Patents

Literature

555results about How to "Uniform length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

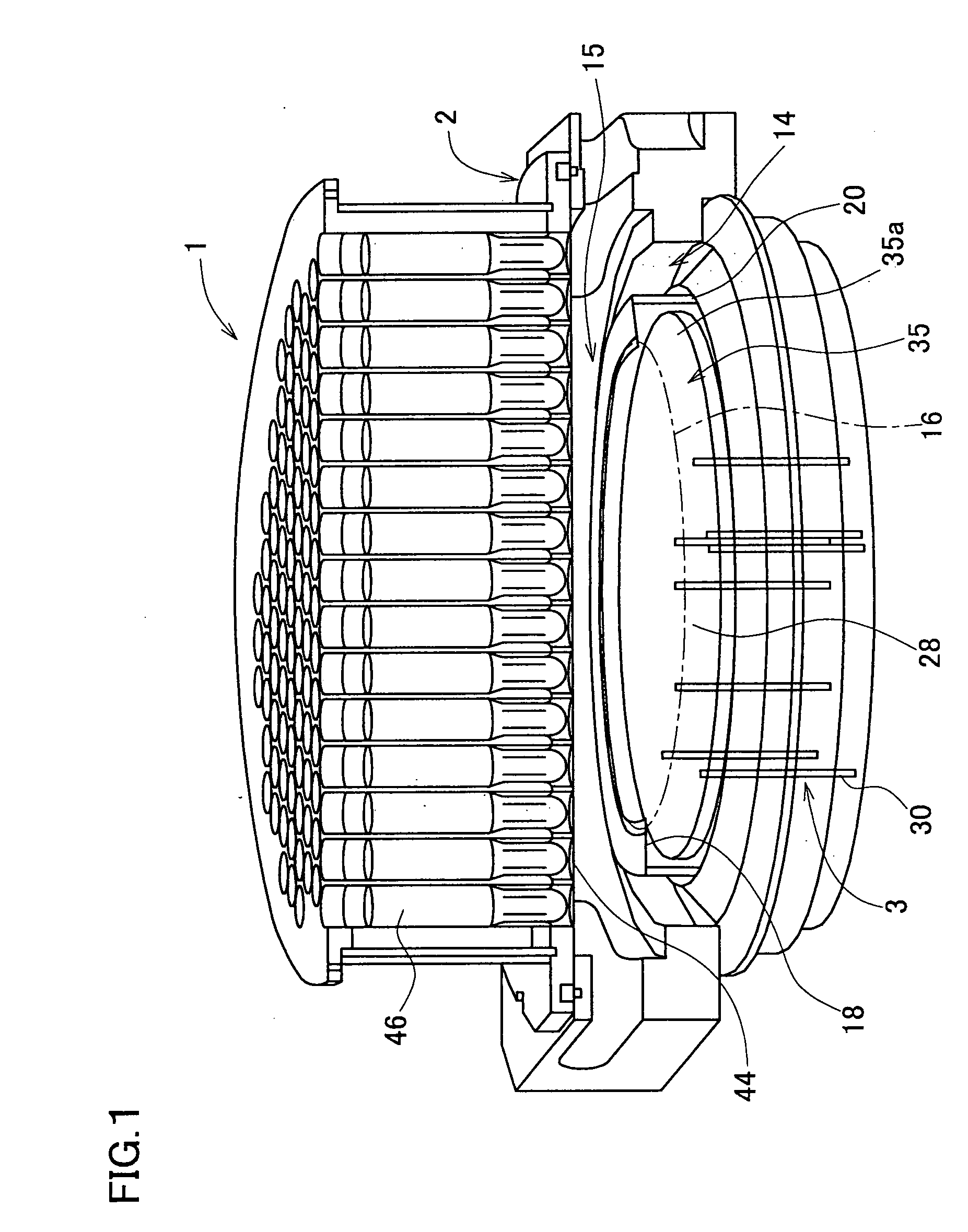

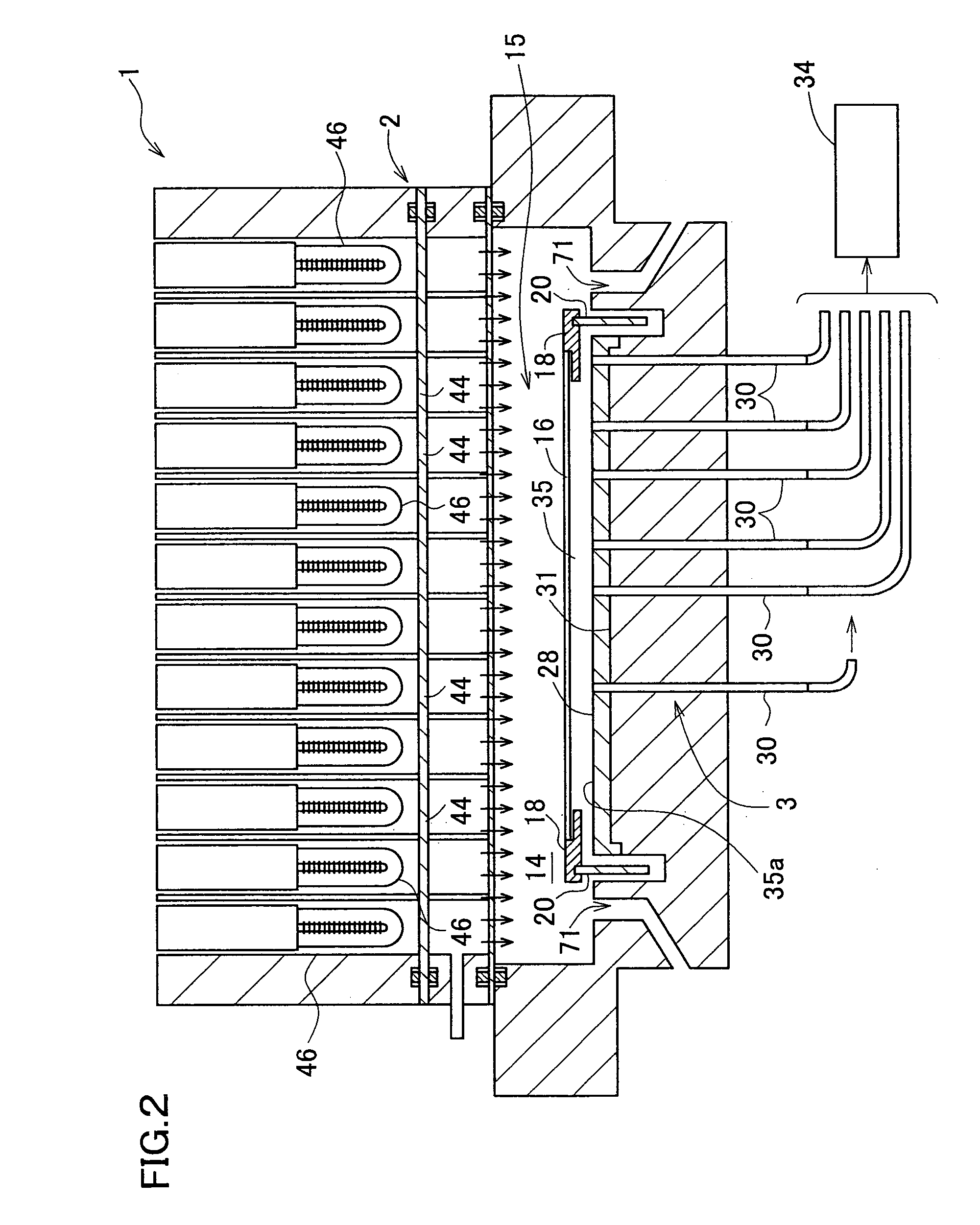

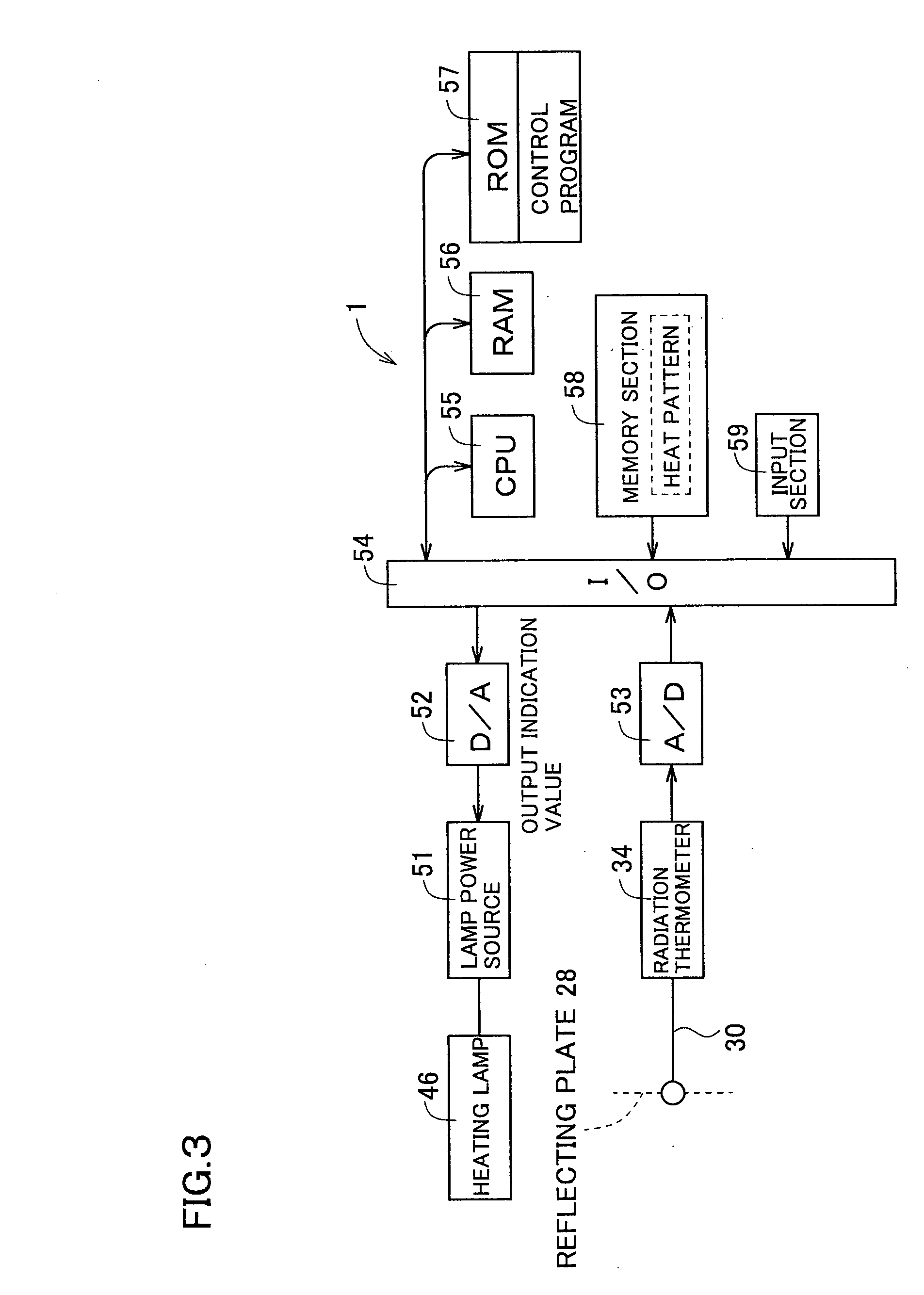

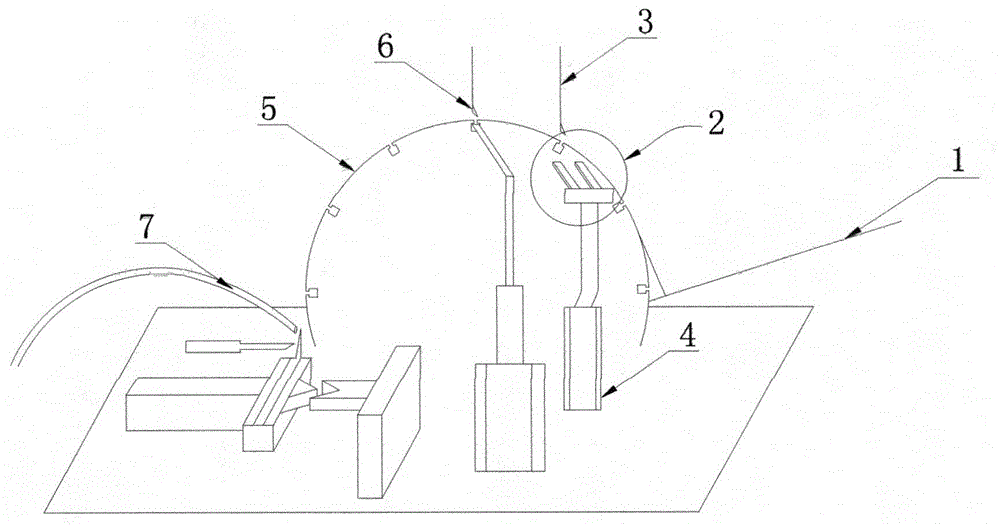

Temperature measuring system, heating device using it and production method for semiconductor wafer, heat ray insulating translucent member, visible light reflection membner, exposure system-use reflection mirror and exposure system, and semiconductor device produced by using them and vetical heat treating device

InactiveUS20050063451A1Necessary numberGood choiceRadiation pyrometryDoor/window protective devicesDevice materialRadiation thermometer

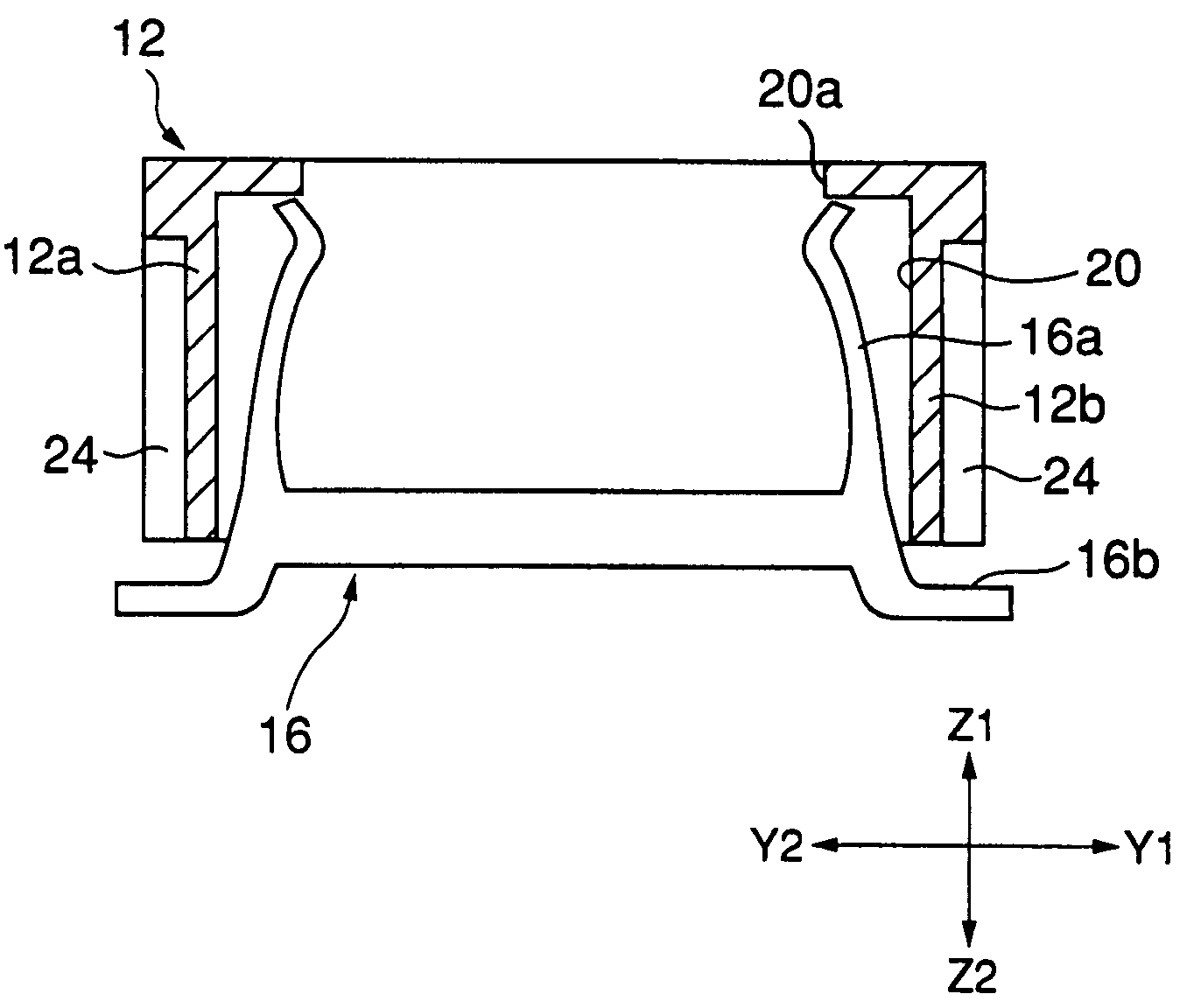

Oppositely of a temperature measuring surface of an object-to-be-measured 16, a reflecting member 28 is disposed while being spaced by a reflection gap 35 from the temperature measuring surface. The reflecting member 28 is composed of a heat ray reflecting material capable of reflecting heat ray in a specific wavelength band, in a portion including a reflection surface 35a. A heat ray extraction pathway section 30 is disposed through the reflecting member 28 so that one end thereof faces the temperature measuring surface. Heat ray extracted through the heat ray extraction pathway section from the reflection gap is detected by a temperature detection section 34. The heat ray reflecting material is configured in a form of a stack comprising a plurality of element reflecting layers composed of a material having transparent properties to the heat ray, in which every adjacent two element reflecting layers are composed of a combination of materials having refractive indices which differ from each other by 1.1 or more. This makes the measurement be hardly affected by radiation ratio of the object-to-be-measured when temperature of the object-to-be-measured is measured by a radiation thermometer, enables to measure its temperature more correctly irrespective of the surface state thereof, and can simplify configuration of a measurement system.

Owner:SHIN-ETSU HANDOTAI CO LTD

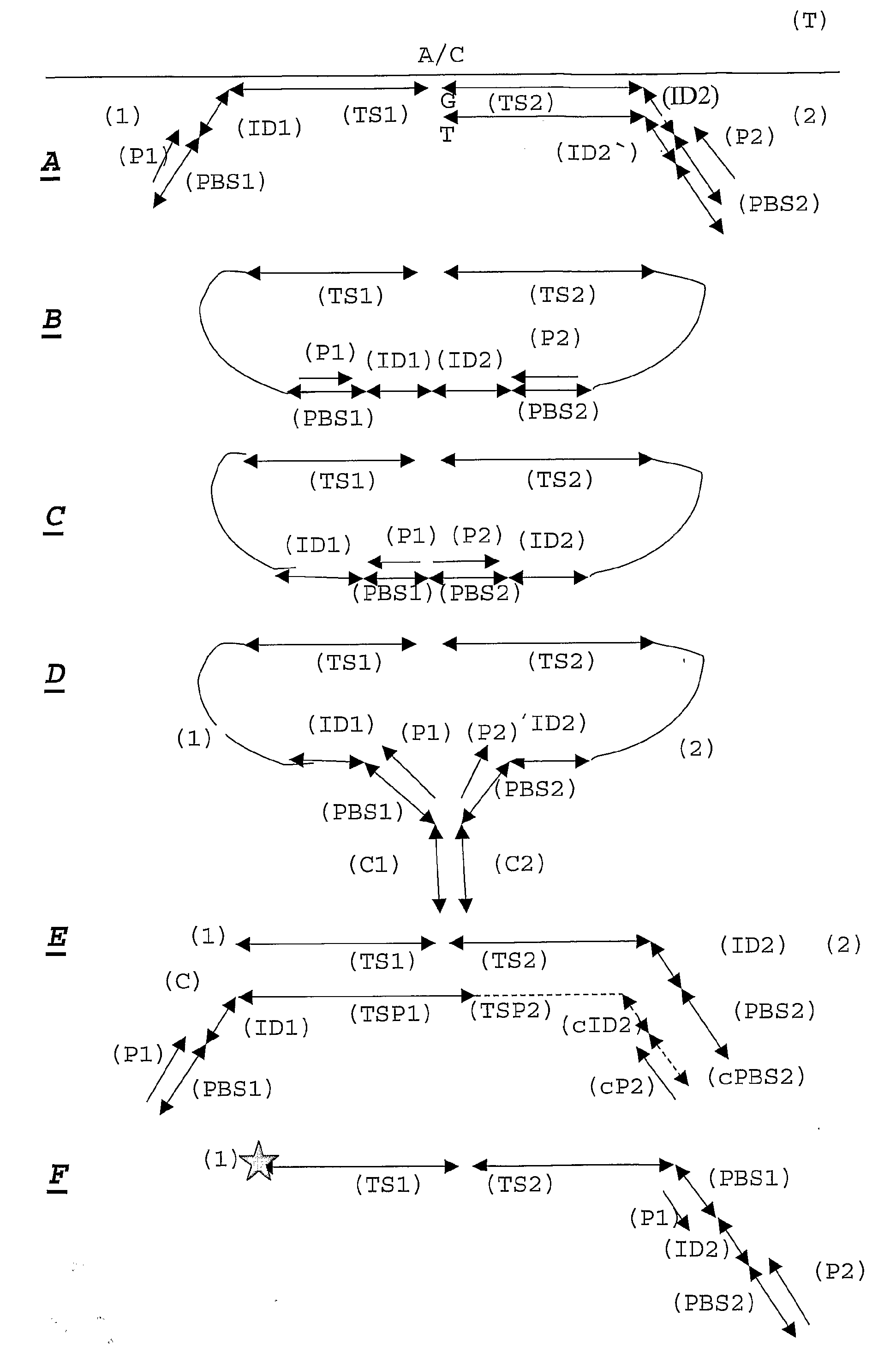

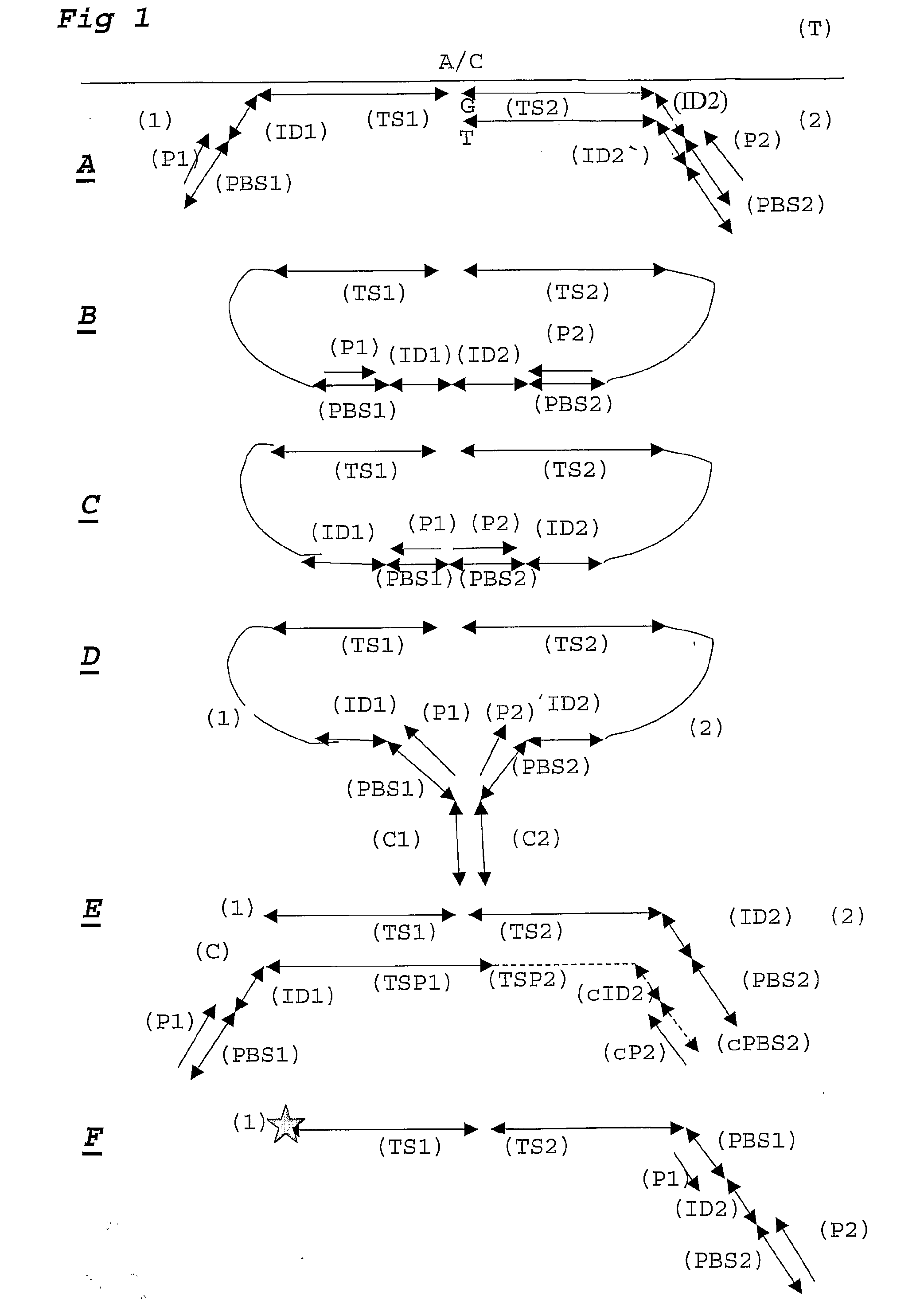

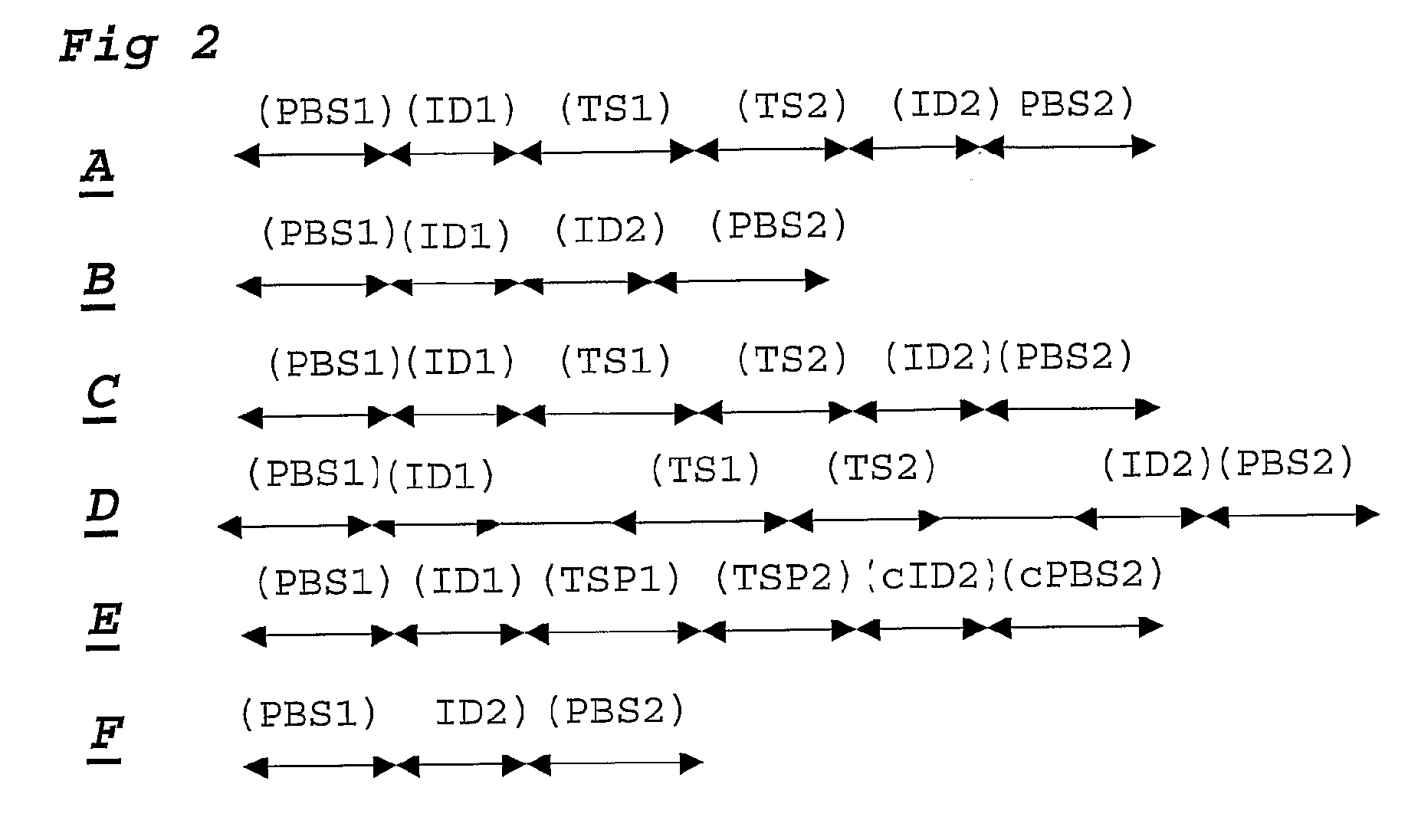

High throughput sequence-based detection of snps using ligation assays

ActiveUS20090215633A1Compromise reliabilityEasy to detectSugar derivativesMicrobiological testing/measurementHigh throughput sequenceOligonucleotide

Method for the detection the presence or absence of one or more target sequences in one or more samples based on oligonucleotide ligation assays with a variety of ligatable probes containing identifiers and the subsequent identification of the identifiers in the amplicons or ligated probes using high throughput sequencing technologies.

