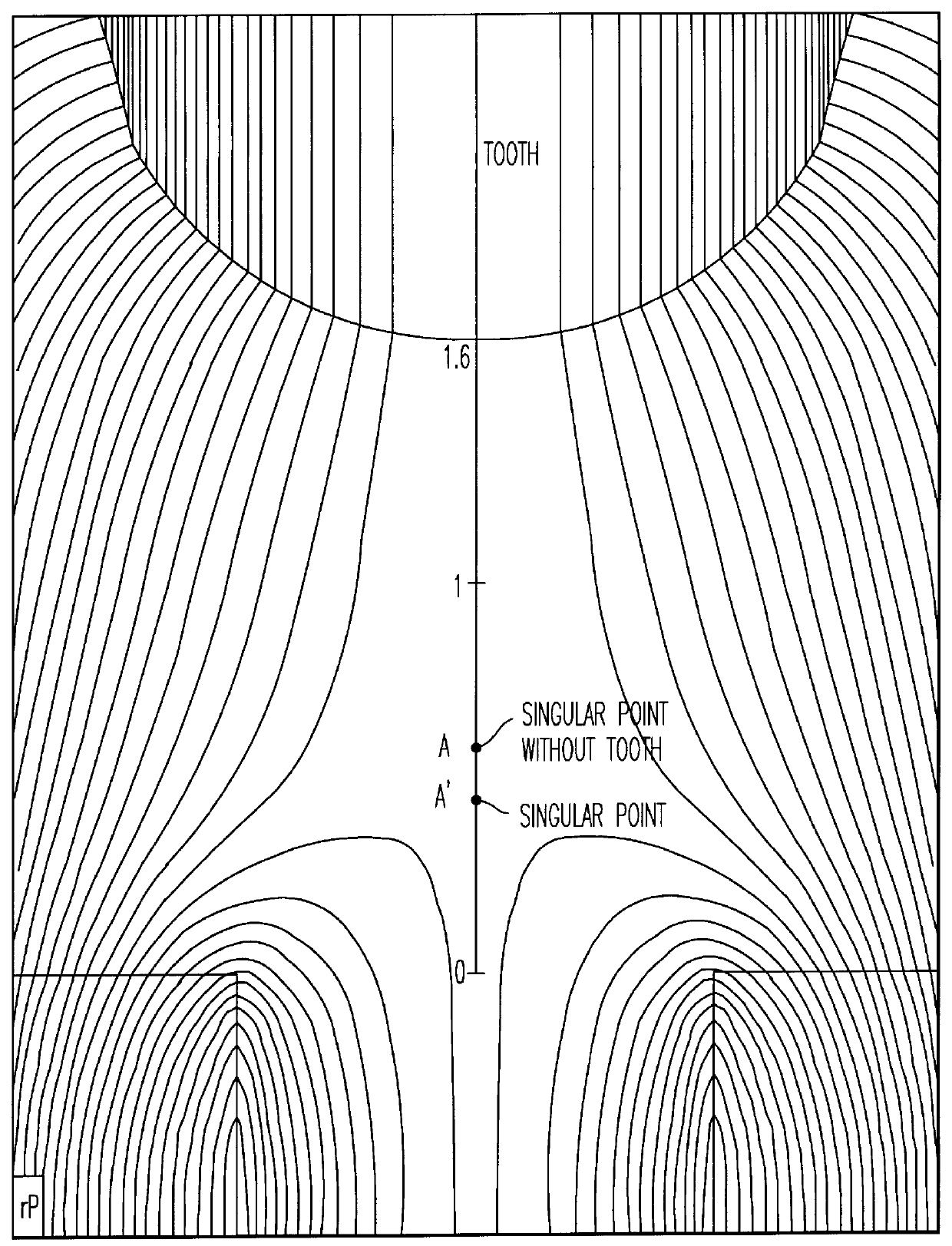

This invention pertains to an incremental sensor of position and / or speed, of the type which includes a moving component made of a soft material that has at least one moving tooth in a direction OZ with respect to a permanent magnet magnetized along the direction OY, which is approximately perpendicular to the OZ axis, and a probe which is sensitive to the direction and strength of the magnetic field, such as a Hall-effect gaussmeter, arranged in the air gap between the magnet and the tooth of the moving component so that its axis of greatest sensitivity is approximately oriented along the OZ axis. The Hall-effect gaussmeter is located near a singular point of the OZ axis where the average value of the magnetic field is weak and preferably less than .+-.20 mT and approximately equal to the average value of the alternating field of the integrated circuit connected to the Hall-effect gaussmeter. The permanent magnet can also be laser trimmed to achieve the desired operation in the Hall-effect gaussmeter.

Owner:MOVING MAGNET TECH

Method and system for high-speed precise laser trimming and electrical device produced thereby

InactiveUS20060199354A1Precise TrimmingReduced stabilitySemiconductor/solid-state device manufacturingResistor manufactureHeat-affected zoneHigh absorption

A method and system are provided for high-speed, laser-based, precise laser trimming at least one electrical element along a trim path. The method includes generating a pulsed laser output with a laser, the output having one or more laser pulses at a repetition rate. A fast rise / fall time, pulse-shaped q-switched laser or an ultra-fast laser may be used. Beam shaping optics may be used to generate a flat-top beam profile. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance, high absorption and reduced or eliminated heat-affected zone (HAZ) along the trim path, but not so short so as to cause microcracking. In this way, resistance drift after the trimming process is reduced.

Owner:ELECTRO SCI IND INC

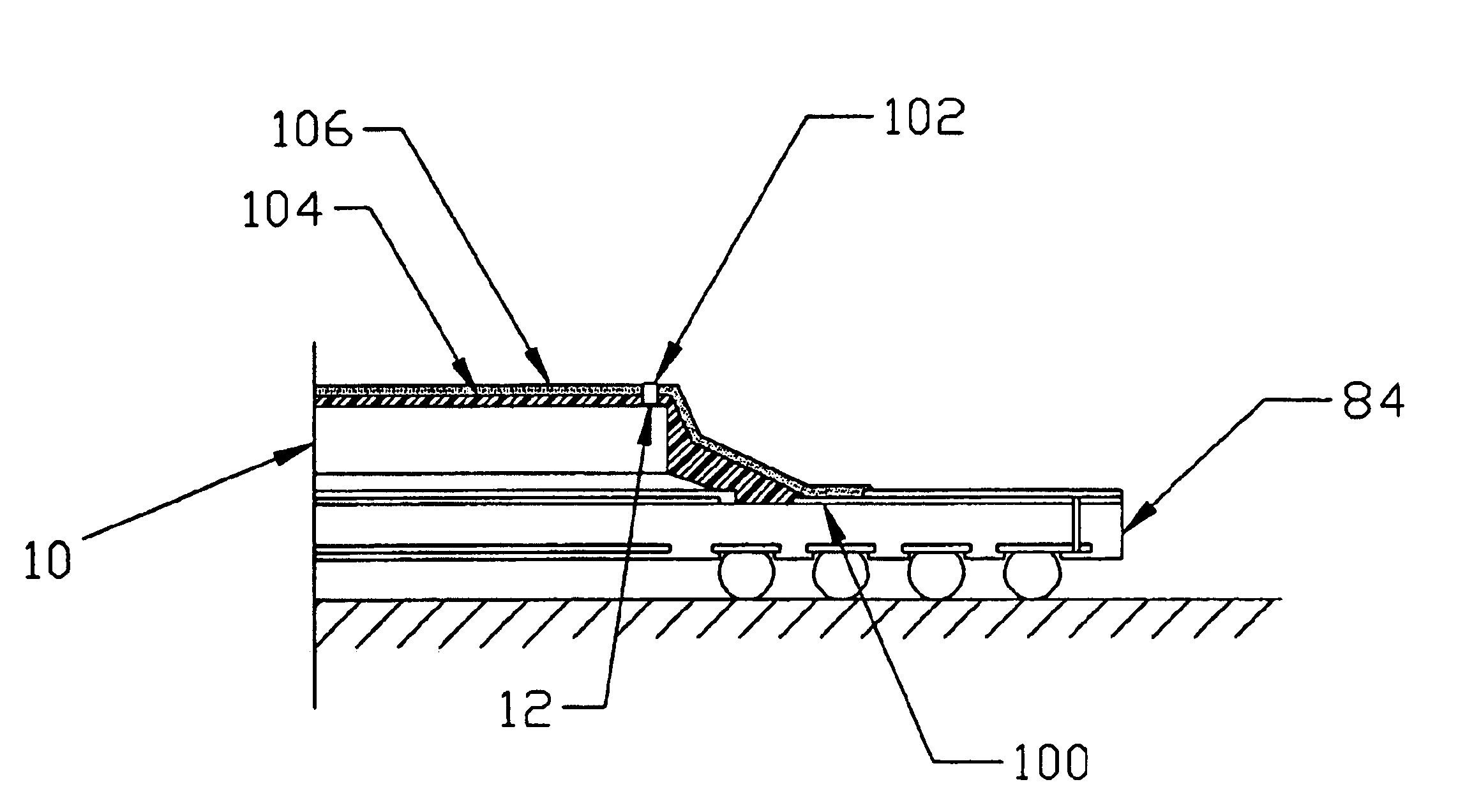

Multilayer laser trim interconnect method

InactiveUS20040173892A1Avoid problemsMore assembledSemiconductor/solid-state device detailsSolid-state devicesContact padConductive materials

A method for creating electrical interconnects between a semiconductor die and package. In the preferred embodiment, an insulating material is applied over the die and extends to the substrate contact pads, leaving a portion of each contact pad exposed. Holes are then trimmed through the insulating material, exposing at least a portion of each die bond pad. A conductive material is then applied over the die, flowing into the holes, contacting the die bond pads, and extending out to contact at least a portion of each substrate contact pad. In another preferred embodiment, an electrically conductive bump may be formed on each die bond pad, protruding through said non-conductive material and at least partially through said conductive material. The conductive layer is then laser trimmed, forming conductive patches that serve as electrical interconnects between the die and package substrate.

Owner:NAKANISHI NOBORU

Optical disk, an optical disk barcode forming method, an optical disk reproduction apparatus, a marking forming apparatus, a method of forming a laser marking on an optical disk, and a method of manufacturing an optical disk

Disclosed is an optical disk barcode forming method wherein, as information to be barcoded, position information for piracy prevention, which is a form of ID, is coded as a barcode and is recorded by laser trimming on a reflective film in PCA area of an optical disk. When playing back the thus manufactured optical disk on a reproduction apparatus, the barcode data can be played back using the same optical pickup.

Owner:PANASONIC CORP

Method and system for high-speed precise laser trimming, scan lens system for use therein and electrical device produced thereby

InactiveUS7358157B2Small spot sizeTight toleranceSemiconductor/solid-state device manufacturingResistor manufactureHigh absorptionPulse energy

A method, system and scan lens system are provided for high-speed, laser-based, precise laser trimming at least one electrical element. The method includes generating a pulsed laser output having one or more laser pulses at a repetition rate. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The method further includes selectively irradiating the at least one electrical element with the one or more laser pulses focused into at least one spot having a non-uniform intensity profile along a direction and a spot diameter as small as about 6 microns to about 15 microns so as to cause the one or more laser pulses to selectively remove material from the at least one element and laser trim the at least one element while avoiding substantial microcracking within the at least one element. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance and high absorption, but not so short so as to cause microcracking.

