Substrate processing apparatus

a processing apparatus and substrate technology, applied in the direction of grinding machines, manufacturing tools, edge grinding machines, etc., can solve the problems of poor efficiency of operators, no attention to the accessibility of bevel polishing devices for operators, and difficulty in polishing substrates, etc., to improve the process efficiency of polishing substrates, short time period, and efficient maintenance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

5. FIRST EMBODIMENT OF POLISHING UNIT

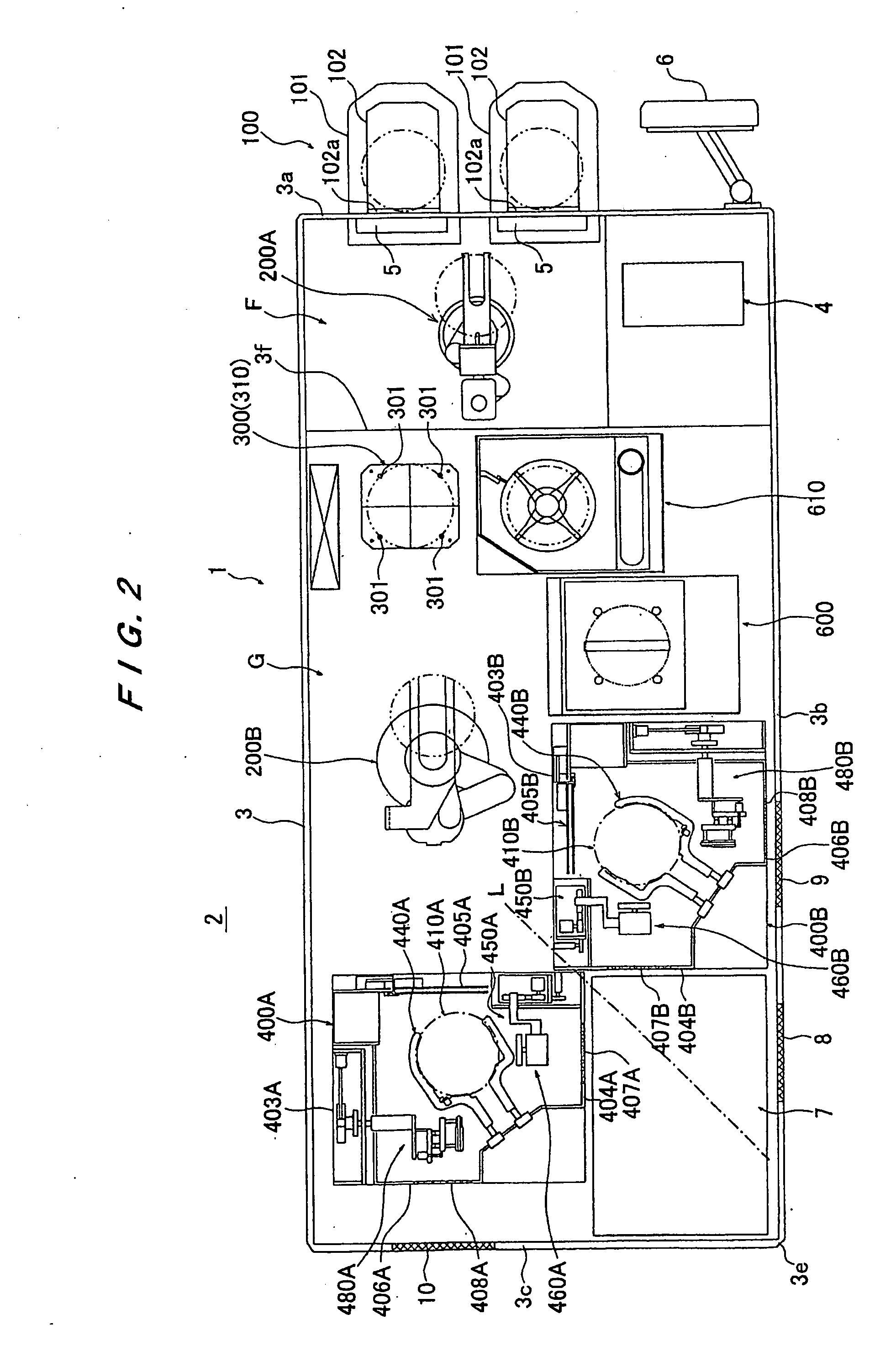

[0121]Next, structures of the first polishing unit 400A and the second polishing unit 400B will be described below. The first and second polishing units 400A and 400B have common structures. As shown in FIG. 2, respective components in casings of the first polishing unit 400A and the second polishing unit 400B are arranged symmetrically with respect to a center line L indicated by a dashed line. Specifically, the center line L is an axis of axial symmetry. The structures common to the first and second polishing units 400A and 400B will be described.

