Patents

Literature

114results about How to "Increase chip space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

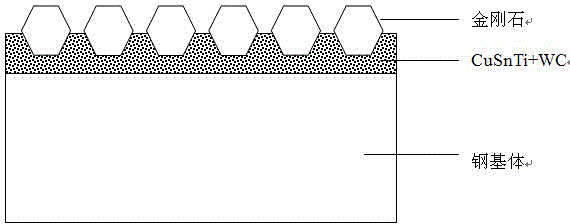

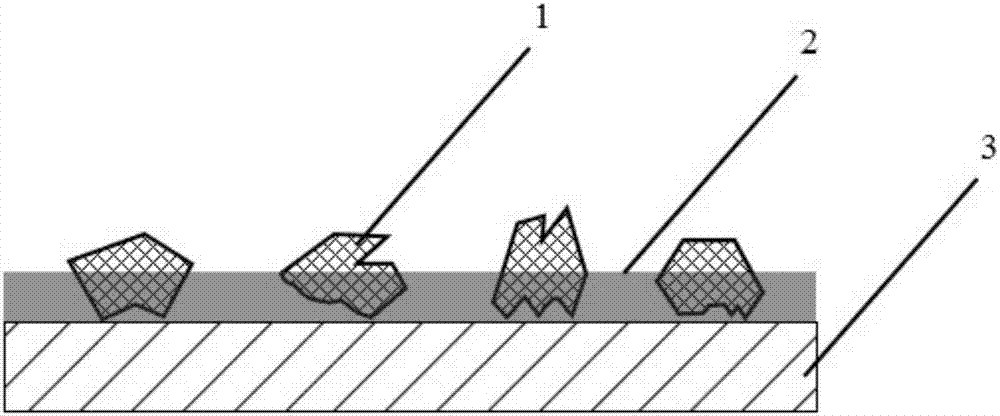

Manufacturing method of single-layer brazing diamond grinding wheel

InactiveCN103817610ALow costImprove wear resistanceAbrasion apparatusGrinding devicesChemical reactionFiller metal

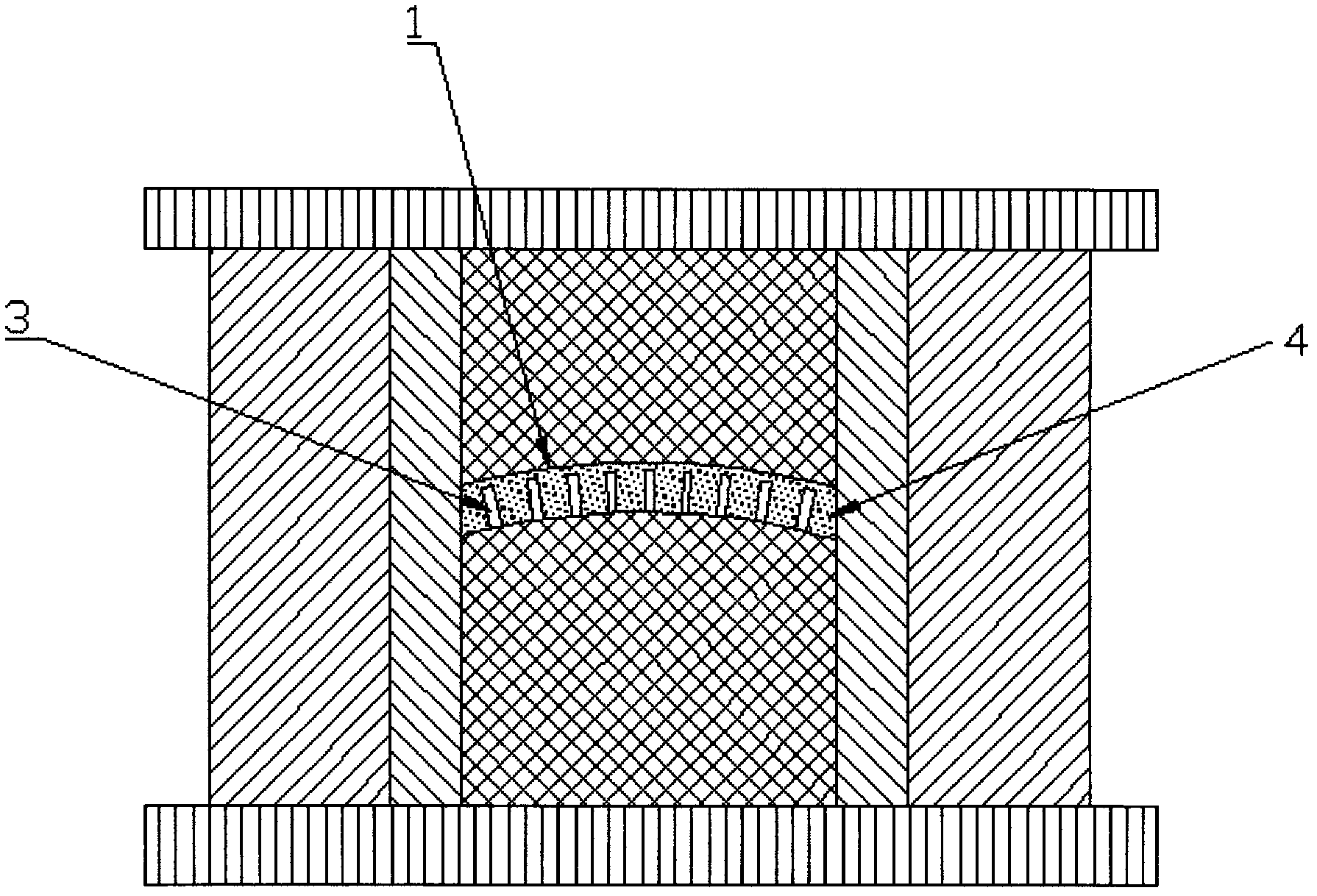

The invention discloses a manufacturing method of a single-layer brazing diamond grinding wheel. The manufacturing method includes steps of preparing a base body of the diamond grinding wheel by a machining method, deoiling and descaling; utilizing mixture of Cu powder, Sn powder, TiH2 powder and WC (wolfram carbide) powder as brazing filler metal of the diamond grinding wheel, and mechanically blending uniformly; sequentially arranging the base body, the brazing filler metal and diamond grains of the diamond grinding wheel to manufacture a tool forming blank; placing the tool forming blank into a vacuum furnace, subjecting the brazing filler metal and the diamond grains to chemical reaction by means of brazing process, cooling to the room temperature along with the furnace, and discharging. Cost for raw materials can be reduced to some extent and oxidation pollution can be avoided by utilizing TiH2 as a Ti source, wear resistance and heat resistance of the brazing filler metal can be improved by adding the superfine WC powder into the Cu powder, the Sn powder and the TiH2 powder, graphitization of diamond can be reduced, thereby heat damage of the diamond can be reduced, and the diamond grinding tool can sufficiently give into play.

Owner:ZHONGYUAN ENGINEERING COLLEGE

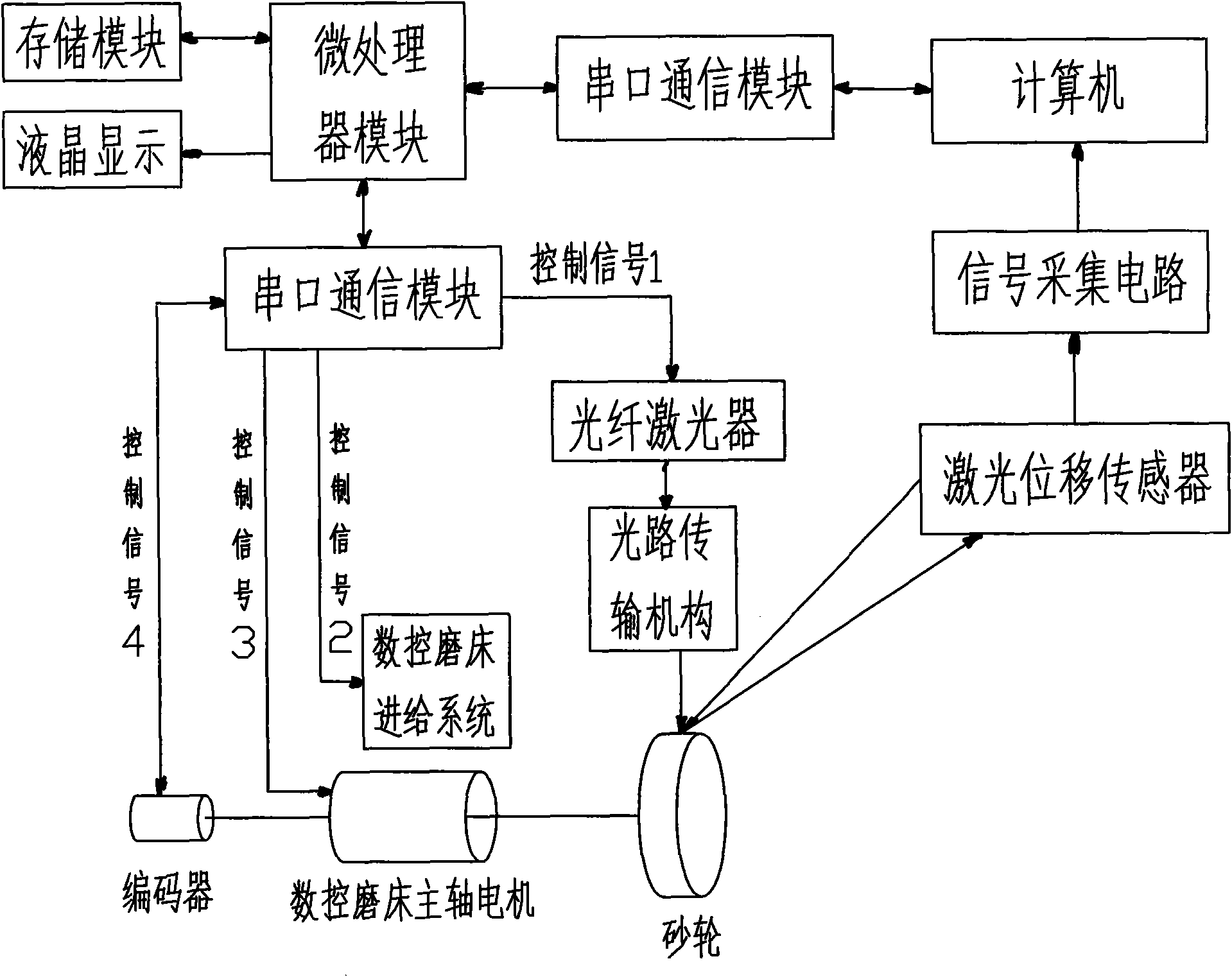

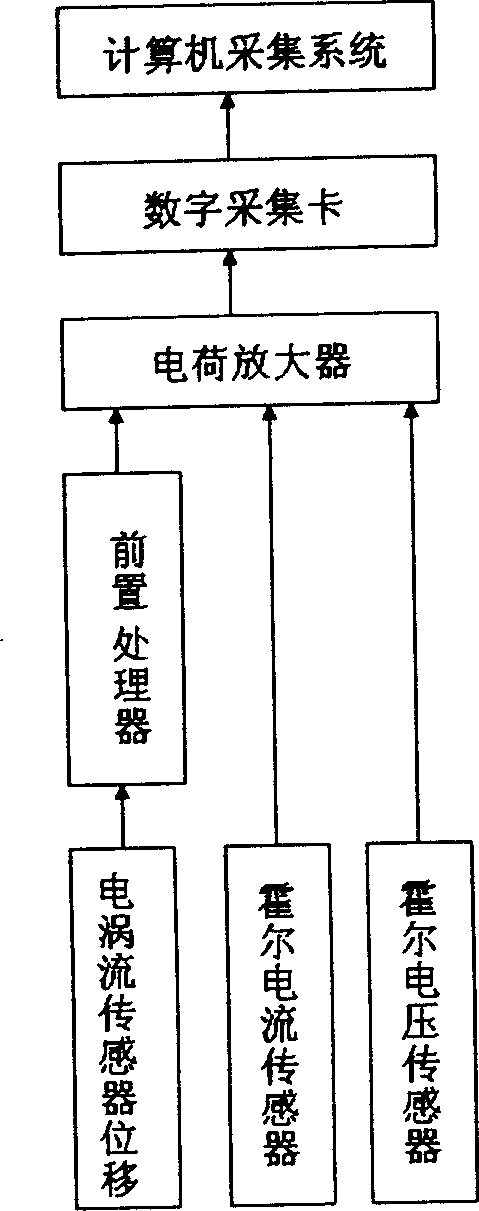

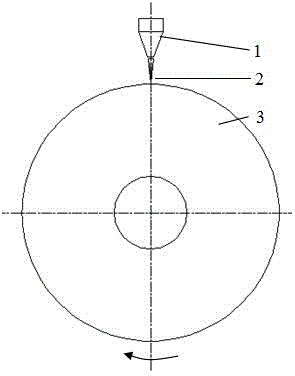

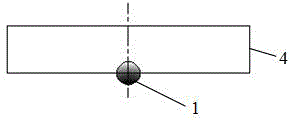

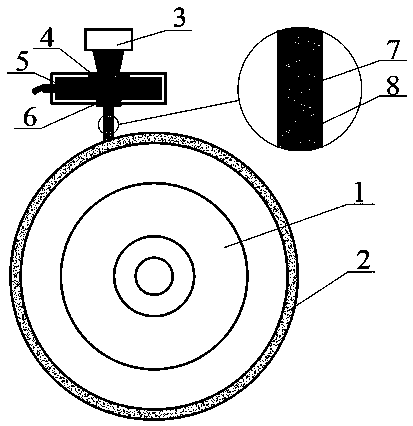

Laser trimming method for super-abrasive grinding wheel

InactiveCN101642895ANo lossImprove power densityAbrasive surface conditioning devicesNumerical controlControl signal

The invention discloses a laser trimming method for a super-abrasive grinding wheel, comprising the following steps: a, a grinding wheel is mounted on a numerical control grinding machine and is driven to rotate; b, a laser displacement sensor is aligned to the surface of the grinding wheel, does axial feeding movement relative to the grinding wheel and scans the surface of the grinding wheel, scanning data is input into a computer storing an ideal profile of the grinding wheel to form an actual profile of the grinding wheel on the surface, the actual profile is compared with the ideal profileof the grinding wheel to obtain a distribution condition of allowance removal; c. the computer sends trimming control signals to the numerical grinding machine and a laser through a microprocessor controller, so that the laser emits an appropriate laser pulse to burn a point to be trimmed on the grinding wheel according to the control signals, the laser displacement sensor detects present remained allowance of the point, and the allowance of the point in the computer is updated timely; and d, the step c is carried out repeatedly till the trimming precision as required is achieved.

Owner:HUNAN UNIV

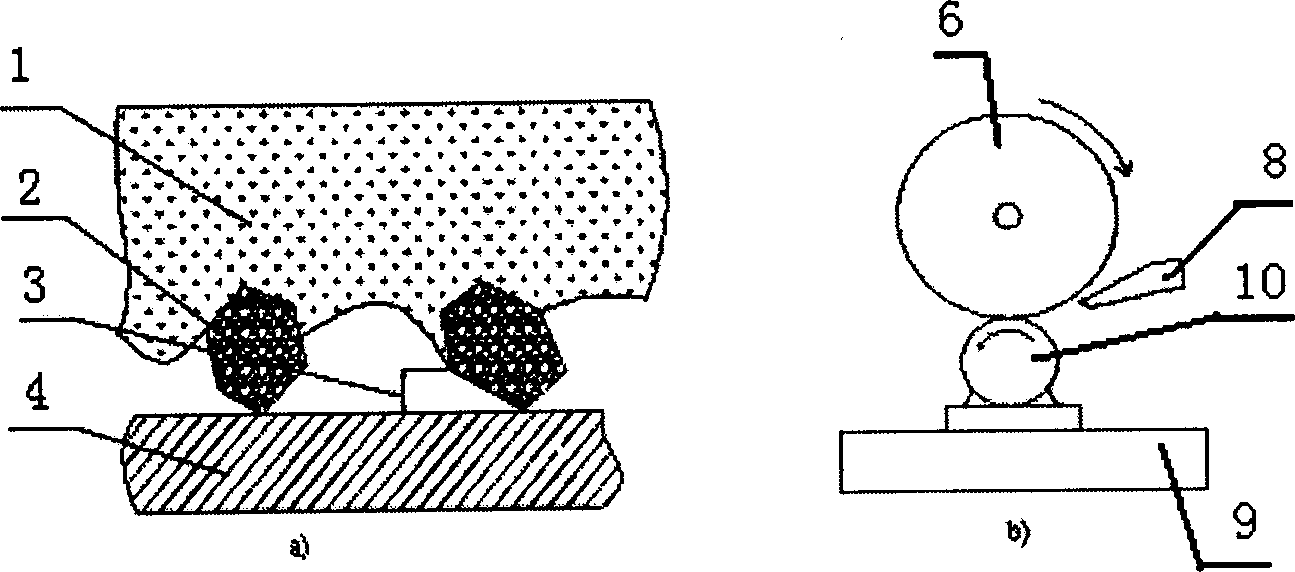

Wide/fine machining integrated processing device for emery belt centerless grinding and polishing

InactiveCN101195205AImprove grinding efficiencyImprove securityPolishing machinesBelt grinding machinesDrive wheelGear wheel

The invention discloses a process device with the combination of rough machining and fine machining of centreless grinding and lapping and polishing of an abrasive belt. The device comprises a piece riding wheel, a guide wheel, an abrasion head, a transition gear, a fixing gear, a two-shaft motor, a centreless abrasive head of the abrasive belt, and a supporting member of the piece riding wheel, wherein the centreless abrasive head of abrasive belts is composed of an abrasion head driving gear, the abrasive belt and an abrasive head contacting gear, and the abrasion head driving gear is connected with the abrasive head contacting gear via the abrasive belt. One end of the two-shaft motor is in fixed connection with the abrasive head driving gear, and the other end is connected with a fixed gear which is matched with the transition gear. The transition gear is matched and connected to the abrasive head. The device resolves the problems of poor rigidity, a lot of process procedures, a plurality of devices, much transport, complex operation, inconvenient installation and the like in the prior art of the coarse grinding, fine grinding, polishing and the like of the outer circle with elongated circular rods. The device increases the integral efficiency, reduces manufacture cost, enlarges the manufacture range and combines the rough process, semi-fine process, fine process, lapping and polishing.

Owner:GUANGDONG IND TECHN COLLEGE

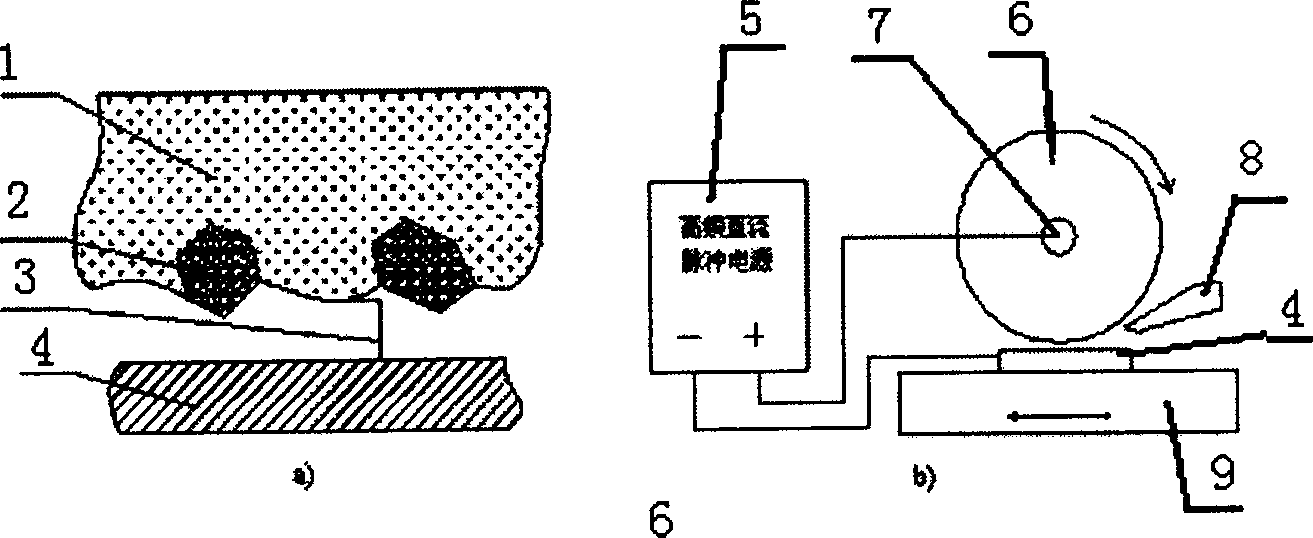

Electric spark-mechanical compound shaping method of metal bindnig agent extra hard abradant sand wheel

An electrospark-mechanical method for shaping the abrasive disc made of metallic binder and superhard abrasive material includes such steps as electrospark shaping until the electrospark can not be generated, mechanical shaping by brake-type silicon carbide roller for removing all projected abrasive particles, alternatively repeating said steps for 2 hr, lowering the electric parameters, and sequentially repeating said steps until its shaping accuracy reaches 6 microns.

