Automatic seaming machine for all-glass vacuum heat pipe

A vacuum heat pipe and all-glass technology, applied in glass production, glass molding, glass reshaping, etc., can solve problems such as production efficiency dependence, human injury, energy waste, etc., and achieve reduced damage, reliable sealing quality, The effect of reducing potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

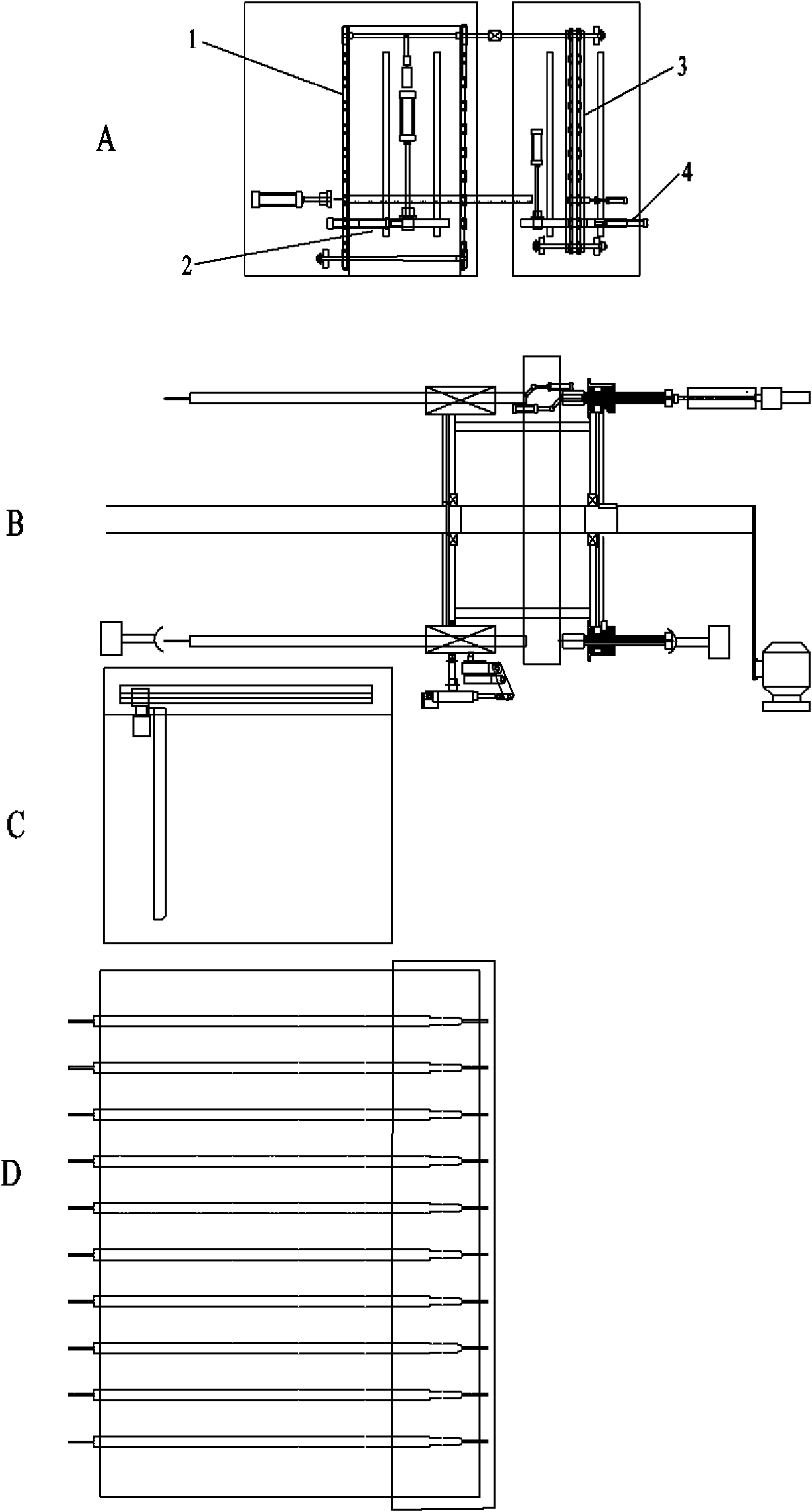

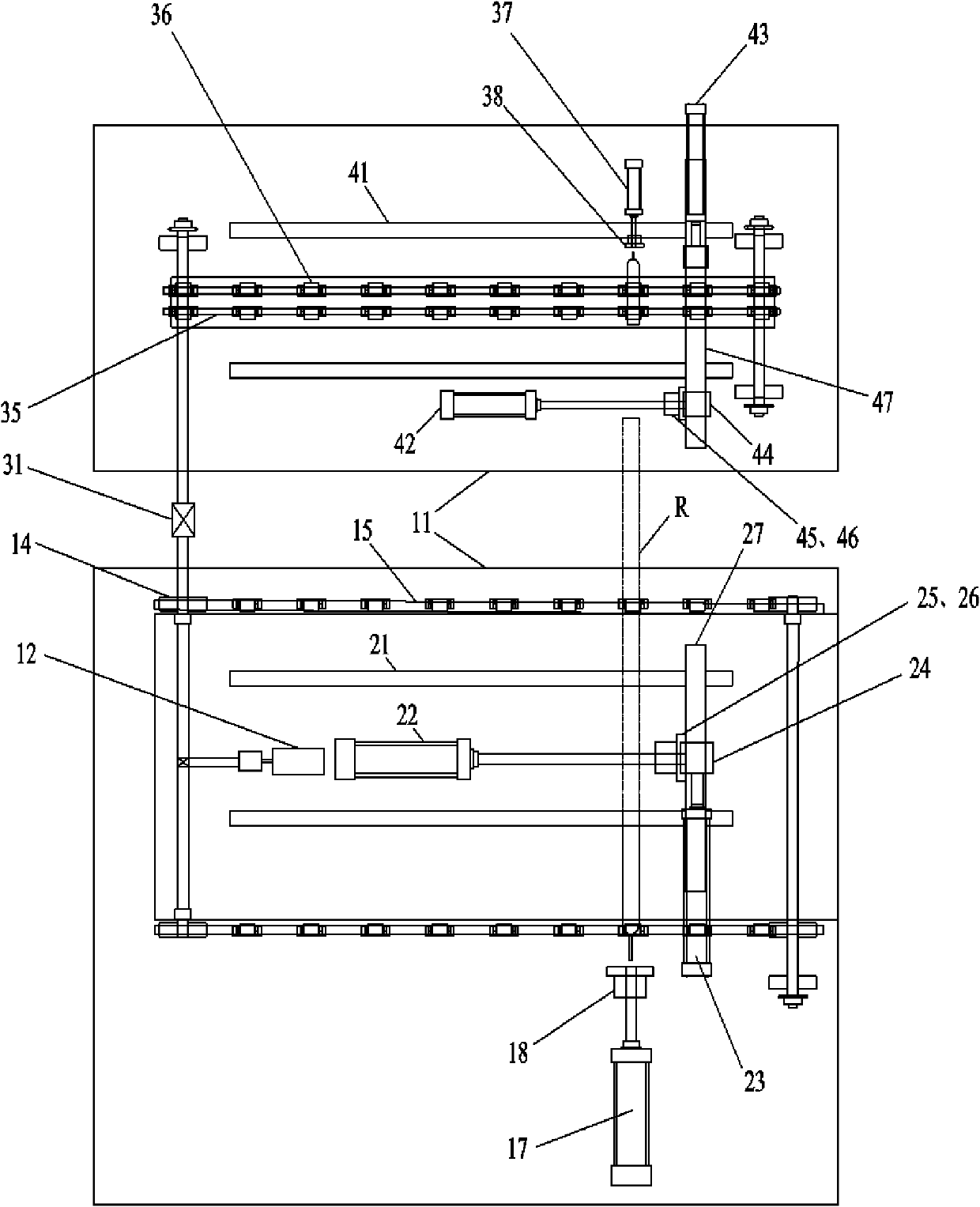

[0051] see Figure 1 to Figure 4 , Figure 4A , Figure 4B , Figure 9 and Figure 10 , the present invention provides an automatic sealing machine for the condensation end of an all-glass vacuum heat pipe, which sequentially includes a feeding transfer device A, a sealing device B, a feeding device C, and an annealing device D. The condensing end is provided to the sealing device B, and the sealing device B welds the heat collecting tube and the condensing end into a fused heat pipe, and the unloading device C removes the fused heat pipe from the sealing device, and then takes off the fused heat pipe The heat pipe is placed in the annealing device D, and the annealing treatment is completed in the annealing device D.

