Patents

Literature

198 results about "Si doped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium nitride compound semiconductor device and manufacturing method

ActiveUS20060175600A1Improve luminous efficiencyLight emission efficiencySolid-state devicesSemiconductor/solid-state device manufacturingGallium nitrideLength wave

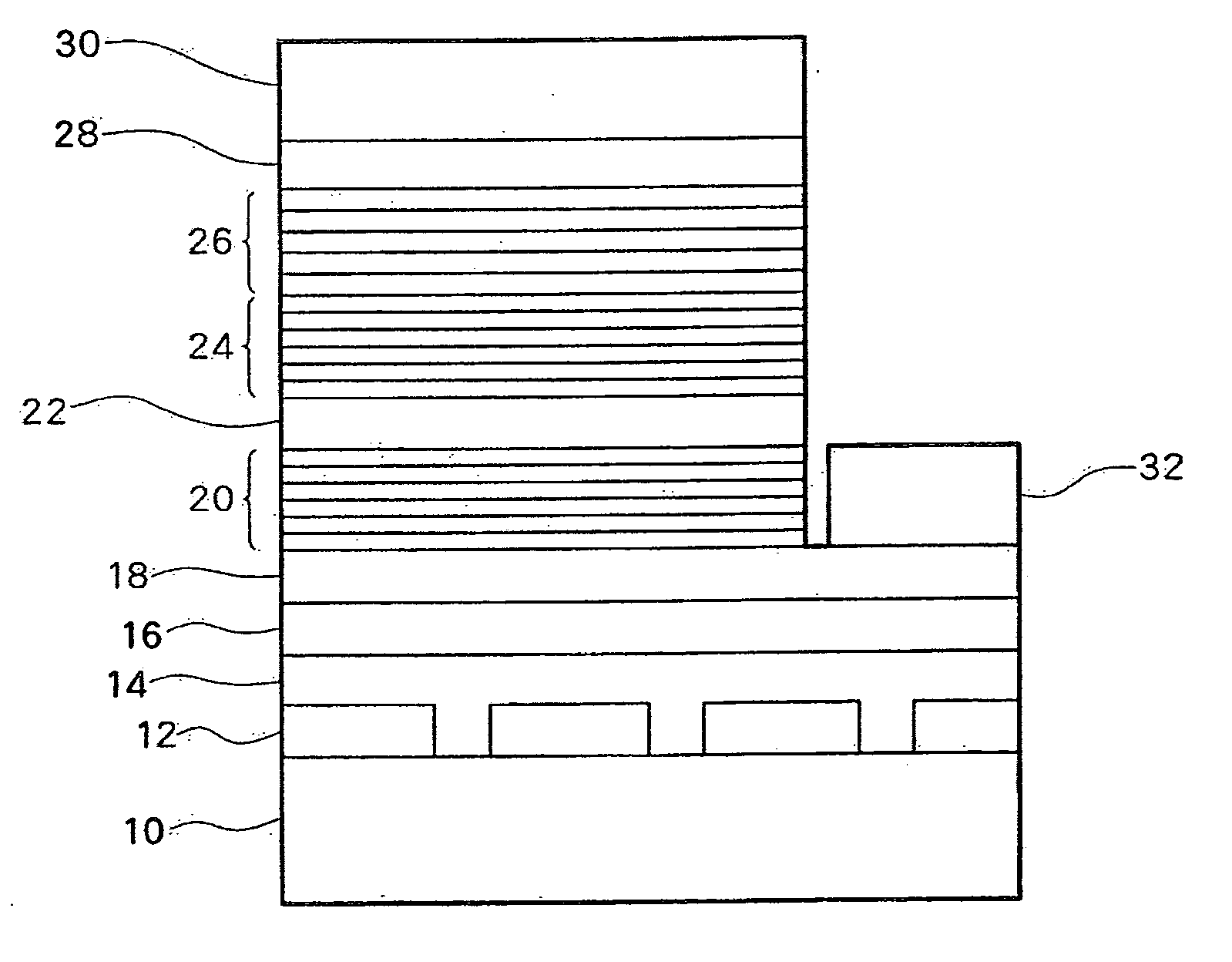

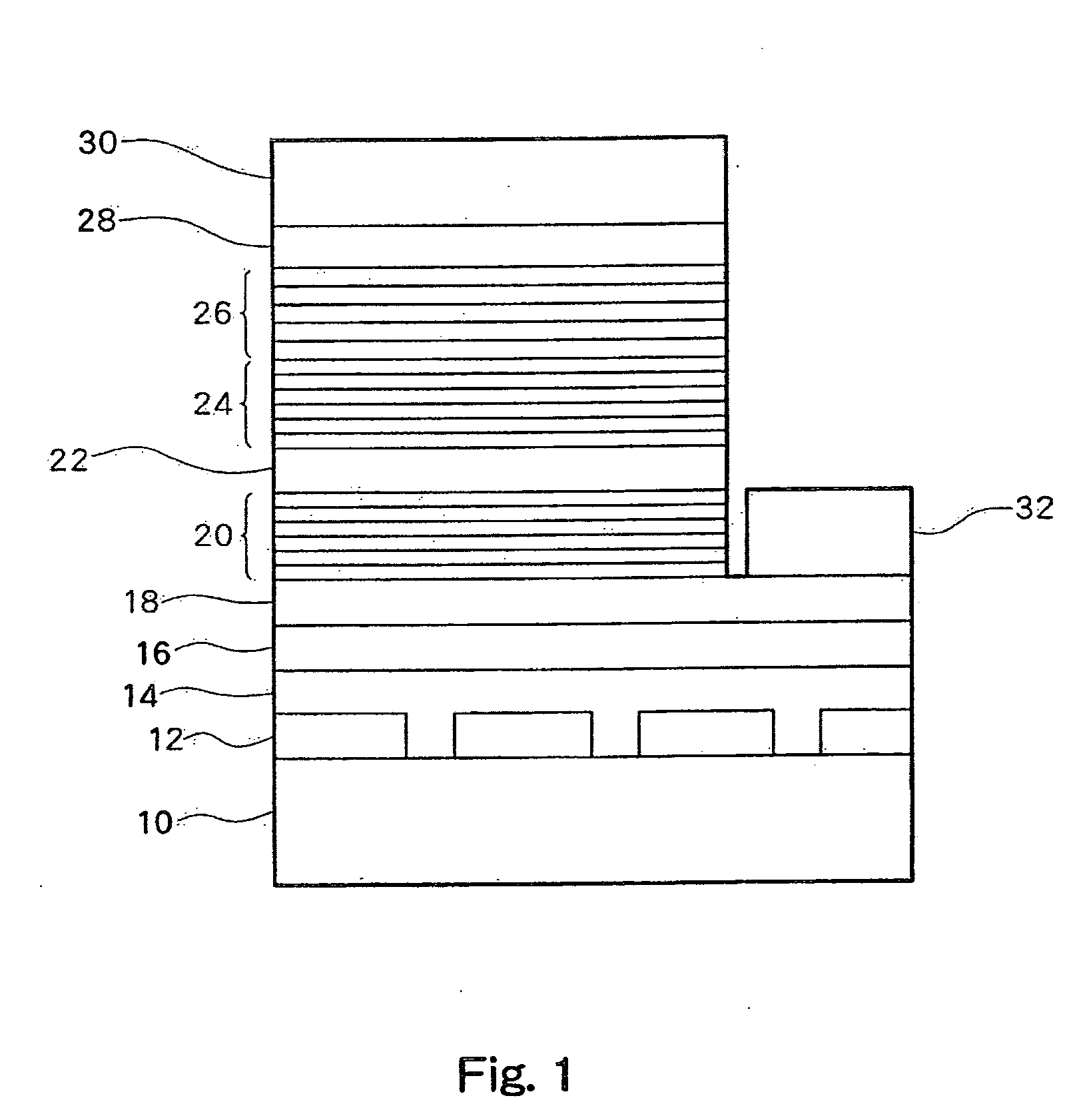

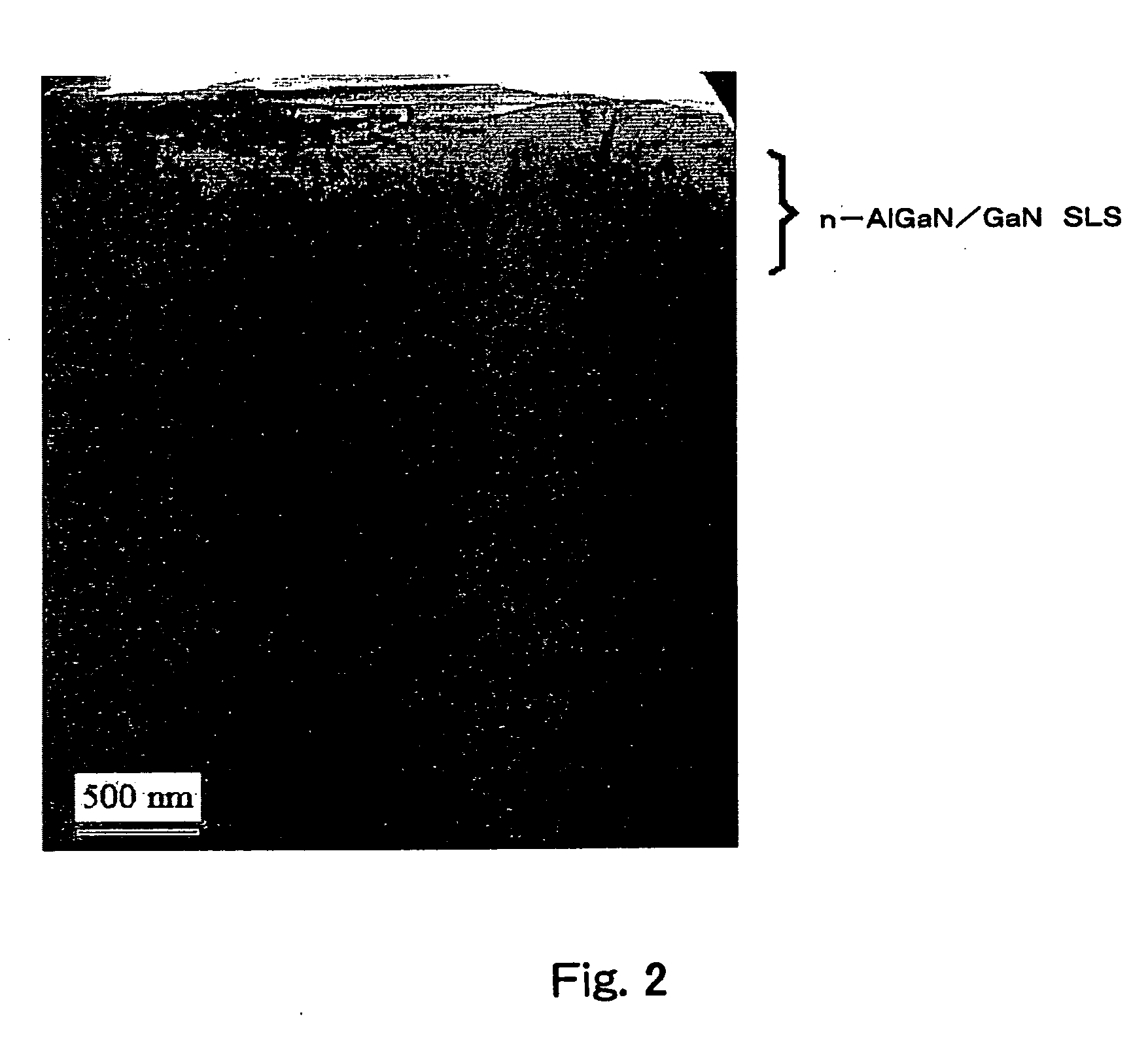

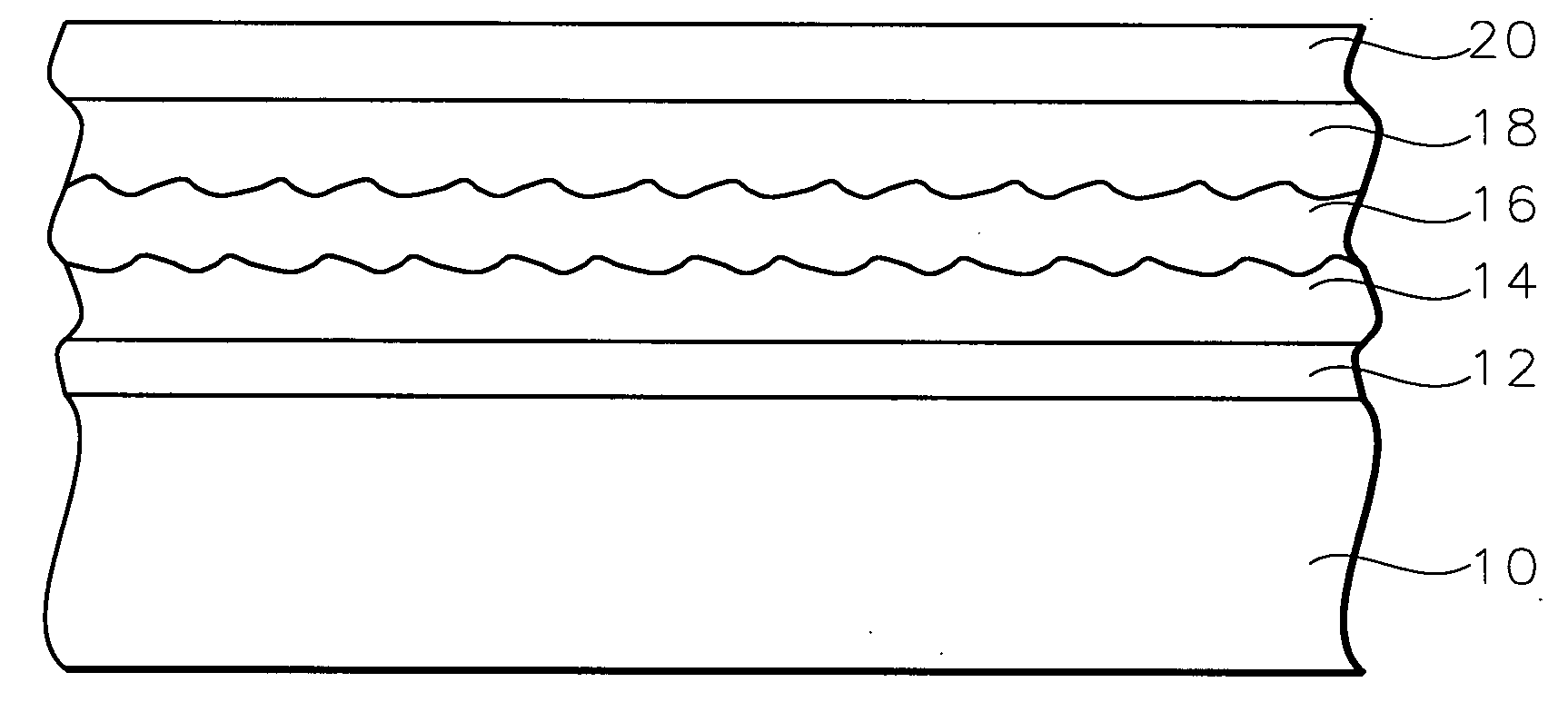

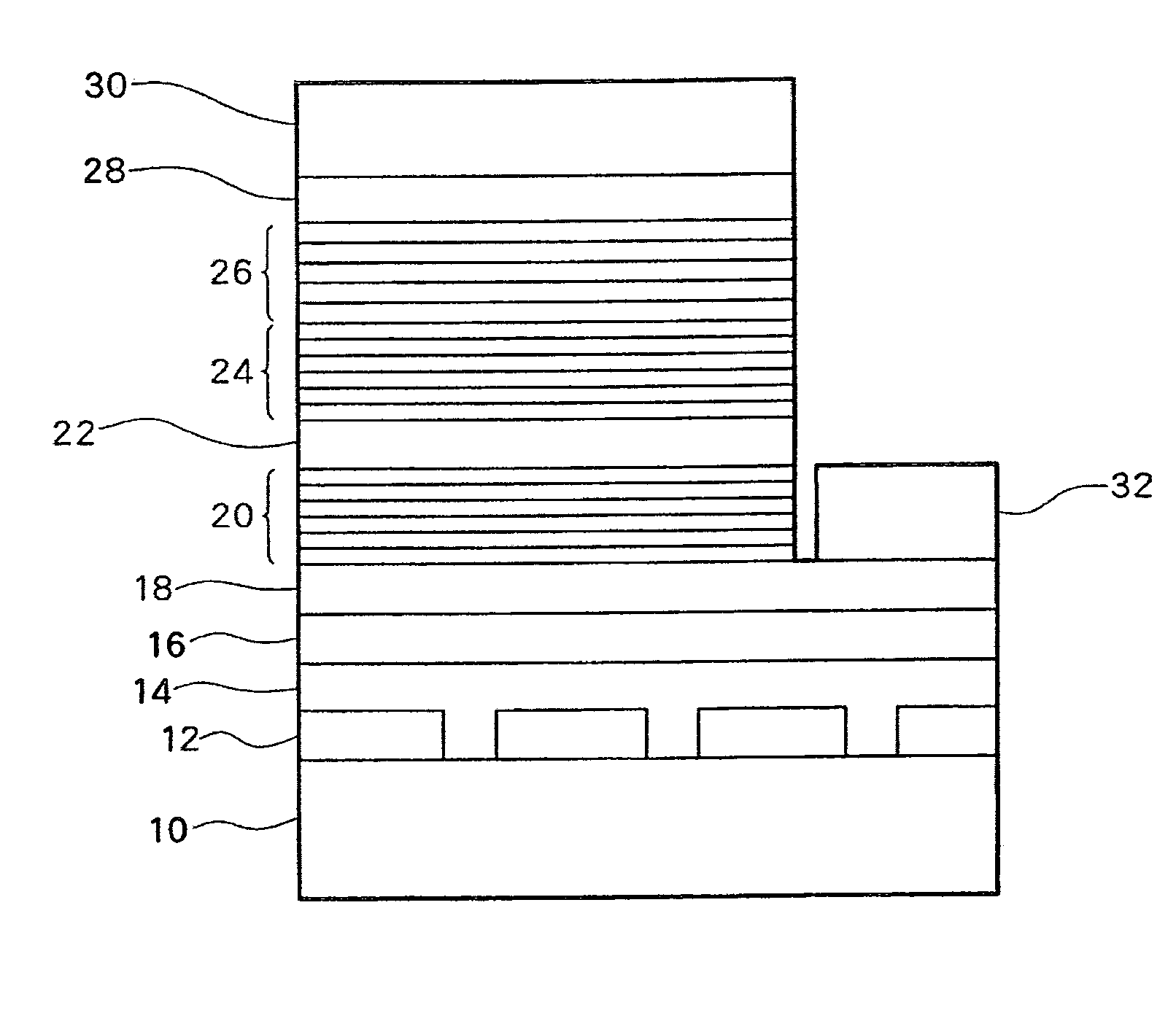

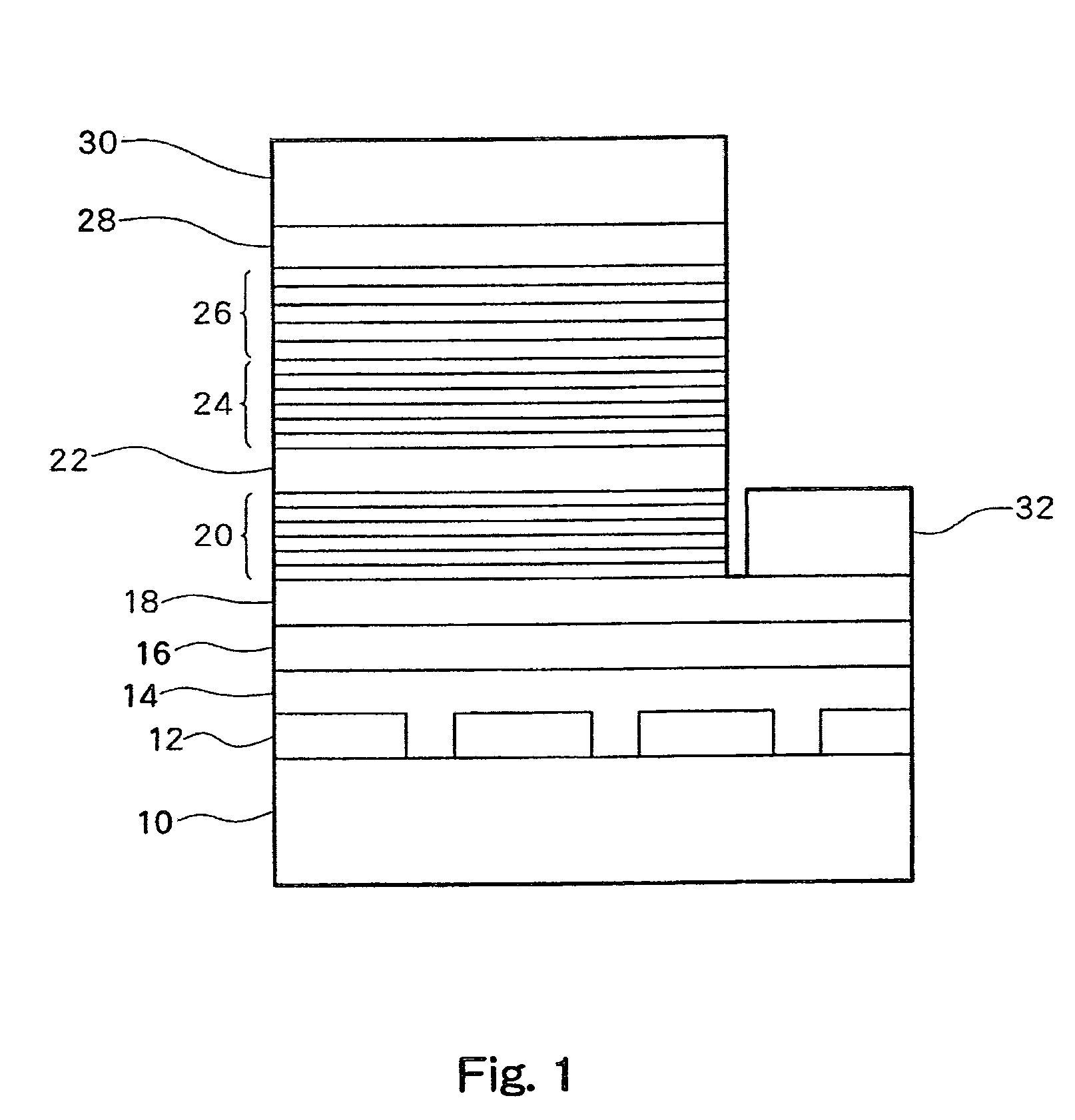

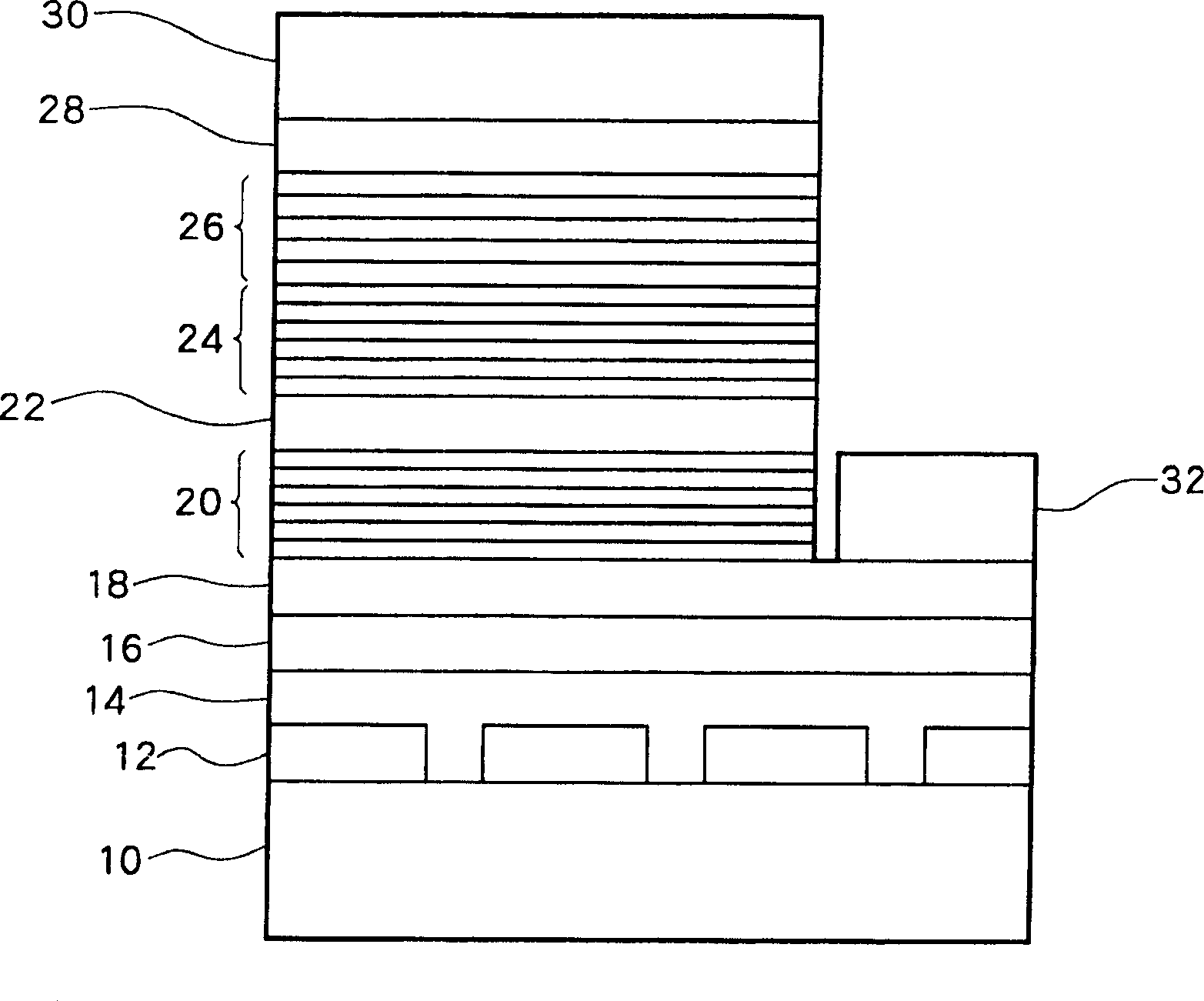

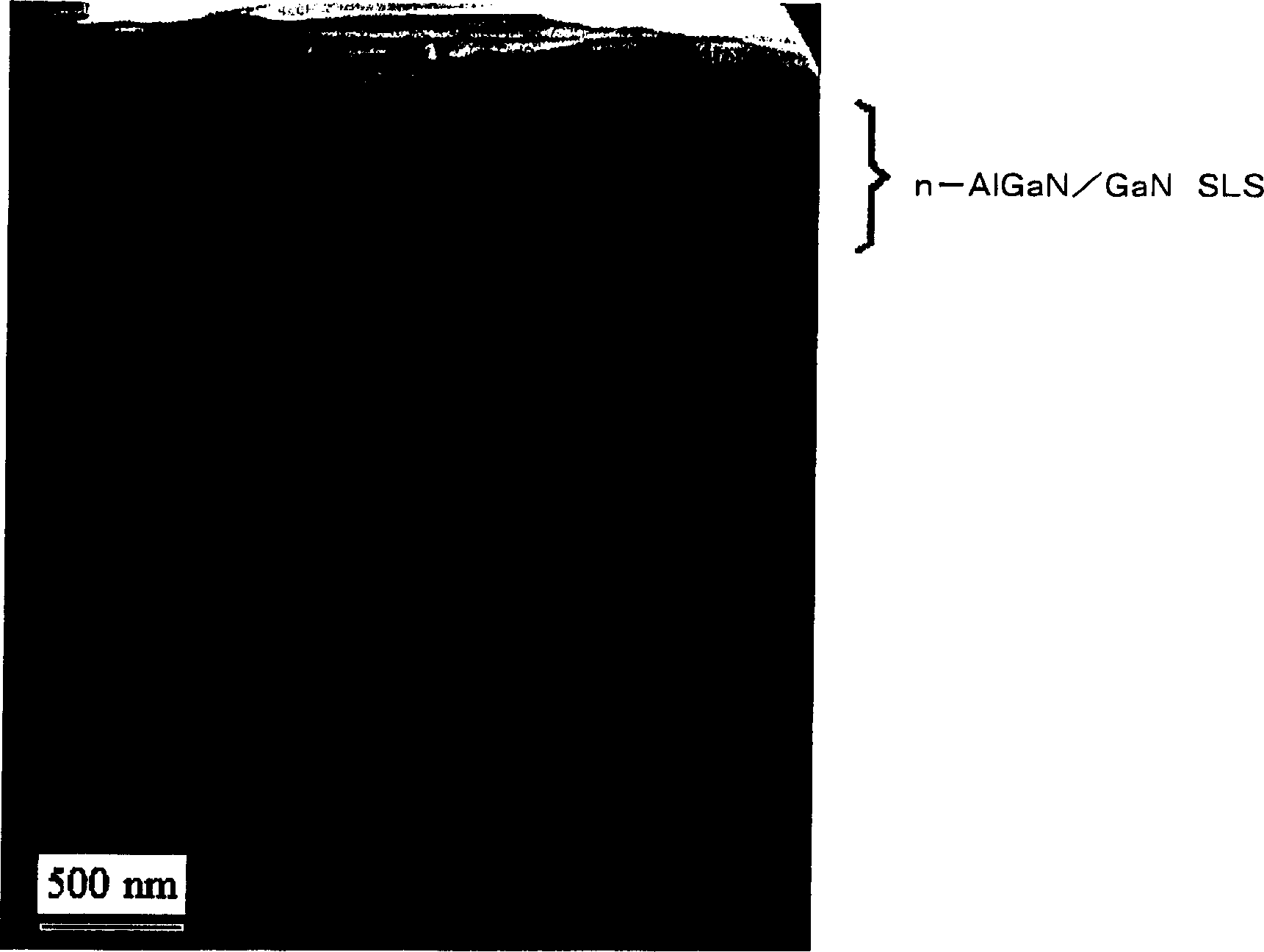

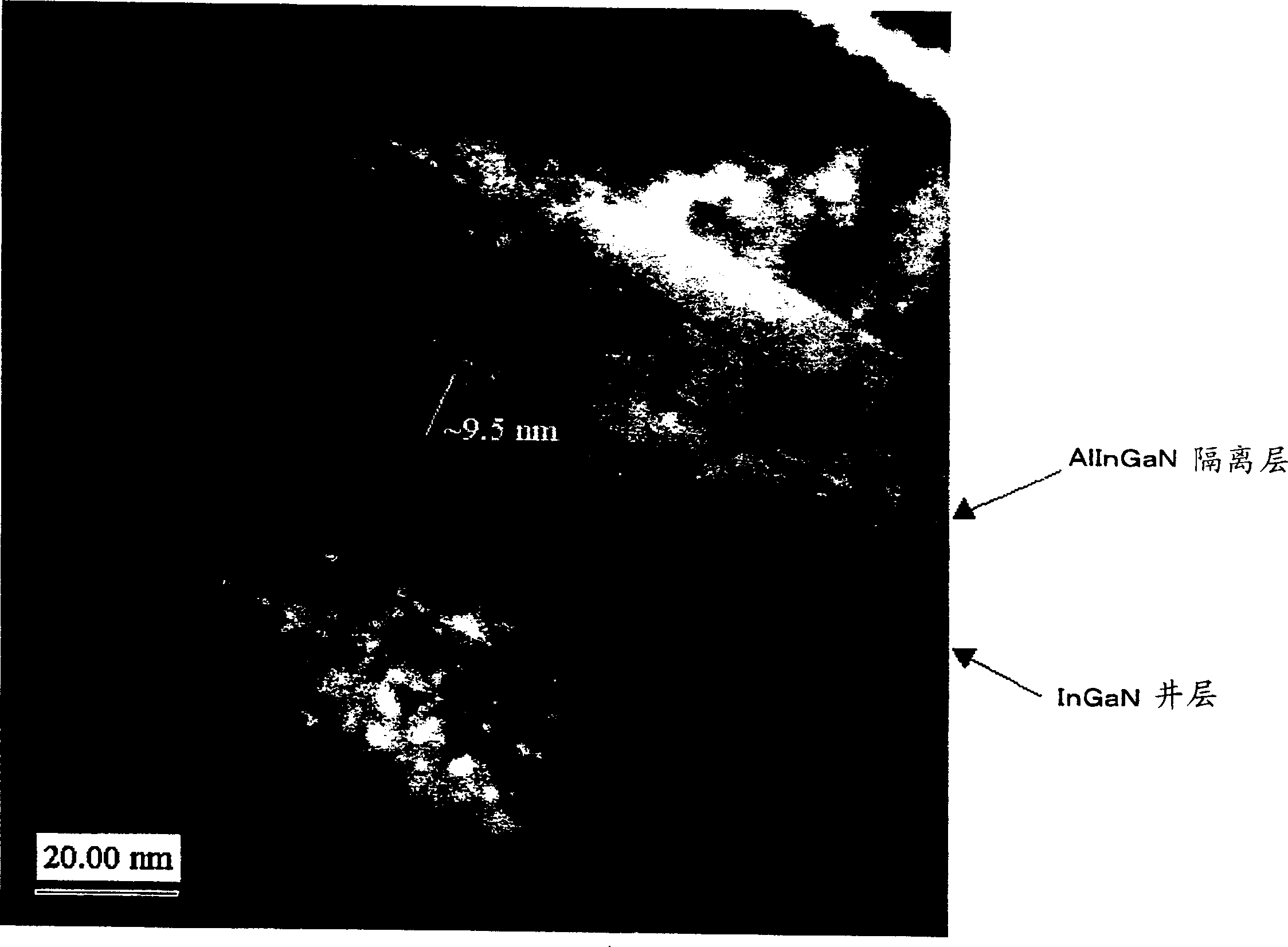

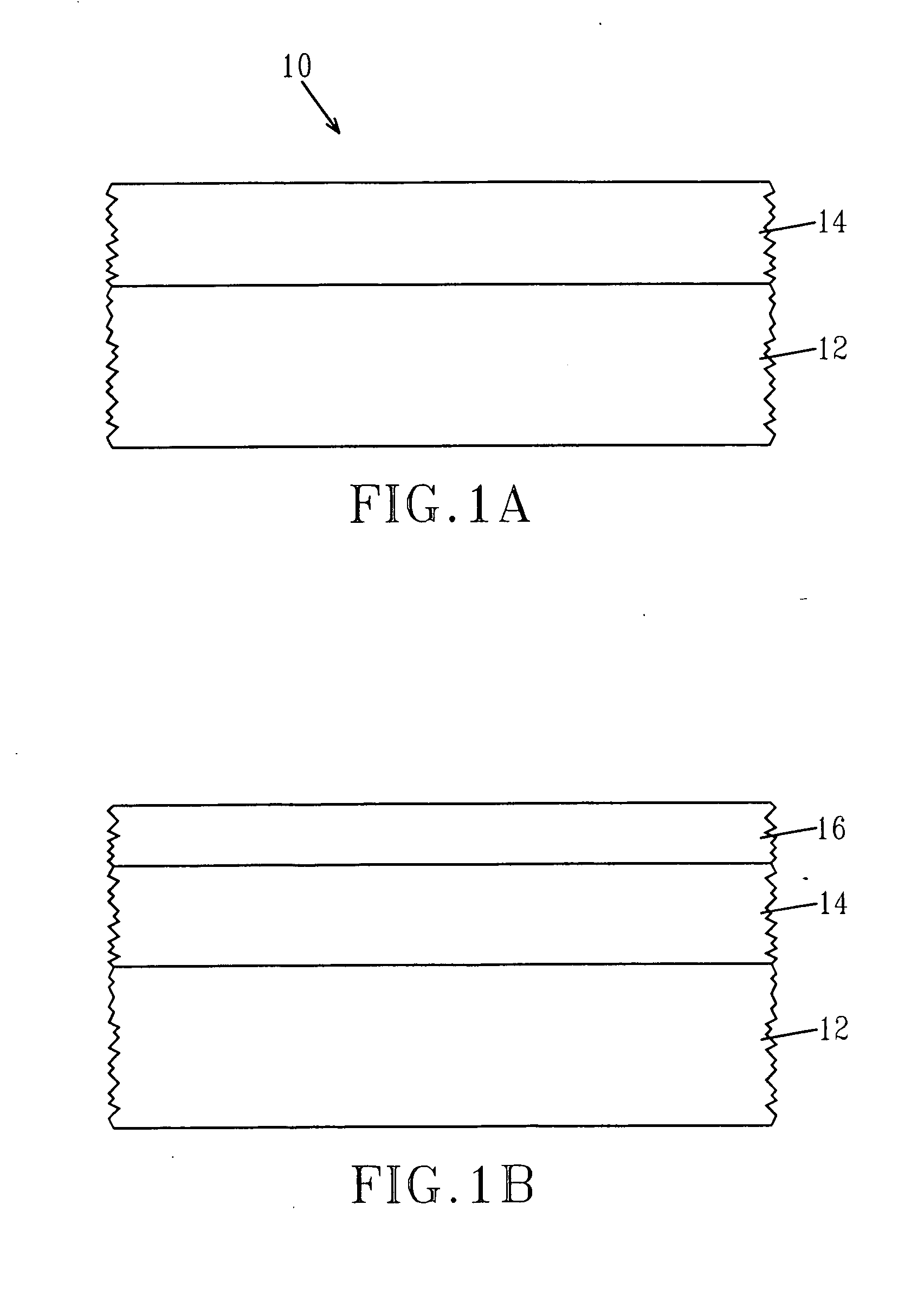

A light-emitting element using GaN. On a substrate (10), formed are an SiN buffer layer (12), a GaN buffer layer (14), an undoped GaN layer (16), an Si-doped n-GaN layer (18), an SLS layer (20), an undoped GaN layer (22), an MQW light-emitting layer (24), an SLS layer (26), and a p-GaN layer (28), forming a p electrode (30) and an n electrode (32). The MQW light-emitting layer (24) has a structure in which InGaN well layers and AlGaN barrier layers are alternated. The Al content ratios of the SLS layers (20, and 26) are more than 5% and less than 24%. The In content ratio of the well layer in the MQW light-emitting layer (24) is more than 3% and less than 20%. The Al content ratio of the barrier layer is more than 1% and less than 30%. By adjusting the content ratio and film thickness of each layer to a desired value, the light luminous efficiency for wavelength of less than 400 nm is improved.

Owner:NITRIDE SEMICON

Growth of indium gallium nitride (InGaN) on porous gallium nitride (GaN) template by metal-organic chemical vapor deposition (MOCVD)

InactiveUS20090001416A1Increase indium incorporationLarge emissionsPolycrystalline material growthSemiconductor/solid-state device manufacturingIndiumGallium nitride

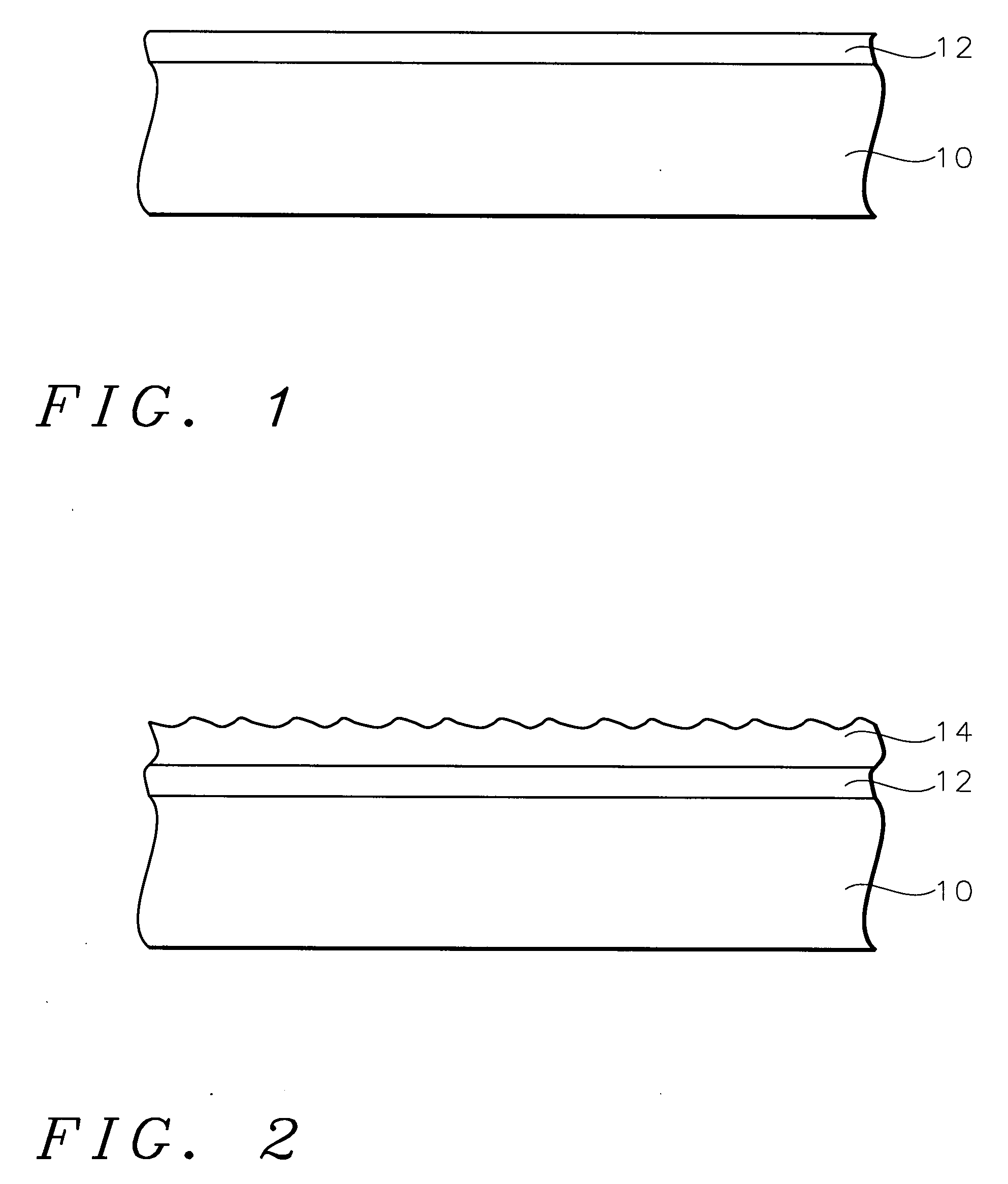

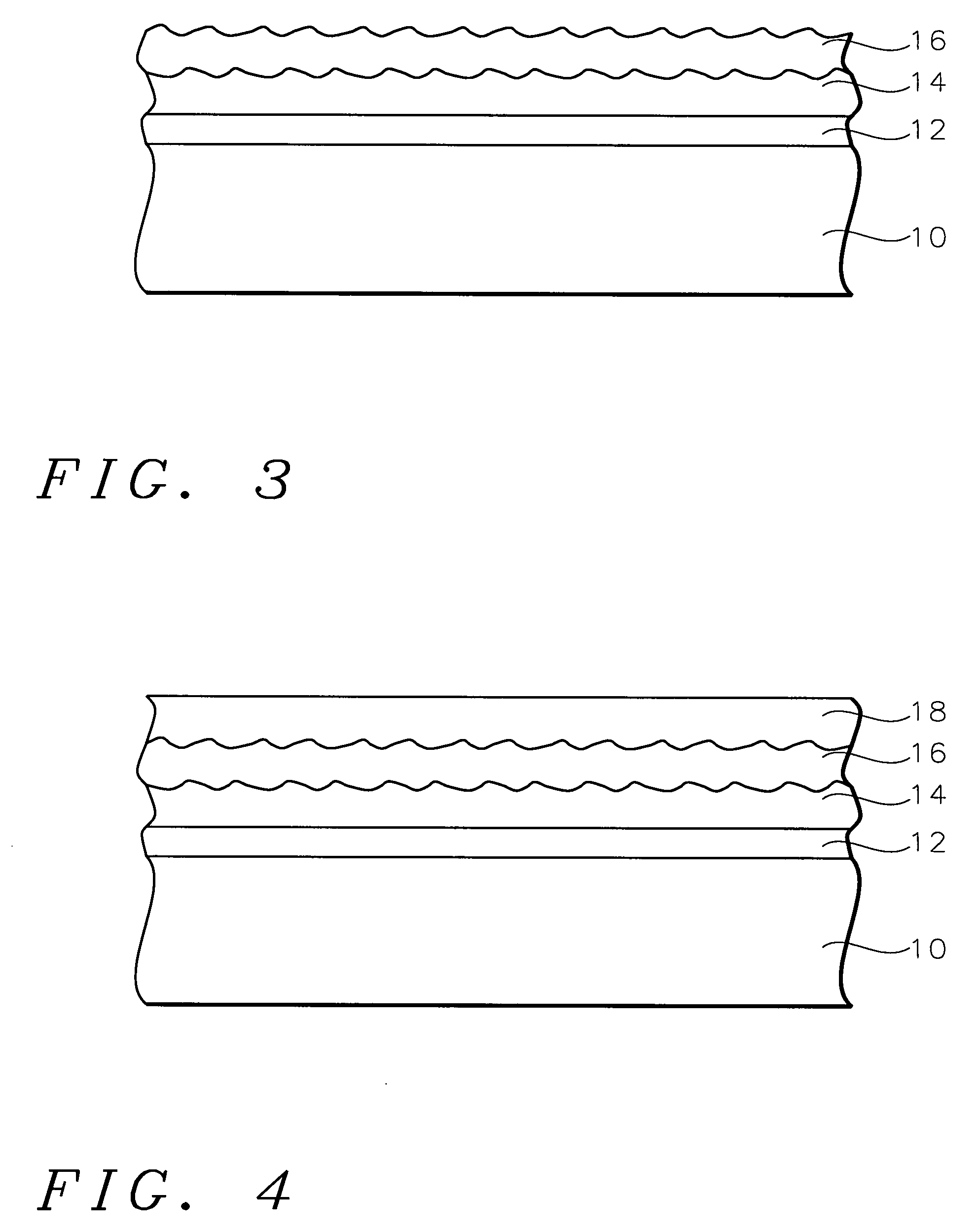

Si-doped porous GaN is fabricated by UV-enhanced Pt-assisted electrochemical etching and together with a low-temperature grown buffer layer are utilized as the template for InGaN growth. The porous network in GaN shows nanostructures formed on the surface. Subsequent growth of InGaN shows that it is relaxed on these nanostructures as the area on which the growth takes place is very small. The strain relaxation favors higher indium incorporation. Besides, this porous network creates a relatively rough surface of GaN to modify the surface energy which can enhance the nucleation of impinging indium atoms thereby increasing indium incorporation. It shifts the luminescence from 445 nm for a conventionally grown InGaN structure to 575 nm and enhances the intensity by more than two-fold for the growth technique in the present invention under the same growth conditions. There is also a spectral broadening of the output extending from 480 nm to 720 nm.

Owner:NAT UNIV OF SINGAPORE

Gallium nitride compound semiconductor device and manufacturing method

