Patents

Literature

729 results about "Acoustic speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The velocity at which a small disturbance will propagate through the medium is called Acoustic Velocity or Speed of Sound. The acoustic velocity is related to the change in pressure and density of the substance and can be expressed as. c = (dp / dρ) 1/2 (1) where. c = speed of sound (m/s, ft/s)

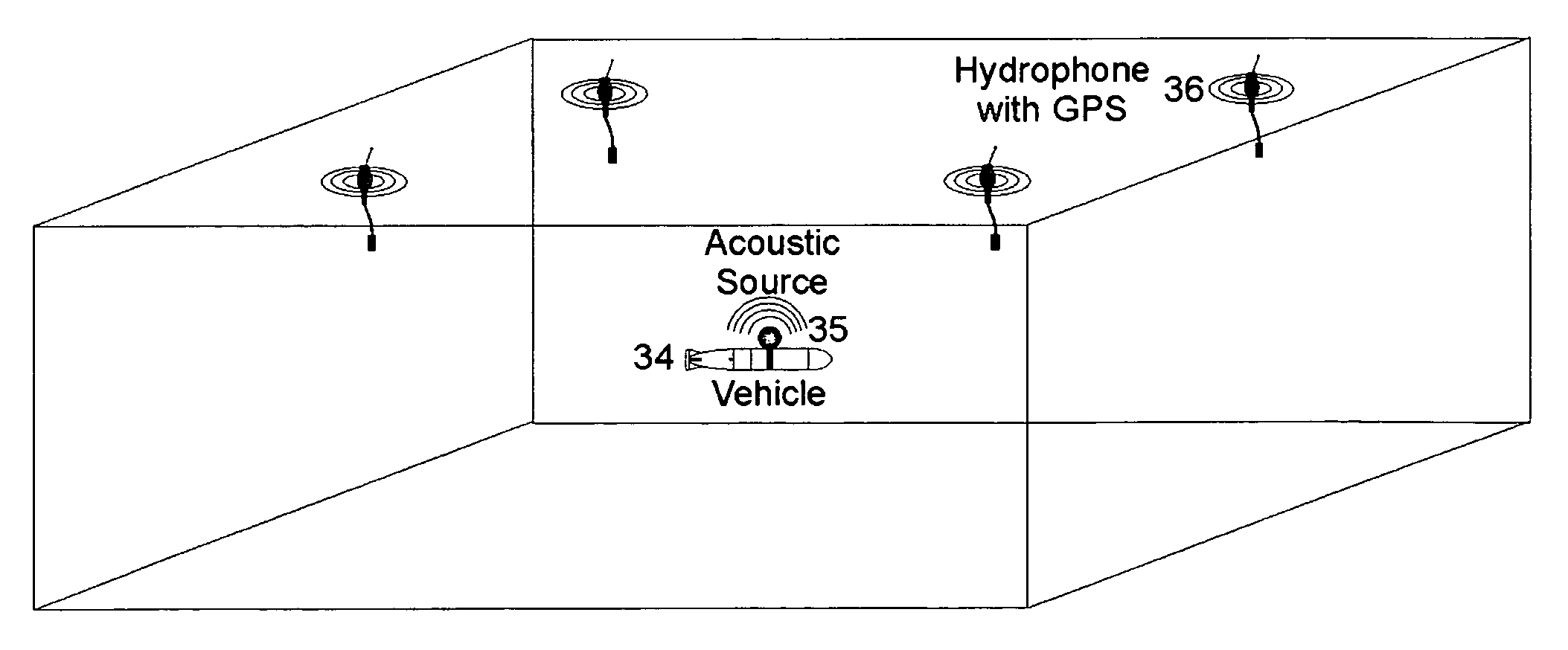

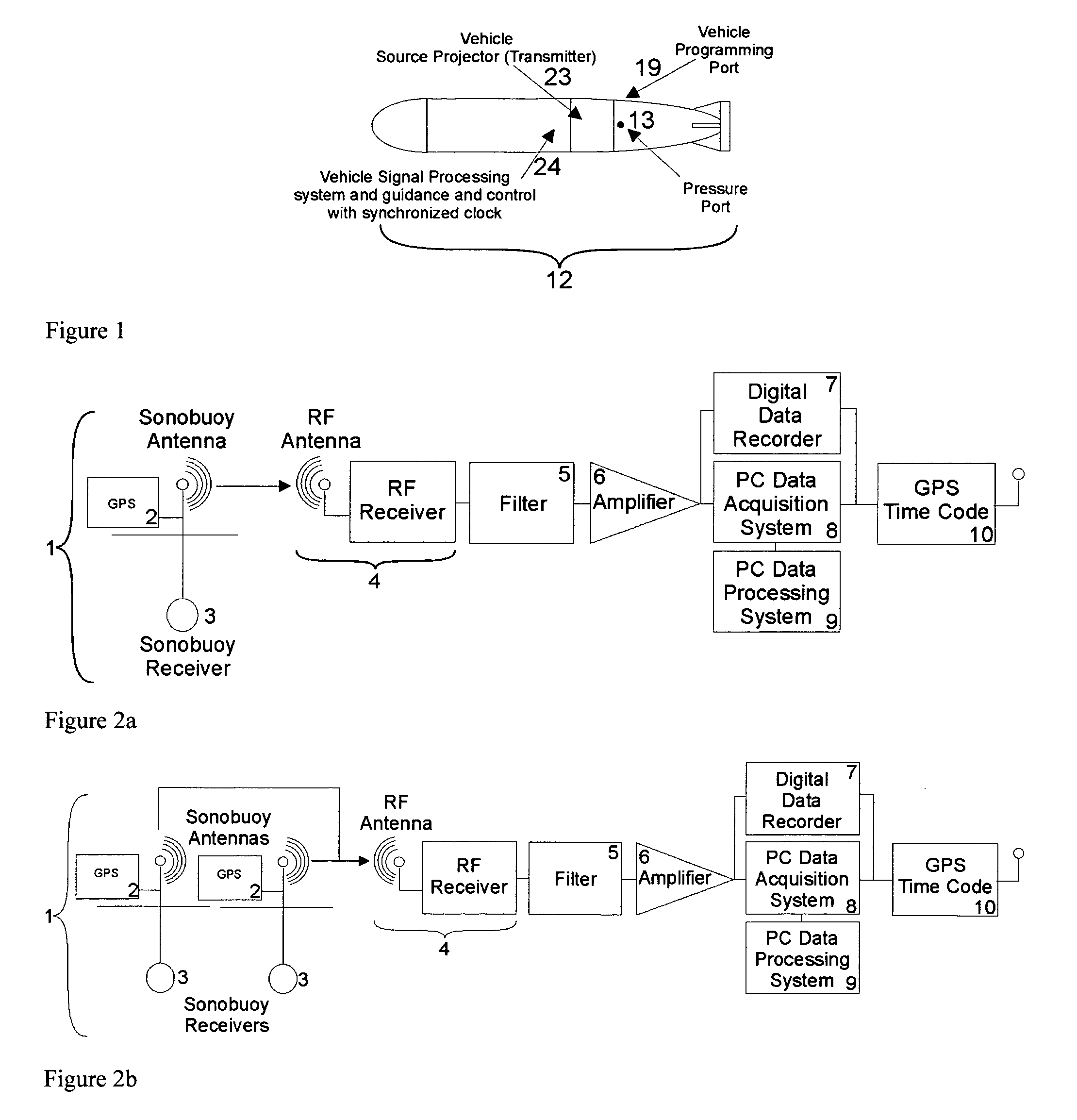

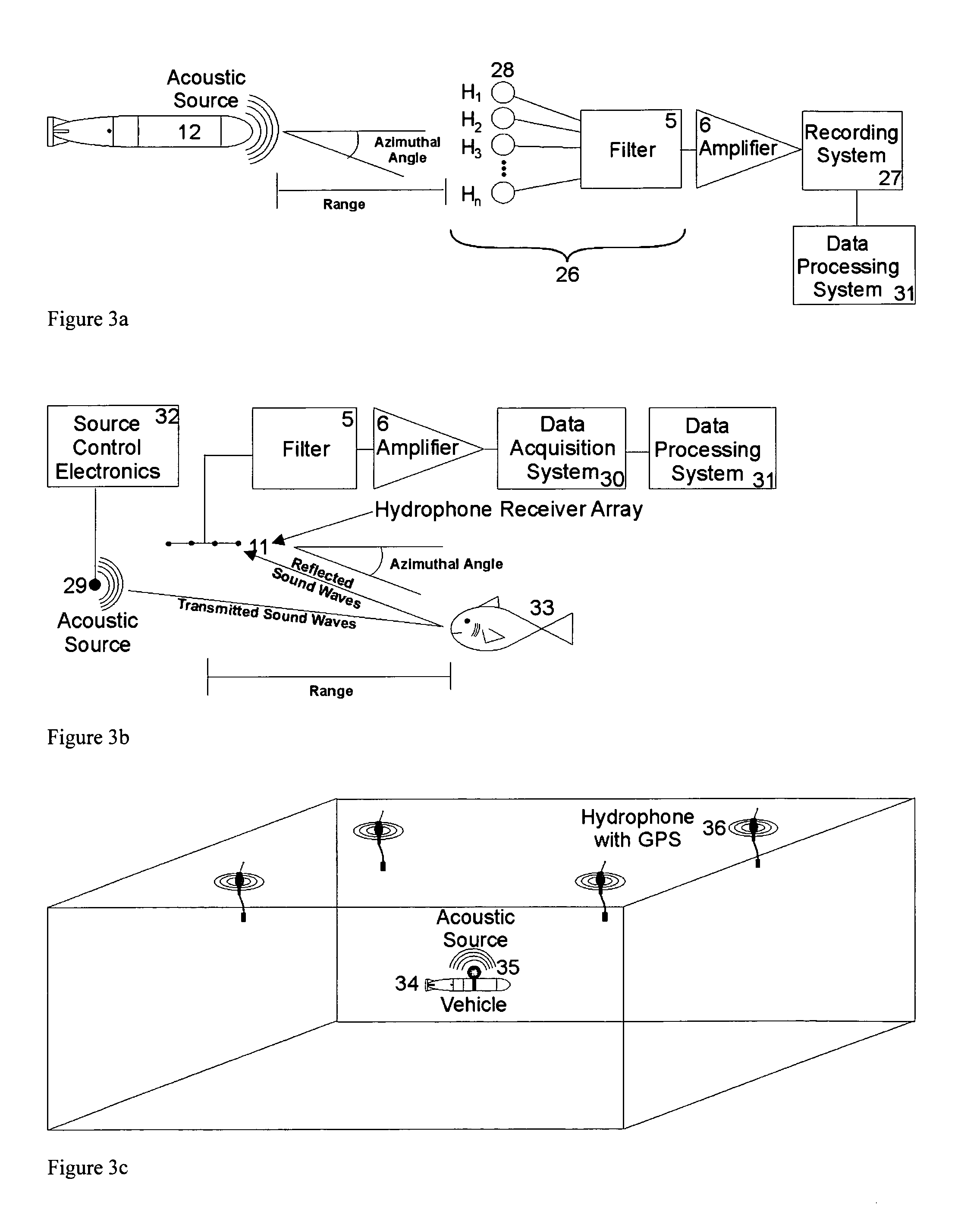

Methods of and systems for continually measuring the range between mobile underwater vehicles carrying acoustical signal transmitters and remotely deployed synchronized underwater acoustical receivers provided with signal processing for continually determining such range during the underwater moving of the vehicle, and for measuring acoustic underwater transmission loss, geoacoustical properties and for other purposes

ActiveUS20080165617A1Improve practicalitySonic/ultrasonic/infrasonic transmissionAcoustic wave reradiationOcean bottomContinuous measurement

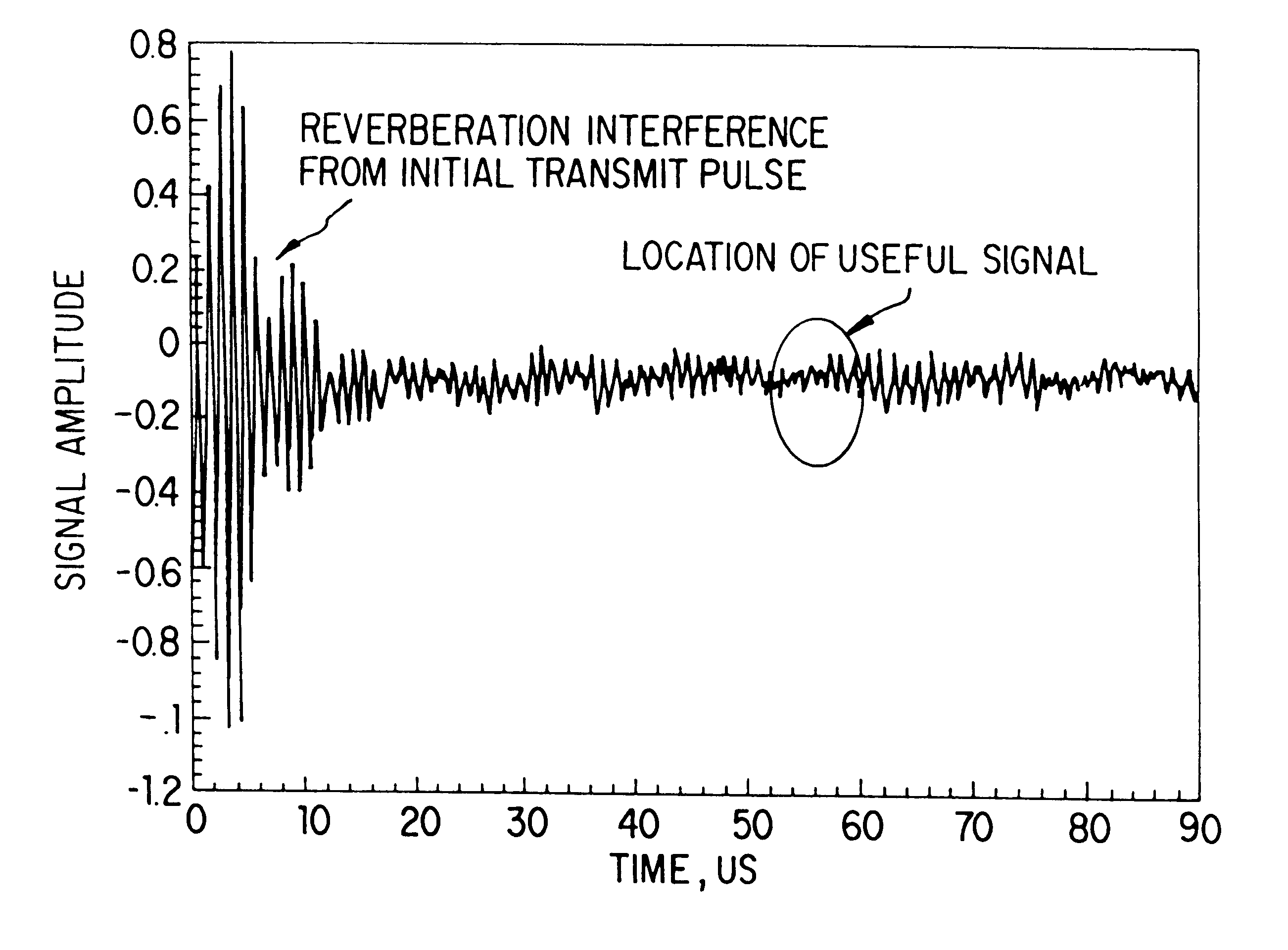

Invention relates to a novel method of and system for ranging between an acoustic source carried on an unmanned or autonomous undersea mobile vehicle (UUV or AUV) and preferably a plurality of hydrophone receivers remotely deployed from the vehicle in predetermined patterns, generally suspended from sonobuoys equipped with above-the-sea relay radio transmitting antennas, and with time synchronization provided amongst the source and the receivers, wherein the time delay from the transmissions of the source is measured by utilizing special signal processing, enabling range to be measured in close to real time by determining the product of the sound velocity and the measured time delay, and with the process continually and periodically being repeated throughout the duration of the vehicle run. Given the range, the system may then be used to measure the acoustical properties of and / or receiver system performance in the sea or other water body, such as transmission or propagation loss TL, channel impulse response, bottom geoacoustic properties, source level, receiver sensitivity calibration, sonar operator readiness and sonar receiver performance and the like. Further, in situ measured data can be assimilated with models to enable more accurate prediction of the ocean environment than could be obtained from either individually.

Owner:OCEAN ACOUSTICAL SERVICES ADN INSTR SYST OASIS INC

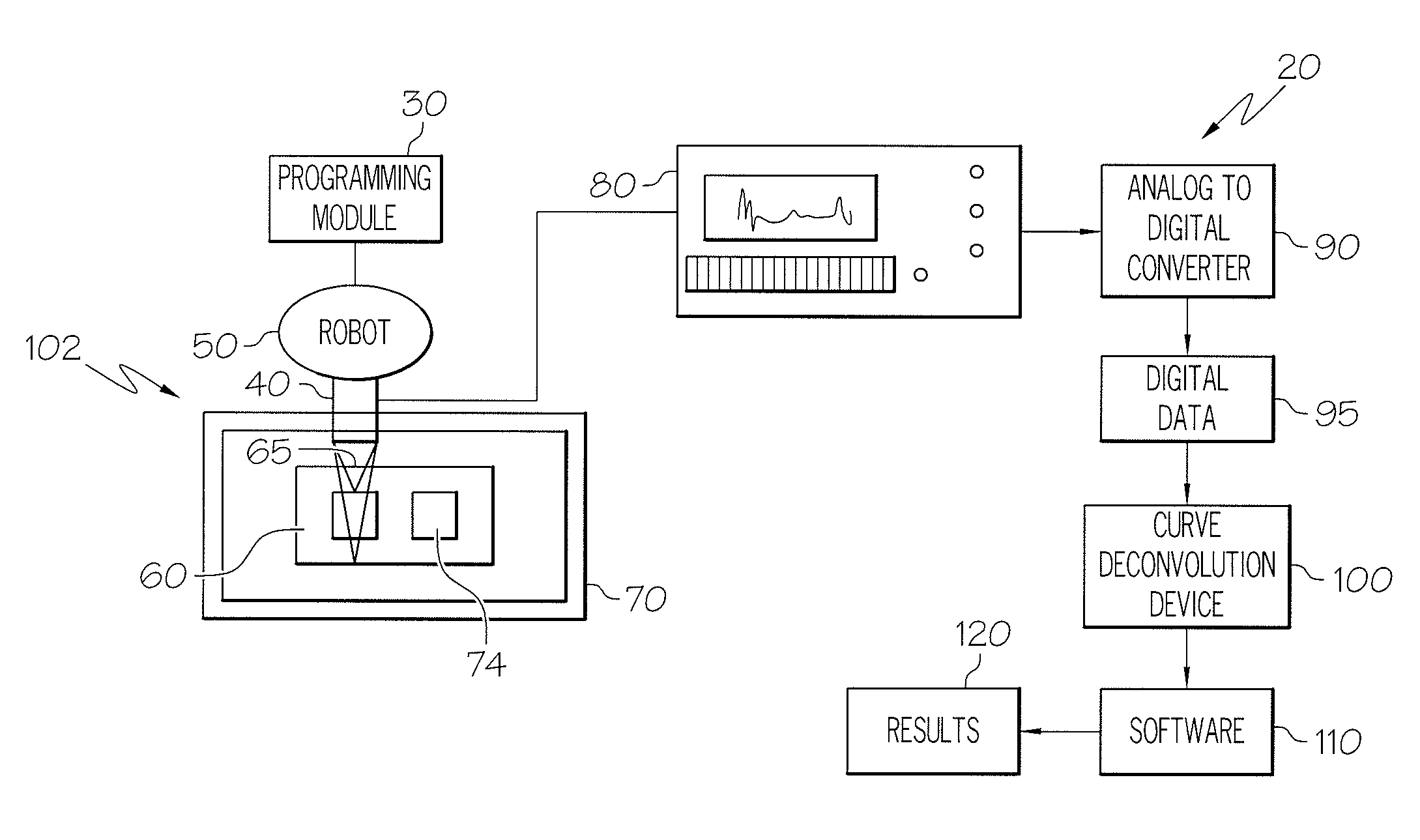

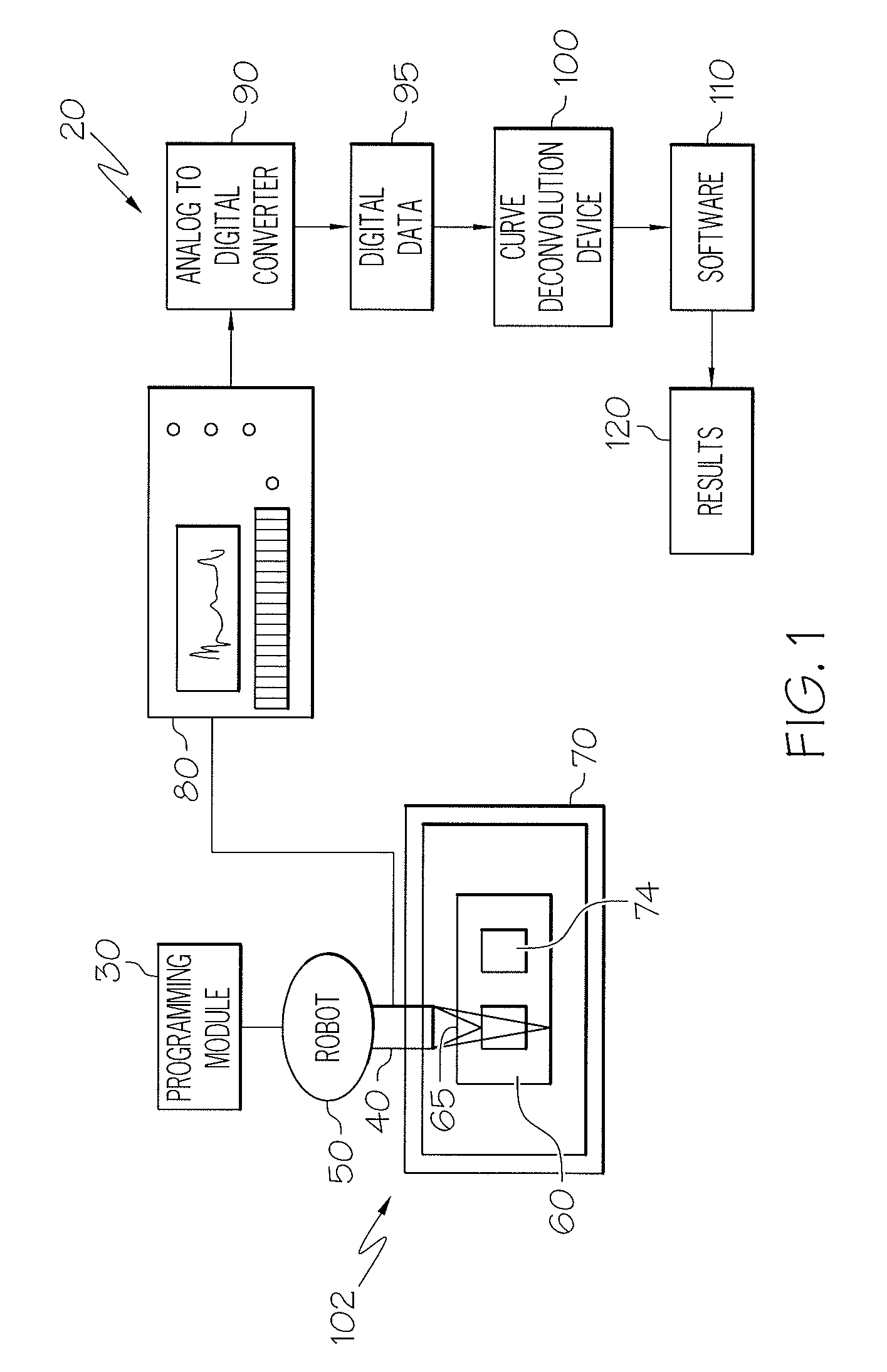

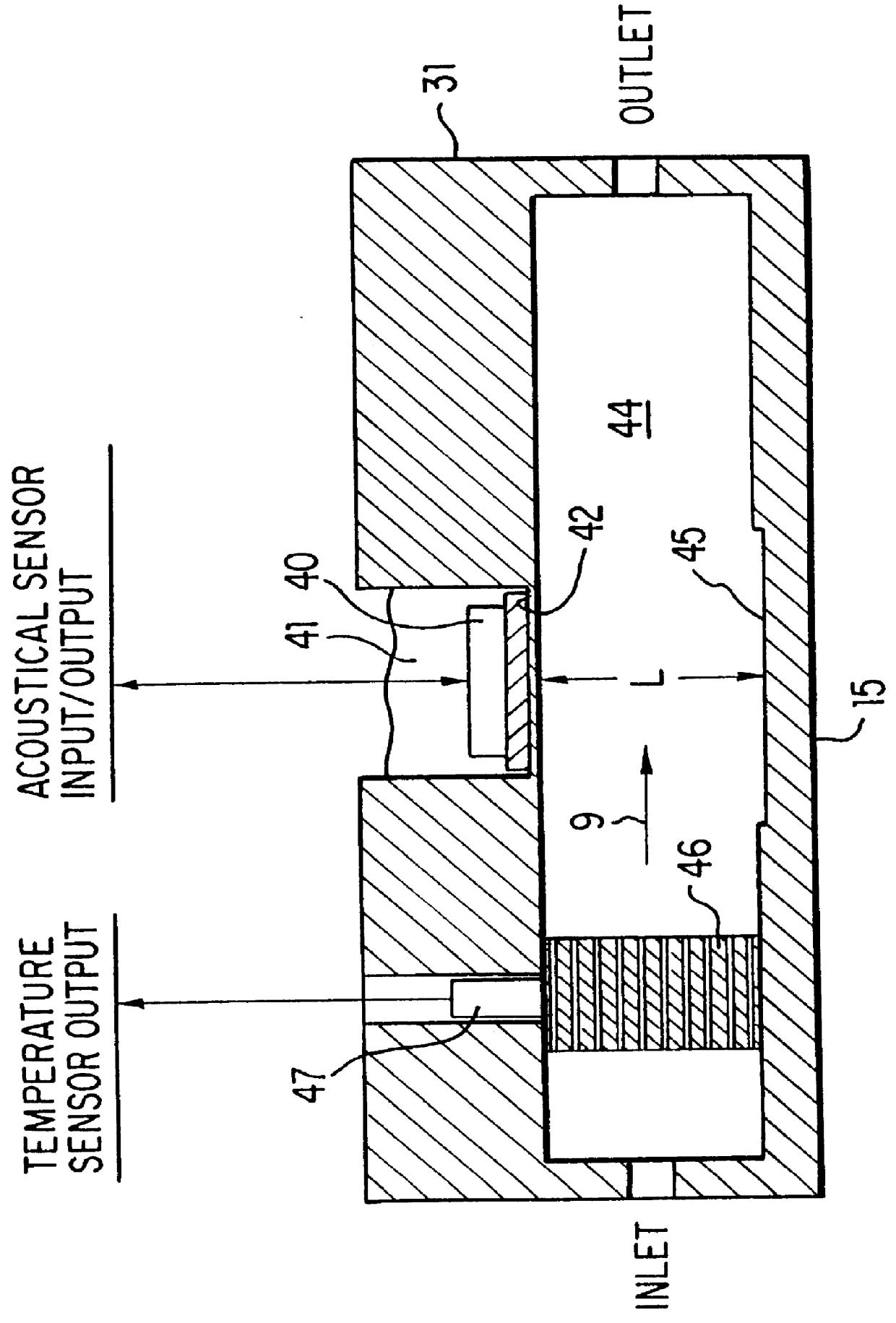

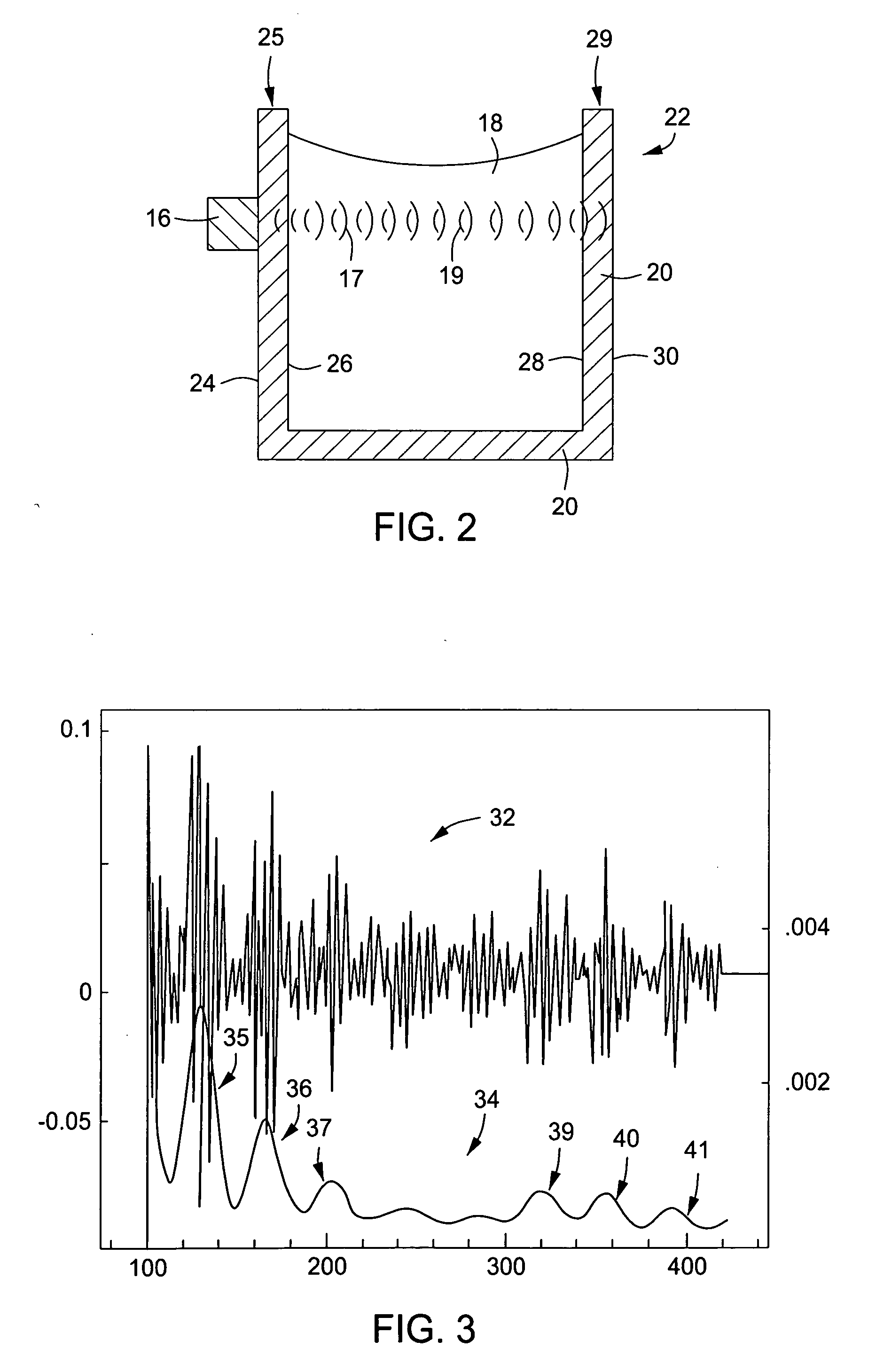

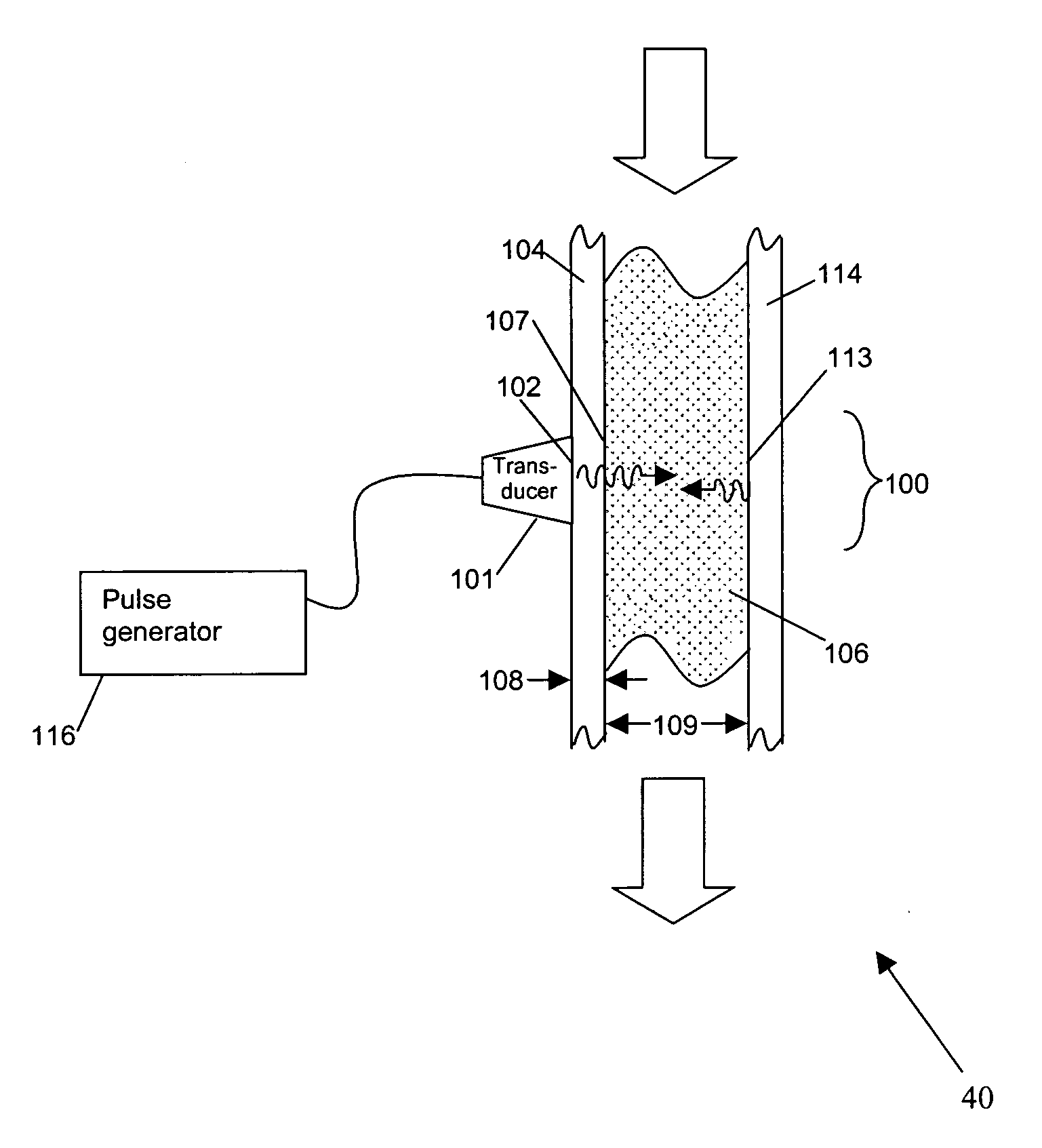

Apparatus and methods for performing acoustical measurements

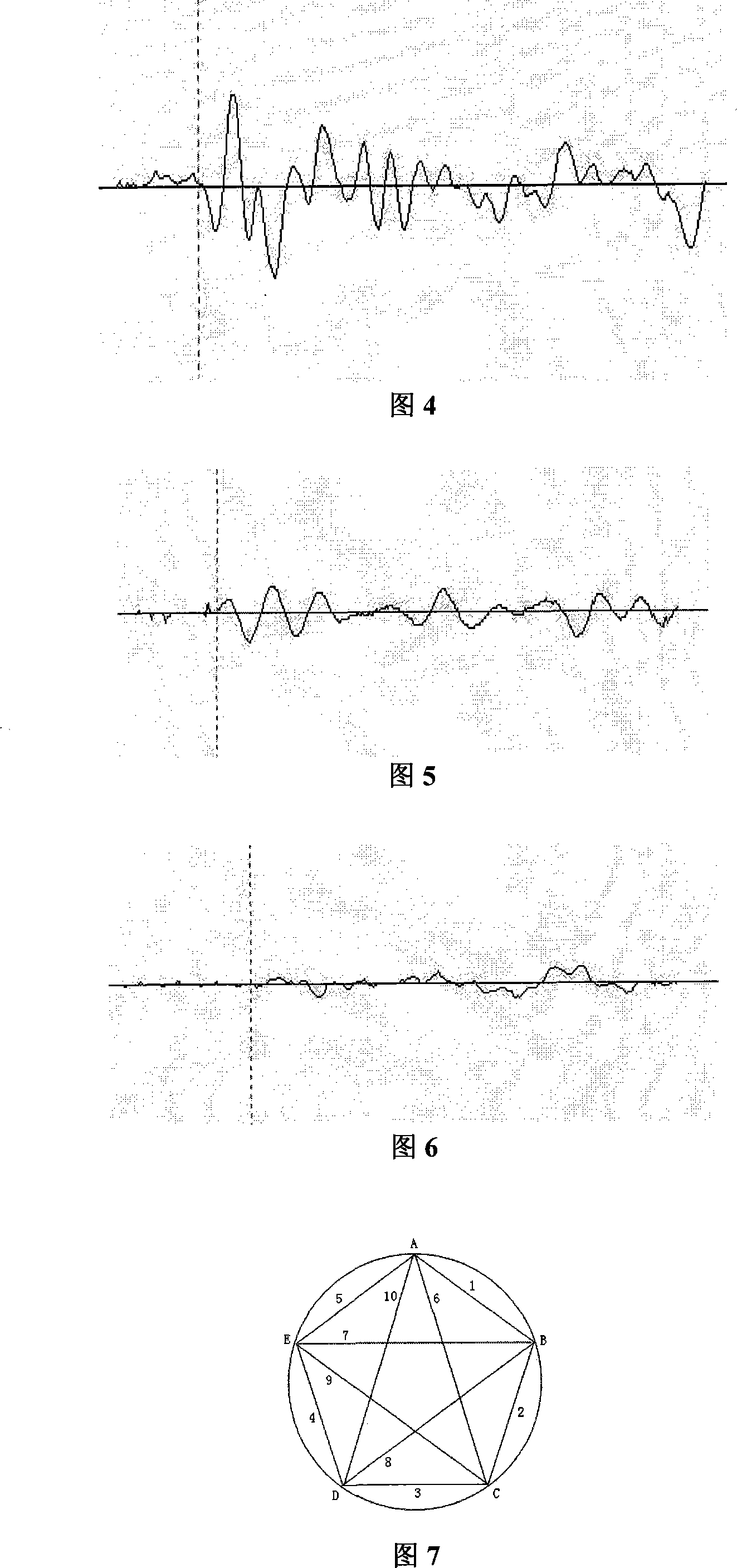

InactiveUS6279379B1Good repeatabilityAbsenceVibration measurement in solidsSpectral/fourier analysisFast Fourier transformCorrelation function

