Automatic assembly machine for touch switch

An automatic assembly machine and tactile switch technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of low production efficiency, low assembly efficiency, high labor intensity, etc., and achieve production cost savings, accurate assembly, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and drawings:

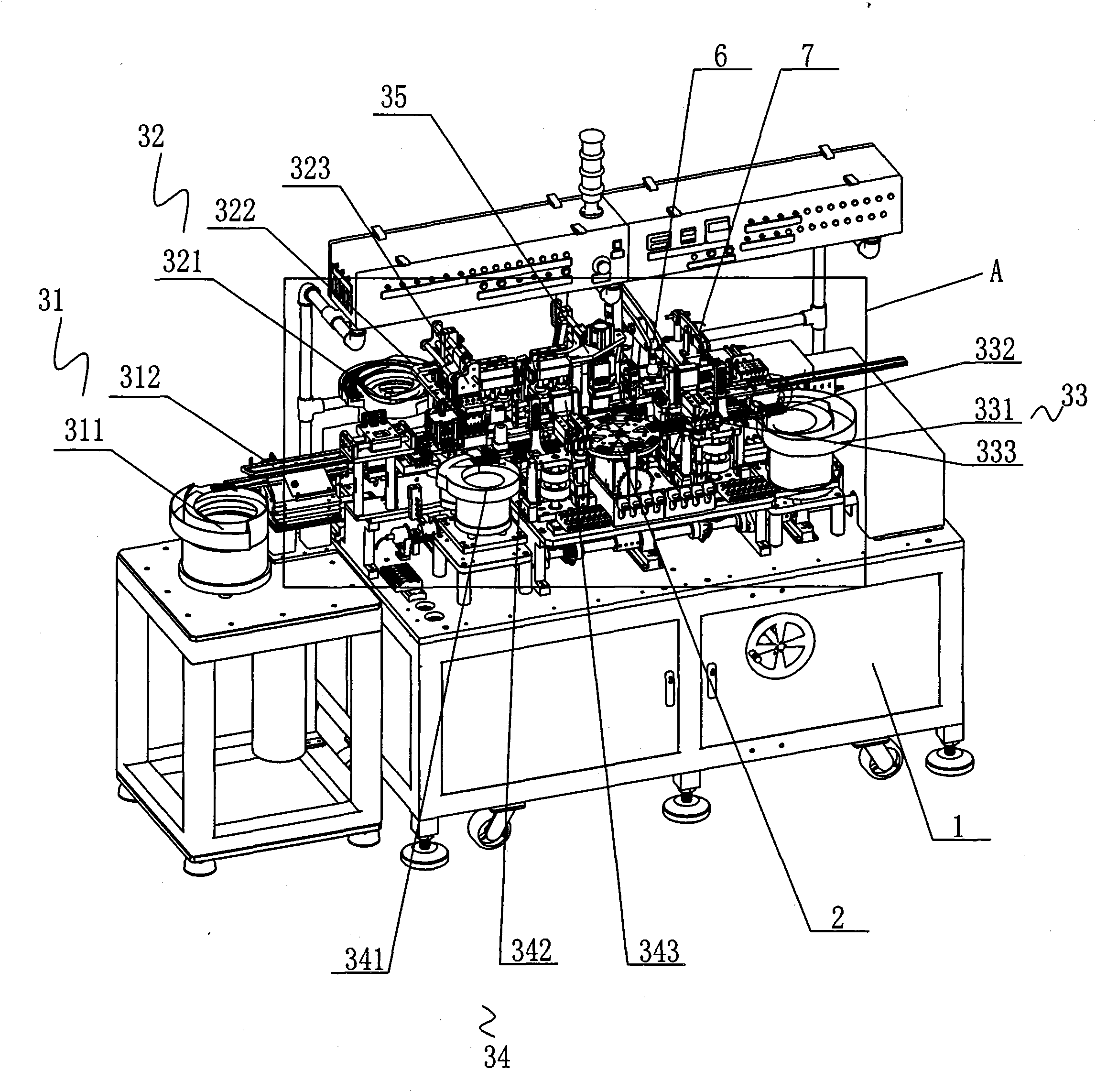

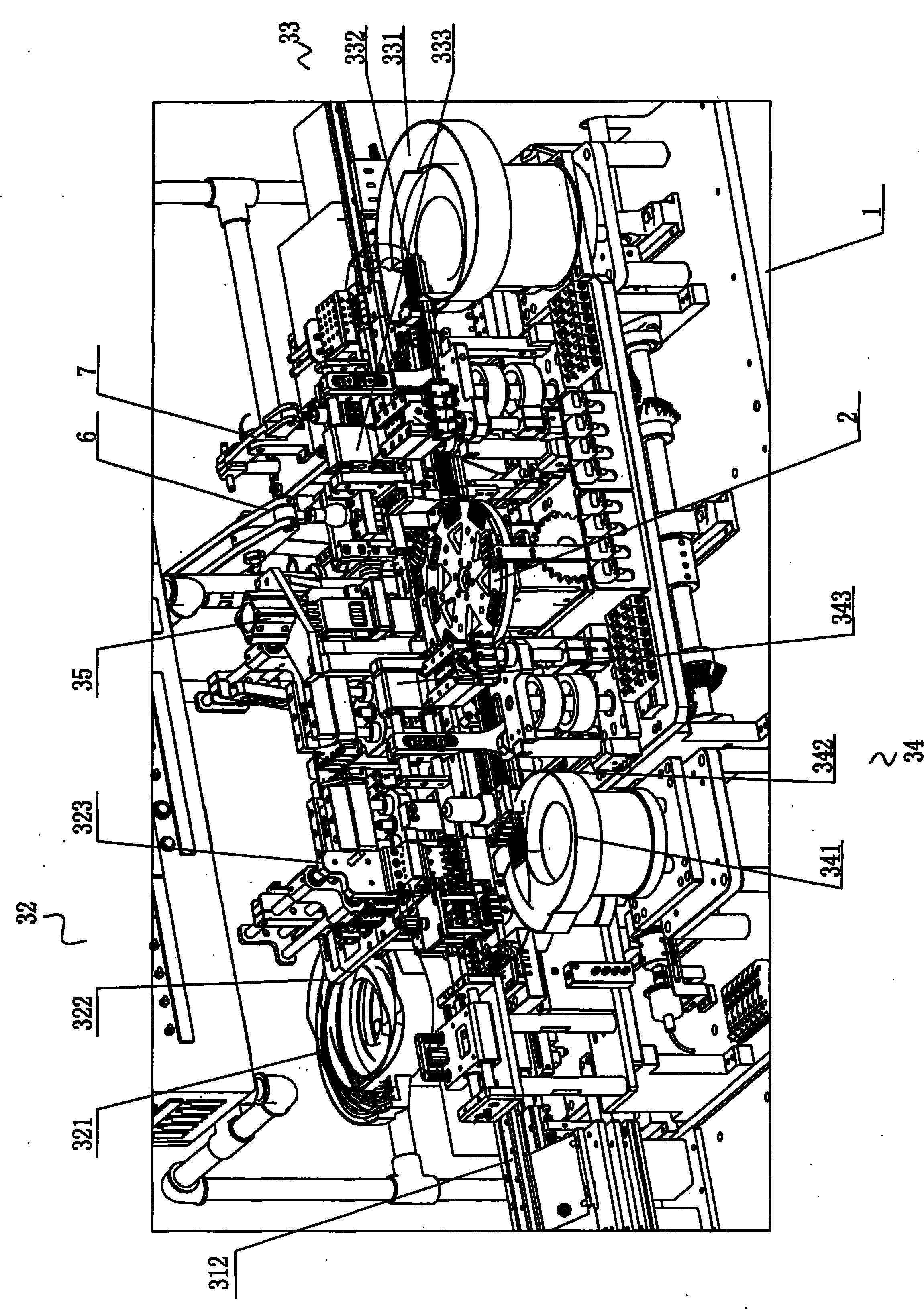