ActiveUS7372066B2Improve luminous efficiencyLight emission efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLength waveGallium nitride

A light-emitting element using GaN. On a substrate (10), formed are an SiN buffer layer (12), a GaN buffer layer (14), an undoped GaN layer (16), an Si-doped n-GaN layer (18), an SLS layer (20), an undoped GaN layer (22), an MQW light-emitting layer (24), an SLS layer (26), and a p-GaN layer (28), forming a p electrode (30) and an n electrode (32). The MQW light-emitting layer (24) has a structure in which InGaN well layers and AlGaN barrier layers are alternated. The Al content ratios of the SLS layers (20, and 26) are more than 5% and less than 24%. The In content ratio of the well layer in the MQW light-emitting layer (24) is more than 3% and less than 20%. The Al content ratio of the barrier layer is more than 1% and less than 30%. By adjusting the content ratio and film thickness of each layer to a desired value, the light luminous efficiency for wavelength of less than 400 nm is improved.

Owner:NITRIDE SEMICON

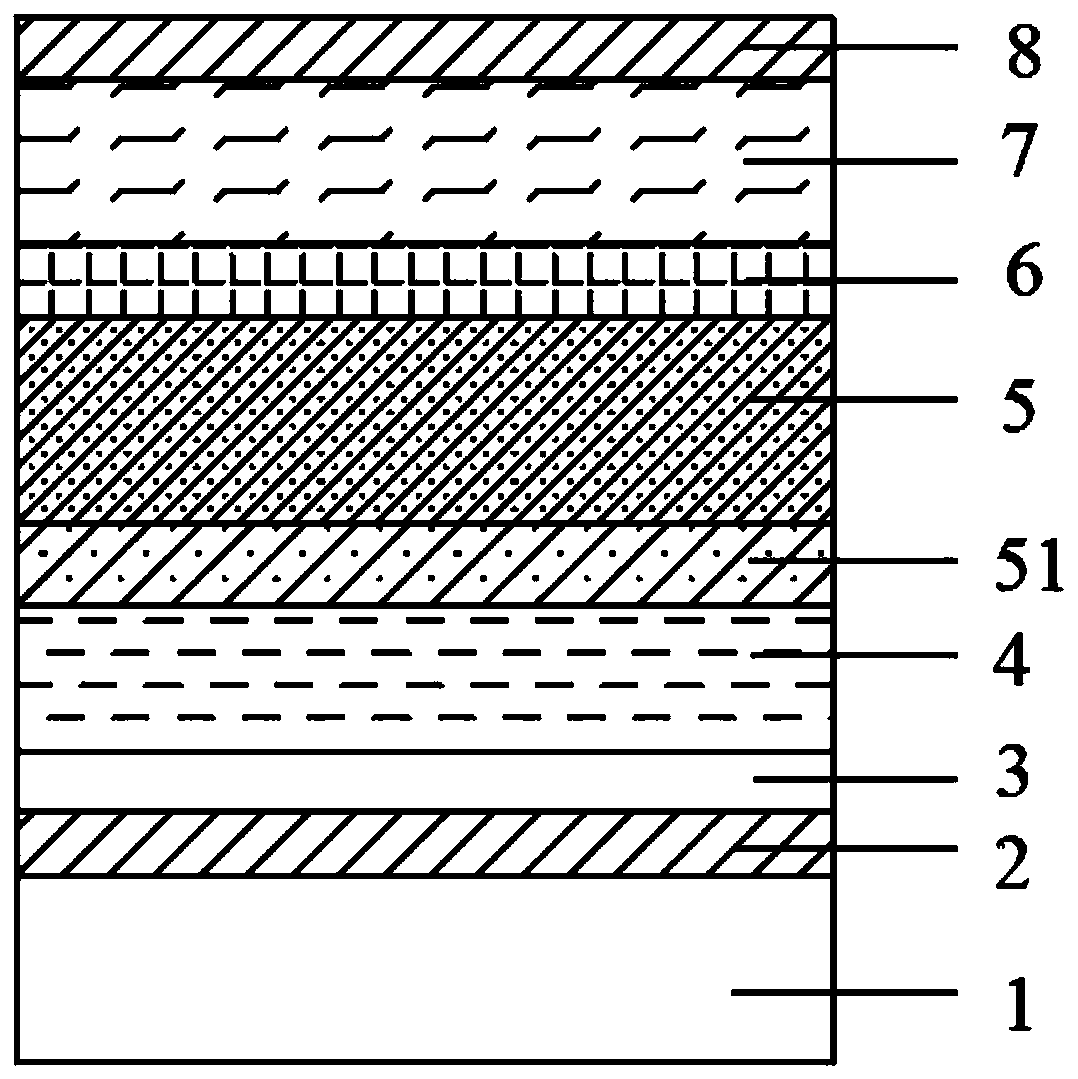

Epitaxial growth method for improving GaN-based light-emitting diode (LED) quantum well structure to improve carrier recombination efficiency

InactiveCN102881788AHigh luminous intensityImprove luminous brightnessSemiconductor devicesLuminous intensityContact layer

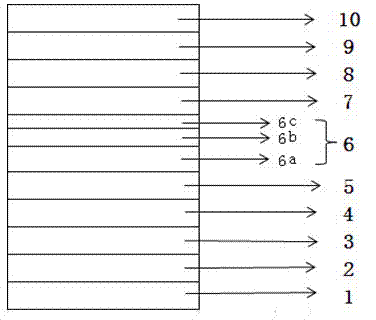

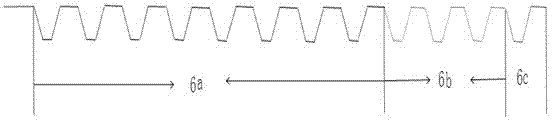

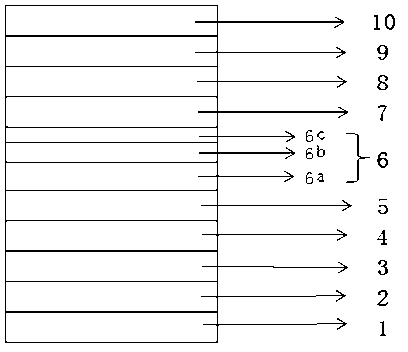

The invention discloses an epitaxial growth method for improving a GaN-based light-emitting diode (LED) quantum well structure to improve carrier recombination efficiency. The method comprises the following steps of: annealing a substrate, and nitriding; growing a low temperature GaN buffer layer; growing a non-doped high temperature GaN buffer layer; growing a Si-doped N-type GaN layer with stable doping density; growing a low temperature shallow quantum well; growing a low temperature multi-quantum well luminous layer, wherein the multi-quantum well luminous layer is divided into three parts which grow under different growth conditions; growing a low temperature P-type GaN layer by taking nitrogen as carrier gas; heating to grow a P-type AlGaN electron barrier layer; growing a high temperature P-type GaN layer; growing a P-type contact layer; and reducing the temperature of a reaction chamber, annealing, and cooling to room temperature. When multi-quantum wells are grown, the position of a PN junction can be regulated in an optimized way, more carriers are captured and recombined, the luminous efficiency is improved, the inner quantum well effect is increased, and a high luminous intensity GaN-based LED is obtained.

Owner:合肥彩虹蓝光科技有限公司

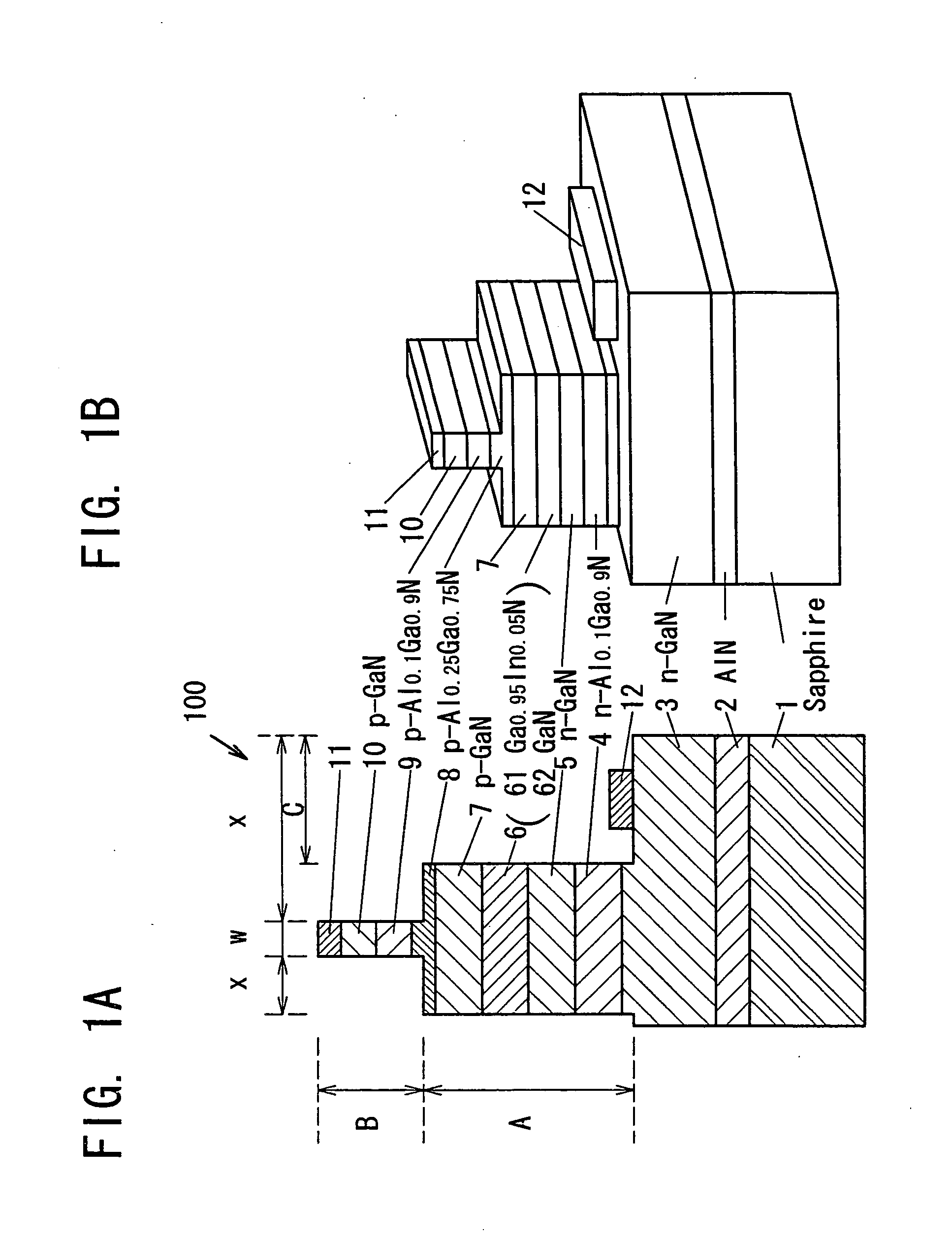

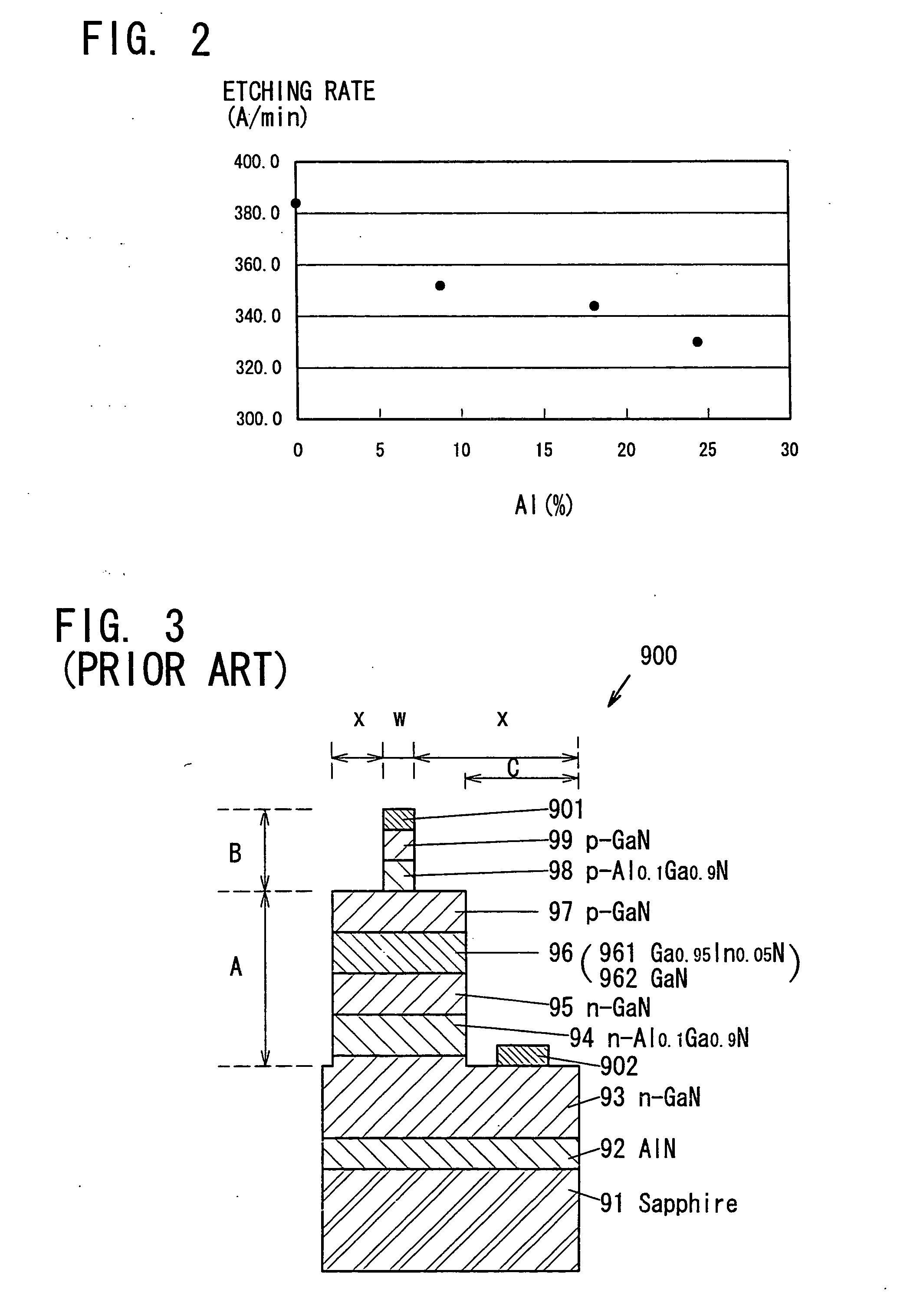

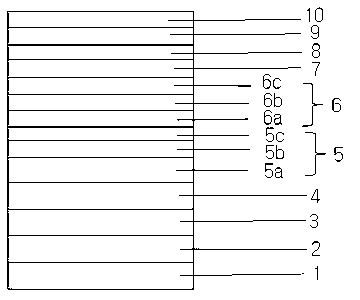

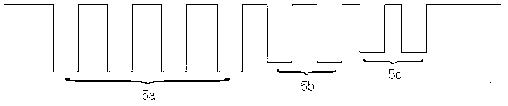

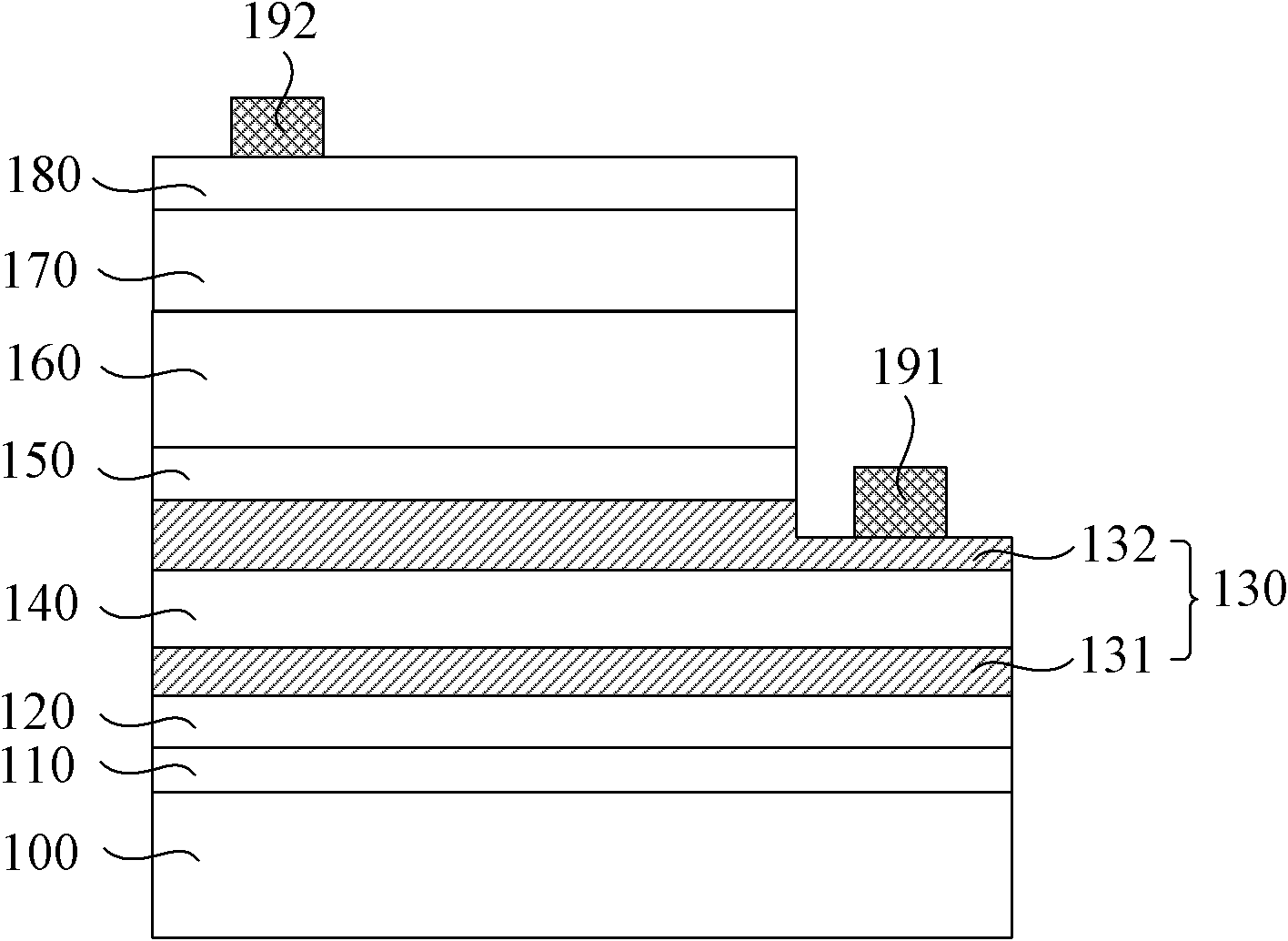

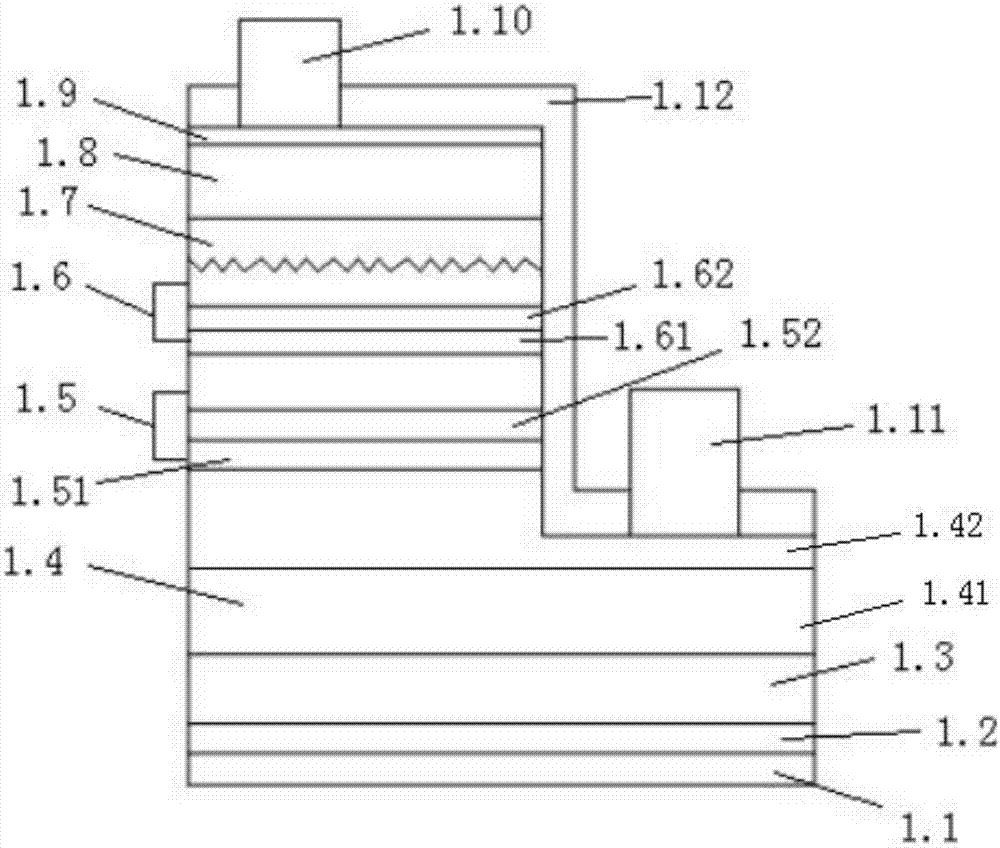

Group III nitride compound semiconductor laser

InactiveUS20050032344A1Thickness is easy to controlEasy to makeOptical wave guidanceLaser detailsContact layerActive layer

