Patents

Literature

303results about How to "Reduce solder joints" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

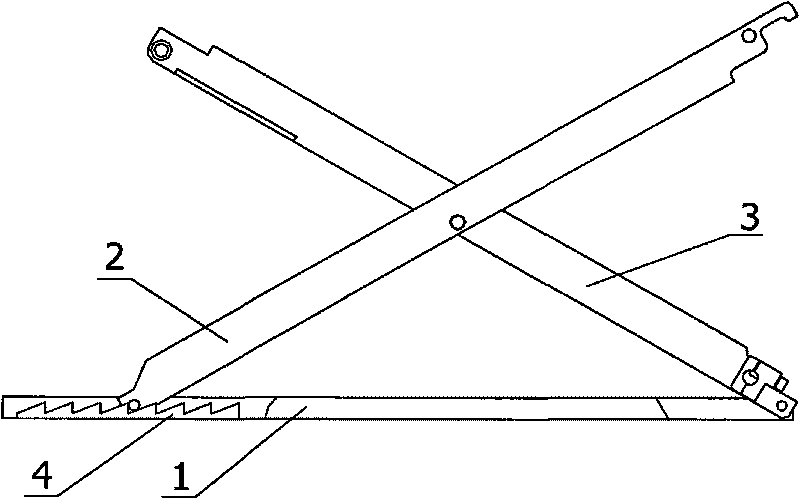

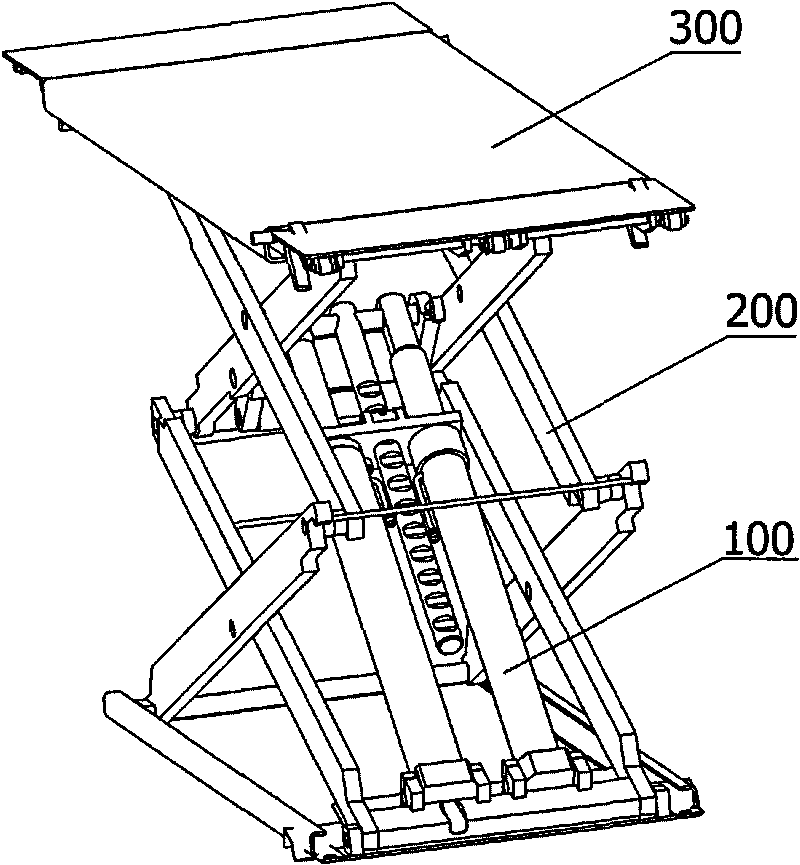

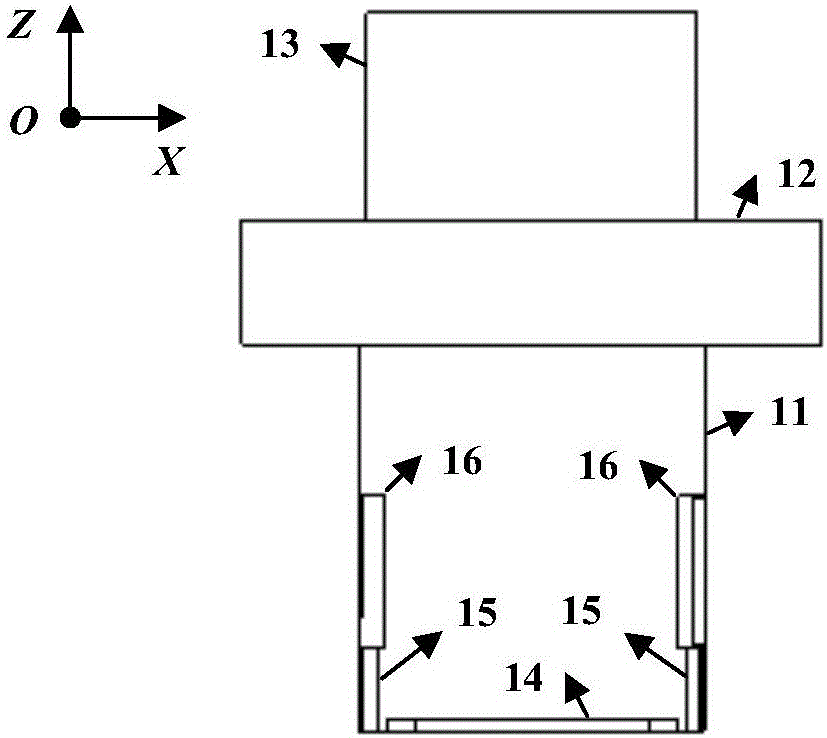

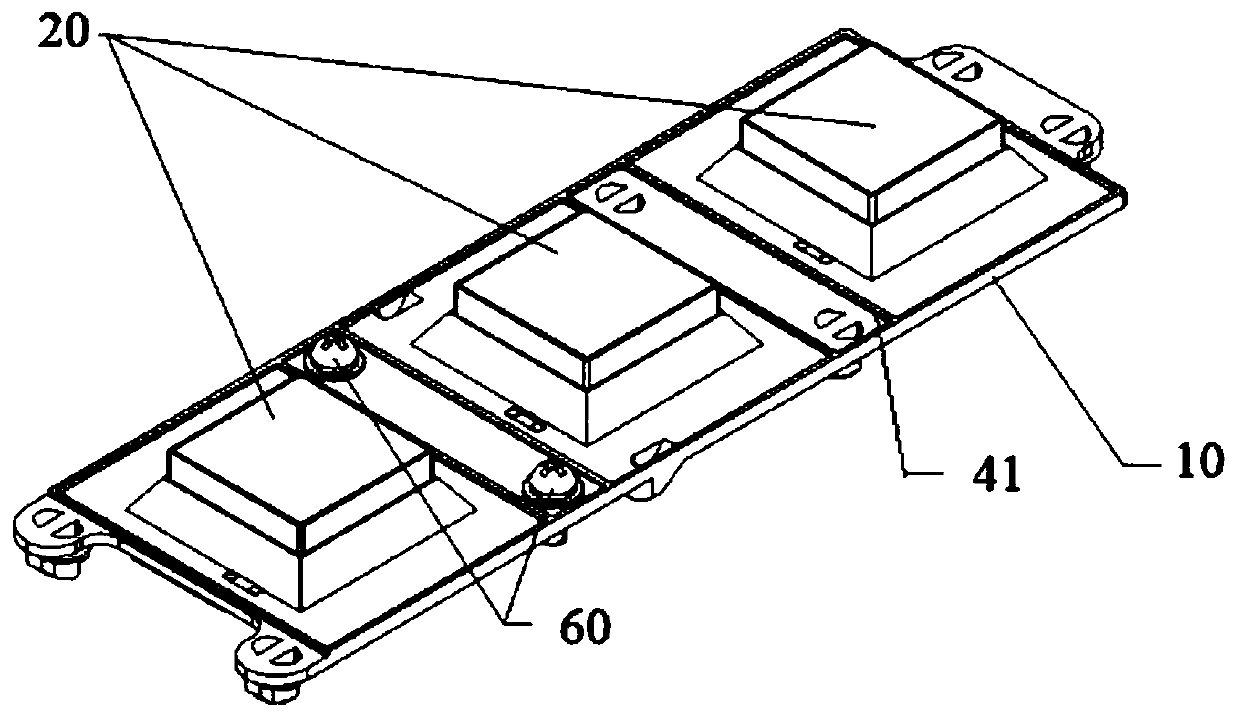

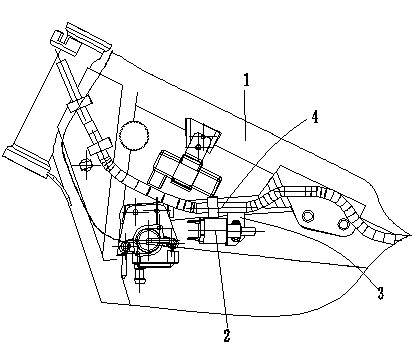

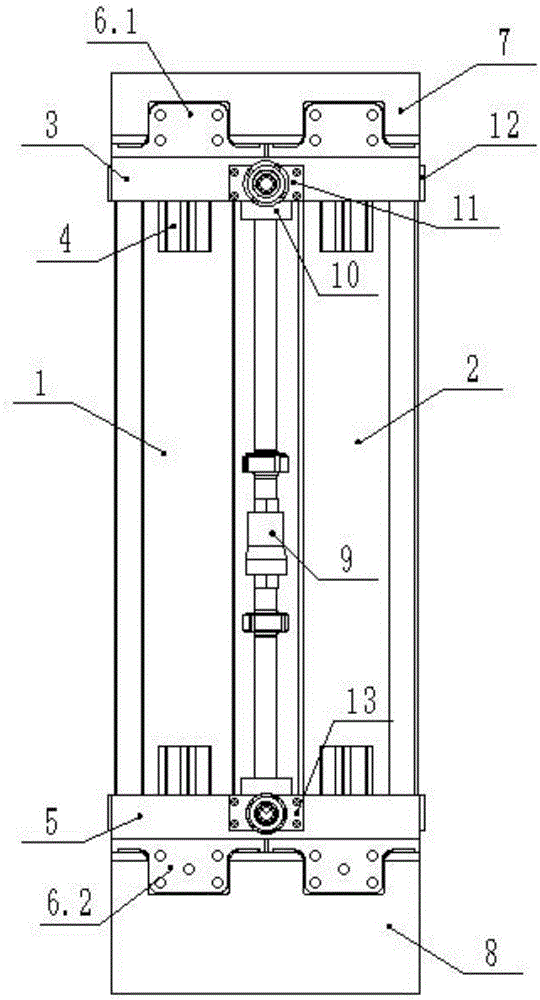

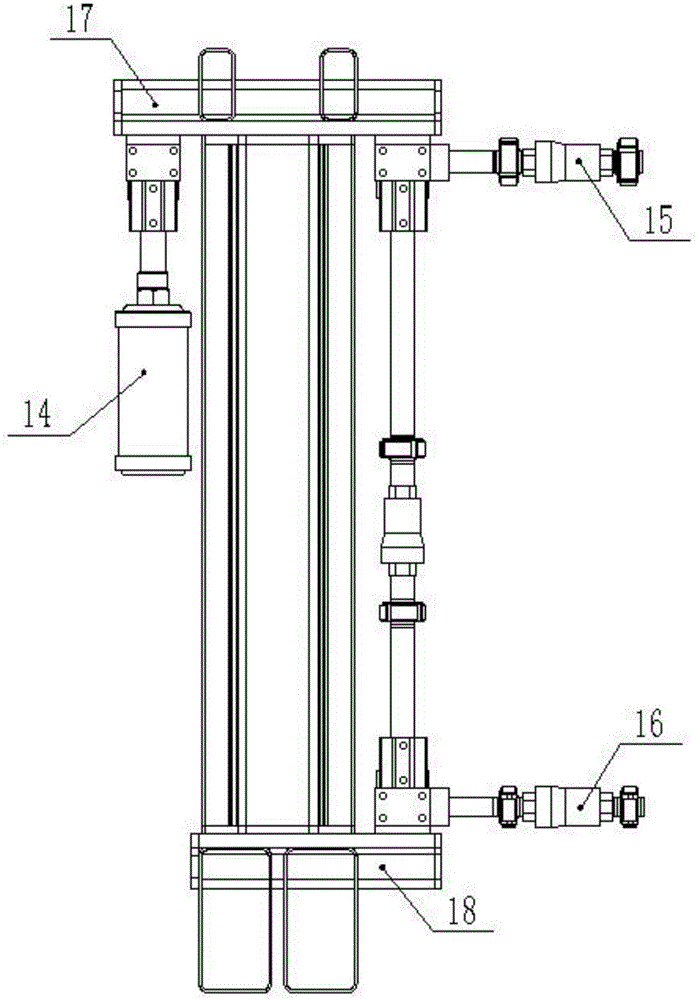

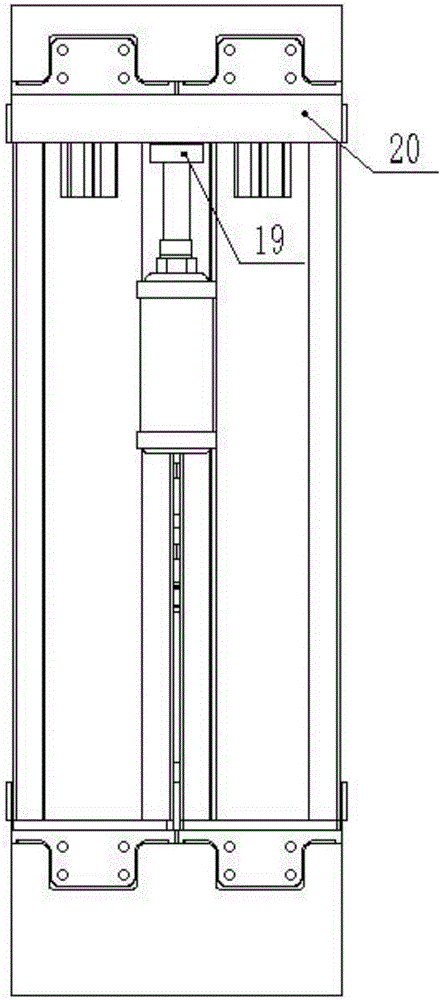

Scissor type lift and lifting device thereof

InactiveCN101734574AReduce height differenceReduce solder jointsLifting framesEngineeringHeight difference

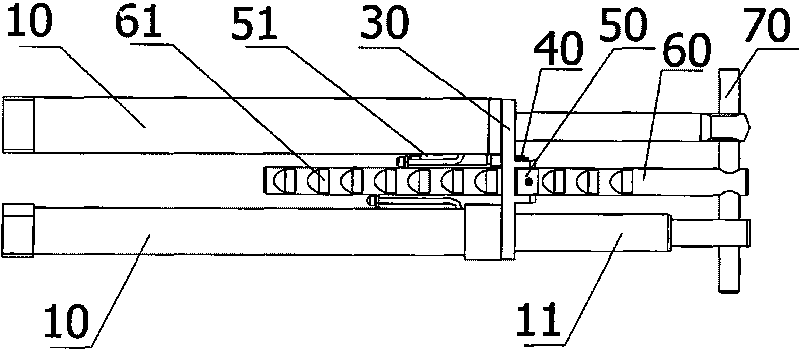

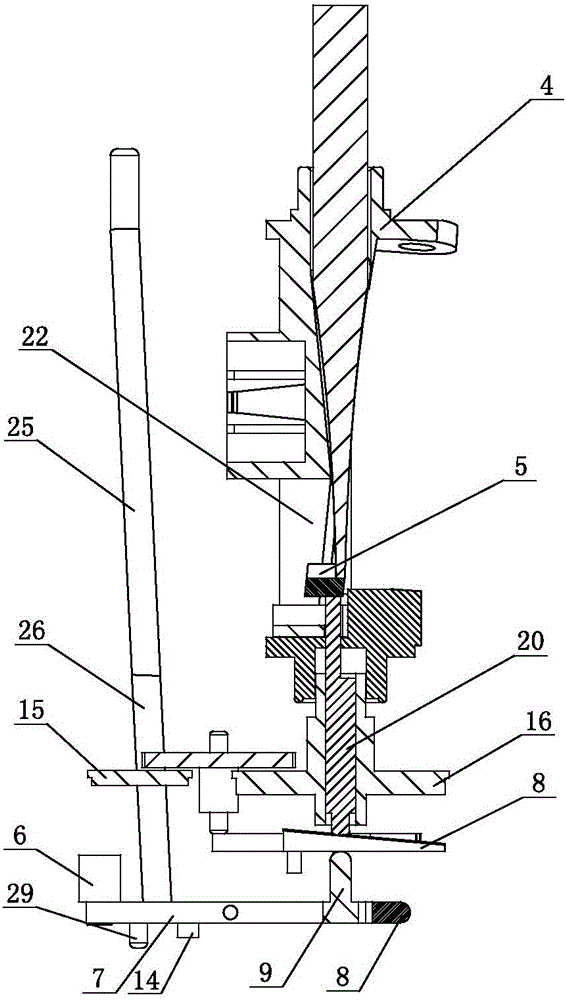

The invention discloses a scissor type lift and a lifting device thereof. The lifting device comprises a protective supporting plate, a lock, a bumper, a head shaft and at least two parallel engine-driven telescopic devices, wherein each engine-driven telescopic device comprises a telescopic rod at one end thereof respectively; the head shaft is pivoted with tail ends of telescopic rods of the at least two parallel engine-driven telescopic devices respectively; the two ends of the protective supporting plate are fixed to the at least two parallel engine-driven telescopic devices respectively; the lock is arranged on the protective supporting plate between the two engine-driven telescopic devices; one end of the bumper is pivoted with the head shaft; the rod is close to the lock and is provided with a plurality of notches distributed along the axial direction; and the notches and the lock forms a self-locked structure locked in one way. The scissor type lift and the lifting device thereof of the invention can ensure the safety of the lifting operation, reduce the height difference between two platforms of the scissor type lift and meet the standard requirement.

