Intelligent laser trimming system and method based on binocular vision

A binocular vision and laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high environmental requirements of laser sensors, inability to operate continuously for a long time, and high cost of laser vision systems, saving programming and teaching time, easy operation, low skill level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

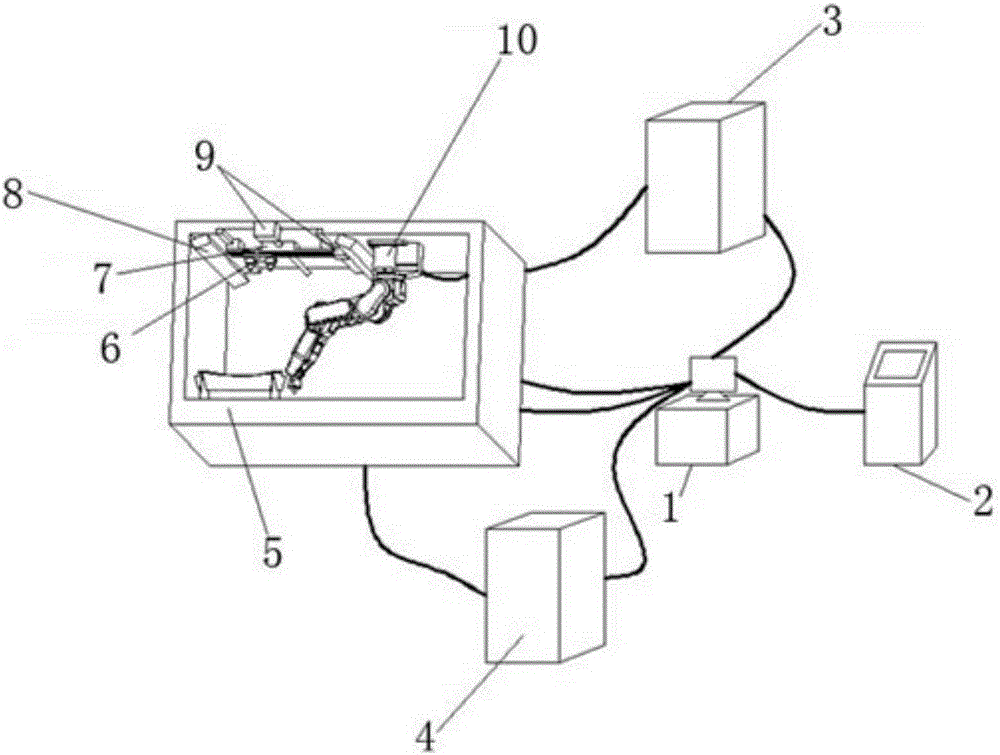

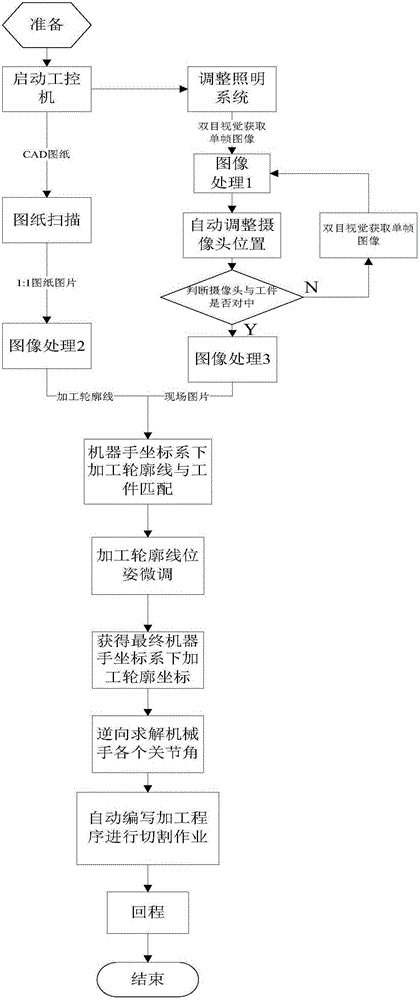

[0041] like figure 1 As shown, an intelligent laser trimming system based on binocular vision includes an industrial computer 1, a scanner 2, a box-type cutting platform 5, and the box-type cutting platform 5 is equipped with a manipulator 10, a servo motor 9, and a visual moving platform 7. , a lighting system 8 and a CCD binocular vision camera 6; the industrial computer 1 controls the movement of the CCD binocular vision camera 6 installed on the visual mobile platform 7 through the servo motor 9, and the manipulator 10 is connected to the industrial computer 1 by setting a manipulator control cabinet 3 , the visual mobile platform 7 is connected with the industrial computer 1 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com