Patents

Literature

1284results about How to "Avoid bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

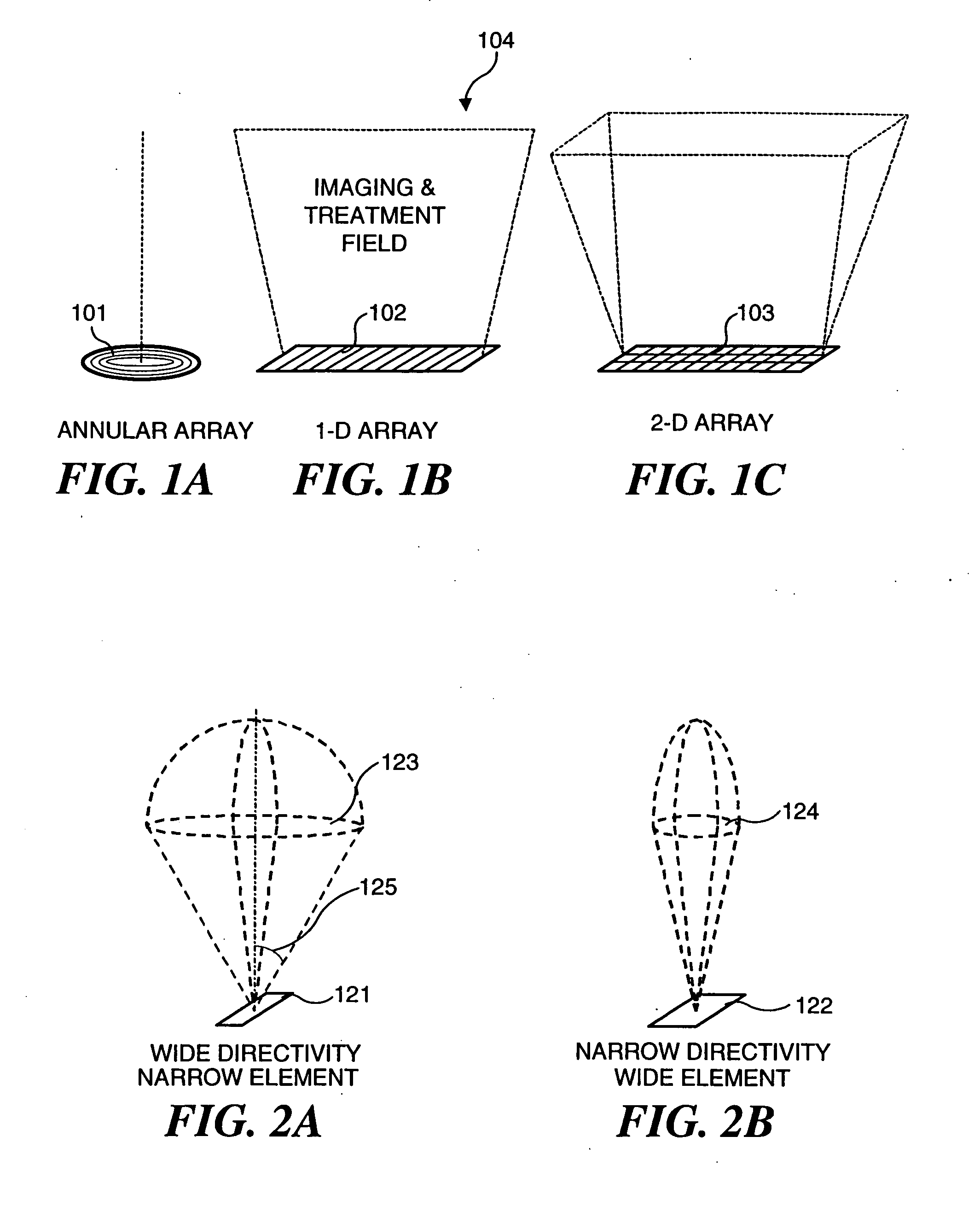

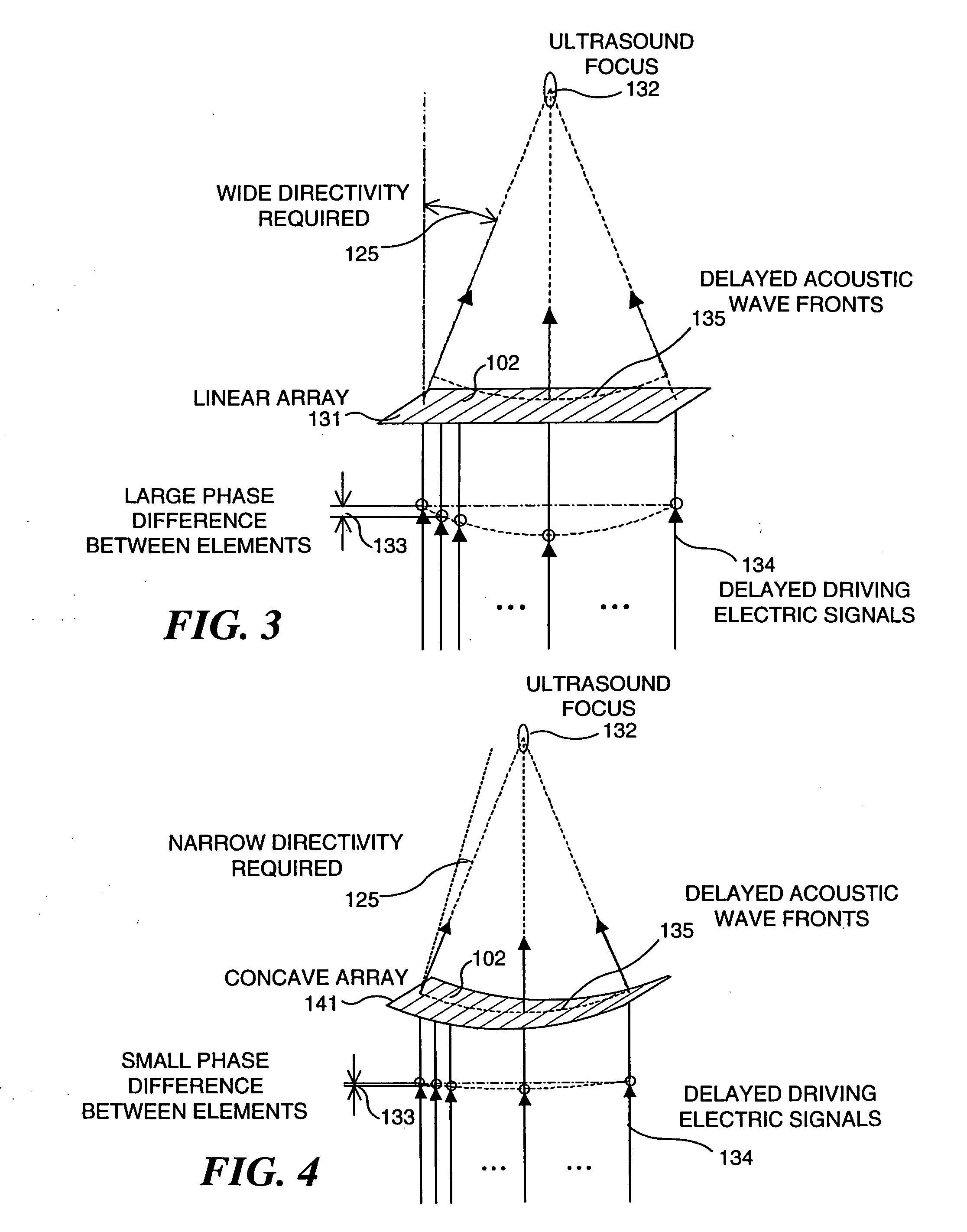

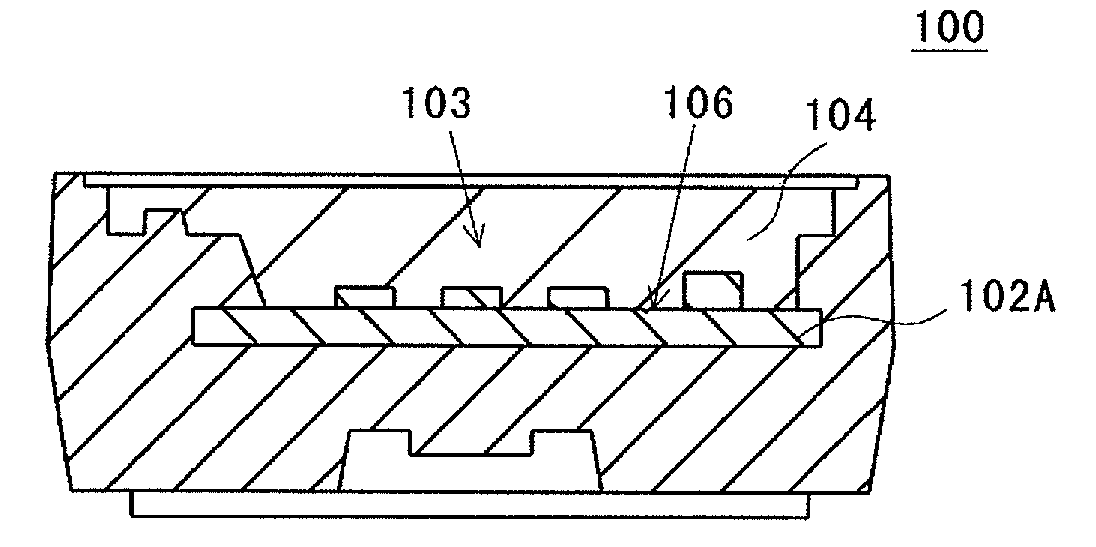

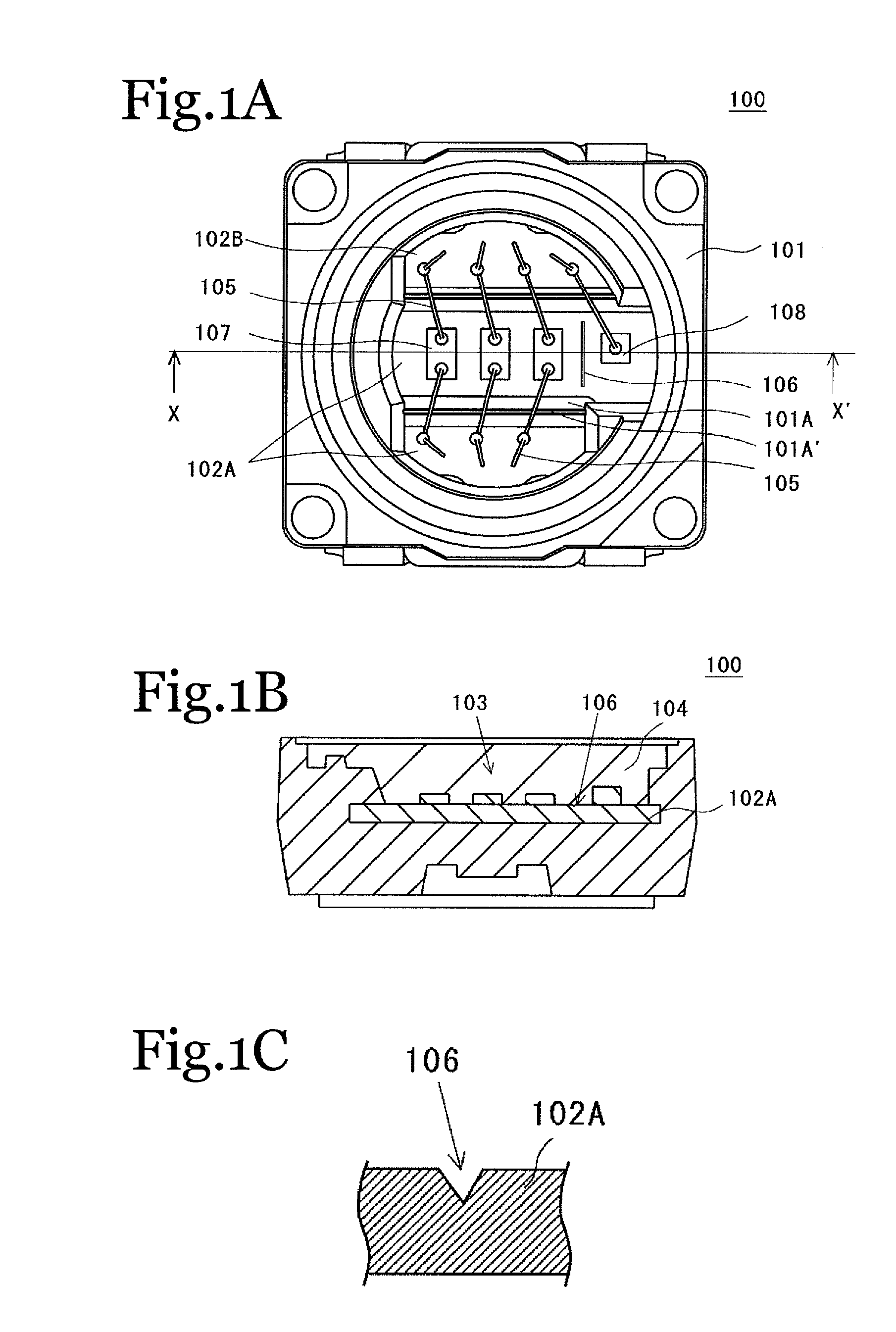

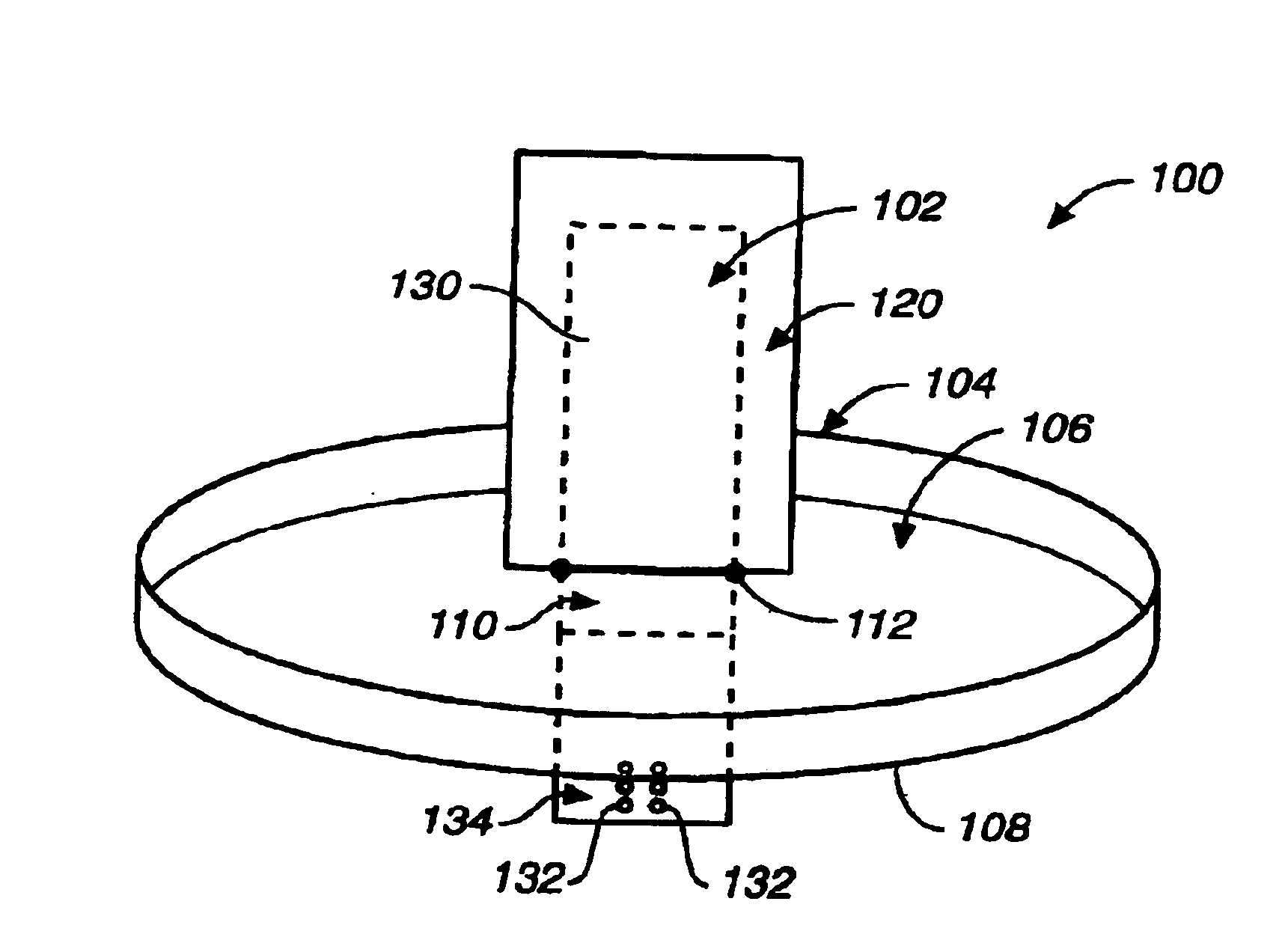

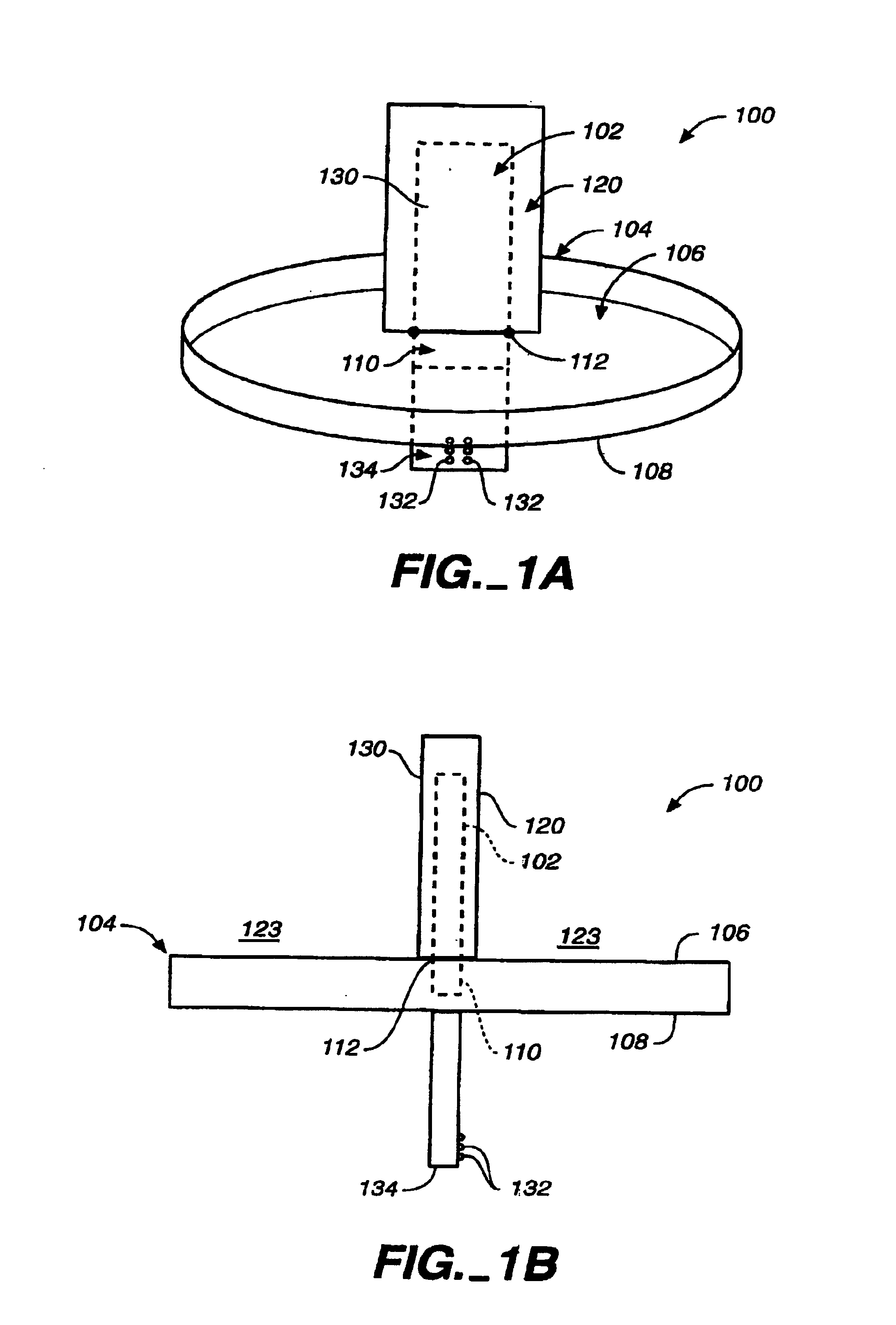

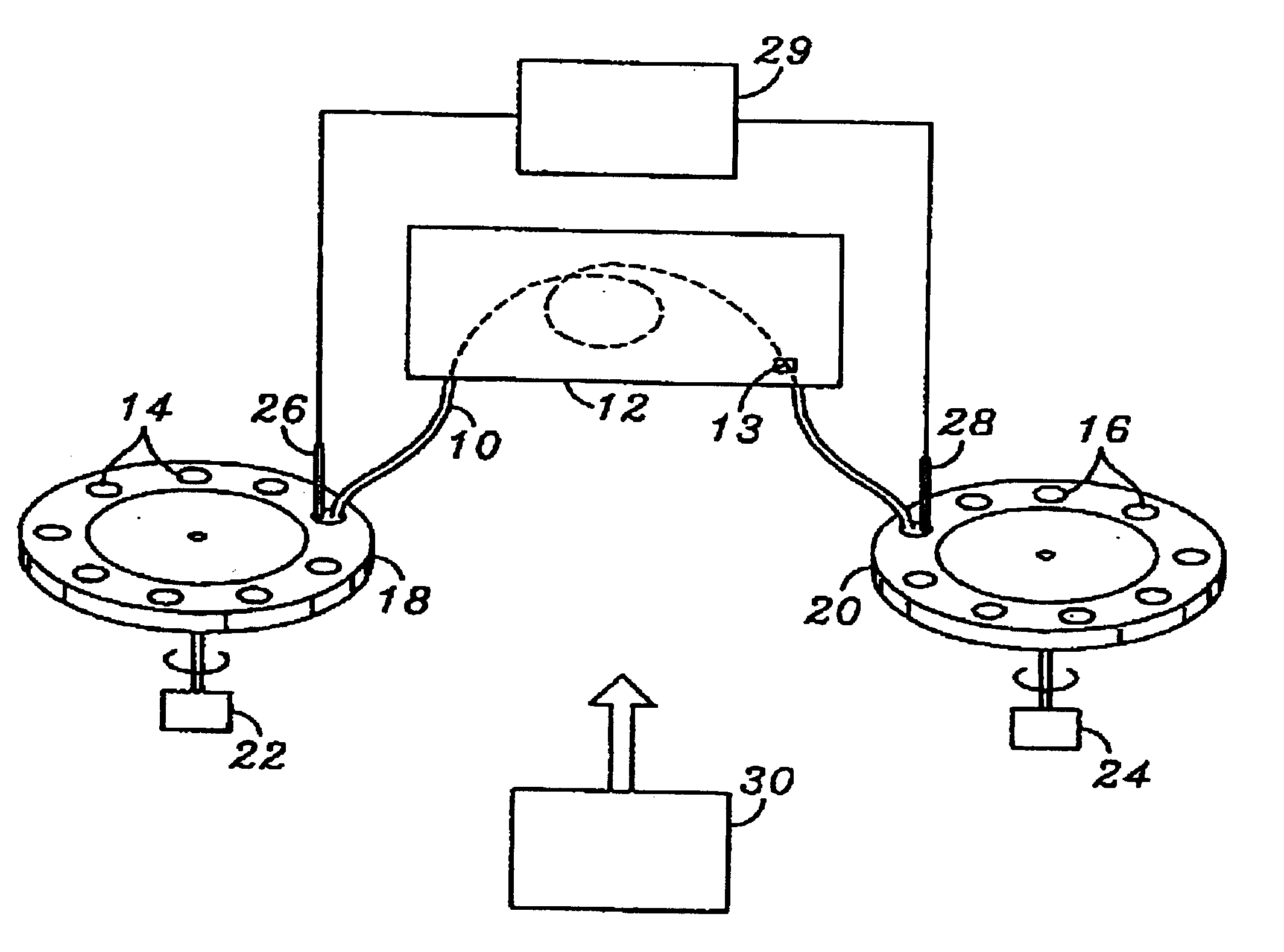

Ultrasound transducers for imaging and therapy

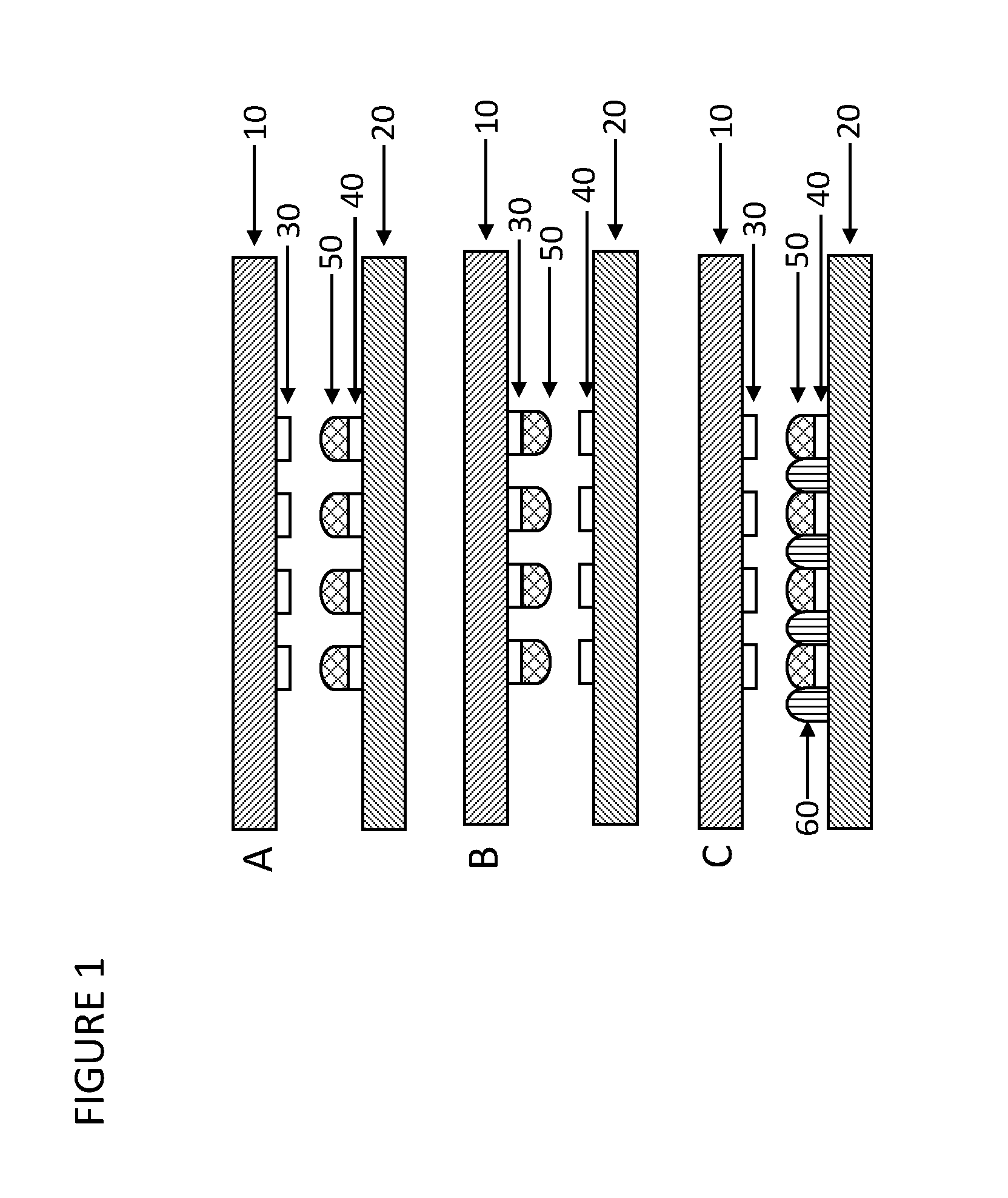

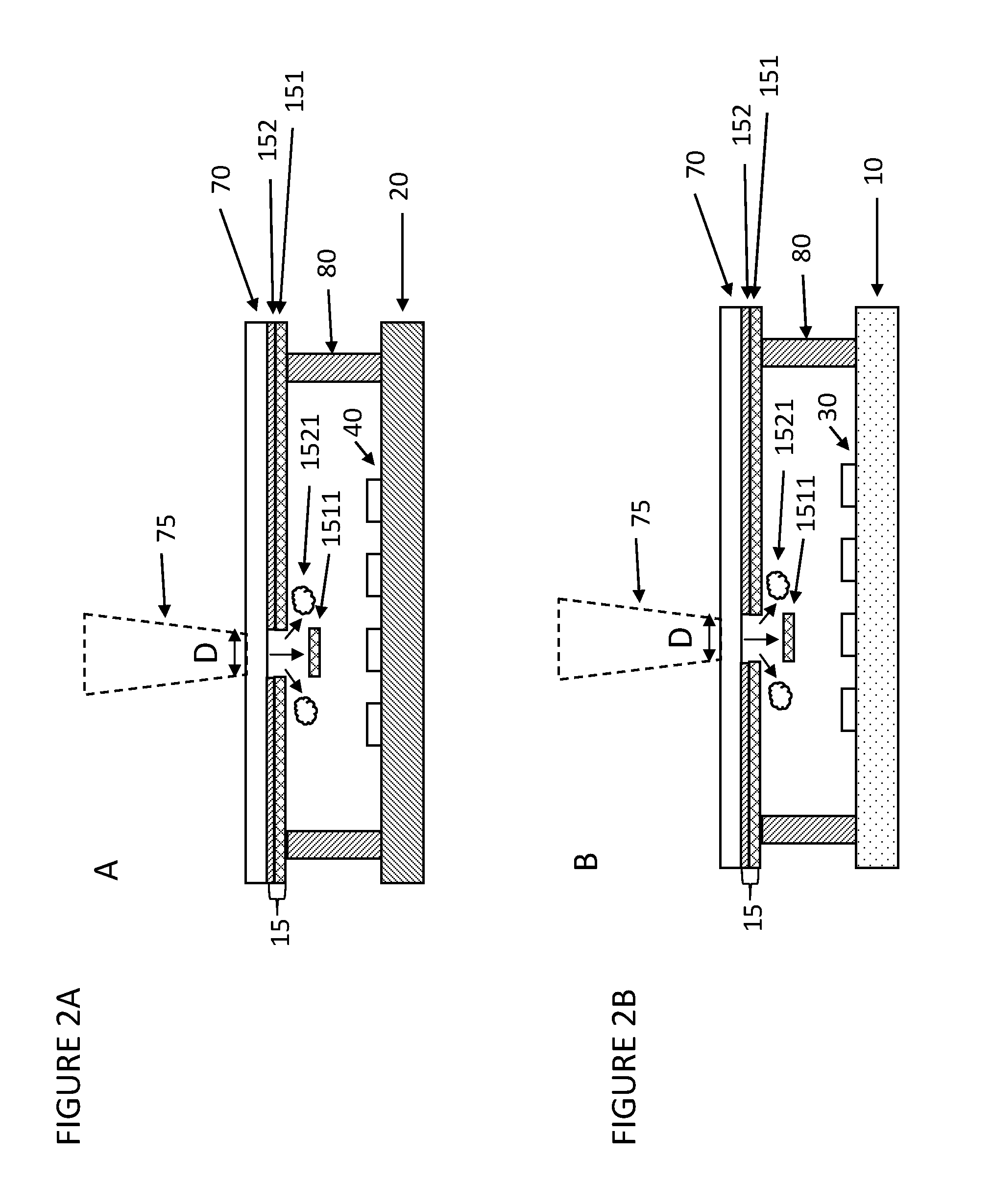

InactiveUS7063666B2Reduce in quantityReducing cross-talk and heatingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectrical resistance and conductanceSonification

Owner:OTSUKA MEDICAL DEVICES

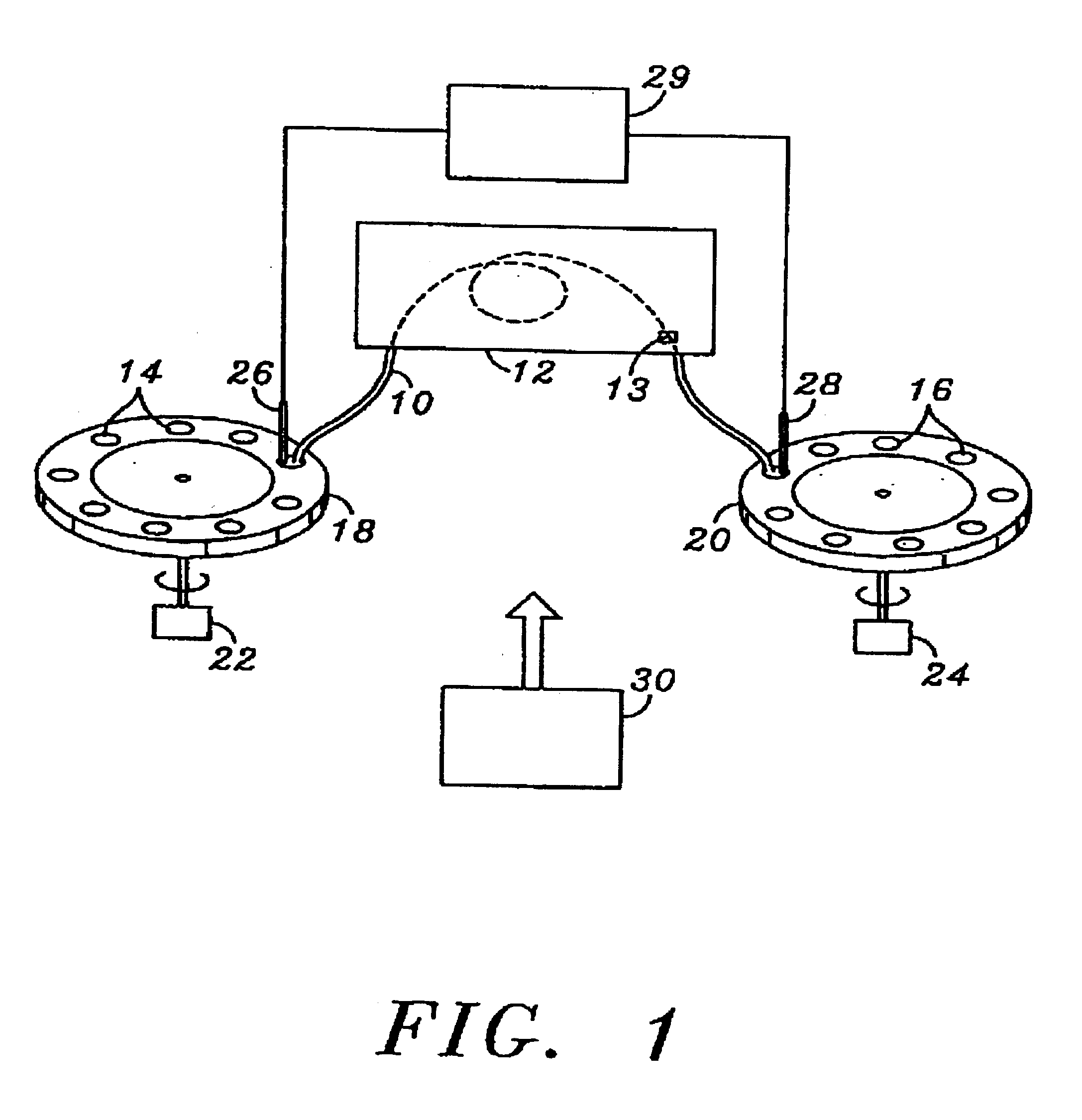

Ultrasound transducers for imaging and therapy

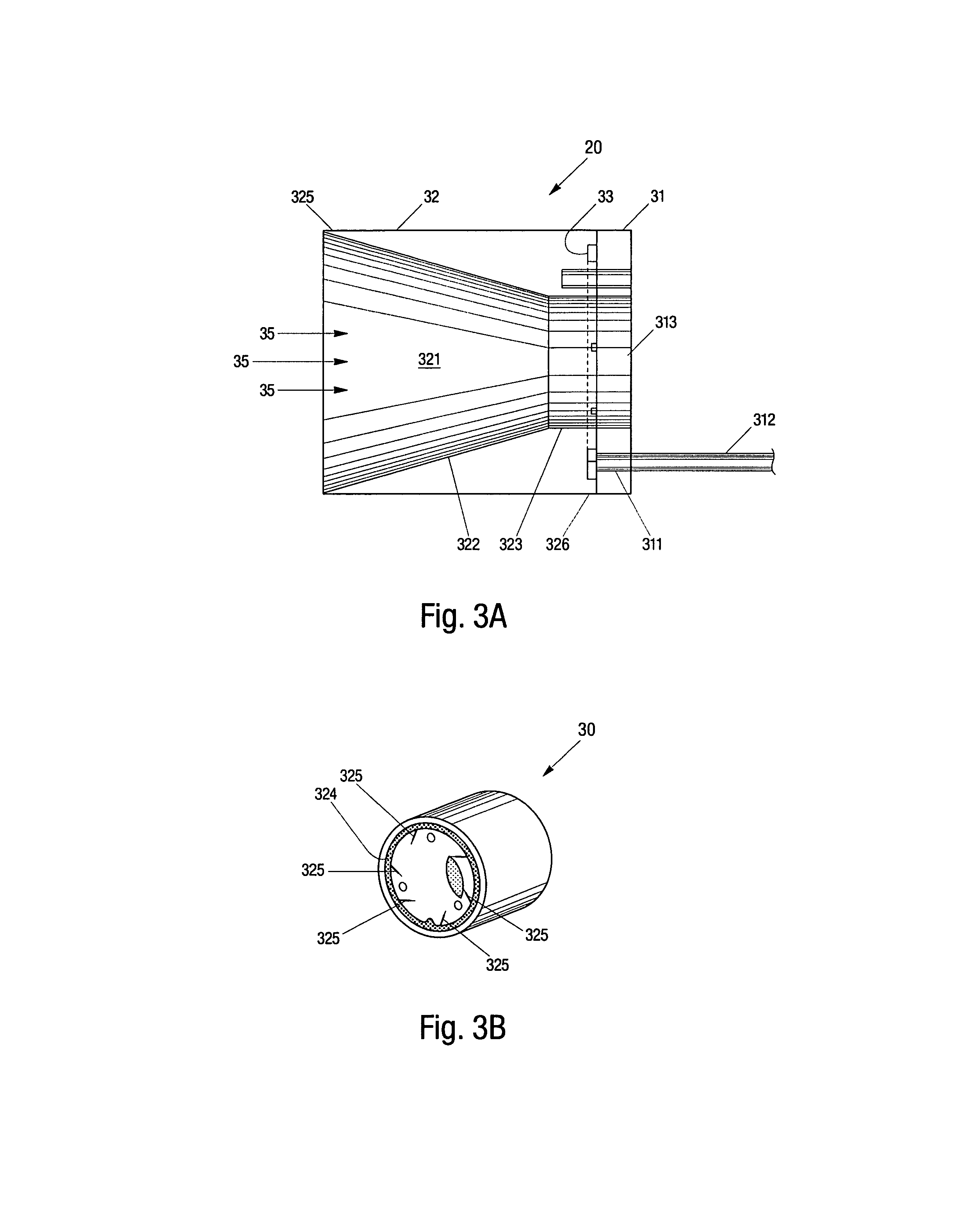

InactiveUS20050096542A1Improve likelihoodImprove bonding strengthUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationUltrasonic beam