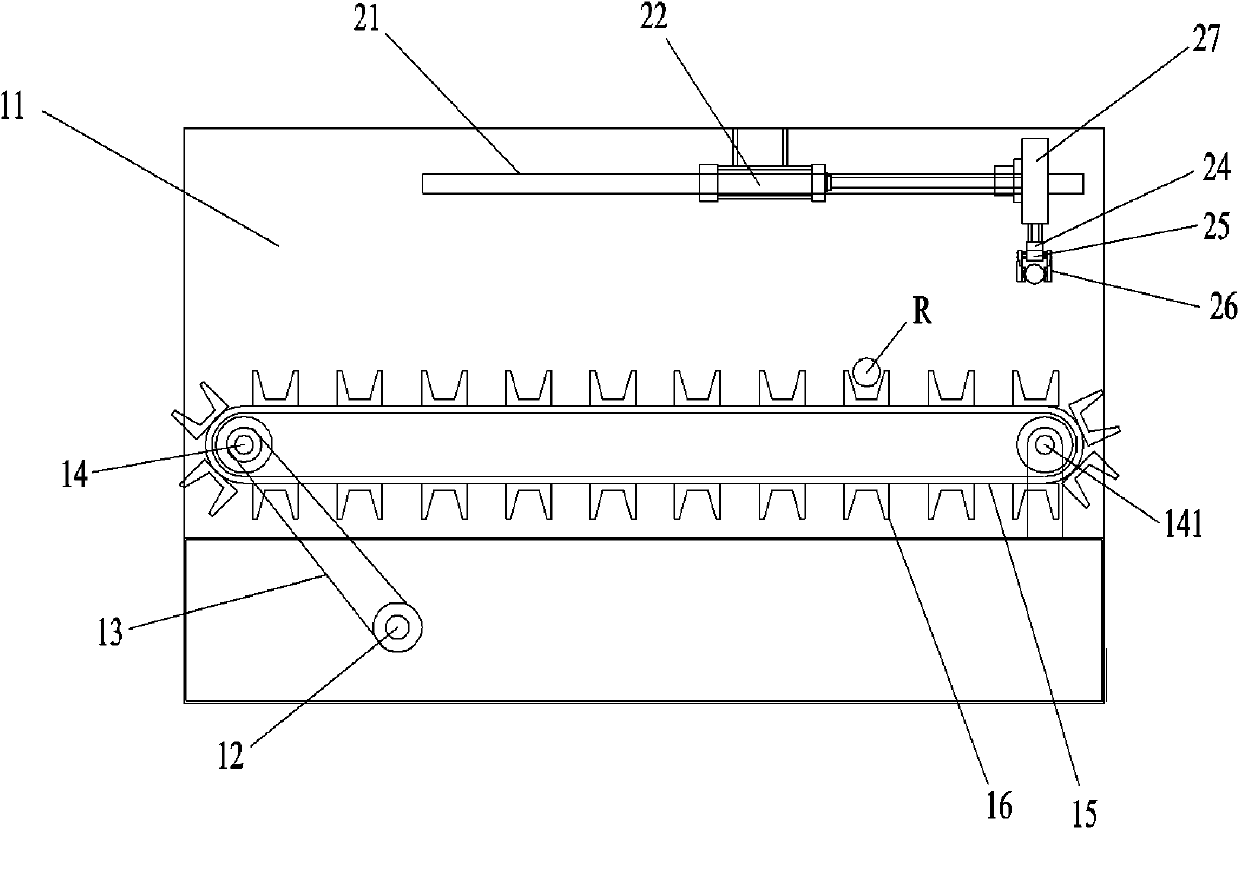

[0052] The feeding transfer device A includes: a heat collecting tube transfer mechanism 1 and a heat collecting tube feeding manipulator 2 responsible for feeding the heat collecting tubes, and a condensing end transfer mechanism 3 and a condensing end fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com