Patents

Literature

106results about How to "Improve assembly success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

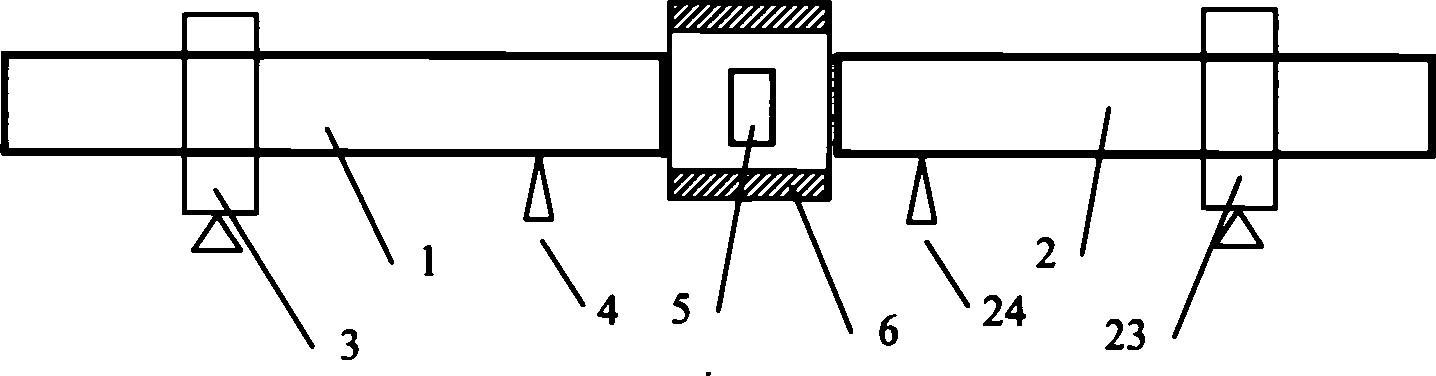

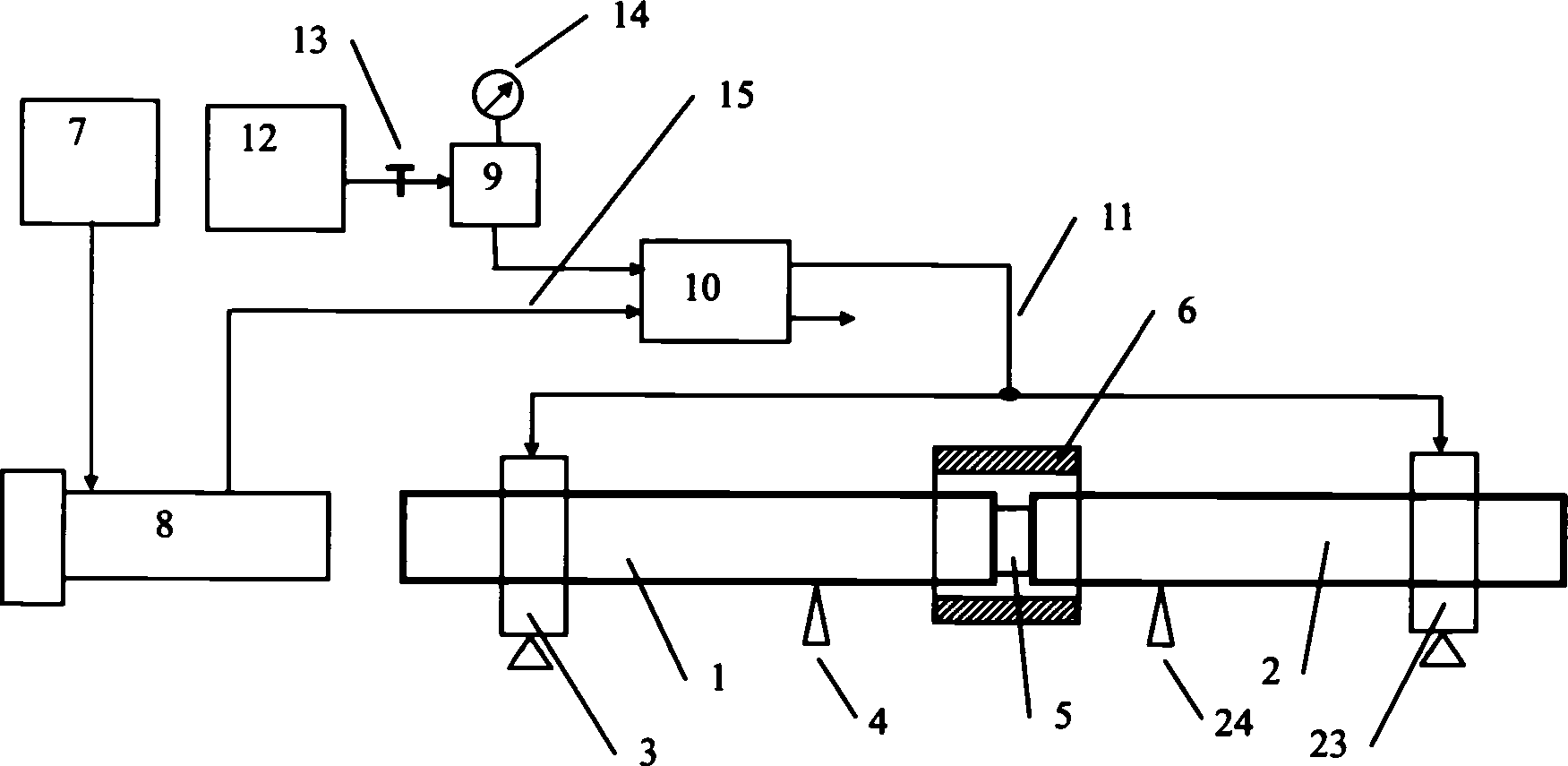

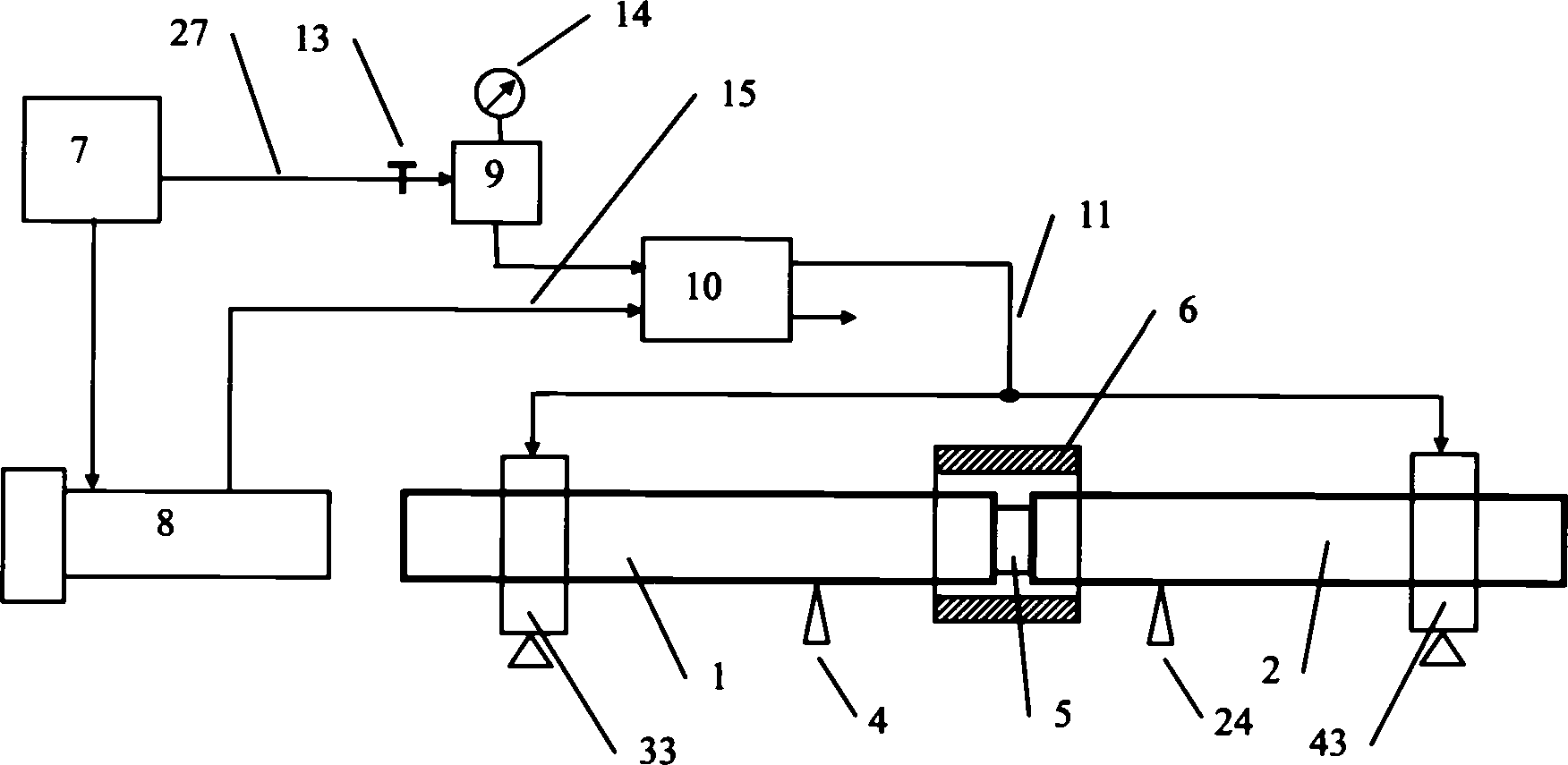

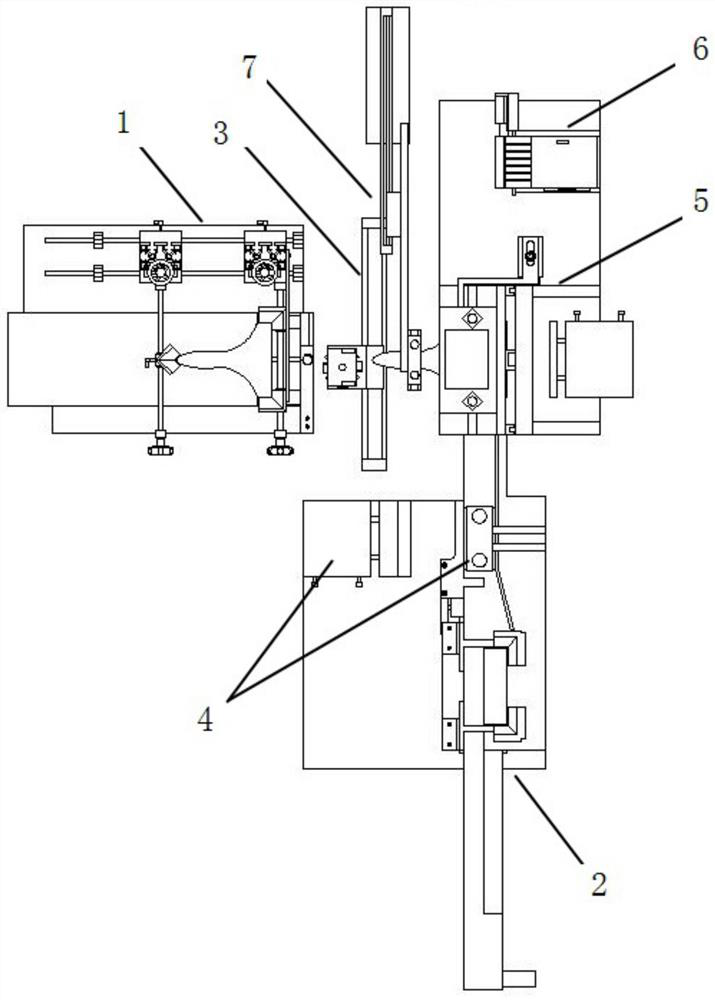

Double-air path bidirectional automatic assembling device for high-temperature Hopkinson pressure bar experiment

InactiveCN1888851AGuaranteed synchronicityReduce temperature unevennessStrength propertiesEngineeringAtmospheric pressure

Two-way double steam paths self-motion assembled equipment for high temperature Hopkinson pressure-bar experiment belongs to material high temperature dynamic mechanics capability research field. Each gas driving rack set on incidence perch and transmission perch and push them towards specimen in assembling to form two-way assemble in order to keep specimen in the availability heating range. Push the driving gas path of rack and separate setting of air cannon startup gas path and set gas chief valve control the switch of driving gas path and air cannon startup gas path. It makes the driving rack and air cannon startup linkage without influence. Set small gas storage tin as driving gas source and control its air pressure to control the driving speed of the driving rack. It can keep the assembled stability of the equipment and enhance assembled success probability. It assures the synchronism of assembled equipment when the stress wave arrives to specimen to avoid the temperature of specimen rapidly drop for leaving heat fountain.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