Owner:ELECTRO SCI IND INC

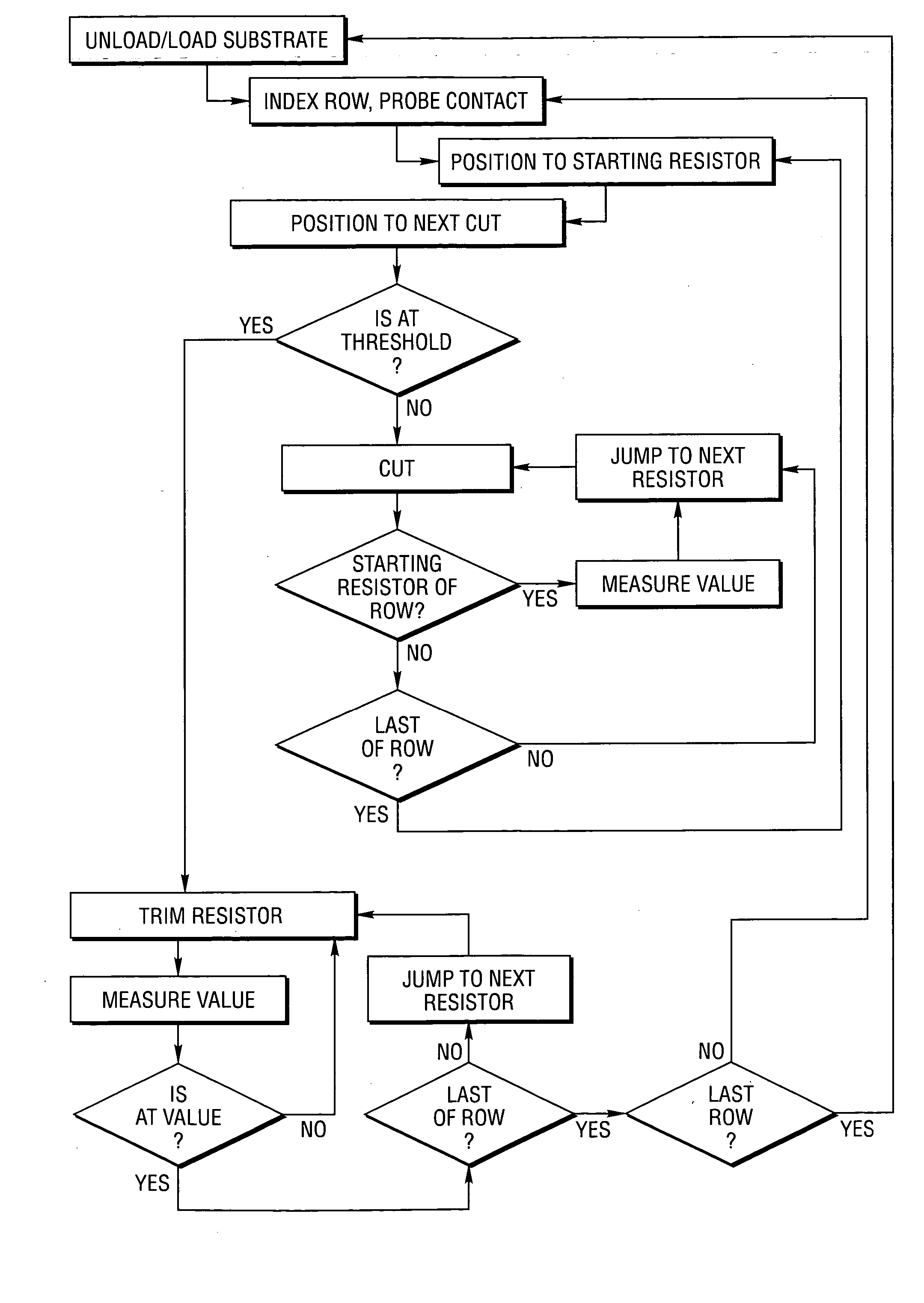

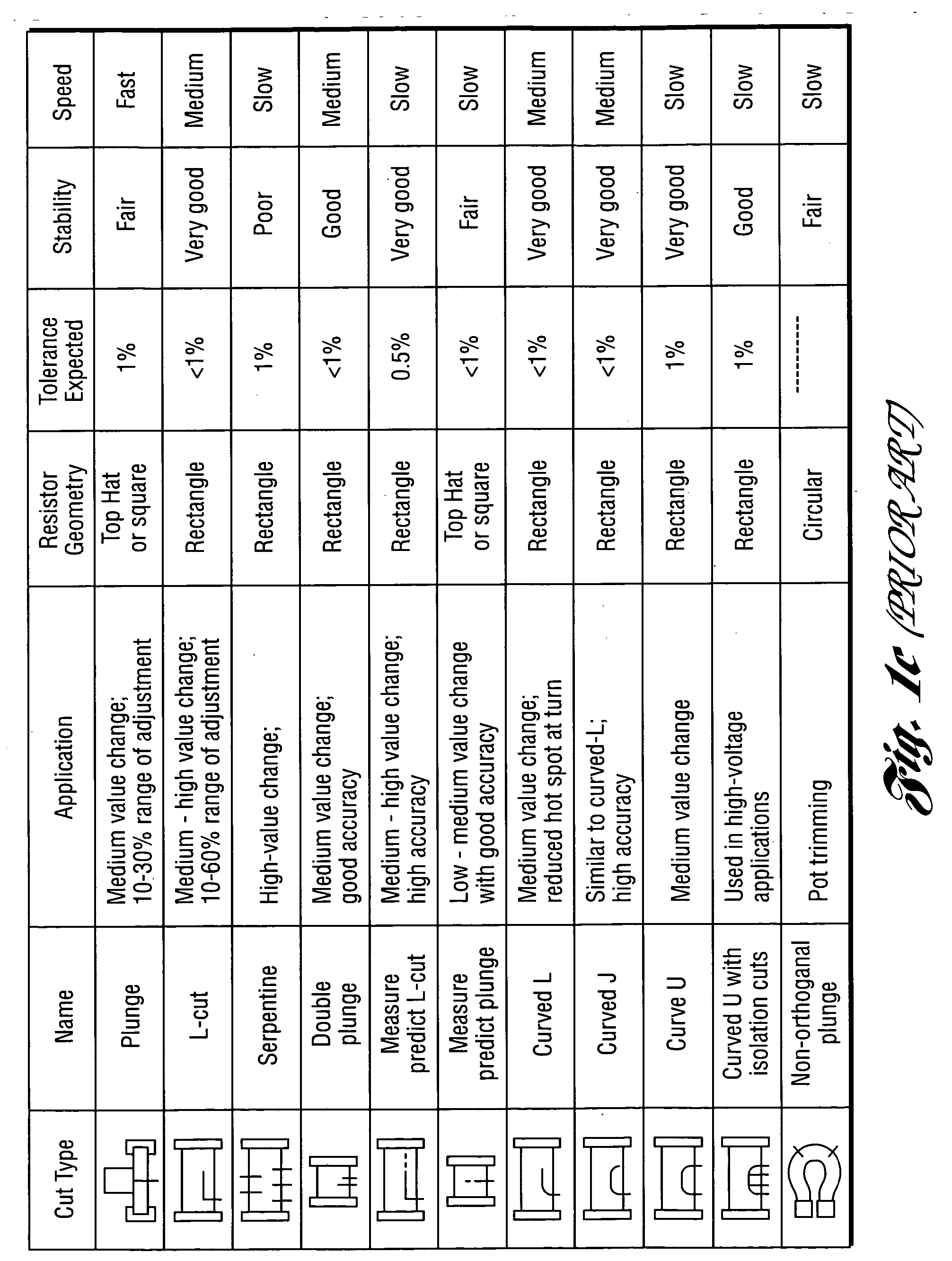

Drift-sensitive laser trimming of circuit elements

InactiveUS20050062583A1Reduce driftPrinted electric component incorporationResistor manufactureLaser trimmingInductor

