Method and system for detecting internal stress ultrasonic longitudinal wave of GIS basin type insulator epoxy test block

A basin-type insulation and detection method technology, applied in the field of detection, can solve problems such as inability to measure, workpiece damage, measurement of internal stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

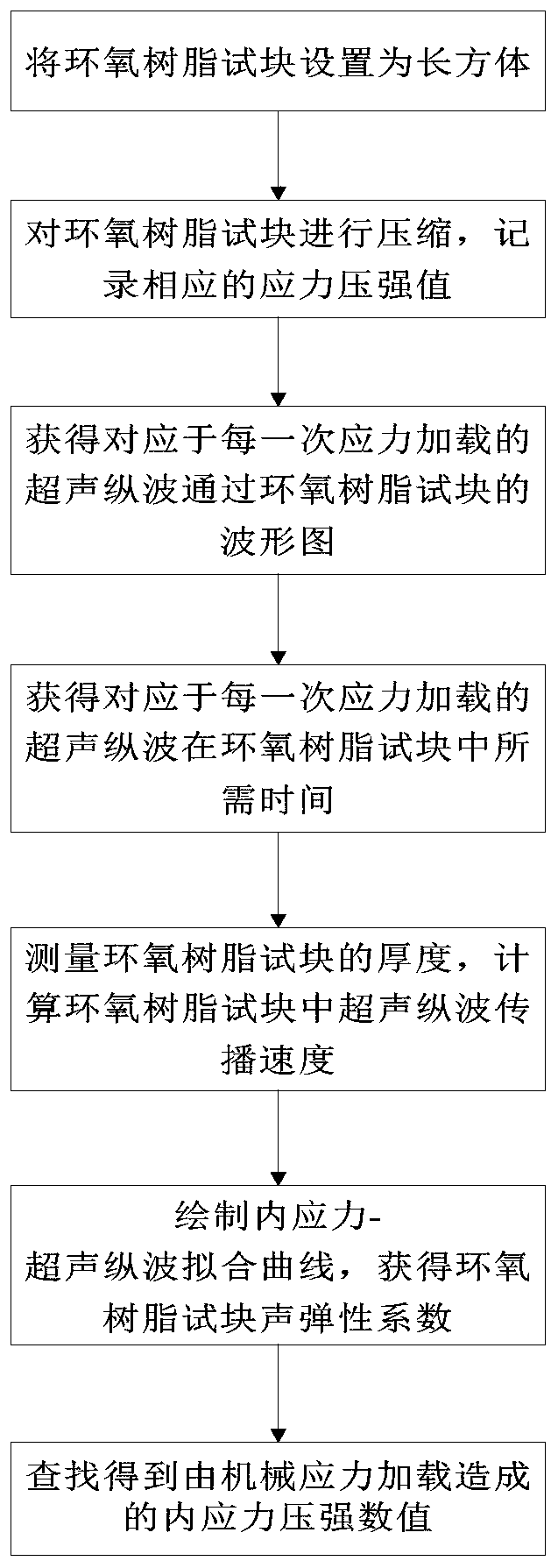

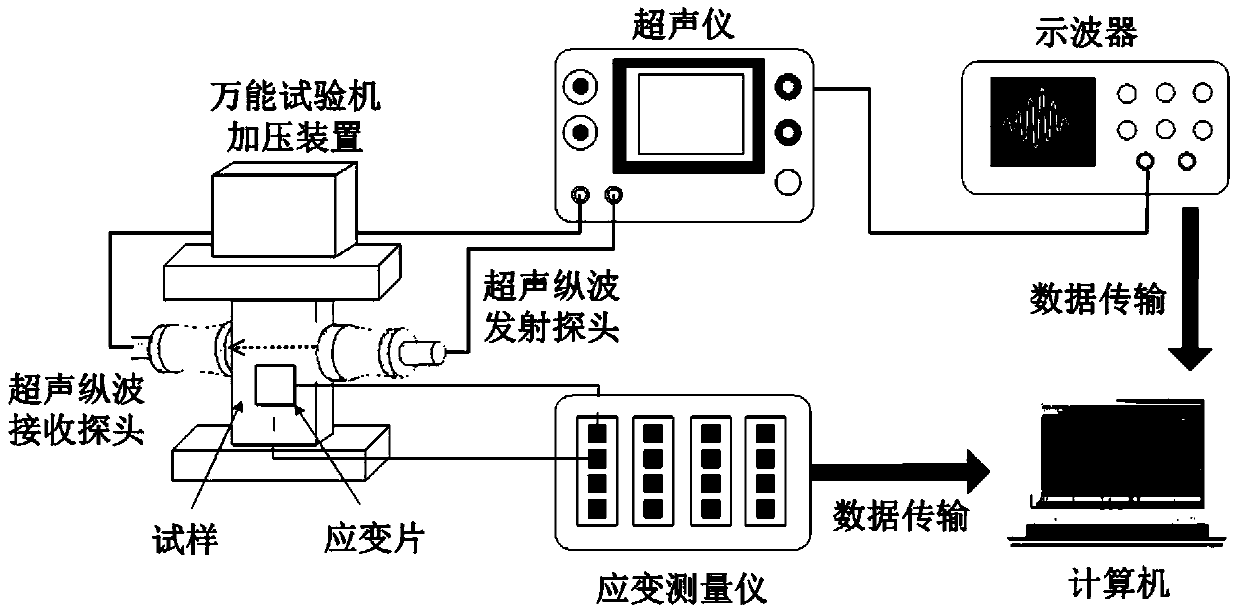

[0042] Such as figure 1 Shown is the flow chart of the ultrasonic longitudinal wave detection method for the internal stress of the epoxy test block, and the specific steps include:

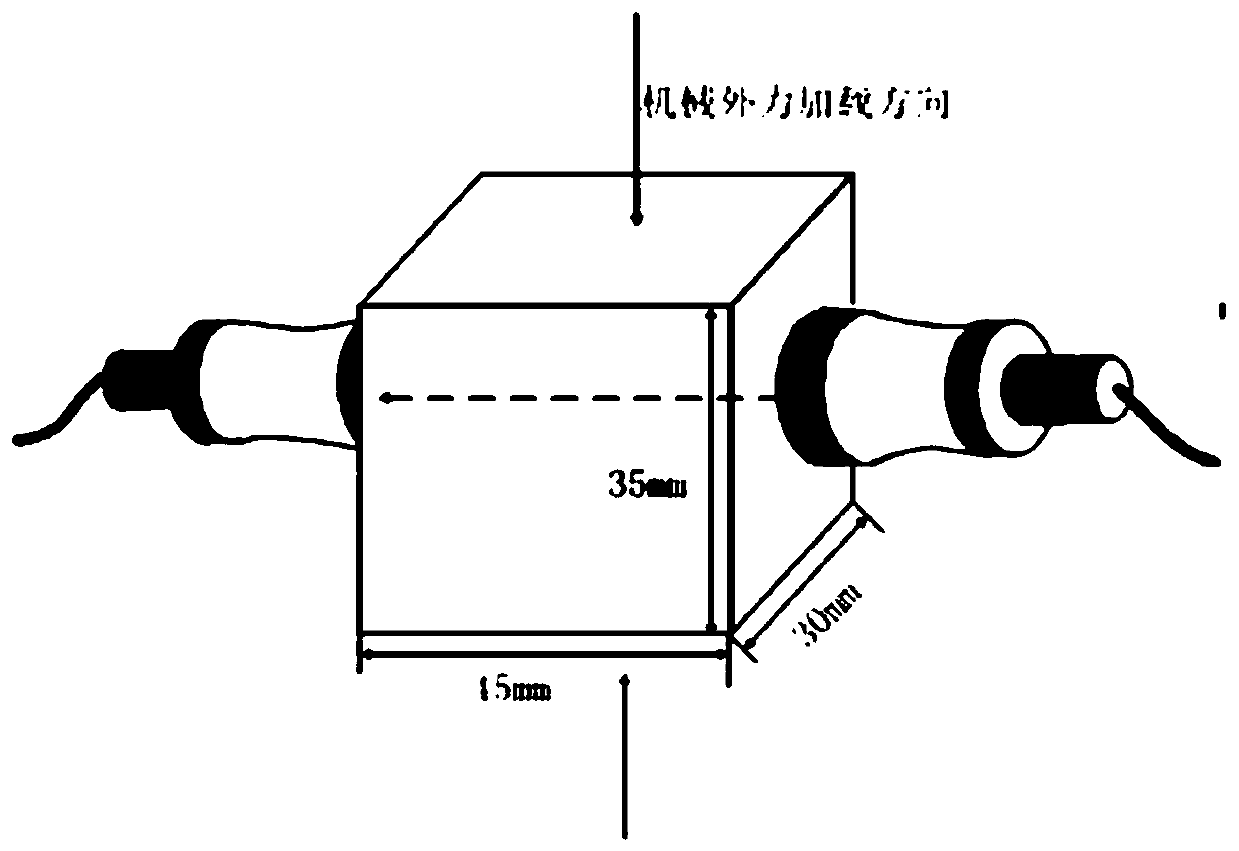

[0043] (1) The epoxy test block is set as a cuboid;

[0044] (2) Increase the pressure to compress the epoxy test block, and record the corresponding stress and pressure values;

[0045] (3) Obtain the waveform diagram of the ultrasonic longitudinal wave passing through the epoxy test block corresponding to each stress loading through the ultrasonic flaw detector;

[0046] (4) Calculate the acoustic time difference between the ultrasonic transmitting wave and the ultrasonic receiving wave according to the obtained waveform diagram, and obtain the time required for the ultrasonic longitudinal wave corresponding to each stress loading in the epoxy test block;

[0047] (5) Measure the ultrasonic sound path, and calculate the ultrasonic longitudinal wave propagation velocity in the epoxy test block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com