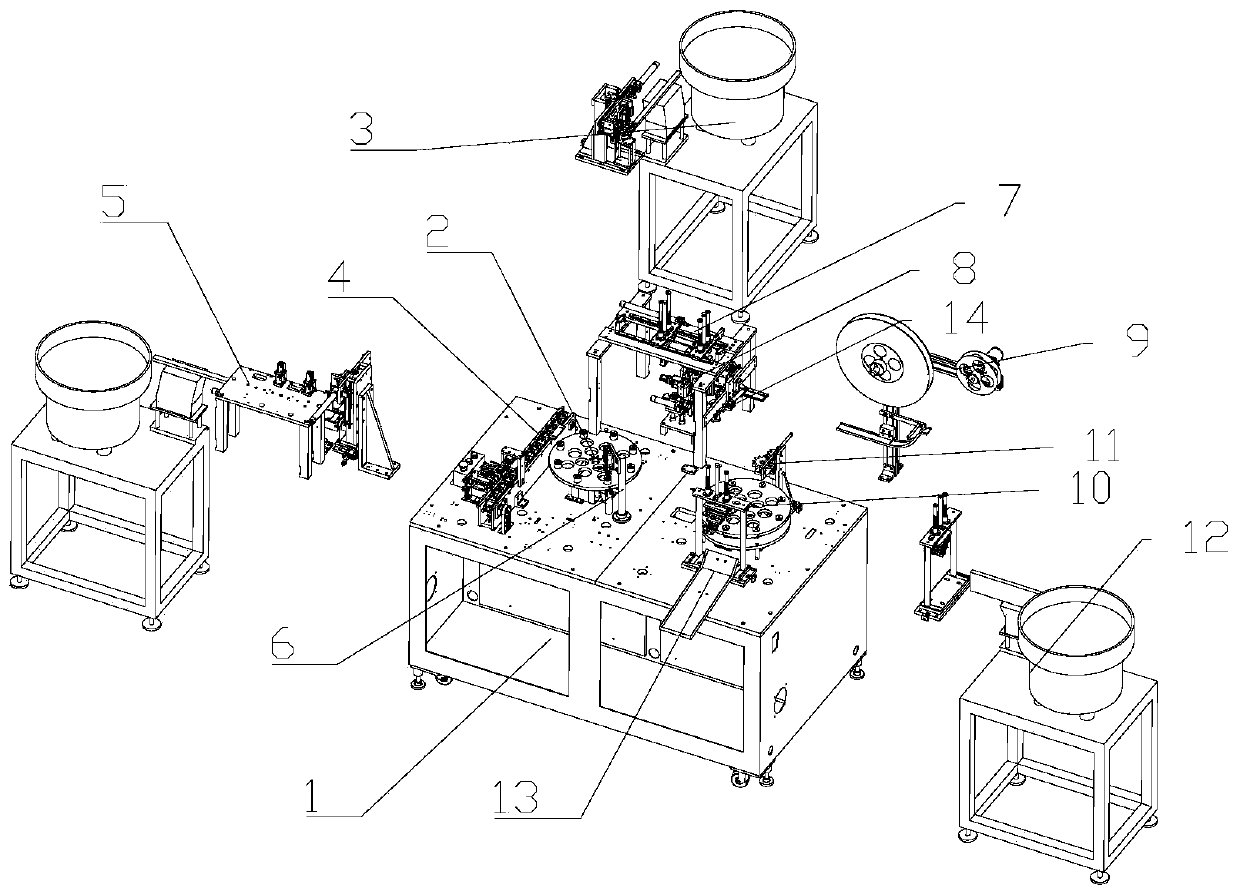

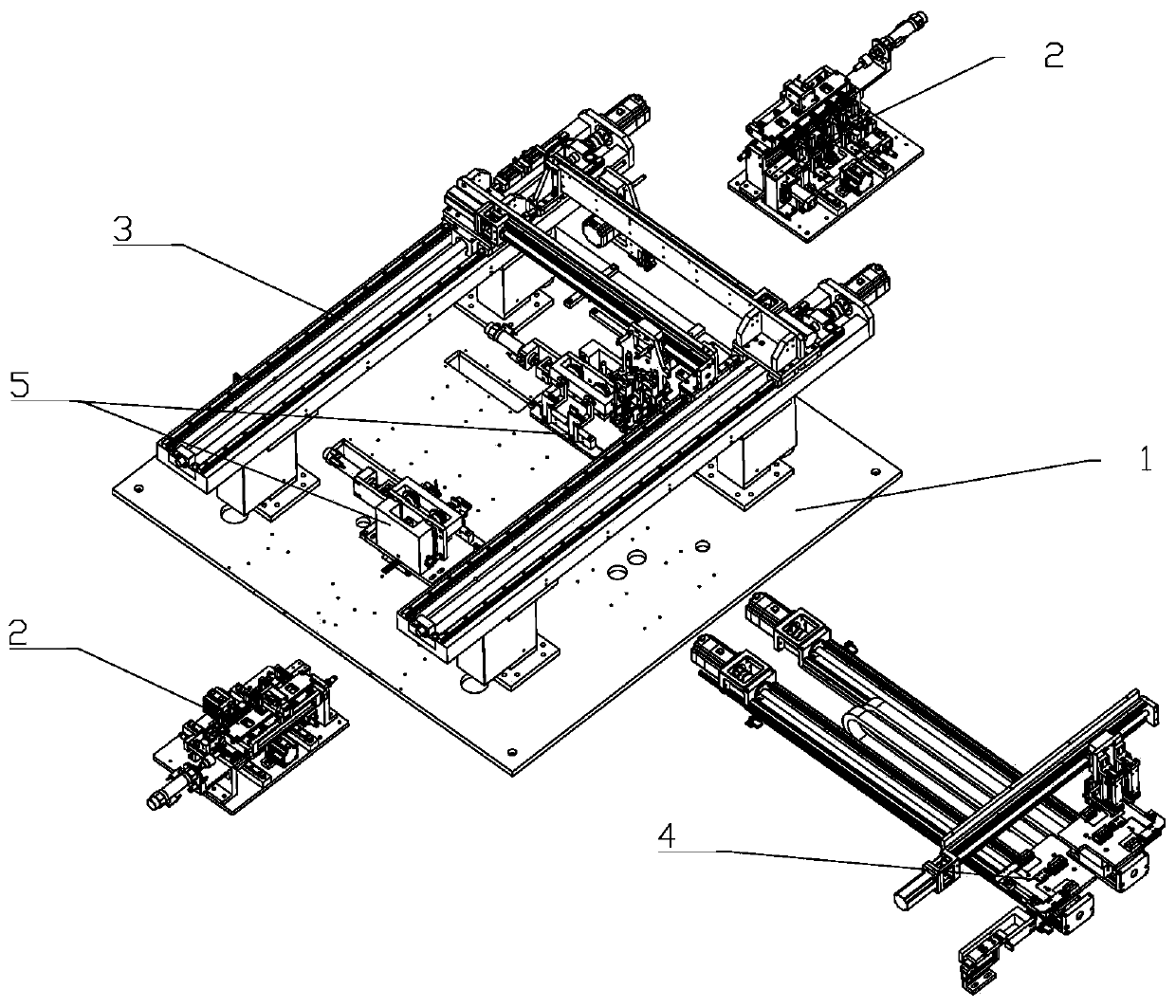

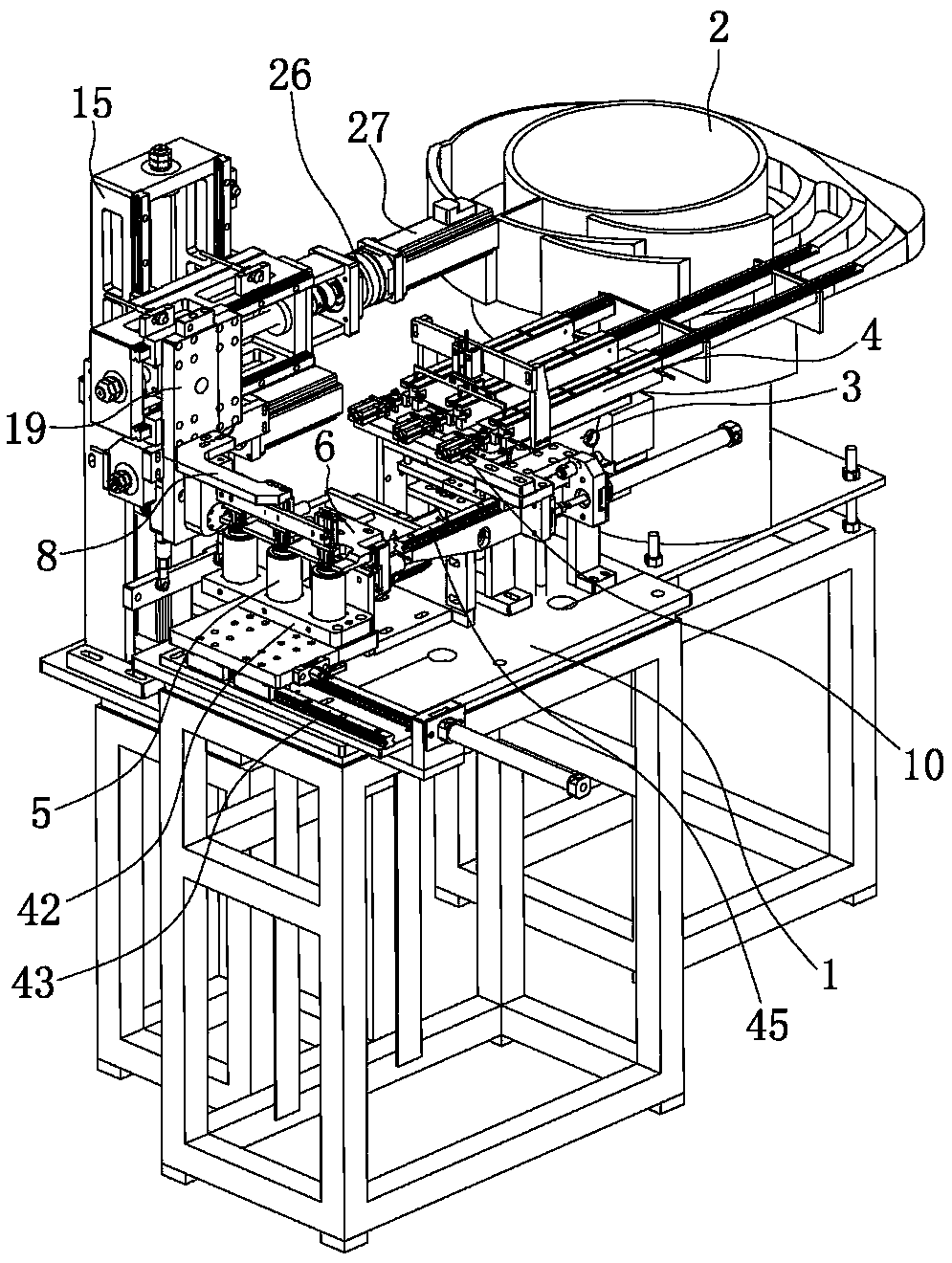

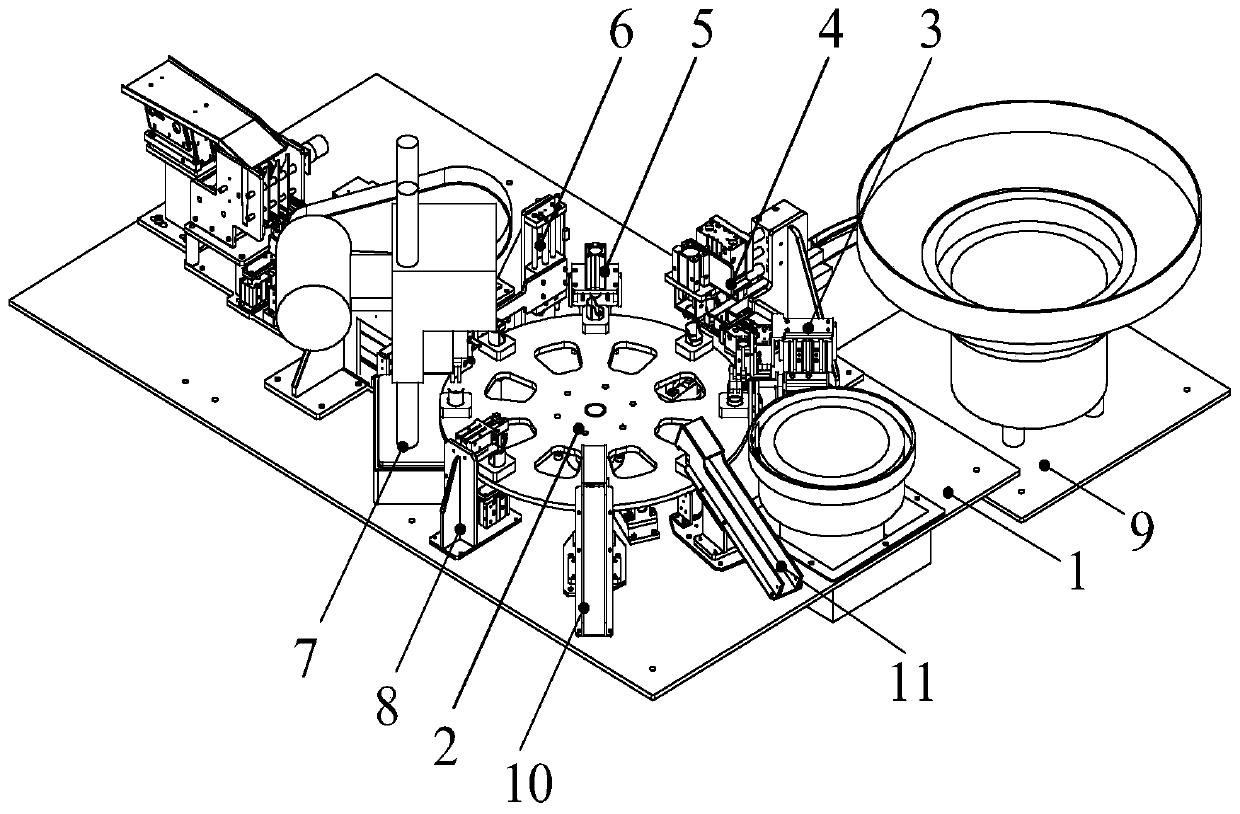

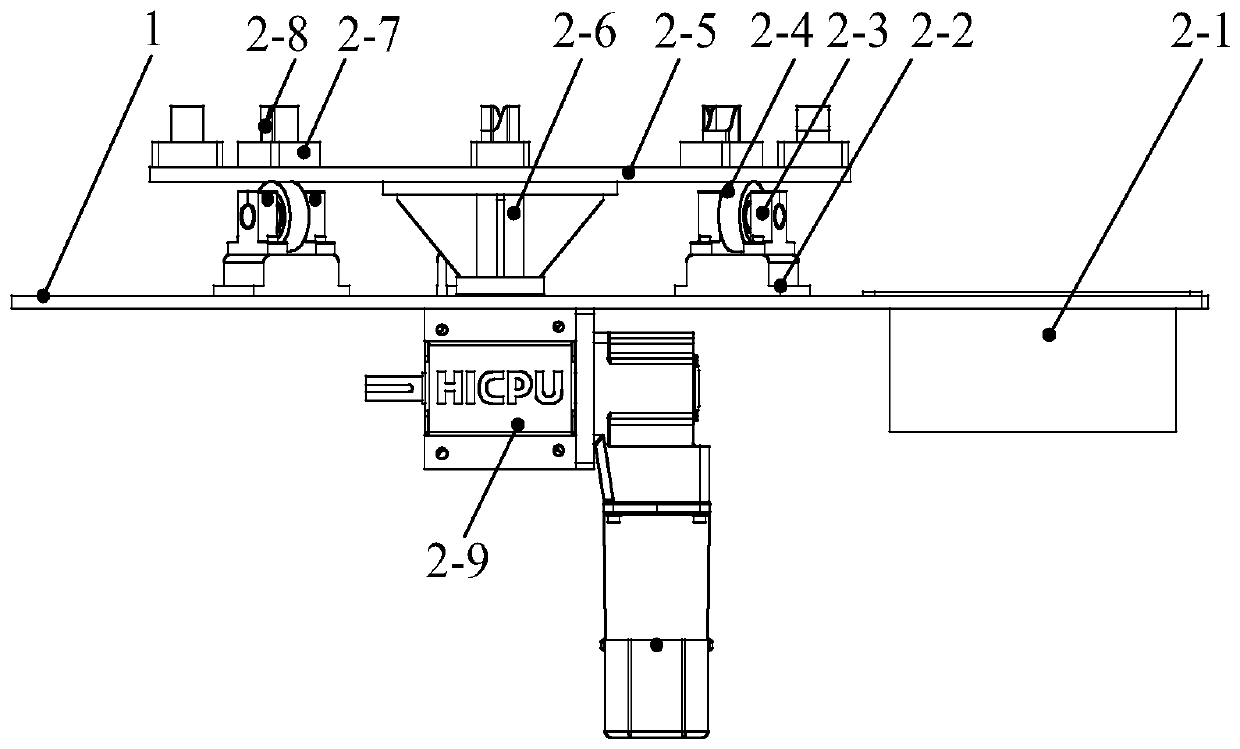

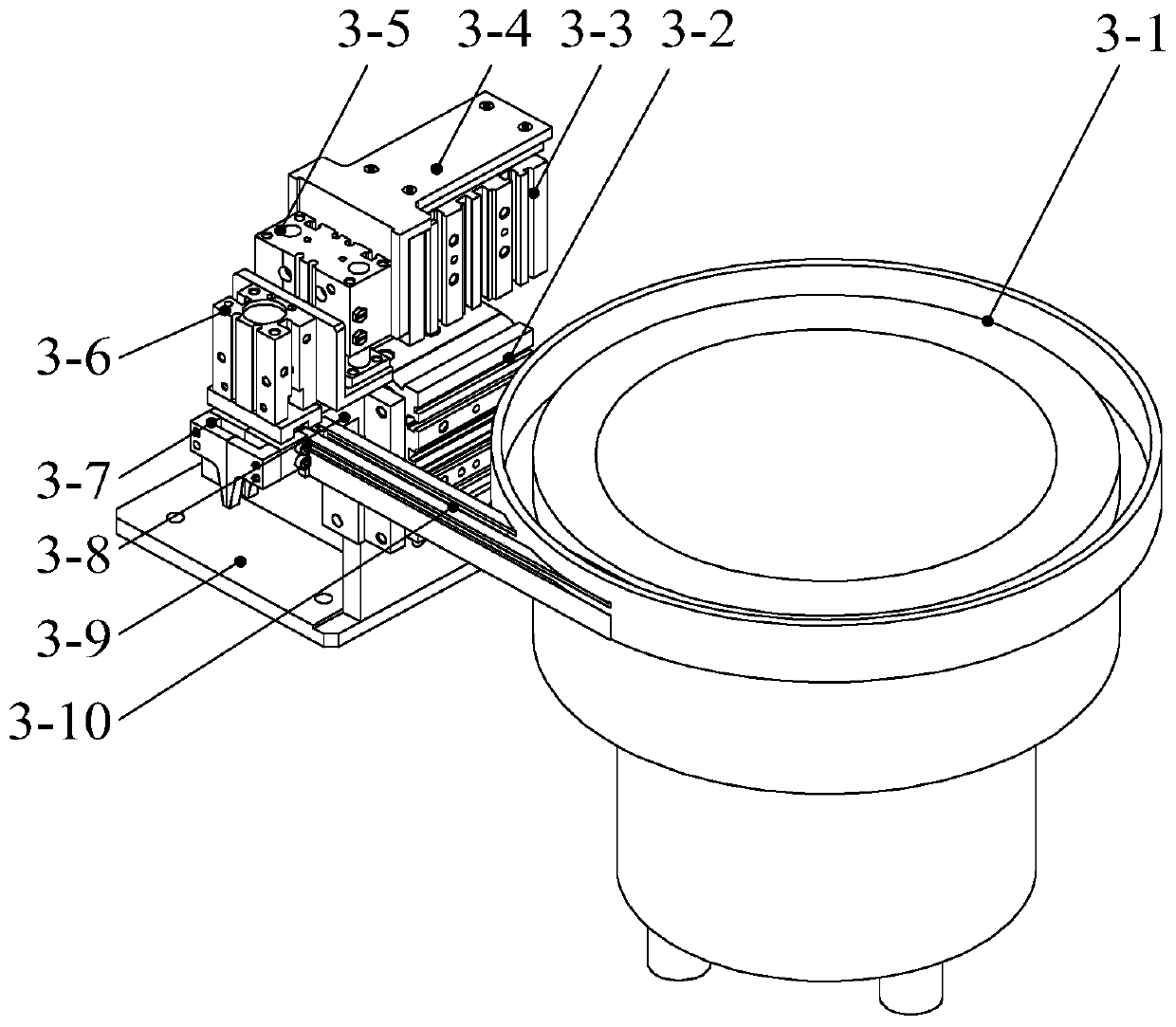

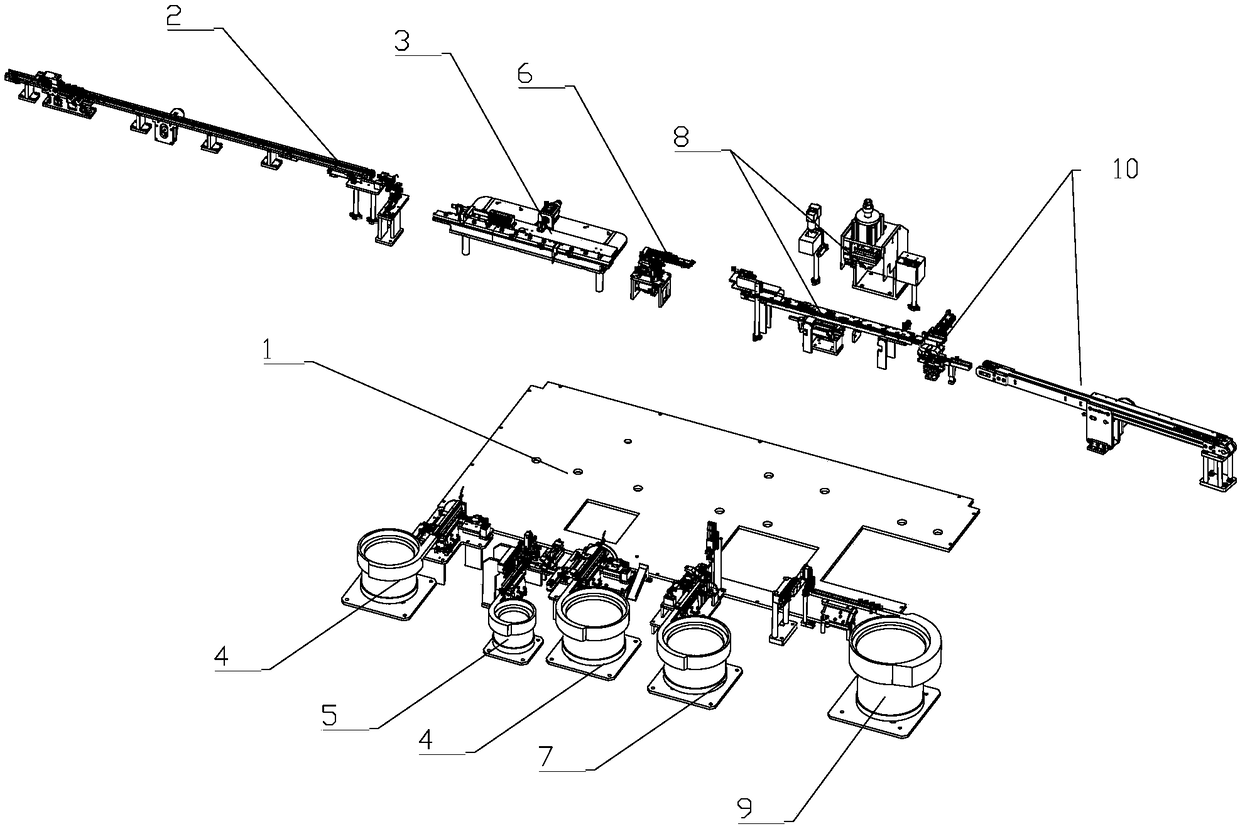

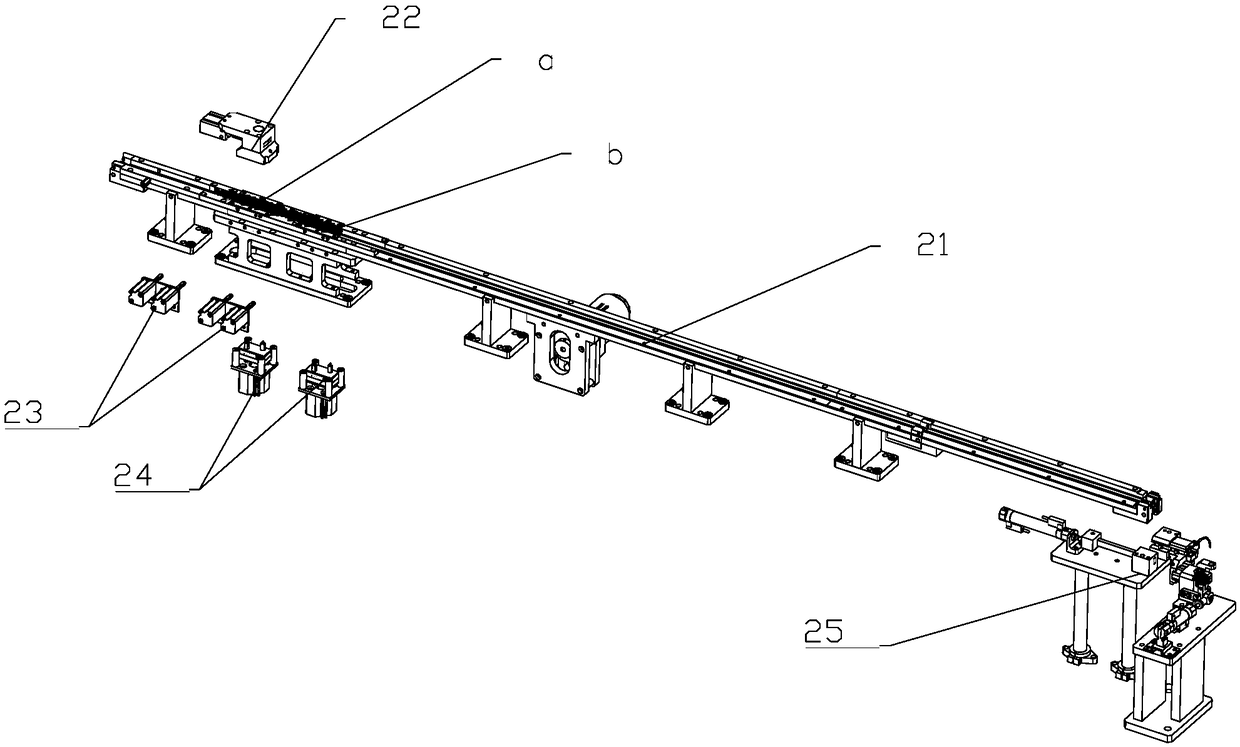

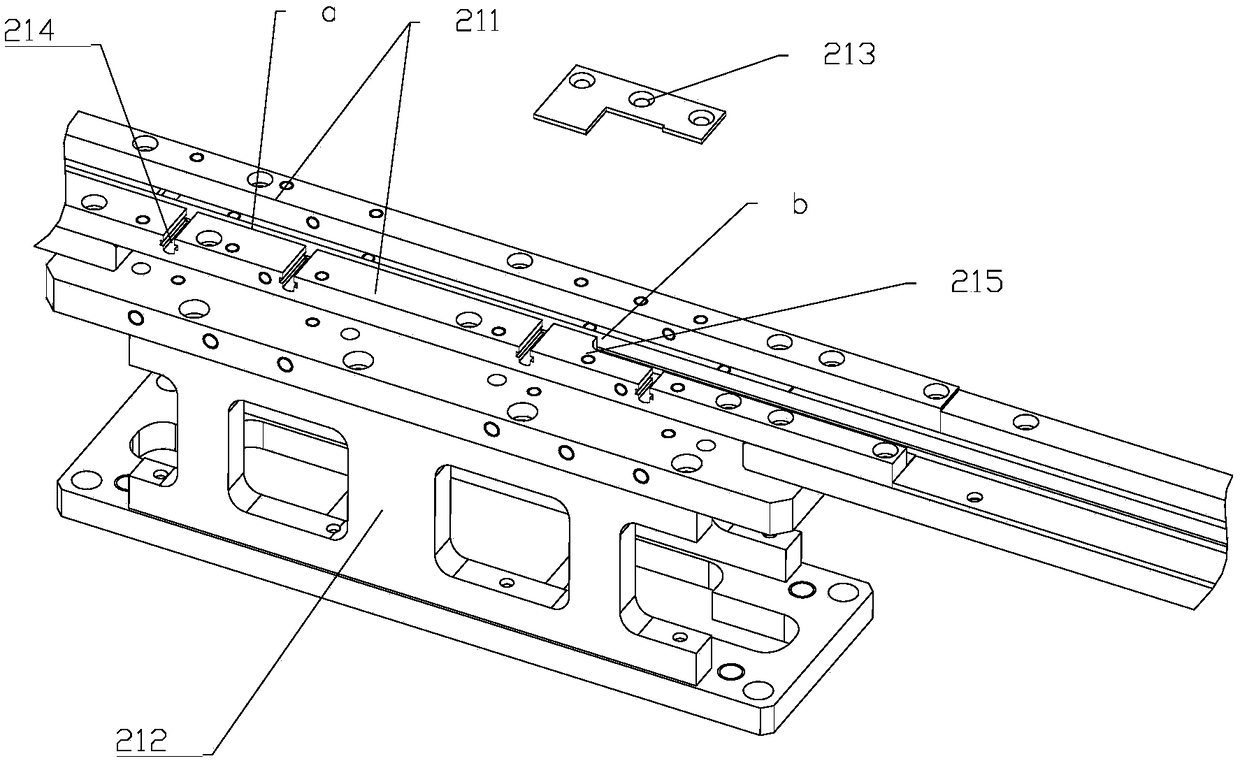

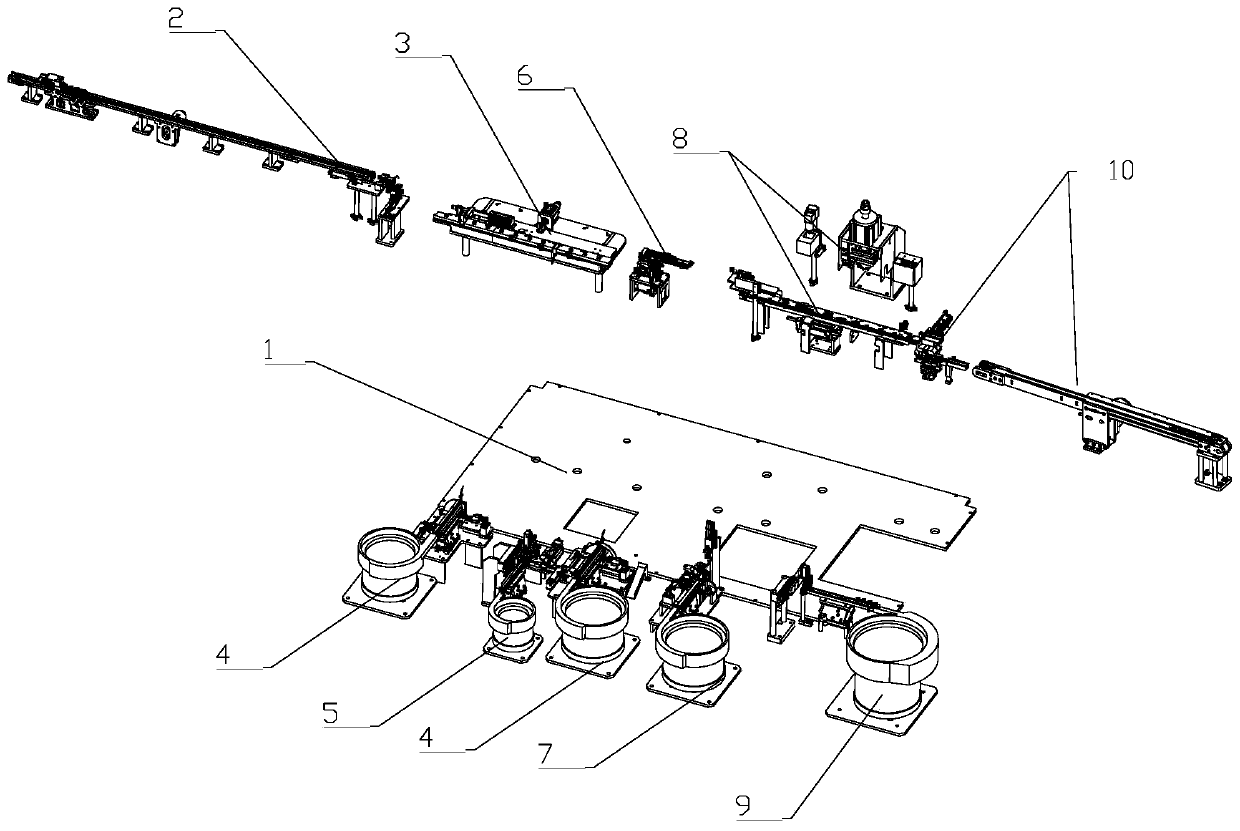

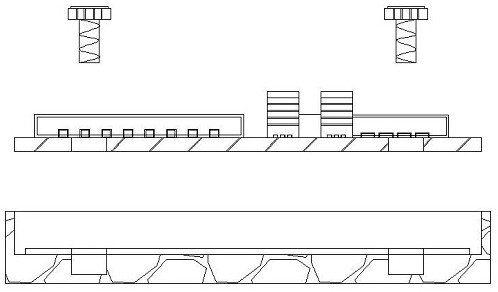

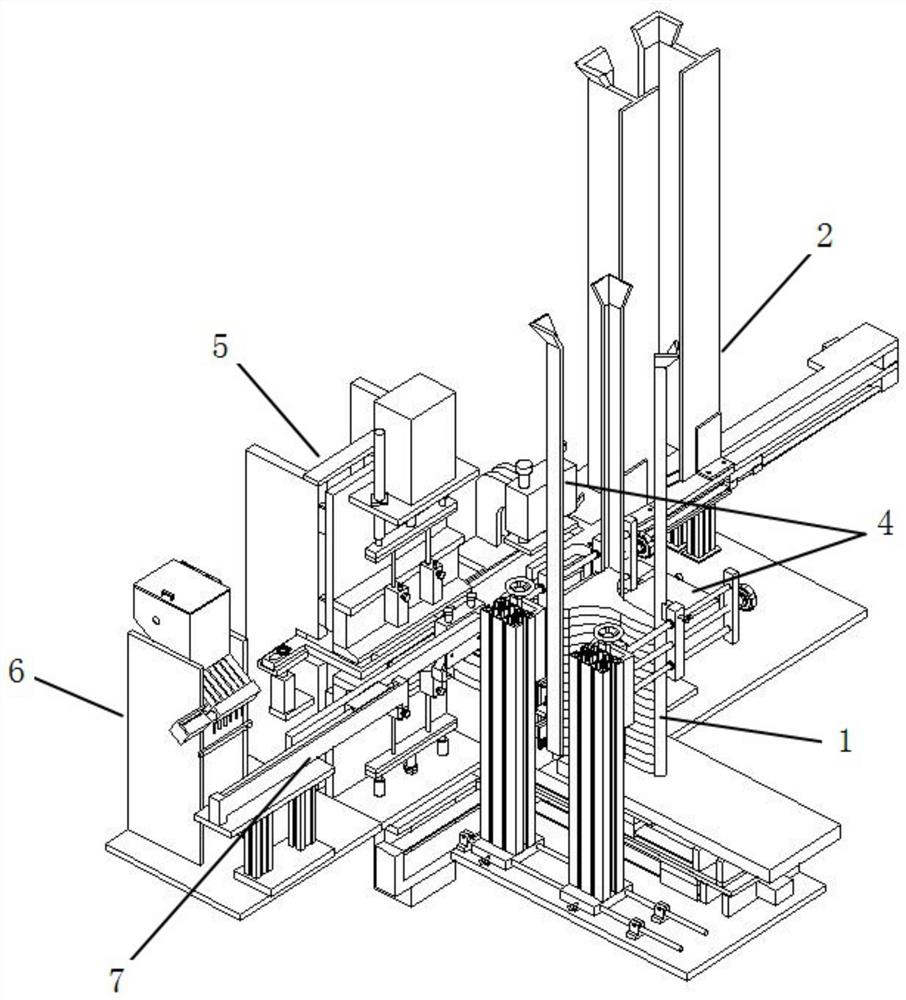

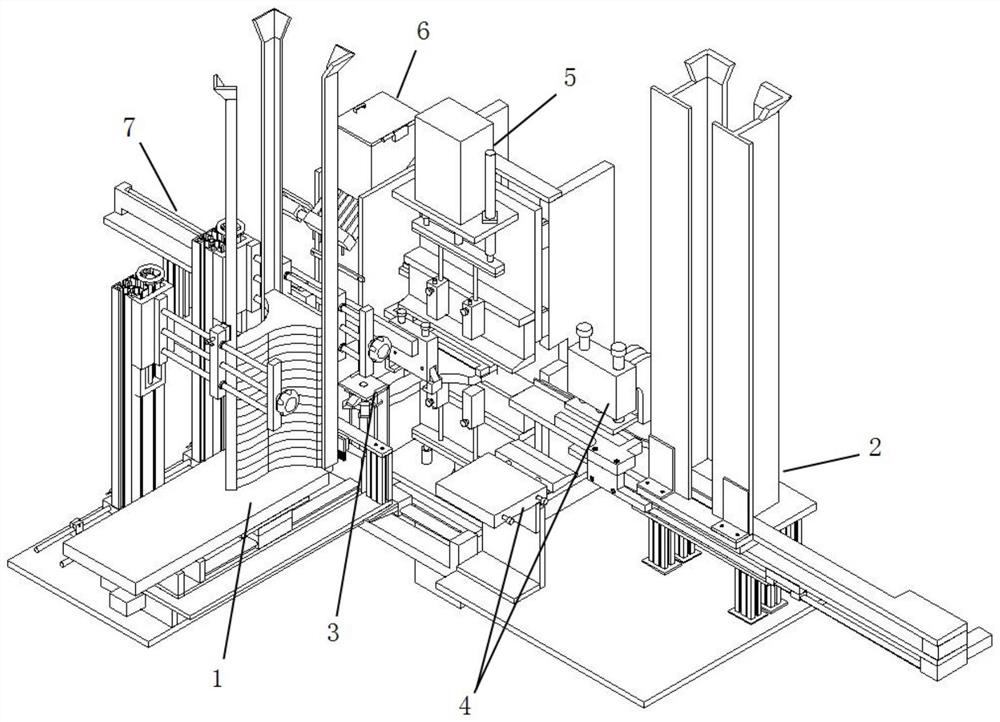

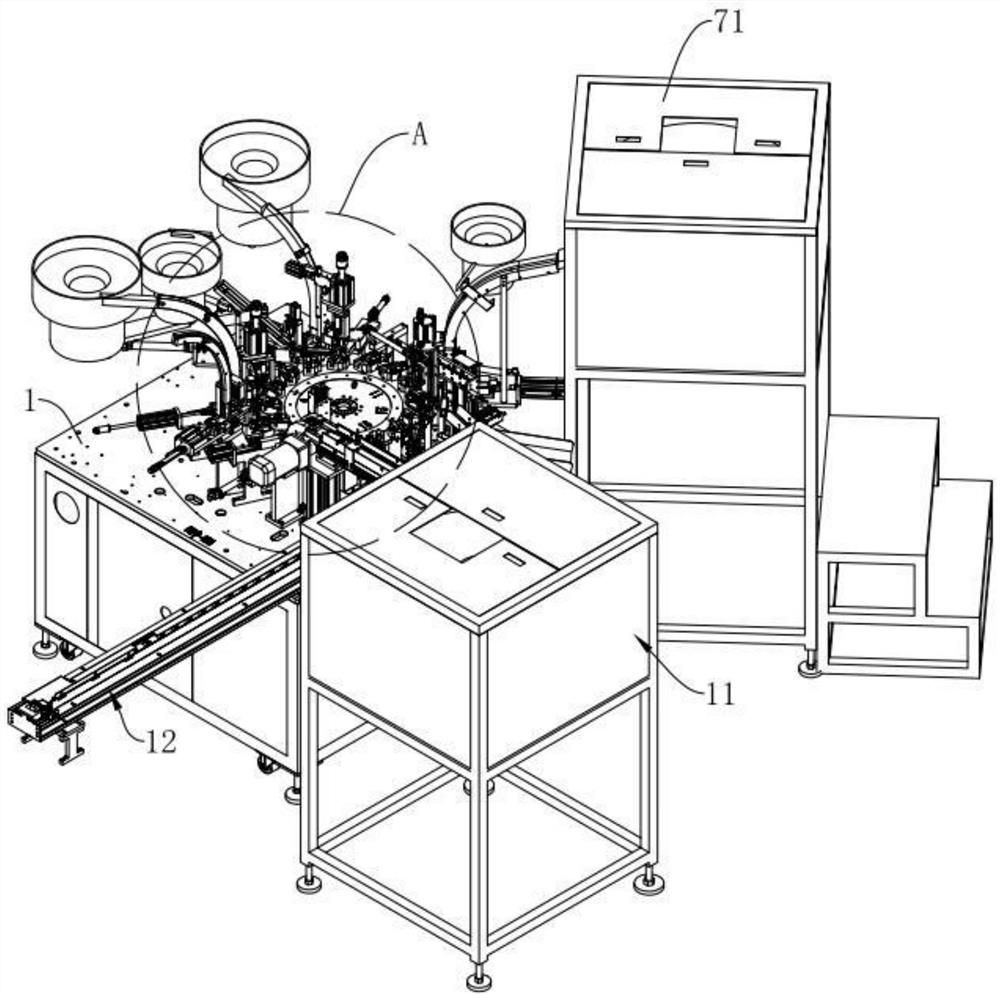

Electronic antenna and full automatic assembling method and production system thereof

The invention relates to the field of communication equipment manufacturing. An electronic antenna full automatic assembling method sequentially comprises the following steps that rotation piece feeding is conducted, specifically, a rotation piece is fed to a first rotary disc device through a rotation piece feeding device; an antenna core and an sma connector are assembled into a core body, specifically, the antenna core and the sma connector are fed and assembled through an antenna core feeding transferring device and an sma connector feeding assembling device, the connector is fixed, and the antenna core is inserted into the connector; the rotation piece and the core body are pressed, specifically, pressing is conducted through a pressing device; copper sheet assembling is conducted, specifically, a carrying device carries a product into a copper sheet pressing device to be assembled; and protection bar assembling is conducted, specifically, a protection bar is fed by an antenna protection bar feeding device, and then, final product assembling is conducted through a protection bar assembling device. An electronic antenna full automatic assembling production system adopted the technical scheme is high in automation degree, working efficiency and finished product percent of pass.