Owner:LAUNCH TECH CO LTD

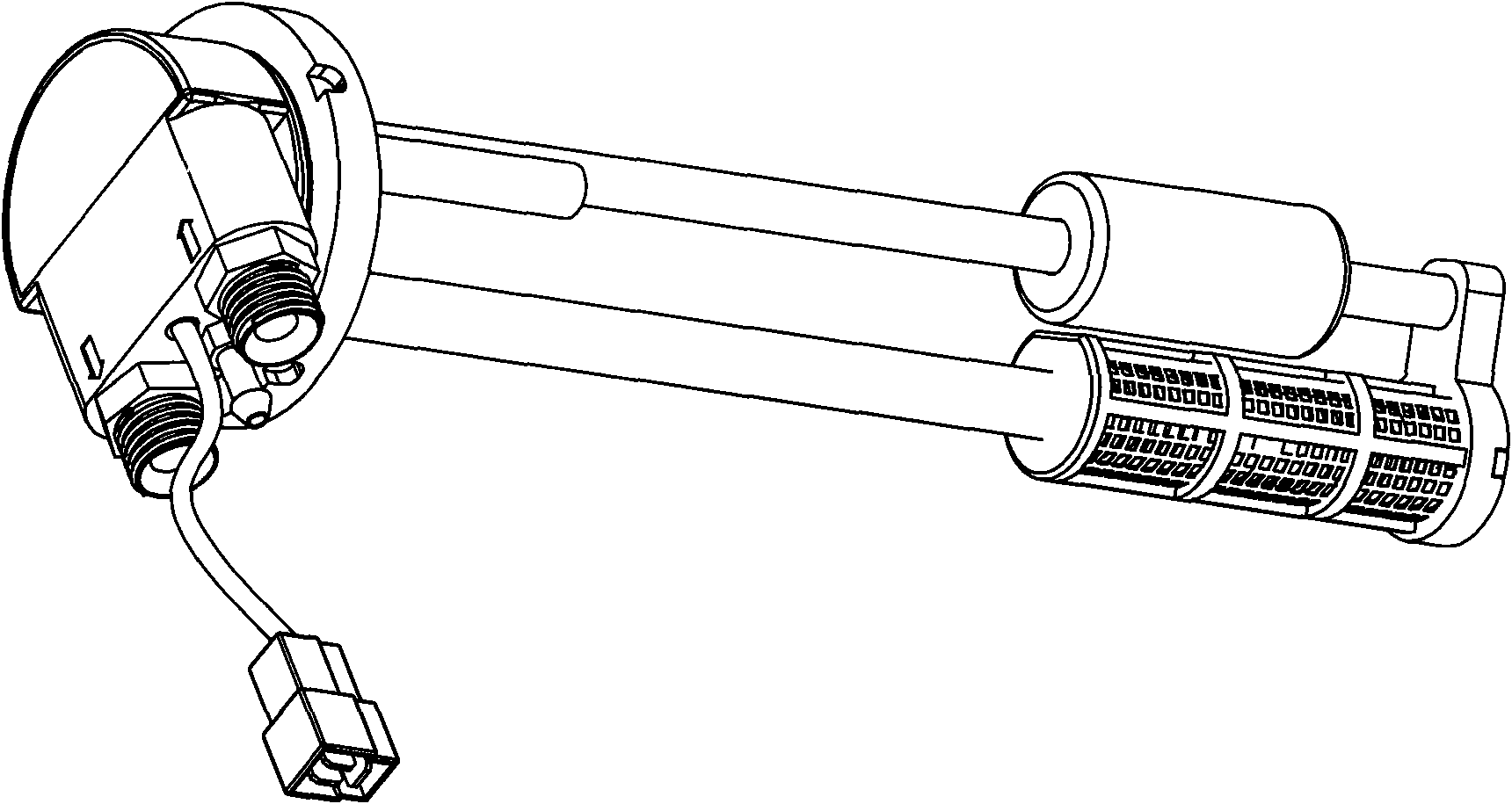

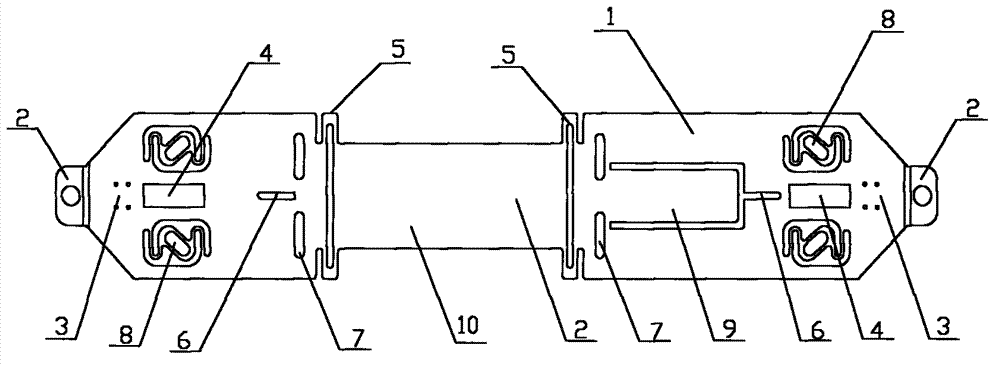

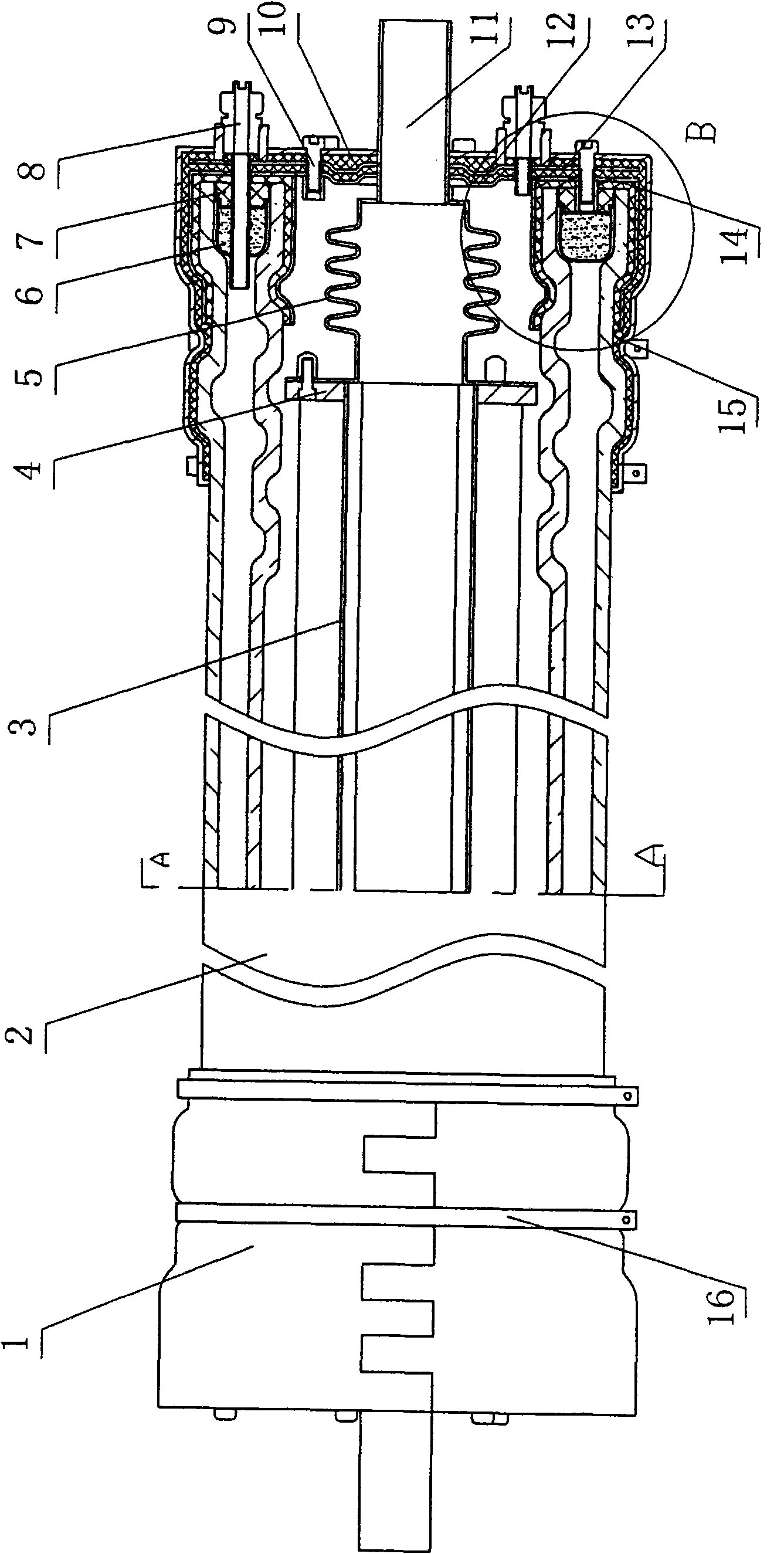

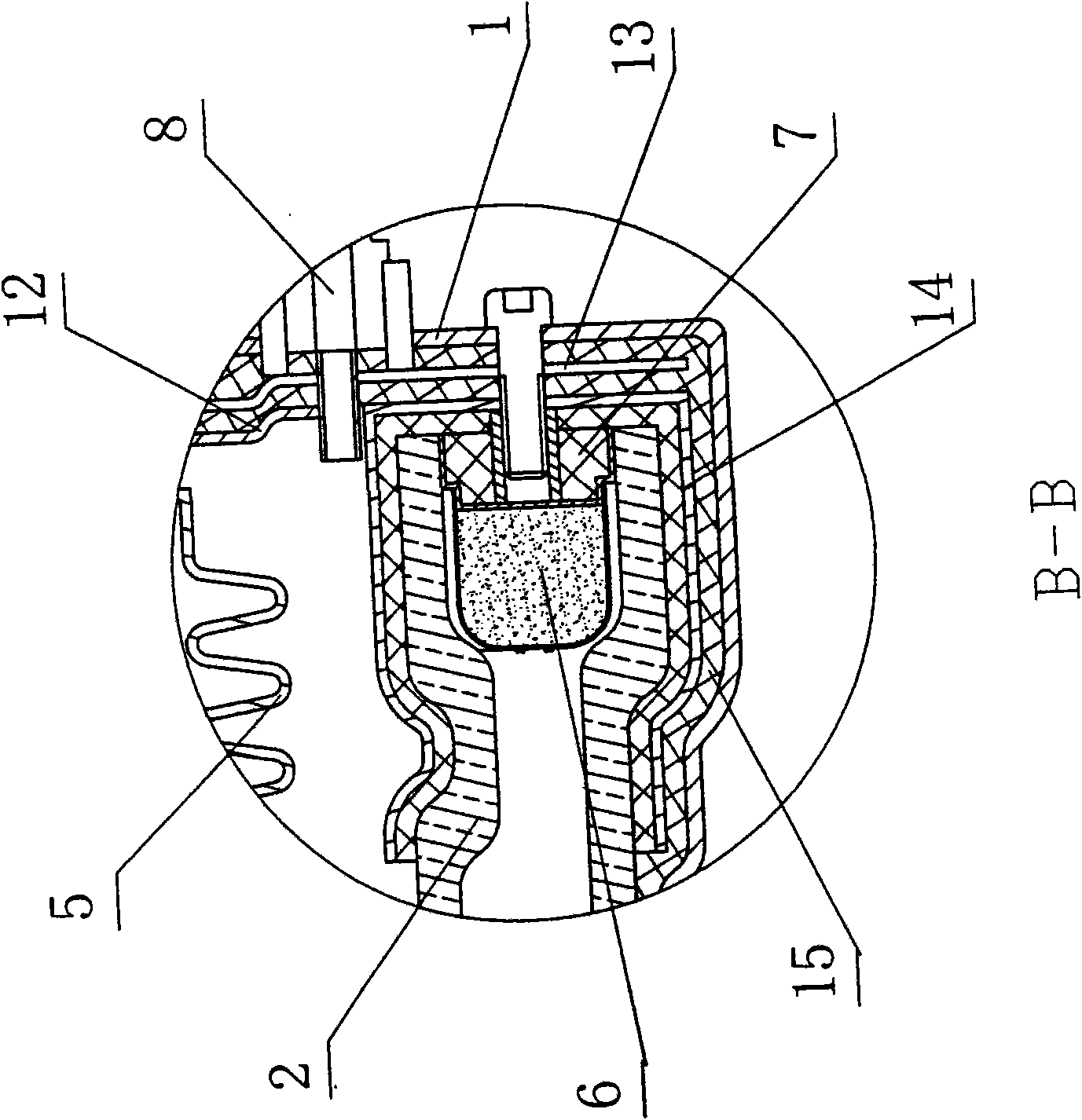

Fiber Bragg grating strain sensor

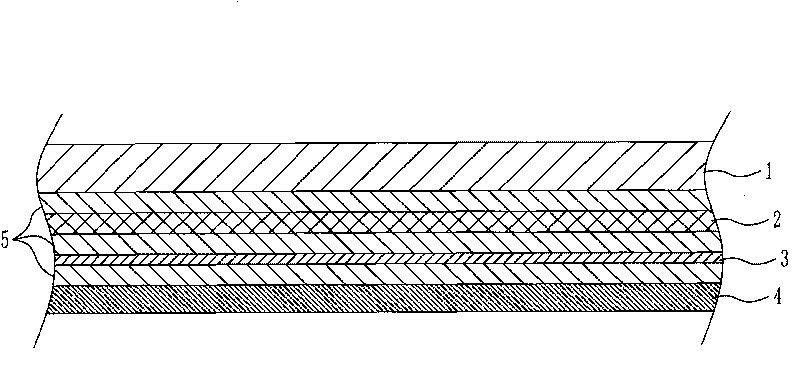

InactiveCN102865827AExtended service lifeFree from external corrosionUsing optical meansFiberGrating

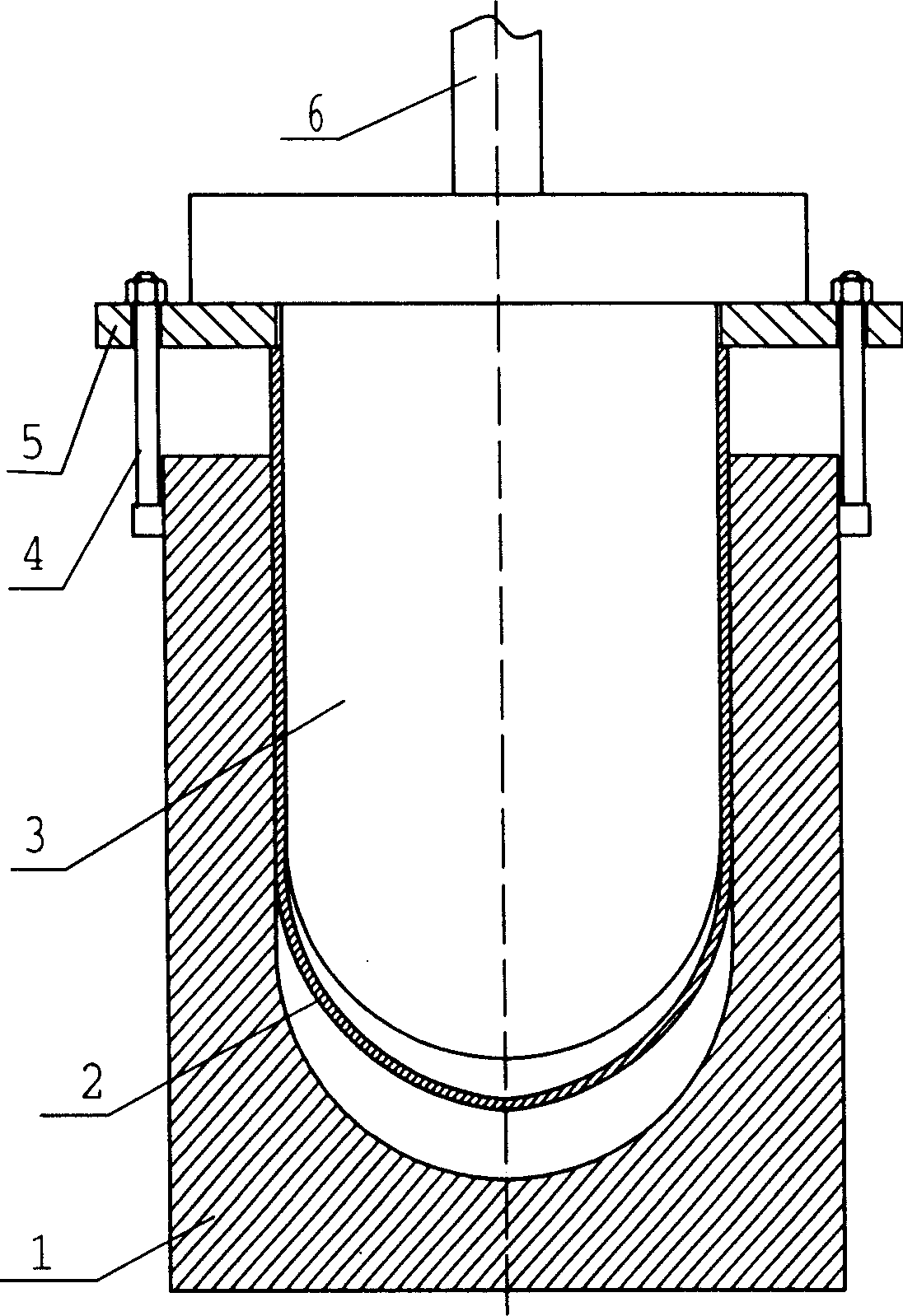

The invention relates to a fiber Bragg grating strain sensor which comprises an elastic structure, an optical fiber grating, protective sleeves, sealing rings, fixed structures and sealing joints. The elastic structure comprises an elastic area with alternately spaced cavities, metal sheets and thread screws. The elastic area, the metal sheets and the thread screws are in an integral structure. The cavities forming the elastic area are vertical to the central axis of a cylinder, pass over the central axis of the cylinder and are distributed on the elastic structure in a staggered arrangement manner. Both ends of the elastic structure are in threaded connection with the fixed structures. The metal sheets are arranged in the fixed structures. The other ends of the fixed structures are in threaded connection with one ends of the sealing joints for fixing armored jackets. Both ends of the fiber Bragg grating passing through the central axis of the elastic structure are fixedly arranged on protruding metal sheets at both ends of the elastic structure by glass solder. The sealing rings arranged at the inner side of the thread screws of the fixed structures and the protective sleeves seal the elastic area. When the sensor is buried, the fixed structure is a flange structure. The fiber Bragg grating strain sensor provided by the invention has the advantages of large measuring range and simpleness in installation.

Owner:杭州珏光物联网科技有限公司

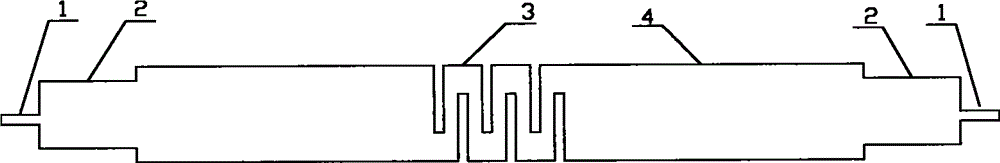

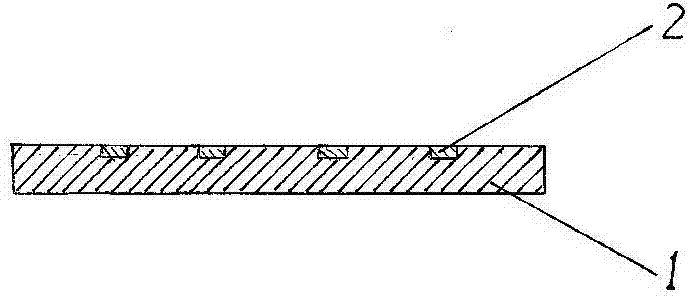

Flat circuit board and manufacturing method thereof

InactiveCN103945644AConductiveMeet the technical requirements of surface sliding contact conductionPrinted circuit secondary treatmentConductive material chemical/electrolytical removalEngineeringMechanical engineering

The invention relates to a flat circuit board and a manufacturing process thereof. A conductive circuit graph strip is arranged on an insulation base board of the flat circuit board, the circuit graph strip is embedded in the upper surface of the insulation base board, and the outer surface of the circuit graph strip and the upper surface of the insulation base board are located on the same plane. The flat circuit board has the advantages of being high in reliability and good in smoothness. After the circuit graph strip is embedded in the insulation base board, circuit external damage is avoided, the strip is broken only when physical damage is caused to the base board, conductivity reliability is high, and the technical requirement for surface sliding contact communication is met. The flat circuit board is especially applicable to precision operation with the strict environment requirement in the fields of aerospace, aviation, military and medical treatment.

Owner:邢台市海纳电子科技有限责任公司

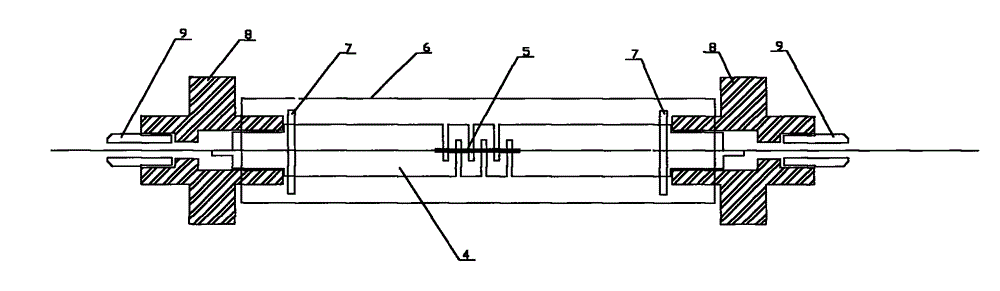

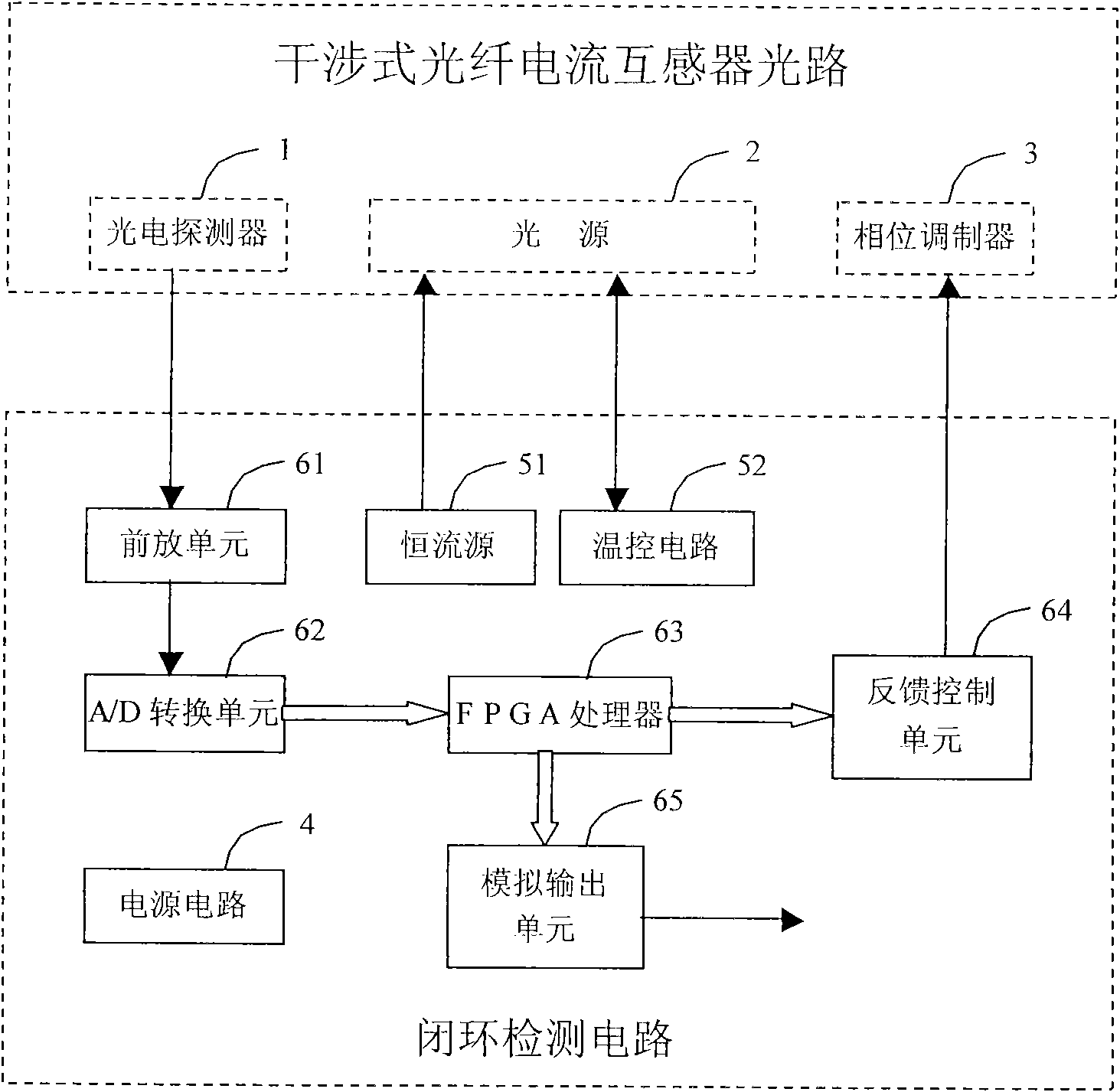

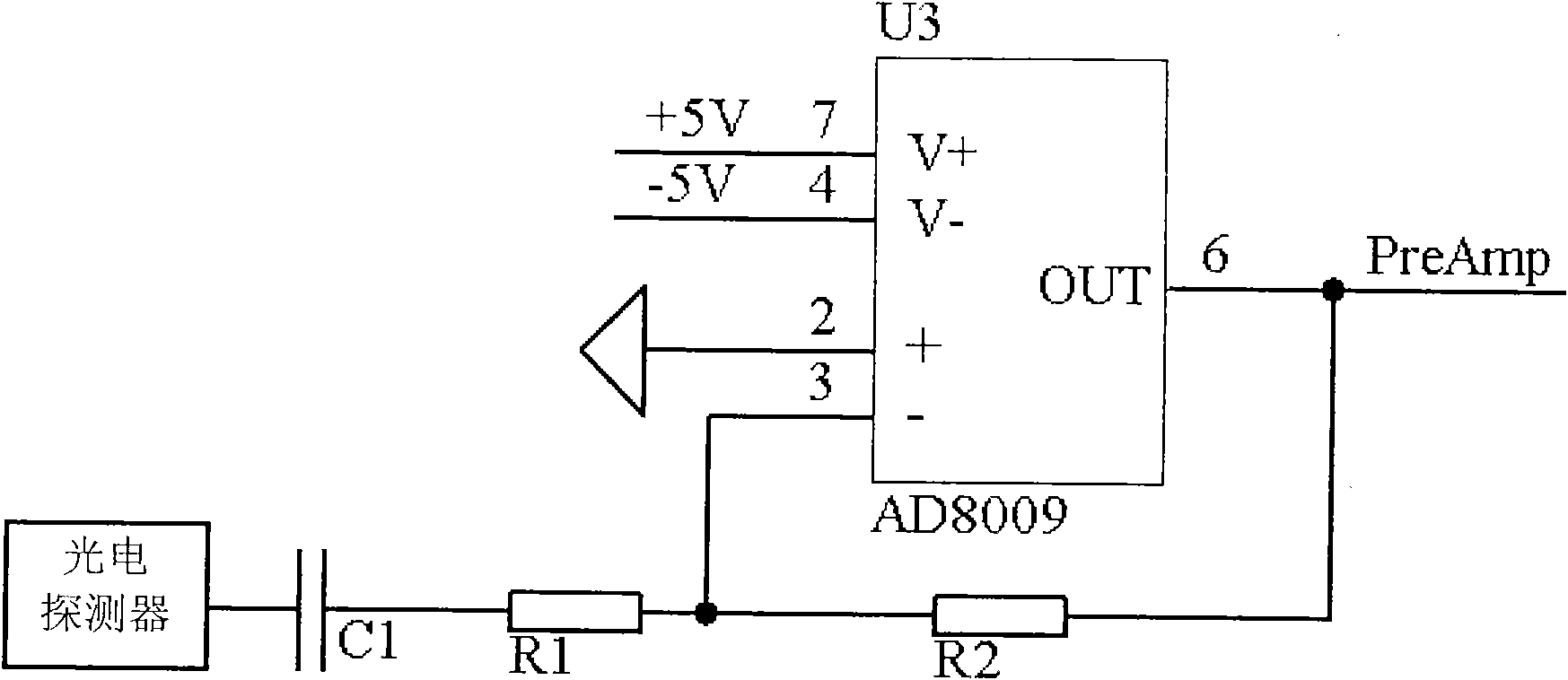

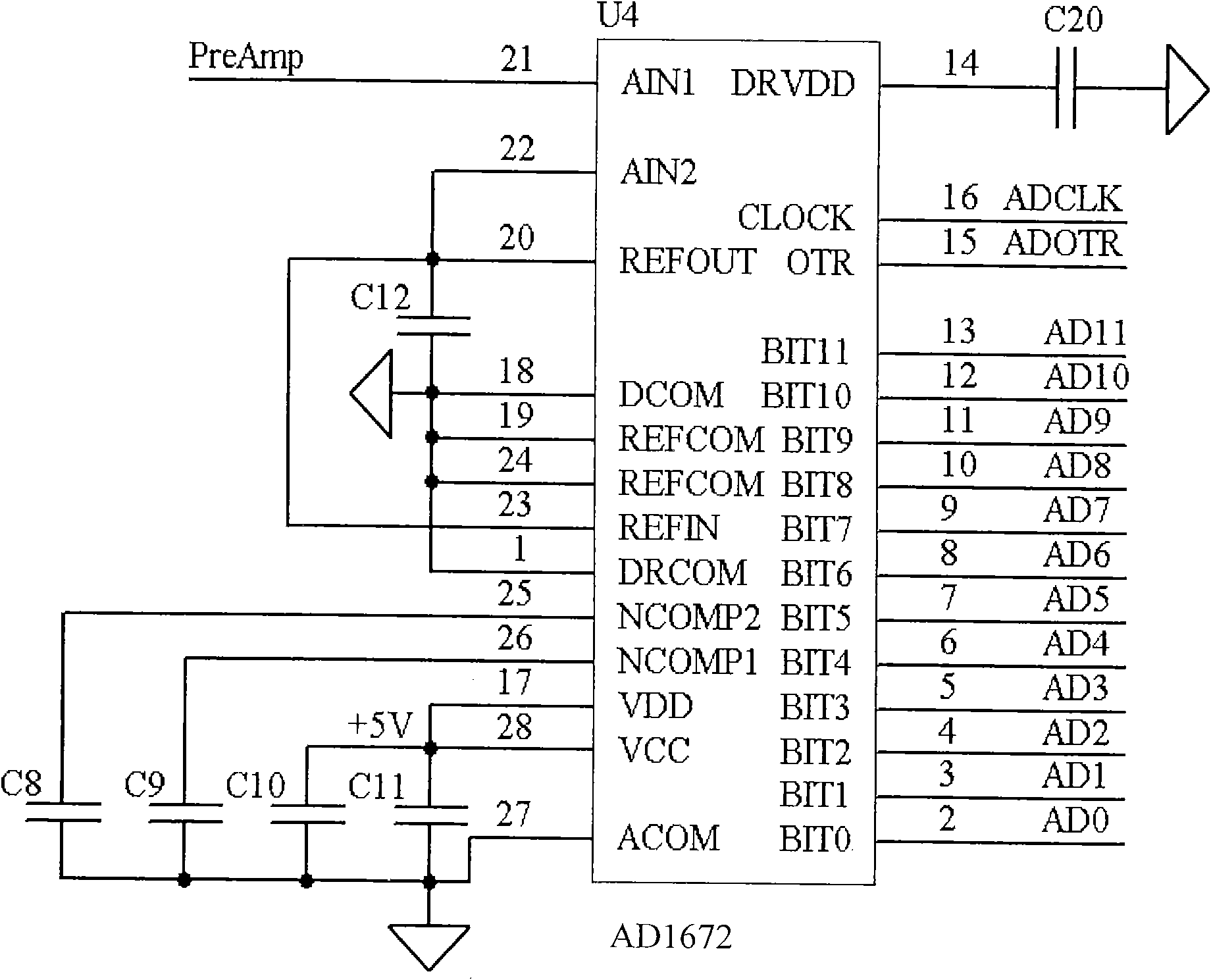

Closed-loop detection circuit of interferential full optical-fiber current mutual inductor

InactiveCN101620244ASimplify complexityHigh sensitivityCurrent/voltage measurementVoltage/current isolationSignal processing circuitsClosed loop

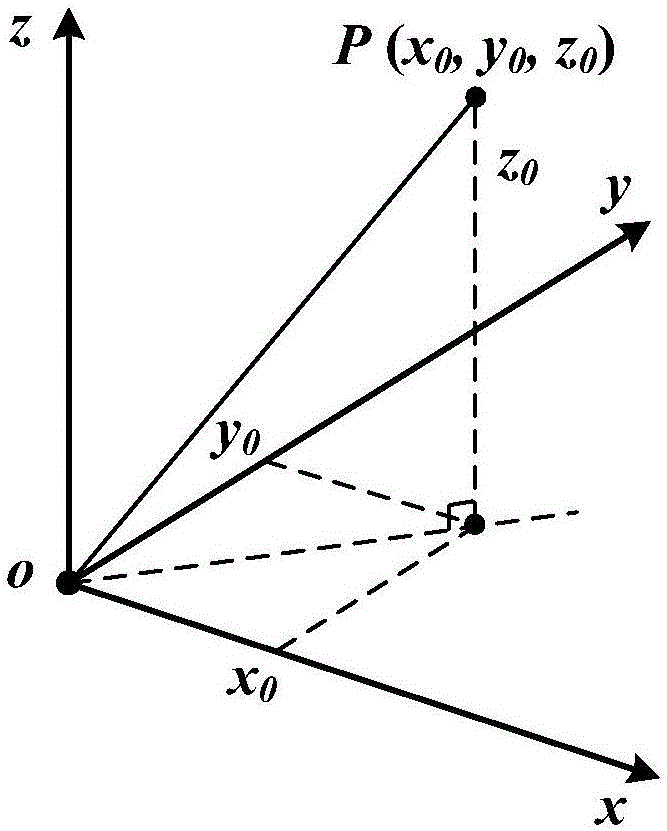

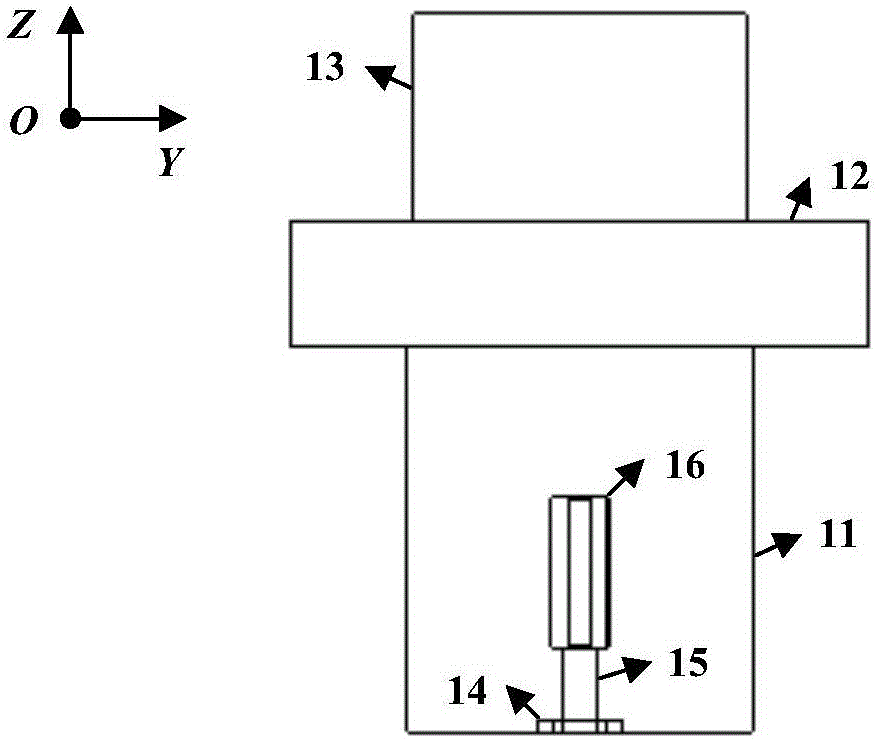

The invention discloses a closed-loop detection circuit of an interferential full optical-fiber current mutual inductor, which comprises a power supply circuit, an optical-source driving circuit, a signal processing circuit and a closed-loop detection circuit, wherein the closed-loop detection circuit aims at a ring-type optical-fiber optics interferential current mutual inductor and a reflecting interferential current mutual inductor and is based on FPGA. The gauge head of the optical-fiber current mutual inductor converts current intensity into optical-phase deviation. A front amplifier unit in a closed-loop detector receives an optical-intensity signal outputted by an optical-fiber detector, and after A / D conversion, the optical-intensity signal is outputted to the FPGA; the FPGA processes the received optical-intensity signal and decodes out a corresponding phase signal which generates a corresponding feedback-control signal by D / A, and the feedback-control signal is amplified by an operational amplifier and outputted to control a phase modulator; and an instant current value is obtained by internal operation, and converted into an analog voltage signal by a second path of D / A and outputted to a merging unit. The closed-loop detection circuit has the advantages of broad measuring frequency band, high measuring precision, wide dynamic range and the like, and is suitable for the electric transmitting and transforming trade and occasions of measuring heavy current.