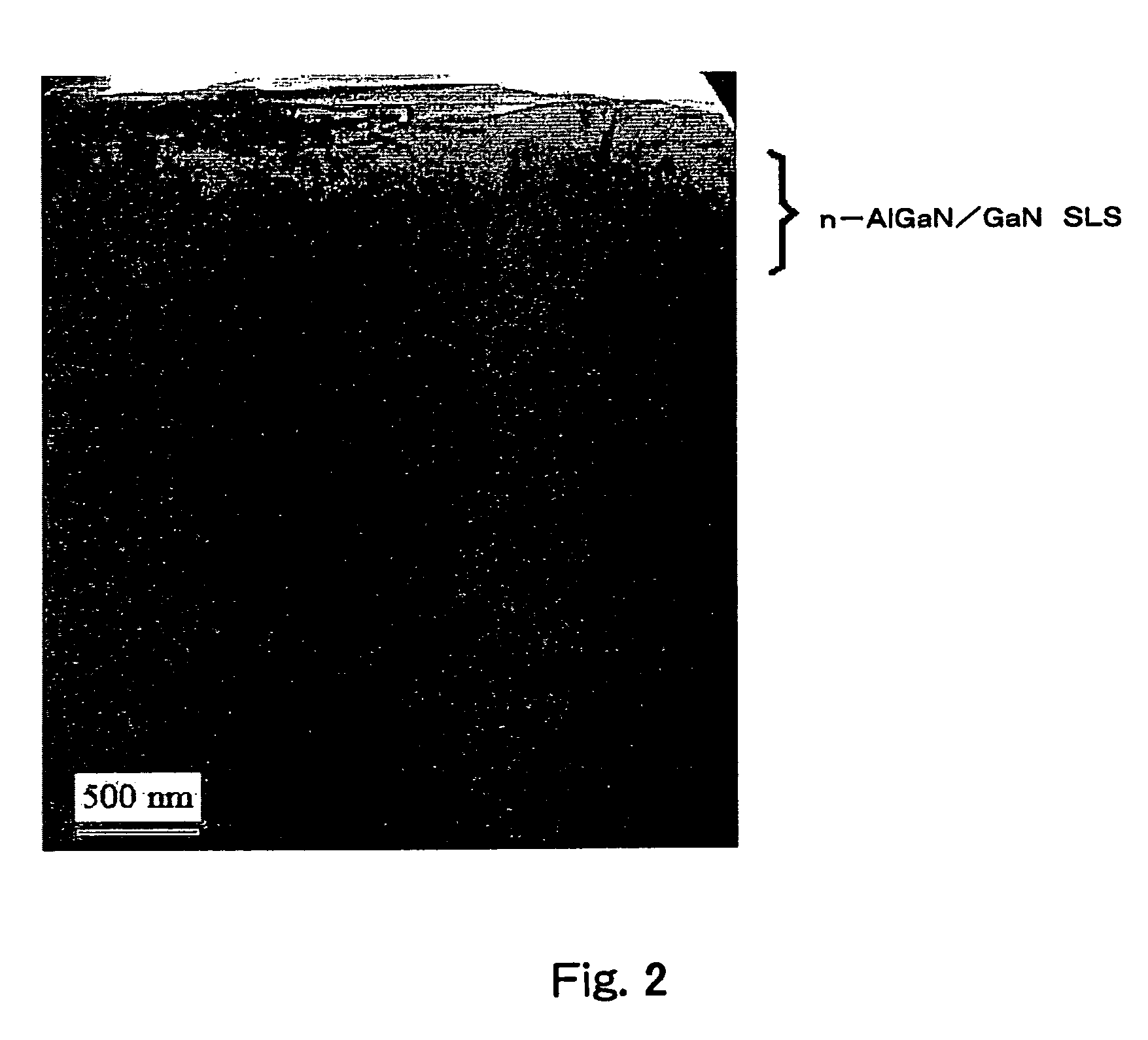

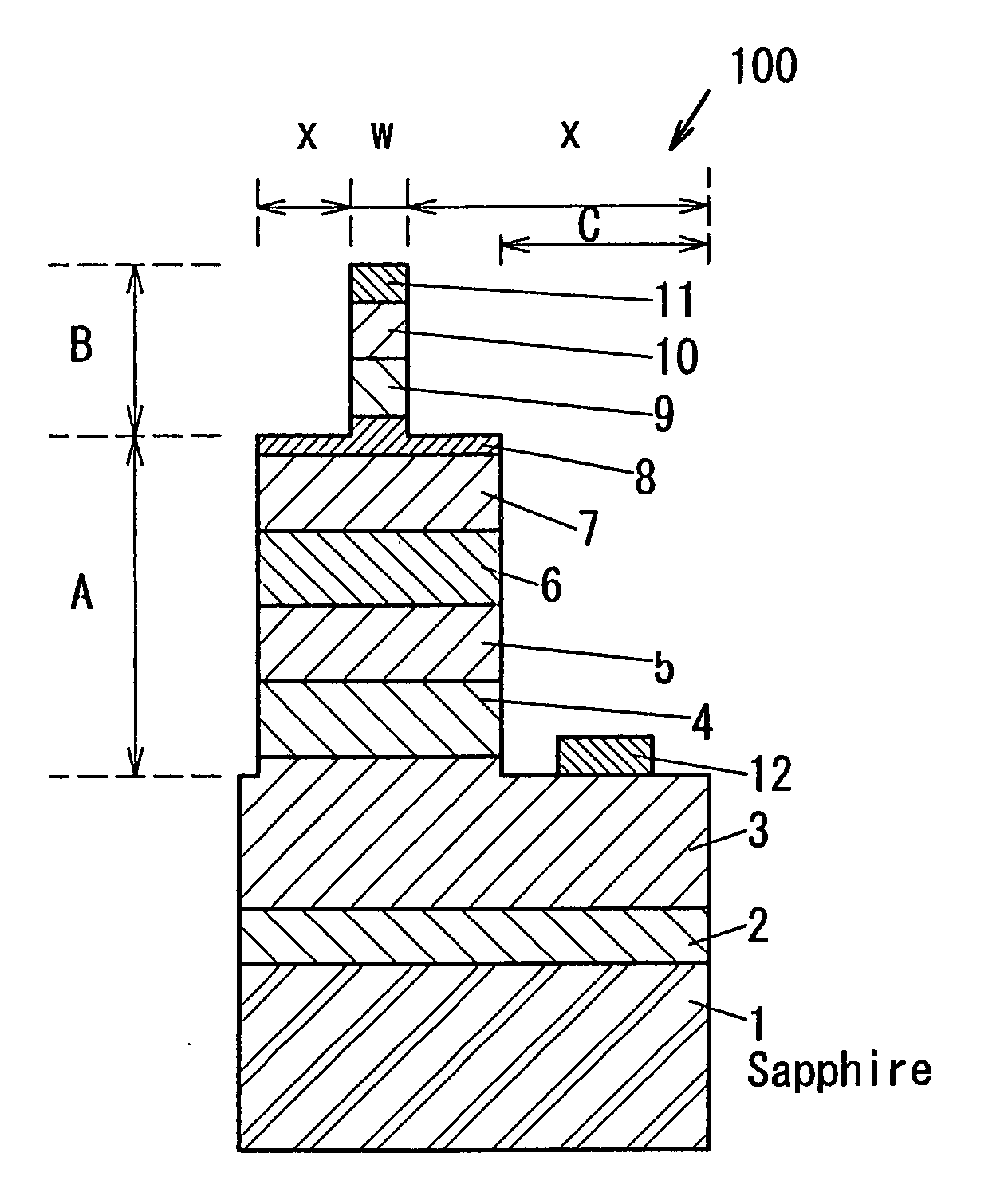

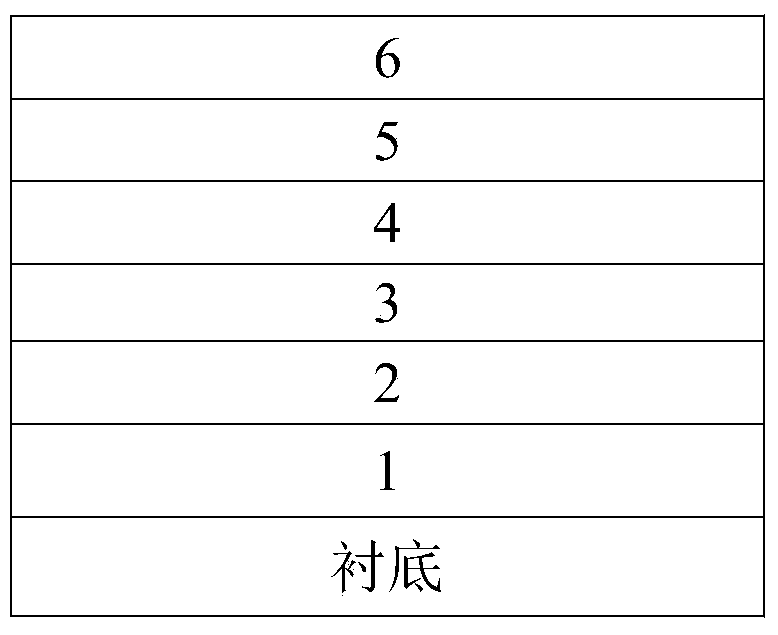

A semiconductor laser comprises a sapphire substrate, an AlN buffer layer, Si-doped GaN n-layer, Si-doped Al0.1Ga0.9N n-cladding layer, Si-doped GaN n-guide layer, an active layer having multiple quantum well (MQW) structure in which about 35 Å in thickness of GaN barrier layer 62 and about 35 Å in thickness of Ga0.95In0.05N well layer 61 are laminated alternately, Mg-doped GaN p-guide layer, Mg-doped Al0.25Ga0.75N p-layer, Mg-doped Al0.1Ga0.9N p-cladding layer, and Mg-doped GaN p-contact layer are formed successively thereon. A ridged hole injection part B which contacts to a ridged laser cavity part A is formed to have the same width as the width w of an Ni electrode. Because the p-layer has a larger aluminum composition, etching rate becomes smaller and that can prevent from damaging the p-guide layer in this etching process.

Owner:TOYODA GOSEI CO LTD

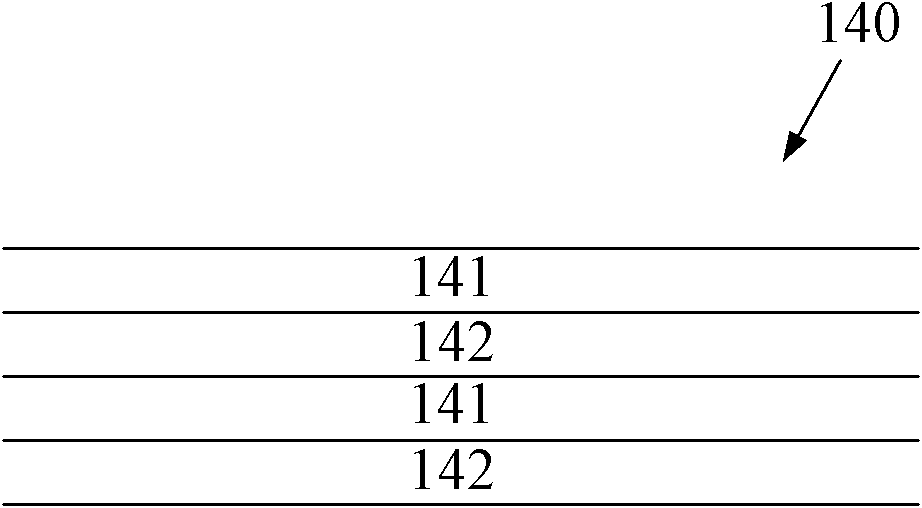

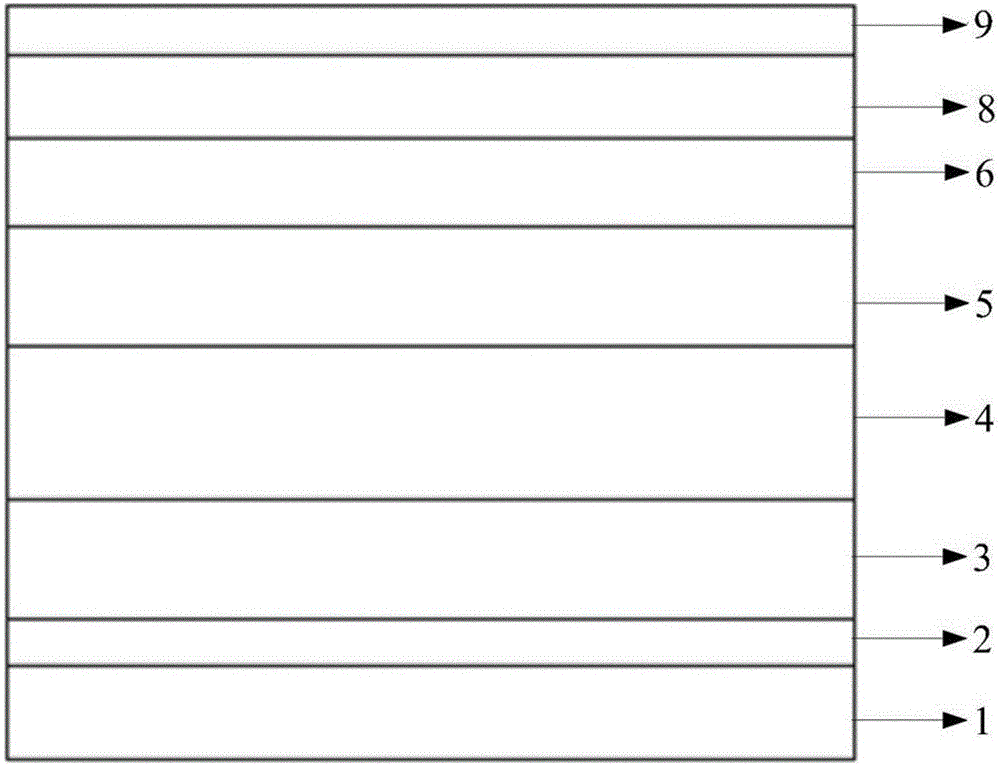

Multi-quantum well layer growing method capable of improving LED luminance

ActiveCN103022285AImprove luminous efficiencyReduce defect densityPolycrystalline material growthSingle crystal growth detailsIndiumQuantum well

The invention relates to a multi-quantum well layer growing method capable of improving LED luminance. An LED epitaxial wafer structurally comprises a substrate layer, a low-temperature GaN buffer layer, an undoped high-temperature GaN buffer layer, a Si-doped n-type GaN layer, a light-emitting layer multi-quantum well, a low-temperature p-type GaN layer, a p-type AlGaN electron barrier layer, a high-temperature p-type GaN layer and a p-type GaN contact layer sequentially from bottom to top, the light-emitting layer multi-quantum well comprises a low-temperature shallow quantum well and a low-temperature multi-quantum well light-emitting layer sequentially from bottom to top, the low-temperature shallow quantum well comprises three shallow quantum well portions, well layers of the three shallow quantum well portions grow in a manner that indium content is gradually decreased, and barrier layers grow in a manner that content of TMAl (trimethylaluminum) fed to the barrier layers is gradually decreased. By the method, the LED luminance is improved by improving a shallow quantum well growth structure in the GaN-based LED quantum well.

Owner:宁波安芯美半导体有限公司

Gallium nitride compound semiconductor device and manufacturing method

A light-emitting element using GaN. On a substrate (10), formed are an SiN buffer layer (12), a GaN buffer layer (14), an undoped GaN layer (16), an Si-doped n-GaN layer (18), an SLS layer (20), an undoped GaN layer (22), an MQW light-emitting layer (24), an SLS layer (26), and a p-GaN layer (28), forming a p electrode (30) and an n electrode (32). The MQW light-emitting layer (24) has a structure in which InGaN well layers and AlGaN barrier layers are alternated. The Al content ratios of the SLS layers (20, and 26) are more than 5% and less than 24%. The In content ratio of the well layer in the MQW light-emitting layer (24) is more than 3% and less than 20%. The Al content ratio of the barrier layer is more than 1% and less than 30%. By adjusting the content ratio and film thickness of each layer to a desired value, the light luminous efficiency for wavelength of less than 400 nm is improved.

Owner:NITRIDE SEMICON

Strained semiconductor-on-insulator (sSOI) by a simox method

ActiveUS20070164356A1Reduce manufacturing costAvoiding wafer bondingSolid-state devicesSemiconductor/solid-state device manufacturingOxygen ionsSemiconductor

A strained (tensile or compressive) semiconductor-on-insulator material is provided in which a single semiconductor wafer and a separation by ion implantation of oxygen process are used. The separation by ion implantation of oxygen process, which includes oxygen ion implantation and annealing creates, a buried oxide layer within the material that is located beneath the strained semiconductor layer. In some embodiments, a graded semiconductor buffer layer is located beneath the buried oxide layer, while in other a doped semiconductor layer including Si doped with at least one of B or C is located beneath the buried oxide layer.

Owner:TAIWAN SEMICON MFG CO LTD

An InGaN-based multi-quantum well structure and a method for preparing the same

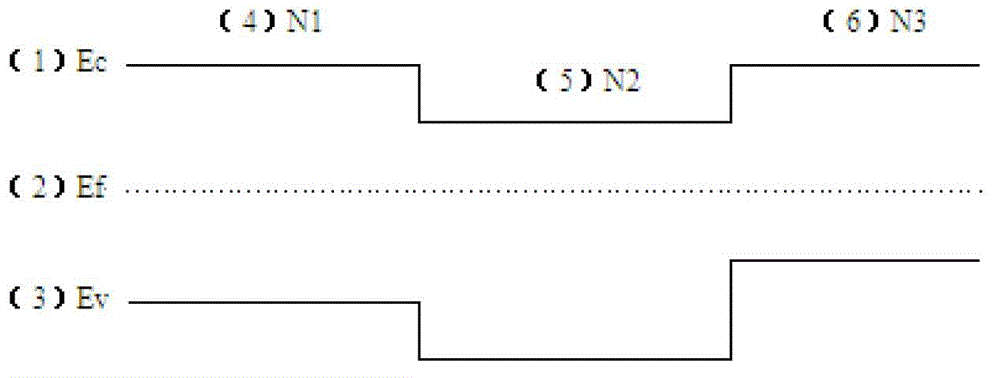

ActiveCN103746052AImprove luminous efficiencyStress reliefSemiconductor devicesElectron holeQuantum efficiency

The invention relates to an InGaN-based multi-quantum well structure. Multilayer structures in which In constituent gradual increase quantum well layers and Si-doped GaN barrier layers are arranged alternately are successively grown on a GaN barrier layer. Then, along a growth direction, multiplayer structures in which fixed-In-constituent quantum well layers, In constituent gradual decrease quantum well layers, and GaN barrier layers are arranged periodically are further grown. Therefore, the InGaN-based multi-quantum well structure may effectively alleviate stress at the interface between a barrier and a well and curving of an energy band, control a radiation recombination area of electrons and electron holes, increase the injection efficiency and the radiation recombination efficiency so as to be beneficial to further acquisition of a GaN-based LED structure with good crystal quality, high internal quantum efficiency, and high light-emitting efficiency. In addition, the light-emitting peak of the GaN-based LED structure has a low full width at half maximum and uniform wavelengths of emitted light.

Owner:TAIYUAN UNIV OF TECH

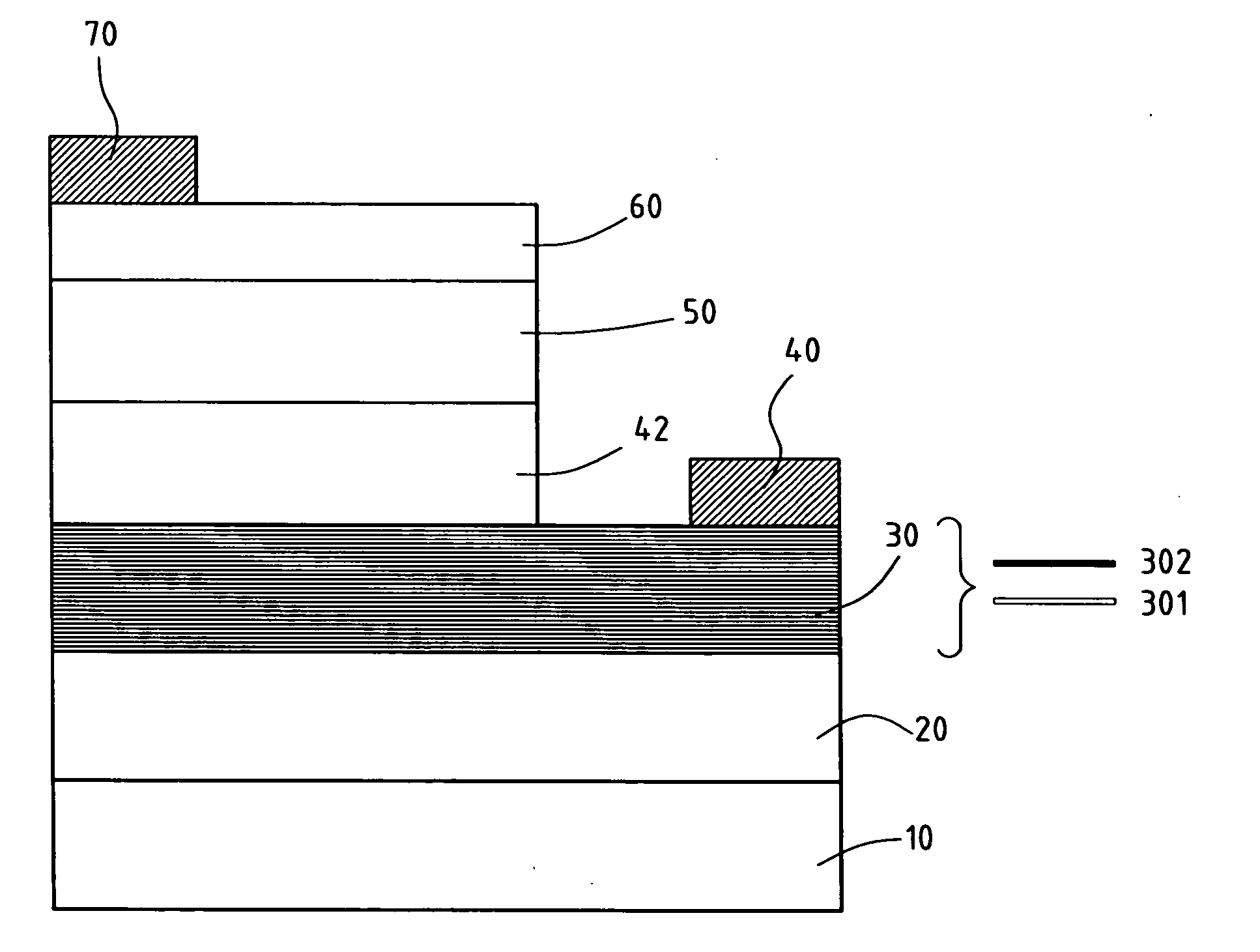

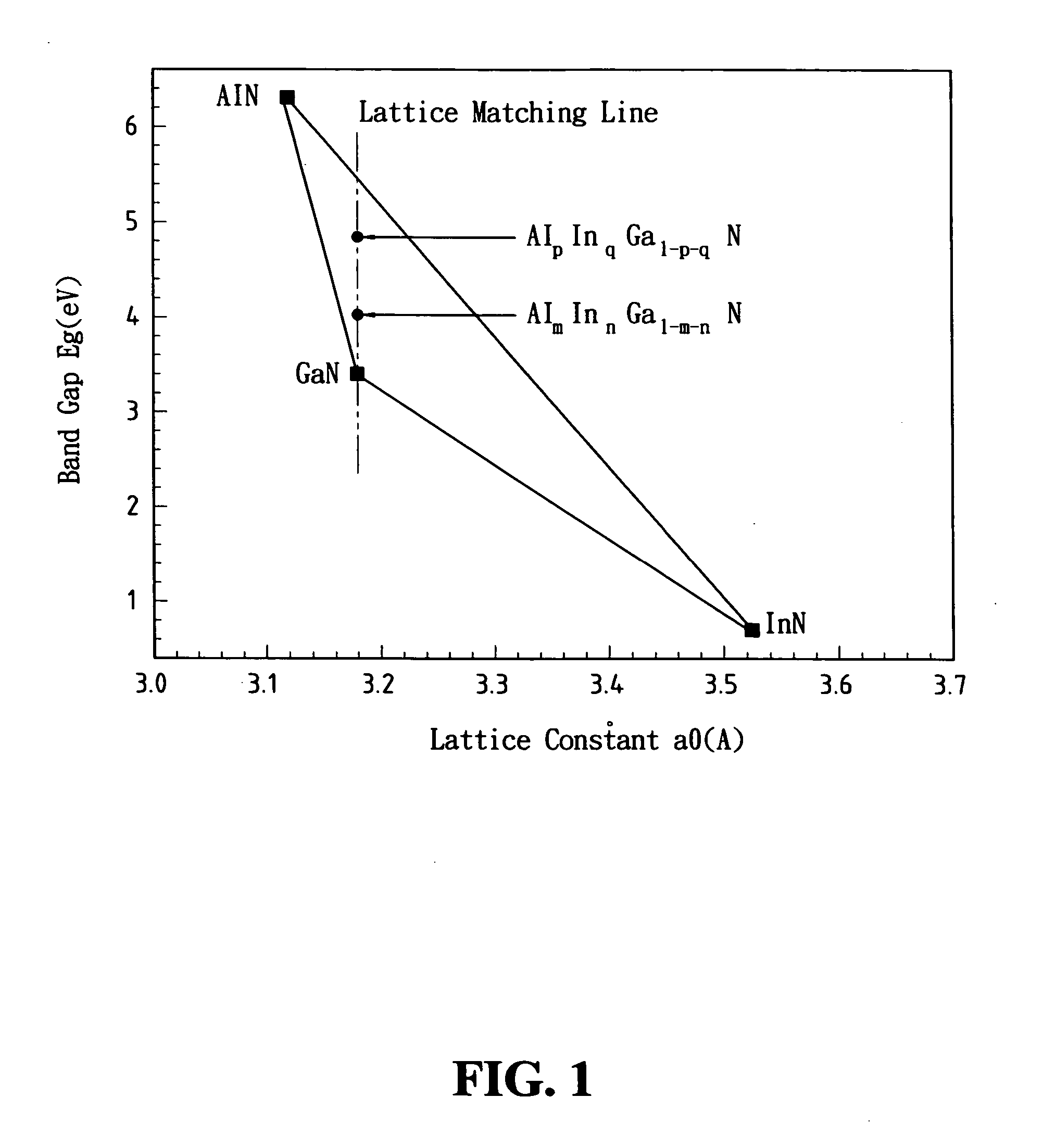

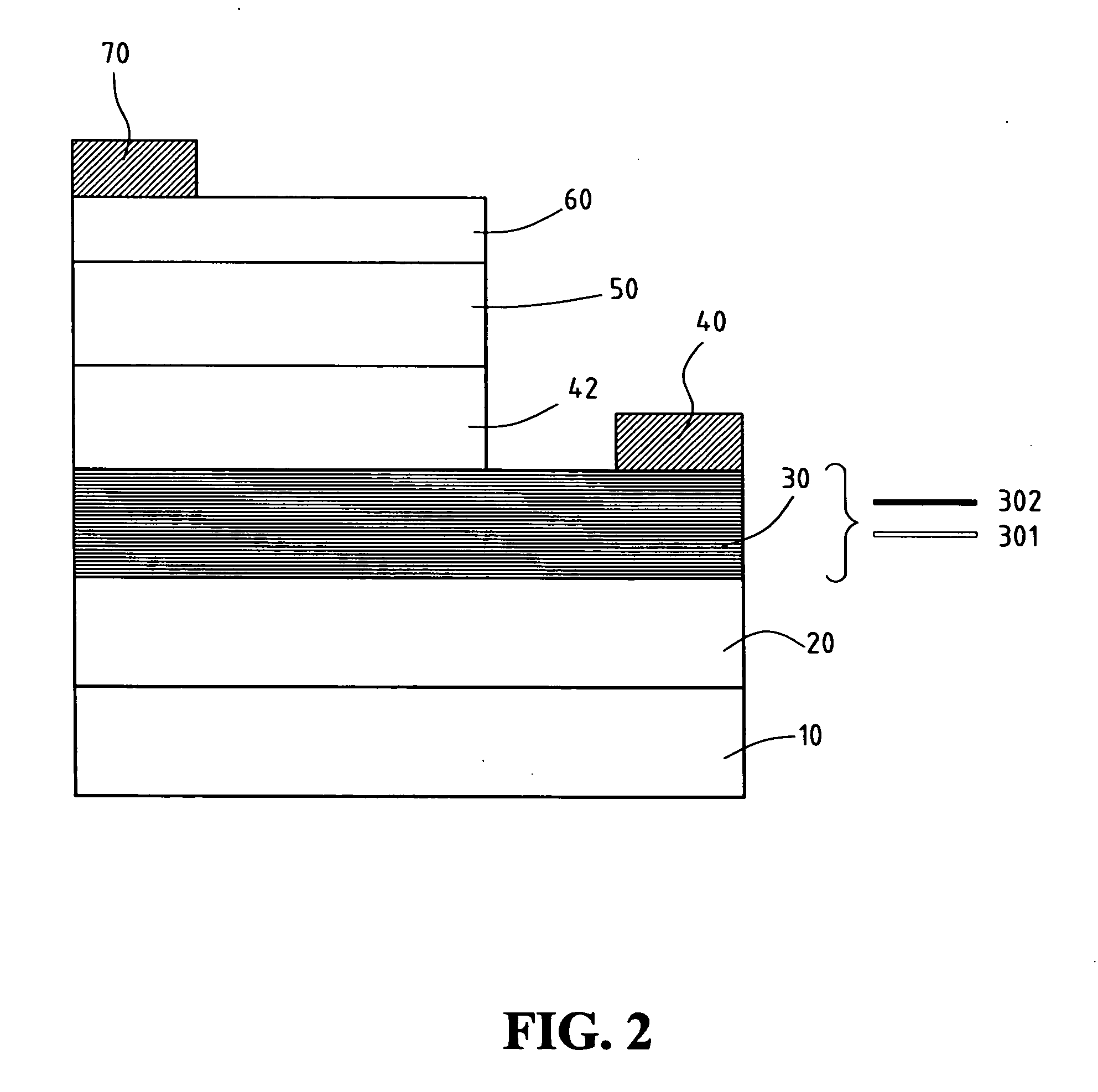

Gallium-nitride based multi-quantum well light-emitting diode n-type contact layer structure