Owner:王朝火

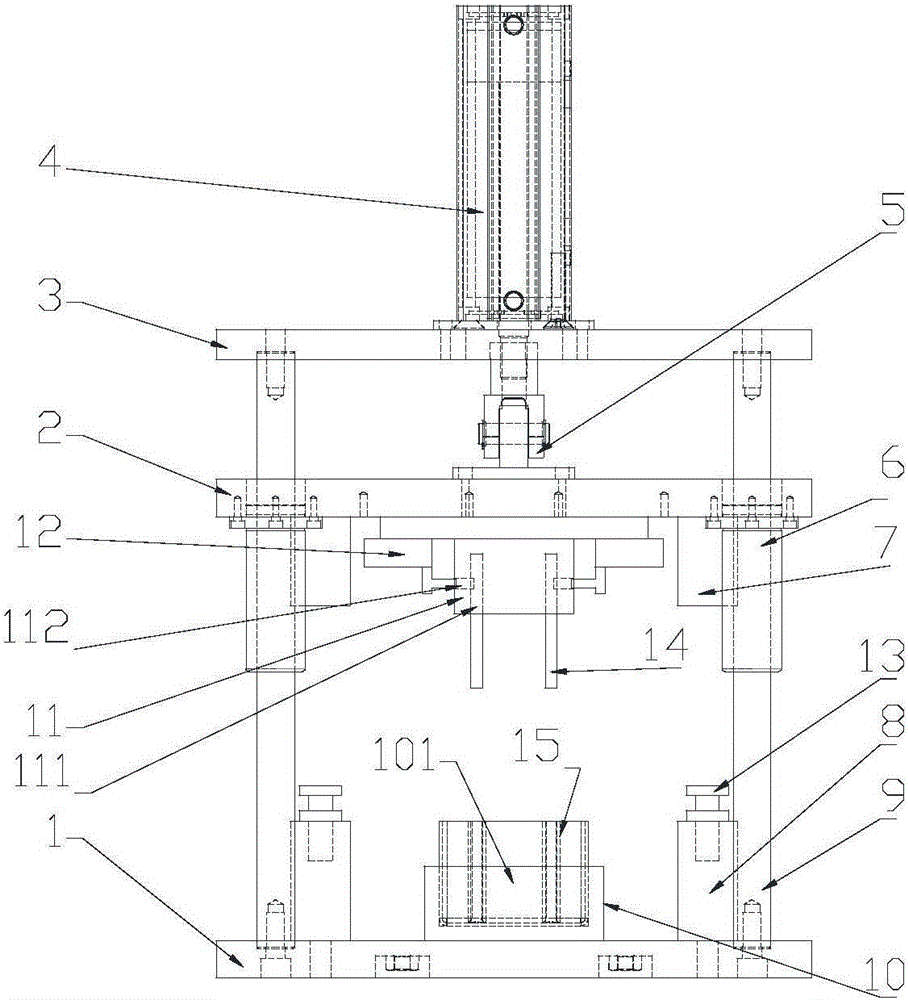

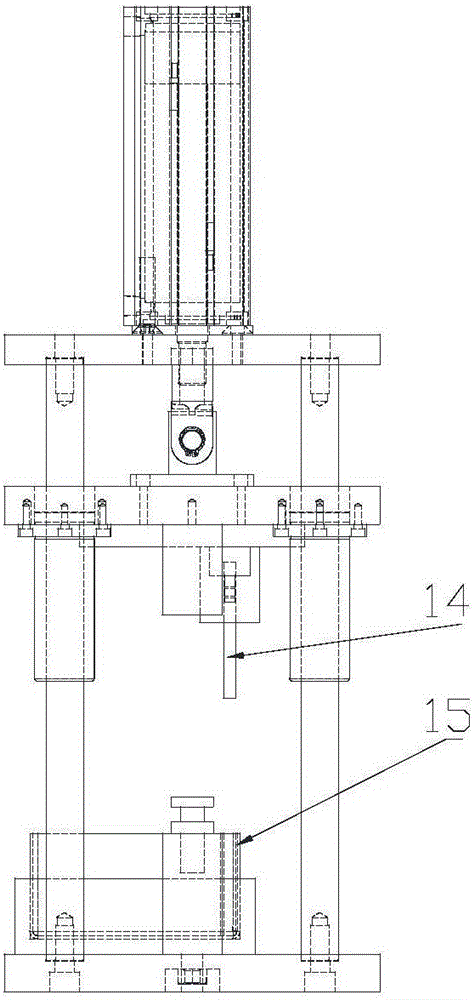

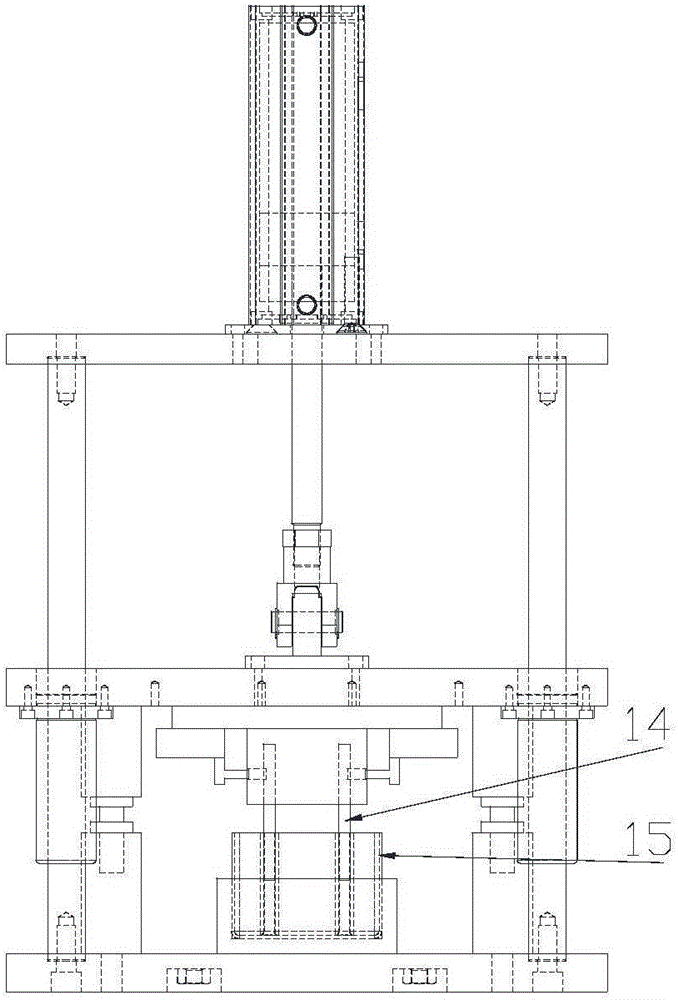

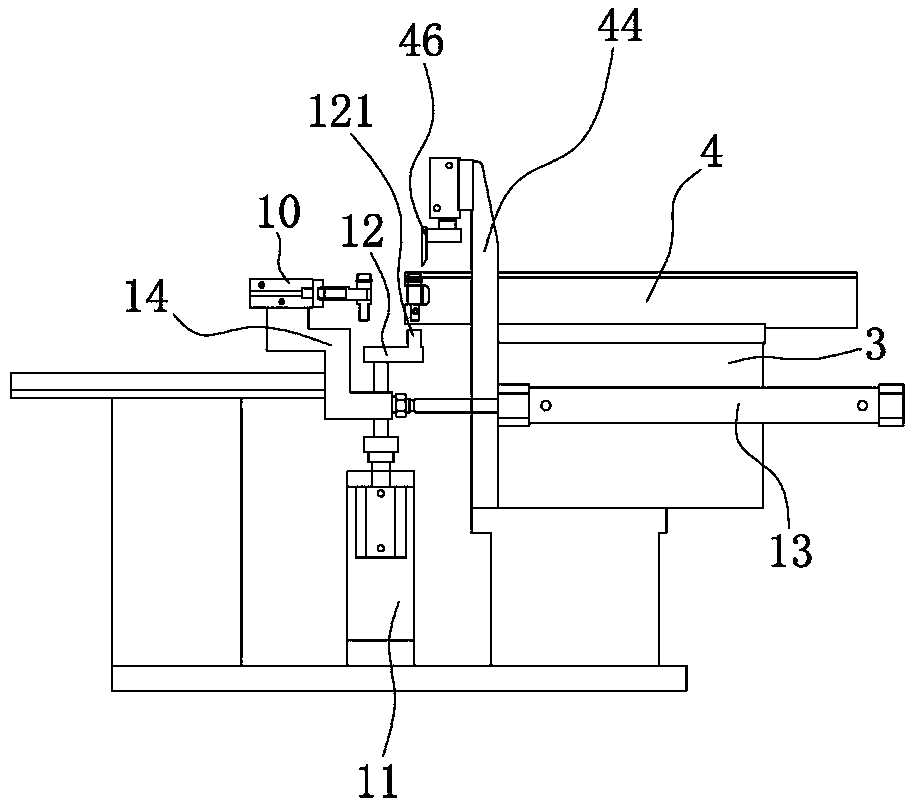

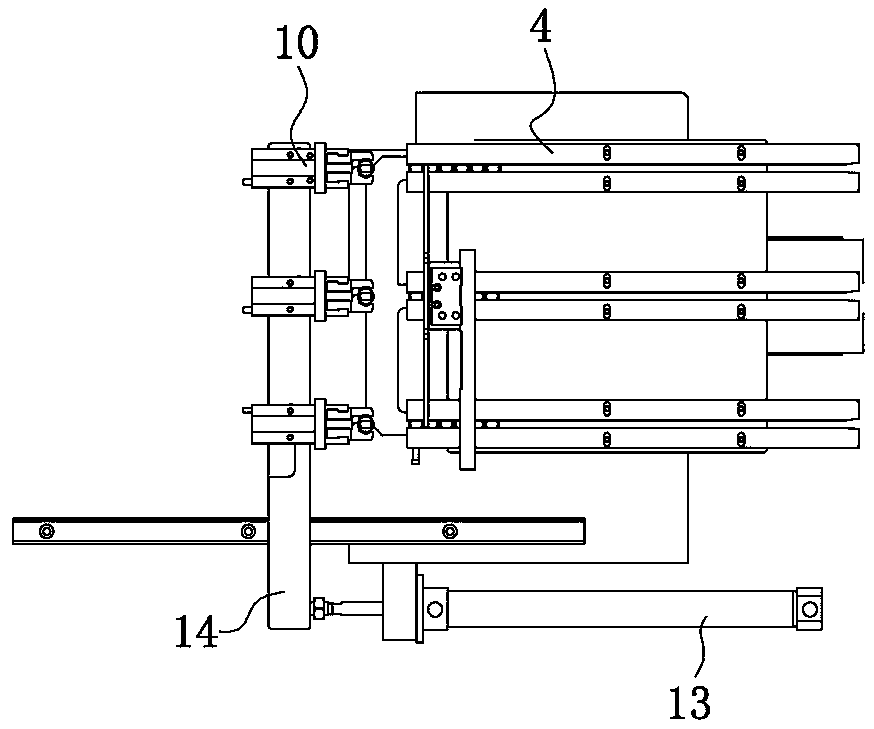

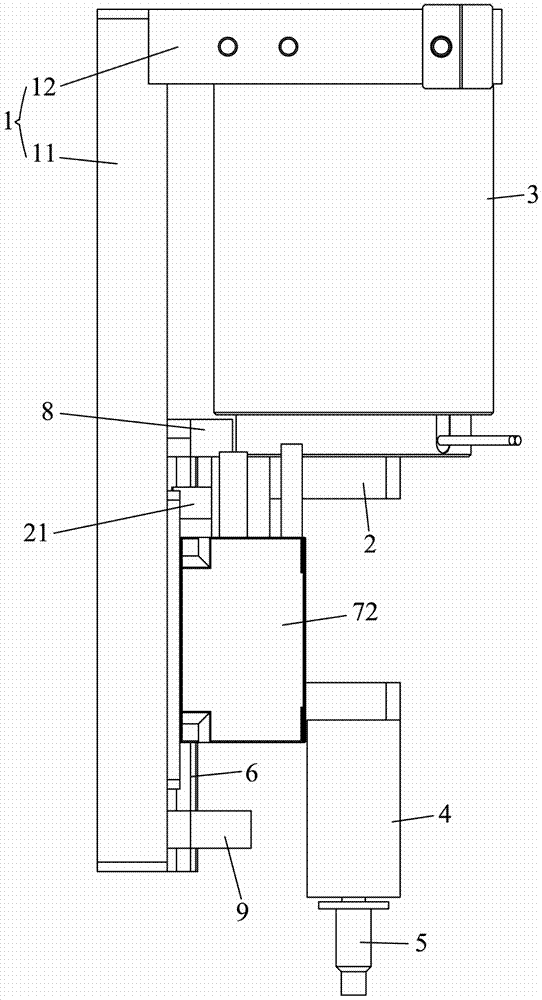

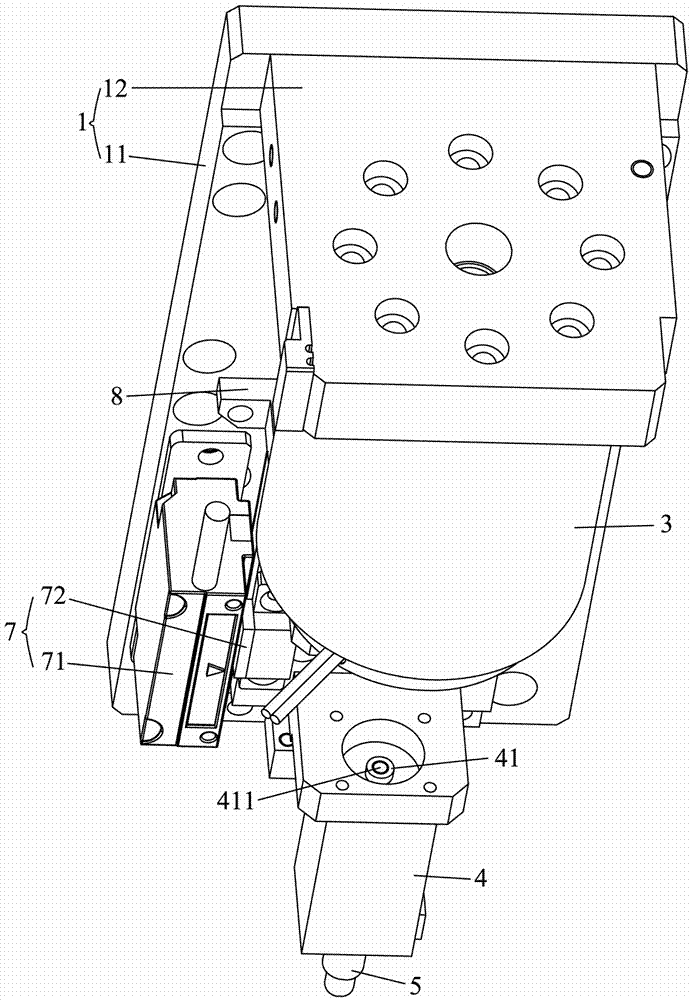

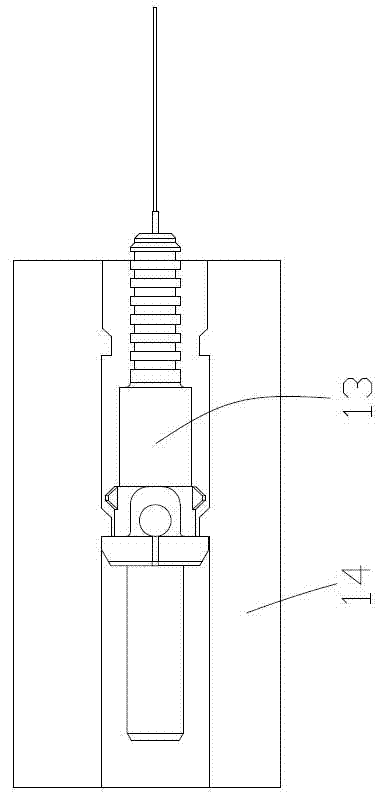

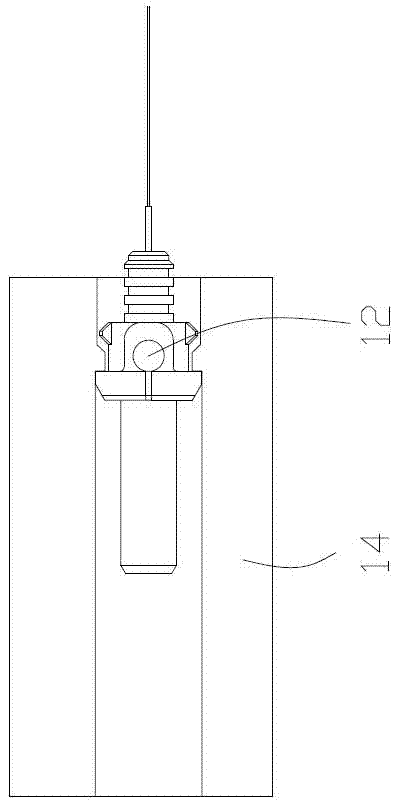

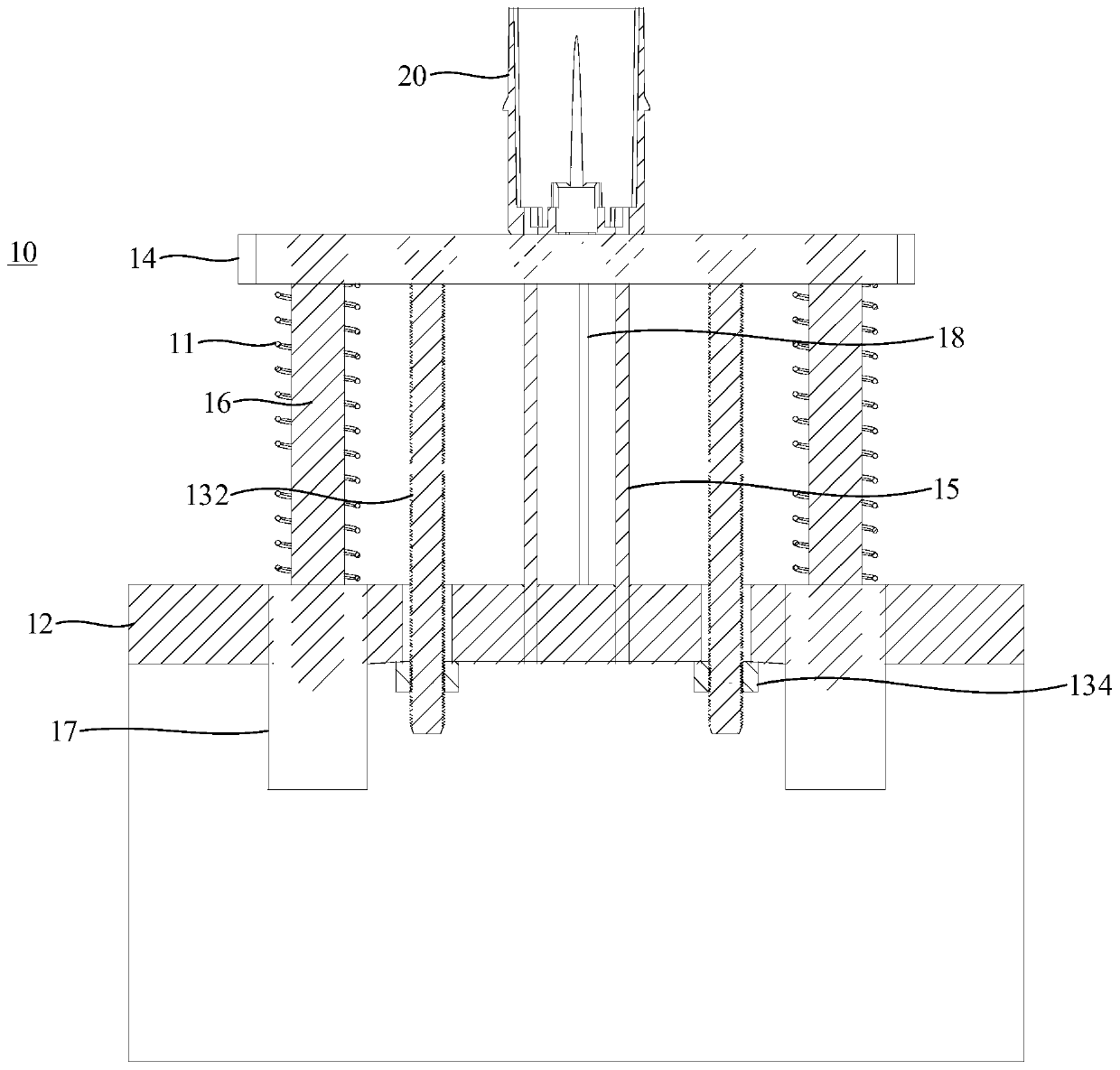

Diaphragm gas meter vertical shaft mounting device

ActiveCN105729095AAvoid deformationThe overall structure is simple and reliableMetal working apparatusHydraulic cylinderEngineering

Owner:CHONGQING RUILIBI GAS EQUIP

Capacitor feeding device for capacitor set assembly equipment

InactiveCN110626783ASo as not to damageUniform lengthCapacitor manufactureConveyor partsCapacitanceEngineering

The invention relates to the technical field of circuit element production fabrication and provides a capacitor feeding device for capacitor set assembly equipment. The capacitor feeding device comprises an installation plate, a support seat, a horizontal moving air cylinder, a clamping mechanism, a cutting component, conduction detection components, an overturning component, a material receivingcomponent, sliding bottom plates and clamping air cylinders, wherein the support seat is arranged on the installation plate, the clamping mechanism is movably connected to the support seat through a sliding rail component, the horizontal moving air cylinder is horizontally arranged on the support seat, the stretching and contracting end of the horizontal moving air cylinder is connected with the clamping mechanism, the clamping air cylinders are fixedly arranged on the installation plate, the stretching and contracting ends of the clamping air cylinders are connected with the installation plate, the cutting component, the conduction detection components, the overturning component and the material receiving component are all installed on the two sliding bottom plates, in the processing direction, the sequence is the cutting component, the conduction detection component, the overturning component, the conduction detection component and the material receiving component, and the installation plate is provided with a vibrating material feeder. The capacitor feeding device for the capacitor set assembly equipment has the advantages of being capable of performing positive pole and negative pole detection, shaping capacitor wire connection poles and feeding materials efficiently and reliably.

Owner:何国标

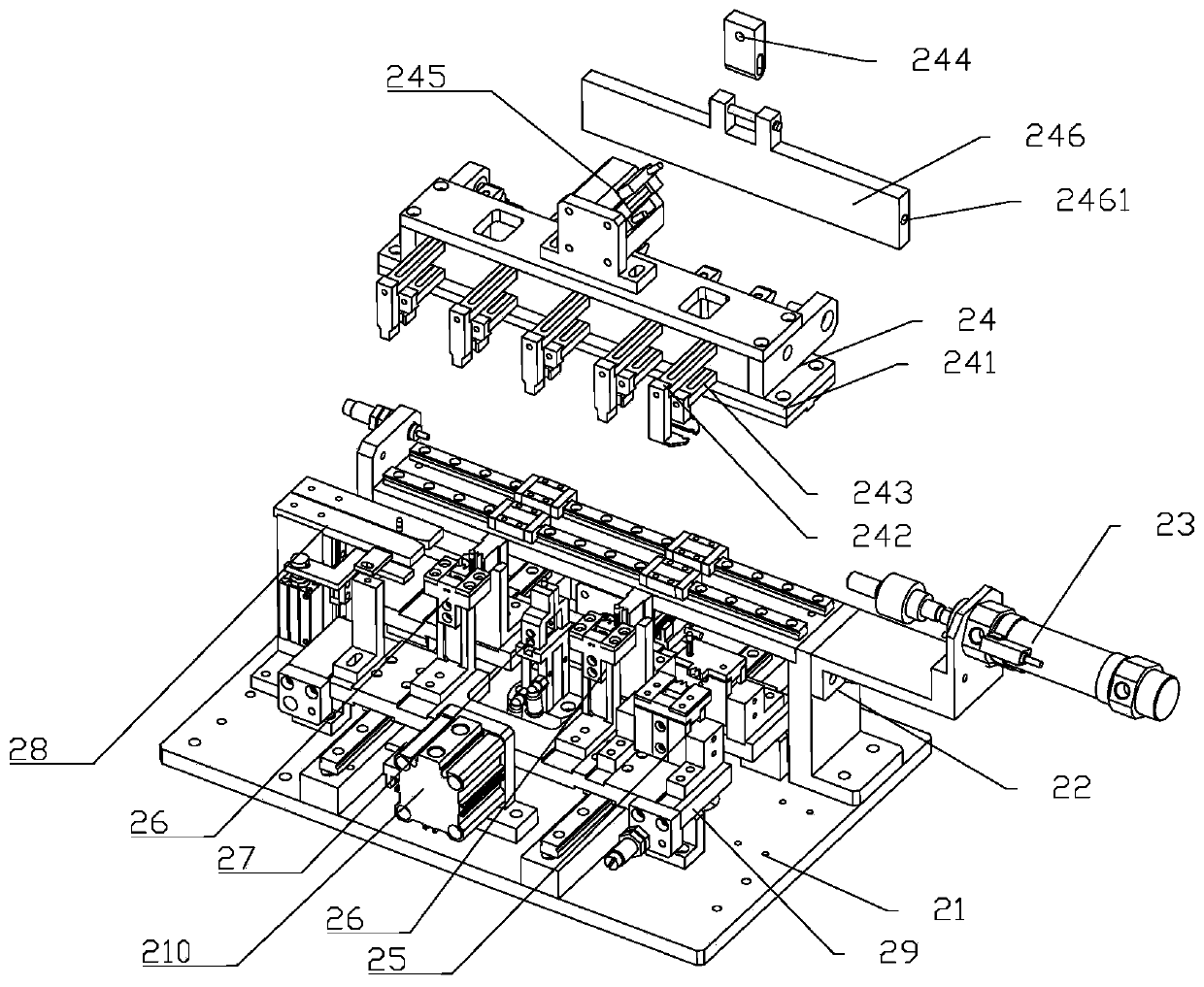

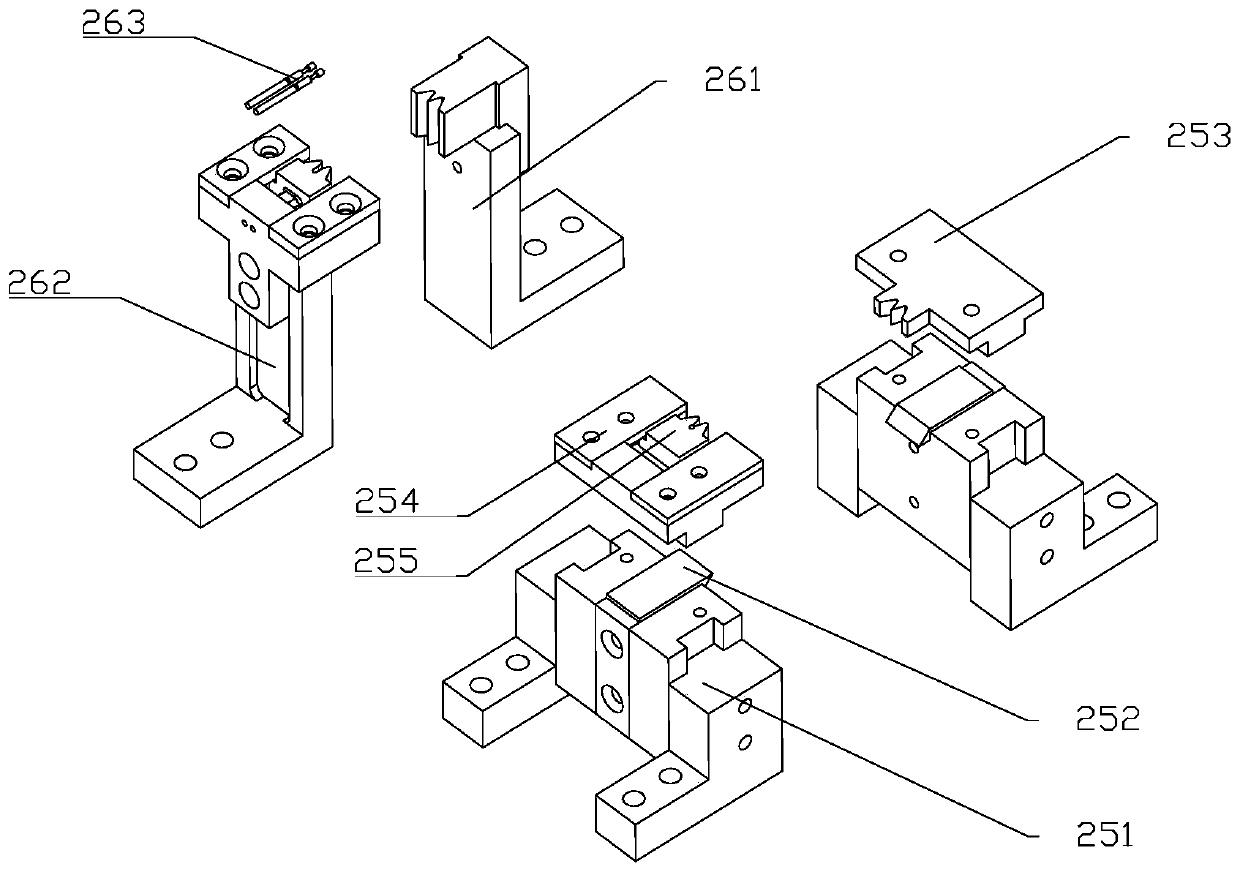

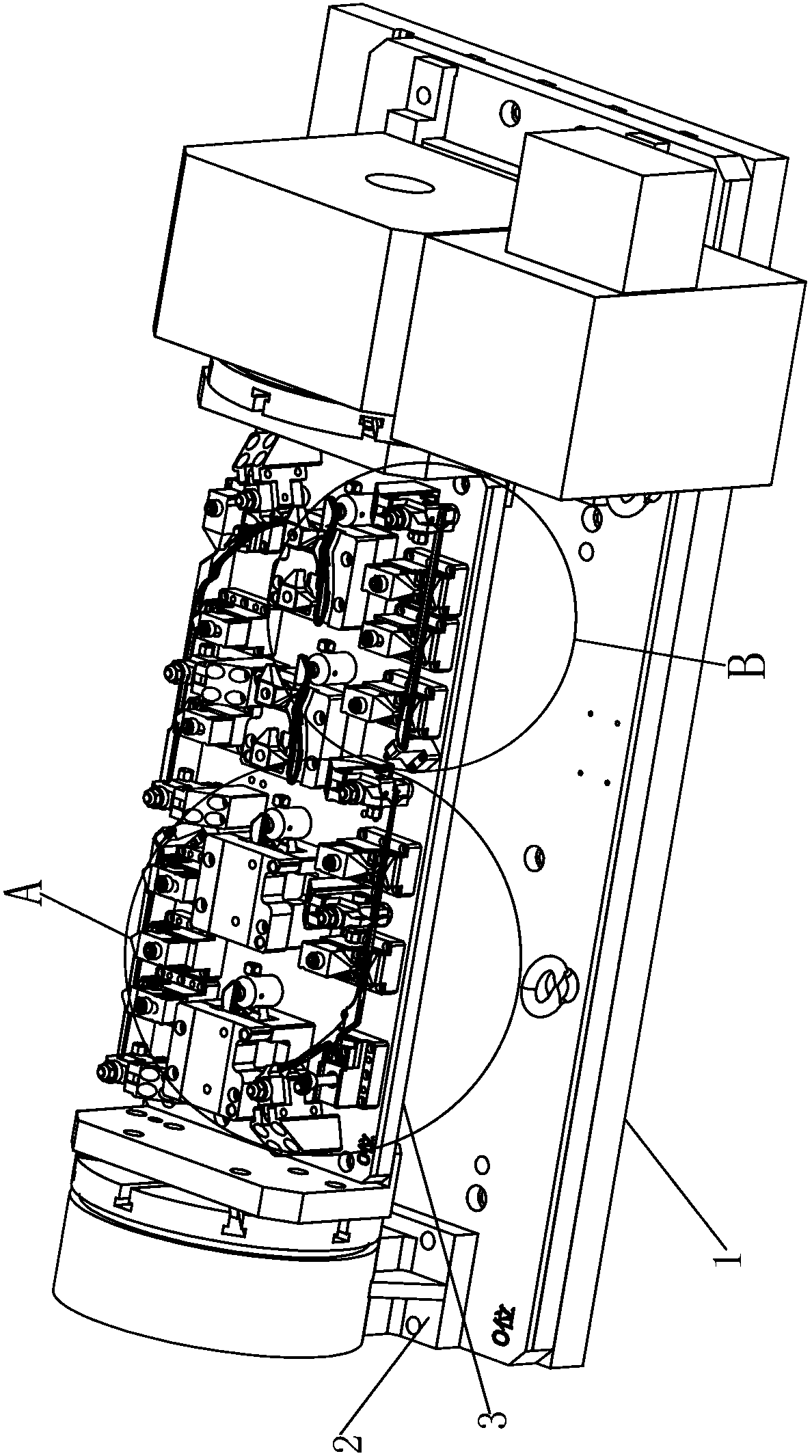

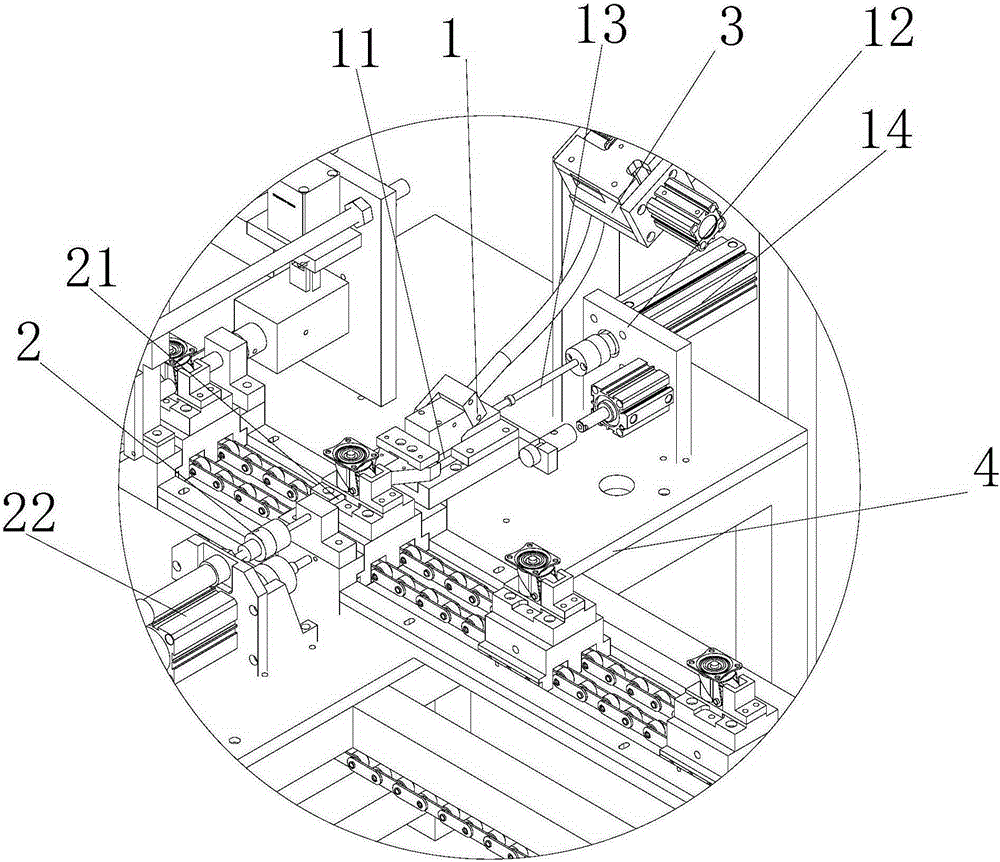

Valve rod and valve body assembling machine

PendingCN109304589AHigh positioning accuracyHigh clamping accuracyMetal working apparatusEngineeringVALVE PORT

The invention provides a valve rod and valve body assembling machine, and belongs to the technical field of machines. The problem that an existing valve rod and valve body assembling machine is low inassembling success rate is solved. The valve rod and valve body assembling machine comprises a workbench, a die base is provided with a notch for a valve rod hole of a valve body to be exposed, a positioning plate is located at the opening part position of an installing cavity for jacking contact of a valve port of the valve body, and the positioning plate is provided with an arranging port. Theworkbench is provided with a supporting structure and a positioning structure, and the die base and / or the positioning plate are / is driven by a displacement mechanism to move. A valve rod arranging device comprises a drive structure, a rotation shaft and a rotation base, the rotation shaft is located at the front end of the drive structure and driven by a rotation mechanism to rotate around the axis of the rotation shaft, the rotation base is fixedly connected to the rotation shaft and fixedly connected with a gas claw, and the distance is formed between the clamping end of the gas claw and the axis of the rotation shaft. After the gas claw clamps the valve rod, the circle center line of the bottom face of the valve rod is basically located at the extension line of the axis of the rotationshaft. The valve rod and valve body assembling machine has the advantages that the assembling precision is high, and the success rate is high.