Apparatus (15, 30) and methods for performing acoustical measurements are provided having some and preferably all of the following features: (A) the system (15, 30) is operated under near-field conditions; (B) the piezoelement (40) or piezoelements (40, 48) used in the system are (i) mechanically (41, 49) and electrically (13, 16) damped and (ii) efficiently electrically coupled to the signal processing components of the system; (C) each piezoelement (40, 48) used in the system includes an acoustical transformer (42, 50) for coupling the element to a gaseous test medium (9); (D) speed of sound is determined from the time difference between two detections of an acoustical pulse (81, 82) at a receiver (40, FIG. 3; 48, FIG. 7); (E) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (F) forward and inverse Fourier transforms employing fast Fourier transform techniques are used to implement the cross-correlation techniques; in such a mathematical manner that the peak of the cross-correlation function corresponds to the detection of a pulse at the receiver and (G) stray path signals through the body (31) of the acoustic sensor (15, 30) are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measured and on mixtures of compressible gases. Methods and apparatus (29) for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

Granule graininess, concentration and density measuring method and device

InactiveCN101169363AImprove versatilityGuaranteed accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesParticle size analysisParticulatesSonification

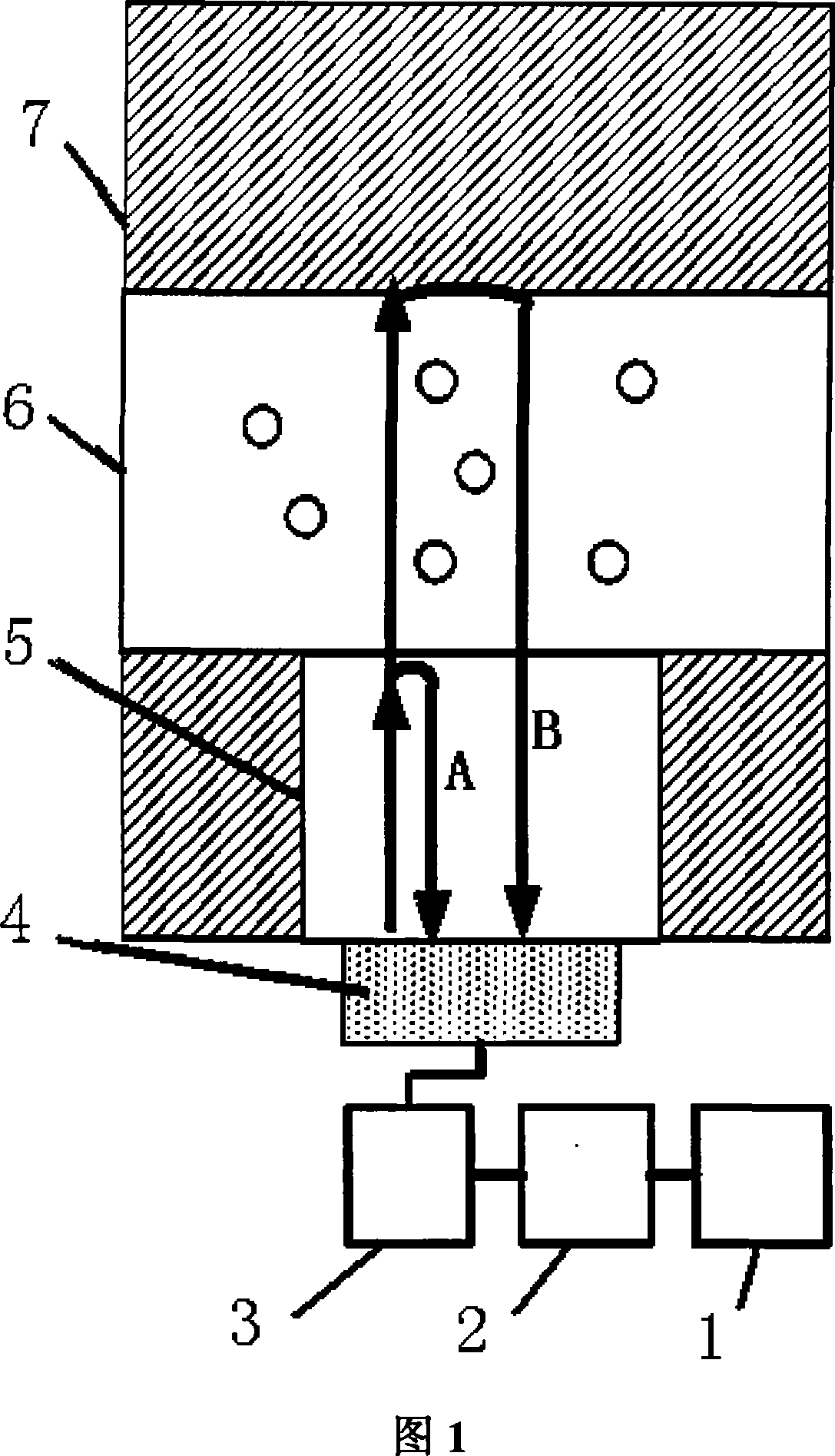

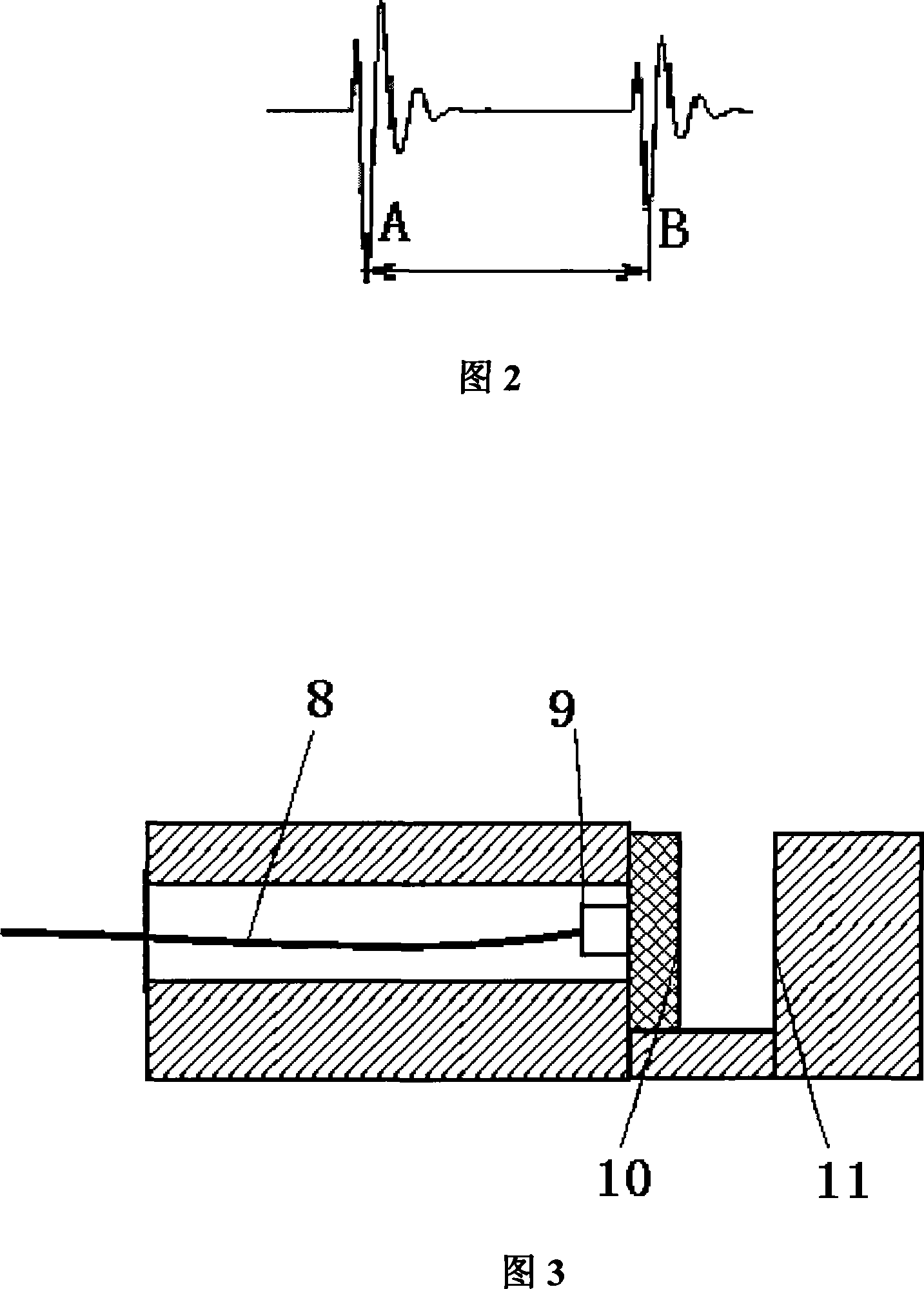

The invention discloses a measuring method and device for measuring the particle granularity, consistency and density, which relates to the technical field of ultrasonic measurement. The invention aims at solving the technical problem of increasing the commonality and the precision of the ultrasonic measurement. The measuring device includes a computer, a signal process circuit, a pulse wave launch / receive circuit and a broadband transducer, which are orderly connected together; the broadband transducer is arranged at the external side of a baffle plate. The process procedures of the computer are as follows: ultrasonic amplitude phase spectrum is obtained after the rapid Fourier transformation of the signal, and then the phase spectrum is converted to obtain a reflection coefficient, the acoustic characteristic impedance, the acoustic attenuation coefficient and the sound velocity; the compound density can be calculated by the measuring value, and the consistency can be calculated through the known particle and the density of the continuous medium; the frequency analysis of the direct reflection wave and the transmission echo is carried out to obtain difference between the acoustic attenuation spectrum and the theoretical acoustic attenuation spectrum, and the difference is then regarded as the objective function, and then is optimized with optimization method to calculate the distribution of the particle granularity. The invention has the advantages of measuring and analysis basing on the reflecting ultrasonic, great commonality and precise measuring result.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

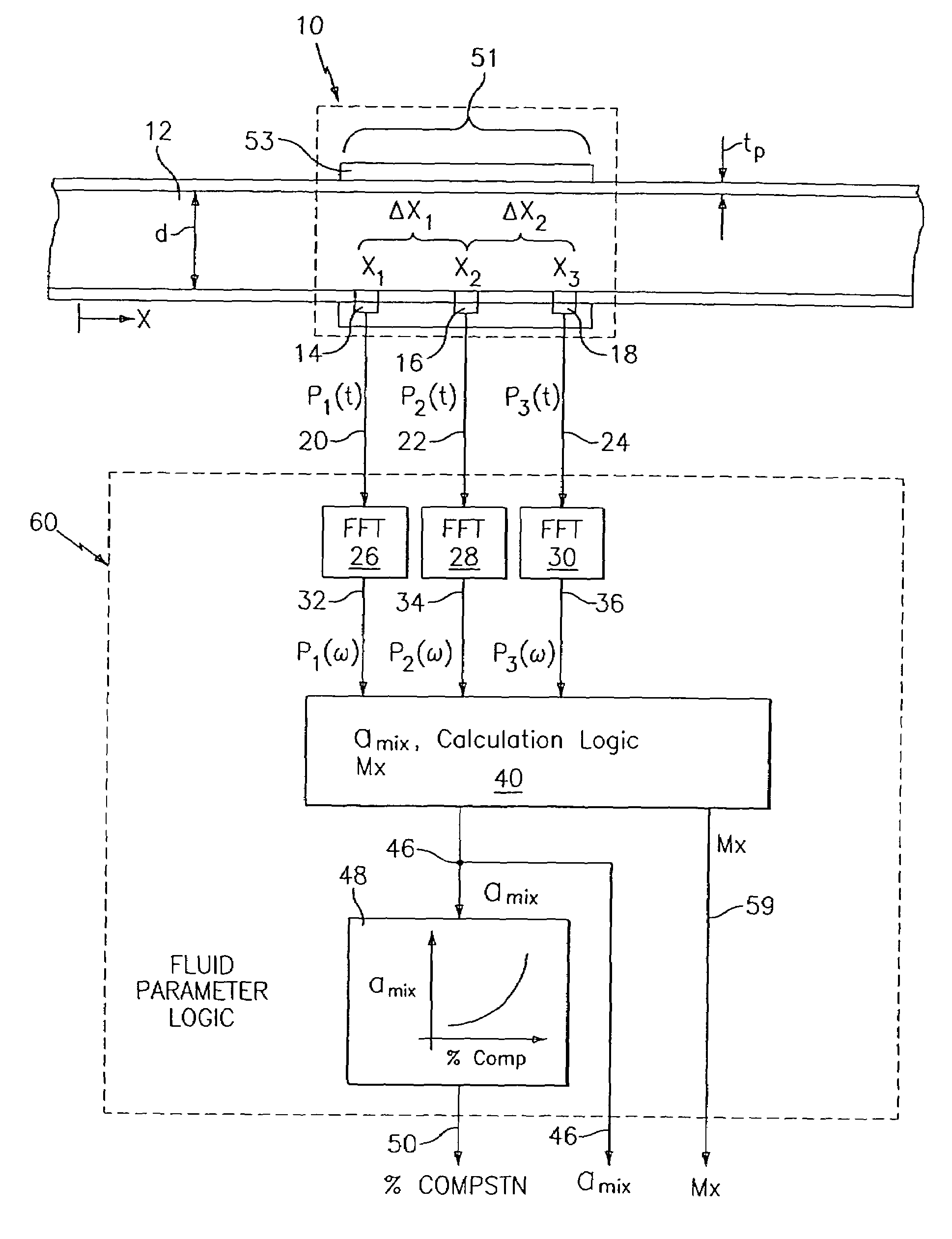

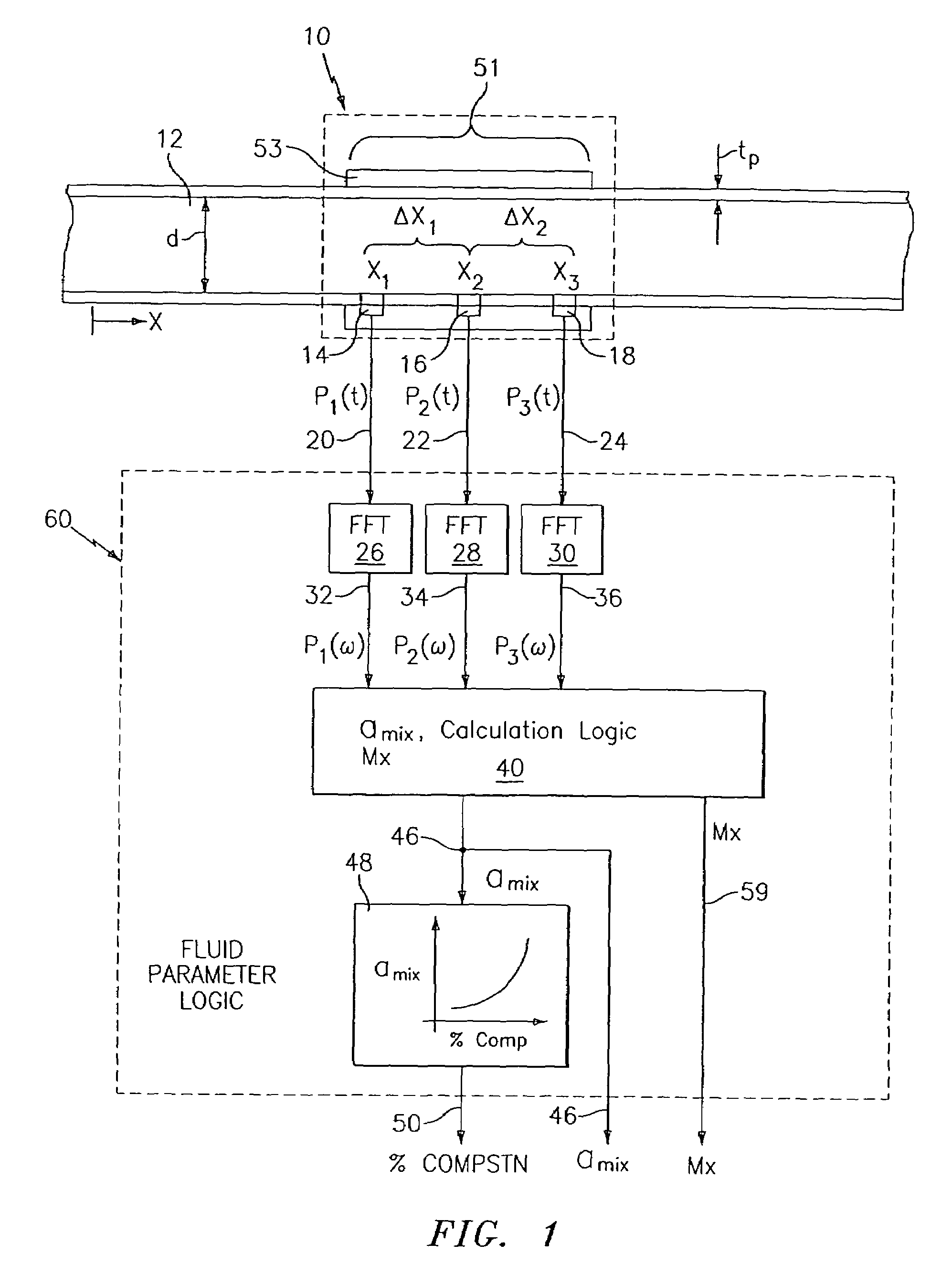

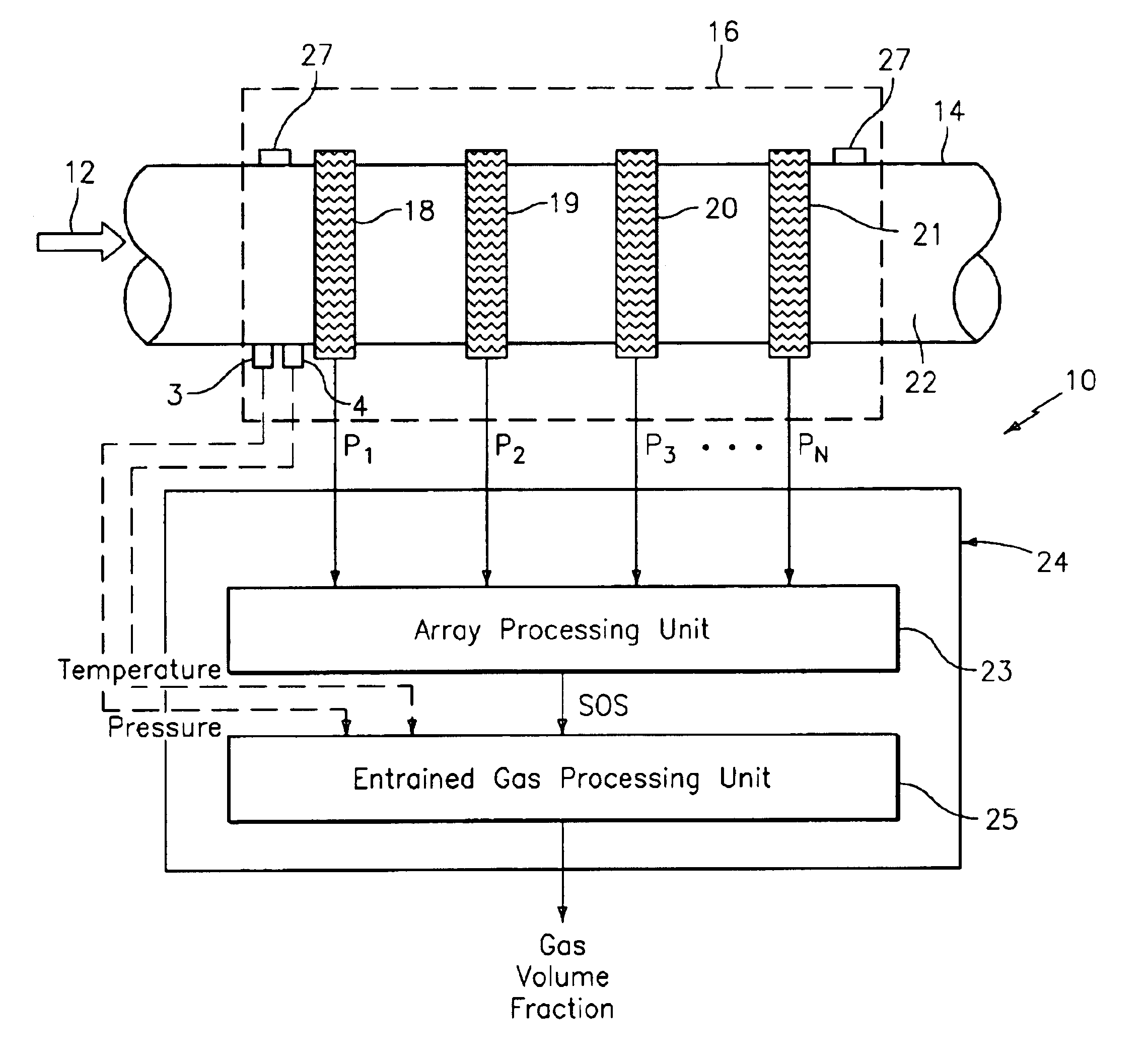

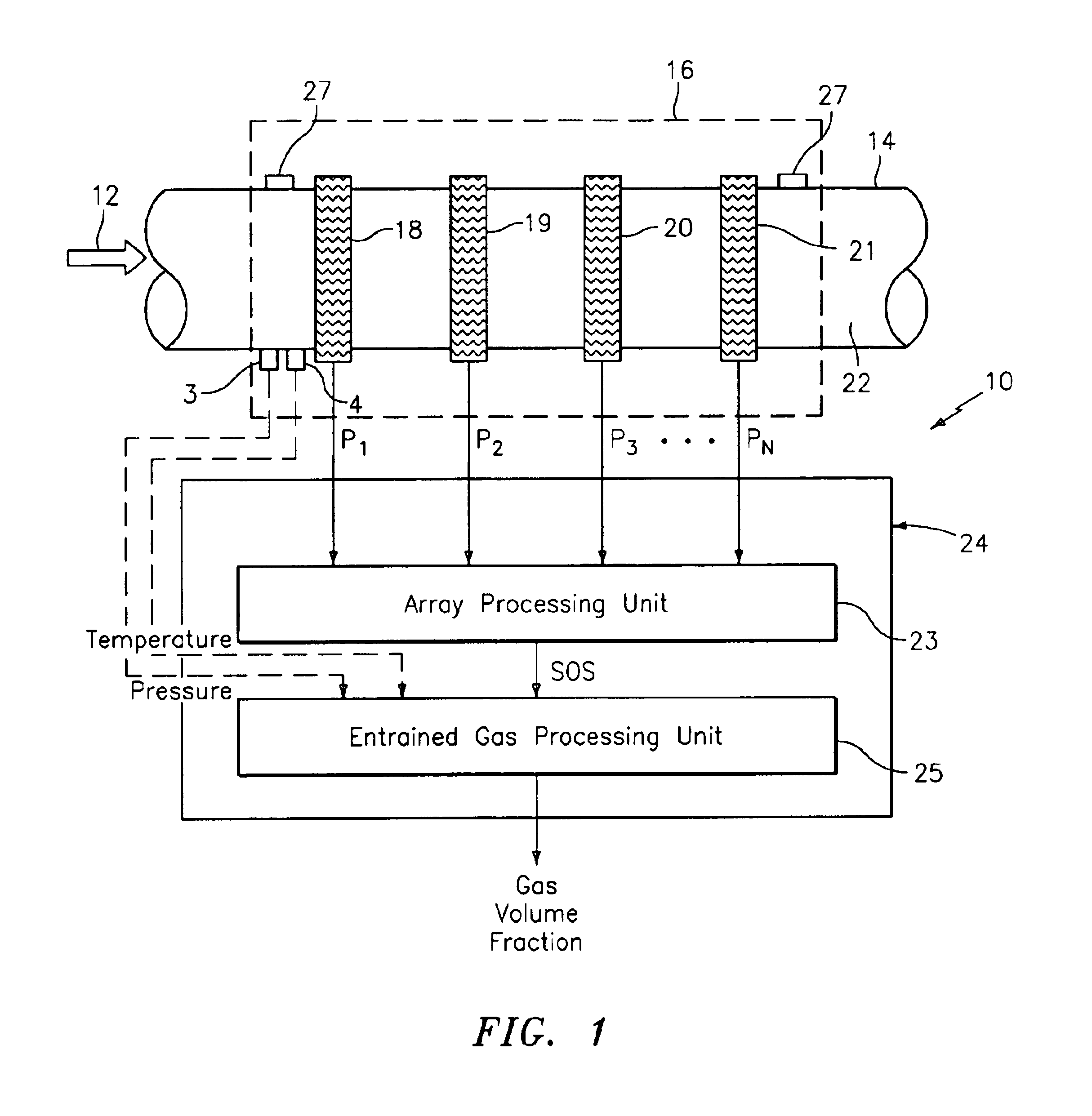

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS6988411B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSound pressure

