Patents

Literature

688results about How to "Solve the accumulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mine filling cementing material slurry and preparation method thereof

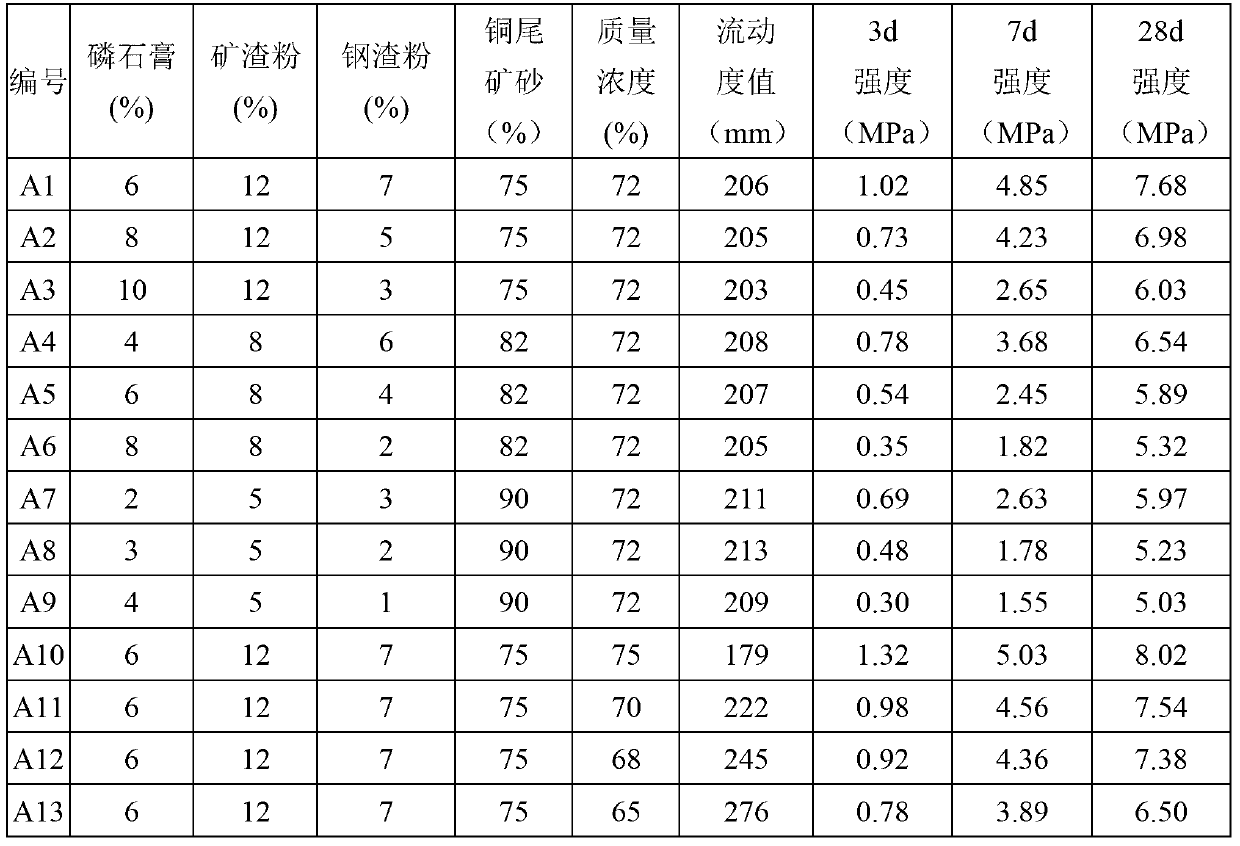

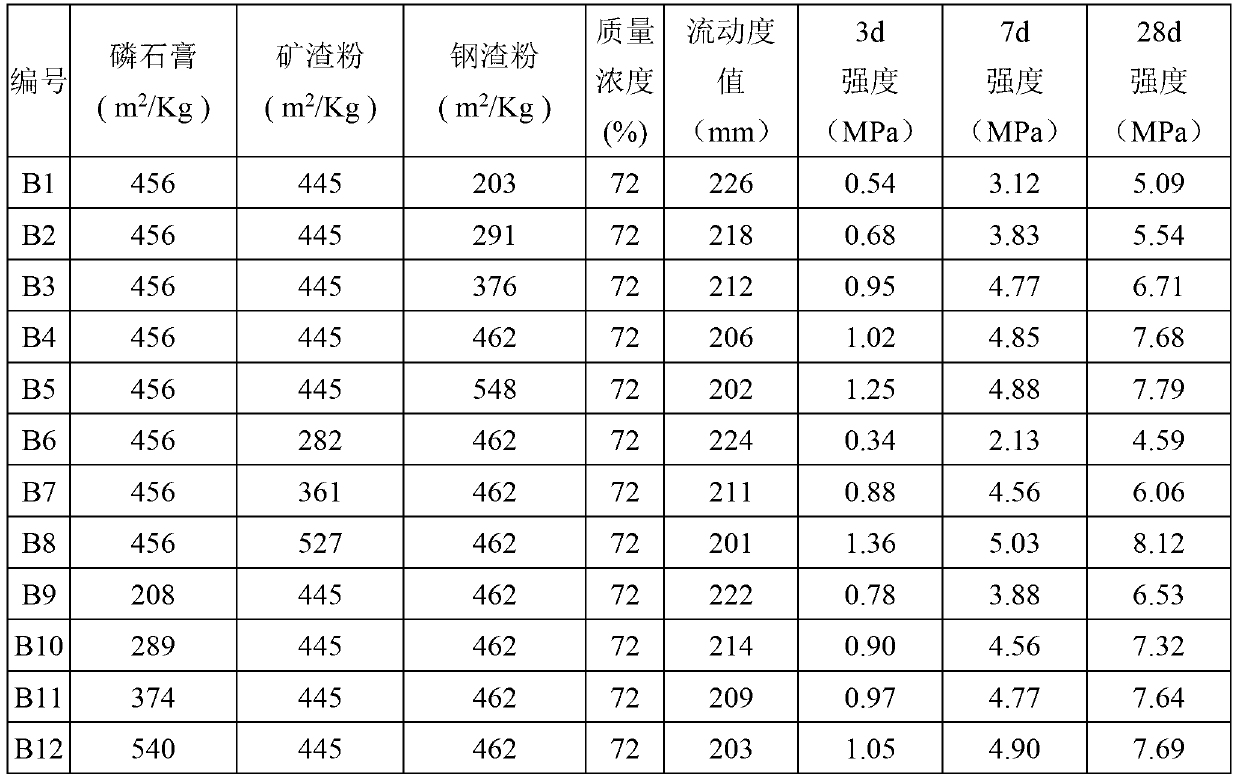

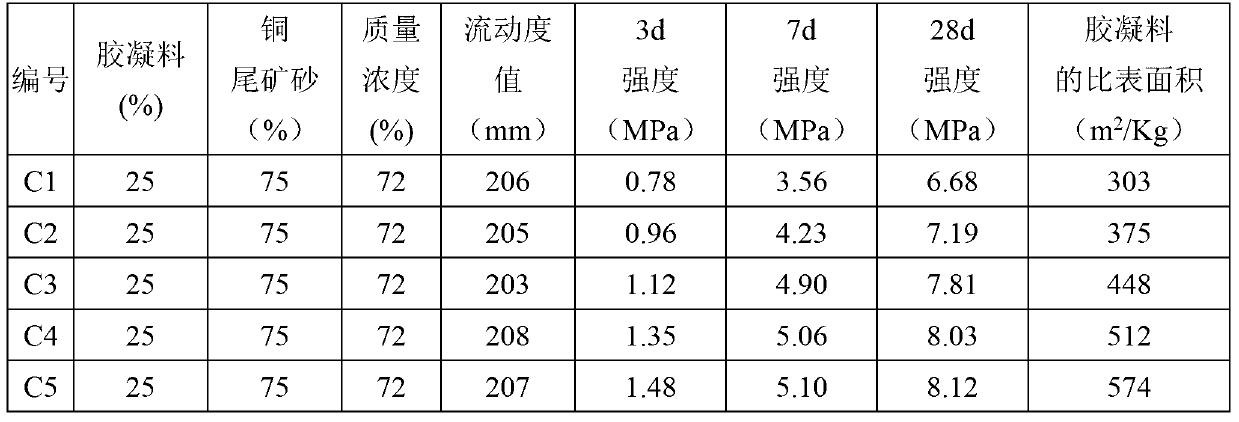

The invention belongs to the technical field of mining engineering and building materials and particularly relates to a mine filling cementing material slurry and a preparation method thereof. The preparation method comprises the following steps of: with steel slag, mineral slag and industrial byproduct gypsum as cementing agents and tailing sand as a filling aggregate, adding water, mixing and stirring uniformly to prepare mine filling cementing material slurry, wherein a dry basis of raw materials comprises the following components in percentage by weight: 1-7% of steel slag, 5-12% of mineral slag, 2-10% of industrial byproduct gypsum and 75-90% of tailing sand, and the sum of the weight percentage of the dry basis of all the raw materials is 100%; adding water to regulate the mass concentration of the filling cementing material slurry to be between 65-75%. The mine filling cementing material slurry has the beneficial effects of higher strength, simple process, high flowability and suitablity for self-flowing filling; no cement or cement clinker or additives are added in the components of the filling cementing material slurry which is completely made of solid wastes, so that the utilization rate of the tailing sand is high, and the production cost is very low.

Owner:WUHAN UNIV OF TECH

Method for preparing earthworm cultivation substratum

InactiveCN102812931AEnhance immune functionImprove digestion and absorption rateAnimal husbandryBiotechnologyEdible mushroom

The invention discloses a method for preparing earthworm cultivation substratum. By mixing livestock dung and edible fungus residue without foreign matters to carry out anaerobic fermentation, the method obtains the substratum for cultivating and reproducing earthworms, the livestock dung is pig dung or cow dung or the mixture of pig dung and cow dung, and the edible fungus residue is residue which is left over in the growth of cultured saprophytic lignicolous fungi or coprophilous fungi. Since the method utilizes the livestock dung and the edible fungus residue as the cultivation substratum to raise the earthworms, the method not only solves the problem of dung accumulation and waste and prevents environment pollution, but also increases the cultivation scale and growth quality of the earthworms by adding the edible fungus residue, thus effectively increasing the output of the earthworms.

Owner:NANJING AGRICULTURAL UNIVERSITY

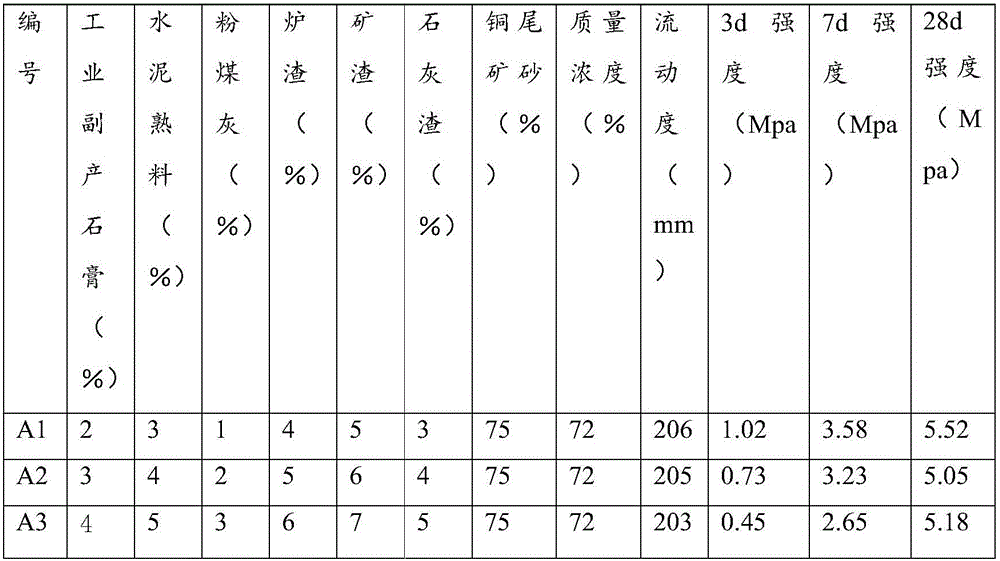

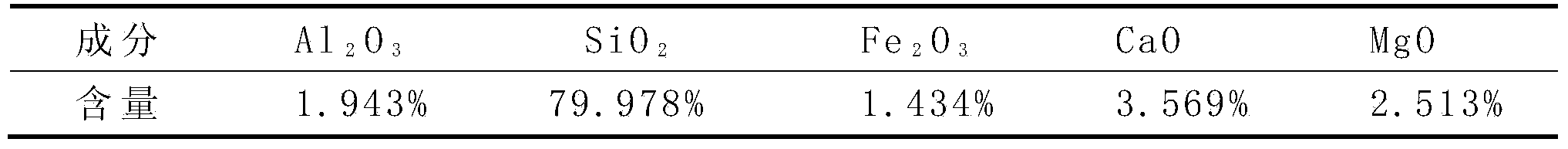

Tailing cementing agent

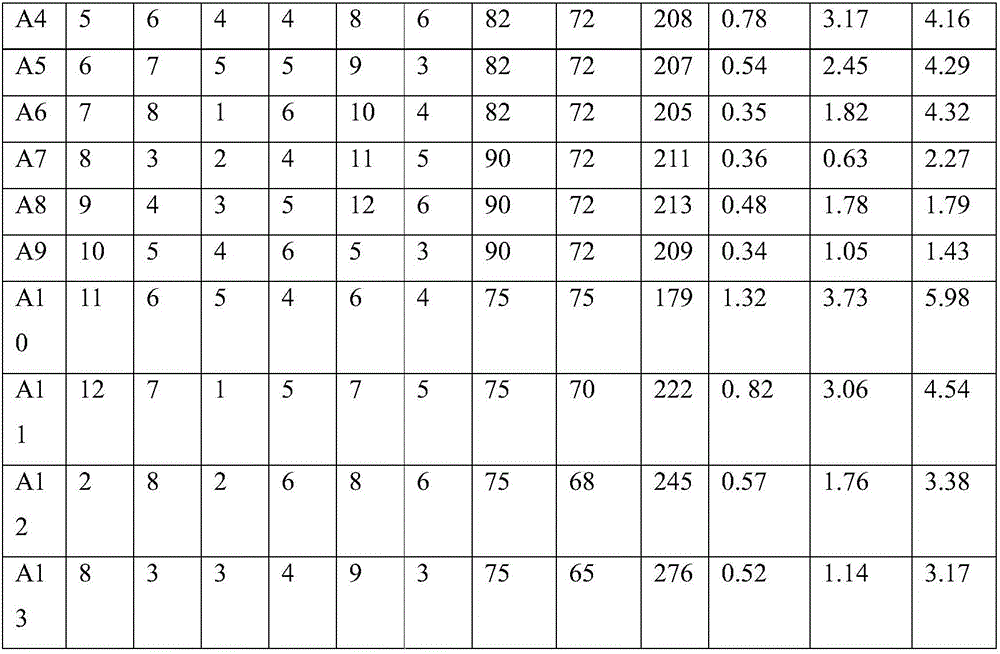

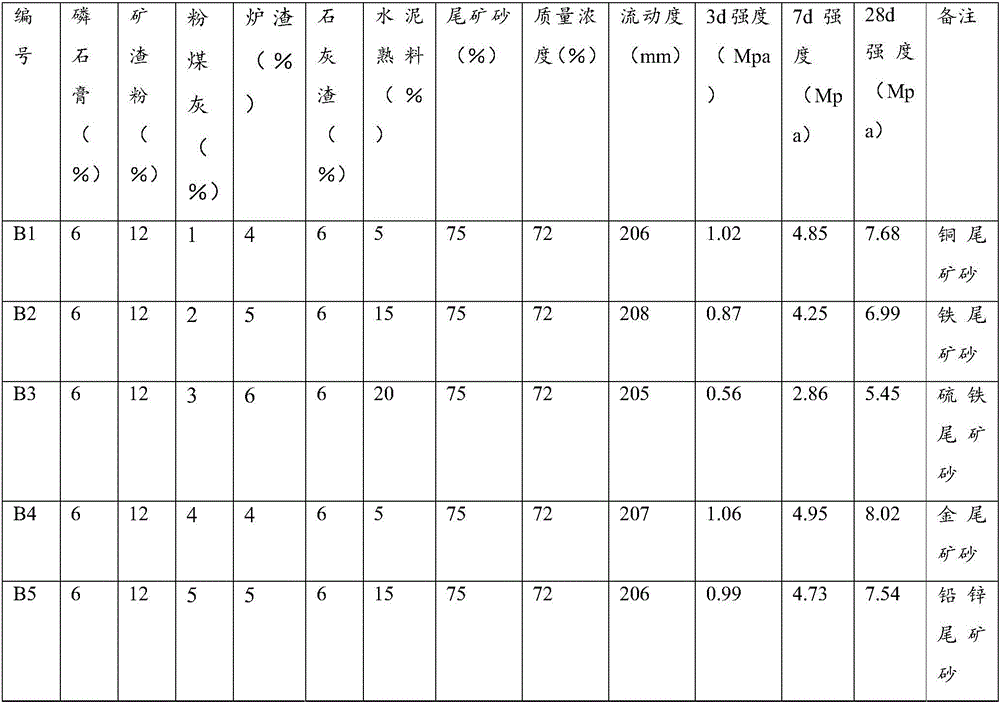

The invention provides a tailing cementing agent which is formed by mixing a raw material dry basis and water. The tailing cementing agent is characterized in that the dry basis is prepared from, by weight, 5%-12% of slag, 1%-5% of fly ash, 4%-6% of furnace slag, 3%-6% of lime sludge, 5%-20% of cement clinker, 2%-10% of industrial by-product gypsum and 75%-90% of tailing sand; the weight percentage of the raw material dry basis ranges from 65% to 75%, and the weight percentage of the water ranges from 25% to 35%. The tailing cementing agent is high in strength, simple in process, large in fluidity and suitable for gravity-flowed filling; less cement or cement clinker exists in the component of filling slurry, the utilization rate of the tailing sand is high, and the production cost is very low; the tailing sand is not subjected to stage treatment, the tailing cementing agent is not limited to single tailing, the application range is wide, stacking and pollution problems of the tailings are partially solved, resource utilization of other industrial waste residues such as steel slag, the slag and the industrial by-product gypsum is achieved, and the environmental protection effect is very significant.