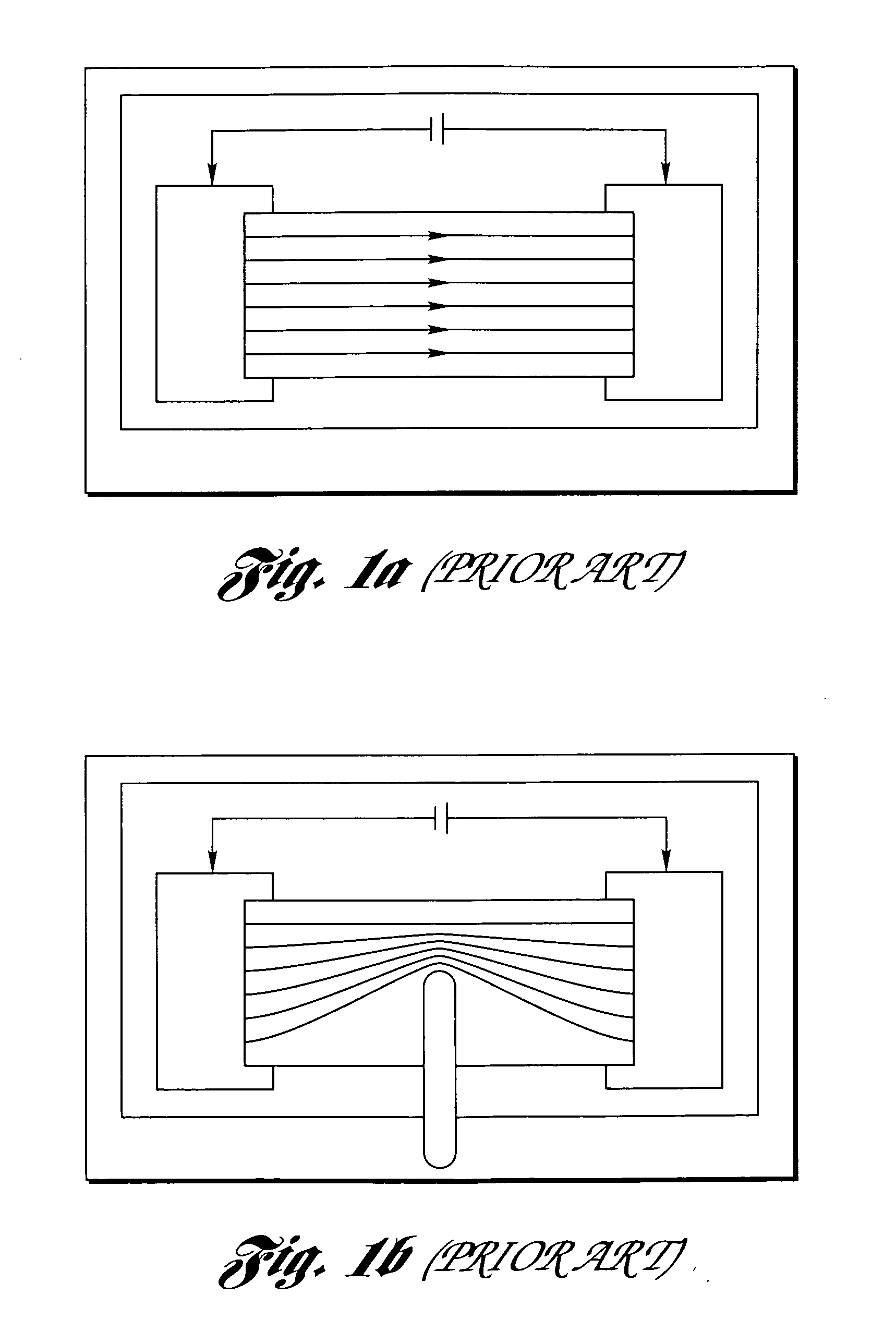

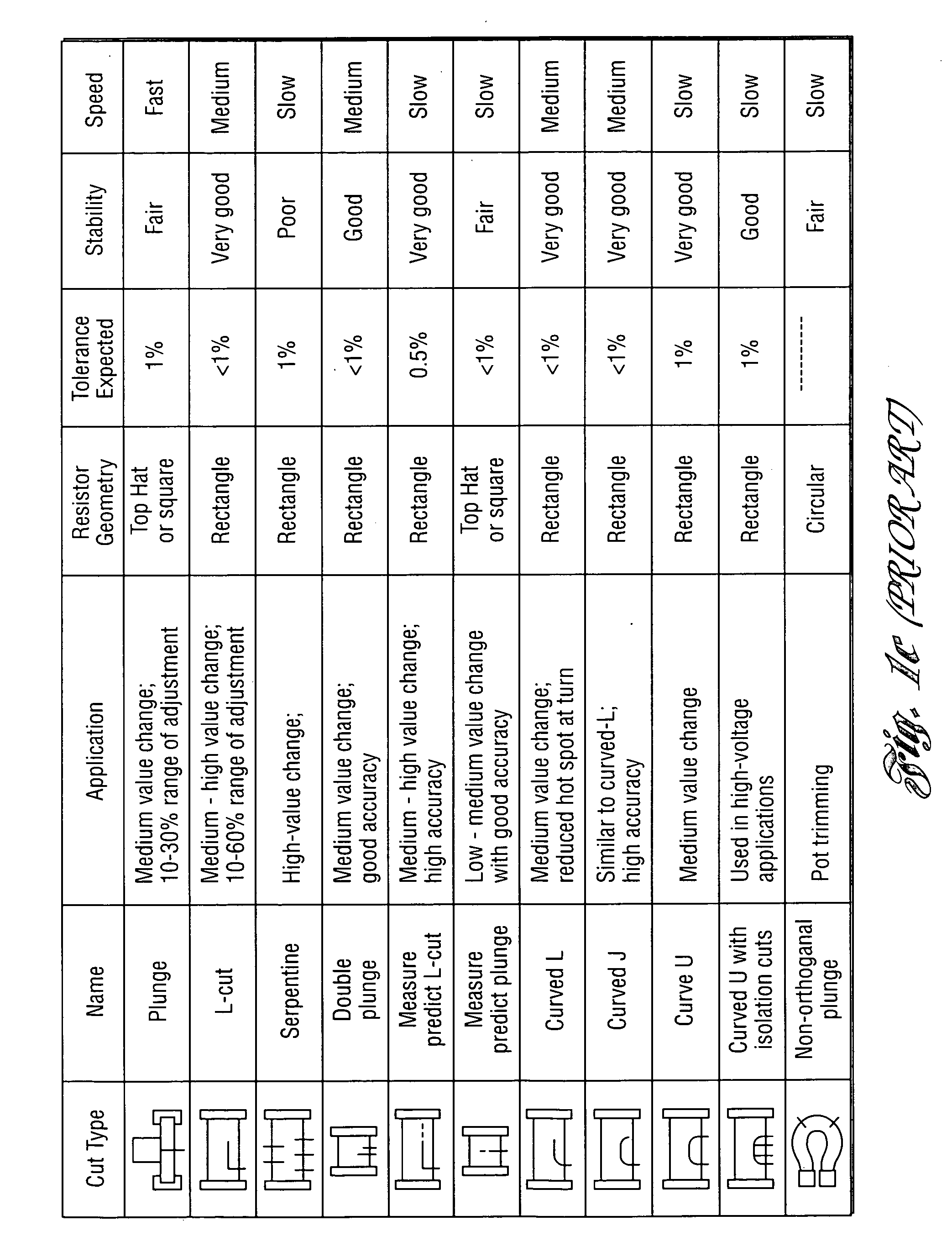

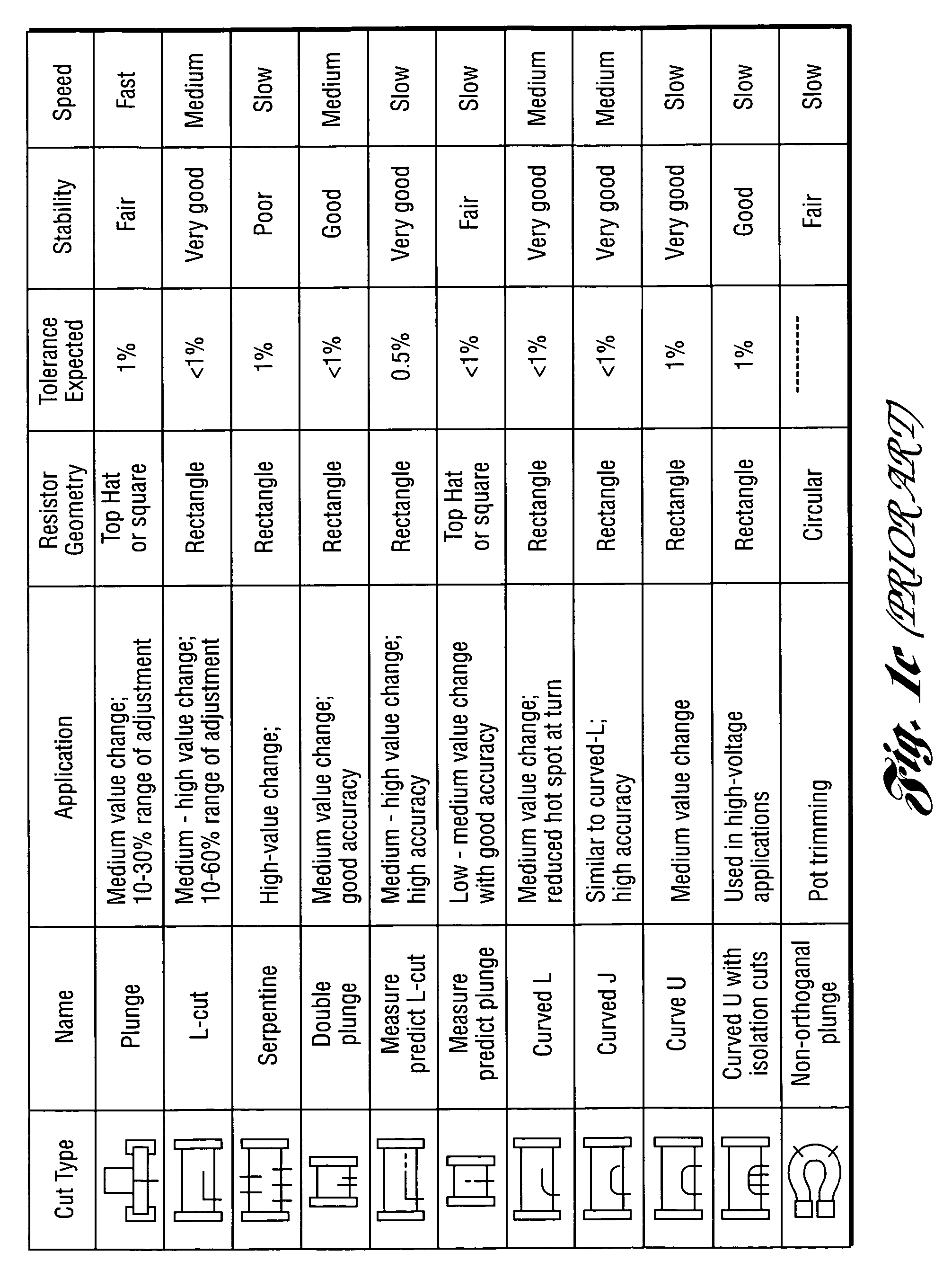

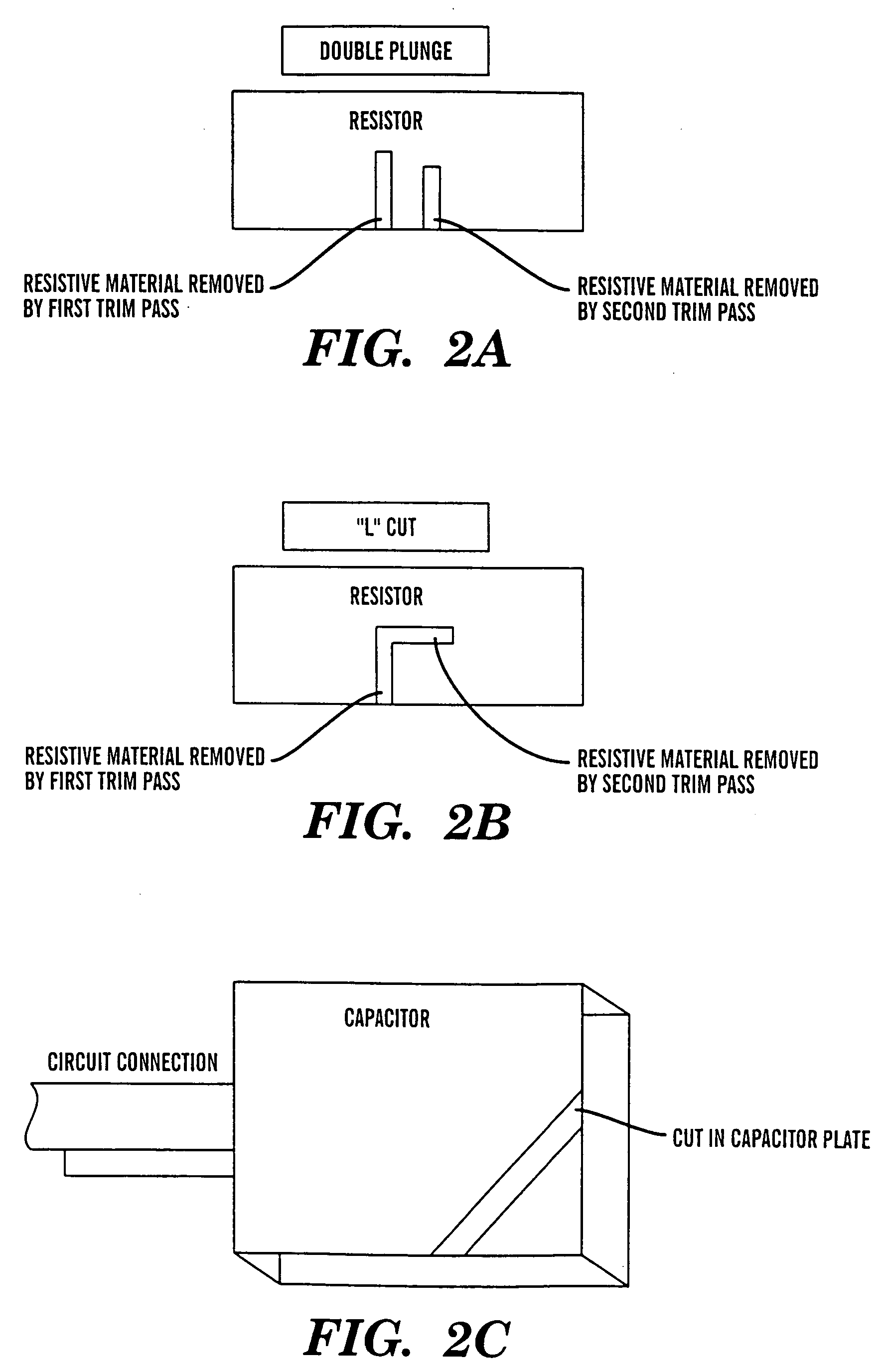

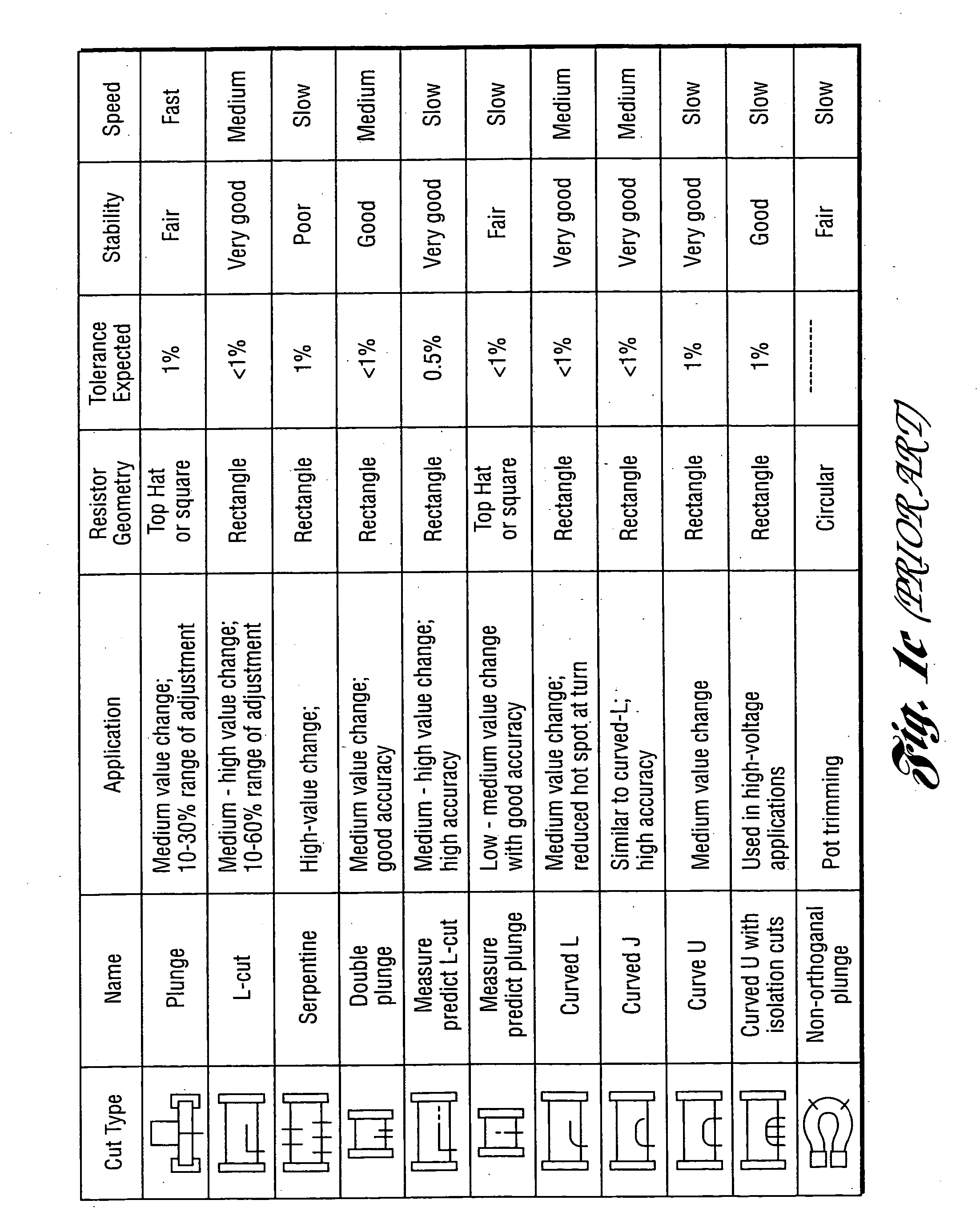

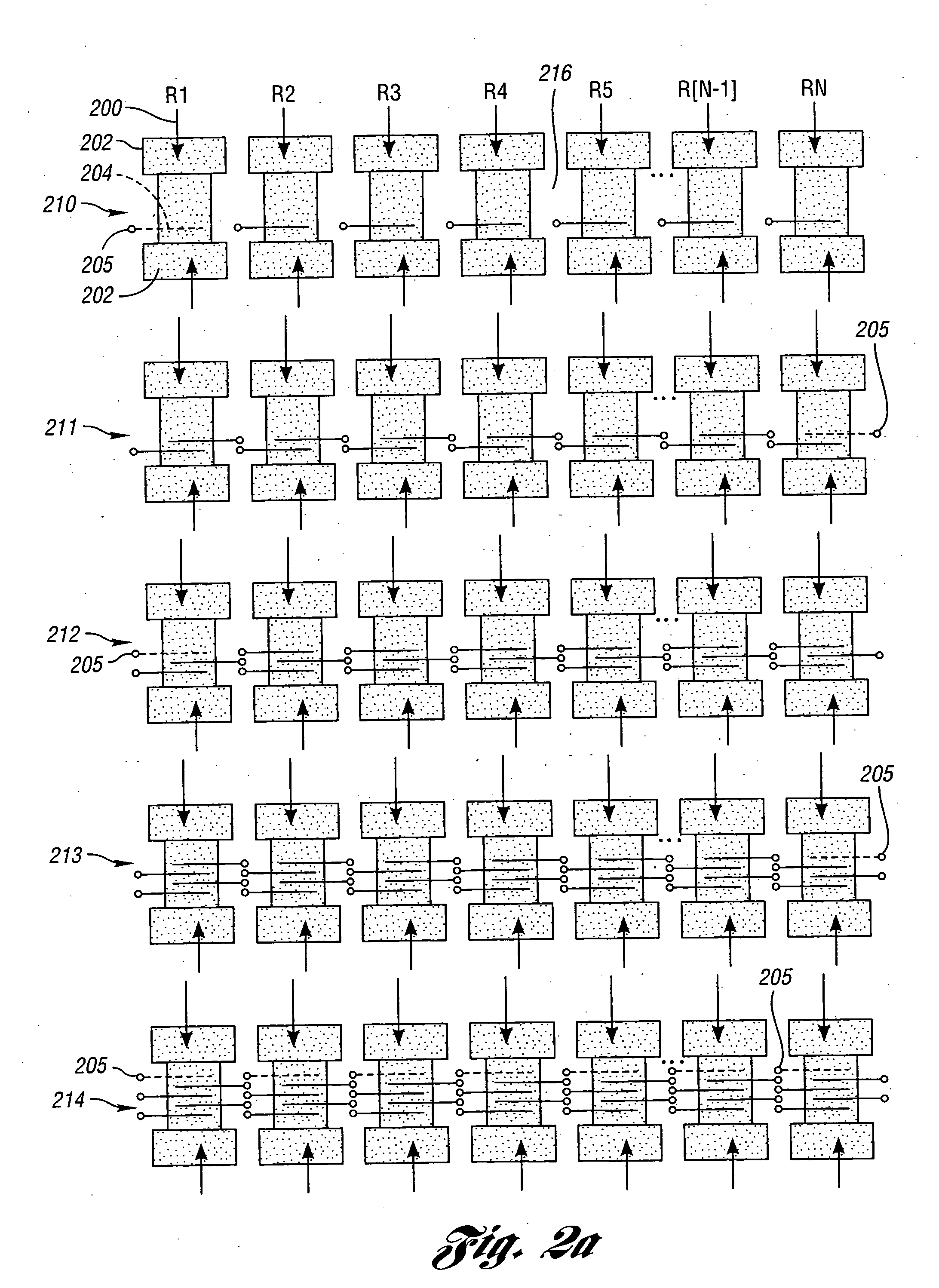

In the laser trimming of passive circuit elements such as resistors, capacitors and inductors, various trimming parameters must be selected. To select a parameter, such as a cut type or speed, a value of a parameter, such as the resistance or impedance of a resistor, of each of a plurality of elements is measured. The measured parameter value of each element is compared with a target value for the parameter to determine an offset value between the measured parameter value and the target value. The relevant trim parameters are then selected based on the determined offset values.