Owner:HUNAN UNIV

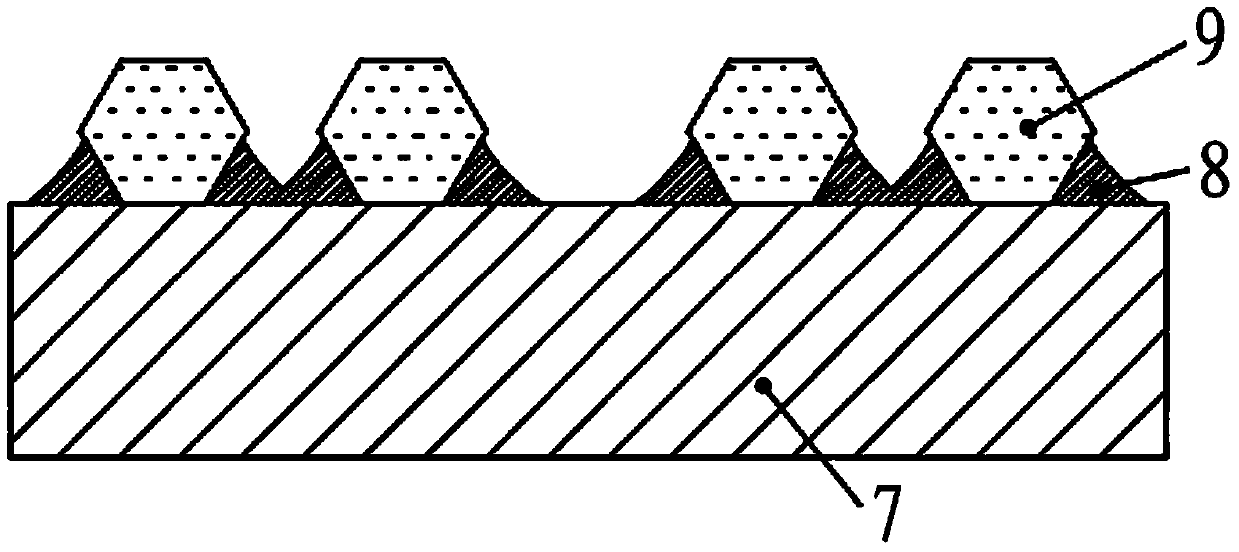

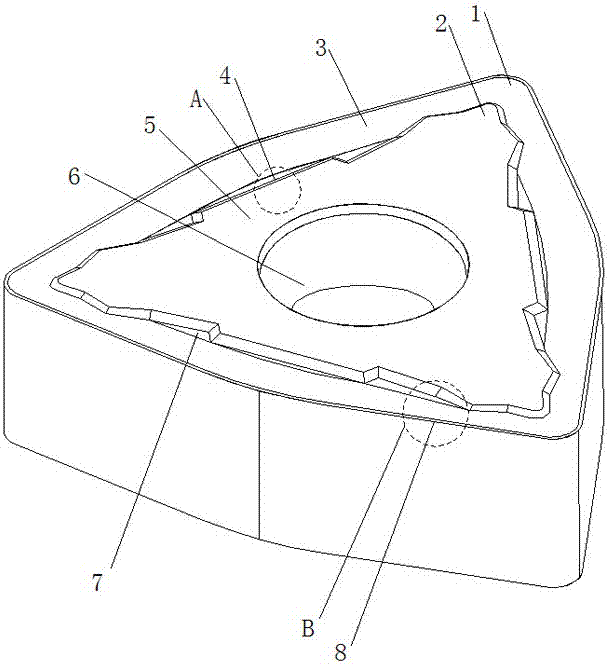

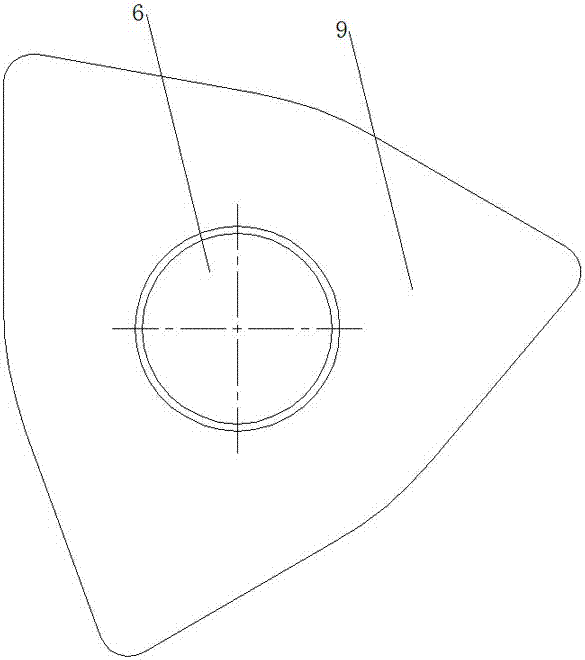

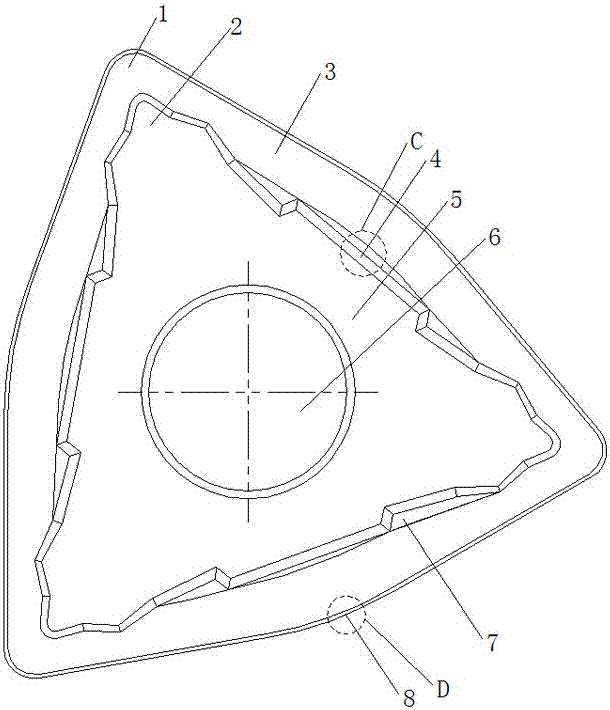

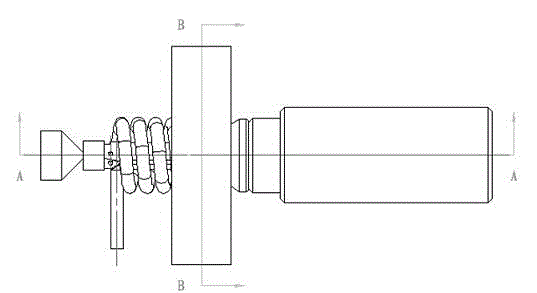

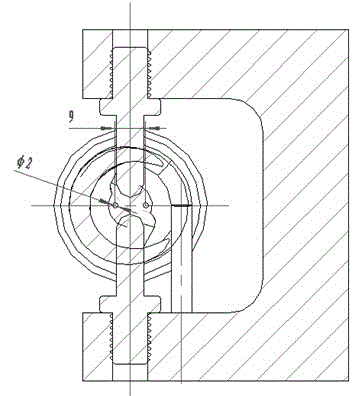

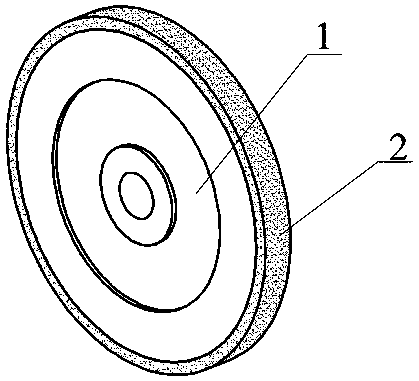

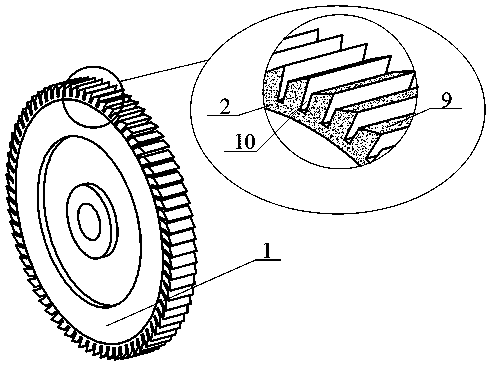

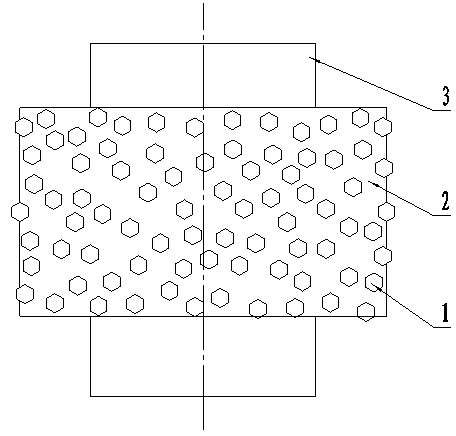

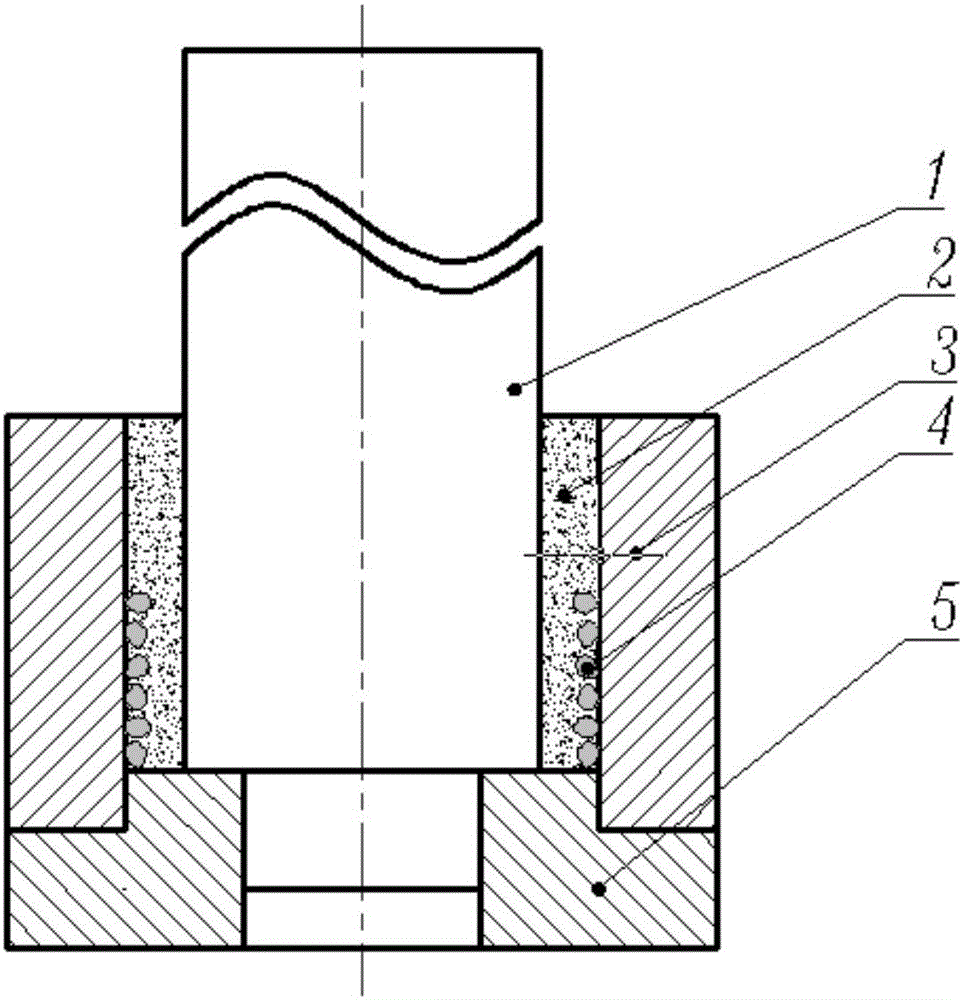

Diamond grinding wheel and method for manufacturing tool bit thereof

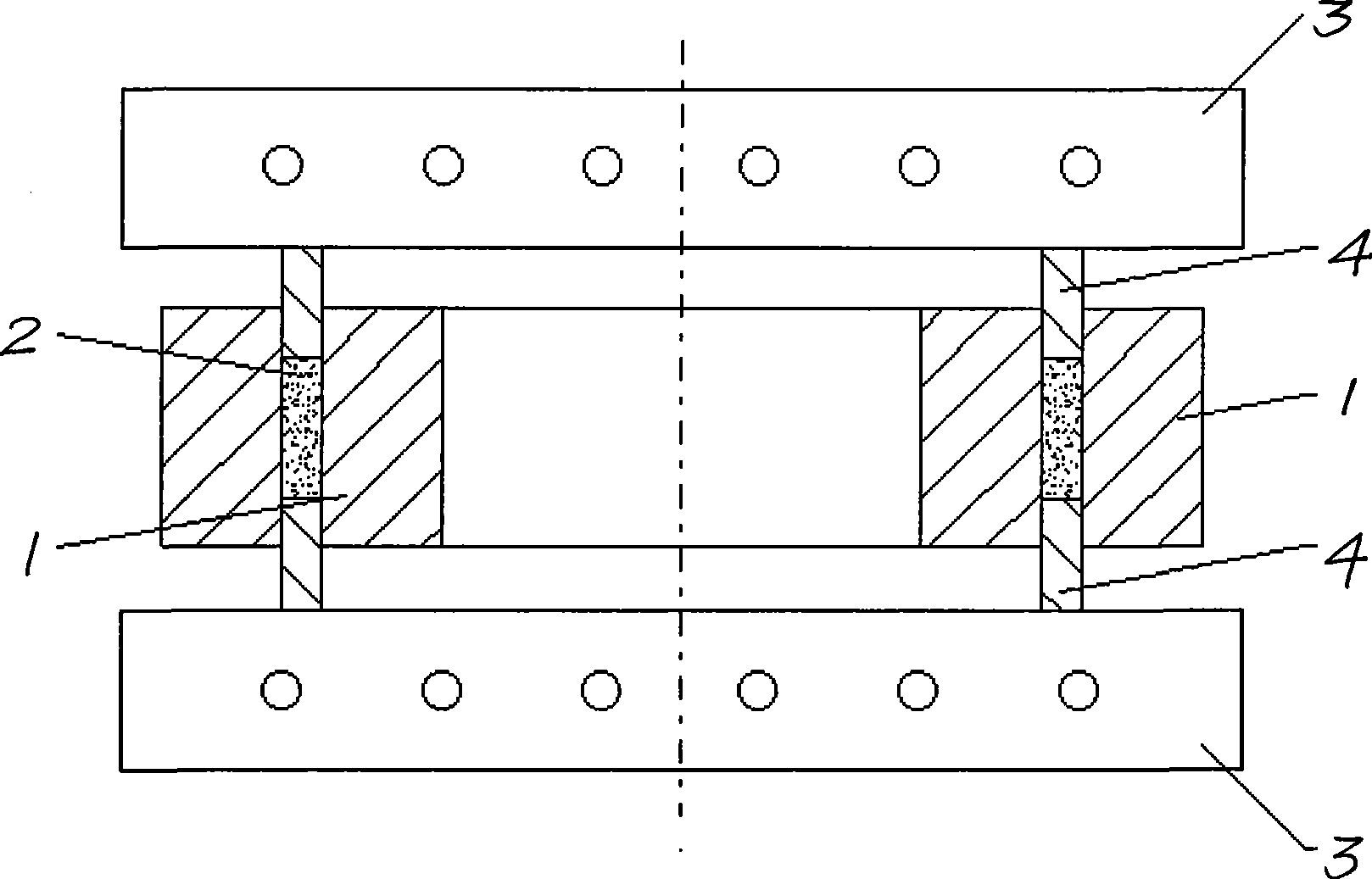

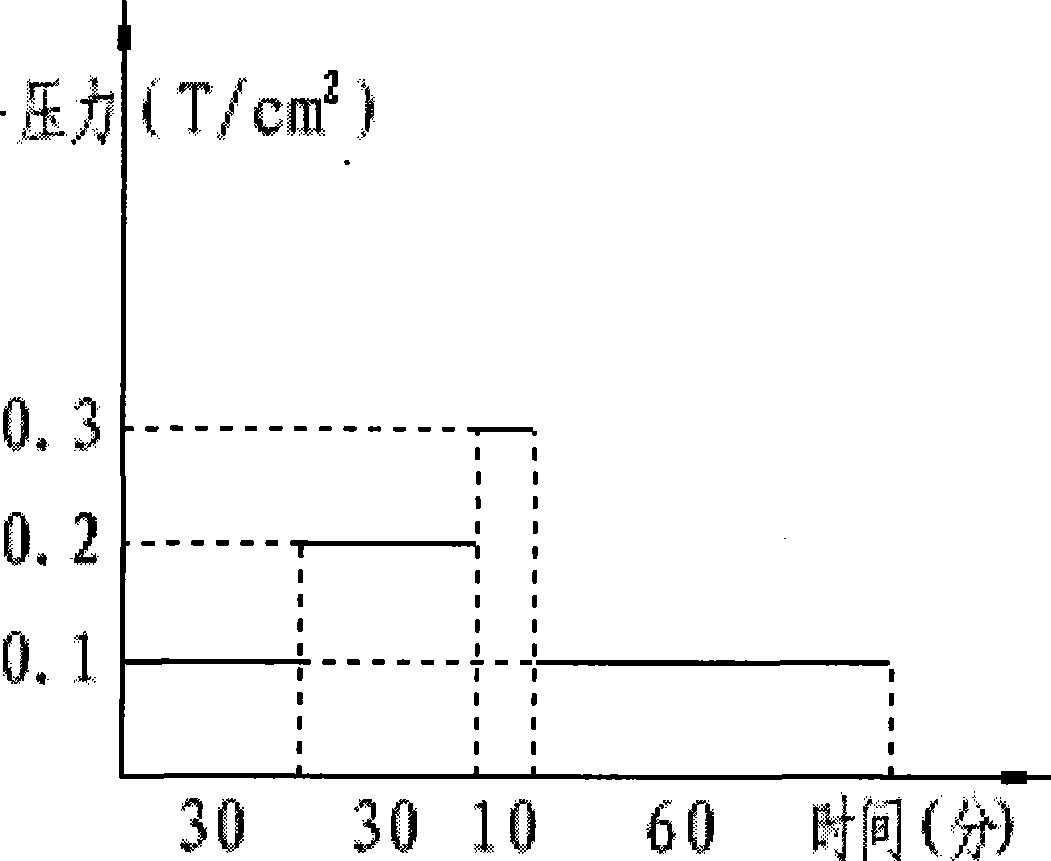

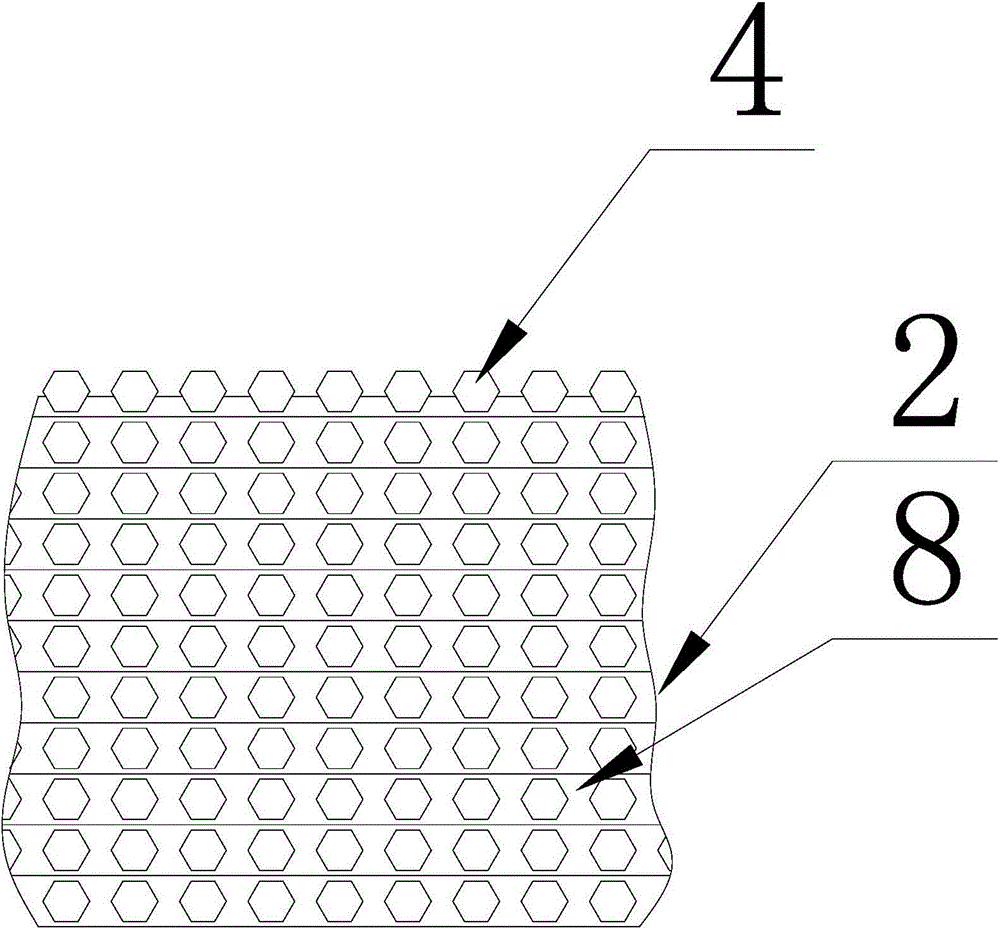

ActiveCN101412207AImprove self-sharpening abilityIncrease chip spaceAbrasion apparatusGrinding devicesSilicon chipDiamond grinding

The invention provides a diamond grinding wheel for precise polishing for the surface of a silicon material and a manufacturing method for a tool bit thereof. Surface roughness Ra of a silicon chip polished by the grinding wheel is lower than 0.03, Ry is lower than 0.27, and Rz is lower than 0.29. The diamond grinding wheel comprises a steel basal body and the tool bit embedded in the steel basal body; the tool bit is manufactured by the following steps: putting a mixed material into a die cavity of a die; and heating and pressurizing the mixed material, so as to press the mixed material to the required size; and a preparation method for the mixed material comprises the following steps: preparing powder from the following components in volume percentage: 20 to 40 percent of phenolic resin, 12. 5 to 25 percent of diamond, 10 to 15 percent of Fe2O3, 10 to 15 percent of CeO2, 5 to 10 percent of Al2O3, and 5 to 10 percent of Cu powder; and then 20 to 50 percent powder mass of pore forming agent is added into the powder.