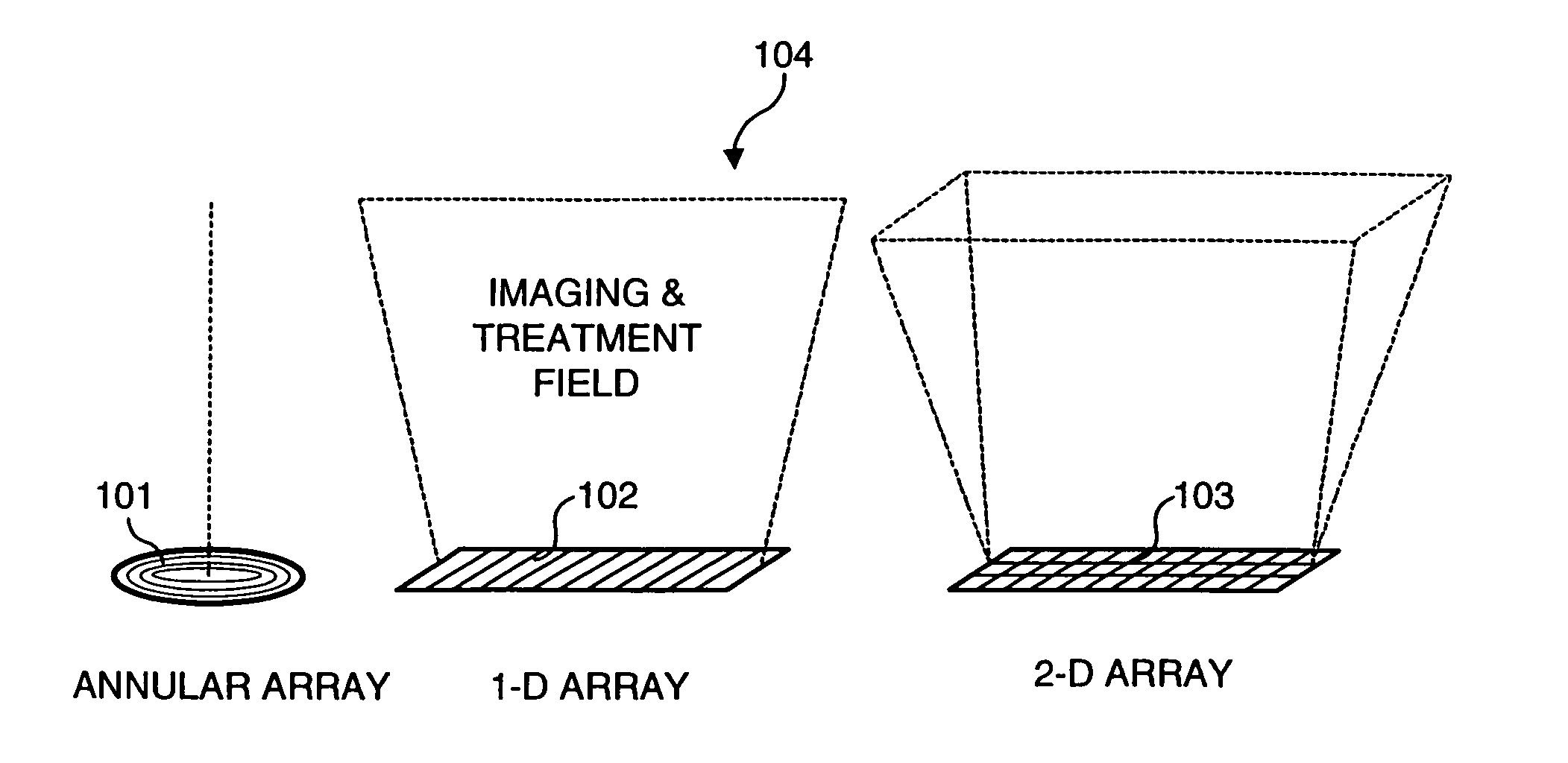

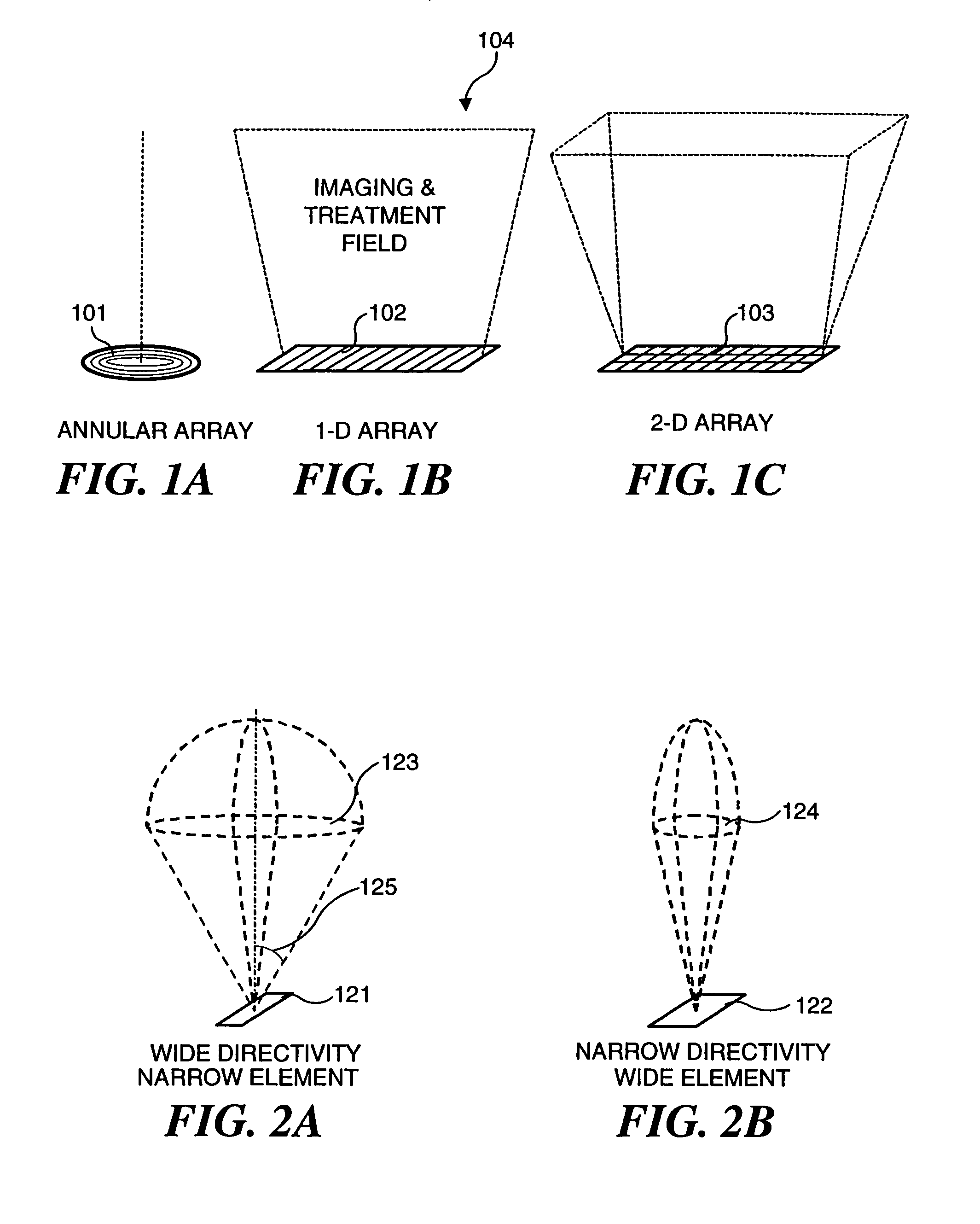

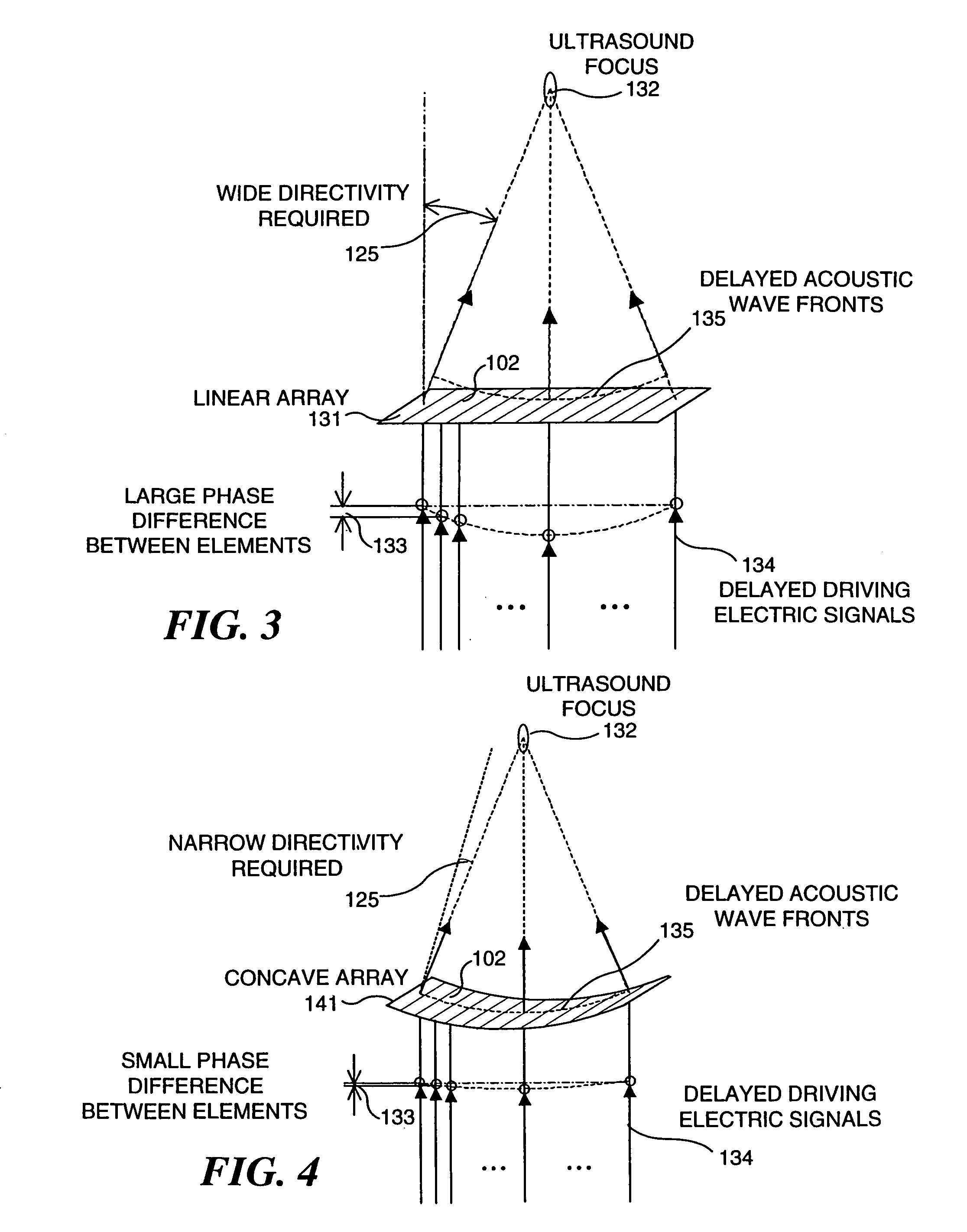

Ultrasound applicators able to both image a treatment site and administer ultrasound therapy include an array of transducer elements that can be focused. In several embodiments, an electronically phased array is used for controlling the focal point of an ultrasound beam. The ultrasound beam produced thereby can also be electronically steered. To reduce the quality factor or Q of the array when the array is used for imaging, an electronic switch is selectively closed, placing a resistance in parallel with each of the array elements. A flexible array is employed in several embodiments and is selectively bent or flexed to vary its radius of curvature and thus control the focal point and / or a direction of focus of the array. In another embodiment, each of the transducer elements comprising the array are individually mechanically pivotable to steer the ultrasonic beam produced by the transducer elements.

Owner:OTSUKA MEDICAL DEVICES

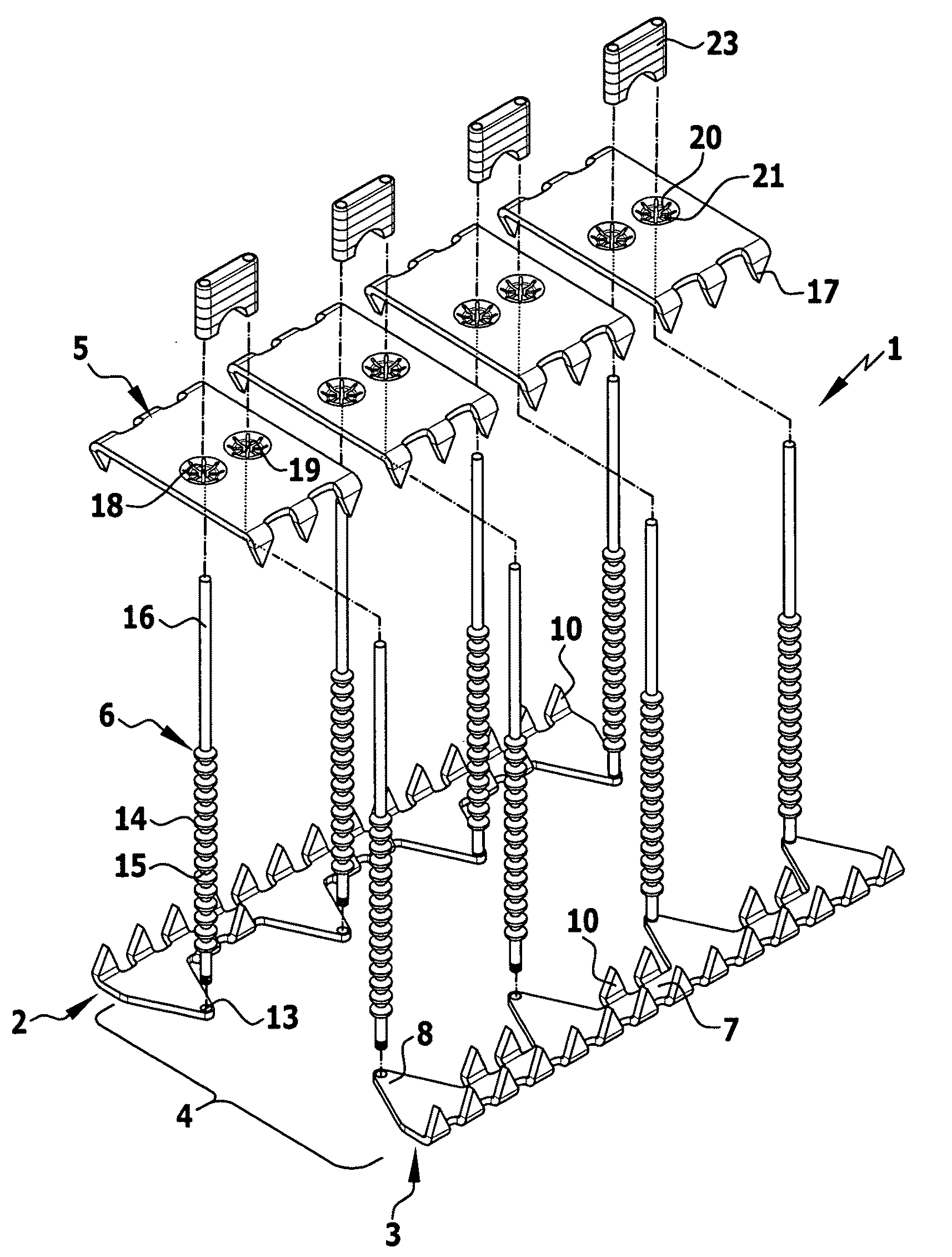

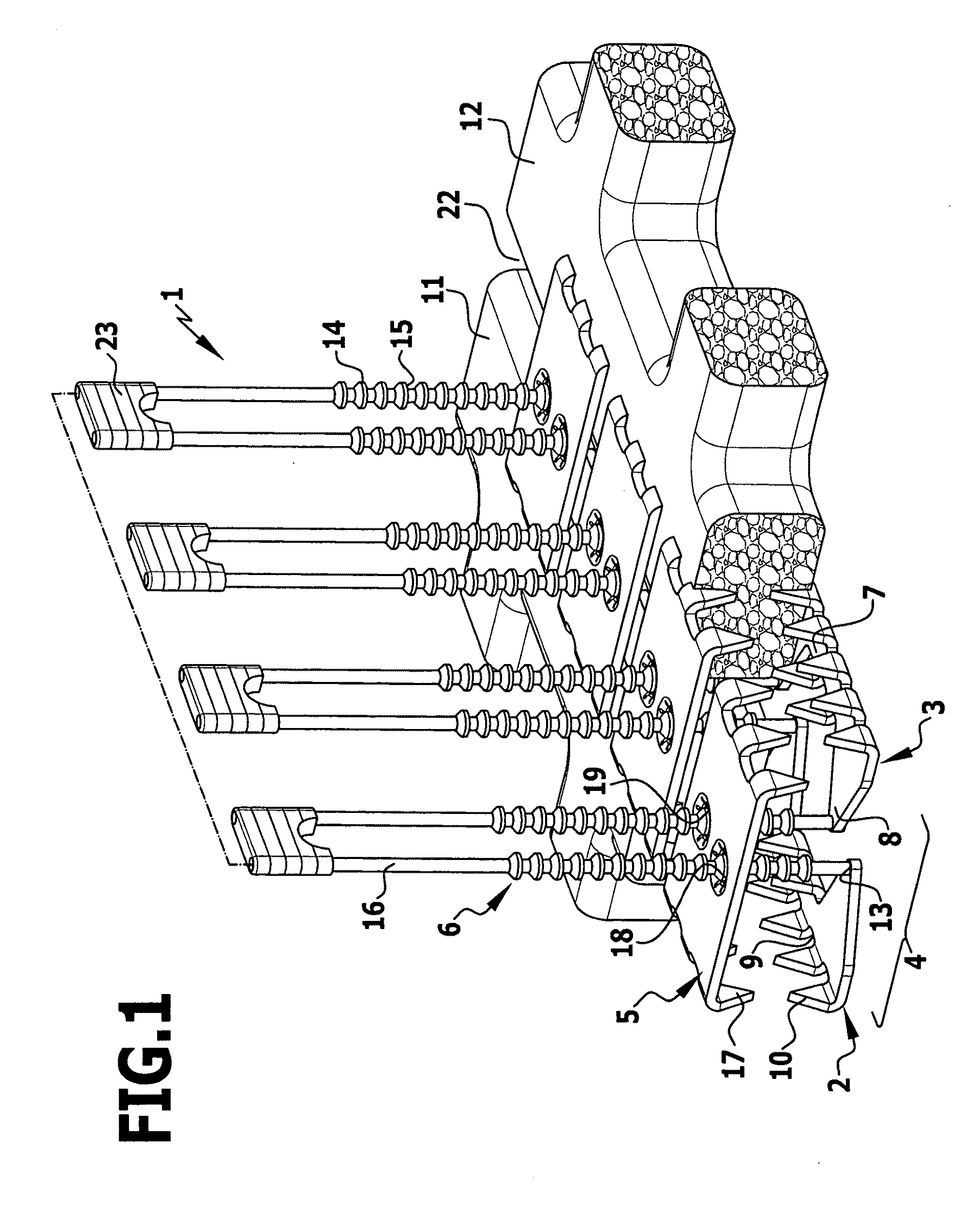

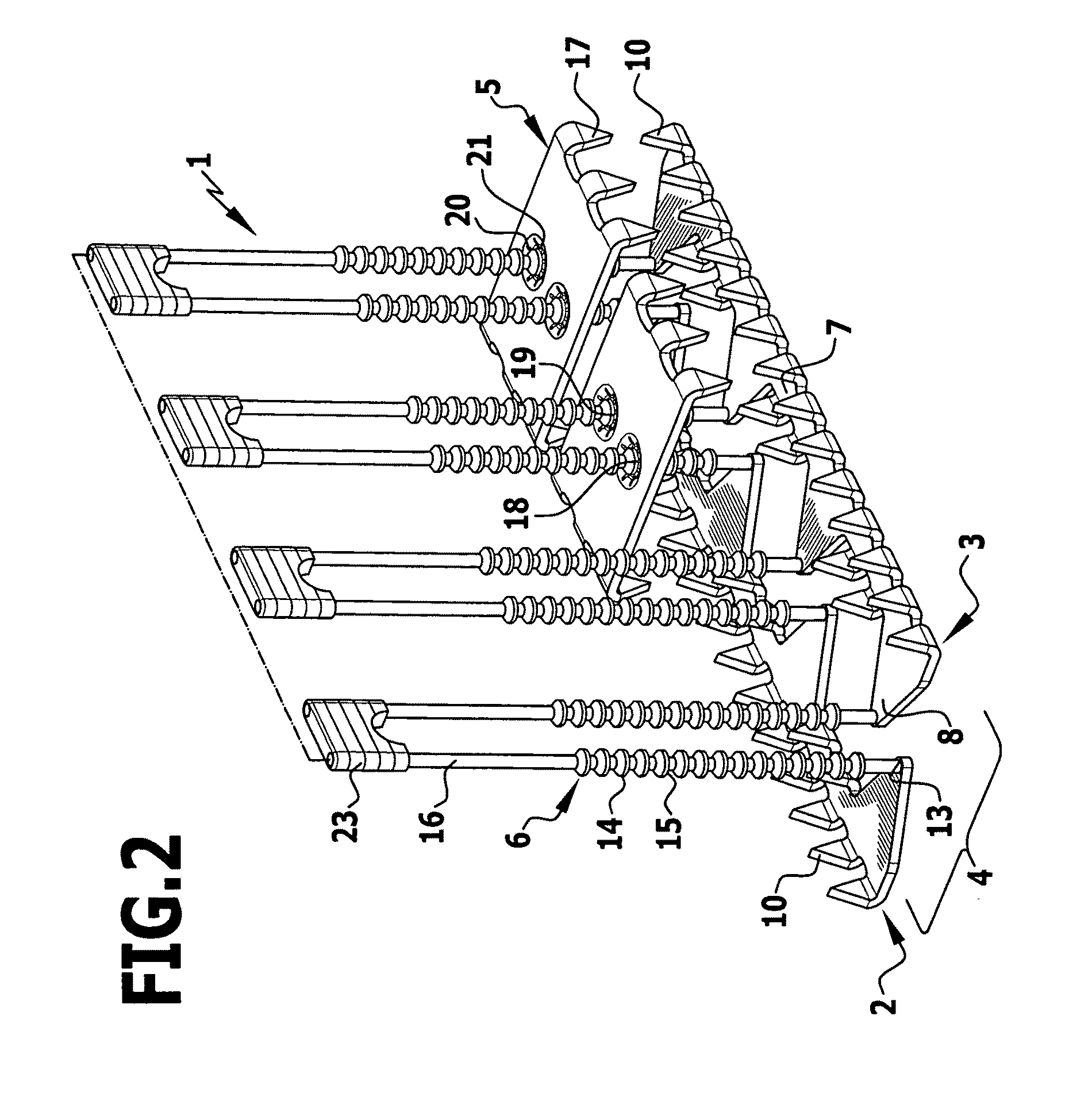

Sternum closure device

InactiveUS20090234358A1Improve stabilityOuter contact elementsInternal osteosythesisJoint implantsSternum partAbutment

In a sternum closure device for fixing two sternum portions to be connected to one another, comprising an inner contact element for abutment on the inner surface of the sternum, at least one clamping element fixed to this contact element and projecting transversely from it and at least one outer contact element for abutment on the outer side of the sternum which can be clamped against the inner contact element by means of the clamping element guided through the intermediate space between the sternum portions, it is suggested in order to hinder the separation of the sternum as little as possible during any renewed operation that the inner contact element consist of two parts which are separate from one another and each of which is designed to abut on one of the two sternum portions and that connecting means be provided for the releasable connection of the two parts arranged next to one another.

Owner:AESCULAP AG

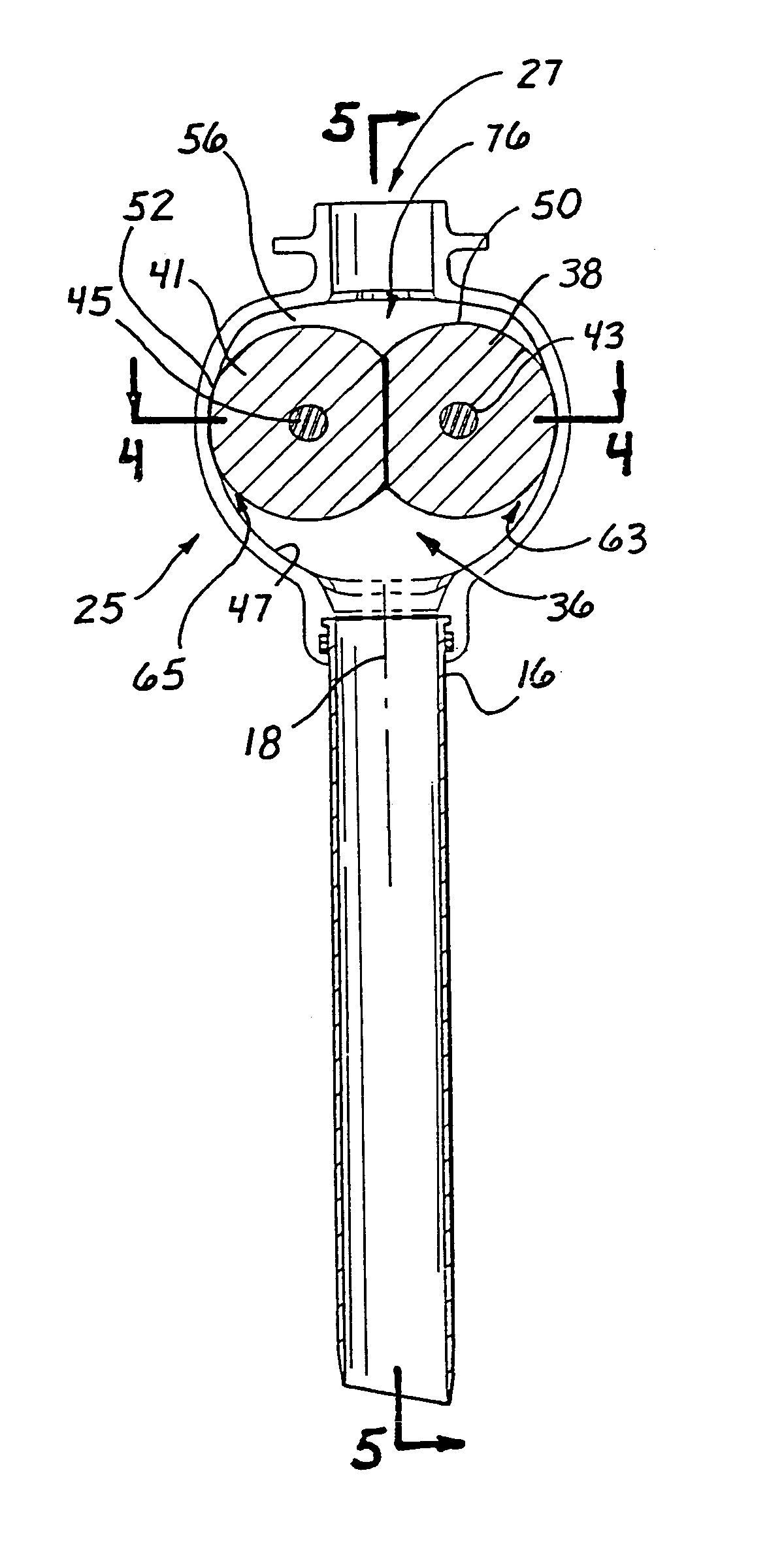

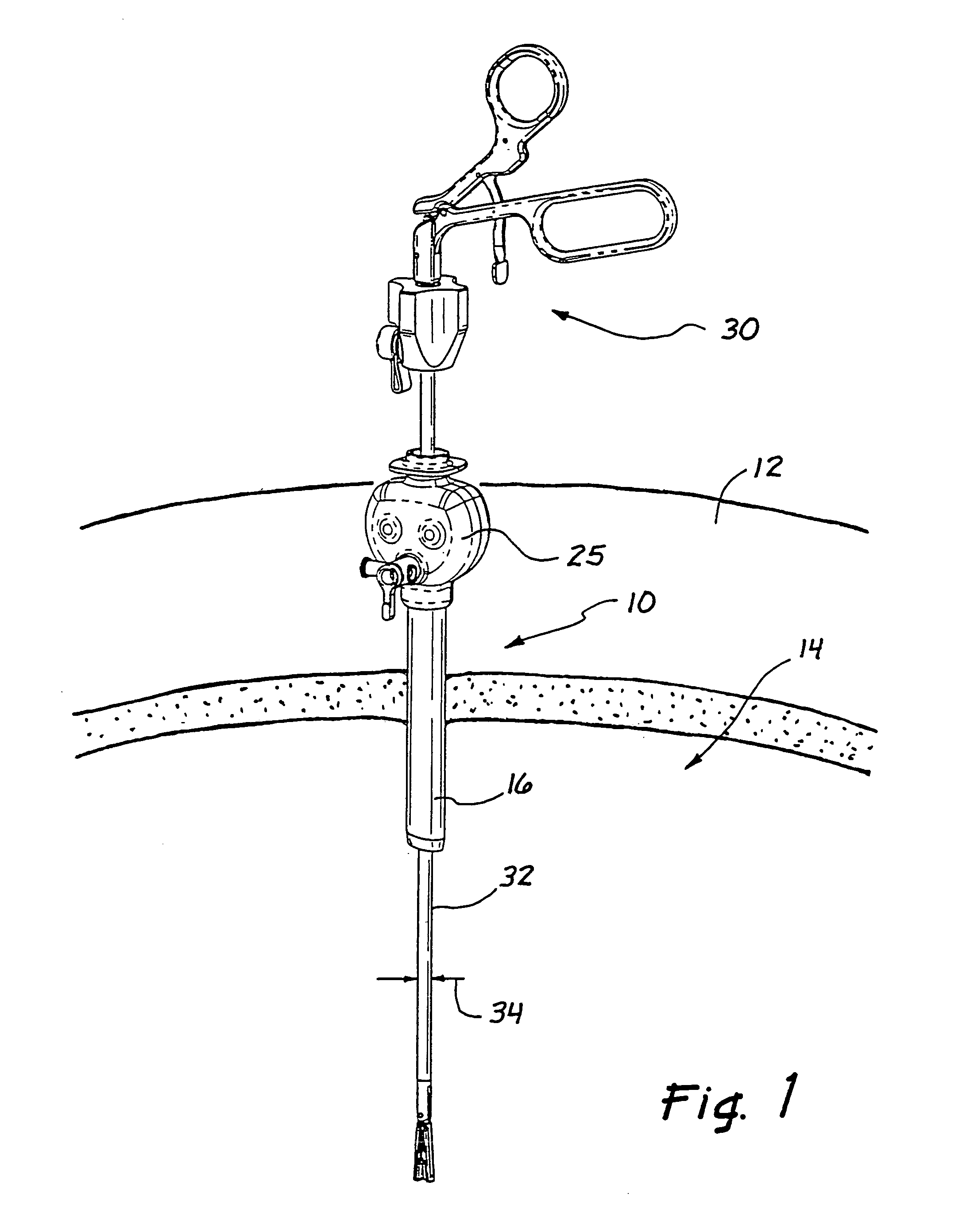

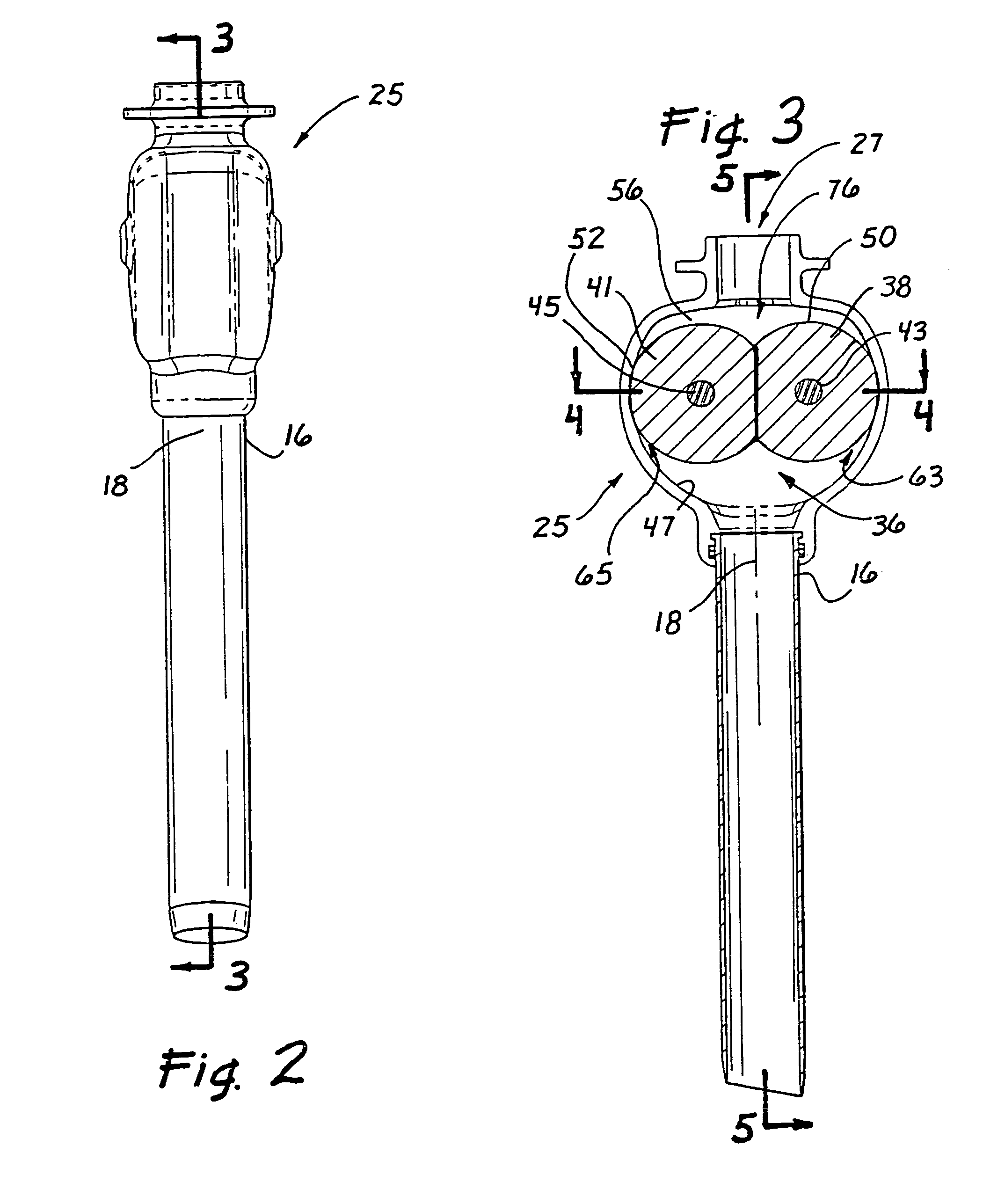

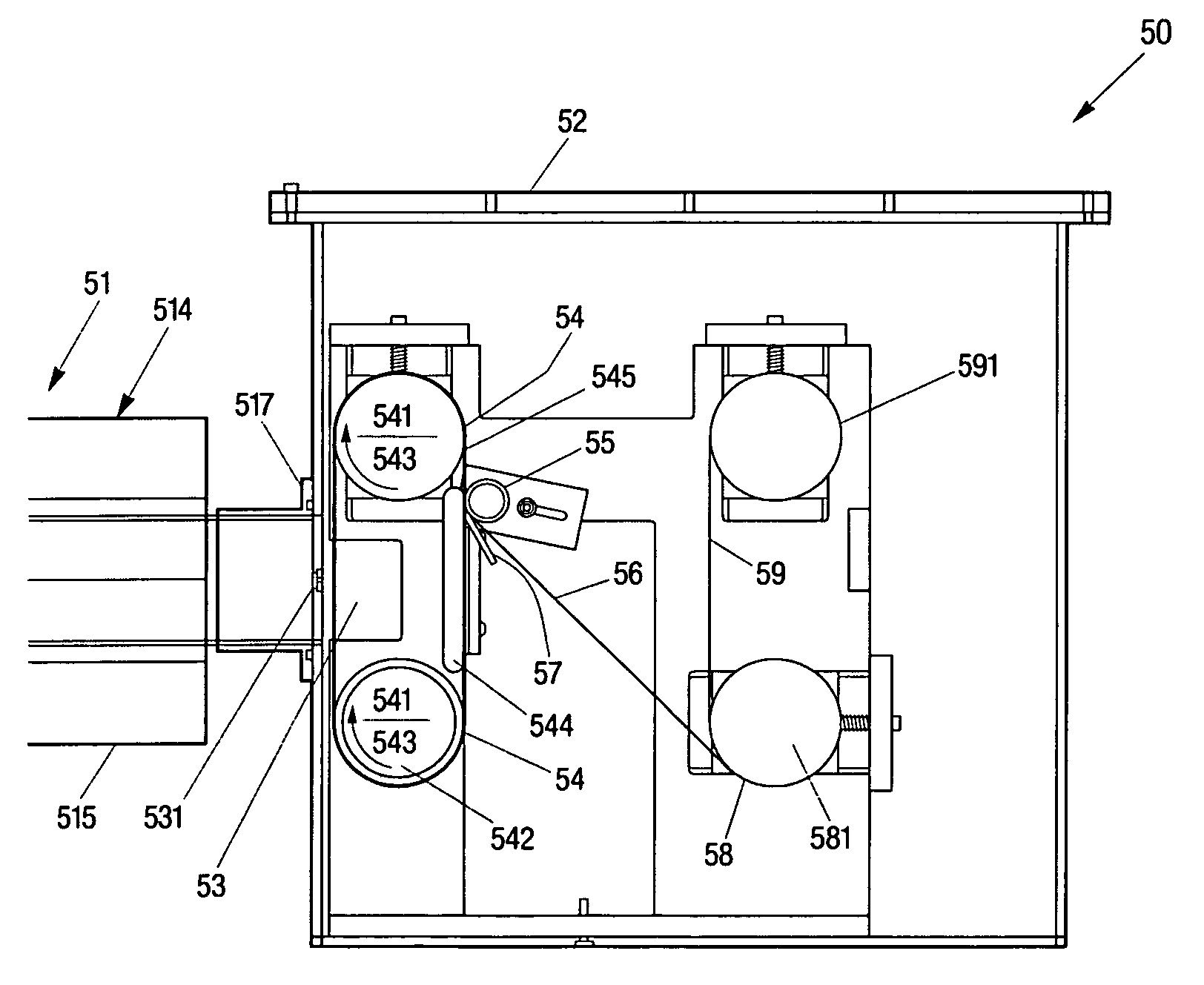

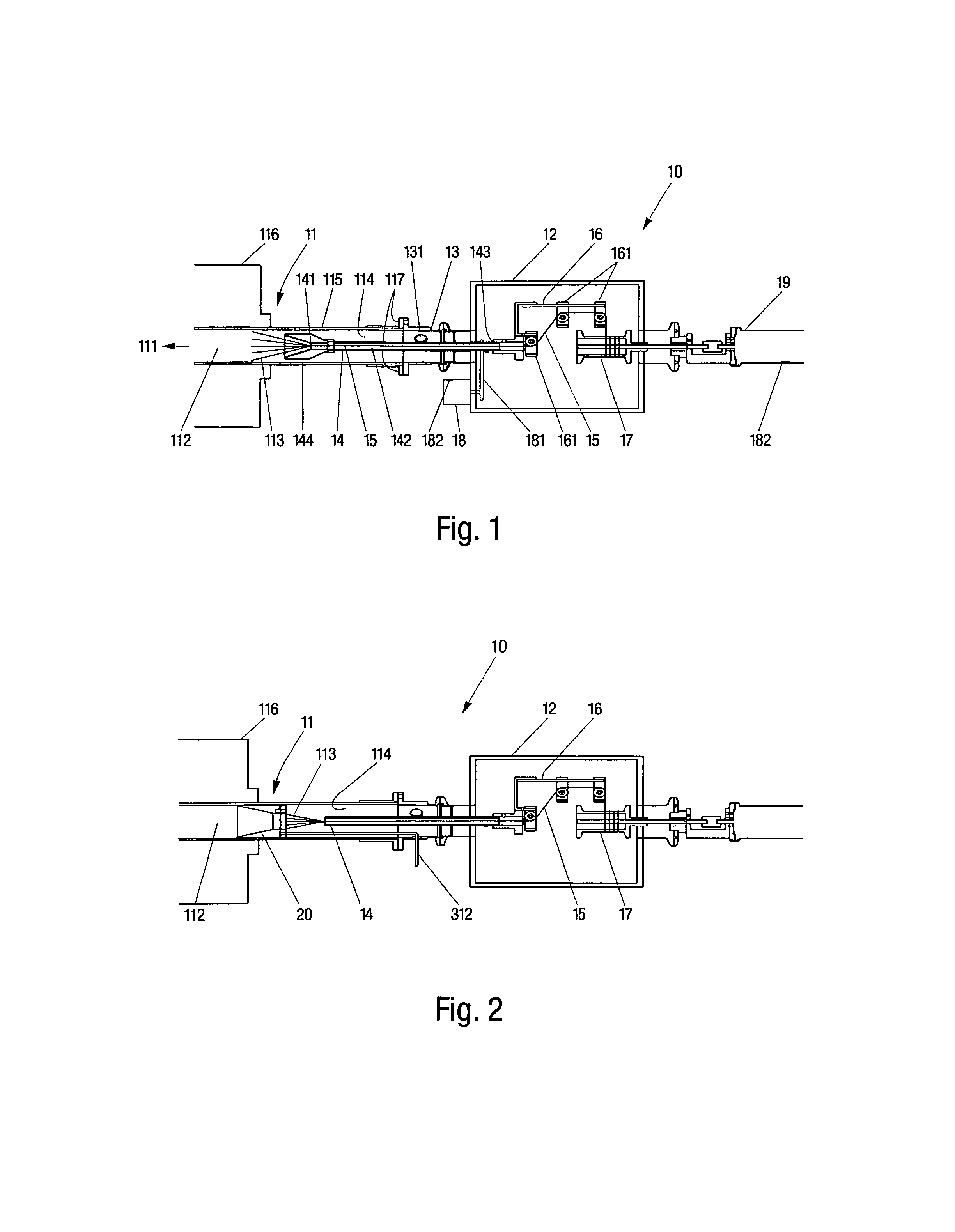

Access device maintenance apparatus and method

InactiveUS7105009B2Avoid bondingInhibition formationInfusion syringesSurgical needlesEngineeringBiological activation