Owner:GSI LUMONICS CORP

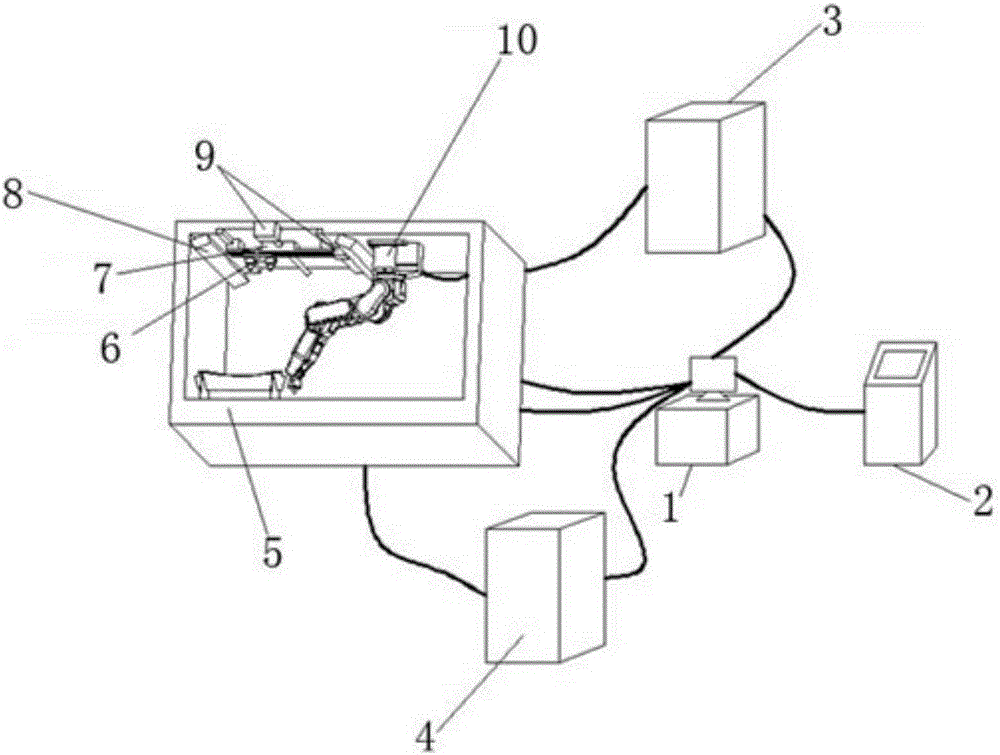

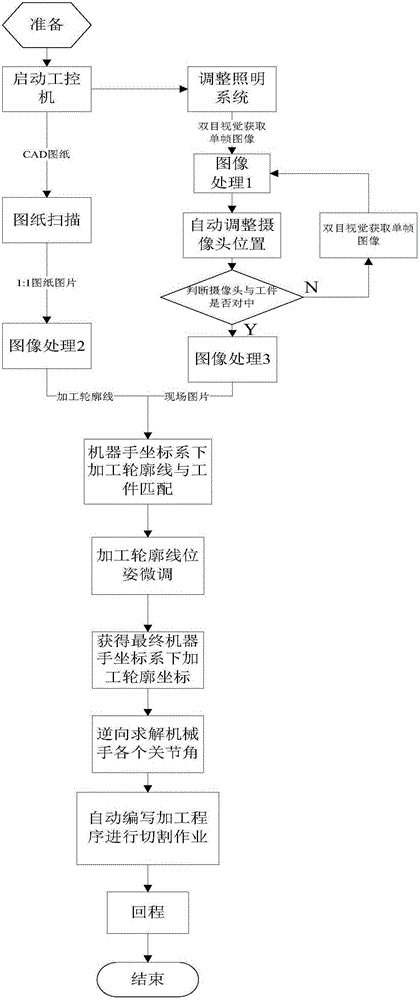

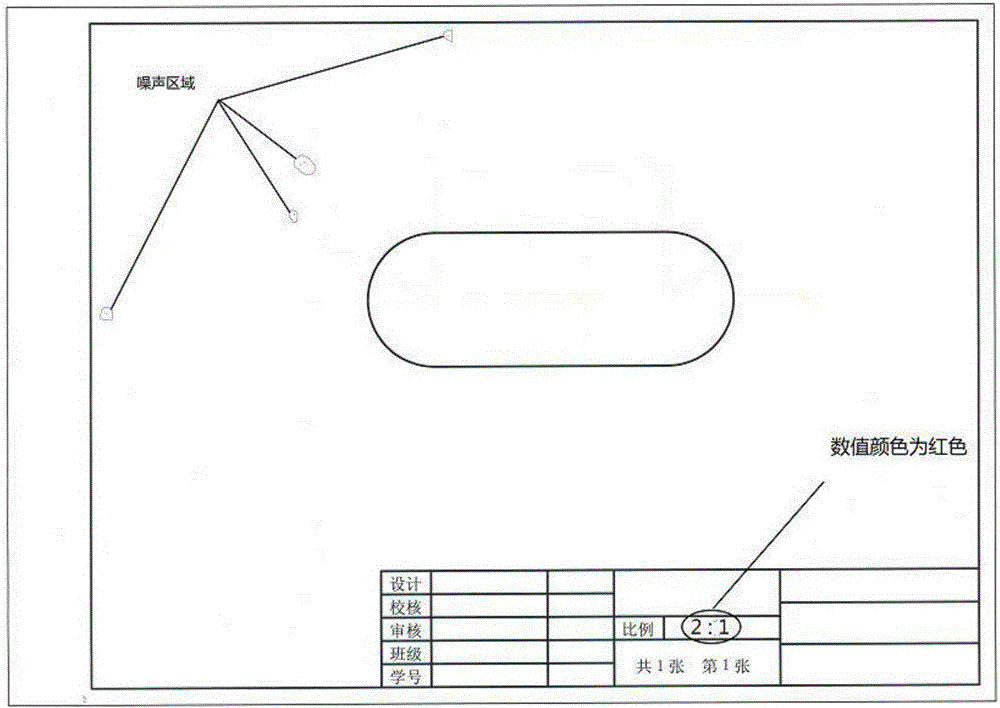

Intelligent laser trimming system and method based on binocular vision

InactiveCN105149794ALow skill level requiredHigh degree of intelligenceLaser beam welding apparatusPersonal computerLighting system

The invention discloses an intelligent laser trimming system and method based on binocular vision. The system comprises an industrial personal computer, a scanner and a box-type cutting platform. A mechanical hand, servo motors, a vision moving platform, a lighting system and a CCD binocular vision camera are installed in the box-type cutting platform. The industrial personal computer controls the CCD binocular vision camera installed on the vision moving platform to move through the servo motors. The mechanical hand is connected with the industrial personal computer through an arranged mechanical hand control cabinet. The vision moving platform is connected with the industrial personal computer through an arranged vision moving platform control cabinet. The system is high in intelligence degree, the automatic calibration and automatic scanned drawing programming functions are achieved, and production efficiency is greatly improved.

Owner:HOHAI UNIV CHANGZHOU

Method and system for high-speed precise laser trimming and scan lens for use therein

InactiveUS20070178714A1Precise TrimmingReduced stabilitySemiconductor/solid-state device manufacturingResistor manufactureHigh absorptionHeat-affected zone

A method, system and scan lens for use therein are provided for high-speed, laser-based, precise laser trimming at least one electrical element along a trim path. The method includes generating a pulsed laser output with a laser, the output having one or more laser pulses at a repetition rate. A fast rise / fall time, pulse-shaped q-switched laser or an ultra-fast laser may be used. Beam shaping optics may be used to generate a flat-top beam profile. Each laser pulse has a pulse energy, a laser wavelength within a range of laser wavelengths, and a pulse duration. The wavelength is short enough to produce desired short-wavelength benefits of small spot size, tight tolerance, high absorption and reduced or eliminated heat-affected zone (HAZ) along the trim path, but not so short so as to cause microcracking. In this way, resistance drift after the trimming process is reduced.

Owner:ELECTRO SCI IND INC

Manufacturing method for plate type thin film resistor

InactiveCN101593588AImprove productivityReduce manufacturing costResistors adapted for applying terminalsResistive material coatingSheet resistanceLaser trimming

The invention discloses a manufacturing method for a plate type thin film resistor, which belongs to a manufacturing method for a plate type resistor. The invention aims to provide a manufacturing method for producing the plate type thin film resistor with high productivity and low cost. The manufacturing method comprises the manufacture of a gauge, a back electrode and a resistor body, encapsulating, trimming, splintering, sintering, end coating and electroplating; and the concrete steps comprise substrate burnishing and cleaning, printing for the gauge and the back electrode, electrode sintering, baffle layer printing, vacuum sputtering, baffler layer removing, thermal treatment, laser trimming, protective layer printing, protective layer curing, primary splintering, end coating for the electrode, end electrode sintering, secondary splintering, nickel plating and tinlead plating. The manufacturing method has the advantages of high productivity, low cost and the like, and is an ideal method for producing the plate type thin film resistors on a large scale.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

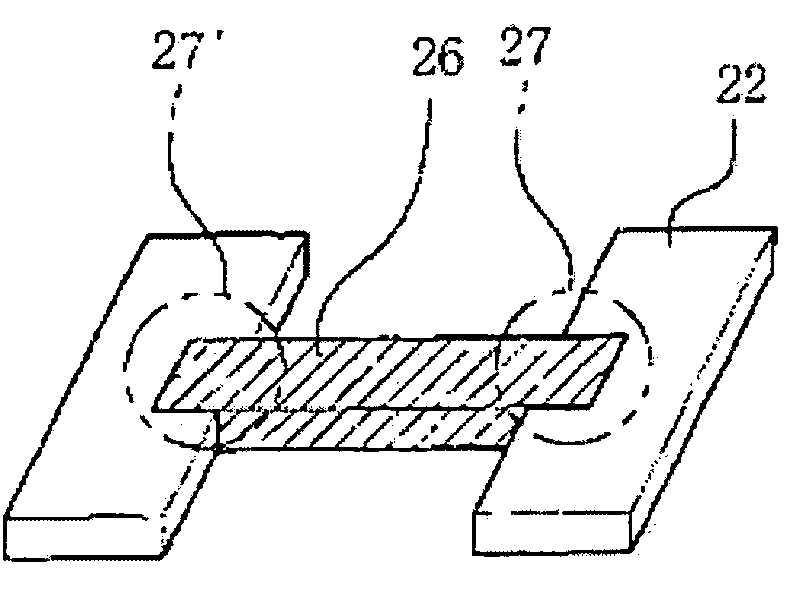

Passive component

InactiveUS6529116B2High resistivityImprove signal-to-noise ratioThin/thick film capacitorStacked capacitorsElectrical resistance and conductanceEngineering