Owner:NANJING SANCHAO ADVANCED MATERIALS

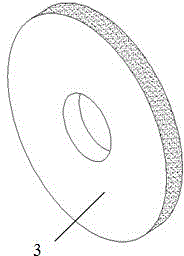

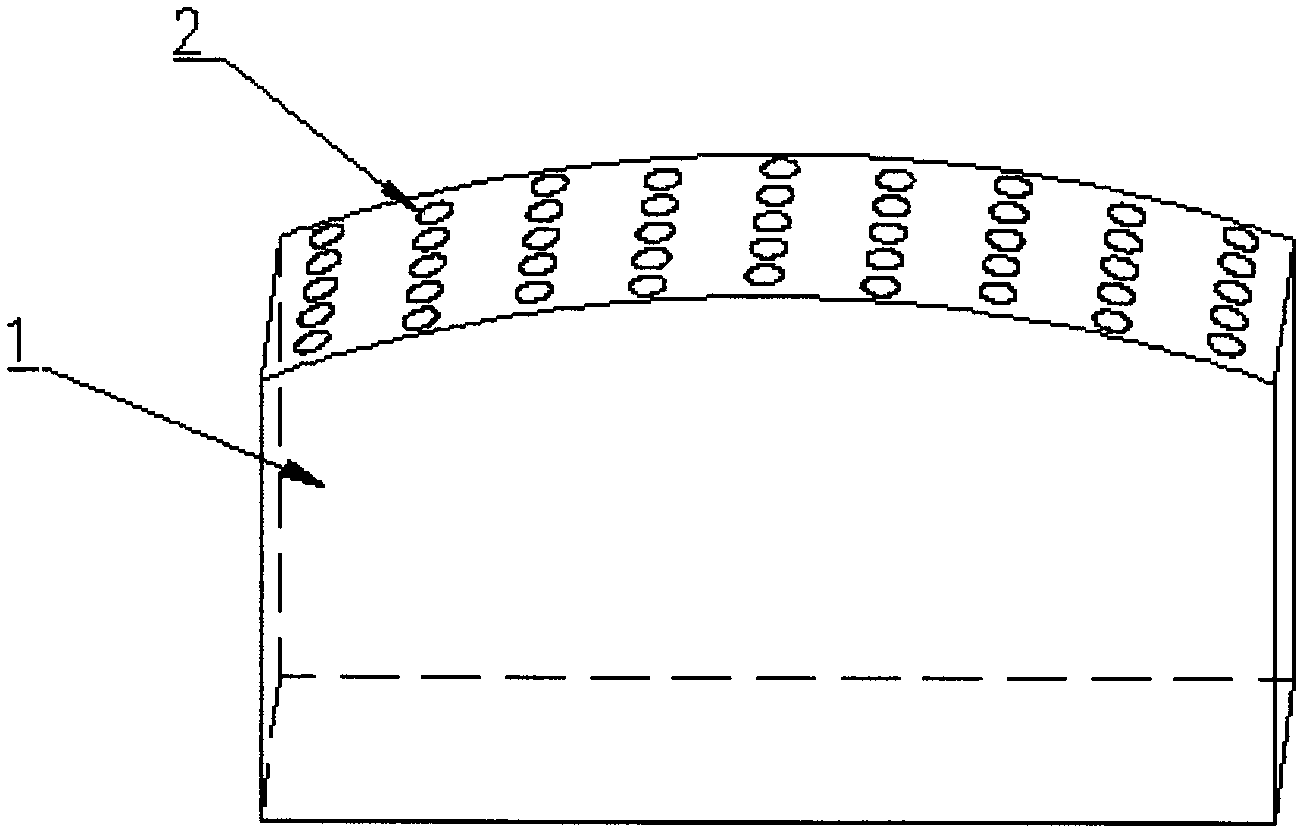

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

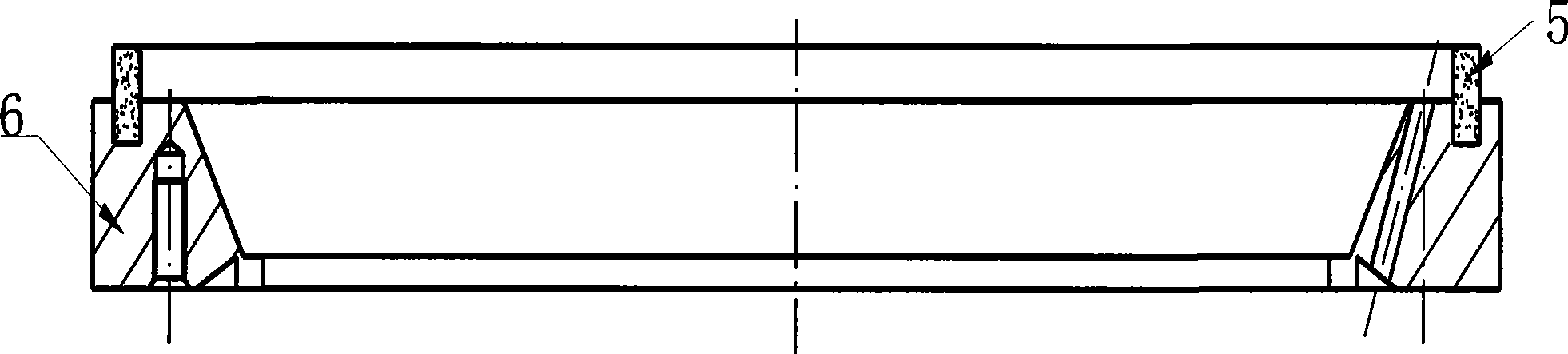

Production method of brazed diamond wire saw

InactiveCN101596749AIncrease productivityReduce manufacturing costFine working devicesStone-like material working toolsDiamond wire sawInduction welding

The invention relates to a production method of a brazed diamond wire saw, comprising the following process steps: 1. a steel wire enters a vessel stored with paste solder; 2. the steel wire adhered with solder enters a first wire-drawing die to facilitate the steel wire passing through the first wire-drawing die to be evenly coated with a layer of solder; 3. the steel wire adhered with solder enters a sealed dust box which contains diamond powder with diameter being 20-30 mum, a blower device blows the diamond fine powder, and the steel wire adhered with solder is evenly coated with a layer of diamond powder after passing through the dust box; 4. the steel wire adhered with solder enters a second wire-drawing die and is evenly and tightly coated with a layer of diamond powder; 5. the steel wire adhered with solder enters the center of a coil of high frequency induction welding, the solder melts down instantly, and diamond and the wire are fixedly and metallurgically bonded; and 6. a roll-up wheel evenly winds the finished diamond wire by welding. The method of the invention has quick production speed, and the prepared brazed diamond wire saw has long service life.

Owner:江苏中博钻石科技有限公司

Manufacturing method of electroplated grinding wheel of ordered structure

The invention discloses a manufacturing method of an electroplated grinding wheel of an ordered structure. The method includes: adopting a pulse laser beam to process a fine spiral groove with the pitch of hundreds of micrometers and the notch size of dozens of micrometers in the working surface of the outer annulus of a grinding wheel base body made of metal, filling the groove with epoxy resin, and enabling the metal and the epoxy resin on the working surface of the outer annulus of the grinding wheel base body to be in spiral regularly-spaced layout; then electroplating the working surface of the outer annulus of the grinding wheel base body with abrasive grains by adopting an electroplating method. Since the groove is filled with the non-conductive epoxy resin, the region cannot be electroplated with the abrasive grains. By the steps, the electroplated grinding wheel with the abrasive grain layer and the epoxy resin being in spiral regularly-spaced layout can be obtained. The manufactured electroplated grinding wheel of the ordered structure is in favor of solving the problems that the grinding wheel is blocked easily during grinding and grinding fluid cannot enter the grinding region easily, workpieces can be prevented from being burnt, and the grinding quality is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Spiral fluted tap and method for processing same

The invention discloses a spiral fluted tap and a method for processing the same. The spiral fluted tap comprises a tap body provided with a plurality of uniformly distributed spiral flutes on a front cut part, wherein the spiral flute is an S-shaped smooth curved groove formed by sequentially connecting four sections of tangential circular arcs end to end; and the four sections of tangential circular arcs are a cutting circular arc, a chip curling circular arc, a chip accommodating circular arc and a blade back circular arc respectively. The method for processing the spiral fluted tap comprises the following steps of: (1) preparing before processing; (2) processing the spiral flute by a special tool: fitting a blade shape of a cutter by a computer, and then manufacturing the cutter according to the fitted cutter blade shape so as to process the spiral flute; and (3) carrying out subsequent treatment by using a machining process so as to obtain a finished product of the tap body. The spiral fluted tap processed by the method has simple structure and can be molded in one step. Moreover, the processing method is suitable for different processing materials, particularly for processing fluted taps made of light alloys, such as an aluminum alloy and the like.

Owner:XIAN TECHNOLOGICAL UNIV

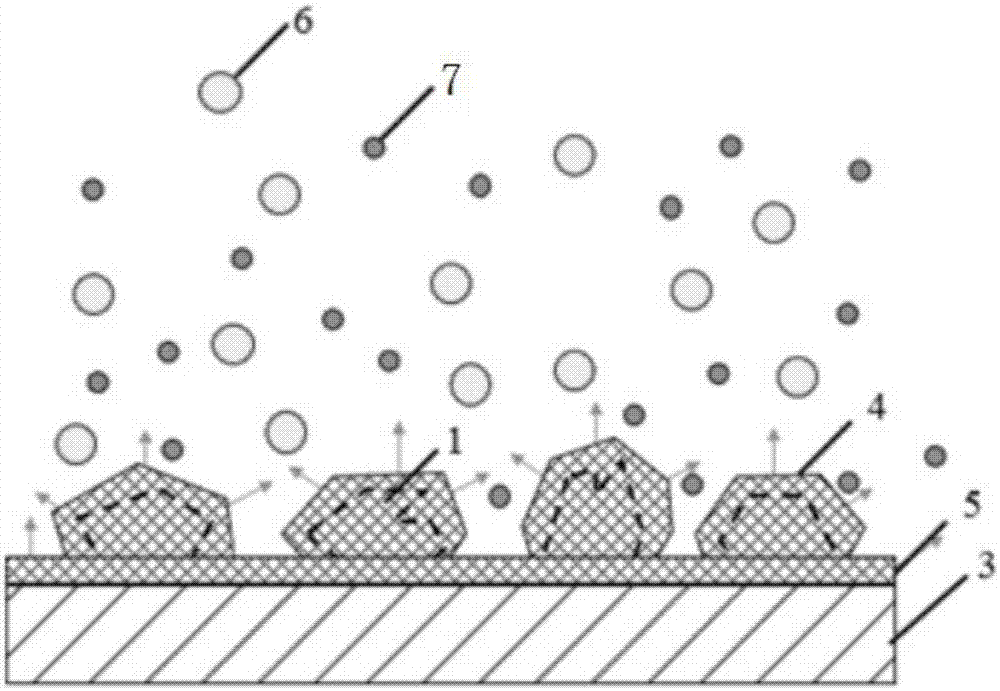

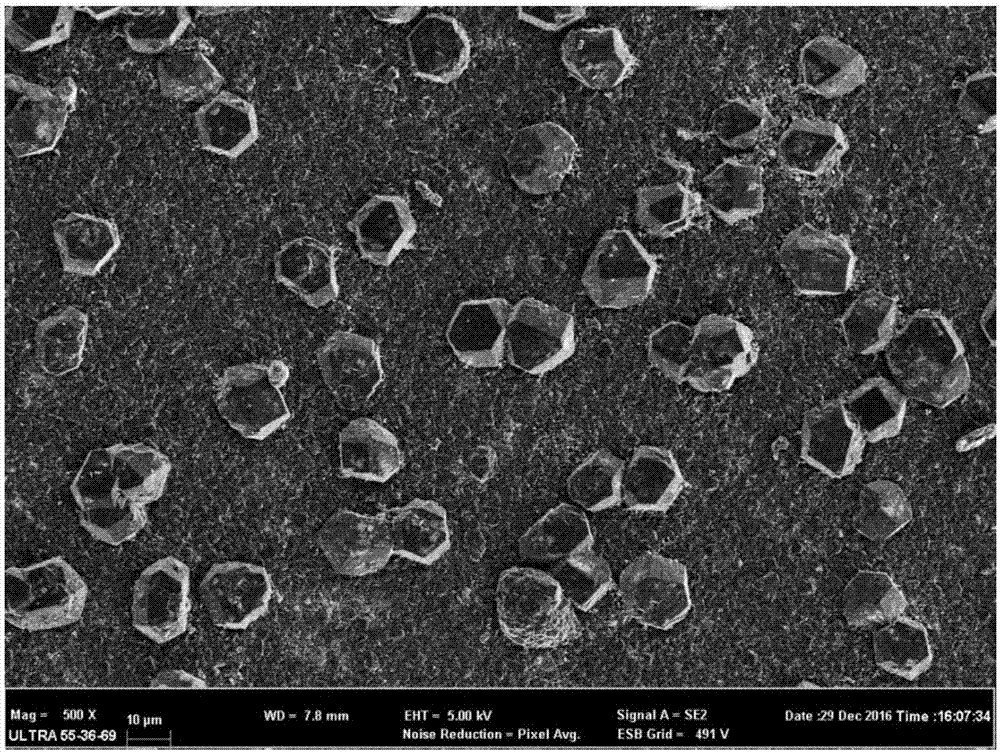

Method for preparing single-layer diamond abrasive tool through chemical vapor deposition

The invention discloses a method for preparing a single-layer diamond abrasive tool through chemical vapor deposition. According to a silicon carbide base body, a diamond abrasive material is mixed into a photoresist solution and is subject to ultrasonic vibration, rotating whirl coating is used for evenly dispersing diamond abrasive particles, uniform distribution of the particles on a base body substrate can be achieved, the CVD method is adopted to enable the diamond coating bonding agent to be subject to deposition between the diamond abrasive particles and the silicon carbide base body, the abrasive material and the base body are firmly connected together, and meanwhile, the abrasive particles grow to become high-grade cubic octahedral single-crystal particles. The prepared single-layer diamond abrasive tool is high in abrasive particle holding force, the exposure height is large, the chipping containing space is large, defects of electroplating and brazing single-layer diamond abrasive tools are overcome, and the method is suitable for preparing fine granularity (five micrometers to 100 micrometers) single-layer diamond abrasive tools. The prepared single-layer diamond abrasive tool has the wide application prospect in high-precise grinding fields of crisp and hard materials of semiconductors, optical crystals, artificial sapphire, glass and the like

Owner:SHANGHAI JIAO TONG UNIV +1

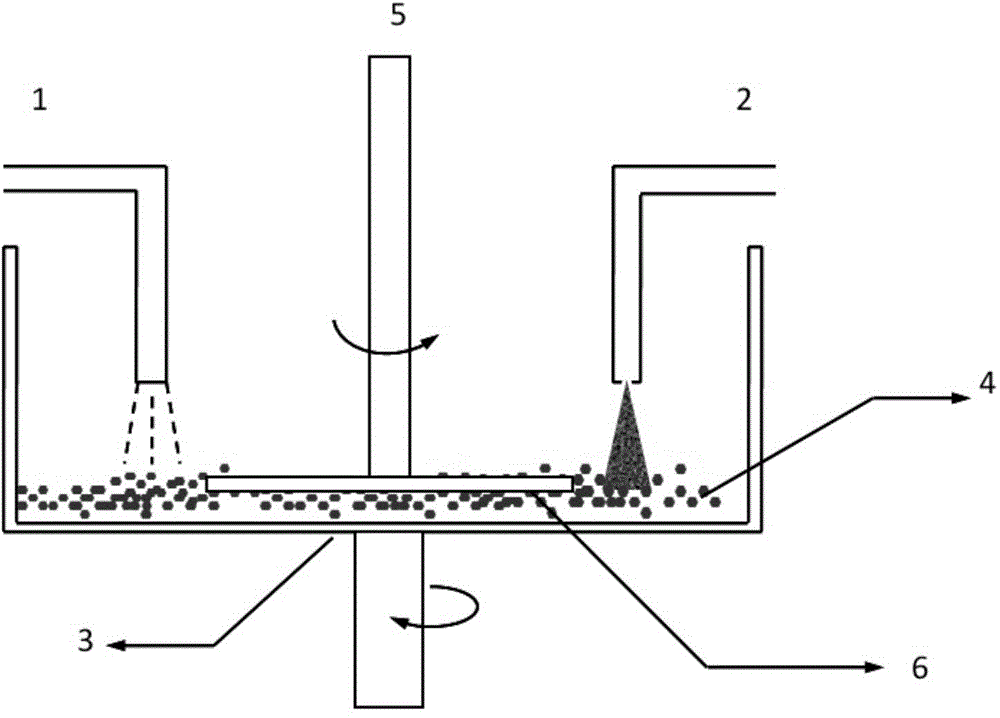

Gradient alloying granulation method of diamond abrasive grain surface binding agent

ActiveCN104592938AImprove performanceThe preparation method is efficientOther chemical processesAbrasion apparatusSprayerCarbide

The invention discloses a gradient alloying granulation method of a diamond abrasive grain surface binding agent. The diamond abrasive grains with a gradient alloying binding agent layer comprise diamond grains; an inner binding agent, a middle binding agent and an outer binding agent are arranged on the surfaces of the diamond grains in sequence; and the content of carbide forming elements in the binding agent is gradually decreased layer by layer. A gradient alloying granulation device of the diamond abrasive grain surface binding agent is used for preparing the diamond abrasive grains and comprises a roller, a slurry feeding sprayer, a power feeding sprayer and an ultrasonic stirrer. The gradient alloying granulation method of the diamond abrasive grain surface binding agent uses at least three sets of above devices, and comprises the following steps: a, wrapping the inner binding agent on the surfaces of the diamond grains; b, wrapping the middle binding agent on the surfaces of the diamond grains; and c, wrapping the outer binding agent on the surfaces of the diamond grains. The prepared abrasive grains have relatively good performance and the preparation method is high in efficiency.

Owner:GUANGDONG UNIV OF TECH

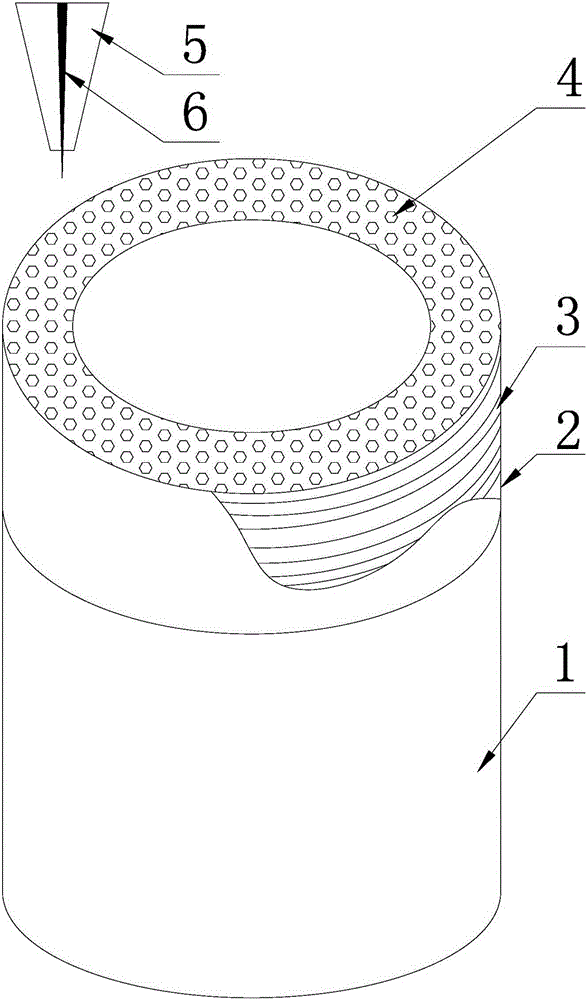

Preparation method for diamond fiber grinding wheel and section mold

InactiveCN103381577AExtended service lifeNot easy to fall offAbrasion apparatusGrinding devicesFiberSmall hole

The invention discloses a preparation method for a diamond fiber grinding wheel and a section mold. The preparation method for the diamond fiber grinding wheel comprises the following steps: step 1, preparing a grinding wheel section: uniformly fixing strip-shaped diamond fiber to the periphery of the designed section mold, wherein one end of the diamond fiber points to the center of the section mold in radiation arrangement, then adding section mold to the carcass material to perform hot press formation, so that the grinding wheel section is prepared; step 2, performing overall hot press formation for the grinding wheel section: performing hot press formation for a plurality of grinding wheel sections and grinding wheel base material to obtain the diamond fiber grinding wheel. A plurality of rows of small holes are formed in the periphery of the section mold provided by the invention; the prepared diamond grinding wheel has a long service life, the diamond cannot fall off easily, the scrap containing capacity and dissipation capacity are increased, and heat damage of the workpiece can be effectively avoided or reduced.