Owner:APPL MEDICAL RESOURCES CORP

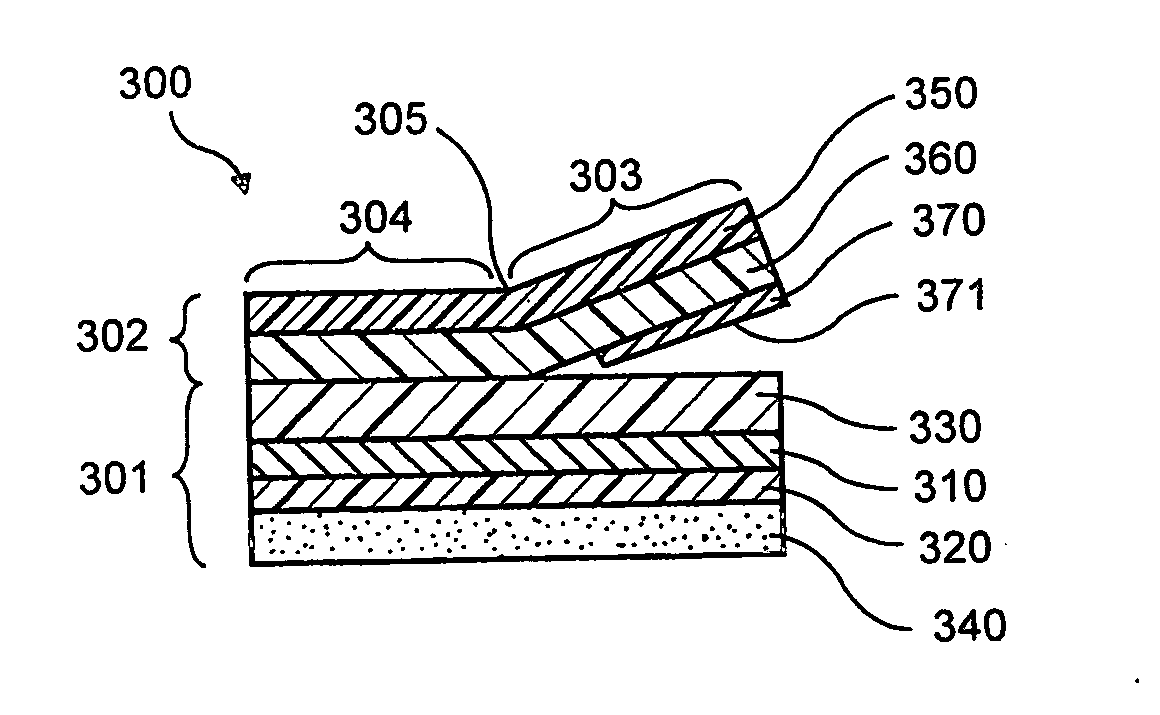

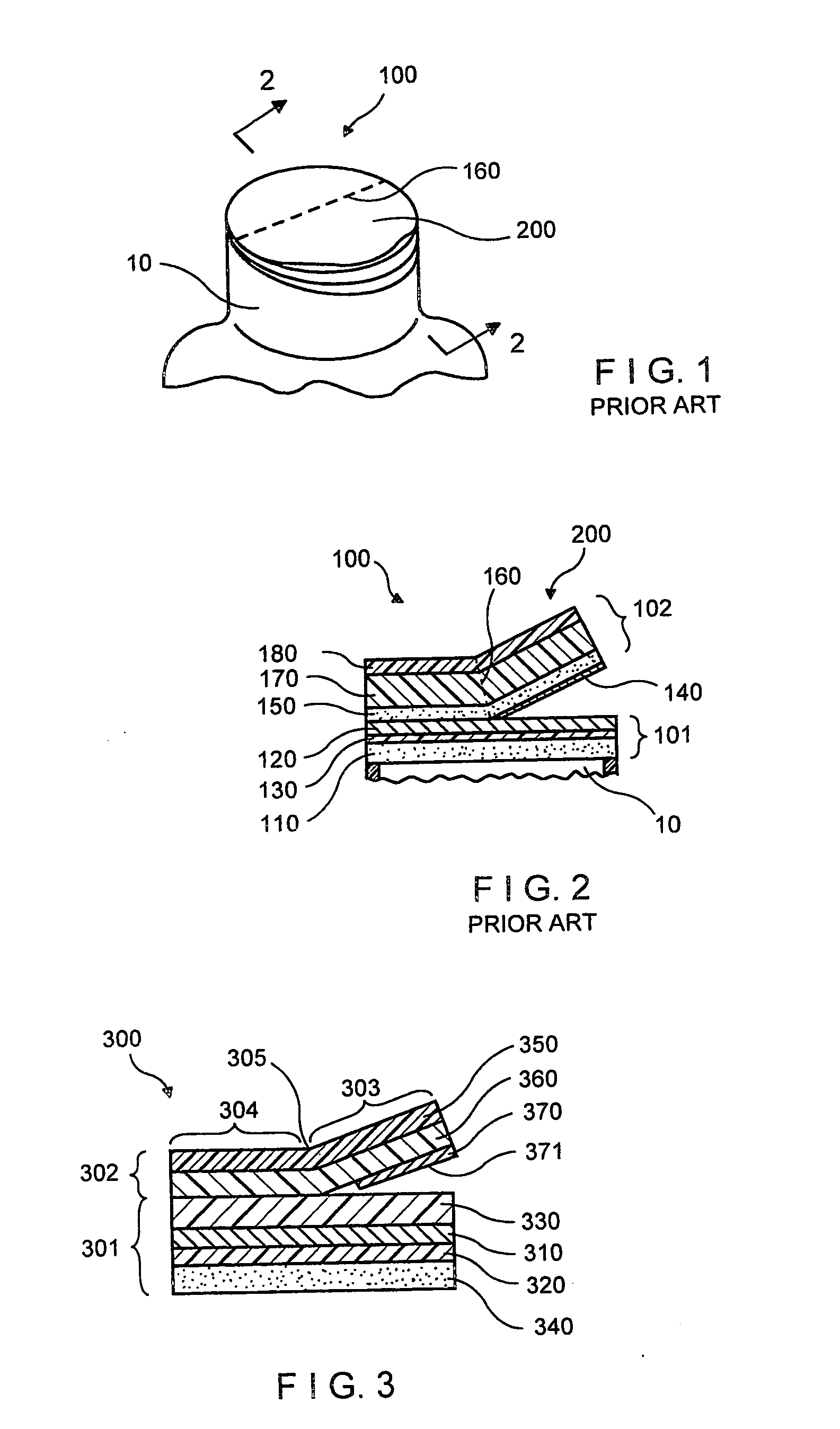

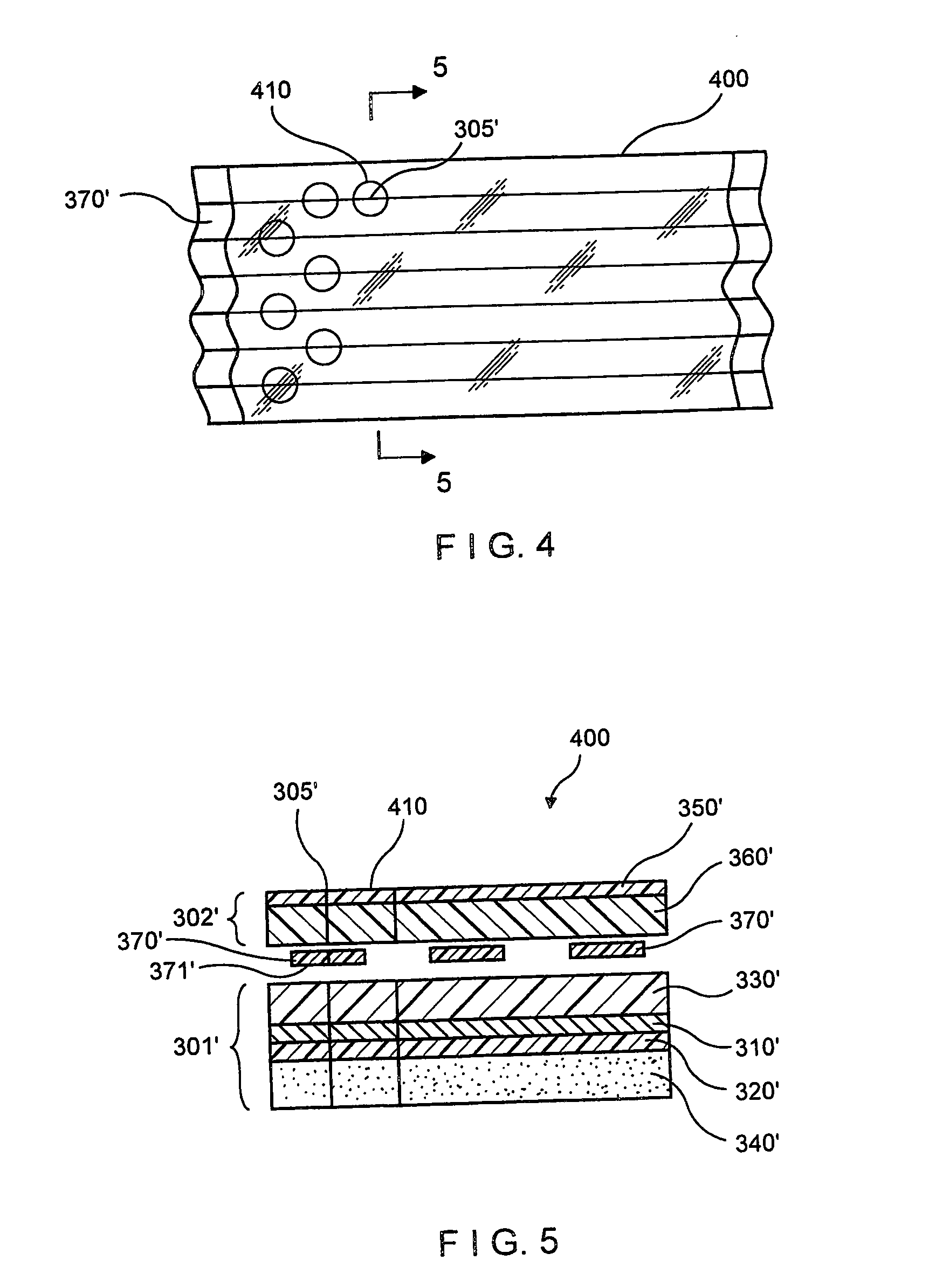

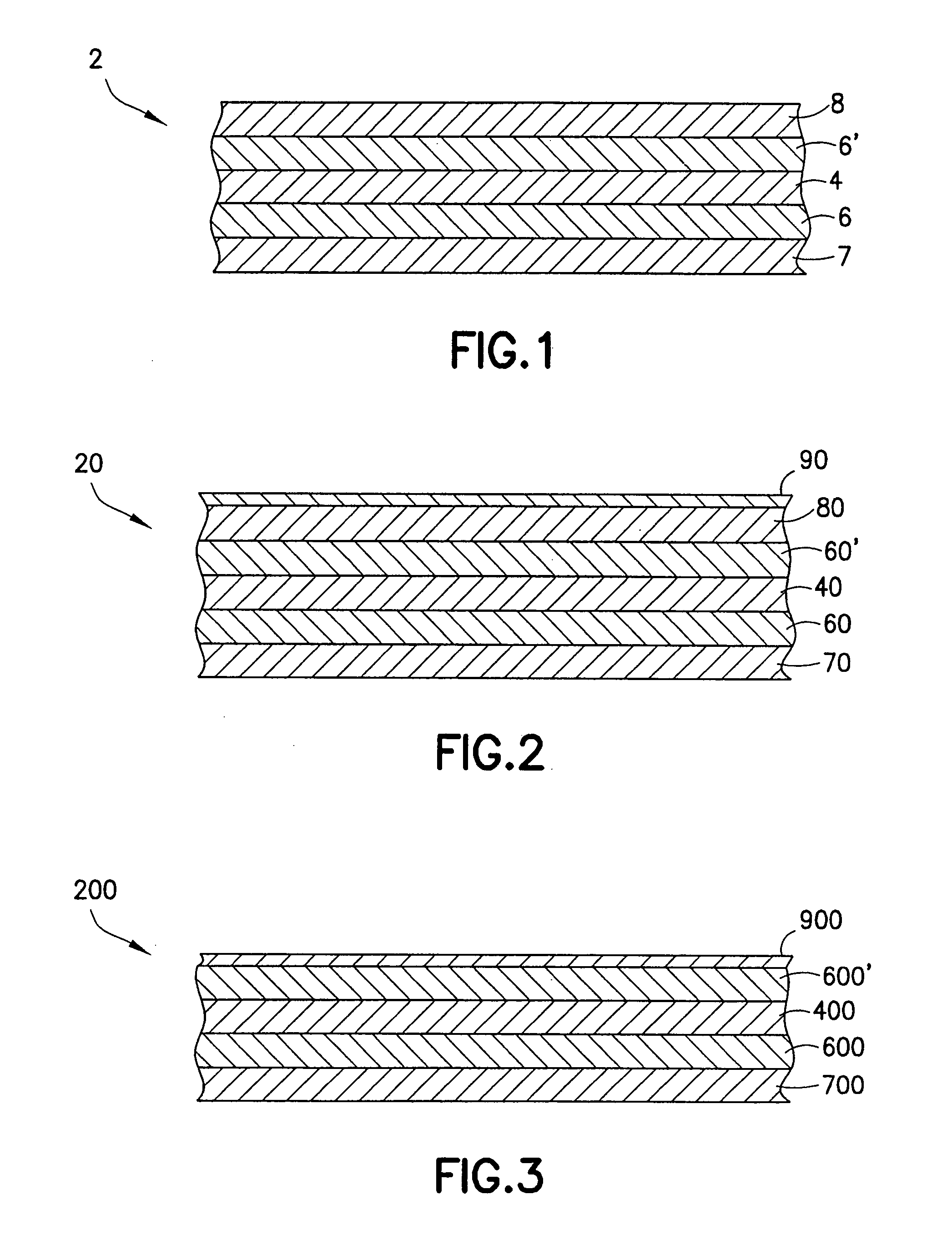

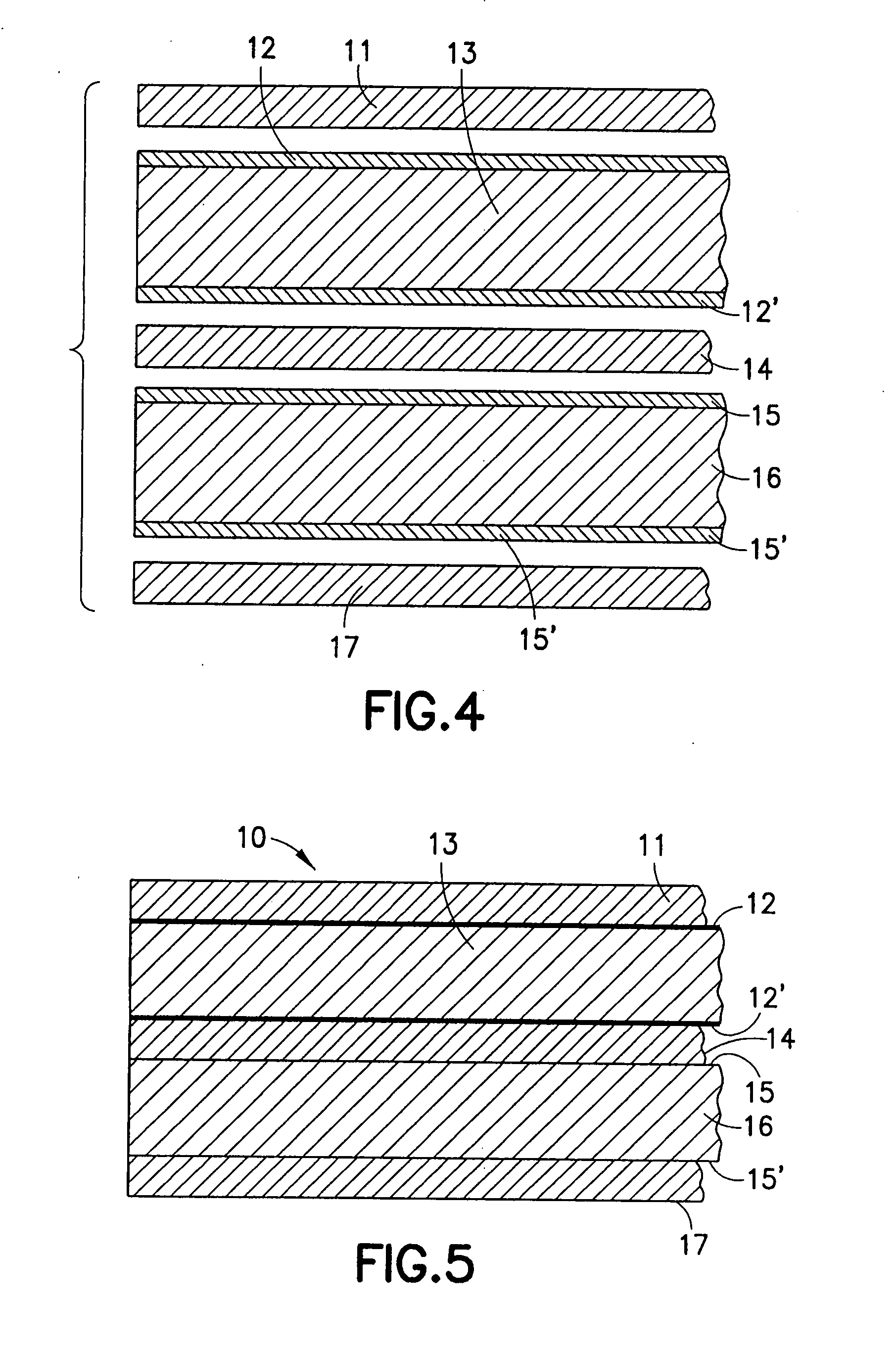

Pull-tab sealing member with improved heat distribution for a container

A seal and method of manufacture is provided for sealing containers such as bottles, jars and the like. The seal (i.e., closure) is formed with a lower sheet-like structure having a non-foam, heat-distributing layer thereon. The lower structure includes a foil support layer and has a polymer layer, such as a PET layer disposed on its bottom surface. A heat-activated sealant layer is provided under the bottom surface of the PET layer to bond the seal to a container opening. The non-foam, heat-distributing layer is preferably a polyolefin film. Seals in accordance with preferred embodiments of the invention also include a top portion, which is only partially bonded (directly or indirectly) to the bottom portion, so as to leave a tab portion extending from the seal. The top portion is advantageously bonded from periphery to periphery of the bottom portion and at or slightly offset from the diameter (middle) of the bottom portion. The top portion is advantageously formed with polymer material, such as an ethylene vinyl acetate (EVA) layer, having a layer of PET bonded on the top thereof. A release strip, which can have a release layer coated on the bottom thereof, is adhered to the top or bottom structures and used to prevent the tab from adhering to the lower structure.

Owner:SELIG SEALING PROD INC

Method for forming interphase layers in ceramic matrix composites

InactiveUS7666475B2Avoid bondingSacrificing crack deflection and toughnessPretreated surfacesChemical vapor deposition coatingMatrix densitySlurry

A method for forming interphase layers in ceramic matrix composites. The method forms interphase layers in ceramic matrix composites thereby enabling higher matrix densities to be achieved without sacrificing crack deflection and / or toughness. The methods of the present invention involve the use fugitive material-coated fibers. These fibers are then infiltrated with a ceramic matrix slurry. Then, the fugitive material is removed and the resulting material is reinfiltrated with an interphase layer material. The ceramic matrix composite is then fired. Additional steps may be included to densify the ceramic matrix or to increase the strength of the interphase layer. The method is useful for the formation of three dimensional fiber-reinforced ceramic matrix composites envisioned for use in gas turbine components.

Owner:SIEMENS ENERGY INC

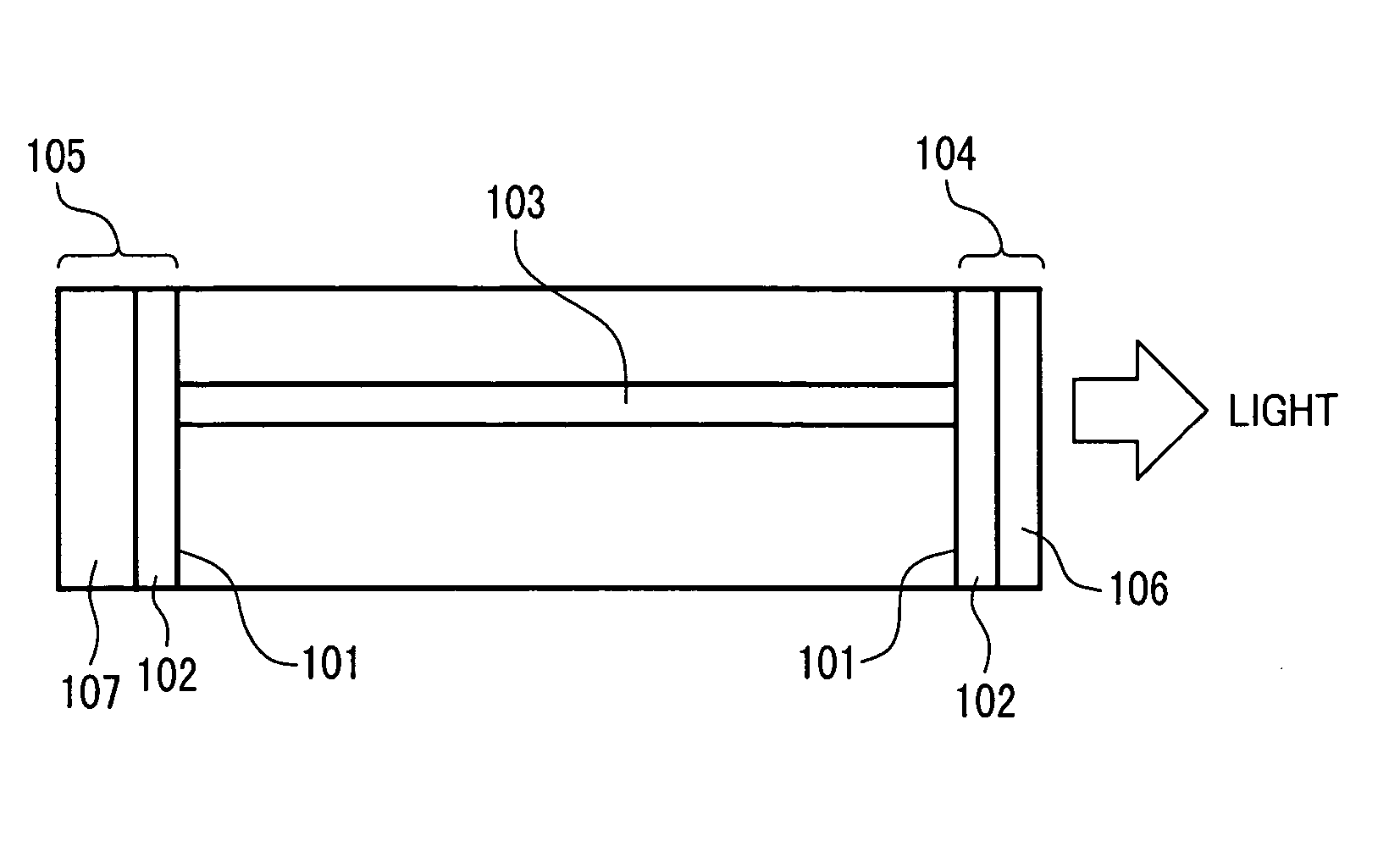

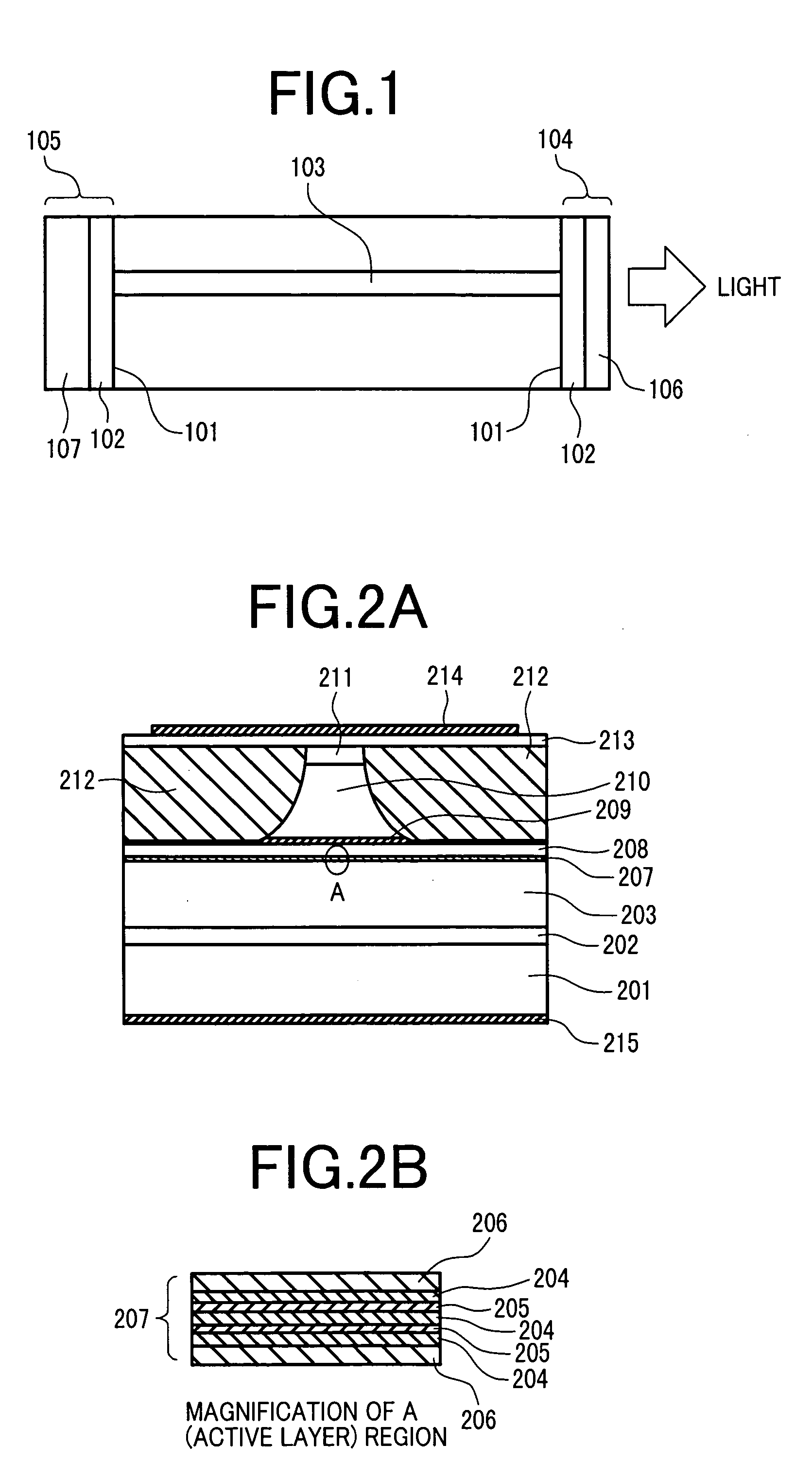

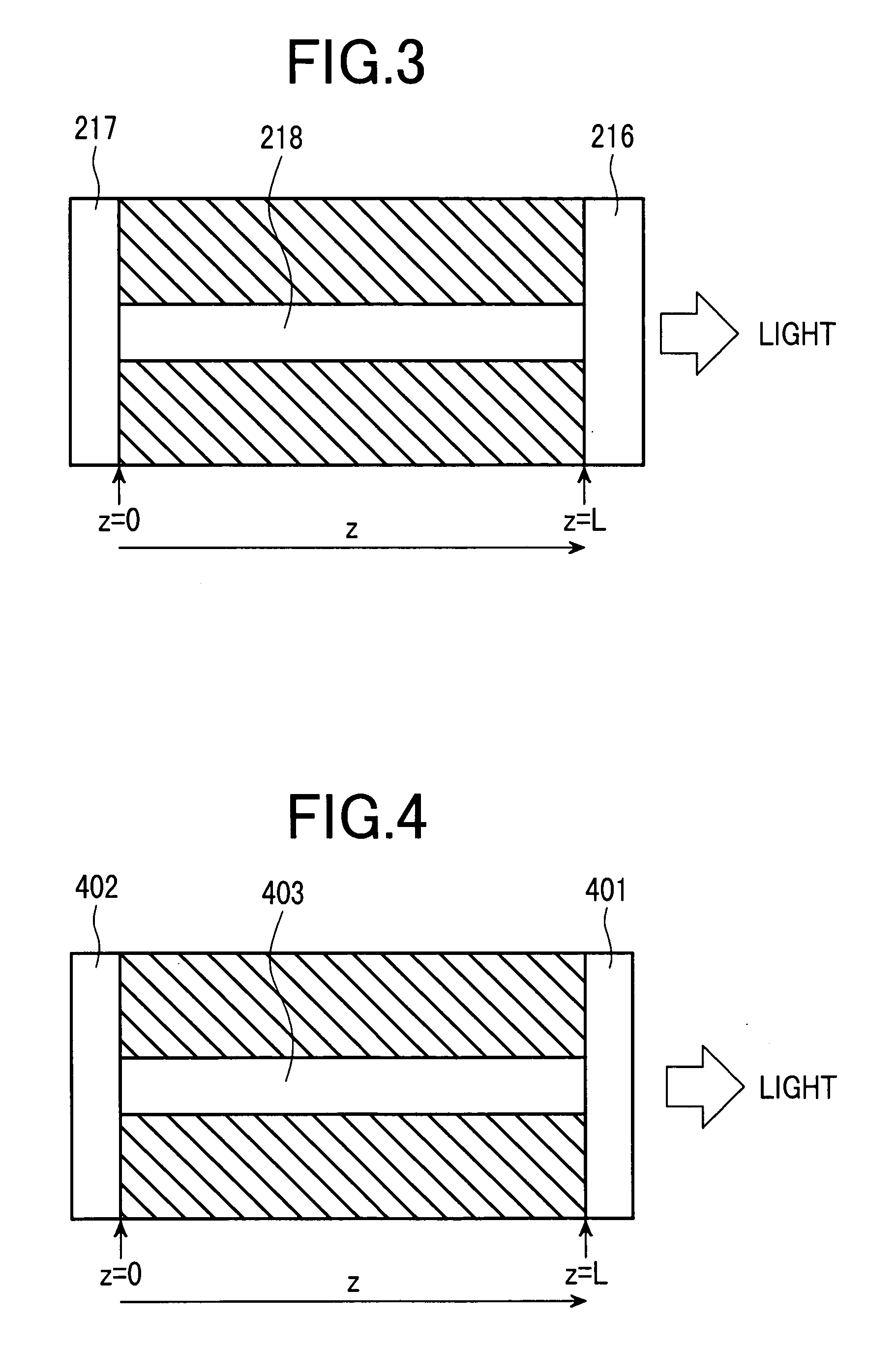

Laser diode and manufacturing method thereof

ActiveUS20050127383A1Lower resistanceLight increaseLaser detailsLaser optical resonator constructionPhysicsResonator

Laser diodes containing aluminum at high concentration in an active layer have been usually suffered from remarkable facet deterioration along with laser driving operation and it has been difficult for the laser diodes to attain high reliability. An aluminum oxide film lacking in oxygen is formed adjacent to the semiconductor on an optical resonator facet, by which facet deterioration can be minimized and, accordingly, the laser diode can be operated with no facet deterioration at high temperature for long time and a laser diode of high reliability can be manufactured at a reduced cost.