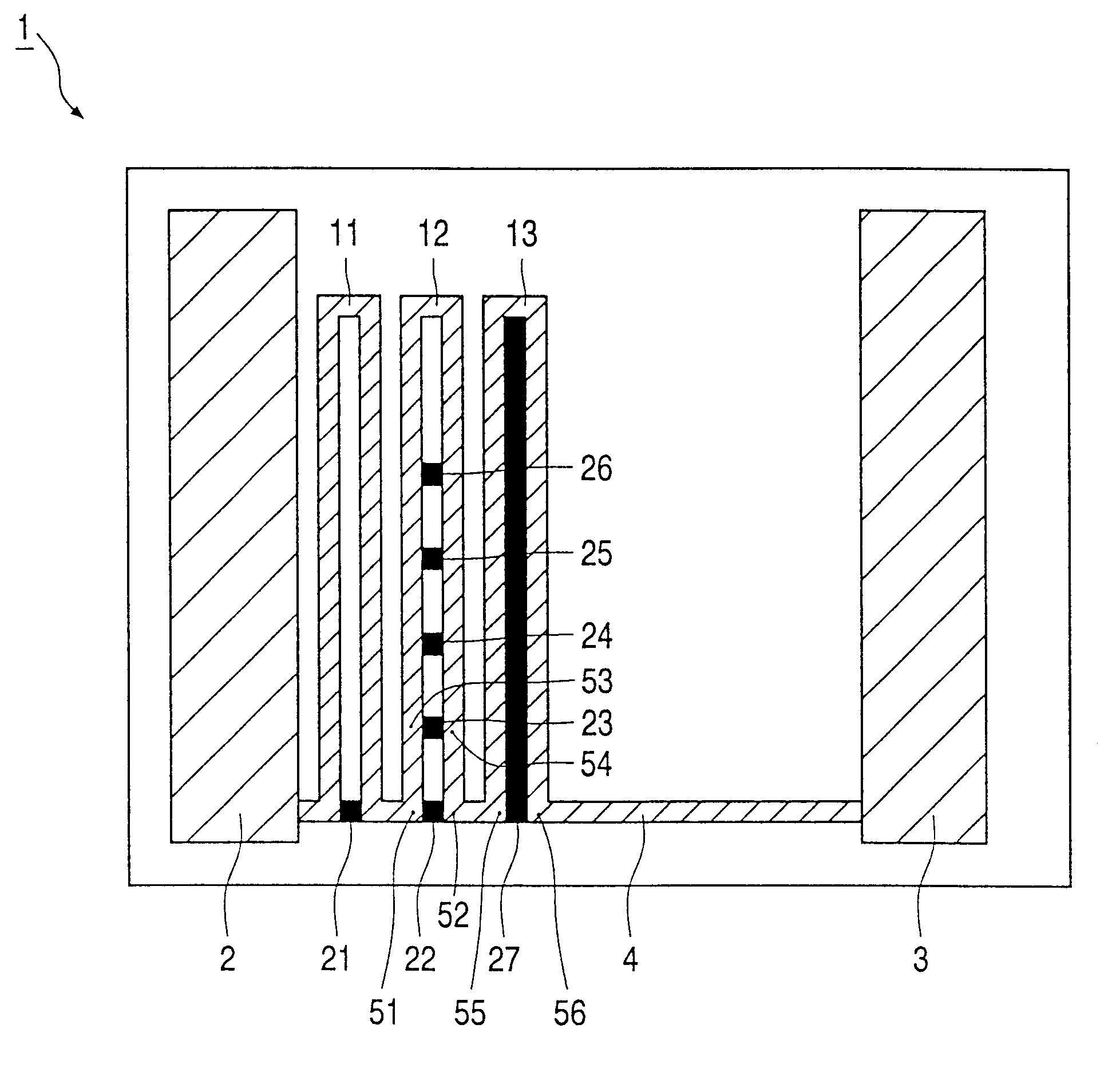

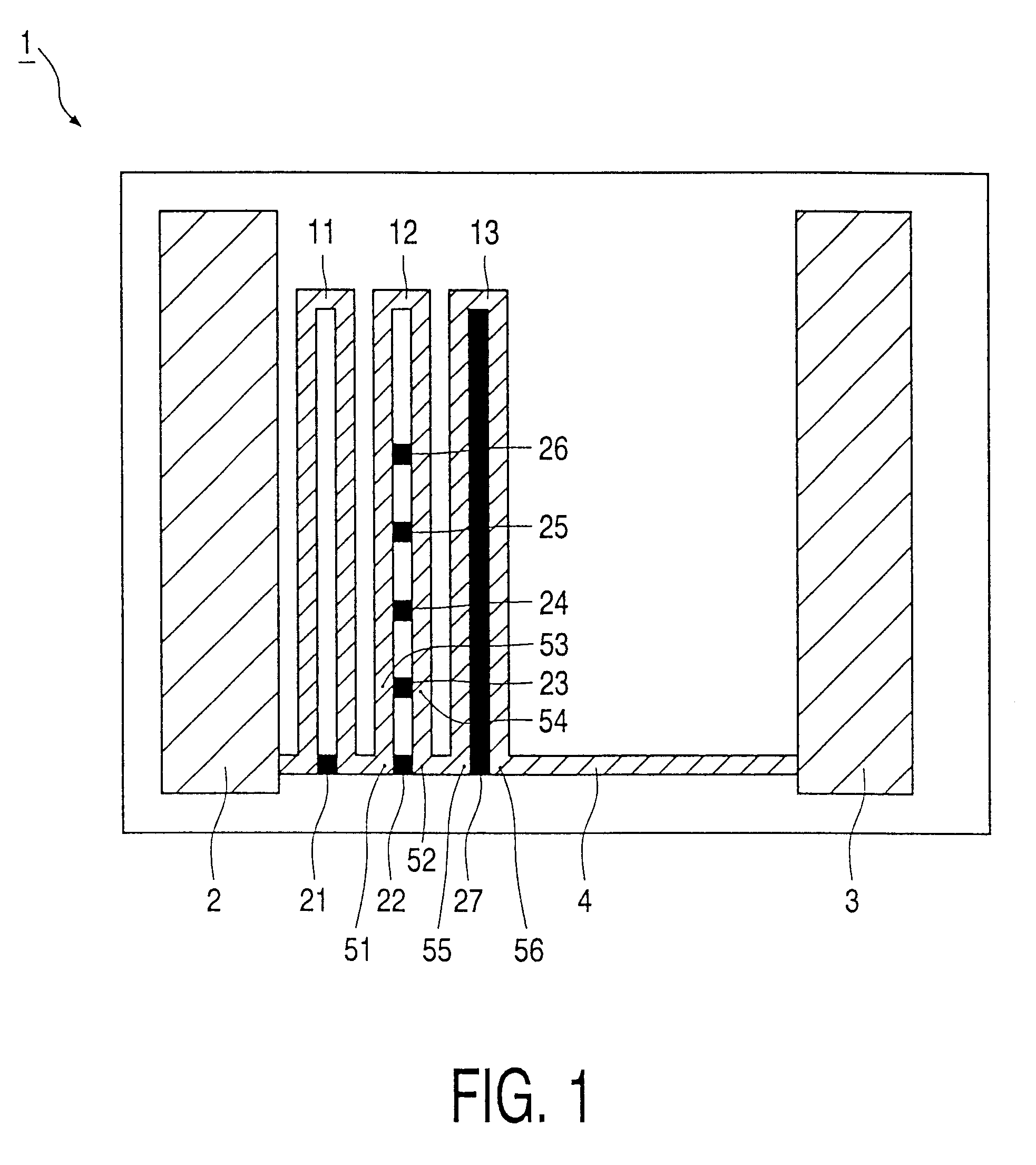

The passive component (1) has a first part (22) of a material with a first resistance value, which value can be lowered to a second value by laser trimming. The second value is at most one tenth of the first value and preferably less. The material crystallizes in a laser trimming process, which locally heats the material to at least a transition temperature. The material contains at least two different elements, which are preferably aluminum and germanium.The passive component (1) may be, for example, a resistor or a capacitor and may be part of a thin-film network of resistors, capacitors and / or inductors. In a resistor, it is preferred to have a second part (4) which contains a different resistance material with a resistance value lower than the first value and preferably higher than the second value.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Optical disk, optical disk barcode forming method, optical disk reproduction apparatus, a marking forming apparatus, a method of forming a laser marking on an optical disk, and a method of manufacturing an optical disk

InactiveUS6122373APossible to separateDigitally marking record carriersDigital data processing detailsOptical pickupBarcode

Disclosed is an optical disk barcode forming method wherein, as information to be barcoded, position information for piracy prevention, which is a form of ID, is coded as a barcode and is recorded by laser trimming on a reflective film in a PCA area of an optical disk. When playing back the thus manufactured optical disk on a reproduction apparatus, the barcode data can be played back using the same optical pickup.

