Patents

Literature

4055results about "Portable grinding machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled electro-pneumatic power tools and interactive consumable

Owner:FORGUES SYLVAIN +1

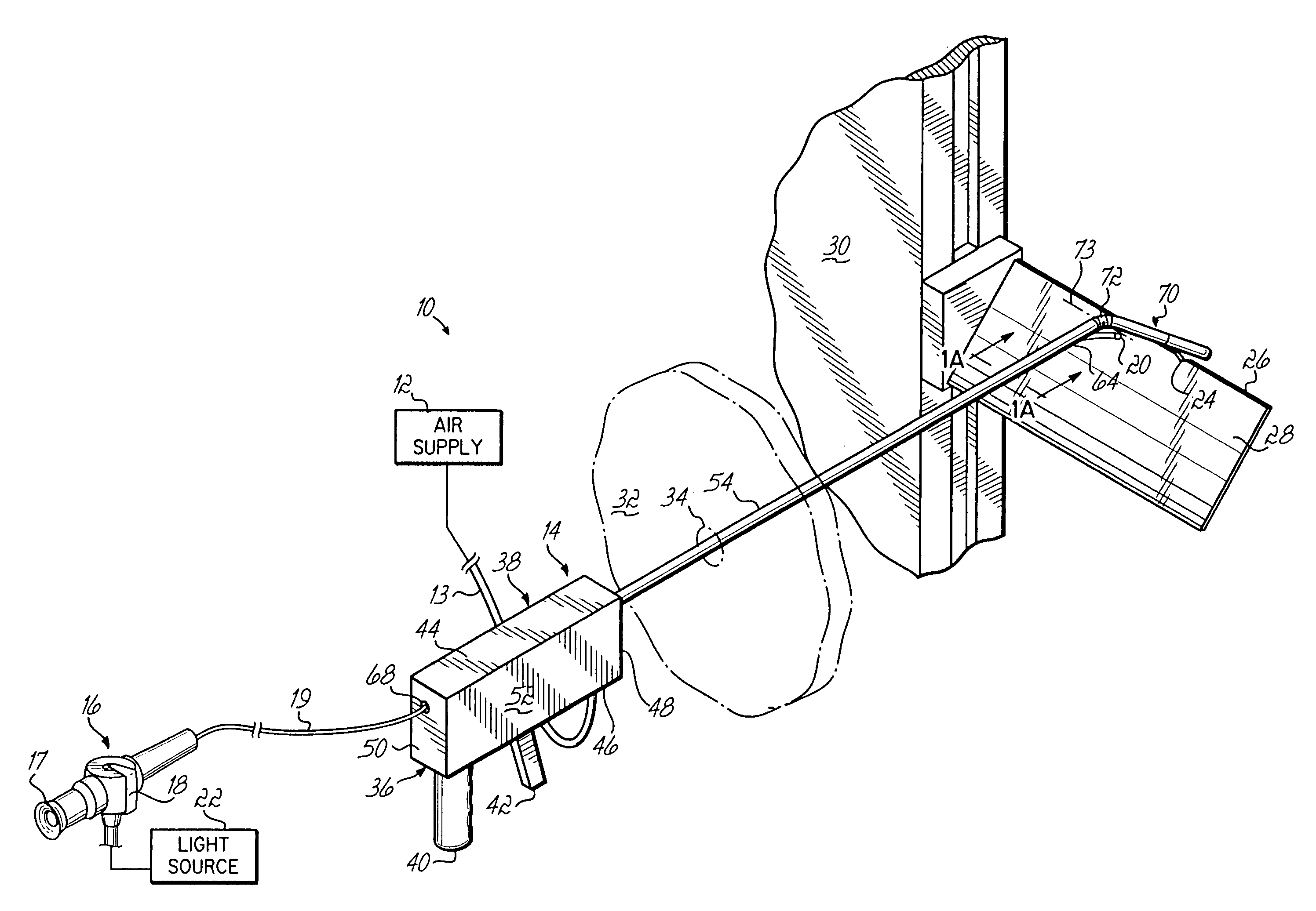

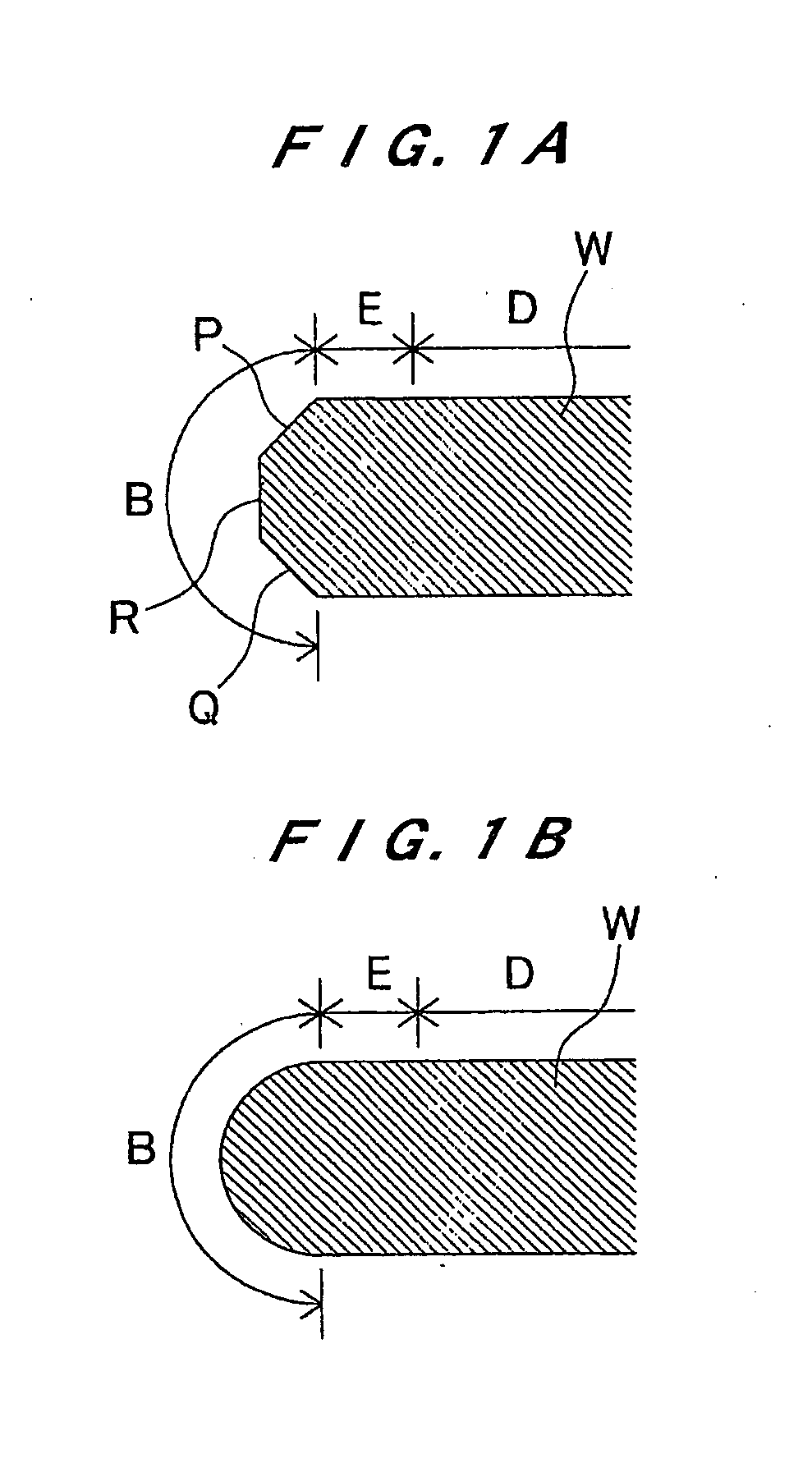

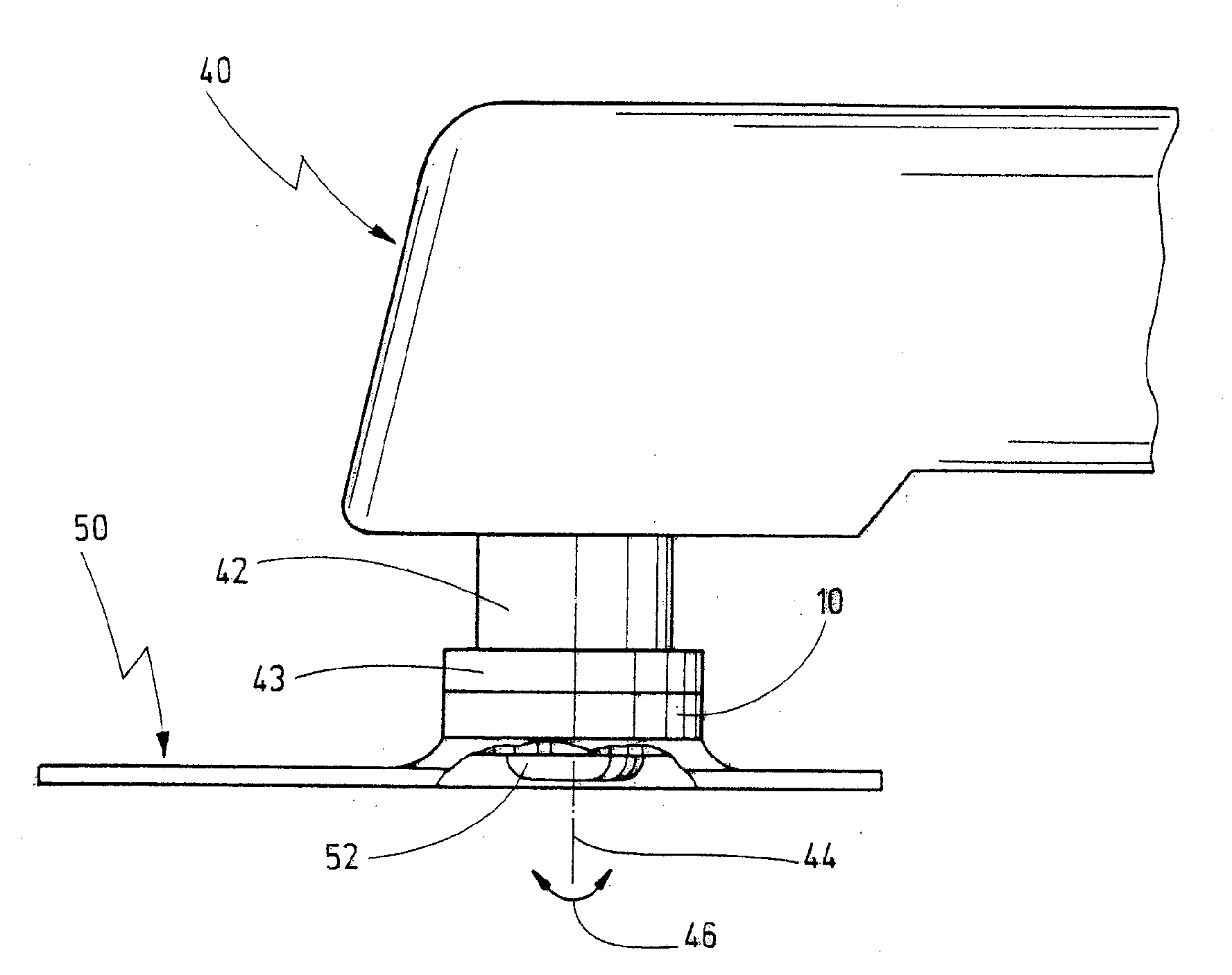

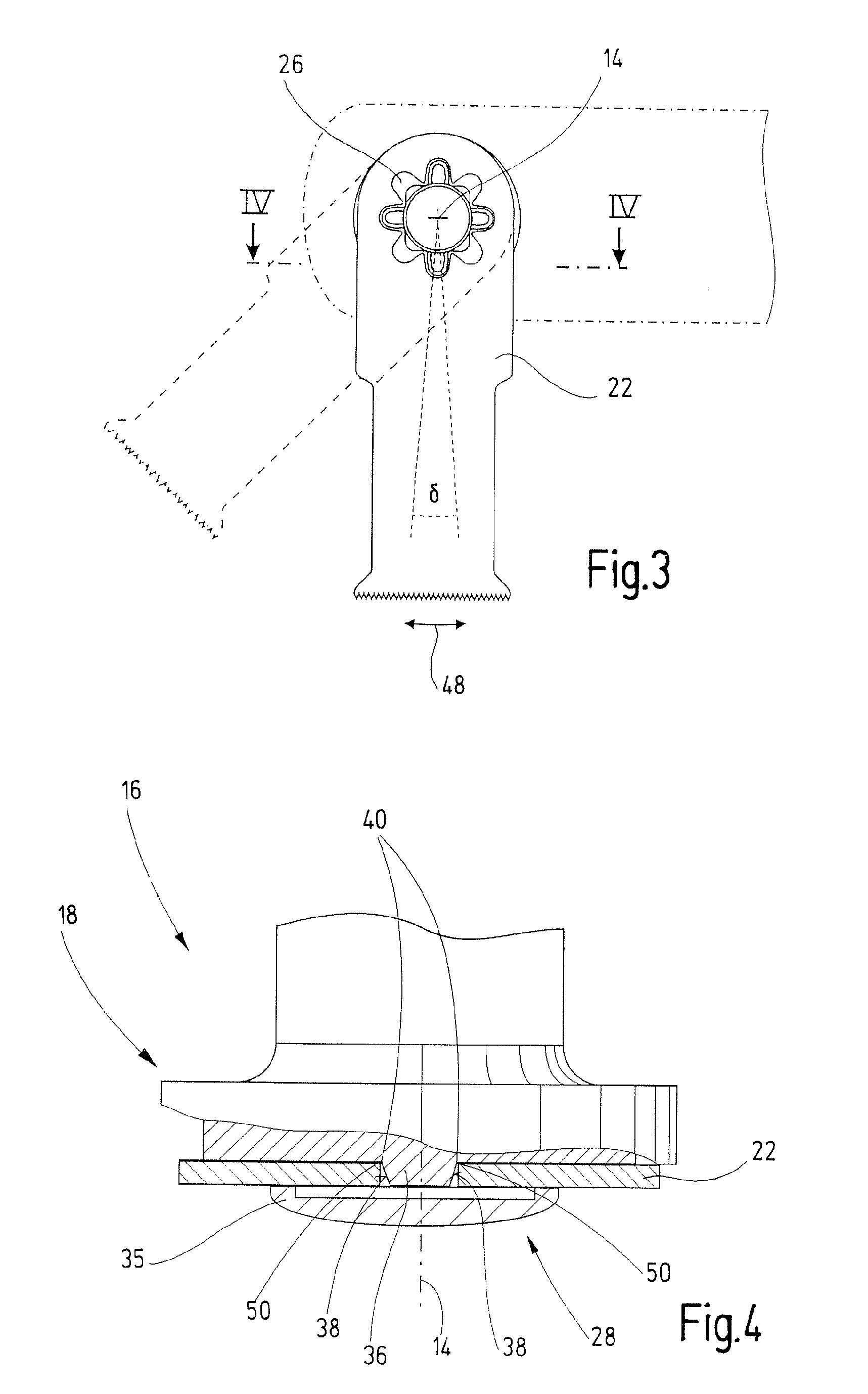

Grinding apparatus for blending defects on turbine blades and associated method of use

InactiveUS6899593B1Revolution surface grinding machinesBlade accessoriesReciprocating motionTurbine blade

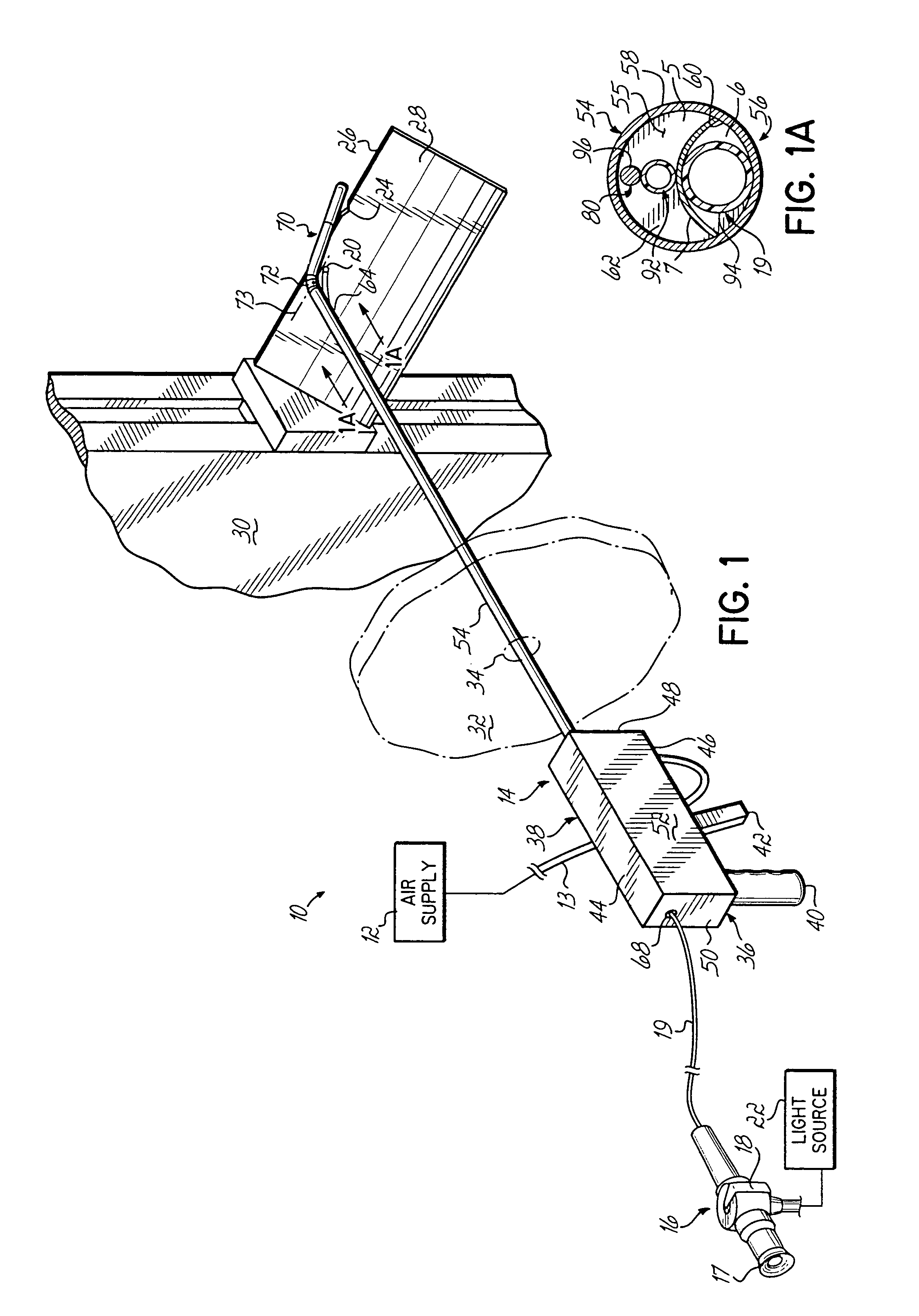

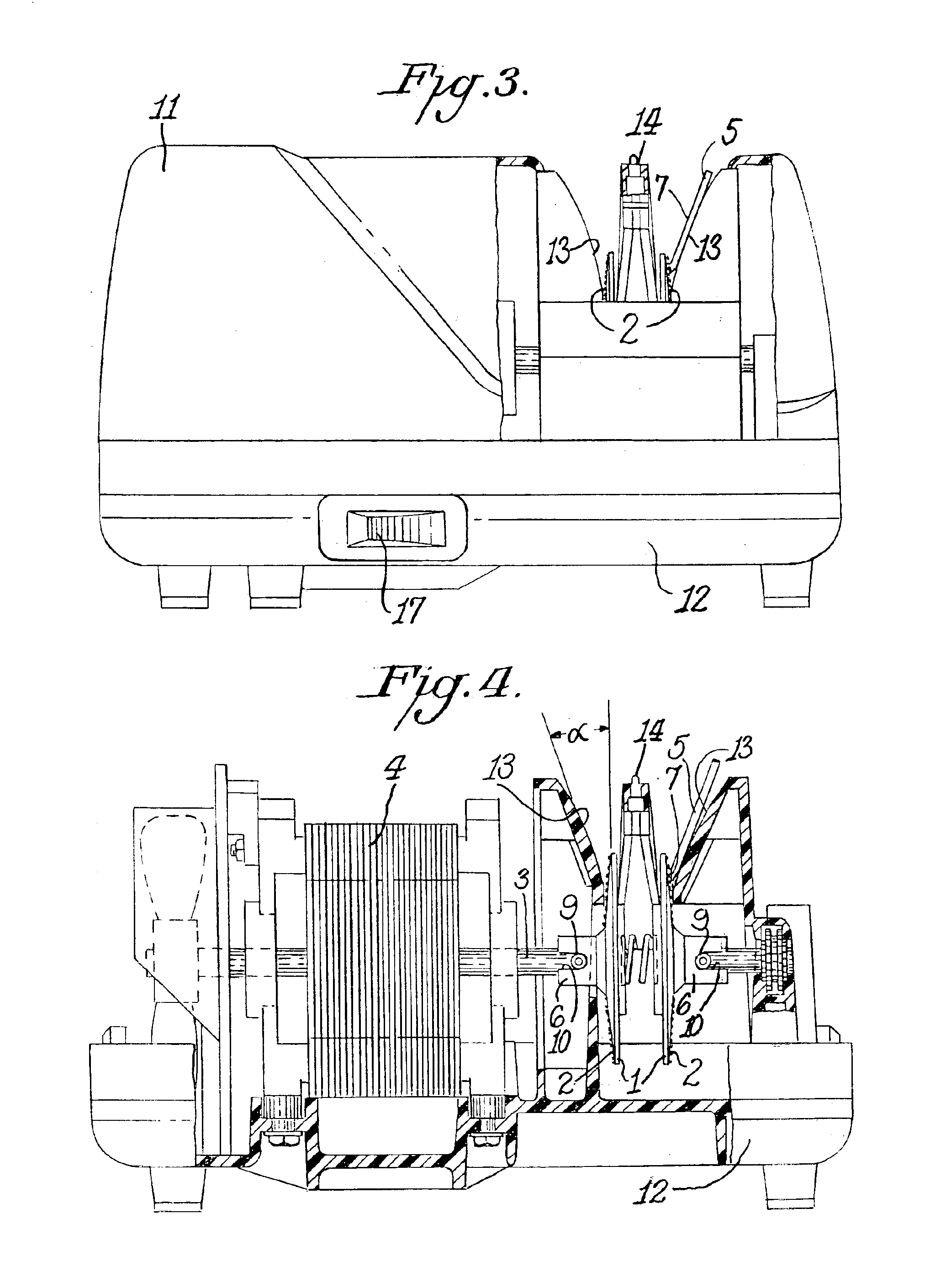

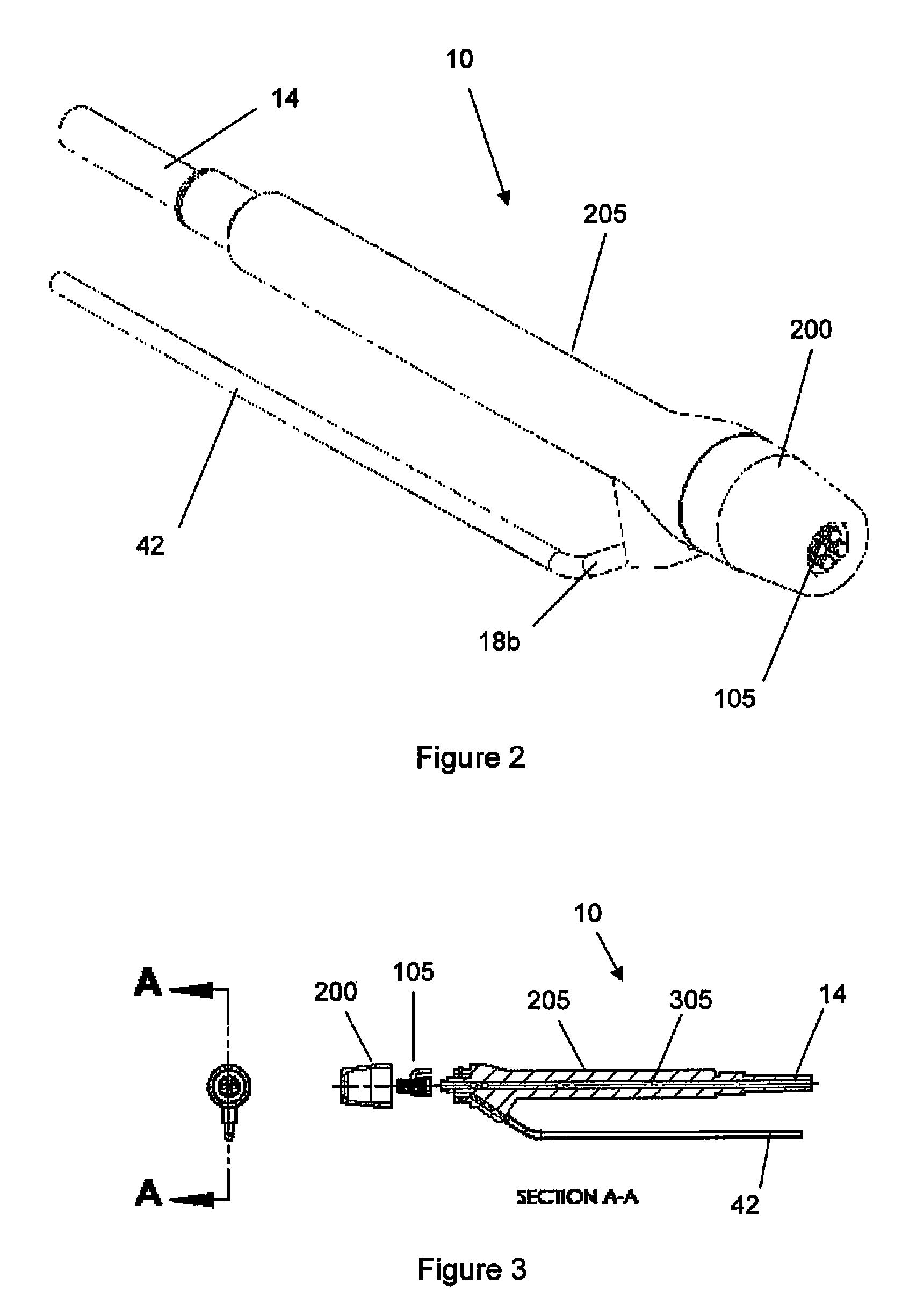

A grinding apparatus for use with an endoscope for viewing and blending defects on a turbine engine blade is provided. In one preferred embodiment air pulses from an air supply cause a grinding head on the end of a grinding tool to reciprocate at a predetermined speed. The position of the grinding head is fixed via the operator via a trigger on the grinding tool which articulates an outer portion of a support tube of the grinding tool. In another preferred embodiment, fluid is used to reciprocate the grinding head.

Owner:MOELLER DIETER +2

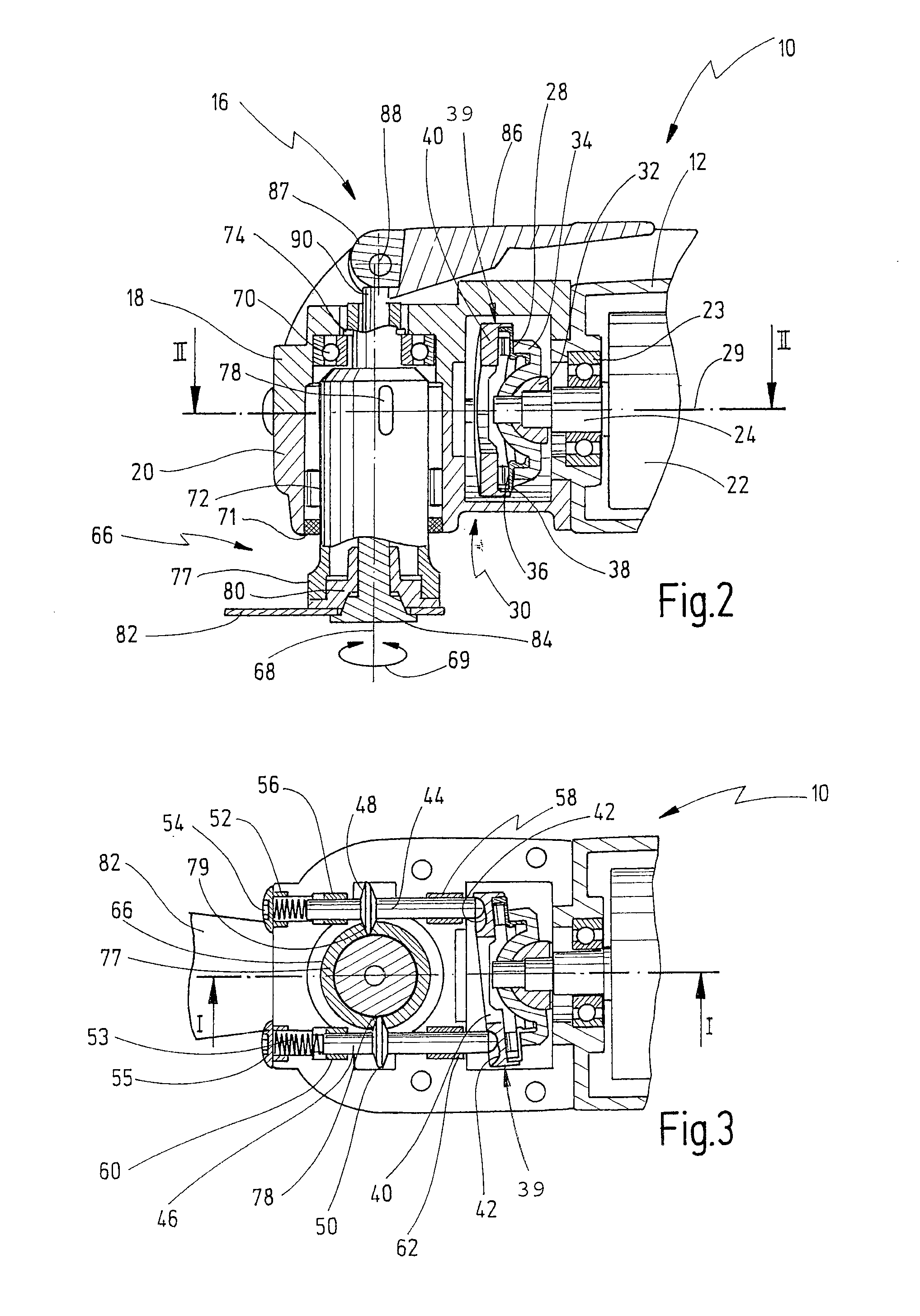

Hand tool machine having an oscillatory drive

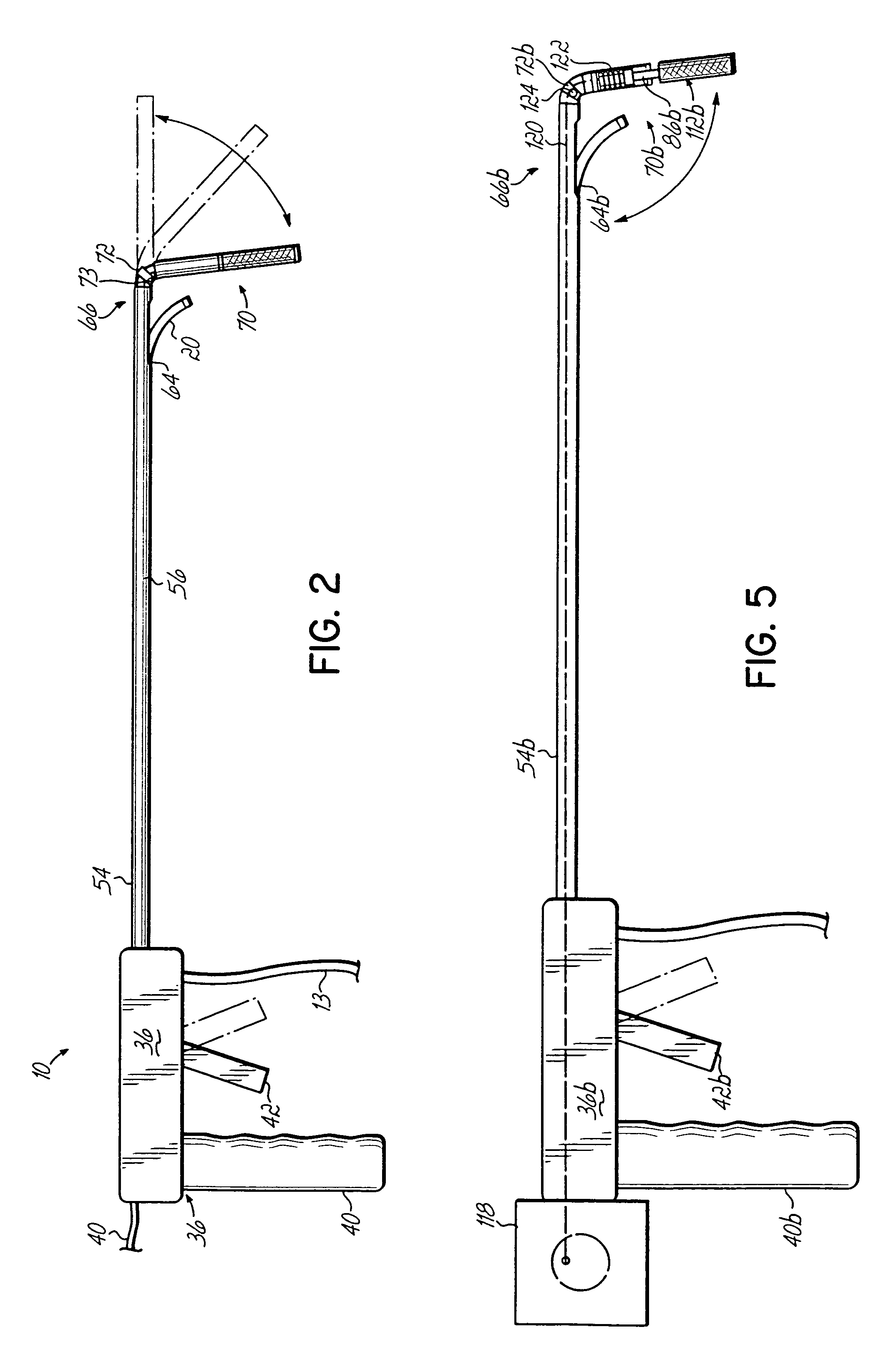

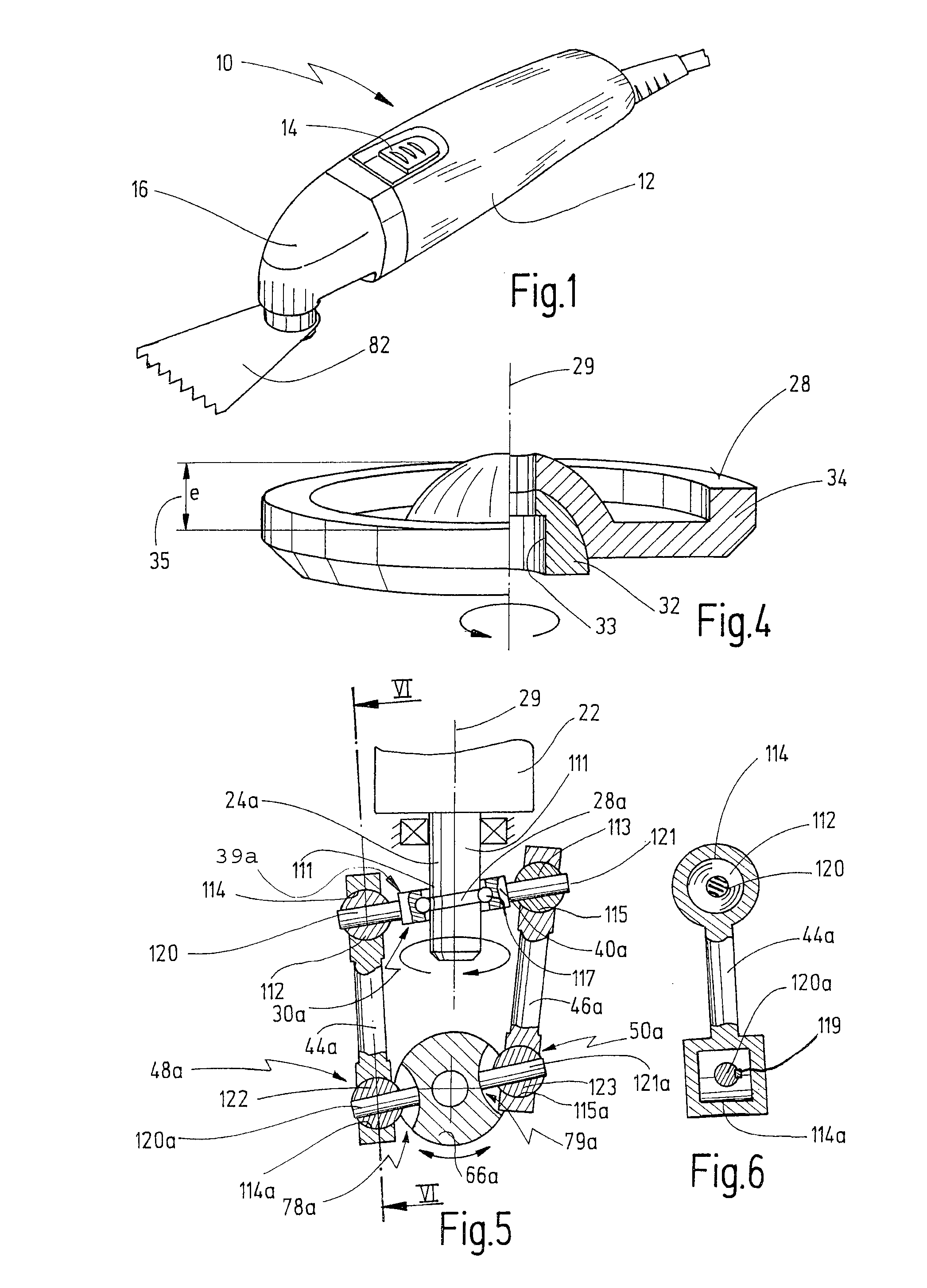

A hand tool is disclosed, comprising a housing, a motor shaft being coupled to a drive motor, a working spindle configured for being driven rotatingly oscillatingly about its longitudinal axis, and a coupling element being driven rotatingly by the motor shaft and having a closed guide surface that revolves around the motor shaft. The guide surface is coupled, via transmission means, to at least one driver for driving the latter. The at least one driver is arranged movably relative to the working spindle and engages the working spindle at a circumferential region thereof for driving the latter rotatingly oscillatingly.

Owner:C & E FEIN GMBH & CO KG

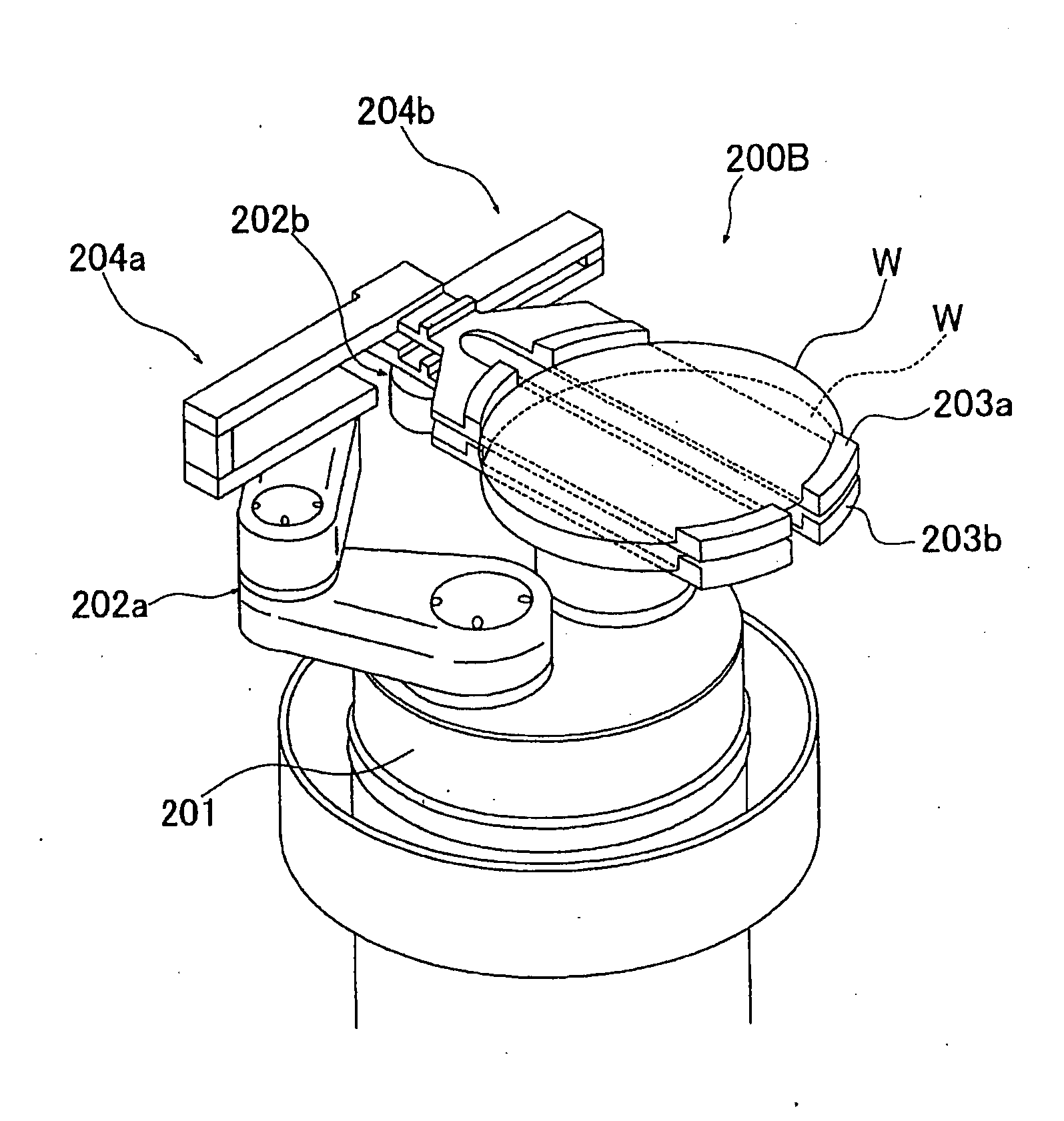

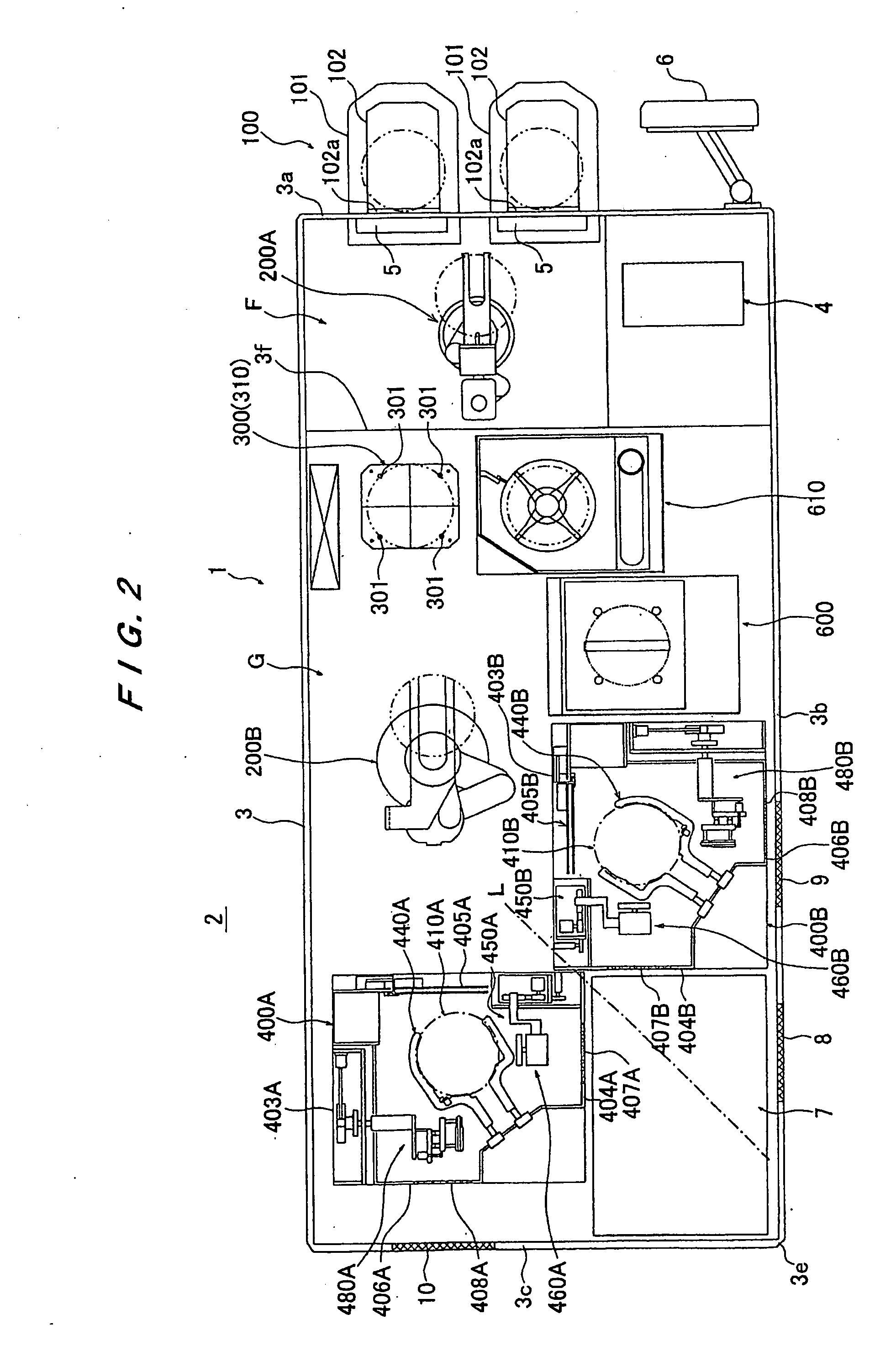

Substrate processing apparatus

InactiveUS20090017733A1Improve processing efficiencyEfficiently conductedEdge grinding machinesPolishing machinesEngineering

A substrate processing apparatus (1) has a first polishing unit (400A) and a second polishing unit (400B) for polishing a peripheral portion of a substrate. Each of the two polishing units (400A, 400B) includes a bevel polishing device (450A, 450B) for polishing a peripheral portion of a substrate and a notch polishing device (480A, 480B) for polishing a notch of a substrate. The substrate processing apparatus (1) has a maintenance space (7) formed between the two polishing units (400A, 400B). The bevel polishing devices (450A, 450B) in the two polishing units (400A, 400B) face the maintenance space (7) so as to be accessible from the maintenance space (7).

