Rotary type fluid passage changeover valve

A flow path switching and rotary technology, applied to valve details, multi-way valves, safety valves, etc., can solve problems such as increasing motor input torque, wear of moving parts, and uncertain air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

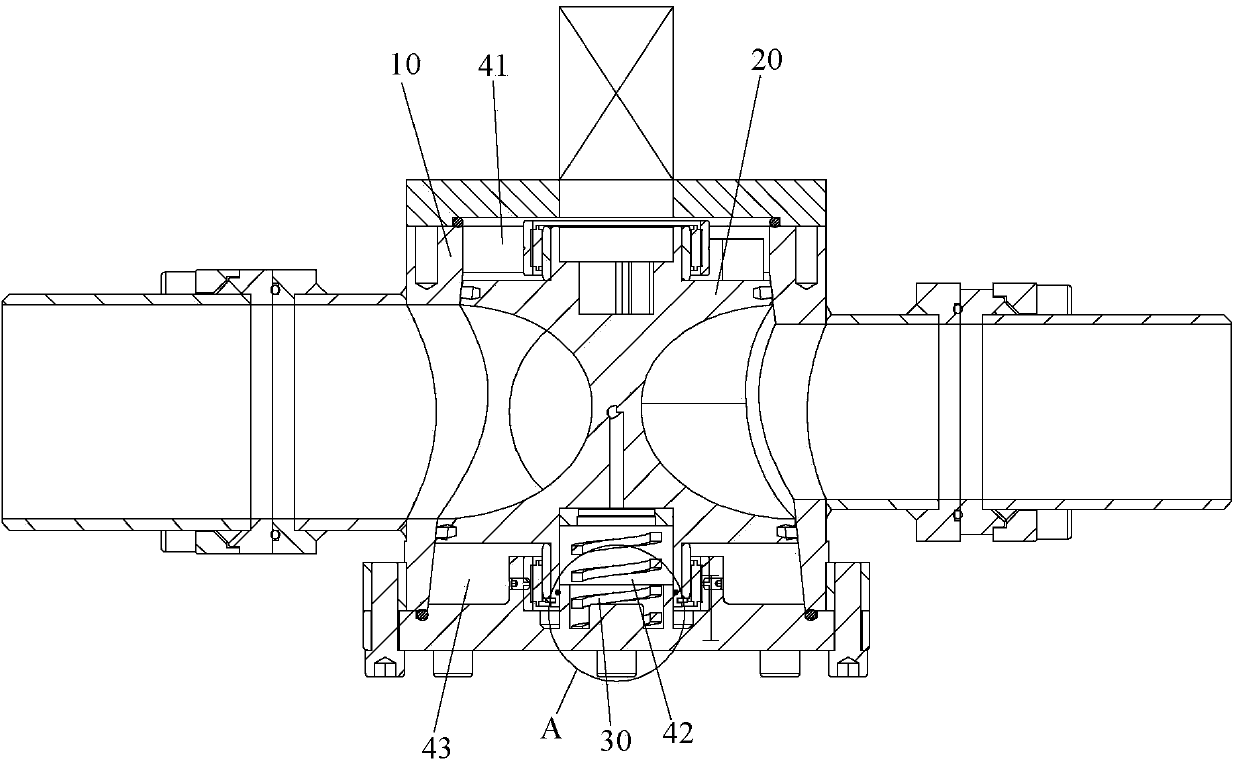

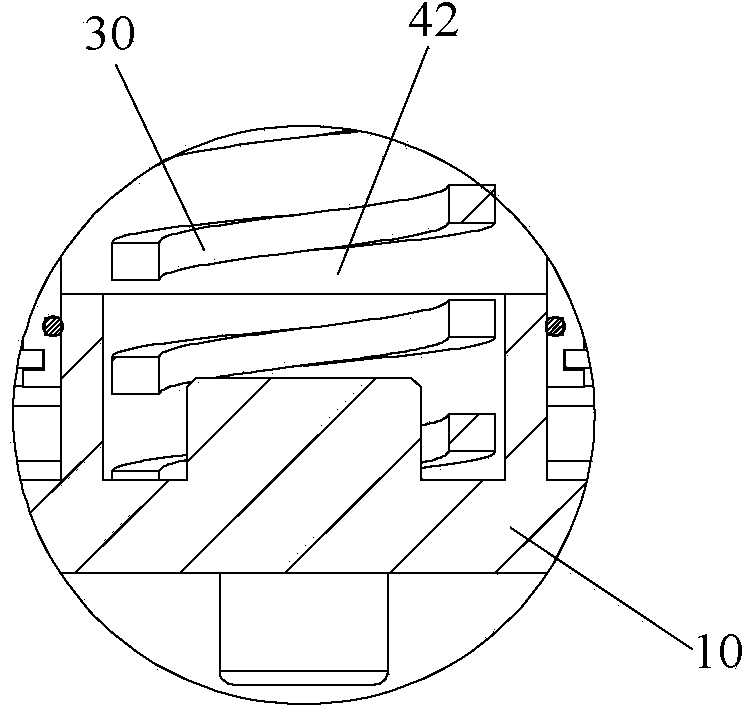

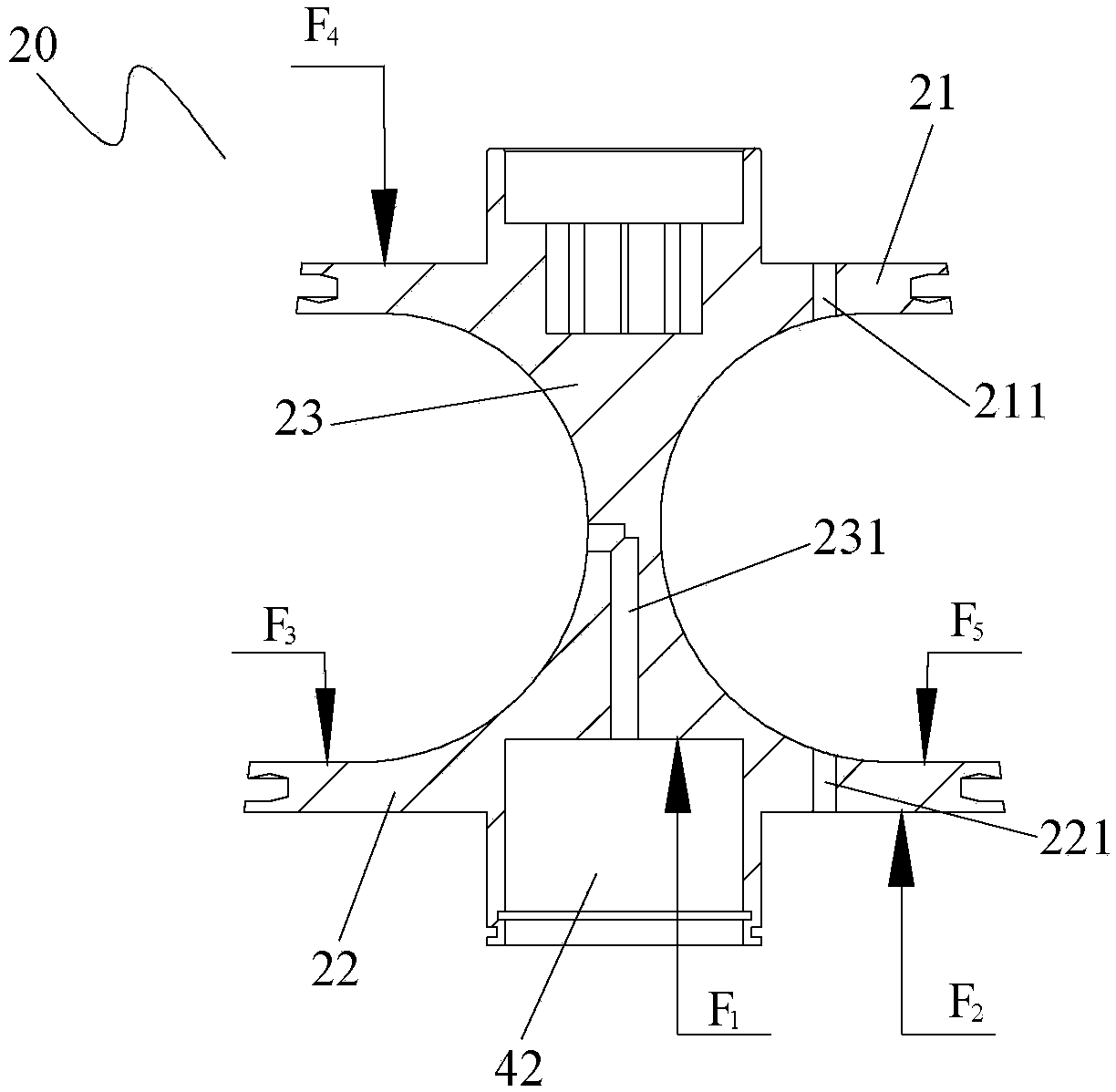

[0026] Such as Figure 1 to Figure 5 As shown, the rotary flow switching valve of this embodiment includes: a valve body 10 , a valve core 20 , a driving device and an elastic member 30 . In the above structure, the valve body 10 has a valve cavity, the valve cavity is in the shape of a frustum of a cone, the valve core 20 is adapted to the shape of the valve cavity, and the valve core 20 is rotatably arranged in the valve cavity, the valve core 20 and the valve body 10 Independent high-pressure passages and low-pressure passages are formed between the side walls. The spool 20 has a first end and a second end along its axis. The area of the first end of the spool 20 is smaller than the area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com