Owner:台州中通智能科技有限公司

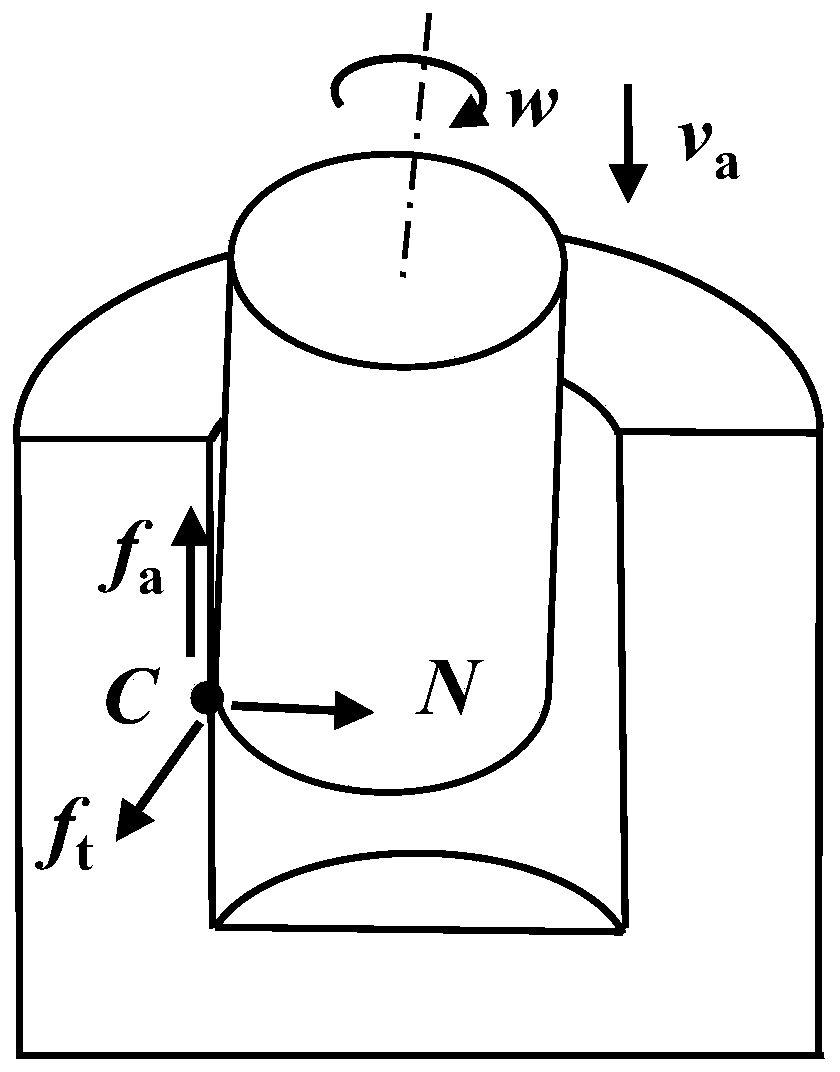

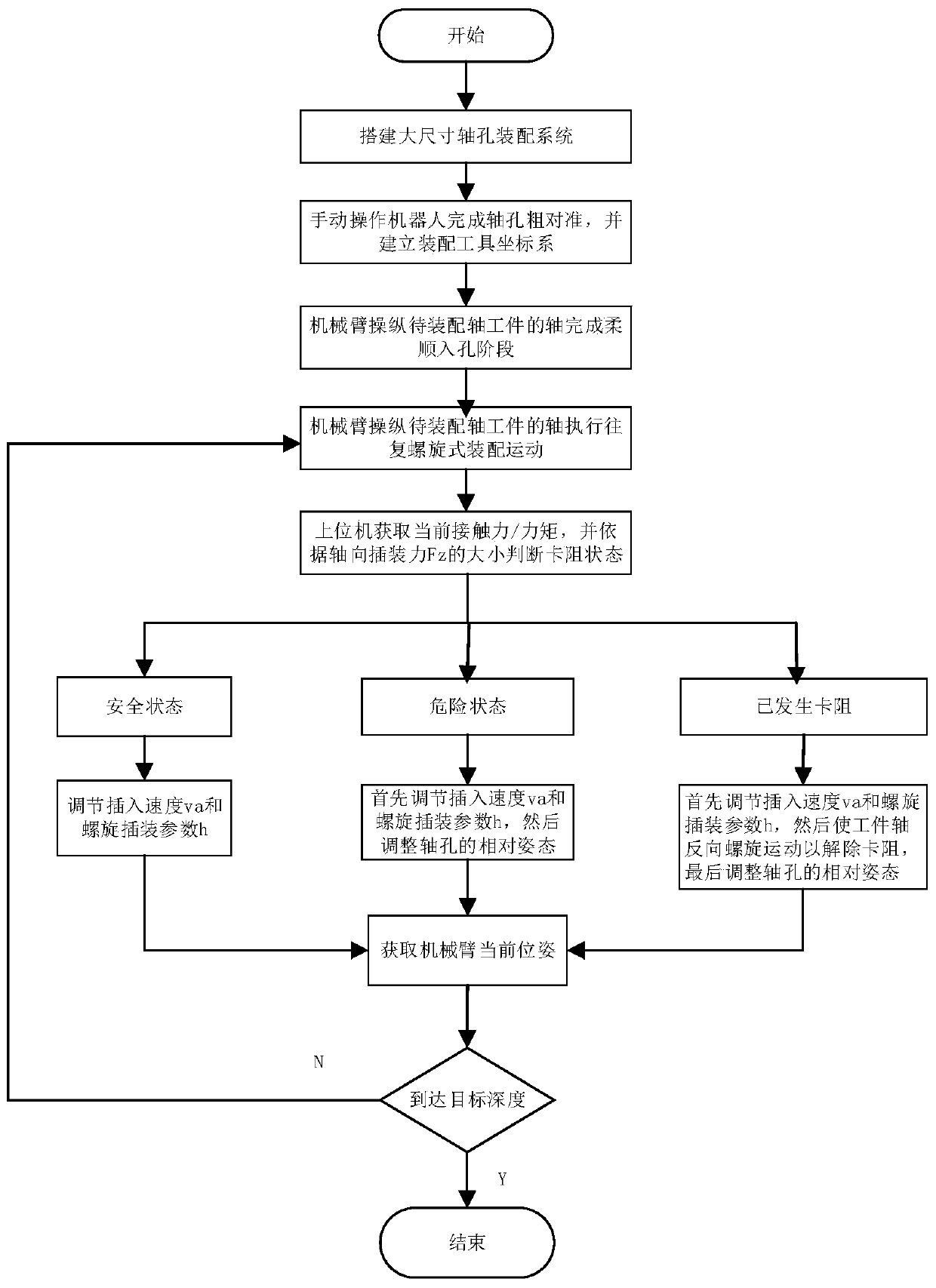

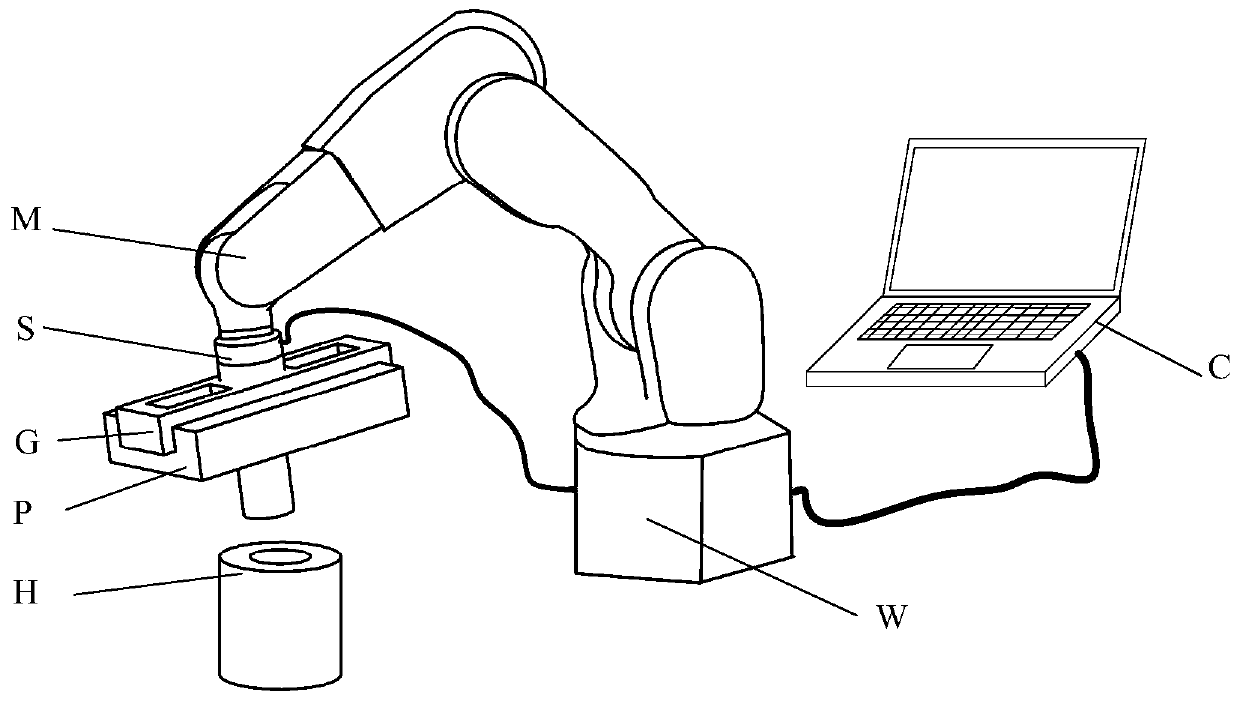

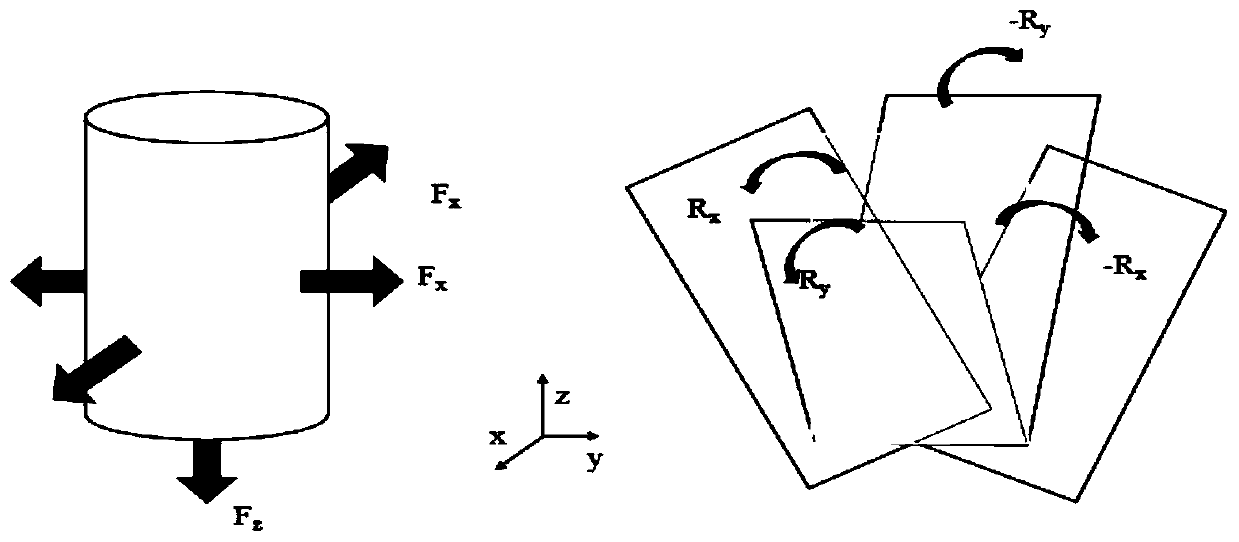

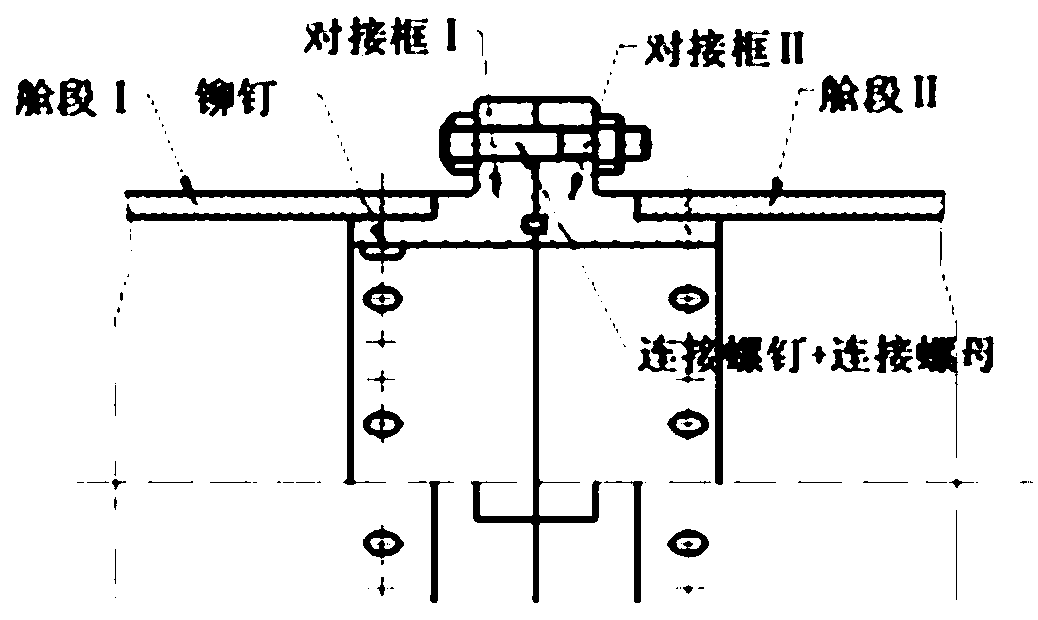

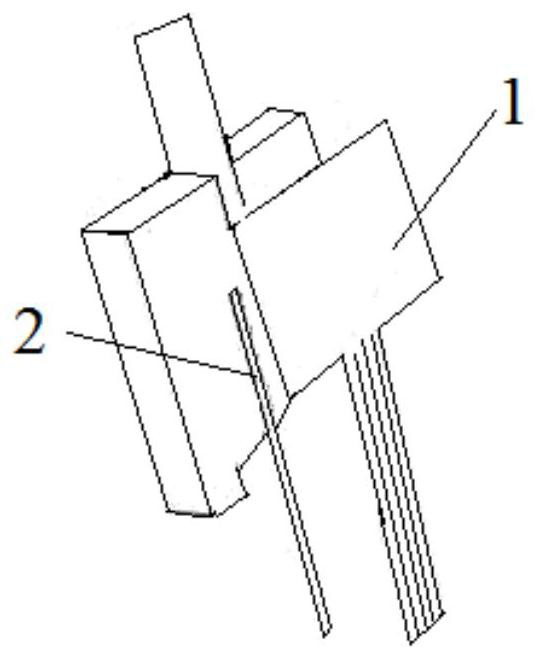

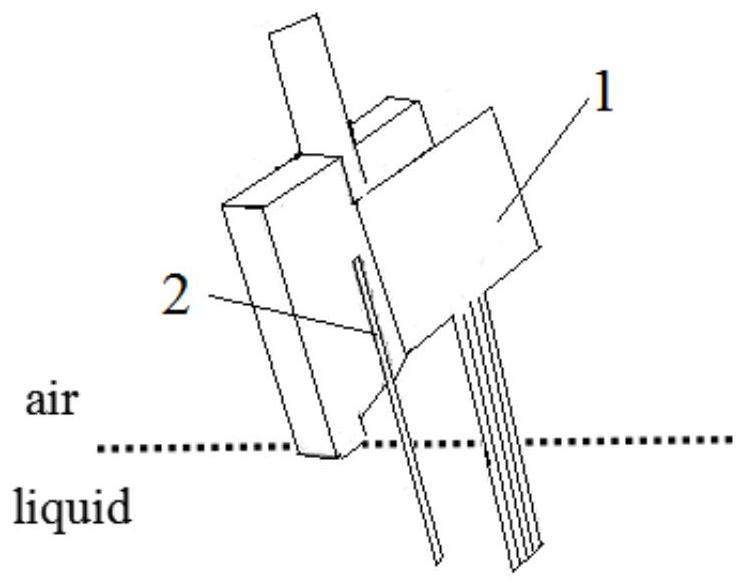

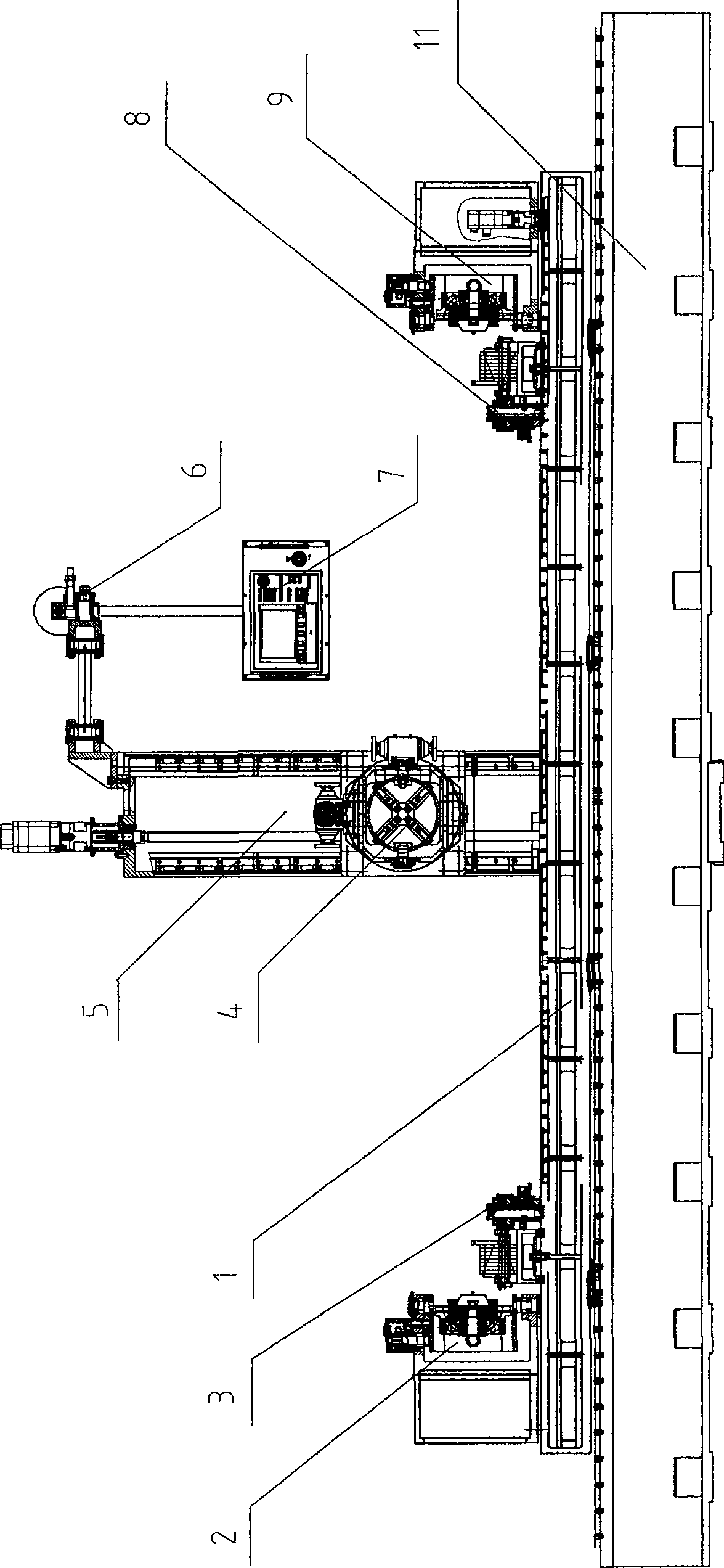

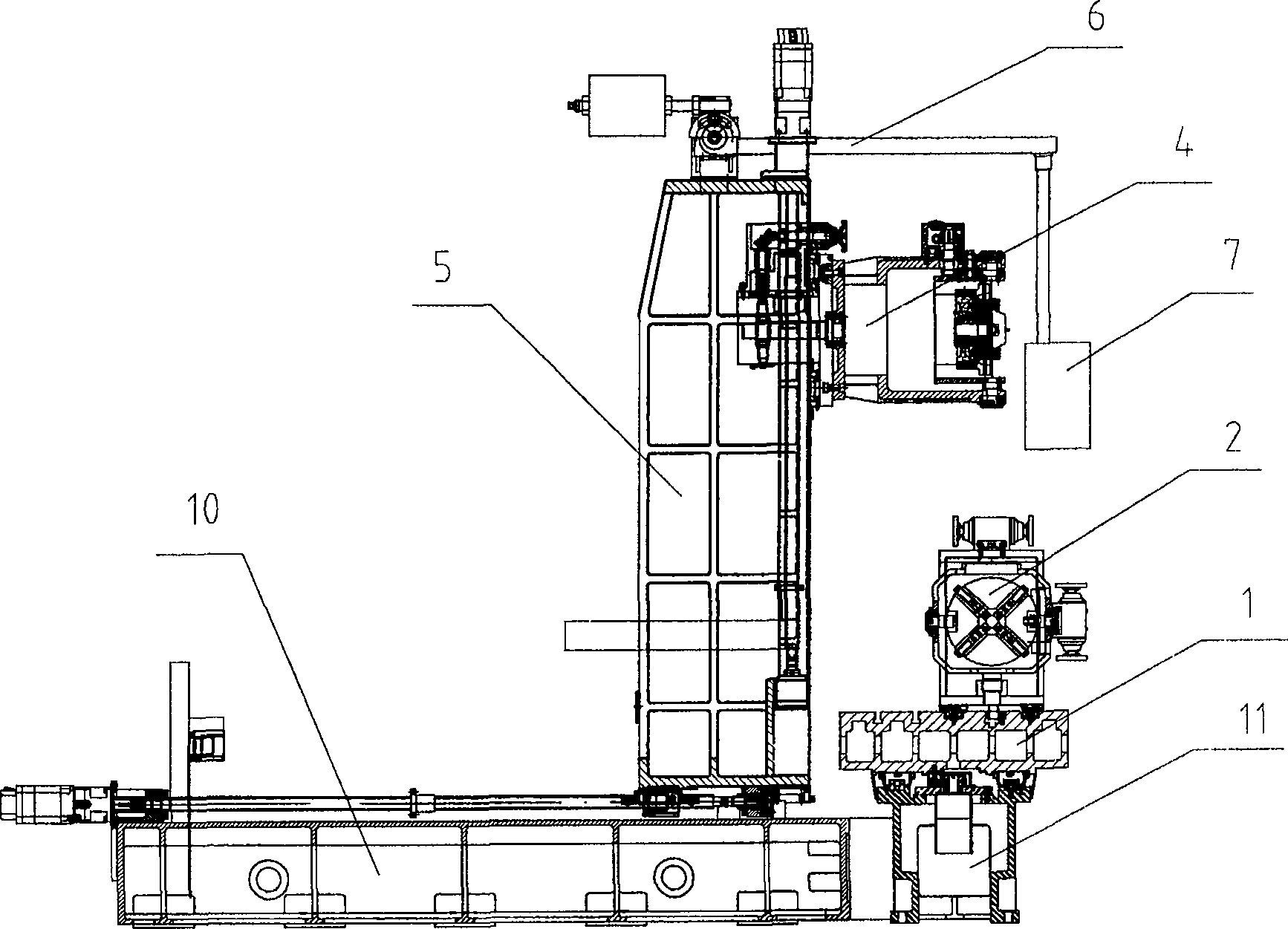

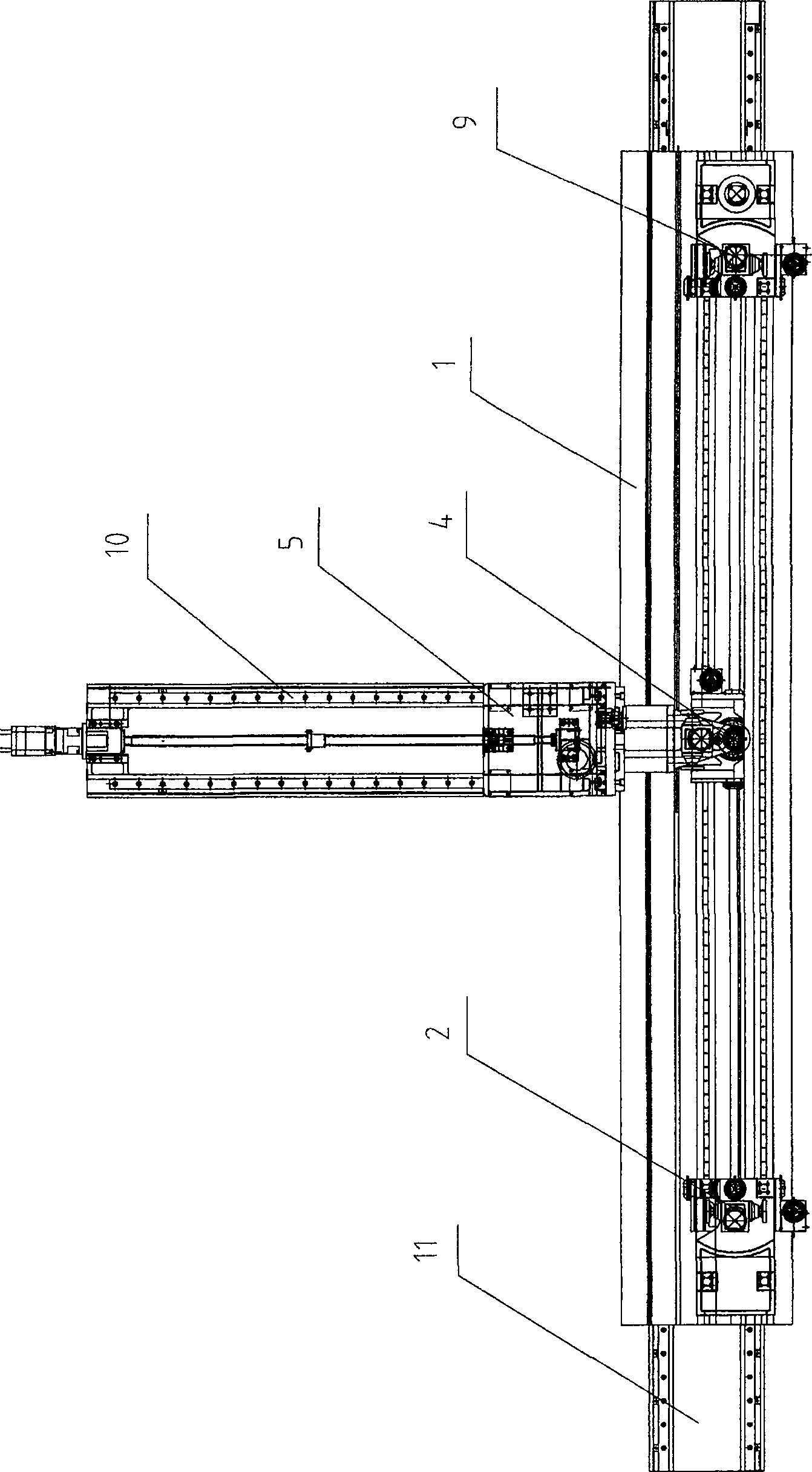

Spiral plug-in mounting method for large-sized shaft-hole workpiece

ActiveCN110355557AReduce axial frictional resistanceEasy to operateMetal working apparatusMotion parameterContact force

The invention provides a spiral plug-in mounting method for a large-sized shaft-hole workpiece and belongs to the technical field of assembly of the large-sized shaft-hole workpieces. According to theimplementation process of the spiral plug-in mounting method, a mechanical arm receives a motion instruction of an upper computer and operates the large-sized workpiece shaft to be inserted into a large-sized workpiece hole in a reciprocating spiral motion manner, a force sensor monitors the contact force / moment between the shaft and the hole in real time, the upper computer utilizes the pose ofthe tail end of the mechanical arm in the assembly process and the contact force / moment between the shaft and the hole to achieve the function of adjusting the relative poses between the shaft and the hole, meanwhile the upper computer is used for monitoring the jamming state of shaft-hole assembly and adjusting the motion parameters of spiral plug-in mounting, so that the friction resistance between the large-sized workpiece shaft and the large-sized workpiece hole is reduced, and mechanical jamming is avoided. By the adoption of the spiral plug-in mounting method for the large-sized shaft hole workpiece, in the assembly process of the large-sized shaft-hole workpieces, mechanical jamming can be more easily avoided, the operation method is simple and easy to operate, and the assembly efficiency and assembly success rate can be effectively improved.