Owner:EBARA CORP

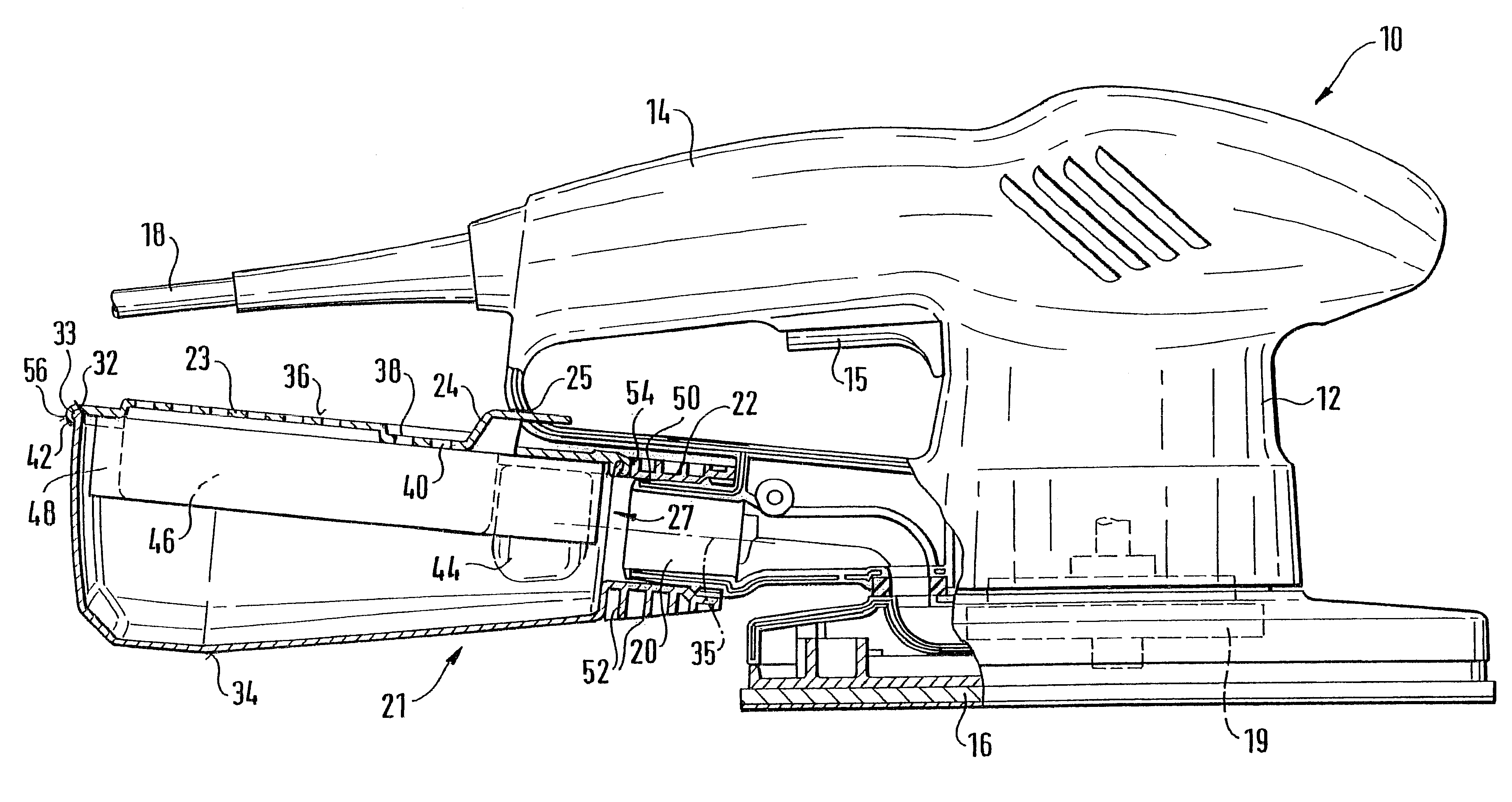

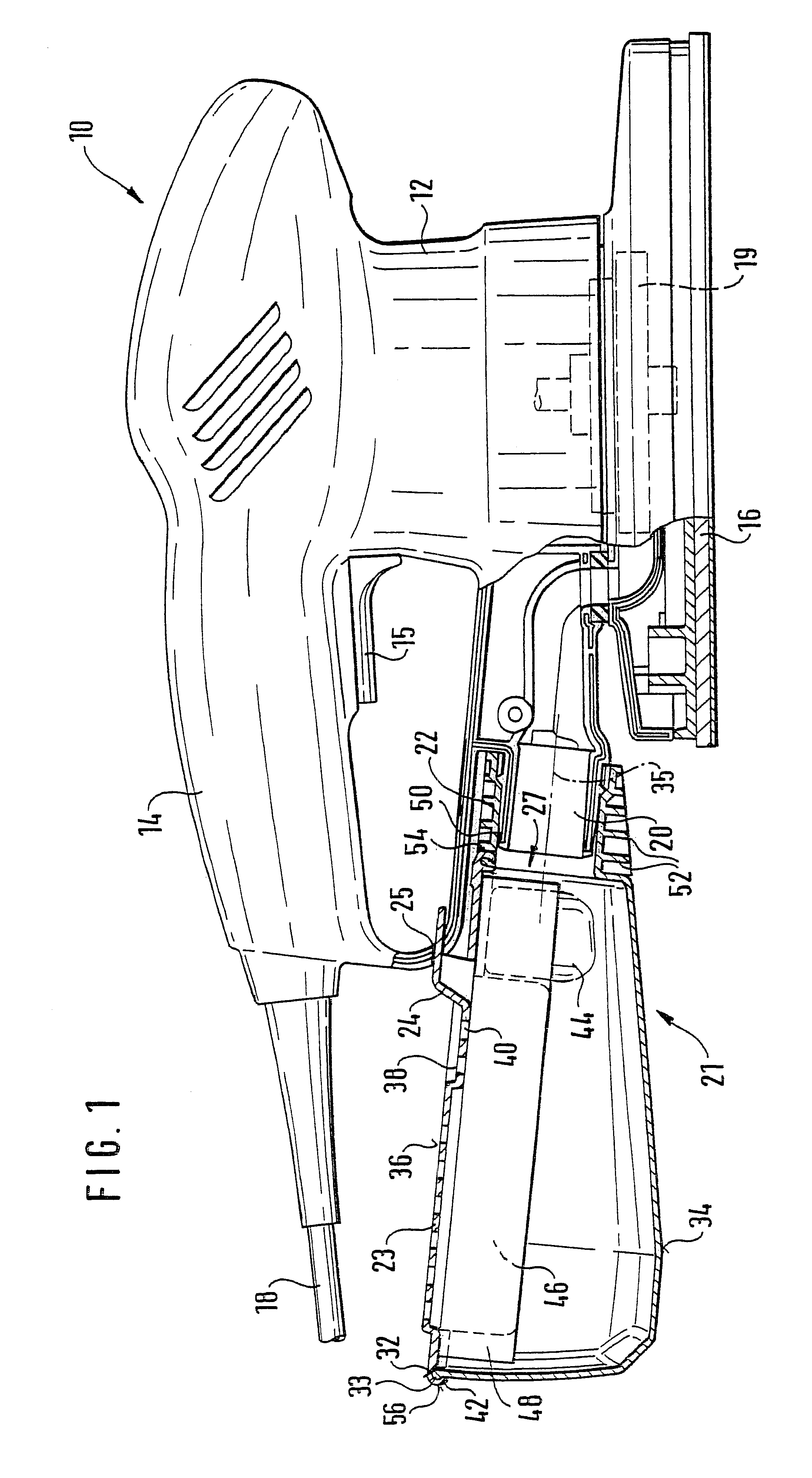

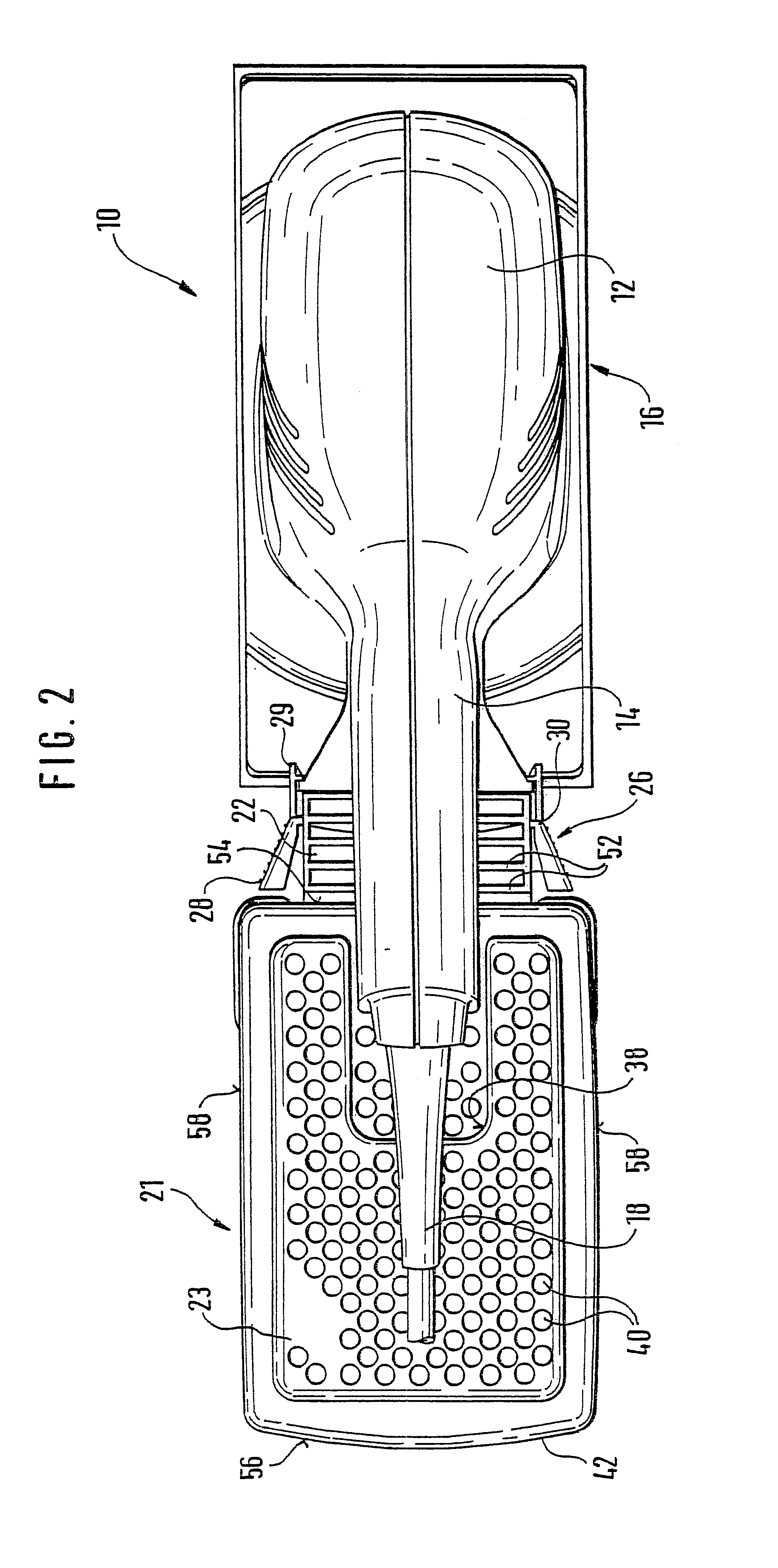

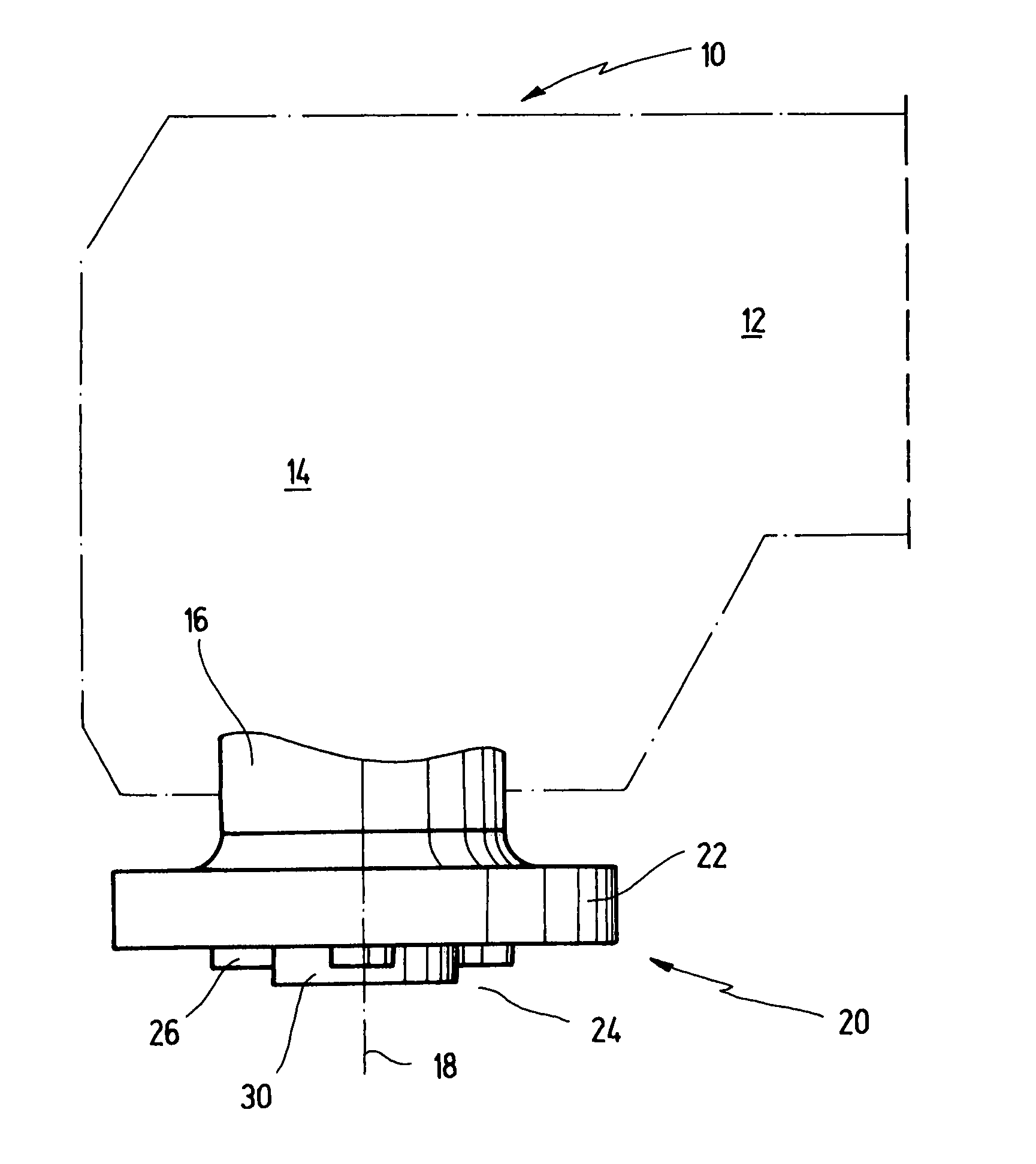

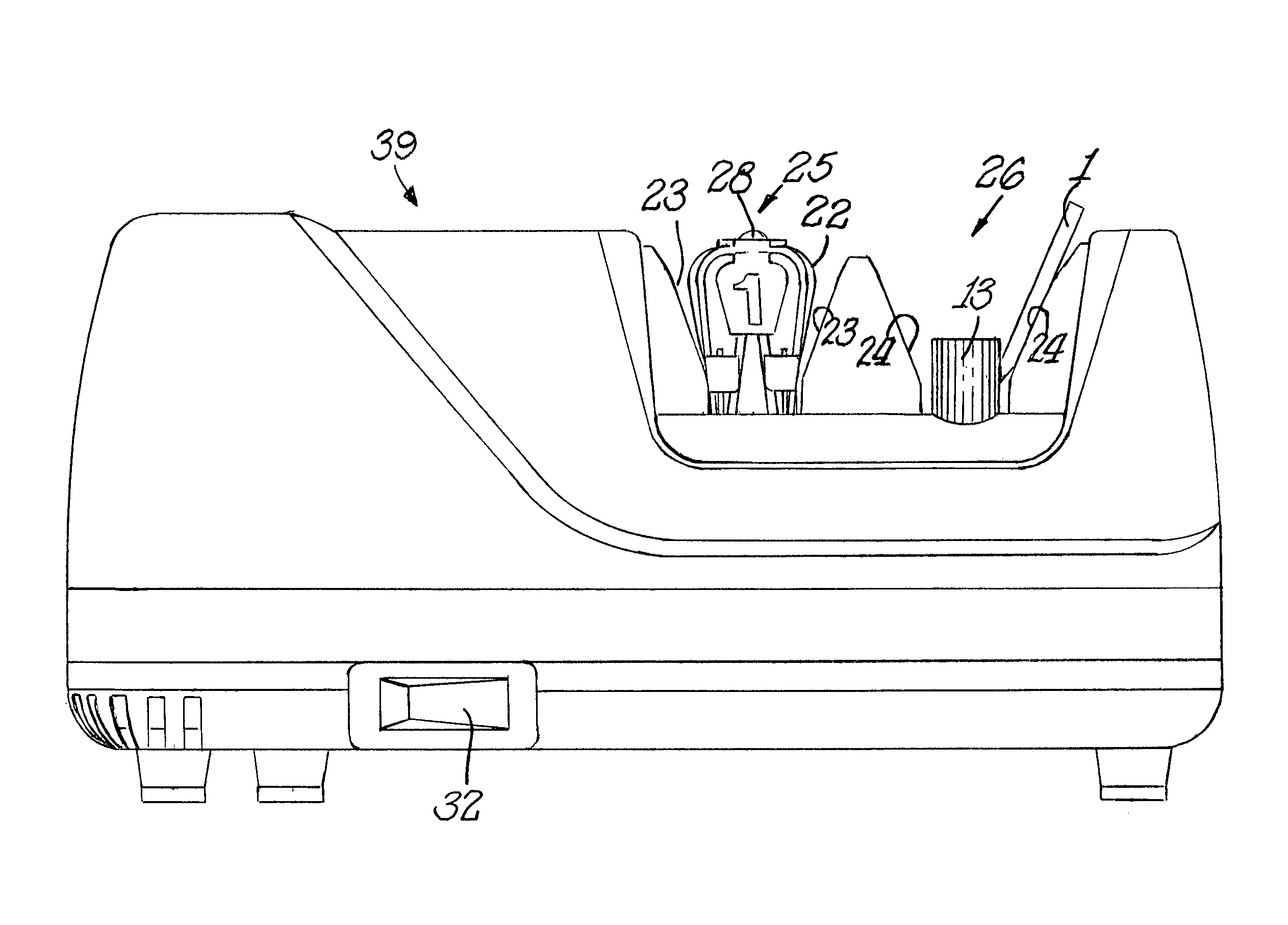

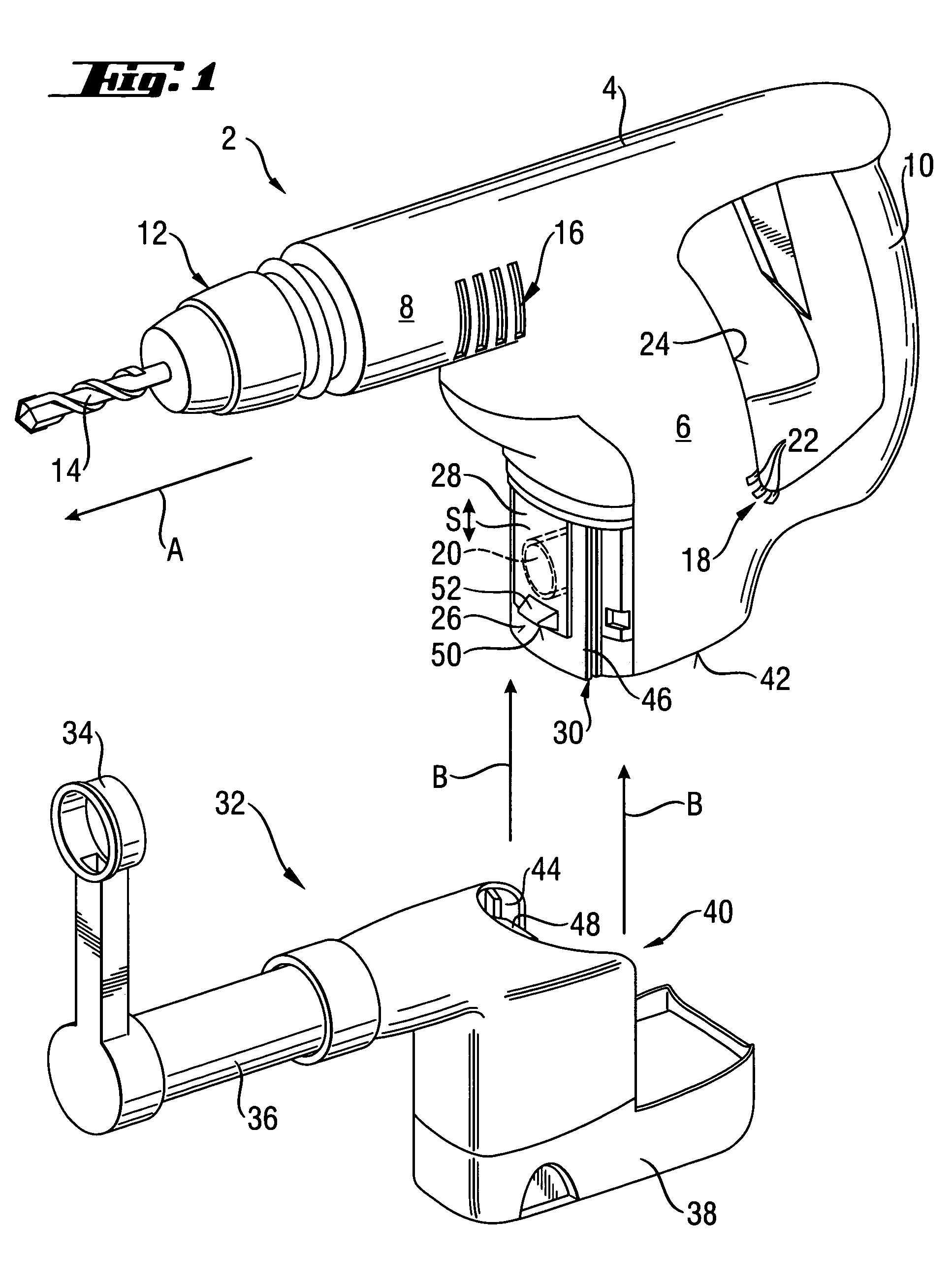

Hand-held machine tool with dust extraction

InactiveUS6514131B1Large filter areaHigh degreePortable grinding machinesMaintainance and safety accessoriesHand heldPower tool

A power tool (10) having a dust suction device (19) integrated into its housing (12) and having an ejection fitting (20) which is connected to the dust suction device (19) and can be detachably fastened with its injection fitting (22) to a dustproof dust box (21) is particularly suitable for containing sanding dust because of a number of side walls (34) of the dust box (21) have air openings (40) and on the inside, support at least one filter element (48), in particular a folded filter, which overlaps the air openings (40).

Owner:ROBERT BOSCH GMBH

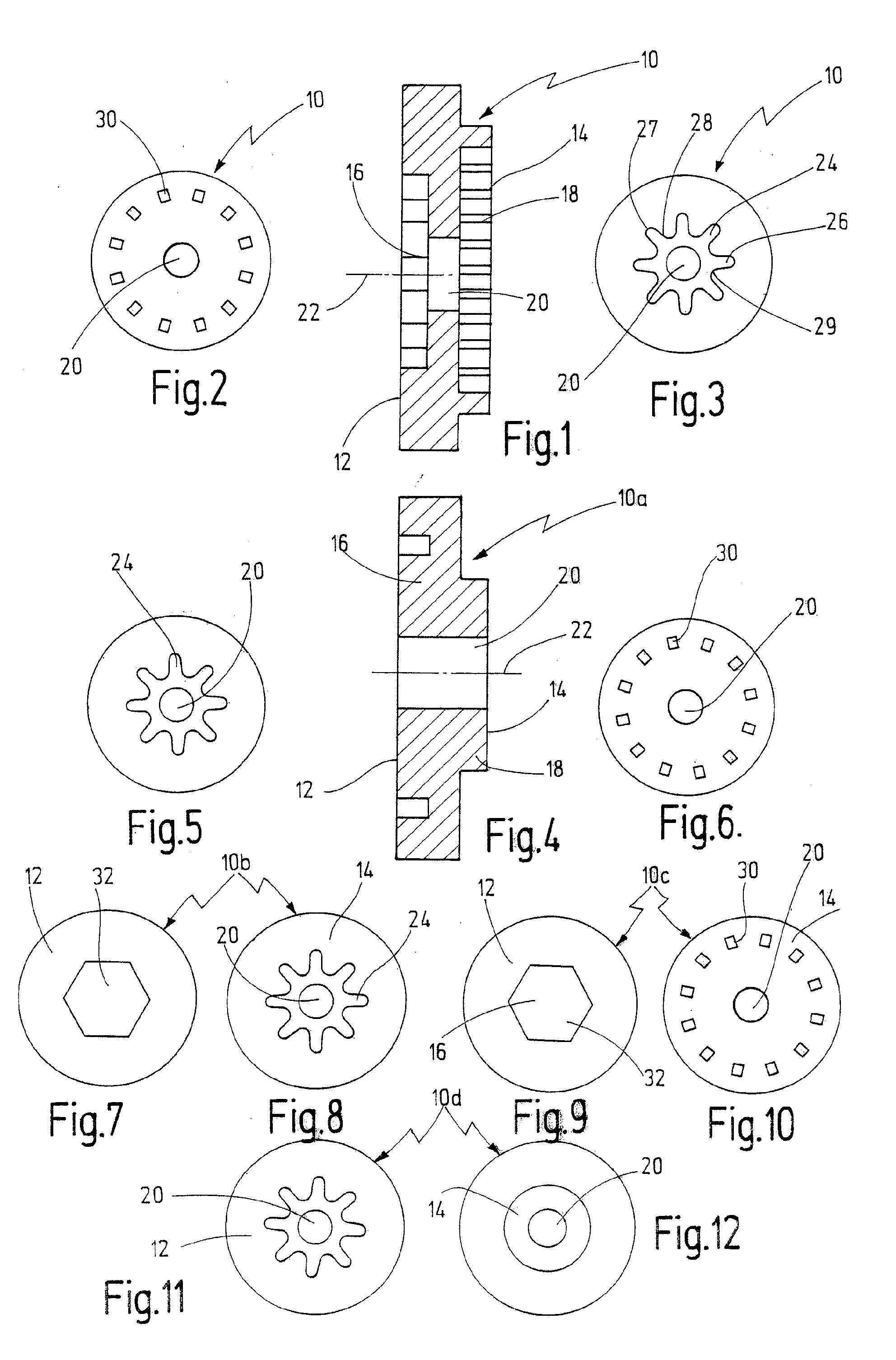

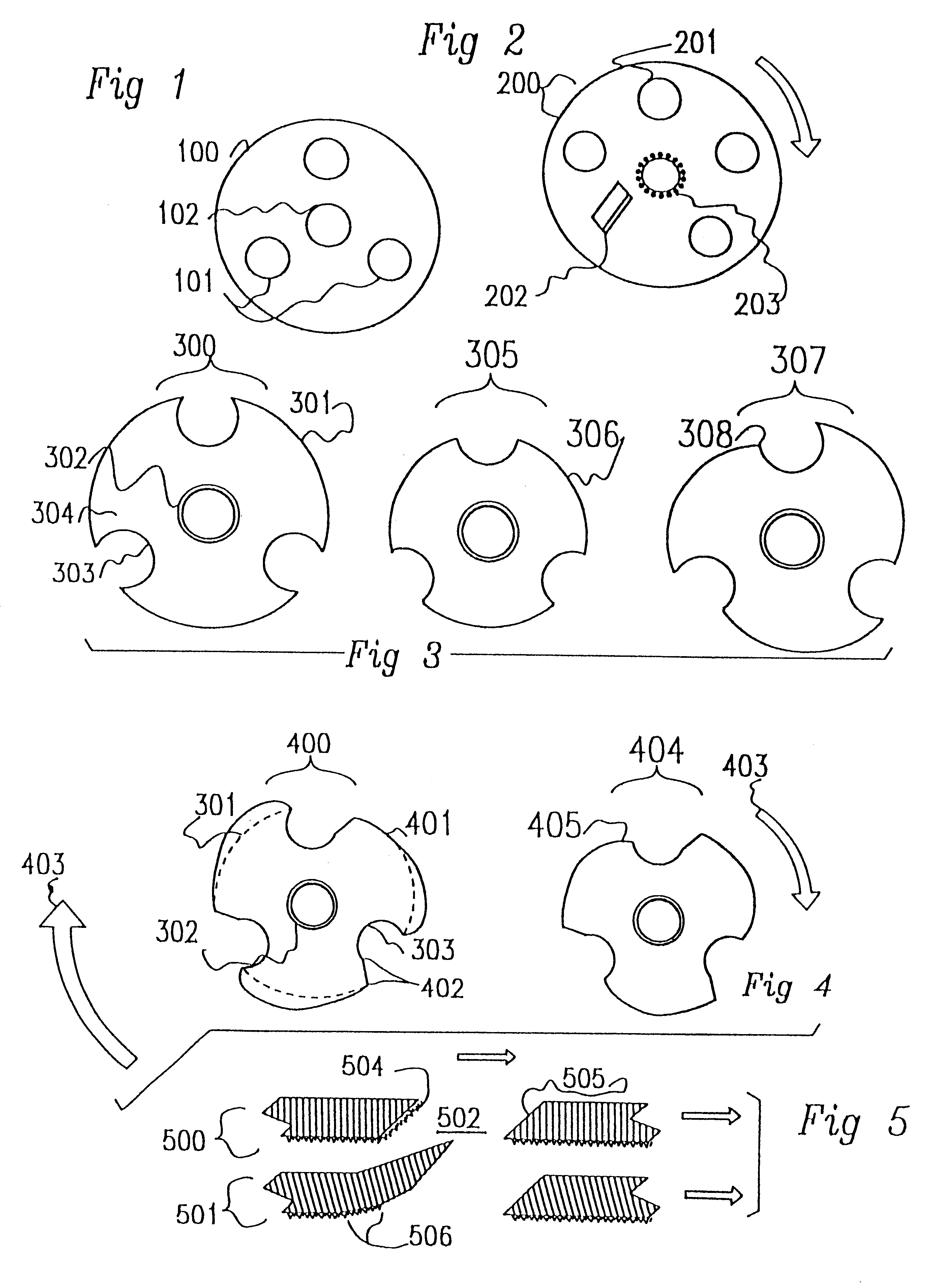

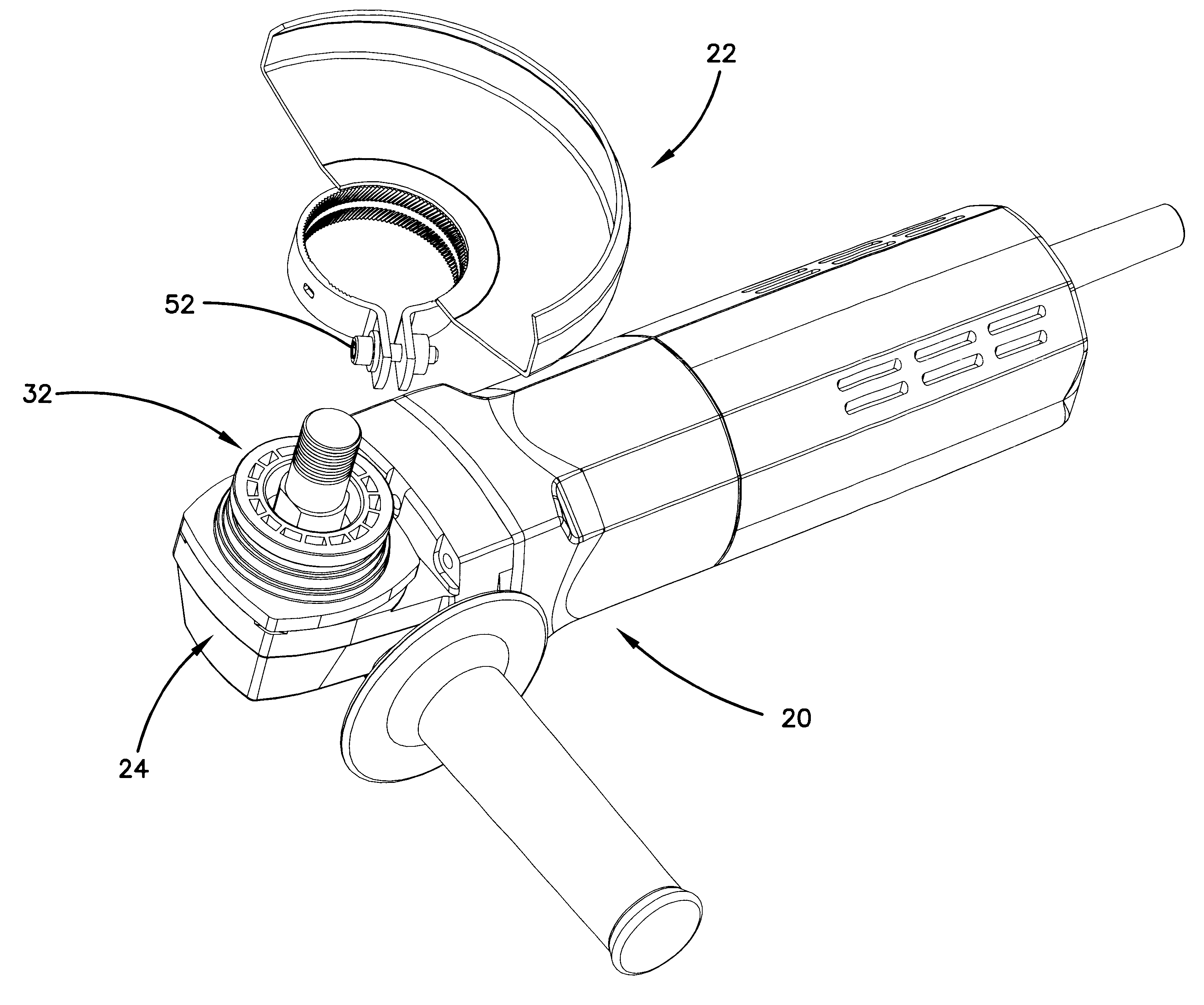

Power tool having a receptacle for securing a tool

InactiveUS6945862B2Reduce riskImprove transmittanceGrinding wheel securing apparatusMetal sawing toolsDrive shaftPower tool

A power tool having a receptacle for securing a tool to a drive shaft thereof is disclosed. The receptacle comprises a receiving opening, preferably being arranged on the tool. The receiving opening engages a securing section preferably being provided in a raised fashion on the drive shaft of the power tool, thereby effecting a positive fit. The securing section comprises a plurality of rounded tips arranged at even radial distances from said longitudinal axis, at angular intervals between each other, each rounded tip having a pair of lateral flanks extending from a common apex toward an intermediate section connecting lateral flanks of a pair of adjacent rounded tips. Preferably the receiving opening comprises a number of rounded tips which is twice the number of rounded tips provided on the raised section.