Owner:贾志奎 +1

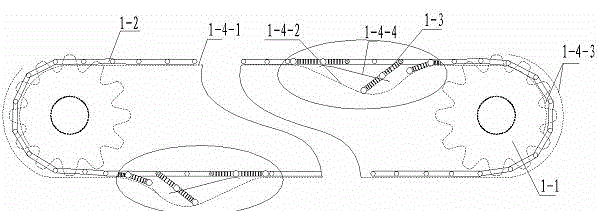

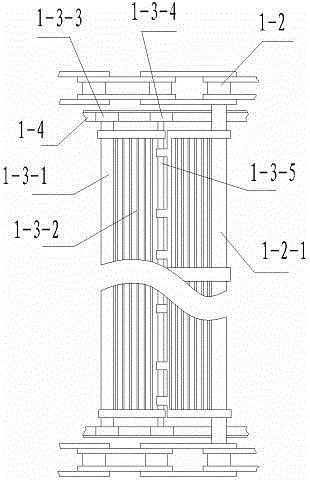

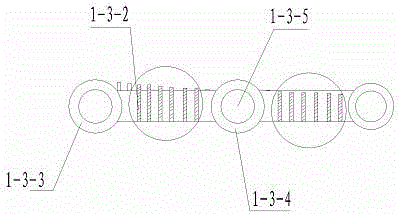

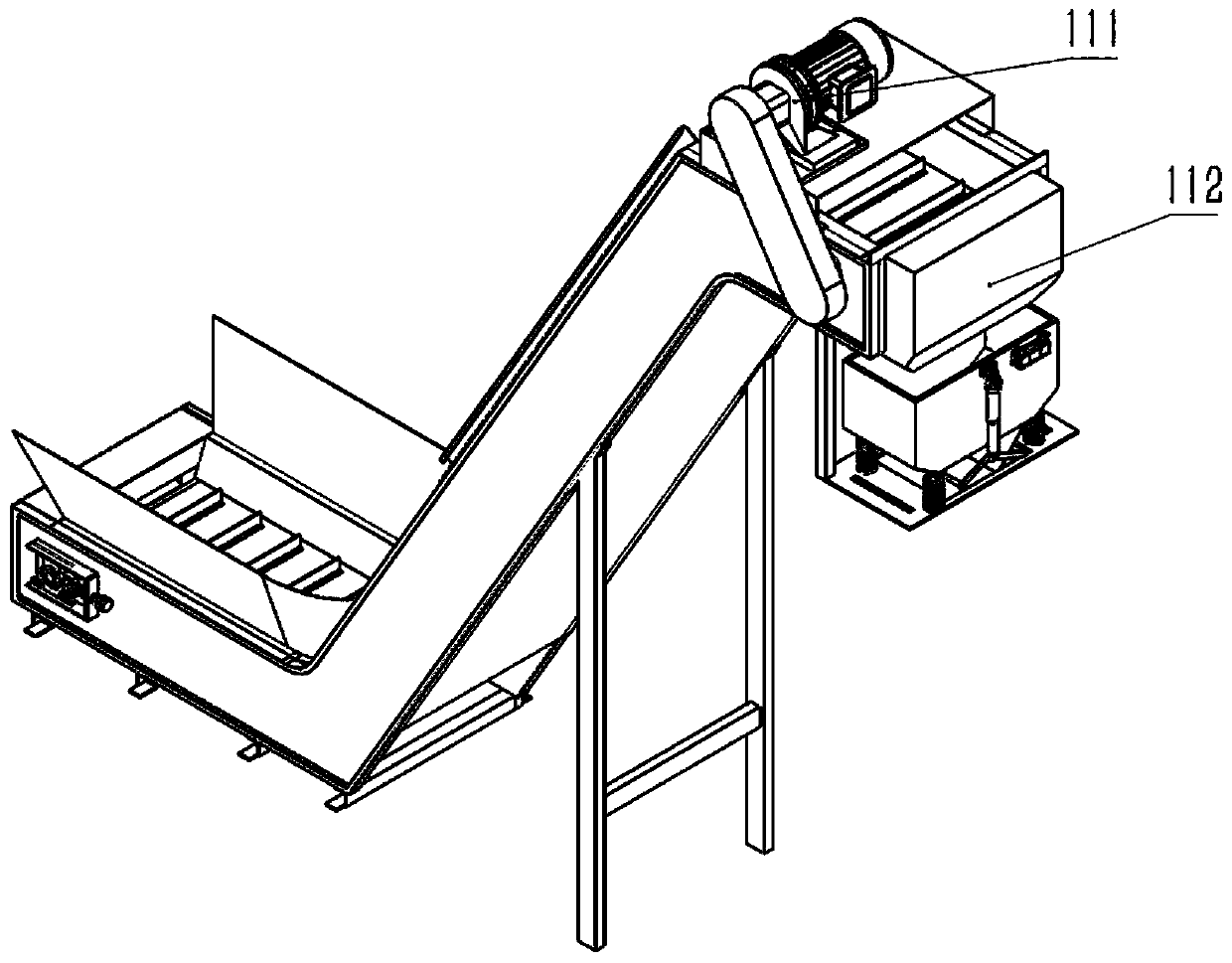

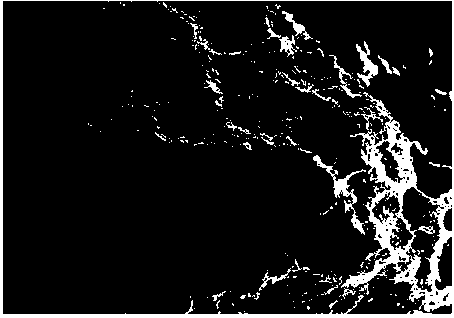

Chain plate conveying coal ball heat conduction oil dryer

ActiveCN104154728AUse diameter reductionImprove utilization efficiencyDrying machines with progressive movementsDrying solid materialsChain structureHeating effect

A chain plate conveying coal ball heat conduction oil dryer belongs to the field of drying equipment. The chain plate conveying coal ball heat conduction oil dryer comprises a heat insulation outer shell, a chain plate conveying mechanism, a feeding conveying belt, a discharging opening, a heating device and a waste heat using device. The chain plate conveying mechanism comprises a double-driving chain structure, a matched chain wheel, a bearing chain plate and a guiding sliding track. The bearing chain plate is a hollow-out structure formed by a frame and a grid bar and is located on a chain shaft in a hinge mode. The guiding sliding track is divided into an upper sliding track part and a lower sliding track part which have the same structure sequence. Each part is divided into a horizontal section, a V-shaped blanking section and an arc groove-shaped turning section which are connected in sequence. A falling zone corresponds to a lowering edge section of each V-shaped blanking section of the guiding sliding part. The heating device is connecting heat conduction oil furnace heat conduction calandrias which are distributed above and below a conveying interface formed by the bearing chain plate. An improved double-chain strip plate type conveyor is used, a high-efficiency heat conduction oil furnace is used as a heat source, a controllable heat conduction oil pipe composite layer distribution structure is used for improving the heating effect, and the effects of small space size, energy saving and environment protection are achieved.

Owner:HEBEI GOLD BANGZI BOILER

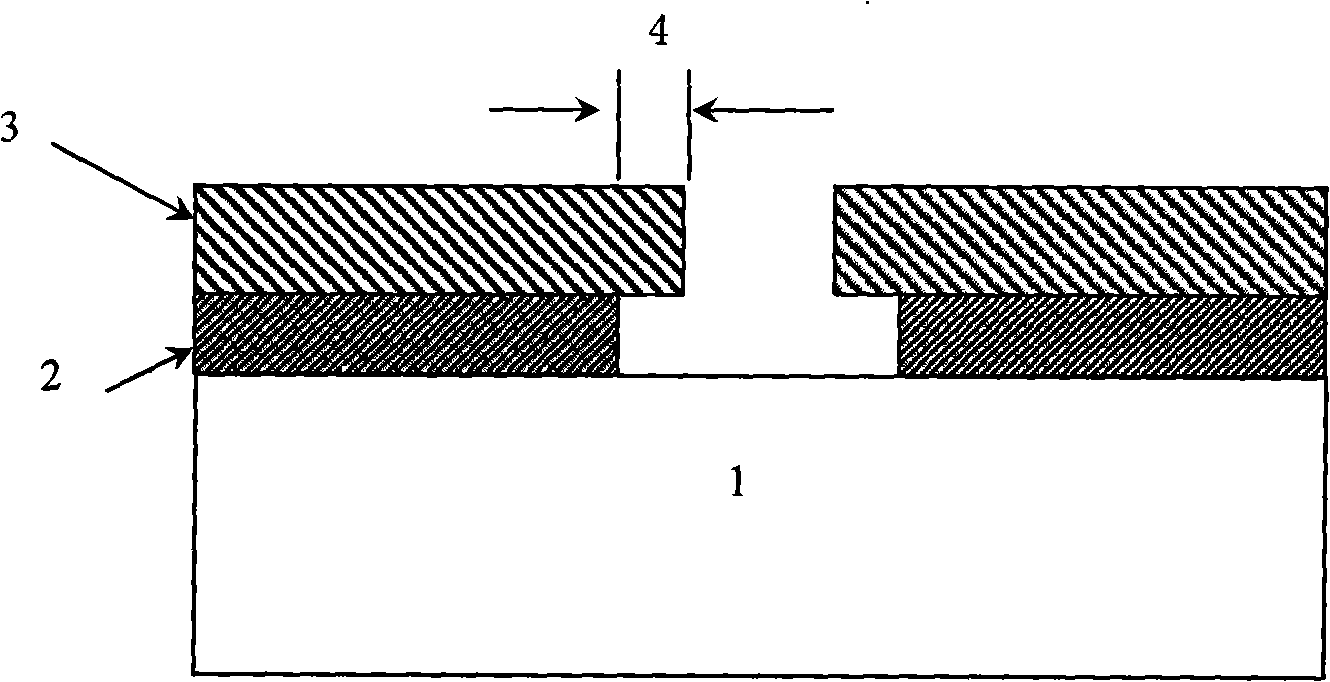

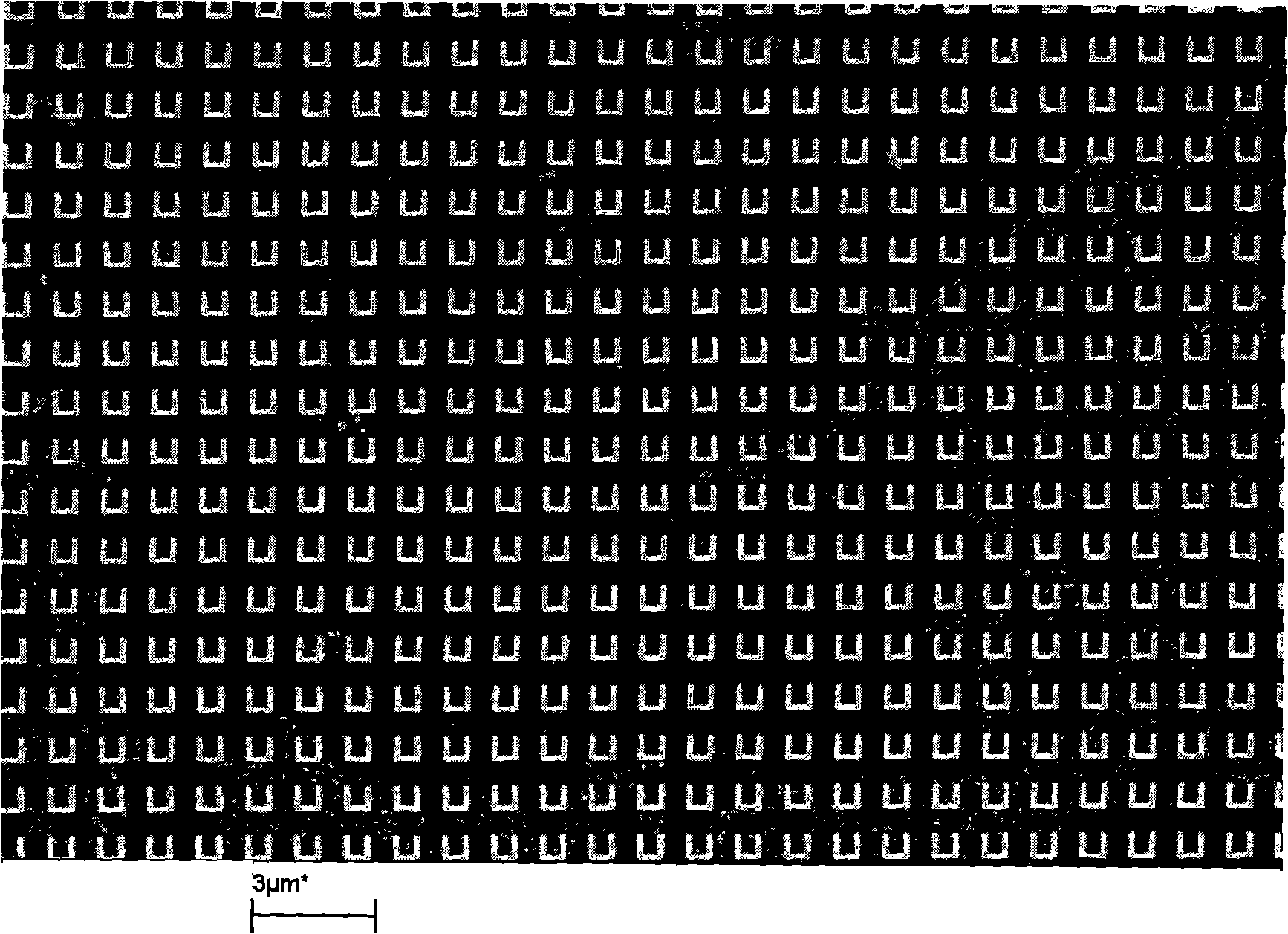

Method for producing nano-structure on insulated underlay

InactiveCN101295131AExcellent solubility propertiesSolve the accumulationPhotomechanical apparatusSemiconductor/solid-state device manufacturingElectron resistsNano structuring

The invention relates to a method for preparing nanometer structures on an insulating substrate. The method comprises the following steps of: selecting and disposing the insulating substrate; spin-coating electronic anti-corrosion adhesive after an aluminium film with suitable thickness is aggraded on the substrate by coating equipment; designing the shape and the dimension of the required surface nanometer structure according to the requirement; realizing the precise exposal of the design graphics on the surface of the substrate in an electron beam exposal system; realizing suitable undercut structure at the exposal line position in a dual-layer structure of electronic anti-corrosion adhesive and aluminium by controlling the process parameters such as temperature of alkali liquor, consistency of alkali liquor and corrosion disposal time; finally realizing the sediment of nanometer structure material by the coating equipment and completing the preparation of the nanometer structure by solubilisation process and alkali liquor disposal. The method overcomes the charge accumulation effect of the insulating substrate in the electron beam exposal system and realizes the exposal of the nanometer graphics; meanwhile, the prepared undercut structure can extremely effectively assist the subsequent solubilisation process, thus ensuring that the surface nanometer structure is effectively, integrally and precisely realized on the insulating substrate material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

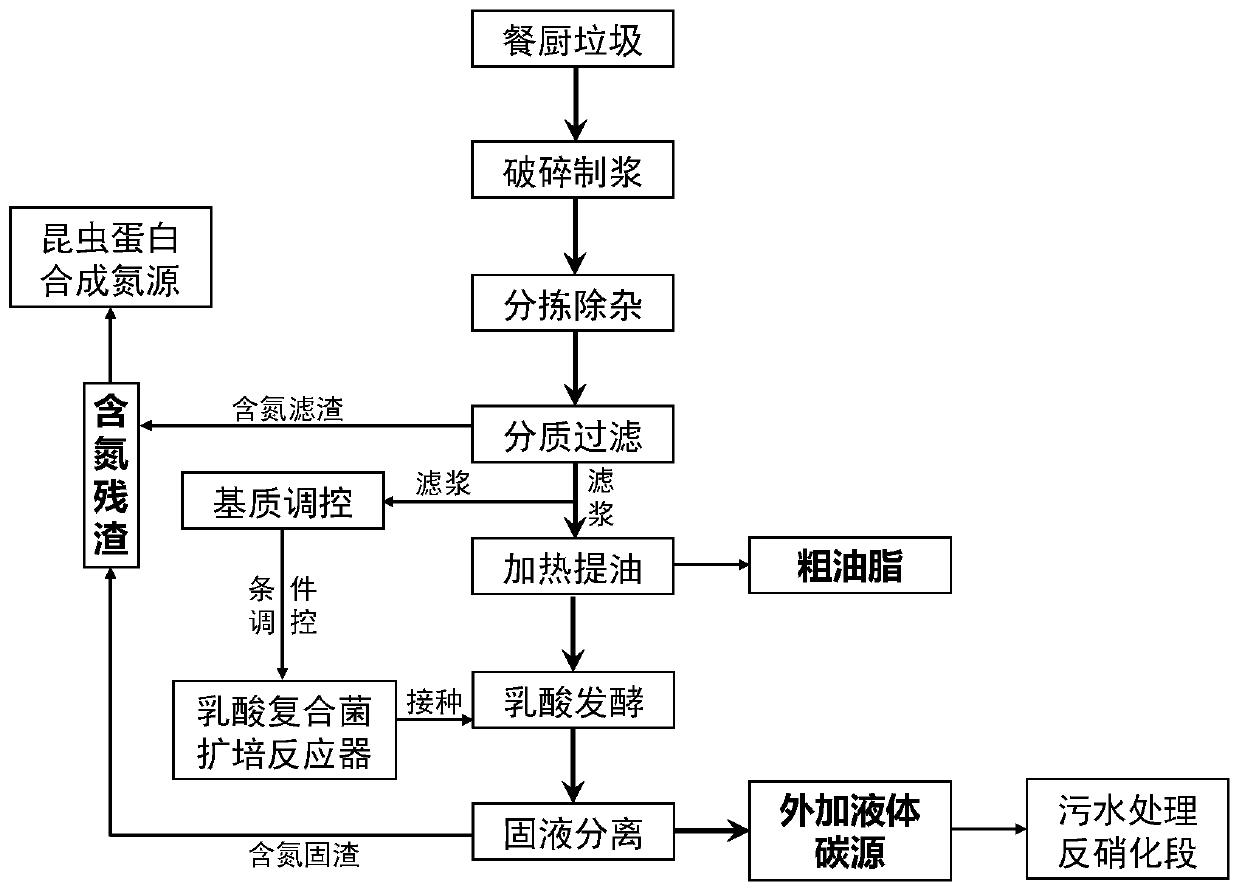

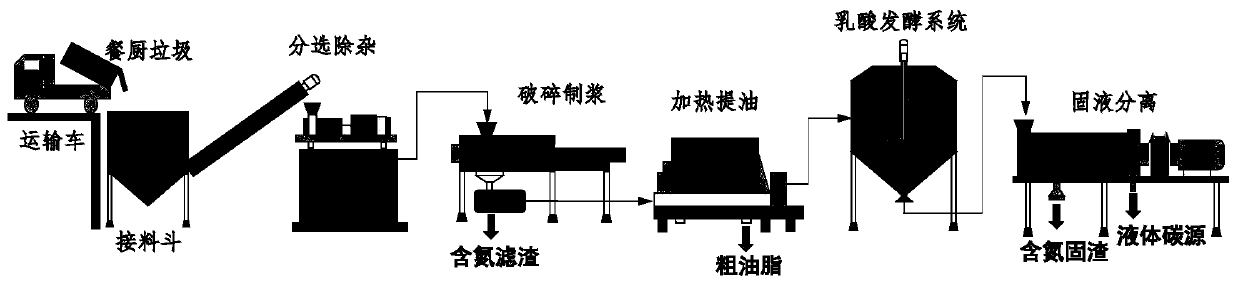

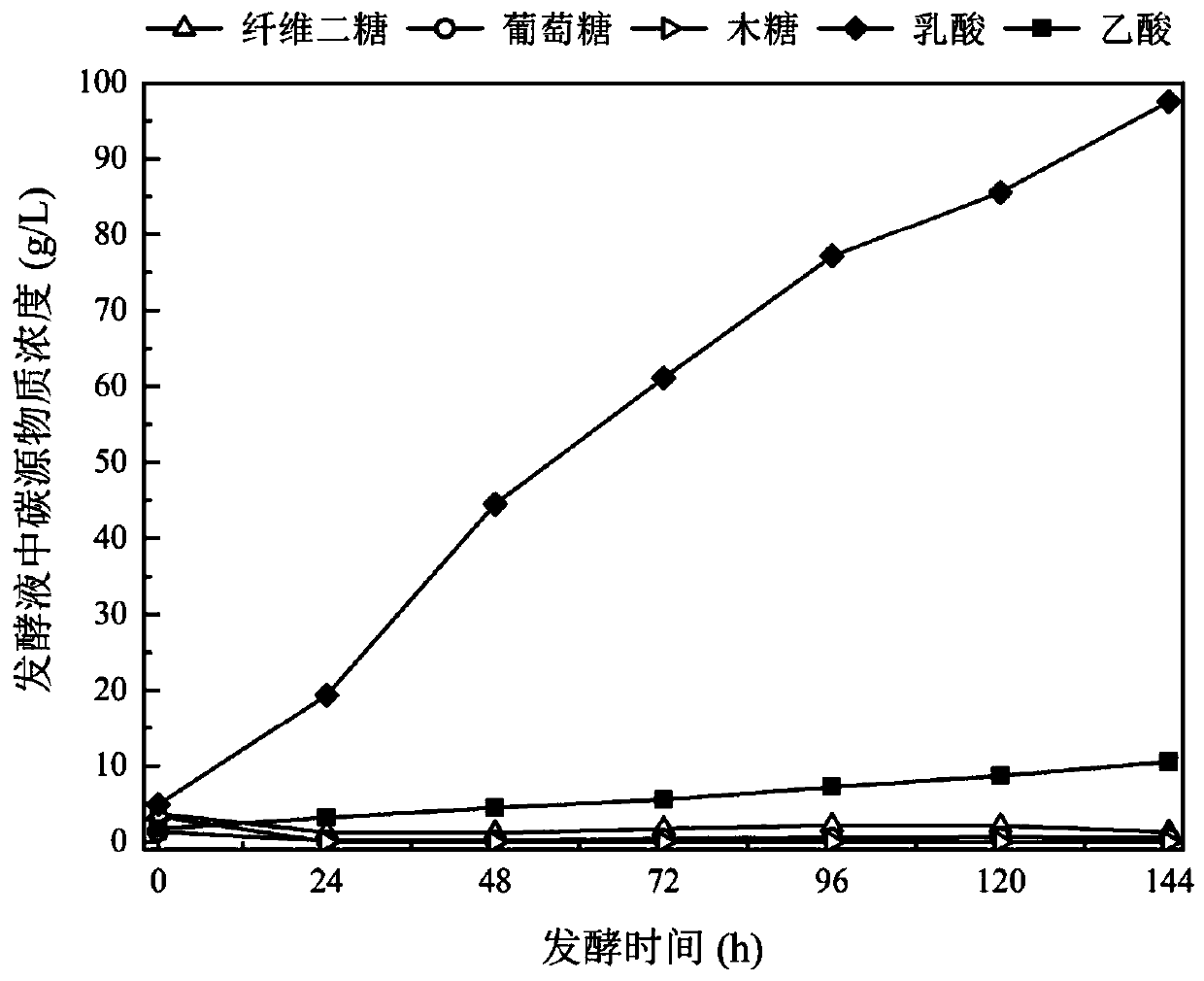

Method for producing wastewater denitrification carbon source through lactic acid fermentation of kitchen waste

ActiveCN111333179ASolve the problem of low COD/TNEfficient resource utilizationWater treatment compoundsTreatment with anaerobic digestion processesNutritionWaste oil

The invention discloses a method for producing a wastewater denitrification carbon source through lactic acid fermentation of kitchen waste, and belongs to the technical field of solid waste resourceful treatment. The method comprises the steps of adopting kitchen waste as a raw material; sorting and impurity removal, controlling the solid-to-liquid ratio, grinding, pulping, and carrying out quality-based and phase-splitting treatment; after the waste oil is heated and recycled, the residual garbage slurry is injected into an anaerobic fermentation tank for batch lactic acid fermentation, after fermentation is finished, solid-liquid separation is carried out, lactic acid-containing supernatant can be directly used as a liquid carbon source in the sewage denitrification stage, a good biological denitrification effect is achieved, nitrogen-containing residues can be collected and recycled, and full recycling is achieved. According to the invention, kitchen waste is directly used for efficient open lactic acid fermentation; according to the method, the indigenous microbial flora in the kitchen waste is fully utilized to hydrolyze the substrate and efficiently and directionally convertthe substrate into lactic acid, exogenous nutrition and industrial enzyme preparations do not need to be added, the process is simple, the production cost is low, a cheap carbon source is provided for a denitrification section of a sewage treatment plant while resource utilization of the kitchen waste is realized, and the biological denitrification efficiency is improved.

