Patents

Literature

77 results about "Trimethylgallium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylgallium, Ga(CH₃)₃, often abbreviated to TMG or TMGa, is the preferred metalorganic source of gallium for metalorganic vapour phase epitaxy (MOVPE) of gallium-containing compound semiconductors, such as GaAs, GaN, GaP, GaSb, InGaAs, InGaN, AlGaInP, InGaP and AlInGaNP.

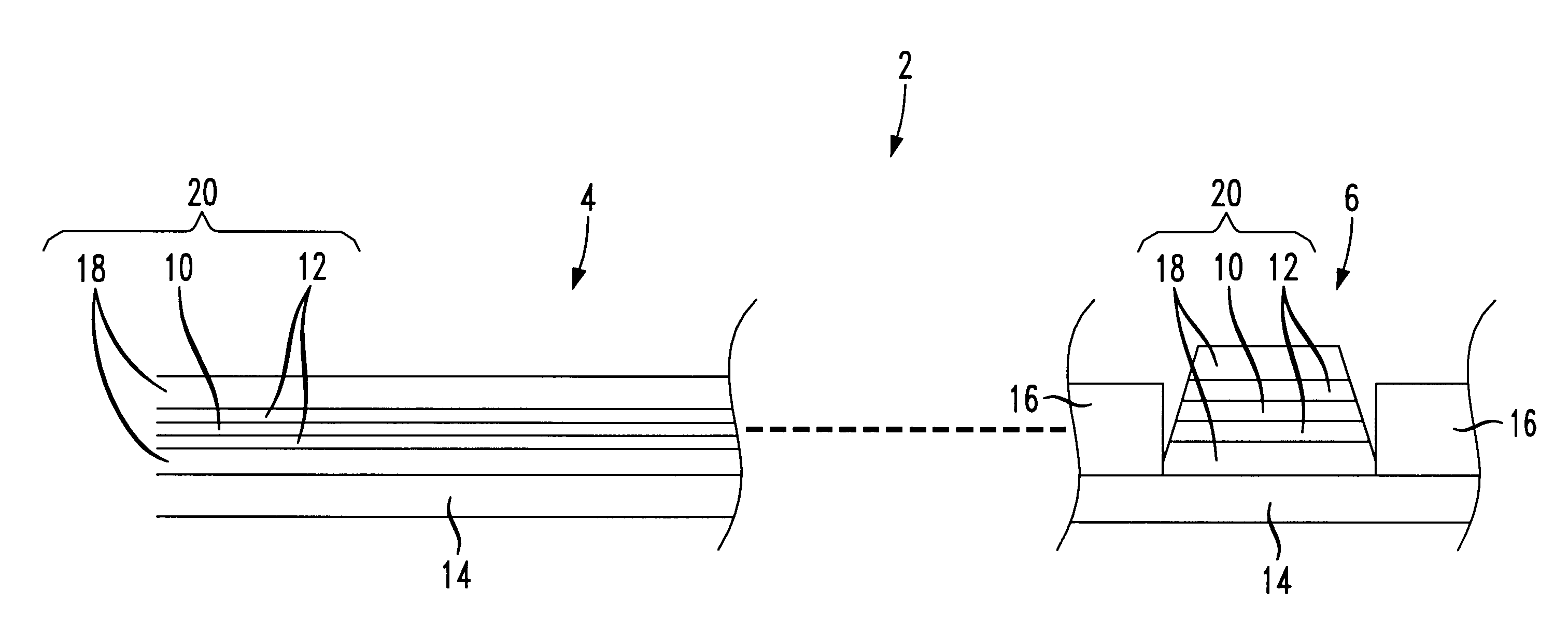

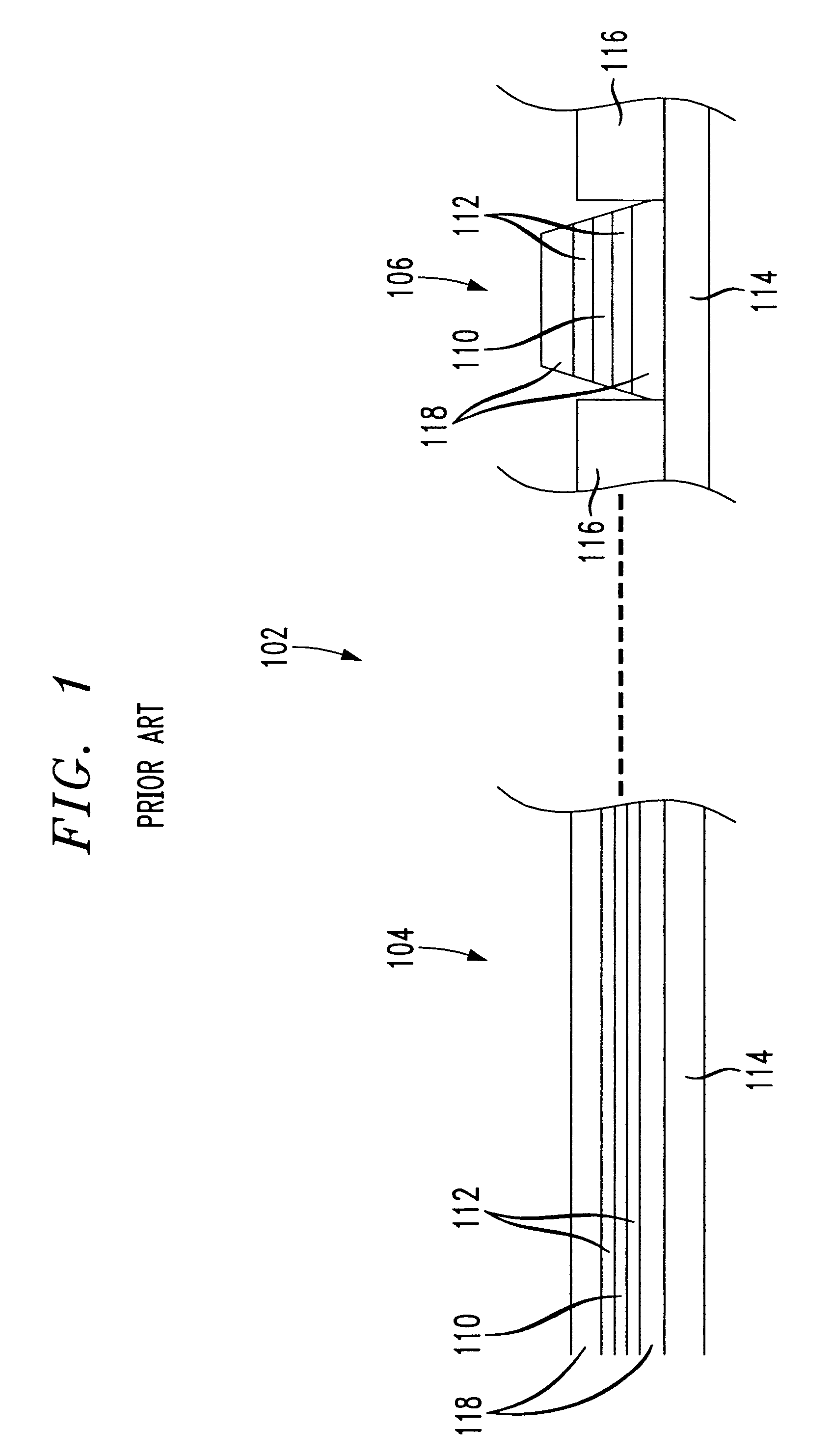

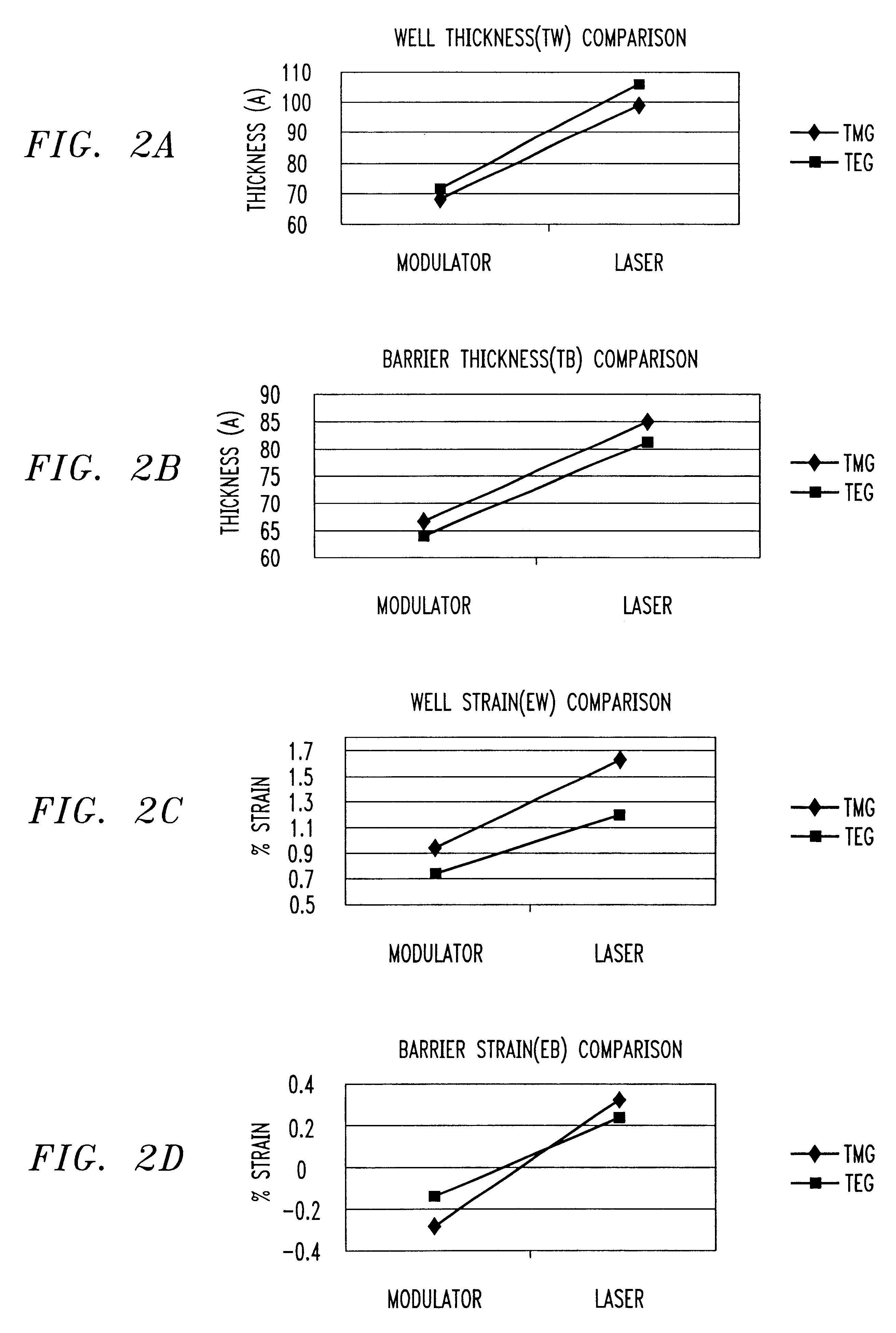

Net strain reduction in integrated laser-modulator

A semiconductor device including first and second epitaxial layers grown in a selective area growth region on a substrate includes an active layer or well layer comprising a first composition formed using a trimethylgallium precursor material and a barrier layer comprising a second composition formed using a triethylgallium precursor material. The use of the first and second compositions in the well layer and barrier layer respectively maximizes the strain in the well layer while simultaneously minimizing the net strain of the selective area growth region.

Owner:LUCENT TECH INC

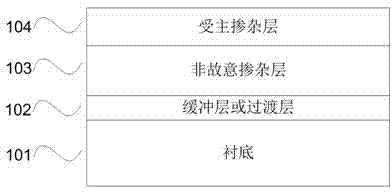

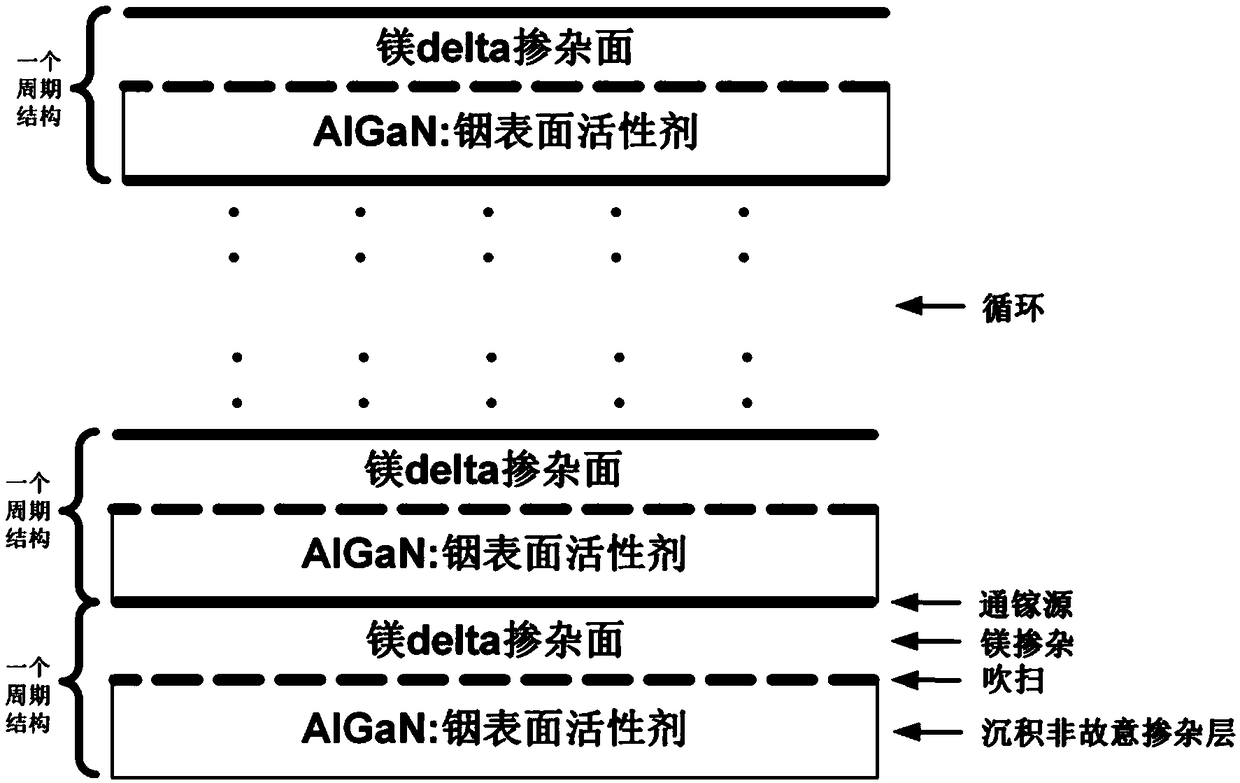

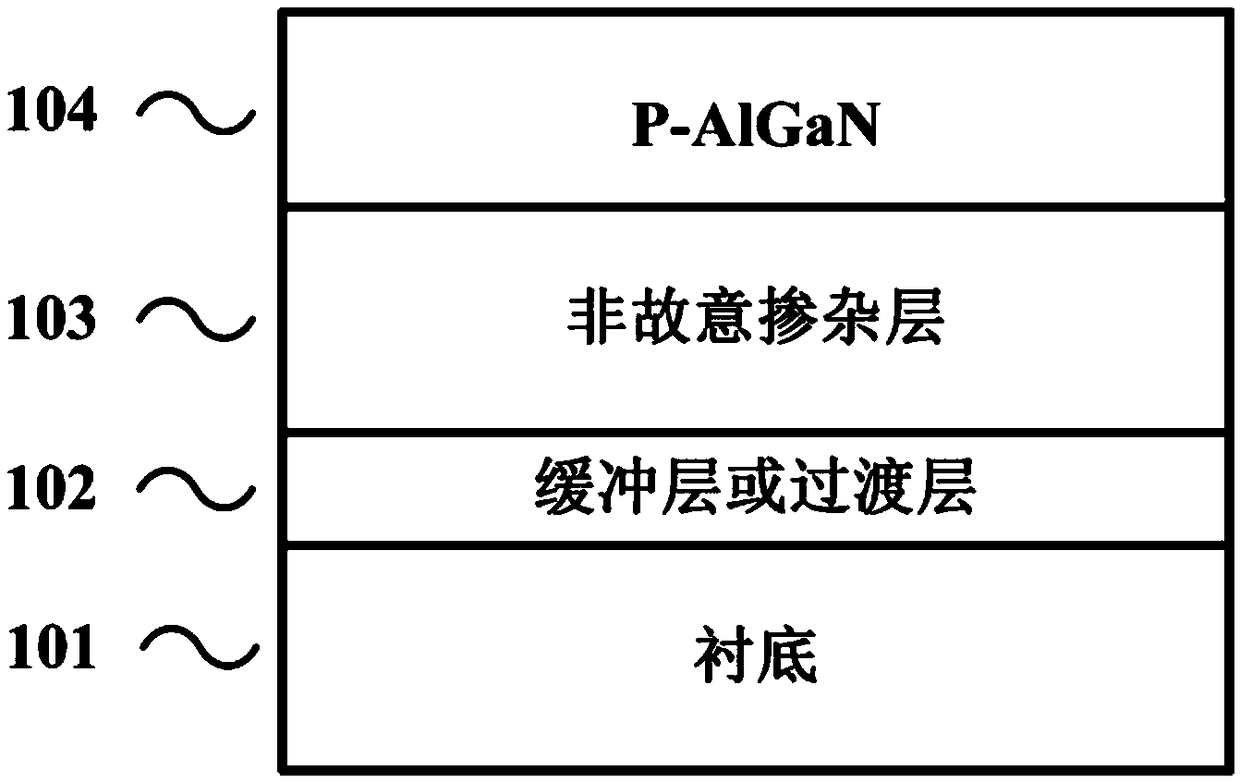

Preparation method of p type GaN and AlGaN semiconductor material

ActiveCN102903615AEasy to desorbImprove bindingSemiconductor/solid-state device manufacturingDimethylhydrazineSemiconductor materials

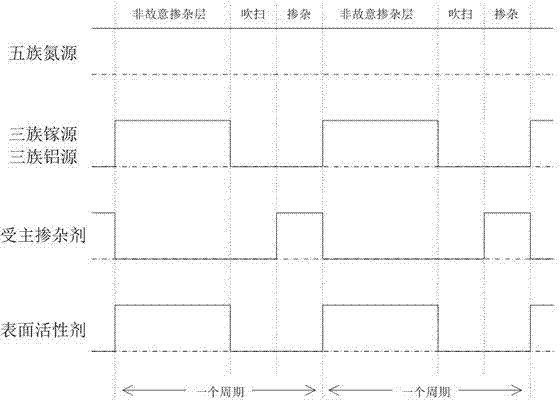

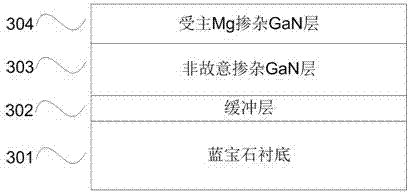

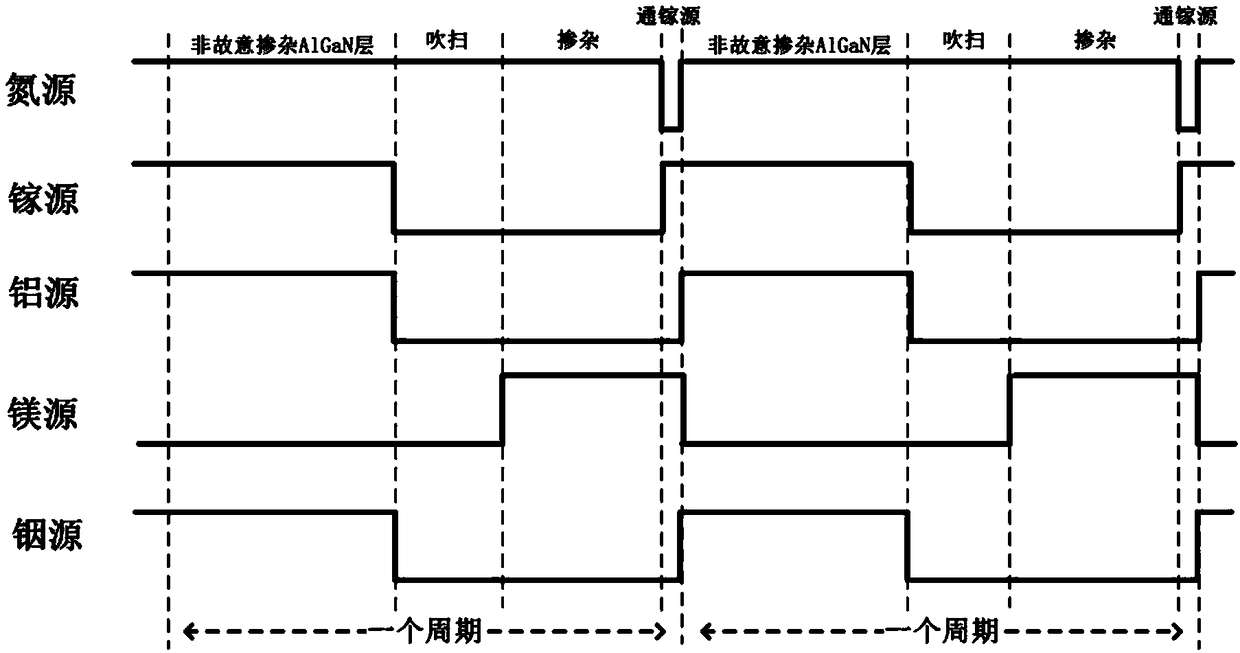

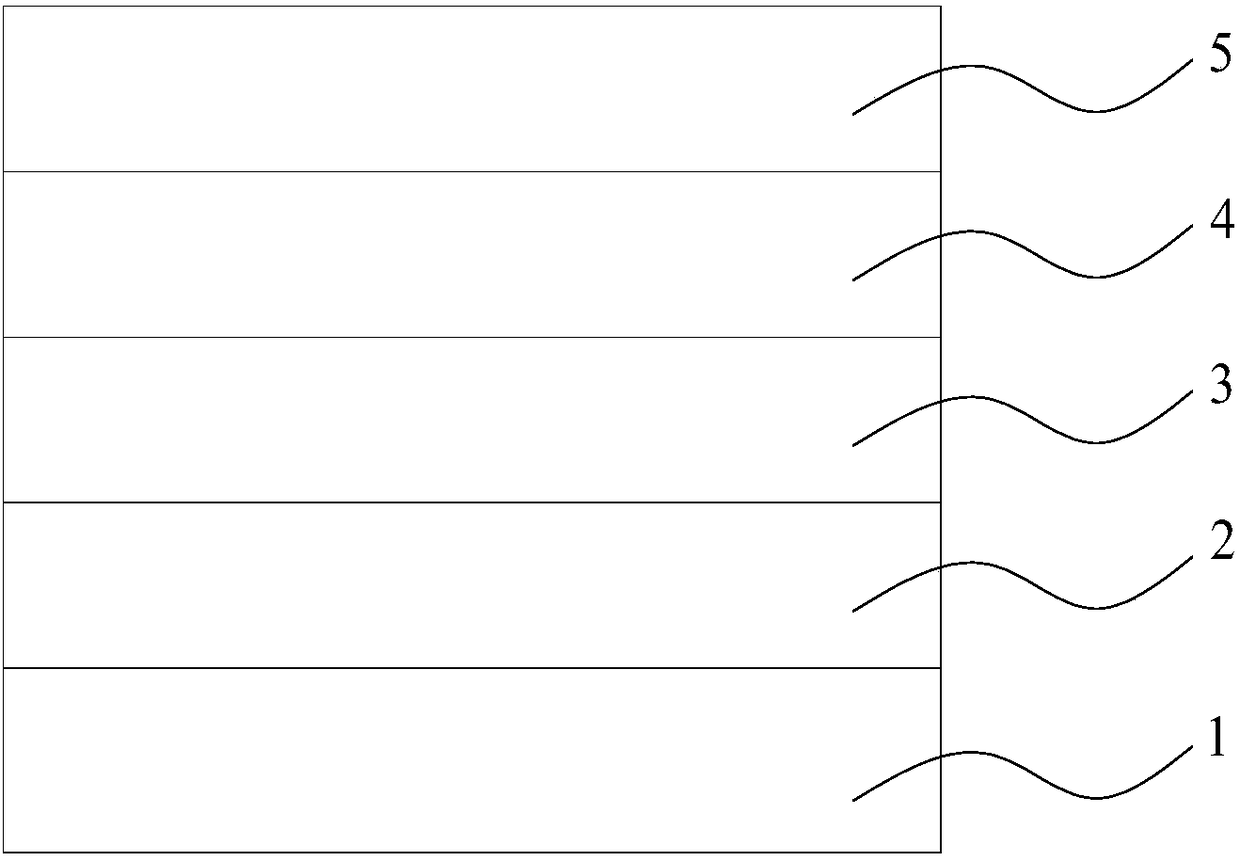

The invention discloses a preparation method of a p type GaN and AlGaN semiconductor material. A substrate, and a buffer layer or a transition layer, an unintended doped layer and an acceptor doped layer grown on the substrate from bottom to top are contained; in a growth process of the structure, ammonia or nitrogen dimethylhydrazine is used as a five-group nitrogen source; trimethyl gallium or TEGa used as a three-group gallium source, trimethylaluminium or triethyl aluminum used as a three-group aluminium source, and trimethylindium or TEIn used as a three-group indium source are collectively called three-group metal sources; and the trimethylindium or the TEIn is also used as a surface active agent and used in the acceptor doped layer. According to the method, the trimethylindium or the TEIn is used as the surface active agent to assist growth, and simultaneously, the acceptor doped layer is prepared by adopting a delta doping method. According to the method, the doping efficiency of acceptor doped magnesium atoms is increased, and simultaneously, the self-compensation effect is suppressed, so that the p type GaN and AlGaN semiconductor material with favorable crystalline quality and high hole concentration is obtained.