Owner:C & E FEIN GMBH & CO KG

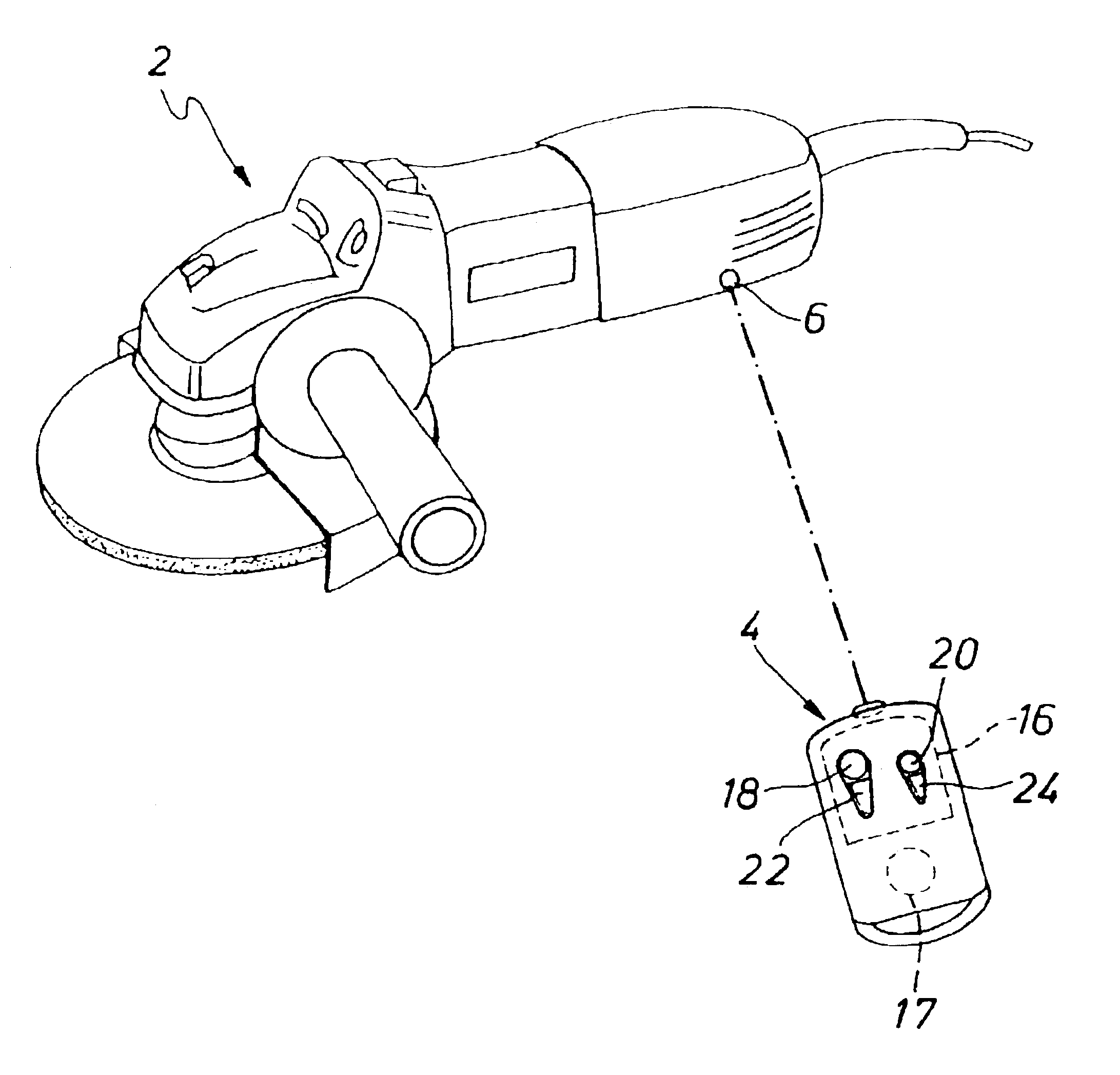

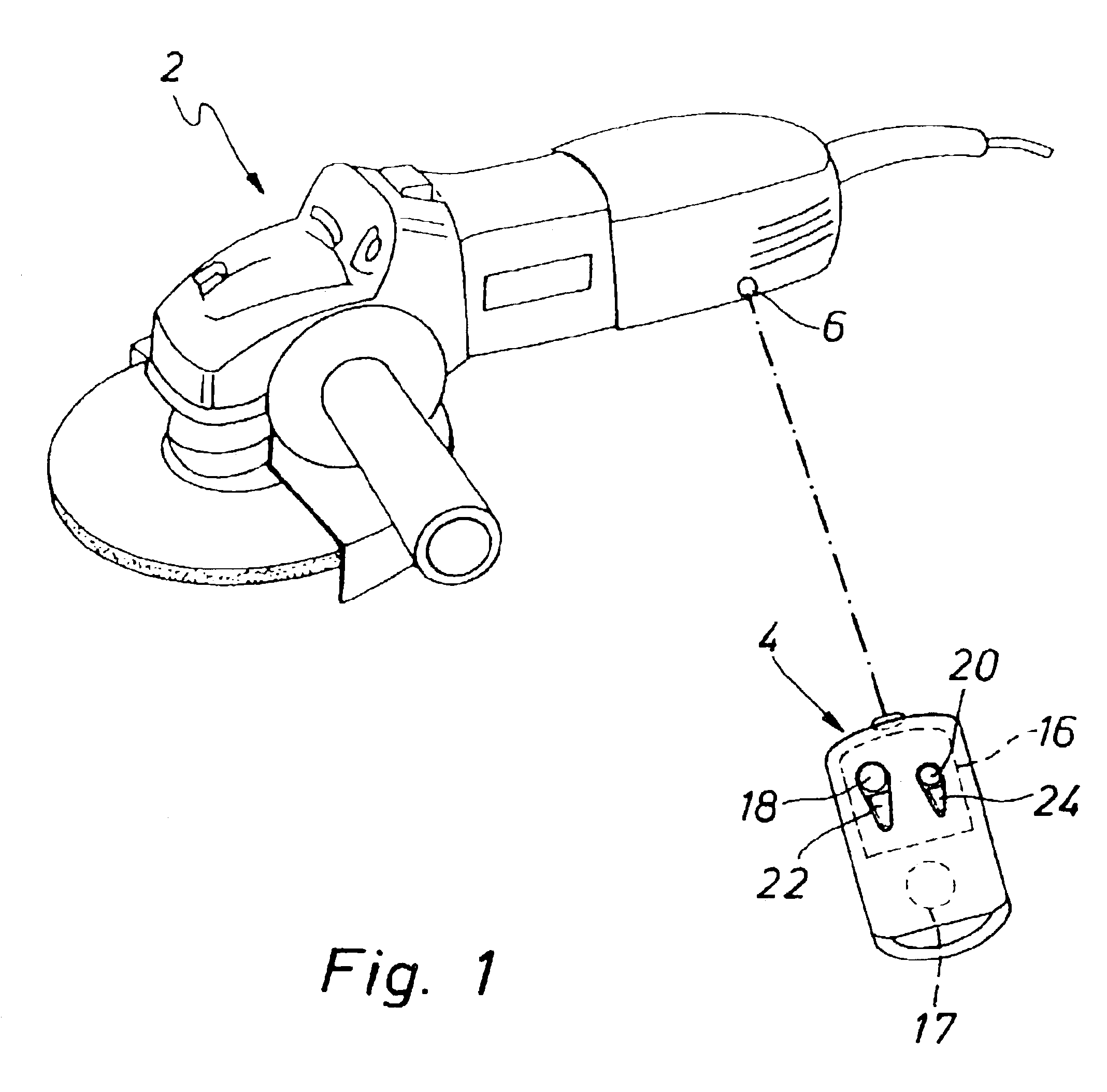

Electrical hand tool device

InactiveUS6872121B2Reduce sensitivityElectric signal transmission systemsDerricks/mastsContact freeControl electronics

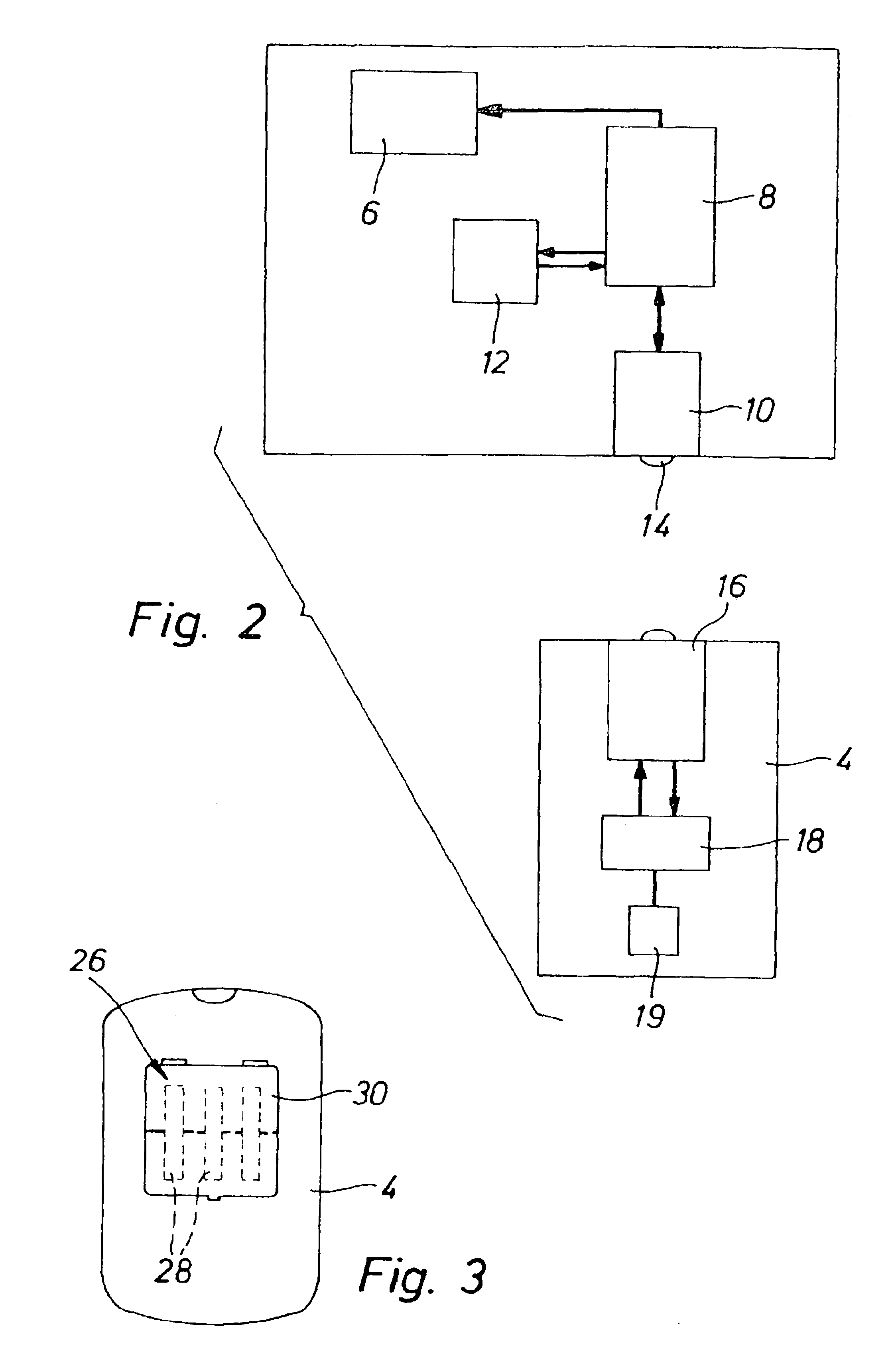

An electrical hand tool device (2) comprises a control electronics (8) and a transmitter and receiver (10) which is responsive in a wireless and contact-free fashion, and with a storage medium (12) in which an authorization code is stored, wherein an operation locking state and an operation release state can be differentiated, and with an external transmitter and receiver means (16) which is accommodated in a separate portable device (4), wherein communication with the transmitter and receiver means (10) of the electrical hand tool device can be produced in a defined fashion through actuation of the external transmitter and receiver means (16) to change the operation state, and communication is provided only to change the operation state and optionally to change the authorization code.