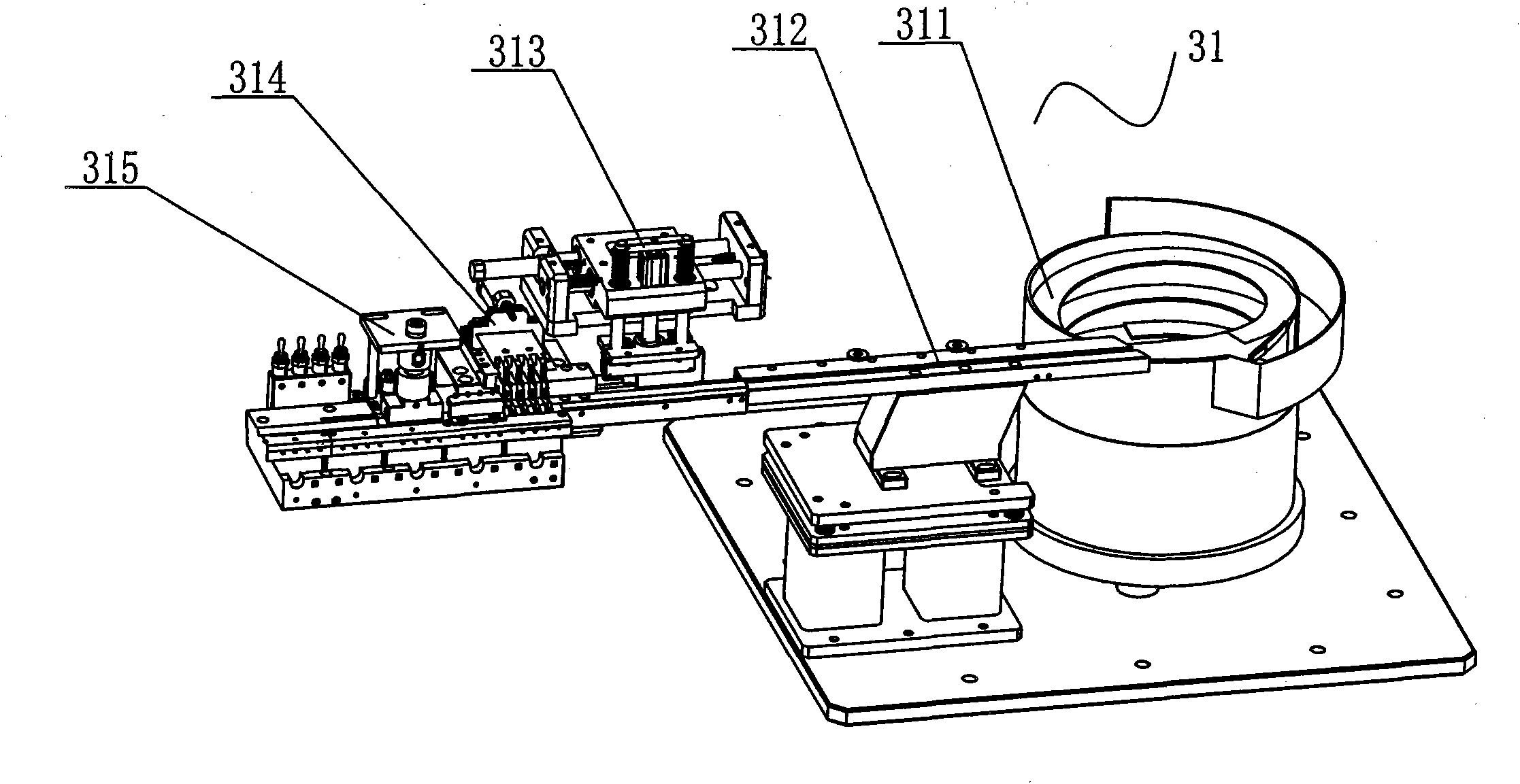

[0025] As attached Figure 1-9 , Tact switch automatic assembly machine, including a body 1 and a main conveying track 4 carrying the body. The body 1 is provided with an assembly turntable 2 and the body, shrapnel, buttons and cover components of the tact switch are respectively sent to the assembly station Feeding mechanism; below the main conveying track 4 is provided with a transfer mechanism that clamps the body and makes regular vertical or horizontal feeding motions. The body feeding mechanism 31 is provided at the input end of the main conveying track 4, and the shrapnel feeding mechanism 32, button feeding The mechanism 33 and the cover feeding mechanism 34 are arranged in sequence along the main conveying track 4. The assembly turntable is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com