Method for manufacturing substrate

A manufacturing method and substrate technology, applied in the field of substrate manufacturing, can solve problems such as large thickness of components, and achieve the effects of reducing manufacturing cost, reducing thickness, and reducing unnecessary parasitic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

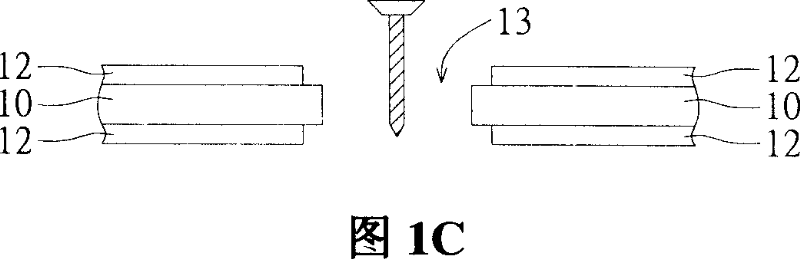

[0024] Then, an element (for example, a passive element such as a capacitor, an inductor, or a resistor) 14 is buried in the accommodating space 13, and an insulating part (ie, the first insulating layer 15 and the second insulating layer 16 mentioned later) is formed. The components 14 , the core board 10 , and the inner circuit 12 on the upper and lower sides of the core board 10 are covered. One of the possible implementation methods is as follows:

[0025] Firstly, the element 14 is arranged under the core board 10, so that the accommodating space 13 corresponds to the position of the element 14, and a first insulating layer 15 is provided under the element 14, and a second insulating layer is provided above the core board 10 16, as shown in Fig. 1D. Generally, materials that have not yet fully hardened (still have some fluidity) can be used as the first insulating layer 15 and the second insulating layer 16, so that the element 14 can be completely covered by the core bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com