Owner:LUMENTUM JAPAN INC

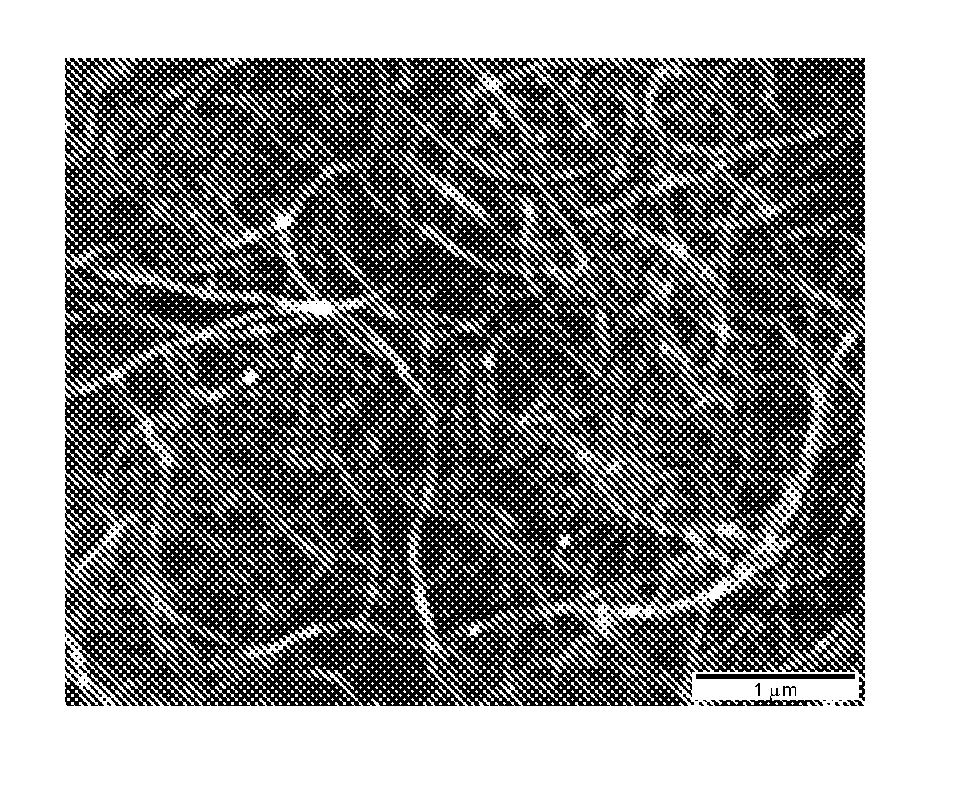

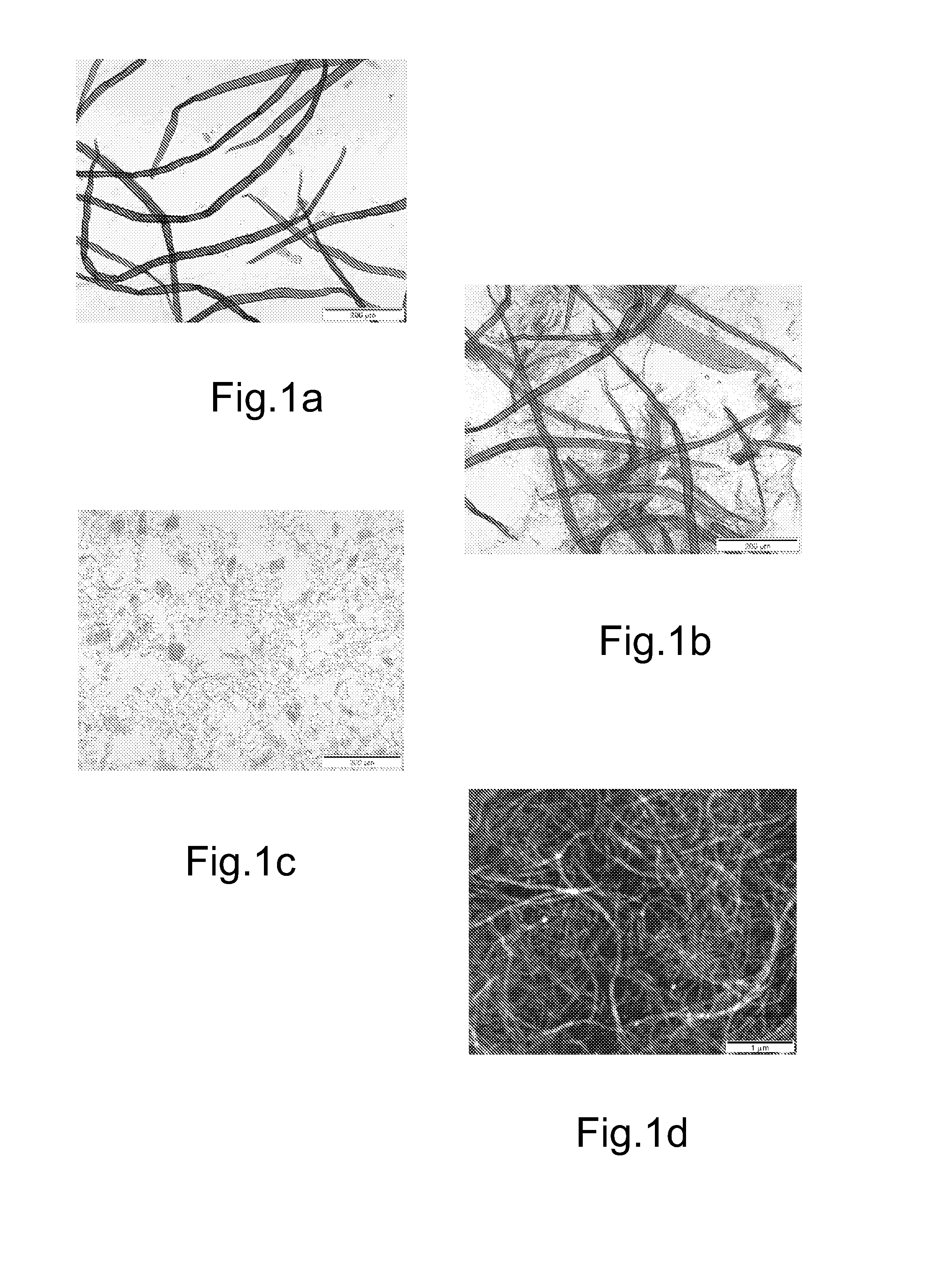

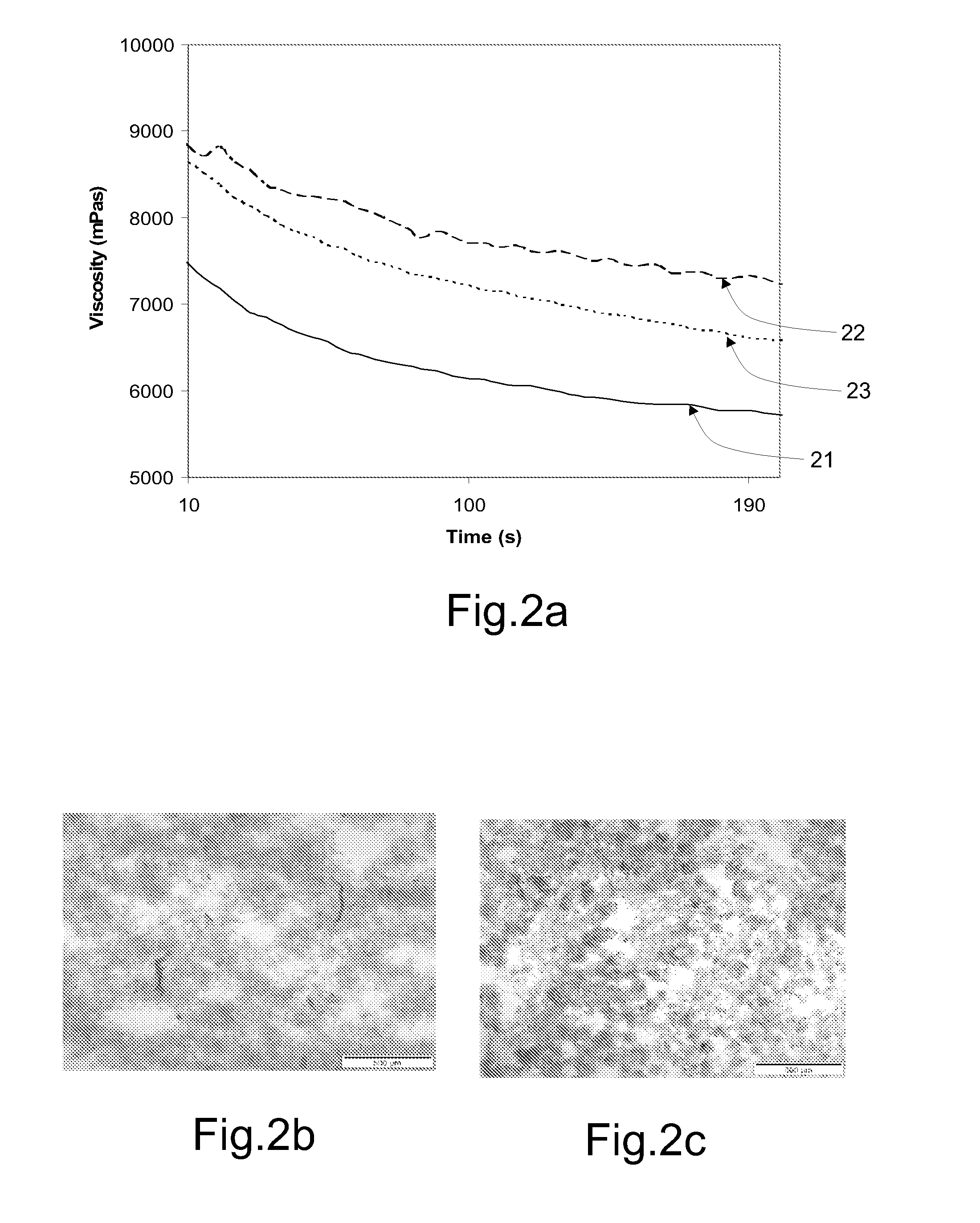

Systems and methods for formation and harvesting of nanofibrous materials

ActiveUS7993620B2Minimize bondingHinder integrityMaterial nanotechnologyTransportation and packagingFiberYarn

Owner:NANCOMP TECHNOLOGIES INC

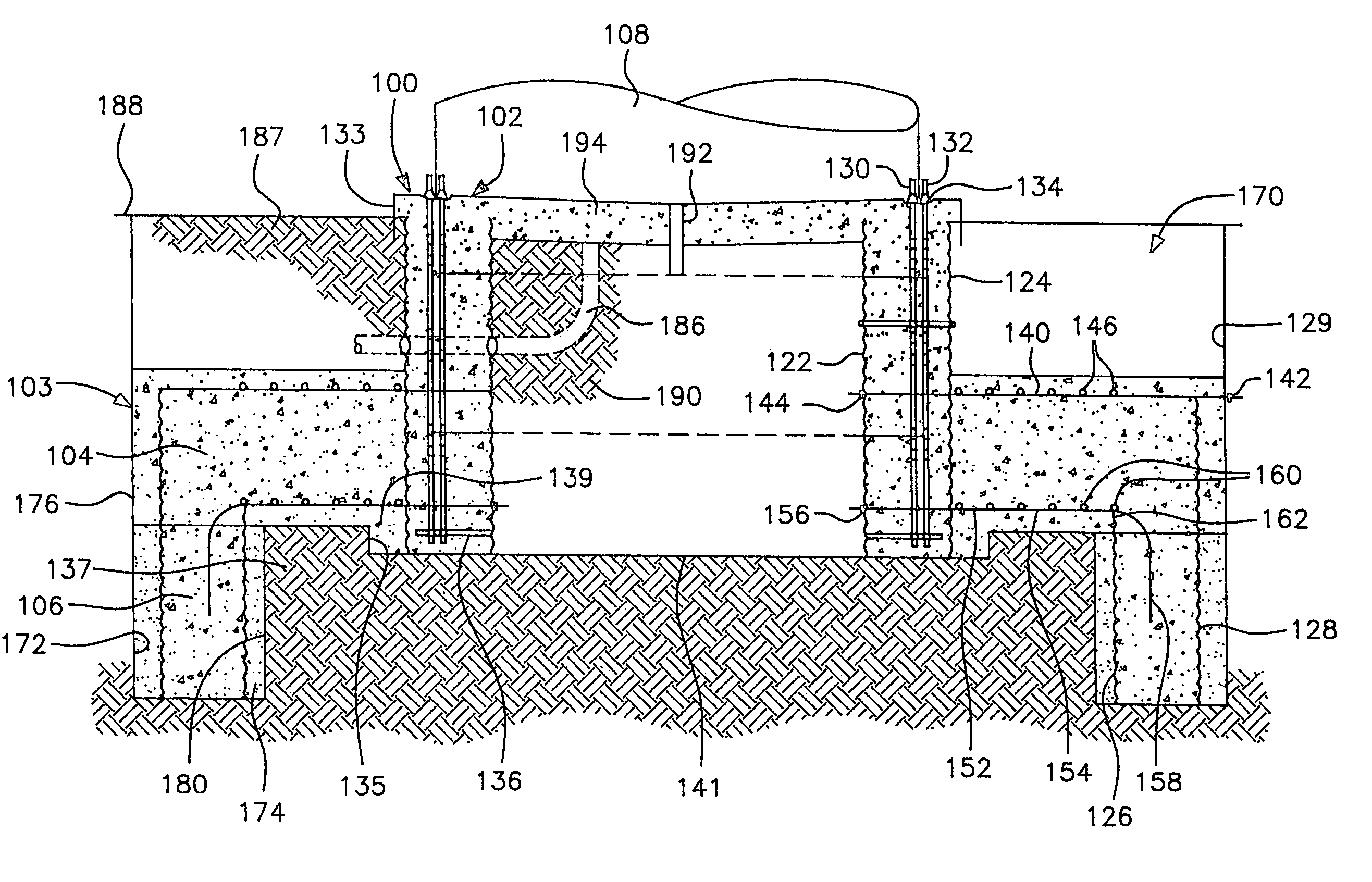

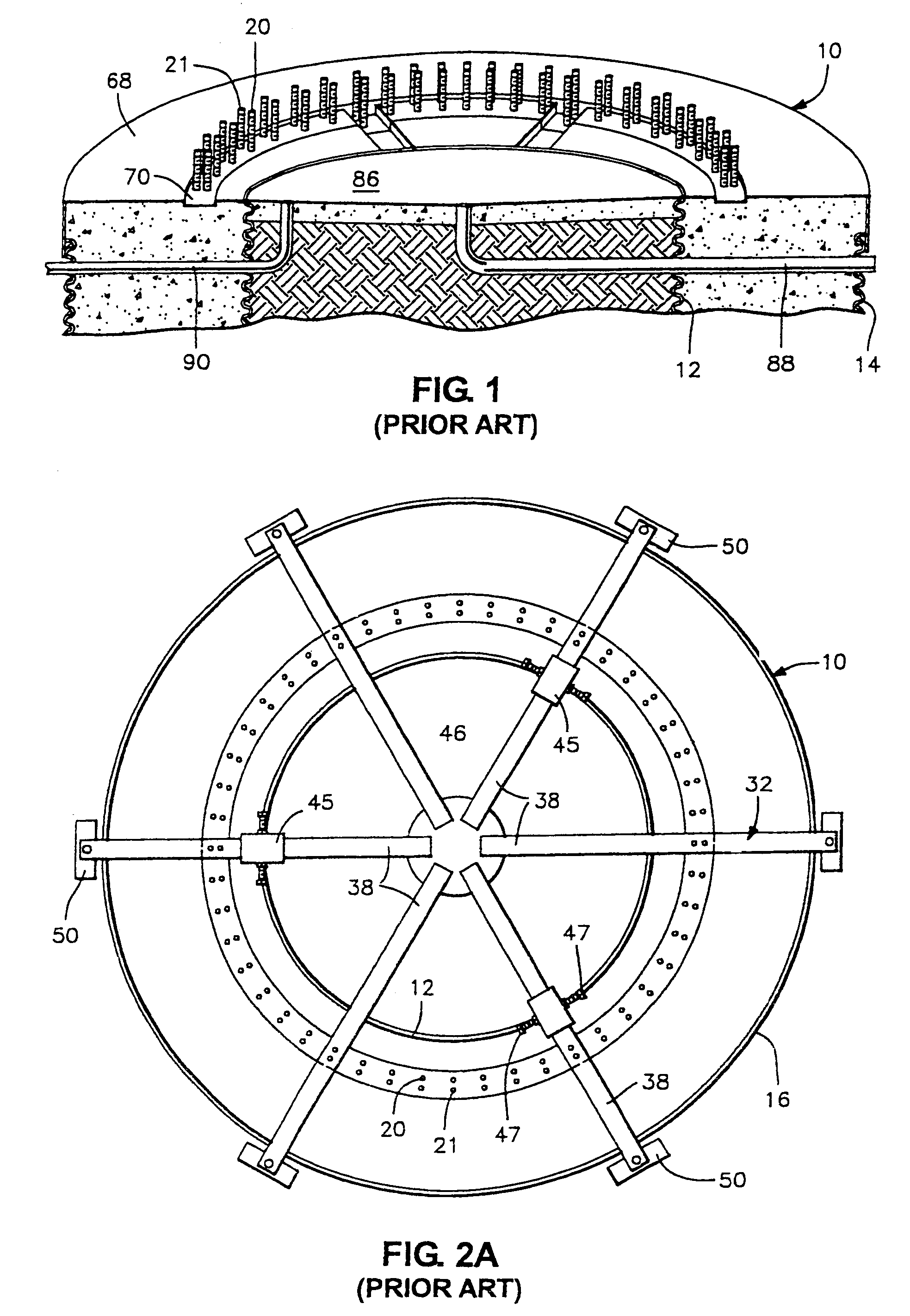

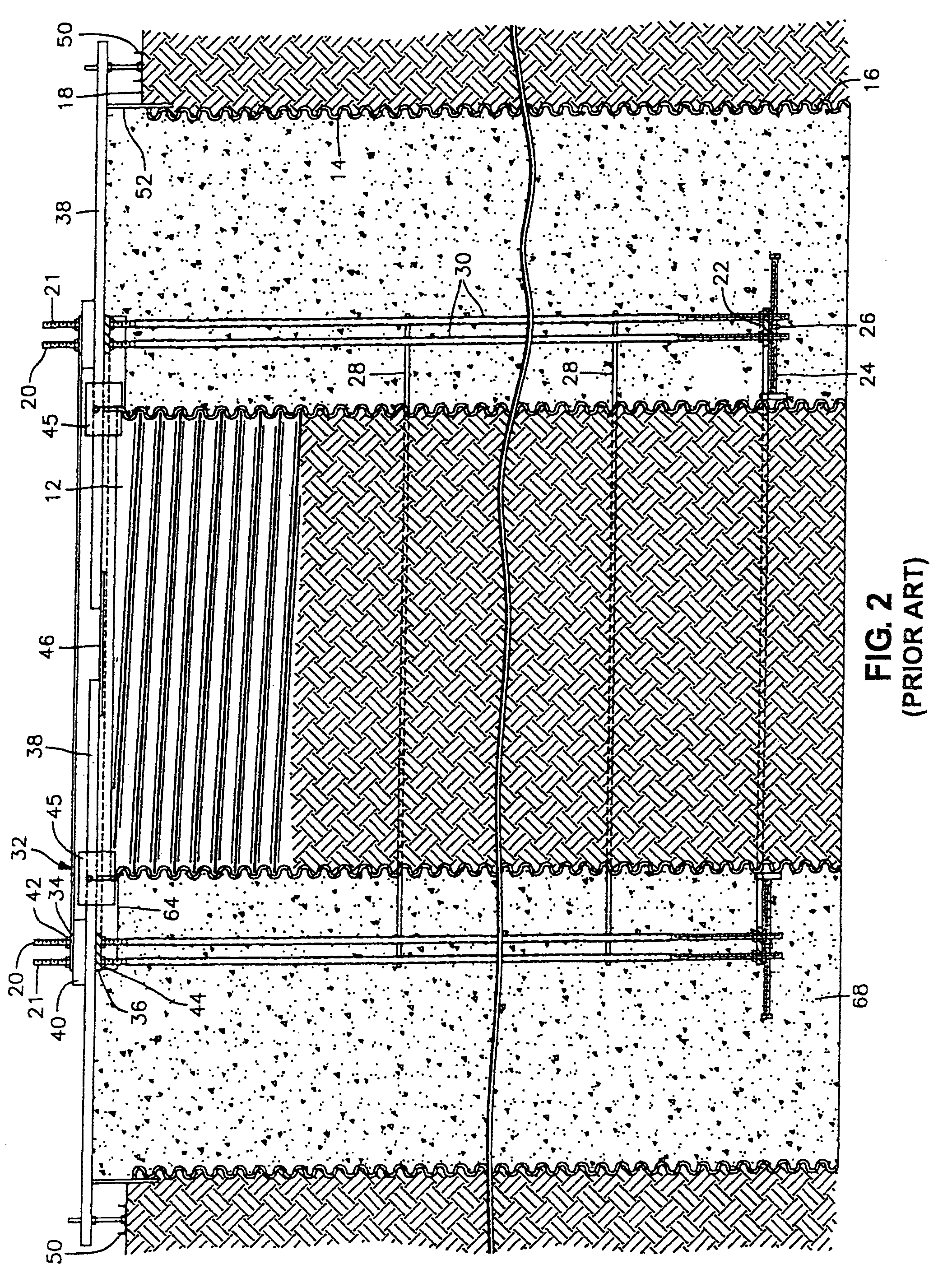

Method of forming a perimeter weighted foundation for wind turbines and the like

InactiveUS7155875B2Increases the foundation's resistance to an overturning momentIncreased compressive loadWind motor supports/mountsBuilding repairsWind forceTurbine

A perimeter weighted foundation has a central pier pedestal and an enlarged base spaced outwardly and extending below the pedestal. The enlarged base includes an outer concentric perimeter wall section with a radially extending, disk-shaped spread section interconnecting the bottom of the pedestal section and the top of the perimeter wall section. The pedestal section includes vertically extending post-tensioning anchor bolts sleeved through substantially the entire height of the cylindrical pedestal in accordance with earlier U.S. Pat. Nos. 5,586,417 and 5,826,387 and the spread section includes two layers of similarly sleeved post-tensioning bolts which extend through the bottom of the pedestal section and into or through the top of the perimeter wall section, thus tying together the enlarged base to the pier pedestal. After the concrete is poured, hardened and cured, the vertical bolts of the pedestal section and the radially extending horizontal bolts in the spread section are post-tensioned to impart a heavy unit compressive loading on the concrete in the pier pedestal and enlarged base. After back filling soil onto the spread section and to the interior of the pedestal section, the foundation is able to withstand high upset forces imparted to the foundation by any large structure supported thereon.