Owner:UNIV OF SCI & TECH BEIJING

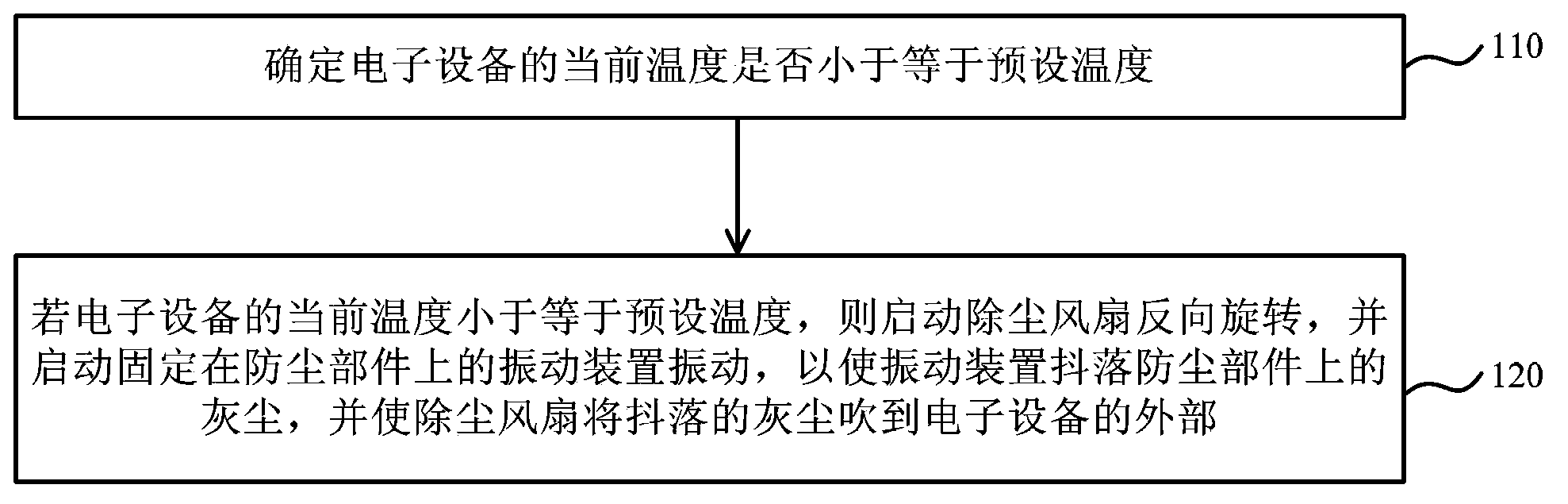

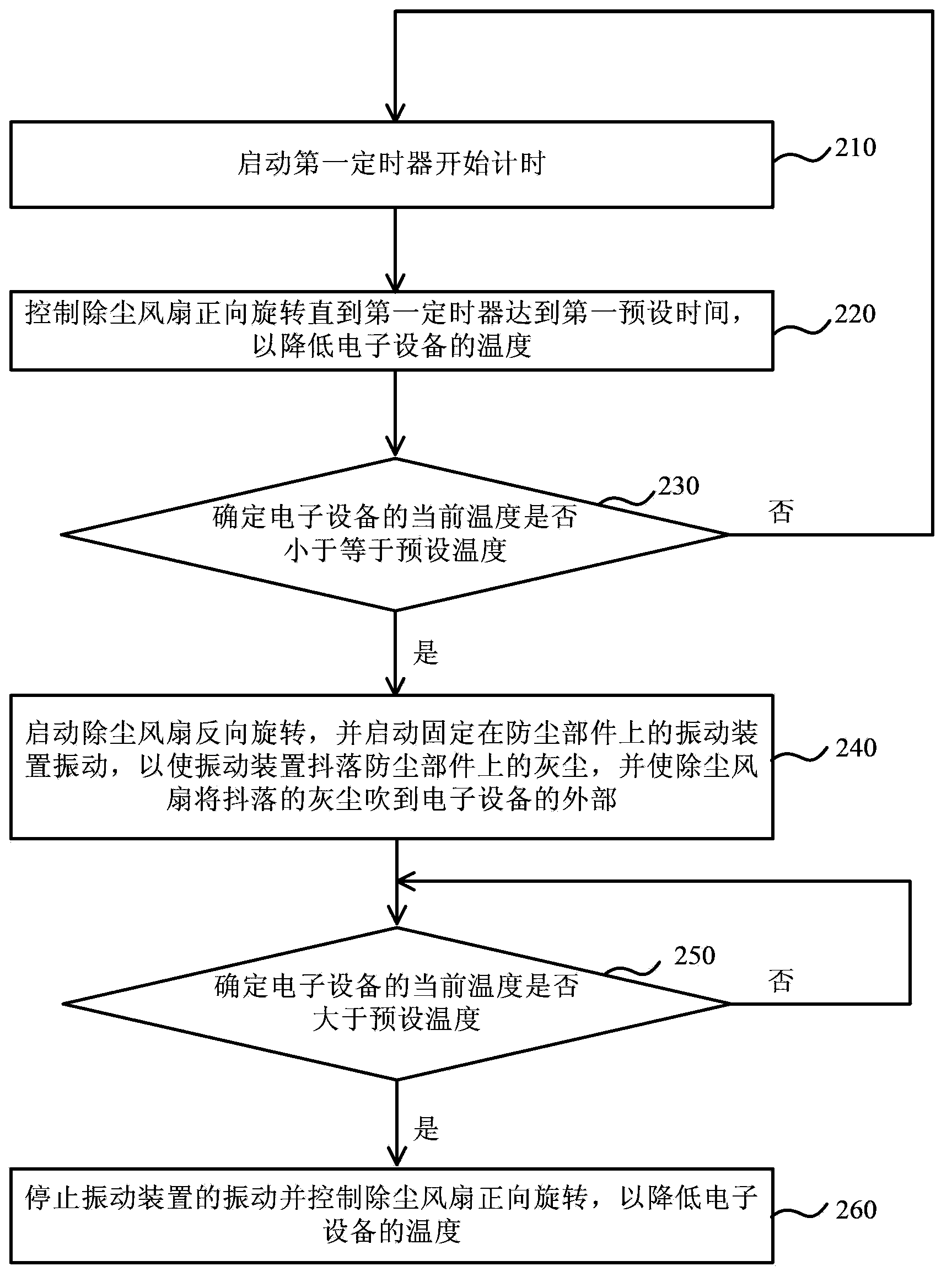

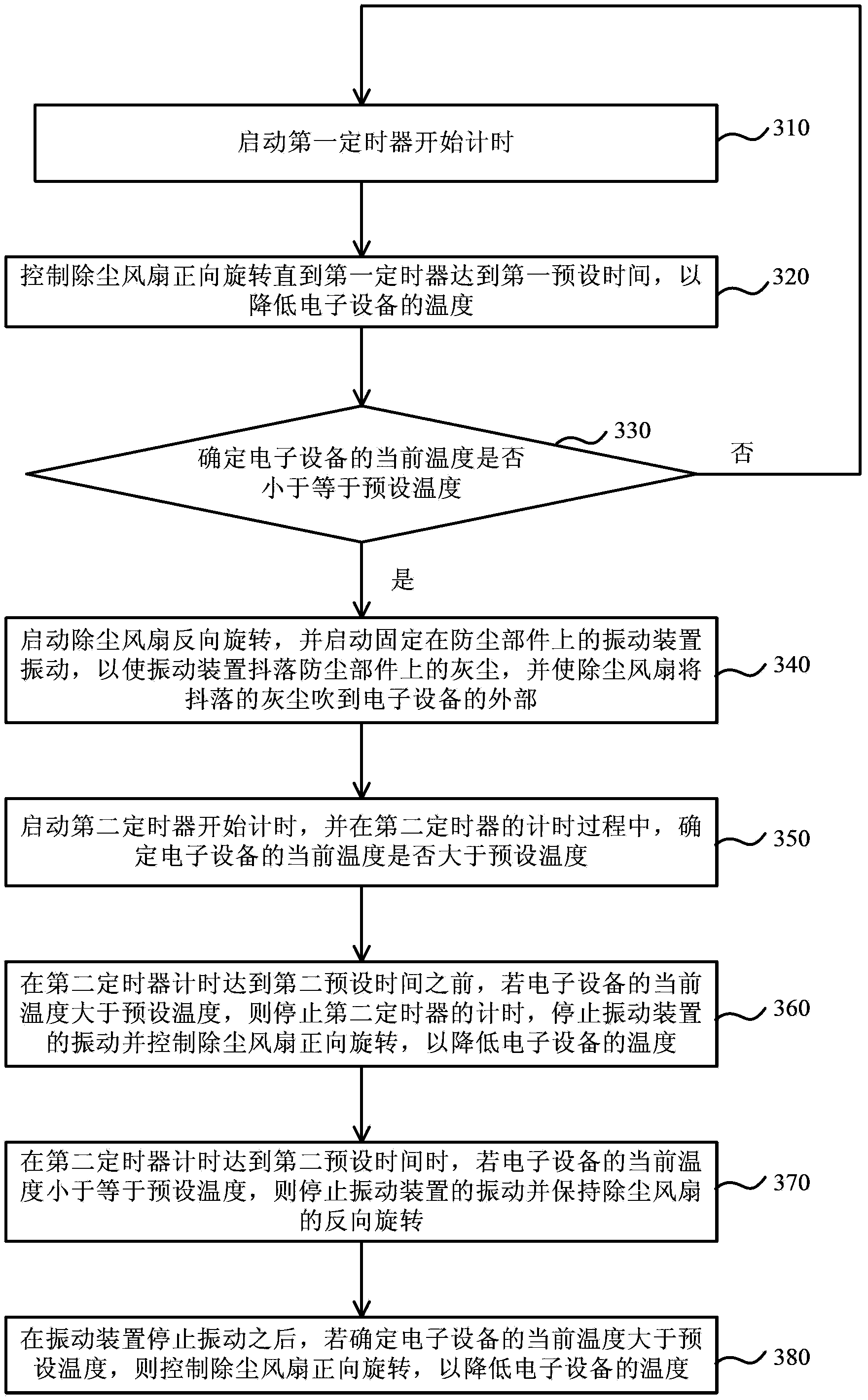

Dust removing method and dust removing device of electronic equipment and electronic equipment

ActiveCN103433247ASolve the accumulationGuaranteed cooling effectCleaning processes and apparatusCooling/ventilation/heating modificationsEngineeringElectronic equipment

The embodiment of the invention provides a dust removing method and a dust removing device of electronic equipment and the electronic equipment. The dust removing method of the electronic equipment comprises the steps of determining whether the current temperature of the electronic equipment is less than or equal to a preset temperature or not; starting a dust removing fan to rotate reversely if the current temperature of the electronic equipment is less than or equal to the preset temperature, and starting a vibration device which is fixedly arranged on a dustproof component to vibrate so that dust on the dustproof component can be shaken off by the vibration device and the shaken-off dust can be blown to the outer part of the electronic equipment by the dust removing fan. According to the dust removing method and the dust removing device of the electronic equipment and the electronic equipment, which are provided by the embodiment of the invention, the problem of dust accumulated on a dustproof component in the prior art is solved, the automatic cleaning of the dust accumulated on the dustproof component can be realized, and thus the normal heat dissipation of an electronic device in the electronic equipment can be ensured.

Owner:HUAWEI DIGITAL TECH SUZHOU

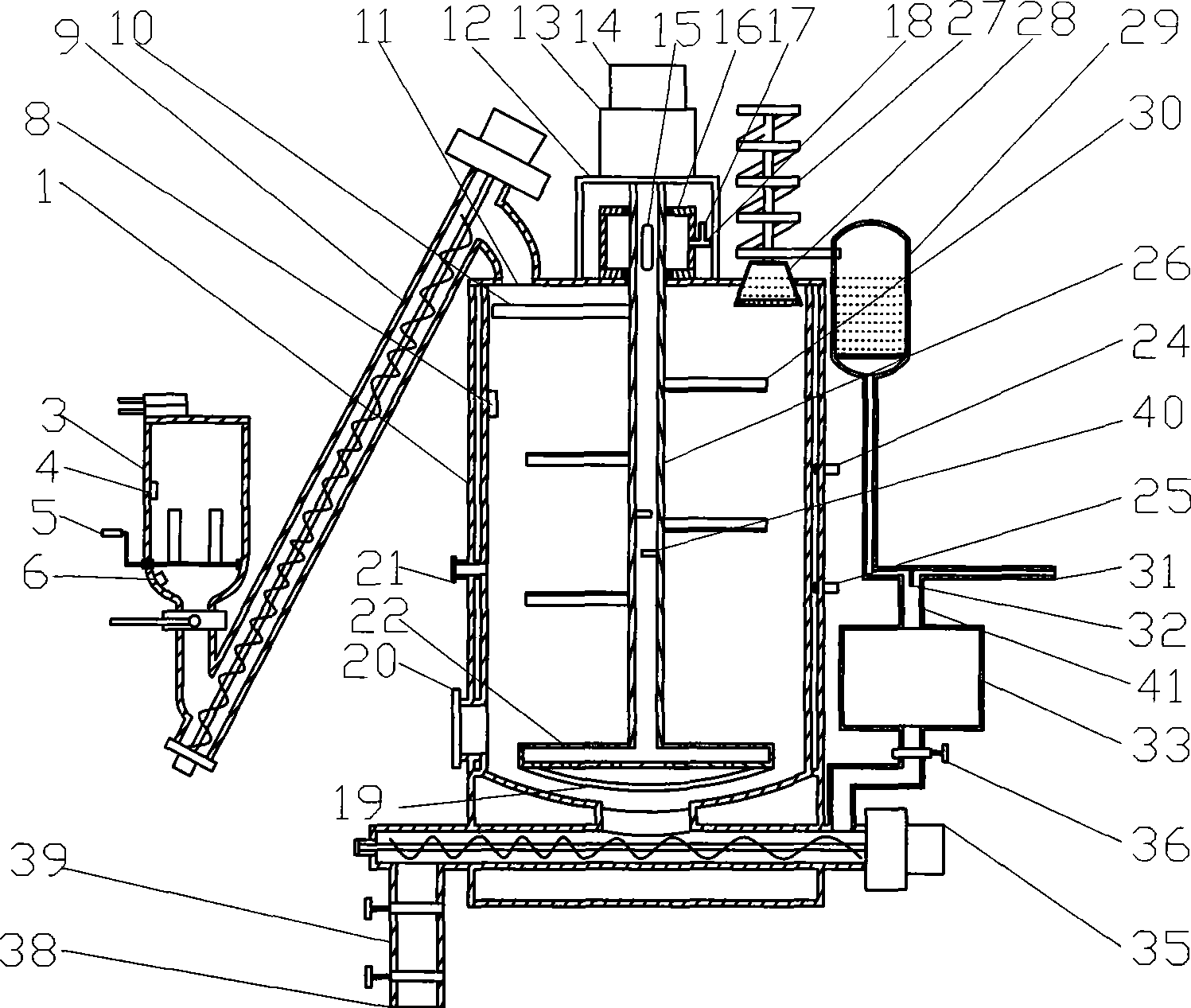

Biomass gasification furnace

InactiveCN101481630AIncrease contentAdjustable temperatureCombined combustion mitigationCombustible gas productionCombustionWater vapor

The invention relates to a biomass gasification furnace which comprises a furnace body, a feed inlet opened on the top of the furnace body, a filter embedded on the top of the furnace body, a fire observation hole and a lighting-up hole which are arranged on the side wall of the furnace body, a radiator connected with the filter, a purifier connected with the radiator, an exhaust pipe connected with the purifier, an ash hole communicated with the bottom of the furnace body, a mixer shaft arranged inside the furnace body, stirring teeth arranged on the mixer shaft, a mixer shaft motor arranged outside the furnace body, a feeding storage hopper that is connected at the front end of the feed inlet and can control the inlet and outlet materials, and a ash discharge hopper that is used for communicating the ash hole and the bottom of the furnace body and can control the inlet and outlet ash. The invention has the advantages that the biomass gasification furnace can continuously supply gas when the material is added and the ash is discharged, the gas dust in the furnace is not discharged outside, the position of a gasification layer in the furnace is unchangeable, water vapor can be used for combustion-supporting, etc.

Owner:蒋启富

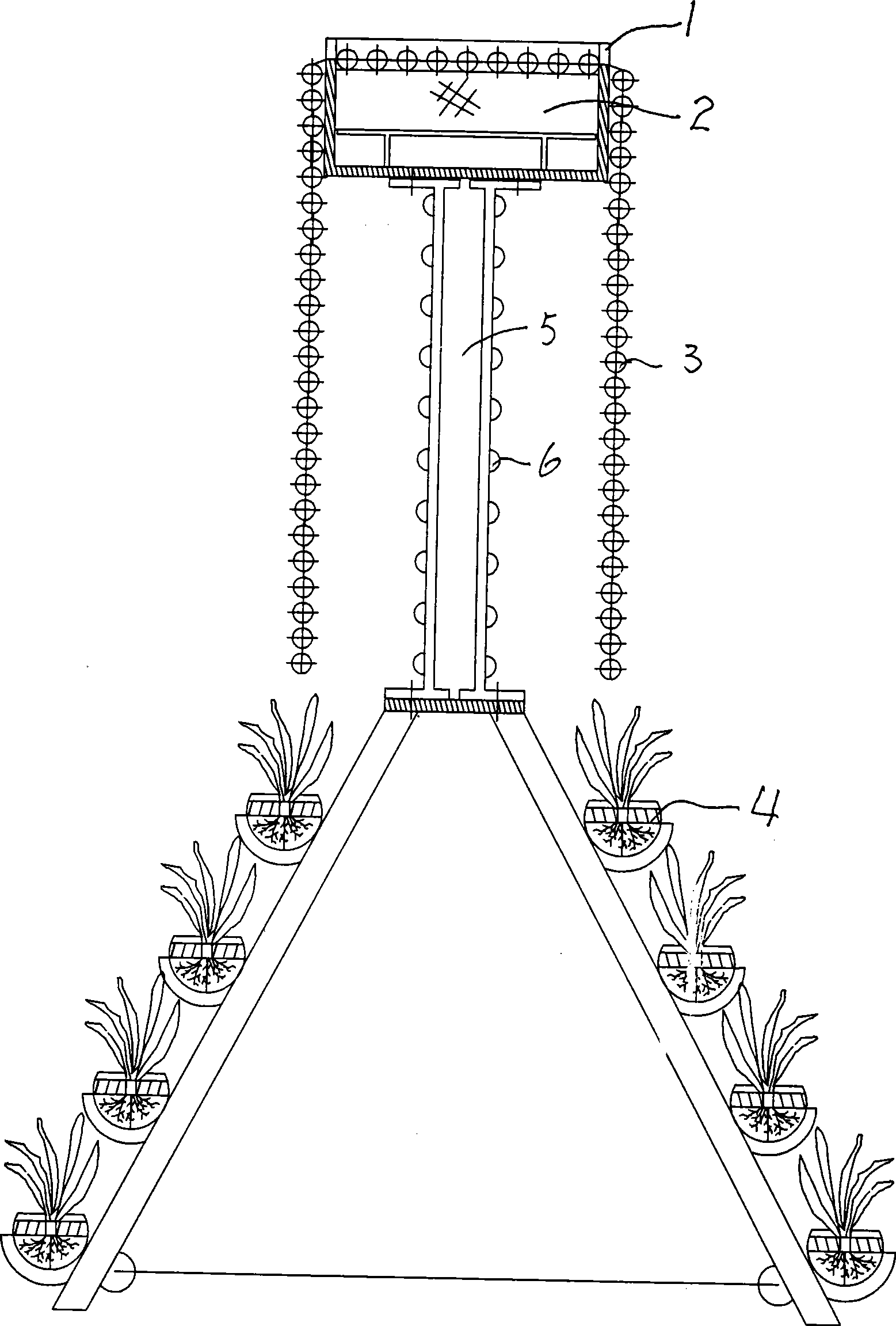

Photocatalysis-plant cooperated water purifying method for pisciculture water

InactiveCN101475282ASolve the accumulationRelease fullyWater/sewage treatment by irradiationEnergy based wastewater treatmentGlass ballPhotocatalytic reaction

