Patents

Literature

919results about "Baking vessels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

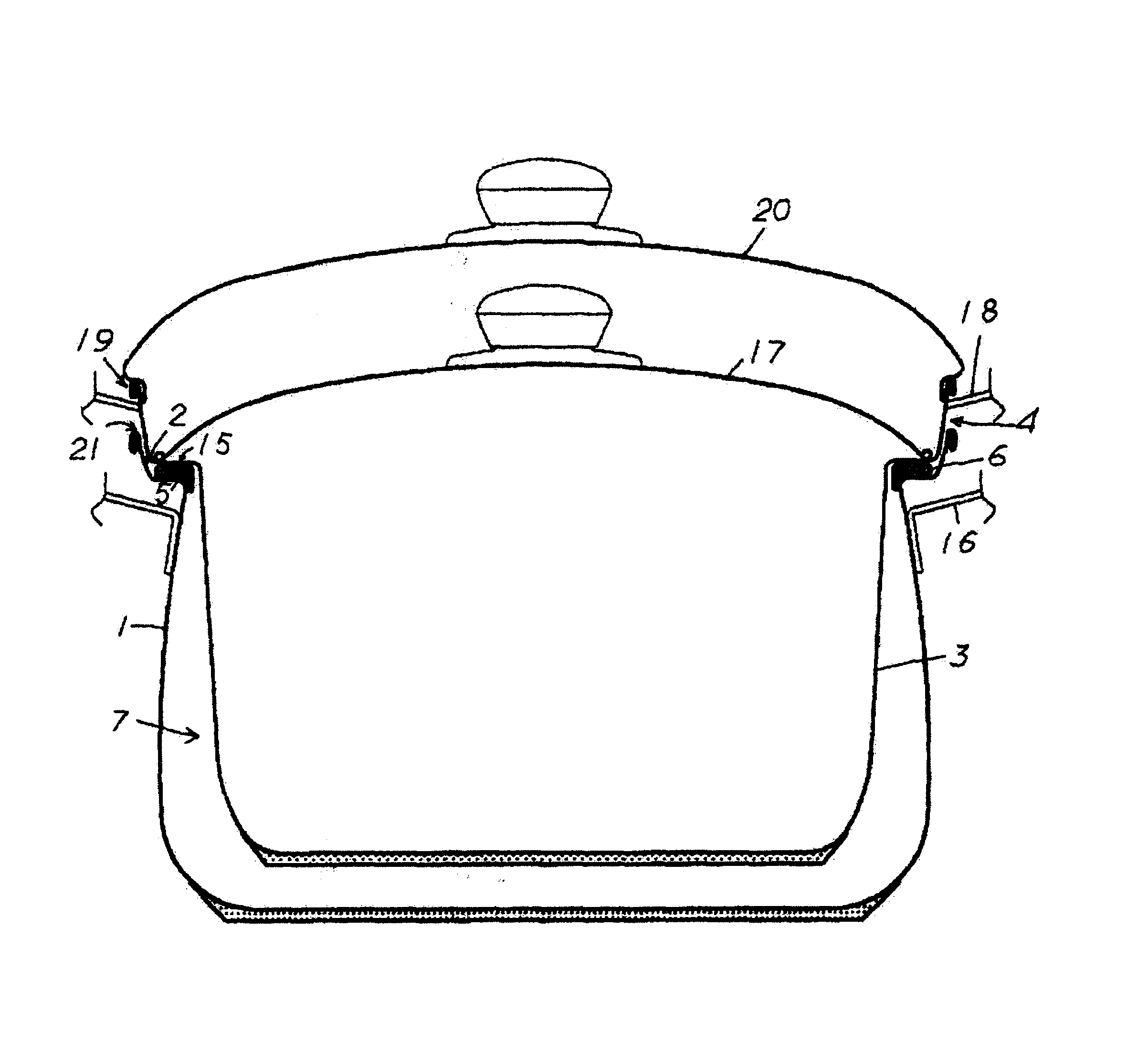

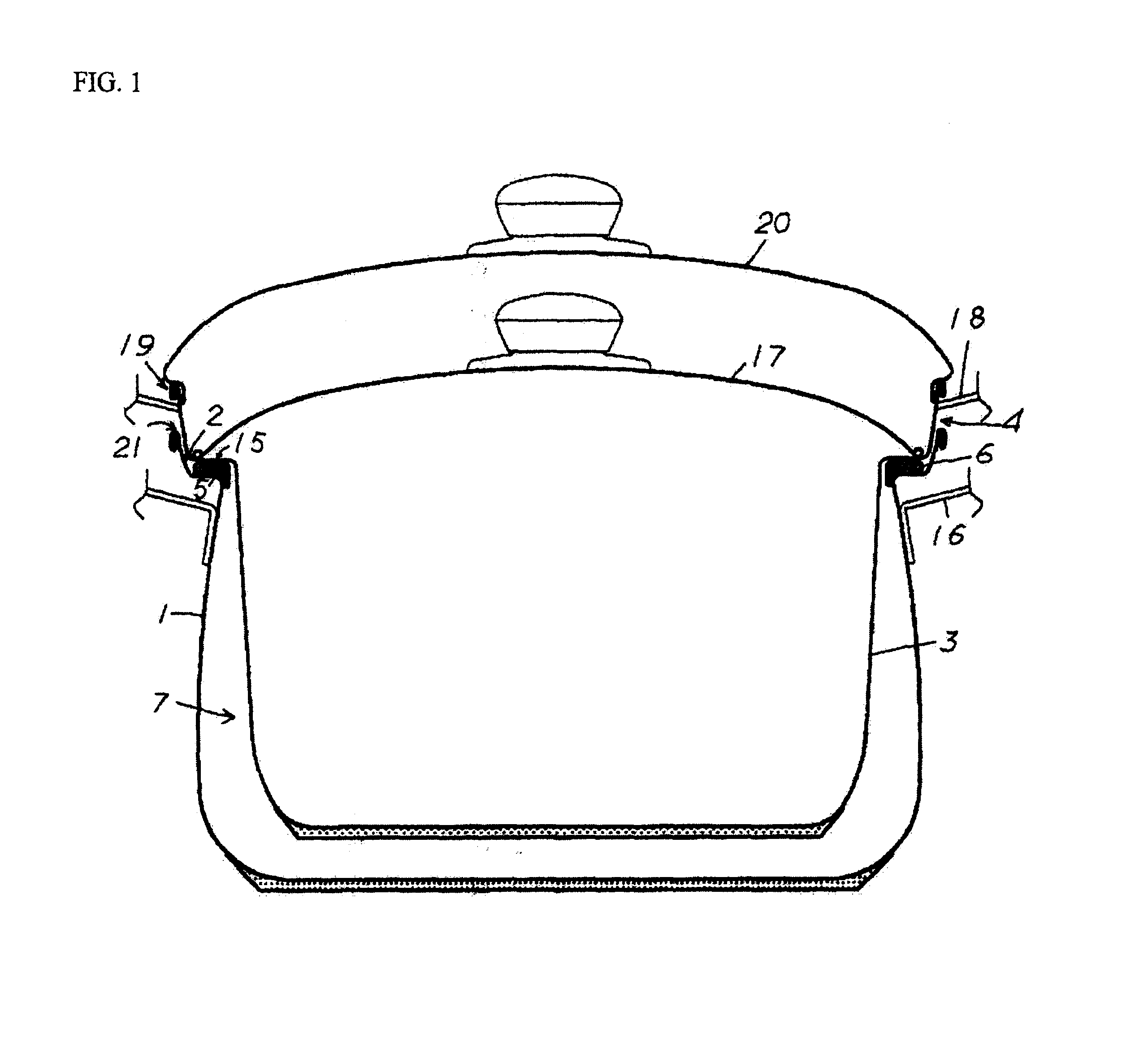

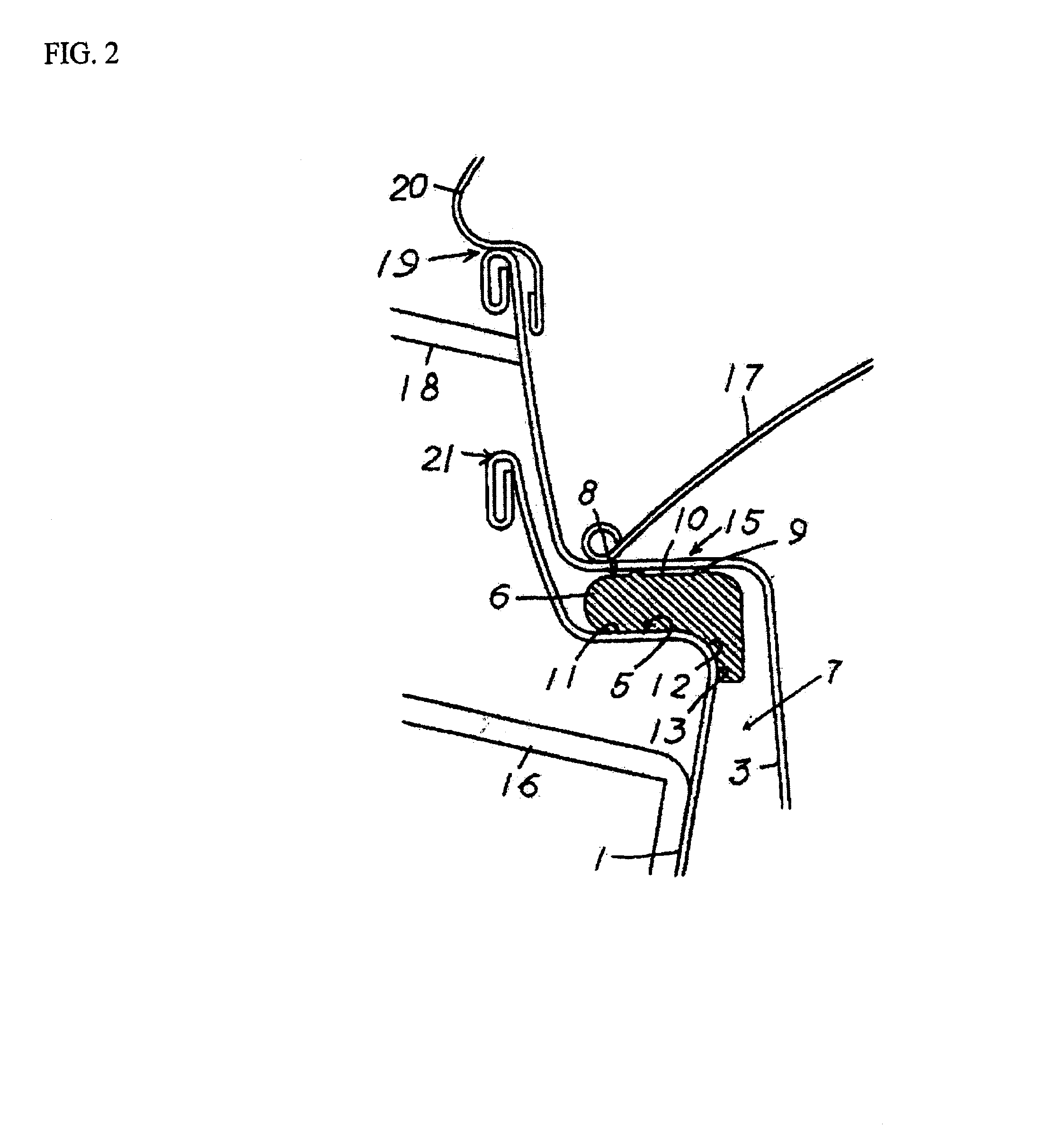

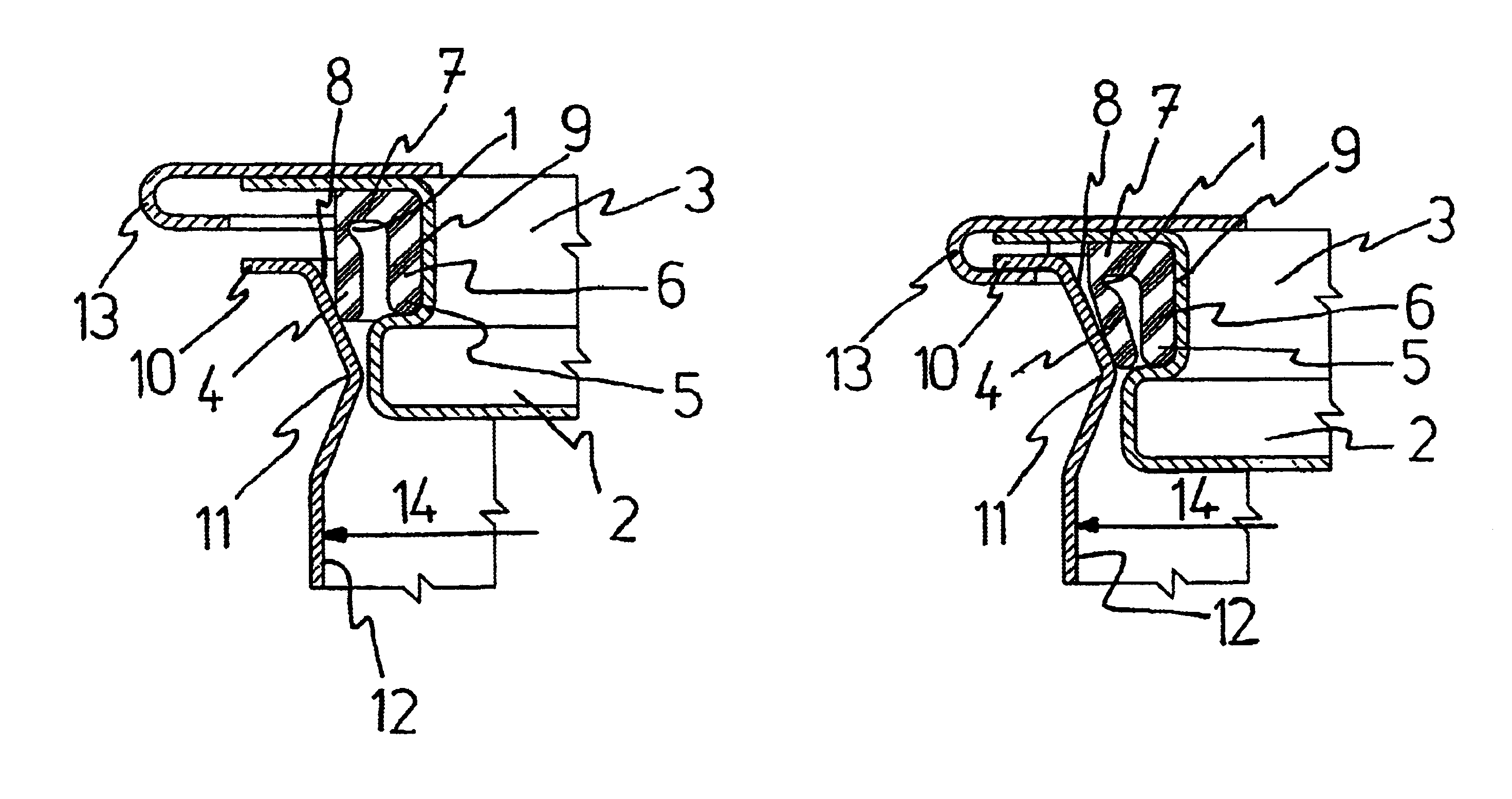

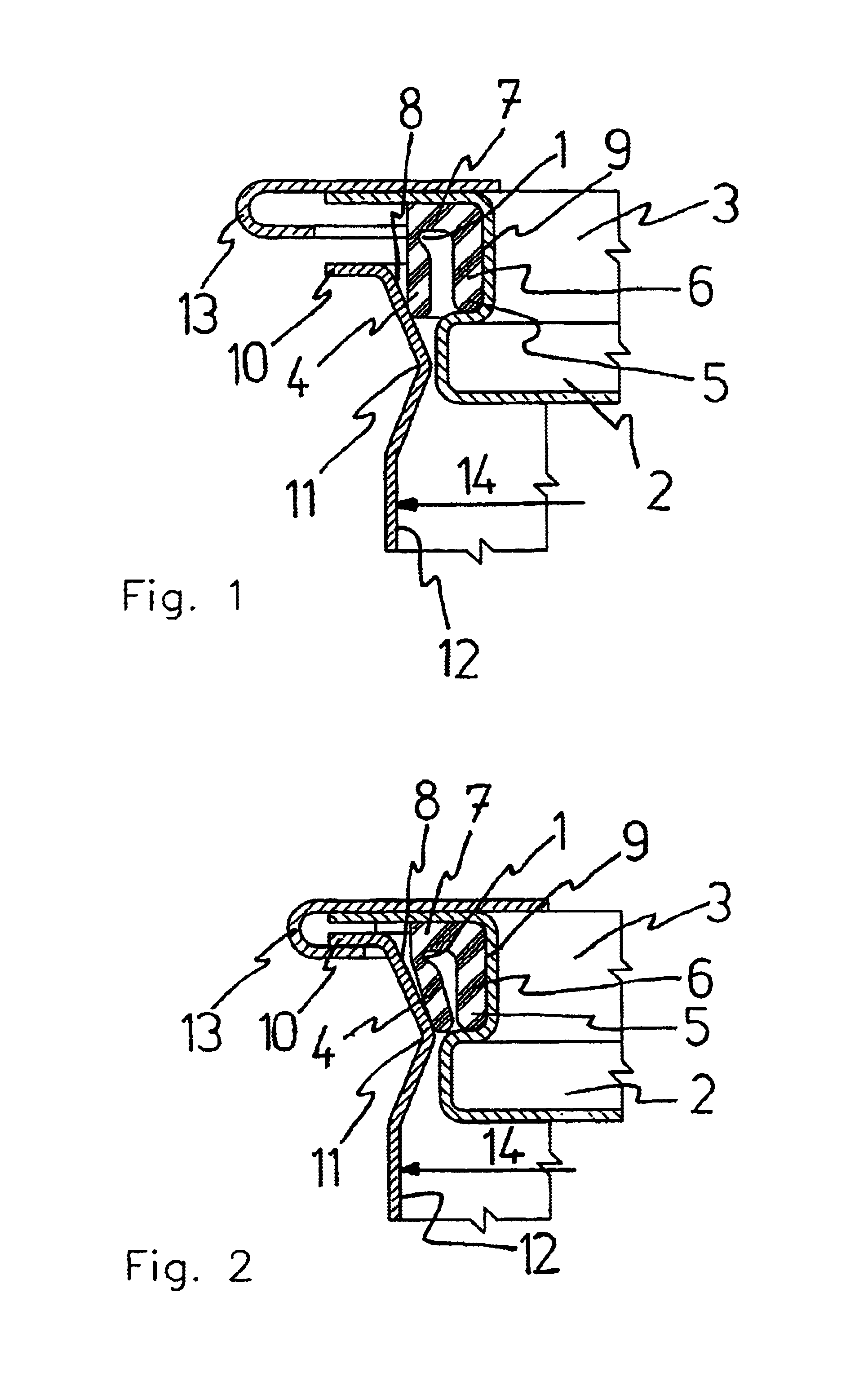

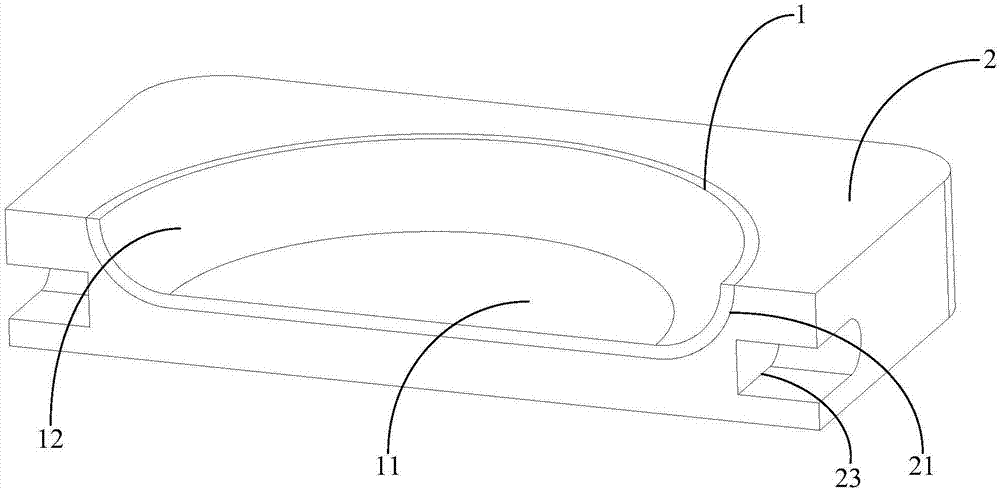

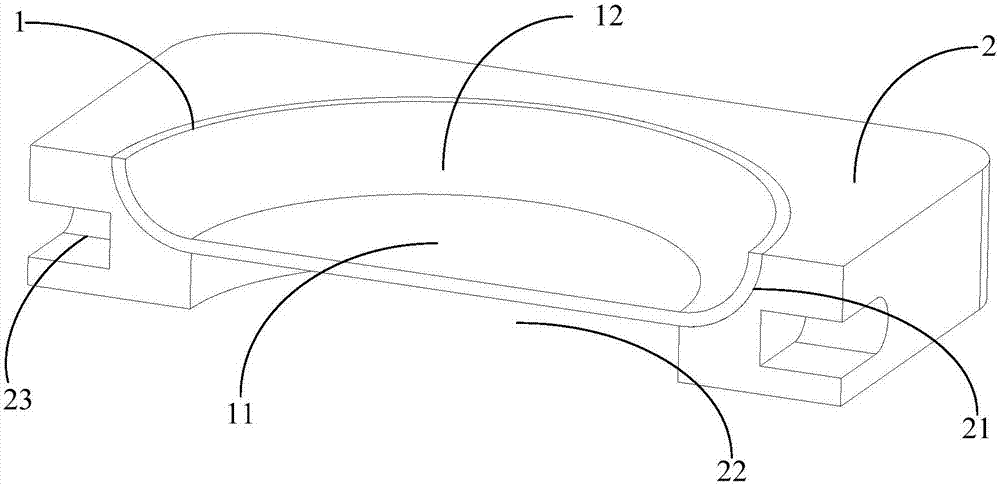

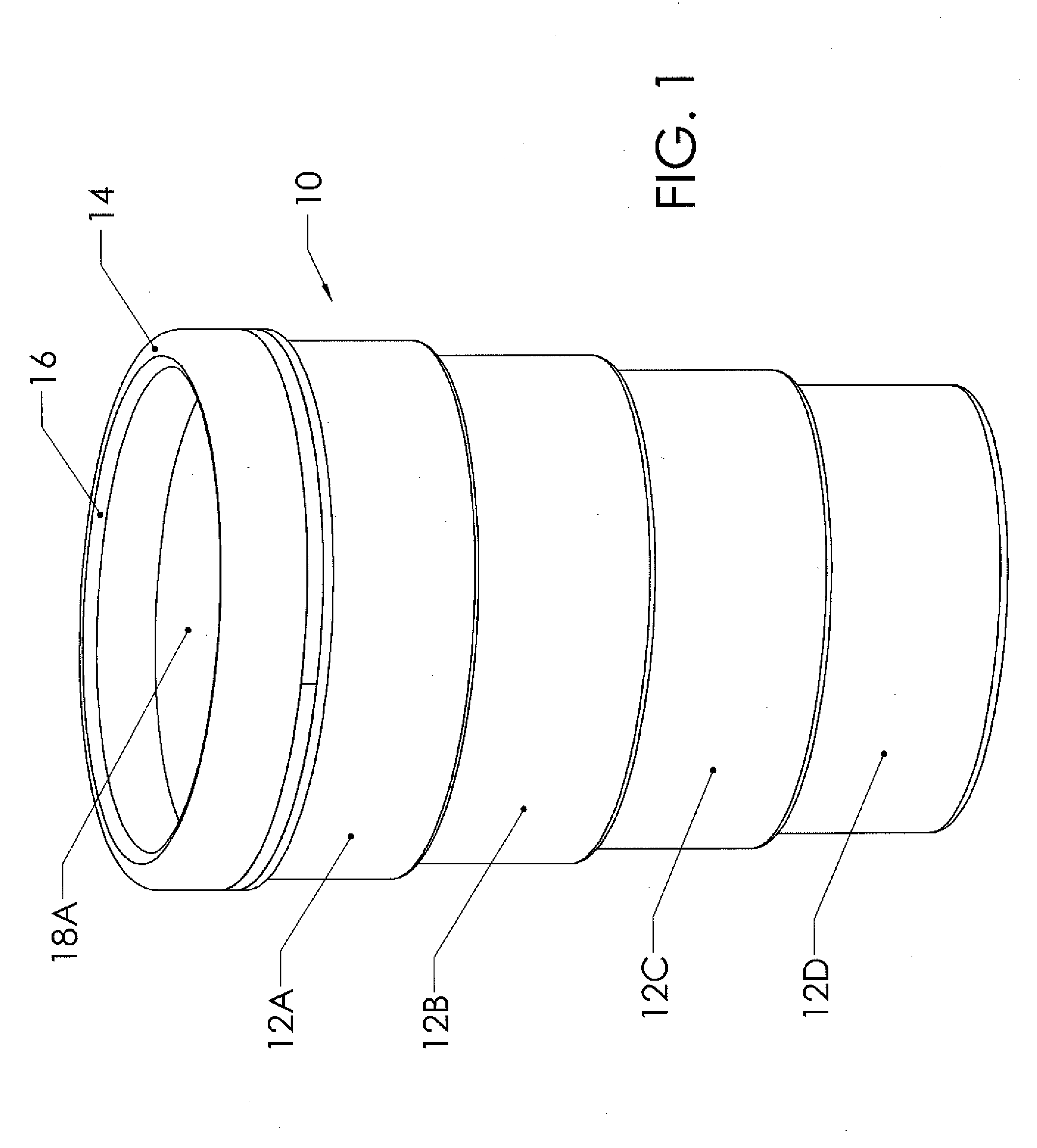

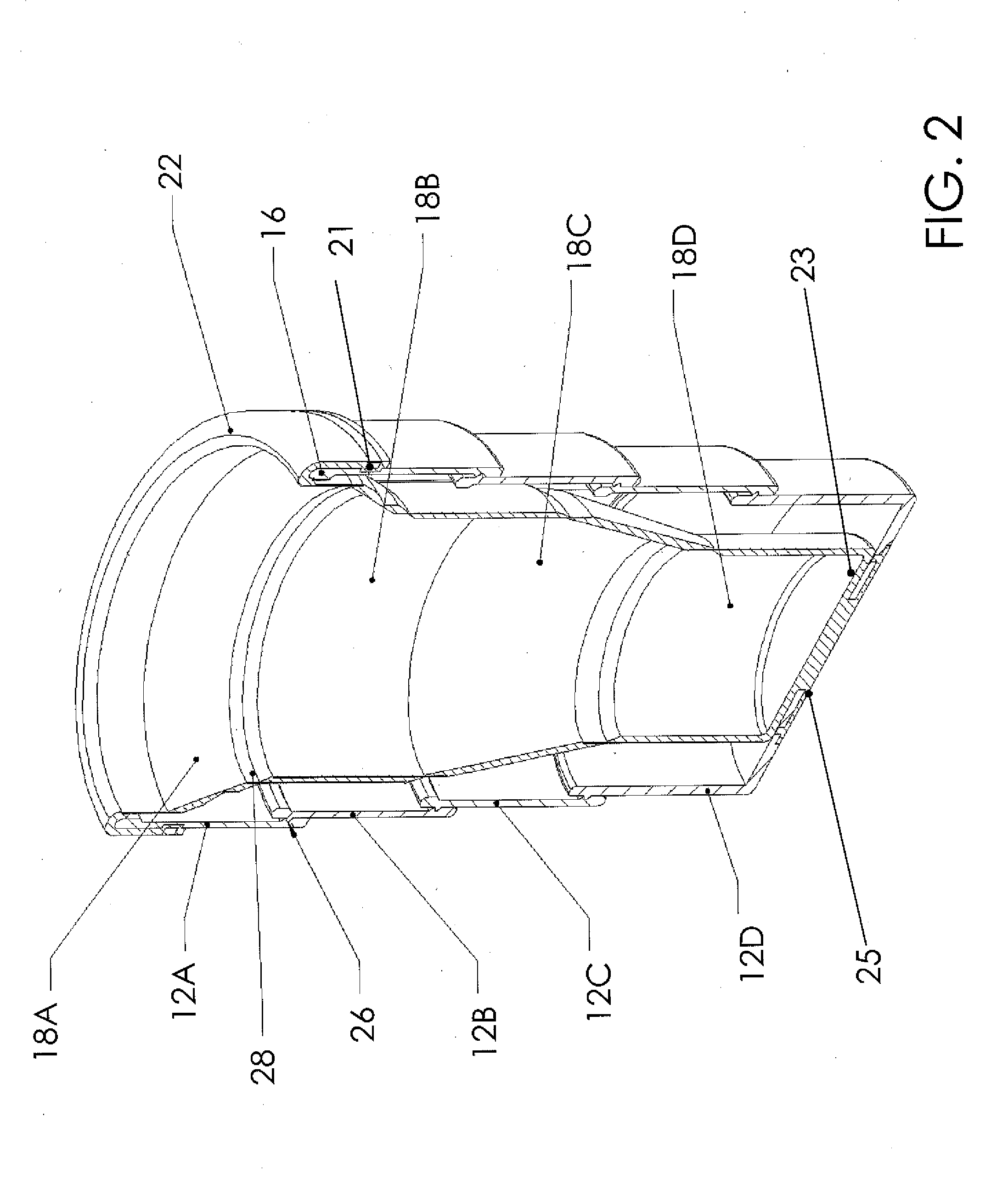

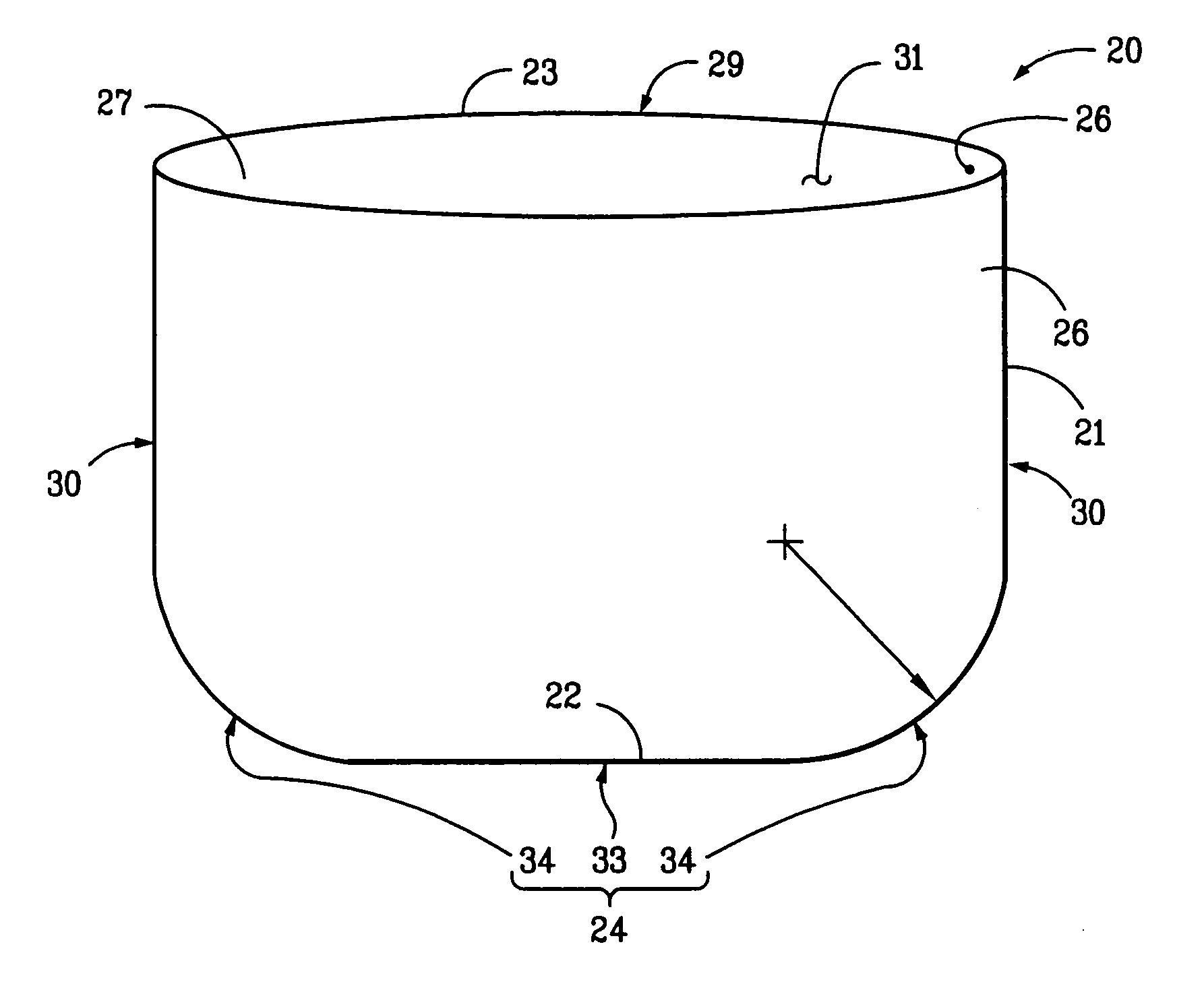

Thermally insulated pot

InactiveUS7086326B2Improve insulation effectImprove sealingWater heating stoves/rangesStove/ranges for heating waterThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

