Multistage continuous large deformation part internal high-pressure forming method and device

A technology of internal high pressure forming and large deformation, which is applied in the field of advanced manufacturing of metal hollow components, can solve problems such as feeding difficulties, forming problems of multi-stage continuous large deformation parts, accumulation of nozzle materials, etc. The method is simple and feasible, and the effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

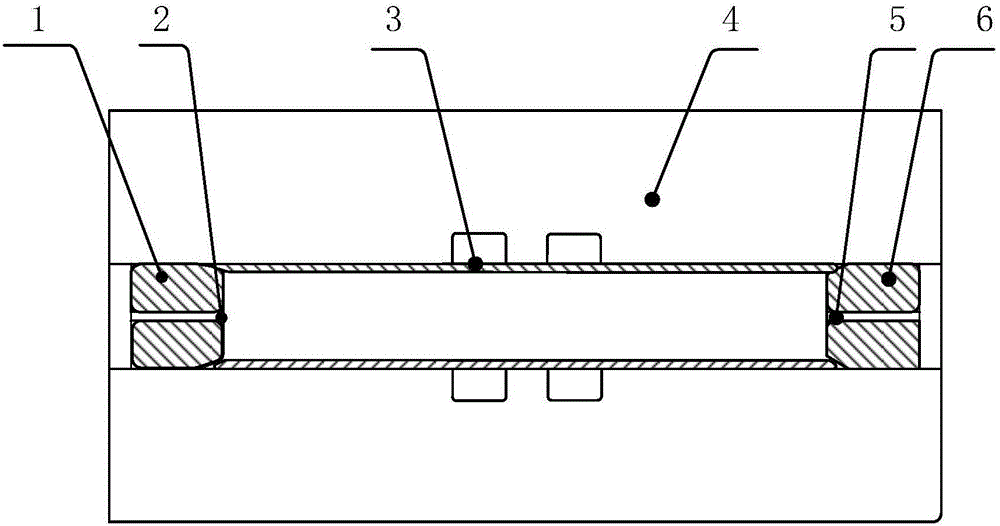

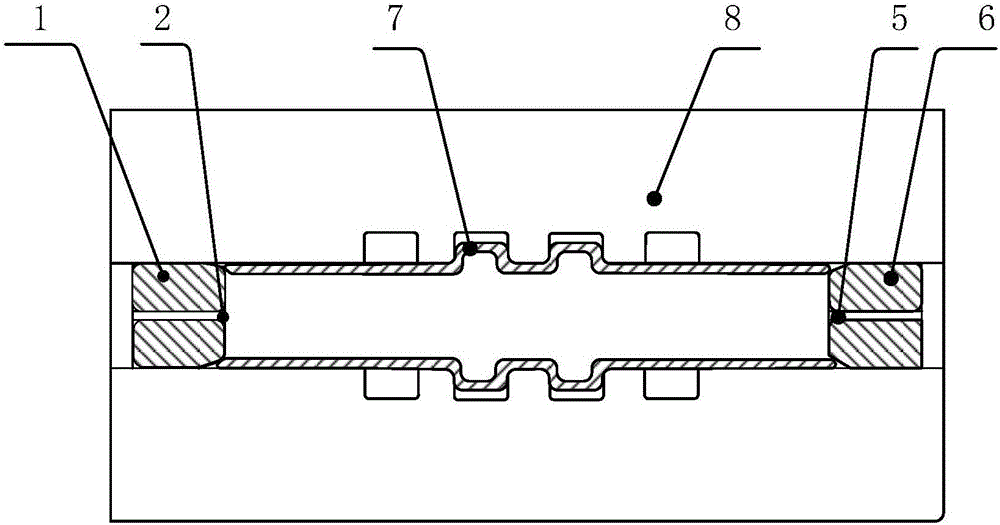

[0036] refer to figure 1 , figure 2 , In this embodiment, the stainless steel pipe fittings with four projections are formed, the two projections in the middle are formed first, and then the two projections on both sides are formed.

[0037] In the first step, put the 304 stainless steel tube blank with a length of 300mm, a diameter of 50mm, and a wall thickness of 2mm into the preforming mold, and the upper and lower molds are closed. The preforming mold has a cavity corresponding to the two protrusions in the middle of the formed part ;

[0038] The second step is to seal the left and right ends of the 304 stainless steel tube blank, and inject high-pressure liquid (water) through the left and right liquid inlets;

[0039] The third step is to use the hydraulic cylinder to push the left and right two feed punches to realize axial feeding, and the height of the two protrusions in the middle is 85%-95% of the protrusion height of the formed part, and the pressure is maintai...

Embodiment 2

[0044] In this embodiment, a stainless steel pipe fitting with three protrusions is formed, and one protrusion in the middle is formed first, and then two protrusions on both sides are formed.

[0045] In the first step, the 304 stainless steel tube blank with a length of 300mm, a diameter of 50mm, and a wall thickness of 2mm and a low-carbon steel tube blank with a length of 300mm, a diameter of 52mm, and a wall thickness of 2mm are exploded and composited to form a composite tube blank, which is put into a preforming mold, and the upper and lower molds Clamping;

[0046]The second step is to seal the left and right ends of the carbon steel / stainless steel bimetal composite tube blank, and inject high-pressure liquid through the left and right liquid inlets;

[0047] The third step is to use the hydraulic cylinder to push the left and right two feed punches to realize axial feeding, and the height of a convex in the middle is 85%-90% of the convex height of the formed part, a...

Embodiment 3

[0052] In this embodiment, the stainless steel pipe fittings with six protrusions are formed. First, the two protrusions in the middle are formed, and then the two protrusions next to the two sides of the middle protrusion are formed, and finally the two outermost protrusions are formed.

[0053] The first step is to put a low carbon steel tube blank with a length of 400mm, a diameter of 40mm and a wall thickness of 2mm into the preforming mold, and the upper and lower molds are closed;

[0054] The second step is to seal the left and right ends of the low-carbon steel billet, and inject high-pressure liquid through the left and right liquid inlets;

[0055] The third step is to use the hydraulic cylinder to push the left and right two feed punches to realize axial feeding. The height of the two protrusions in the middle is 90%-95% of the protrusion height of the formed part, and the pressure is maintained ( 3-5 minutes);

[0056] The fourth step is to release the pressure, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com