The invention relates to a photocatalysis-plant synergy water purifying method for fish-farming water, which comprises the following steps that: 1) sewage in a fish pond is pumped into a filter tank by a diving pump, solid impurities are filtered by sponge foam, and the intercepted solid impurities are discharged by a blowdown valve; 2) clear water filtered by sponge foam falls into a nacreous glass catalytic reaction curtain which is vertically hung on the side wall of the filter tank to contact and react with a photocatalysis material, wherein the nacreous glass catalytic reaction curtain is formed by connecting glass balls in series and in parallel, and the surfaces of the glass balls are burnt and plated with a TiO2 series catalytic material; and 3) the catalyzed water falls into a plant culture tank; and the water flows into the fish pond after pollutants in the water are reduced. The method has the advantages of good natural light transmission, high mass transfer efficiency, no oxygen supplement and nitrogen release power consumption and no blockage, and the practical characteristics of low cost and continuous work. Except for the water pollution treatment for circulating water fish-farming, the method can also be applied to low concentration water treatment of the occasions of environmental protection, civicism, landscape greenbelts and the like.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI +1

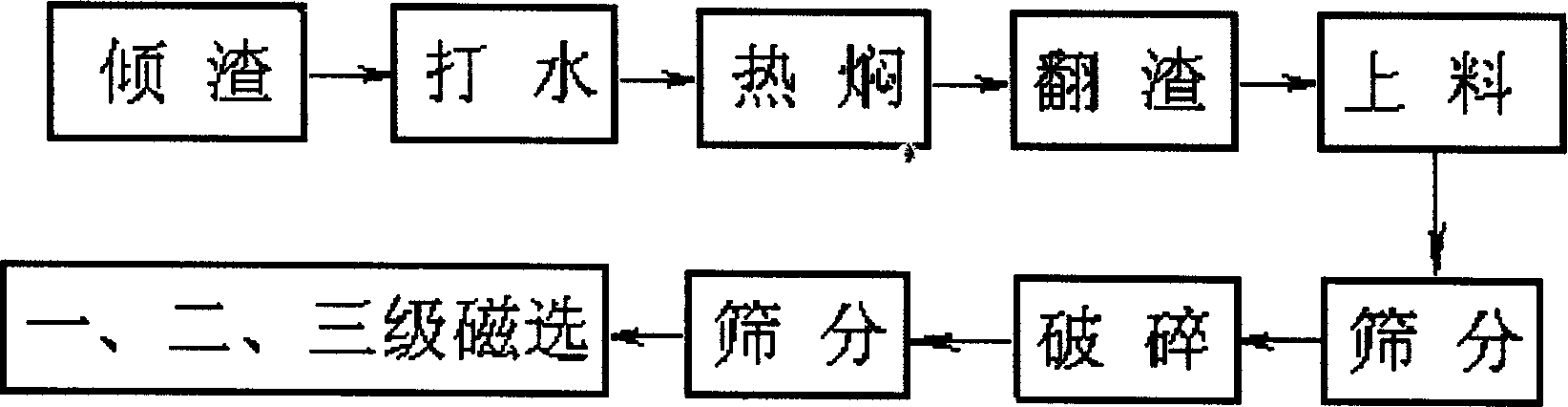

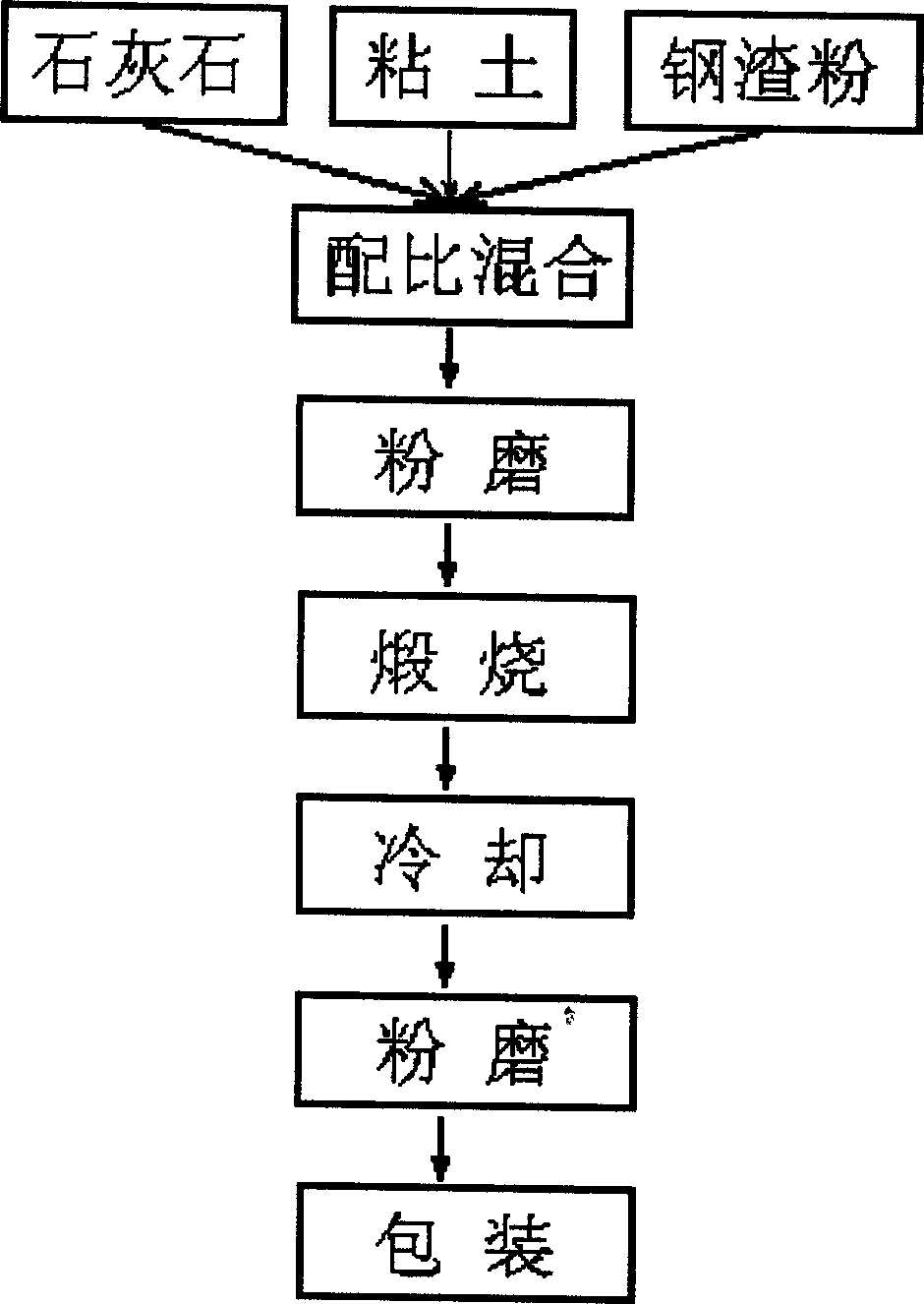

Method of using vanadium titanium rotary furnace steel slag as cement iron correction material

The present invention relates to a method capable of using vanadium-titanium converter steel slag as cement iron correction raw material. Said method includes the following steps: cooling molten steel slag, breaking, magnetic separation to obtain steel slag powder, mixing steel slag powder, limestone and clay, grinding them, calcining, cooling and secondary grinding so as to obtain the invented cement clinker.

Owner:WASTE & OLD MATERIAL BRANCH OF PANGANG GROUP GANGCHENG ENTERPRISE CORP

Method for smelting reduction production of zinc smelting slag

InactiveCN107699699ASolve the accumulationTake advantage ofProcess efficiency improvementIndiumBismuth

The invention discloses a method for smelting reduction production of zinc smelting slag. The method for smelting reduction production of the zinc smelting slag comprises the following steps that S1,the zinc smelting slag is added into an insulation device or a smelting reaction device allowing slag to flow out, calcium minerals and additives are added, all the components are heated to be in themolten state, one or more of copper oxide minerals, copper sulfide minerals and copper-containing materials are added into the insulation device or the smelting reaction device at the moment, reactionslag is monitored in real time, and molten slag is obtained by regulating and controlling the temperature and the CaO / SiO2 basicity ratio of the reaction slag; and S2, the molten slag is obtained, aferrum-containing silicate mineral phase, a copper-rich phase, a ferrum-rich phase and dust containing zinc, lead, bismuth and smoke are obtained through settlement separation, gold and silver are migrated and enriched to enter the copper-rich phase, and all the phases are separated. According to the method for smelting reduction production of the zinc smelting slag, the slag copper content (lowerthan 0.1 wt%) can be decreased, efficient recovery of components such as copper, ferrum, gold, silver, lead, zinc, indium, bismuth, sodium and potassium can be achieved, and low-copper ferrum-containing materials are obtained; and the metal recovery rate is high, the production cost is low, environmental friendliness is achieved, and economic benefits are high.

Owner:NORTHEASTERN UNIV

Method for treating ammonia nitrogen wastewater by using heterotrophic nitrification-aerobic denitrification pseudomonas strain

ActiveCN110655199AHigh removal rateSolve the accumulationBacteriaWater contaminantsNitrogen removalMicroorganism

The invention discloses a method for treating ammonia nitrogen wastewater by using a heterotrophic nitrification-aerobic denitrification pseudomonas strain, wherein the ammonia nitrogen wastewater contains organic acid sodium, and a C / N ratio is 8-120. The method comprises: inoculating a heterotrophic nitrification-aerobic denitrification pseudomonas seed liquid into ammonia-nitrogen wastewater, and carrying out am oscillation reaction for 6 h-7 d at a temperature of 25-40 DEG C at a rotating speed of 90-180rpm so as to finish the treatment of the ammonia nitrogen wastewater, wherein the strain is pseudomonas LJ9, is preserved in the Guangdong culture collection center, has the preservation number of GDMCC NO:60339, and has high tolerance to high C / N and high ammonia-nitrogen concentrationwastewater and high ammonia-nitrogen removal rate, so that the method has huge application value in the fields of ammonia nitrogen removal of high carbon-nitrogen ratio and high-concentration ammonia-nitrogen wastewater.

Owner:LONGYAN UNIV

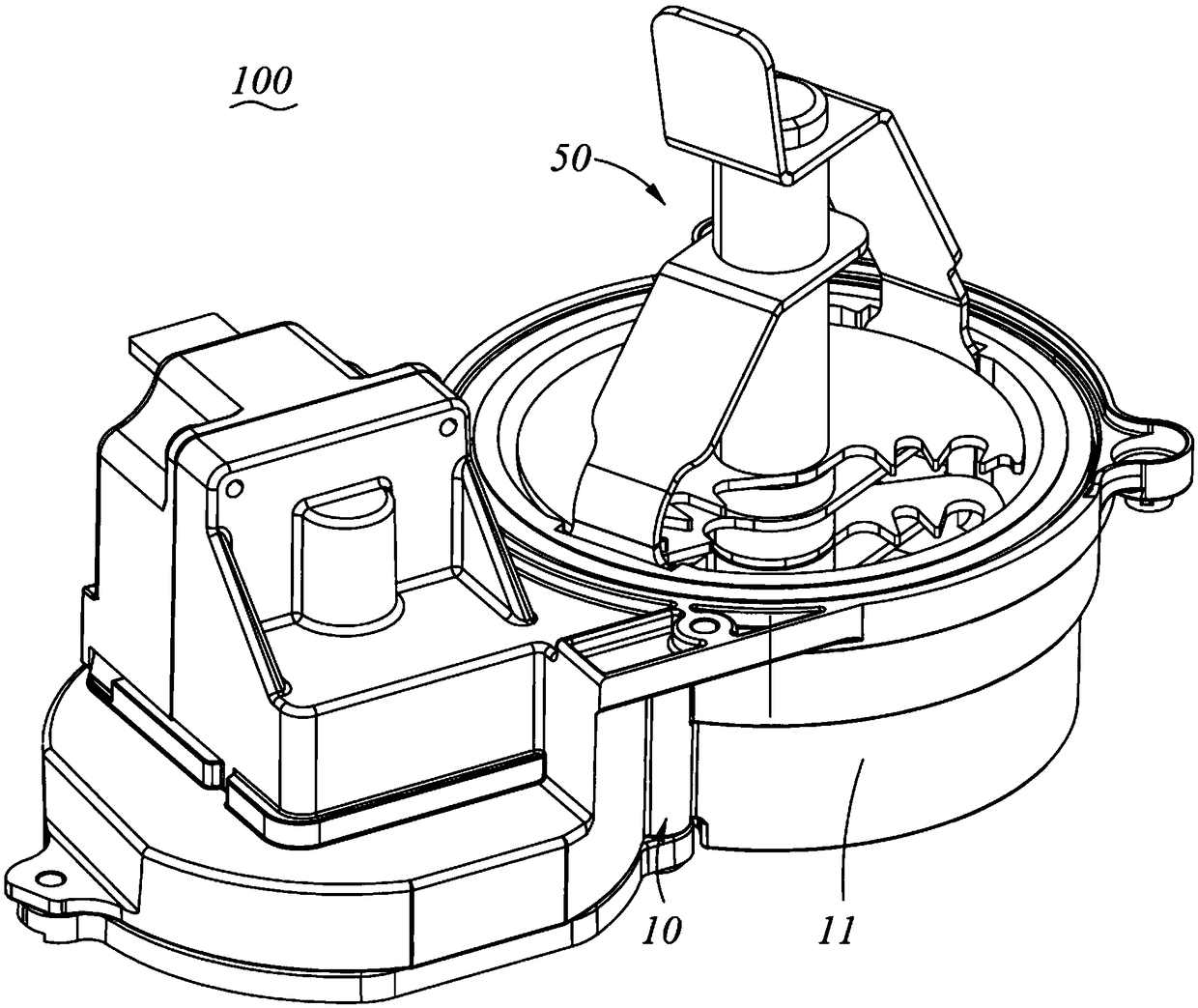

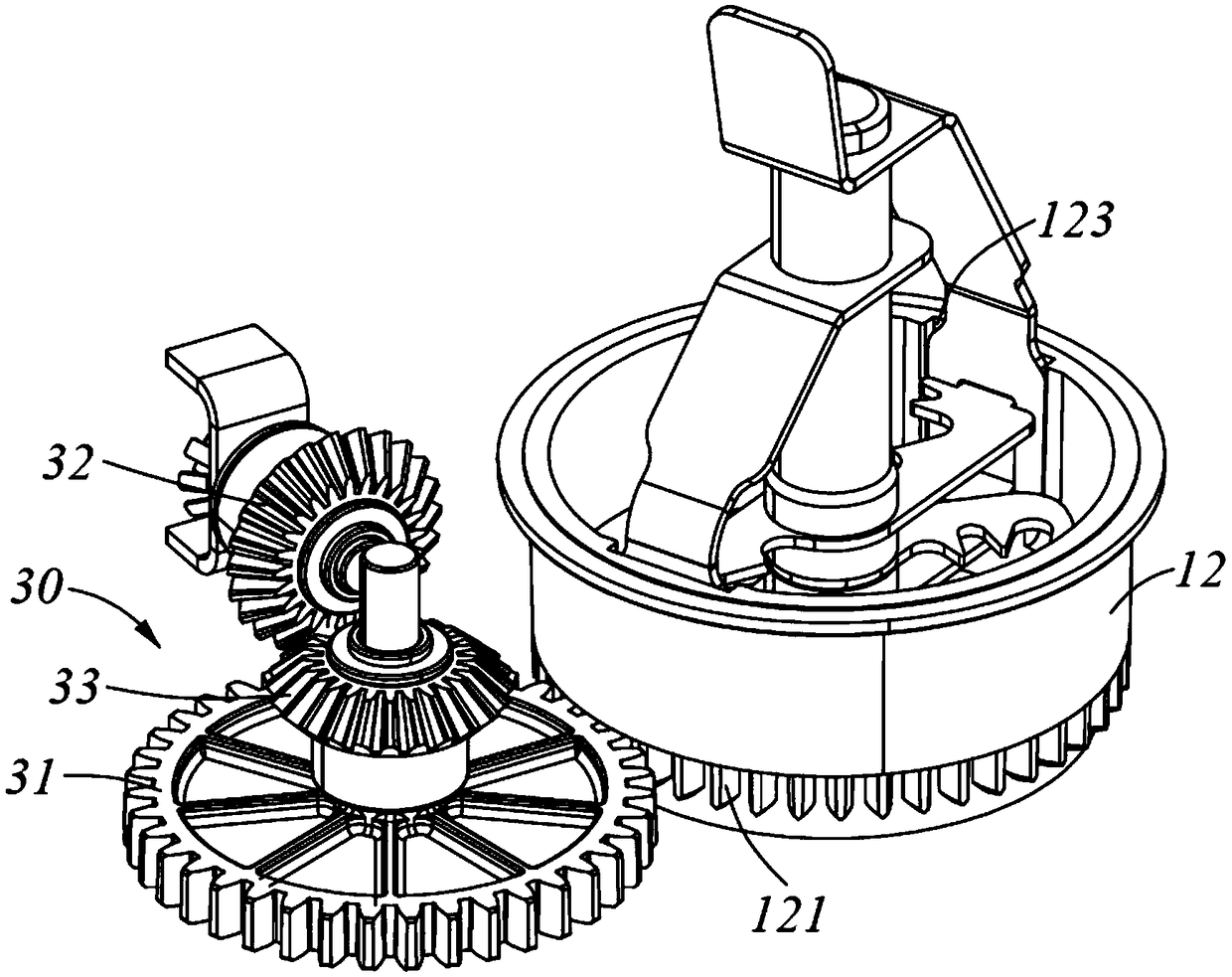

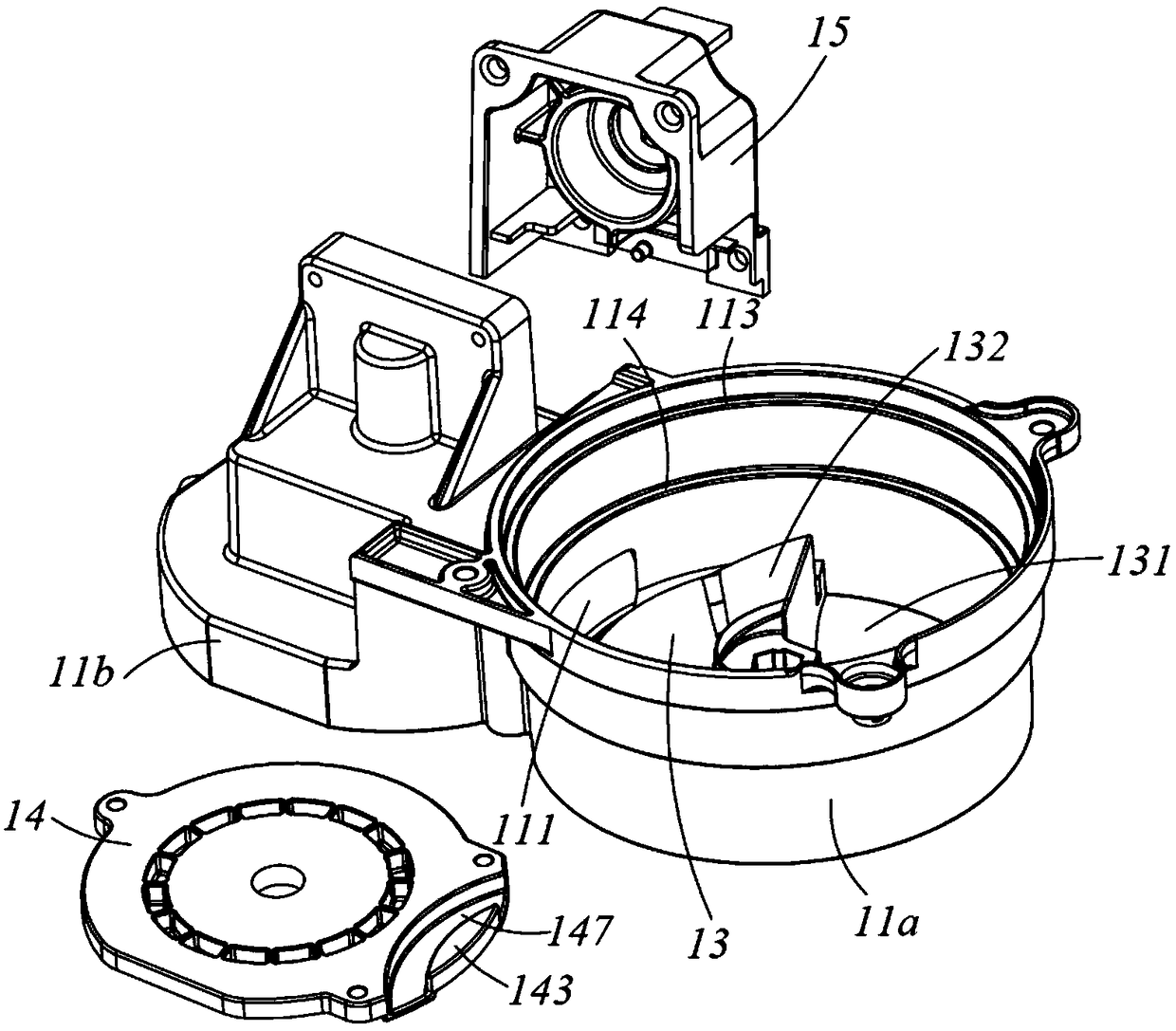

Ice breaking device and refrigerator

ActiveCN108759216ASolve the accumulationDoes not affect power transmissionLighting and heating apparatusIce storing/distributionEngineeringRefrigerated temperature

The invention discloses an ice breaking device and a refrigerator. The ice breaking device comprises a shell body assembly, the shell body assembly comprises an outer shell and an ice bucket, a driving mechanism, and an ice breaking mechanism, which the ice bucket is supported in the outer shell; the driving mechanism is used for driving the ice bucket to rotate, and at least a part of the drivingmechanism is installed in the outer shell; the ice breaking mechanism is arranged in the ice bucket; the shell body assembly further comprises an ice discharging base plate arranged at the bottom ofthe ice bucket, an ice discharging port communicating with the ice bucket is formed in the ice discharging base plate, ice blocks obtained through an ice making mechanism are crushed by the ice breaking mechanism in the ice bucket and then are discharged from the ice discharging port; the outer shell comprises a first part for accommodating the ice bucket and a second part for installing the driving mechanism, a groove which extends along the circumferential direction of the ice bucket is formed between the ice discharging base plate and the first part, the groove communicates with the ice discharging port, and the lower edge of the ice bucket extends into the groove. The ice breaking device and the refrigerator are more reliable in use.