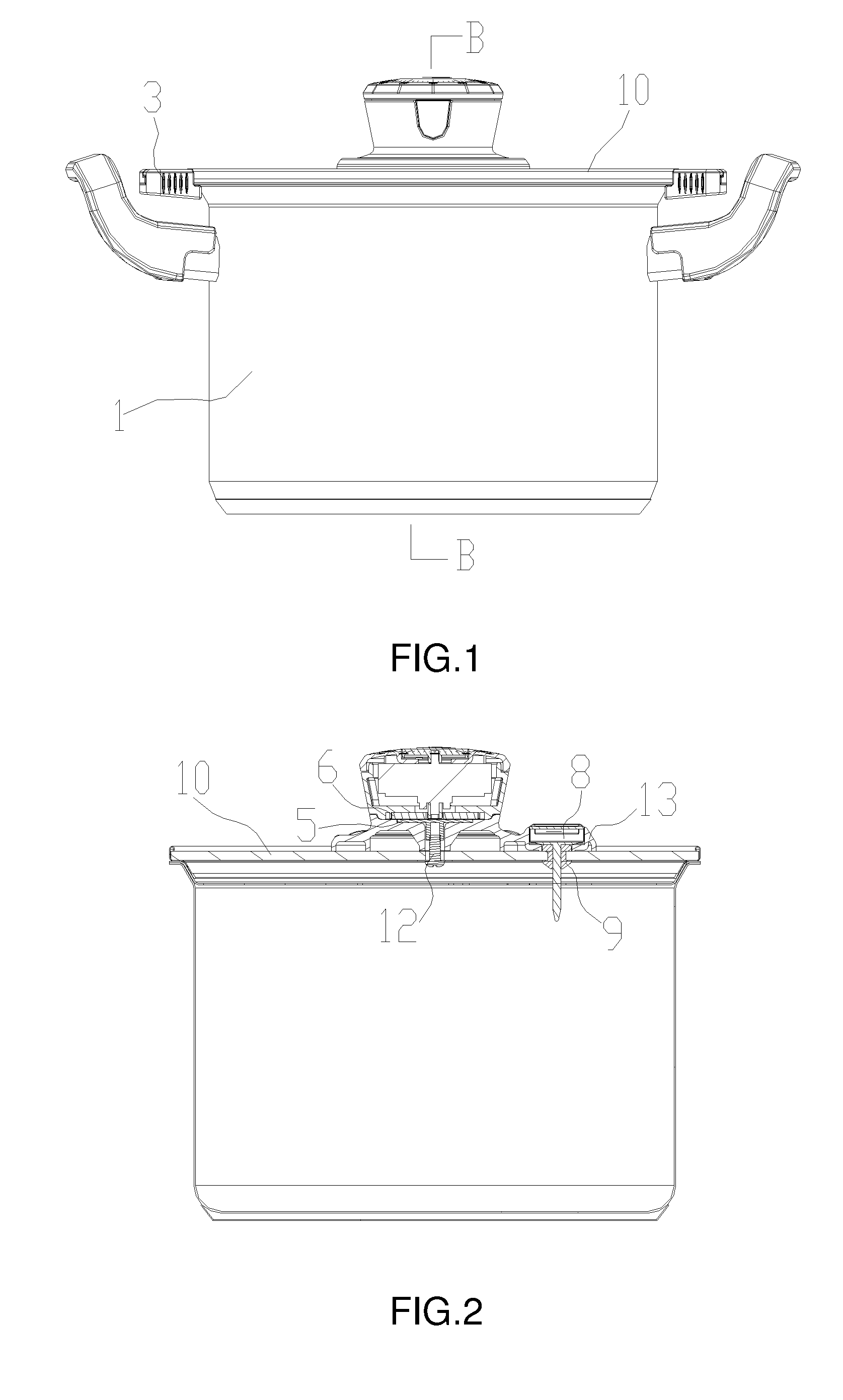

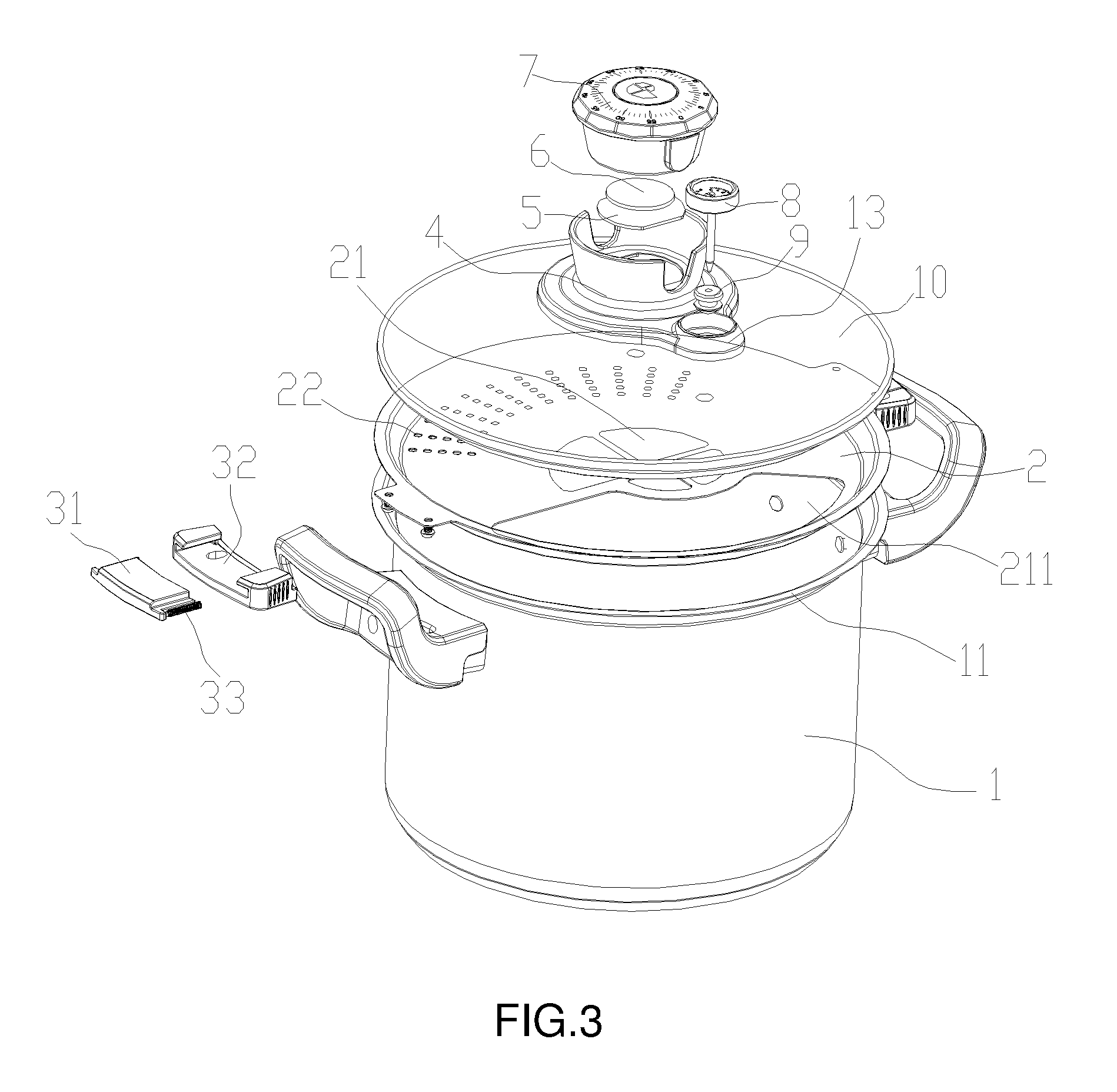

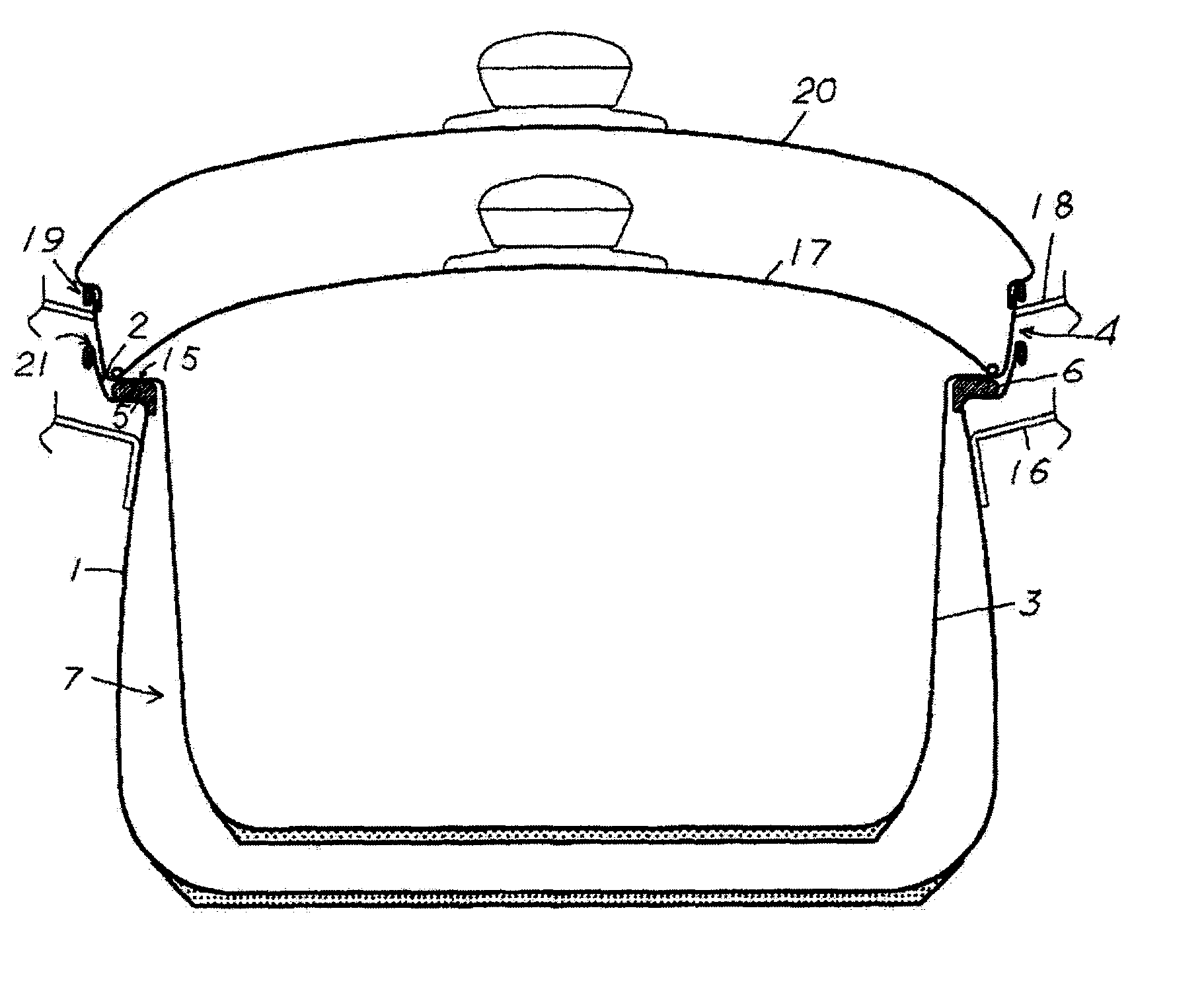

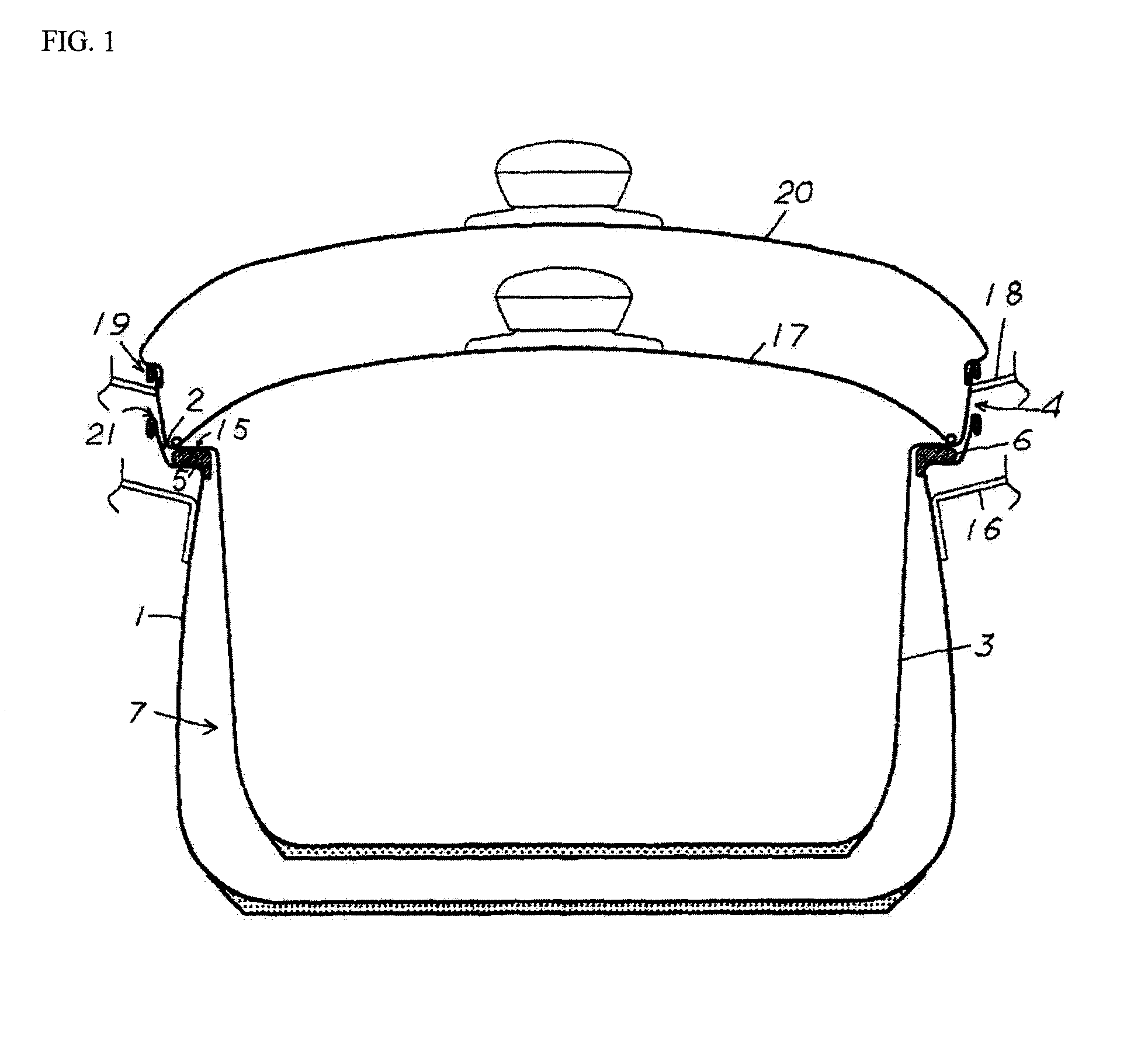

Multi-purpose stock pot

InactiveUS20140353316A1Avoid wastingSimple structureCooking-vessel lids/coversBaking vesselsFunctional featuresTimer

The multi-purpose stock pot includes a pot body and a lid; the lid has a lid knob, inside which a timing device is provided. The timing device has a magnetic plate, a magnet and a timer; the magnetic plate is fixed inside the lid knob; the timer is mounted onto the magnet; the magnet is attracted onto the magnetic plate to form a detachable connection. A temperature sensing opening is disposed on the lid and a sealing ring is disposed in the temperature sensing opening; a thermometer passes through the sealing ring and extends into an interior cavity of the pot body for temperature sensing. A strainer is rested on an upper periphery of the pot body. The functional features of the stock pot are configured practically. It is simple in structure and convenient to use. The timer has a reminder function to remind the user about the cooking time.

Owner:GUANGDONG ZHONGBAO KITCHENWARE

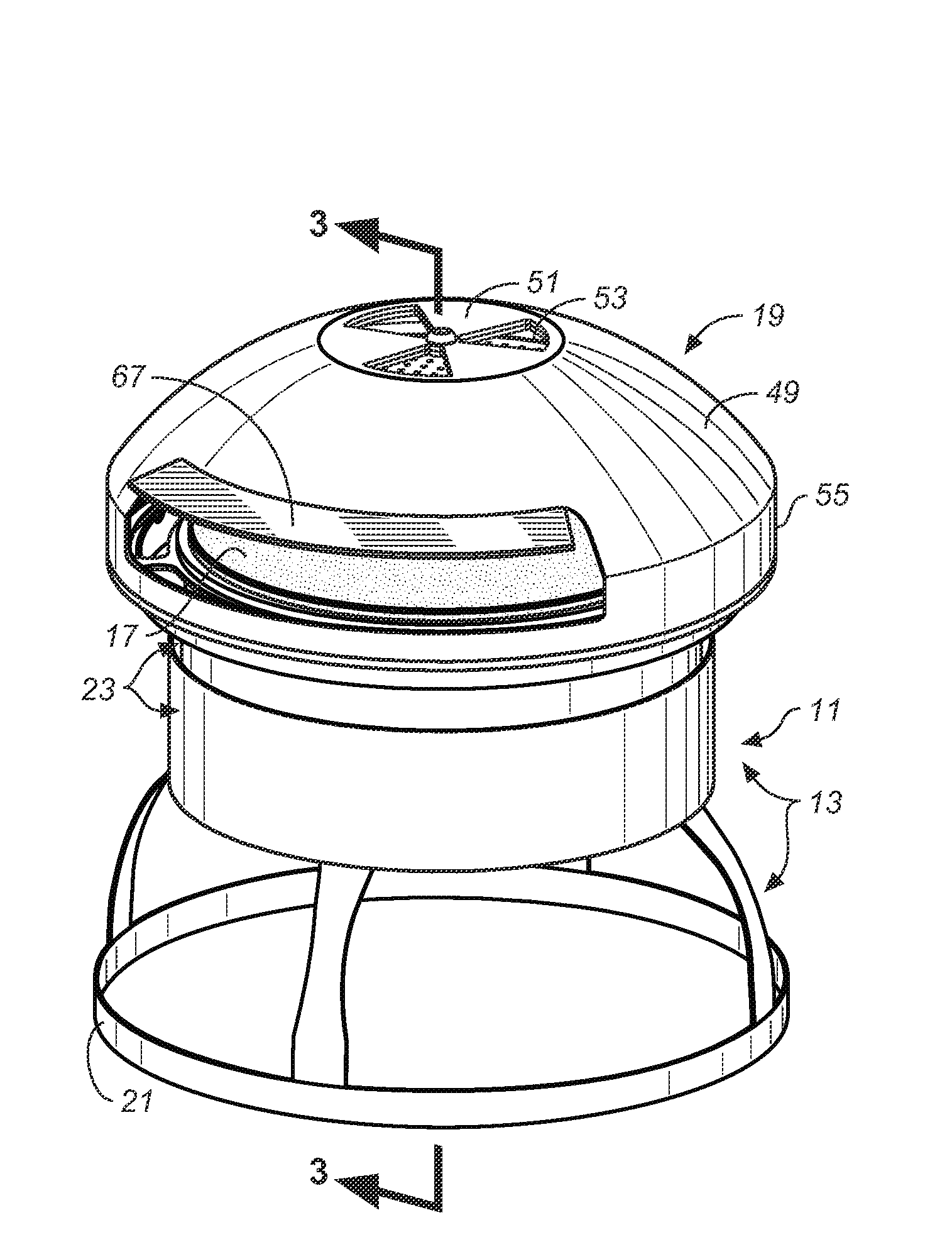

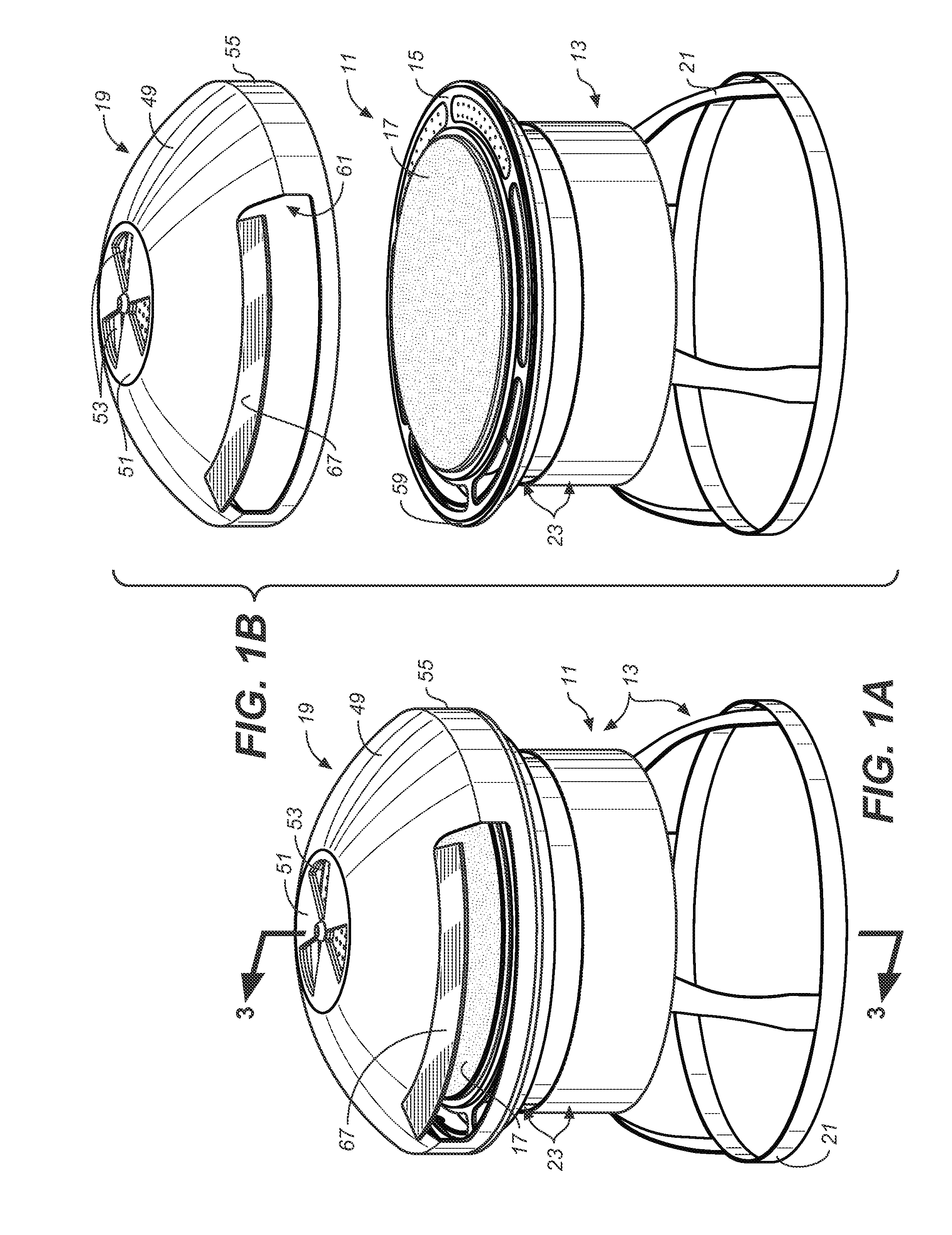

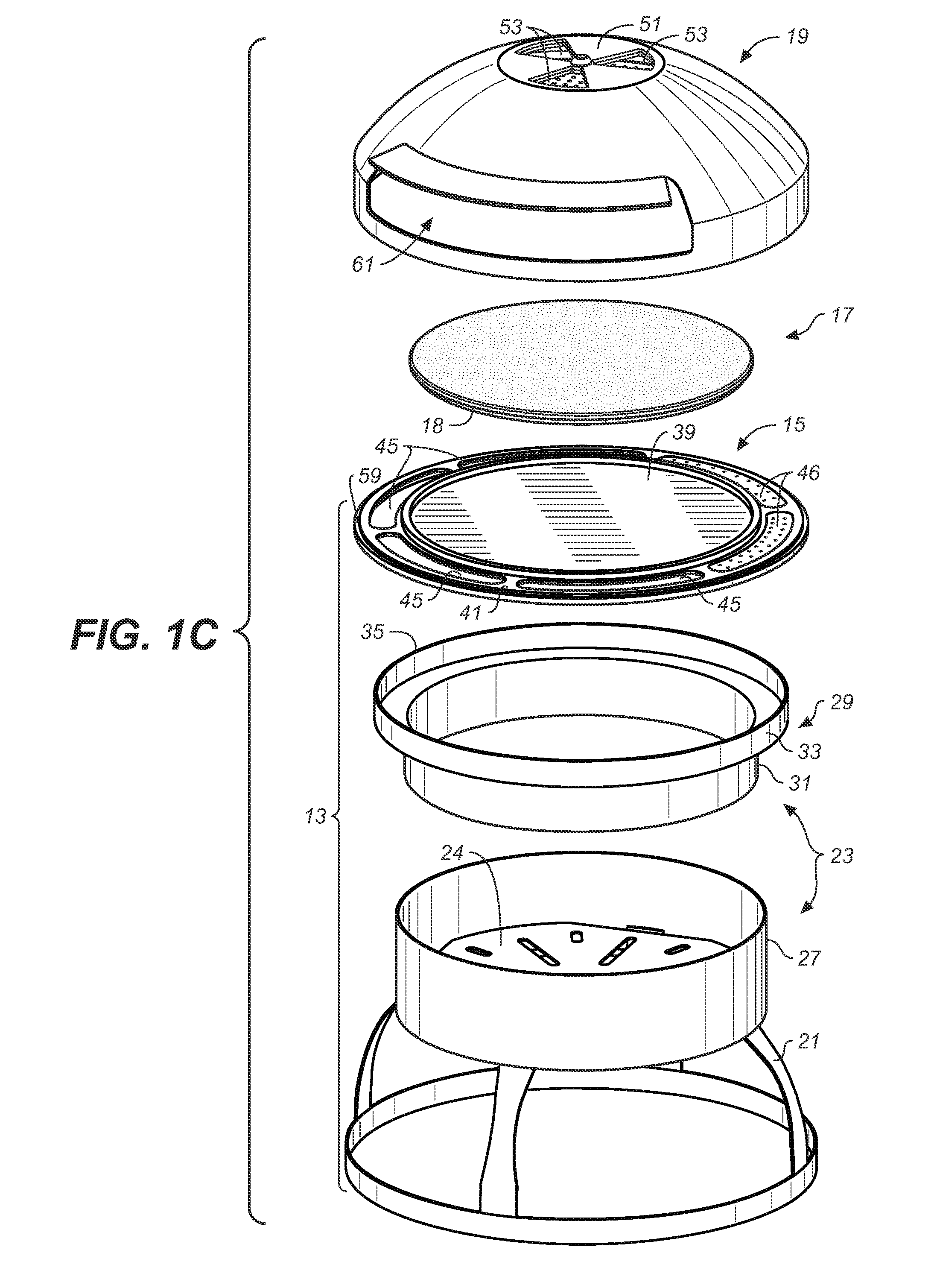

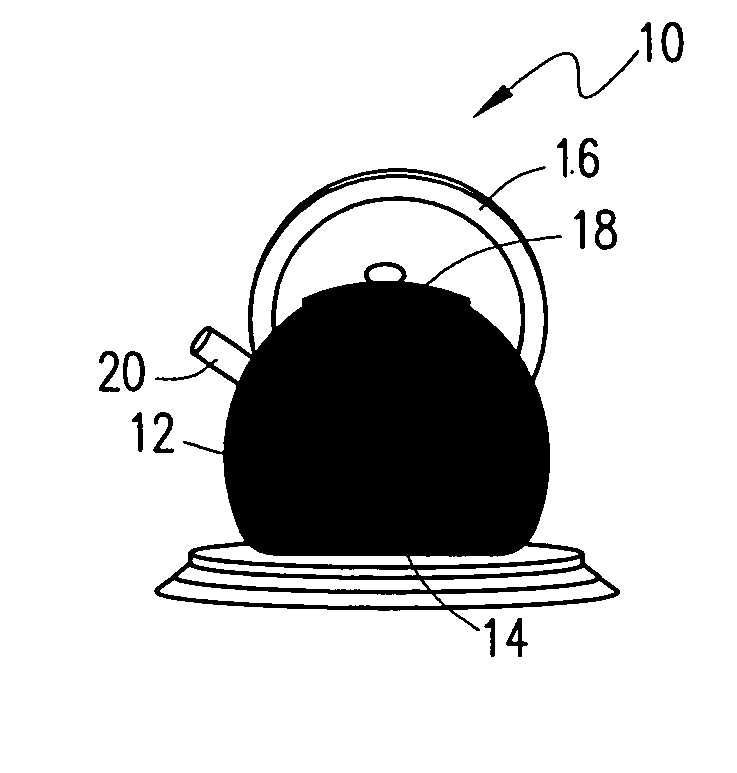

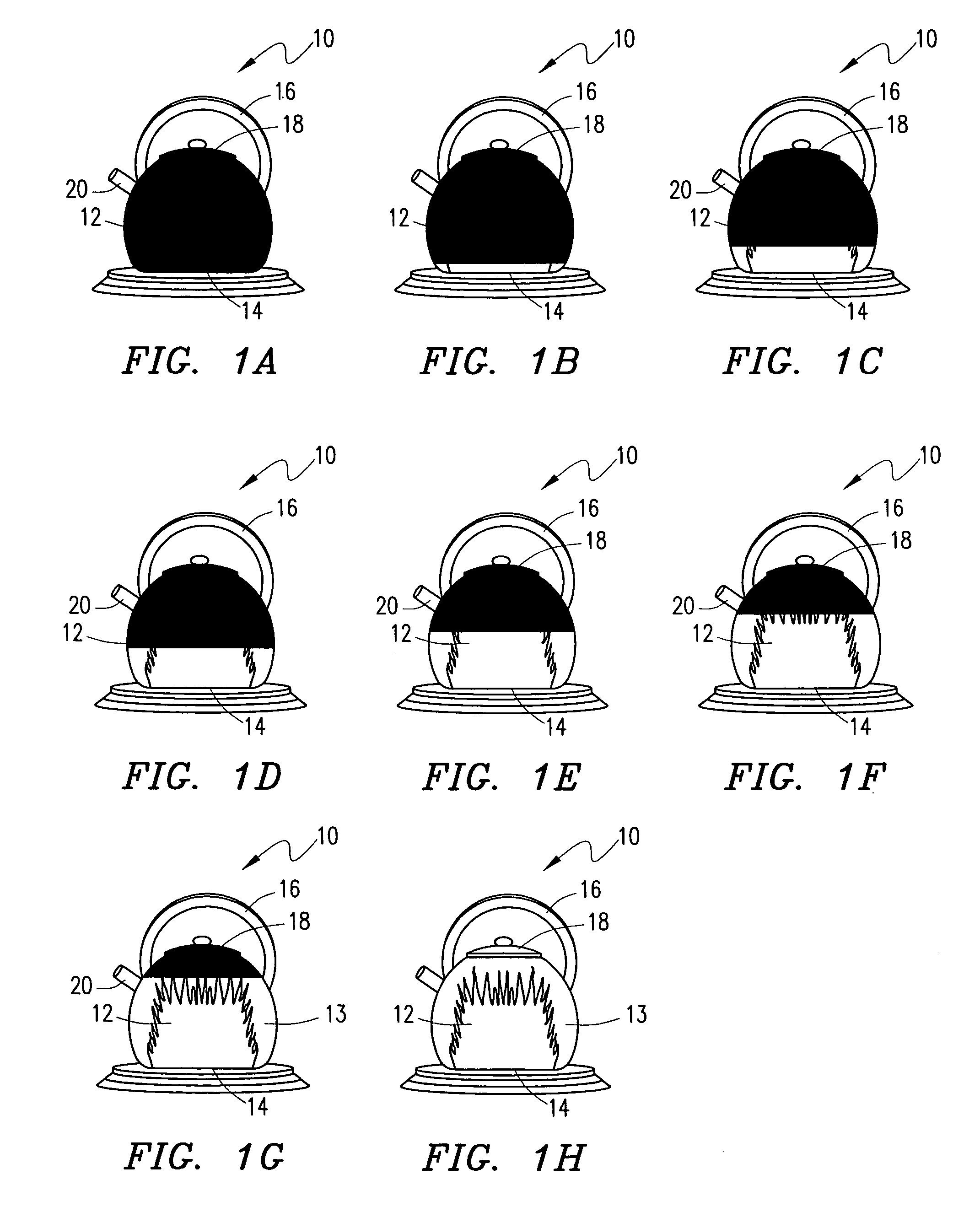

Portable baking oven

ActiveUS20130276643A1Effective redirectingEvenly heatedDomestic stoves or rangesLighting and heating apparatusEngineeringMoisture

A portable baking oven for a pizza or other food item includes a food item heating plate, a base having a heating chamber, and a top cover having a moisture vent and a heat reflector structure extending across the inside of said top cover. When placed on said base, the top cover forms a baking chamber above the heating plate. Heat produced in the base's heating chamber circulates up through air passageways in the base into the baking chamber above the food item heating plate. This circulated heat is reflected back down toward the food item heating plate by the top cover's heat reflecting structure to accelerate baking of the top of a food item placed on the heating plate. The top cover's moisture vent can be located above the heat reflector structure in the top cover, and openings can be provided in the heat reflector structure which allow moisture emitted by a food item being baked in the oven to pass through the reflector structure and out through the top cover moisture vent.

Owner:CHARCOAL COMPANION LTD

Cooking pot and lid thereof

Owner:TALL & STOUT INDAL CORP

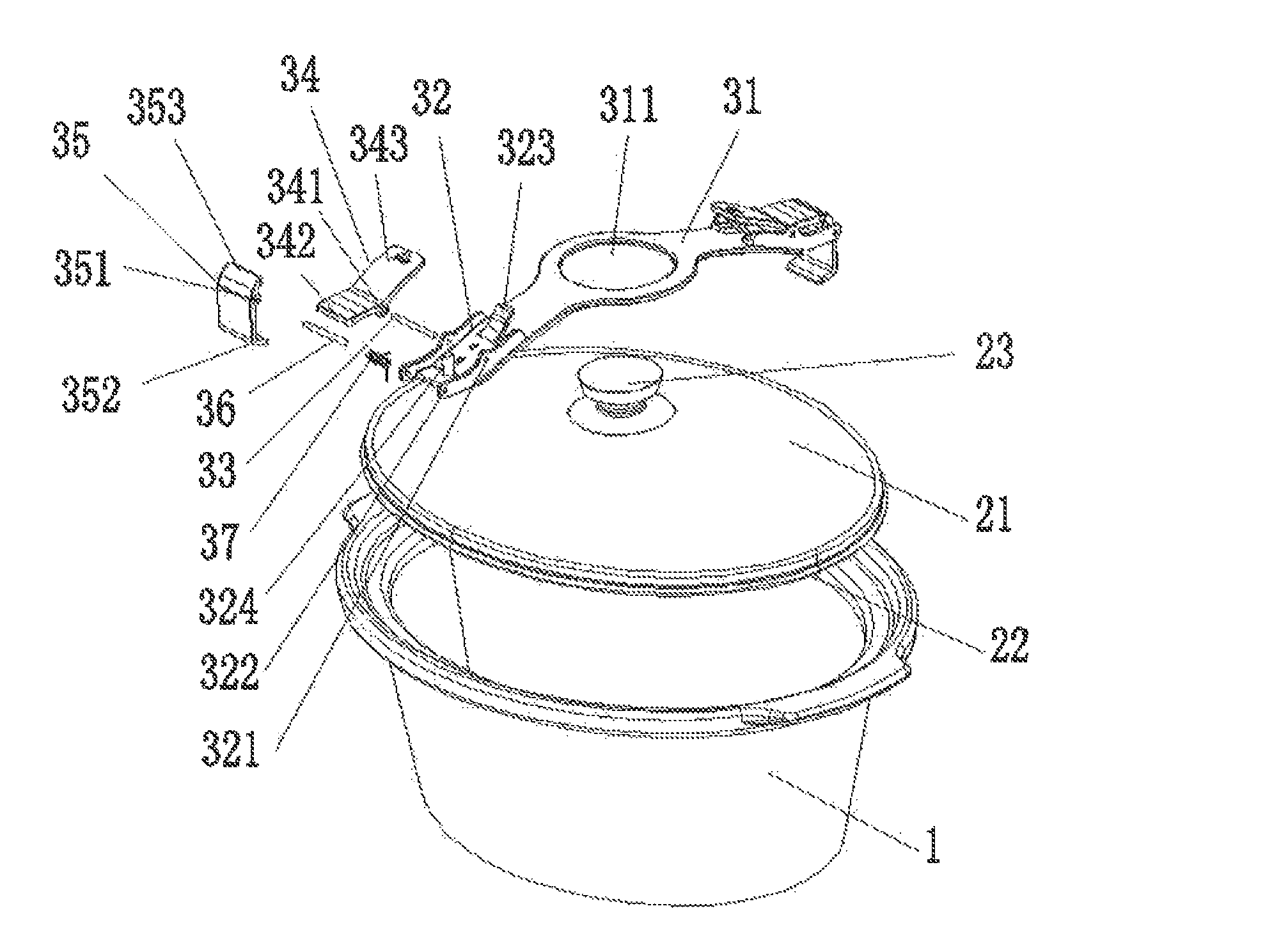

Steam pressure cooker

InactiveUS6877633B2Thinner nominal wall thicknessSame strength propertyRefuse receptaclesSealingSteam pressureLocking mechanism

A steam pressure cooker includes a pot having an outwardly directed horizontal pouring rim and formed with a V-shaped circumferential depression which points inwardly to define a conical surface in an upper rim area. A lid can be placed upon the pot for closing and includes a circumferential groove. Positioned between pot and lid is a rubberized elastic sealing element which is held in the circumferential groove. The sealing element has a sealing body of substantially U-shaped configuration to define two sealing lips in coaxial parallel relationship to the vertical pot axis. One sealing lip bears against an inner wall of the pot and interacts with the conical surface of the pot, when the lid is placed upon the pot. A locking mechanism embraces and thereby clamps the lid and the pouring rim, when the steam pressure cooker is closed, and clears the pouring rim, when the steam pressure cooker is opened.