Owner:SUN YAT SEN UNIV

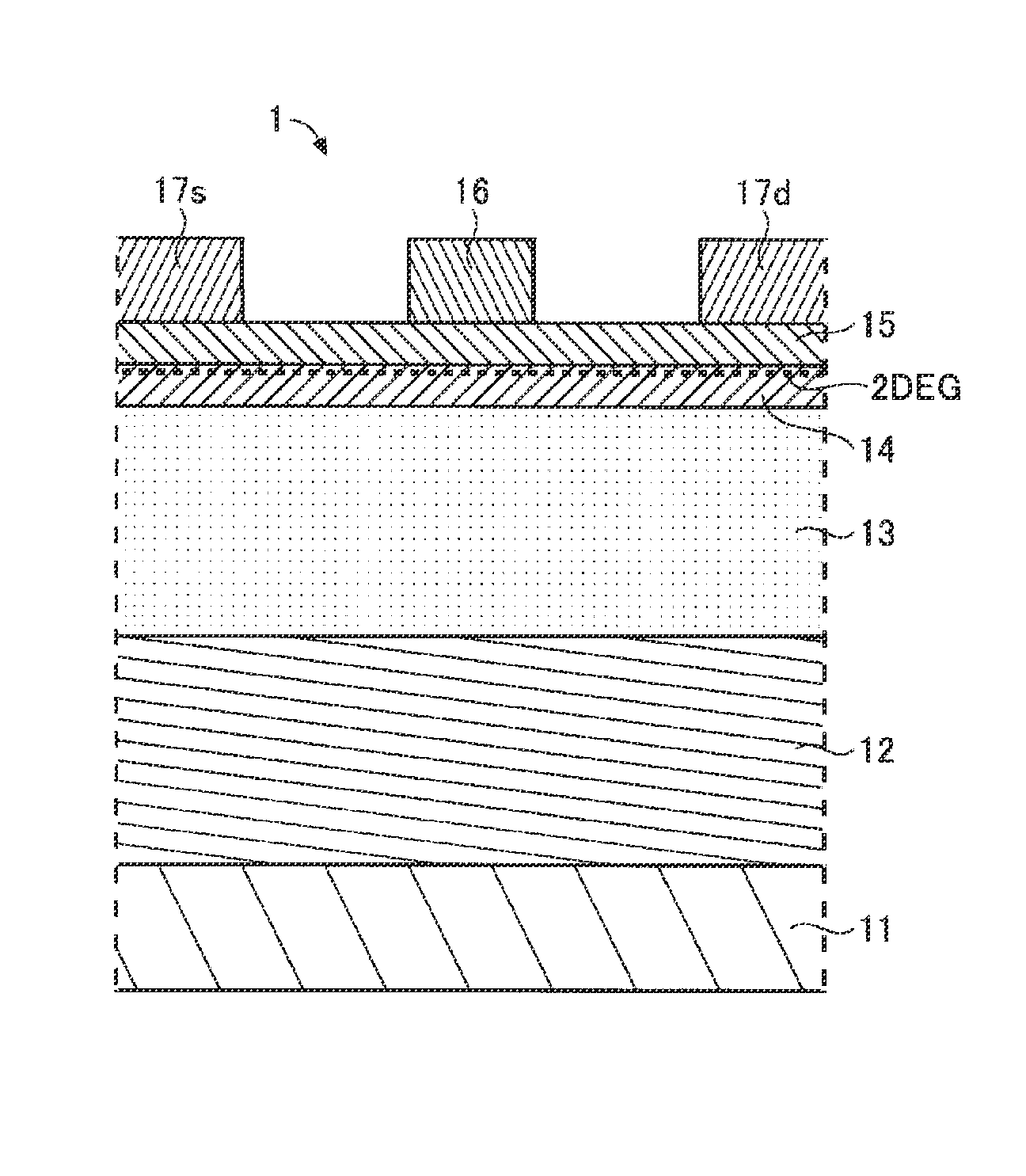

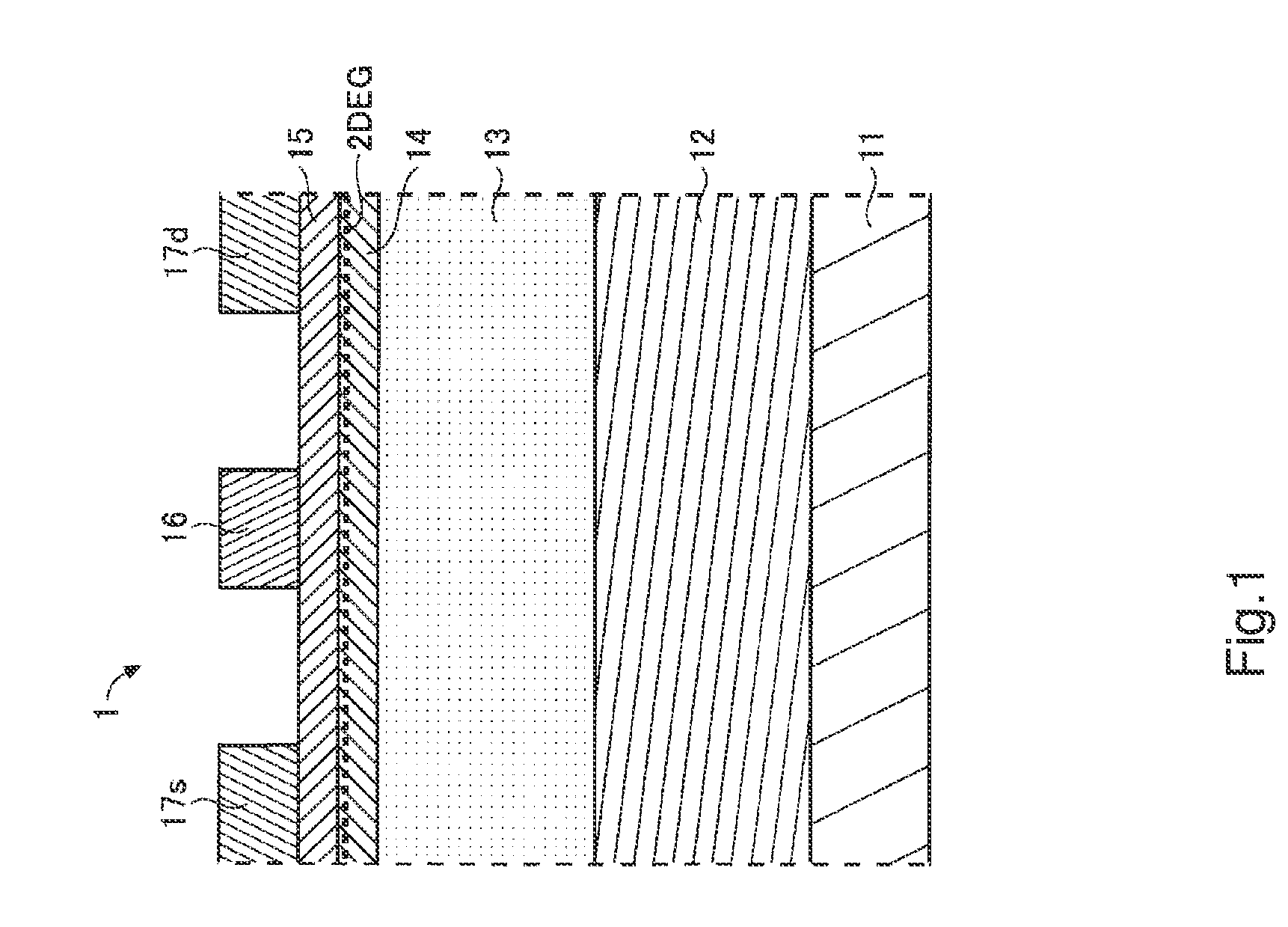

Semiconductor device and method for manufacturing the same

InactiveUS20100244101A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsOrganic compound

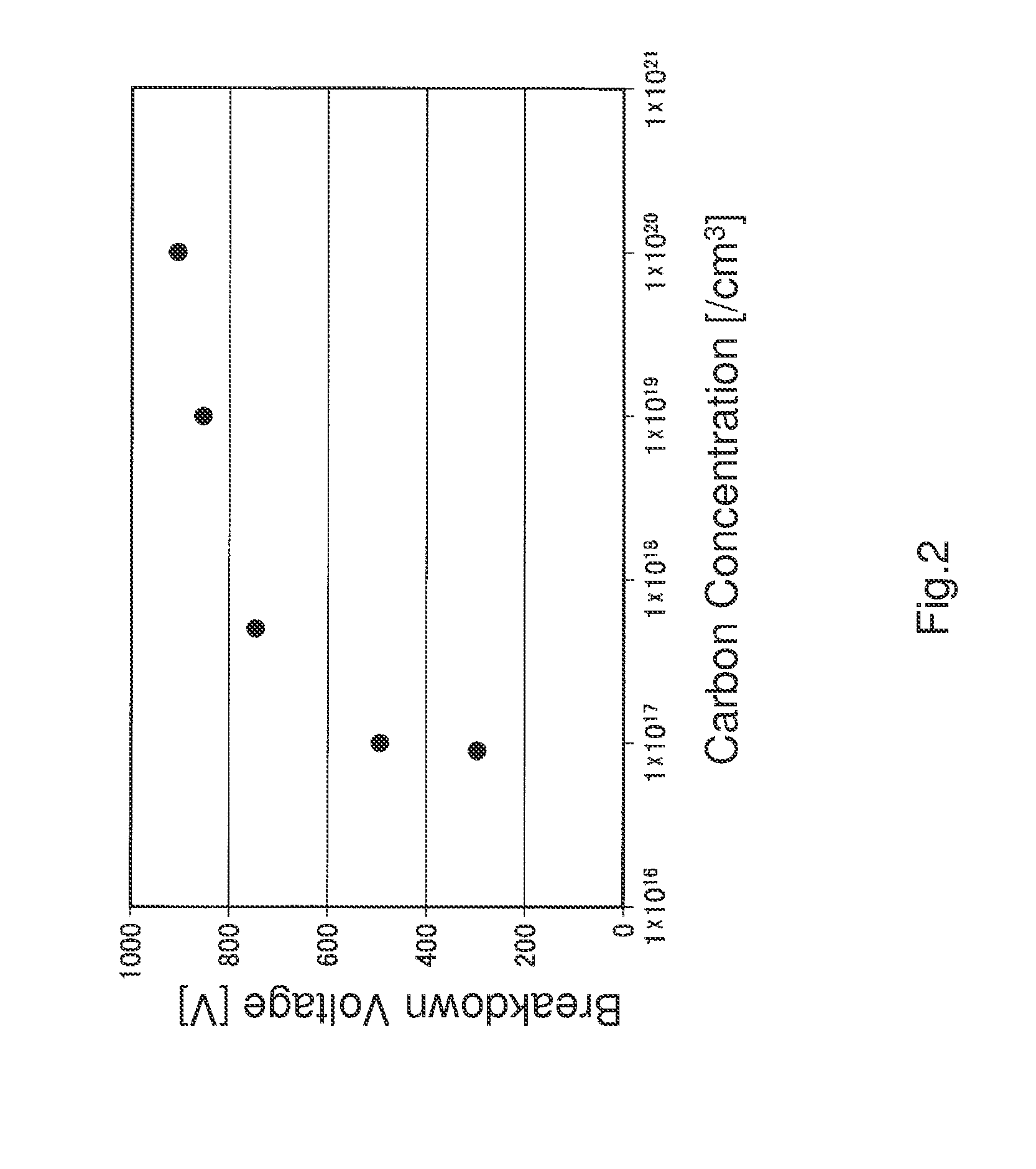

There is provided a method for fabricating a semiconductor device capable of setting carbon concentration within crystal to a desirable value while improving electron mobility. The carbon concentration within a buffer layer is controlled by introducing material gas of hydrocarbon or organic compounds containing carbon such as propane as a dopant in forming the buffer layer by introducing trimethylgallium (TMGa) and ammonium (NH3) as gaseous nitride compound semiconductor materials into a chamber in which a substrate is disposed.

Owner:FURUKAWA ELECTRIC CO LTD

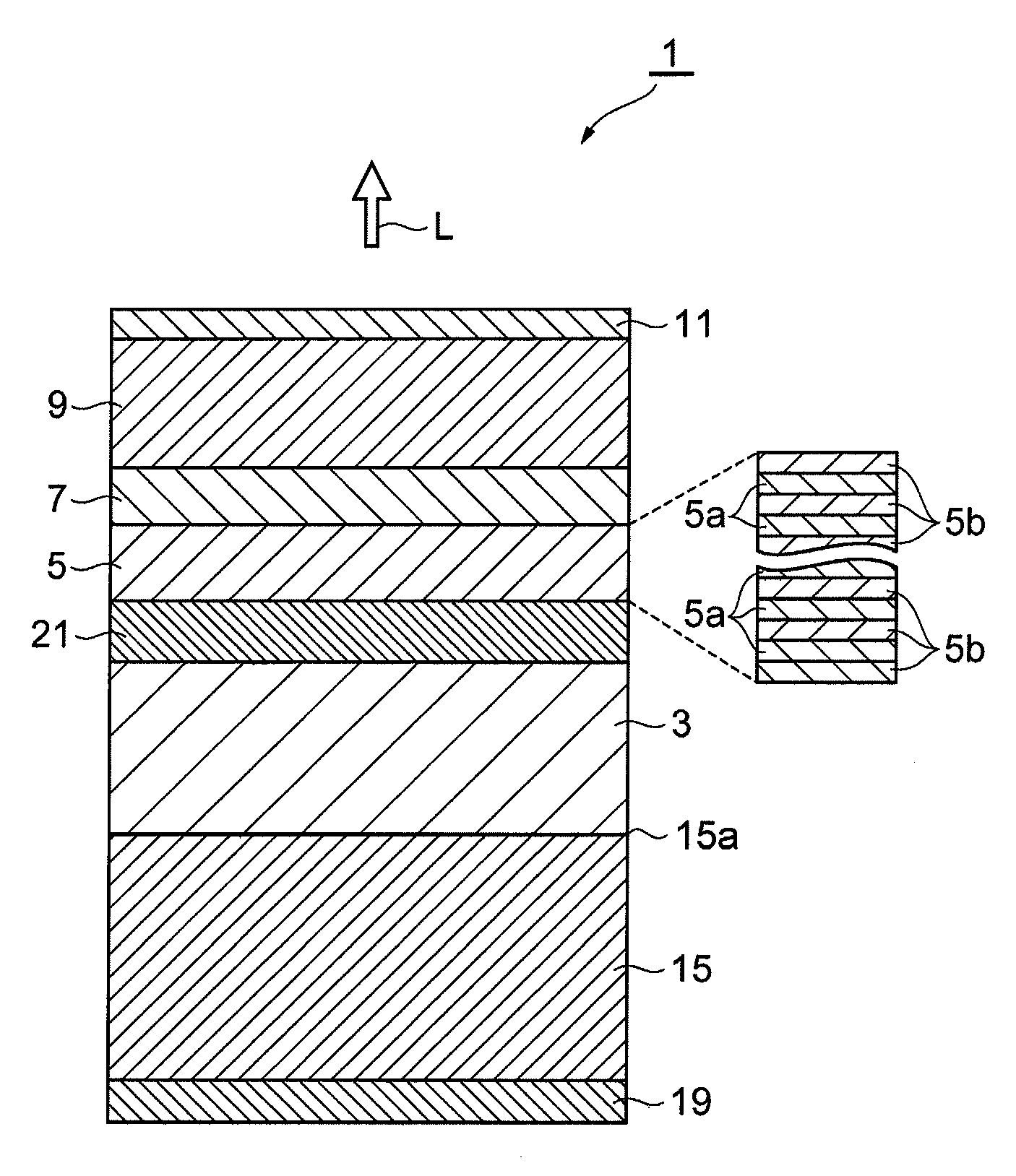

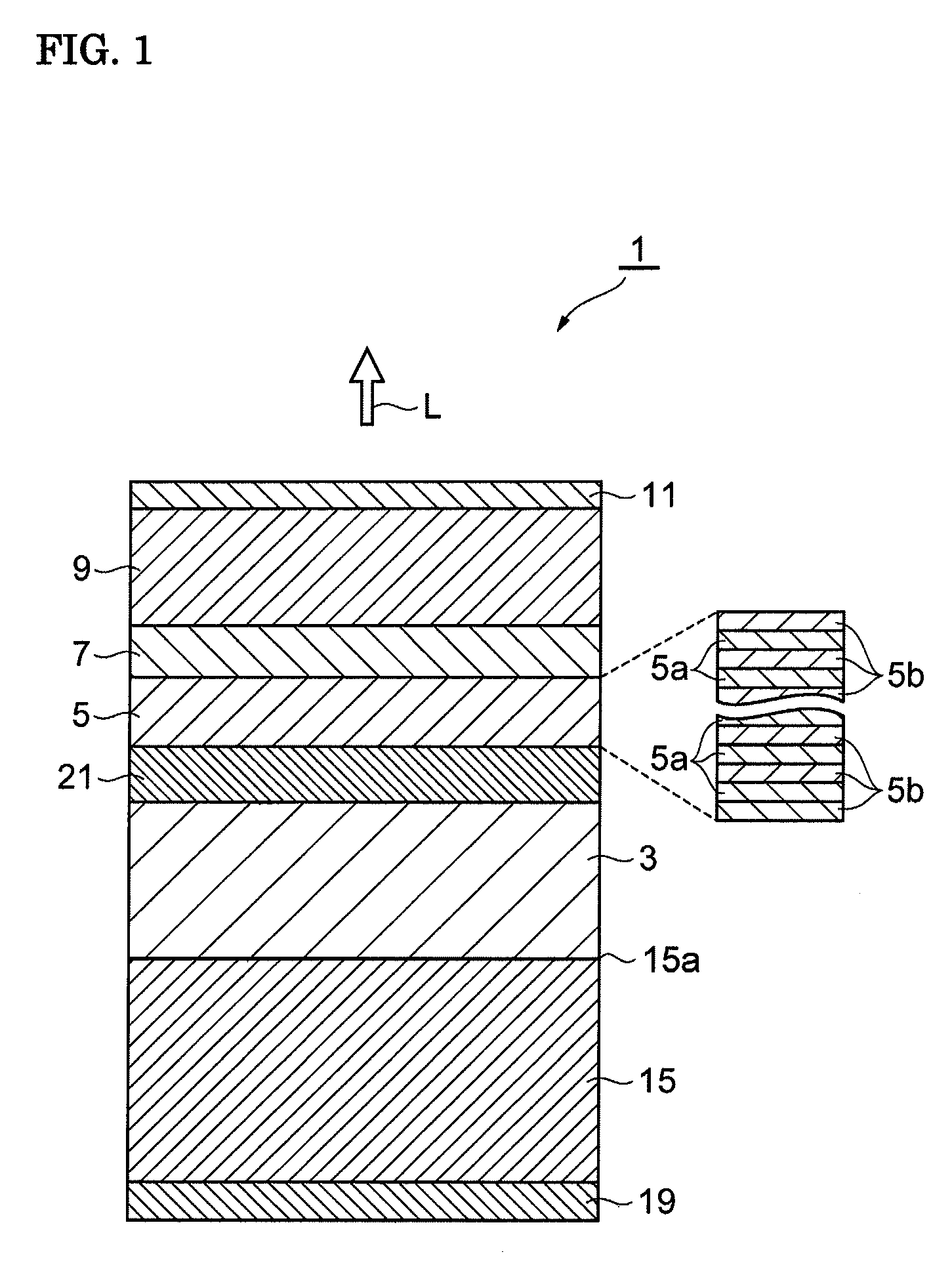

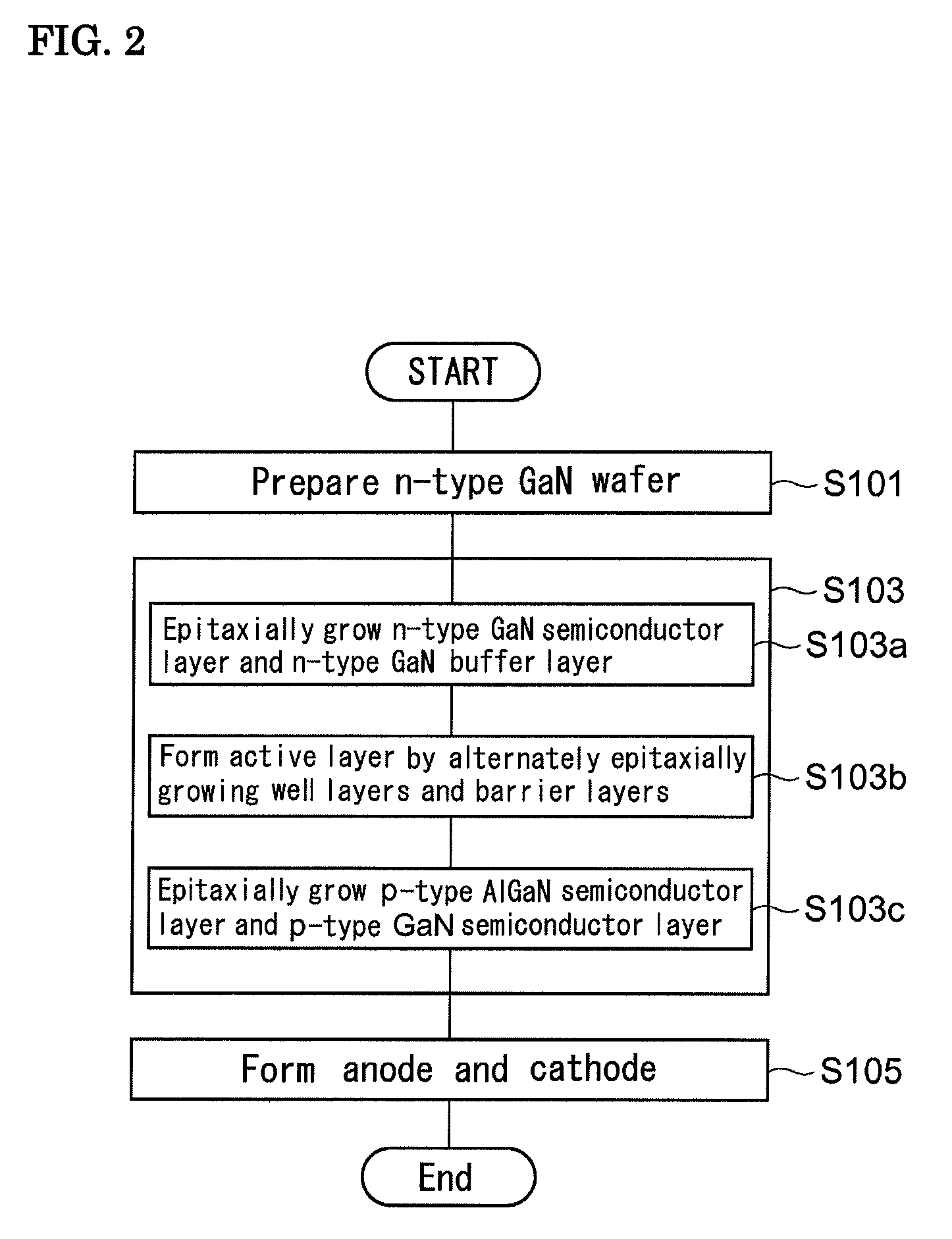

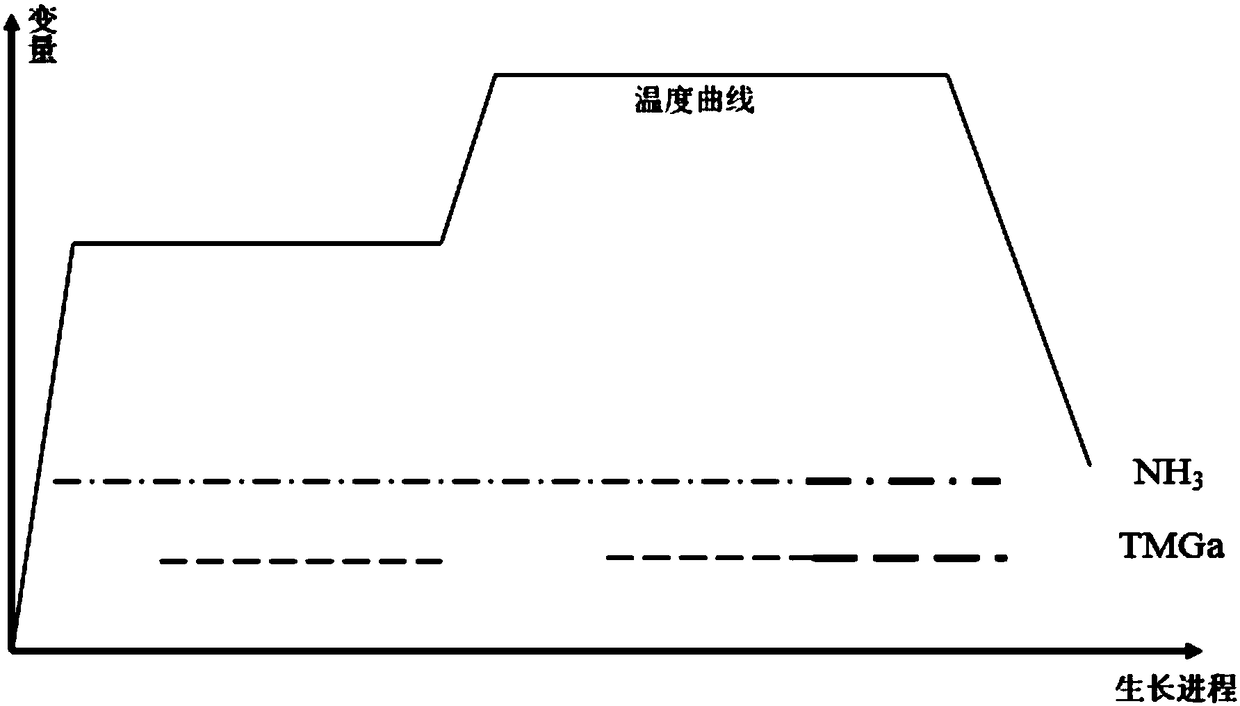

Method for forming quantum well structure and method for manufacturing semiconductor light emitting element

ActiveUS20090258452A1Reduce variationVariation in compositionNanoinformaticsSemiconductor/solid-state device manufacturingQuantum wellProduct gas

A method for forming a quantum well structure that can reduce the variation in the In composition in the thickness direction of a well layer and a method for manufacturing a semiconductor light emitting element are provided. In a step of forming a quantum well structure (active layer) by alternately growing barrier layers and well layers on a primary surface of a GaN substrate, the well layers are each formed by growing InGaN, the barrier layers are each grown at a first temperature, the well layers are each grown at a second temperature which is lower than that of the first temperature, and when the well layers are each formed, before a starting material gas for Ga (trimethylgallium) is supplied, a starting material gas for In is supplied.