Owner:HAIER SMART HOME CO LTD

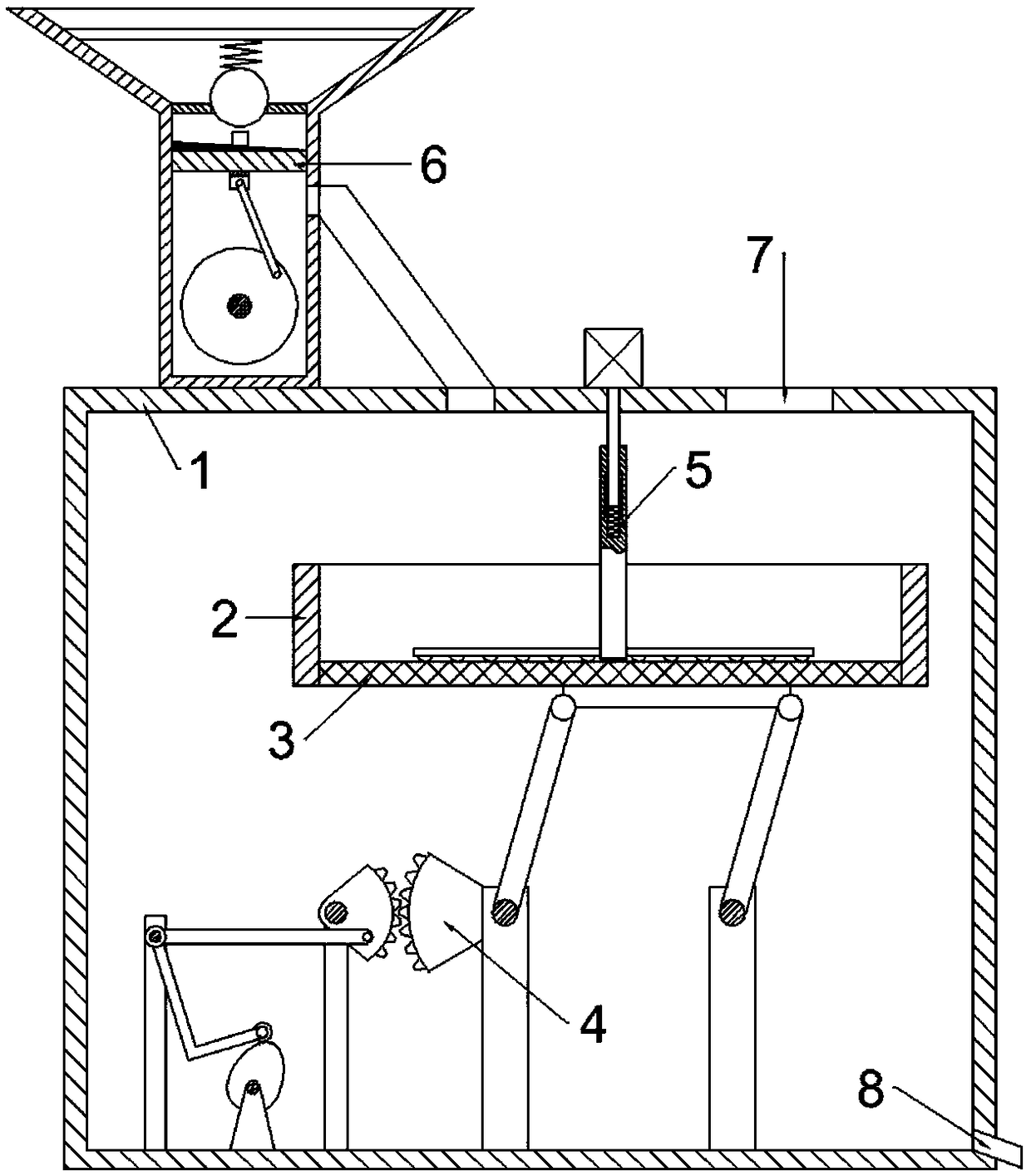

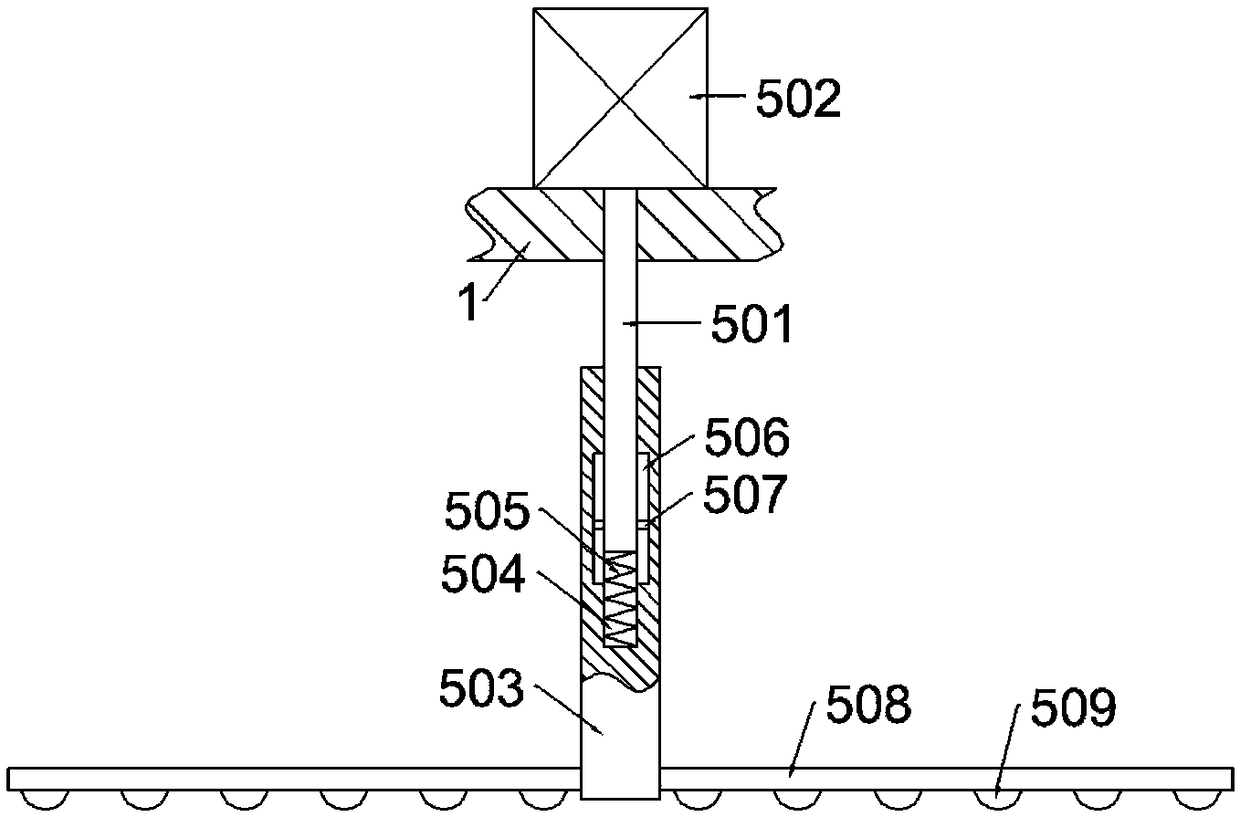

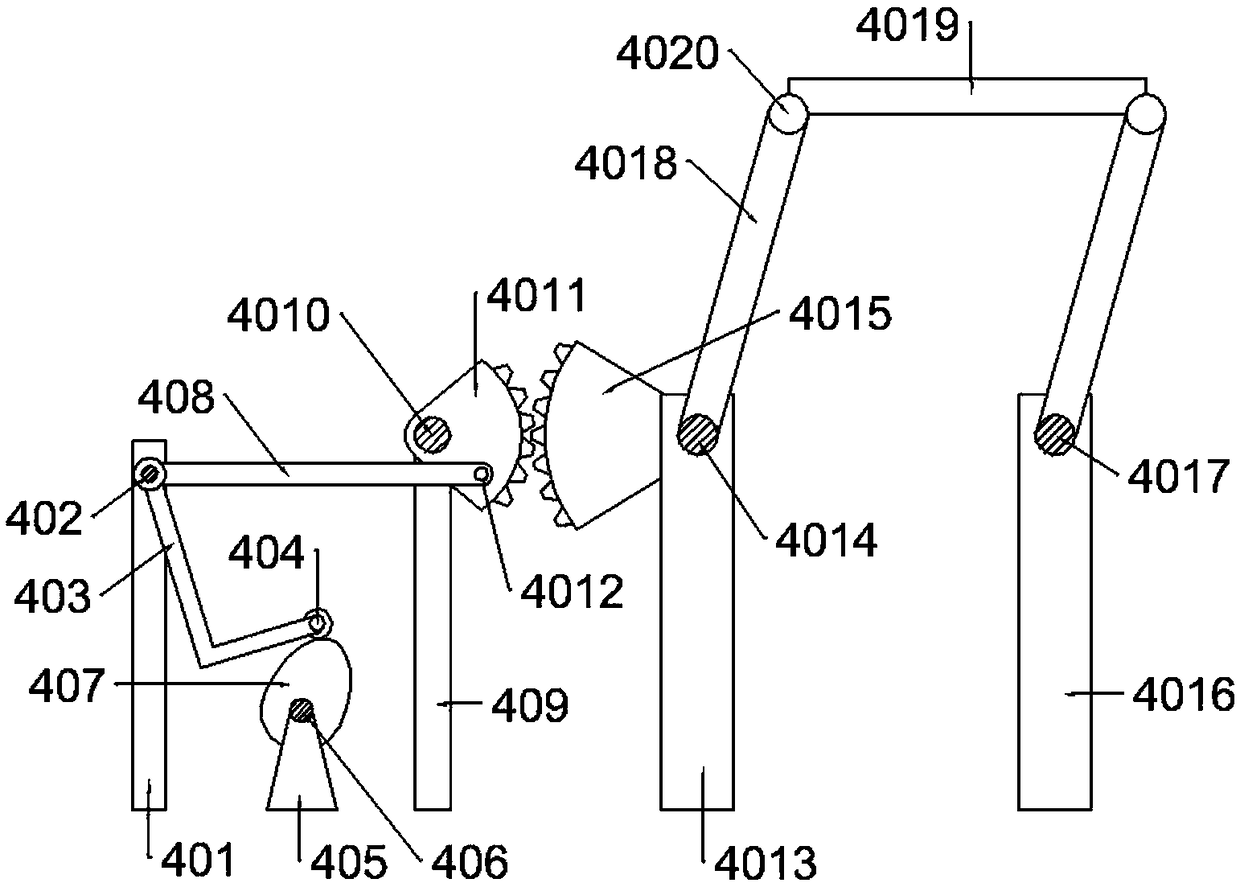

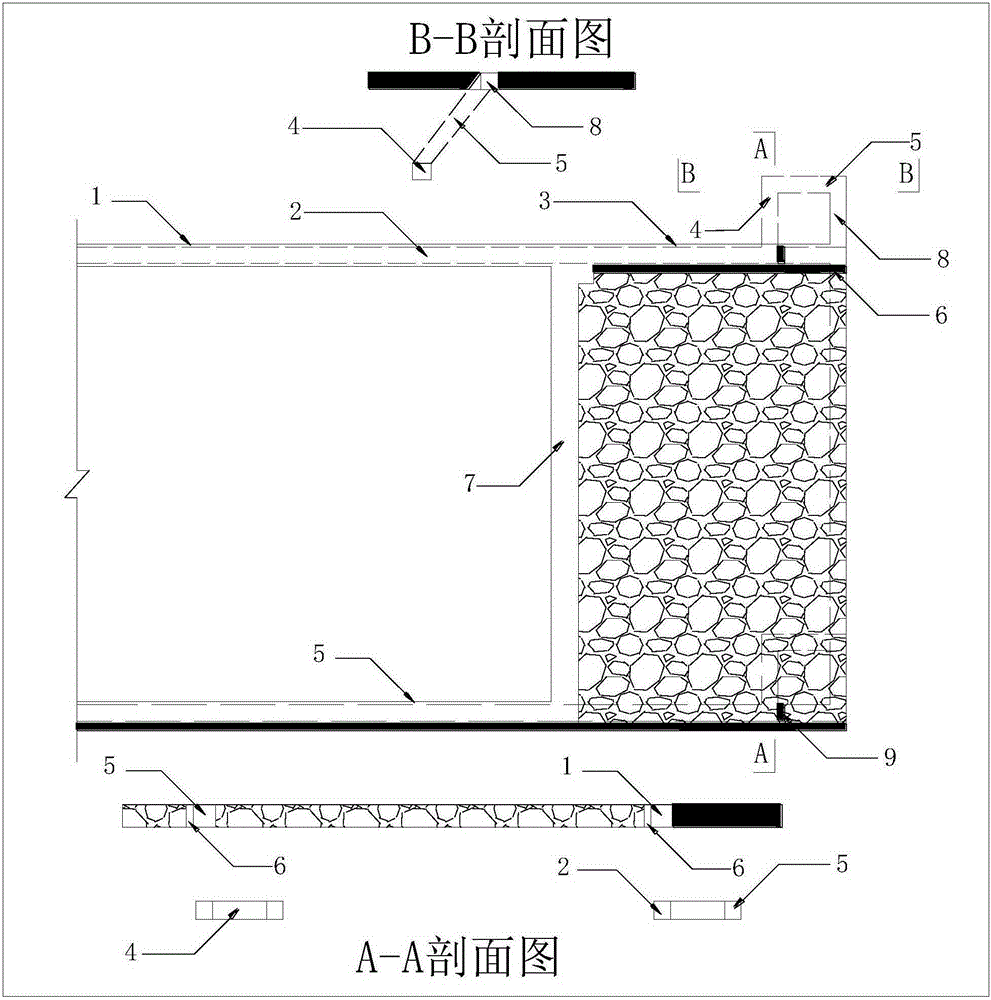

Working method of vibratory screening equipment with intermittent feeding function for granular material

ActiveCN108639786ASolve the accumulationGuaranteed to proceed normallySievingScreeningEngineeringMechanical engineering

To achieve the purpose, the invention provides a working method of vibratory screening equipment with an intermittent feeding function for a granular material. The vibratory screening equipment comprises an enclosure, wherein an annular support plate is arranged in the enclosure; a sieve is fixedly connected to the bottom of the annular support plate and connected with the inner bottom of the enclosure through a sieve vibrating device; a material disturbance device is arranged at the upper side of the sieve and comprises a first rotating shaft; and the top end of the first rotating shaft penetrates the enclosure and extends upwards and is fixedly connected to an output shaft of a first motor. The following beneficial effects are achieved: first, the first rotating shaft drives a disturbance bulge to rotate through a coordinating rod, and the disturbance bulge disturbs the material on the sieve to guarantee normal proceeding of sieving, so that the problem of material accumulation is effectively solved; and second, a first spring arranged here can enable the rotating coordinating rod to move up and down so as to adapt to the sieve which moves up and down.

Owner:JIANGSU JINENGDA ENVIRONMENTAL ENERGY SCI & TECH

High-gas mine Y-shaped ventilation method

ActiveCN105221179AEliminate outstanding hazardsImprove securityTunnel/mines ventillationGas removalEngineeringCoal

The invention provides a high-gas mine Y-shaped ventilation method. The method comprises the following steps of: before the crossheading tunneling, tunneling a floor suction roadway in a coal seam floor rock layer, wherein the position of the floor suction roadway corresponds to a working face rail crossheading and open-off cut; arranging a gas drainage pipe in a roadway; tunneling the rail crossheading and open-off cut in a working coal seam right above the floor suction roadway to form a ventilation system; excavating a coal roadway along the coal seam strike at the tail end of the rail crossheading; tunneling an air return inclined roadway in an inclined downward direction along the coal seam at the tail end of the coal roadway; communicating the floor suction roadway after the same seam position of the floor suction roadway is reached; then, building a sealing wall at the floor suction roadway in the communicating position; and building a roadway-side filling body to remain a rail roadway in the working face extraction process, and arranging a gas drainage pipeline for draining gas in a goaf. The method solves the problem of gas bursting in the working face corner gas accumulation and tunneling process; the safety is high; one roadway has multiple purposes; the mining cost is low; the working face does not pass through an abandoned roadway; and the process is simple.

Owner:TAIYUAN UNIV OF TECH

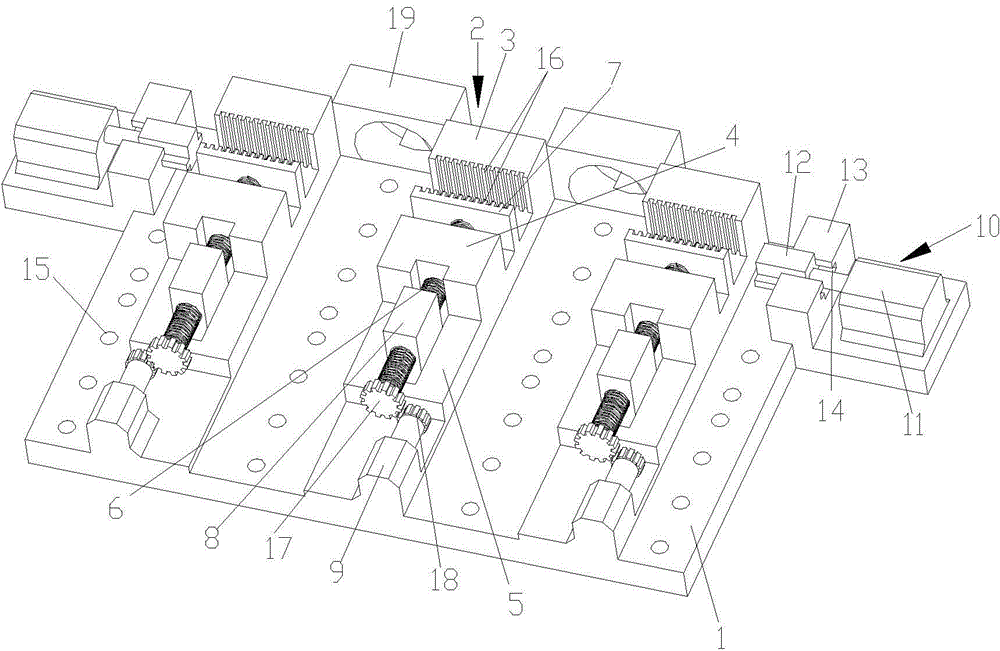

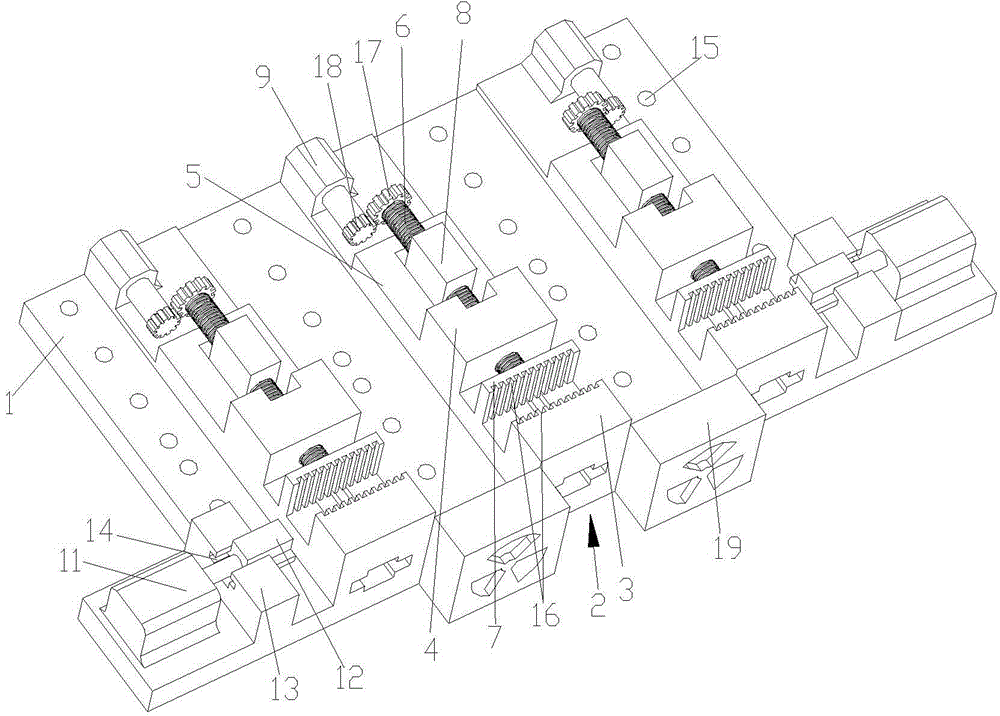

Air blowing clamp for numerical control machine tool

ActiveCN104400490AGuaranteed cleanlinessSolve the accumulationWork clamping meansPositioning apparatusNumerical controlGear wheel

The invention discloses an air blowing clamp for a numerical control machine tool. The air blowing clamp comprises a pedestal and total three groups of processing workstations, wherein each processing workstation comprises a fixed baffle plate, a supporting seat and a moving groove; a clamping block connected by a screw rod is arranged between each of the fixed baffle plates and the corresponding supporting seat; one end of each of the screw rods penetrates through the supporting seat, and is installed in a moving seat; moreover, the end, stretching out of the moving seat, of each of the screw rods is connected with a first gear; the first gears are respectively engaged with second gears arranged on motors on the pedestal; moreover, the screw rods are driven to rotate through the rotation of the motors; the moving seats are respectively installed in the moving grooves, and can move in the moving grooves; the total three groups of processing workstations are arranged on the pedestal in parallel; an air blowing device is arranged between every two adjacent groups of processing workstations; the outer sides of the processing workstations on the pedestal are also respectively provided with a tightly-pushing structure. By applying the clamp, the stability of a product in processing is improved greatly, the precision of processing is guaranteed, the quality of the product is improved, and the defective rate is lowered.

