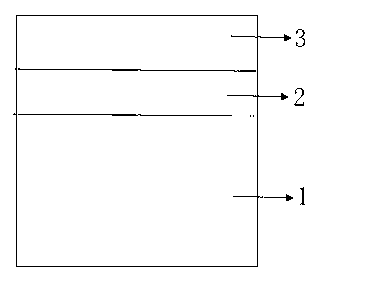

Preparation method of surface acoustic wave filter in AlN/GAZO/self-supporting diamond film structure

A technology of surface acoustic wave filtering and diamond film, which is applied in electrical components, metal material coating process, gaseous chemical plating, etc. The effect of excellent sound speed transmission performance, easy process control and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

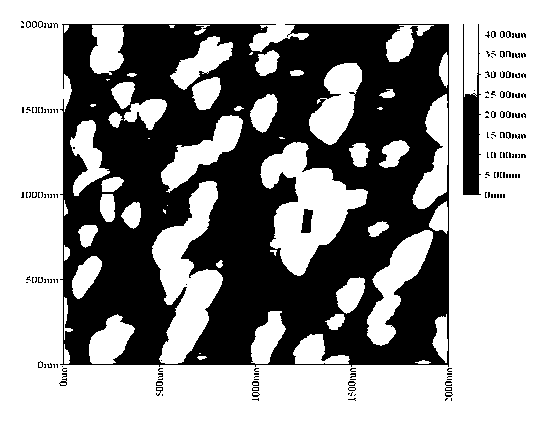

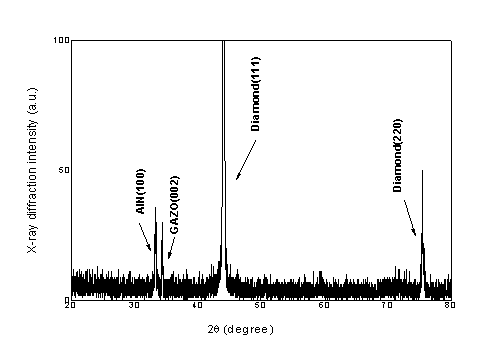

[0024] Using the self-supporting diamond film as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen and sent to the vapor deposition reaction chamber;

[0025] Vacuum the vapor deposition reaction chamber to 8.0×10 -4 Pa, the substrate is heated to 485°C, and the flow rate of 120sccm of oxygen, the flow rate of 0.3sccm of trimethylaluminum, the flow rate of 0.8sccm of trimethylgallium and the flow rate of 1.0sccm of diethylzinc into the reaction chamber , control the microwave power to 600W, and deposit a GAZO film with a thickness of 100nm on the substrate;

[0026] Stop feeding trimethylaluminum, trimethylgallium and diethylzinc after the deposition finishes, purge the vapor deposition reaction chamber with nitrogen, then pass into the trimethylaluminum that the flow rate is 0.9sccm, and control the nitrogen flow rate as 130sccm, the The substrate is heated to 600°C, the microwave power is contr...

Embodiment 2

[0028] Using the self-supporting diamond film as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen and sent to the vapor deposition reaction chamber;

[0029] Vacuum the vapor deposition reaction chamber to 8.0×10 -4 Pa, heat the substrate to 485°C, and feed into the reaction chamber oxygen with a flow rate of 80 sccm, trimethylaluminum with a flow rate of 1.0 sccm, trimethylgallium with a flow rate of 0.5 sccm and diethylzinc with a flow rate of 0.6 sccm , control the microwave power to 600W, and deposit a GAZO film with a thickness of 80nm on the substrate;

[0030] Stop feeding trimethylaluminum, trimethylgallium and diethylzinc after the deposition finishes, purge the vapor deposition reaction chamber with nitrogen, then pass into the trimethylaluminum that the flow rate is 0.3sccm, and control the nitrogen flow rate as 80sccm, the The substrate was heated to 500°C, and the microwave power wa...

Embodiment 3

[0032] Using the self-supporting diamond film as the substrate, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence, dried with nitrogen and sent to the vapor deposition reaction chamber;

[0033] Vacuum the vapor deposition reaction chamber to 8.0×10 -4 Pa, the substrate is heated to 485°C, and the flow rate of 200 sccm of oxygen, the flow rate of 2.0 sccm of trimethylaluminum, the flow rate of 2.0 sccm of trimethylgallium and the flow rate of 3.0 sccm of diethylzinc into the reaction chamber , control the microwave power to 600W, and deposit a GAZO film with a thickness of 80nm on the substrate;

[0034] After the deposition, stop feeding trimethylaluminum, trimethylgallium and diethylzinc, purge the vapor deposition reaction chamber with nitrogen, then feed the trimethylaluminum with a flow rate of 2.0sccm, and control the nitrogen flow rate to be 150sccm. The substrate was heated to 900°C, and the microwave power was controlled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com