Owner:PANASONIC CORP

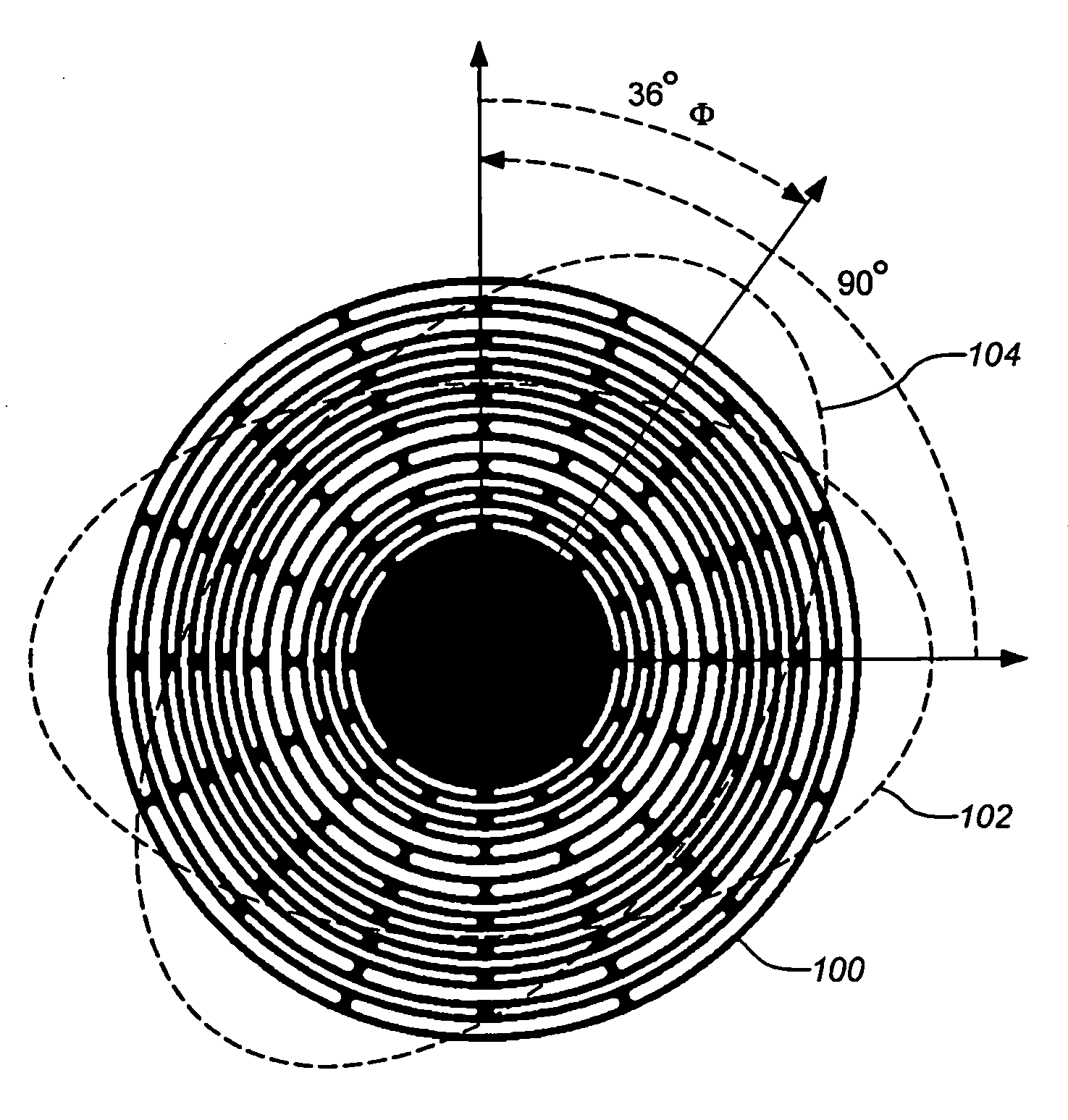

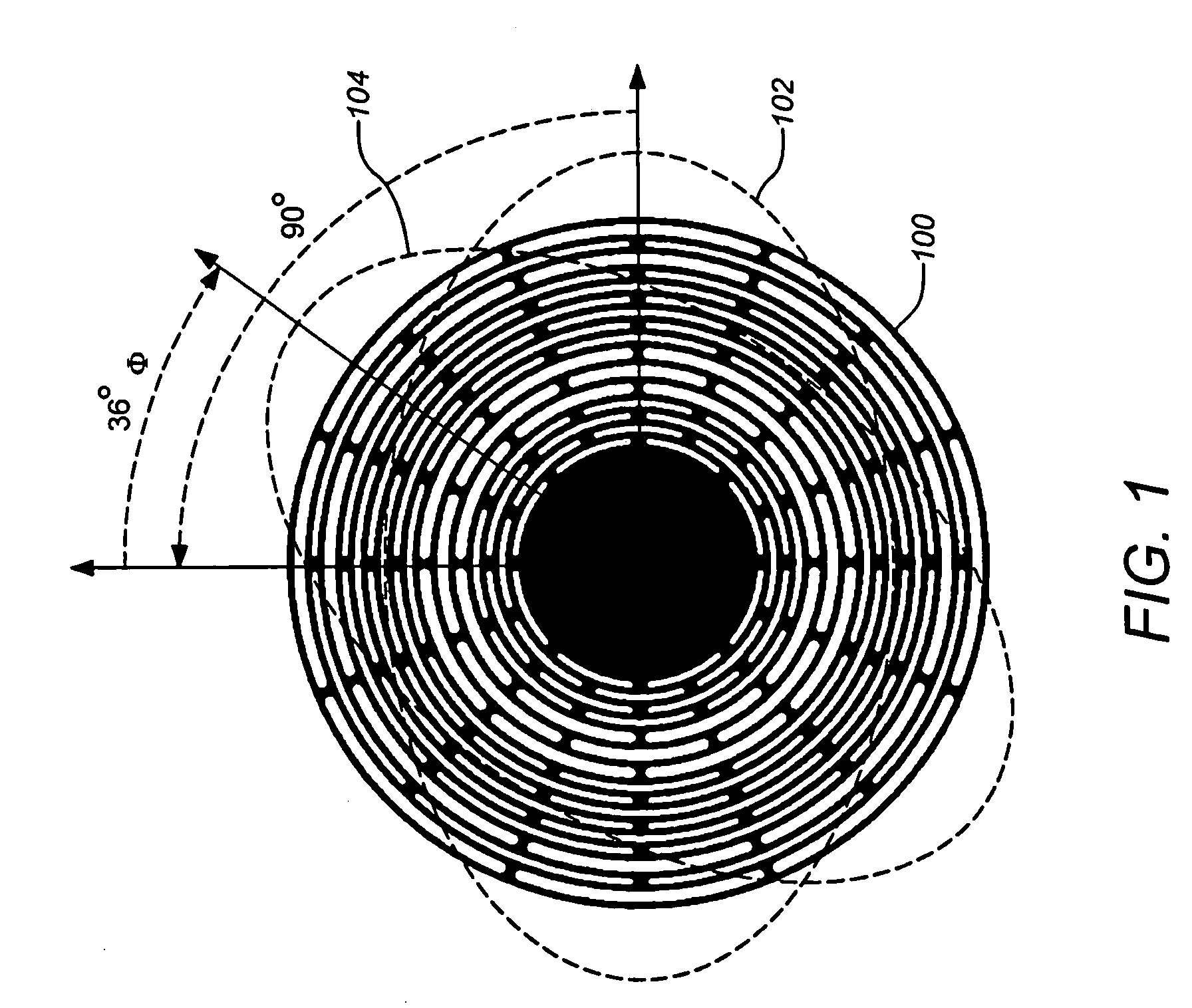

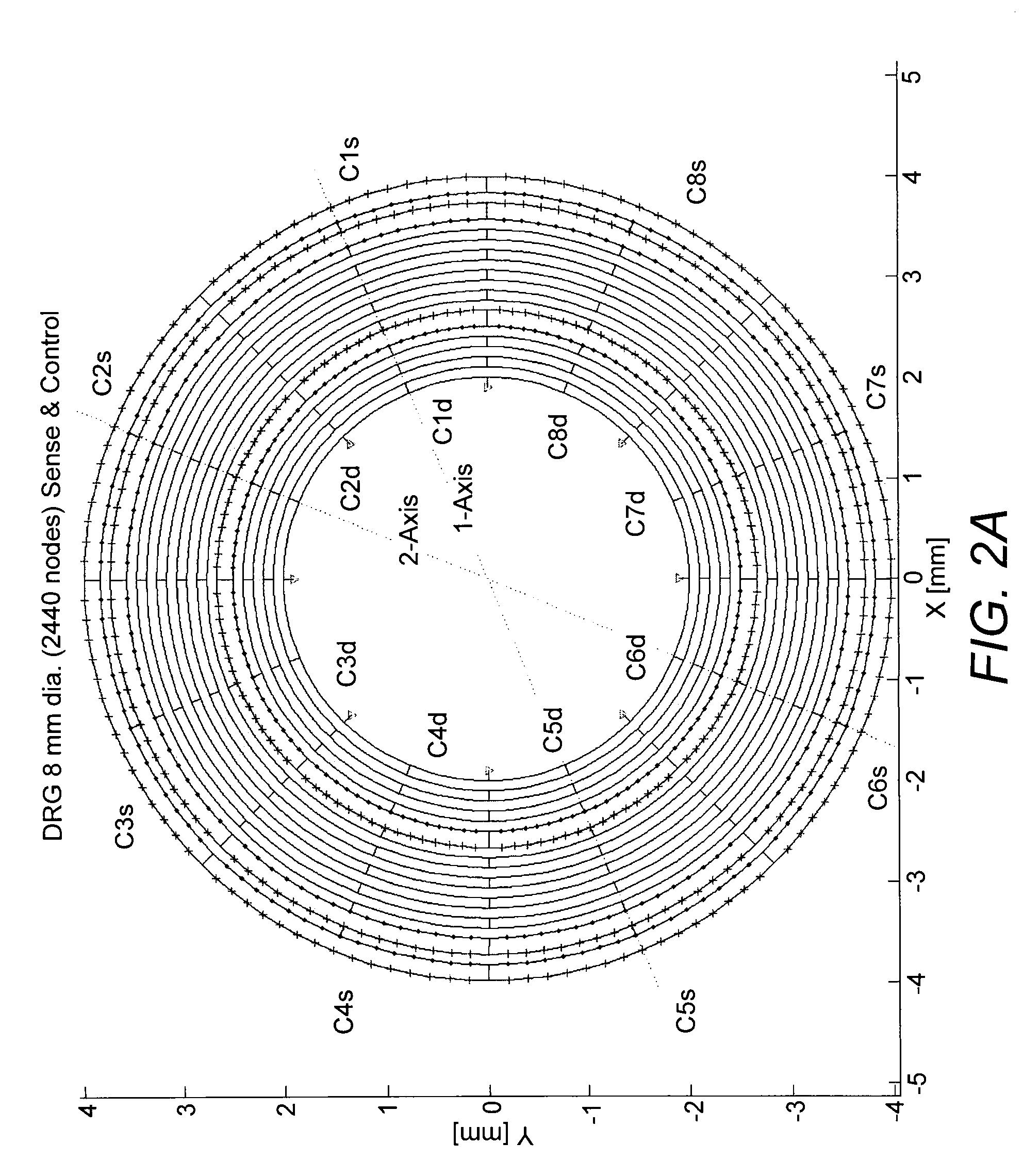

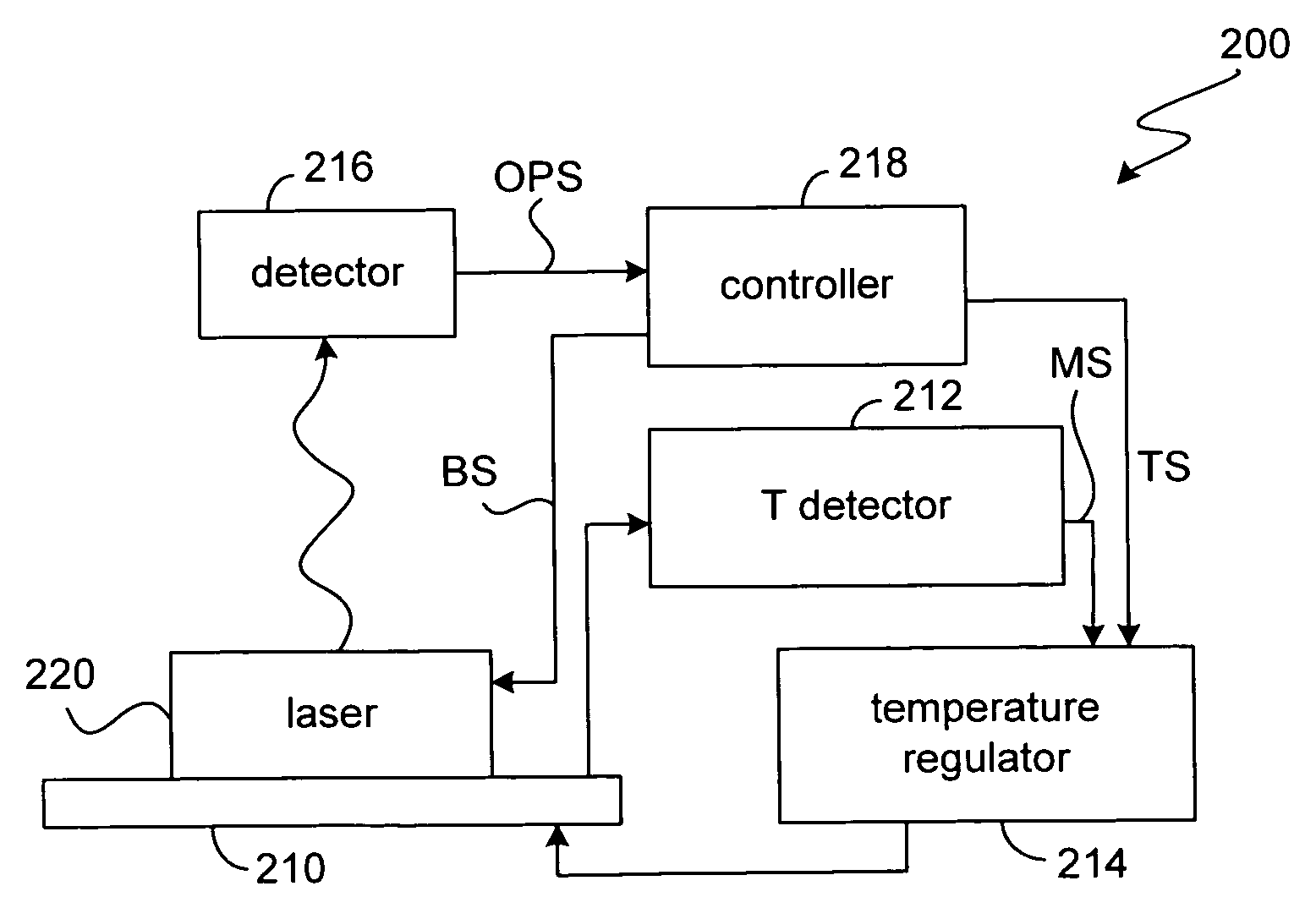

Systematic disc resonator gyroscope tuning

ActiveUS20090301194A1Acceleration measurement using interia forcesWave based measurement systemsElement modelGyroscope

Tuning an axisymmetric resonator such as in a disc resonator gyroscope (DRG) is disclosed. Frequency tuning a DRG in a single step informed by a systematic physical model of the resonator structure, sensing and actuation elements, such as a finite element model, is provided. The sensitivity of selected trimming positions on the resonator to reducing asymmetry terms is determined via perturbations of the systematic model. As well, the dependence of the parameters of model transfer functions between actuation and sensing elements on resonator asymmetry are systematically determined. One or two measured transfer functions may then be analyzed according to the systematic model to fully determine the needed asymmetry correction components of the DRG. One or two of four groups of four electrostatic bias electrodes or four groups of four laser trimming locations for the DRG are utilized to correct the asymmetry components which can give rise to mistuning.