Owner:HUNAN UNIV OF SCI & TECH

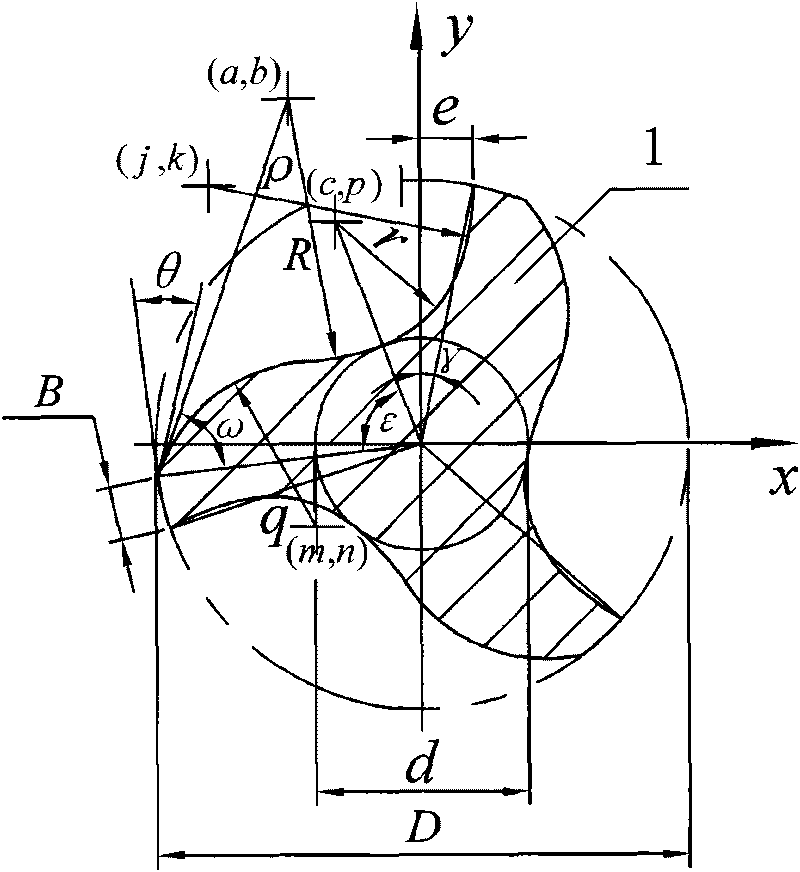

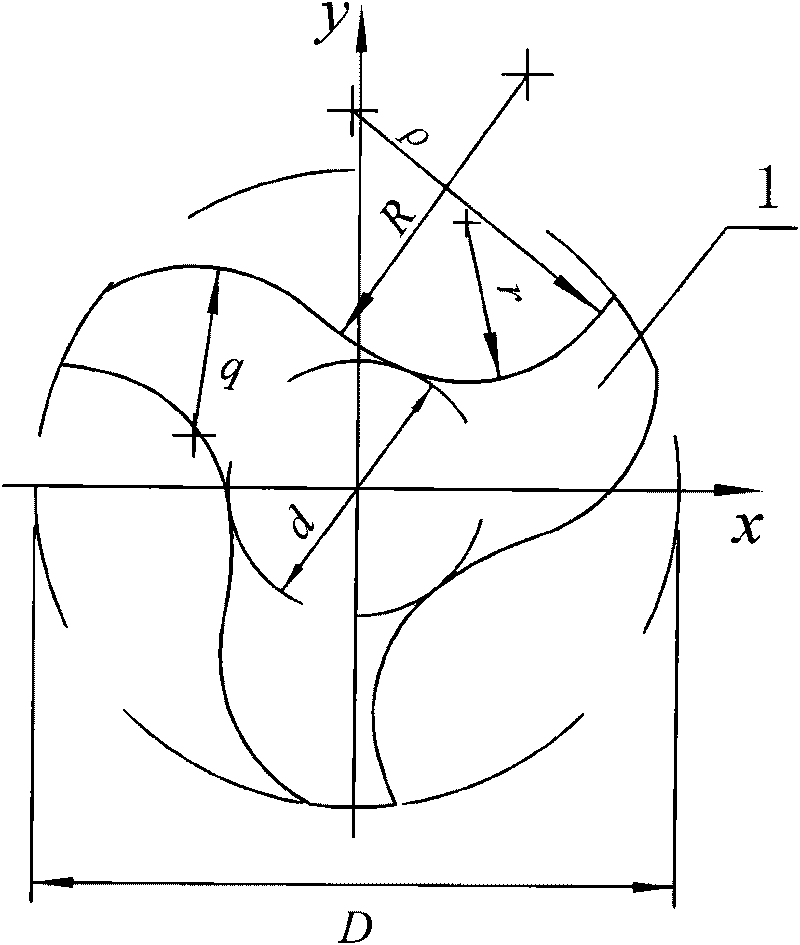

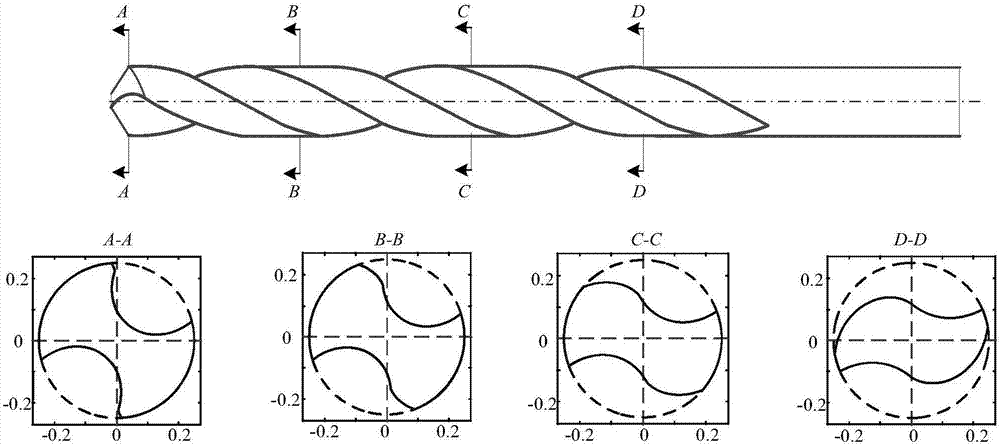

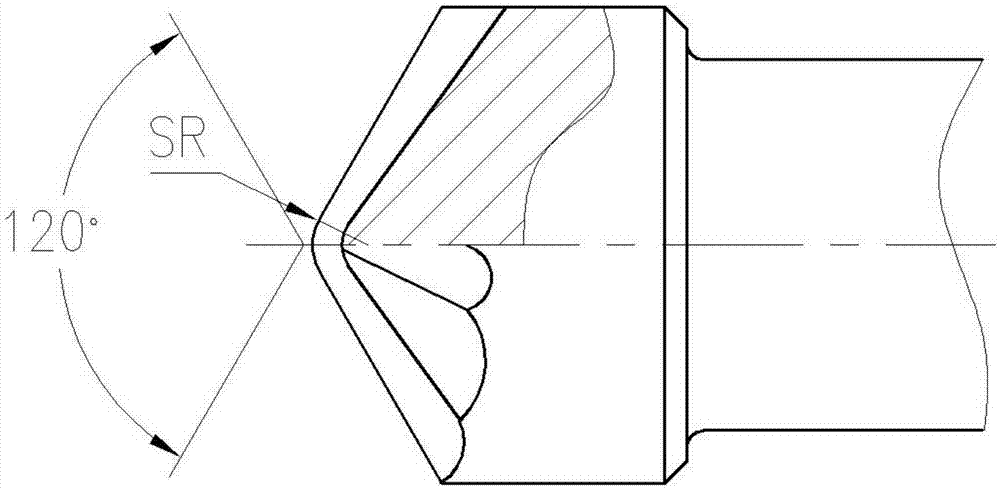

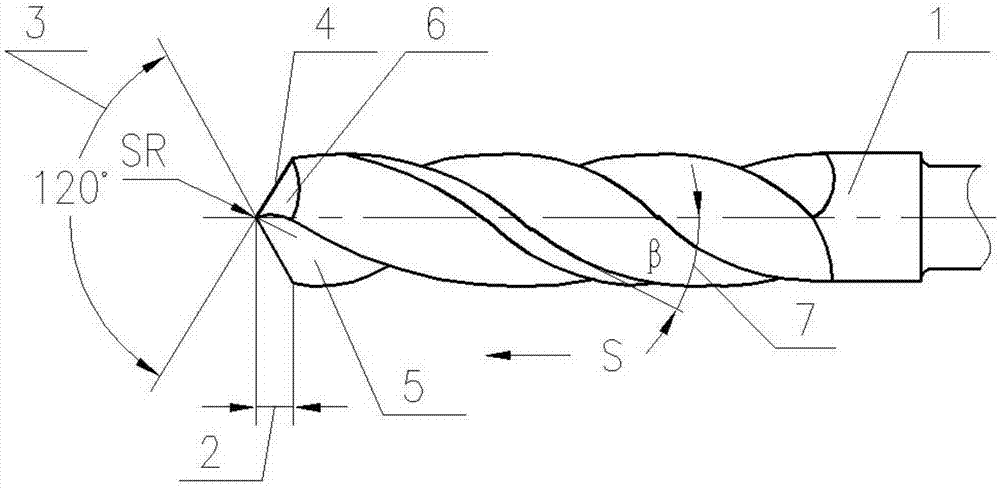

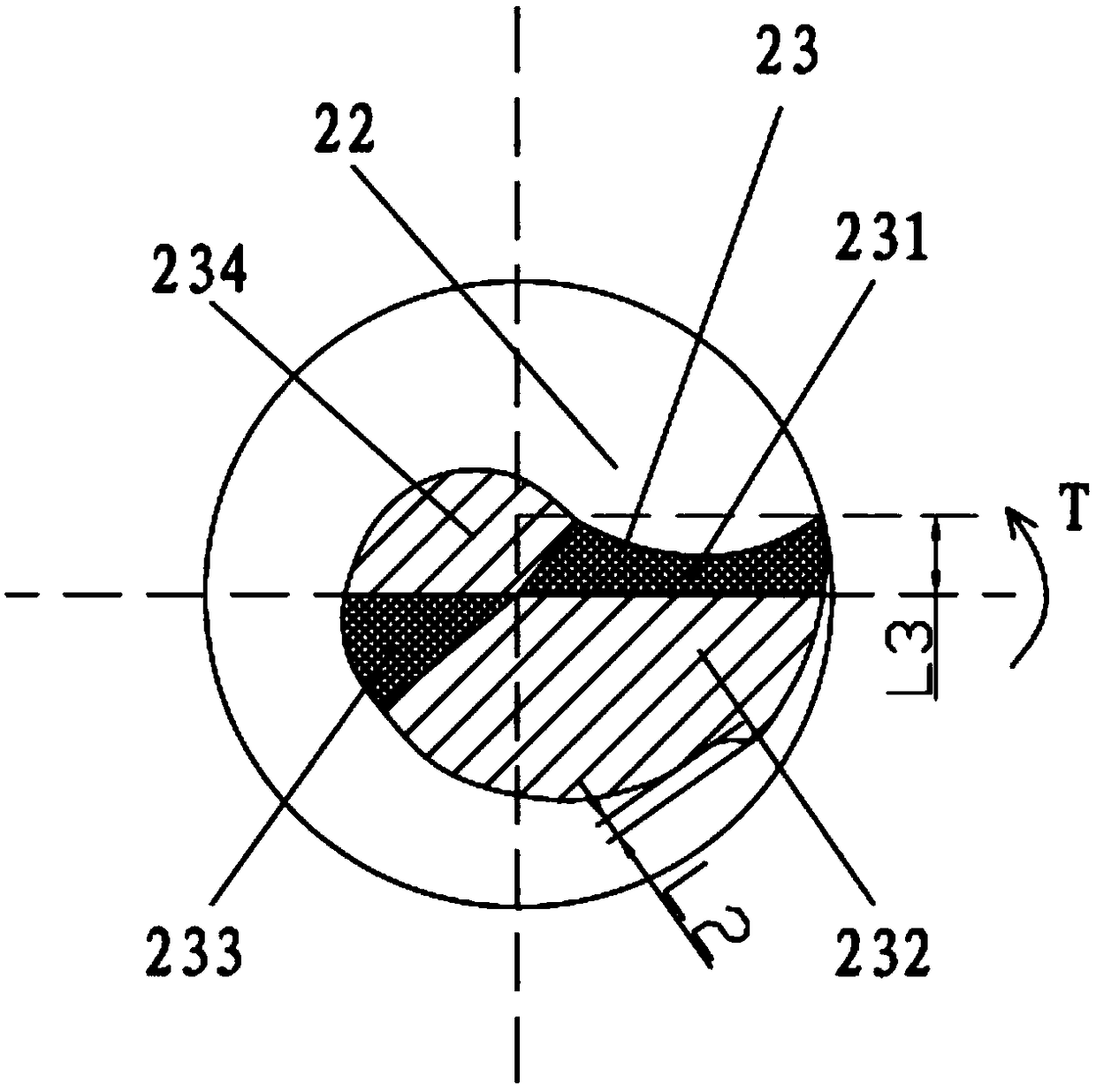

Twist drill with spiral cutting back tool

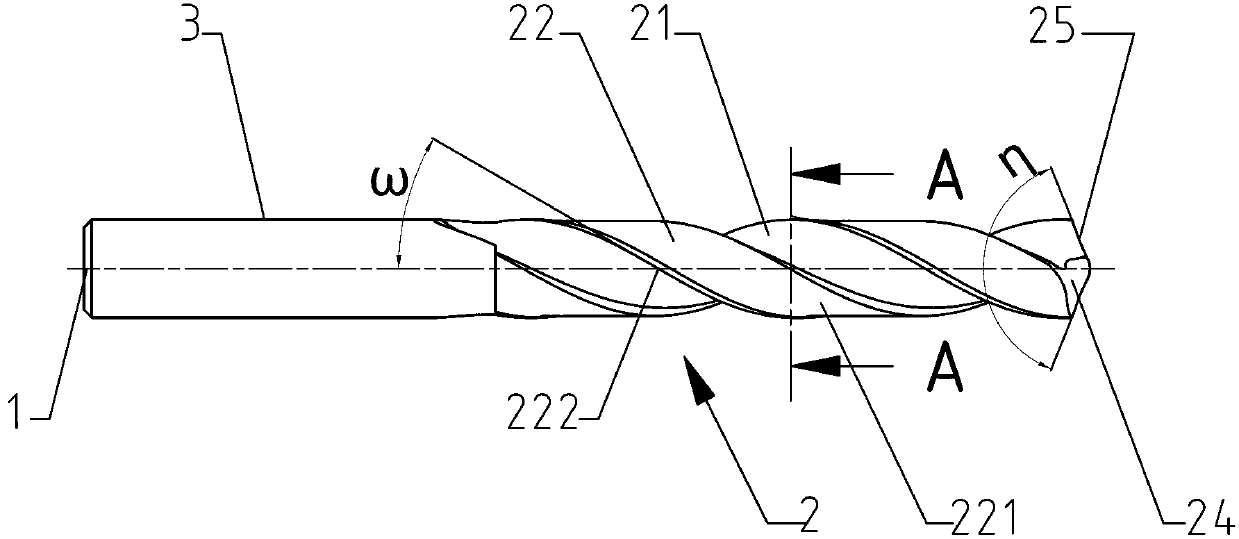

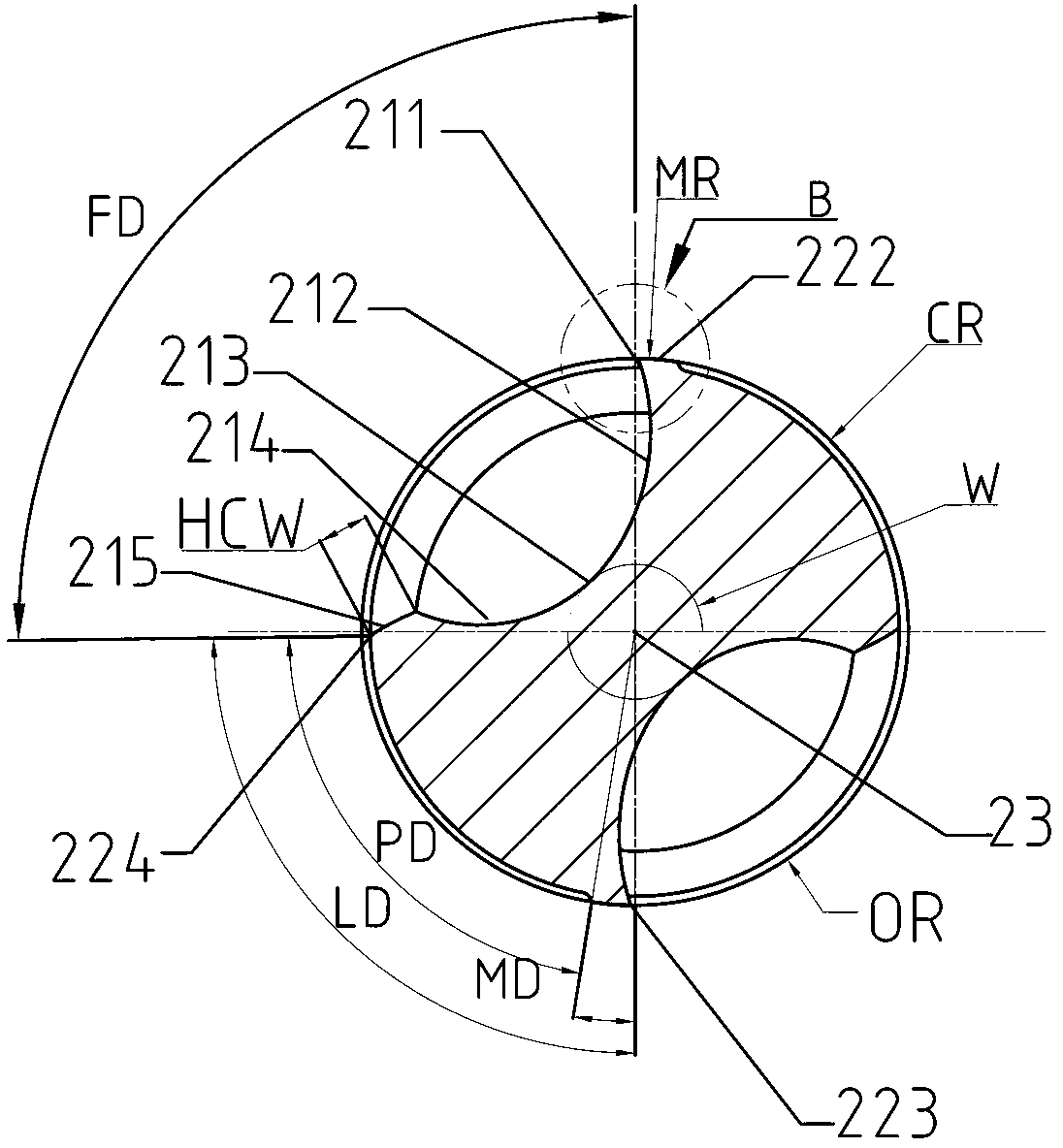

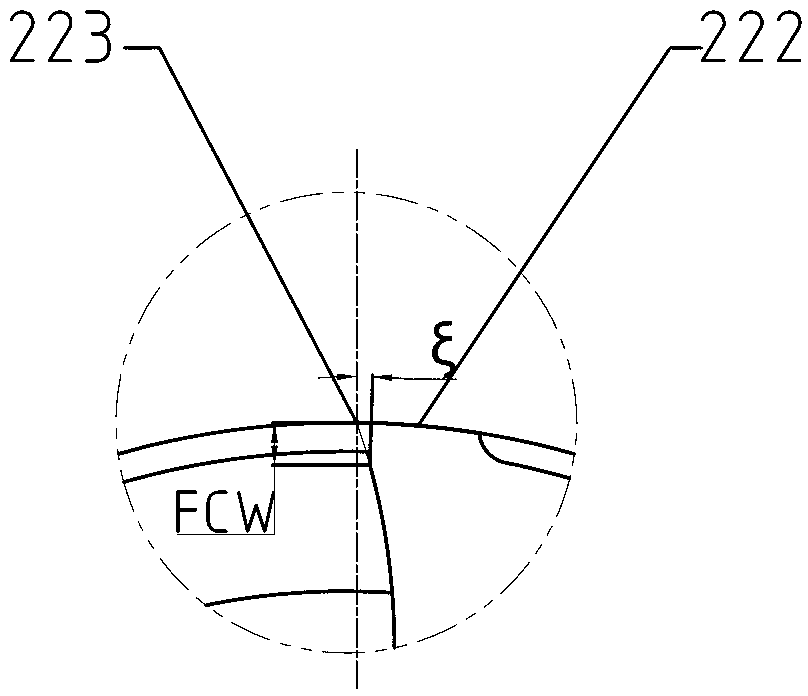

ActiveCN103128346AExcellent machinabilityGood centering effectTwist drillsStress concentrationEngineering

The invention discloses a twist drill with a spiral cutting back tool. The twist drill with the spiral cutting back tool comprises a cutting portion which rotates around an axis and a handle portion which matches with a jacket. Two grooves which extend from the front end of the cutting portion to the handle portion in a spiral mode and are sued for discharging cutting chips are formed in the cutting portion. The cutting portion is further provided with blade backs which are respectively connected with the periphery of the two grooves. The twist drill with the spiral cutting back tool is characterized in that the grooves form two spiral cutting back tool faces at the front end of the cutting portion, the two cutting back tool faces are intersected in a drill core position to form an S-shaped drill core cutting blade and two main cutting blades, the main cutting blade is connected with the S-shaped drill core cutting blade through a cutting blade connection portion in a smooth mode, each cutting back tool face begins from the main cutting blade and is formed by smoothly connecting a main back blade face, a transition face and a the cutting back tool face stop face. According to the twist drill with the spiral cutting back tool, the spiral cutting back tool faces are intersected to form the S-shaped drill core cutting blade which is connected with the main cutting blade in a smooth mode, stress concentration is greatly reduced, drilling load and centring capacity are further improved, and the twist drill with the spiral cutting back tool is easy to be widely popularized.