Owner:KEYGENE NV

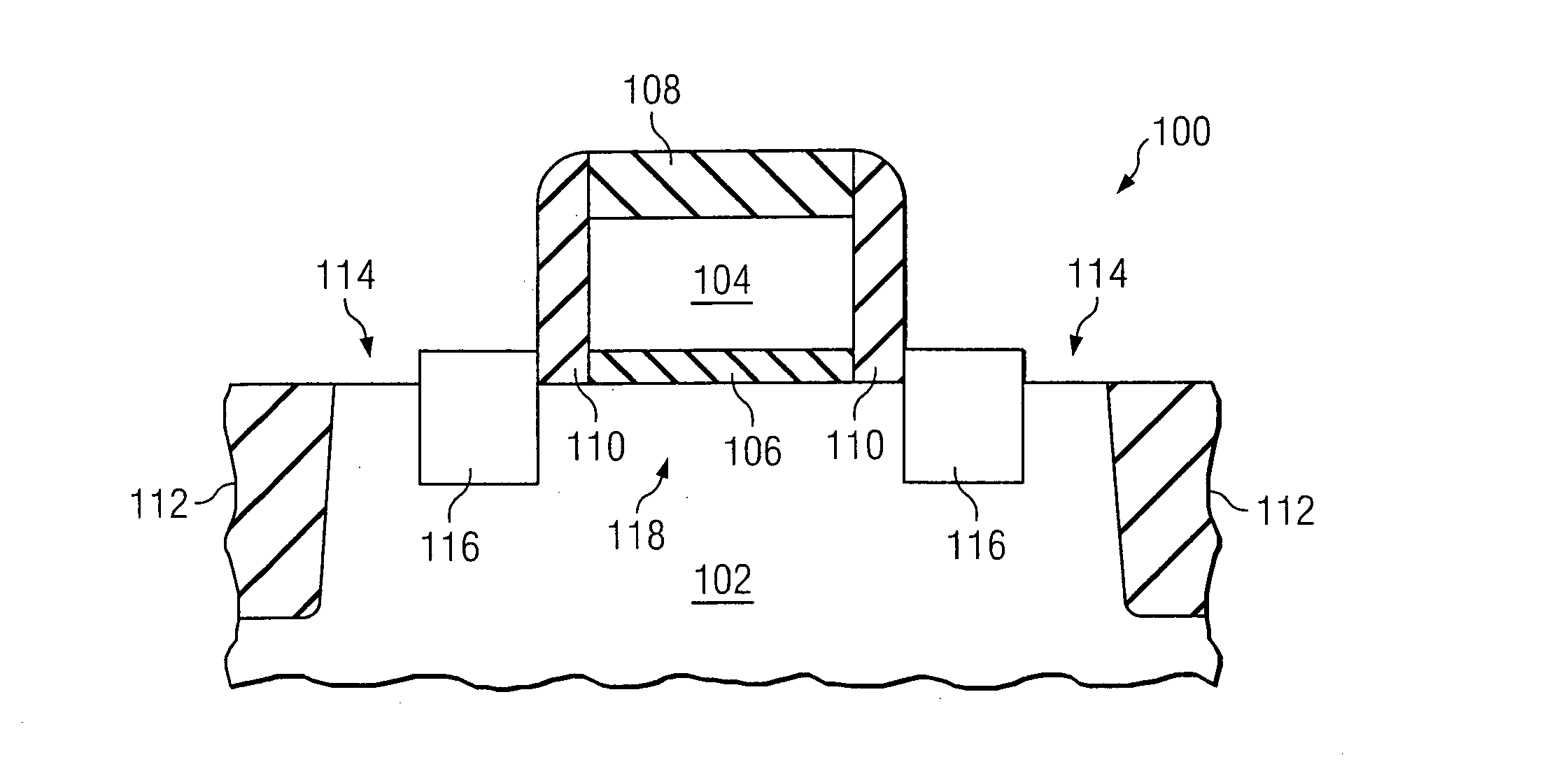

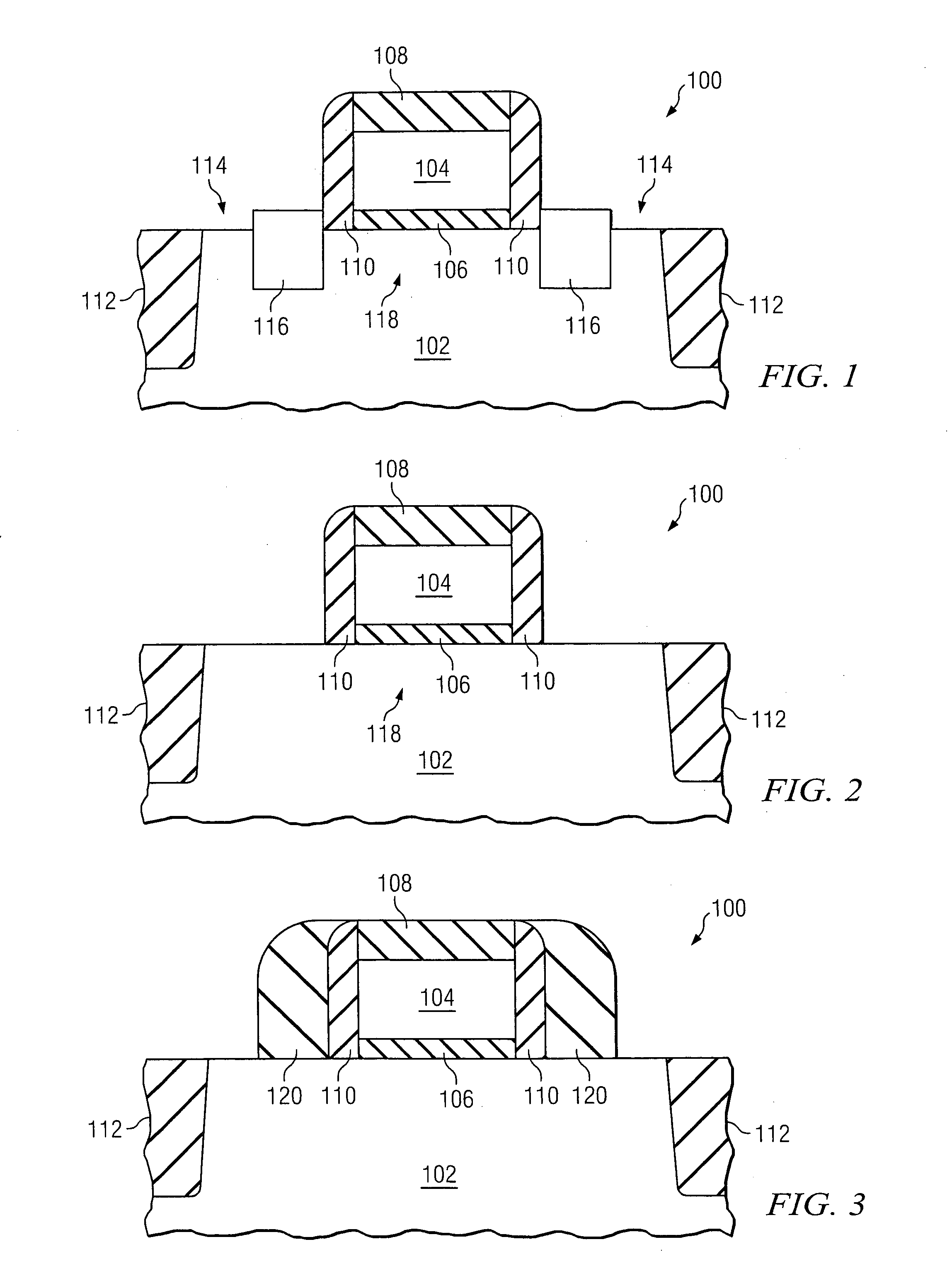

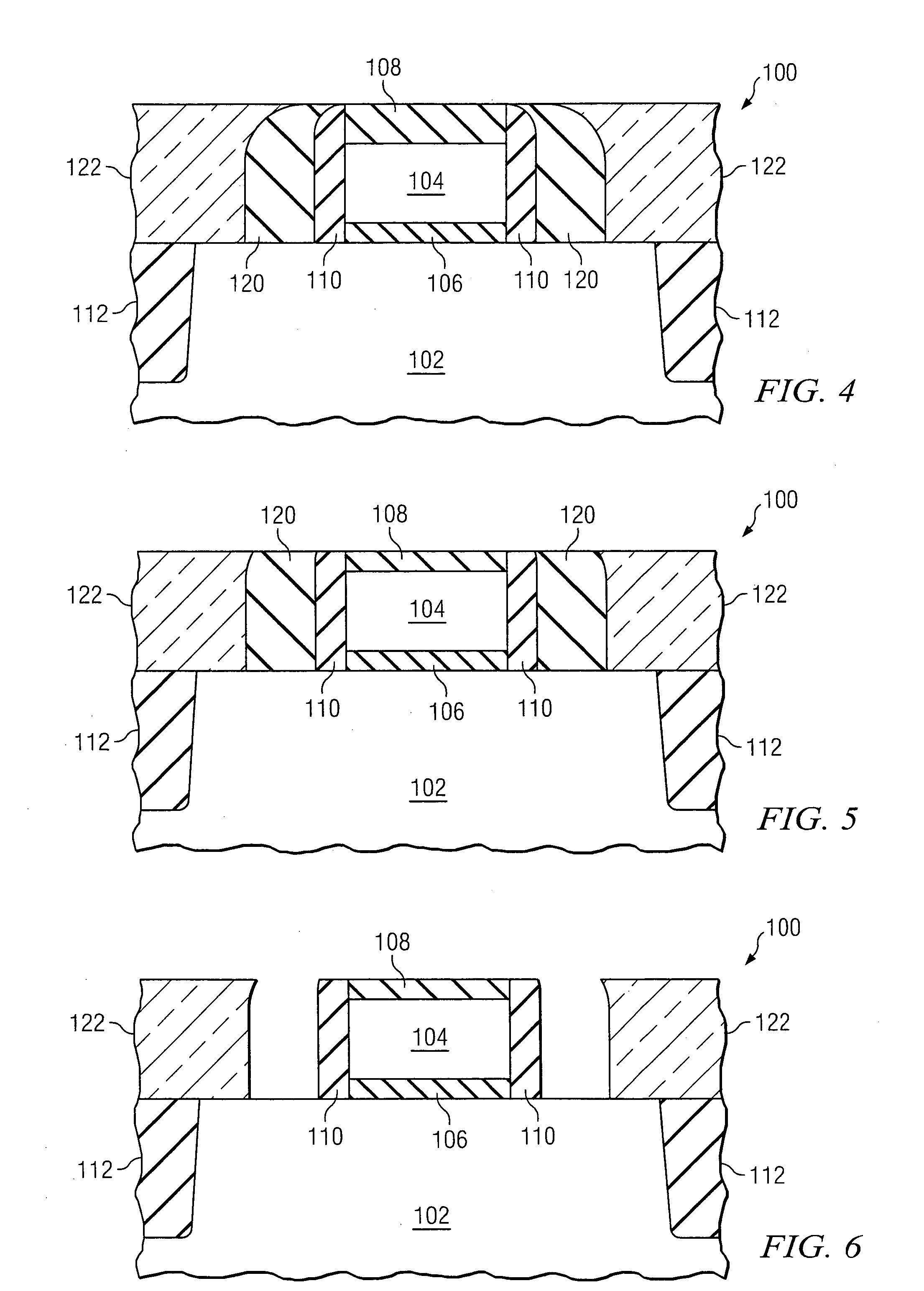

Strained semiconductor device and method of making the same

InactiveUS20070057324A1High carrier mobilityImprove performanceTransistorSolid-state devicesSemiconductor materialsDevice material

In a method for forming a semiconductor device, a gate electrode is formed over a semiconductor body (e.g., bulk silicon substrate or SOI layer). The gate electrode is electrically insulated from the semiconductor body. A first sidewall spacer is formed along a sidewall of the gate electrode. A sacrificial sidewall spacer is formed adjacent the first sidewall spacer. The sacrificial sidewall spacer and the first sidewall spacer overlying the semiconductor body. A planarization layer is formed over the semiconductor body such that a portion of the planarization layer is adjacent the sacrificial sidewall spacer. The sacrificial sidewall spacer can then be removed and a recess etched in the semiconductor body. The recess is substantially aligned between the first sidewall spacer and the portion of the planarization layer. A semiconductor material (e.g., SiGe or SiC) can then be formed in the recess.

Owner:INFINEON TECH AG

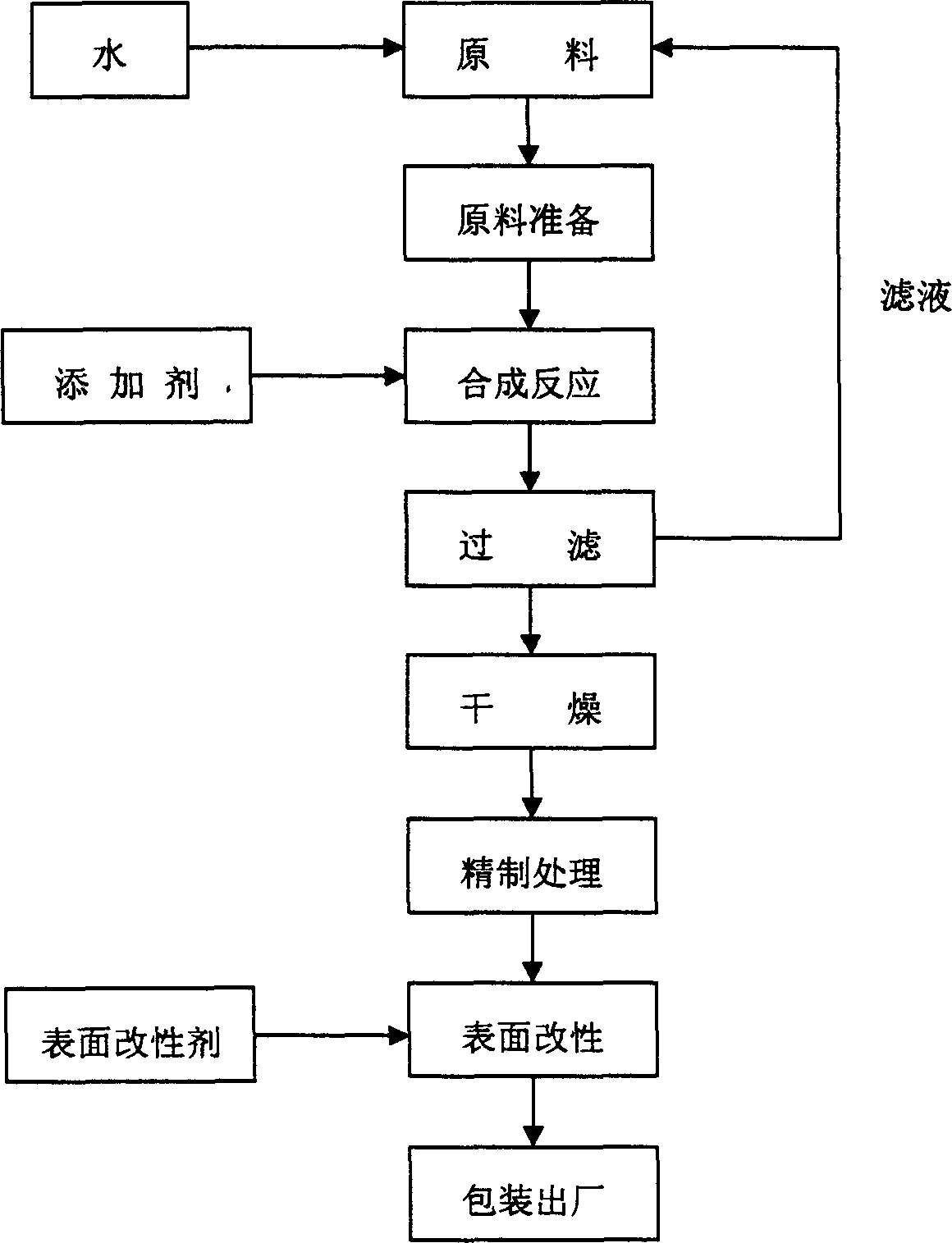

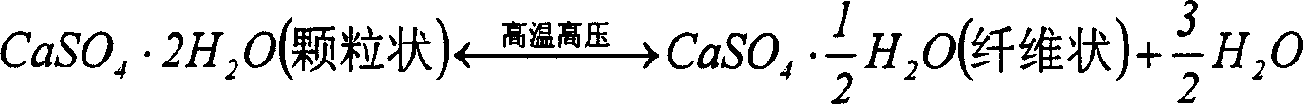

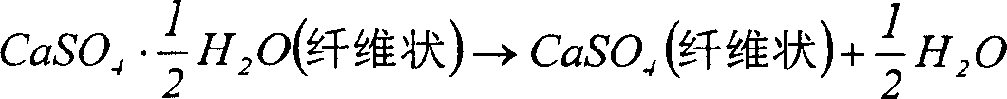

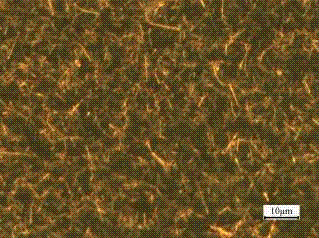

Process for preparing calcium sulfate whisker

InactiveCN1598083AControl lengthIncrease production capacityPolycrystalline material growthCalcium/strontium/barium sulfatesChemical reactionSulfate

This invention is a preparation method of calcium sulfate crystal whisker. The material is plaster stone (CaSO4.2H2O) and water in the entire production. After raw material preparation, building up reactions, dehydrate, refine and edulcoration. Its characteristic is that the active content of plaster stone up to above 95%, the whiteness is above 90%. Mixed with water and turn into plaster stone slime, then put them into reactor to make them have chemical reaction, then on the other procedures. The calcium sulfate crystal whisker made by this method has good performance, low cost, and can be used in all kinds of industries.

Owner:NORTHEASTERN UNIV

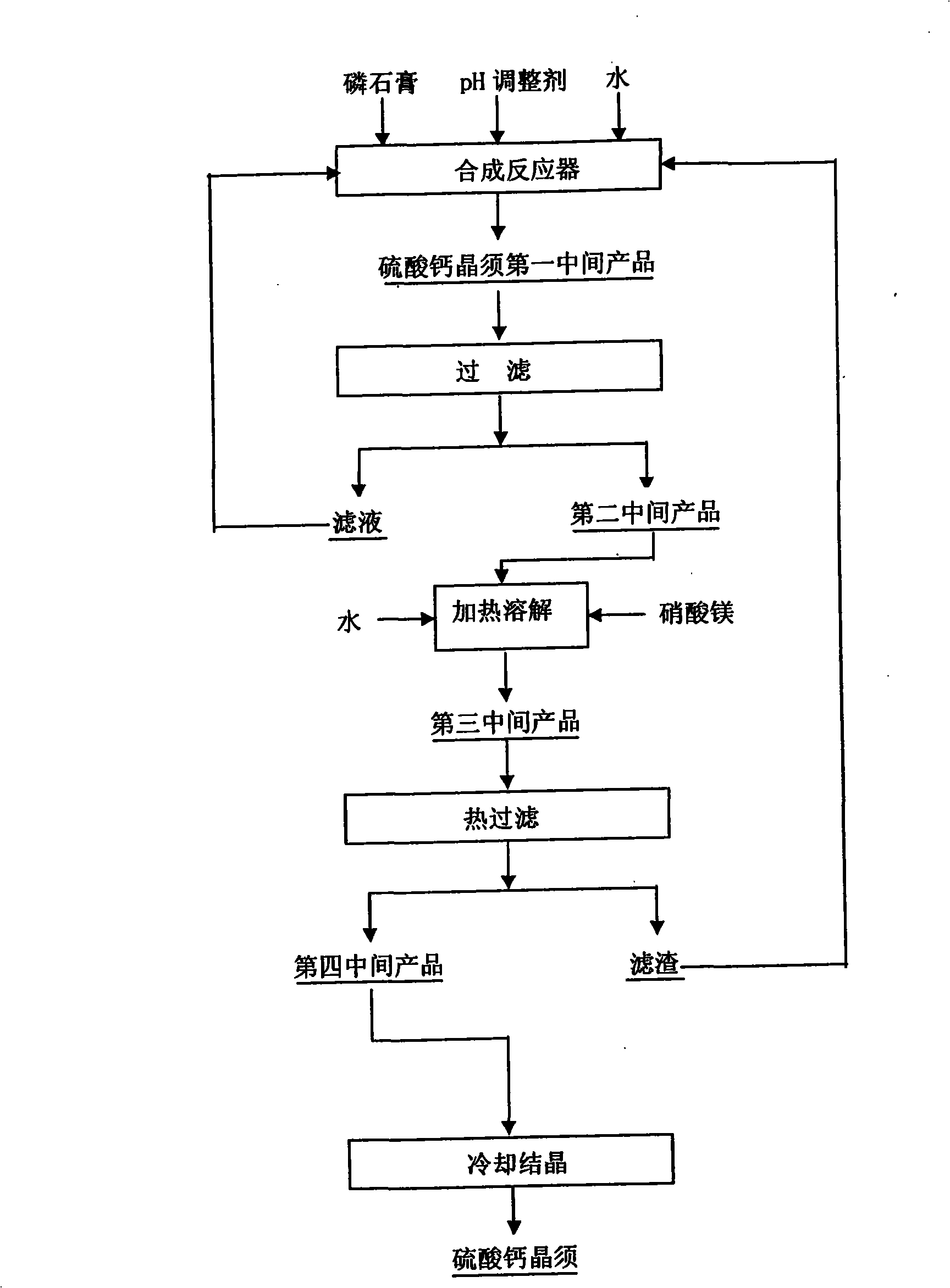

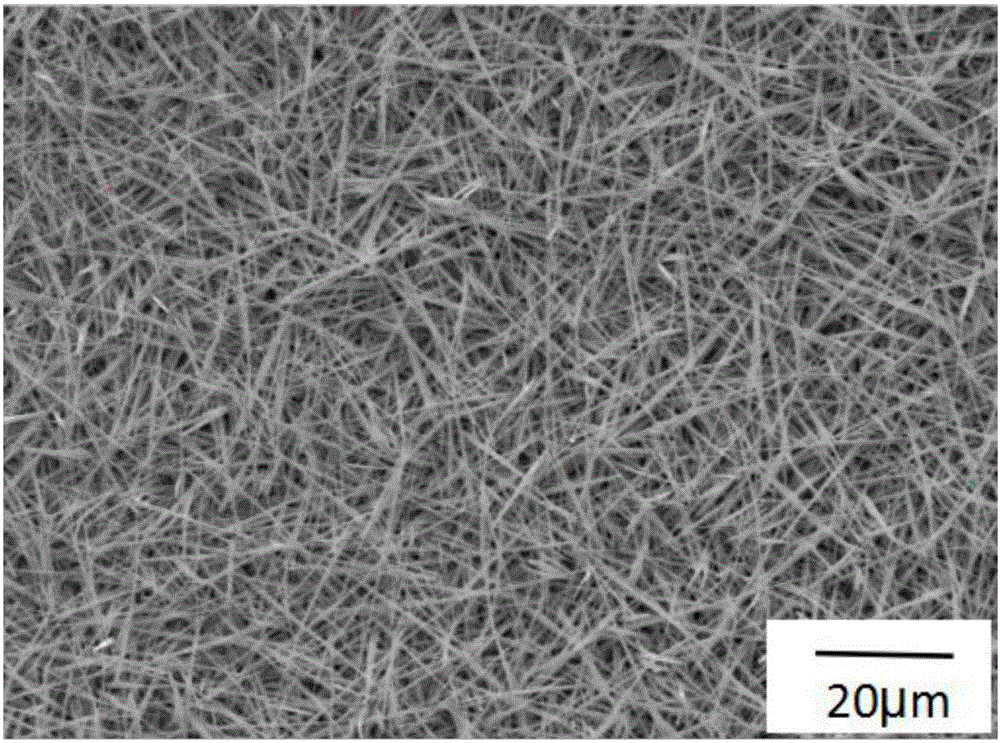

Process for preparing calcium sulphate whiskers from ardealite

InactiveCN101311355AUniform lengthImprove qualityPolycrystalline material growthFrom normal temperature solutionsSulphate IonChemical preparation

The invention relates to a method for preparing calcium sulphate crystal whisker by using phosphogypsum, which belongs to the technical field of phosphorous chemical preparation. Solid drogs phosphogypsum is used as raw material; after a synthetic reaction, filtering, heating and dissolving, thermal filtering and cooling crystallization for the raw material, the calcium sulphate crystal whisker product with the controllable diameter and length is prepared, the diameter of the crystal whisker is 1-4mum and the length of the crystal whisker is 50-200mum. The adoption of the solid drogs phosphogypsum for preparing the calcium sulphate crystal whisker reduces the production volume of natural plaster, saves resources, turns the waste into benefit, lowers the production cost of the calcium sulphate crystal whisker and improves added value of the product in the process of utilizing the phosphogypsum. The obtained calcium sulphate crystal whisker has excellent property, low cost and wide application.

Owner:YUNNAN MINZU UNIV

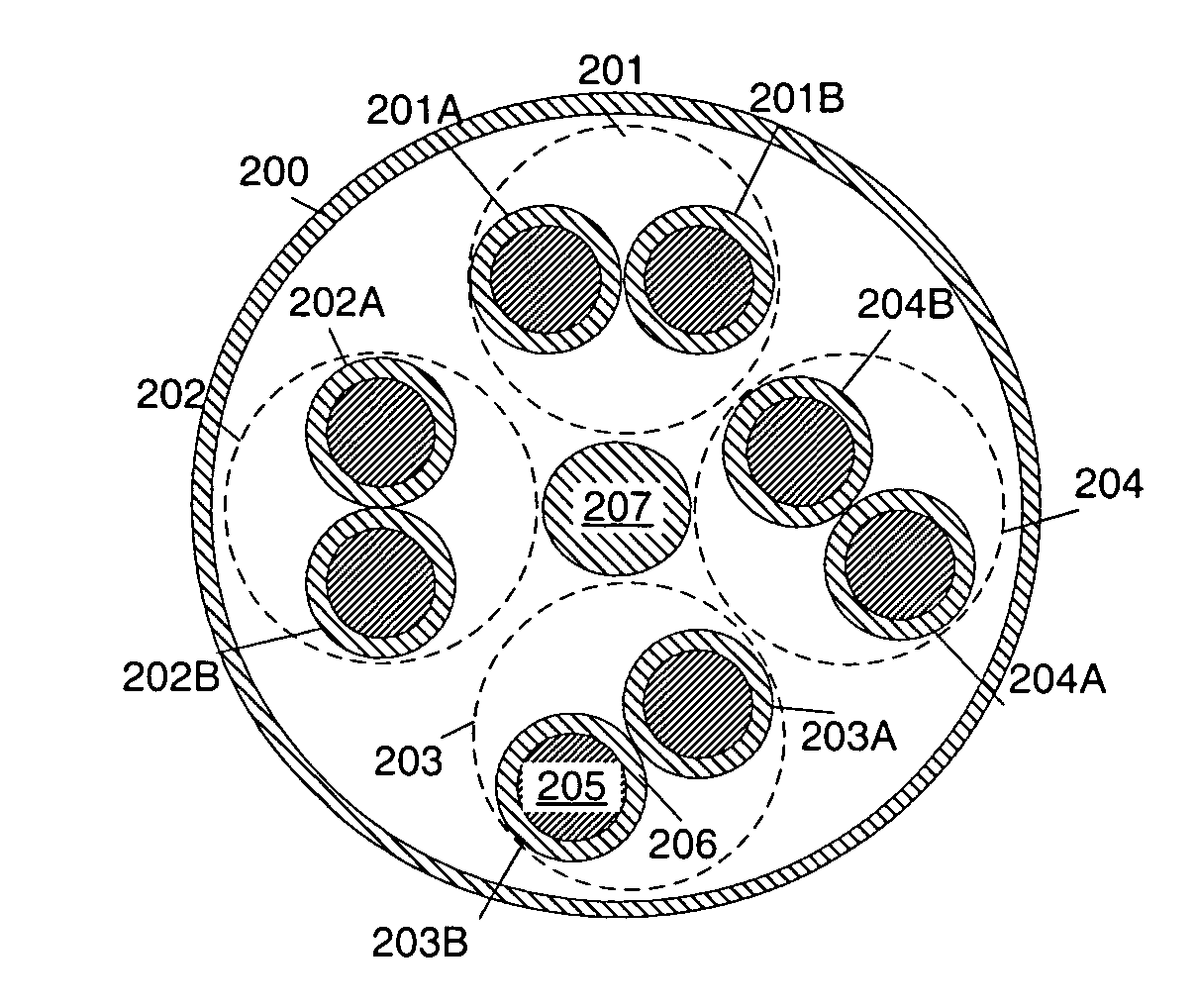

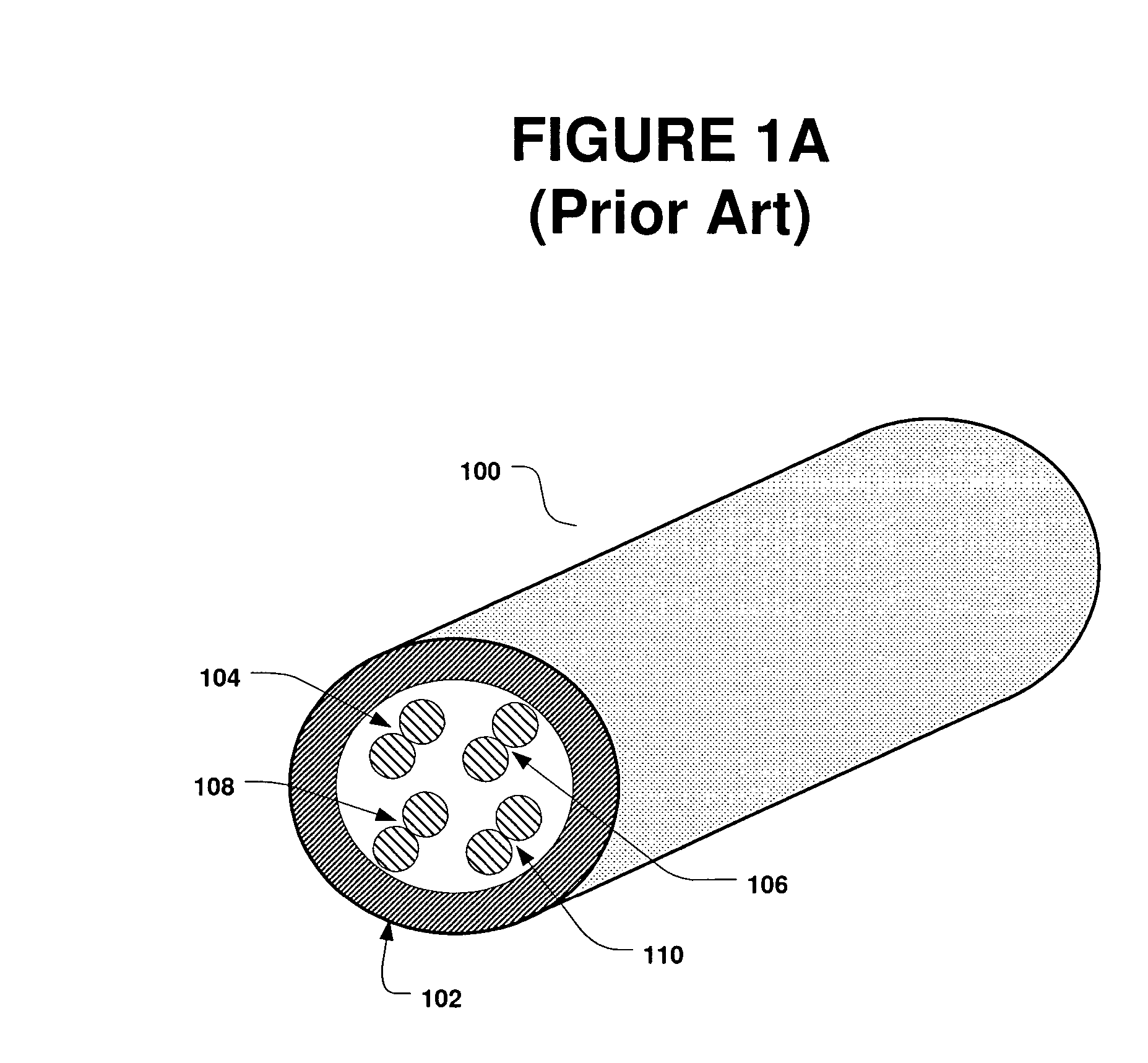

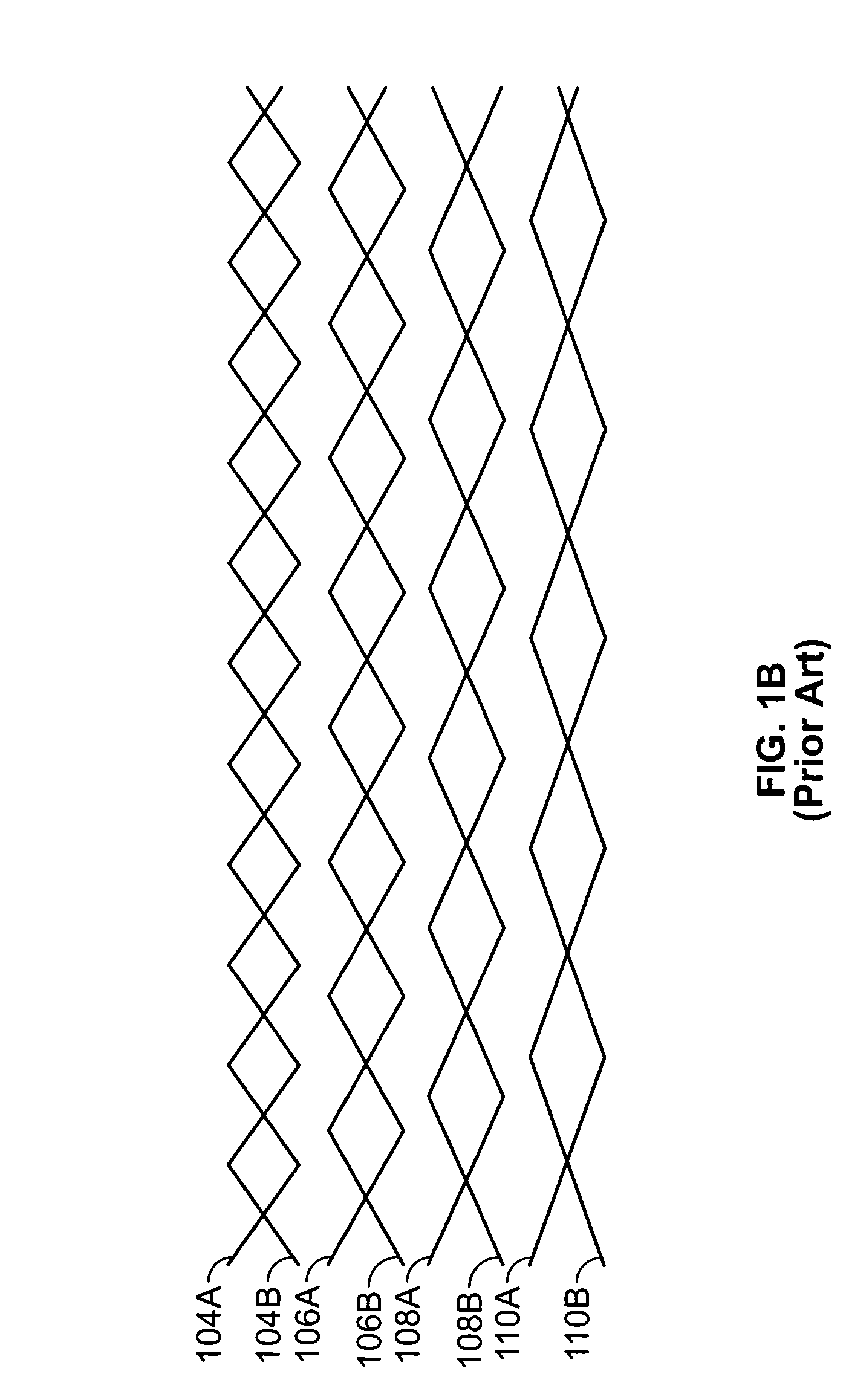

UTP cable apparatus with nonconducting core, and method of making same

InactiveUS20050045367A1Improve signal qualityReduce crosstalkCables with twisted pairs/quadsEngineeringAnalog signal

An unshielded twisted pair (UTP) cable minimizes skew delay of analog signals by enforcing a common electrical length among twisted pairs that carry those analog signals. By applying a different lay length and lay direction to the twisted pair that carries the digital signal, cross-talk from the digital signal onto the analog signals is minimized. A nonconductive filler provides a central core about which the twisted pairs are wound during the bundling process. The presence of the nonconductive core ensures that a minimum distance (i.e., the diameter of the core) is maintained between non-adjacent pairs for the length of the cable.

Owner:RGB SYST INC

Balloon wing forming apparatus and method

An apparatus and method for shaping at least a portion of a medical balloon comprise a balloon shaping device capable of applying a radial inward force to at least a portion of the medical balloon and at least one vibratory device capable of applying vibratory energy to the at least a portion of the medical balloon.

