Patents

Literature

114results about How to "Reduce the potential for damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

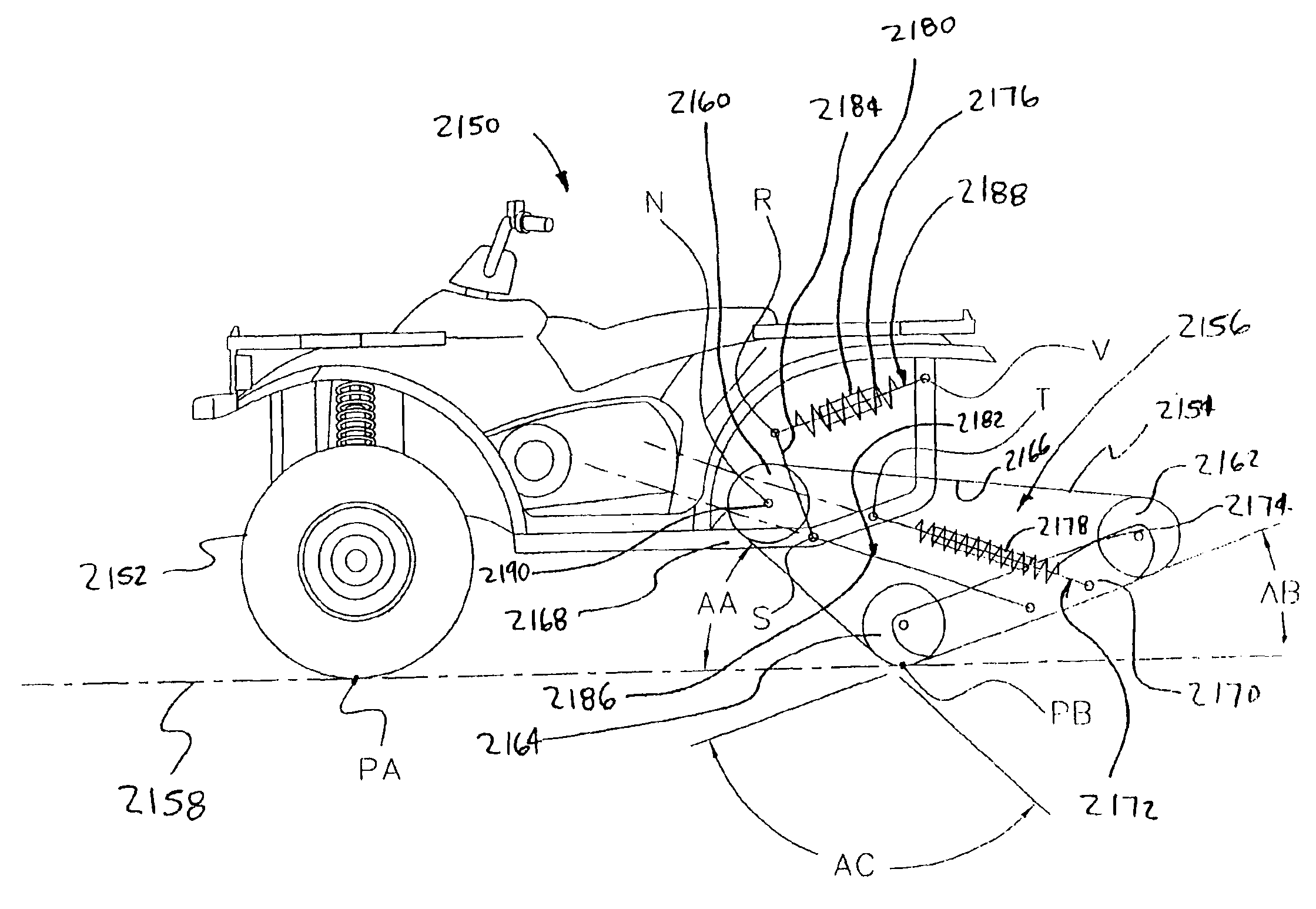

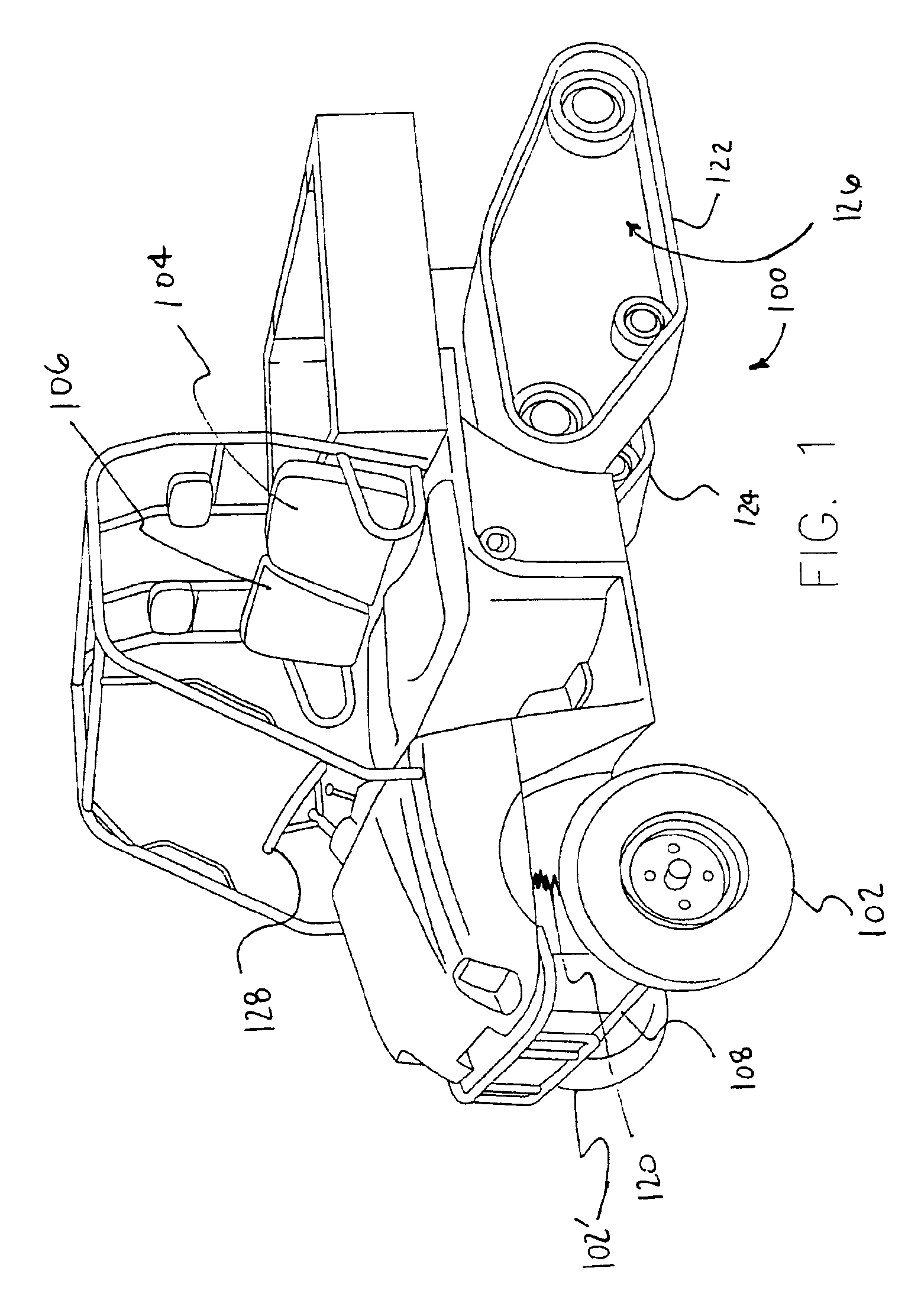

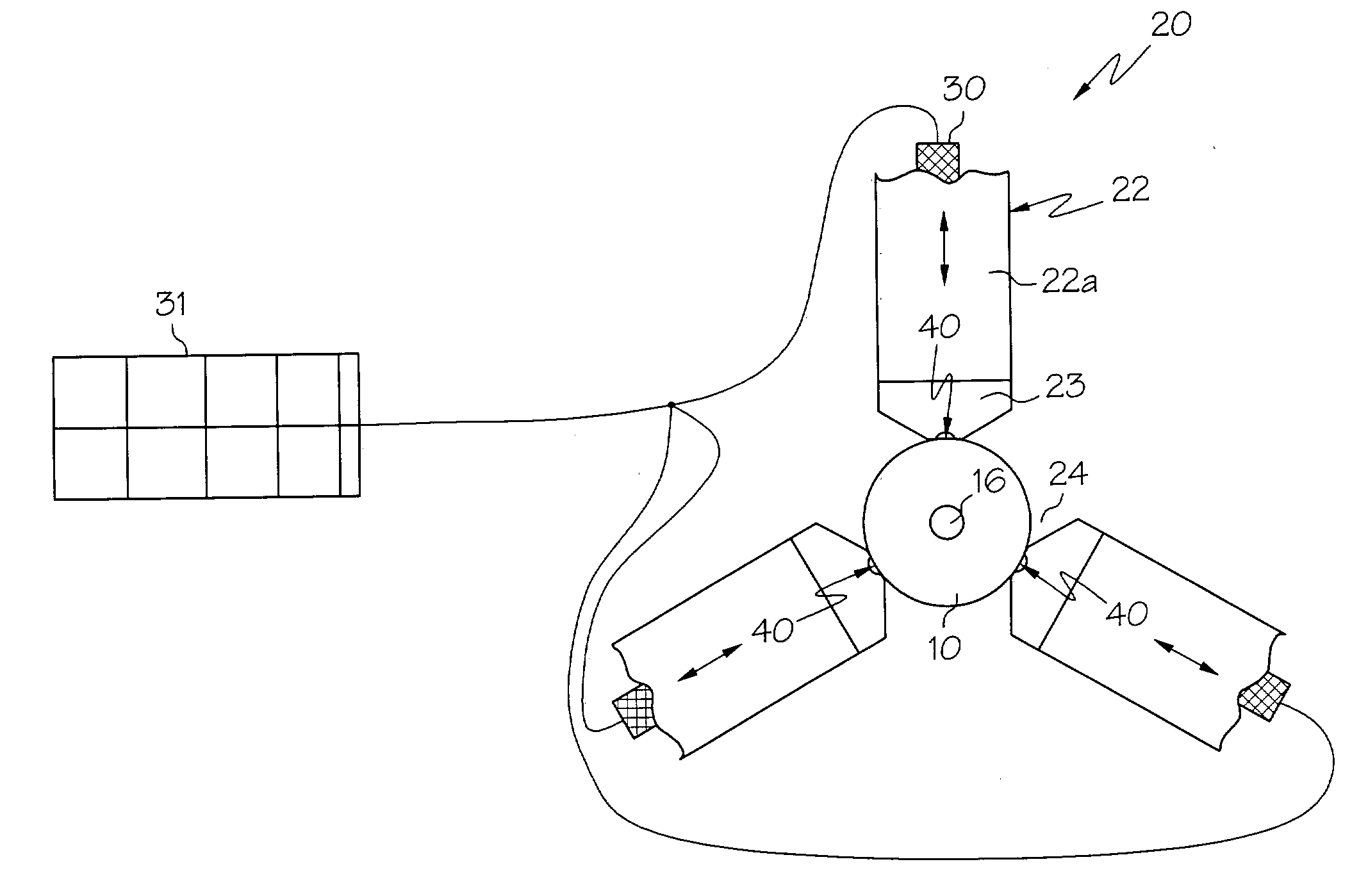

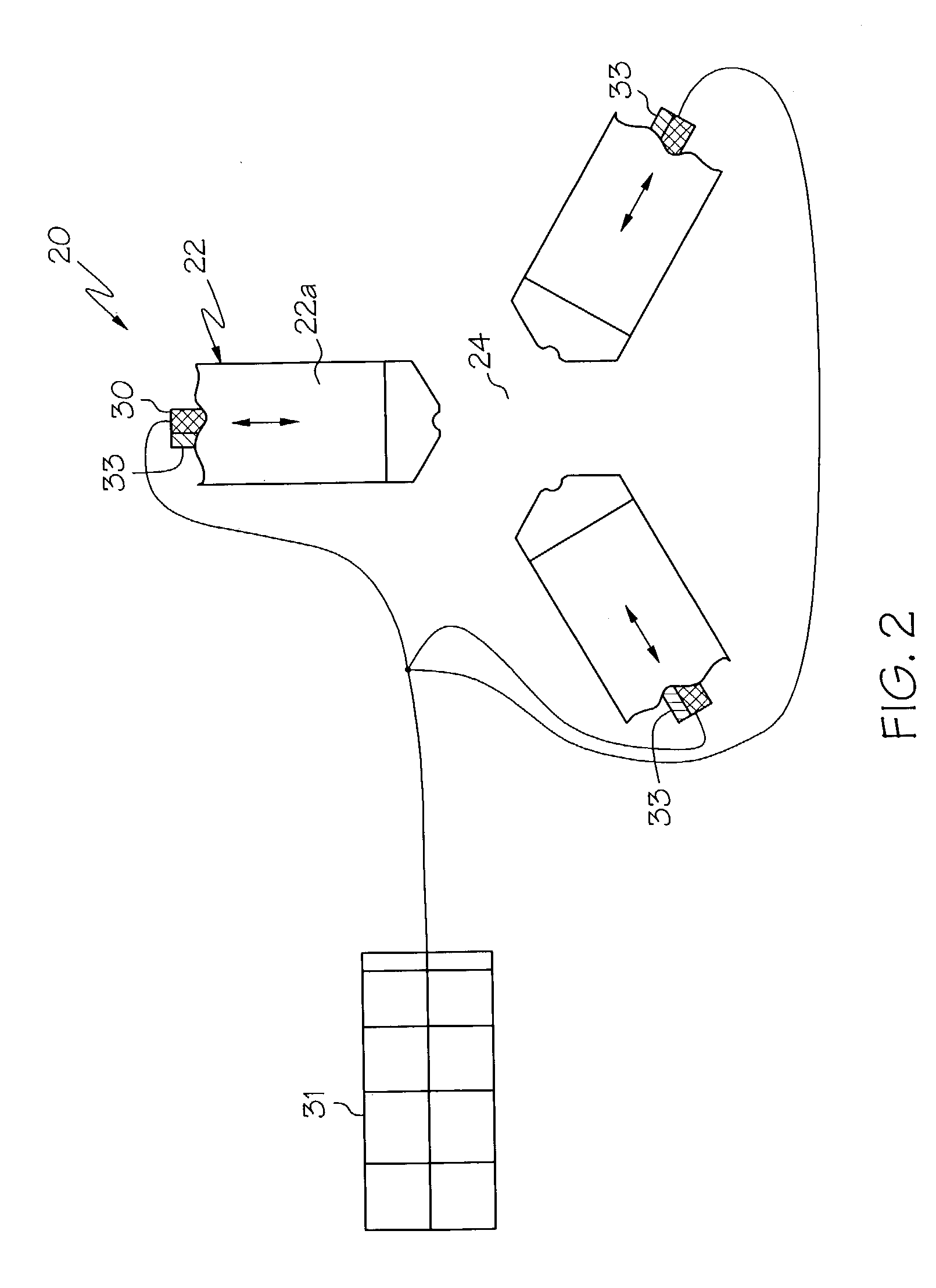

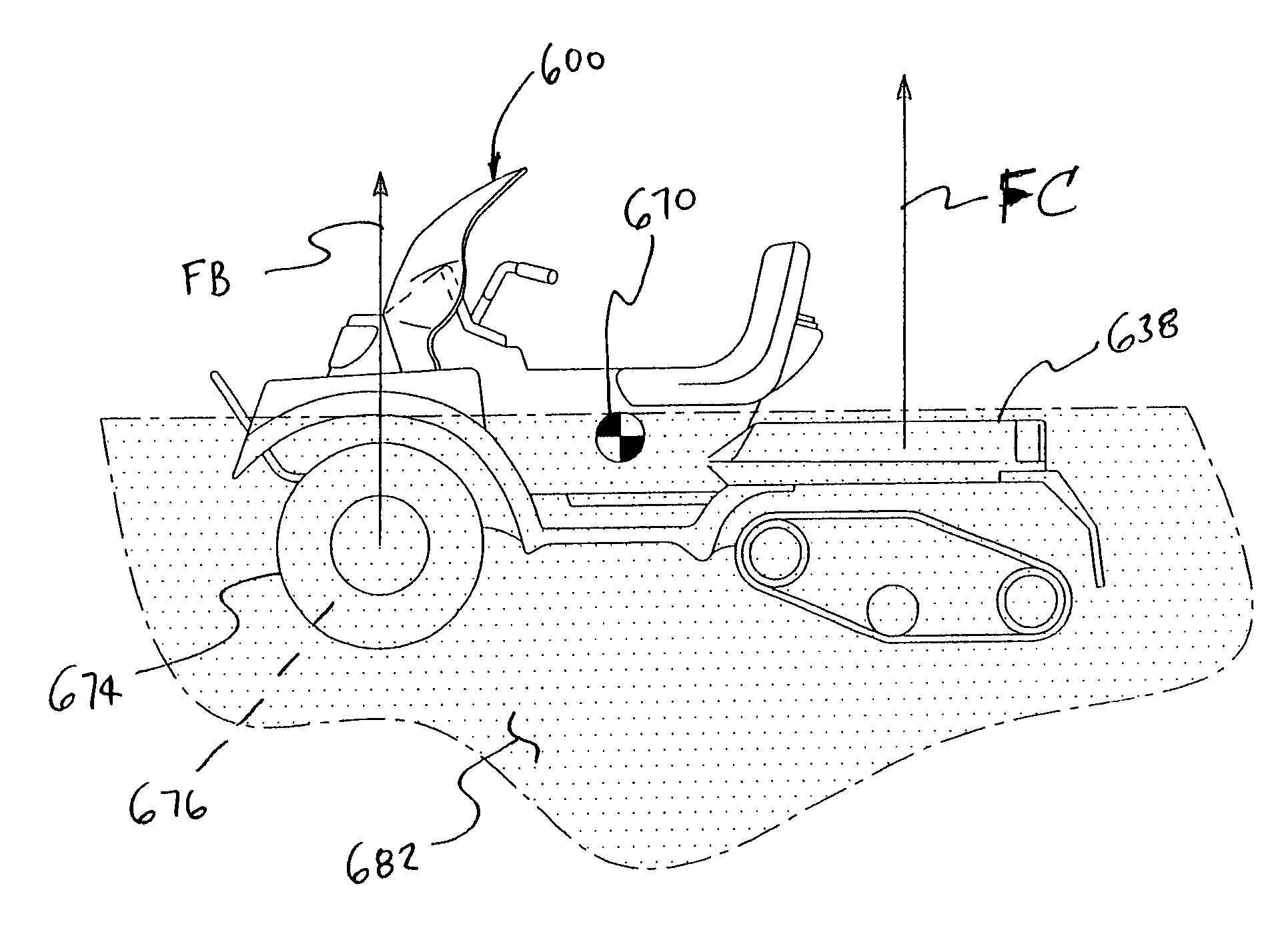

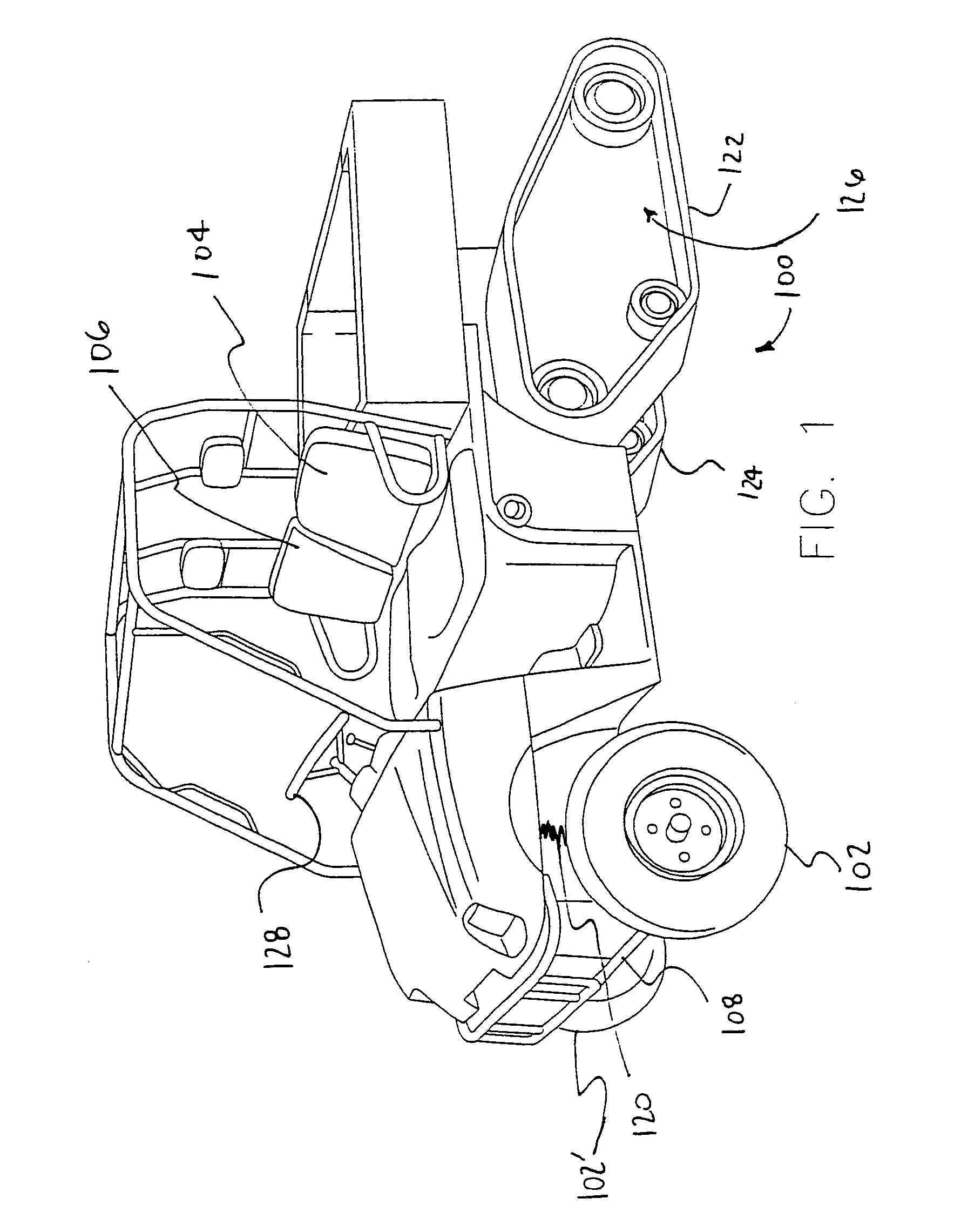

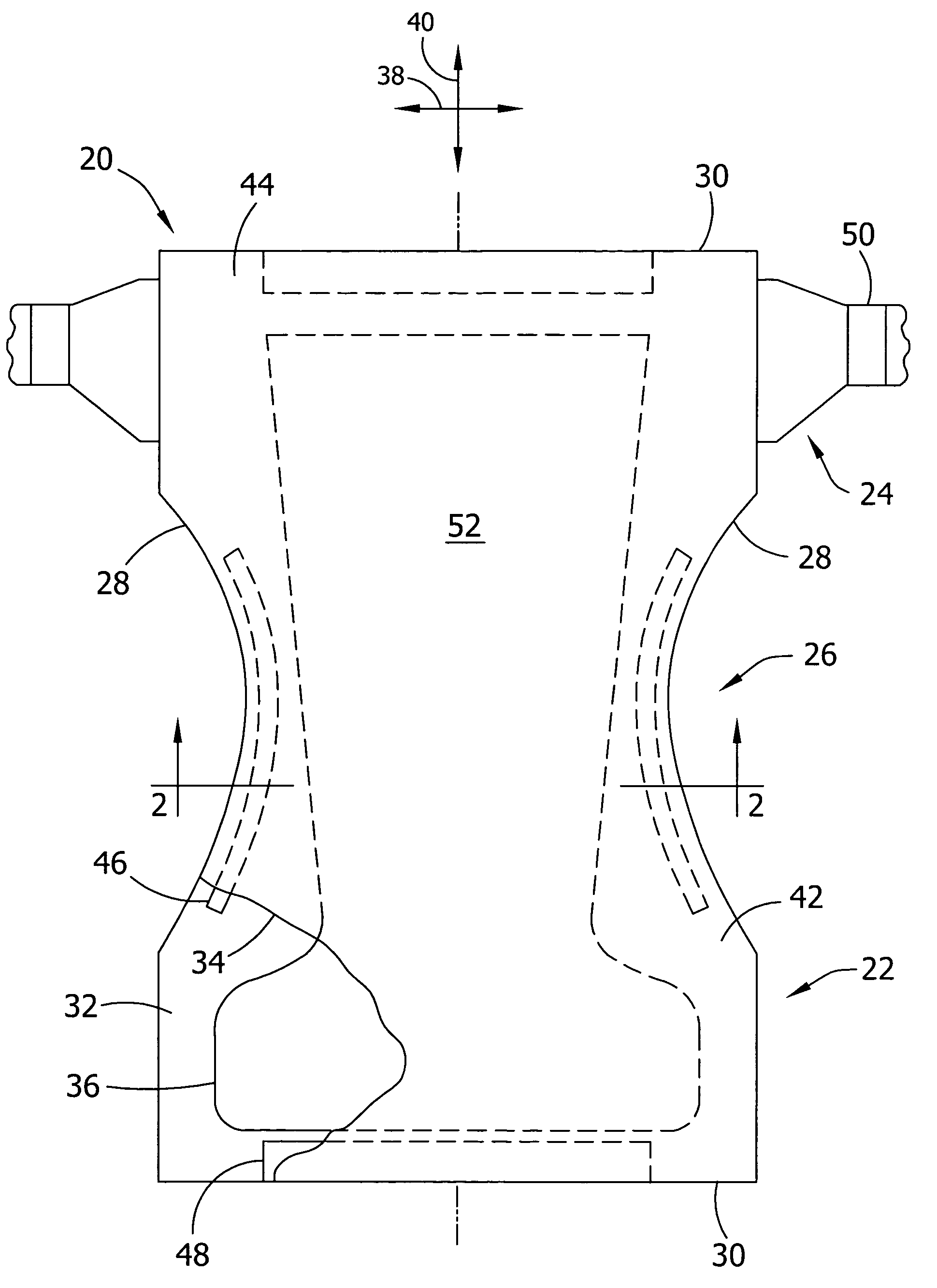

Suspension for a tracked vehicle

InactiveUS7040426B1Easy to adjustGreat tractionEndless track vehiclesRider propulsionTerrainEngineering

The present invention relates generally to recreational vehicles. More particularly, the present invention relates to methods and apparatus for traversing challenging terrain with a recreational vehicle. A vehicle in accordance with an exemplary embodiment of the present invention comprises a first drive track that is supported by a first rear suspension and a second drive track of vehicle is supported by a second rear suspension. The first drive track and the second drive track may be operatively coupled to an engine by a drive train for propelling the vehicle.

Owner:POLARIS IND INC

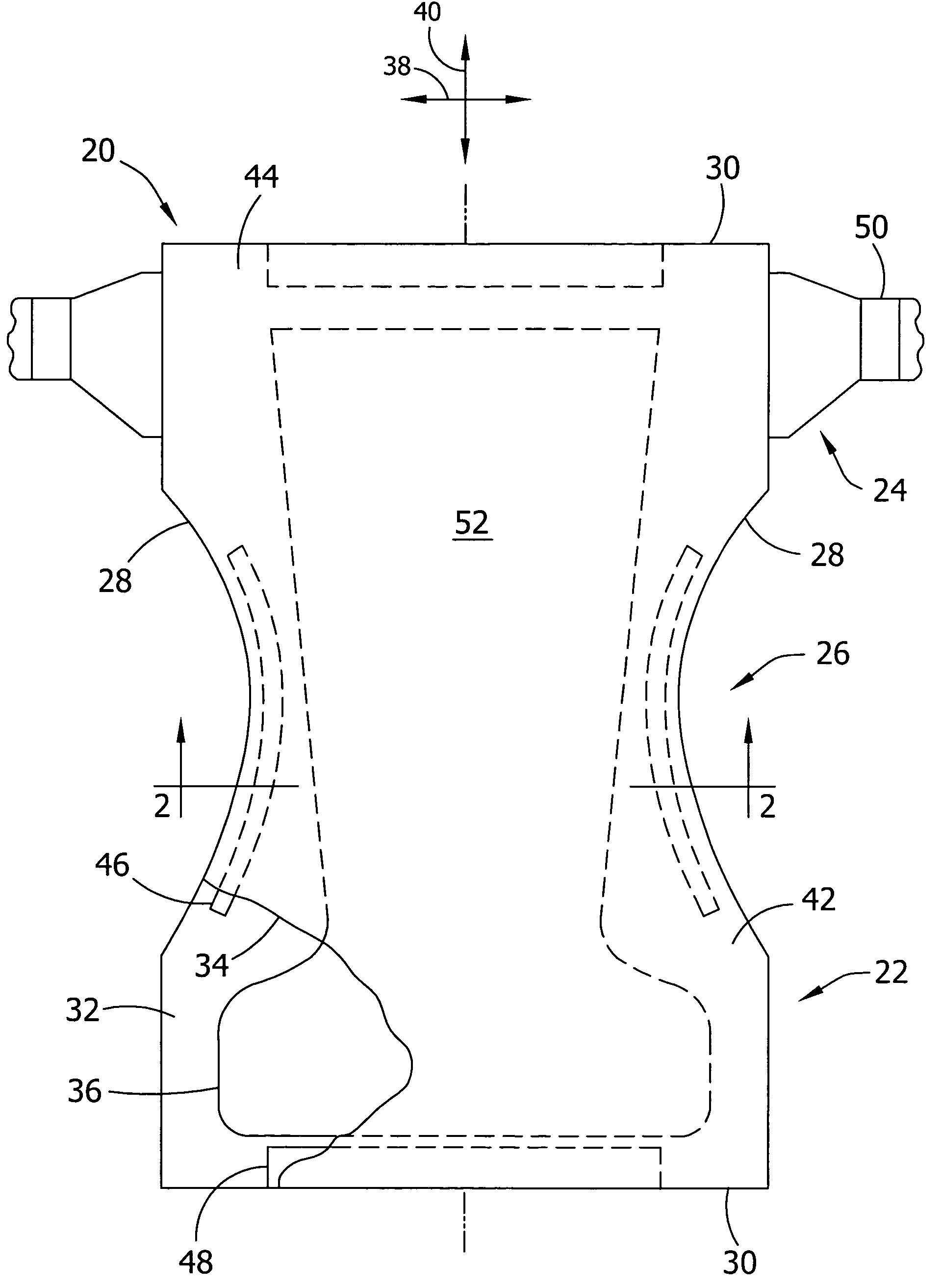

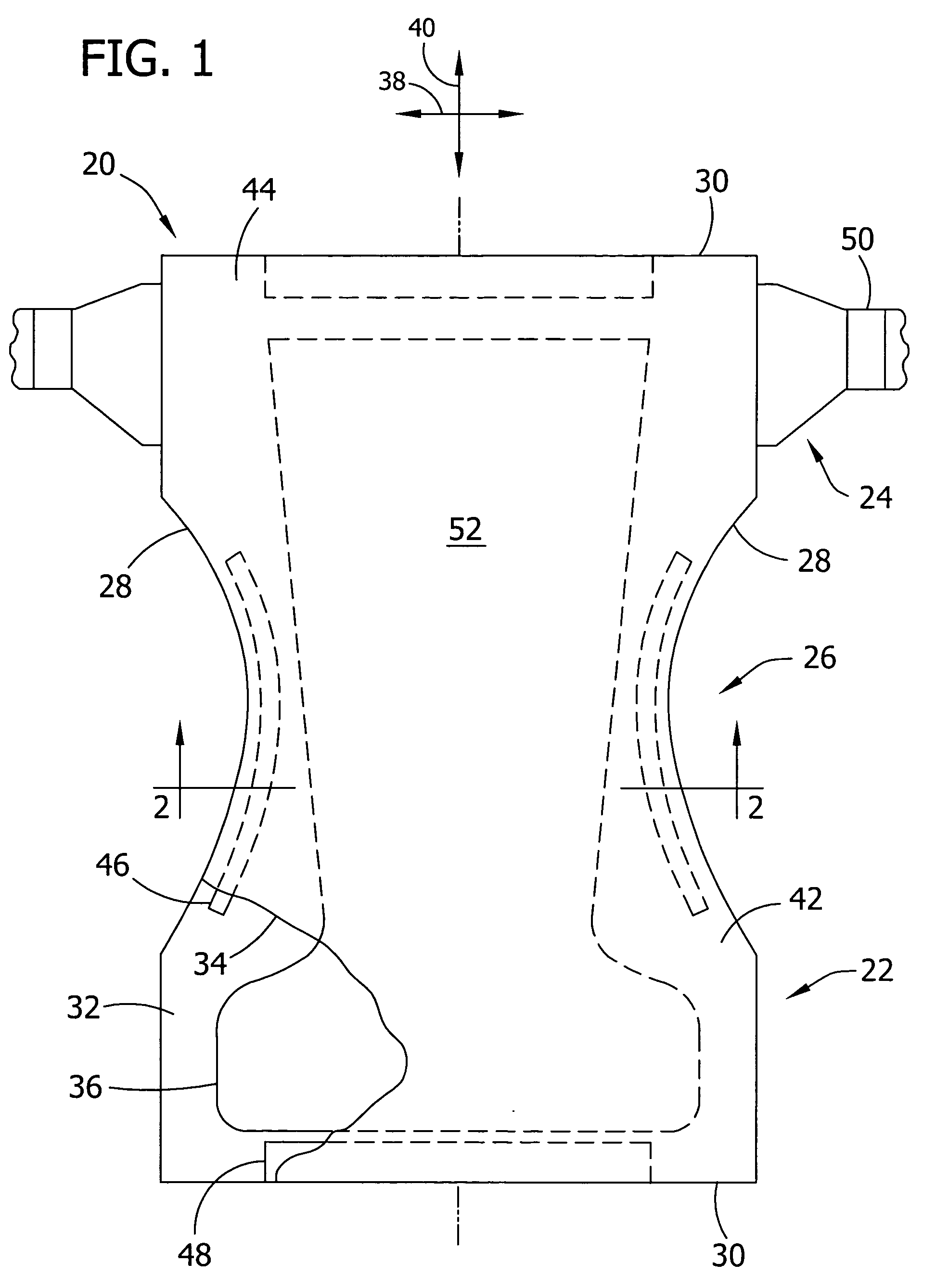

Absorbent articles comprising a bodily exudate modifying agent and a skin care formulation

ActiveUS20060036222A1Promote absorptionLow viscosityMaterial nanotechnologyBaby linensSkin barrier functionAnimal feces

Absorbent articles having enhanced absorption of bodily exudates are disclosed. The absorbent articles comprise a bodily exudate modifying agent and a skin care formulation. The bodily exudate modifying agent is capable of reducing the viscosity of bodily exudates such as feces and menses. The skin care formulation comprises a bodily exudate modifying agent neutralizer to neutralize the possible negative effects on skin barrier function caused by the bodily exudate modifying agents coming into direct contact with the wearer's skin.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Balloon wing forming apparatus and method

An apparatus and method for shaping at least a portion of a medical balloon comprise a balloon shaping device capable of applying a radial inward force to at least a portion of the medical balloon and at least one vibratory device capable of applying vibratory energy to the at least a portion of the medical balloon.