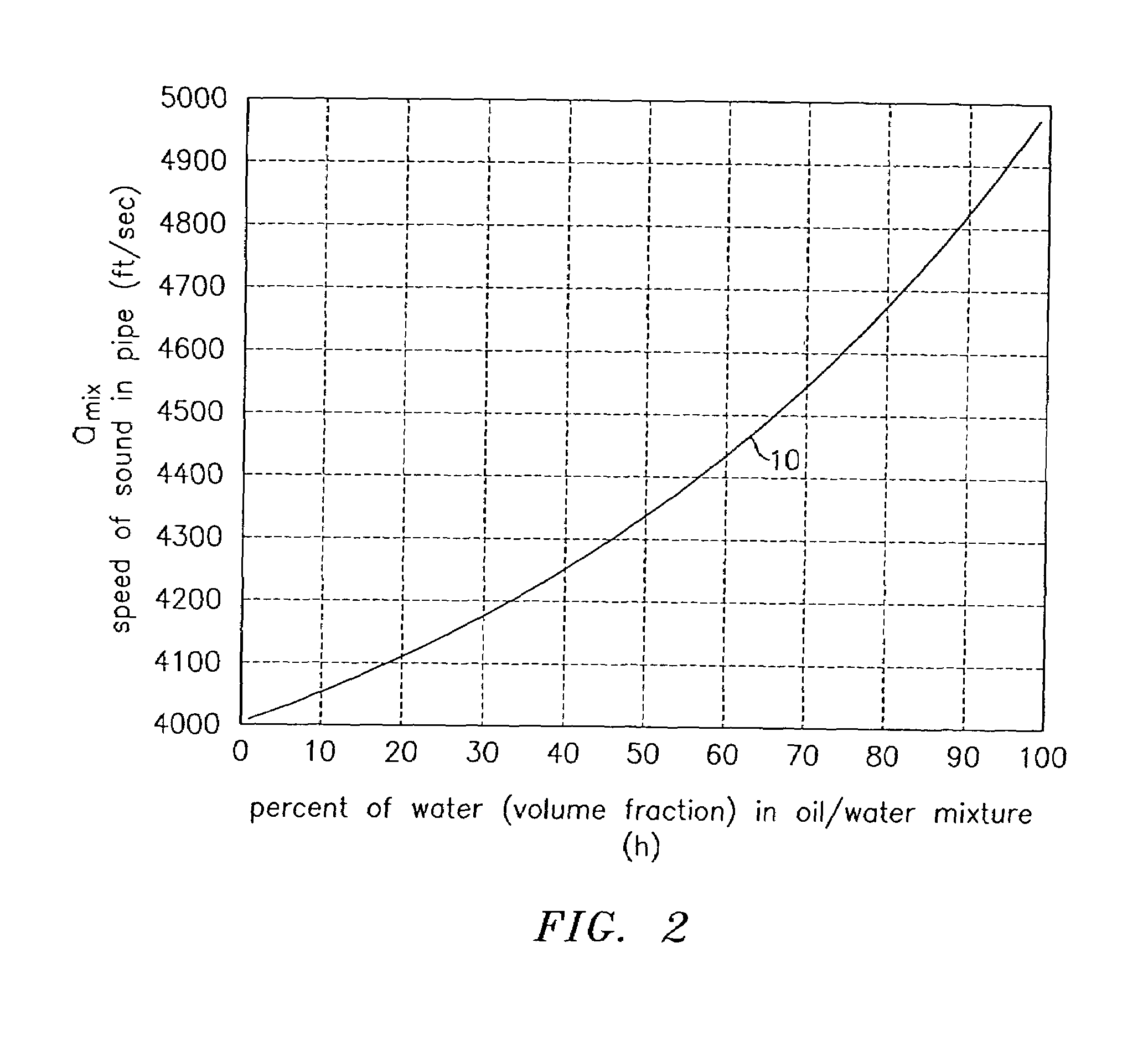

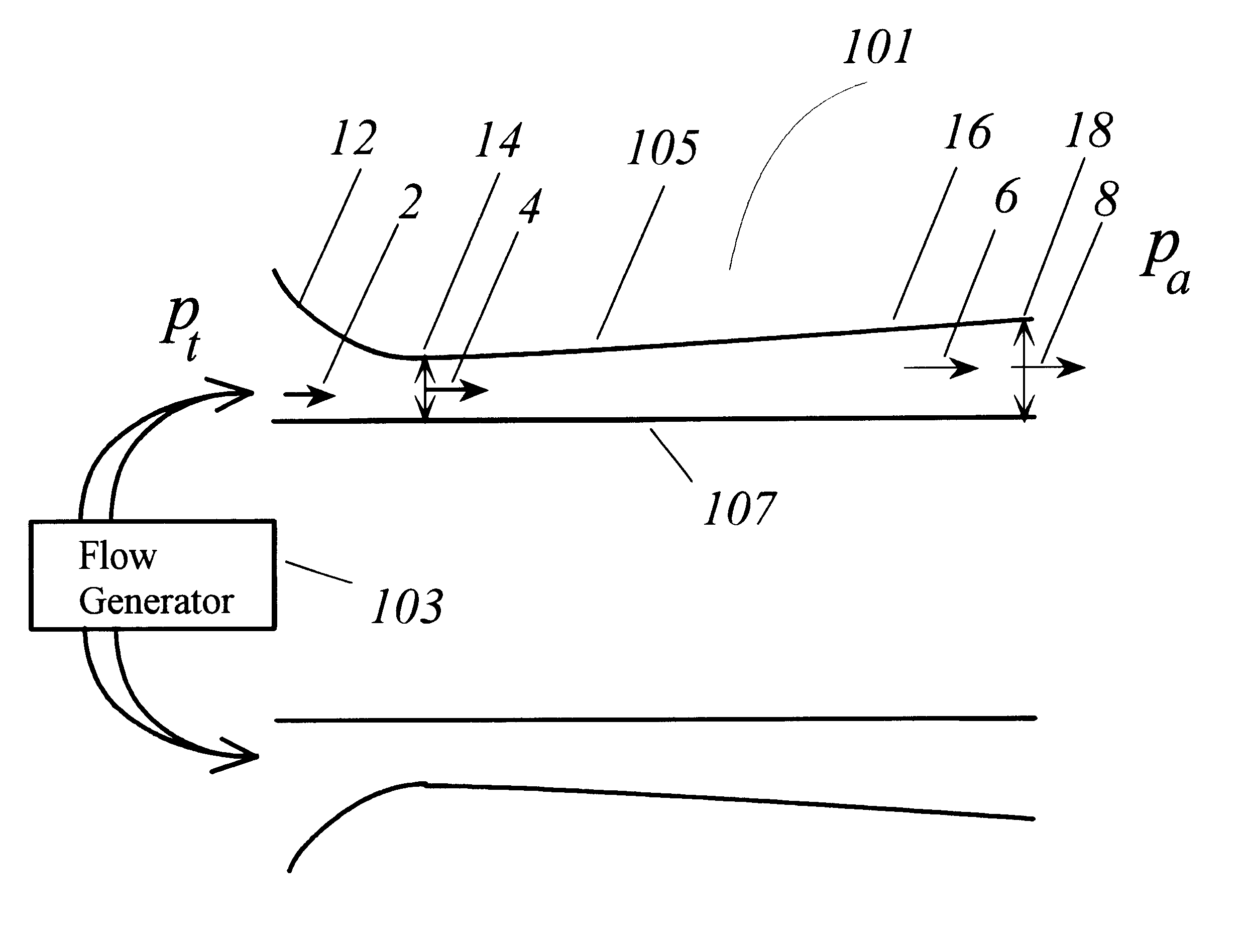

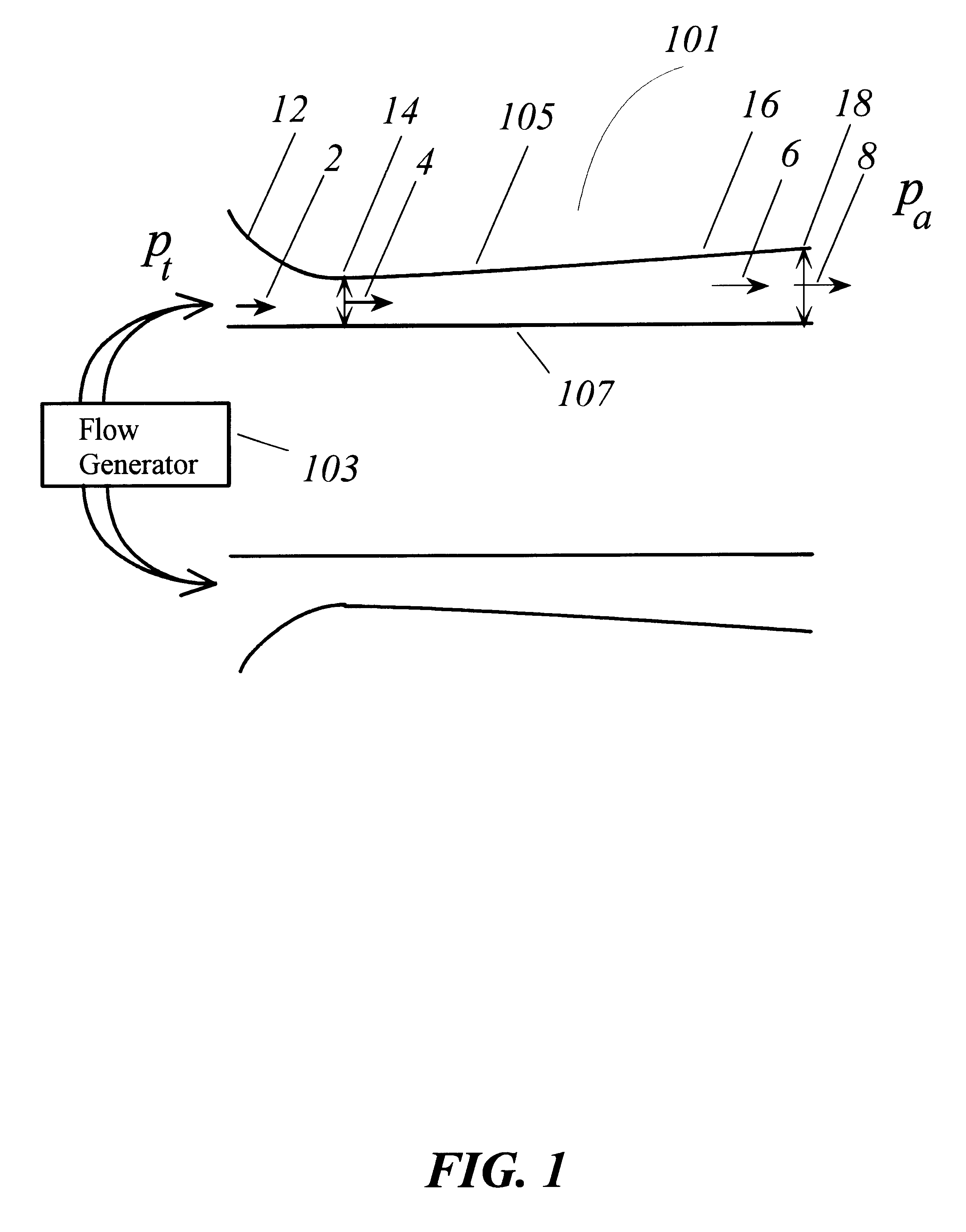

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

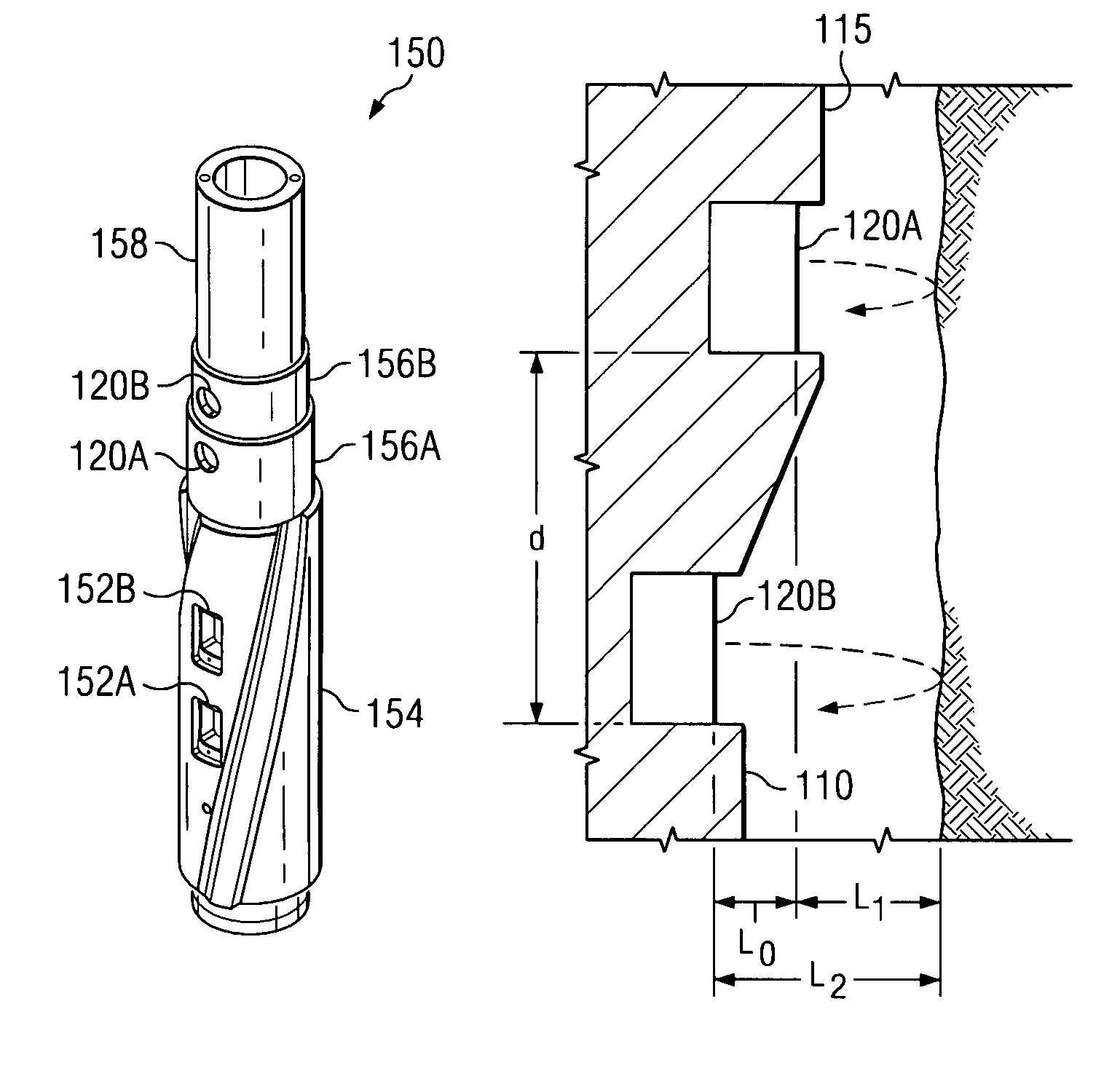

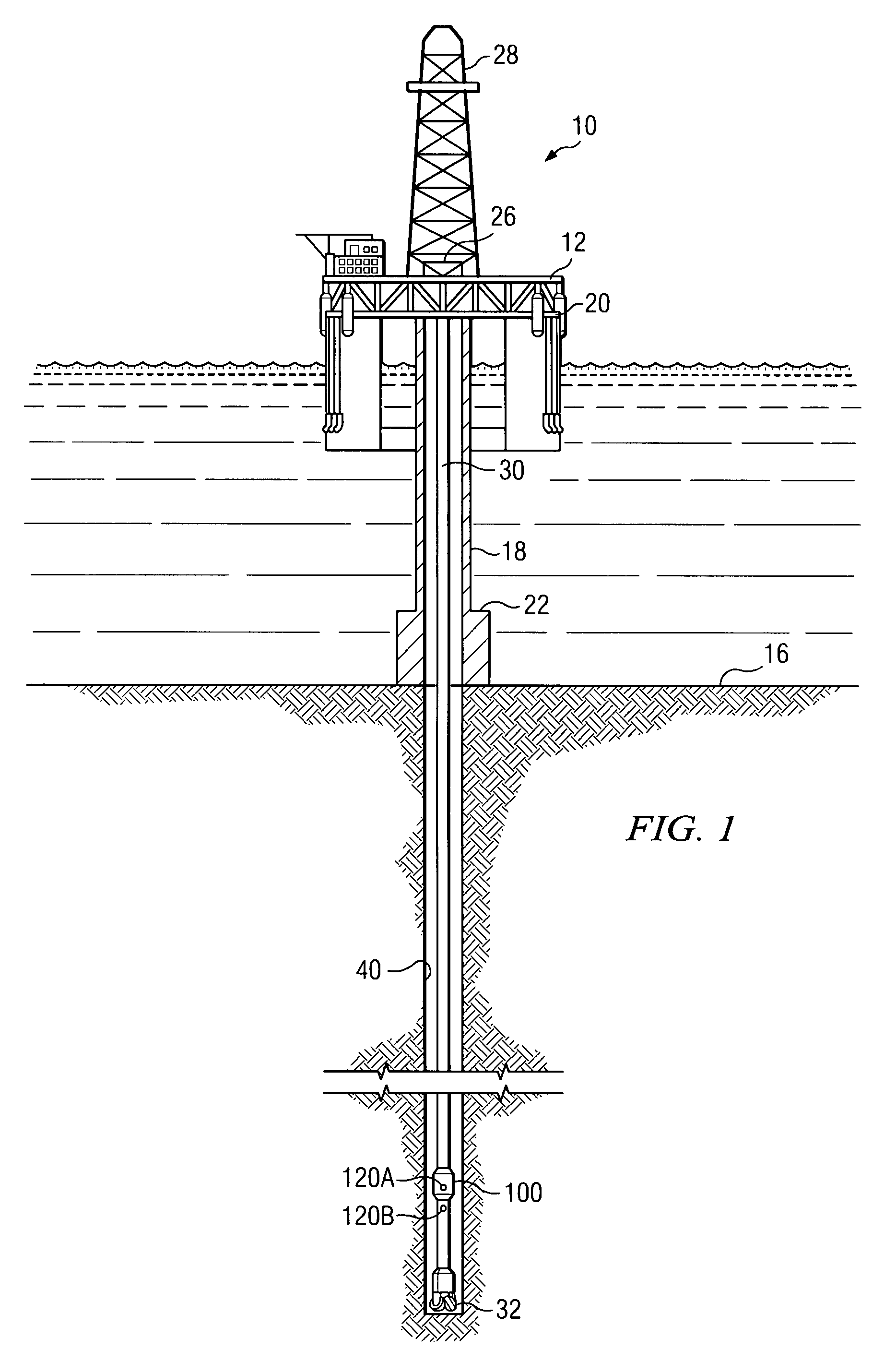

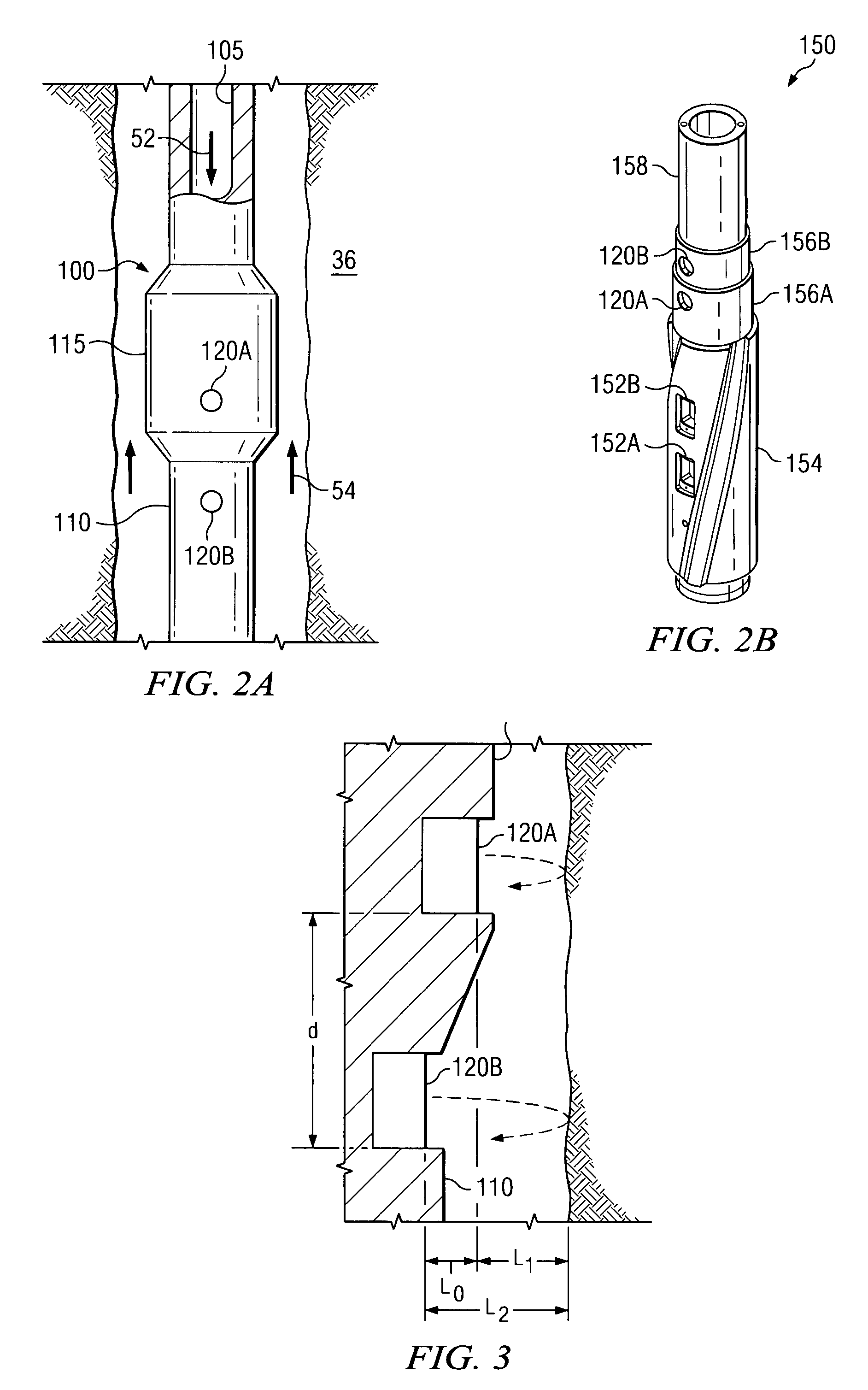

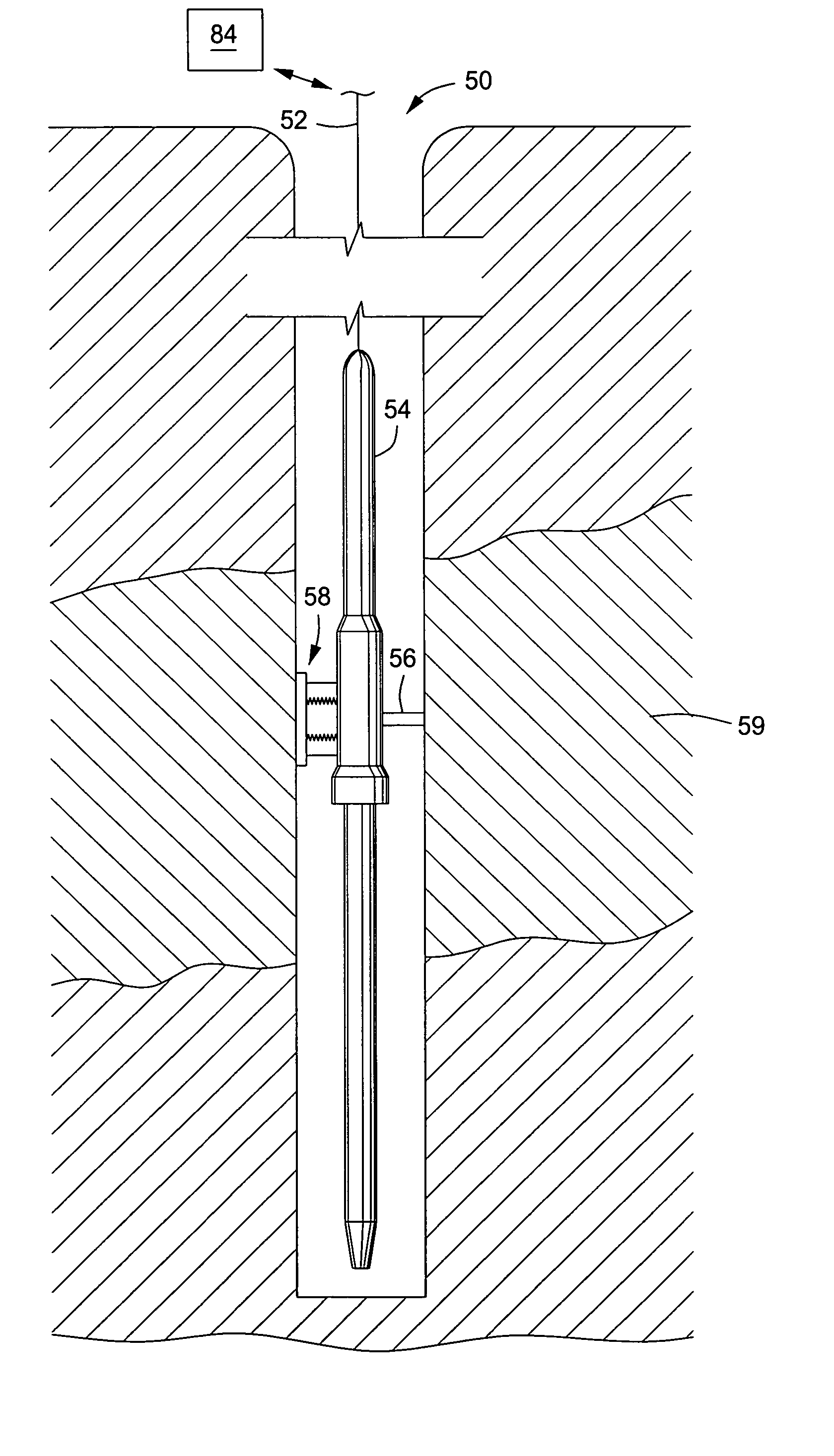

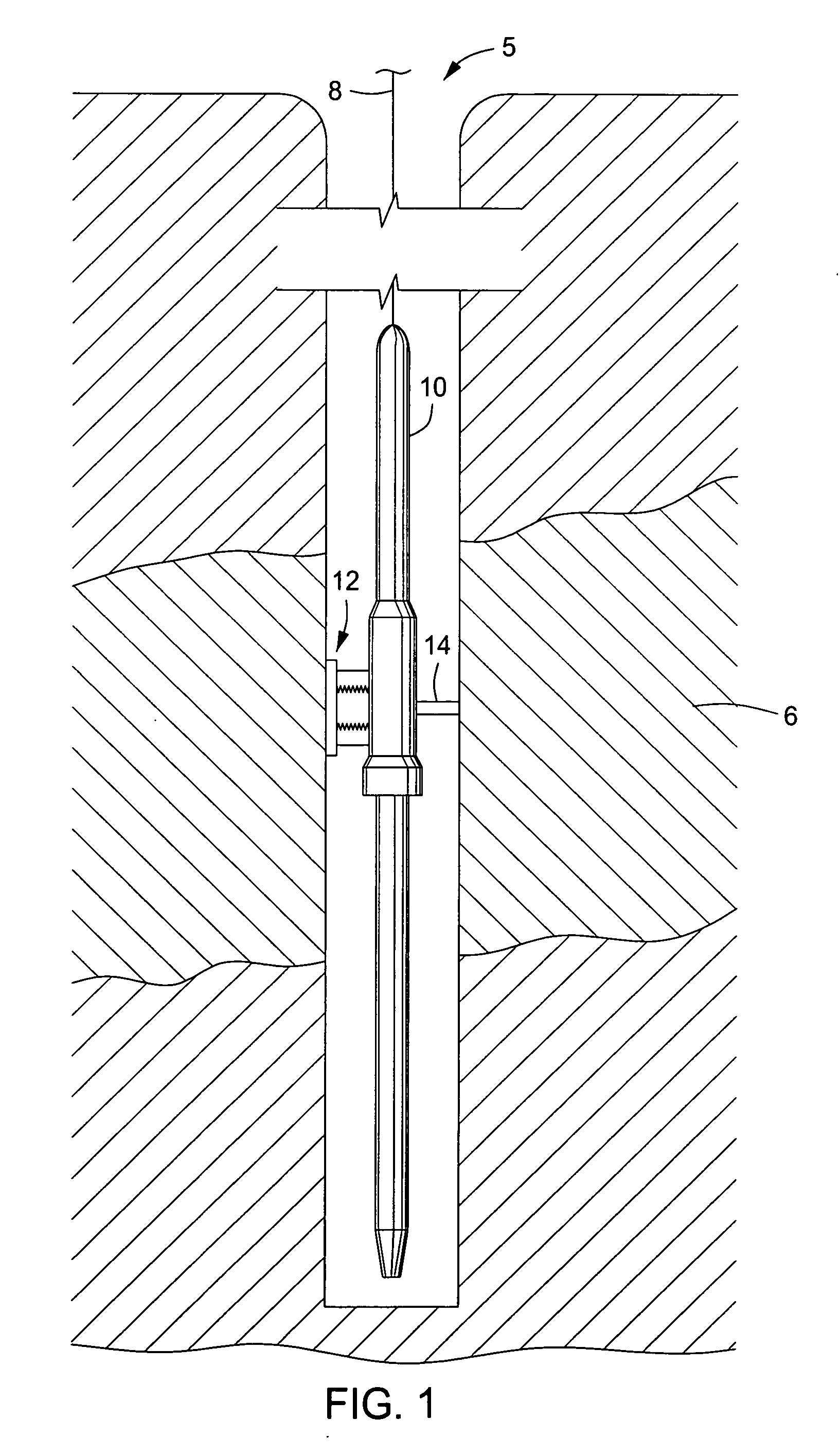

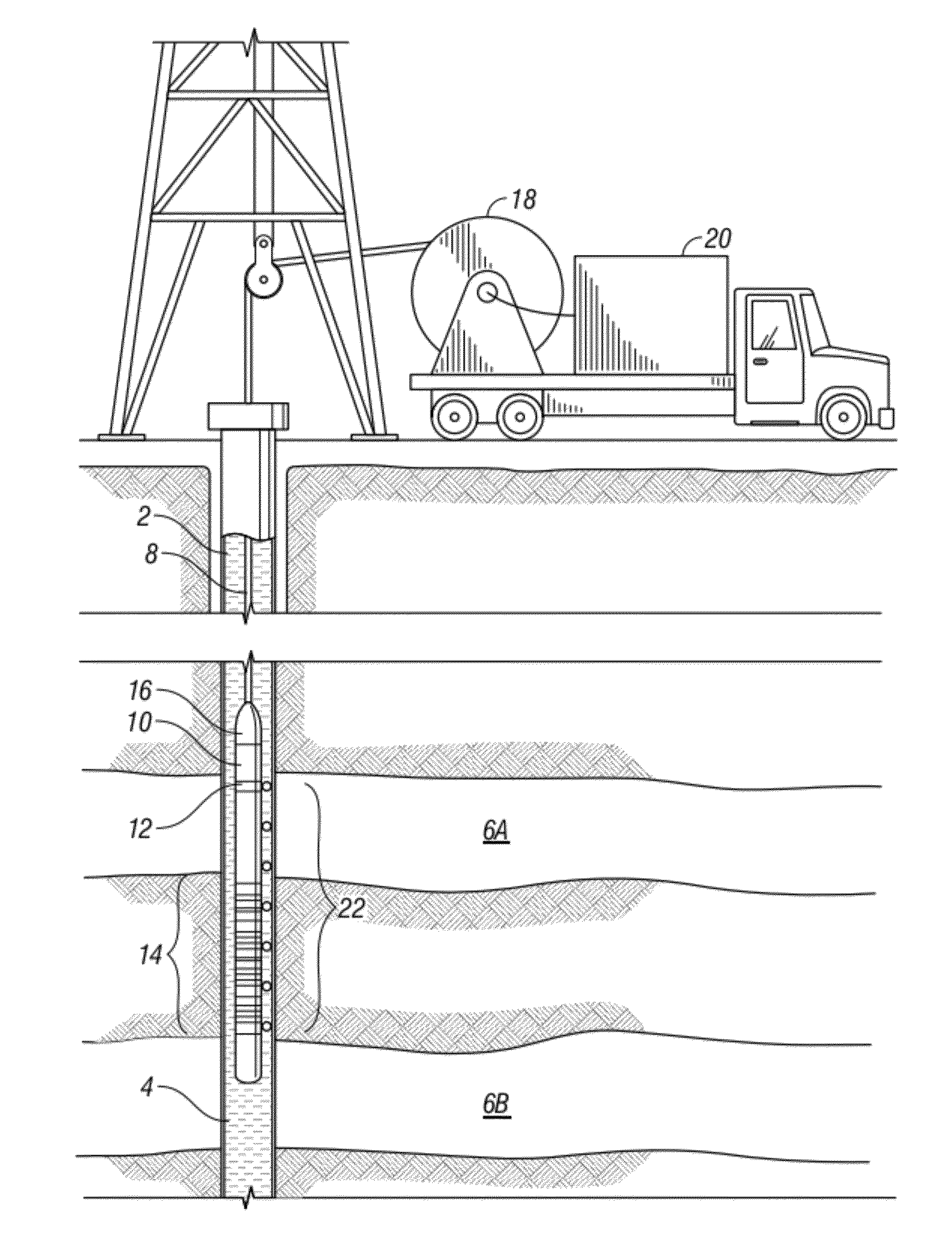

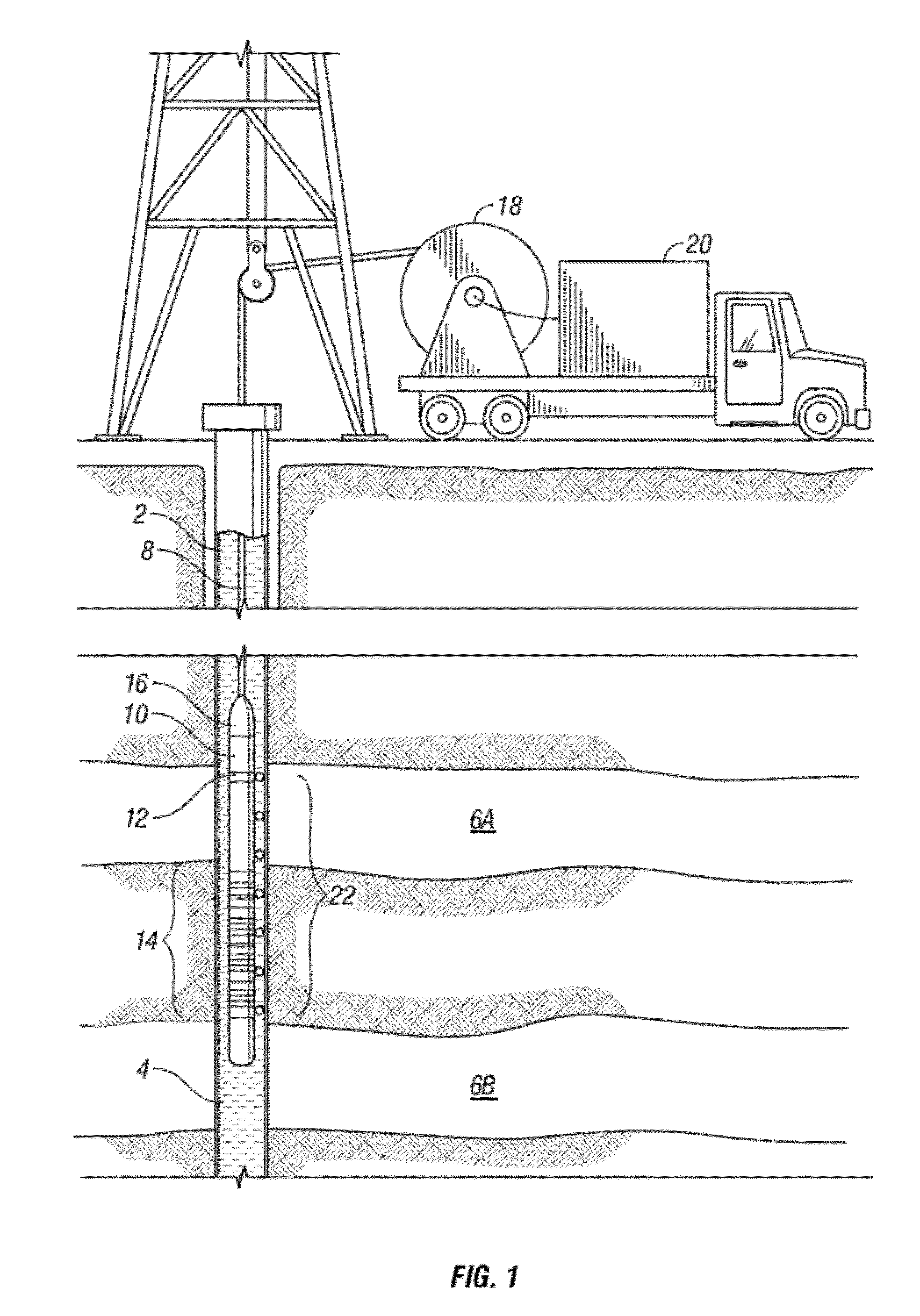

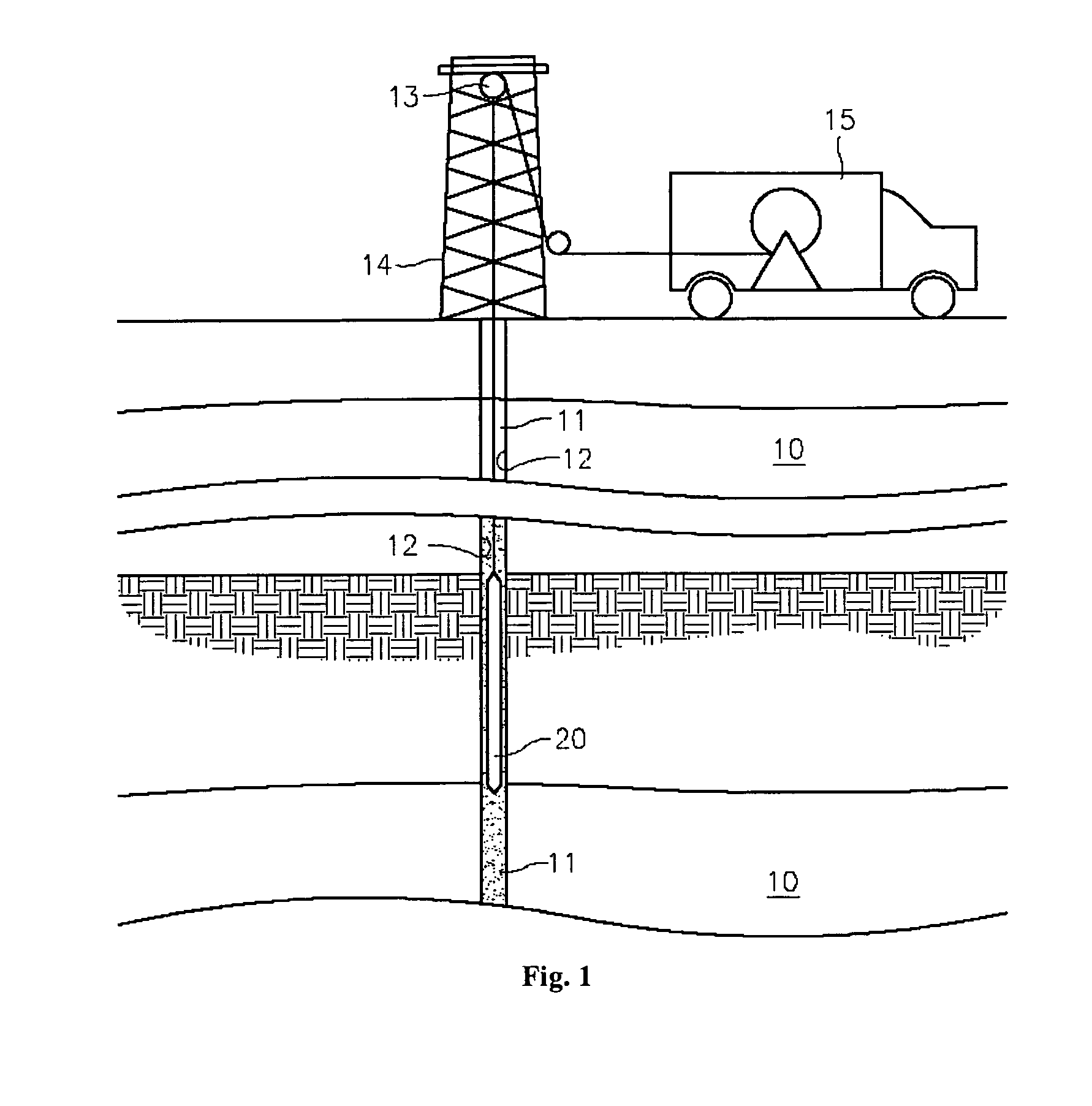

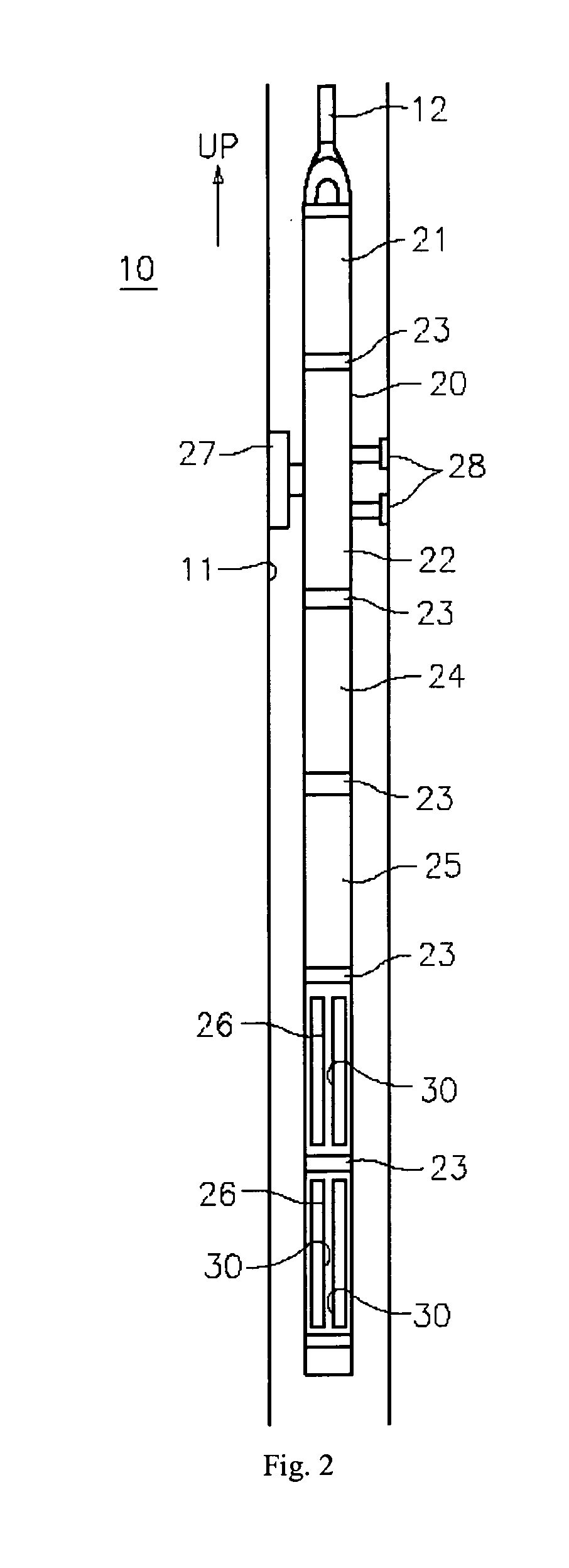

Apparatus and method for determining drilling fluid acoustic properties

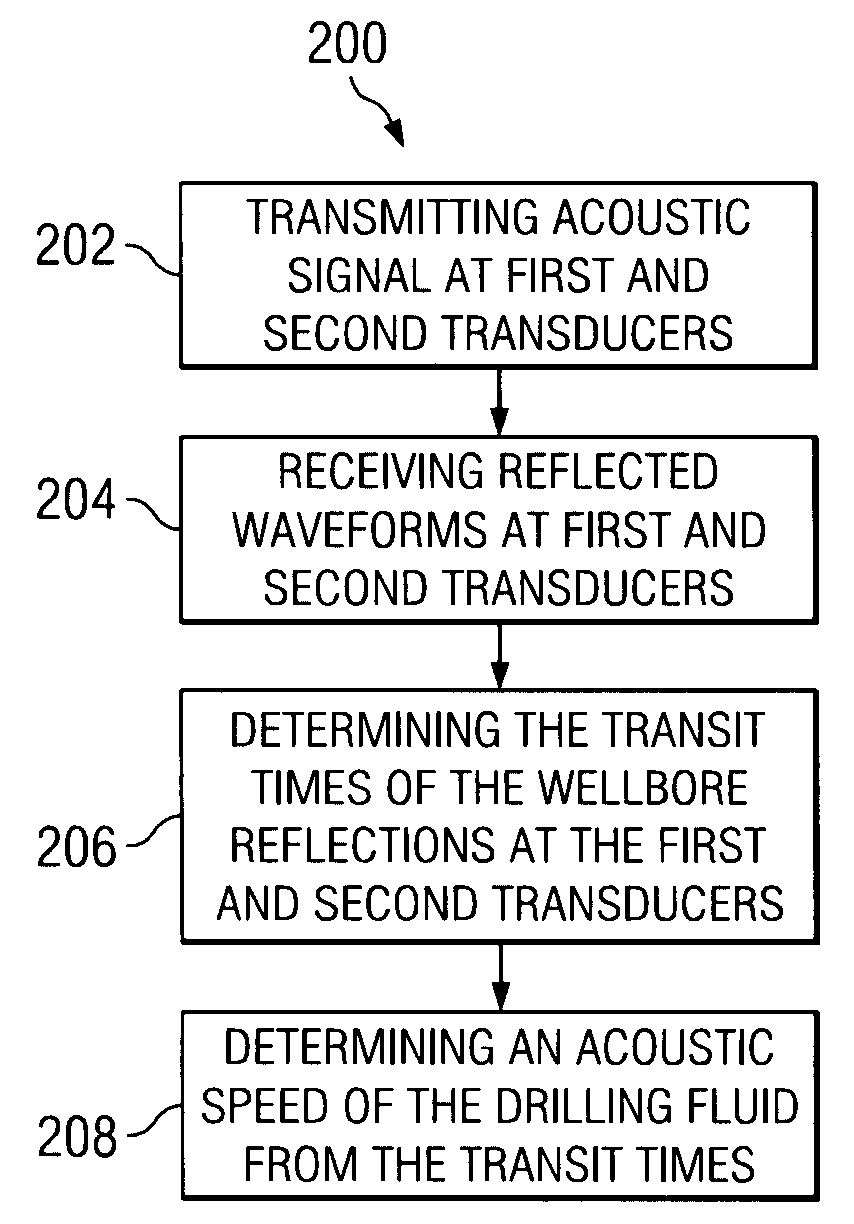

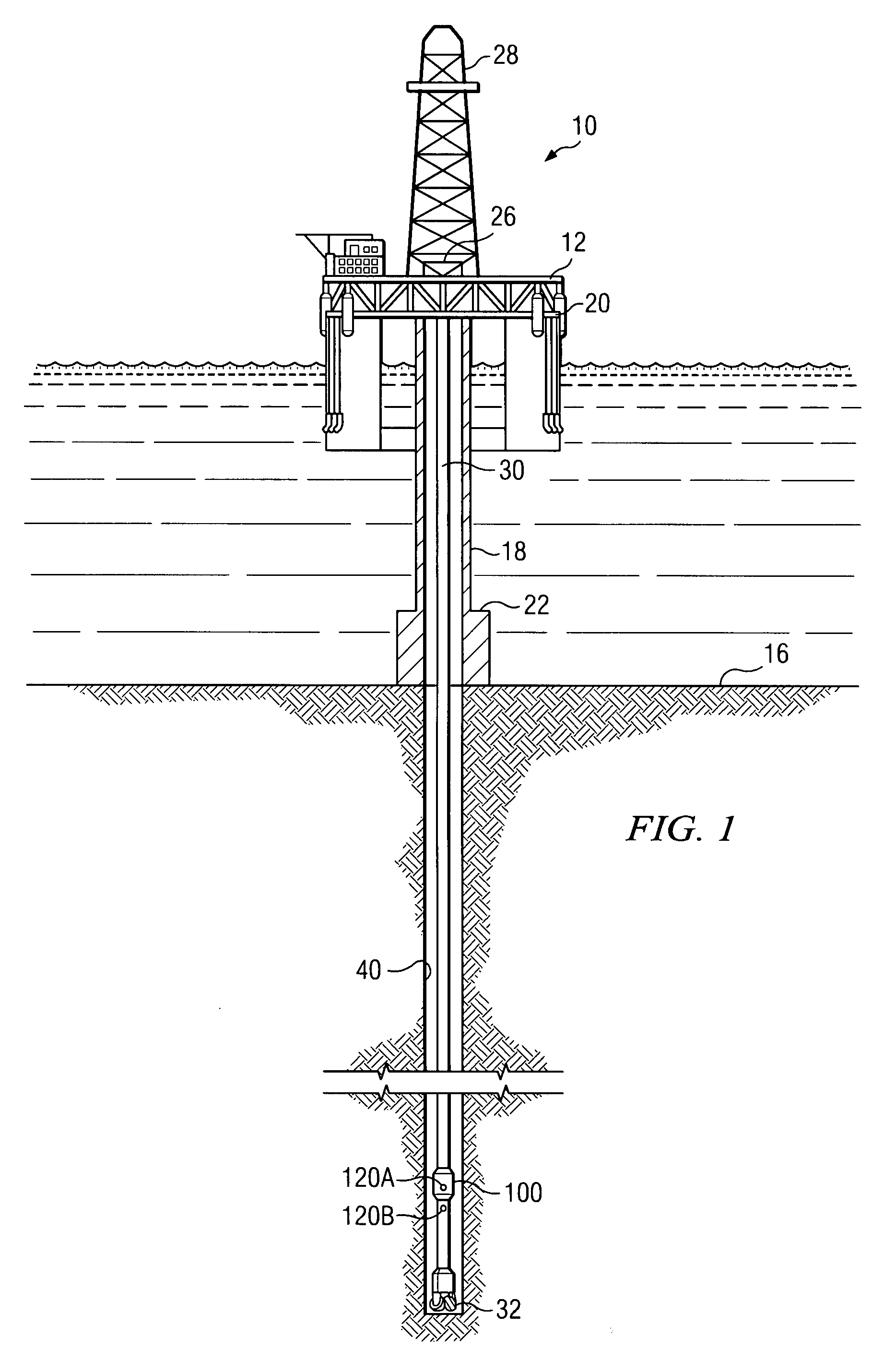

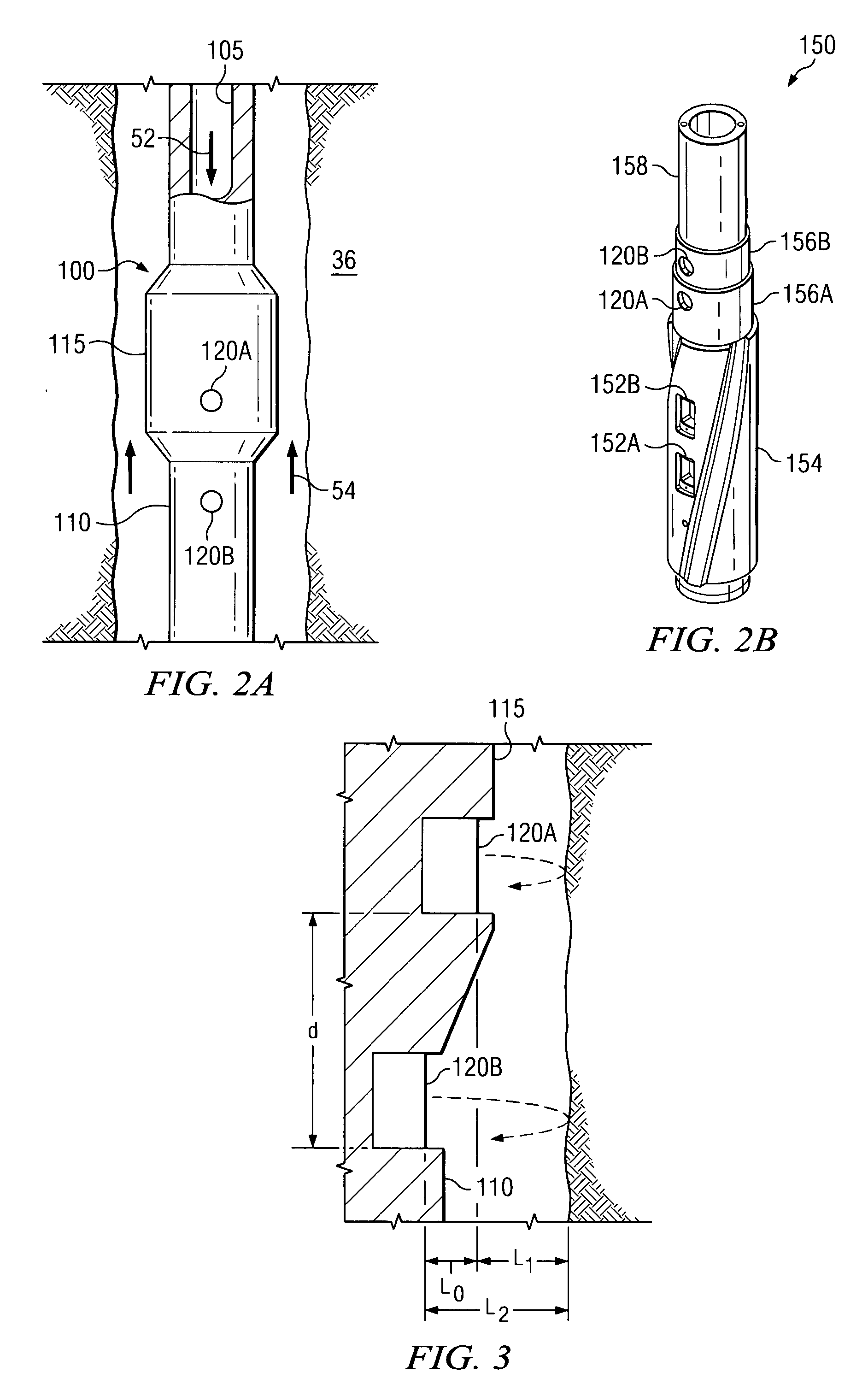

ActiveUS20080186805A1Improve accuracyProvide goodAnalysing fluids using sonic/ultrasonic/infrasonic wavesSurveyReflection coefficientAttenuation coefficient

Aspects of this invention include a downhole tool having first and second radially offset ultrasonic standoff sensors and a controller including instructions to determine at least one of a drilling fluid acoustic velocity and a drilling fluid attenuation coefficient from the reflected waveforms received at the standoff sensors. The drilling fluid acoustic velocity may be determined via processing the time delay between arrivals of a predetermined wellbore reflection component at the first and second sensors. The drilling fluid attenuation coefficient may be determined via processing amplitudes of the predetermined wellbore reflection coefficients. The invention advantageously enables the acoustic velocity and attenuation coefficient of drilling fluid in the borehole annulus to be determined in substantially real-time.

Owner:SCHLUMBERGER TECH CORP

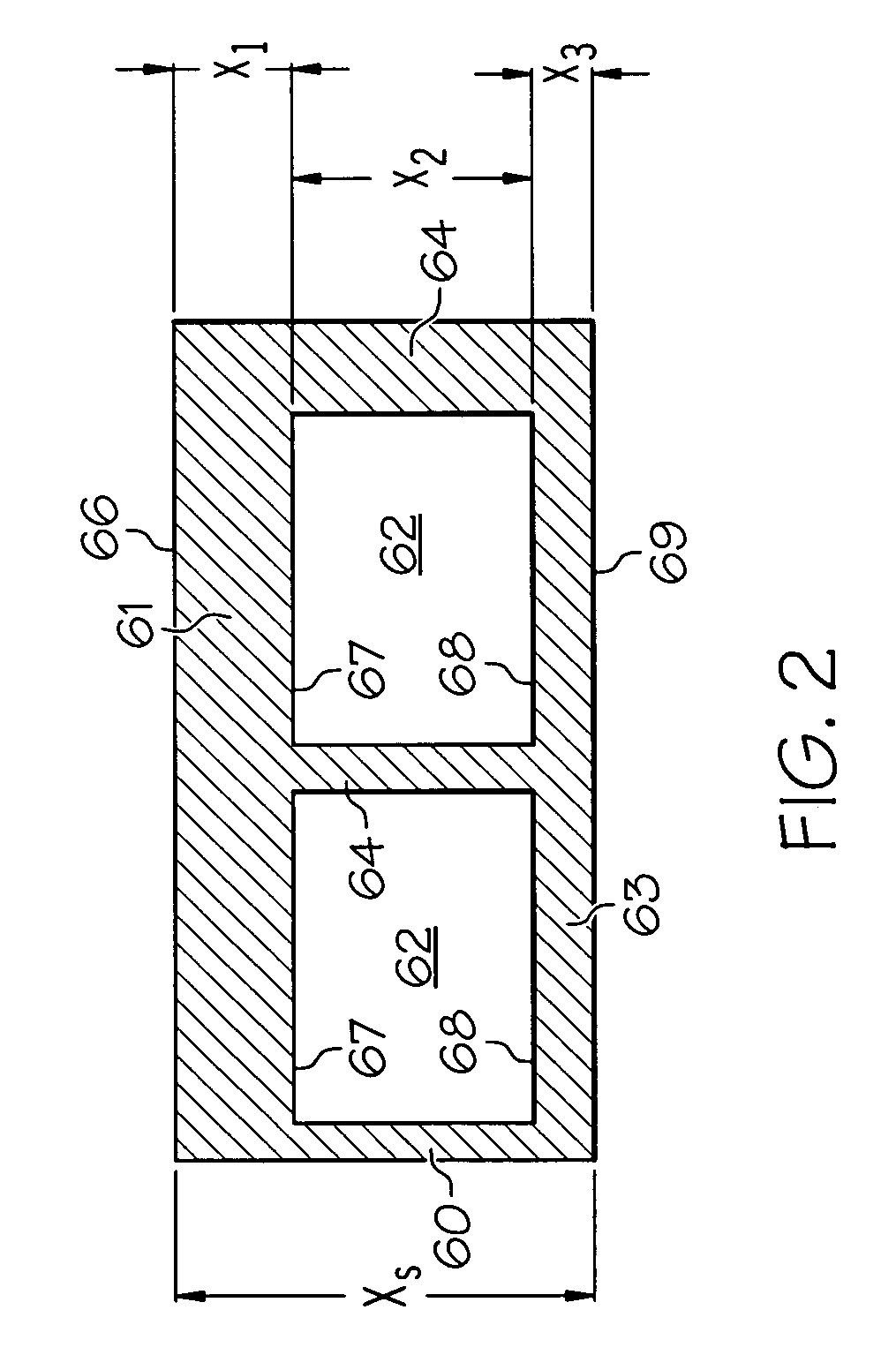

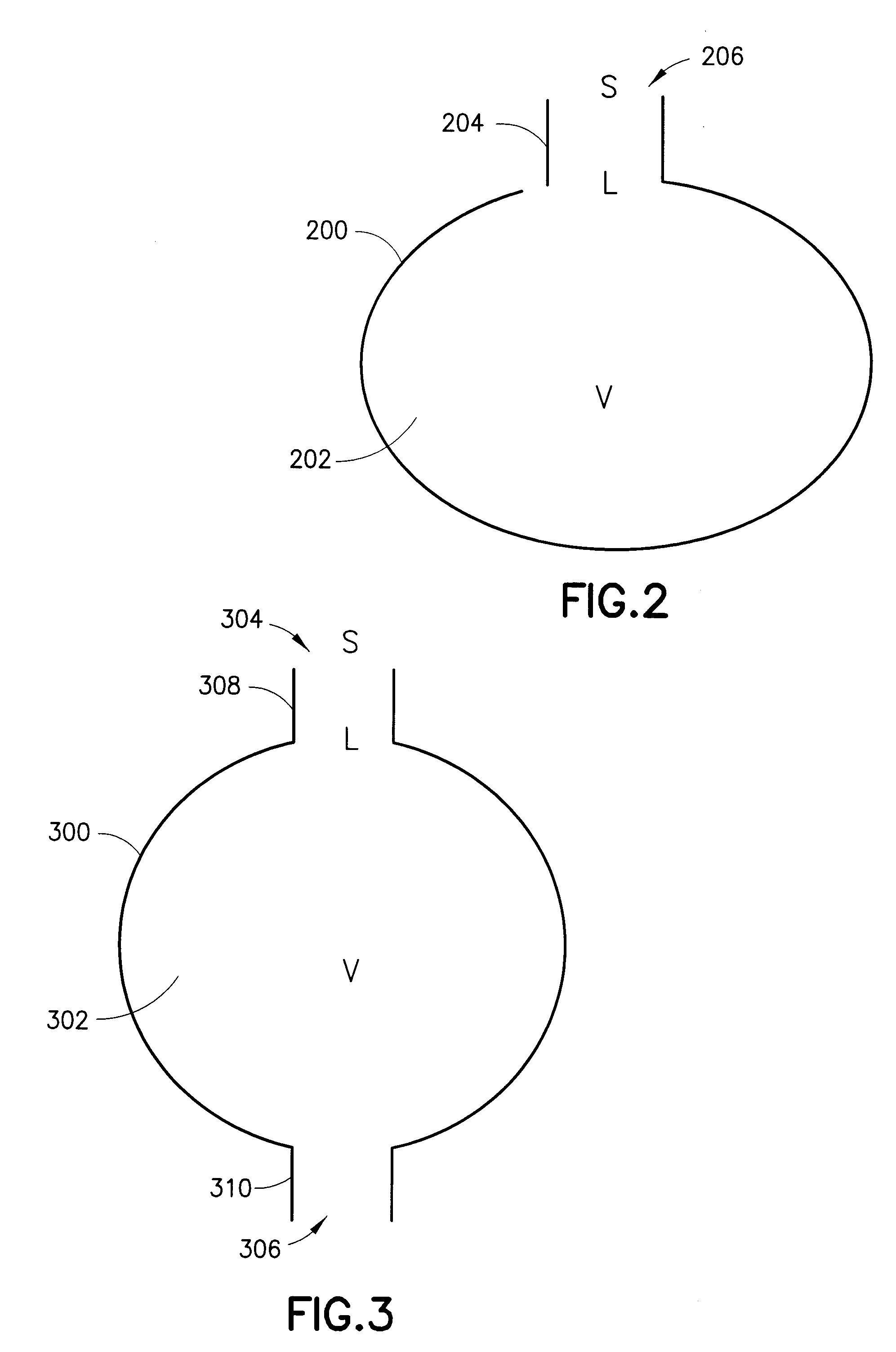

Dual wall turbine blade ultrasonic wall thickness measurement technique

InactiveUS7272529B2Ultrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringMechanical engineering

A method and apparatus is provided to analyze a dual wall structure having at least one hollow core therein and having the same unknown material sound velocities in walls and in post as well. A transducer is located in at least two different positions with respect to the structure, whereby the transducer propagates an ultrasonic wave toward the dual wall structure. A portion of the ultrasonic wave is reflected back to the transducer. One wave traverses a portion of the dual wall structure that has a core filled with a medium having a known material acoustic property. A second wave traverses a portion of the post that has an unknown material sound velocity. From time of flight measurements of the above mentioned waves, the wall thickness and core shift, if any, can be determined.