Owner:BOSTON SCI SCIMED INC

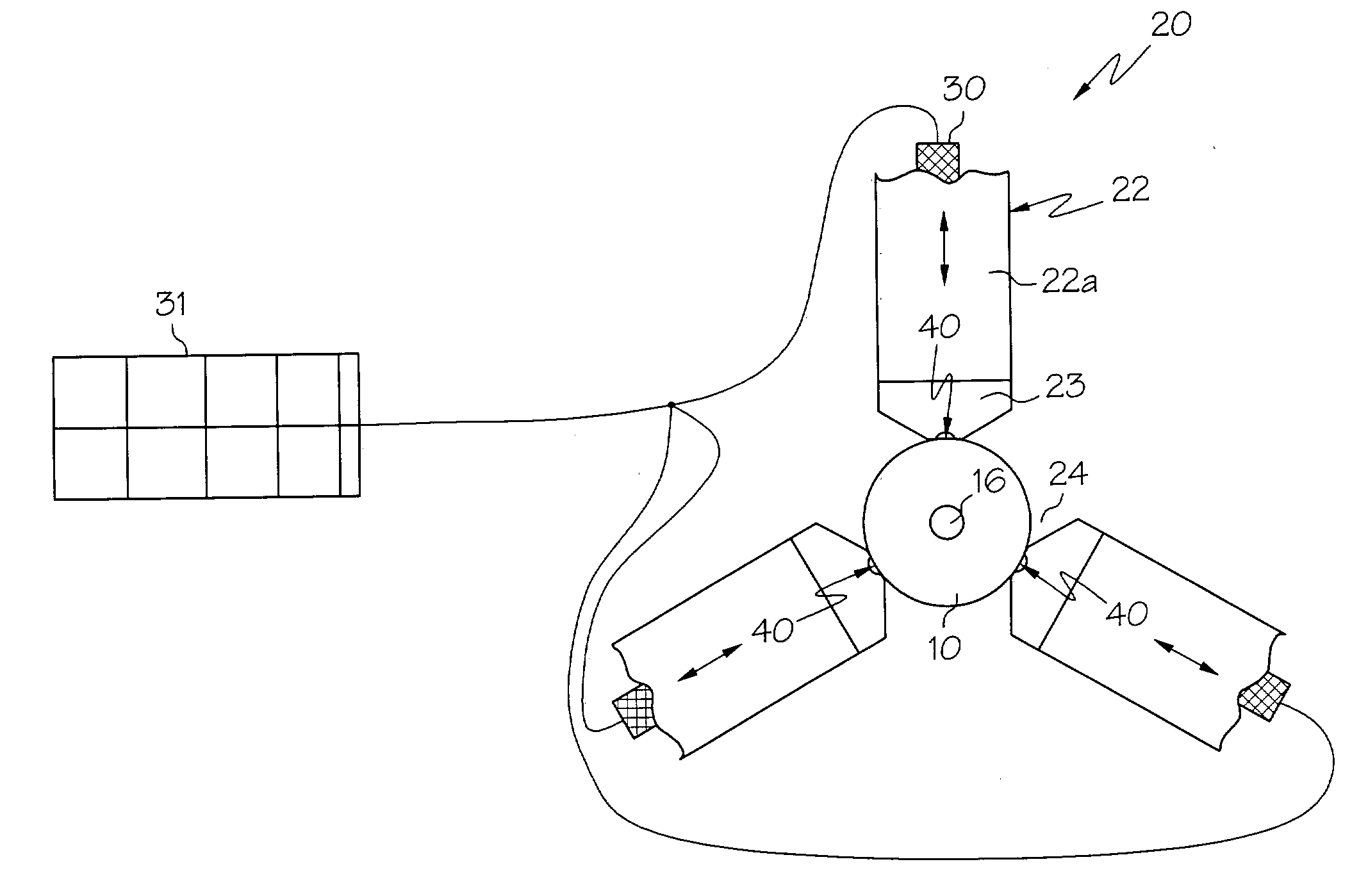

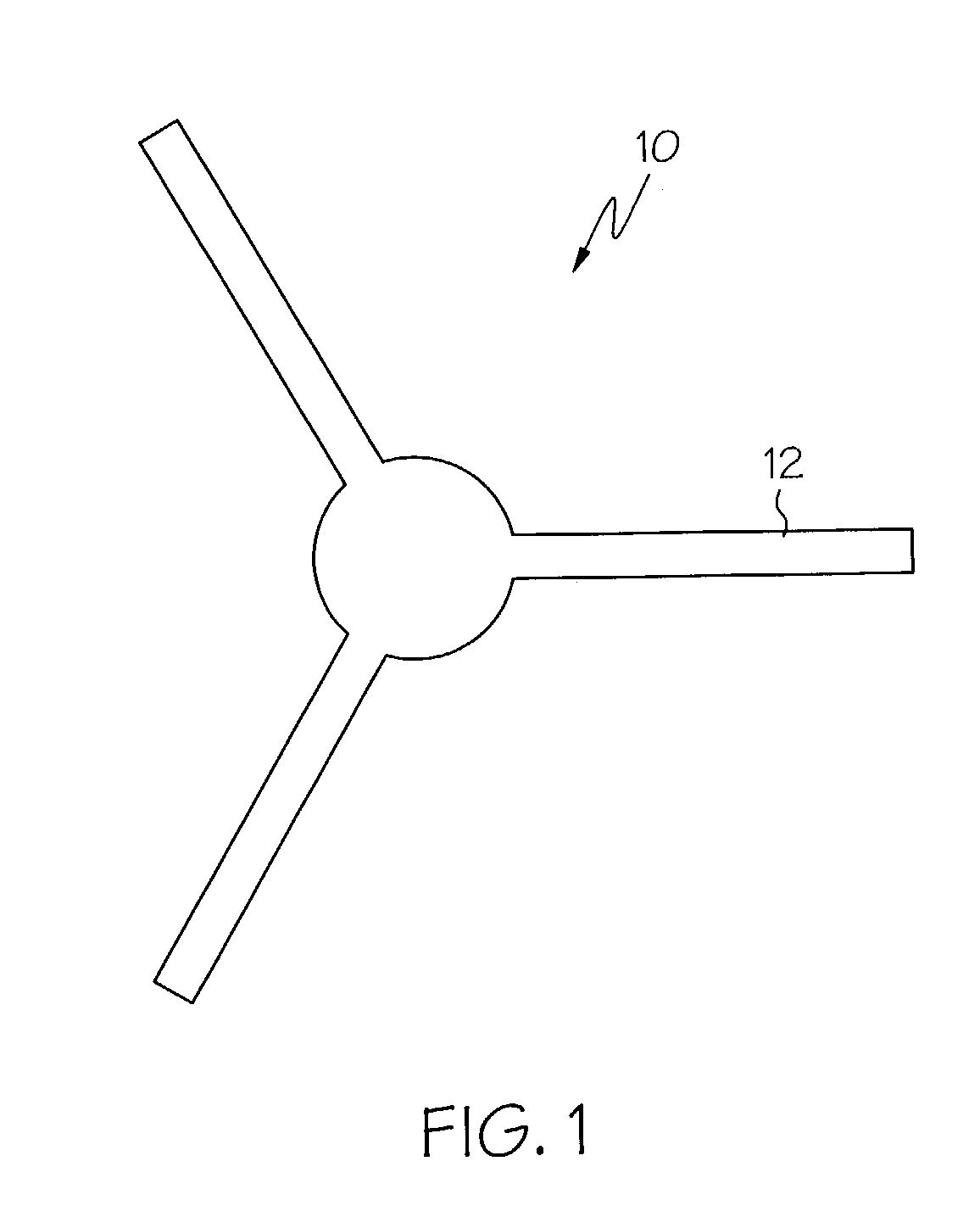

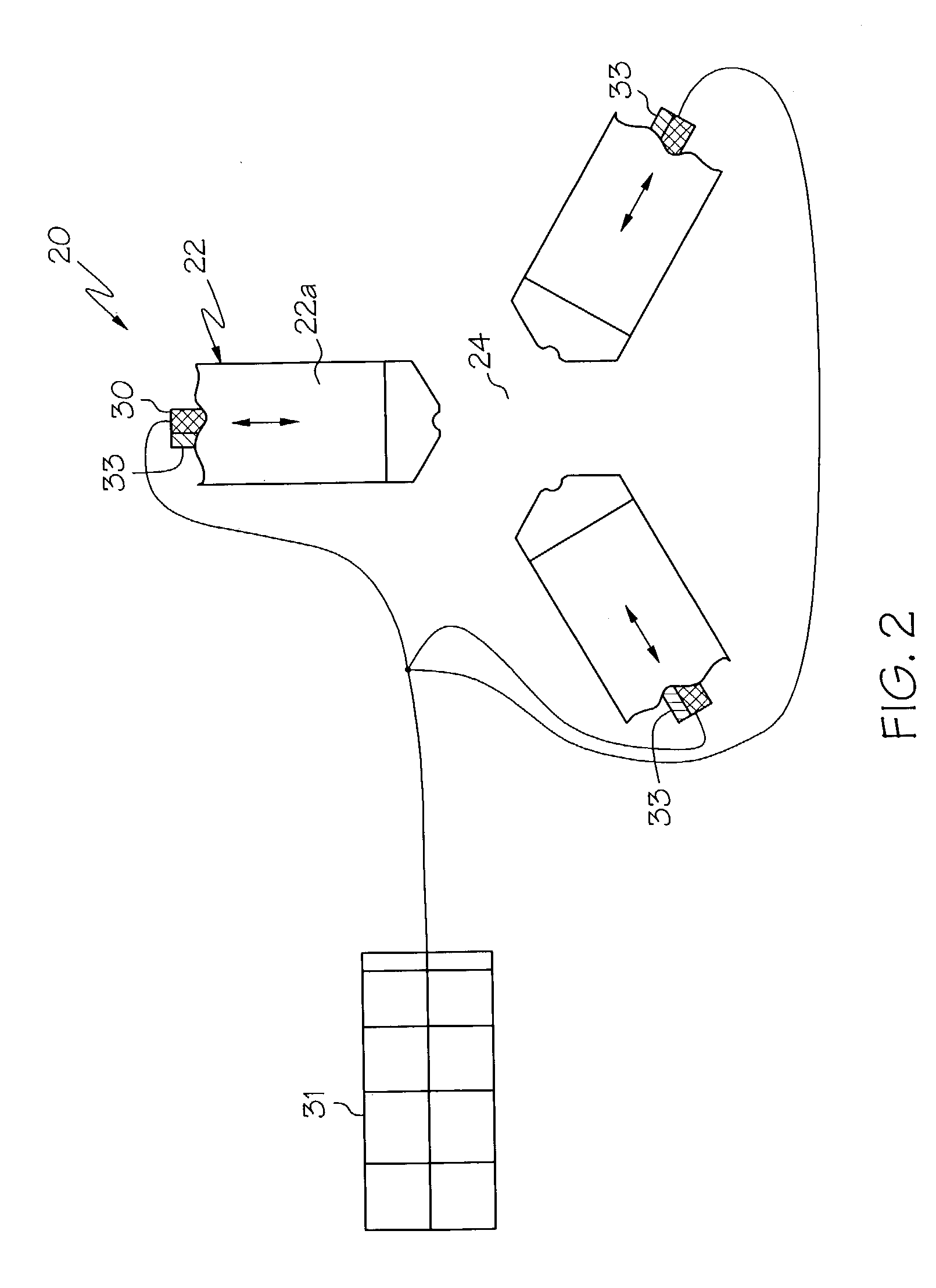

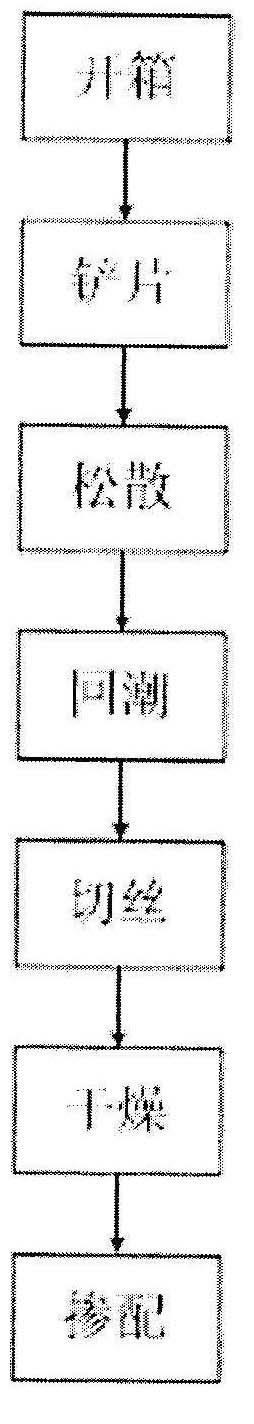

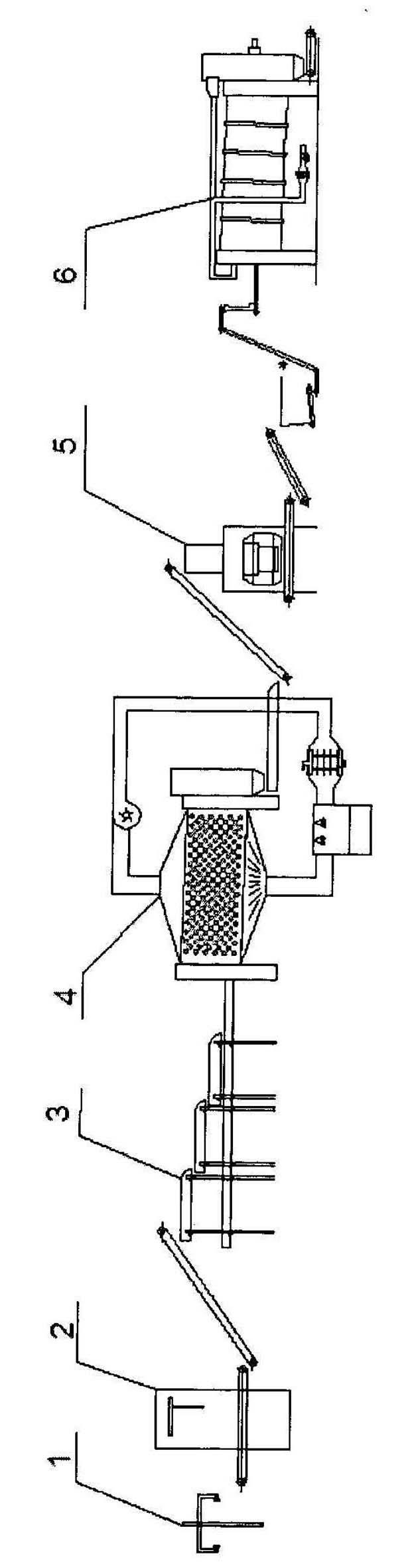

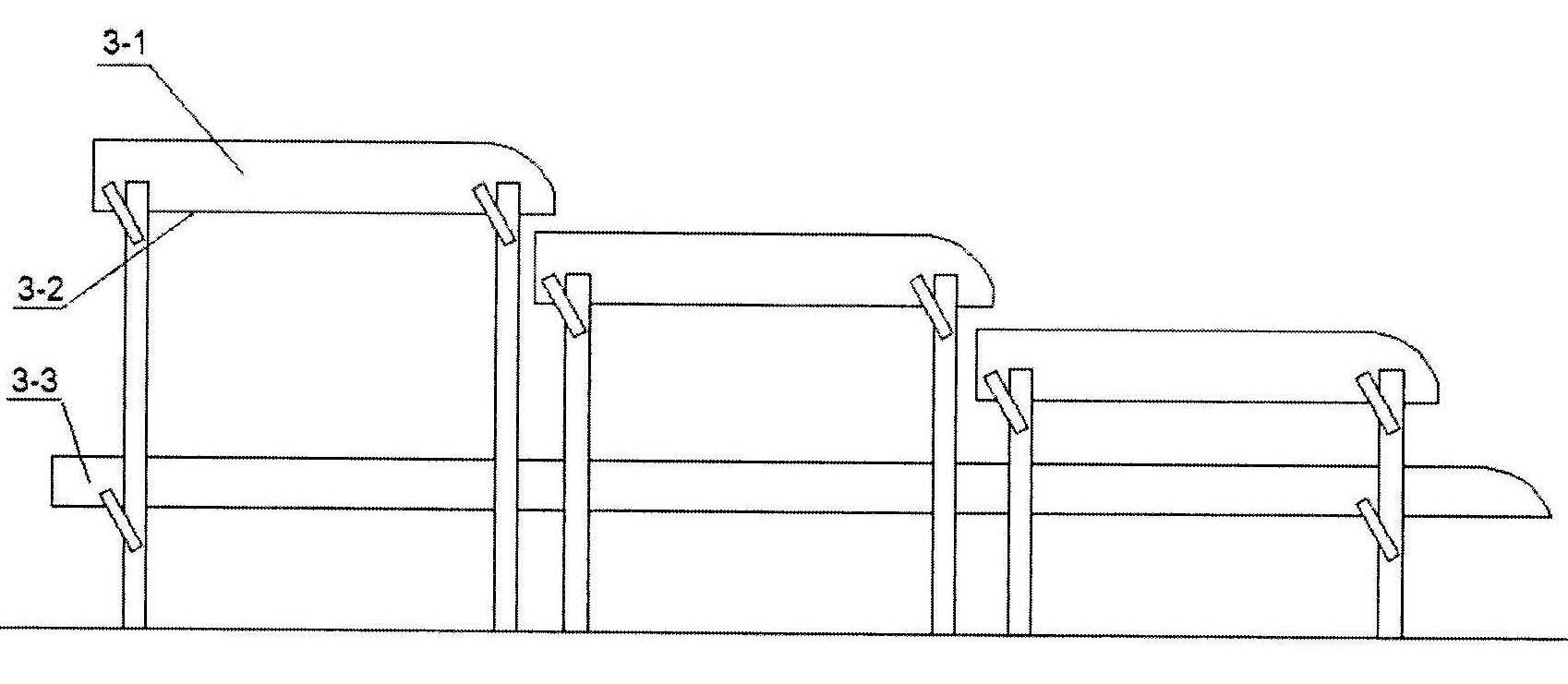

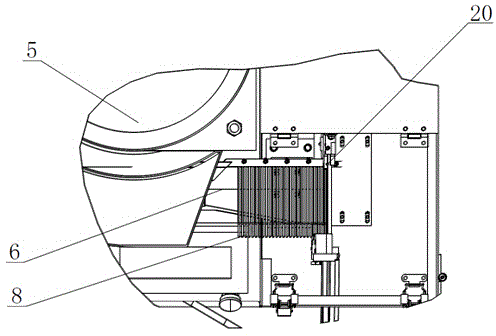

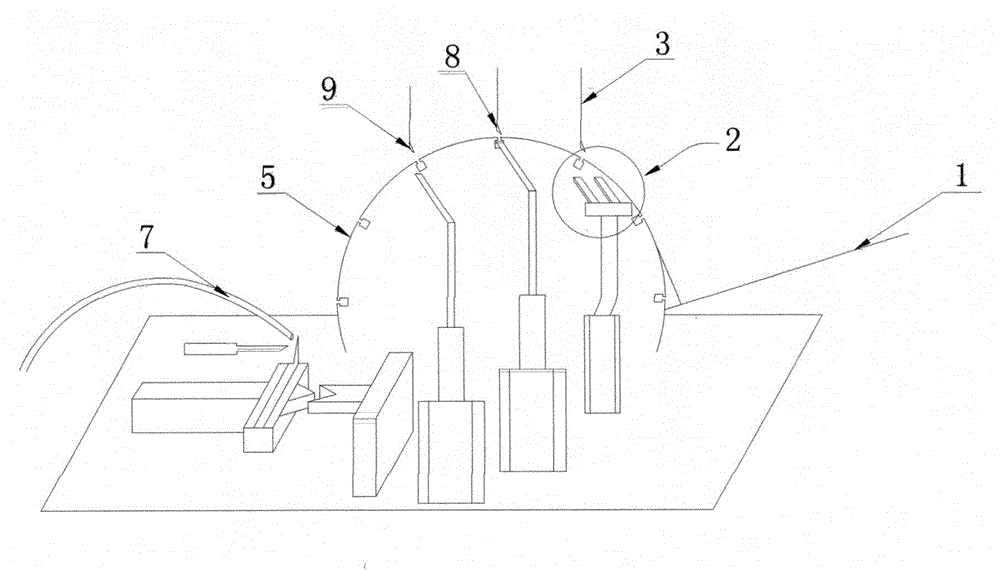

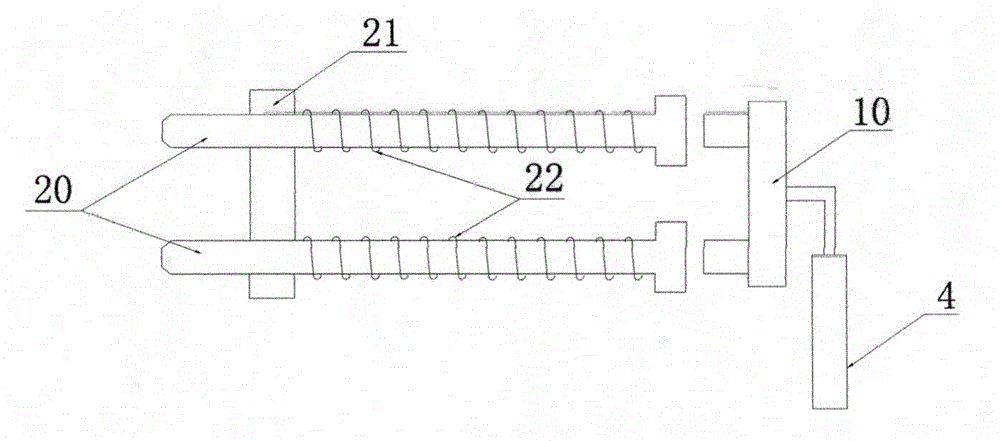

Independent tobacco cutting process and equipment based on paper making method regenerated tobacco leaf processing characteristics

ActiveCN102178337ASolve the strength problemAvoid pulling forceTobacco preparationPulp and paper industryMoisture regain

The invention discloses an independent tobacco cutting process and independent tobacco cutting equipment based on paper making method regenerated tobacco leaf processing characteristics. The process comprises the following process steps: opening a box, shoving tobacco leaves, loosening, regaining moisture, cutting, drying and mixing. The equipment comprises a box opening machine, a tobacco leaf shoving machine, a high-frequency-vibrating loosening machine, a moisture regaining machine, a cutting machine and a roller cut tobacco drying machine, wherein the mechanisms can be arranged and can operate alone or in combination through the connection by a material conveying and feeding mechanism. The process and the equipment can cut the boxed regenerated tobacco leaves independently according to the processing characteristics of the boxed regenerated tobacco leaves, thereby improving the effective utilization rate of the paper making method regenerated tobacco leaves, effectively retaining fragrance, improving visual quality, and making the prepared regenerated cut tobacco uniform in length and good in looseness so that the cut tobacco can be blended with other cut tobacco uniformly. The process and the equipment have high adaptability; meanwhile, according to the change in the form of supplied materials, 'three-step method' tobacco cutting adopted in the prior art is changed into one-step cutting with the same effect, the production efficiency is improved and the production cost is lowered.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

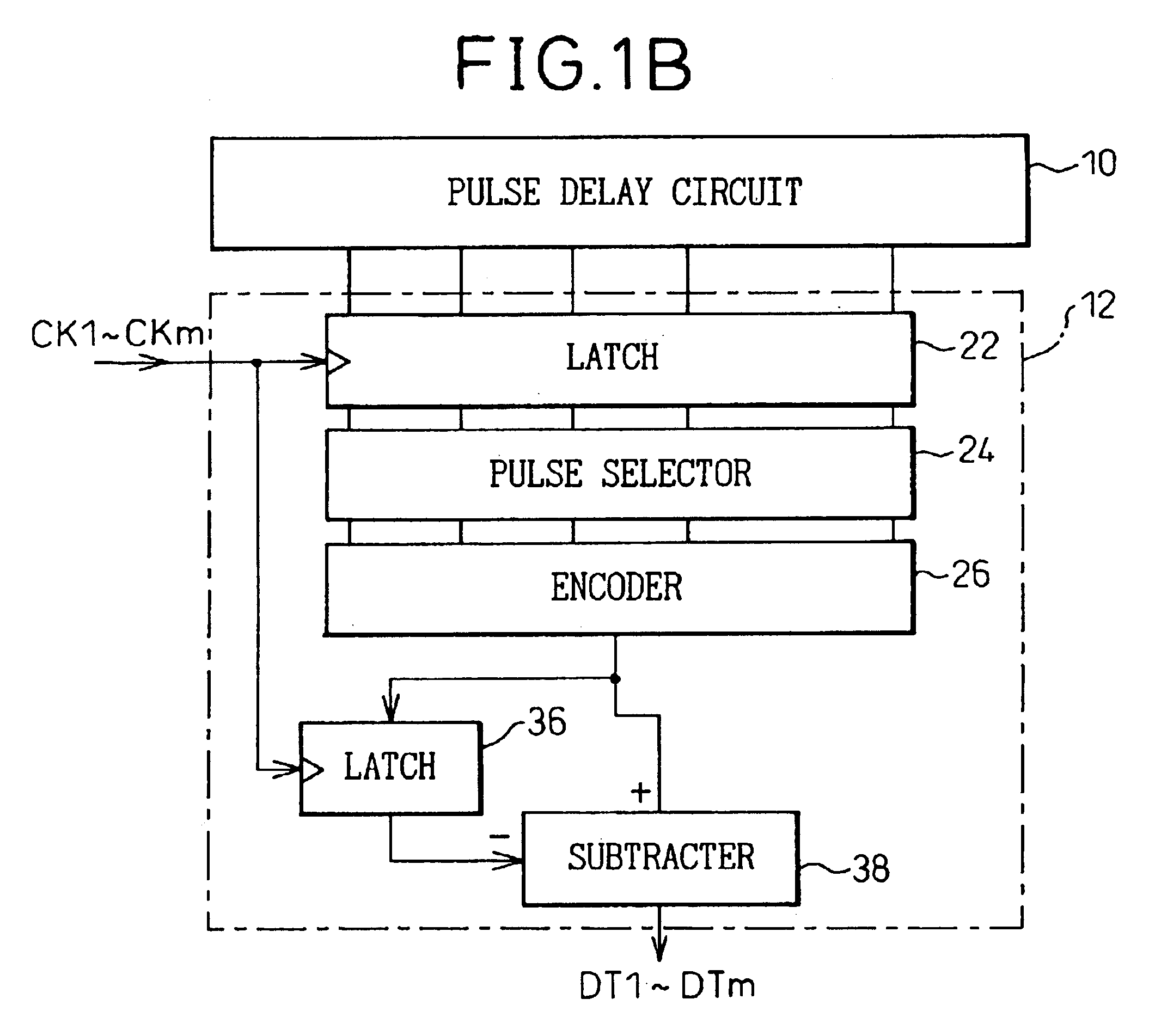

Analog-to-digital conversion method and device

InactiveUS6771202B2Improve accuracyShorten the timeElectric signal transmission systemsPulse generation by logic circuitsDelayed timeEngineering

Owner:DENSO CORP

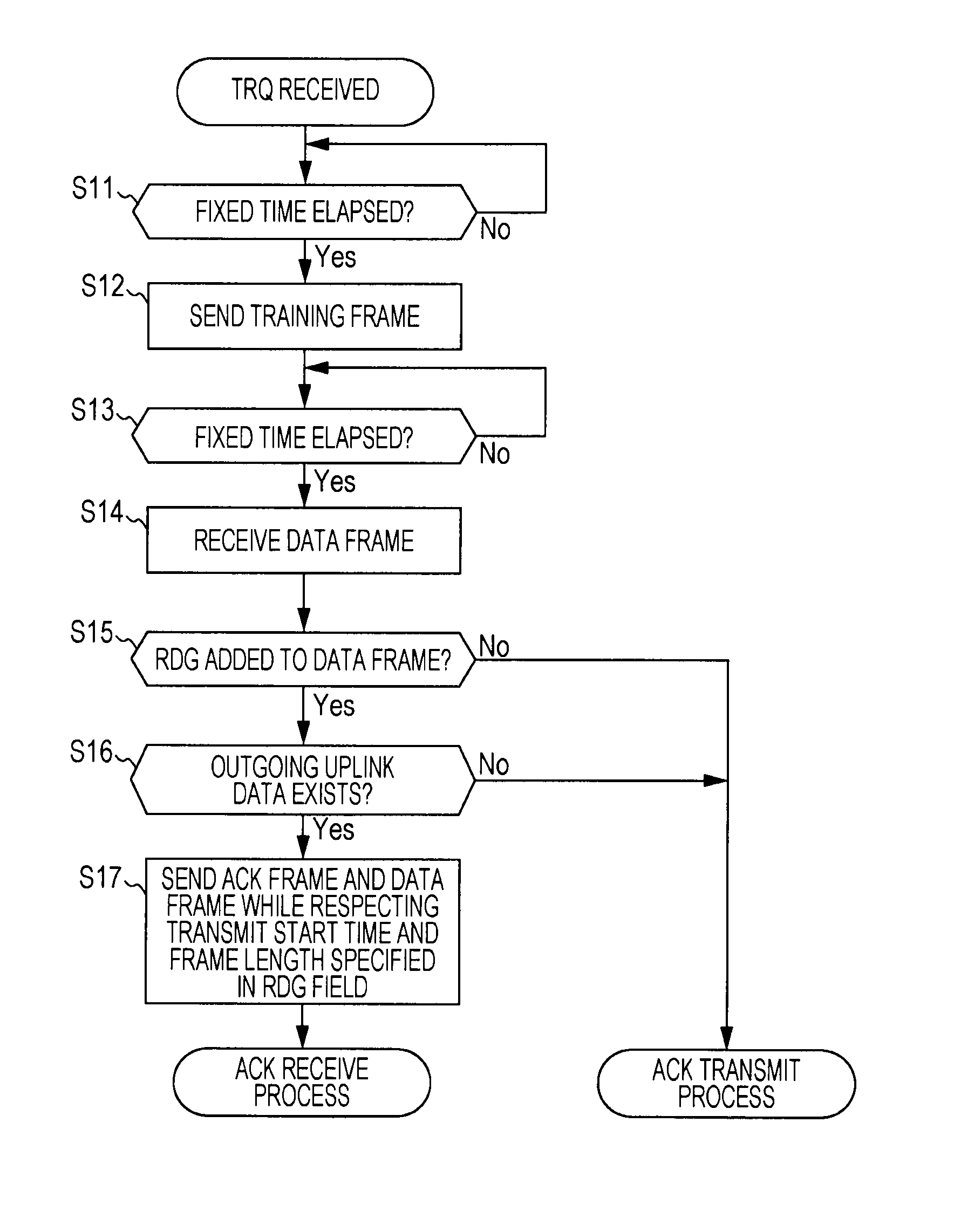

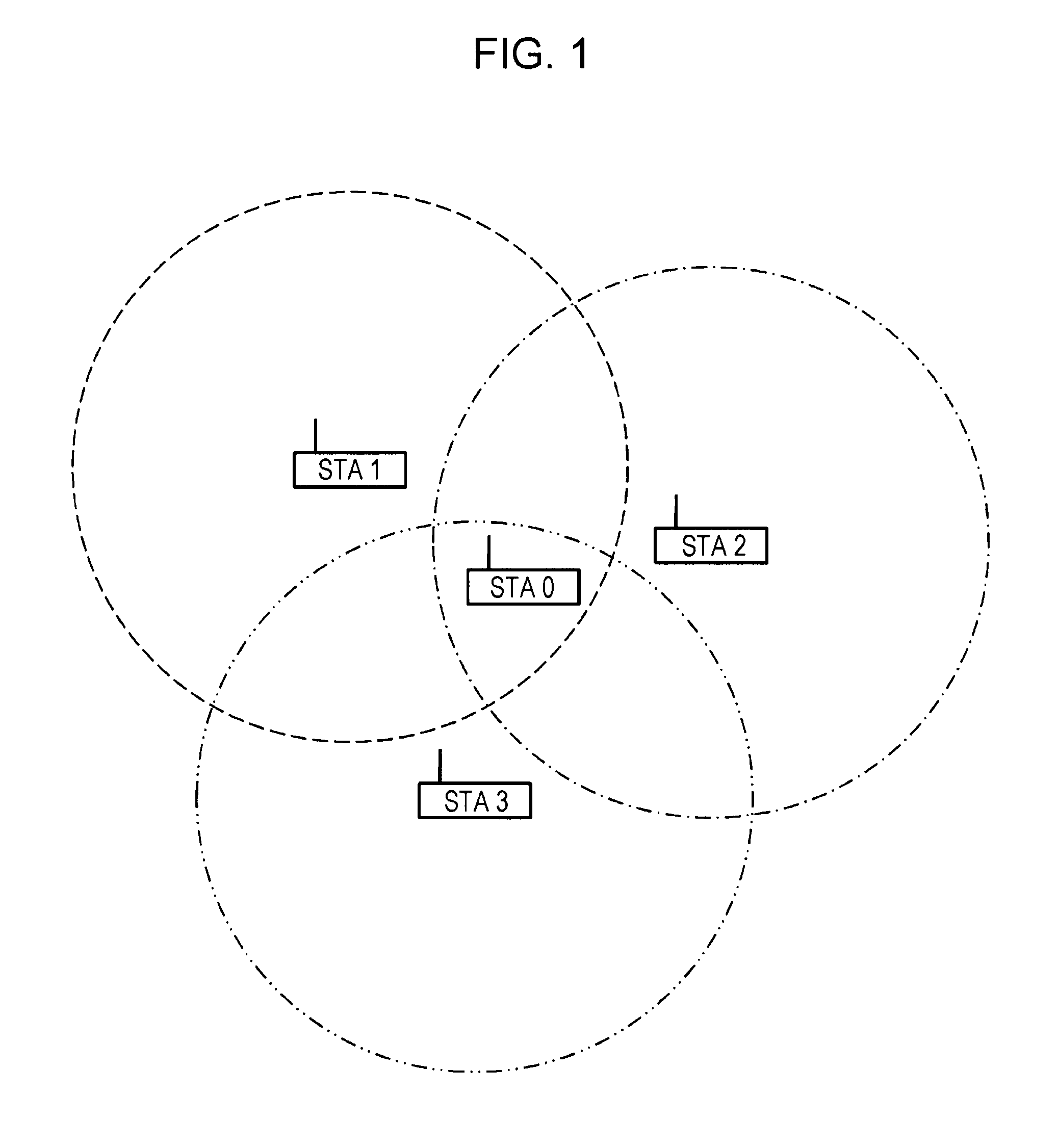

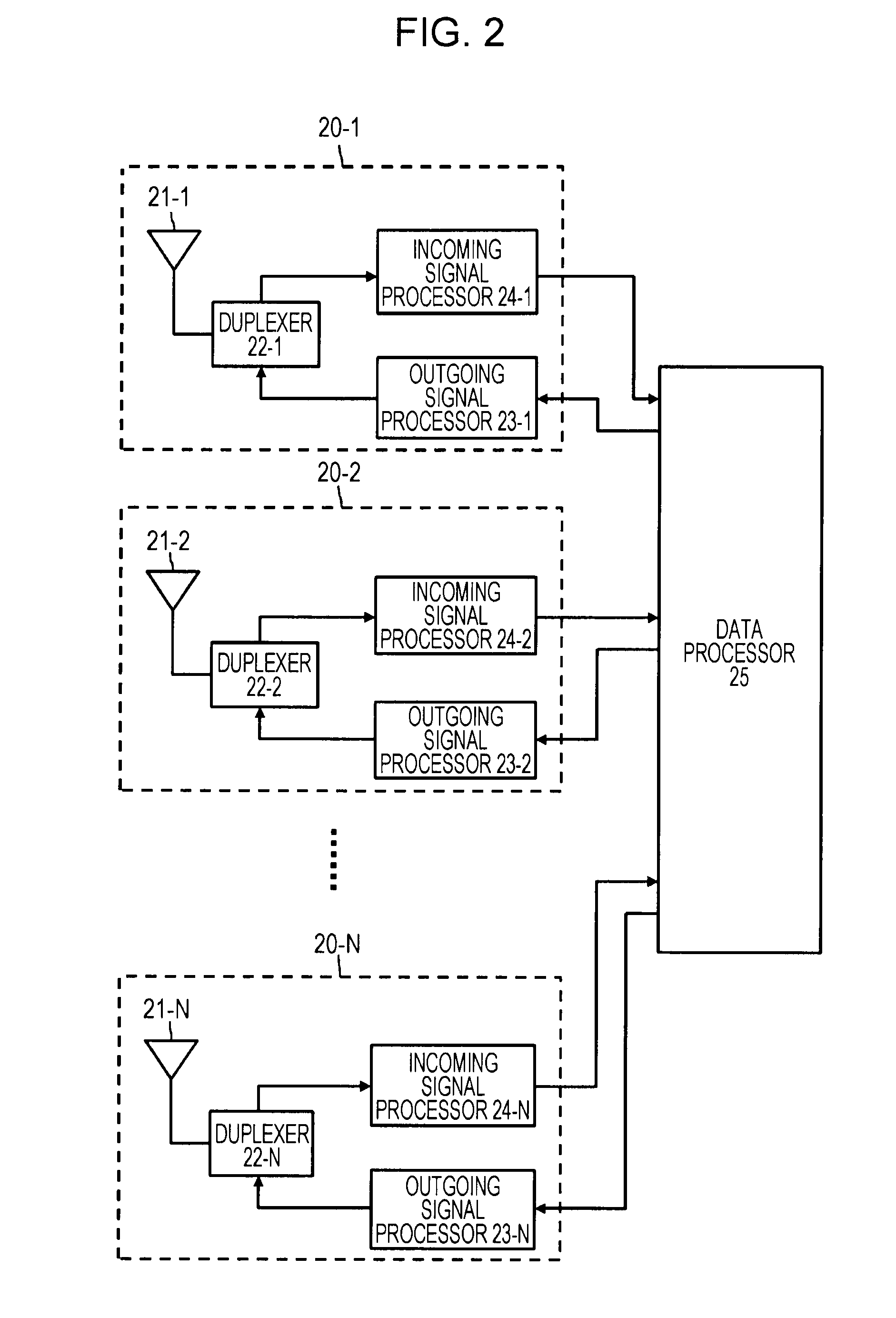

Communication apparatus and method, computer program, and communication system

ActiveUS20120099530A1Facilitate communicationIncrease volumeSpatial transmit diversityNetwork topologiesStart timeCommunications system