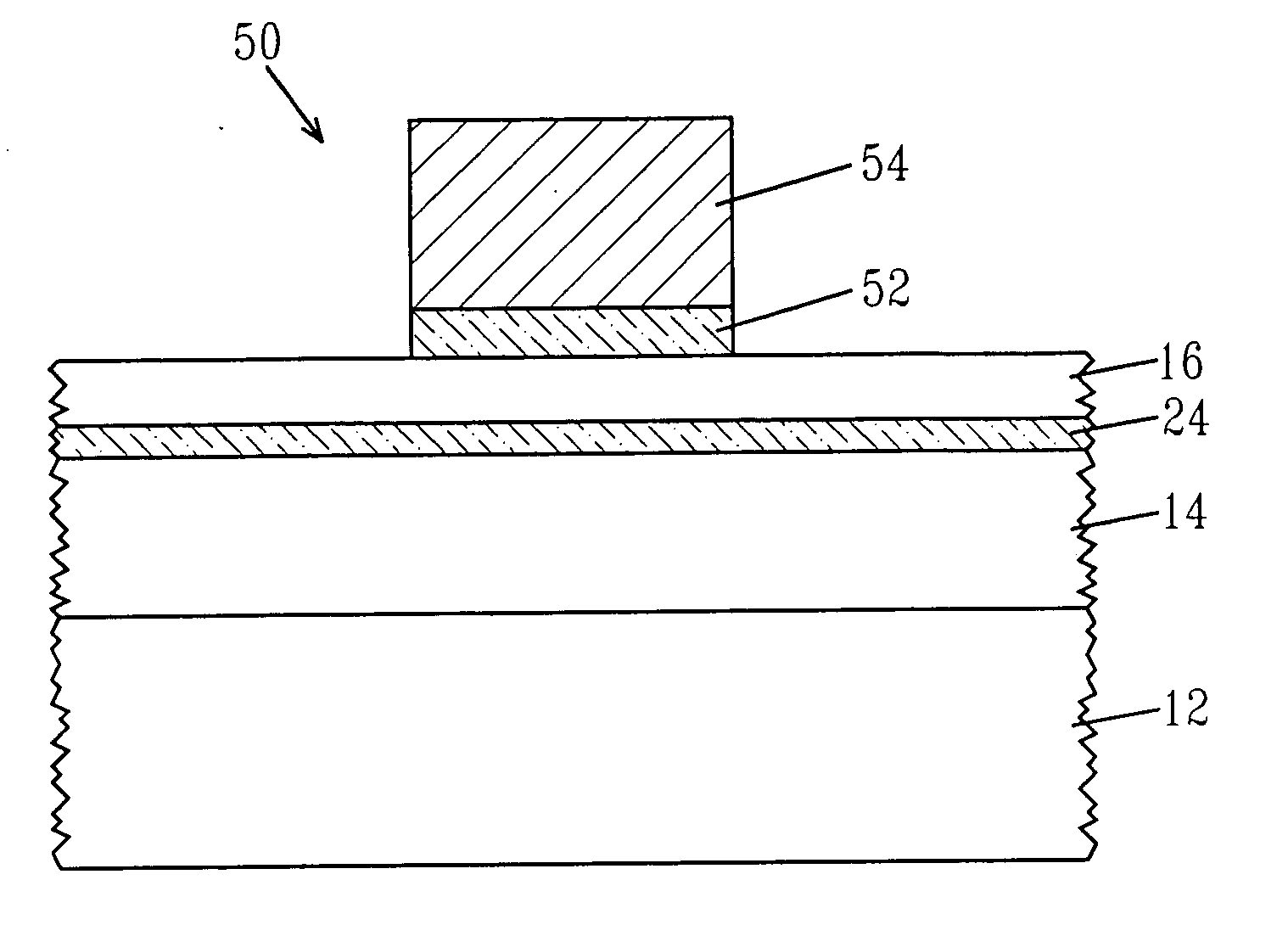

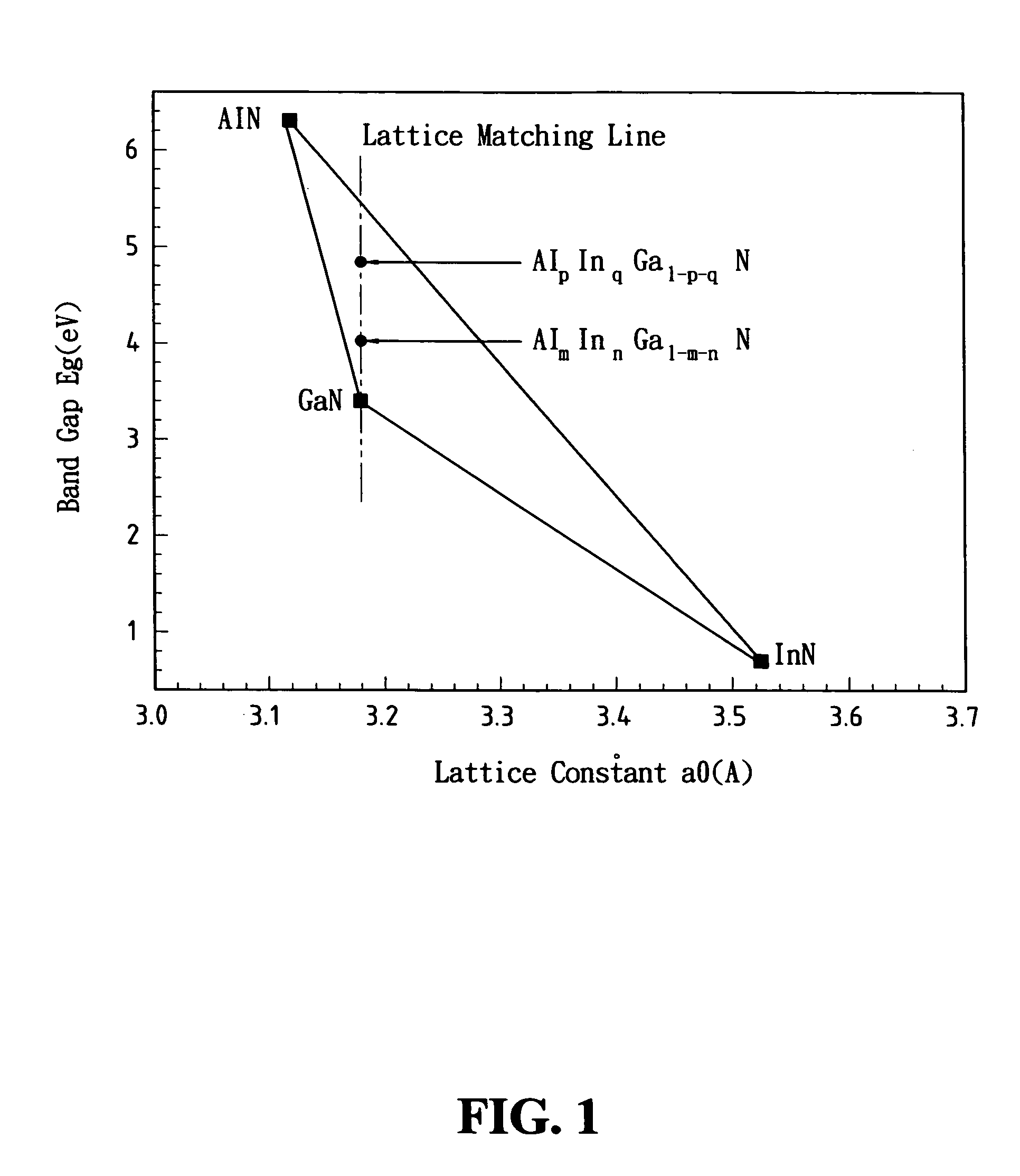

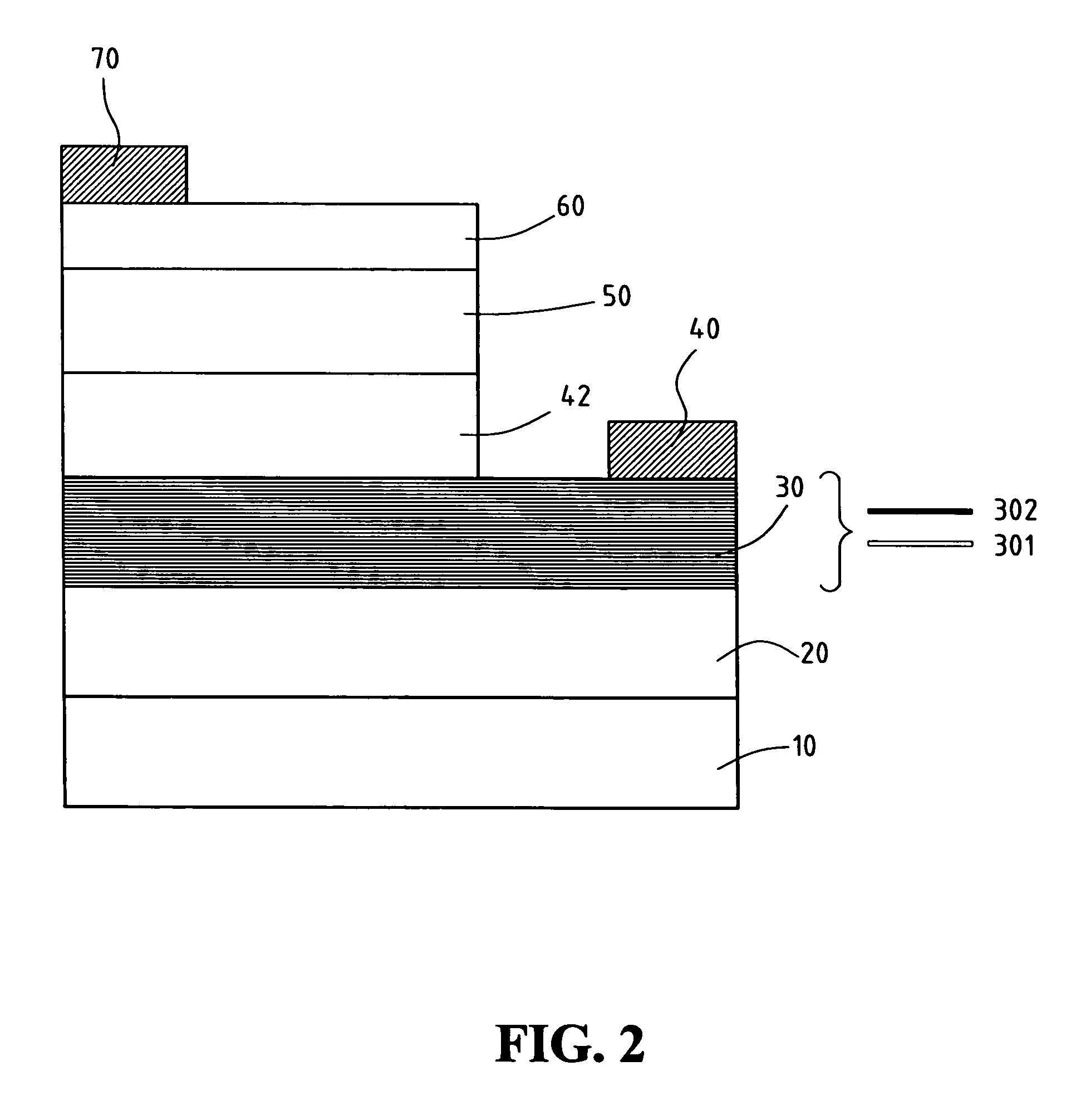

ActiveUS20060081861A1Increase the doping concentrationLow resistivitySemiconductor/solid-state device manufacturingNanoopticsGalliumContact layer

A structure for the n-type contact layer in the GaN-based MQW LEDs is provided. Instead of using Si-doped GaN as commonly found in conventional GaN-based MQW LEDs, the n-type contact layer provided by the present invention achieves high doping density (>1×1019 cm−3) and low resistivity through a superlattice structure combining two types of materials, AlmInnGa1-m-nN and AlpInqGa1-p-qN (0≦m, n<1, 0<p, q<1, p+q≦1, m<p), each having its specific composition and doping density. In addition, by controlling the composition of Al, In, and Ga in the two materials, the n-type contact layer would have a compatible lattice constant with the substrate and the epitaxial structure of the GaN-based MQW LEDs. This n-type contact layer, therefore, would not chap from the heavy Si doping, have a superior quality, and reduce the difficulties of forming n-type ohmic contact electrode. In turn, the GaN-based MQW LEDs would require a lower operation voltage.

Owner:LUMENS +1

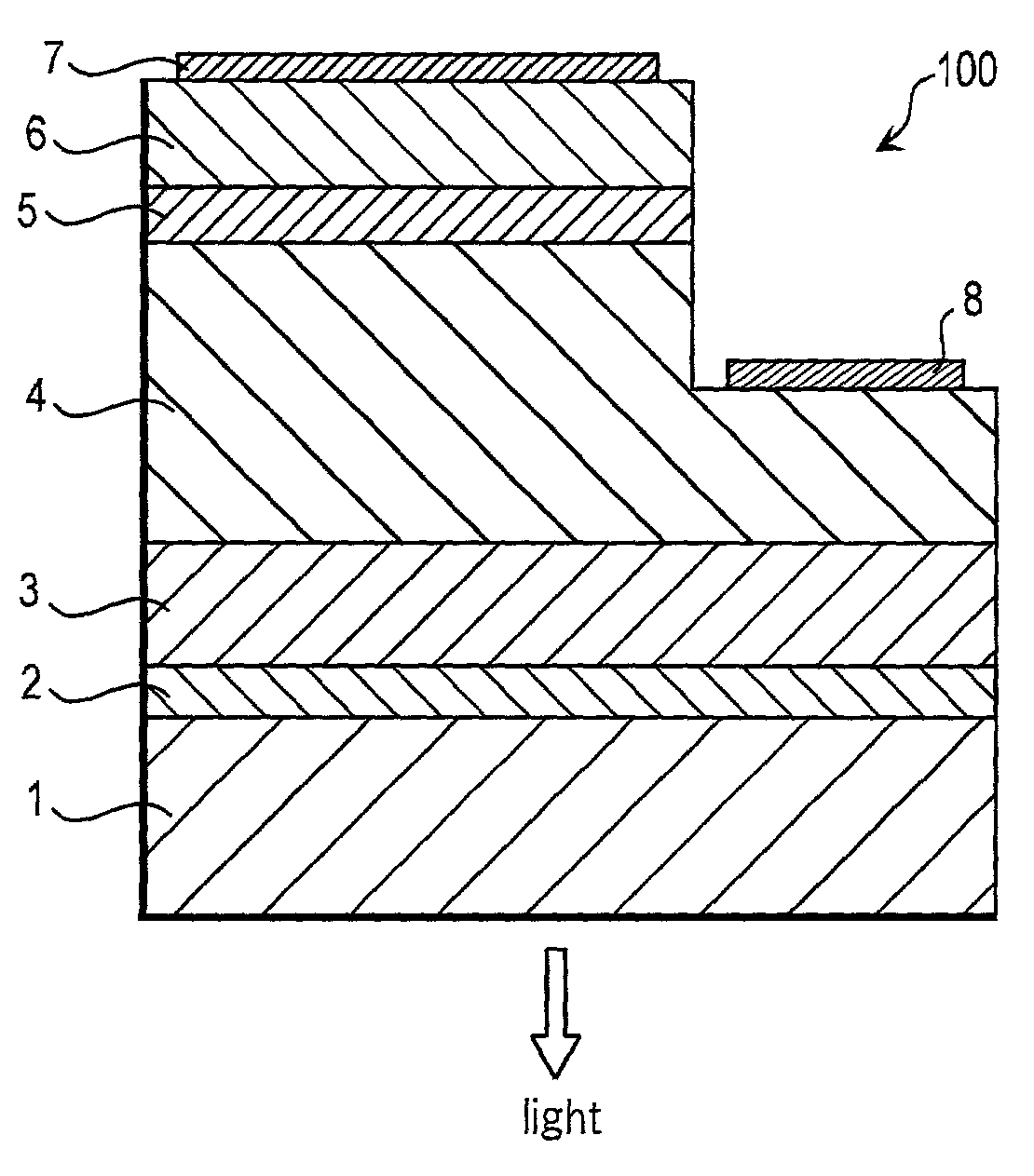

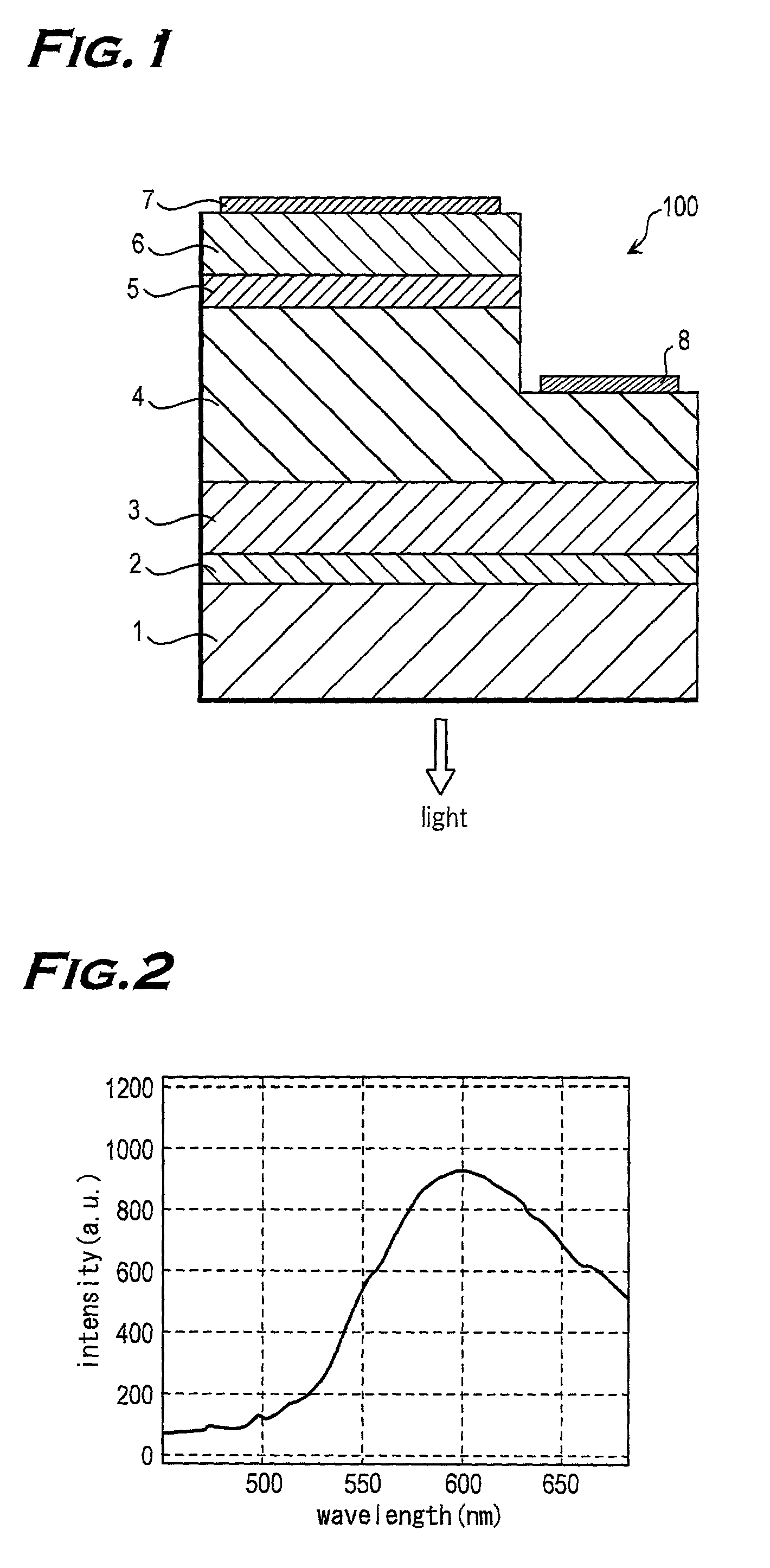

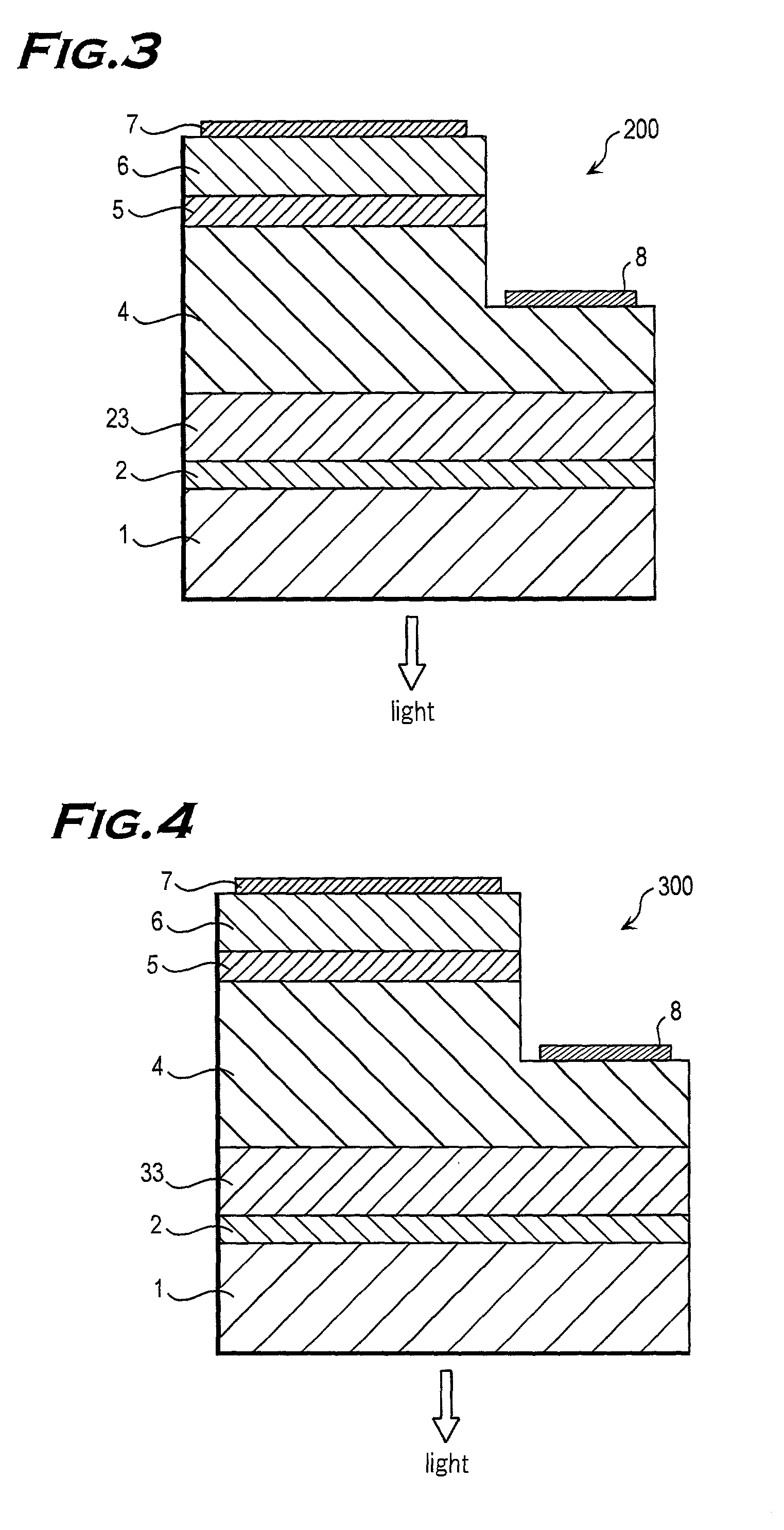

Semiconductor light-emitting device and methods for fabricating the same

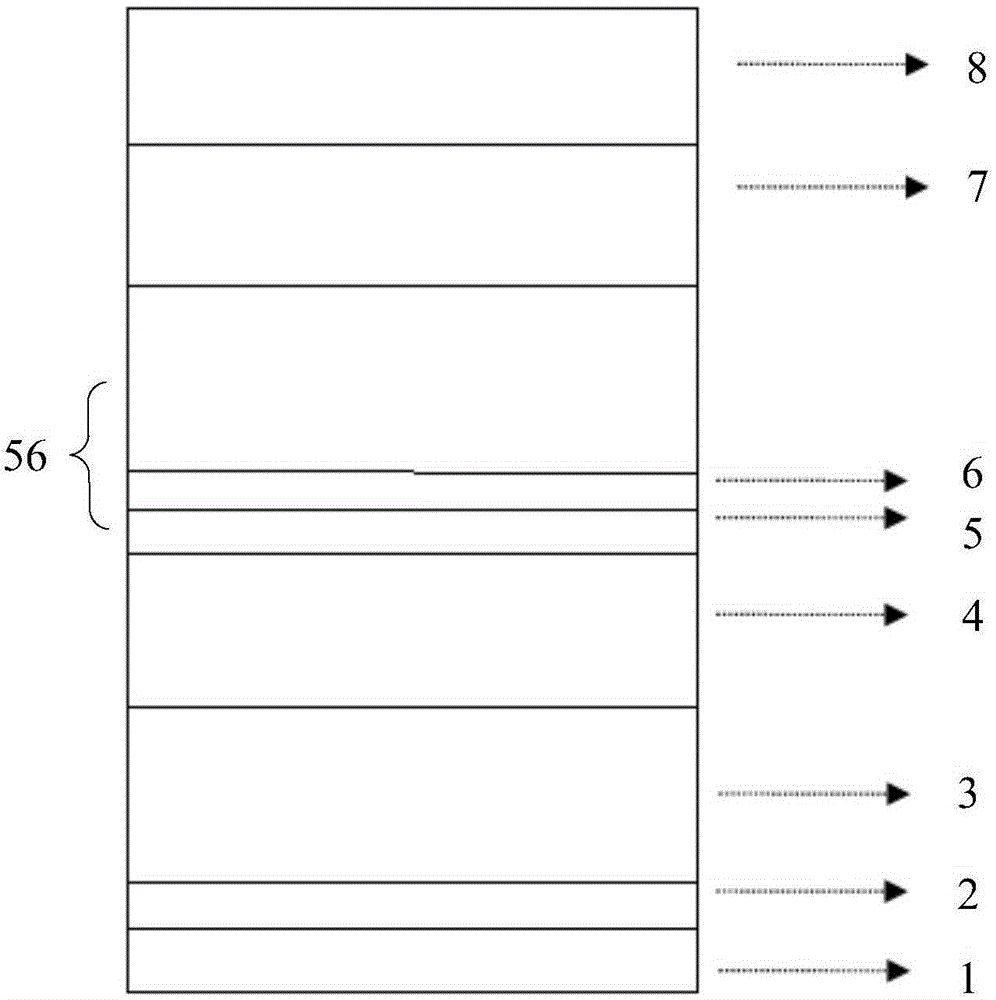

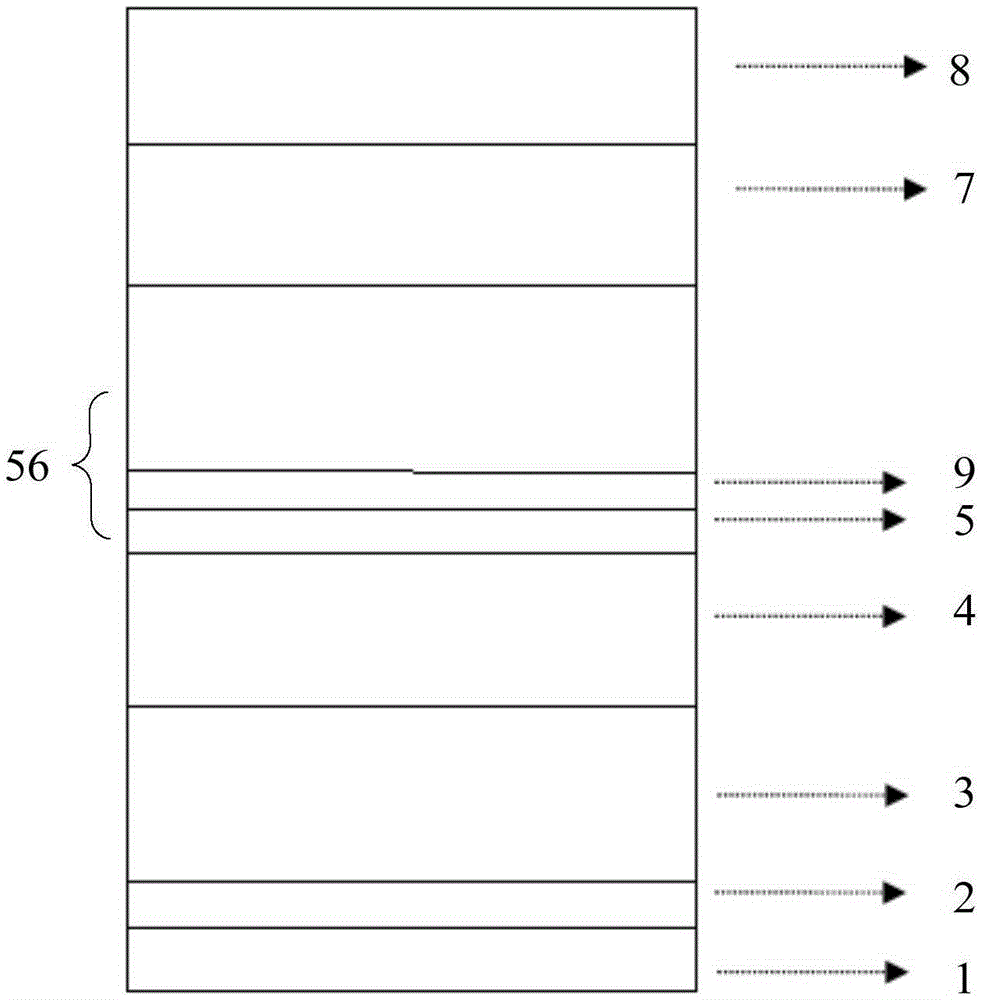

InactiveUS20030080343A1Improve distributionGood fluorescence propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationCrystallinity

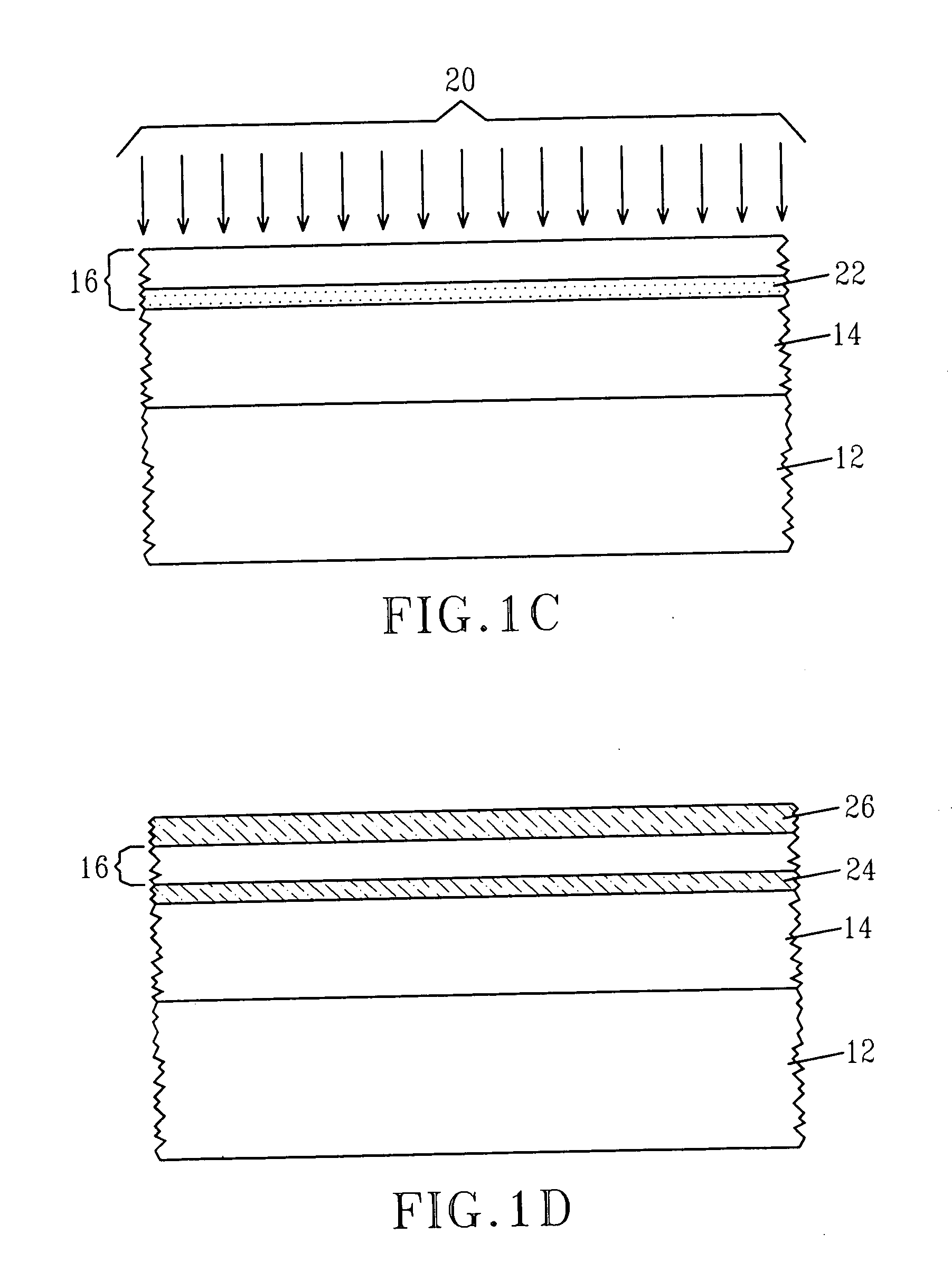

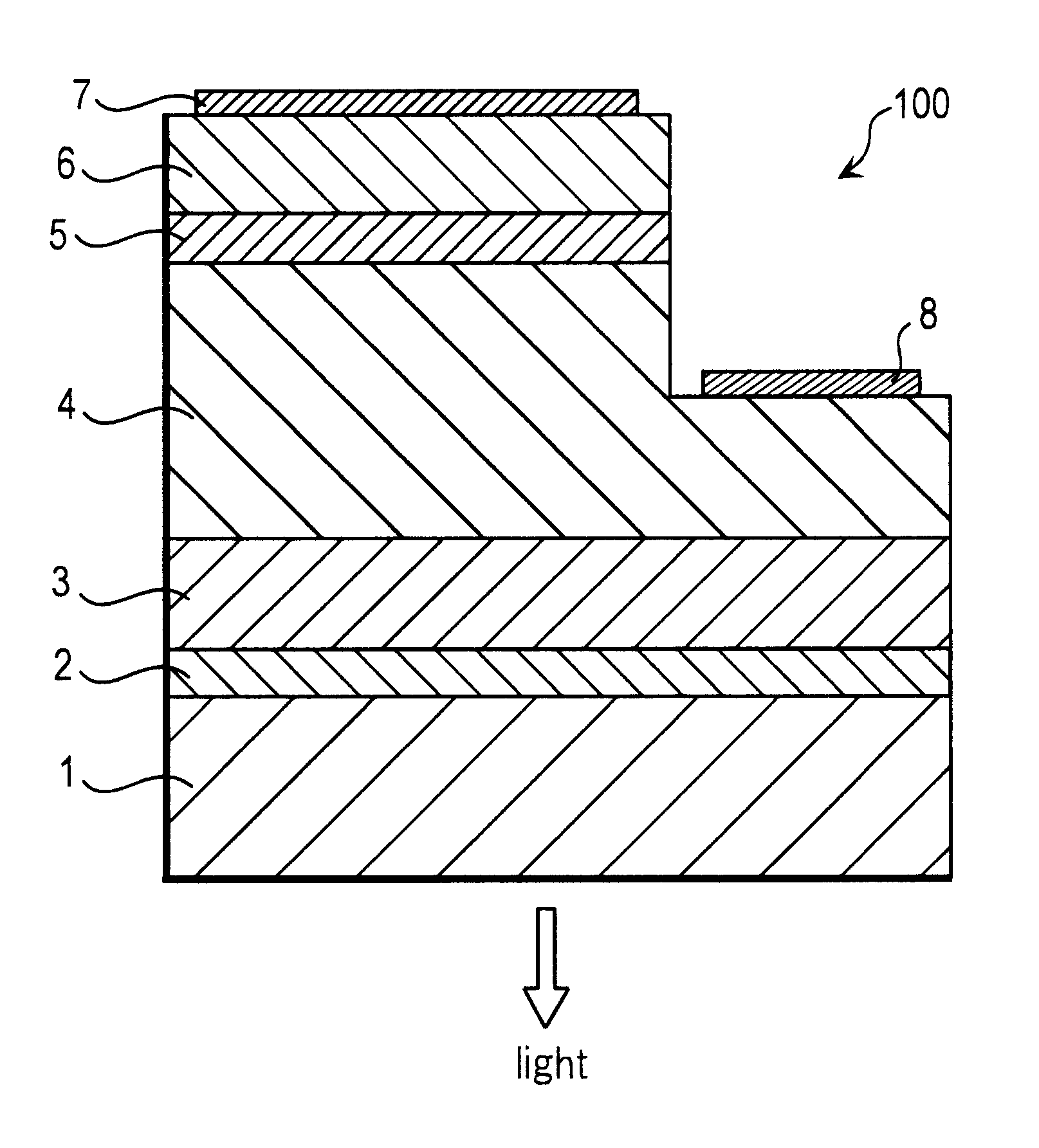

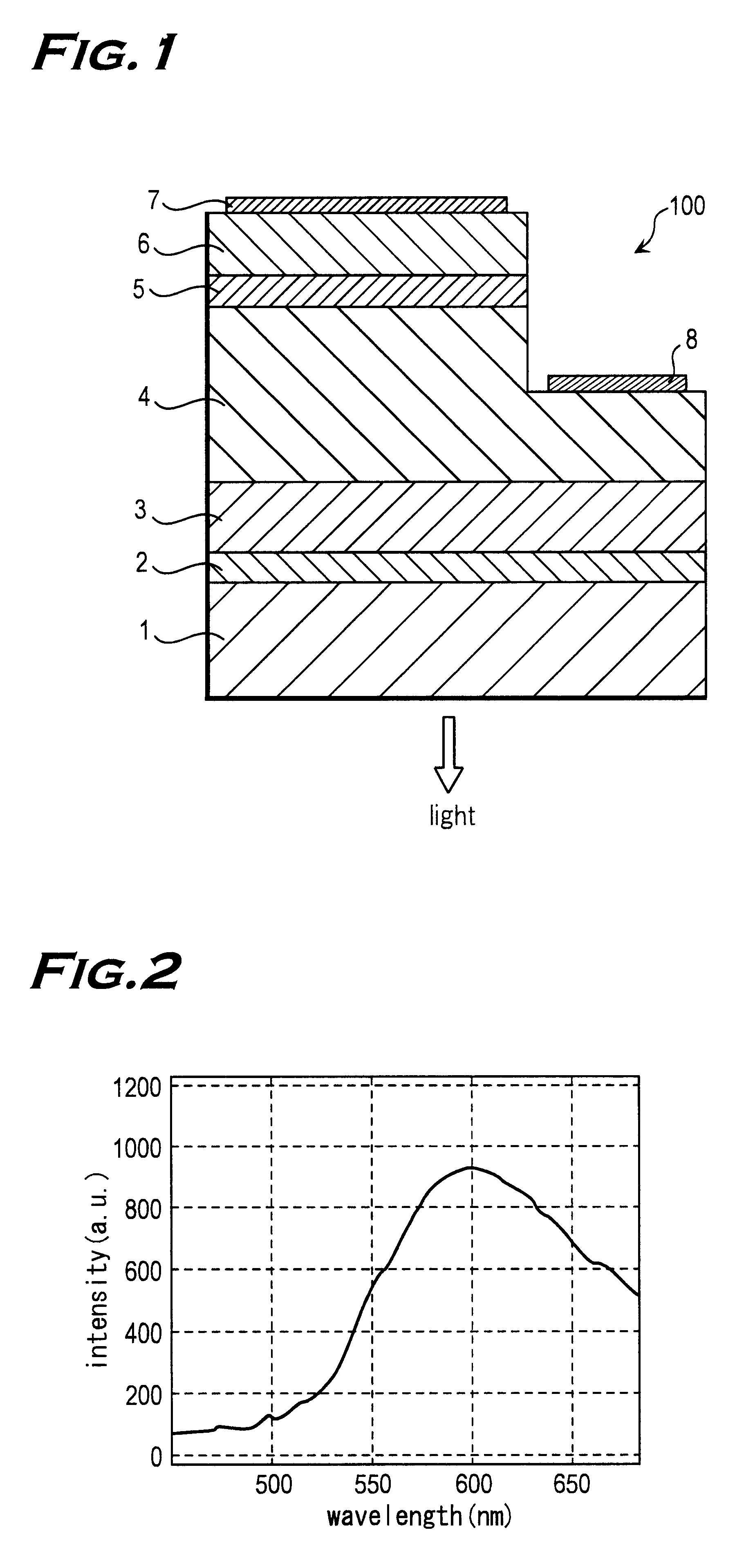

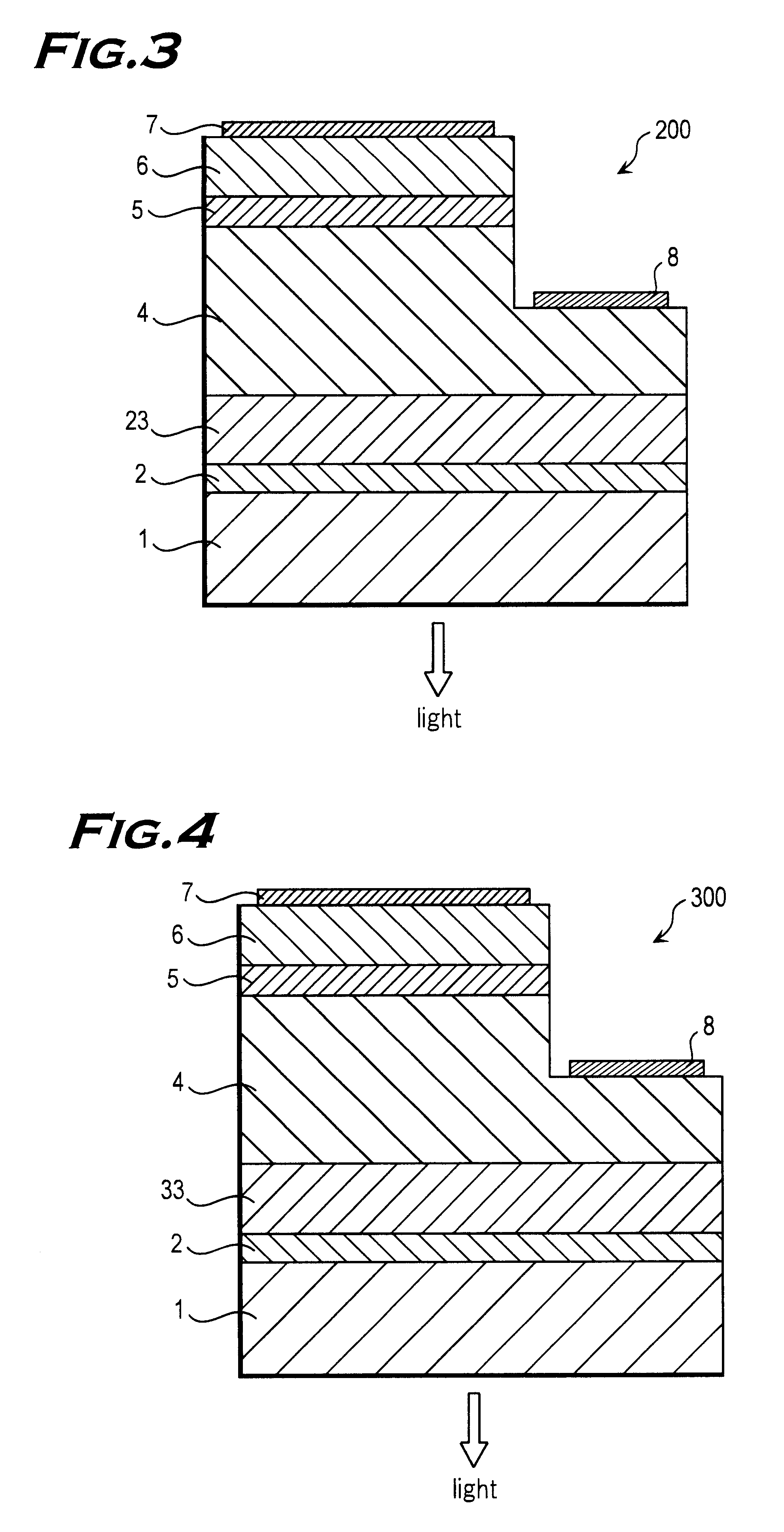

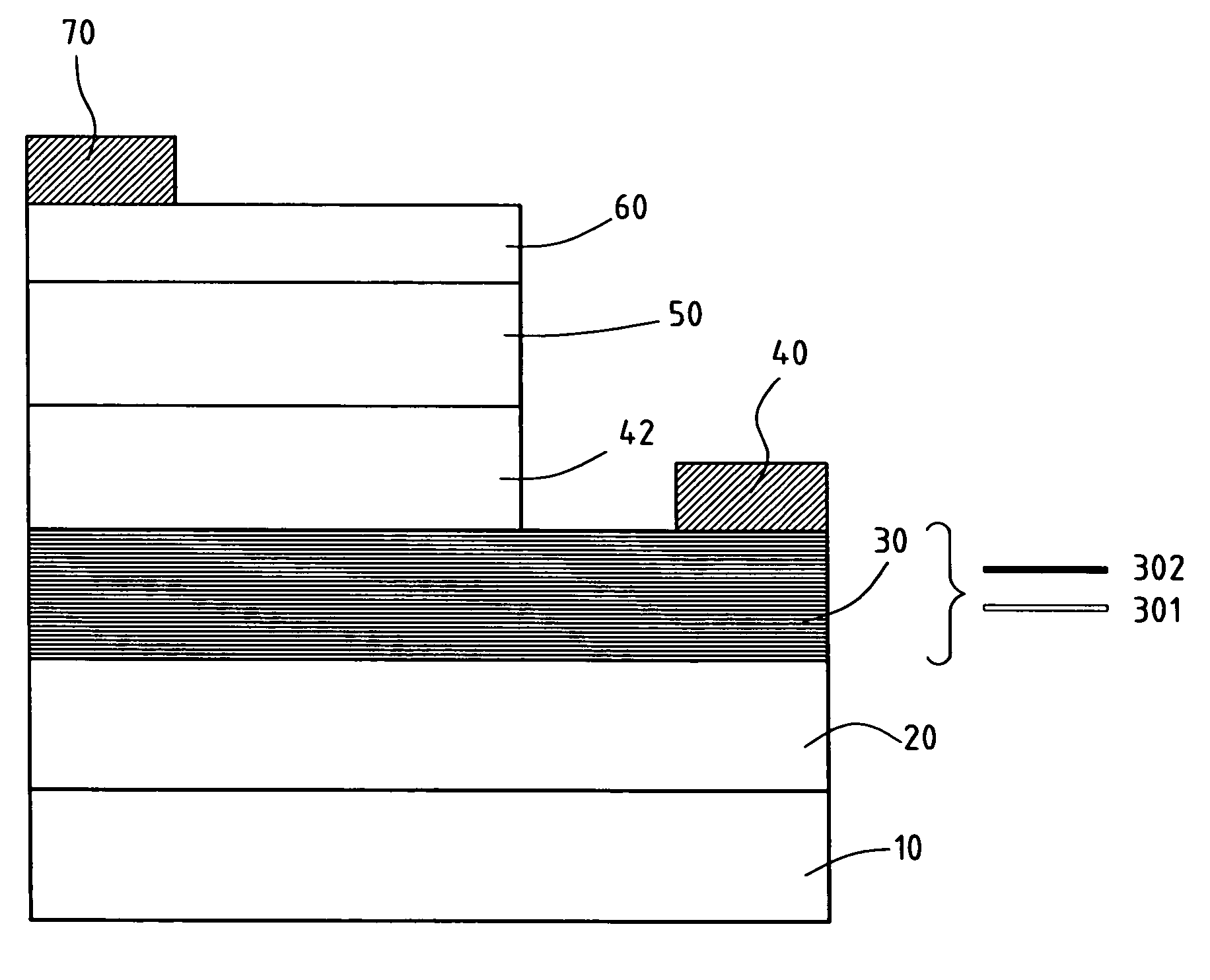

This invention provides a light-emitting diode which is capable of extracting white light, manufactured readily and highly reliable. The light-emitting diode is fabricated by laminating a buffer layer 2, an Si (silicon)-doped GaN fluorescent layer 3, an n-GaN layer 4, an MQW emission layer 5 and a p-GaN layer 6 on a sapphire substrate 1 in this order. The Si-doped GaN fluorescent layer 3 is doped higher concentration of Si (silicon) than a conventional Si-doped GaN layer with sufficient good crystallinity. Such a Si-doped GaN fluorescent layer is excited by blue light generated in the MQW emission layer and emits yellow light. The yellow light is the complement for the blue light generated in the MQW emission layer. White light can be obtained by blending and extracting both of blue light and yellow light.

Owner:EPISTAR CORP

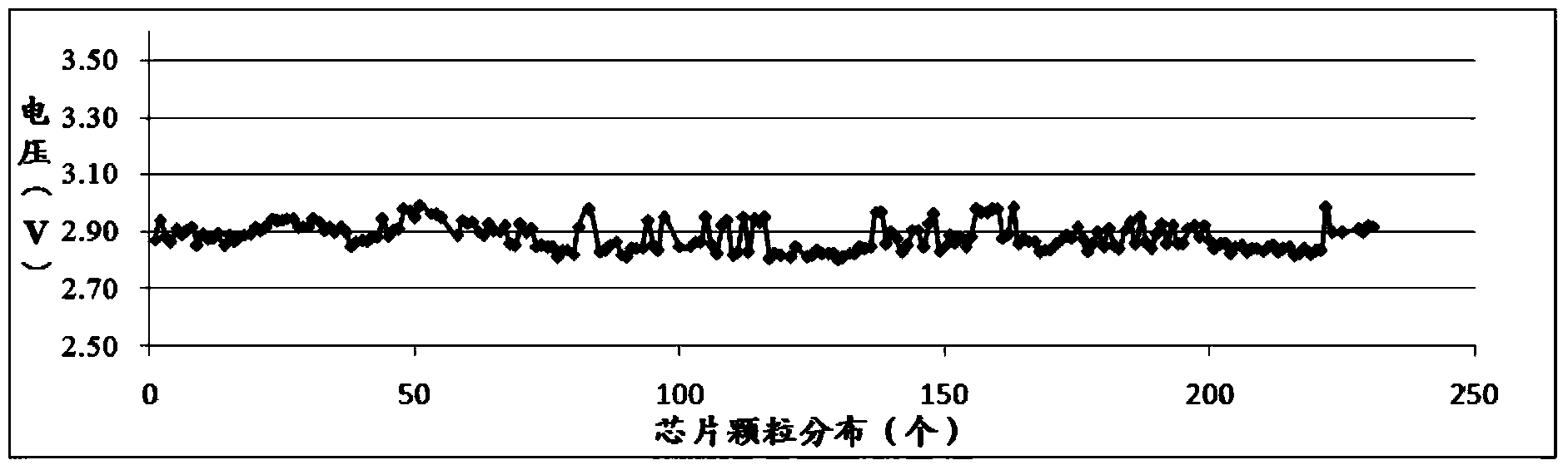

LED epitaxy structure and preparation method thereof

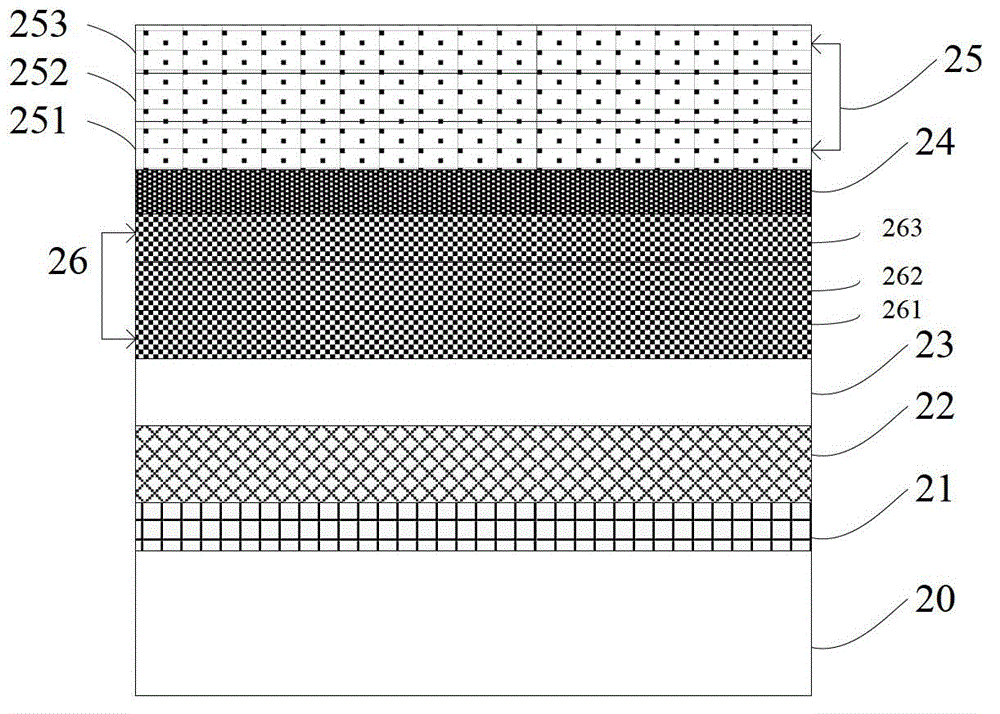

ActiveCN103531680AReduce the driving voltageIncrease concentrationSemiconductor devicesCapacitanceHigh density

The invention relates to an LED (light-emitting diode) epitaxy structure. An N-type GaN layer adopts a peridoic gradient doped structure; Si doped GaN layers and undoped GaN layers are alternately arranged; electrons can be gathered in the undoped GaN layers to form high-density two-dimensional electron gas, so that the concentration and mobility of a carrier are effectively improved; a more important fact is that a multijunction capacitance structure is formed between a U-shaped superlattice layer on a multiple quantum well layer and the N-type GaN layer; the transverse expansion ability of the carrier can be effectively improved; the distribution area of current flowing into the multiple quantum well layer is enlarged; and LED driving voltage is effectively reduced. The invention further relates to a preparation method of the LED epitaxy structure. The N-type GaN layer is simple in doped structure and small in layer number; the superlattice layer adopts an undoped structure; a technology is simple; and the manufacturing cost is low.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

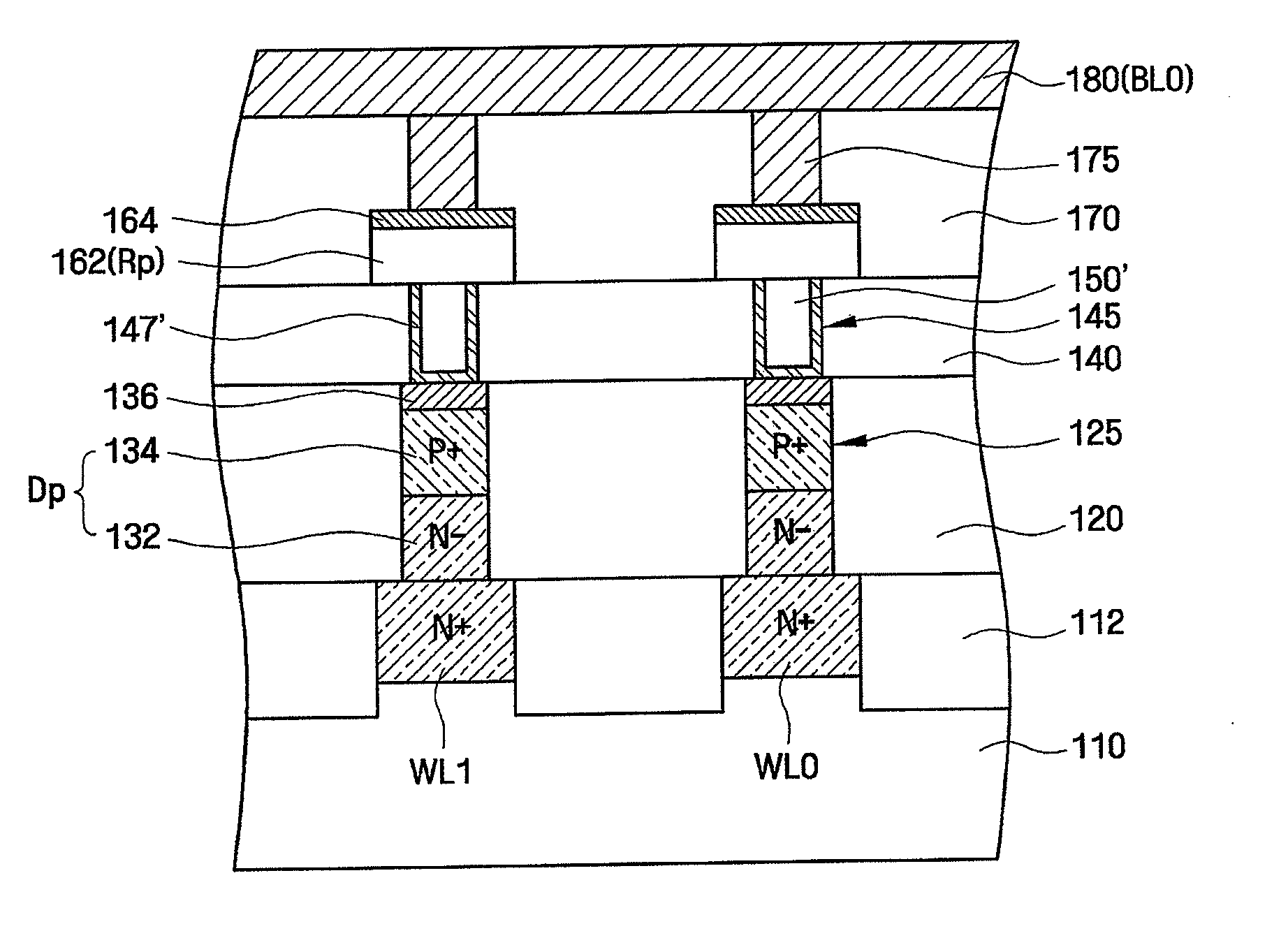

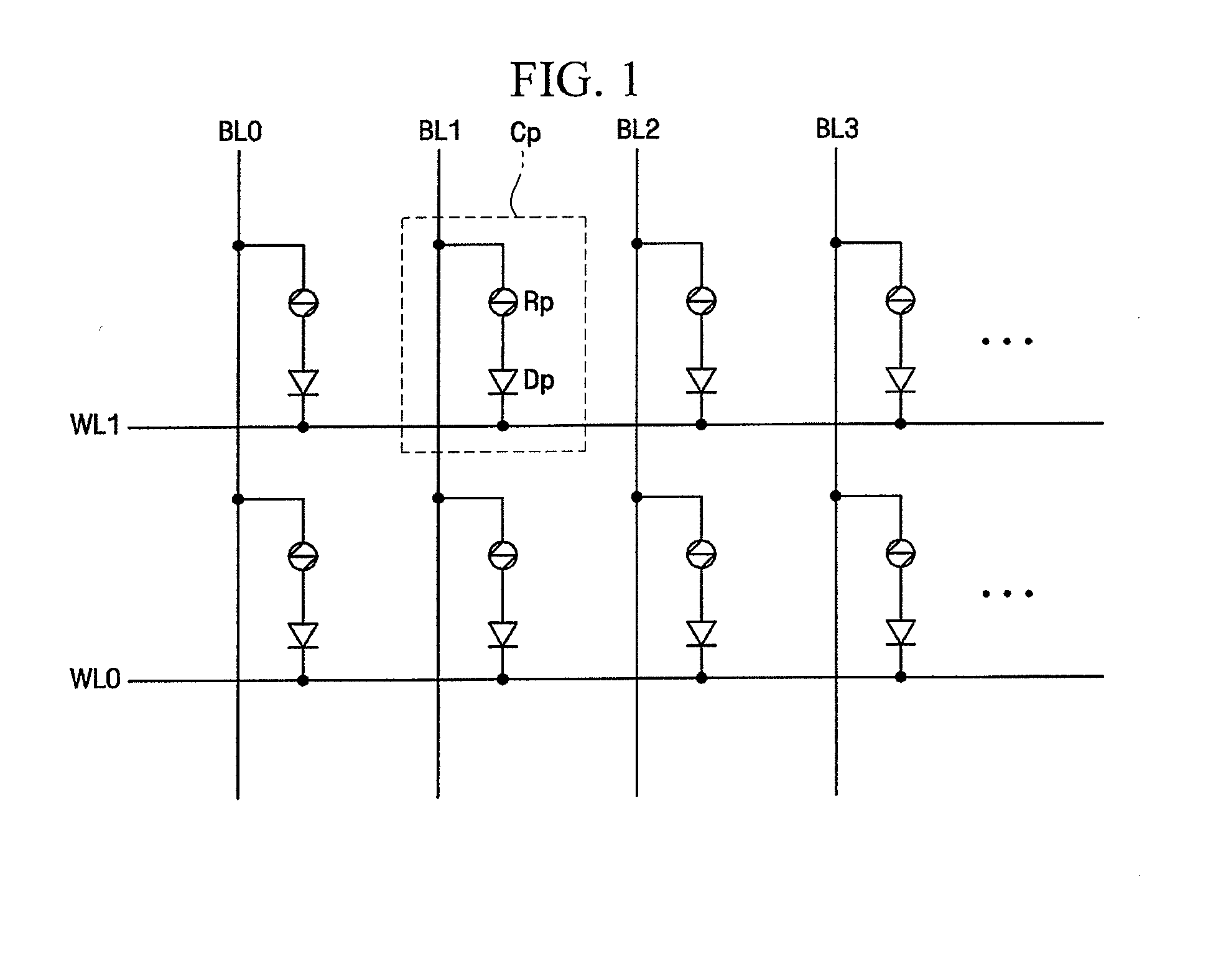

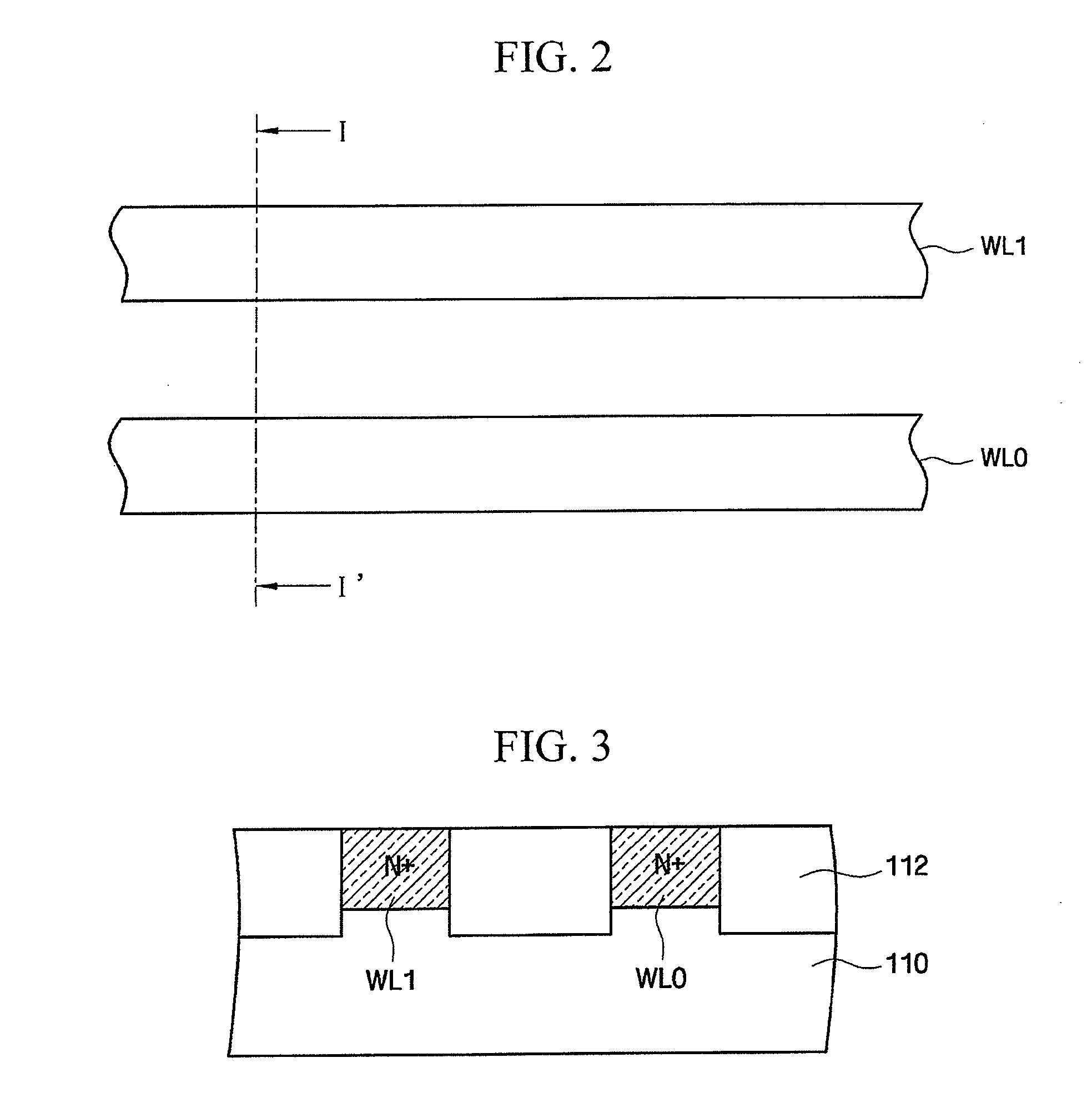

METHOD OF FORMING TITANIUM NITRADE (TiN) FILM, NONVOLATILE MEMORY DEVICE USING THE TiN FILM, AND METHOD OF MANUFACTURING THE NONVOLATILE MEMORY DEVICE

InactiveUS20120149166A1Increased durabilitySolid-state devicesSemiconductor/solid-state device manufacturingTitanium nitrideSi doped

A method of manufacturing a nonvolatile memory device includes forming an insulating film pattern, which includes apertures, on a substrate, forming a switching element in each of the apertures, forming a bottom electrode on the switching element by using a silicon (Si)-doped titanium nitride (TiN) film, and forming a variable resistance material pattern on the bottom electrode. The Si-doped TiN film is formed by repeatedly forming a TiN film and doping the TiN film with Si.