Owner:TSINGHUA UNIV

Assembling and detecting method for cable with terminal and a plastic housing

InactiveCN110744299AInhibit productionImprove assembly accuracyAssembly machinesSortingEngineeringStructural engineering

The invention discloses an assembling and detecting method for a cable with a terminal and a plastic housing. An existing cable and plastic housing assembling method cannot achieve online detection. According to the assembling and detecting method, automatic feeding of the cable with the terminal is achieved, the direction of the cable terminal is positioned and aligned through a photoelectric sensor, the arranged cable terminal is turned over, then current on-off detection of the terminal and the cable is conducted, the cable with the terminal which is in poor contact is removed, and the situation that waste products are produced due to poor contact of the terminal and the cable is avoided as soon as possible; the cable with the terminal which is in good contact is detected to pass through a terminal guiding mechanism and then is assembled with the plastic housing, the assembling precision and the success rate are increased, an assembled lamp holder assembly is subjected to stamping treatment, current on-off detection of a copper needle and the cable is conducted before discharging, the lamp holder assembly which is in poor contact is screened out from a waste opening, the lamp holder assembly which is in good contact is popped out from a finished product discharging opening, the subsequent labor cost is saved, and the efficiency is remarkably improved.

Owner:HANGZHOU DIANZI UNIV

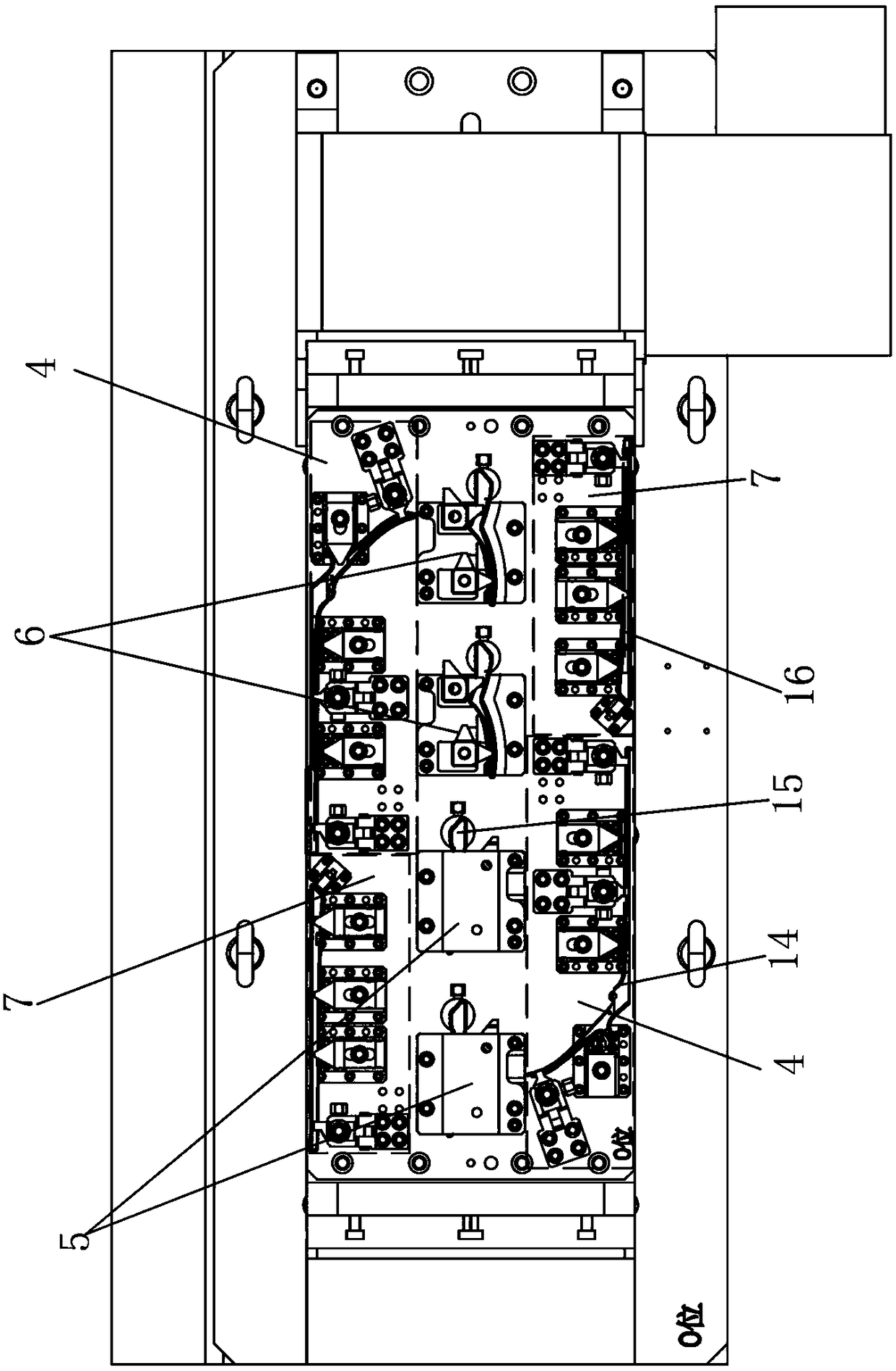

Micro switch fully-automatic assembly production system and terminal sorting loading device

ActiveCN109014845ALow resolutionPrevent looseningAssembly machinesMetal working apparatusFully automaticPhotoelectric sensor

The invention relates to the production field of electronic elements, in particular to a micro switch fully-automatic assembly production system and a terminal sorting loading device. The terminal sorting loading device used for micro switch fully-automatic assembly comprises a terminal centrifugal disc, a terminal vibrating material rail assembly, a rotary receiving frame assembly, a rotary rod,a ninth air cylinder, a rear guide base, a front discharge base, a rotary base, a pushing terminal assembly, a second photoelectric sensor assembly and a fourth mounting base. The micro switch fully-automatic assembly production system solves the problem that the terminal is low in precision in an assembly process; the inner structure of the rotary receiving frame assembly guarantees that the terminal is not loosened in a transportation process; and moreover, in a terminal push-out process, the front discharge base is used for guiding, so that assembly precision of the terminal is improved, and an assembly success rate is also increased.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

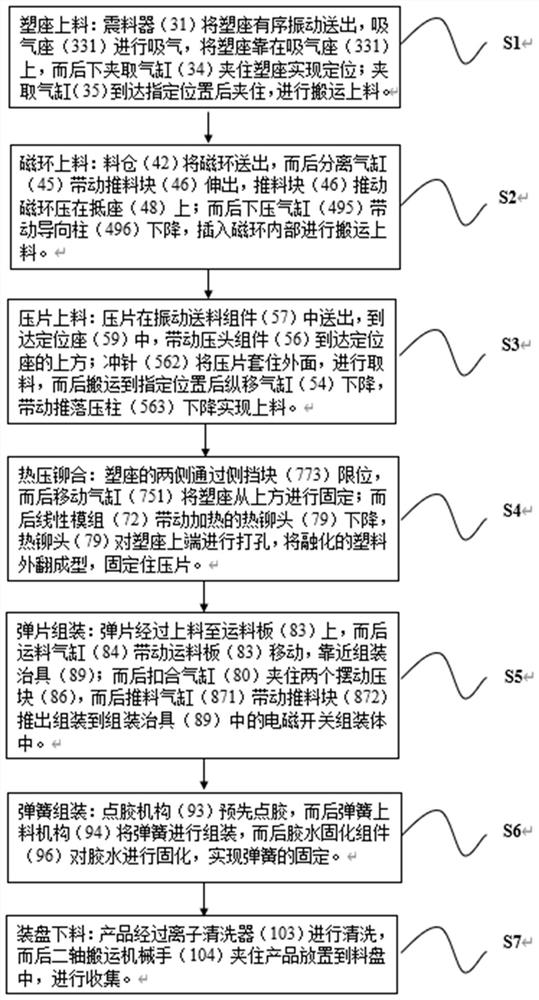

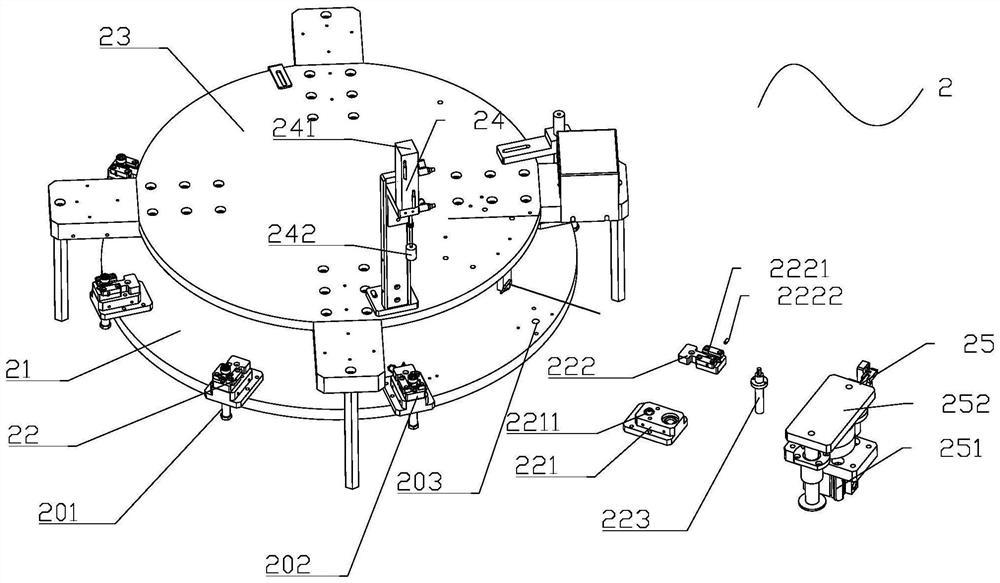

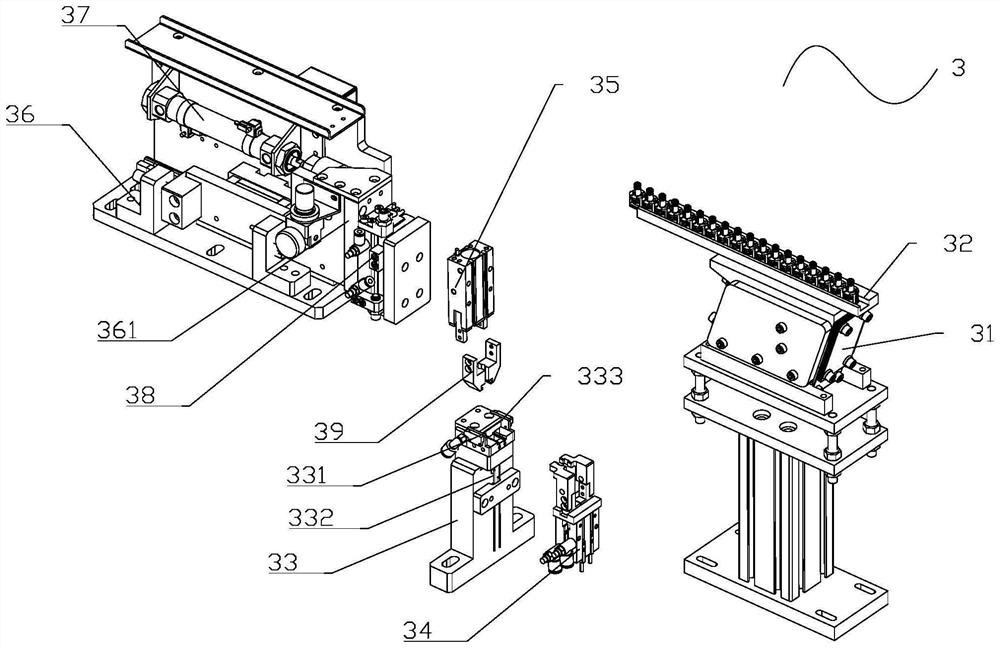

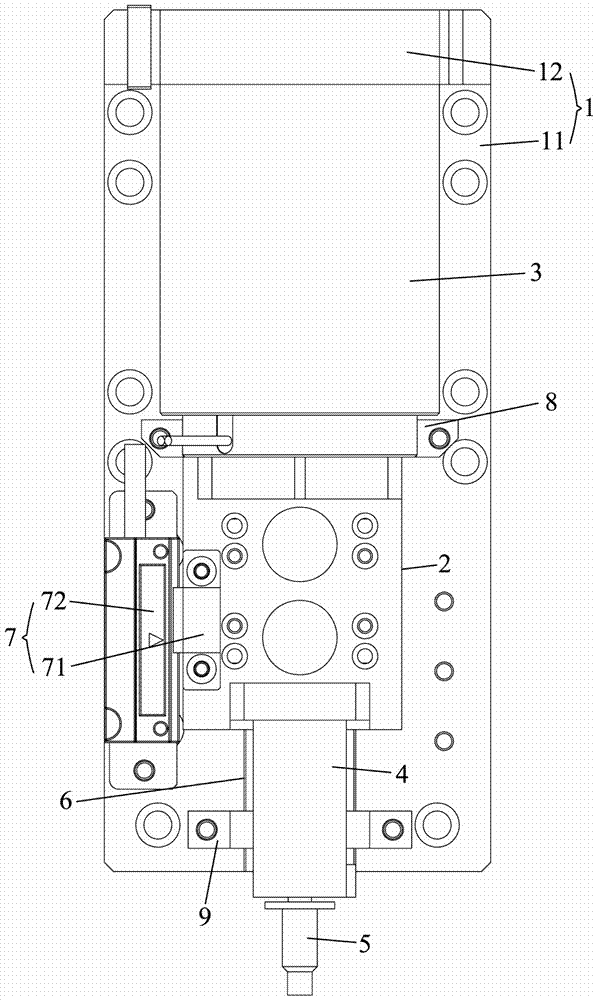

Electromagnetic switch production method and production equipment thereof

InactiveCN112017884AAvoid bending deformationAchieve positioningElectric switchesAdhesive glueEngineering

The invention discloses electromagnetic switch production equipment. The electromagnetic switch production equipment comprises a rack and a turntable conveying device, a plastic seat feeding device, amagnetic ring feeding device, a pressing sheet feeding device, a linear conveying device, a hot melting assembling device, a fixed clamping seat assembling device, a spring assembling device and a cleaning discharging device which are mounted on the rack, wherein the turntable conveying device is connected with the linear conveying device, and the plastic base feeding device, the magnetic ring feeding device and the pressing sheet feeding device are sequentially arranged on the outer side of the turntable conveying device. The hot melting assembling device and the fixed clamping seat assembling device are arranged on the side of the linear conveying device; the linear conveying device and the spring assembling device are connected through a transferring jig mechanism. And the cleaning discharging device is connected with the spring assembling device. The turntable is efficient in conveying and accurate in machining; the plastic base, the pressing sheet and the fixed clamping base areaccurate in feeding, efficient, accurate in spring separation and firm in glue connection; and cleaning and discharging are conducted in sequence, and the product collecting efficiency is high.

Owner:李丹

Lens assembling mechanism

The present invention discloses a lens assembling mechanism comprising a base, a slide carriage, a voice coil linear motor, a rotary drive device and a gripping device, the base being mounted on a moving frame and movable along with the moving frame above a lens fetching station and a lens assembling station. The slide carriage is mounted on the base and moves vertically along the base. The voice coil linear motor is mounted on the base and used for driving the slide carriage to move vertically along the base. The rotary drive device is mounted on the slide carriage and moves vertically. The gripping device is mounted a lower part of the rotary part of the rotary drive device and can rotate under the driving of the rotary part. The gripping device grips the lens at the lens fetching station, and presses the lens into a lens barrel and loosens the lens at the lens assembling station. The mechanism can be used in the process of assembling the lens to avoid the situation that the lens assembly is not in place or the lens is crushed due to the insufficient pressure or the large pressure, and the success rate of the lens assembly is improved.

Owner:东莞市研杰自动化设备有限公司

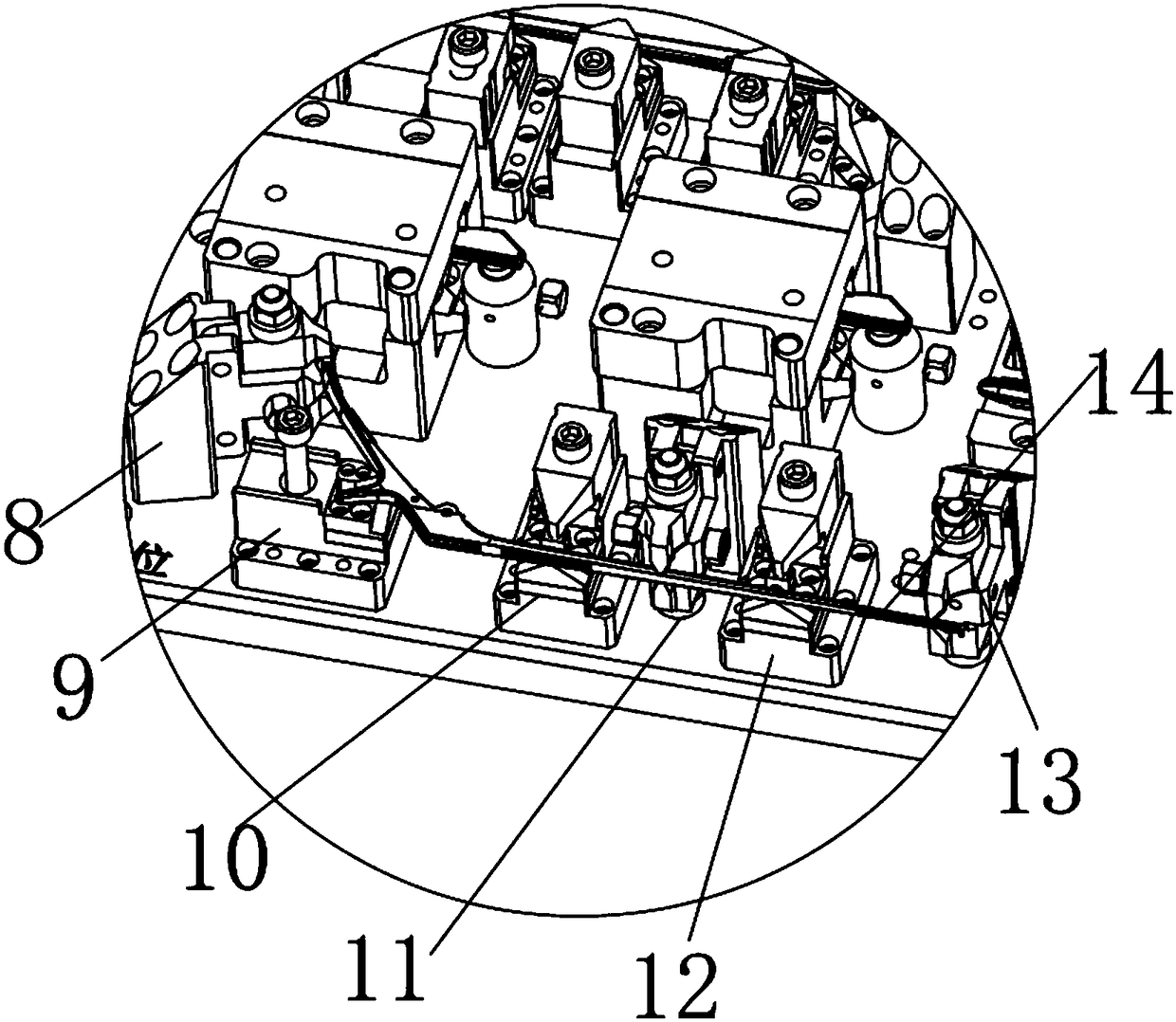

Vertebral plate rongeur machining clamp

PendingCN108544267AReduce setup timeImprove assembly success ratePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention provides a vertebral plate rongeur machining clamp. The vertebral plate rongeur machining clamp comprises a machine tool worktable, a four-axis dividing plate, a right handle clamping device, a left handle upper portion machining clamping device, a left handle lower portion machining clamping device and a cover plate machining clamping device; the right handle clamping device is usedfor machining a right handle of a vertebral plate rongeur, the left handle upper portion machining clamping device is used for machining a left handle upper portion of the vertebral plate rongeur, the left handle lower portion machining clamping device is used for machining a left handle lower portion of the vertebral plate rongeur, and the cover plate machining clamping device is used for machining a cover plate of the vertebral plate rongeur; multiple parts are clamped at one time, equivalently, workpiece centralized clamping is achieved, compared with previous one-piece clamping, clampingtime is reduced, in the previous method, clamping needs to be carried out at eight times, now, only one concentrated one-time clamping is needed, during assembly, whole-set one-to-one corresponding assembling is needed during machining, and the assembling success rate of the parts is high.

Owner:NINGBO SKY MASTER PRECISION MASCH CO LTD

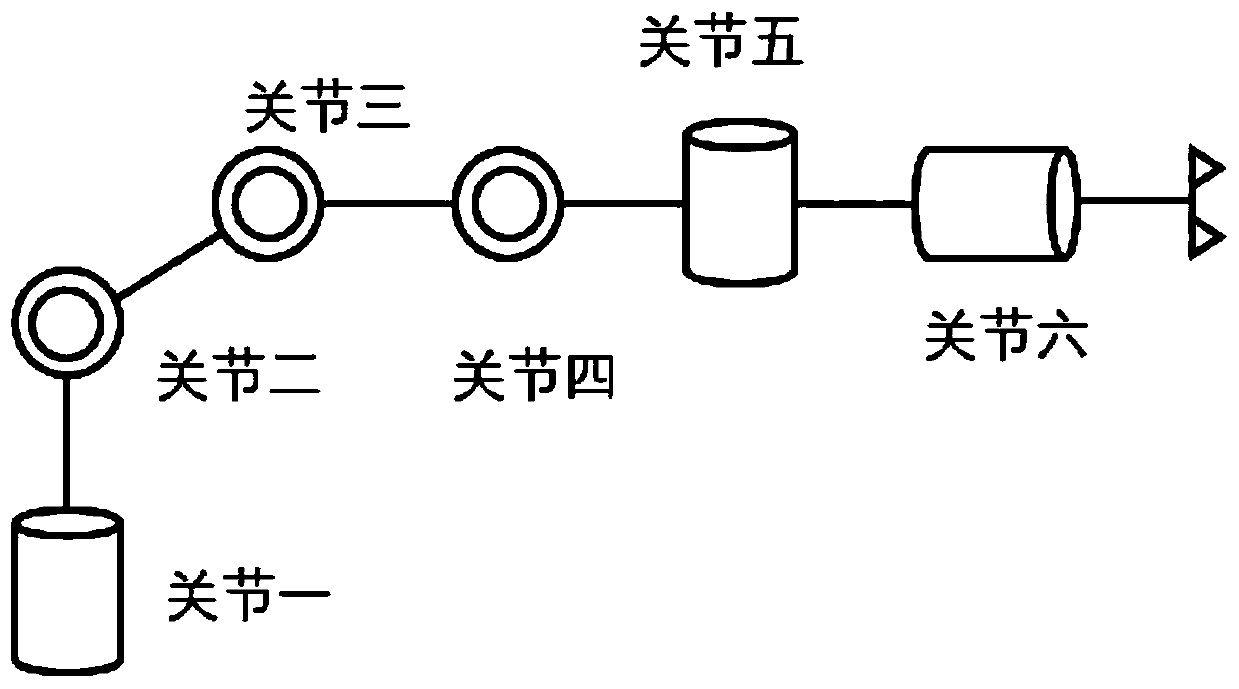

Mechanical arm motion control system

ActiveCN111515928ASolve the problem of high assembly failure rateSo as not to damageProgramme-controlled manipulatorTotal factory controlControl systemCollision detection

The invention provides a mechanical arm motion control system. The mechanical arm motion control system comprises an intelligent compliant assembly platform, a motion assembly workpiece and a static assembly workpiece, wherein the intelligent compliant assembly platform controls a six-degree-of-freedom cooperative mechanical arm, the six-degree-of-freedom cooperative mechanical arm comprises an end effector, and the intelligent compliant assembly platform generates state information of the six-degree-of-freedom cooperative mechanical arm; the intelligent compliant assembly platform establishesa training model according to the state information of the six-degree-of-freedom cooperative mechanical arm to realize dragging teaching and collision detection, and a force control algorithm and a search assembly algorithm are obtained; and the six-degree-of-freedom cooperative mechanical arm executes the force control algorithm and the search assembly algorithm to reach a designated station, the end effector clamps the motion assembly workpiece for assembly, and the motion assembly workpiece is assembled to the static assembly workpiece.