Communication operations are optimally conducted by applying space-division multiple access in which wireless resources on a spatial axis are shared among a plurality of users.By applying an RD protocol to a communication system that conducts space-division multiple access, spatially multiplexed frames in a TXOP are made more efficient. By specifying a frame length for reverse direction frames with reverse direction permission information and having respective transmitters of reverse direction frames make their frame lengths uniform while respecting the specification, AGC operation stabilizes. Also, a transmit start time for reverse direction frames can be specified by reverse direction permission information, and respective transmitters of reverse direction frames can transmit frames at the same time while respecting the specification.

Owner:SONY CORP

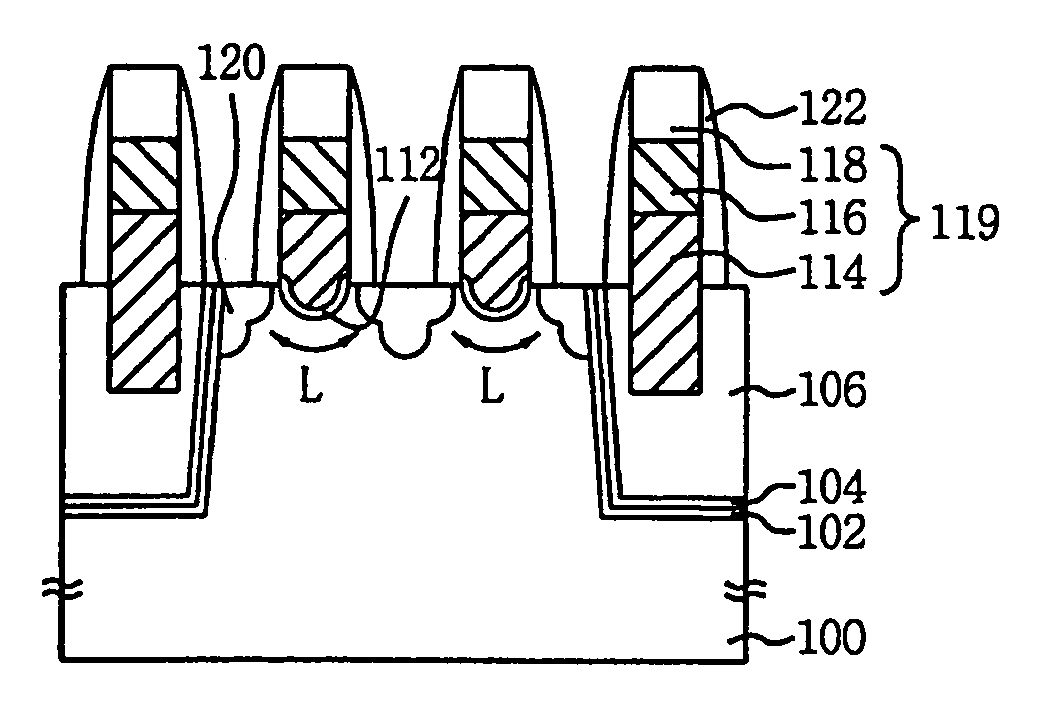

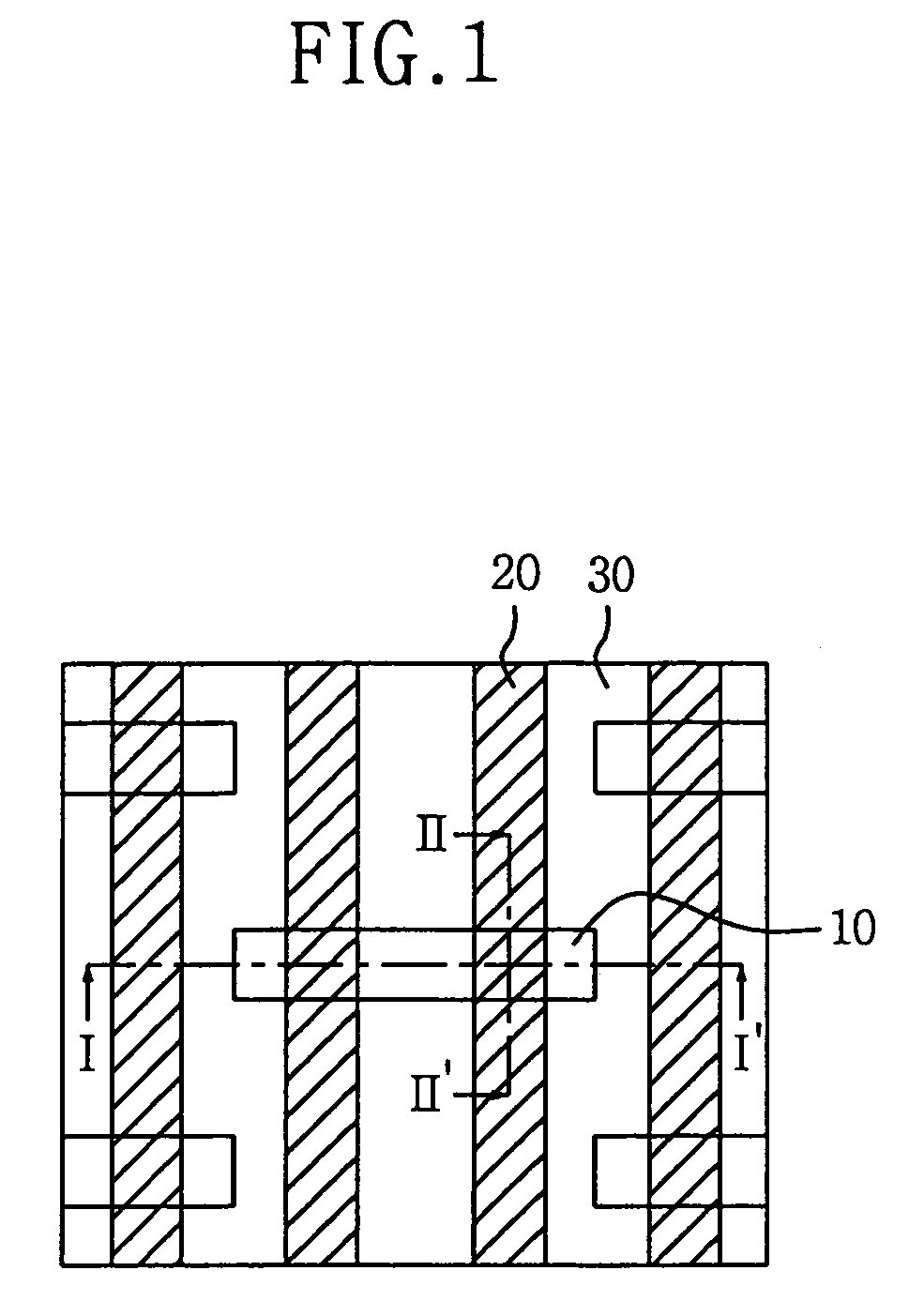

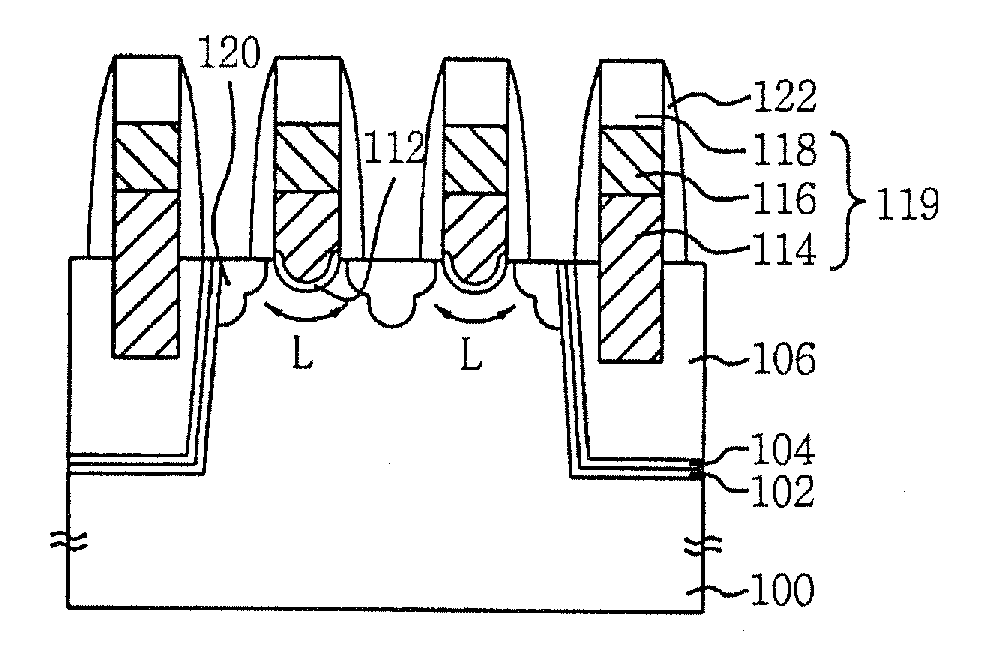

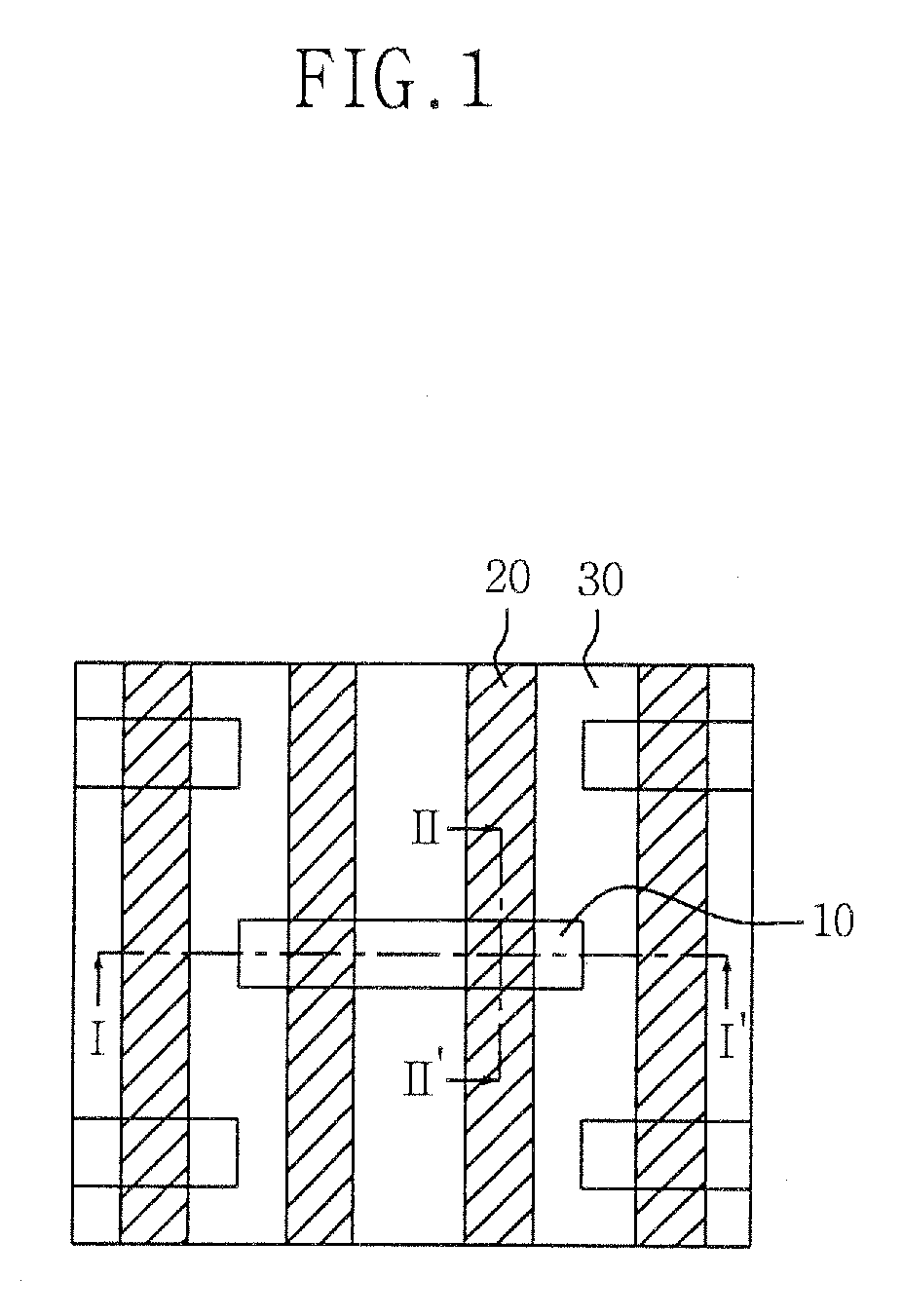

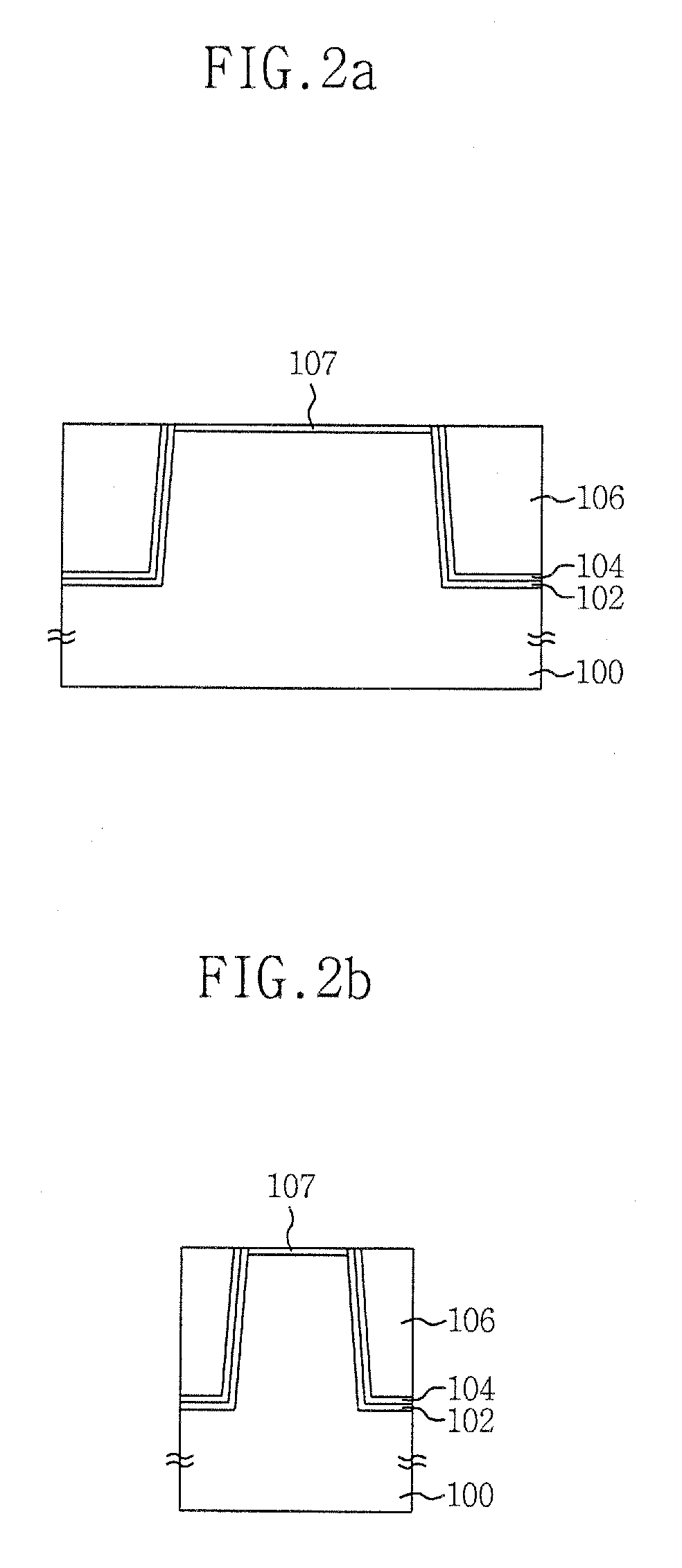

Fin FET and method of fabricating same

ActiveUS7217623B2Improving swing characteristicReducing electric fieldTransistorSolid-state devicesInsulation layerEngineering

A fin field effect transistor (fin FET) is formed using a bulk silicon substrate and sufficiently guarantees a top channel length formed under a gate, by forming a recess having a predetermined depth in a fin active region and then by forming the gate in an upper part of the recess. A device isolation film is formed to define a non-active region and a fin active region in a predetermined region of the substrate. In a portion of the device isolation film a first recess is formed, and in a portion of the fin active region a second recess having a depth shallower than the first recess is formed. A gate insulation layer is formed within the second recess, and a gate is formed in an upper part of the second recess. A source / drain region is formed in the fin active region of both sides of a gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

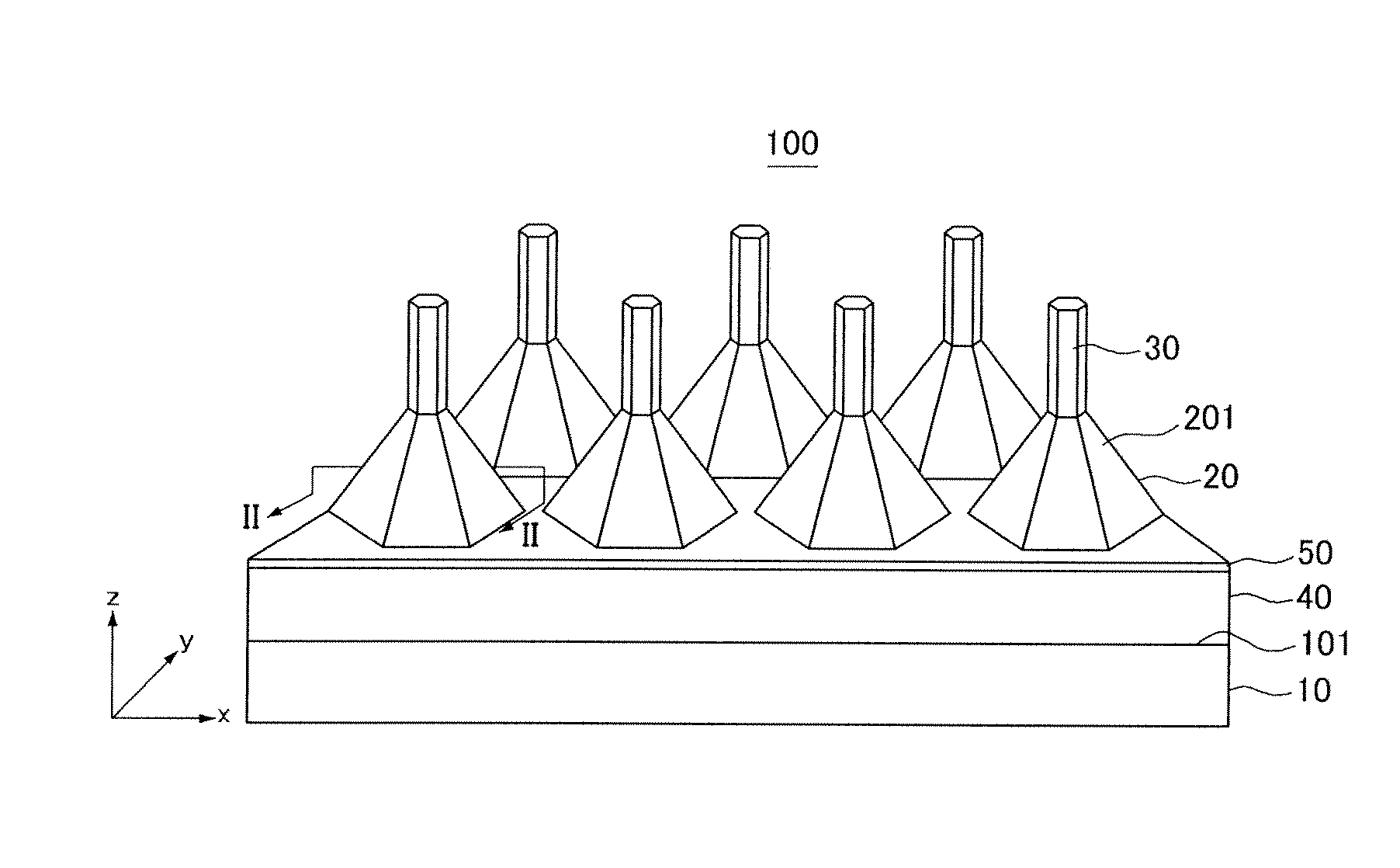

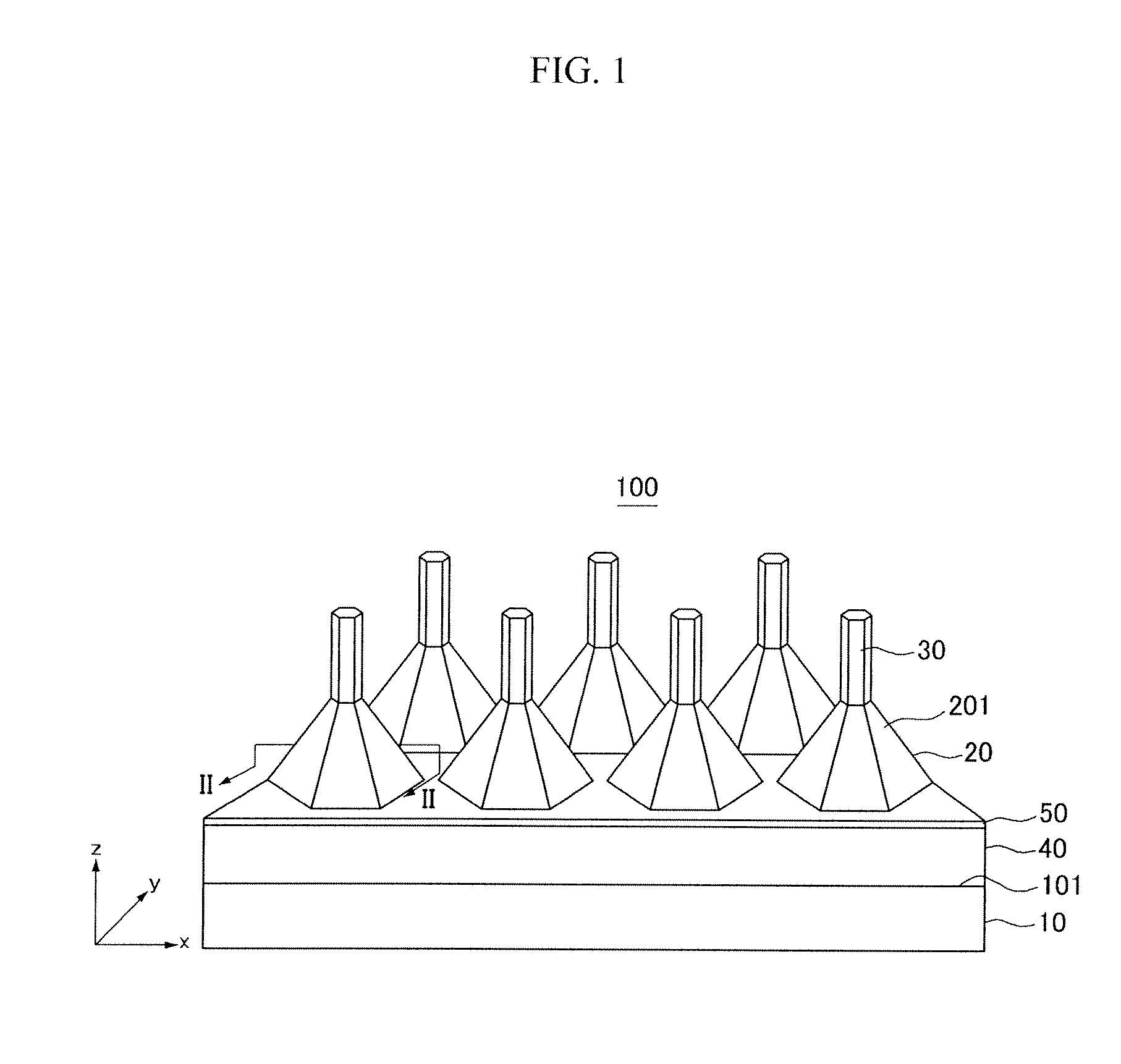

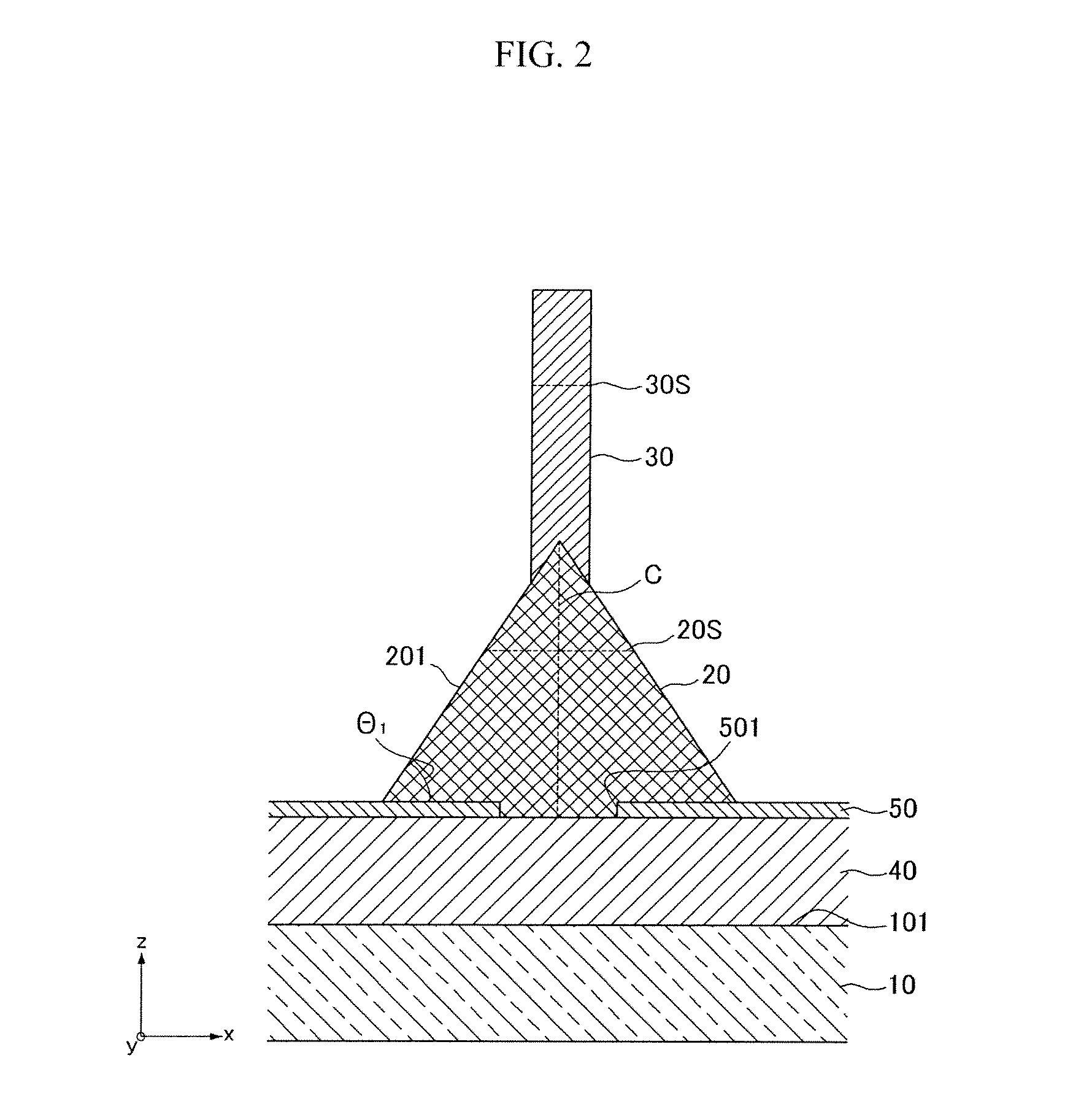

Nanodevice Comprising a Nanorod and Method for Manufacturing the Same

ActiveUS20090068411A1High purityHighly integratedPolycrystalline material growthLayered productsOptoelectronicsNanodevice

A nanodevice including a nanorod and a method for manufacturing the same is provided. The nanodevice according to an embodiment of the present invention includes i) a substrate; ii) at least one crystal that is located on the substrate and includes a plurality of side surfaces forming an angle with each other; and iii) at least one nanorod that is located on the crystal and extends along a direction that is substantially perpendicular to a surface of the substrate