Owner:METABOWERKE

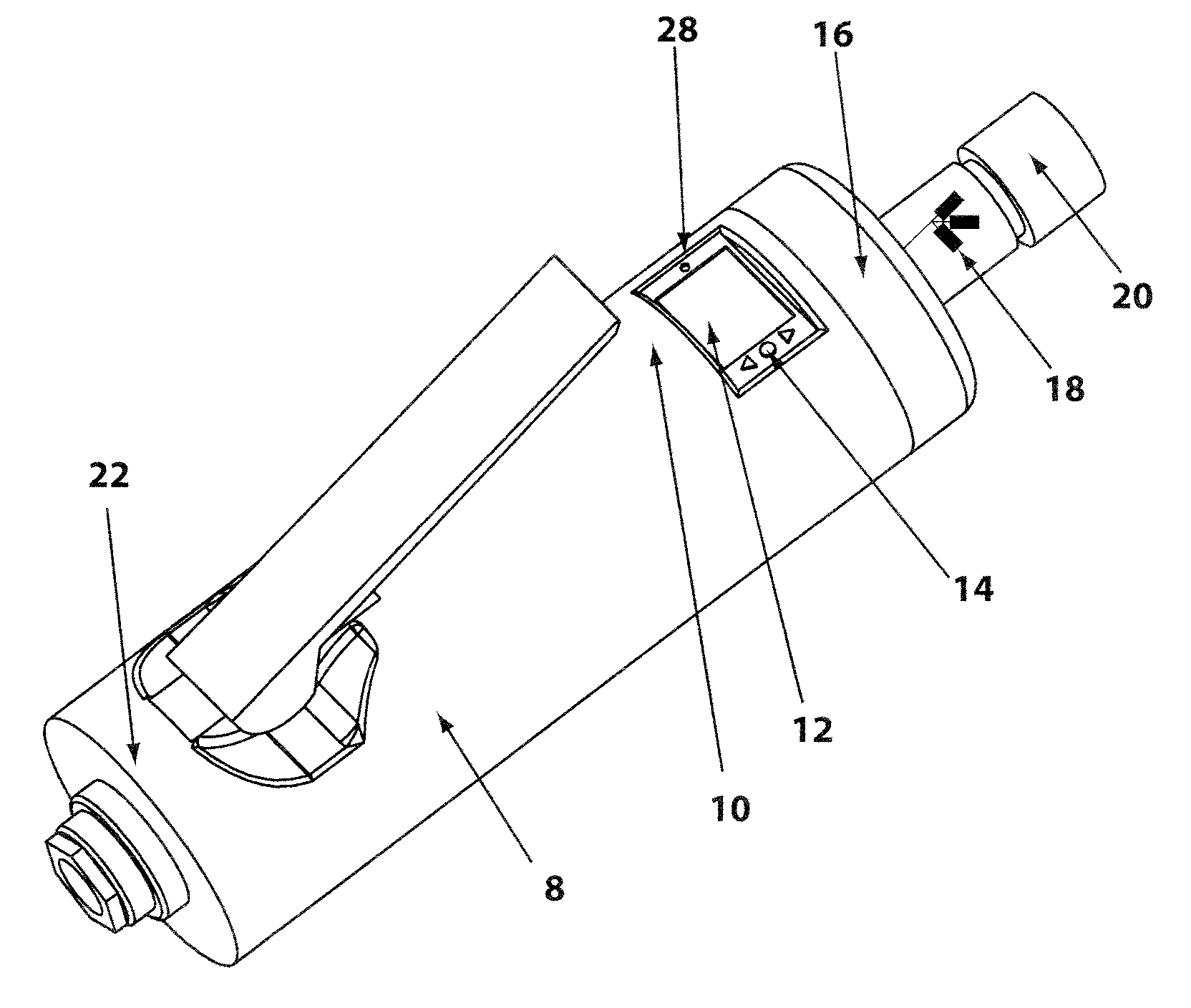

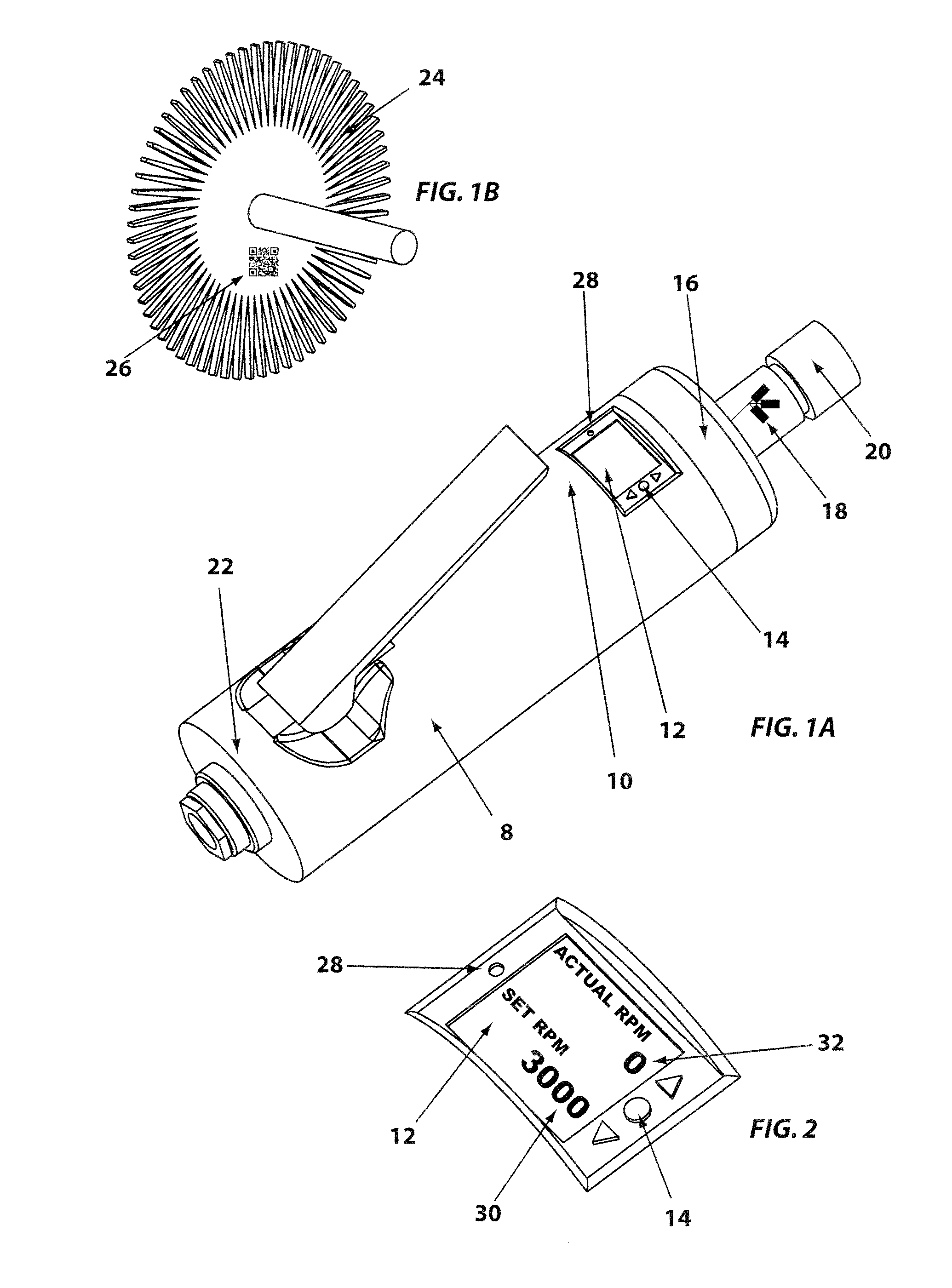

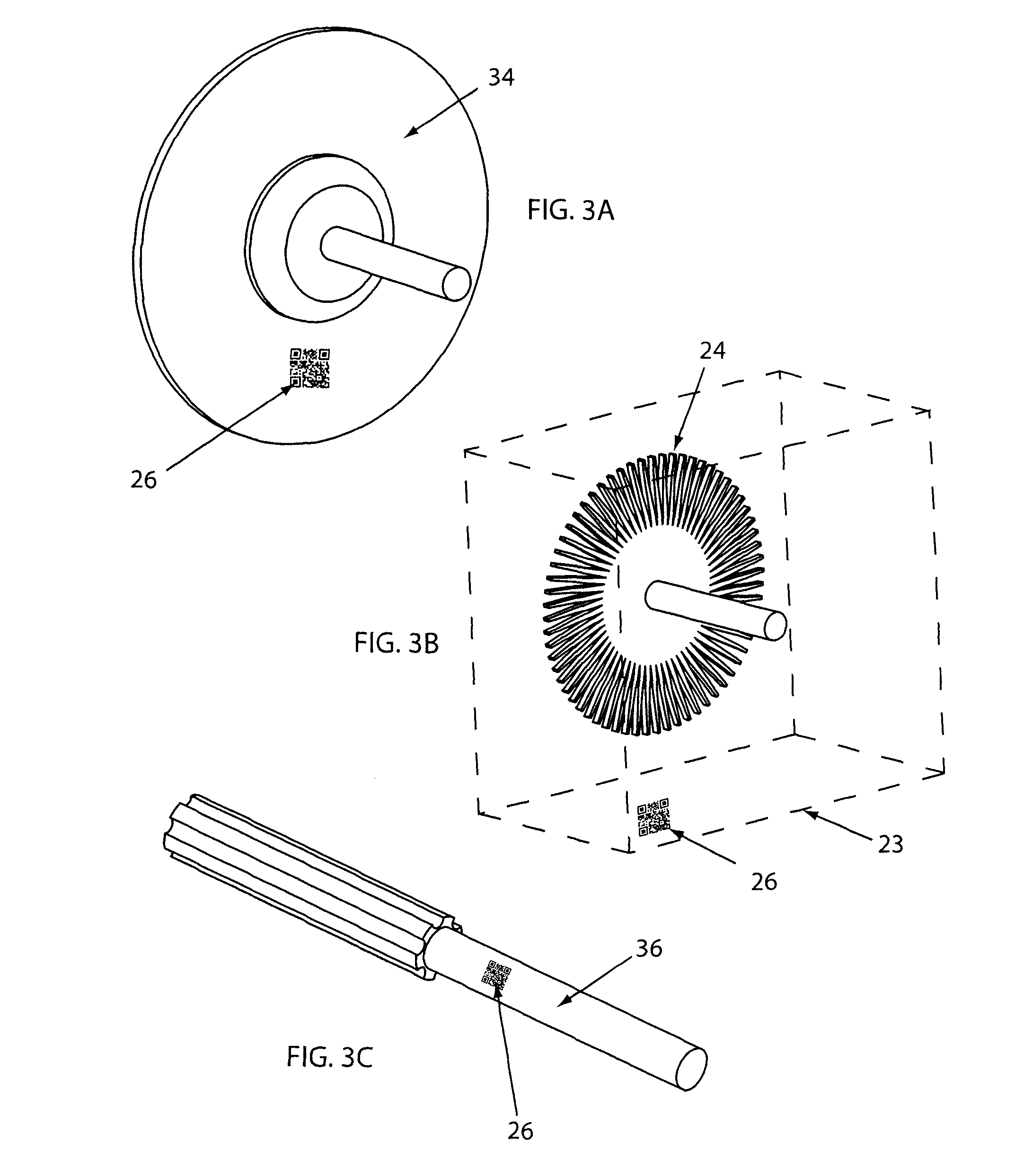

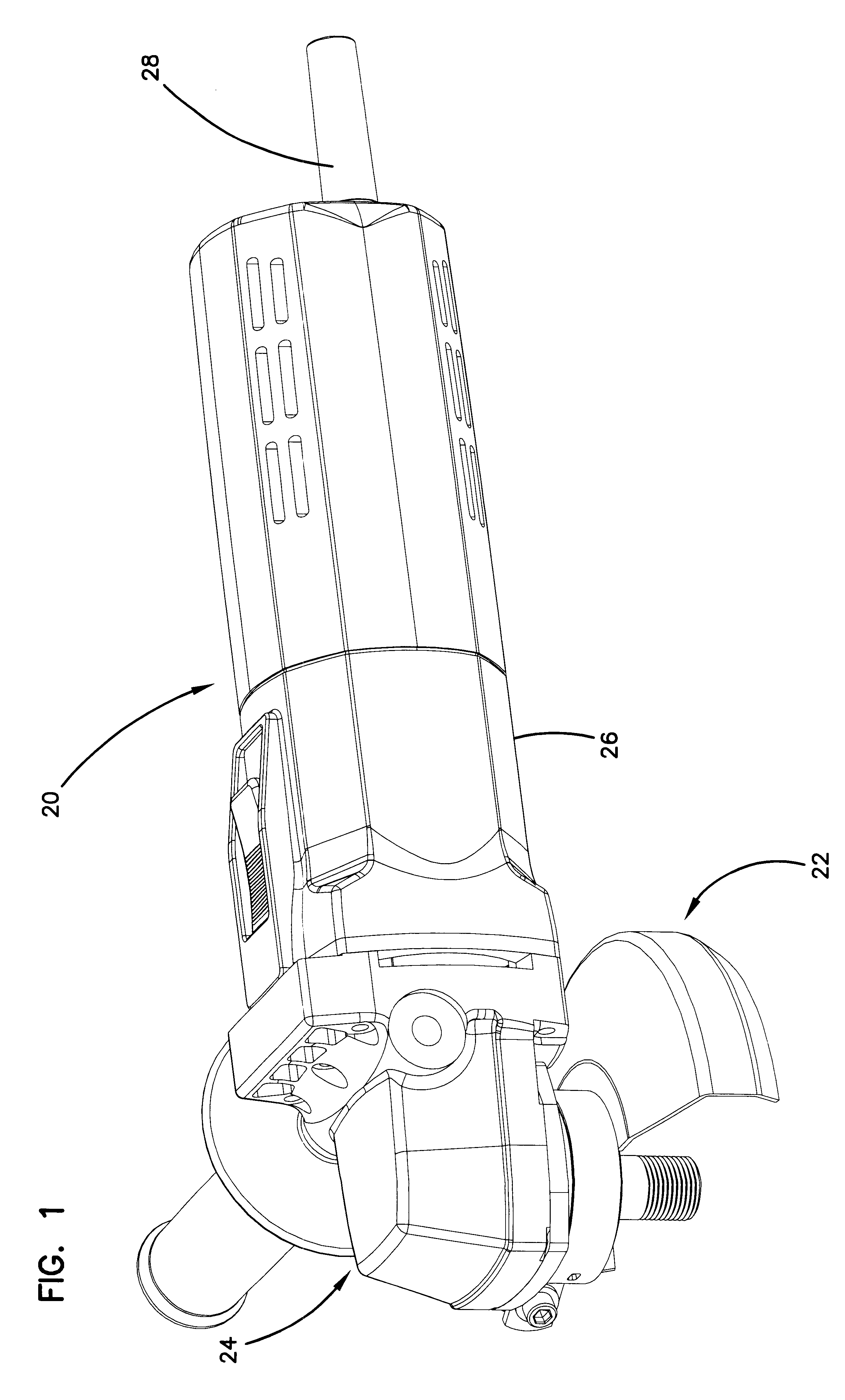

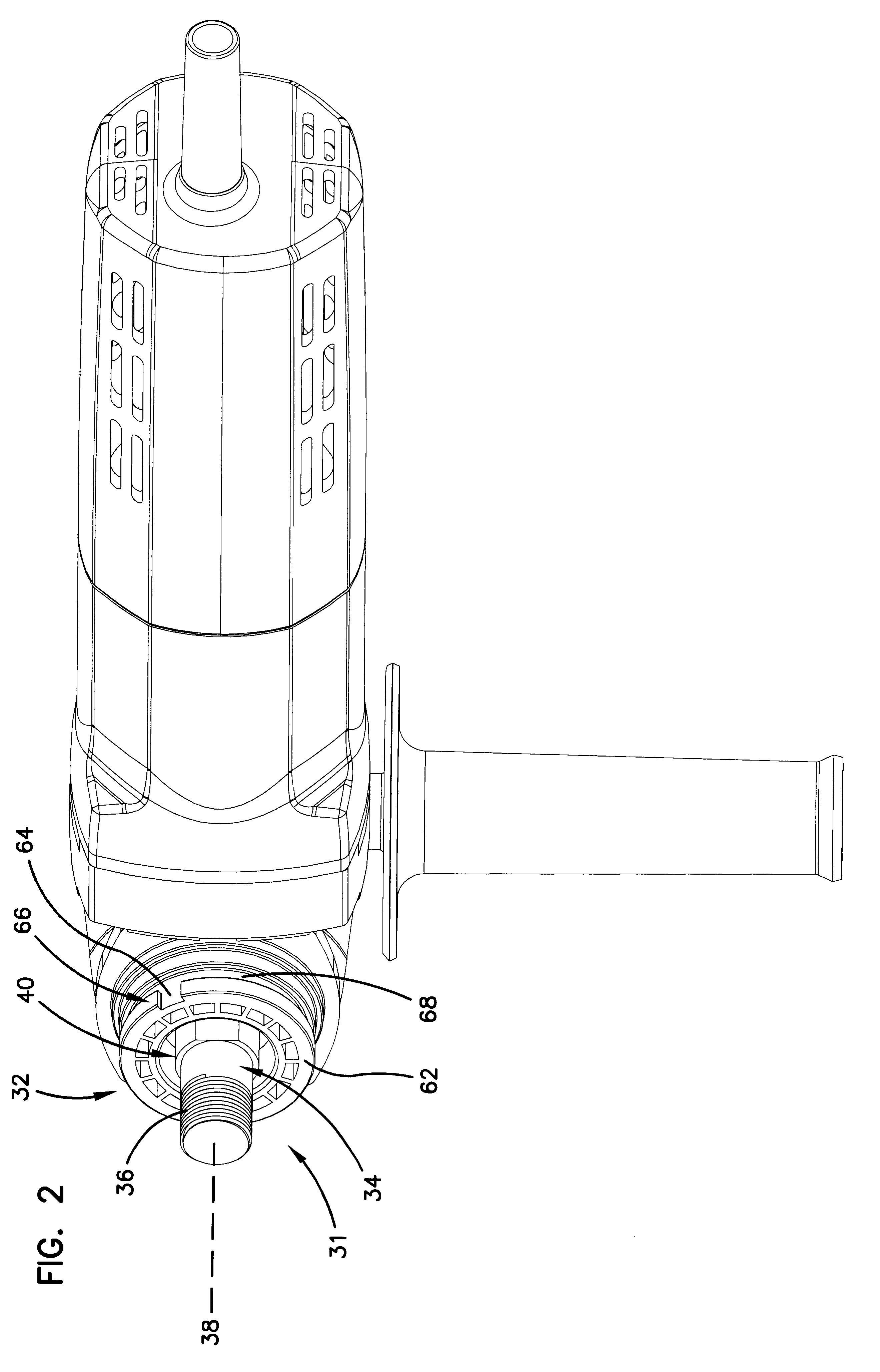

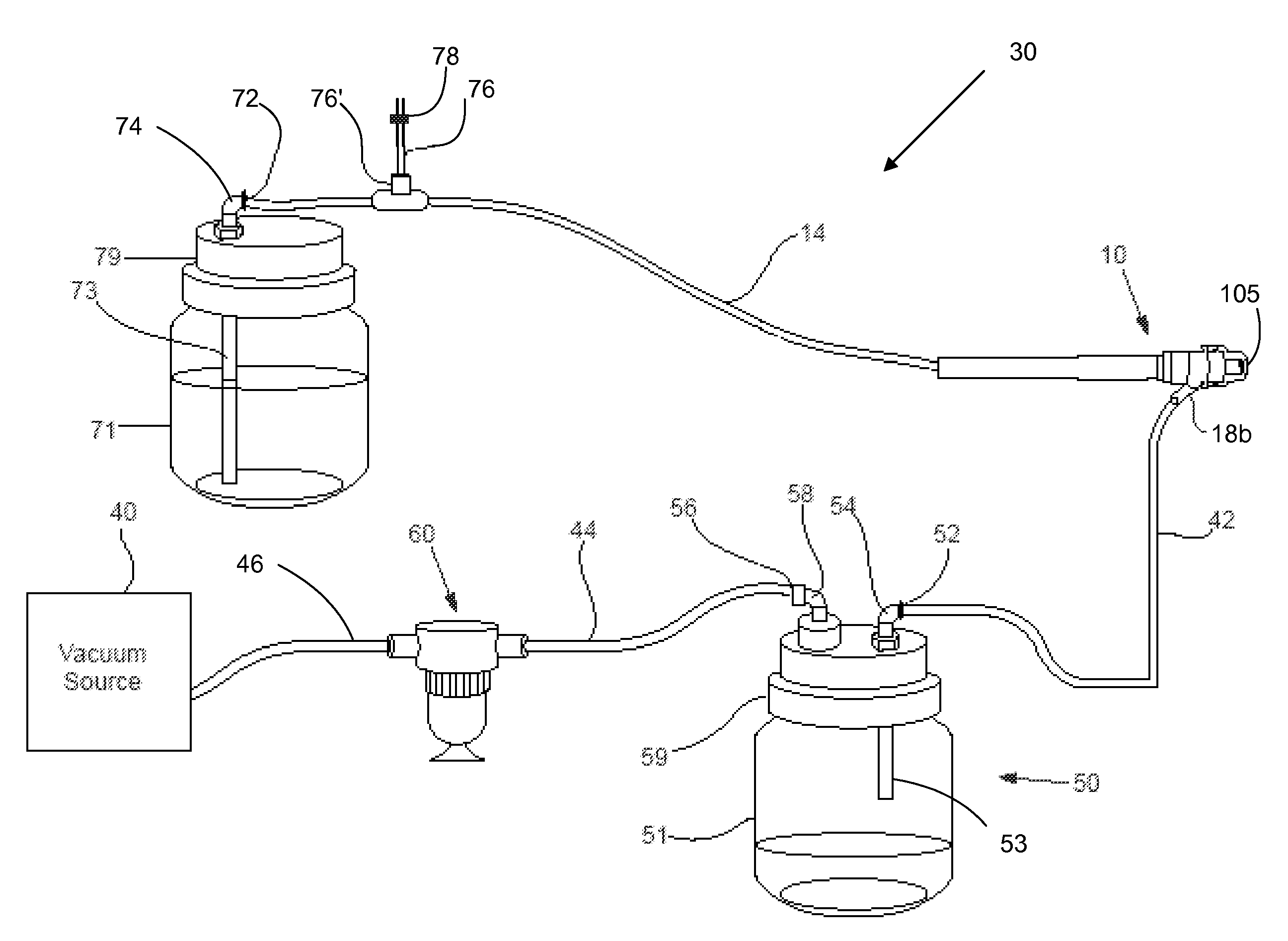

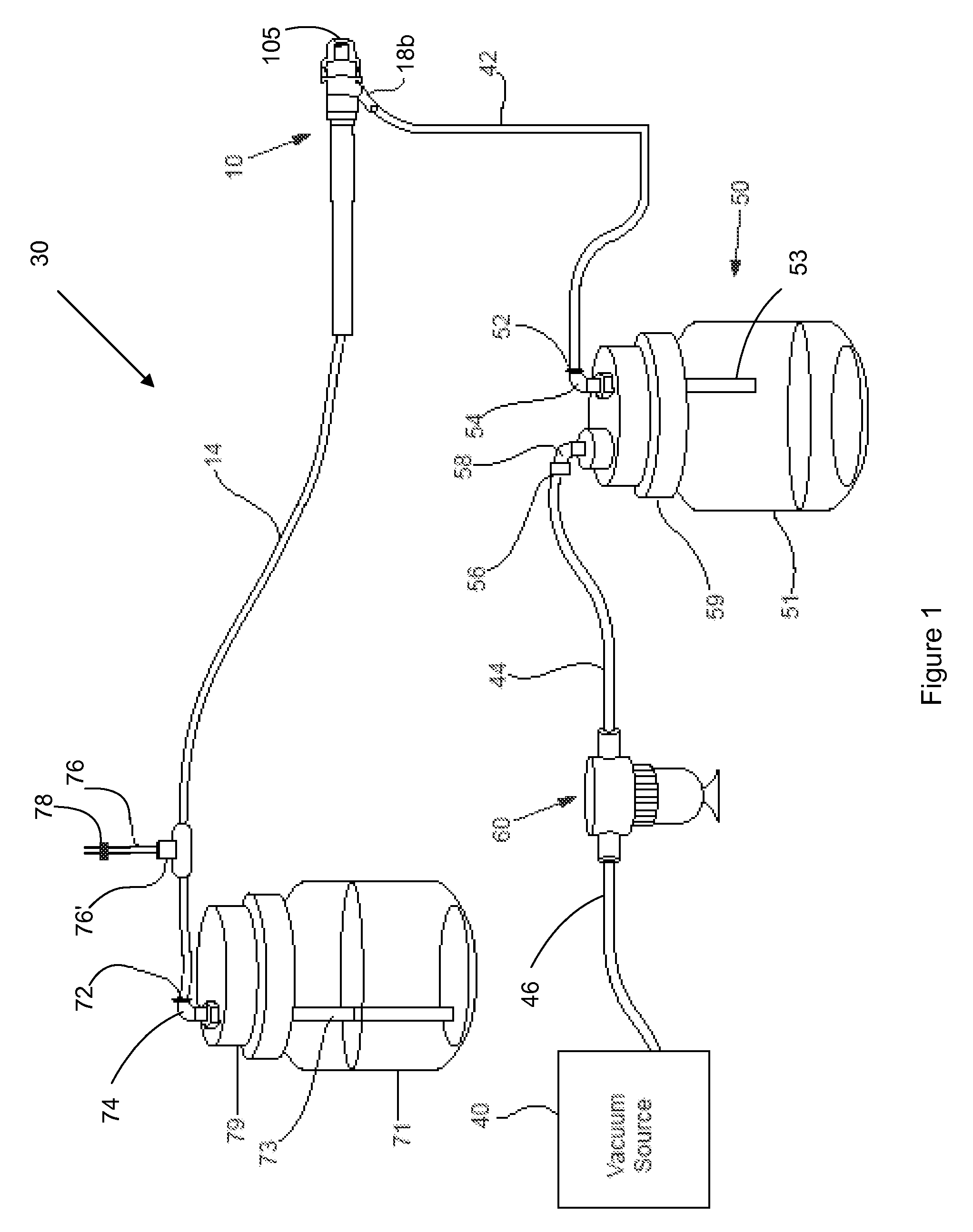

Controlled electro-pneumatic power tools and interactive consumable

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

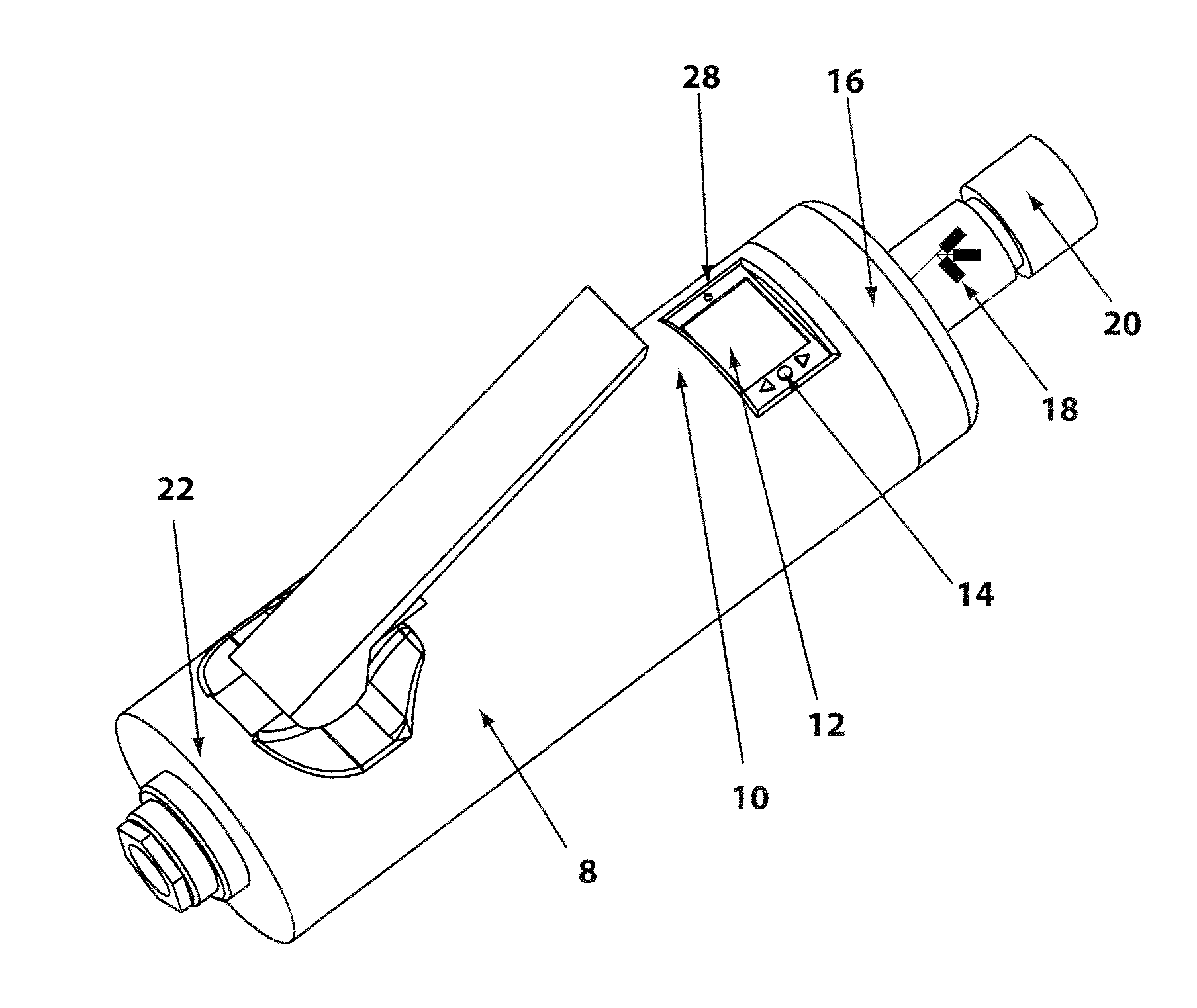

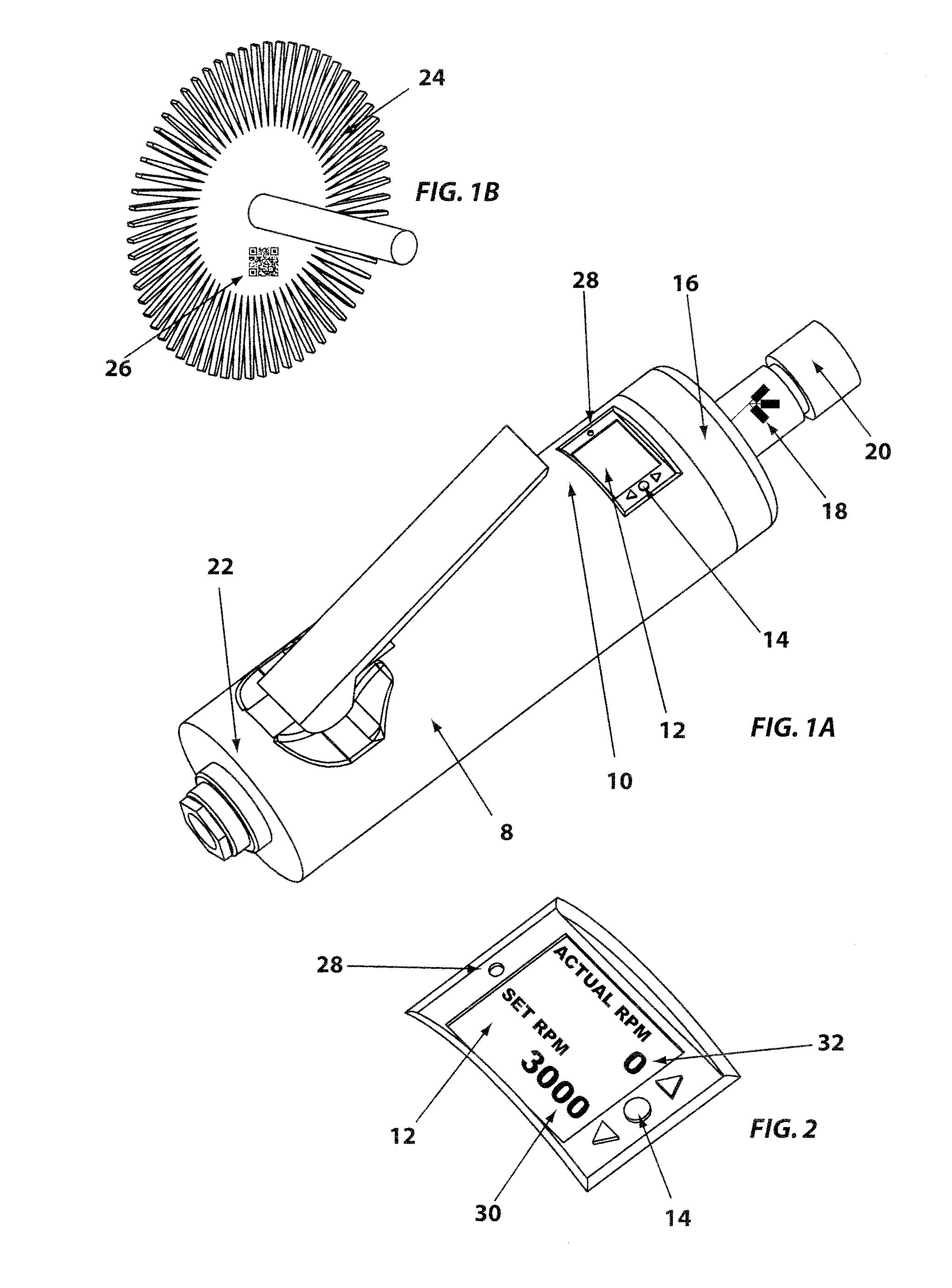

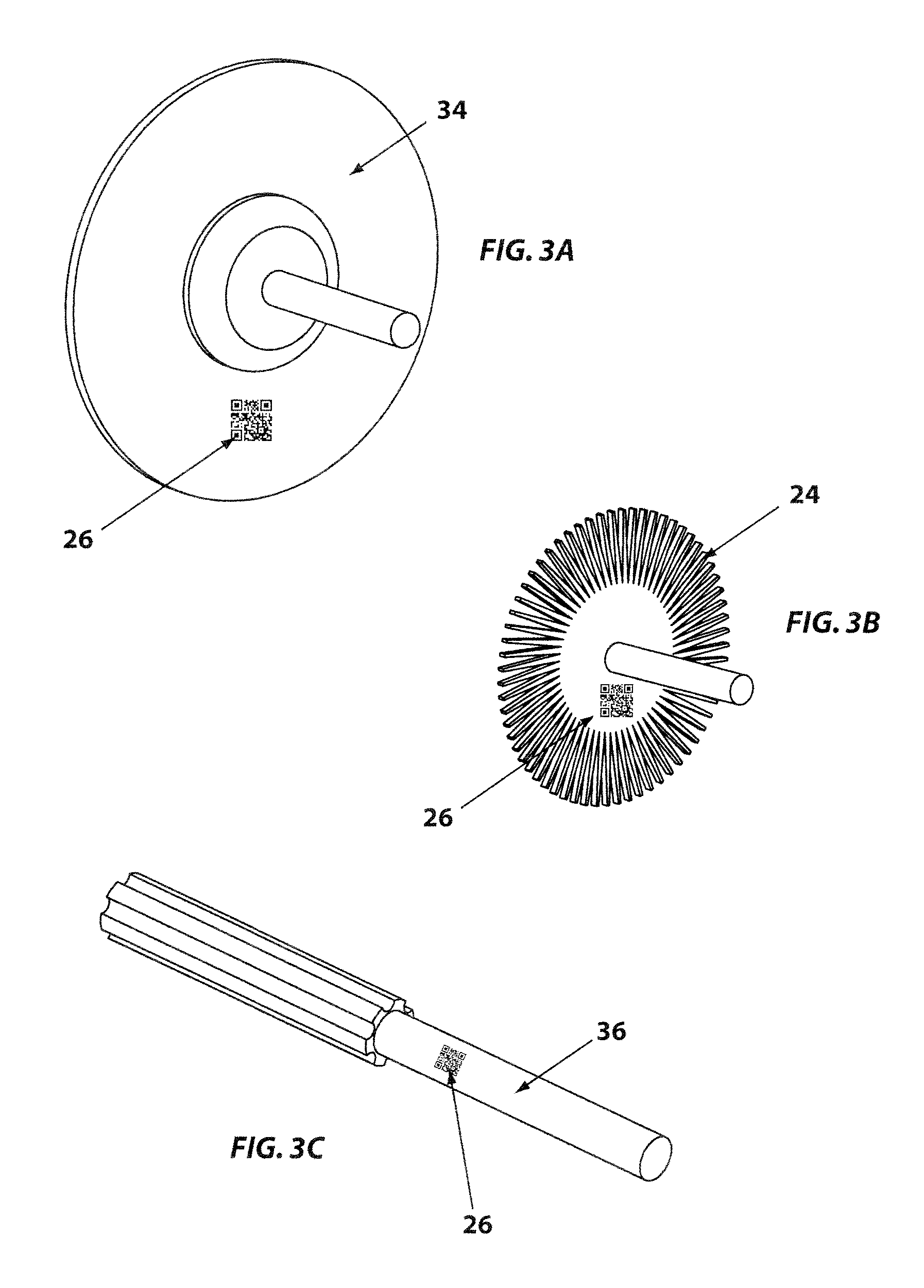

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

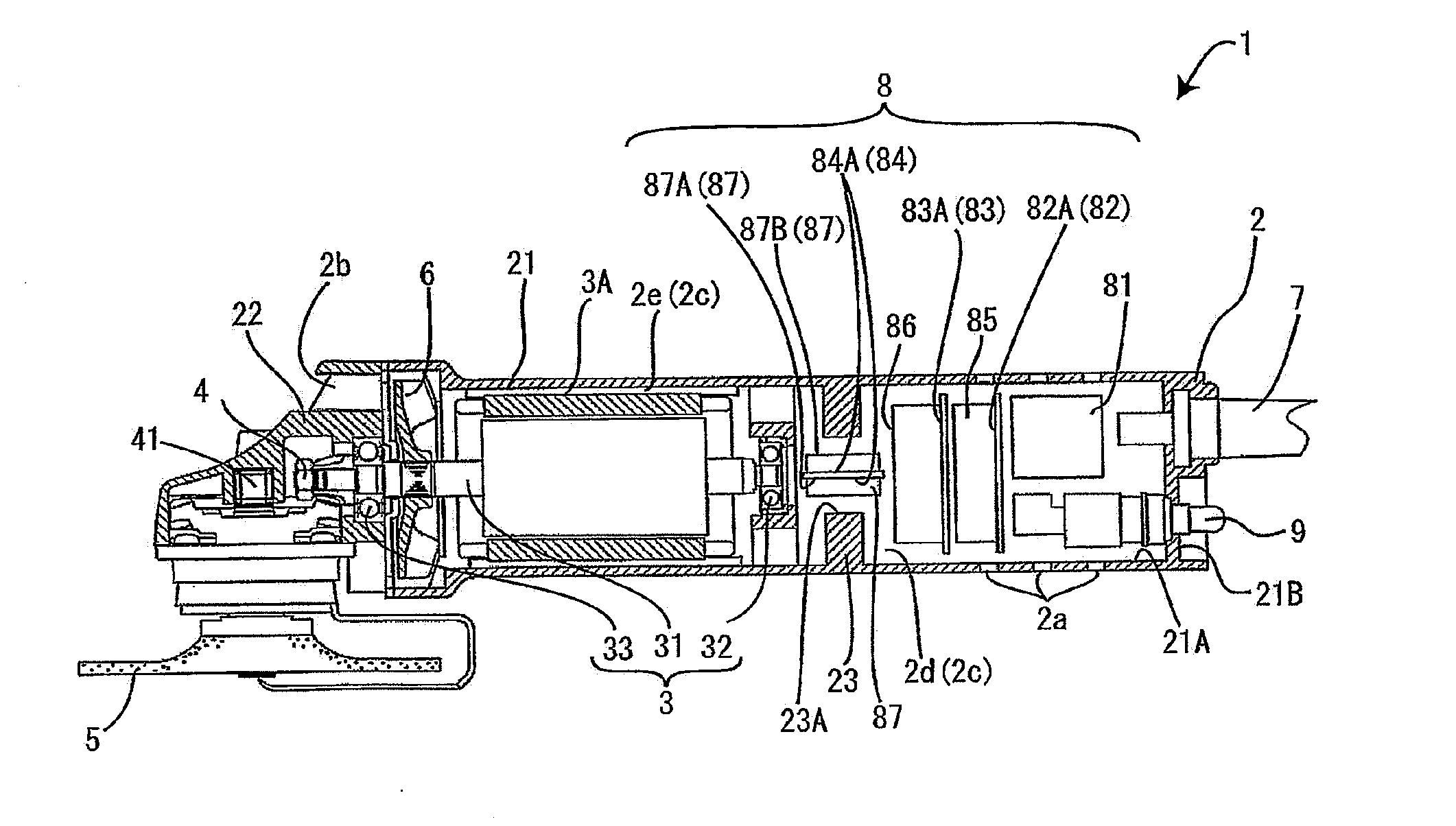

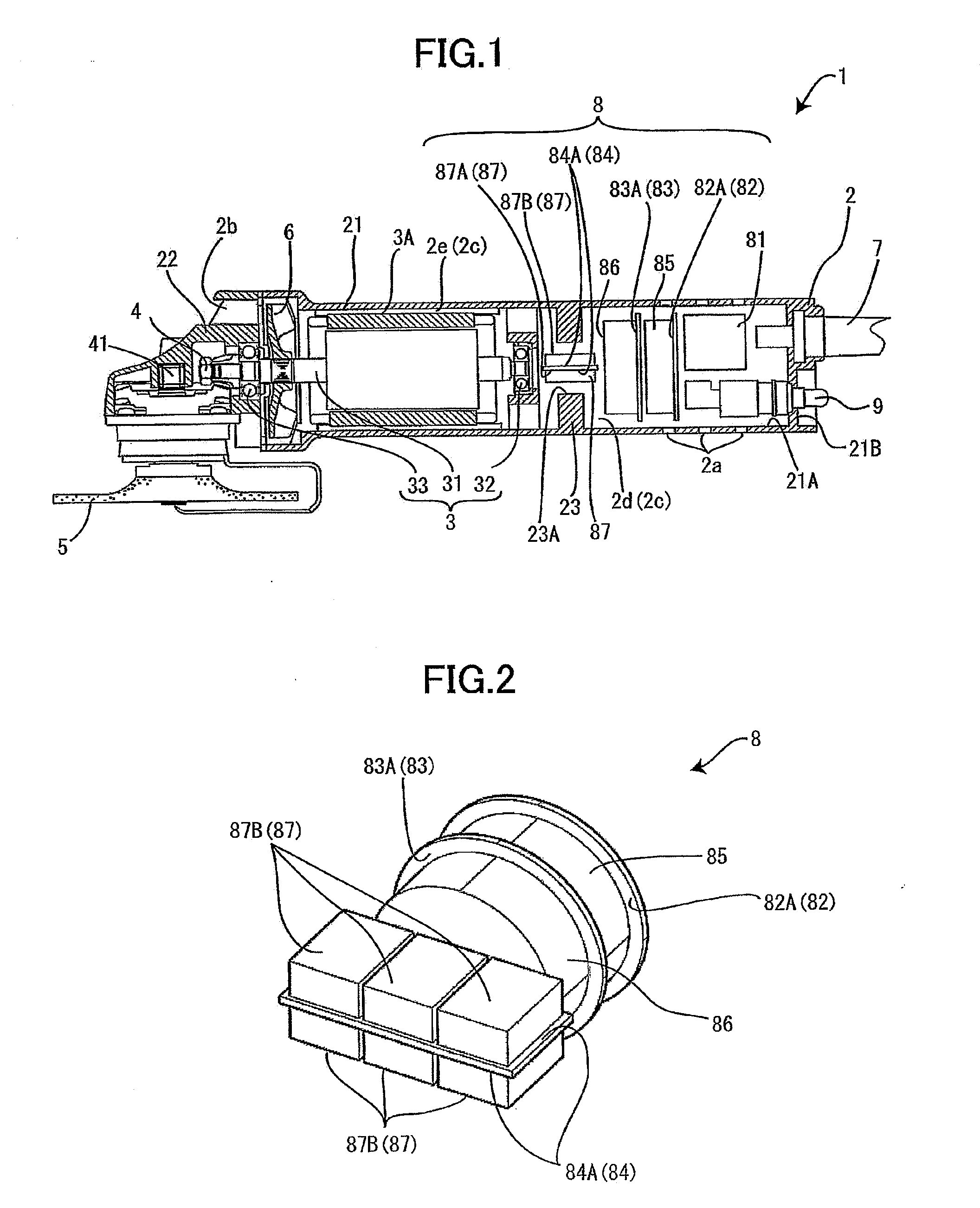

Power Tool

ActiveUS20110171887A1Easy to assembleIncrease productionAssociation with control/drive circuitsMagnetic circuitBrushless motorsDriver circuit

An electric power tool includes a housing, a brushless motor, an output shaft, and a motor driver circuit. The housing defines an axial direction. The brushless motor is accommodated in the housing and having a drive shaft. The output shaft extends in a direction generally perpendicular to the drive shaft. The motor driver circuit is accommodated in the housing for driving the brushless motor. The housing has a cylindrical shape and has a part functioning as a grip portion.

Owner:HITACHI KOKI CO LTD

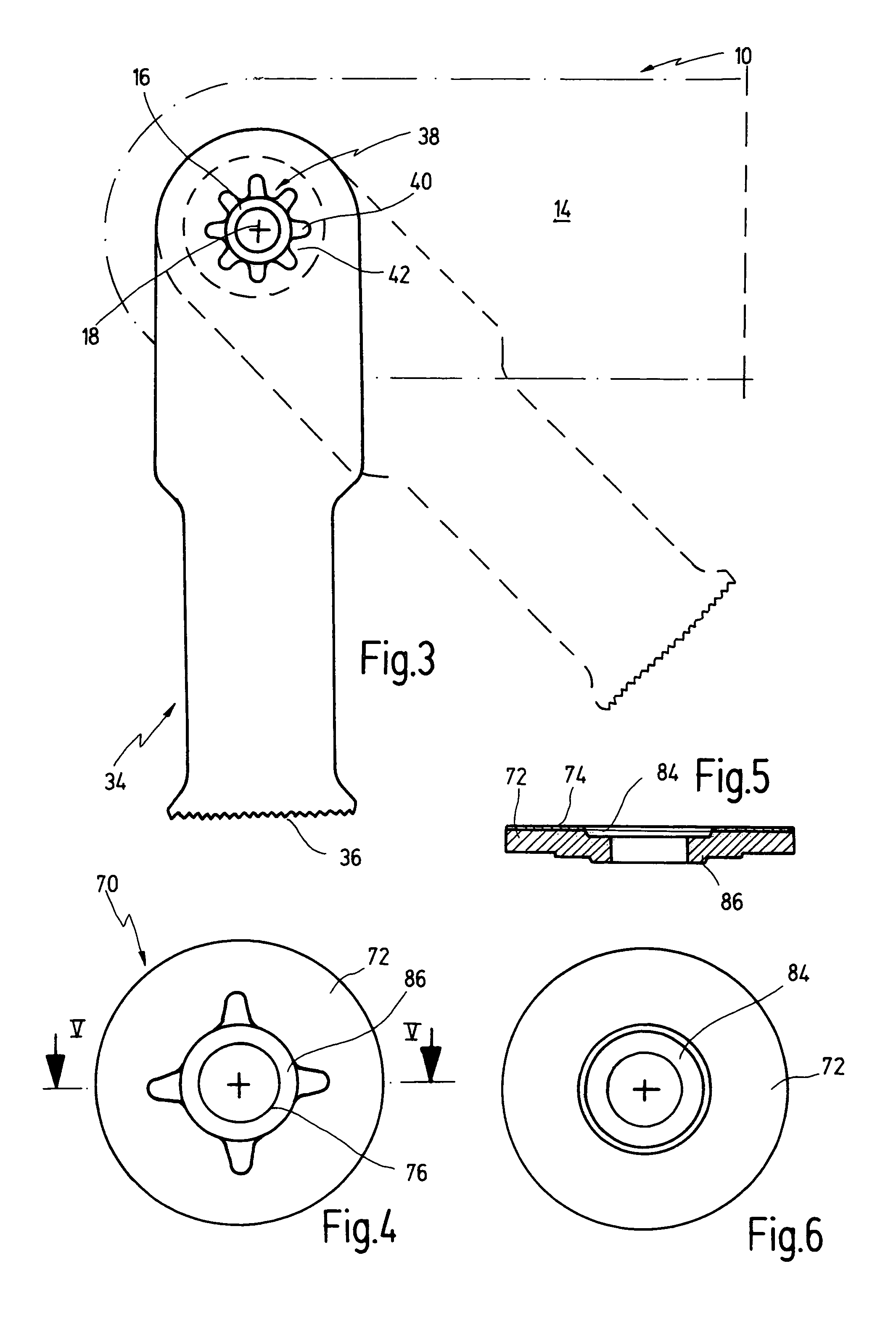

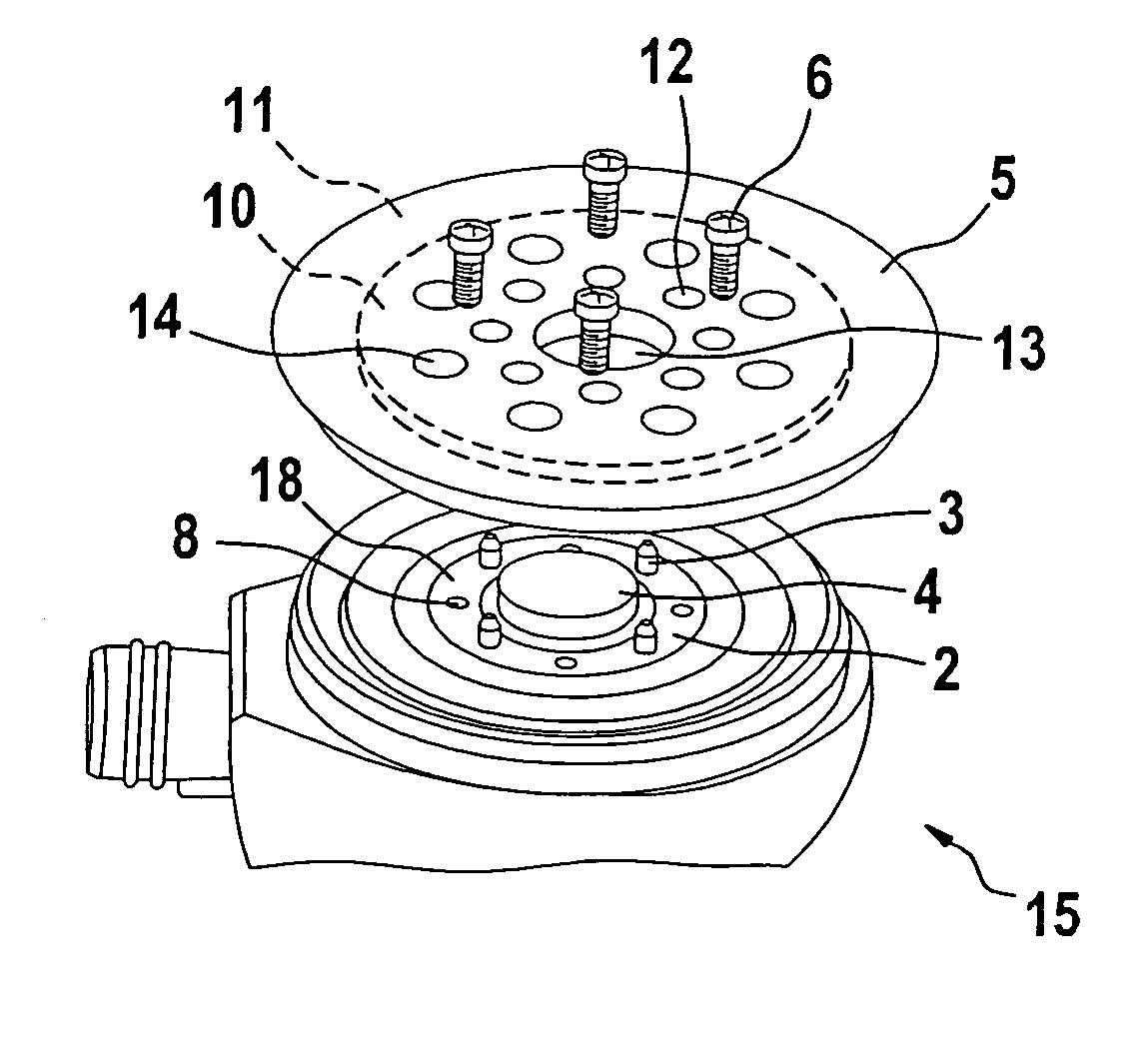

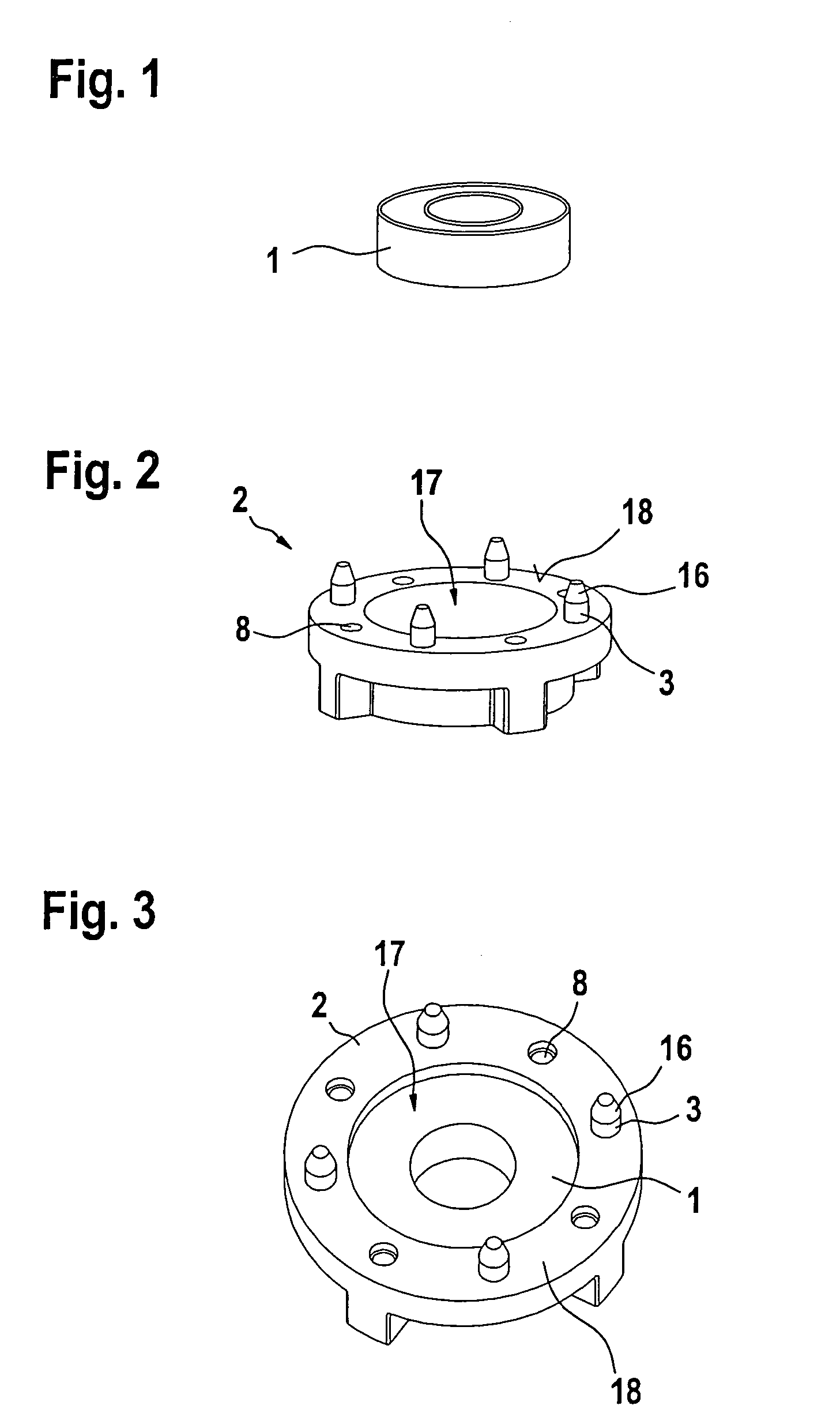

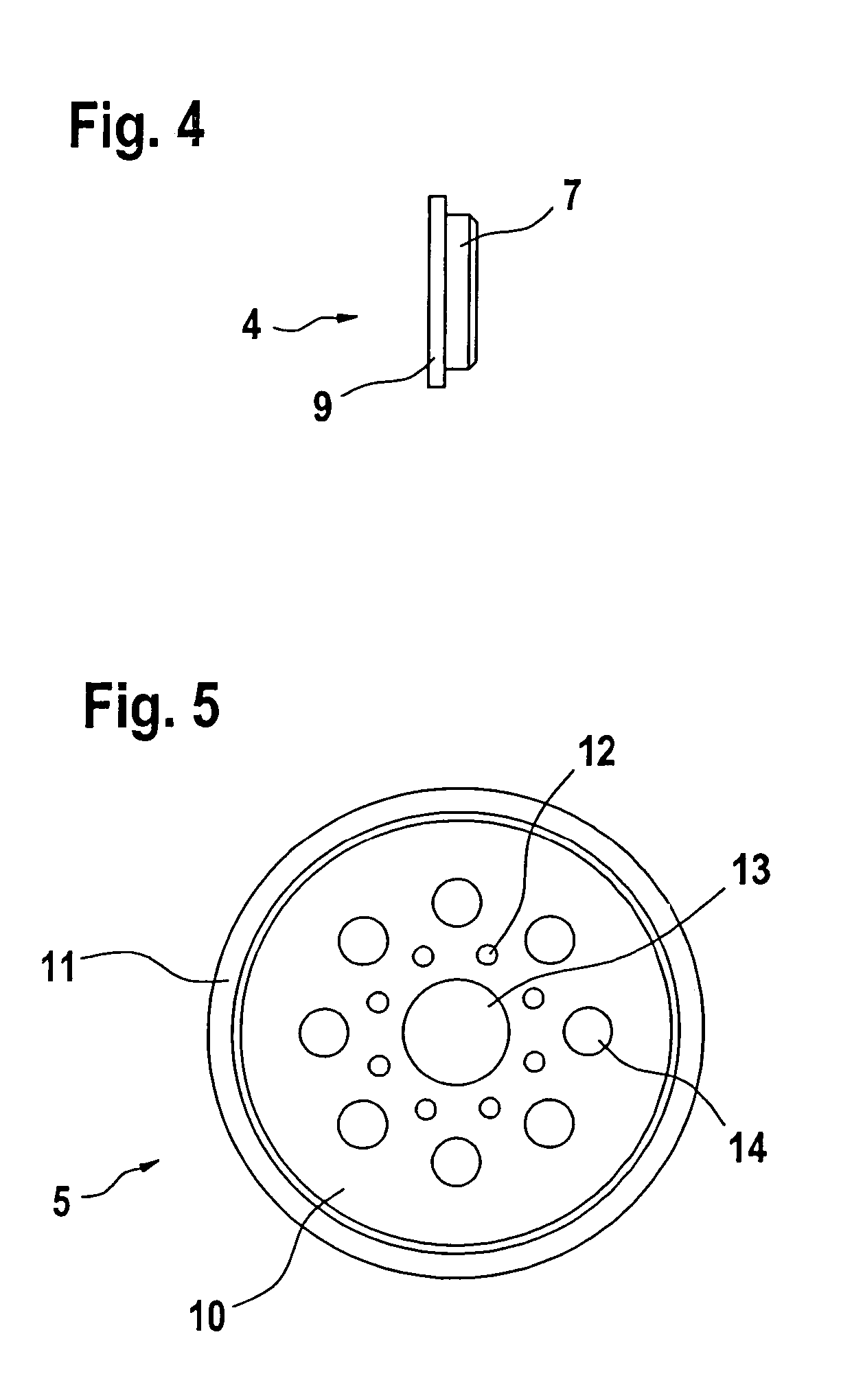

Adapter For Mounting A Tool On An Oscillating Drive

ActiveUS20100056029A1Reduce tool typesLow costGrinding wheel securing apparatusGrinding drivesMating connectionDrive shaft

An adapter is disclosed for mounting a tool on an oscillating drive having a drive shaft that can be driven to oscillate about its longitudinal axis, wherein the adapter is passed by a central opening, and has at its drive end at least one positive-locking element for positive connection with the tool, the positive-locking element having the shape of a regular polygon, or a plurality of positive-locking elements arranged on a circle concentric to the center axis, or a plurality of outwardly extending convex projections having rounded tips and being connected with neighboring projections via rounded concave lateral flanks, wherein the positive-locking elements on the drive end are configured for positive-locking connection with a matching positive-locking counter-element on the drive shaft, and wherein the adapter has a second receptacle on its tool end for effecting connection with a tool having a shape different from the first receptacle and being configured as a circle, or as a plurality of positive-locking elements arranged along a circle concentric to the center axis, or as plurality of outwardly extending convex projections with rounded tips and being connected with neighboring projections via rounded concave lateral flanks.

Owner:C & E FEIN GMBH & CO KG

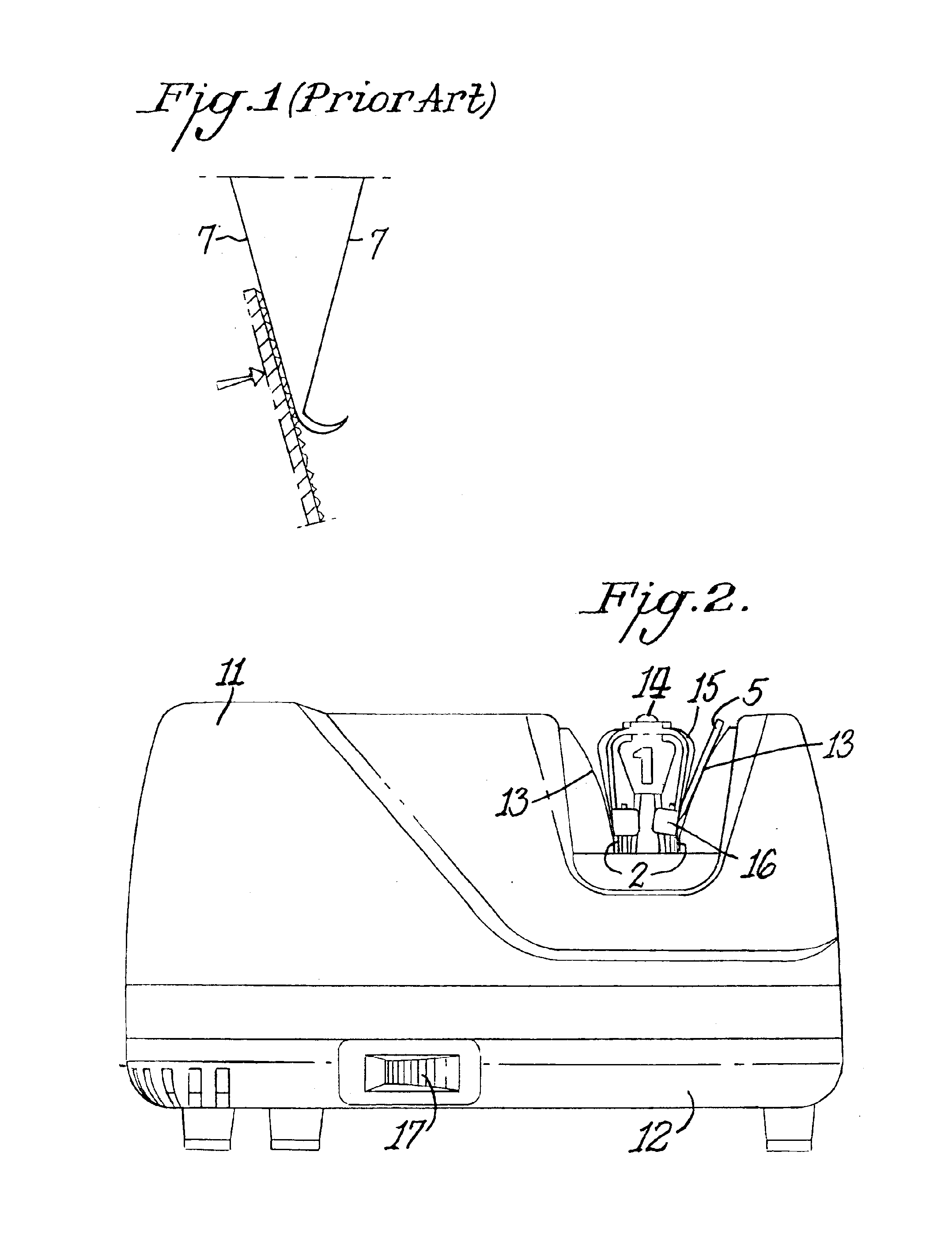

Sharpening device

ActiveUS6875093B2Highly effectiveReduce spring forceEdge grinding machinesPortable grinding machinesMotor driveUltra fine

A sharpener includes a motor driven shaft with at least one slidably mounted sharpening assembly consisting of a supporting hub structure mounted by its central bore hole on the shaft. The hub structure supports a symmetrically shaped rotating surface containing an ultra fine abrasive material. The rotating surface is pressed with a force of less than 0.2 lb. by a spring action to make sustained rotating abrading contact with a facet of a knife positioned by a knife guide to align the facet into contact with the surface containing the abrasive materials.

Owner:EDGECRAFT

Reciprocating wire saw for cutting hard materials

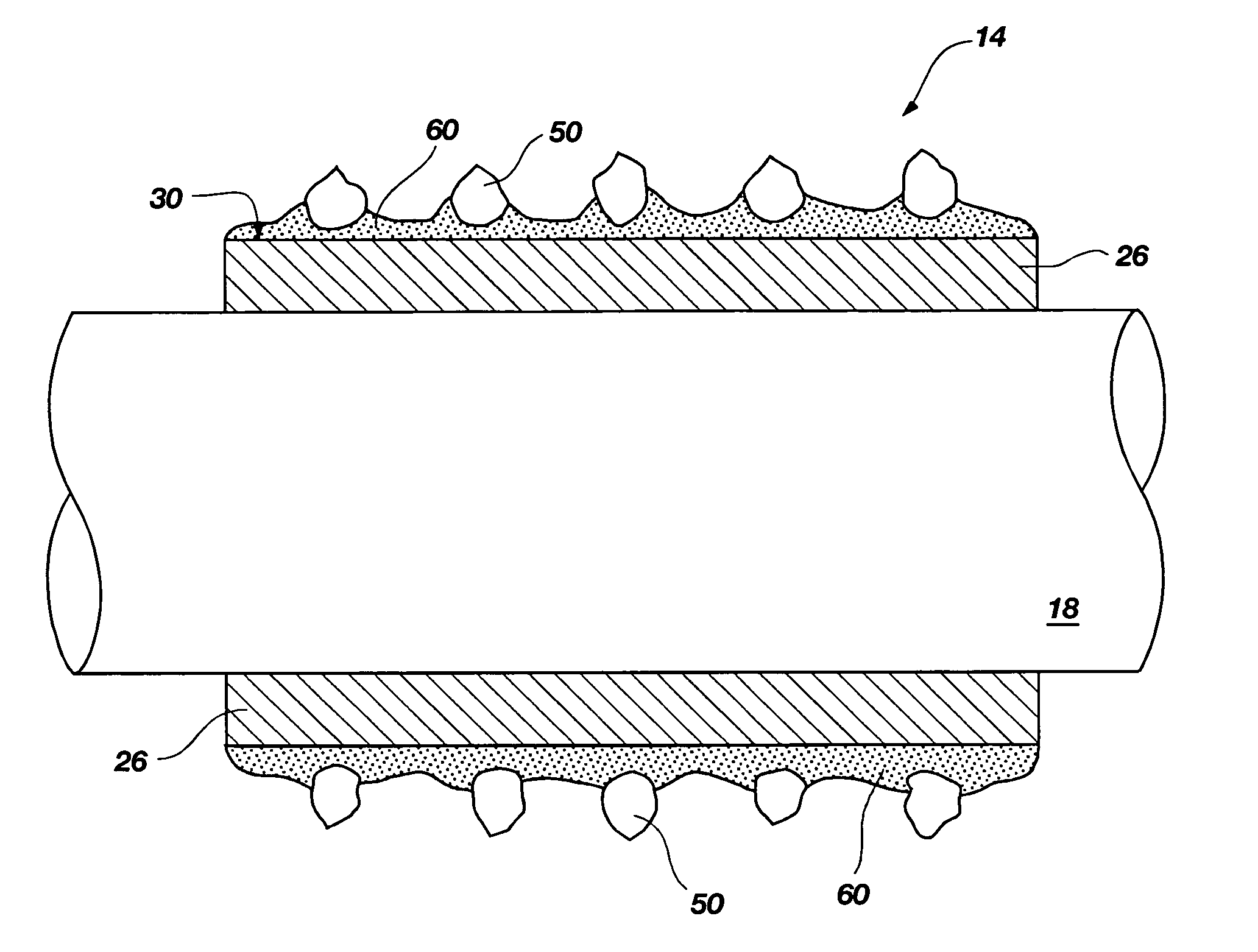

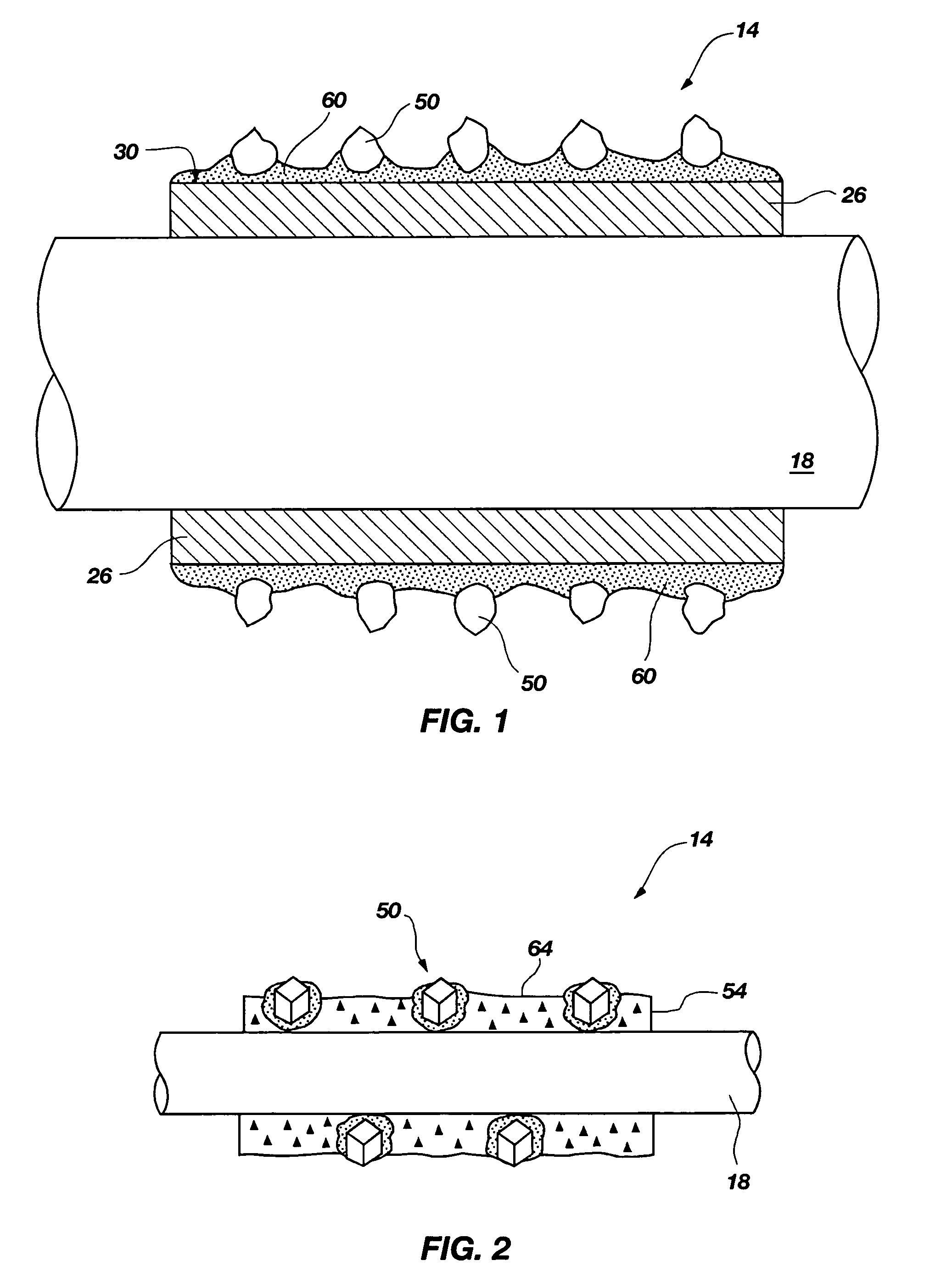

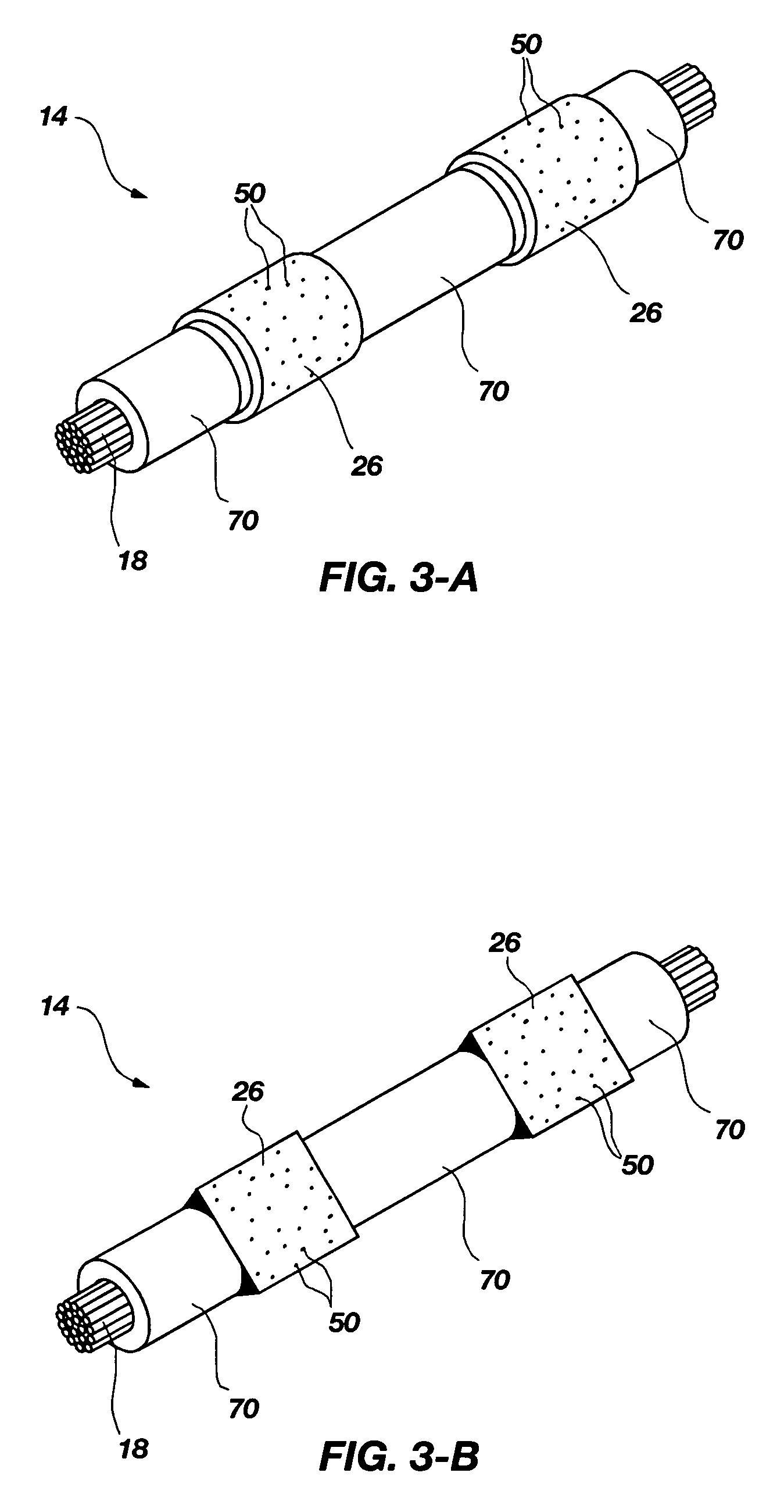

InactiveUS7089925B1Low costIncrease valueBelt grinding machinesMetal sawing toolsEngineeringWire saw

The present invention features a reciprocating wire saw particularly adapted or configured for cutting hard materials. In one aspect, the reciprocating wire saw comprises (a) a flexible wire; (b) a plurality of cutting segments fittable onto the flexible wire, wherein each of the cutting segments comprises an outer surface; and a (c) plurality of superabrasive particles braze bonded onto the outer surface of the cutting segments to form a cutting wire. In another aspect, the reciprocating wire saw comprises a plurality of superabrasive particles braze bonded directly to the wire itself to form a cutting wire. The cutting wire is unique in that it comprises a pre-determined superabrasive particle concentration and is configured to cut various materials, such as granite, in a reciprocating manner.