Owner:SHANGHAI XINYUE METER FACTORY

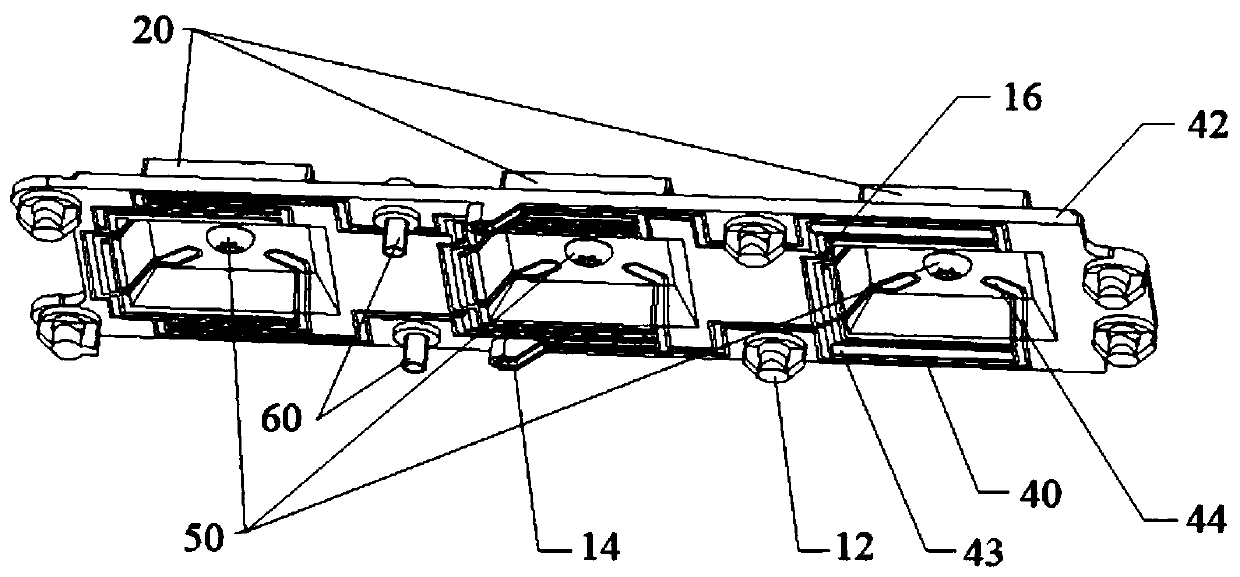

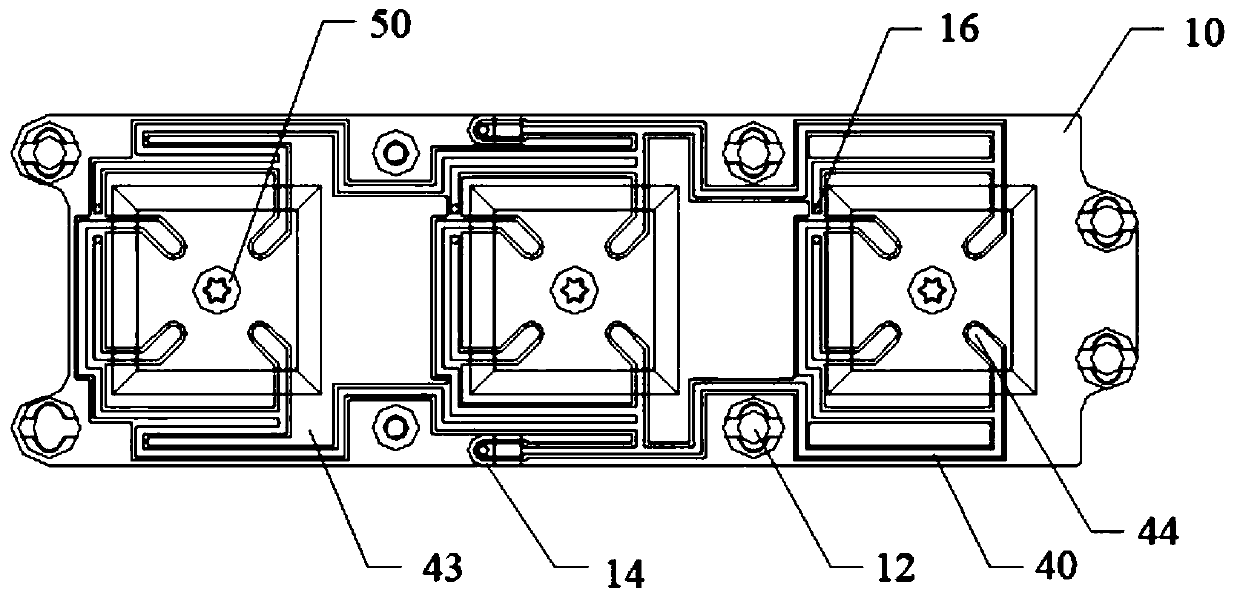

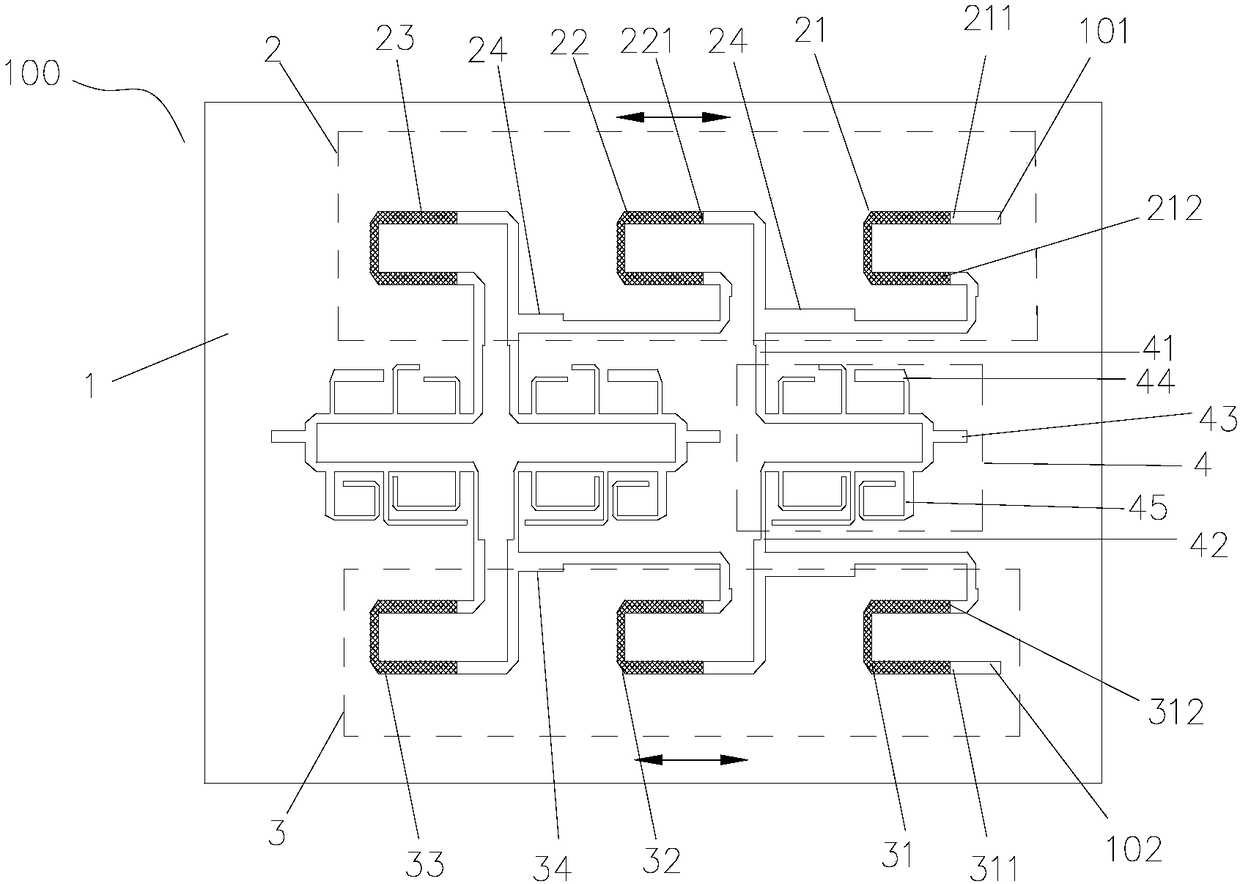

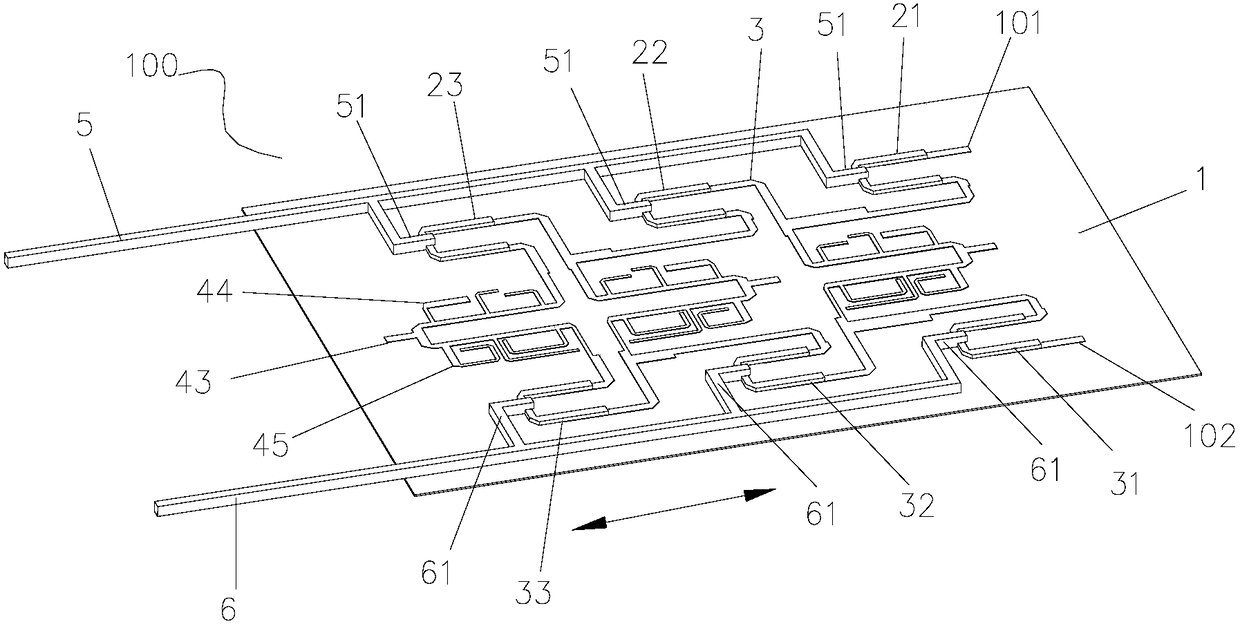

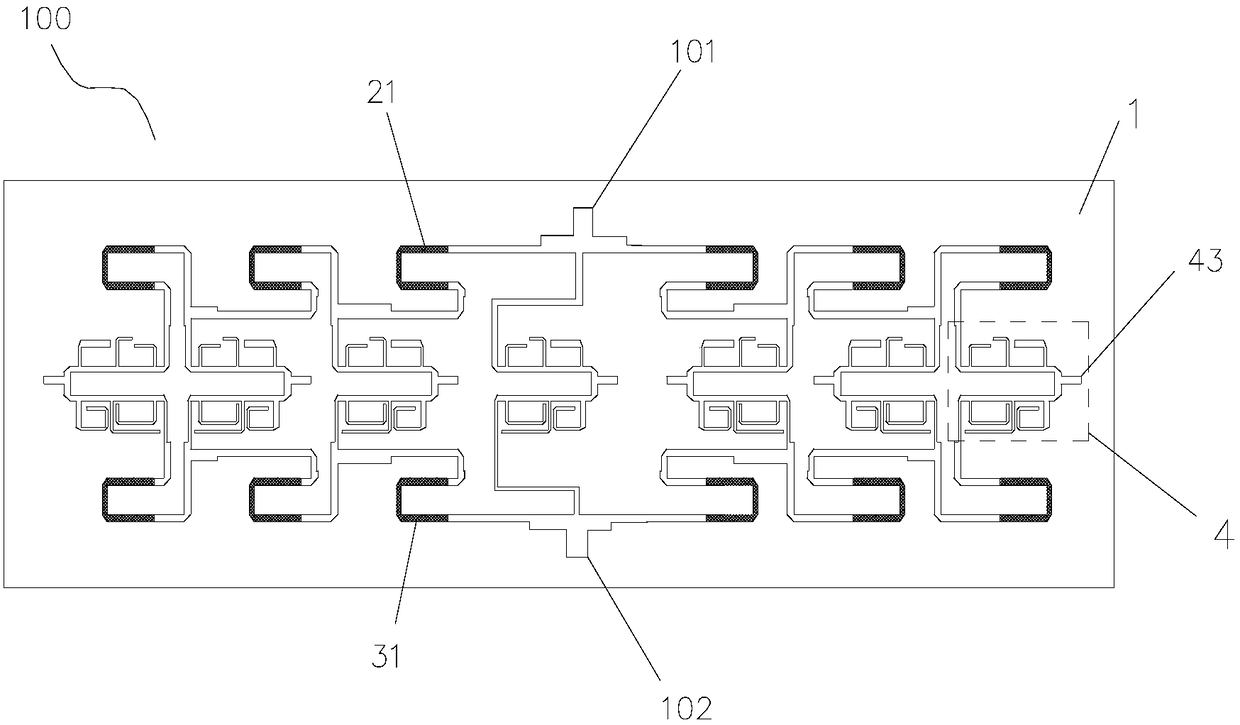

Double-frequency high-gain dielectric resonant array antenna

ActiveCN106602232ASimple designLow costParticular array feeding systemsSimultaneous aerial operationsCouplingBroadband

The invention provides a double-frequency high-gain dielectric resonance array antenna. The antenna comprises a substrate, two microstrip feed networks and a dielectric resonant unit array composed of N dielectric resonant units, N >=1, the microstrip feed networks are arranged on the substrate, the N dielectric resonant units are arranged on the substrate in a coaxial or collinear arrangement manner, feed points of the dielectric resonant units are coupled to the output ends of the two microstrip feed networks, first feed slots are arranged in two side surfaces of each dielectric resonant unit, and a second feed slot is arranged in the bottom surface of each dielectric resonant unit. One microstrip feed network is provided with a group of coupling apertures close to the output end of a dielectric cube, the other microstrip feed network is provided with a group of coupling probes close to the output end of a dielectric cube, the coupling probes and the first feed slots form a coupling power, the coupling apertures are formed in the substrate and coupled with the second feed slots. The high-gain dielectric resonance array antenna is compact in structure, low in weight, low in loss, high in efficiency, low in cost, easy to assemble and suitable for batch production and includes fewer welding points, and can be used to provide effective or beneficial references for design and improvement of other broadband, multi-frequency, low-gain dielectric resonant units or array antennas.

Owner:TONGYU COMM INC

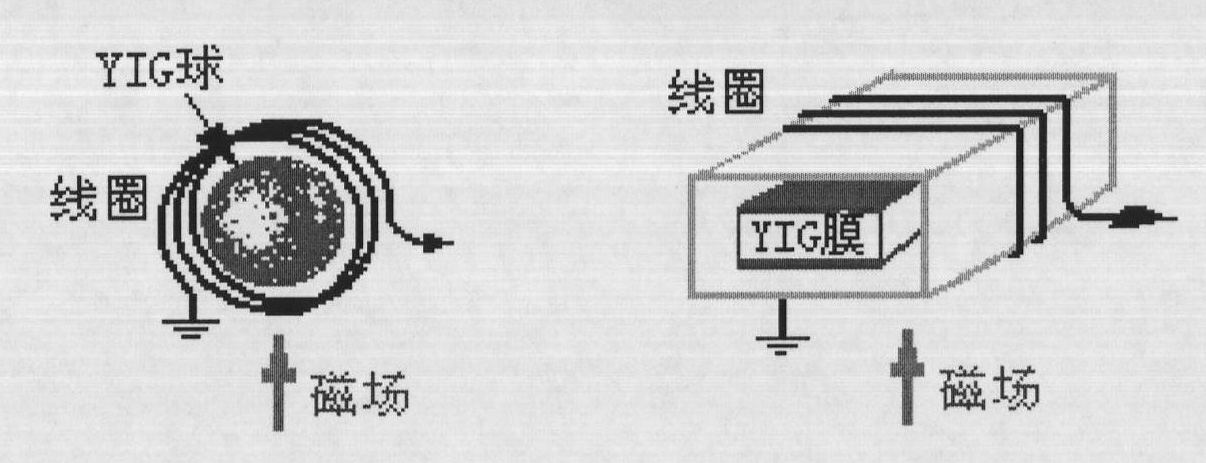

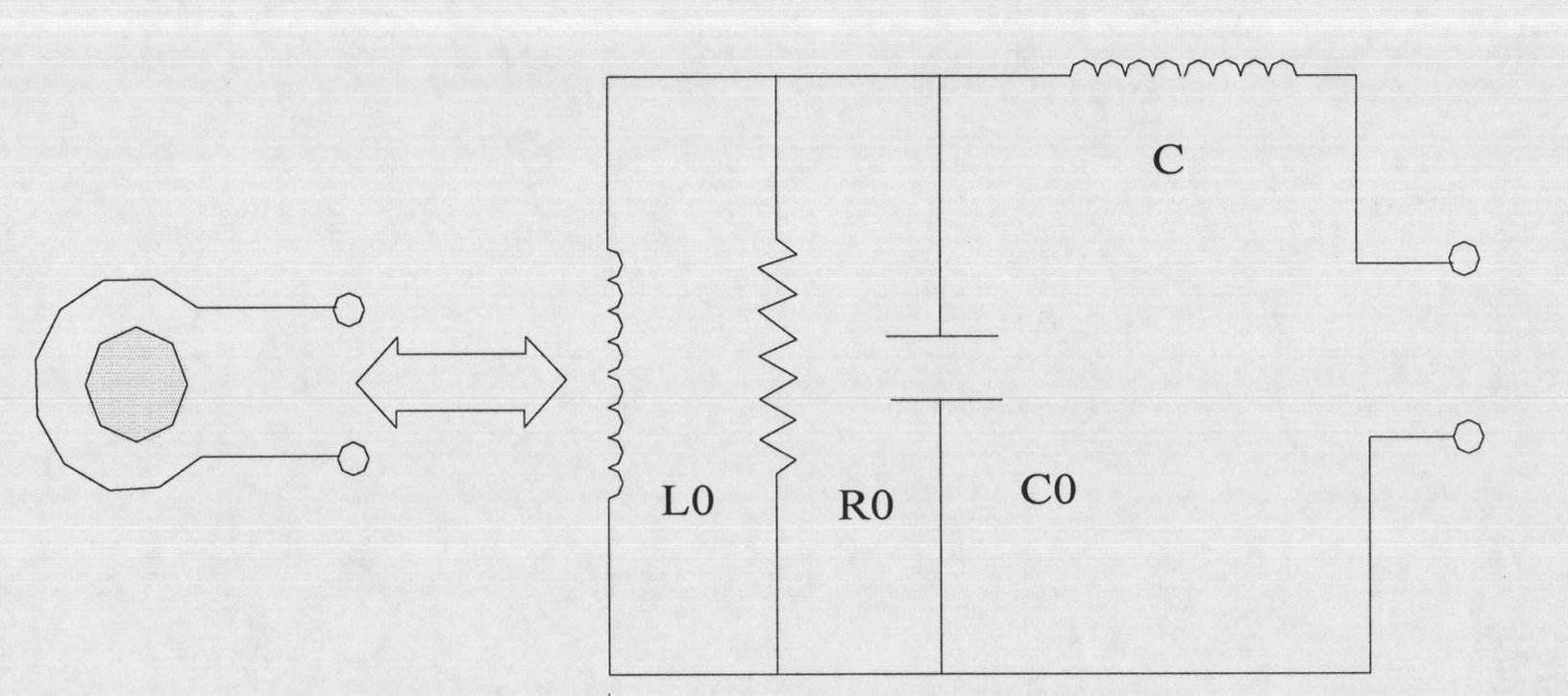

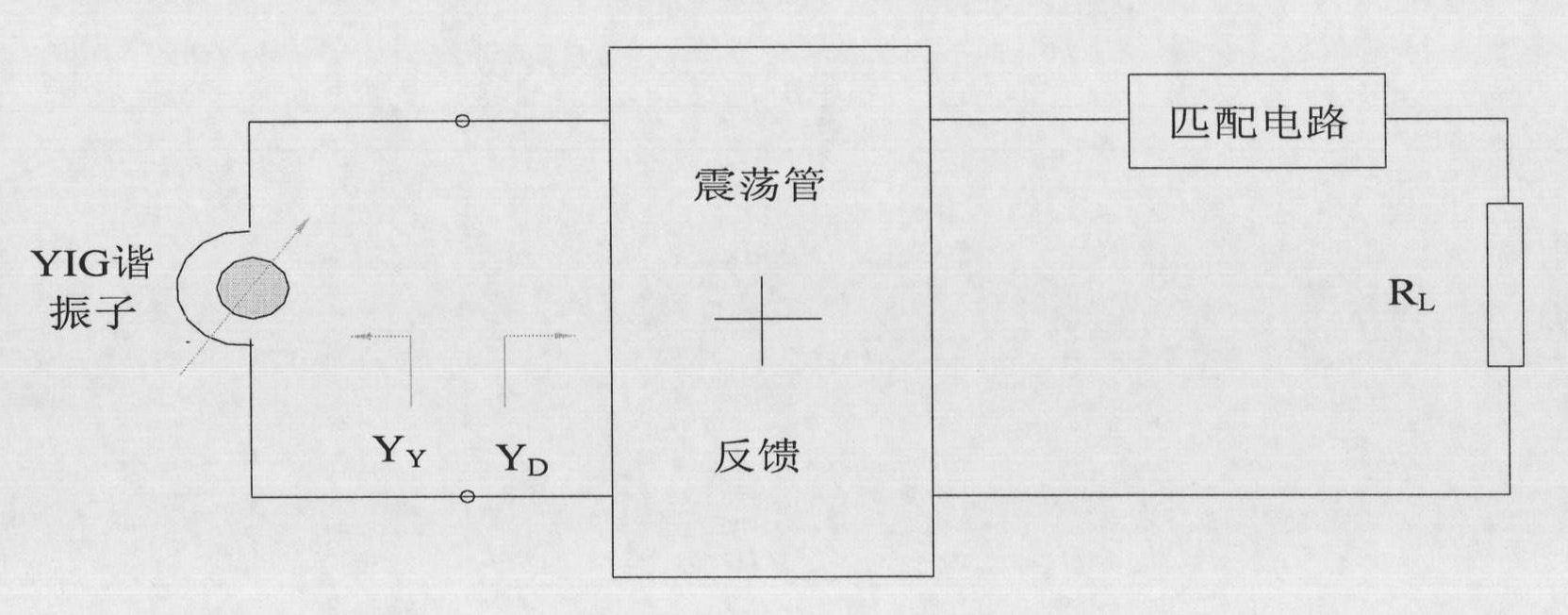

YIG harmonic oscillator, YIG oscillator and manufacturing methods thereof

ActiveCN101841312ARealize mass productionOvercome consistencyImpedence networksCouplingSingle crystal

The invention discloses a YIG harmonic oscillator, a YIG oscillator and manufacturing methods thereof; the YIG harmonic oscillator comprises a coupling ring and YIG monocrystals which are deployed in the coupling ring, wherein the coupling ring is a coupling ring which is deployed in a multi-layered ceramic substrate according to a preset coupling type through a low-temperature co-fired ferrite process; and the YIG monocrystals are inlaid in the coupling ring and sintered together with the coupling ring through an LTCC process. The YIG harmonic oscillator overcomes the defects of poor consistency, poor precision and the like in the manual winding of the coupling ring, and ensures the consistency and the precision of coupling ring manufacturing.