Owner:THE BOEING CO

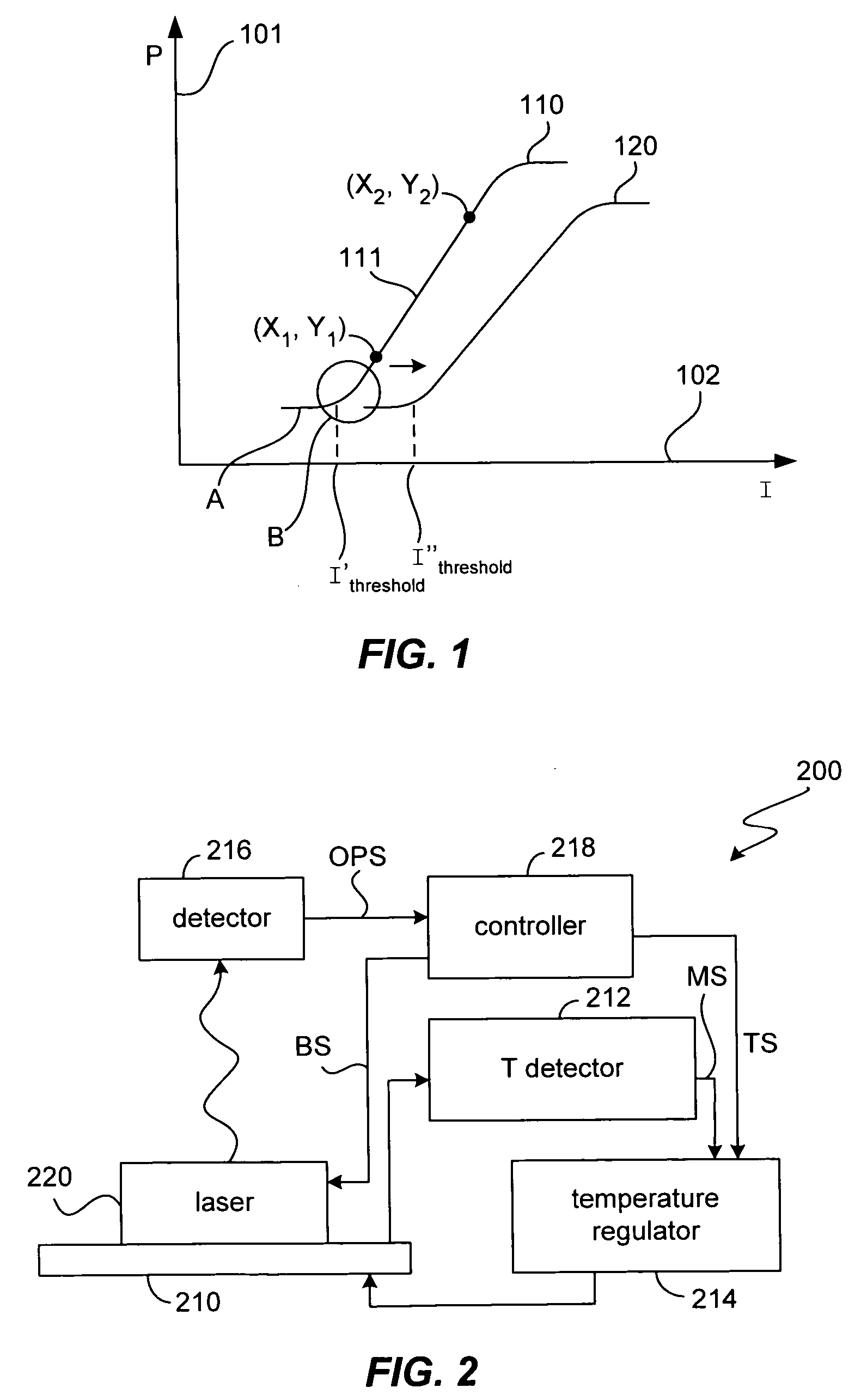

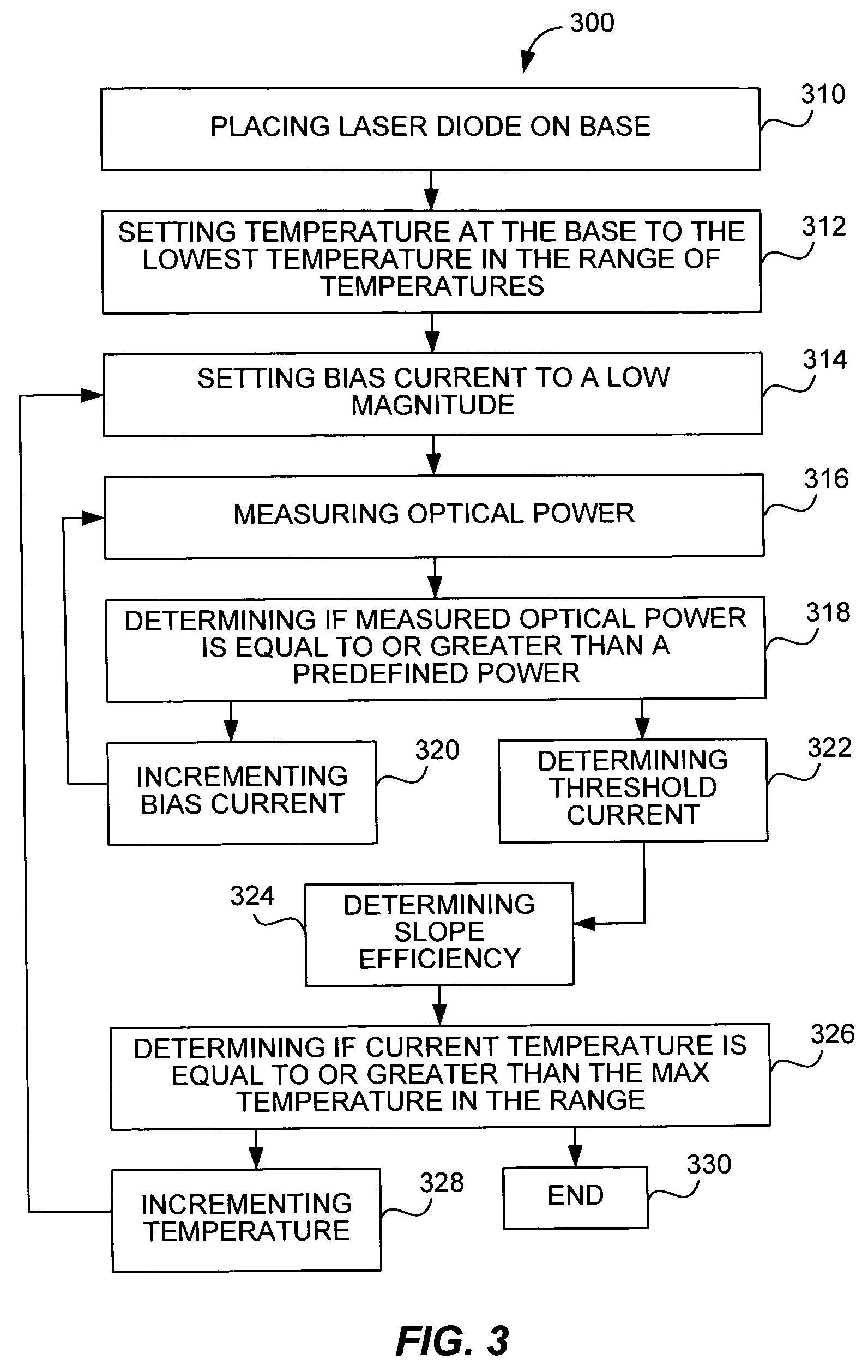

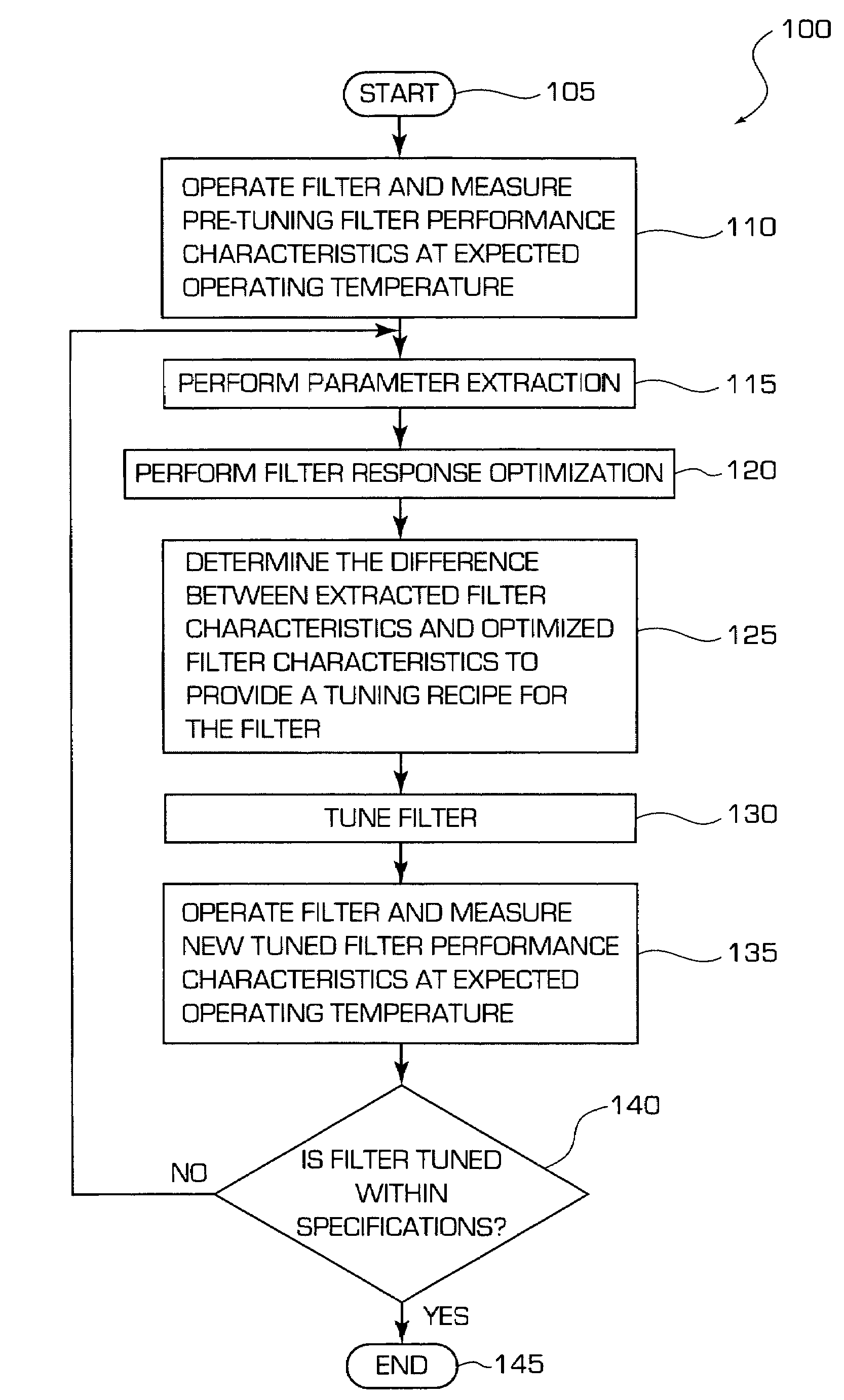

Laser trim and compensation methodology for passively aligning optical transmitter

A method includes a scheme for trimming and compensation for a laser emitter in a fiber optic link. Data models of laser performance are provided and used to determine a base power level. It is then confirmed that the base power level is satisfactory. If necessary, adjustments are made to a set of user specified performance parameters until a satisfactory base power level is obtained. Then a table or relation of temperatures and associated current and target average optical power values is generated such that they can be used to regulate laser emitter performance over a range of temperature. Additionally, fiber optic links capable of trimming and compensation are also disclosed.

Owner:NAT SEMICON CORP

Systems and Methods for Tuning Filters

InactiveUS7482890B2Reduce sensitivityError in sensitivityTransmission control/equlisationAutomatic frequency controlFir filter designFilter tuning

Methods, systems and apparatus for filter design, analysis and adjustment are provided. Various embodiments may include, for example, methods, systems and apparatus for electric signal filter tuning. Embodiments may also include design techniques for planar electric signal (e.g., RF signals) filter tuning. In at least an embodiment of the present invention a technique for filter tuning is provided which may include parameter extraction, optimization and tuning recipes techniques that may require only a single permanent filter tuning. In at least another embodiment a system and method of filter design, analysis and adjustment according to the present invention includes use of tuning that may be set using a mechanical scribing tool or a laser trimming device. In at least one other embodiment, a filter tuning technique may be provided and include providing trimming tabs on a resonator edge that may be disconnected or trimmed for filter tuning.

Owner:SUPERCONDUCTOR TECHNOLOGIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com