Owner:BOSTON SCI SCIMED INC

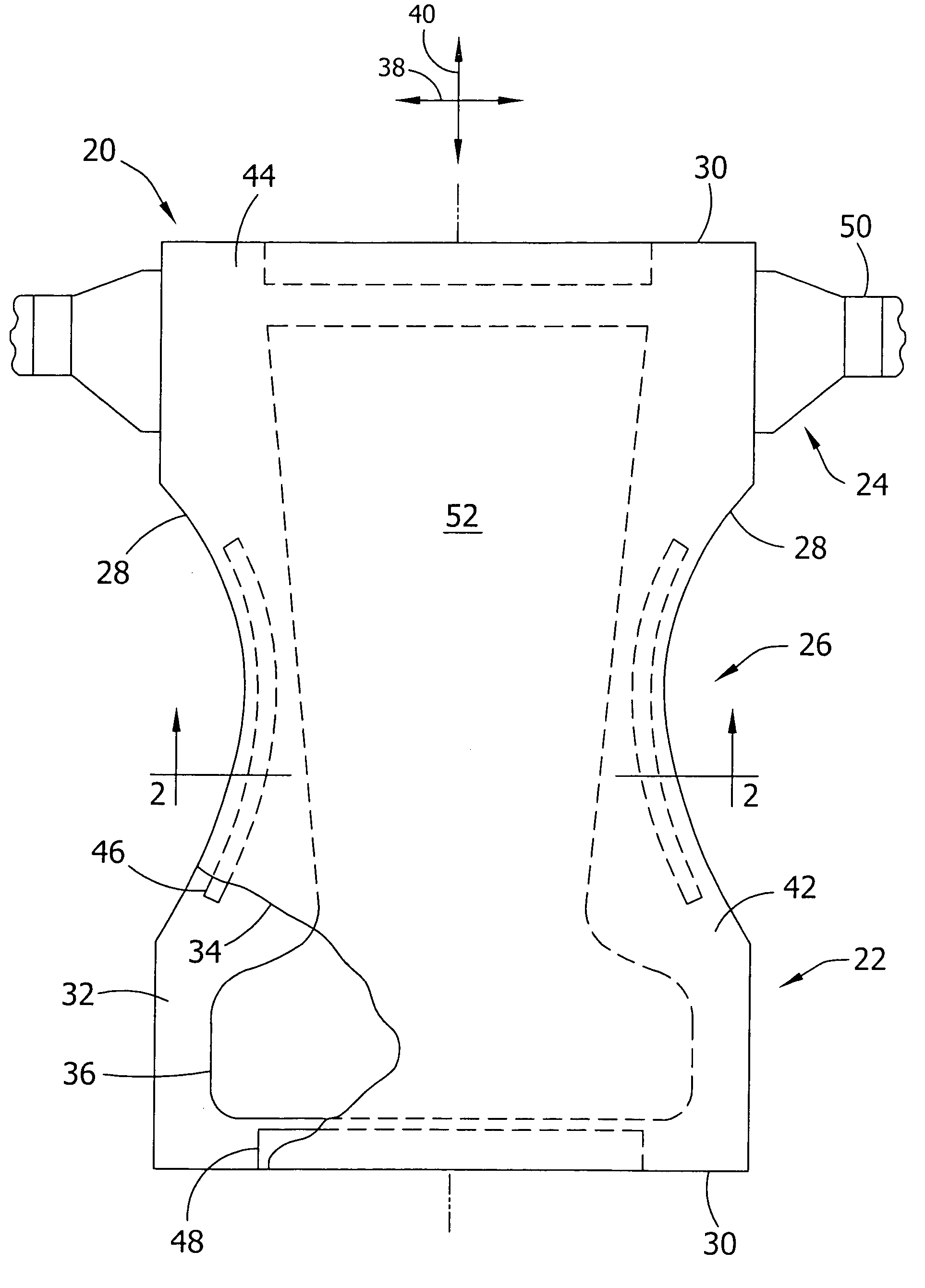

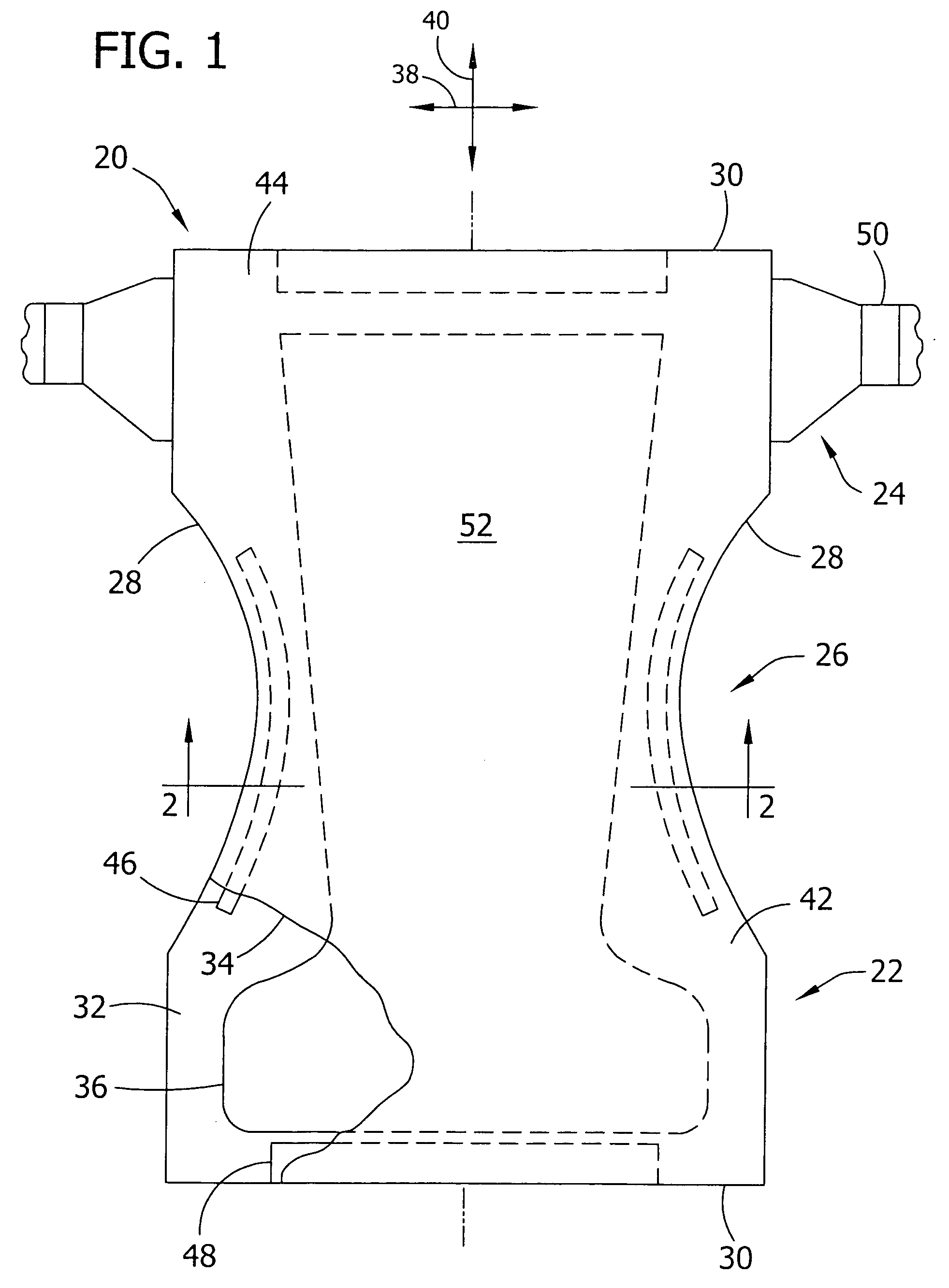

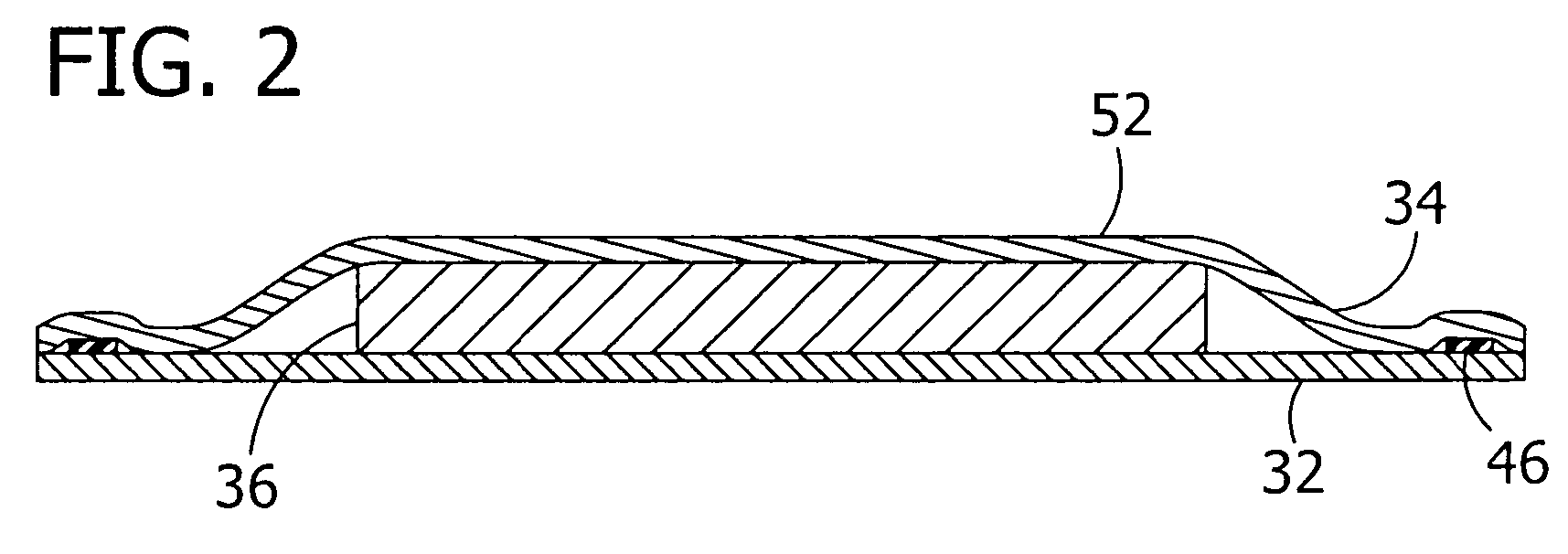

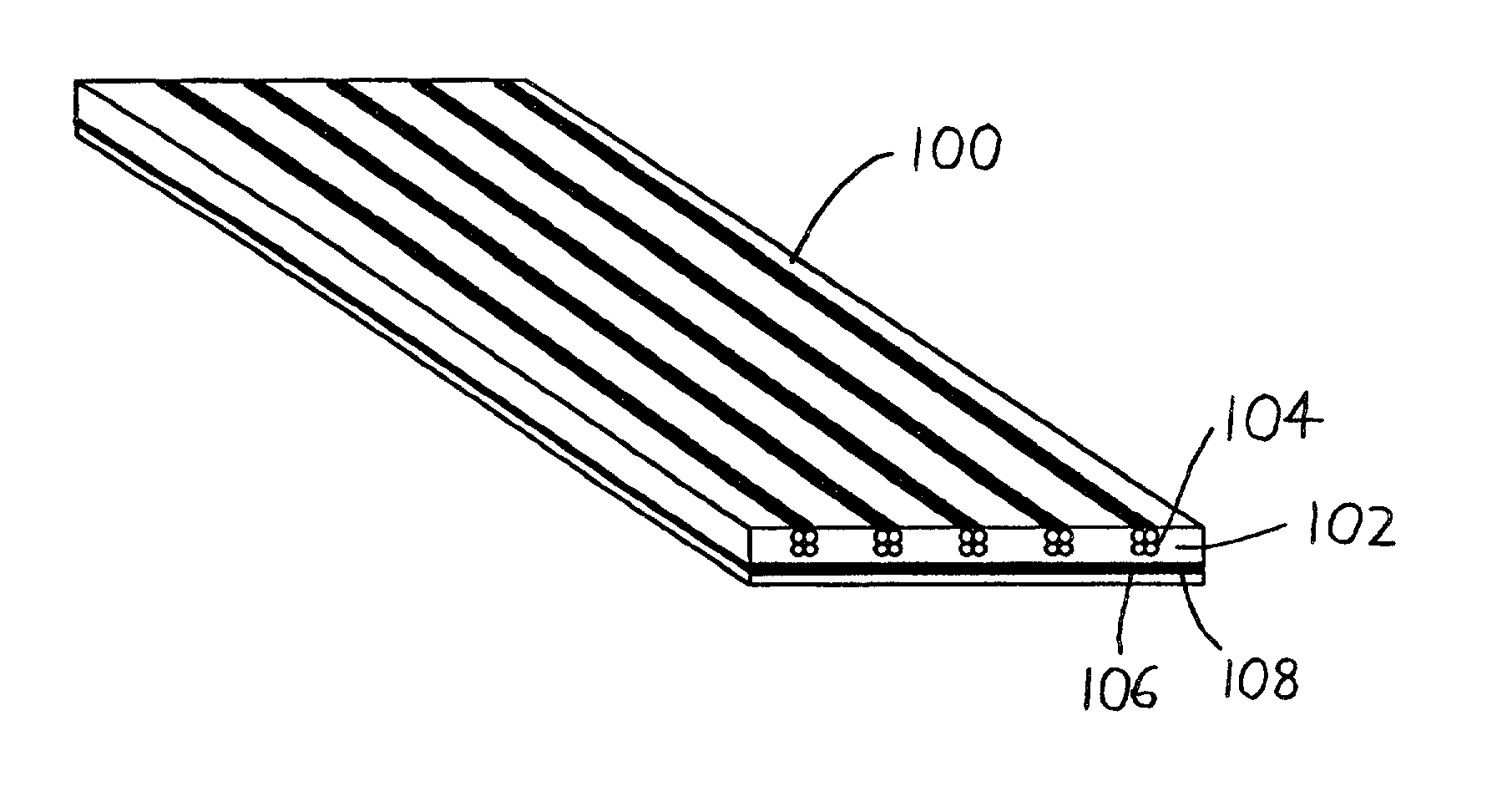

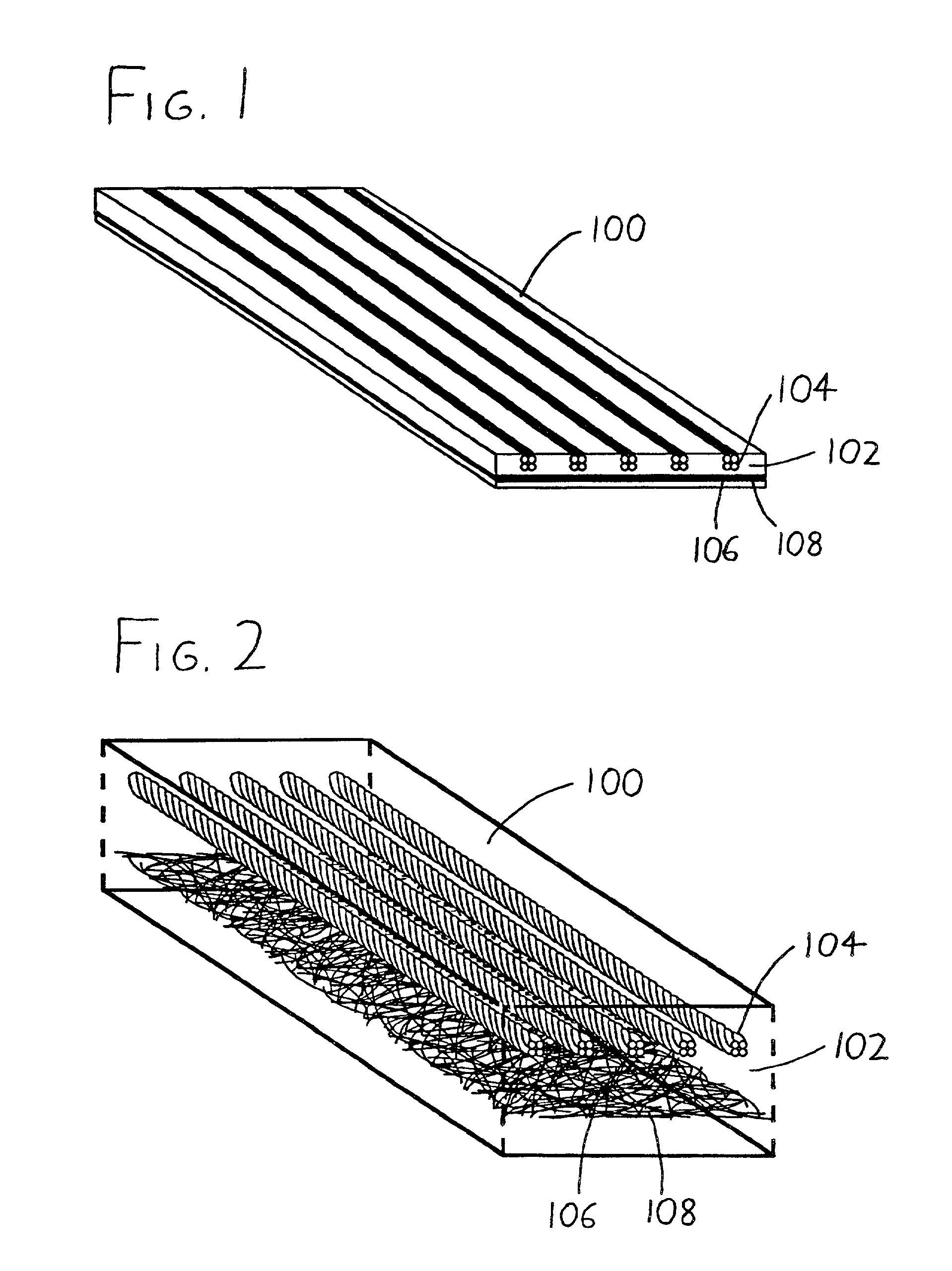

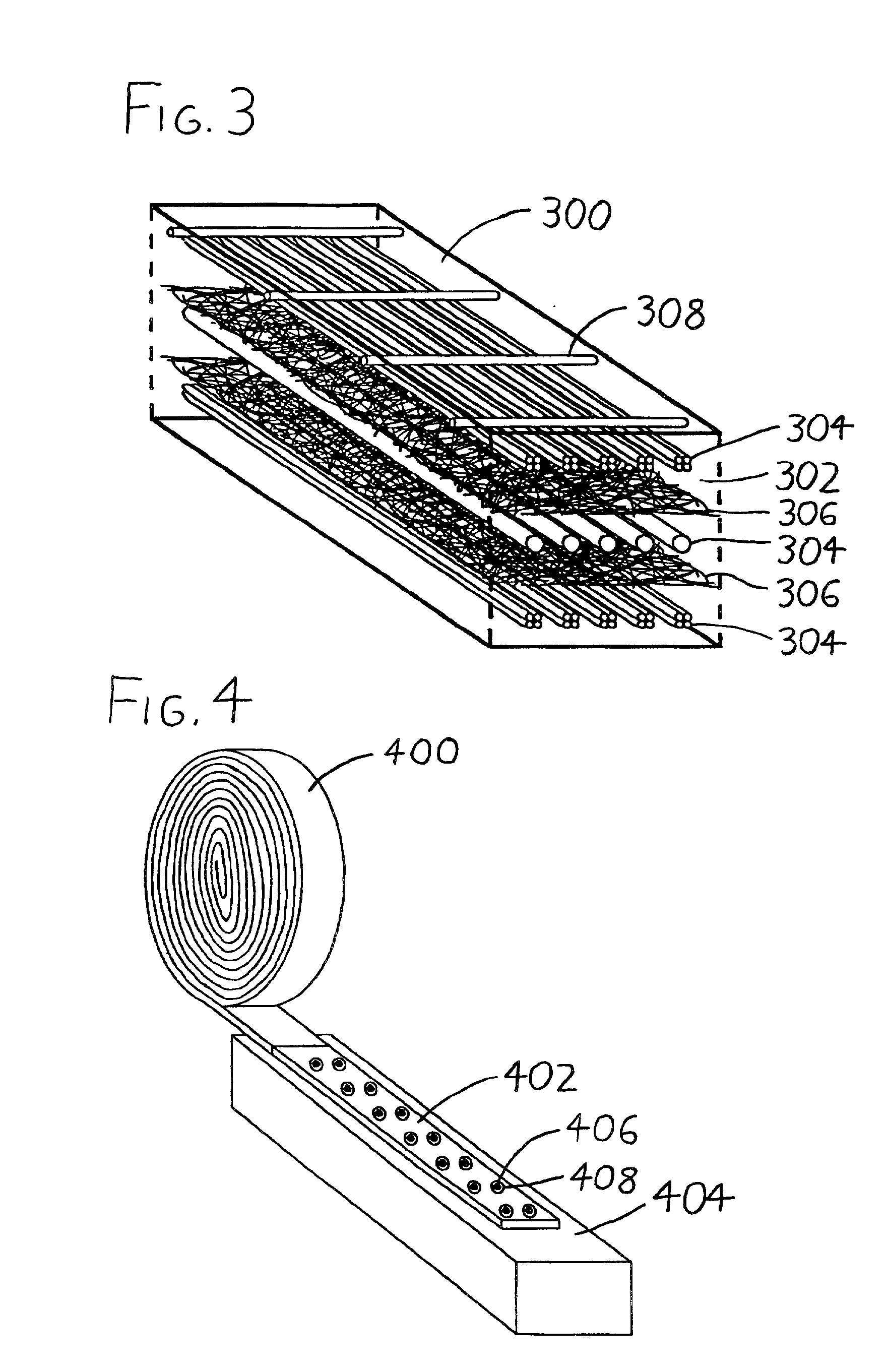

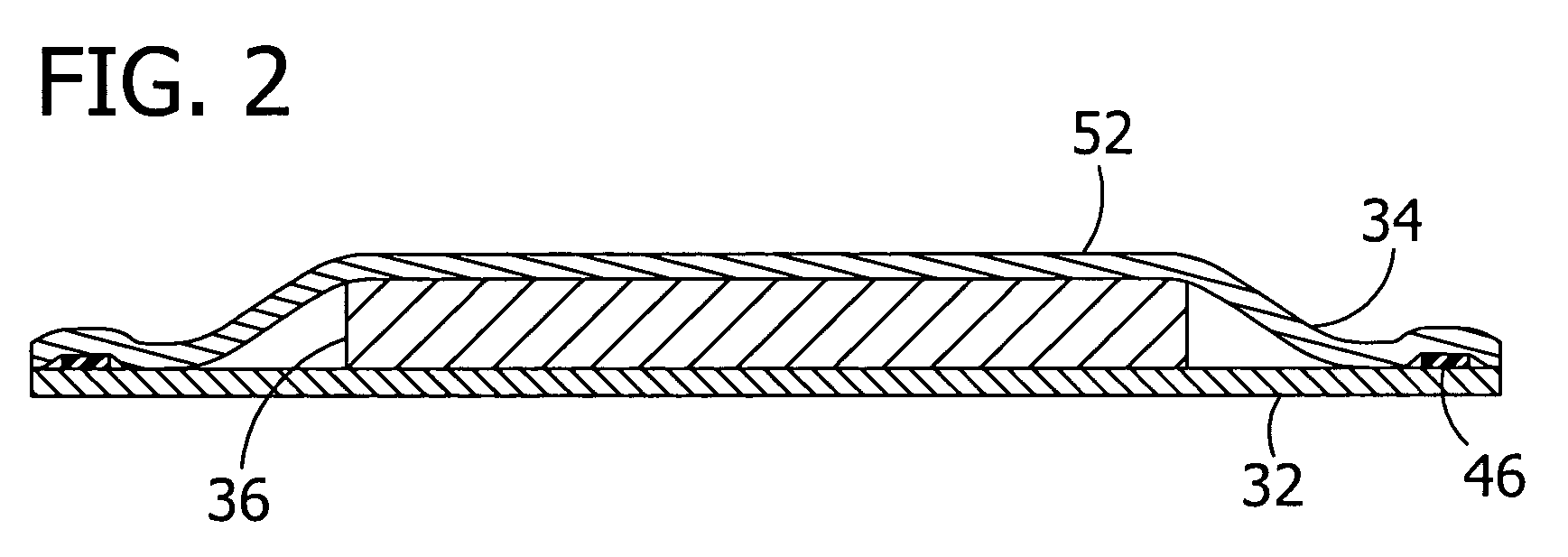

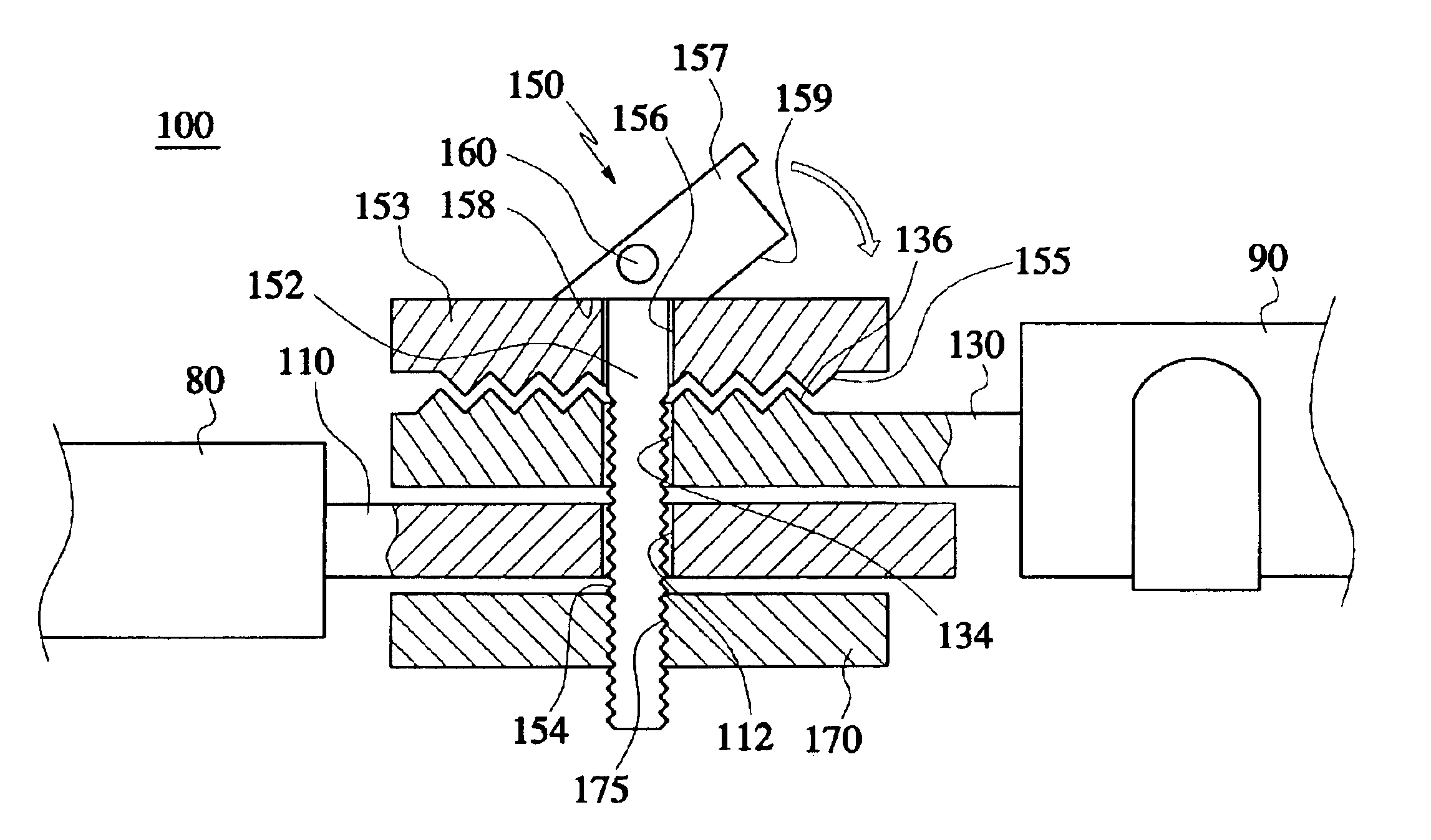

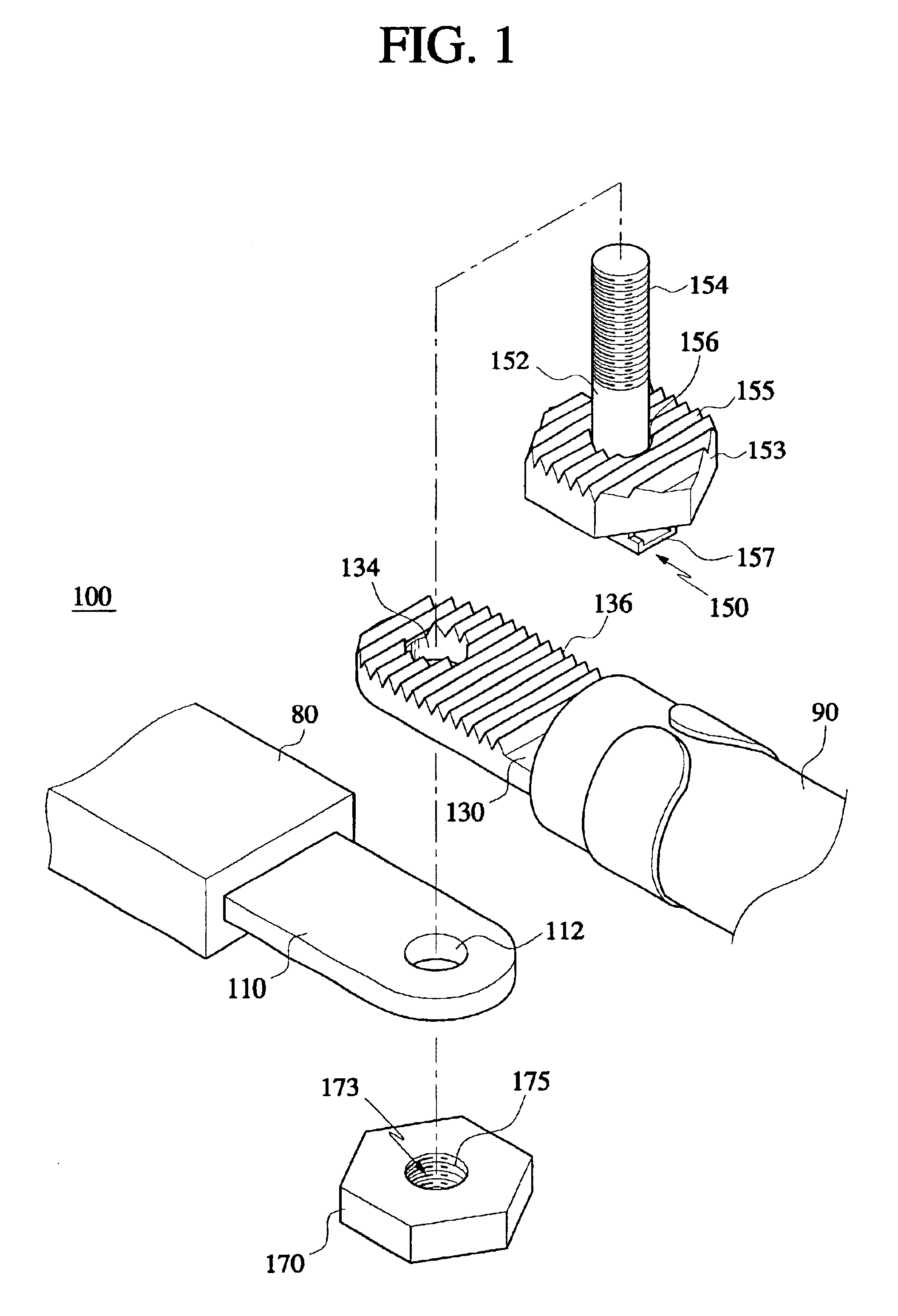

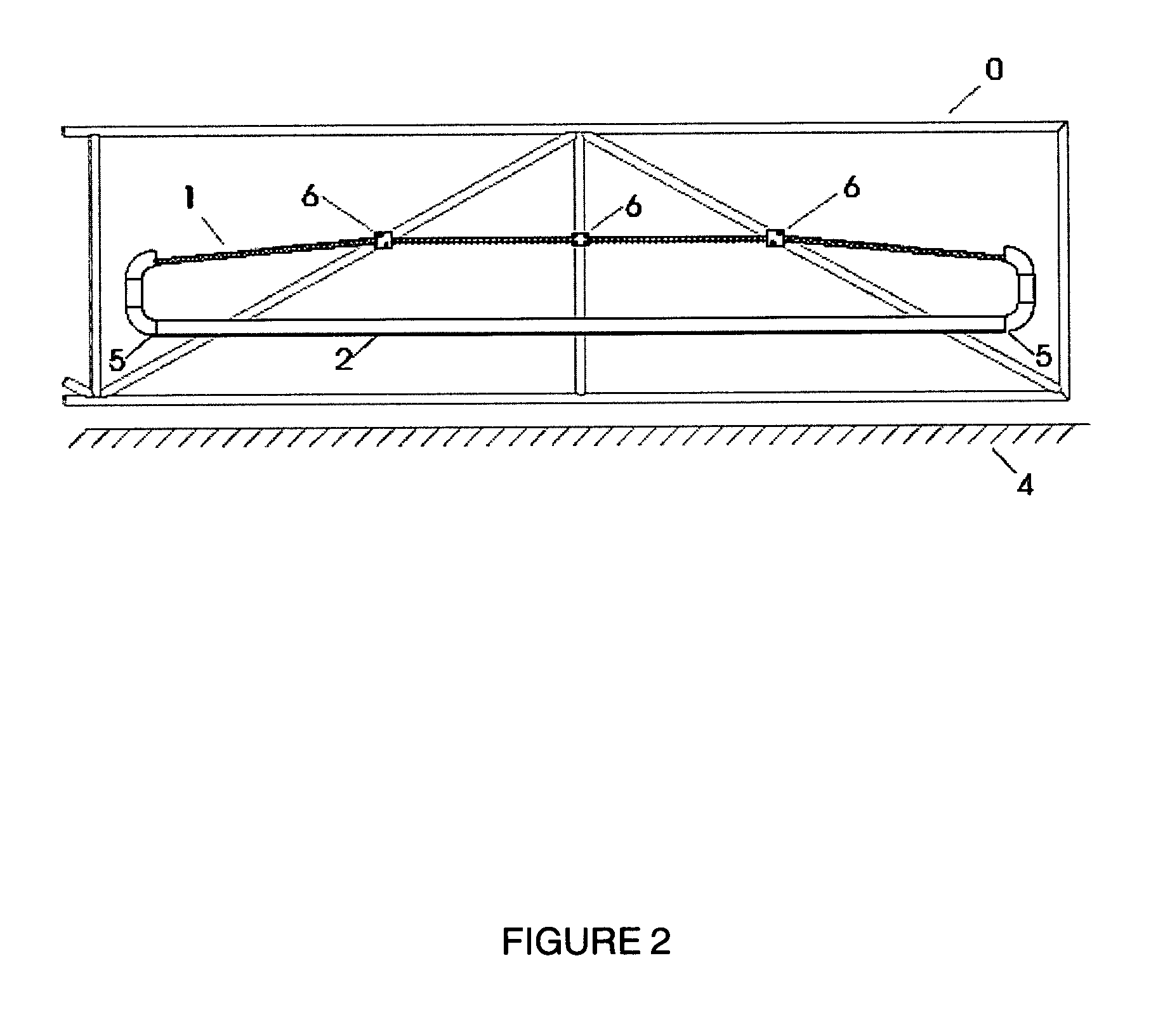

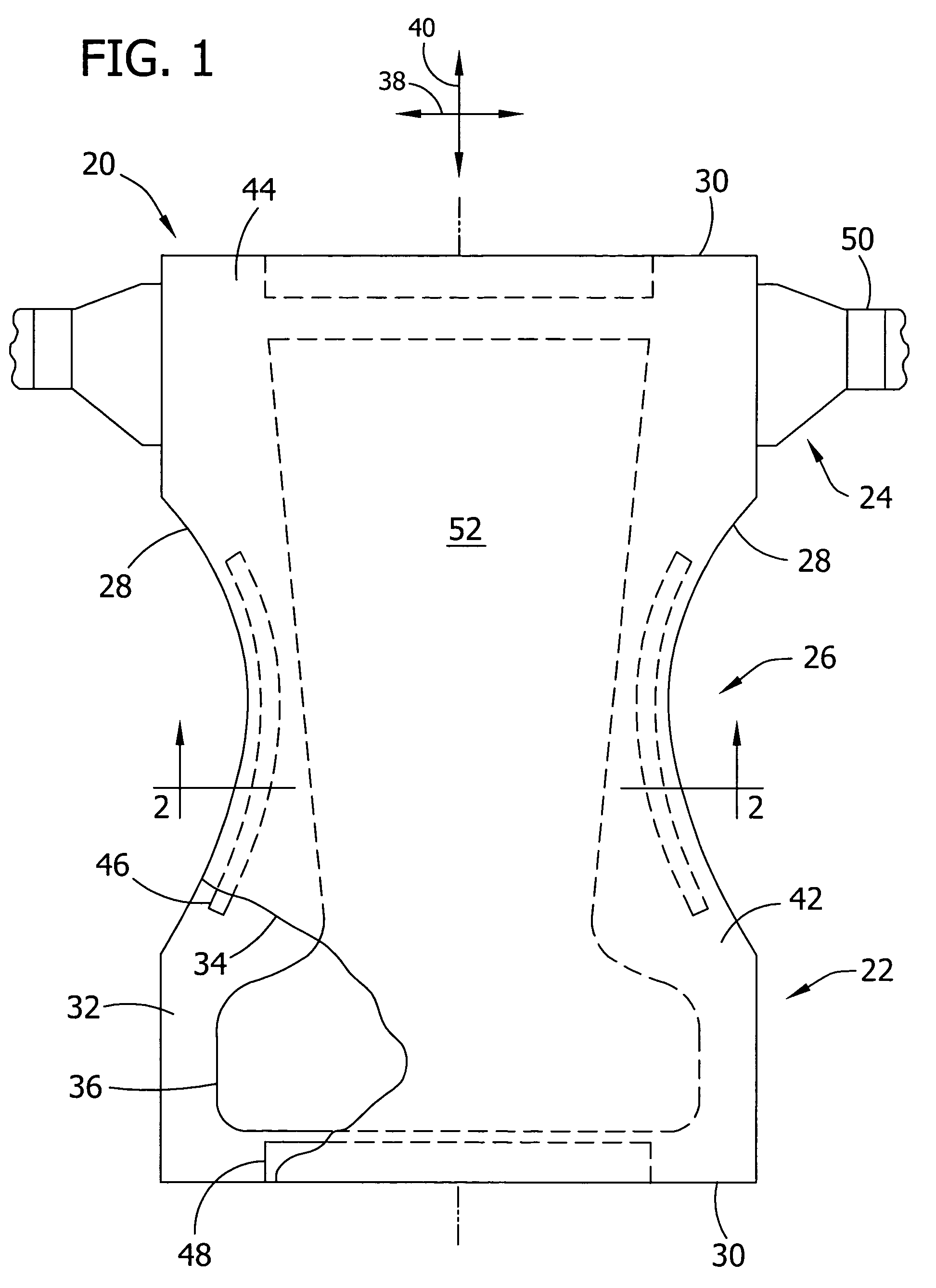

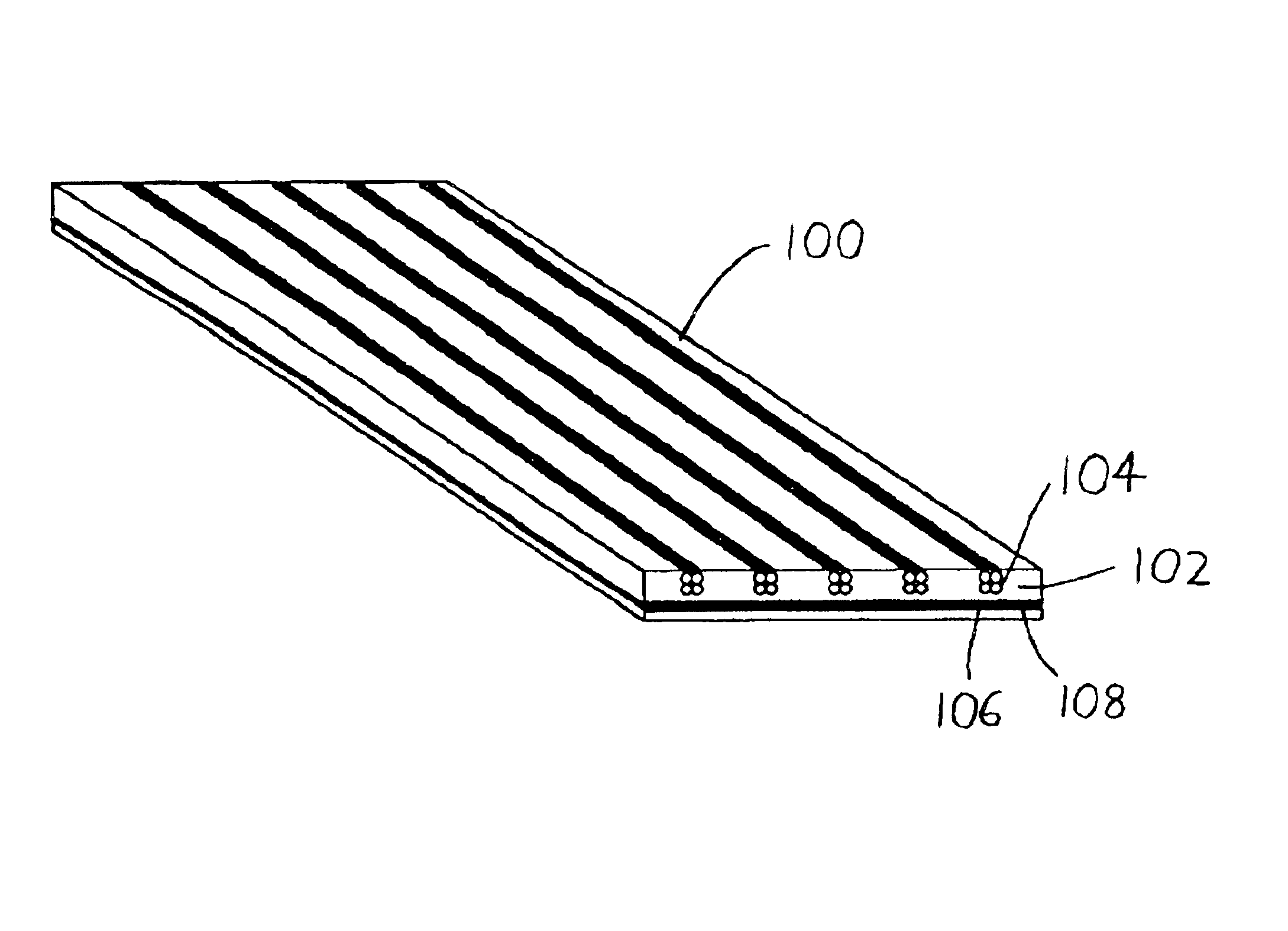

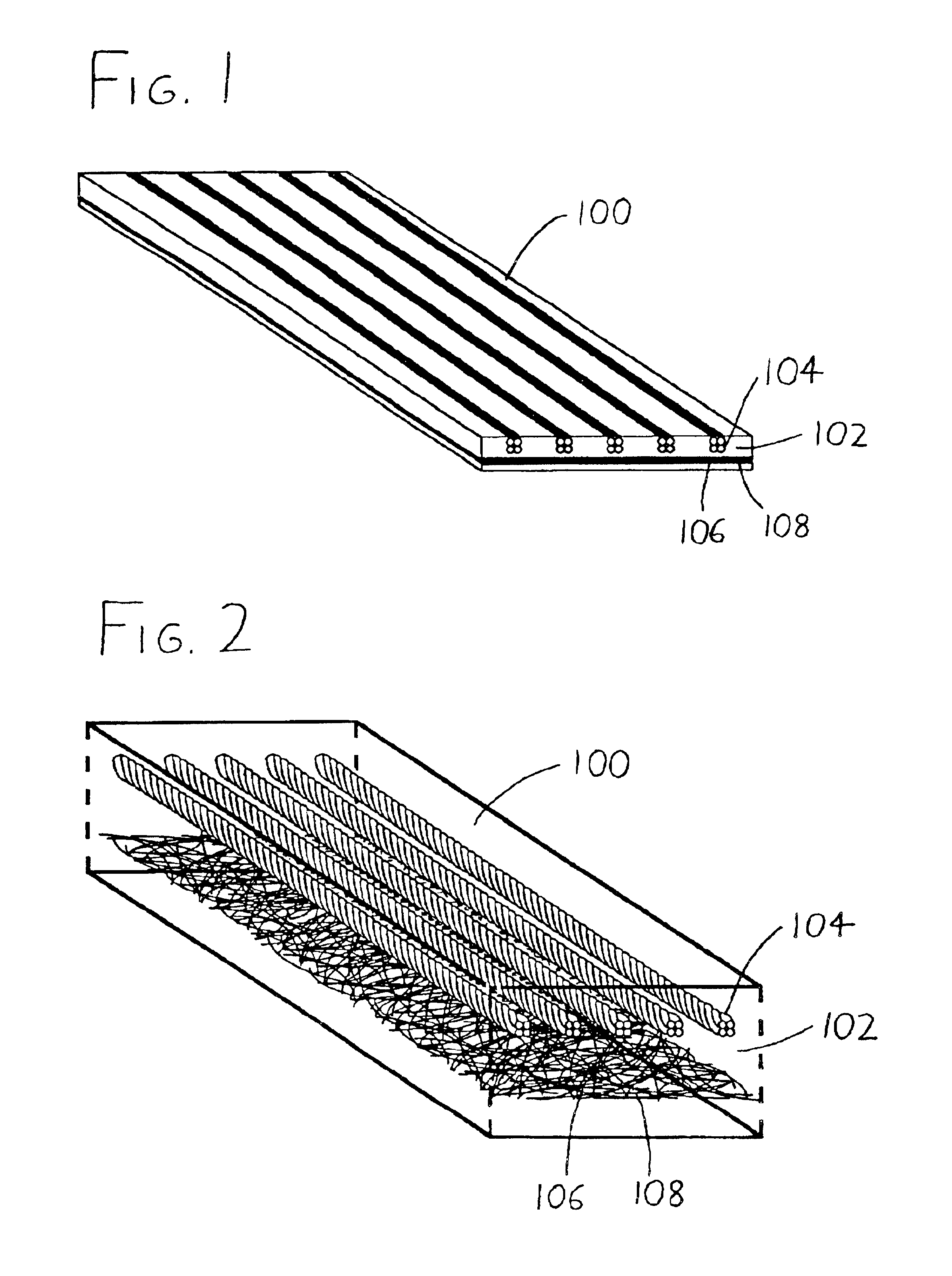

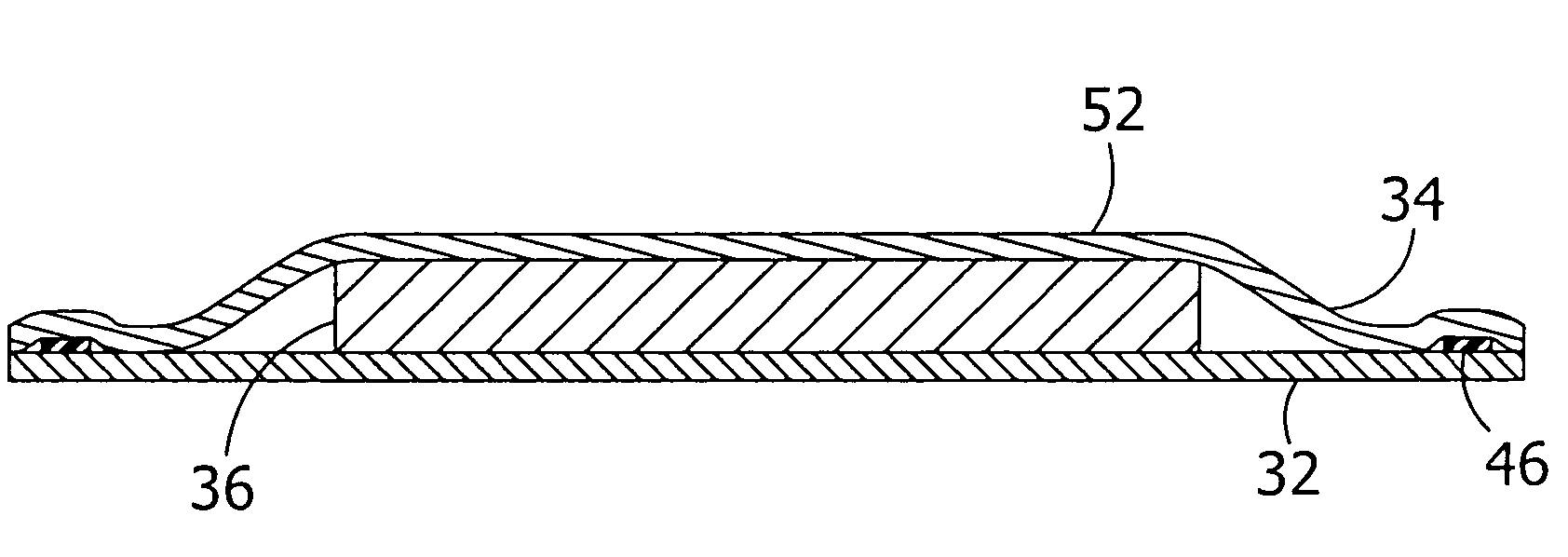

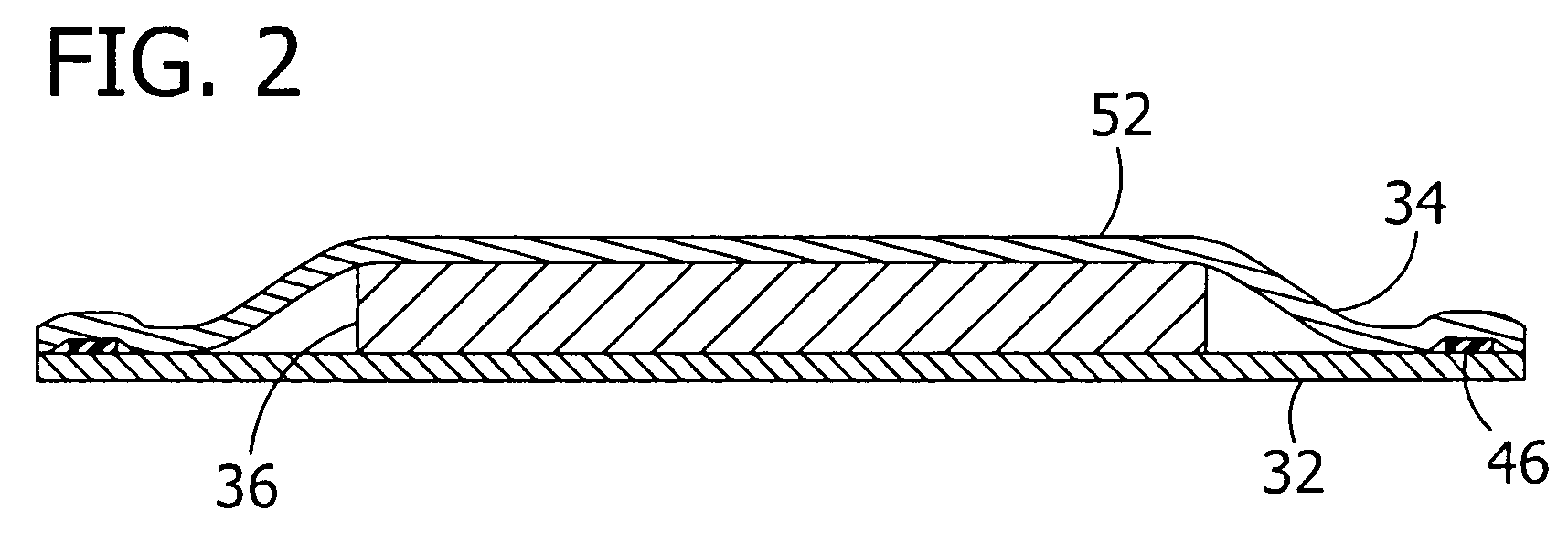

Structural reinforcement using composite strips

InactiveUS20020110680A1Reduce the potential for damageEasy to transportSynthetic resin layered productsBuilding repairsFiberEngineering

A composite structural reinforcing strip is affixed to a structure to be reinforced (such as a bridge span, foundation pillar, or similar structure) by the use of several fasteners which extend through the strip and into the structure. The reinforcing strip preferably includes elongated continuous parallel fibers which have lengths extending along the length of the strip, and nondirectional fibers distributed transversely across the strip, with a polymer matrix affixing the parallel and nondirectional fibers. The strip may be placed on the structure to be reinforced, and may be attached thereon by actuating a common powder-actuated fastener gun to send fasteners through the strip and into the structure.

Owner:WISCONSIN ALUMNI RES FOUND

Absorbent articles comprising a bodily exudate modifying agent and a film-forming skin care formulation

