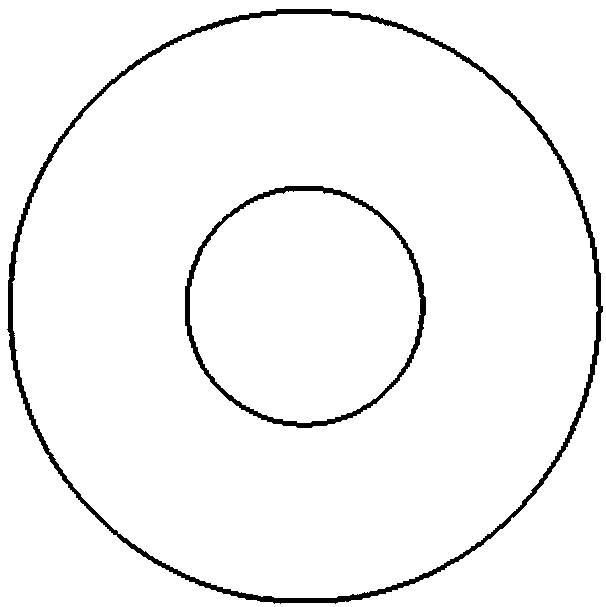

O-shaped sealing ring automatic assembly device and method

An O-ring and assembly device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of poor consistency of O-rings, low work efficiency, and high labor costs, and meet production needs and structure. Simple, highly automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