Owner:HONEYWELL INT INC

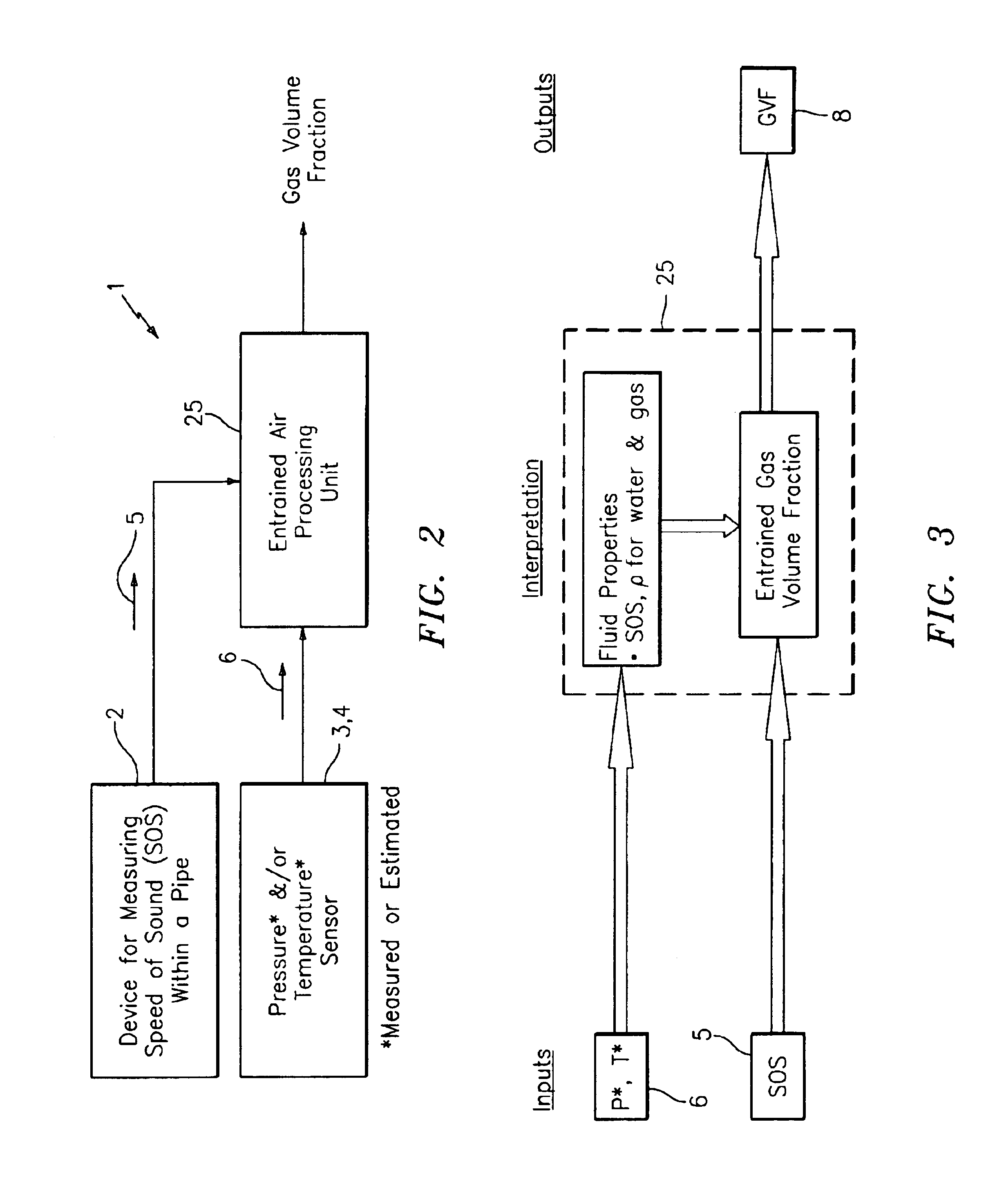

Apparatus and method of measuring gas volume fraction of a fluid flowing within a pipe

ActiveUS7062976B2Material analysis using sonic/ultrasonic/infrasonic wavesFlow propertiesEngineeringGas volume fraction

An apparatus 10,110 is provided that measures the speed of sound or acoustic disturbances propagating in a fluid or mixture having entrained gas / air to determine the gas volume fraction of the flow 12 propagating through a pipe 14. The apparatus includes an array of pressure sensors disposed axially along the length of the pipe. The apparatus measures the speed of sound propagating through the fluid to determine the gas volume fraction of the mixture using adaptive array processing techniques to define an acoustic ridge in the k-ω plane. The slope of the acoustic ridge 61 defines the speed of sound propagating through the fluid in the pipe.

Owner:EXPRO METERS

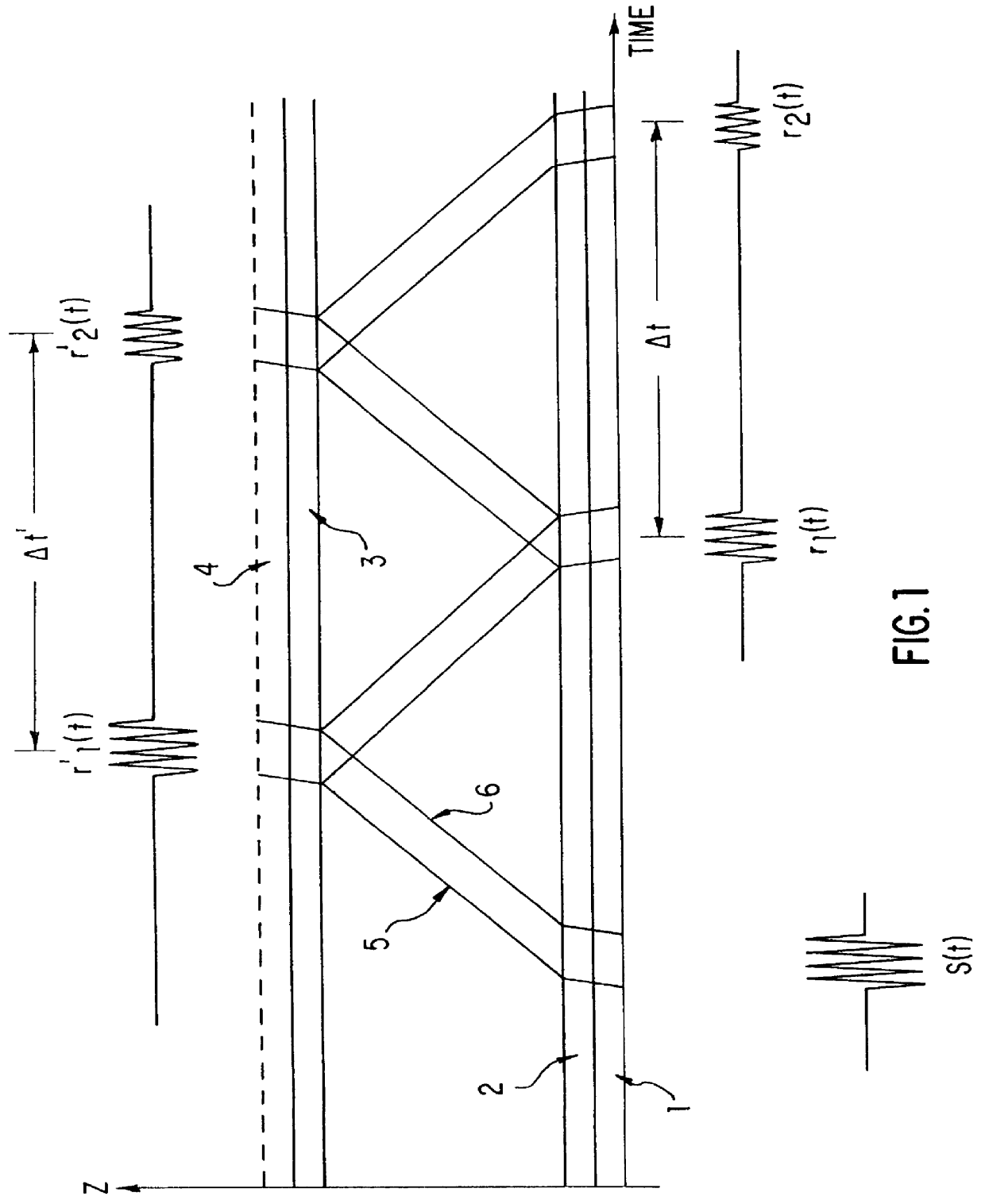

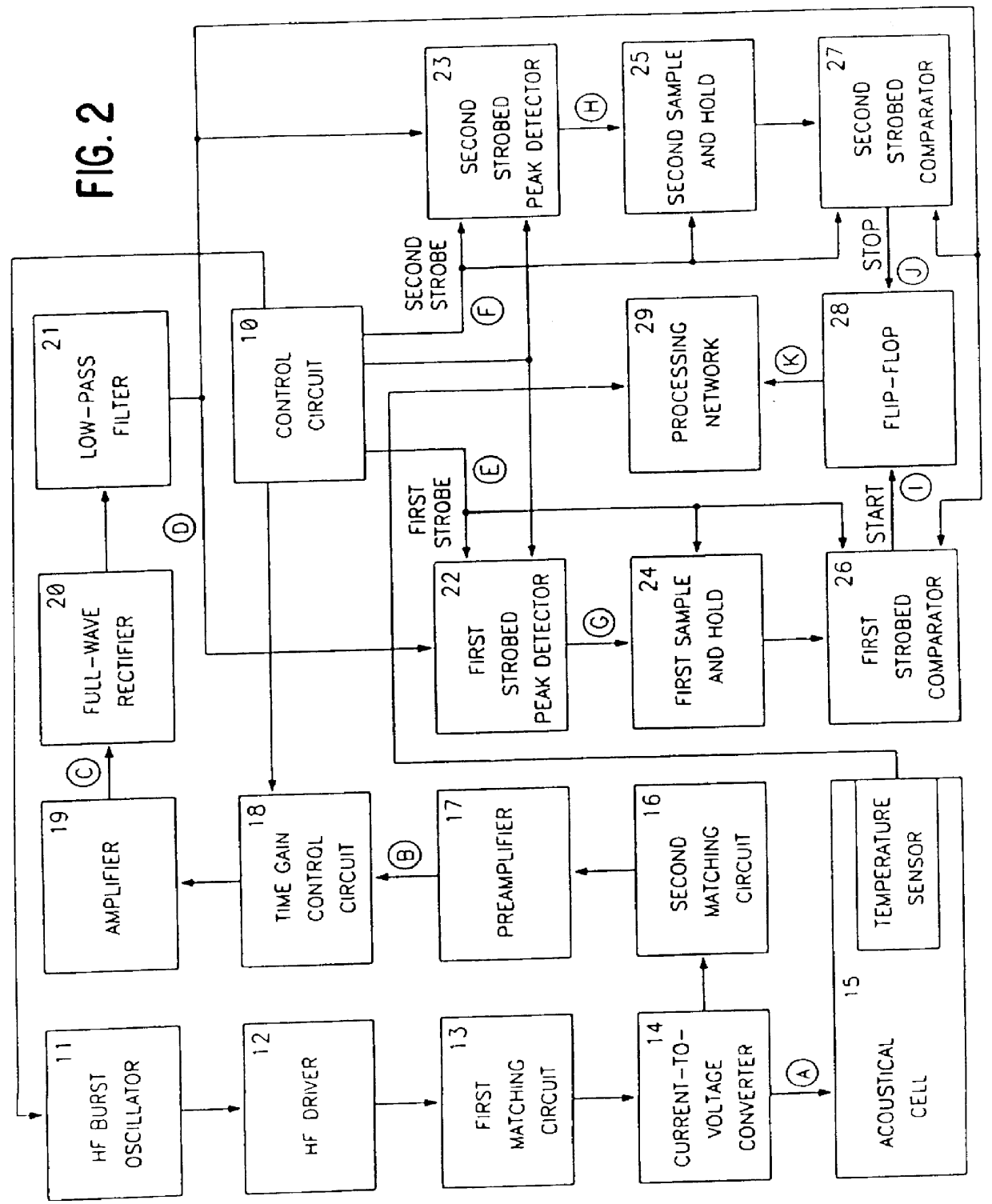

Apparatus and methods for performing acoustical measurements

InactiveUS6116080AGood repeatabilityAbsenceAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesFast Fourier transformTransformer

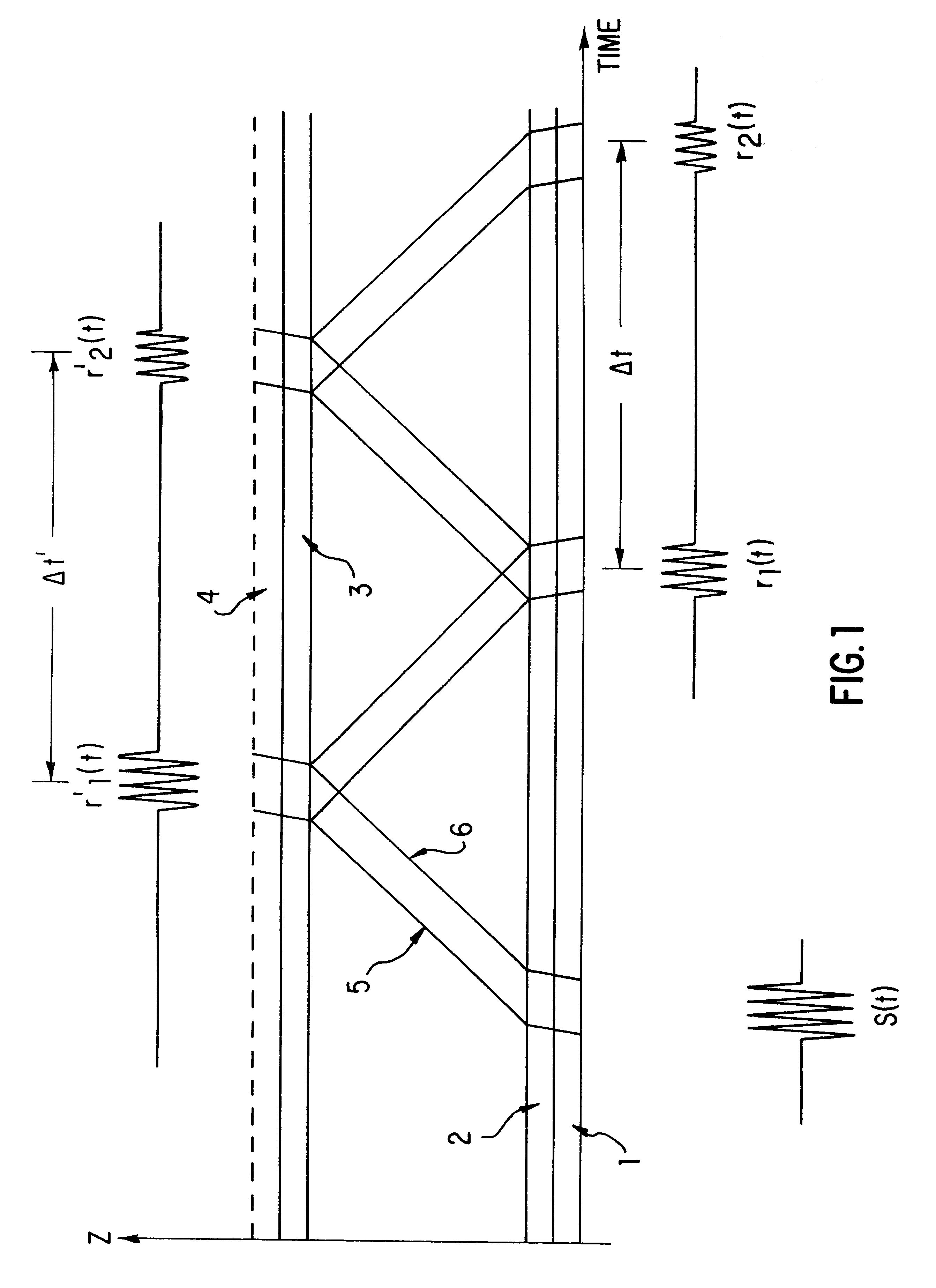

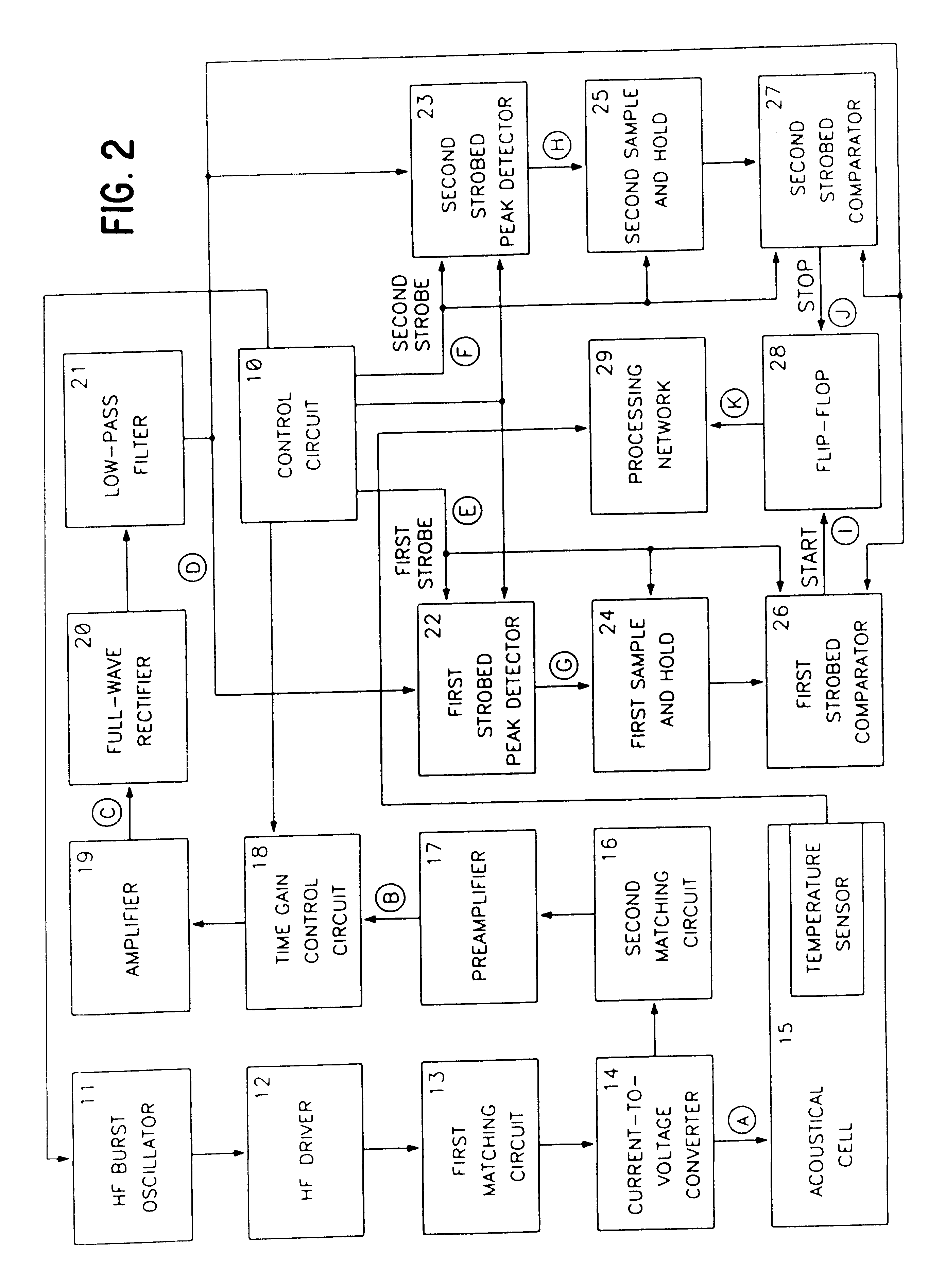

Apparatus and methods for performing acoustical measurements are provided having some and preferably all of the following features: (1) the system is operated under near-field conditions; (2) the piezoelement or piezoelements used in the system are (a) mechanically and electrically damped and (b) efficiently electrically coupled to the signal processing components of the system; (3) each piezoelement used in the system includes an acoustical transformer for coupling the element to a gaseous test medium; (4) speed of sound is determined from the time difference between two detections of an acoustical pulse at a receiver; (5) cross-correlation techniques are employed to detect the acoustical pulse at the receiver; (6) fast Fourier transform techniques are used to implement the cross-correlation techniques; and (7) stray path signals through the body of the acoustic sensor are removed from detected signals prior to signal analysis. Techniques are also provided for performing acoustical measurements on gases whose thermodynamic properties have not been measures and on mixtures of compressible gases. Methods and apparatus for performing feedback control of a gas of interest in a mixture of that gas and a carrier gas are provided in which the controlled variable is the flow of the carrier gas.