Owner:LG DISPLAY CO LTD

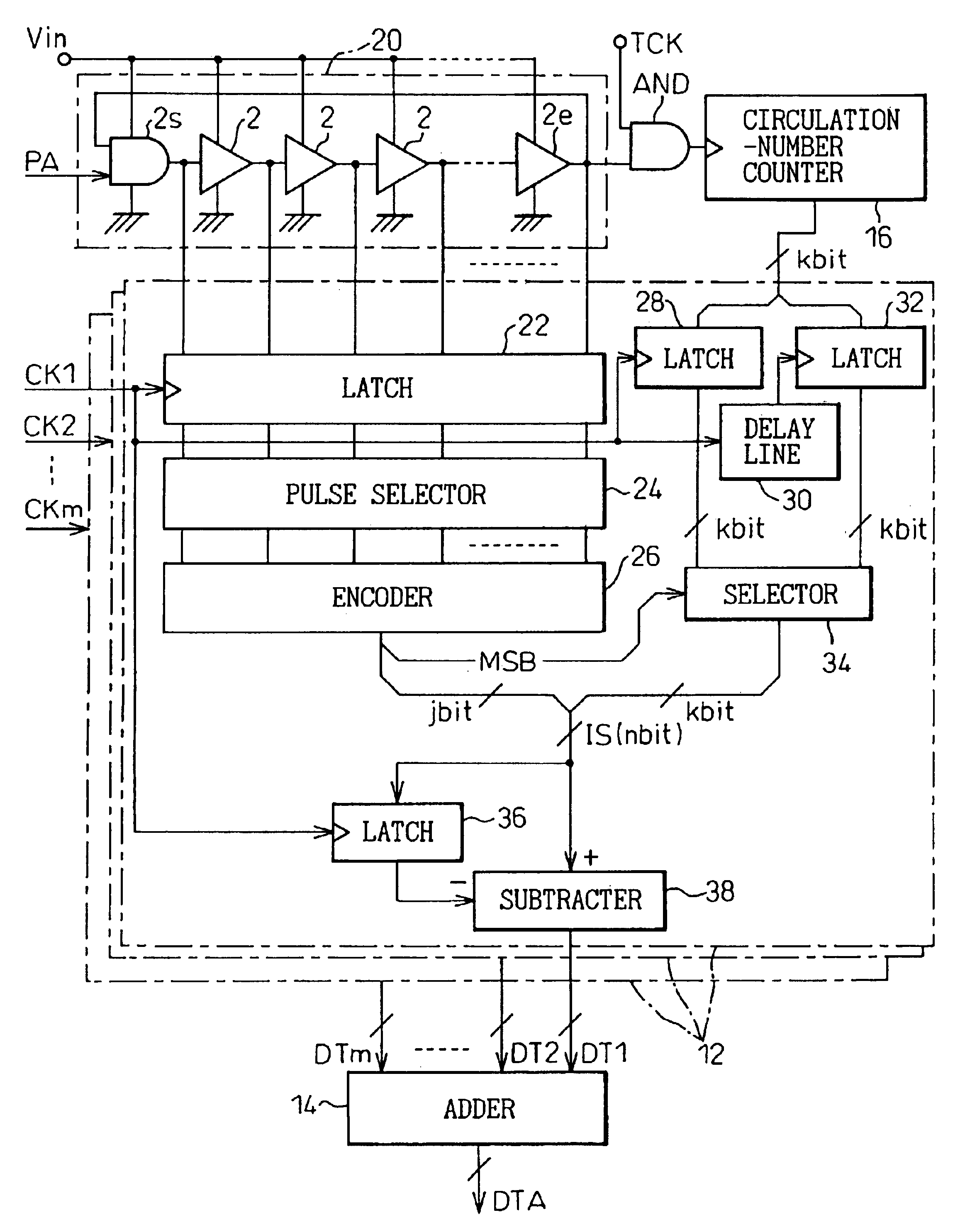

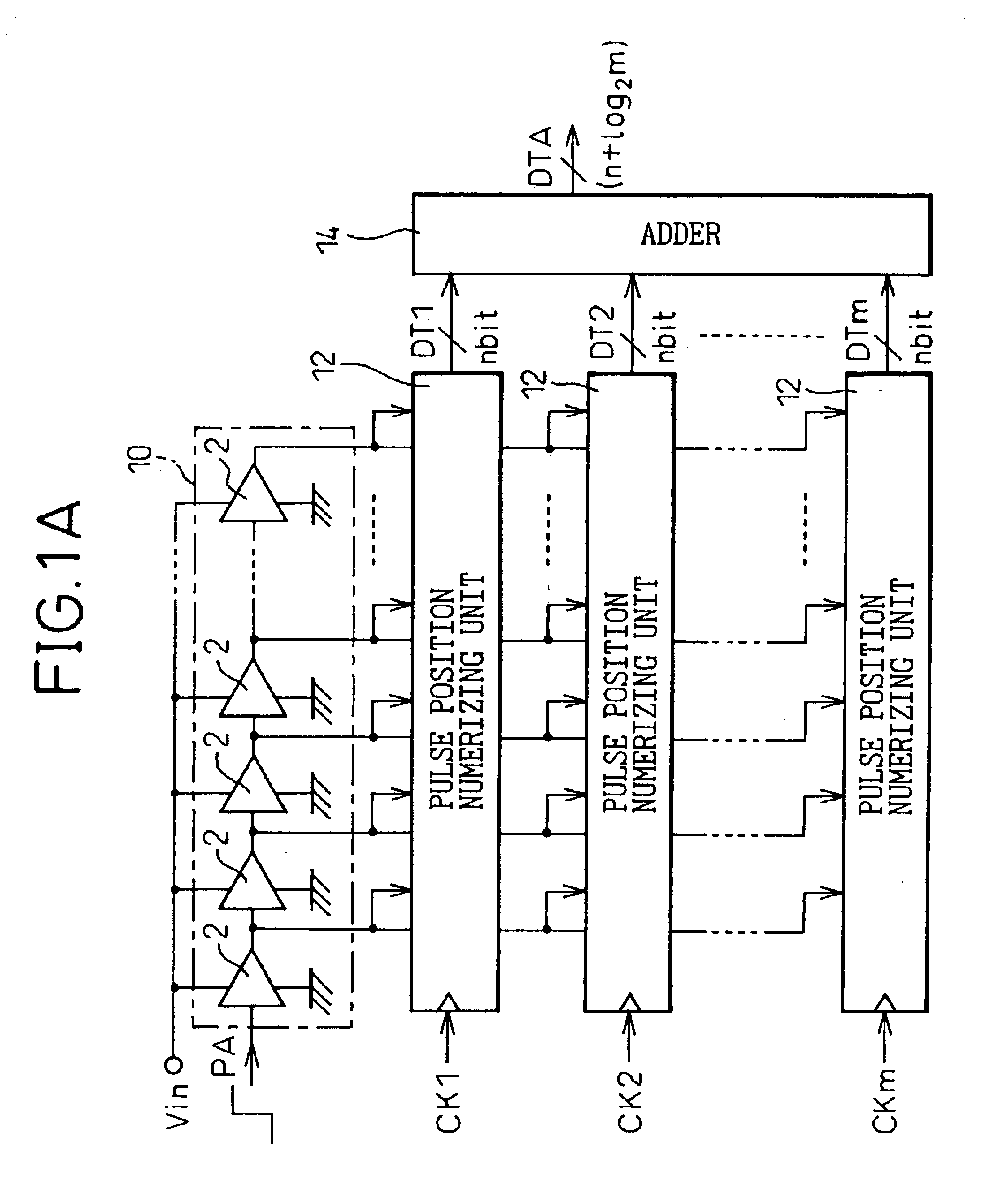

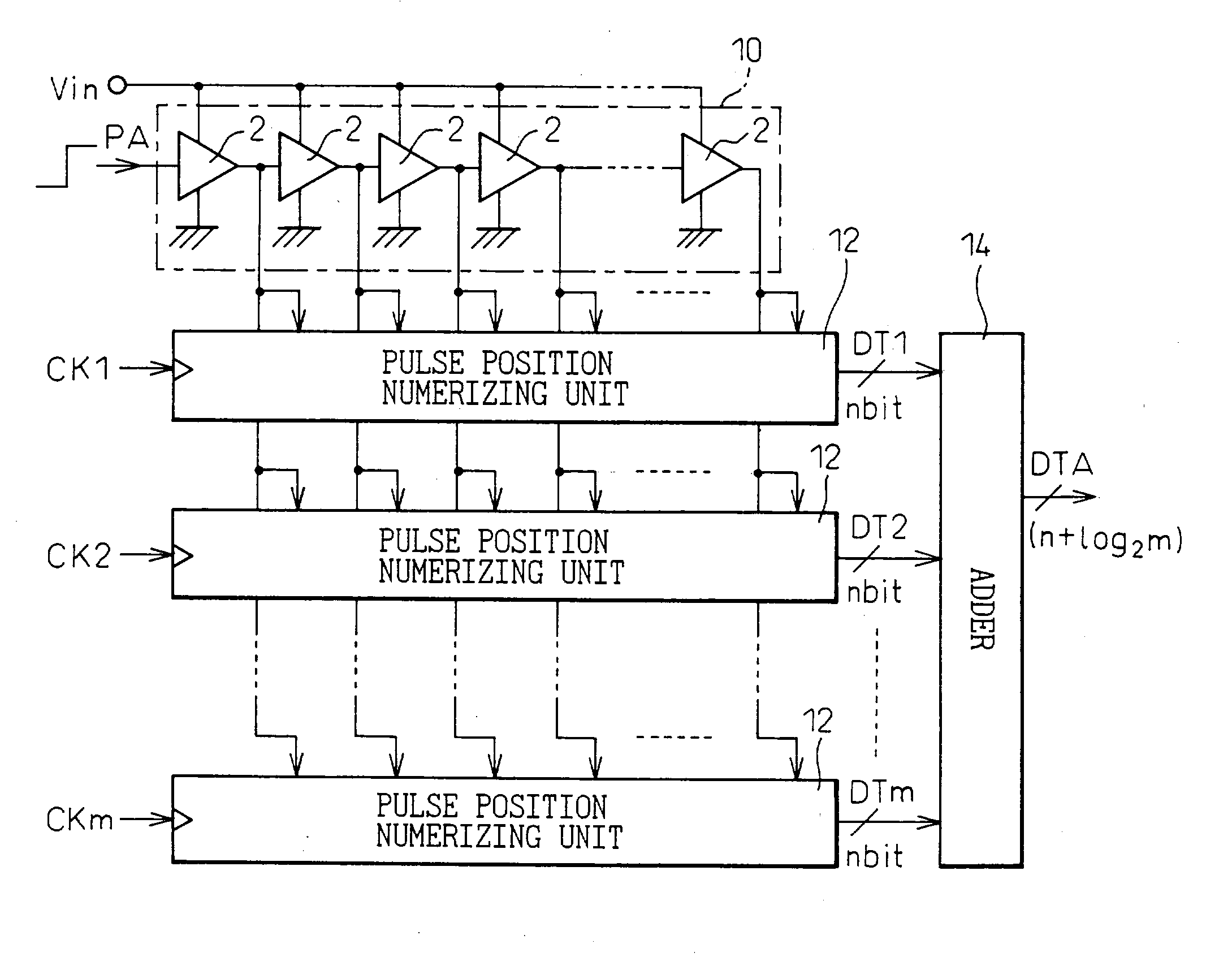

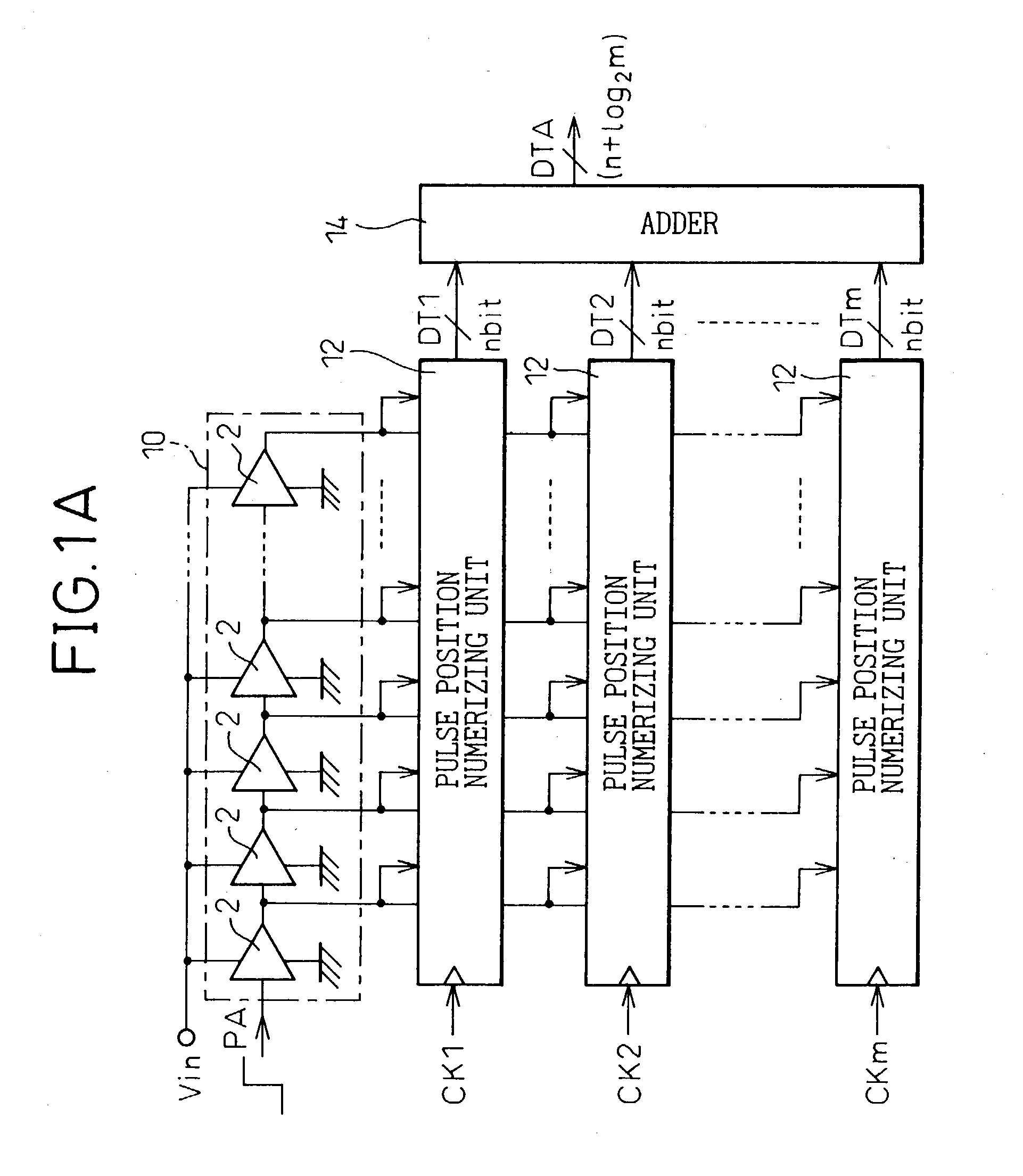

Analog-to-digital conversion method and device

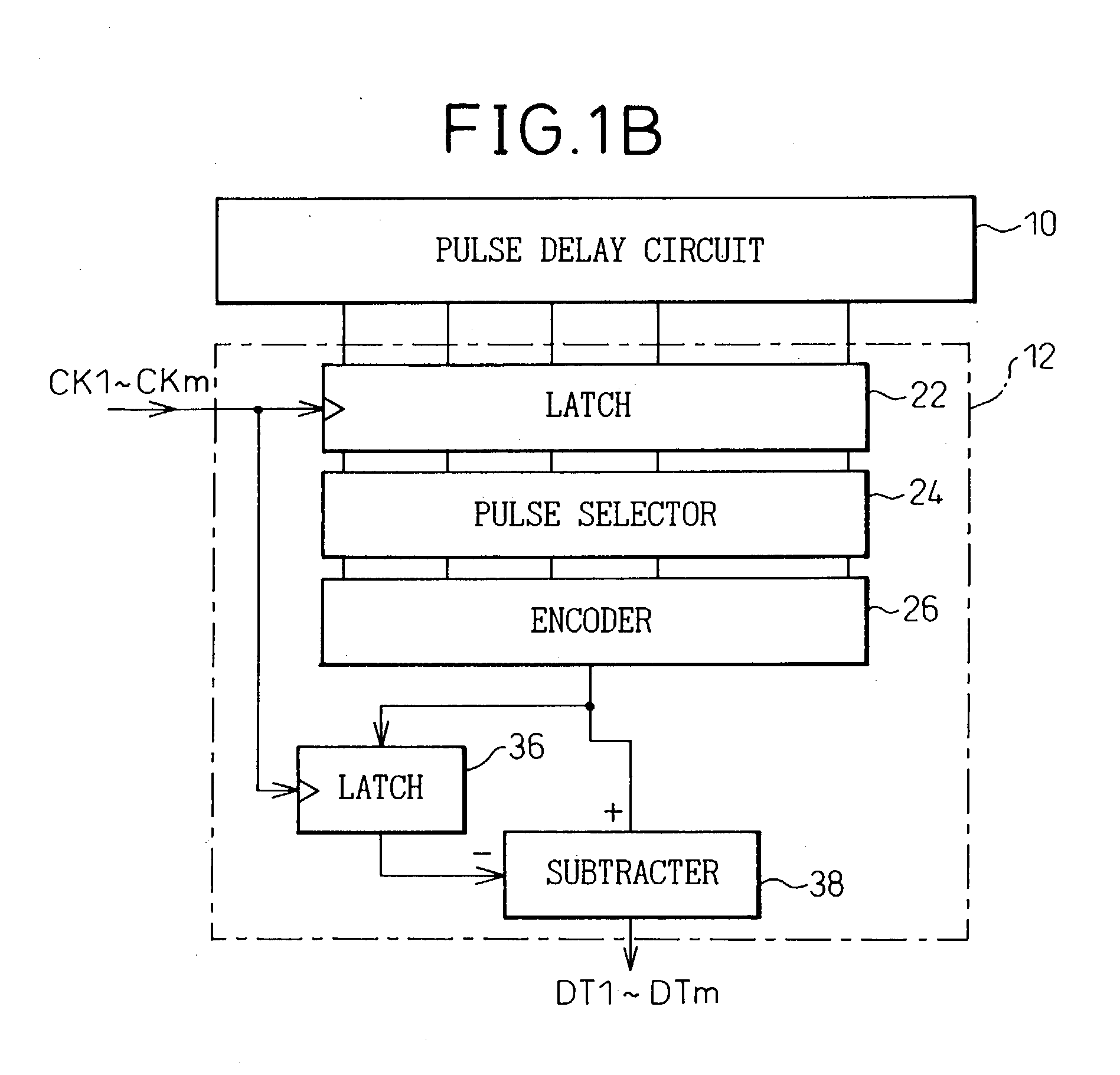

InactiveUS20030201927A1Improve accuracyShorten the timeElectric signal transmission systemsPulse generation by logic circuitsDelayed timePulse delay

In a device for analog-to-digital converting an input signal, the input signal is applied to a plurality of delay units constituting a pulse delay circuit in order to change a delay time to be given by the delay units. The number of delay units through which a pulse signal has passed during one period of sampling clocks is numerically expressed. The A / D conversion device has a plurality of pulse position numerizing units that is used for A / D conversion. Sampling clocks of which the phases are different from one another are applied to the respective pulse position numerizing units. An adder summates numerical data items produced by the respective pulse position numerizing units so as to generate final numerical data representing a result of A / D conversion.

Owner:DENSO CORP

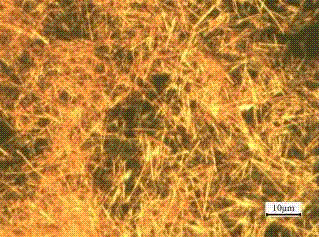

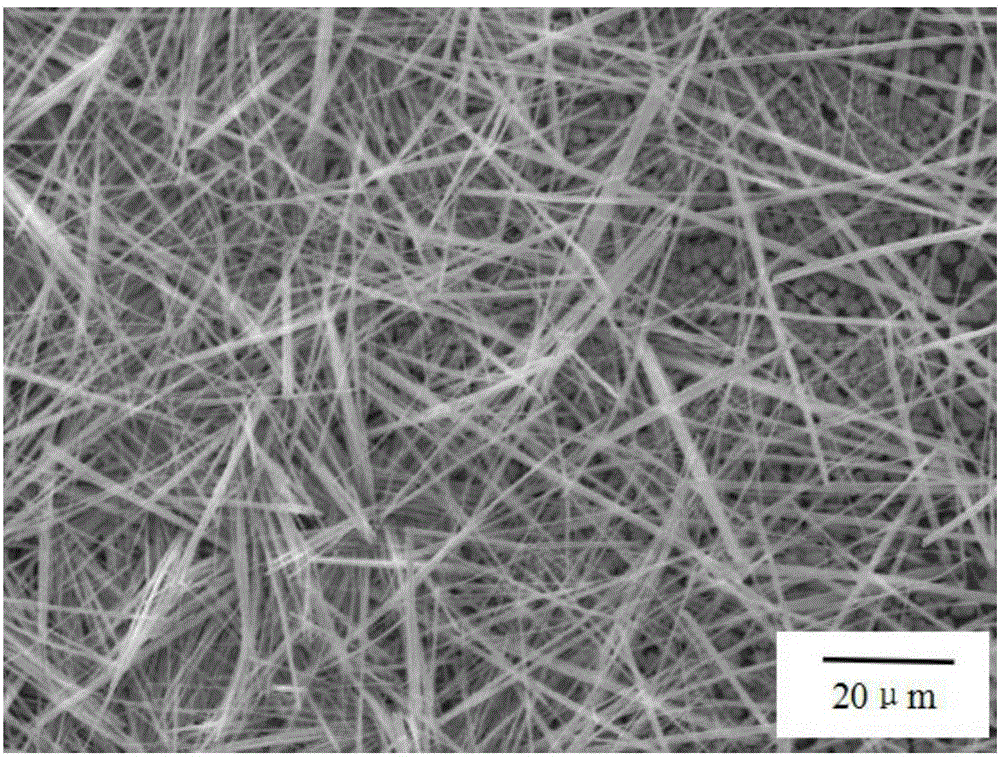

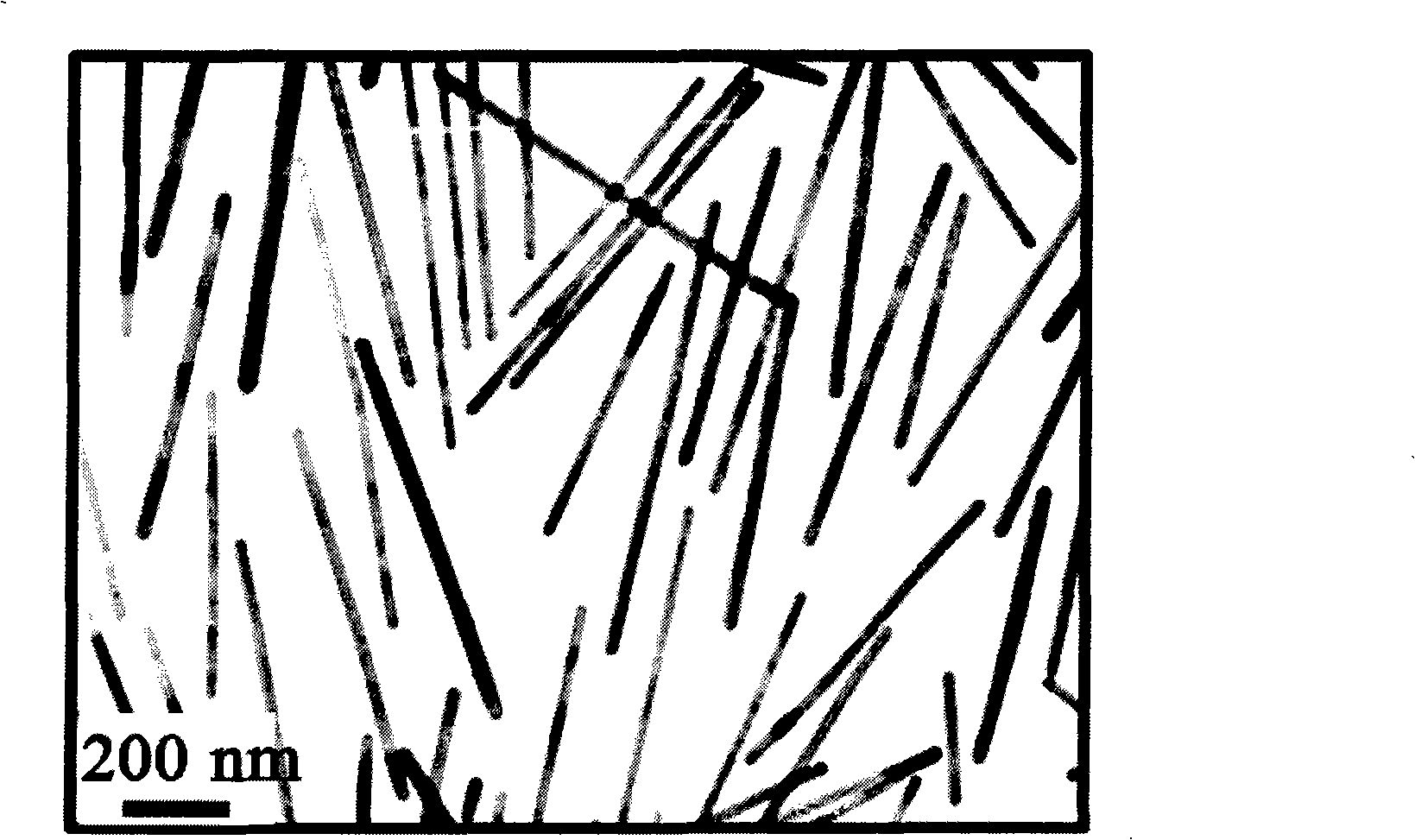

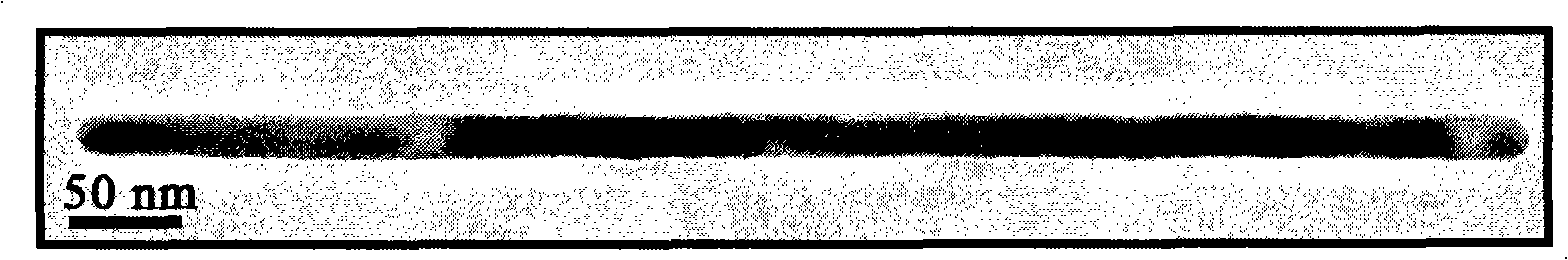

Controllable preparation method of monocrystal copper nanowires

InactiveCN102251278AFlat surfaceUniform radial thicknessPolycrystalline material growthFrom normal temperature solutionsDivalent metalIon

The invention relates to a preparation method of copper nanowires and in particular relates to a controllable preparation method of high-yield monocrystal copper nanowires in a liquid-phase reduction manner. The controllable preparation method comprises the steps: firstly, mixing a divalent metal copper salt solution and ethylenediamine, and heating in a water bath to form a single and stable copper ion chelate compound; mixing a strong base solution with hydrazine hydrate, and preparing a reducing agent in the water bath at the same temperature; then transferring the two mixture solutions into a reaction vessel, fully stirring to reach a uniform state, covering well, and placing in the water bath at the same temperature for heating reaction to prepare the copper nanowires; and fishing out flaky copper nanowires floating on the upper layer of the solution, washing the flaky copper nanowires with deionized water and absolute ethyl alcohol in sequence three times, and drying at room temperature under an Ar gas protection condition to prepare the copper nanowires. The controllable preparation method provided by the invention has the advantages of simple process, low cost and high yield, and the prepared copper nanowires are of monocrystal structures, and have relatively smooth surfaces, uniform radial thickness, and controllable and more uniform length and diameter.

Owner:CHANGZHOU UNIV

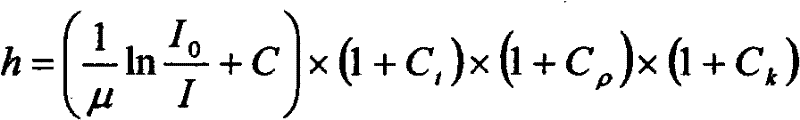

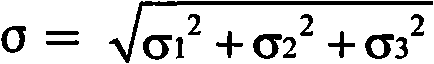

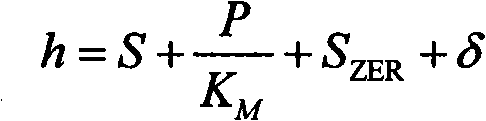

A Method for Controlling the Thickness Accuracy of Medium and Heavy Plate

ActiveCN102294362AUniform lengthUniform thickness along the lengthRoll mill control devicesMetal rolling arrangementsControl measureSteel plates

The invention provides a thickness accuracy control method for a medium-thickness plate. In the method, various influence factors and constraint conditions are comprehensively considered, various measures such as setting, actual measurement, metering and the like are specially and comprehensively utilized, and five control measures, i.e., thickness control of a steel plate in the length direction, thickness control of the steel plate in the width direction, absolute thickness control of the steel plate, accuracy control of a thickness meter and secondary rolling target thickness control are performed, so that the model accuracy is more practical, the application design is more scientific, the hardware setting and functions are more standard, optimization of a target thickness is realized under the condition of meeting the constraint conditions, the rolling thickness accuracy of the steel plate is increased remarkably, the surface quality is improved, the depth of a recess is reduced from 0.5 millimeter to 0.13 millimeter, the rolling size spot rate is reduced by 0.76 percent, the yield is increased by 0.80 percent, and remarkable economic benefit and popularization value are achieved.

