Electric pencil sharpener

A pencil sharpener and electric technology, which is applied in the field of stationery, can solve the problems of large overall volume of the pencil sharpener, complicated control mechanism structure, increased assembly difficulty for workers, etc., and achieves the effects of simple structure, simple control mechanism and good use stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

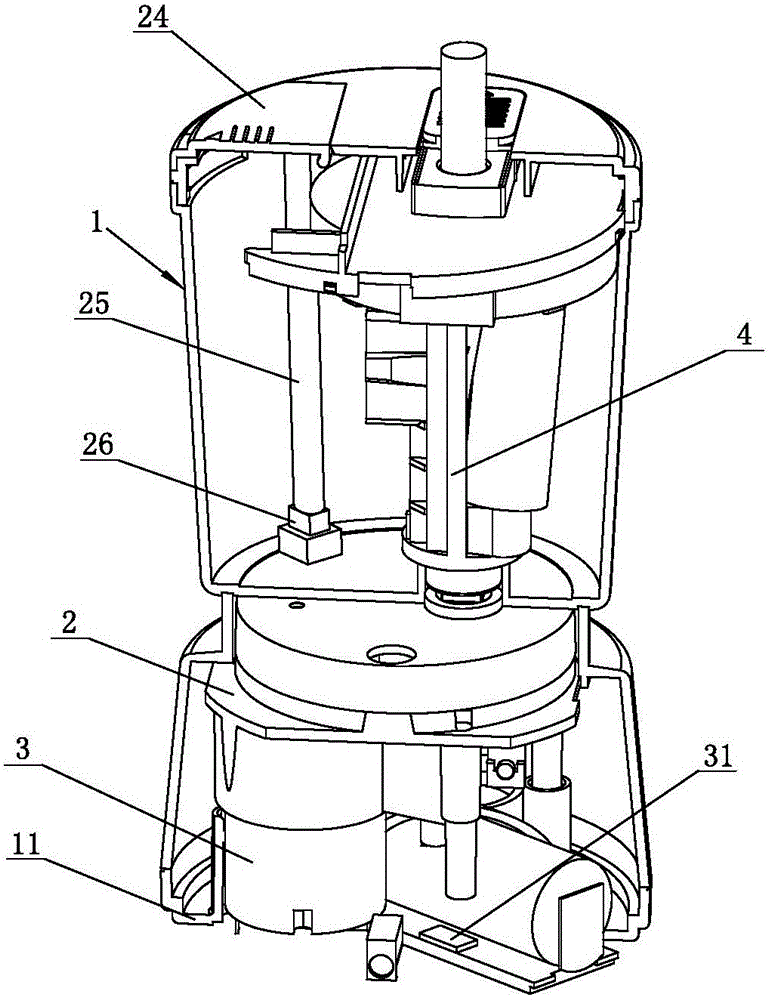

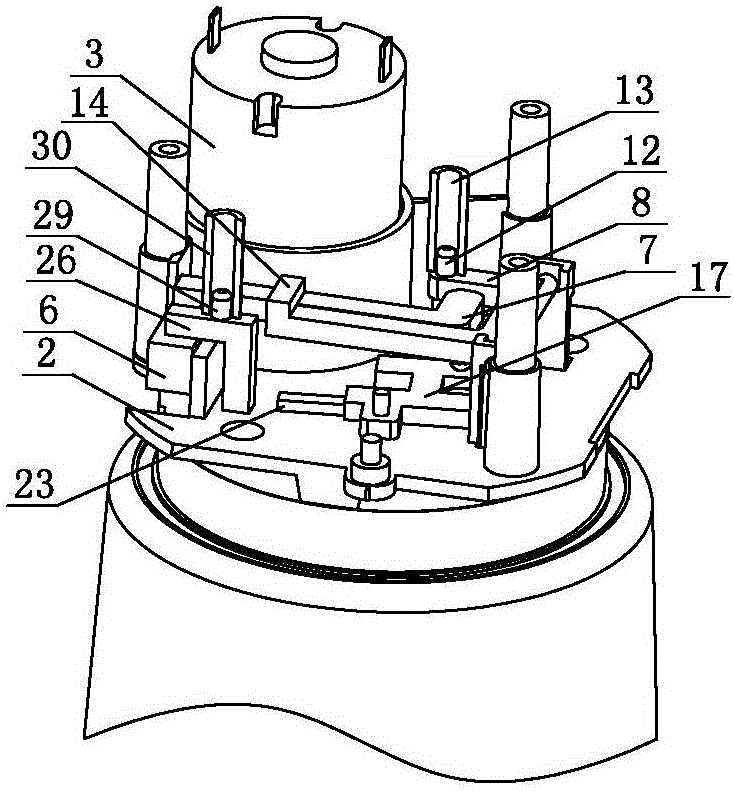

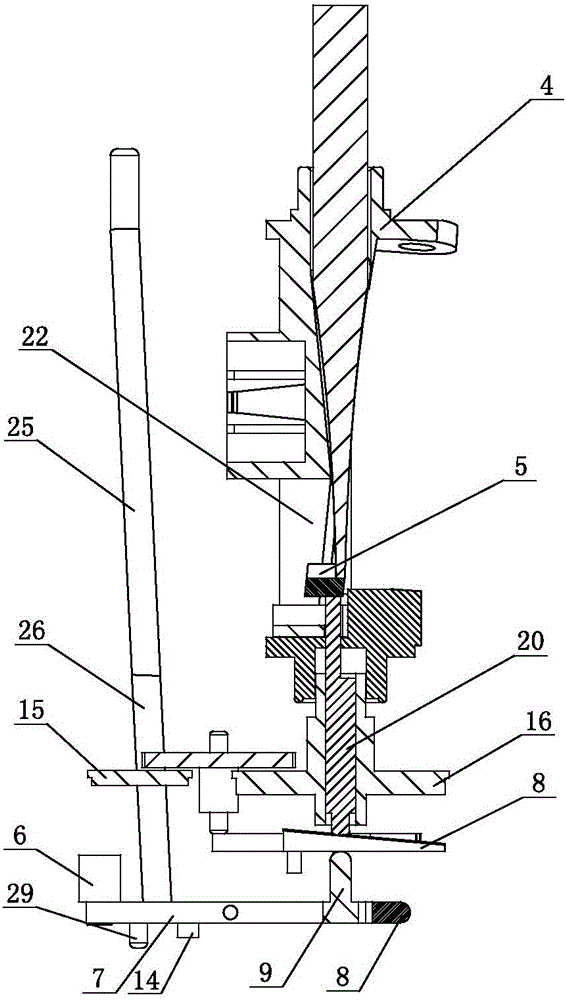

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, a kind of electric pencil sharpener, it comprises housing 1 and be positioned at the base 2 in housing 1, motor 3, knife rest 4 and transmission assembly (also comprise other components of course, but because relate to the invention of the present invention Invention point, so no more details here), the base 2 is connected to the housing 1, the motor 3 and the transmission assembly are connected to the base 2, the knife rest 4 is connected to the housing 1 in rotation, the knife The frame 4 is provided with a pen block 5, and the tool holder 4 is connected to the output end of the transmission assembly. The housing 1 is provided with a micro switch 6, and the micro switch 6 is electrically connected to the motor 3. The base 2 There is a link mechanism for controlling the micro switch 6, one end of the link mechanism is attached to the micro switch 6, and the other end of the link mechanism is ...

Embodiment 2

[0034] The middle part of the starting connecting rod 8 is hinged with the base 2, and one end of the starting connecting rod 8 is connected with the lower end of the second contact rod 10, and the upper end of the second contact rod 10 abuts against the output end of the transmission assembly, and the sharpening stops The middle part of the connecting rod 7 is hinged with the starting connecting rod 8, and one end of the sharpened stop connecting rod 7 is connected with the lower end of the first contact rod 9, and the upper end of the first contact rod 9 abuts against the block 5, and the sharpened stop connecting rod 7 The other end is attached to the micro switch 6, and the other end of the start link 8 is connected to the other end of the sharpened stop link 7 in a limited position.

[0035] Such as Image 6 As shown, the adjustment block 17 is an "H"-shaped structure (in this embodiment, there are three cross bars in the middle of the H), one side of the "H"-shaped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com