Owner:VEECO INSTR

Apparatus and method for determining drilling fluid acoustic properties

ActiveUS7587936B2Improve accuracyImprove the accuracy of standoff measurementsAnalysing fluids using sonic/ultrasonic/infrasonic wavesSurveyAttenuation coefficientTime delays

Aspects of this invention include a downhole tool having first and second radially offset ultrasonic standoff sensors and a controller including instructions to determine at least one of a drilling fluid acoustic velocity and a drilling fluid attenuation coefficient from the reflected waveforms received at the standoff sensors. The drilling fluid acoustic velocity may be determined via processing the time delay between arrivals of a predetermined wellbore reflection component at the first and second sensors. The drilling fluid attenuation coefficient may be determined via processing amplitudes of the predetermined wellbore reflection coefficients. The invention advantageously enables the acoustic velocity and attenuation coefficient of drilling fluid in the borehole annulus to be determined in substantially real-time.

Owner:SCHLUMBERGER TECH CORP

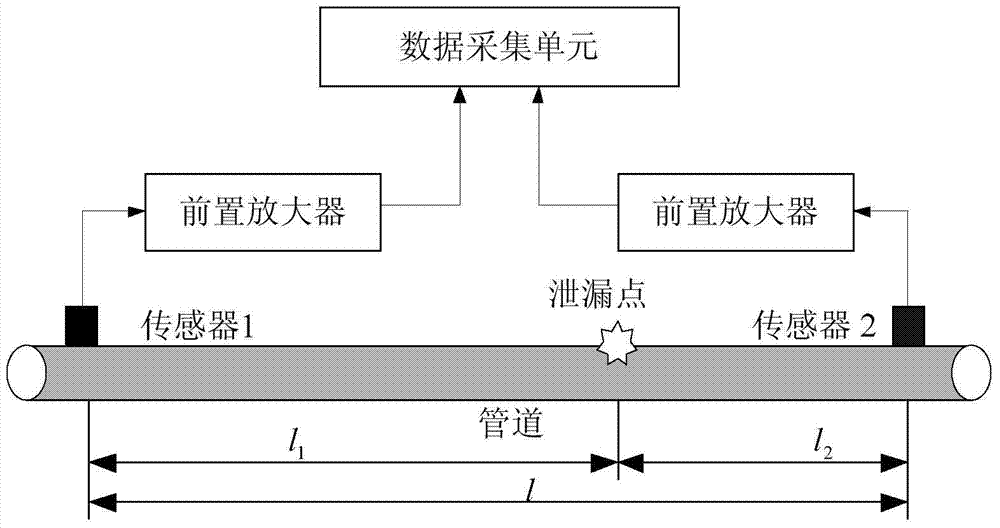

Fluid conveying pipe leakage acoustic emission time-frequency positioning method

ActiveCN104747912AImprove completenessSolve the problem of large leak location errorsPipeline systemsFrequency spectrumTime delays

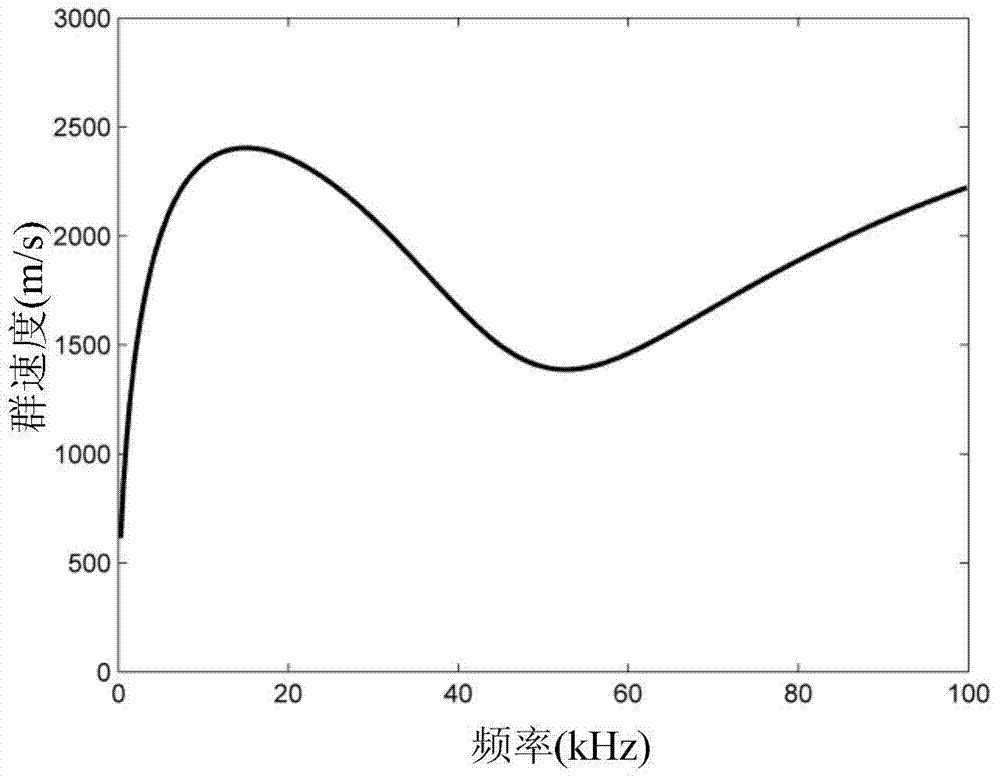

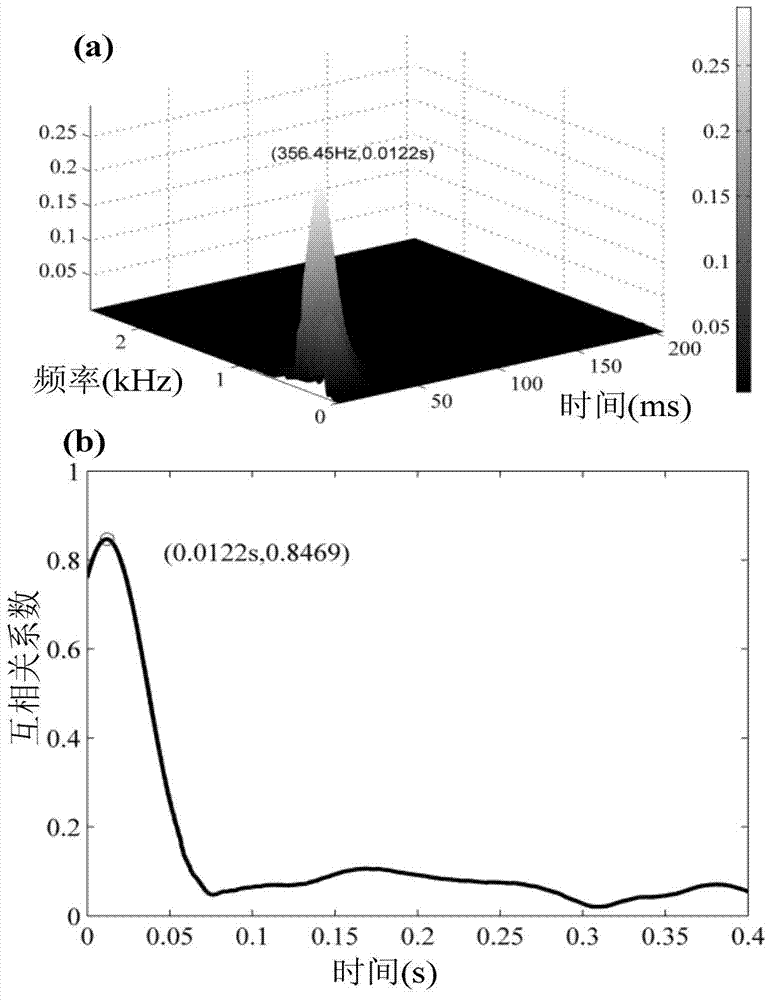

The invention relates to a fluid conveying pipe leakage acoustic emission time-frequency positioning method. The fluid conveying pipe leakage acoustic emission time-frequency positioning method comprises the following steps of picking up acoustic emission signals through an acoustic sensor and a vibration sensor which are arranged at two ends of a pipe leakage point respectively and performing cross-correlation analysis on the acoustic emission signals which are picked up; performing time-frequency analysis on cross-correlation functions of the two channels of acoustic emission signals through smooth pseudo Wigner-Ville time-frequency distribution; extracting the time and frequency information corresponding to time-frequency spectrum peak values of the cross-correlation functions of the acoustic emission signals during pipe leakage; serving the time information corresponding to the peak values as the time delay of two observation signals and determining the transmission speed of the leakage acoustic emission signals along a pipe through table look-up on a frequency dispersion curve according to the frequency information of the peak values; determining the pipe leakage position through the time delay and the timely determined acoustic speed. The fluid conveying pipe leakage acoustic emission time-frequency positioning method can be used for performing accurate positioning on the leakage point under the conditions that the leakage acoustic emission frequency dispersion of the fluid conveying pipe is serious and the acoustic speed is difficult to be determined and meanwhile the correlation functions of the single frequency leakage signals are extracted for the time delay estimation and accordingly the degree of correlation of the leakage signals is enhanced and the leakage positioning error is further reduced.

Owner:重庆富世恒睿物联网科技有限公司

Boundary acoustic wave device

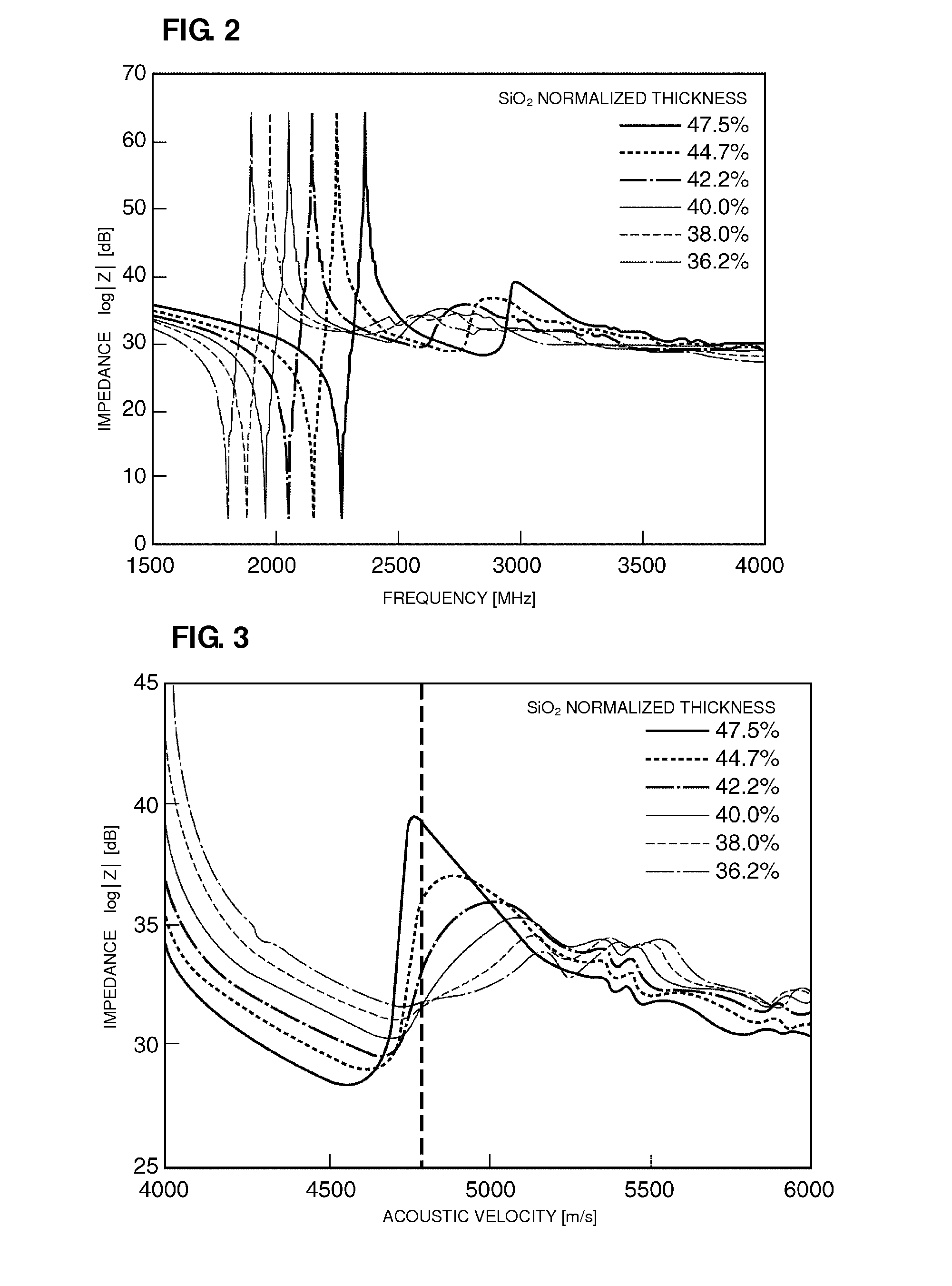

ActiveUS20110050034A1Preventing spurious responseReduce material thicknessPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic waveMedia layer

A boundary acoustic wave device includes a first medium layer made of a first dielectric material and a second medium layer made of a second dielectric material having an acoustic velocity different from the acoustic velocity of the first dielectric material. The first medium layer and the second medium layer are disposed on a piezoelectric substrate, and an IDT electrode is arranged along the interface between the piezoelectric substrate and the first medium layer. When the fast transverse bulk wave of the piezoelectric substrate has an acoustic velocity V1 and a higher-order mode boundary acoustic wave has an acoustic velocity Va at an anti-resonance point, the boundary acoustic wave device satisfies the relationship Va>V1.

Owner:MURATA MFG CO LTD

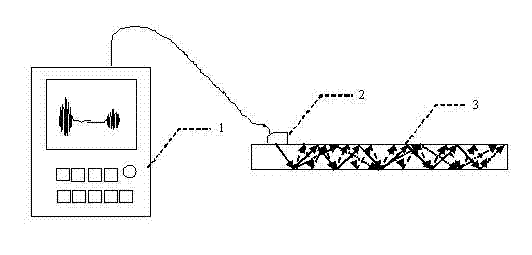

Judging method of incompactness defect in node of concrete structure by detection by ultrasonic method

ActiveCN102012403AMultiple frequency differenceRealize quantitative descriptionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalAlgorithmHead wave

The invention relates to a judging method of an incompactness defect in a node of a concrete structure by detection by an ultrasonic method. On the basis of the traditional method for detecting the concrete defect by the ultrasonic method, besides an acoustic velocity and a head wave amplitude, two variable acoustic parameters, namely a complex frequency difference and a cross-correlation coefficient, are added; each acoustic parameter is processed into an acoustic parameter judging factor and each acoustic parameter judging factor is processed into a normalized comprehensive acoustic parameter judging factor; a position detecting chromatogram is drawn out according to the comprehensive acoustic parameter judging factor; and the position and range of a suspicious defect are determined according to a red area in the chromatogram. By the method, the compactness quality distribution of concrete can be directly and accurately described; errors and judgment loss caused by adoption of a single acoustic parameter for judgment can be avoided or reduced; and the difficulty in final judgment when the judgment result of the single acoustic parameter is inconsistent is also avoided. The judging method can be widely applied to the judgment of the incompactness defect in the node of the concrete structure or other complex structures.

Owner:BEIJING MUNICIPAL ENG RES INST +1

Acoustic fluid analysis method

ActiveUS20070129901A1Magnetic property measurementsVelocity propogationSpeed of soundEnvironmental geology

A method of analyzing acoustic data comprising, determining fluid sound speed through connate fluid. The method involves sampling the fluid, sending an acoustic signal into the fluid between a first and a second reflective interface. Data is recorded that represents acoustic signals over time as they are reflecting from the interfaces. A smoothed first derivative with respect to time of the cumulative sum of squares (CSS) of the filtered amplitude data is determined. This first derivative is cross correlated to the time-shifted versions of itself.

Owner:BAKER HUGHES INC

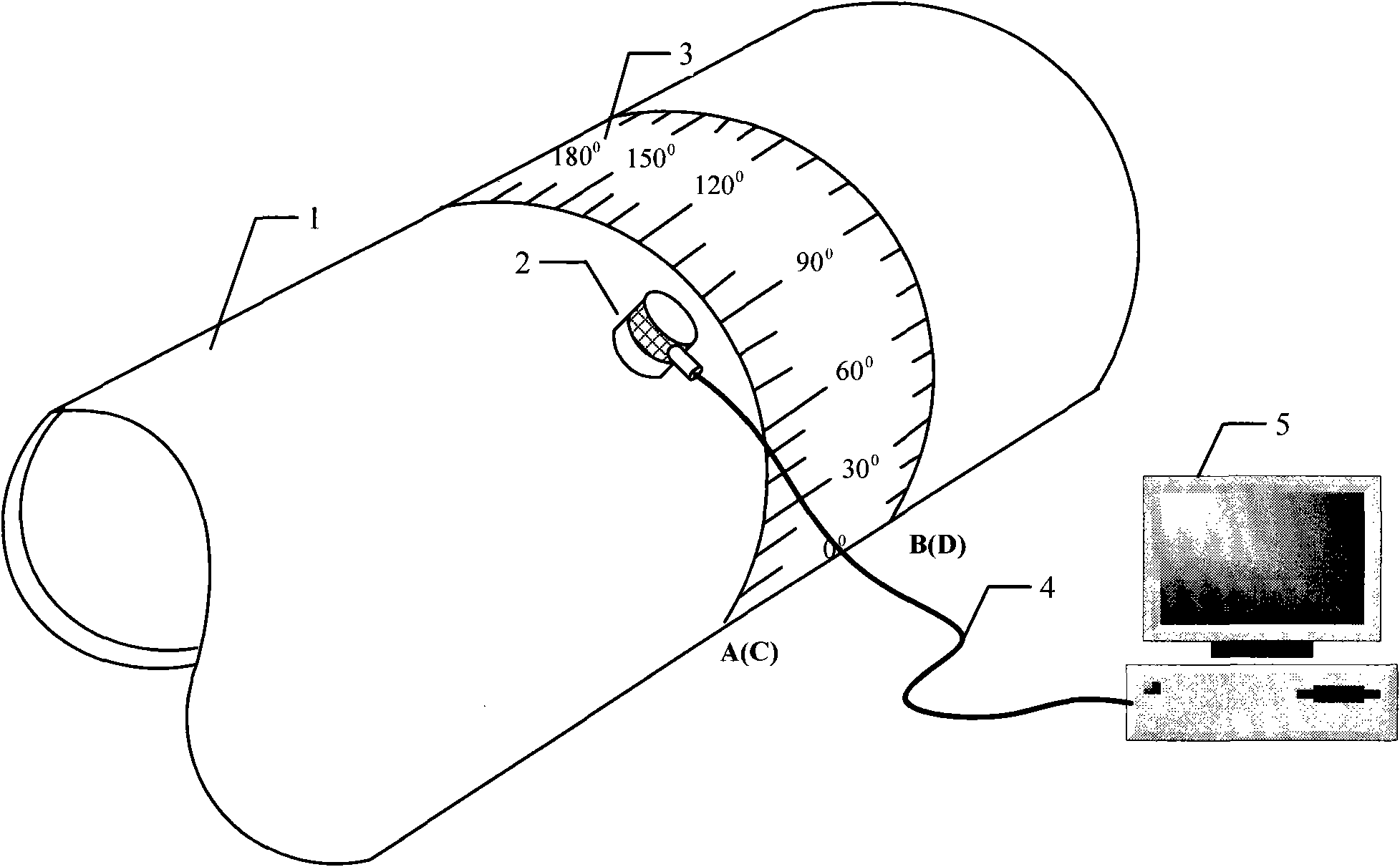

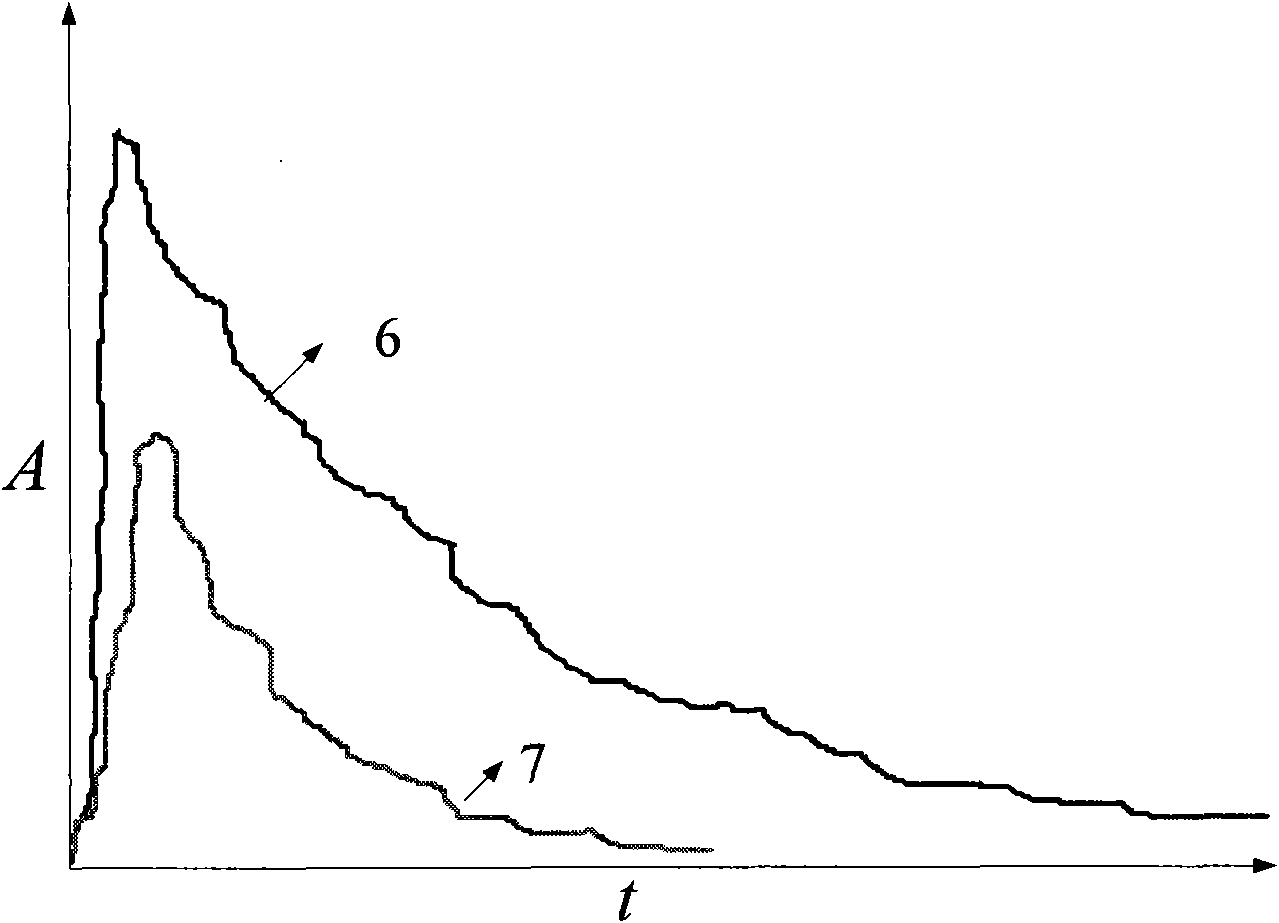

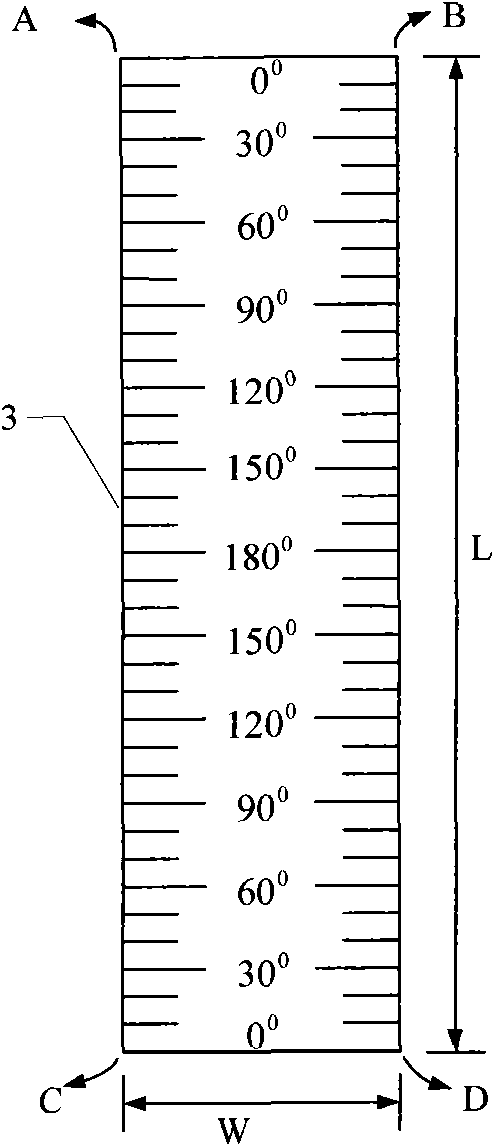

Method and device for measuring accumulated liquid of natural gas pipeline

InactiveCN101839746ASave energyNo security issuesMachines/enginesLevel indicatorsLiquid mediumLine tubing

The invention discloses a method and a device for measuring accumulated liquid of a natural gas pipeline. The method comprises the following steps of: vertically transmitting high-frequency ultrasonic wave into the pipeline by an ultrasonic probe coupled to the outer wall of the measured pipeline, wherein the energy of reflection echo has great difference due to different properties of gas and liquid media; judging that the pipe inner wall is contacted with gas or liquid at the position of the probe according to the characteristic of echo received by the ultrasonic probe and reflected by the pipe inner wall; gradually adjusting the measurement position of the ultrasonic probe on the pipe outer wall along the circumferential direction; and recording a circumferential angle of the ultrasonic probe by a circumferential angle ruler when the echo has mutation, and further calculating the height of the accumulated liquid. The method is a non-intrusive accumulated liquid measurement method, does not change the structure of the conventional pipeline, has no medium leakage risk, does not affect the operation such as cleaning the pipeline and the like, meanwhile is not affected by the composition of gas and liquid phase media in the pipeline and parameters such as temperature, pressure and the like, overcomes the defect that the conventional ultrasonic technology needs complex sound velocity correction, and is particularly suitable for measuring the accumulated liquid inside the pipeline for conveying corrosive and toxic media.

Owner:SINOPEC ZHONGYUAN PETROLEUM ENG DESIGN

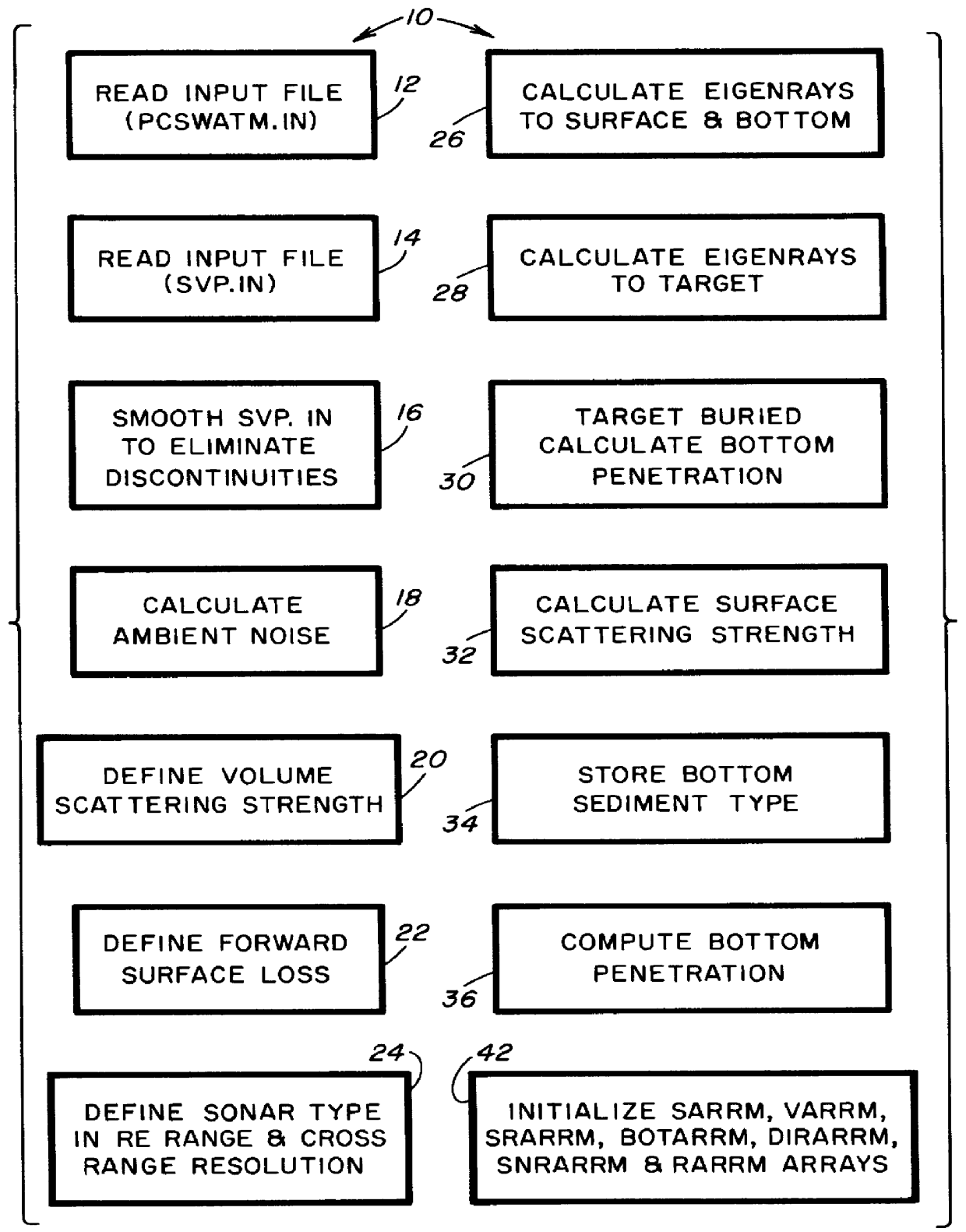

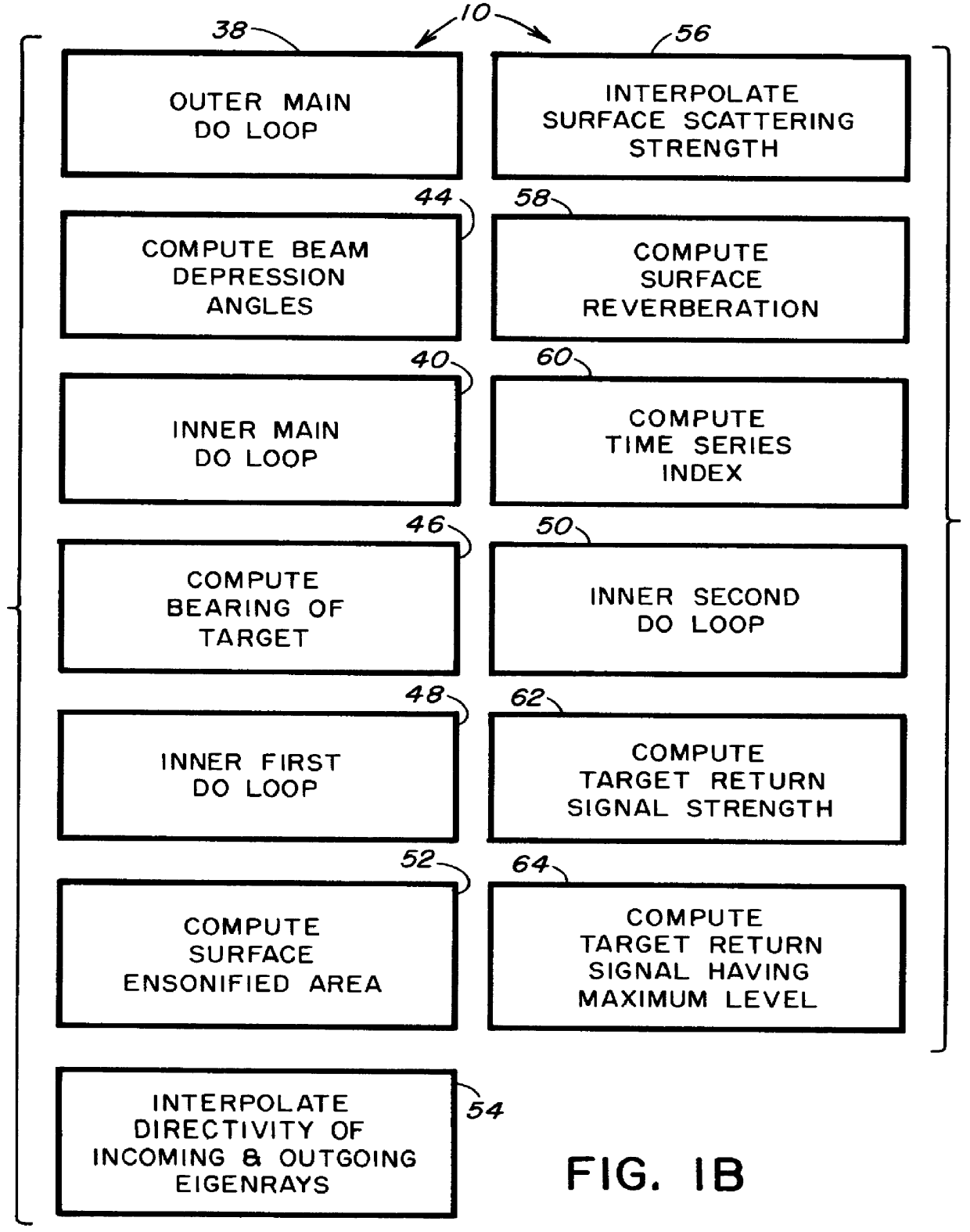

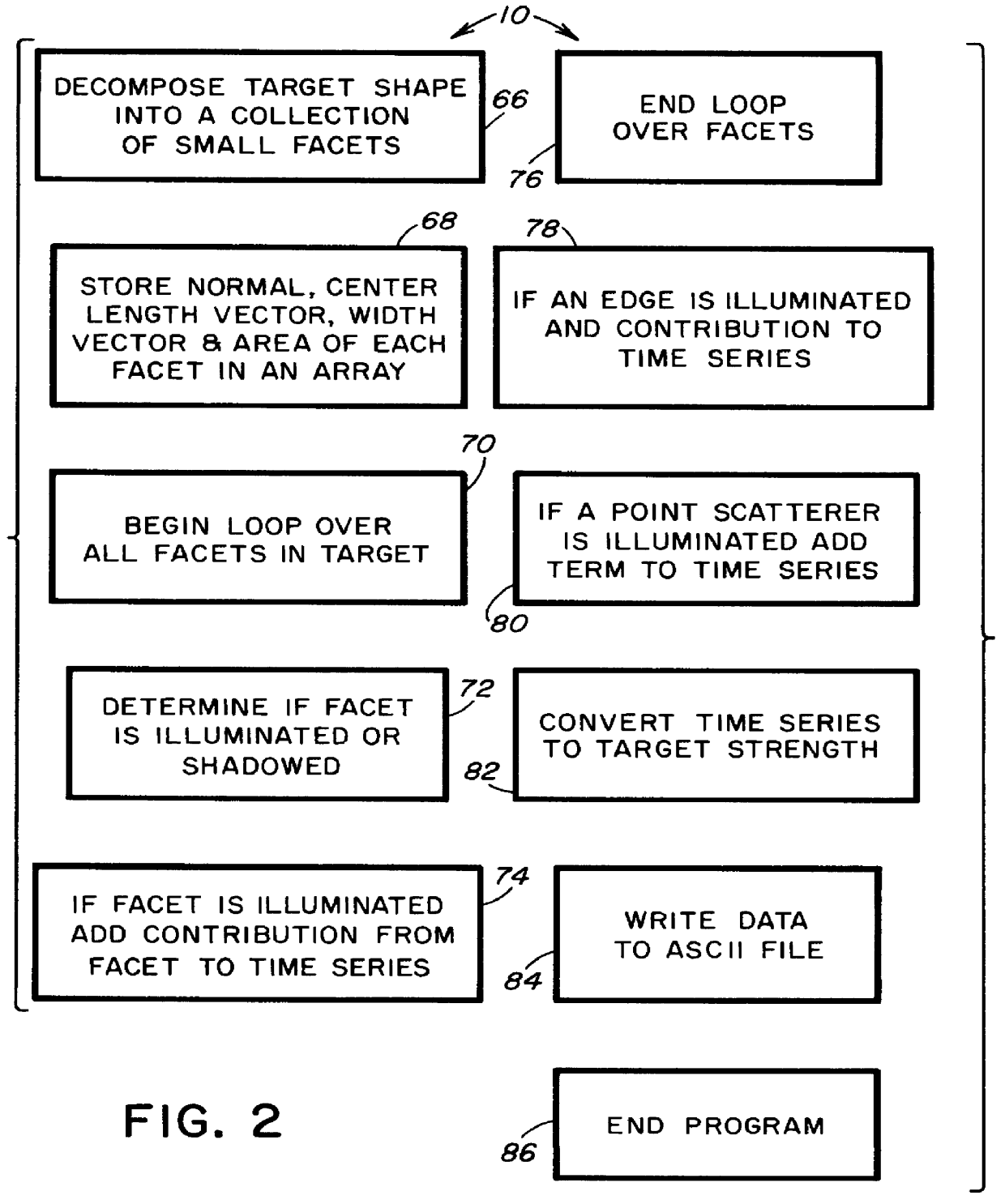

Computer-readable software and computer-implemented method for performing an integrated sonar simulation