Owner:中国电子科技集团公司第九研究所

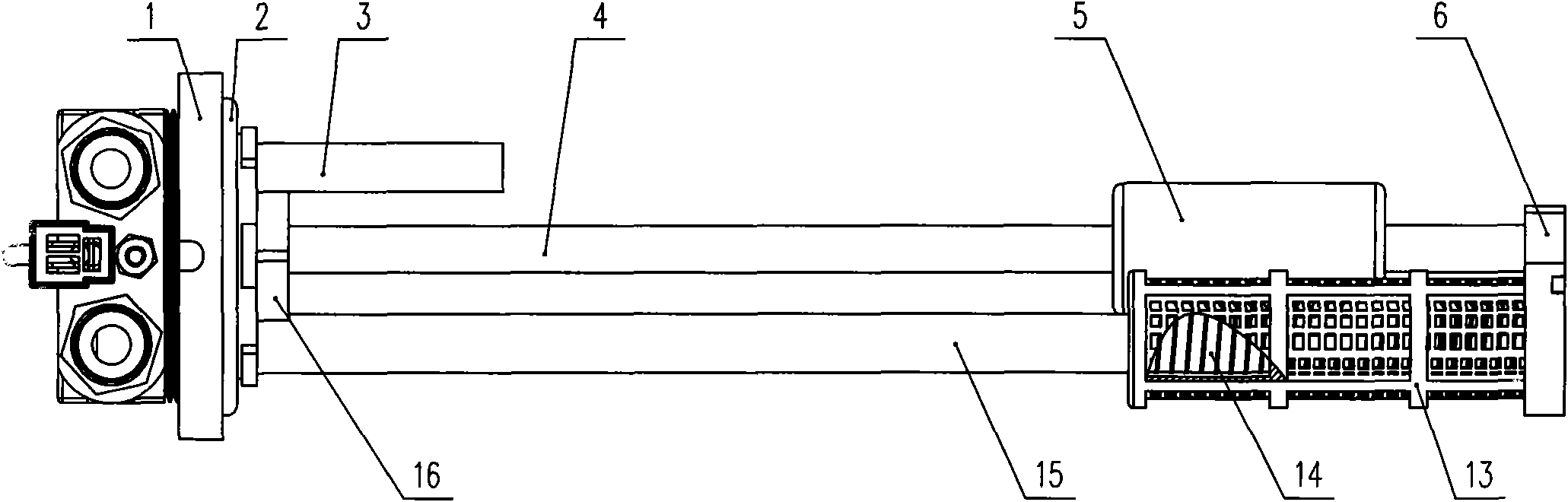

Diesel oil heating oil quantity sensor

InactiveCN101566493AImprove reliabilityReduce solder jointsMachines/enginesThermal treatment of fuelHeating oilBreather

Owner:SHIYAN YIPAI AUTOMOBILE ELECTRONICS

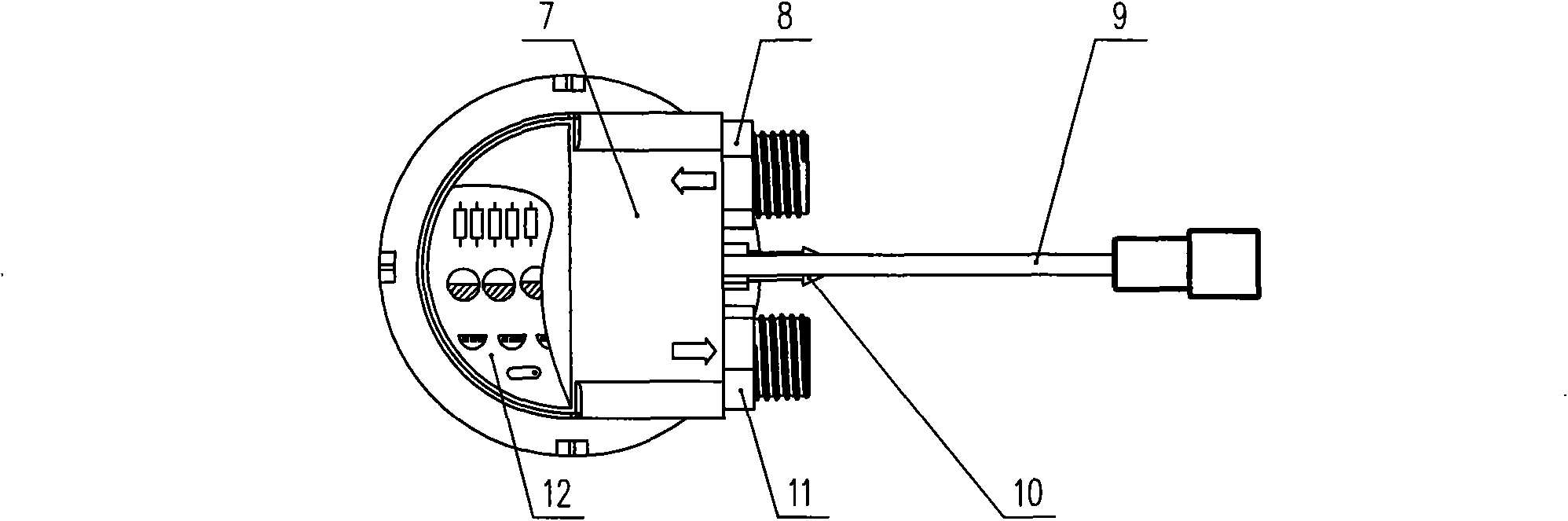

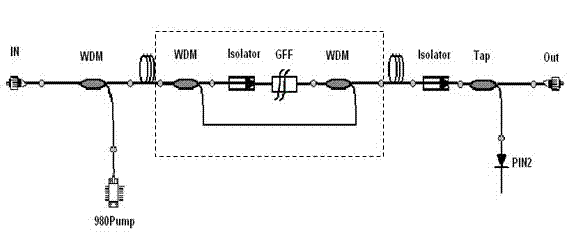

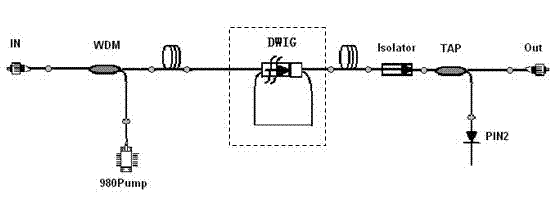

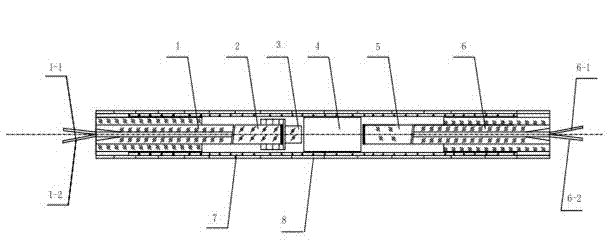

Pump integrated optical device

ActiveCN103033884AReduce package sizeReduce noise figureCoupling light guidesMultiplexerSignal light

The invention discloses a pump integrated optical device comprising a first two-core glass pin, a first collimating optical lens, a gain flatness filter assembly, a second collimating optical lens, and a second two-core glass pin which are arranged in the inside sealed glass tube from left to right, and a metal outside sealed tube which is arranged outside the inside sealed glass tube. An isolator chipware is placed at the front end or the tail end of the gain flatness filter assembly. The first collimating optical lens and the second collimating optical lens are provided with filter membranes which can transmit signal light and reflex pump light. The first two-core glass pin comprises a first optical fiber, a second optical fiber, a first two-core capillary tube and a first glass tube. The second two-core glass pin comprises a third optical fiber, a fourth optical fiber, a second two-core capillary tube and a second glass tube. The first optical fiber, the second optical fiber, the third optical fiber and the fourth optical fiber are optical fibers after being processing in a beam expanding mode. The pump integrated optical device integrates the multiple functions of a wavelength division multiplexer, an isolator and a gain flatness filter.

Owner:GUANGXUN SCI & TECH WUHAN

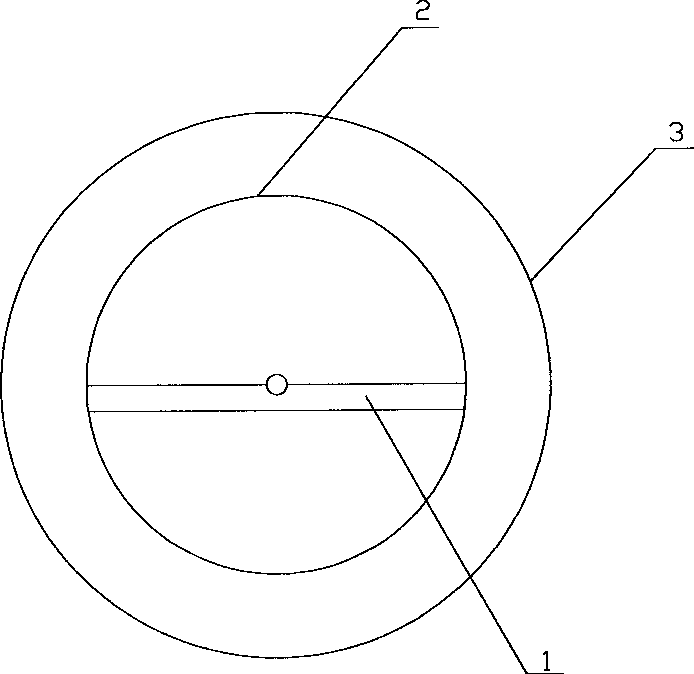

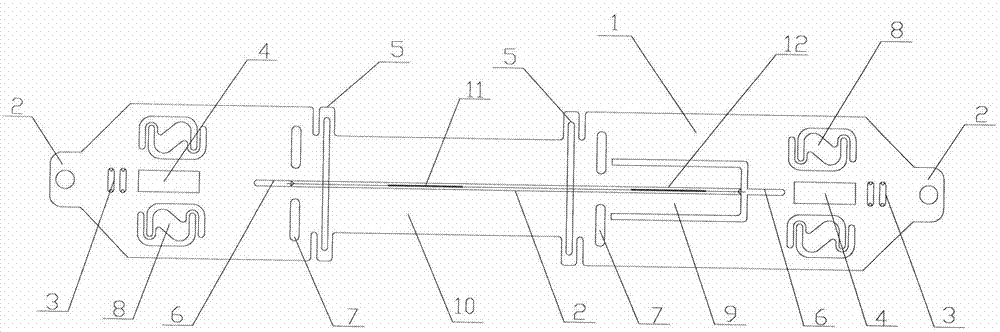

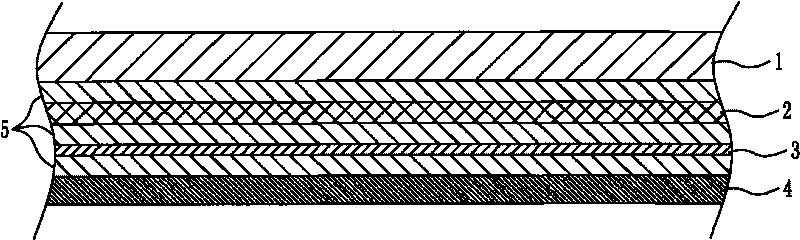

Fiber grating strain sensor

InactiveCN102853778ALarge measuring rangeProne to elastic deformationUsing optical meansFiberShaped beam

The invention relates to a fiber grating strain sensor. An elastic strain sheet is provided with a longitudinal shaft and is symmetrical along the longitudinal shaft, the elastic strain sheet comprises a pair of symmetrical U-shaped beam elastic structures, a flat plate for connecting the U-shaped beam elastic structures, a groove used for placing fiber grating and located on the longitudinal axis of the elastic strain sheet, a pair of rectangular holes used for a tail fiber to penetrate and located at two ends of the groove, a temperature compensation device, a fixed device and a sheath fixing device. The fiber grating is arranged in the groove, two ends of the fiber grating are fixed at corresponding positions by using glass welding materials through a point welding mode, the tail fiber penetrates through the rectangular holes and are located on the other surface of the elastic strain sheet, a sheath is used for protecting, and the fiber grating strain sensor is formed by the elastic strain sheet, the fiber grating, the sheath and an auxiliary device. The fiber grating strain sensor is simple in structure, large in measuring range, convenient to install and capable of eliminating interference of temperature on the sensor effectively.

Owner:杭州珏光物联网科技有限公司

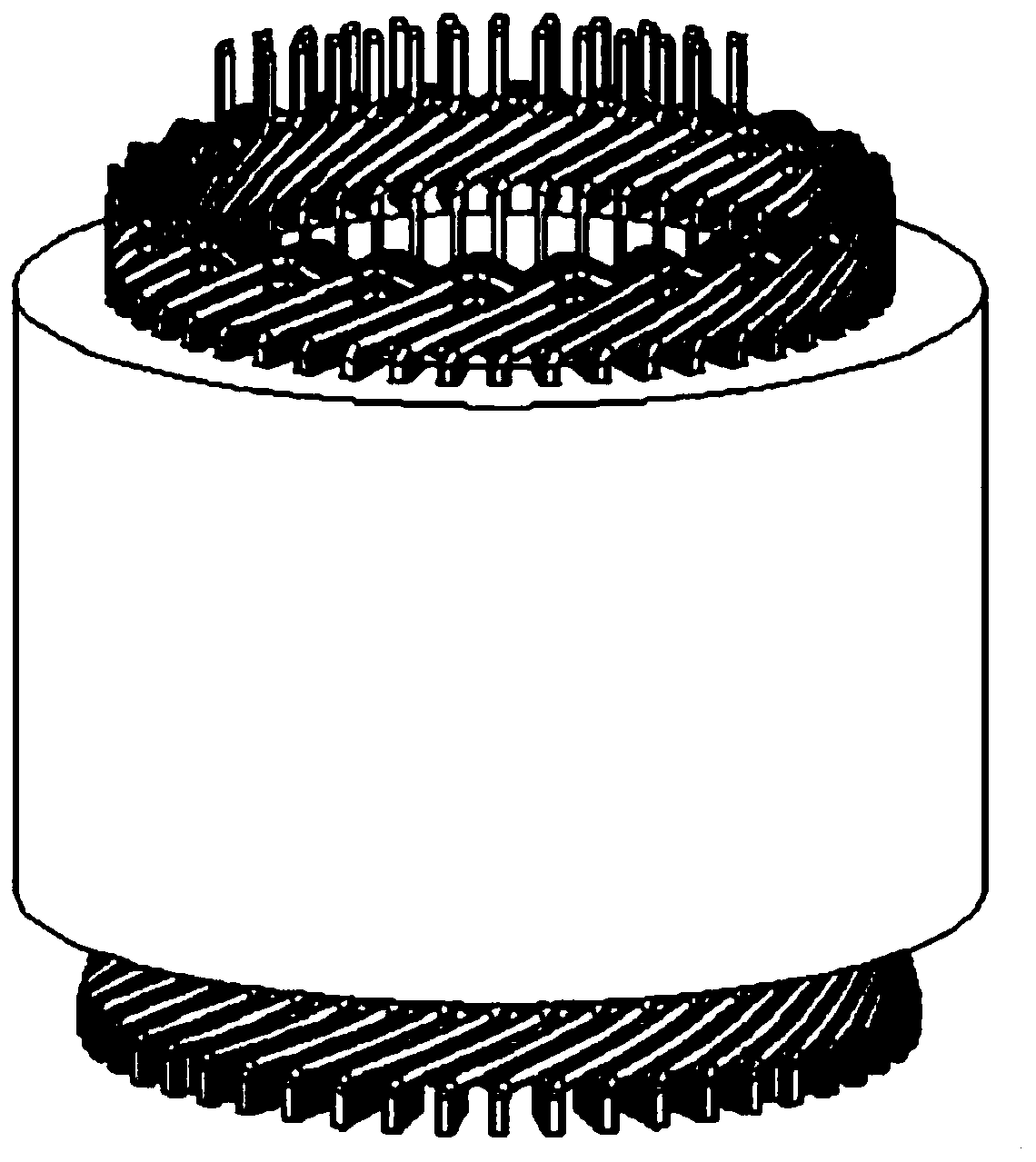

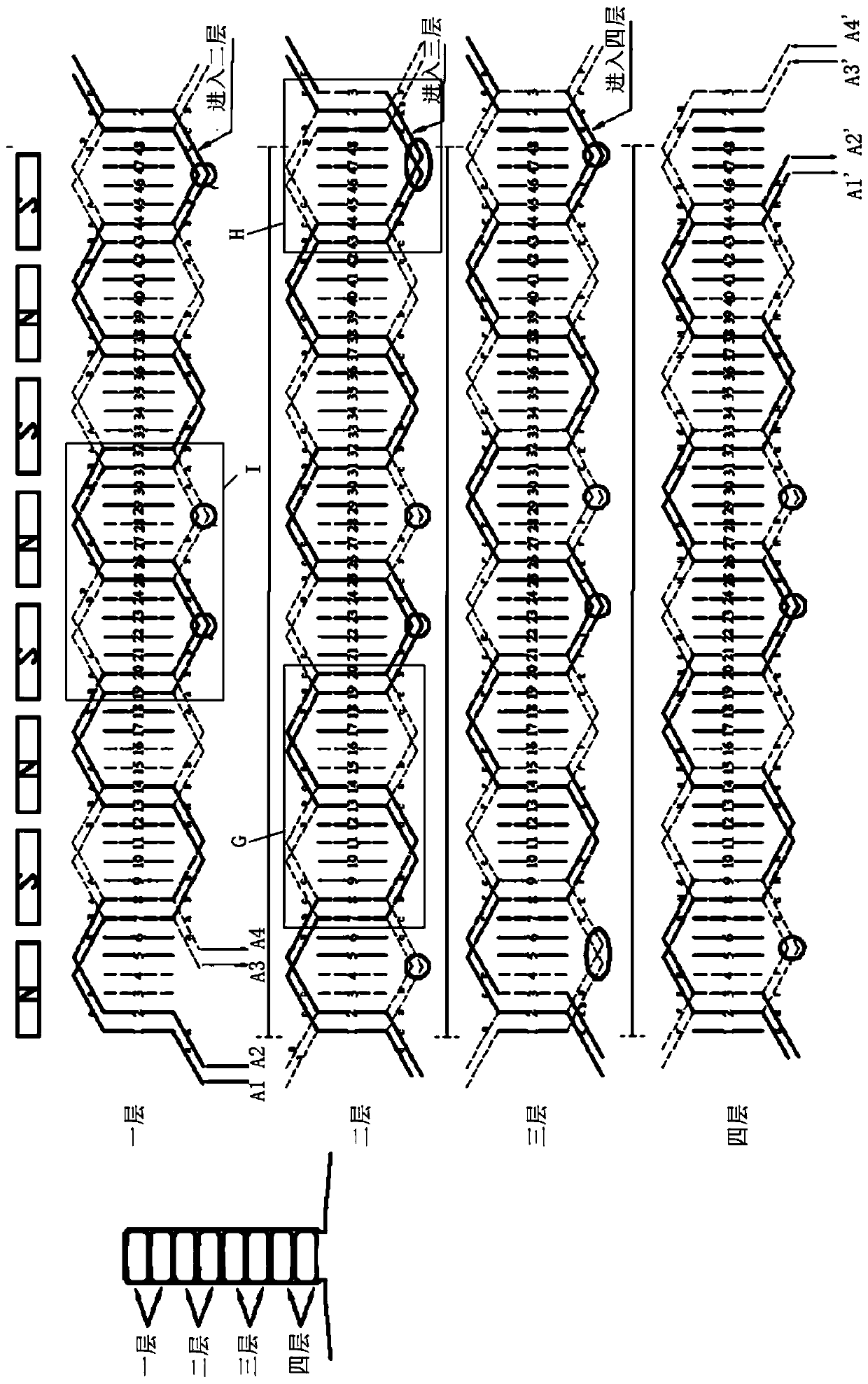

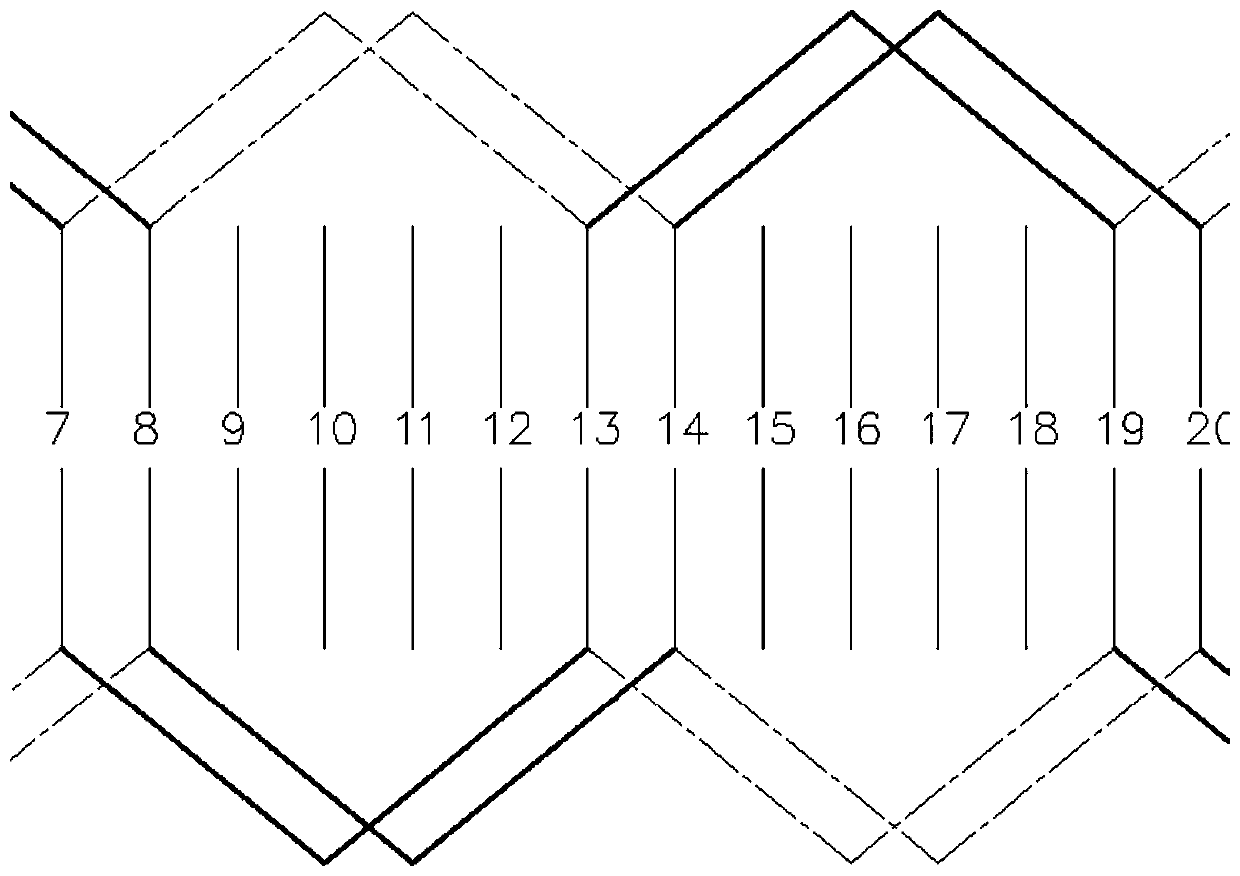

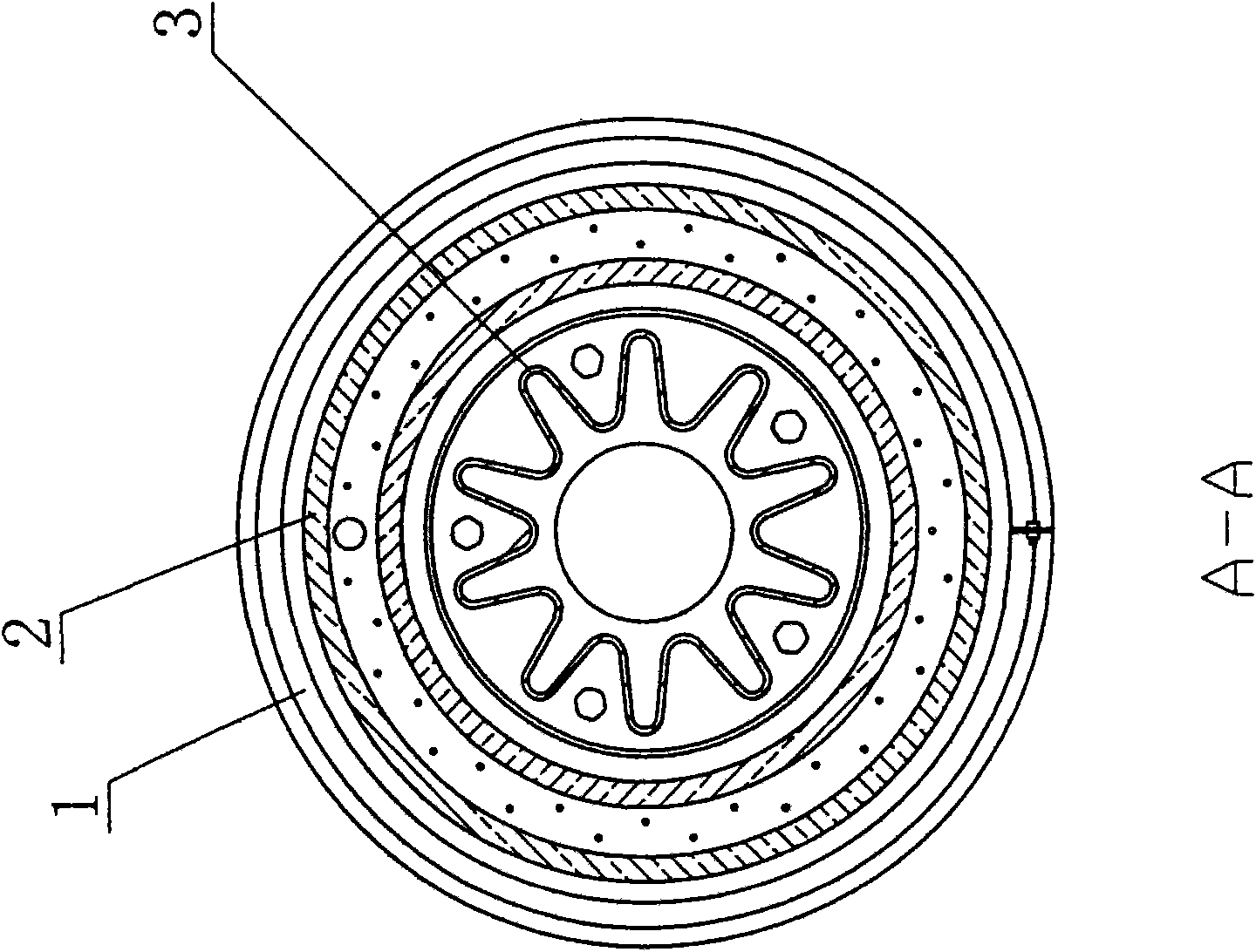

Flat wire continuous wave winding, stator and motor

PendingCN111446797AReduce noiseImprove noiseMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineEngineering

The invention belongs to the technical field of test equipment, and particularly provides a flat wire continuous wave winding, a stator and a motor. The invention aims to solve the problems of difficult production and easy damage caused by many welding spots of a flat wire motor in the prior art. The flat wire continuous wave winding comprises a wire inlet end, a wire outlet end and an S-shaped wave winding located between the wire inlet end and the wire outlet end. The number of winding layers of the flat wire continuous wave winding is 2N, and the pitch is y. A jump winding part is arrangedat the joint of the Nth layer and the (N + 1) th layer of the flat wire continuous wave winding. The pitch of each phase of wire group at the jump winding part is y + 1, wherein N and y are both natural numbers greater than or equal to 1. According to the flat wire continuous wave winding, a scheme of continuously winding a flat wire is adopted, so that welding spots are reduced.