InactiveUS20060036223A1Low viscosityPromote absorptionMaterial nanotechnologyBaby linensEnhanced absorptionFilm-forming agent

Absorbent articles having enhanced absorption of bodily exudates are disclosed. The absorbent articles comprise a bodily exudate modifying agent and a skin care formulation. The bodily exudate modifying agent is capable of reducing the viscosity of bodily exudates such as feces and menses. The skin care formulation comprises a film forming agent that, upon transfer to the skin, can form a continuous film layer on the skin to retard harmful agents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

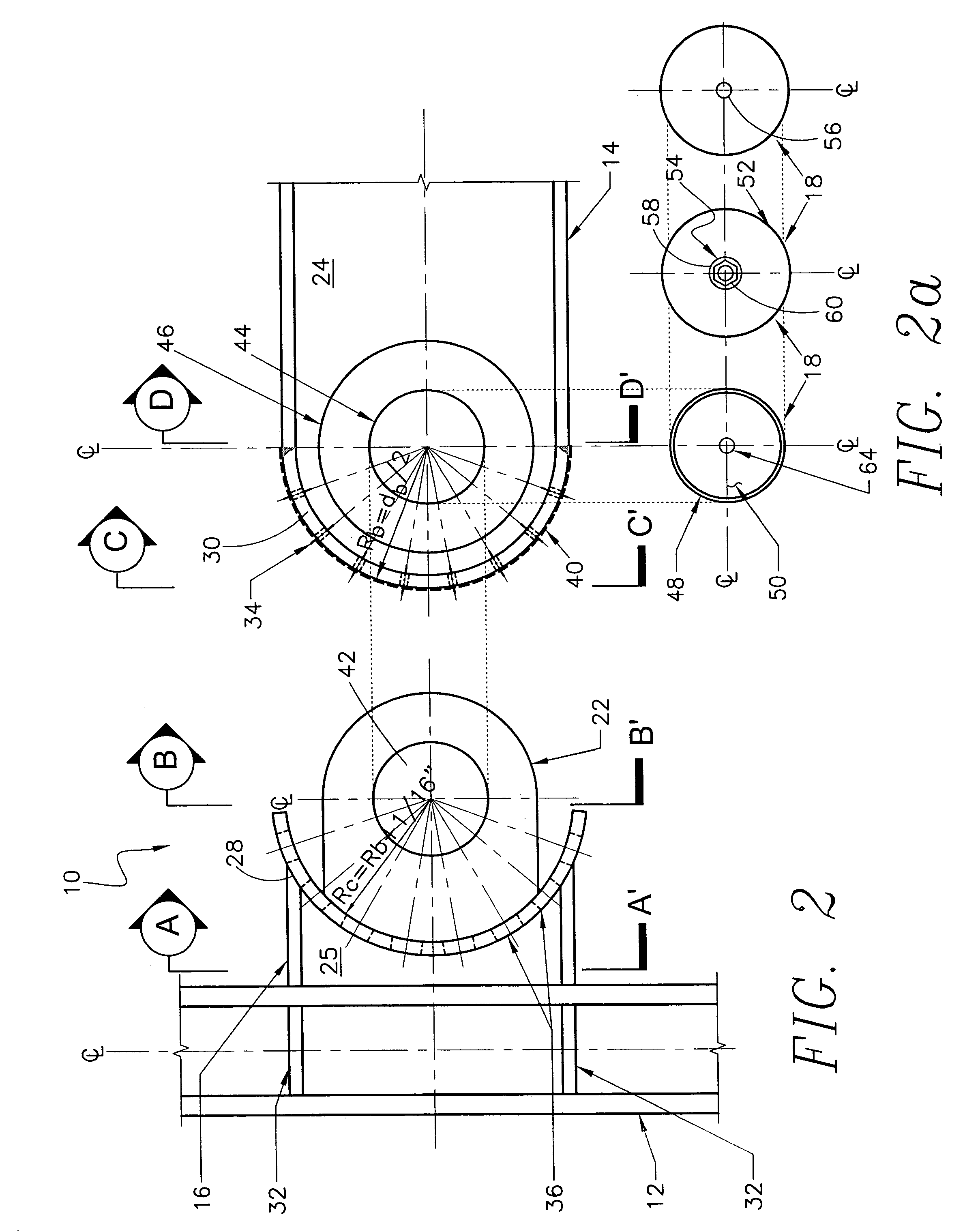

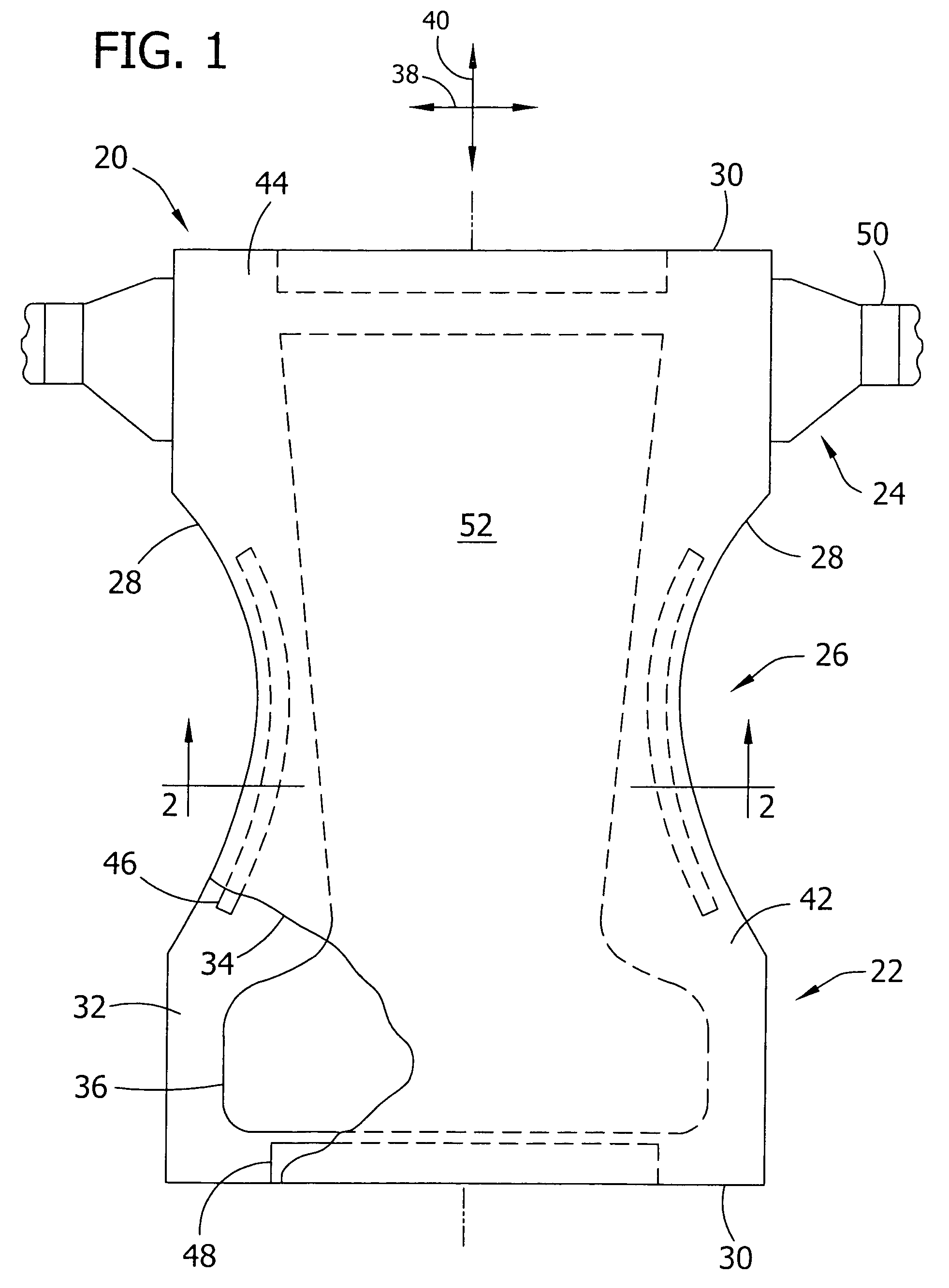

Tracked vehicle

ActiveUS7673711B1Easy to adjustGreat tractionCyclesEndless track vehiclesTerrainAutomotive engineering

The present invention relates generally to recreational vehicles. More particularly, the present invention relates to methods and apparatus for traversing challenging terrain with a recreational vehicle. A vehicle in accordance with an exemplary embodiment of the present invention comprises a first drive track that is supported by a first rear suspension and a second drive track of vehicle is supported by a second rear suspension. The first drive track and the second drive track may be operatively coupled to an engine by a drive train for propelling the vehicle.

Owner:POLARIS IND INC

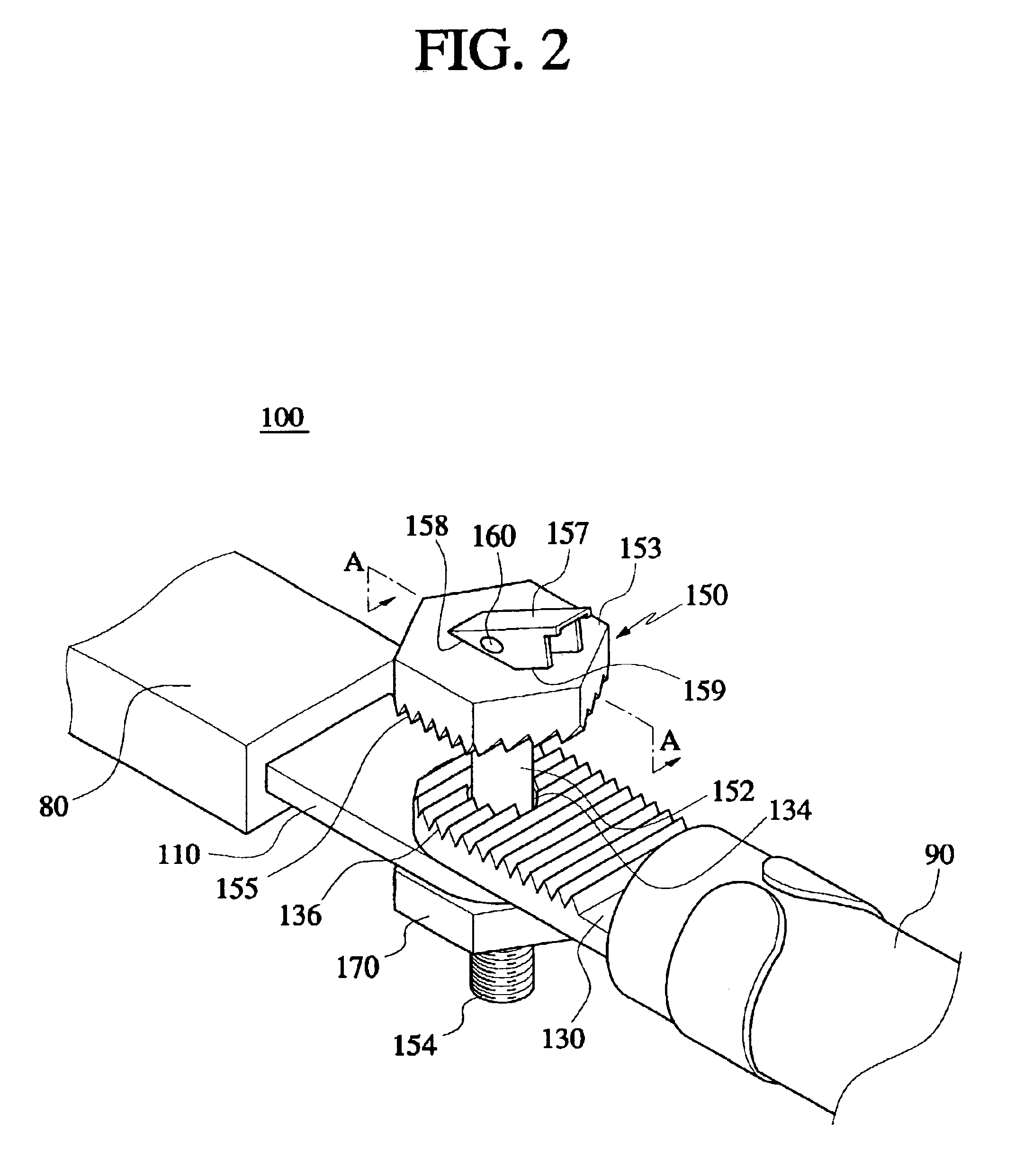

High capacity electrical terminal connection

InactiveUS6855012B2Reduce the potential for damageAvoid swingingBus-bar/wiring layoutsCoupling device detailsElectricityEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