Owner:大连远东工具有限公司

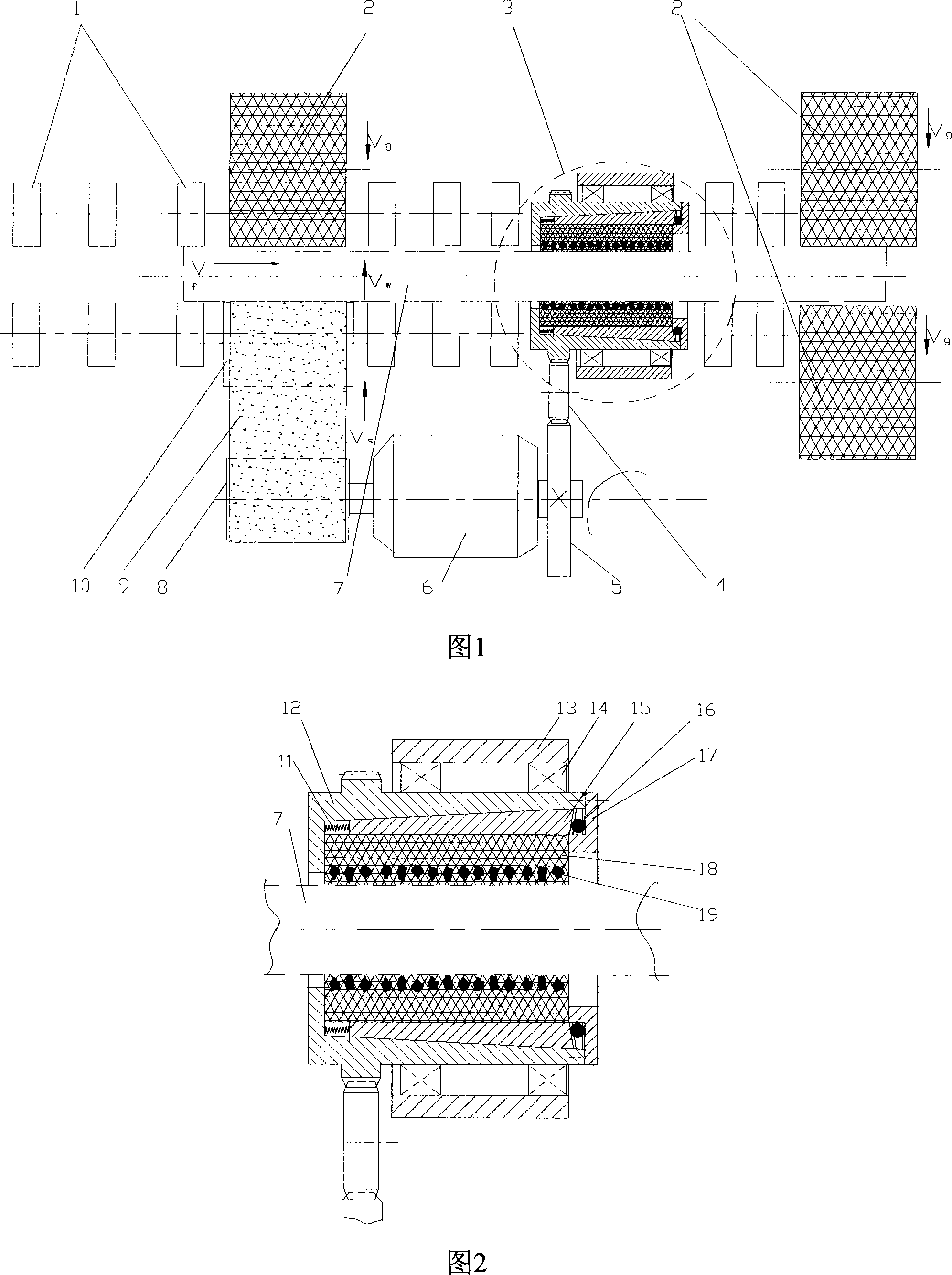

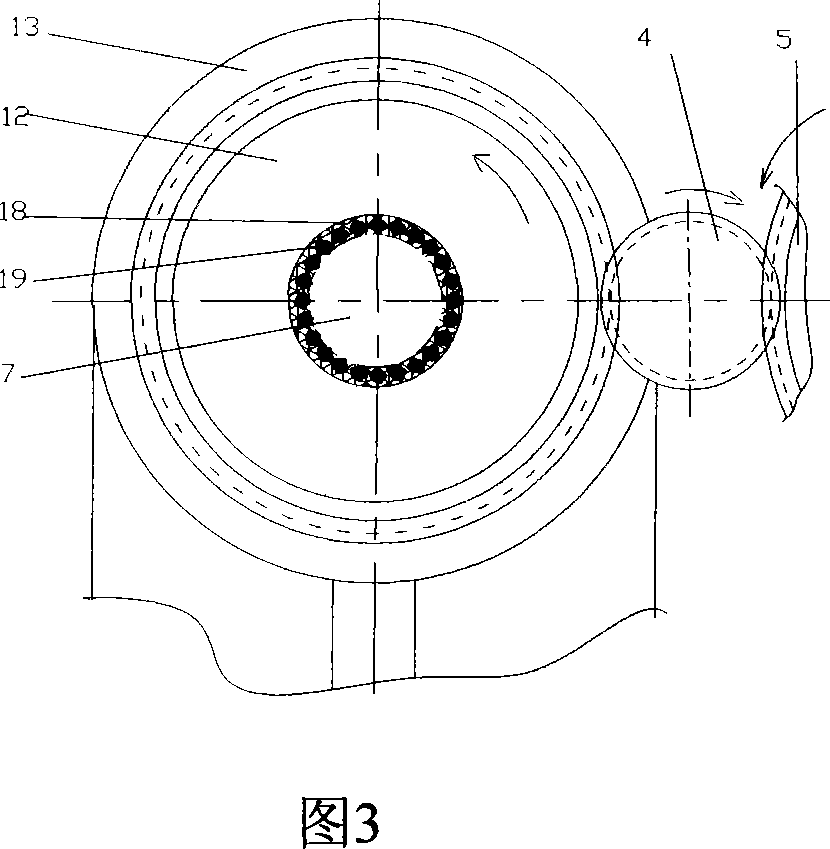

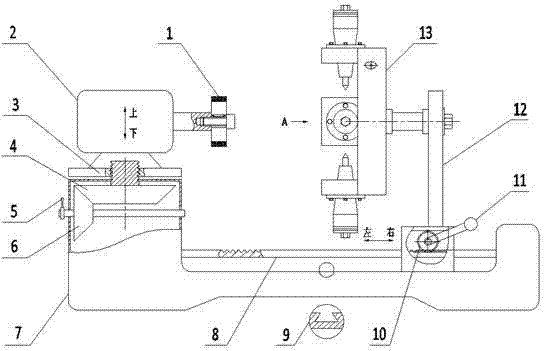

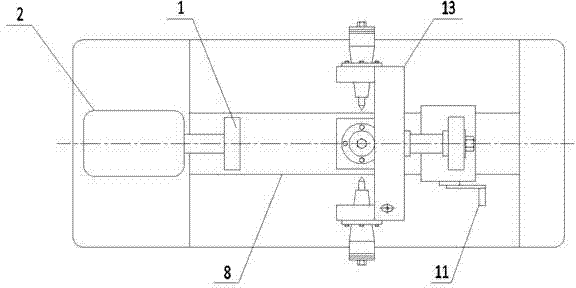

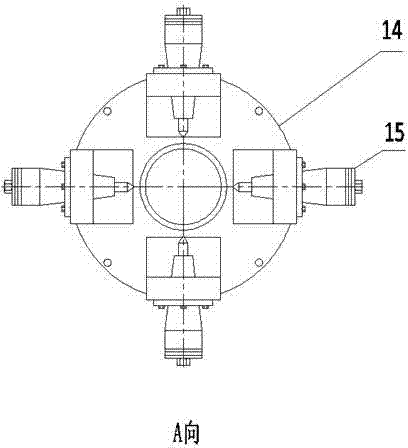

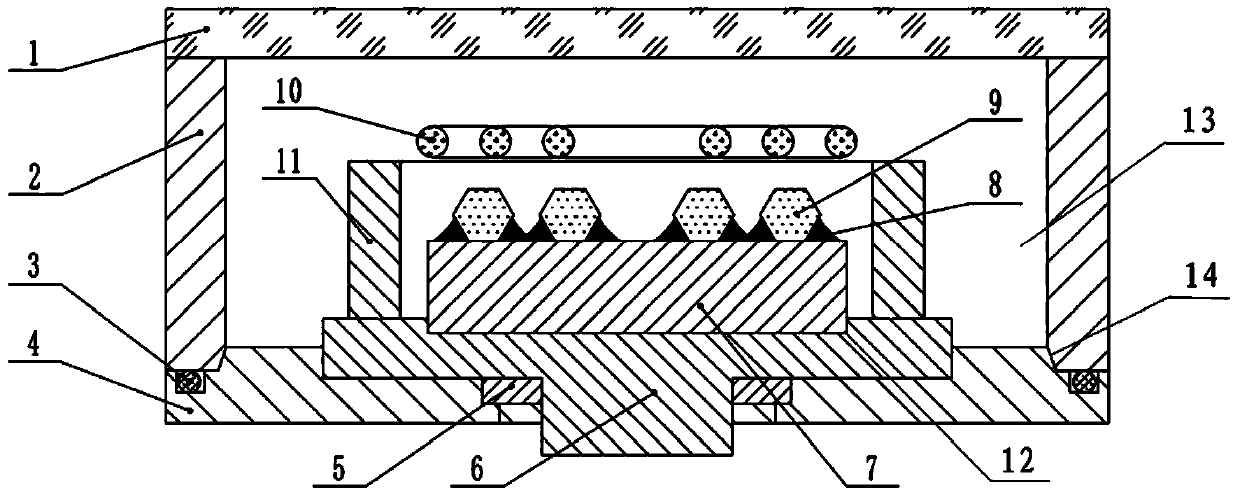

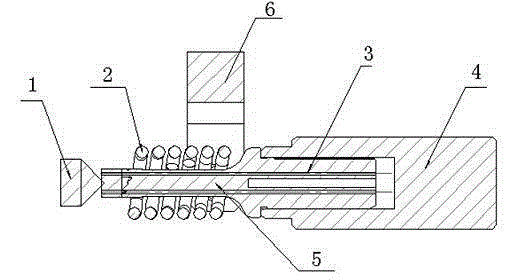

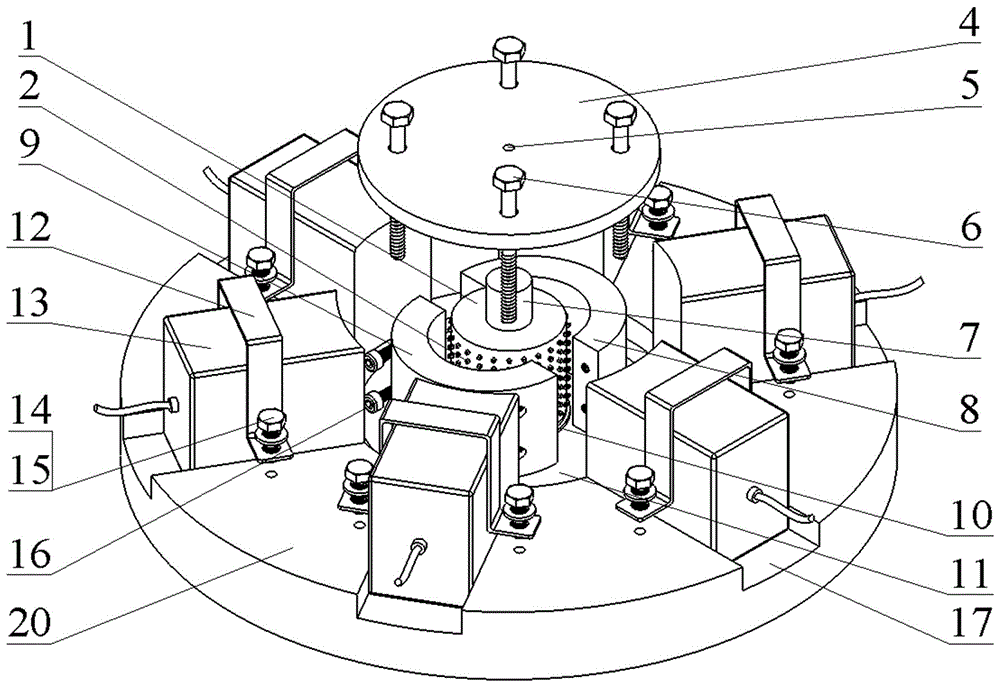

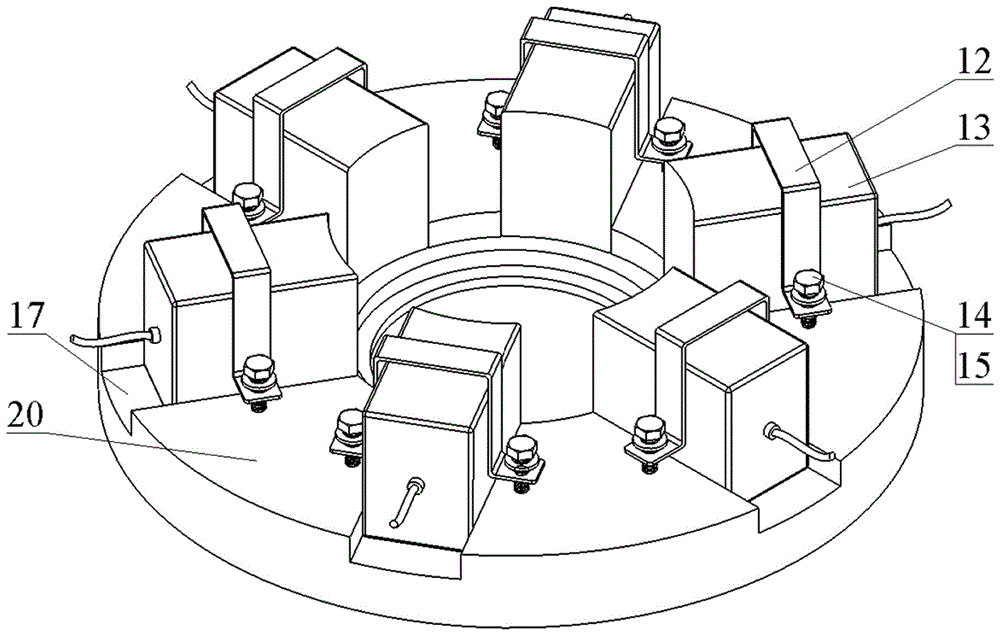

Multipoint ultrasonic vibration CBN grinding wheel dressing device

ActiveCN103921213AIncrease stiffnessImprove stabilityAbrasive surface conditioning devicesEngineeringUltrasonic vibration

The invention discloses a multipoint ultrasonic vibration CBN grinding wheel dressing device mainly comprising a bed (7), a three-phase asynchronous motor (2), a grinding wheel (1), a support plate (12) and a four-point positioning chuck. The three-phase asynchronous motor is disposed above the left end of the bed. The grinding wheel is disposed at the right end of the three-phase asynchronous motor. A vertical adjustment is arranged between the three-phase asynchronous motor and the bed. The support plate is slidably connected with the bed. The four-point positioning chuck is fixed at the upper end of the support plate. The multipoint ultrasonic vibration CBN grinding wheel dressing device is simple in structure and easy to operate; four sliders move along a normal by rotating a voltaic wrench, cutting forces of symmetric positions are mutually counteracted, and rigidity of a cutting system and cutting stability are improved; a slider structure employs the ultrasonic vibration technology, abrasive particles on the dressed surface of the CBN grinding wheel are sharp, and chip containing space is large. Compared with the laser dressing method, the multipoint ultrasonic vibration CBN grinding wheel dressing device has the advantages that deformation of the surface of the CBN grinding wheel and the cutting force are greatly decreased, cutting speed is significantly lowered, and the service life of the CBN grinding wheel is prolonged.

Owner:CONPROFE TECH GRP CO LTD +1

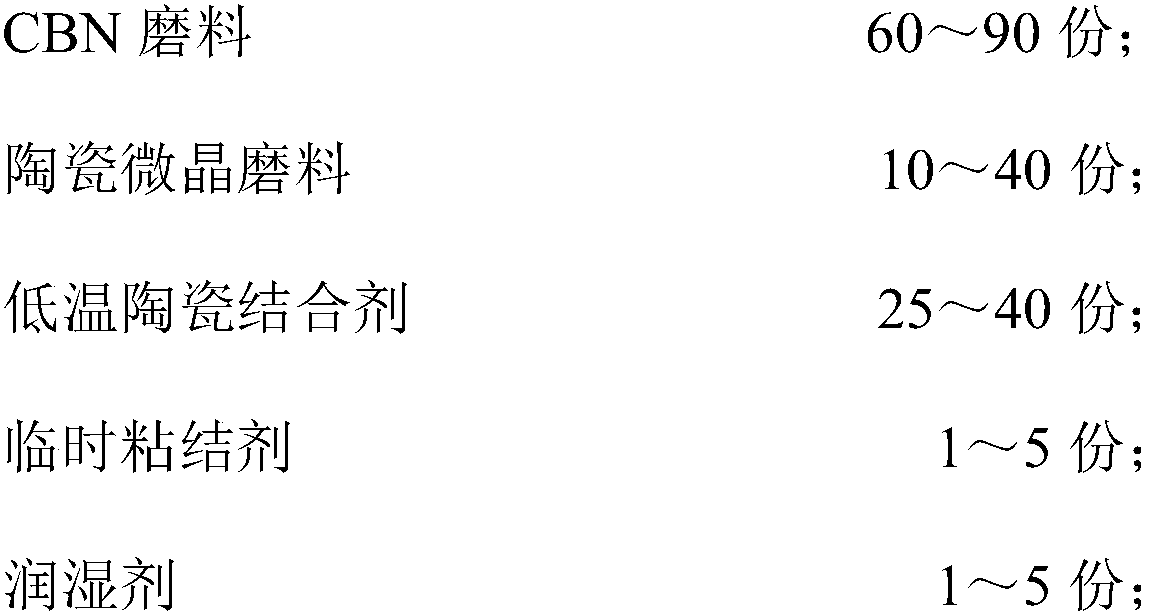

Ceramic bond CBN composite grinding wheel for grinding titanium alloys and preparation method

InactiveCN109465758AHigh bonding strengthImprovement effortsAbrasion apparatusGrinding devicesSurface finishTitanium

The invention belongs to the technical field of grinding, and in particular, relates to a ceramic bond CBN composite grinding wheel for grinding titanium alloys and a preparation method. The compositegrinding wheel comprises a basal body, and a composite patch fixed on the basal body by using an adhesive layer and used for grinding the titanium alloys. Through cooperation between ceramic microcrystal abrasives and CBN abrasives, the composite grinding wheel is prepared, sharp cutting edges can be continuously generated, more chip accommodating space is provided, the heat dissipating effect isimproved, the stable grinding effect is maintained, the finishing amount is reduced, and the production efficiency is improved; and through bonding and holding effects of low-temperature ceramic bondreinforcing abrasives with a specific ratio, the self-sharpening property is better, the chip accommodating space is larger, and the surface smoothness of grinded workpieces is further improved. Based on brand new raw material formulas, the preparation method forms a stable grid structure through low-temperature ceramic bonds, the CBN abrasives and the ceramic microcrystal abrasives to improve the mechanical strength of the composite grinding wheel.