Owner:SUMITOMO ELECTRIC IND LTD

Method for MOVCD growth nitride epitaxial layer

InactiveCN101343733AEasy to removeImprove pollutionChemical vapor deposition coatingIndiumLight-emitting diode

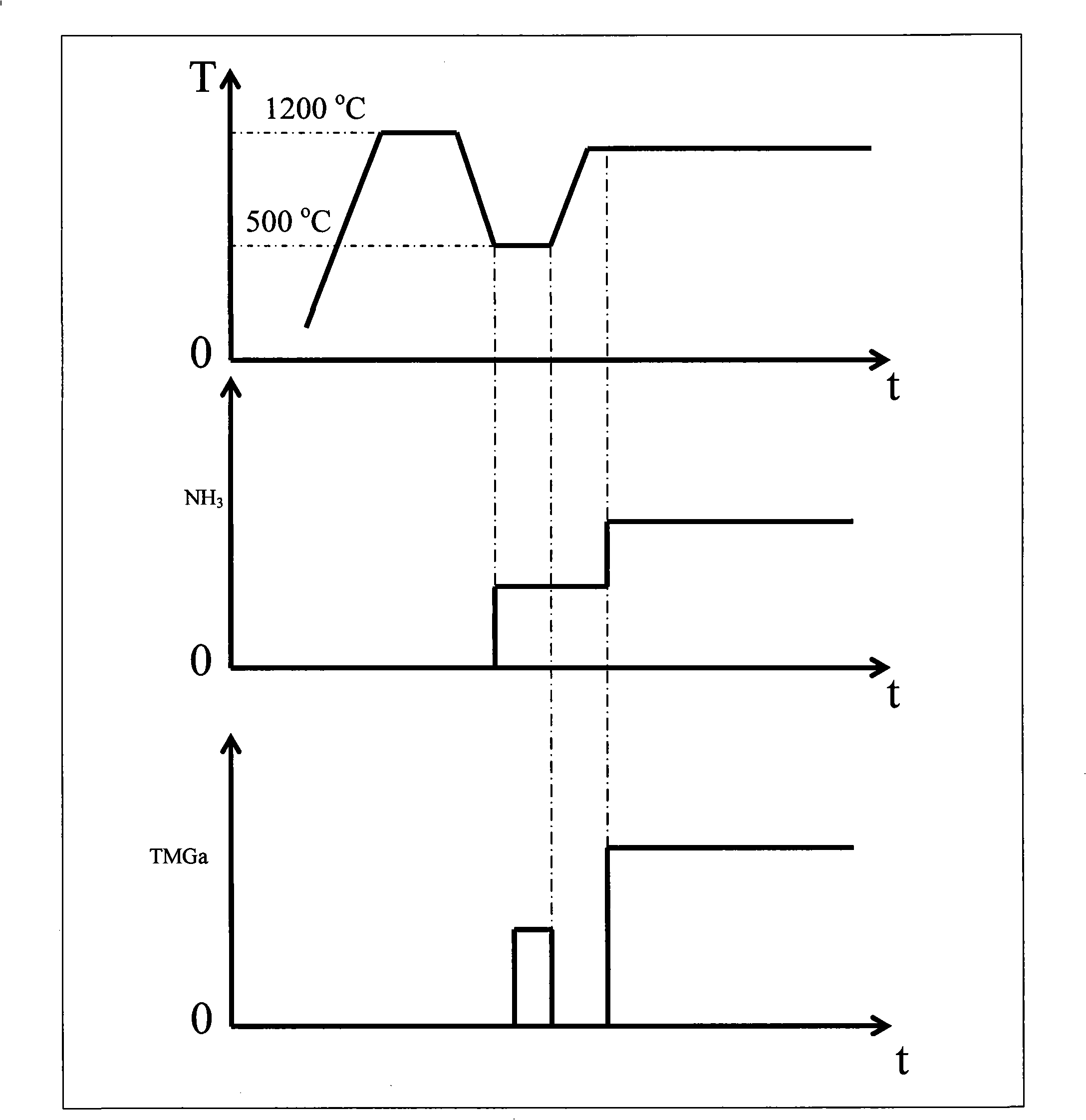

The invention relates to a method to generate nitride epitaxial layer and nitride light emitting diode structure epitaxial wafer through MOVCD. The MOVCD technology is adopted, high purity NH3 is utilized as N source, high purity H2 or N2 is utilized as the carrier gas, and trimethyl gallium (TMGa) or triethyl gallium (TEGa), trimethyl indium (TMIn) and trimethyl aluminium (TMAl) are respectively utilized as Ga source, In source and Al source; the substrate adopts sapphire (Al2O3); the sapphire substrate is heated to 500 DEG C in the MOCVD reaction chamber, in the atmosphere of H2, trimethyl gallium (TMGa) is filled to generate a GaN layer, in the high temperature (1200 DEG C) H2 atmosphere, reaction is generated between GaN and the sapphire(Al2O3) on the substrate surface, the surface damage and the surface pollution of the sapphire can be better removed, micro pits of the nanometer grade can be corroded on the sapphire surface, the micro pits is favorable to the improvement of the epitaxial layer, and to the most important, the LED emitting efficiency is enhanced.

Owner:EPILIGHT TECH +2

Method for growing high-quality gallium nitride epitaxial film on basis of gallium nitride substrate

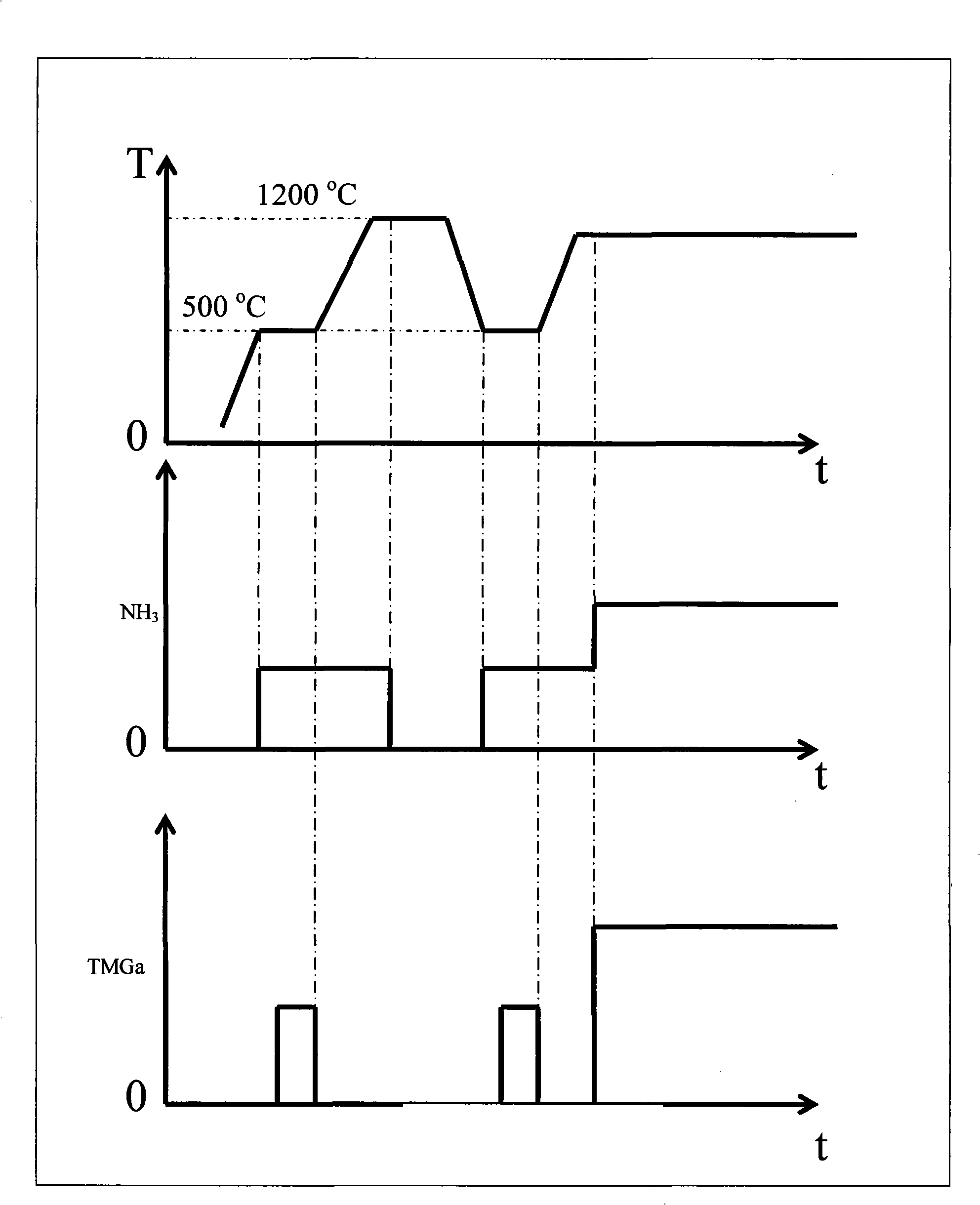

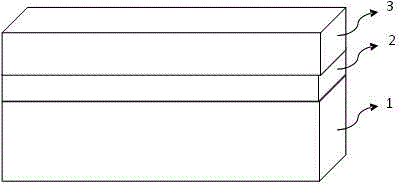

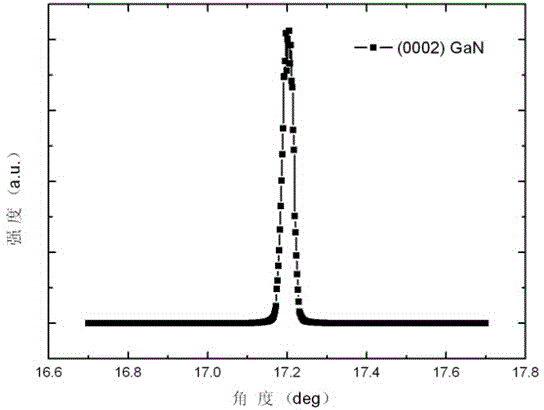

ActiveCN102719887AImprove crystal qualityQuality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingGallium nitrideGrowth cycle

The invention relates to a method for growing a high-quality gallium nitride epitaxial film on the basis of a gallium nitride substrate. The method is carried out in MOCVD (metal organic chemical vapor deposition) equipment and includes the following steps of selecting a substrate, placing the substrate into an MOCVD reaction chamber, heating and baking the substrate; introducing ammonia gas (NH3) for nitriding the substrate; cooling to the growth temperature and introducing trimethyl gallium (TMG) and the ammonia gas (NH3) at the same time; growing a first gallium nitride (GaN) optimized layer at lower pressure and high V / III, and growing a second layer of a high-quality GaN epitaxial film by boosting the pressure and reducing the V / III. The method for growing a high-quality gallium nitride epitaxial film on the basis of the gallium nitride substrate has the advantages that the method is simple and practical and is an effective resolution for growing high-quality low-cost GaN epitaxial films, and the growing period is short, materials are fine in performance.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

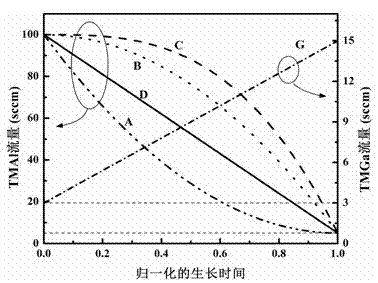

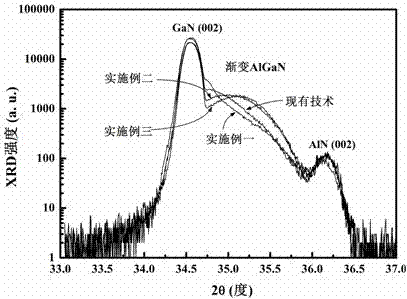

Gradient AlGaN layer preparation method and device prepared by same

ActiveCN103117209AChange rate of changeControl distributionSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorTrimethylgallium

The invention relates to the technical field of semiconductors, in particular to a gradient AlGaN layer preparation method and a device prepared by the same. When a gradient AlGaN layer is grown, flow of trimethylaluminum fed into a reaction chamber is gradually decreased, and flow of trimethylgallium is increased gradually. The function of the trimethylaluminum flow satisfies yTMAl=a-bx<m> or yTMAl=a(1-x)<m>+b, the function of the trimethylgallium flow satisfies yTMGa=cx<n>+d or yTMGa=c-d(1-x)<n>, x refers to normalization time of growing of the gradient AlGaN layer, and m and n are 1 asynchronously. By the aid of the different flow functions, change rates of TMAl and TMGa in different flows are changed, so that distribution of aluminum in the gradient AlGaN layer can be controlled effectively, further stress and crystalline quality of a GaN film growing on the gradient AlGaN layer are regulated and controlled, and a thick GaN film high in crystalline quality and free of crazing is grown.

Owner:SUN YAT SEN UNIV

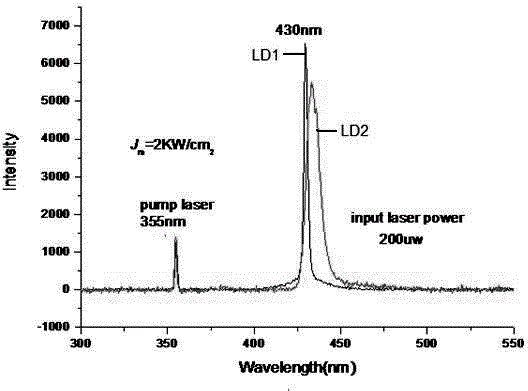

Method for preparing novel GaN-based laser and GaN-based laser

ActiveCN104319631AIncrease limit factorHigh gainLaser detailsLaser active region structureSilanesTrimethylgallium

The invention provides a method for preparing a novel GaN-based laser and a GaN-based laser. According to the method of the invention, a series of critical technologies and scientific problems in the preparation of a GaN-based laser can be solved through adopting a metal organic chemical compound vapor phase epitaxy technique. According to the technical scheme of the invention, the method for preparing the novel GaN-based laser includes the step that with trimethylgallium, trimethylindium and trimethylaluminum adopted as a III-family source, ammonia adopted as a V-family source, and silane adopted as an n type doping source, and magnesocene adopted as a P type doping source, the metal organic chemical compound vapor phase epitaxy technique is utilized to prepare the novel GaN-based laser. According to the method for preparing the novel GaN-based laser of the invention, a multi-cycle In component linear graded InxGa1-xN / GaN superlattice structure, replacing a traditional single GaN layer, is adopted as the waveguide layer of the GaN-based blue laser, and therefore, limiting factors of a light field in a laser emission region can be effectively improved, and the gain of the active regions of quantum wells can be improved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