Owner:ANGANG STEEL CO LTD

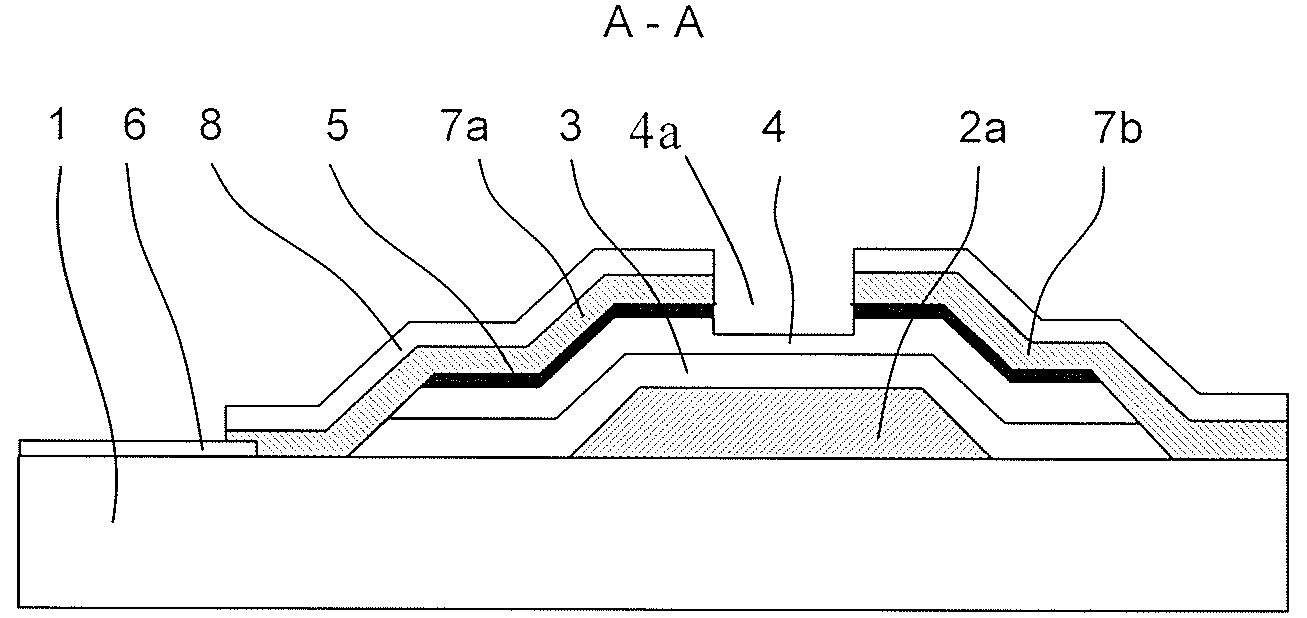

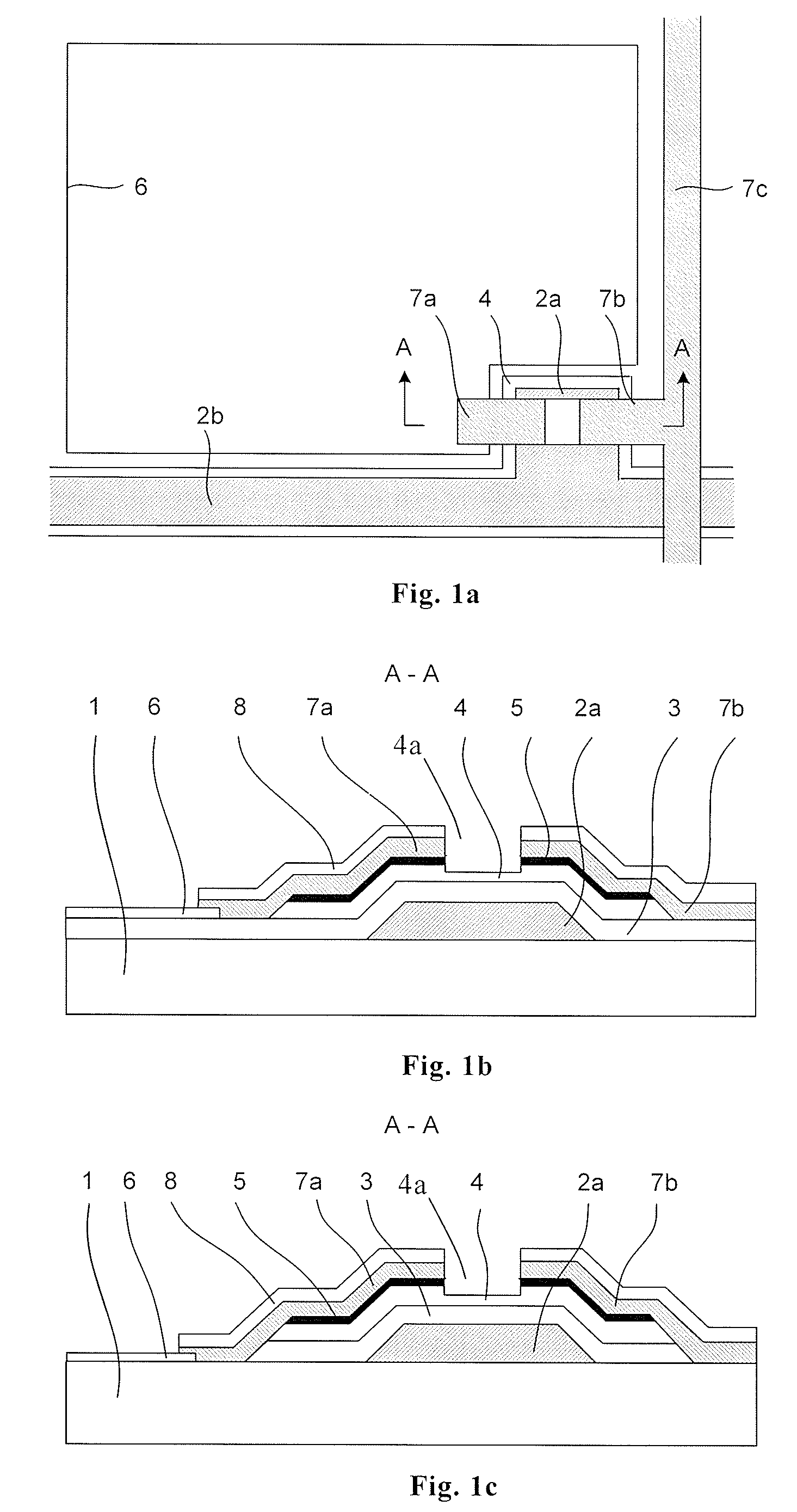

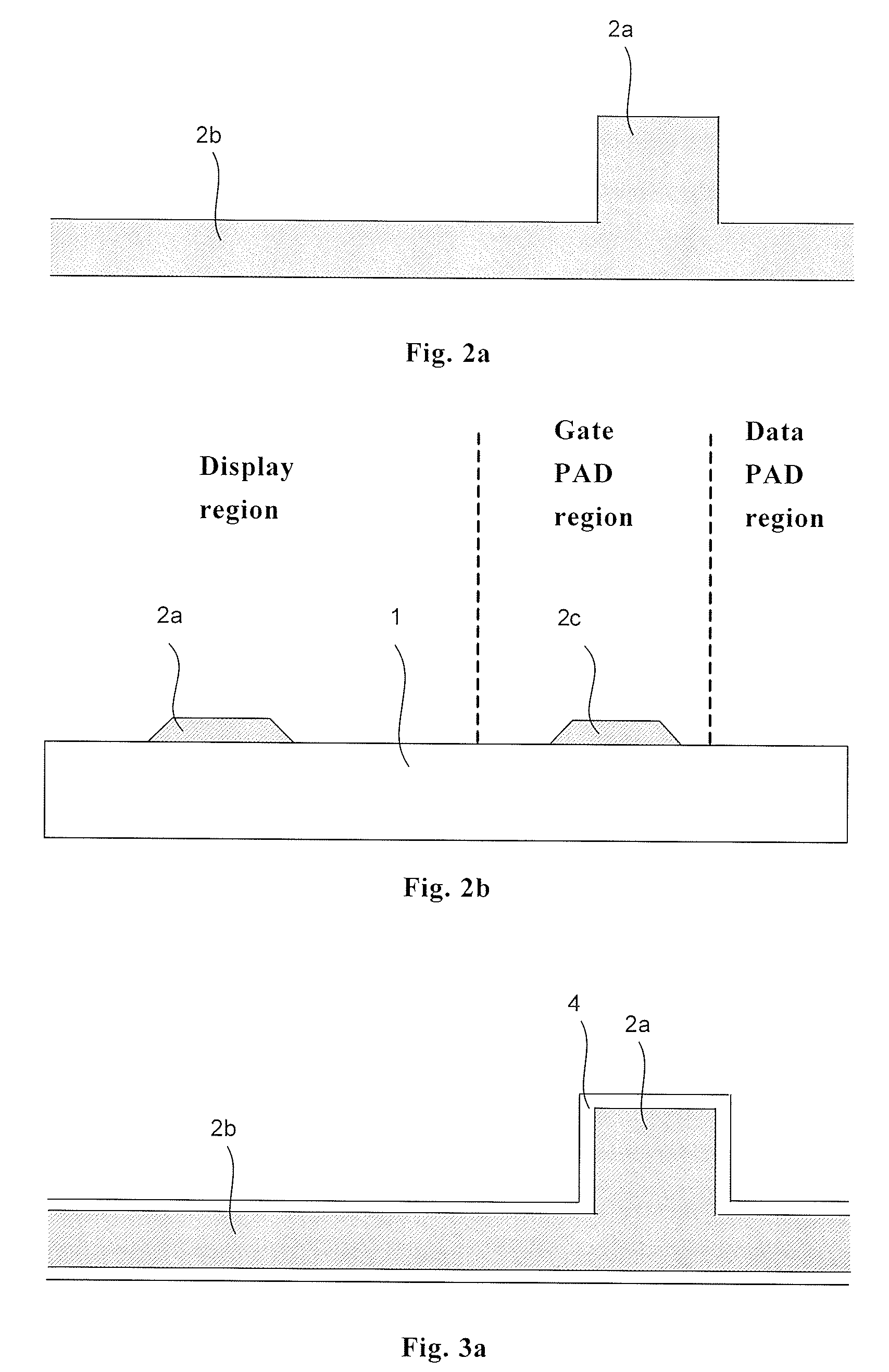

Thin film transistor array substrate and manufacturing method thereof

ActiveUS20090225249A1Improve production yieldQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A thin film transistor (TFT) array substrate for a liquid crystal display comprises a gate line and a data line formed in a display region, a gate connecting line and a data connecting line formed in a PAD region, and a TFT formed at an intersection between the gate line and the data line. The TFT comprises a gate electrode on a base substrate, a gate insulating layer on the gate electrode, a semiconductor layer on the gate insulating layer, a doped semiconductor layer on the semiconductor layer, and a source electrode and a drain electrode that are on the doped semiconductor layer, and a TFT channel is defined in the semiconductor layer between the source electrode and the drain electrode. The array substrate further comprises a passivation layer that is formed on the source electrode and the drain electrode and a pixel electrode, a portion of which is formed under the drain electrode and connected with the drain electrode.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

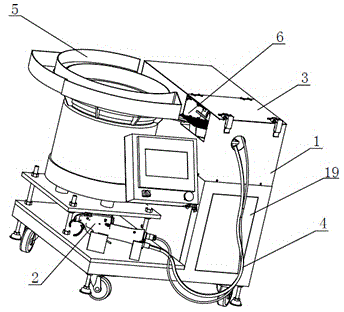

Hand-held automatic binding tool

ActiveCN104150006AImprove the efficiency of strapping operationsUniform tensionBinding material applicationBundling machine detailsHand heldEngineering

The invention provides a hand-held automatic binding tool which comprises a main machine, a gun head, a feeding pipe and a data line. The main machine is connected with the gun head through the feeding pipe and the data line. The hand-held automatic binding tool further comprises a vibrating plate and straight vibrator. The vibrating plate is located on the left side of the main machine. The straight vibrator is connected to the right side of the vibrating plate. The straight vibrator is connected with a pushing chamber. The vibrating plate screens and sorts bulk binding bands. When an optical fiber sensor detects that the front-most binding band is in position, an air cylinder pushes the front-most binding band into the feeding pipe, a trigger is pulled to allow compressed air to feed the binding band into the gun head, and the gun head completes winding, perforating, tightening and cutting off. The hand-held automatic binding tool has the advantages that binding efficiency is increased greatly, binding can be completed while hands are not in contact with the binding bands, labor intensity of workers is relieved greatly, the gun head is small in size and lightweight, and the gun head is connected with main machine through the flexible pipeline.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

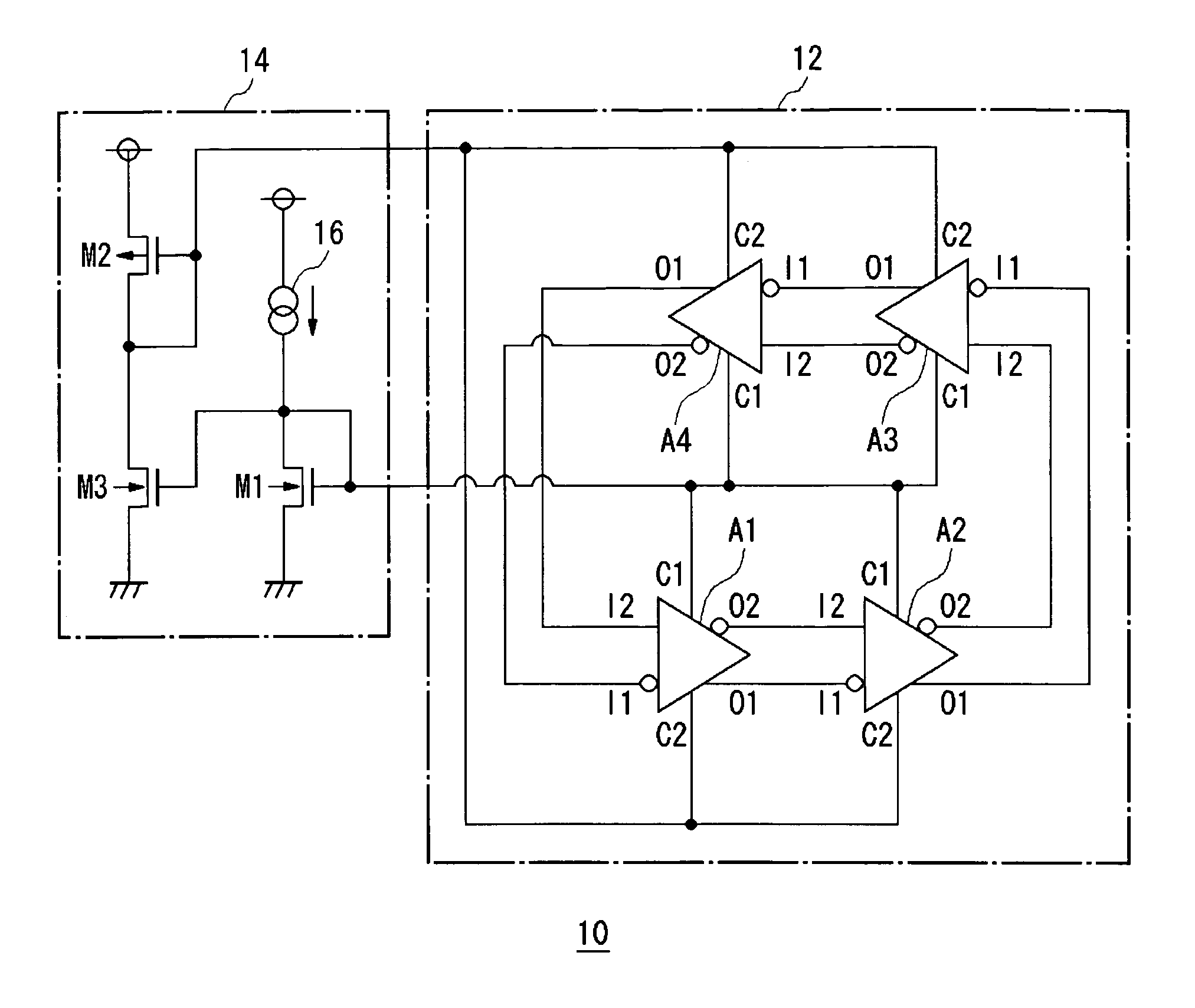

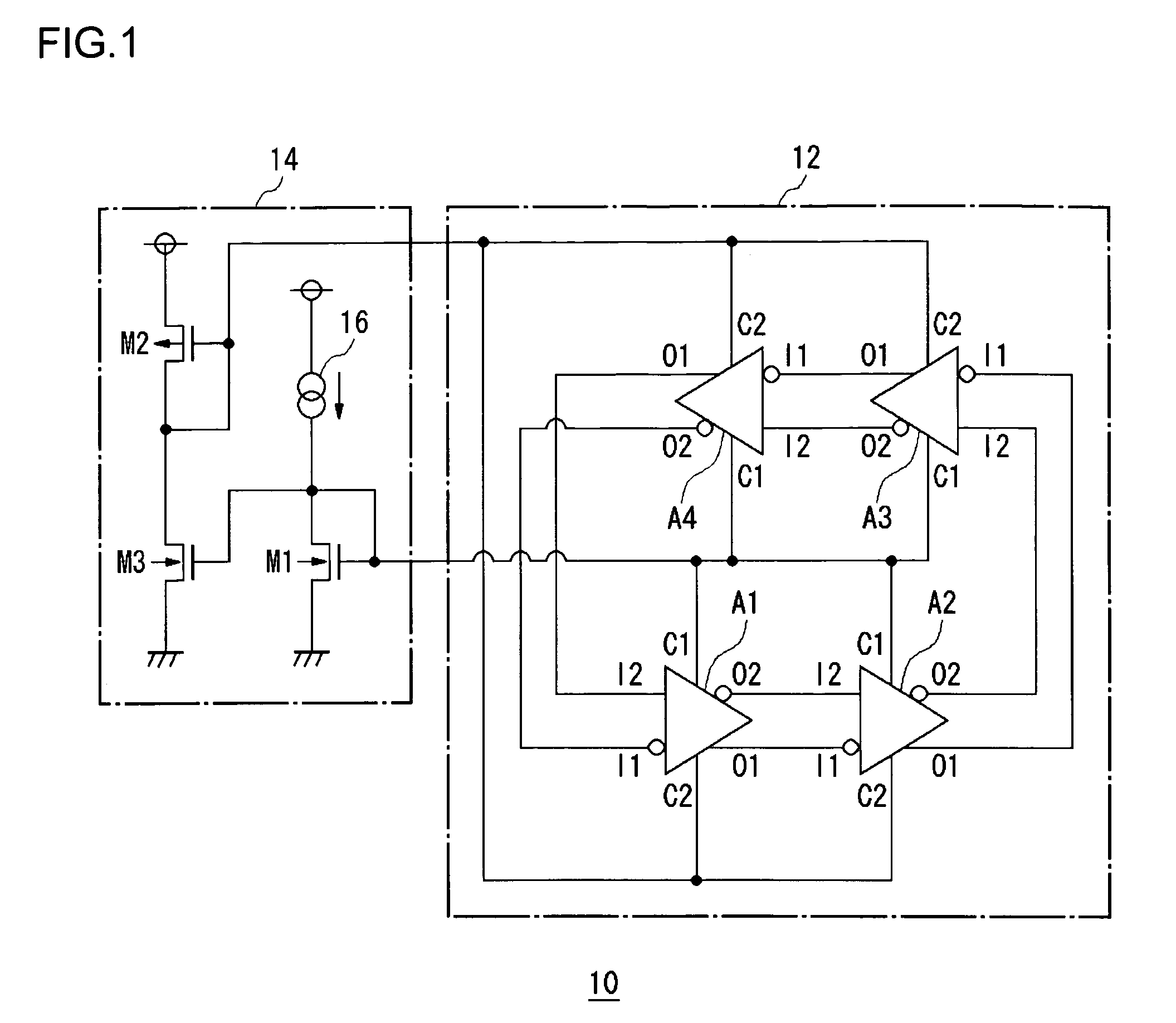

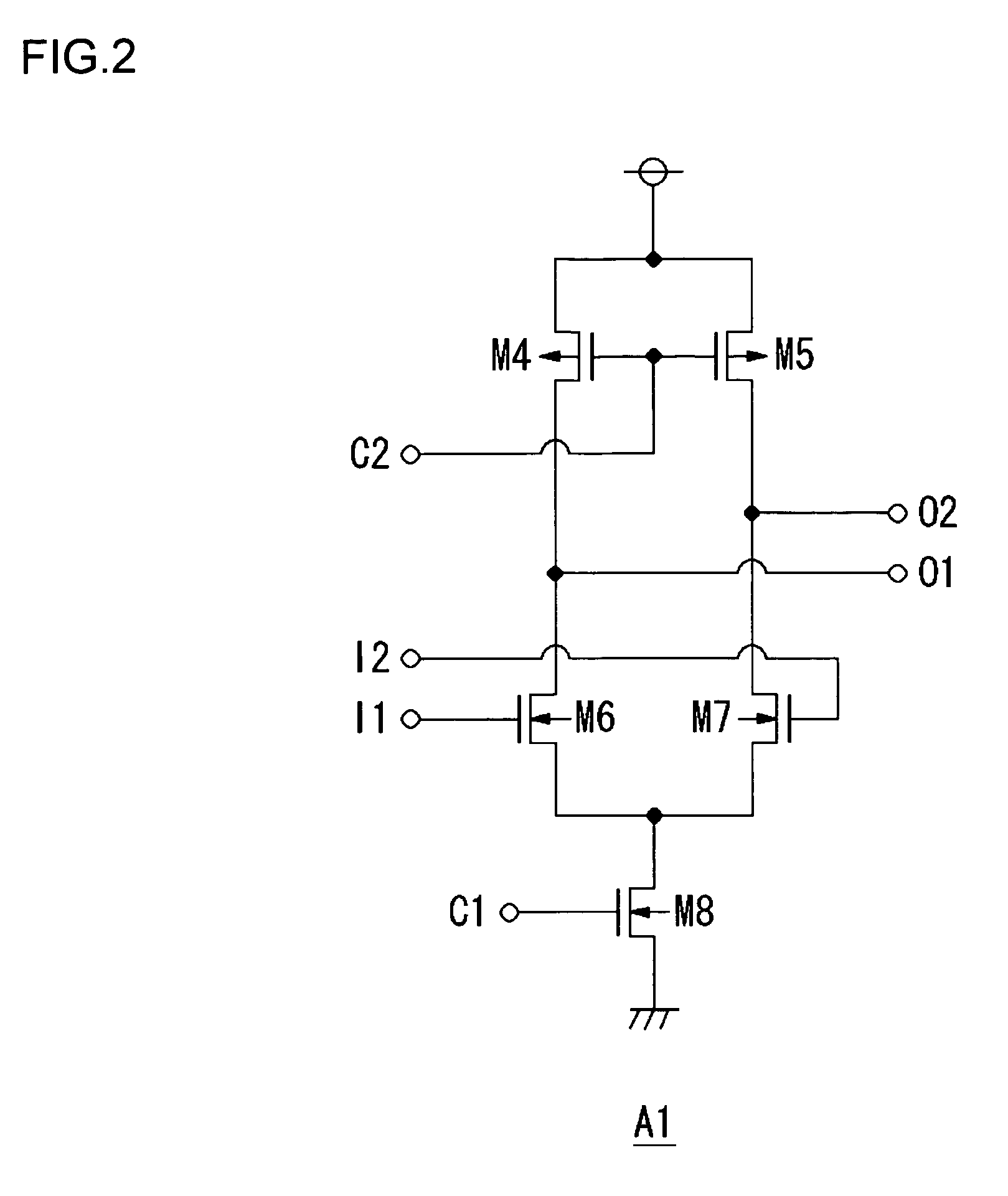

Ring oscillator circuit

InactiveUS7078978B2Reduce distortionSuppress mutationPulse generation by logic circuitsPropagation delayEngineering

A turn-round is provided in the middle of a plurality of differential amplifiers A1–A4. A first-stage differential amplifier A1 is provided in close proximity to a final-stage differential amplifier A4 so that distances between adjacent differential amplifiers are substantially equal to each other. With this, signal lines between the differential amplifiers are uniform in length and propagation delays are uniform. As a result, a high single-frequency oscillation signal is output.

Owner:ROHM CO LTD

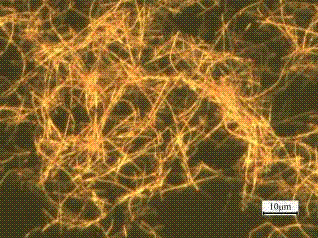

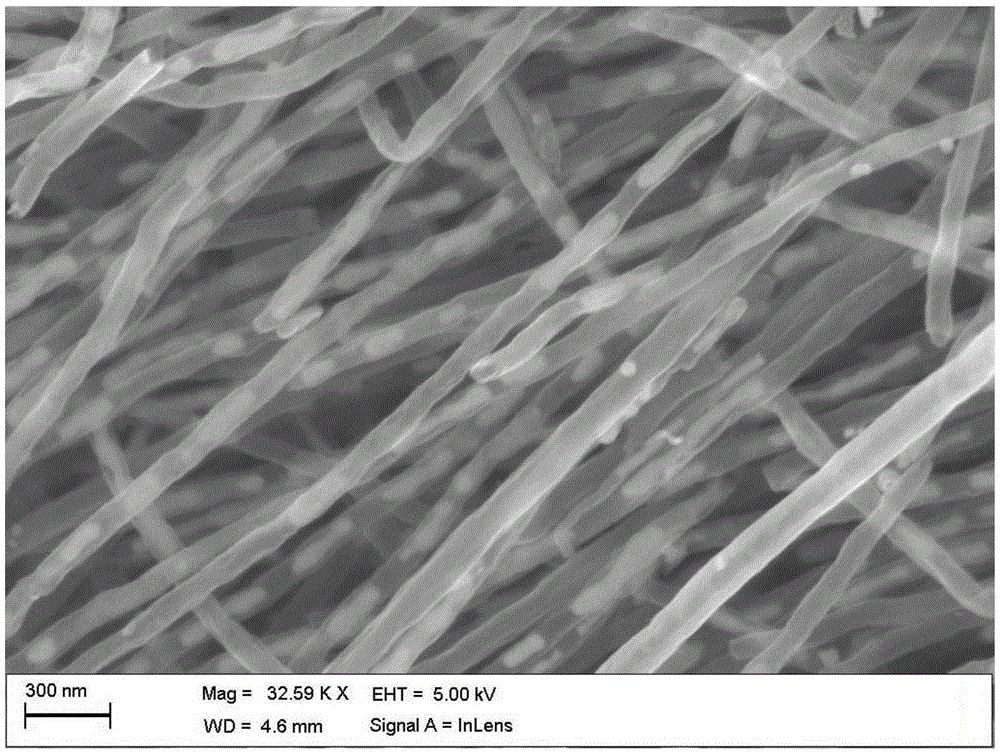

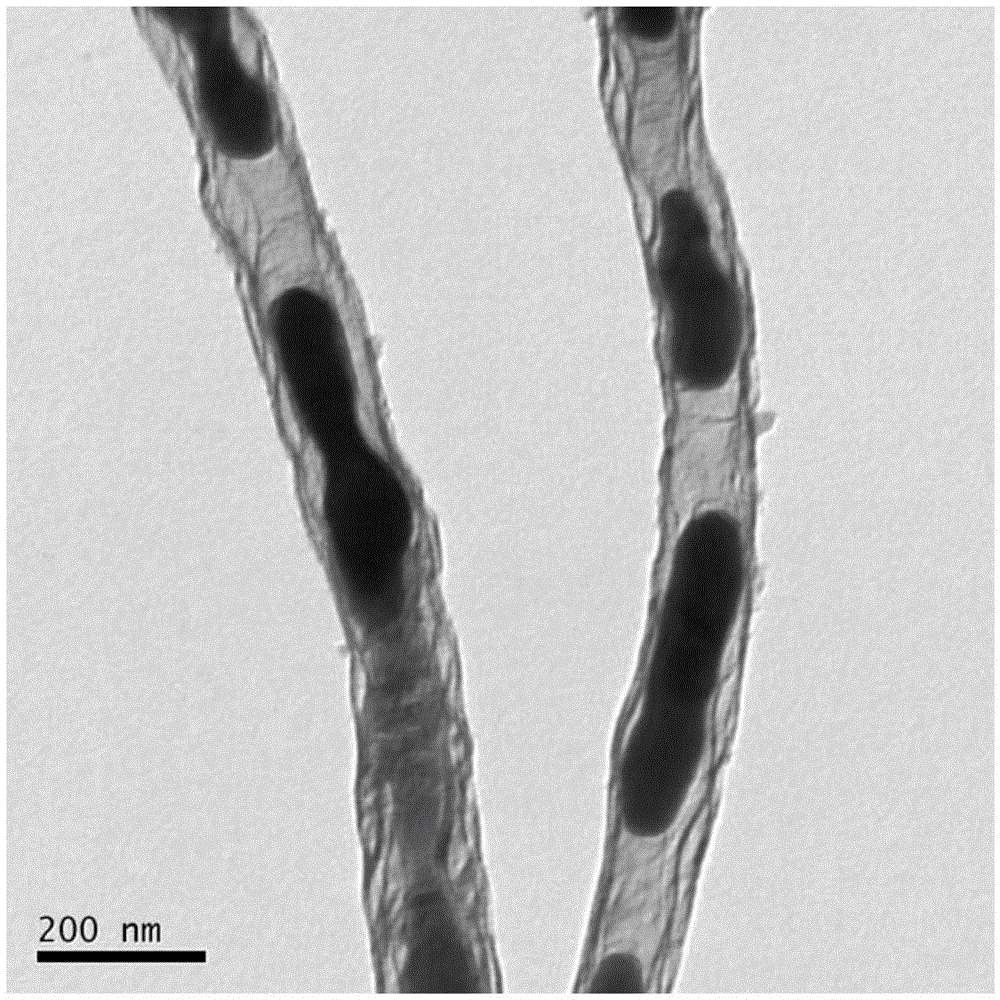

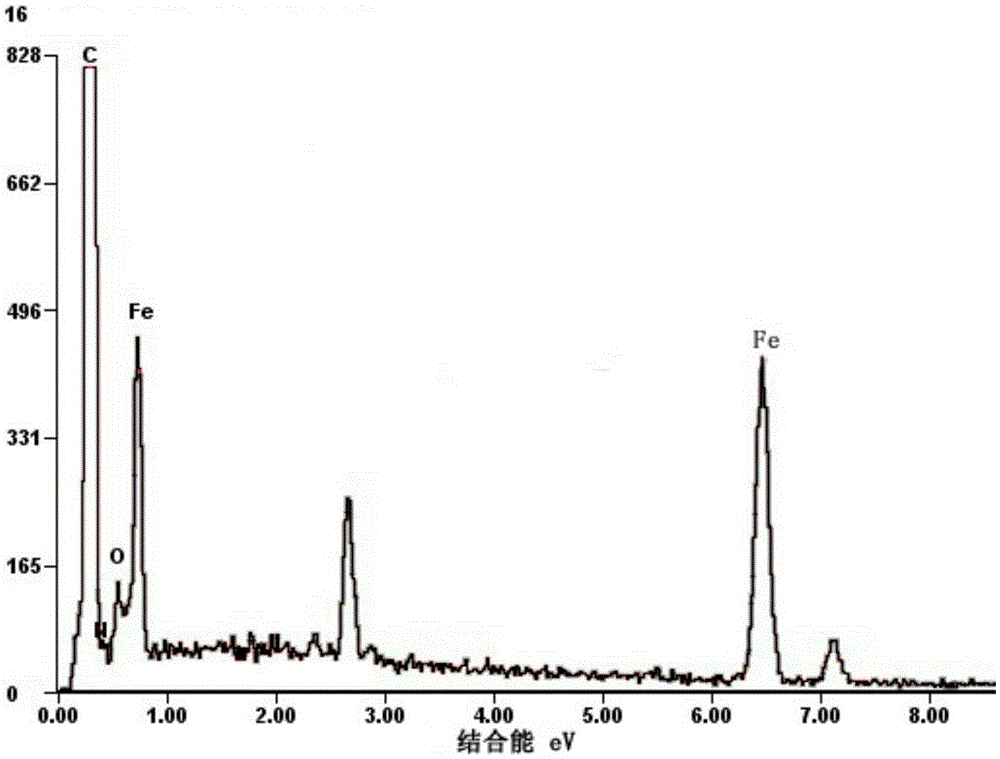

Method for in-situ preparation of iron carbide filled doped carbon nanotube

InactiveCN105271229AHigh iron filling rateIncrease productionMaterial nanotechnologySimple Organic CompoundsTube furnace

The invention discloses a method for in-situ preparation of an iron carbide filled doped carbon nanotub. The method includes: mixing an iron salt, a cyanamide nitrogenous organic compound precursor and a doping precursor evenly, then conducting high temperature pyrolysis in a tube furnace, and carrying out pickling to remove impurities, thus obtaining the iron carbide filled doped carbon nanotub. Compared with the traditional method, the method provided by the invention uses cheap precursor, reaches high utilization ratio, lower equipment requirement, improves the safety of the preparation process, and can be used for large-scale preparation, The prepared iron carbide filled doped carbon nanotub has uniform size, iron carbide is filled evenly, the filling content is high, and the product yield is high.