Owner:安徽上禾阜机械配件有限公司

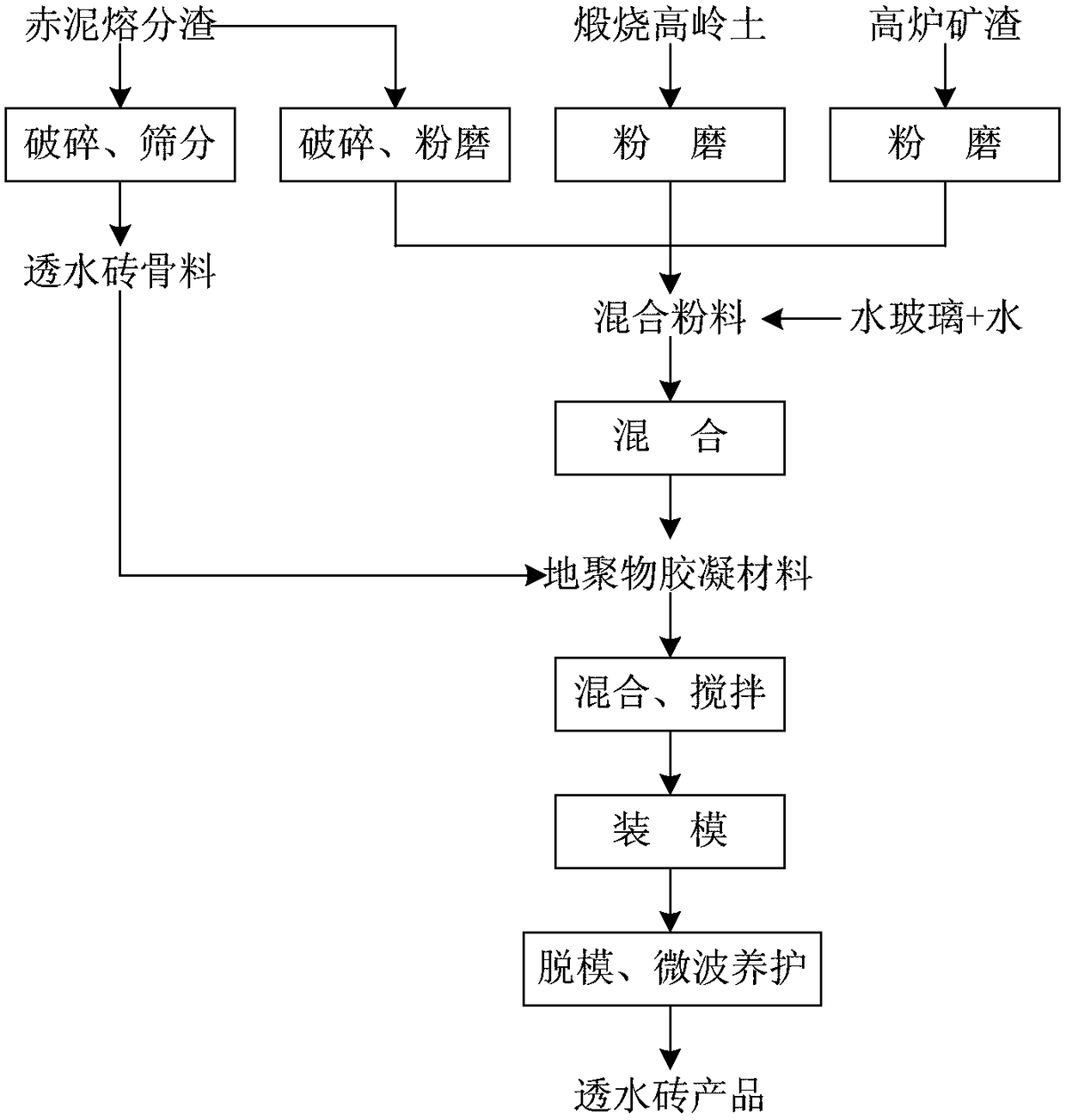

Preparation method of geopolymer-based permeable brick

PendingCN108117321AIncrease dosageSolve the accumulationSolid waste managementCement productionBrickSlag

The invention discloses a preparation method of a geopolymer-based permeable brick. The preparation method comprises the following steps: crushing and screening first red mud slag to obtain permeablebrick aggregate; uniformly mixing crushed, screened and ground second red mud slag, ground calcined kaolin and ground blast furnace slag to obtain mixed powder; uniformly mixing and stirring the mixedpowder, an activator and water to obtain a geopolymer cementing material; adding the geopolymer cementing material into the permeable brick aggregate, stirring, then filling into a mould, and moulding to a semifinished geopolymer-based permeable brick; and curing the obtained semifinished geopolymer-based permeable brick at room temperature, then demoulding to obtain the demoulded semifinished geopolymer-based permeable brick, and curing the demoulded semifinished geopolymer-based permeable brick by using microwave to obtain the finished geopolymer-based permeable brick. By the preparation method, the consumption of cement and the emission of CO2 greenhouse gas are reduced; and the obtained geopolymer-based permeable brick has excellent strength and a long service life.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

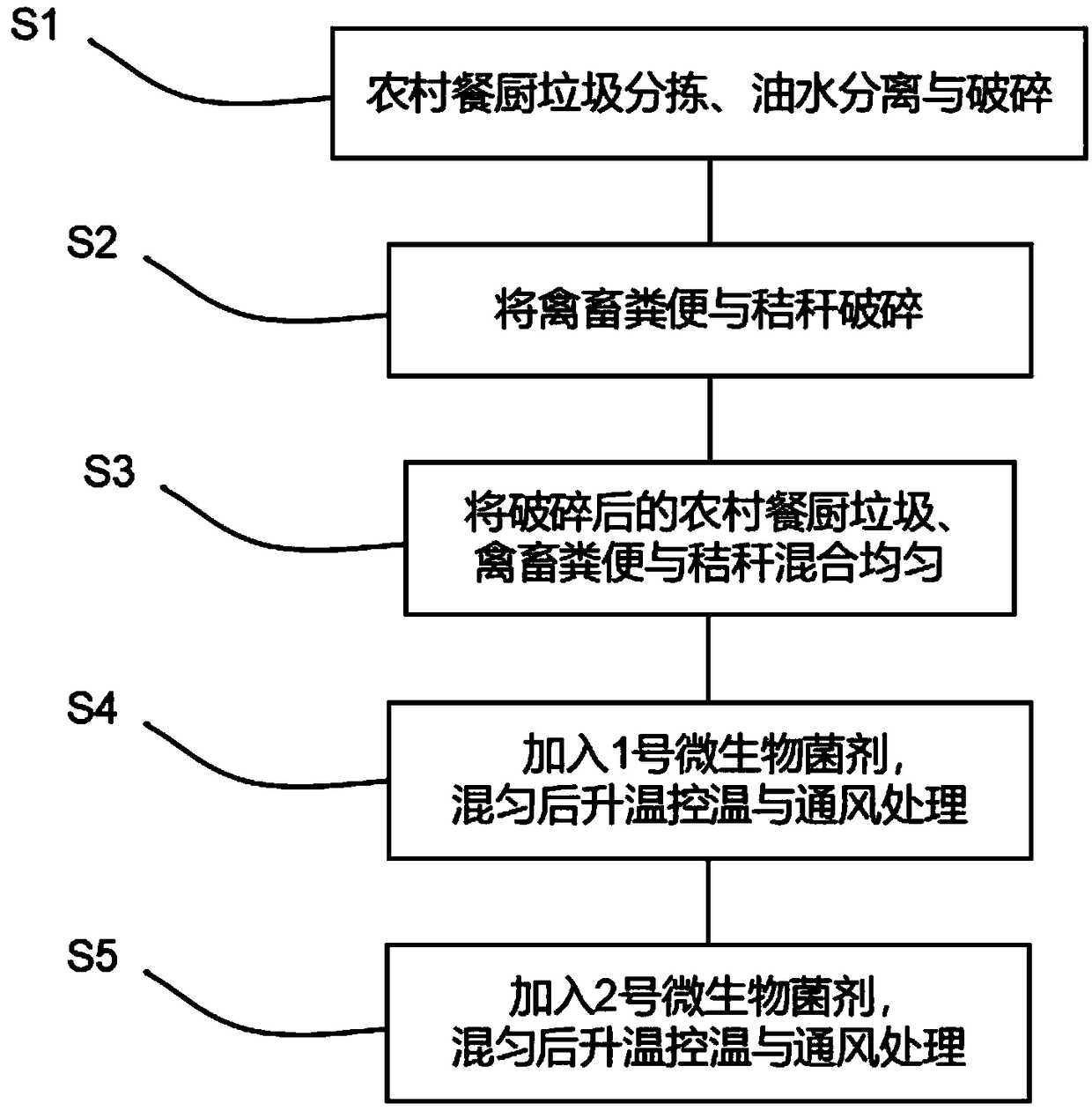

Method for high-temperature efficient aerobic composting of rural organic wastes

InactiveCN109503219AEfficient use ofReduce releaseBatteries circuit arrangementsClimate change adaptationLitterMicrobial agent

The invention relates to the technical field of rural waste treatment and specifically relates to a method for high-temperature efficient aerobic composting of rural organic wastes. The method comprises the following steps: treating rural kitchen wastes in the manner of sorting, oil-water separation and breaking; uniformly mixing the treated rural kitchen wastes with broken animal dung and strawsat a certain ratio, thereby forming a composting material; adding a defined amount of No.1 microbial agent, uniformly mixing and then increasing temperature, controlling temperature and aerating; adding a defined amount of No.2 microbial agent, uniformly mixing and then increasing temperature, controlling temperature and aerating, thereby forming an organic fertilizer. According to the invention,a high-quality fertilizer can be acquired by harmlessly and stably recycling the rural organic wastes within a short period of time. The technology is simple and can be easily popularized.

Owner:SUN YAT SEN UNIV

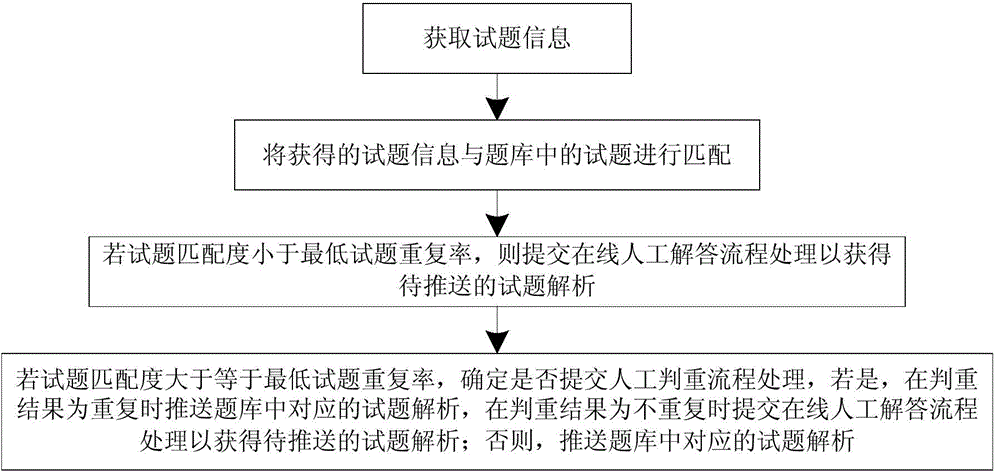

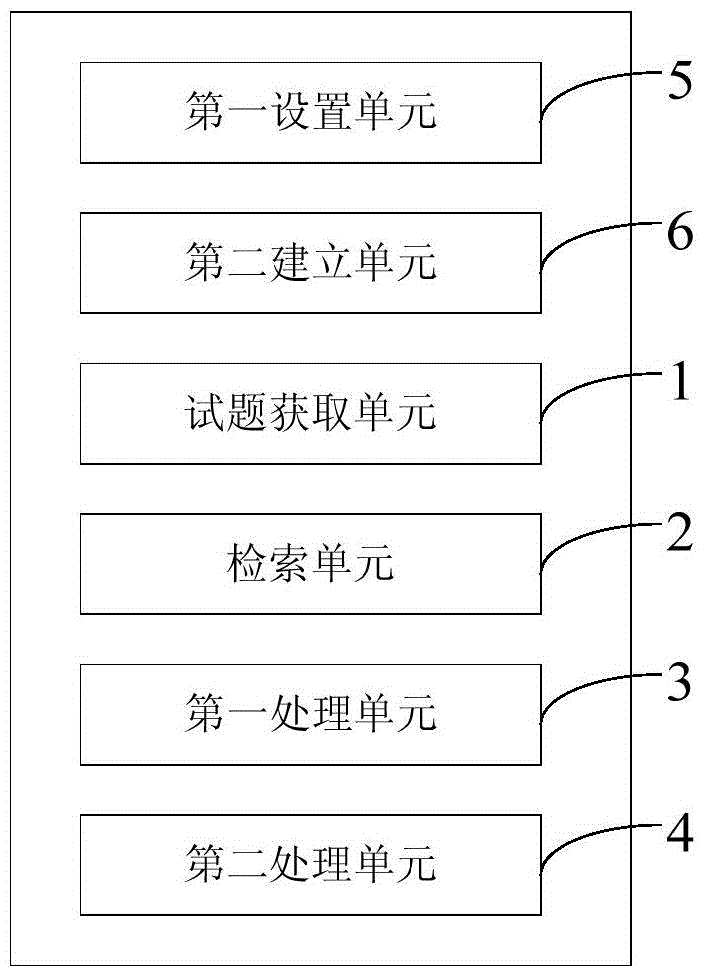

Examination question duplicate checking and judging method and device

ActiveCN104657923ASolve efficiency problemsResolve accuracyData processing applicationsTeaching apparatusLearning machineQuestion analysis

The invention relates to an examination question duplicate checking and judging method and device. The method comprises the following steps: acquiring the information of examination questions; matching the acquired information of the examination questions with the examination questions in a question bank; if the matching degree of the examination questions is lower than minimum repetition rate of the examination questions, submitting the examination questions to on-line manual answering process for treatment to acquire to-be-pushed examination question analysis; if the matching degree of the examination questions is greater than or equal to minimum repetition rate of the examination questions, confirming whether to submit the examination questions to manual duplicate judging process for treatment or not; if the examination questions are submitted to the manual duplicate judging process, pushing the corresponding examination question analysis in the question bank when the duplicate judging result is repetitive; submitting the examination questions to the on-line manual answering process for treatment to acquire to-be-pushed examination question analysis when the duplicate judging result is not repetitive; otherwise, pushing the corresponding examination question analysis in the question bank. Through the combination of two manners of an image recognition technology and manual duplicate judging, the problem that teachers answer repetitive examination questions and repetitive examination questions are accumulated in the question bank due to immaturity of current image recognition technologies is solved; burden of manual answering questions is reduced; the method and device can be applied to educational electronic products of learning machines, and the like.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Tailing pond reclamation greening method

InactiveCN104106324AEasy accessSolve the problem of tailings accumulationSoil lifting machinesSoil-working methodsEcological environmentGreening

The invention discloses a tailing pond reclamation greening method. The tailing pond reclamation greening method includes: selecting mine waste tailings and adding modifying agents of peat soil and sawdust to modify the tailings, wherein the volume proportion of the base materials of the tailings, the peat soil and the sawdust is 2-4:0.8-1.2:0.8-1.2, 20g / m<2>-30g / m<2> of water retaining agents are added in the base materials, and reclamation greening operation is performed on mine waste land by using the base materials. Accordingly, not only are good ecological reclamation greening effects achieved, but also accumulation quantity of the tailings in a mine and harm from the tailings to mine ecological environment are effectively reduced, and furthermore soil is not used in the base materials, and therefore the disadvantage that secondary damage is caused to the environment due to the fact that replacement soil is used as growth base material of plants in a traditional replacement soil spraying greening method is avoided.