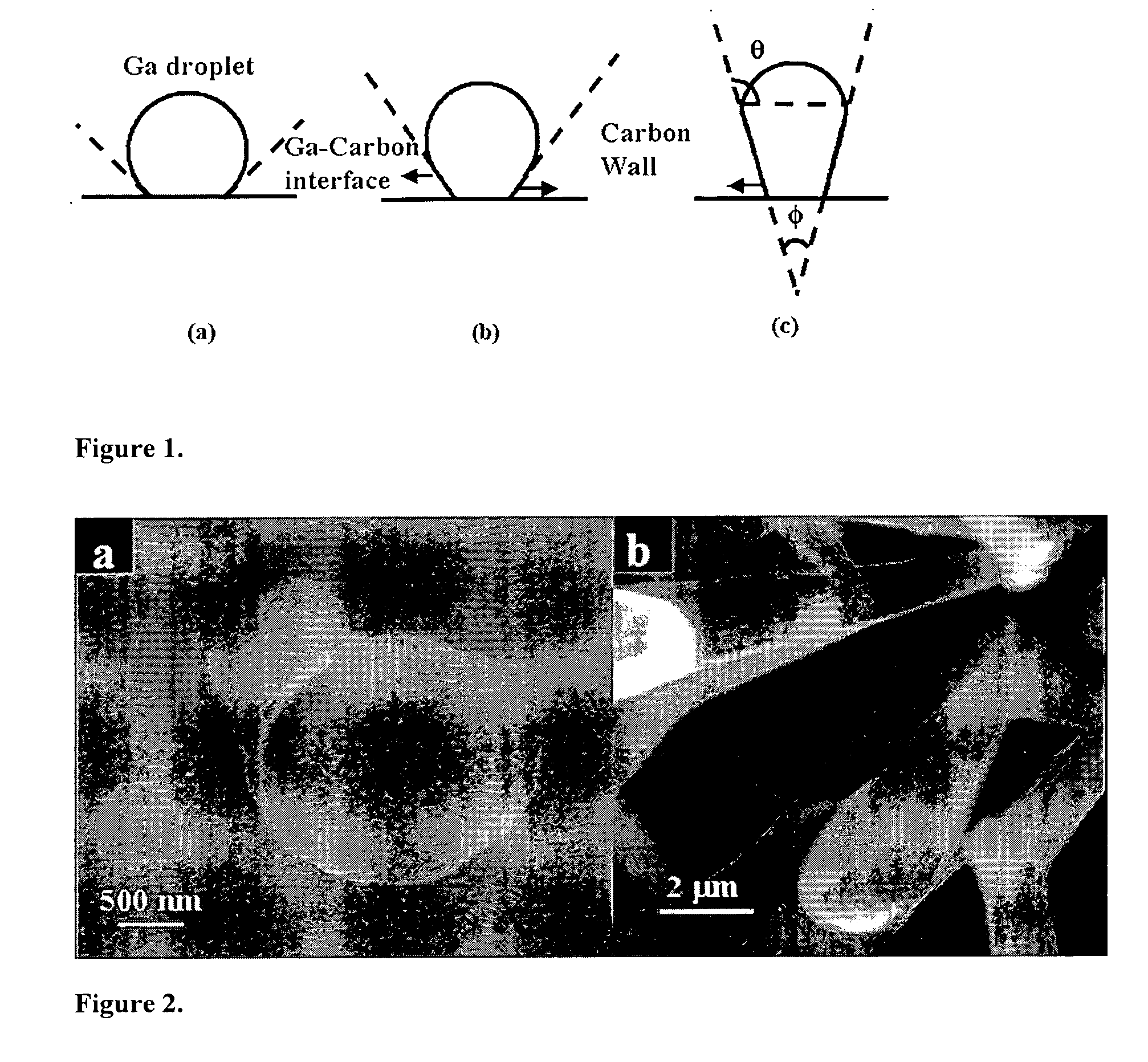

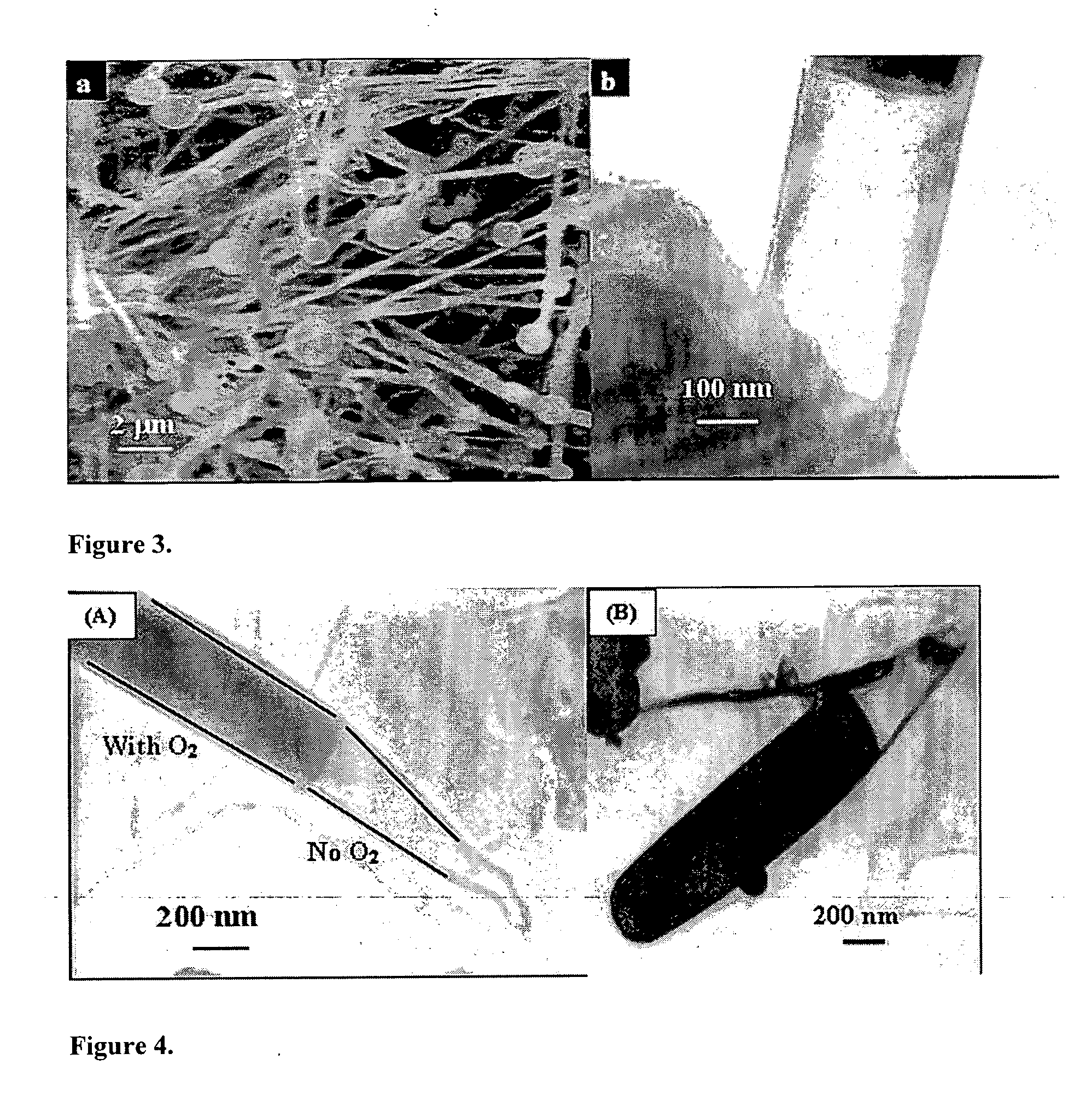

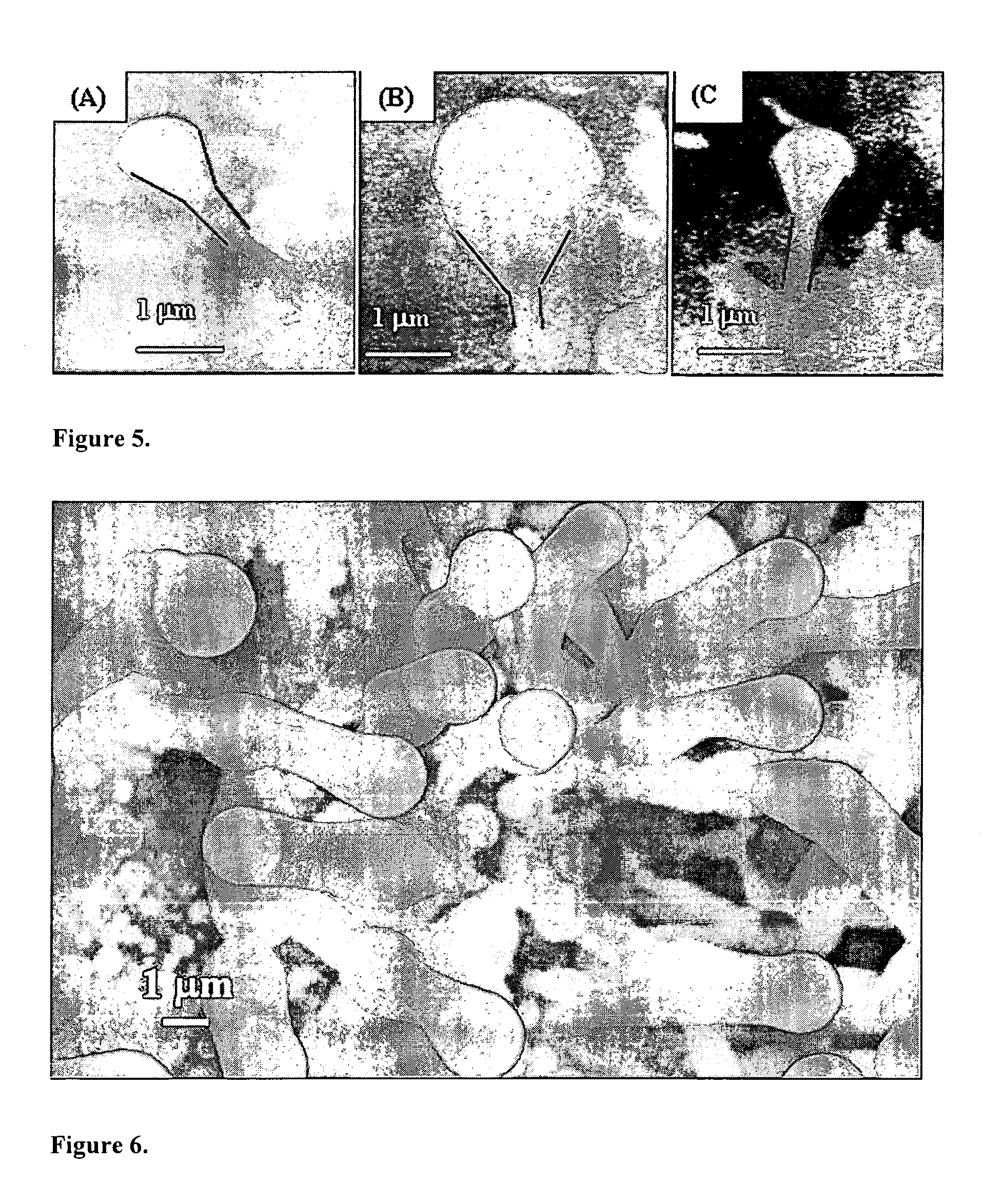

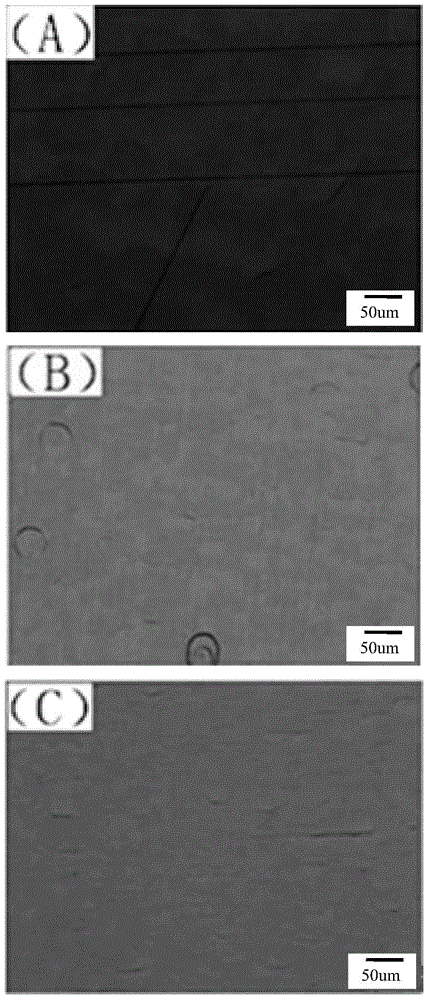

Tubular carbon nano/micro structures and method of making same

A method of synthesizing and controlling the internal diameters, conical angles, and morphology of tubular carbon nano / micro structures. Different morphologies can be synthesized included but not limited to cones, straight tubes, nozzles, cone-on-tube (funnels), tube-on-cone, cone-tube-cone, n-staged structures, multijunctioned tubes, Y-junctions, dumbbell (pinched morphology) and capsules. The process is based on changing the wetting behavior of a low melting metals such as gallium, indium, and aluminum with carbon using a growth environment of different gas phase chemistries. The described carbon tubular morphologies can be synthesized using any kind of gas phase excitation such as, but not limited to, microwave excitation, hot filament excitation, thermal excitation and Radio Frequency (RF) excitations. The depositions area is only limited by the substrate area in the equipment used and not limited by the process. The internal diameters of the carbon tubular structures can be varied from a few nm to as high as about 20 microns. The wall thickness is about 10-20 nm. The carbon tubular structures can be formed open on both ends are directly applicable to micro-fluidics. Gallium required for the growth of the carbon tubes can be supplied either as a thin film on the substrate or could be supplied through the gas phase with different precursors such as Tri-methyl gallium. Seamless Y-junctions with no internal obstructions can be synthesized without the need of templates. Multi-channeled junctions can also be synthesized without any internal obstructions. Gallium that partially fills the carbon structures can be removed from the tubes by simple heating in vacuum at temperature above 600°.

Owner:UNIV OF LOUISVILLE RES FOUND INC +1

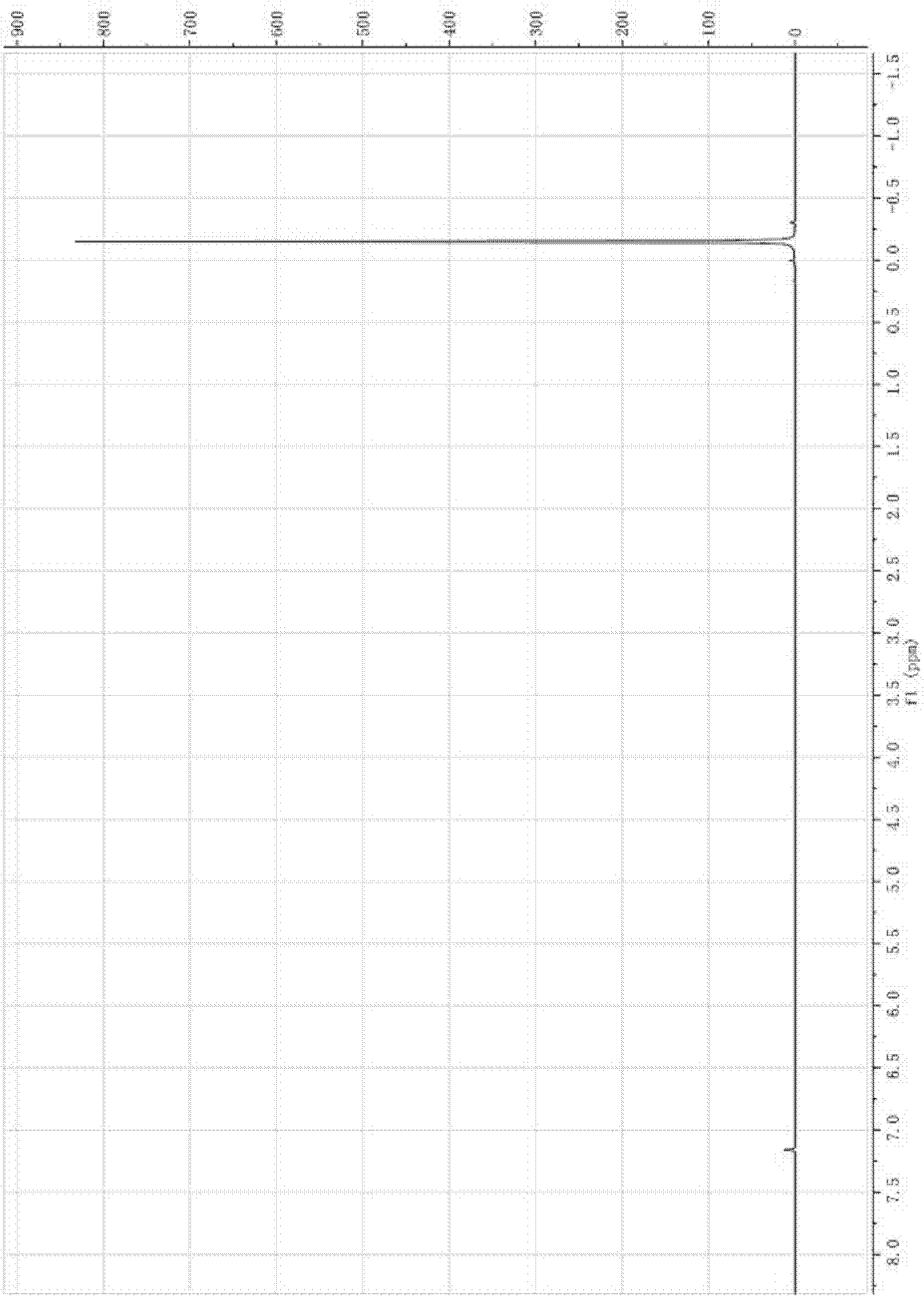

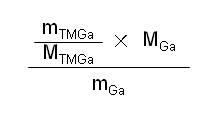

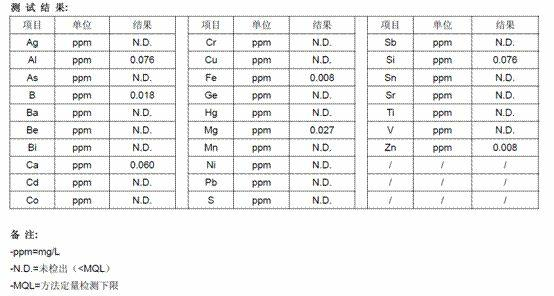

Method for production of trimethyl gallium at high efficiency and low cost

InactiveCN103333184AHighlight substantive featuresSignificant progressGroup 3/13 element organic compoundsMg alloysDistillation

The invention relates to a method for production of trimethyl gallium at high efficiency and low cost. The method includes: adding a gallium-magnesium alloy into a reaction kettle filled with an inert gas, in the presence of an ether solvent, conducting heating to 30-80DEG C under a stirring condition, adding an initiator, initiating a reaction, then introducing methane chloride continuously till the end of the reaction, controlling the reaction rate by controlling the introduction speed of the methane chloride, evaporating the solvent after the end of the reaction, carrying out distillation under a pressure reduction condition to obtain a complex of trimethyl gallium and ether, adding the complex into high boiling point organic amine N(R')3, conducting distillation to remove the ether solvent, then further removing ether and low boiling point impurities under a reduced pressure, finally performing decomplexation to obtain an oxygen-free trimethyl gallium crude product, and rectifying the trimethyl gallium crude product so as to obtain high purity trimethyl gallium. By employing the methane chloride gas and the gallium-magnesium alloy to react to prepare trimethyl gallium, the reaction conversion rate reaches over 85%. Due to the low price of methane chloride, the production cost of trimethyl gallium can be greatly reduced.

Owner:JIANGSU NATA OPTO ELECTRONICS MATERIAL

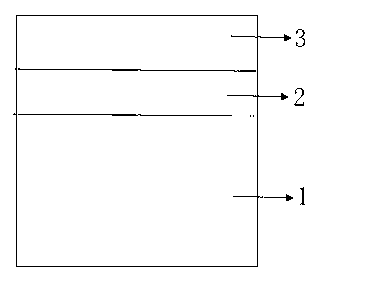

Method of preparing low-dislocation density GaN thin film on Si substrate by adopting carbon nanotubes as periodic dielectric mask

The invention provides a method of preparing a low-dislocation density GaN thin film on a Si substrate by adopting carbon nanotubes as a periodic dielectric mask. The method comprises steps: trimethylgallium (TMGa) and trimethylaluminum (TMAl) are used as an III-group source, an ammonia gas (NH3) serves as a V-group source, silane (SiH4) serves as an n-type doping source, after a high-temperature AlN nucleation layer grows on the Si substrate, two layers or three layers or four layers one-way (crossed) carbon nanotube periodic dielectric masks are prepared to pattern the AlN / Si substrate layer; then, a selective area epitaxial method is adopted to grow a low-Al component AlxGa1-xN merged layer with a thickness of 0.3 to 0.5 micrometer and the Al component no more than 0.25 on the patterned AlN / Si substrate template; then, four layers of GaN grow respectively, three layers of low-temperature AlyGa1-yN stress control layers are inserted in two GaN layers, wherein the Al component y is gradually decreased along with the increasing of layers and y is no less than 0.5 but no more than 1; and thus, the low-dislocation density, non-crack and high-crystal quality GaN / Si thin film can be acquired, wherein the thin film has a thickness of 2 micrometer, the half width of the 002 surface is 500 aresec, and the half width of the 102 surface is 610 aresec.

Owner:SINO NITRIDE SEMICON +1

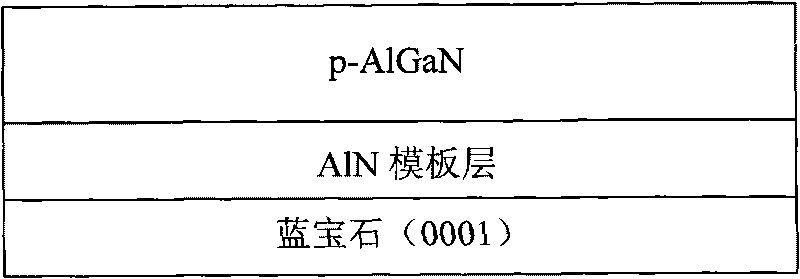

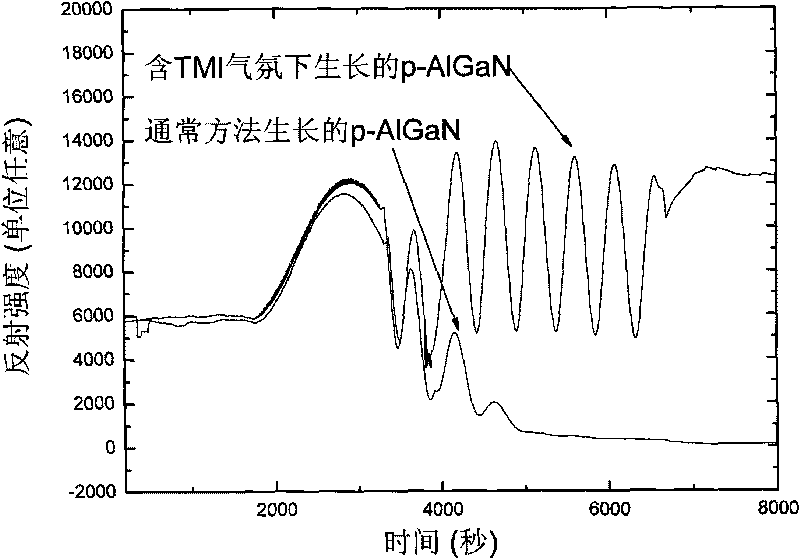

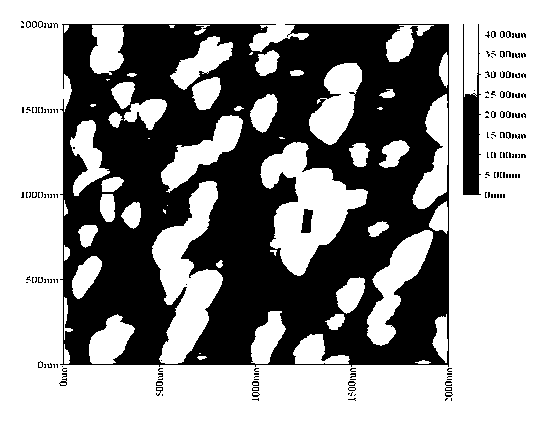

Method for growing p-type AlGaN

InactiveCN101728250AAct as an active agentImprove surface topographyFinal product manufactureSemiconductor/solid-state device manufacturingLuminous intensityGas phase

The invention discloses a method for growing p-type AlGaN. The method comprises the following steps: introducing trimethylindium serving as an activating agent while growing a p-type AlGaN layer by a metal organic chemical vapor deposition method, generally adopting high-purity hydrogen gas as carrier gas, trimethylgallium, trimethyl aluminium and ammonia gas as a Ga source, an Al source and an N source respectively and magnesium as a p-type doping agent, introducing the trimethylindium and other raw materials into a reaction chamber for epitaxially growing p-AlGaN, and generally controlling the flow rate of the trimethylindium to between 20 and 300 sccm. The method is simple and feasible, has obvious effect, can improve the surface appearance of the p-AlGaN, and reduces square resistance of the p-AlGaN; moreover, when applied to the preparation of a device, the method can effectively reduce the series resistance and cut-in voltage of the device, enhance the luminous intensity of the device, and particularly has more remarkable effect on the p-AlGaN with high Al component and deep ultraviolet LED devices.

Owner:PEKING UNIV

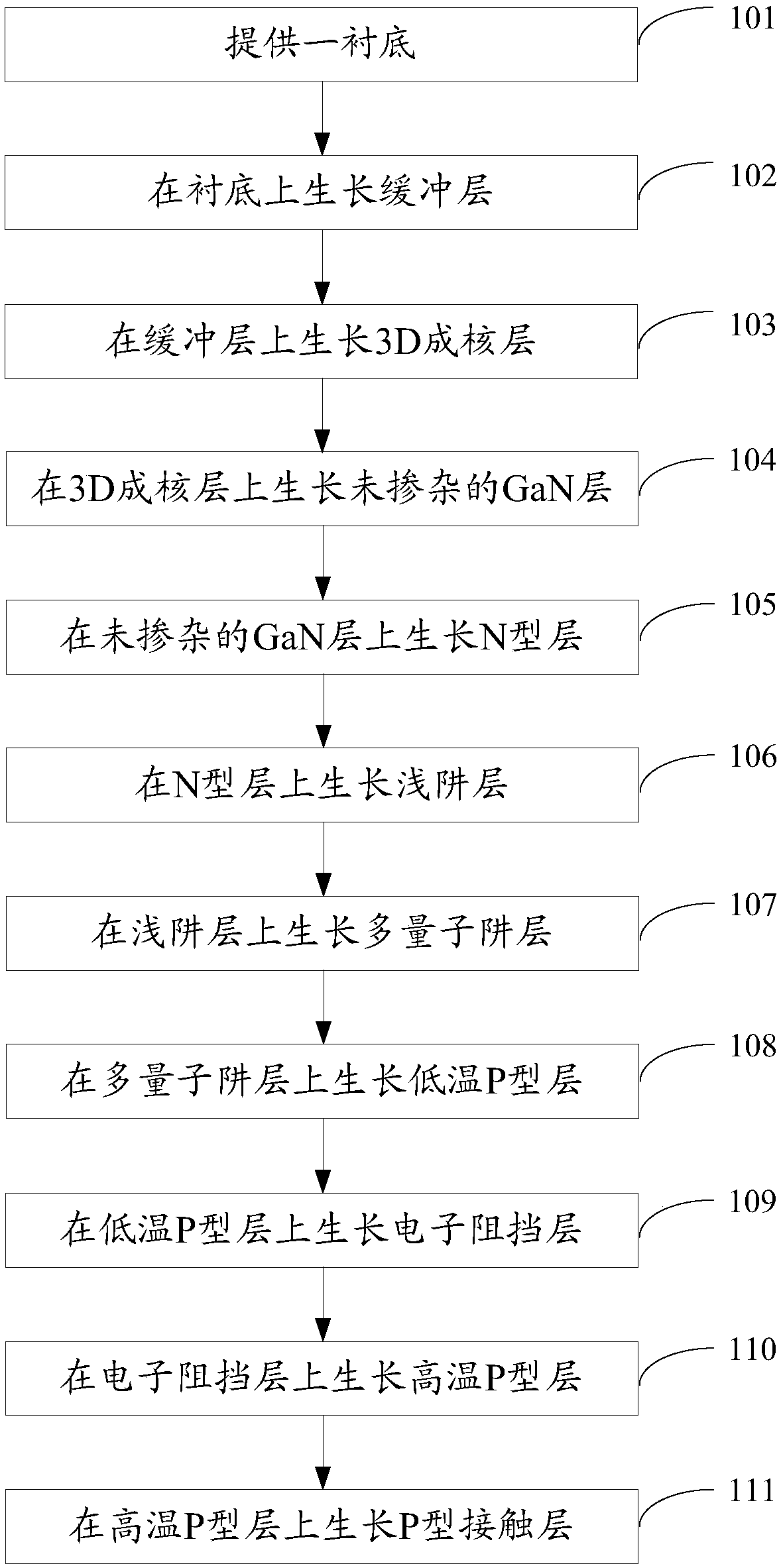

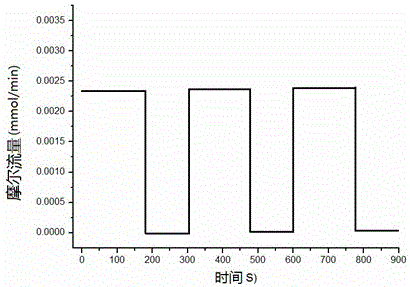

Manufacturing method of epitaxial wafer of light emitting diode

InactiveCN109326698AImprove crystal qualityResidue reductionSemiconductor devicesPower flowQuantum well

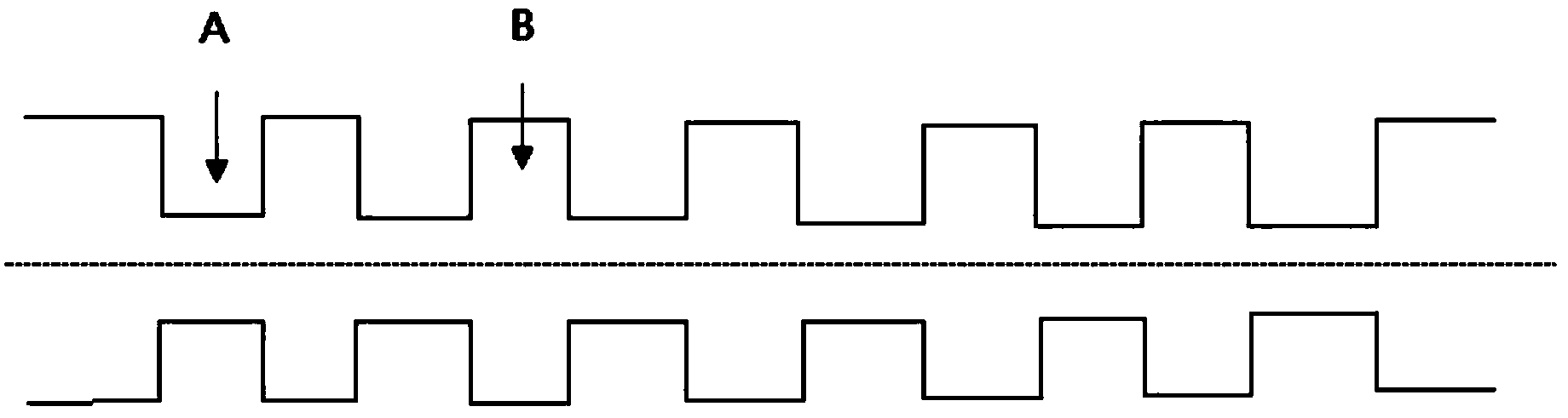

The invention discloses a manufacturing method of an epitaxial wafer of a light emitting diode, and belongs to the technical field of semiconductors. The manufacturing method comprises the following steps: providing a substrate; growing a buffer layer on the substrate; growing a 3D nucleation layer on the buffer layer; during the growth of the 3D nucleation layer, continuously feeding ammonia intoa reaction chamber, and intermittently feeding trimethylgallium; and growing an undoped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer sequentially on the 3D nucleation layer. The 3D nucleation layer adopts a segmented growth mode, that is, after the 3D nucleation layer grows for a period of time, the surface of the grown 3D nucleation layer is treated by the ammonia, which can reduce the existence of elemental Ga on the surface of the 3D nucleation layer, so that the wafer quality of the 3D nucleation layer is improved, the antistatic capacity of an LED (Light Emitting Diode) under a large current density is increased, and the light emitting efficiency of the LED is finally improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