Owner:KINIK

Reinforced abrasive wheels

InactiveUS6942561B2Minimize empty spaceSaving in layer materialGrinding machine componentsRevolution surface grinding machinesGlass fiberEngineering

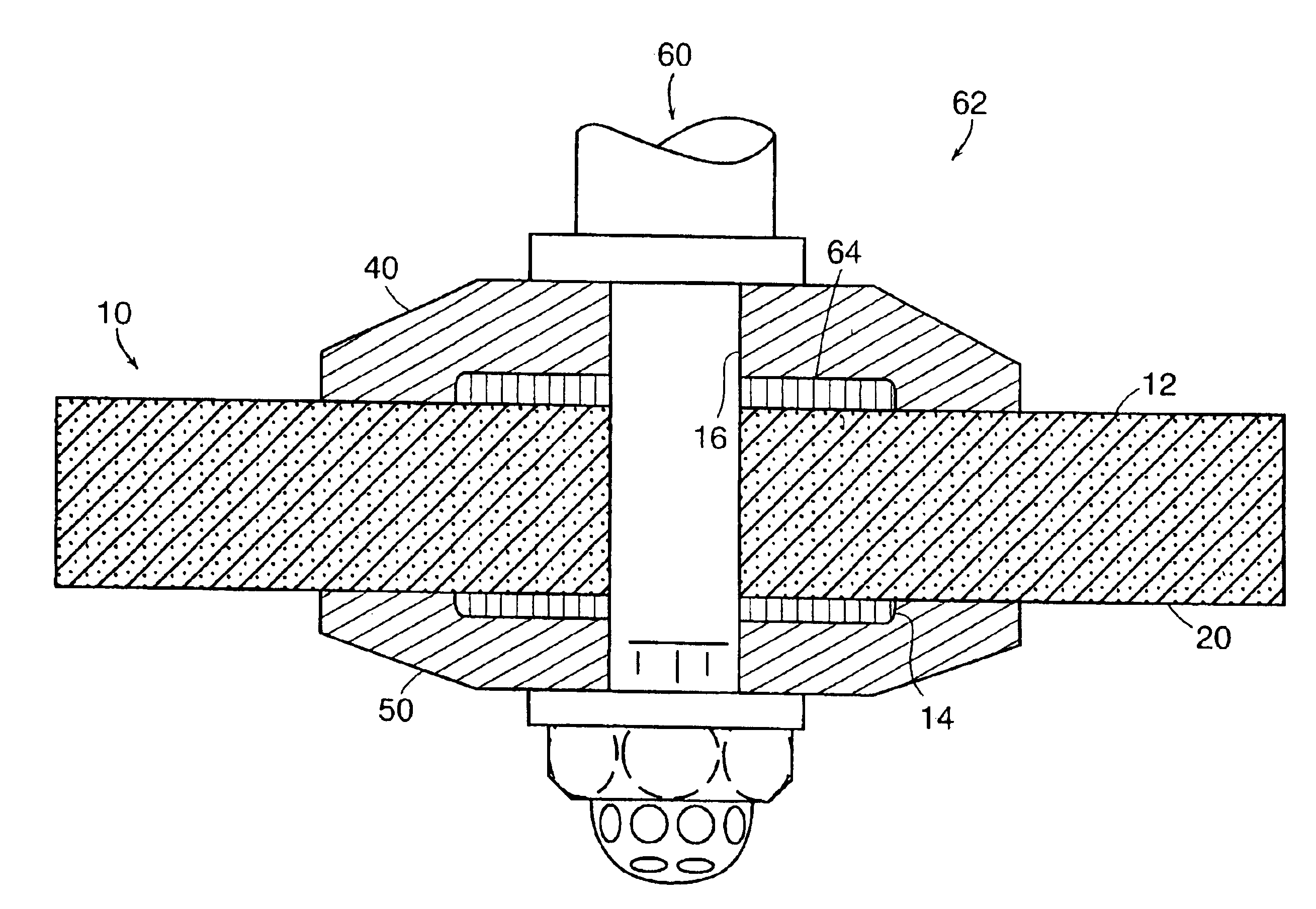

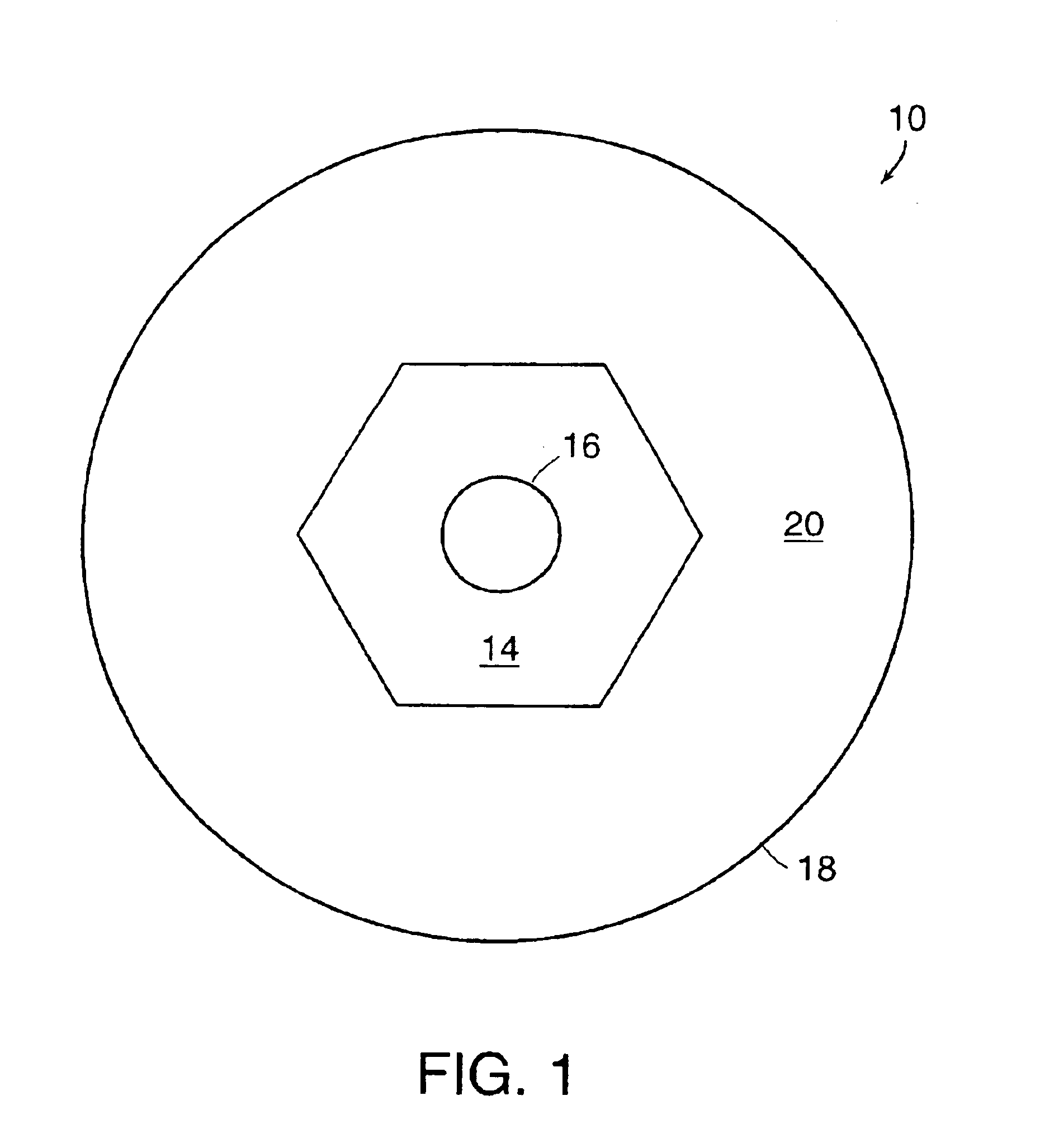

In a depressed-center abrasive wheel assembly a reinforcement layer of polygonal shape is located between a front face of the abrasive wheel and a front flange. The reinforcement layer is dimensioned to entirely cover the depressed center portion of the wheel. An example of polygonal reinforcement layer has a hexagonal shape and is made of fiberglass cloth. A polygonal shape reinforcement layer can also be employed between the front flange and the front face in an abrasive flat wheel assembly that employs a wheel without internal reinforcement.

Owner:SAINT GOBAIN ABRASIVES INC

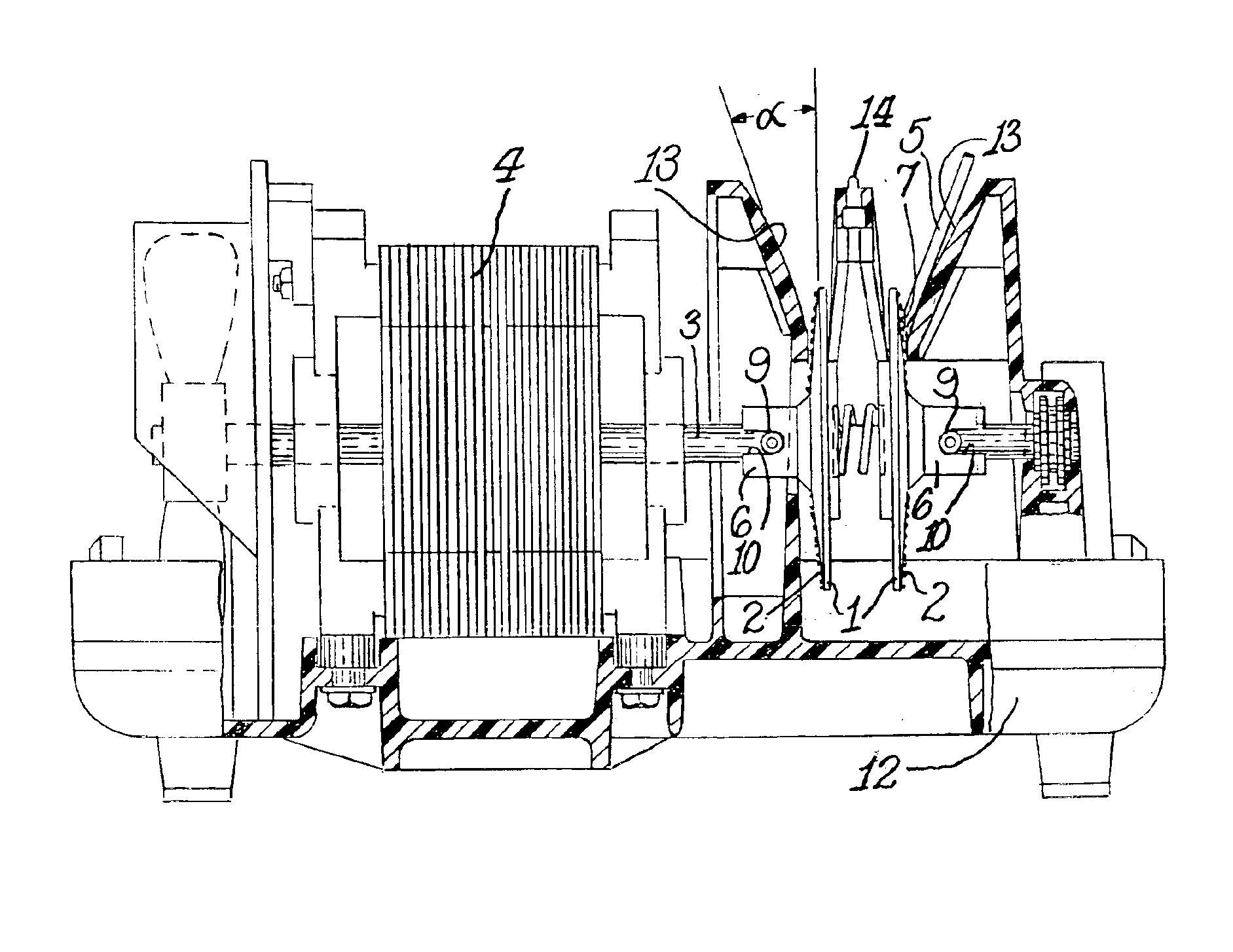

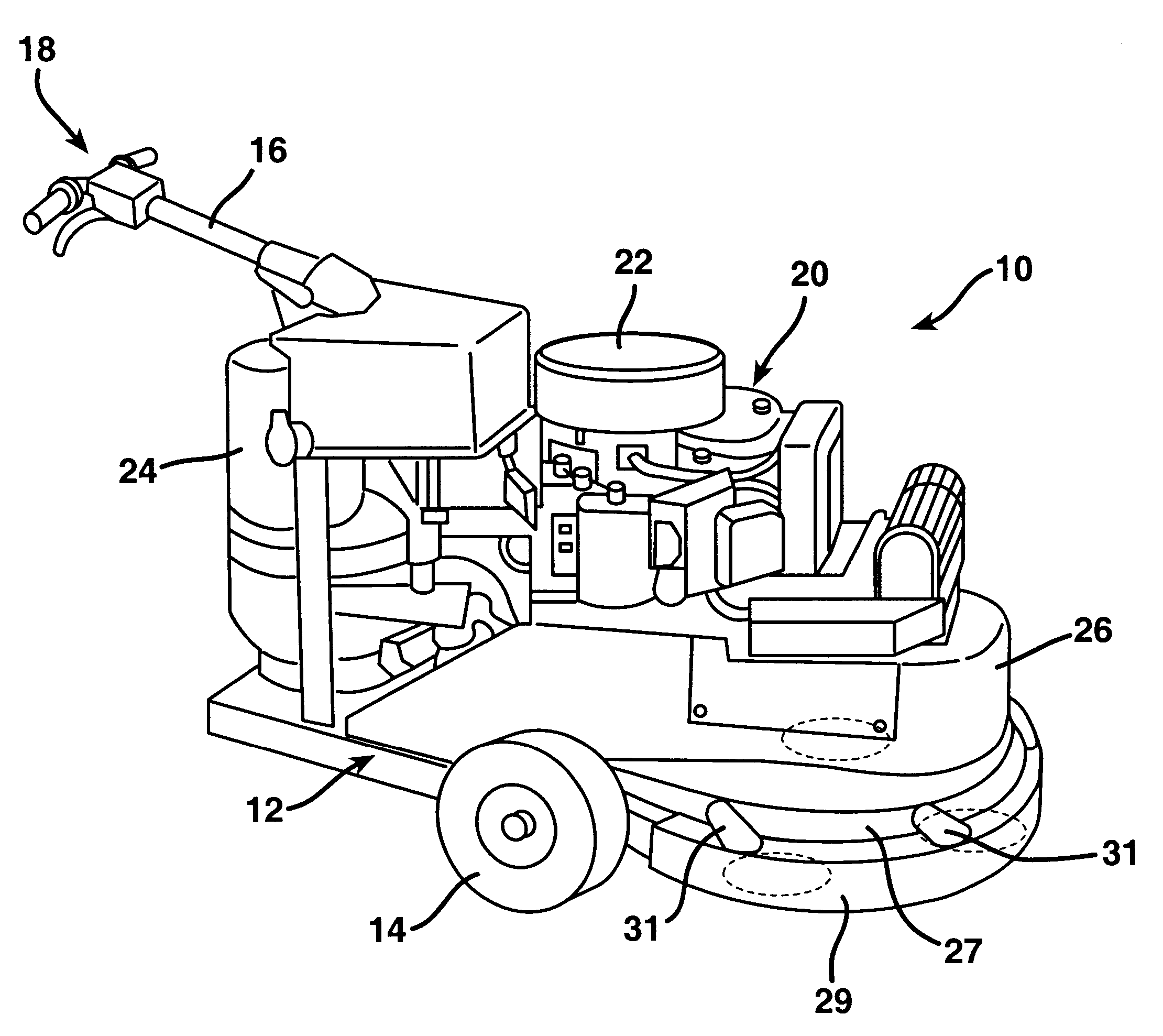

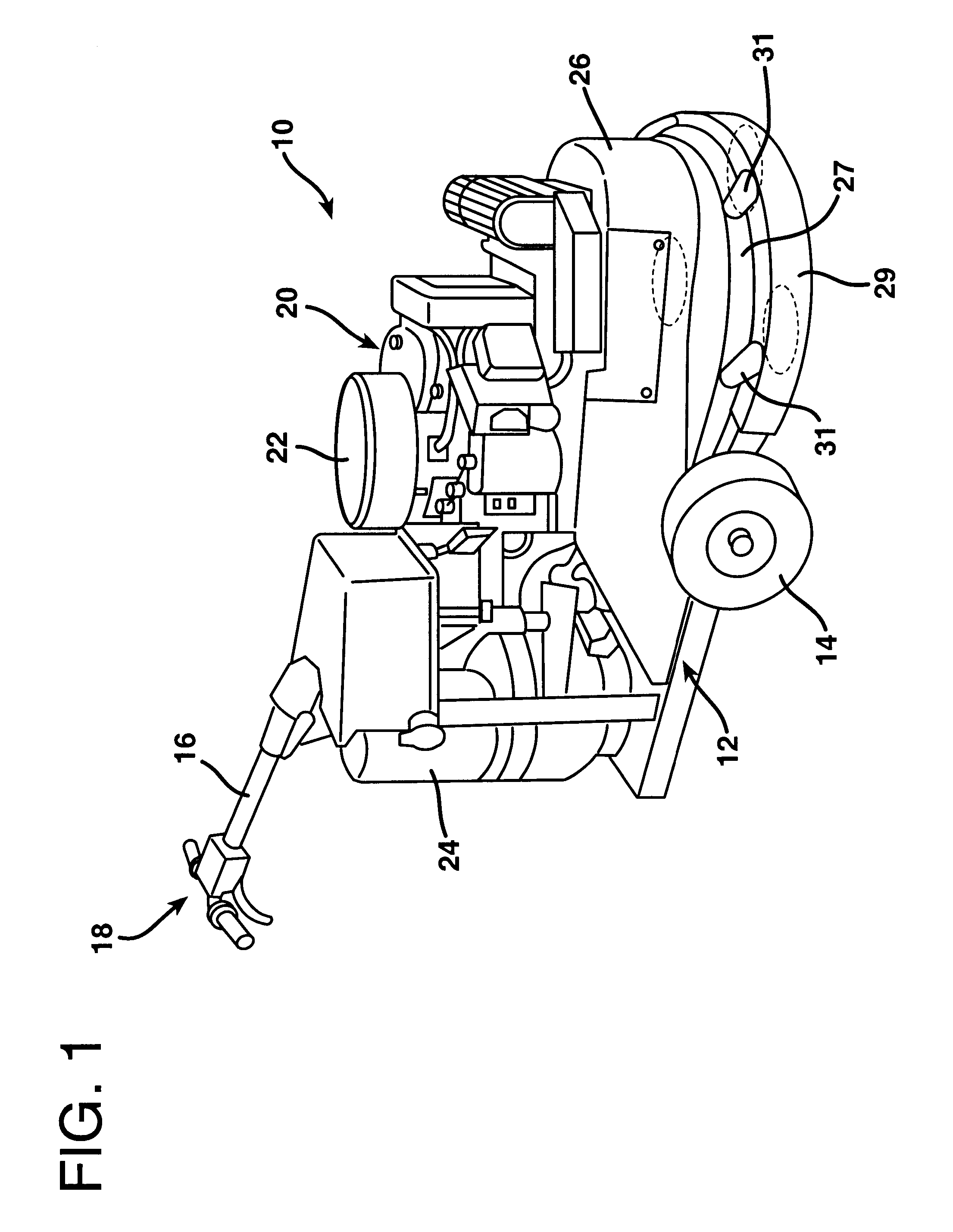

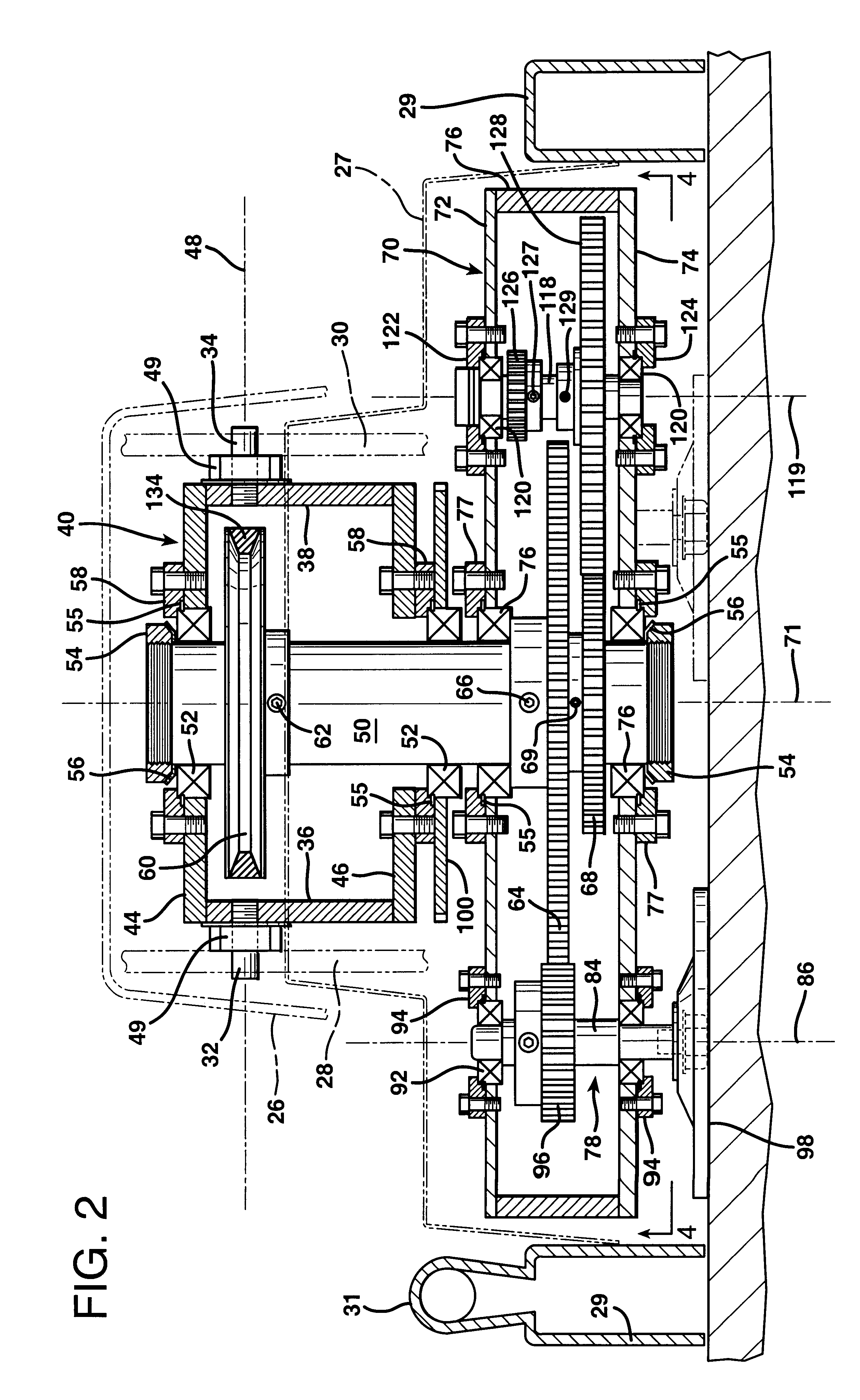

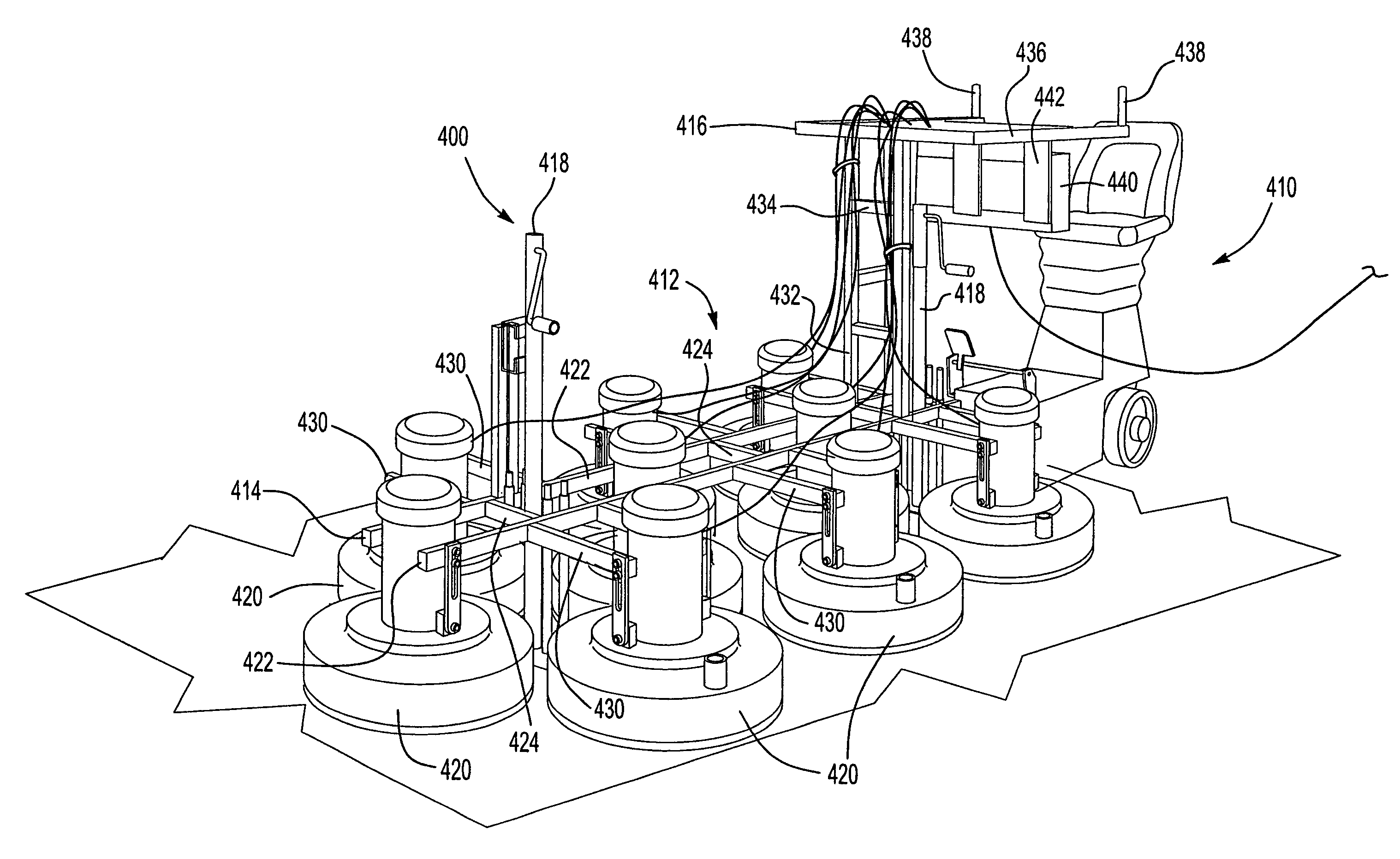

Multidisc floor grinder

A multidisc floor grinder is constructed as a wheeled device that may be moved about the floor by means of a handle. The chassis of the floor grinder supports a bearing housing on gimbals that allow the bearing housing to vary in orientation as the device is moved across an uneven floor. The gimbals are aligned to allow rotation of the bearing housing about a bearing housing axis that is parallel to the floor. The bearing housing supports a main drive shaft which extends downwardly from the bearing housing. The main drive shaft is rotatable relative to the bearing housing within its bearings. A grinder mounting frame is rotatably mounted about the main drive shaft and is supported therefrom. The grinder mounting frame is driven in rotation about the main drive shaft at a greatly reduced speed relative to the rotation of the main drive shaft. The grinder mounting frame carries a plurality of grinding elements which are also driven from the main drive shaft, but at a substantially increased speed of rotation relative thereto. The grinding elements thereby rotate not only about their own axes, but also about the axis of the main drive shaft so as to cover a relatively large floor area with relatively small grinding elements. This arrangement substantially reduces the time required to grind paint or other matter from a floor surface.

Owner:DUNCAN +1

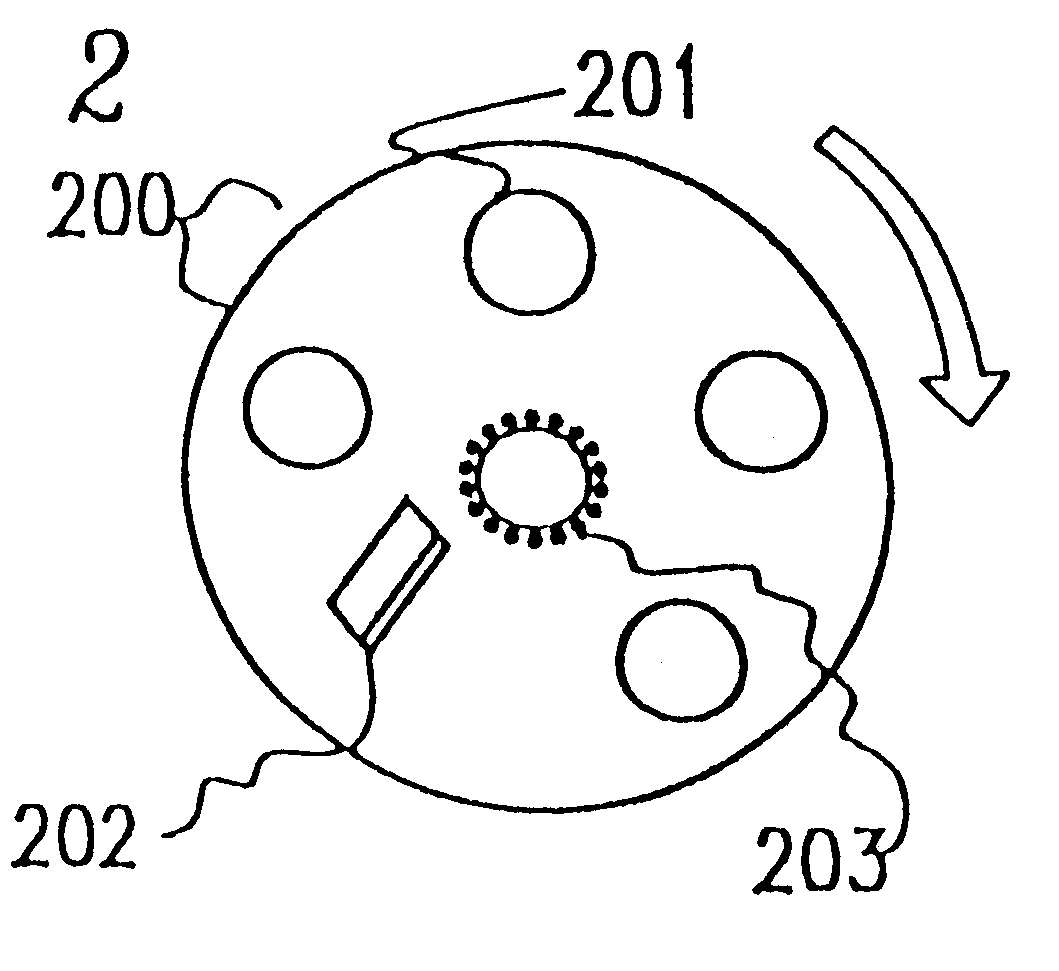

Sanding disks

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

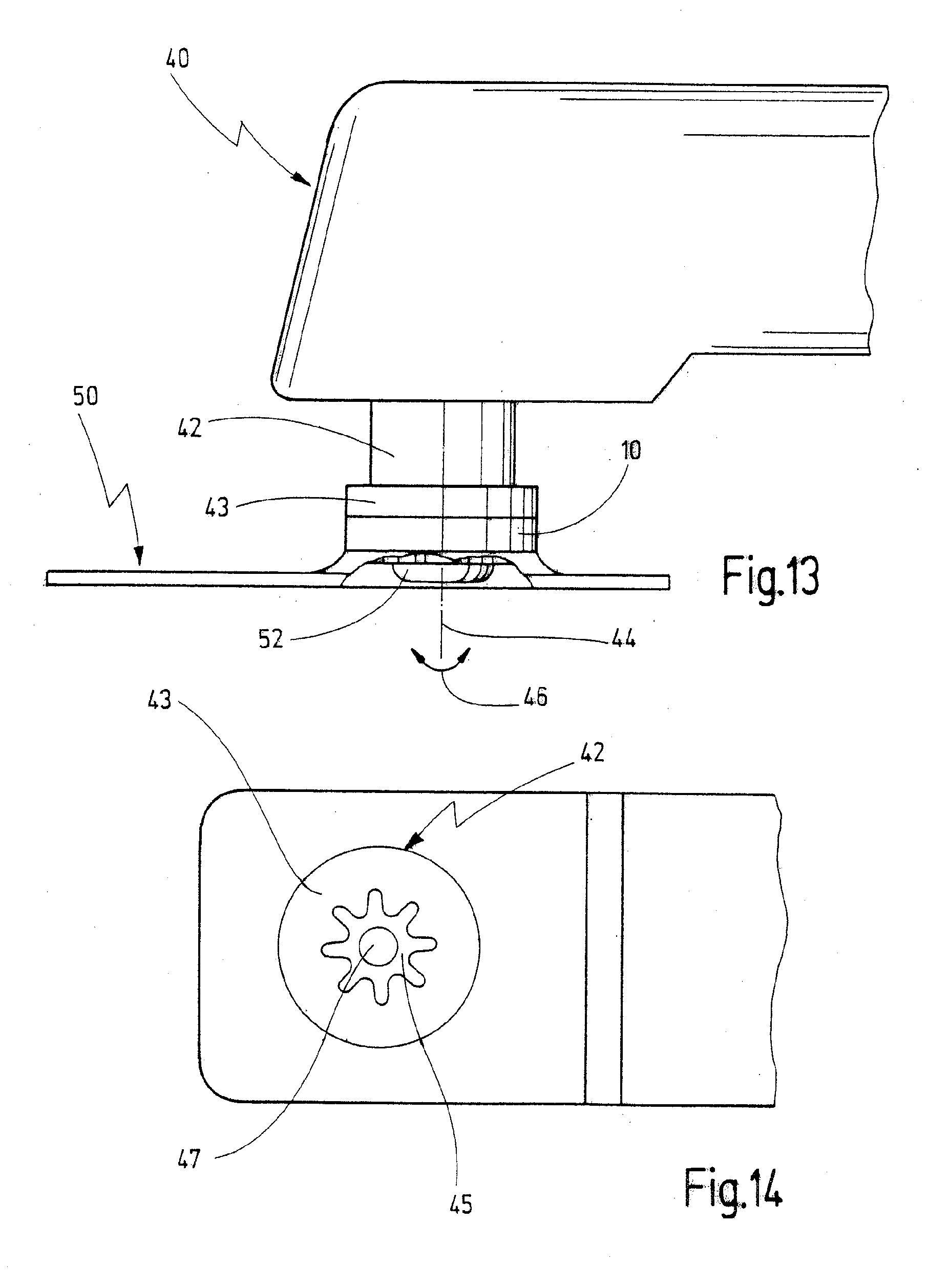

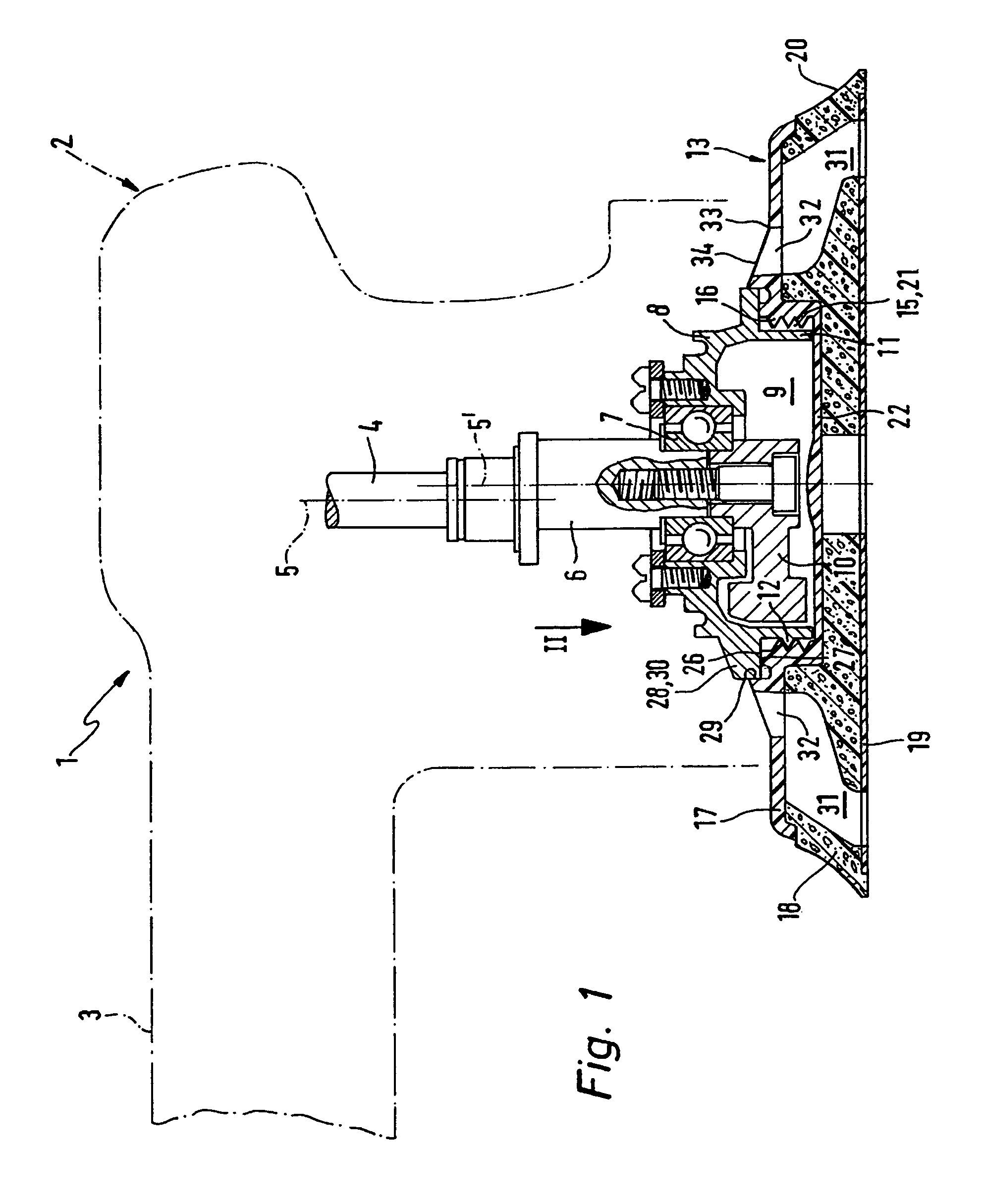

Power-Driven Hand Tool With Clamping Fixture For A Tool

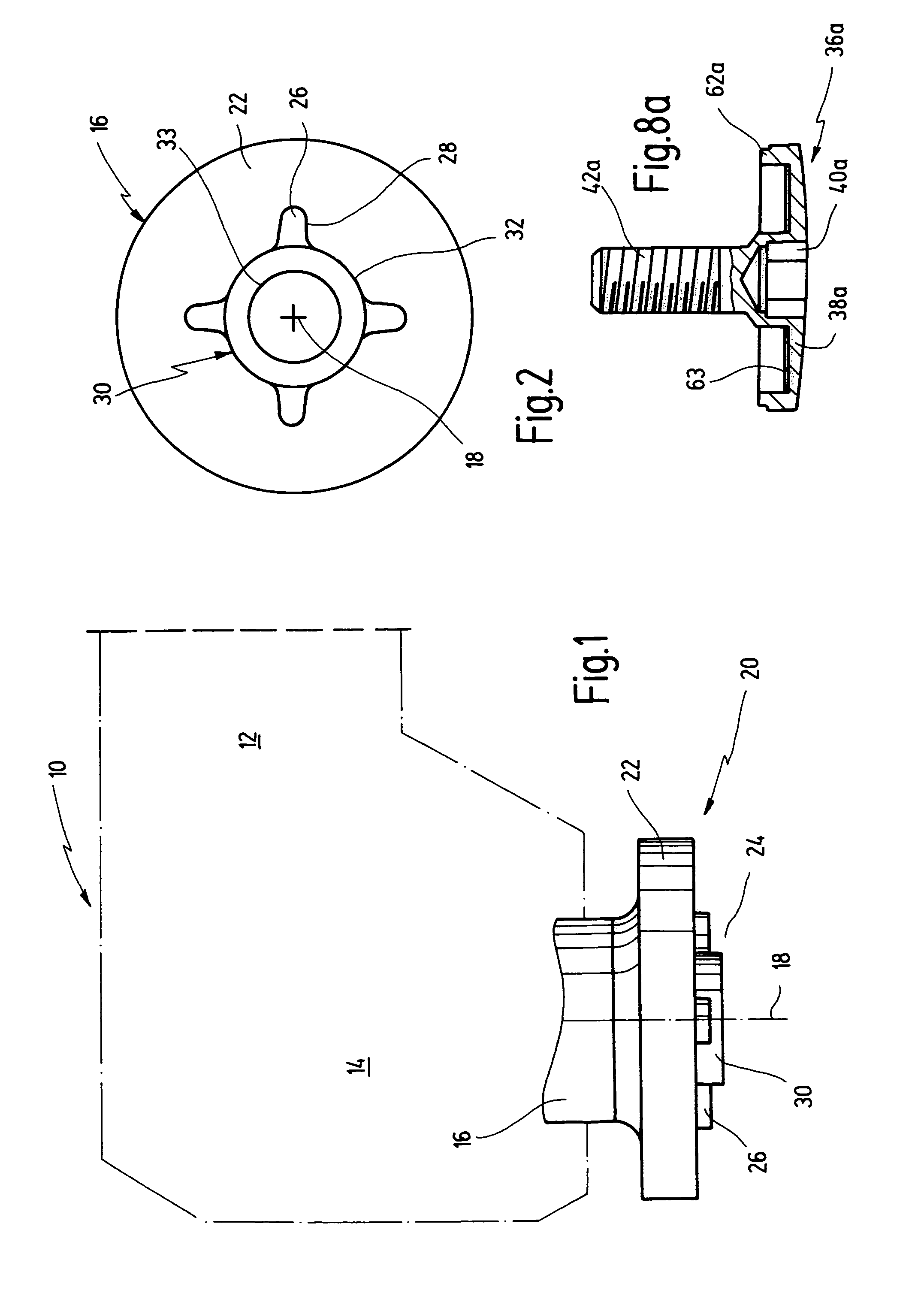

InactiveUS20100197208A1Easy to handleEasy to installGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

A power-driven hand tool is disclosed comprising a housing, a work spindle for driving a tool, which tool can be located between a tool end of the work spindle and a fixing mechanism, further comprising a displacing mechanism with a clamping lever, adapted to pivot about a pivot axis for displacing the fixing mechanism between a releasing position, in which the fixing mechanism can be released from the work spindle, and a clamping position in which the fixing mechanism is clamped on the work spindle by a spring. An impeding mechanism is provided that interacts with the clamping lever for impeding the pivoting movement of the clamping lever between the releasing position and the clamping position.

Owner:C & E FEIN GMBH & CO KG

Power-Driven Hand Tool

ActiveUS20090023371A1Closer form-locking connectionFirmly connectedGrinding wheel securing apparatusPortable grinding machinesEngineeringHand tool

A power-driven hand tool comprises a drive spindle adapted to drive a tool, that can be driven to oscillate about its longitudinal axis, which tool can be fixed on a retaining section of the dive spindle by a securing element, and further comprises a displacing device that serves to displace the securing element between a releasing position in which the securing element can be released from the drive spindle and a clamping position in which the securing element is clamped on the retaining section by a spring element, the securing element comprising a clamping shaft adapted to be inserted into the securing element, which is axially fixed in the drive spindle for clamping the tool in the clamping position, and which can be detached in the releasing position. For clamping of the tool a split chuck is provided which is clamped on the retaining section by the securing element in the clamped position and is connected with the retaining section in form-locking engagement.