Owner:NIESE URSULA

Thermally insulated pot

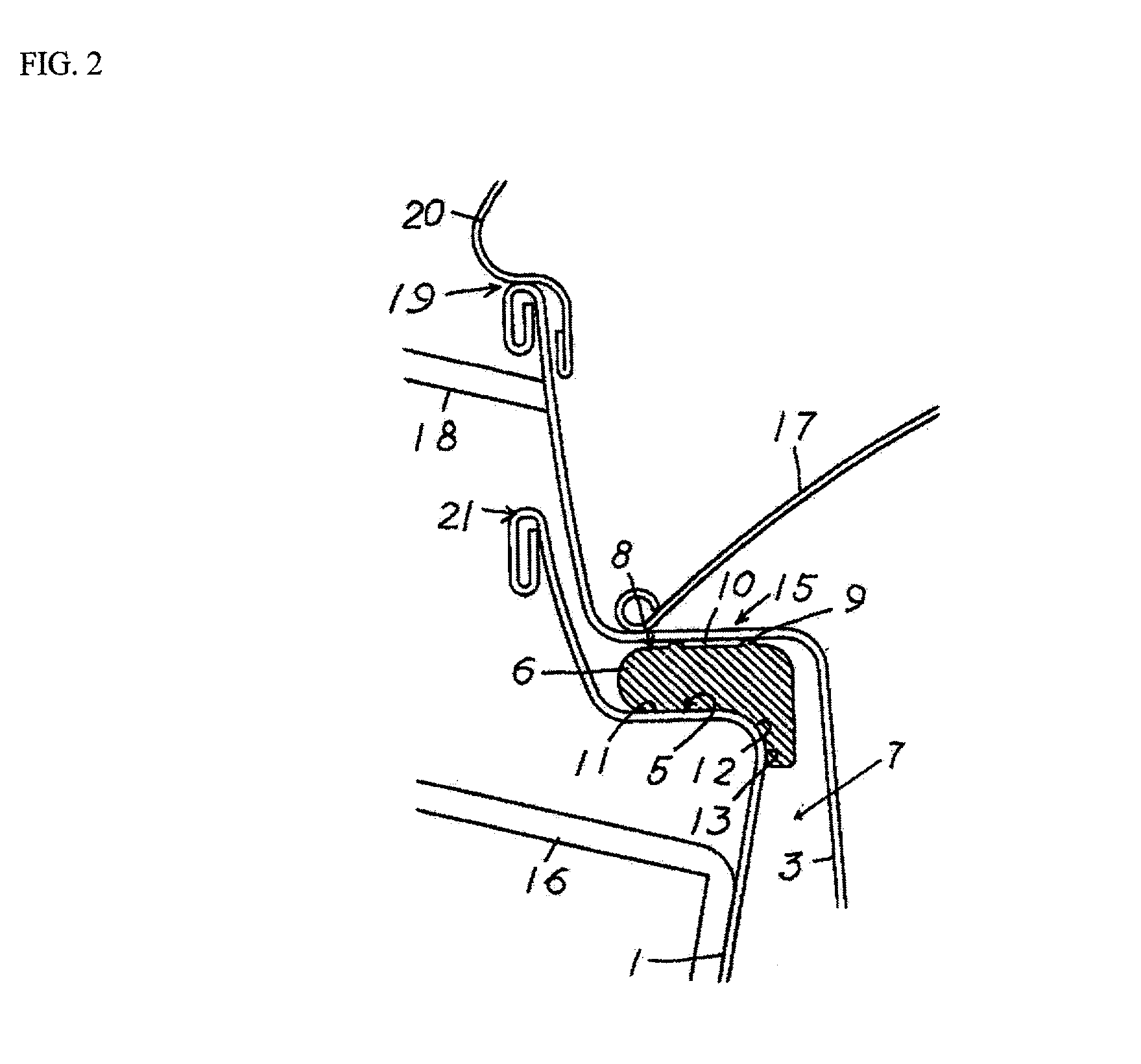

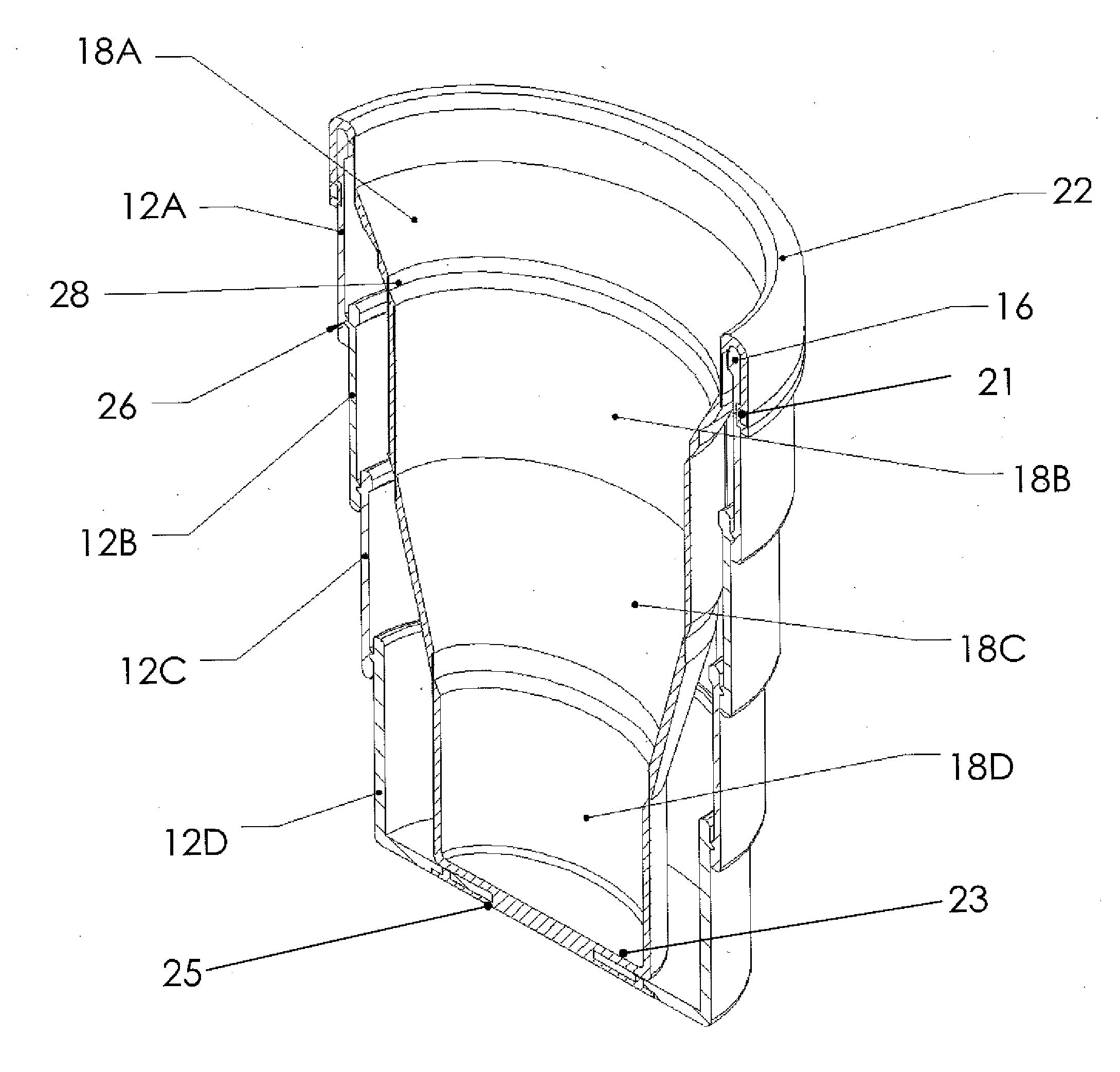

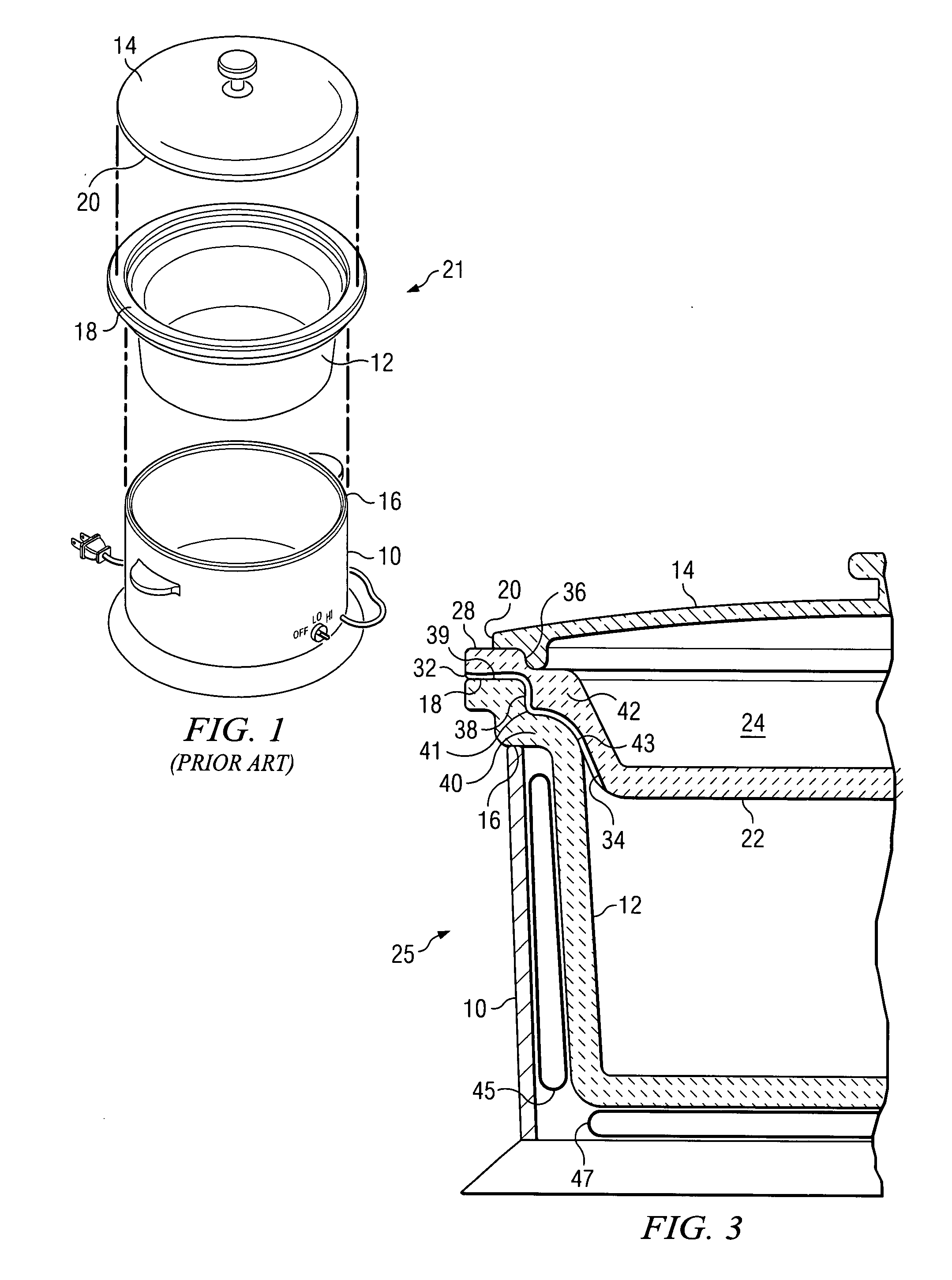

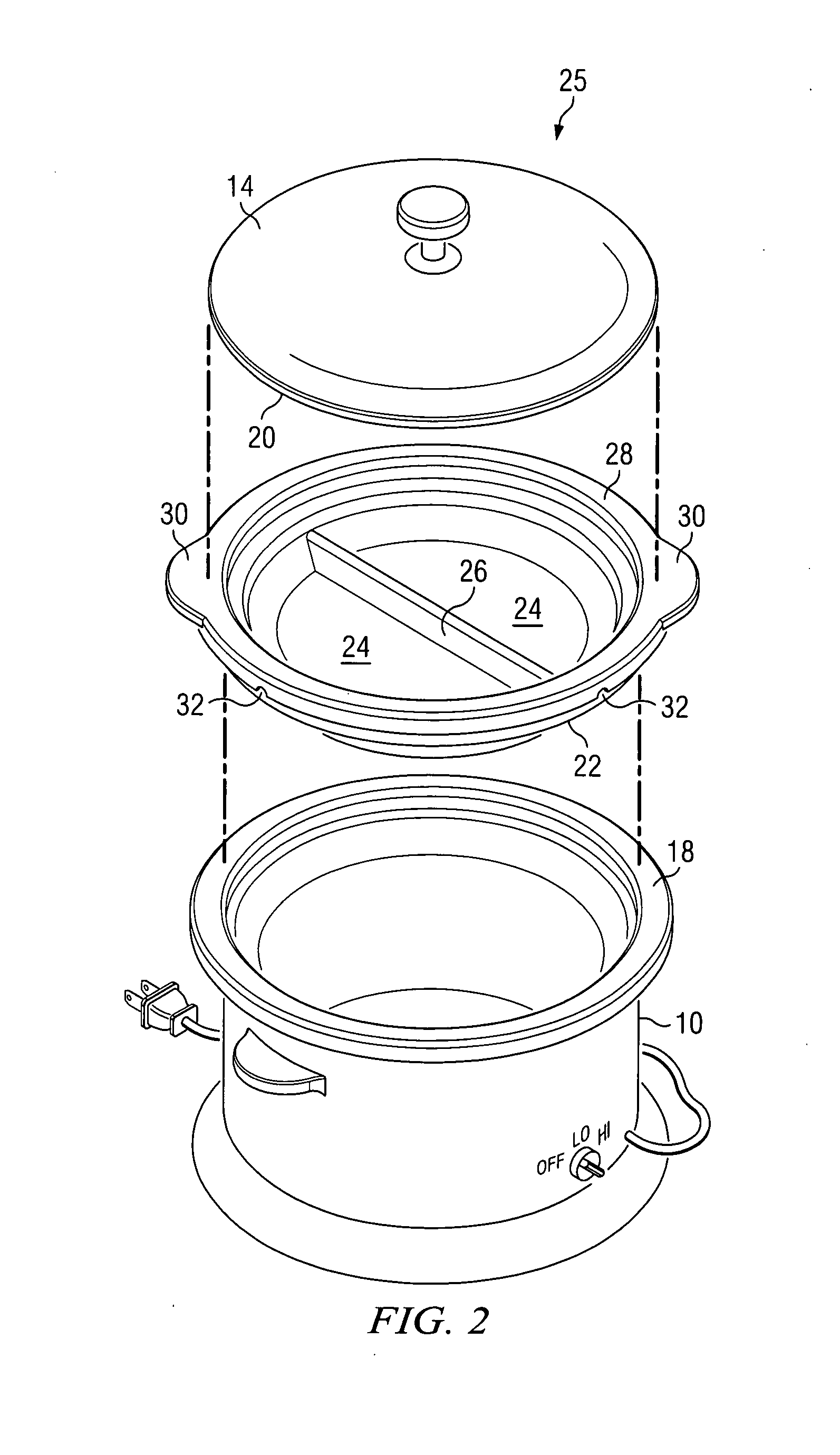

InactiveUS20020185012A1Multiple-unit cooking vesselsWater heating stoves/rangesThermal insulationEngineering

A thermally insulated cooking pot consists of an outer pot and an inner pot. The inner pot is suspended within the outer pot by hanging from the top inner circumferential area of the outer pot with its own top outer circumferential area. The space between the inner and outer pots becomes an insulation cavity. The contact point between the two pots is sealed by a pliable packing ring with an L-shaped cross-section, thereby sealing the insulation cavity. This sealed insulation cavity provides excellent thermal insulation. The packing ring contains a plurality of protrusions on the surface that come into contact with the inner pot to prevent the packing ring from sticking to the inner pot. The gap formed between the packing ring protrusions and the inner pot prevents the inner pot from sticking to the packing ring.

Owner:PATERSONS ENTERPRISES

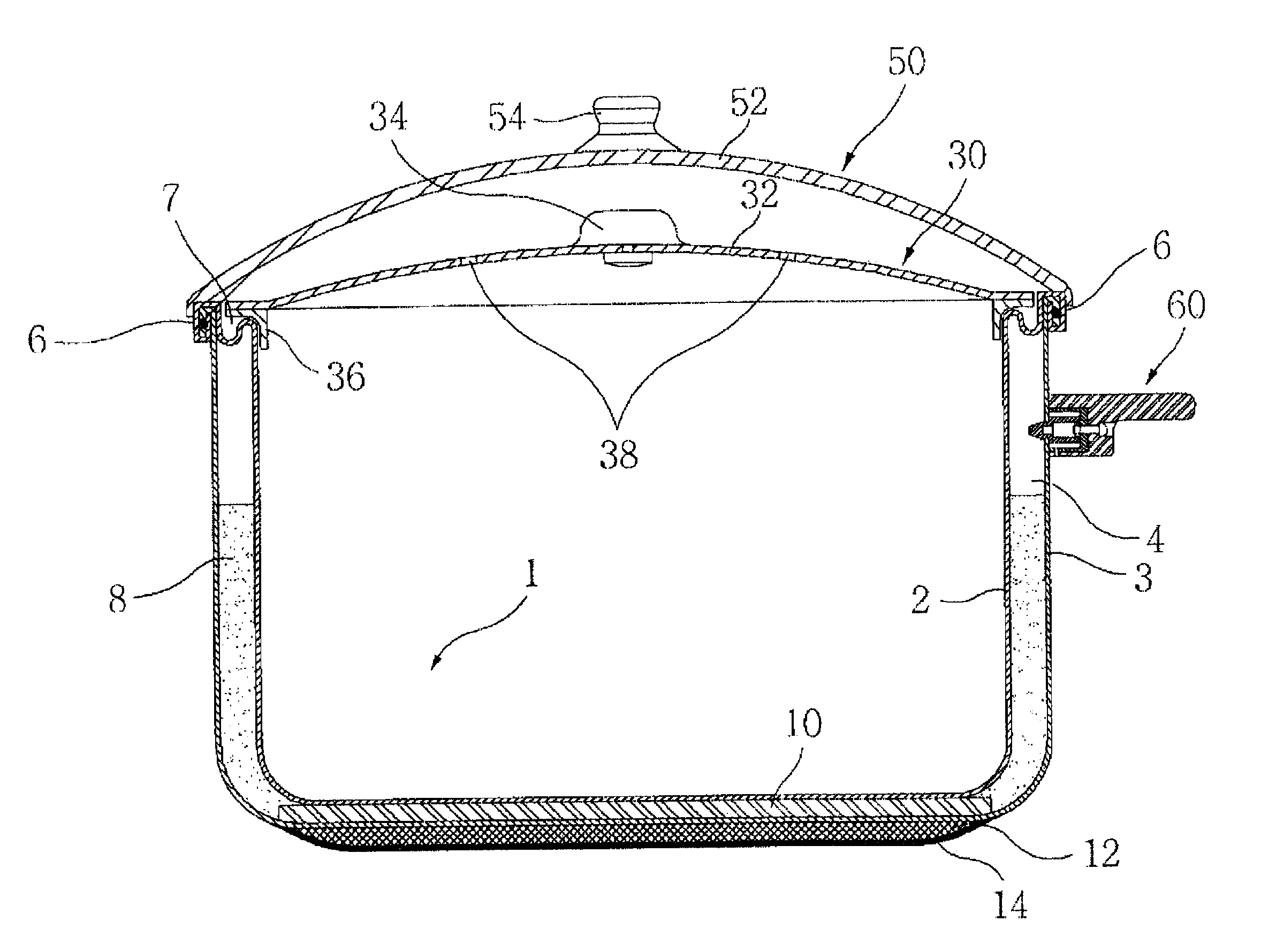

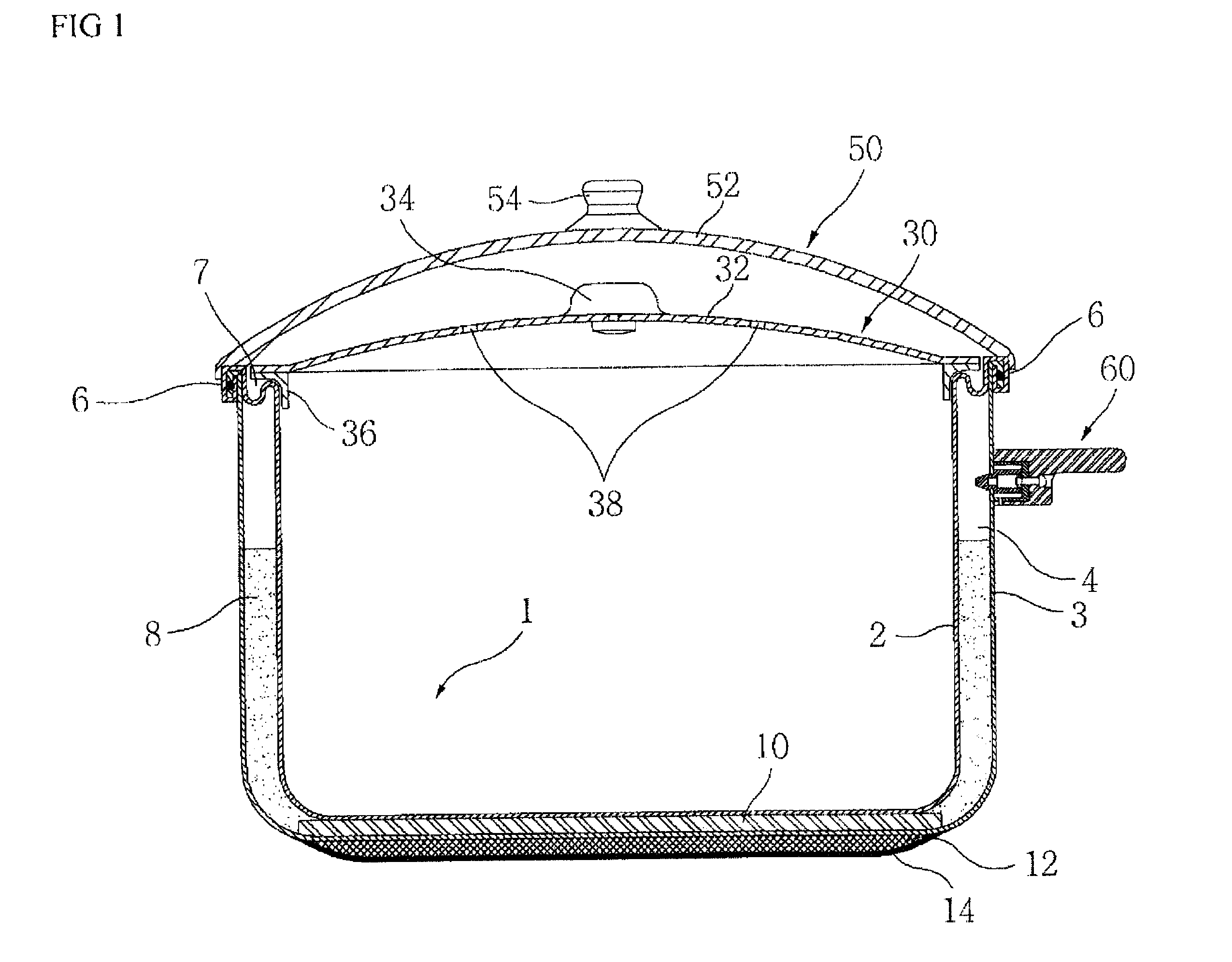

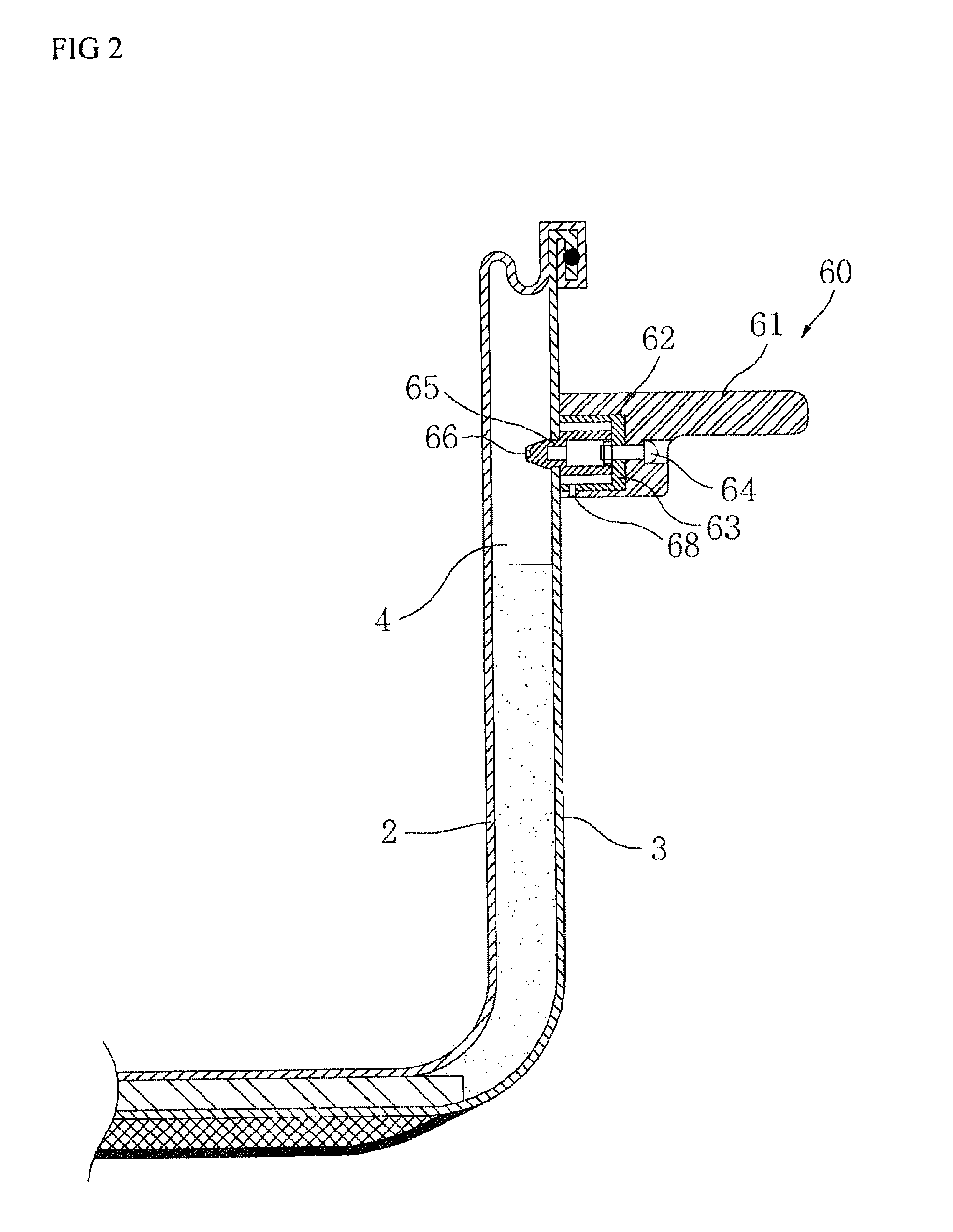

Cookware that functions as a low pressure cooker

ActiveUS8689680B2Add flavorSave energyDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

An eco green cookware is provided, having a double-layered wall structure and comprising a heat transfer medium within a cavity of the double-layered wall structure. The eco green cookware comprises: a container comprising an inner shell and an outer shell, wherein upper parts of the inner shell and outer shell are rolled a number of times together to form a rolled joint, an upper part of the inner shell is provided with a concave member, a heat transfer medium is provided within said cavity, a first heat transfer member is inserted and installed at the bottom portion of said cavity, and a second heat transfer member is affixed to the bottom surface of the first heat transfer member; an inner cover comprising an inner peripheral portion in the form of an inverted “L” whose inside bend forms a round portion; an outer cover; and pressure release devices.

Owner:PARK JONG PETER

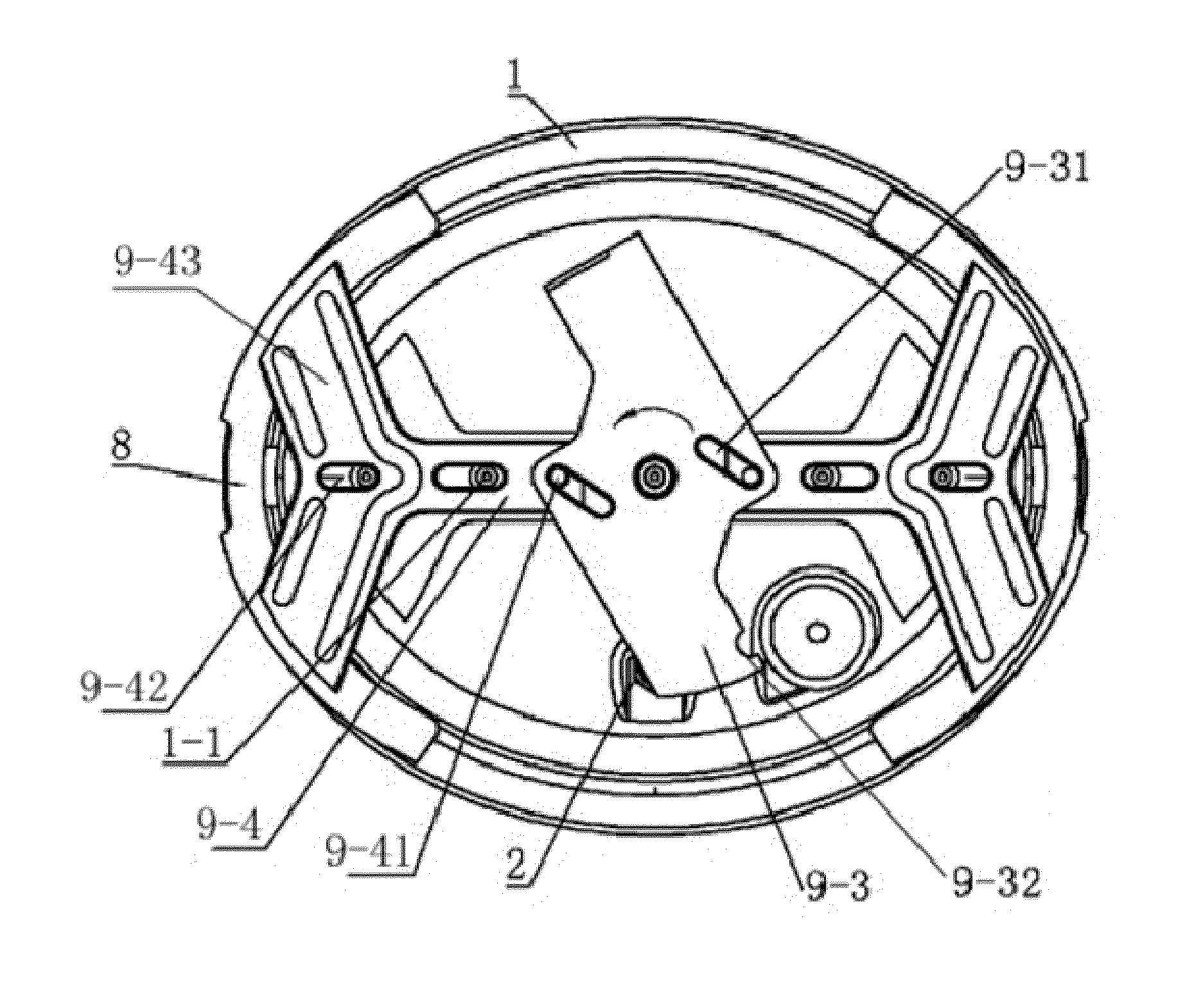

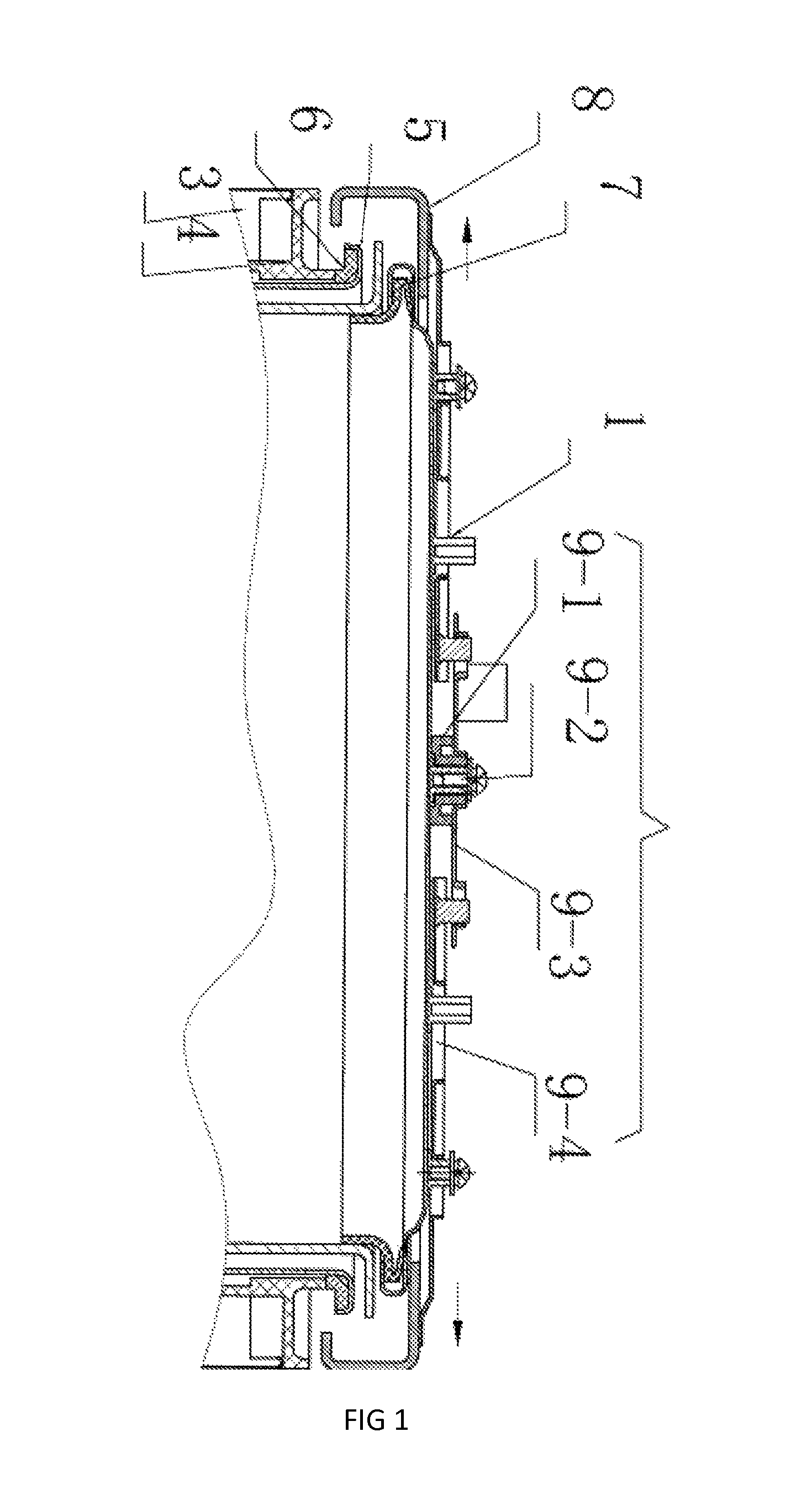

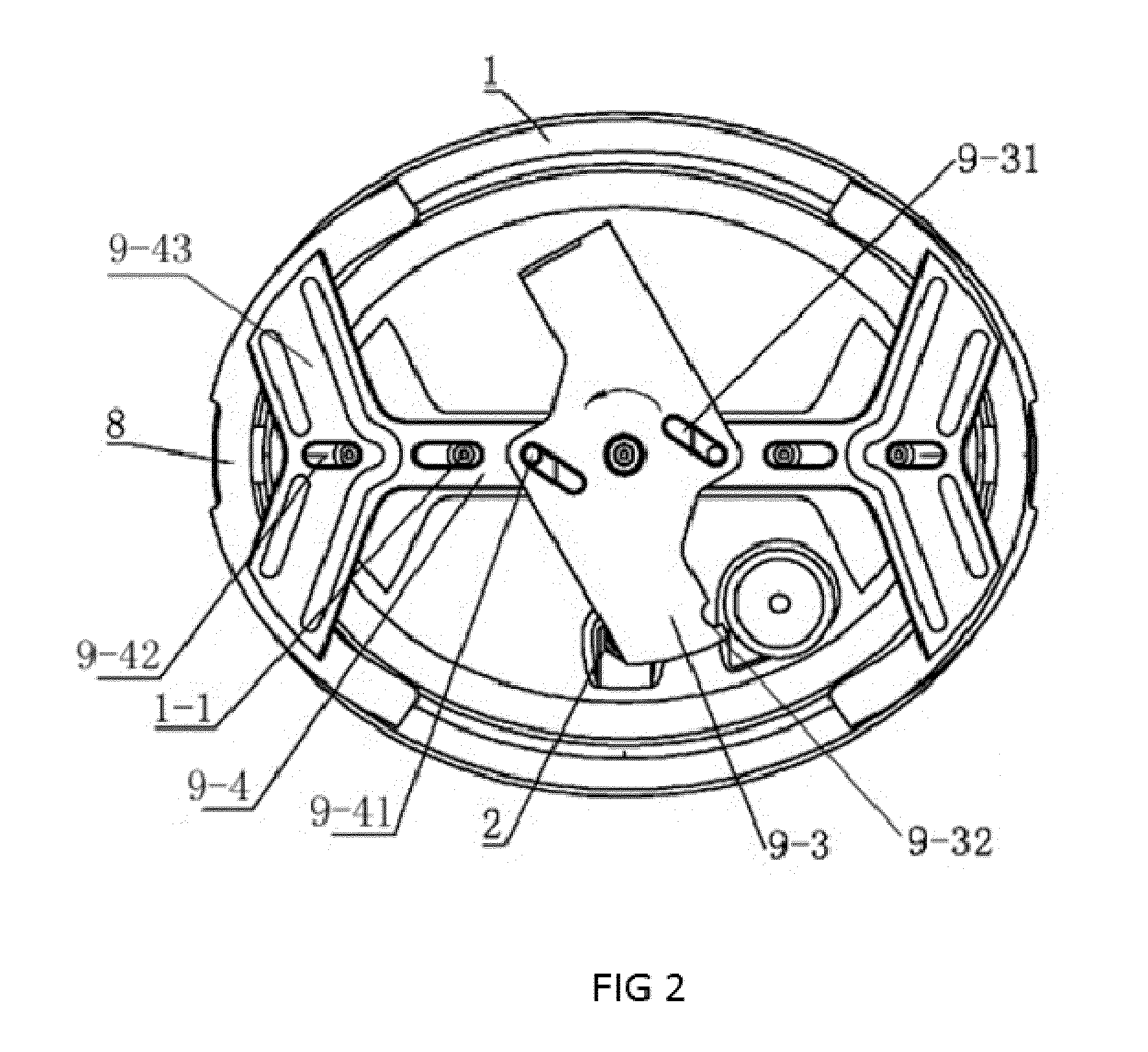

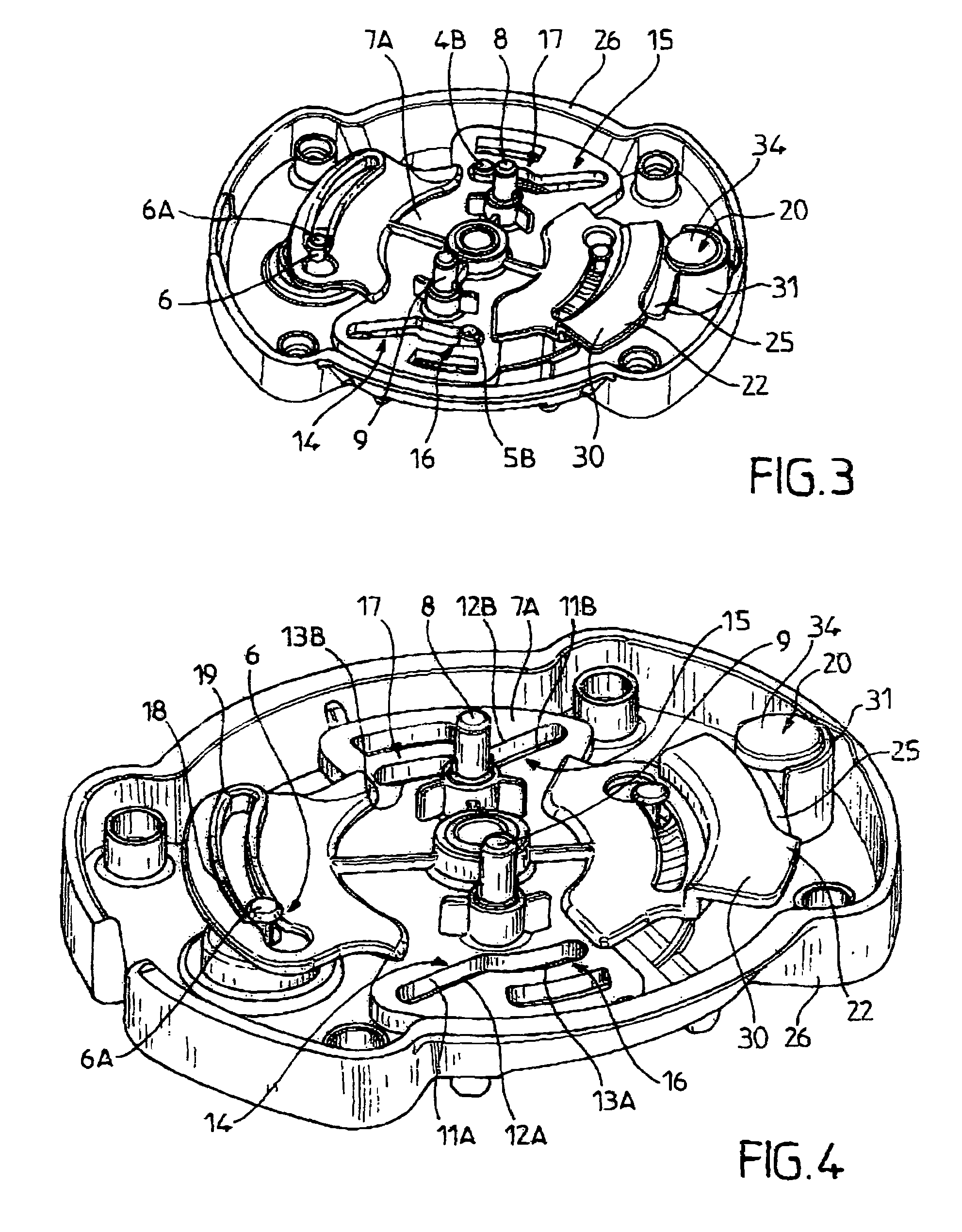

Cover for pressure cooker with locking pieces

A pressure cooker cover comprises a cover (1) and a float valve (2), wherein a seal ring (7) is installed in the inner edge of the cover while hooks (8) are installed in the two side edges of the cover. A push-pull device (9) which can move the hooks back and forth is mounted in the ends of the hooks. The push-pull device comprises a rotating base (9-1) arranged in the middle portion of the cover, a rotating shaft (9-2) and a locking piece (9-3) which is coupled with the rotating shaft (9-2). Sliding chutes (9-31) are provided at the two sides of the locking piece. Guide columns (8-1) which are slidingly matched with the sliding chutes are set at two ends of the hooks (8).