Owner:CENT SOUTH UNIV

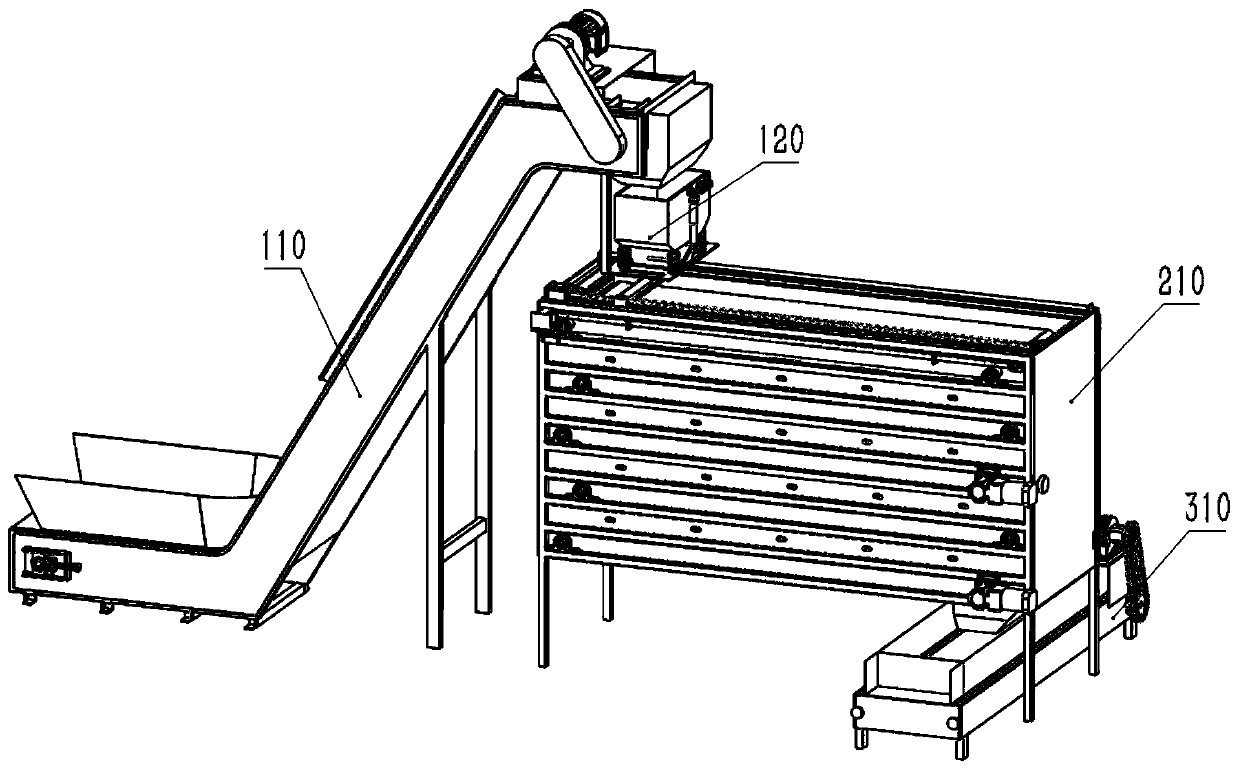

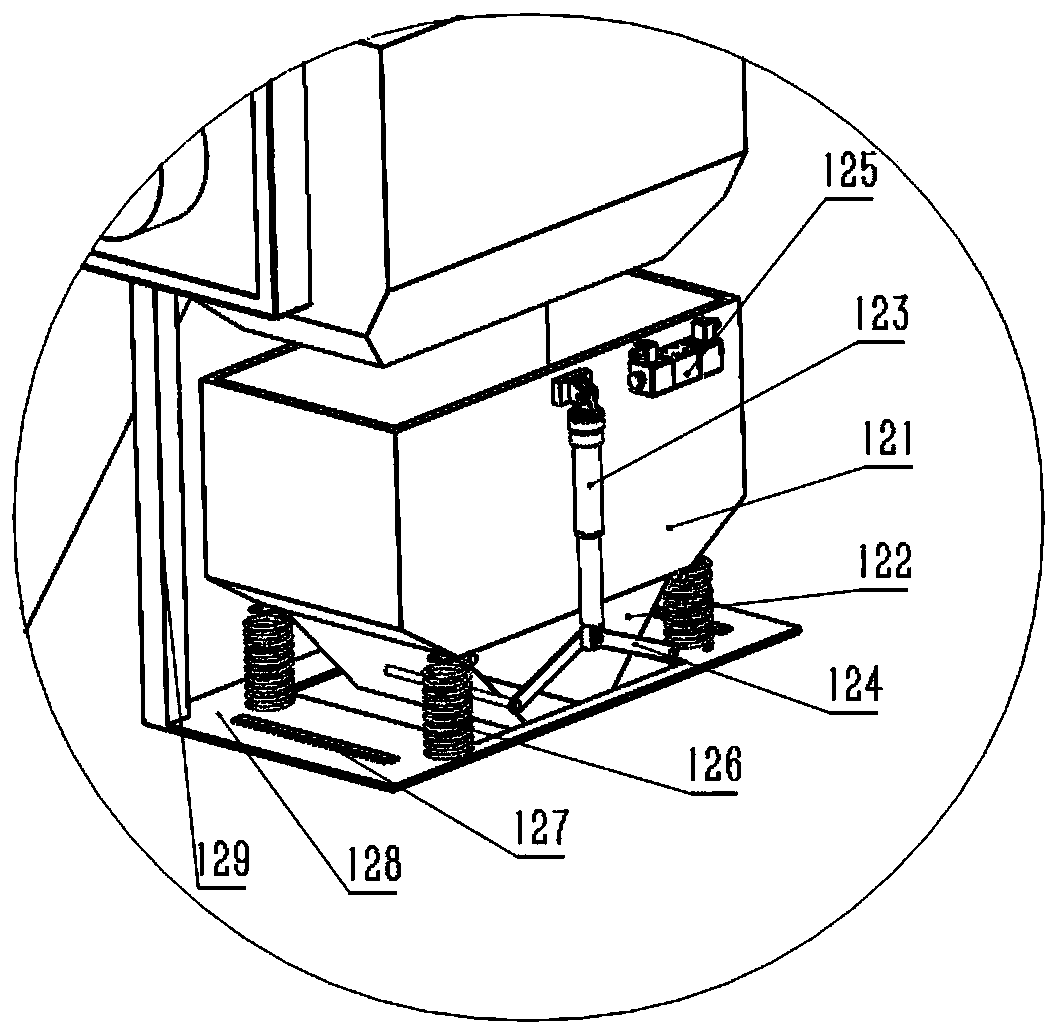

Multi-layer conveying belt tea leaf fragrance extraction machine and control method

PendingCN111217080AGuaranteed uniformityAchieve uniformitySievingConveyorsAgricultural engineeringTea leaf

The invention relates to a multi-layer conveying belt tea leaf fragrance extraction machine and a control method. The fragrance extraction machine comprises a PLC control unit, an automatic tea leaf feeding unit, a fragrance extraction and baking unit and an automatic tea leaf discharging unit, wherein the automatic tea leaf feeding unit comprises a vertical elevator and an automatic tea leaf weighing device, and the fragrance extraction and baking unit comprises a transferring conveying belt, a transverse leaf evening device, a longitudinal leaf evening device and a multi-layer conveying beltbaking unit; and the transferring conveying belt is arranged below a discharge port of the automatic tea leaf weighing device and conveys tea leaves to the multi-layer conveying belt baking unit, thetransverse leaf evening device moves in the length direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, the longitudinal leaf evening device moves in the width direction of the transferring conveying belt to evenly scrape the tea leaves on the transferring conveying belt, and the multi-layer conveying belt baking unit comprises a plurality of layers of conveying belts for conveying the tea leaves from top to bottom and heating baking units arranged on the two sides of the conveying belts. The multi-layer conveying belt tea leaf fragrance extraction machine and the control method solve the problem that the tea leaves are stacked on the conveying belts, and guarantees the tea leaf baking uniformity.

Owner:ANHUI AGRICULTURAL UNIVERSITY

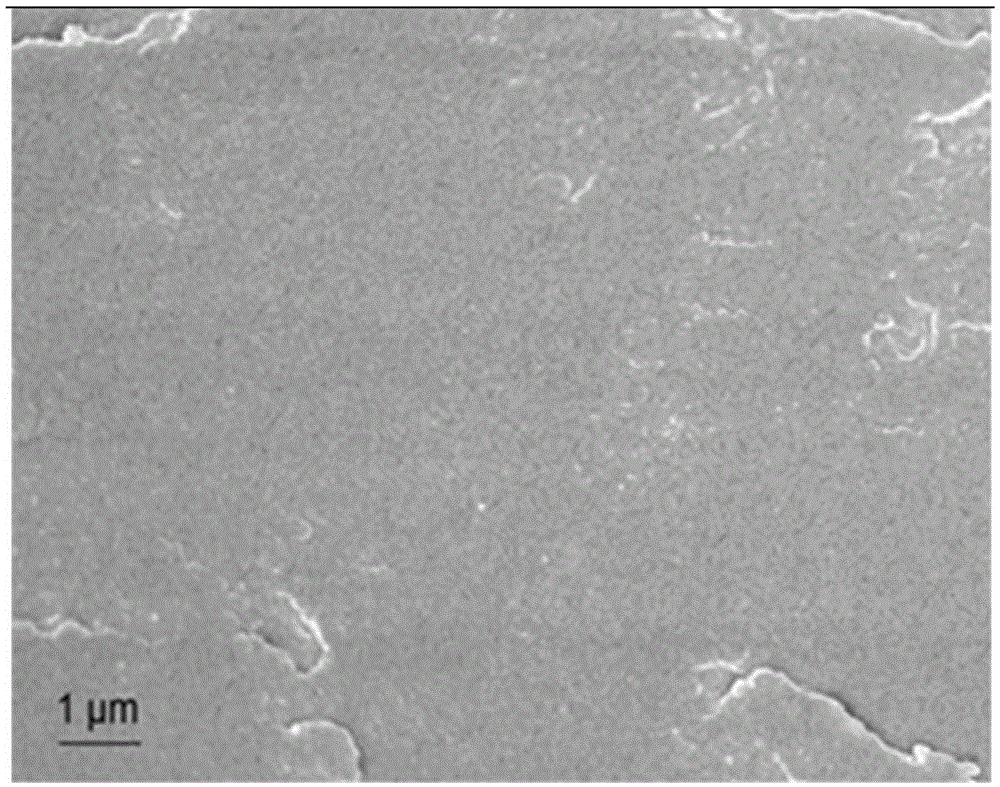

TiO2-loaded graphene oxide sheet layer material and preparation method thereof

The invention discloses a TiO2-loaded graphene oxide sheet layer material. A preparation method of the TiO2-loaded graphene oxide sheet layer material comprises the following steps of 1 graphene oxide preparing; 2 modified TiO2 preparing; 3 TiO2-GO preparing, wherein 0.05 g of modified TiO2 is weighed and added into 100 mL of DMF, ultrasonic dispersion is performed for 15 min, graphene oxide is continuously added, ultrasonic dispersion is performed for 15 min, stirring reacting is performed at 105 DEG C for 5 h, centrifugation is performed, solid matter is washed with absolute ethyl alcohol, the solid is placed in a 60-DEG C vacuum oven to be dried for 24 h, grinding is performed to obtain the TiO2-loaded graphene oxide sheet layer material, and the weight ratio of the added modified TiO2 to the graphene oxide is 1:2-5. The product prepared through the preparation method has the better compatibility and dispersibility when the product is applied to an epoxy coating.

Owner:SOUTHWEST PETROLEUM UNIV

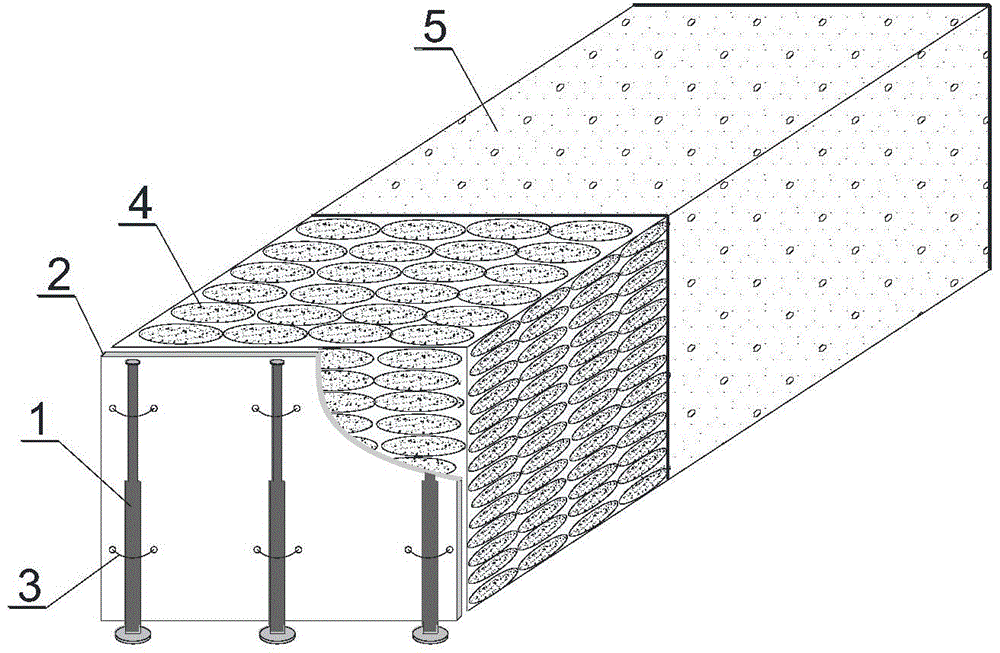

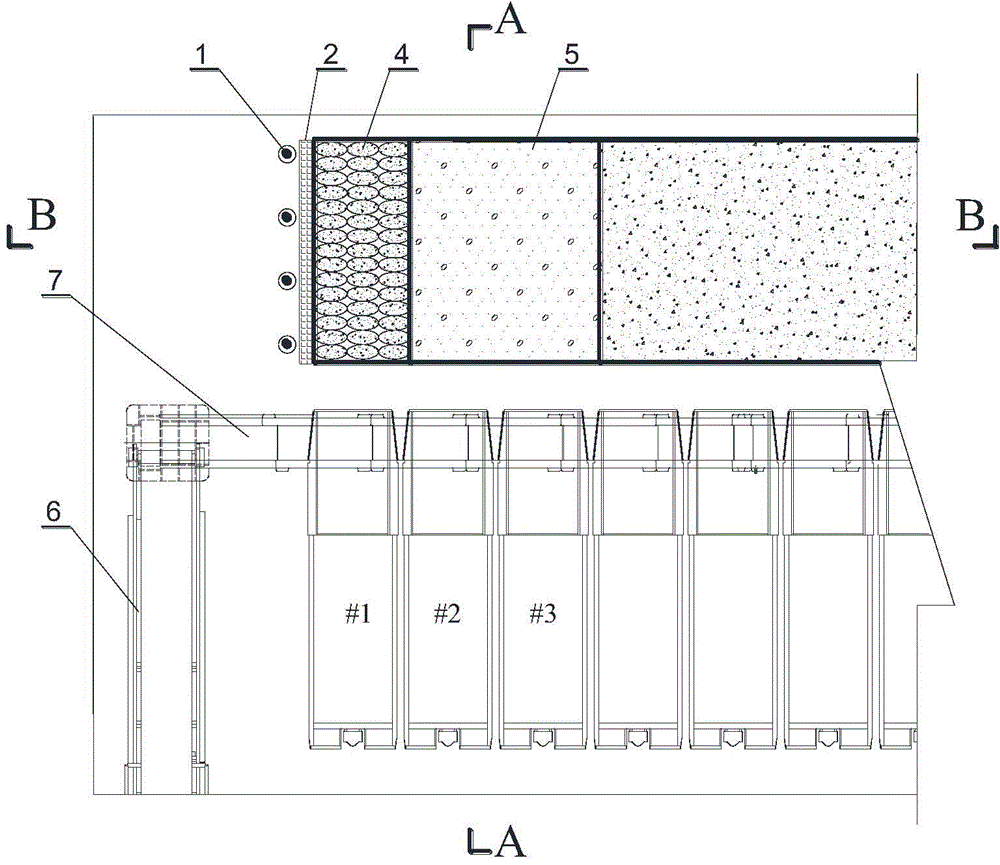

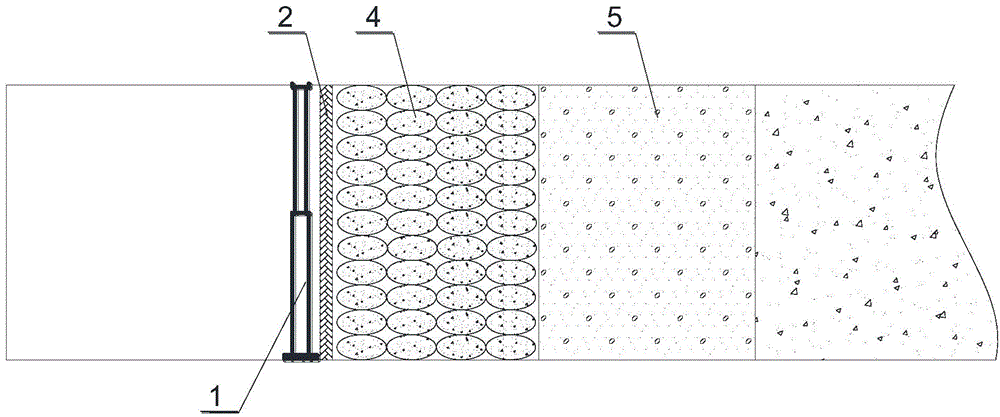

Construction method of gob-side entry retaining wall of solid filling coal mining

InactiveCN104088662AImprove recovery rateSave excavation costsMaterial fill-upSingle supportRetaining wall

The invention discloses a construction method of a gob-site entry retaining wall of solid filling coal mining. The retaining wall is composed of a gangue-piled wall and a compact cementing filling body. The construction method comprises the following steps: cleaning float coal close to an end head after mining and removing frame at a working face; arranging a row of single supporting columns at inner side of a roadway, close to a gob; arranging a wooden backboard at the gob side, close to the single supporting columns; connecting the backboard with the top and bottom; fixing the backboard to the single supporting columns through iron wires; piling the gangue wall at the gob side, close to the backboard; filling the gangue and cement mixing filling material into the gob at the back of two brackets of the gangue-piled wall after the gangue wall is piled; compacting through a rammer compactor to form the compact cementing filling body. With the adoption of the method, the recovery ratio of coal resources can be raised; in addition, the operation at the filling working surface is simple and convenient to carry out, and is also safe and reliable, and high practicability is also brought.

Owner:CHINA UNIV OF MINING & TECH +1

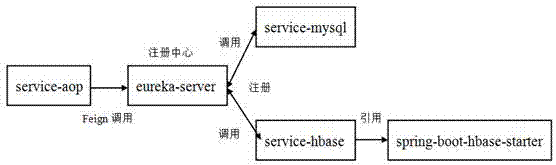

Establishment method for aop (Aspect Oriented Programming) interception type HBase data storage microservice architecture

ActiveCN108011768AEasy to expandReduce intrusionDatabase management systemsData switching networksMicroservicesData store

The invention discloses an establishment method for aop (Aspect Oriented Programming) interception type HBase (Hadoop Database) data storage microservice architecture. According to the method, an oldsystem employing a traditional relationship type mysql database is abstracted to a service module. In a new microservice architecture system, data storage of add*() and save*() methods is interceptedthrough aop, and data is written into an HBase database through an HBase service module. Code invasion to an original system is reduced to a great extent. A new microservice architecture system is beneficial for expansion of new business and is easy to be expanded into a distributed architecture system.

Owner:HANGZHOU DIANZI UNIV

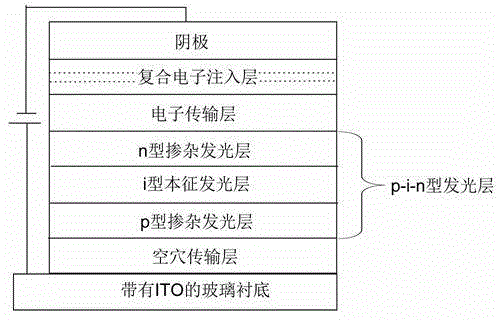

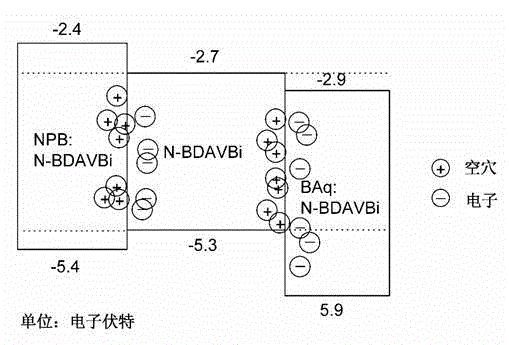

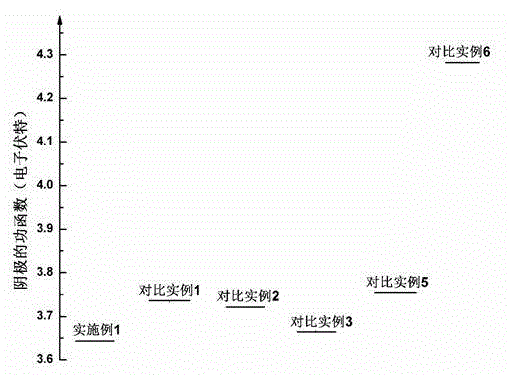

Low-voltage and high-efficiency organic LED and preparation method thereof

InactiveCN104409649ALower injection barrierImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceMaterials science

The invention provides a low-voltage and high-efficiency organic LED. The low-voltage and high-efficiency organic LED comprises a glass substrate with an ITO, a hole-transmission layer, a p type doped luminescence layer, an i type intrinsic luminescence layer, an n type doped luminescence layer, an electronic transmission layer, a composite electron injection layer and a cathode which are sequentially overlapped to form an overlapping layer; the p type doped luminescence layer is prepared through hole transmission material in which blue fluorescent dye is doped; the i type intrinsic luminescence is prepared through blue fluorescent dye; the n type doped luminescence layer is prepared through the electron transmission material in which blue fluorescent dye is doped; the three luminescence layers are named p-i-n type luminescence layer; and the composite electronic injection layer is prepared through cesium carbonate in which a thin aluminum layer is inserted. The low-voltage and high-efficiency organic LED has the advantages that the composite electron injection layer with a thin aluminum layer inserted into the cesium carbonate layer and the p-i-n type luminescence layer are arranged, so that the luminescence efficiency is improved, and the reduction of the efficiency is delayed; the driving voltage is low, the luminance is high, the efficiency is high, the stability is improved, and the preparation process is simple.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

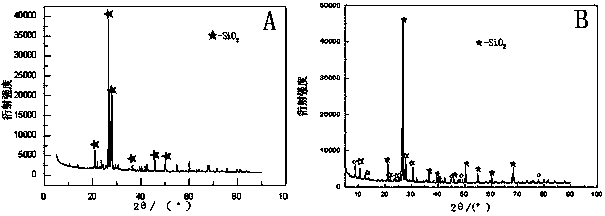

Method for preparing inorganic mineral polymers through lead and zinc mine tailings

InactiveCN104003632AGood heat insulation at high temperatureIncreased durabilityCement productionMining engineeringMetakaolin

The invention discloses a method for preparing inorganic mineral polymers through lead and zinc mine tailings. The method includes the steps that activating treatment is carried out on the lead and zinc mine tailings through the wet-process alkalize calcination, alkali-activator is added for inorganic polymerization reaction after metakaolin and sand are added and stirred, the inorganic mineral polymers of a net structure are formed, and a foaming agent and a foam stabilizer can be added into the obtained inorganic mineral polymers to be further prepared into foamed inorganic mineral polymers. The obtained finished inorganic mineral polymers are good in durability, have good high temperature heat insulating property, will not release poisonous substances even when exposed in flame, and can be used for backfill and sealing after a mine is mined, building materials and other aspects. Not only can the stacking problem of the lead and zinc mine tailings be effectively solved and environmental pollution be reduced, but also a new path is developed for developing and utilizing waste lead and zinc mine tailings in China, a new exploration direction is provided for relevant research on recycling of tailings, and the method has a great significance to energy conservation, emission reduction, environmental protection, waste utilization and creation of the environment-friendly society.