Owner:SOUTH CHINA UNIV OF TECH

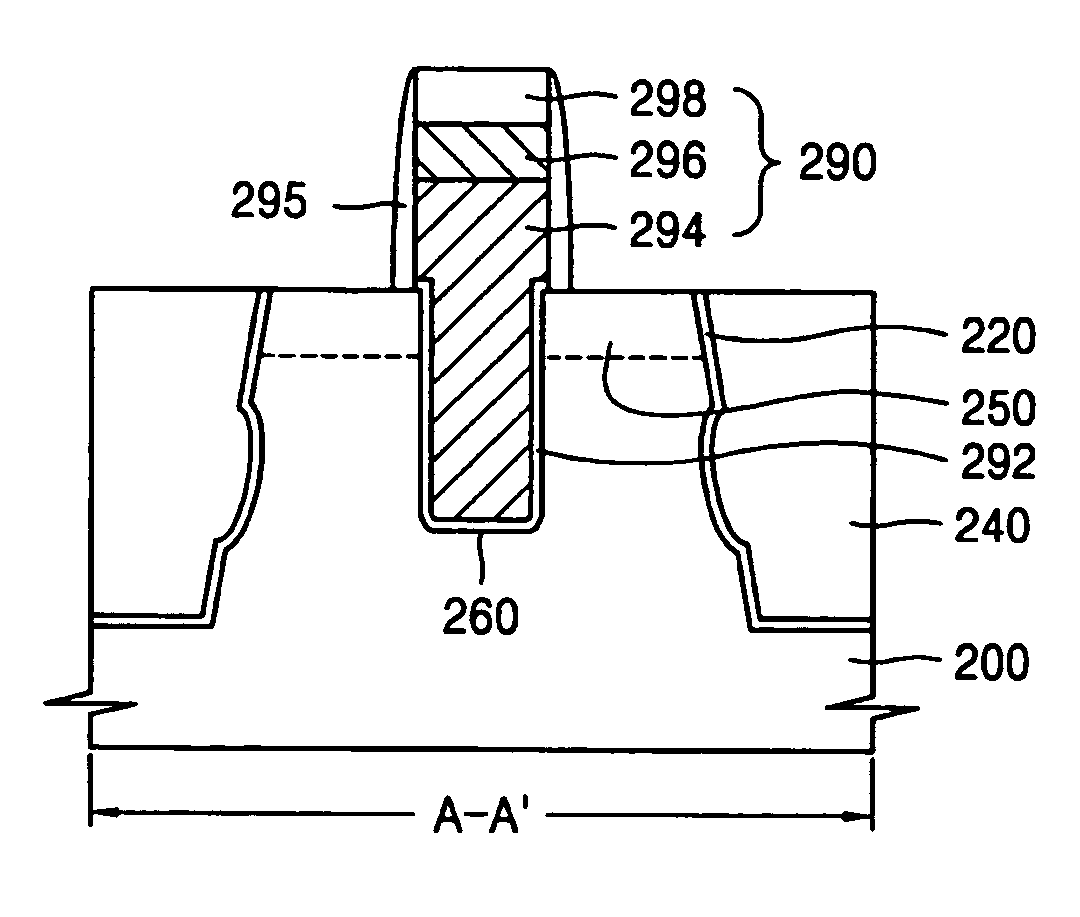

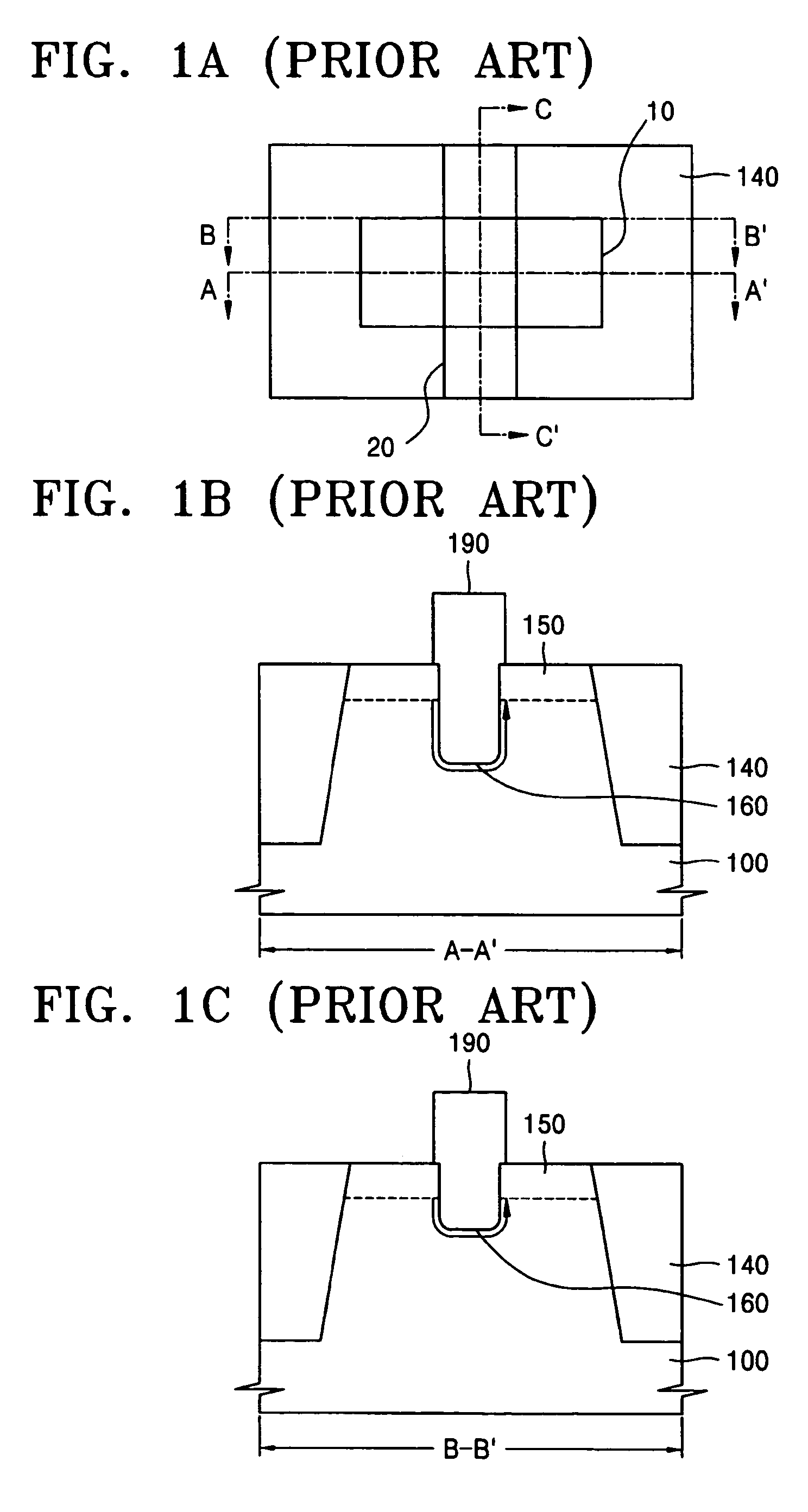

Fin FET and method of fabricating same

ActiveUS20070176245A1Improving swing characteristicReducing electric fieldTransistorSolid-state devicesInsulation layerSilicon

A fin field effect transistor (fin FET) is formed using a bulk silicon substrate and sufficiently guarantees a top channel length formed under a gate, by forming a recess having a predetermined depth in a fin active region and then by forming the gate in an upper part of the recess. A device isolation film is formed to define a non-active region and a fin active region in a predetermined region of the substrate. In a portion of the device isolation film a first recess is formed, and in a portion of the fin active region a second recess having a depth shallower than the first recess is formed. A gate insulation layer is formed within the second recess, and a gate is formed in an upper part of the second recess. A source / drain region is formed in the fin active region of both sides of a gate electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

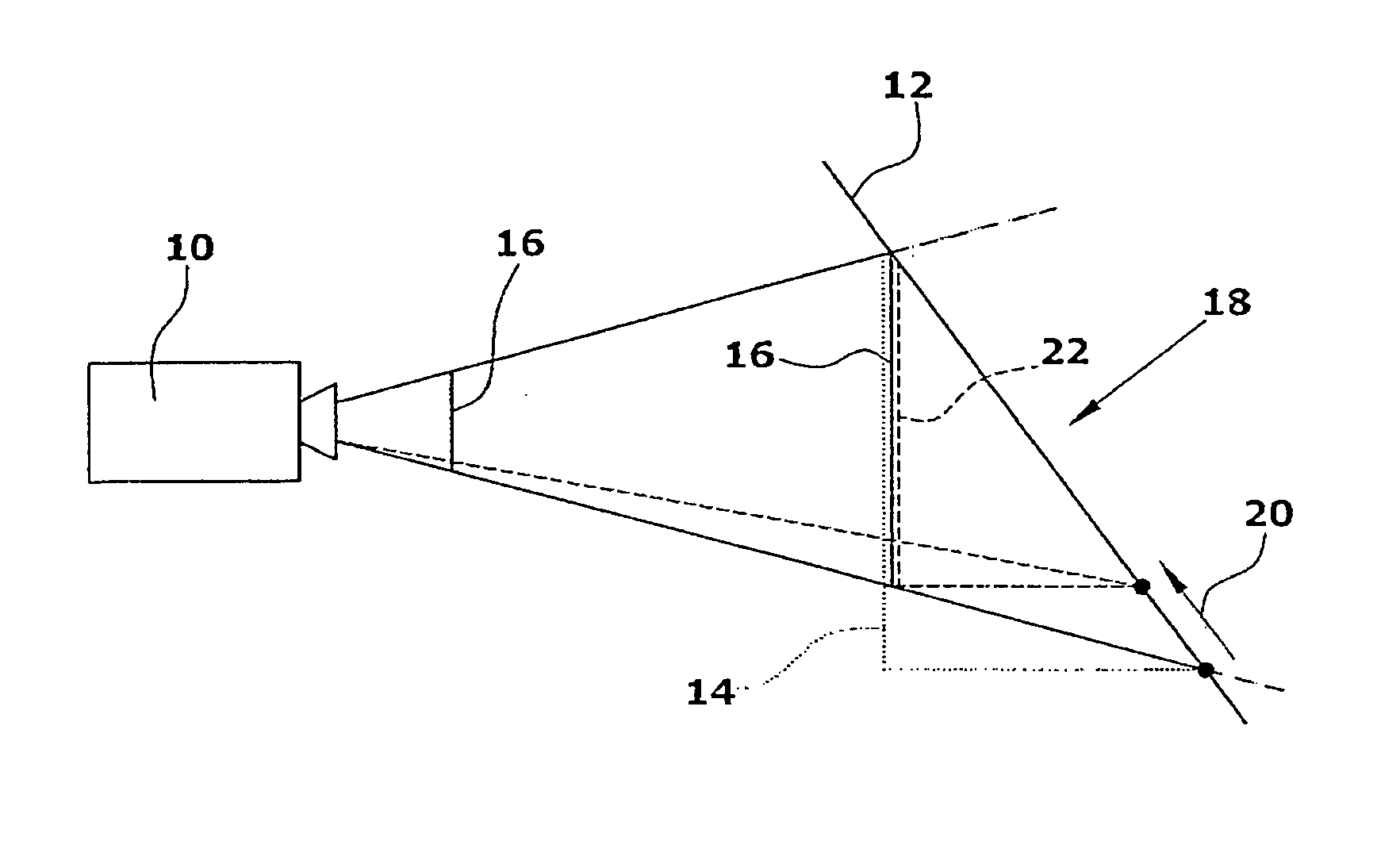

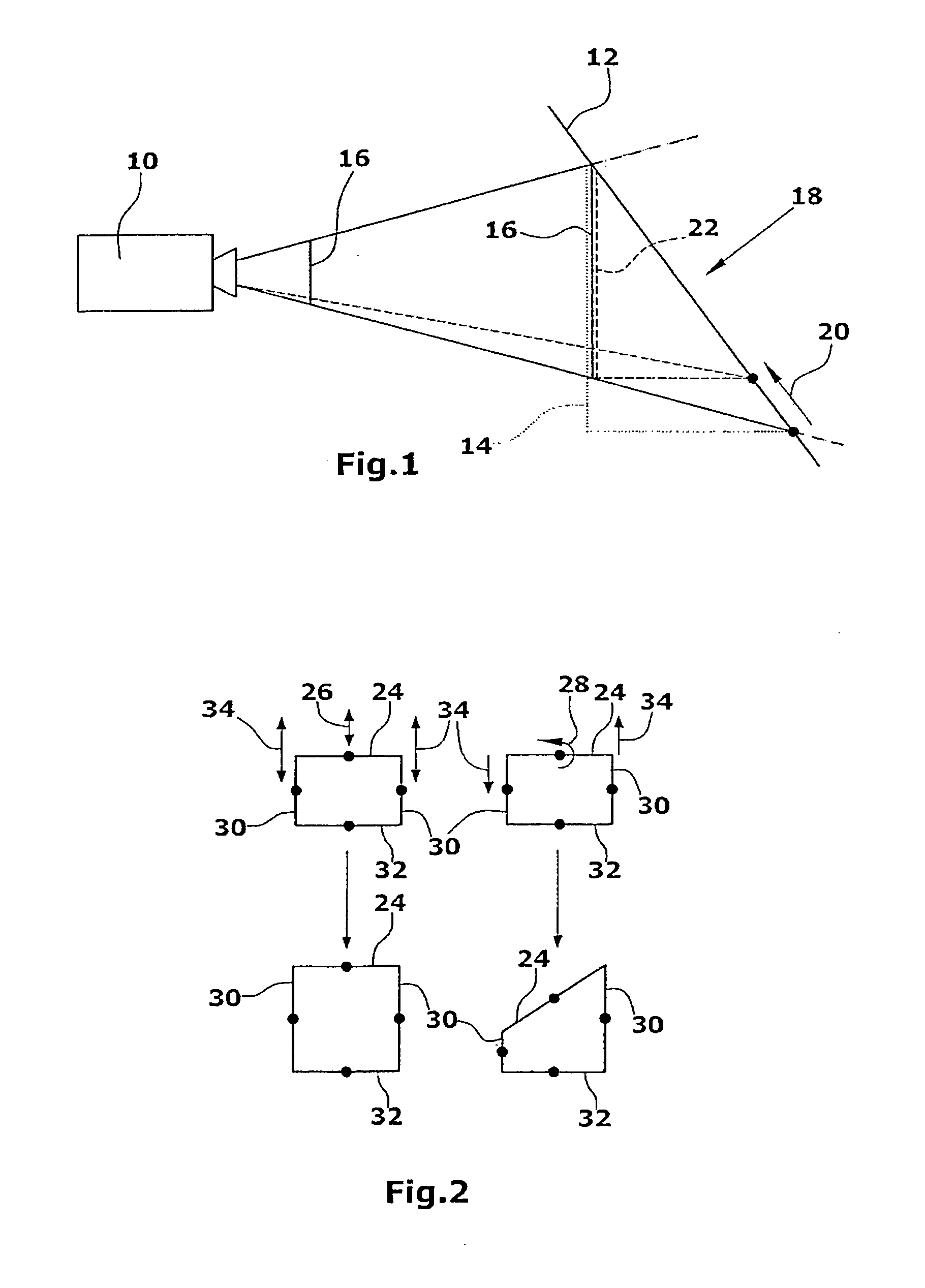

Image processing method and image processing device

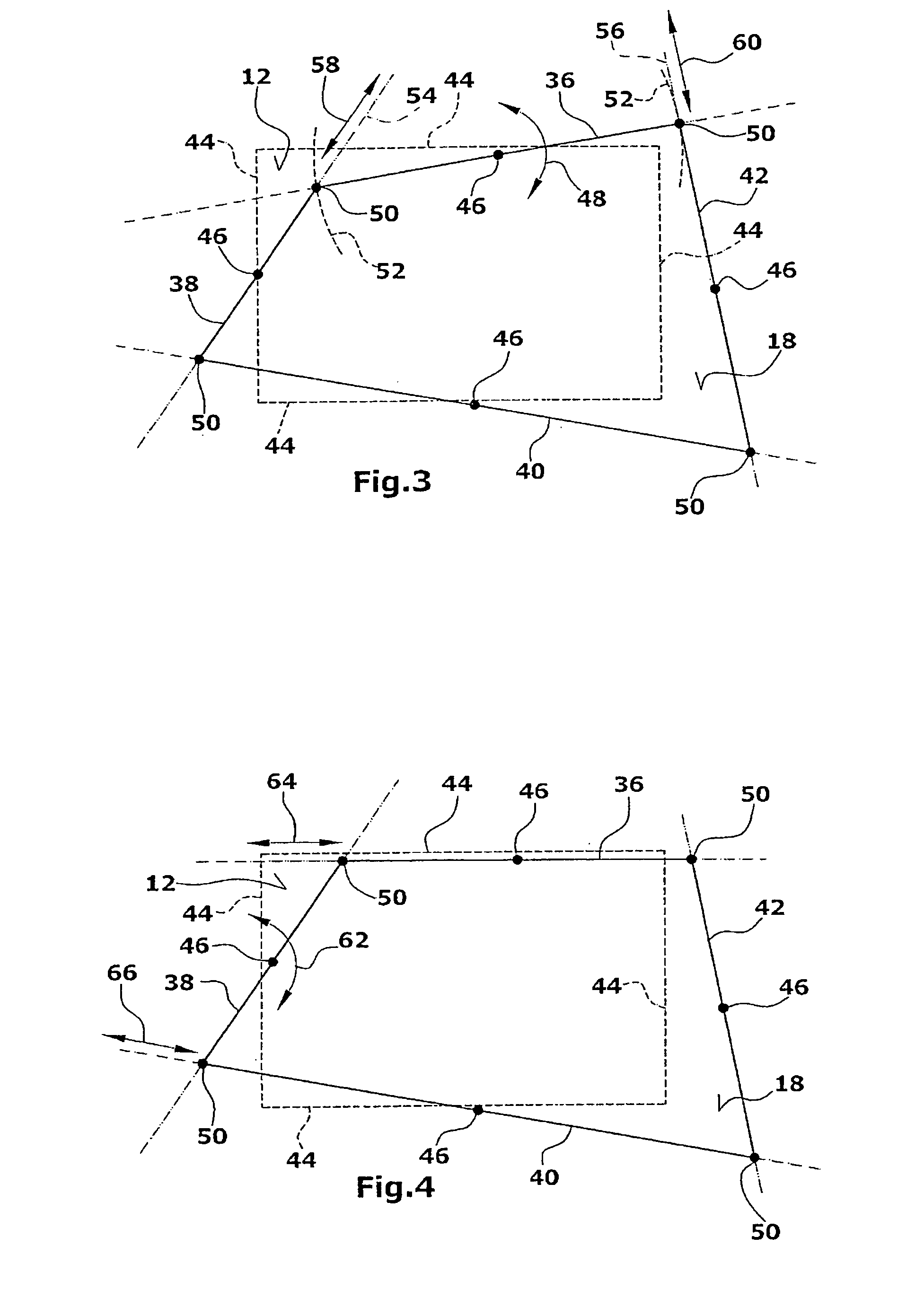

ActiveUS20060050243A1Simple and intuitive mannerLess timeProjectorsPicture reproducers using projection devicesImaging processingElectronic form

For keystone correction of the perspective distortion of an image (18) projected onto a projection surface (12), an image existing in electronic form is processed by a processing device to reverse the perspective distortion. For this purpose, the processing device, respectively rotates and shifts exactly one image line (36) at a time, respectively, while the orientation of the other image lines (40,42,46) is maintained fixed. In addition or alternately, the image lines (36,40,42,46) of the original electronic image comprise a plurality of partial sections of equal lengths which are differently stretched and / or compressed by the processing device. Subsequently, the image is newly computed under consideration of all of the image lines (36,40,42,46) and is projected onto a projection surface (12) by a projector.

Owner:CHRISTIE DIGITAL SYST USA INC

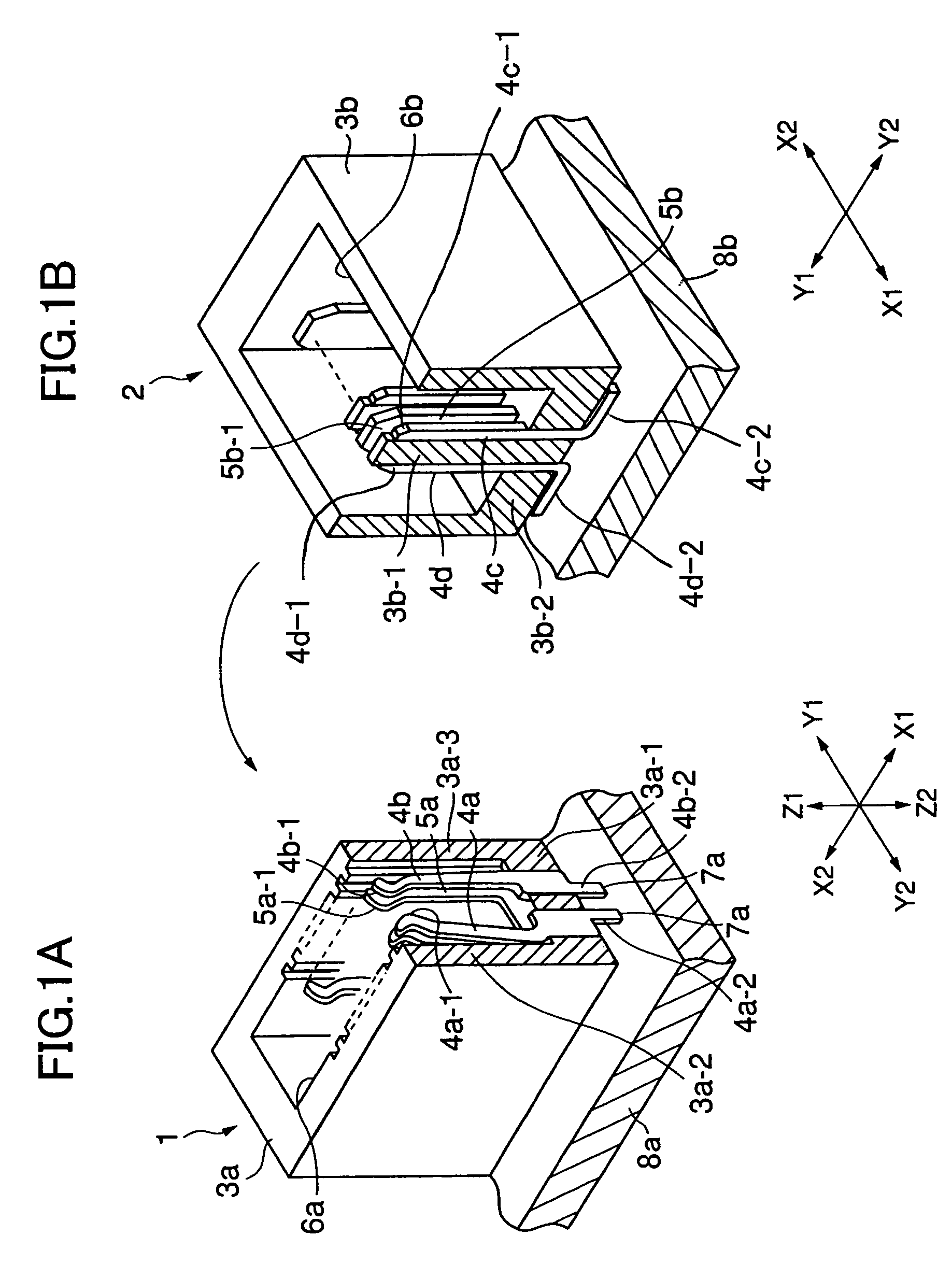

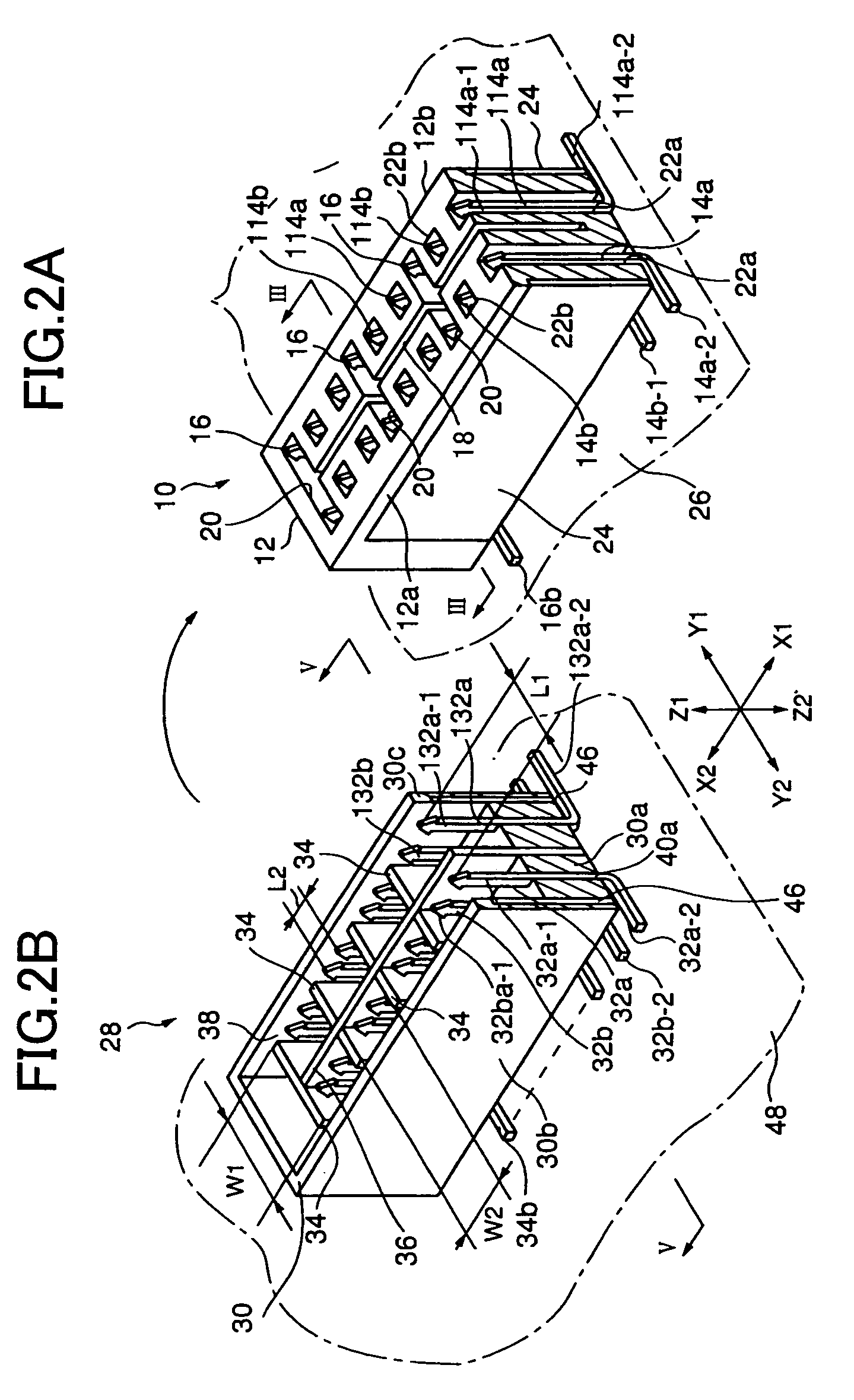

Connector

InactiveUS6981898B2Facilitates wiring design and wiring operationSimple designTwo-part coupling devicesPrinted circuitsEngineeringElectrical and Electronics engineering

A connector includes multiple pairs of signal contacts arranged in a housing, and facilitates the wiring design and the wiring operation for substrates. The two signal contacts in each of the multiple pairs are arranged at a distance in the longitudinal direction of the housing. With this arrangement, excellent coupling can be established between the two signal contacts, and signals can be balanced-transmitted without causing a phase difference. Also, the lengths of each pair of wires of a wiring substrate to be connected to the multiple pairs of signal contacts can be easily made uniform. Accordingly, there is no need to prepare excessive wiring areas, and the substrate wiring design and the wiring operation can be simplified.

Owner:FUJITSU COMPONENENT LTD

Method for using recrystallization method to prepare lead-halide perovskite nanowire

The invention discloses a method for using a recrystallization method to prepare a lead-halide perovskite nanowire. The method comprises the step of dropwise adding a poor solvent and a polar aprotic solvent in a spin coating process of preparation of APbI3 perovskite through a one-step method to prepare the lead-halide perovskite nanowire. The preparing method has the advantages that the operation is simple and convenient, and the reaction time can be saved. One-dimensional perovskite nanocrystalline film prepared through the one-step method is uniform in length and good in coverage degree, and can be used as a candidate material for an optical detector and a laser device. Compared with pure perovskite, the perovskite nanowire has a better optical conduction capability, and can be used in devices like an optical conductor and the laser device.

Owner:NANJING UNIV OF SCI & TECH

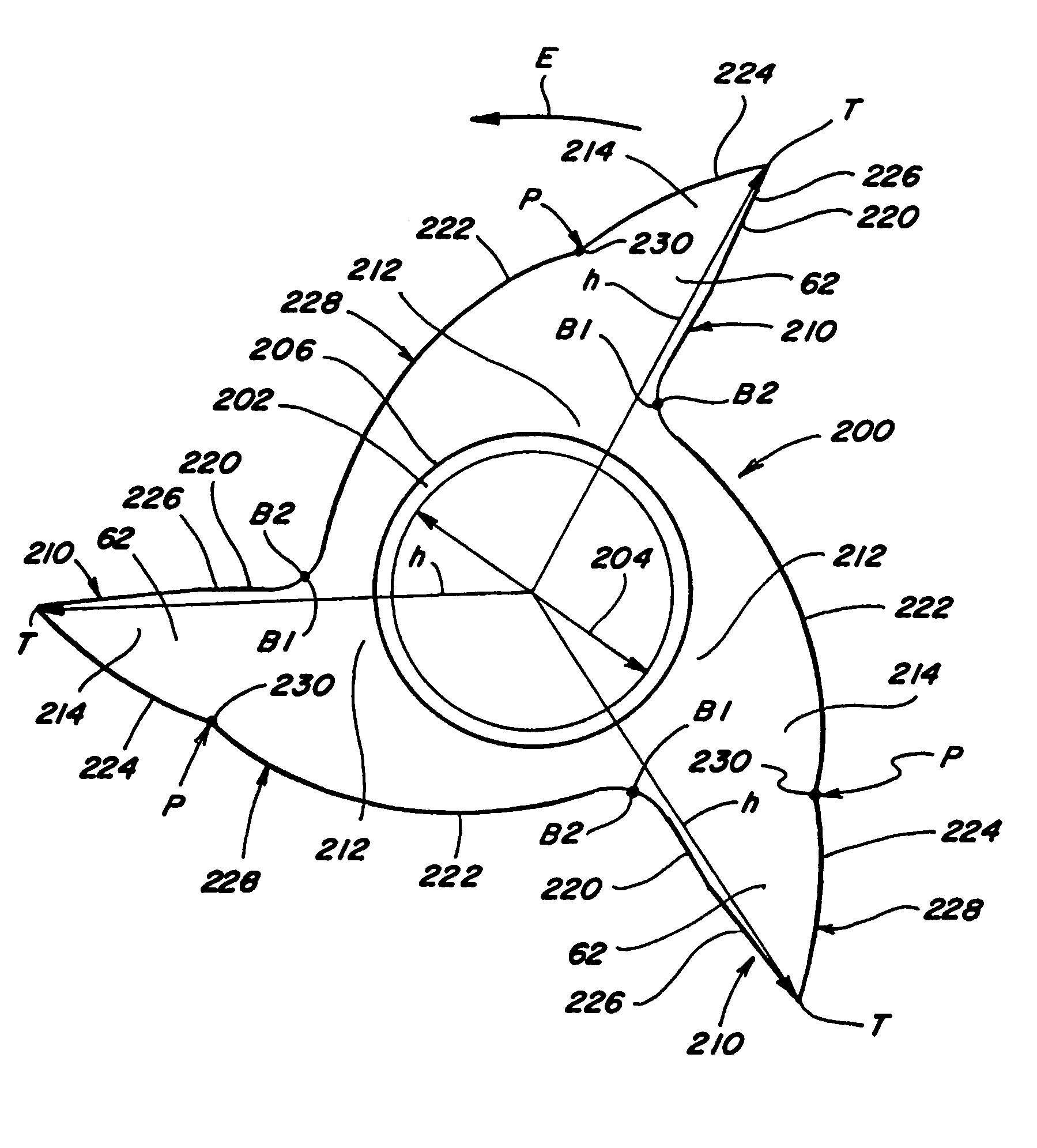

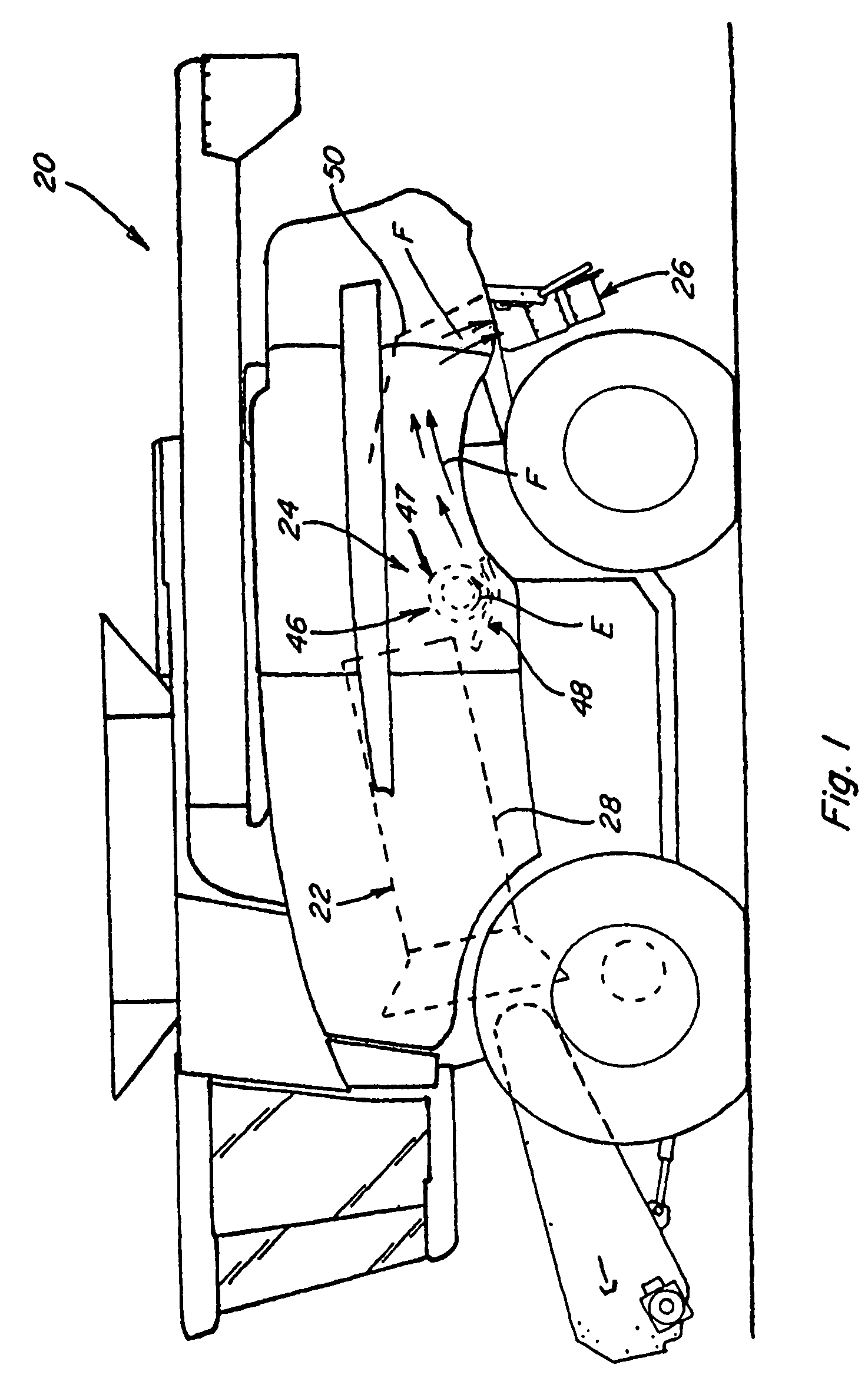

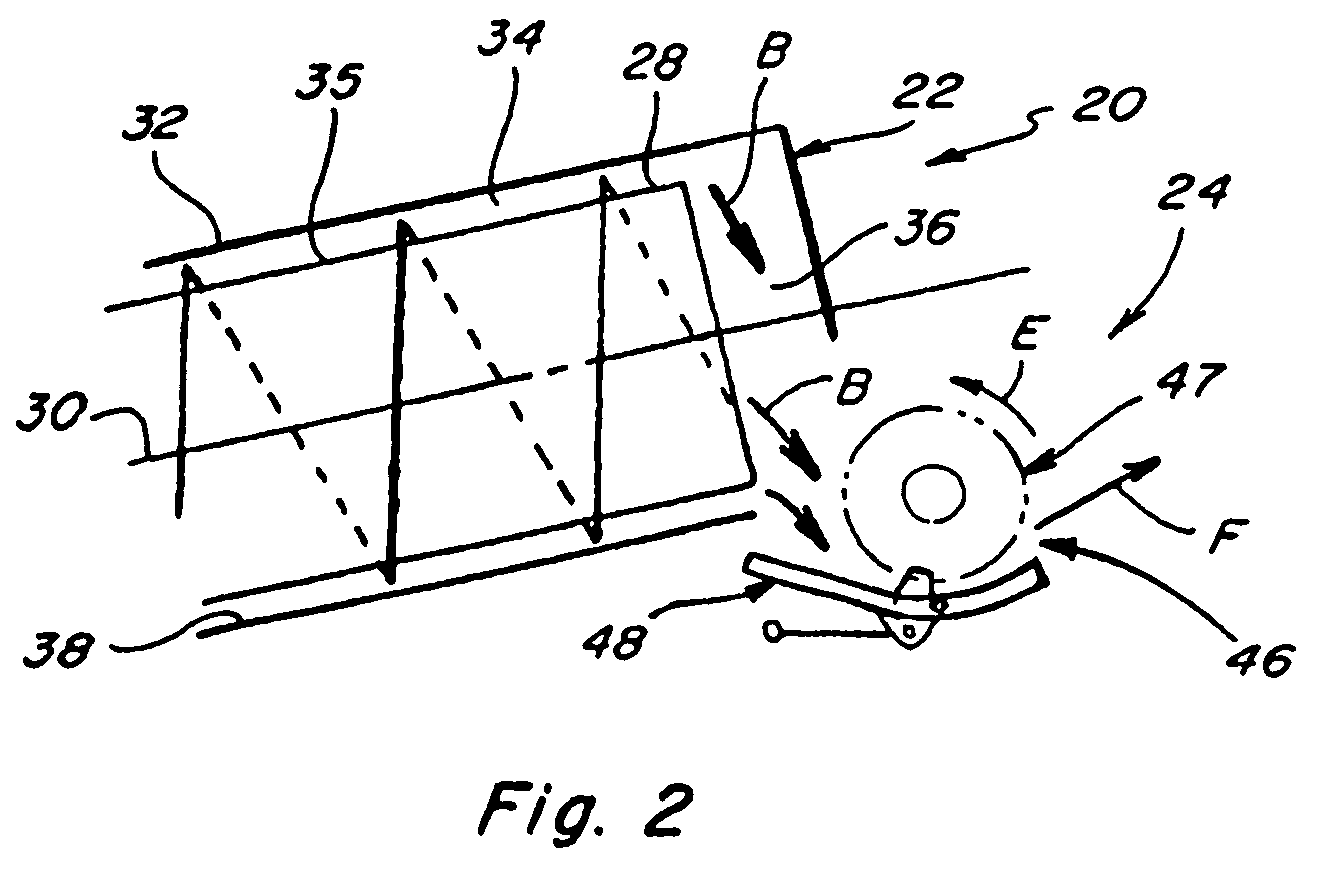

Rotor tine and rotary element configuration for crop residue treatment systems

A rotor tine construction for a rotary element of a crop residue treatment system for effecting improved transport of crop residue along a material flow path and, if a counter knife assembly is spaced from the rotary element across the material flow path, for also effecting improved shear cutting of such crop residue by the knife elements of the counter knife assembly and more efficient operation of the crop residue treatment system, which rotor tine construction includes a base portion generally mountable to the rotary member of the rotary element, at least one rotor tine extending outwardly from such base portion and including three distinct blade edges, one of which forms a trailing edge and the other two of which are upper and lower edge portions forming a leading edge, with the lower and upper edge portions configured and intersecting with one another to form a notch-like indentation along the leading edge at an intersection point P defined to be the point of cut contact position, such that, as the rotary member rotates forwardly the rotor tine is rotated through the material flow path to engage and concentrate engaged lengths of crop residue near intersection point P for an improved cut as such material is moved past the knife elements of the counter knife assembly.

