High-frequency acoustic wave resonator and preparation method thereof

A high-frequency acoustic wave and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of low resonance frequency, low electromechanical coupling coefficient, and temperature drift of acoustic wave resonators, so as to improve temperature stability and reduce temperature. Drift and reduce the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

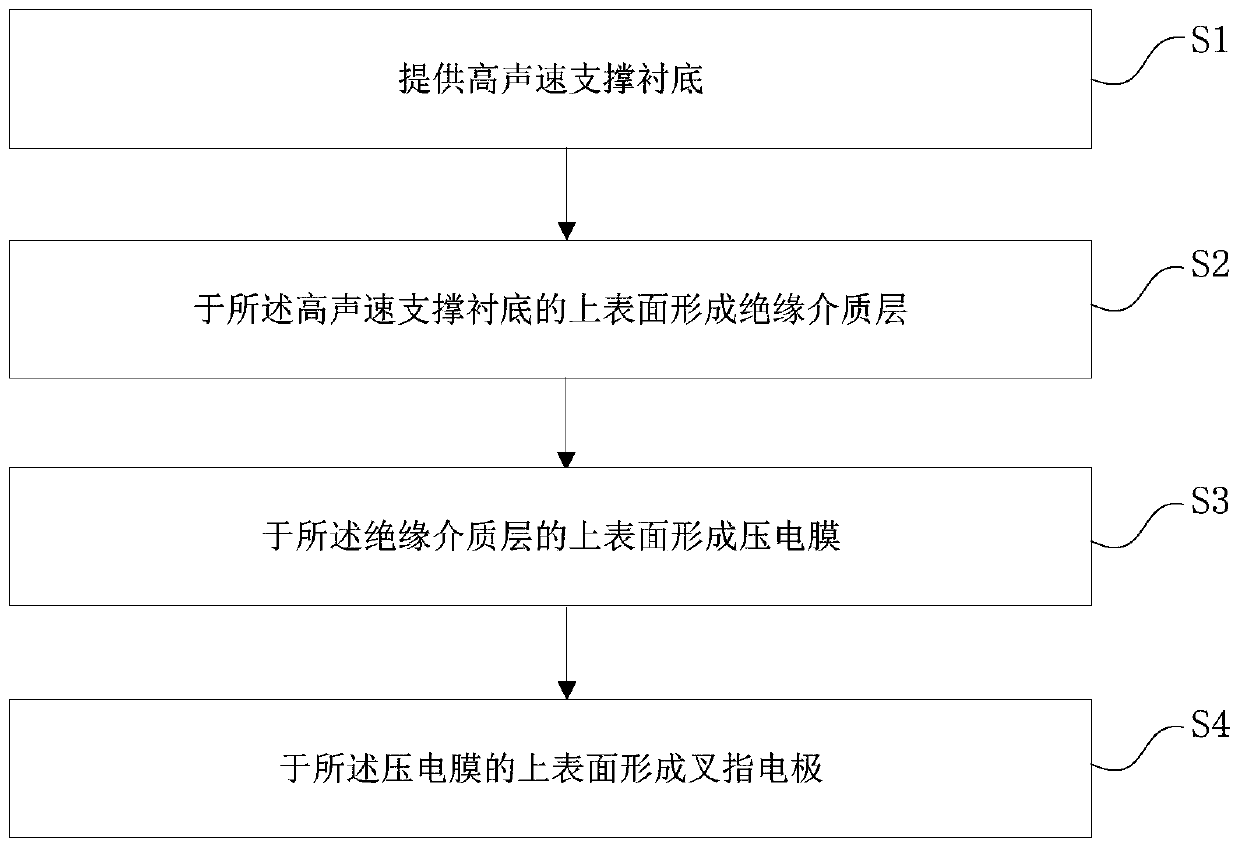

[0053] On the other hand, the embodiment of the present application discloses a method for preparing the above-mentioned high-frequency acoustic wave resonator, figure 2 It is a schematic flow chart of a method for preparing a high-frequency acoustic resonator according to an embodiment of the present application. The method includes the following steps:

[0054] S1: Obtain a high-sonic support substrate 1;

[0055] S2: Prepare and form an insulating dielectric layer 2 on the upper surface of the high-sonic support substrate 1; the formation method of the insulating dielectric layer includes a deposition method, an epitaxy method or a thermal oxidation method;

[0056] S3: Prepare and form the piezoelectric film 3 on the upper surface of the insulating medium layer 2; the forming method of the piezoelectric film 3 includes deposition method, epitaxy method, ion beam stripping method or bonding method.

[0057] S4: prepare and form the interdigital electrode 4 on the upper surf...