Owner:TERRACON CONSULTANTS INC

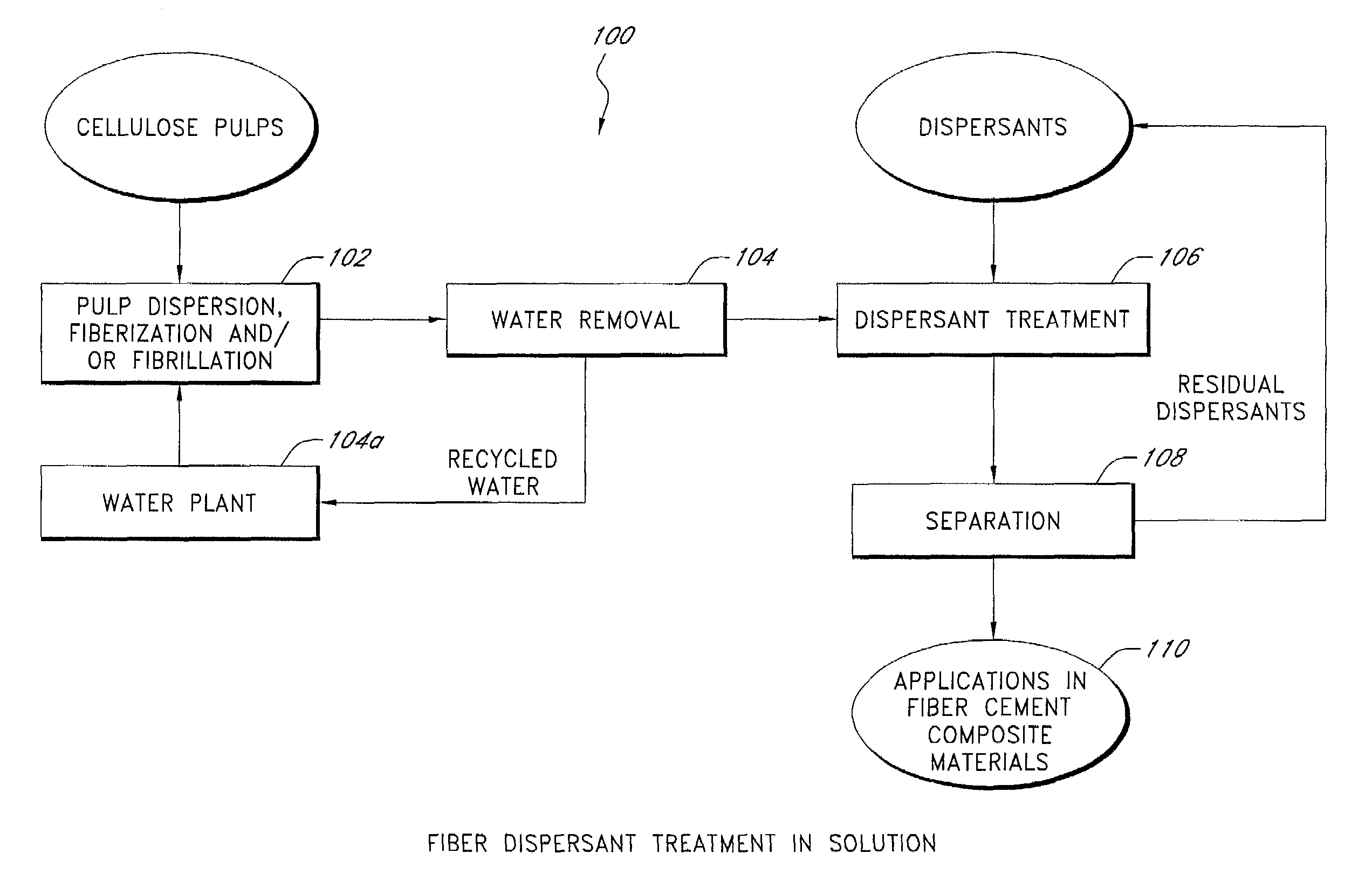

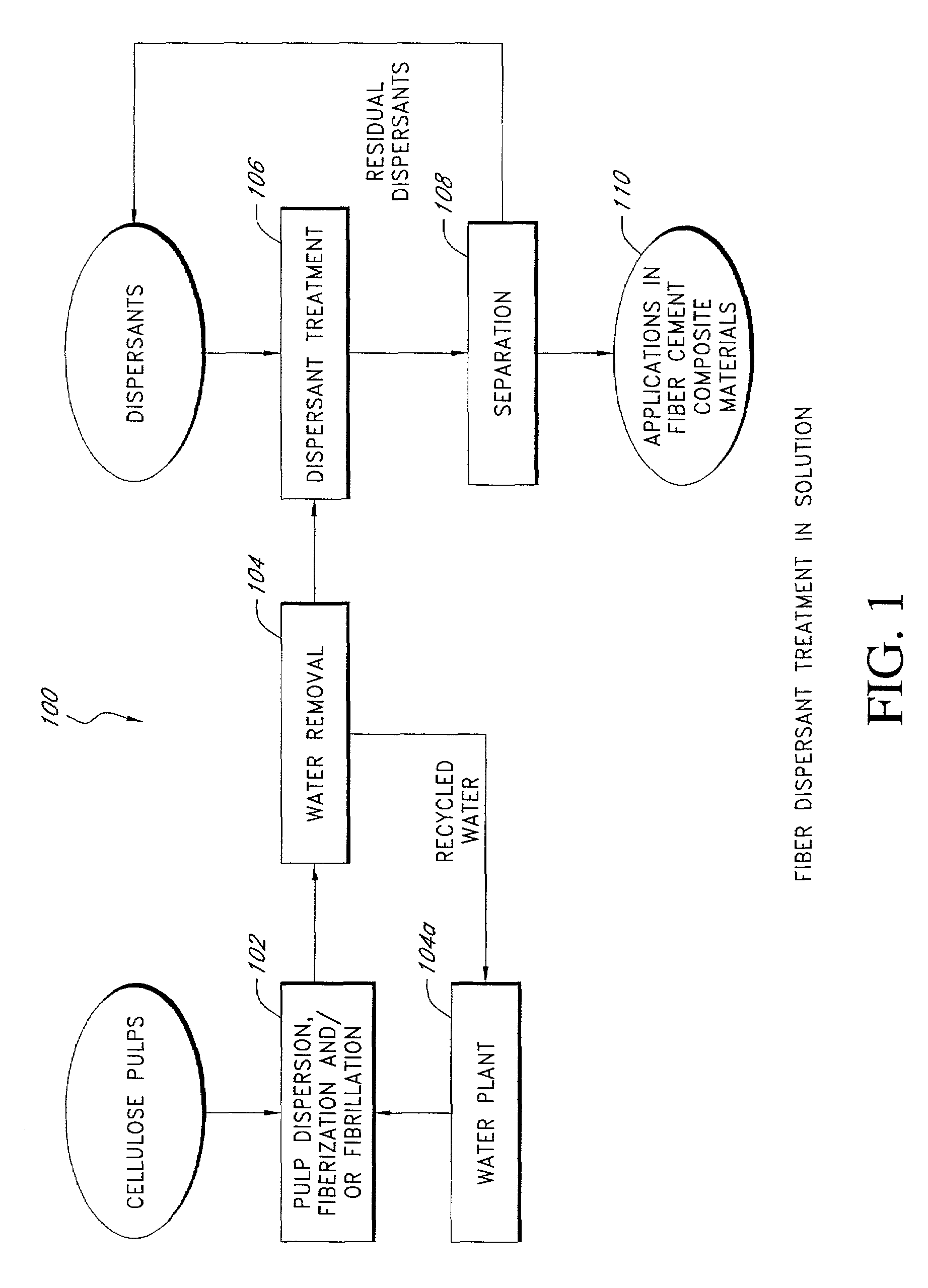

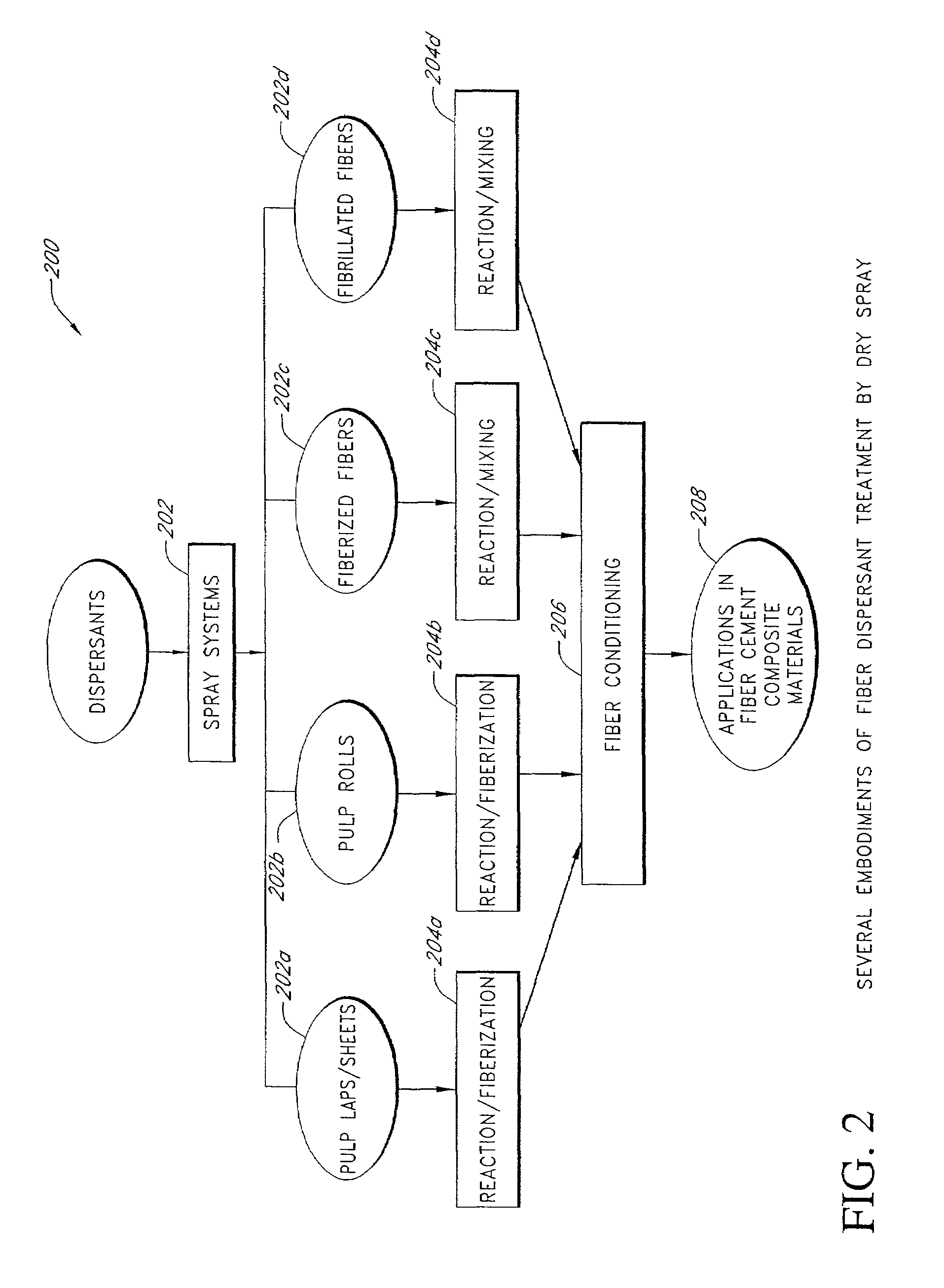

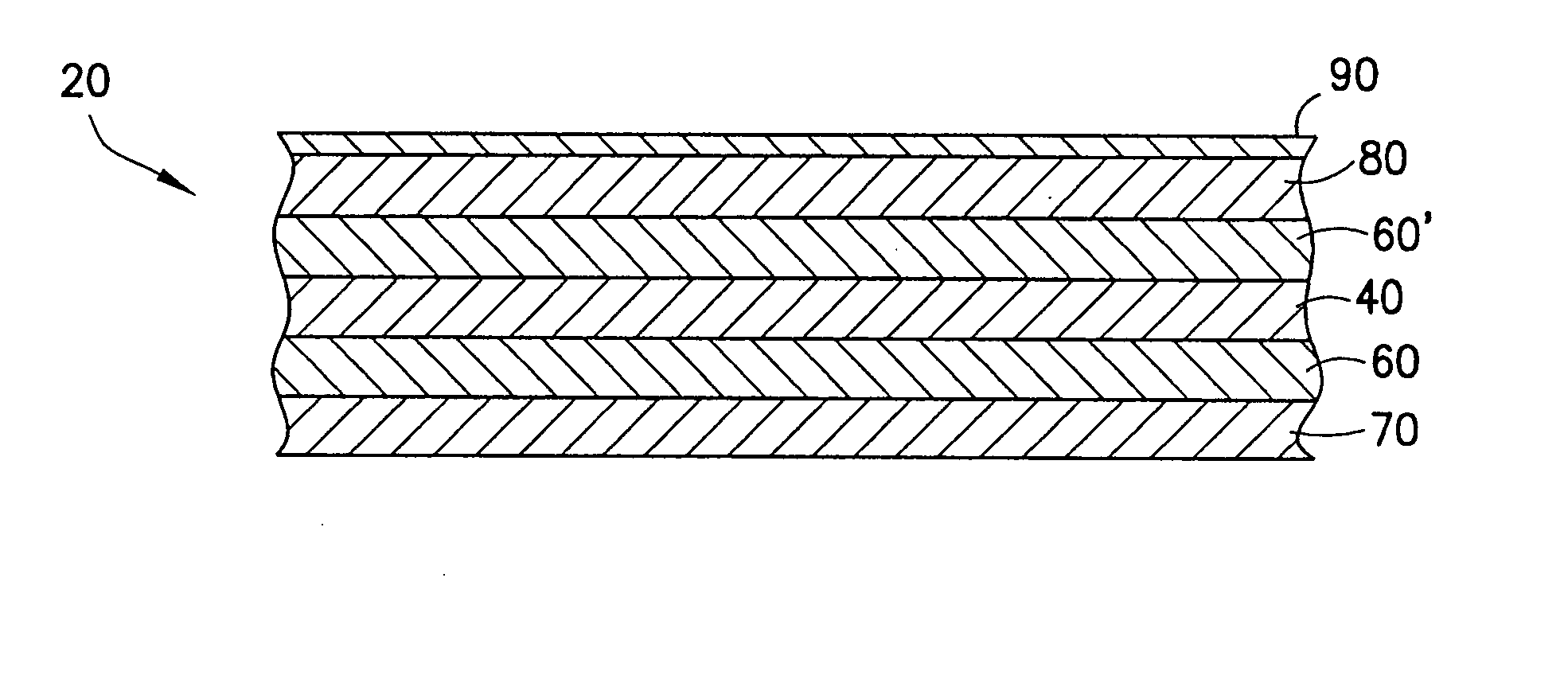

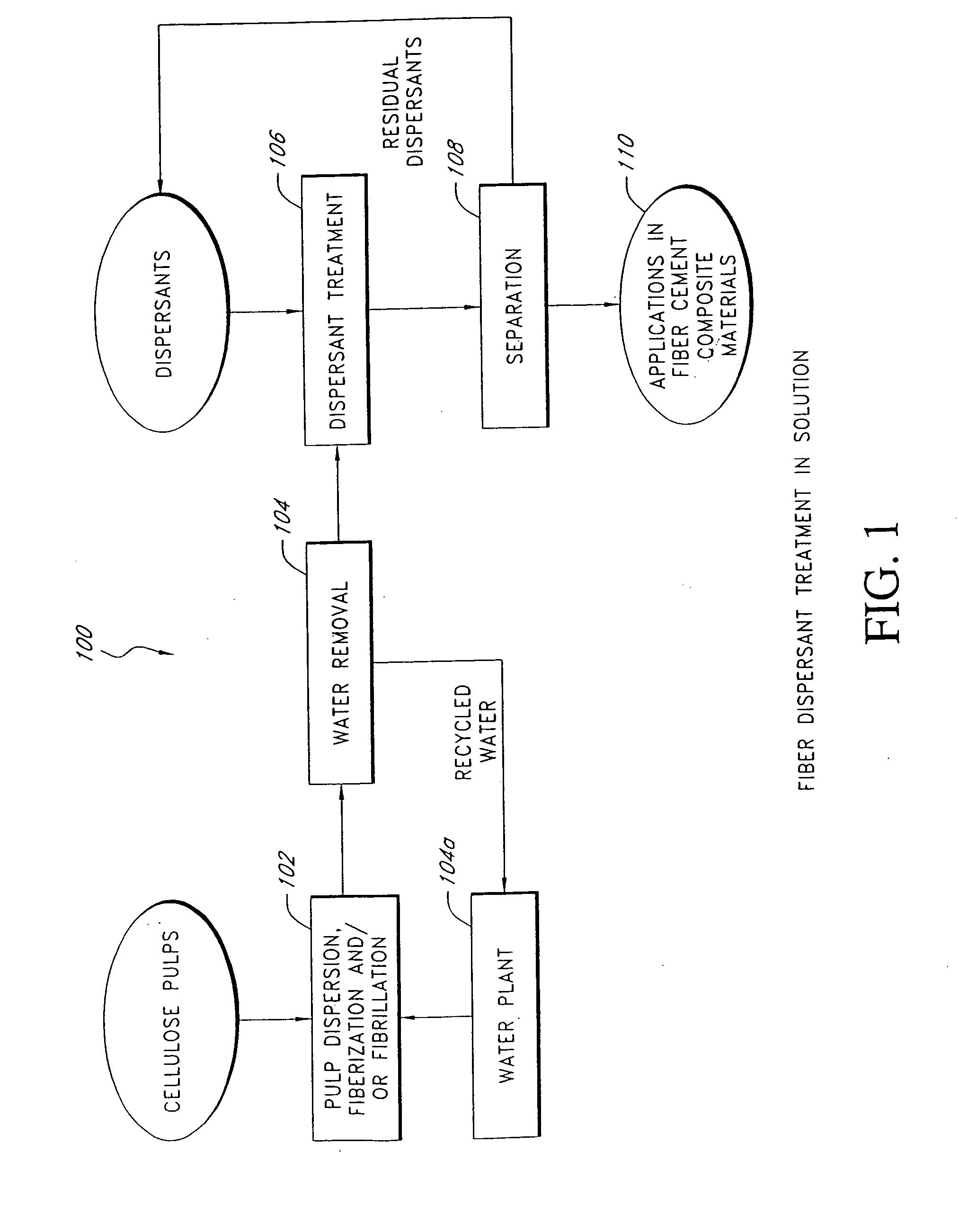

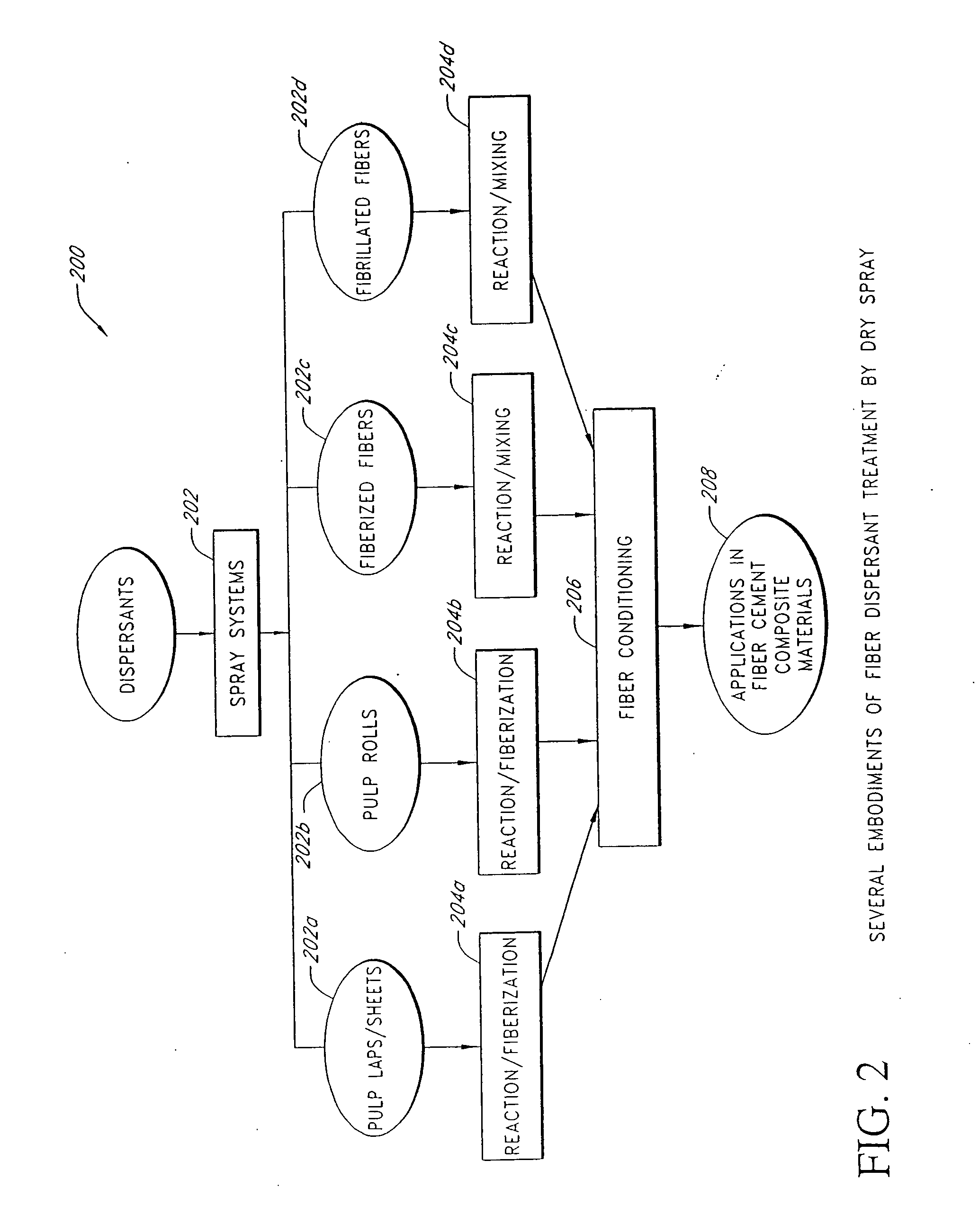

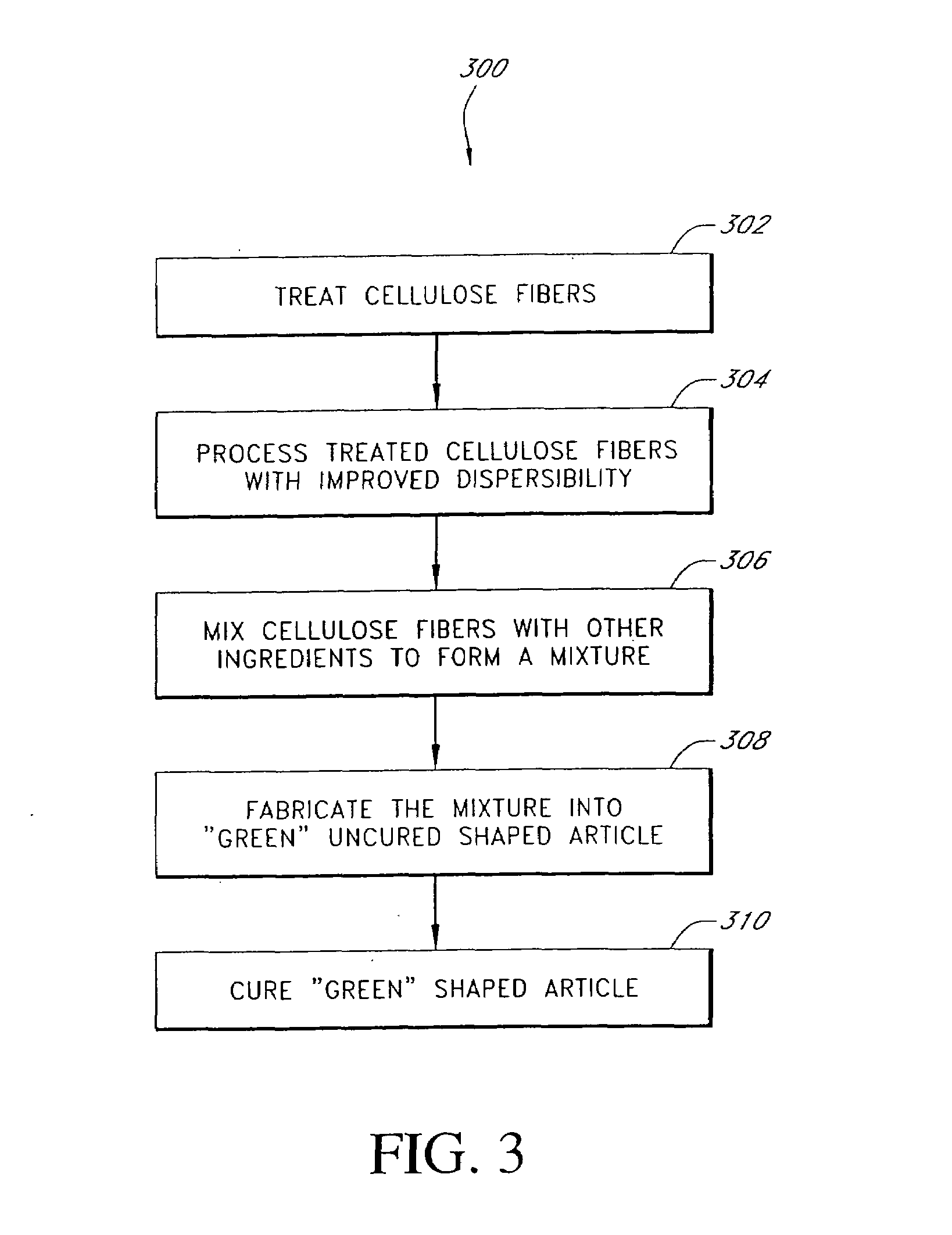

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS7344593B2Improve material propertyIncrease modulusPulp properties modificationSolid waste managementBuilding materialFibre reinforcement

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH

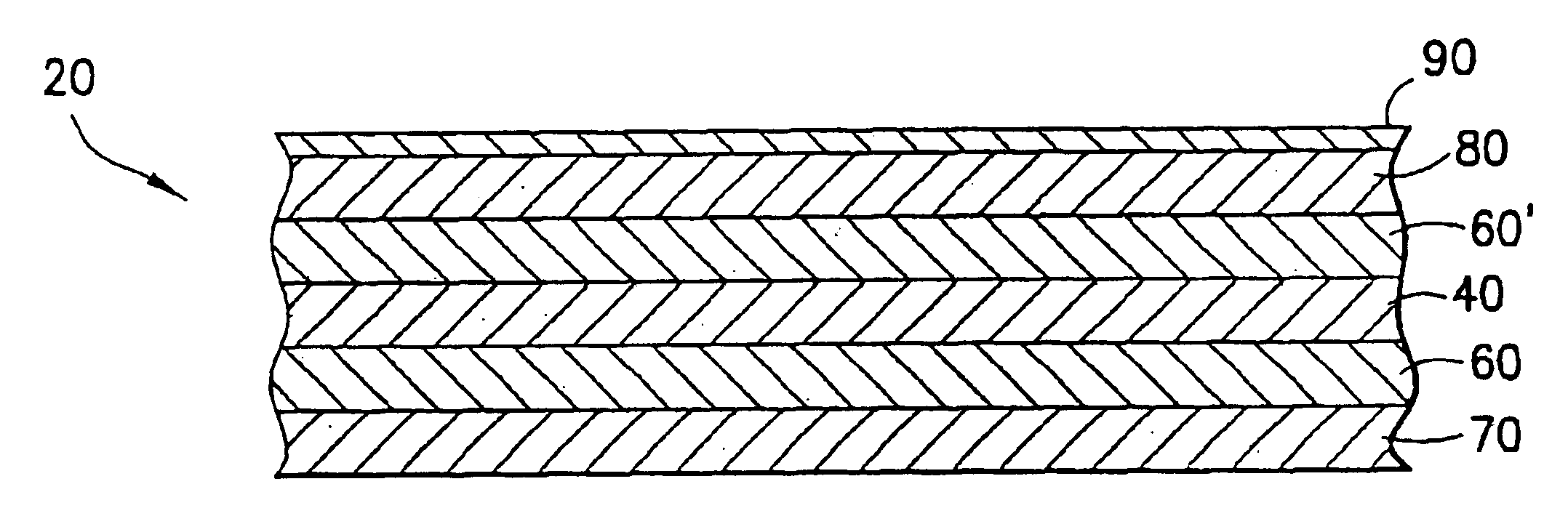

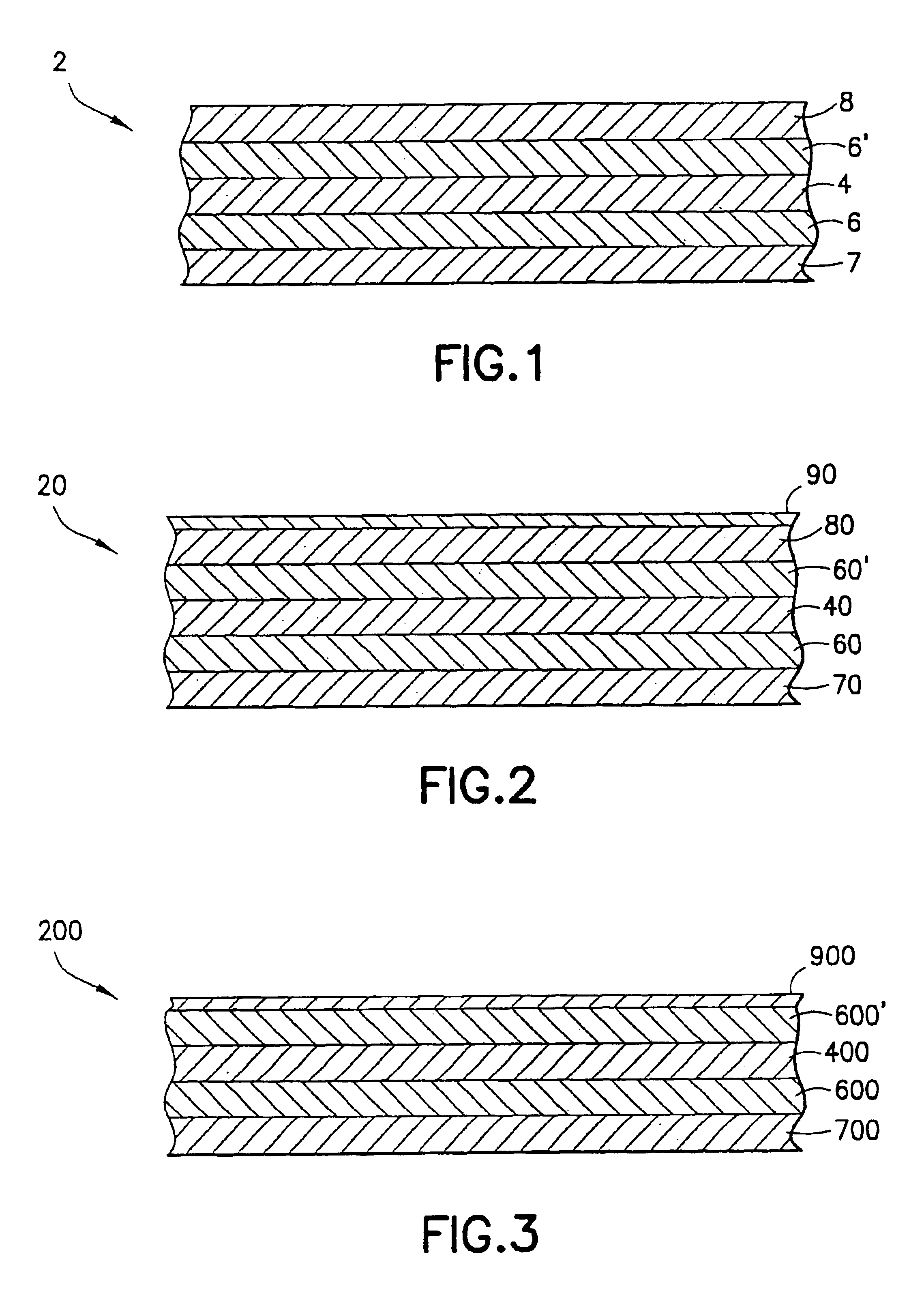

Bonded metal components having uniform thermal conductivity characteristics and method of making same

ActiveUS20070275263A1Avoid bondingHigh bonding strengthCooking-vessel materialsHot-dipping/immersion processesHeat distributionThermal conductivity

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of stainless steel roll bonded at or near the core of the composite to act as a thermal barrier and provide more uniform heat distribution on the cook surface. The stainless layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel or aluminum or copper. The layer of stainless steel adjacent to the cooking range may be a ferromagnetic grade of stainless steel if induction-type heating is desired. The cookware may include a non-stick surface applied thereto.

Owner:CLAD METALS

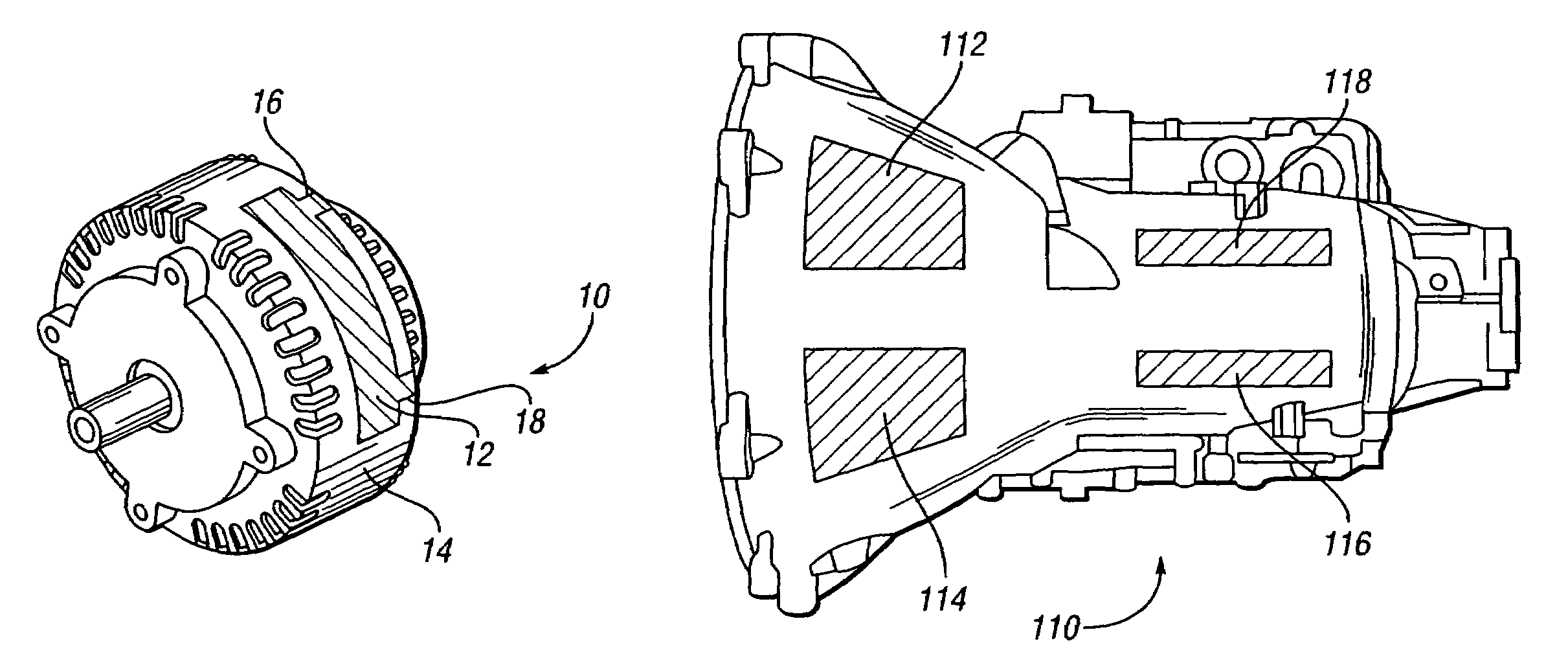

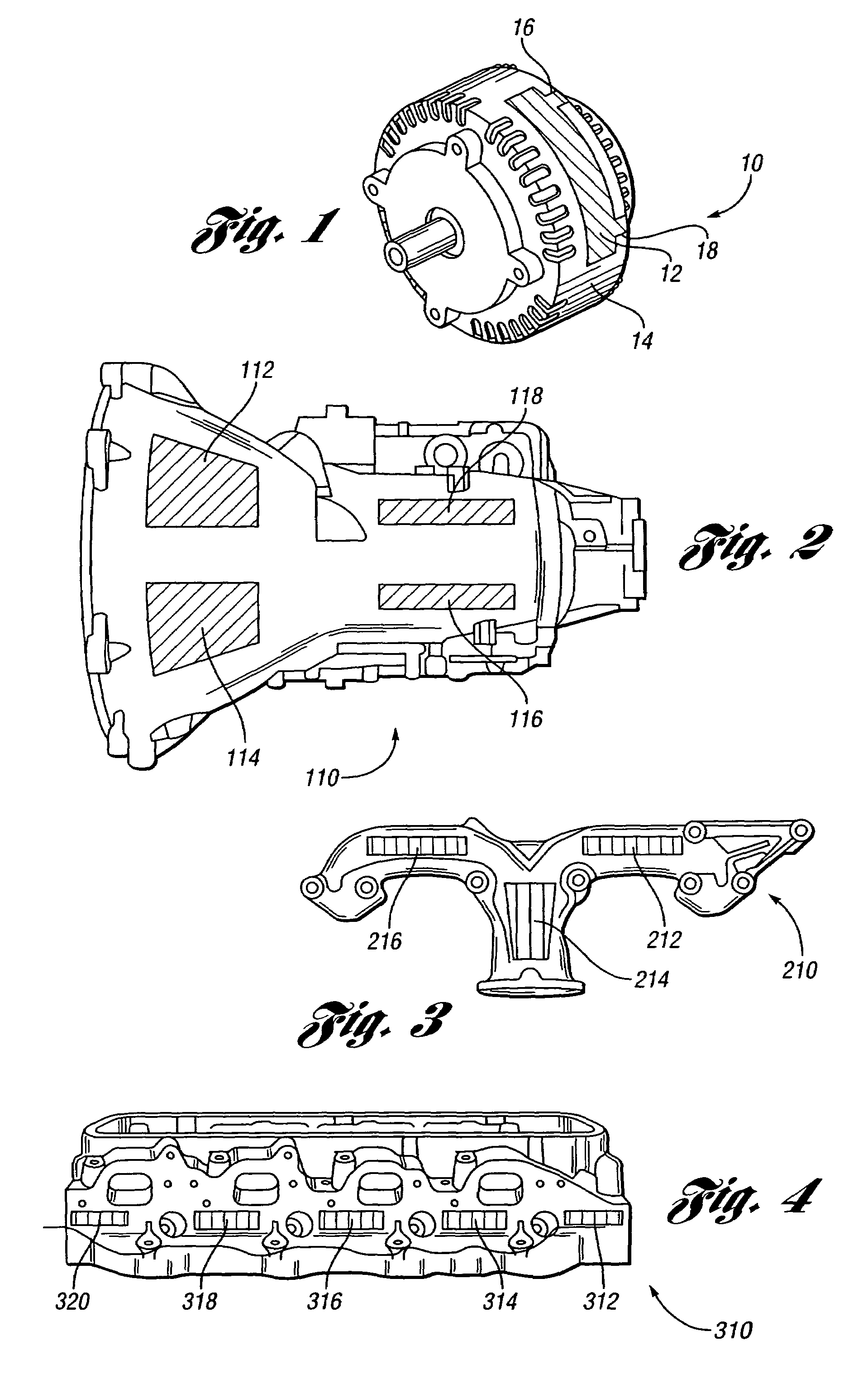

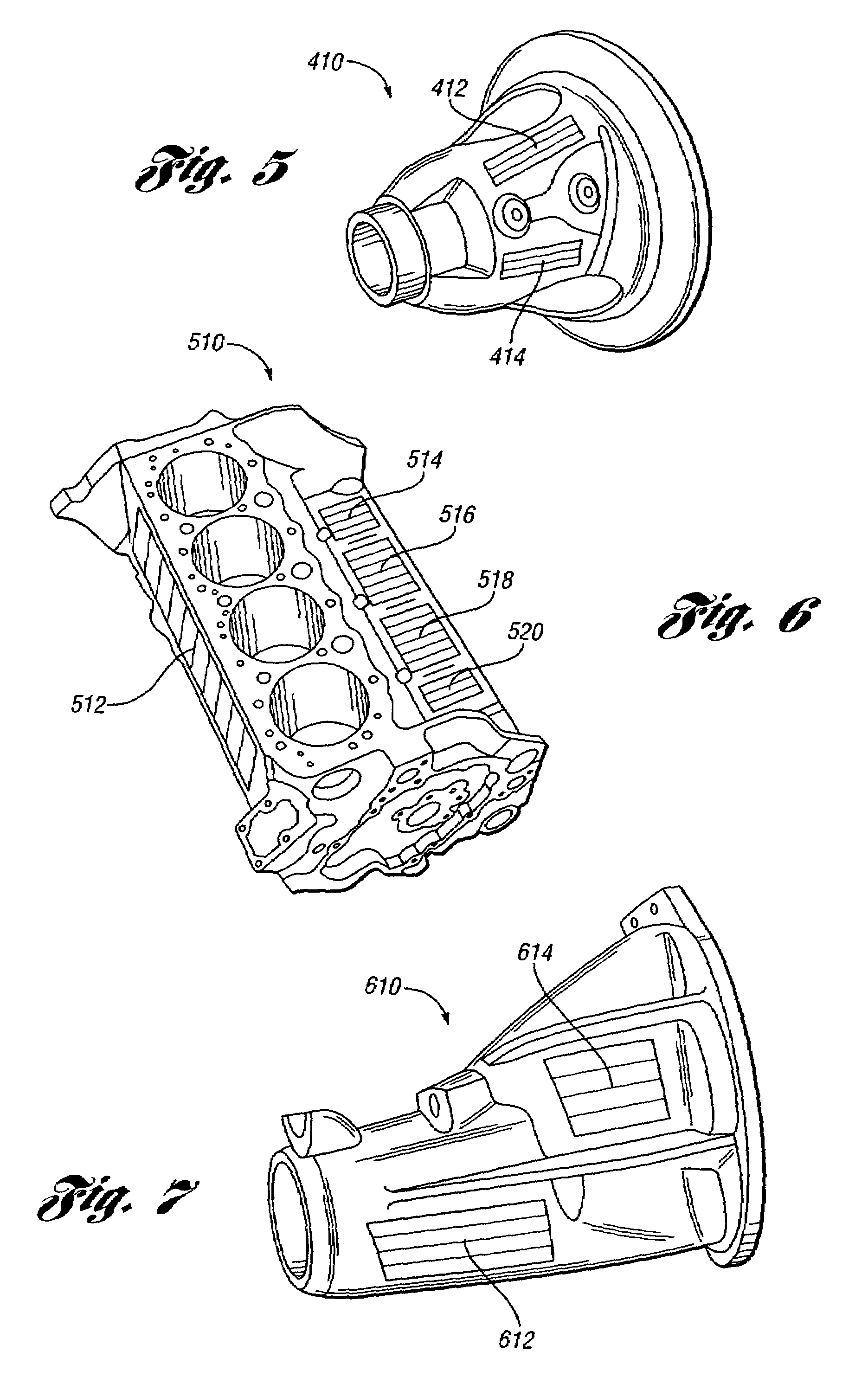

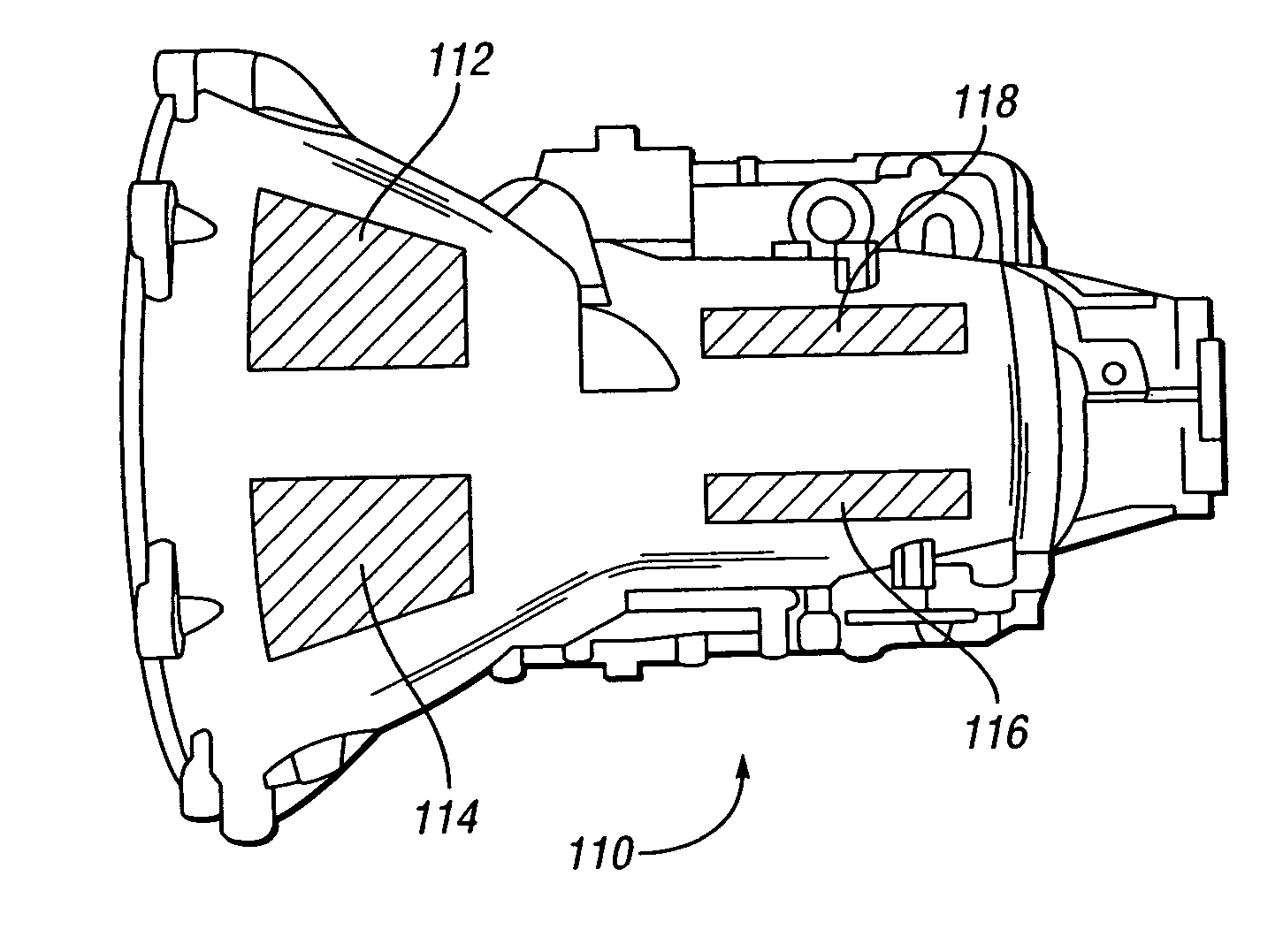

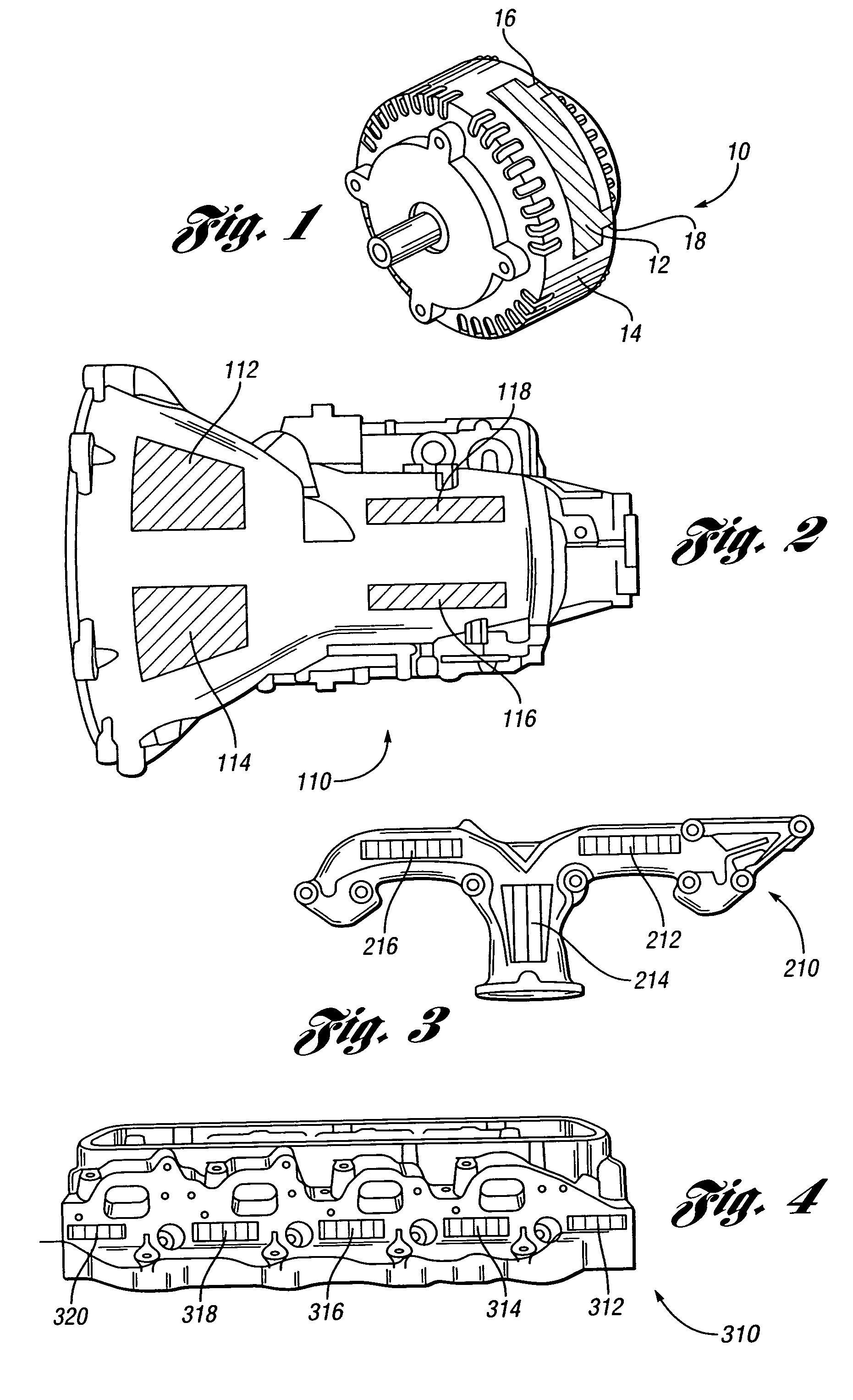

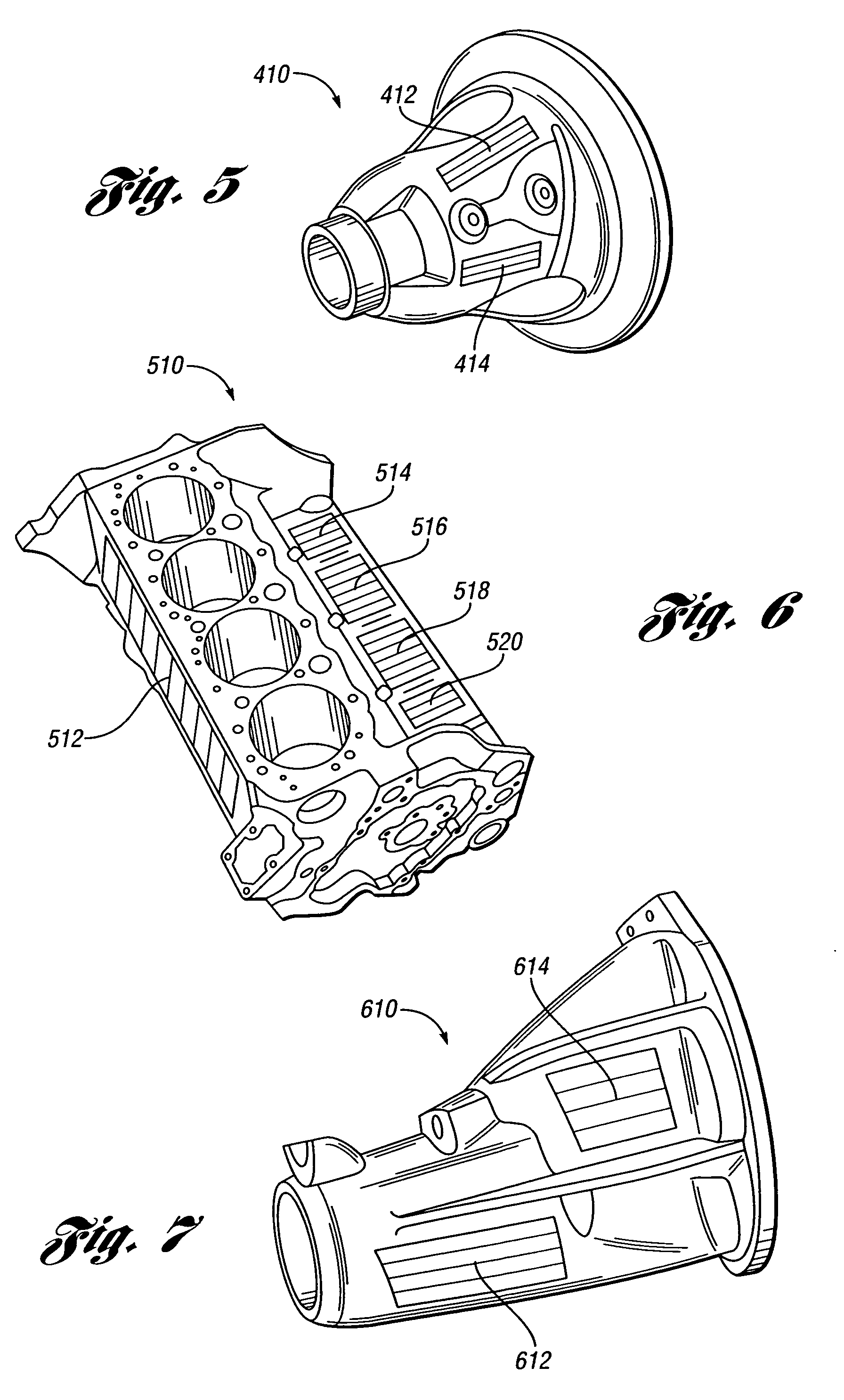

Method of casting components with inserts for noise reduction

ActiveUS7644750B2Avoid bondingIncrease surface areaFoundry mouldsStatorsAcoustic noise reductionMaterials science