Owner:HE ZHIGANG +1

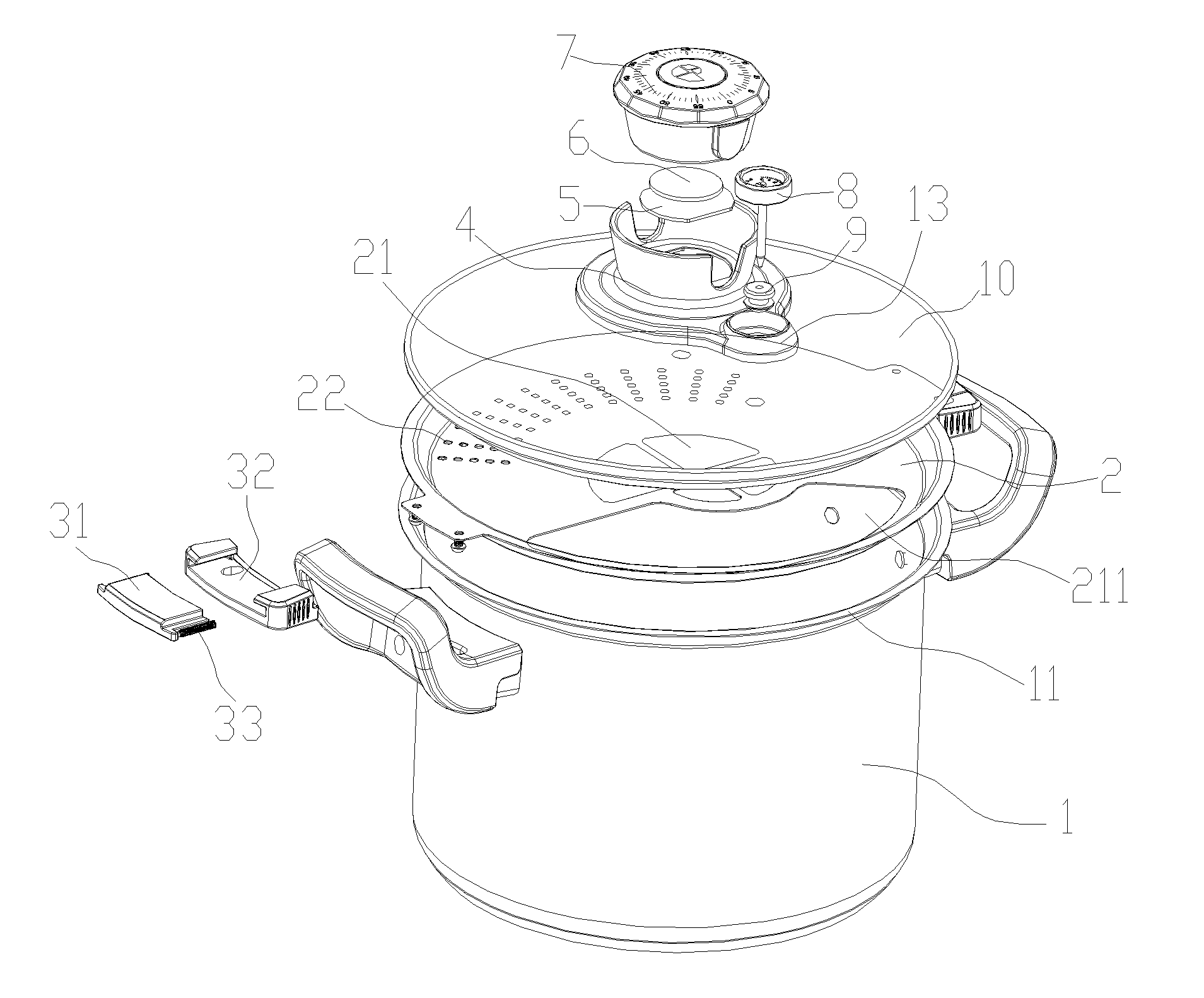

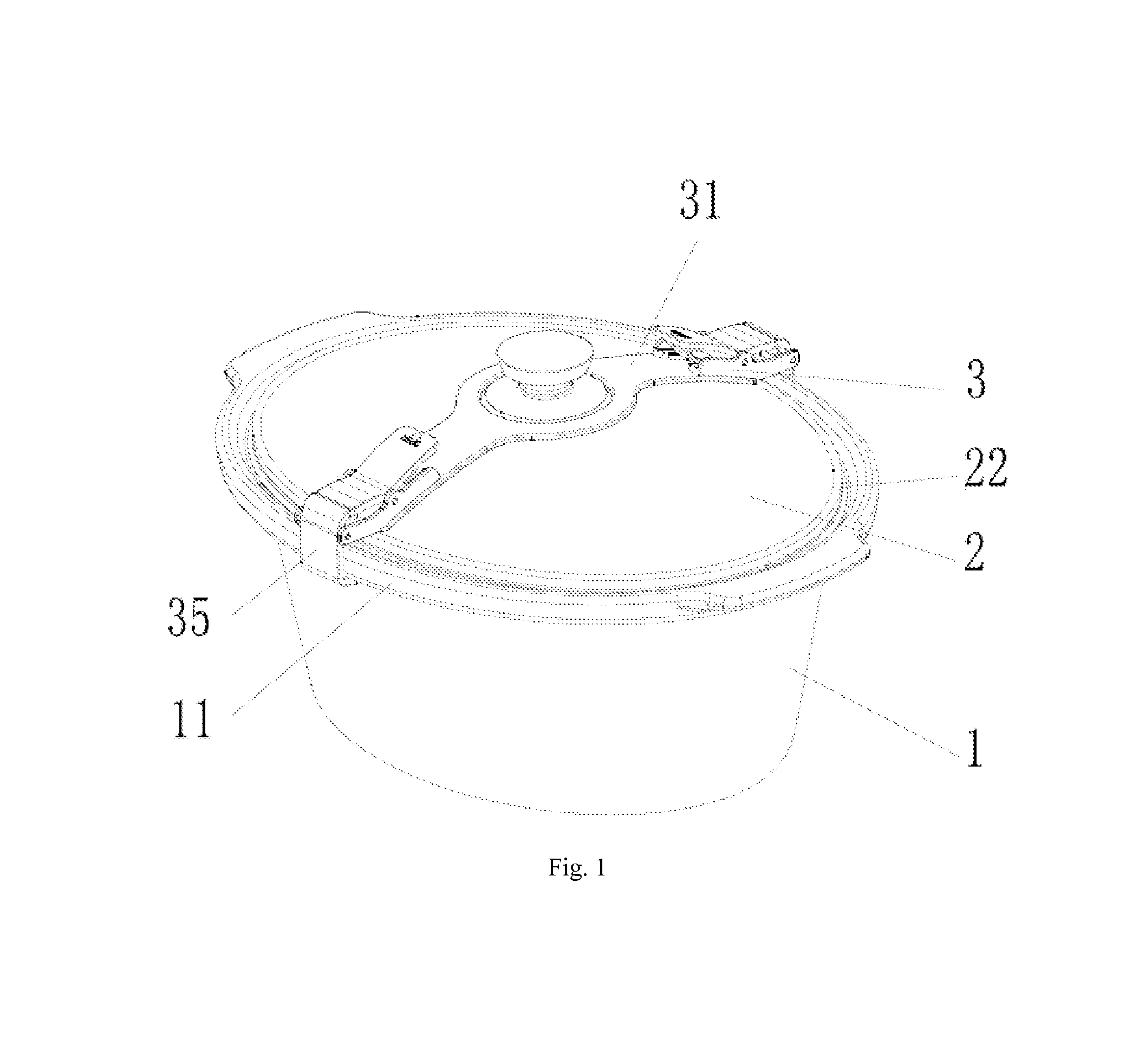

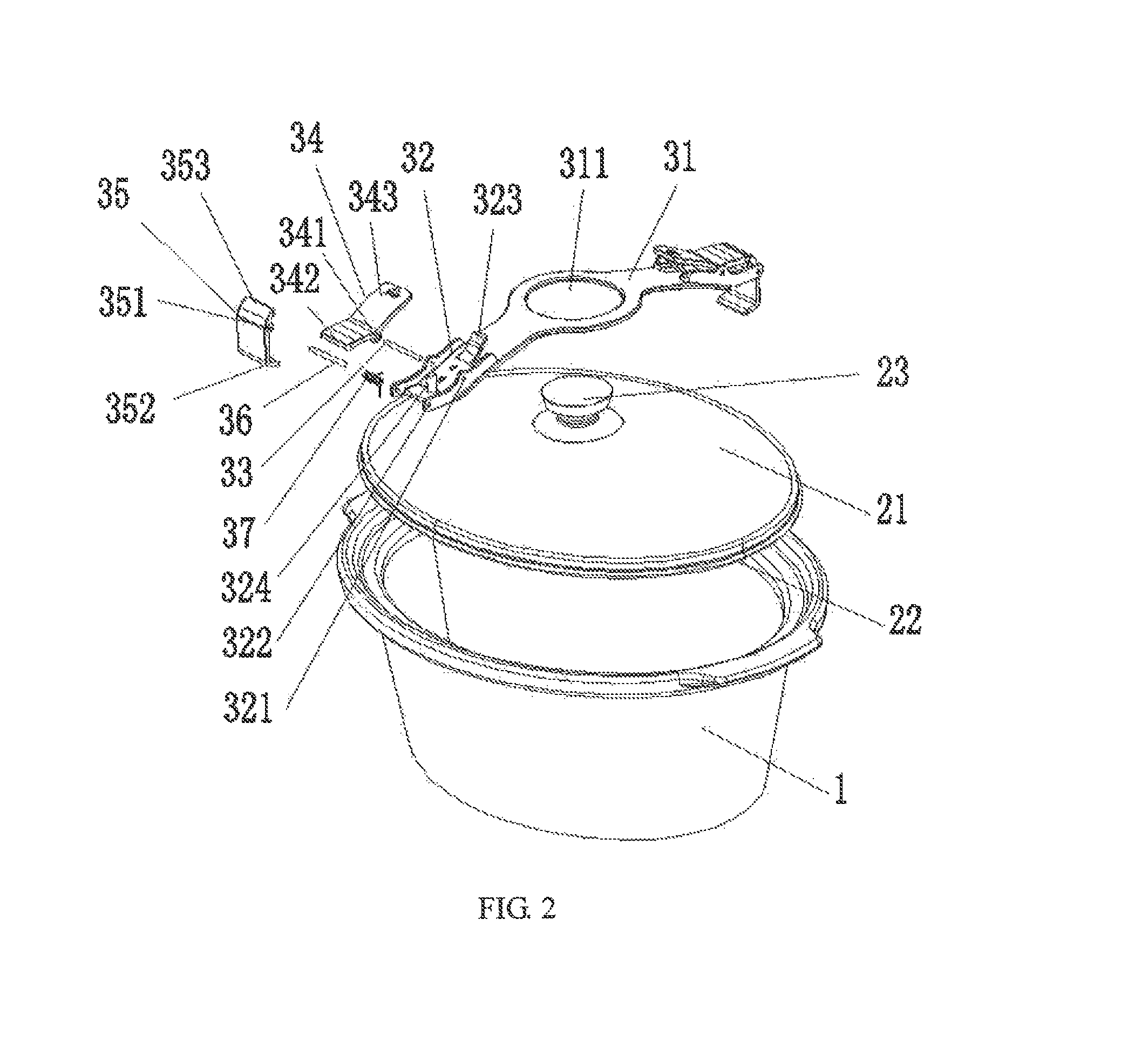

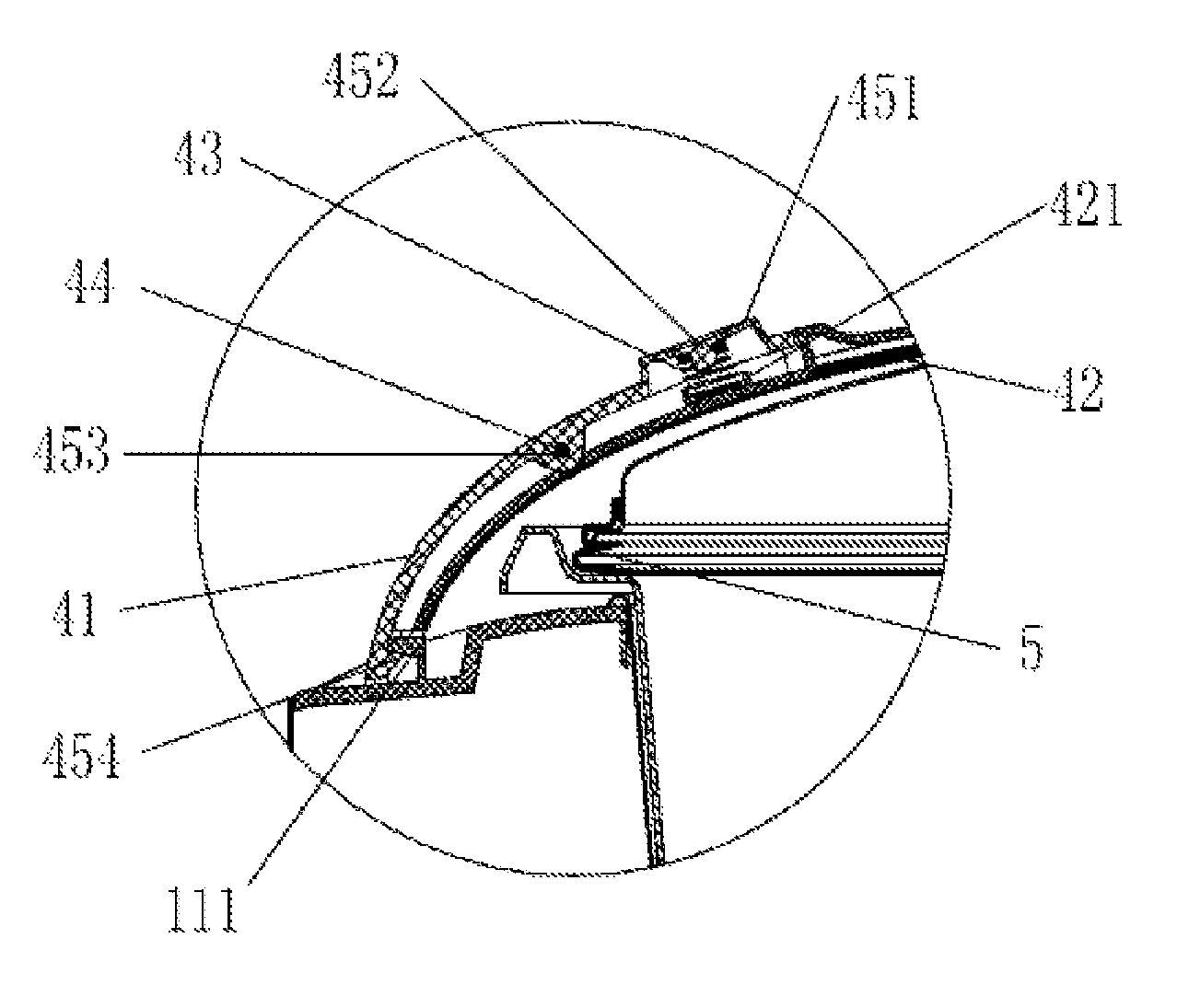

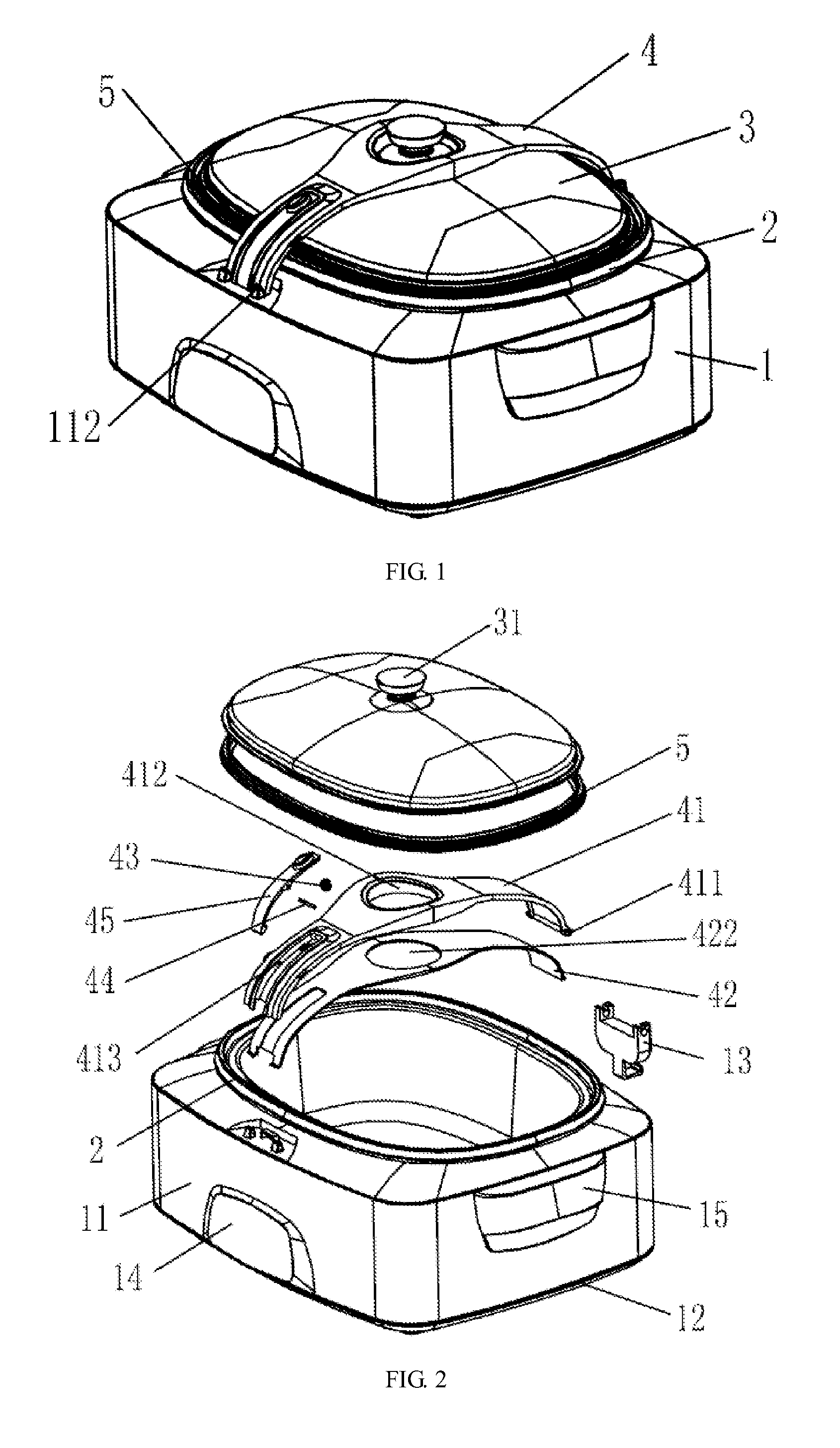

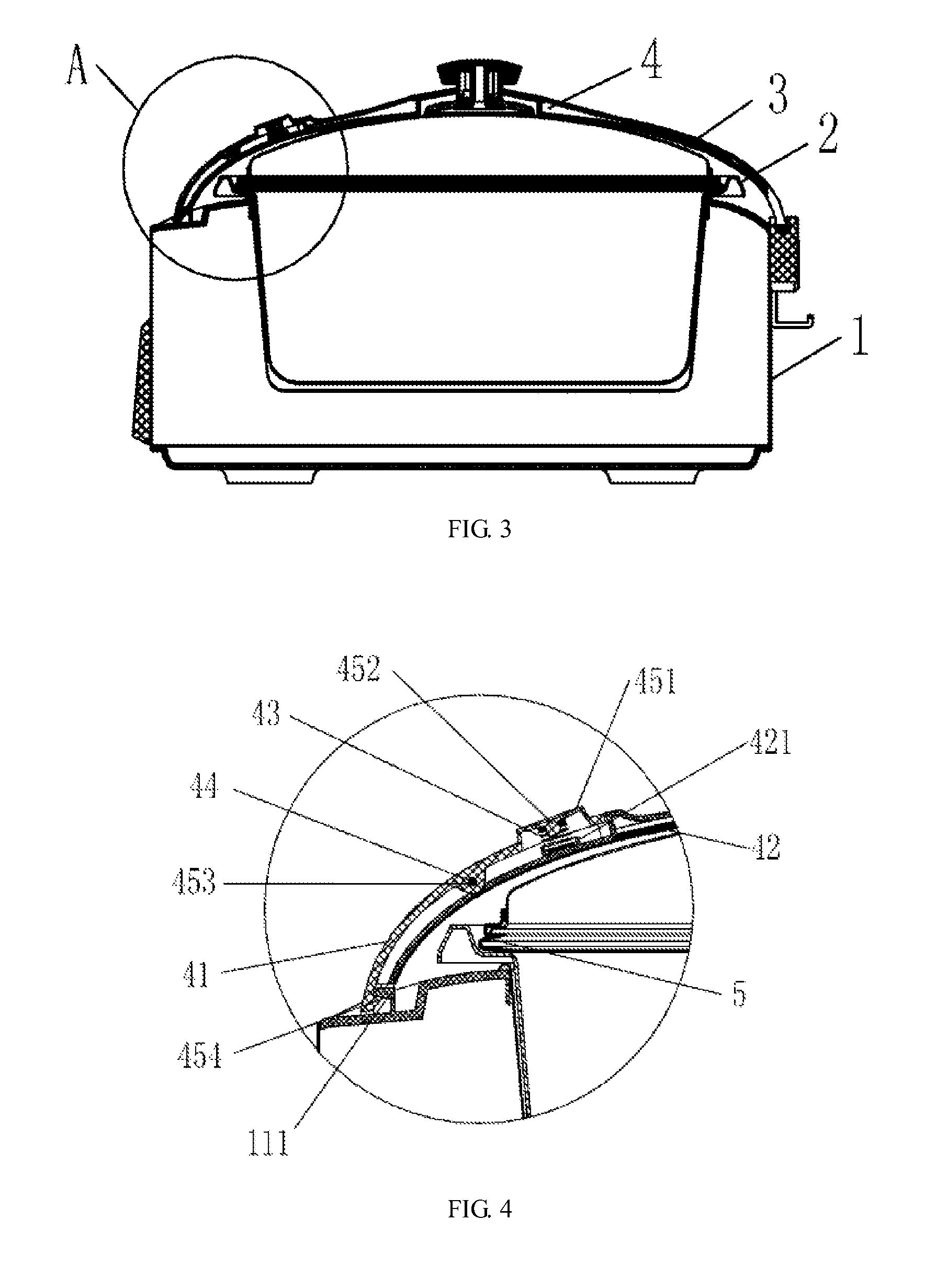

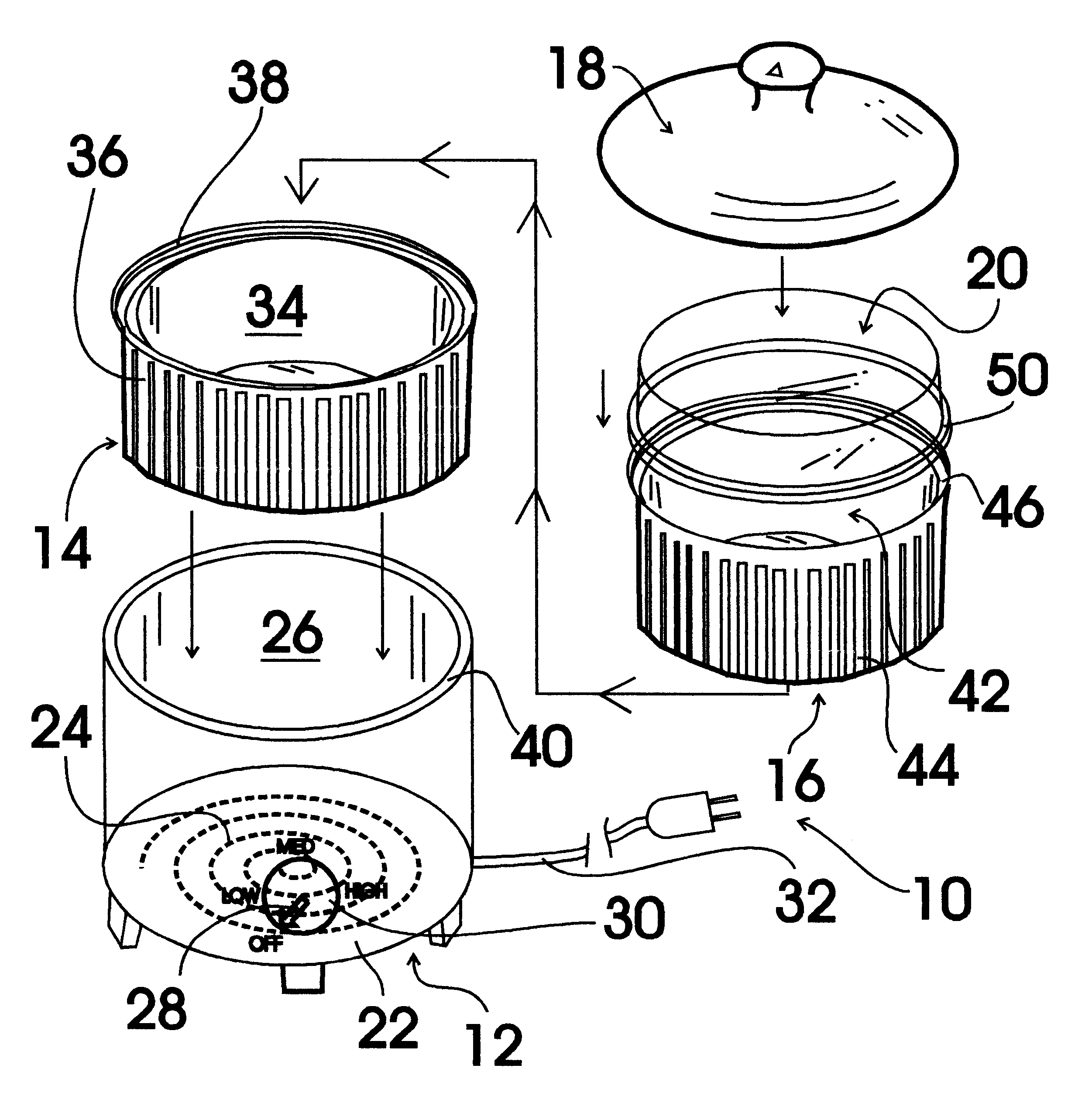

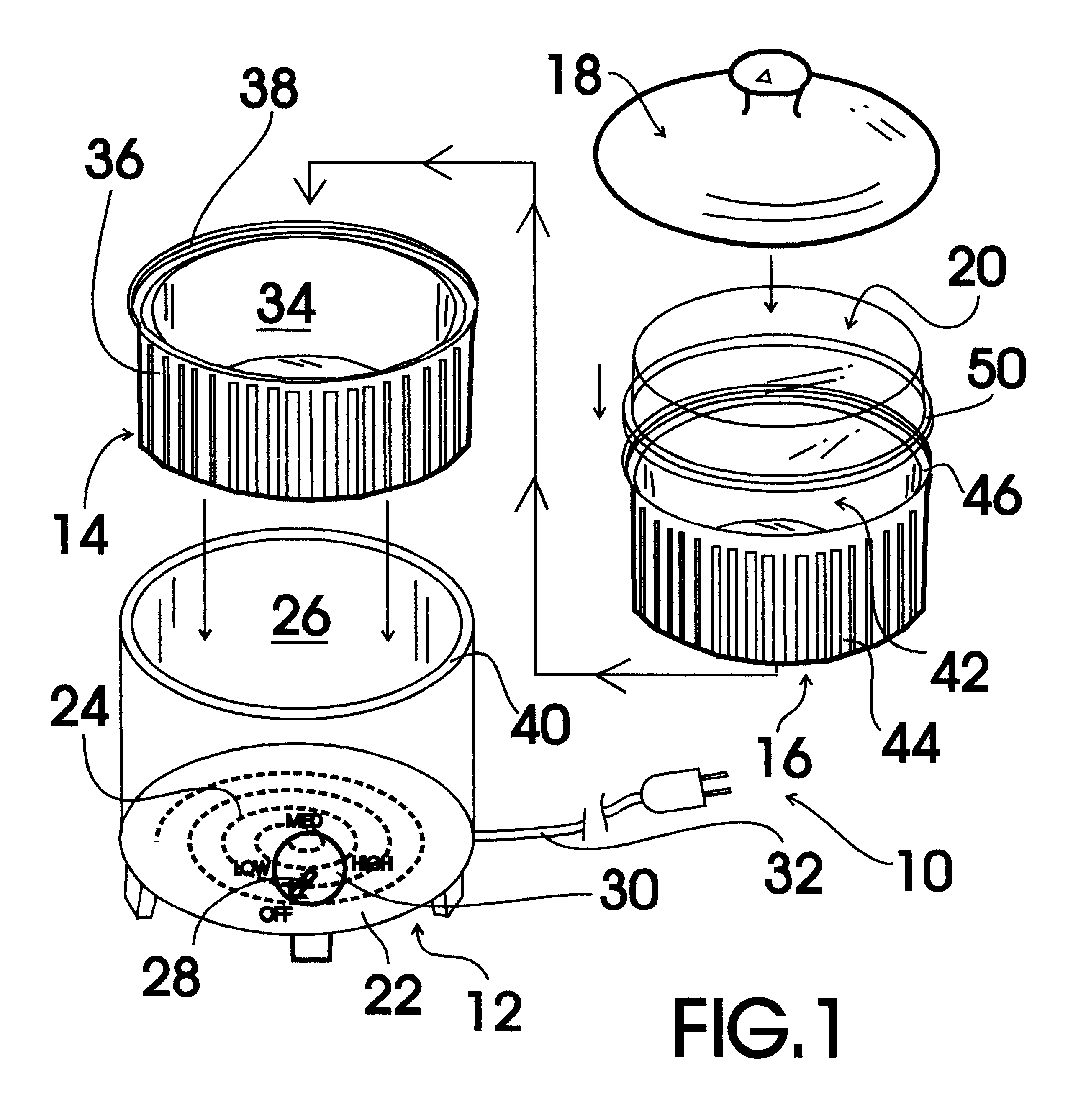

Slow cooker and locking assembly

ActiveUS8985372B2Simple and practical structureEasy to cleanCooking-vessel lids/coversBaking vesselsCookerEngineering

Owner:MIDEA GRP CO LTD

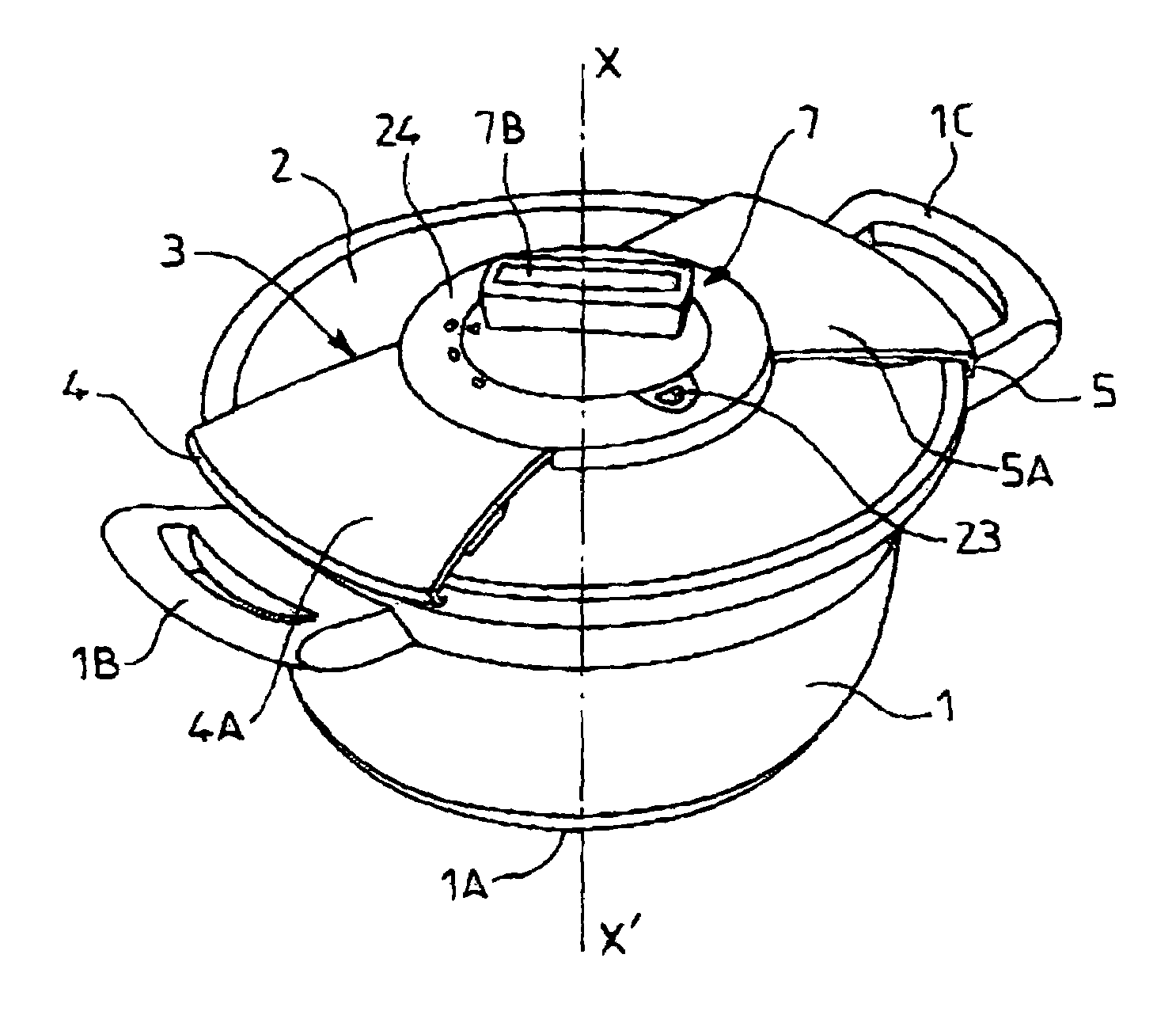

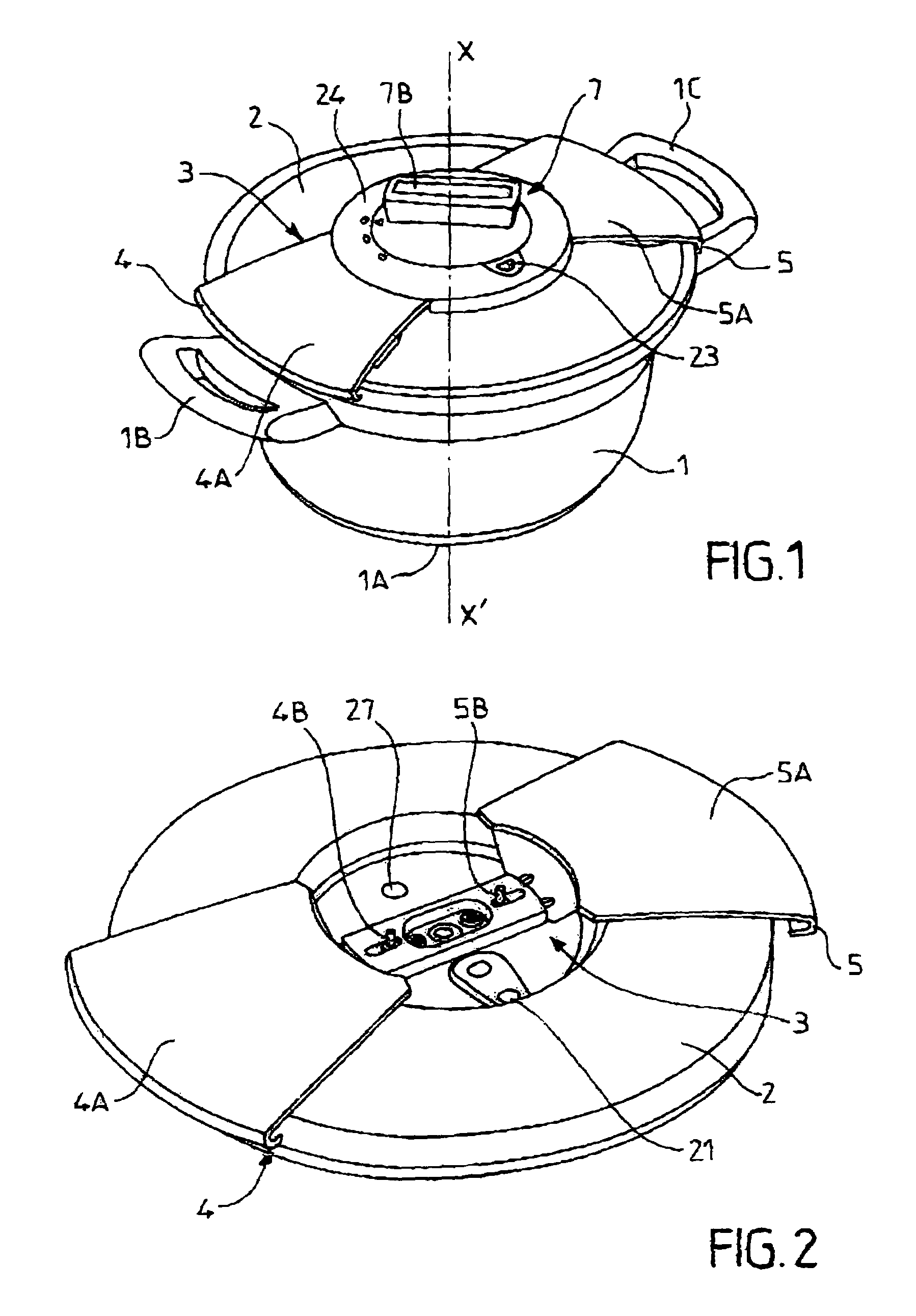

Pressure-cooking appliance including opening safety means

ActiveUS7523696B2Easy to useHigh speedWater heating stoves/rangesStove/ranges for heating waterHome applianceNeutral position

The invention relates to an appliance for cooking under pressure, the appliance comprising:a bowl and a lid; andopening safety means suitable for going between a neutral position, in which they allow the lid to be unlocked, and a blocking position, in which they prevent the lid from being unlocked, said safety means being designed to find themselves in the blocking position when the pressure prevailing inside the vessel is greater than or equal to a predetermined value or “rise pressure”, and / or when the temperature prevailing inside the vessel is greater than or equal to a predetermined value or “rise temperature”;said appliance being further comprising actuating means for actuating the safety means, which actuating means are arranged to make it possible to place the safety means in the blocking position. The invention is applicable to household appliances for cooking under pressure.

Owner:SEB SA

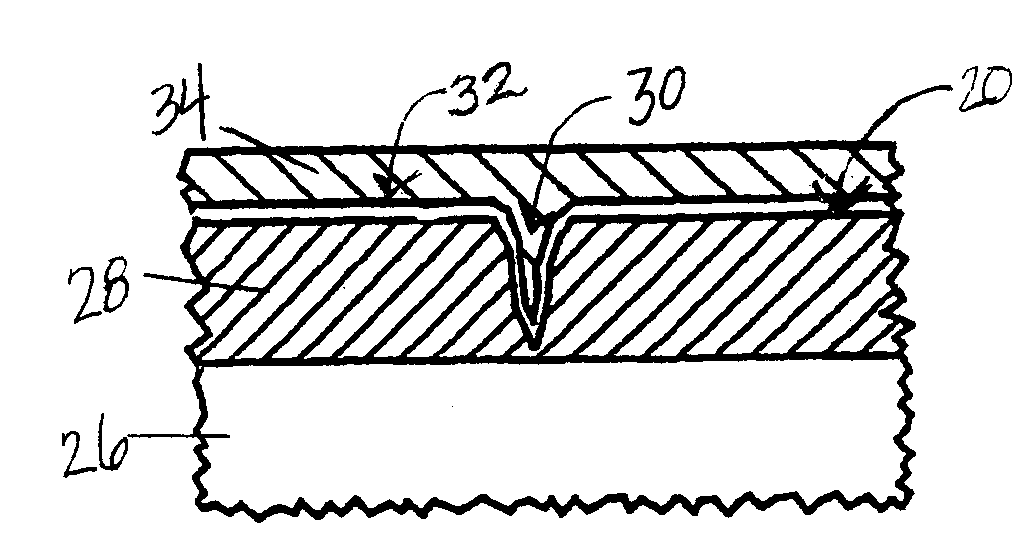

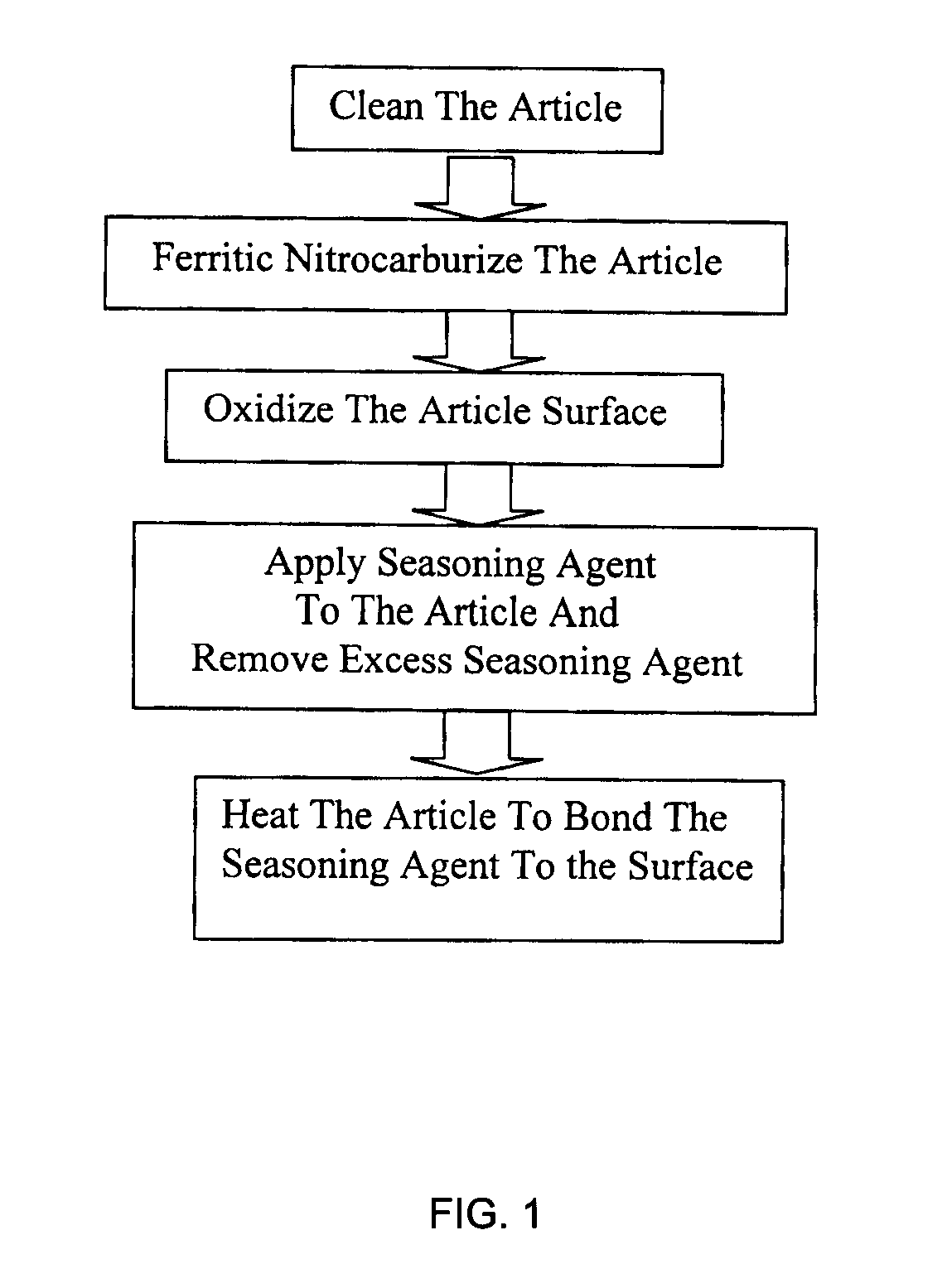

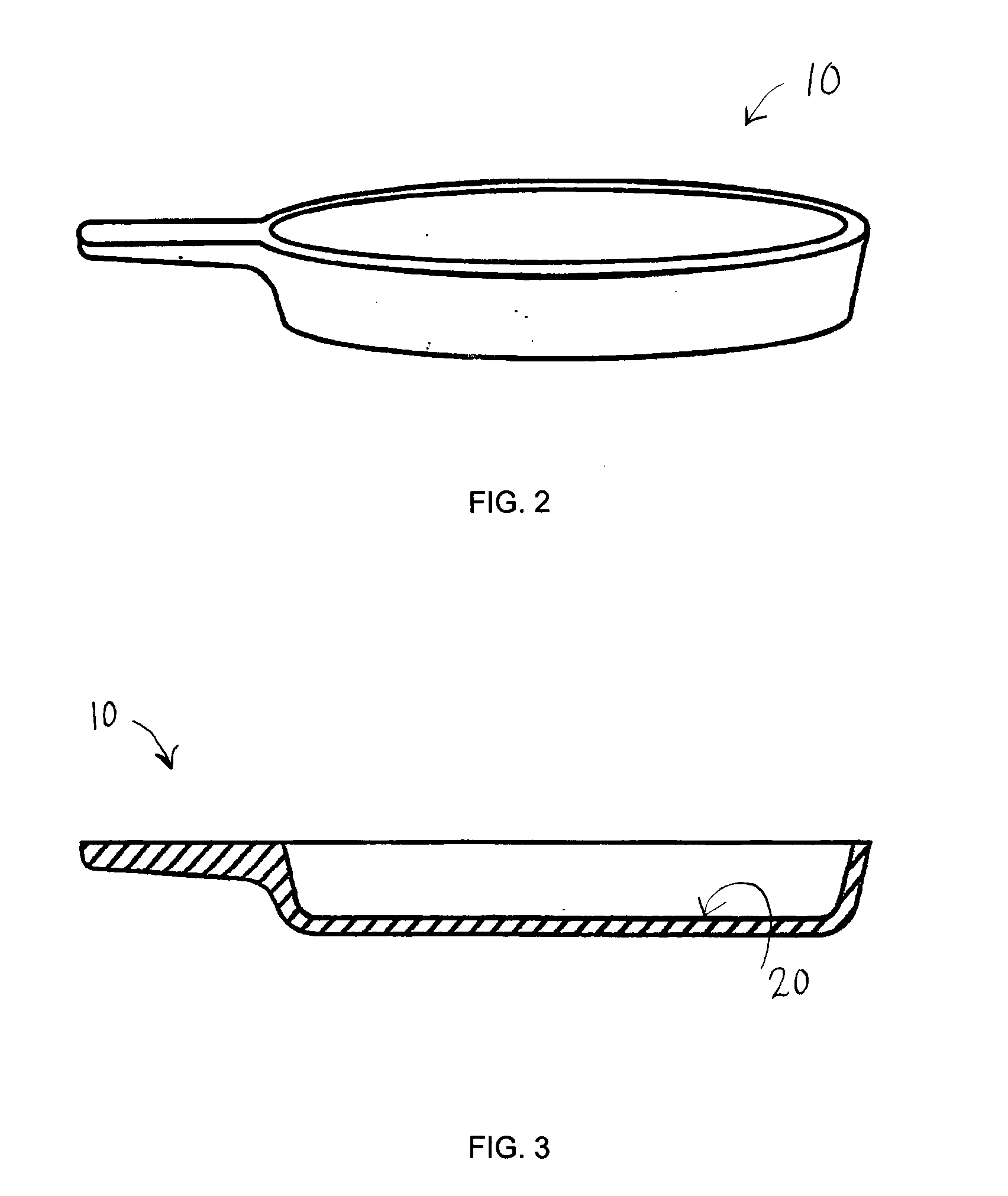

Seasoned Ferrous Cookware

ActiveUS20080118763A1Excellent abrasion resistanceImprove corrosion resistanceCooking-vessel materialsPretreated surfacesNitrogenAmmonia

A method, and an article produced thereby, of providing a corroson-resistant, scratch-resistant, and stick-resistant, surface on a ferrous-metal-containing article, including forming microcavities in a ferrous-metal-containing article surface by ferritic nitrocarburization and seasoning the surface, including a non-stick agent deposited thereon. In preferred embodiments, the surface of the article including the exposed microcavities is oxidized before seasoning. The article includes cookware. Certain preferred embodiments include forming microcavities by ferritic nitrocarburization wherein the article is heated in an atmosphere including ammonia, nitrogen, and carbon-containing gas to a nitriding temperature of between about 800° F. and about 1300° F. for a time of about 0.5 hours to about 10 hours.

