Laser trimming method for super-abrasive grinding wheel

A technology of laser dressing and superabrasives, which is used in the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc. The problem of large loss of the device is achieved, and the effect of small thermal action area, easy control and high trimming efficiency is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

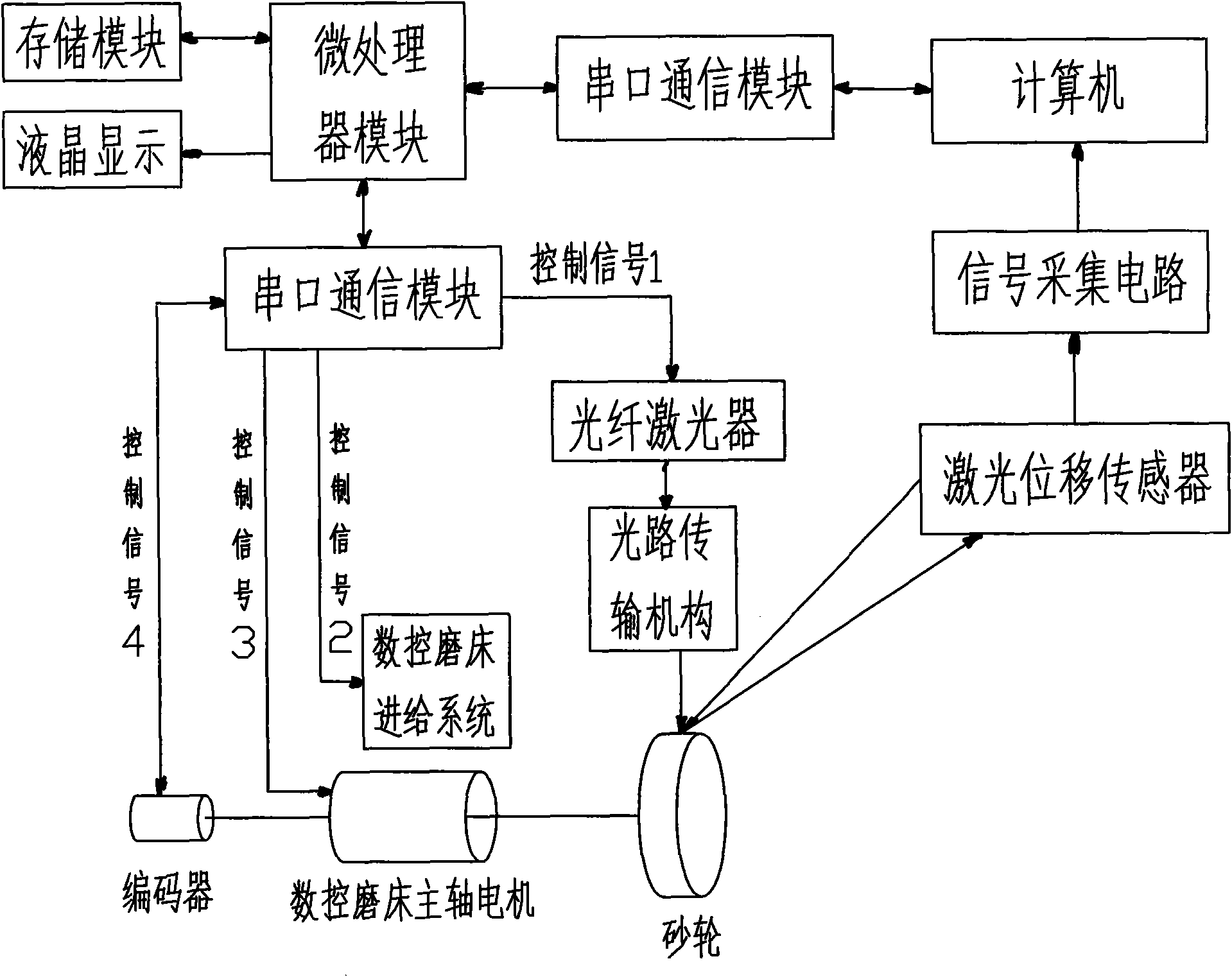

[0013] Equipment needed:

[0014] CNC grinding machine, computer, microprocessor controller, laser displacement sensor, fiber laser, encoder.

[0015] The method of dressing the grinding wheel is carried out as follows:

[0016] a. Install the grinding wheel on the CNC grinding machine to rotate the grinding wheel, and make the laser displacement sensor feed relative to the grinding wheel;

[0017] b. Store the ideal contour data of the grinding wheel in the computer, turn on the laser displacement sensor, emit the detection laser to the surface of the grinding wheel, the computer sends a start scanning signal, and the microprocessor simultaneously sends a start signal to the encoder, the CNC grinding machine spindle motor and the feed motor , the encoder is used to record the starting position of the grinding wheel, the CNC grinding machine spindle and the feed motor rotate and feed according to the specified method, the laser displacement sensor starts to collect data, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com