Owner:C & E FEIN

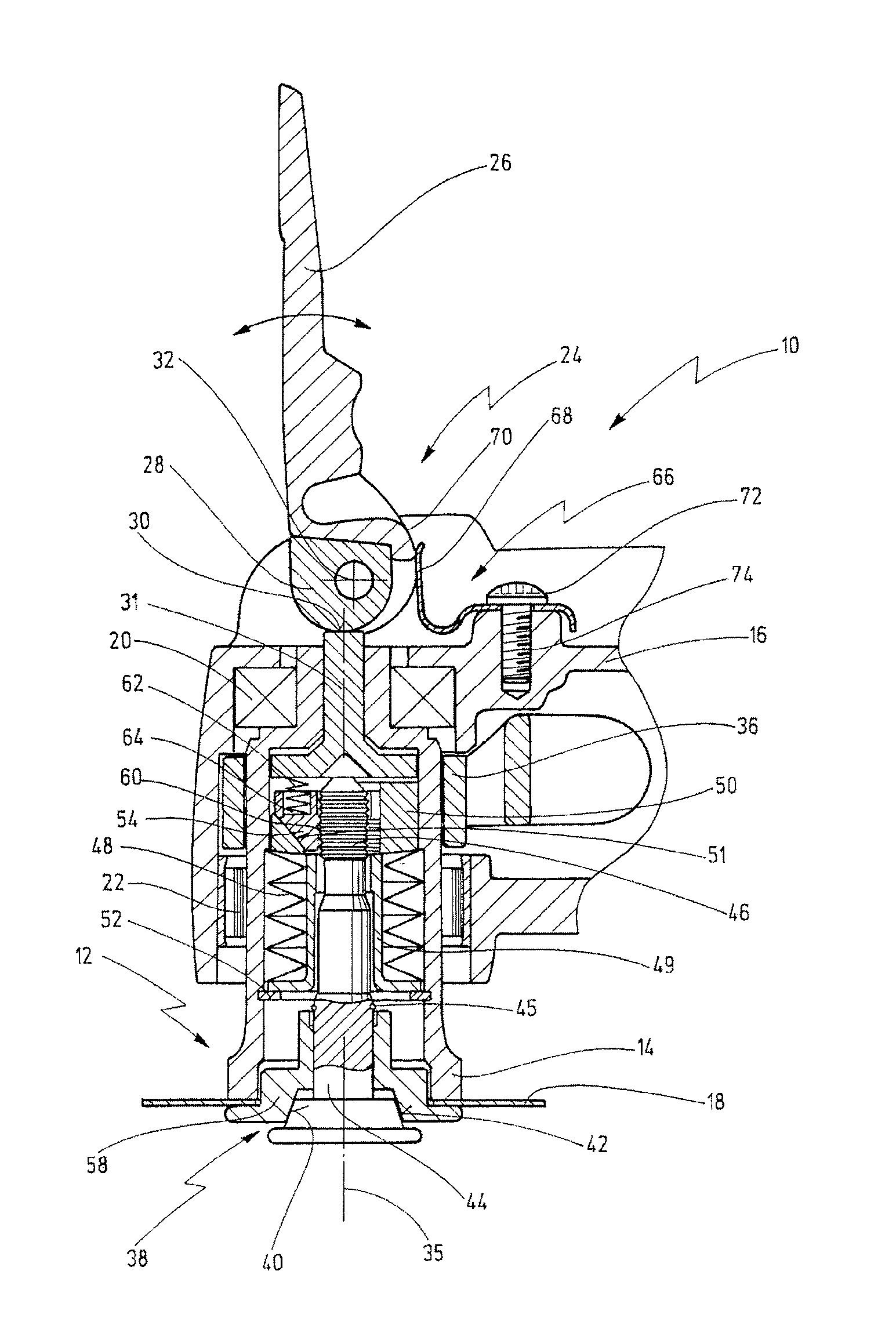

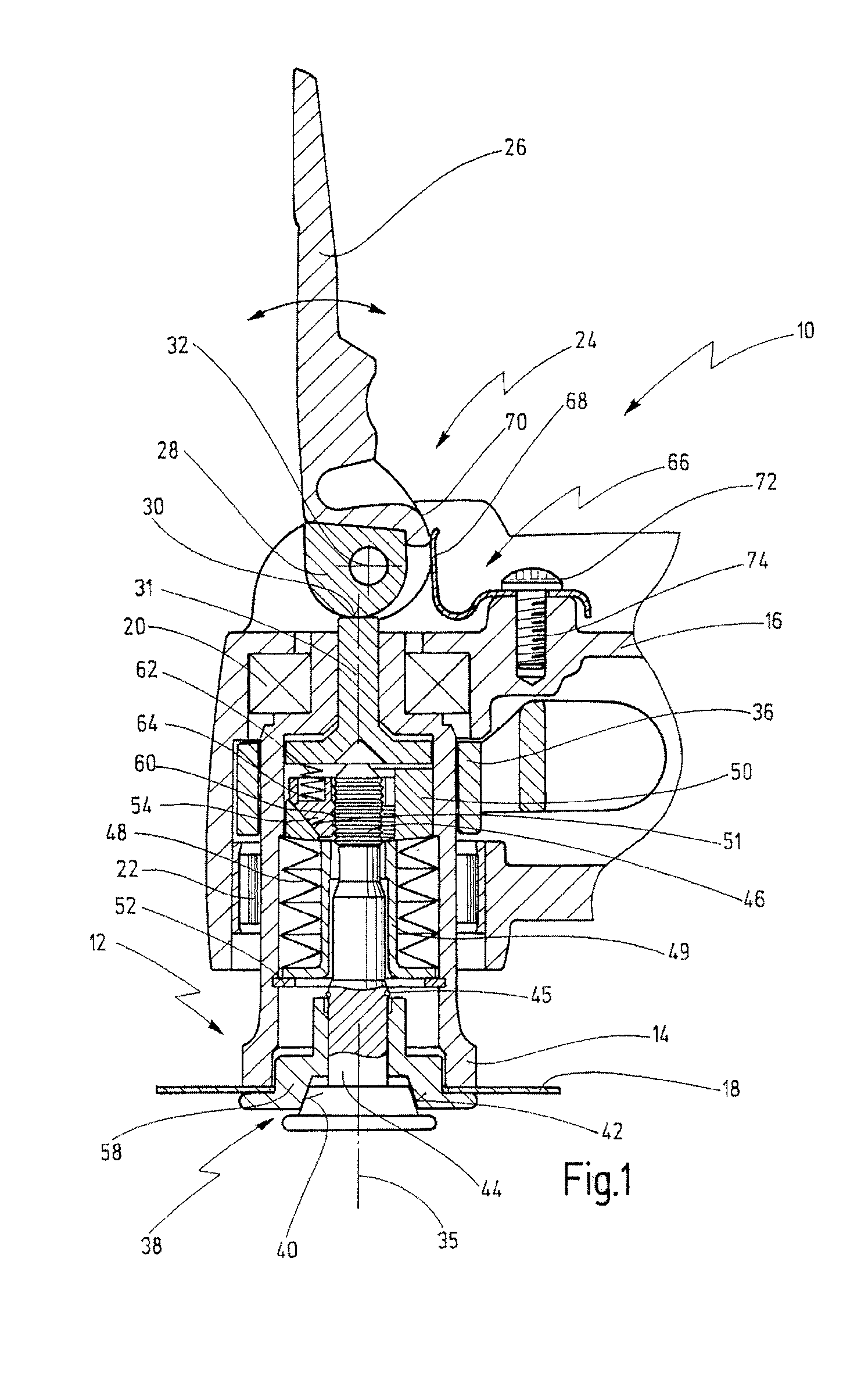

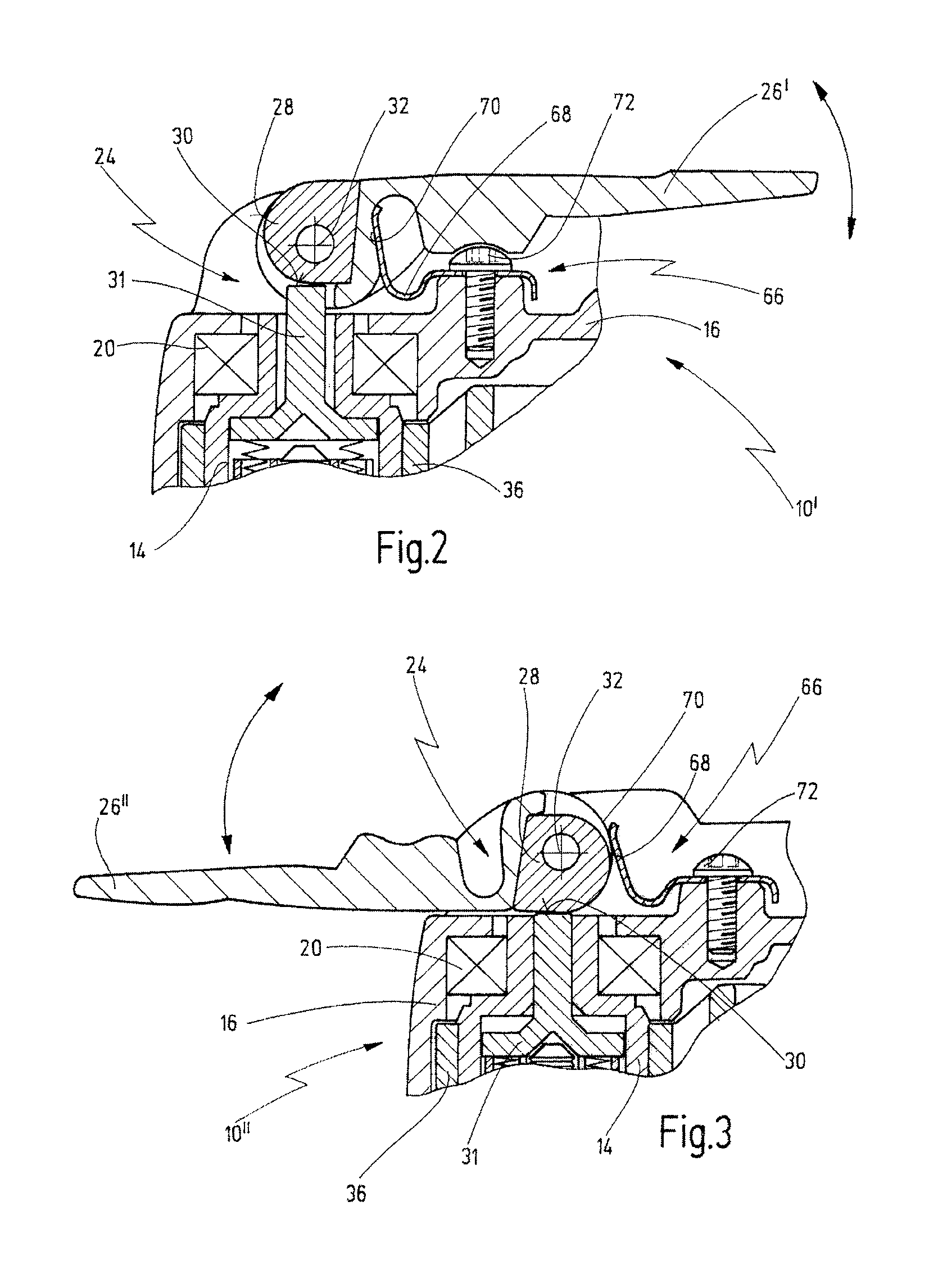

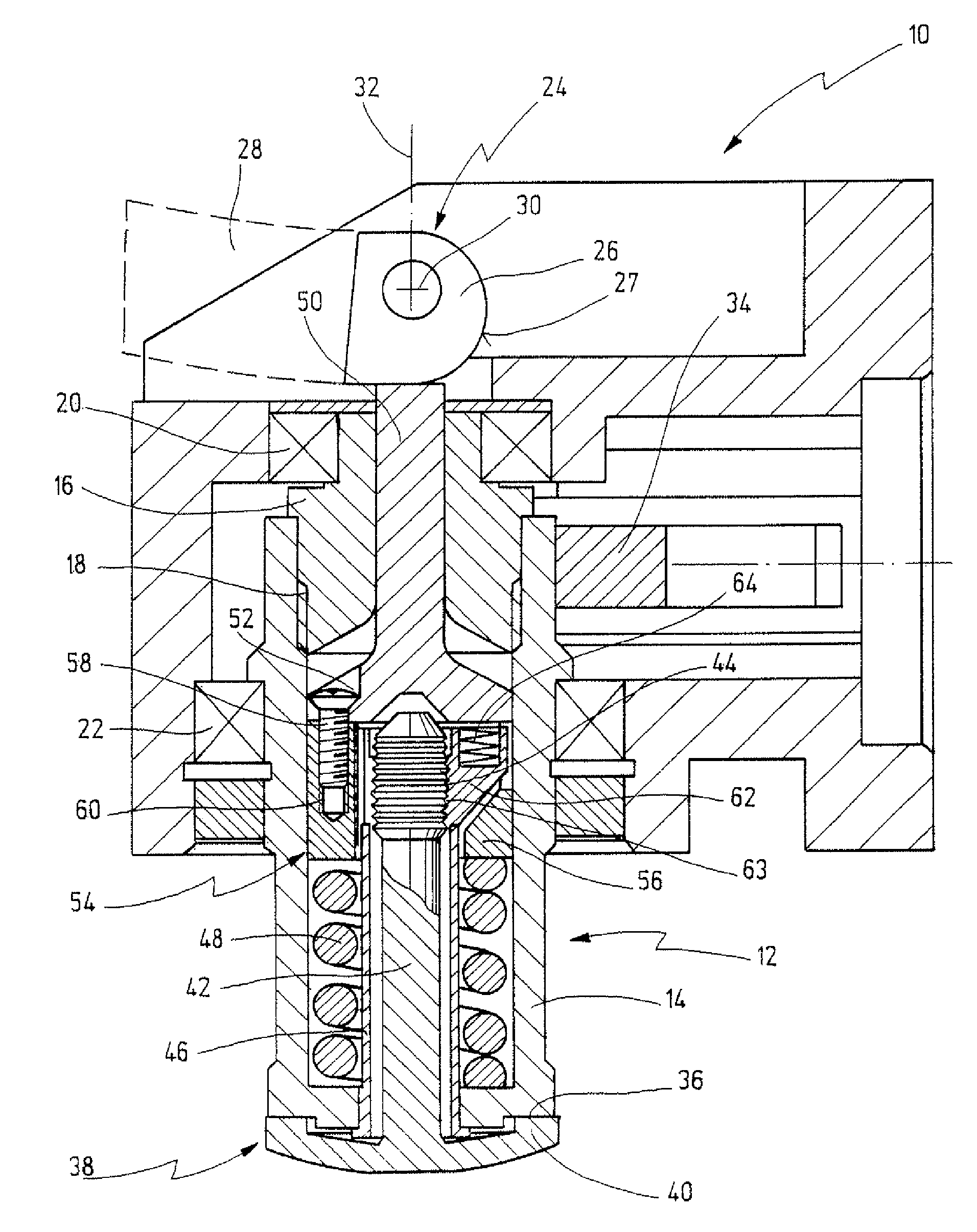

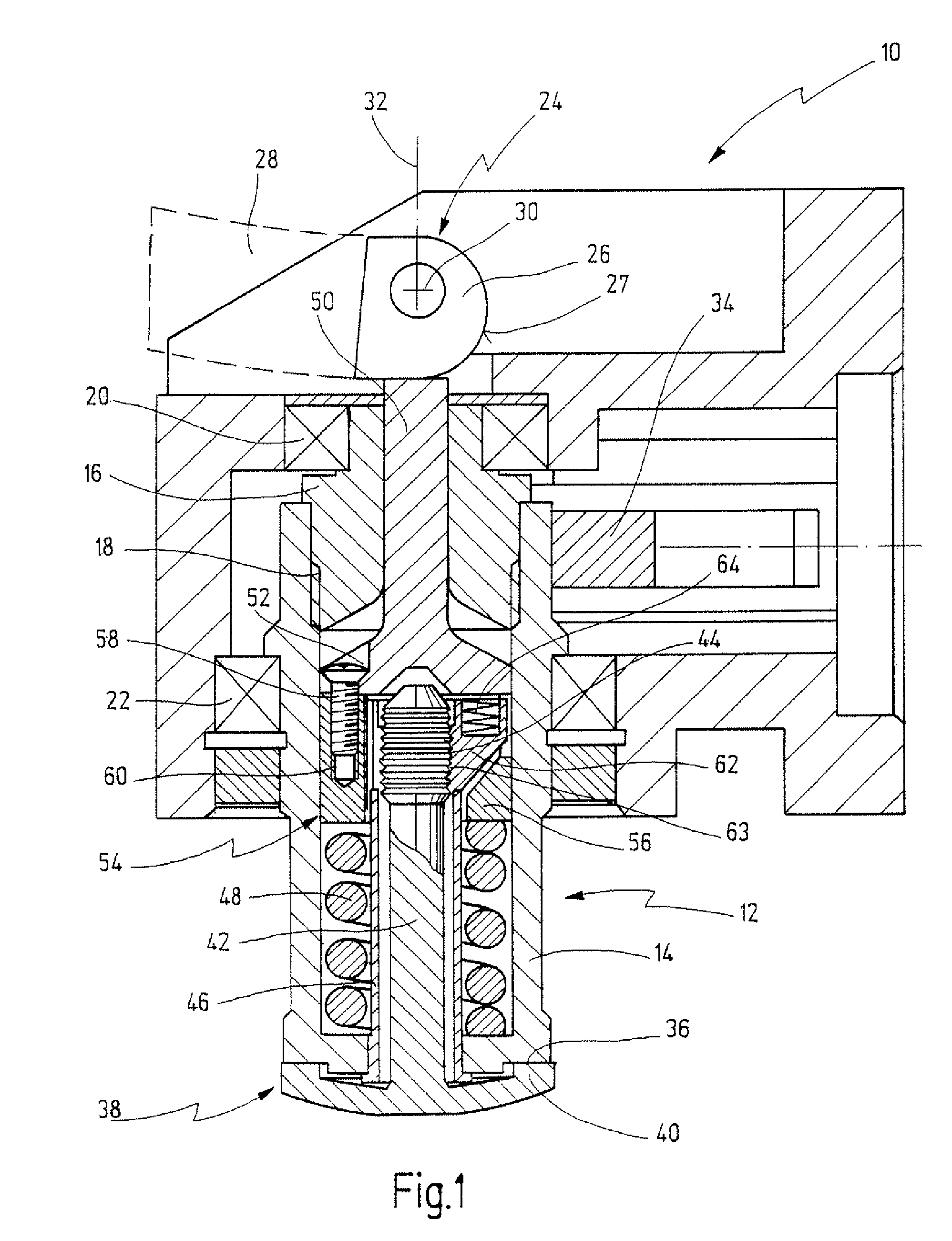

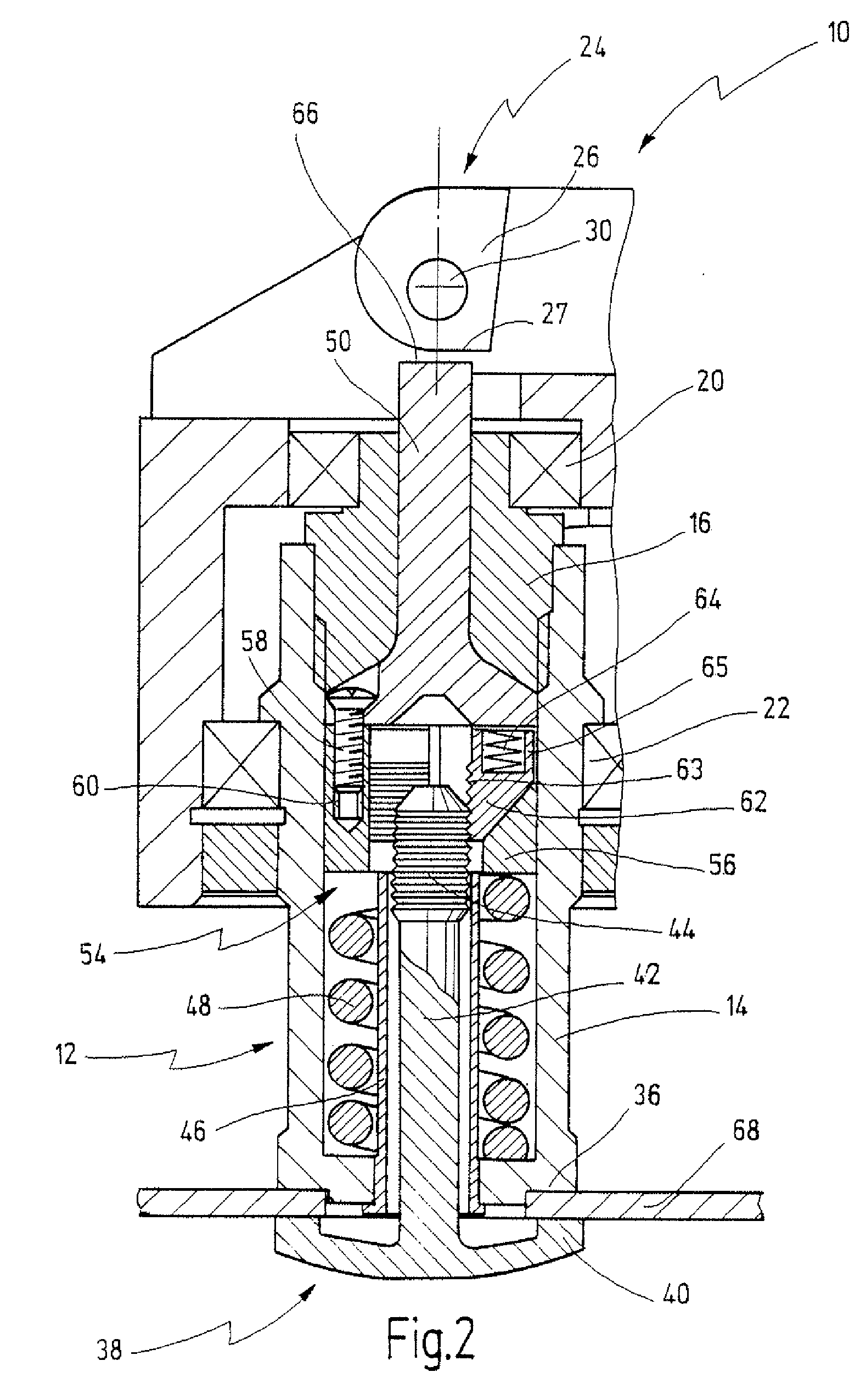

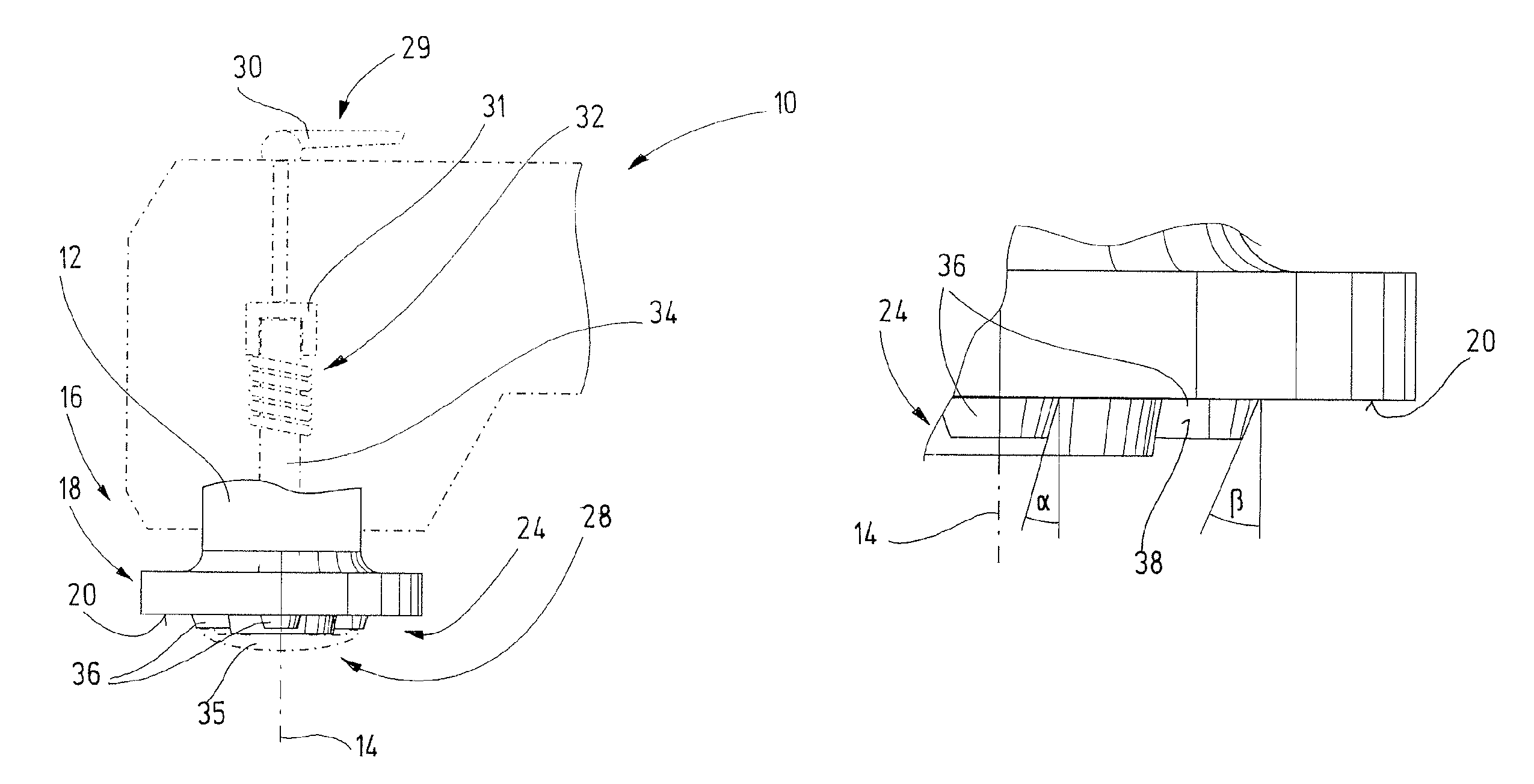

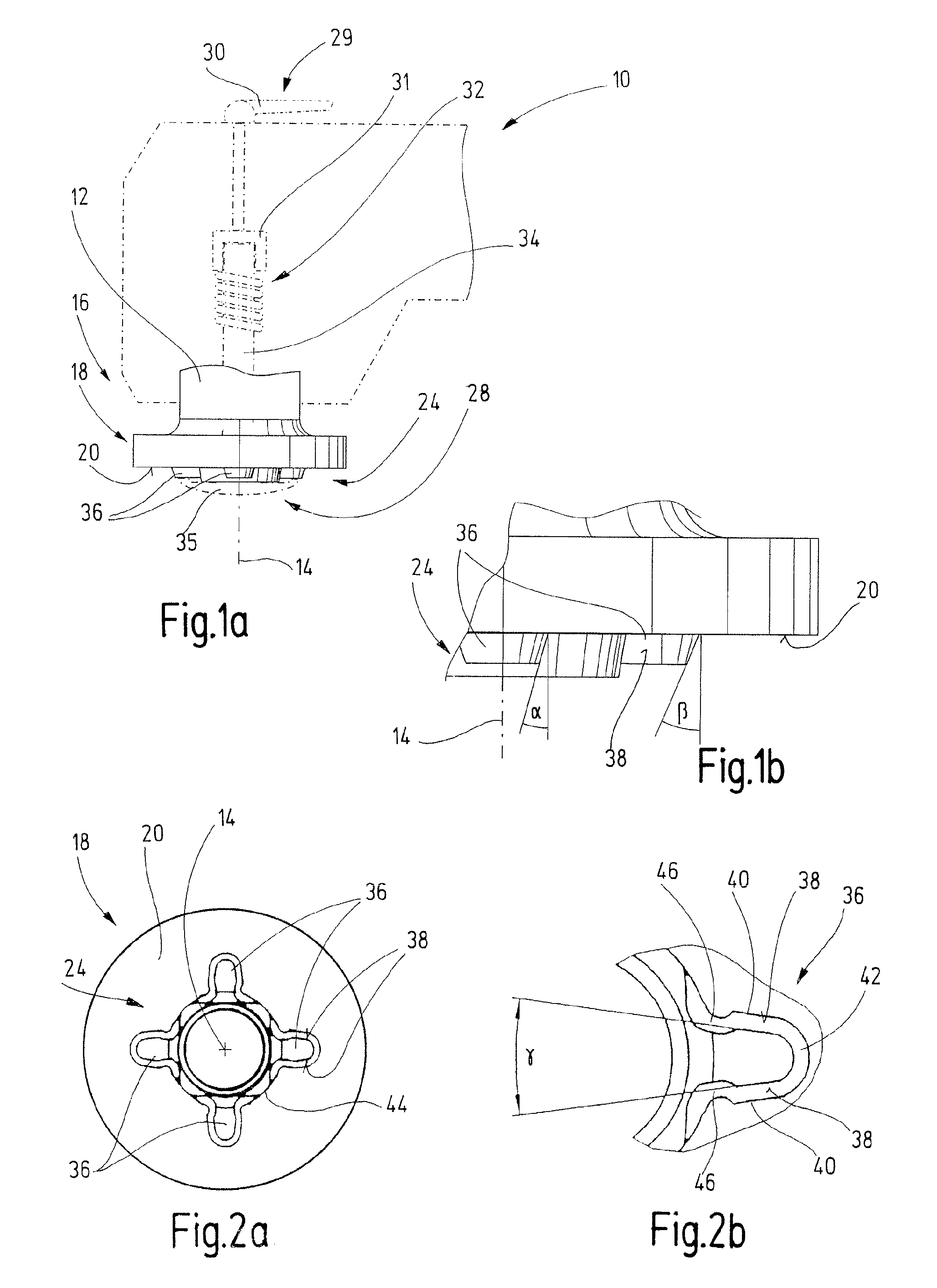

Hand-held power tool with clamping device for a tool

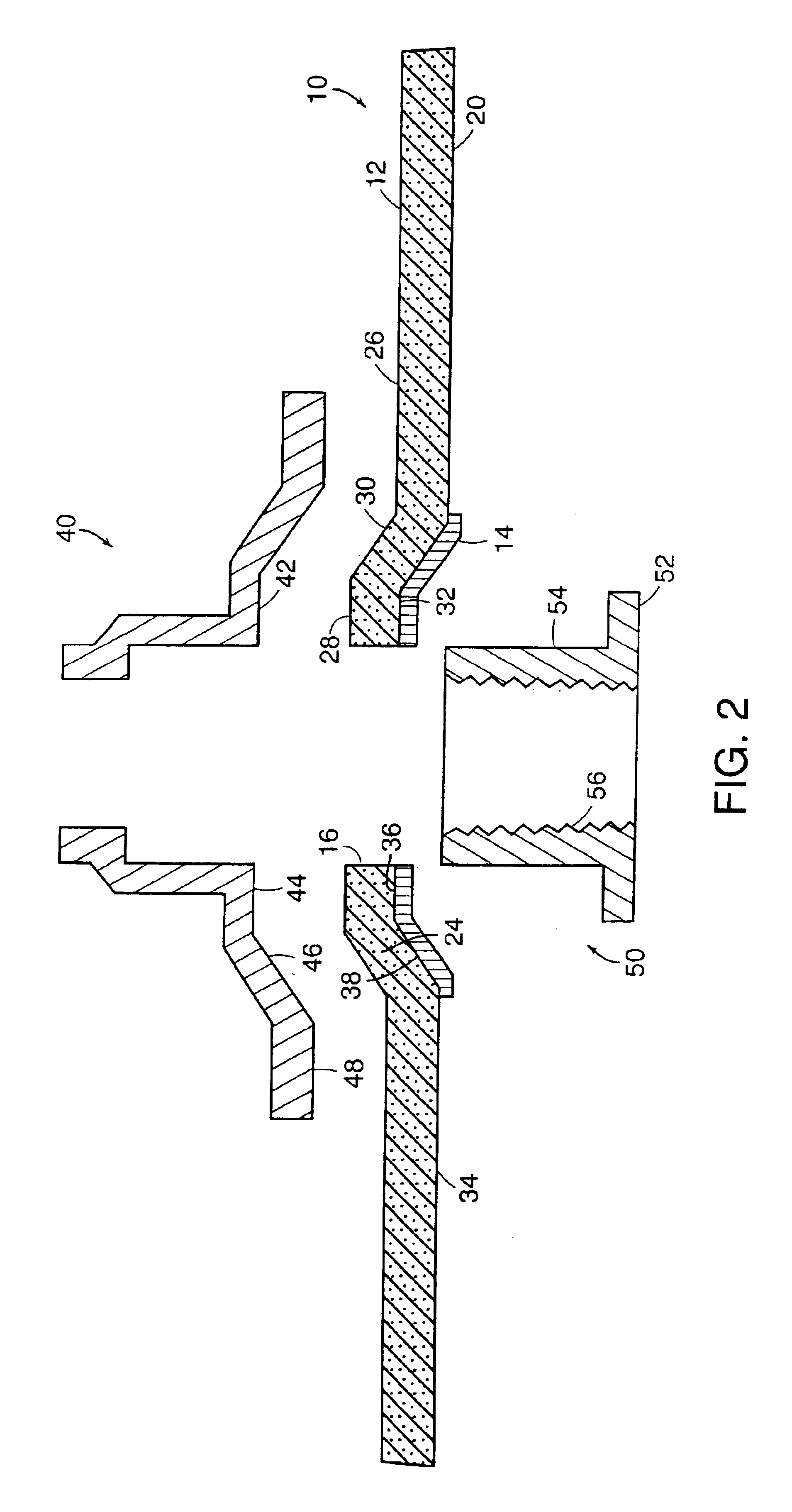

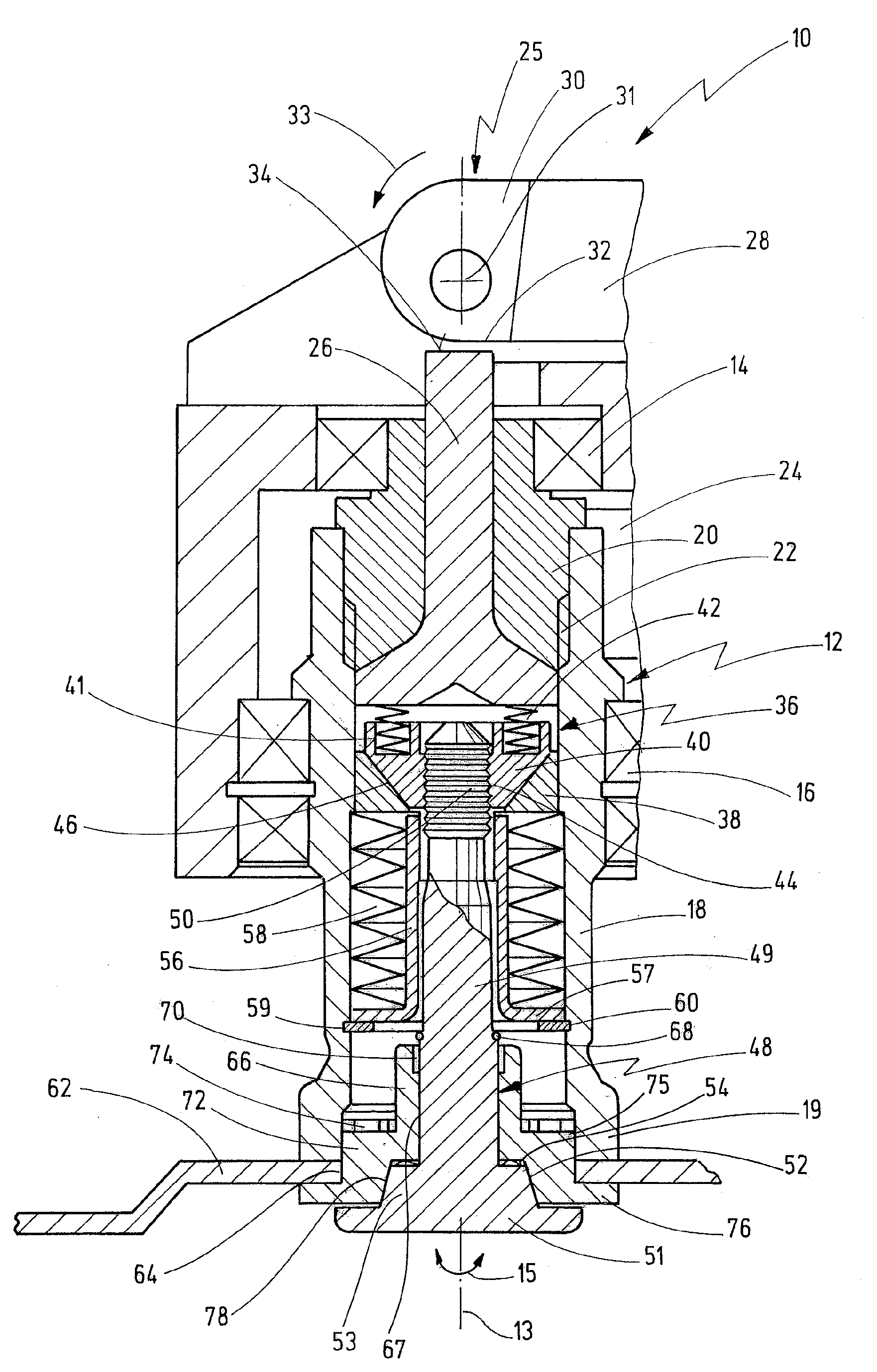

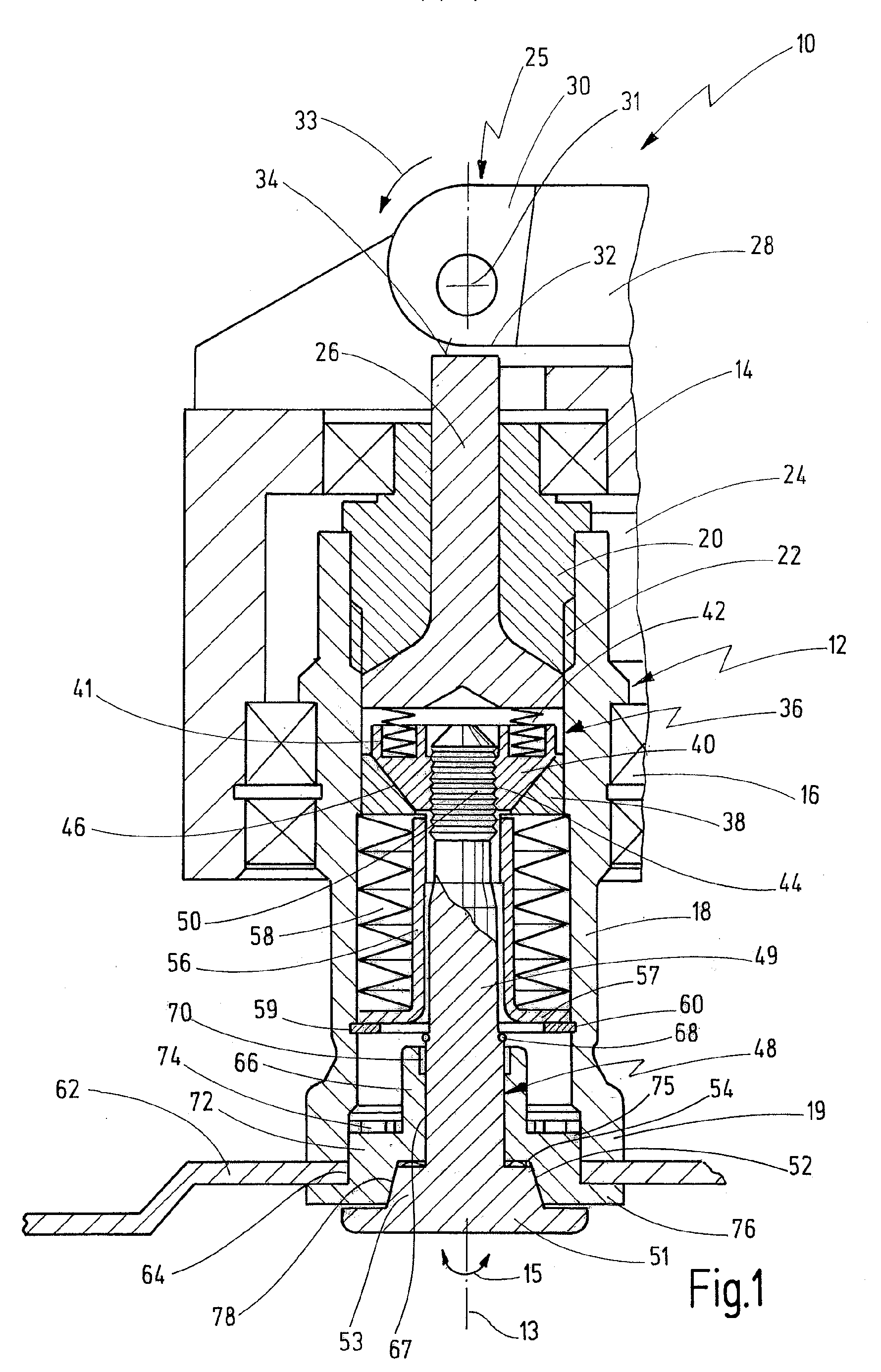

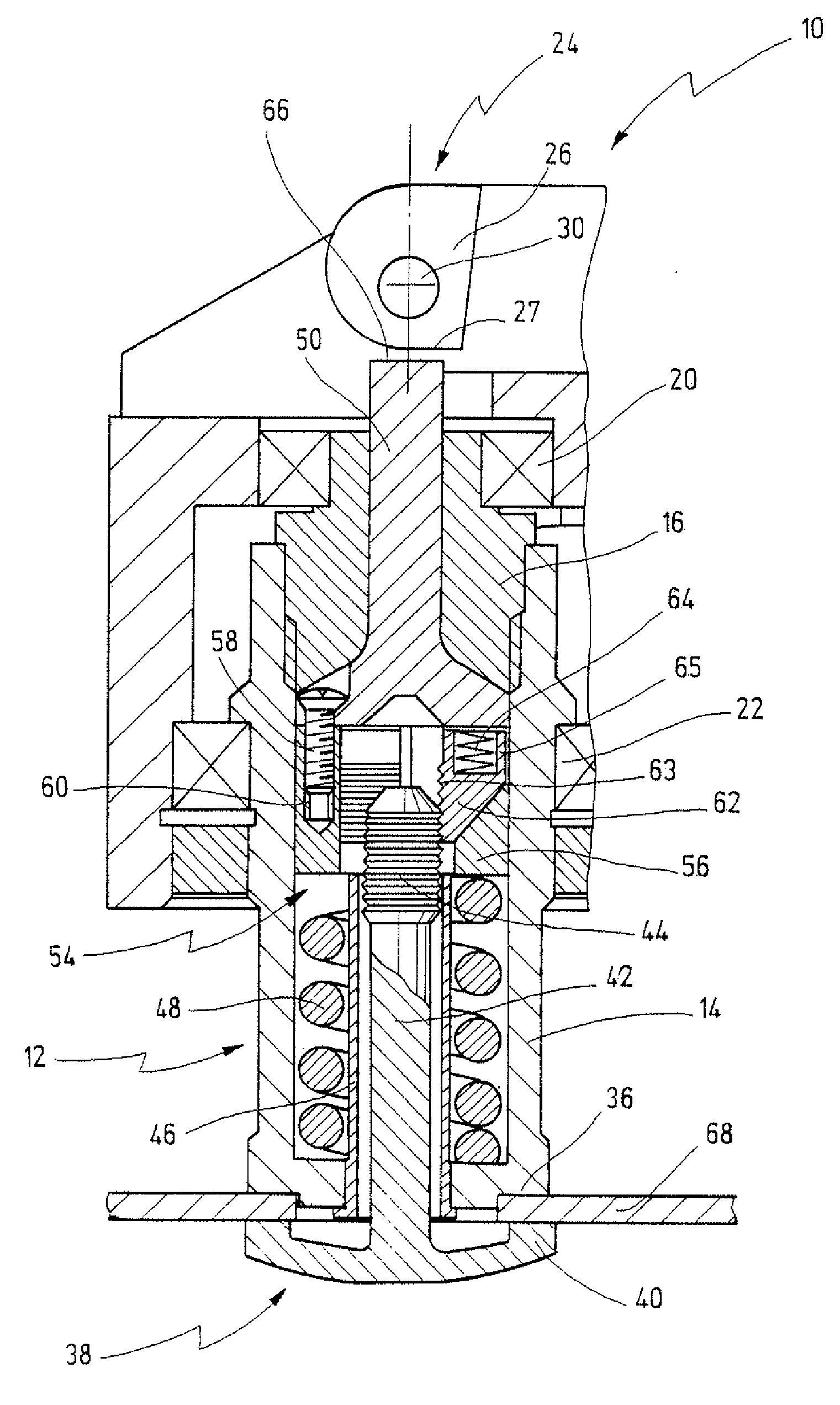

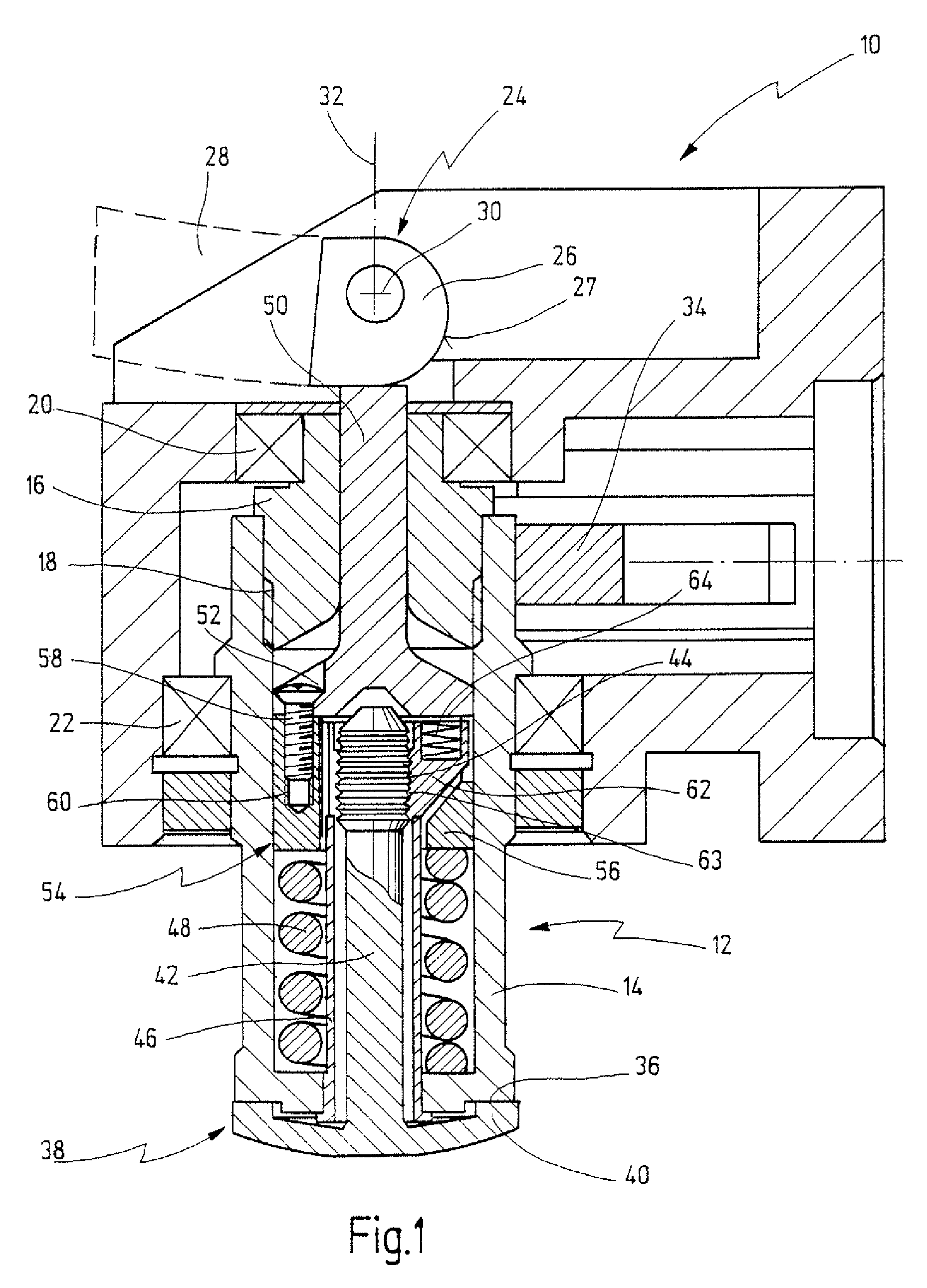

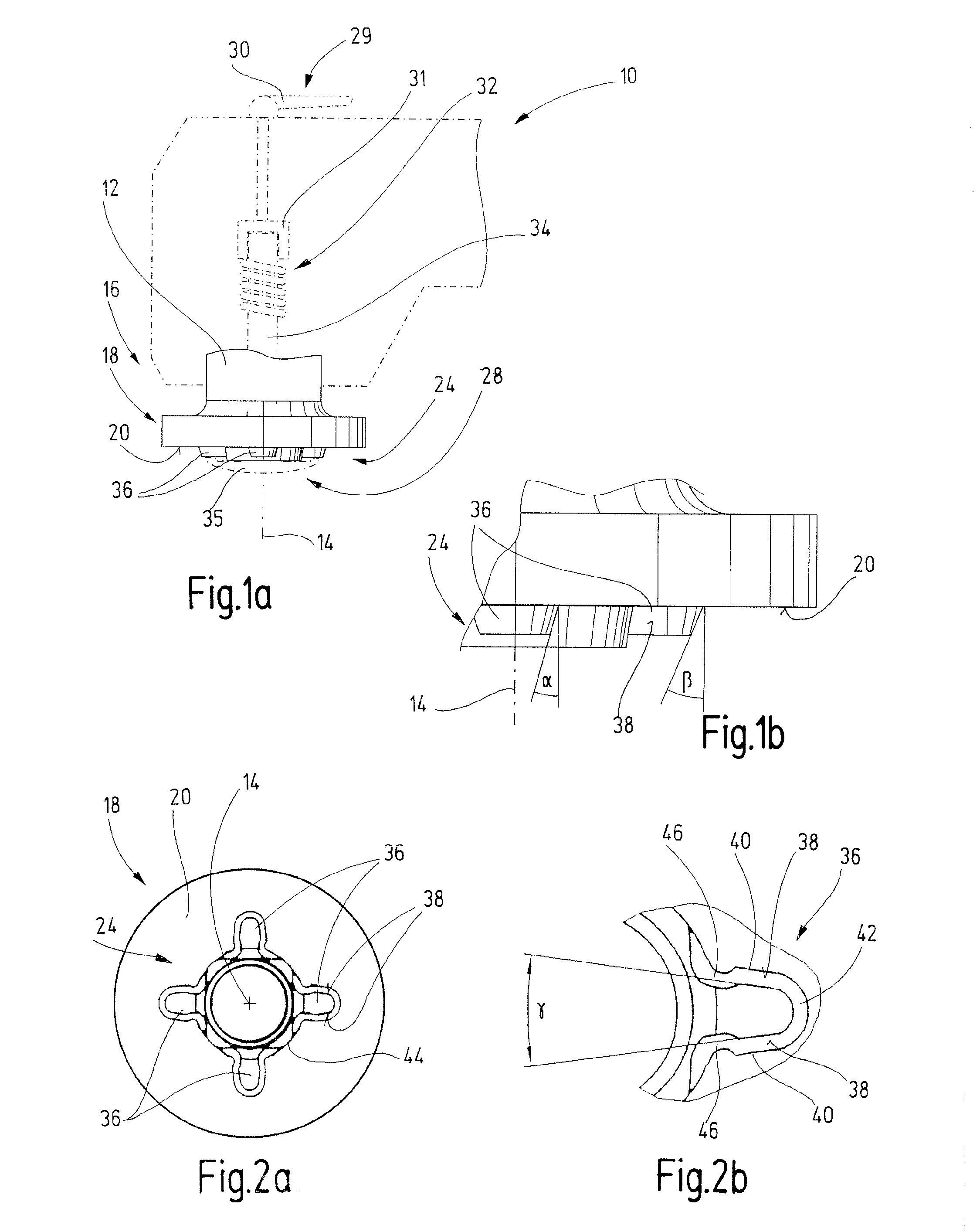

ActiveUS7344435B2The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

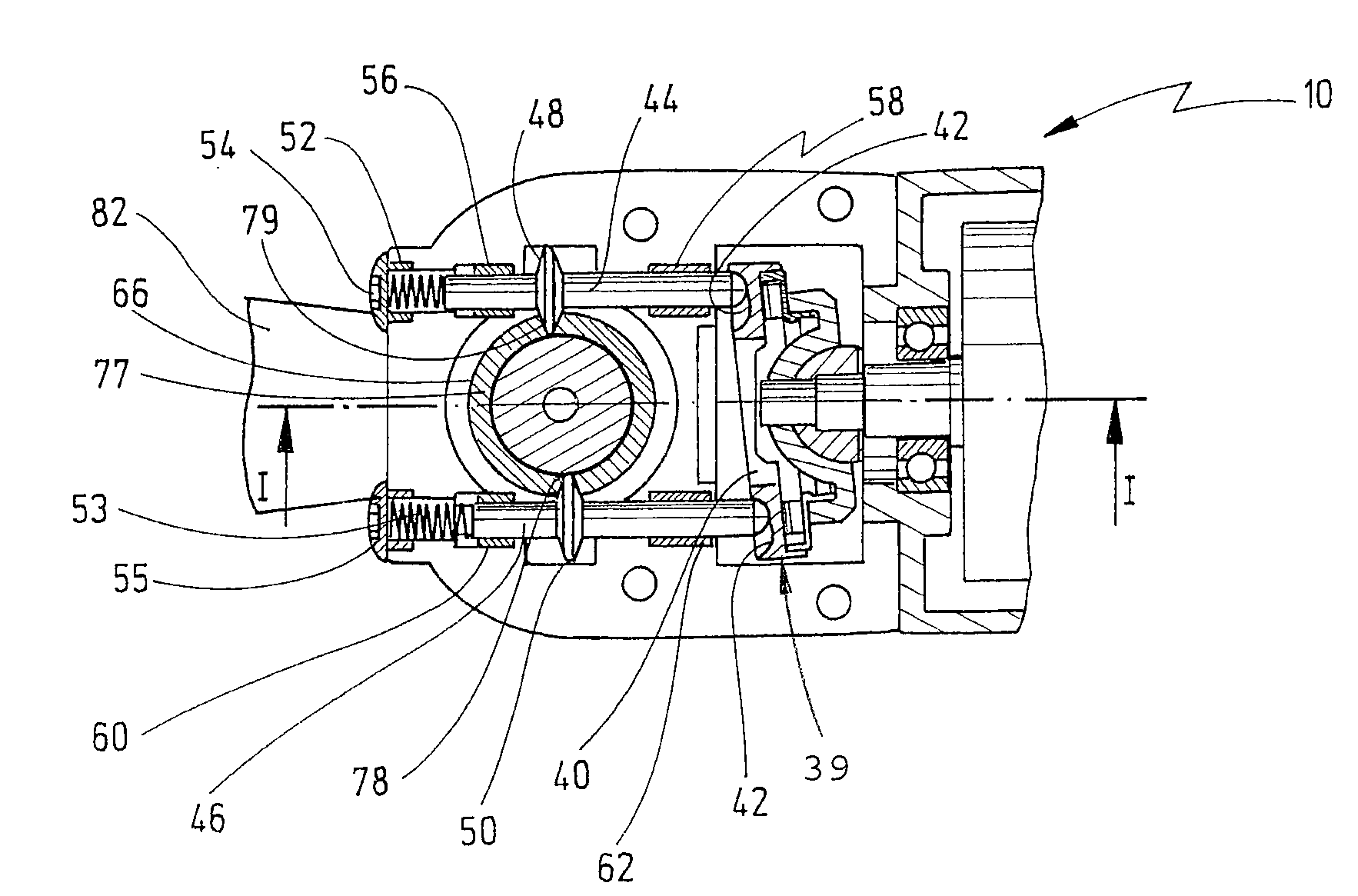

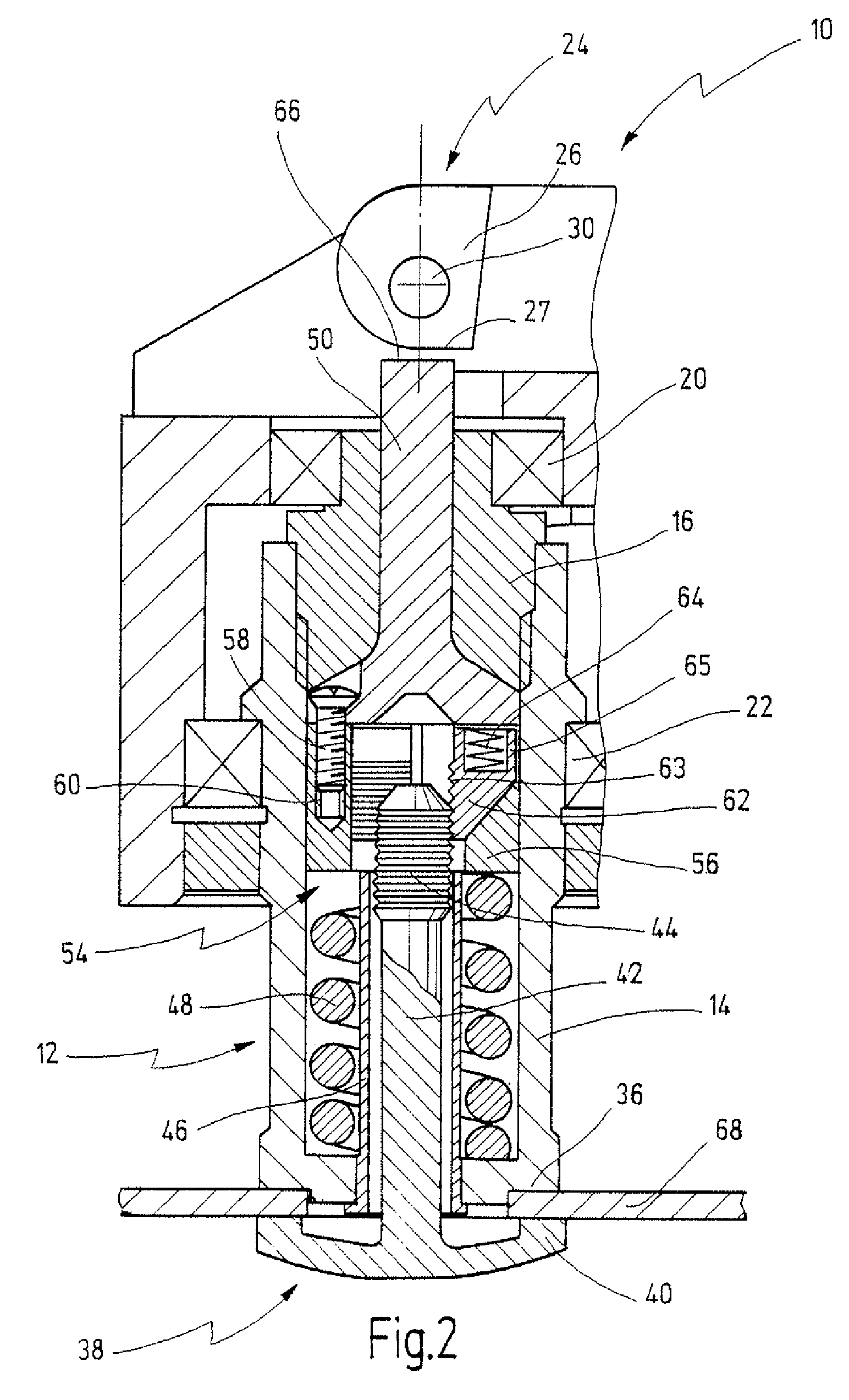

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

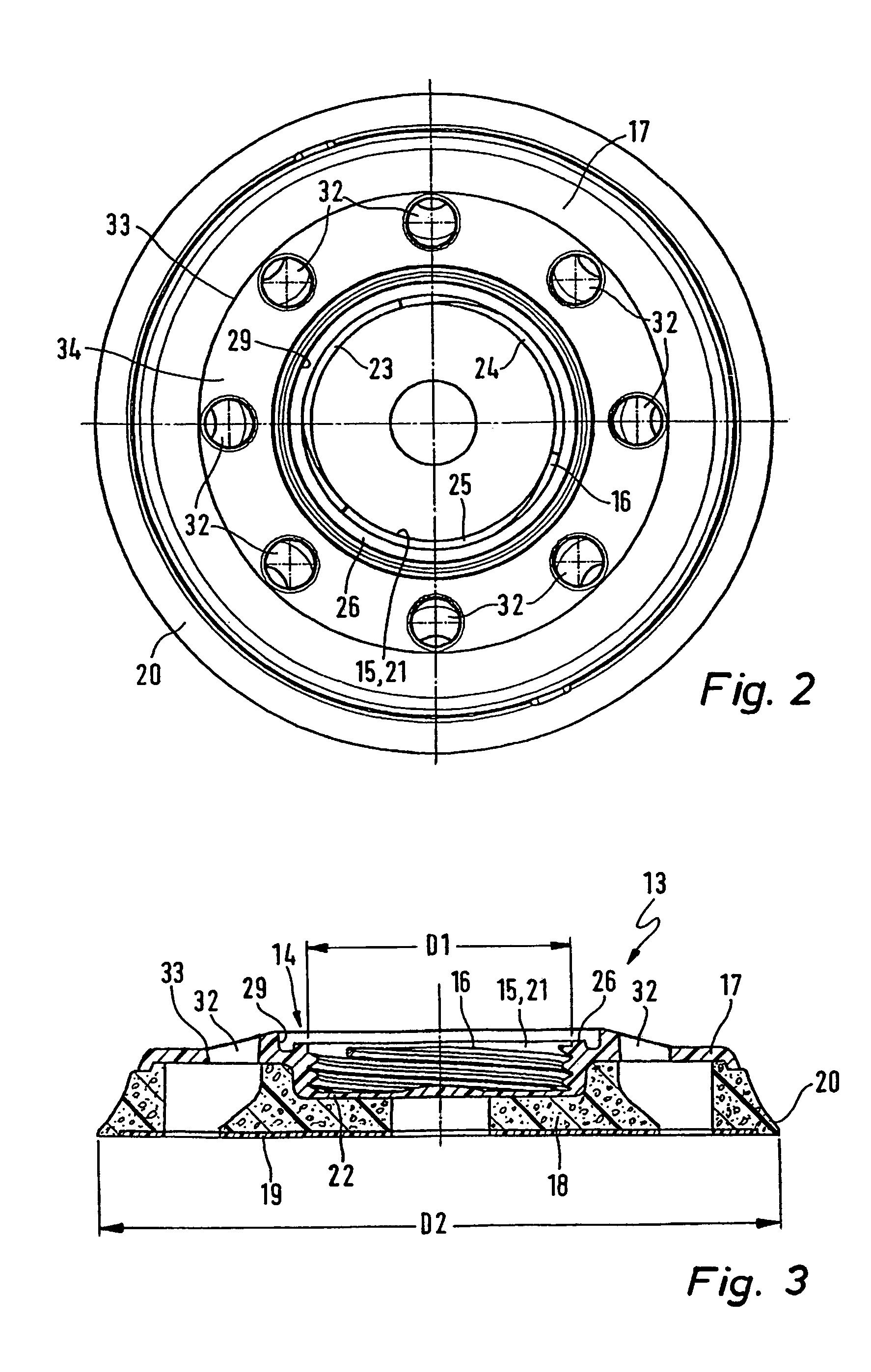

Grinding-disk receiving element especially for a hand-guided electric grinding tool

ActiveUS7217177B2Easy to installEasy to driveGrinding wheel securing apparatusSupport wheelsSanderEngineering

Owner:ROBERT BOSCH GMBH

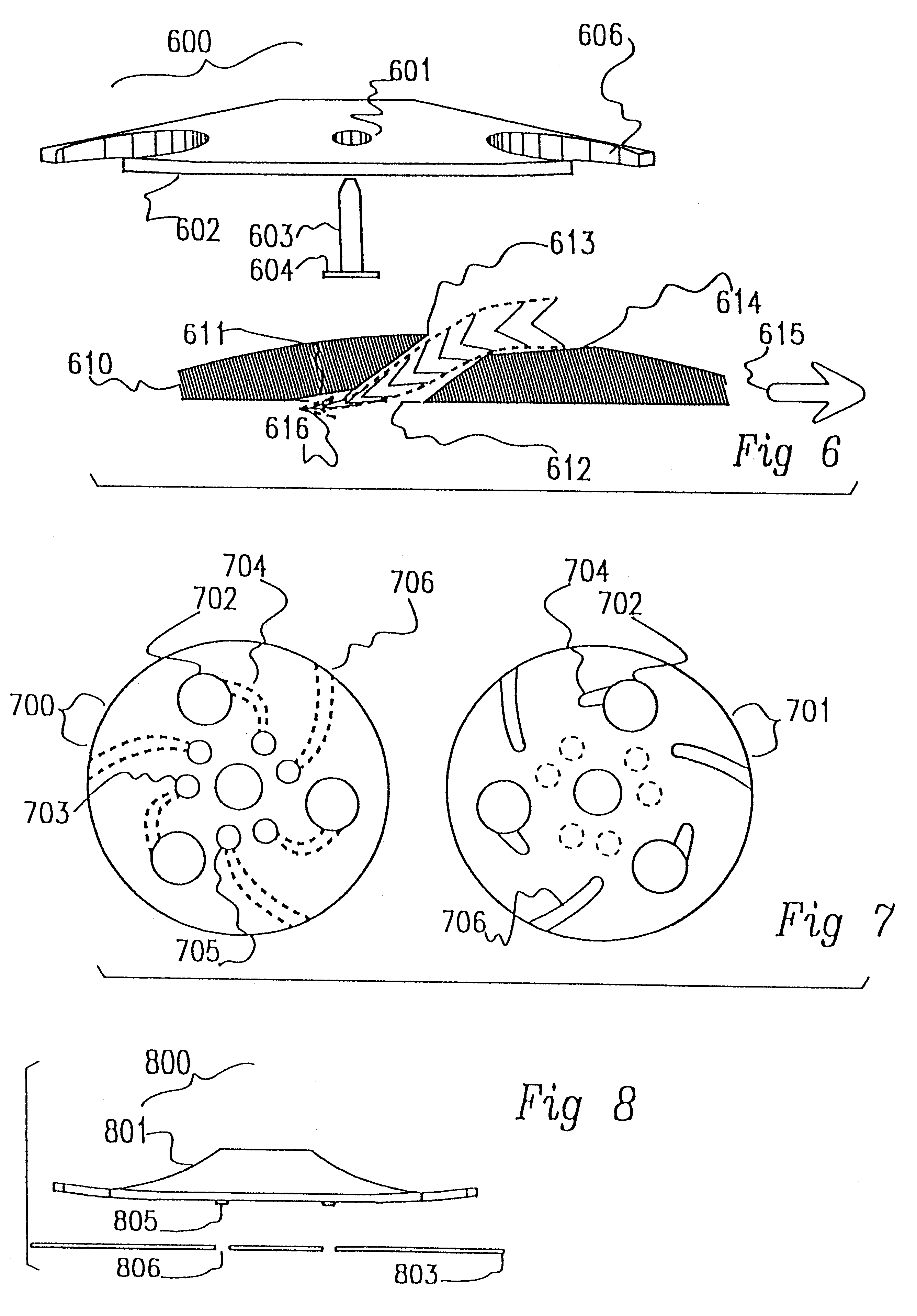

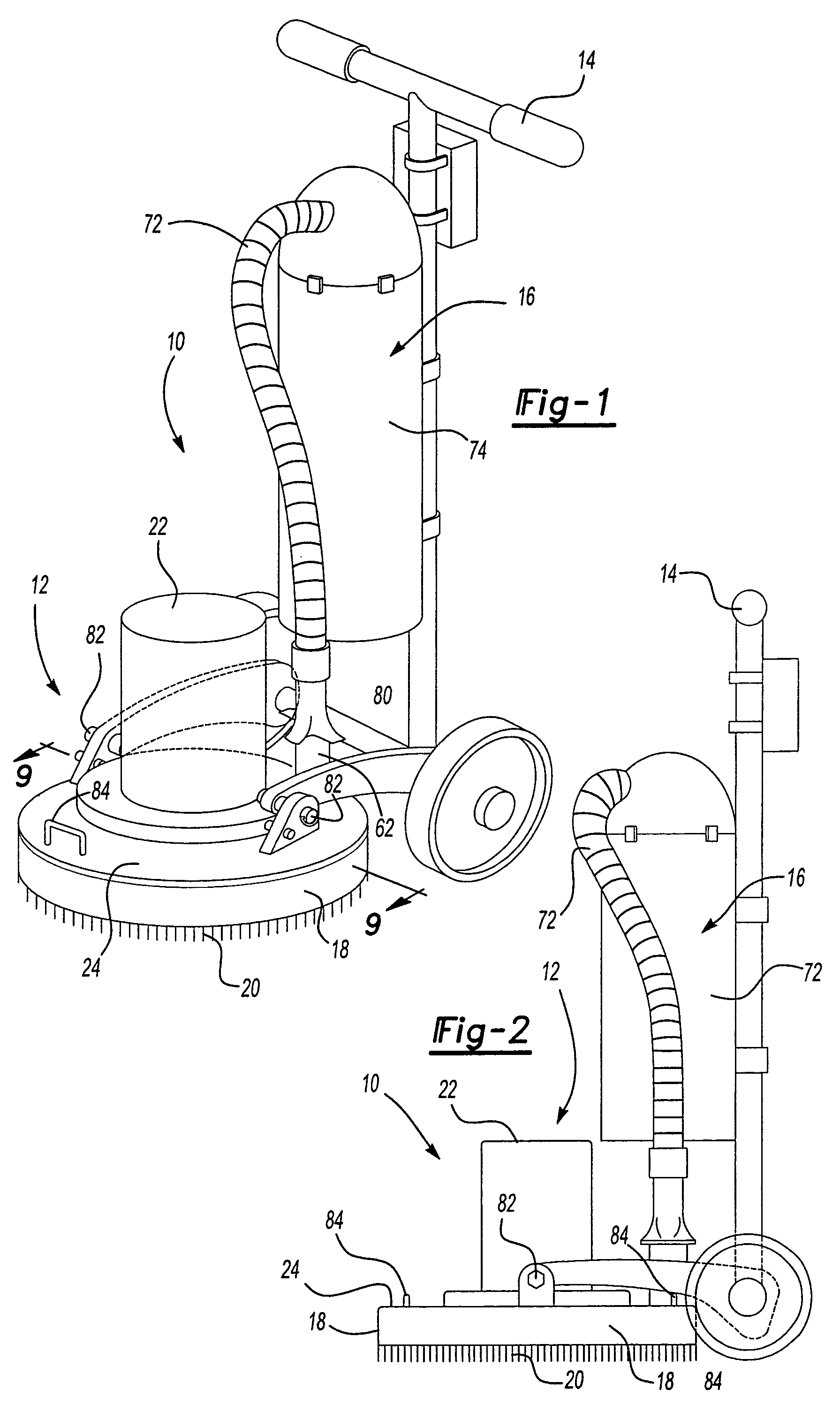

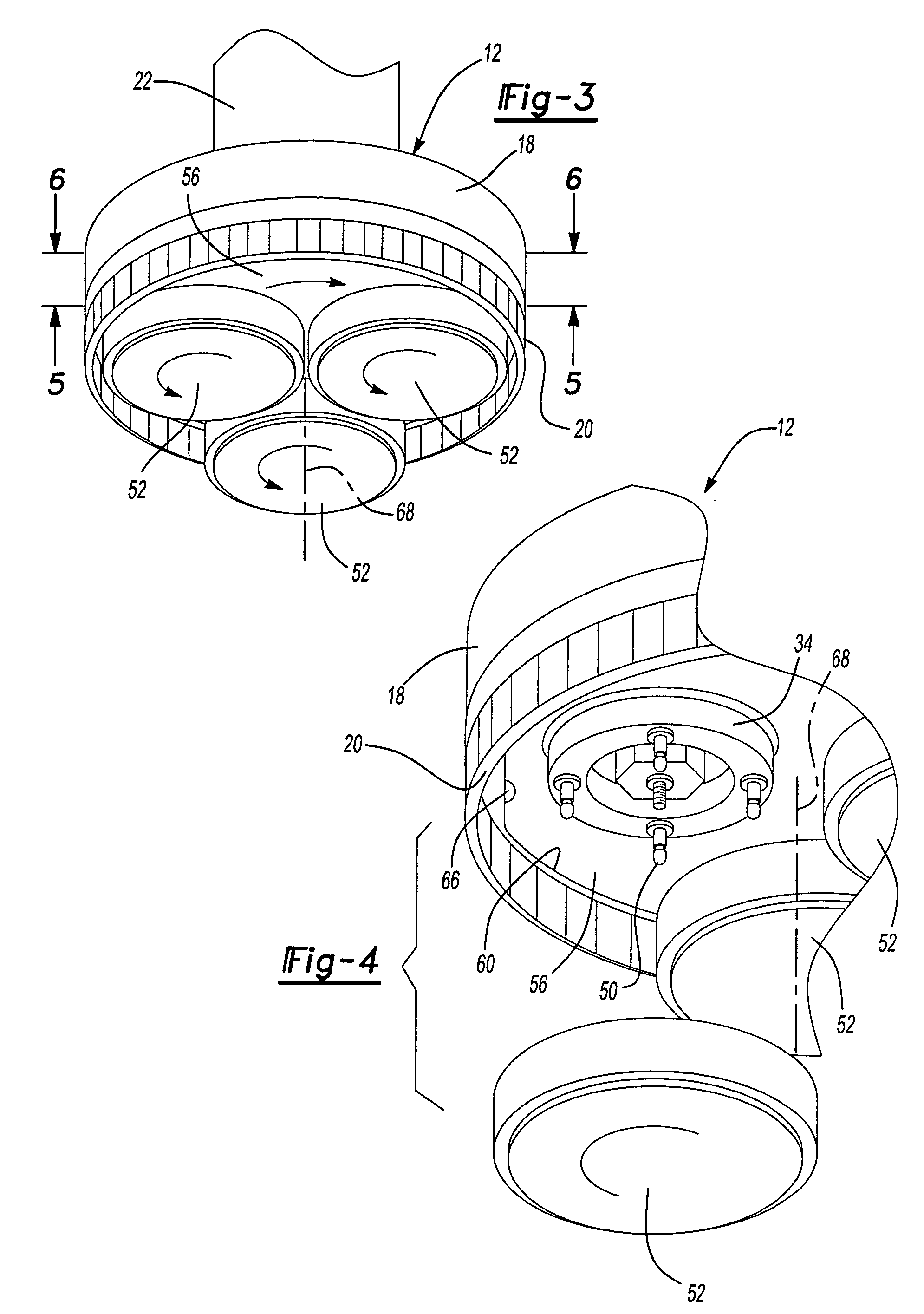

Wood floor sanding machine

A power sanding machine (10) has three circumferentially spaced cogged belts (40) to drive three discs (52) rotatably mounted to an inner bowl (30) which is rotatably mounted to a housing (12), which in turn is connected to an operating handle (14). Mechanical lock can rotationally affix the inner bowl (30) to the housing to circumferentially position a pulley at the left or right edge (326, 322) of the sanding machine or at the front end (330) of the sanding machine. Power cleaning and sanding machines (412, 500, 600) incorporate the three disc (52) arrangement or a direct-drive one disc arrangement (572, 672). The machines (412, 500, 600) include multiple floor finishing units (420, 514, 614) ganged together in unique arrangements.