Owner:LODGE MFG CO

Slow cooker

ActiveUS8640908B2Prevent overflowEasy to operateCooking-vessel lids/coversBaking vesselsCookerEngineering

A slow cooker is provided which comprises a cooking body having a hollow cavity, a liner container received in the hollow cavity, a lid selectively engageable with the liner container, and a locking assembly for locking the lid with the cooking body. The locking assembly is hinged at one side of the cooking body at one end and selectively engaged with an opposite side of the cooking body at the other end, with the locking assembly being disposed above the lid.

Owner:MIDEA GRP CO LTD

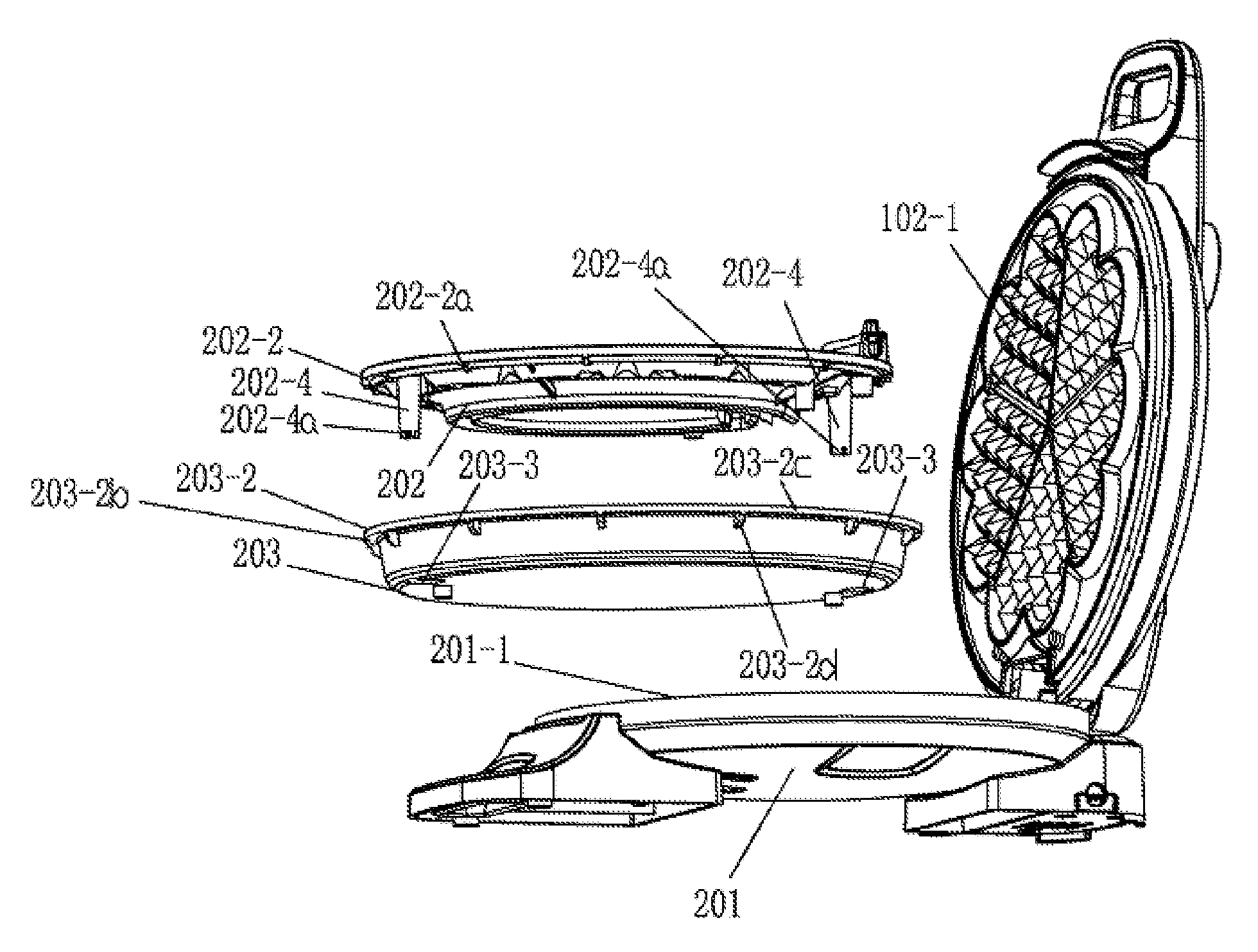

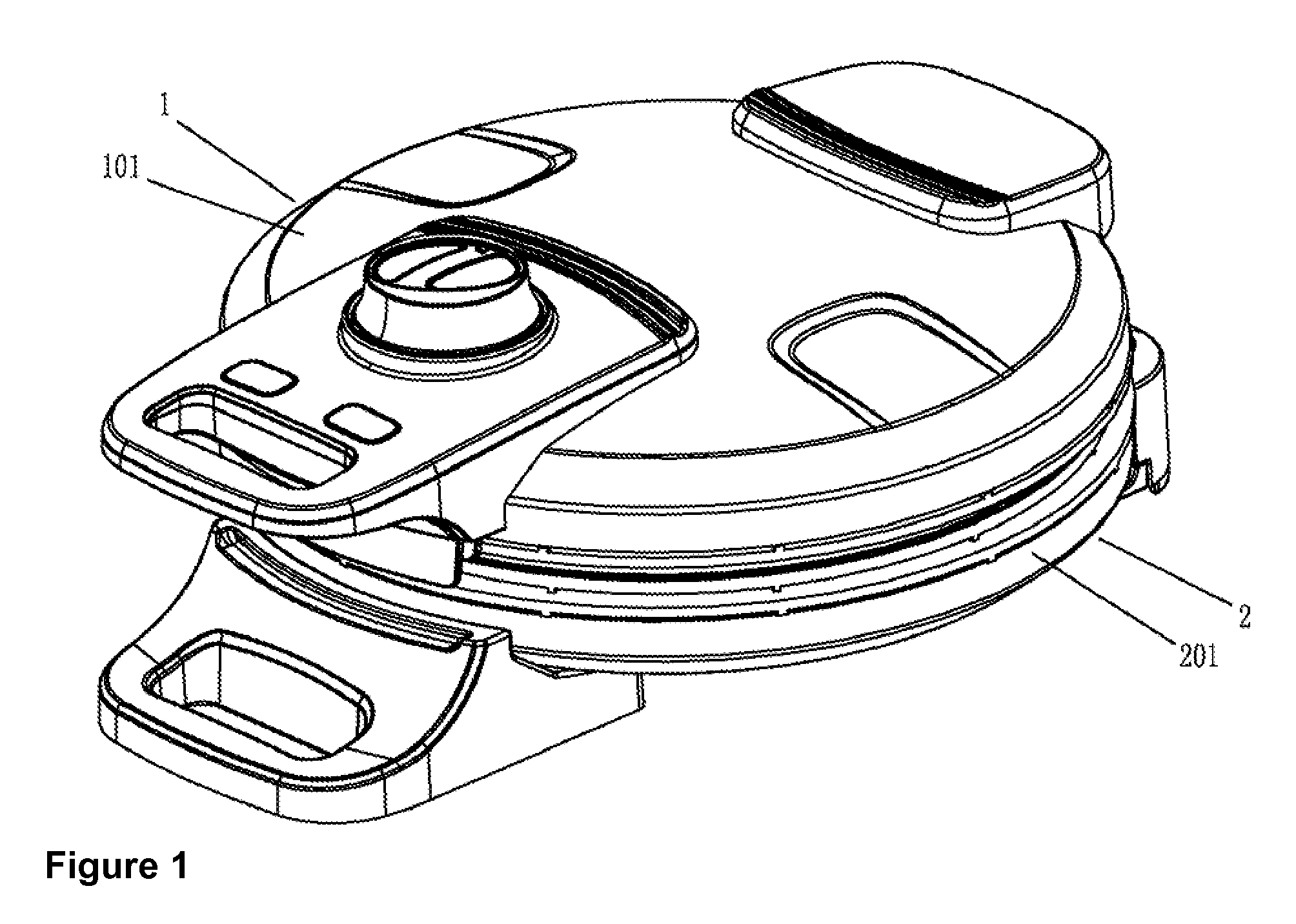

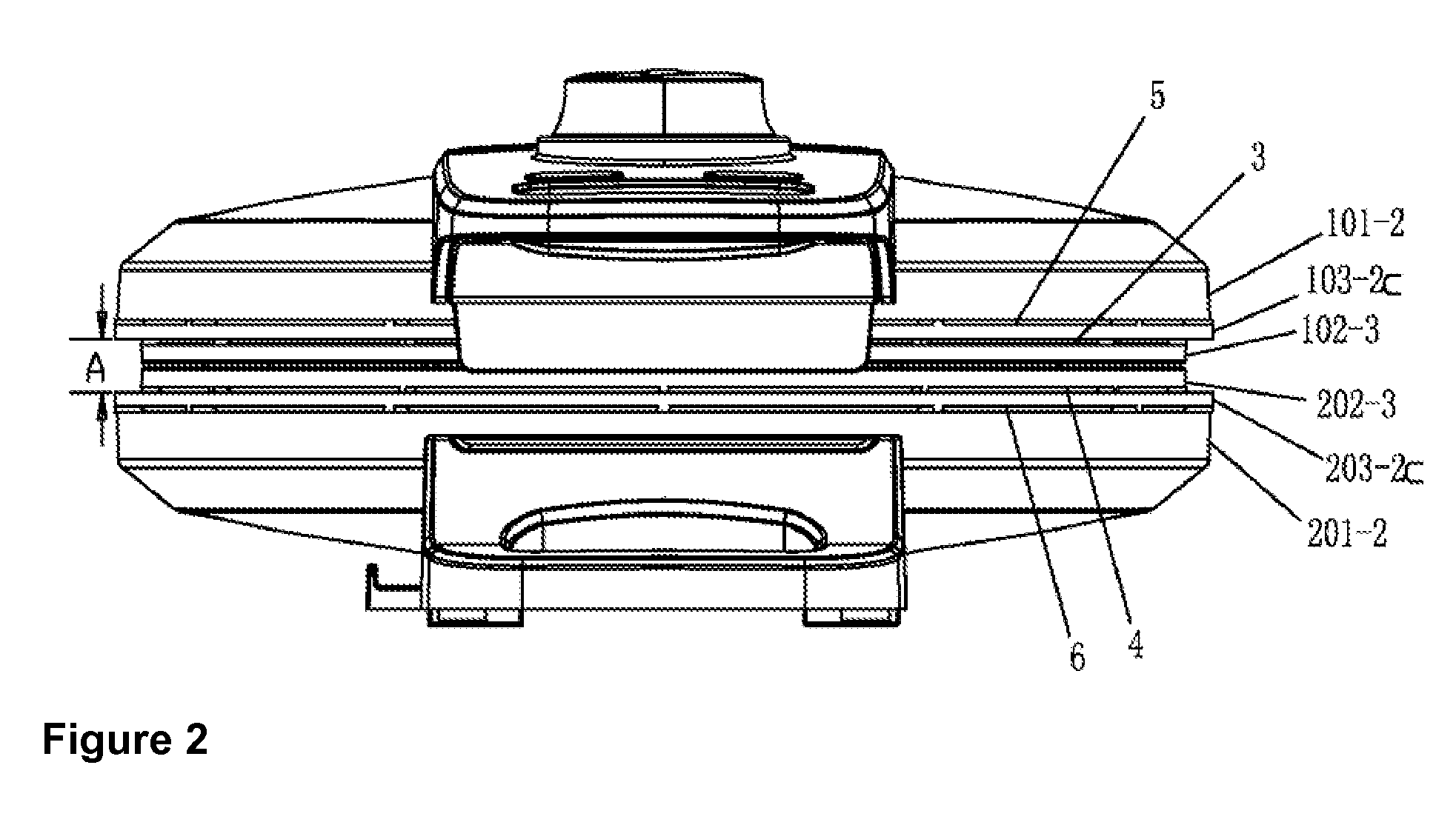

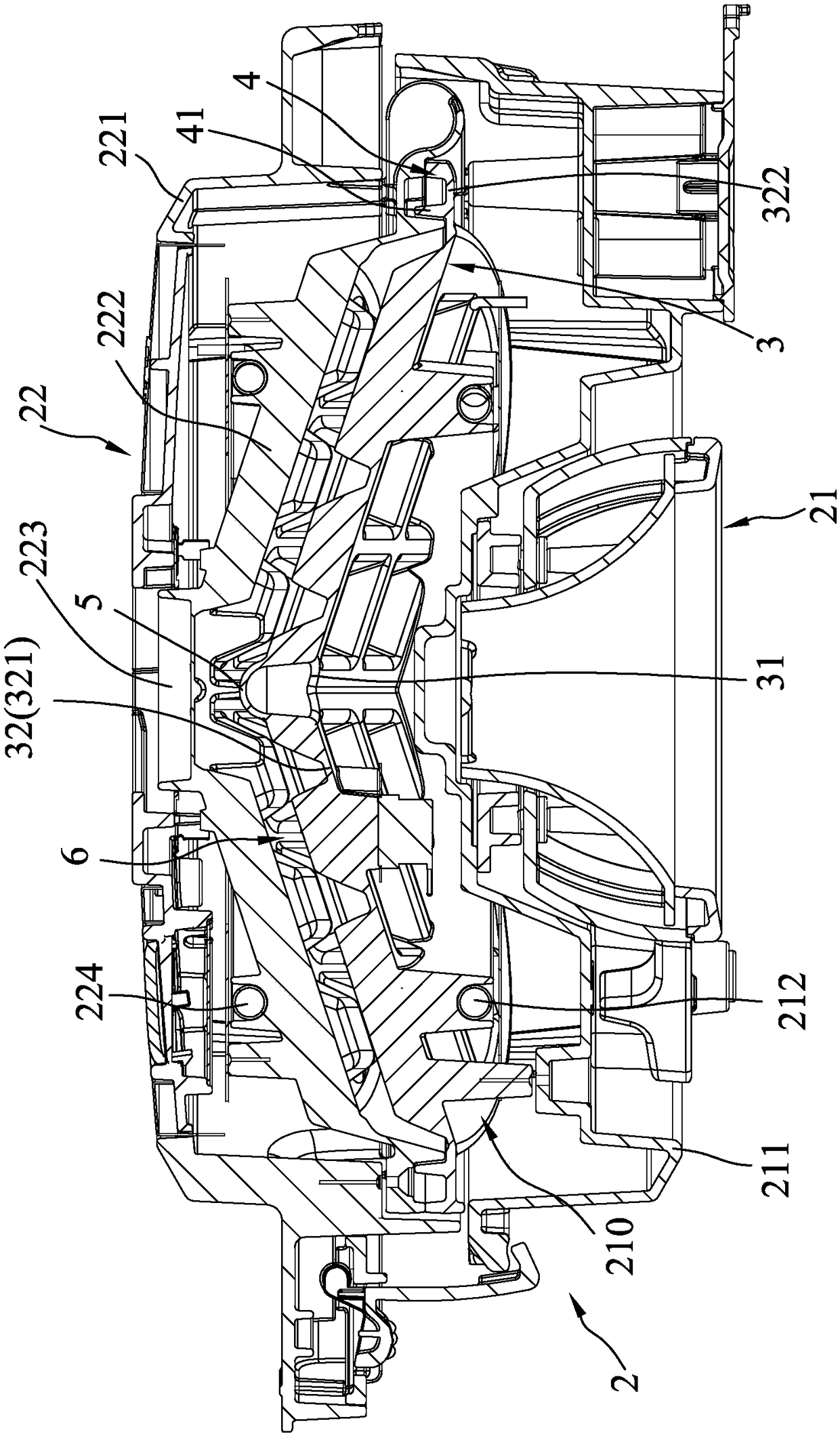

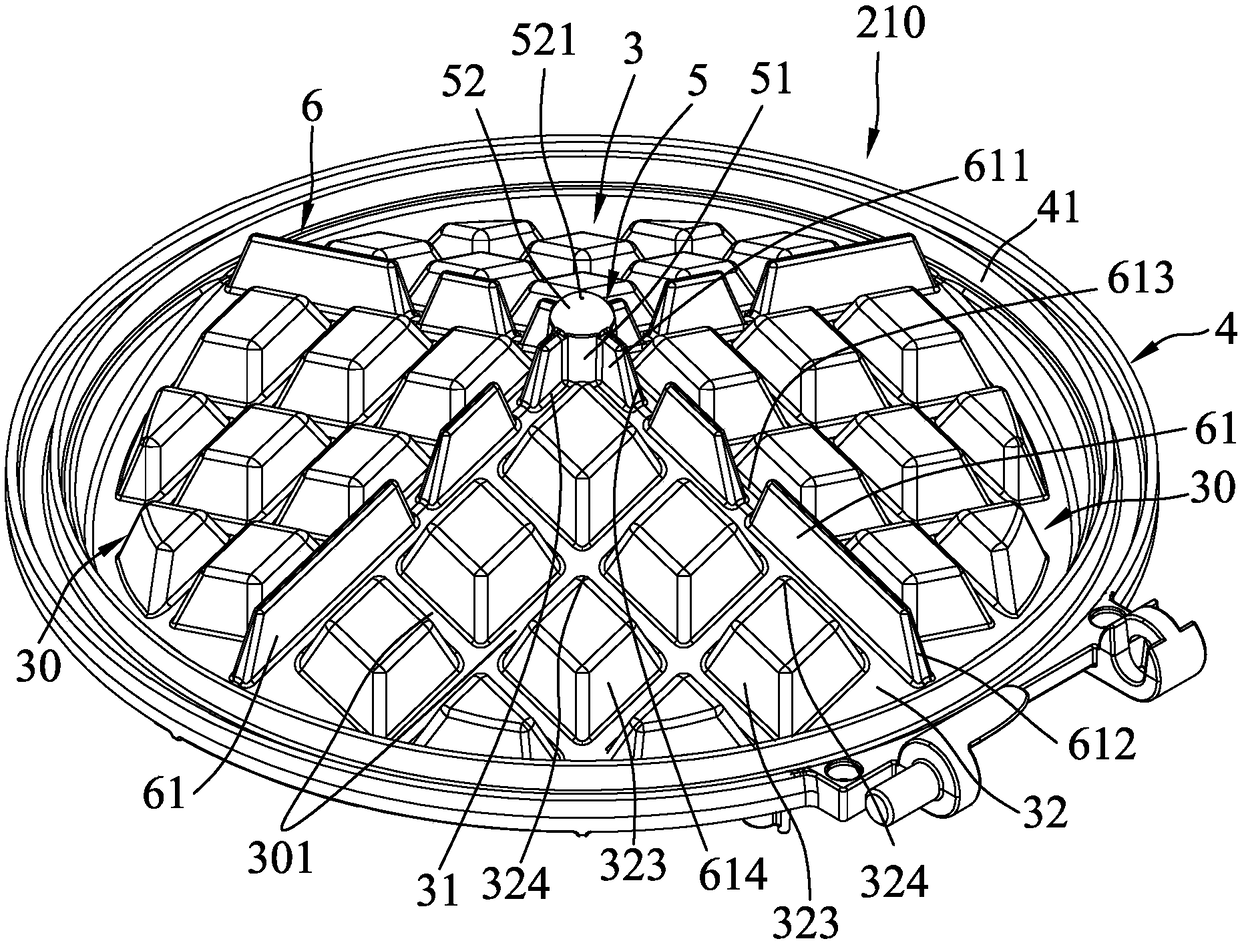

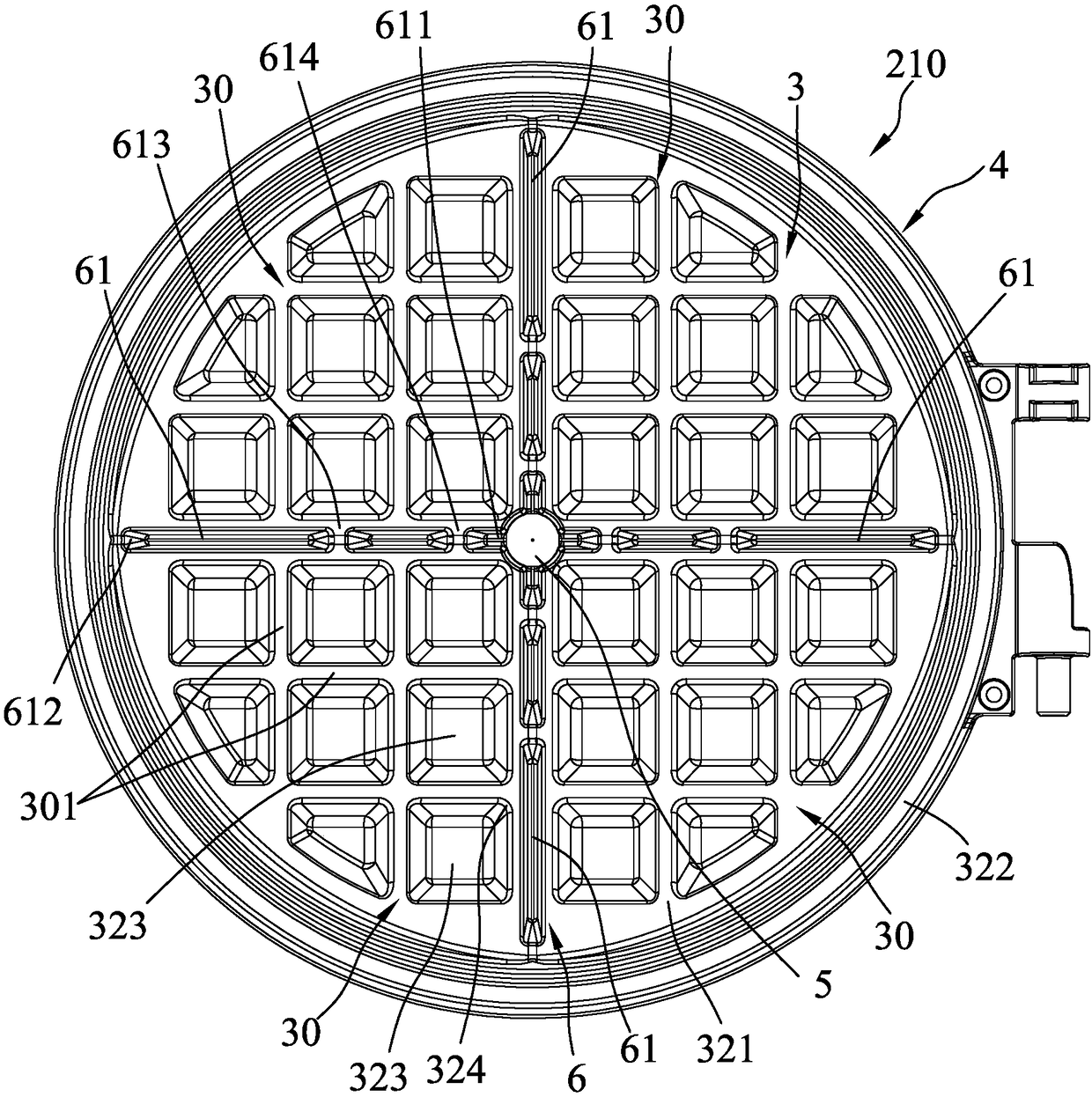

Electric waffle maker or steak grill

InactiveUS9414713B2Simple and economical structureImprove insulation performanceBaking vesselsRoasters/grillsEngineering

An electric scone machine or steak machine comprises hinge-connected upper and lower bakeware bodies (1, 2). The upper and lower bakeware bodies (1, 2) consist of upper and lower metal housings (101, 201) and upper and lower heating plates (102, 202). The upper and lower heating plates (102, 202) are correspondingly mounted in the upper and lower metal housings (101, 201), and are formed in a manner that baking hot surfaces (102-1, 202-1) of the upper and lower heating plates (102, 202) are opposite to each other when closed. Nonmetallic disk-shaped upper and lower heat insulating housings (103, 203) are disposed between the upper metal housing (101) and the upper heating plate (102) and between the lower metal housing (201) and the lower heating plate (202) respectively. The upper and lower heating plates (102, 202) are embedded in cavities (103-1, 203-1) of the upper and lower heat insulating housings (103, 203) respectively, and have opening edges (102-2, 202-2) borne on support surfaces (103-2a, 203-2a) of extended support platforms (103-2, 203-2) of openings of the upper and lower heat insulating housings (103, 203). Opening edges (101-1, 201-1) of the upper and lower metal housings (101, 201) abut against another end surfaces (103-2b, 203-2b) opposite to the support surfaces (103-2a, 203-2a) of the extended support platforms (103-2, 203-2). Outer end surfaces (103-2c, 203-2c) of the extended support platforms (103-2, 203-2) extend out of outer sides of outer end surfaces (101-2, 201-2, 102-3, 202-3) of the upper and lower metal housings (101, 201) and the upper and lower heating plates (102, 202). The electric scone machine or steak machine of this structure has a simple and reasonable structure, and has the desirable heat insulating effect.