Owner:NIO CO LTD

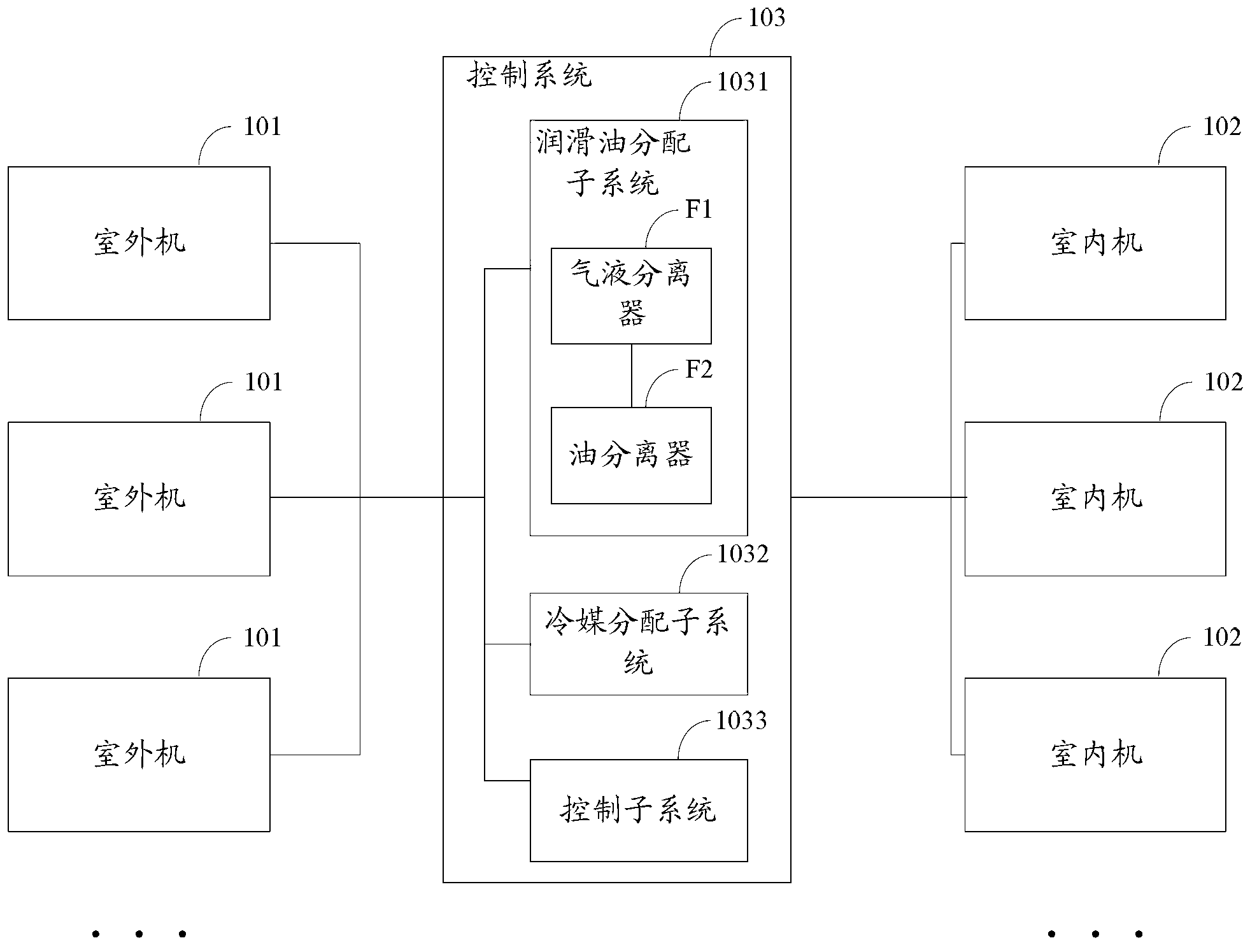

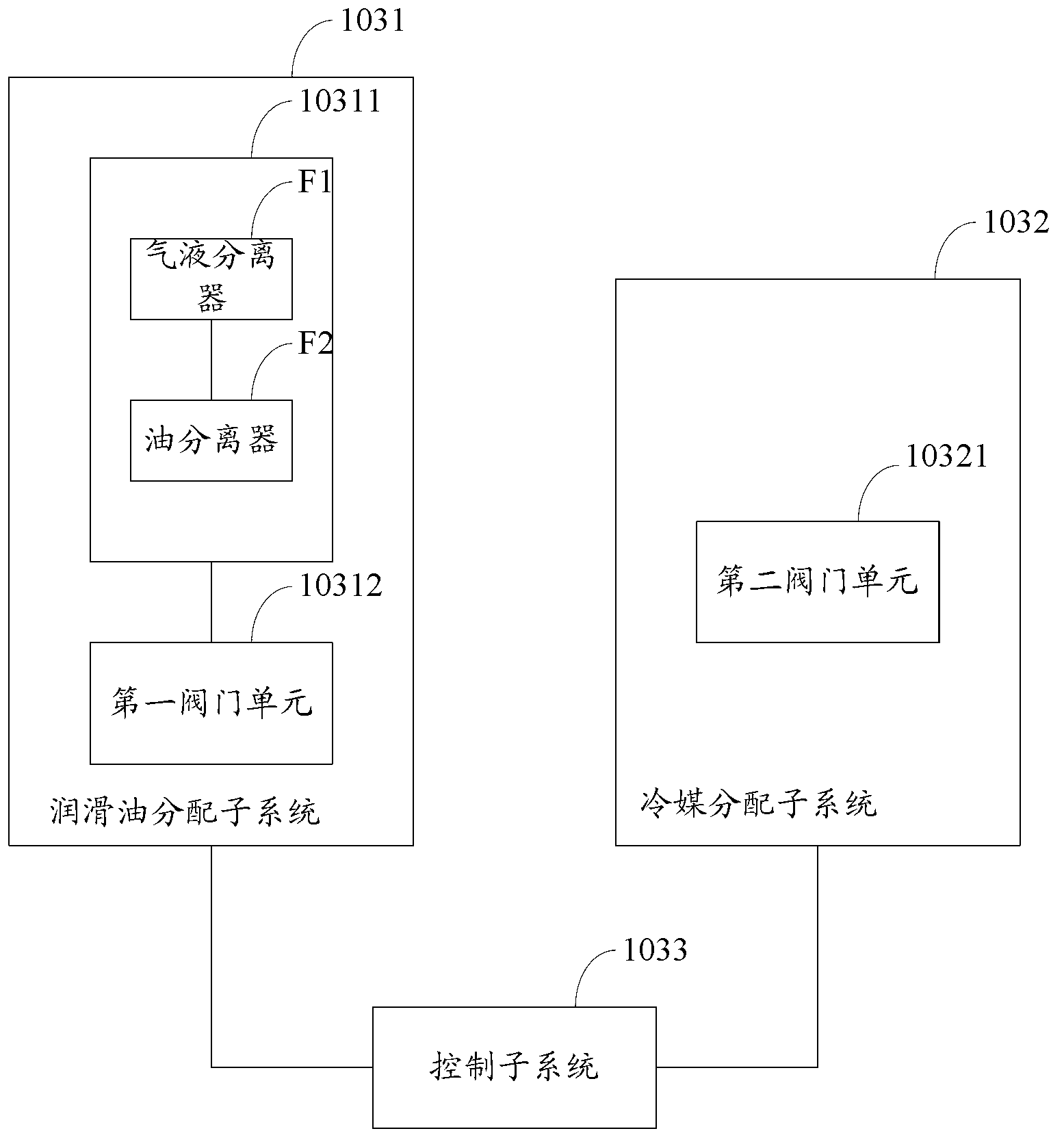

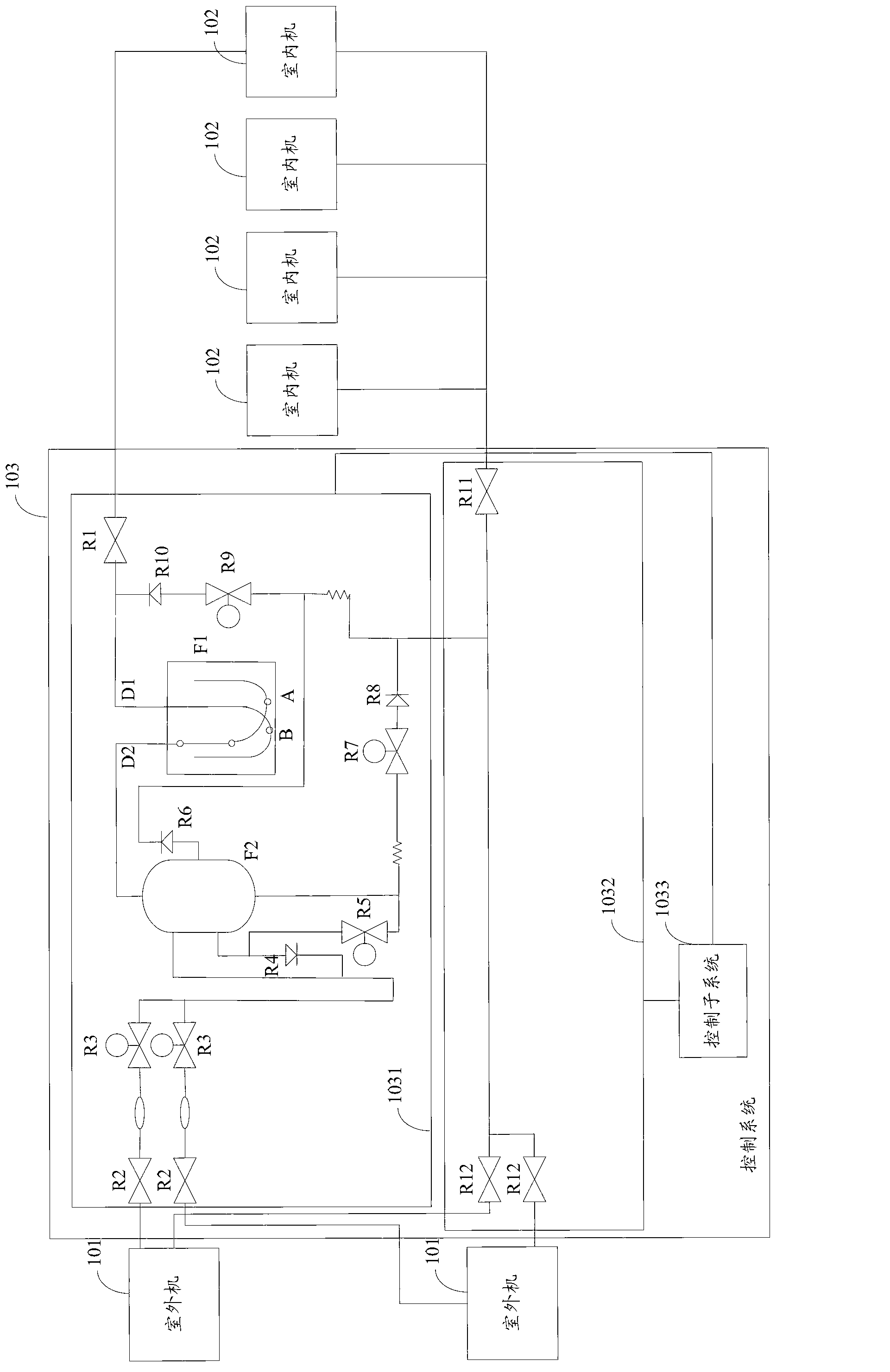

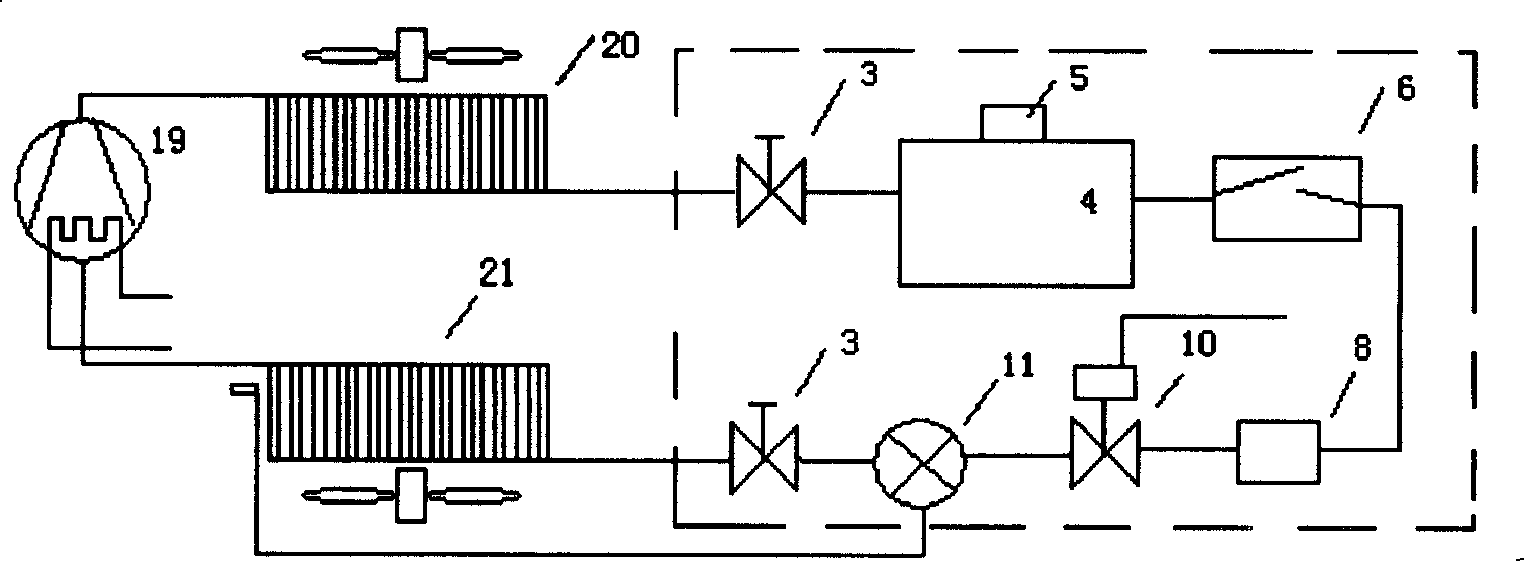

Air-conditioning system, control system and air-conditioning control method

ActiveCN103062840ALow costReduce connectivityCompressorMechanical apparatusRefrigerant distributionVapor–liquid separator

The invention discloses an air-conditioning system. The reliability of the system is improved. The air-conditioning system comprises M outdoor units, N indoor units and a control system; the M outdoor units are used for supplying heat sources or cold sources, and the M is a positive integer; the N indoor units are used for receiving at least one heat source or cold source which is provided by one or more outdoor units, and the N is a positive integer; and the control system comprises a lubricating oil distribution subsystem, a refrigerant distribution subsystem and a control subsystem, the lubricating oil distribution subsystem is connected with the M outdoor units and comprises a gas-liquid separator and an oil separator which are connected with each other by a first connecting pipeline, the refrigerant distribution subsystem is connected with the M outdoor units, and the control subsystem is connected with the N indoor units, the M outdoor units, the lubricating oil distribution subsystem and the refrigerant distribution subsystem. The invention further discloses the control system and an air-conditioning control method.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Sn-zn or Sn-AgBi series leadless parent metal containing trace doped metal and its preparation method

InactiveCN1651180AHigh mechanical strengthAvoid lostWelding/cutting media/materialsSoldering mediaMetalTin

A non-lead Sn-Zn Sn-Ag-Bi solder containing trace doped metals and its preparing process are disclosed. It features that the Ni, Mn and Co or Fe are contained for low smelting point, and high mechanical performance and infiltration performance.

Owner:FUDAN UNIV

Low-profile radiating element and base station antenna

ActiveCN110190382AImprove gainReduce solder jointsAntenna supports/mountingsRadiating elements structural formsManufacturing efficiencyDirect radiation

The invention relates to the technical field of mobile communication equipment, and provides a low-profile radiating element and a base station antenna. The low-profile radiation element comprises a base and a plurality of direct radiation blocks, the base is provided with a plurality of support platforms in an extrusion mode towards the same direction, the plurality of direct radiation blocks arepressed and connected with the support platforms in a one-to-one correspondence mode, the lower surface of the base is provided with a micro-strip circuit in a laser etching mode, and the substrate is provided with a plurality of sliding buckles matched with a reflecting plate. Each direct radiation block comprises an injection molding body, and the two opposite sides of each injection molding body are respectively subjected to laser etching plating or full electric plating to form a direct surface and a radiation surface. According to the low-profile radiation element provided by the invention, the direct radiation blocks and the support platforms are pressed and connected with no need for welding operation; the sliding buckles are used to connect the base with the reflecting plate withno need for welding; the micro-strip circuit is subjected to laser etching at the lower surface of the base, the direct surface formed through laser etching plating or full electric plating improves the gain, a power division network is integrated, welding points are reduced to facilitate improvement of the manufacturing efficiency and reduction of the manufacturing cost.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

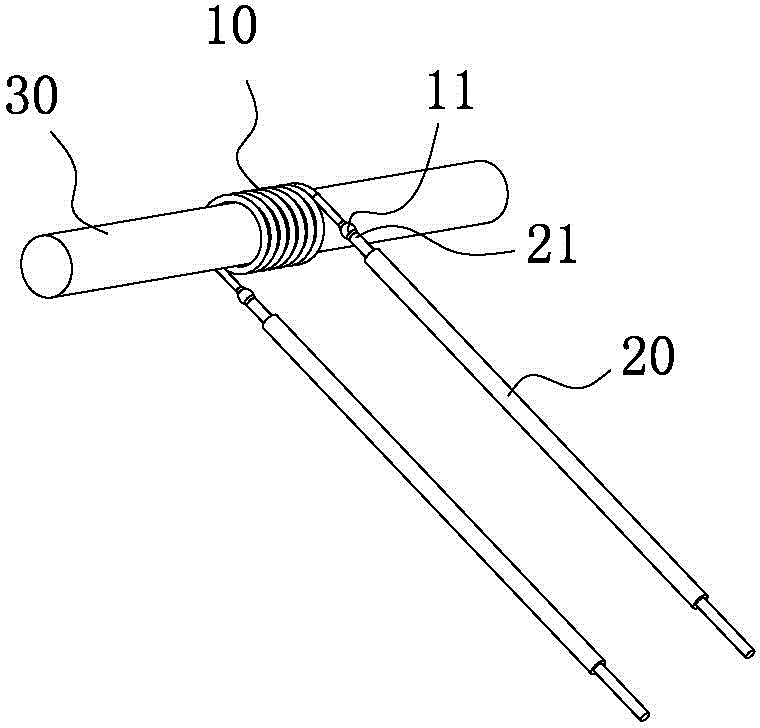

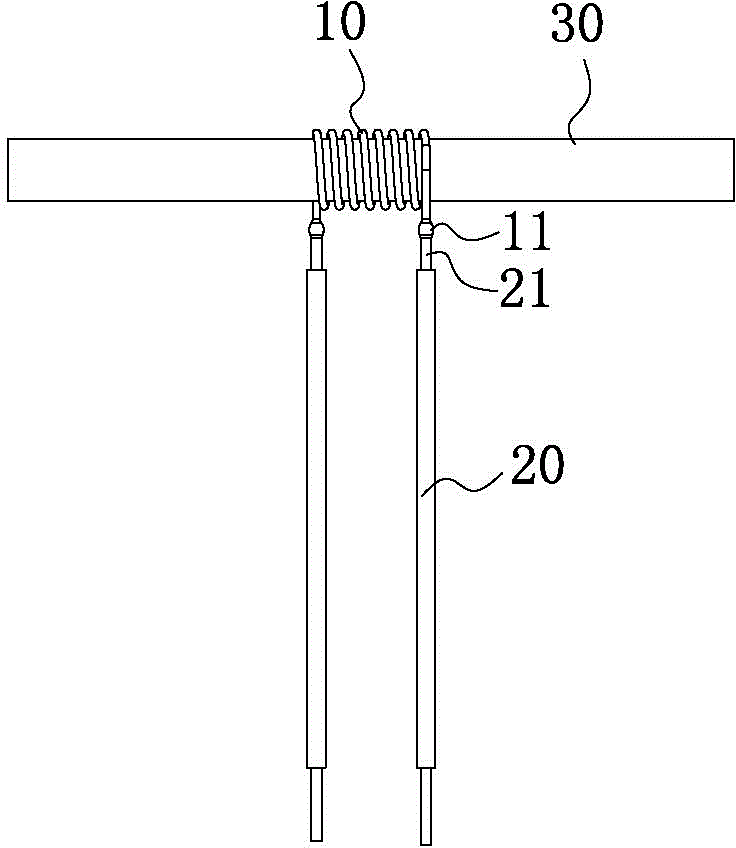

Heating wire component in electronic cigarette and welding method of heating wire component

InactiveCN103549664AThere will be no false welding phenomenonLittle changeTobacco devicesWelding/soldering/cutting articlesElectricityElectrical resistance and conductance

The invention relates to the technical field of electronic cigarettes, in particular to a heating wire component in an electronic cigarette and a welding method of the heating wire component. The to-be-welded heating wire component in the method comprises electric leads and a heating wire which is wound on an oil suction rope. The method includes the following steps: step 1, removing outer skin of a connecting end of each electric lead to enable a core wire inside the corresponding electric lead to be exposed outside; step 2, electrically connecting one working electrode in a laser spot welder with the electric leads; step 3, enabling the core wire on the connecting end of each electric lead and a connecting end of the heating wire to be connected and to oppositely collide on another working electrode of the laser spot welder simultaneously, and enabling the laser spot welder to output current to integrally weld the core wire on the connecting end of each electric lead and the connecting end of the heating wire. After adopting the above scheme for welding, a welding point is enabled to be small and firm after welding, and faulty welding and false welding are avoided; resistance change is small, the welding point is free of heat energy conversion due to electrification and cannot be corroded by tobacco tar, and pure mouthfeel of smoke taste during smoking can be guaranteed.

Owner:林光榕

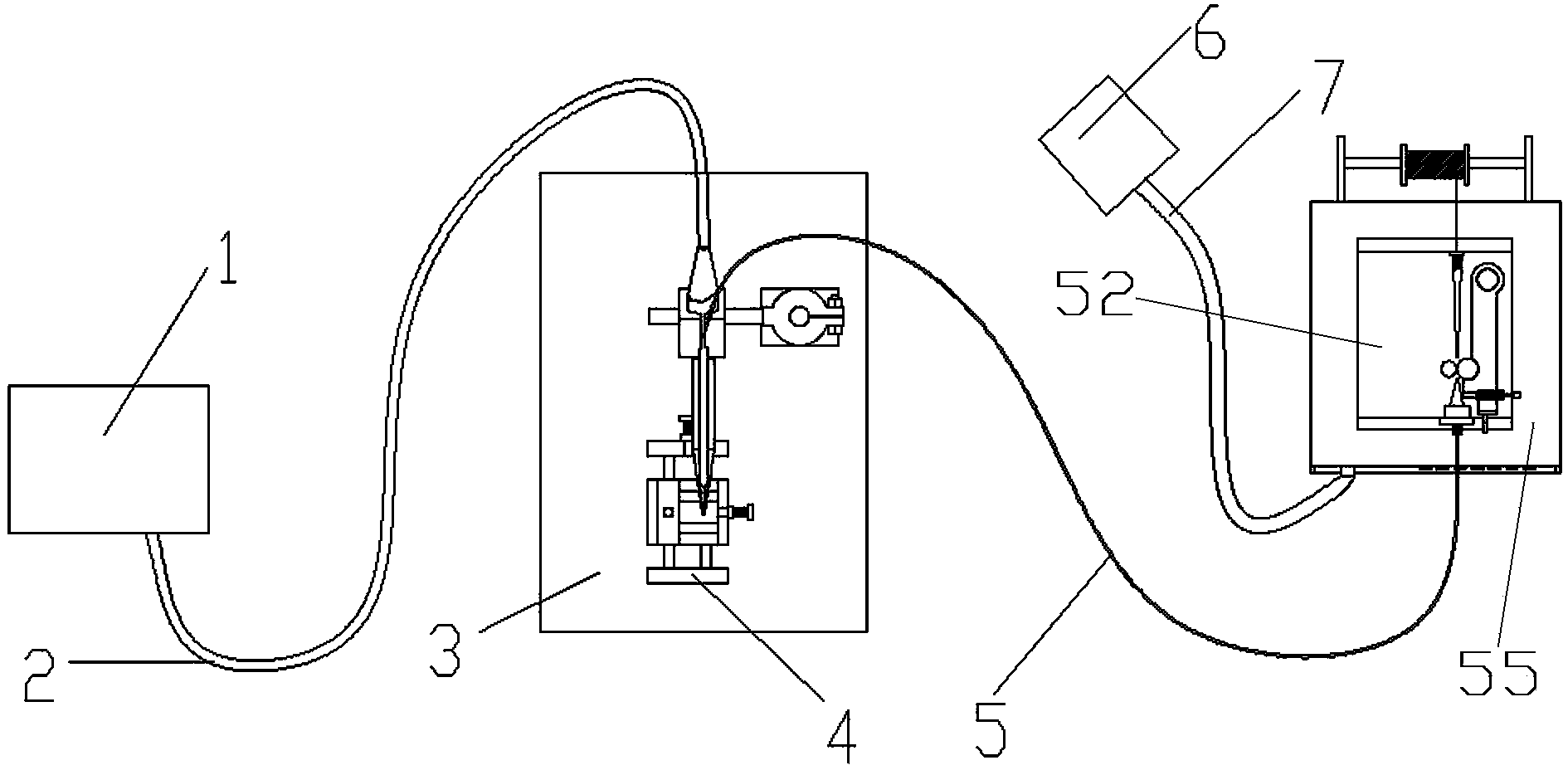

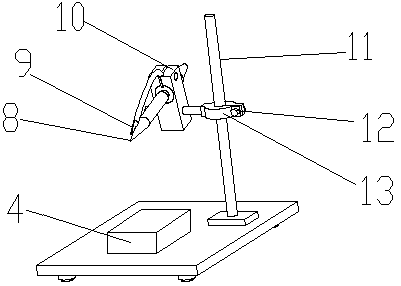

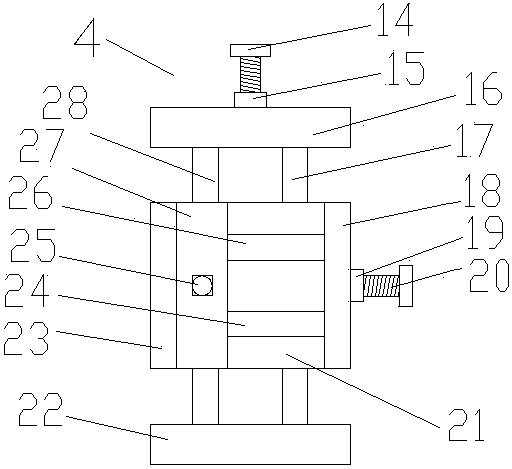

Precision spot welder

InactiveCN103752979AReasonable designCompact structureSoldering ironMetal working apparatusMicrocomputerPins needles

The invention relates to precision spot equipment suitable for no-pin needle type miniature frameworks and products with small welding spots and provides a precision spot welder. The precision spot welder is suitable for precision frameworks and the occasions that welding spots are required to be smooth, plump and small and the requirements for welding spot positions are high. The precision spot welder comprises a soldering iron control instrument, an automatic tin wire discharge device and a tin soldering operating device. The soldering iron control instrument is provided with a control box, the control box is provided with an operation panel, and a microcomputer controller is arranged in the control box; the automatic tin wire discharge device is formed by a tin wire mounting rack, an automatic tin wire discharge control box, a tin wire feed nozzle, a locating nut, a tin wire transmission wheel, a tin wire transmission motor, a tin wire clamping wheel, a tin wire passing nozzle, an adjusting spanner, a spring, a first screw, a connecting piece, a vertical piece at the front end of the connecting piece, a mounting table, a tin wire guide pipe and a pedal. The tin soldering operating device is formed by a base, a support, a movable flame, an installation block, a locating screw, a tin wire discharge nozzle, a soldering iron head and a tin soldering product locating movable device.