InactiveUS6096085AWave based measurement systemsComputation using non-denominational number representationSonarBeam pattern

A computer-readable software stored on a storage medium and executed on a computer to perform an integrated sonar simulation, includes a parameter definition code for defining a plurality of parameters of a sonar, target and sonar environment, and a SNR computation code for computing a SNR of the sonar as a function of range to target, based upon the parameters defined by the parameter definition code. The parameters defined by the parameter definition code include ambient noise, volume scattering strength of the sonar environment, sound velocity profile of the sonar, beam patterns of both projector and receiver of the sonar, type of sonar, range resolution of the sonar, number of eigenrays striking the surface and bottom of the sonar environment, number of eigenrays striking the target, ray trajectories to the target, and surface and bottom scattering strength as a function of angle. The software also includes a target strength model generating code for computing scattering from a selected complex target of a stored set of complex target selections, to thereby generate a target strength model for the selected complex target.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

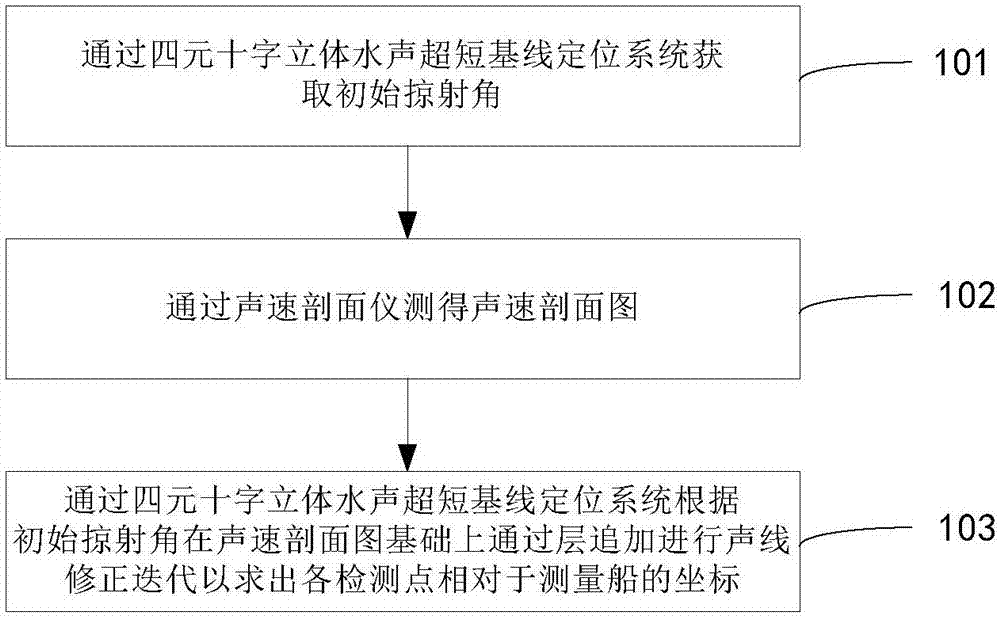

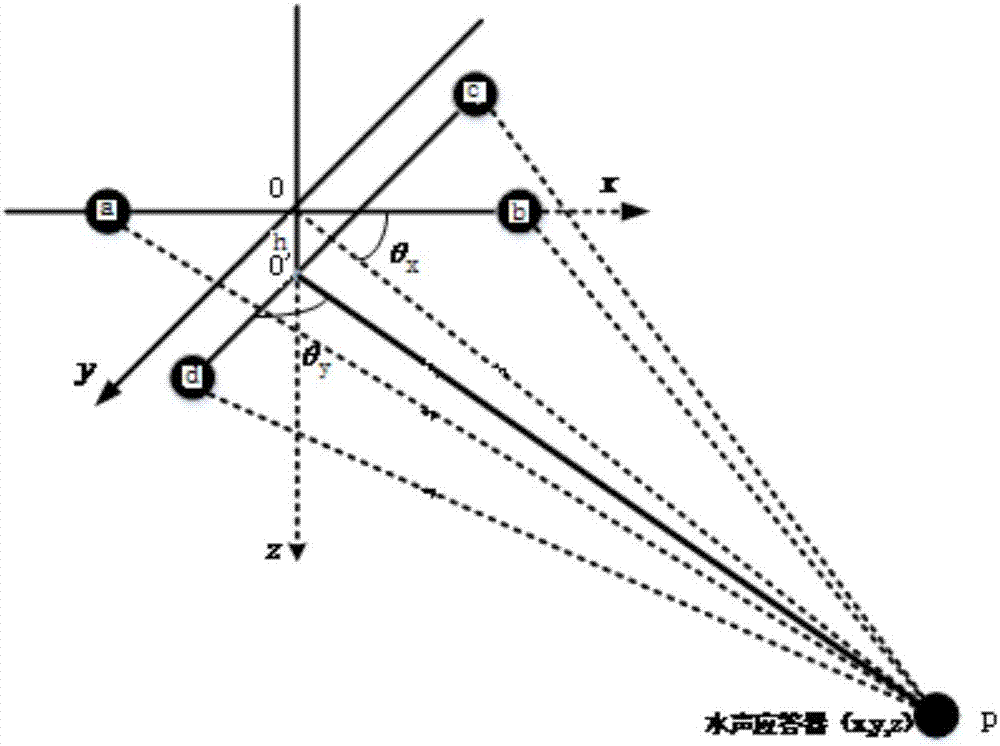

Sound ray correction method and system based on water sound ultrashort baseline positioning system

ActiveCN107132520AWide pointing opening angleThe positioning result is accurateWave based measurement systemsPhase differenceSelf adaptive

The invention provides a sound ray correction method based on a water sound ultrashort baseline positioning system. The method comprises the following steps: obtaining an initial glancing angle theta0 through a quaternary cross-shaped stereoscopic water sound ultrashort baseline positioning system; measuring the sound velocity profile through a sound velocity profiler; carrying out the sound ray correction iteration on the basis of the sound velocity profile in a mode of layer adding according to the initial glancing angle theta0 through the quaternary cross-shaped stereoscopic water sound ultrashort baseline positioning system, so as to solve the coordinates of each detection point relative to a measurement ship. According to the invention, the method obtains a phase difference estimation value according to a quaternary stereoscopic water sound ultrashort baseline array, and the iteration is carried out through employing an adaptive layered adding method, thereby solving the coordinates of each detection point relative to the measurement ship. Compared with a conventional mean sound velocity algorithm, the method greatly improves the range finding precision, effectively corrects a curved propagation path of sound rays in an underwater complex environment, and improves the underwater range finding and positioning precision of the water sound ultrashort baseline positioning system.

Owner:江苏中海达海洋信息技术有限公司

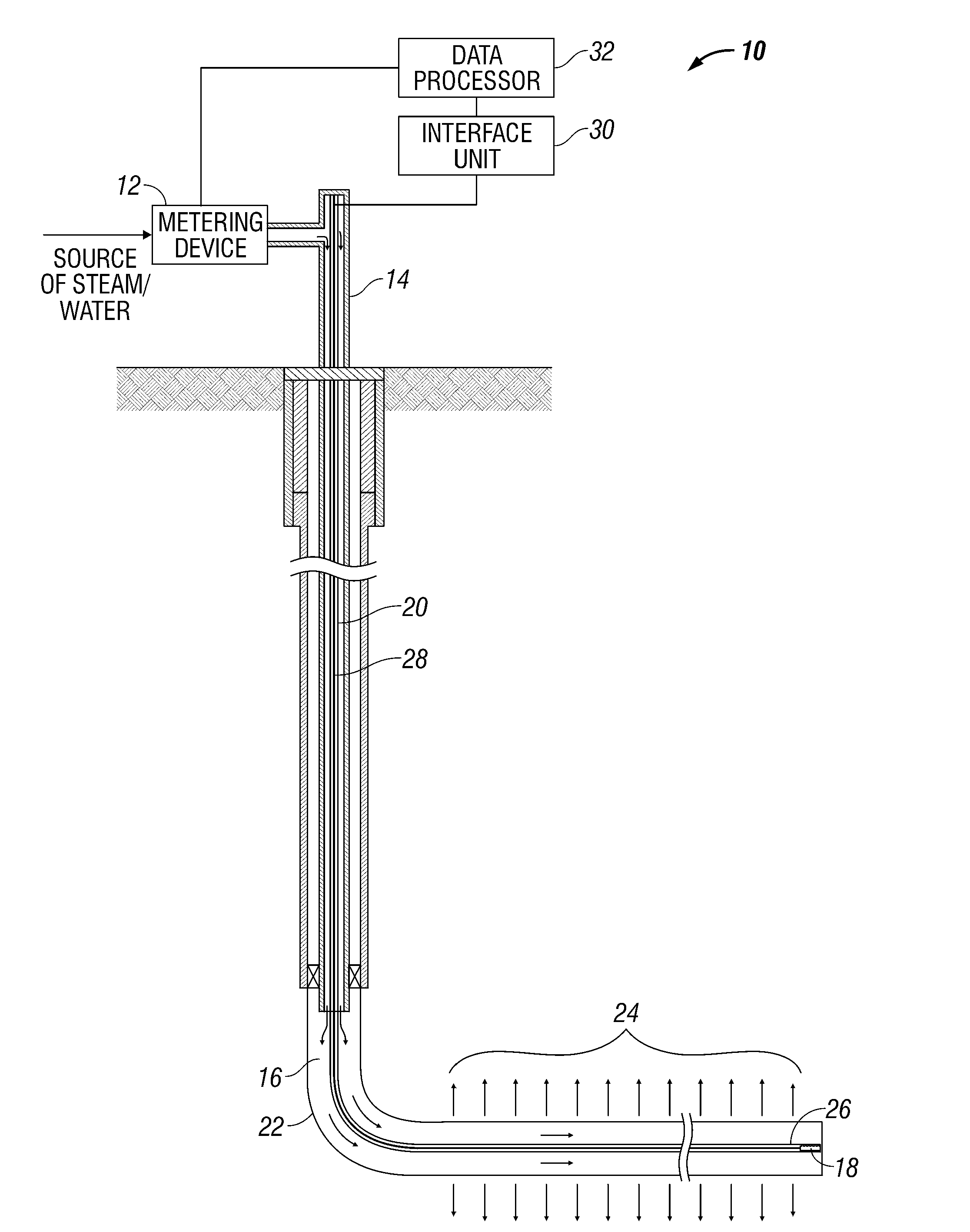

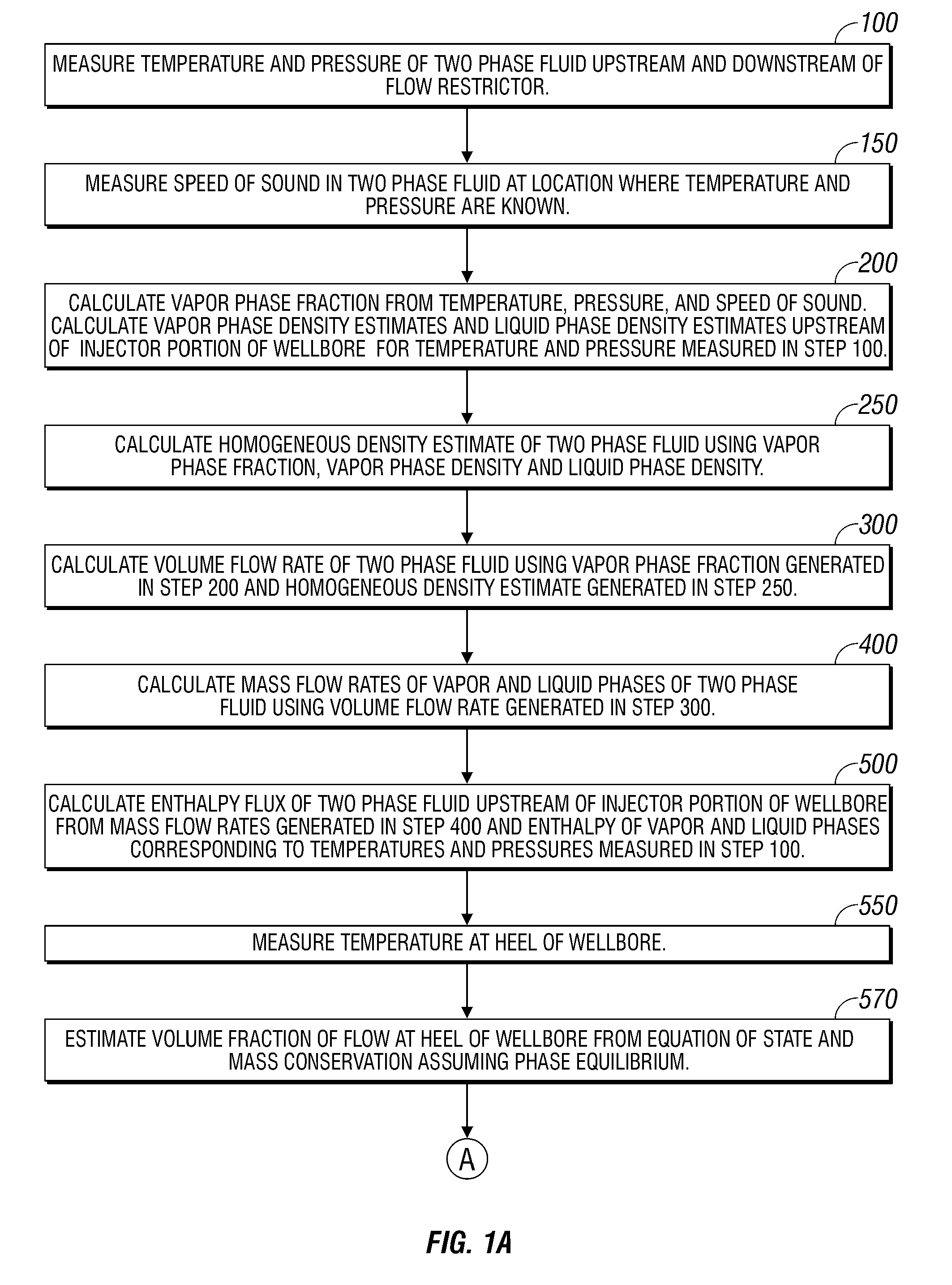

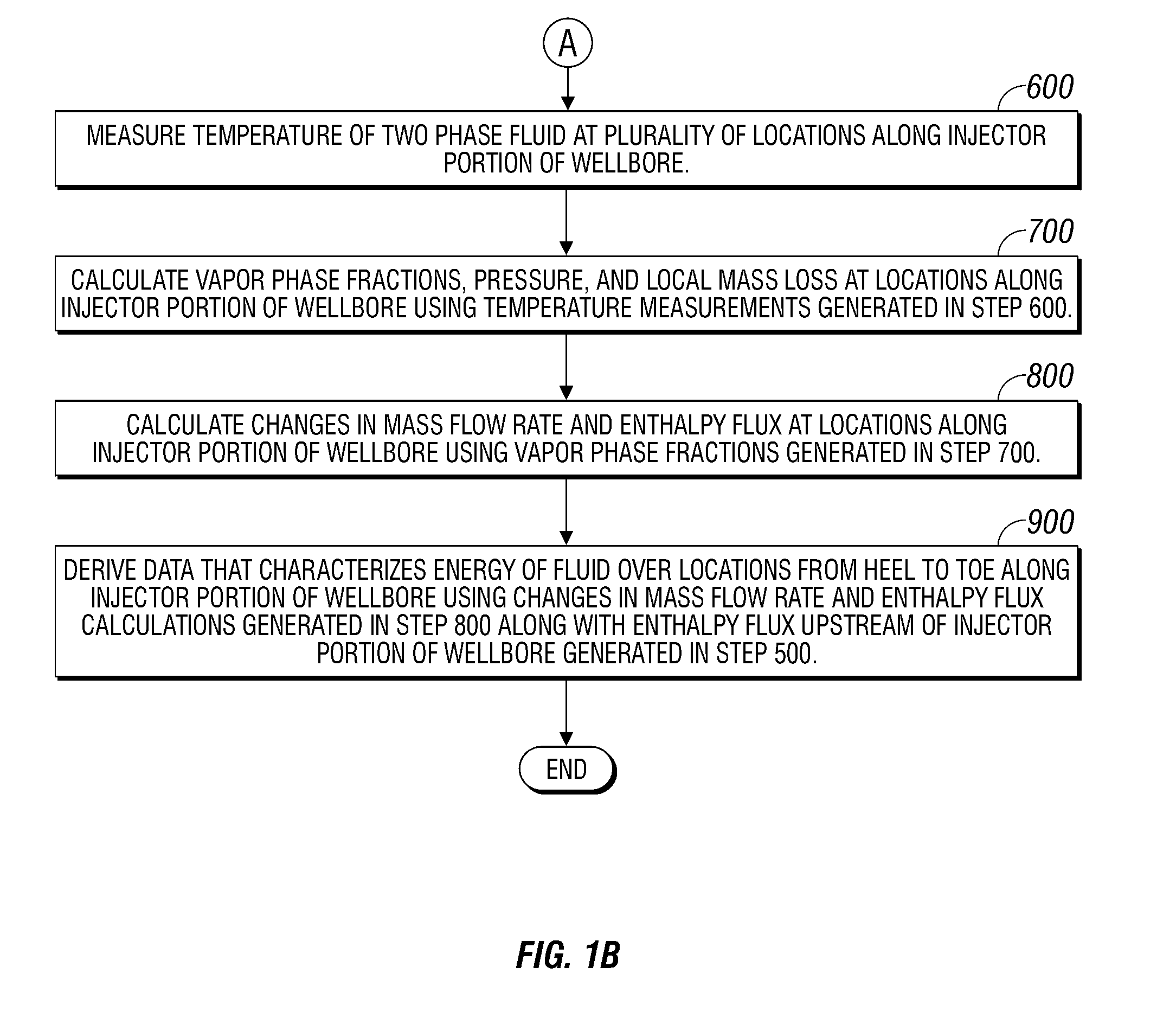

Apparatus and method for characterizing two phase fluid flow

InactiveUS20090266175A1Easy to controlEasy to optimizeSurveyMaterial moisture contentGas phaseEngineering

An apparatus (and corresponding method) for characterizing the fluid properties of a two phase fluid includes a restriction element (e.g., orifice plate or nozzle) along the flow path of the two phase fluid. At least one temperature sensor measures temperature of the two phase fluid flowing through the restriction element. A pressure sensor measures the pressure downstream of the restriction element. Time-of-flight measurements of pulses passing through the two phase fluid are made. The speed of sound within the two phase fluid is calculated from the time-of-flight measurements. At least one fluid property (e.g., a vapor phase fraction) of the two phase fluid is calculated from the measured pressure, the measured temperature, and the calculated speed of sound.

Owner:SCHLUMBERGER TECH CORP

Method and device for measuring compression coefficient and expansion coefficient of material on line

InactiveCN103499642AAnalysing solids using sonic/ultrasonic/infrasonic wavesPropagation timeSpecific volume

The invention relates to a method and a device for measuring and representing the compression coefficient and the expansion coefficient of a material on line. A temperature sensor, a pressure sensor and an ultrasonic probe are respectively arranged on one cross section of a closed material cavity of a pressure-volume-temperature (PVT) calibration device and are used for testing the volume, the temperature T, the pressure P and ultrasonic signals of the closed material synchronously. The sound velocity of the ultrasonic wave, which passes through the material with the thickness l in the material cavity is c=l / delta t within the propagation time delta t; the temperature is maintained constant, and the pressure measurement volume is changed, so that a constant temperature compression coefficient can be obtained; the pressure is maintained constant, and the temperature measurement volume is changed, so that a constant pressure expansion coefficient can be obtained; a material specific volume, a compression coefficient or expansion coefficient and sound velocity correspondence curve is established, and a corresponding equation is obtained by regression; or the compression coefficient (alpha) and the expansion coefficient (beta) can be obtained by the specific volume curve or the state equation. At certain temperature and under certain pressure, the propagation velocity of the ultrasonic wave in the material can be tested on line, and the compression coefficient and the expansion coefficient at the temperature and under the pressure can be obtained by the established corresponding curve or corresponding equation. The method has the advantages of being lossless and being easy in online representation, and the device is simple and convenient to install.

Owner:BEIJING UNIV OF CHEM TECH

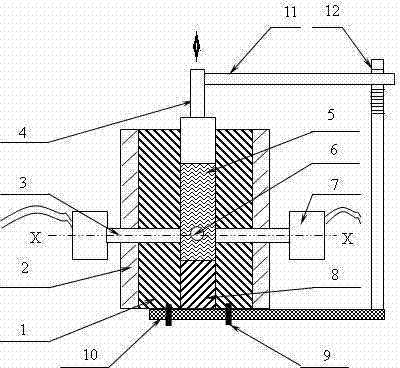

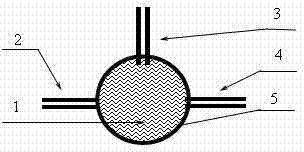

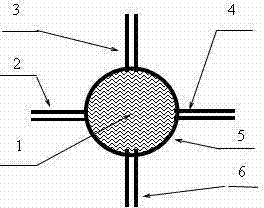

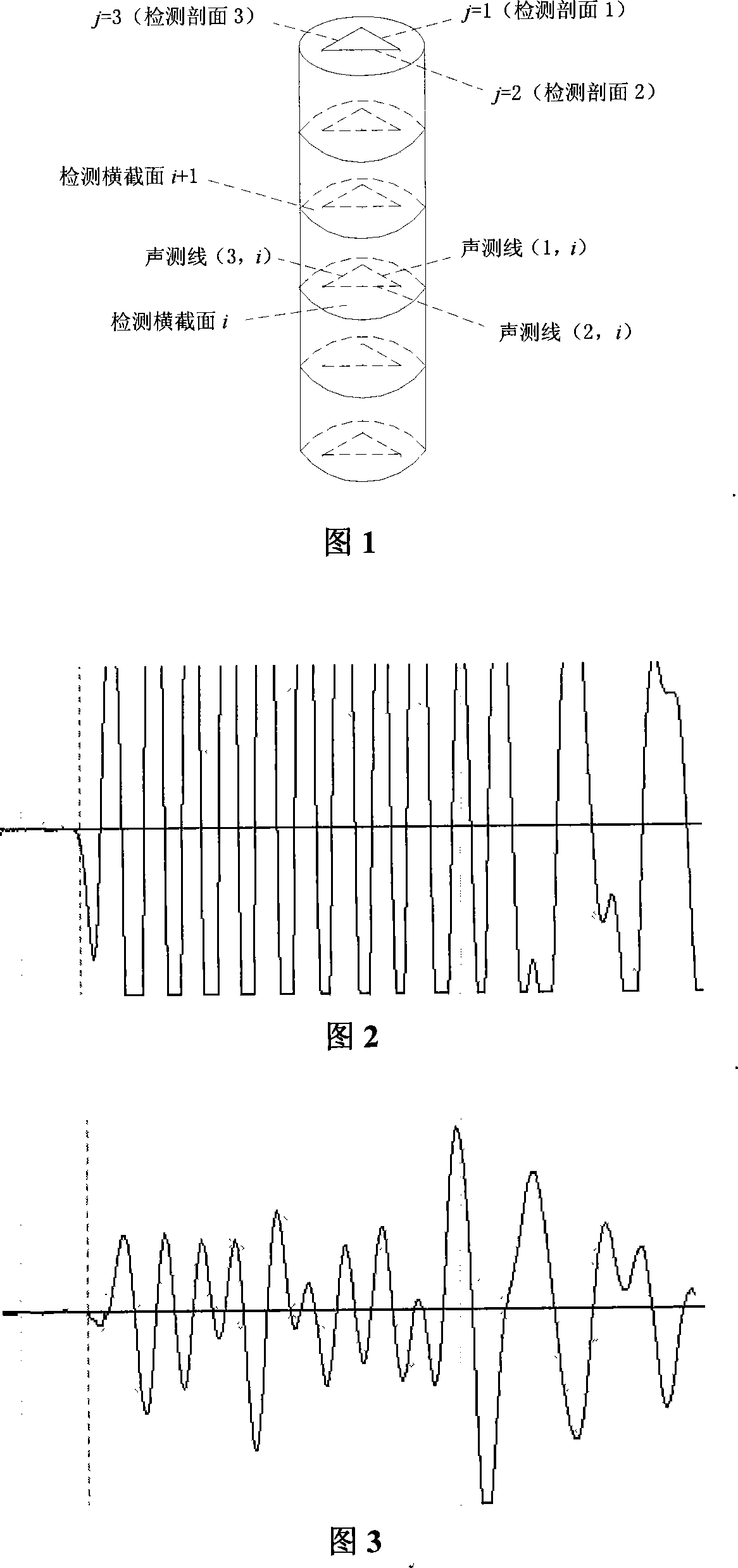

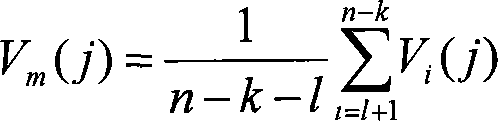

Method for detecting data aggregation judgment by foundation pile sound wave transmission method

InactiveCN101226170ASure reasonableEliminate subjective arbitrarinessAnalysing solids using sonic/ultrasonic/infrasonic wavesFoundation testingEconomic benefitsData aggregator

The invention relates to a foundation pile sound wave transmission method detection data comprehensive evaluation method, which is characterized in that (1), using dual-edge low-high value removing method to calculate sound parameter abnormal judgment critical value, comprehensively considering the normal ranges of the sound speed critical value and concrete sound speed of probability method, according to the bias degrees of the sound parameter detection value and the abnormal judgment critical value, making defect degree judgment standard, (2), using a sound test line to replace general test point to describe the sound parameters of sound wave transmission method, according to the physical character of different sound parameters and the data stability, making a standard for comprehensively evaluating the completeness classification of each sound test line in a detection section, (3), using the pile section as basic judgment unit to combine the completeness of each sound test line on the section to judge the completeness of each section, to evaluate completeness classification at the point of whole pile. The invention can effectively improve the objectiveness and scientific property of detection data analysis and processing, save material and human resource and improve significant social and economic benefits.

Owner:GUANGDONG CONSTR ENG GRP +1

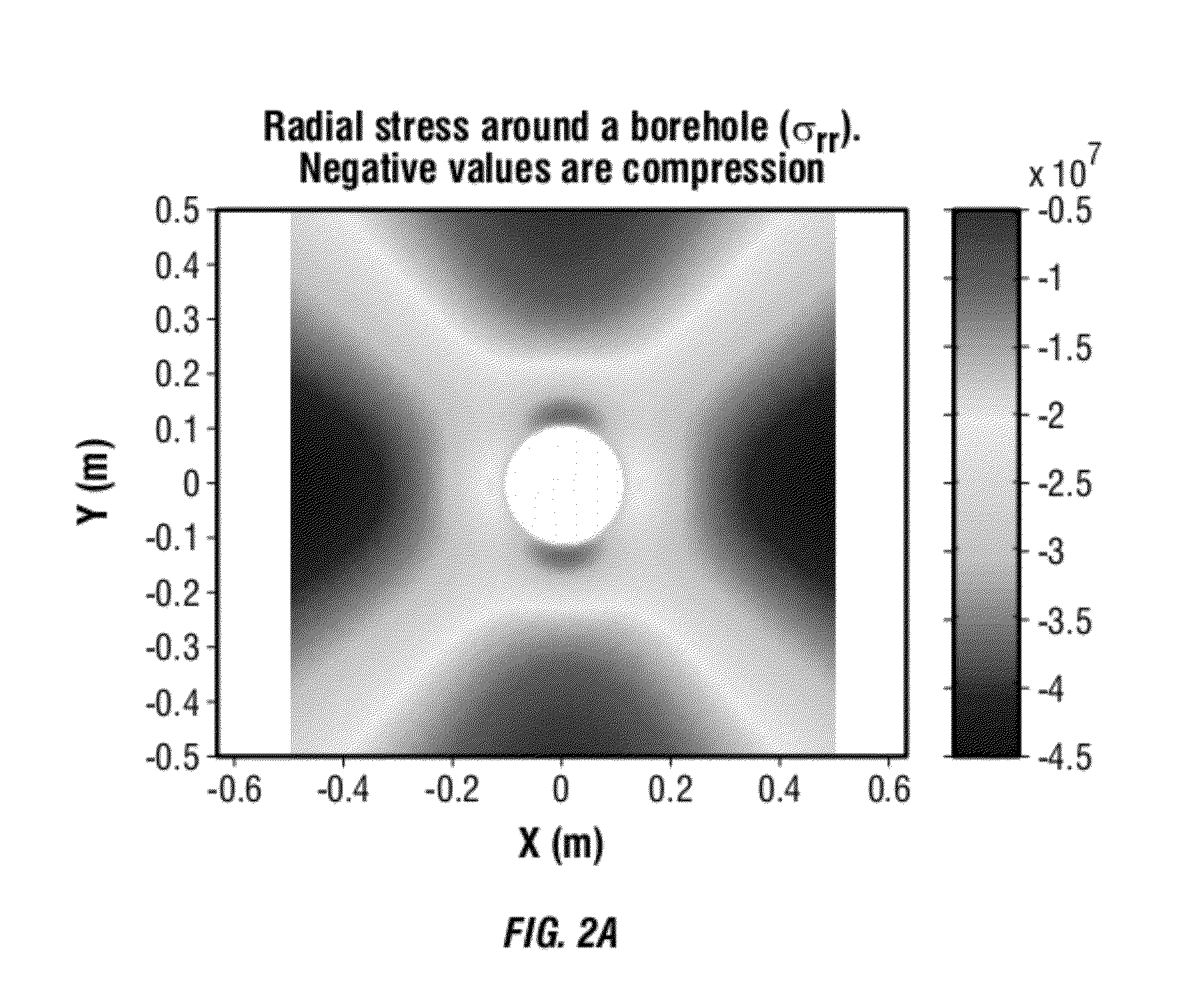

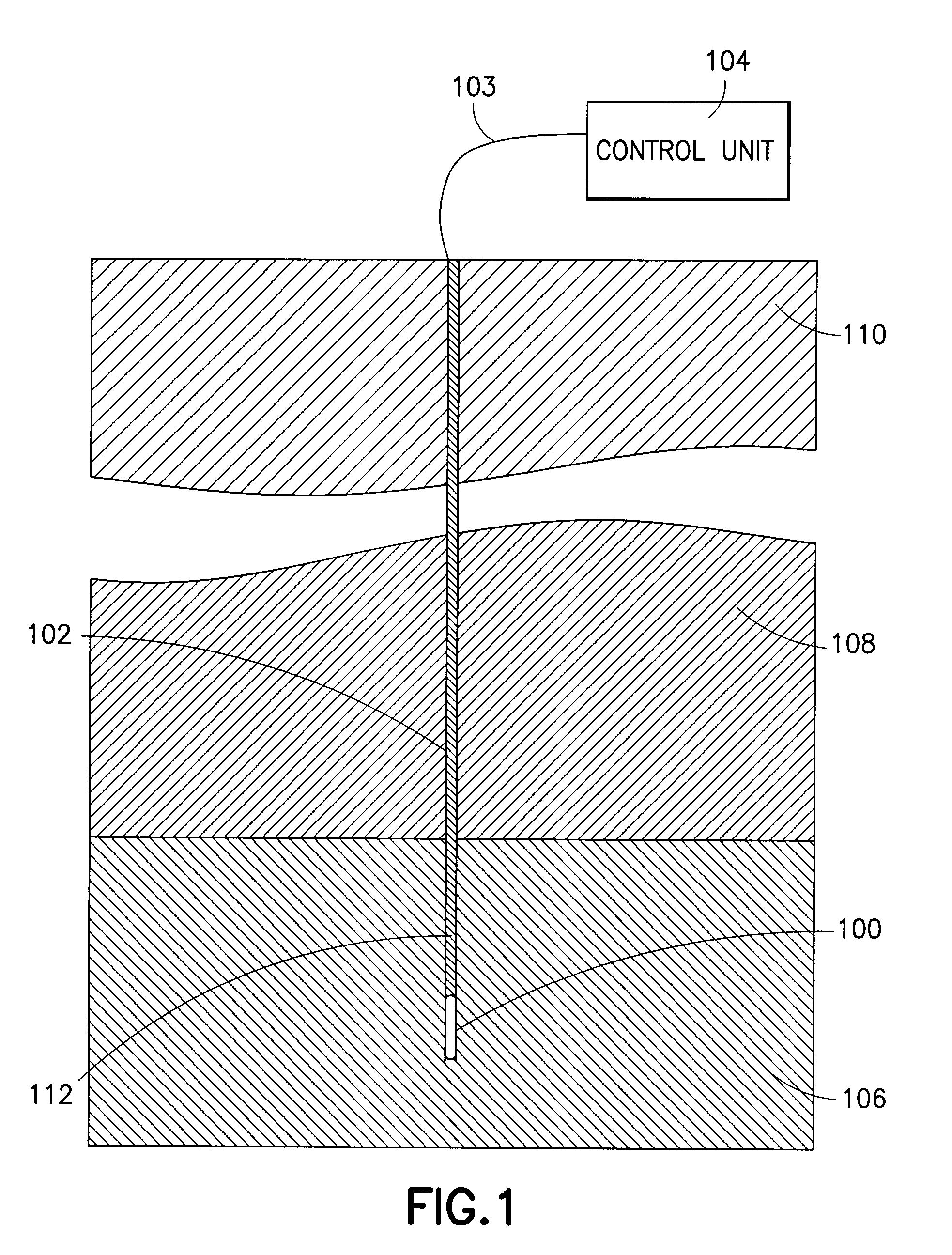

Stress in formations from azimuthal variation in acoustic and other properties

ActiveUS20120163123A1Seismic signal processingSeismology for water-loggingHorizontal stressWell logging

The present disclosure is related to methods and apparatuses for acoustic velocity well logging. The method may include estimating a magnitude of a principal horizontal stress in a borehole in a formation. The method may include obtaining a far field stress orientation and making a measurement of near borehole stress orientation. The present disclosure also includes an apparatus configured to be conveyed into a borehole and perform the method. Formation stresses and directions may be estimated.