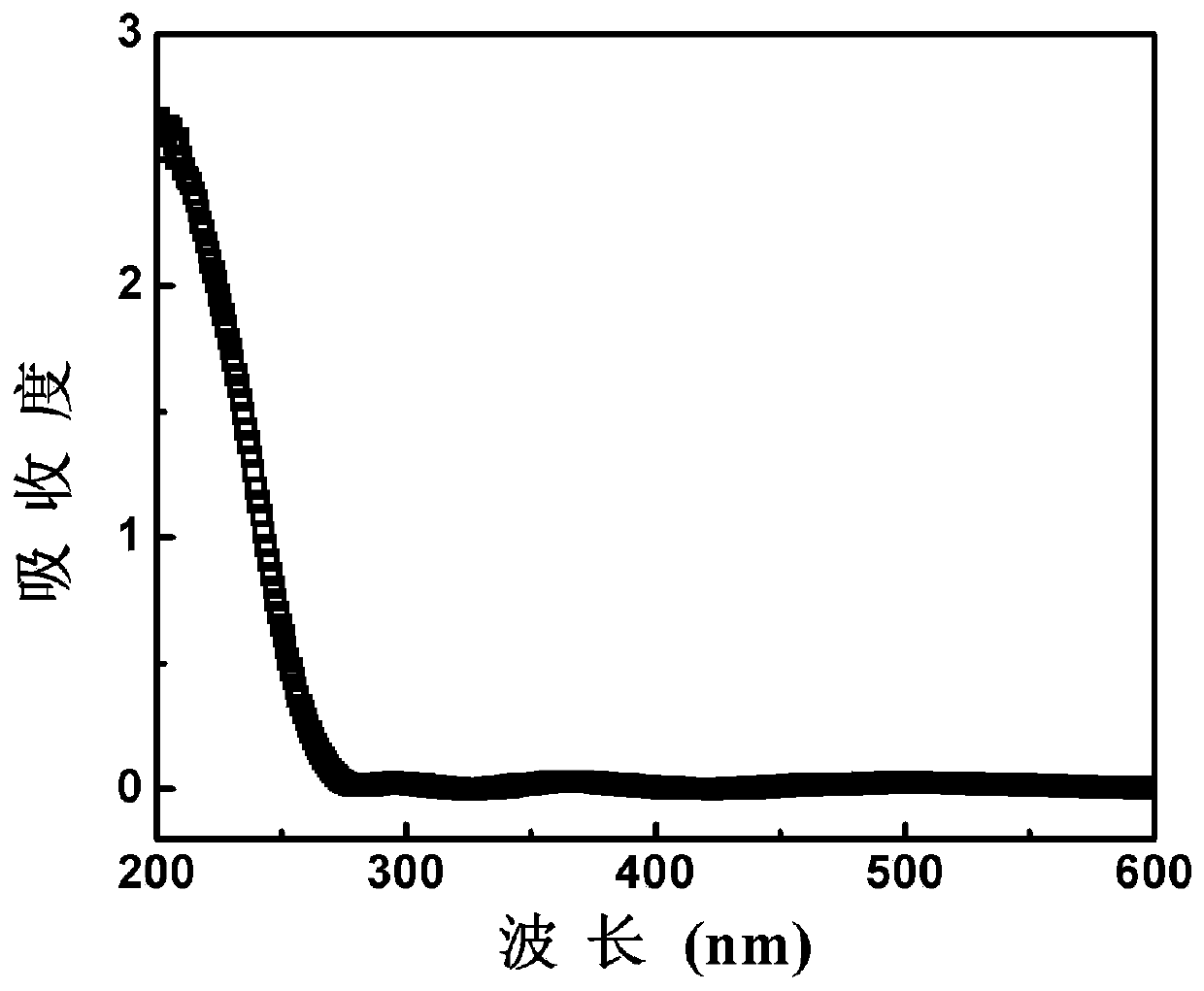

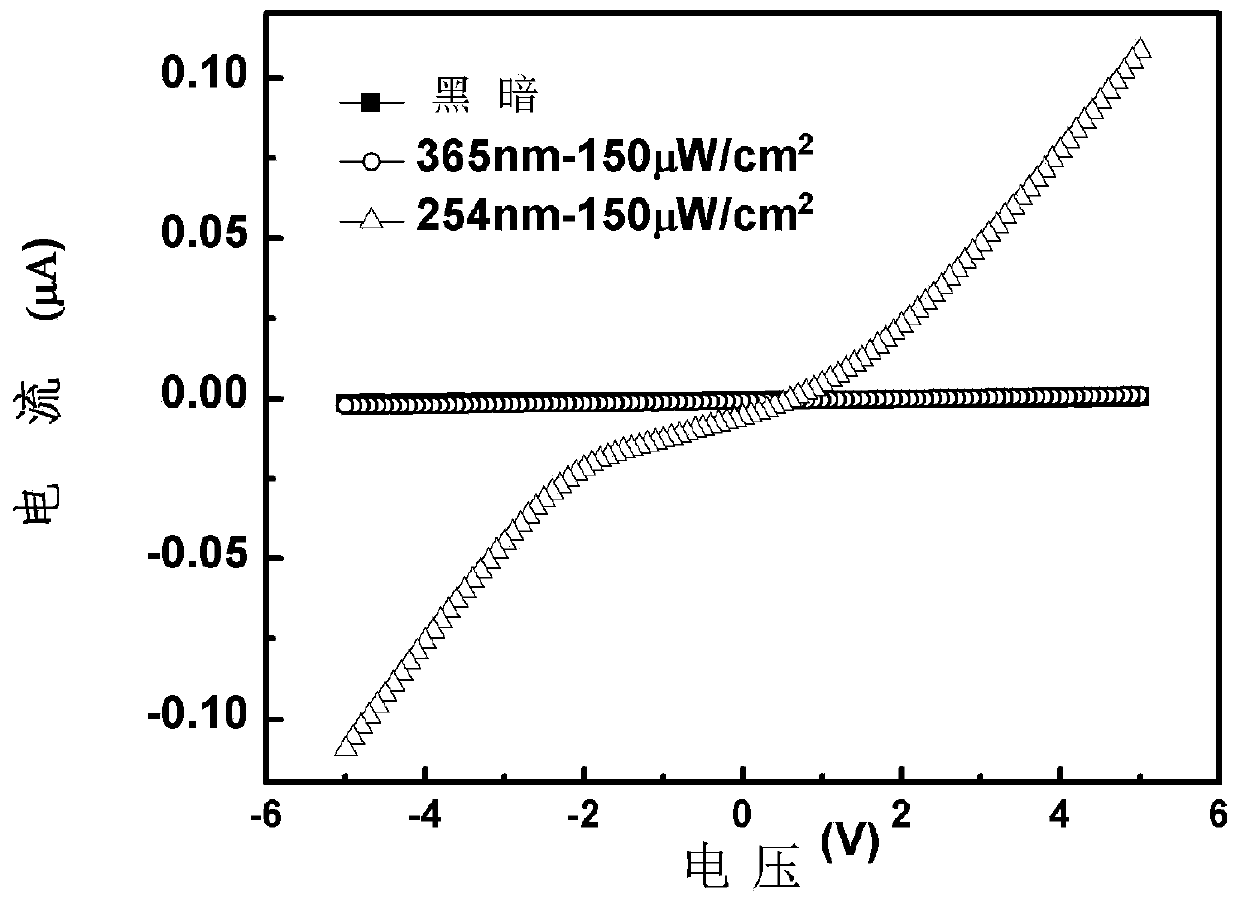

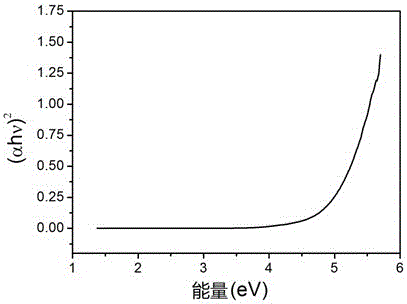

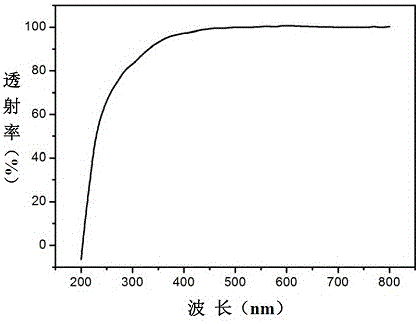

Ga2O3-film-based solar-blind ultraviolet detector and preparation method and application thereof

ActiveCN110854233AImprove efficiencyQuality improvementFinal product manufactureSemiconductor devicesUltraviolet detectorsImage resolution

The invention belongs to the field of safety detection of high-voltage power transmission and transformation equipment, and specifically relates to a Ga2O3-film-based solar-blind ultraviolet detectorand a preparation method and application thereof. The preparation method comprises the steps: taking (0001) surface Al2O3 as a substrate and trimethyl gallium as a gallium source, growing a beta-Ga2O3film layer on the (0001) surface Al2O3 substrate through a plasma enhanced chemical vapor deposition method, and forming an Au / Ti interdigital electrode on the beta-Ga2O3 film layer through magnetronsputtering. The Ga2O3-based corona detection device has the advantages of being high in response speed, high in resolution ratio, long in action distance, free of interference of sunlight, capable ofachieving accurate positioning and the like, and is particularly suitable for being applied to various severe environments such as a high-voltage power transformation system and a high-voltage powertransmission line. The device has a great commercial value for detecting the corona generated by overhead transmission lines and power transformation equipment.

Owner:金华紫芯科技有限公司

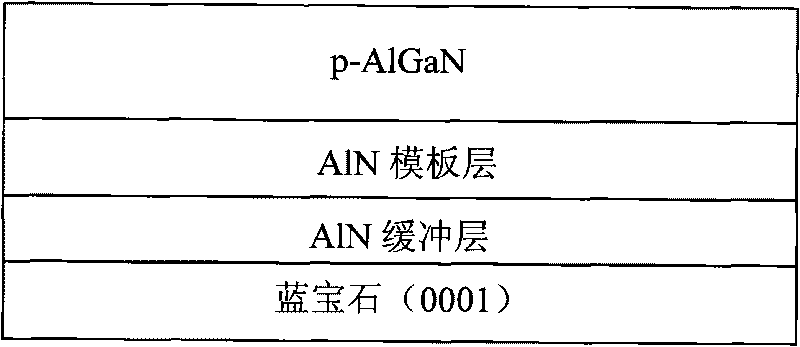

Growth method of p-type AlGaN semiconductor material

ActiveCN108987256AReduced Displacement Formation EnergyImprove retentionSemiconductor/solid-state device manufacturingDimethylhydrazineIndium

The invention discloses a growth method of p-type AlGaN semiconductor material, the semiconductor material is grown by a technical method of adding a gallium source through step into a surfactant-assisted magnesium delta doping, Ammonia gas or dimethylhydrazine nitrogen is used as group V nitrogen source in the growth of p-type AlGaN semiconductor material, Trimethylgallium or triethylgallium is used as a Group III gallium source, trimethylaluminum or triethylaluminum is used as a Group III aluminum source, trimethylindium or triethylindium is used as a Group III indium source, collectively referred to as a Group III metal source, and trimethylindium or triethylindium is also used as a surfactant in the acceptor doping layer. The method of the invention can improve crystal quality, increase doping concentration of acceptor doped magnesium atoms, reduce acceptor ionization energy by enhancing valence band modulation, and further suppress self-compensation effect, thereby obtaining p-type AlGaN semiconductor material with high crystal quality and high hole concentration.

Owner:SUN YAT SEN UNIV

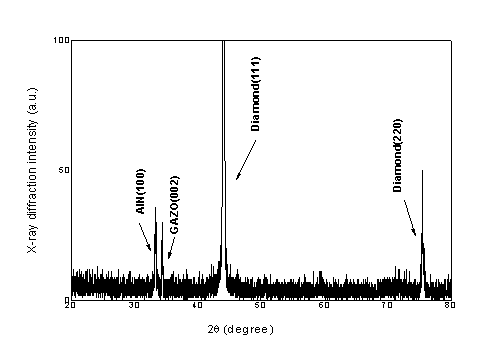

Preparation method of surface acoustic wave filter in AlN/GAZO/self-supporting diamond film structure

InactiveCN103014653AHigh crystallinityMeet high frequencyImpedence networksChemical vapor deposition coatingSurface acoustic waveNitrogen gas

The invention belongs to the field of piezoelectric thin-film materials, and particularly relates to a preparation method of a surface acoustic wave filter in an AlN / GAZO / self-supporting diamond film structure. The method comprises the following steps: cleaning a self-supporting diamond film used as a substrate, sending the self-supporting diamond film into a vapor deposition reaction chamber, introducing nitrogen gas, trimethyl aluminum, trimethyl gallium and diethyl zinc into the reaction chamber to deposit a GAZO film with the thickness of 80-120nm on the substrate, introducing trimethyl aluminum to deposit an AlN thin film with the thickness of 800nm on the substrate carrying the GAZO film, cooling the inside of the vapor deposition reaction chamber to room temperature, and opening the deposition chamber to obtain the surface acoustic wave filter in an AlN / GAZO / self-supporting diamond film structure. The method provided by the invention is simple, the technique is easy to control, and the prepared piezoelectric thin-film device has the advantages of favorable uniformity and excellent acoustic speed transmission performance and can be used for manufacturing high-power high-frequency surface acoustic wave filters.

Owner:SHENYANG INST OF ENG +1

A kind of preparation method of gallium oxide epitaxial film and gallium oxide epitaxial film

ActiveCN103489967BImprove performanceAvoid pollutionSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsHydrogen

The invention relates to the field of semiconductor material preparation, and discloses a method for preparing a gallium oxide epitaxial film and the gallium oxide epitaxial film. Trimethyl gallium or triethyl gallium is used as a gallium source, gas state oxygen-containing substances are used as an oxygen source, a hydrogenous compound is used as auxiliary reaction gas, and then the gallium oxide epitaxial film is prepared. According to the method for preparing the gallium oxide epitaxial film and the gallium oxide epitaxial film, an MOCVD system is used, and the gallium oxide epitaxial film is prepared by adjusting growth parameters, adding auxiliary reactants and optimizing a subsequent processing method. By the adoption of the method, an organic source can be fully reacted, reaction products can be completely separated, and pollution on the surface of the gallium oxide film caused by secondary deposition of carbon and the relevant compounds of carbon is avoided. The gallium oxide epitaxial film prepared from the method is good in performance and meets the requirement for industrialization mass production in the future.

Owner:DALIAN UNIV OF TECH

Method for preparing ZnO transparent conductive film through metal organic chemical vapor deposition

InactiveCN102102193ASimple and proven preparation processChemical vapor deposition coatingOxygenTrimethylgallium

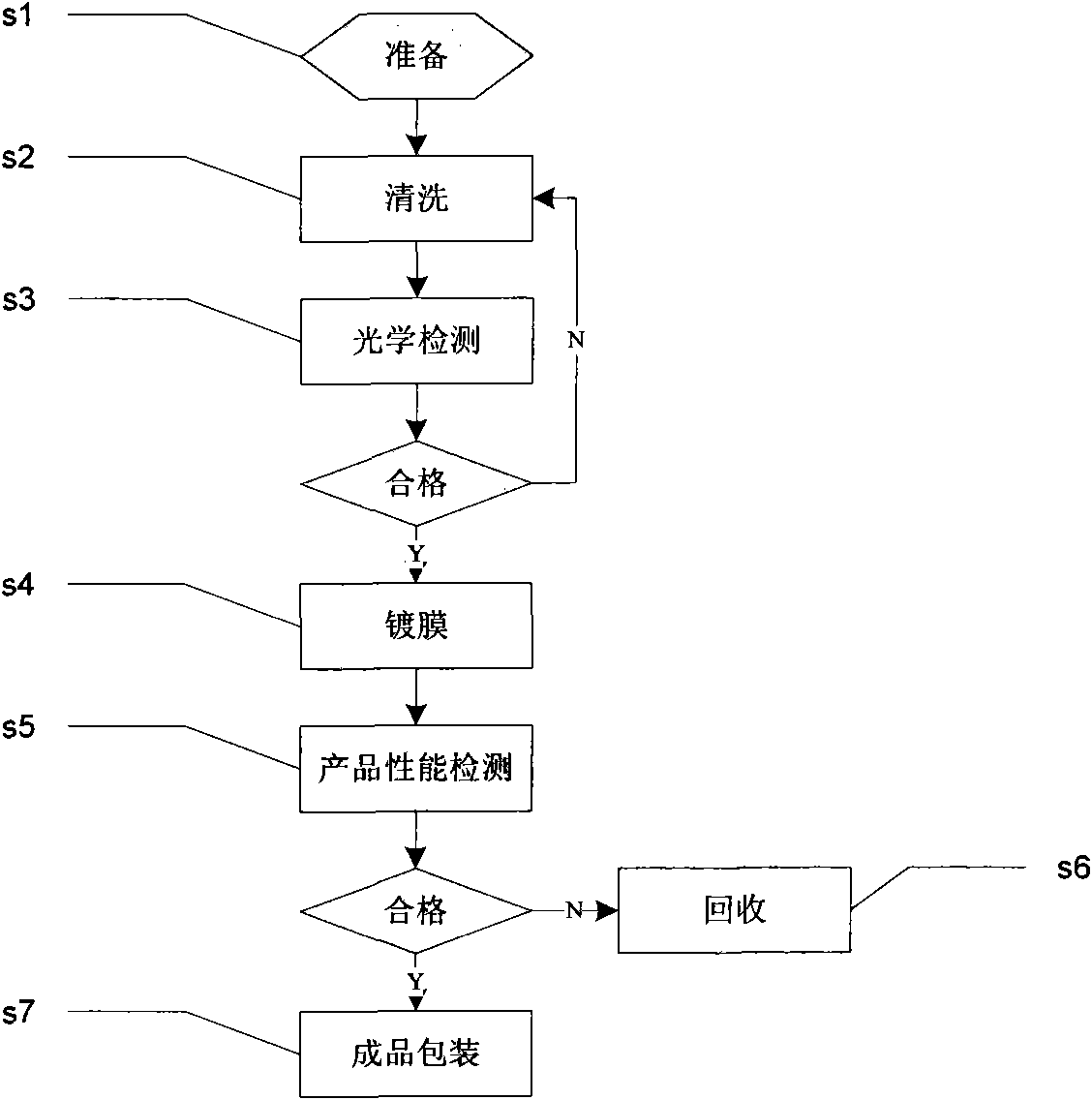

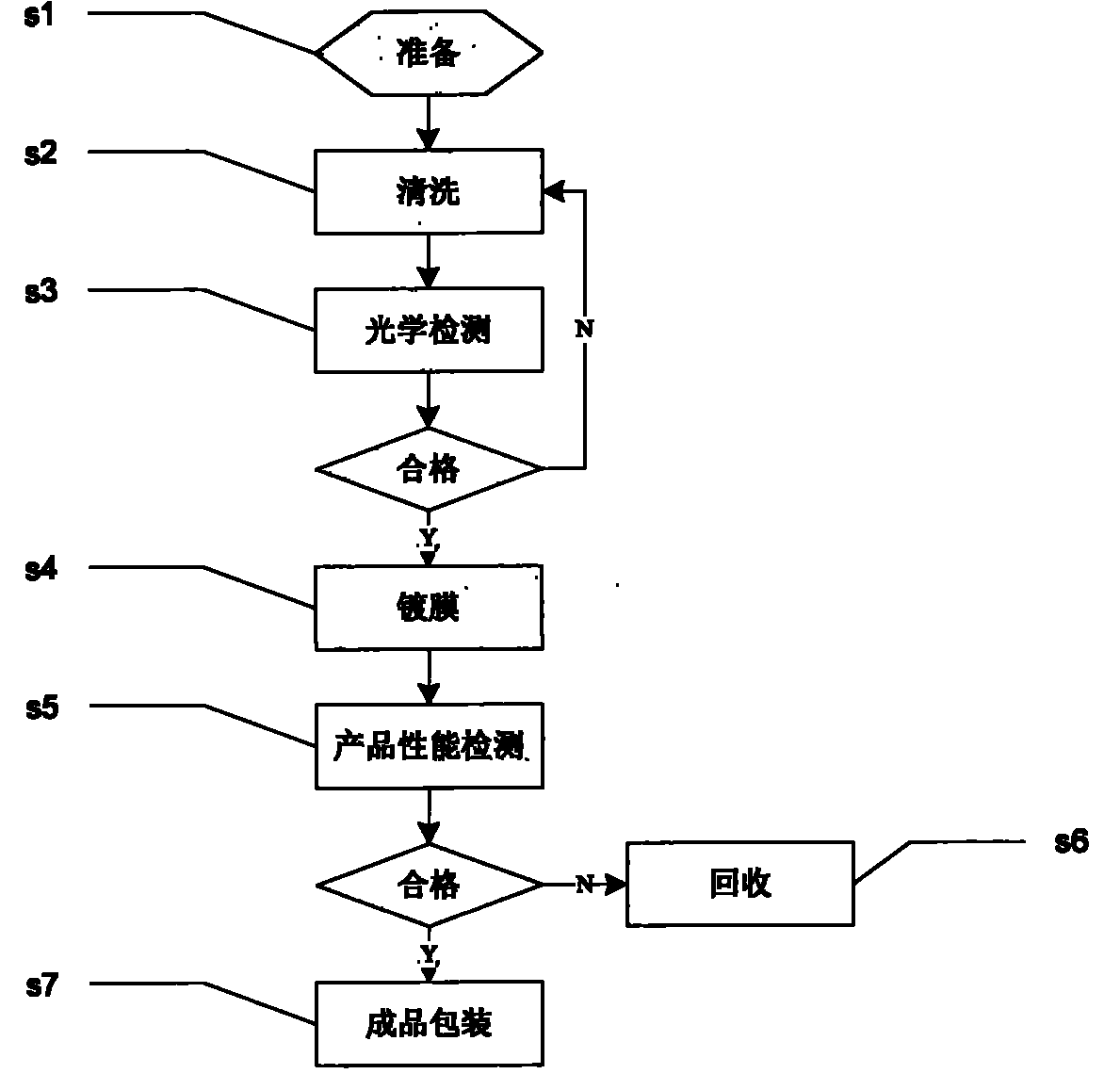

A method for preparing a ZnO transparent conductive film through metal organic chemical vapor deposition (MOCVD) comprises the following six steps: preparing, cleaning, optical detection, chemical vapor deposition (CVD) coating, product performance detection and finished product packaging, wherein the CVD coating method is as follows: in a CVD coating chamber, dimethylzinc and oxygen are used as sources to be sprayed on a heated glass sheet through nozzles and dimethylzinc is oxidized to generate ZnO. In the coating process, trimethylgallium or aluminum oxide can be used as dopant source to obtain gallium-doped ZnO (GZO) or aluminum-doped ZnO (AZO). The glass which is not qualified in the optical detection can be cleaned again; and the product which is not qualified in the product performance detection can be sent to a corrosive tank with hydrochloric acid to erode off the ZnO on the surface of glass and recycle glass. The method of the invention fully considers each link of the industrial production of the ZnO transparent conductive film and has the advantages of excellent product performance and capability of industrialization.

Owner:SHANGHAI JUNTIAN TECH

Growth method of GaN nanowire

InactiveCN103757693AAvoid tarnishingLow densityPolycrystalline material growthNitrogen-metal/silicon/boron binary compoundsNanowireIndium

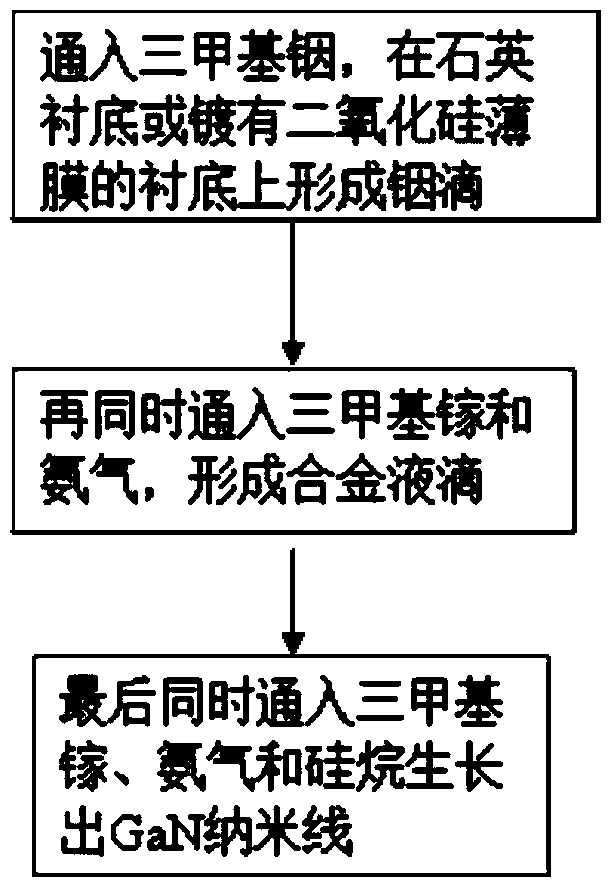

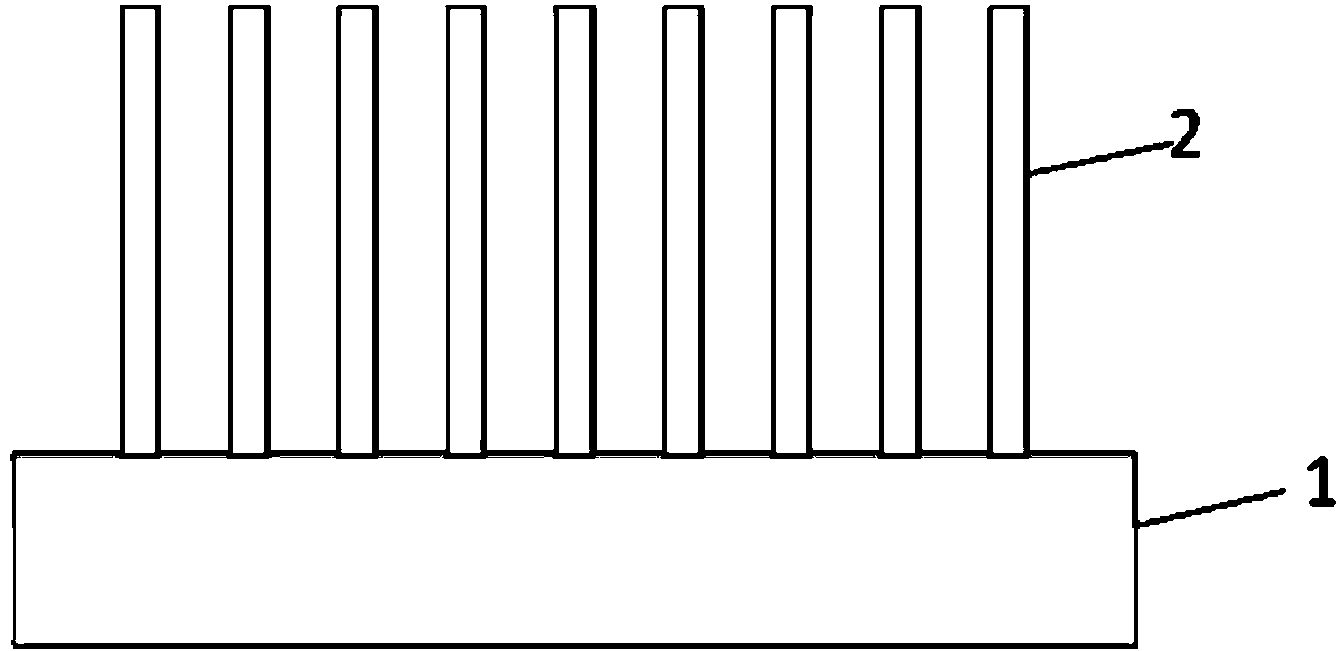

The invention discloses a growth method of a GaN nanowire. The method comprises the following steps: leading trimethylindium to a quartz substrate or a substrate coated with a layer of silica film on the surface in advance, forming a liquid-phase indium drop on the bottom surface of the substrate, and then leading trimethyl gallium and an ammonia gas simultaneously, so as to form an alloy liquid drop; finally, simultaneously leading the trimethyl gallium, the ammonia gas and silicane; growing the GaN nanowire on the alloy liquid drop. By adopting the method, the trimethylindium is adopted as a tin catalyst source, a high-quality GaN nanowire grows on the cheap and available quartz or the substrate coated with the silica film on the surface, the method belongs to in-situ introduction, and is free of fussy processes of transferring and cleaning between different equipments, staining of a product in the transferring process is effectively avoided, a complicated buffer layer design is not needed, and the growth method is simple and convenient, and feasible to operate, and beneficial to industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