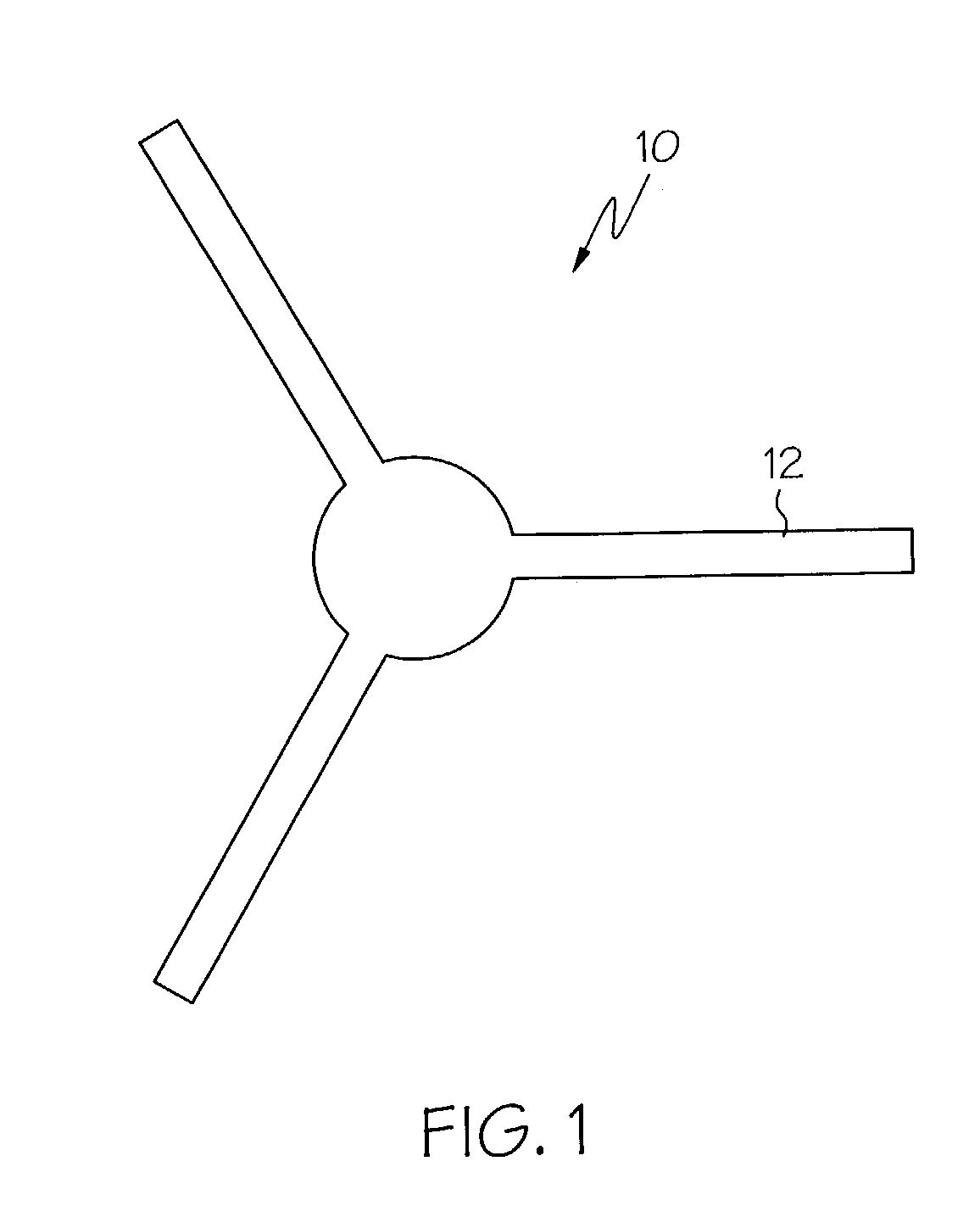

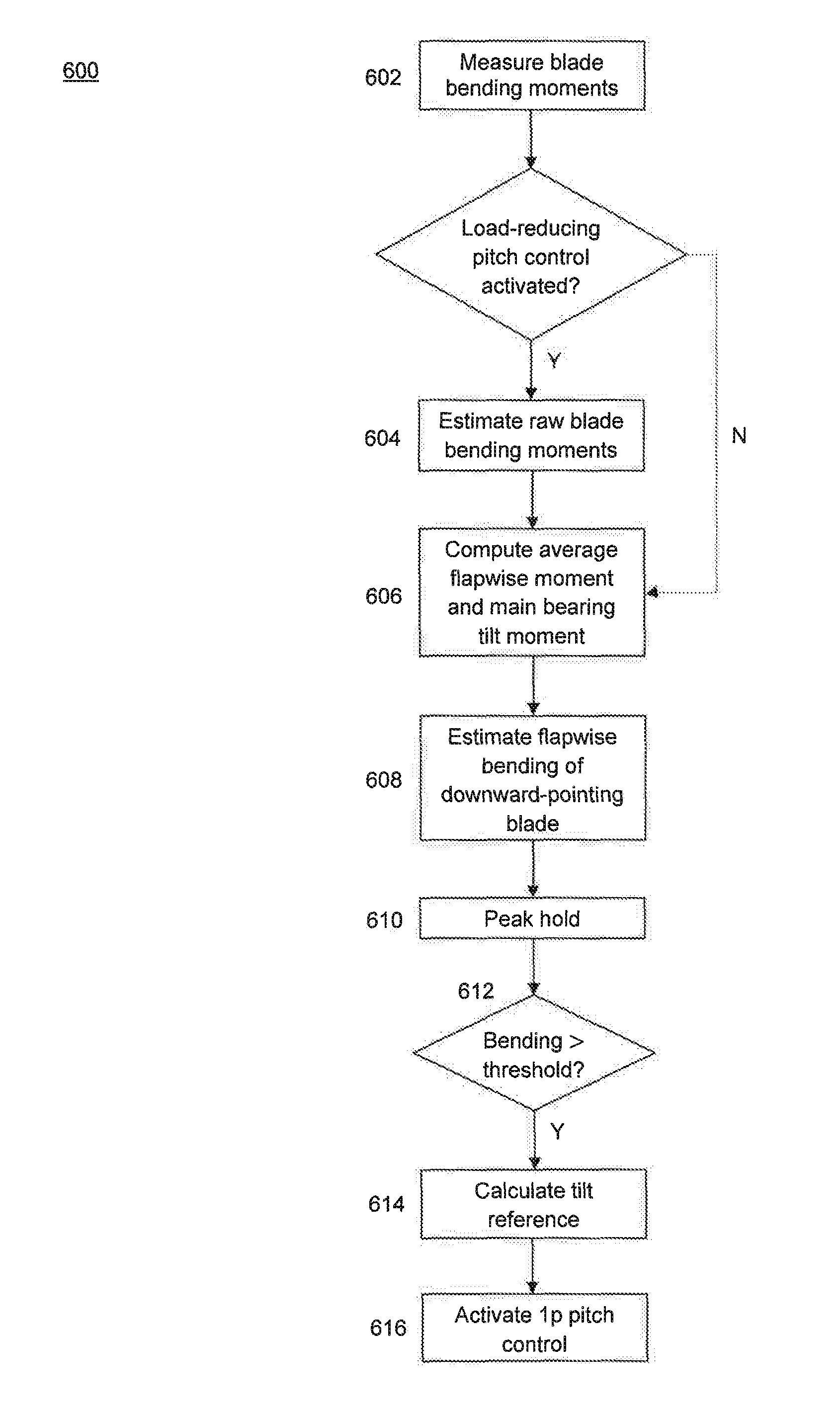

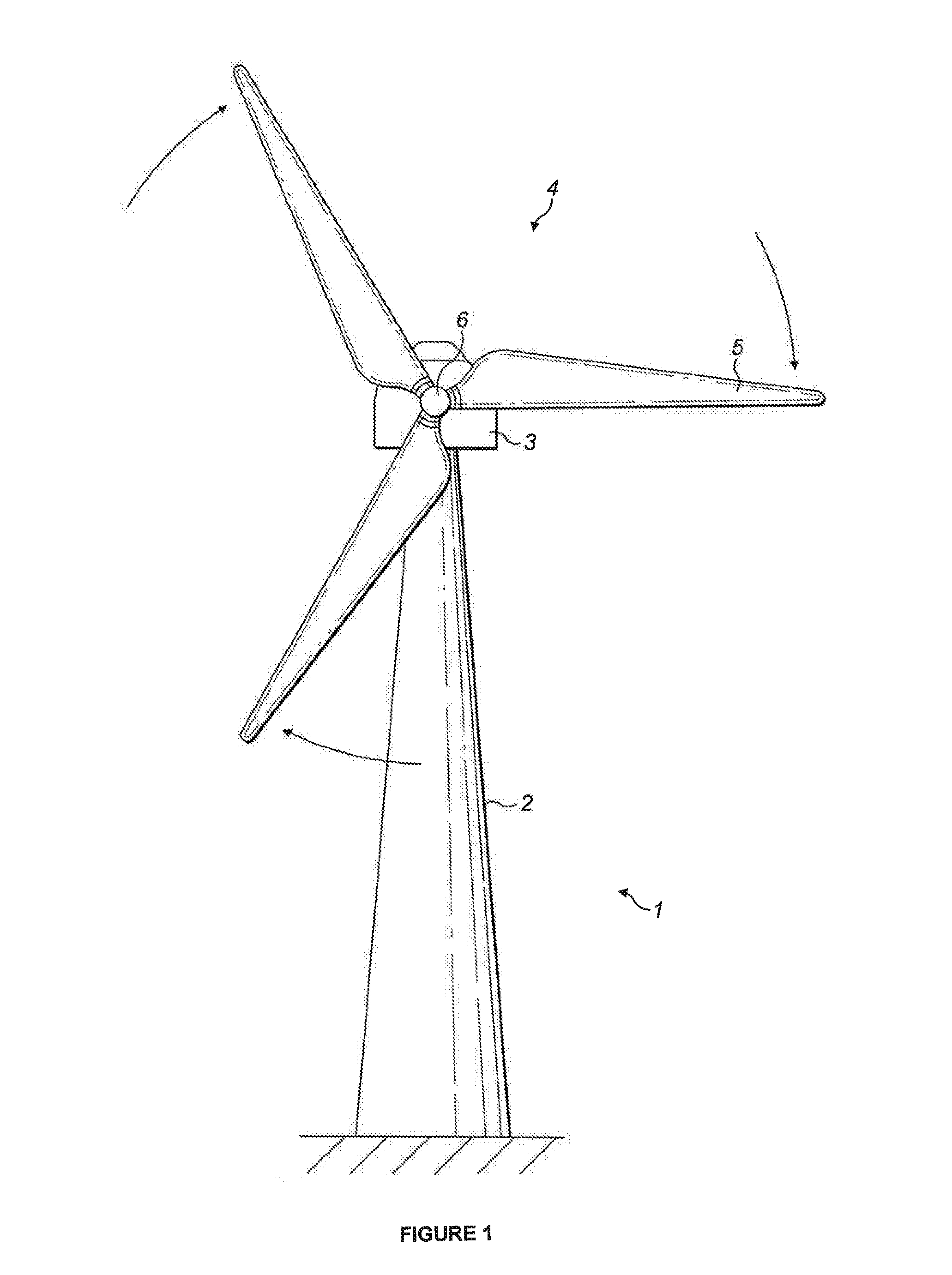

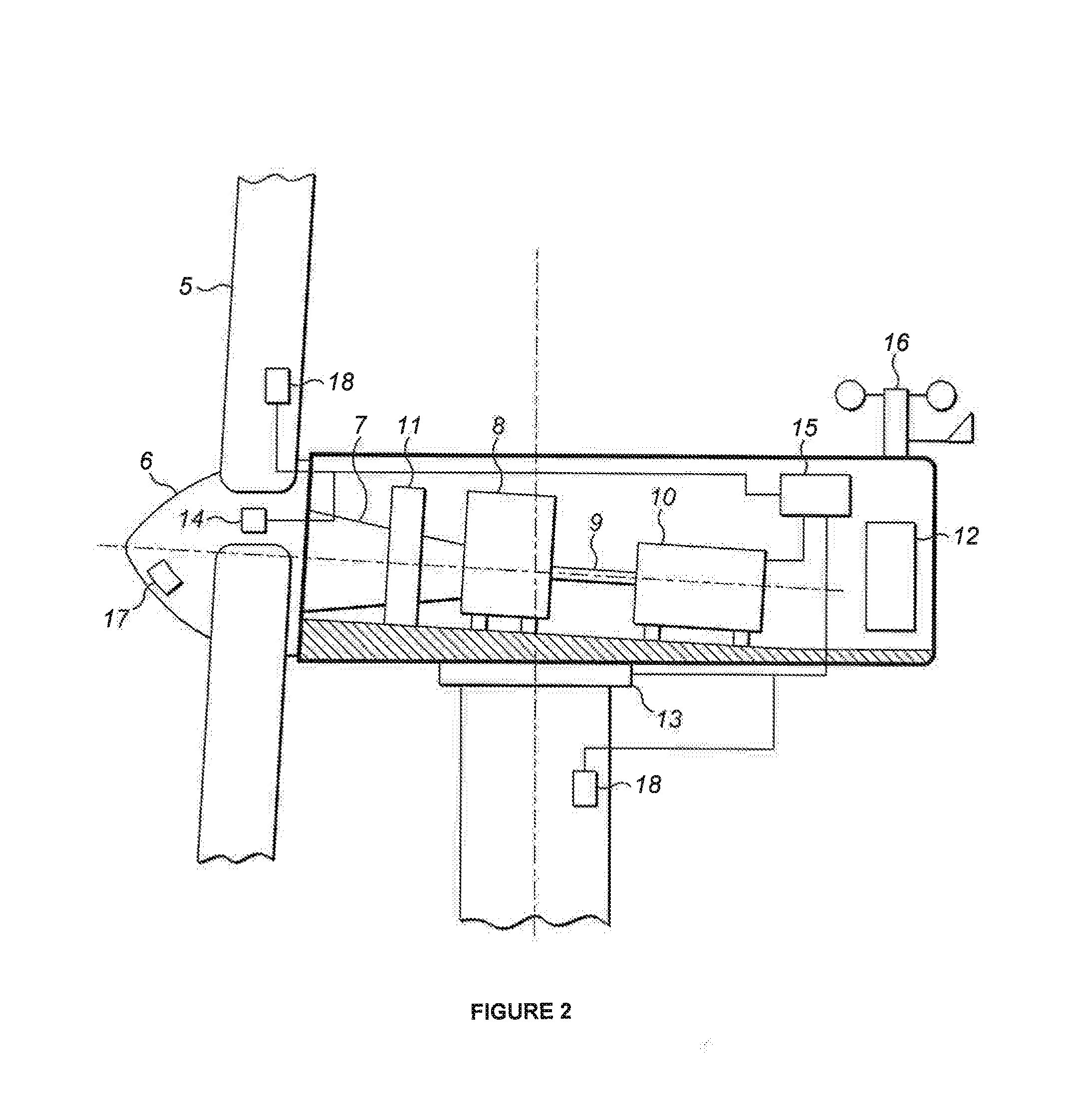

Methods and apparatus for controlling wind turbines

ActiveUS20160252075A1SelectivityImprove balanceWind motor controlMachines/enginesMarine engineeringControl theory

Methods and systems for controlling a wind turbine in a manner that takes into account the degree of loading of and damage to one or more components of the turbine are provided. An operational load on a wind turbine part is determined, and is used to compute a damage signal. The damage signal is indicative of the potential damage to the component or to the turbine as a whole that will result if action is not taken to reduce or mitigate the determined load. When the damage signal exceeds a pre-determined threshold, load-reducing wind turbine control means are activated to obviate the estimated damage.

Owner:VESTAS WIND SYST AS

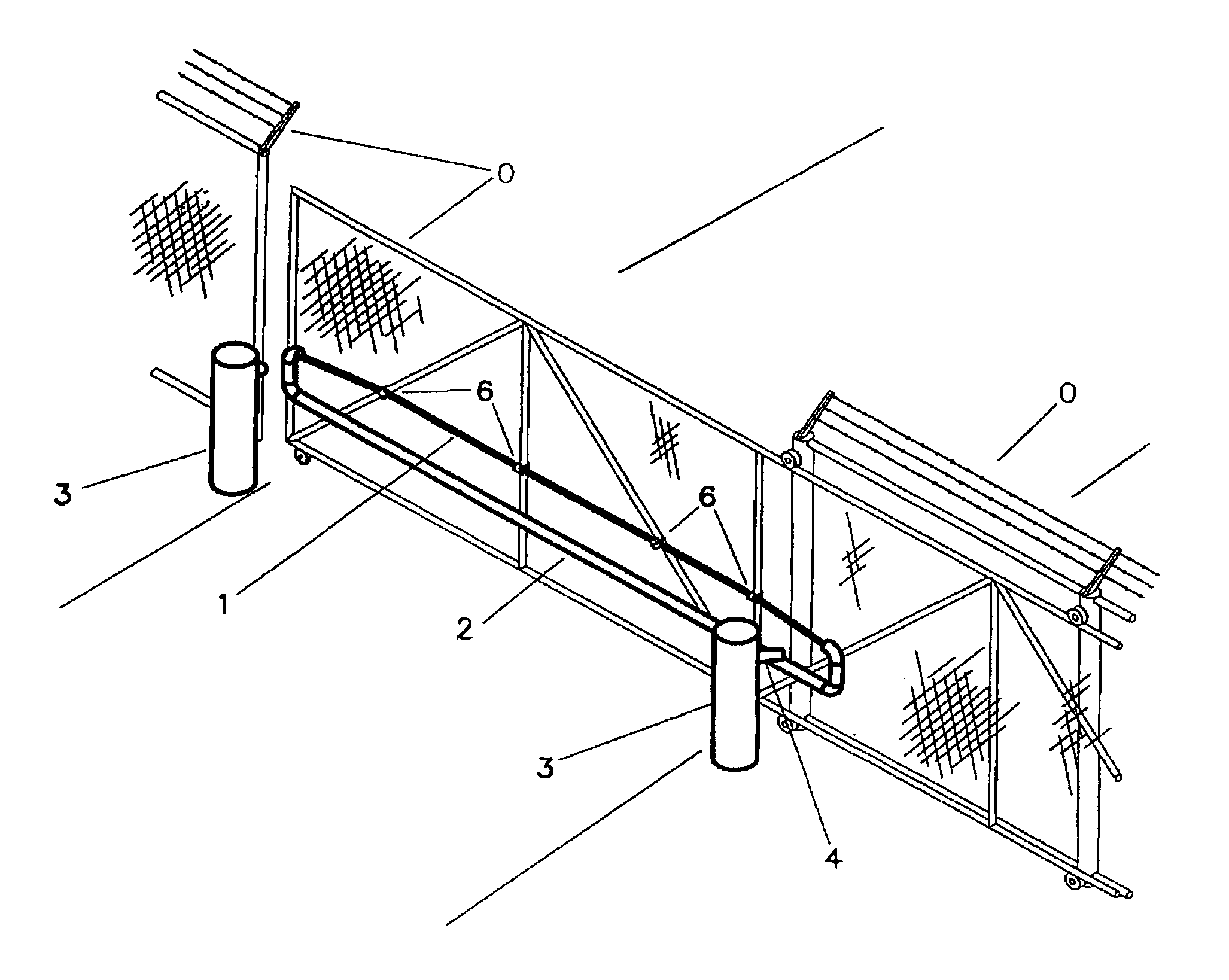

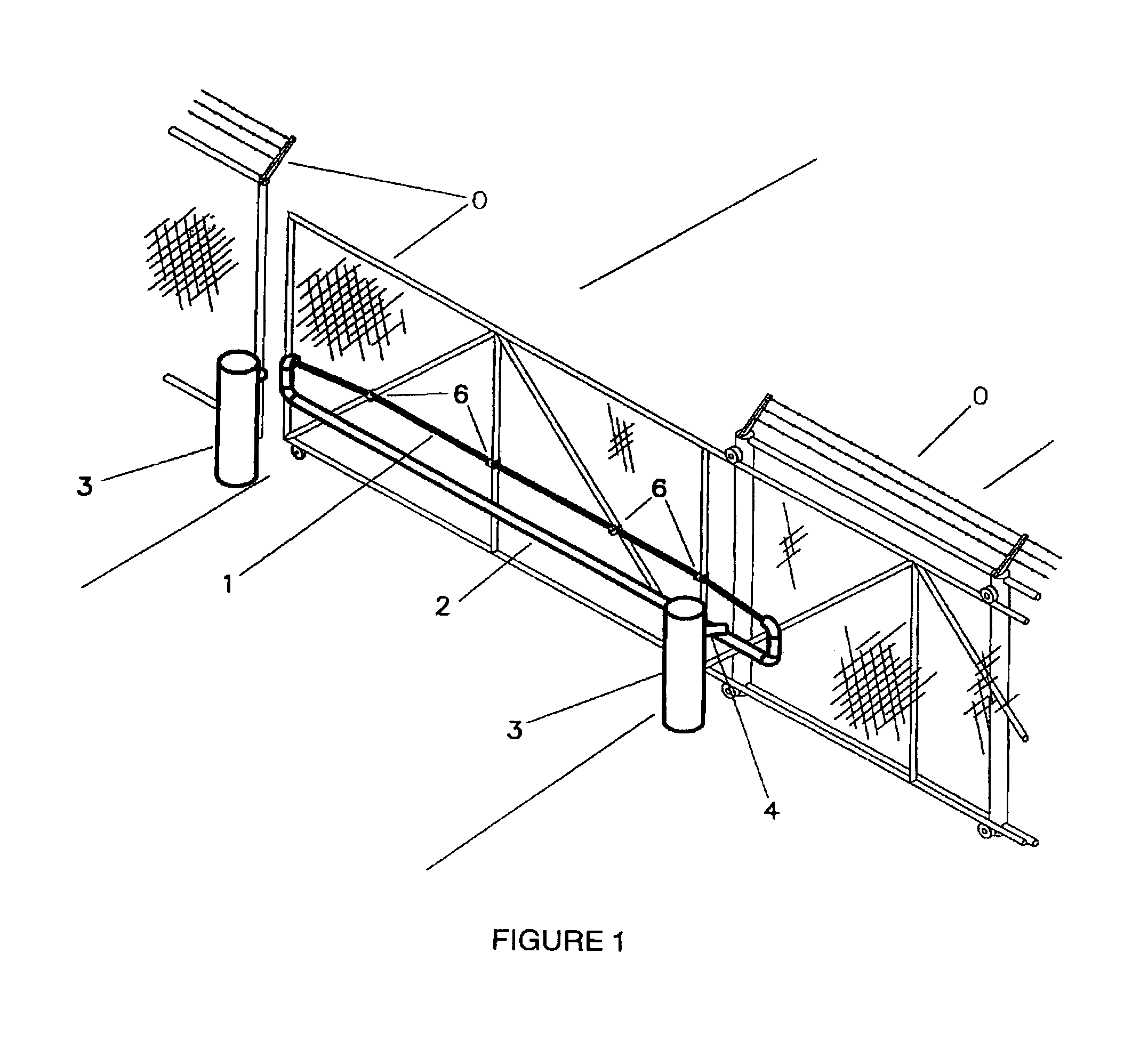

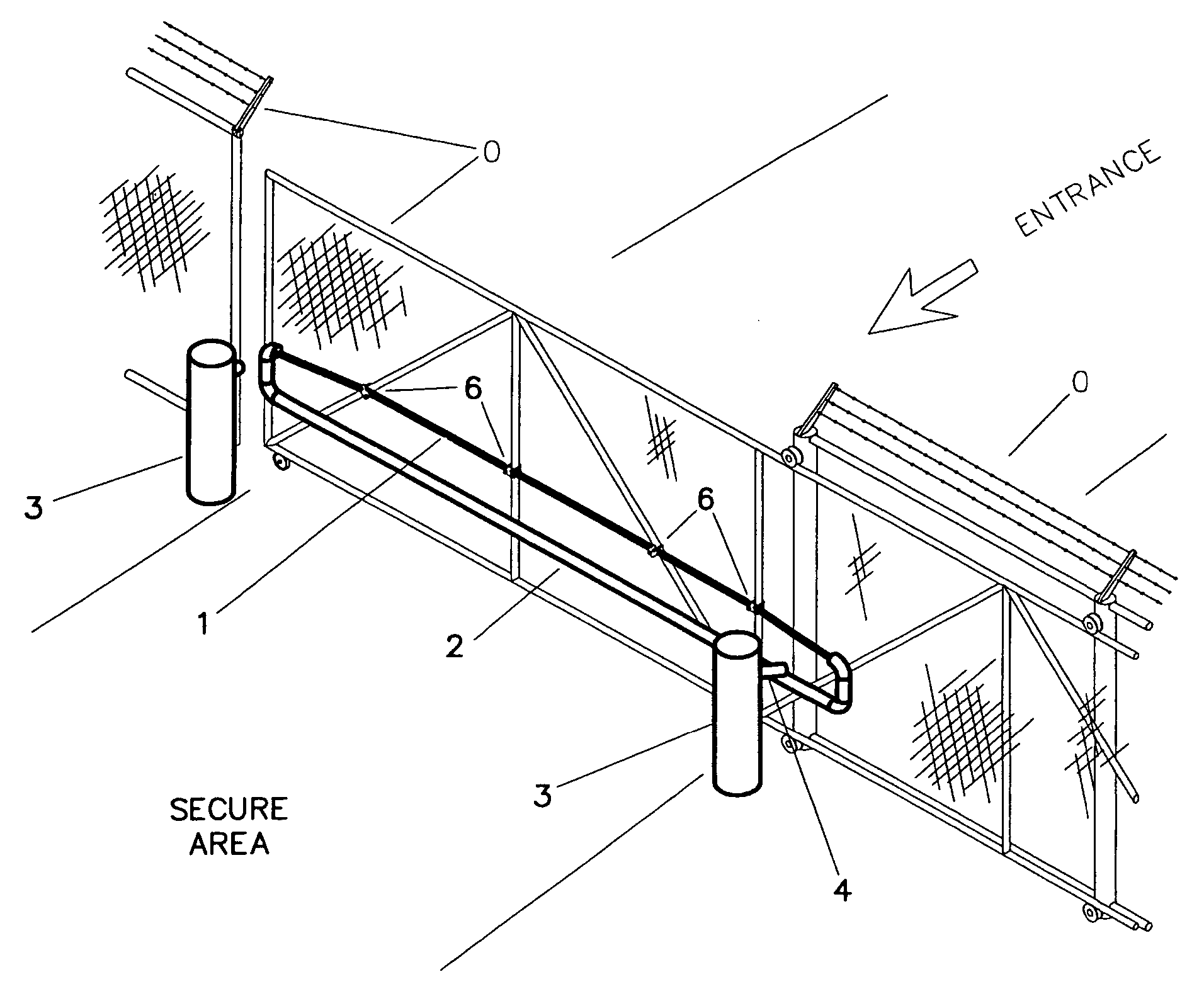

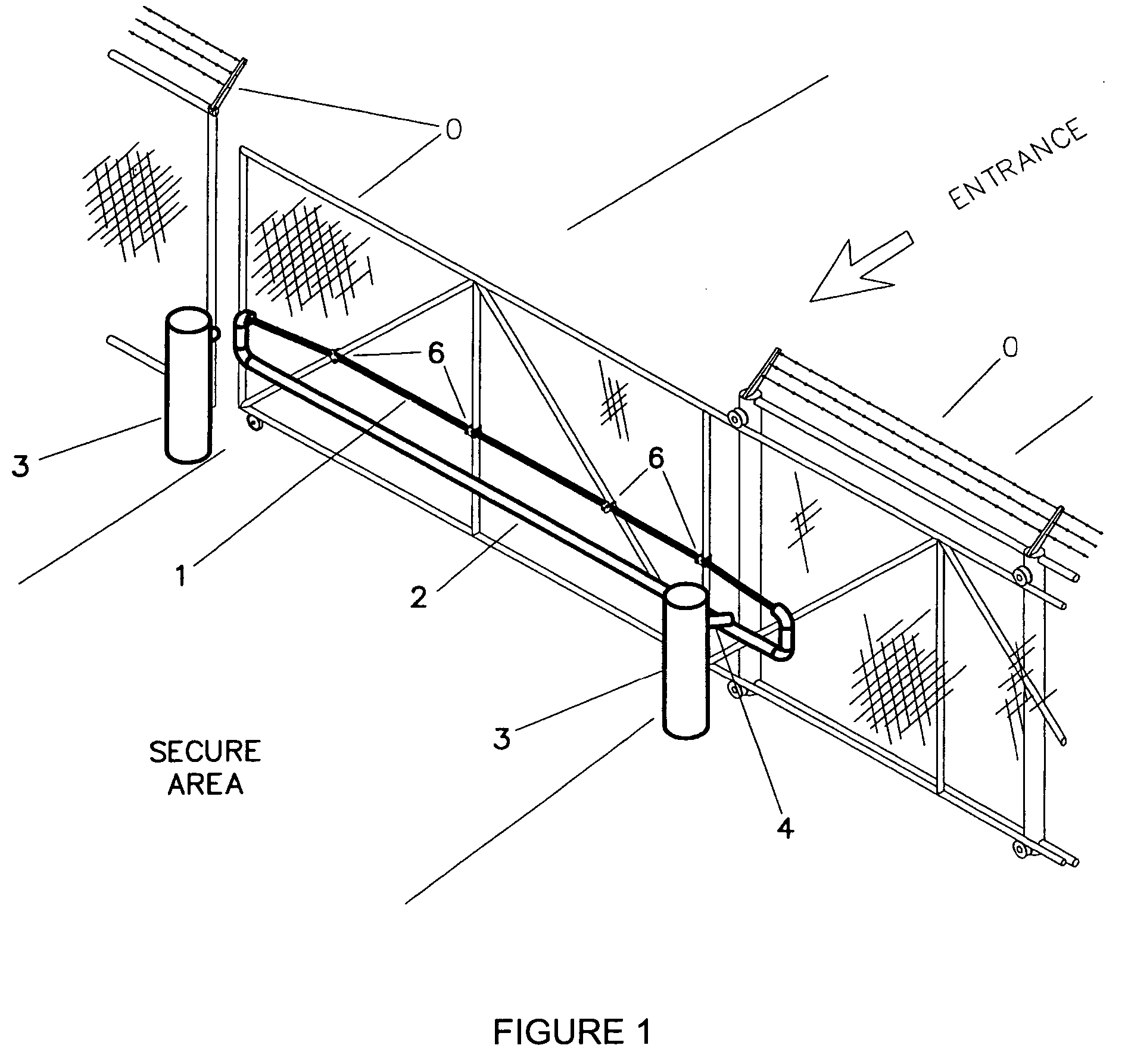

Security barrier reinforcing system

ActiveUS7121041B2Reduce the potential for damageEvenly loadedFencingTraffic restrictionsEngineeringLoad distribution

A system for upgrading new and existing gates or barriers to provide improved crash barrier rating. This system comprises a reinforcing attachment to the gate or barrier and improved reinforced bollards with catch hooks to absorb the energy of impact from a vehicle. The reinforcing attachment is an arrangement of cable and structural members that provide for increased reinforcement by ensuring that the load is distributed on the cable to minimize the risk of breakthrough as a result of cable failure. The bollards have been improved by strengthening the catch hook attachments and adding reinforcement positioning elements to facilitate proper assembly.

Owner:GLOBAL GRAB TECH INC

Absorbent articles comprising a bodily exudate modifying agent and a film-forming skin care formulation

InactiveUS7265257B2Promote absorptionImprove protectionMaterial nanotechnologyBaby linensEnhanced absorptionFilm-forming agent

Absorbent articles having enhanced absorption of bodily exudates are disclosed. The absorbent articles comprise a bodily exudate modifying agent and a skin care formulation. The bodily exudate modifying agent is capable of reducing the viscosity of bodily exudates such as feces and menses. The skin care formulation comprises a film forming agent that, upon transfer to the skin, can form a continuous film layer on the skin to retard harmful agents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

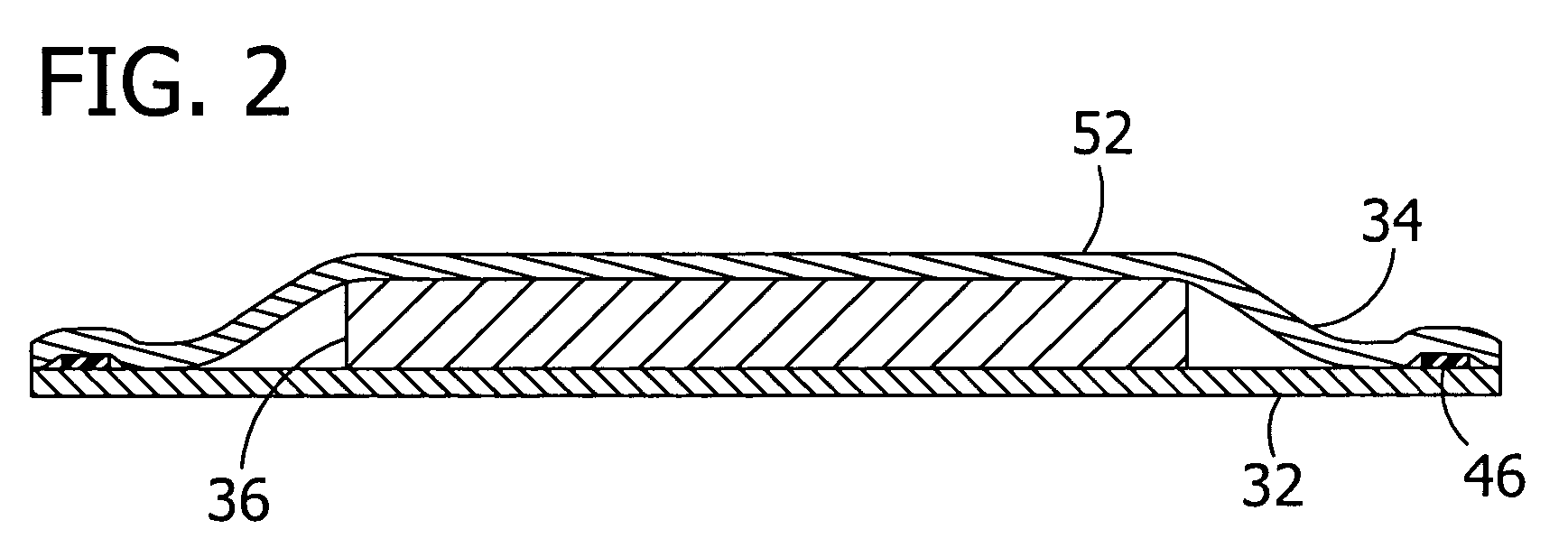

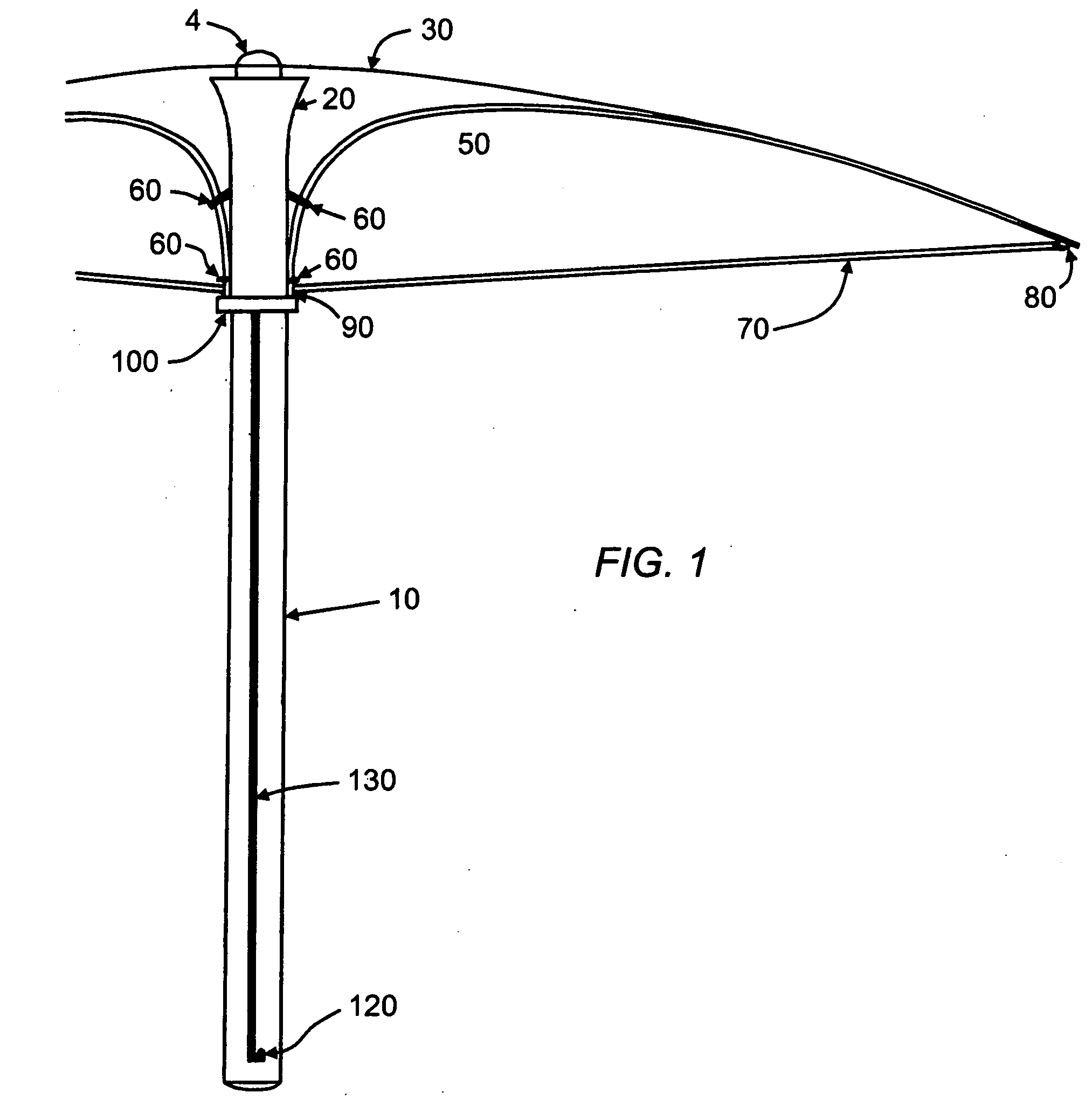

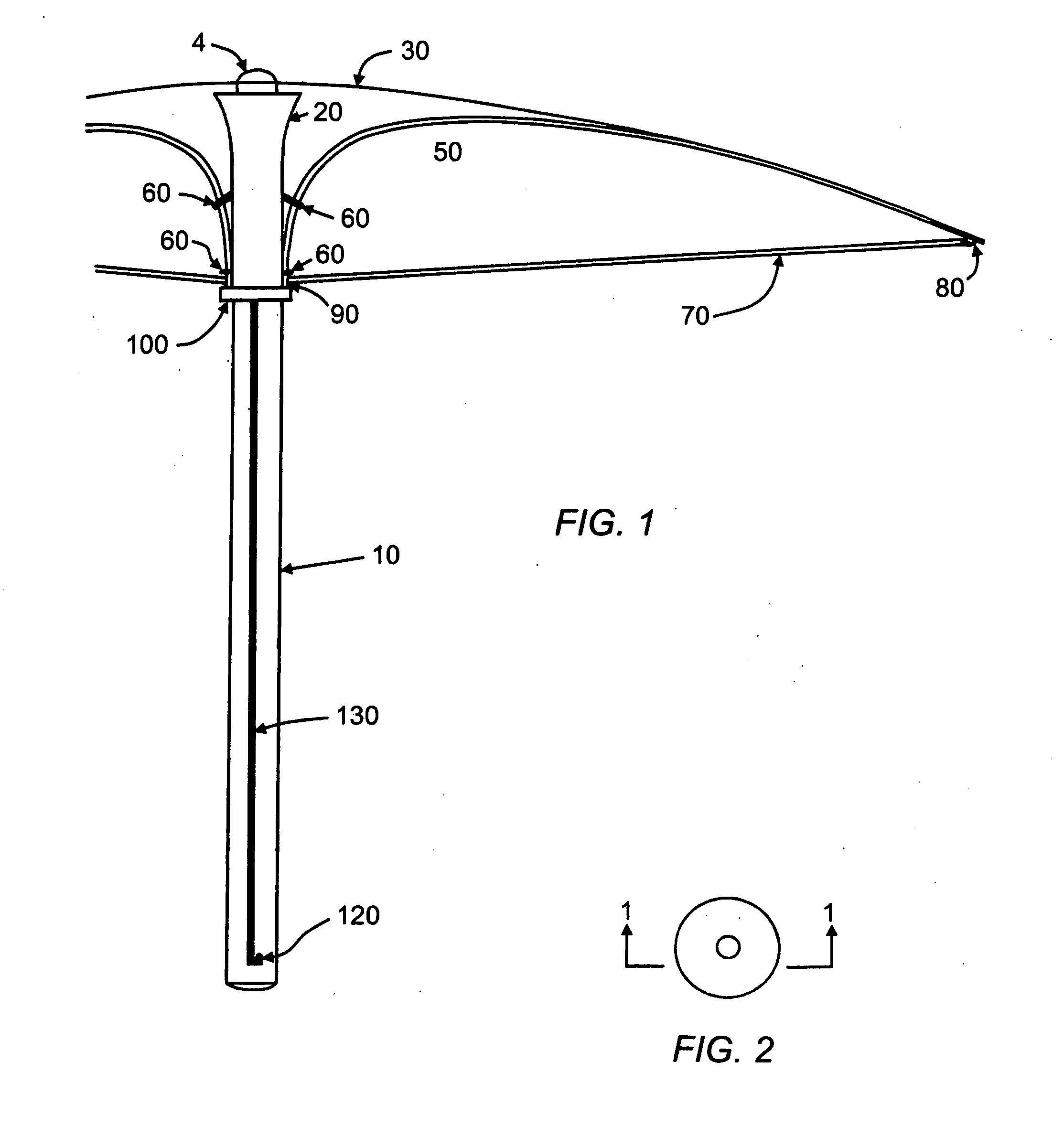

Umbrella system with support for internal storage of cover and external sliding ribs and stretchers

InactiveUS20090223545A1Reduce the potential for damageWalking sticksUmbrellasGlass fiberReady to use

The present invention relates to an umbrella system, substantially comprising an umbrella with elements that include a hollow shaft, a cover, as well as a frame consisting of ribs and stretchers mounted on the exterior of the hollow shaft. When retracted, the cover is stowed inside the shaft. When deployed, the umbrella's cover is supported by ribs and stretchers as well as by the shaft. Ribs and stretchers slide along the hollow shaft's exterior as the invention's cover is deployed and retracted.This configuration of deployment elements is not seen in the prior art of umbrella construction. It allows use of accouterments that expand the invention's use and convenience.The umbrella may be constructed using materials having low coefficients of electrical conductivity such fiberglass, plastics, or composites, thereby reducing shock risks. The manner of the invention's construction also enhances its ability to resist damage due to excessive wind as well as unwanted transfer of moisture from its retracted cover.