Owner:BAKER HUGHES INC

Downhole fluid characterization based on changes in acoustic properties with pressure

ActiveUS20070227241A1Material analysis using sonic/ultrasonic/infrasonic wavesSurveyTransducerFormation fluid

Techniques for evaluating physical aspects of a formation fluid from within a wellbore include changing pressure on a sample of the formation fluid and transmitting at least one acoustic pulse through the fluid sample and analyzing acoustic information collected. Apparatus and methods for the evaluating involve using at least one acoustic transducer. Analyzing typically involves use of formulae that relate the fluid's equation of state and other properties to a change in the sound speed in the fluid as a function of pressure.

Owner:BAKER HUGHES INC

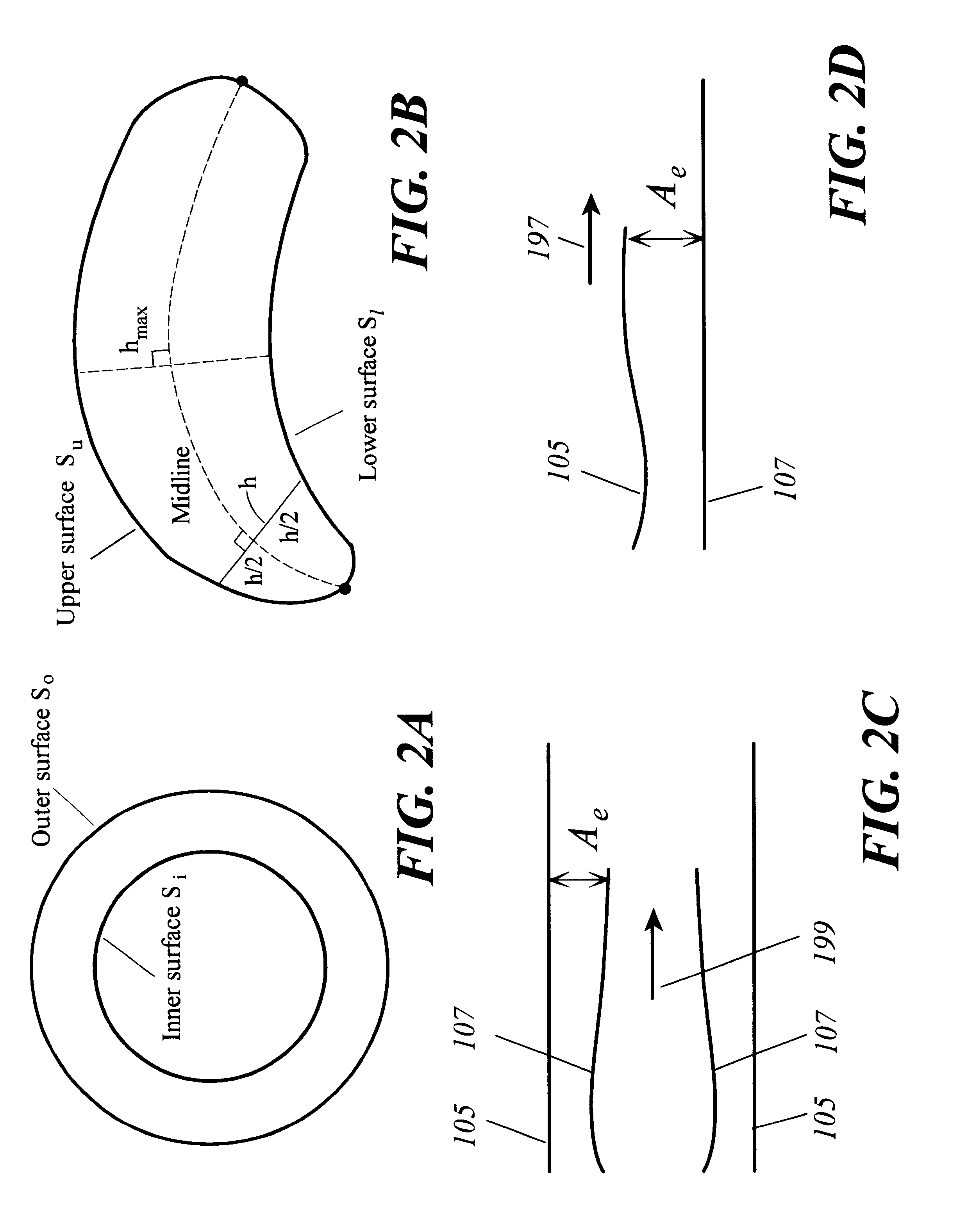

Mixing enhancement using axial flow

A method and an apparatus for enhancing fluid mixing. The method comprises the following: (a) configuring a duct to have an effective outer wall, an effective inner wall, a cross-sectional shape, a first cross-sectional area and an exit area, the first cross-sectional area and the exit area being different in size; (b) generating a first flow at the first cross-sectional area, the first flow having a total pressure and a speed equal to or greater than a local speed of sound; and (c) generating a positive streamwise pressure gradient in a second flow in proximity of the exit area. The second flow results from the first flow. Fluid mixing is enhanced downstream from the duct exit area.

Owner:RGT UNIV OF CALIFORNIA

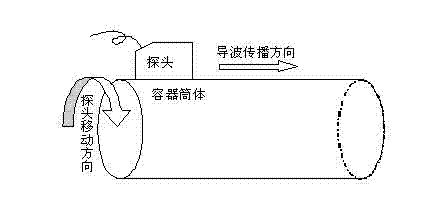

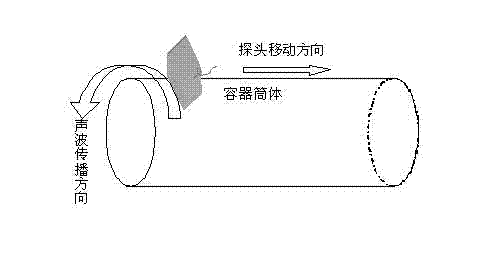

Integral ultrasonic guide wave detecting method for barrel of pressure vessel

ActiveCN102636569AComprehensive detectionEfficient detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesGeneral ultrasoundEngineering

The invention relates to an integral ultrasonic guide wave detecting method for a barrel of a pressure vessel. The integral ultrasonic guide wave detecting method includes steps of 1, calculating a phase speed and group speed frequency dispersion chart of longitudinal or peripheral guided waves; 2, determining a range of detecting guide wave excitation frequency; 3, determining the best detecting guide wave frequency and a guide wave incident angle; 4, utilizing a common ultrasonic flaw detector and setting sound speed options of the ultrasonic flaw detector; and 5, correctly connecting a probe with the detector, placing the probe onto the barrel of the vessel to axially or peripherally scan, and utilizing reflecting echo of a weld joint of the barrel of the vessel to adjust sensitivity or processing an artificial reflector to determine the detection sensitivity according to defects required to be detected until detection is finished. The method can be used for efficiently and comprehensively detect the defects of the barrel of the pressure vessel.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

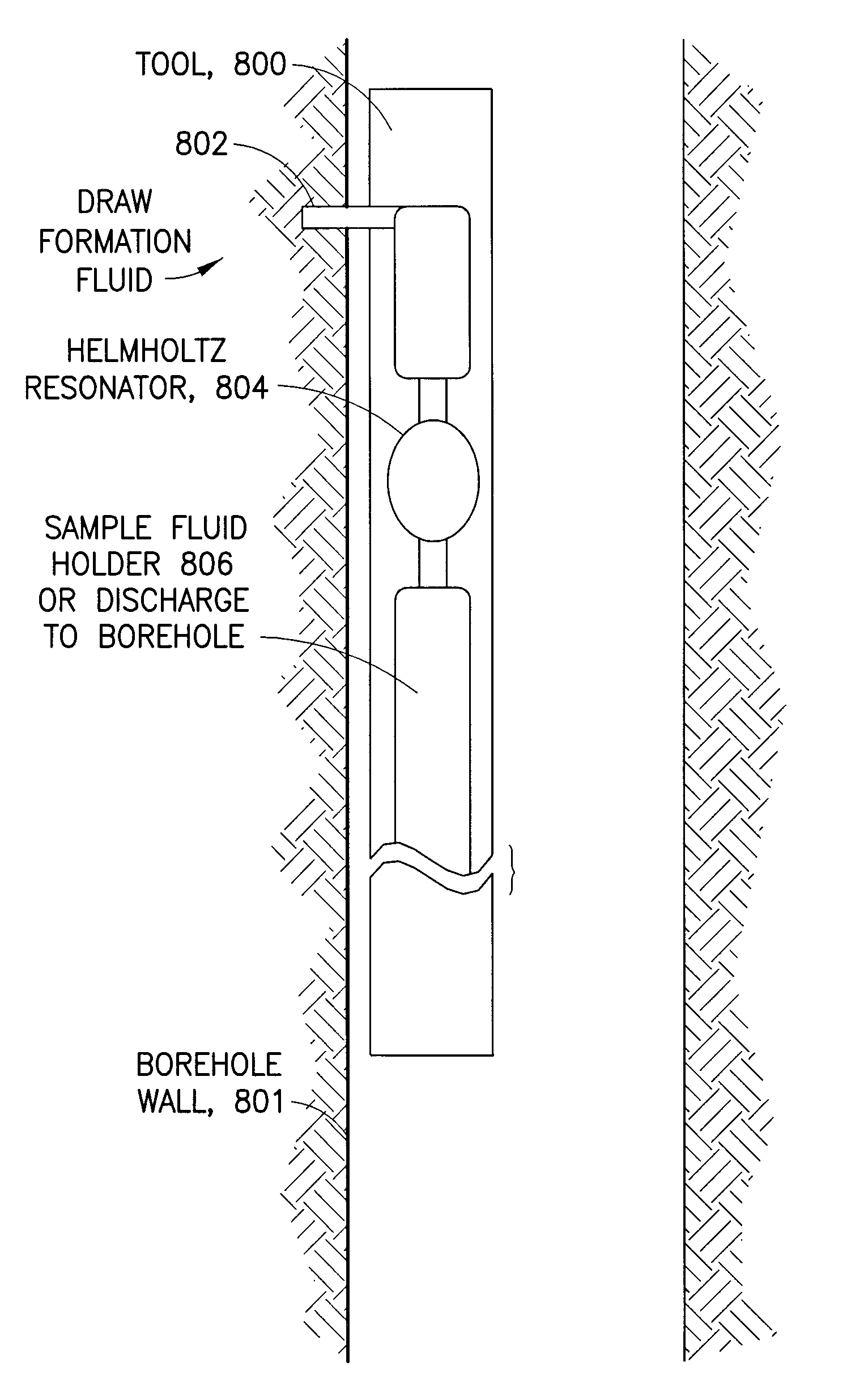

Measurement of sound speed of downhole fluid by helmholtz resonator

ActiveUS20090101432A1High measurement accuracyAccurate calculationElectric/magnetic detection for well-loggingFlow propertiesHelmholtz resonatorFormation evaluation

A downhole logging tool is equipped with a modified Helmholtz resonator for facilitating acoustic formation evaluation and reservoir characterization. The resonator permits calculation of sound speed and viscosity of the fluid in the resonator cavity. The presence of gas bubbles in the fluid may also be detected. The modified Helmholtz resonator includes at least two openings so that fluid can flow through the resonator cavity. Because fluid can flow through the resonator cavity, local fluid can be measured under local conditions, e.g., downhole temperature, pressure, and gas influx from formations. Further, the modified Helmholtz resonator utilizes an acoustic signal at or near the frequency of interest for at least some acoustic logging tools.

Owner:SCHLUMBERGER TECH CORP

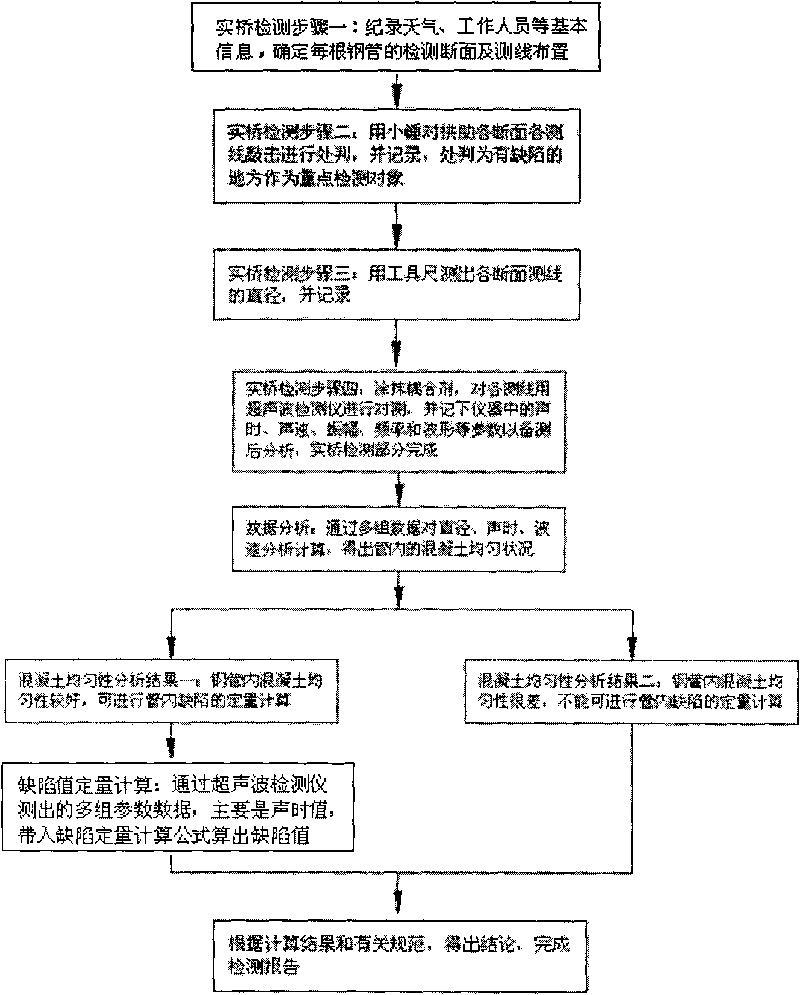

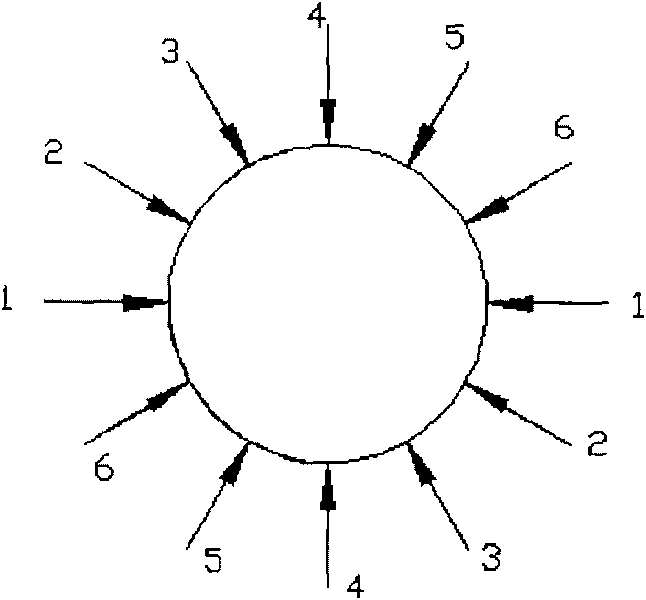

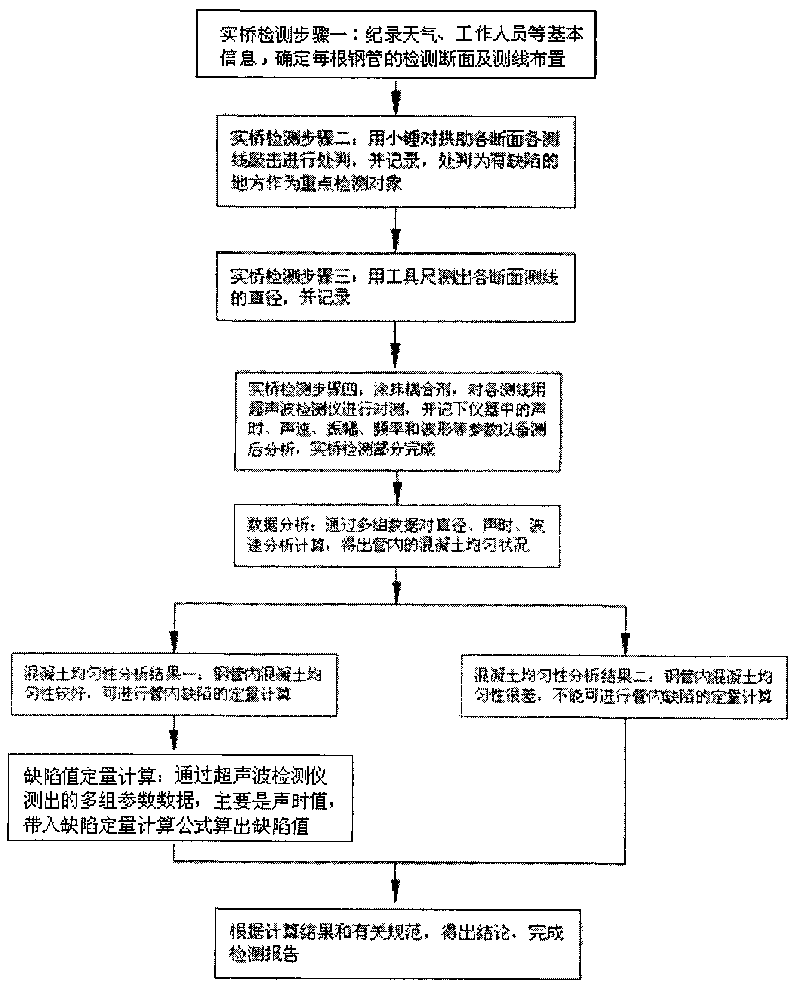

Ultrasonic testing method for steel pipe void

InactiveCN101710101AReduce uniformitySave human effortAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringPipe

The invention relates to an ultrasonic testing method for steel pipe void, which comprises the following steps of: confirming a tested fracture surface of each steel pipe and arranging a plurality of survey lines on the surface of each steel pipe in a uniform distribution way; knocking each survey line on each fracture surface of arch ribs by a small hammer, preliminarily judging the compaction rate of concretes inside the steel pipe according to the knock, and recording judging results; measuring diameters of the survey lines on each fracture surface by using a tooling scale and recording; coating a coupling agent on the surface of each steel pipe, detecting each survey line by using an ultrasonic detector, and recording parameters of sound time, sound velocity, amplitude and wave form which are displayed in the detector; analyzing and calculating the recorded multi-group data to obtain the uniformity state of the concretes inside the steel pipes; if the uniformity state is favorable, then carrying out a quantitative calculation on inner pipe defects, and working out an inner pipe defect value of each fracture surface through a sound time value detected by the ultrasonic detector; and if the uniformity state is unfavorable, then obtaining a detection conclusion.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

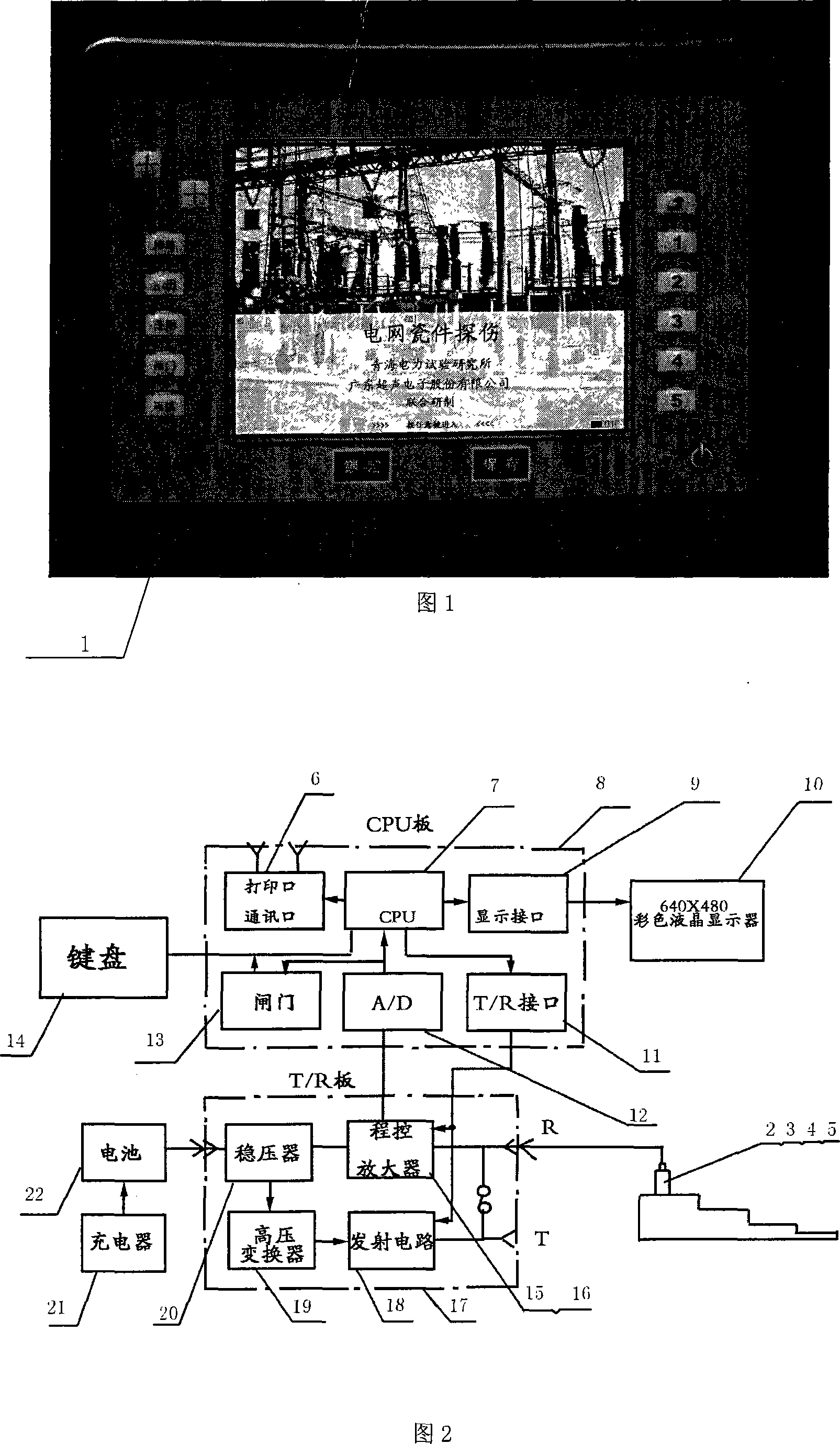

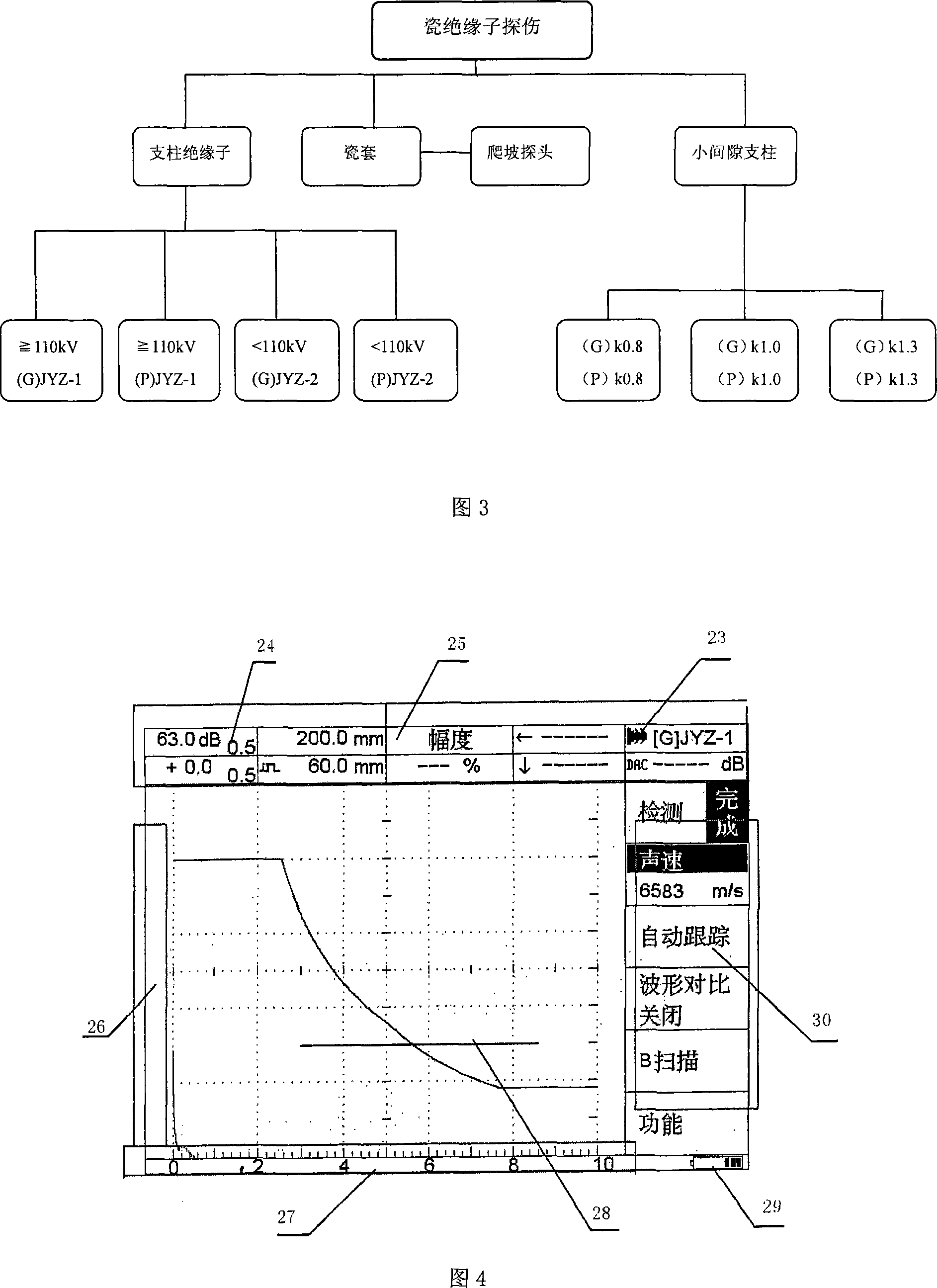

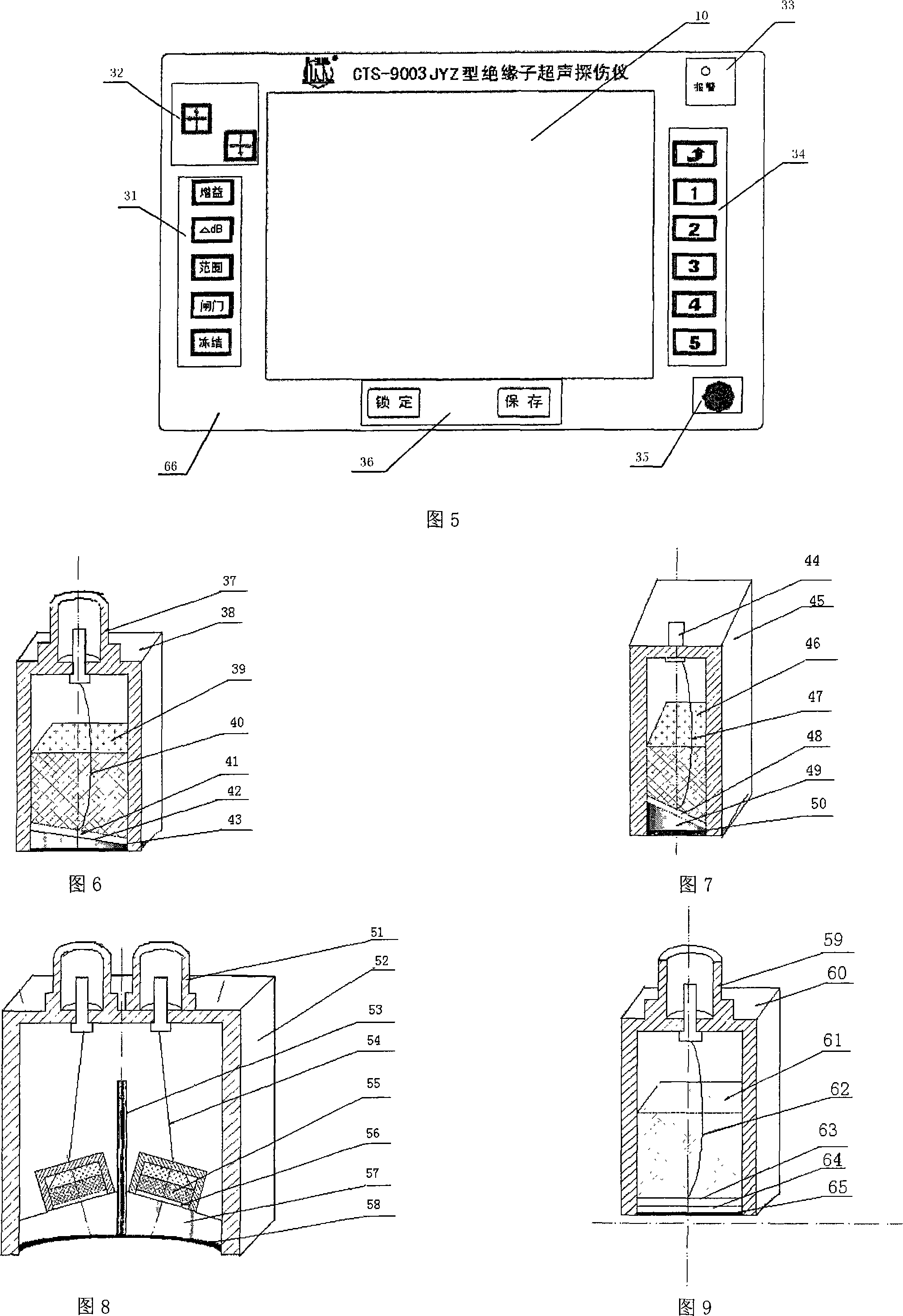

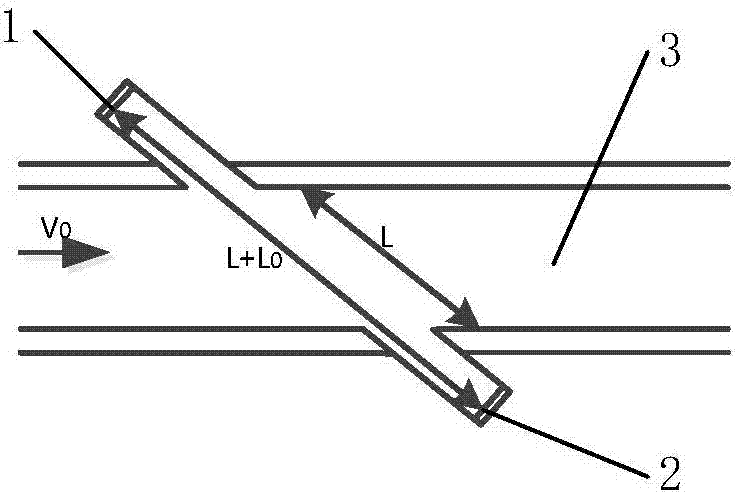

Prop porcelain insulator and porcelain bushing ultrasonic wave detecting method

ActiveCN101135672AReduce RegulatorIncrease detection functionAnalysing solids using sonic/ultrasonic/infrasonic wavesWave formEngineering

The method comprises: 1) selecting the type of the insulator; 2) measuring the sound speed; 3) selecting the probe; 4) crank detection; 5) automatically tracing; 6) comparing the wave forms; 7) displaying the detection result. By making the intellectualized modification for the original supersonic detector, the invention enhances the detection function and reduces the program for adjusting the metering device.

Owner:STATE GRID CORP OF CHINA +1

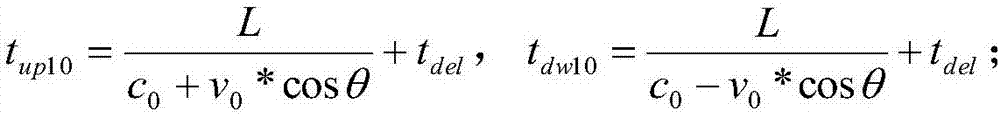

Gas flow metering method

ActiveCN106932040ALow costUnlimited locationVolume/mass flow measurementStreamflowCalculation methods

The invention relates to the technical field of metering instruments and concretely relates to a gas flow metering method. The metering method comprises the following steps of controlling a first ultrasonic probe to send an ultrasonic signal to a second ultrasonic probe, receiving an ultrasonic signal based on the first ultrasonic probe to the second ultrasonic probe and fed back by the second ultrasonic probe to achieve upgoing flying time tup10, controlling the second ultrasonic probe to send an ultrasonic signal to the first ultrasonic probe, receiving an ultrasonic signal based on the second ultrasonic probe to the first ultrasonic probe and fed back by the first ultrasonic probe to achieve downgoing flying time tdw10, correcting the upgoing flying time tup10 and the downgoing flying time tdw10 according to hardware delay time, calculating real-time sound speed c0 during the sampling, calculating real-time flow speed v0 according to the real-time sound speed c0, and calculating real-time flow Q0 according to the real-time flow speed v0 and a flow path cross section S. The real-time flow Q0 can be accurately achieved via the calculation method, and further standard gas volume dVc can be accurately achieved by the use of the metering method.