Owner:惠涌

Mounting structure of motorcycle ignition coil and frame

InactiveCN102582733ASo as not to damageImprove stability and securityCycle equipmentsVehicle frameIgnition coil

The invention discloses a mounting structure of a motorcycle ignition coil and a frame, comprising a mounting bracket arranged between the frame and the ignition coil, wherein the mounting bracket is entirely L-shaped and composed of a first mounting plate and a second mounting plate which are vertical to each other; a first mounting support lug arranged on the ignition coil and a first mounting plate of the mounting bracket are fastened and connected by bolts and nuts; a second mounting plate of the mounting bracket and a second mounting support lug arranged on the frame are fastened and connected by bolts and welded nuts; the connections of the mounting bracket, the frame and the ignition coil are provided with positioning structure design and are simple in assembling and reliable in structure; the number of welding points on the frame is reduced to that the deformation of the frame body due to excessive welding is reduced; even if the welding stress deformation is generated due to one welding point, the mounting bracket only can generate entire displacement within a certain range due to the welding stress deformation, and the ignition coil cannot be damaged, so that the safety and stability of the whole vehicle are improved.

Owner:力帆科技(集团)股份有限公司

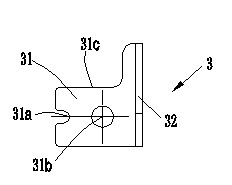

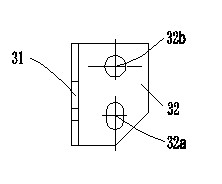

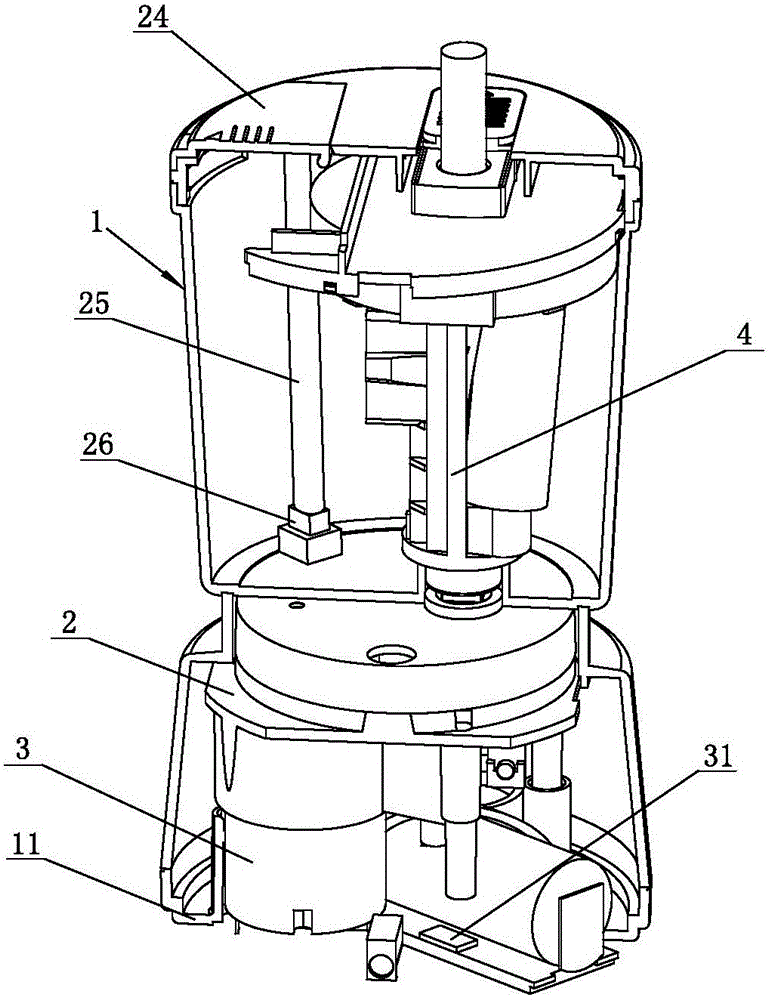

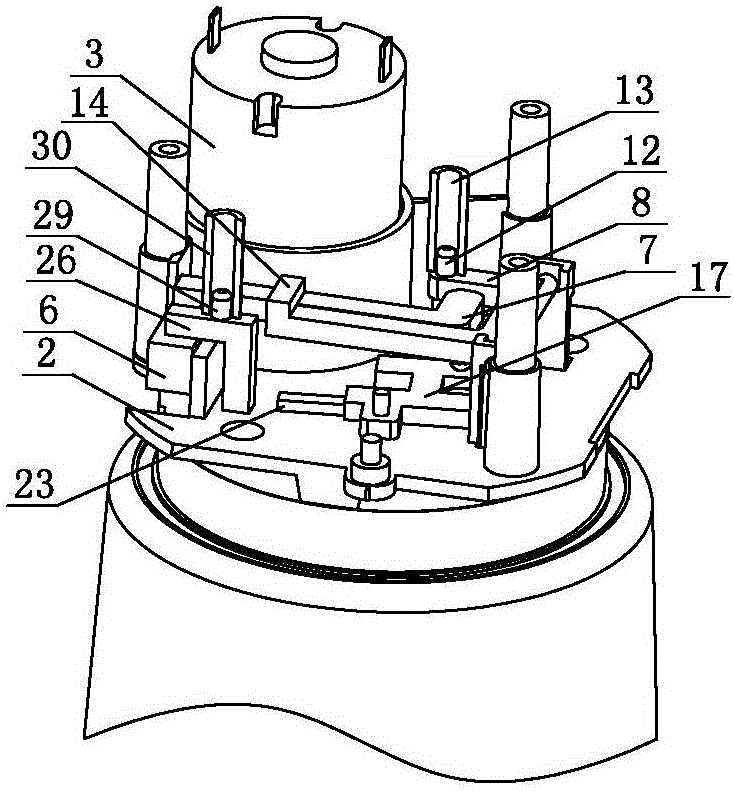

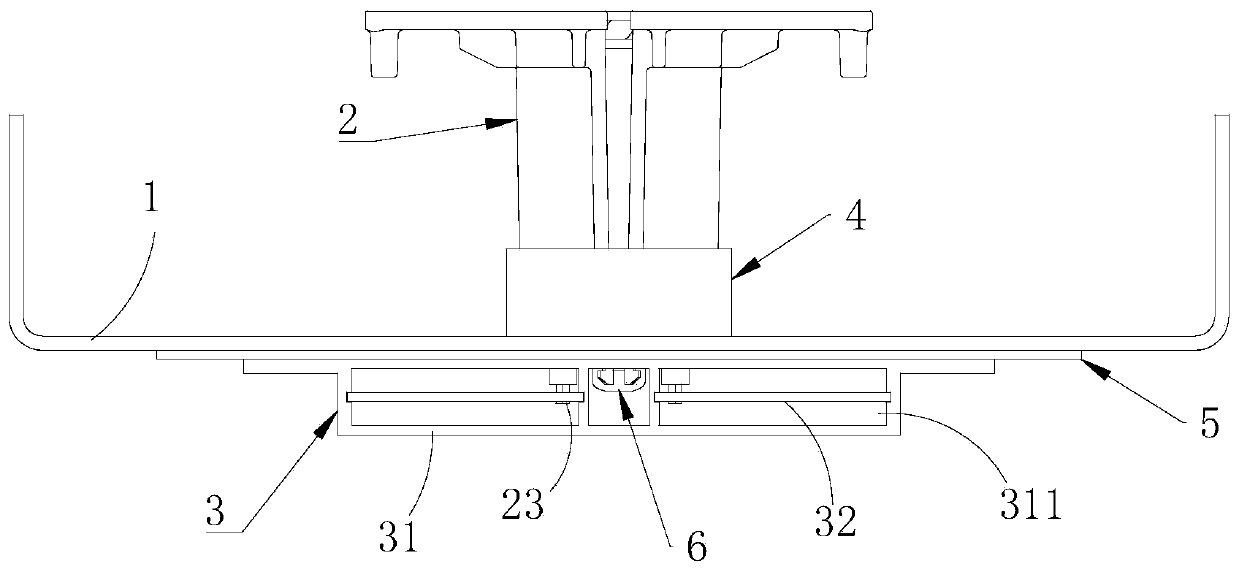

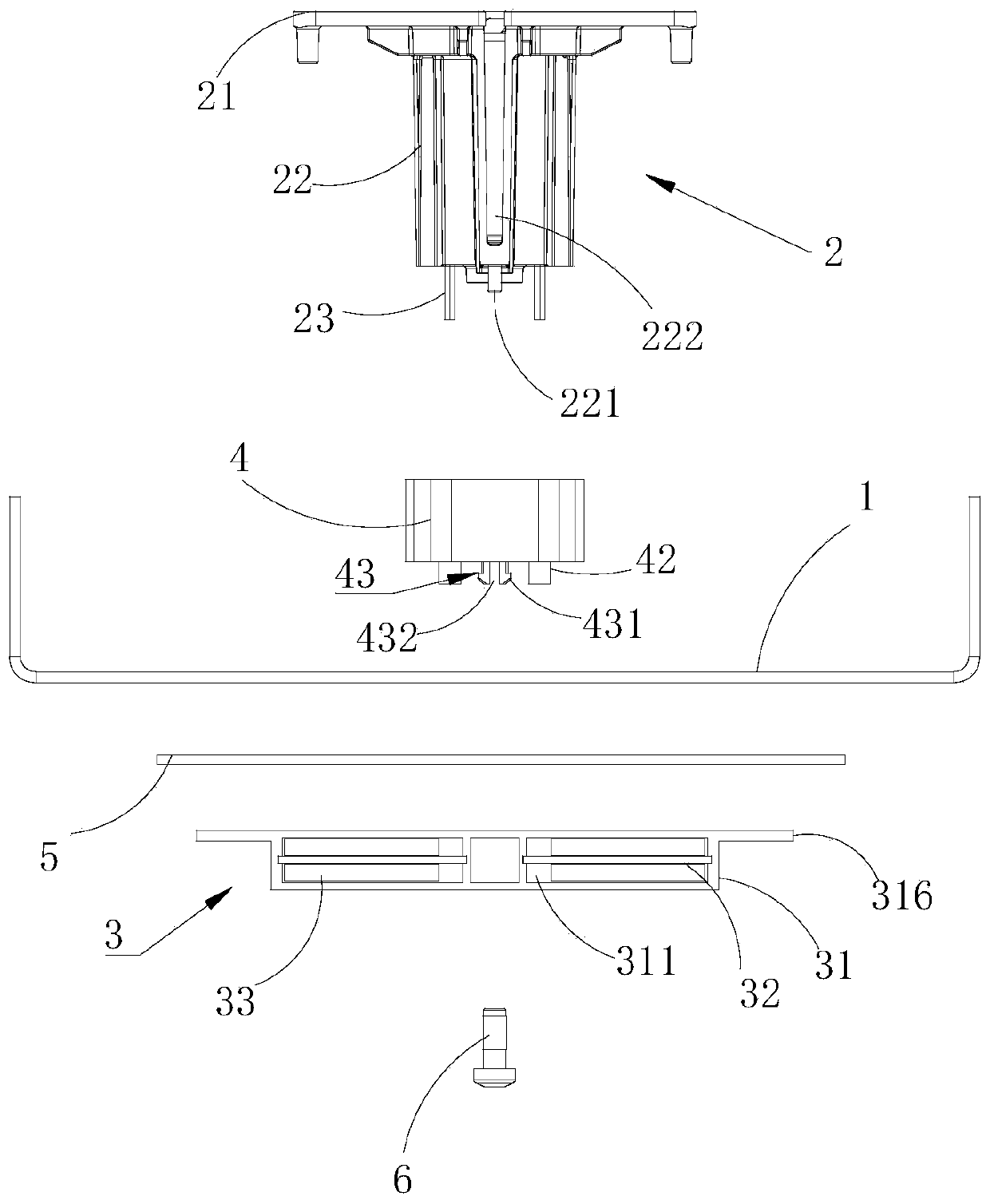

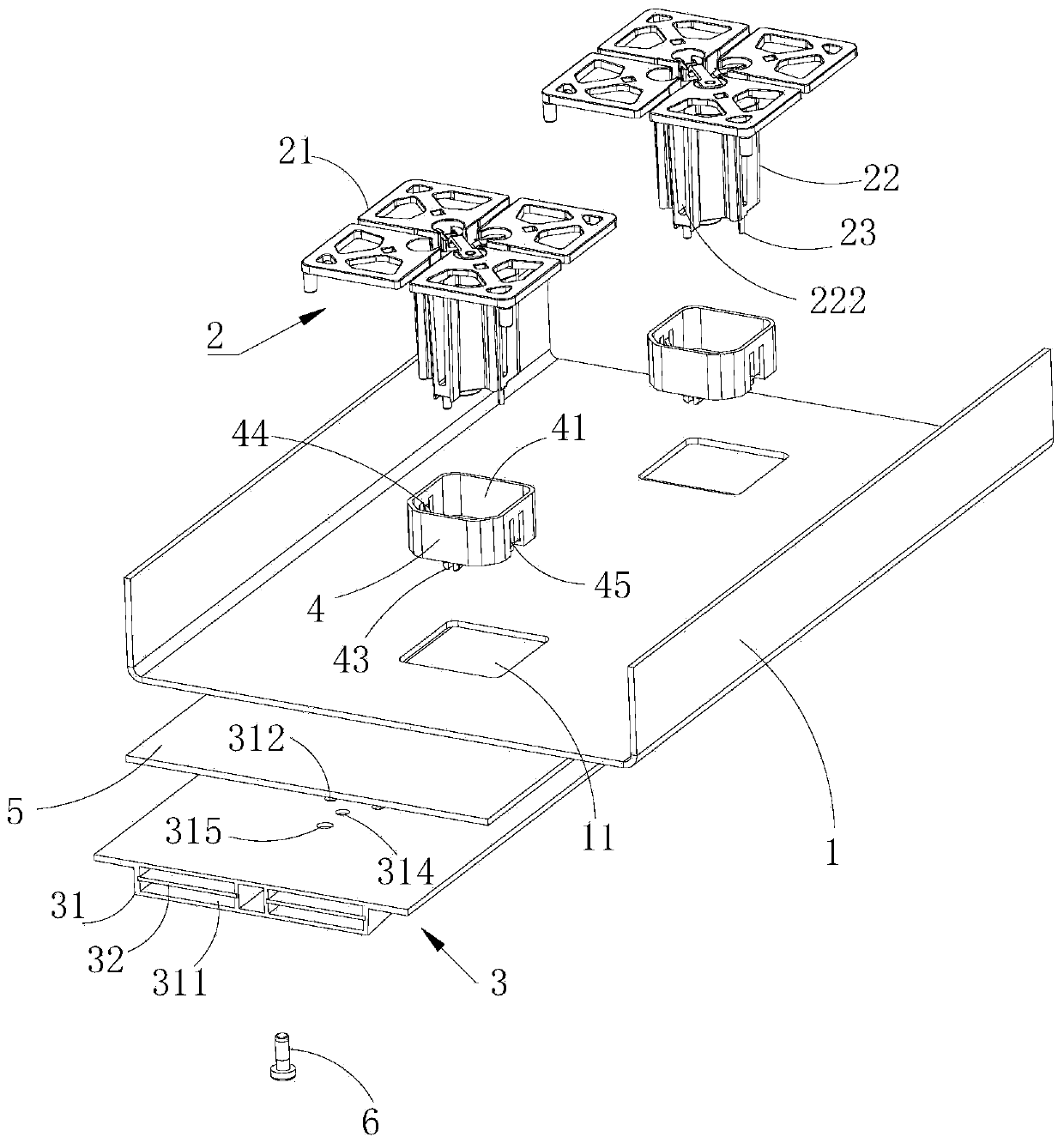

Electric pencil sharpener

An electric pencil sharpener comprises a casing (1) as well as a base (2), a motor (3), a tool rest (4) and a transmission assembly which are located in the casing (1), wherein the base (2) is connected with the casing (1), the motor (3) and the transmission assembly are connected onto the base (2), the tool rest (4) is rotationally connected with the casing (1), a pencil stopping block (5) is arranged in the tool rest (4), the tool rest (4) is connected with an output end of the transmission assembly, a micro-switch (6) is arranged in the casing (1) and is electrically connected with the motor (3), a link mechanism for controlling the micro-switch (6) is arranged on the base (2), one end of the link mechanism is attached to the micro-switch (6), and the other end of the link mechanism abuts against the pencil stopping block (5) and the output end of transmission assembly. Compared with the prior art, the electric pencil sharpener has the characteristics that a control mechanism is simple, fewer welding spots exist, the use stability is better, the electric pencil sharpener is easily and conveniently used, the assembling efficiency of workers can be substantially improved, and the cost is lower.

Owner:宁海县金益文具有限公司

Production method of 90íÒelbow steel skeleton of composite tube and dedicated die therefor

InactiveCN1807007AHigh strengthImprove yieldShaping toolsOther manufacturing equipments/toolsSheet steelButt welding

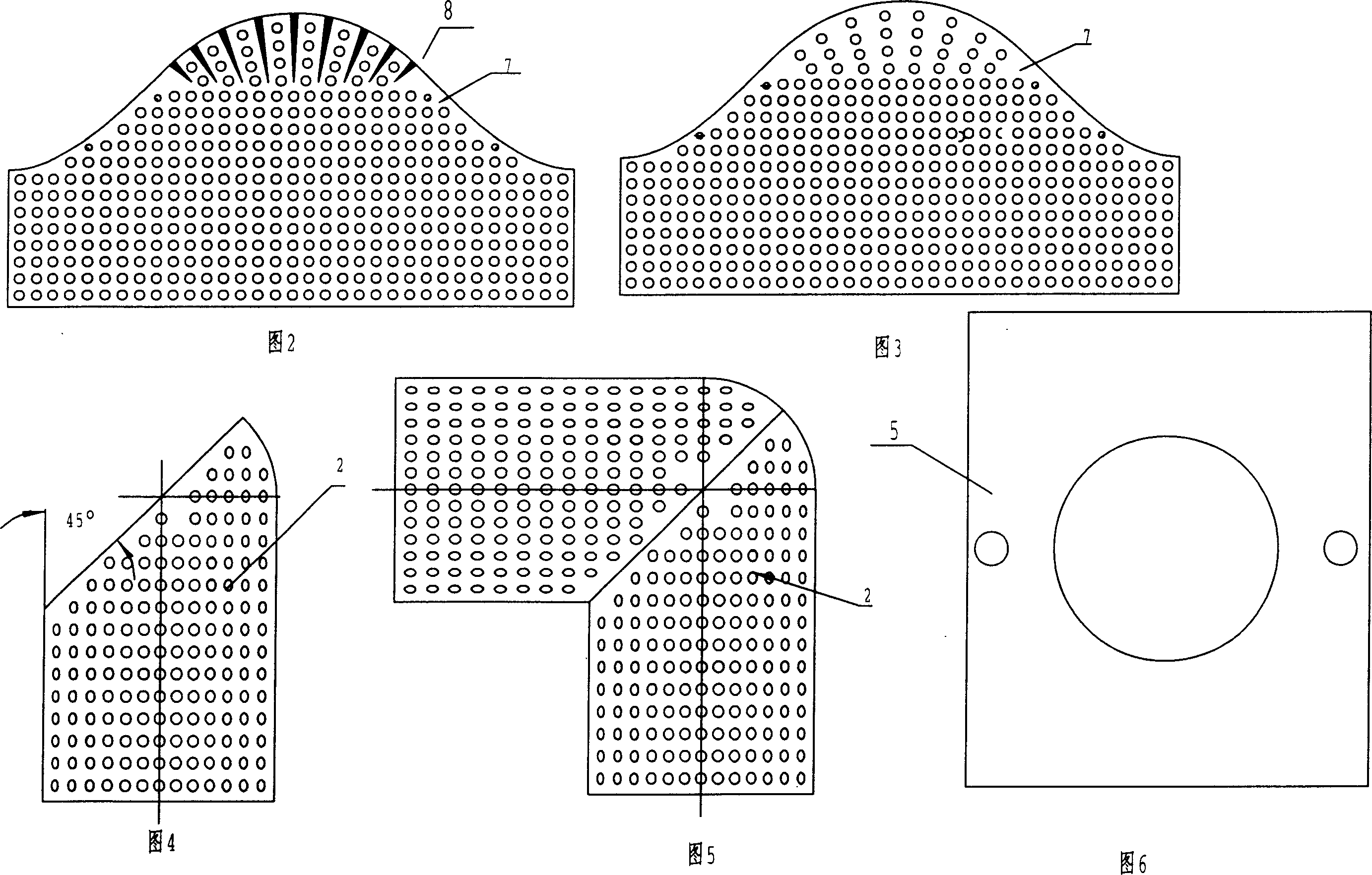

The invention relates the manufacturing method and special die of multiple-unit tube 90Deg steel skeleton. The method comprises the following steps: cutting the steel plate to roll bending 7; rolling the roll bending 7 into cylindrical shape, butt welding and making the tubular steel skeleton 2; putting it into female die 1, inserting the terrace die 3 into steel skeleton 2, pushing terrace die 3 by compression bar 6, terrace die 3 and charging plate 5 pressing the steel skeleton 2 into female die 1, then ejecting the terrace die 3 and steel skeleton 2; then welding the steel skeleton 2 to form 90Deg angle head steel skeleton; the female die and the bottom of female die being spherical surface. The productivity is high, spherical degree error is little, welding spot is little and strength is big.

Owner:HUACHUANG TIANYUAN IND DEVING

Common part afflux assembly of refrigerating device

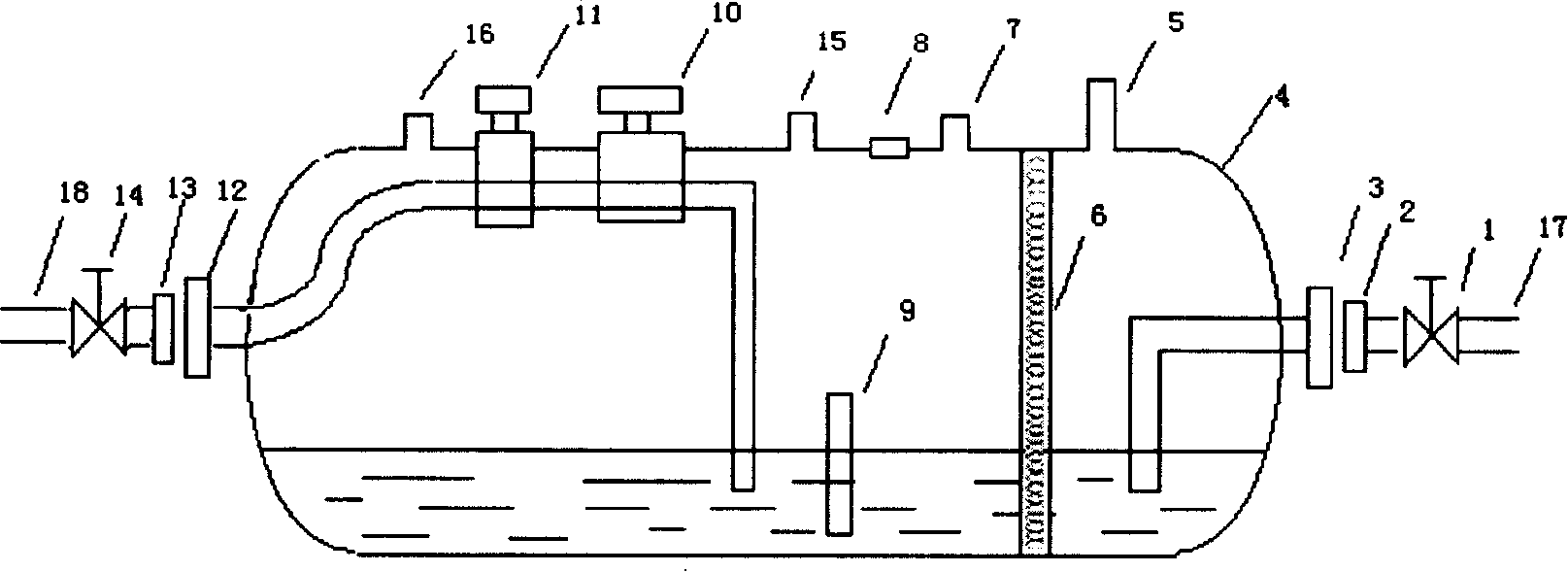

InactiveCN101201208AReduce solder jointsReduce processing difficultyFluid circulation arrangementWhole bodyLiquid storage tank

The invention is suitable for an air conditioner and a refrigeration plant. The invention integrates the parts between an outlet of a condenser and an evaporator in a refrigeration system like a valve, a liquid storage tank, a safety valve, a filter, a visual liquid mirror, a solenoid pilot actuated valve and an expansion valve as a whole body. the invention has the advantages of reducing the welding points when a unit is assembled, reducing the techinics difficulty of on spot mounting and detecting, reducing the fault rate and reducing the detecting time for unit fault, thus leading the on spot maintenance and repairing work to be very simple and simultaneously the time for on spot operation is reduced greatly.