Owner:SHANGHAI UNIV OF ENG SCI

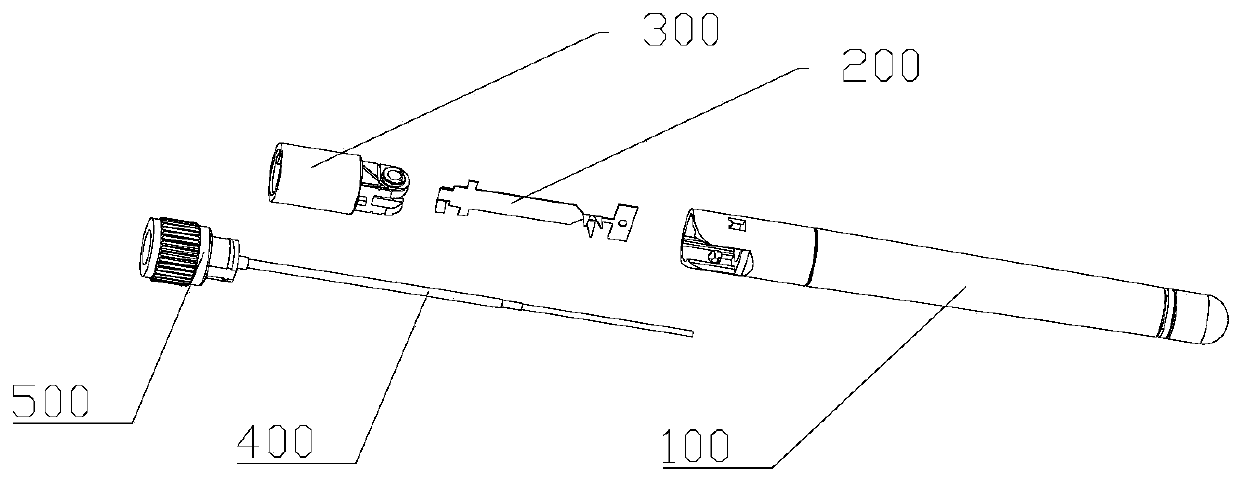

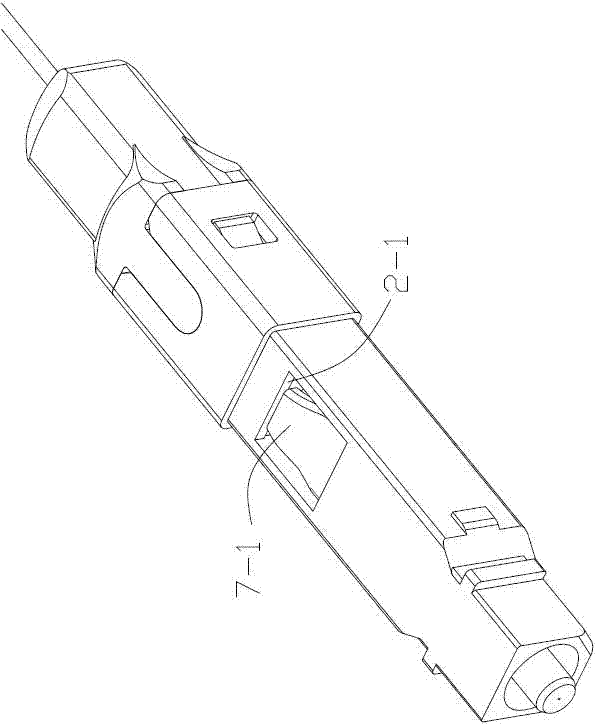

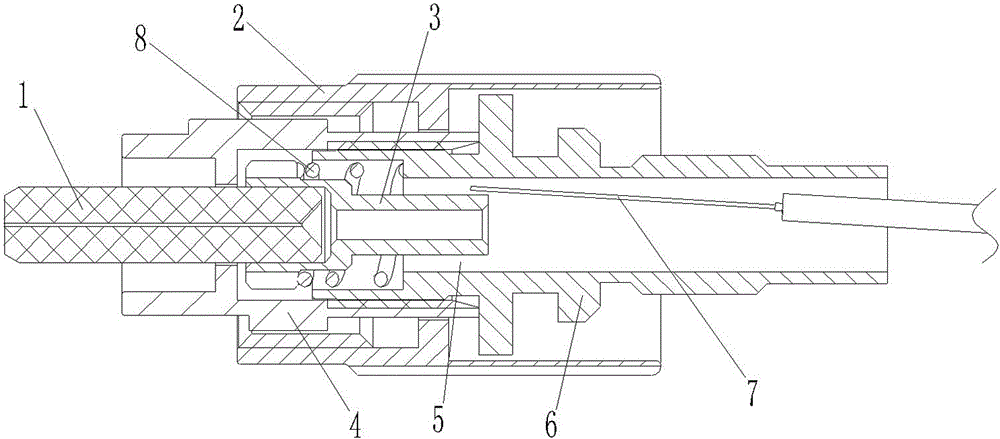

Hot-melt field-assembled optical fiber connector

ActiveCN102928924AImprove the shortcomings of poor performanceImprove assembly success rateCoupling light guidesFiberHot melt

The invention relates to a hot-melt field-assembled optical fiber connector. The connector comprises a preset optical fiber, a ferrule, a spring, a front bracket, a connecting bracket, a heat-shrinkable protective casing, a rear seat, an optical fiber holder, an extension casing, a jacket and a reed. When the hot-melt optical fiber connector is assembled, completion of two-time welding in the same optical fiber connector can be achieved by controlling the length of the cut fiber and the position of the heat-shrinkable protective casing. The connector has the following advantages: the connector breaks through the defect that the traditional hot-melt field-assembled optical fiber connectors can be just welded once and can be reused, thus greatly increasing the assembly success rate, saving the field assembly time and effectively lowering the cost; and the welding method and structure are suitable for various types of hot-melt field-assembled optical fiber connectors such as SC and LC.

Owner:NANJING PUTIAN TELEGE INTELLIGENT BUILDING

Easily assembled capillary tube

InactiveCN102865698AAvoid Soldering SituationsNo cloggingFluid circulation arrangementBiomedical engineeringMental detachment

The invention discloses an easily assembled capillary tube, which comprises a body, wherein an anti-detachment step is arranged on the external surface of a port part of the body. Preferably, the anti-detachment step is in the shape of a reverse tooth; and the port part of the body is provided with a thickened layer, and the anti-detachment step is located on the external surface of the thickened layer. The easy assembly capillary tube provided by the invention has the advantages that assembly is easy and assembly success rate is high.

Owner:泰州市海陵区欧菱自动化设备有限公司

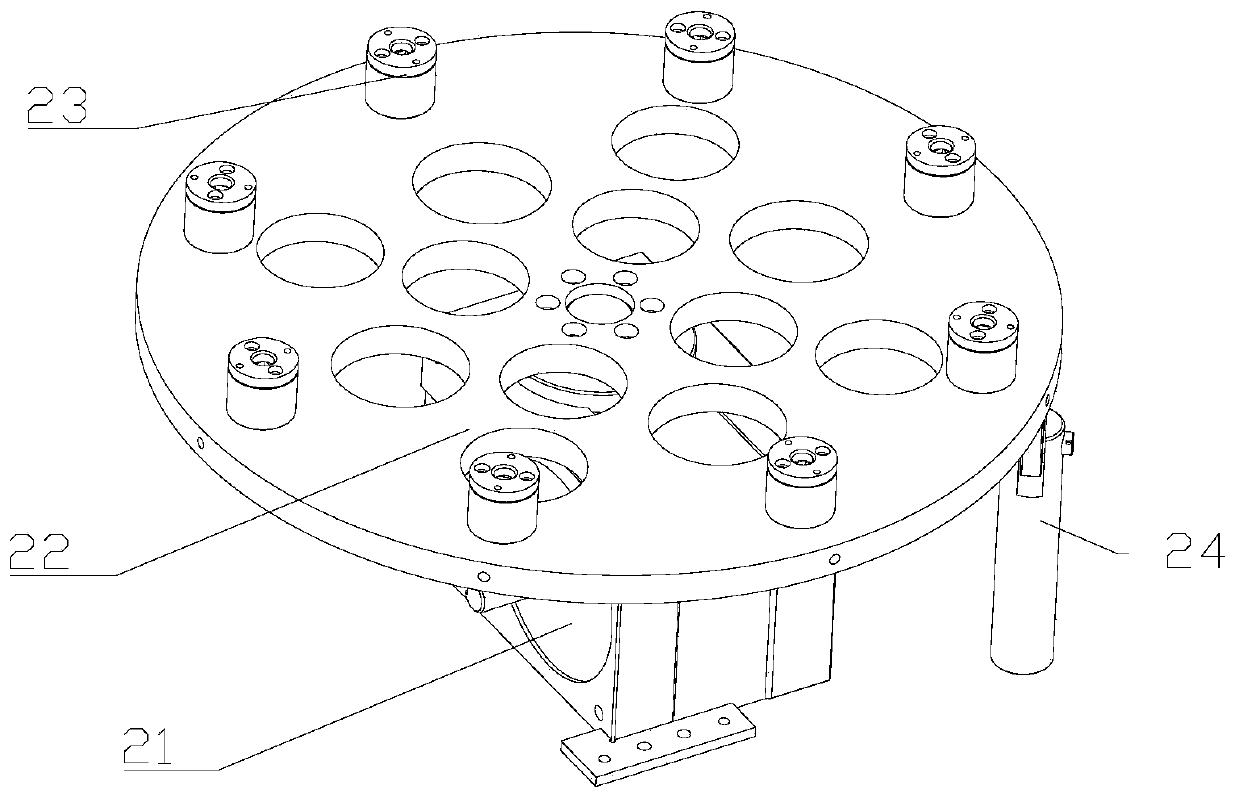

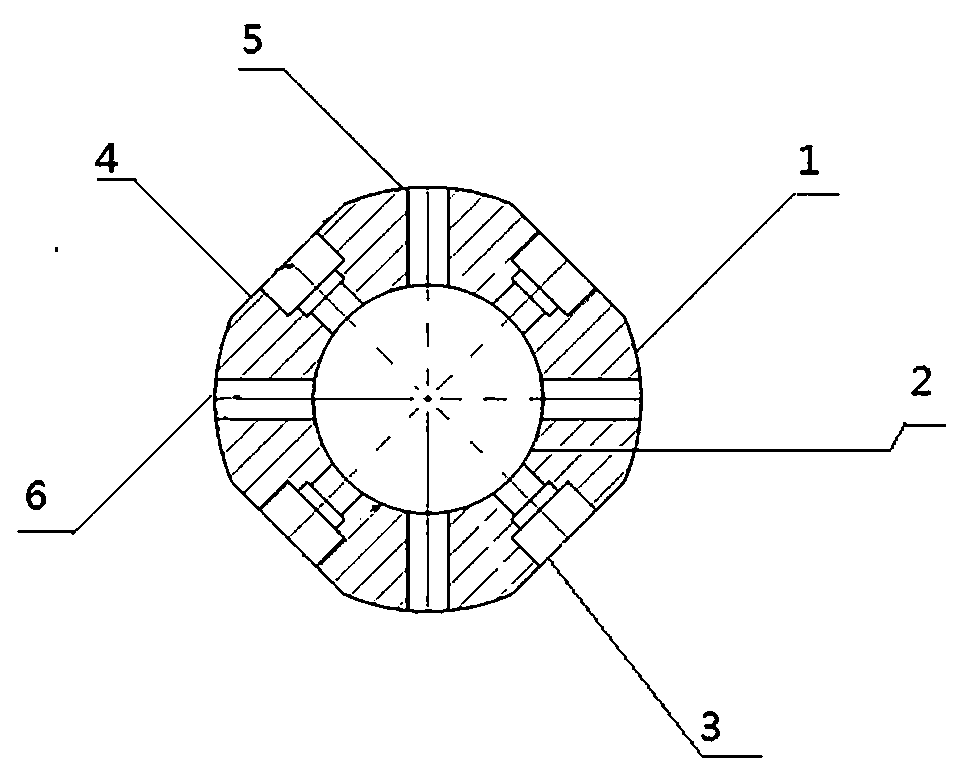

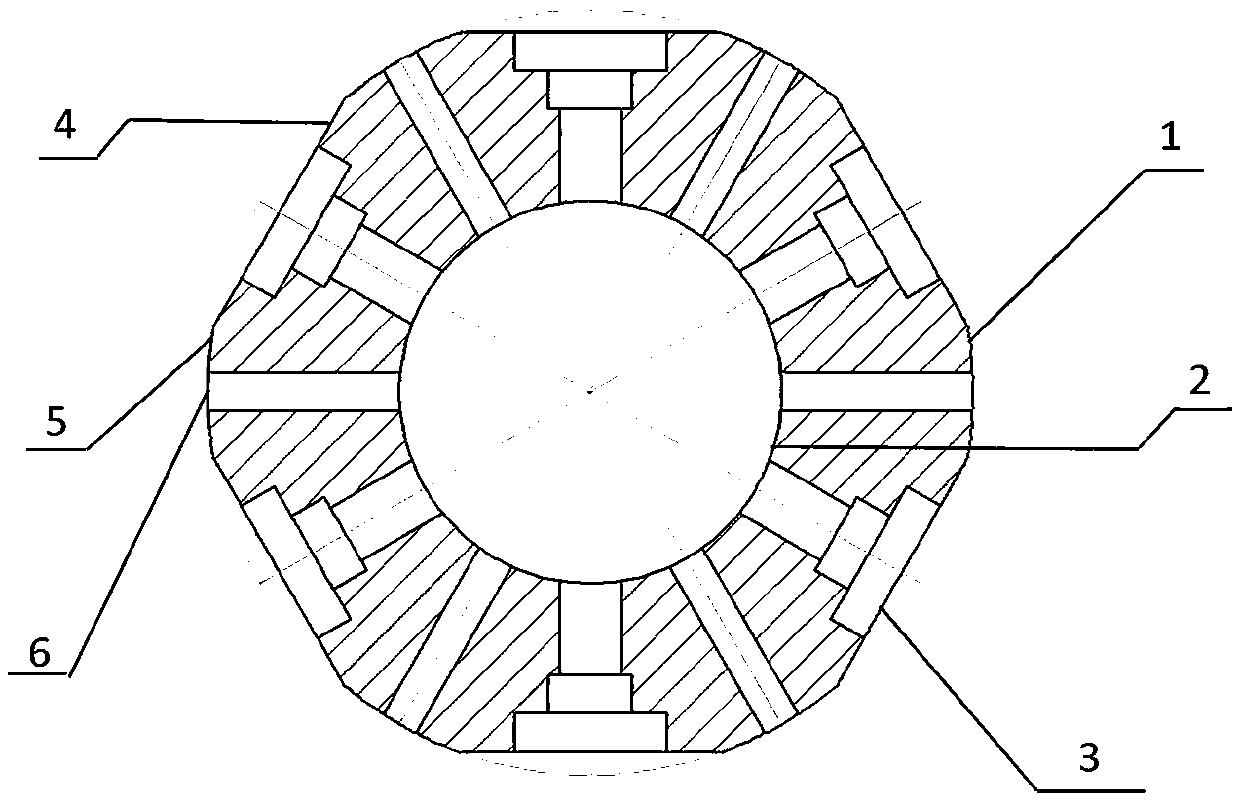

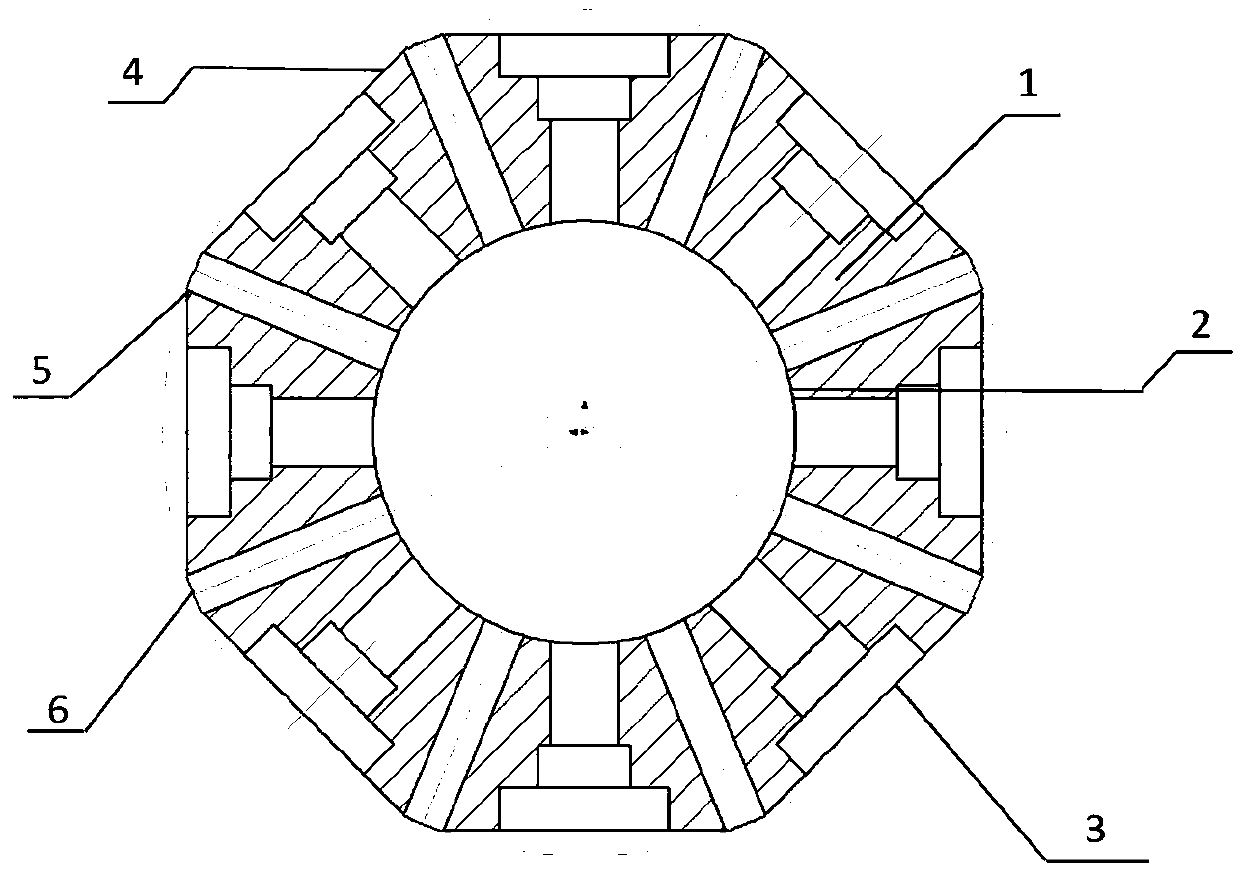

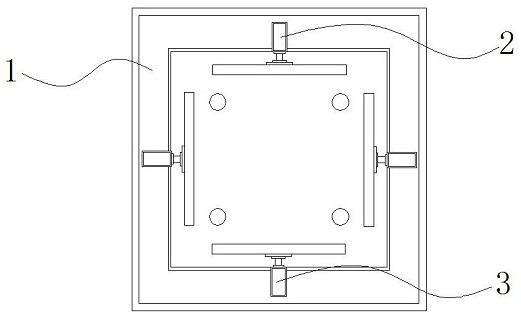

Multi-pole rod support device with single cylindrical surface positioning function, multi-pole rod device and multi-pole rod mounting method

InactiveCN111043119AGuaranteed verticalityGuaranteed parallelismStability-of-path spectrometersBoltsMass analyzerMechanical engineering

The invention provides a multi-pole rod support device with a single cylindrical surface positioning function, a multi-pole rod device comprising the multi-pole rod support device and a multi-pole rodmounting method adopting the multi-pole rod support device. According to the multi-pole rod support device, aiming to overcome the defects in the prior art, the inner wall surface, namely a positioning surface, of a support is set as the single cylindrical surface, and step screw hole positions are uniformly arranged on the outer wall surface in a circumferential mode; and by the aid of technicalmeans that a multi-pole rod is fixed by the step screws and the like, the multi-pole rod support device has the technical effects of being small in machining difficulty, stable in assembly and easy in machining precision control, and the multi-pole rod mounting method adopting the multi-pole rod support device is simple and stable in assembly and has great significance for improving the use stability of mass spectrometers.

Owner:CHENGDU ALIEBN SCI & TECH CO LTD

A micro switch automatic assembly production system and terminal sorting and feeding device

ActiveCN109014845BLow resolutionPrevent looseningAssembly machinesMetal working apparatusElectronic componentFully automatic

The invention relates to the production field of electronic elements, in particular to a micro switch fully-automatic assembly production system and a terminal sorting loading device. The terminal sorting loading device used for micro switch fully-automatic assembly comprises a terminal centrifugal disc, a terminal vibrating material rail assembly, a rotary receiving frame assembly, a rotary rod,a ninth air cylinder, a rear guide base, a front discharge base, a rotary base, a pushing terminal assembly, a second photoelectric sensor assembly and a fourth mounting base. The micro switch fully-automatic assembly production system solves the problem that the terminal is low in precision in an assembly process; the inner structure of the rotary receiving frame assembly guarantees that the terminal is not loosened in a transportation process; and moreover, in a terminal push-out process, the front discharge base is used for guiding, so that assembly precision of the terminal is improved, and an assembly success rate is also increased.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

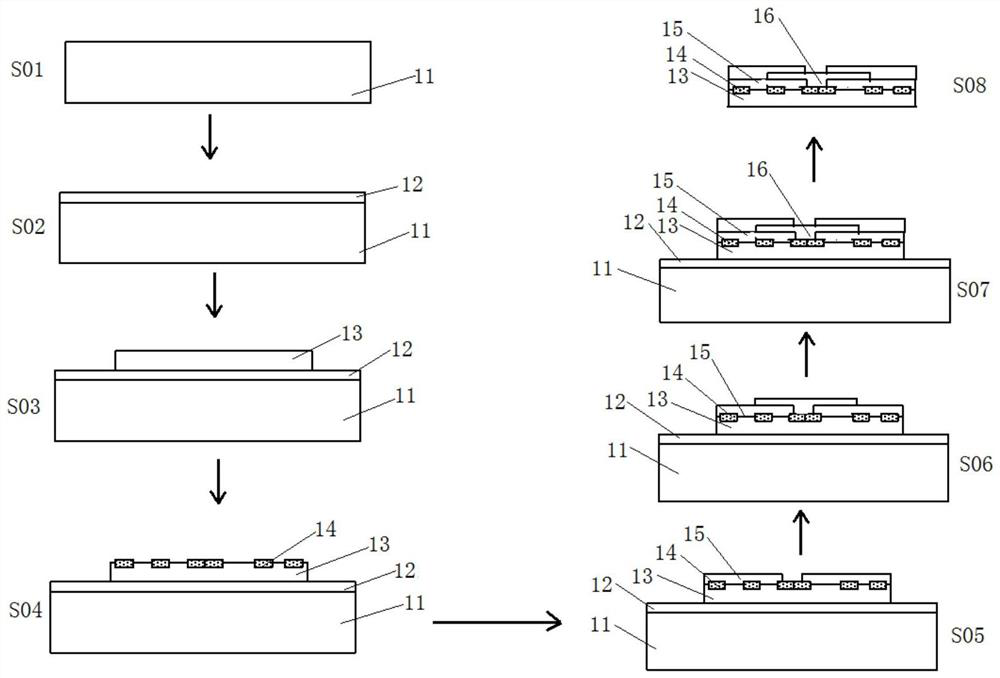

Manufacturing method of integrated sealed galvanic pile

ActiveCN110010923AResolve Assembly EffectsResolve failureFinal product manufactureSealing/support meansManufacturing technologySteady state

The invention discloses a manufacturing method of an integrated sealed galvanic pile, belonging to the technical field of manufacturing. The manufacturing method comprises the following steps that: 1)according to the galvanic pile design drawing data, the processing of a bipolar plate and the processing of a membrane electrode are completed; 2) an in-situ online dispensing process is adopted, namely dispensing operation is performed at two sides of the bipolar plate; 3) an in-situ online glue filling process is adopted. The process route of equal-interval sealing, glue pouring or glue dispensing in-situ packaging of the bipolar plate provided by the invention fundamentally solves the technical defects of the existing galvanic pile assembly process; by adopting the in-situ dispensing or glue injection process and the equidistant steady-state sealing process, the assembly process is simplified, the influence of factors such as labor and dimensional tolerance on the assembly of the galvanic pile is reduced, and the consistency, the safety, the durability and the production efficiency of the galvanic pile are improved.