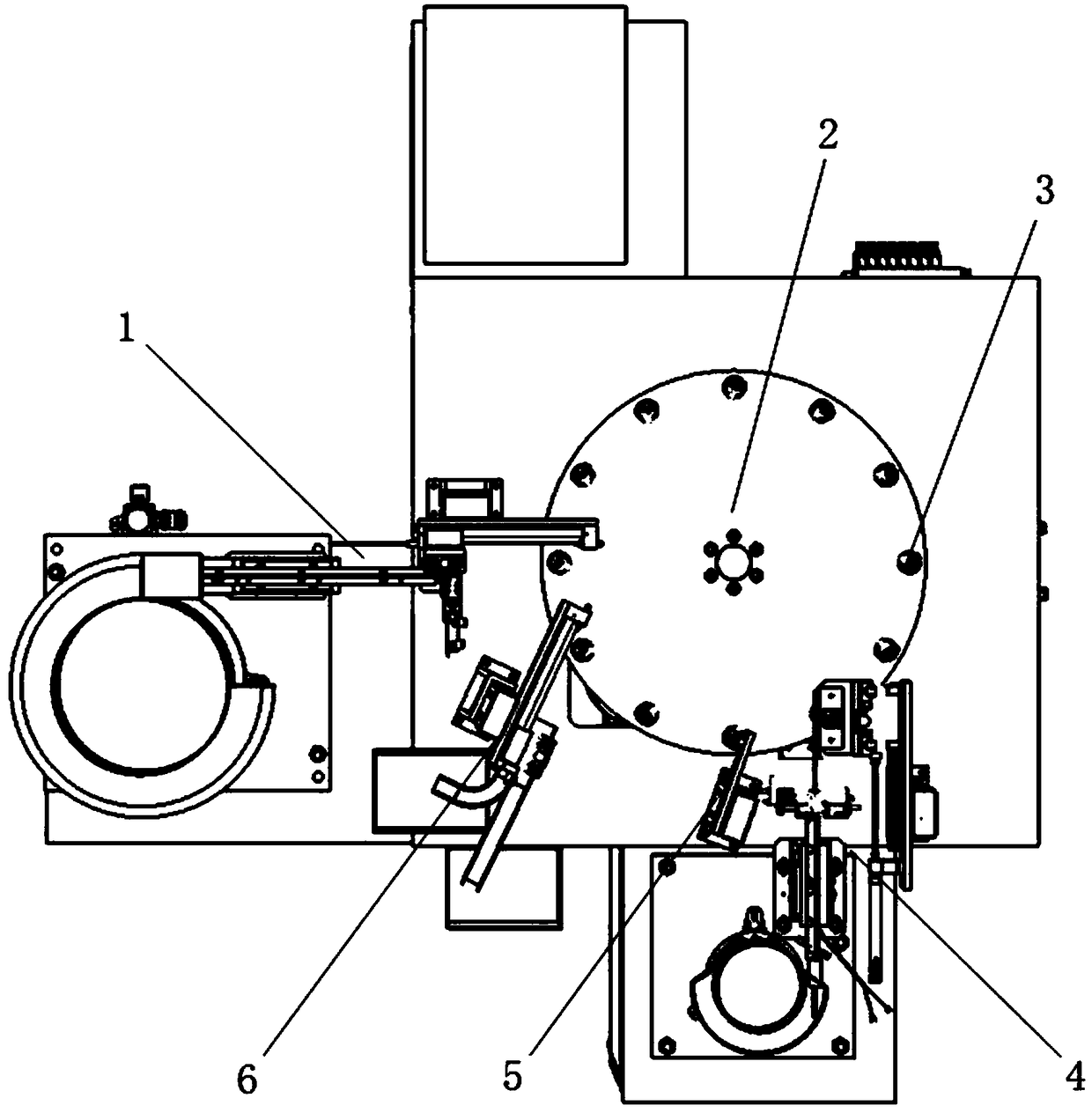

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

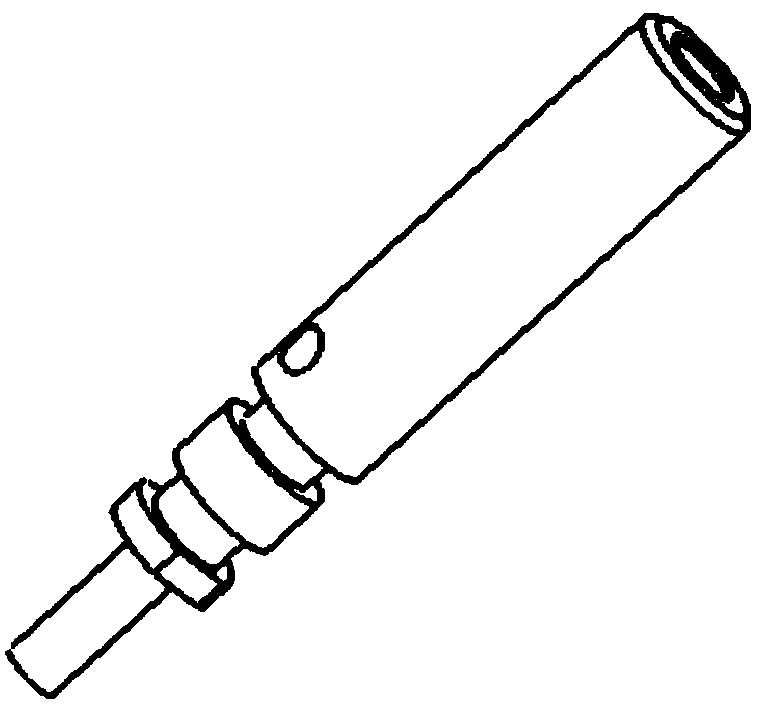

[0039] Such as Figure 1-3Shown is an O-ring automatic assembly device, including a rotary table component 2, a sleeve automatic loading component 1, an O-ring automatic loading component 4, an automatic detection component 5, and a finished product sorting component 6;

[0040] Wherein, the rotary table assembly 2 includes a rotating motor, a synchronous belt, a synchronous wheel, a divider, an indexing plate, and three-jaw cylinder clamps 3 uniformly distributed on the indexing plate along the circumference. , The transmission structure formed by the divider is connected with the indexing plate drive;

[0041] The sleeve automatic feeding assembly 1, the O-ring automatic feeding assembly 4, the automatic detection assembly 5, and the finished product sorting assembly 6 are sequentially arranged outside the rotary table assembly 2 along the circumferential direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com