Owner:SUZHOU FAR EAST ABRASIVES

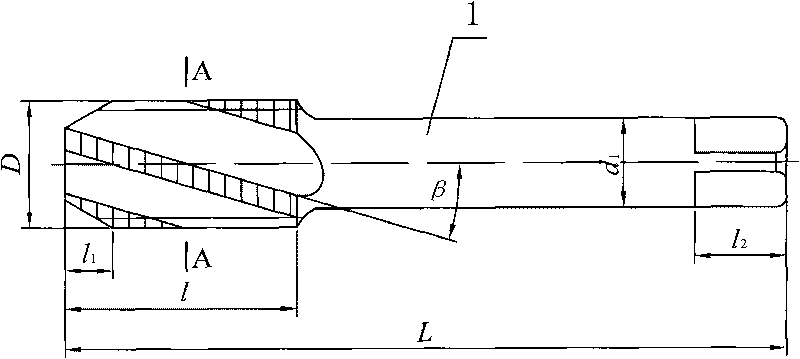

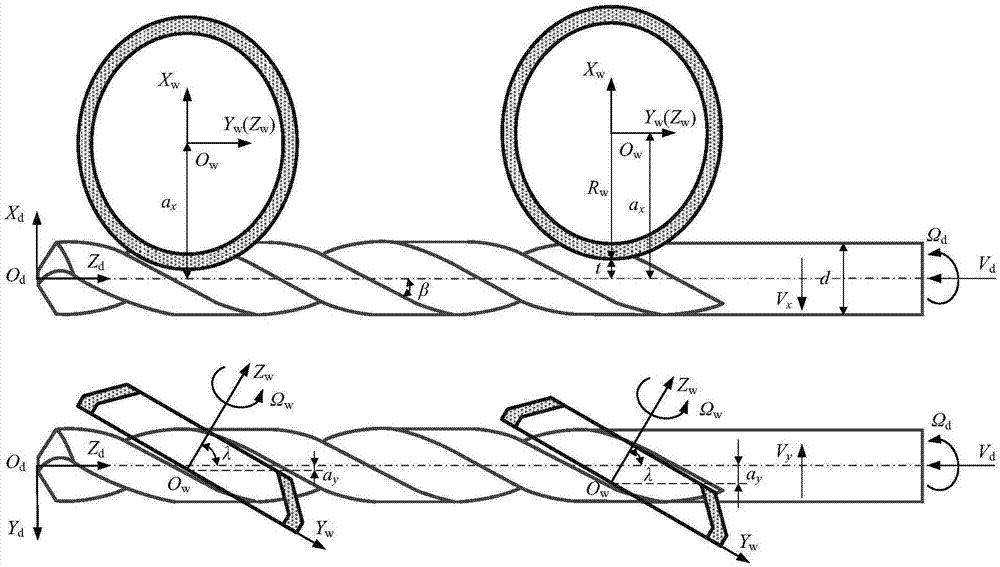

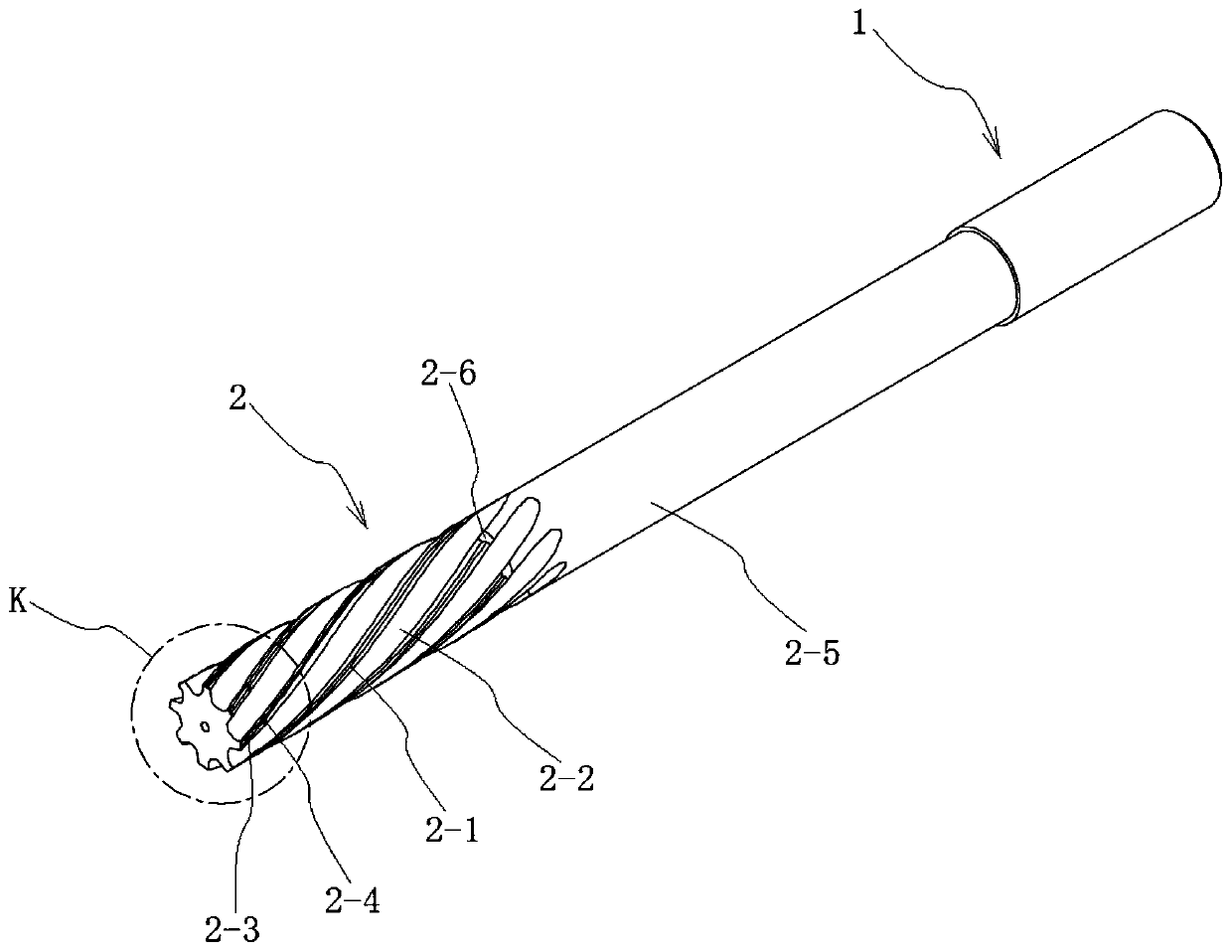

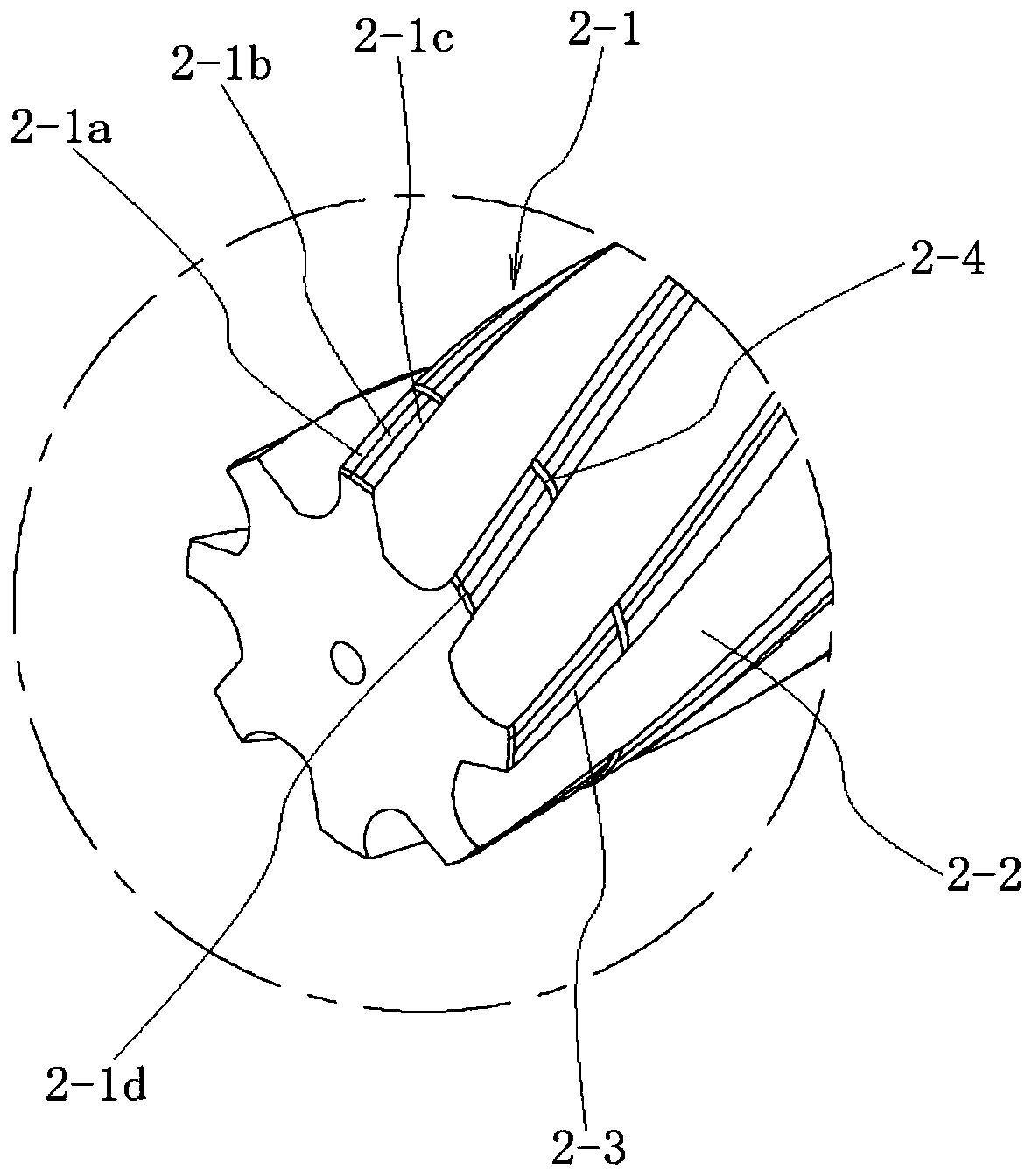

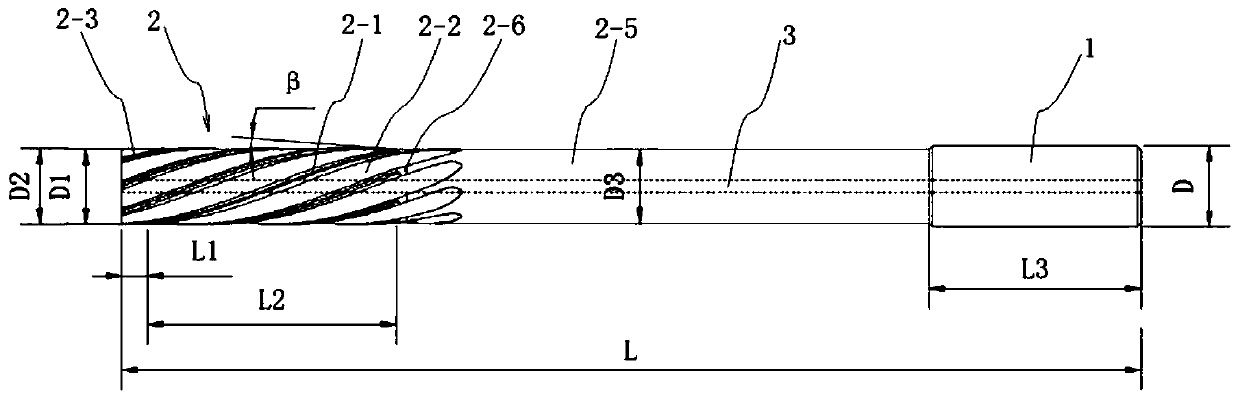

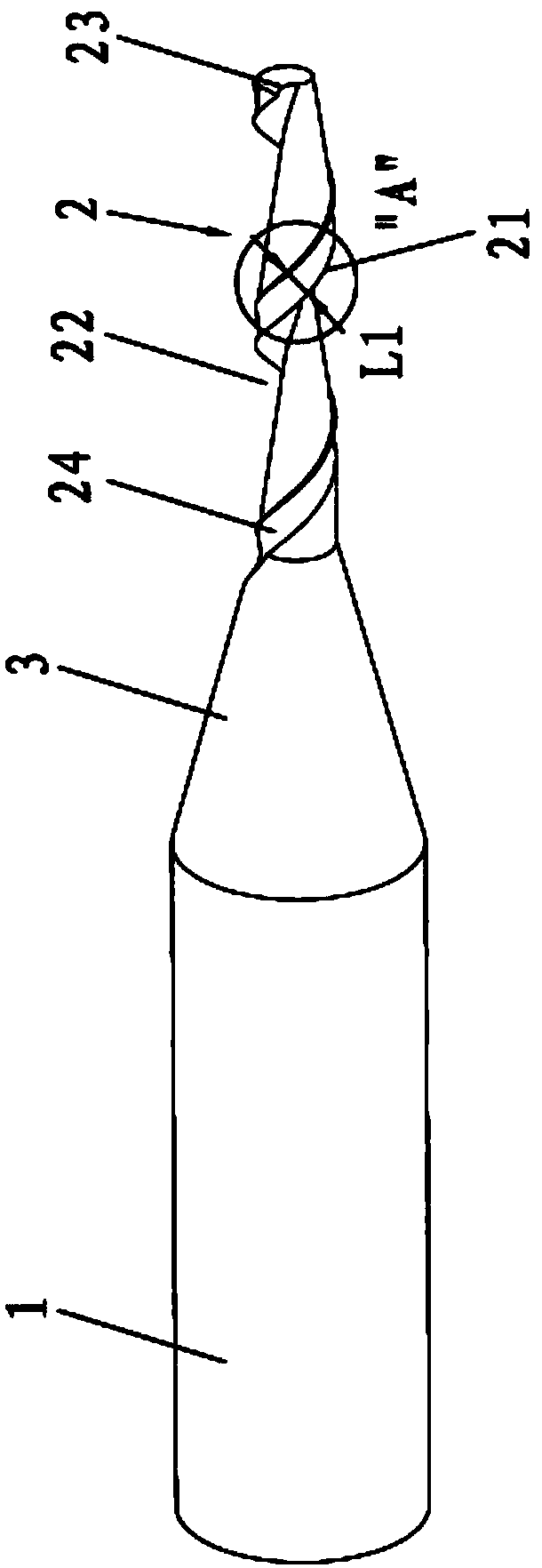

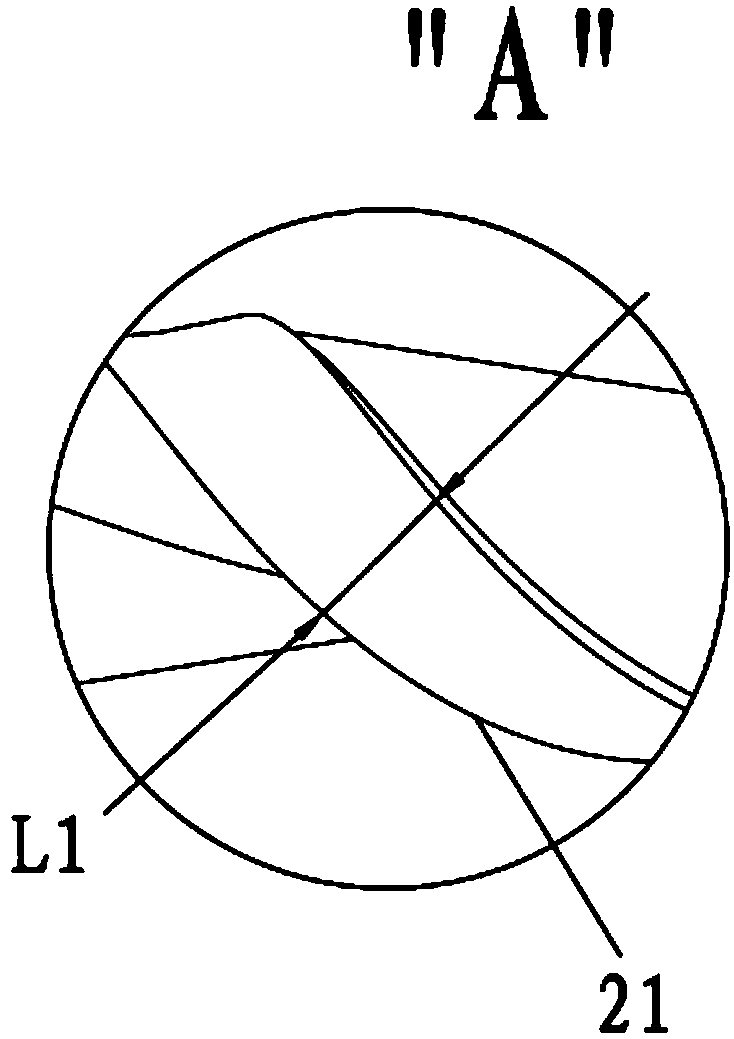

Tiny deep hole drilling cutter with variable core thickness and variable groove width and sharpening method of cutter

ActiveCN107363301AIncrease chip spaceExtended service lifeTransportation and packagingTrepanning drillsGroove widthOffset distance

The invention discloses a tiny deep hole drilling cutter with the variable core thickness and the variable groove width and a sharpening method of the cutter, and belongs to the technical field of machining. The cutter is structurally characterized in that the core thickness and the groove width of a spiral groove are simultaneously increased linearly from a drill point part to the tail part of the spiral groove. According to the drilling cutter, in the process of spiral groove sharpening, by controlling linear increasing of the relative distance of a grinding wheel axis and a drill bit axis, linear increasing of the core thickness is achieved; and by controlling linear increasing of the offset distance of a grinding wheel center and a drill bit center, linear increasing of the groove width of the spiral groove is achieved. According to the tiny deep hole drilling cutter with the variable core thickness and the variable groove width, for characteristics of tiny deep hole drilling and cutting machining of difficulty-machined materials, on the one hand, through the linear increasing of the core thickness from a drill point to the tail part of the spiral groove, the rigidity and the strength of the cutter are improved, and phenomena of bending and breaking-off of the cutter can be reduced; and on the other hand, through the linear increasing of the groove width of the spiral groove from the drill point to the tail part of the spiral groove, a scrap storing space of the cutter is enlarged, the scrap discharging capability of the cutter during tiny deep hole drilling and cutting is improved, phenomenon of torsional fracture of the cutter caused by scrap cutting blocking can be reduced, and the service life of the cutter is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Superhard grinding tool and preparation method thereof

ActiveCN104209875ARealize the combinationHigh holding strengthElectrolytic coatingsBonded abrasive wheelsMetal alloyElectroplating

The invention discloses a superhard grinding tool and a preparation method thereof. The superhard grinding tool comprises a grinding tool substrate and a grinding material, wherein the grinding material is solidified on the grinding tool substrate through a plating layer, and the plating layer comprises the following components by mass percentage: 10% to 20% of Cr, 5% to 15% of P, and the balance of Ni. According to the superhard grinding tool provided by the invention, the chemical metallurgy binding of the grinding material, a plating metal alloy and the grinding tool substrate is realized, the holding strength of the grinding material is greatly improved, the problems of the existing plating superhard grinding tool that the grinding material is easily shed or the plating layer is peeled off under the efficient grinding conditions, resulting in the overall failure of the grinding tool are solved, and the service life of the grinding tool is prolonged; the chip space of the grinding tool is large, and the plugging is not easily generated; the quality is stable, the service life is long, and the superheard grinding tool is suitable for being popularized and applied.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Straight fluted drill

InactiveCN102554323AIngenious structural designIncrease chip spaceTransportation and packagingTrepanning drillsFluteSpecial design

The invention aims to provide a straight fluted drill, which is long in service life so that production cost is reduced. The straight fluted drill comprises a handle and an edge, a side edge and a chip flute are axially arranged at the edge, and pivotally, a platform is arranged at the bottom of the chip flute. By the aid of the special fluted design, on the premise of ensuring a large core thickness, more chip containing spaces are available, double edges formed by the platform are fine in guidance, and the quality of a machined product can be ensured more effectively. The straight fluted drill is ingenious in structural design, large in core thickness, large in chip containing space and fine in guidance, and a drill bit cannot break, so that production cost is reduced.