Owner:SAMSUNG ELECTRONICS CO LTD

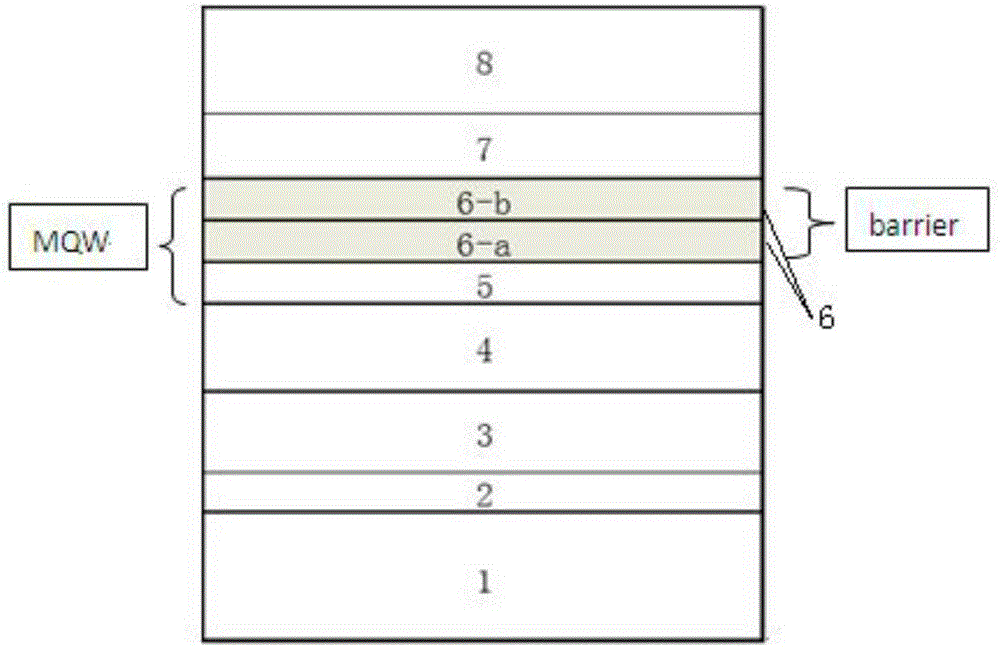

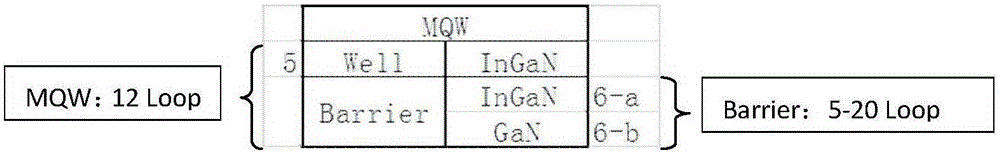

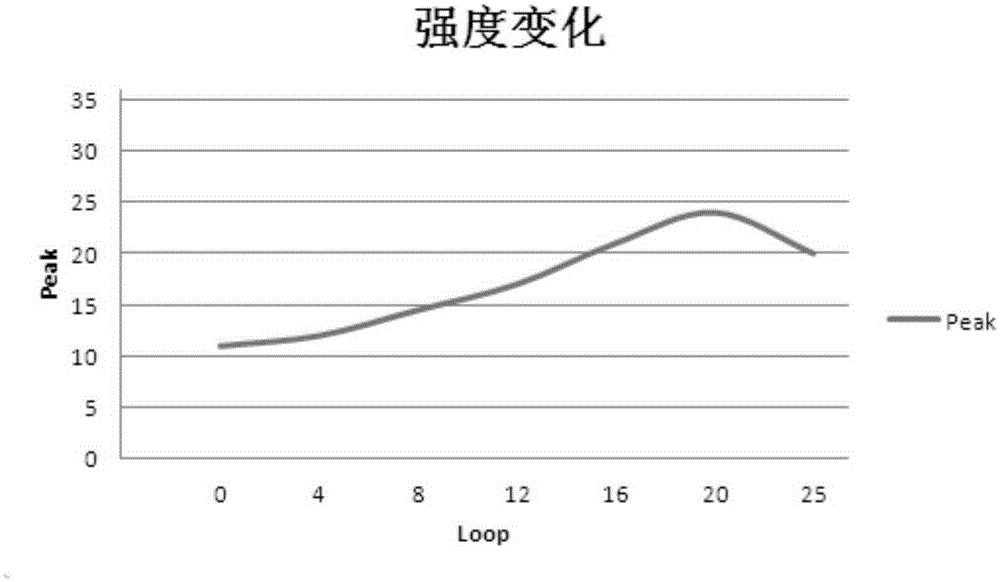

LED structure and growth method thereof

InactiveCN105206726AGood electrical propertiesChange crystal qualitySemiconductor devicesPotential wellElectron hole

The invention relates to an LED structure. The LED structure comprises a substrate layer, a GaN buffer layer, a non-doped GaN layer, a Si-doped GaN layer, a P-type AlGaN layer and a P-type GaN layer. The LED structure is characterized in that a multi-quantum well active region containing InGaN / GaN superlattice barrier layers is located between the Si-doped GaN layer and the P-type AlGaN layer. According to the LED structure of the invention, the InGaN / GaN superlattice barrier layers are adopted to replace traditional GaN barrier layers, and therefore, lattice mismatch between barrier layers and potential well layers can be decreased, and the crystal quality of the MQW can be can effectively changed, and the overlap probability of electron-hole wave function can be improved, and the spontaneous emission rate and internal quantum efficiency of the multi-quantum well can be improved, and finally, the luminous efficiency of a GaN-based LED device can be improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Method for designing quantum barrier used for enhancing light emitting diode (LED) brightness

InactiveCN103346217AImprove luminous efficiencyPromote migrationSemiconductor devicesLuminous intensityContact layer

The invention discloses a method for designing a quantum barrier used for enhancing light emitting diode (LED) brightness. An epitaxial slice structure of an LED comprises a substrate layer, a low-temperature GaN buffer layer, a non-doped high-temperature GaN buffer layer, a Si doped n-type GaN layer, a luminescent layer multiple quantum well, a low-temperature p-type GaN layer, a p-type AlGaN electronic barrier layer, a high-temperature p-type GaN layer and a p-type GaN contact layer in sequence from bottom to top. The luminescent layer multiple quantum well comprises a low-temperature shallow quantum well and a low-temperature multiple quantum well luminescent layer from bottom to top, wherein the multiple quantum well luminescent layer is divided into three parts, namely a first quantum well barrier layer, a second quantum well barrier layer and a third quantum well barrier layer. The first quantum well barrier layer grows in the mode that aluminum components are not doped; the second quantum well barrier layer grows in the mode that 10% of the aluminum components are doped, and the total thickness is kept unchanged; the third quantum well barrier layer grows in the mode that 5%-8% of the aluminum components are doped, and the total thickness is also kept unchanged. By means of the method, GaN series light emitting diodes with high luminous intensity can be obtained.

Owner:合肥彩虹蓝光科技有限公司

NASICON-type sodion solid electrolyte material and preparation method thereof

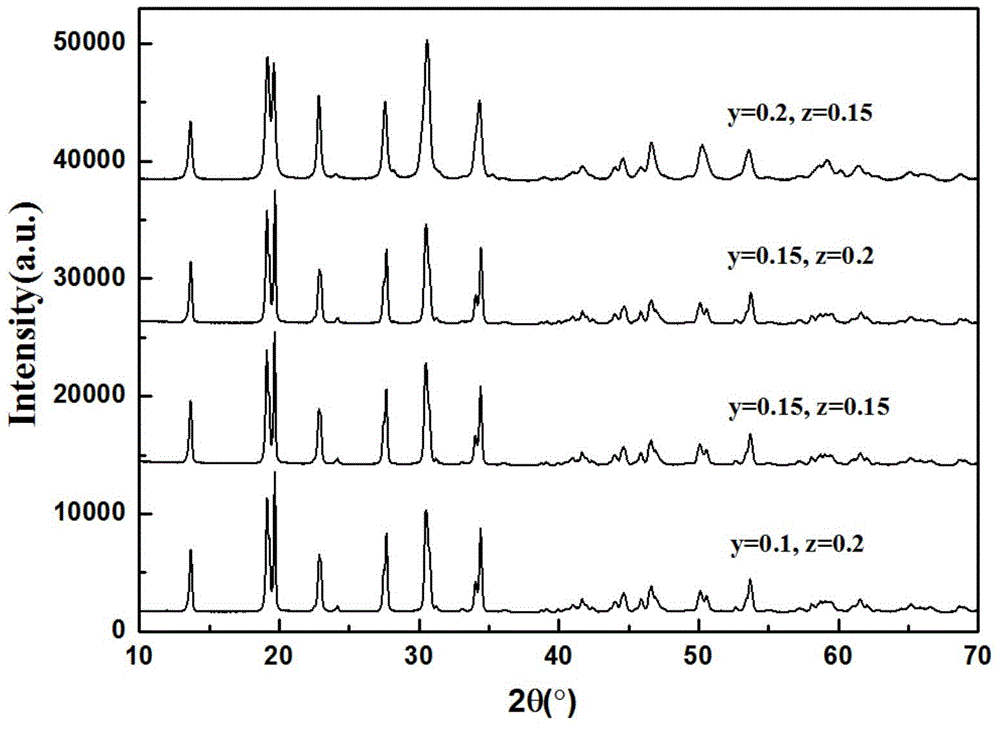

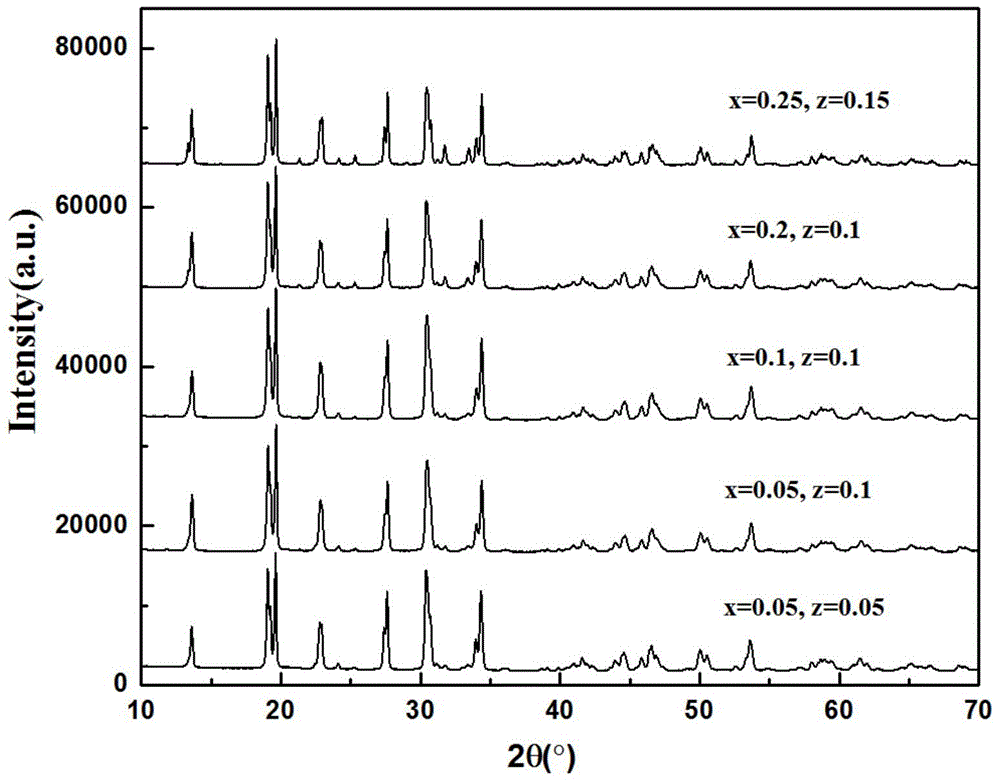

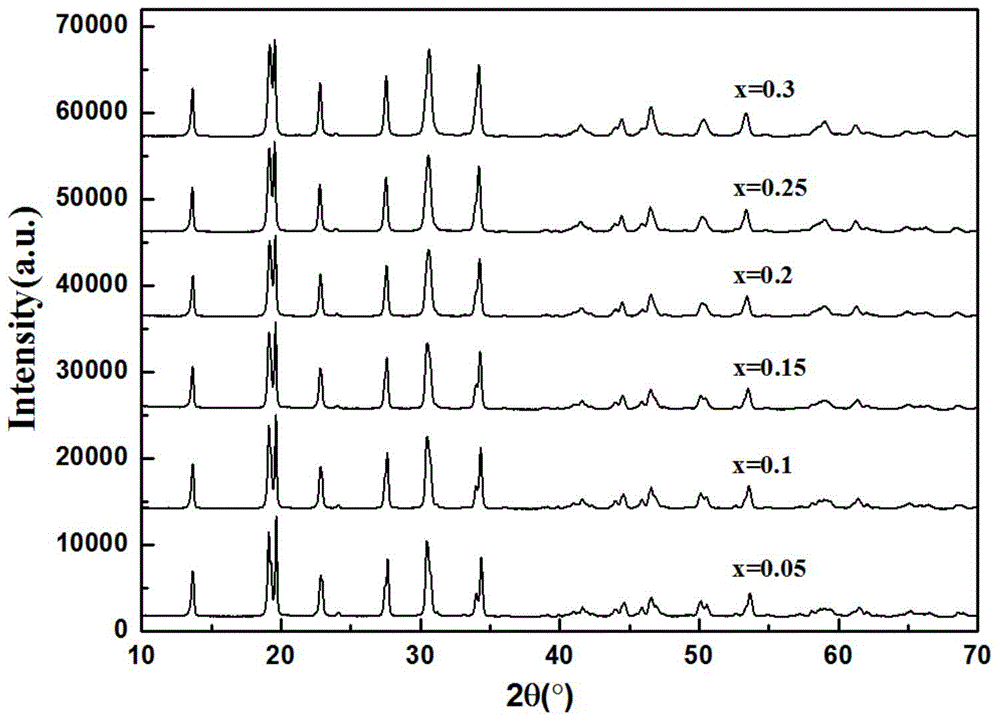

ActiveCN105742698ASimple preparation processRaw materials are cheap and easy to getNon-aqueous electrolyte accumulatorsAlkaline earth metalSi doped

The invention discloses an NASICON-type sodion solid electrolyte material and a preparation method thereof. A chemical general formula of the solid electrolyte material is [Na<3+x-2y>A<y>][Zr<2-x>M<x>][Si<2-z>M'<z>]PO<12>, wherein A is an Na-doped and substituted bivalent alkaline-earth metal element, particularly one or more of Ca, Sr and Ba; M is an octahedral Zr-doped and substituted element, in particularly one or more of La, Y, Al, In and Ga; M' is an Si-doped and substituted element, in particularly one or two of Ge and Se; x, y and z are mol percentages of the corresponding elements respectively; x is smaller than or equal to 0.3 and greater than or equal to 0; y is smaller than or equal to 0.2 and greater than or equal to 0; z is smaller than or equal to 0.3 and greater than or equal to 0; and x, y and z are not 0 at the same time.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

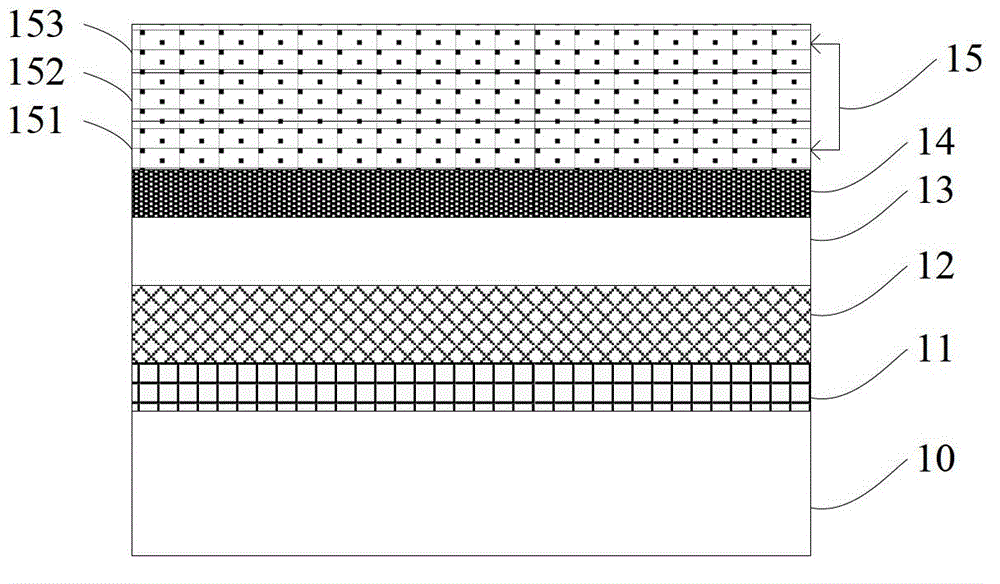

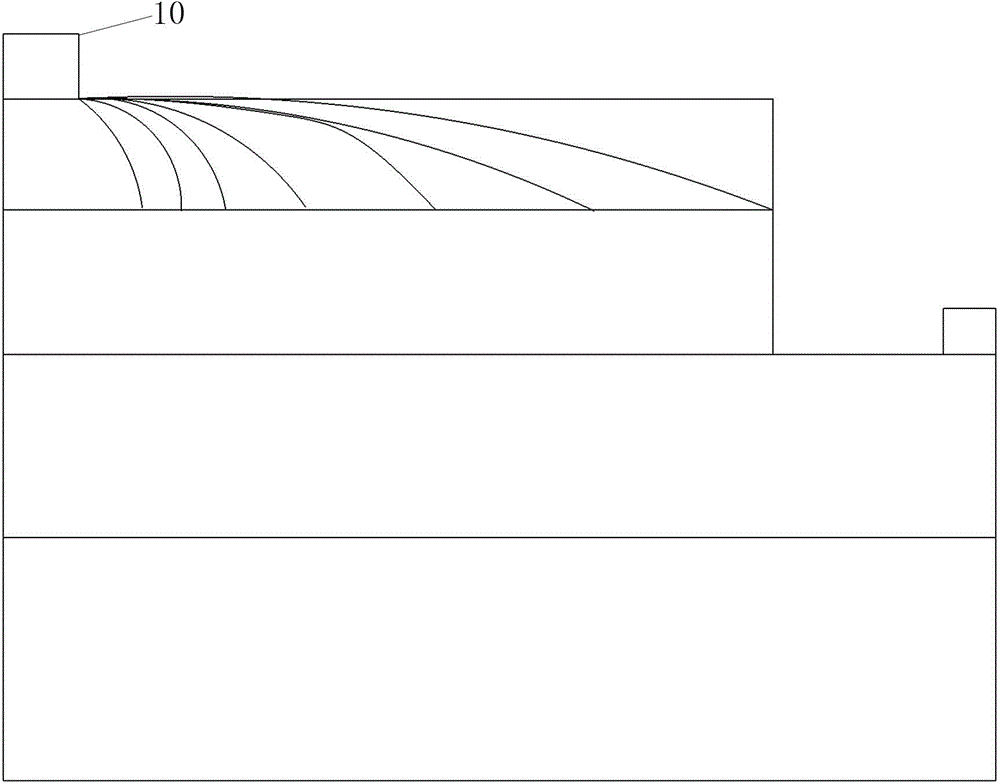

Epitaxial structure capable of improving light effect of large-sized chip and growing method thereof

InactiveCN103187497ARaise the verticalHigh electron mobilitySemiconductor devicesActive layerLight-emitting diode

The invention provides a preparation method for an epitaxial structure capable of improving the light effect of a large-sized chip. The preparation method comprises the following steps: growing a GaN buffer layer on a PSS substrate; growing a UGaN layer on the GaN buffer layer; growing a Si-doped N type GaN layer on the U type GaN layer; alternately growing to form a first NAlGaN layer doped with Si and Al and a first UGaN layer not doped with Si and alternately growing for 38 to 40 cycles; alternately growing to form a second NAlGaN layer doped with Si and Al and a second UGaN layer not doped with Si and alternately growing for 25 to 26 cycles; alternately growing to form a third NAlGaN layer doped with Si and Al and a third UGaN layer not doped with Si and alternately growing for 15 to 16 cycles; and periodically growing an active layer MQW and a PGaN layer. By adopting the method that a NAlGaN / NGaN superlattice structure replaces the traditional N type GaN layer (NGaN), the external quantum luminous efficiency of a light-emitting diode (LED) is improved effectively, so that the device can increase the mobility ratio of electrons, reduce the forward voltage of the large-sized chip and improve the luminous efficiency.

Owner:SHANGHAI PN STONE PHOTOELECTRIC

Light-emitting diode and manufacturing method thereof

InactiveCN102185055AImprove luminous brightnessPrevent proliferationSemiconductor devicesNon dopedActive layer

The invention discloses a light-emitting diode and a manufacturing method thereof. The light-emitting diode comprises a substrate, a buffering layer, a non-doped layer, an n type semiconductor layer, an active layer, a p type semiconductor layer, a current diffusion layer, a first insertion layer and / or a second insertion layer, wherein the buffering layer, the non-doped layer, the n type semiconductor layer, the active layer, the p type semiconductor layer and the current diffusion layer are positioned on the substrate; the first insertion layer is arranged in the n type semiconductor layer; and the second insertion layer is arranged between the n type semiconductor layer and the active layer. The first insertion layer and the second insertion layer consist of at least one layer of non-doped AlxInyGa1-x-yN layer and / or at least one layer of Si-doped AlxInyGa1-x-yN layer, wherein x and y are more than or equal to 0 and less than 0.2. When current is injected into an n type area, the insertion layers play a role of buffering to prevent electrons from diffusing into a p type area, so the conformity efficiency of the electrons and holes is improved and then the illumination brightness of the light-emitting diode is improved. In addition, the insertion layers can achieve the effect similar to charging and discharging, so the anti-static ability of materials is effectively improved.

Owner:ENRAYTEK OPTOELECTRONICS

Semiconductor LED composed of group III nitrided emission and fluorescent layers

InactiveUS6677617B2Improve distributionGood fluorescence propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationCrystallinity

This invention provides a light-emitting diode which is capable of extracting white light, manufactured readily and highly reliable. The light-emitting diode is fabricated by laminating a buffer layer 2, an Si (silicon)-doped GaN fluorescent layer 3, an n-GaN layer 4, an MQW emission layer 5 and a p-GaN layer 6 on a sapphire substrate 1 in this order. The Si-doped GaN fluorescent layer 3 is doped higher concentration of Si (silicon) than a conventional Si-doped GaN layer with sufficient good crystallinity. Such a Si-doped GaN fluorescent layer is excited by blue light generated in the MQW emission layer and emits yellow light. The yellow light is the complement for the blue light generated in the MQW emission layer. White light can be obtained by blending and extracting both of blue light and yellow light.

Owner:EPISTAR CORP

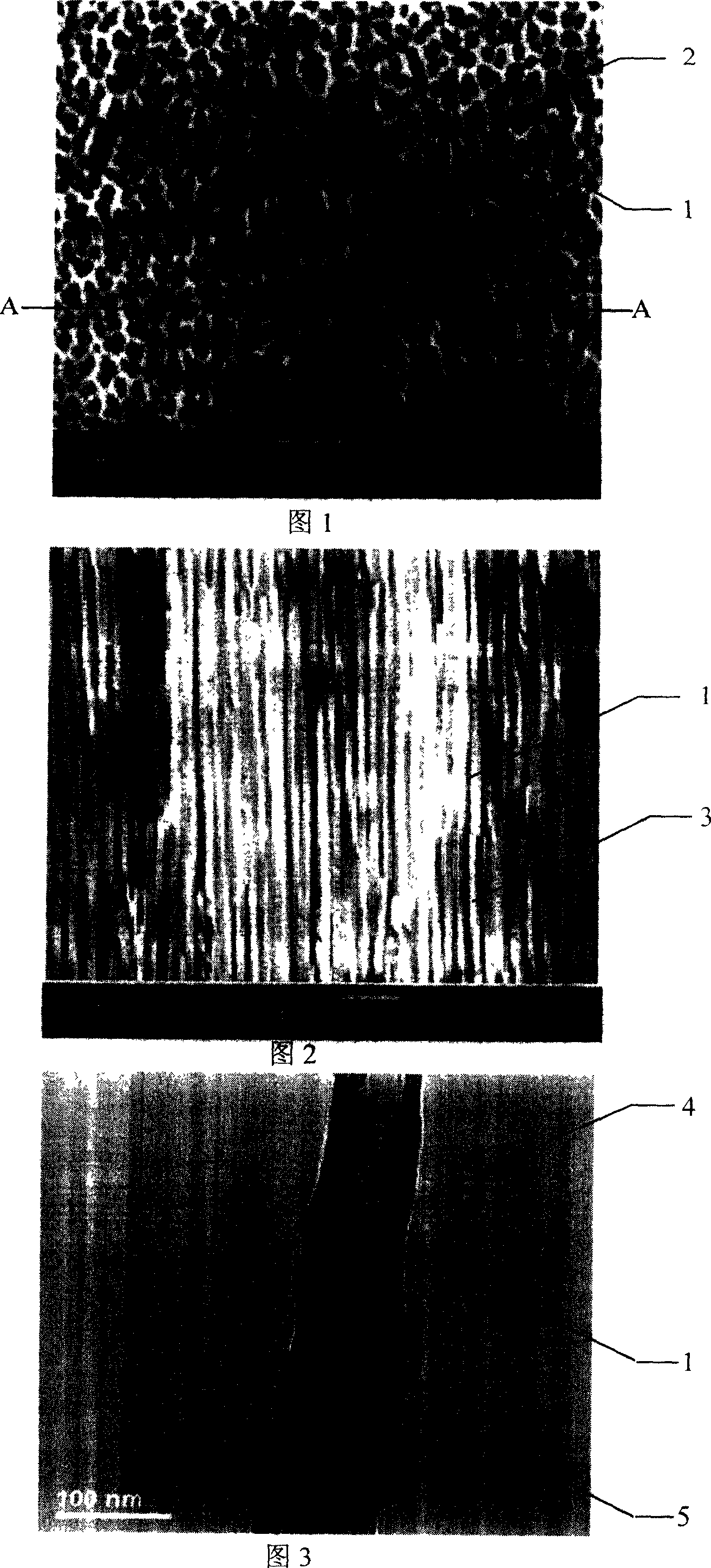

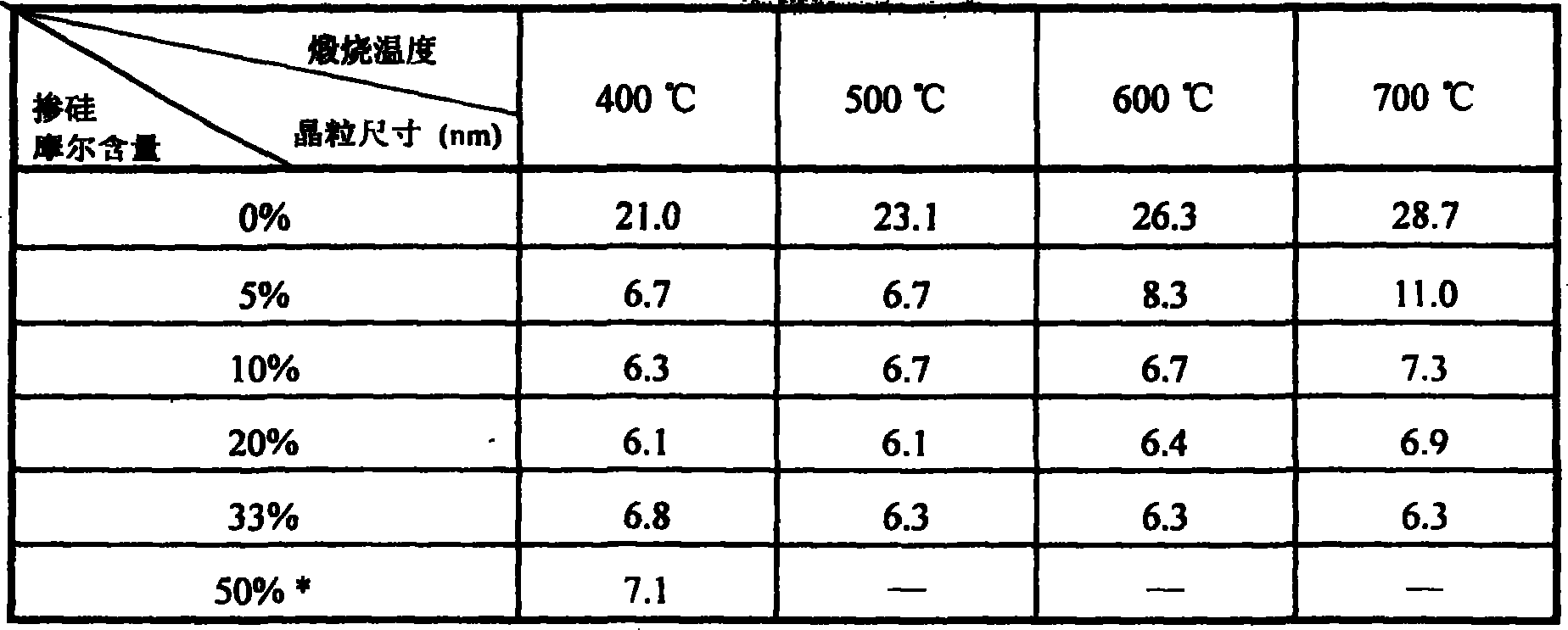

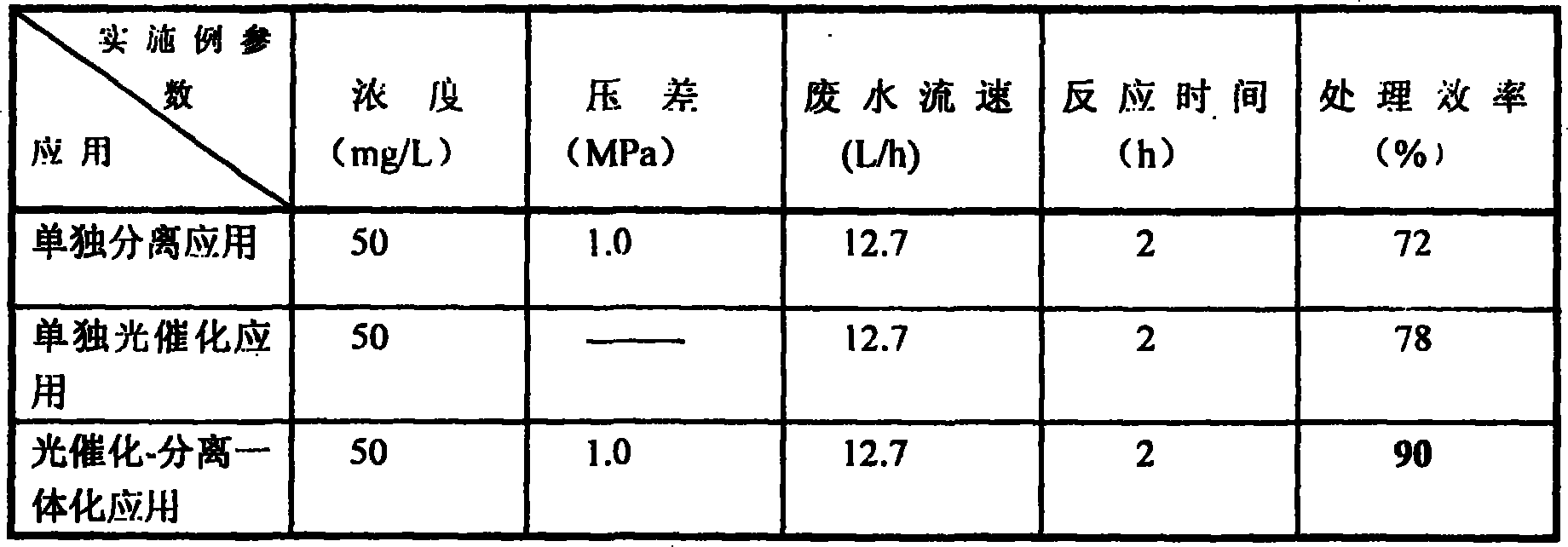

Composite separating membrane of Si-doped TiO2 nanotube and its preparing method and application

ActiveCN1986037ALarge apertureReduce retentionSemi-permeable membranesCatalyst carriersTio2 nanotubeMembrane technology

The present invention relates to membrane technology, and is especially composition separating membrane of Si-doped TiO2 nanotube and its preparation and application. The process of preparing composition separating membrane of Si-doped TiO2 nanotube includes the following steps: cleaning and stoving porous inorganic ceramic membrane carrier with pores of 10-200 nm diameter, preparing TiO2 sol containing Si in 5-50 mol%, soaking the carrier in the sol, drying, roasting at 400-700 deg.c, and cooling to obtain the composition separating membrane with TiO2 nanotube of inside diameter 1-200 nm. The composition separating membrane of Si-doped TiO2 nanotube is used in water treatment.