Owner:GM GLOBAL TECH OPERATIONS LLC

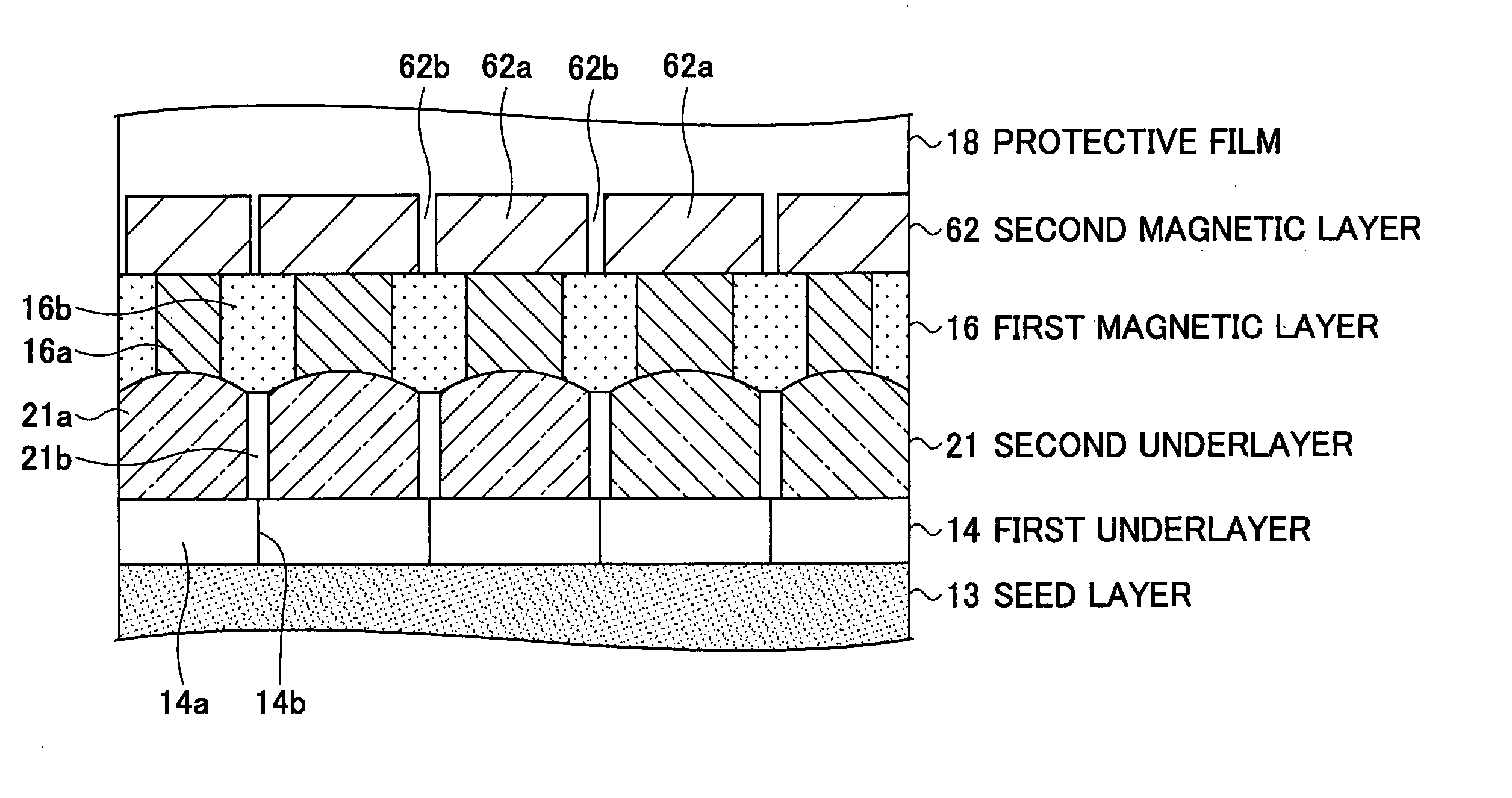

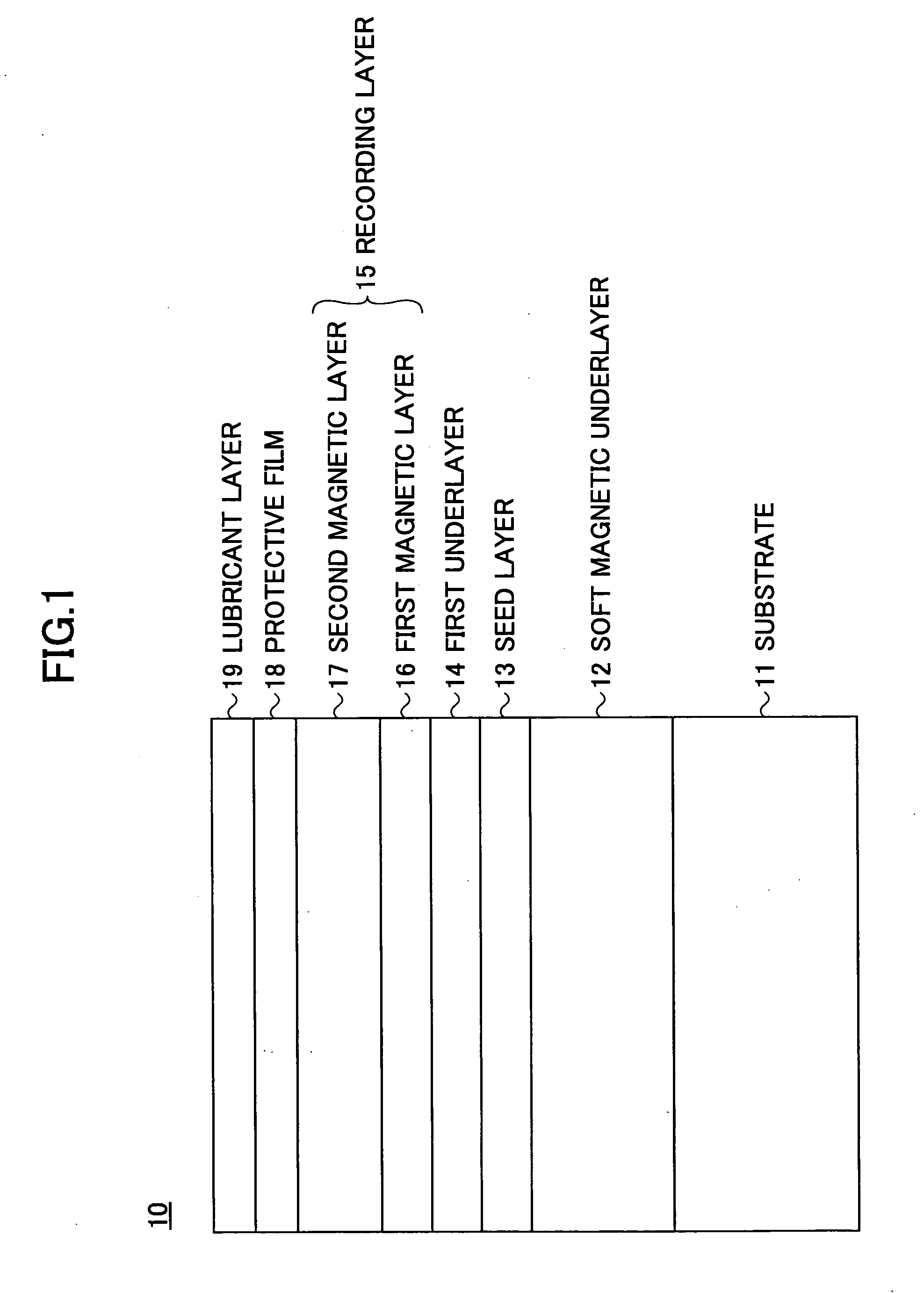

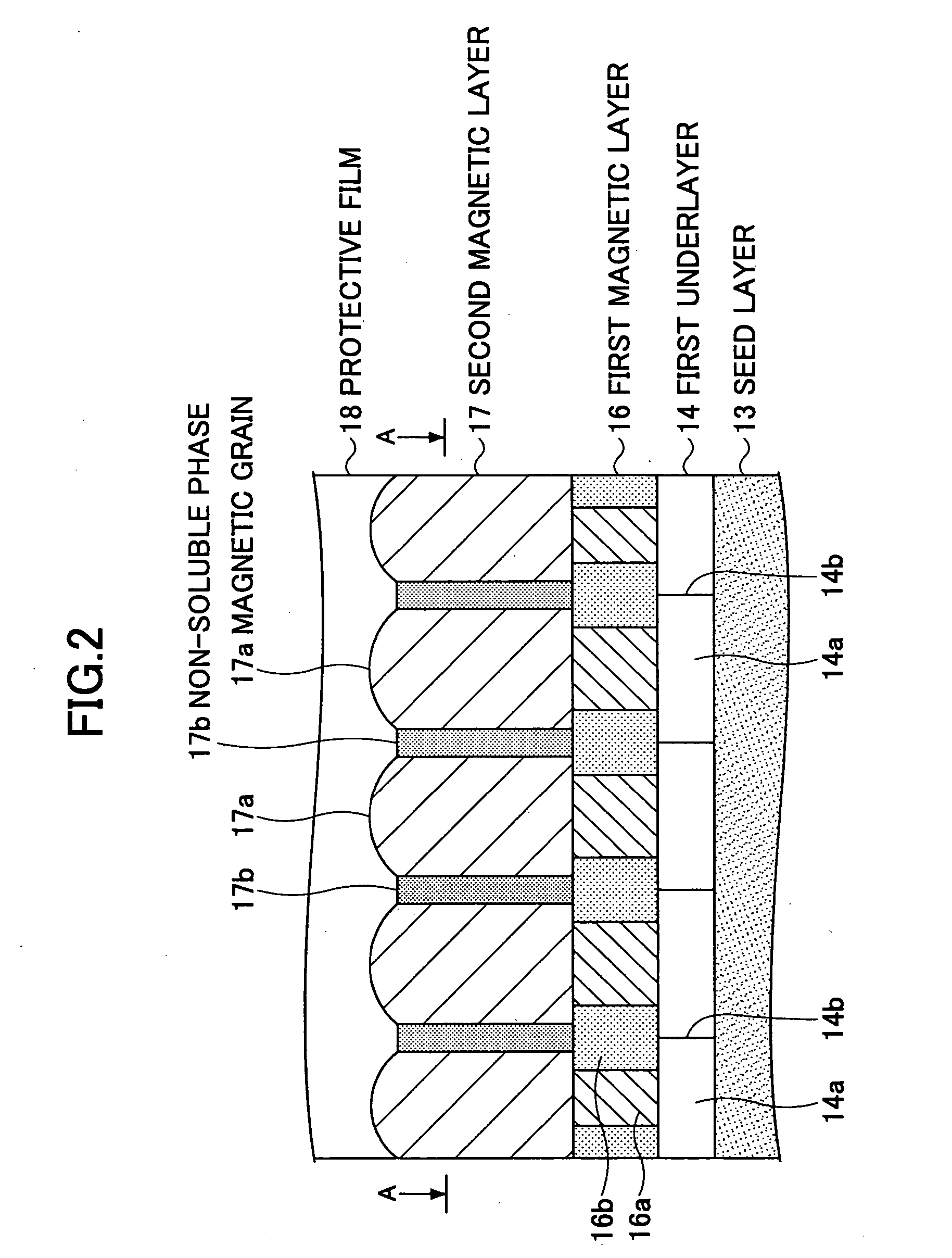

Perpendicular magnetic recording medium, manufacturing method thereof, and magnetic storage device

InactiveUS20060222902A1Medium noise is reducedImprove signal-to-noise ratioVacuum evaporation coatingSputtering coatingHigh densityMagnetic storage

A perpendicular magnetic recording medium for enabling high density recording is disclosed. The perpendicular magnetic recording medium includes a substrate on which a soft magnetic underlayer, a seed layer made of a non-crystalline material, an underlayer made of Ru or an Ru alloy including Ru as a main component, and a recording layer including a first magnetic layer and a second magnetic layer. The first and second magnetic layers include a plurality of magnetic grains having easy magnetization axes in a substantially perpendicular direction with respect to the substrate surface, and first and second nonmagnetic non-soluble phases segregating the magnetic grains of the first and second magnetic layers, respectively. The first magnetic layer includes the first non-soluble phase at a first atomic concentration that is higher than a second atomic concentration of the second non-soluble phase in the second magnetic layer.

Owner:SHOWA DENKO KK

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

InactiveUS20130000855A1Increase productivityPrevents hydrogen bondPulp properties modificationLuminescent/fluorescent substance additionPaper manufacturingPulp and paper industry

Owner:UPM-KYMMENE OYJ

Method of casting components with inserts for noise reduction

ActiveUS20070062664A1Avoid bondingIncrease surface areaFoundry mouldsStatorsNoise reductionMaterials science

The invention provides a method for manufacturing a powertrain component enclosure member, including the steps of: (A) positioning at least one insert into a mold, wherein the insert is provided with a coating to prevent bonding between the insert and the casting material; and (B) casting a wall of the powertrain component enclosure member in the mold around the insert such that a major portion of the insert is substantially non-bonded with the casting material to provide a proper interfacial boundary with the casting material for damping.

Owner:GM GLOBAL TECH OPERATIONS LLC

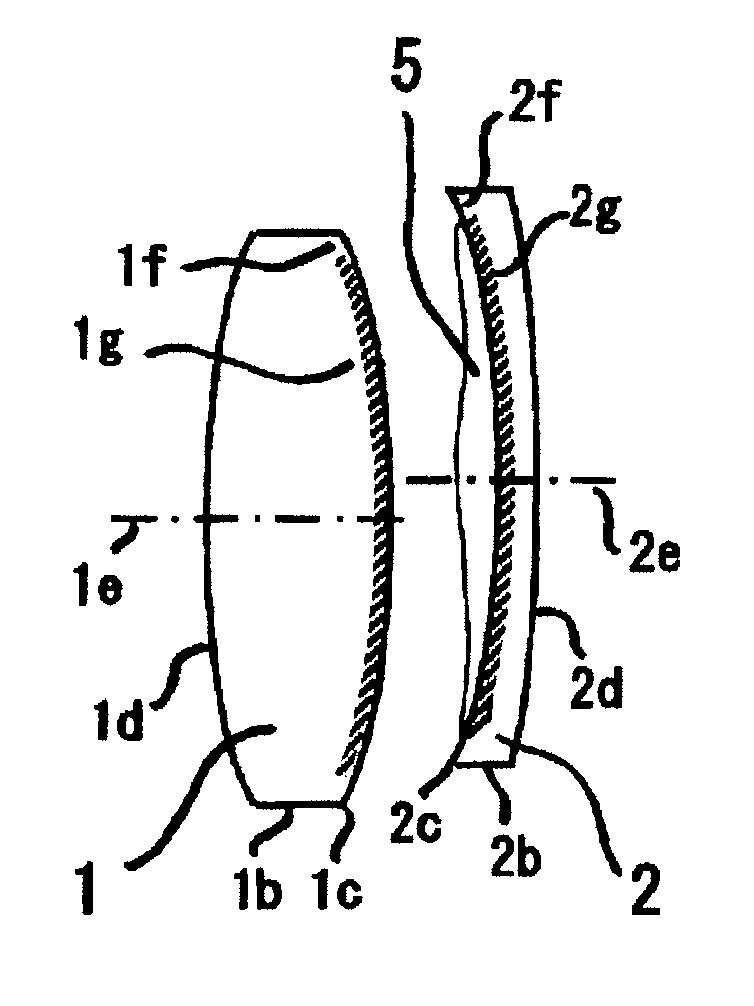

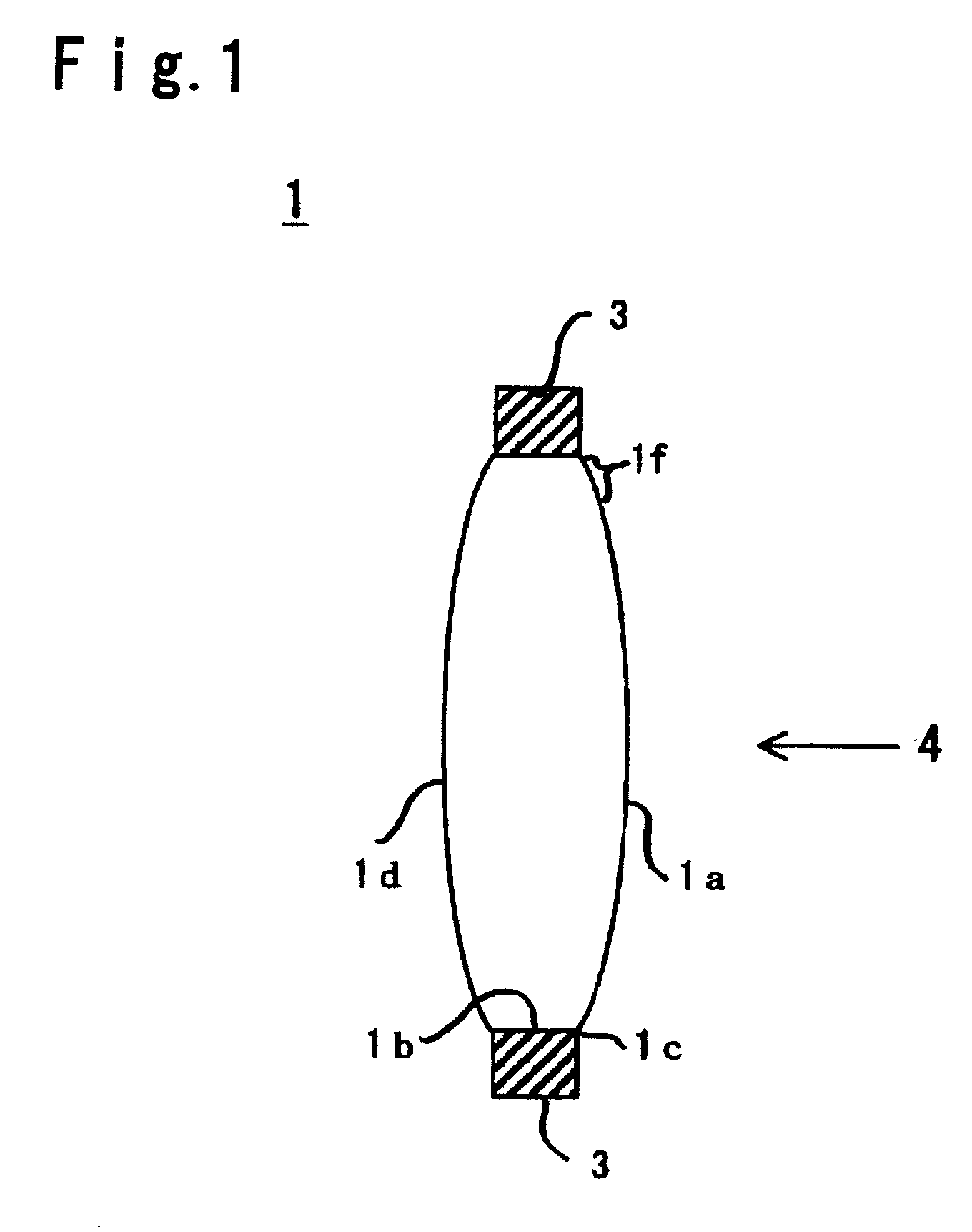

Method for producing an optical element

InactiveUS20070089827A1High bonding strengthAvoid separationGlass/slag layered productsCoatingsEngineeringBonding strength

A method for producing an optical element by bonding a plurality of optical member with an adhesive, which is capable of providing the optical element with sufficient optical performance and with such a sufficient bonding strength to prevent separation from being made at bonded portions, and of making alignment easily, is provided. The method for producing an optical element, which comprises bonding two or more optical members with an adhesive, is characterized in that at least one of confronting bonded surfaces on at least one pair of contact surfaces of the optical members is subjected to dry cleaning in such a state that at least a surface connecting to a bonded surface is masked, followed by applying a liquid adhesive as the adhesive on the cleaned surface and curing the liquid adhesive to bond the optical members.

Owner:ASAHI GLASS CO LTD

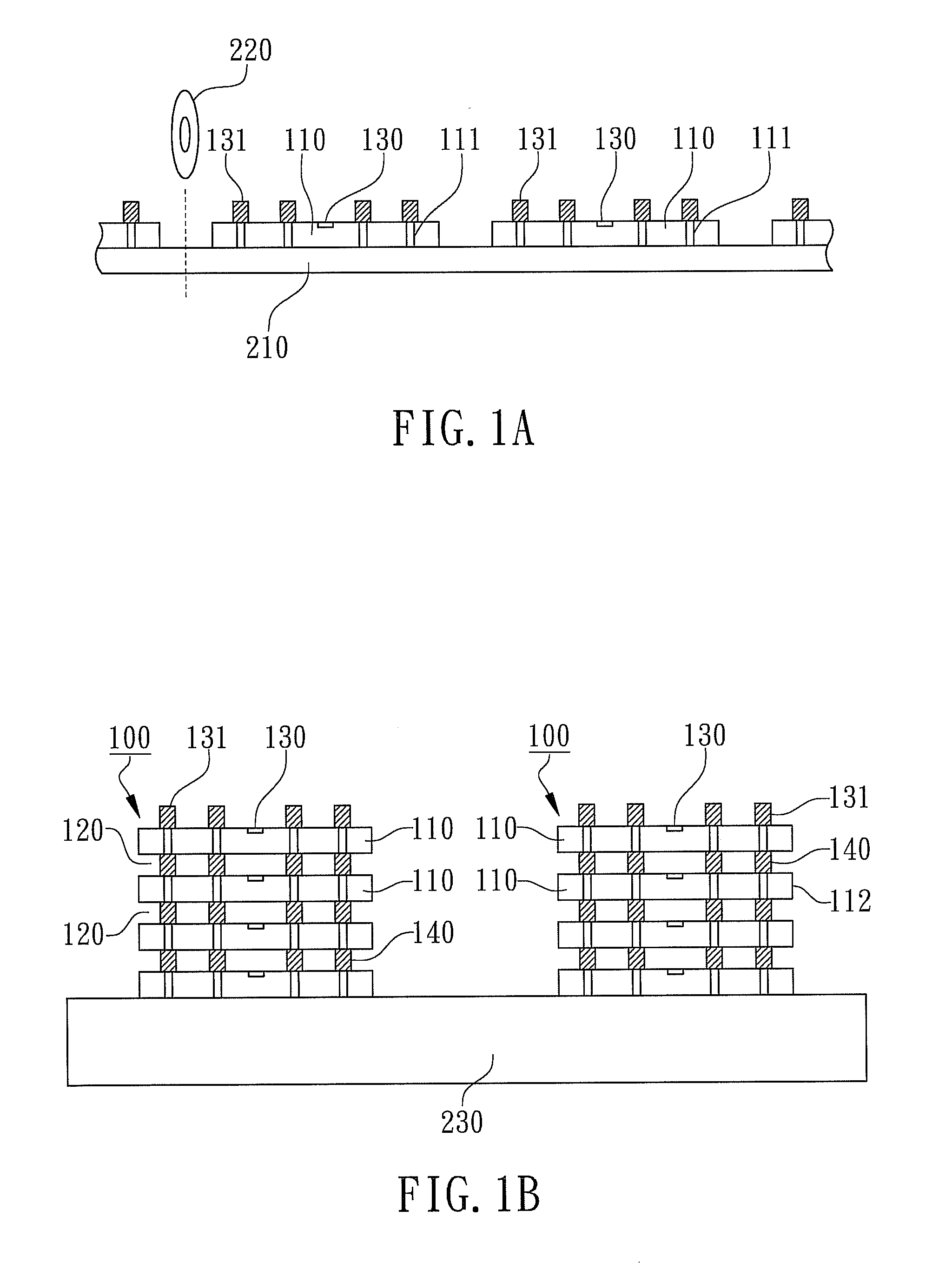

Semiconductor Light emitting device, LED package using the same, and method for fabricating the same

InactiveUS20080217640A1Prevent performanceAvoid bondingSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsReflectivity

A semiconductor light emitting device is provided which can prevent the reflectance of a metal film from deteriorating due to heat aging and can prevent wire bonding performance of the semiconductor light emitting element from deteriorating due to the diffusion of Ni contained in a Ni barrier metal layer to the reflection layer during die-bonding of the semiconductor light emitting element. The semiconductor light emitting device includes a metal film formed on a substrate and a semiconductor light emitting element. The metal film includes a barrier metal layer configured to prevent a predetermined material from being diffused into the substrate, a metal layer formed on the barrier metal layer; and a reflection layer formed on the metal layer. The reflection layer is configured to reflect light emitted from the semiconductor light emitting element, and the metal layer is made of Ti or Pd.

Owner:STANLEY ELECTRIC CO LTD

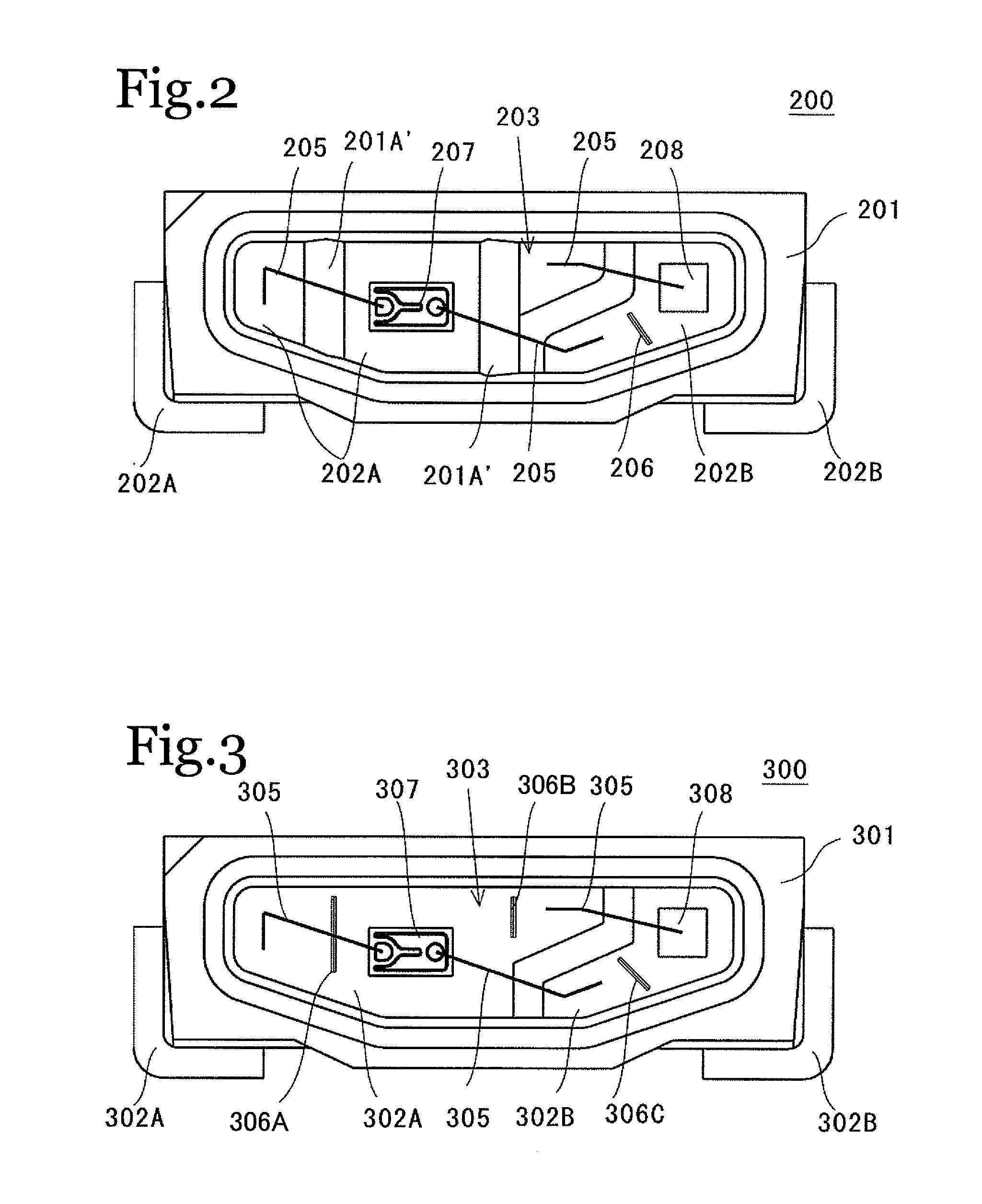

Light emitting device

ActiveUS20080083931A1Avoid flowBlocking may occurSolid-state devicesSemiconductor laser optical deviceEngineeringLight emitting device

A light emitting device includes a package having a recess defined by an inner wall and a bottom surface and a lead terminal exposed at the bottom surface of the recess and protruded outward from the package. The lead terminal exposed at the bottom surface of the recess portion including a semiconductor light emitting element mounting region and a wire connecting region for connecting a conductive wire from the semiconductor light emitting element thereto. At least one of regions between the semiconductor light emitting element mounting region and the wire connecting region has a groove portion disposed in a position spaced apart from a peripheral edge portion of the lead terminal that is exposed at the bottom surface of the recess.

Owner:NICHIA CORP

Bonded metal components having uniform thermal conductivity characteristics and method of making same

InactiveUS6926971B2High bonding strengthAvoid bondingHot-dipping/immersion processesCooking-vessel materialsTitaniumMetal

Cookware having improved uniform heat transfer over the entire cross section thereof, the cookware formed from a multi-layered composite metal having a layer of titanium roll bonded at or near the core of the composite. The titanium layer is roll bonded to layers of aluminum which, in turn, is roll bonded to layers of stainless steel. The layer of stainless steel adjacent to the cooking range may be a ferritic stainless steel if induction-type heating is desired. The multi-layered composite is also suitable for making a sole plate for an iron. Both the cookware and sole plate may include a non-stick surface applied thereto.

Owner:CLAD METALS

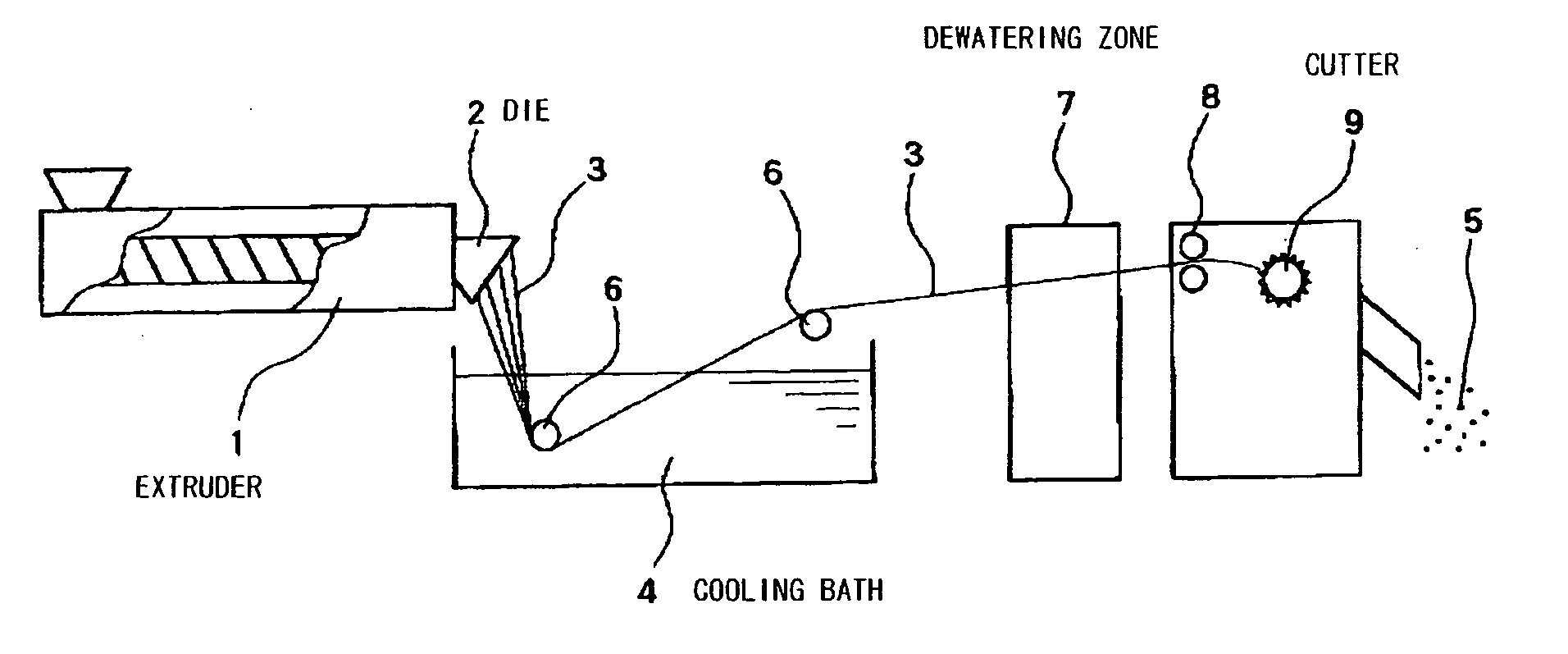

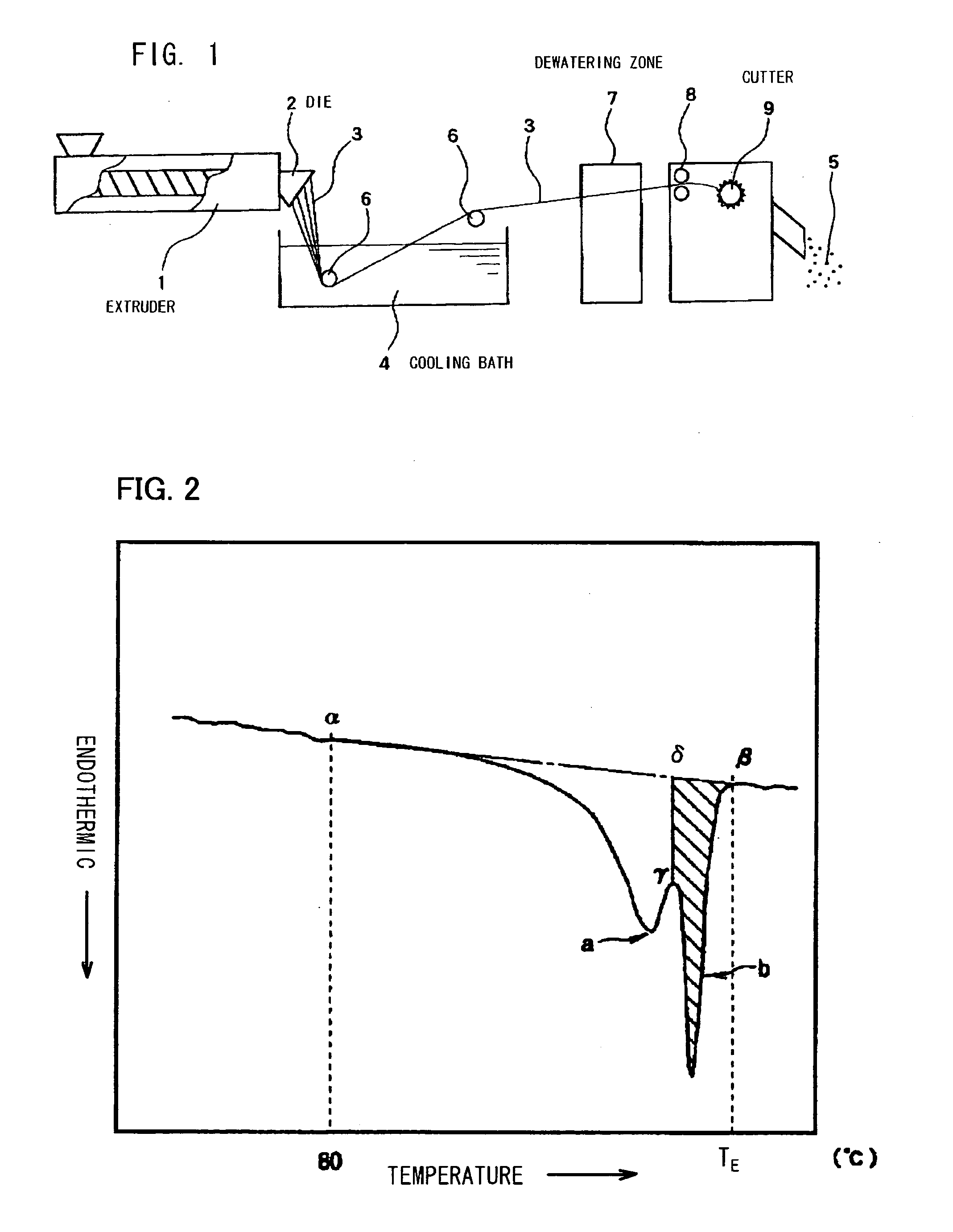

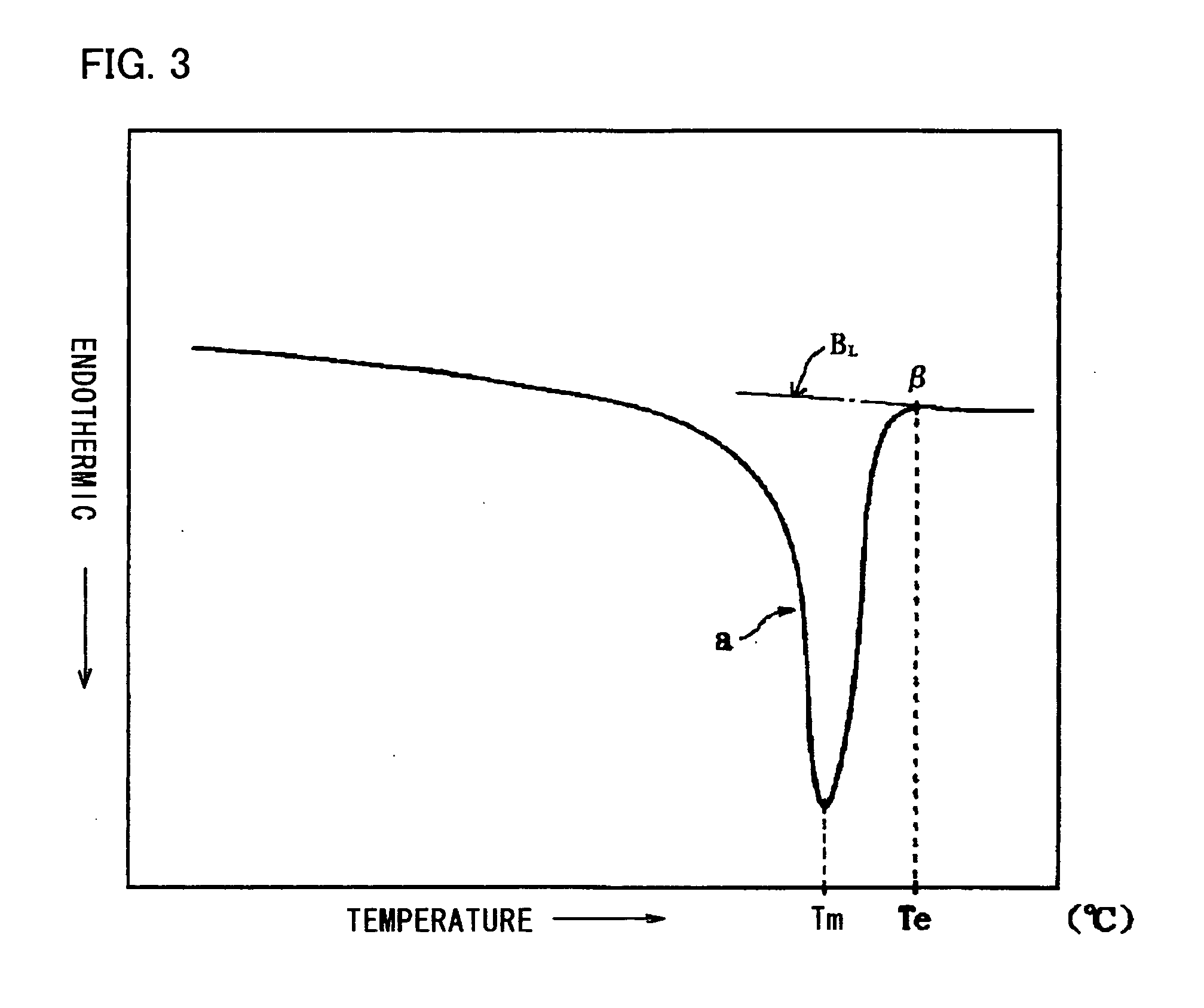

Thermoplastic resin pellet, process for preparing thermoplastic resin pellets and expanded thermoplastic resin bead

InactiveUS20050153134A1Small thermoplastic resin pelletsImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsGas phaseSURFACTANT BLEND

A process for preparing thermoplastic resin pellets, including extruding a melt of a thermoplastic resin into a gas phase through a die in the form of strands, immersing the strands in a bath containing water and a surfactant to cool the strands, taking the cooled strands out of the bath, and cutting the taken-out strands into pellets.