Owner:ZHEJIANG CHINT INSTR & METER

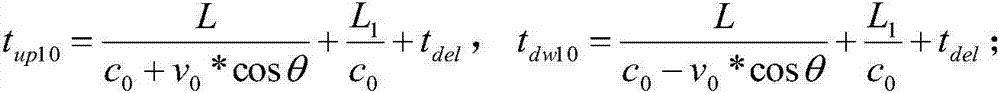

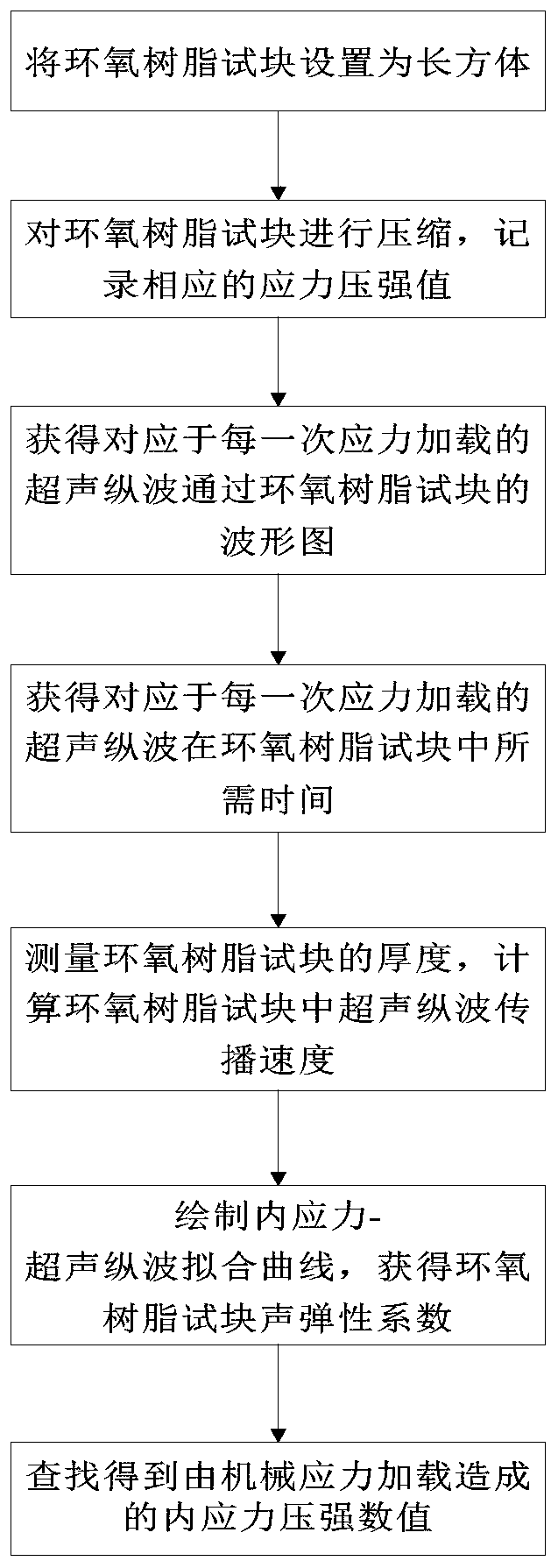

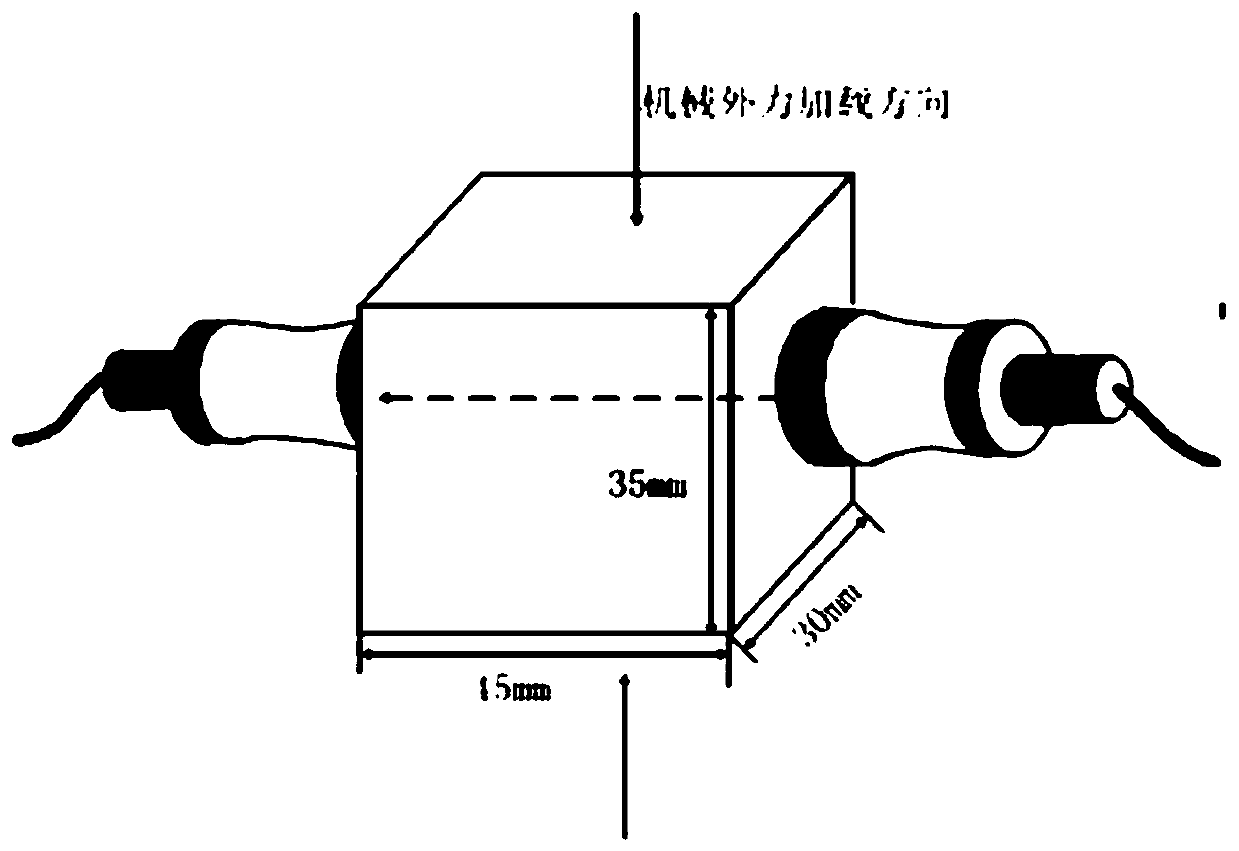

Method and system for detecting internal stress ultrasonic longitudinal wave of GIS basin type insulator epoxy test block

ActiveCN109959477ADetect internal stress and pressure valueForce measurementApparatus for force/torque/work measurementEpoxyLongitudinal wave

The invention provides a method for detecting the internal stress ultrasonic longitudinal wave of a GIS basin type insulator epoxy test block. The method comprises: step one, setting an epoxy test block to be in a shape like a cuboid; step two, compressing the epoxy test block and recording a corresponding stress pressure intensity value; step three, acquiring a waveform diagram of an ultrasonic longitudinal wave corresponding to each stress loading through the epoxy test block; step four, calculating an acoustic time difference between an ultrasonic transmitted wave and an ultrasonic receiving wave and acquiring time needed by the ultrasonic longitudinal wave corresponding to each stress loading in the epoxy test block; step five, measuring an ultrasonic sound path and calculating an ultrasonic longitudinal wave propagation velocity in the epoxy test block; step six, drawing an internal stress-ultrasonic longitudinal wave fitting curve to obtain an acoustic elasticity coefficient of the epoxy test block; and step seven, searching an internal stress pressure intensity value caused by mechanical stress loading. According to the invention, with the ultrasonic longitudinal wave soundvelocity, the internal stress pressure intensity value of the GIS basin type insulator epoxy test block can be detected rapidly without destruction.

Owner:SOUTH CHINA UNIV OF TECH

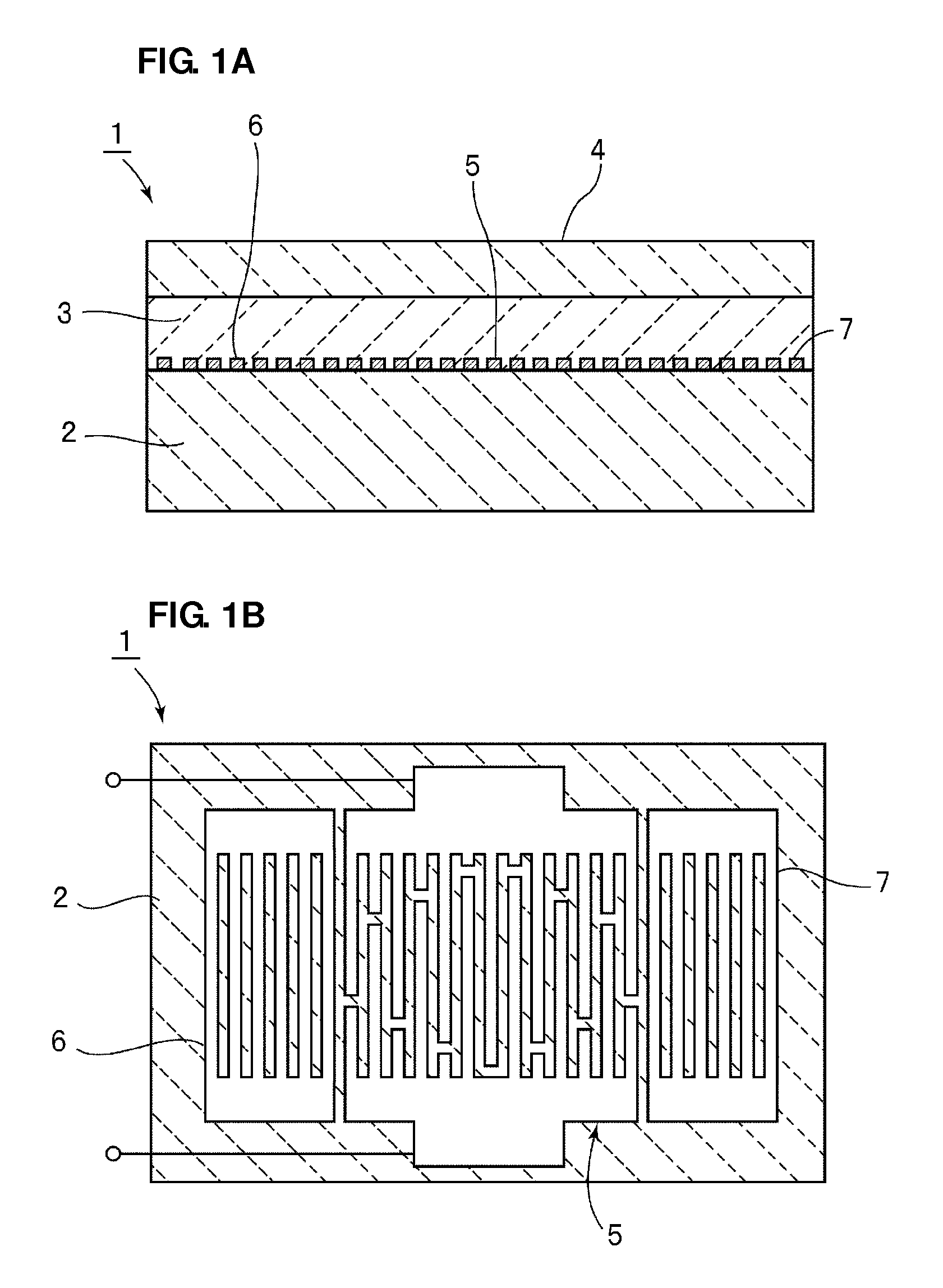

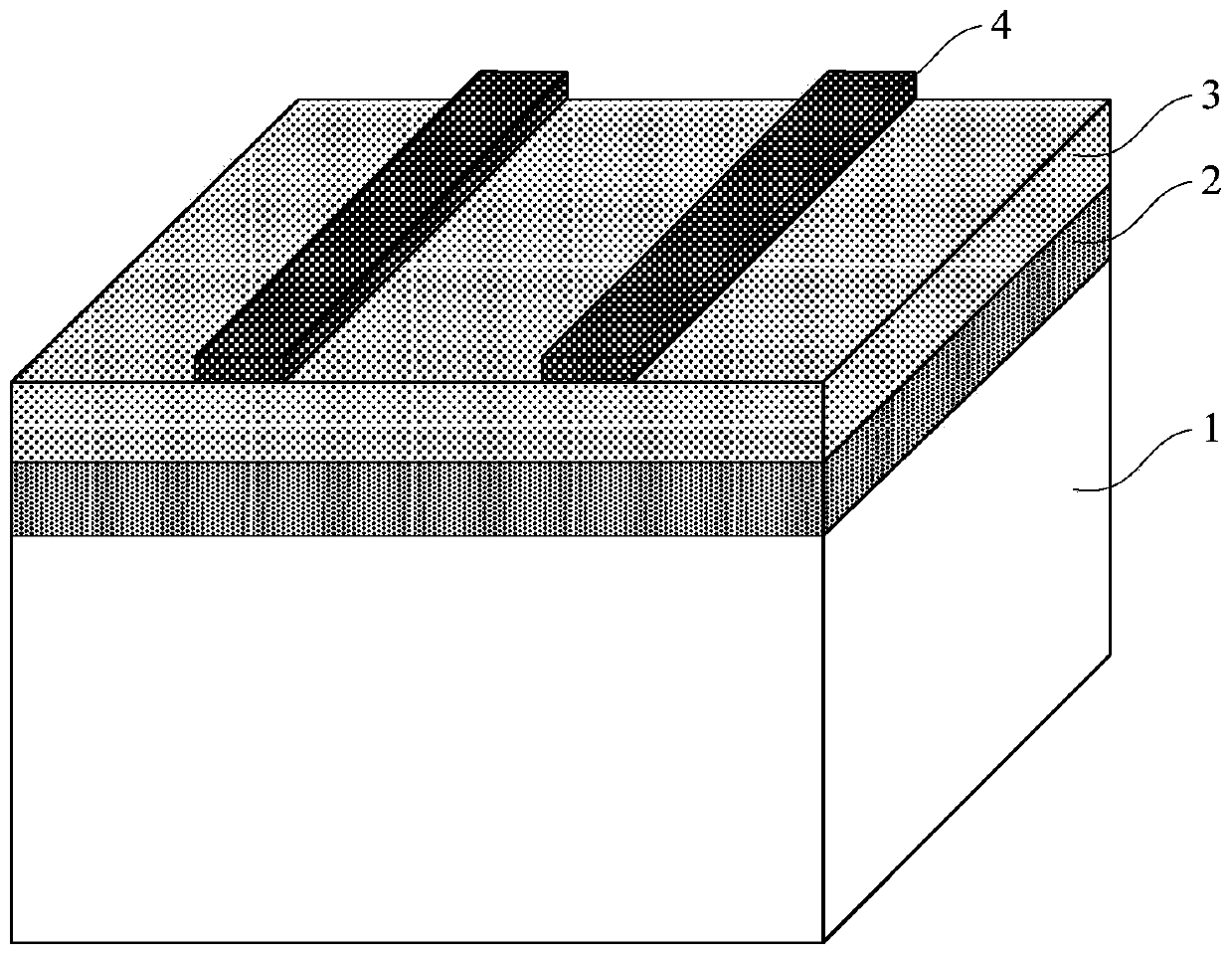

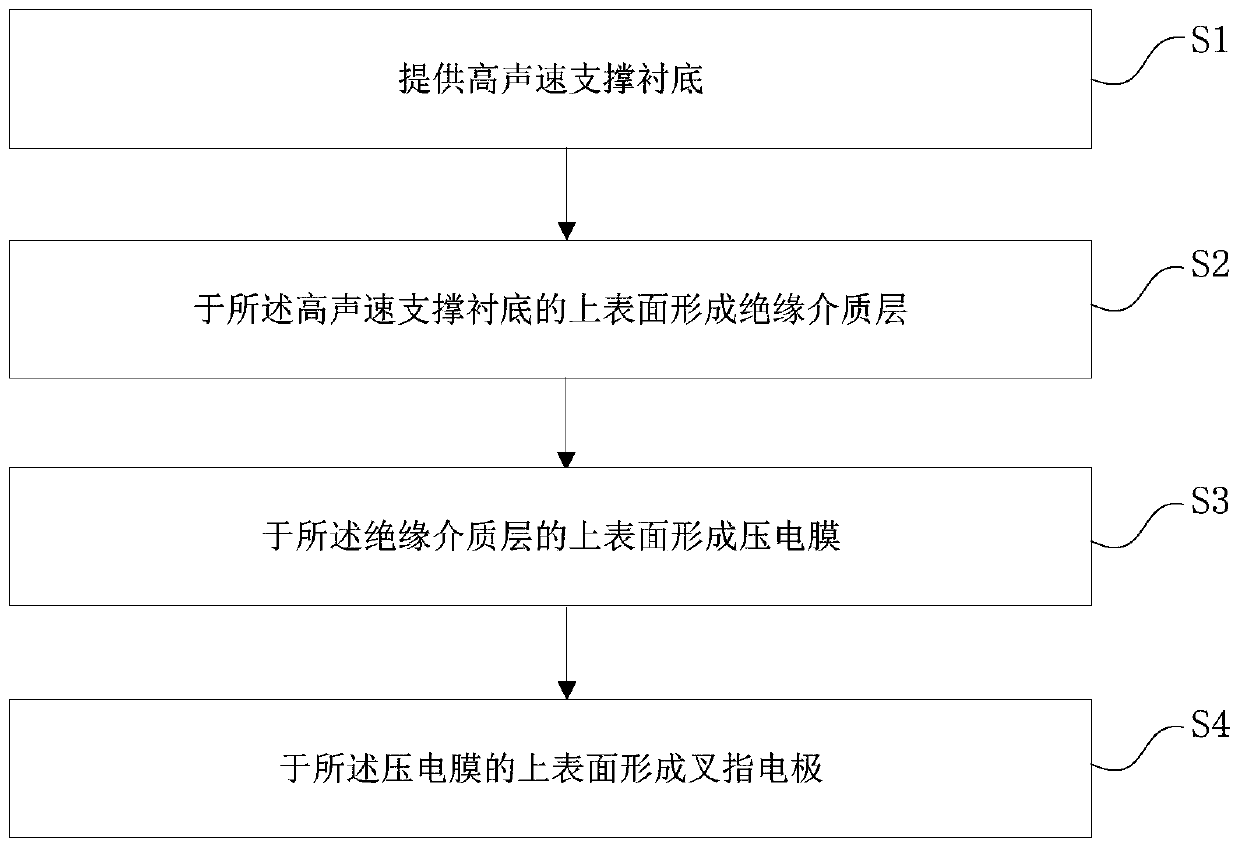

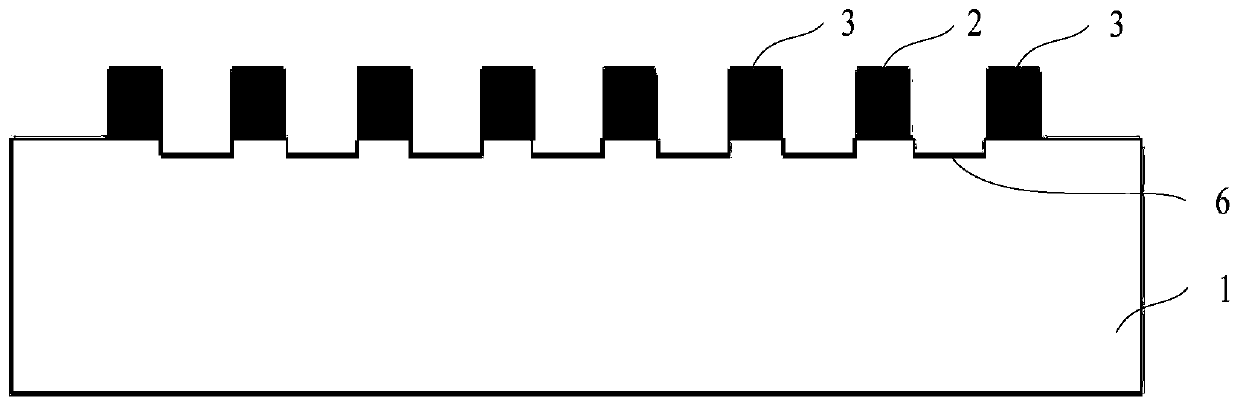

High-frequency acoustic wave resonator and preparation method thereof

ActiveCN111416590ARaise the resonant frequencyHigh electromechanical coupling coefficientImpedence networksHigh level techniquesElectromechanical coupling coefficientAcoustic wave

The invention provides a high-frequency acoustic wave resonator and a preparation method thereof. The high-frequency acoustic wave resonator comprises a high-acoustic-velocity support substrate, an insulating dielectric layer which is located on the upper surface of the high-sound-velocity supporting substrate, a piezoelectric film which is located on the upper surface of the insulating dielectriclayer, and an interdigital electrode which is located on the upper surface of the piezoelectric film. By arranging the high-sound-velocity supporting substrate below the piezoelectric film, the soundvelocity of target elastic waves excited and propagated in the piezoelectric film can be increased, propagation of the target elastic waves can be effectively restrained, and the resonant frequency of the high-frequency sound wave resonator is improved; the insulating dielectric layer is arranged between the piezoelectric film and the high-sound-velocity supporting substrate, the leakage of electric field energy in the piezoelectric film can be effectively reduced, and the electromechanical coupling coefficient of the high-frequency sound wave resonator can be enhanced; by selecting the appropriate insulating dielectric layer, temperature compensation can be carried out on the high-frequency acoustic wave resonator, temperature drift of the high-frequency acoustic wave resonator is reduced, and temperature stability of the high-frequency acoustic wave resonator is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

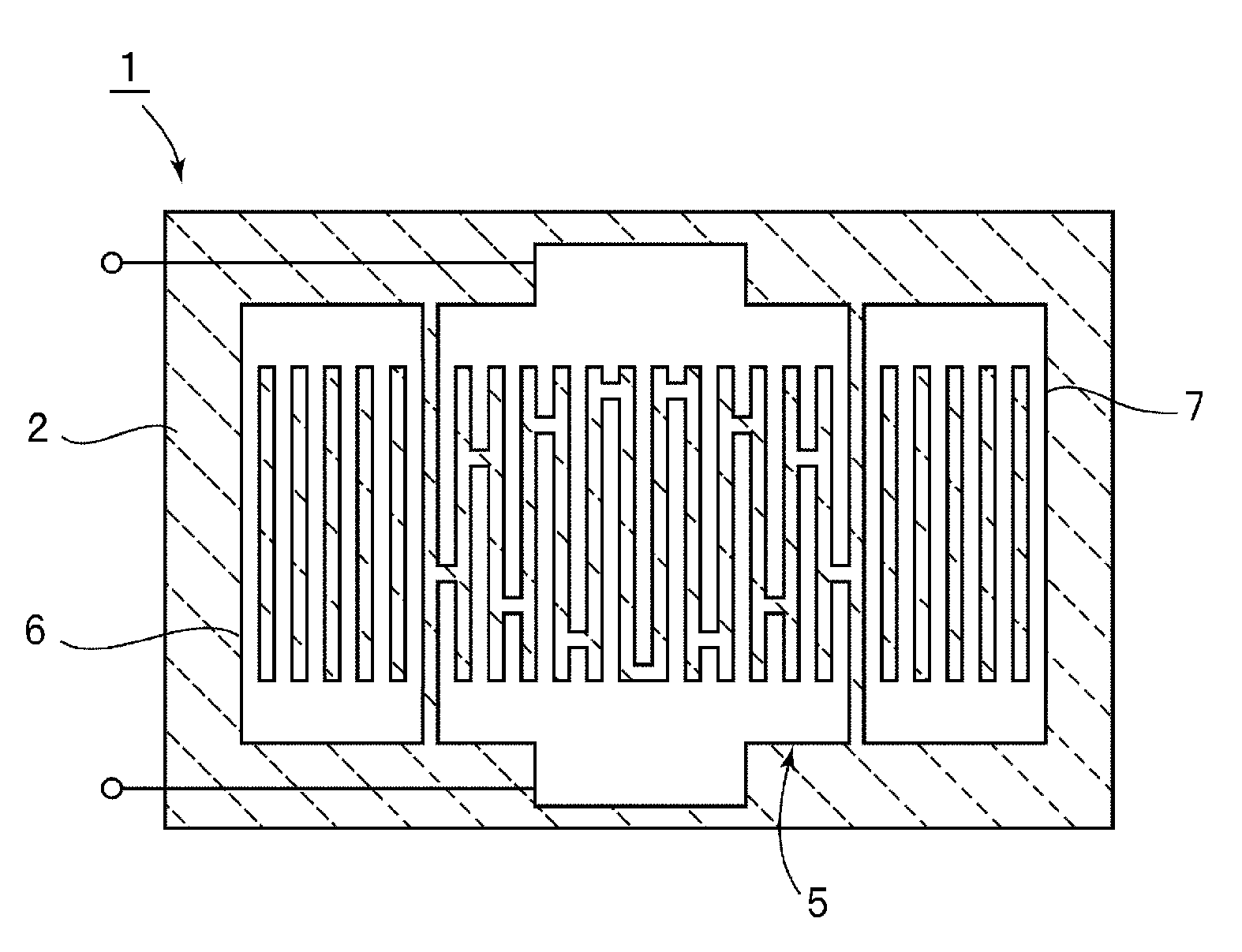

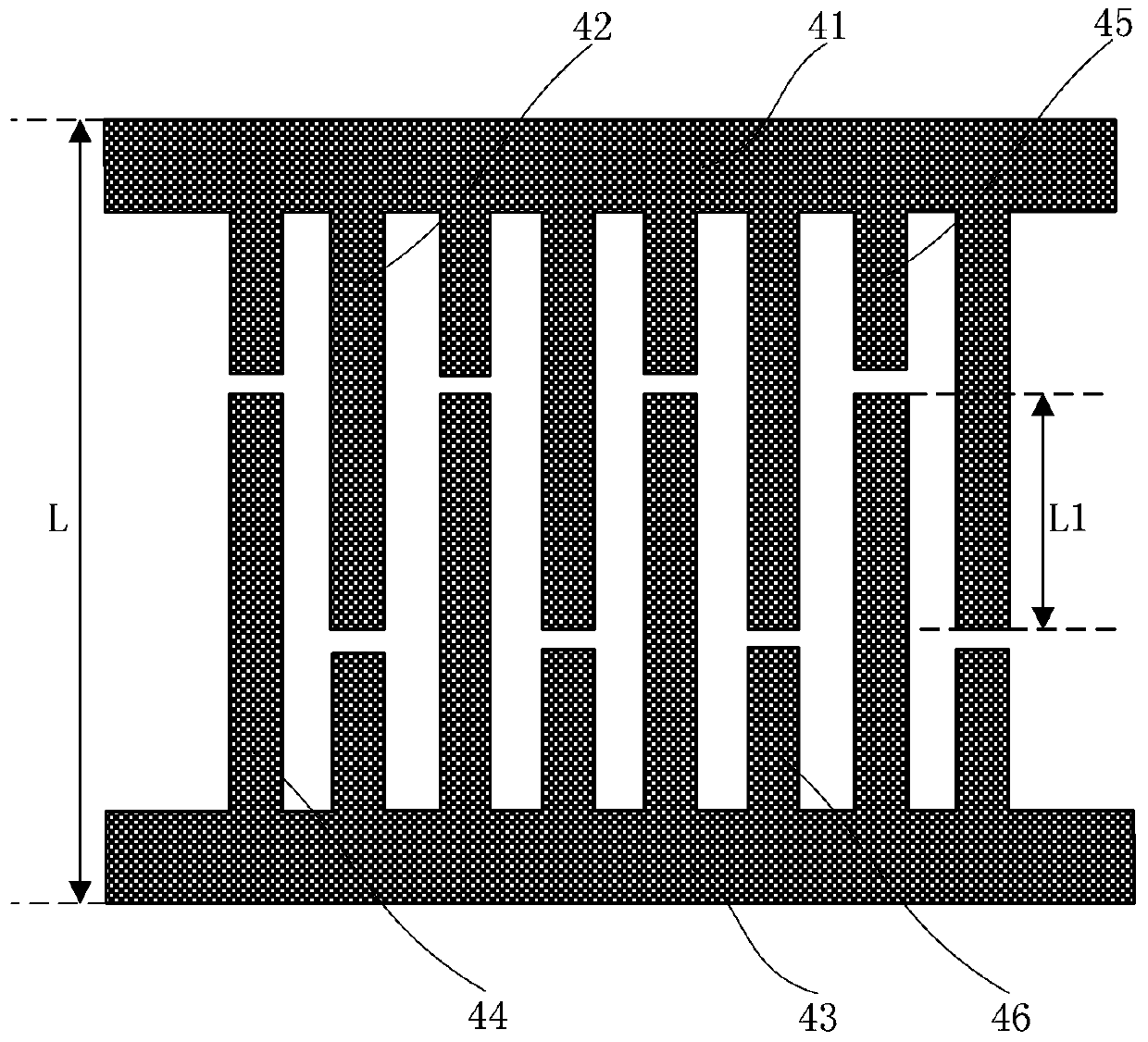

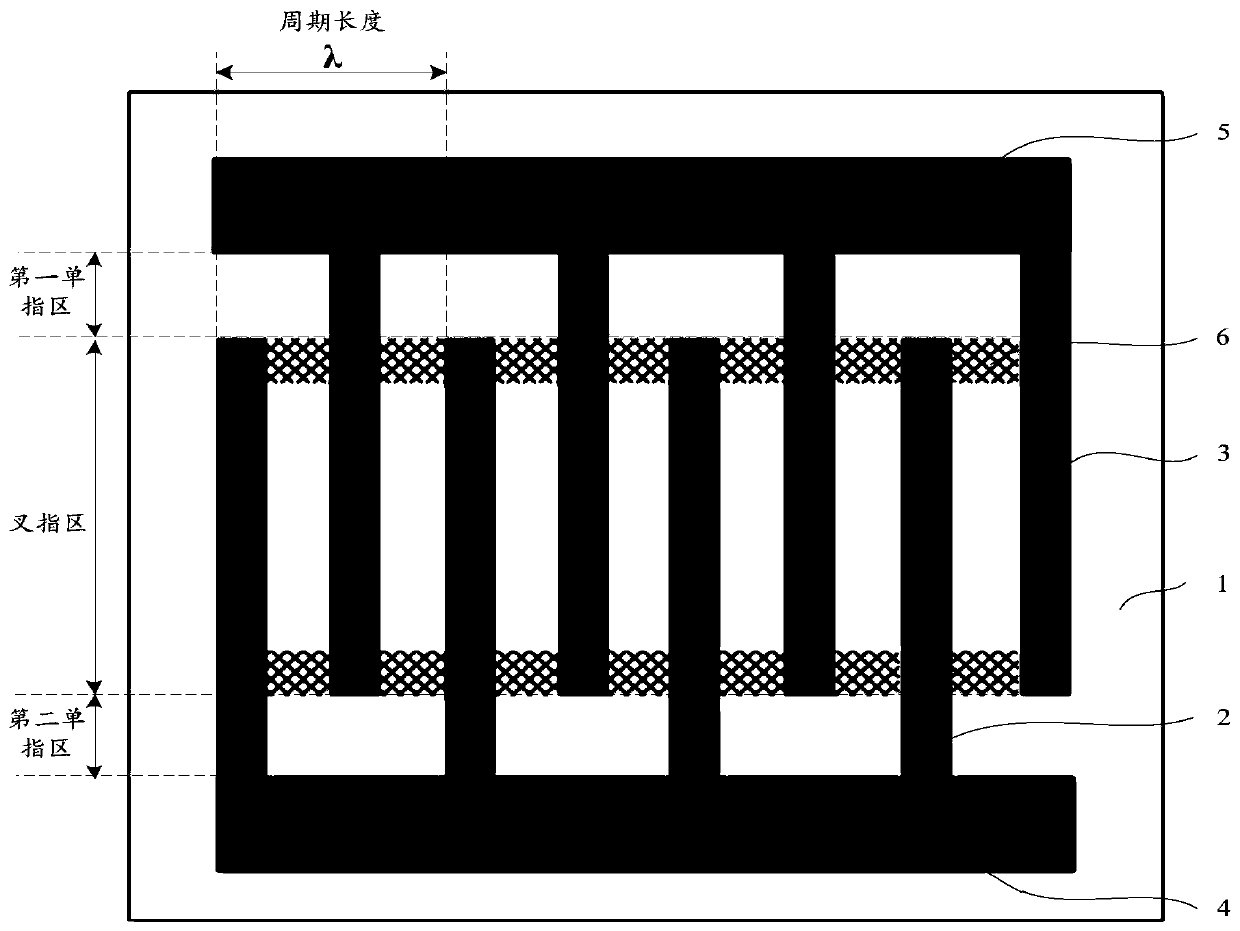

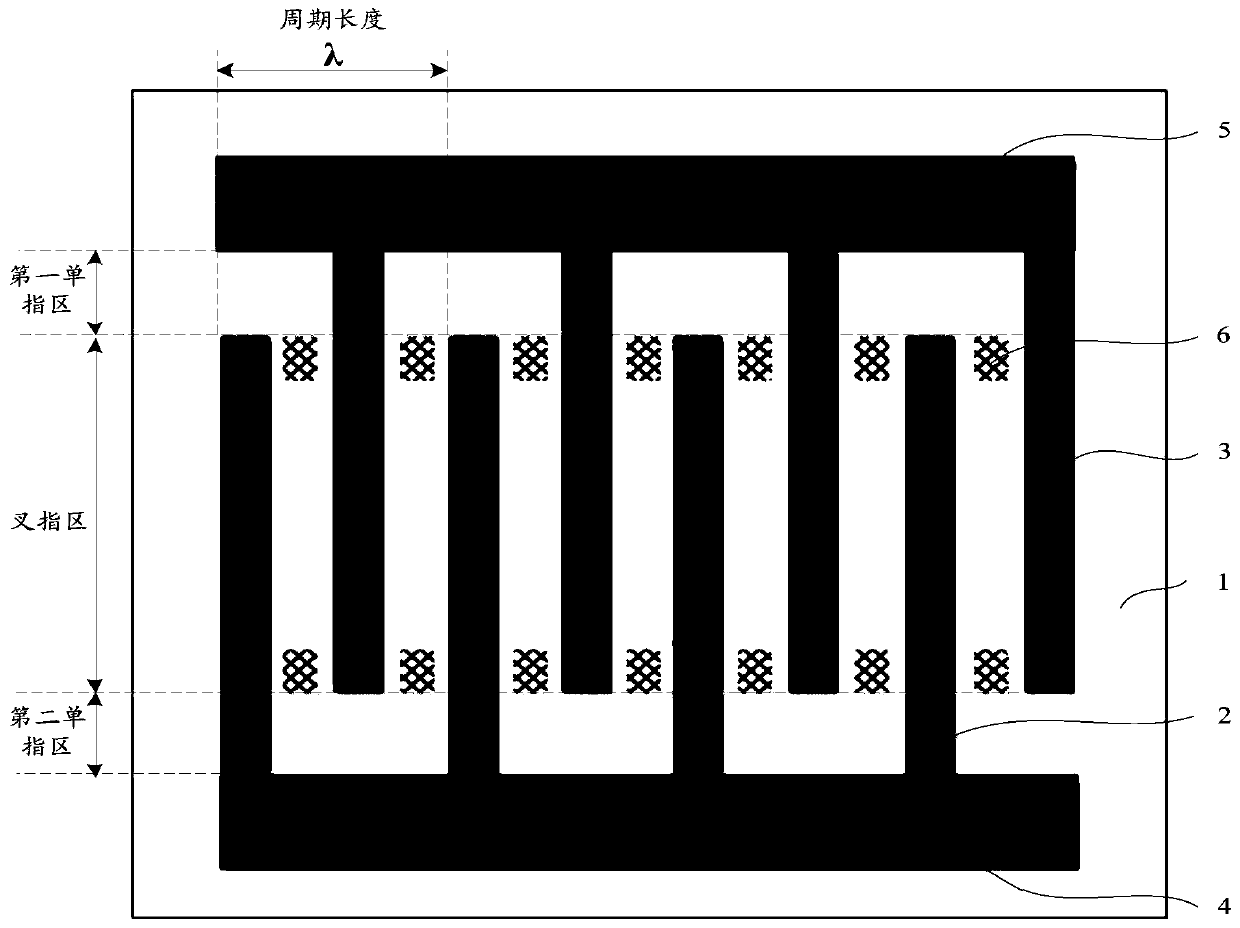

Surface acoustic wave transducer with transverse mode suppression function and preparation method thereof

ActiveCN111200417AReduce clutter responseIn-band fluctuation is smallImpedence networksEngineeringTransverse mode

The invention discloses a surface acoustic wave transducer with a transverse mode suppression function and a preparation method thereof. The invention relates to the field of surface acoustic wave devices and manufacturing thereof. The structure comprises a piezoelectric substrate and an interdigital transducer arranged on the piezoelectric substrate. The interdigital transducer comprises a firstinterdigital electrode, a second interdigital electrode, a first bus bar and a second bus bar, wherein the first interdigital electrode and the second interdigital electrode are crossed. According tothe structure of the interdigital transducer, the interdigital transducer is further divided into an interdigital region, a first single-finger region and a second single-finger region; grooves are formed in interdigital gaps between adjacent interdigital electrodes in the interdigital region, and the grooves are located in the interdigital regions at the junctions of the interdigital region and the edges of the first single-finger region and the second single-finger region respectively; by forming the grooves, the sound velocity of the edge of the interdigital region of the surface acoustic wave transducer is lower than that of the center of the interdigital region, and the sound velocity of the first single-finger region and the second single-finger region is higher than that of the center of the interdigital region, so that the transverse wave mode of sound waves can be effectively inhibited; clutter response is inhibited; and the performance of the surface acoustic wave transduceris greatly improved.

Owner:SHOULDER ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com