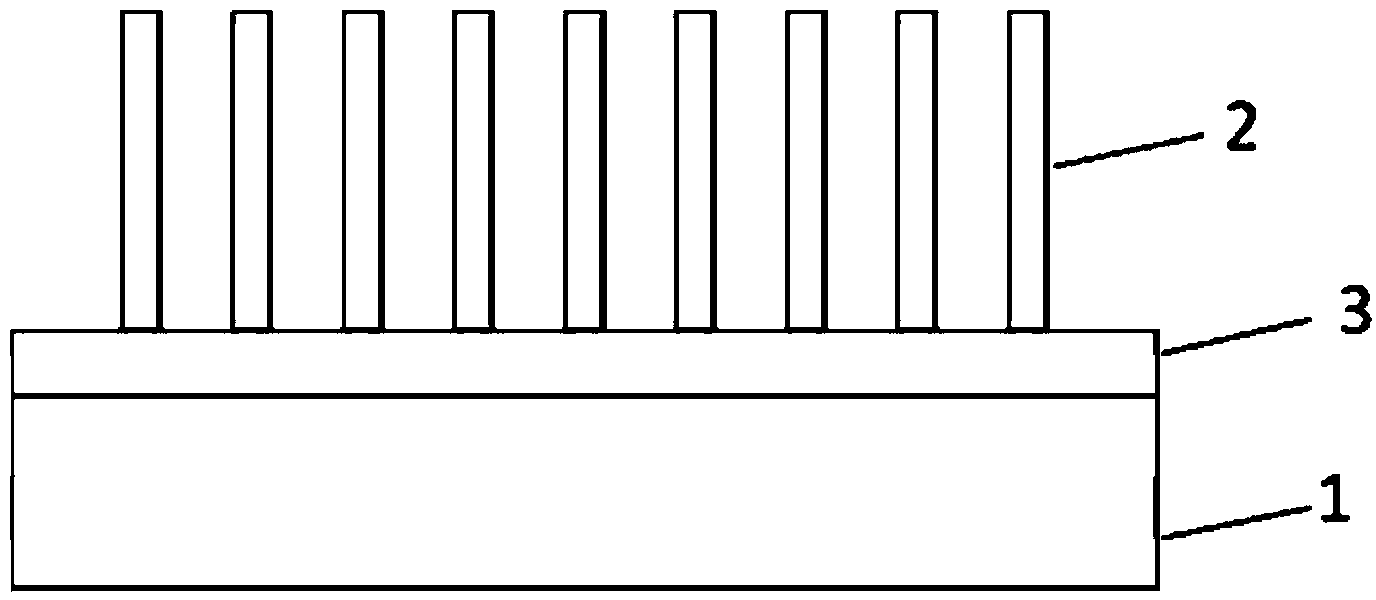

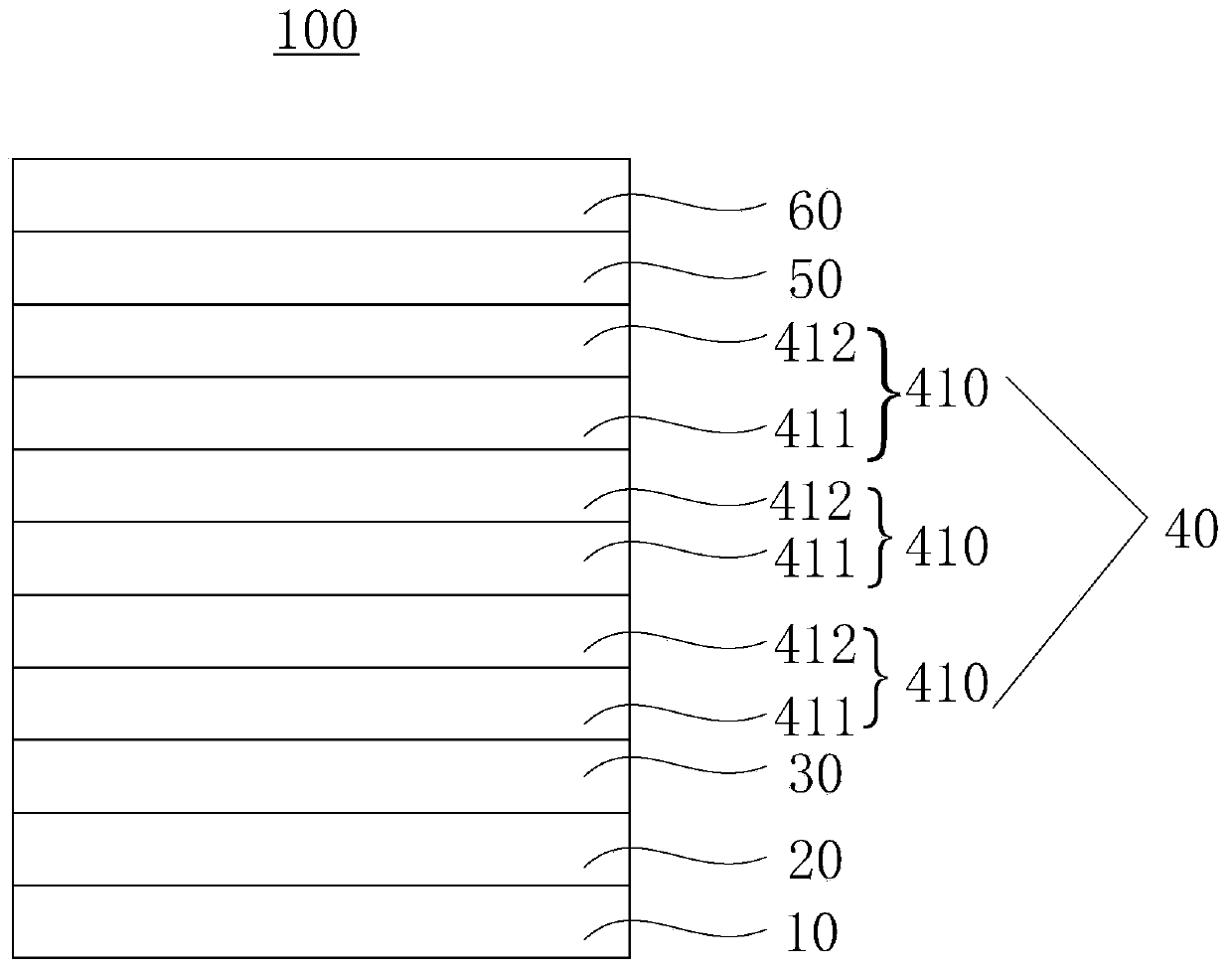

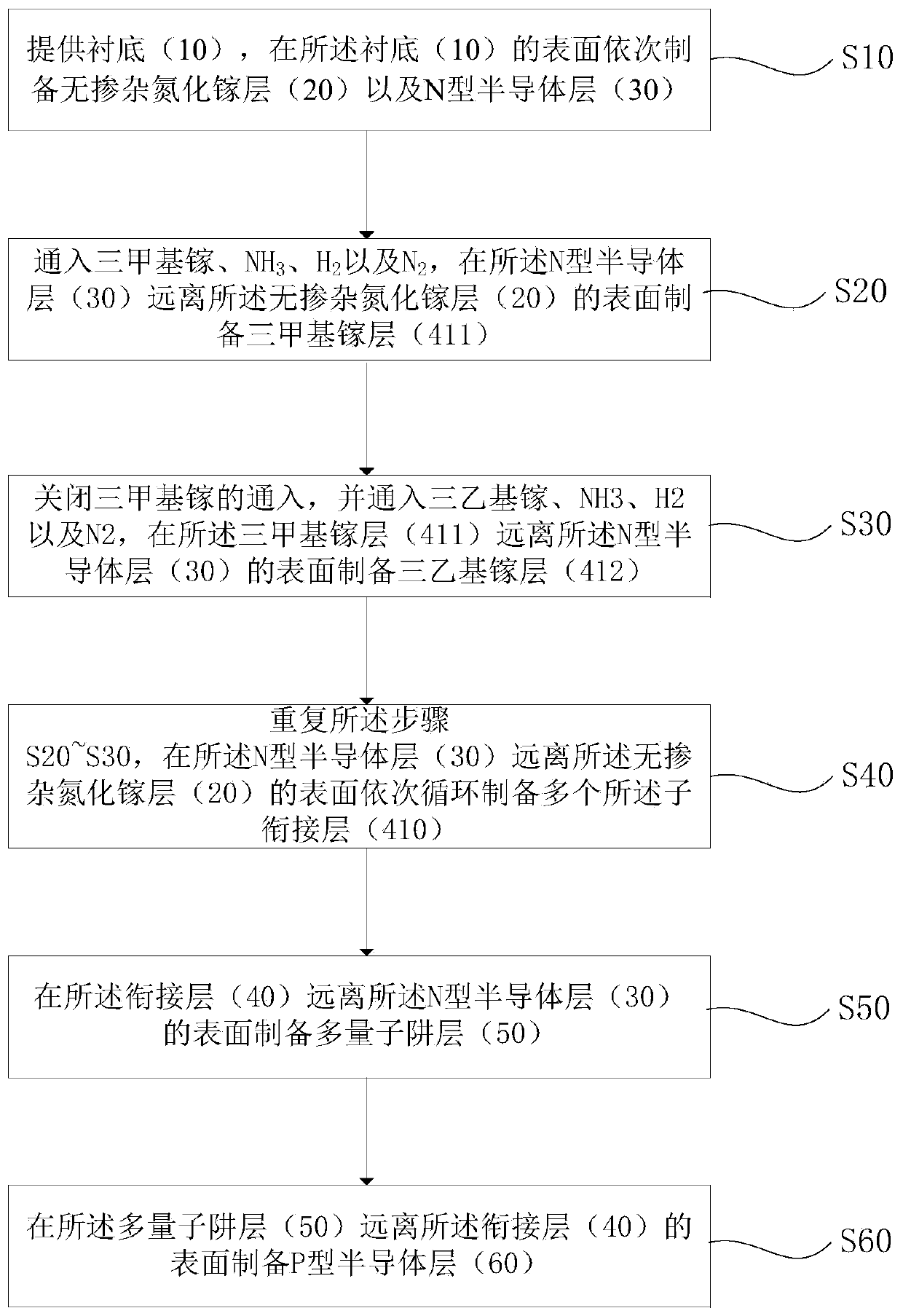

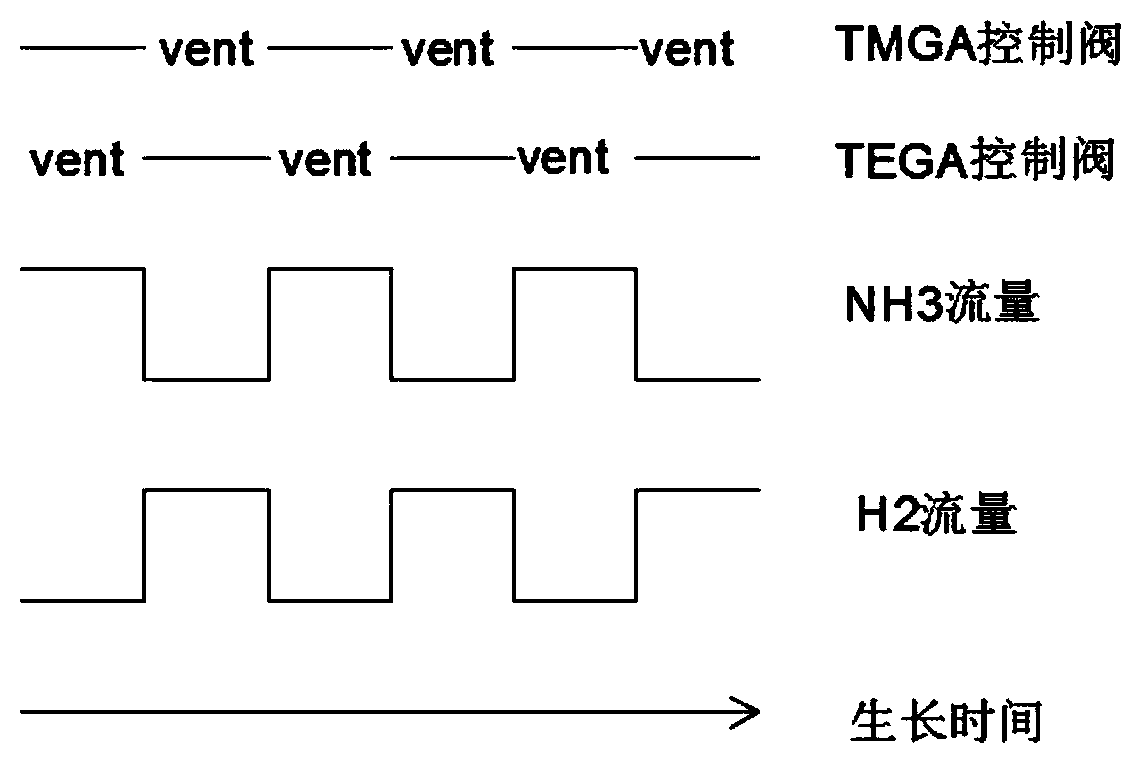

Light-emitting diode preparation method and light-emitting diode

The invention provides a light-emitting diode preparation method and a light-emitting diode. When a trimethyl gallium layer grows, the NH3 flow is increased, and the H2 flow is decreased, so that thegrowth speed of trimethyl gallium is relatively high and is controlled to be 1 / 3-1 / 5 of the growth speed of an N-type semiconductor layer; and when a triethyl gallium layer grows, the NH3 flow is reduced, and the H2 flow is increased, so that the growth speed of the triethyl gallium is low and is about 1 / 10-1 / 20 of the growth speed of the trimethyl gallium layer. By controlling the growth speed ofthe triethyl gallium layer, surface atoms can be fully recombined; moreover, with the growth of triethyl gallium and increasing of the amount of H2, the content of C is reduced, so that V-pits are reduced, and the defect density is reduced; through S20 and S30, the defects caused by too fast growth of V-pits are avoided, the epitaxial growth quality is improved, the surface appearance of the epitaxial wafer is normal, and the defects caused by excessive V-pits are reduced; and the epitaxial wafer is not easy to extend to a quantum well layer, so that the growth quality of the multi-quantum well layer is further improved, and the recombination efficiency of holes and electrons is improved.

Owner:ELEC TECH OPTOELECTRONICS TECHWUHUCO

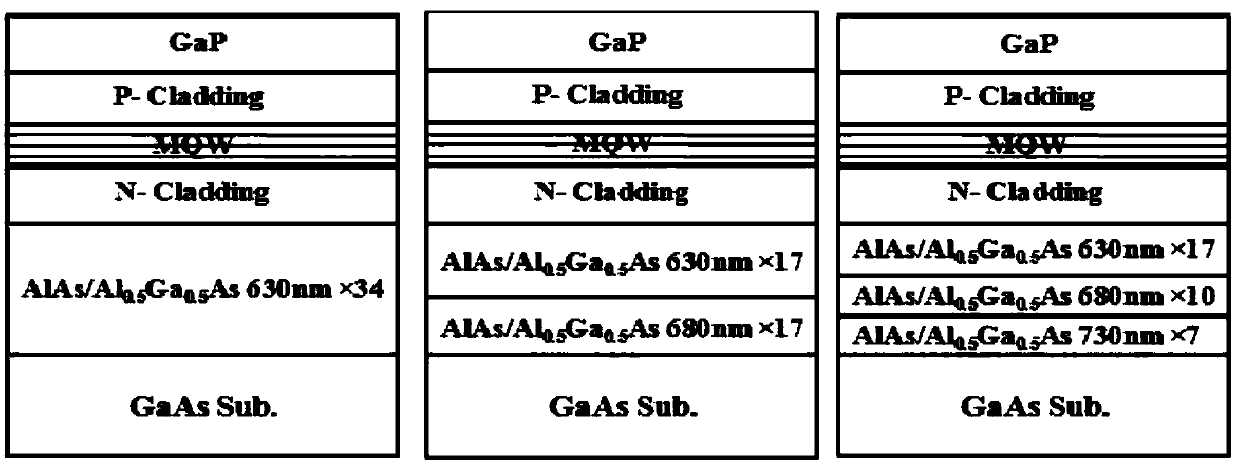

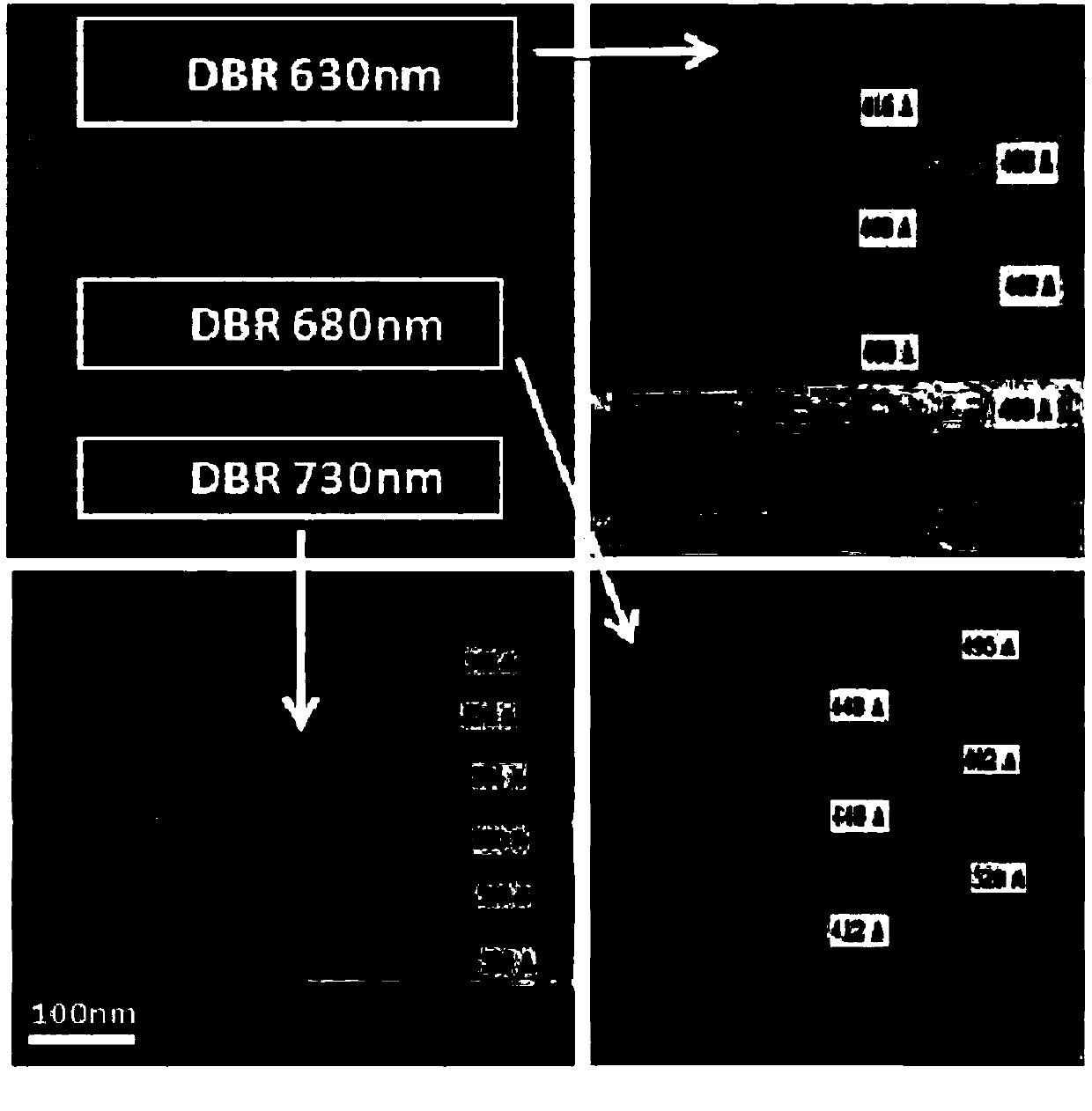

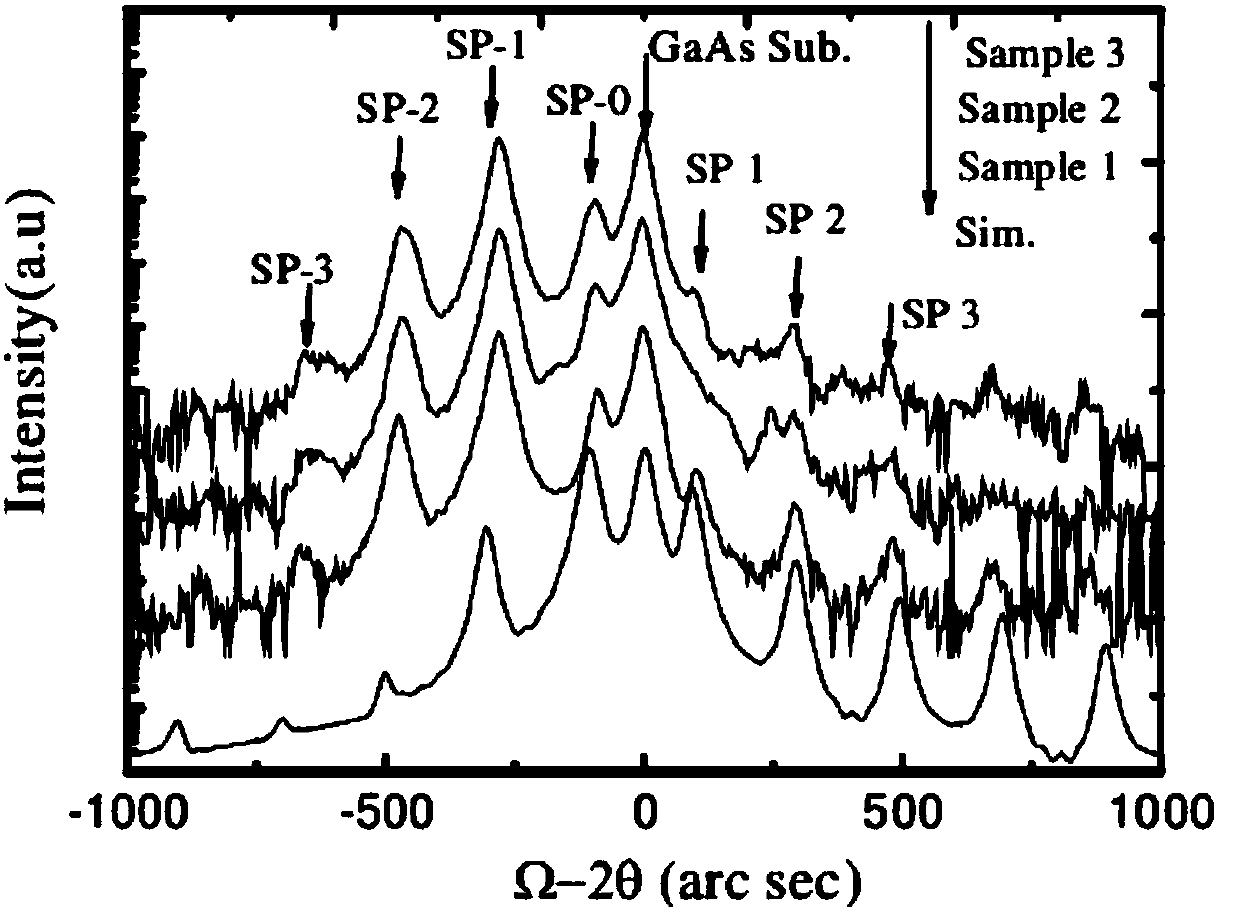

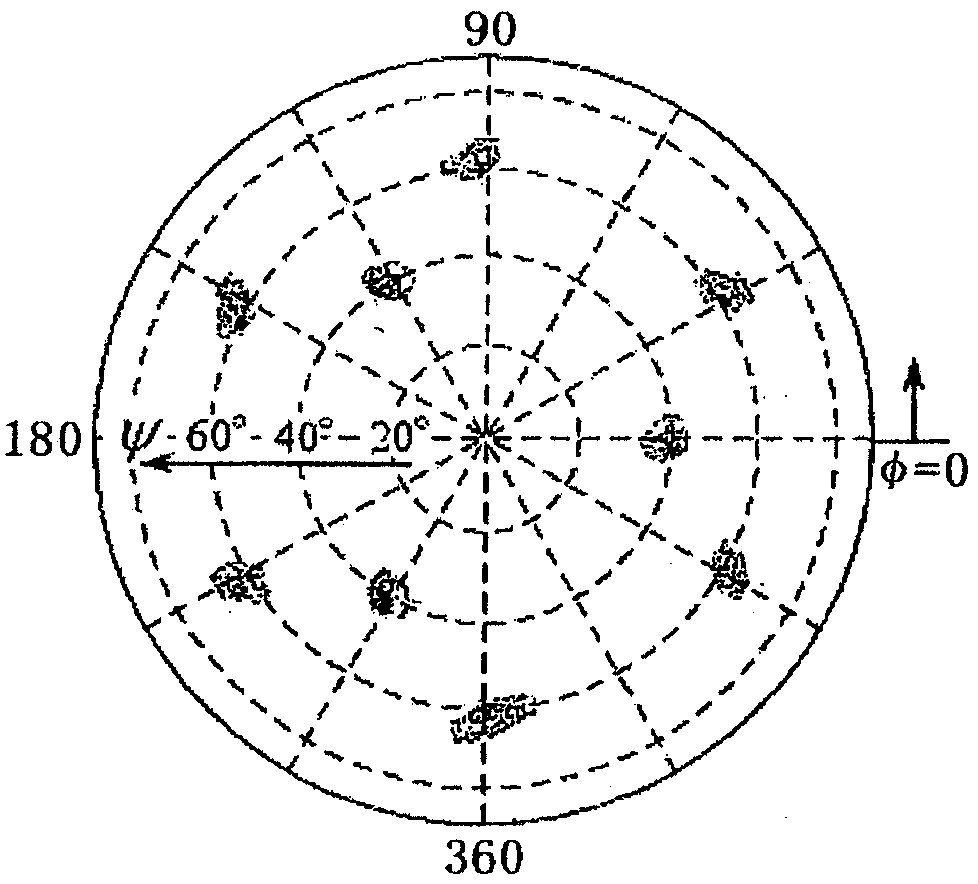

Composite-DBR-structure-based AlGaInP light-emitting diode

InactiveCN108091739AImprove photoelectric performanceImprove optical output powerSemiconductor devicesDisilaneChemical vapor deposition

The invention provides a composite-DBR-structure-based AlGaInP light-emitting diode. The preparation method comprises: a metal organic chemical vapor deposition system uses high-purity hydrogen as carrier gas, trimethyl gallium, trimethylaluminum, trimethylindium, arsine and phosphorane as Ga, Al, In, As, and P sources, and disilane and magnesocene as N and P type dopants. According to the invention, with the three-reflected central wavelength composite DBR, the reflection efficiency is high and the luminous efficiency of the AlGaInP LED is improved substantially. The influences on the luminous efficiency of the LED by the composite DBR with many reflected central wavebands is studied.