Owner:JSP CORP

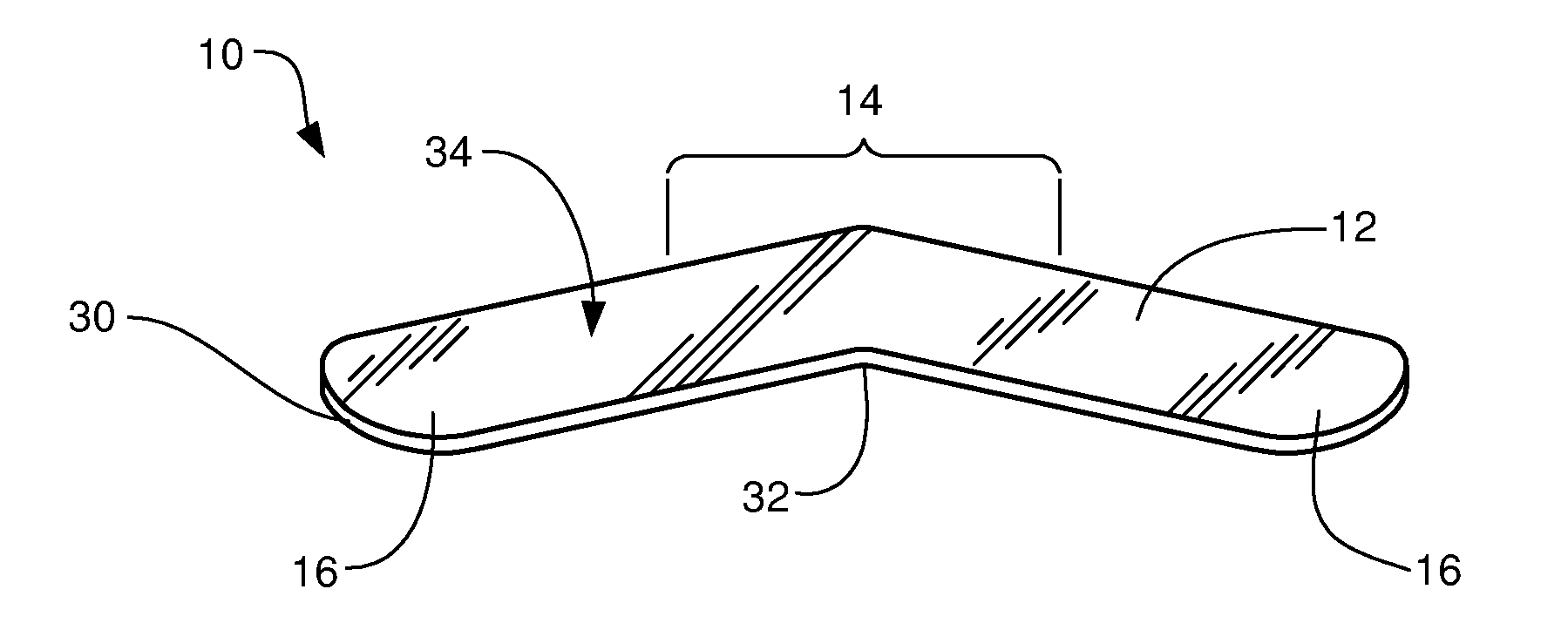

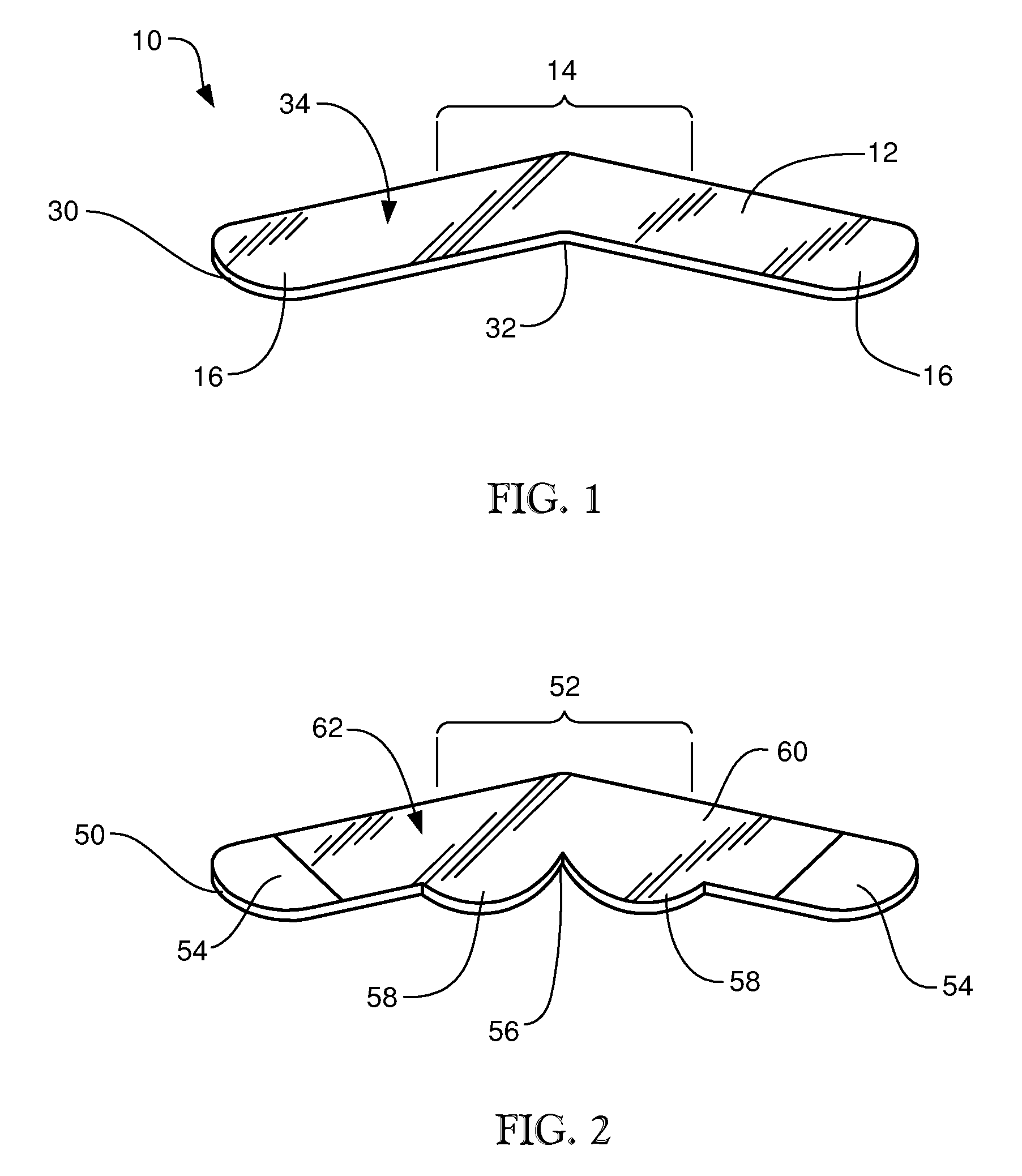

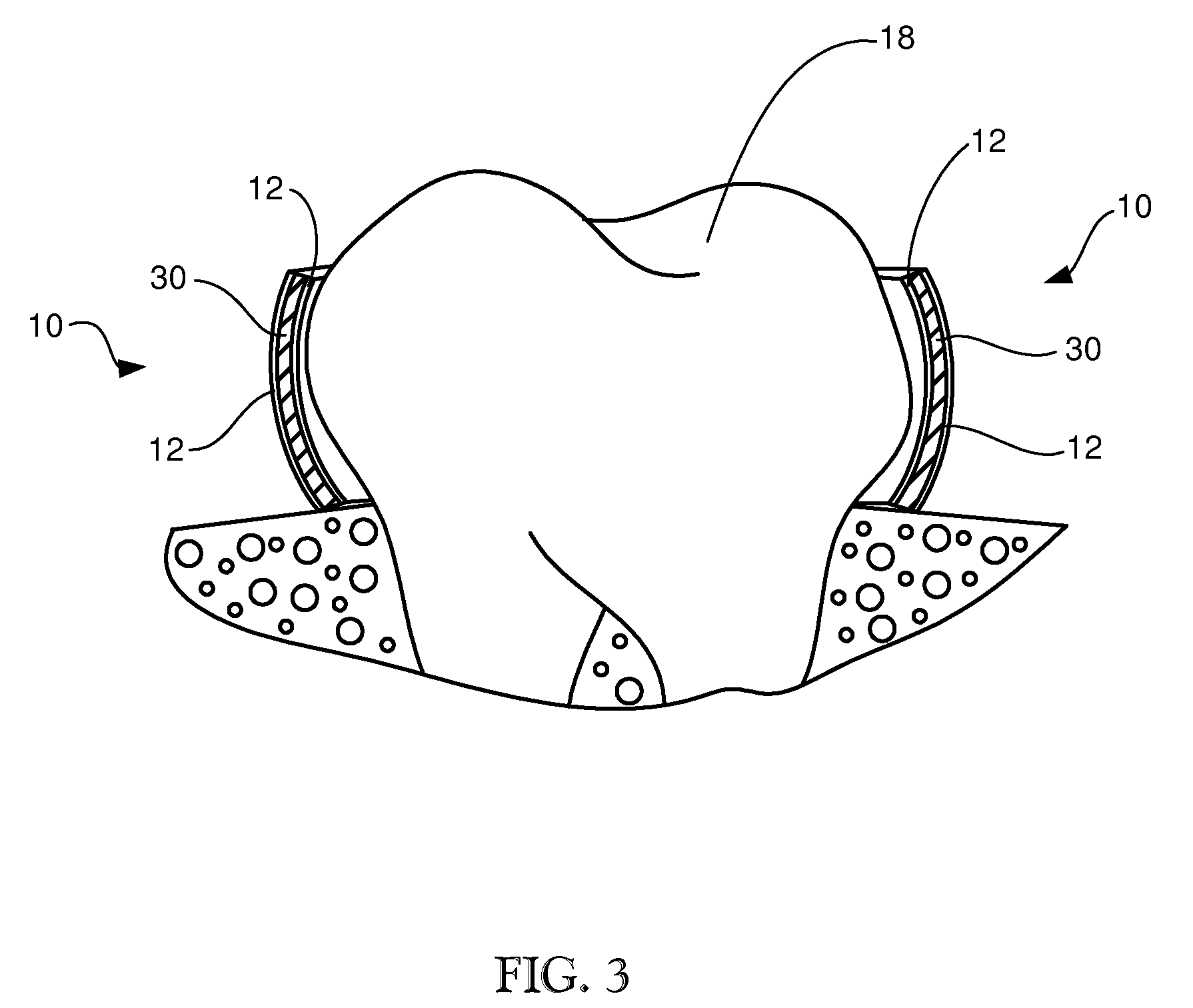

Dental matrix band

InactiveUS20090142725A1Avoid bondingDam holdersTooth clampsDental restorative materialsFluoropolymer

A dental matrix band includes a body portion, having a fluoropolymer layer disposed thereon. The fluoropolymer layer reduces undesirable adhesion between dental restorative material and the matrix band. In one embodiment, the fluoropolymer is applied onto the body portion of a stainless steel matrix band in a layer having a thickness in the range of from approximately 0.0005 inches to 0.001 inches.

Owner:BRYANT PAUL +1

Method for bonding bare chip dies

ActiveUS20150294951A1Avoid bondingSuitable for bondingSemiconductor/solid-state device detailsSolid-state devicesElectronic componentDie bonding

A method is provided for assembly of a micro-electronic component comprising the steps of: providing a conductive die bonding material comprising of a conductive thermosettable resin material or flux based solder and a dynamic release layer adjacent to the conductive thermoplastic material die bonding material layer; and impinging a laser beam on the dynamic release layer adjacent to the die bonding material layer; in such a way that the dynamic release layer is activated to direct conductive die bonding material matter towards the pad structure to be treated to cover a selected part of the pad structure with a transferred conductive die bonding material; and wherein the laser beam is restricted in timing and energy, in such a way that the die bonding material matter remains thermosetting. Accordingly adhesive matter can be transferred while preventing that the adhesive is rendered ineffective by thermal overexposure in the transferring process.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO) +1

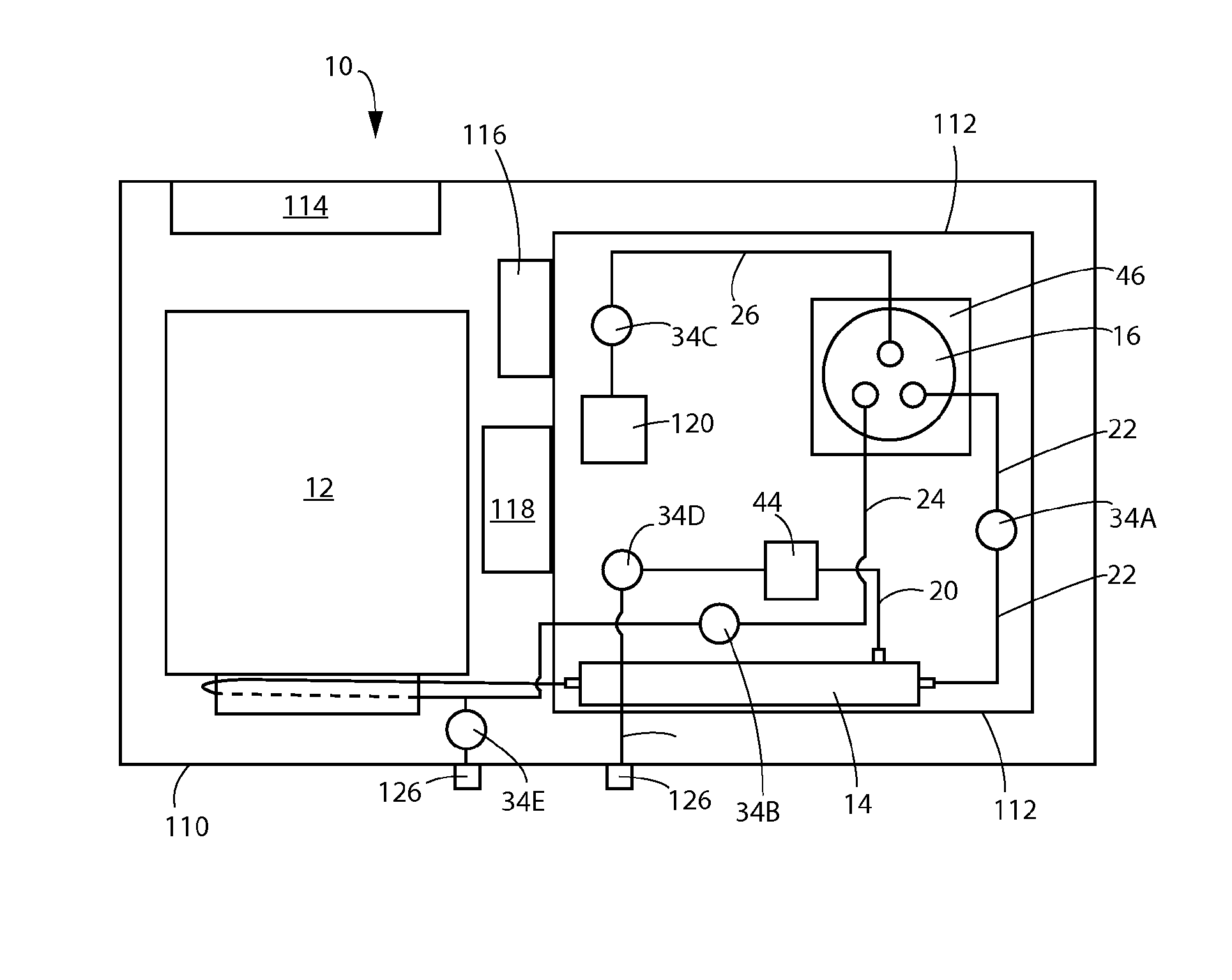

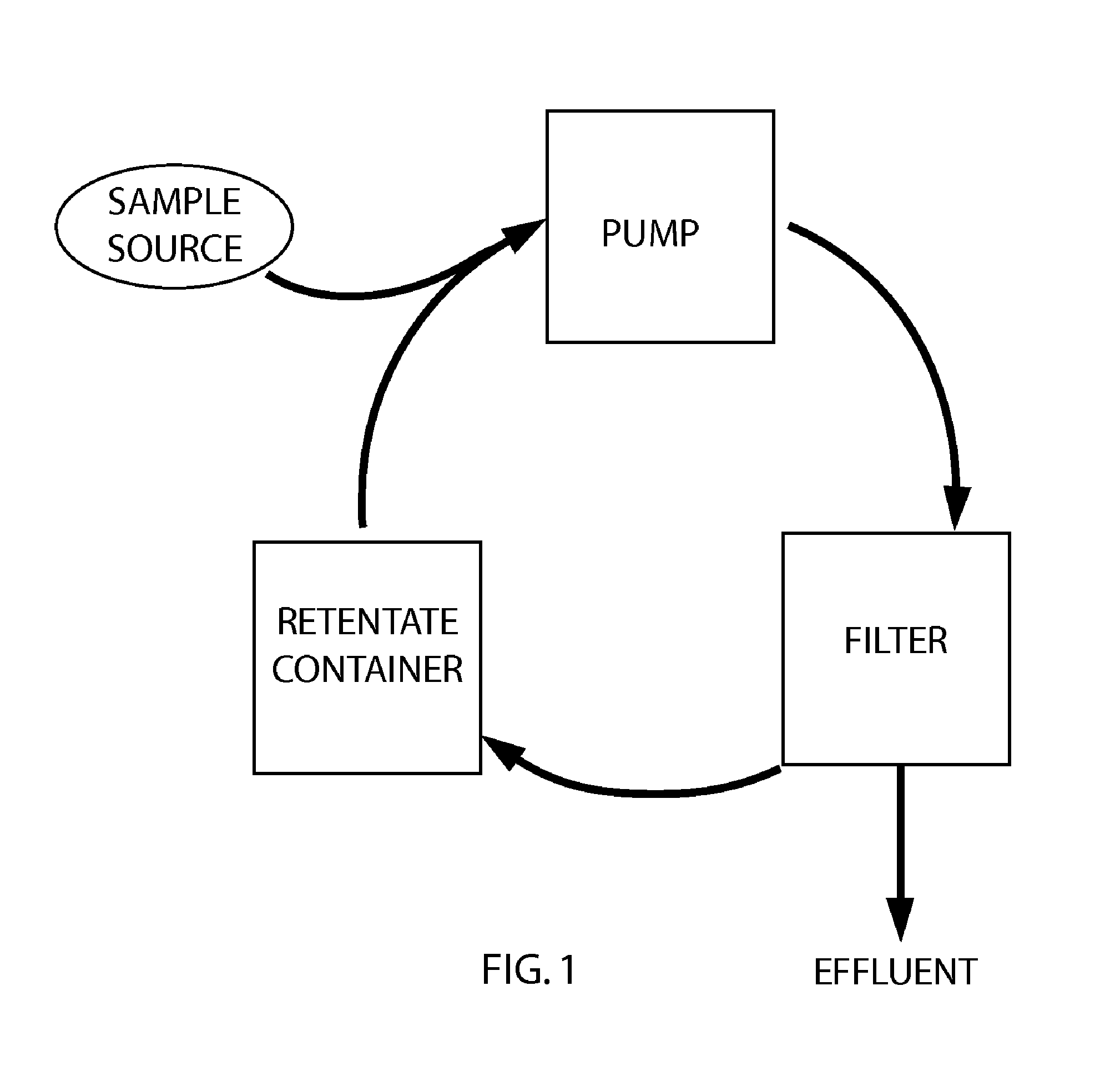

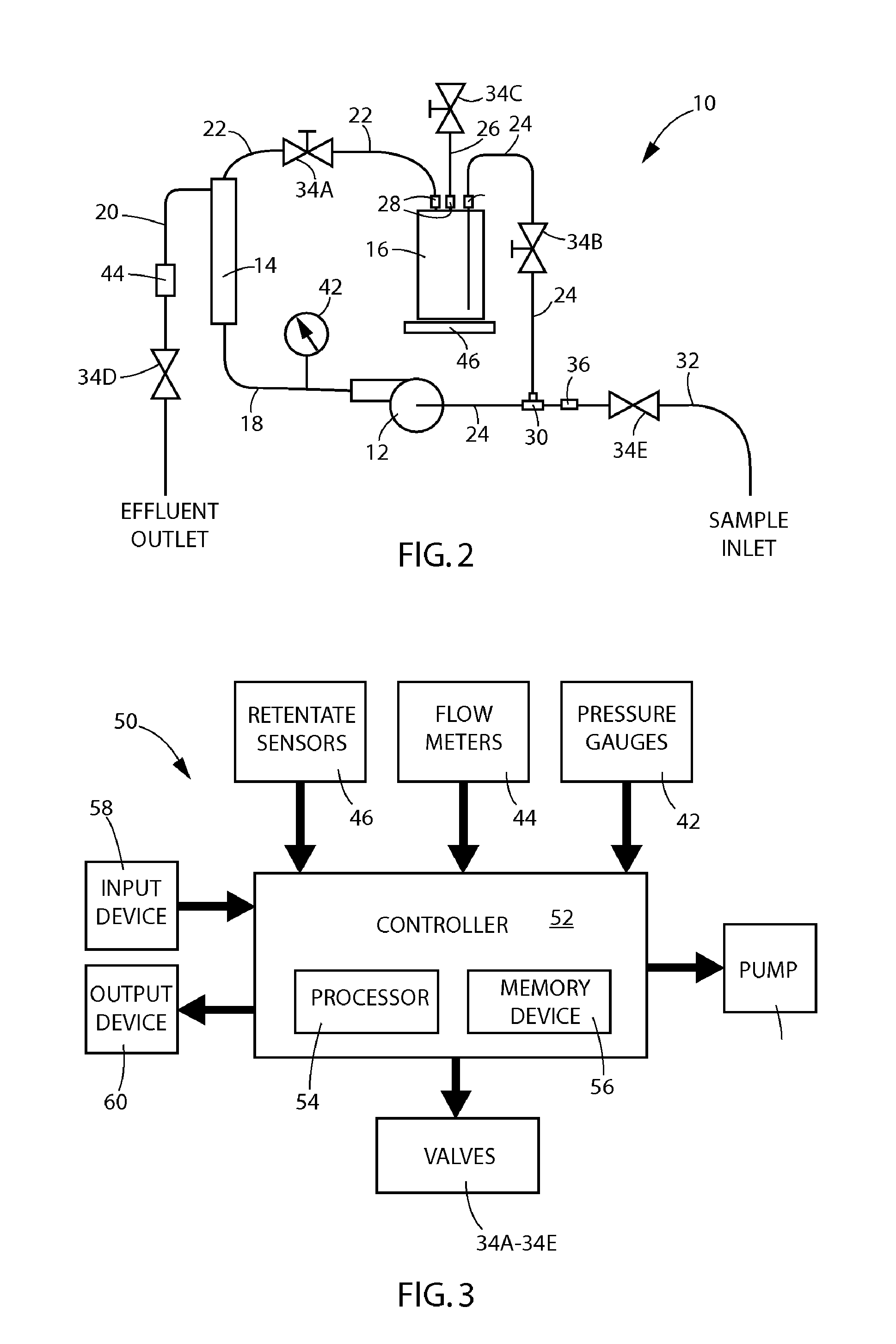

Systems and Methods for the Detection of Low-Level Harmful Substances in a Large Volume of Fluid

ActiveUS20130239666A1Lower the volumeObstruct passageSemi-permeable membranesComponent separationControl systemAmount of substance

A method and device for the detection of low-level harmful substances in a large volume of fluid comprising using a concentrator system to produce a retentate and analyzing the retantate for the presence of at one harmful substance. The concentrator system performs a method comprising pumping at least 10 liters of fluid from a sample source through a filter While pumping, the concentrator system diverts retentate from the filter into a container. The concentrator system also recirculates at least part of the retentate in the container again through the filter. The concentrator system controls the speed of the pump with a control system thereby maintaining a fluid pressure less than 25 psi during the pumping of the fluid; monitors the quantity of retentate within the container with a control system, and maintains a reduced volume level of retentate and a target volume of retentate.

