Lighter grinding wheel assembling machine

A technology for grinding wheel sets and lighters, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of easy assembly deviation, low assembly efficiency, time-consuming and labor-intensive problems, achieve accurate assembly, high work efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

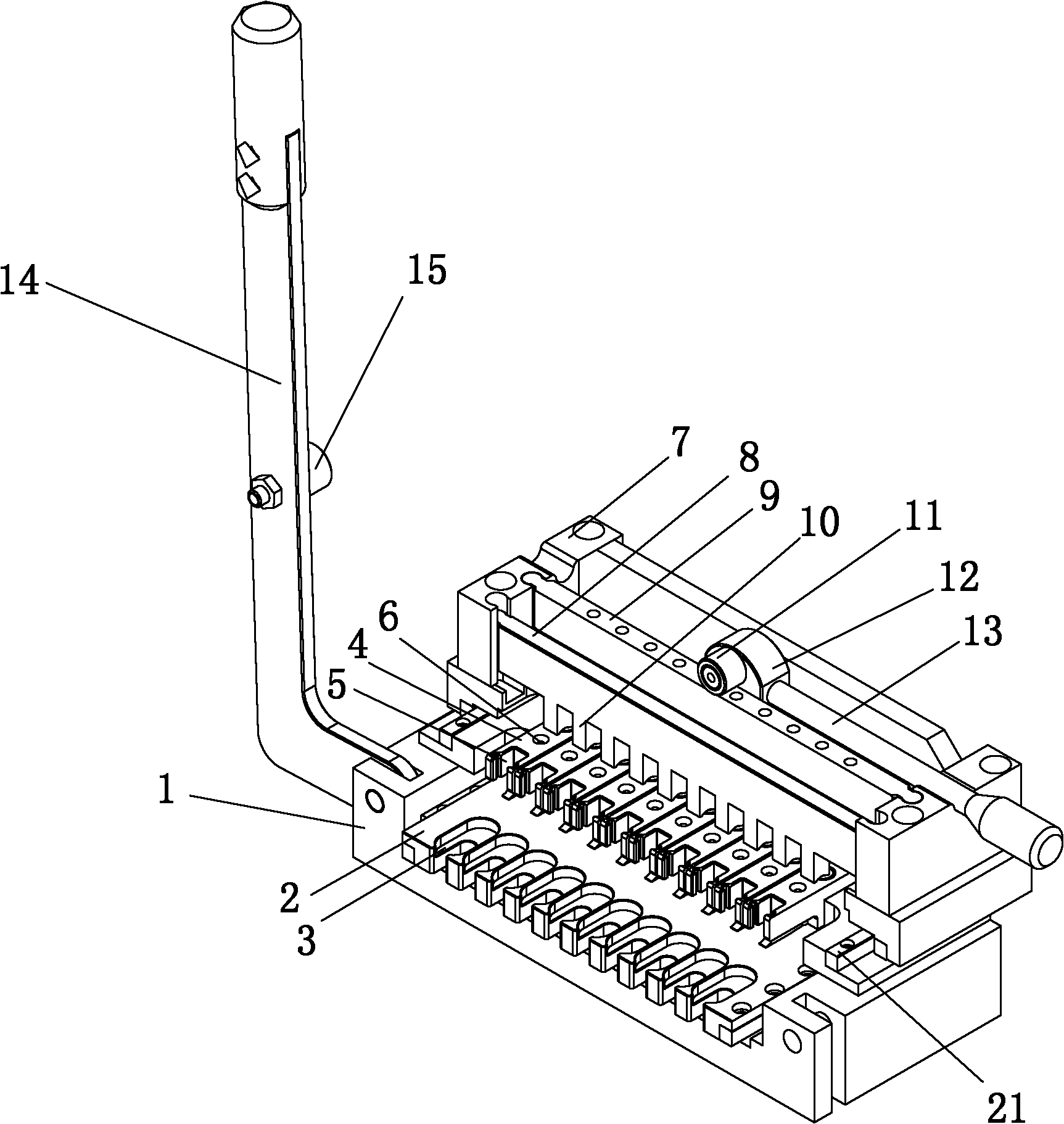

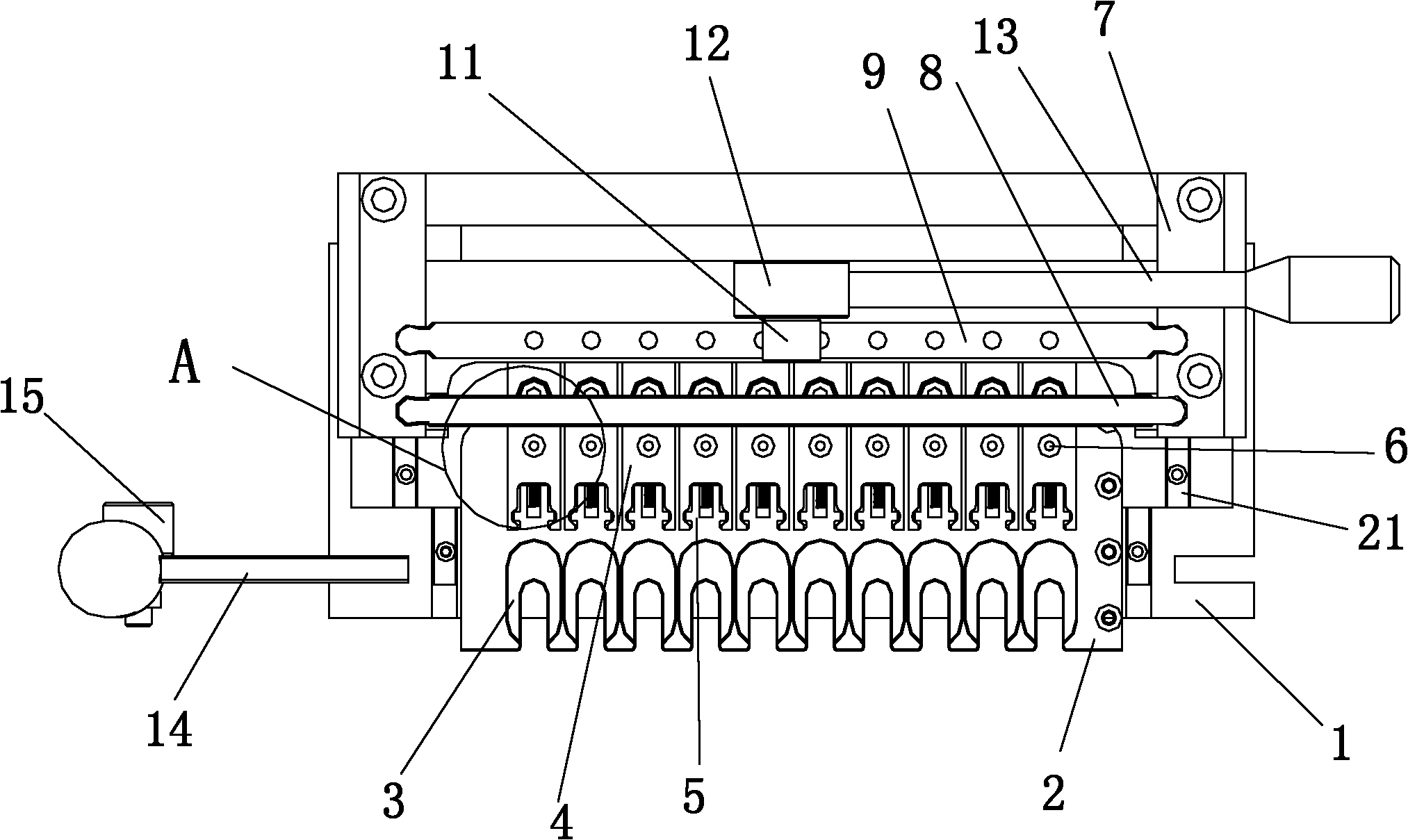

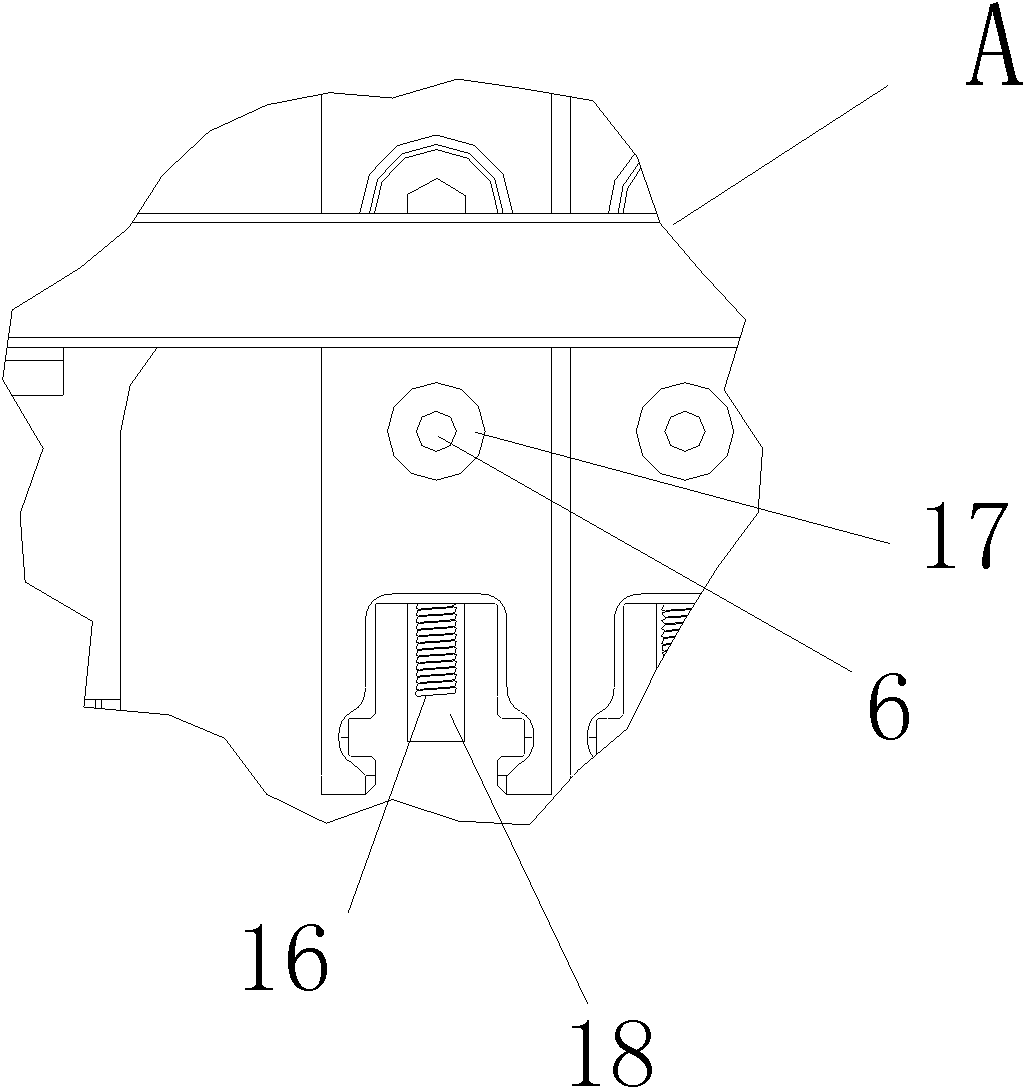

[0020] Such as figure 1 The shown grinding wheel assembly machine for lighters includes a base 1 forming an inner groove, in which a nose clamp 2 that can slide back and forth is provided, and a plurality of nose clamping parts 3 are formed at the outer end of the nose clamp 2 . The top of the nose clamp 2 is provided with a plurality of positioning blocks 4 used in conjunction with the nose clamping part 3, and the number of the positioning blocks 4 is the same as the number of the nose clamping parts 3 and arranged in a row. The middle part of the positioning block 4 is provided with a vertical hole 6 for accommodating the spring and the flint, and the upper end of the vertical hole 6 forms a tapered opening 17 . The outer ends of the positioning block 4 form parallel support arms 19, and the grinding wheel clamping opening 5 is formed between the two support arms 19. The inner sides of the two support arms 19 are provided with symmetrical grinding wheel positioning grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com