Owner:FOSHAN DONGSHEN METAL PROD CO LTD

Method for film depositing group iii nitride such as gallium nitride

InactiveUS20090170294A1Set become largeImprove reaction speedPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenGallium nitride

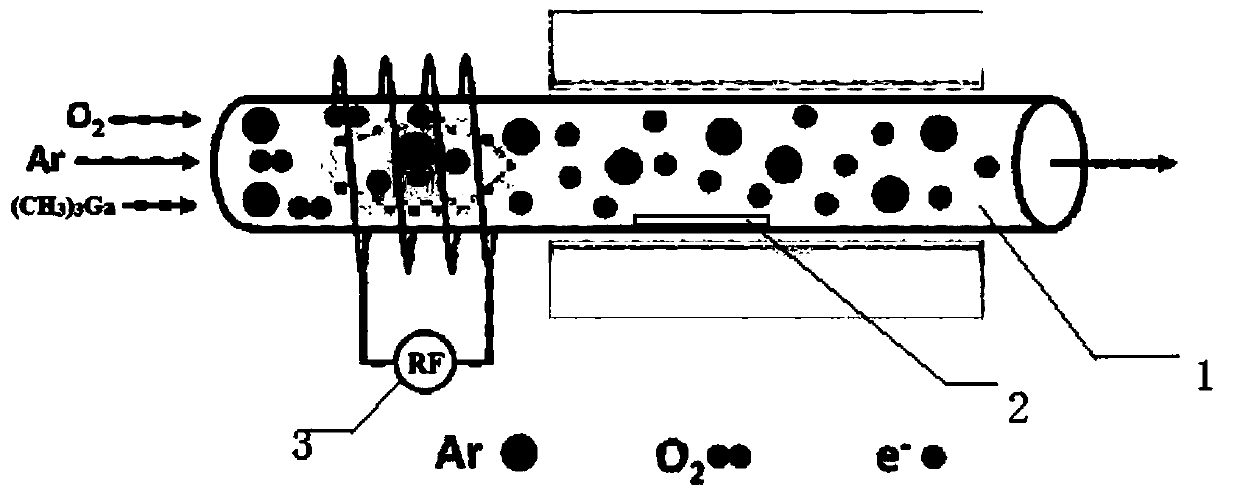

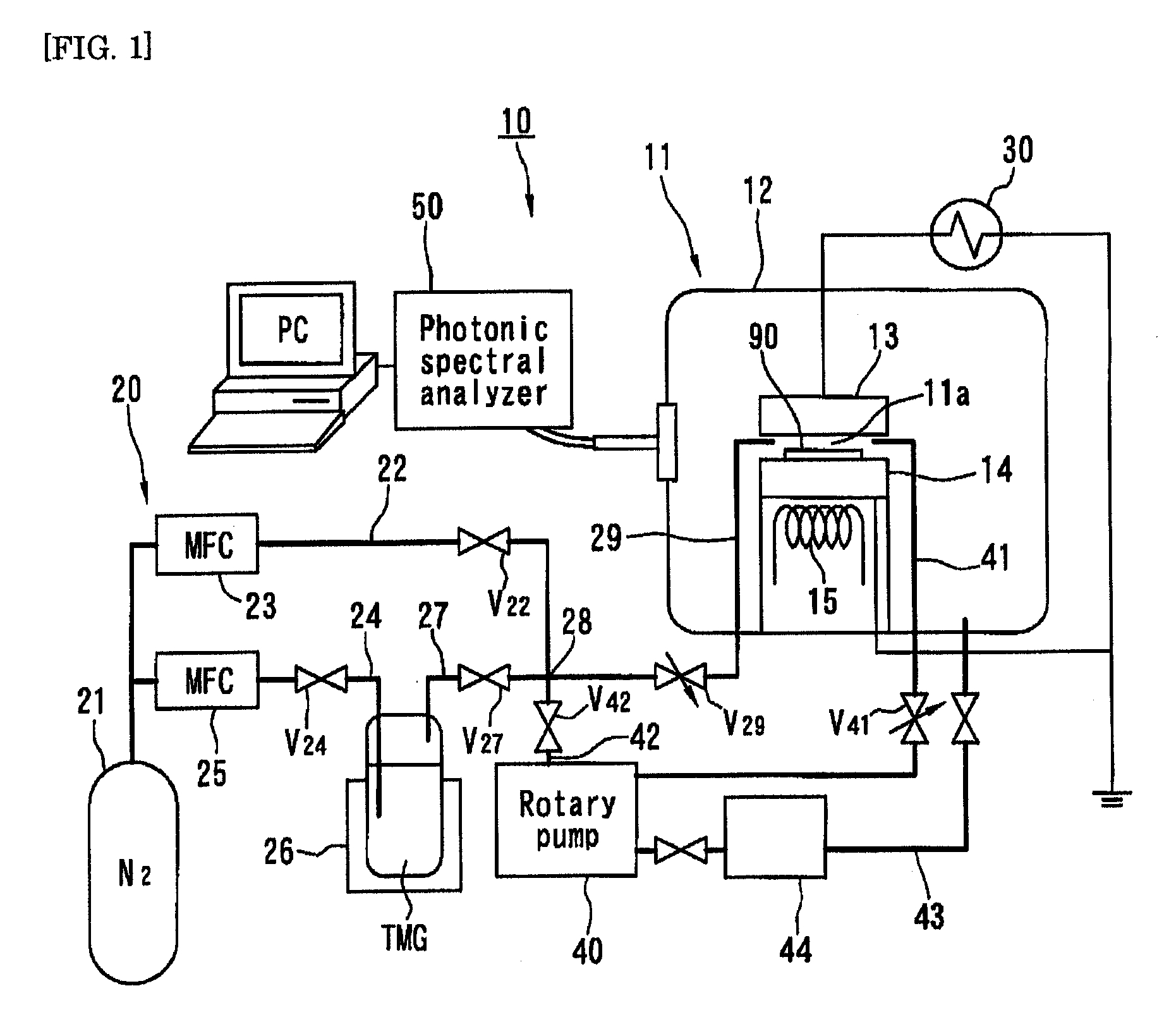

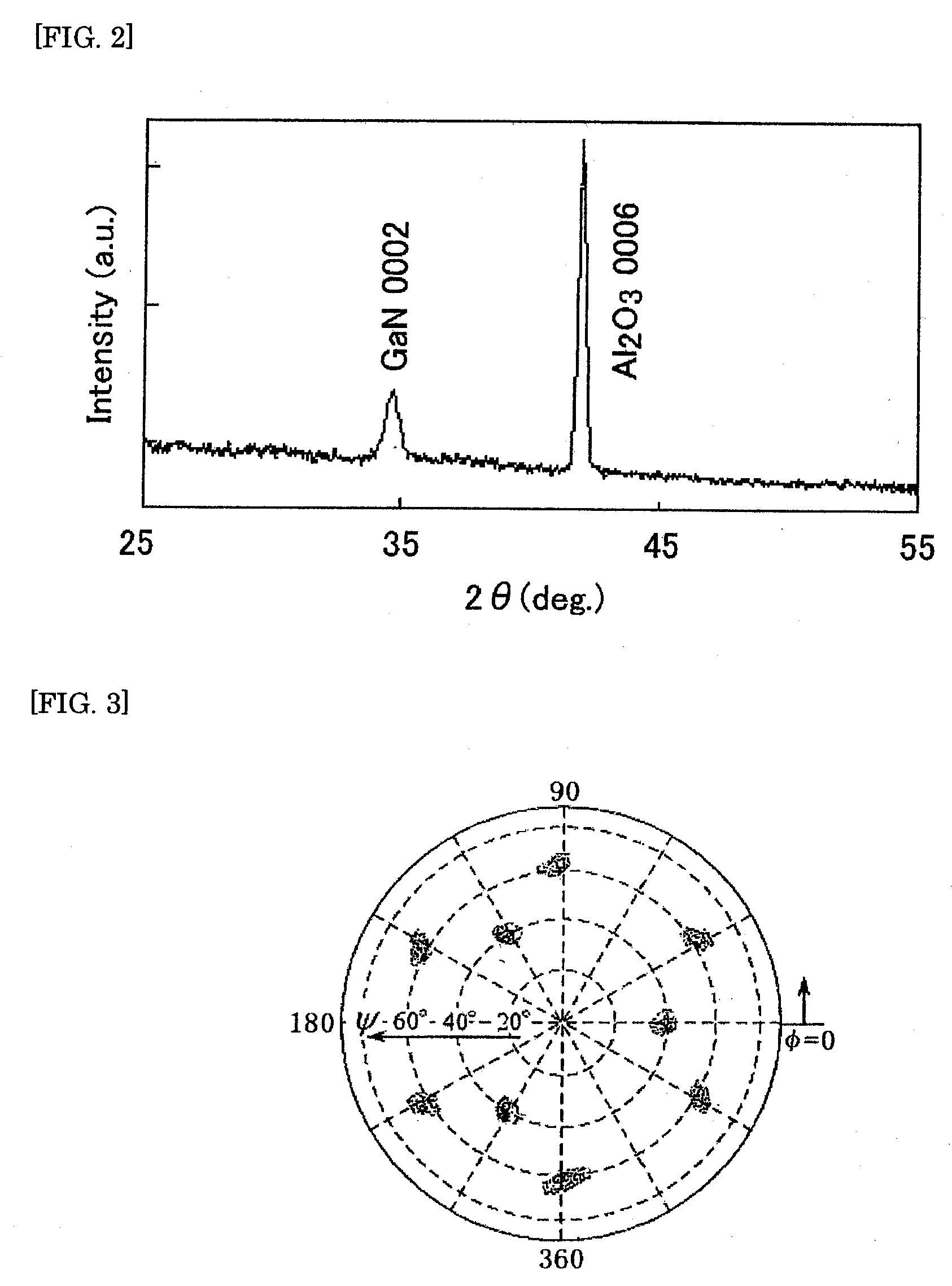

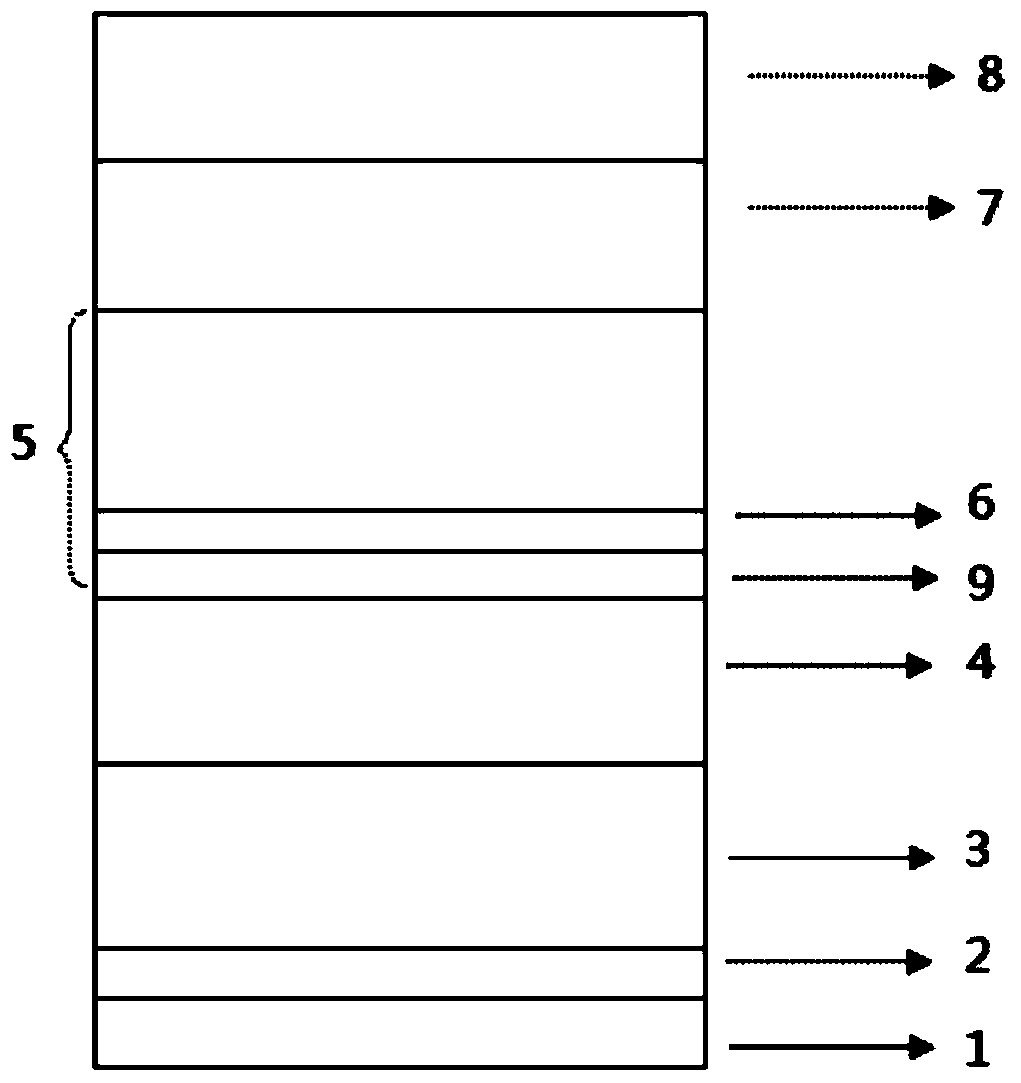

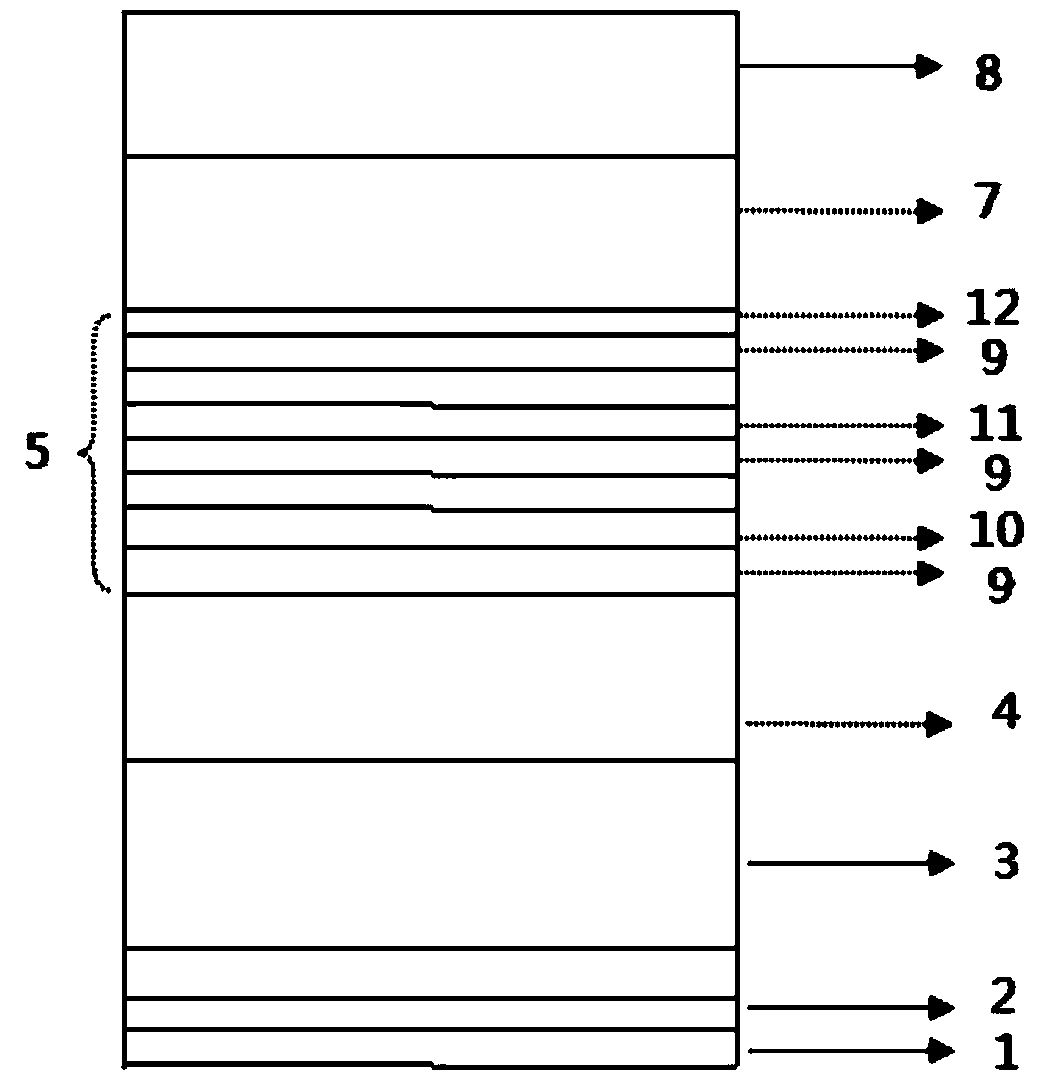

[Problem to be Solved] To film deposit a group III nitride such as GaN using atmospheric pressure plasma.[Solving Means] A reactor chamber 12 is filled with a pure nitrogen of approximately atmospheric pressure of about 40 kPa. A c-face sapphire substrate 90 is placed on an electrode 14. The substrate temperature is brought to 650 degree centigrade by a heater 15. An electric field is applied between electrodes 13, 14 to form a discharge space 11a therebetween. In a gas feed system 20, a small quantity of trimethylgallium is added to N2, the resultant is fed into a discharge space 11a and brought into contact with the sapphire substrate 90. A V / III ratio on the substrate 90 is brought into a range of from 10 to 100000.

Owner:SEKISUI CHEM CO LTD

Epitaxial growth method and structure of light-emitting diode (LED) structure including potential barrier with gradually-varied thickness

ActiveCN103474537AReduce thicknessLower resistanceSemiconductor devicesElectron holeTrimethylgallium

The invention provides an epitaxial growth method of a light-emitting diode (LED) structure including a potential barrier with gradually-varied thickness. The light-emitting layer multiple quantum well (MQW) growing step is that H2 and / or N2 serve / serves as carrier gas, an In-doped InxGa(1-x)N layer with the 2.5-3nm thickness grows in a reaction chamber with the 730-750 DEG C temperature and the 100-800mbar pressure, wherein x=0.20-0.21; the temperature of the reaction chamber is adjusted to be 800-840 DEG C, trimethyl gallium is led into the reaction chamber for a time period R, and a first GaN layer with the thickness D grows; an InGaN layer grows repeatedly, trimethyl gallium is led into the reaction chamber for 0.75-0.95 time of a time period R, and a second GaN layer with the 0.75-0.95 times of thickness D grows; by the analogy, the thickness of the GaN layers is gradually decreased layer by layer. The GaN thickness of a light-emitting layer is changed and gradually decreased, accordingly distribution of electrons and electron holes is improved, and the LED lighting effect is improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

Method for preparing high-purity trimethylgallium at one step

ActiveCN102503969AAdequate responseLow costGroup 3/13 element organic compoundsChemical recyclingPoly(ethylene glycol) dimethyl etherPolyethylene glycol

The invention belongs to the field of preparation of compounds including the III groups of elements in a periodic chart, and relates to a method for preparing high-purity trimethylgallium at one step, which includes the steps: under the protection of inert gas, utilizing polyethylene glycol dimethyl ether as dissolvent and utilizing gallium-magnesium alloy and magnesium metal as raw materials, adding methinehalide into a reaction system with stirring and controlling reaction speed by controlling dropping speed; after reaction is completed, distilling and removing low-boiling-point substance, and then releasing a complex of the polyethylene glycol dimethyl ether and the trimethylgallium so that the trimethylgallium is obtained. The method is simple in process and operation, stable in reaction conditions and convenient to control so as to be safer. Compared with a traditional industrialized method, the method has the advantages that raw materials are cheaper, reaction yield is high, safety is higher, unreacted raw materials are recyclable, production cost is greatly reduced, the raw materials contain no natural substance, safety factor is high in the reaction process, and the method is particularly suitable for industrialized production.