Owner:TSINGHUA UNIV +1

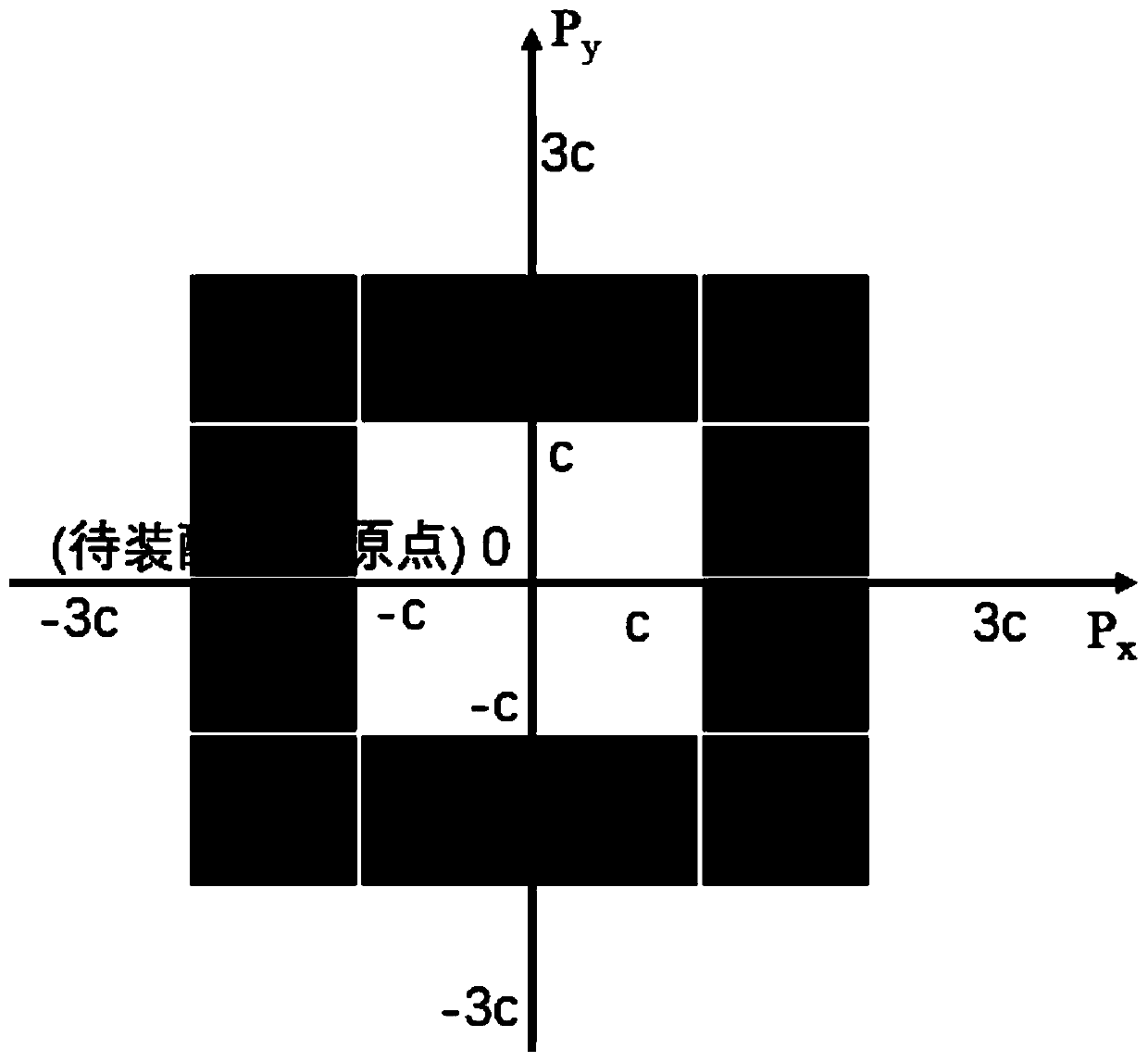

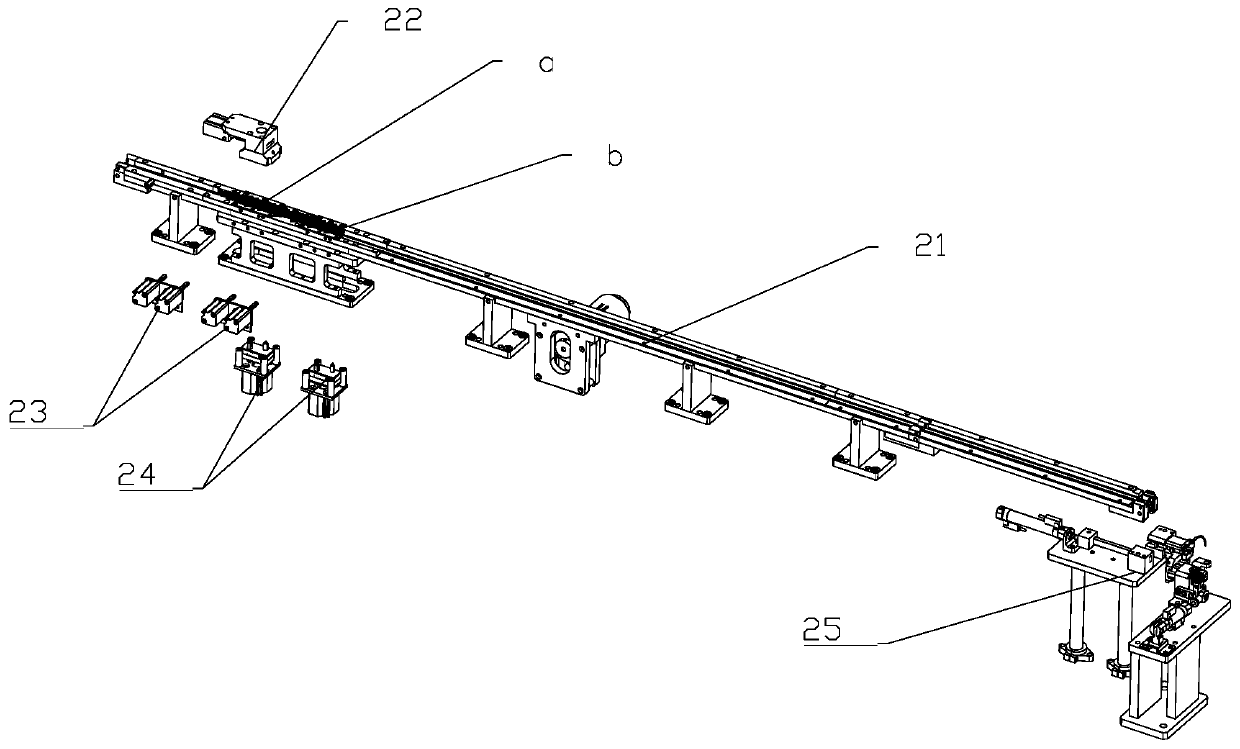

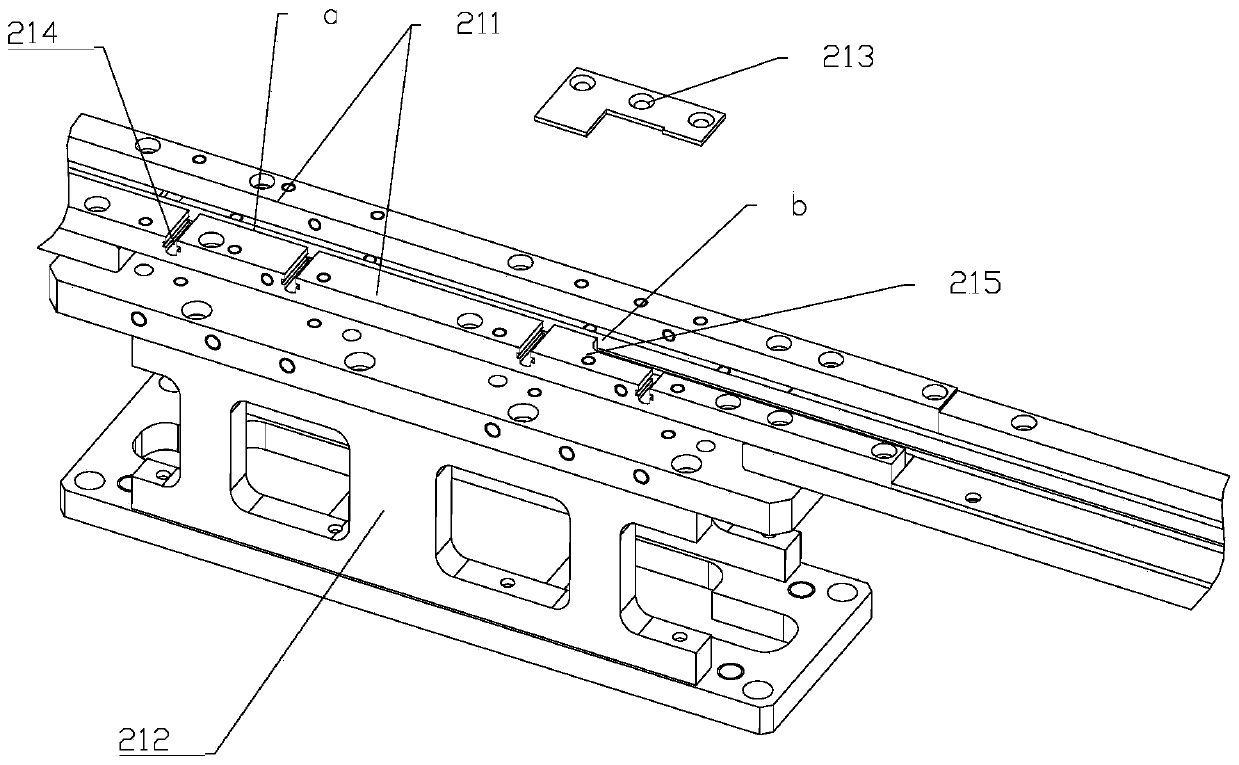

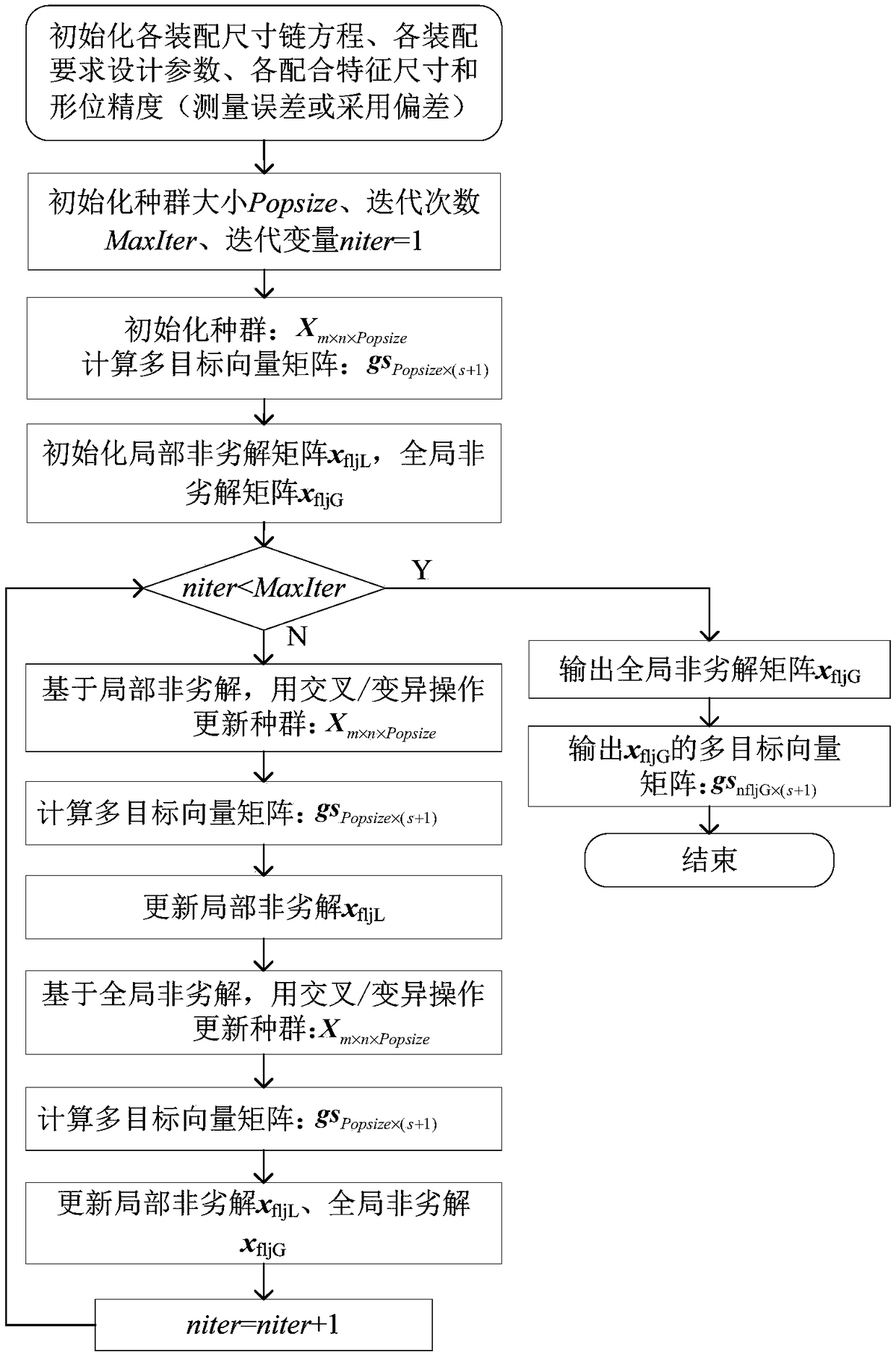

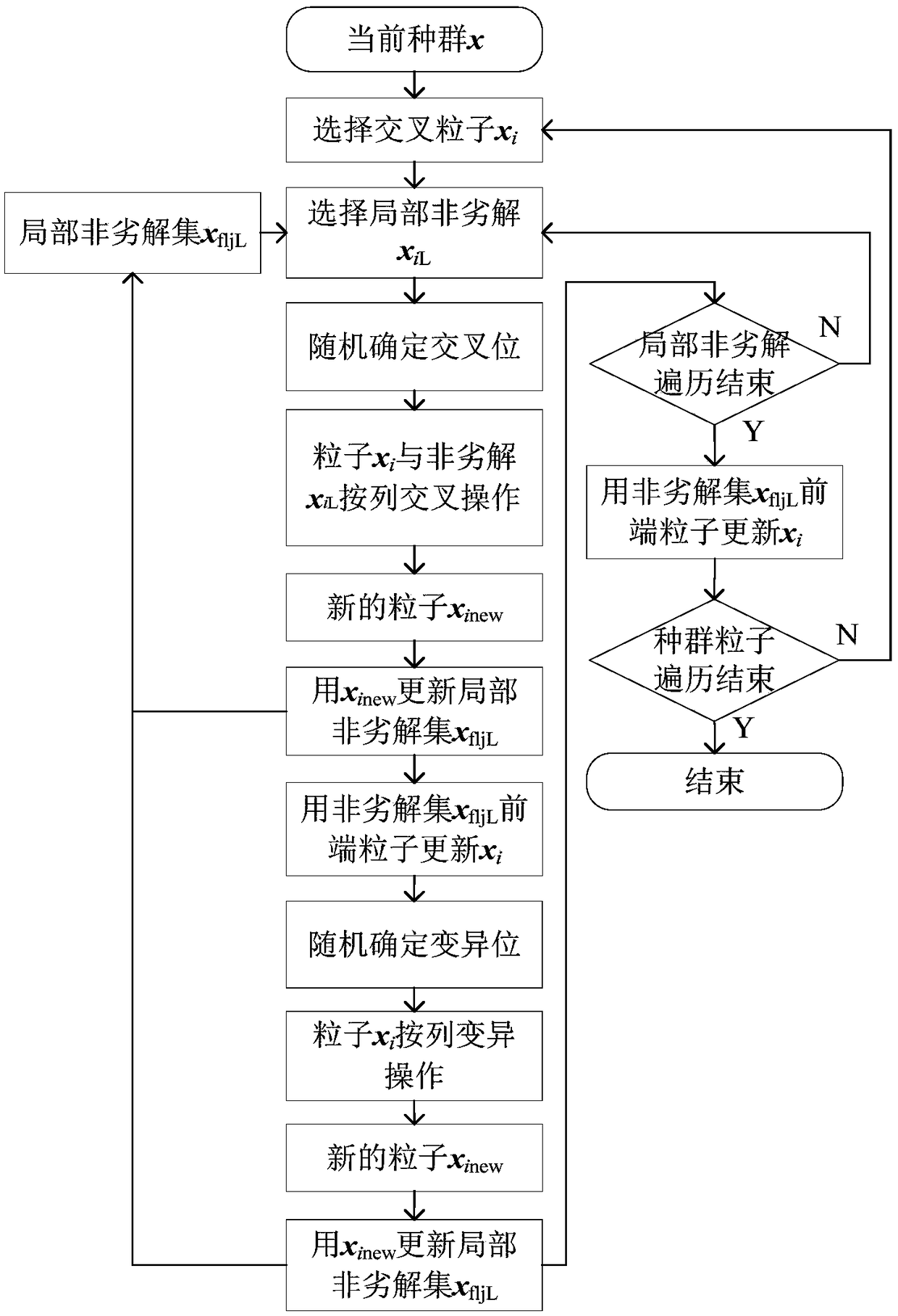

A multi-dimensional direction selection assembly optimization method based on hybrid particle swarm optimization algorithm

ActiveCN109086491AHigh average assembly accuracyImprove assembly success rateArtificial lifeDesign optimisation/simulationParticle swarm algorithmMulti dimensional

The invention discloses a multi-dimensional direction selection assembly optimization method based on a hybrid particle swarm algorithm, which comprises the following steps: S1, constructing a multi-dimensional dimension chain model aiming at the batch assembly problem of a plurality of parts; S2, based on the multi-dimensional dimension chain model, constructing a multi-objective optimization model for batch selection assembly of a plurality of parts; S3, solving the multi-objective optimization model by using the hybrid particle swarm optimization algorithm, and finally obtaining a pluralityof assembly pairing schemes in batch selection assembly of parts. Based on the hybrid particle swarm optimization algorithm, the invention solves the assembly matching problem of batch assembly of aplurality of parts in the selection assembly, obtains the average assembly precision of the batch products, has higher assembly success rate, and considers the assembly matching optimization of the multi-dimensional dimension chain model of the part assembly, and has more practical value.

Owner:SOUTH CHINA UNIV OF TECH

Screw mounting equipment convenient for hole alignment and used for electronic part assembling

InactiveCN112157413AEasy accessAchieve alignmentWork holdersMetal working apparatusEngineeringScrew thread

Owner:深圳市辉迪机电科技有限公司

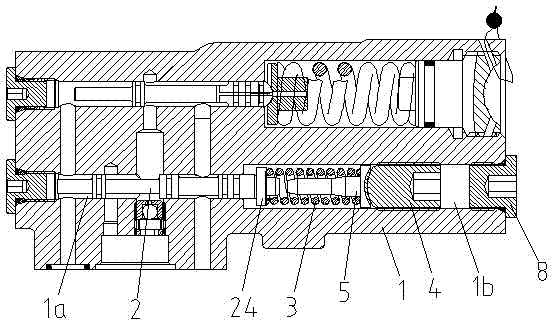

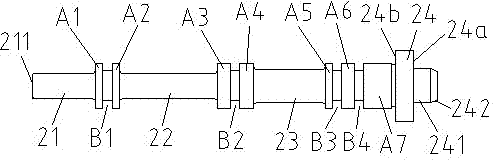

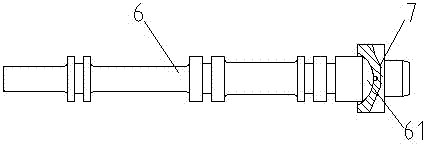

Novel valve core with spring seat

InactiveCN103032400AIncrease guide lengthReduce assembly requirementsServomotor componentsTorsion springMachining

The invention discloses a novel valve core with a spring seat. The novel valve core comprises a valve core rod body which is slidably assembled in a lower valve cavity of a valve body, wherein seven annular sealing bosses are arranged on the valve core rod body; the circumferential surface of each annular sealing boss is slidably matched with the inner peripheral wall of the lower valve cavity through liquid sealing; the tail part of the valve core rod body is integrally provided with the spring seat connected to a back face of the seventh annular sealing boss to form a novel spring seat valve core structure with the spring seat; a spring guide rod is arranged in the center of the spring seat; a compression spring is sleeved on the spring guide rod; the front end of the compression spring is abutted against and matched with a positioning annular face of the spring seat; the valve core rod body is abutted against and assembled in the lower valve cavity of the valve body through the compression spring; and a pressure adjusting spiral plug is spirally pressed at the rear end of the compression spring. The novel valve core has the advantages of simple structure, convenience in machining, low assembly requirement and capabilities of greatly improving the mounting success rate of a PVECVP valve and reducing the production and manufacturing cost, and has the characteristics of high mounting speed and stable performance.

Owner:SAIKESI HYDRAULIC TECH CO LTD

Rivet perforation guide device of rotation wheel assembling machine

InactiveCN105312477AHigh degree of automationImprove assembly efficiencyEngineeringMaterial Perforation

The invention discloses a rivet perforation guide device of a rotation wheel assembling machine. The rivet perforation guide device is arranged at a perforation position of the rotation wheel assembling machine and comprises a propelling device and a guide device which are symmetrically arranged on two sides of the perforation position and cooperate for perforating a rivet, wherein the propelling device comprises a feeding device and an ejector pin device mounted behind the feeding device; a through hole used for horizontally placing the rivet is formed in the feeding device; the through hole directly faces the axle center of a trundle at the perforation position; the ejector pin device comprises an ejector pin used for ejecting the rivet in the through hole; the ejector pin is connected to an ejector pin cylinder which drives the ejector pin to move; the guide device comprises a guide pin capable of penetrating through the axle center of the trundle at the perforation position and then guiding the rivet to the axle center of the trundle; the guide pin is connected to a guide pin cylinder which drives the guide pin to move. Through the rivet perforation guide device of the rotation wheel assembling machine, the guide pin penetrates through the axle center of the trundle; when the rivet is pushed out by the ejector pin, one cap-free end of the rivet perforates along the guide pin and enters the axle center of the trundle; the perforation deviation of the rivet can be avoided; the perforation success rate of the rivet is increased; the automatic perforation is achieved; the perforation efficiency is improved.

Owner:平湖市高鑫自动化设备科技有限公司

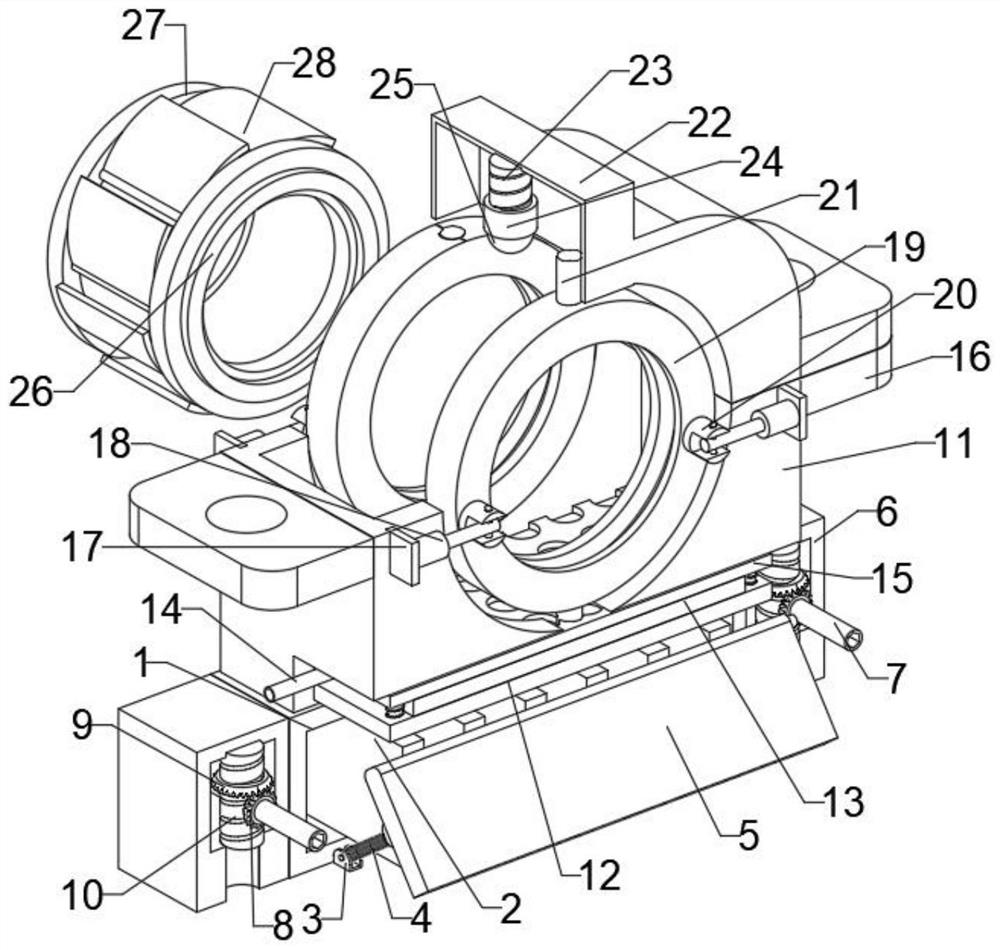

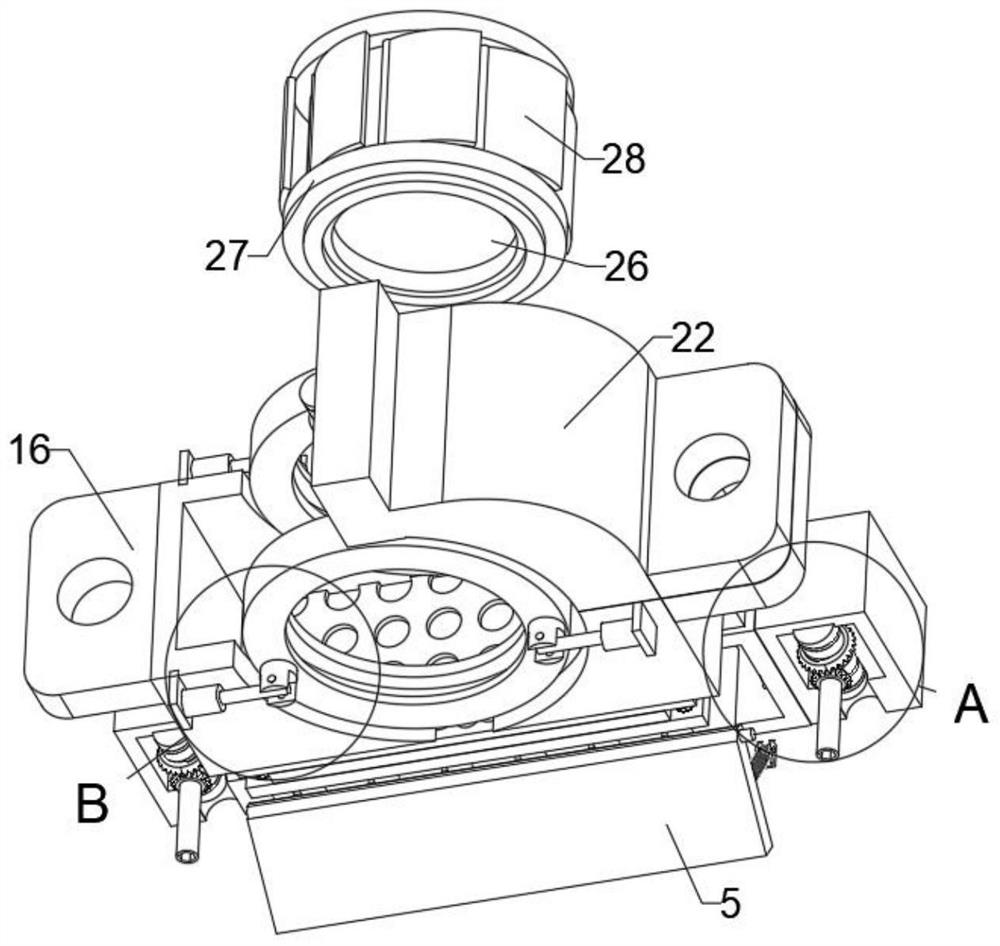

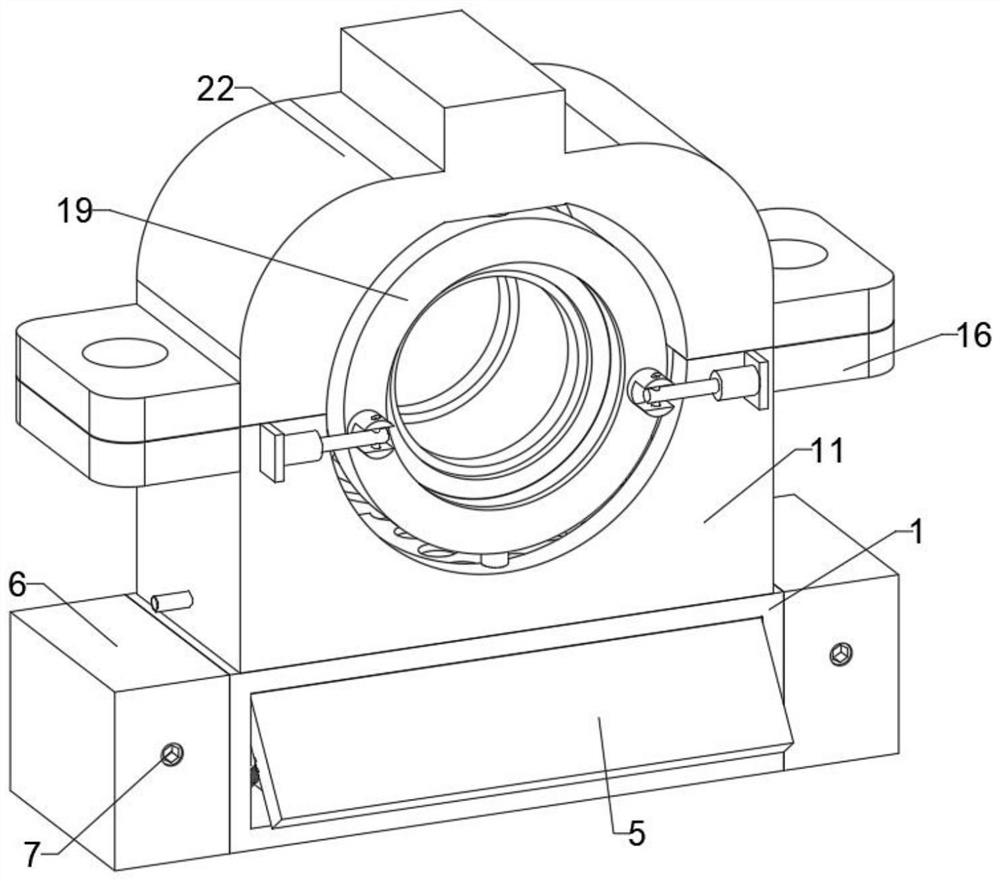

Split type heat dissipation bearing seat with overheating prevention function

PendingCN114810840AAvoid damageFast lubrication operationBearing assemblyBearing coolingThermal dilatationEngineering

The invention provides an anti-overheating split type heat dissipation bearing pedestal, and relates to the technical field of bearing pedestals, the bearing pedestal comprises a base, the main body of the base is of a box body structure, cooling fins are mounted in the base in a linear array, a mounting seat is fixedly connected in the base, a temperature sensing pipe is hinged in the mounting seat, and the temperature sensing pipe is of a telescopic structure; the temperature sensing pipe is arranged on the base, the temperature sensing pipe is filled with thermal expansion liquid, baffles are hinged to the front side and the rear side of the base, and the base and the baffles jointly form a closed structure, so that the problem that when an existing bearing seat is not used, the internal structure of the bearing seat is continuously exposed outside, and dust enters the bearing seat easily to cause damage is solved; the traction push rod installed on one side of the side plate is started to pull the limiting base fixedly connected to the front side of the bearing base so as to forcibly rectify the bearing base rotationally connected to the inner side of the supporting base A and the inner side of the supporting base B through the connecting rod, and then the purpose of being more practical is achieved.

Owner:陈治国

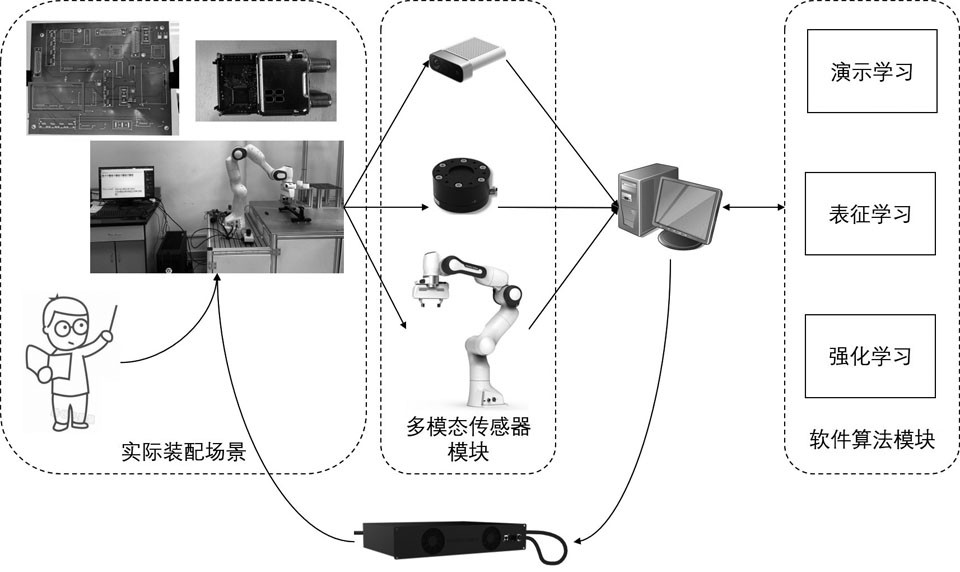

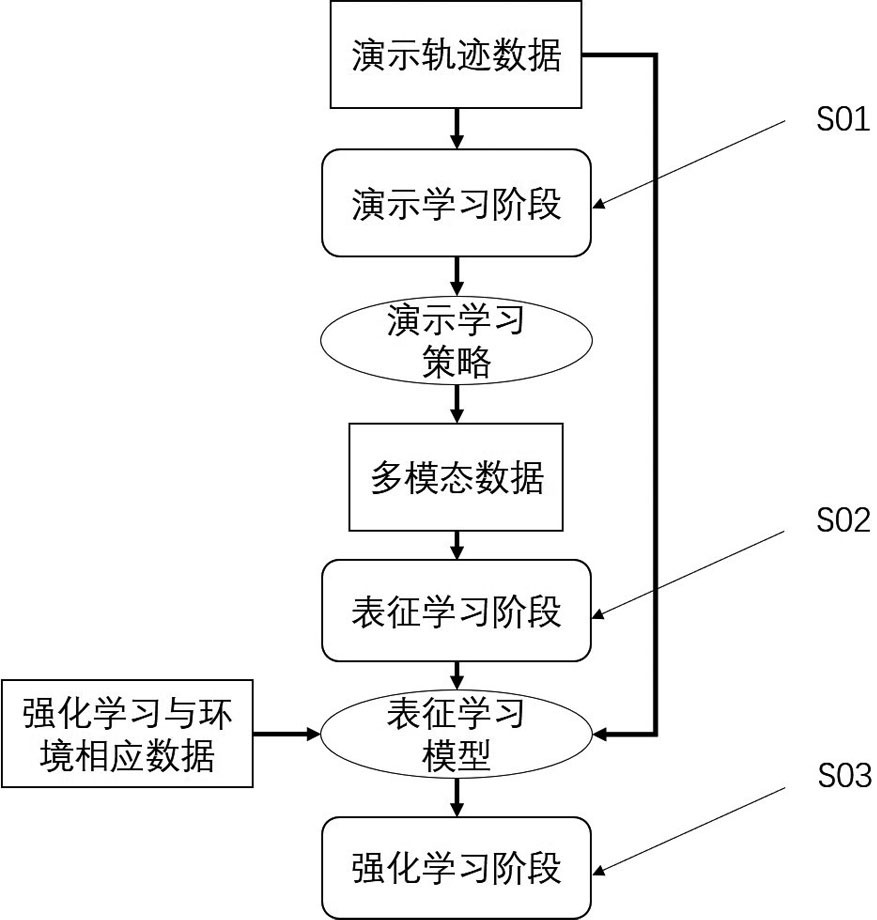

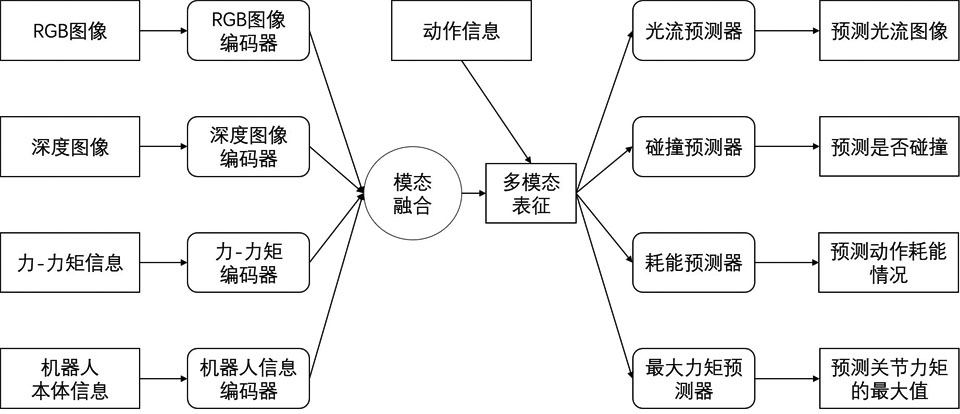

Robot assembly motion planning method based on demonstration trajectory

PendingCN114800515AImprove assembly success rateAvoid strange phenomenaProgramme-controlled manipulatorRobotic systemsFeature learning

The invention belongs to the field of robot autonomous assembly. The invention particularly relates to a robot assembly motion planning method based on a demonstration track. The method comprises the following steps: a robot demonstration learning stage: obtaining an assembly demonstration track of a robot, wherein the robot learns assembly operation skills based on the demonstration track; a multi-modal representation learning stage: the robot introduces noise and environment interaction by using an imitation learning strategy to obtain multi-modal data and labels, and learns the representation of the corresponding multi-modal data by fully considering the energy consumption and singularity of the robot in the movement process; and a robot reinforcement learning stage: building a robot trajectory planning reinforcement learning process based on the multi-modal representation and demonstration trajectory, and performing reinforcement learning training to obtain a final planning strategy. The method can be applied to a robot system which comprises a demonstration assembly track and needs to realize a flexible assembly task in an uncertain environment, and is used for improving the success rate and efficiency of the assembly task.