Owner:刘东波

Straight-way solar energy heat exchange heat collector

InactiveCN101581506AUnique structureObvious technical advantagesSolar heating energySolar heat devicesEngineeringMetal

The invention relates to a straight-way solar energy heat exchange heat collector using solar energy as a heat source and belongs to the technical field of medium and high temperature solar energy utilization. The straight-way solar energy heat exchange heat collector comprises a straight-way transparent tube, a multi-curved face metal heat exchange tube, heat exchange tube end enclosures, a metal expansion joint, adsorbent storage rings, concave spacing sealing rings, metal snap rings, a working medium channel pipe, metal cover plates, sealing fixed plates, card type shield covers and vacuum connectors, wherein the two ends of the multi-curved face metal heat exchange tube are welded and fixed with the heat exchange tube end enclosures; the working medium channel pipe is connected with the heat exchange tube end enclosures; the multi-curved face metal heat exchange tube is provided with the metal expansion joint; the working medium channel pipe passes through the center of the metal cover plate to form an multi-curved face metal heat exchange tube component which is integrally sleeved in the straight-way transparent tube and the two ends of which are sequentially provided with the adsorbent storage rings, the concave spacing sealing rings and the metal snap rings; the sealing fixed plates seal and fix the metal snap rings and the metal cover plates; the two ends of the straight-way transparent tube are provided with the card type shield covers; and the vacuum connectors are fixed on the card type shield covers.

Owner:WUXI C SOLAR NEW ENERGY TECH

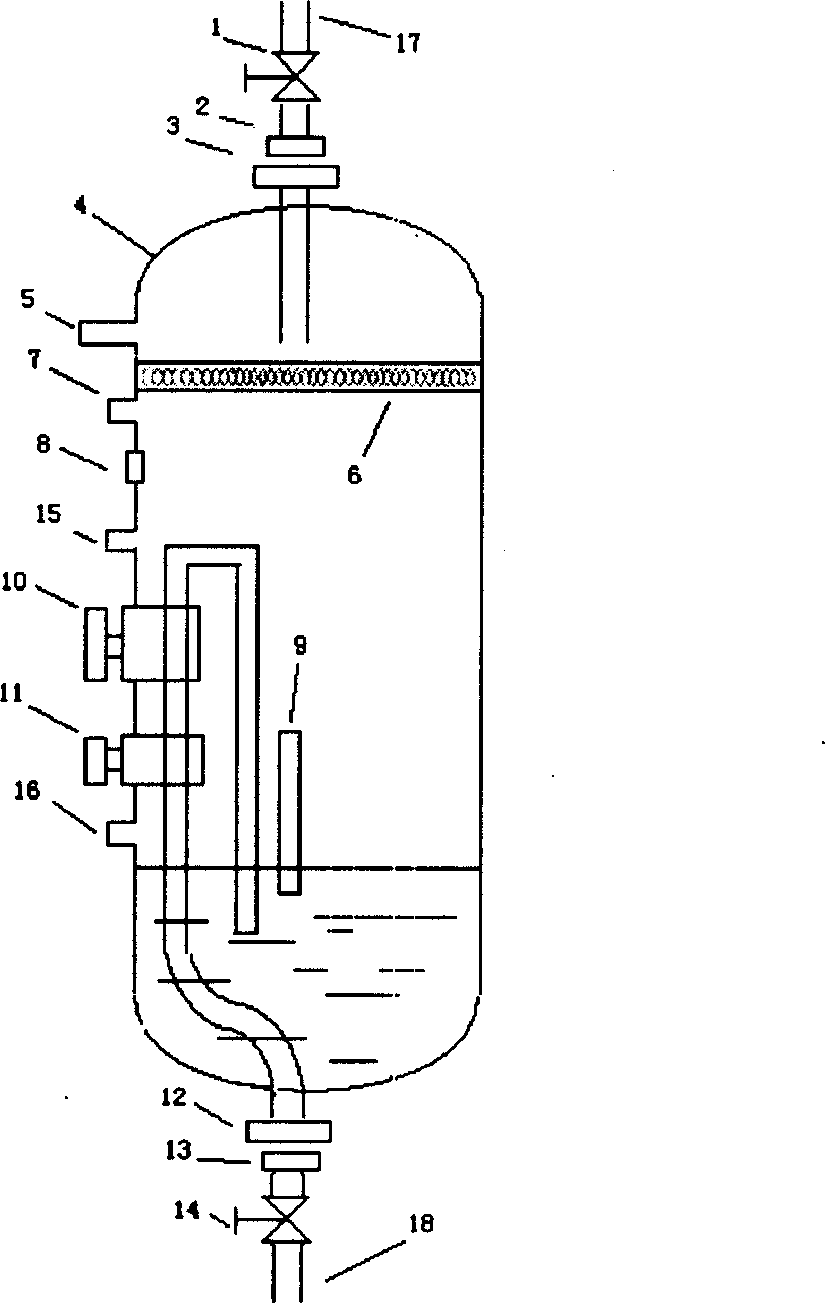

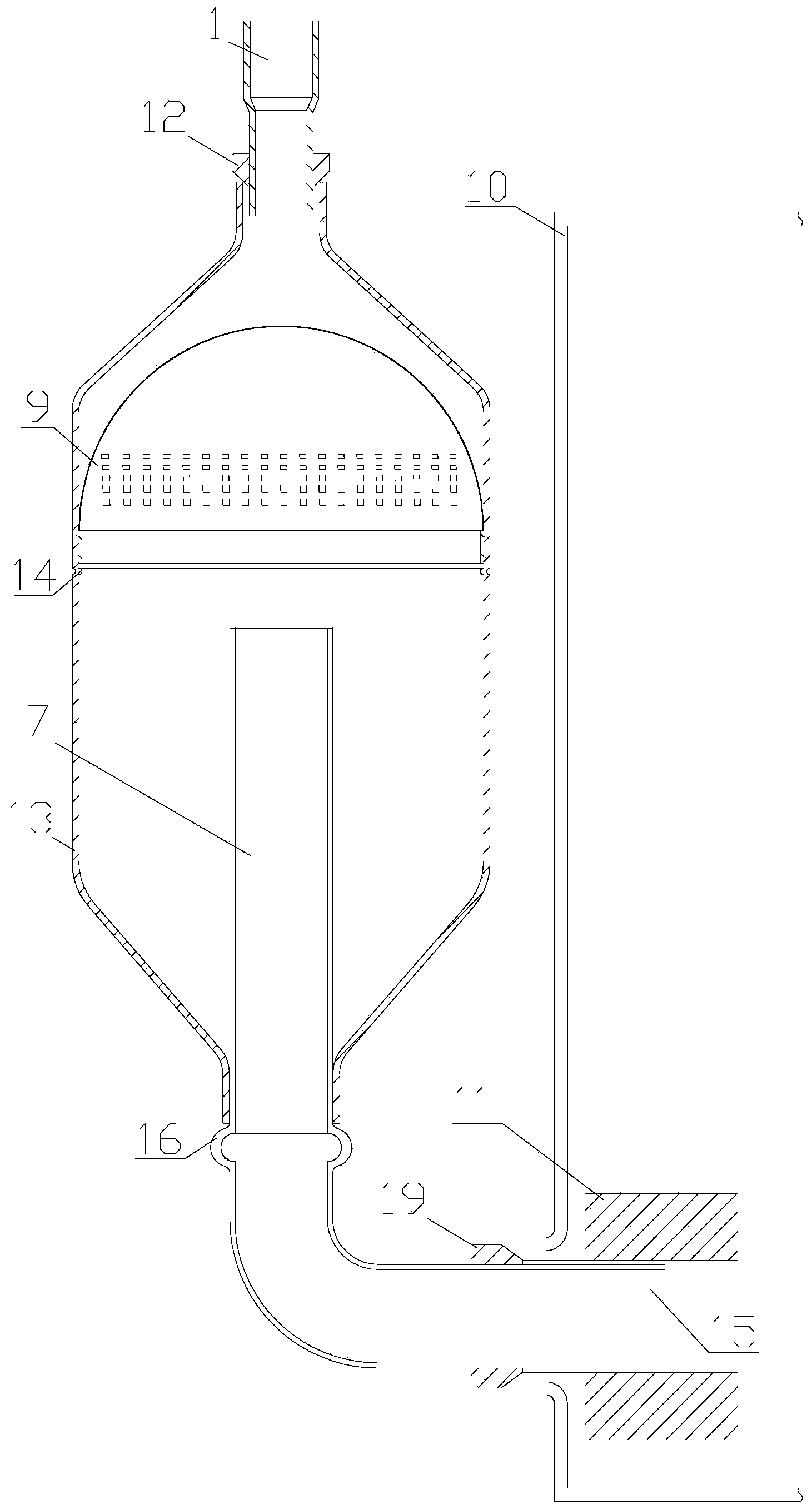

Novel PSA (pressure swing adsorption) oxygen generator

The invention discloses a novel PSA (pressure swing adsorption) oxygen generator. The novel PSA oxygen generator comprises a first adsorption separator module, a second adsorption separator module, gas holders, gas collection pipes and gas cylinders, wherein the gas holders comprise an upper gas inlet holder, an upper gas outlet holder and a lower gas outlet holder; the gas collection pipes comprise upper gas collection pipes and lower gas collection pipes, the upper gas collection pipes and the lower gas collection pipes are mounted at the upper ends and the lower ends of the first adsorption separator module and the second adsorption separator module respectively and distributed in parallel after mounting, the upper gas inlet holder and the upper gas outlet holder are mounted at two ends of each of two upper gas collection pipes respectively, the lower gas outlet holder is mounted at one end of each of two lower gas collection pipes and located on the same side with the upper gas inlet holder, and the gas cylinders are mounted on the upper gas inlet holder, the upper gas outlet holder and the lower gas outlet holder respectively. The novel PSA oxygen generator has the advantages of small overall size, simple pipelines, simple and stable structure, attractive appearance, low production cost and the like.

Owner:HUNAN TECHRAY MEDICAL

Antenna

PendingCN111525230ASimple assembly structureHigh gainAntenna supports/mountingsRadiating elements structural formsDielectric lossAntenna gain

The invention provides an antenna. The key points of the technical scheme are that the antenna comprises a reflecting plate, and a radiation unit and a phase shifter which are arranged at two sides ofthe reflection plate; the reflecting plate is respectively connected with the radiation unit and the phase shifter in an insulating manner, the radiation unit comprises a feed sheet for feeding the radiation arm, the phase shifter comprises a cavity and a phase shifting circuit arranged in the cavity, and the feed sheet penetrates through the reflecting plate, penetrates into the cavity and is electrically connected with the phase shifting circuit. The radiation unit, the reflecting plate and the phase shifter are arranged in a stacked manner; the feed sheet of the radiation unit extends intothe phase shifter to be connected with the phase shift circuit, and an external feed cable is not needed, so that the assembly structure of the antenna is simpler, welding spots are reduced, hidden dangers caused by the welding spot problem are avoided, the feed cable is reduced, the dielectric loss is also avoided, and the antenna gain is improved.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD +1

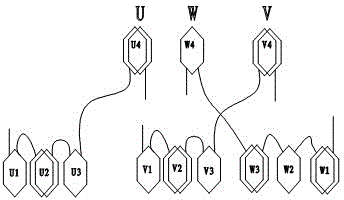

Effective alternating-current motor stator winding preparation method

InactiveCN104617721AGood winding processEasy windingManufacturing dynamo-electric machinesEngineeringAlternating current

The invention discloses an effective alternating-current motor stator winding preparation method. The effective alternating-current motor stator winding preparation method includes wire wrapping, wiring and wire inserting. The wire wrapping technique includes that each phase U, V or W has six coils U1, U2, U3, U4, V1, V2, V3, V4, W1, W2, W3 and W4, wherein 6 coils of each phase wrap continuously, the wrapping directions of the wrapped coils are consistent, and there is no joint between the six coils of each phase; each of the W1, W3, V2, V4, U2 and U4 comprises two large coils, the span of the large coil is 1 to 9 tanks, the W2, W4, V1, V3, U1 and U3 are small coils, and the span is 1 to 8 tanks. The wiring is performed after the wire wrapping technique and before the wire inserting technique, and the wiring enables the wrapping directions of the large coils of each phase to be opposite to the winding direction of the small coil. The effective alternating-current motor stator winding preparation method is good in coil winding technique, enables the cost to be saved and enables the motor winding reliability to be improved.

Owner:江苏利得尔电机有限公司

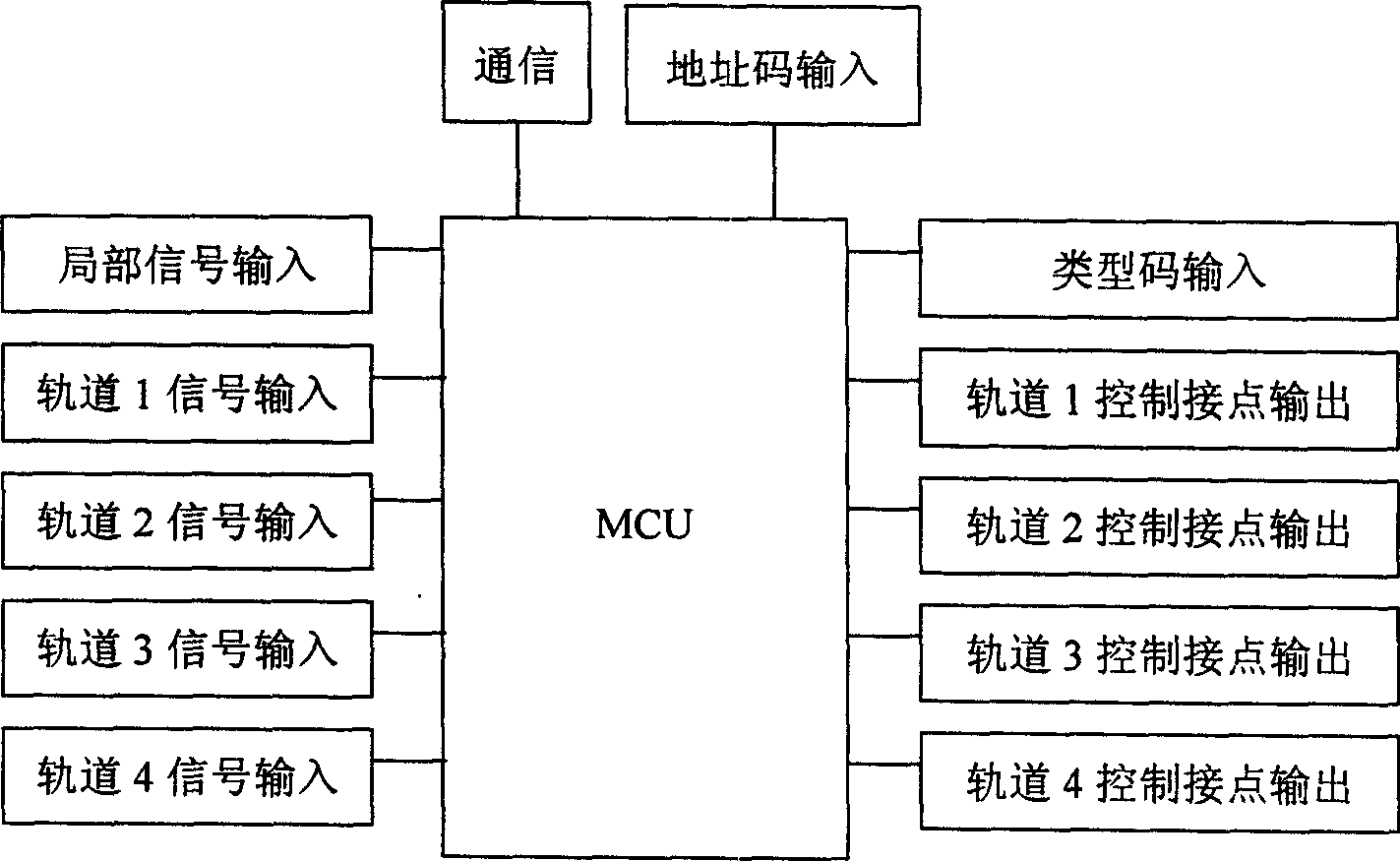

Digital phase sensitive rail circuit receiver

InactiveCN1588475AImprove reliabilityImprove anti-interference abilityElectric signal transmission systemsRailway signalling and safetyPhase differenceComputer module

The invention provides a digital phase sensitive railway rail circuit receiver. The host circuit of the mentioned device uses micro controller with analogue amount / digital amount conversion and programming function. It collects railway signal through software, and it transmits signal with noncontact electron switch and communication bus, eliminates the vibration. It improves the system stability, reliability and anti-interference property. The invention collects local signals, it measures and calculating track voltage and phase difference more precisely.

Owner:兰州大成科技股份有限公司 +1

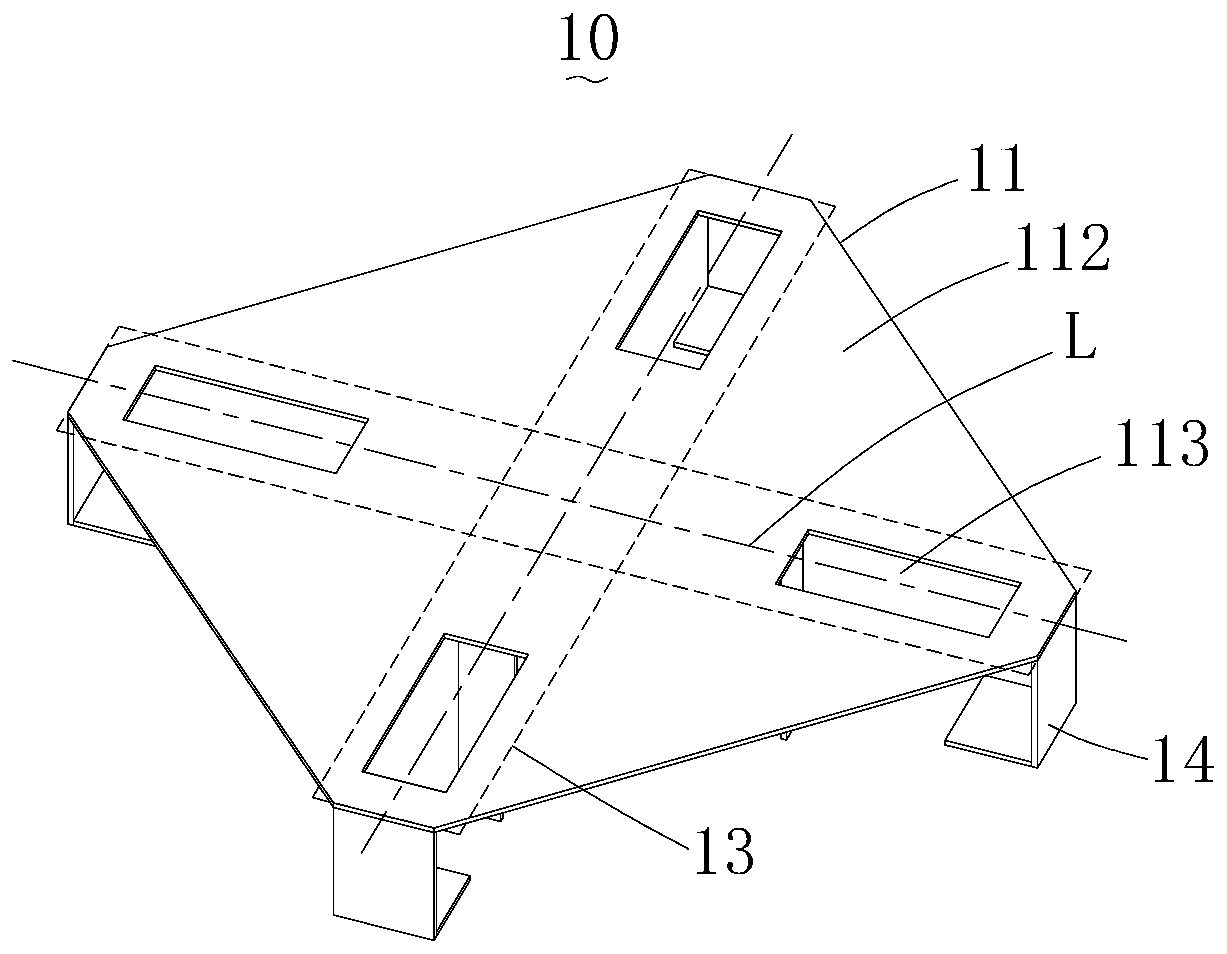

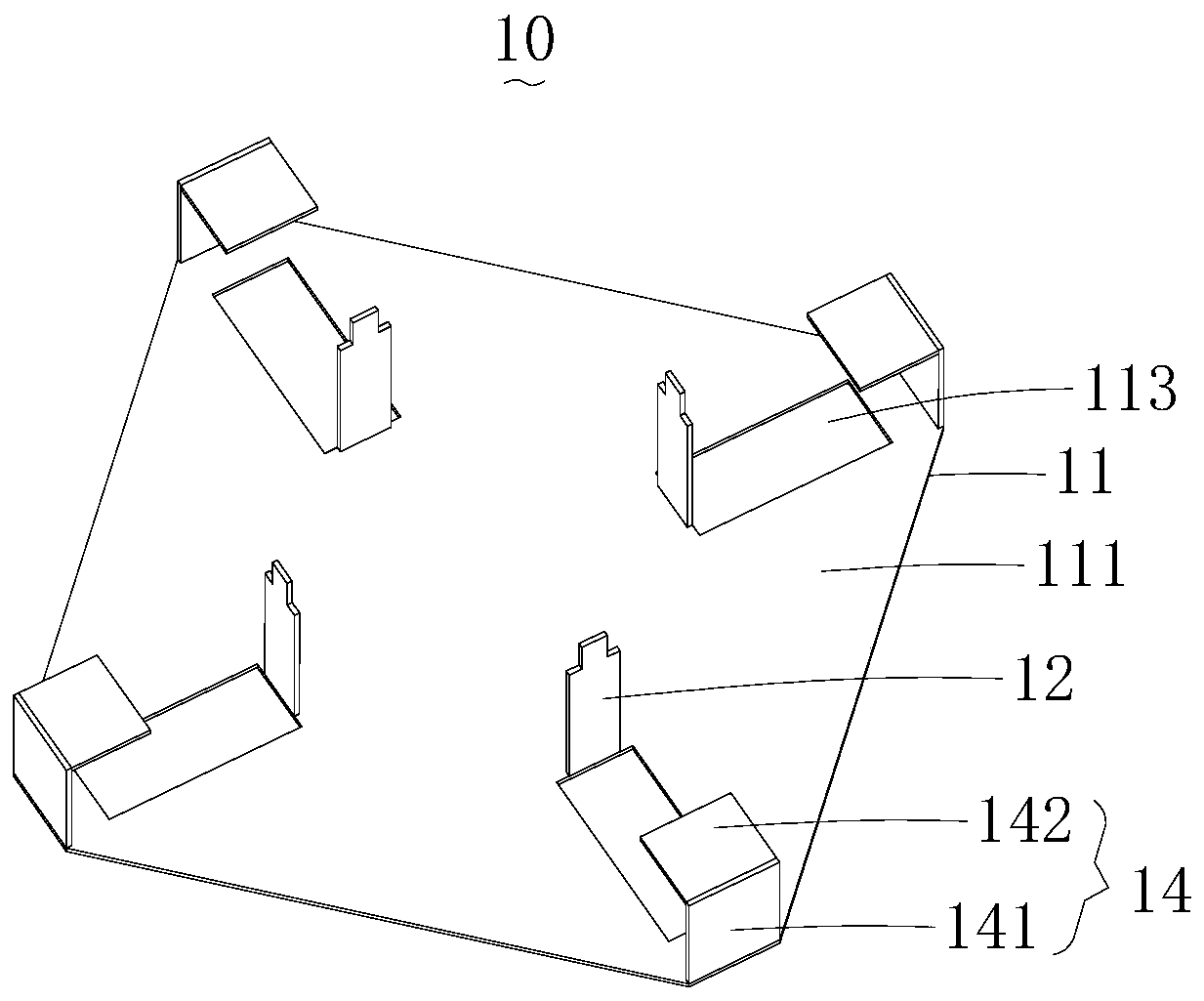

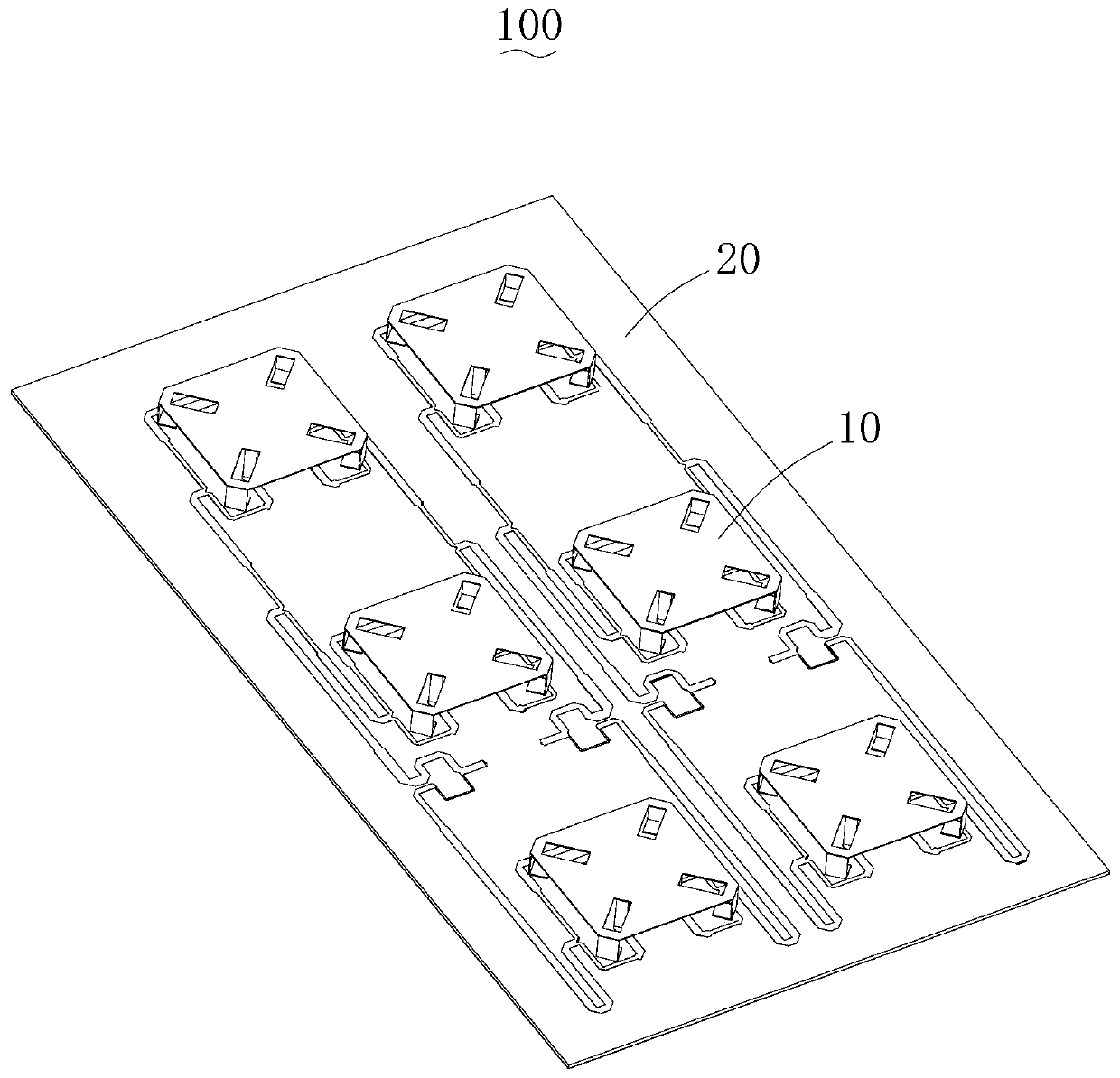

Antenna oscillator and array antenna

InactiveCN110247172AReduce thicknessReduce weightParticular array feeding systemsRadiating elements structural formsPunchingPhysics

The invention provides an antenna oscillator and an array antenna. The antenna oscillator comprises a radiation sheet and a feed branch. The radiation sheet is provided with a first surface and a second surface opposite to the first surface. The radiation sheet is provided with a hollow part penetrating through the first surface and the second surface. One end of the feed branch is connected with the side wall of the hollow part, and the other end of the feed branch extends from the first surface to the direction far away from the first surface. The radiation sheet and the feed branch are formed through integrated punching of a sectional material. According to the invention, the radiation sheet and the feed branch formed through integrated punching of the sectional material, so that the manufacturing is simple, and the cost can be effectively reduced; the antenna oscillator formed through punching can be relatively small in thickness and light in weight, so that large-scale array formation is facilitated; and in addition, the antenna oscillator formed through punching has few welding spots and is easy to assemble.