Owner:NOMURA USA

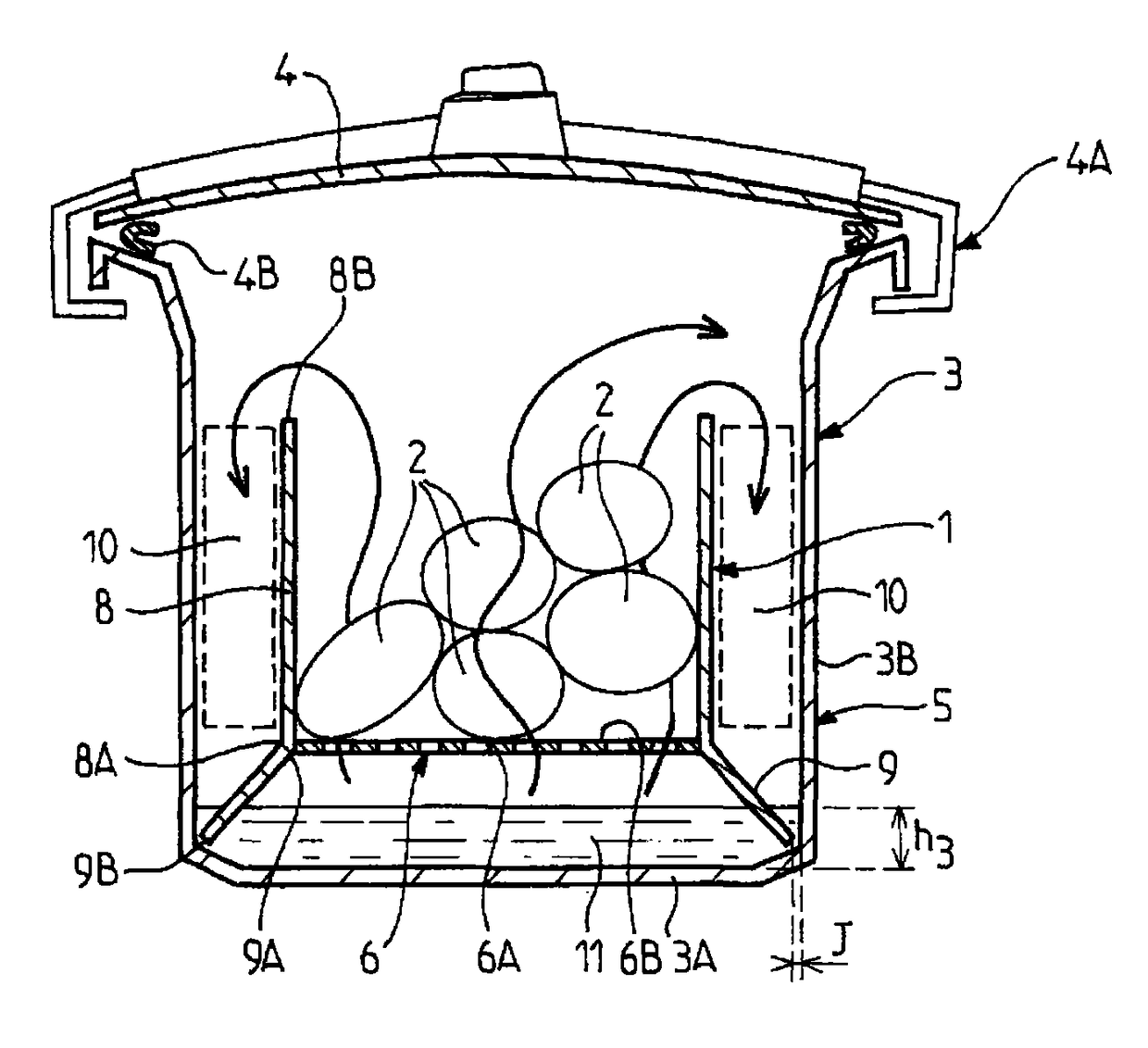

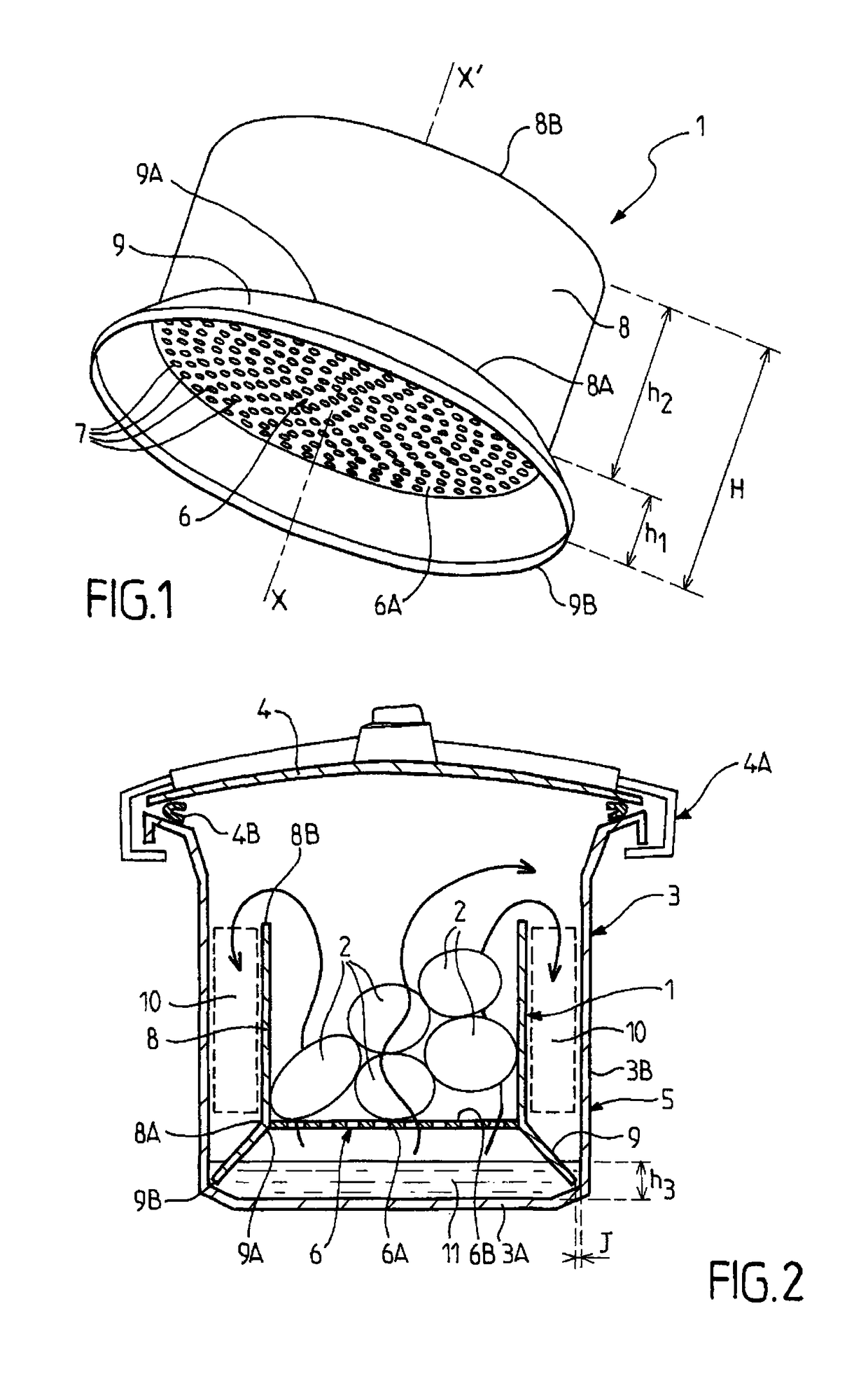

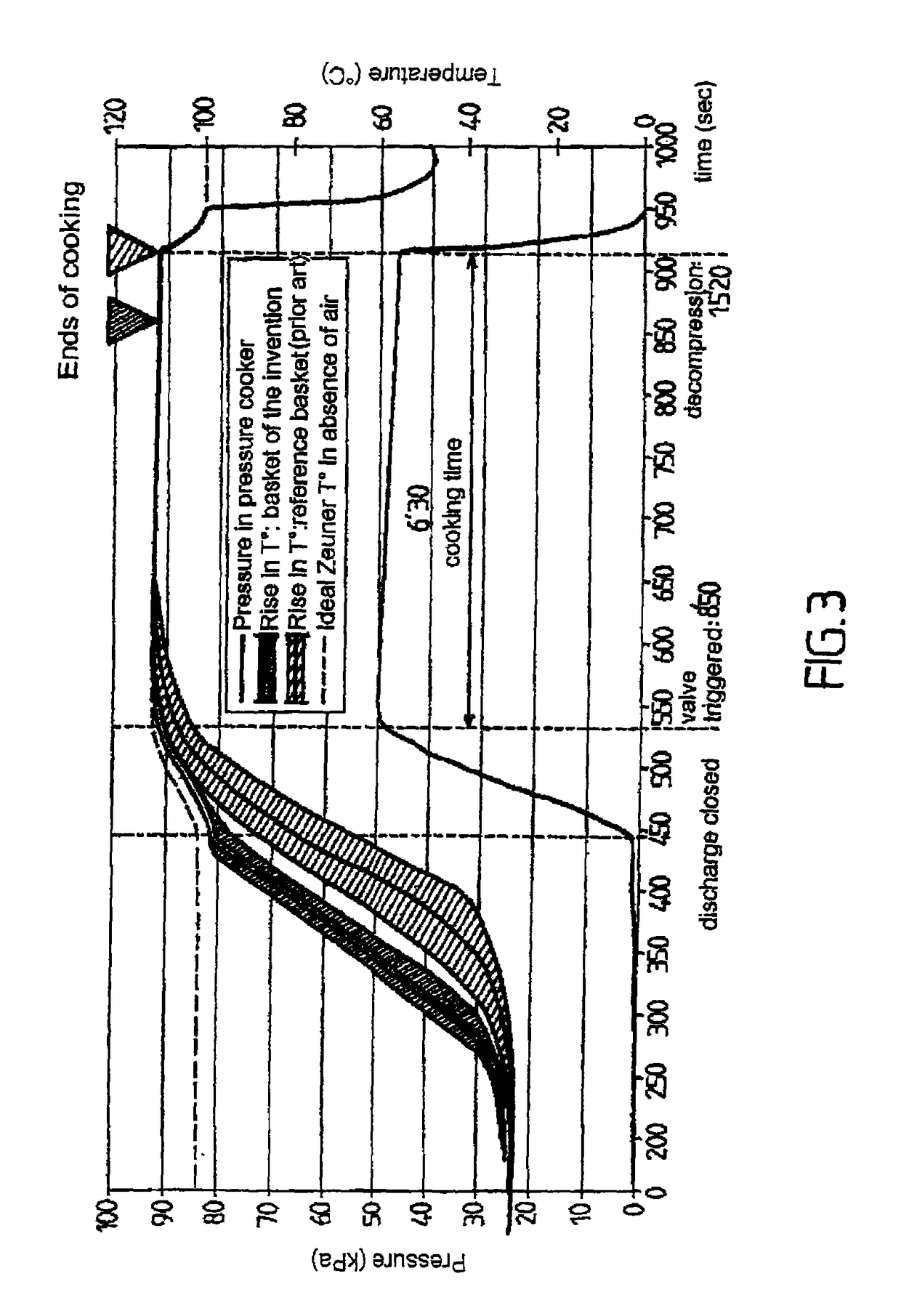

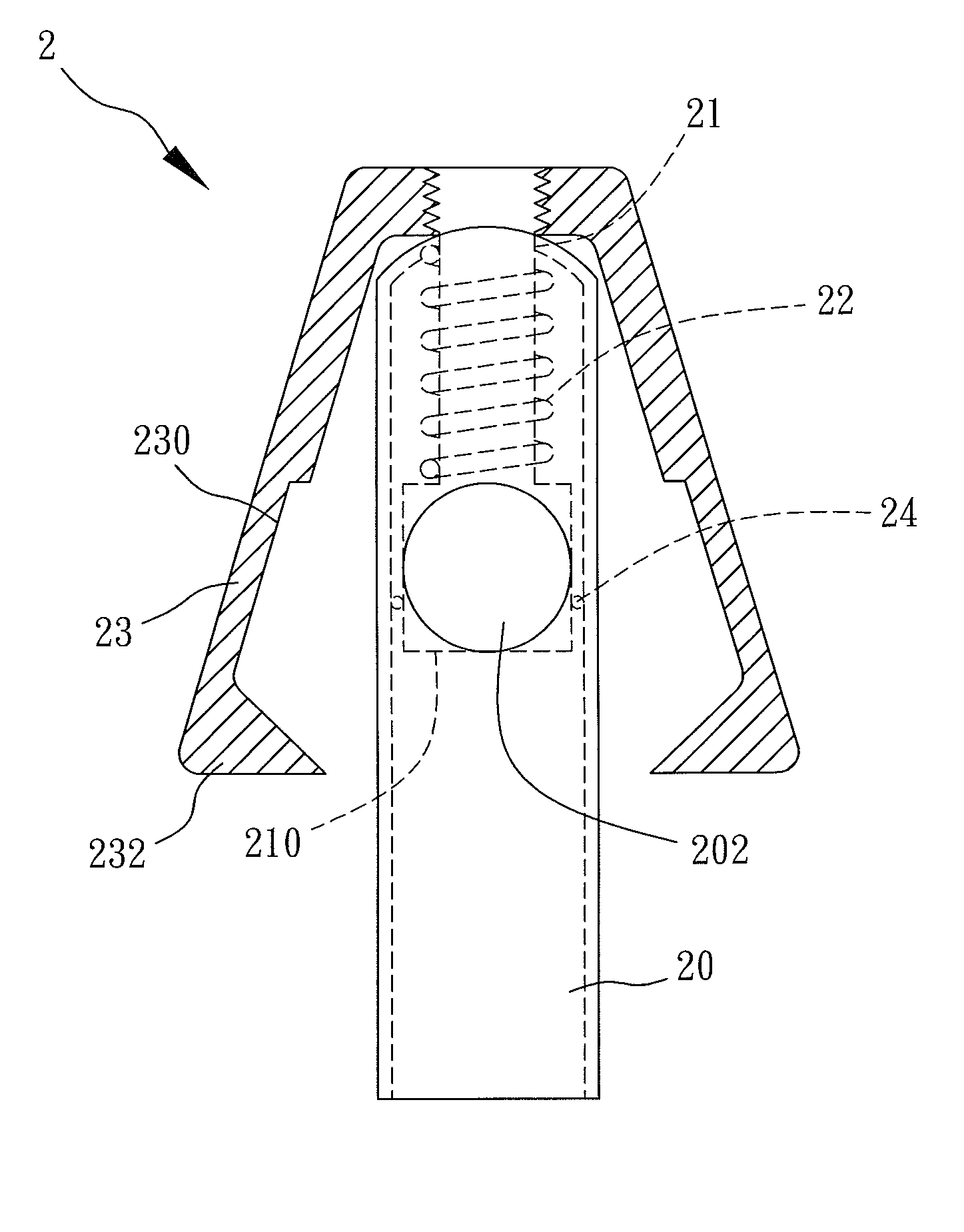

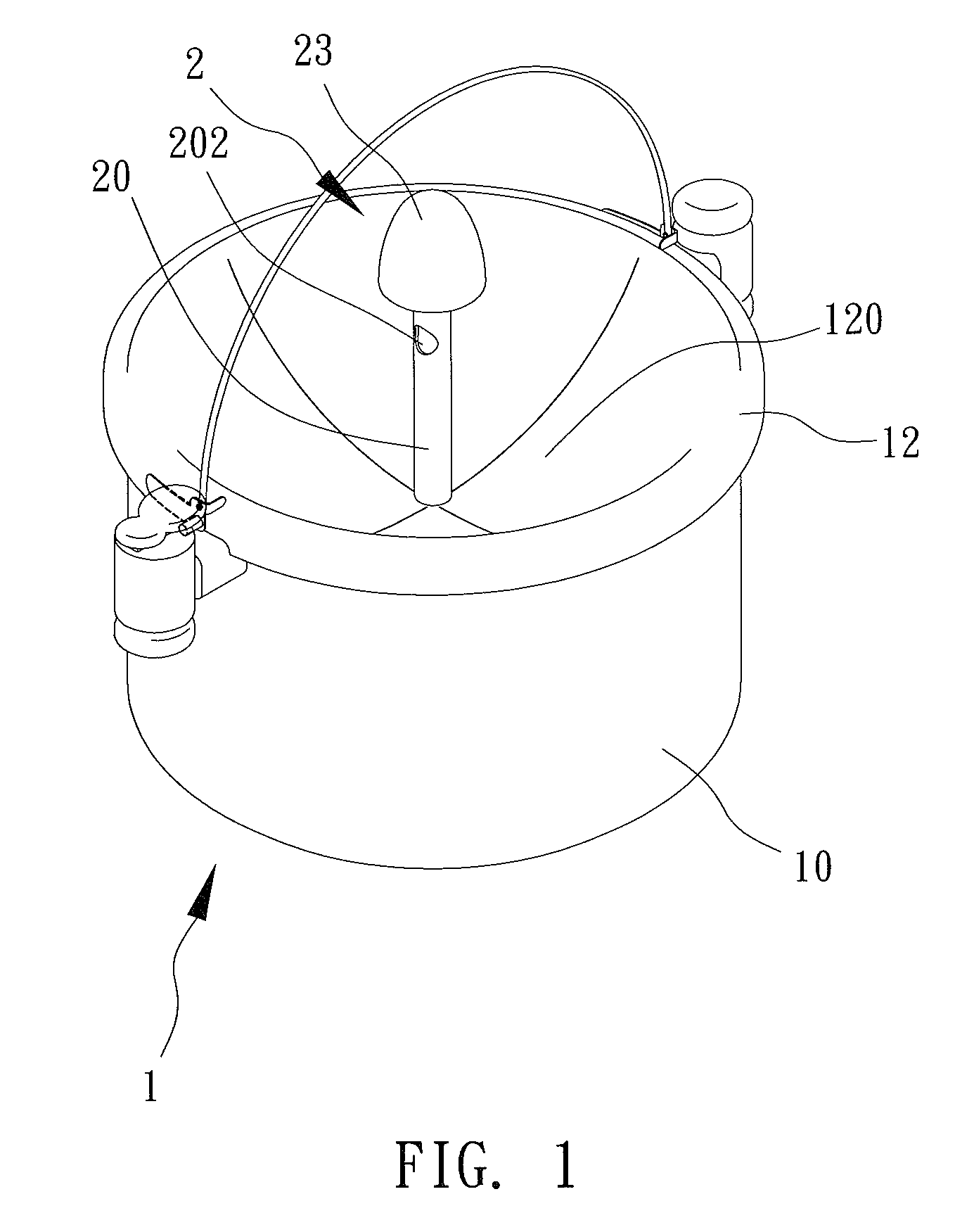

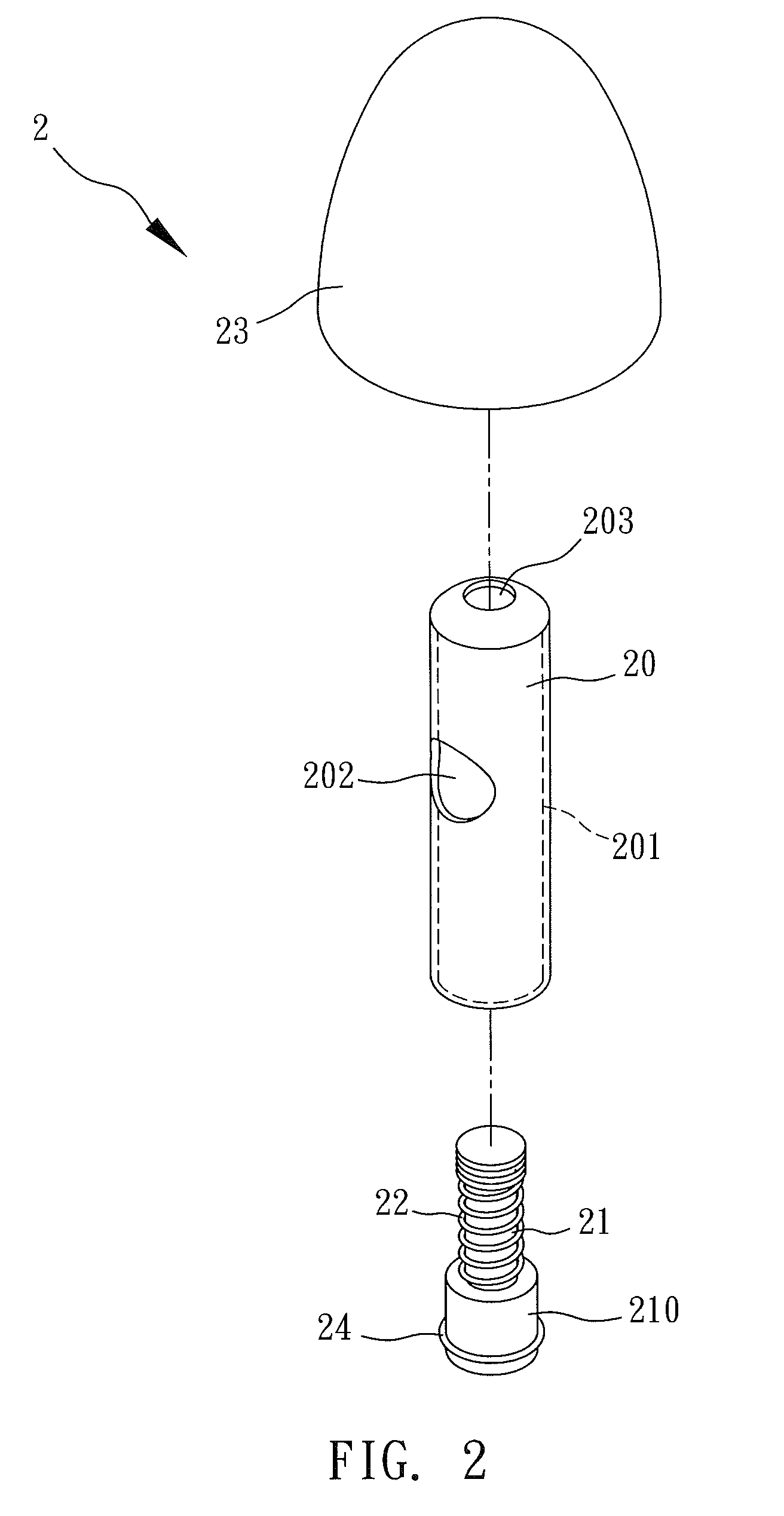

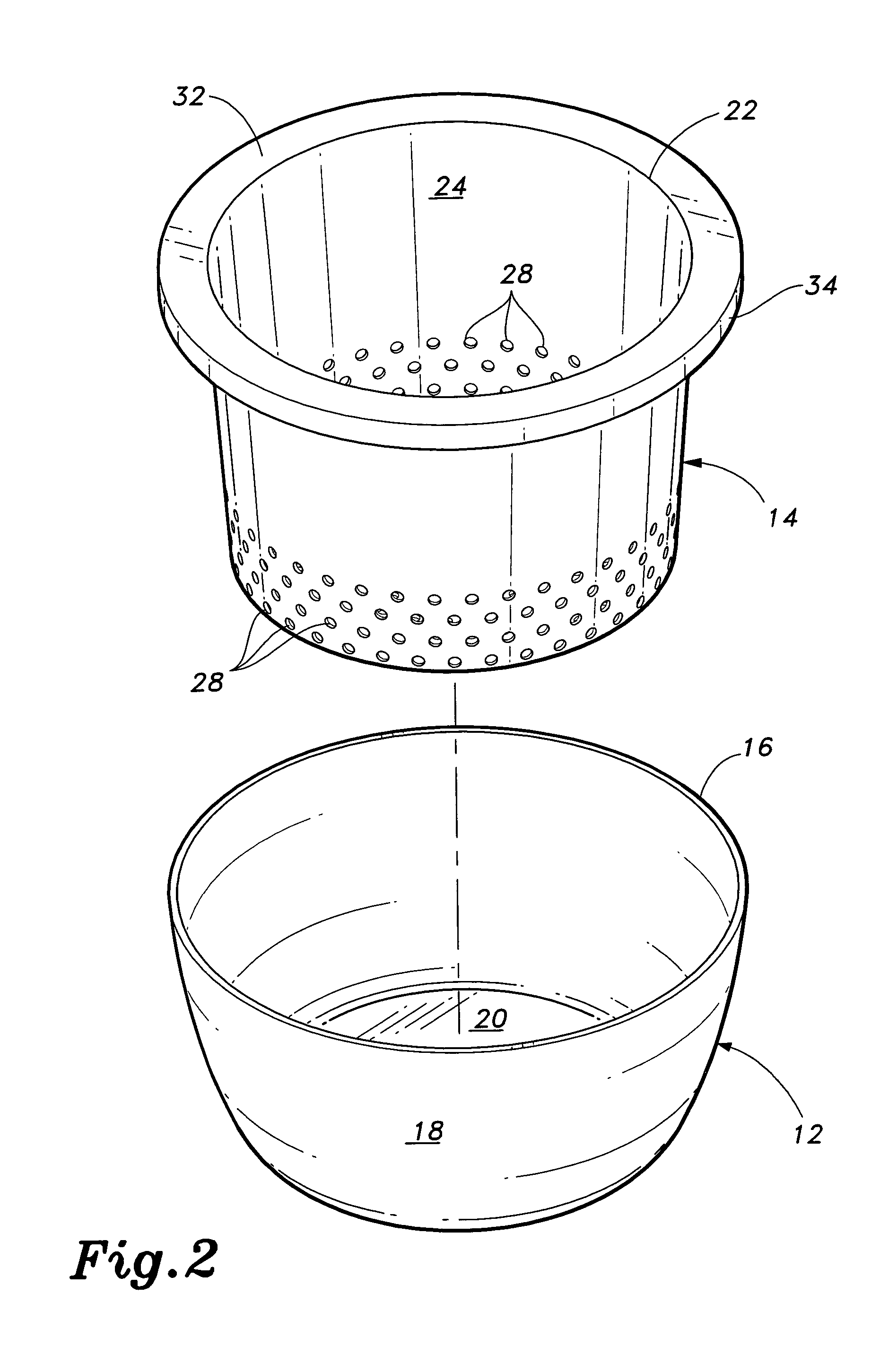

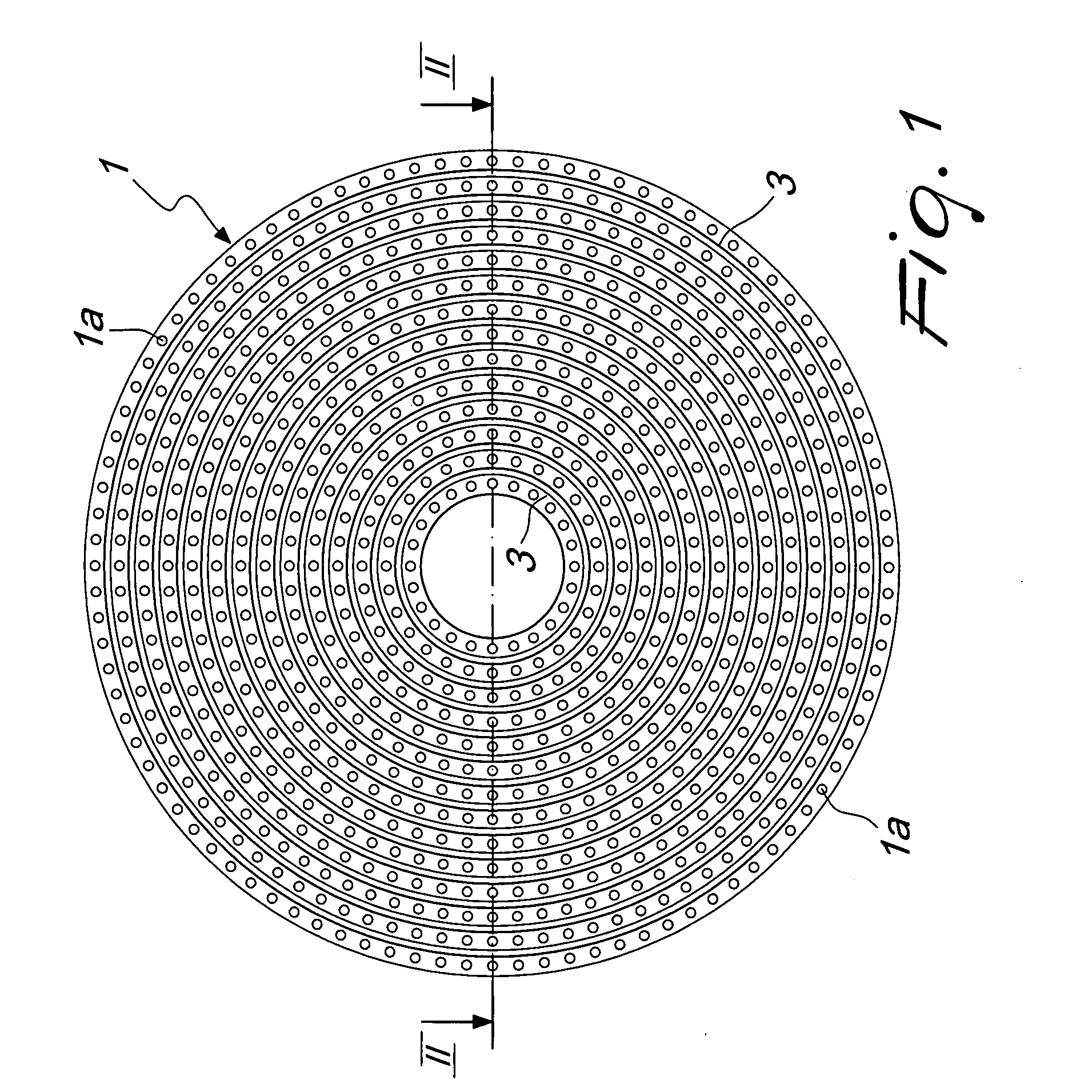

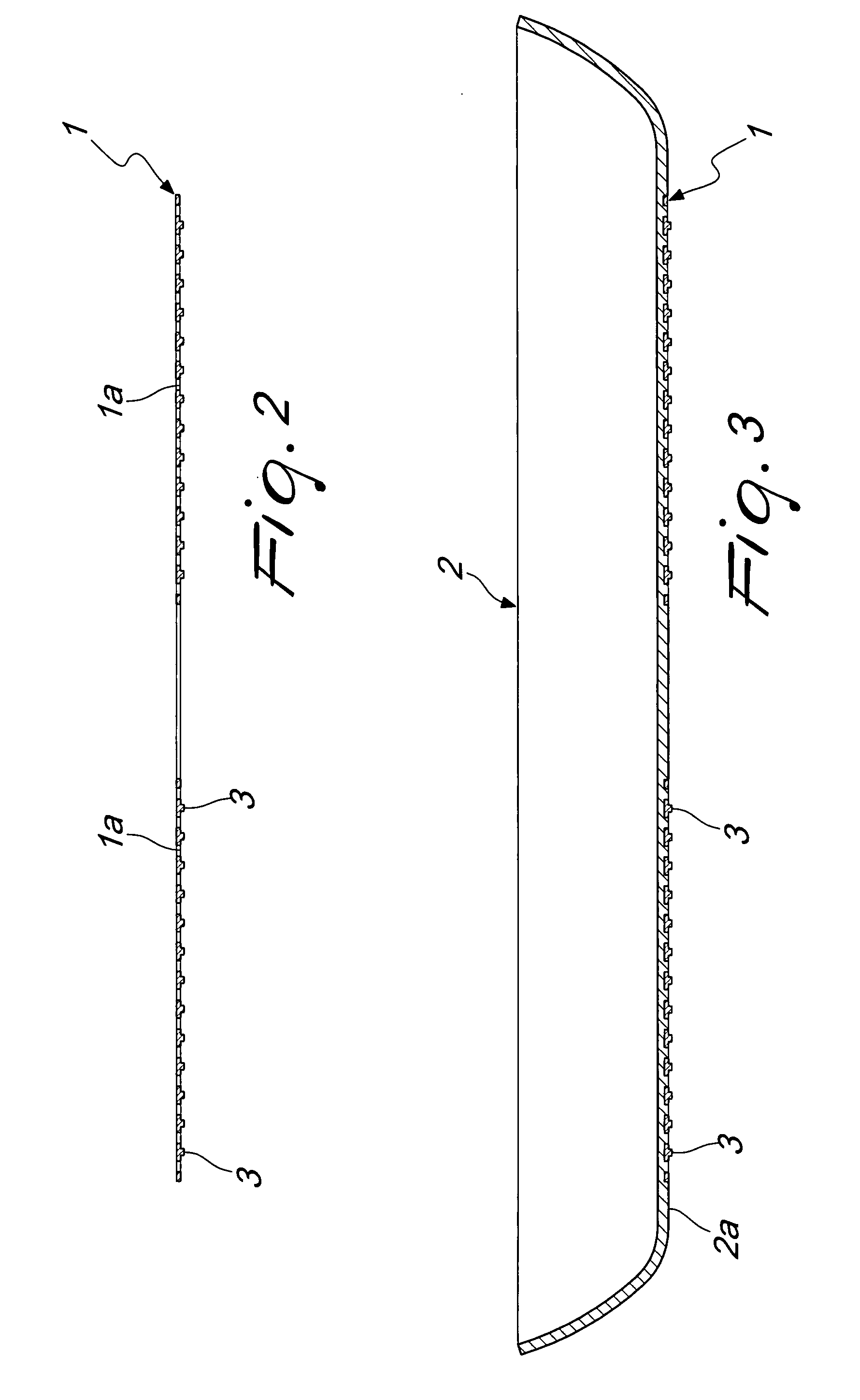

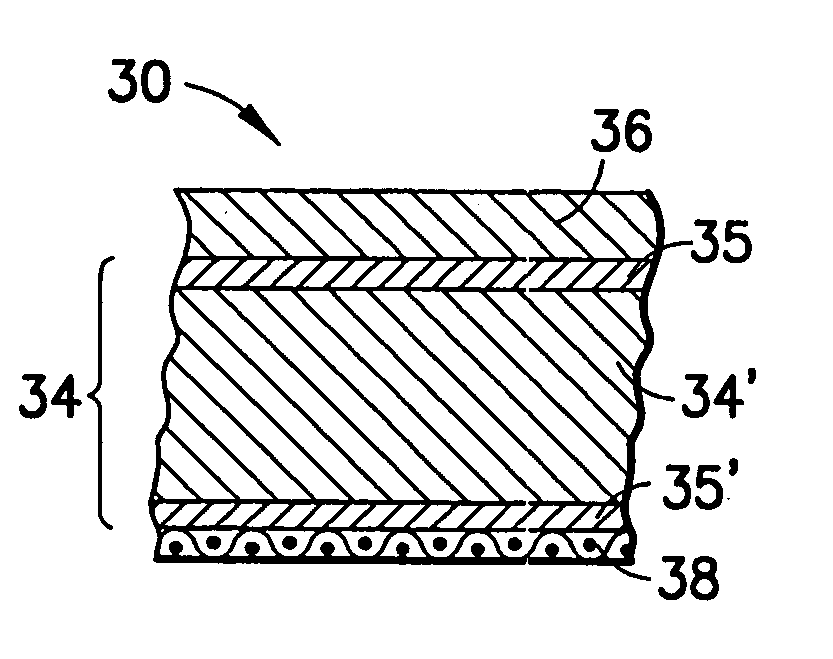

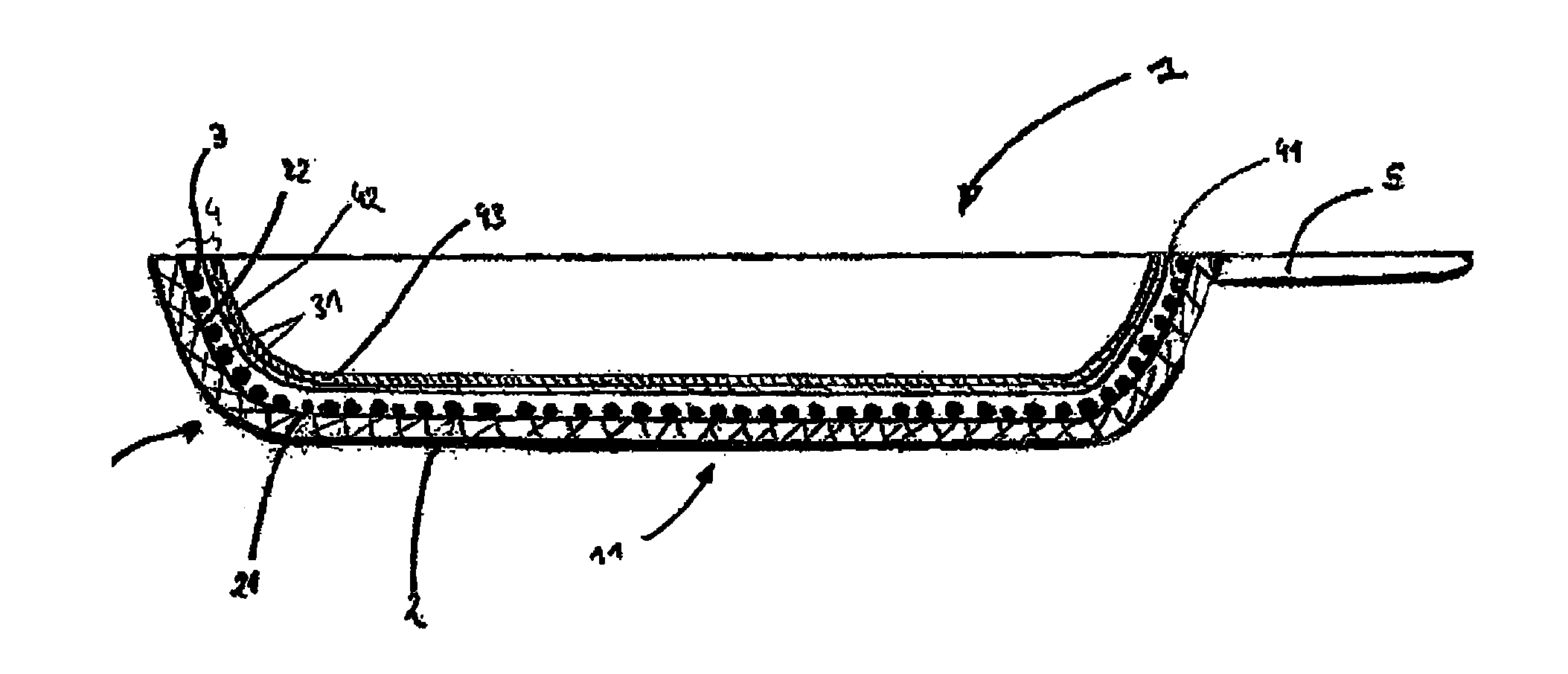

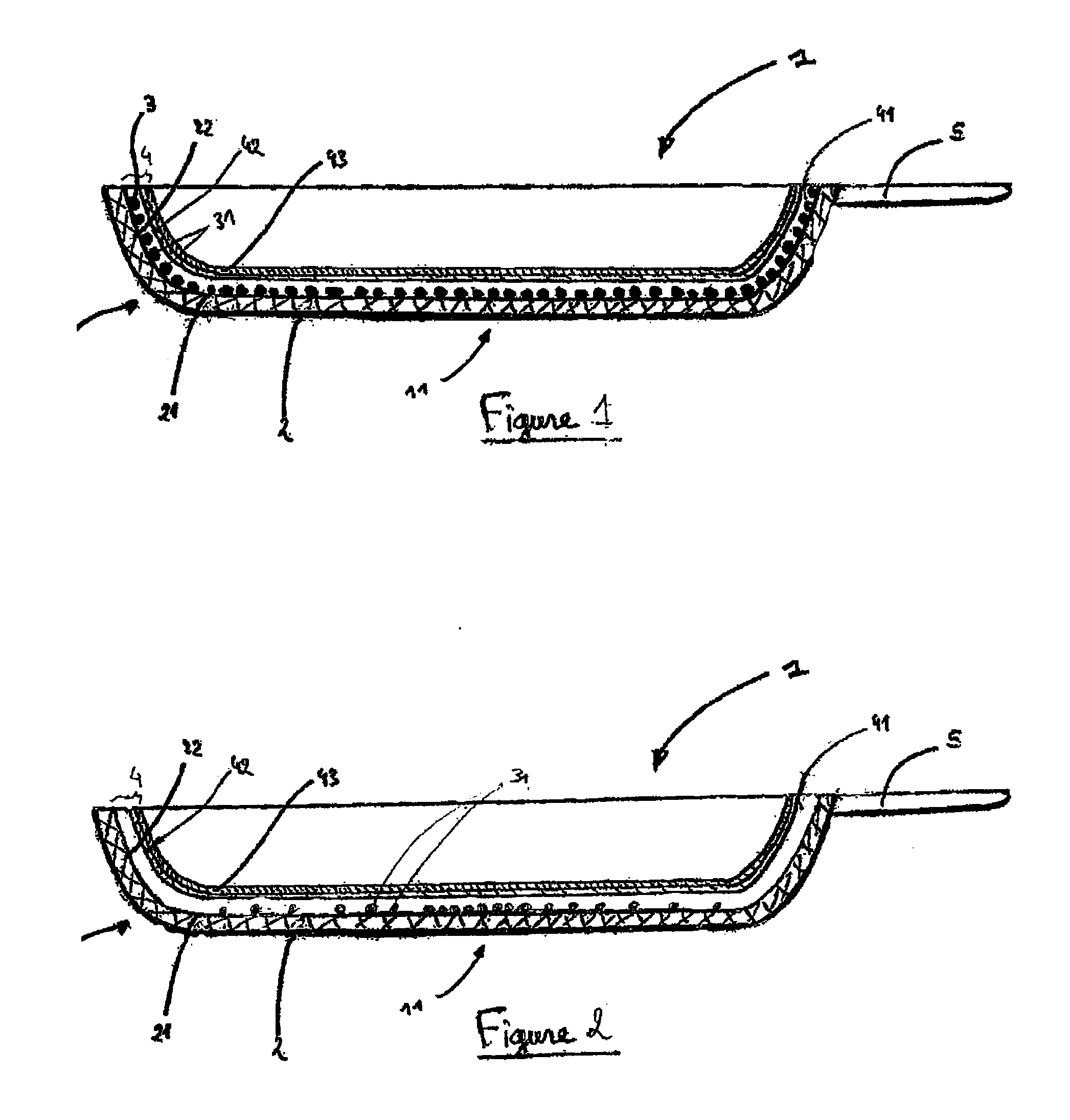

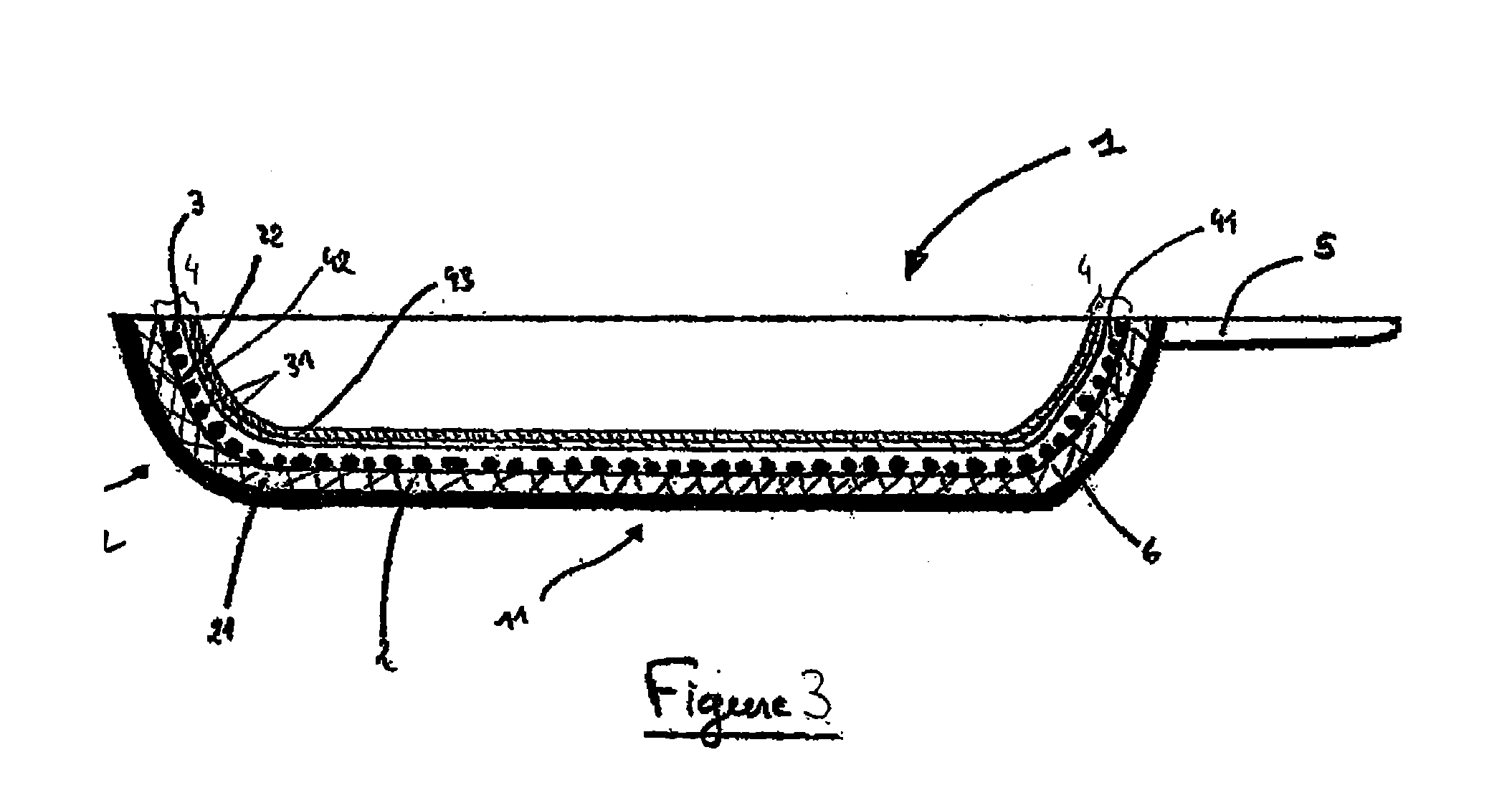

Food cooking basket and corresponding cooking system

InactiveUS9801491B2Shorten the timeEasy to installBoiling over preventionBaking vesselsThermodynamicsIngested food

The invention relates to a basket (1) for cooking food for a cooking utensil designed to cook the food in an atmosphere charged with steam, said basket (1) having a bottom (6) that is permeable to steam and an upper annular side wall (8) extending upwards from said bottom (6) so as to co-operate therewith to form a receptacle for receiving said food, said basket being characterized in that it further has a lower annular side wall (9) extending downwards from said bottom (6), said lower annular side wall (9) being shaped to channel the steam towards said bottom (6) so that the steam channeled in this way passes at least locally through said bottom (6).

Owner:SEB SA

Air relief valve structure of pressure cooker

Owner:ZAO AN

Food frying and baking device

ActiveCN108720633ARapid and uniform diffusionImprove qualityBaking vesselsRoasters/grillsCooking & bakingFluid - substance

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Baking tray and baking oven

ActiveCN107495849AAchieve heatingAchieve rapid heat conductionBaking vesselsRoasters/grillsCooking & bakingFood material

The invention discloses a baking tray and a baking oven, wherein the baking tray comprises a metal article carrying body and a heat storage body; the upper surface of the metal article carrying body is used for carrying food materials to be baked, so that the heat of a heating device of the baking oven can be conducted to the food materials to be baked; and the heat storage body is made of heat storage materials and is in heat conduction connection with the metal article carrying body. According to the technical scheme provided by the invention, the heat is transferred to the food materials through the metal article carrying body; the heating on the food materials is realized, so that the fast heat conduction on the food materials can be realized; the heat storage body can store heat; when the heating device of the baking oven stops heating, the heat stored by the heat storage body is used for continuously conducting heat to the metal article carrying body to realize the heating on the food materials; on one hand, the mouthfeel of the food materials is improved; and on the other hand, the utilization rate of the heat of the baking oven is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

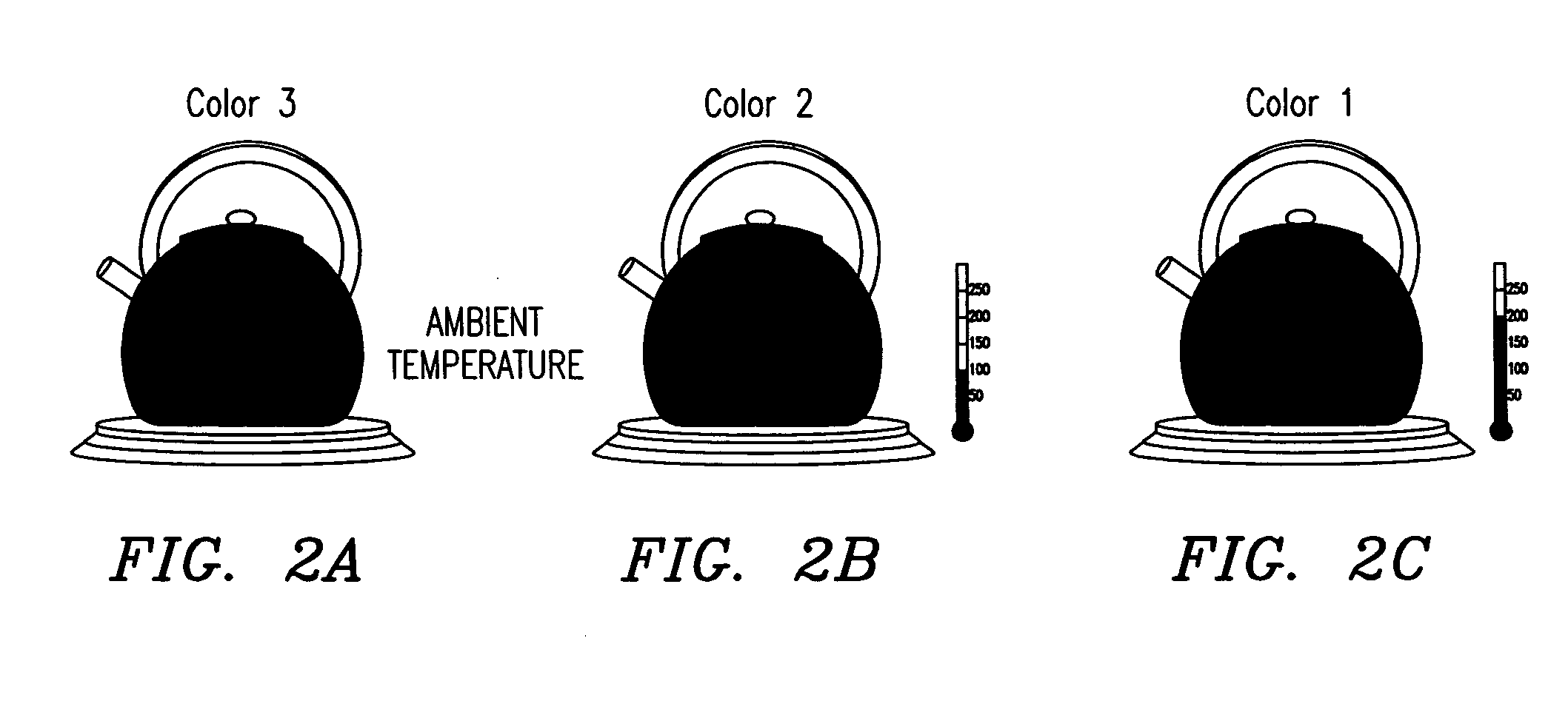

Thermochromic cookware

A cookware for providing a visual indication to a user to suggest if a surface of the cookware is at an elevated temperature above room temperature. The cookware includes a circular body having a first coating of paint. The circular body is further coated with a second coating of thermochromic paint having an initial color to obscure the first coating of paint. Upon heating the base of the cookware, heat is transferred to the body causing the second coating of paint to gradually change its initial color to substantially transparent causing the first coating of paint to become visible.