Owner:DALIAN UNIV OF TECH

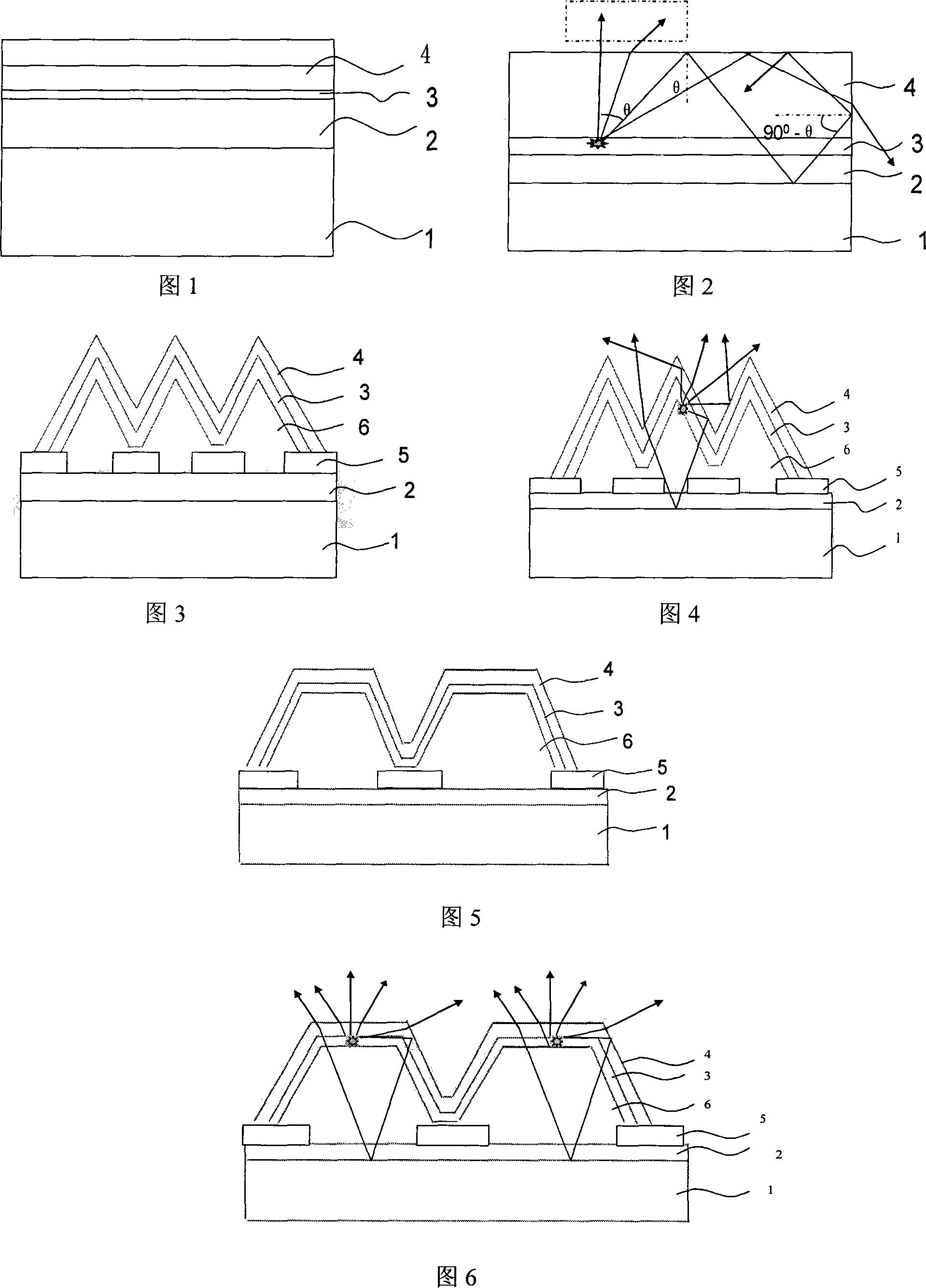

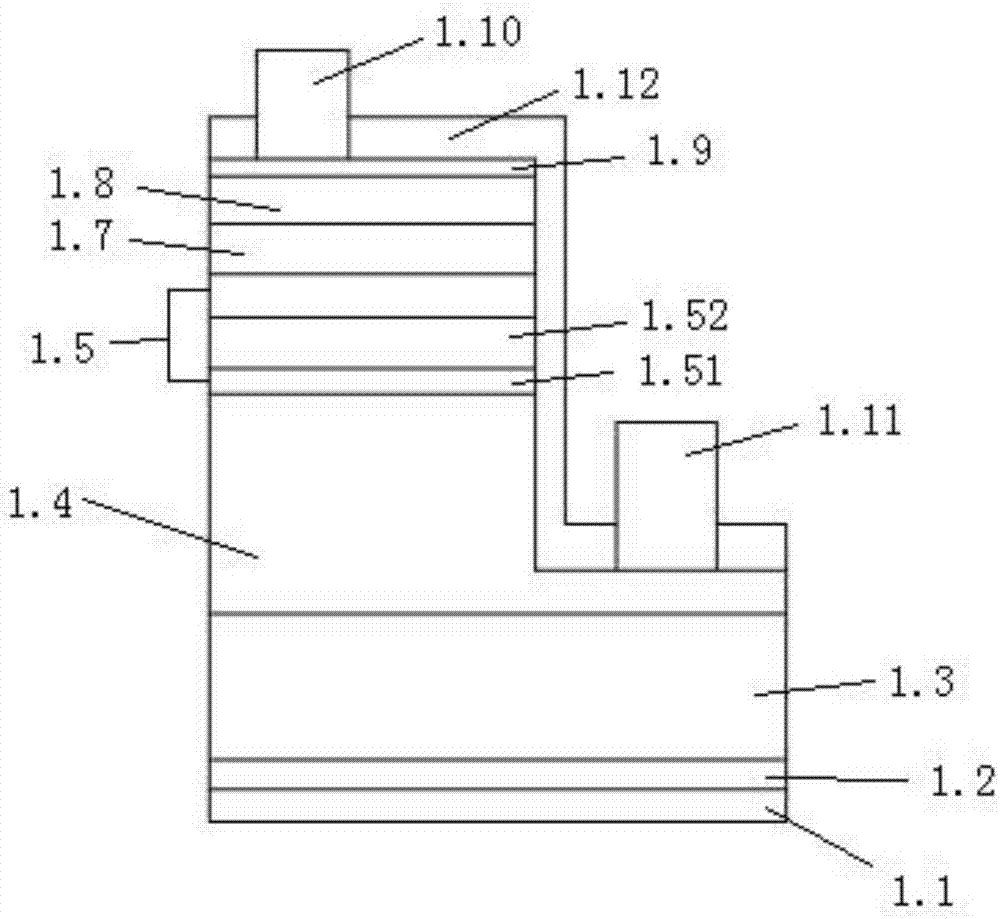

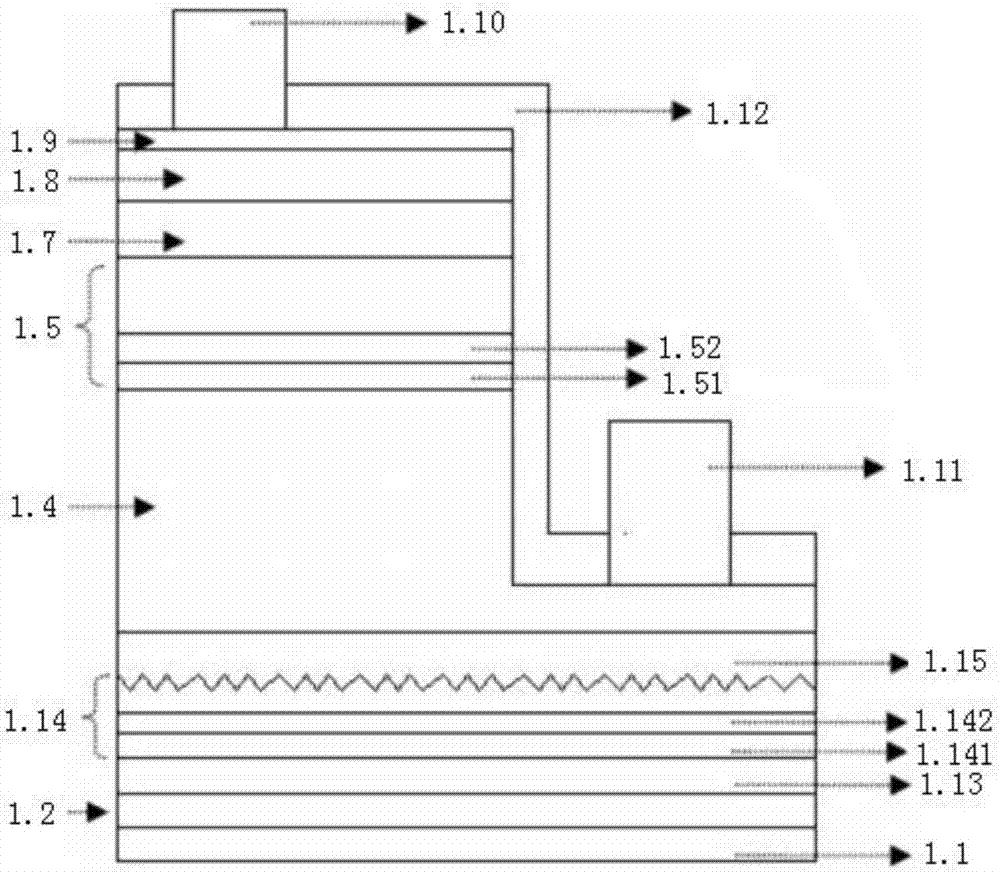

Gallium nitride based LED epitaxial slice structure and method for preparing the same

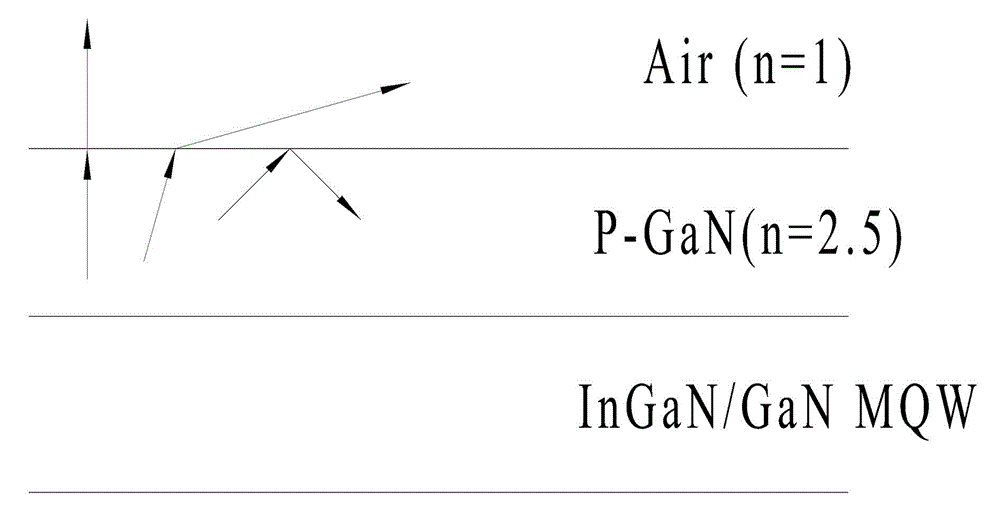

InactiveCN101183697ASolve the problem of total reflectionImprove light extraction efficiencySemiconductor devicesGallium nitrideLight-emitting diode

The invention relates to a nitride-based LED epitaxial wafer structure and a processing method, belonging to the LED field. The nitride-based LED epitaxial wafer structure has high light extraction efficiency and good crystal quality. A GaN buffer layer, a first si-doped GaN layer, a dielectric layer, a second si-doped GaN layer, an InGaN / GaN multiple quantum well, a mg-doped AlGaN layer and a mg-doped GaN layer are arranged on the substrate of the nitride-based LED epitaxial wafer structure in a bottom-up order. A sapphire substrate with (0001) face is put into the reaction chamber and heat treated under the atmosphere of H2; the temperature is lowered to grow the GaN buffer layer, on which the first si-doped GaN layer grows; then the temperature is lowered and the sample is taken out.

Owner:JIANGXI EPITOP OPTOELECTRONICS

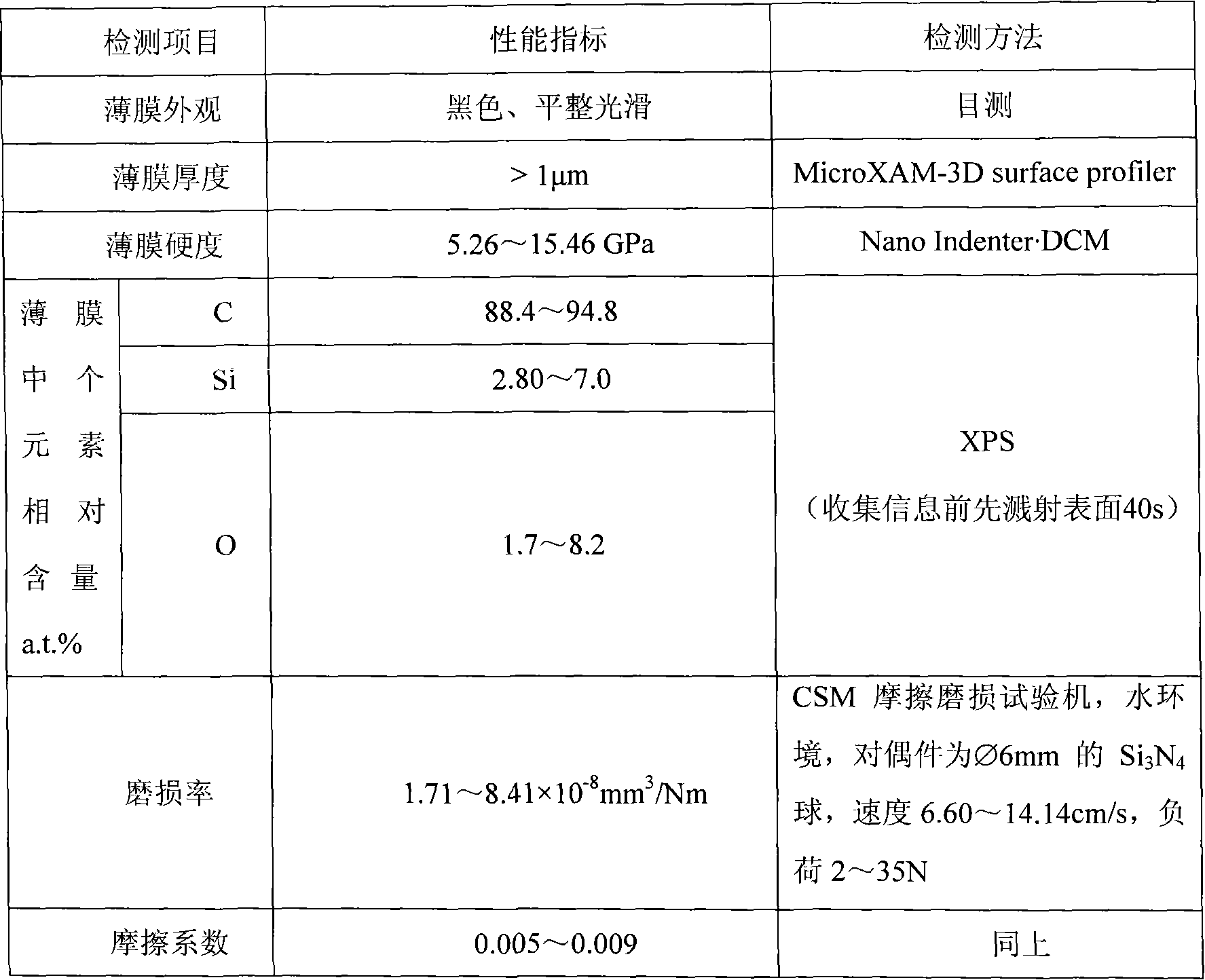

Super lubricating Si-doped diamond film preparation method

InactiveCN101619455AEasy to makeEasy to operateVacuum evaporation coatingSputtering coatingWear resistantGas phase

The invention discloses a super lubricating Si-doped diamond film preparation technology with very low friction coefficient and wear rate in water environment. The invention adopts methane and argon gas as feed gas and a compound deposition technology combined by radio frequency plasma enhanced chemical vapor deposition and mid-frequency sputtering silicon target to deposit the super lubricating Si-doped diamond film on the surface of stainless steel. The film shows good wear resistant and lubricating property in water environment and has very low friction coefficient (0.005-0.009) and wear rate (1.71-8.41*10<-8>mm<3> / Nm) in a big range of load and velocity. In addition, the technology has accessible raw materials, simple devices and processes, high efficiency, fast operation, and high yield and the technology can protect the environment, save the energy and reduce the cost. The technology is estimated to have important application prospect in mechanical friction, food industry and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

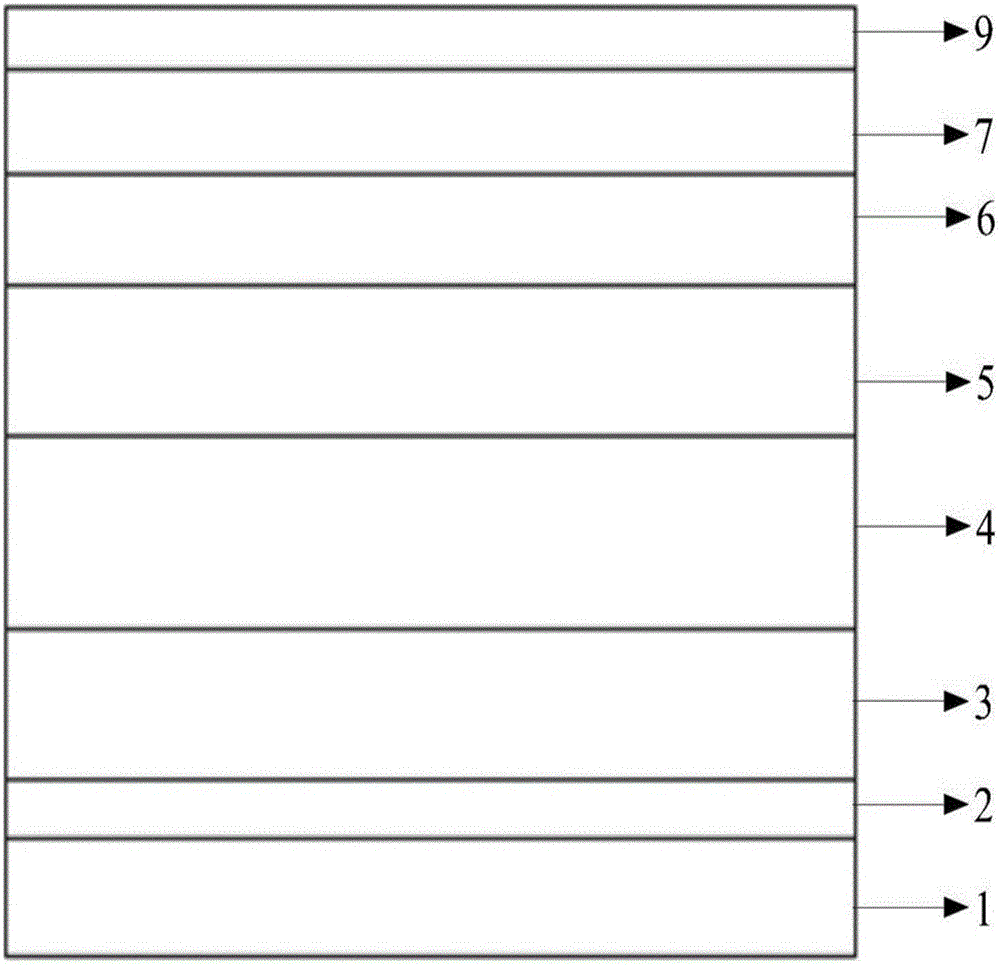

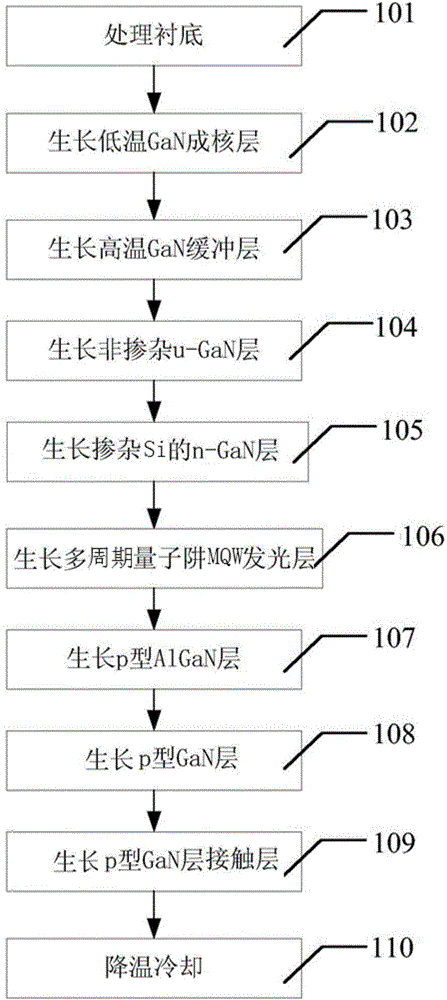

LED epitaxial structure and growth method therefor

ActiveCN106531855AImprove activation efficiencyLow working voltageSemiconductor devicesQuantum wellNon doped

The invention aims to provide an LED epitaxial structure and a growth method therefor. The growth method specifically comprises the steps of processing a substrate, enabling a low-temperature GaN core-forming layer, a high-temperature GaN buffer layer, a non-doped u-GaN layer, a Si-doped n-GaN layer, a multi-period quantum well (MQW) light emitting layer, a P type AlGaN layer, a P type GaN layer and a P type GaN contact layer to be grown, and then reducing temperature and cooling, wherein the step of growing a p type GaN layer is performed by the steps of enabling the P type GaN layer to be grown at a low temperature in N<2> atmosphere firstly, then enabling the P type GaN layer to be grown at a high temperature in H<2> atmosphere, and finally enabling the P type GaN layer to be grown at a high temperature in N<2> / H<2> mixed gas so as to lower the working voltage of the LED and improve the light emitting efficiency of the LED. The invention also aims to provide the LED epitaxial structure produced by the growth method for the epitaxial structure; according to the structure, the conventional high-temperature p type GaN layer structure is changed into the p type GaN layer structure with the variable atmospheres of low-temperature N<2> atmosphere, high-temperature H<2> atmosphere and high-temperature N<2> / H<2> mixed gas, so that the problems that the luminous power of the LED is limited by P layer hole concentration and the driving voltage is limited by P layer hole mobility are solved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

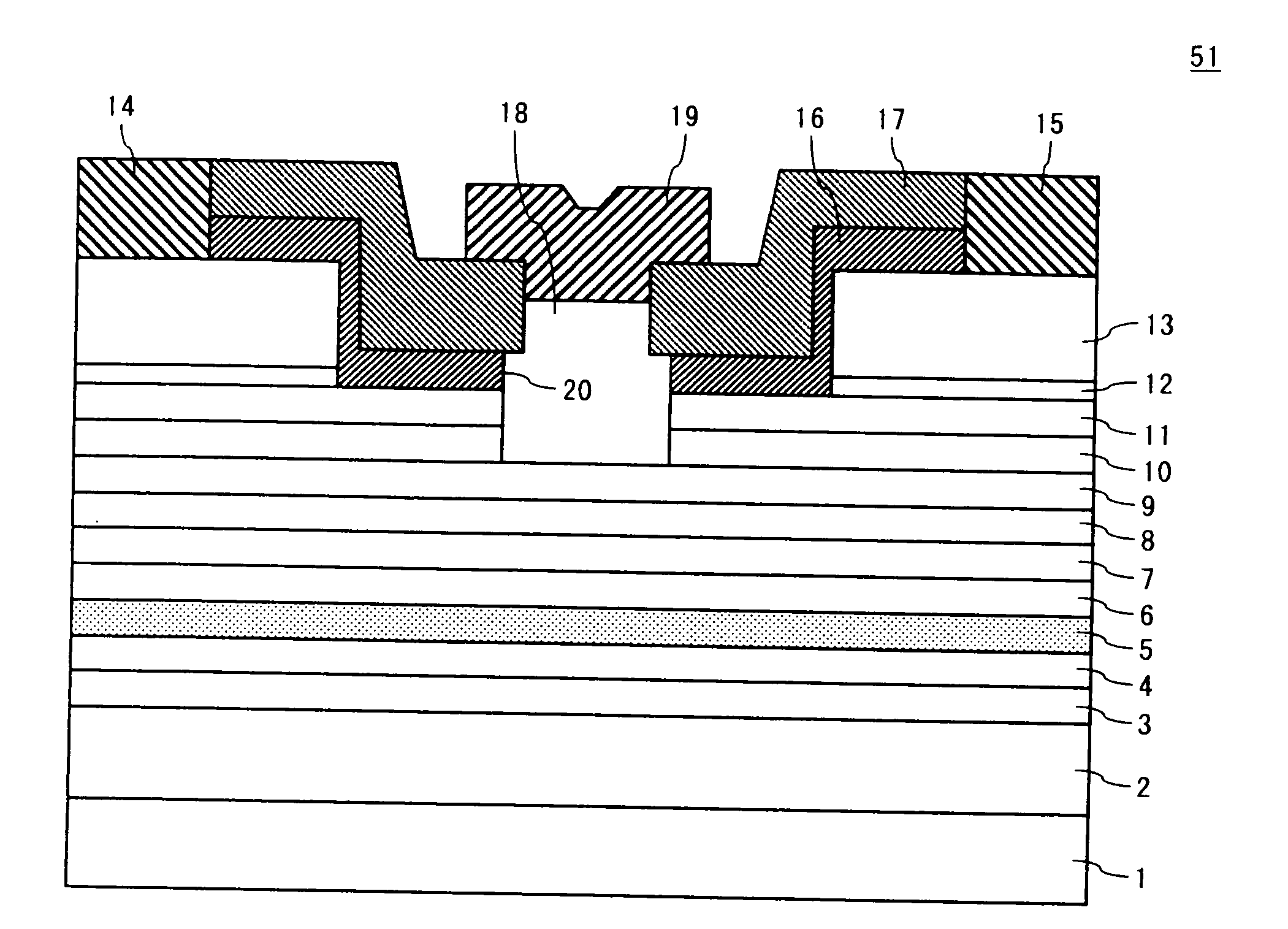

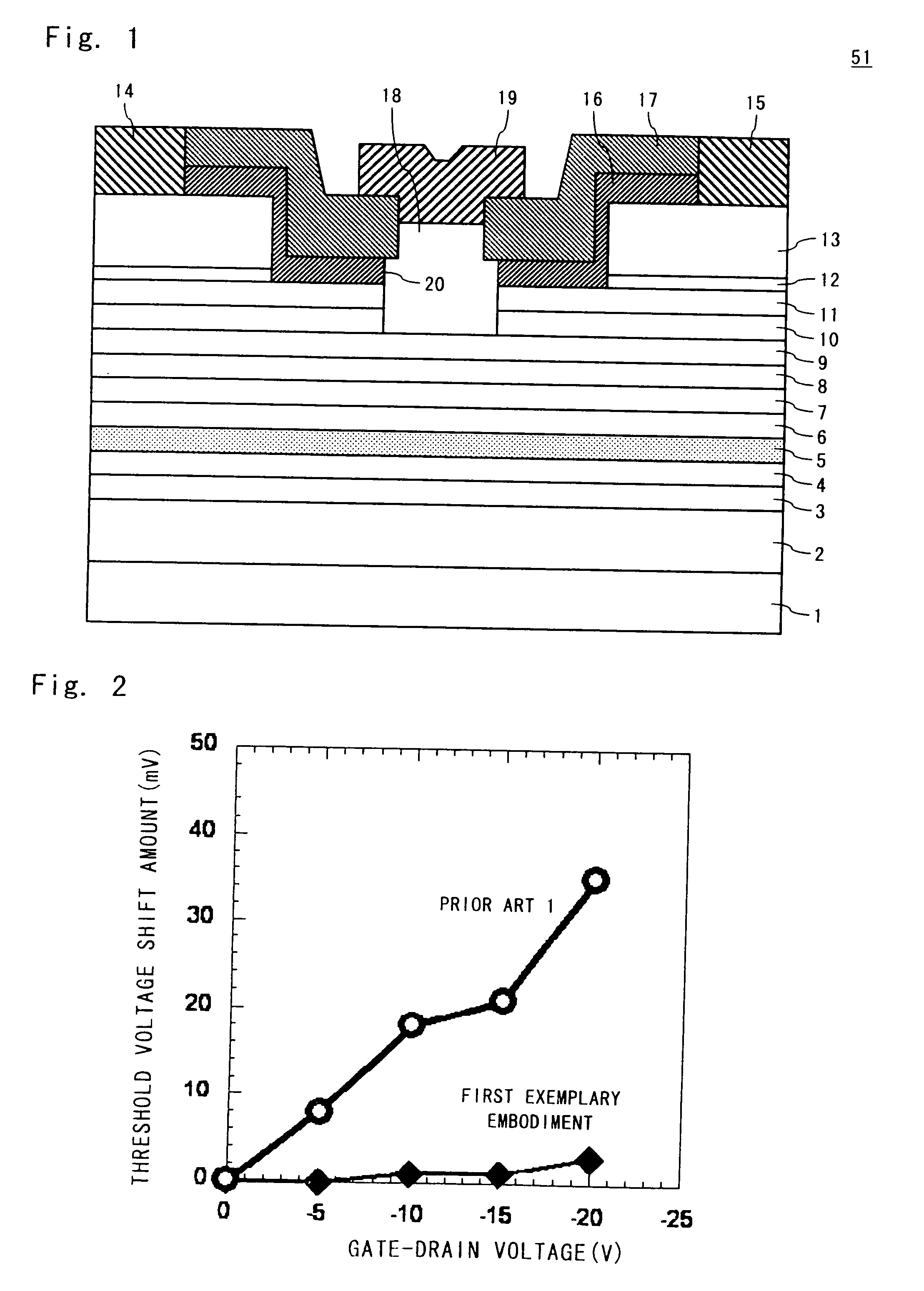

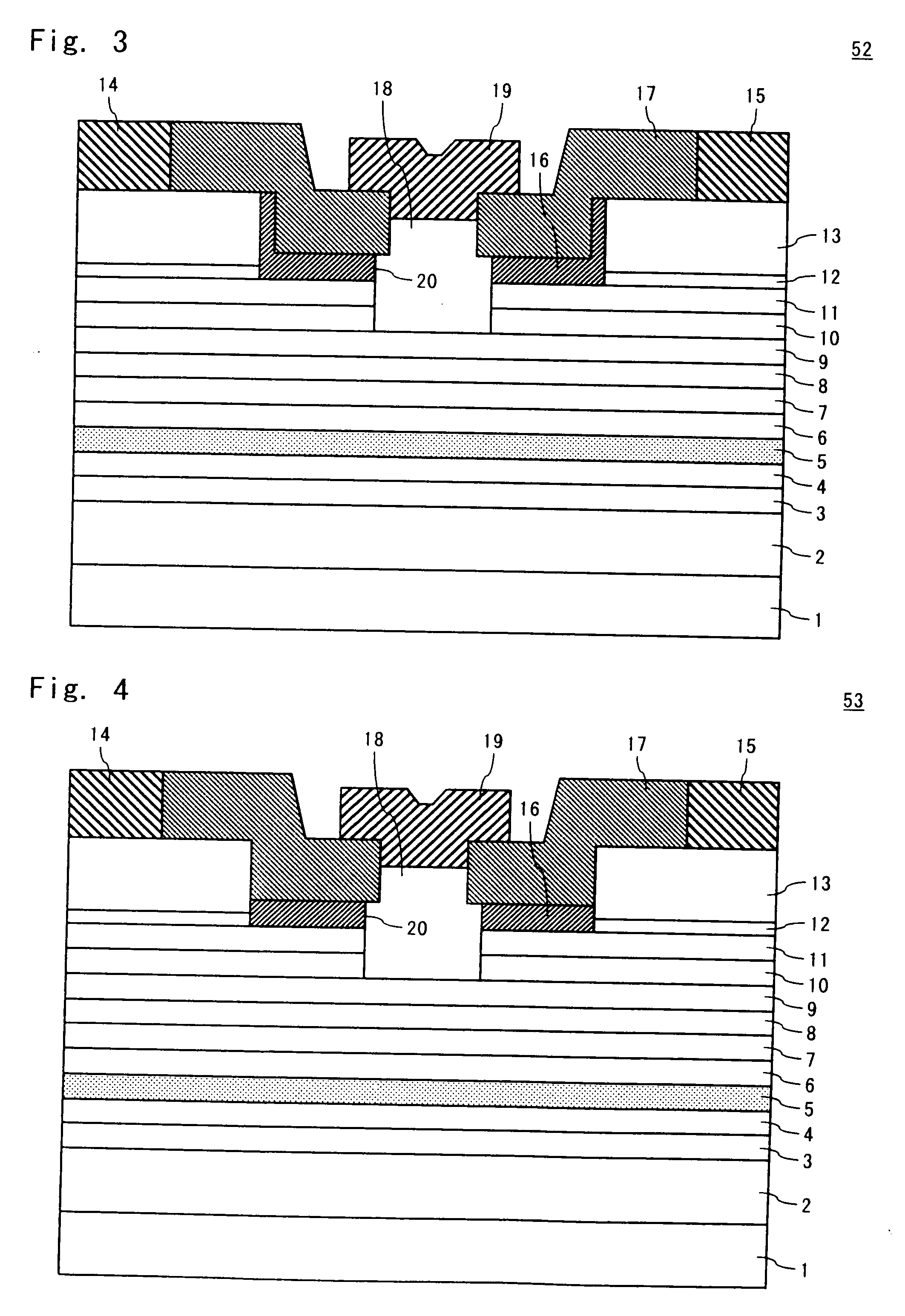

Field effect transistor, method of manufacturing the same, and semiconductor device