Owner:AAC PRECISE MFG TECH CHANGZHOU

Solar battery for solar mobile phone battery and preparation method thereof

InactiveCN101728460AImprove photoelectric conversion efficiencyGood lookingFinal product manufacturePhotovoltaic energy generationEpoxyGlass fiber

The invention discloses a preparation method for a solar battery of a solar mobile phone battery module, comprising the following steps: (1) after an epoxy resin plate is cleaned, adhesives, a glass fiber surfacing mat and a crystalline silicon battery are sequentially laminated on the epoxy resin plate; (2) an extraction electrode of the crystalline silicon battery is welded with a welding point at the bottom surface of the epoxy resin plate, and then a polyvinyl fluoride adhesive tape is pasted on the crystalline silicon battery, corresponding to the position of the extraction electrode; (3) the adhesives and tempering glass are laminated on the crystalline silicon battery; (4) the laminated battery modules are laminated, the temperature is 140-150 DEG C, the atmosphere pressure is 0.5-0.6, and the time is 10-20mins; (5) cooling formation is carried out, so as to obtain the solar battery of the solar mobile phone battery module. The solar battery which has high photoelectric conversion efficiency and good appearance is prepared, and the solar battery is assembled with the lithium battery and the shell, so as to obtain the solar mobile phone battery module.

Owner:CHANGSHU CANADIAN SOLAR ELECTRIC POWER TECHCO +6

Phase shifting device, antenna and base station

ActiveCN108232378AReduce volumeHighly integratedAntenna supports/mountingsWaveguide type devicesElectrical and Electronics engineeringBase station

The invention provides a phase shifting device. The phase shifting device comprises two phase shifters and at least one circuit combiner arranged between the two phase shifters, wherein the circuit combiner comprises an output end and two input ends; each phase shifter comprises at least one output end, one input end of the circuit combiner is connected with the output end of one of the two phaseshifters, and the other input end of the circuit combiner is connected with the output end of the other phase shifter; and each phase shifter comprises at least two U-shaped phase shifting circuits which are sequentially connected, and an output end of each of any two adjacent U-shaped phase shifting circuits is connected with an input end of the other U-shaped phase shifting circuit and the inputend of the circuit combiner, respectively. By utilizing relatively few cables and welding points, the phase shifting device has relatively small volume and relatively high integration level. Correspondingly, the invention further provides an antenna and a base station which adopt the phase shifting device.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

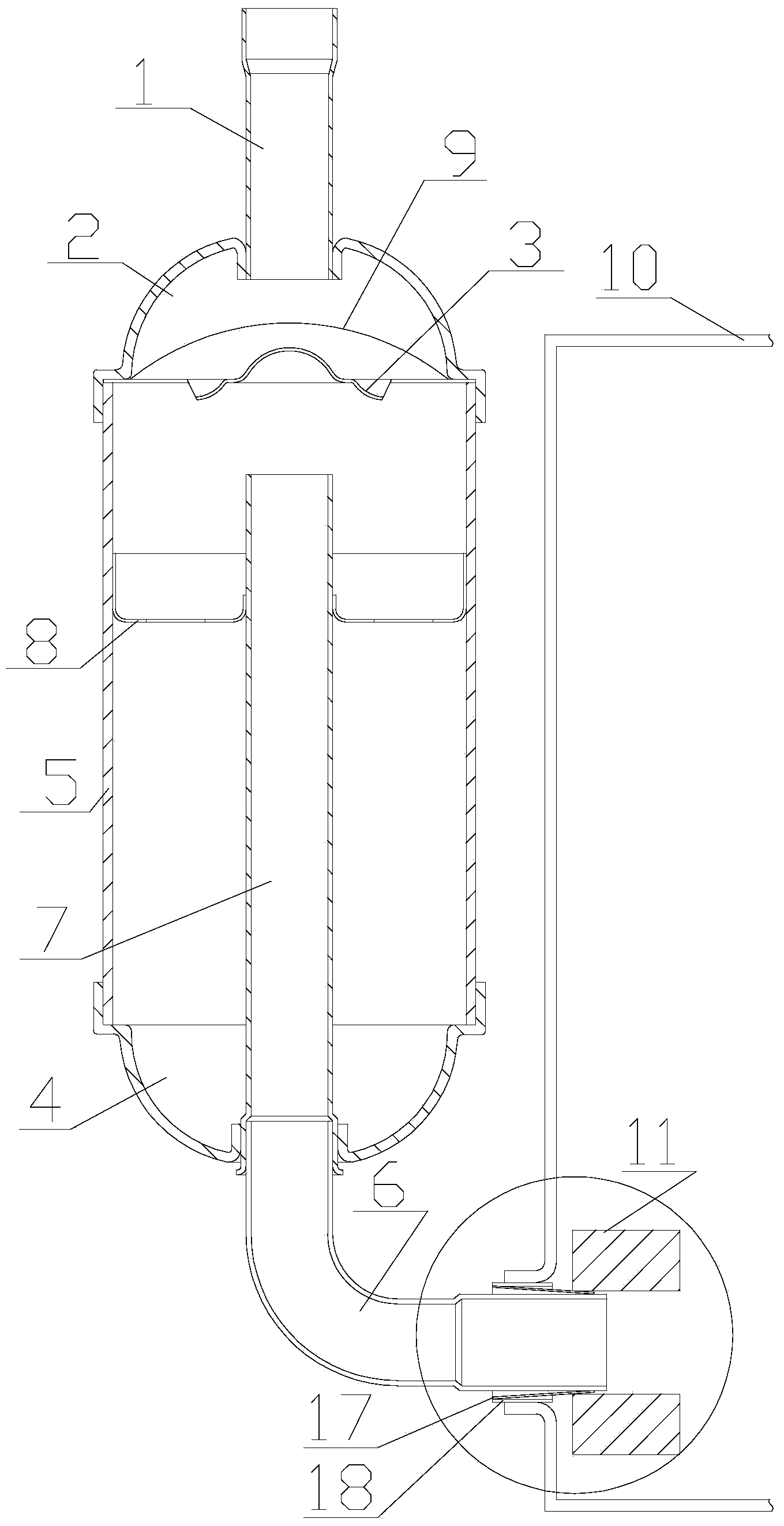

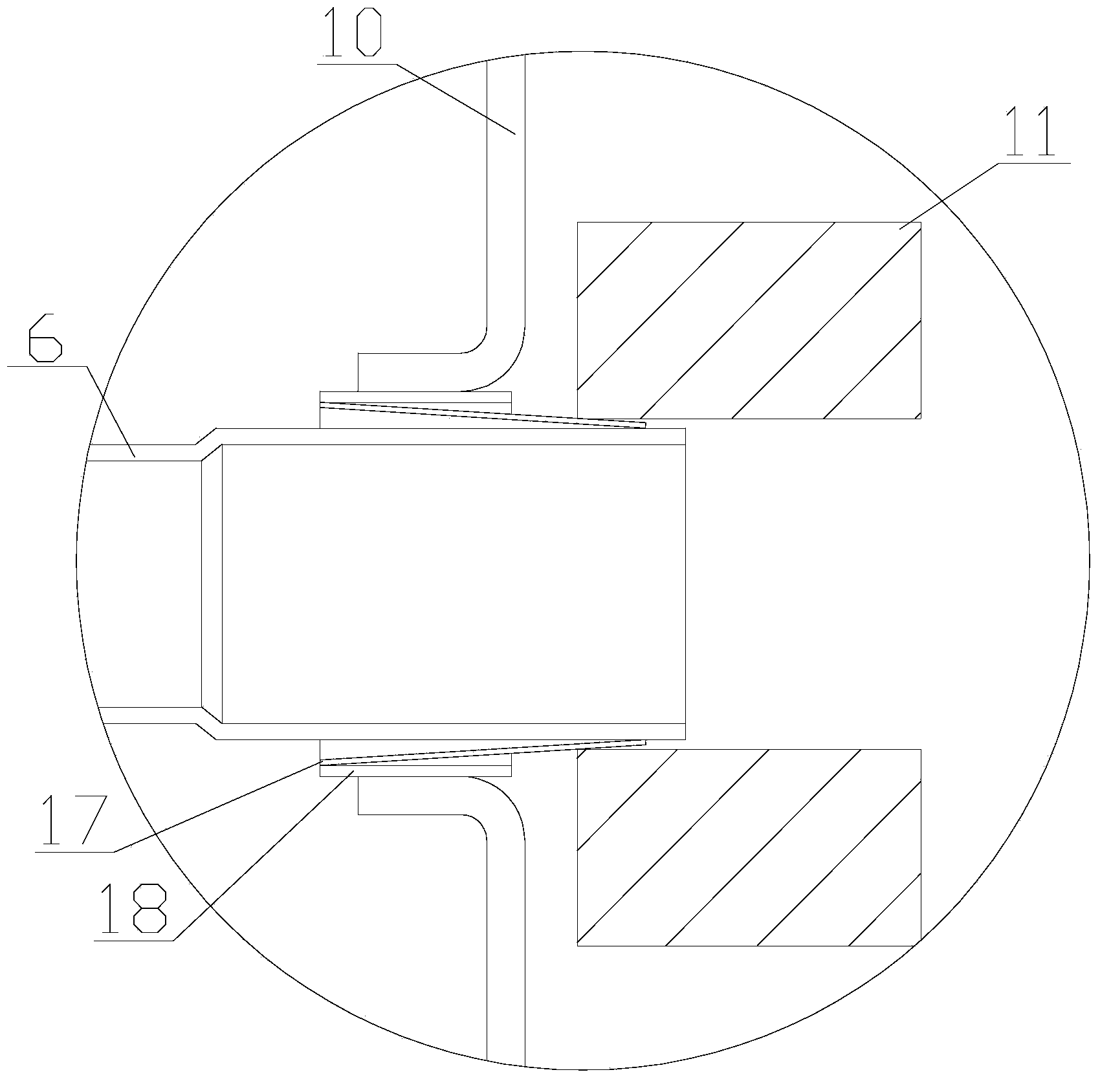

Liquid receiver

ActiveCN103851845AReduce solder jointsIncrease productivityRefrigeration componentsCenterless grindingEngineering

The invention provides a liquid receiver. The liquid receiver is connected with a compressor and comprises a cylinder body, wherein an intake tube is arranged at the front end of the cylinder body and is provided with a first flange; an iron tube is arranged at the back end of the cylinder body, a centerless grinding iron tube is arranged at the tail end of the iron tube, and a second flange is sleeved outside a connection part of the iron tube and the centerless grinding iron tube and is connected with a compressor shell cylinder body; the centerless grinding iron tube is connected with an air cylinder hole of the compressor through interference fit; the flanges, the cylinder body and the iron tubes are made of an iron material, and the intake tube is made of a copper material; a filter screen and locating bumps are also arranged in the cylinder body, and the locating bumps fix the filter screen on the cylinder body by utilizing a rolling process; the iron tube is provided with locating points for helping the iron tube and the cylinder body to be located in a welding process.

Owner:绍兴科辉电器有限公司

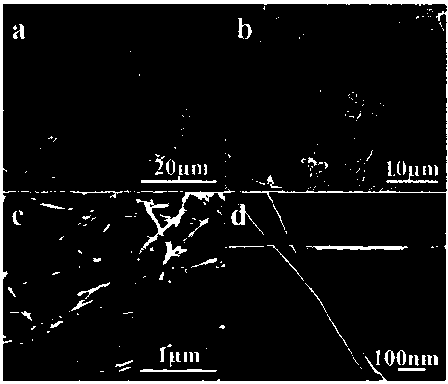

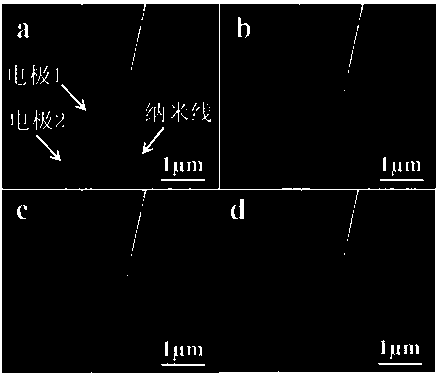

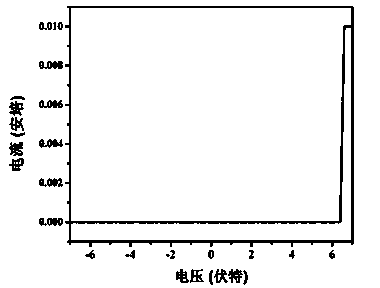

One-dimensional nanomaterial welding method based on electrically-induced heating effect

InactiveCN103624388ATo achieve the welding effectCreate pollutionNanostructure manufactureWelding/cutting media/materialsHeating effectUltimate tensile strength

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

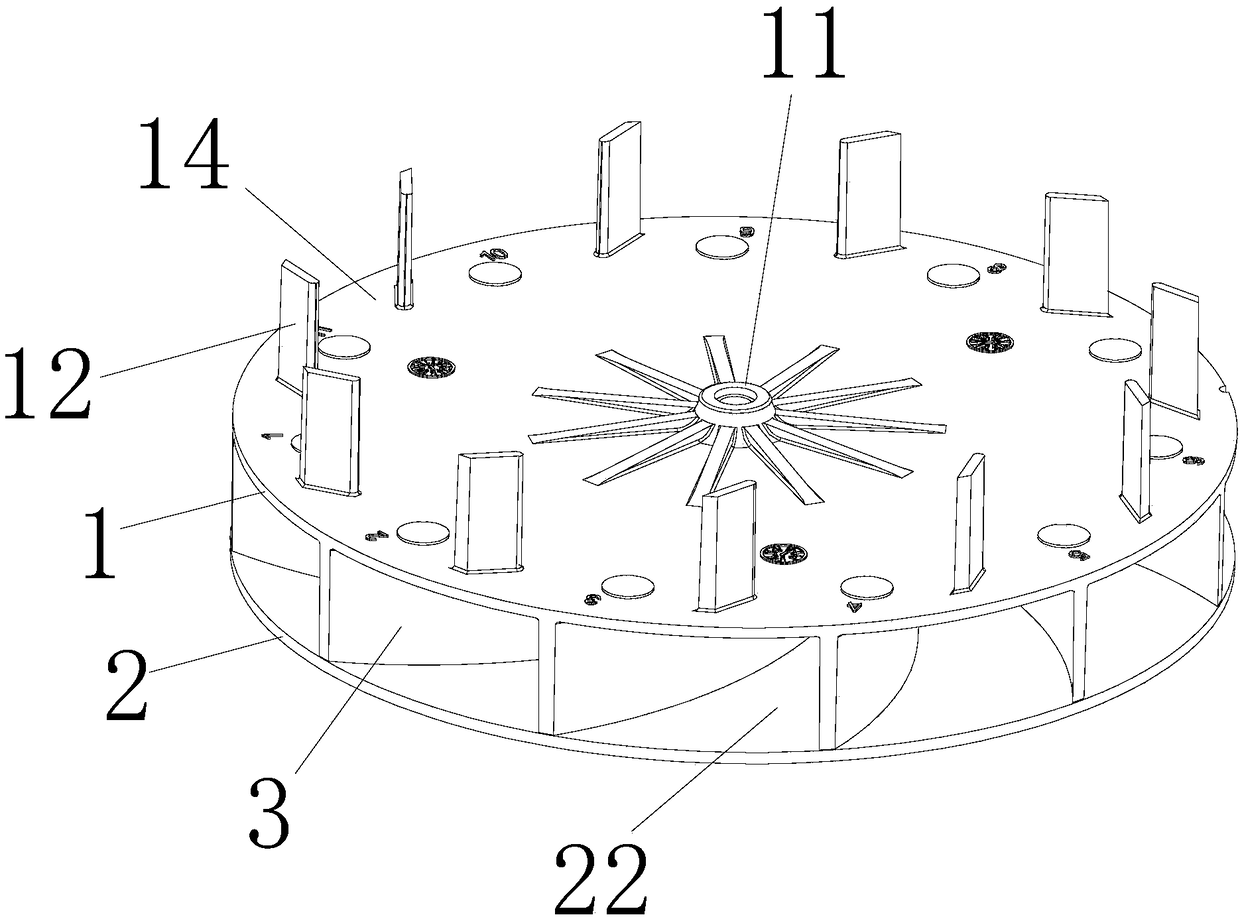

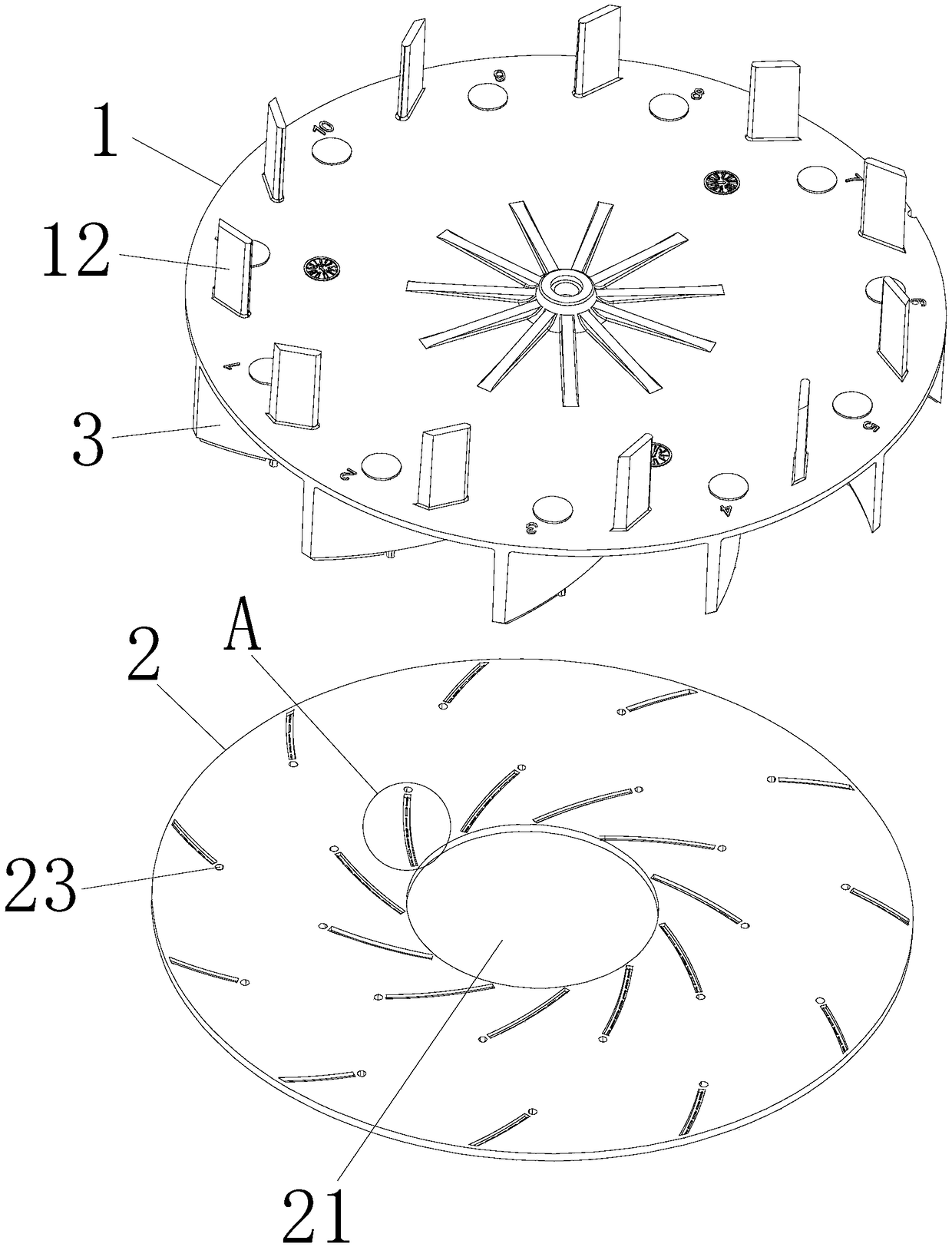

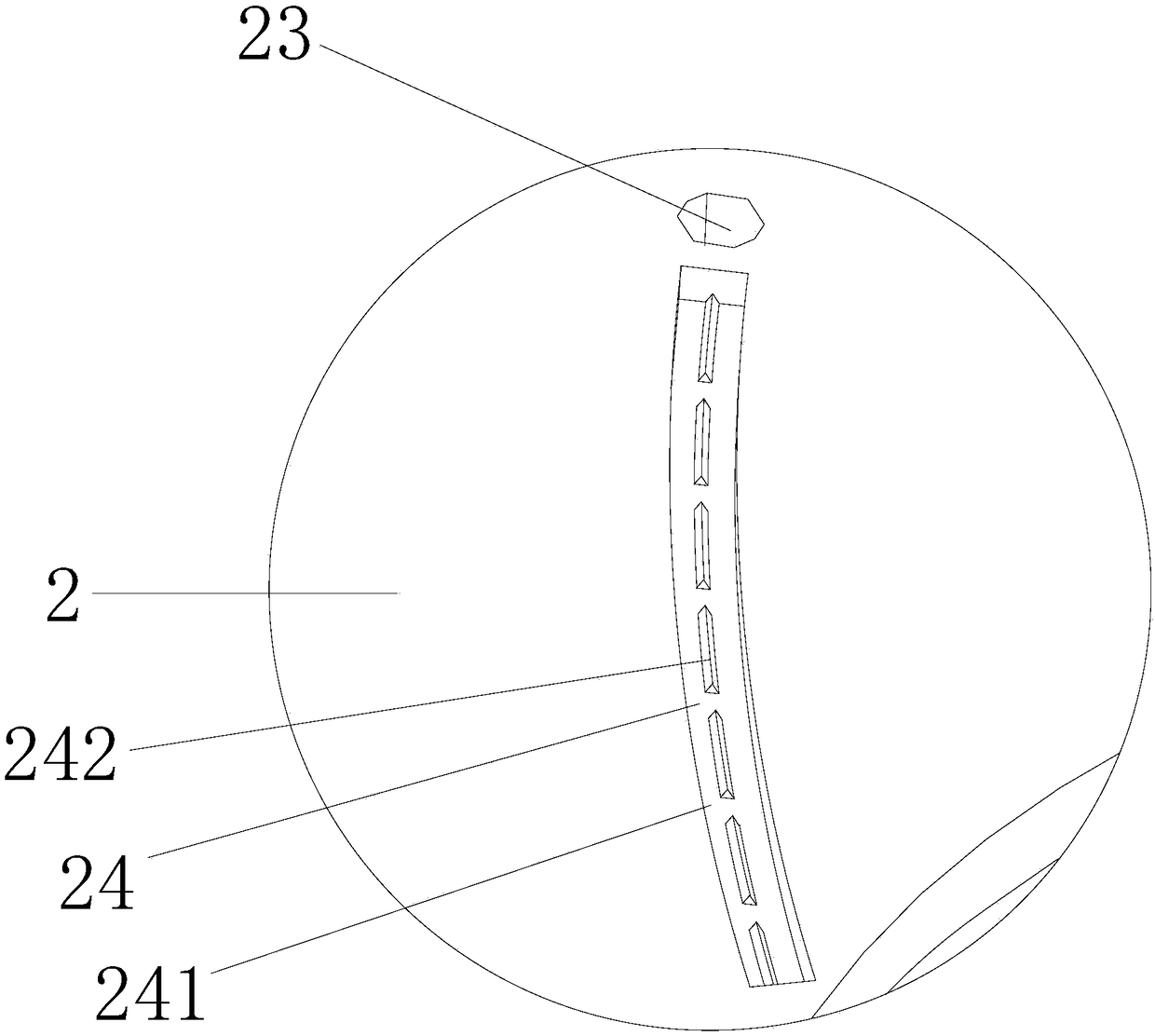

Wind wheel and air blower applying wind wheel

PendingCN108223443ASolve the big jumpSolve the problem of poor horizontalityPump componentsPumpsEngineeringInjection moulding

The invention discloses a wind wheel and an air blower applying the wind wheel. The wind wheel comprises a top panel provided with a plurality of wind blades and a bottom panel. The multiple wind blades protrude out of the lower end face of the top panel, and the multiple wind blades and the top panel are integrally formed through injection molding. The multiple wind blades are located between thetop panel and the bottom panel. An air inlet is formed in the middle of the bottom panel. An air flue is formed between every two adjacent wind blades. A connecting base connected with a motor shaftis arranged in the center of the top panel. A plurality of positioning columns protrude out of the end faces, connected with the bottom panel, of the wind blades. The bottom panel is provided with installing holes for the positioning columns to penetrate, and the wind blades and the bottom panel are fixed together through welding. The end faces of the wind blades are further provided with a plurality of first bosses. The bottom panel is provided with grooves matched with the first bosses. The first bosses are embedded in the grooves, the first bosses and the grooves are combined together through welding, welding points are reduced, and the problem about solder skips is reduced; and the welding precision is improved, welding is firm, and the problems that during wind wheel running, jumpingis great, and balance performance is poor are effectively solved.

Owner:ZHONGSHAN BROAD OCEAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com