Owner:锑玛(苏州)精密工具股份有限公司

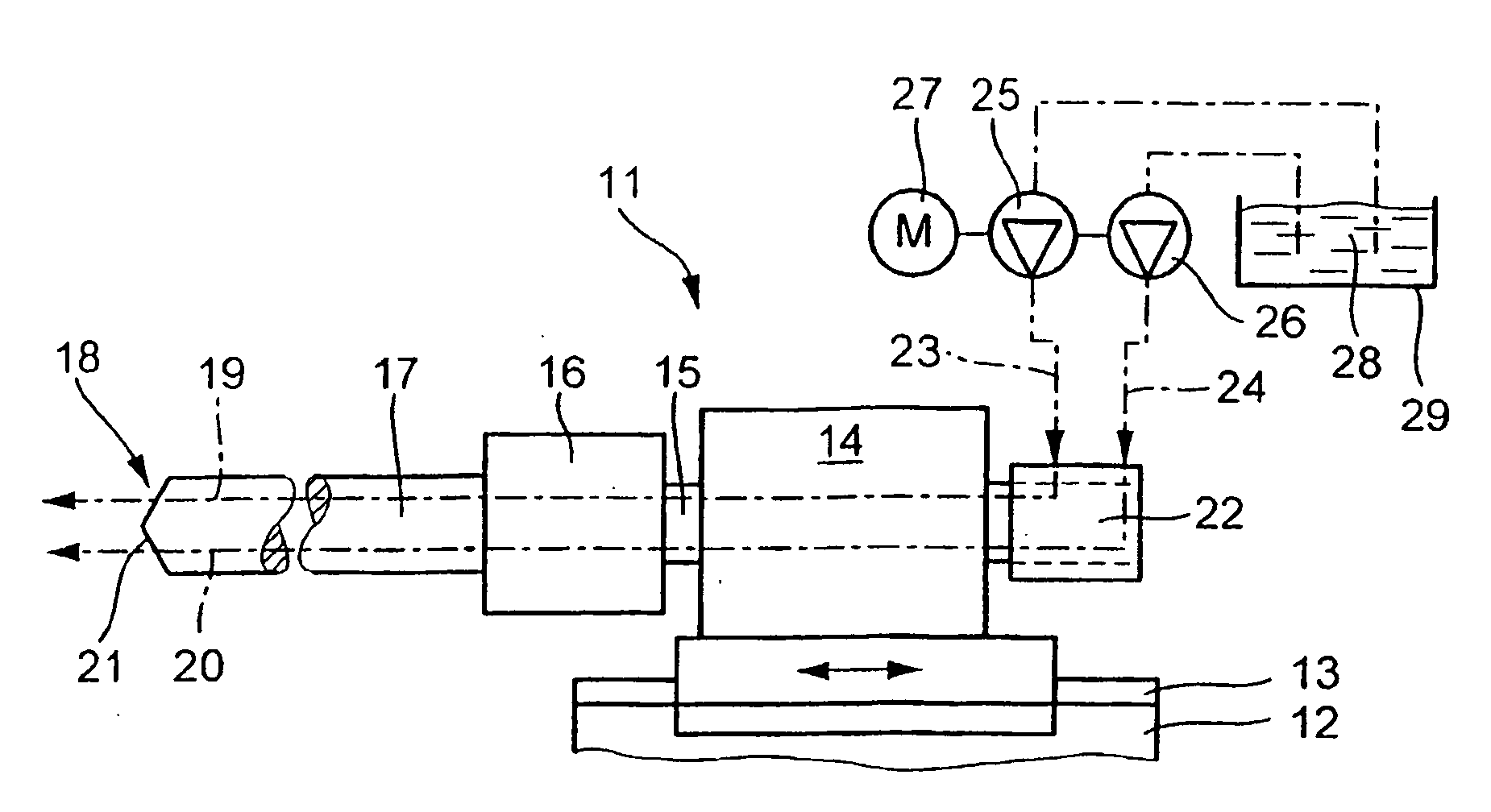

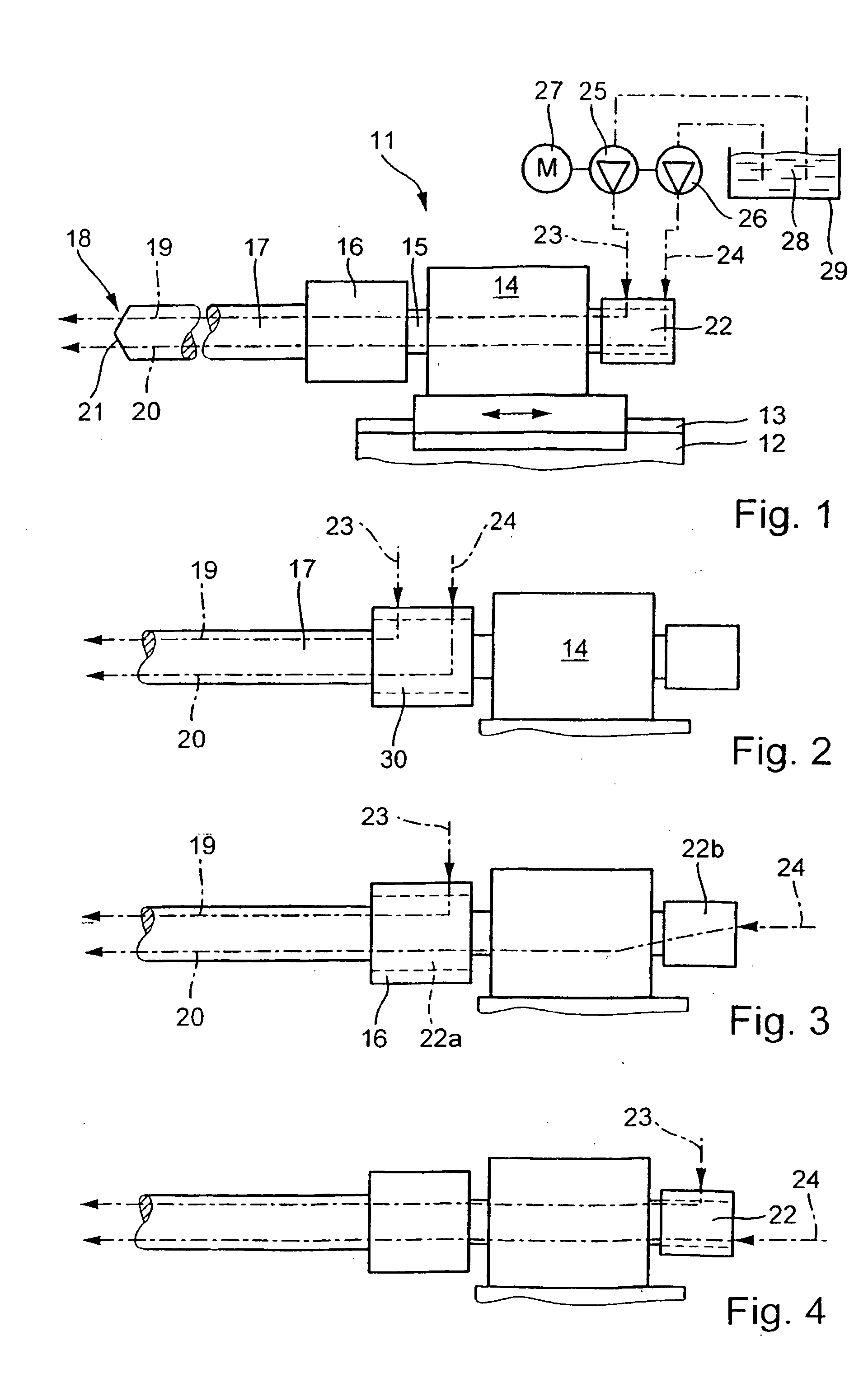

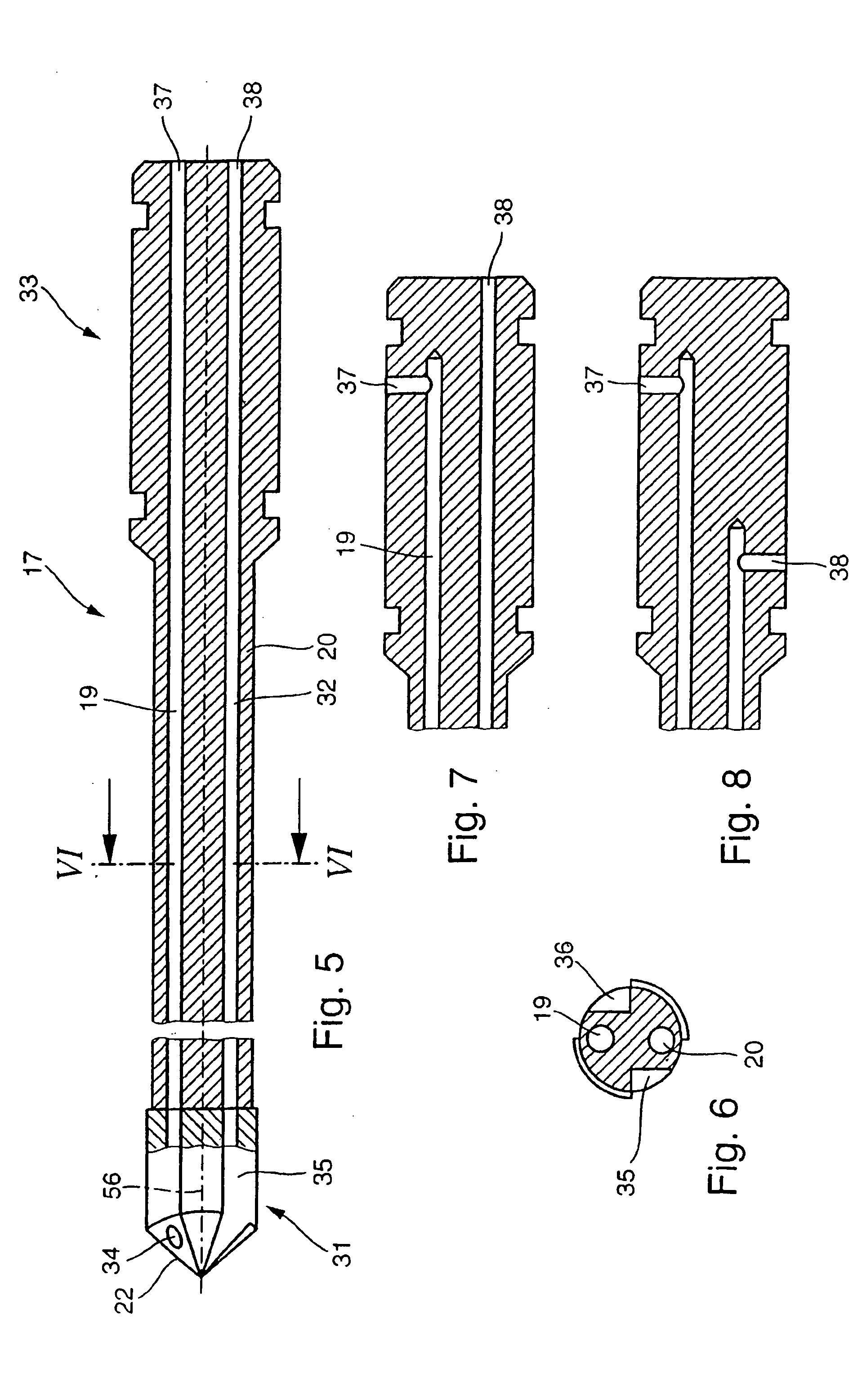

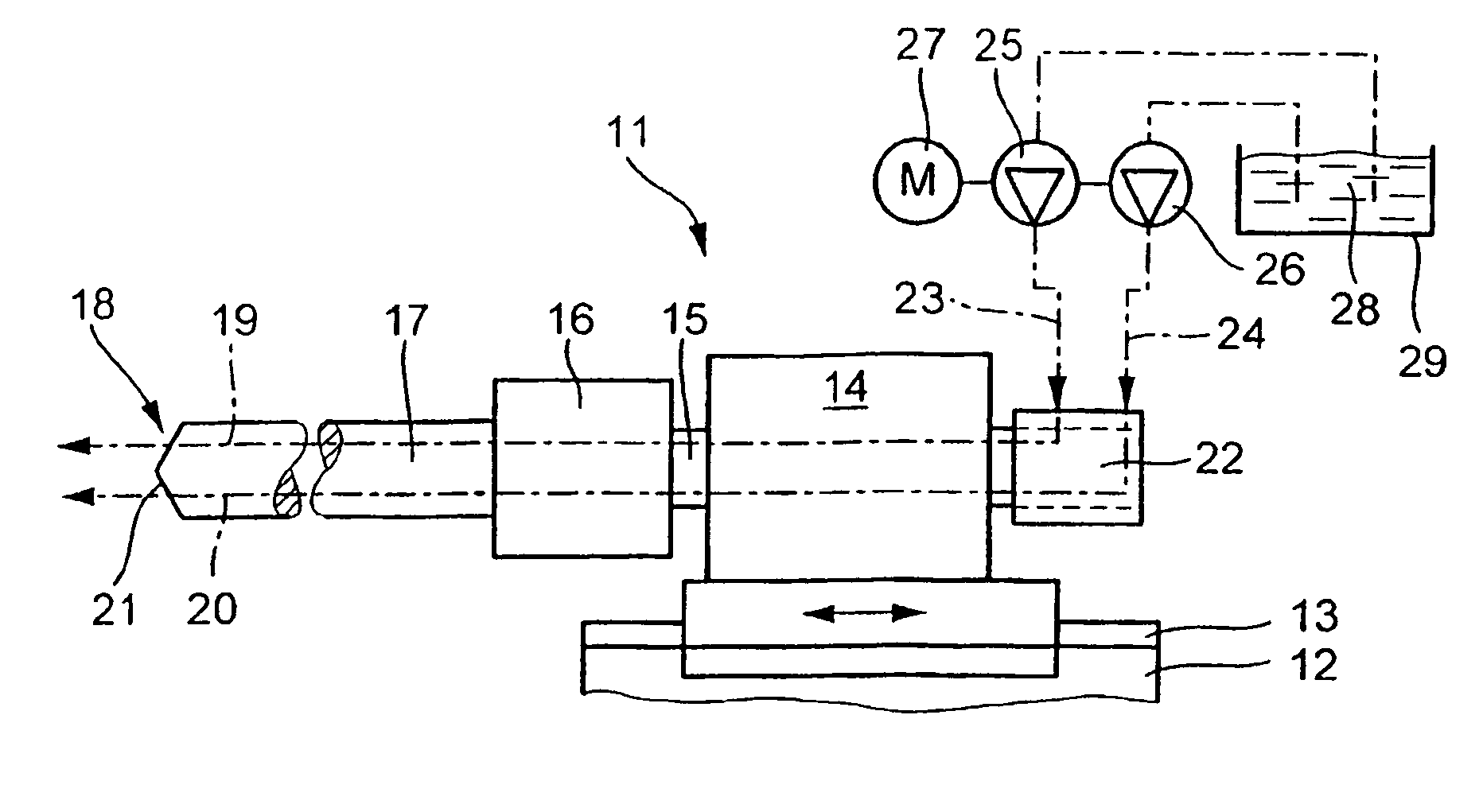

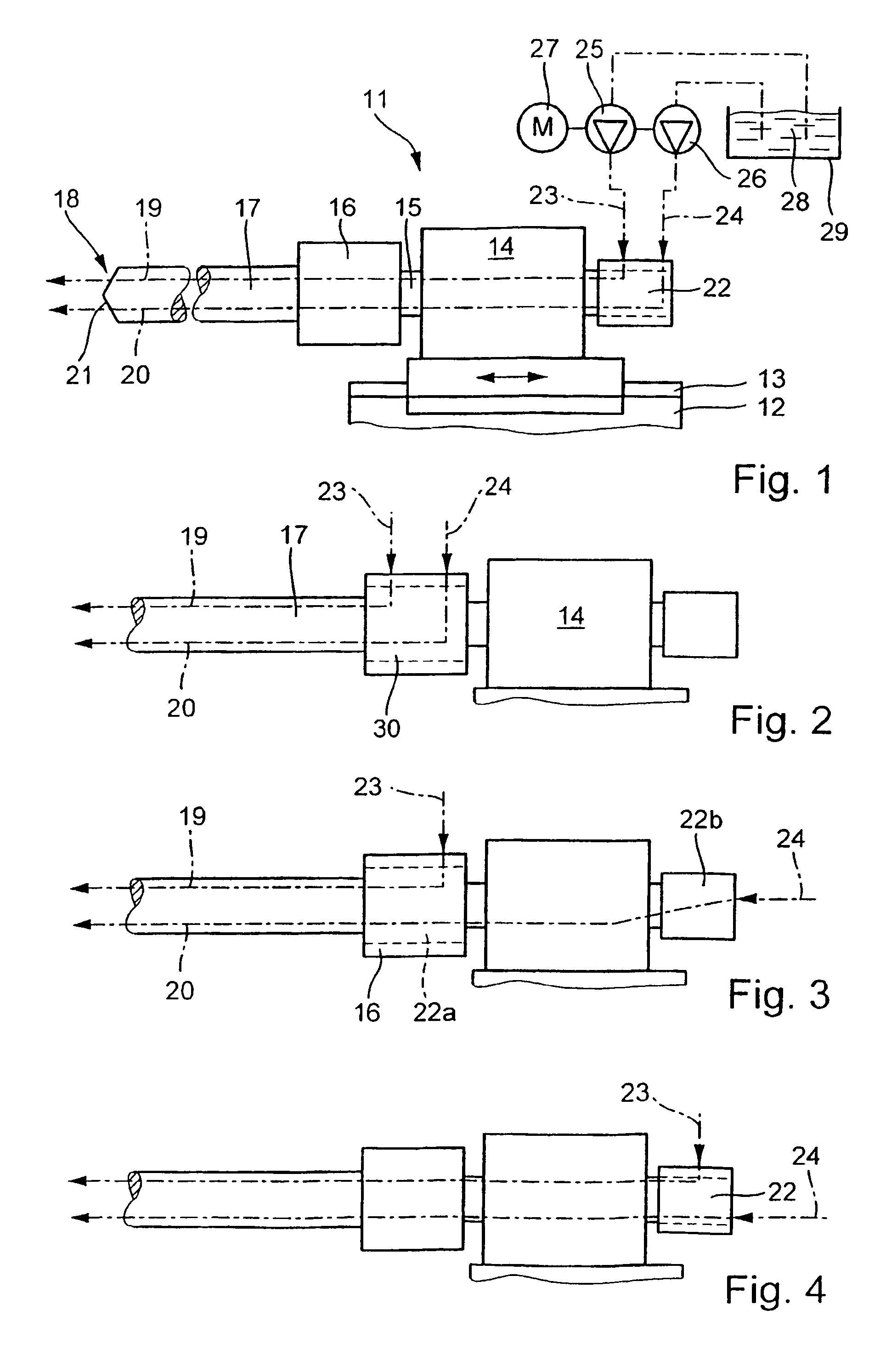

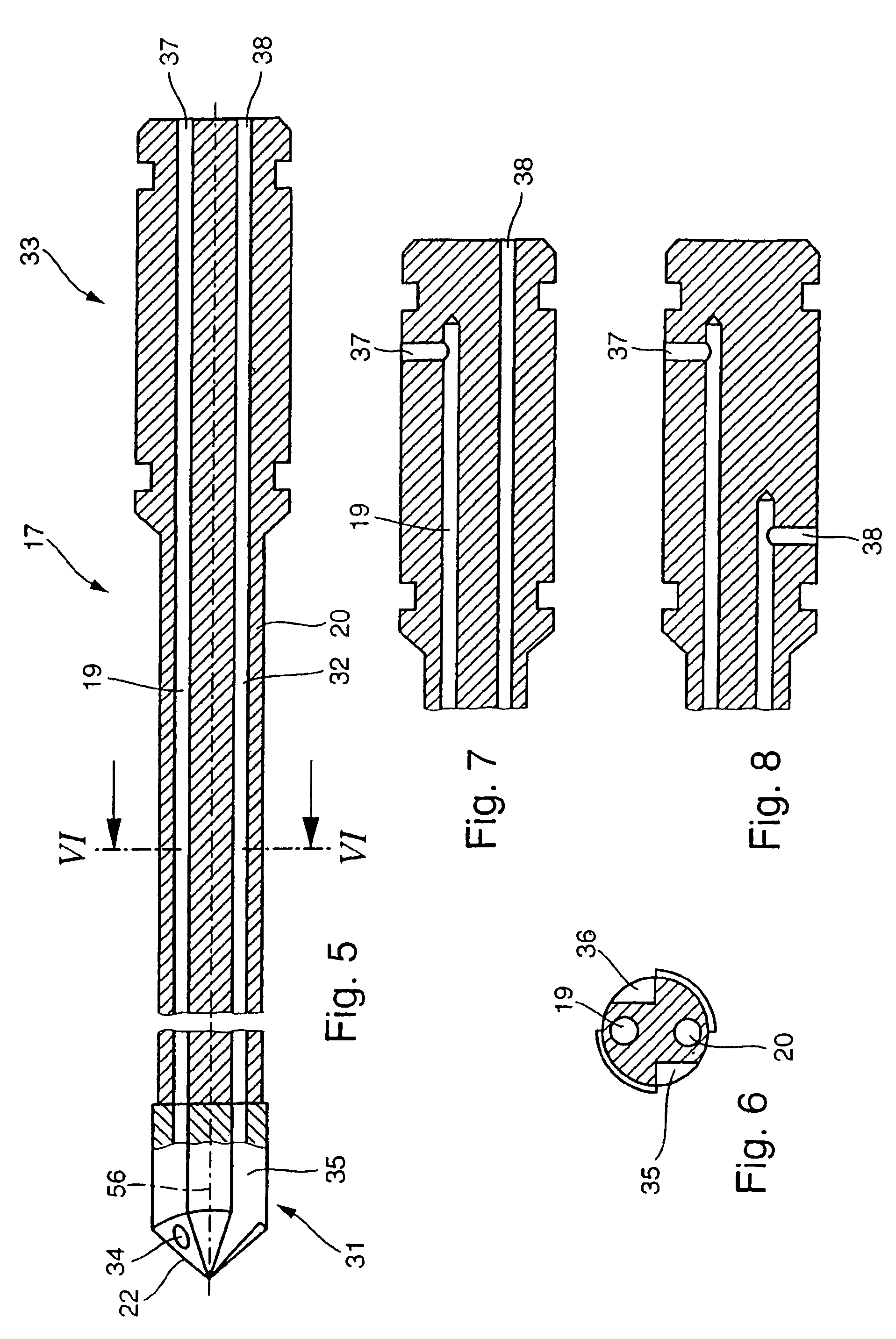

Drilling device provided with a multi-bladed drilling tool, especially a deep drilling tool

InactiveUS20050163578A1Increase the diameterDeliberate asymmetryWood turning toolsTransportation and packagingEngineeringLubrication

The invention relates to a multi-bladed deep drilling tool (17) comprising a cooling lubricant channel (19, 20) provided for each chip space (74) allocated to each cutter (71). Said channels (19,20) are supplied with a lubricant independently from each other, by means of either jointly drives or separately drives lubricating pumps (25, 26). Said channels being associated with either the drilling devise (11) or integrated into an adapter (30) which is pivoted with a common flow of lubricant, but which supplies independent individual flows. Lubrication of the individual cutting zones is guaranteed even if the chip removal channel is blocked, by chips for example. The pressure of the cooling lubricant channel increases in said area whereupon the channel in question is cleared.

Owner:TBT TIEFBOHRTECHN

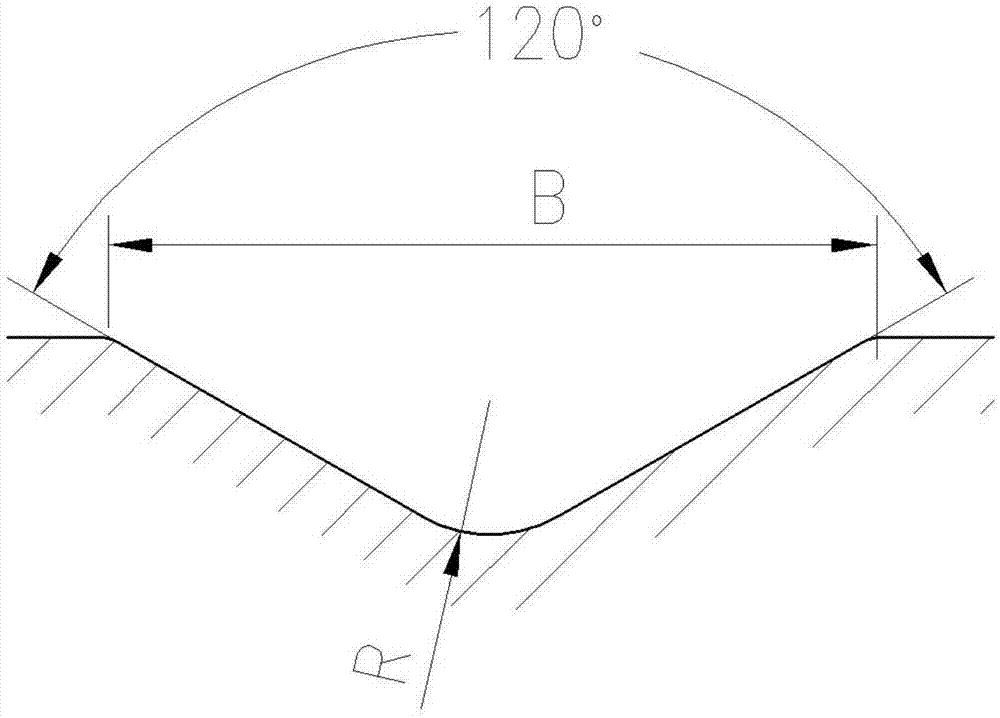

Twist-drill oil-groove milling cutter

InactiveCN106891051ASolution to short lifeIncrease chip spaceTransportation and packagingMilling cuttersMilling cutterEngineering

The invention relates to a twist-drill oil-groove milling cutter. The twist-drill oil-groove milling cutter is optimized based on a normal twist-drill and can make full use of the cutting performance of the twist-drill. The vertex angle 2 Phi of the twist-drill oil-groove milling cutter is 120 degrees, and two main cutting edges are forward and backward spatial spiral C-Shaped curves with chip dividing grooves. By adoption of the two main cutting edges and the milling cutter provided with two big right-handed-rotation chip-hold and chip-removal spiral grooves, compared with a multi-tooth straight blade ball oil-groove milling cutter, chip deformation is less, chip- breaking, chip-removal and cooling are convenient. The twist-drill oil-groove milling cutter has the advantages of big chip holding spaces and smooth chip removing, progressive cut-in, stable cutting, high machining quality, long lifetime of cutting tools, and the like. The twist-drill oil-groove milling cutter is low in manufacturing cost, convenient to cutter sharpening, high in machining efficiency, and beneficial to promotion and application in production, and is a good cutter tool with excellent drilling and milling functions.

Owner:SINOSTEEL HENGYANG MACHINERY

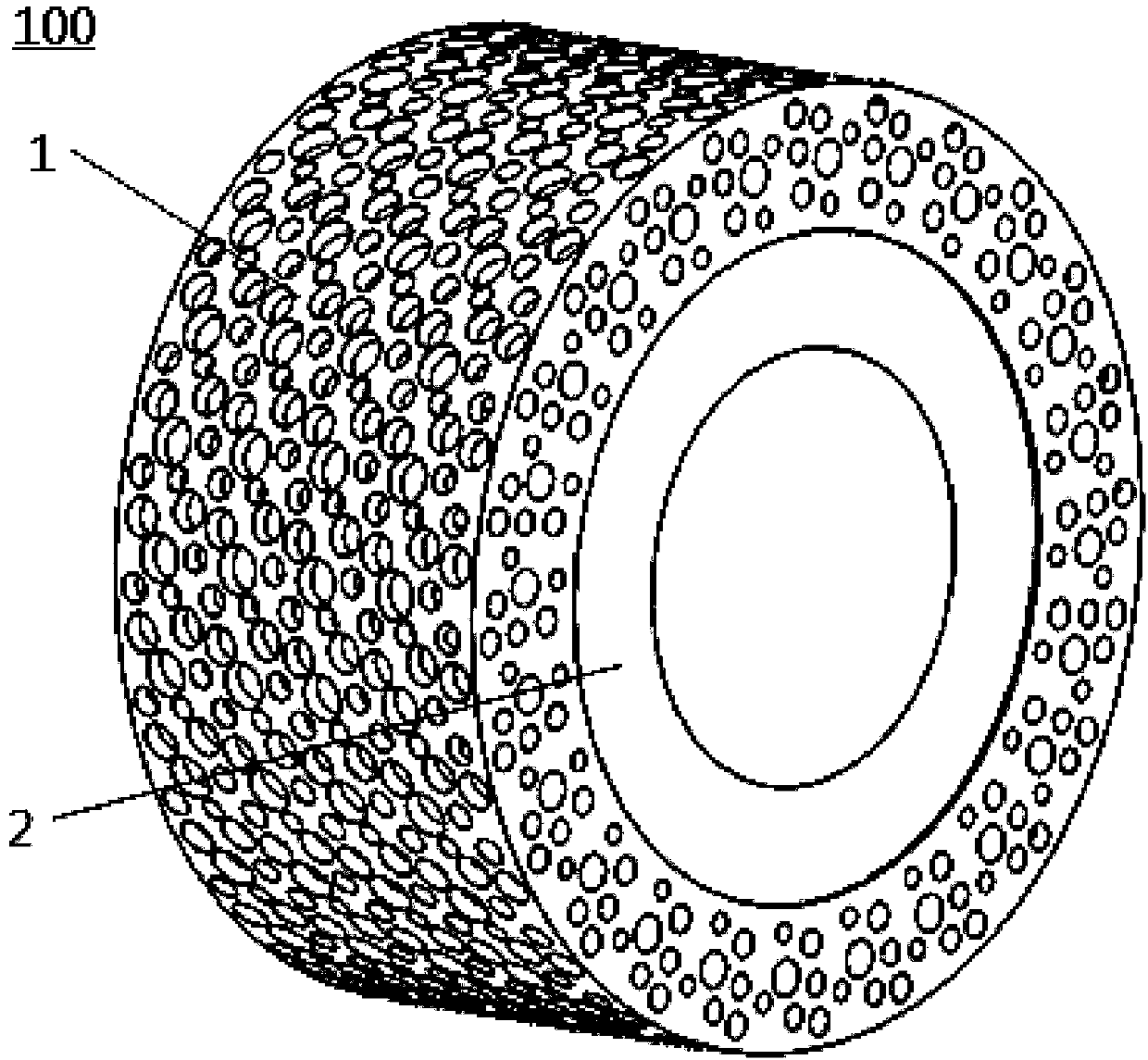

Metal bonding agent 3D printing grinding wheel with random porous structure and device and method

PendingCN107914216AHigh porosityIncrease chip spaceAdditive manufacturing apparatusBonded abrasive wheelsPorosityEngineering

The invention discloses a metal bonding agent 3D printing grinding wheel with a random porous structure and a device and method. The metal bonding agent 3D printing grinding wheel comprises a grindingwheel base body and a grinding wheel grinding main body, wherein the grinding wheel grinding main body is arranged at the outer side of the grinding wheel base body in a sleeving manner. The grindingwheel grinding main body is formed through 3D printing and provided with the random porous structure and comprises a metal bonding agent and a superhard grinding material. The ratio of the volume ofthe random porous structure to the volume of the grinding wheel grinding main body ranges from 15% to 45%. By means of the metal bonding agent 3D printing grinding wheel, the porosity and chipping containing space of the metal bonding agent 3D printing grinding wheel can be greatly increased; heat dissipation of a grinding area is improved; grinding burns are reduced; and grinding surface qualityis improved.

Owner:TSINGHUA UNIV +1

High-efficiency unequal multi-blade expanding reamer

PendingCN110893488AImprove seismic performanceReduce vibrationReaming toolsStructural engineeringChip formation

The invention discloses a high-efficiency unequal multi-blade expanding reamer, and belongs to the technical field of reamers. The multi-edge reamer comprises a reamer handle and a cutting part, the cutting part is provided with a plurality of spiral cutting edges distributed in the circumferential direction, and in the cross section of the cutting part, the difference between the maximum tooth pitch included angle between two adjacent cutting edges and the minimum tooth pitch included angle between two adjacent cutting edges ranges from 6 degrees to 9 degrees; and the tooth width of each cutting edge and the tooth pitch included angle in the rear side in the rotary cutting direction of the cutting edge satisfy corresponding change rules. By adopting the design of combining multi-blade unequal division with multi-blade unequal teeth, the surface roughness and cylindricity of a machined hole are improved, the reaming allowance and cutting efficiency can be improved, and the intermittentand efficient finish machining requirements of a (deep) hole are met; the front end of the multi-edge reamer is of a layered structure, the machining allowance is increased, the machining reliabilityof the reamer is enhanced, chips can be broken and small, cleaning of the chips in a hole is facilitated, and the multi-edge reamer is particularly suitable for multi-channel interrupted hole machining.