[0122]FIG. 12 is a schematic plan view showing a polishing unit 400-1 according to a first embodiment of the present invention. FIG. 13 is a cross-sectional side view of FIG. 12. FIG. 14 is a cross-sectional side view taken along a direction perpendicular to the cross-section of FIG. 13. As shown in FIGS. 12, 13, and 14, the polishing unit 400-1 has a casing 403, which defines a polishing chamber 401 a...

second embodiment

6. SECOND EMBODIMENT OF POLISHING UNIT

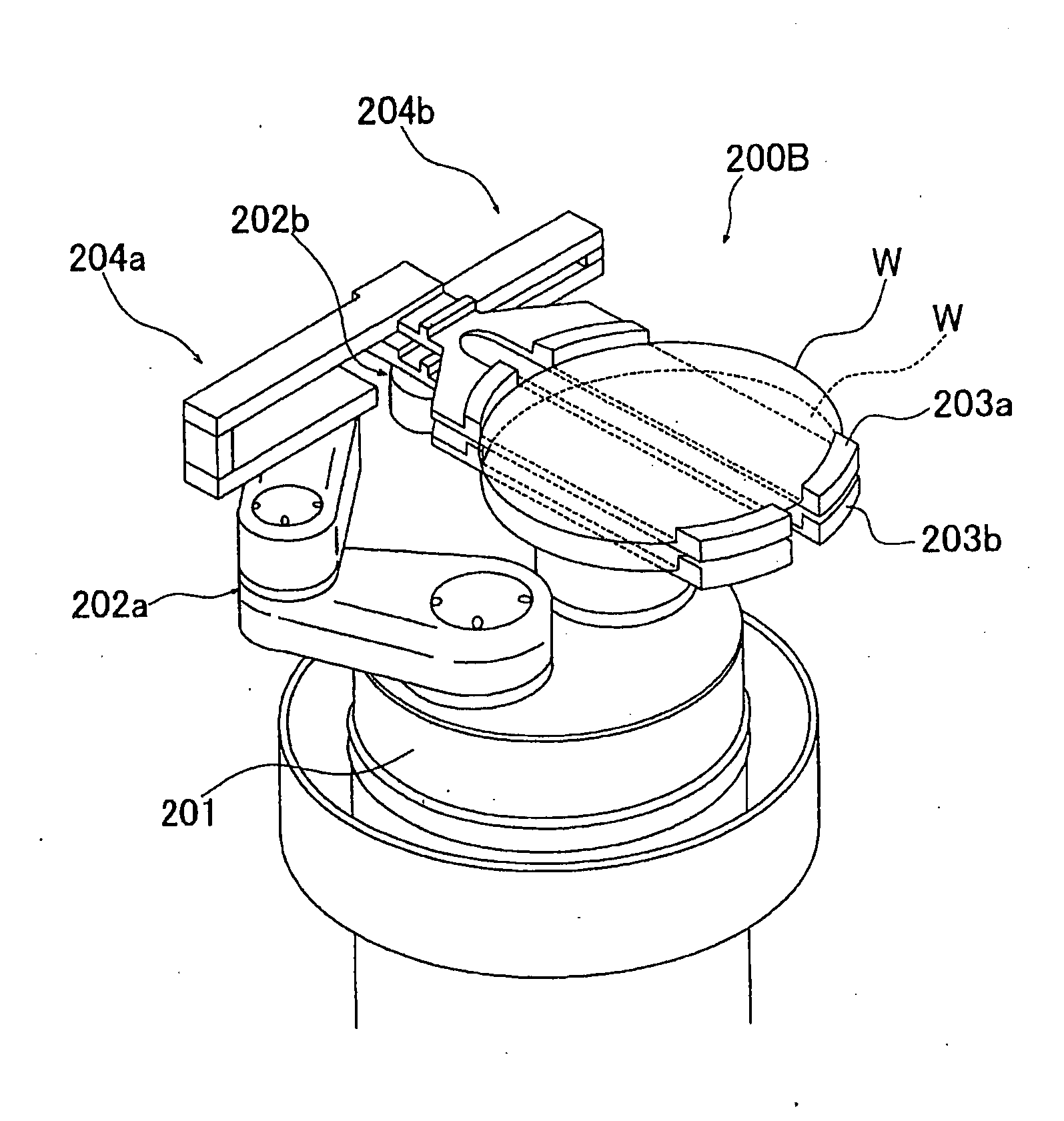

[0172]Another example of the polishing unit 400 will be described below. FIG. 23 is a schematic plan view of a polishing unit 400-2 according to a second embodiment of the present invention. FIG. 24 is a cross-sectional side view schematically showing a portion of the polishing unit 400-2 shown in FIG. 23. In the polishing unit 400-2, similar portions to those of the polishing unit 400-1 are denoted by the same reference numerals and will not be described repetitively. The following description relates mainly to differences between the polishing unit 400-2 and the polishing unit 400-1.

[0173]The polishing unit 400-2 has a substrate holding and rotating mechanism 550 for holding and rotating a wafer, a substrate transfer mechanism 565 for receiving, centering, and delivering the wafer, a bevel polishing device 560 for polishing a bevel portion of the wafer, a notch polishing device 580 for polishing a notch of the wafer, and a notch sensor (not sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| average particle diameter | aaaaa | aaaaa |

| average particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com