Gallium nitride compound semiconductor device and manufacturing method

一种半导体、化合物的技术,应用在氮化镓类化合物半导体装置及其制造领域,能够解决发光元件成本增加、降低差排密度、花费工夫等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

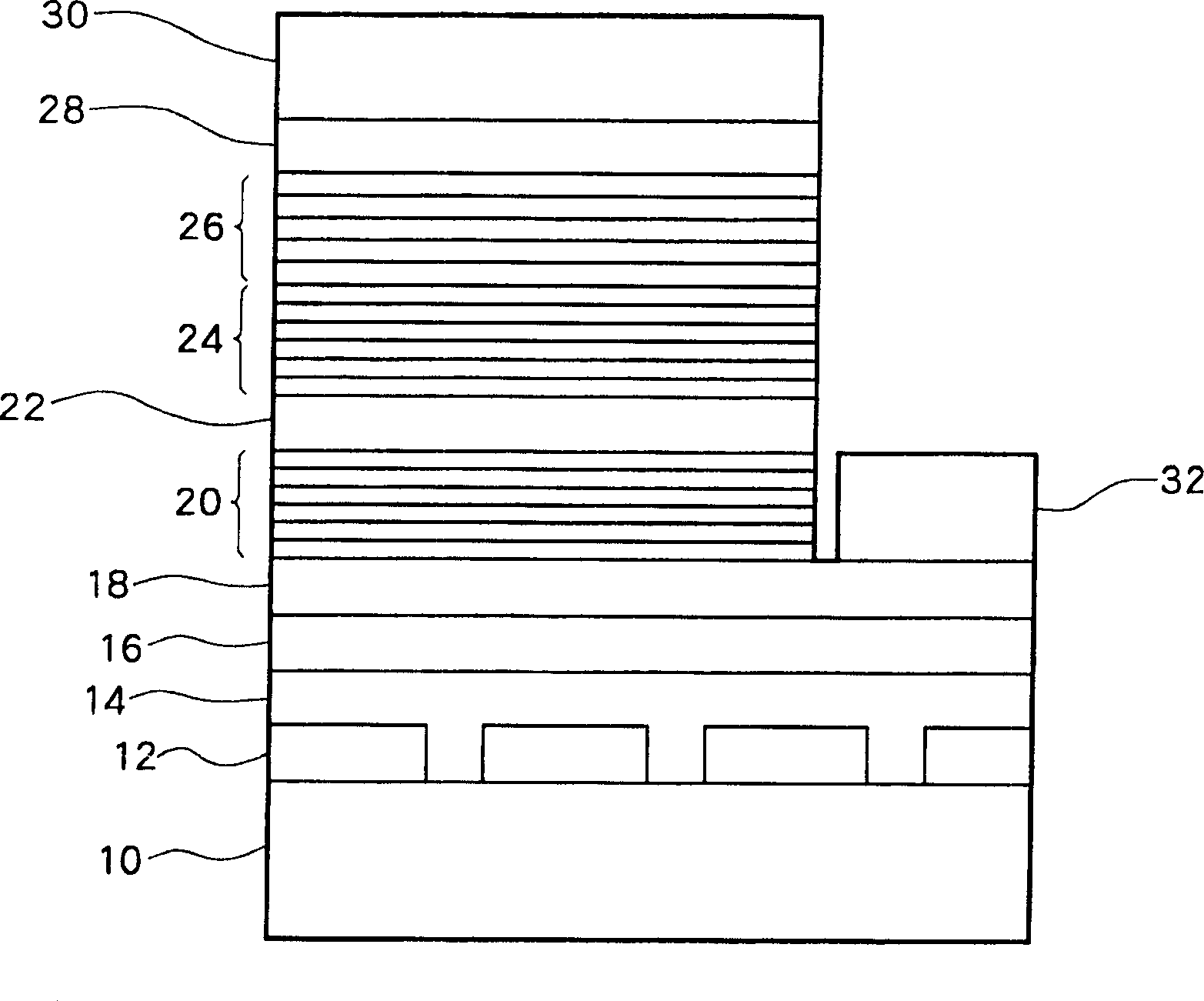

[0027] exist figure 1, shows the structure of a light-emitting element (LED (light-emitting diode)) that is the GaN-based compound semiconductor device of the present embodiment. A light-emitting element is manufactured by growing multiple layers on a substrate by MOCVD (Metal Organic Chemical Vapor Growth). Specifically, it was manufactured as follows. In addition, the MOCVD apparatus itself is known, but when the apparatus structure is outlined, a sensor and a gas introduction pipe are provided in a reaction tube. On the sensor, the substrate is placed, and the substrate is heated by the heater, and at the same time, the raw material gas is supplied, and the reaction proceeds on the substrate. The gas introduction part is provided, for example, on two sides of the reaction tube. One side introduces raw material gas such as trimethylgallium or silane gas from the side of the substrate, and the other side starts from the top of the substrate and passes through the gas-permea...

no. 2 Embodiment approach

[0070] Even under visible light, characters or figures cannot be seen even if they are drawn with a commercially available black pen (highlighter pen). However, when ultraviolet rays are irradiated here, the drawn characters or figures appear. Colored black pens (colored patterns appear when irradiated with ultraviolet light) are also commercially available, but in order to reproduce the color, the wavelength of the irradiated ultraviolet light must be 400nm or less, more precisely, the wavelength must be 380nm or less. Conventionally, fluorescent black lights or mercury lamps have been used as light sources, but they have the disadvantages of large size, large power consumption, and increased power supply.

[0071] Therefore, when using figure 1 When the light emitting element device (LED) shown is used as a light source for image reproduction, it can also be driven by a small battery. The figures drawn by the black pen were irradiated with LEDs having peak wavelengths of 40...

no. 3 Embodiment approach

[0075] The light from the LED of this embodiment was irradiated on human skin for a short time, and its influence was investigated. LED light with a peak wavelength of 400nm (5mW), 385nm (3mW), and 372nm (1mW) was irradiated on the skin for 10 minutes to investigate changes in the skin (so-called tanning). As a result, almost no influence was found at the peak wavelength of 400nm (5mW), and a slight change was observed at 385nm (3mW). On the other hand, at 372nm (1mW), a clear trace was seen. This means that LEDs with a wavelength of 365-380nm cause tanning of the human body. Using this LED as a light source, a tanning device is manufactured. An apparatus for tanning only dots with a diameter of 5 mm and an apparatus for tanning lines by arranging LEDs on a straight line with a length of 3 cm were fabricated and tested. Either device was irradiated for 10 minutes to obtain a tan. In addition, skin damage was considered to occur when irradiated for 30 minutes or more.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com