Owner:ONFLOOR TECH

Guard attachment system with knurled clamp ring

InactiveUS6464573B1Portable grinding machinesMaintainance and safety accessoriesHand heldEngineering

A removable guard for a hand-held power tool. The guard is configured to cover an area proximate a spindle assembly of the tool between the spindle assembly and a user of the tool. The guard is further configured to be securely mounted to a semi-elastic lower bearing housing supporting the spindle assembly of the tool. The guard, when mounted to the semi-elastic lower bearing housing of the tool, and when in use during operation of the tool, must remain functional under conditions of flying debris, such as under conditions of an exploding, rotating abrasive grinding wheel mounted on the spindle assembly of the tool.The guard includes a clamp ring depending from a guard hood. The clamp ring's inner circumferential portion has at least a partially-knurled surface, whereby when securely tightened around the semi-elastic lower bearing housing, the at least partially-knurled surface of the clamp ring inner circumferential portion compresses into the semi-elastic lower bearing housing to securely mount the guard to the tool.

Owner:BLACK & DECKER INC

Microdermabrasion Treatment Heads

ActiveUS20090222023A1Shorten the time periodPortable grinding machinesIntravenous devicesBiomedical engineering

Owner:ENVY MEDICAL

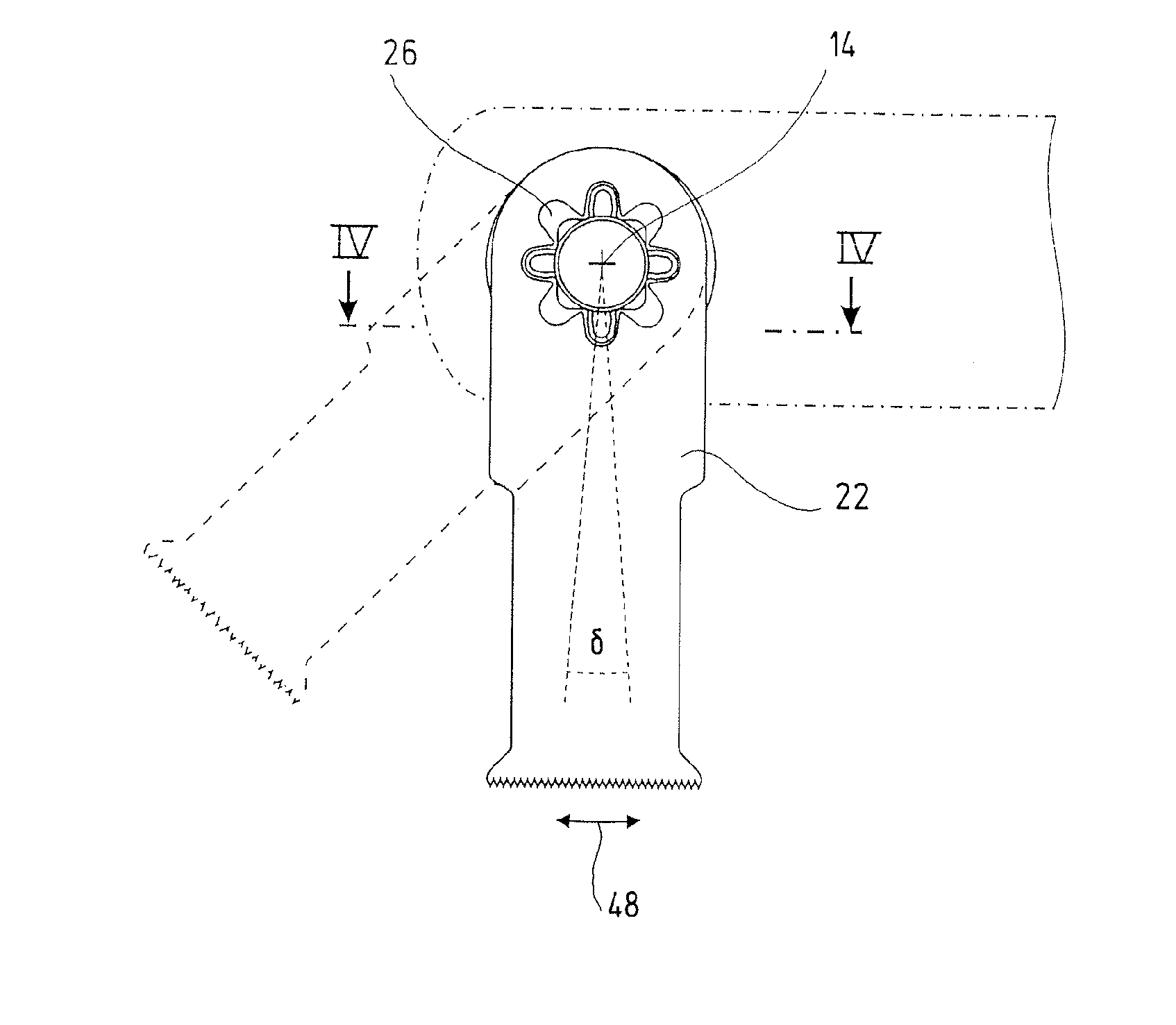

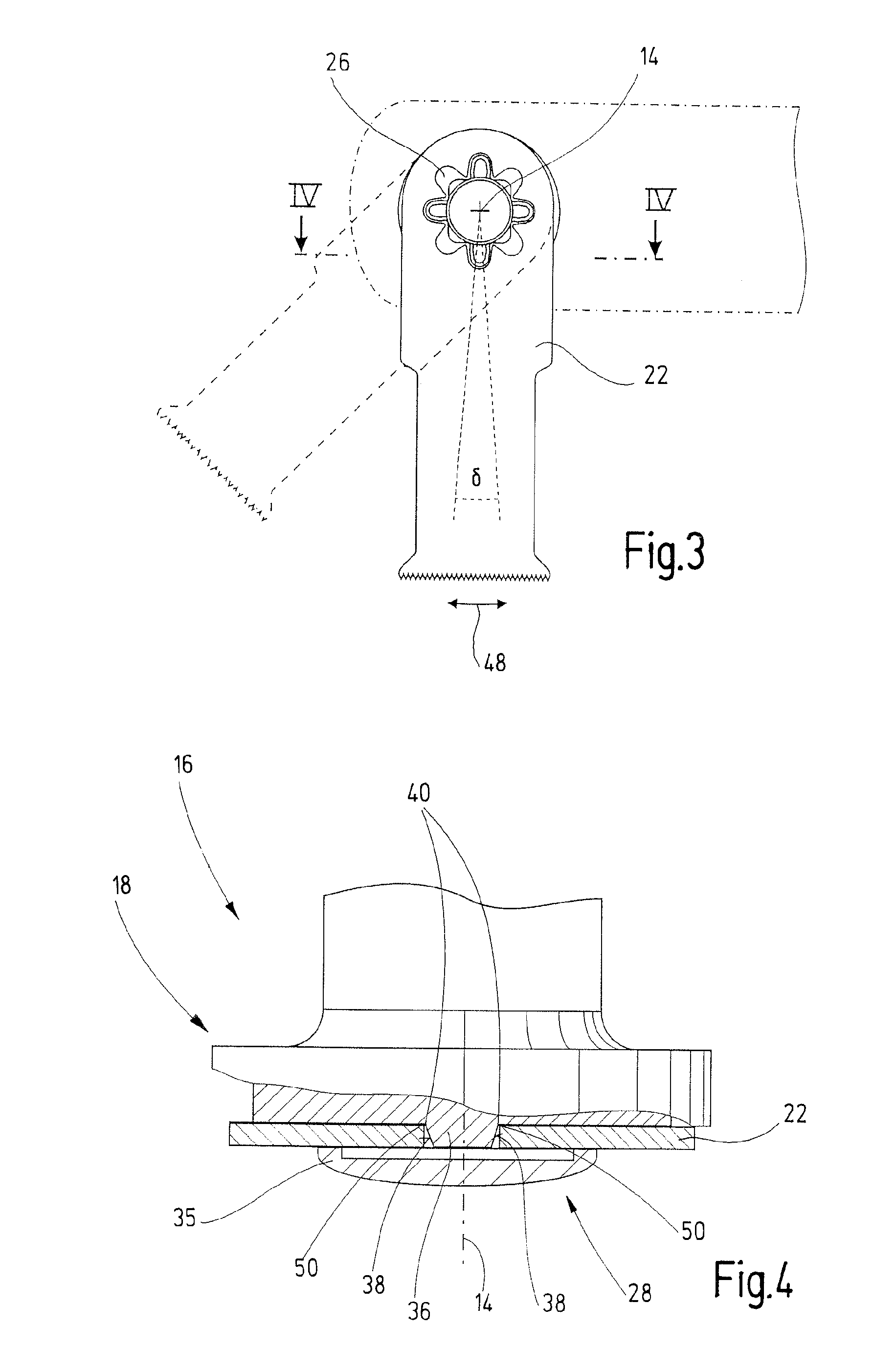

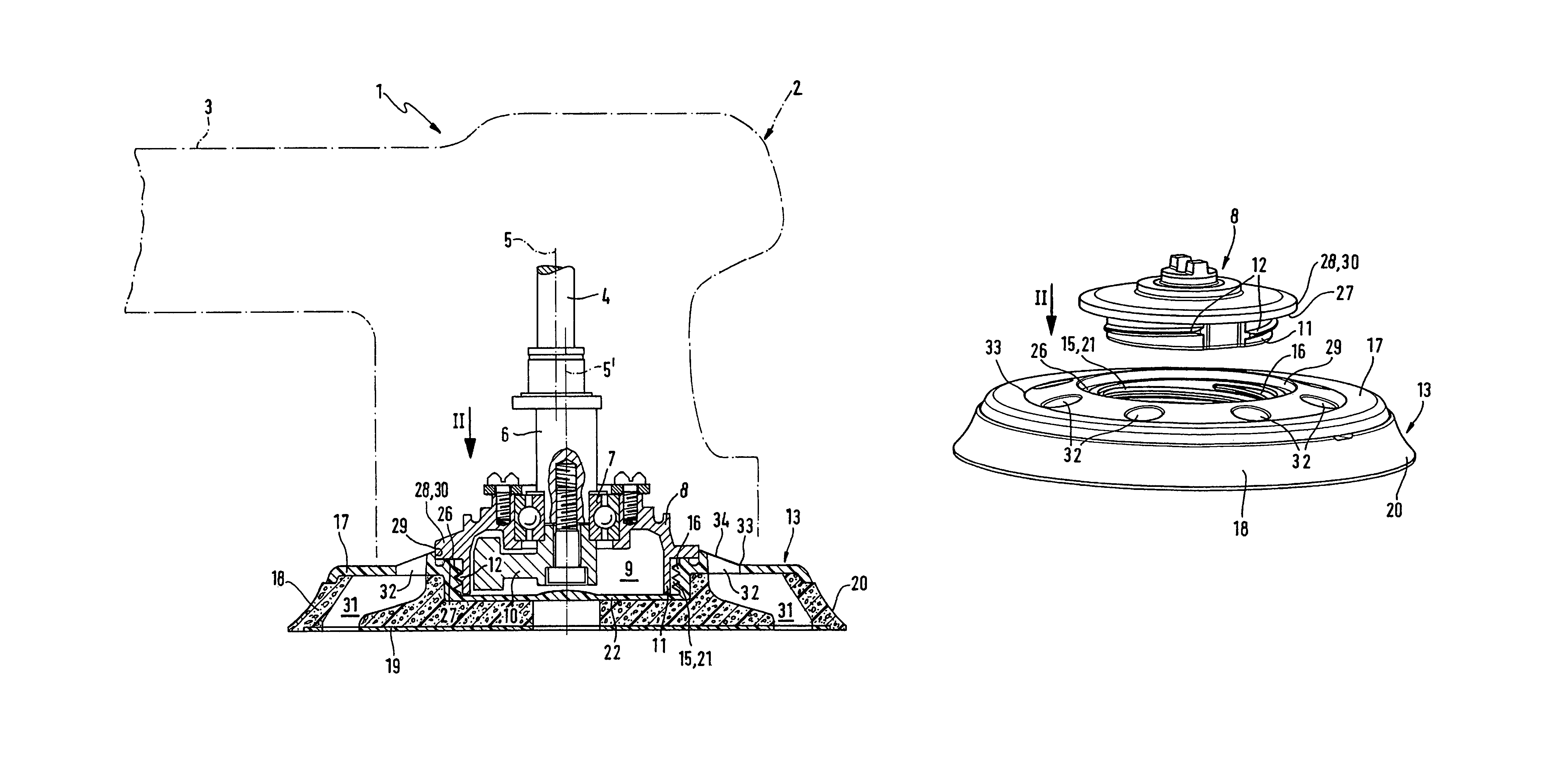

Oscillatory Drive

ActiveUS20070295156A1Reduce disadvantagesImprove transmittanceGrinding wheel securing apparatusTurning machine accessoriesPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN

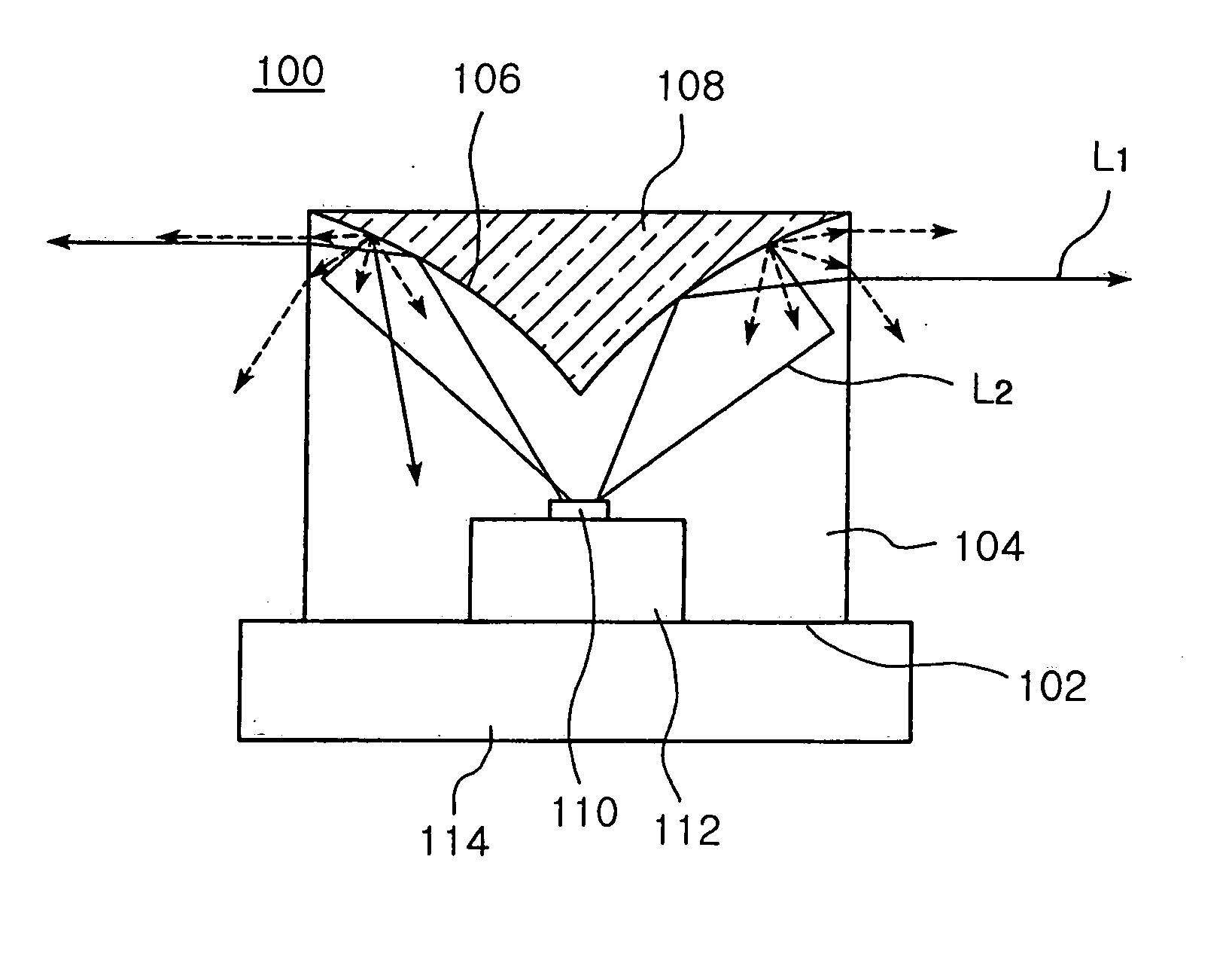

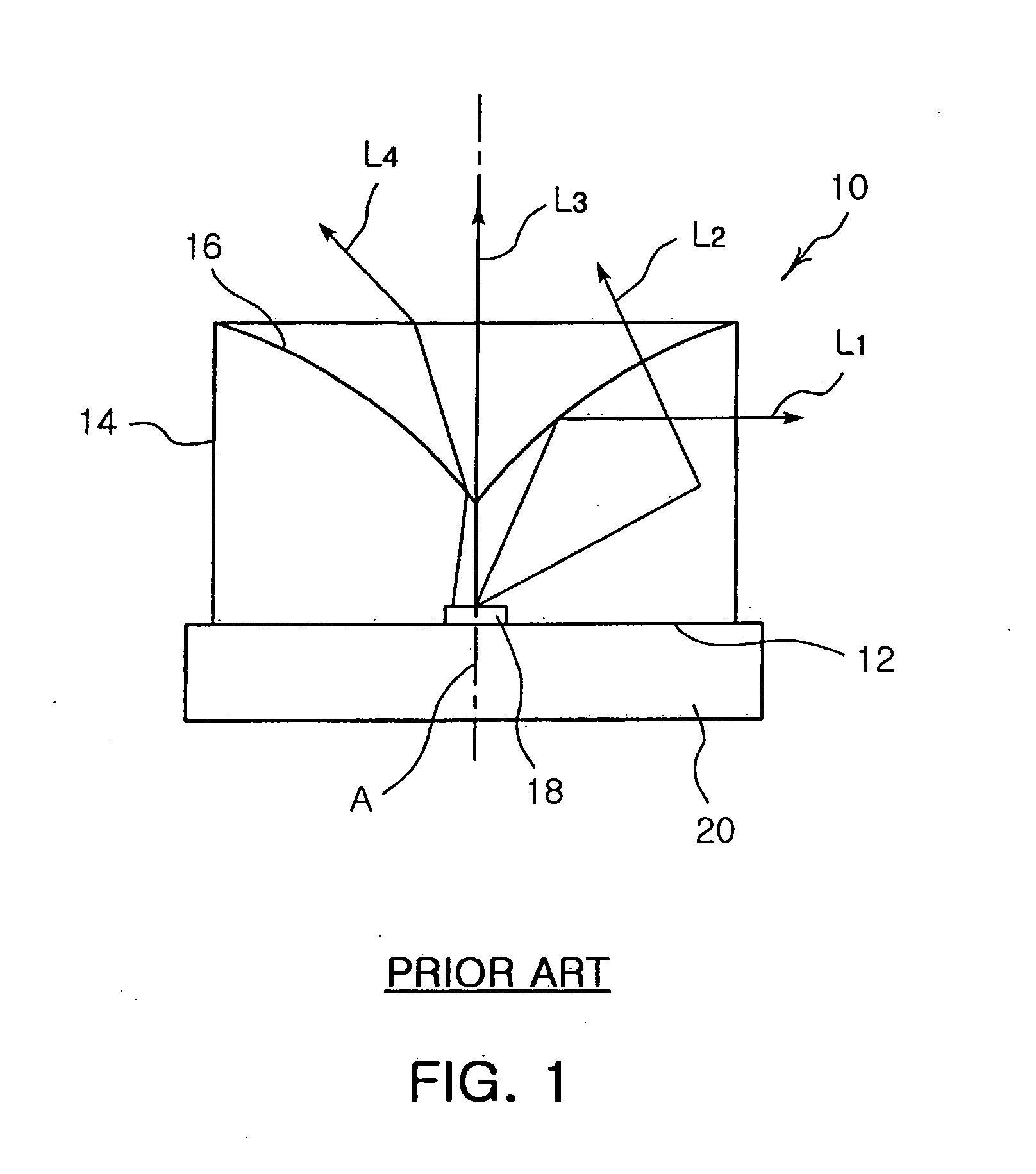

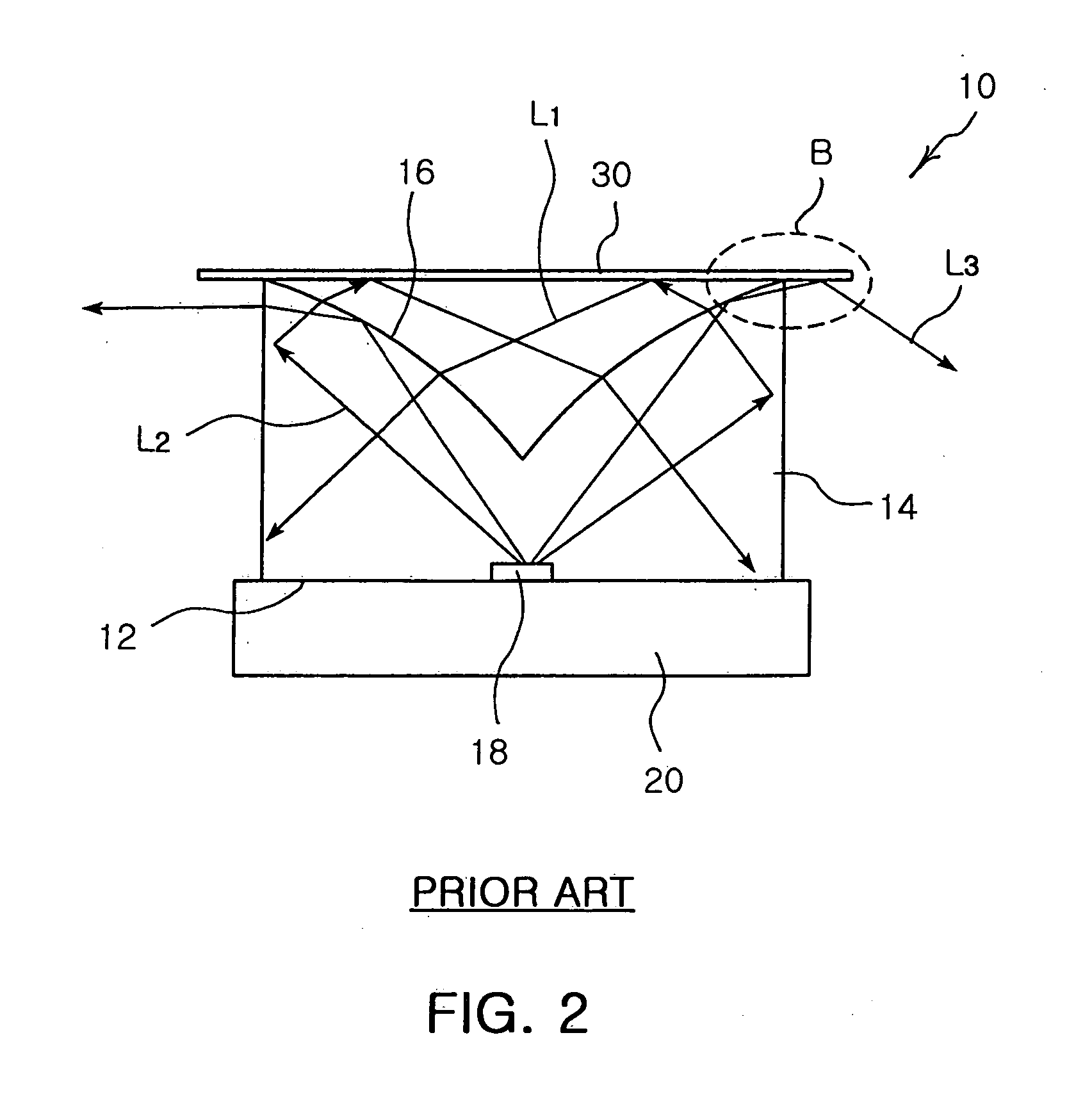

Side-emitting LED package having scattering area and backlight apparatus incorporating the LED lens

ActiveUS20060208269A1Avoid light lossPoint-like light sourceSolid-state devicesOptoelectronicsExit surface

The invention provides an LED package and a backlight device incorporating the LED lens. The LED package has a bottom surface and a light exiting surface cylindrically extended around a central axis of the package from the bottom surface. Also, a reflecting surface is positioned on an opposite side of the bottom surface and symmetrical around the central axis such that light incident from the bottom surface is reflected toward the light exiting surface. Further, a scattering area is formed on the reflecting surface. According to the invention, by applying scattering materials on the reflecting surface of the LED package, a reflecting paper does not need to be attached, thereby simplifying a process and reducing the manufacture time and cost.

Owner:SAMSUNG ELECTRONICS CO LTD

Hand-Held Power Tool With Clamping Device For A Tool

ActiveUS20070060030A1The method is simple and reliableStrong clamping forceGrinding wheel securing apparatusPortable grinding machinesHand heldEngineering

A hand-held power tool (10) is specified, comprising a work spindle (12) for driving a tool (68), said tool (68) being fastenable between a fastening element (38) and a holding portion (36) on a tool end of the work spindle (12), and a displacement device (24) for sliding the fastening element (38) between a released position in which the fastening element (38) can be detached from the work spindle (12) and a clamped position in which the fastening element (38) is clamped against the holding portion (36) by a spring element (48). The fastening element (38) includes a clamping shaft (42) that is insertable into the work spindle (12) and held in the clamped position by a lock assembly (54) inside the work spindle (12), and which can be removed when in the released position (FIG. 2).

Owner:C & E FEIN GMBH & CO KG

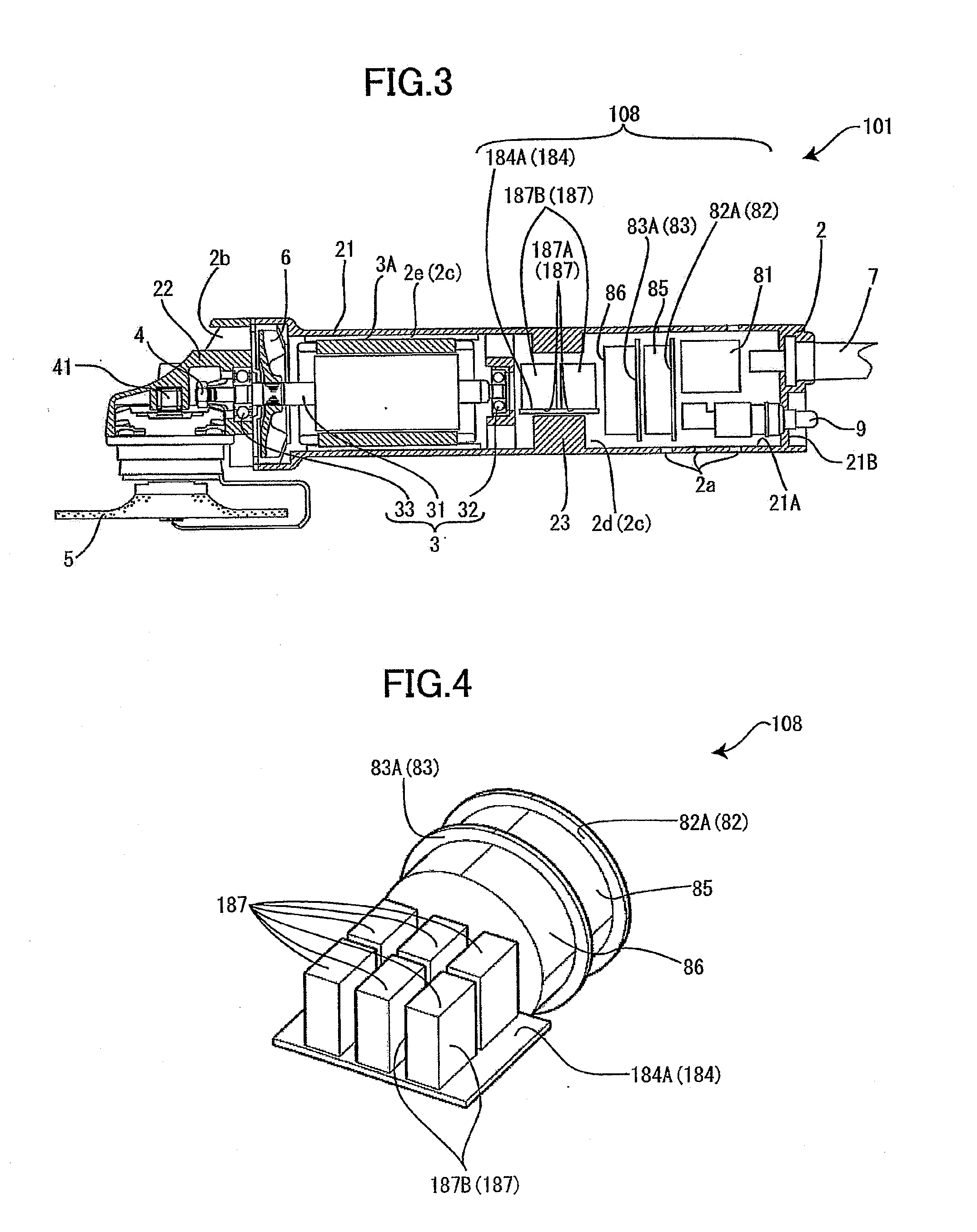

Oscillatory drive

ActiveUS7997586B2Reduce disadvantagesImprove balanceGrinding wheel securing apparatusControlling membersPre stressPre stressing

The invention relates to an oscillatory drive having an output shaft that can be driven to perform a rotationally oscillating movement about its longitudinal axis and that comprises a free end, a holding fixture at the free end of the output shaft comprising a contact surface for attachment of a tool, a mounting section on the holding fixture, raised relative to the contact surface, that projects to the outside in the direction of the longitudinal axis and that is designed for form-locking connection with a mounting opening of a tool placed in contact with the contact surface, and having a securement for fixing the tool with its mounting opening on the holding fixture, the securement permitting the tool to yield in axial direction under the action of a torque, against a pre-stress, and the mounting section permitting the tool to rotate by a certain angle of rotation when the tool gives way axially.

Owner:C & E FEIN GMBH & CO KG

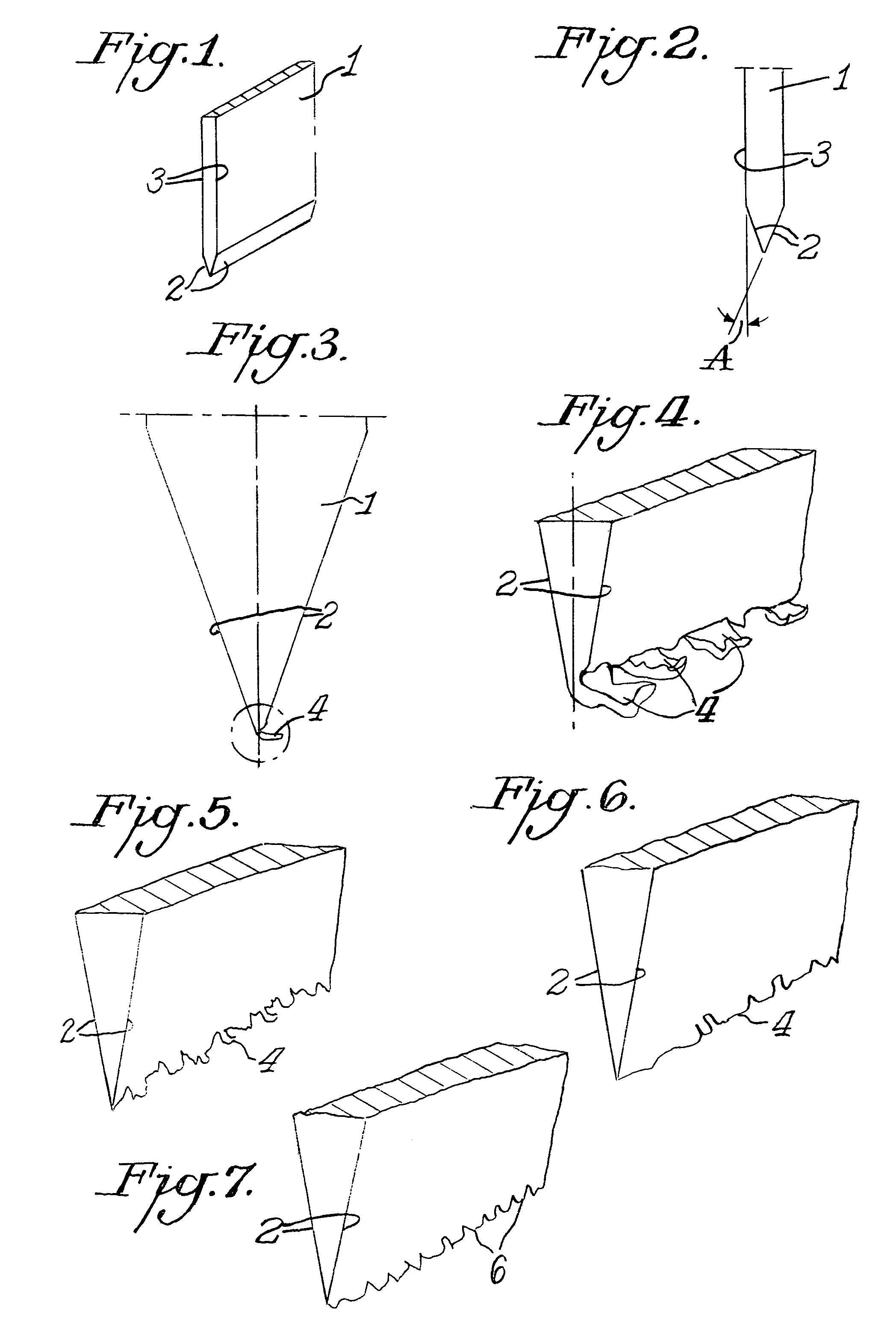

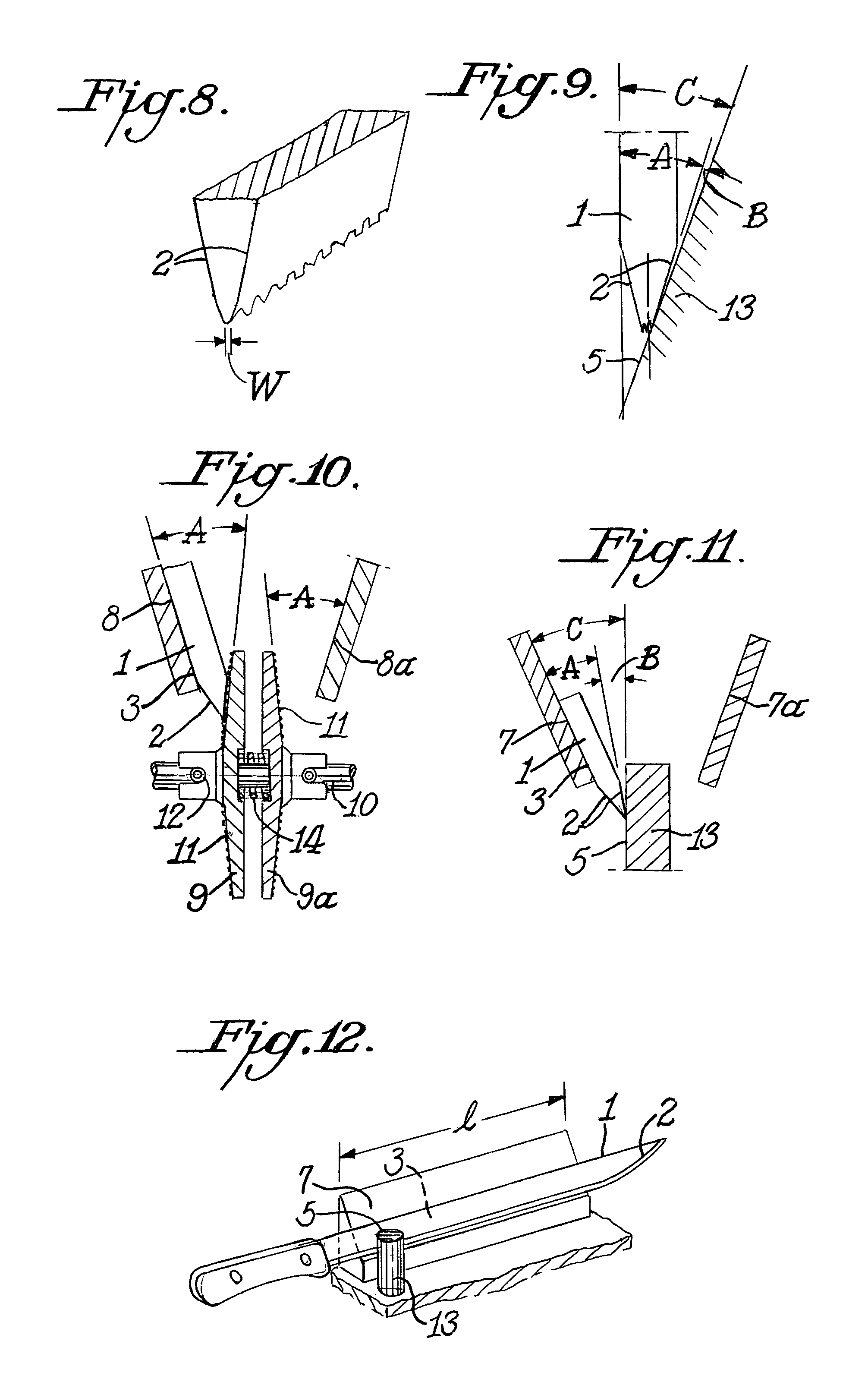

Precision means for sharpening and creation of microblades along cutting edges

A knife-edge conditioning apparatus comprises at least one precision angled knife guide with one face of the knife blade maintained in sustained sliding or rolling contact and which guides the elongated edge of the blade into sustained contact with the hardened surface of an object and positions the plane of the adjacent edge facet at a precise predetermined angle relative to the contact plane of the hardened surface made of a material of equal or greater hardness than the metal of the knife blade without any tendency to abrade as the blade face is moved along the guide with its elongated edge in sustained contact with the hardened surface.

Owner:EDGECRAFT

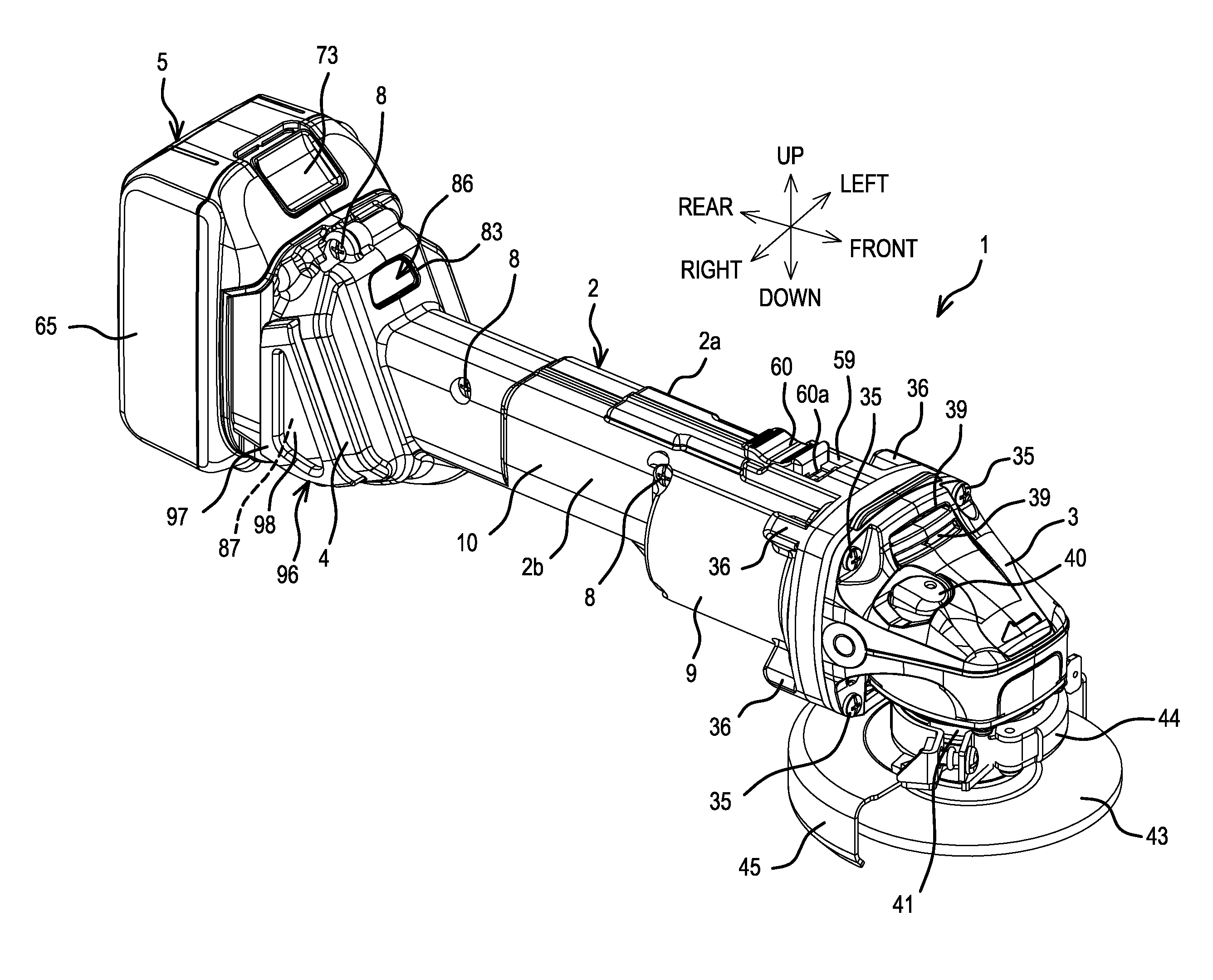

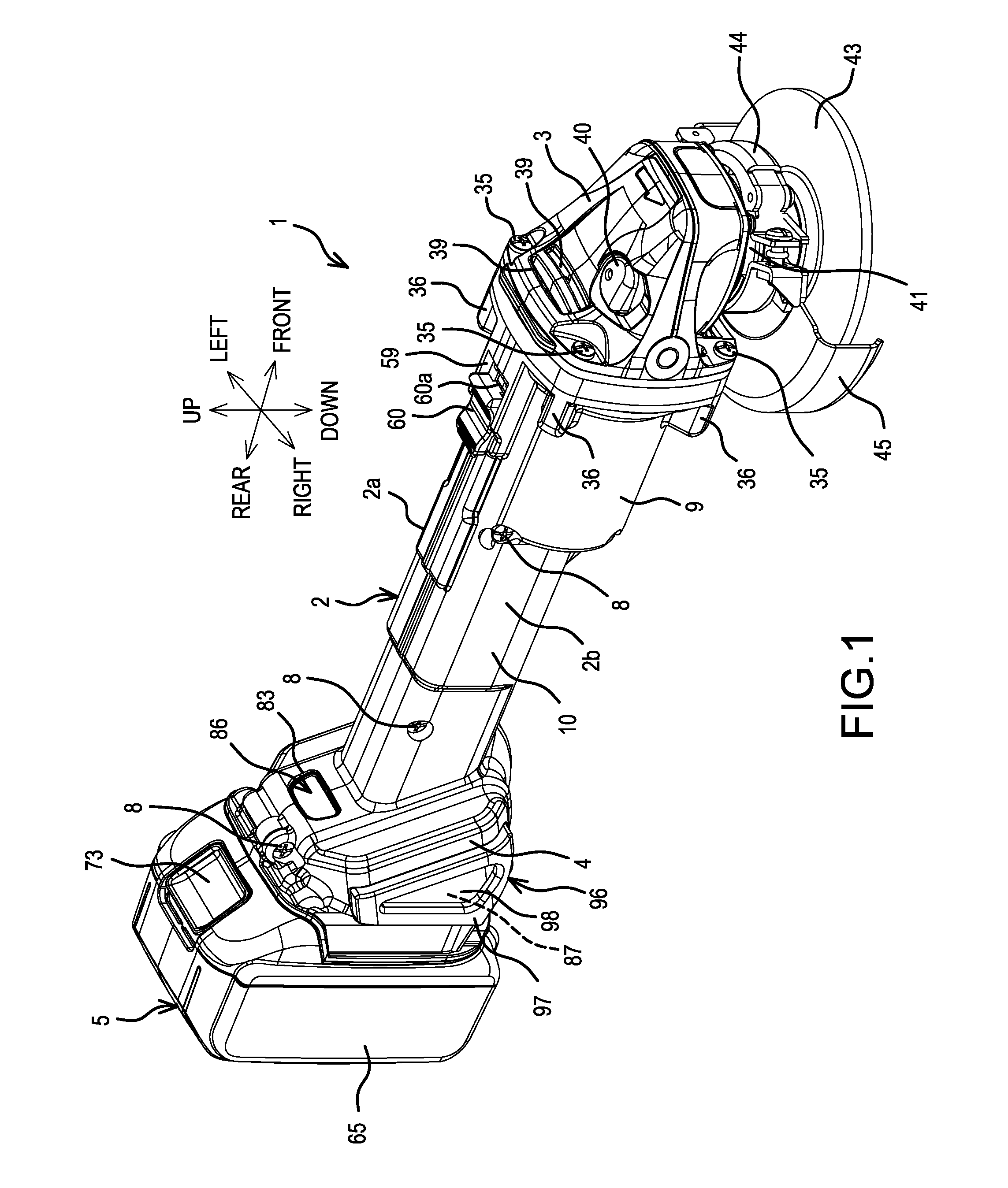

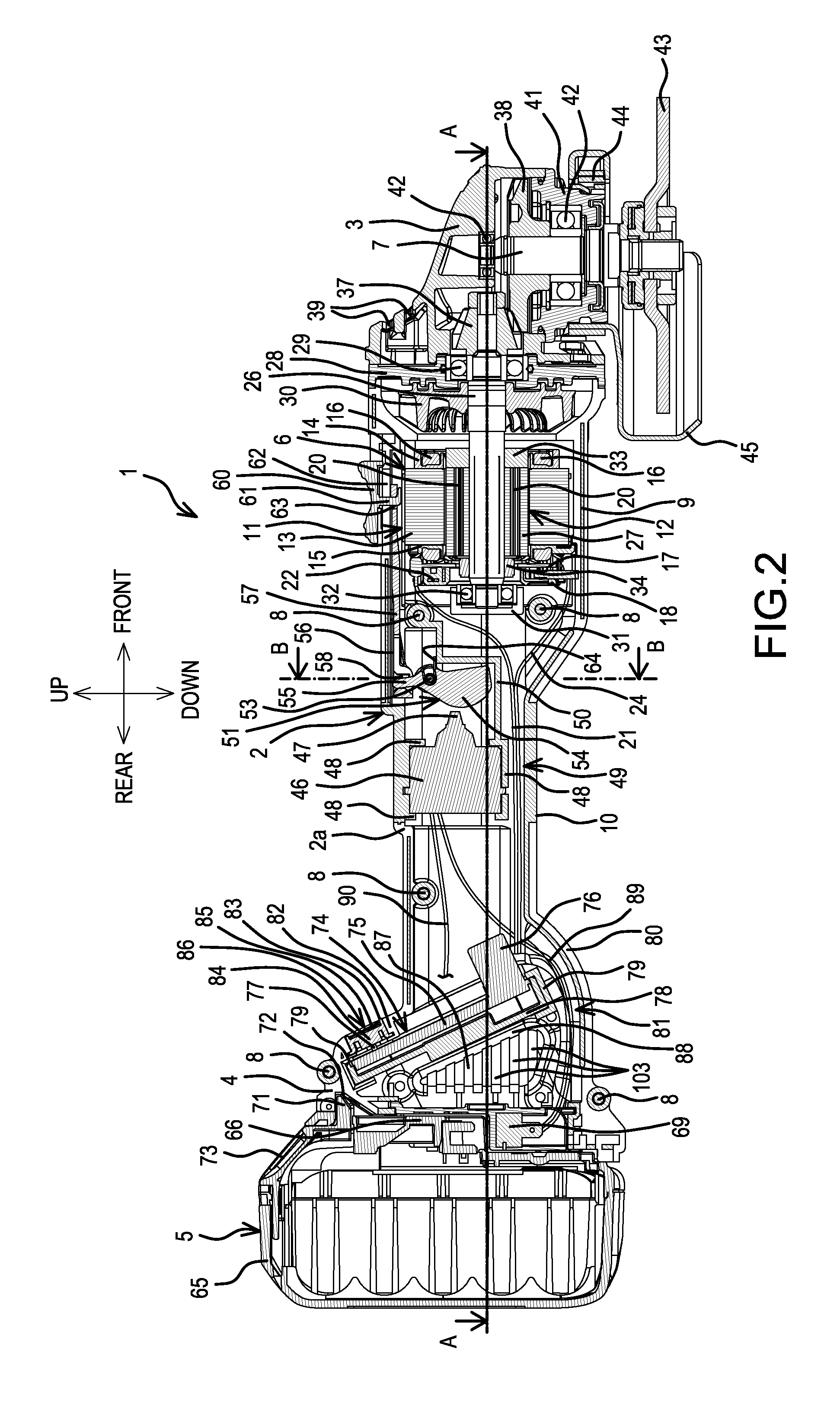

Power tool

ActiveUS20150263592A1Comfortable to holdImprove cooling effectWindingsPortable grinding machinesBrushless motorsEngineering

A power tool includes a brushless motor having a stator and a rotor, which includes a rotary shaft extending in a front-rear direction of the power tool. The rotary shaft rotates a spindle that extends in an up-down direction of the power tool. A fan is fixedly coupled to the rotary shaft and rotates therewith. A switch is disposed rearward of the brushless motor and a controller is disposed rearward of the switch in the front-rear direction. A battery pack is disposed rearward of the controller. A main-body housing houses the brushless motor, the switch and the controller. The main-body housing includes a first tubular part, which houses the brushless motor, and a second tubular part, which houses the switch. The diameter of the second tubular part is smaller than the diameter of the first tubular part.

Owner:MAKITA CORP

Grinding disk

ActiveUS7029384B2High torqueFine pitchGrinding wheel securing apparatusRevolution surface grinding machinesDiameter ratioEngineering

A grinding disk (13) for manually held, motor-driven grinders (1) has a centrally arranged fastening recess (15) open at the grinding disk upper side with an internal thread arrangement (16), with which the grinding disk (13) can be screwed onto a connecting part (8), which is arranged on the side of the grinder and is driven for the grinding motion during operation, and which connecting part has a thread section (11) with an external thread arrangement (12), which is associated with the internal thread arrangement (16) of the grinding disk (13). The internal thread arrangement (16) is formed by a multiple thread with at least two thread courses, which are arranged angularly offset to one another. The diameter ratio between the diameter of the internal thread arrangement (16) and the outside diameter of the grinding disk (13) is at least approximately 0.25.

Owner:FESTOOL GMBH

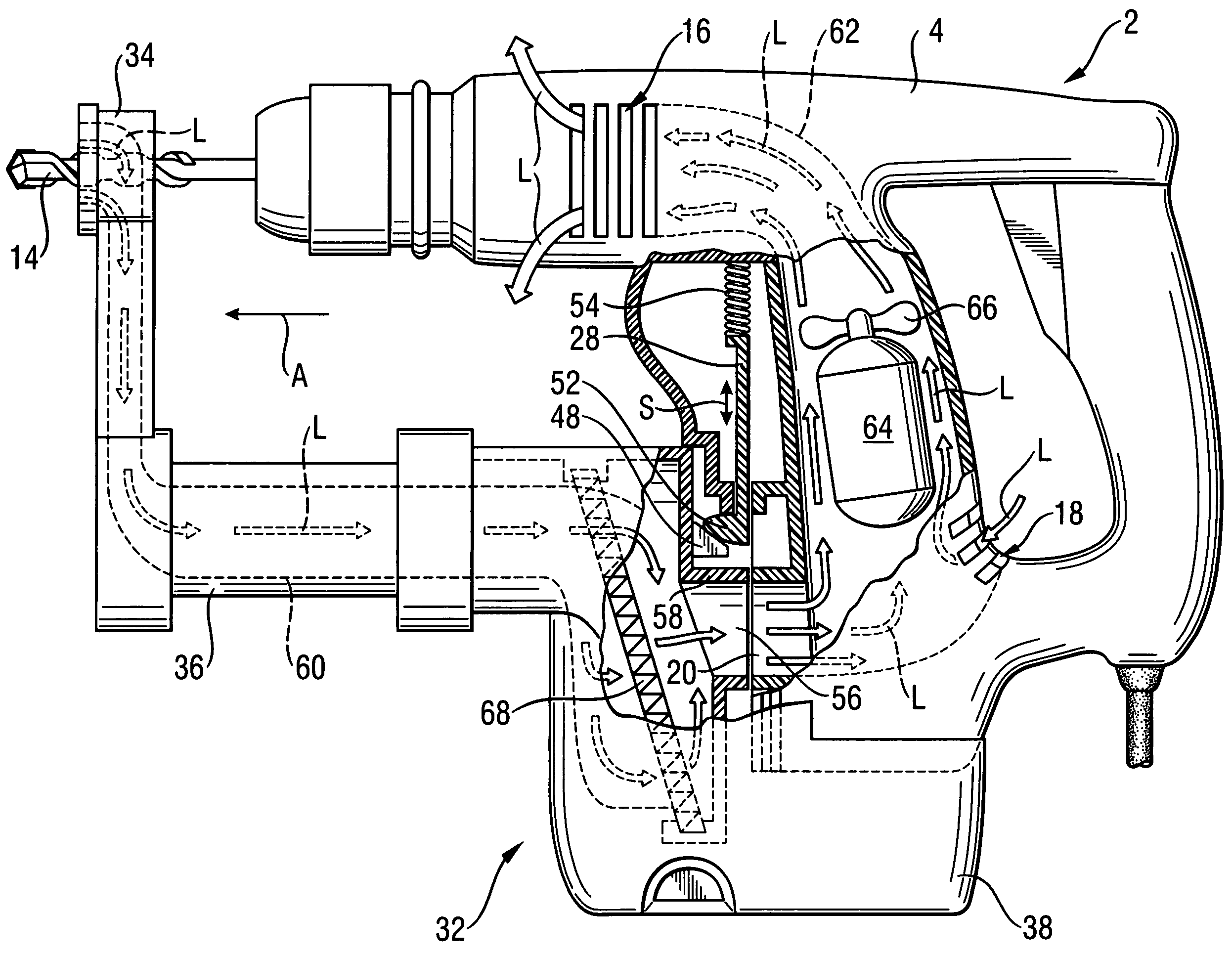

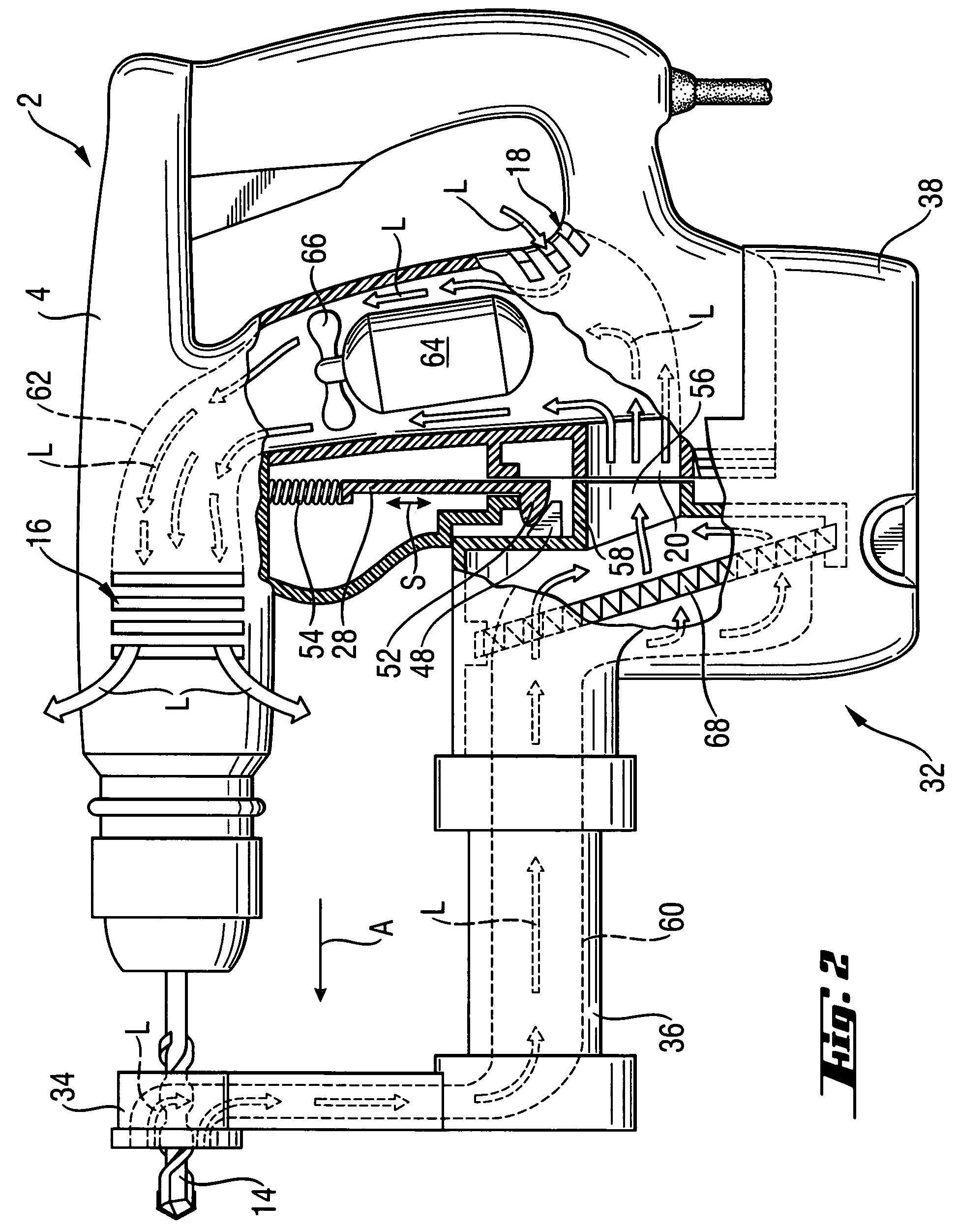

Hand-held power tool with a dust suction module

InactiveUS7354226B2Cost-effectiveAccurate guidanceThread cutting feeding devicesDrilling rodsSeparated stateHand held

A hand-held power tool (2) connectable with a dust suction module (32) includes a motor (64) and an air flow generator (66) which for cooling the motor (64) is located, together with the motor (64), in air flow path (62) between an air inlet and an air outlet (16) both formed in the tool housing, (4, 6), with an air inlet having a side opening (18) and a connection opening (20) connectable with the suction path (60) of the dust suction module (32) and the dust suction module (32) having a suction conduit (58) for connecting the suction path (60) with the air flow path (62) and adjoining the connection opening (20) in a connected condition of the dust suction module (32) with the power tool, and with the power tool (2) further having a closing member provided on the connection opening (20), operable by the dust suction module (32), and having, in an attached position of the dust section module (32), an open position, and having a closed position in the detached condition of the dust suction module (32).

Owner:HILTI AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com