A plane capacitance resonator and its making method

A technology of resonators and capacitors, which is applied in the field of planar capacitor resonators and its preparation, can solve the problem of resonance loss limiting the Q value of flexible nanomechanical resonators, manufacturing process, manufacturing cost restrictions, wide application, and cantilever beam sensor mass detection sensitivity reduction etc. to achieve the effects of reducing equivalent motion impedance, improving detection sensitivity, and reducing parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

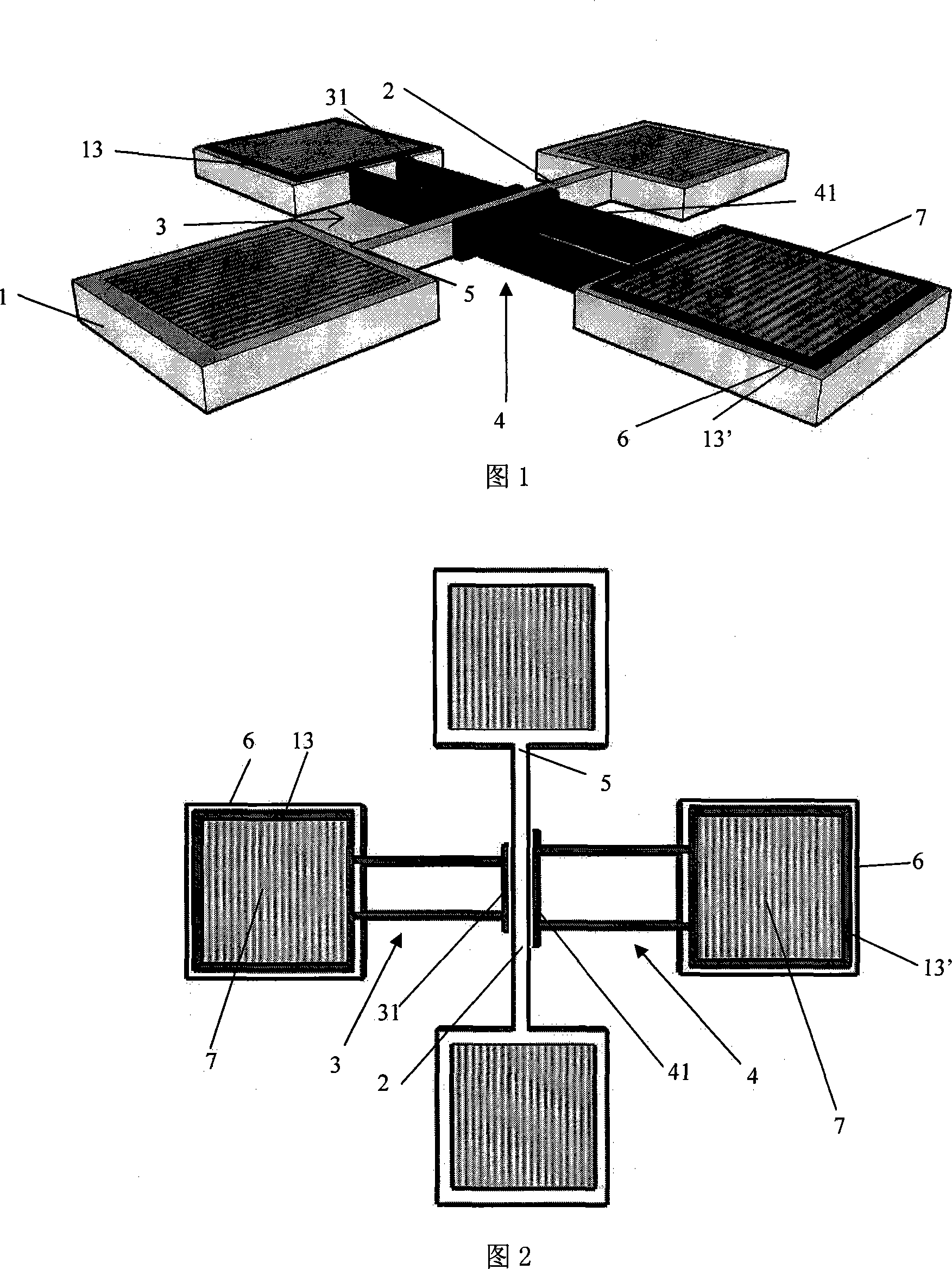

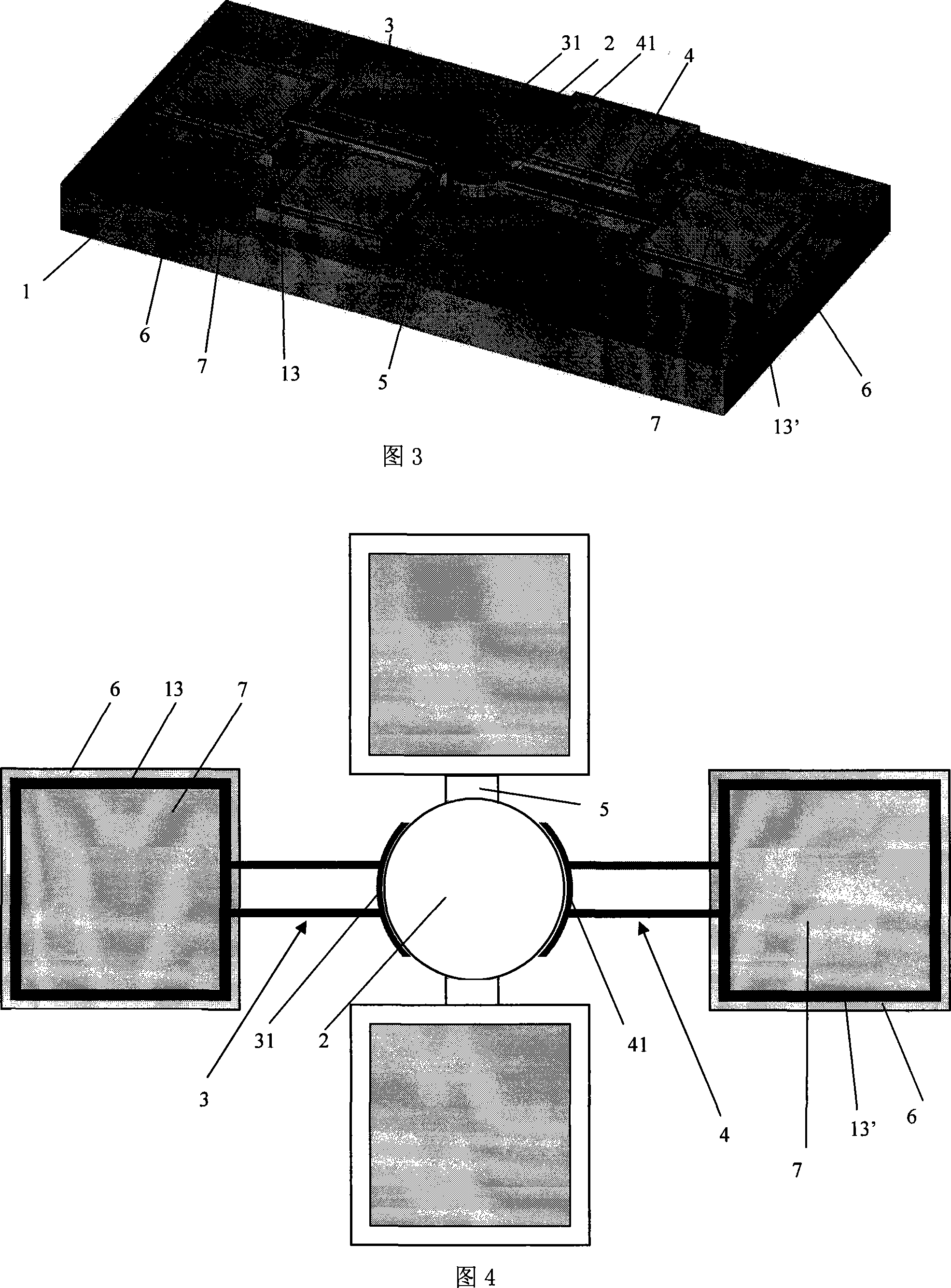

Embodiment 1

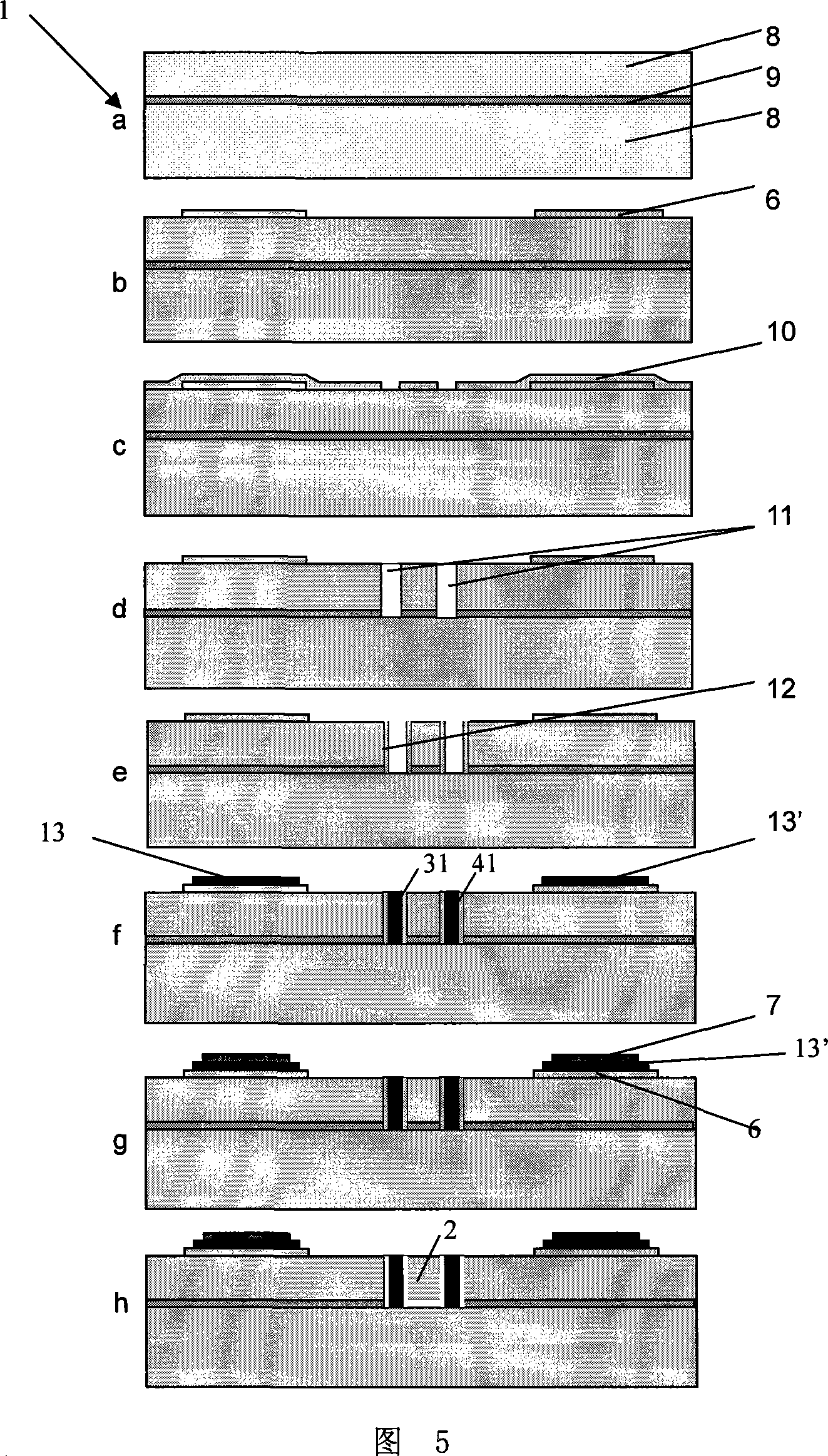

[0050] Fig. 5 is the preparation flowchart of the resonator of the present invention, and specific steps are as follows:

[0051] 1) Using SOI silicon wafer 1 as the processing substrate, the device layer 8 is N-type, (100) crystal plane, the thickness of the device layer 8 is 10 microns and 20 microns respectively, and the thickness of the middle buried oxide layer 9 is 3 microns (Fig. 5a );

[0052] 2) On the surface of SOI silicon wafer 1 device layer 8, LPCVD (low pressure chemical vapor deposition) a layer of SiNx with a thickness of 150nm, use photoresist for the first photolithography, and dry in a reactive ion etching system (RIE) SiNx is etched by method to form a SiNx insulating layer 6, and the SiNx insulating layer 6 is used to isolate the polysilicon pad 13 from the substrate 1 (FIG. 5b);

[0053] 3) The second photolithography, patterning the positions of the pole plates 31, 41 and the resonator 2 of the driving electrode 3 and the sensing electrode 4, and using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com