Owner:ENVIRONMENTAL PROTECTION AGENCY US +1

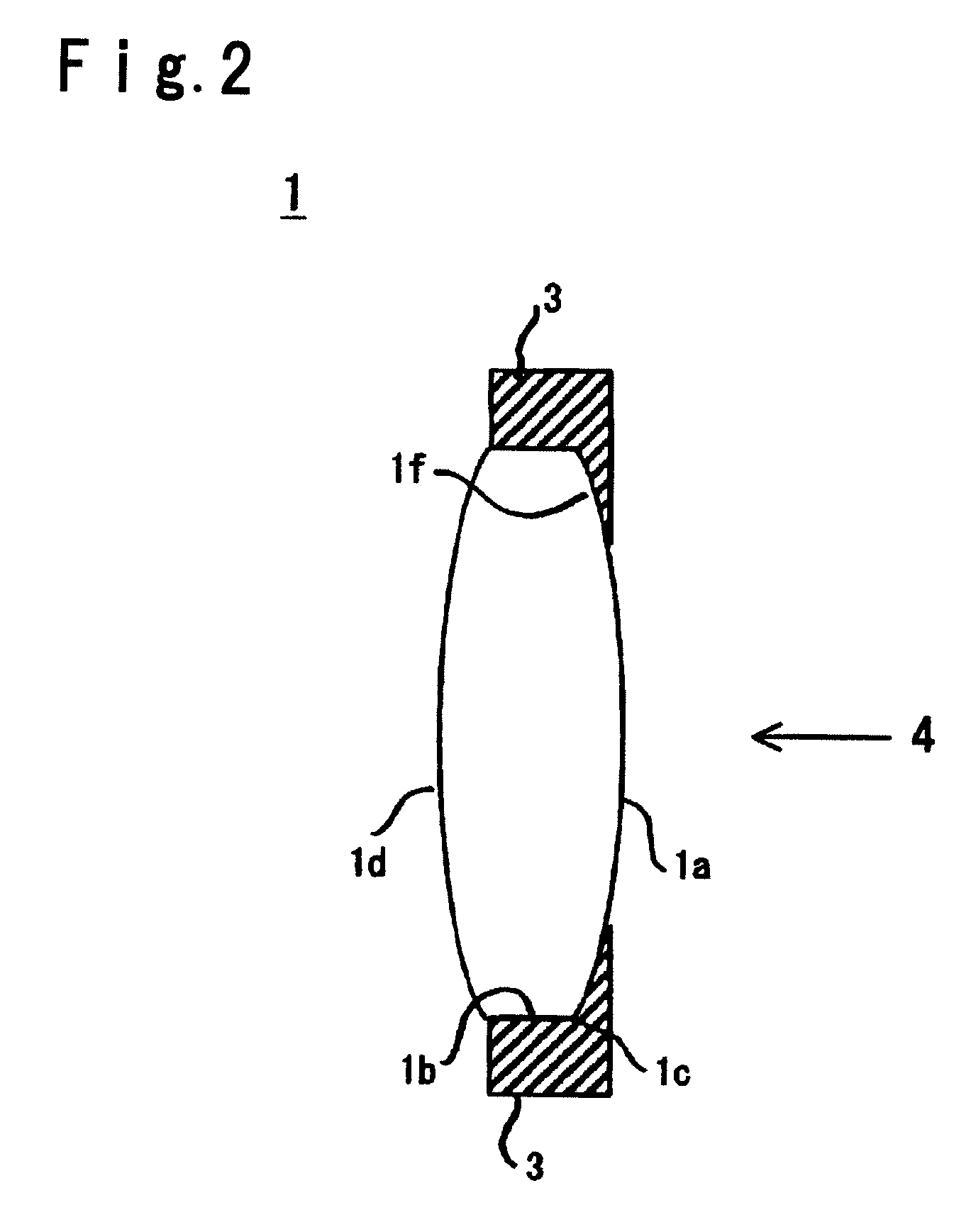

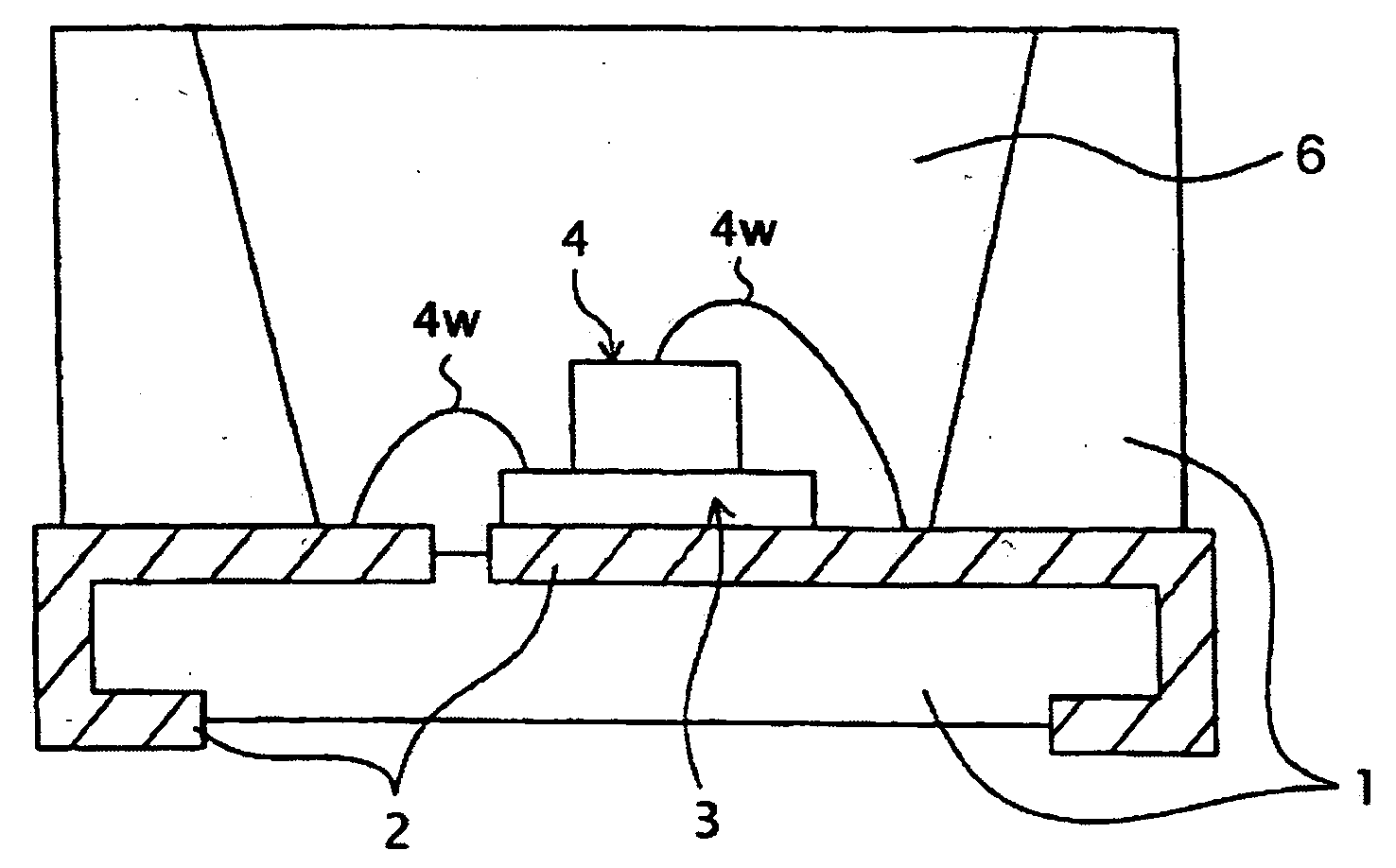

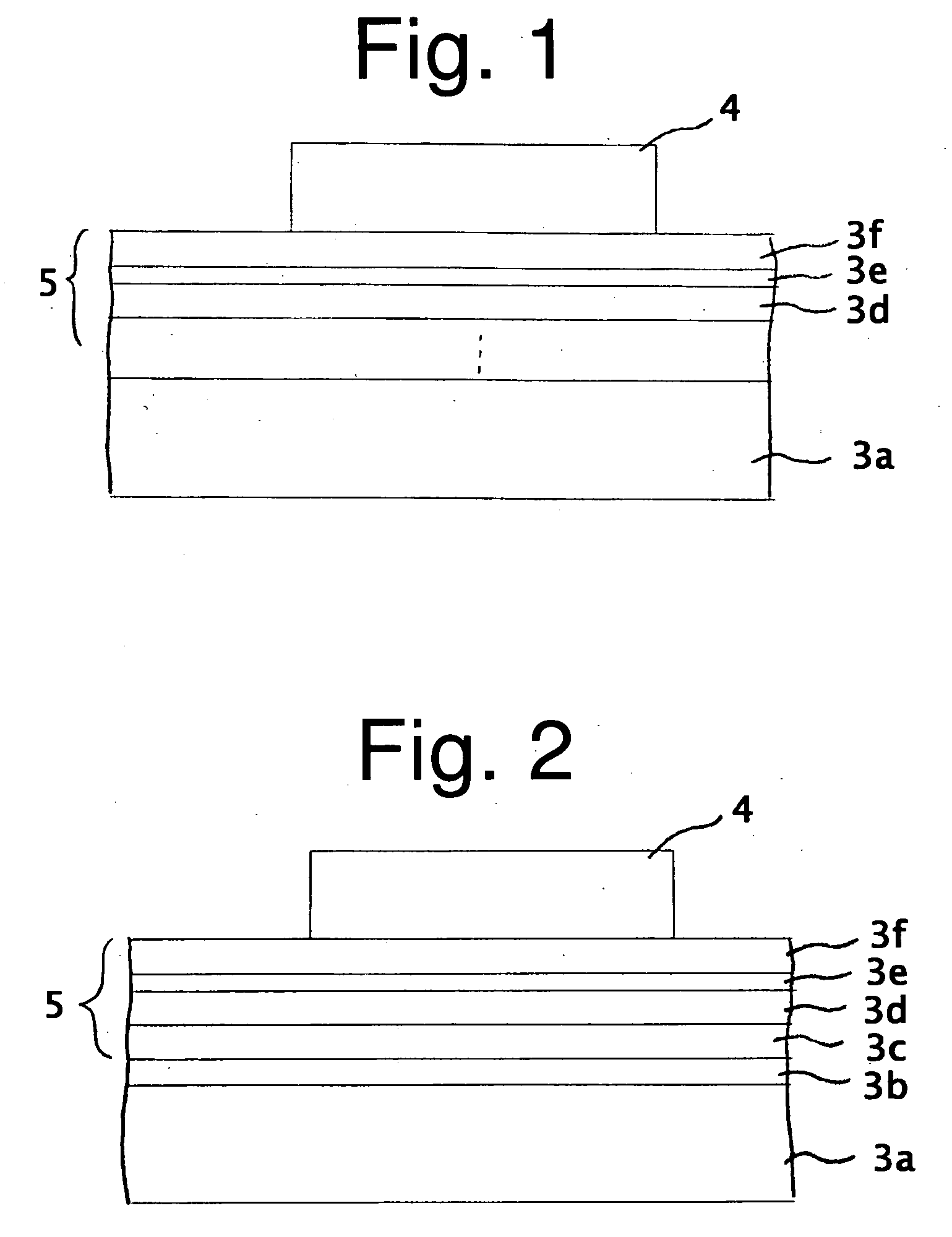

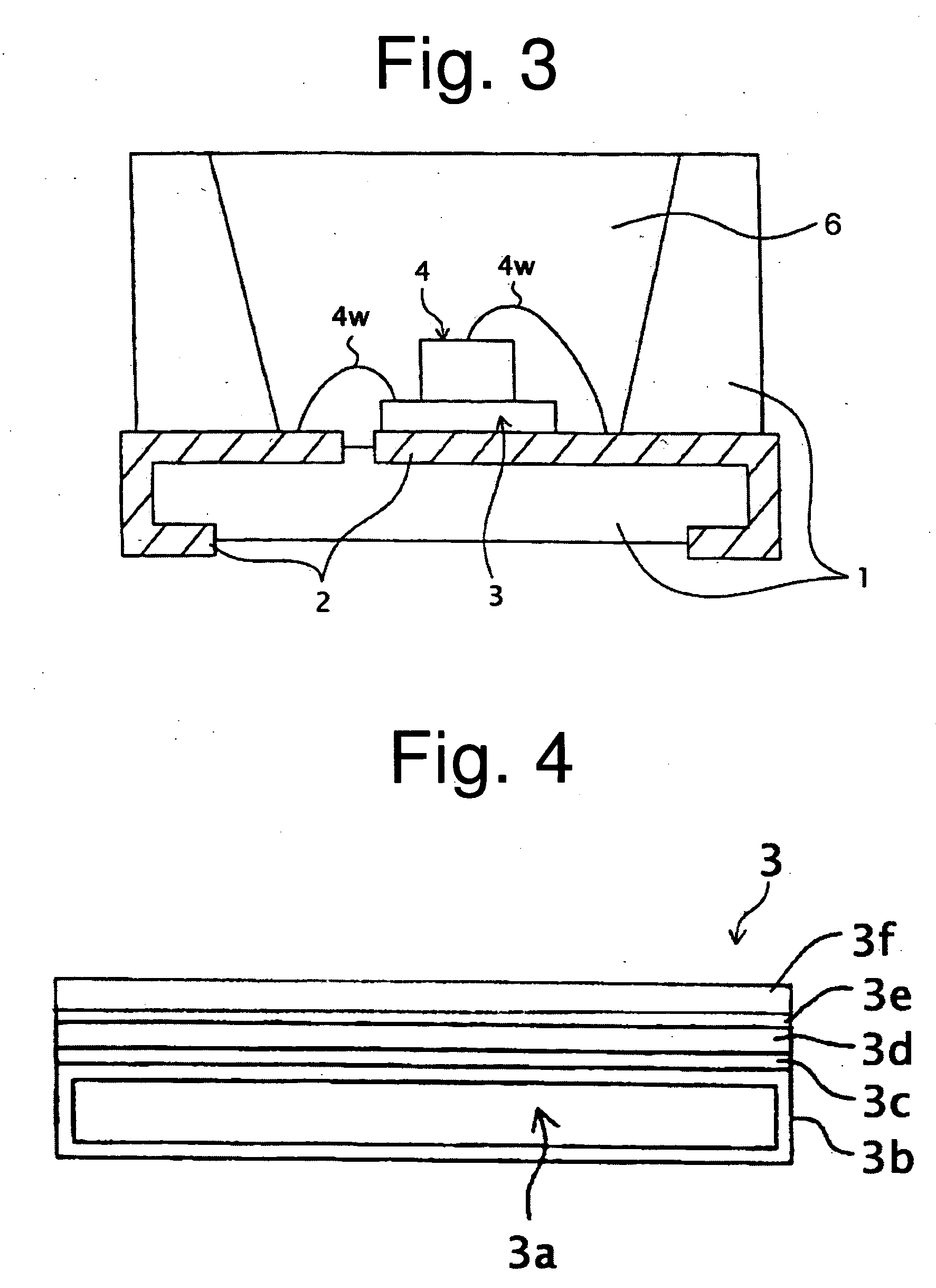

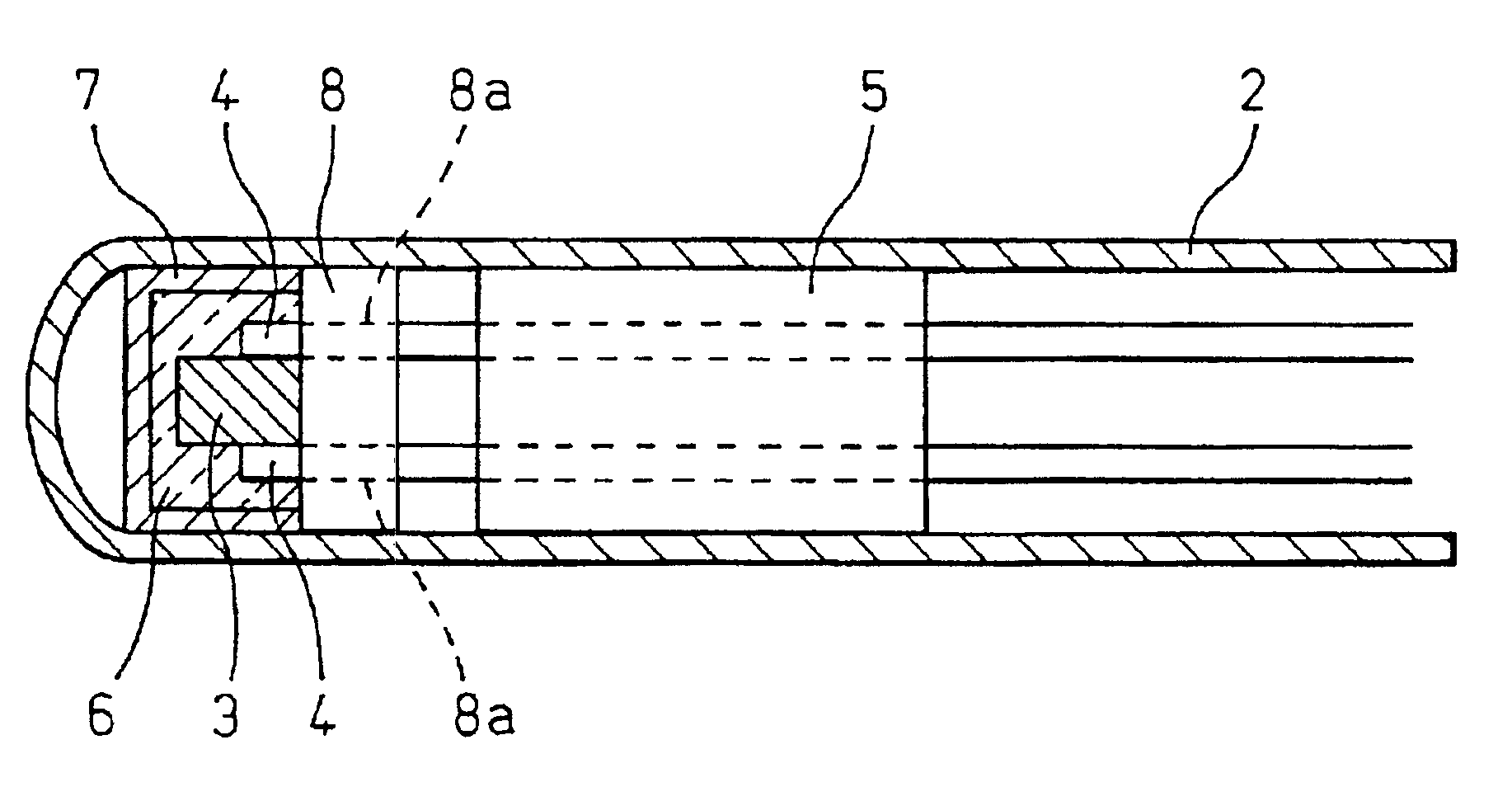

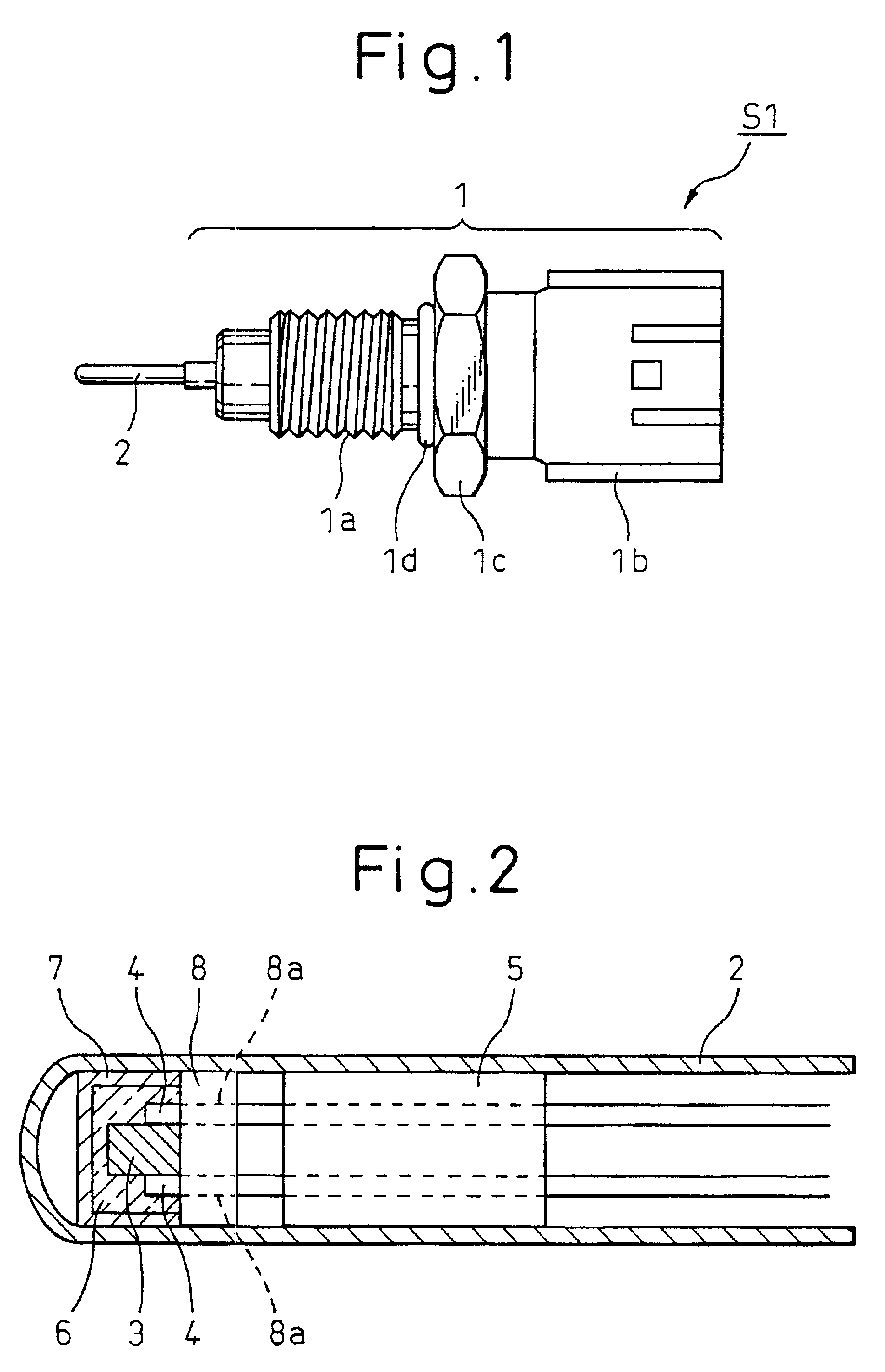

Temperature sensor and production method thereof

InactiveUS6880969B2Easily determineImprove heat resistanceThermometer detailsResistor terminals/electrodesThermistorEngineering

In a temperature sensor including a pair of electrode wires for signal lead-out, bonded to both opposing end faces of a thermistor device, this invention aims at preventing peeling, of bond portions, between the electrode wires and the thermistor device. This object can be accomplished by sealing the thermistor device 3 and the bond portions between the thermistor device 3 and the electrode wires 4 by using an electrically insulating glass member 6, and holding the pair of electrode wires 4 by using a holding member 8 made of an electrically insulating ceramic while a gap is kept between them.

Owner:DENSO CORP +1

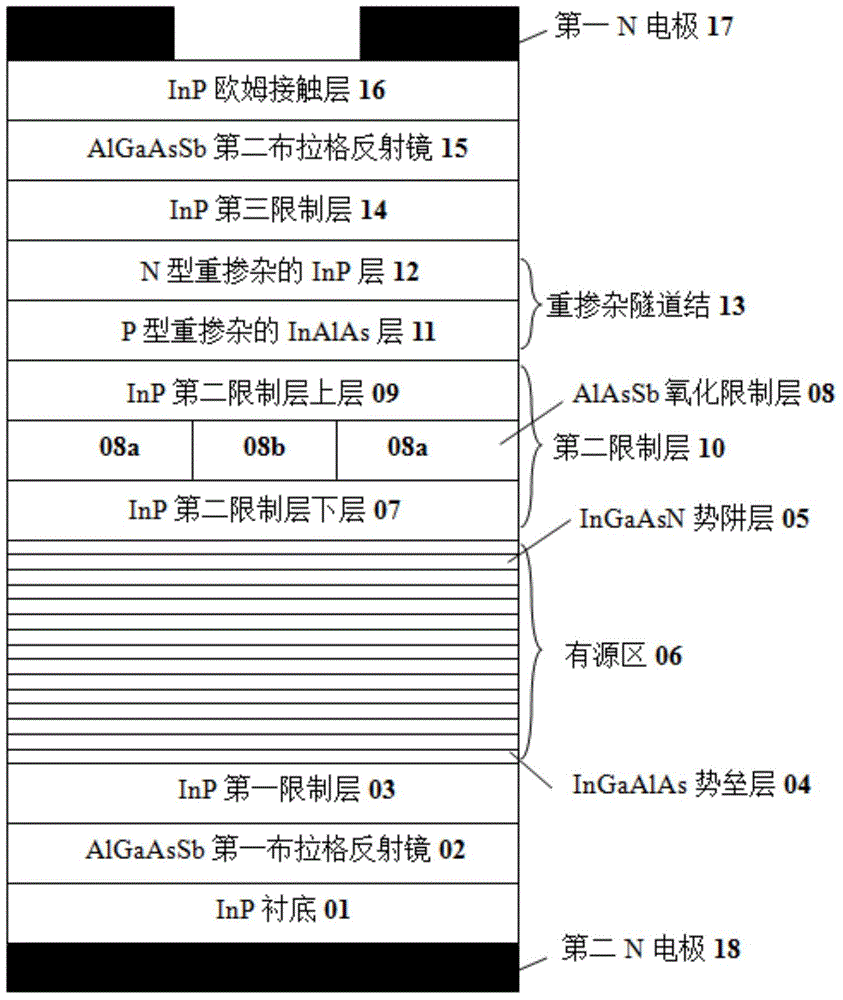

Vertical-cavity surface-emitting laser and manufacturing method thereof

InactiveCN104577711AHigh gainEffective limitLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserPotential well

The invention discloses a vertical-cavity surface-emitting laser which comprises a substrate, a first Bragg reflector, a first limiting layer, an active region, a second limiting layer, a second Bragg reflector and an Ohmic contact layer which are arranged in a laminated manner, wherein the active region adopts a quantum well structure, a potential barrier layer is made of InGaAlAs, and a potential well layer is made of InGaAsN; a heavily-doped tunnel junction and a third limiting layer are also arranged between the second limiting layer and the second Bragg reflector; an oxidized limiting layer is also arranged in the second limiting layer. The invention also provides a preparation method of the laser. The laser has the advantages that the laser uses an InGaAsN / InGaAlAs material system as the active region, has large conduction band order ratio and can effectively limit injected carriers, so that the threshold current is reduced, and the laser gain is improved; on an isometric wavelength band of 1550 nm, the content of N required by an active region material is lower, and devices with high material quality are easy to obtain.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Pressure sensor assembly

InactiveUS6848316B2Avoid bondingFluid pressure measurement by electric/magnetic elementsForce measurementEngineeringPressure sensor

A pressure sensor assembly includes an elongate pressure sensor mounted to a sensor mounting block. A protective element covers the elongate pressure sensor to prevent the pressure sensor from contacting process fluid.

Owner:ROSEMOUNT INC

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS20080148999A1Good dispersionAvoid bondingPulp properties modificationSolid waste managementChemical treatmentSurface finish

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH LTD

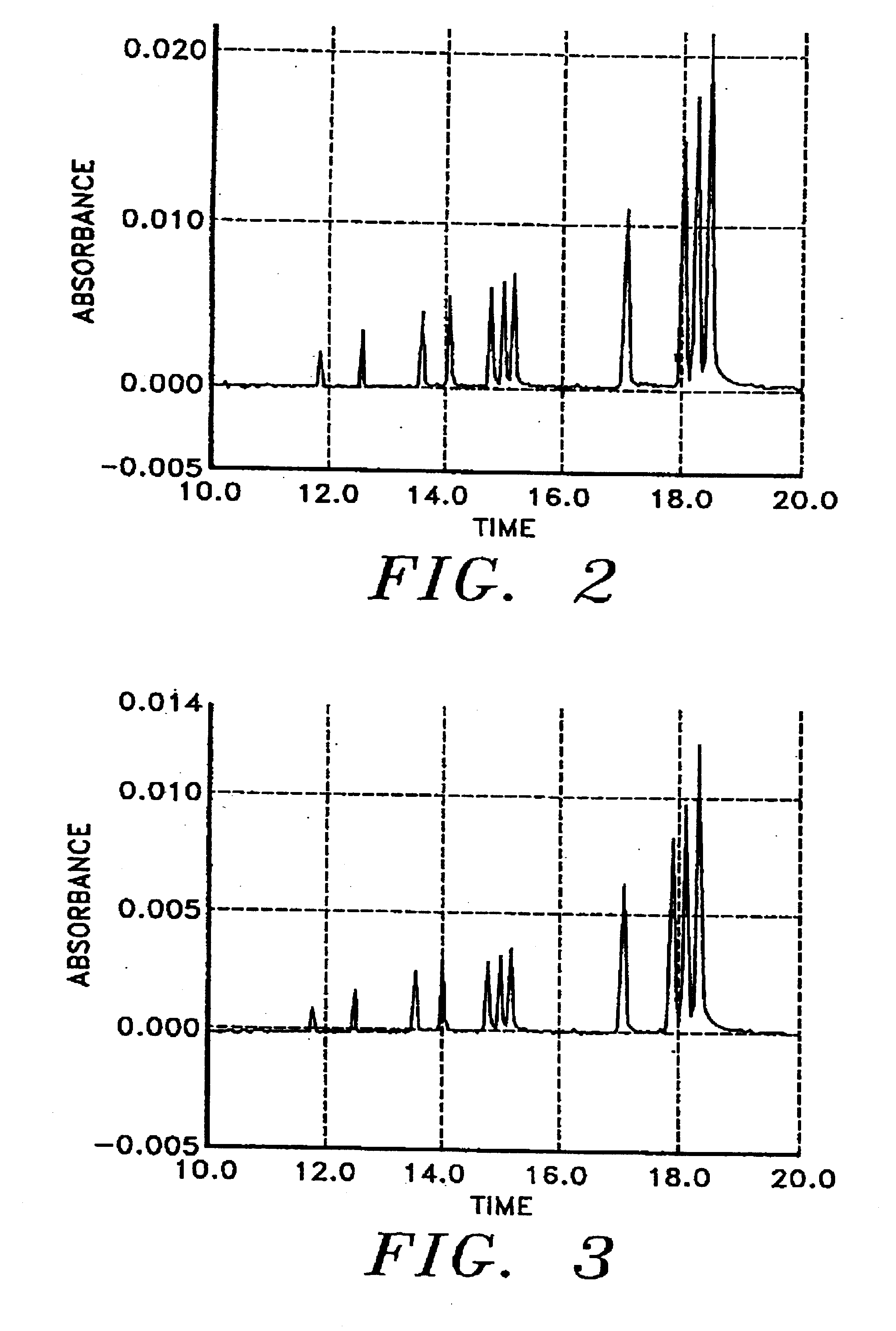

Capillary electrophoresis using replaceable gels

InactiveUSRE37941E1Avoid bondingSludge treatmentVolume/mass flow measurementElectrophoresesCapillary electrophoresis

The filling of an internally coated capillary with a gel in its polymerized state without damaging the gel. The coating prevents bonding of the gel to the inside of the capillary, The gel comprises up to 6% acrylamide and 0-5% crosslinker. The gel can be advantageously and conveniently used in automated electrophoresis systems for automatic replacement of spent gel.

Owner:BECKMAN COULTER INC

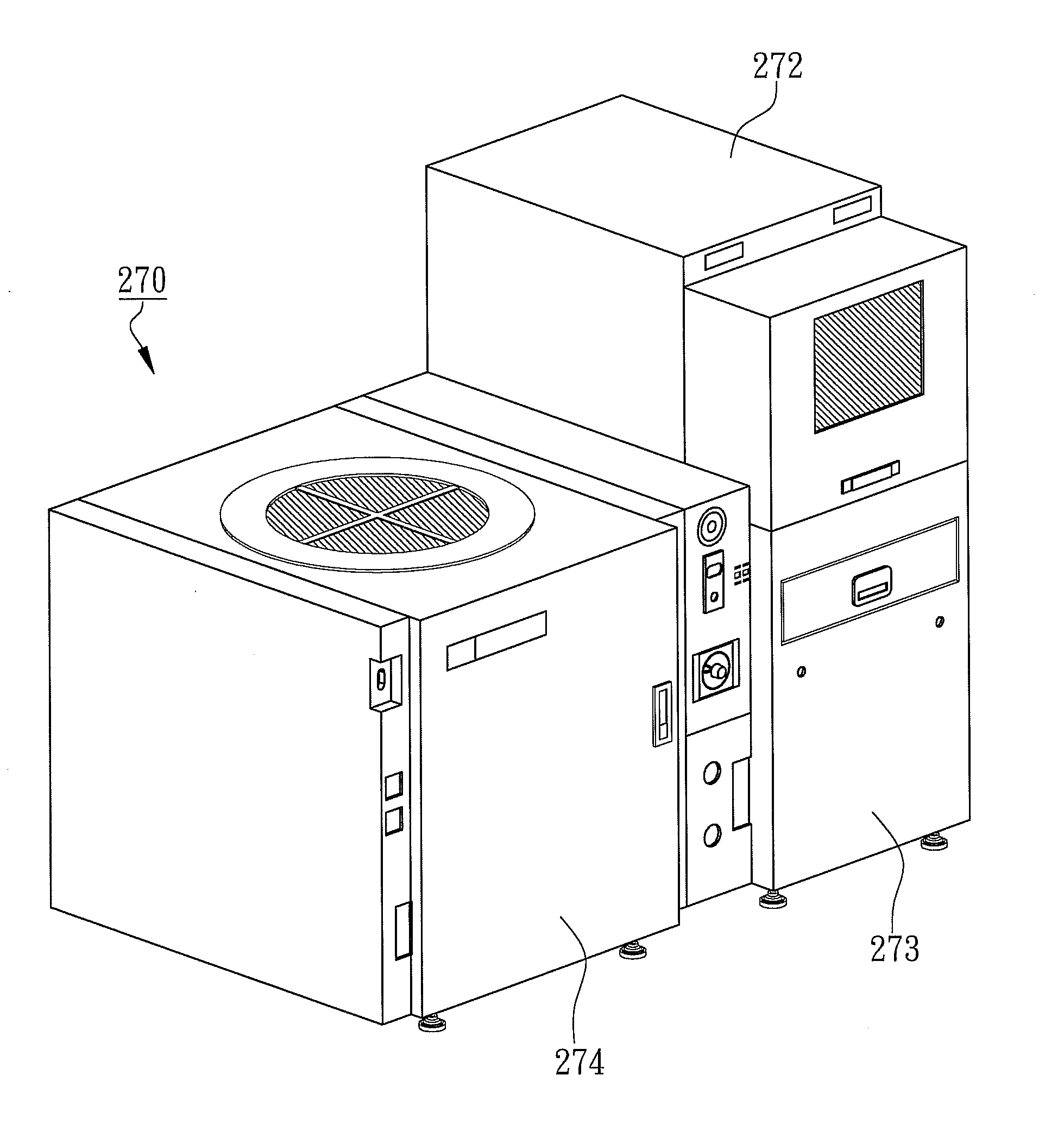

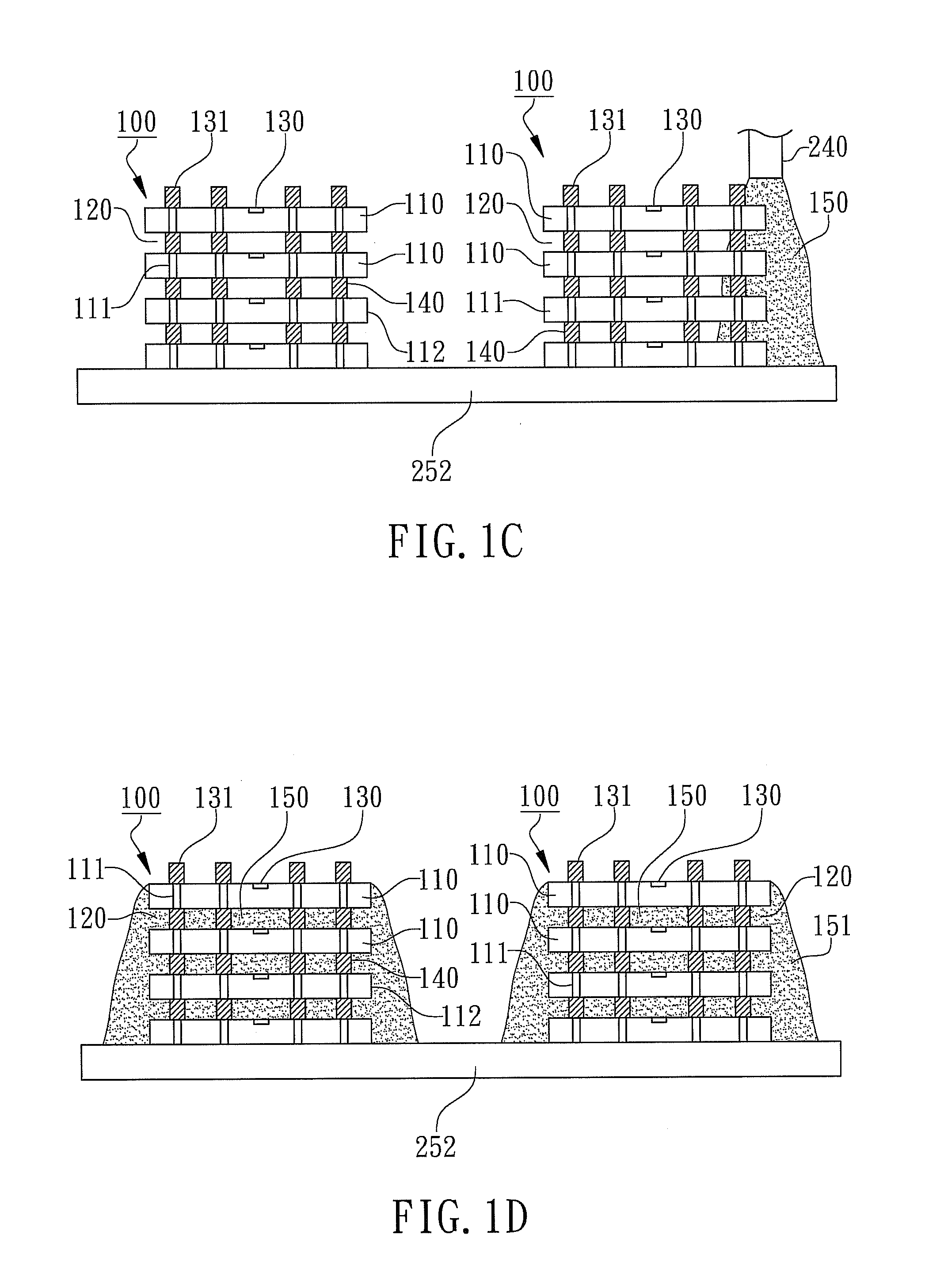

Method for testing multi-chip stacked packages

InactiveUS20130076384A1Easy to integrateReduce in quantityElectronic circuit testingAdhesive beltEngineering

Disclosed is a method for testing multi-chip stacked packages. Initially, one or more substrate-less chip cubes are provided, each consisting of a plurality of chips such as chips stacked together having vertically connected with TSV's where there is a stacked gap between two adjacent chips. Next, the substrate-less chip cubes are adhered onto an adhesive tape where the adhesive tape is attached inside an opening of a tape carrier. Then, a filling encapsulant is formed on the adhesive tape to completely fill the chip stacked gaps. Next, the tape carrier is fixed on a wafer testing carrier in a manner to allow the substrate-less chip cubes to be loaded into a wafer tester without releasing from the adhesive tape. Accordingly, the probers of the wafer tester can be utilized to probe testing electrodes of the substrate-less chip cubes so that it is easy to integrate this testing method in TSV fabrication processes.

Owner:POWERTECH TECHNOLOGY

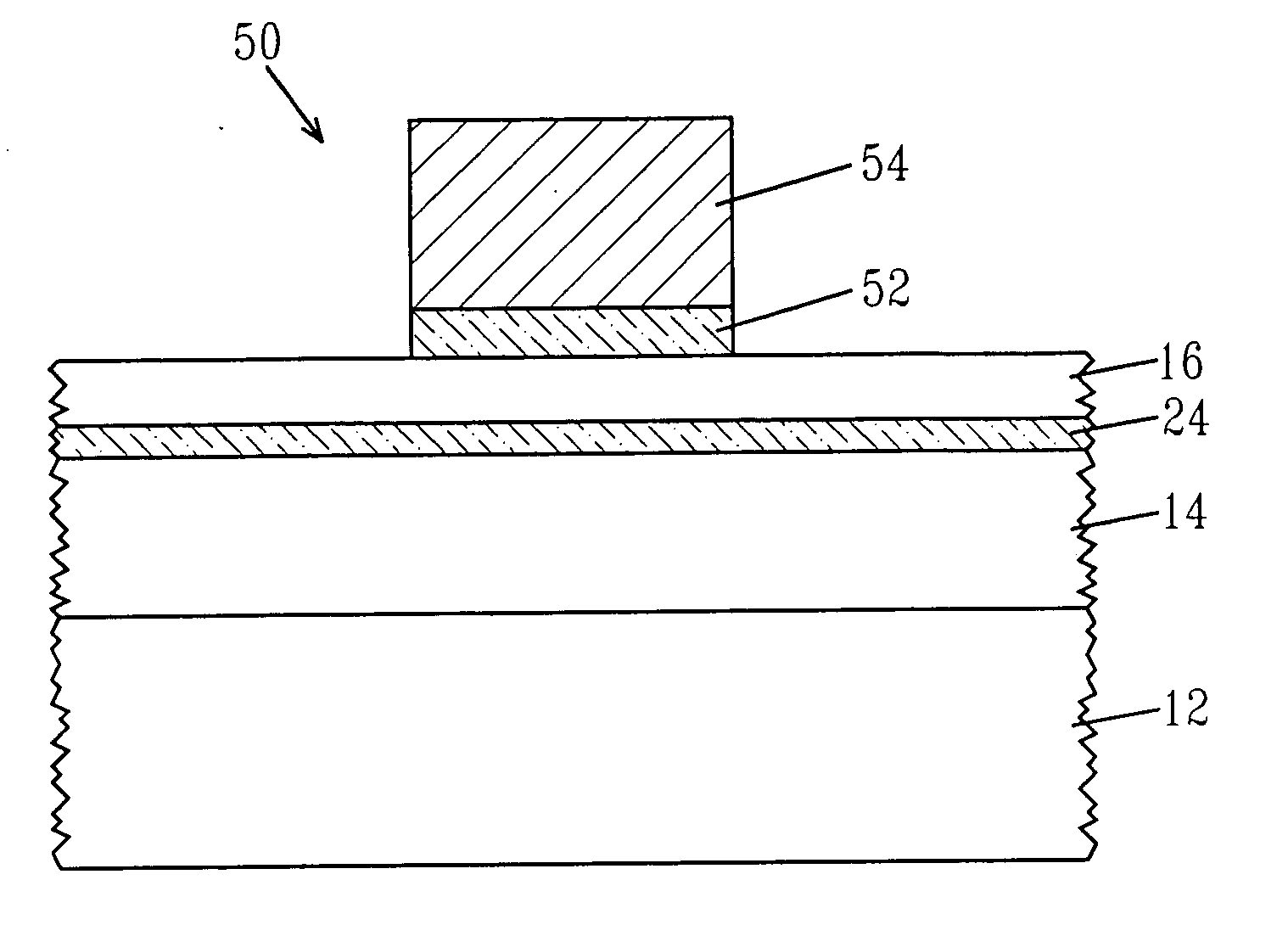

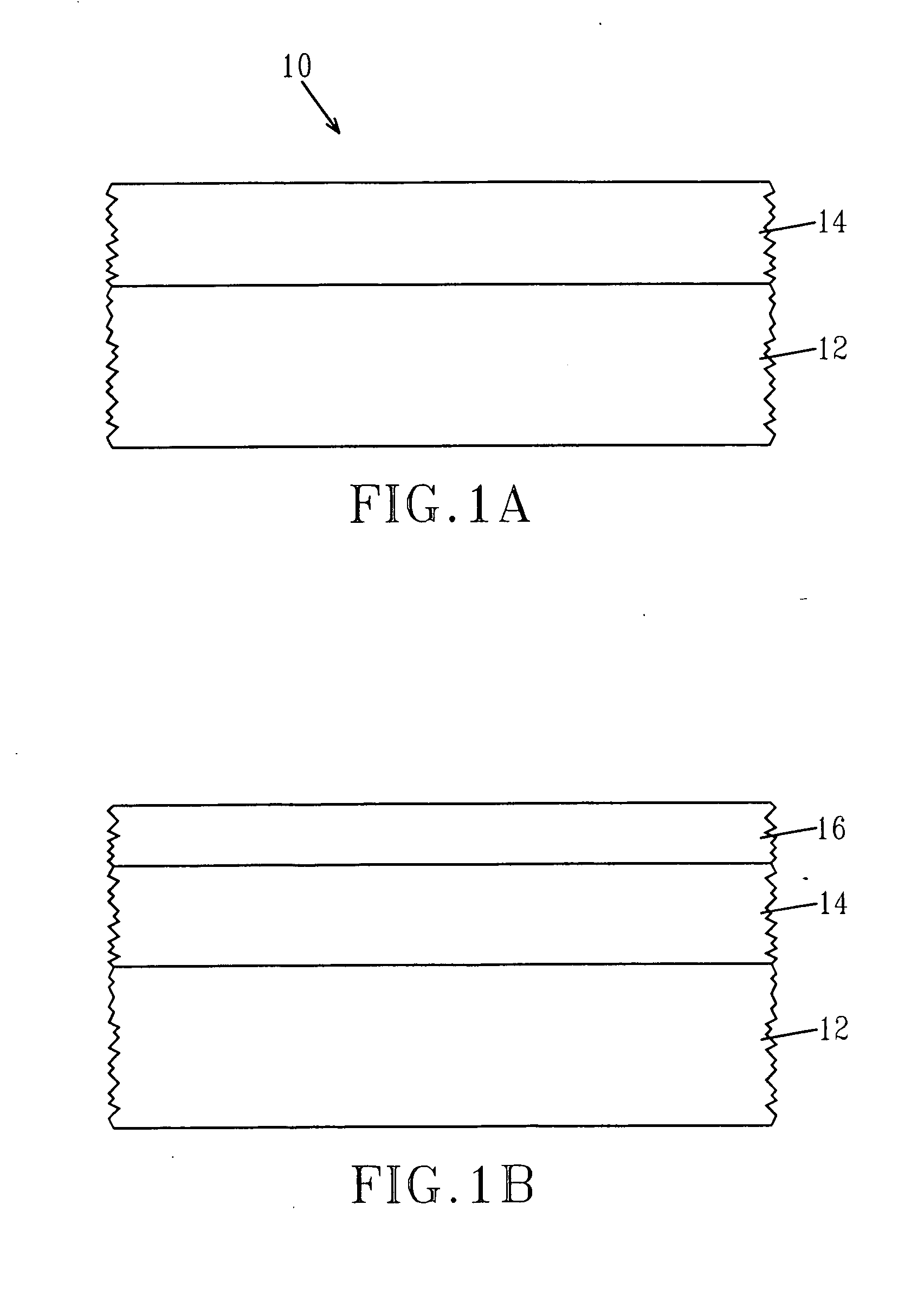

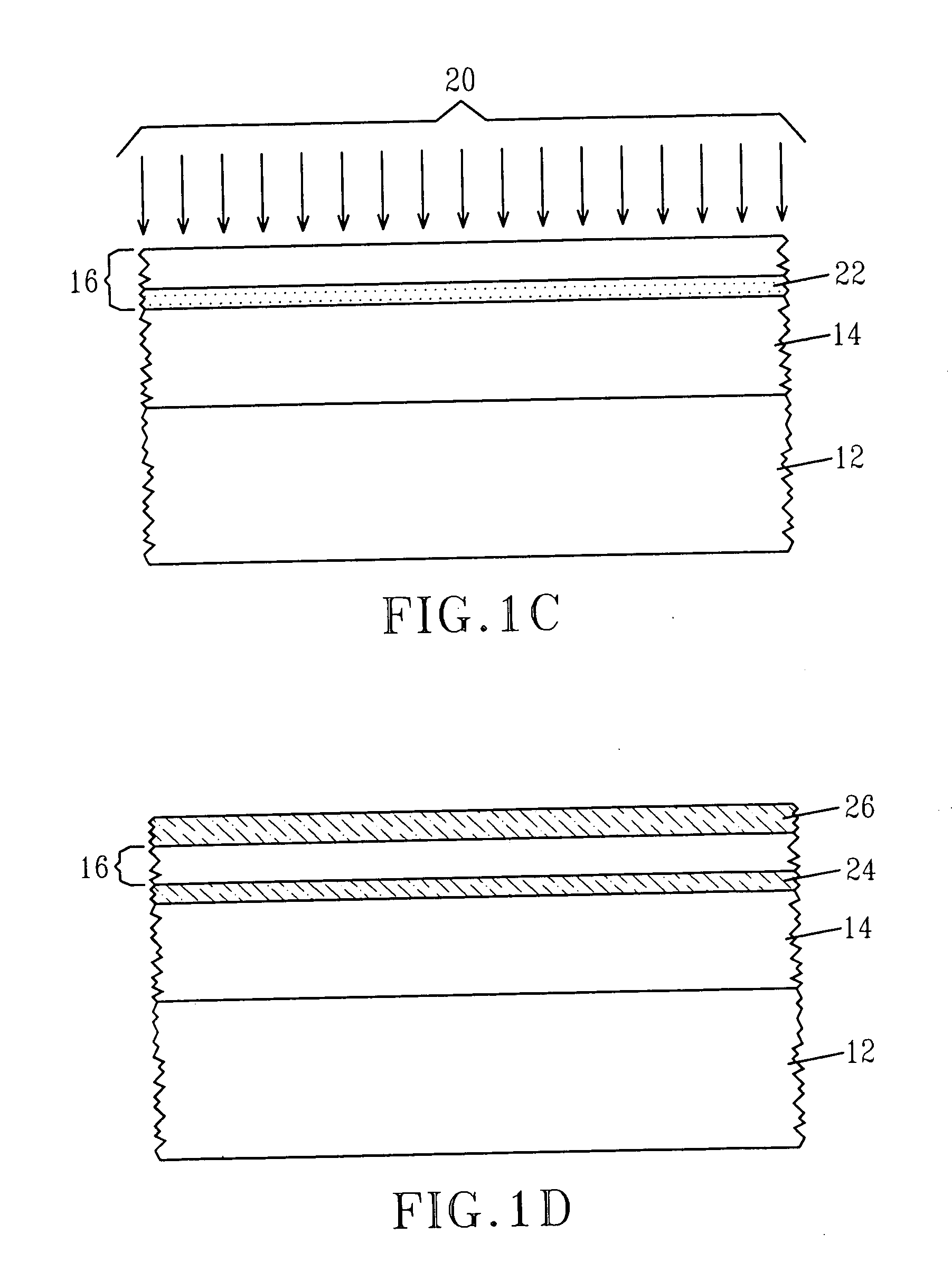

Strained semiconductor-on-insulator (sSOI) by a simox method

ActiveUS20070164356A1Reduce manufacturing costAvoiding wafer bondingSolid-state devicesSemiconductor/solid-state device manufacturingOxygen ionsSemiconductor

A strained (tensile or compressive) semiconductor-on-insulator material is provided in which a single semiconductor wafer and a separation by ion implantation of oxygen process are used. The separation by ion implantation of oxygen process, which includes oxygen ion implantation and annealing creates, a buried oxide layer within the material that is located beneath the strained semiconductor layer. In some embodiments, a graded semiconductor buffer layer is located beneath the buried oxide layer, while in other a doped semiconductor layer including Si doped with at least one of B or C is located beneath the buried oxide layer.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com