ActiveUS20100001318A1Reduce processInhibitionSolid-state devicesSemiconductor/solid-state device manufacturingField-effect transistorNitride

A J-FET includes a channel layer of a first conductivity type (a Si-doped n-type AlGaAs electron supply layers 3 and 7, undoped AlGaAs spacer layers 4 and 6, and an undoped InGaAs 5 channel layer 5) formed above a semi-insulating GaAs substrate, an upper semiconductor layer made up of at least one semiconductor layer and formed above the channel layer of the first conductivity type, a semiconductor layer of a second conductivity type (C-doped p+-GaAs layer 18) formed in a recess made in the upper semiconductor layer or formed above the upper semiconductor layer, a gate electrode placed above and in contact with the semiconductor layer of the second conductivity type, and a gate insulating film including a nitride film formed above and in contact with the upper semiconductor layer and an oxide film formed above the nitride film and having a larger thickness than the nitride film.

Owner:RENESAS ELECTRONICS CORP

Gallium-nitride based multi-quantum well light-emitting diode n-type contact layer structure

ActiveUS7042019B1Increase the doping concentrationLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingQuantum wellOhmic contact

A structure for the n-type contact layer in the GaN-based MQW LEDs is provided. Instead of using Si-doped GaN as commonly found in conventional GaN-based MQW LEDs, the n-type contact layer provided by the present invention achieves high doping density (>1×1019 cm−3) and low resistivity through a superlattice structure combining two types of materials, AlmInnGa1-m-nN and AlpInqGa1-p-qN (0≦m,n<1, 0<p,q<1, p+q≦1, m<p), each having its specific composition and doping density. In addition, by controlling the composition of Al, In, and Ga in the two materials, the n-type contact layer would have a compatible lattice constant with the substrate and the epitaxial structure of the GaN-based MQW LEDs. This n-type contact layer, therefore, would not chap from the heavy Si doping, have a superior quality, and reduce the difficulties of forming n-type ohmic contact electrode. In turn, the GaN-based MQW LEDs would require a lower operation voltage.

Owner:LUMENS +1

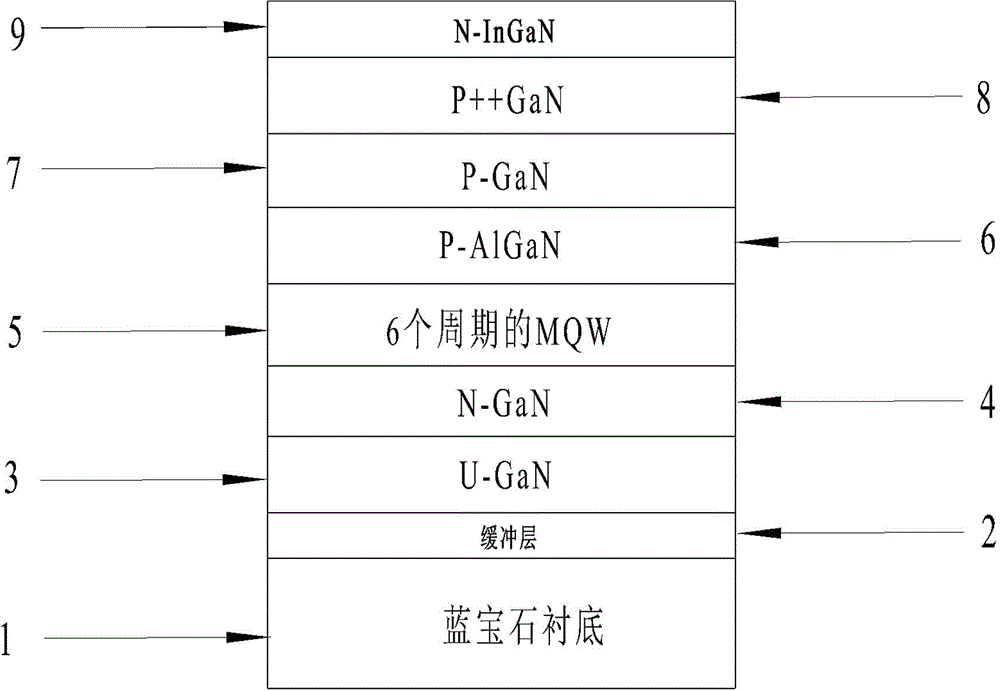

GaN-based light-emitting diode structure improving light extraction rate and preparation method

ActiveCN104157761AIncrease the carrier concentrationImprove acceleration performanceSemiconductor devicesNon dopedLead structure

The invention belongs to the field of photoelectric devices, and particularly relates to a GaN-based light-emitting diode structure improving the light extraction rate and a preparation method. The GaN-based light-emitting diode structure improving the light extraction rate and the preparation method solve the technical problems that the carrier concentration of a P-type area of an existing LED structure is not high, currents are distributed unevenly, and the light emitting efficiency is low. The GaN-based light-emitting diode structure improving the light extraction rate comprises a substrate, a GaN buffer layer growing on the substrate, a non-doped GaN layer growing on the GaN buffer layer, a Si-doped GaN layer growing on the non-doped GaN layer, multiple-quantum well structures, growing on the Si-doped GaN layer, of six periods, a p-AlGaN electronic blocking layer growing on the multiple-quantum well structures, a Mg-doped p-type GaN layer growing on the p-AlGaN electronic blocking layer, a heavily-doped p-type GaN layer growing on the Mg-doped p-type GaN layer, and an n-type InGaN layer growing on the heavily-doped p-type GaN layer. According to the GaN-based light-emitting diode structure improving the light extraction rate and the preparation method, the currents are distributed evenly, the light emitting efficiency is high, and the preparation process is simple.

Owner:太原理工大学建筑设计研究院有限公司

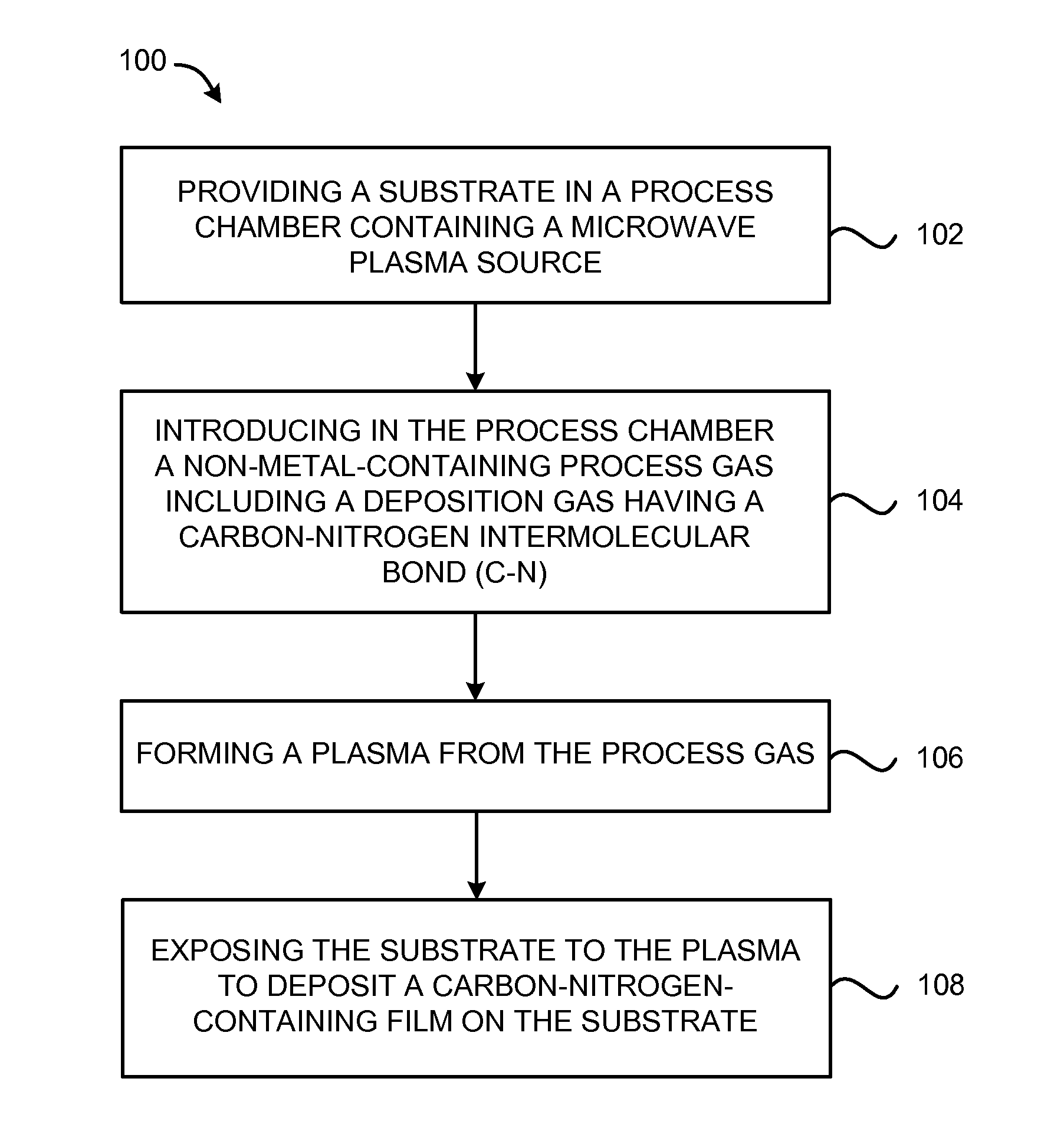

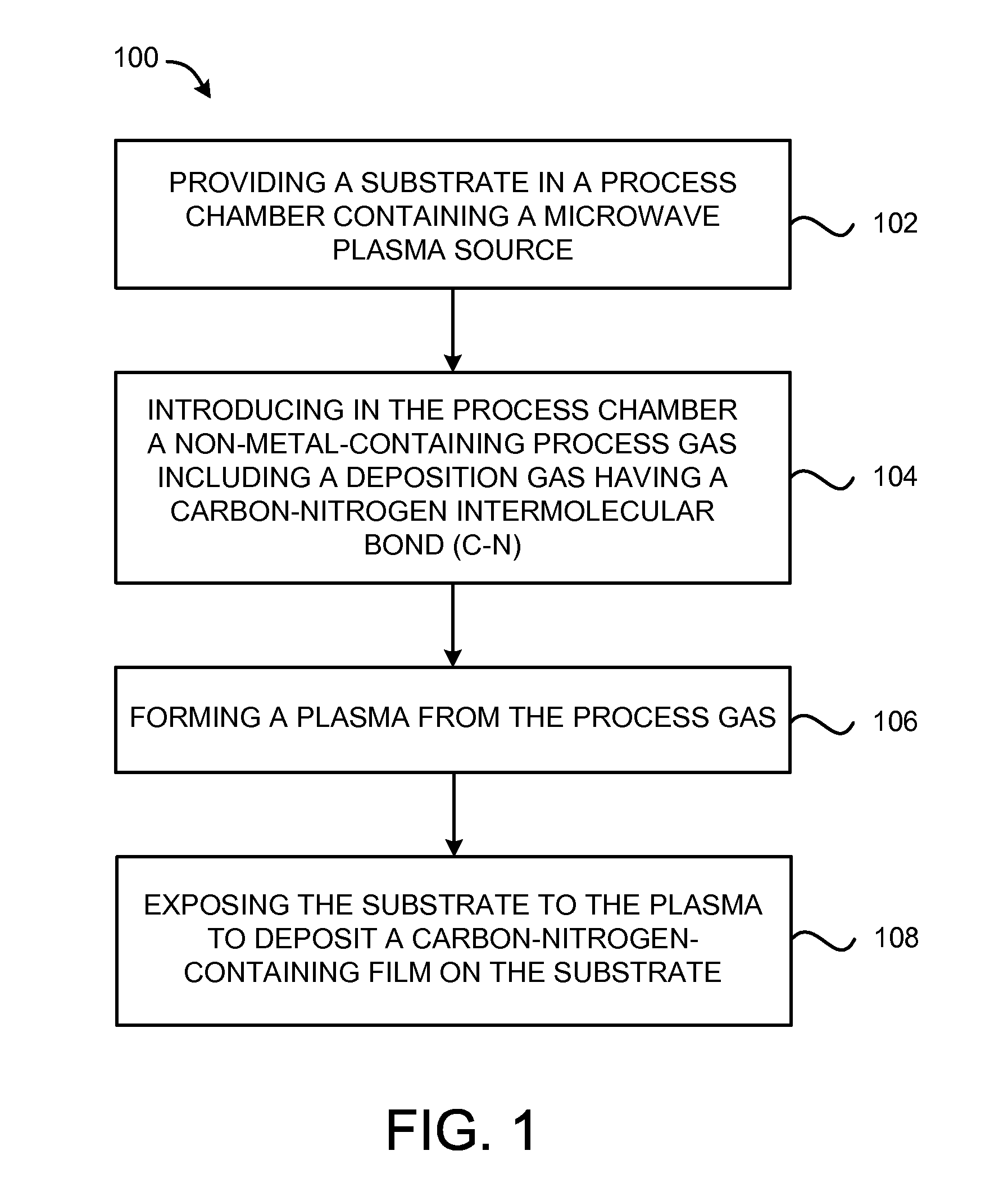

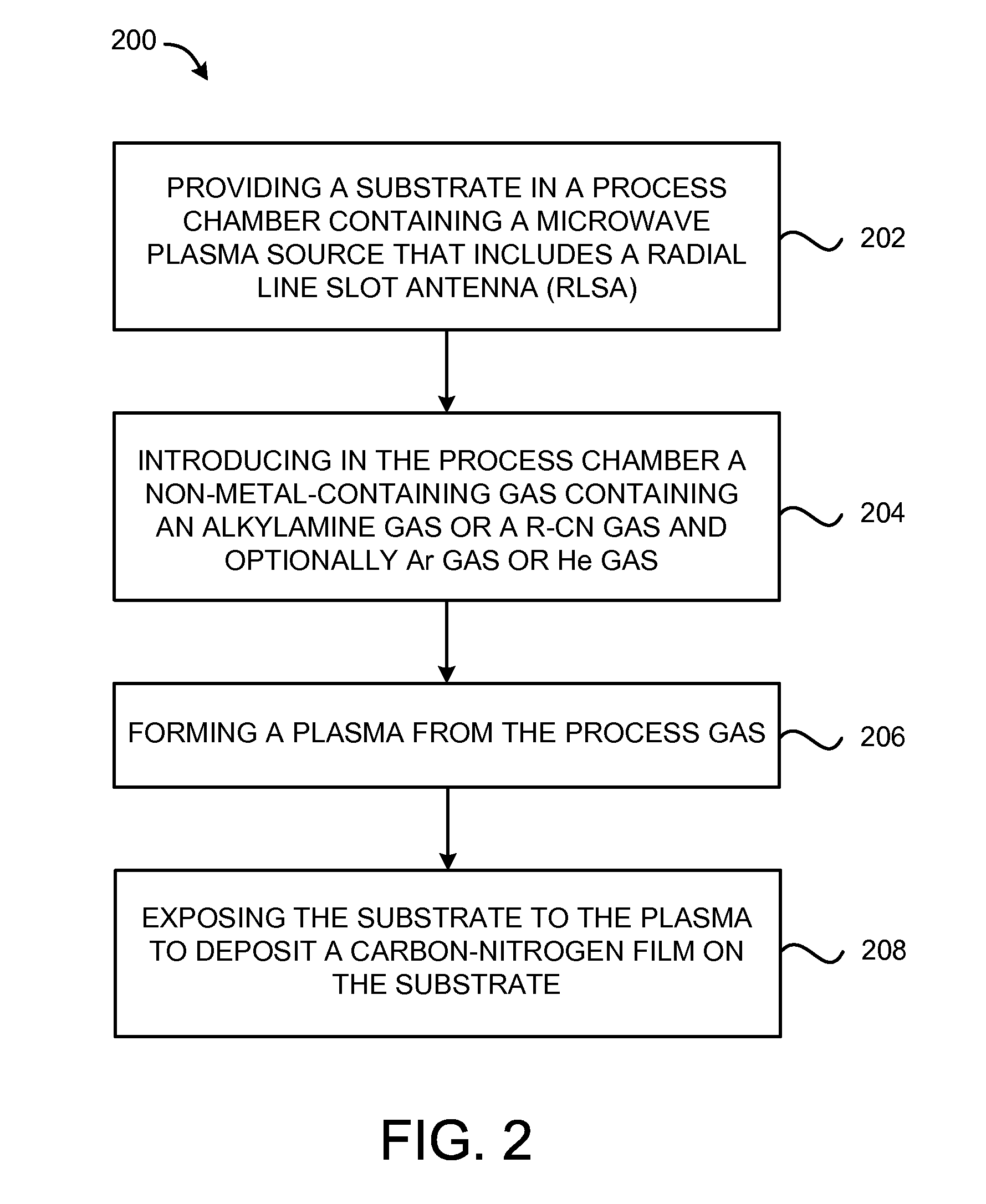

Method of depositing dielectric films using microwave plasma

Embodiments of the invention describe a method for forming dielectric films for semiconductor devices. The method includes providing a substrate in a process chamber containing a microwave plasma source, introducing into the process chamber a non-metal-containing process gas including a deposition gas having a carbon-nitrogen intermolecular bond, forming a plasma from the process gas, and exposing the substrate to the plasma to deposit carbon-nitrogen-containing film on the substrate. In some embodiments, the carbon-nitrogen-containing film can include a CN film, a CNO film, a Si-doped CN film, or a Si-doped CNO film.

Owner:TOKYO ELECTRON LTD

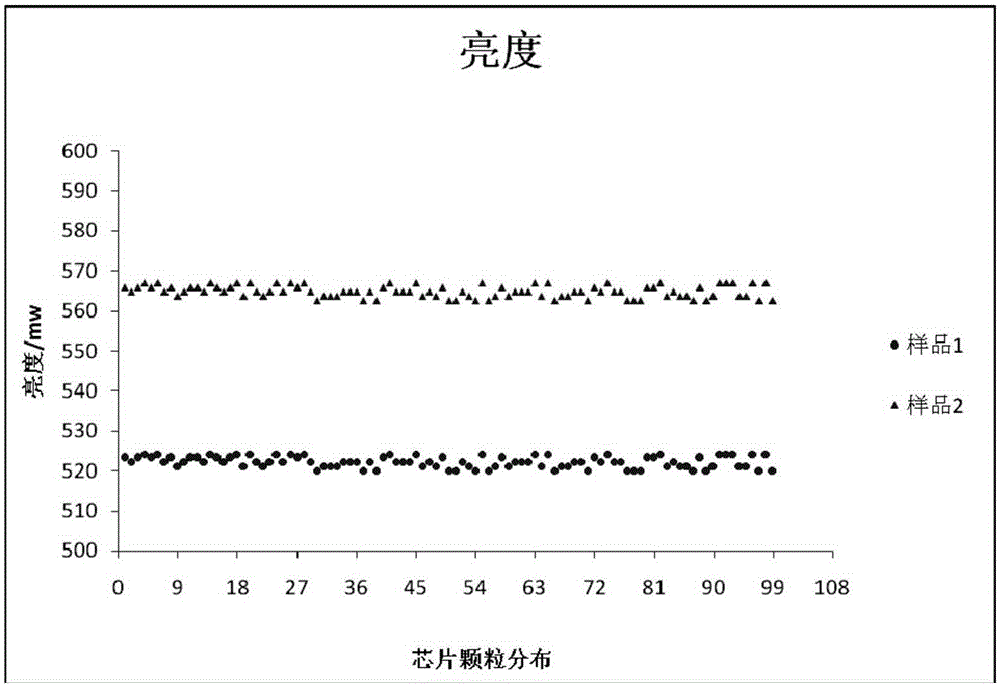

Epitaxial growth method for increasing LED internal quantum efficiency

ActiveCN105261678AImprove quantum efficiencyImprove compound efficiencySemiconductor devicesQuantum efficiencyLight-emitting diode

The invention provides an epitaxial growth method for increasing LED internal quantum efficiency. The method comprises steps of processing a substrate; generating a low-temperature buffer layer GaN; generating an undoped GaN layer; generating an Si-doped N-type GaN layer; generating a light emitting layer; generating a P-type AlGaN layer; generating an Mg-doped P-type GaN layer; and reducing temperature and cooling.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

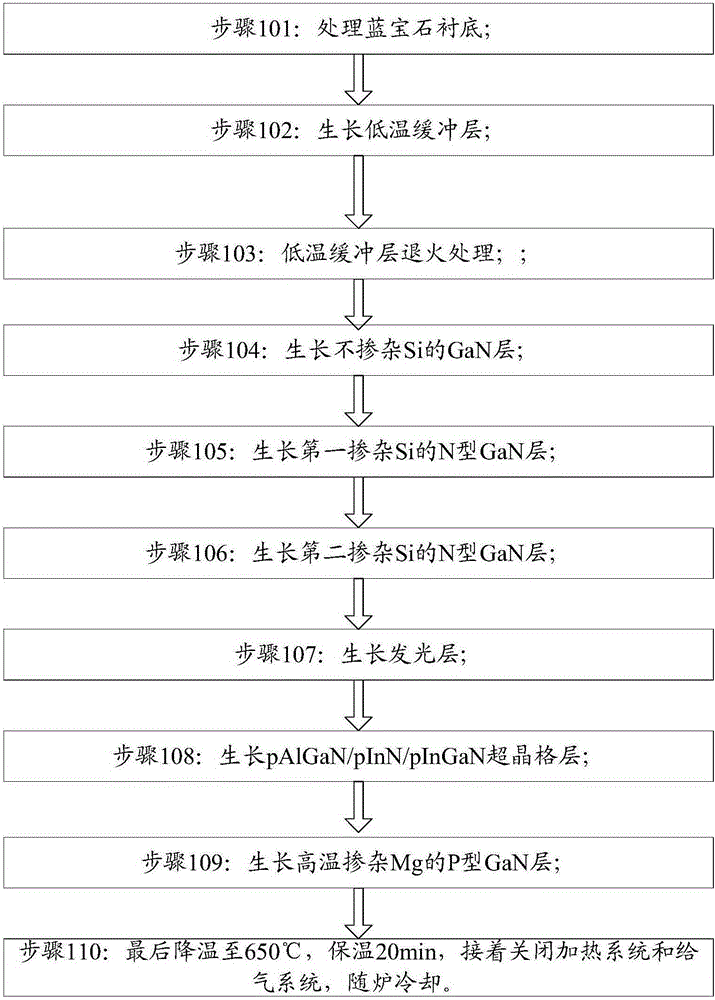

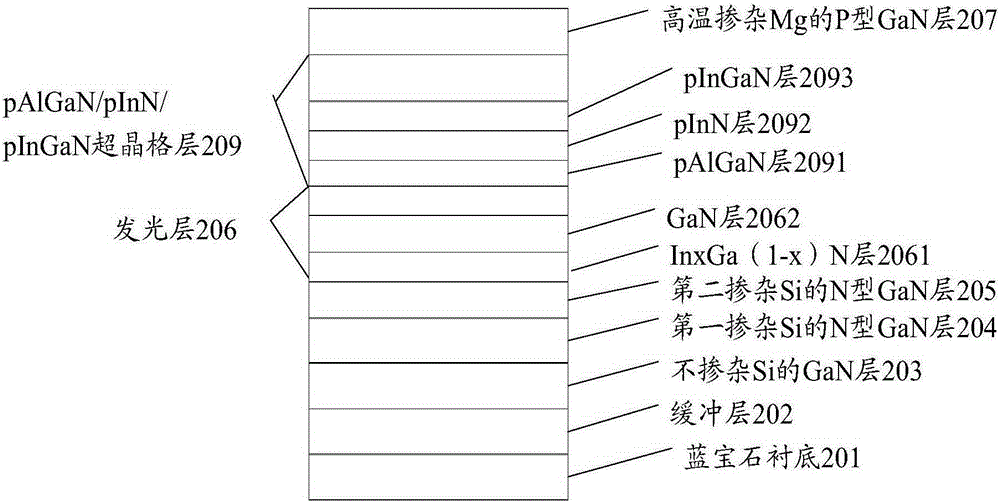

Epitaxial growth method for improving luminous efficiency of LED (Light Emitting Diode) device

ActiveCN105244424AImproving Epitaxial Growth MethodsLower activation energySemiconductor devicesActivation energyBiological activation

The invention discloses an epitaxial growth method for improving the luminous efficiency of an LED (Light Emitting Diode) device. The epitaxial growth method comprises the following steps: treating a sapphire substrate; growing a low-temperature buffer layer; annealing the low-temperature buffer layer; growing an N-type GaN layer without being doped with Si; growing a first Si-doped N-type GaN layer; growing a second Si-doped N-type GaN layer; growing a luminous layer; growing a pAlGaN / pInN / pInGaN super-lattice layer; growing a high-temperature Mg-doped P-type GaN layer; finally, cooling to 650-680 DEG C, preserving the heat for 20-30min, closing a heating system and a gas supply system, and performing furnace cooling. According to the method, the new material pAlGaN / pInN / pInGaN super-lattice layer is used as a new electron blocking layer, and the activation energy of Mg is reduced by using the atomic activity of In, so that the activation efficiency of Mg is improved; smooth transition from pAlGaN to pInGaN is realized in the super-lattice through the transition of pInN, thus solving the problem that hole injection is blocked by high contact interface energy band due to high adaptability of pAlGaN and pInGaN lattices.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

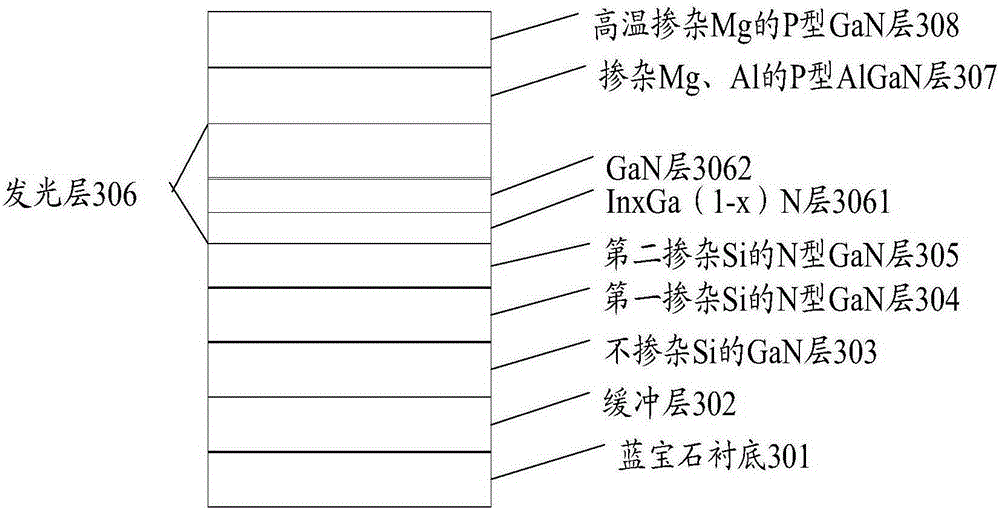

LED epitaxial structure with high light extraction efficiency and growing method thereof

InactiveCN107068822ALower activation energyImprove activation efficiencySemiconductor devicesUltrasound attenuationOptoelectronics

The invention provides an LED epitaxial structure which comprises a substrate, a low-temperature buffer layer, a non-doped GaN layer, an Si-doped n-type GaN layer, an InxGa(1-x)N / GaN light emitting layer, an InX / Mg3N2 super-lattice inner roughed layer, a p-type AlGaN layer and a magnesium-doped p-type GaN layer, wherein the substrate, the low-temperature buffer layer, the non-doped GaN layer, the Si-doped n-type GaN layer, the InxGa(1-x)N / GaN light emitting layer, the InX / Mg3N2 super-lattice inner roughed layer, the p-type AlGaN layer and the magnesium-doped p-type GaN layer are successively laminated. The InX / Mg3N2 super-lattice inner roughed layer comprises 8-10 monomers which are arranged in an overlapped manner. Each monomer comprises an InN layer and a Mg3N2 layer. The LED epitaxial structure provided by the invention is advantageous in that the InX / Mg3N2 super-lattice inner roughed layer covers the light emitting layer; the InX / Mg3N2 material has an advantage of low mismatch with the GaN crystal lattice; high quality of the epitaxial layer crystal is realized; not only is light efficiency improved, but also antistatic capability can be improved; and LED product quality is improved. As an integral technical solution, the InX / Mg3N2 super-lattice inner roughed layer has advantages of increasing number of photons extracted from the LED in light unit time, reducing number of attenuation times of the photons in the LED, and correspondingly improving light extraction strength. The invention further discloses a growing method of the LED epitaxial structure. The growing method of the LED epitaxial structure has advantages of concise steps, easy process parameter control and convenient industrial production.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com