Owner:BEYER ANDREA ELGIN +1

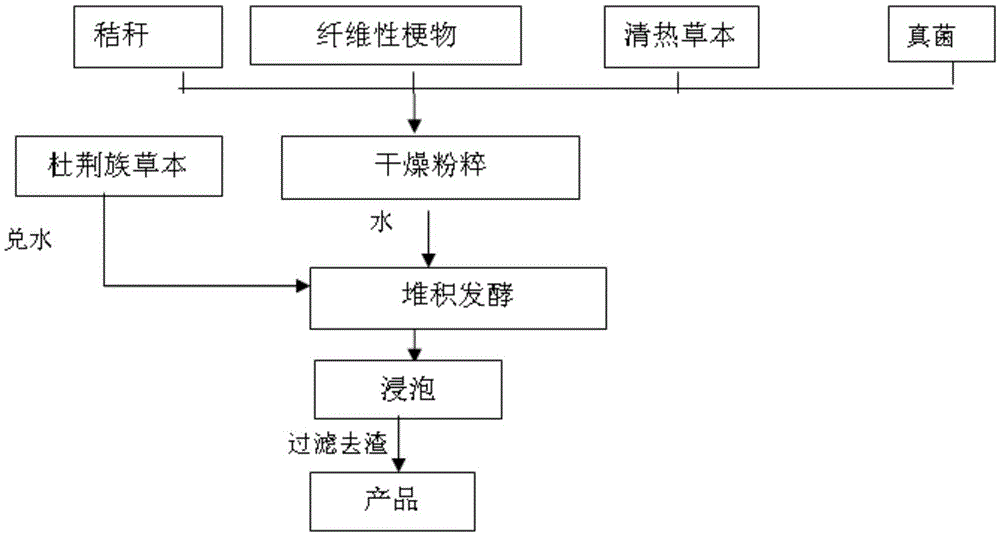

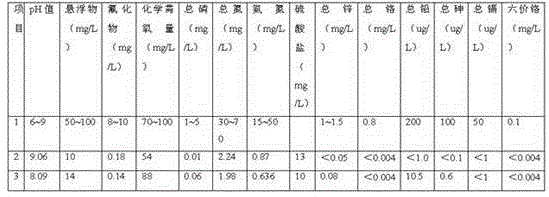

Herbaceous plant rare-earth precipitating agent and preparation method thereof

InactiveCN105603222AGood environmental effectRemarkable convenience for recyclingProcess efficiency improvementNitrogenVitex

The invention relates to the field of preparation of rare earth, in particular to a herbaceous plant rare-earth precipitating agent and a preparation method thereof. The herbaceous plant rare-earth precipitating agent is prepared from, by weight, 30-50 parts of straw, 25-65 parts of fibrous stalks, 0.5-5 parts of herb for clearing away heat, 0.5-5 parts of Vitex.negundo L.var. cannabifolia (sieb. et Zucc.) Hand.-Mazz. herb and 0.08-5 parts of fungi, and the raw materials are weighed, smashed, fermented and soaked so that the herbaceous plant rare-earth precipitating agent can be prepared. By means of the herbaceous plant precipitating agent, the mother liquid precipitating effect can reach 99.6% or above after mineral leaching is performed on rare earth minerals in different types, the concentration of ammonia and nitrogen in supernatant after precipitation is 0.94 mg / L, secondary pollution of ammonia and nitrogen is avoided, herb precipitate contained in the supernatant can be directly used circularly, and the herbaceous plant rare-earth precipitating agent is a natural and environment-friendly precipitating agent.

Owner:GUANGXI HAOZHAO ENVIRONMENT PROTECTION TECH CO LTD

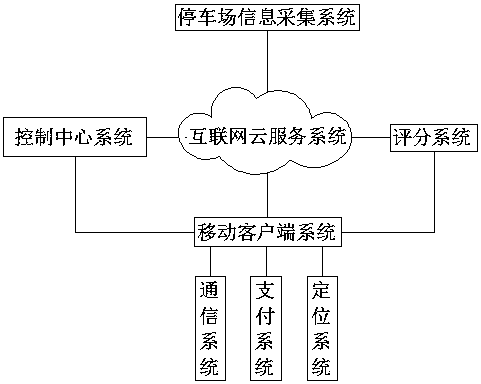

Parking space sharing system based on Internet-of-things and cloud computing

InactiveCN107591022ALessen the imbalanceAlleviate parking difficultiesIndication of parksing free spacesThe InternetPositioning system

The invention discloses a parking space sharing system based on Internet-of-things and cloud computing. The parking space sharing system comprises a control center system, a parking lot information acquisition system, an Internet cloud server system, a communication system, a mobile client system, a payment system, a positioning system and a scoring system. The mobile client system and the parkinglot information acquisition system upload parking space information to the Internet cloud server system. The control center acquires the parking space information from the Internet cloud server system and updates parking space occupation or idle information in time. A user can utilize the mobile client system for realizing reserving, renting, paid use or exchange of the shared parking space, anda route for arriving at the parking space is obtained. The scoring system performs scoring on the user according to historical record of the user and generates a credit grade. When a plurality of users reserves the same parking space, a parking space owner can check the user credit grade and performs selection for realizing no supplying of the parking space to the reserving user with relatively low credit grade.

Owner:NANJING LVZHICHENG PATENT TECH DEV CO LTD

Structural reinforcement using composite strips

InactiveUS6811861B2Reduce the potential for damageSimple structureStrutsSynthetic resin layered productsFiberParallel fiber

A composite structural reinforcing strip is affixed to a structure to be reinforced (such as a bridge span, foundation pillar, or similar structure) by the use of several fasteners which extend through the strip and into the structure. The reinforcing strip preferably includes elongated continuous parallel fibers which have lengths extending along the length of the strip, and nondirectional fibers distributed transversely across the strip, with a polymer matrix affixing the parallel and nondirectional fibers. The strip may be placed on the structure to be reinforced, and may be attached thereon by actuating a common powder-actuated fastener gun to send fasteners through the strip and into the structure.

Owner:WISCONSIN ALUMNI RES FOUND

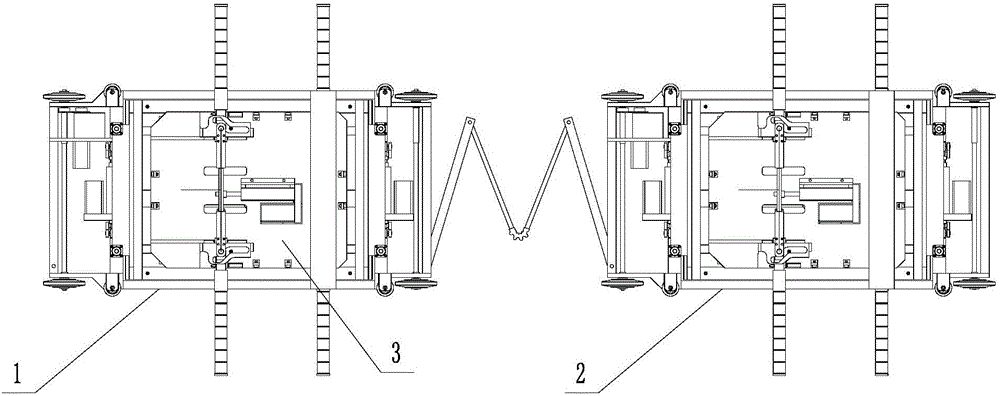

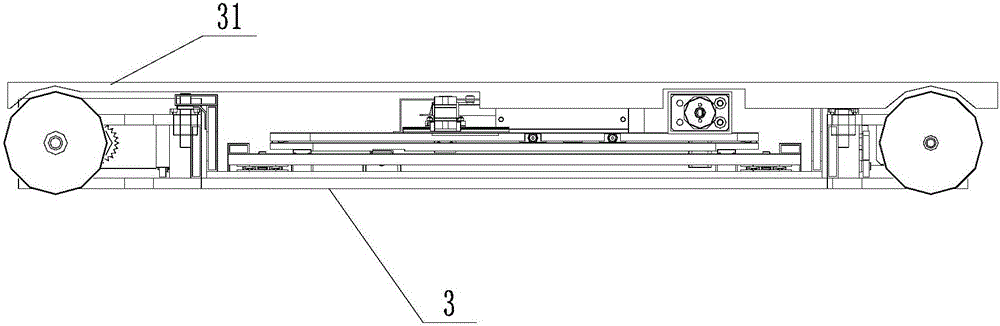

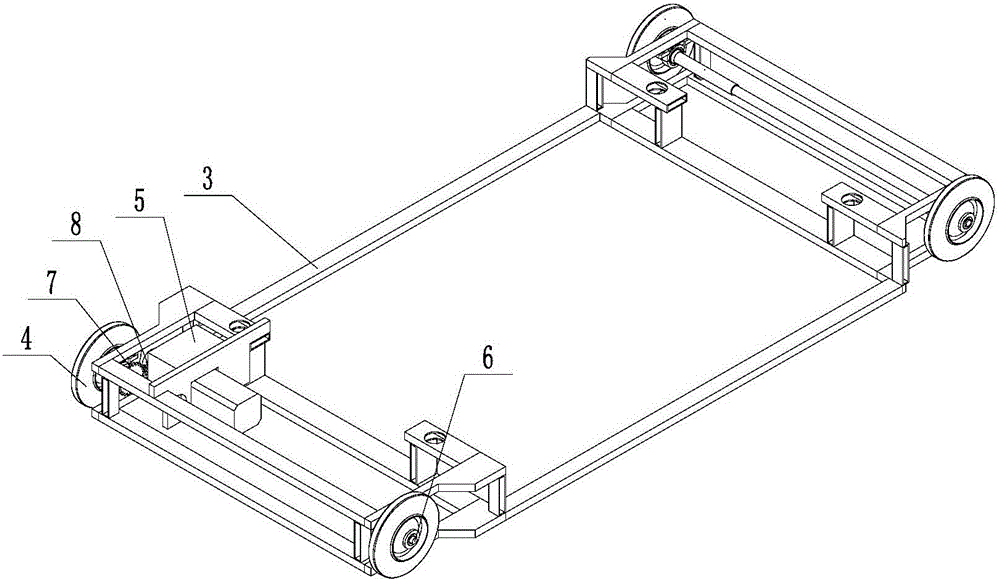

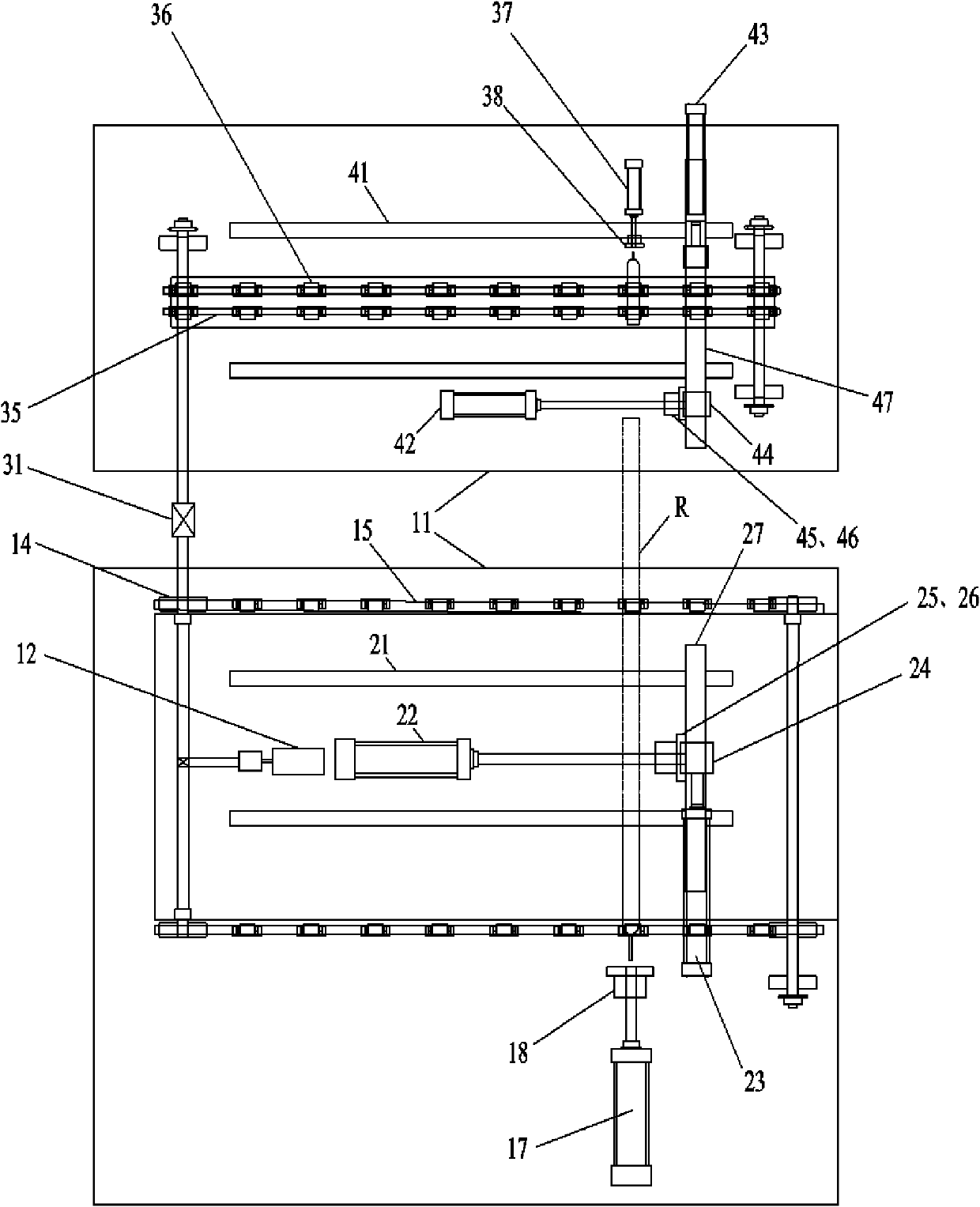

Combined type bidirectional moving intelligent garage carrying robot

ActiveCN106812361ALower requirementExtended service lifeParkingsAutomotive engineeringGround vibrations

The invention discloses a combined type bidirectional moving intelligent garage carrying robot. A traveling mechanism for driving a first trolley to move forwards and backwards, a sliding eliminating mechanism for eliminating a parking deviation of a vehicle, a lifting mechanism for lifting the vehicle and a clamping mechanism for clamping tires of the vehicle are arranged on the first trolley. According to the combined type bidirectional moving intelligent garage carrying robot, no comb tooth exchange is needed, and reduction of the service life of each tire due to excessive squeezing on the tire is avoided; automatic matching with the consistent clamping degree of the position and the size of each tire can be realized; in an alignment process, no friction is generated on the tires, the ground vibration is isolated, and the universality is high; the combined type bidirectional moving intelligent garage carrying robot has the advantages of low civil engineering requirement, high carrying efficiency and the like; meanwhile, the combined type bidirectional moving intelligent garage carrying robot is simple in structure, low in cost, high in working efficiency, long in service life and easy and convenient to operate.

Owner:JIANGSU ZHONGTAI PARKING IND CO LTD

Method for manufacturing fracturing fluid

The invention discloses a method for manufacturing fracturing fluid, and belongs to the technical field of chemicals for oil and gas production. The method is characterized in that refined cotton with a high polymerization degree is used as a cellulose raw material, and celluloses are alkalified and etherified and are subjected to micro-crosslinking to obtain a high-viscosity thickening material (semi-synthesis polymer gel) with high salt resistance; the high-viscosity thickening material is used as a thickener and a substitute for guar gum, and metal aluminum salt or titanium salt or zircon salt or a composite of the metal aluminum salt, the titanium salt and the zircon salt is used as a crosslinking agent to develop the all-clean aqueous fracturing fluid. The method has the advantages that shortcomings of the traditional guar gum fracturing fluid and a fracturing technology of the traditional guar gum fracturing fluid are overcome; the fracturing fluid is high in viscosity and salt resistance and excellent in high-temperature sand-carrying and sand-suspending performance; the fracturing fluid is free of residues after gel breaking, is low in damage to formations and is not easy to mildew, and potential damage to reservoir due to gel breakage dead space and accumulation of residual gel is reduced; the fracturing fluid can resist the high temperature of 150 DEG C.

Owner:山东金晓阳生物科技有限公司

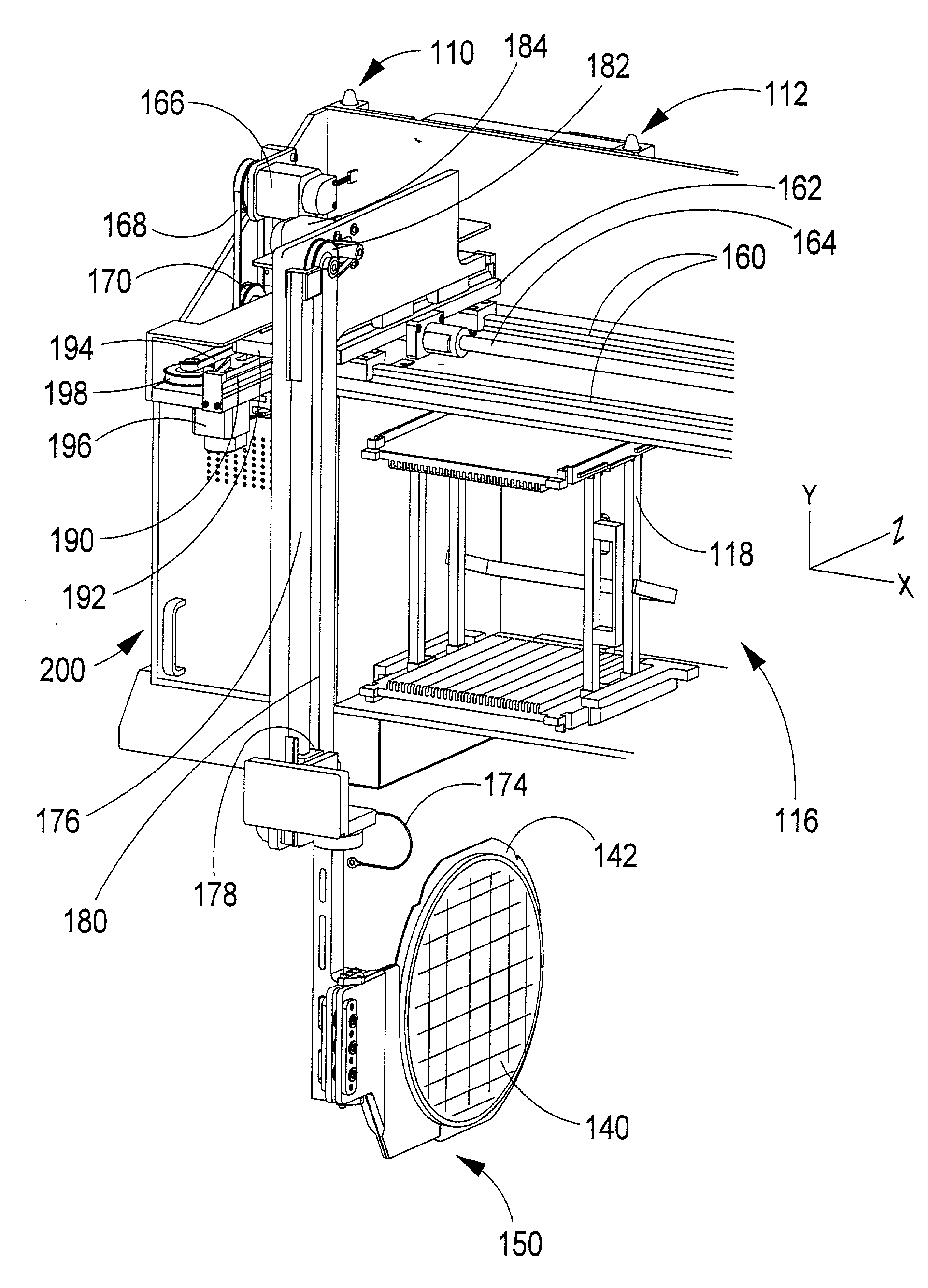

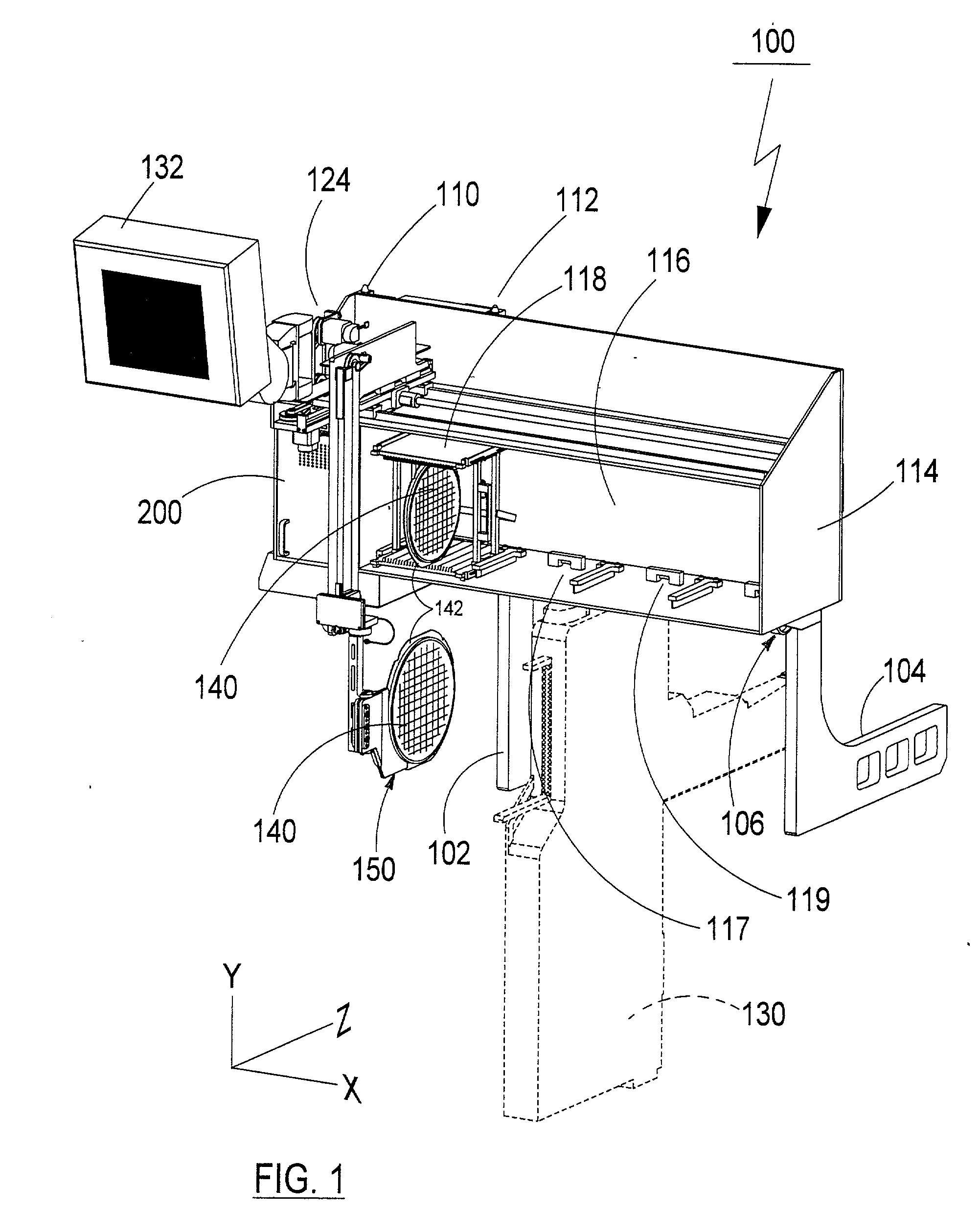

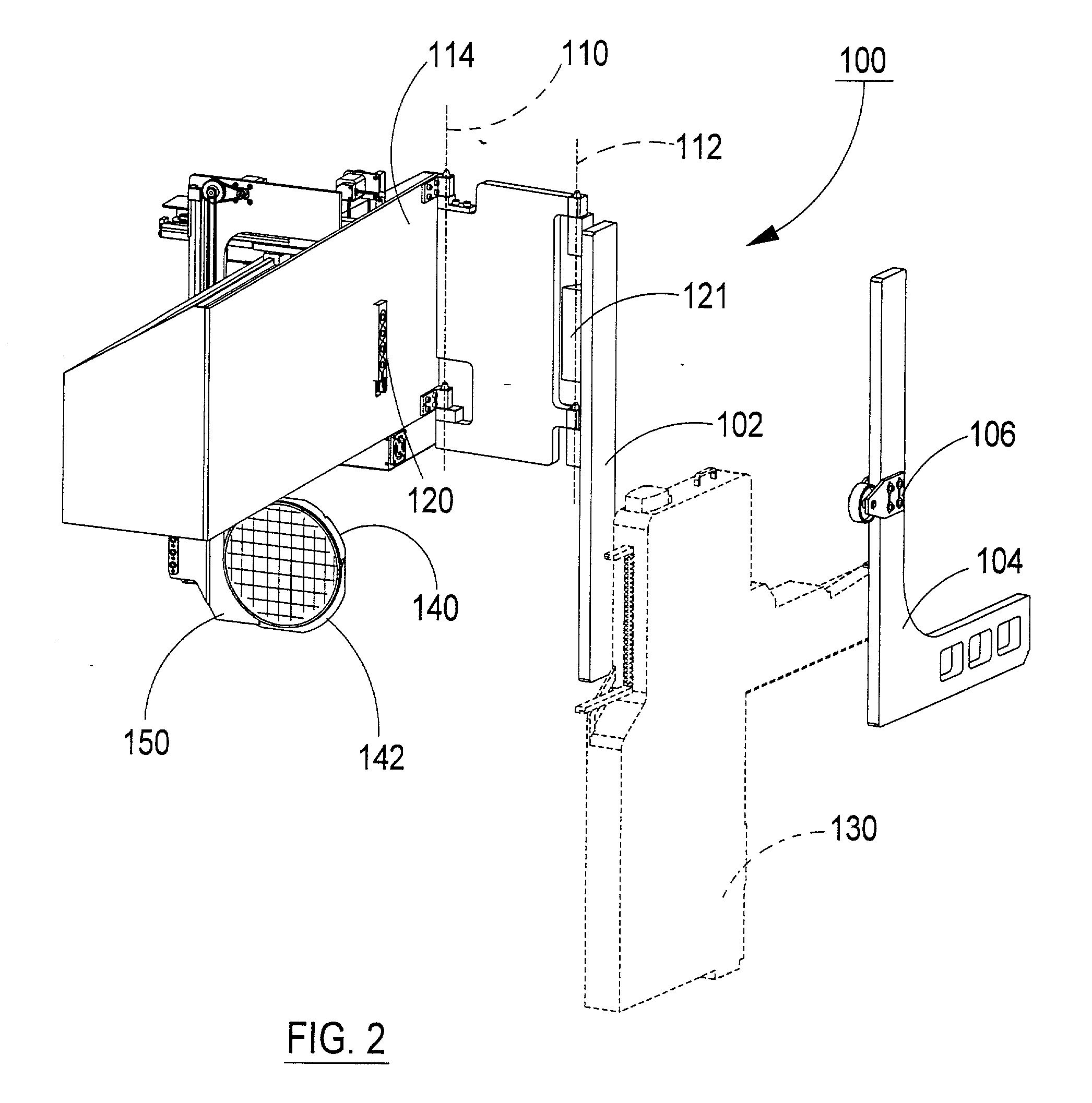

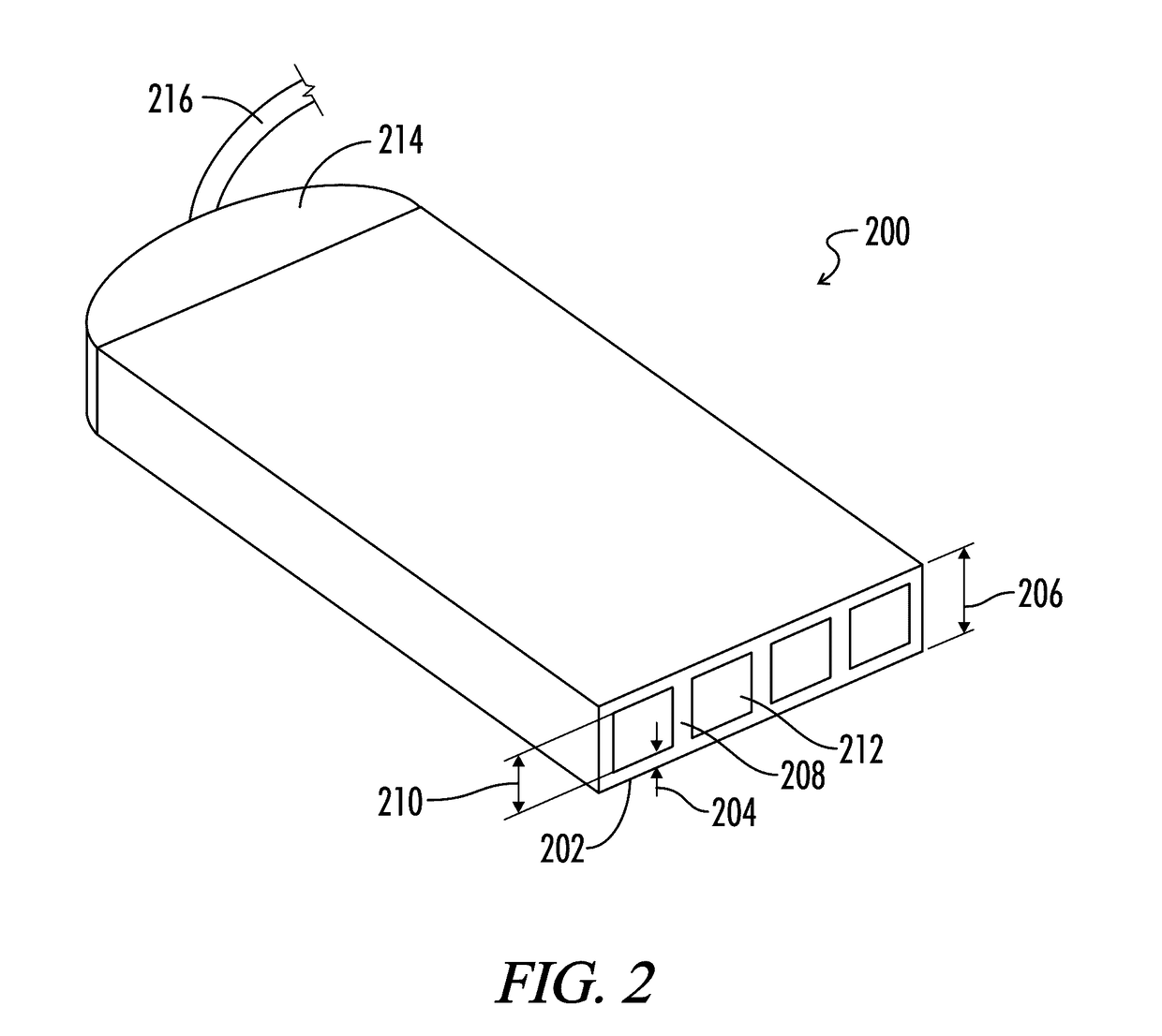

Component source interchange gantry

InactiveUS20020003994A1Reduce the potential for damageImprove reliabilitySemiconductor/solid-state device manufacturingPackagingPrinted circuit boardAssembly systems

The present invention is a method and apparatus for automatically storing and replenishing expandable wafers used in component feeders used in automated printed circuit board assembly systems, for example the Hover-Davis Direct Die Feeder (DDF). In the mass production of printed circuit boards automated pick-and-place equipment accepts die from "chip feeders" and then mounts them at a predetermined location on the circuit board. The present invention includes a wafer or tape reel storage bay and a gripping assembly that is moved by a gantry robot to retrieve a wafer or reel from the storage bay and automatically deposit it into a component feeder.

