Preparing device and method for spirally and orderly arranged fiber abrasive wheel

A technology for preparing devices and fabricating fibers, which is applied in grinding devices, bonded grinding wheels, manufacturing tools, etc., can solve the problems of reducing grinding accuracy, reducing the service life of grinding wheels, and small holding force of abrasive grains, achieving good versatility and Interchangeability, improved heat transfer performance, and improved machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

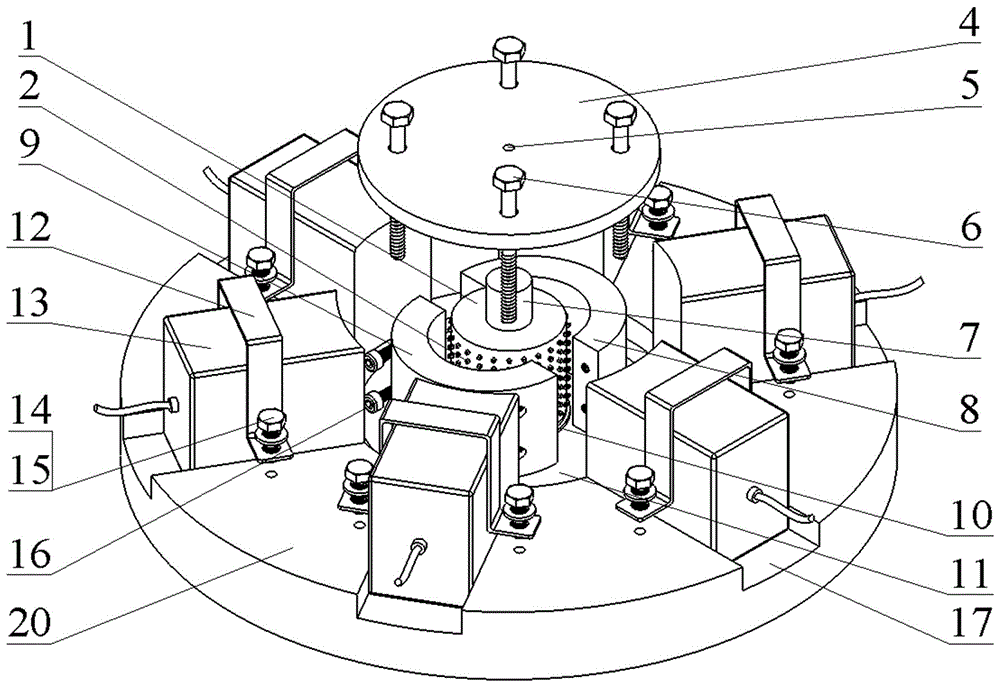

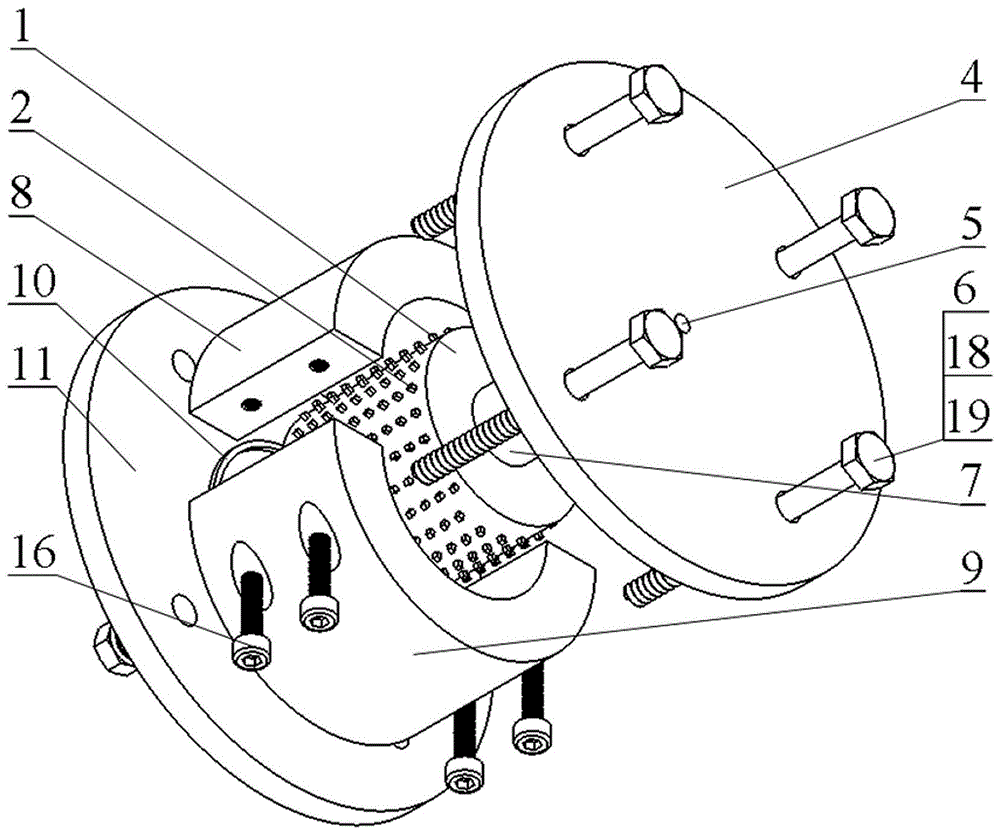

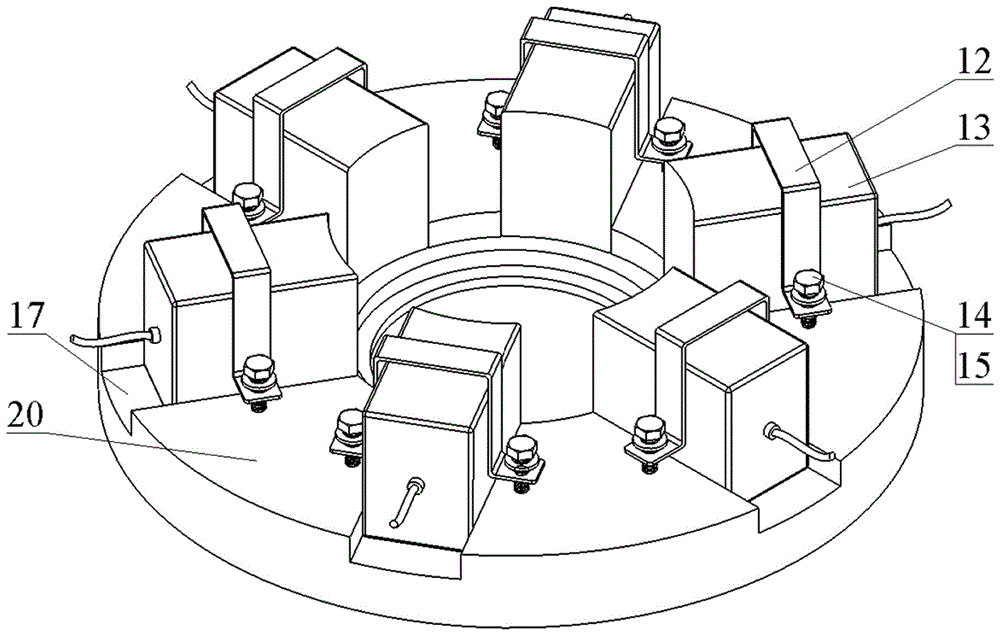

[0037] see Figure 1 to Figure 9 , a preparation device for spirally and orderly arranged fiber grinding wheels, including a grinding wheel forming mechanism and a fiber etc. protruding blade mechanism. The grinding wheel forming mechanism includes an upper template 4, a lower template 11, a mold case I8, a mold case II9, a mandrel 7, a bolt I6, a flat washer I18, a nut 19 and an inner hexagon bolt 16. The blade-exiting mechanism for fiber etc. includes clamp 12, electromagnet 13, bolt II 14, flat pad II 15 and support 20. The upper template 4, the lower template 11, the mold casing I8 and the mold casing II9 should have good strength, hardness, wear resistance, thermal stability and corrosion resistance, so the mold casing I8, the mold casing II9, and the upper template 4 And the material of the lower template 11 is 40Cr. The mandrel 7 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com