Owner:BLUE LEAF I P INC

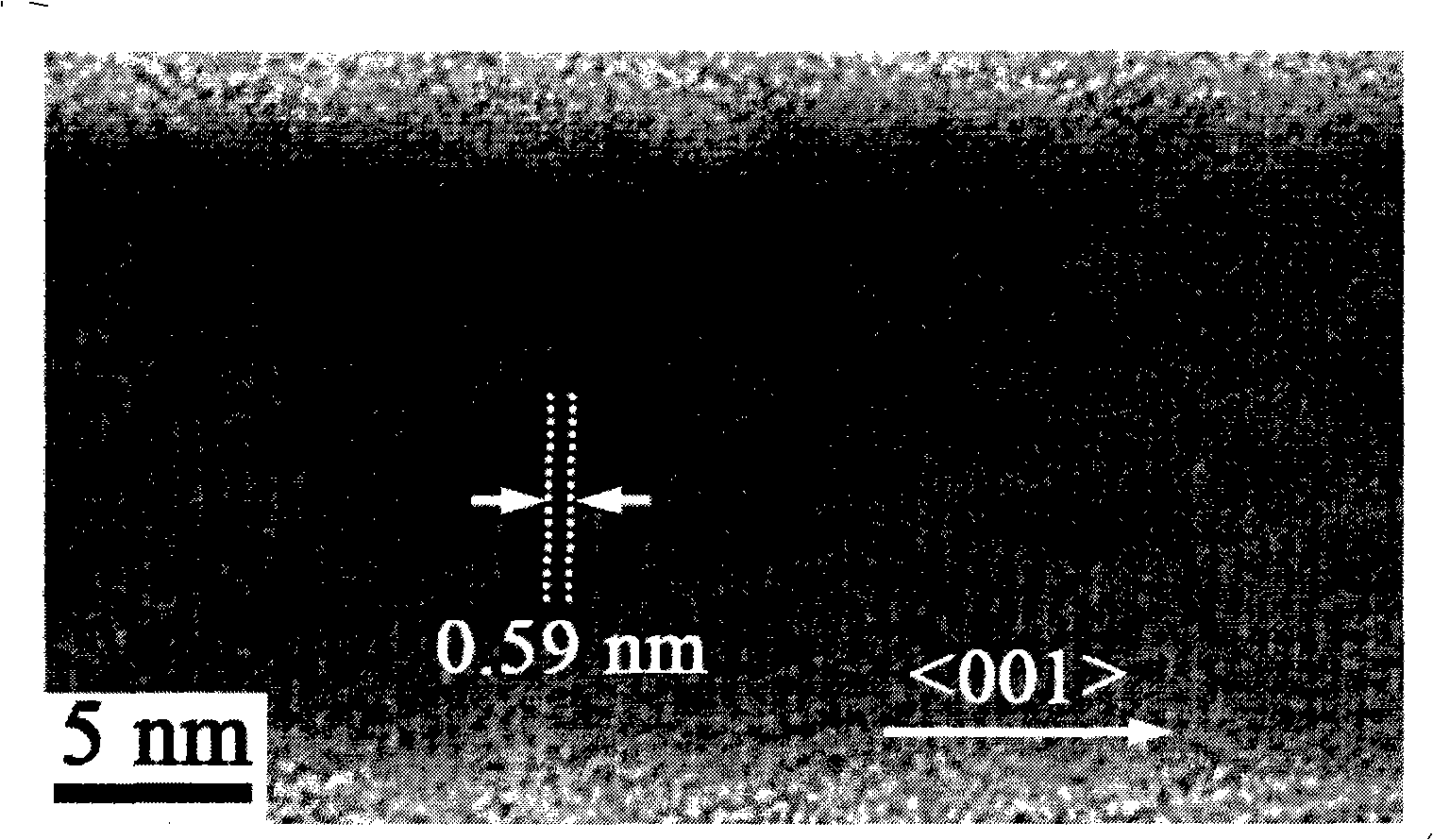

Te/Bi or Te/Bi2Te3 nucleocapsid heterojunction structure nanometer wire and method for preparing same

InactiveCN101311382AGood dispersionModerate diameterPolycrystalline material growthSingle crystal growth detailsThermoelectric materialsHeterojunction

The invention relates to a core-shell heterojunction structure nano-wire of Te / Bi or a Te / Bi2Te3 and a preparation method thereof. The nano-wire is characterized in that the preparation method applies liquid phase epitaxial method with glycol as solvent, PVP as an organic additive and a Te nano-wire as an in-situ template to synthesize the Te / Bi and the Te / Bi2Te3 core-shell heterojunction structure nano-wires; the nano-wire grows along the direction of and lt;001andgt;, and takes simple substance Te single crystal nano-wire with a hexagonal structure as core material, and has single crystal coating material formed by the extension of simple substance Bi with a hexagonal structure and alloy Bi2Te3; the extension relation between the simple substance and the alloy is as follows: Te(100) crystal plane is parallel to Bi(100) crystal plane or Bi2Te3 (100) crystal plane, and Te and lt;001 and gt; direction axis is parallel to Bi and lt;001and gt; direction axis or Bi2Te3 and lt;001and gt; direction axis. The heterojunction structure nano-wire of the invention can improve the thermoelectric properties of materials and quicken the application of thermoelectric materials.

Owner:UNIV OF SCI & TECH OF CHINA

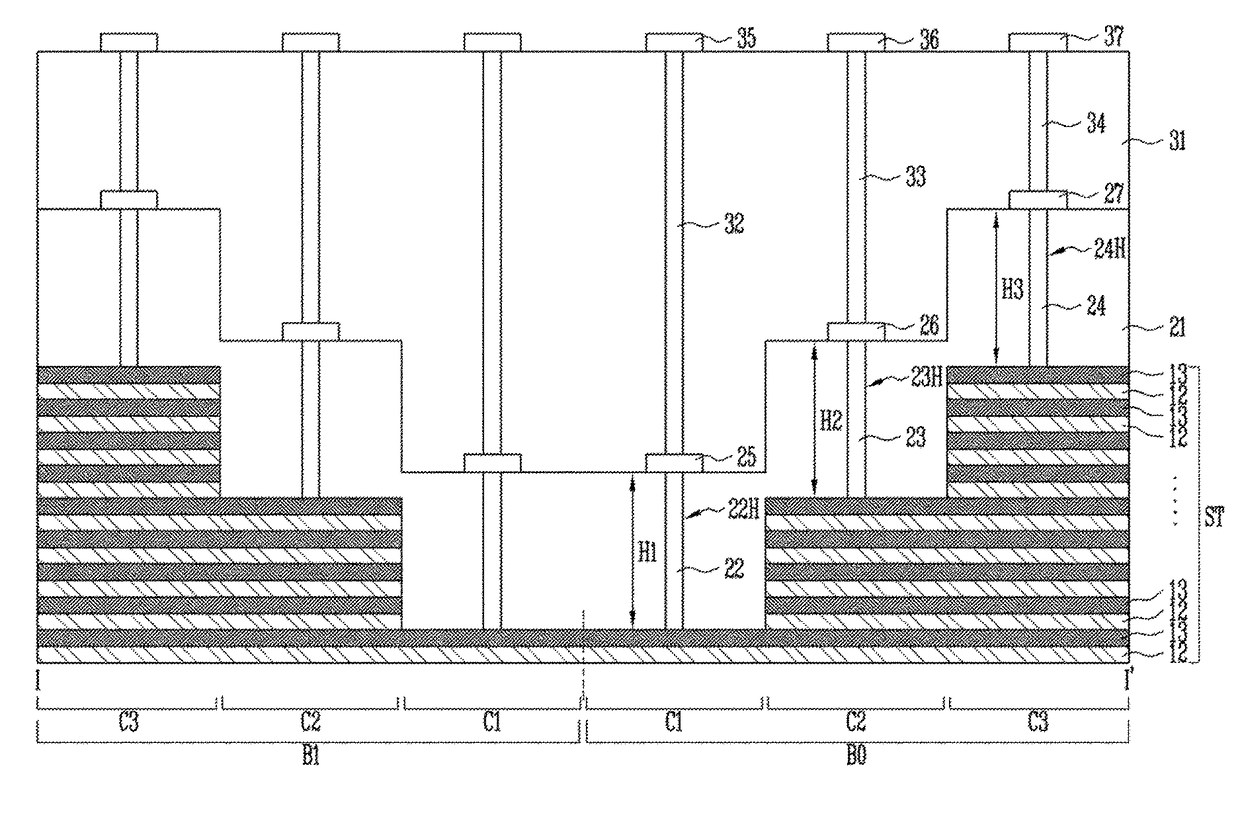

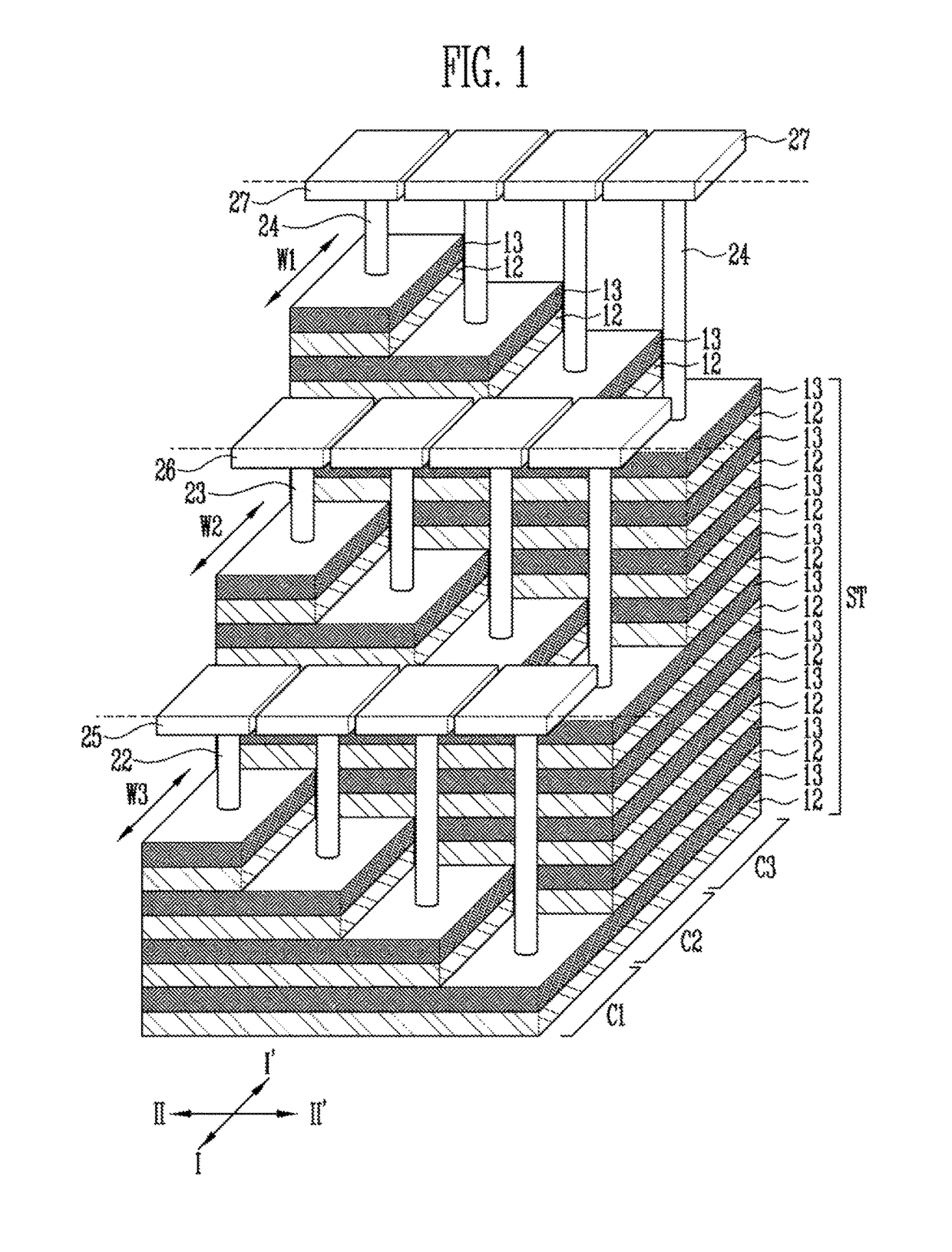

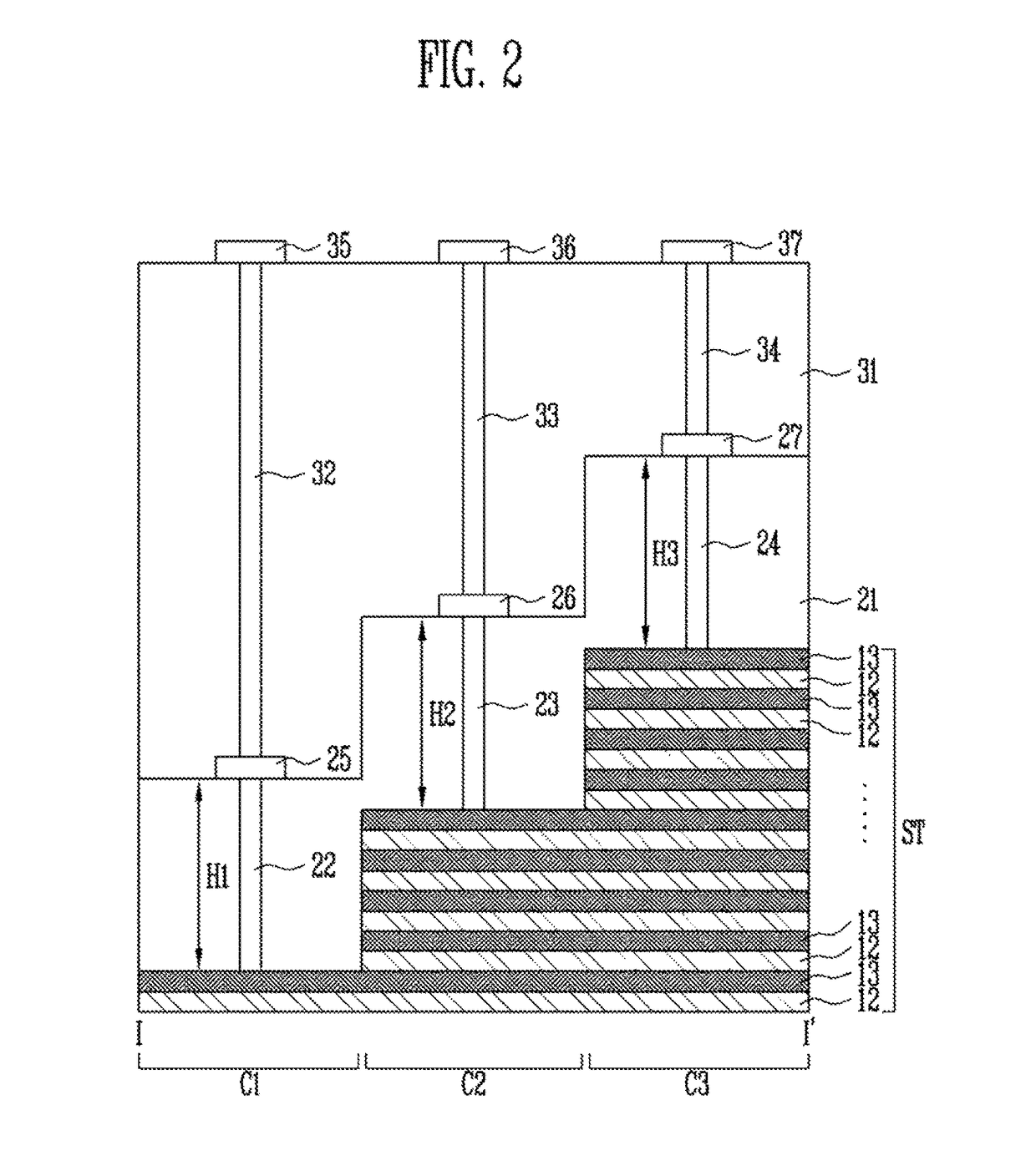

Semiconductor device and manufacturing method thereof

ActiveUS9633944B2Reduce generationUniform lengthSemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A semiconductor device and a manufacturing method thereof are provided. A semiconductor device includes a stack structure including conductive layers stacked in a step shape, a first interlayer insulating layer formed over the stack structure, the first interlayer insulating layer including contact holes with a uniform depth, which expose the conductive layers, lower contact plugs formed in the contact holes, the lower contact plugs being respectively contacted with the conductive layers, and lower contact pads respectively connected to the contact plugs.

Owner:SK HYNIX INC

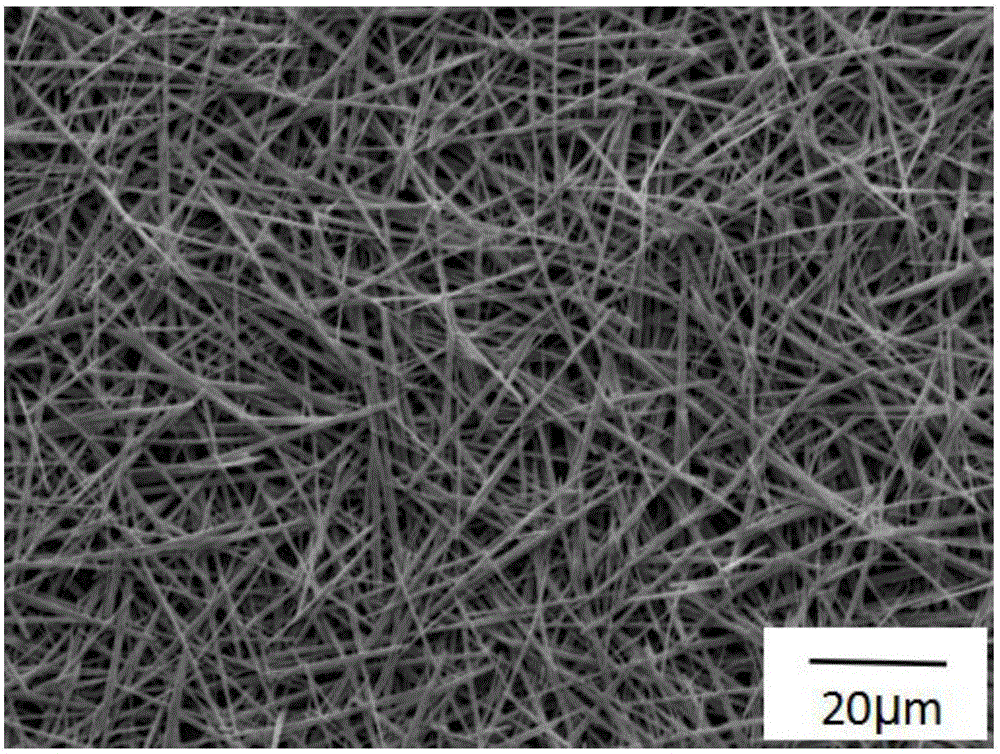

Method of comprehensive utilization of industrial waste acid and ardealite

ActiveCN102383179AImprove economic benefitsUniform lengthPolycrystalline material growthFrom normal temperature solutionsChemistryIndustrial waste

The invention provides a method for preparing calcium sulfate crystal whisker with industrial waste acid and ardealite, which comprises the following steps: mixing ardealite and industrial waste acid, adjusting pH of the solution with ammonia water, and then stirring; immediately filtering the solution, cooling the filtrate, all crystal being separated out, and performing conventional stabilizing process on the surface of the crystal; and then drying, and obtaining calcium sulfate crystal whisker. The diameter of the obtained calcium sulfate crystal whisker is 1-4mum, the length is 50-200mum, the moh's hardness is 3-4, the tensile strength is 20.5Gpa, the elastic modulus is 178GPa, and the refractive index is 1.585. With the invention, industrial waste acid and solid waste ardealite can be utilized, the waste product of the two kinds of industries can be utilized, so the goal of treatment of wastes with processes of wastes against one another can be achieved; exploitation of natural gypsum can be reduced, resource can be saved, and meanwhile the production cost of calcium sulfate crystal whisker can be reduced; and the limit on the ingredients of the raw material ardealite and industrial waste acid is not strict, the application range is wide, the condition is wide, and the process is simpler.

Owner:KUNMING UNIV OF SCI & TECH

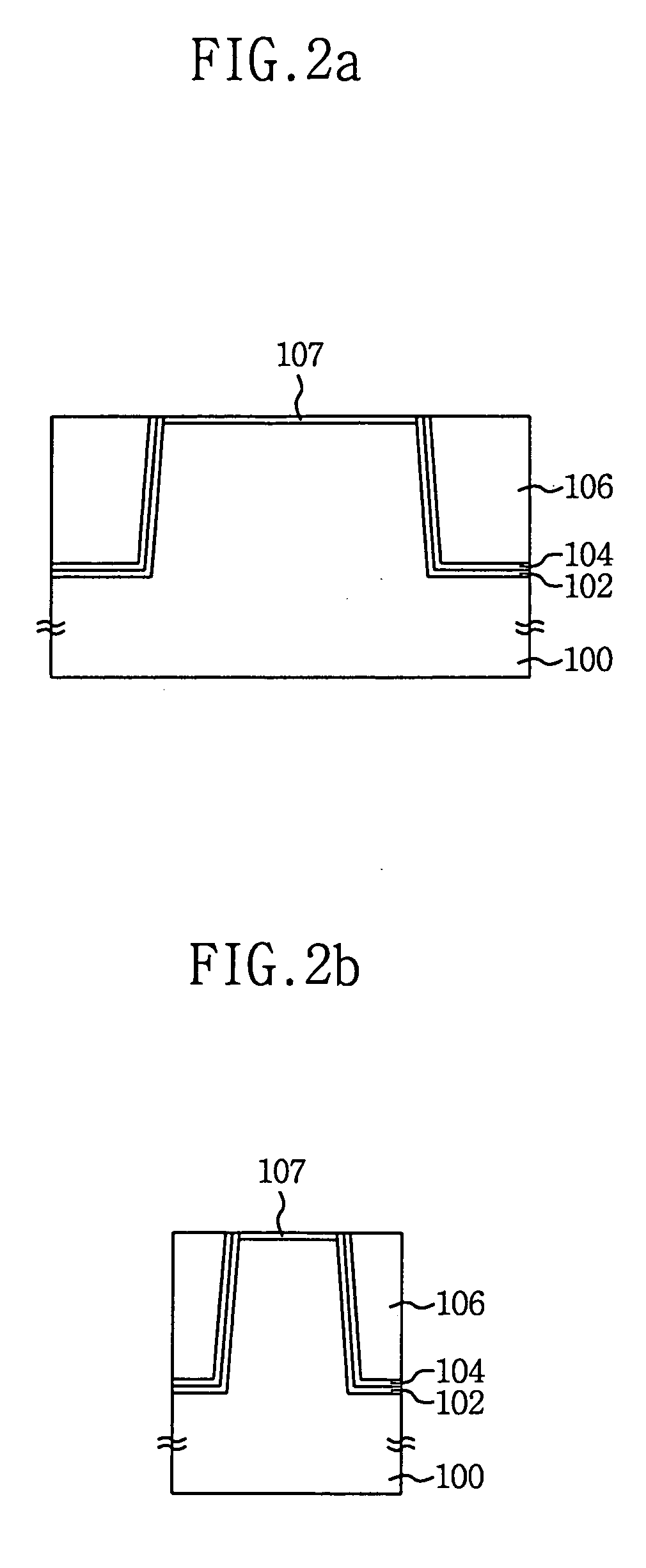

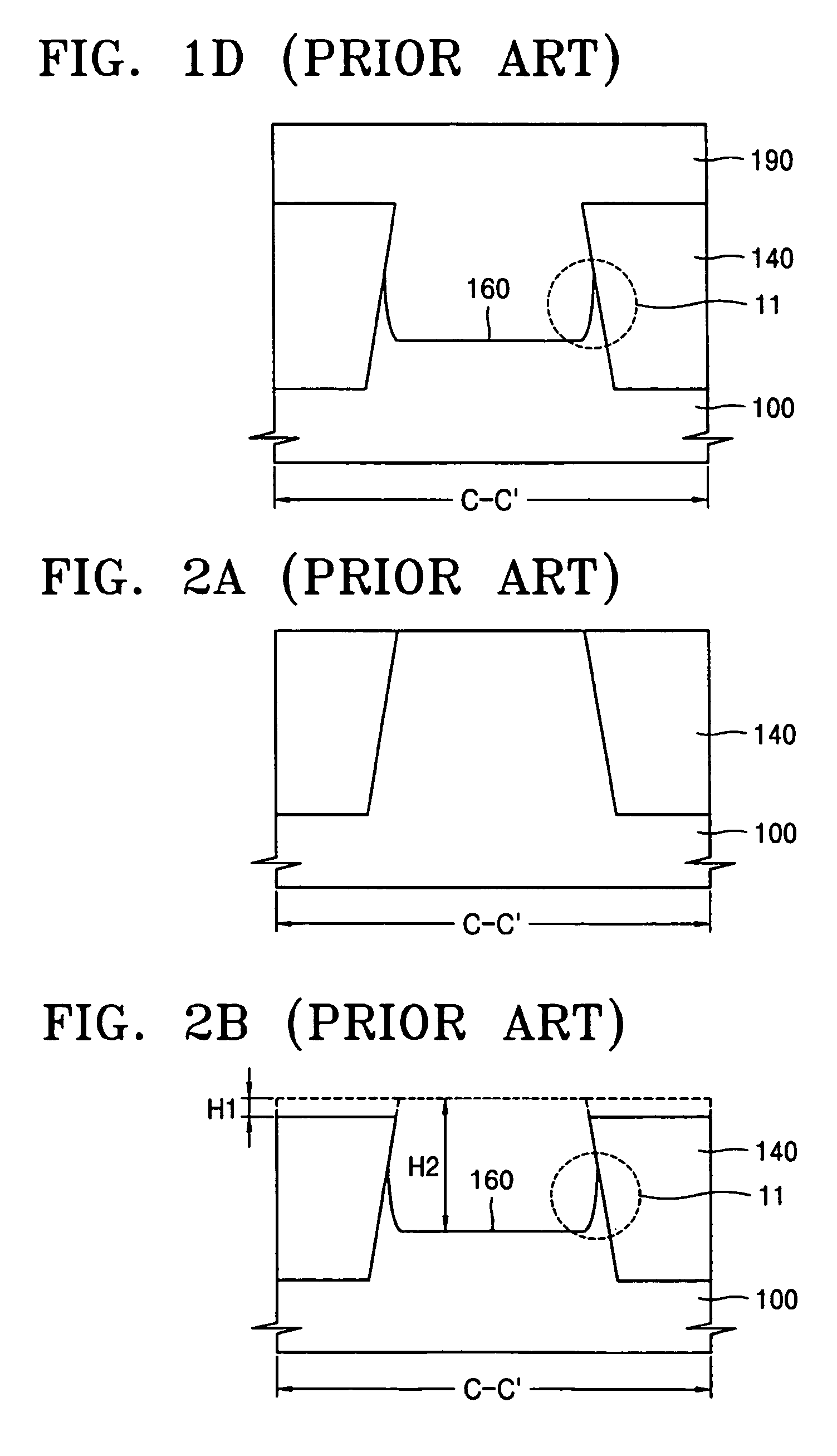

Shallow trench isolation and method of forming the same

InactiveUS7160789B2Improve featuresUniform lengthSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorTransistor

A shallow trench isolation (STI) structure and a method of forming the STI structure. The STI structure defines an active region formed with a recess channel transistor. The STI structure includes a STI trench has a laterally curved rounding portion on the bottom of the recess channel trench. In order to form the STI trench with the rounding portion, a semiconductor substrate is selectively and anisotropically dry etched to form the trench. Then, the semiconductor substrate is isotropically etched around the bottom height of the recess channel trench to form the rounding portion, and then further anisotropically dry etched, thereby forming the STI trench. After an insulating layer that fill the STI trench is formed on the resultant structure, an upper surface of the resultant structure is planarized to expose a surface of the semiconductor substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Cotton and spun silk segment-color yarn and production method thereof

The invention relates to a type of cotton and spun silk segment-color yarn and a production method thereof. The cotton and spun silk segment-color yarn comprises colored decorative yarn and white base yarn, wherein the colored decorative yarn is spun silk yarn, and the white base yarn is pure cotton yarn. The process comprises the following steps that scouring, opening and carding are carried out on spun silk raw materials, then, combing is carried out, four drawing is carried out so that spun silk drawn slivers can be made, the spun silk drawn slivers are cut into spun silk fibers with a fiber cutting-off machine, the average length of the spun silk fibers ranges from 28 mm to 35 mm, dyeing is carried out, and colored spun silk roving is made through roving; cotton fibers is processed through opening picking, carding, combing, drawing and roving to form white cotton roving; in the working procedure of spun yarn, the spun silk serves as the colored decorative yarn, cotton serves as base yarn, and spinning is carried out to form the cotton and spun silk segment-color yarn. By the adoption of the process, resource allocation is fully utilized, the cotton fibers serve as the main body of the yarn, the expensive spun silk is used for forming colored segments, the production of the high value-added cotton and spun silk segment-color yarn is achieved, and the product profit is increased.

Owner:安徽寿县银丰棉业有限责任公司

Fishhook forming machine

The invention provides a fishhook forming machine. The fishhook forming machine comprises a transmission mechanism, a feeding mechanism, a tail forming mechanism, a barb cutting mechanism, a hooking mechanism and a separation mechanism. The fishhook forming machine is characterized in that a length determination mechanism used for determining the length of a fishhook forming base stock and cutting off the unnecessary portion is additionally arranged between the feeding mechanism and the tail forming mechanism; the separation mechanism comprises an air gun matched with the hooking mechanism, and after a fishhook is formed at the hooking mechanism, the air gun jets air to enable the formed fishhook to be separated from the hooking mechanism under the action of air flow. Automatic cutting according to the required material length determined according to the specification of to-be-produced fishhooks can be realized by the length determination mechanism after feeding, and accordingly production efficiency is improved, uniformity in material length is guaranteed, and uniformity of the formed fishhooks is guaranteed as well. In addition, since the formed fishhooks are separated from the hooking mechanism under the action of air flow, damages of the formed fishhooks are avoided.

Owner:郭永青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com