Owner:DELAWARE CAPITAL FORMATION

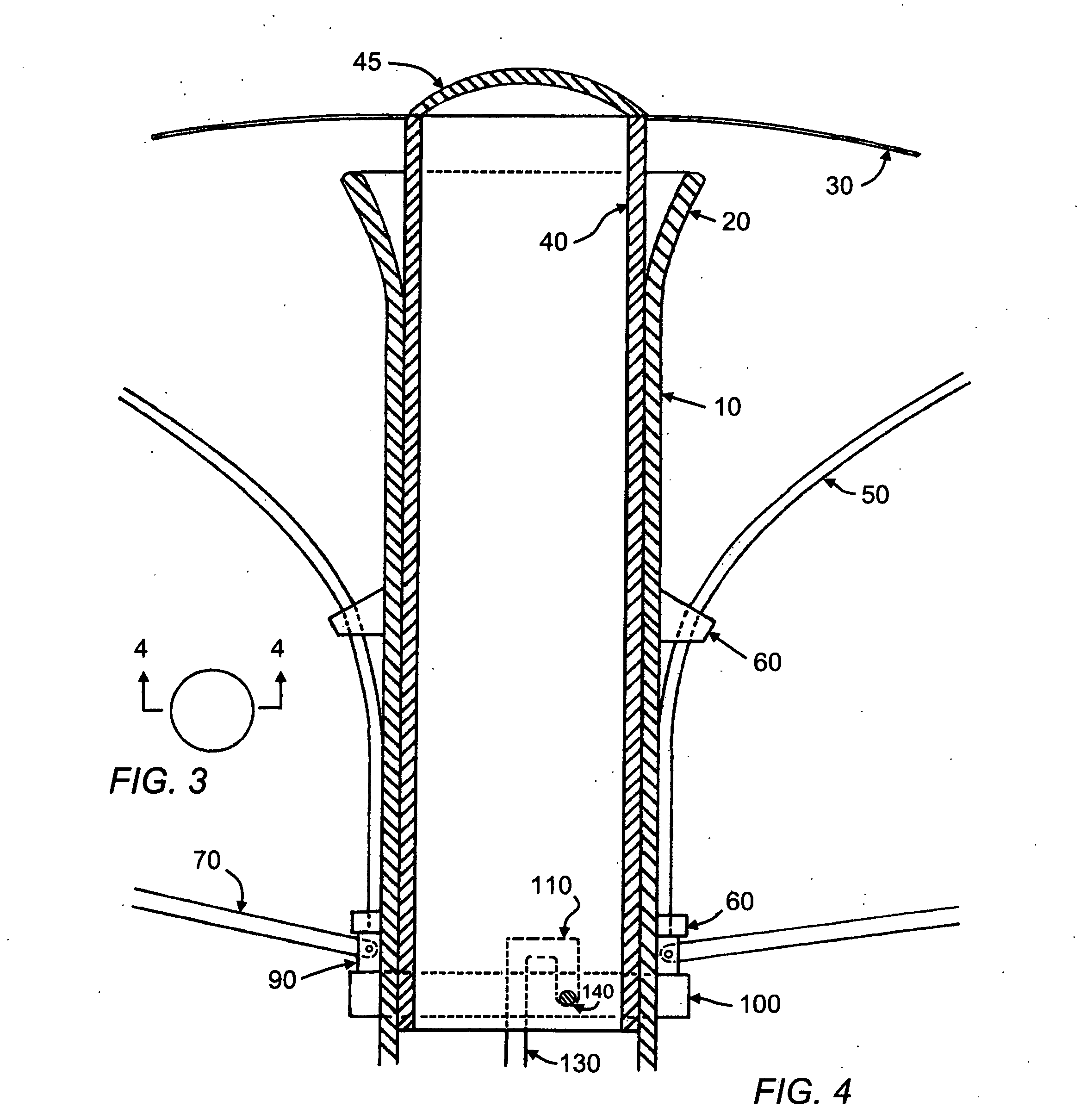

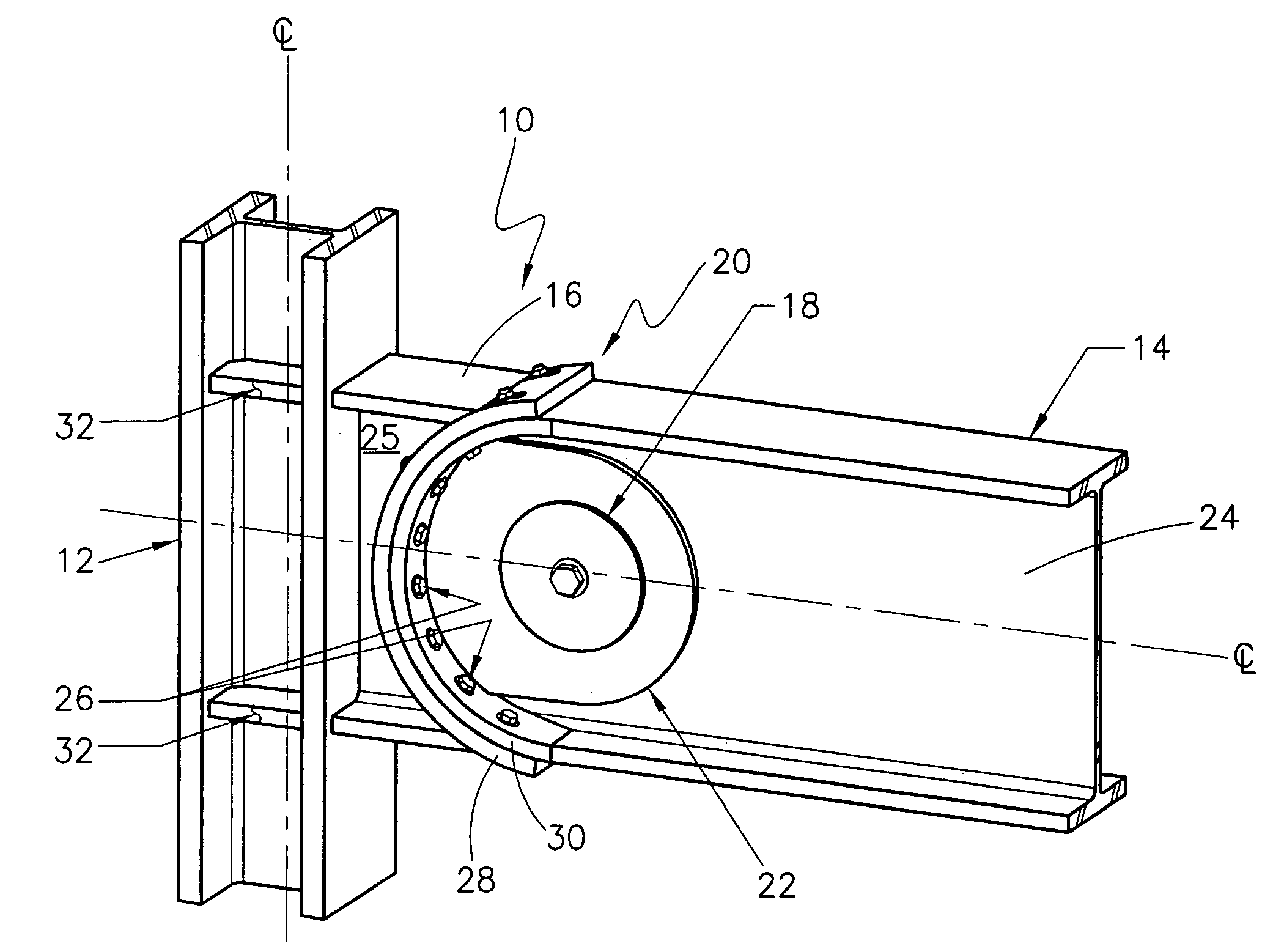

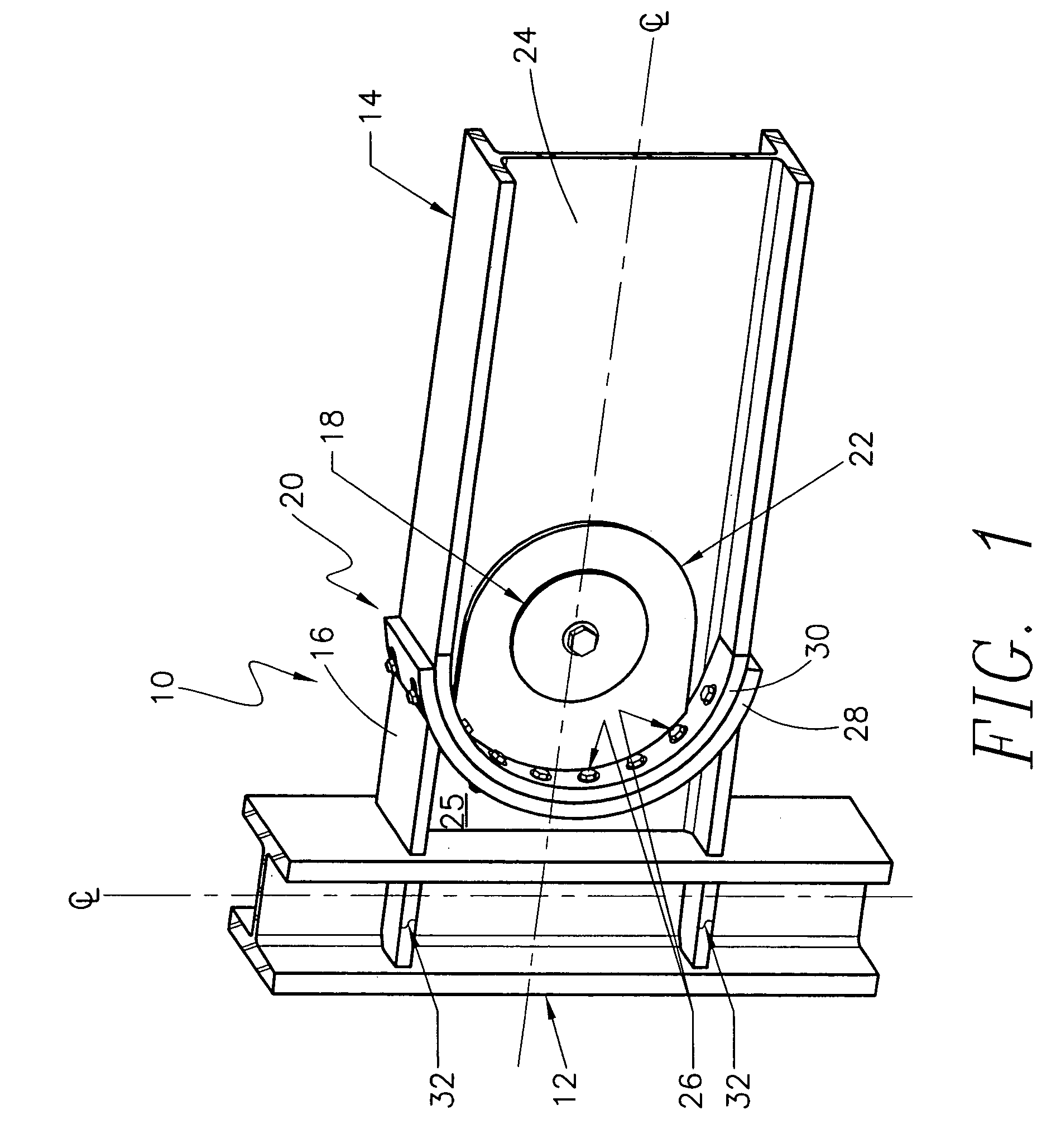

Seismic structural device

InactiveUS7000304B2Simple structureExtended maintenance periodRoof coveringRod connectionsResistEarthquake resistant structures

A pin-fuse joint generally utilized in a beam-to-column joint assembly subject to extreme seismic loading is described. The pin-fuse joint resists bending moments and shears generated by these loads. The joint is comprised of standard structural steel building materials, but may be applied to structures comprised of structural steel, reinforced concrete, and or composite materials, e.g., a combination of structural steel and reinforced concrete. The beam-to-column assembly is comprised of a column and a beam and a plate assembly that extends between the column and the beam. The plate assembly is welded to the column and is attached to the beam via the pin-fuse joint. The pin fuse joint is created by a pin connection through the beam and the connection plates of the plate assembly at the web of the beam. Additionally, both the plate assembly and the beam have curved flange end connectors that sit flush against one another separated only by a brass shim when the beam and plate assembly are joined. The curved flange end connectors of the beam and plate assembly are then secured against one another by torqued high-strength bolts.

Owner:SKIDMORE OWINGS & MERRILL LLP

Absorbent articles comprising a bodily exudate modifying agent and a skin care formulation

ActiveUS7642397B2Promote absorptionLow viscosityMaterial nanotechnologySanitary towelsSkin barrier functionEnhanced absorption

Absorbent articles having enhanced absorption of bodily exudates are disclosed. The absorbent articles comprise a bodily exudate modifying agent and a skin care formulation. The bodily exudate modifying agent is capable of reducing the viscosity of bodily exudates such as feces and menses. The skin care formulation comprises a bodily exudate modifying agent neutralizer to neutralize the possible negative effects on skin barrier function caused by the bodily exudate modifying agents coming into direct contact with the wearer's skin.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Security barrier reinforcing system

ActiveUS20050178065A1Distribute the load evenlyReduce the potential for damageFencingTraffic restrictionsEngineeringMechanical engineering

An improved system for upgrading new and existing gates or barriers to provide improved crash barrier rating. This system comprises a reinforcing attachment to the gate or barrier and improved reinforced bollards with catch hooks to absorb the energy of impact. The reinforcing attachment is an arrangement of cable and structural members that provide for increased reinforcement by ensuring that the load is distributed on the cable to minimize the risk of breakthrough as a result of cable failure. The bollards have been improved by strengthening the catch hook attachments and adding reinforcement positioning elements to facilitate proper assembly.

Owner:GLOBAL GRAB TECH INC

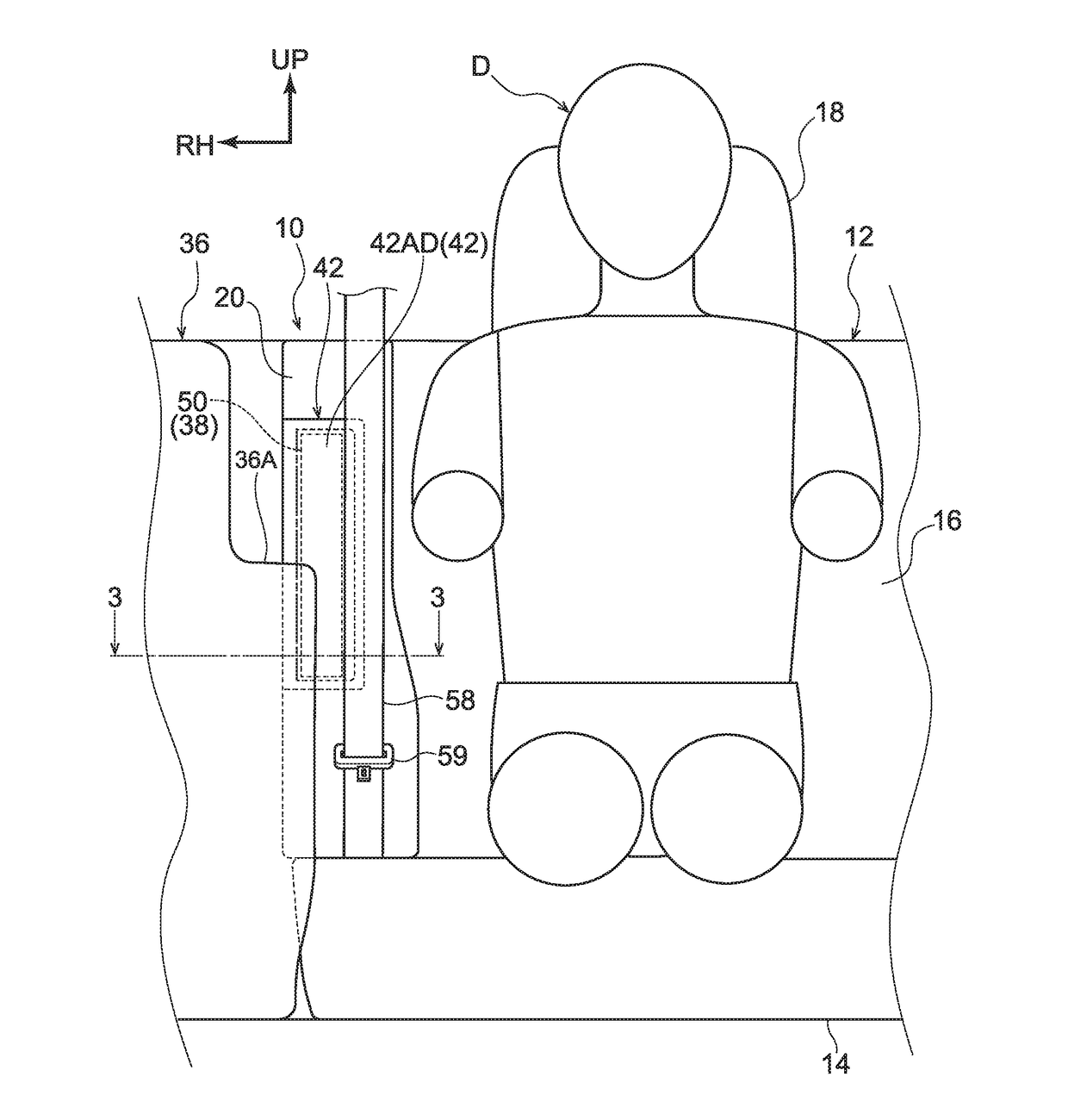

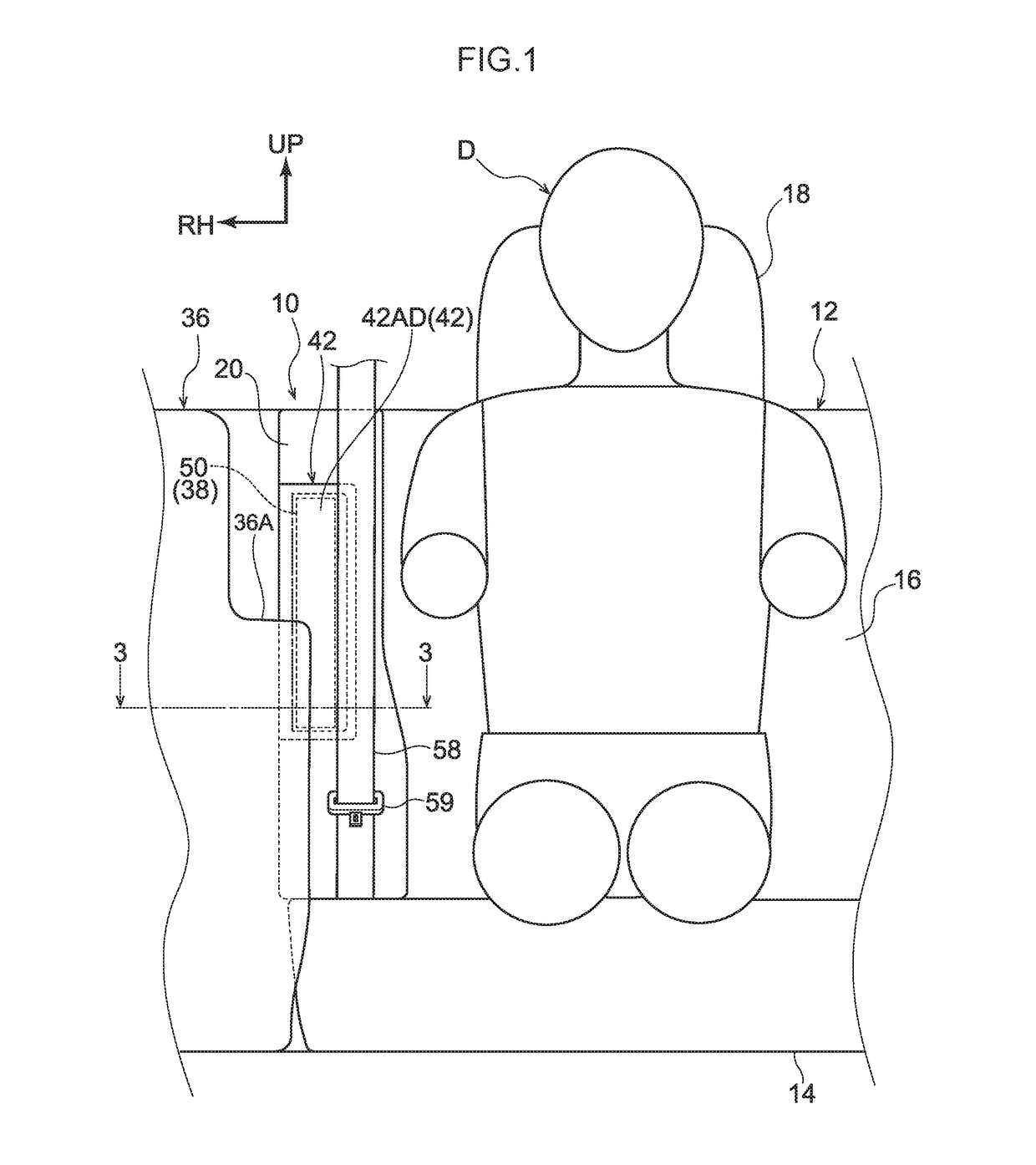

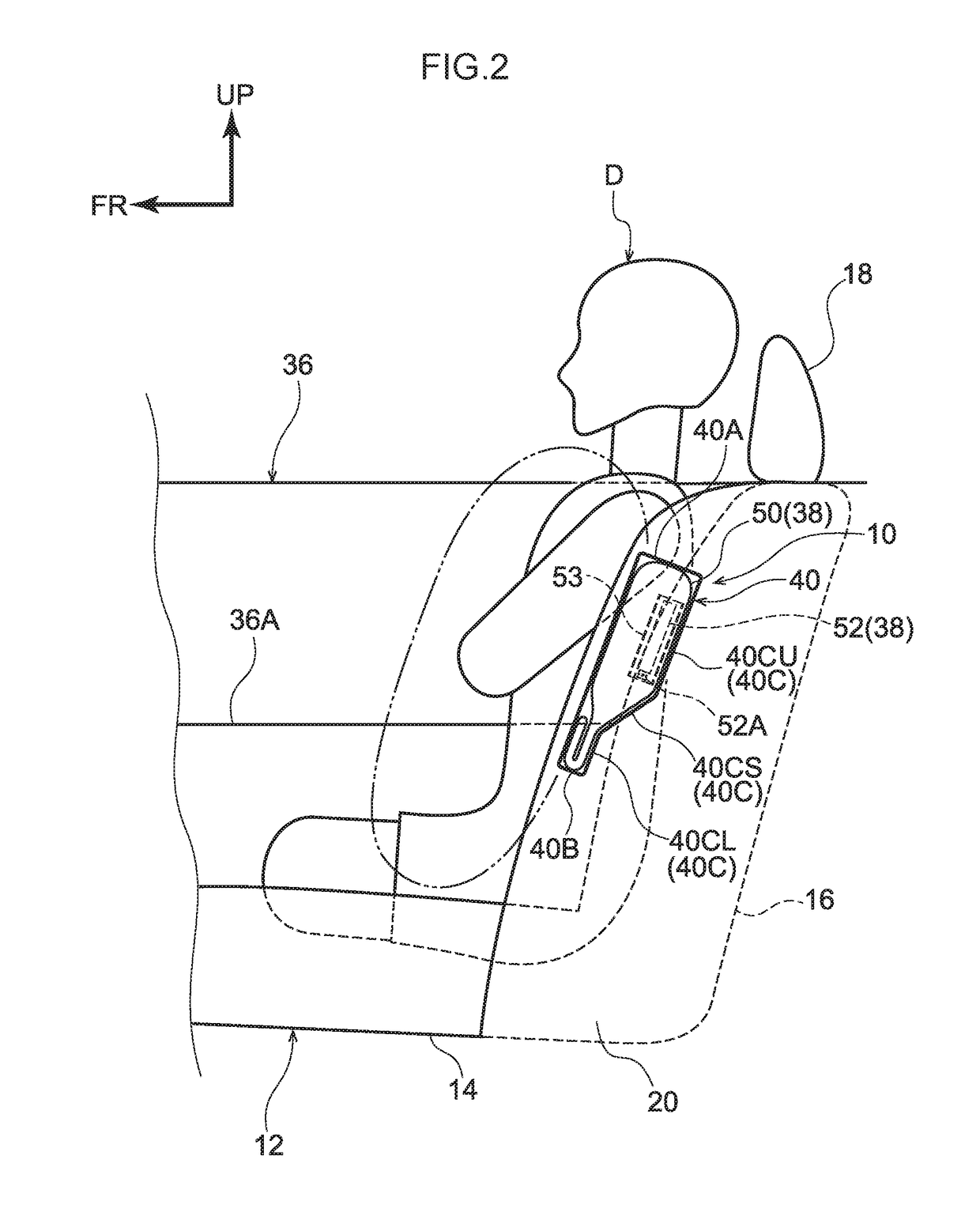

Side airbag device for rear seat

ActiveUS20170072900A1Reduce the potential for damageImprove acceleration performancePedestrian/occupant safety arrangementLateral airbagHandrail

There is provided a side airbag device for a rear seat, the side airbag including (i) a side airbag that is provided between a vehicle body and a side portion of a seatback of a rear seat, and at least a portion of the side airbag is disposed further toward a vehicle lower side than a top surface of an armrest, and the side airbag is expanded at a side of a passenger at a time of a collision, and (ii) an airbag door garnish that covers the side airbag from a vehicle cabin side, and that has a door portion that, due to inflation pressure of the side airbag, opens toward a vehicle front side and a vehicle transverse direction outer side and abuts the armrest.

Owner:TOYOTA JIDOSHA KK

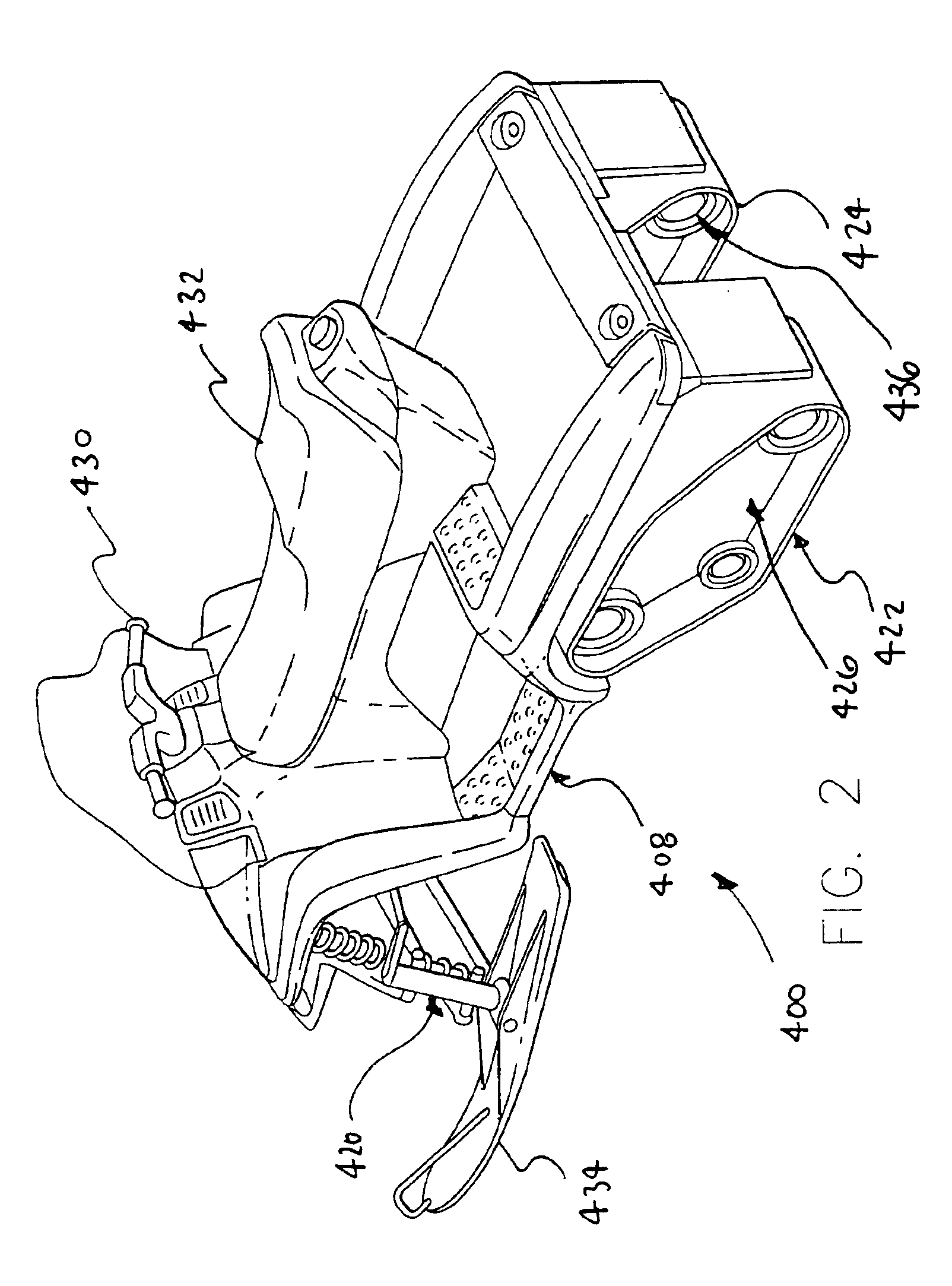

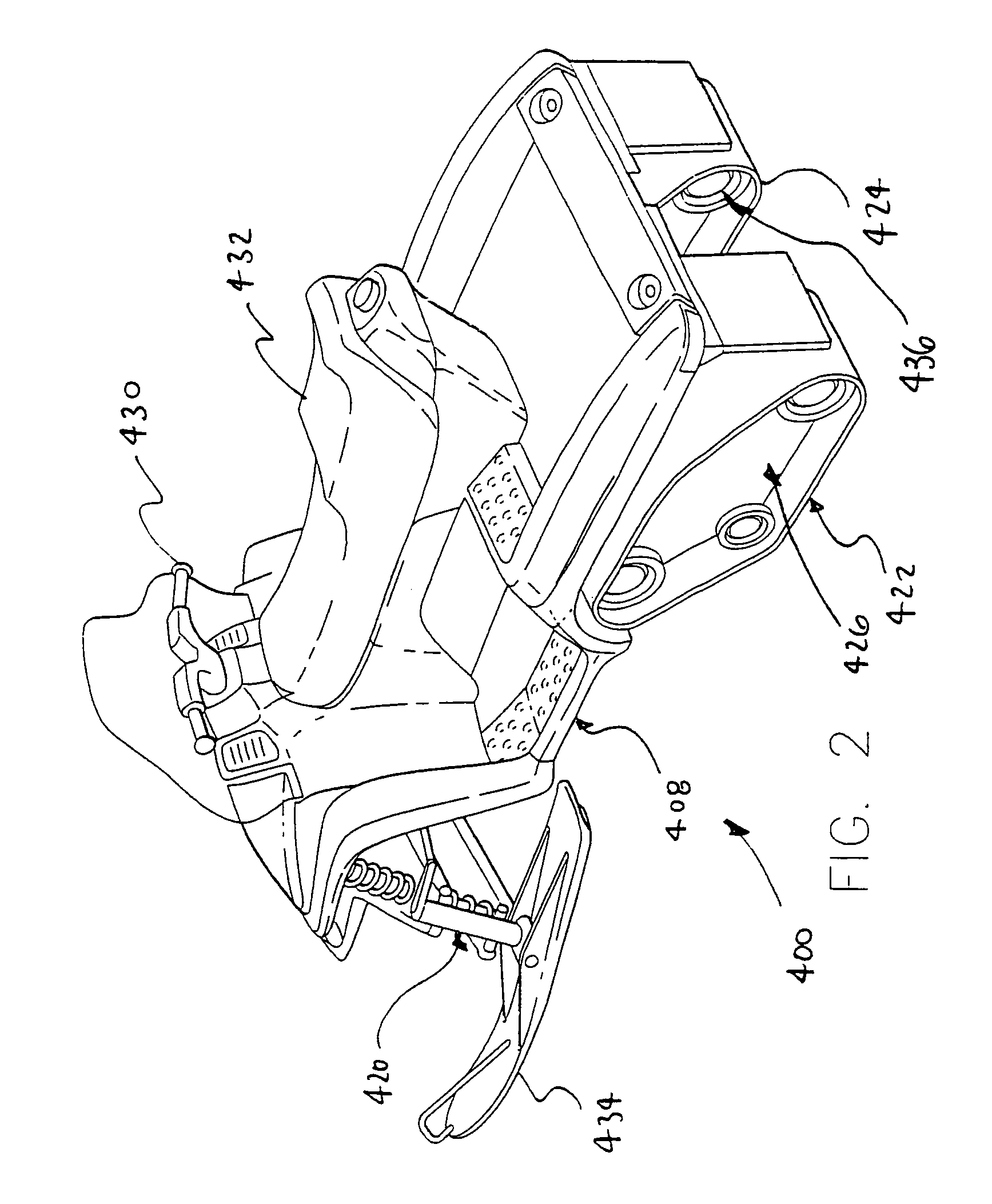

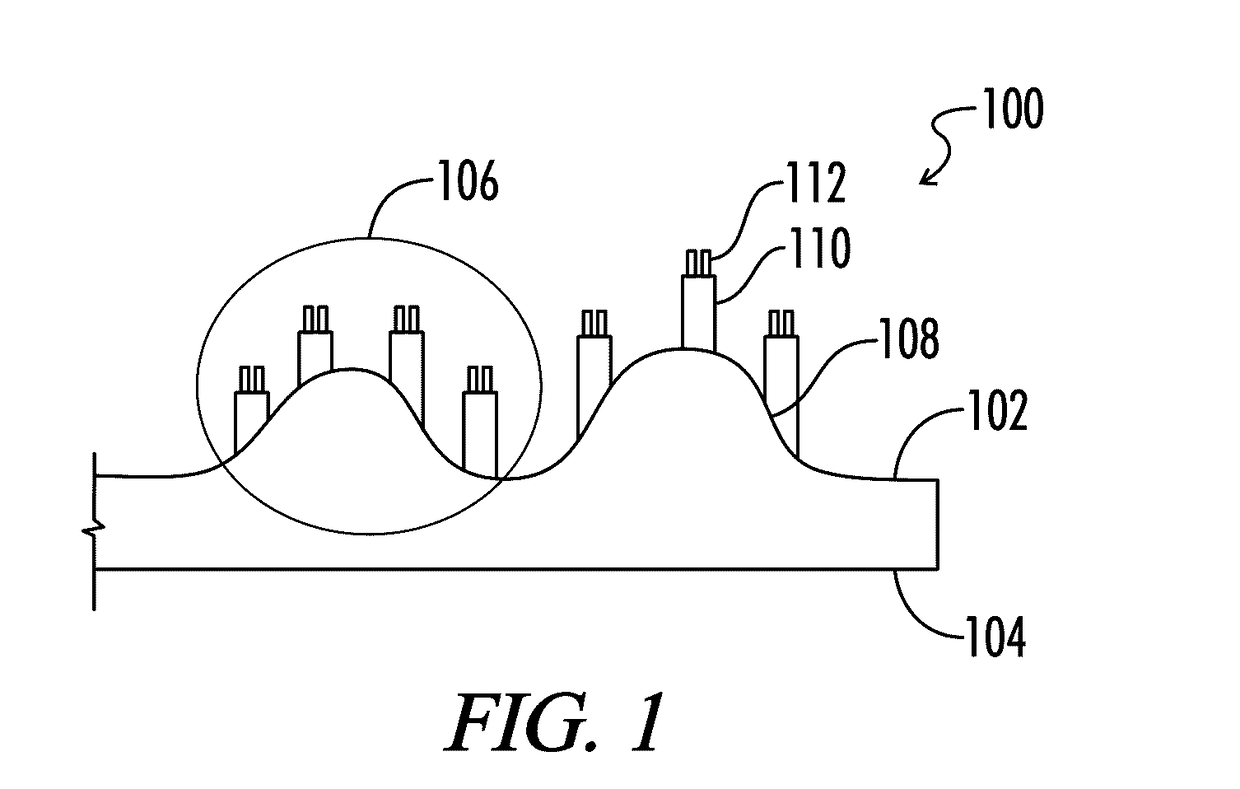

Low Normal Force Retracting Device Comprising a Microtextured Surface

Retraction of one or more three-dimensional or planar amorphous objects is provided to gain access for a procedure where the retracted elements are easily damaged by application of normal forces. For example, a surgical instrument to provide access to an organ or tissue plane. Microtextured surfaces are provided that provide immobilization of amorphous objects, the immobilization of which is characterized by low normal forces and high shear or in plane forces. The retraction device is comprised of microstructured surfaces on one or more arms. Preferably these arms are soft and flexible to minimize damage to retracted objects. In some instances, these arms resemble and are used as a nonslip tape. Alternatively, parts or whole arms of the retraction device are rigid to provide a supportive aspect. These arms may be configured around a handle. Furthermore, the microtextured aspect may be further augmented with conventional gripping surfaces, such as a sticky surface, or a surface comprised of one or more hooks or barbs. The handle means may be distributed over the retraction device, for example, holes distributed along the arms through which anchoring means are tied. The retraction device is particularly well suited for grasping wet, oily, slimy or living surfaces by applying a small nondestructive normal force.

Owner:BVW HLDG

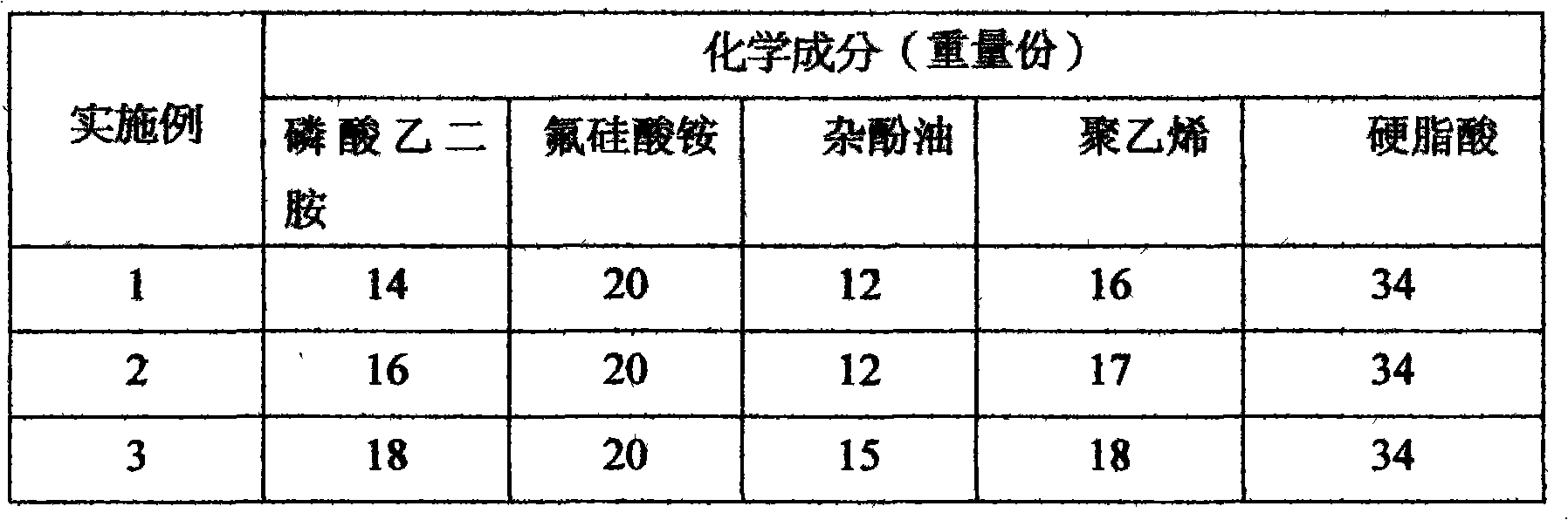

Asphalt viscosity reduction modifier and manufacturing method thereof

InactiveCN102311649AImproved high temperature rheological propertiesImprove high temperature resistanceBuilding insulationsStearic acidEnergy expenditure

The invention relates to an asphalt viscosity reduction modifier, which is characterized in that the modifier comprises the following components in part by weight: 14-18 parts of activating agent, 20 parts of ammonium fluosilicate, 10-15 parts of kreosote, 15-18 parts of polyethylene and 34 parts of stearic acid. The manufacturing method comprises the steps that the components are added into a reaction container, the temperature is raised to 250 DEG C, and the asphalt viscosity reduction modifier disclosed by the invention is obtained after full stirring and reaction are completed. After the asphalt viscosity reduction modifier disclosed by the invention is simply mixed with asphalt, the asphalt viscosity can be obviously reduced, the construction temperature is reduced, poisoned dust emission is reduced, energy consumption is reduced, simultaneously the compaction of asphalt concrete can be obviously improved, the high temperature performance of the asphalt is improved, and the anti-aging capacity of the asphalt is obviously improved.