Owner:FUZHOU UNIV

Outburst-prevention, dust collection and slag discharging integrated device for coal roadway drilling construction

InactiveCN104453751AMeet drilling requirementsRealize integrationConstructionsGas removalSlagEngineering

The invention discloses an outburst-prevention, dust collection and slag discharging integrated device for coal roadway drilling construction. The device comprises a drilling machine system, a hydraulic system, a compressed air system and a power supply system and further comprises an orifice dust collection device, a movable outburst-prevention baffle, a hydraulic automatic feeding device, a fixed connection device, a dust removal and slag discharging device, a hydraulic branch system and a compressed air branch system. A compressed air branch connector is formed in the upper portion of the rear end of the orifice dust collection device, a slag discharging pipe is arranged below the compressed air branch connector and inclined downwards, the movable outburst-prevention baffle is fixed to the orifice dust collection device, the hydraulic automatic feeding device is connected with the orifice dust collection device, the fixed connection device fixes the hydraulic automatic feeding device to a drilling machine, and the dust removal and slag discharging device is connected with the slag discharging pipe of the orifice dust collection device through a connecting flexible hose. The integrated device organically combines the outburst-prevention device, the dust collection device and the slag discharging device, the problem that existing orifice-series dust removal device equipment is disperse is effectively solved, multiple functions are achieved through one device, and the integrated device is easy to operate and low in cost.

Owner:HUNAN UNIV OF SCI & TECH

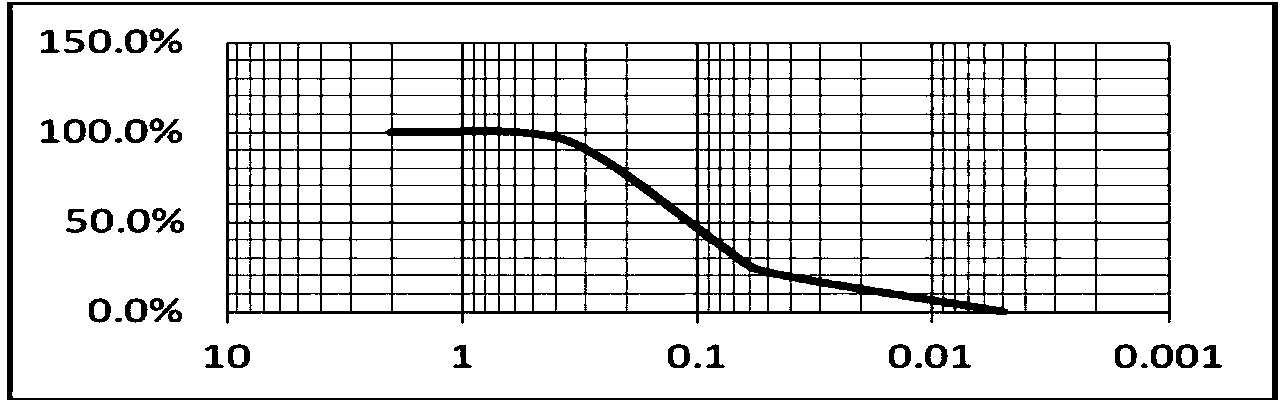

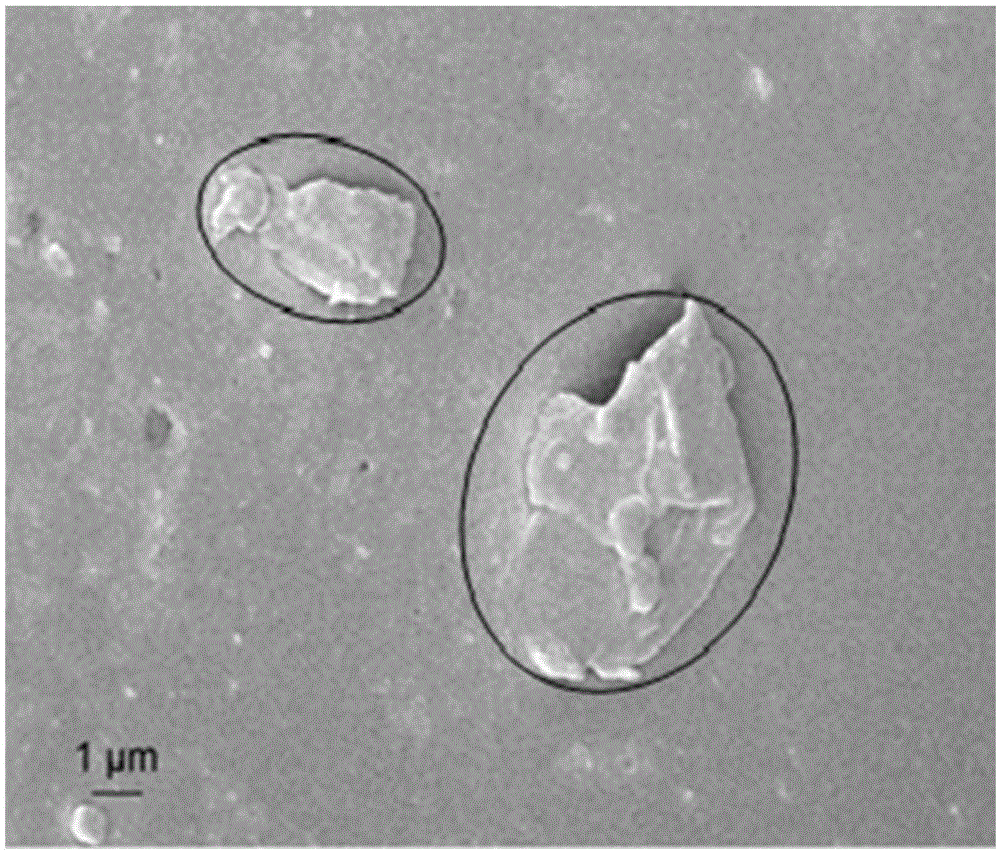

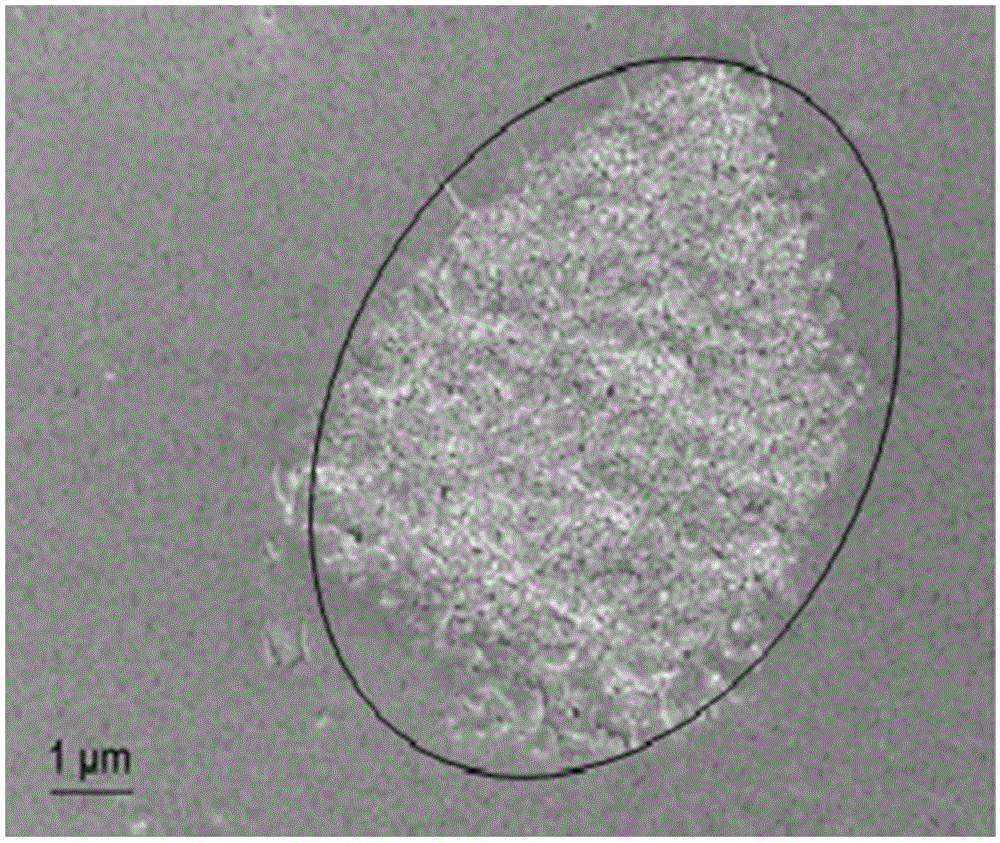

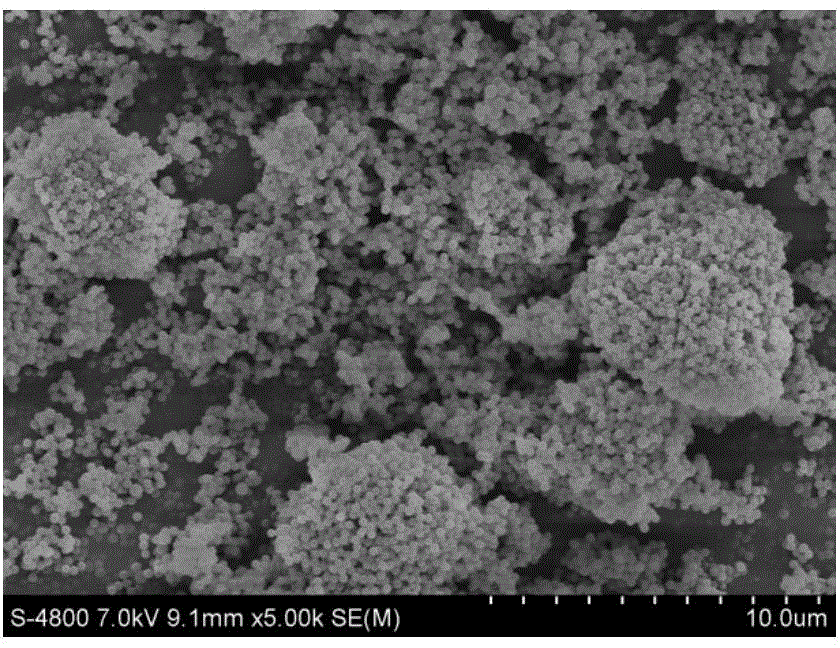

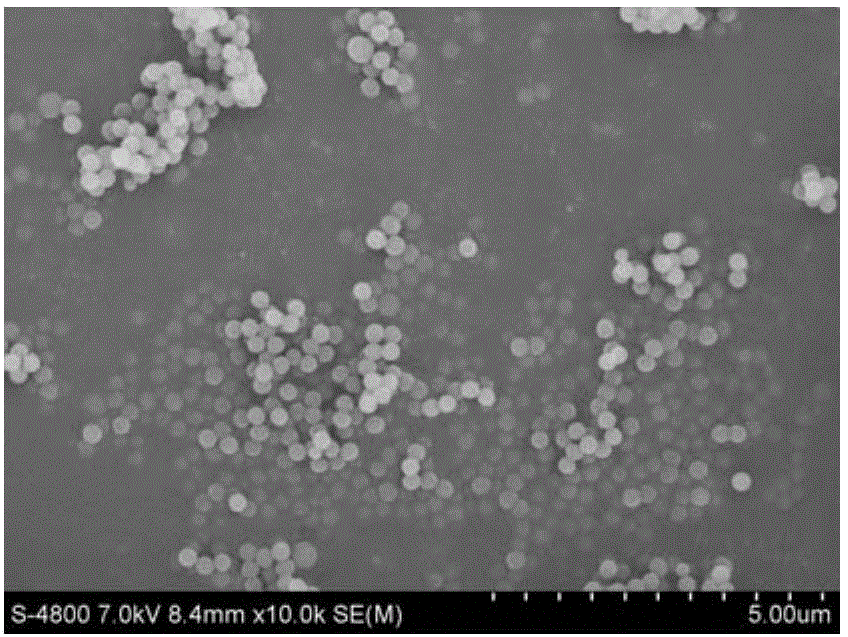

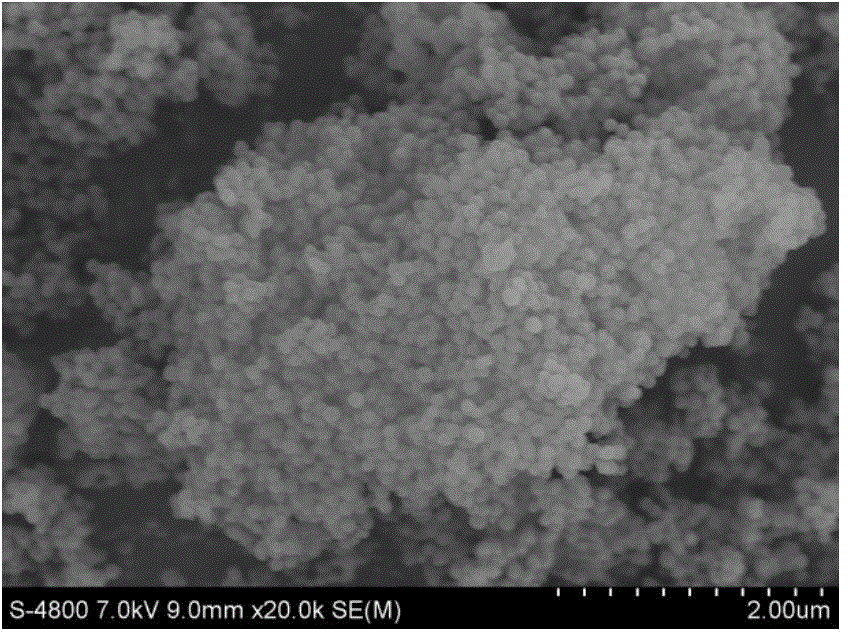

Method for observing morphology of ultrafine powder sample by using scanning electron microscope

InactiveCN104990840ALow costReduce testing costsMaterial analysisScanning tunneling microscopeGranularity

The objective of the invention is to provide an analytical method for observing the morphology of an ultrafine powder sample by using a scanning electron microscope. The method provided by the invention comprises the following steps: 1) adsorbing the ultrafine powder sample by using an electrostatically charged smooth surface of an adsorbate; 2) bonding powder adsorbed onto the adsorbate, i.e., a film, with one side of a double-sided conducting adhesive tape; 3) adhering the other side of the double-sided conducting adhesive tape onto a sample table of the scanning electron microscope; 4) carrying out gold plating on the powder adhered on the double-sided conducting adhesive tape; and 5) carrying out observation with the scanning electron microscope. With the method, a part of powder with a uniform particle size in the ultrafine powder sample can be obtained, the powder adsorbed under the action of electrostatic attraction is fine particles in the ultrafine powder sample, and only particles with similar particle sizes can be adsorbed at the same time, so a picture with uniform granularity can be obtained in observation with the scanning electron microscope.

Owner:OCEAN UNIV OF CHINA

Method for producing copper-containing slag

InactiveCN107641717ARealize comprehensive utilizationSolve the accumulationProcess efficiency improvementThermal stateCopper oxide

The invention relates to a method for producing copper-containing slag. The method comprises the following steps: S1, furnace slag mixing: adding copper slag into a reaction device, and adding a calcium-system mineral and an additive; heating the slag into a molten state, and adding one or more of a copper oxide mineral, a copper sulphide mineral and a copper-containing material; uniformly mixingthe materials to obtain reaction slag, monitoring the reaction slag in real time, and treating the mixed reaction slag through regulation and control to enable the mixed reaction slag to simulatenously meet conditions a and b, thus obtaining reacted slag; S2, separation and recycling. According to the method, both thermal-state slag and cold-state furnace slag can be treated; by full use of moltencopper slag physical thermal resources and a thermal-state metallurgical flux, treatment of copper-containing furnace slag and treatment of the copper oxide mineral are realized; the problem of bulkdeposition of furnace slag at present is solved; simultaneous production of copper and iron is realized; two world problems that the copper oxide mineral is difficult to treat and an iron component isdifficult to recycle are solved; meanwhile, the problems of environmental pollution and heavy metal pollution are solved.

Owner:NORTHEASTERN UNIV

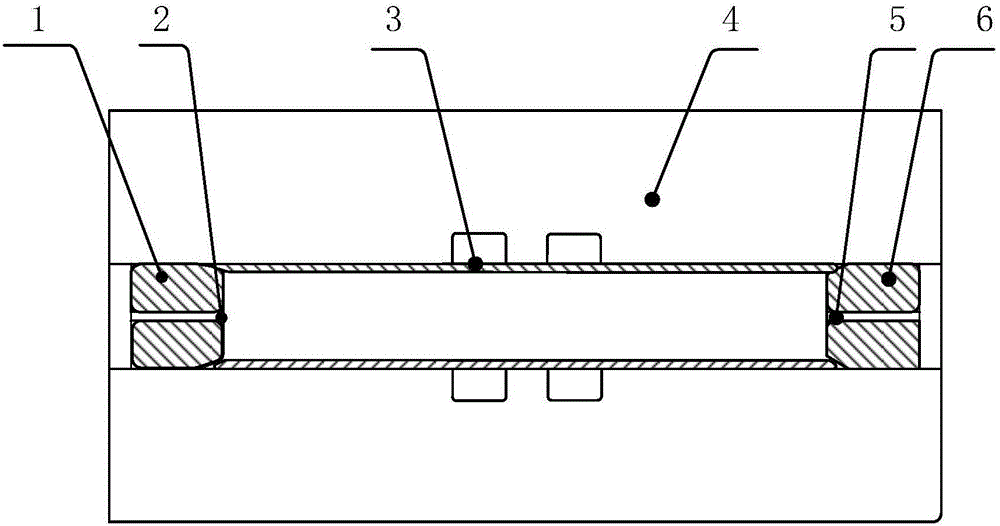

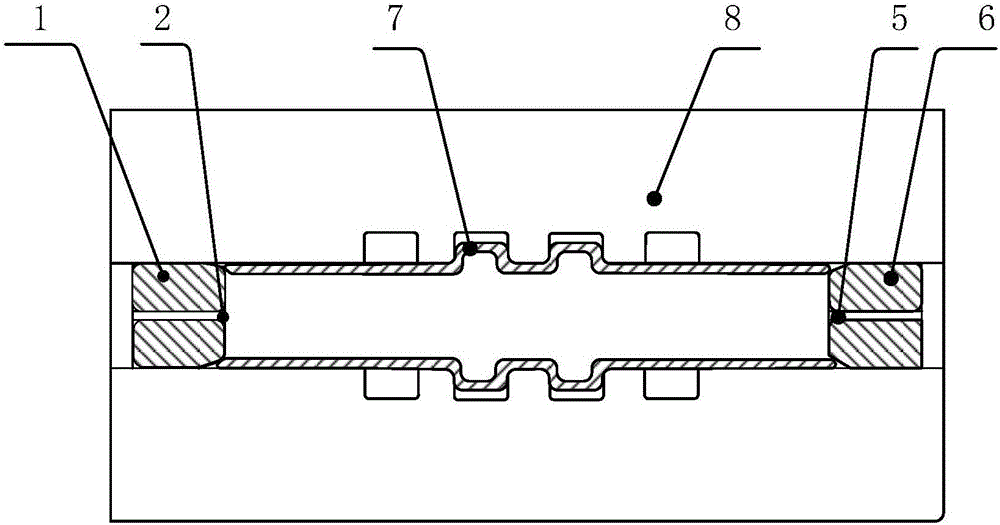

Multistage continuous large deformation part internal high-pressure forming method and device

The invention discloses a multistage continuous large deformation part internal high-pressure forming method and device. The multistage continuous large deformation part internal high-pressure forming device comprises a preforming mold, at least one subsequent forming mold, a left feeding plunger chip, a right feeding plunger chip, a left liquid inlet and a right liquid inlet. The multistage continuous large deformation part internal high-pressure forming method comprises the following steps of: firstly putting an initial pipe billet in the preforming mold, filling high-pressure liquid into the metal pipe billet through a port sealing device, and pushing the left feeding plunger chip and the right feeding plunger chip under the effect of a horizontal cylinder; carrying out preliminary bulging on a material located in the middle under the coordination effect of axial thrust and liquid pressure, wherein the bulging height of the material is 85%-95% of the bulging height of a forming part, and taking out a middle blank after unloading; secondly, putting the middle blank in the subsequent forming mold, and bulging bulged adjacent positions of the middle blank; and carrying out bulging in sequence from the middle to two ends till obtaining a final forming part.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com