Owner:CHANGZHOU LEAD CUTTING TECH CO LTD

Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

InactiveCN107214353AReduce wearImprove chip breaking abilityCutting insertsTurning toolsEngineeringHigh pressure

The invention relates to an indexable turning blade for high temperature alloy semifinishing under high-pressure cooling, and belongs to the technical field of turning tools. The turning blade comprises a turning blade body, the shape of the outline of the horizontal cross section of the turning blade body is hexagon, a fastening screw hole is formed in the geometrical center of the hexagonal turning blade body, a front cutter face is arranged on the outer periphery of the top face of the hexagonal turning blade body, and the six vertex angles of the hexagonal turning blade body are composed of three 80-degree angles and three 160-degree angles which are sequentially and alternatively arranged; arc cutter tips are arranged at the three 80-degree angles of the hexagonal turning blade body, negative chamfered edge cutting edges are arranged at the six outer edges of the top face of the hexagonal turning blade body, and protrusions are arranged nearby each arc cutter tip; and fold line step-shaped chip breaker grooves are arranged on the top face of the hexagonal turning blade body and the corresponding positions of the 160-degree angles on the front cutter face, chip grooves are composed of the fold line step-shaped chip breaker grooves and the front cutter face, and the bottom face of the hexagonal turning blade body is a blade installing supporting face. The indexable turning blade is used for high temperature alloy semifinishing under high-pressure cooling.

Owner:HARBIN UNIV OF SCI & TECH

Cutter processing process

The invention discloses a cutter processing process, which comprises the following steps that A, the appearance of a cutter is processed by a lathe according to a drawing; B, cooling holes are processed, and two symmetrical through holes are processed in the cutter; C, straight chip discharging grooves are processed, and two straight chip discharging grooves are processed on the outer circumference of the cutter; D, high-temperature-resistant materials are fully filled in the cooling holes; E, high-frequency heating is carried out, the products are fixedly arranged on a clamp, a layer of high-frequency coil is arranged on the outer circle of the products, and the heating temperature is 300 to 450 DEG C; F, the straight chip discharging grooves are twisted into spiral grooves. The cutter processing process has the advantages that through the processing method, the processing difficulty is reduced, meanwhile, the step of forming a cooling groove in the center of the cutter is omitted, the rigid of the cutter is guaranteed, meanwhile, the depth of the chip discharging grooves is also increased, the depth of the chip discharging grooves twisted by a hot twisting process is greater than the depth of the chip discharging grooves processed by a traditional method, the chip accommodating space is greater, iron chips can be conveniently discharged out, the smoothness of inner holes and the precision of the hole diameter dimension can be perfectly guaranteed.

Owner:NINGBO RONGKE MAITE NC TOOLS

PCD grinding wheel capable of performing positive rake angle processing and provided with ordered micro slot structure and manufacturing method for PCD grinding wheel

ActiveCN108747858AImprove efficiencyImprove grinding efficiencyBonded abrasive wheelsGrinding devicesLaser processingPolycrystalline diamond

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Single-blade milling cutter

PendingCN108581001AIncrease chip spaceEasy to useMilling cuttersMilling cutterAgricultural engineering

The invention discloses a single-blade milling cutter applicable to the technical field of milling cutter structures. The single-blade milling cutter comprises a cutter handle and a cutter body connected to one end of the cutter handle. The cutter body is provided with a spiral cutting blade, a chip discharging groove and a main cutting blade. The chip discharging groove and the spiral cutting blade are spirally arranged around the axis of the cutter body in the direction from the front end of the cutter body to the cutter handle. The spiral cutting blade and the chip discharging groove are same in the spiral angle. The main cutting blade is arranged at the front end of the cutter body and is adjacent to the chip discharging groove. The cutting edge of the main cutting blade is of an arc concave structure, and the main cutting edge is provided with an arc-shaped relief angle. Through the single-blade milling cutter provided by the invention, the overall stiffness strength of the milling cutter and the sharpness of the cutting edges can be improved, and meanwhile, the effect that chips are discharged smoothly is ensured.

Owner:SHENZHEN JINZHOU PRECISION TECH

Drilling device provided with a multi-bladed drilling tool, especially a deep drilling tool

InactiveUS7476066B2Increase the diameterDeliberate asymmetryWood turning toolsTransportation and packagingLubricationDeep drilling

The invention relates to a multi-bladed deep drilling tool (17) comprising a cooling lubricant channel (19, 20) provided for each chip space (74) allocated to each cutter (71). Said channels (19,20) are supplied with a lubricant independently from each other, by means of either jointly drives or separately drives lubricating pumps (25, 26). Said channels being associated with either the drilling devise (11) or integrated into an adapter (30) which is pivoted with a common flow of lubricant, but which supplies independent individual flows. Lubrication of the individual cutting zones is guaranteed even if the chip removal channel is blocked, by chips for example. The pressure of the cooling lubricant channel increases in said area whereupon the channel in question is cleared.

Owner:TBT TIEFBOHRTECHN

Sintered rope saw string bead and production method thereof

PendingCN108908768ASolution to short lifeIncrease chip spaceFine working devicesHardnessMaterials science

The invention discloses a sintered rope saw string bead. The sintered rope saw string bead consists of diamond, a metal mold, a steel body and metal separation bars; the hardness of the metal separation bars is lower than the hardness of the metal mold; the metal separation bars are continuously distributed in the metal mold; the diamond is distributed in the metal mold; and the metal mold is fixedly connected to the surface of the steel body. Based on a traditional sintered rope saw string bead, the low-hardness spiral metal separation bars are implanted in the metal mold; when a rope saw works, the spiral metal separation bars without the diamond are easily rubbed and scoured by cutting chips to form spiral grooves on the surface of the string bead; and the grooves can achieve the effects of reinforced diamond cooling and smooth chip removal in the cutting process, so that the cutting efficiency of the rope saw is improved.

Owner:福州天石源超硬材料工具有限公司

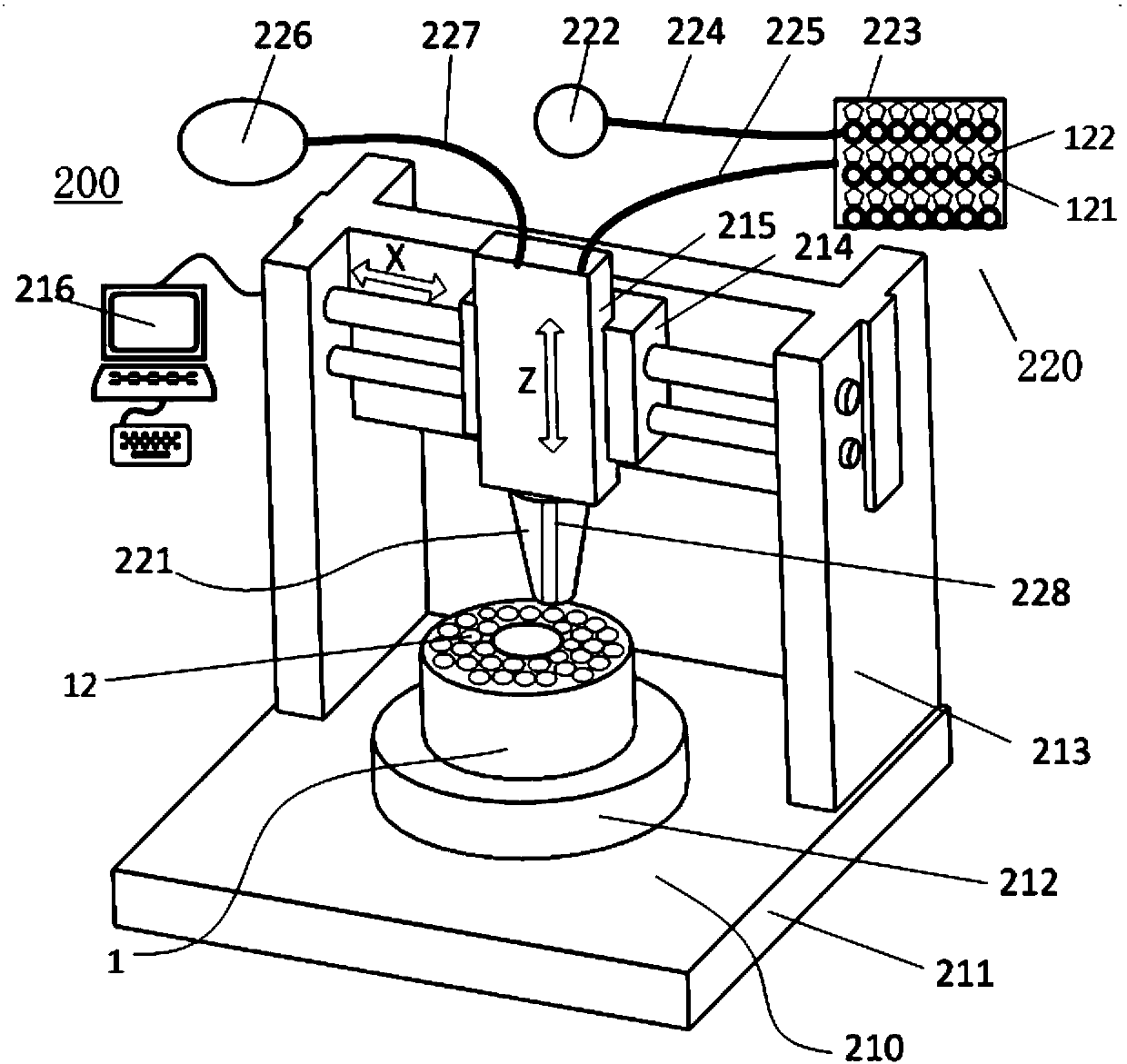

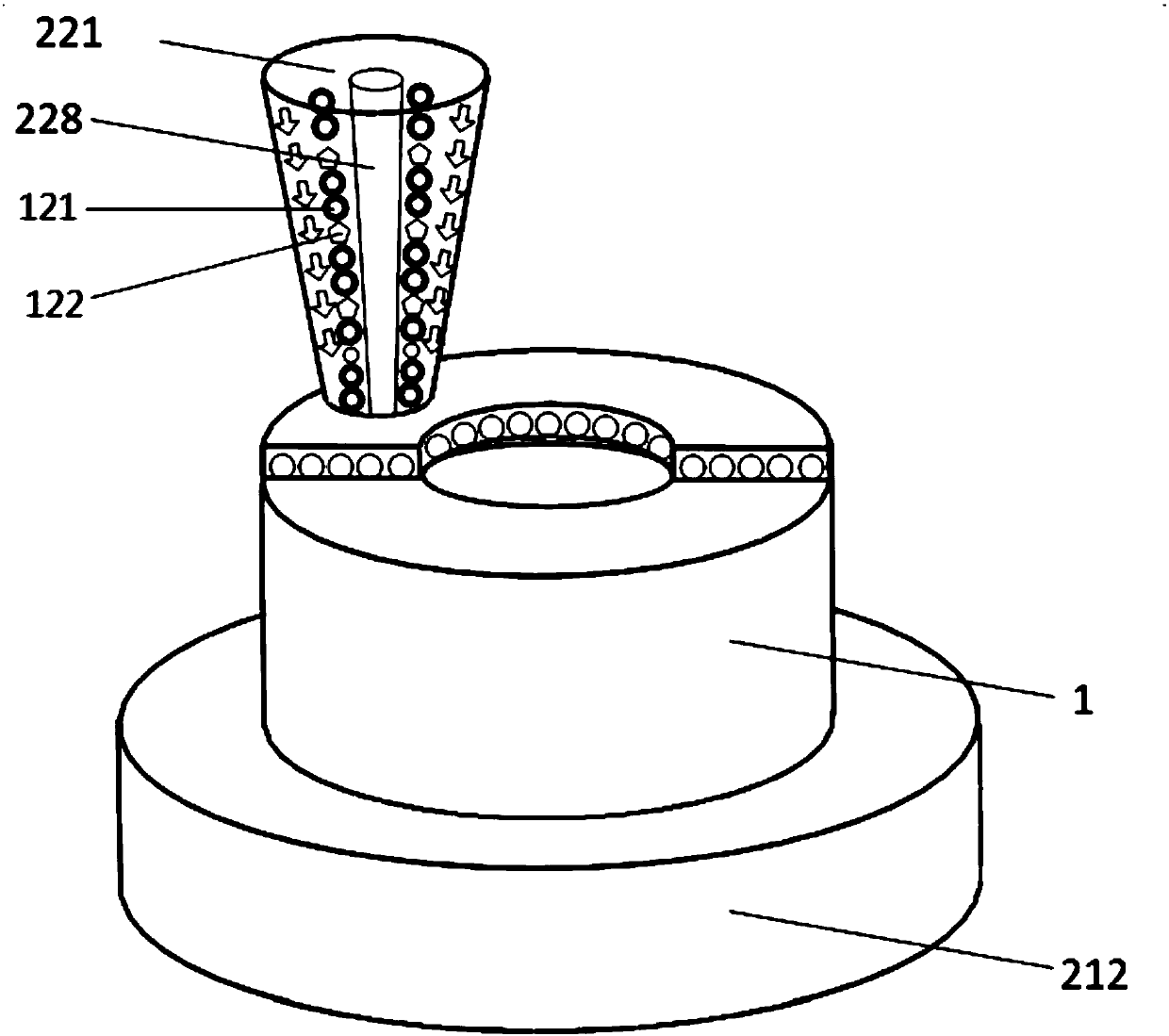

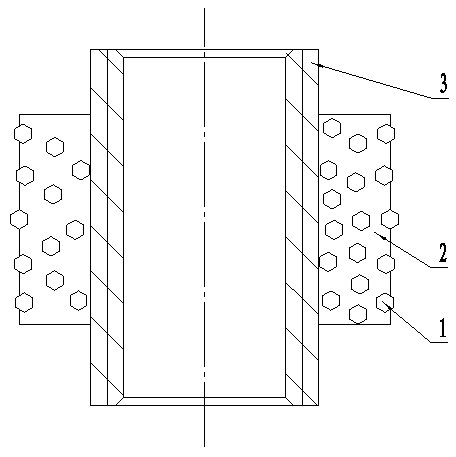

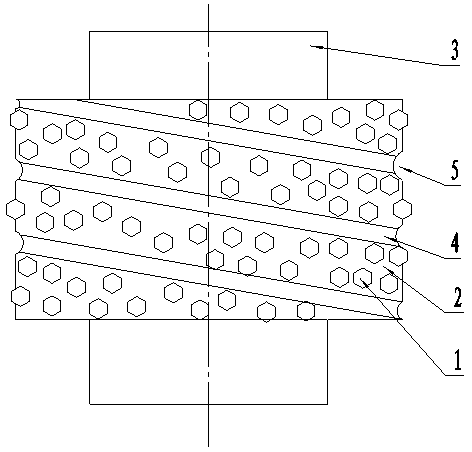

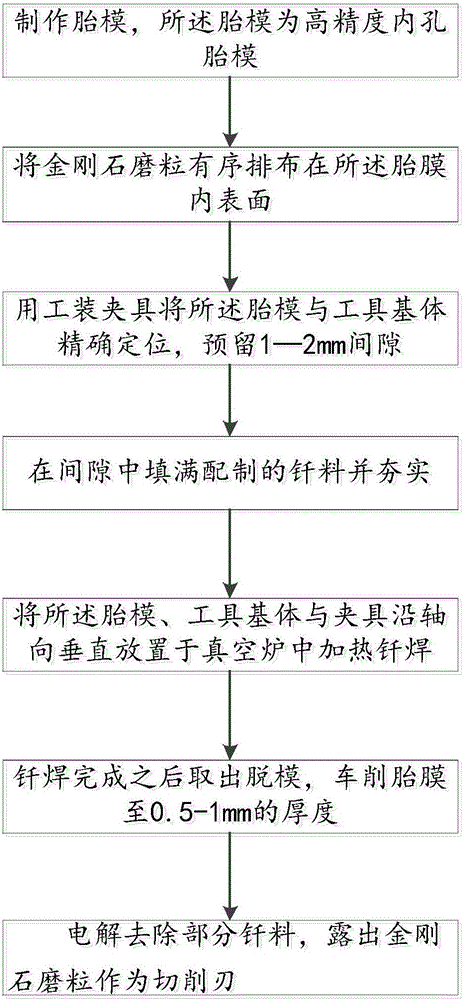

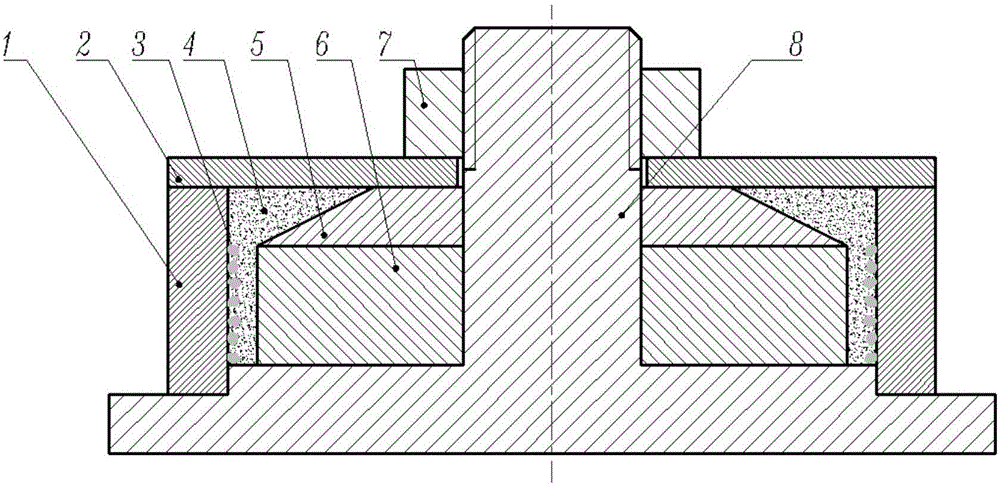

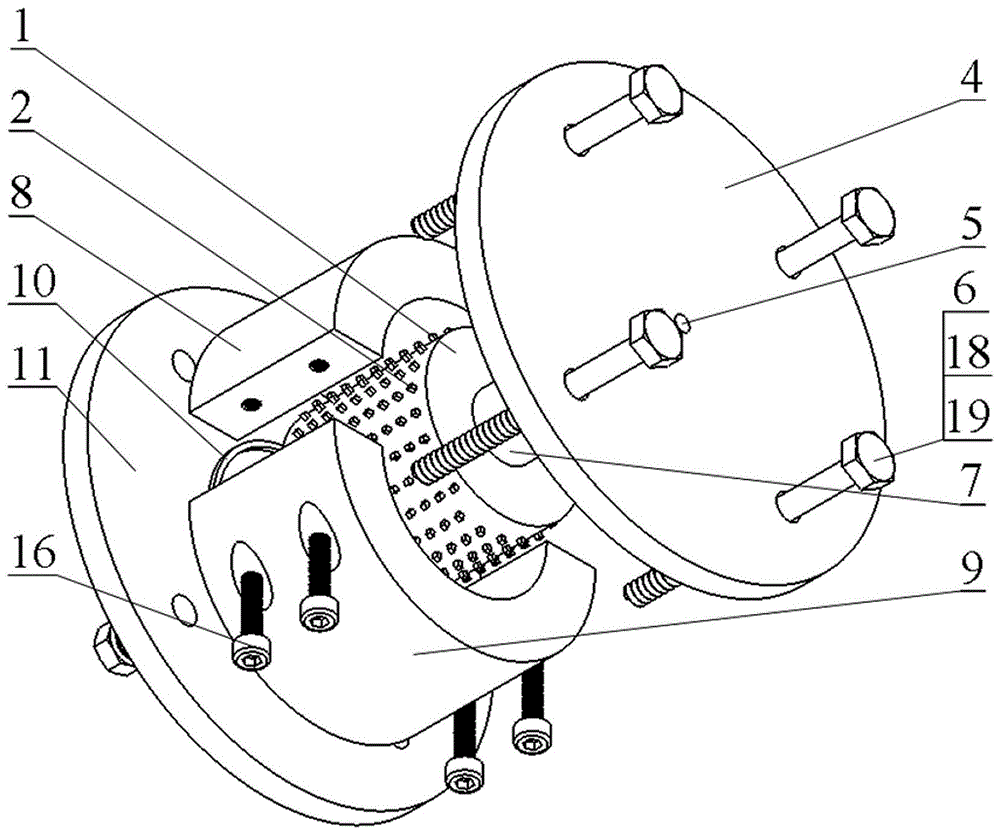

Manufacturing method and device of brazed diamond tool

InactiveCN106625302AHigh precisionImprove grinding performanceGrinding devicesElectrolysisManufacturing technology

The invention discloses a manufacturing method and device of a brazed diamond tool and relates to the technical field of tool manufacturing. According to the manufacturing method and equipment of the brazed diamond tool, the defect that the protruding heights of abrasive particles of an existing brazing tool are poor in consistency is overcome, the advantages of an electroplated tool using an inside-plating method is combined, good equal height performance and high precision of tool abrasive particles can be ensured. The manufacturing method comprises the following steps that a moulding bed is manufactured, and the moulding bed is an inner hole moulding bed; diamond abrasive grains are orderly distributed on the surface of an inner hole of the moulding bed; a tool clamp is used for accurate positioning of the moulding bed and a tool basal body, and a gap of 1-2 mm is reserved; the gap is filled with brazing filler metal, and punning is conducted; the moulding bed, the tool basal body and the clamp are perpendicularly placed in a vacuum furnace in the axial direction and heated and brazed; after brazing is completed, the moulding bed, the tool basal body and the clamp are fetched out, and the moulding bed is turned until the thickness is 0.5-1 mm; and the brazing filler metal on the outer layer part of the moulding bed is removed through electrolysis, and the diamond abrasive grains are exposed and serve as cutting edges.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparing device and method for spirally and orderly arranged fiber abrasive wheel

The invention discloses a preparing device and method for a spirally and orderly arranged fiber abrasive wheel. The device comprises an abrasive wheel forming mechanism and a fiber equal-height protrusion mechanism. The abrasive wheel forming mechanism comprises an upper die plate, a lower die plate, a die sleeve I, a die sleeve II and a core bar. The fiber equal-height protrusion mechanism comprises a support, electromagnets and clamps. The preparing method comprises the steps that phenolic resin, a heat conduction material, metallic oxide, a solid lubricating agent and a pore forming material are mixed according to the proportion, and a blank is manufactured through hot-press forming; a series of circular holes spirally distributed are machined in the outer circumference of the blank through a deep hole drill, and a base body is obtained; the circular holes are filled with epoxy resin, fiber is embedded in the circular holes one by one, and the fiber is fixed to the base body through the abrasive wheel forming mechanism; the consistency of the fiber protrusion height is ensured through the fiber equal-height protrusion mechanism; and the epoxy resin is heated and cured, and the abrasive wheel is formed. The preparing device and method for the spirally and orderly arranged fiber abrasive wheel have the beneficial effects that the fiber protrusion height is consistent, the holding force is large, and the bending resistance is high; and the finishing workload of the abrasive wheel is low, the manufacturing cost is low, and the service life is long.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com