Owner:重庆市广为道路材料有限公司

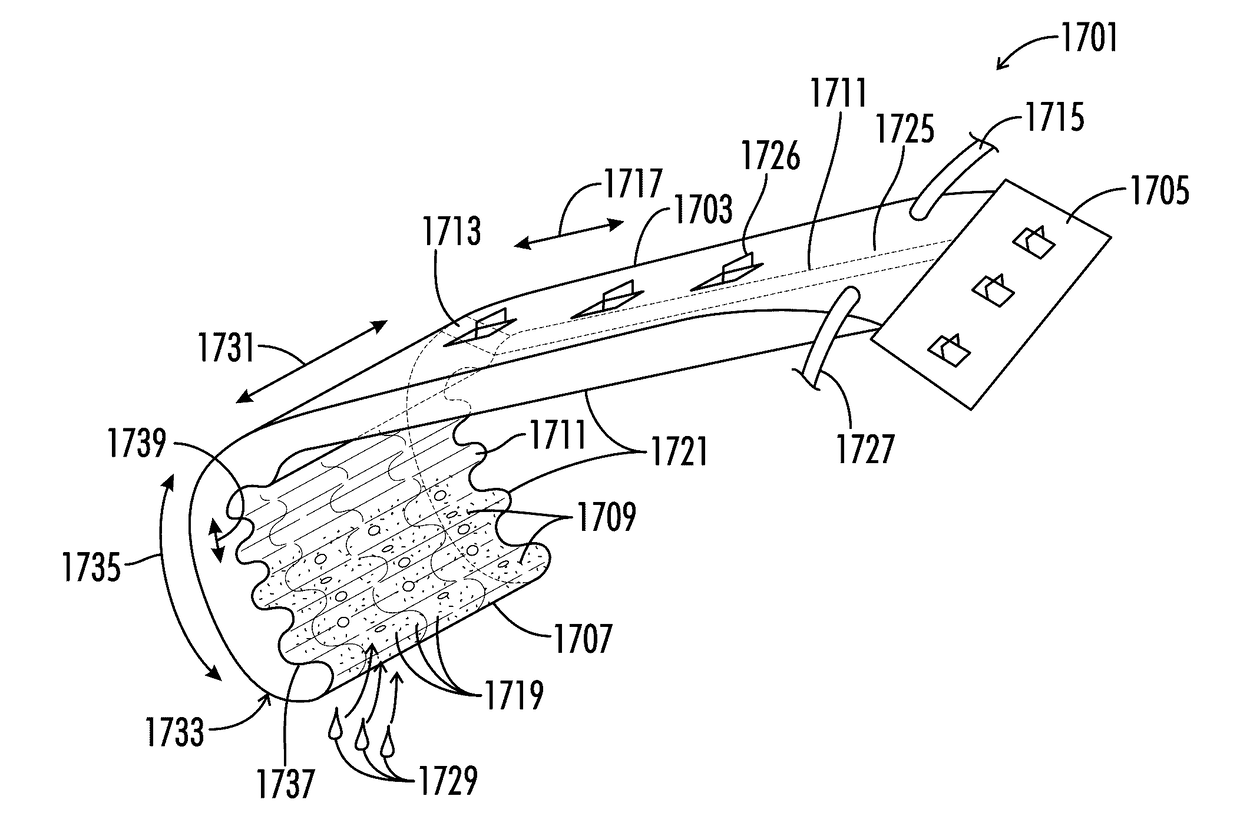

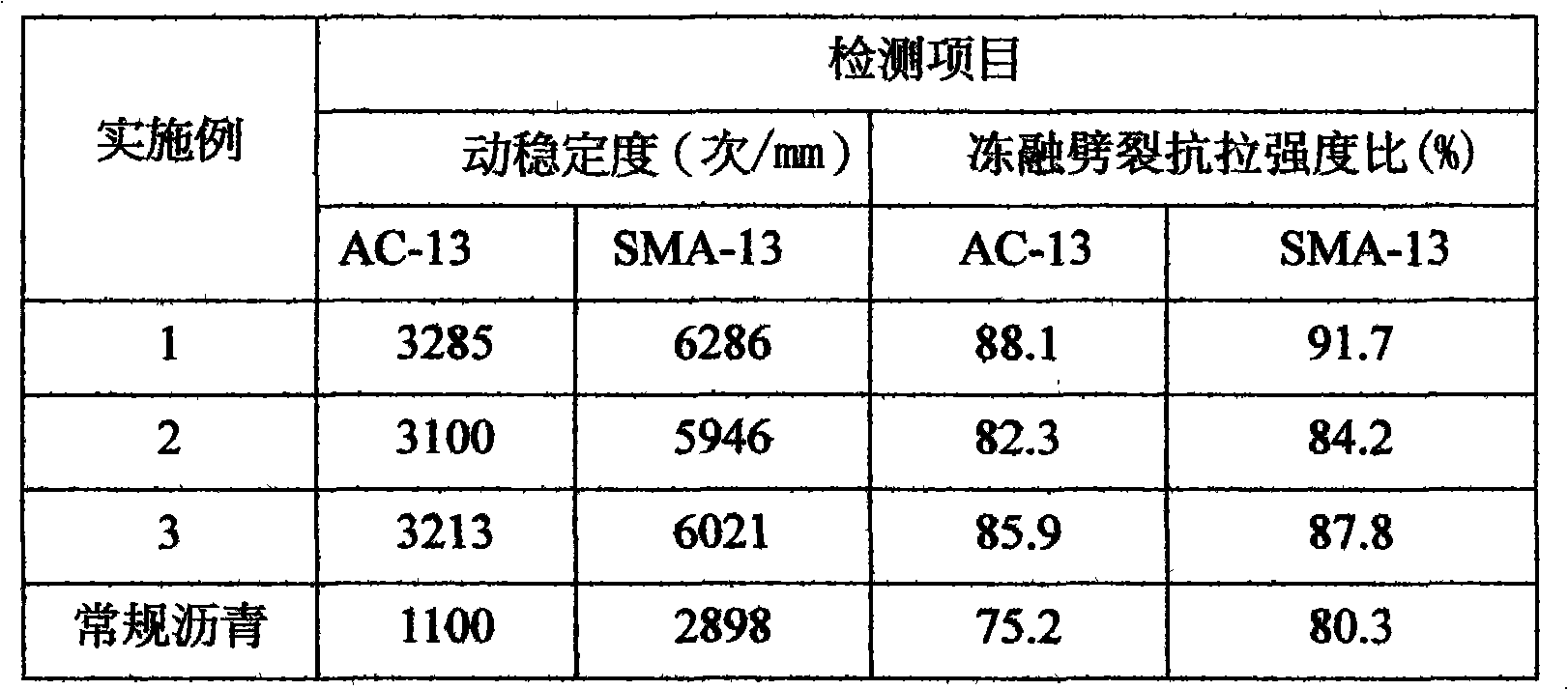

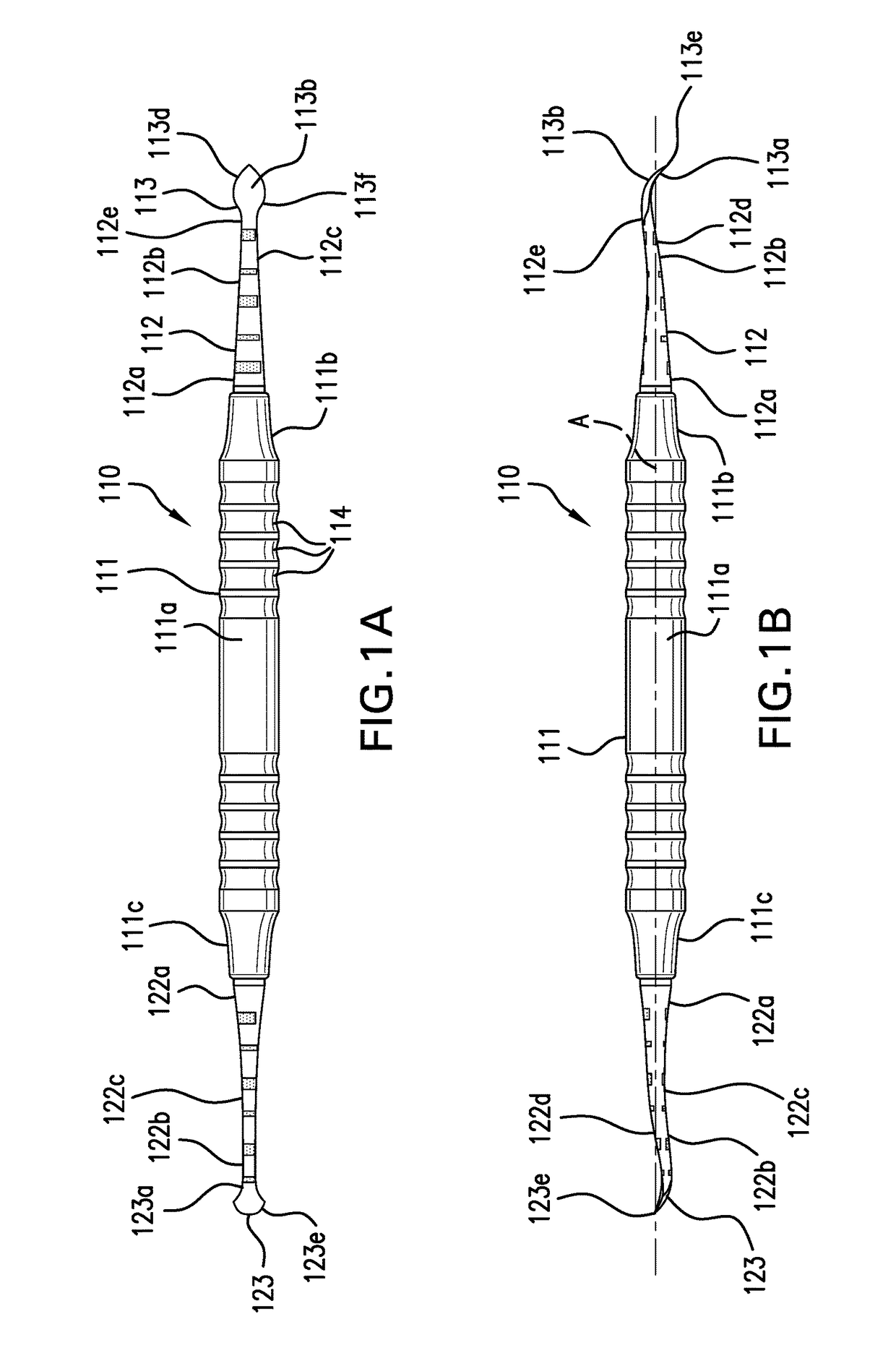

Devices for conducting subperiosteal minimally invasive aesthetic jaw bone grafting augmentation and their use

ActiveUS20170296308A1Facilitate pouch formationReduce the potential for damageDental implantsCosmetic implantsJaw boneDevice tip

Devices for carrying out subperiosteal minimally invasive jaw bone augmentation and reconstruction procedures, to develop a passageway and surgical site in a concealed area of patient tissue, where the surgical site is not exposed. The devices have shanks with specially configured tips to facilitate maneuvering the device through mammalian tissue to develop a tunnel in the tissue and a remote surgical site within the tissue. The device tips have one or more peripheral cutting surfaces that direct the positioning of the tunnel formation when the instrument handle is manipulated, e.g., by rotation, angular, forward or rearward motion. Embodiments of the devices are configured with tips that have a wide spread for cutting and elevating tissue, and with tips that may be maneuvered to condense bone graft material being implanted at a surgical site concealed within the tissue.

Owner:LEE ERNESTO A

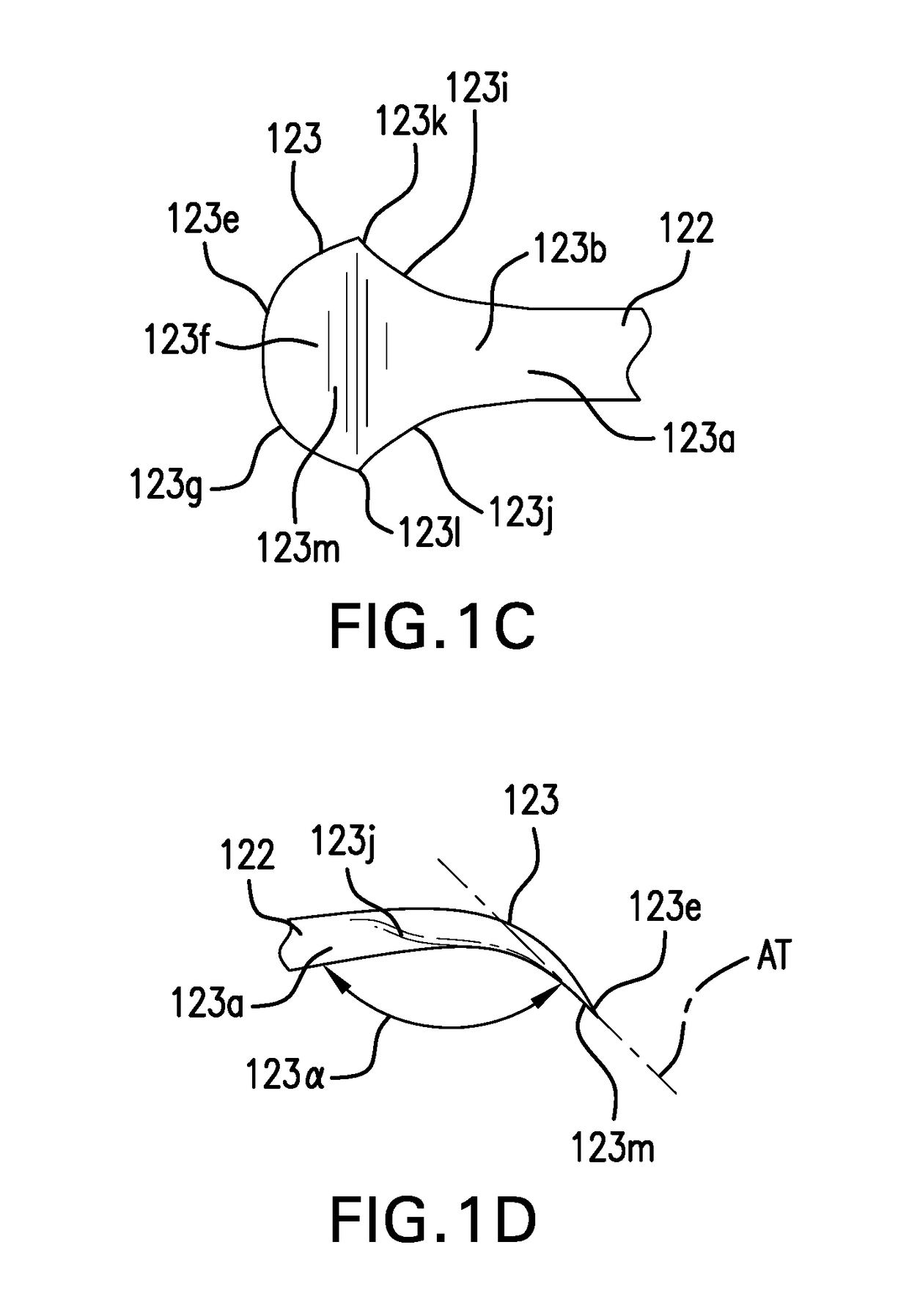

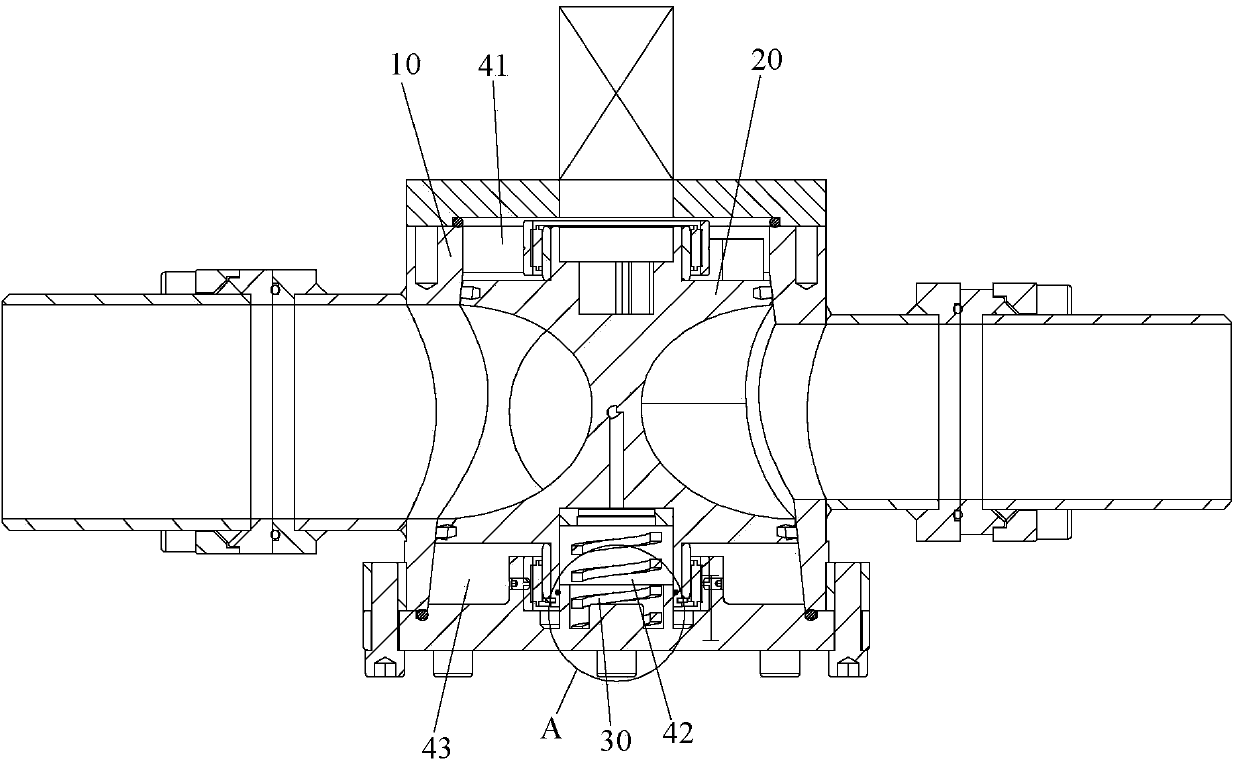

Rotary type fluid passage changeover valve

InactiveCN104197089AReduce output powerReduce torquePlug valvesOperating means/releasing devices for valvesEngineeringHigh pressure

The invention provides a rotary type fluid passage changeover valve. The rotary type fluid passage changeover valve comprises a valve body, a valve element, a driving device and an elastic part, wherein the valve body is provided with a valve cavity; the valve element is arranged in the valve cavity in a rotatable mode, and a high-pressure channel and a low-pressure channel which are independent of each other are formed between the valve element and the side walls of the valve body; the driving device is located at the first end of the valve element and is in drive connection with the valve element so as to drive the valve element to rotate; the elastic part is located at the second end of the valve element and abuts against the valve body and the valve element respectively, a first cavity is formed between the first end of the valve element and the valve body, a second cavity and a third cavity which are independent of each other are formed between the second end of the valve element and the valve body, and the third cavity is located in the outer side of the circumferential direction of the second cavity; at least one of the first cavity, the second cavity and the third cavity is communicated with the high-pressure channel, and the remaining cavities of the first cavity, the second cavity and the third cavity are communicated with the low-pressure channel. The problems of increase of input torque of a motor and abrasion to moving parts in the prior art are effectively solved according to the technical scheme.

Owner:ZHEJIANG SANHUA ROTARY VALVE

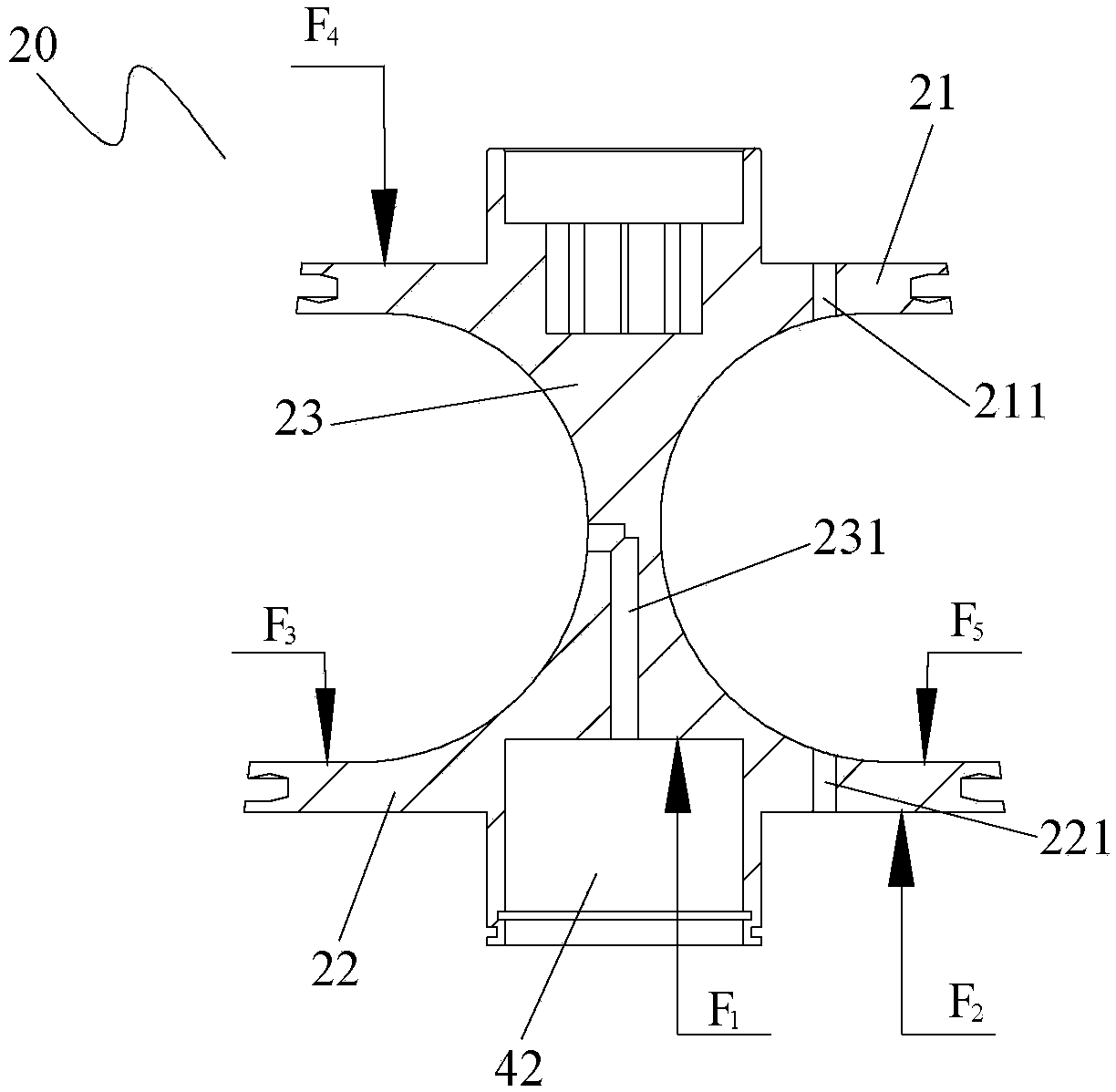

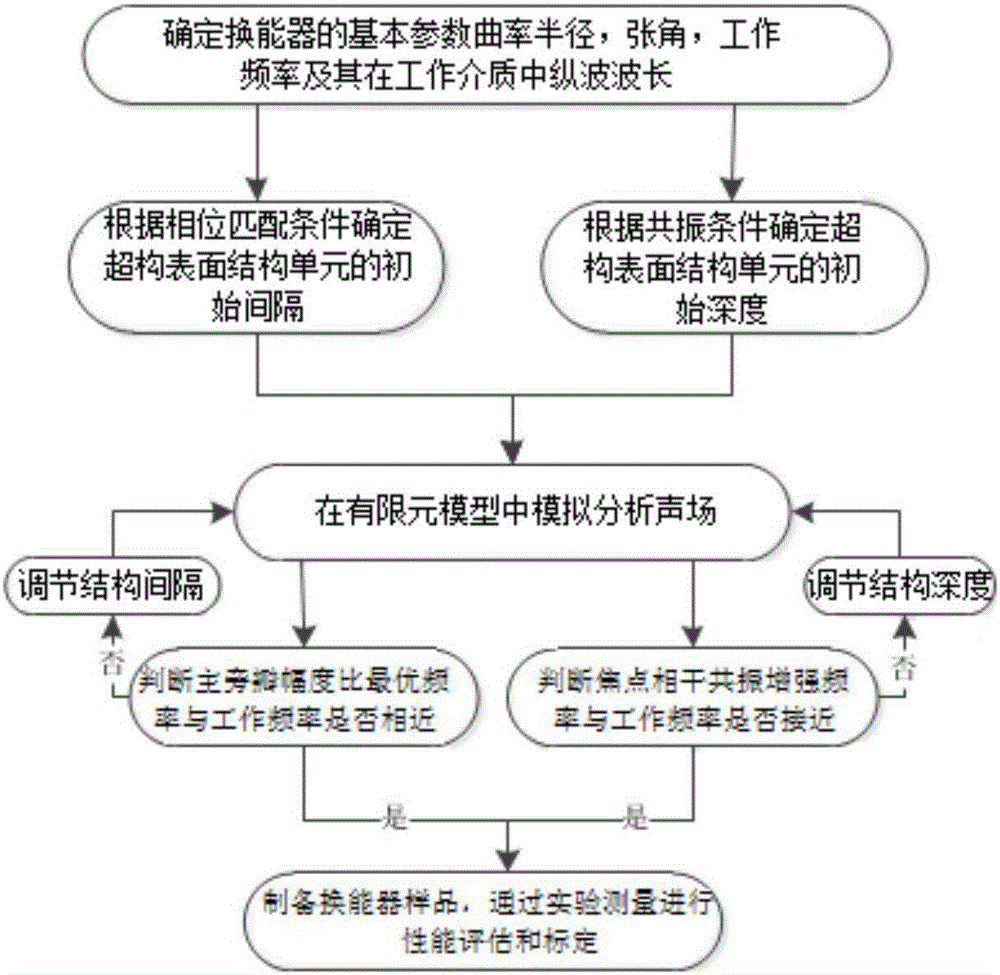

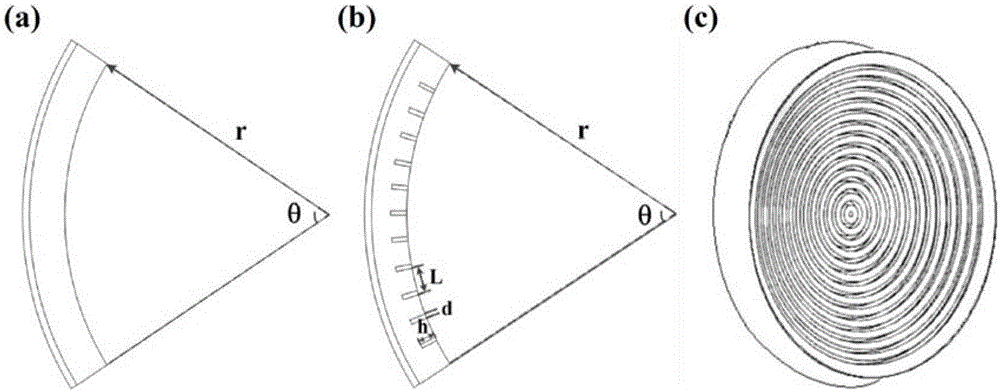

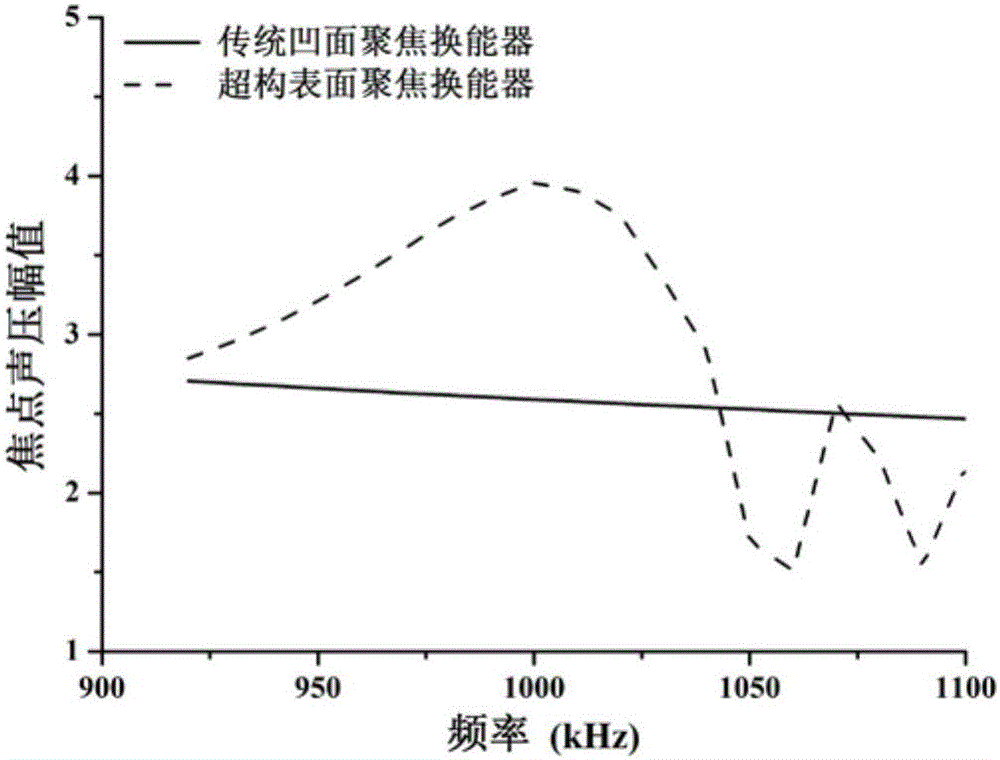

Design method for concave-focusing transducer with super formation surface

The invention discloses a design method for a concave-focusing transducer with a super formation surface and belongs to the technical of ultrasonic focusing. By virtue of constructing a super formation surface structure on the surface of a traditional concave focusing transducer and utilizing a cavity resonance mode of the super formation surface structure, the radiation efficiency of the focusing transducer is enhanced. When surface acoustic evanescent waves supported by the super formation surface structure spatially meets a phase matching condition, a coherent diffraction enhancement effect is caused, and improvement on the focusing property is realized; the concave-focusing transducer belongs to innovation of the ultrasonic focusing field; the super formation surface meets the generalized reflection and refraction Snell's law and is capable of realizing discontinuous modulation on phases; by virtue of modulating the super formation surface through a periodic wavy structure, the super formation surface of the concave focusing transducer is capable of regulating and controlling the sound field distribution within a specific frequency range and thus improving the main sidelobe ratio.