Owner:苏州普耀光电材料有限公司

Preparation method of trimethylgallium

The invention relates to a preparation method of trimethylgallium. The method comprises steps as follows: (1) iodine and molten gallium have a contact reaction in the inert atmosphere, and gallium triiodide is obtained; (2) trimethylaluminium and the gallium triiodide have a contact reaction in the presence of an initiator and in the inert atmosphere. With the adoption of the preparation method, the yield and the purity of the trimethylgallium can be significantly increased, the yield of the trimethylgallium can be higher than 90%, the purity can be 99.9999%, besides, a reaction kettle used in the method can be used as an evaporation kettle, the technology and equipment are simplified, the reaction process is easy to control, the prepared product can be separated from raw materials and byproducts more easily, the method is very applicable to industrial production, in addition, the byproducts can be used for synthesizing aluminum sulfate, almost no waste is produced, use of a large amount of highly toxic products, namely, methyl iodide, can be avoided in the technology, and the method is very environment-friendly.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

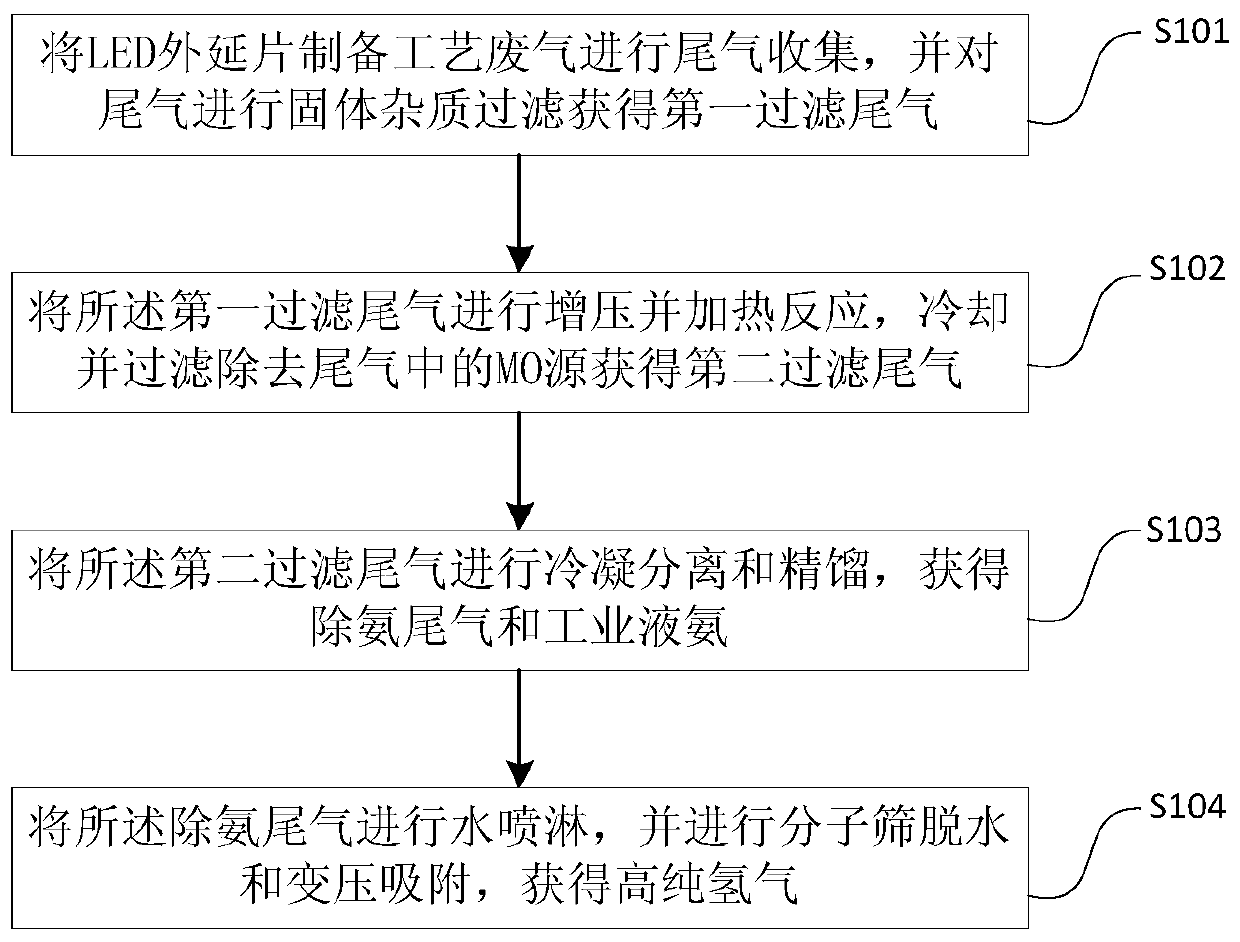

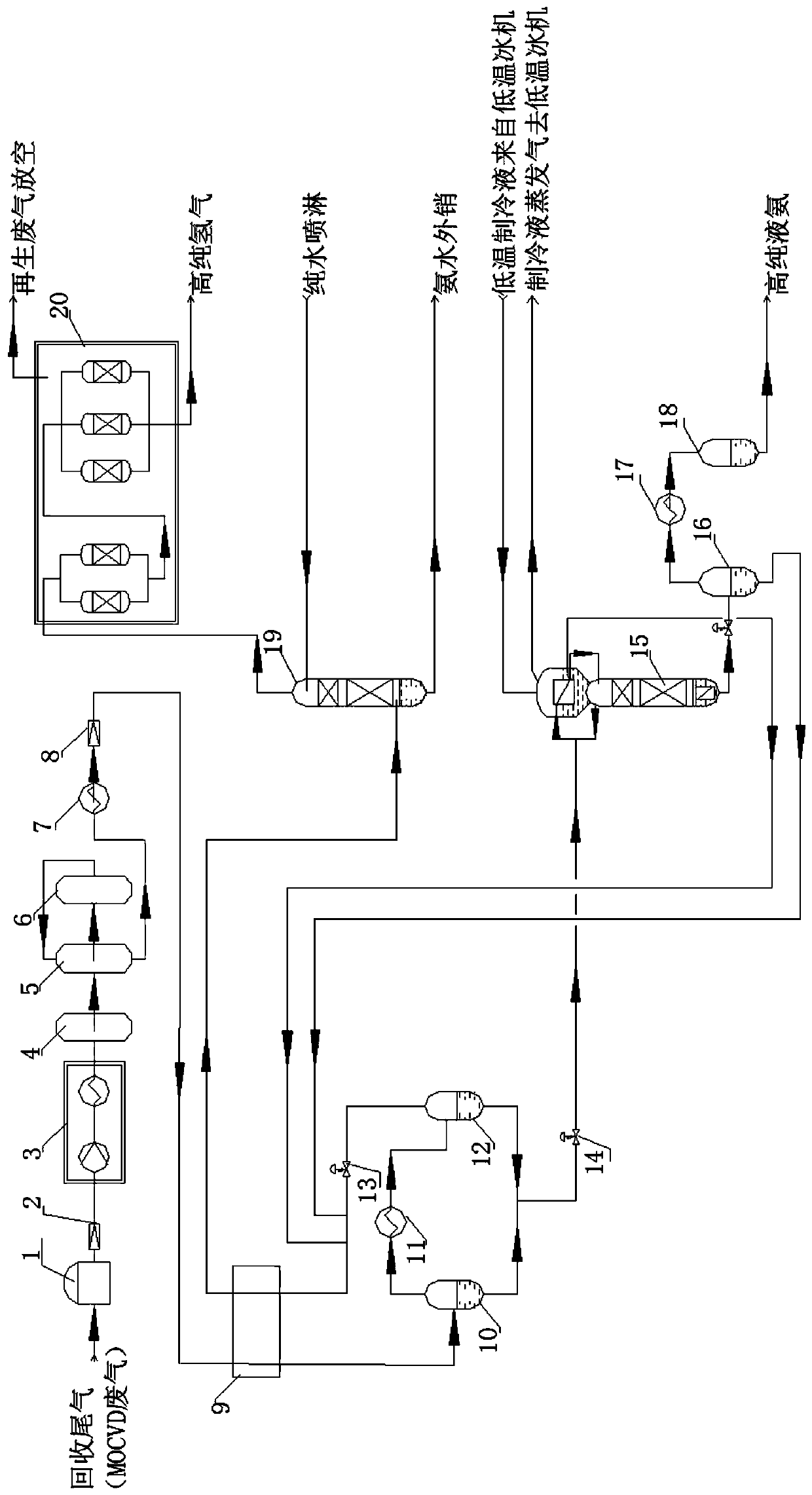

Exhaust gas recovery method and device for LED epitaxial wafer preparation process

PendingCN110143576AEmission reductionSimple processSolidificationLiquefactionRecovery methodMolecular sieve

The invention relates to the technical field of exhaust gas recovery, in particular to an exhaust gas recovery method and a device for an LED epitaxial wafer preparation process. The recovery method includes collecting the exhaust gas of the LED epitaxial wafer preparation process and filtering the dust from the exhaust gas to obtain a first filter exhaust gas; performing pressurization and heating reaction on the first filtered exhaust gas, cooling and filtering to remove an MO source in the exhaust gas to obtain a second filtered exhaust gas; carrying out condensation separation and rectification on the second filtered tail gas to obtain ammonia removal tail gas and industrial liquid ammonia; spraying the ammonia removal tail gas with water, performing molecular sieve dehydration and pressure swing adsorption to obtain high-purity hydrogen. The process of the recovery method is simple, and ammonia, hydrogen and trimethylgallium (TMGa) in the exhaust gas are recovered and utilized, sothat the waste of energy is avoided, the exhaust gas emission is reduced, and the method has good environmental protection and economy.

Owner:上海跃绅能源科技有限公司

Method for epitaxially growing large chamfering angle sapphire substrate-based GaN and application of GaN

InactiveCN108511323AOvercoming the phenomenon of step coalescenceQuality improvementSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum wellGallium nitride

The invention provides a method for epitaxially growing large chamfering angle sapphire substrate-based GaN. The method comprises the steps of S1, placing a large chamfering angle sapphire substrate with a chamfering angle larger than 0.2 degree in an epitaxial growth device, and sequentially growing a nucleating layer ,an unintentionally-doped GaN layer and a first layer of n-type GaN on the large chamfering angle sapphire substrate in a lamination way; and S2, introducing NH3 and trimethyl gallium into the epitaxial growth device, controlling the flowing ratio of the NH3 and the trimethyl gallium to be larger than 600, and simultaneously controlling chamber pressure of the epitaxial growth device to be smaller than 400mbar so that a second layer of n-type GaN is grown on the first layerof n-type GaN at a speed larger than 0.5 nanometer per second and a large chamfering angle sapphire substrate-GaN composite structure is obtained. By optimizing a growth process, high-quality GaN is epitaxially grown on the large chamfering angle sapphire substrate, so that grown on a template of the large chamfering angle sapphire substrate-GaN composite structure can be performed to obtain a high-quality green-light or yellow-light waveband InGaN quantum well.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

Growth method of light emitting diode and light emitting diode

The invention provides a growth method of a light emitting diode and the light emitting diode. The growth method comprises the following steps: 1) nitrogen, ammonia, trimethylaluminum, trimethylgallium and trimethylindium are introduced into reaction equipment at 800-930 DEG C and 200Torr to grow a first AlxInyGa1-x-yN layer on a quantum well luminescent layer and then the introduction of nitrogen, ammonia, trimethylaluminum, trimethylgallium and trimethylindium is stopped; 2) hydrogen is introduced into the reaction equipment to enable the first AlxInyGa1-x-yN layer to be converted into a first AlxGa1-xN layer; and 3) the step 1) to the step 2) are cyclically performed for T times so as to obtain an electron barrier layer AlxGa1-xN, wherein 0 <x<1, 0<y<1 and x>y. The method is helpful togrow the high-quality electron barrier layer on the basis of no negative influence on the quantum well structure.

Owner:EPITOP PHOTOELECTRIC TECH

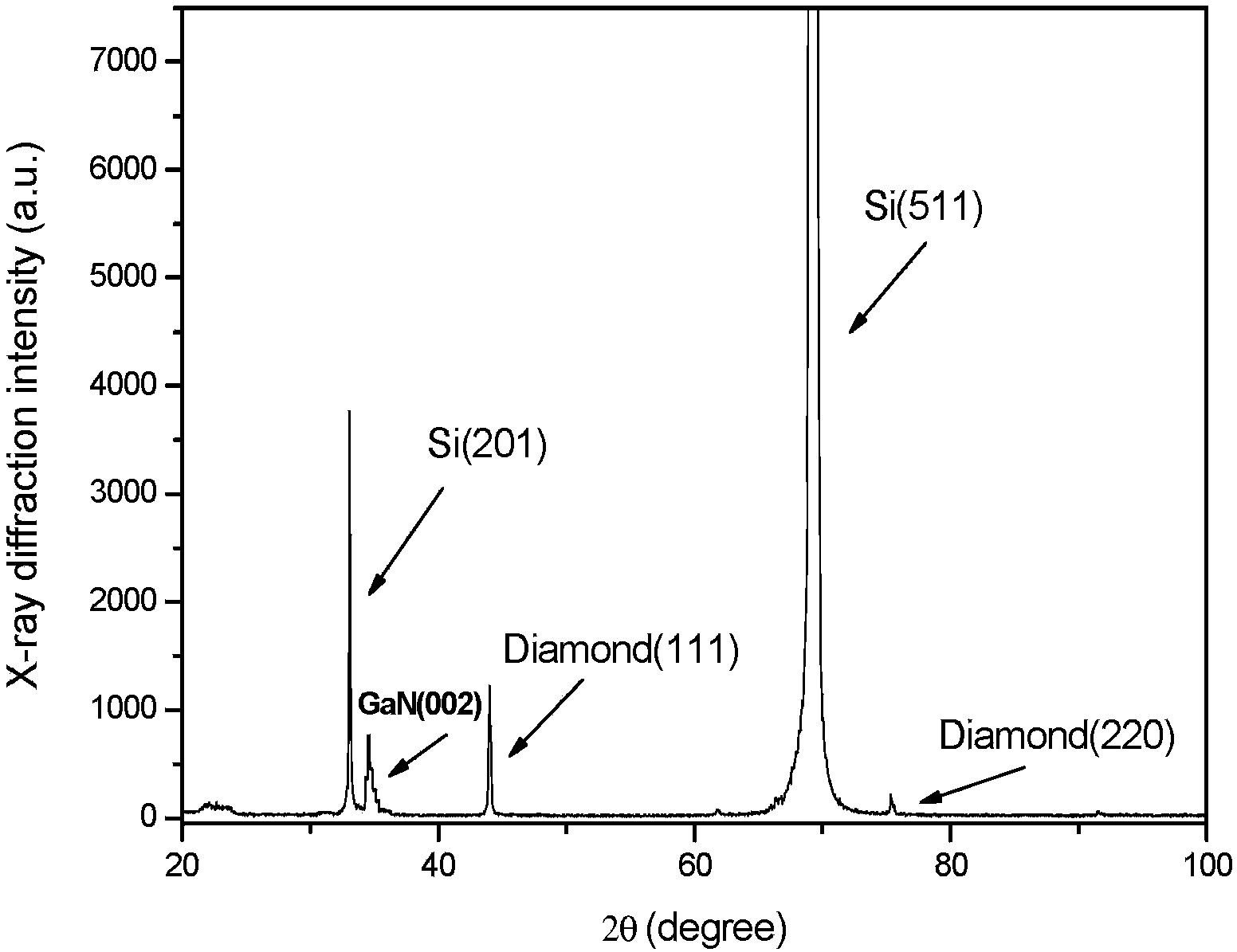

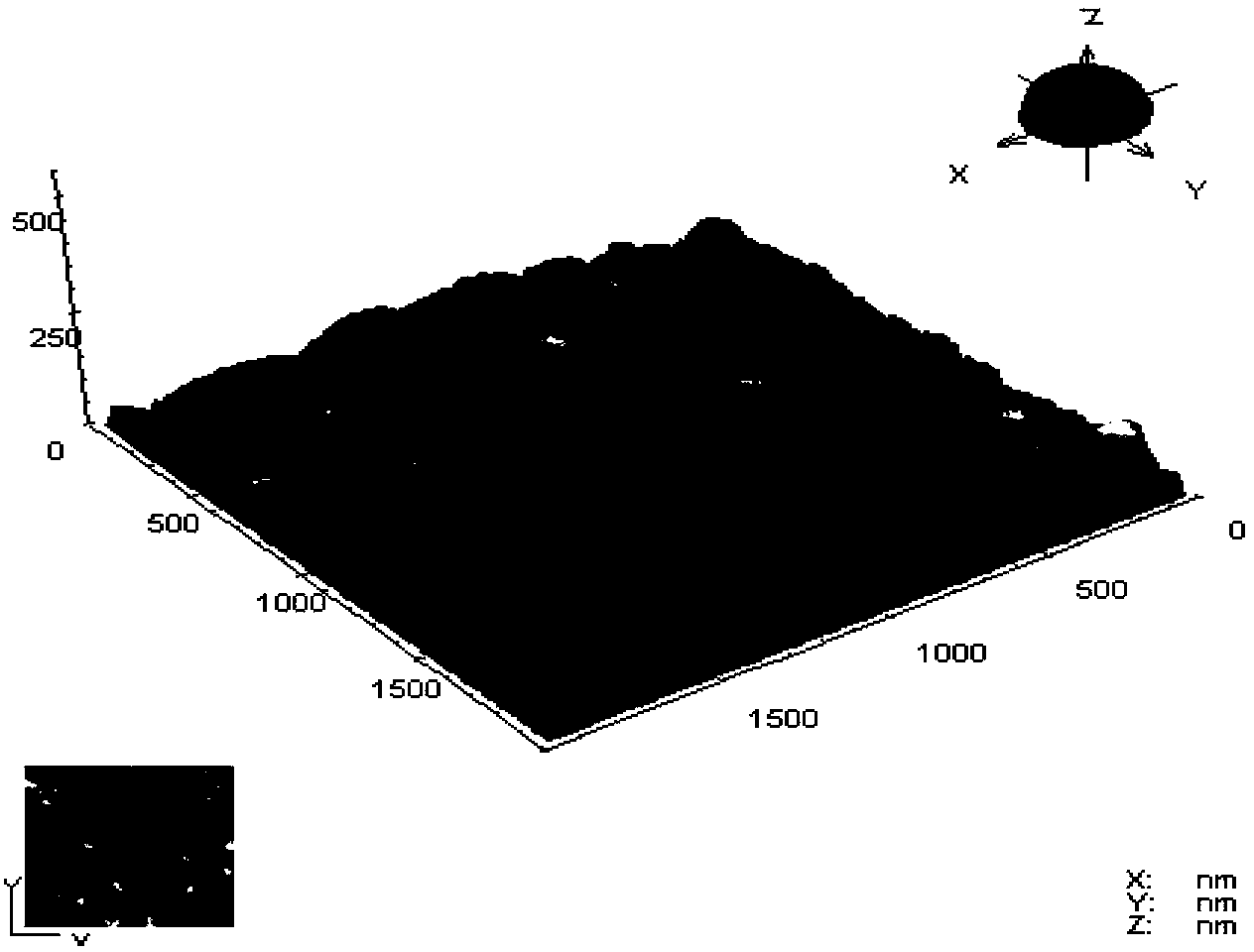

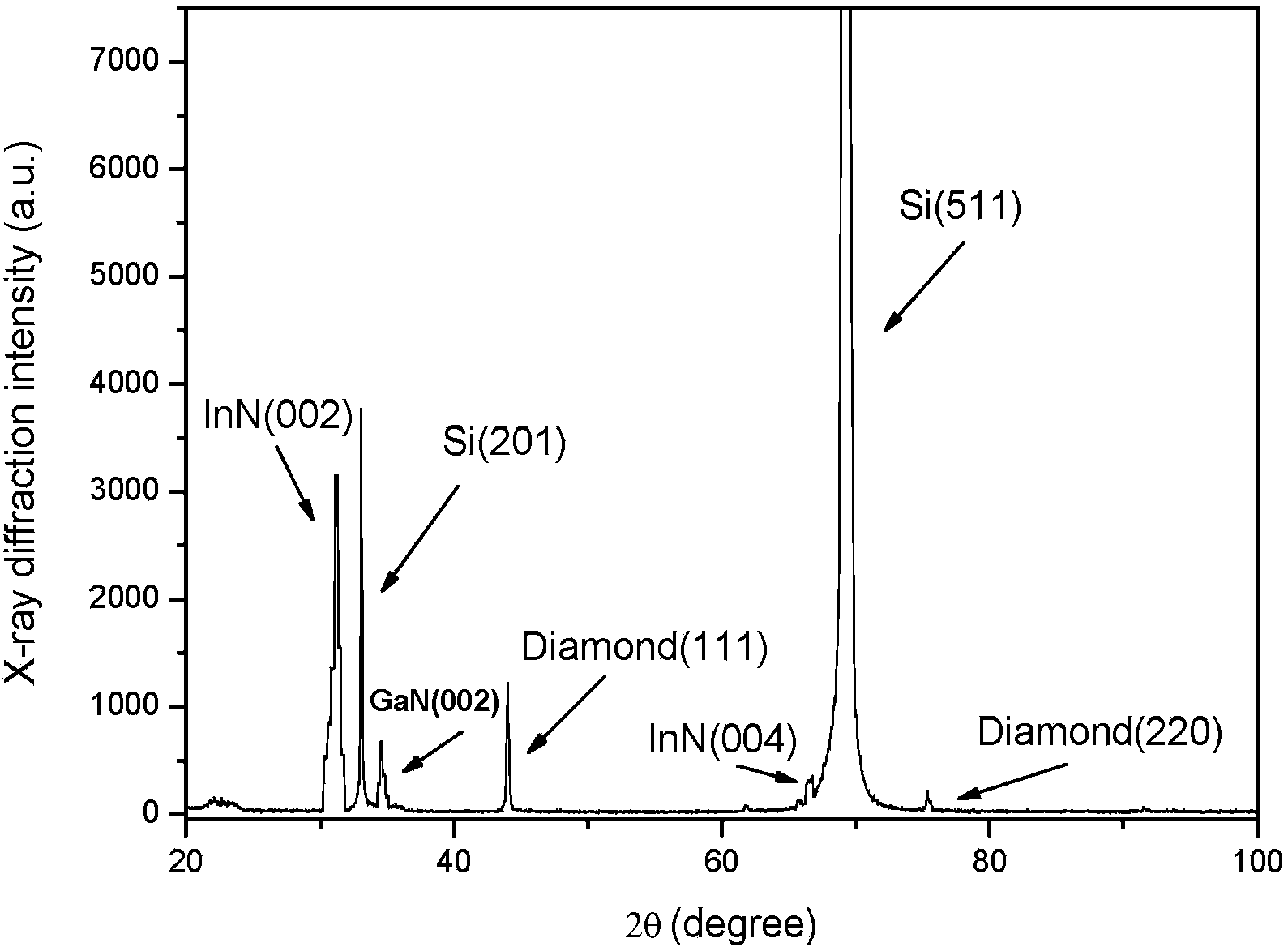

Preparation method for depositing InN film on GaN buffer layer/diamond film/Si multilayer film structure substrate at low temperature by ECR-PEMOCVD (electron cyclotron resonance-plasma-enhanced metal-organic chemical vapor deposition)

ActiveCN103361629AImprove thermal conductivityImprove heat resistanceChemical vapor deposition coatingLow temperature depositionNitrogen gas

The invention belongs to the technical field of deposition preparation of novel photoelectric materials, and provides a preparation method for depositing an InN film on a GaN buffer layer / diamond film / Si multilayer film structure substrate at low temperature by ECR-PEMOCVD (electron cyclotron resonance-plasma-enhanced metal-organic chemical vapor deposition), which can prepare an InN photoelectric film with favorable electric properties at low cost. The invention comprises the following steps: 1) carrying out ultrasonic cleaning on an Si substrate sequentially with acetone, ethanol and deionized water, drying the Si substrate by blowing nitrogen, and sending into a reaction chamber; 2) by using a hot wire CVD (chemical vapor deposition) system, vacuumizing the reaction chamber, heating the Si substrate, and introducing hydrogen and methane gas into the reaction chamber to obtain a diamond film on the Si substrate; and 3) by using an ECR-PEMOCVD system, vacuumizing the reaction chamber, heating the substrate to 200-600 DEG C, and introducing hydrogen-carried trimethyl gallium and nitrogen into the reaction chamber.

Owner:辽宁众城新能源开发有限公司

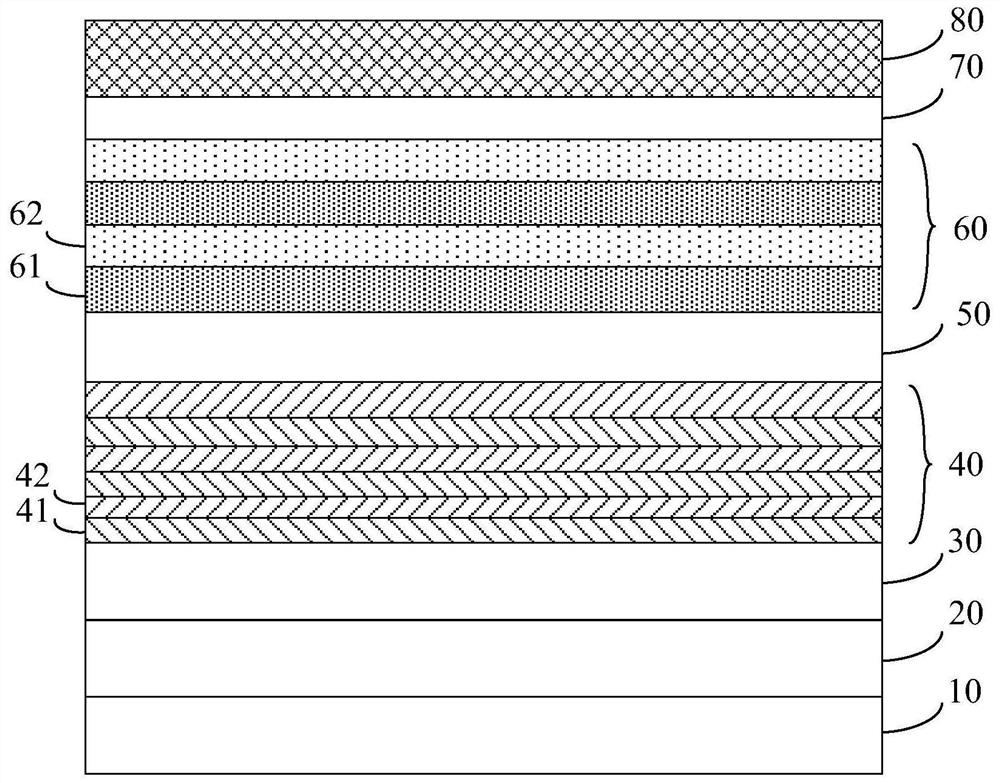

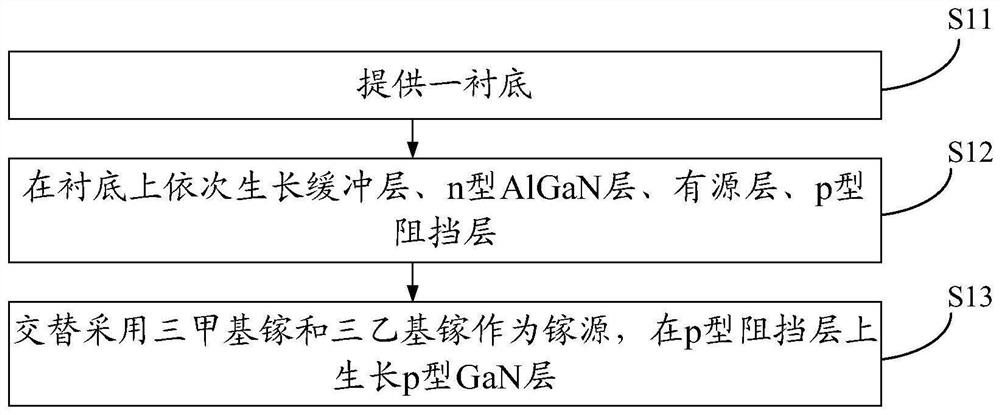

Epitaxial wafer of light emitting diode and manufacturing method thereof

ActiveCN112466999AConducive to total reflectionEasy to dopeSemiconductor devicesElectron holeUltraviolet lights

The invention discloses an epitaxial wafer of a light emitting diode and a manufacturing method thereof, and belongs to the technical field of photoelectrons. The manufacturing method comprises the following steps: providing a substrate; sequentially growing a buffer layer, an n-type AlGaN layer, an active layer and a p-type barrier layer on the substrate; and alternately adopting trimethyl gallium and triethyl gallium as a gallium source, and growing a p-type GaN layer on the p-type barrier layer. When trimethyl gallium serves as a gallium source for growth, the grown surface flatness is low,surface coarsening is facilitated, total reflection of light can be reduced, scattering of the light is improved, and when triethyl gallium serves as the gallium source for growth, a film formed through growth has high crystal quality, Mg doping is facilitated, the hole concentration can be improved, and the improvement of luminous efficiency is facilitated. By reducing the total reflection of light, improving the scattering of light and improving the concentration of holes, the light extraction efficiency of the deep ultraviolet light-emitting diode is improved on the whole.

Owner:HC SEMITEK ZHEJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com