Owner:LIFETIME BRANDS

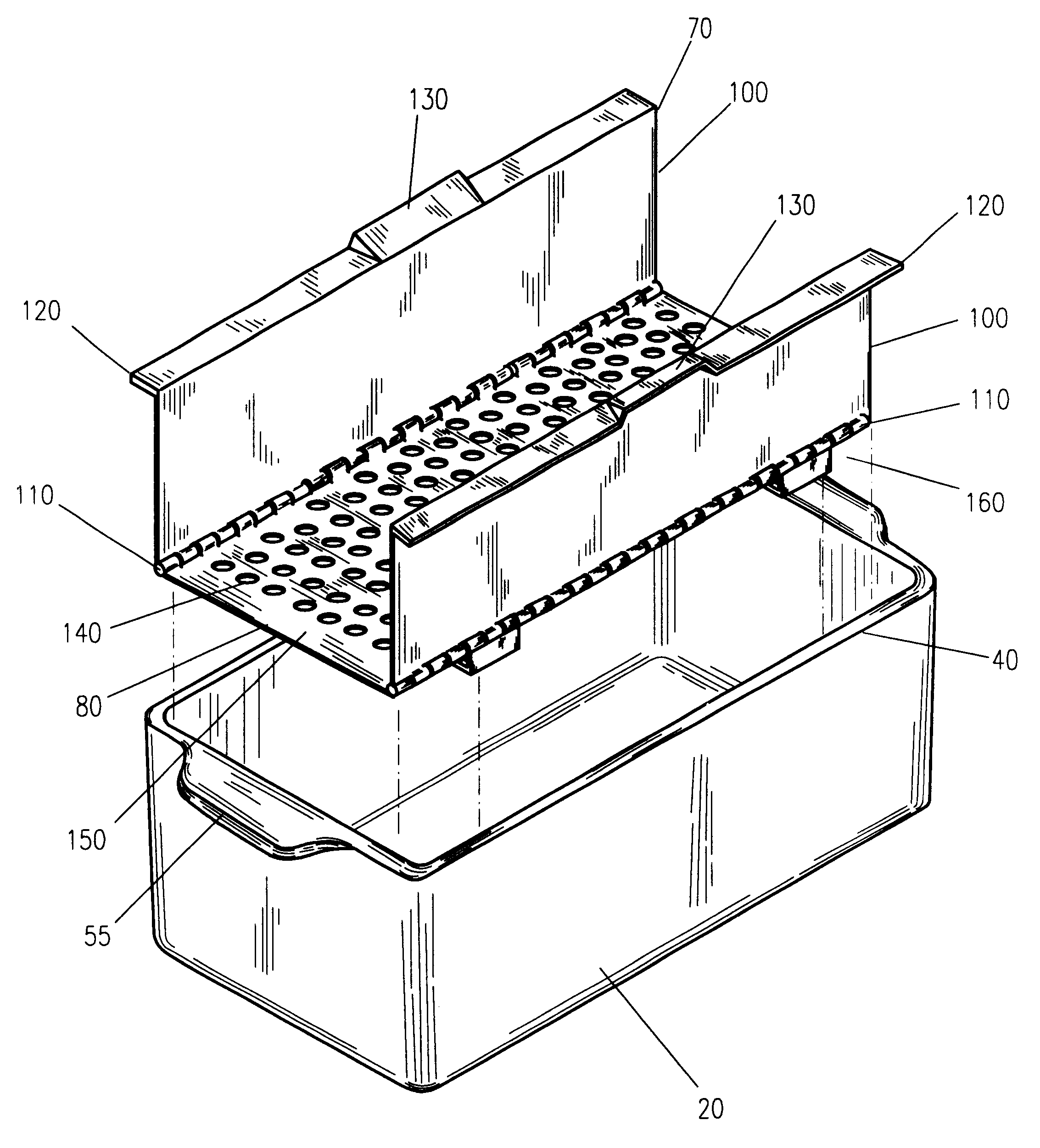

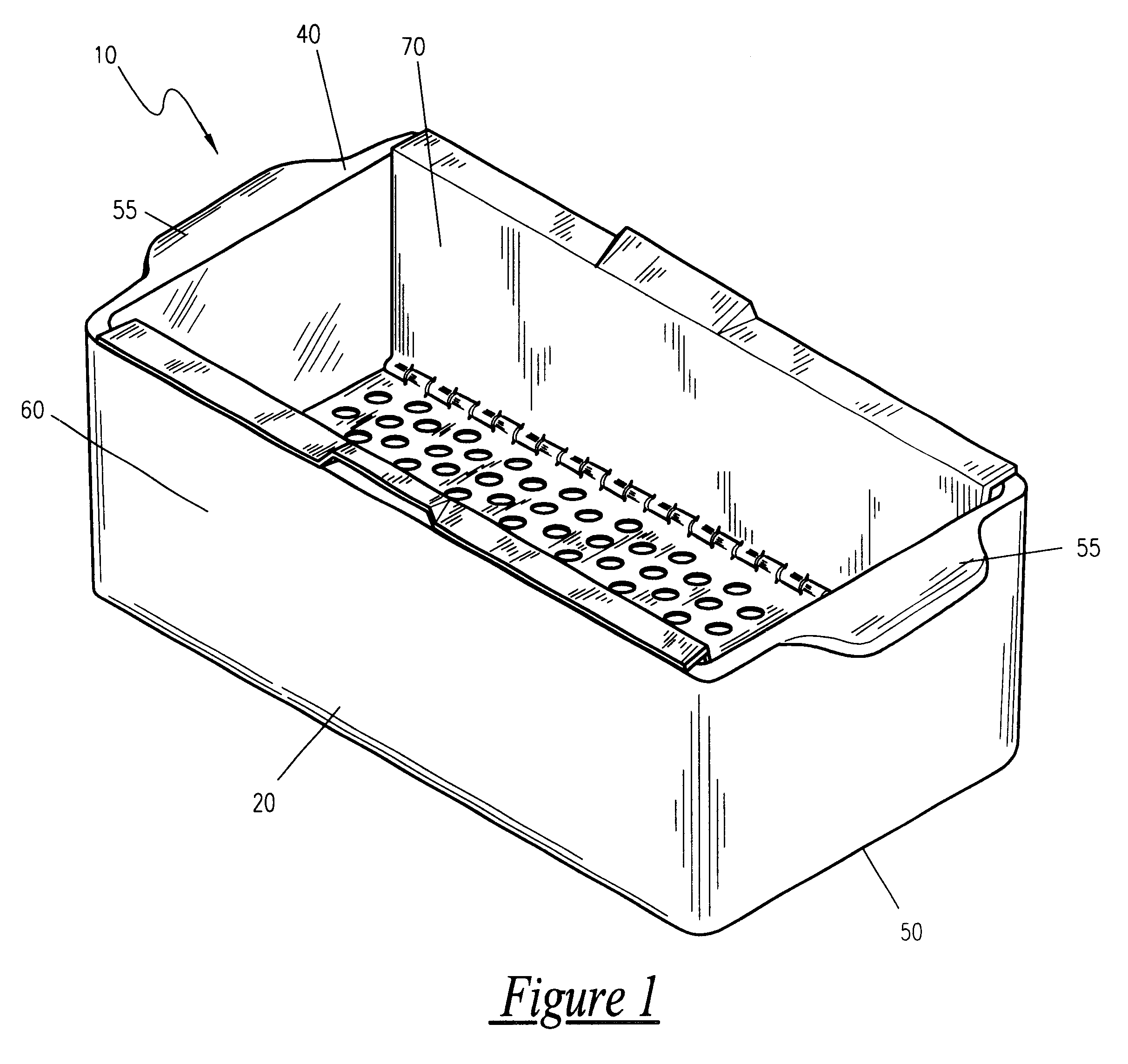

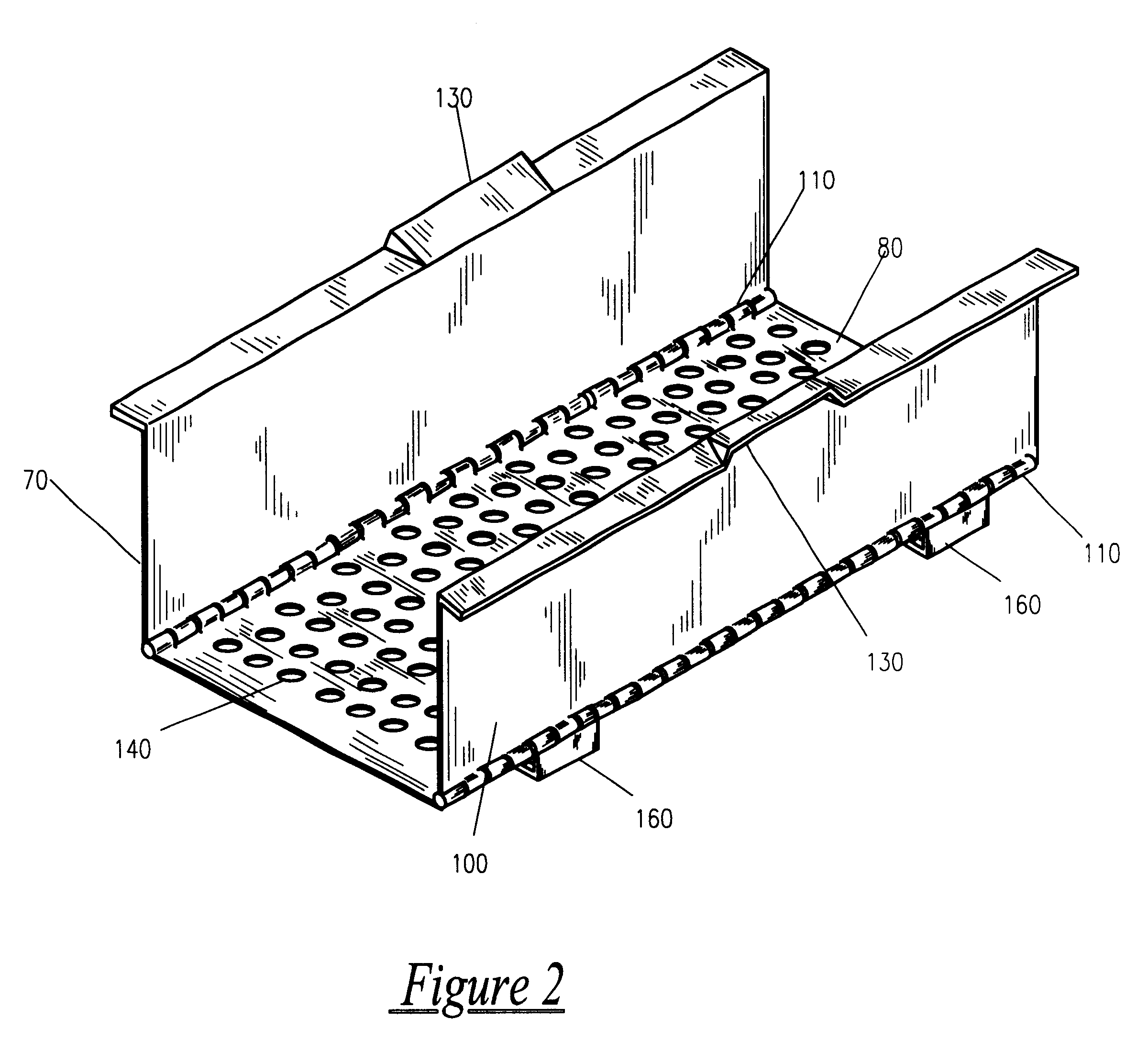

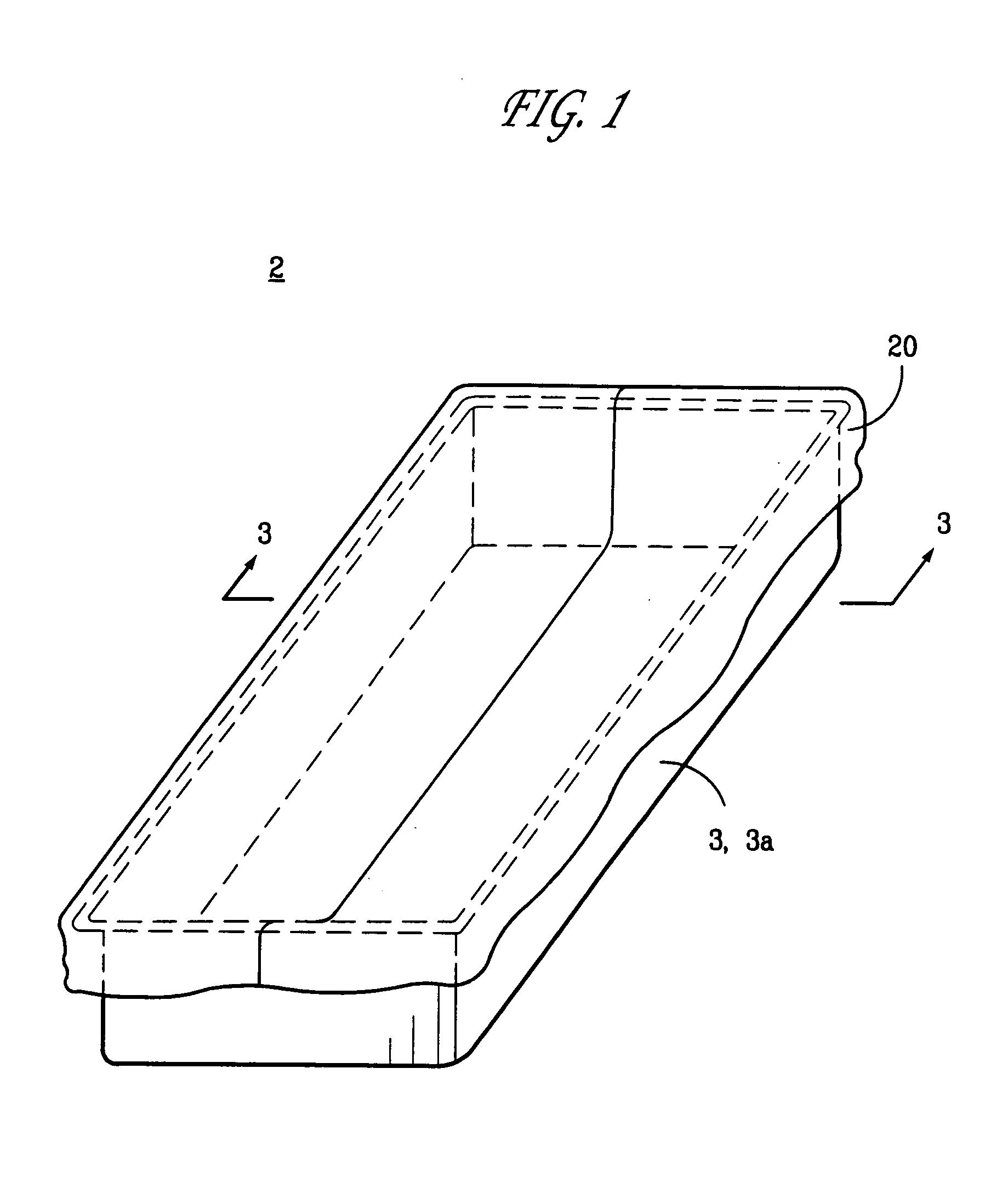

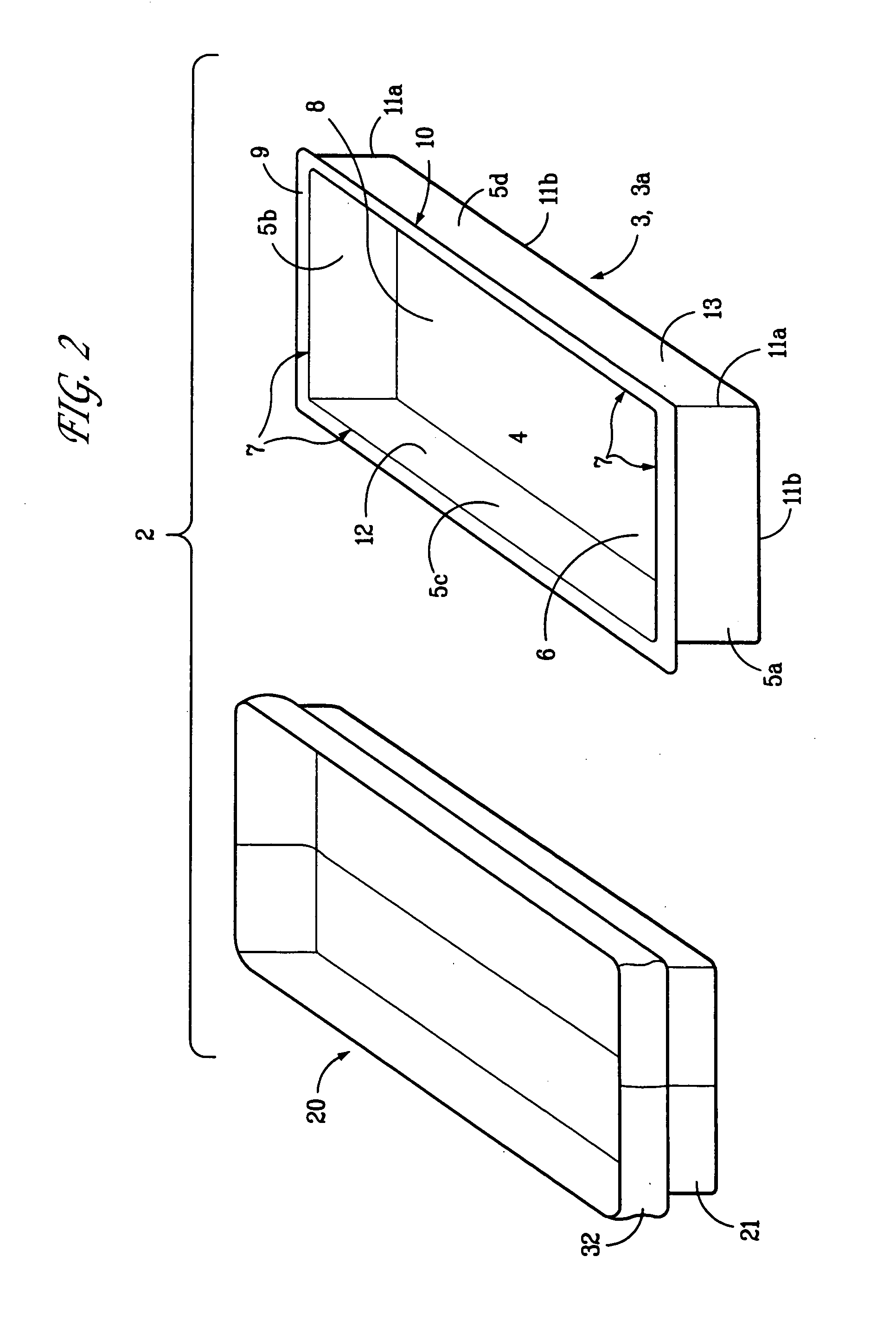

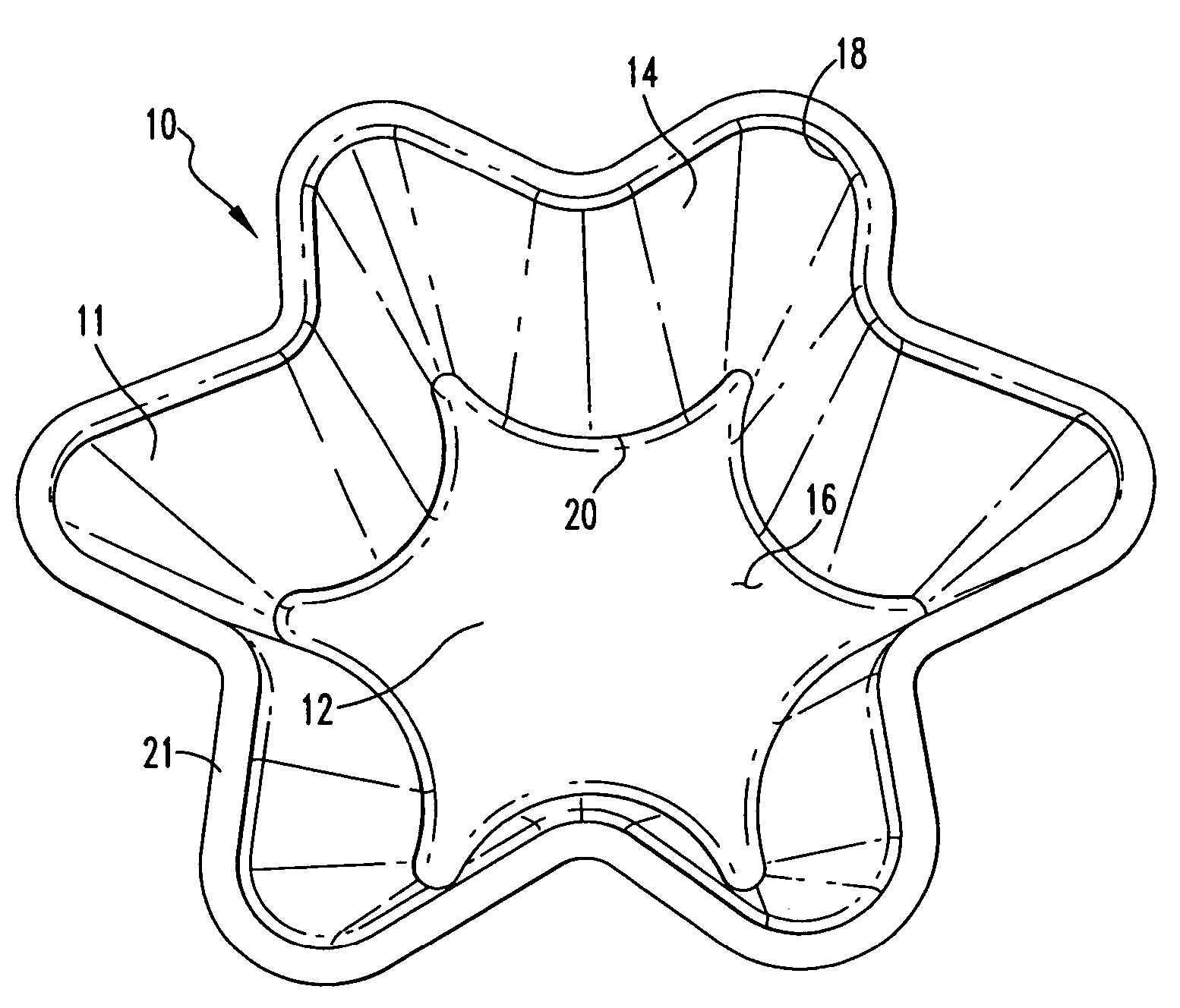

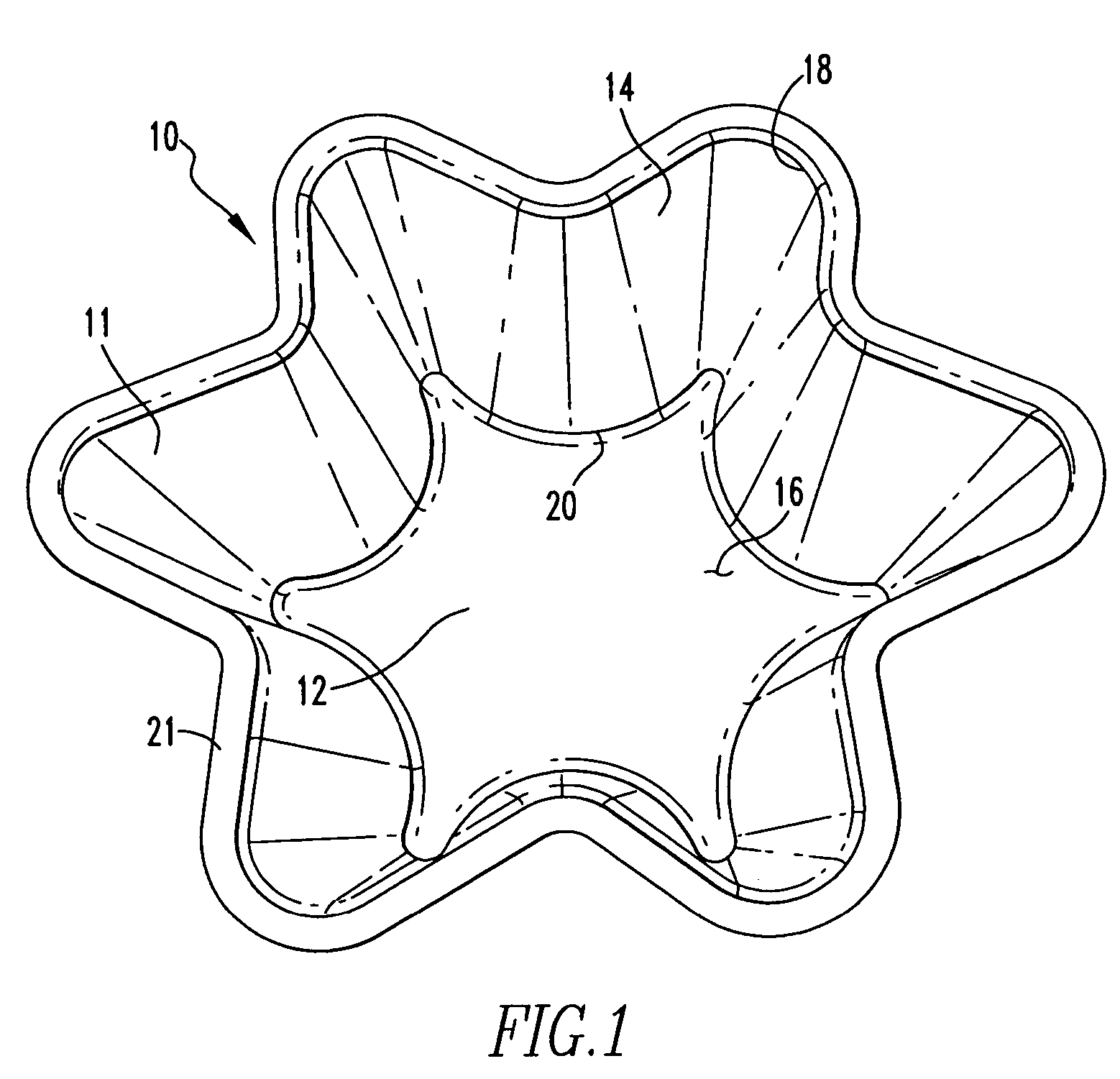

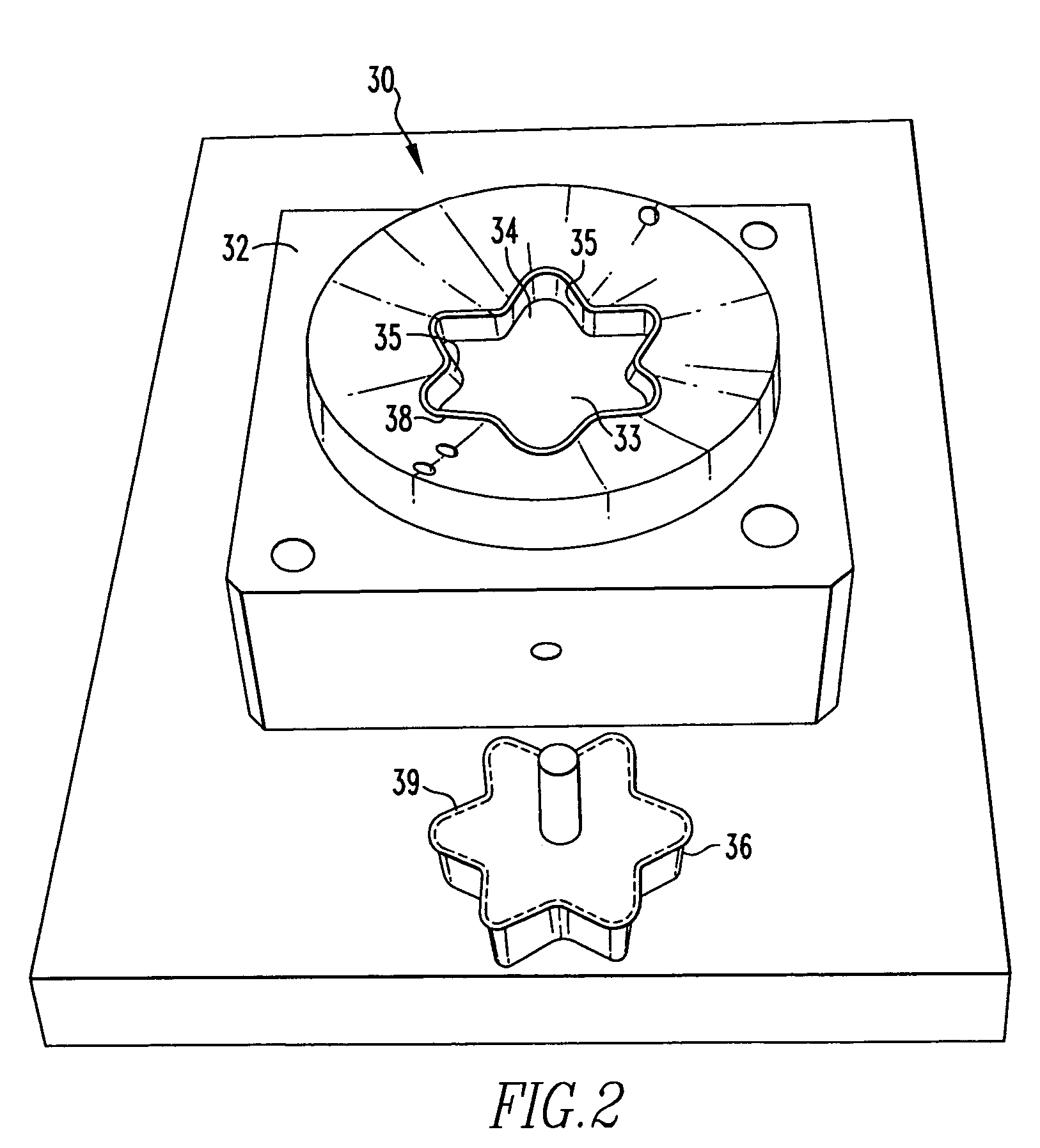

Meatloaf pan with removable, hinged, pan insert

A meatloaf pan with removable, hinged pan insert is disclosed, comprising an elongated, rectangular meatloaf pan and an elongated, rectangular pan insert. The pan insert has two insert side panels that are hinged at their bottom edges to the longitudinal edges of the bottom of the pan insert. The hinges allow the insert side walls to support the meatloaf, bread or other product during baking, and fold downward to allow access to the product for cutting and serving purposes. As such, the present invention can be used as a serving tray. Removal of the pan insert is facilitated in one of three ways. First, built-in hand grips in the flanges located on the pan insert. Second, a set of handles that connect to the flanges located on the pan insert. Third, a sliding unit that slidably inserts into the cavity formed by the rolled edges of the flanges on the pan insert.

Owner:AKIYAMA WARREN YUMI

Collapsible container

InactiveUS20150291309A1Lower the volumeSecurely holdCooking-vessel materialsTravelling sacksEngineeringWall segment