Owner:SICHUAN UNIV

Automatic stapling and handle mounting device

PendingCN112841858AReasonable structural designImprove assembly success rateBrush bodiesEngineeringNail device

The invention discloses an automatic nailing and handle mounting device, and the device comprises a brush handle feeding device, a brush head feeding device, a brush handle trimming device, a brush head pre-supporting device and a nailing device; the brush handle trimming device used for trimming the head of a brush handle is arranged on a conveying line between the brush handle feeding device and the nailing device. And a brush head pre-supporting device for pre-supporting a metal sleeve in the brush head is arranged on the conveying line between the brush head feeding device and the nailing device. The device is reasonable in structural design, on one hand, the brush handle and the brush head can be pretreated, the assembly success rate is greatly increased, the product size precision is not high, and the production cost can be reduced; on the other hand, the nailing device can conduct double-face nailing, overturning operation is not needed, and the production efficiency can be improved.

Owner:安徽艺超智能科技有限公司

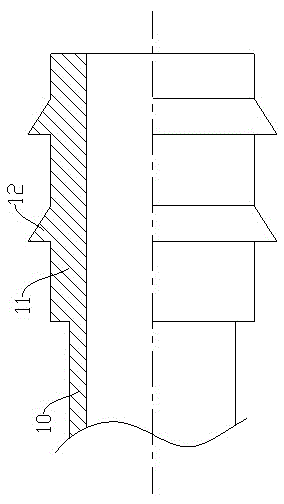

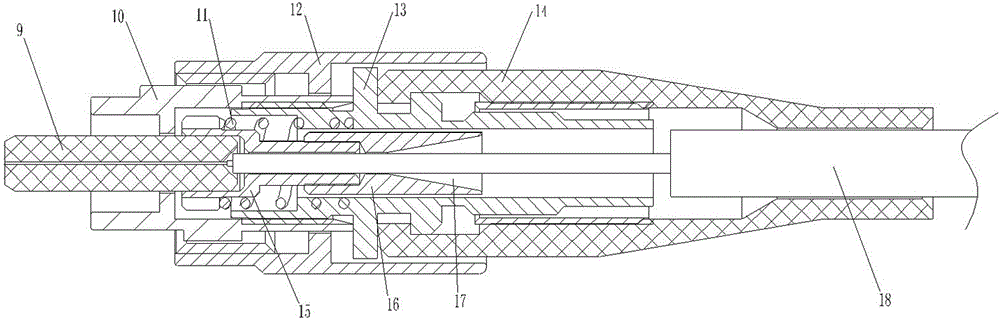

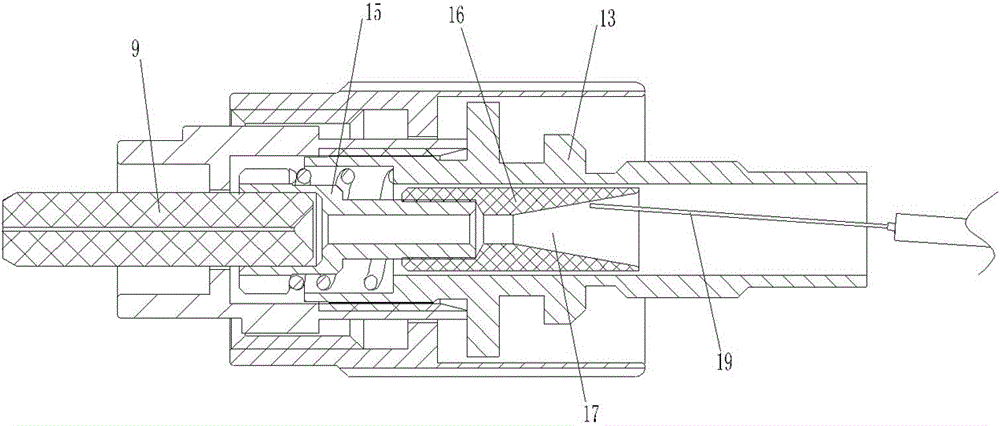

A fiber optic connector

InactiveCN104111502BImprove assembly success rateEasy to insertCoupling light guidesFiberEngineering

The invention relates to an optical fiber connector. The optical fiber connector comprises a flange plate and a back sleeve, a guide structure is arranged on the flange plate or the back sleeve, a guide hole is formed in the guide structure, the front end of the guide hole is communicated with an inner hole of the flange plate, the rear end of the guide hole is communicated with an inner hole of the back sleeve, and the guide hole is in a taper shape with the aperture which is gradually reduced from the rear to the front. The guide structure is arranged on the flange plate or the back sleeve so that when glue injection or fiber penetration is performed, a gluing machine needle head or a wire core penetrates from the rear end of the back sleeve, the gluing machine needle head or the wire core can be gradually guided into the inner hole of the flange plate along the tapered hole walls of the guide hole, the gluing machine needle head and a fiber core can be easily inserted into the inner hole of the flange plate, and the assembly success rate of the optical fiber connector is increased.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

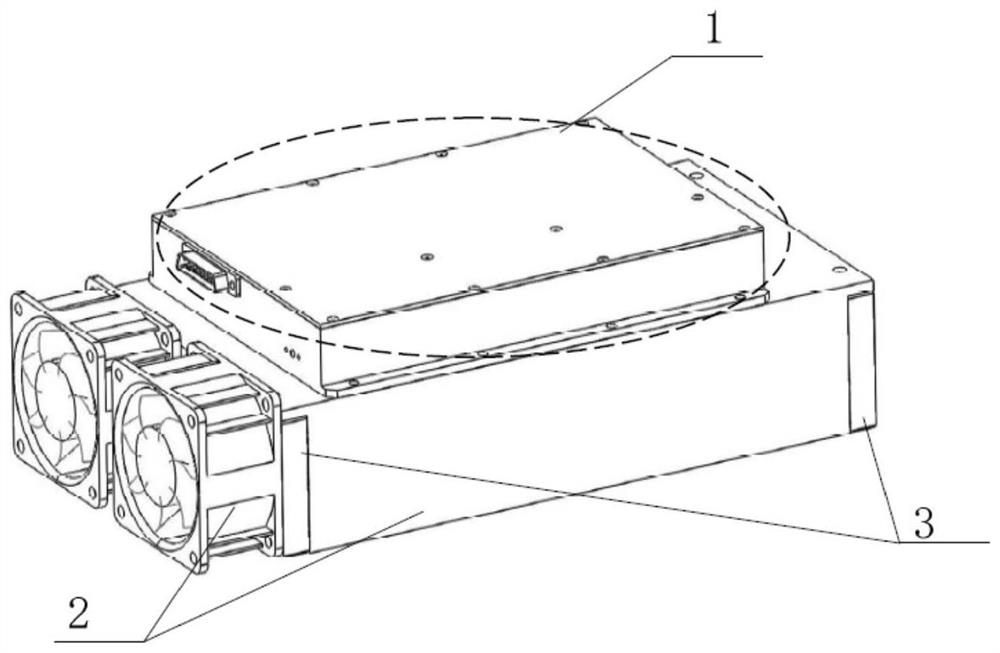

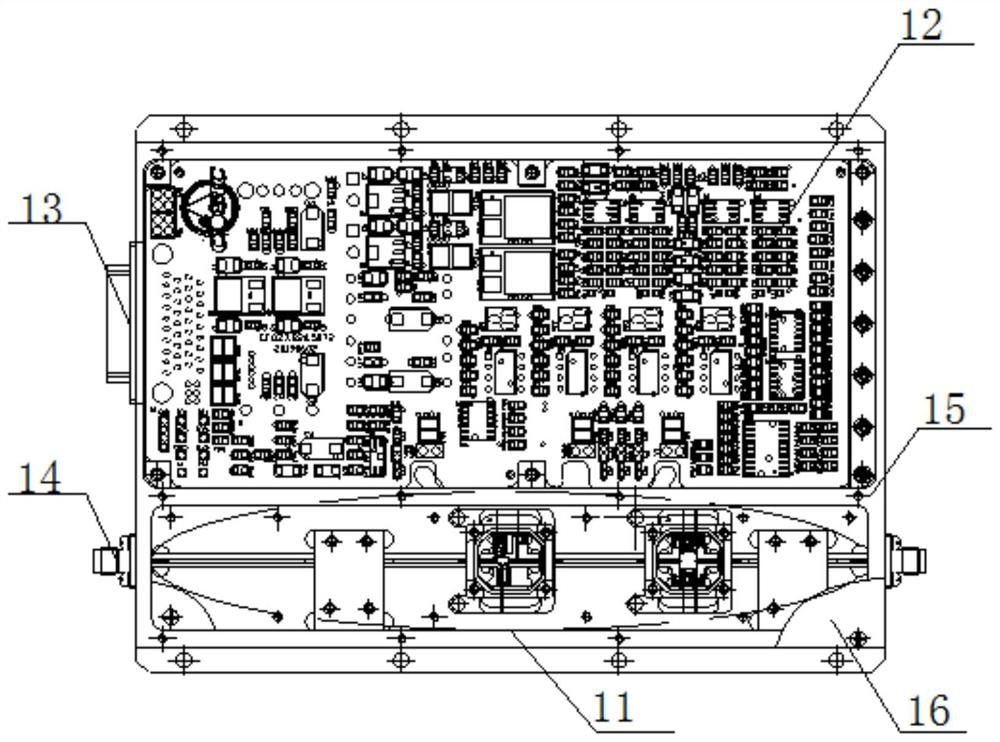

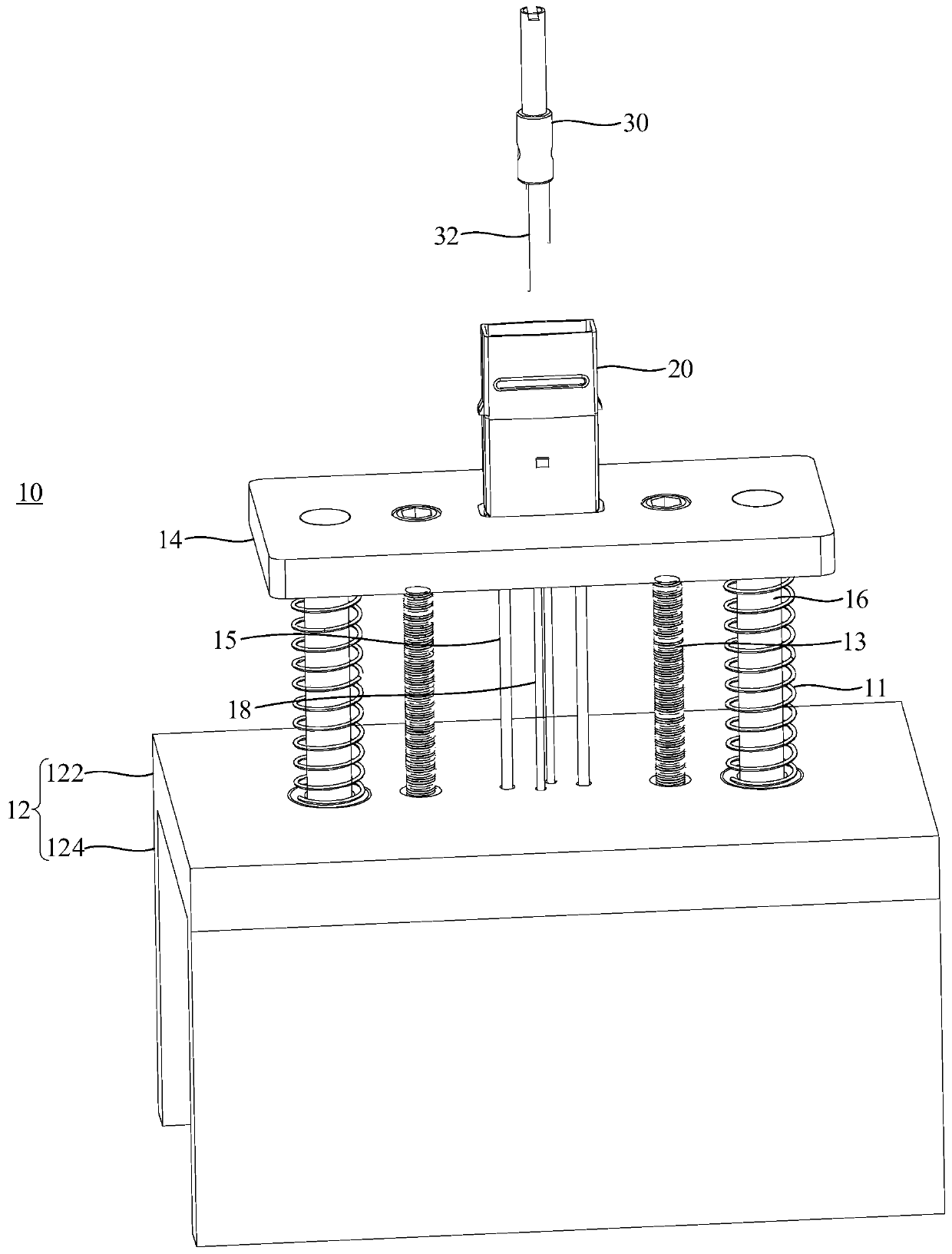

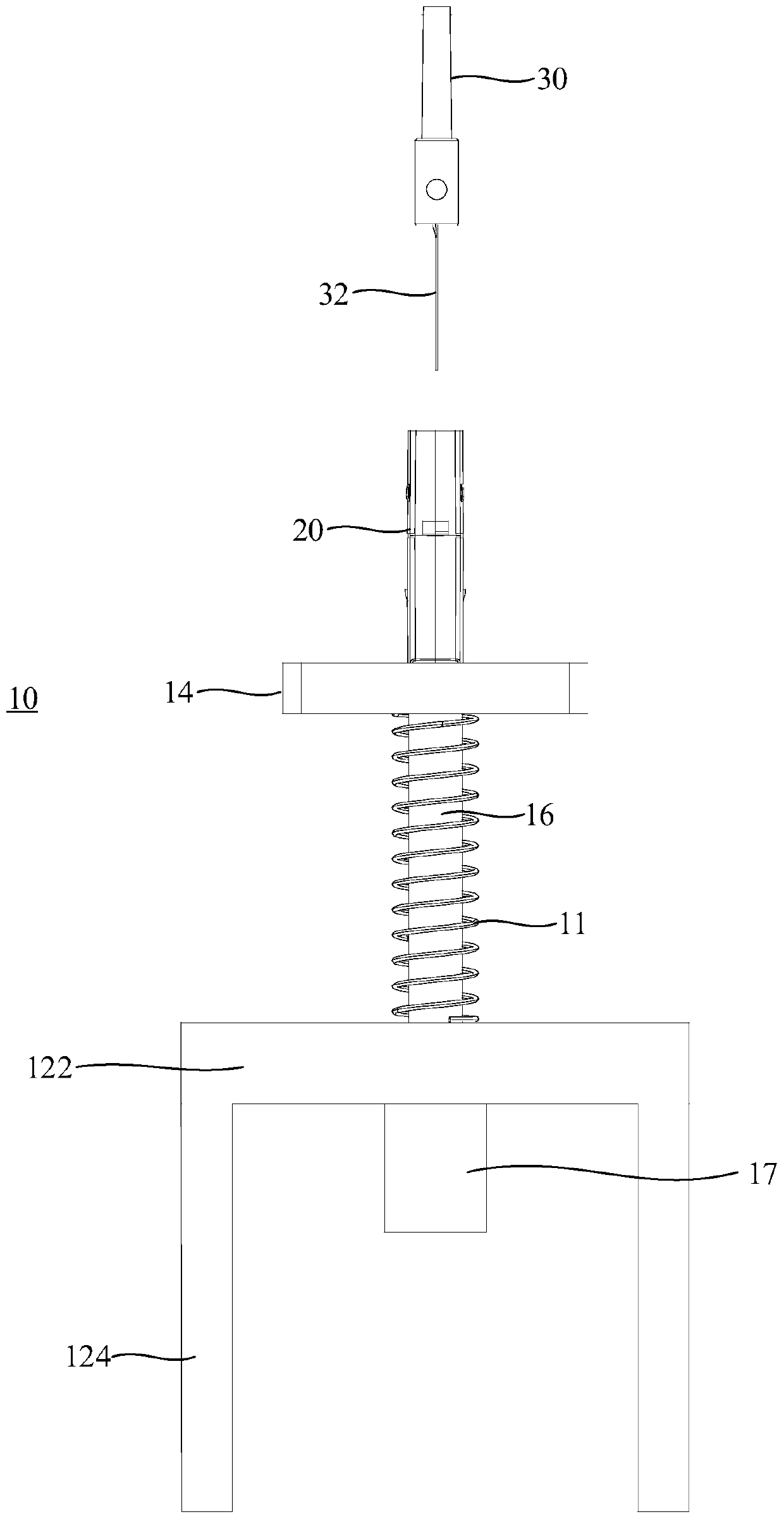

Broadband C-band solid-state power amplifier module

PendingCN112332782AAvoid damageIncrease output powerPower amplifiersAmplifier modifications to raise efficiencySoftware engineeringRadio frequency signal

The invention discloses a broadband C-band solid-state power amplifier module which comprises a C-band solid-state power amplifier assembly, a heat dissipation system and a power amplifier fixing device; the C-band solid-state power amplifier assembly is connected with the heat dissipation system, and the C-band solid-state power amplifier assembly is used for amplifying the power of a radio frequency signal, the heat dissipation system is used for guiding out heat emitted by a C-band solid-state power amplifier assembly power amplifier, and the power amplifier fixing device is connected withthe heat dissipation system. In the aspect of structural layout, modular design is adopted, all the modules can be independently installed and detached, and the advantages of being small in size, convenient to carry, light in weight, high in integration degree, convenient to detach and maintain, high in reliability and the like are achieved.

Owner:NANJING CHANGFENG AEROSPACE ELECTRONICS SCI & TECH

Assembly equipment for electronic cigarettes

ActiveCN110638103AImprove assembly efficiencyImprove assembly success rateTobacco devicesElectronic cigaretteMechanical engineering

The invention relates to assembly equipment for electronic cigarettes. The assembly equipment comprises a base, a fixing part, guide parts and a connecting part, wherein the fixing part is positionedon one side of the base; the side, deviating away from the base, of the fixing part is provided with a fixing position for mounting an oil pipe; the guide parts are arranged between the base and the fixing part in order to drive the fixing part to operably get close to or be far away from the base in the preset direction; one end of the connecting part is fixedly connected to the side, facing thefixing part, of the base; the other opposite end of the connecting part extends lengthwise towards the fixing part; and when the fixing part gets close to the base in the preset direction, the end, far away from the base, of the connecting part can pass through the position, corresponding to the fixing position, on the fixing part in order to be connected with a pin of an atomizing core. Through the arrangement of the assembly equipment, the atomizing core can be rapidly arranged at the mounting position in the oil pipe. Compared with a traditional assembly way, the assembly equipment has theadvantages of the higher success rate and lower assembly cost. Meanwhile, the assembly equipment is relatively simple in structure, so that the assembly cost is further lowered, and popularization isfacilitated.

Owner:SMISS TECH

Deep flexible brain electrode combined with drug delivery channel and preparation method of deep flexible brain electrode

PendingCN112120695AGood biocompatibilityExtend working lifeMedical devicesDiagnostic recording/measuringPharmaceutical drugBiocompatibility

The invention discloses a deep flexible brain electrode combined with a drug delivery channel and a preparation method of deep flexible brain electrode. The deep flexible brain electrode comprises a flexible electrode body and a flexible drug delivery channel parallel to the surface of the flexible electrode body; a silicon substrate is arranged at the rear end of the flexible electrode body; oneend of the flexible drug delivery channel is fixed to the silicon substrate; and a flexible implantation part of the flexible electrode body is attached to the flexible drug delivery channel in parallel. The flexible drug delivery channel is arranged in the flexible electrode body, and the combined deep flexible brain electrode is flexible as a whole and has high biocompatibility and longer service life. The combined operation of the flexible drug delivery channel and the flexible electrode body is relatively convenient and simple, and the assembly success rate is relatively high. The deep flexible brain electrode can achieve drug stimulation and electrophysiological recording at the same time.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

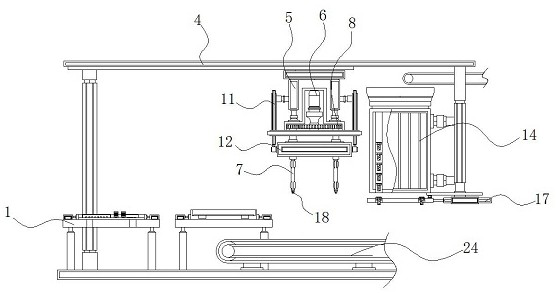

Numerical control pipe fitting assembly machine

ActiveCN100463773CImprove assembly success rateConsider fewer influencing factorsAssembly machinesLarge fixed membersNumerical controlPipe fitting

Owner:WUCHANG SHIPBUILDING IND

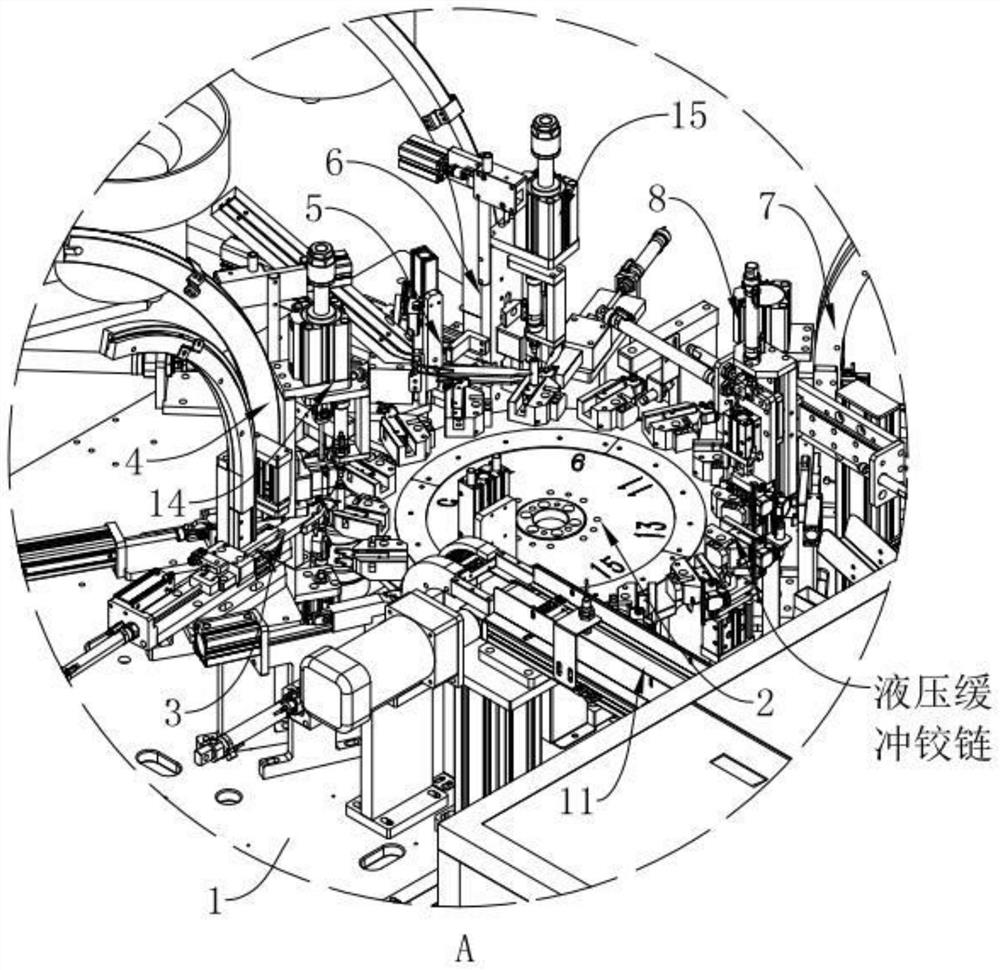

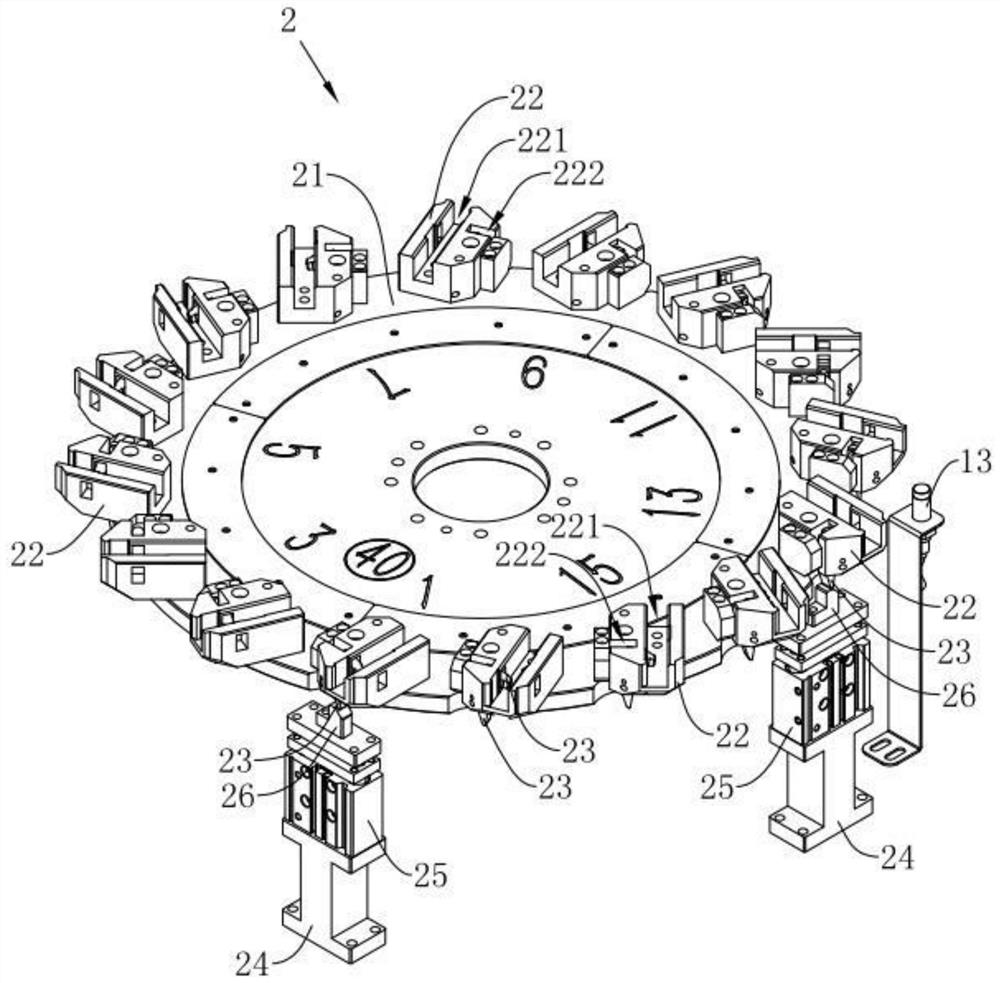

Arm body assembling machine of hydraulic buffer hinge

PendingCN111774857AEasy to assembleImprove assembly success rateAssembly machinesClassical mechanicsStructural engineering

The invention discloses an arm body assembling machine of a hydraulic buffer hinge. The arm body assembling machine is characterized by comprising a rack, the rack is provided with a rotating disc mechanism for installing a product, the rack is provided with a torsional spring mechanism and a plum blossom block mechanism for conveying a torsional spring and a plum blossom block into an arm body respectively, and the rack is provided with a main bolt mechanism for integrating the arm body, the plum blossom block and the torsional spring; the rack is provided with a colloidal particle mechanismand a lamination mechanism which are used for conveying colloidal particles and laminations into the arm body respectively, and the rack is provided with an auxiliary bolt mechanism for integrating the arm body, the laminations and the colloidal particles; and the rack is provided with a pocket mechanism for conveying pockets to be matched with the plum blossom blocks and the laminations, and therack is provided with a U-shaped needle mechanism for integrating the pockets, the plum blossom blocks and the laminations. By the adoption of the arrangement, the torsional spring mechanism, the plumblossom block mechanism, the lamination mechanism and the pocket mechanism are sequentially used for installing the torsional spring, the plum blossom block, the laminations and the pockets on the arm body through the rotating effect of the rotating disc mechanism, and the advantages of intelligently assembling the arm body, improving the percent of pass and improving the production efficiency are achieved.

Owner:佛山市本吉智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com