Owner:ZHEJIANG SUKEAN PHARM CO LTD

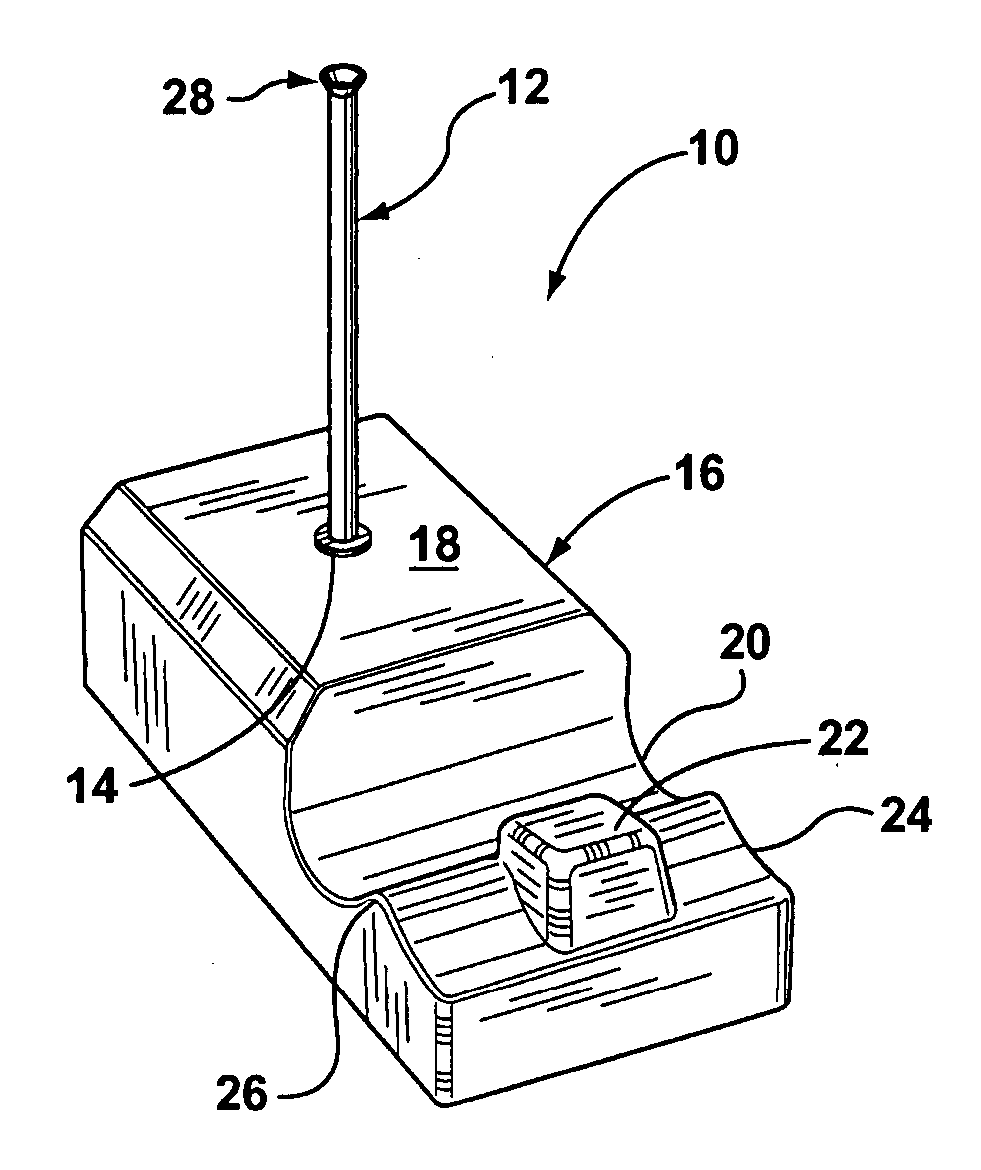

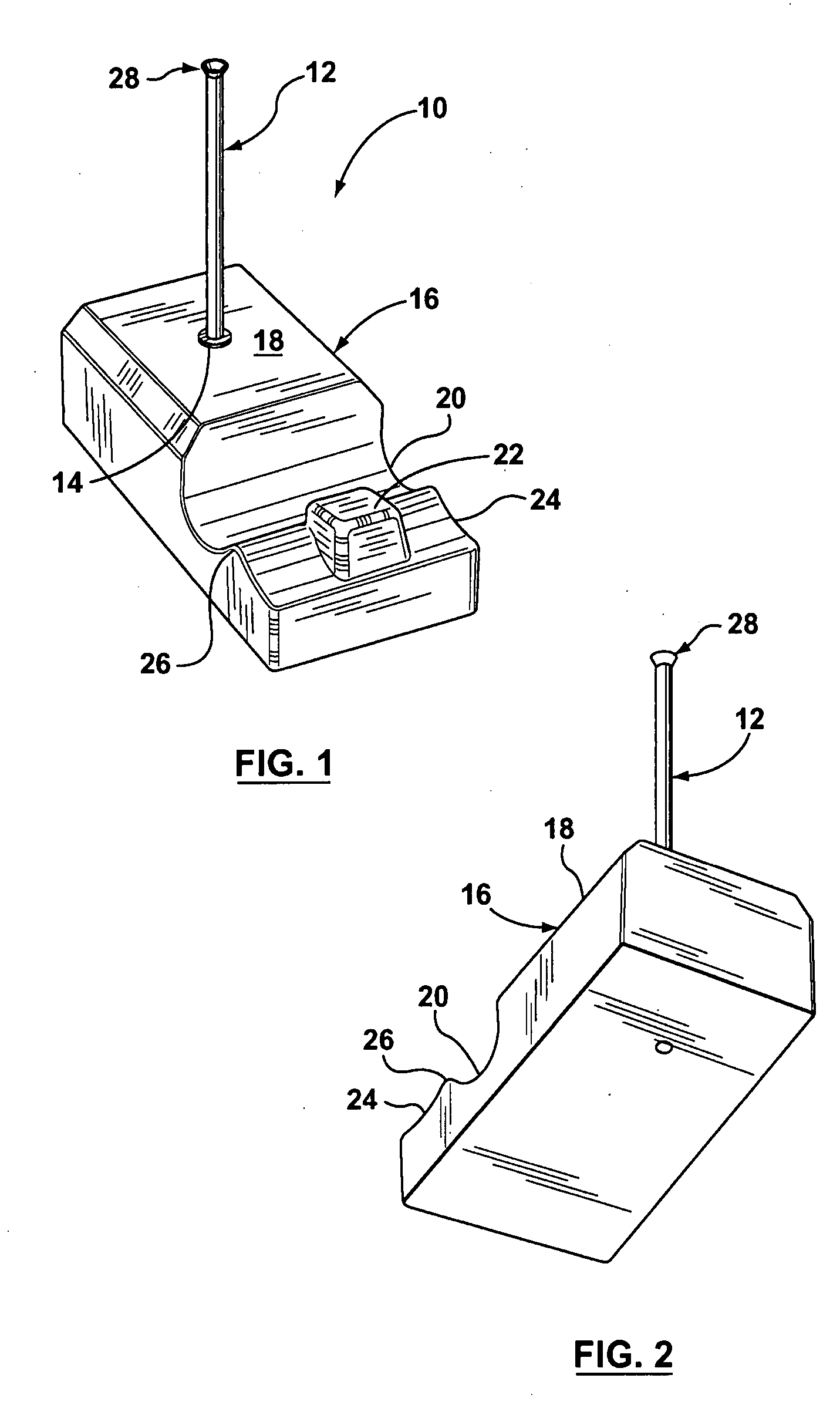

Dental holder

InactiveUS20080008982A1Shorten the timeEasy to prepareDental implantsArtificial teethDenturesProsthesis

An apparatus for holding a dental prosthesis during preparation of the dental prosthesis, the apparatus comprising: at least one base, the at least one base having an upper surface, at least one pin, and the at least one pin comprising a first end and a second end, the at least one pin further comprising a flared portion at the first end, and the first end extending beyond the upper surface of the at least one base, and the second end extending through and into the upper surface of the base. The use of an apparatus for holding a dental prosthesis during preparation of the prosthesis and for holding the dental prosthesis during firing without having to transfer the prosthesis to a second tray for firing. A method for preparing a dental prosthesis, the method comprising the steps of: a) mounting a substructure on an apparatus comprising at least one base, the at least one base having an upper surface, at least one pin, and the at least one pin comprising a first end and a second end, the at least one pin further comprising a flared portion at the first end, and the first end extending beyond the upper surface of the at least one base, and the second end extending through and into the upper surface of the base, b) applying at least one layer of ceramic to prepare a dental prosthesis, and c) firing the prosthesis mounted on the apparatus in a furnace.

Owner:MURSIC JONATHAN CARL

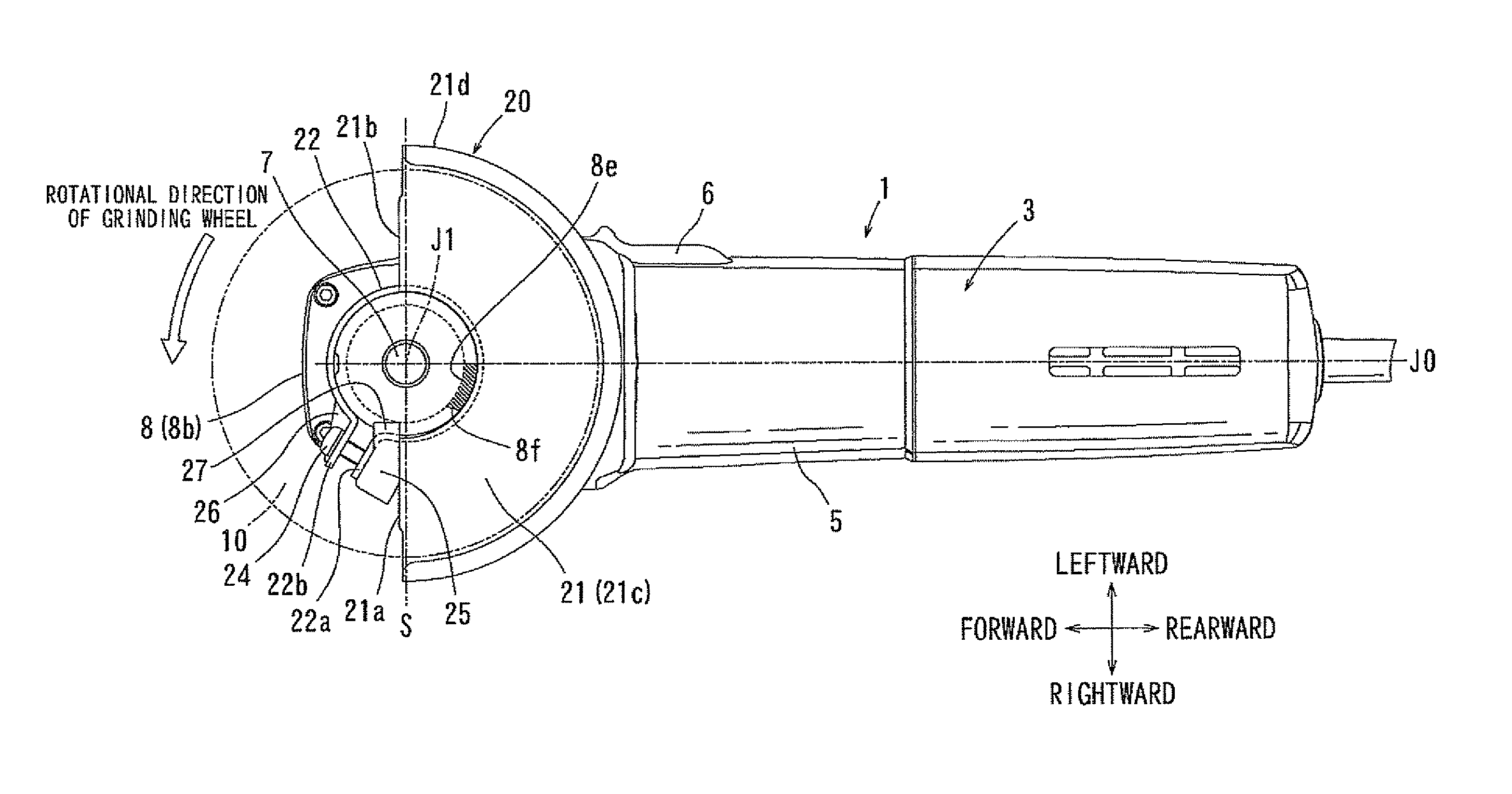

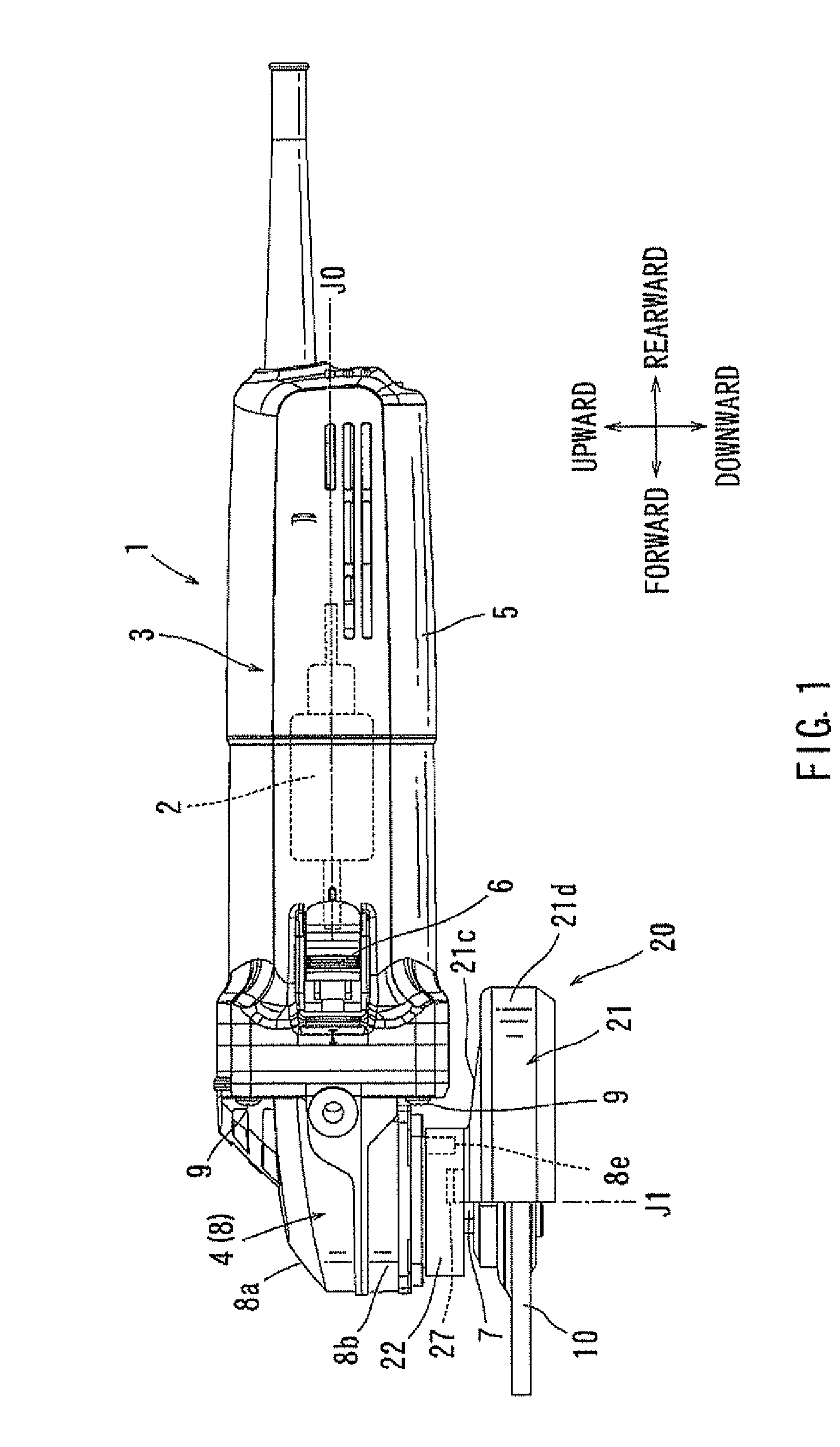

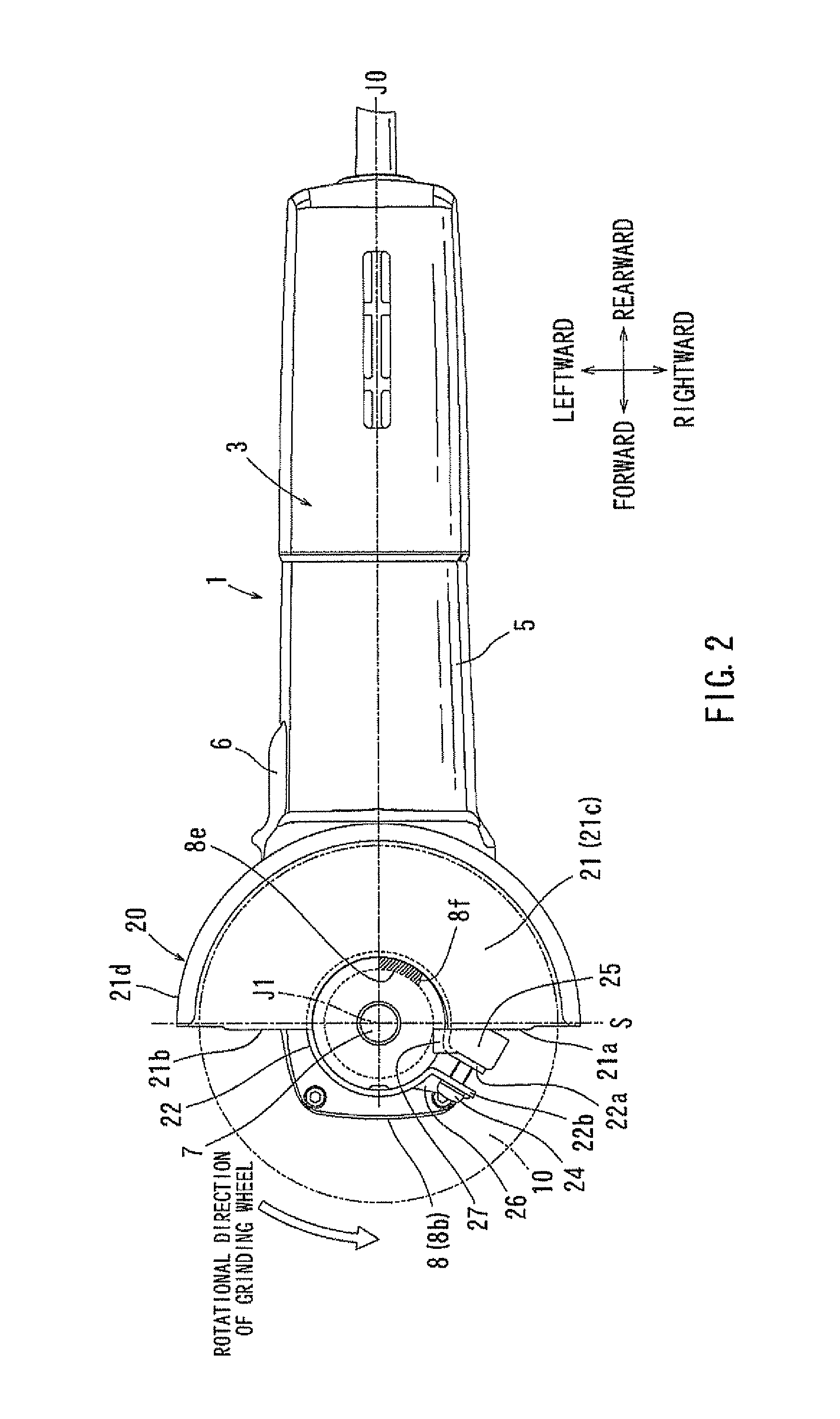

Disc grinders

ActiveUS20120108154A1Limited adjustment rangeReduce the potential for damagePortable grinding machinesGrinding/polishing safety devicesEngineeringGrinding wheel

A disc grinder includes a grinding wheel cover rotatably mounted to a gear housing about an axis of a spindle. A stopper device can restrict a position adjustable range of the grinding wheel cover of the spindle and includes a first stopper on the side of the grinding wheel cover and a second stopper on the side of the gear housing. The first stopper and the second stopper have stopper surfaces for contacting with each other. An impact absorbing device can absorb an impact produced when the stopper surfaces contact with each other.

Owner:MAKITA CORP

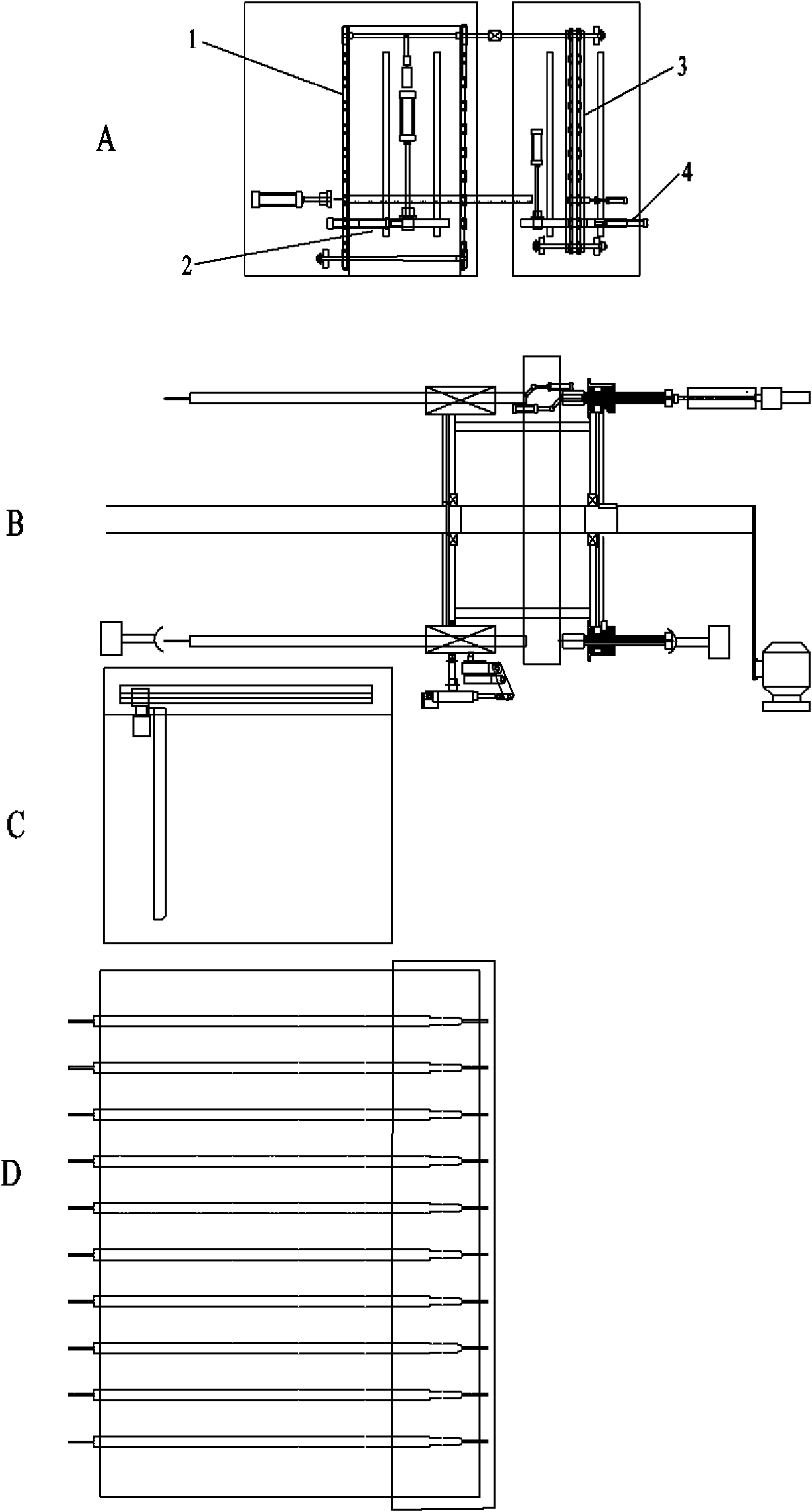

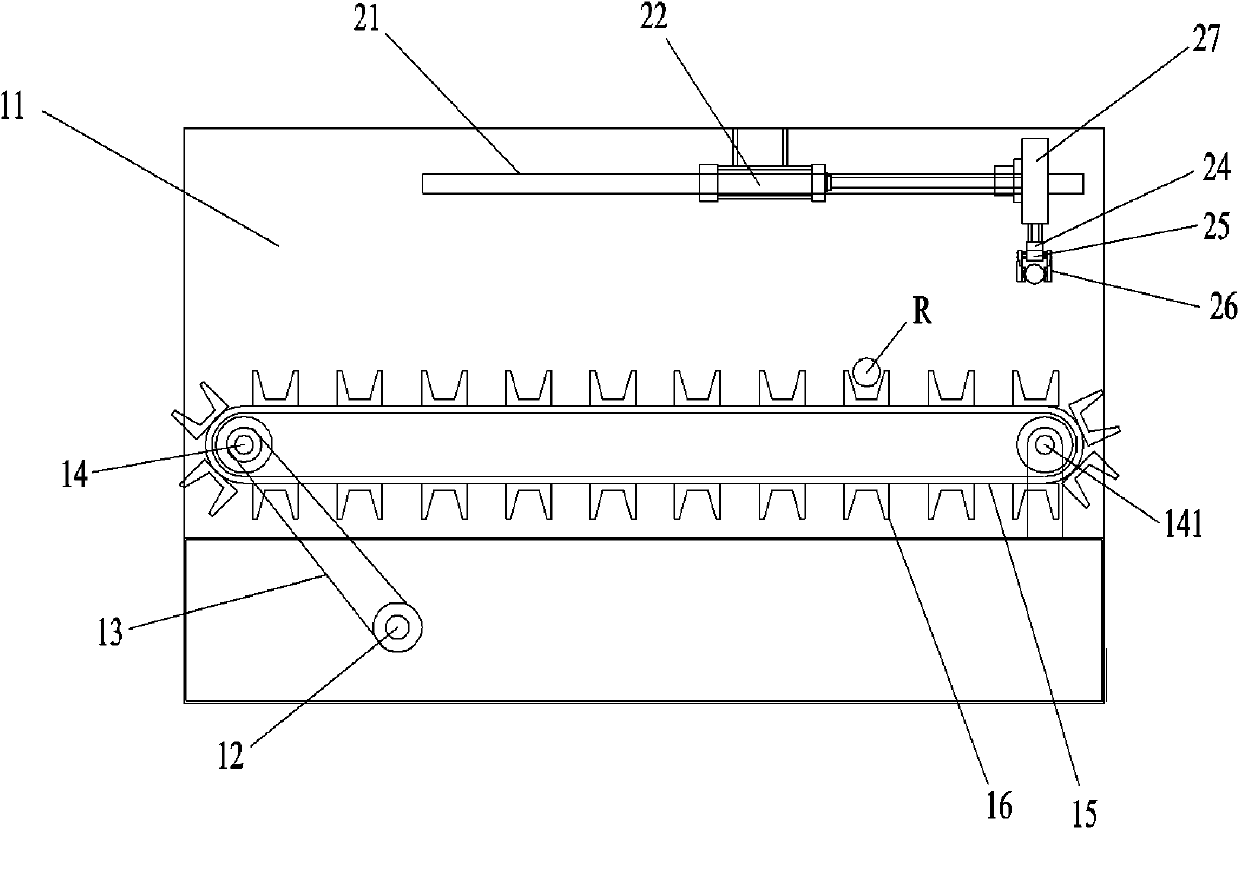

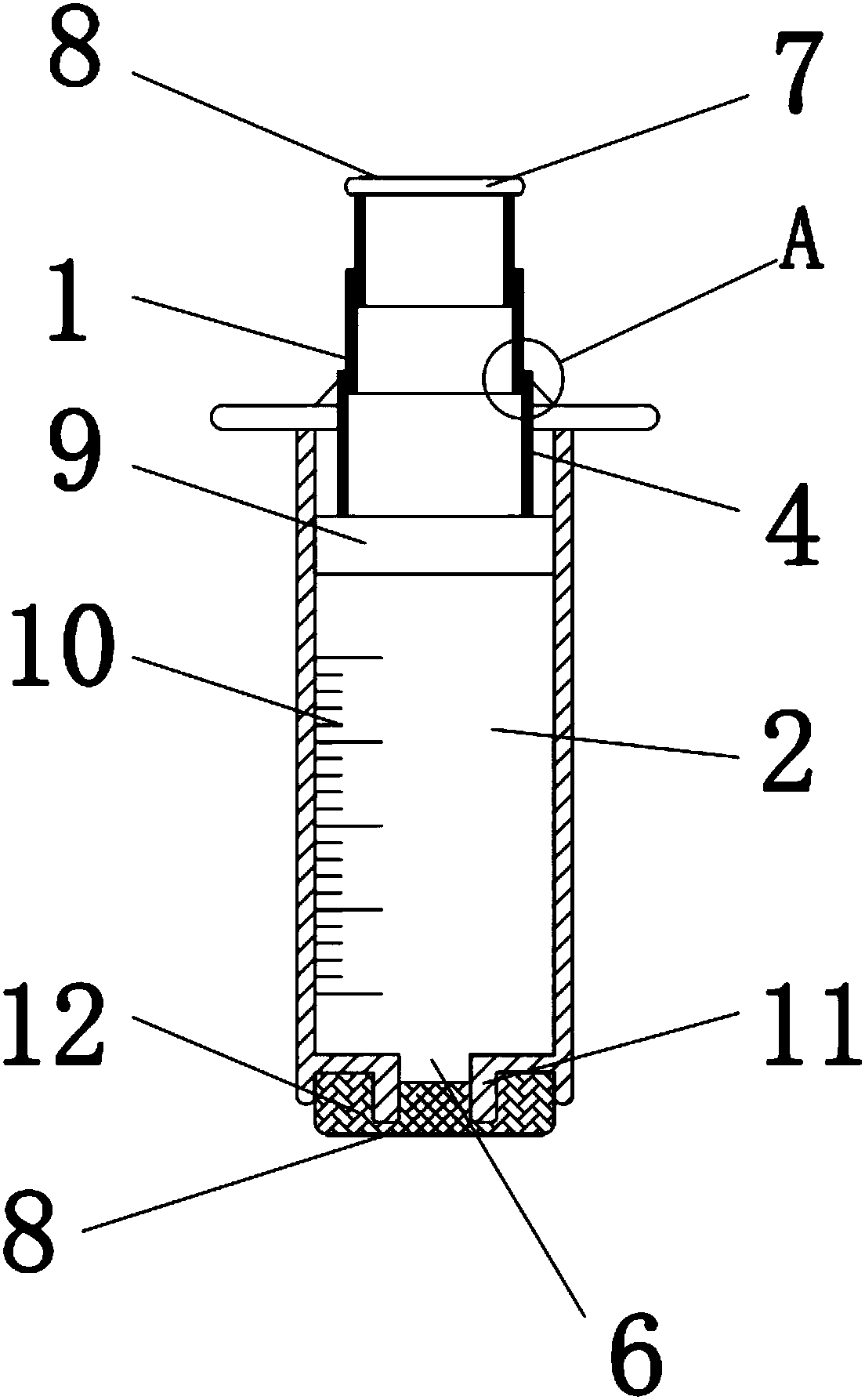

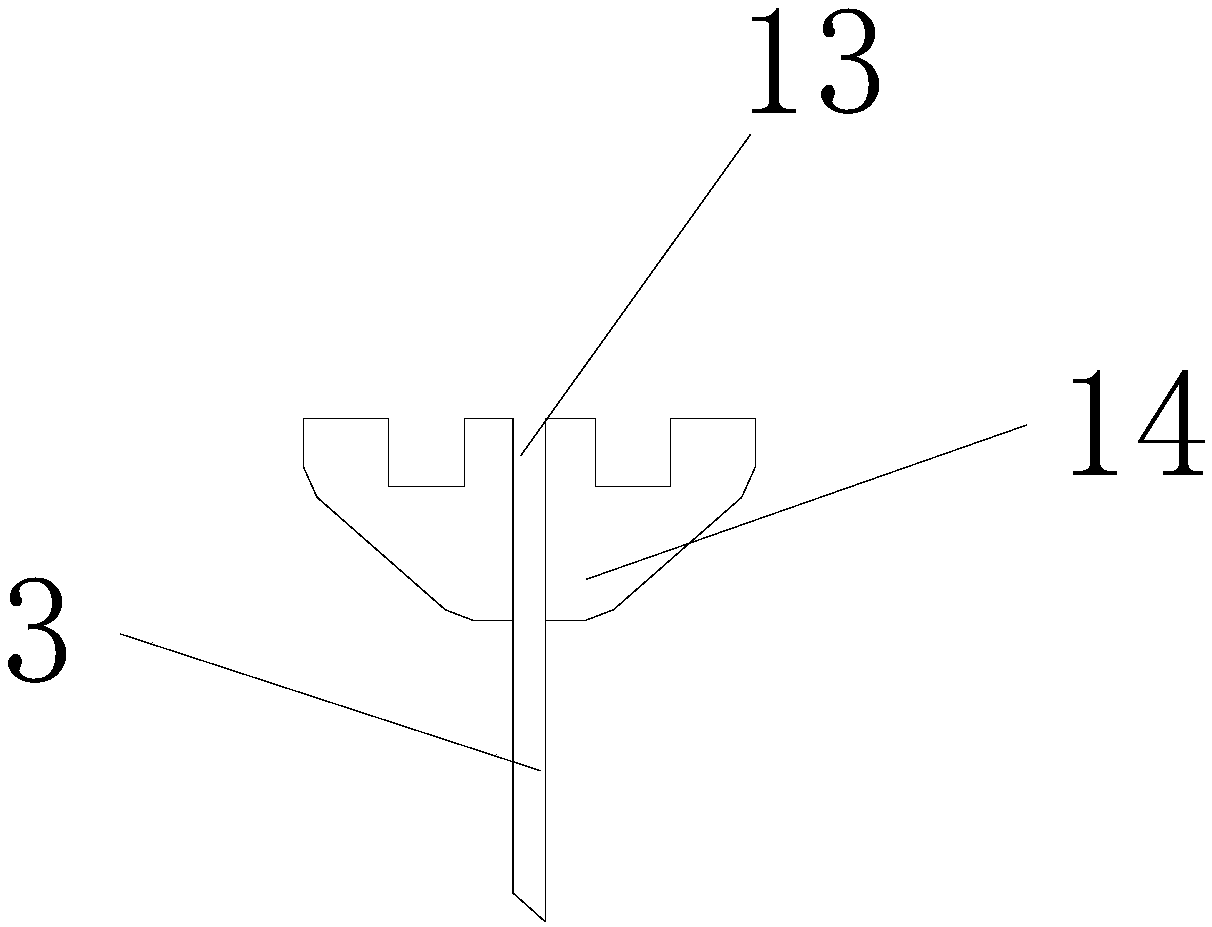

Automatic seaming machine for all-glass vacuum heat pipe

ActiveCN102745886AReduce the potential for damageReduce consumptionGlass reforming apparatusGlass productionPhysical hard workEngineering

The invention discloses an automatic seaming machine for an all-glass vacuum heat pipe. The automatic seaming machine orderly comprises 1, a loading transmission device for providing a heat collection pipe and a condensation end to a seaming device, 2, the seaming device for welding the heat collection pipe and the condensation end into a welded heat pipe, 3, an unloading device for taking down the welded heat pipe from the seaming device and putting the welded heat pipe into an annealing device, and 4, the annealing device for carrying out annealing of the welded heat pipe. Through reasonable arrangement, the automatic seaming machine has the advantages that the whole structure is simple and clear; automatic seaming of an all-glass vacuum heat pipe is realized; manpower is saved; work efficiency is improved; and a reject ratio of production is reduced.

Owner:BEIJING TUS CLEAN ENERGY TECH CO LTD +1

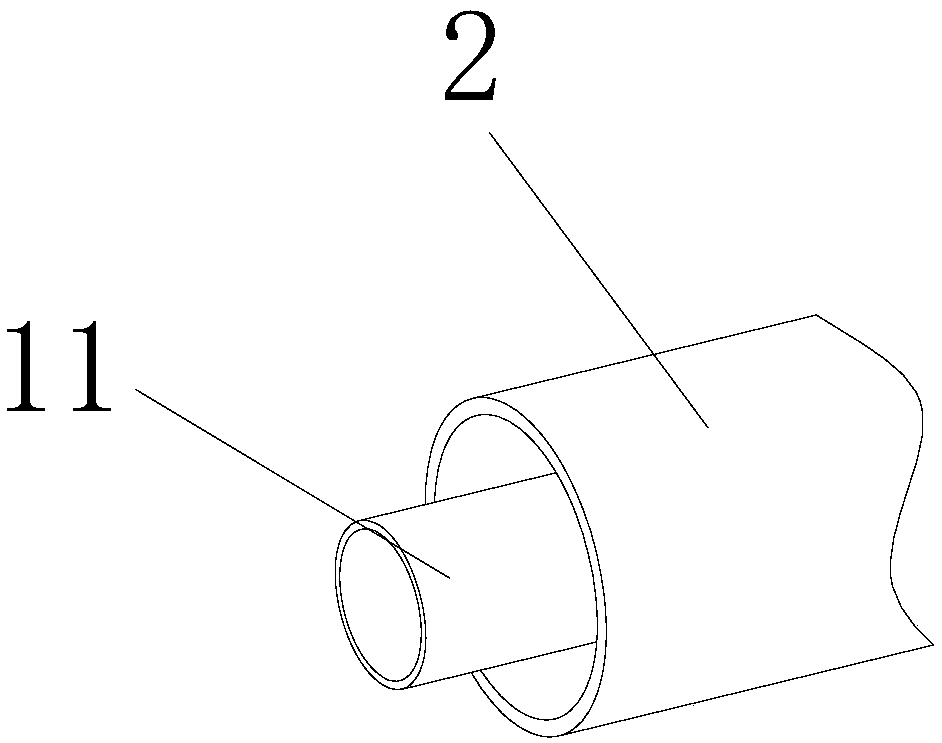

Preparation syringe integrated structure

ActiveCN107929881AReduce wasteReduce the potential for damageInfusion syringesPharmaceutical containersSyringe needleBiomedical engineering

The invention discloses a preparation syringe integrated structure. The preparation syringe integrated structure comprises a stretchable piston, a needle cylinder, a syringe needle, an exposed rubberplug, a sealing fin, a built-in rubber plug, a sealing rubber plug and a cohesion rubber plug, a stretchable piston is arranged at one end of the needle cylinder, and a clamping column is arranged atthe other end of the needle cylinder, the exposed rubber plug is mounted on one side of stretchable piston, away from the needle cylinder, the built-in rubber plug is mounted in the needle cylinder, scale lines are formed on the circumference surface of the needle cylinder. According to the preparation syringe integrated structure, a storage medicine bottle and a syringe are designed as an integrated structure, intermediate links are reduced, and thus the waste of the liquid medicine caused by incomplete liquid medicine suction and liquid medicine overflowing is reduced, at the same time, professional risks of medical workers are reduced, and the problem that particle formed due to repeated puncture causes the potential injure to a patient is reduced; the matched stretchable piston structure reduces the overall length, and provides convenience for the operation of puncturing; and by the syringe needle, of which the section is of an epsilon-shaped structure, the waste of the liquid medicine is effectively avoided as well.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com