Owner:MCGREGOR ROB ROY

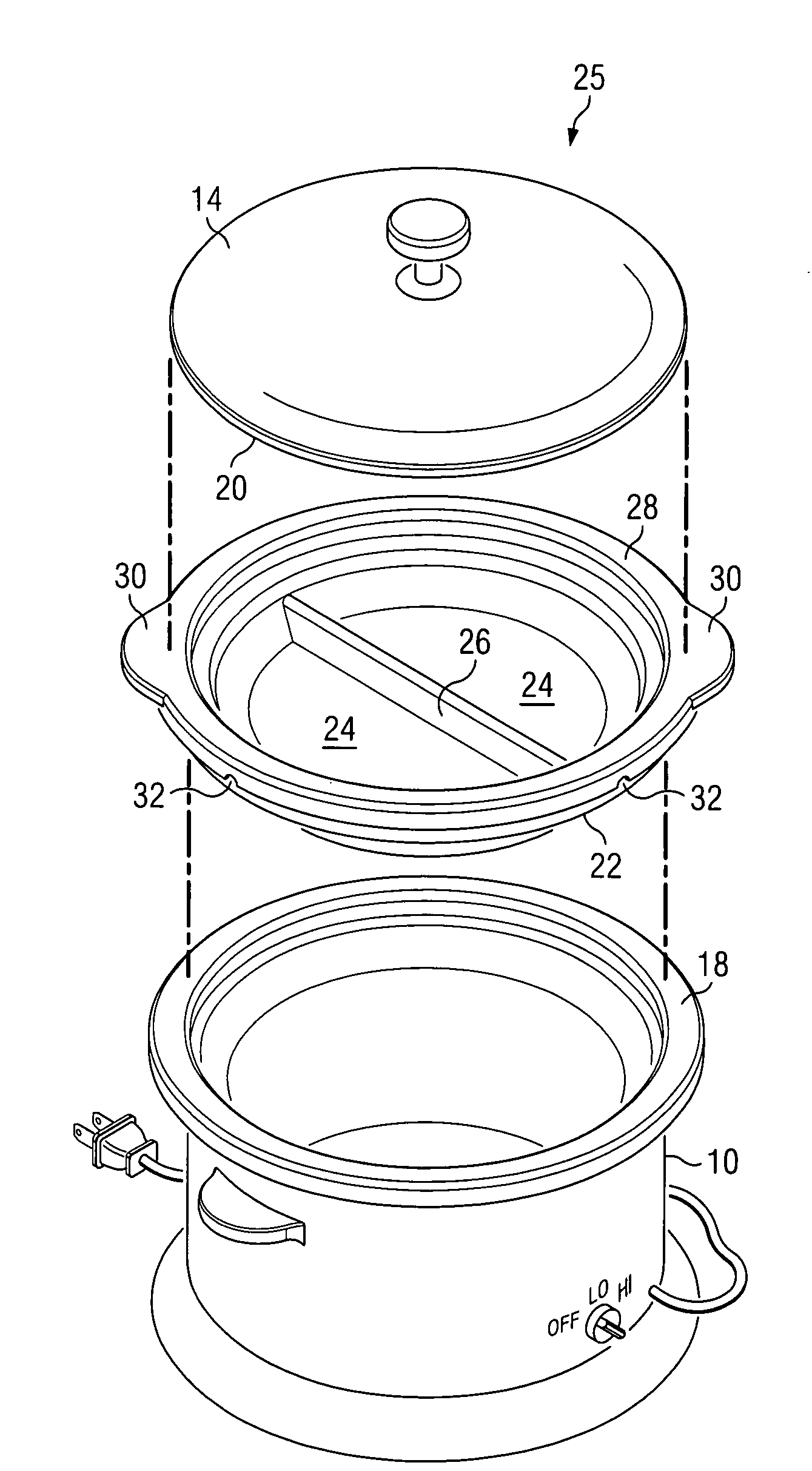

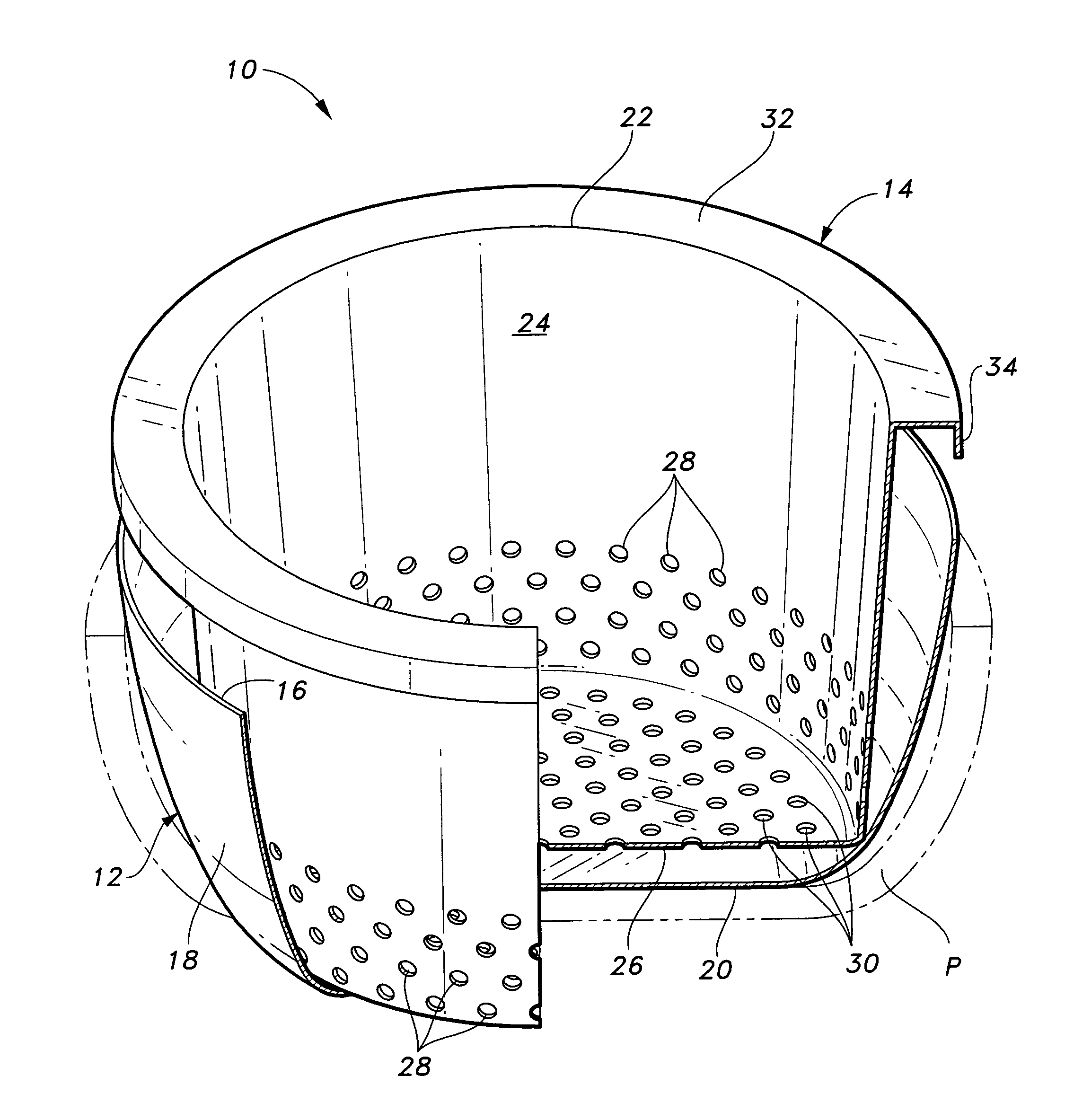

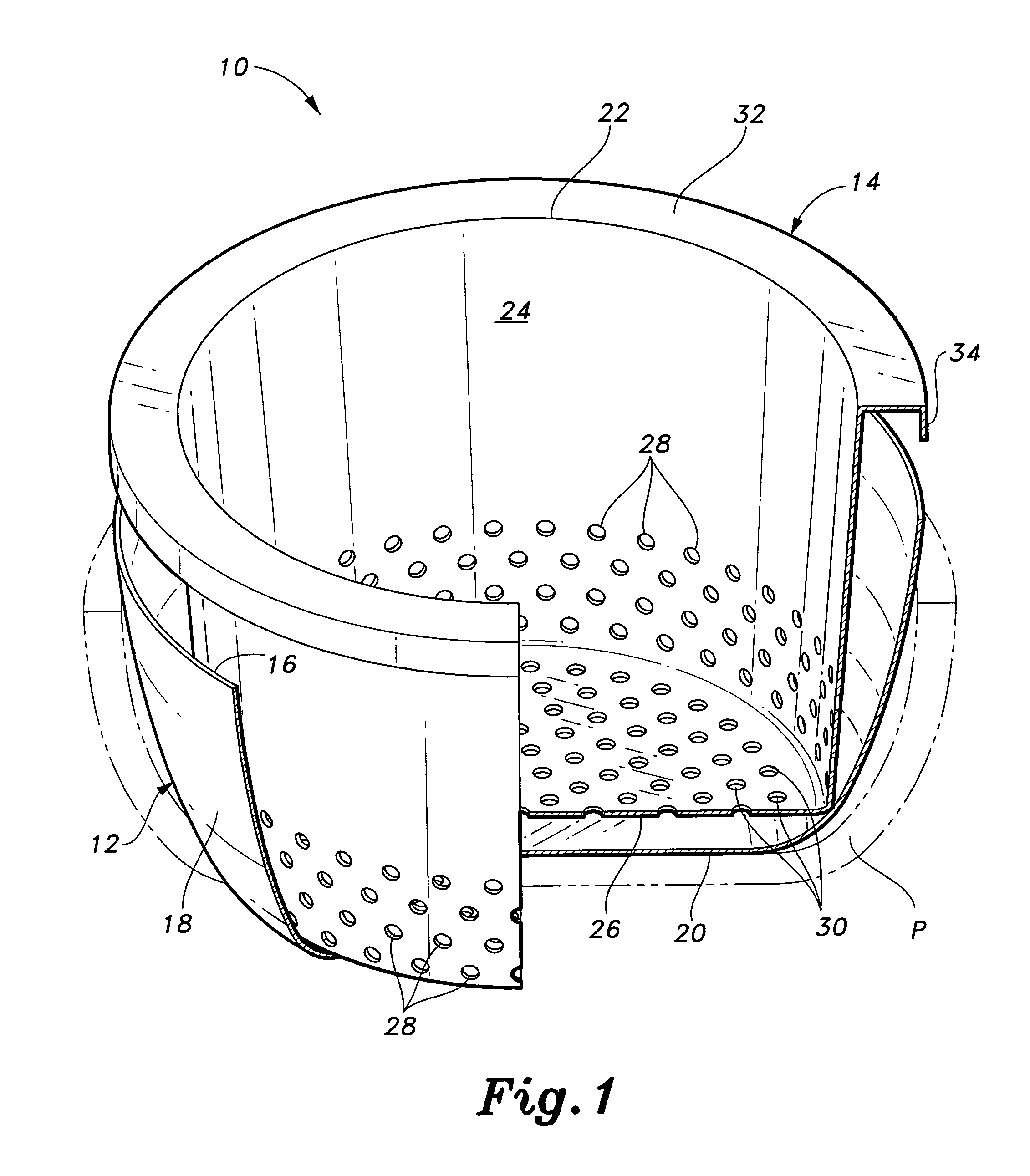

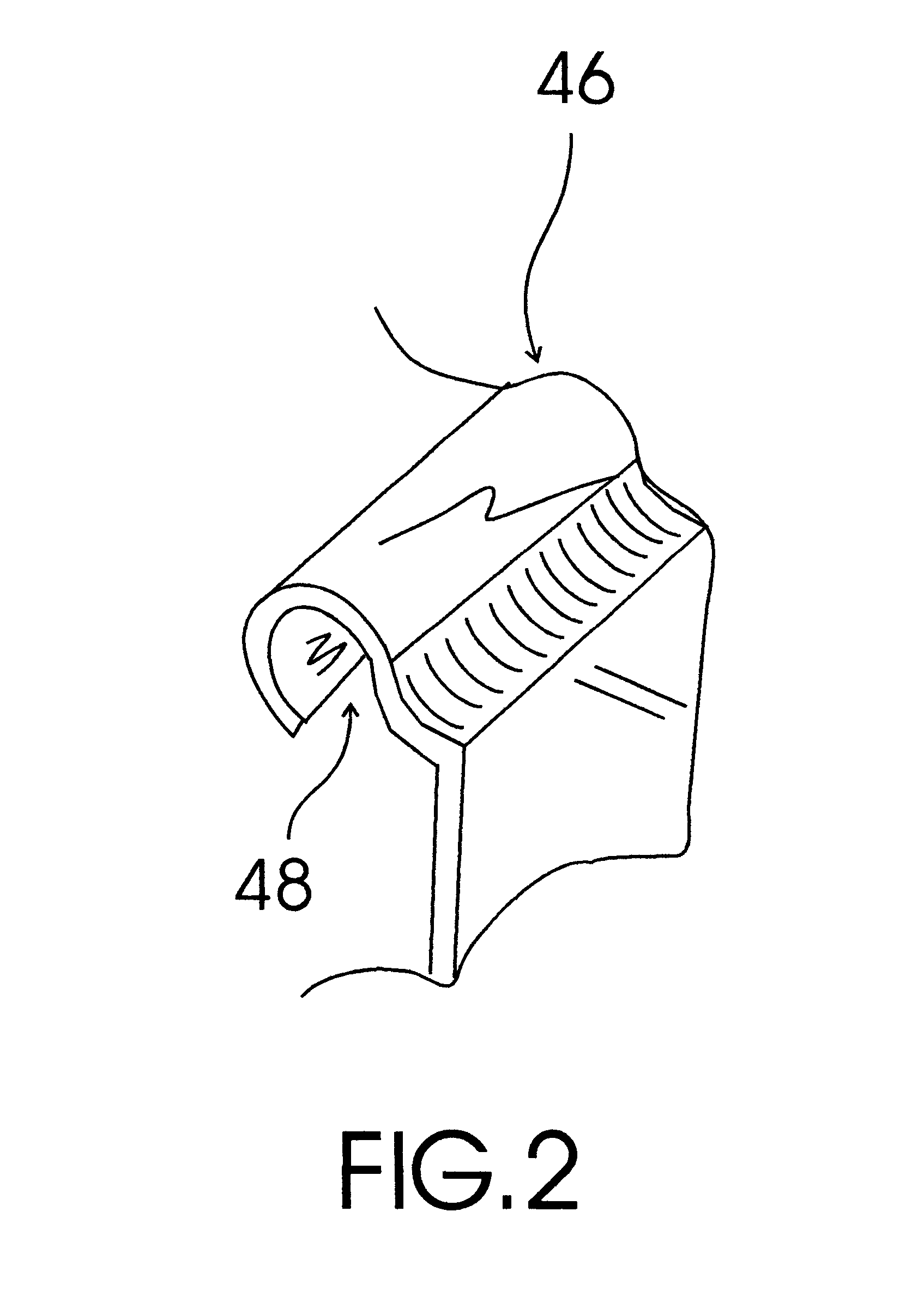

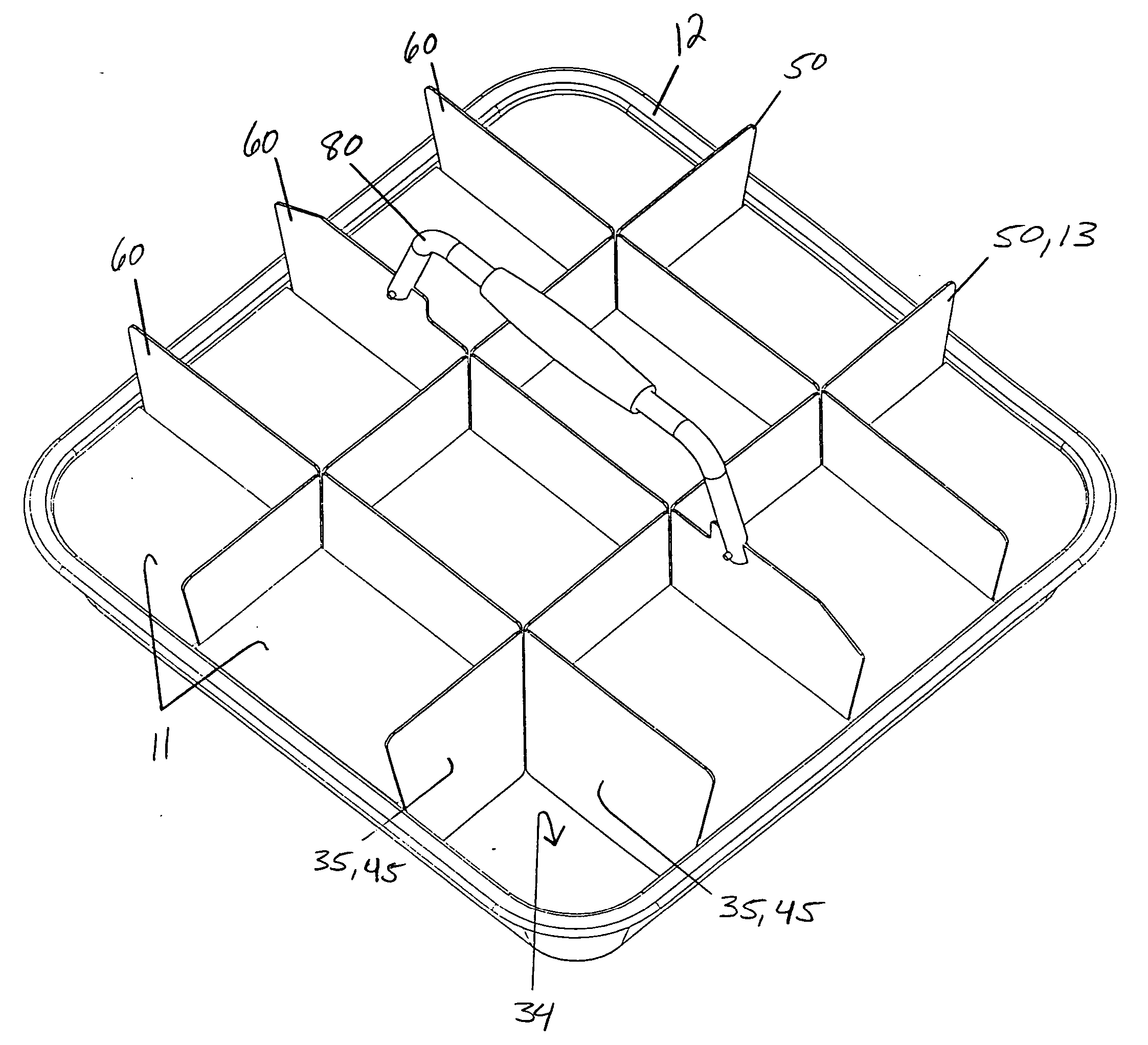

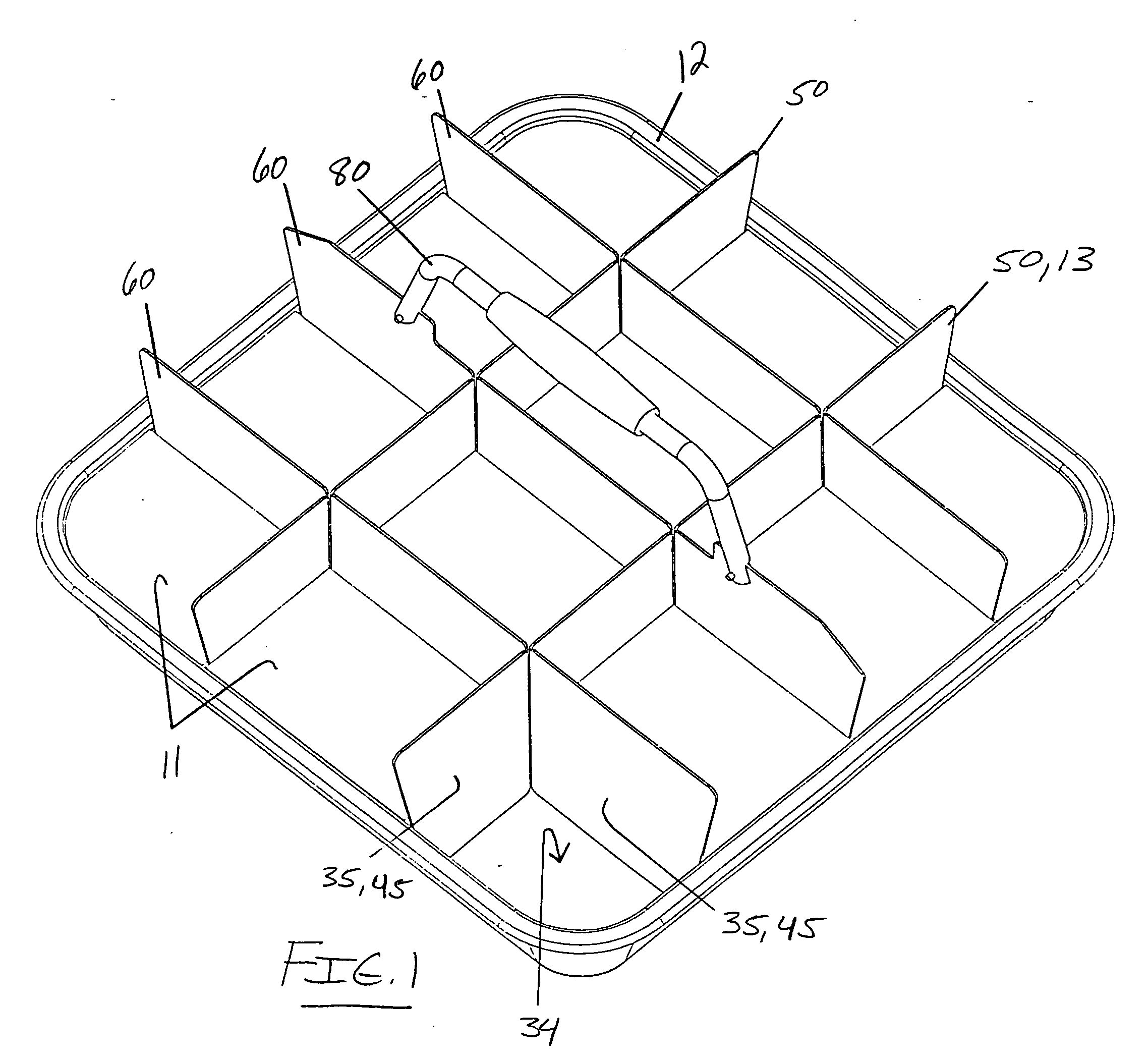

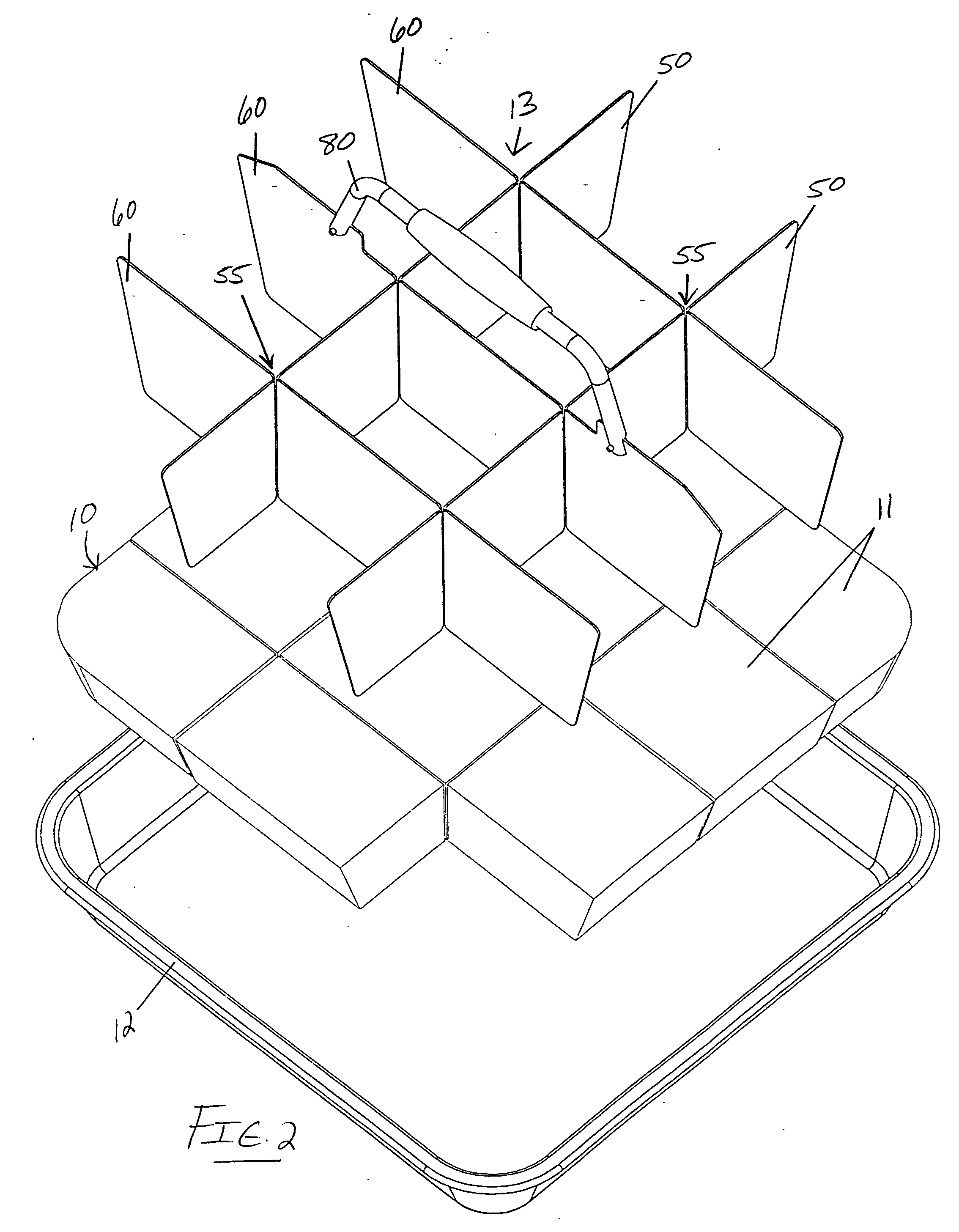

Adapter for a slow cooker

An adapter for a slow cooker having one or more basins for food items and a perimeter configured to fit an upper rim of the slow cooker and also receive the cover of the slow cooker such that the original closure seal of the cover to the slow cooker is maintained. Another embodiment comprises at least first and second identically shaped trays configured to nest in side-by-side fashion when supported within the slow cooker.

Owner:YORK DIANA L

Disposable frying pan insert

A disposable pan, pot, or kettle liner system for deep-frying foods and includes a disposable pot liner and a disposable strainer fitting into the pot liner made of thin aluminum, aluminum alloy or other metal material having a stiffness adequate to be free-standing upon filling with cooking oil and heating to cooking temperatures while being sufficiently inexpensive to be disposable after use. The strainer is made of similar material and fits within the liner, holding foods to be cooked, and has a circular, flange-like upper rim extending upward, beyond the rim of the liner, to serve as a handle for lifting and straining the cooked food from the liner. The inventive disposable system is designed to be used within a non-disposable pot or kettle, but is freestanding. The system may also be used as a stand-alone unit directly on a heating surface such as a stove heating element.

Owner:SIZER LATOYA E

Contour fit pan liner for a food service pan

InactiveUS7163120B1Raise the barrierEasy to disassembleBaking vesselsLinings/internal coatingsEngineeringCustom-fit

An apparatus, system, and method for forming an improved barrier between a pan, such as a food service pan, and a substance, such as food, contained therein using a contour fit pan liner are provided. The apparatus includes a pan liner having a contoured bottom edge that is custom fit within a food service pan to cover an interior surface of the pan. The contoured edge of the pan liner conforms to the shape and size of the food service pan and does not have any dog ears, ears, or tails that are typical of conventional pan liner. The contour fit pan liner system includes a pan and a contoured or shaped liner for forming an improved barrier between an interior surface of the pan and food that can be disposed therein using a pan liner having a contoured bottom edge that is custom fit to the shape and size of the pan. The pan preferably includes a food service pan having a bottom panel, one or more side walls extending upwardly from the bottom panel, a top opening defined by top edges of the side walls, and a flange extending outwardly from the top edges of the side walls. The liner includes a bag shaped structure having a closed bottom end, a contoured bottom edge, one or more side walls extending upwardly from the contoured bottom edge, and a top opening defined by the top edges of the liner side walls. The contoured bottom edge does not have dog ears formed at the bottom corners of the liner, as is typically of conventional pan liners. The liner is disposed within the food receptacle area of the pan to cover the interior surface of the pan and the top of the liner is folded over the top opening of the pan. A method for making an improved contour fit pan liner having a contoured bottom edge is disclosed.

Owner:M&Q IP LEASING

Stand-alone self-supporting disposable baking containers and methods of manufacture

Owner:REYNOLDS CONSUMER PROD INC

Additional bottom adapted to be fixed to the outer surface of the bottom of a vessel

Owner:ATTREZZERIA M V DI MARIN VISINO E C

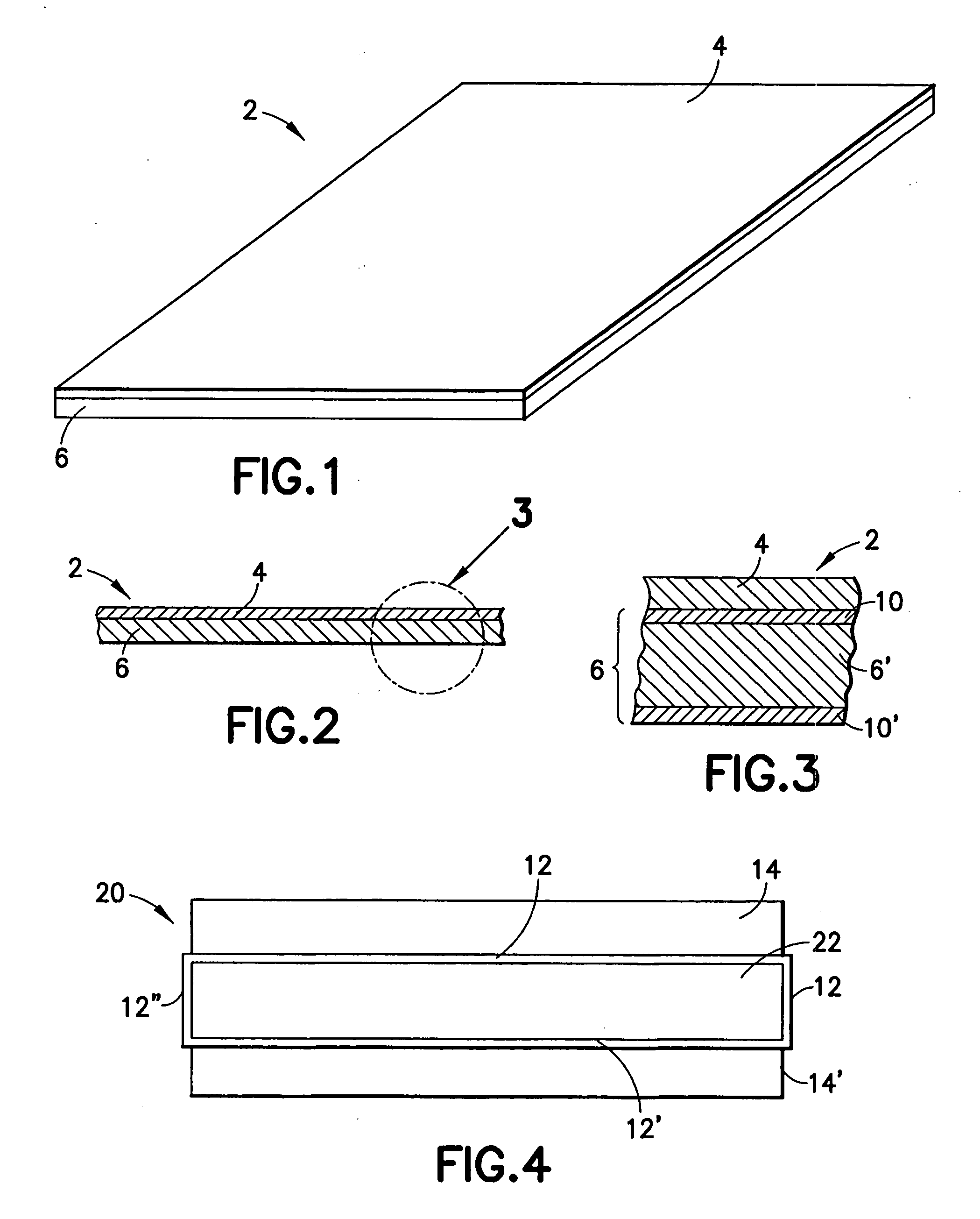

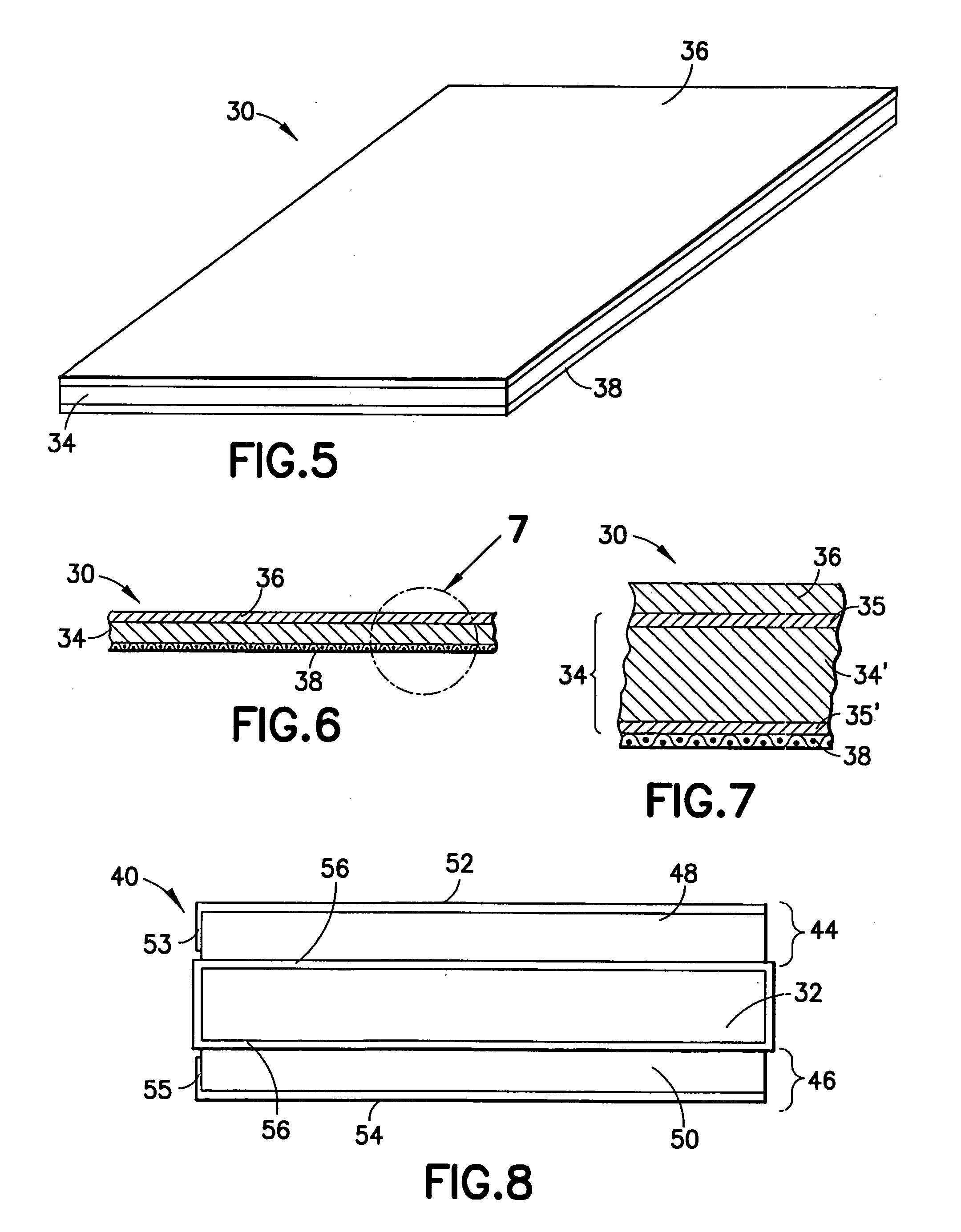

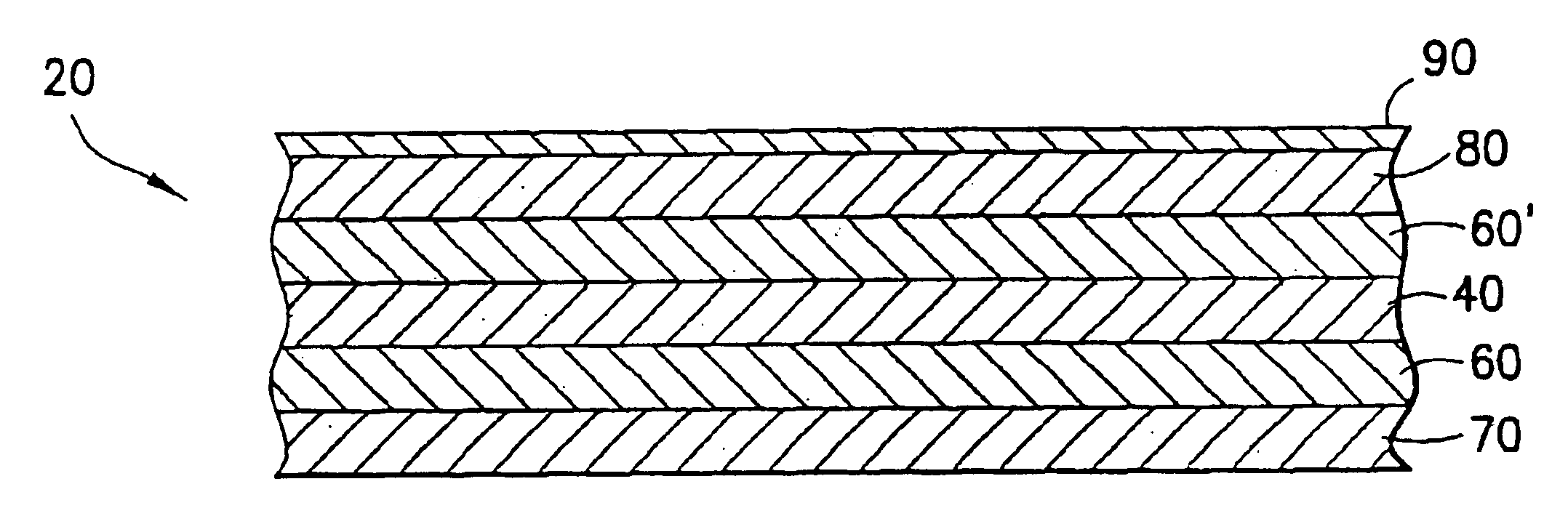

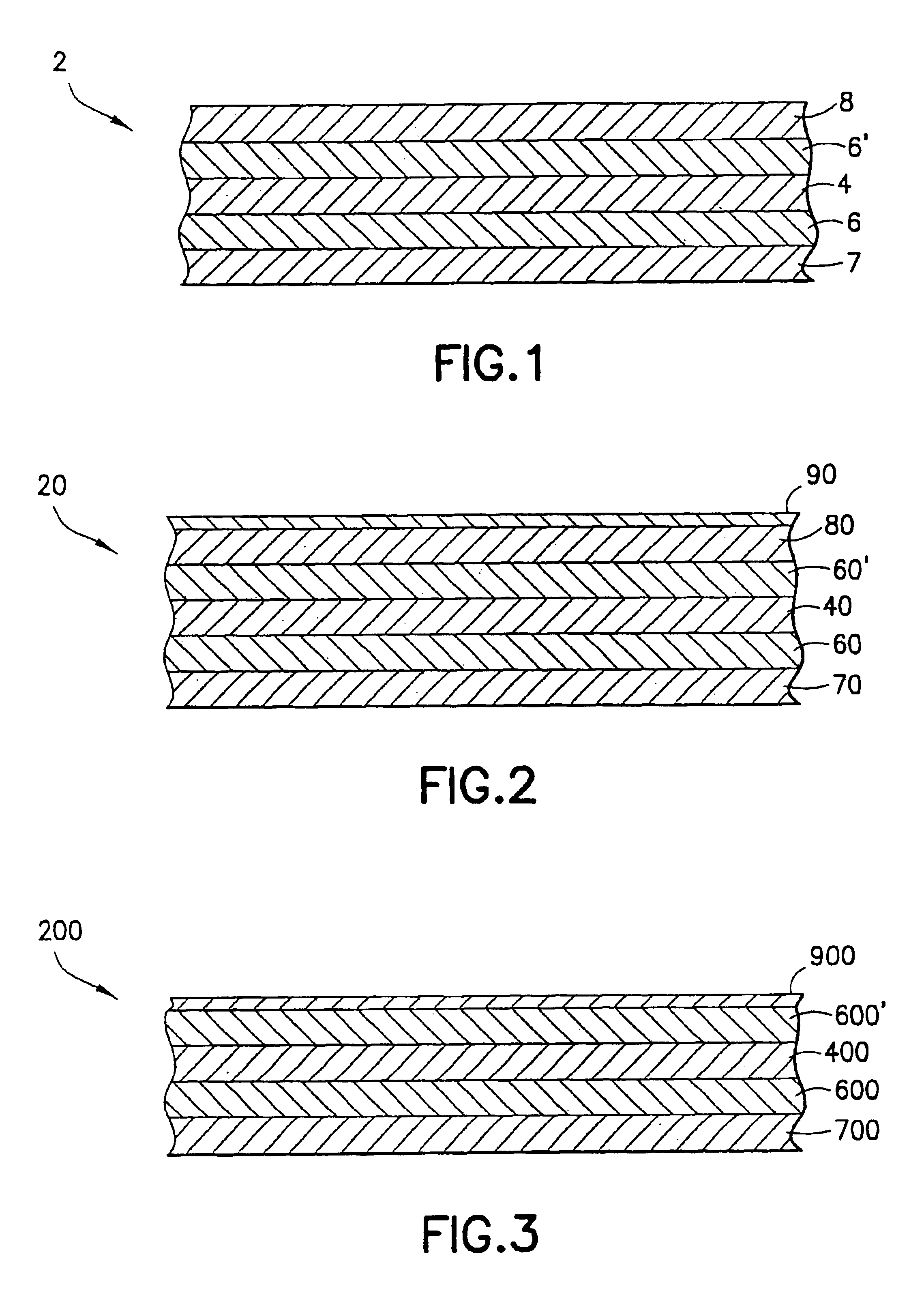

Composite metal construction and method of making suitable for lightweight cookware and a food warming tray

InactiveUS20050158576A1Good lookingImprove efficiencyHot-dipping/immersion processesCooking vesselsFood contactMetal sheet

A composite metal sheet for use in making lightweight cookware or as a food warming tray comprising a layer of aluminum roll bonded to a layer of stainless steel defining a food-contacting surface on a first side. The food warming tray embodiment also includes a layer of stainless steel mesh roll bonded on a second side. A method of making a composite metal sheet for cookware comprising the steps of: providing a roll pack of ordered layers consisting of (a) a layer of Alclad aluminum, (b) a layer of stainless steel foil, (c) a reusable plate or platen of stainless steel, (d) a layer of stainless steel foil, and (e) a layer of Alclad aluminum; heating the roll pack to a rolling temperature of about 725°-775° F., preferably about 750° F.; and rolling the heated roll pack in a rolling mill at a reduction of 10-20% in one pass to provide two roll bonded composite sheets, the first composite sheet comprising layers (a)-(b) above, and the second composite sheet comprising layers (d)-(e) above with plate (c) being reusable, wherein the plate of stainless steel is stationary relative to the layers of stainless steel foil during rolling as the roll pack passes through the mill, and wherein the plate transfers a bonding pressure to the aluminum and foil layers without tearing or displacing the foil. The method for making the food warming tray includes the addition of a layer of stainless steel mesh applied to the outer surfaces of Alclad aluminum.

Owner:CLAD METALS

Article with a ceramic coating and method for producing such an article using a laser

InactiveUS20110198358A1Low melting pointPoint becomes highCooking-vessel materialsRadiation applicationsCeramic coatingLength wave

An article comprising a metal support with two opposing faces at least one of which is covered by a discontinuous ceramic coating. Said coating has a softening point above the melting point of the support and has at least one absorbing element for the laser radiation at a wavelength of the order of 1 μm, being at least 1% of the weight of said coating. The invention further relates to a method for producing said article.

Owner:SEB SA

Disposable liner and cooker system with disposable liner

A disposable liner formed of aluminum sheeting having a liner cooking compartment formed therein and a liner lip formed into an upper perimeter lip engaging configuration; and a cooker system that includes a burner unit, a ceramic pot, a disposable, formed aluminum sheeting liner member, a cooking lid, and a storage lid. The burner unit, ceramic pot and cooking lid are of conventional slow cooker construction. The disposable, formed aluminum sheeting liner member is sized to fit into the cooking cavity of the ceramic pot and has a liner lip formed into an upper perimeter lip engaging configuration for form fitting into connection with the upper perimeter lip of the ceramic pot and to engage and hold the lid lip of the storage lid. In use, the liner member is removed from the ceramic pot and sealed for storage with the storage lid. The ceramic pot then requires little or no clean up.

Owner:JONES TERESA A

Food presentation system and assembly therefor

InactiveUS20060272162A1Easy to foldReduce storage spaceDough shapingBaking vesselsKnife bladesIngested food

A foldable blade assembly enables users to section and display a food preparation within a food preparation container. The blade assembly has an orthogonally configurable lattice of cutting blades sized and shaped to fit within a food preparation container for sectioning and displaying the food preparation. A plurality of hinge connections hingedly connect the cutting blades providing structure for pivotally changing the relationship between the cutting blades from the orthogonal arrangement to a substantially coplanar arrangement for storage. The end portions of the cutting blades are angled to compensate for angularity of the upright side of the food preparation container during use. At least one removable handle is provided to enable manual force perpendicular to the cutting blades for sectioning the food preparation.

Owner:ATWATER ANDREA E +1

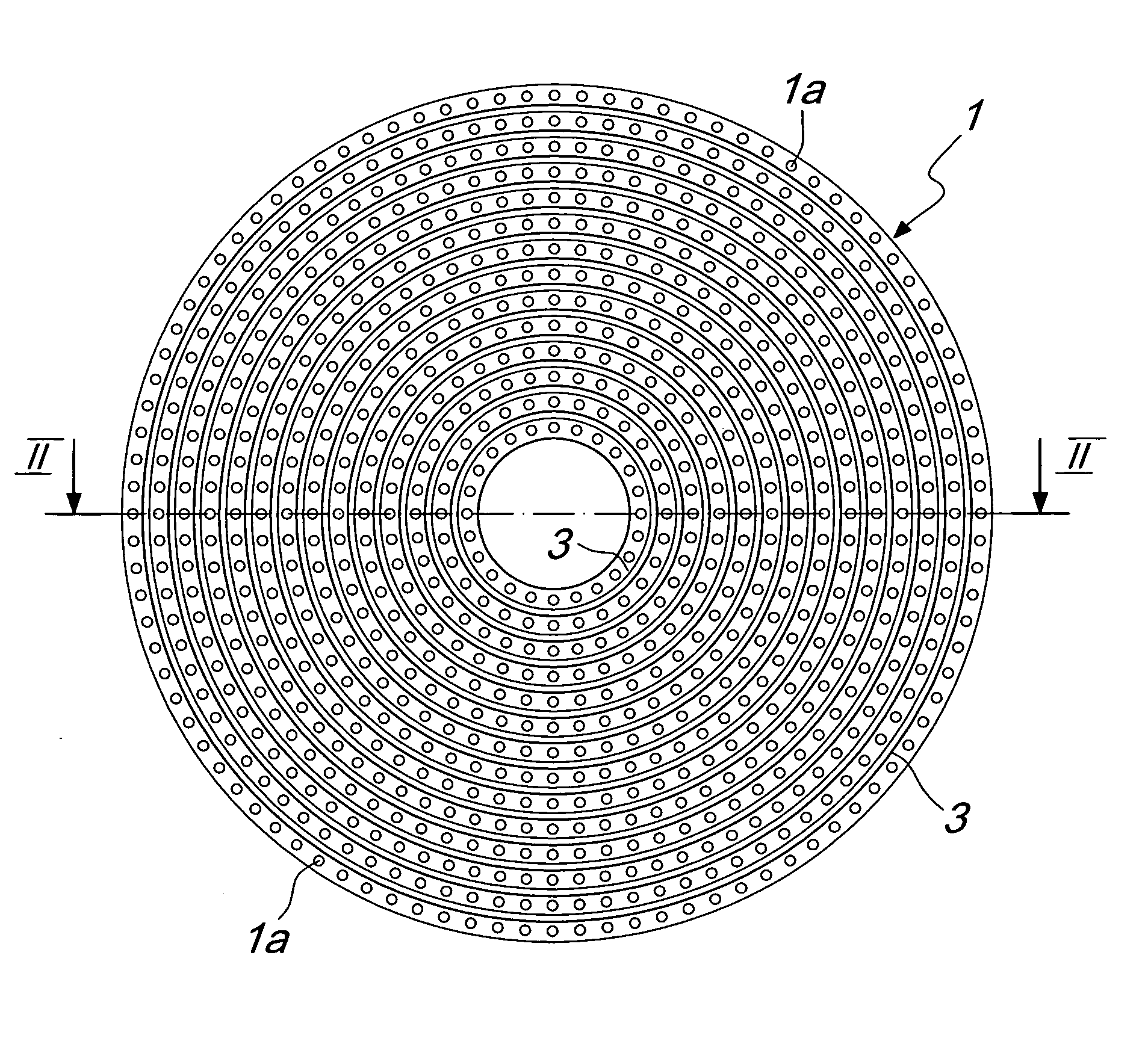

Bonded metal components having uniform thermal conductivity characteristics and method of making same

InactiveUS6926971B2High bonding strengthAvoid bondingHot-dipping/immersion processesCooking-vessel materialsTitaniumMetal

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of titanium roll bonded at or near the core of the composite. The titanium layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel. The layer of stainless steel adjacent to the cooking range may be a ferritic stainless steel if induction-type heating is desired. The multi-layered composite is also suitable for making a sole plate for an iron. Both the cookware and sole plate may include a non-stick surface applied thereto.

Owner:CLAD METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com