Embodiment 1

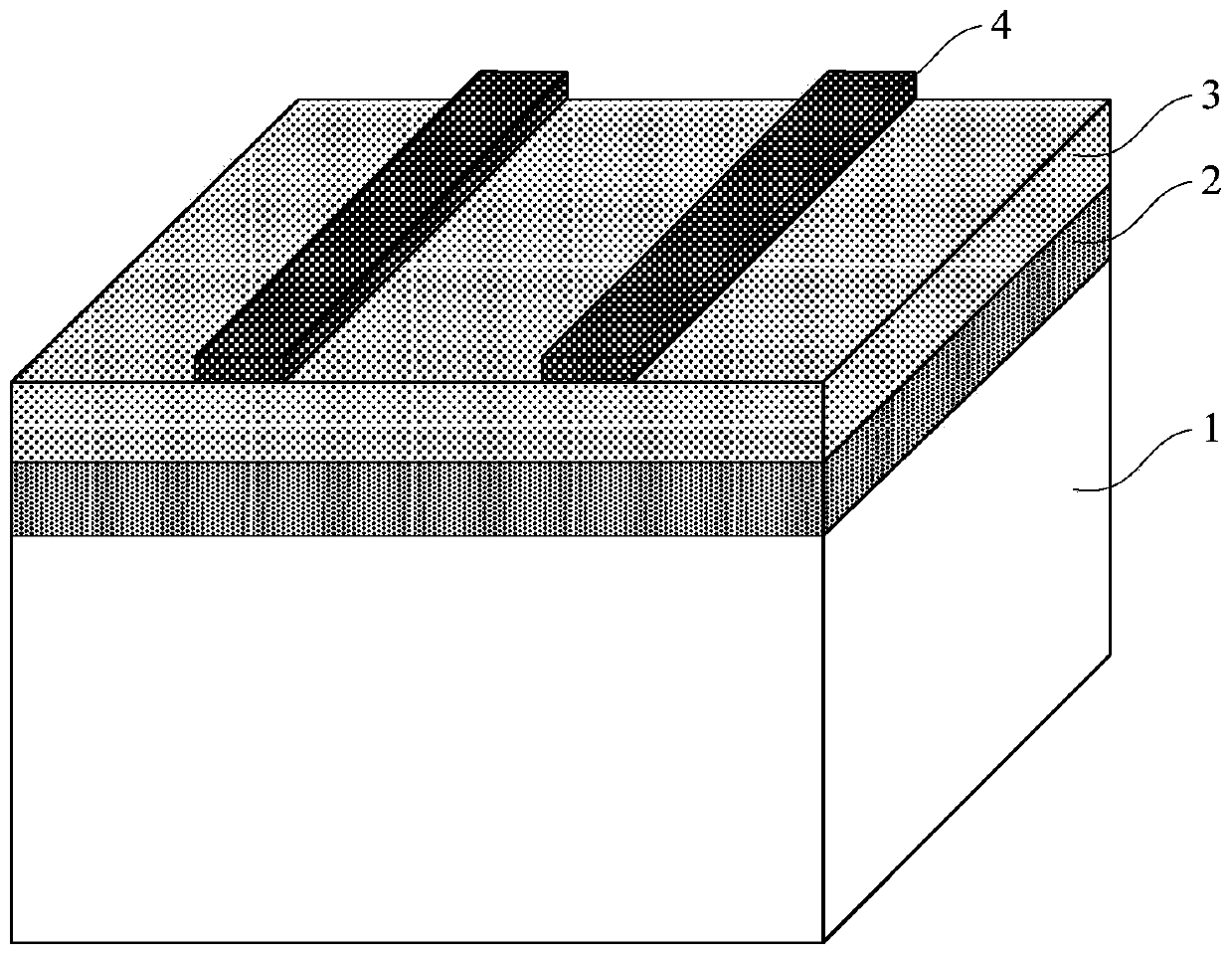

[0072] Embodiment 1 of the present application provides a high-frequency acoustic wave resonator on the one hand, including:

[0073] A high-sonic support substrate 1; the high-sonic support substrate 1 is a SiC substrate;

[0074] An insulating dielectric layer 2, the insulating dielectric layer 2 is located on the upper surface of the high-sonic supporting substrate 1; the insulating dielectric layer 2 is SiO 2 insulating dielectric layer;

[0075] Piezoelectric film 3, the piezoelectric film 3 is located on the upper surface of the insulating medium layer 2; the piezoelectric film 3 is LiNbO 3 single crystal thin film;

[0076] The interdigital electrodes 4 are located on the upper surface of the piezoelectric film 3 .

[0077] Embodiment 1 of the present application provides a method for preparing a high-frequency acoustic wave resonator on the other hand, comprising the following steps:

[0078] Obtain SiC high-sonic support substrate;

[0079] Preparation and format...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com